Patents

Literature

573results about How to "Fast crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

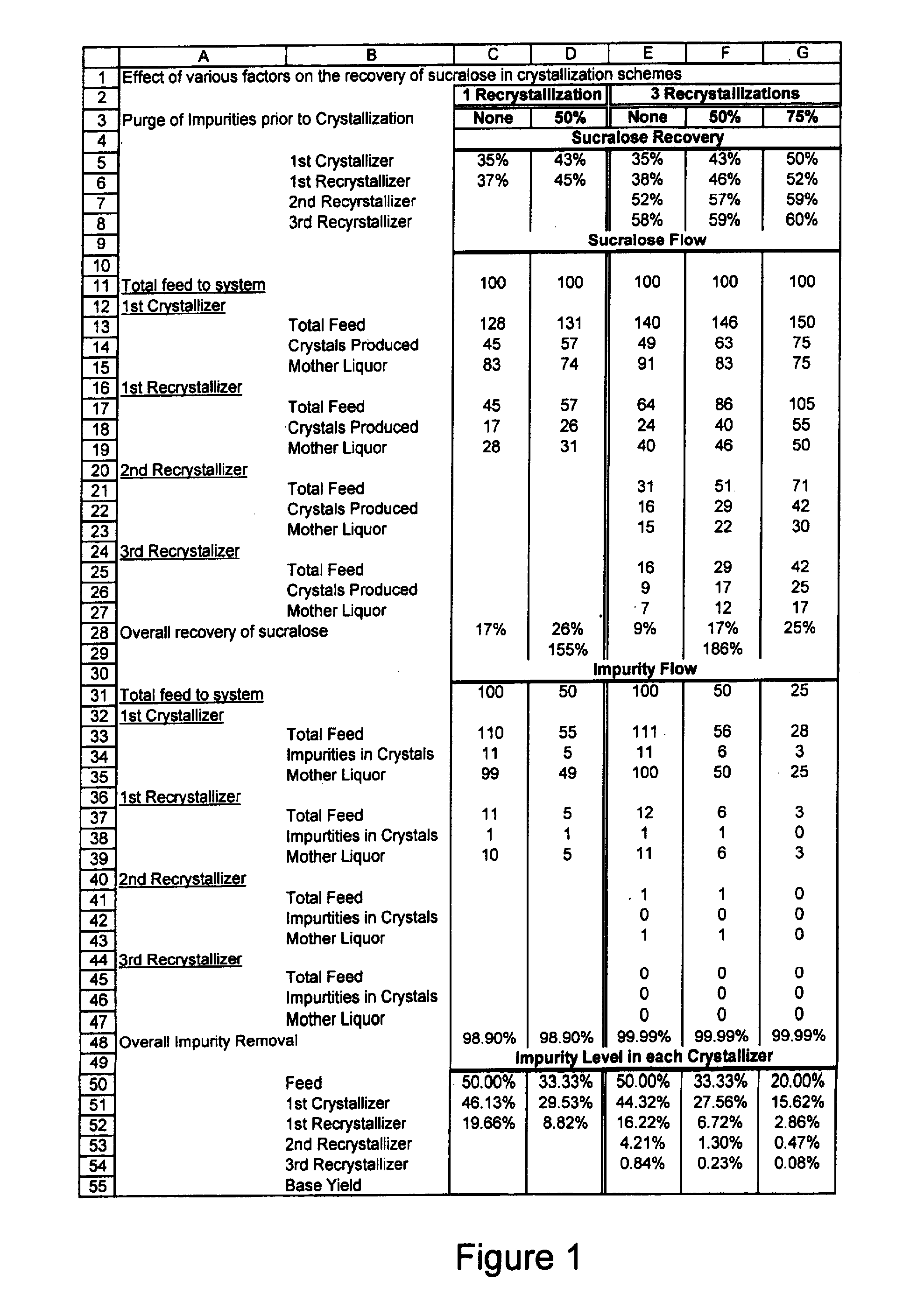

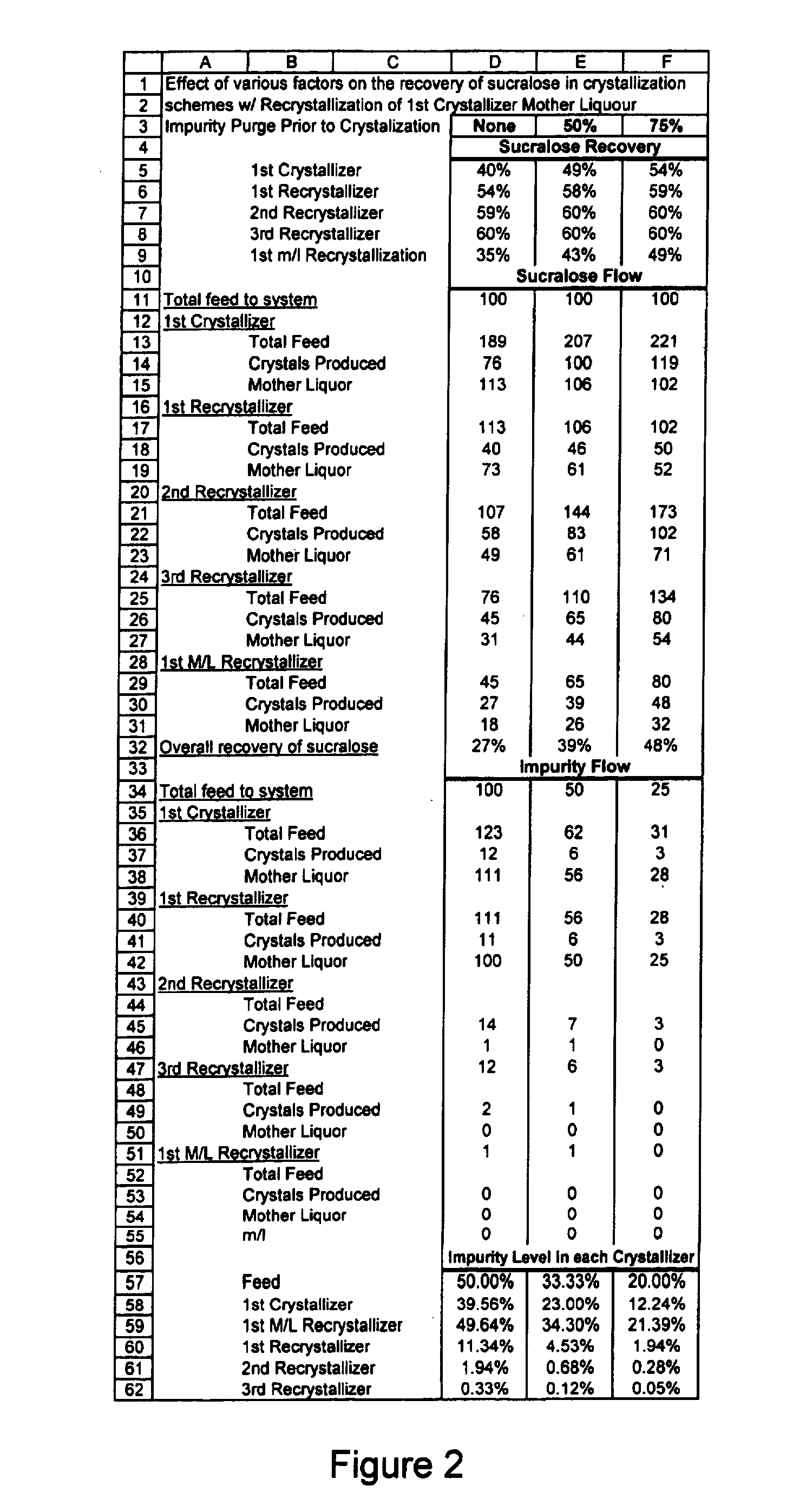

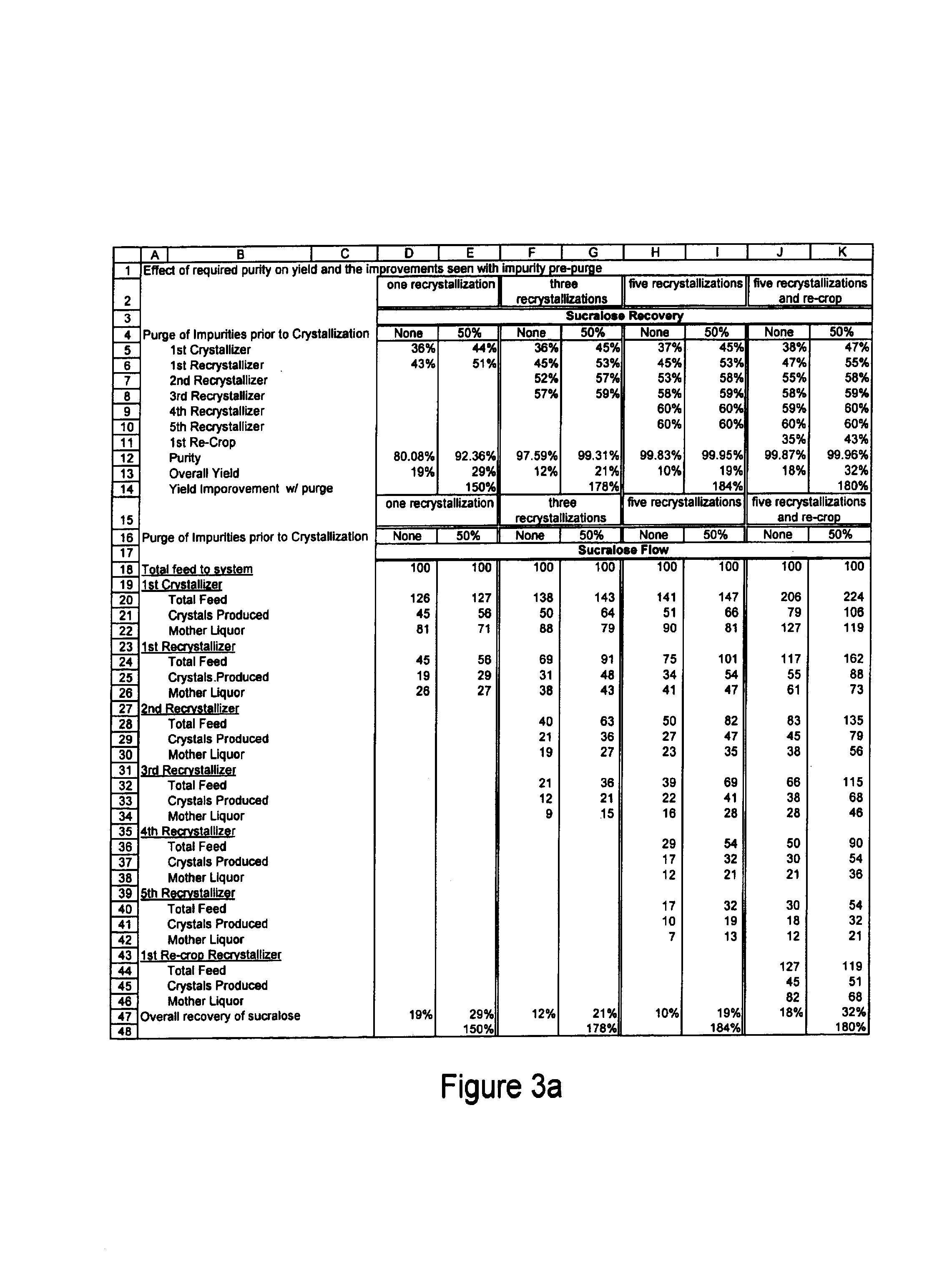

Process for improving sucralose purity and yield

InactiveUS6998480B2Improve efficiencyHigh purityEsterified saccharide compoundsSugar derivativesSucraloseCrystallization Purification

This invention relates to processes for purifying sucralose by the use of an initial non-crystallization purification procedure followed by three or more sequential crystallization steps and recycle of the mother liquor remaining from each crystallization step to the feed of another crystallization or purification step. This invention also relates to sucralose compositions as well as compositions comprising the sucralose compositions of the present invention. These compositions may be highly pure and have a superior taste profile.

Owner:TATE & LYLE TECH LTD

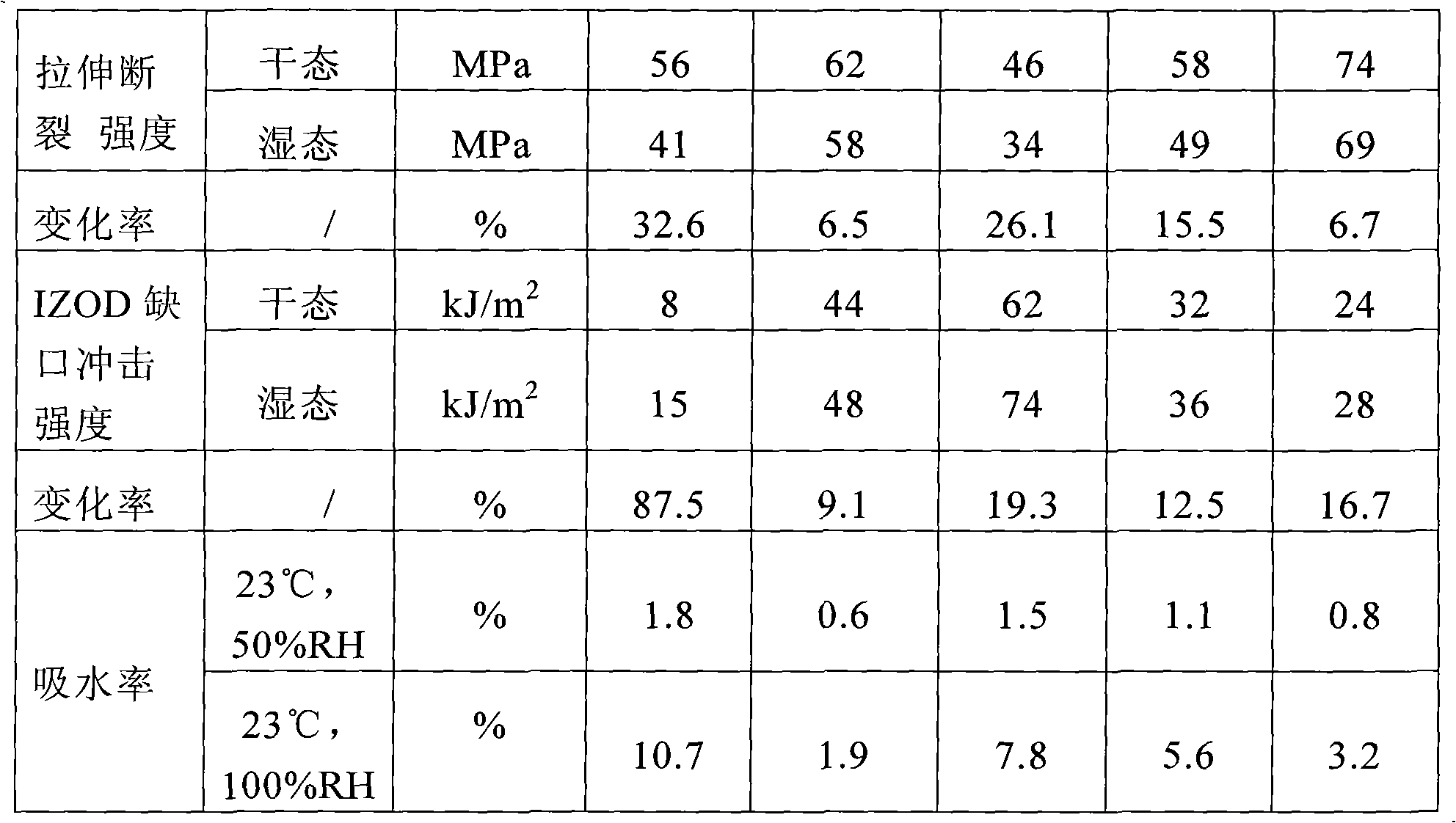

Low water absorption polyamide composite and preparation method thereof

The invention relates to a low water absorption polyamide composite and preparation method thereof. 10-90 parts by weight of polyamide and 3-10 parts by weight of phyllo-silicate clay and less than 2 parts by weight of additive are placed into a high speed mixer to be premixed for 20min and then are added into a double screw extrusion machine, and conveying, melting, cutting, extrusion, cooling and granulation are carried out, thus obtaining polyamide / phyllo-silicate master batch, then the polyamide / phyllo-silicate master batch, 10-60 parts by weight of styrene resin, 2-10 parts by weight of compatilizer and 5-20 parts by weight of short glass fiber are placed into the high speed mixer to be premixed for 20min, temperature is controlled to be 40-60 DEG C, and finally extrusion granulationis carried out in the double screw extrusion machine, thus obtaining the low water absorption polyamide composite. Compared with prior art, the invention has the advantages of solvent resistance, high tenacity and easy processability of polyamide and the advantage of low water absorption of ABS resin; besides, phyllo-silicate clay speeds up crystallization of nylon, degree of crystallization and mechanical strength are improved, extremely low water absorption is obtained, and size stability is greatly improved while impact toughness is maintained.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

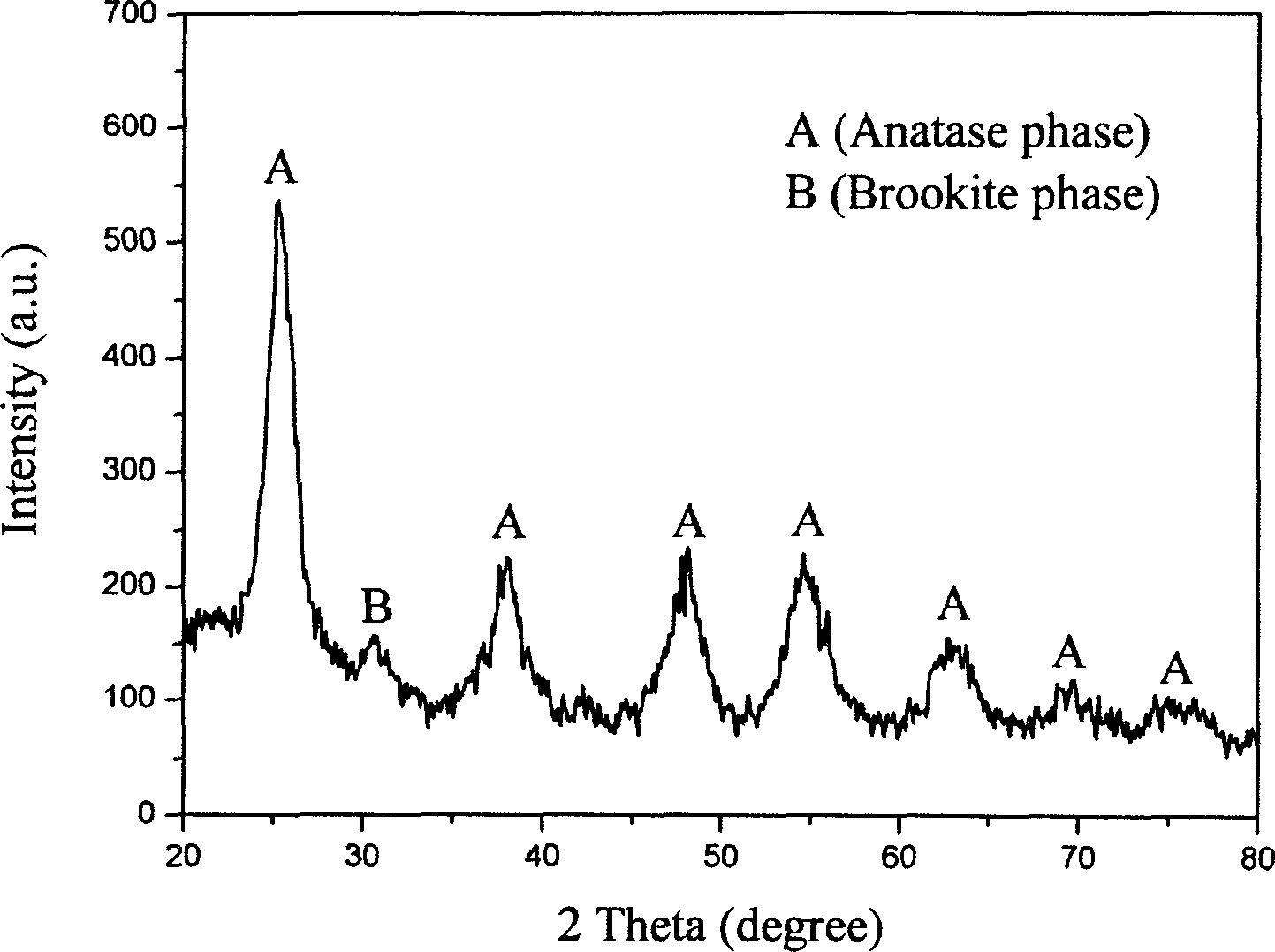

Process for preparing anatase type TiO2 sol

InactiveCN1699181AReduce energy consumptionImprove bindingPhysical/chemical process catalystsTitanium dioxideAlcoholDecomposition

The invention discloses a process for preparing anatase type TiO2 sol which comprises preparing alcoholic solution of titanium compounds from titanium compounds and alcohols by the mol ratio of 1:1.42-12, agitating and dropping the alcoholic solution of titanium compounds into the water solution of acid with pH=1.0-4.0 for hydrolytic decomposition, the mol ratio of titanium compounds and water in the aqueous solution of acids being 1:76-151, inversing flow for 6-48 hours at 65-85 deg. C, evaporating the obtained sol at 50-55 deg. C to remove the alcohols, thus obtaining octahedrite type titanium dioxide collosol.

Owner:SOUTHEAST UNIV

Quickly crystallized polyester engineering plastic and preparation method thereof

The invention relates to a quickly crystallized polyester engineering plastic and a preparation method thereof. The quickly crystallized polyester engineering plastic is prepared with the following components by way of extrusion in a double-screw extruder: 100 parts by weight of modified quickly crystallized polyester A, 0.05 to 5 parts by weight of nucleating agent B, 10 to 40 parts by weight of glass fibers C, 10 to 30 parts by weight of flame retardant D, 1 to 15 parts by weight of flexibilizer E and 0.01 to 3 parts by weight of antioxidant F. The engineering plastic has the advantages of high crystallization speed, high mechanical strength, quick injection moulding and low-temperature demoulding, the finished product cannot be deformed, and the engineering plastic prepared with the quickly crystallized polyester engineering plastic composition has the advantages of high crystallization speed, high mechanical strength, quick injection moulding and low-temperature demoulding.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyester compositions

InactiveUS6986864B2Improve impact performanceIncrease crystallization rateHollow wall articlesBeltsPolyesterPolyolefin

Disclosed are certain novel polyester compositions particularly useful for shaping or forming into containers and similar shaped articles by thermoforming procedures. The polyester compositions comprise a thermoplastic polyester, an impact modifier and a polyester crystallization rate enhancing component selected from poly(tetramethylene terephthalate) homo- and co-polymers. The polyester compositions exhibit improved crystallization rates as compared to similar compositions not including impact modifier or compositions using other types of crystallization rate enhancing components such as polyolefin-based polymers.

Owner:EASTMAN CHEM CO

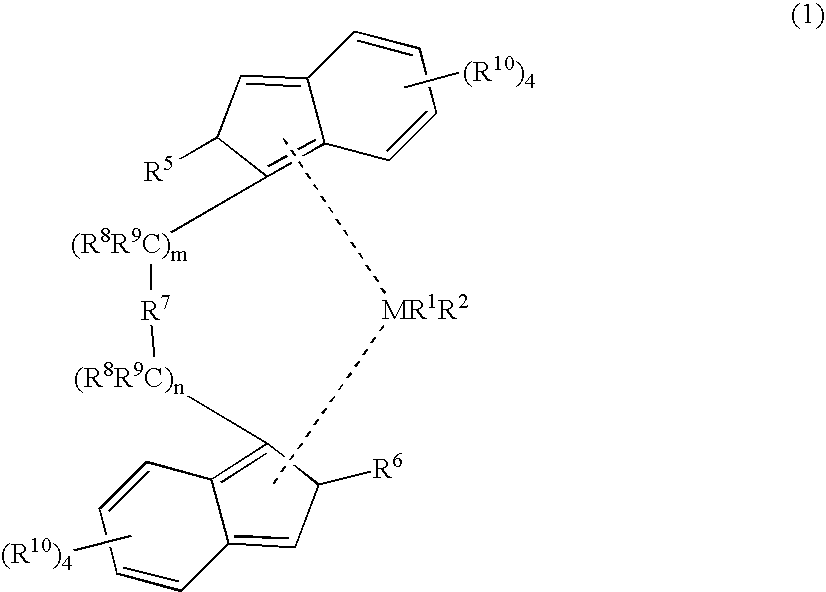

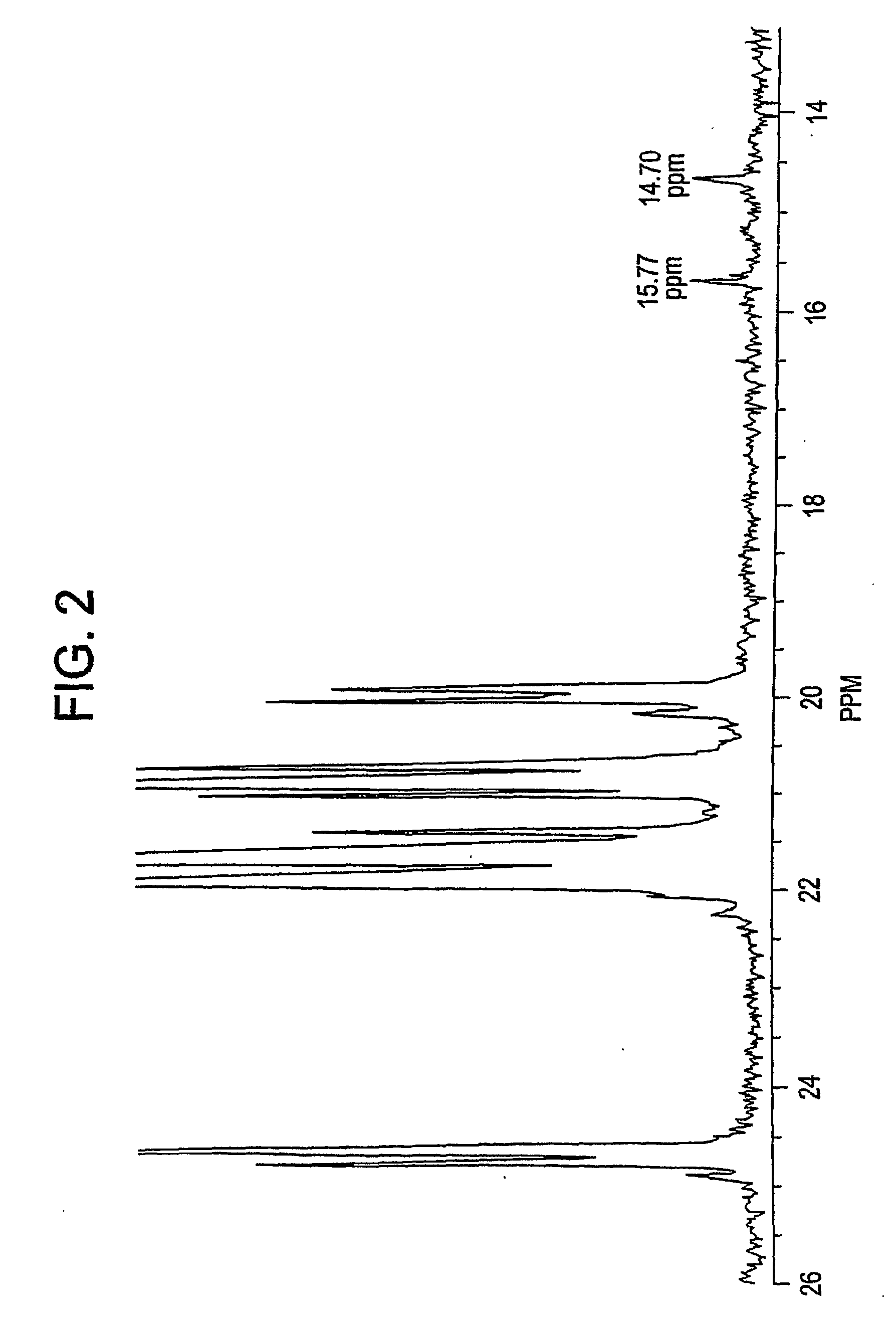

Polypropylene fibers and fabrics

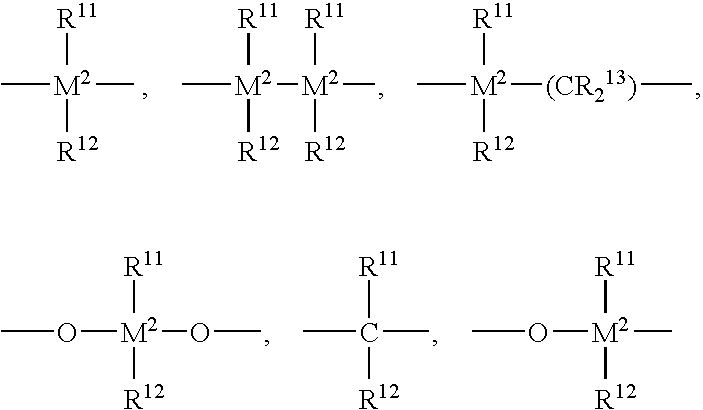

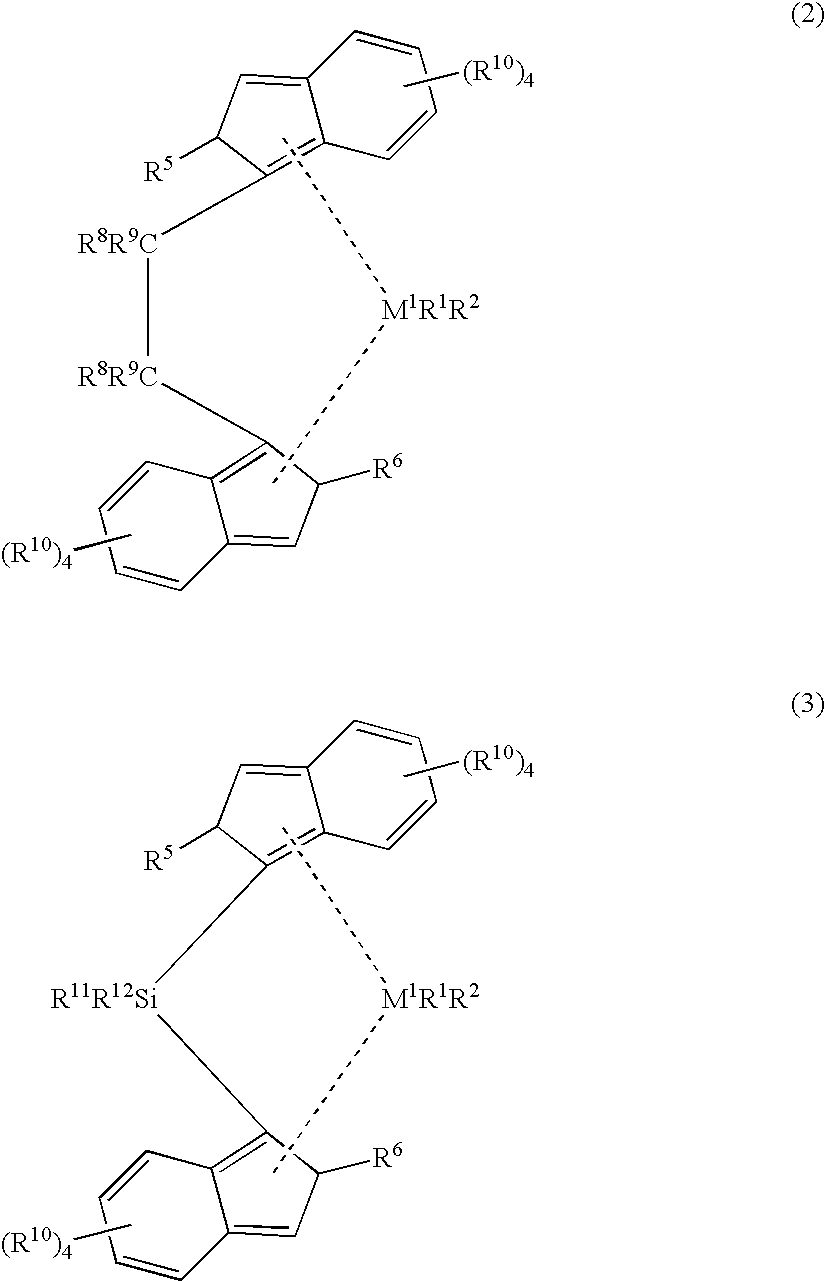

InactiveUS7081299B2Improve featuresShot levelFixed capacitor dielectricSynthetic resin layered productsPolymer scienceNon-coordinating anion

The present invention is a meltblown fiber and a fabric manufactured from the fiber comprising reactor grade polypropylene having a melt flow rate of from 100 to 5000 and having less than 50 stereo defects per 1000 units. Further, the polypropylene is typically produced from a metallocene catalyzed process, the metallocene being at least one bridged 2,4 di-substituted indenyl metallocene in one embodiment, and a bridged 4-phenyl indenyl metallocene in another embodiment. The metallocene is part of a system that can include a fluorided support and a non-coordinating anion activator.

Owner:EXXONMOBIL CHEM PAT INC

Surface treated inorganic particle additive for increasing the toughness of polymers

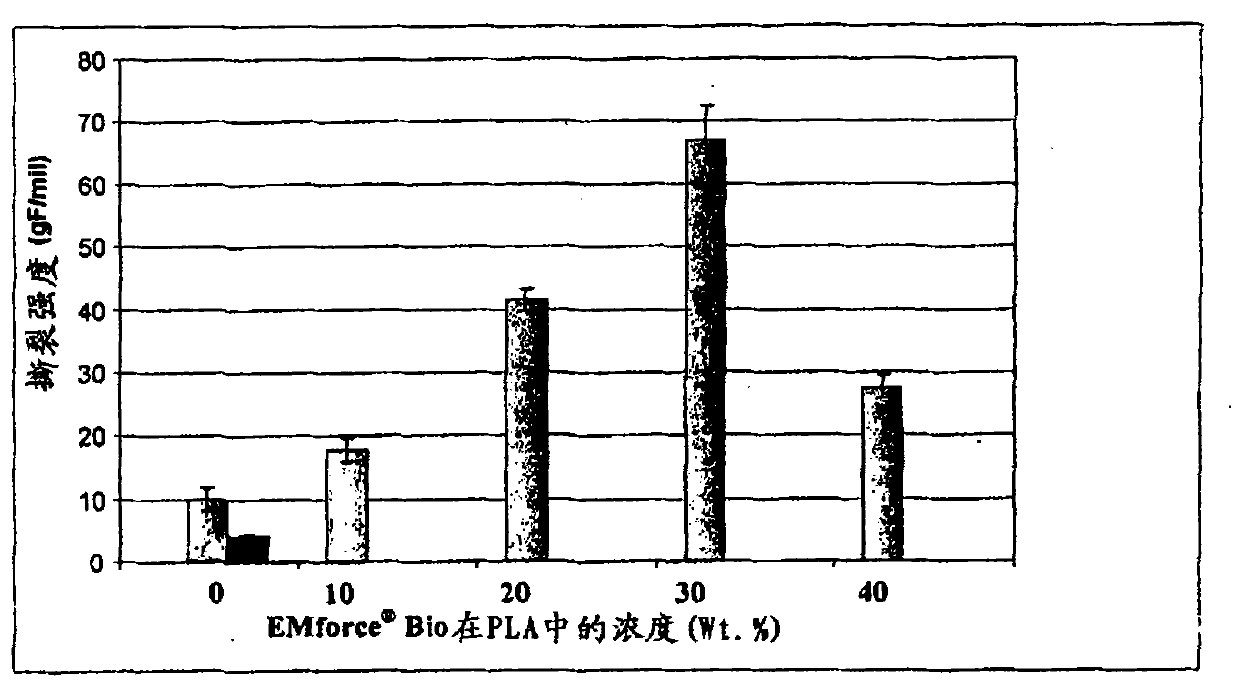

InactiveCN101918485AImproved crystallization kineticsFast crystallizationRefuse receptaclesPolyolefinBiopolymer

A bioplastic composition comprising a biopolymer containing from 10 - 40 wt% of coated inorganic particles; the particles being coated with one or more of fatty acids, fatty acid derivatives, rosins, rosinates, polyolefin based waxes, oligomers and mineral oils, and combinations thereof has improved stiffness and toughness and also has improved crystallisation kinetics rendering it useful for extrusion, injection moulding and thermoforming.

Owner:SPECIALITY MINERALS (MICHIGAN) INC

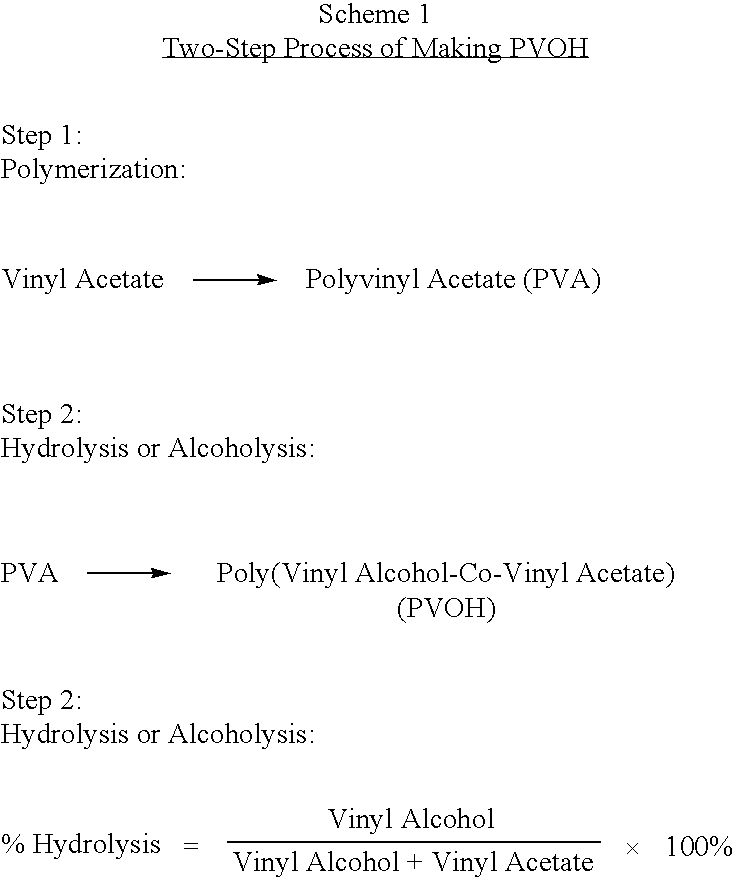

Blend compositions of an unmodified poly vinyl alcohol and a thermoplastic elastomer

InactiveUS7012116B1Good flexibilityImprove ductilityNon-fibrous pulp additionSynthetic resin layered productsPolyvinyl alcoholThermoplastic elastomer

This invention relates, in general, to blend compositions of an unmodified poly vinyl alcohol and a thermoplastic elastomer and thermoplastic film and fiber structures comprising these blend compositions. More specifically, this invention relates to substantially water-free films and fibers comprising unmodified polyvinyl alcohol and a thermoplastic elastomer.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Polyethylene having faster crystallization rate and improved environmental stress cracking resistance

InactiveUS20100105839A1Fast crystallizationAdditional stress crackCrystallization rateMedium molecular weight

Disclosed is a polyethylene composition having faster crystallization rate and improved environmental stress cracking resistance. The polyethylene composition comprises a multimodal polyethylene and a nucleating agent. The multimodal polyethylene comprises from 25 to 50 wt % of a low molecular weight ethylene homopolymer component, from 25 to 50 wt % of a medium molecular weight ethylene copolymer component and from 25 to 50 wt % of a high molecular weight ethylene copolymer component. The polyethylene composition has an environmental stress cracking resistance (ASTM D1693, Condition B in 100% Igepal) greater than or equal to 40 days and a crystallization half time less than or equal to 70% of the crystallization half time of the multimodal polyethylene without nucleating agent.

Owner:EQUSR CHEM LP

Degradable plastic composition as well as preparation method and application thereof

ActiveCN111995848ASolve rigid problemsImprove mechanical propertiesBio-packagingPolymer scienceUltimate tensile strength

The invention discloses a degradable plastic composition as well as a preparation method and application thereof. The degradable plastic composition comprises the following components in parts by weight: 70-99 parts of at least two degradable resins, 0-6 parts of a toughening agent, 0.5-5 parts of a compatilizer, 0.05-3 parts of a chain extender, 0.05-5 parts of an anti-hydrolysis agent, 0.05-5 parts of a nucleating agent and 0.05-3 parts of a slipping agent. By matching two or more degradable resins, the problem of poor toughness or rigidity of the existing single degradable resin is solved,so that the product has excellent comprehensive mechanical properties, excellent rigidity and toughness, high impact property, high nominal strain at break and higher flexural modulus and tensile strength.

Owner:联泓(江苏)新材料研究院有限公司

Process for in-situ quiclely preparing crystalline polyester using nano silicon dioxide

The present invention relates to composite material preparing technology. The production process of nano composite silica / polyester material includes the following steps: coating nano silica as crystallizing nucleartor with organic matter for surface modification to make it capable of distribute well in ethylene glycol as one monomer for polyester; high temperature pre-treating compounded nano silica / ethylene glycol slurry to make nano silica possess average size smaller than 100 nm; and polymerization or copolymerization between nano silica / ethylene glycol slurry and other monomer for polyester inside reactor to obtain in-situ nano composite silica / polyester material. The composite material with 1 wt% of nanometer silica contained has non-isothermal crystallization melting peak temperature raised to 213.4 deg.c and 4-8 times raised isothermal crystallization rate at 185-200 deg.c.

Owner:SHANGHAI JIAO TONG UNIV

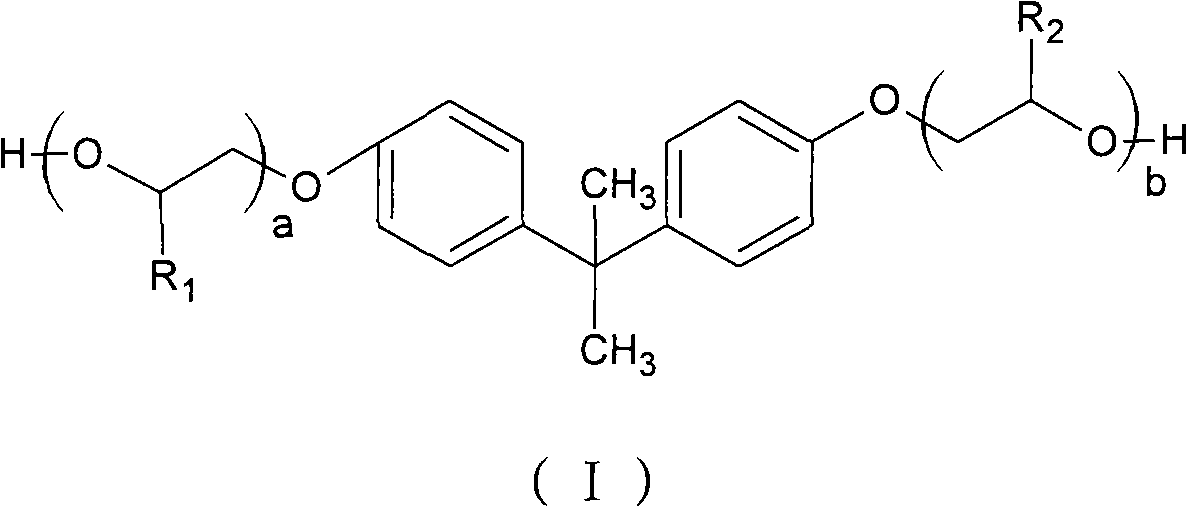

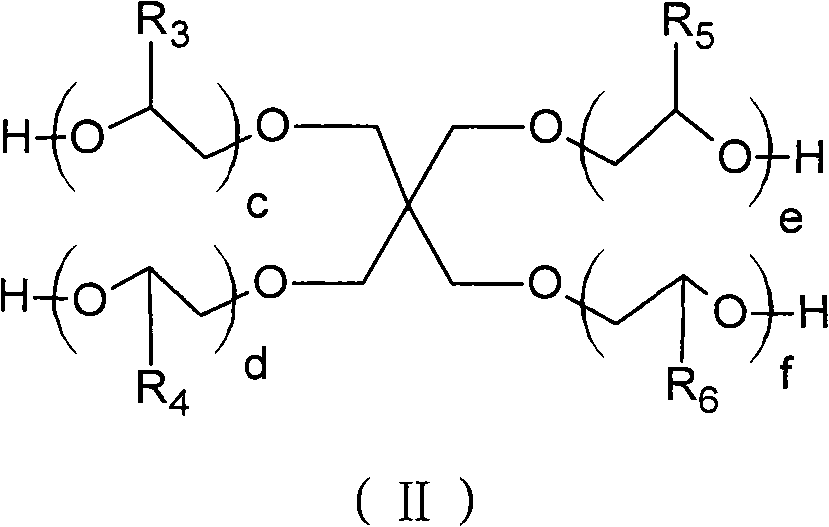

Propylene-Based Elastomeric Composition

The present invention includes a polyolefin elastomeric composition comprising a propylene-based elastomer having at least seventy five weight percent units derived from propylene, the propylene-based elastomer exhibiting a heat of fusion of from 1 to 35 Joules / gram, a weight average molecular weight of from 5400 to 875000 g / mol, and a permanent set of less than 40%; and a homogeneous ethylene-alpha olefin interpolymer having a molecular weight distribution of less than 3.5, a density from 0.885 to 0.915 g / ml, and a heat of fusion of from 65 to 125 Joules / gram, wherein the ratio of the propylene-based elastomer to the homogeneous ethylene-alpha olefin interpolymer is from 97:3 to 80:20, and wherein the composition exhibits a heat of fusion from 2 to 55 Joules / gram, and a 2% secant flexural modulus of less than 69 MPa.

Owner:DOW GLOBAL TECH LLC

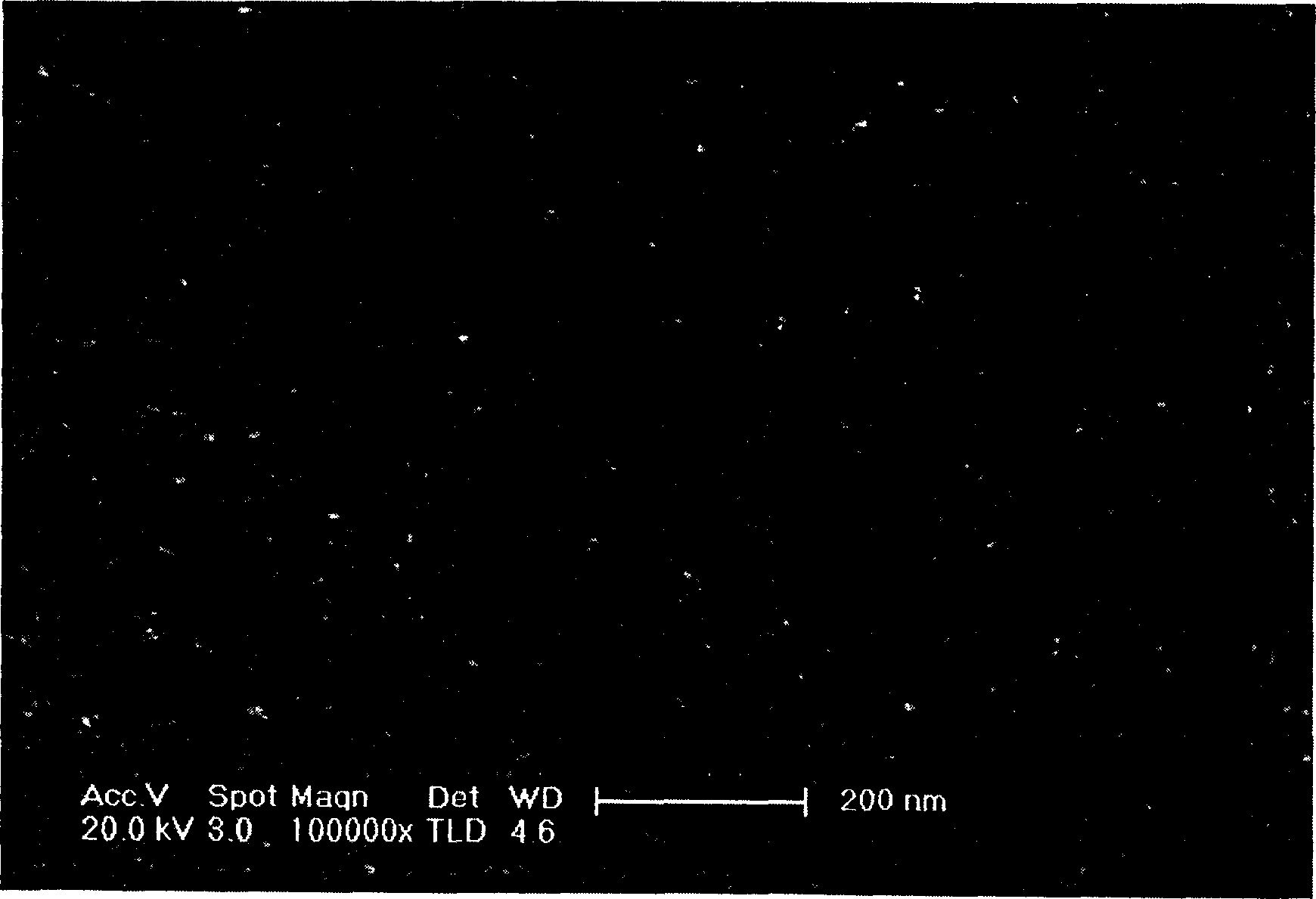

Preparation method of antibacterial silk fibroin fibrous membrane

InactiveCN103361885AFast crystallizationImprove uniformityNon-woven fabricsSpinning solutions preparationSorbentWater insoluble

The invention relates to a preparation method of an antibacterial silk fibroin fibrous membrane. The preparation method comprises the following steps: dissolving silver salt into water and adding aqua ammonia to form clarifying transparent silver ammino and an ionic solution firstly; adding water-insoluble fatty alcohol, and adopting a microwave irradiation technology to prepare silver nanoparticles; adding the obtained silver nanoparticles into a prepared silk fibroin solution, mixing the obtained silver nanoparticles and the prepared silk fibroin solution, so as to form a spinning solution; then preparing the antibacterial silk fibroin fibrous membrane through a static spinning technology. According to the preparation method provided by the invention, the method is simple, an interface system is regarded as a reaction medium, so that the products can be transferred between different phases, the surface adsorbent can be replaced, and good uniformity of the nanoparticles can be guaranteed; the microwave irradiation technology is adopted, so that the crystallization speed of the products can be improved, the operating steps are simple, the cost is low, the reaction speed is high, the efficiency is high, and a certain universality is provided; the nano-silver has hydrophobicity and can be dispersed into the silk fibroin solution very well, which is further in favor of preparing antibacterial silk fibroin membrane with good uniformity.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Bio-degradable polyester and method for preparing same

The invention relates to bio-degradable polyester and a method for preparing the same, and belongs to the technical field of bio-degradable copolyester products. The number-average molecular weight of the bio-degradable polyester material is 6,000 to 135,000g / mol, the molecular weight distribution is 1.2 to 6.5, and the crystallization temperature range is between 15 and 105 DEG C; the bio-degradable polyester overcomes defects existing in conventional products and can be used for producing film-forming materials, sheets and foam materials, the sticking characteristics are greatly changed in the machining process, and the appearance quality is higher; and after the heat resistance is improved, the novel polyester material can also be used in the machining process with a long cycle period, such as an injection machining process, and the bio-degradable aliphatic / aromatic polyester material provided by the invention possesses excellent mechanical properties.

Owner:KINGFA SCI & TECH CO LTD +1

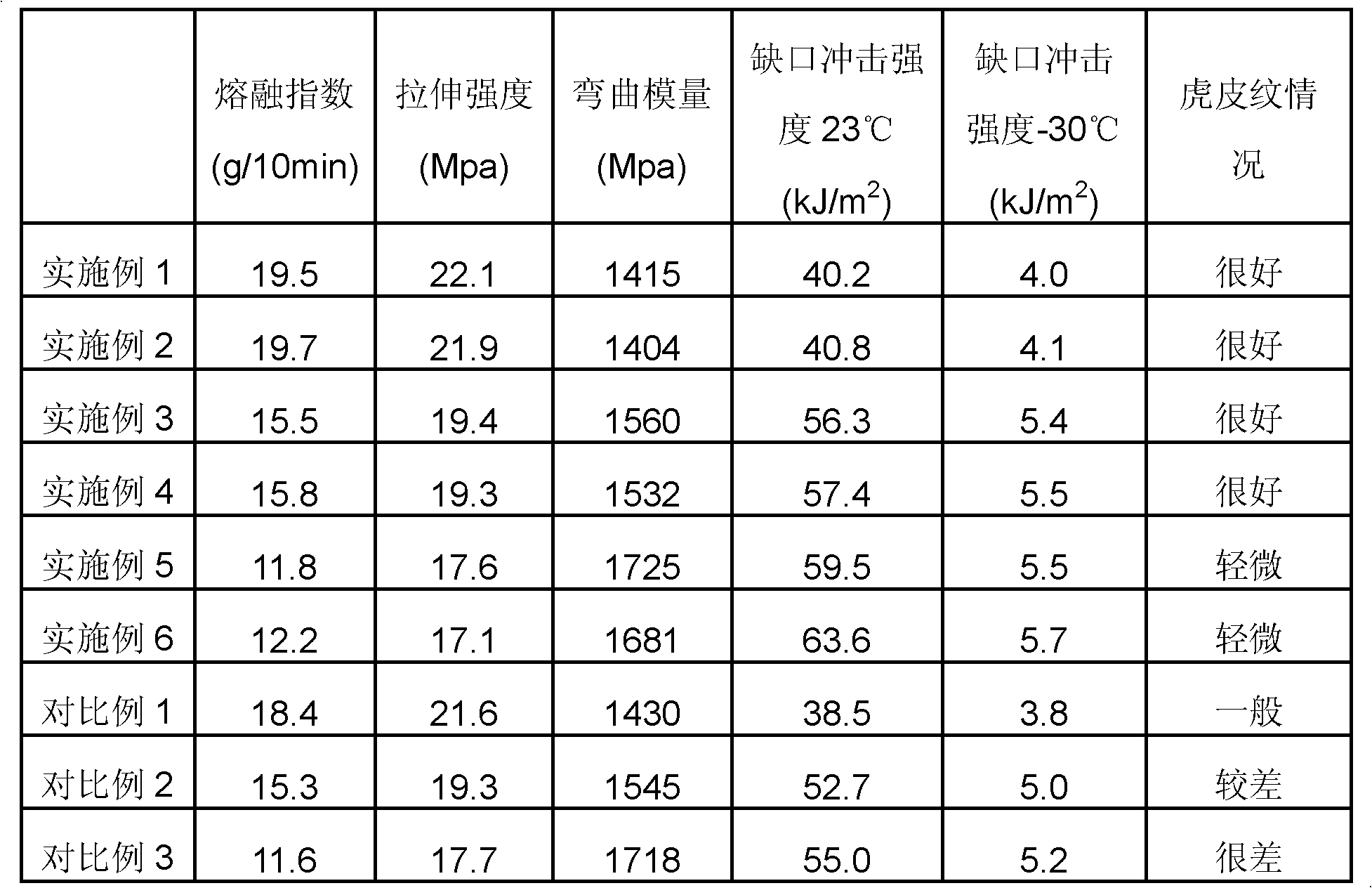

Polypropylene composite material for automotive instrument panel and preparation method for polypropylene composite material

The invention discloses a polypropylene composite material for an automotive instrument panel and a preparation method for the polypropylene composite material. The polypropylene composite material comprises the following components in percentage by weight: 45 to 80 percent of polypropylene, 10 to 30 percent of inorganic filler, 5 to 20 percent of toughening agent polyolefin elastomer (POE), 2 to 10 percent of polybutylene-1, 0.1 to 2 percent of antioxidant, 0.1 to 1 percent of light stabilizer, 0 to 3 percent of anti-scratch aid and 0 to 3 percent of the balance. The polypropylene composite material has excellent rigid-tough balance; the low-temperature notch strength is far higher than that of general polypropylene composite materials; the injection molding cycle is short; apparent defects such as tiger skin and the like are avoided on the surfaces of injection-molded sample pieces; and the characteristics efficiently meet the requirements of automotive instrument panels.

Owner:SHANGHAI PRET COMPOSITES

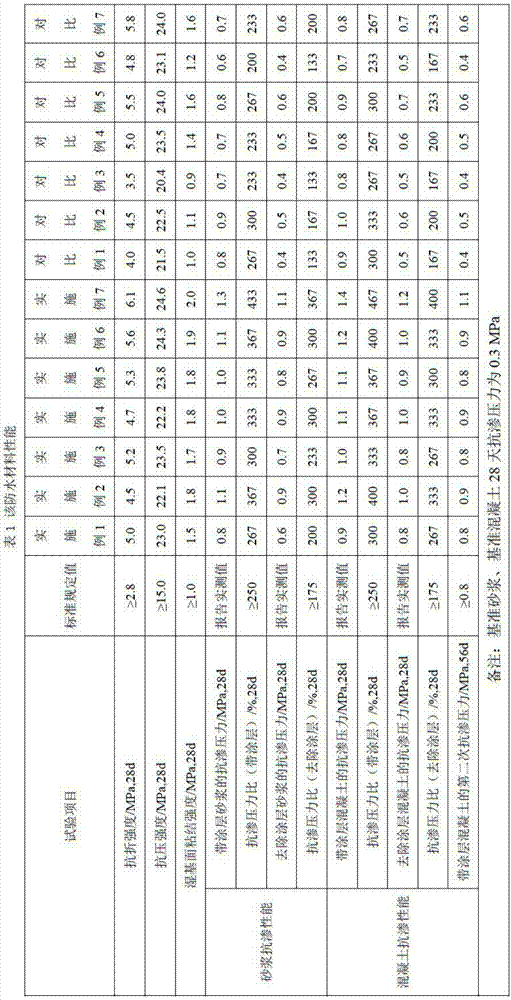

Compound type cement-based permeable crystallization type waterproof material

ActiveCN107540304AImprove permeabilityExcellent waterproof and anti-seepage functionHydration reactionCellulose

The invention discloses a compound type cement-based permeable crystallization type waterproof material. The material comprises the following raw materials in parts by weight: 320-570 parts of Portland cement, 240-480 parts of quartz sand, 60-250 parts of heavy calcium, 5-150 parts of silica fume, 2-125 parts of redispersible latex powder, 0.5-50 parts of a surfactant, 0.5-30 parts of a catalyst,0.05-2 parts of cellulose ether. After the material and water are acted, active chemicals in the waterproof material employ water as a carrier and penetrate into internal porosities of cement concretedue to high permeability, in order to promote generation of hydration reaction of unhydrated cement particles, generate a lot of needle-like crystal, and block closed capillary channels, and the cement concrete has excellent waterproof impervious impermeability function; when new fine cracks are generated in concrete, under a wet condition or water infiltrates, active chemical substances are reactivated, new hydration reactions are generated by catalysis, and new needle-like crystals are generated in slits in order to fill and block fine cracks with excellent self-repairing function.

Owner:KESHUN WATERPROOF TECH CO LTD

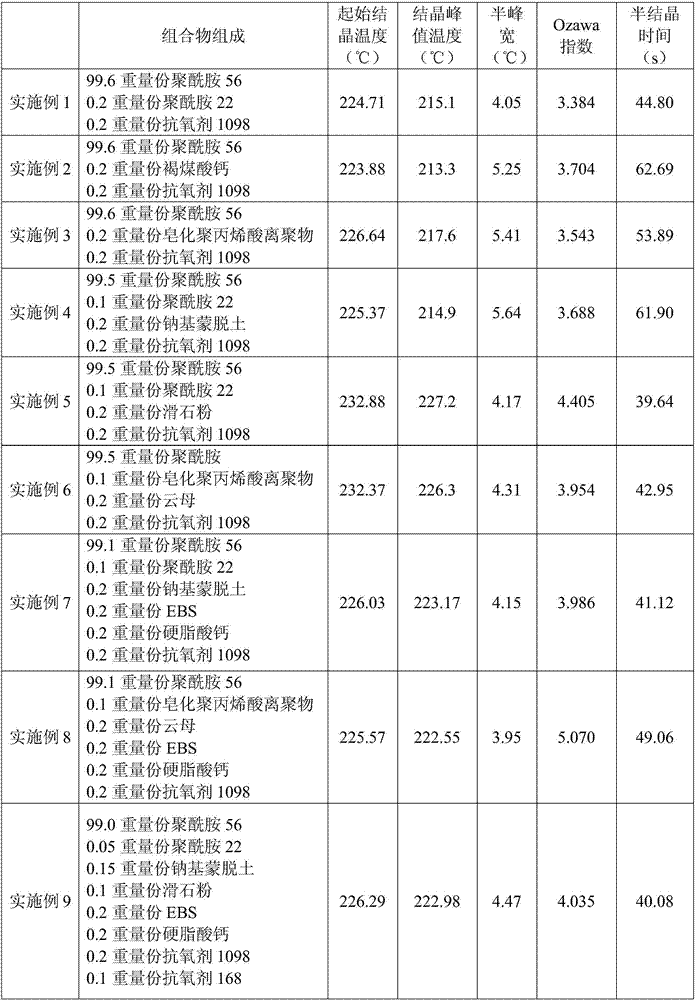

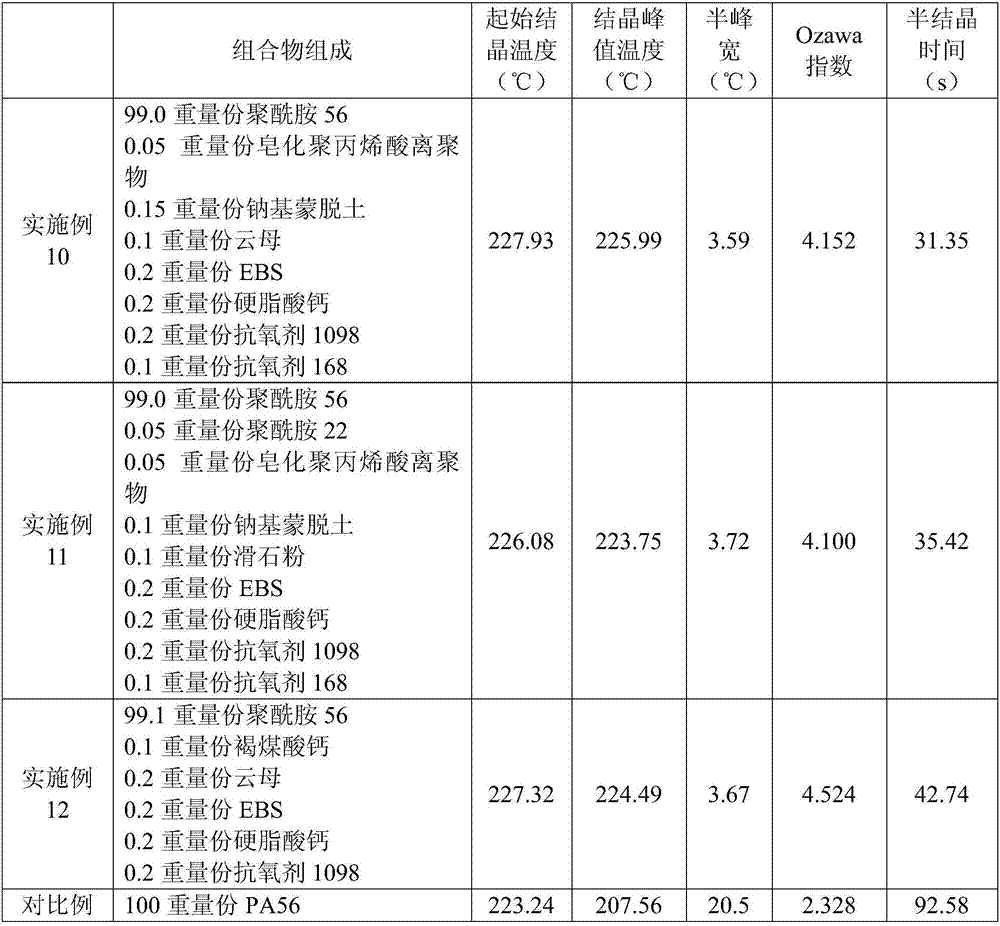

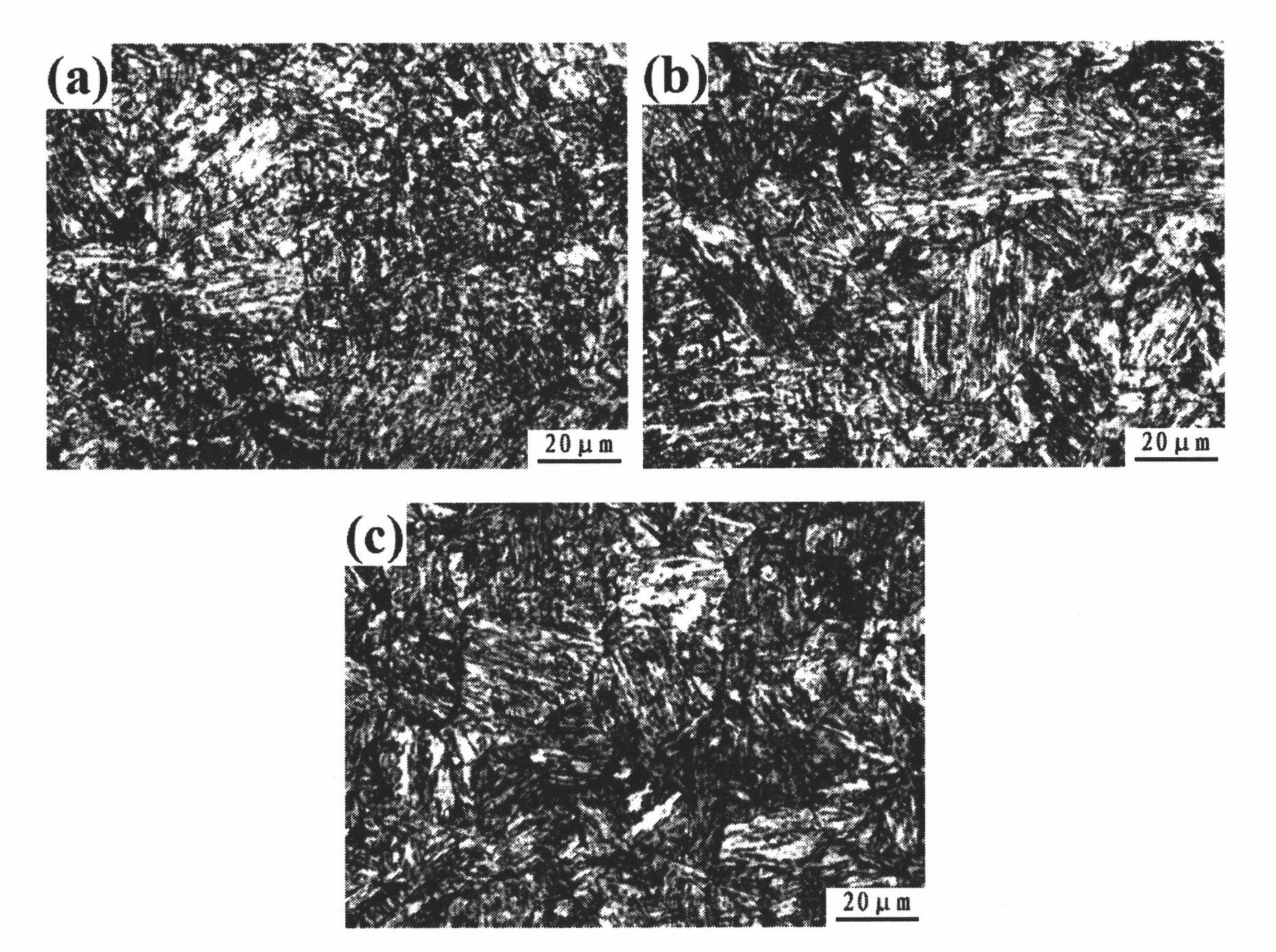

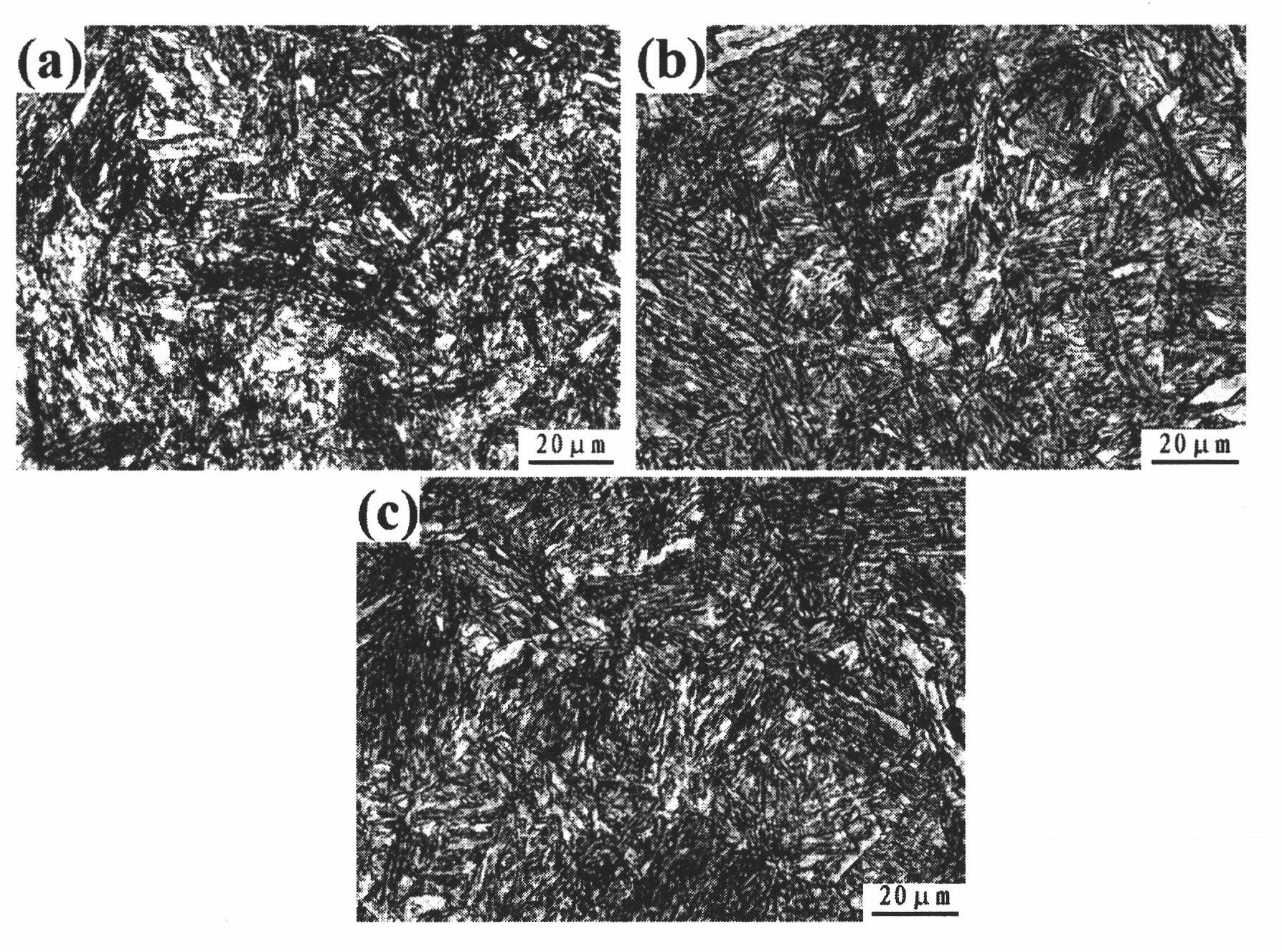

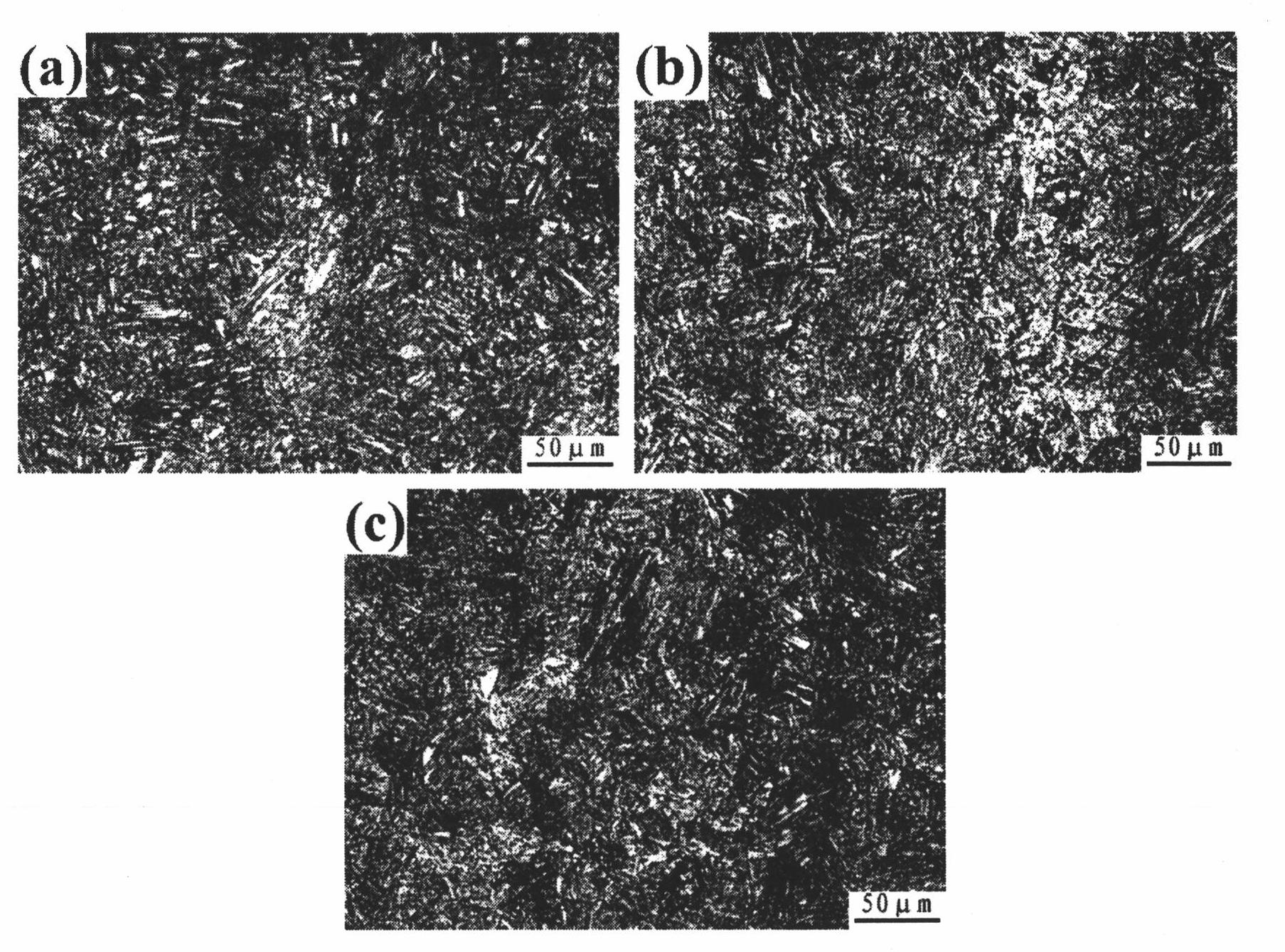

Polyamide composition for quick injection molding and preparation method thereof

InactiveCN106867250AImproved crystallization behaviorGood dimensional stabilityPolymer sciencePolyamide

The invention provides a polyamide composition for quick injection molding and a preparation method thereof. The polyamide composition comprises 95-100 weight parts of polyamide resin and below 0.5 weight part of a nucleating agent, preferably, 0.005-0.5 weight part, and optimally, 0.005-0.03 weight part, wherein the polyamide resin includes polyamide 5X resin. The preparation method for the polyamide composition for quick injection molding comprises the following steps: (1) uniformly mixing the components of the polyamide resin composition, thereby obtaining a mixture; and (2) extruding and granulating the mixture, thereby obtaining the polyamide composition. The crystallizing speed of the polyamide composition prepared according to the invention is obviously increased, so that the purposes of shortening the manufacturing and molding period and increasing the size stability of the quick injection molding product can be achieved.

Owner:CATHAY R&D CENT CO LTD +1

Process for producing thick plate of plastic die steel

The invention discloses a process for producing a thick plate of plastic die steel. The thick plate of the plastic die steel is obtained by the following steps of: pouring by using an open-close type water-cooled die casting machine, performing reasonable heating system, rolling and normalizing and annealing after rolling. Low temperature pouring and a pouring process of feeding on bottom pouring are performed, so molten steel is quickly solidified by forced cooling of circulating water; the molten steel is not born any shrinkage resistance so as to ensure that a wide surface of the die casting blank does not have any crack; the heating temperature of a steel ingot does not exceed 1,280 DEG C, so that alloy elements are fully dissolved; the rough rolling temperature is 1,100 to 1,200 DEG C, and a rough rolling stage is performed at the high temperature under high pressure; after a fine rolling stage is performed at the temperature of 950 DEG C, the finishing temperature is greater than or equal to 920 DEG C; the discharging temperature after rolling is 750 to 830 DEG C, and the steel plate is cooled in pile for 72 hours after rolling; the steel plate is normalized and annealed; and the solution temperature is about 870 DEG C, and the aging temperature is 500 to 550 DEG C, so that the thick age-hardened plastic die steel plate is obtained. After flaw detection, each performance index of the plastic die steel produced by the invention meets the requirement.

Owner:NANJING IRON & STEEL CO LTD

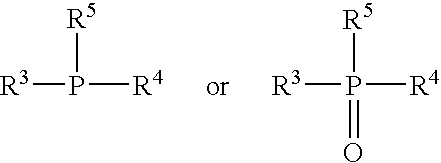

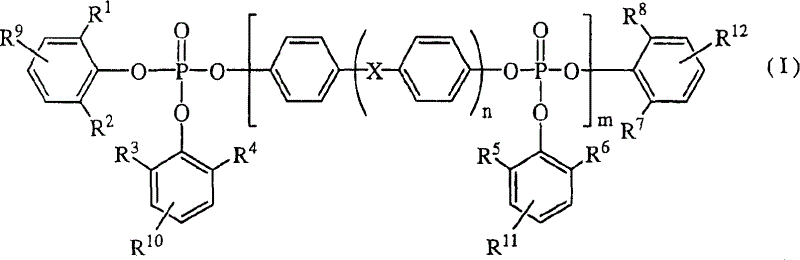

Polyarylene thioether resin composition

Provided is a polyarylene sulfide resin molded article having a good surface state which can be molded at a significantly high crystallization speed without impairing heat resistance, mechanical properties, chemical resistance, dimensional stability and flame retardancy of polyarylene sulfide resins. The resin composition comprises (A) 100 pts. wt. polyarylene sulfide resin, (B) 0.1-10 pts. wt. aromatic phosphate of a specific structure, and (C) 3-35 pts. wt. polyphenylene oxide resin.

Owner:POLYPLASTICS CO LTD

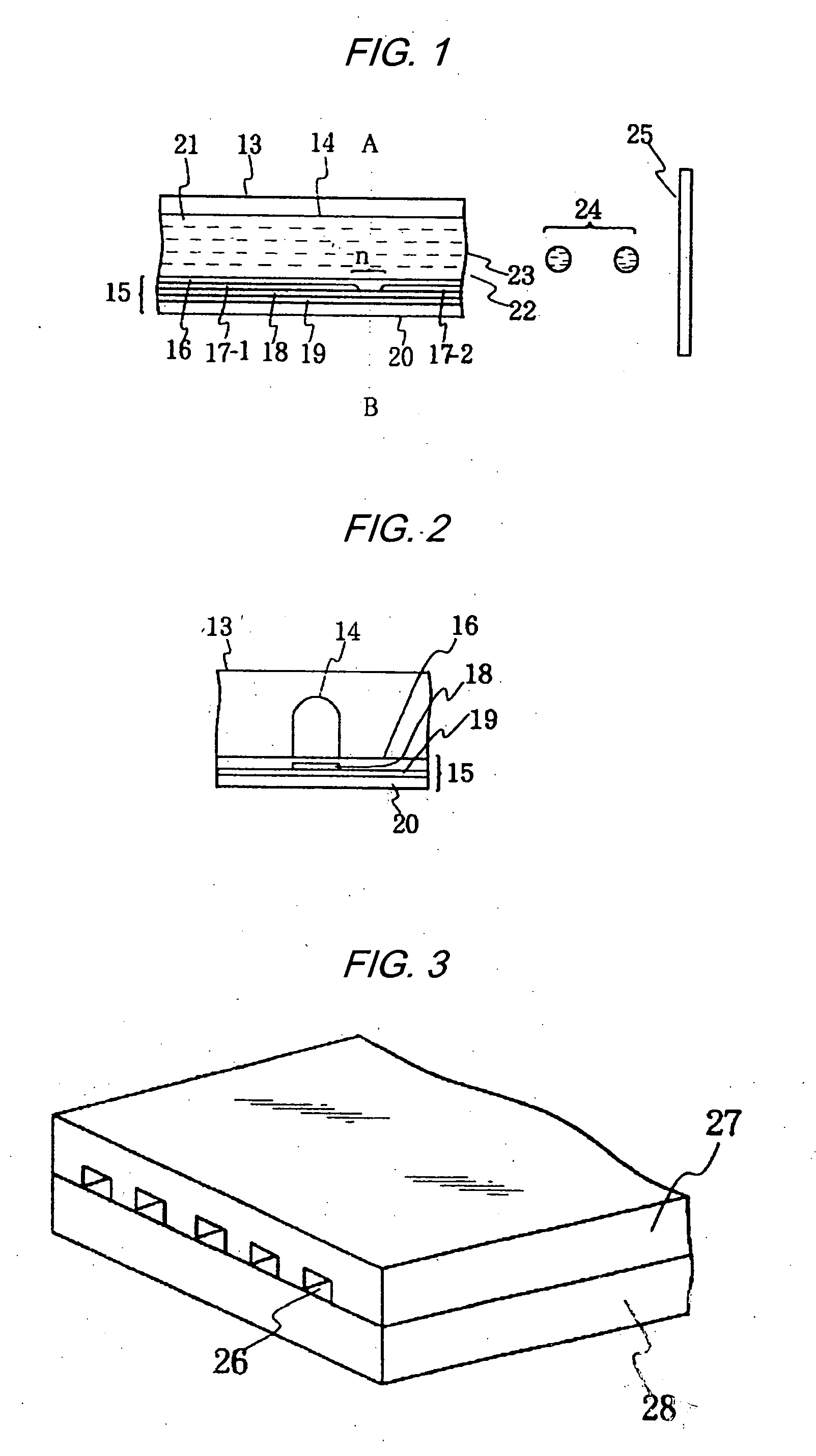

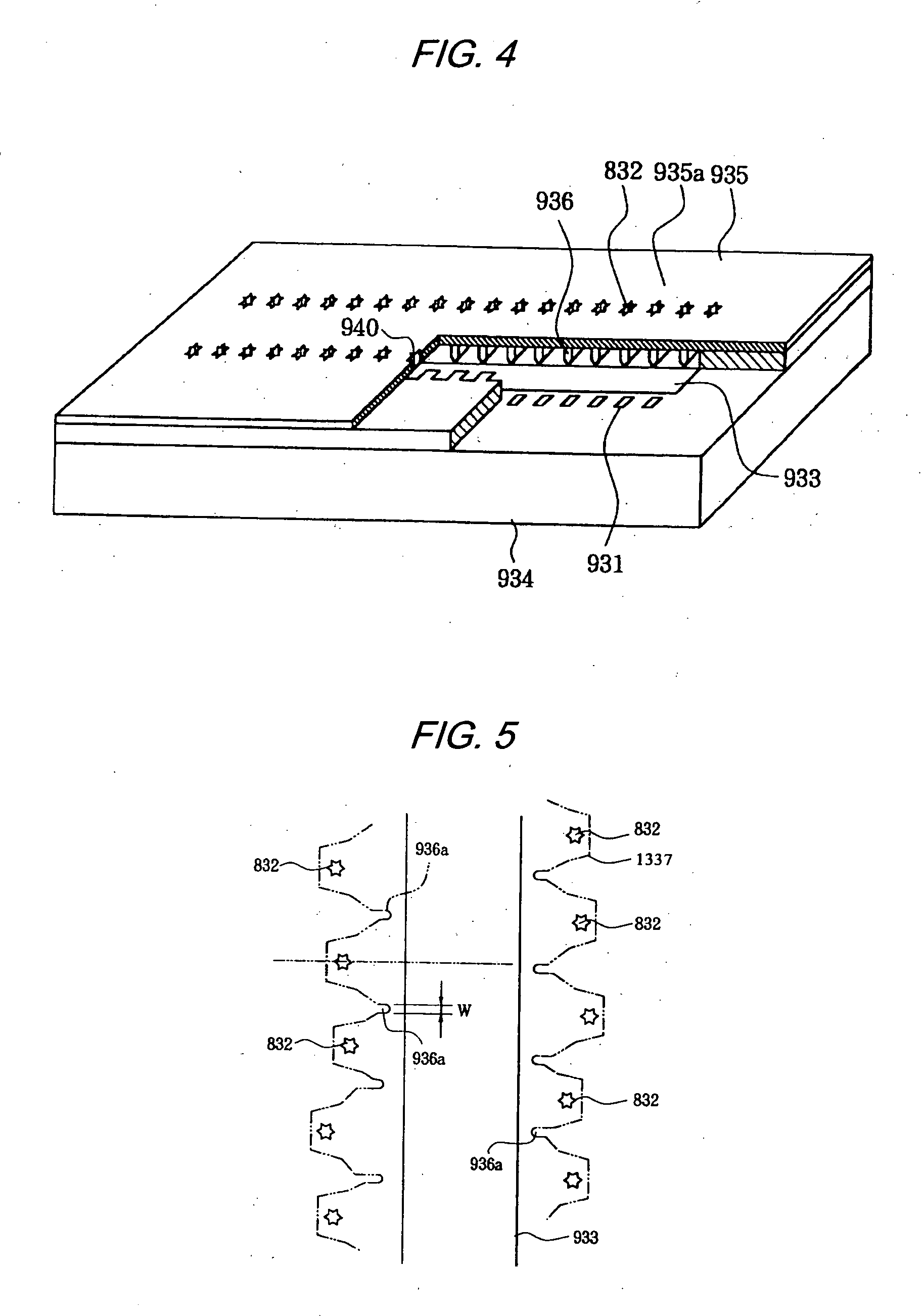

Toner and toner production method

A toner which includes a binder resin, a colorant and a hydrocarbon wax has a ratio W1 / W2 of the half width W1 (° C.) of a endothermic peak derived from melting of the hydrocarbon wax in a first temperature rise process on the toner to the half width W2 (° C.) of a endothermic peak derived from melting of the hydrocarbon wax in a second temperature rise process, as measured with a differential scanning calorimeter, with the ratio W1 / W2 being not less than 0.50 and not more than 0.90.

Owner:CANON KK

Foaming CPET sheet material and method for preparing same

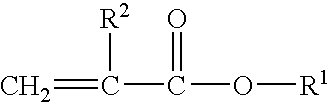

The invention belongs to high molecule material technology field, especially a foaming CPET sheet material and a method for preparing the same. The invention provides a forming CPET sheet material, which is produced by uniformly mixing 100 portions of PET, 0.1-40 portions of blowing promoter and 0.1-5 portions of foaming agent, extruding and forming. The blowing promoter is prepared by uniformly mixing 0.1-30 portions of ethylene-acrylic ester-glyceryl methacrylate tercopolymer or acrylic ester with core-shell structure, 0.1-10 portions of polyfunctional group substance with high activity, 0.3-10 portions of crystal nucleating agent and 10-100 portions of carrier resin. The inventive foamed CPET sheet material has the finished product density range of 0.60-0.95 g / cm[3] and high impact strength, is suitable for producing dual purpose food trays for freezing temperature preservation and microwave / oven heating, and the deep chamber containers in the medicine and electric product.

Owner:SICHUAN YIBIN WULIANGYE GROUP

Polyethylene having faster crystallization rate and improved environmental stress cracking resistance

InactiveUS9187627B2Fast crystallizationIncrease weightEthylene HomopolymersEnvironmental stress cracking

Disclosed is a polyethylene composition having faster crystallization rate and improved environmental stress cracking resistance. The polyethylene composition comprises a multimodal polyethylene and a nucleating agent. The multimodal polyethylene comprises from 25 to 50 wt % of a low molecular weight ethylene homopolymer component, from 25 to 50 wt % of a medium molecular weight ethylene copolymer component and from 25 to 50 wt % of a high molecular weight ethylene copolymer component. The polyethylene composition has an environmental stress cracking resistance (ASTM D1693, Condition B in 100% Igepal) greater than or equal to 40 days and a crystallization half time less than or equal to 70% of the crystallization half time of the multimodal polyethylene without nucleating agent.

Owner:EQUSR CHEM LP

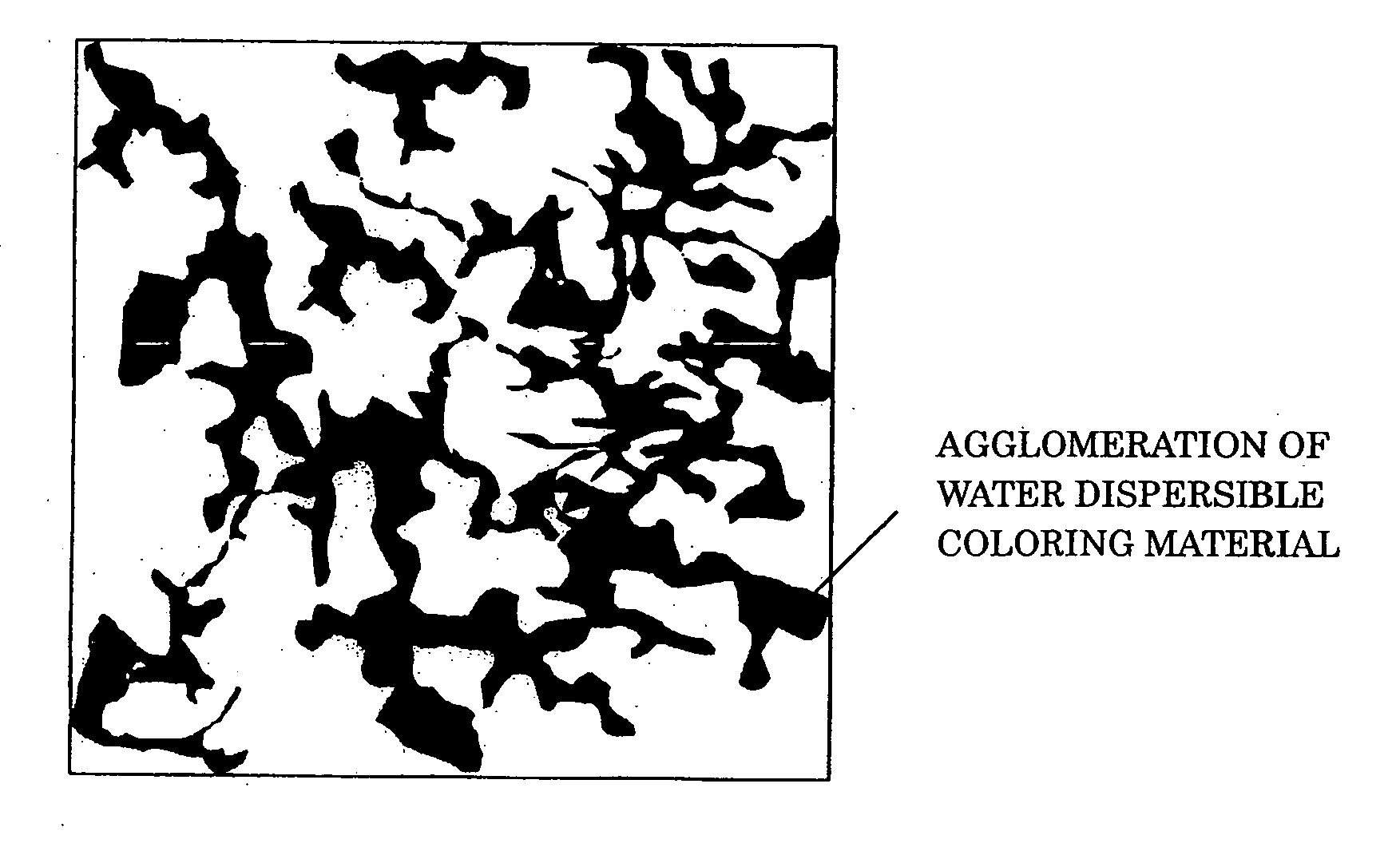

Aqueous ink, image recorded using said aqueous ink and method for forming said image

InactiveUS20060021545A1Good effectHigh image densityMeasurement apparatus componentsDuplicating/marking methodsWater dispersibleWater soluble

An aqueous ink containing at least a water-dispersible coloring material and a water-soluble crystalline component, characterized in that the water-dispersible coloring material forms an aggregate around a crystal of the crystalline component formed as the content of the aqueous ink decreases, which ink may further contain a water-soluble coloring material.

Owner:CANON KK

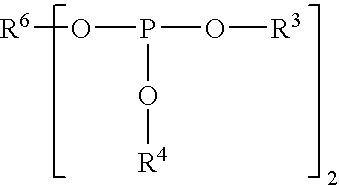

Preparation method of europium oxide (EUO) type molecular sieve

ActiveCN102040230AHigh reactivityImprove solubilityCrystalline aluminosilicate zeolitesMolecular sieveOrganic solvent

The invention provides a preparation method of a europium oxide (EUO) type molecular sieve. The preparation process comprises the steps: adding one or more of ethanol, propylene glycol, methyl alcohol and acetone with a proper amount to be taken as an organic solvent; filling a high-pressure inert gas into a high-pressure kettle, and carrying out sectional type crystallization under a certain condition; filtering and washing the product to be neutral; and drying, roasting to obtain the EUO molecular sieve. The organic solvent is added, so that a template agent precursor is promoted to be dissolved in an aqueous phase, and the generation of a template agent is accelerated; and therefore, the crystallization speed of the molecular sieve is accelerated, and the crystallization time of the molecular sieve is remarkably shortened.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyester / metal fibre conductive, heat conducting and fast crystallization composite material and preparation thereof

InactiveCN101469109AFast crystallizationImprove conductivityNon-conductive material with dispersed conductive materialHeat-exchange elementsMetal fiberHeat conducting

The invention provides a polyester / metal fiber composite material composition, which comprises the following components by weight portion: 100 portions of polyester, 0.5 to 100 portions of metal fiber subjected to surface treatment by a coupling agent, and 0 to 3.8 portions of optionally high-molecule acceptable processing aid. A polyester composite material integrating excellent electric conductivity, heat conductivity and quick crystallization property can be prepared by the polyester / metal fiber composite material composition.

Owner:HEFEI GENIUS NEW MATERIALS

High-temperature-resistant polylactic acid injection molded ceramic-like tableware and preparation method thereof

The invention relates to high-temperature-resistant polylactic acid injection molded ceramic-like tableware and a preparation method thereof, and belongs to the field of high polymer materials. Raw materials comprise 70-90 parts of polylactic acid, 5-15 parts of a toughening agent, 0.05-0.20 part of a chain extender, 0.5-1 part of an organic nucleating agent, 5-20 parts of an inorganic nucleatingagent, 0.05-1.0 part of an antioxidant and 0.5-2 parts of an anti-hydrolysis agent. The high-temperature-resistant polylactic acid injection molded ceramic-like tableware and the method have the advantages that the process is simple and clear, high in processing efficiency and easy to operate; the toughening agent and the nucleating agent are used for synergistically modifying the polylactic acidso that the toughness of the polylactic acid is improved, the heat resistance of the polylactic acid material is achieved, and the toughness and heat resistance of the polylactic acid can be greatly improved. The organic nucleating agent and the inorganic nucleating agent are adopted, so that when the polymer is subjected to melt crystallization, the crystallization speed of the polymer is increased, the spherocrystal size is changed, the thermal deformation temperature of the polymer is remarkably increased, the application of the product is met, in-mold crystallization is used in the injection molding process of the product, the surface gloss of the product is improved, crystallization perfection can be further promoted by using the crystallization nucleating agent, and the product has higher strength and surface gloss.

Owner:JILIN COFCO BIOCHEM +1

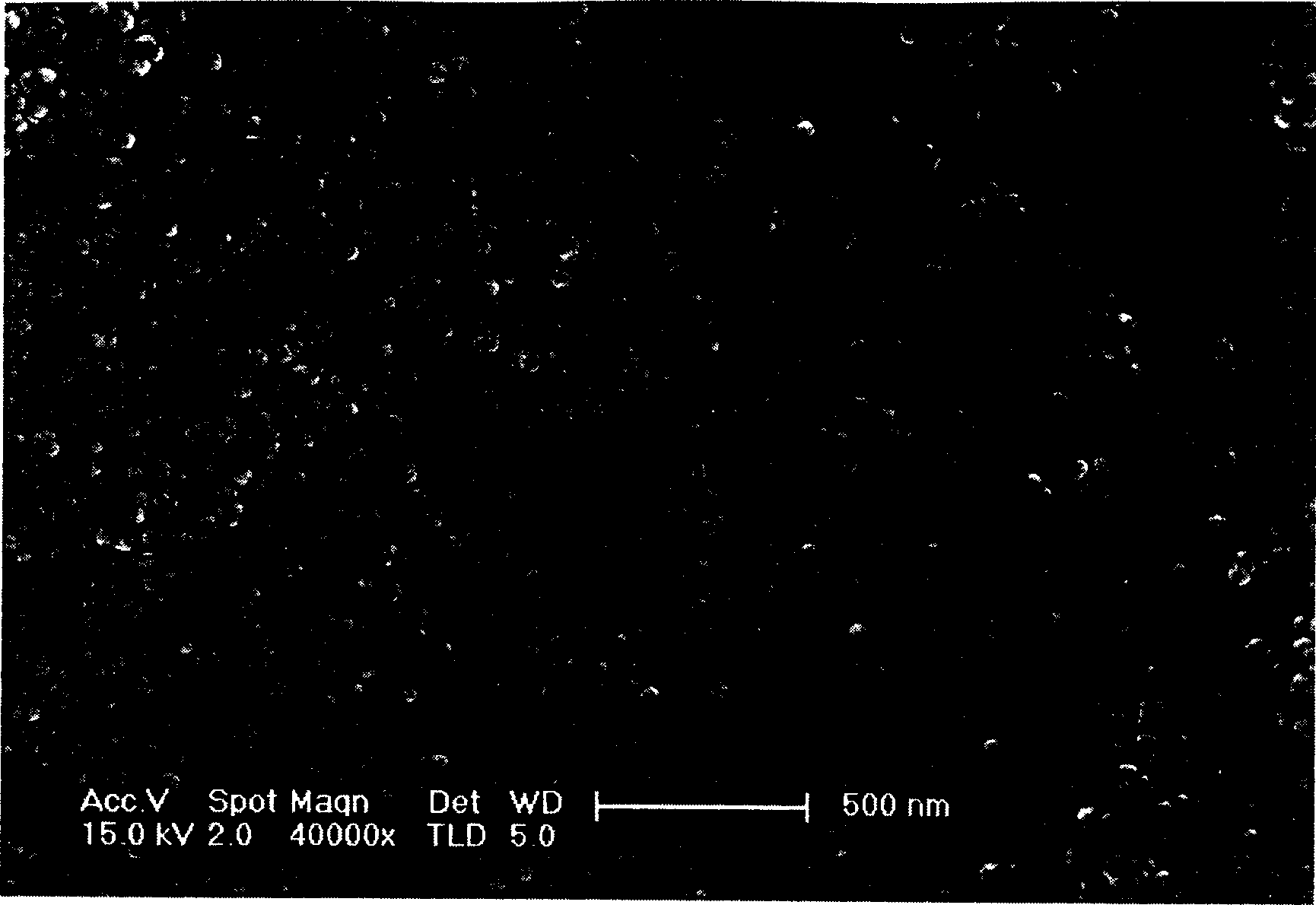

Intumescent flame retardant polybutylene succinate and preparation method thereof

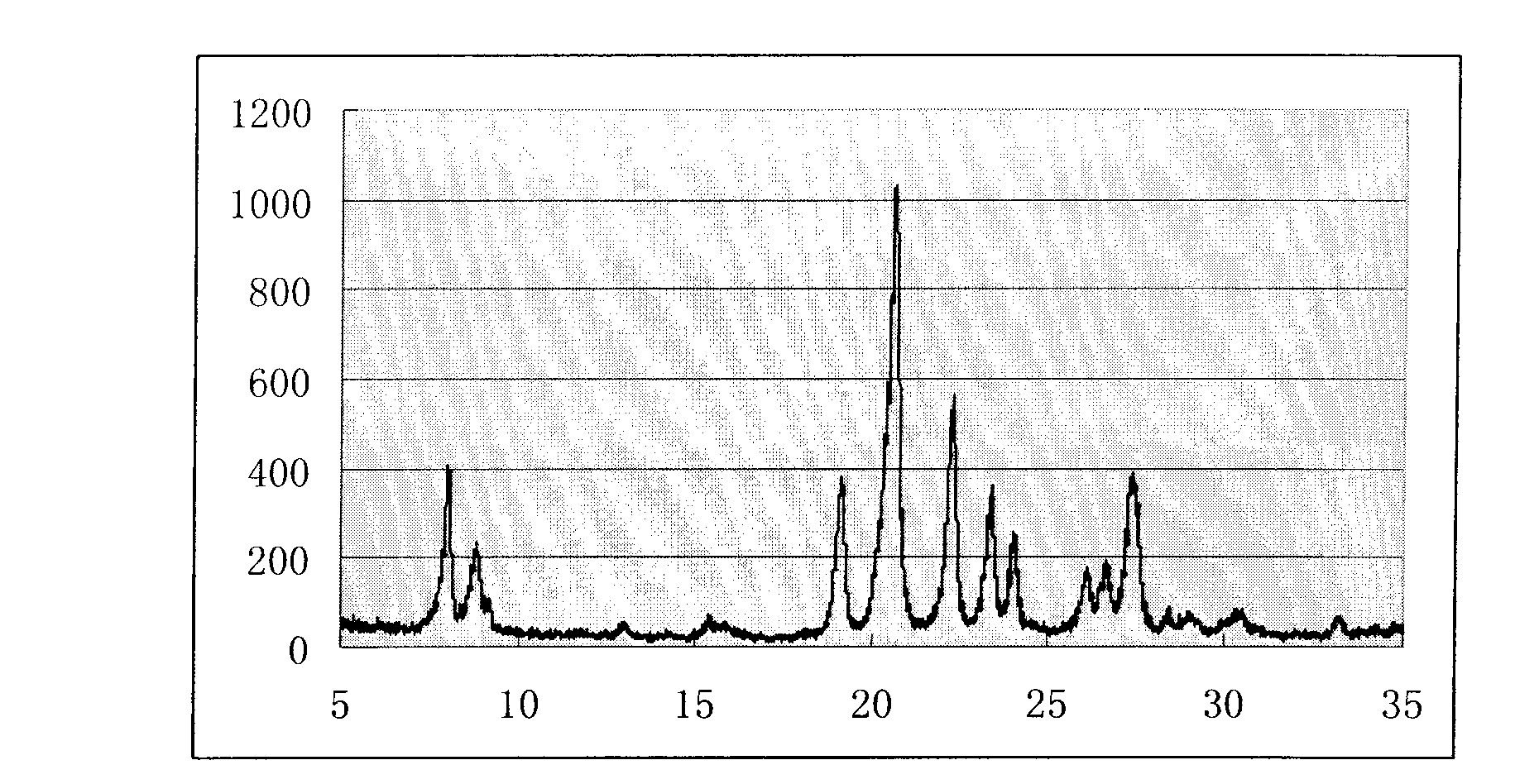

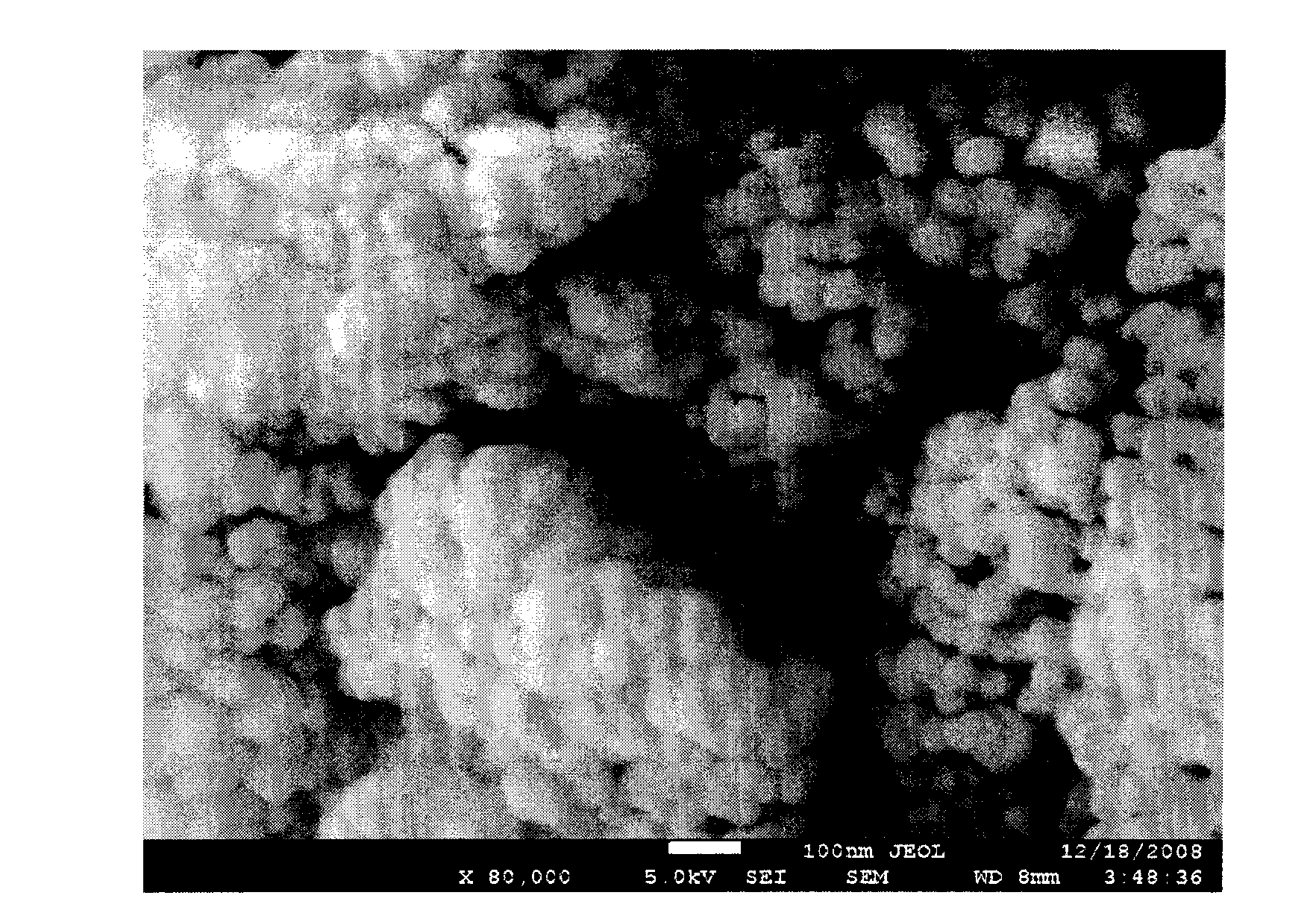

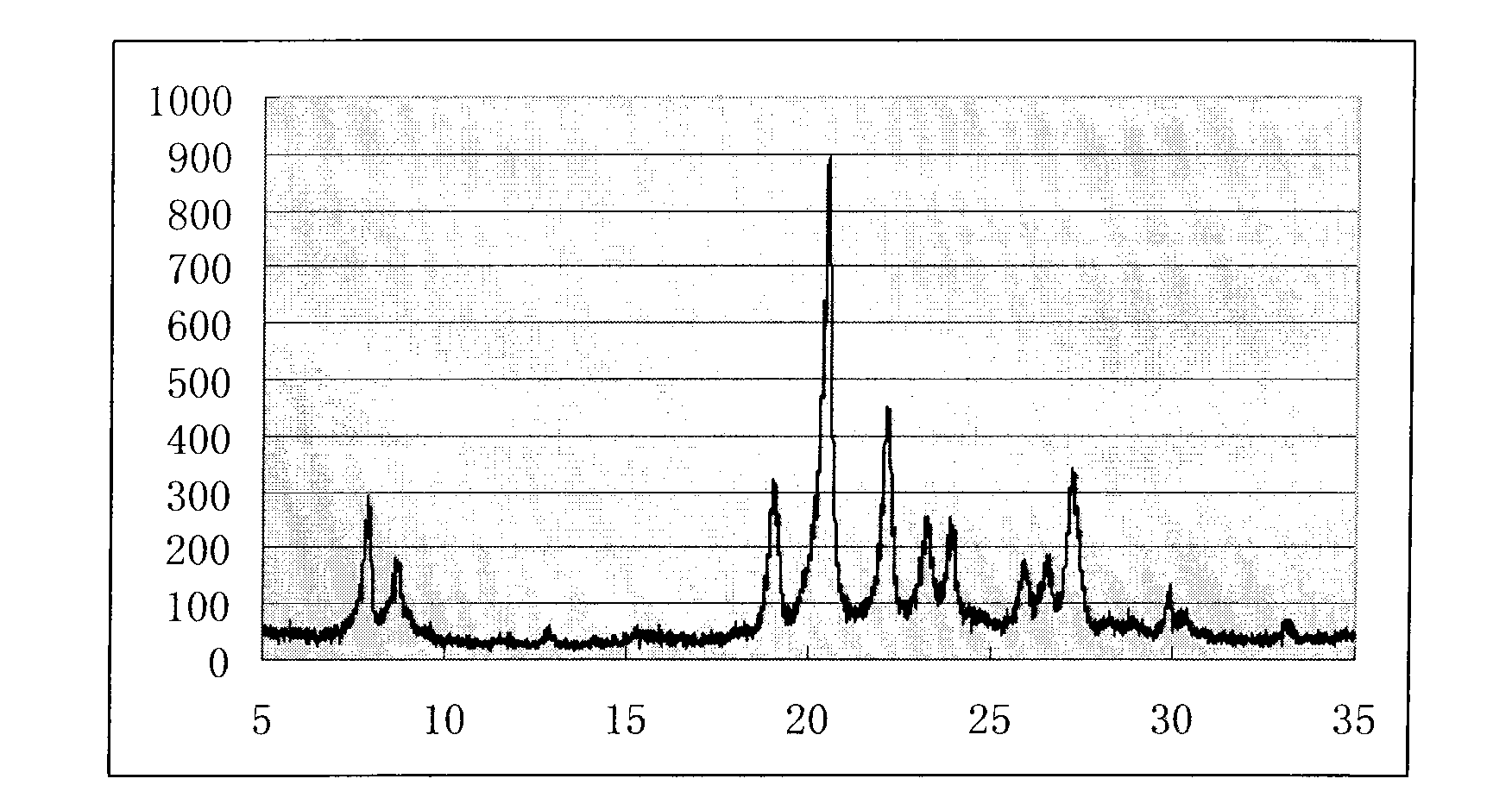

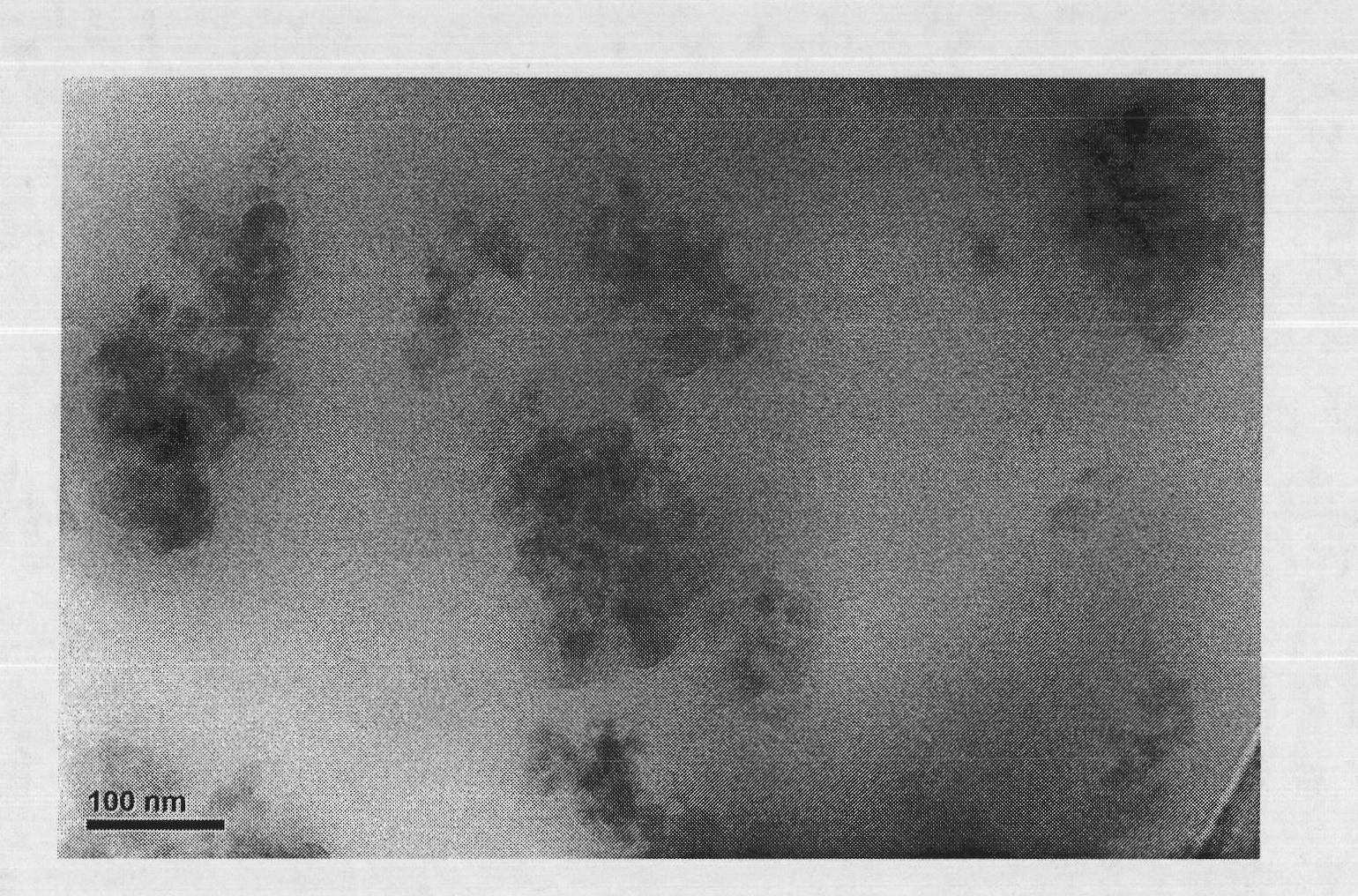

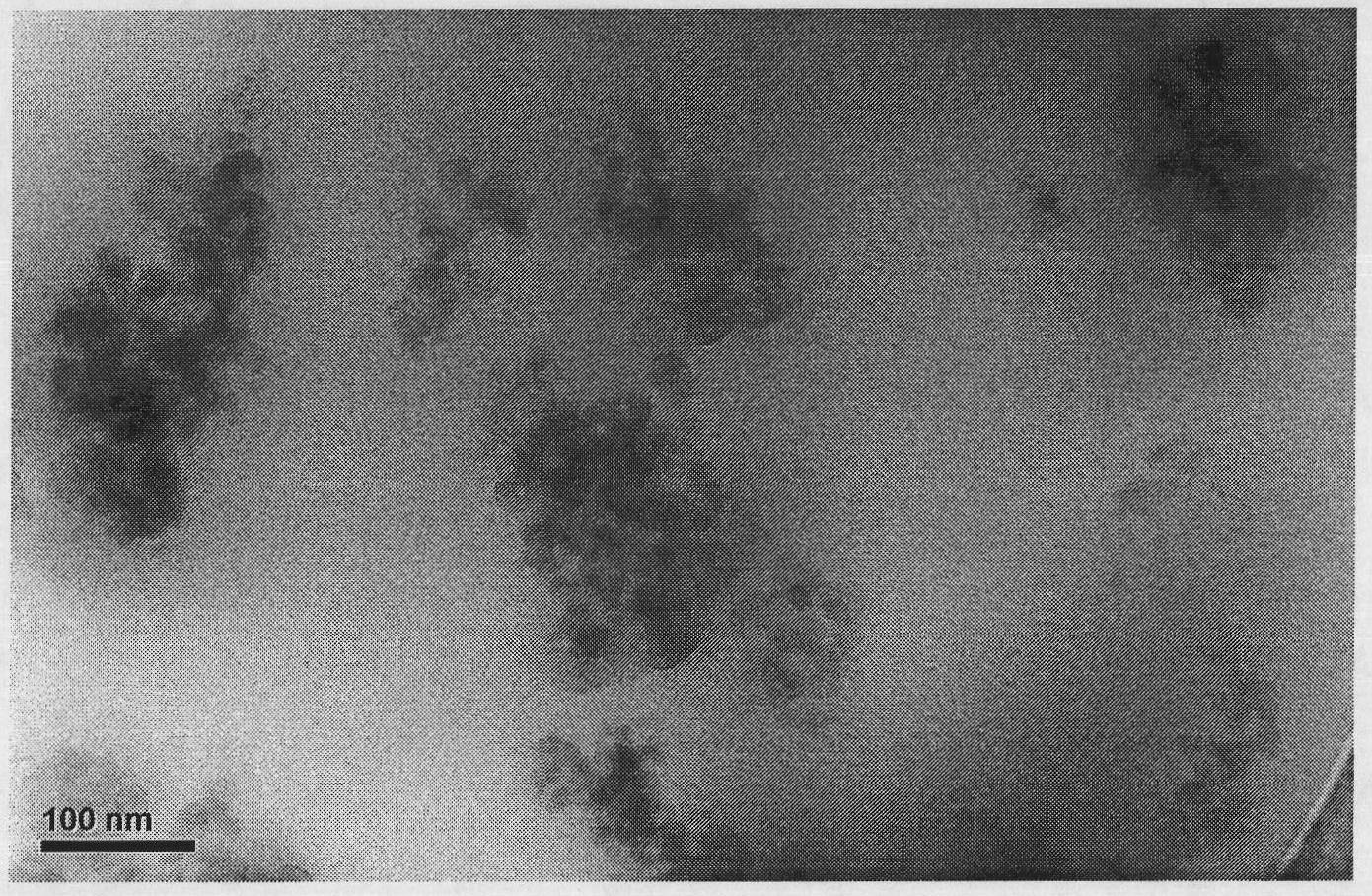

ActiveCN101781445AFast crystallizationImprove the perfection of crystal formChemistryTransmission electron microscopy

The invention discloses intumescent flame retardant polybutylene succinate and a preparation method thereof, which are characterized in that 80 to 85 percent of polybutylene succinate and 15 to 20 percent of intumescent flame retardant agent as well as 0 to 3 percent of synergist are added to an internal mixer to be cut, melt down and blended to obtain the product. Pictures of a high-resolution transmission electron microscope show that nano-grade dispersion is formed in the Polybutylene succinate basal body; the oxygen index reaches 40 and passes through the vertical burning test standard UL-94V0 grade; the initial thermal decomposition temperature is 321 DEG C, the maximum thermal decomposition temperature is 353 DEG C, and the residual quality score is 11.6 percent at the temperature of 700 DEG C; the pictures of the carbon layer shows that a compact intumescent carbon layer is formed, and a plurality of complete bubbles are formed. The intumescent flame retardant polybutylene succinate can be used for the foaming materials and the packing materials of the toy, household appliance, daily chemicals, food and medicines.

Owner:UNIV OF SCI & TECH OF CHINA

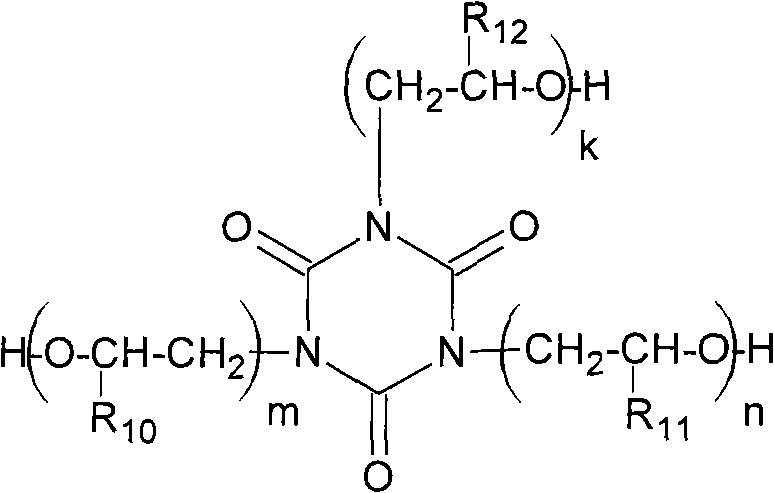

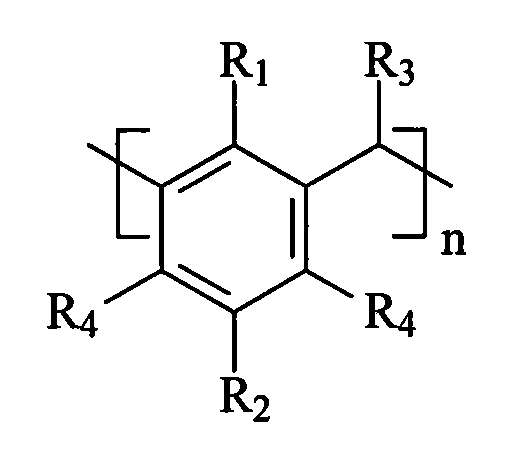

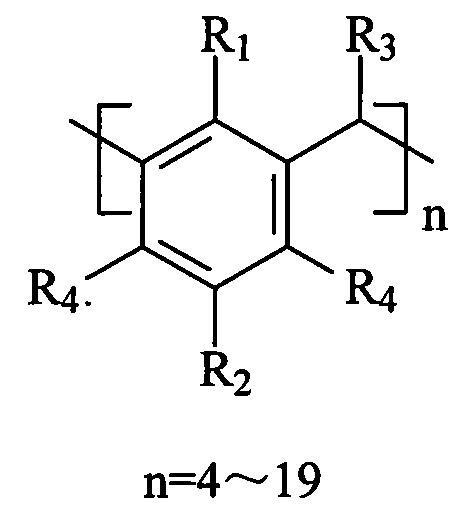

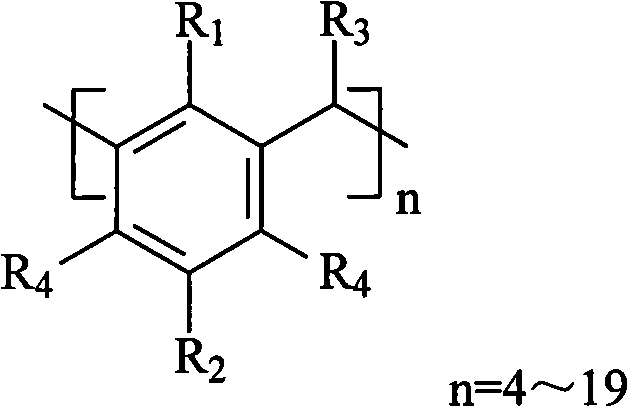

Self-assembled calixarene nucleating agent and application thereof in polylactic resin composition

InactiveCN102020784AIncrease the nucleation rateThere is no problem of degradationAlkaneStructural formula

The invention relates to a self-assembled calixarene nucleating agent and an application thereof in a polylactic resin composition. The self-assembled calixarene nucleating agent is a supermolecular nucleating agent self-assembled by the below A and B, wherein A is calixarene and derivatives thereof expressed by structural formula A while B consists of one or more organic micromolecular compounds as follows: C1-C30 alkane, C1-C30 halogenated alkane, C1-C30 alcohol, C1-C30 nitrile, a 5-6 membered heterocyclic compound, substituted 5-6 membered heterocyclic compound (substituent can be hydroxyl, aldehyde group and alkyl), benzene, naphthalene, substituted benzene and substituted naphthalene. The invention has the advantages of simple production process, relative low cost and great nucleating speed, thereby overcoming the low crystallization rate of polylactic resin and reducing the processing and forming period.

Owner:EAST CHINA UNIV OF SCI & TECH

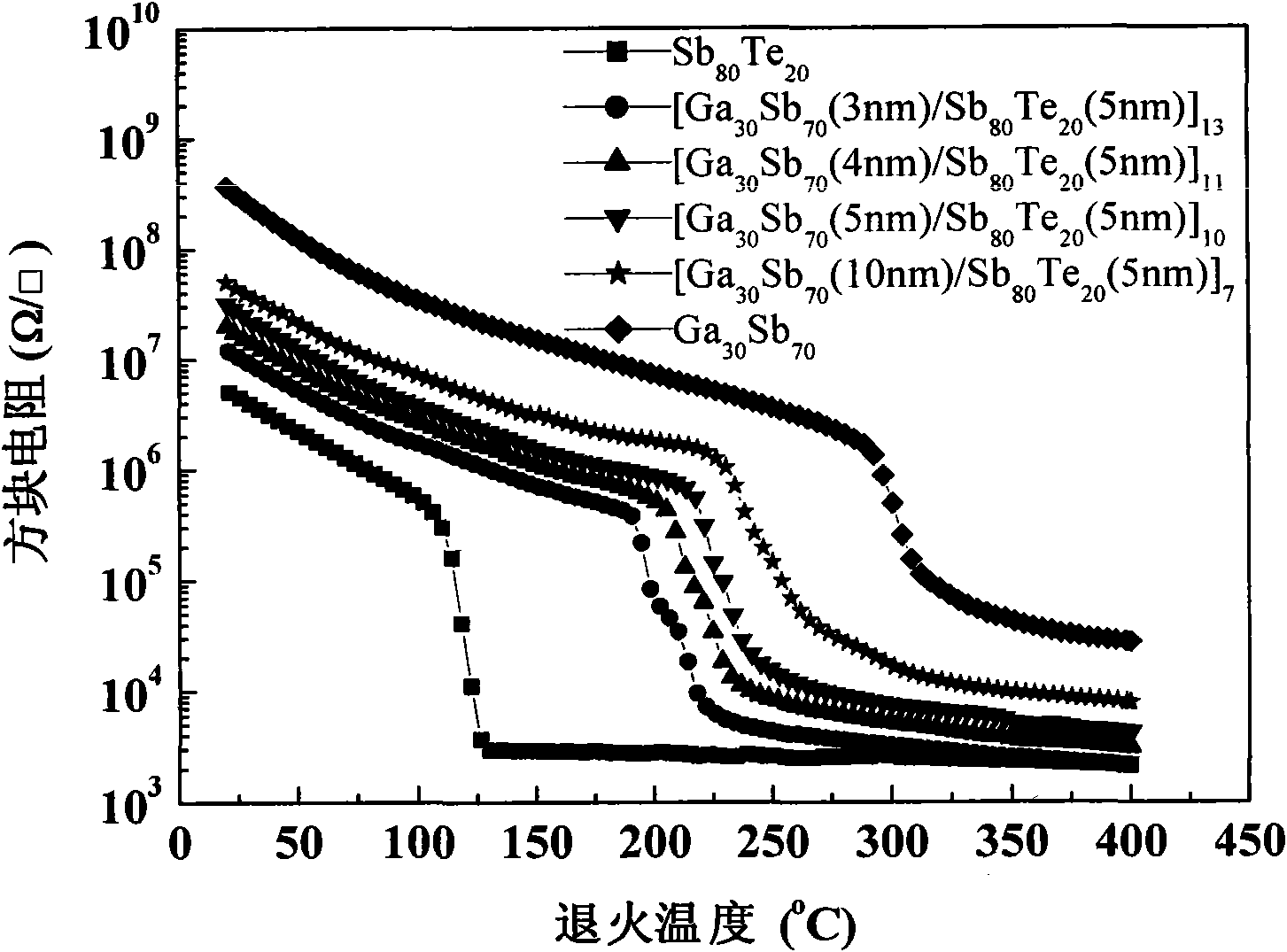

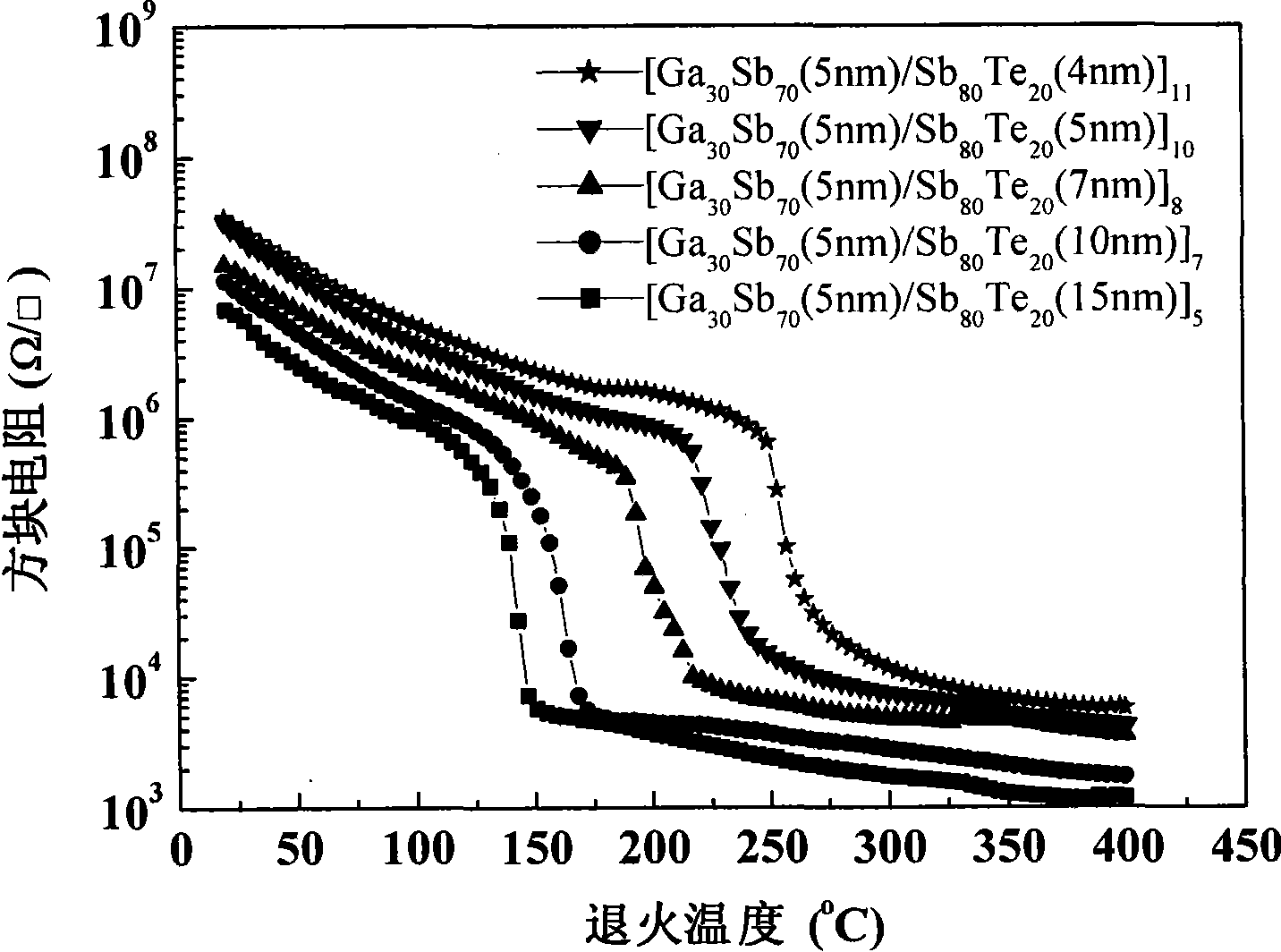

Crystallization temperature-adjustable Ga30Sb70/Sb80Te20 nano composite multi-layer phase-change thin-film material

InactiveCN101807665AIncreasing the thicknessLow power consumption for programmingElectrical apparatusPhase-change memoryCrystallization temperature

The invention belongs to the technical field of microelectronics, in particular to a crystallization temperature-adjustable Ga30Sb70 / Sb80Te20 nano composite multi-layer phase-change thin-film material. The Ga30Sb70 / Sb80Te20 nano composite multi-layer phase-change thin-film material is formed by the alternating arrangement and the nanometer-level compounding of Ga30Sb70 thin films and Sb80Te20 thin films, wherein the thickness range of a monolayer Ga30Sb70 thin film is 3-10nm, and the thickness range of a monolayer Sb80Te20 thin film is 4-15nm. The Ga30Sb70 / Sb80Te20 nano composite multi-layer phase-change thin-film material can be used for a phase change memory; and compared with the conventional phase-change thin-film material, the Ga30Sb70 / Sb80Te20 nano composite multi-layer phase-change thin-film material has adjustable crystallization temperature, and has favorable thermal stability and higher crystallization rate at the same time; and meanwhile, the crystalline resistance of the thin-film material increases with the increasing of the thickness of the Ga30Sb70 thin film in the cycle, thereby being beneficial to the reduction of the programming power consumption of the memory device.

Owner:TONGJI UNIV

High-heat-resisting glass-fiber reinforced polyester composite material and preparing method

The present invention discloses a kind of high-heat-resistant, glass-fiber-enhanced, polyester composite and its preparation method. The components (weight percentage) are: polyester 45-95%; nucleating agent-sodium stearic acid 0.3-5%; brominated flame retardant 5-30%; flame retardant synergist 4-10%; toughening agent 1-6%; antioxidant 0.1-1%; lubricant 0.1-5%; glass fiber 5-50%. The present invention uses organic-nucleating-agent sodium stearic acid, acrylic core-shell copolymer toughening agent and epoxy-group-containing material as chain extender, thus, increases the crystallization rate of PET, makes the prepared composite forming at a lower temperature, that is 70-100 degree C. Therefore, no oil heating machine needs to be added, which reduces the energy consumption, and meanwhile ensures the material's high heat resistance, high strength and high impact resistance; the material is low in cost, simple in preparation process, and easy to control its production process.

Owner:SHENZHEN KEJU NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com