Low water absorption polyamide composite and preparation method thereof

A technology of polyamide composition and low water absorption, which is applied in the field of composition and its preparation, can solve problems such as mechanical property research, product surface roughness, material toughness decline, etc., and achieve accelerated crystallization speed, low water absorption, and increased crystallinity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

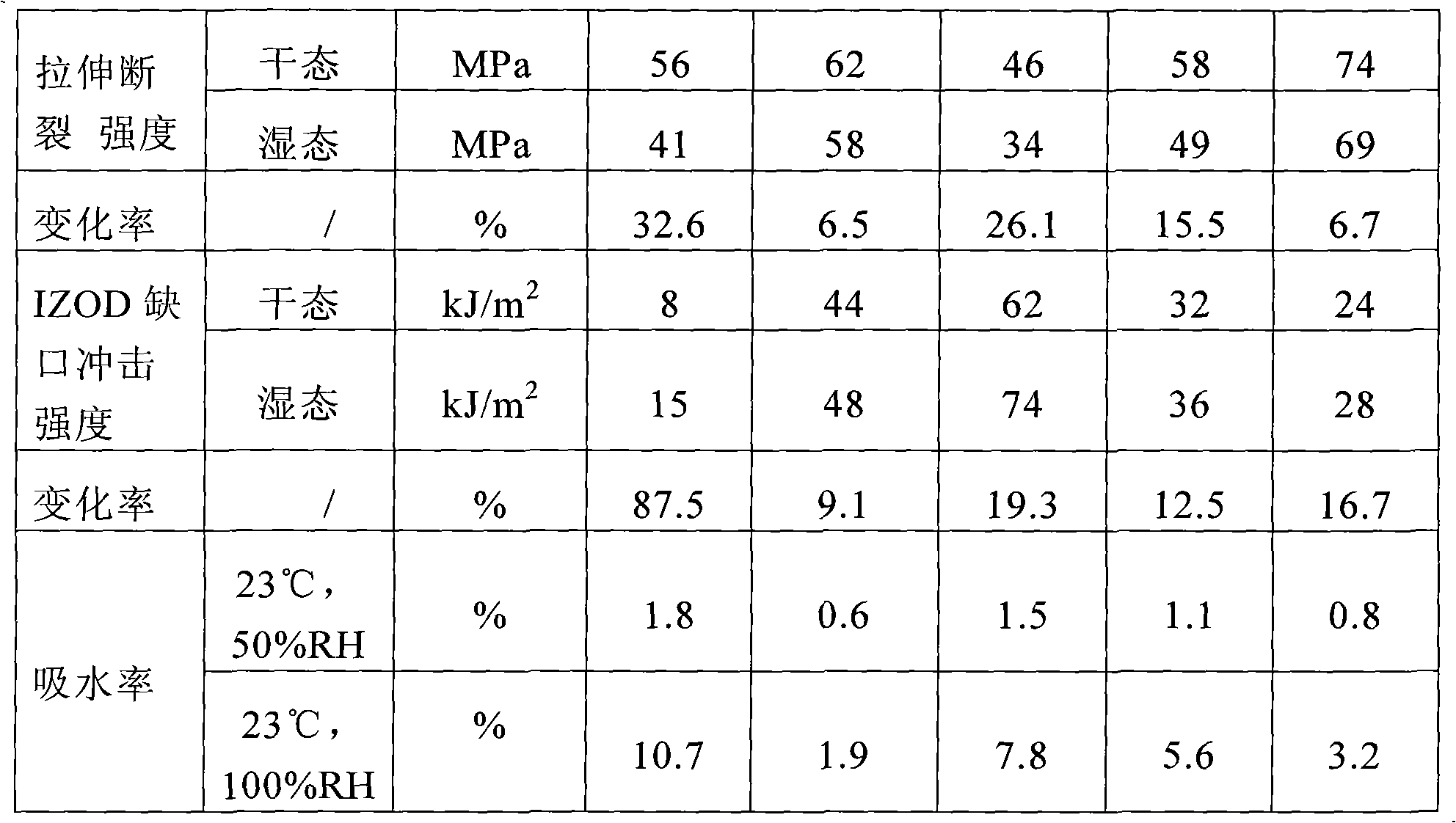

Embodiment 1

[0042] Select polyamide based on nylon 6 (PA6) from Ube, Japan, with a melting point of 225-230°C, an intrinsic viscosity of 2.52g / dL, and a water absorption rate of 1.8 (23°C, 50%RH) and 10.7 (23°C, 100%RH) , molding shrinkage rate 1.8%; styrene-butadiene-acrylonitrile (ABS), commercially available Korea Kumho ABS750, melt index 42g / 10min, glue content 15%; high rubber powder, glue content 60%, melt index 18g / 10min; commercially available compatibilizer SMA, the content of maleic anhydride (MAH) is 18%; layered silicate clay-nanometer montmorillonite, modified by 16-aminohexadecanoic acid ammonium salt, particle size is 2500 mesh, the antioxidant adopts commercially available antioxidant Irganox168 and antioxidant Irganox1010, refined by Ciba Company, and the lubricant adopts diethylene stearamide (EBS).

[0043] A low water absorption polyamide composition was prepared using a two-step process:

[0044] (1) 90kg of PA6 polyamide, 8kg of 16-aminohexadecanoic acid ammonium s...

Embodiment 2

[0060] A preparation method of polyamide composition with low water absorption rate, the method comprises the following steps:

[0061] (1) 40kg of PA46, the melting point is 225-230°C, the intrinsic viscosity is 1.5g / dL, the water absorption rate is 1.8 (23°C, 50%RH) and 10.7 (23°C, 100%RH), and the mold shrinkage rate is 1.8%. , 3kg of 16-aminohexadecanoic acid ammonium salt intercalated modified talcum powder, the particle size is 1000 mesh, 0.5kg of antioxidant Irganox168, 0.5kg of silicone oil is added as an additive in a high-speed mixer and premixed for 20min, the temperature Control the temperature at 40°C, then blend and granulate the above materials through a twin-screw extruder, control the temperature at 200°C, and control the speed of the extruder at 300rpm, and cool and granulate through conveying, melting, shearing extrusion to obtain PA / Talc masterbatch;

[0062] (2) PA / talcum powder 60kg (comprising 40kg of PA66 and 3kg of talcum powder), 60kg of acrylonitri...

Embodiment 3

[0064] A preparation method of polyamide composition with low water absorption rate, the method comprises the following steps:

[0065] (1) 90kg of PA6, with a melting point of 225-230°C, an intrinsic viscosity of 1.5g / dL, 10kg of nano-montmorillonite of 18-aminohexadecanoic acid ammonium salt, a particle size of 1500 mesh, and 0.5kg of anti- Oxygen agent Irganox 1010 and 0.5 kg of barium stearate were added as additives into a high-speed mixer for premixing for 20 minutes, and the temperature was controlled at 60°C. The rotation speed of the machine is controlled at 300rpm, and the PA / montmorillonite masterbatch is obtained by conveying, melting, shearing, extrusion, cooling and granulation;

[0066] (2) PA / nanometer montmorillonite 100kg (comprising 90kg of PA6 and 10kg of nano-montmorillonite), 10kg of acrylonitrile-styrene-butadiene copolymer obtained through the above steps, the melt index is 60g / 10min, 10kg of compatibilizer, glycidyl methacrylate graft rate of 6% and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com