Polymeric aluminium-silica fireproof heat insulation material and preparation method thereof

A technology of heat insulating material and polymerized silicon aluminum, applied in the field of polymer silicon aluminum refractory heat insulating material and its preparation, can solve the problems of thermal conductivity, limited use temperature, lack of high temperature heat resistant heat insulating material, poor water resistance, etc. Outstanding visual strength, convenient industrial application, and the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

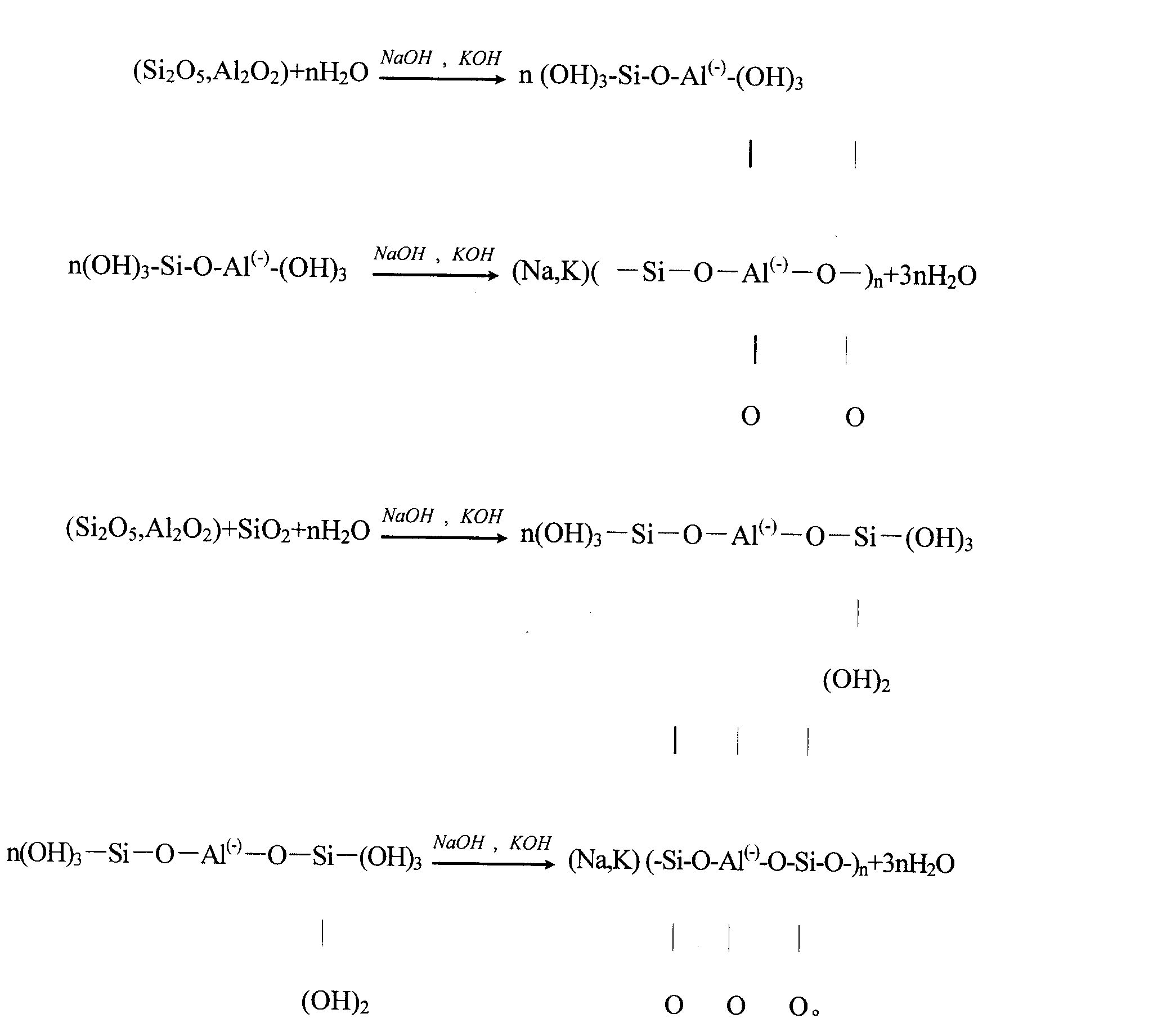

Problems solved by technology

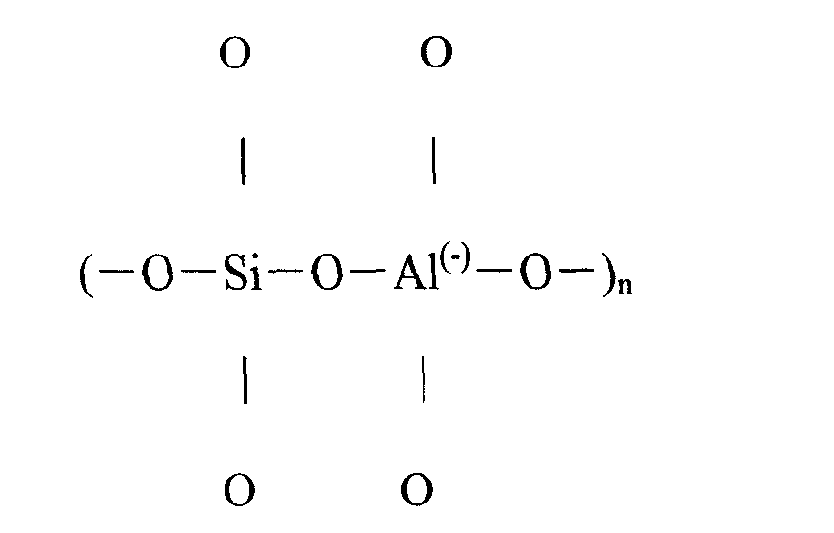

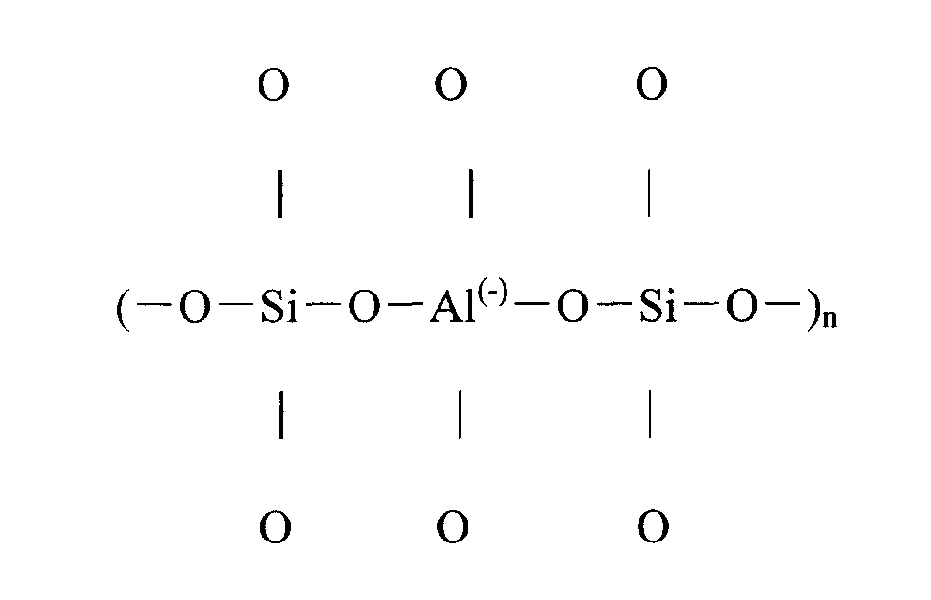

Method used

Image

Examples

preparation example Construction

[0049] A kind of preparation method of polysilicon-aluminum refractory insulation material, its preparation process is to enrich A 2 o 3 , SiO 2 Industrial waste and its composites, where A 2 o 3 The weight content is 20-50%, SiO 2 The weight content is 30-70%; add alkaline activators such as sodium hydroxide, potassium hydroxide, sodium carbonate, potassium carbonate, sodium silicate, sodium fluorosilicate, calcium hydroxide, etc., and polymerize at a temperature of 60-120°C During the preparation process, floating beads or polyphenylene particles are added to form a composite structure. Its preparation process steps include:

[0050] (1) will be rich in A 2 o 3 , SiO 2 Add alkaline activator to the industrial waste and its compound, mix and stir evenly;

[0051] (2) Gas generation: Add appropriate amount of water and 0.1% to 4% gas generating agent at 25-40°C to form a low-viscosity slurry. The apparent form is Newtonian fluid. Stand still to ionize the water to gen...

Embodiment 1

[0055] 1. Raw materials: the amount of fly ash is 67.5%, the amount of slag is 25.0%, and the amount of kaolin is 7.5%;

[0056] 2. Additional alkaline activator: sodium hydroxide, sodium silicate (liquid): 7.4% and 28.9%;

[0057] 3. Dosage of gas generating agent: 0.2%

[0058] 4. Curing molding temperature: 80°C

[0059] 5. The performance index of the material obtained from the inspection is:

[0060] 1) Bulk density (kg / m 3 )510

[0061] 2) Compressive strength (MPa) 0.96

[0062] 3) Heat resistance (no deformation) (℃) ≥ 800

[0063] 4) Thermal conductivity (kcal / m·h·degree) 0.087.

Embodiment 2

[0065] 1. Raw materials: kaolin 33.9%, fly ash 52.9%, slag 13.2%;

[0066] 2. Alkaline activator: 2.6% sodium hydroxide, 2.6% potassium hydroxide, 21.2% sodium silicate, 0.5% sodium fluorosilicate (additional);

[0067] 3. Gas generating agent: 3%

[0068] 4. Curing molding temperature: 60°C

[0069] 5. Performance indicators:

[0070] 1) Bulk density (kg / m 3 )480

[0071] 2) Compressive strength (MPa) 0.86

[0072] 3) Heat resistance (no deformation) (℃) ≥ 800

[0073] 4) Thermal conductivity (kcal / m·hour·degree) 0.077

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com