Patents

Literature

3124results about How to "Ease of industrial application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

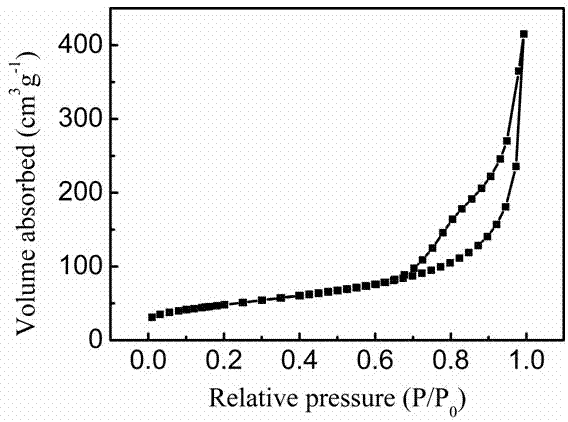

Cracking catalyst

This invention published a fluidization cracking catalyst. The main components of the catalyst are 5~70% (w / w) cracked active component, 5~80%clay and 10~60%agglomerant. Y-type of molecular sieve and 3~20% sialic material which based on catalyst and had been acidized within the cracked active component is the characteristic of the catalyst. The sialic material has a phase structure as thin diaspore. Its formula (calculated by weight of oxidants) is (0-0.3) Na2O . (40-90) Al2O3 . (10-60) SiO2. It has specific area 200~400m2 / g, average aperture 8~20nm, most probable aperture 5~15nm.The acidification treatment mentioned was inorganic acid and sialic material (ratio of the tow: 0.1~0.3) kept contacting for 0.5~3h under room-temperature ~80DEG C.This catalyst has well intensity, high stability of activity, low yield of heavy oil and strong capability of conversion for crude oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for estimating charge state of power cell

InactiveCN101212071AThe estimation error is smallSimplify the modeling processElectrical testingSecondary cells charging/dischargingWork statusEngineering

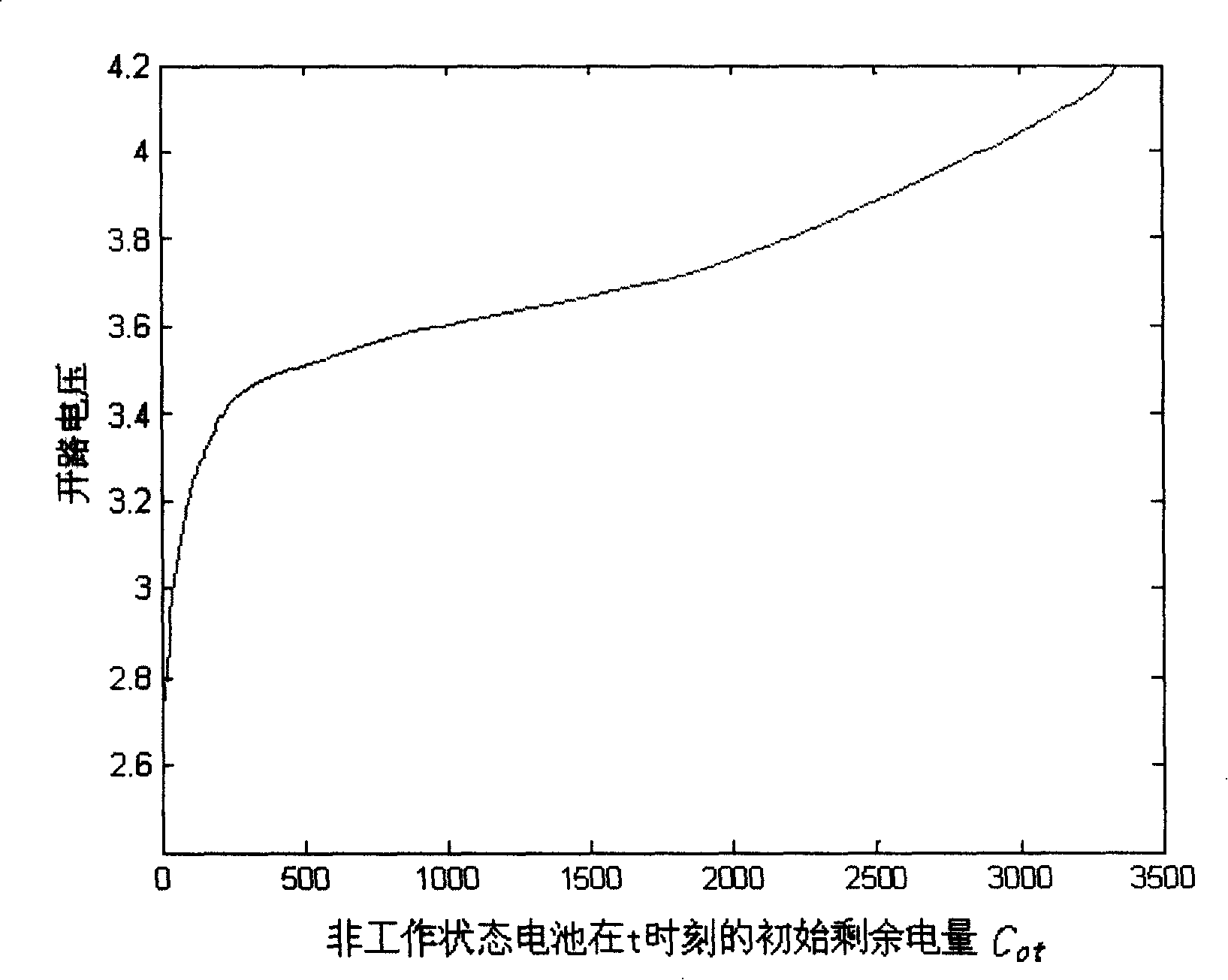

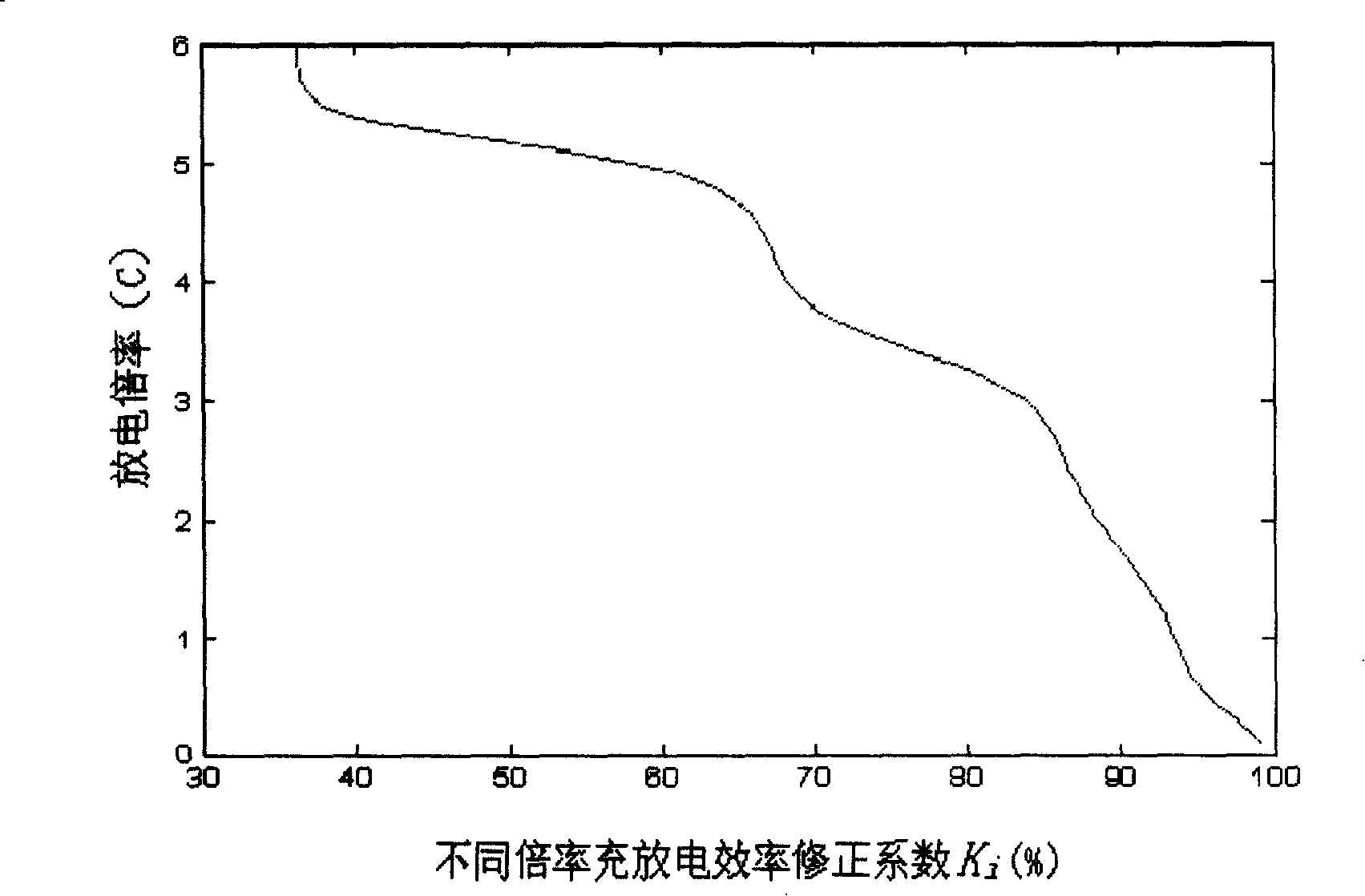

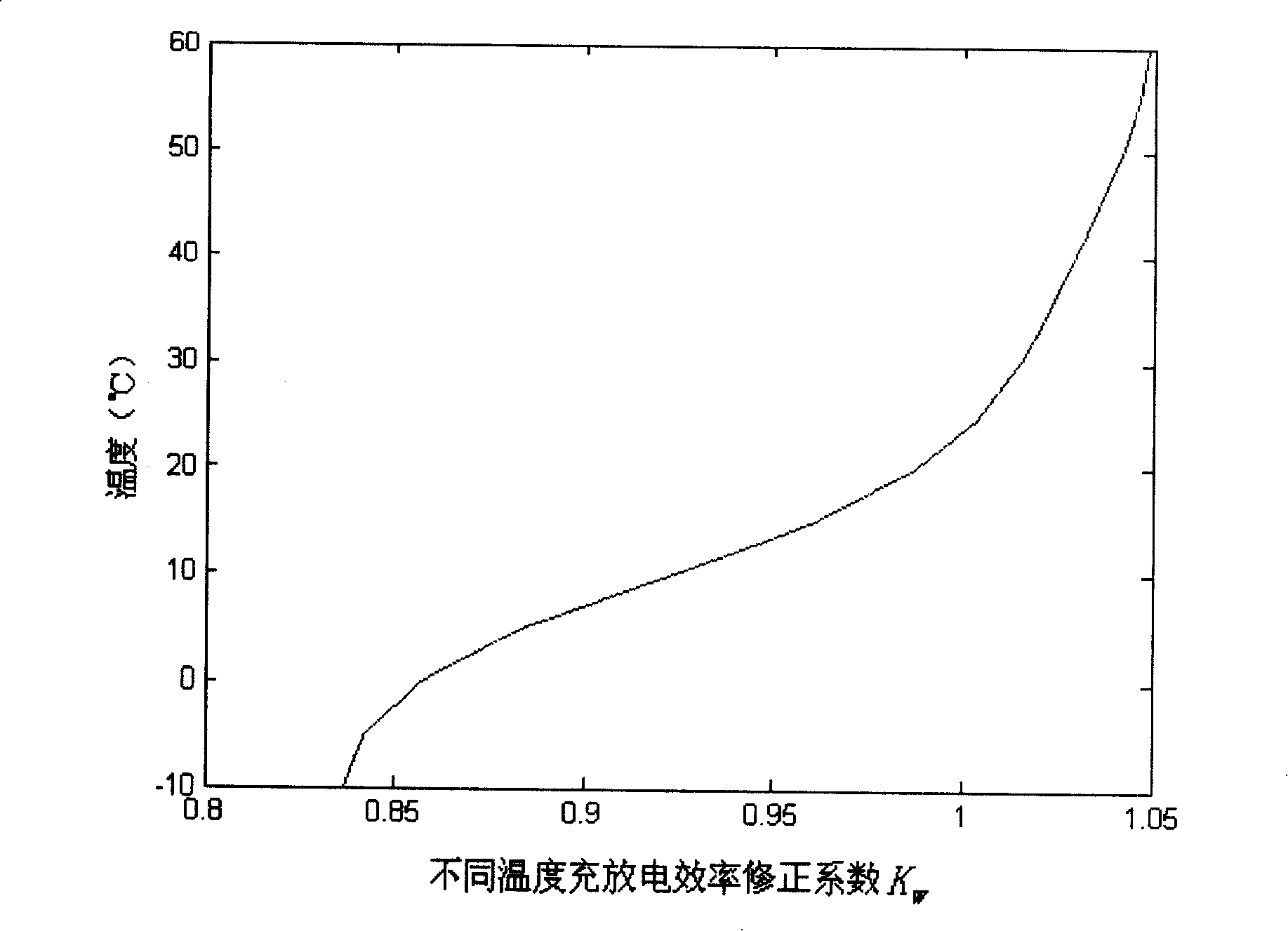

The invention provides a method for estimating a charge state of a power battery with relatively less errors, which includes the following steps: through fitting of measured data, a Ki curve of correction coefficient of charging-discharging efficiency at different rates, a Kw curve of the correction coefficient of the charging-discharging efficiency under different temperature as well as a Kc curve of the correction coefficient of actual electric quantity are obtained and a Kc value can be obtained through a historical record; according to the state of the power, the following formulas are applied: in the working state, Ct = (KCC0 + sigma KiIiti) Kw is applied; in the non-working state and when a self-recovery effect is completed, C = KWKCC0t is applied; in the non-working state and when the self-recovery effect is not completed, Ct = Cm is applied; Ki, Kw, Kc are called from the curves to obtain remaining capacity Ct at the moment of obtaining the power battery so as to complete the estimation of a SOC battery. The invention with easy industrial application of models is applicable to both working state and non-working state of the battery; the errors of the estimation result are relatively less and the relevant curves are established.

Owner:BYD CO LTD

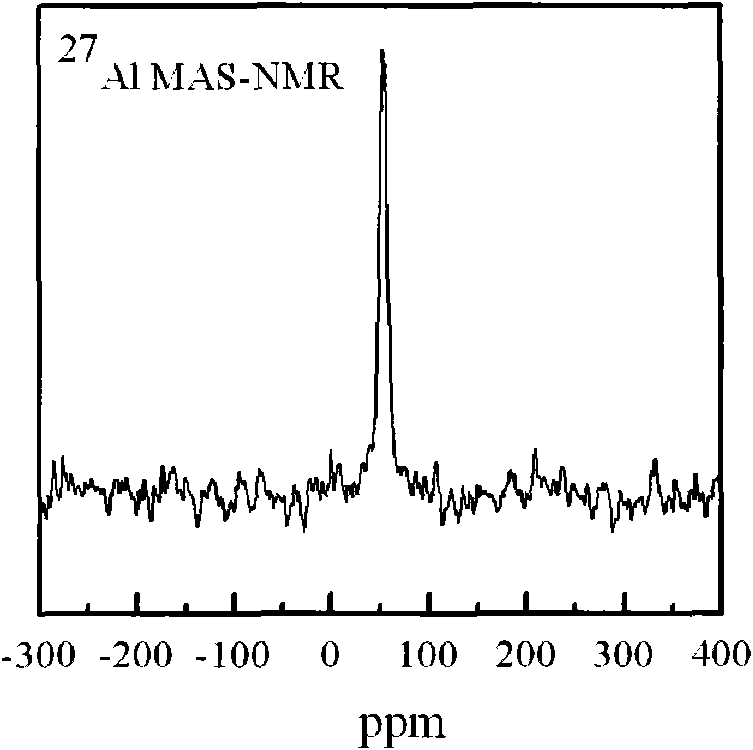

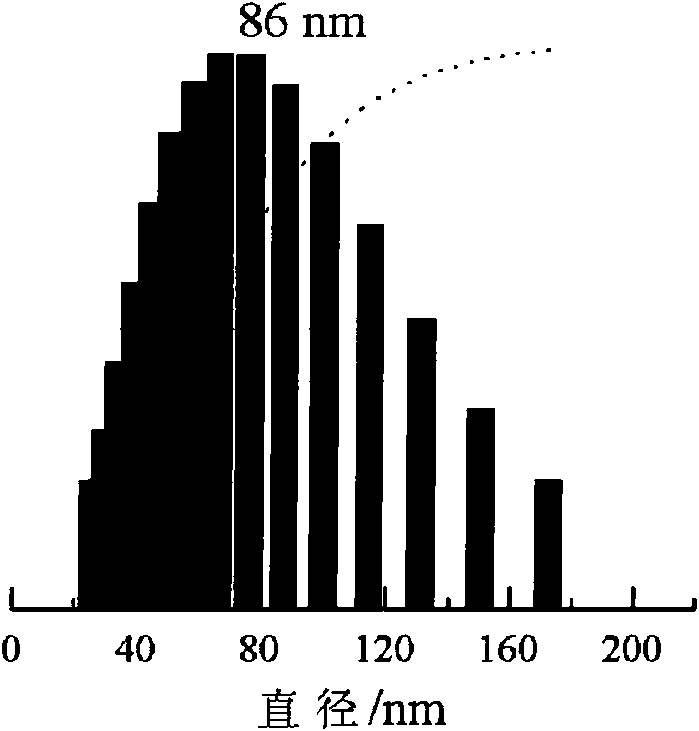

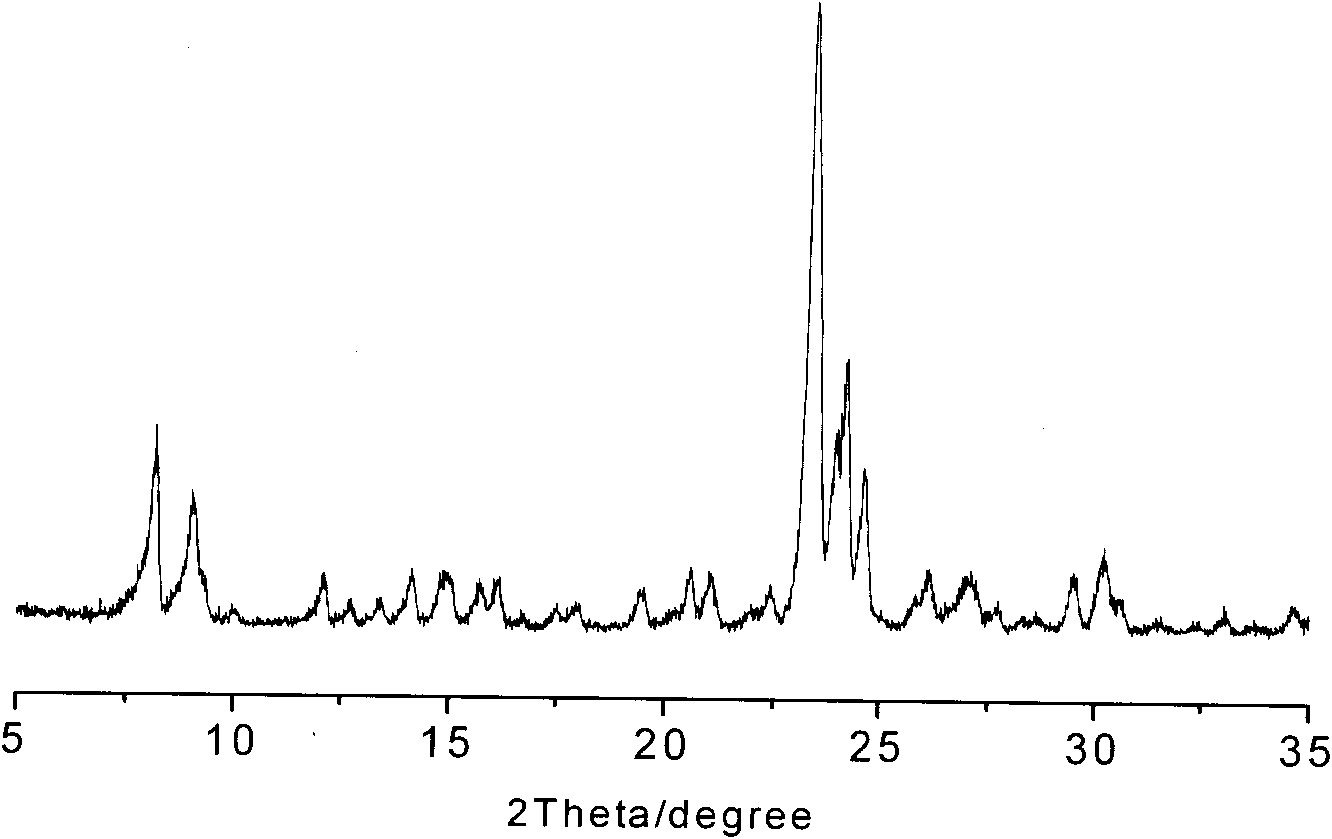

ZSM-5 type molecular sieve for catalyst for reaction for preparing propylene from methanol and/or dimethyl ether

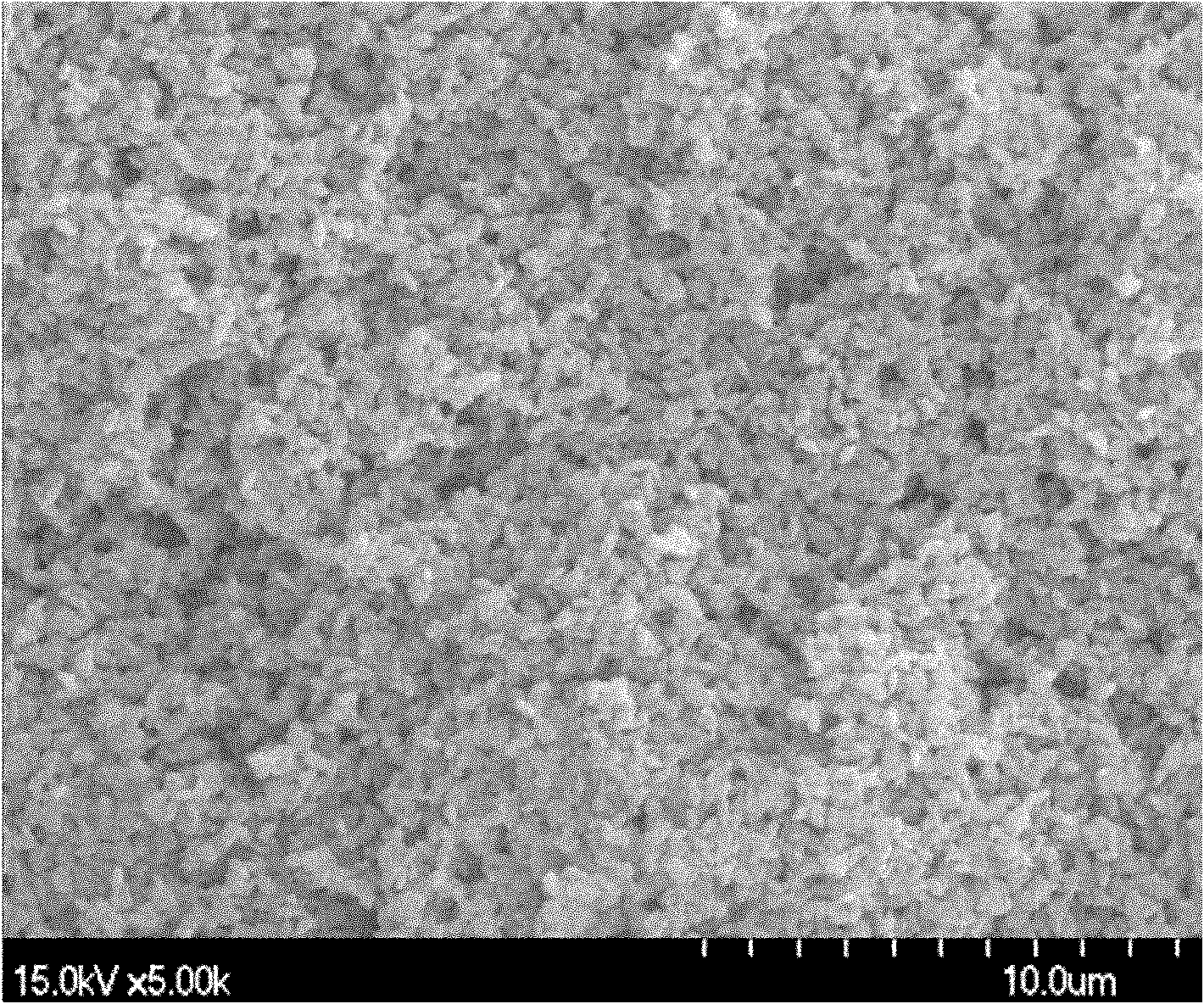

ActiveCN101624192AImprove diffusion abilityHigh P/E ratioMolecular sieve catalystsHydrocarbon from oxygen organic compoundsDispersitySilicon

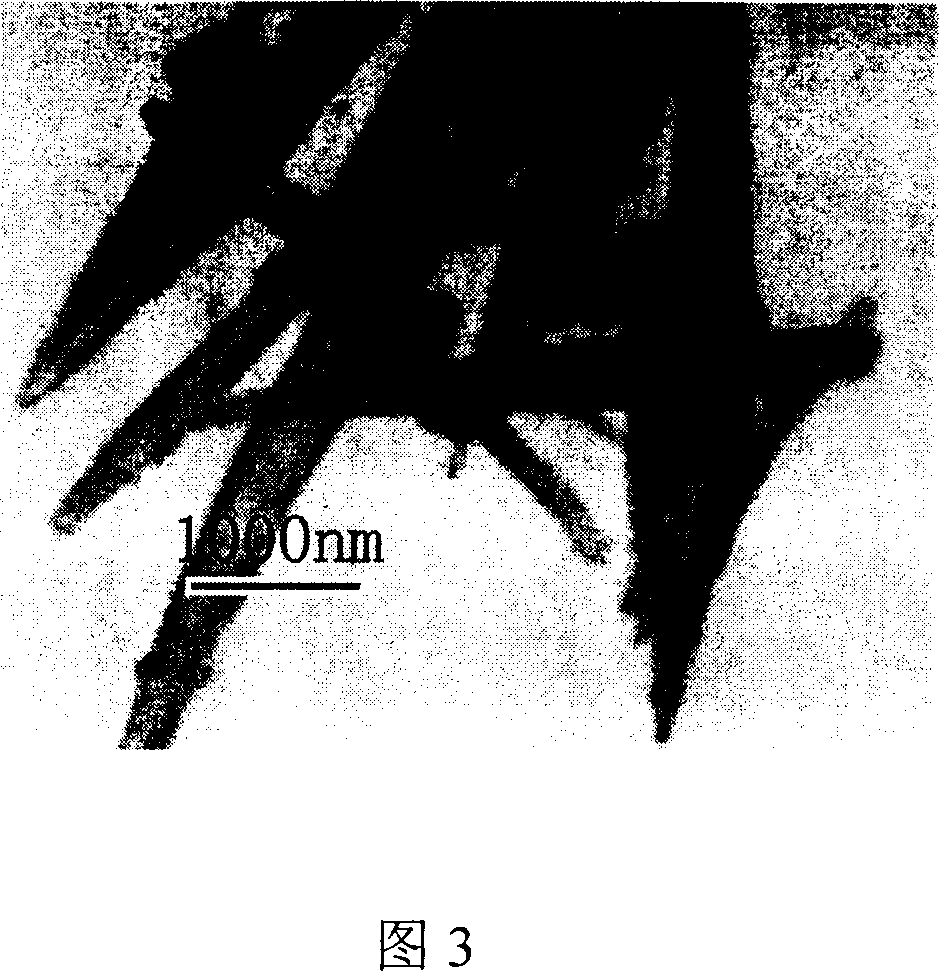

The invention provides a ZSM-5 type molecular sieve for a catalyst for a reaction for preparing propylene from methanol and / or dimethyl ether, which has a silica alumina ratio of 250-1,150 and a grain diameter of 65-250nm. A preparation method of the molecular sieve comprises the following steps: (1) mixing an aluminum source and an organic directing agent and stirring an obtained mixture at constant temperature of 0-30 DEG C for 2-24 hours; (2) adding a silicon source and an organic addition agent to the mixed solution obtained in the step (1) and continuing stirring the mixed solution to obtain gel; (3) stirring the gel obtained in the step (2) at 35-95 DEG C and then carrying out a crystallization reaction for 24-240 hours at 60-200 DEG C, wherein in the raw materials for synthesizing the molecular sieve, and the molar ratio of OH<-1> to SO2 to AL2O3 to H2O to the organic directing agent to the organic directing agent is (0.1-0.35):1:(0.0005-0.01):(10-25):(0.1-0.6):(0.5-8). The ZSM-5 type catalyst has the characteristics of controllable grain size, adjustable silica alumina ratio, high dispersity, and the like and has higher propylene selectivity and P / E ratio in the reaction for preparing low carbon olefin from the methanol and / or the dimethyl ether.

Owner:DATANG INT CHEM TECH RESINST

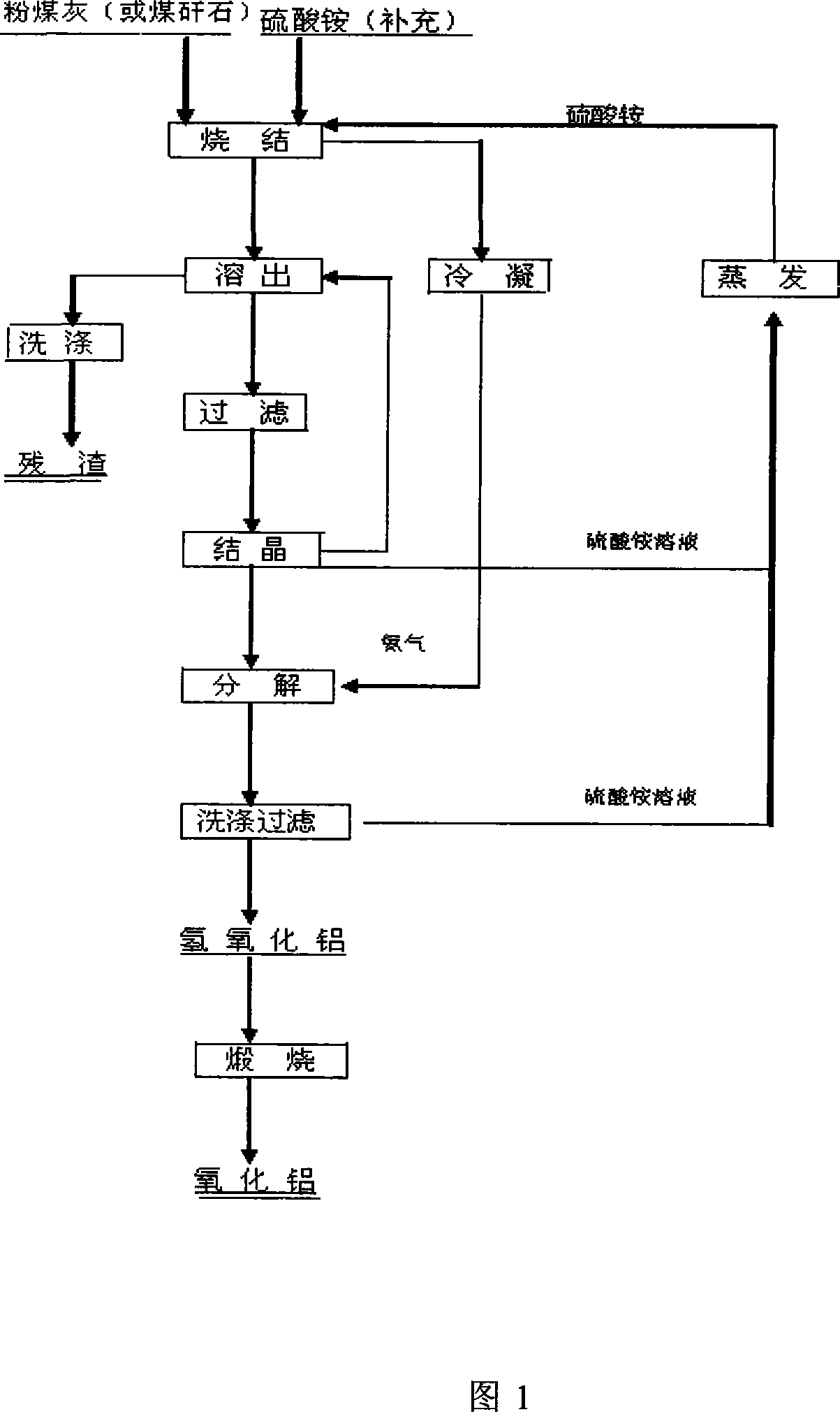

Method for extracting aluminium oxide from coal ash

ActiveCN101117228AEfficient use ofLess corrosiveAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium hydroxideAmmonium aluminium sulfate

The invention provides a method to extract aluminum oxide from a fly ash, and relates to a technological method which is to extract aluminum oxide from the fly ash and comprehensively utilize the residue after extracting aluminum oxide. The invention is characterized in the method which is as follows: ammonium sulfate is mixed into the fly ash to sintering, and the solid is dissolved to obtain the solution containing aluminum-ammonium sulfate; the solution is crystallized to form solid aluminium-ammonium sulfate; solid aluminium-ammonium sulfate reacts with ammonia gas to obtain aluminium hydroxide and ammonium sulfate, and aluminium hydroxide and ammonium sulfate are washed and filtrated to obtain solid aluminium hydroxide; solid aluminium hydroxide is calcined to obtain aluminum oxide; ammonium sulfate can be circularly used after being evaporated in the liquid phase. The ammonium sulfate which is used by the method of the invention is weak acidic, the corrosiveness on the equipment is small, and the ammonium sulfate can be used circularly. The whole process is easy to industrial application. The requirement of the corrosion resistance on the equipment is low. The amount of the residue is small which is beneficial to the comprehensive utilization of the residue after extracting the aluminum oxide.

Owner:河南华慧有色工程设计有限公司 +1

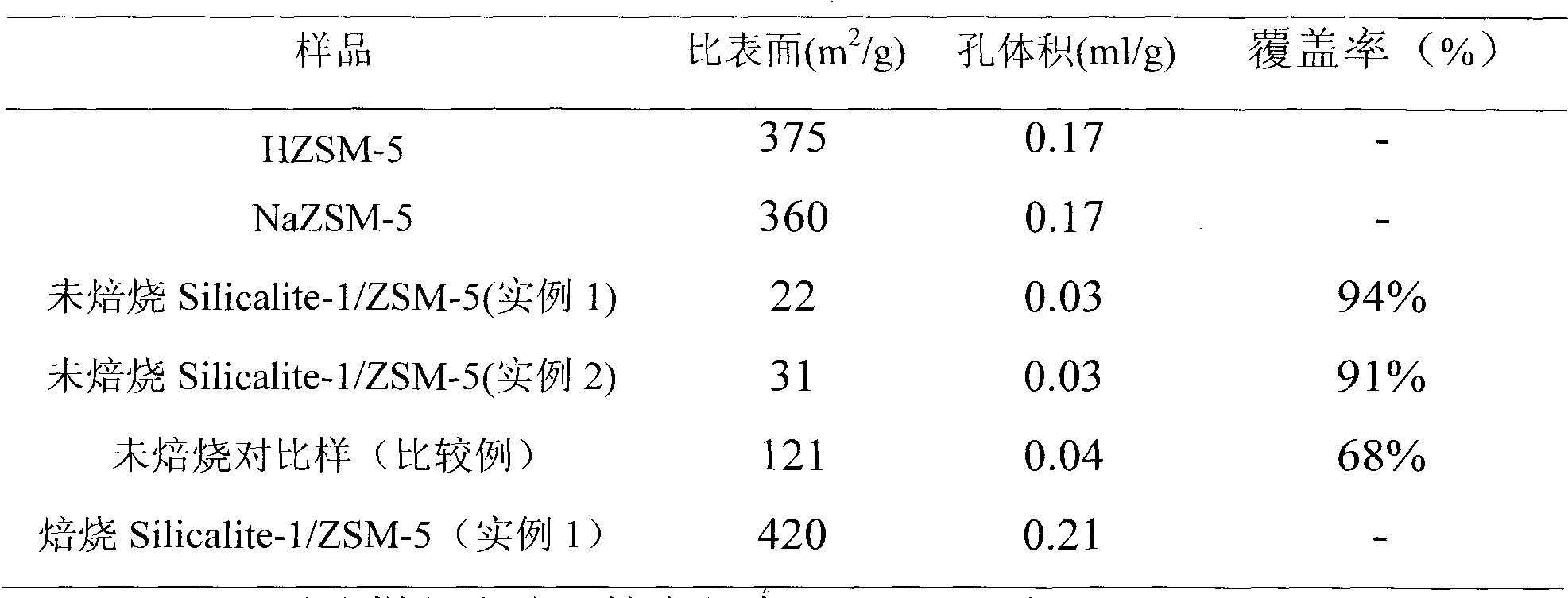

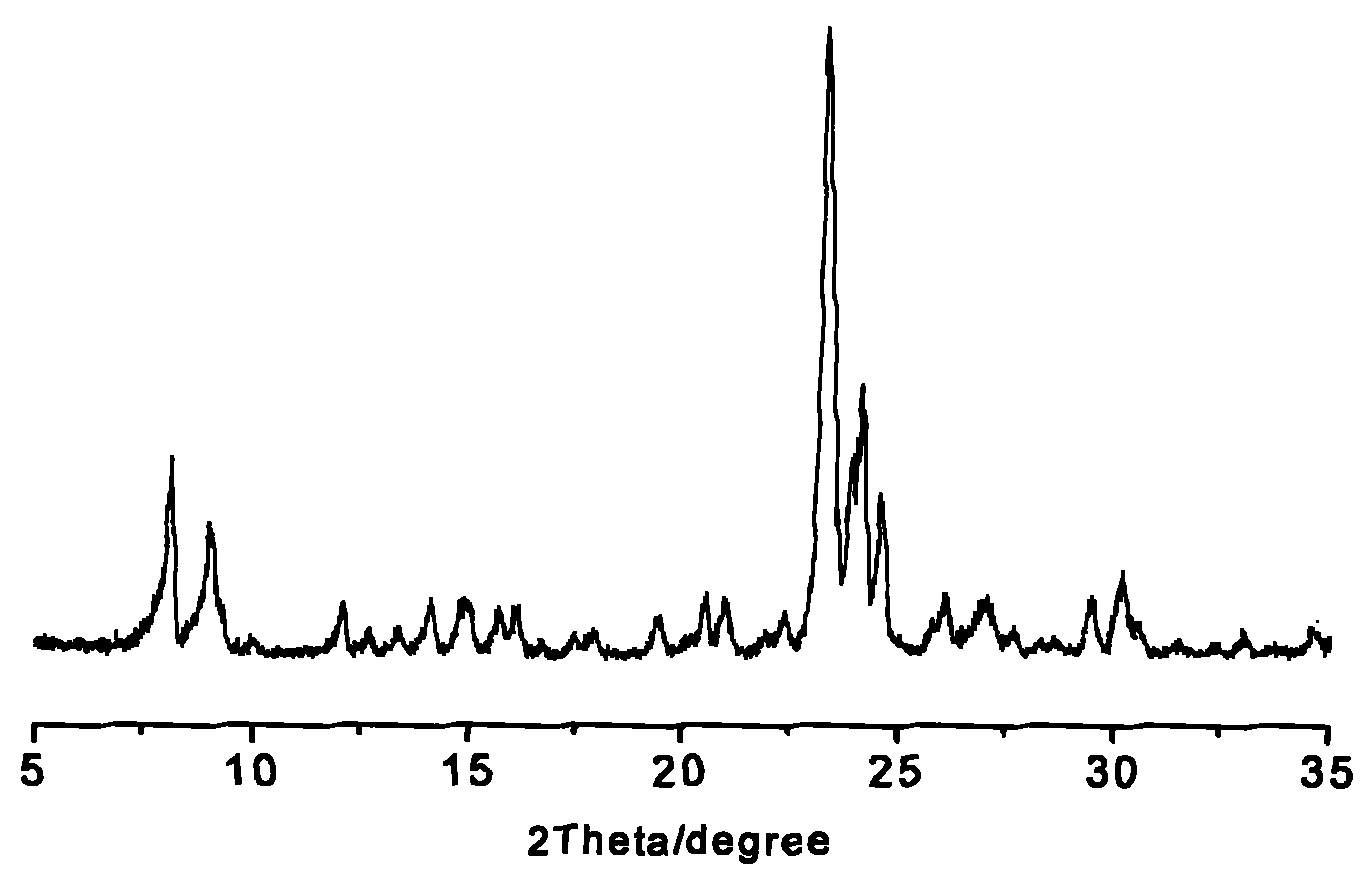

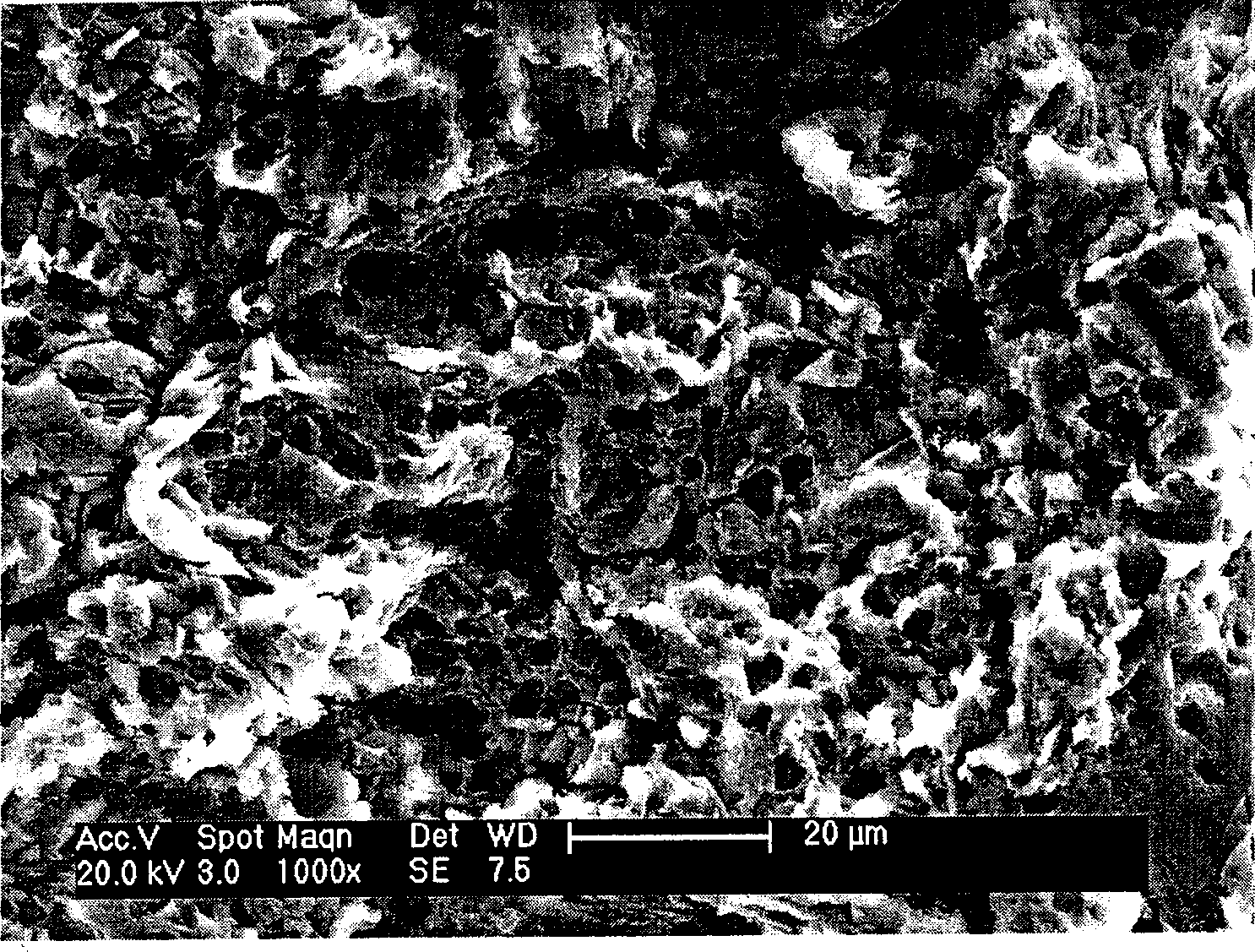

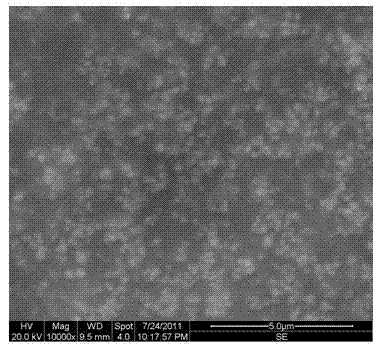

Method for preparing Silicalite-1/ZSM-5 composite molecular sieve

ActiveCN102311124AIncrease coverageEase of industrial applicationCrystalline aluminosilicate zeolitesCore shellSilicon

The invention discloses a method for preparing a Silicalite-1 / ZSM-5 composite molecular sieve. The method comprises the following steps of: crystallizing a mixture containing a silicon source, a ZSM-5 molecular sieve, tetrapropylammonium bromide, sodium hydroxide and water, and drying and roasting a crystallized product to obtain the core-shell structured Silicalite-1 / ZSM-5 composite molecular sieve taking the ZSM-5 molecular sieve as a core and Silicalite-1 molecular sieve as a shell. In the method, cheap template agent and silicon source are adopted and the production cost if greatly reduced; and the prepared Silicalite-1 / ZSM-5 composite molecular sieve has the advantages of high coverage rate, uniform coverage and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalysts for solid base for producing biodiesel

InactiveCN101041130AImprove performanceNothing producedCatalyst carriersPreparation by ester-hydroxy reactionAlkaline earth metalTransesterification

The invention discloses a solid base catalyst for preparing bio-diesel, characterized in that porous material with the same cubage is dipped in alkali metal or alkaline earth metal soluble salt solution and transition metal element or thulium soluble salt solution, whose weight proportion is that porous material: alkali metal or alkaline earth metal soluble salt: transition metal element of thulium soluble salt is 1: 0.02-1: 0.001-0.2; it is dried, baked, rubbed and screened to be obtained. The invention is provided with good catalytic performance, easy treatment after transesterification, no waste liquid generated and easy separation. It can be used repeatedly and it is easy to be used in industry.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

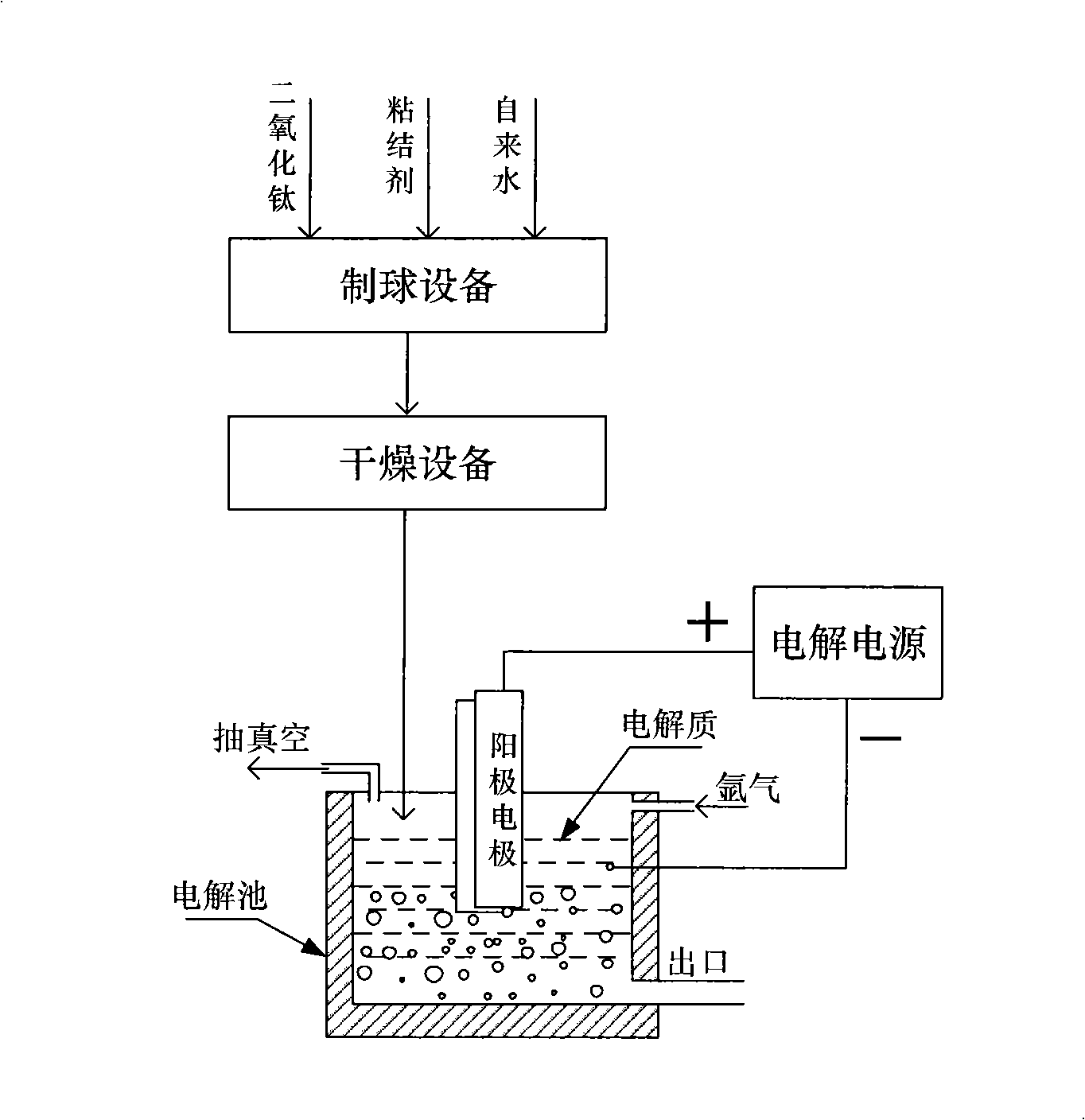

Method for preparing metallic titanium with high temperature fused salt electrolysis of titanium dioxide

The invention discloses a metal titanium preparation method from the high temperature salt-melting electrolyzed titanium dioxide. Through adopting sectional electrolysis temperature to remove the trace amount of iron impurity from titanium dioxide in the molten state, the iron impurity with the weight percentage of 1 to 10 contained in the selected raw material is solved, the range of the raw material for preparing metal titanium is widened, and the production cost of the metal titanium is reduced. Chlorides (CaCl2 and LiCl) are not adopted in the electrolyte in the invention, chlorine hydride gas can not be generated during the electrolysis, and therefore no pollution is caused to the environment.

Owner:北京宝泰丰金属研究所 +1

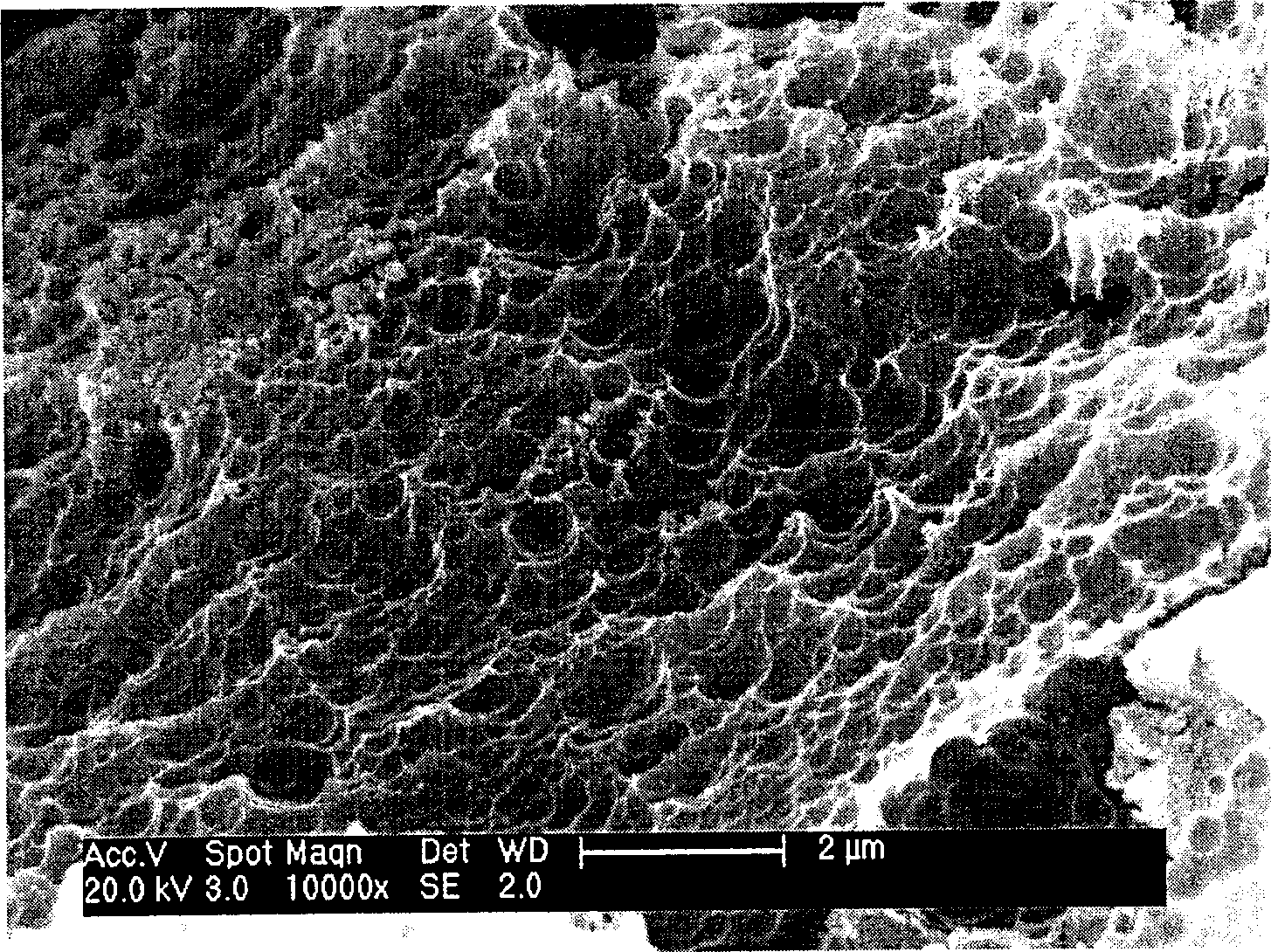

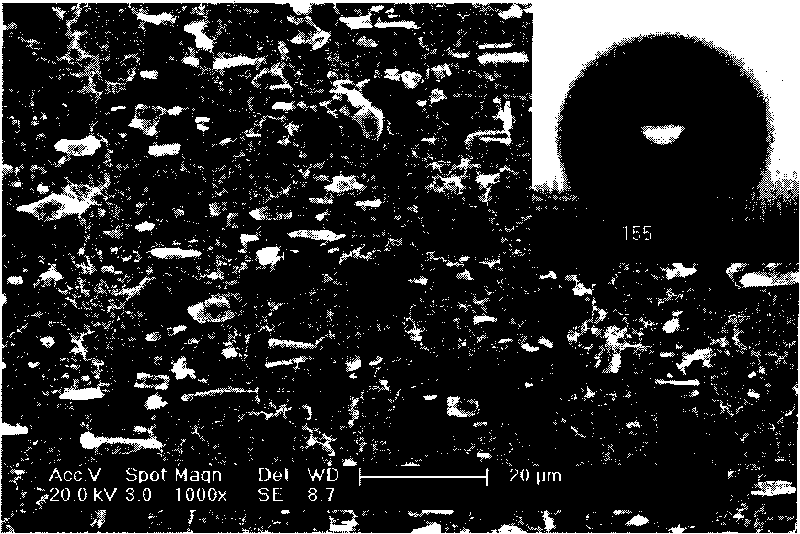

Surface treating method for sea water corrosion-resistant metal aluminum or aluminum alloy

InactiveCN101429672AImprove seawater corrosion resistanceEase of industrial applicationAnodisationMetallic aluminumElectrolysis

The invention relates to a method for treating the surface of seawater corrosion resistant metallic aluminum or aluminum alloy. The method comprises the following steps: 1) sand pellets are used to carry out gritting blasting treatment for the surfaces of aluminum and aluminium alloy through a spray gun so as to bring about the concave and convex surface topography in the micron order for aluminium and aluminium alloy; 2 the aluminium and aluminium alloy is cleaned after degreasing and is taken as the anode of an electrolytic bath, and nickel is taken as a cathode; the electrolyte is prepared and is added into the electrolytic bath, and a DC power supply is connected with the anode and the cathode so as to form nanometer holes on the aluminium or aluminium alloy surface; and 3 silicon fluoride is taken to carry out the surface finish of aluminum or aluminium alloy so as to reduce the surface free energy of aluminium or aluminium alloy. The method for adopting silicone fluoride to carry out the surface finish of aluminum or aluminium alloy comprises the following steps: heating up the aluminium or aluminium alloy processed in step 2 to 90 to 120 DEG C, keeping the temperature for 30 to 40 minutes, taking the aluminium or aluminum alloy out and cooling down the aluminium or aluminum alloy to a room temperature, and then carrying out surface finish through a soak method or a vapor plating method. The processed aluminium metal or aluminum alloy has good resistance to seawater corrosion.

Owner:SOUTHEAST UNIV

Preparation method of particle-enhanced organic anticorrosive coating on surface of neodymium-iron-boron permanent magnet material

InactiveCN102443834AMagnetic has no effectExtended service lifeElectrophoretic coatingsEpoxyMicro nano

The invention relates to a preparation method of a particle-enhanced organic anticorrosive coating on the surface of a neodymium-iron-boron permanent magnet material, and specifically relates to a cathode electrophoresis coating method of the particle-enhanced organic anticorrosive coating on the surface of the neodymium-iron-boron permanent magnet material. According to the invention, first, the surface of the neodymium-iron-boron permanent magnet material is polished; the surface of the neodymium-iron-boron permanent magnet material is subject to degreasing, rust removing by acid cleaning, surface phosphorizing, cathode electrophoresis coating and high-temperature curing, such that a particle-enhanced organic matter coating is formed on the surface of the neodymium-iron-boron permanent magnet material. According to the coating provided by the invention, epoxy resin, acrylic acid and polyurethane are adopted as substrates; micro-nano titanium oxide particles, alumina particles, graphite particles, aluminum particles and the like are adopted as enhancing phases, such that a composite organic coating can be prepared. The coating causes no influence on the inherent magnetic performance of the magnet. The coating has a good bonding force with the magnet, and has a good caking property with bonding glue. The coating is also advantaged in uniform thickness, smooth surface, high corrosion resistance, and low preparation cost.

Owner:NANCHANG HANGKONG UNIVERSITY

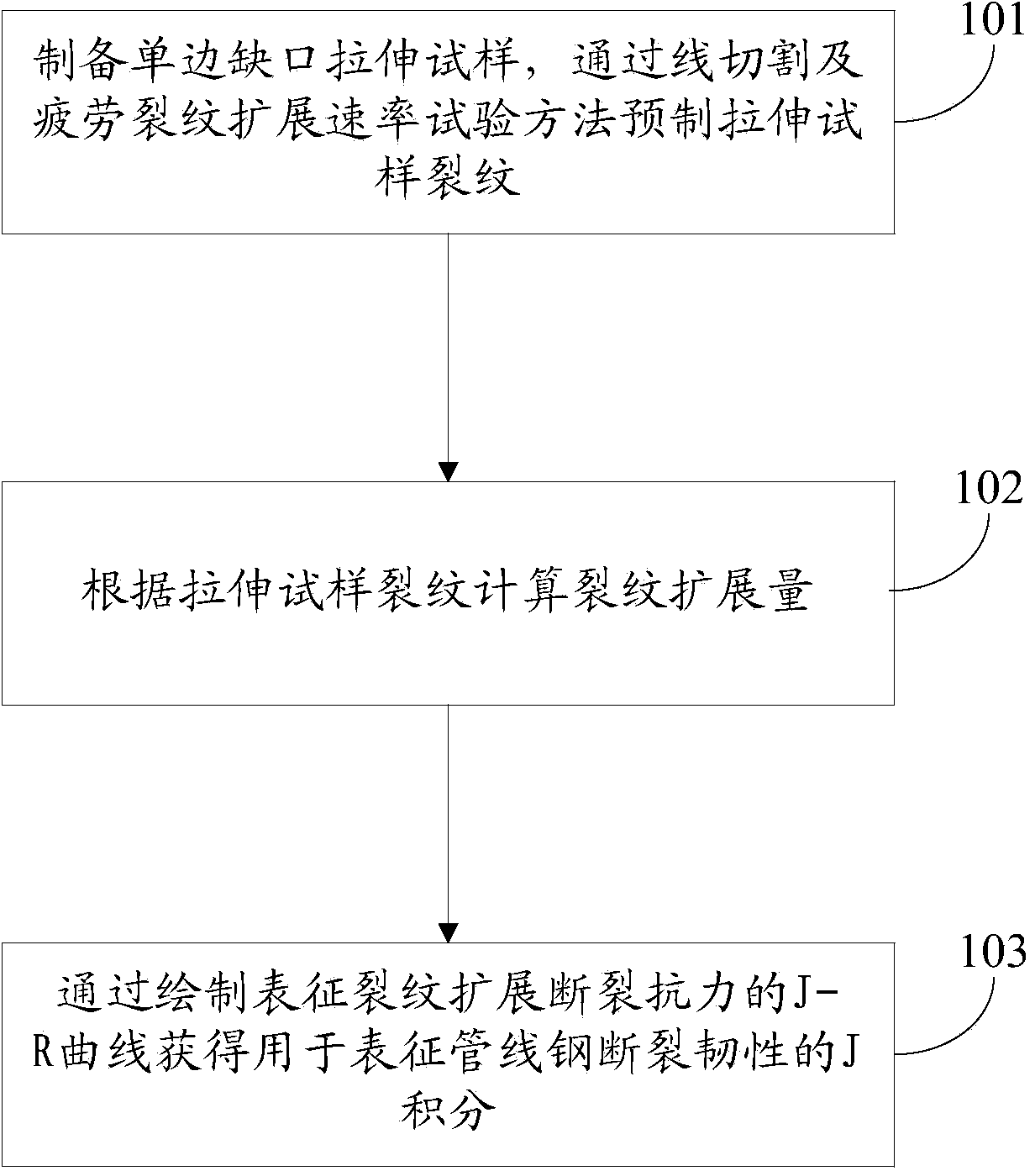

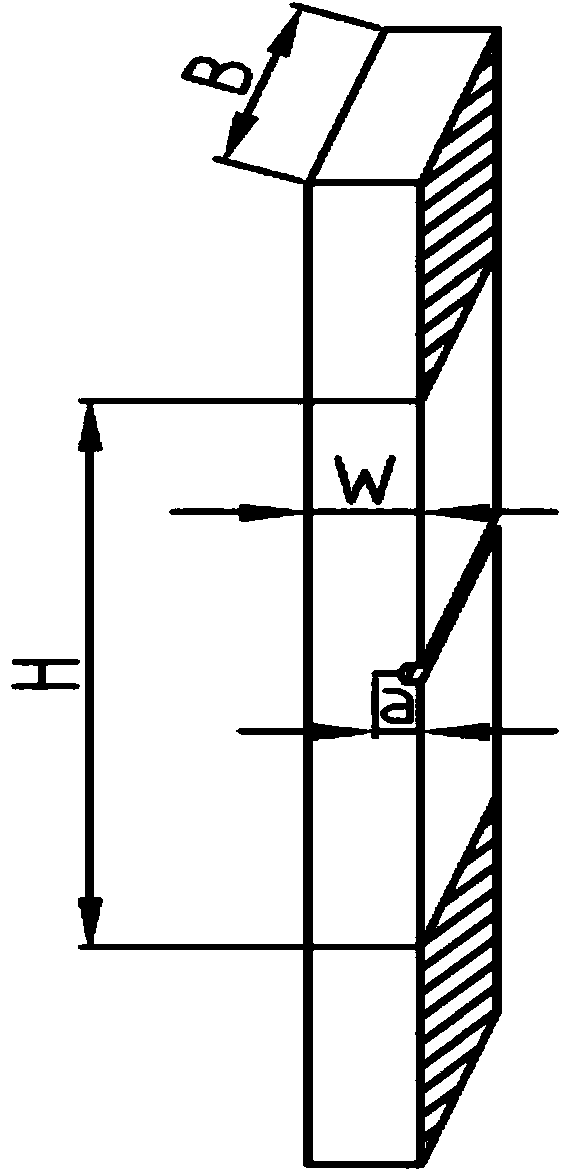

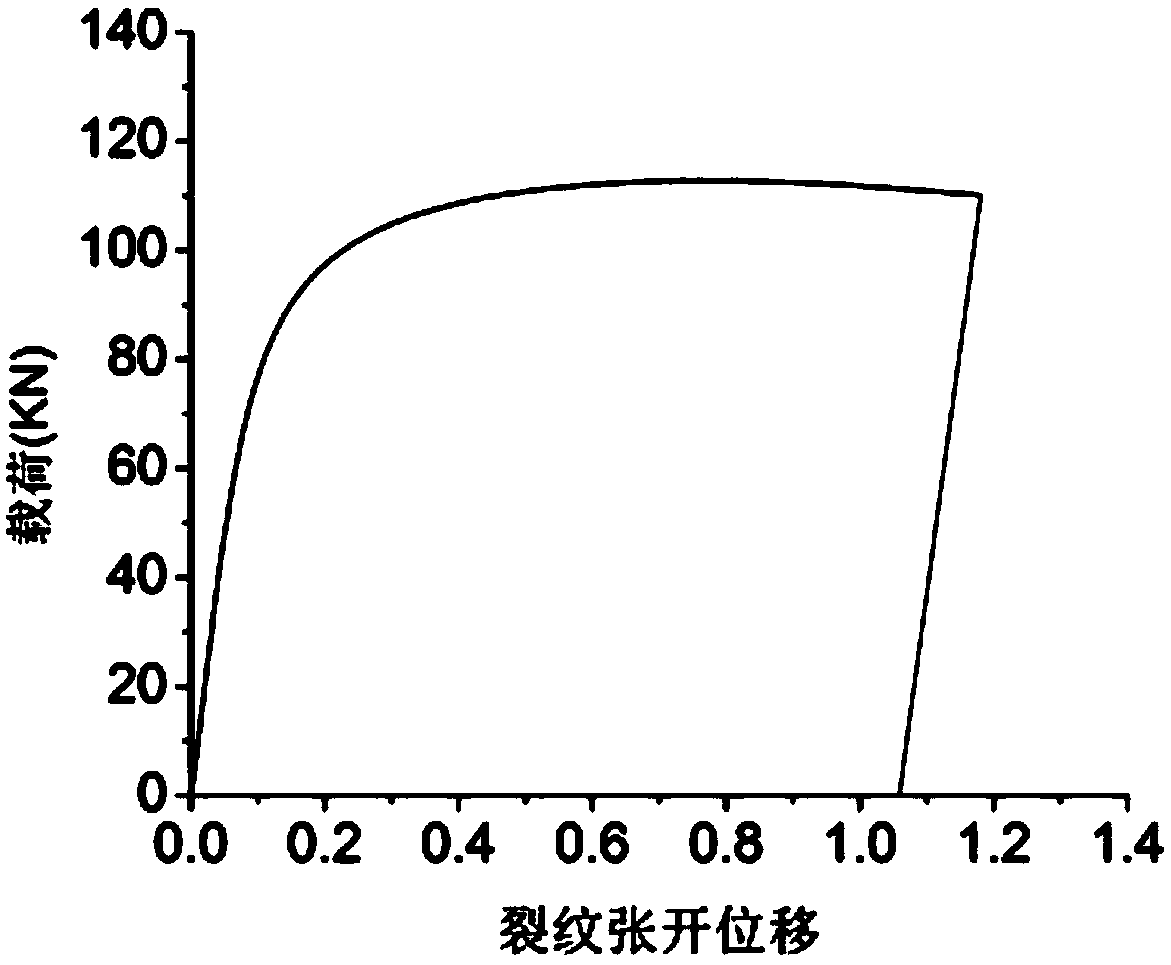

Method for measuring fracture toughness of pipeline steel by using unilateral notched tensile test

ActiveCN103604694AAvoid wastingReasonable fracture toughness valueMaterial strength using tensile/compressive forcesCrack resistanceStress intensity factor

The invention discloses a method for measuring fracture toughness of pipeline steel by using a unilateral notched tensile test. The method is characterized by comprising the steps of preparing a unilateral notched tensile test sample; prefabricating a tensile sample crack by wire-electrode cutting and fatigue crack growth rate test method; calculating crack growth amount according to the tensile sample cracks; and acquiring J integration and stress intensity factor K for characterizing the fracture toughness of the pipeline steel by drawing a J-R curve for characterizing crack resistance of the crack growth. The method measures the fracture toughness of the pipeline steel by using tensile samples (SENT samples), overcomes the defects that the scope of measurement results of tensile samples (SENT samples) by a conventional technology is so small that the fracture toughness of the pipeline steel can not be evaluated; the crack toughness value of the tensile samples (SENT samples) can be more reasonable; waste of test for pipeline steel materials can be prevented; and the method has the advantages of high measurement accuracy.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

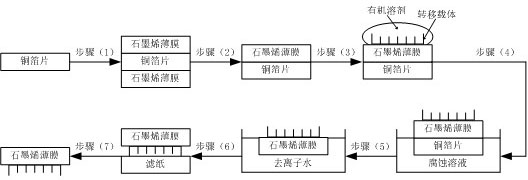

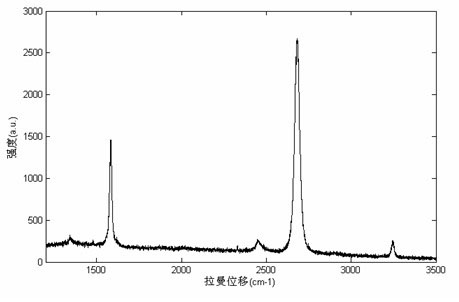

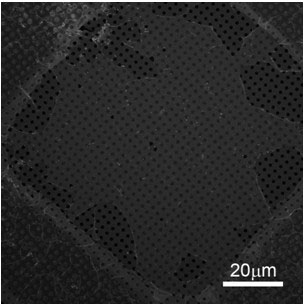

Direct graphene film transfer method

The invention relates to a direct graphene film transfer method. Currently, transferring graphene films from metal surfaces is quite inconvenient. The method includes: using the chemical vapor deposition method to grow a graphene film on a copper foil; using oxygen plasma cleaner to clear graphene on one side of the copper foil to obtain a combination of the single-layer graphene film with the copper foil; flatly attaching a transfer carrier onto the surface of the graphene film and drip adding an organic solvent of a proper quality to increase the interaction between the transfer carrier andthe graphene film; using etchant solution to clear the copper foil to obtain a combination of the single-layer graphene film with the transfer carrier; using deionized water to clean the graphene film for multiple times; and using a filter paper to clear the deionized water on the surface of the graphene film. Using the direct graphene film transfer method avoids the graphene films from being damaged by transfer media such as organic colloid and the like, single-layer graphene films of 100 micrometers or more can be obtained, simple equipment is required, product dimension is controllable, production safety is high, and industrial application is easy to implement.

Owner:ZHEJIANG UNIV

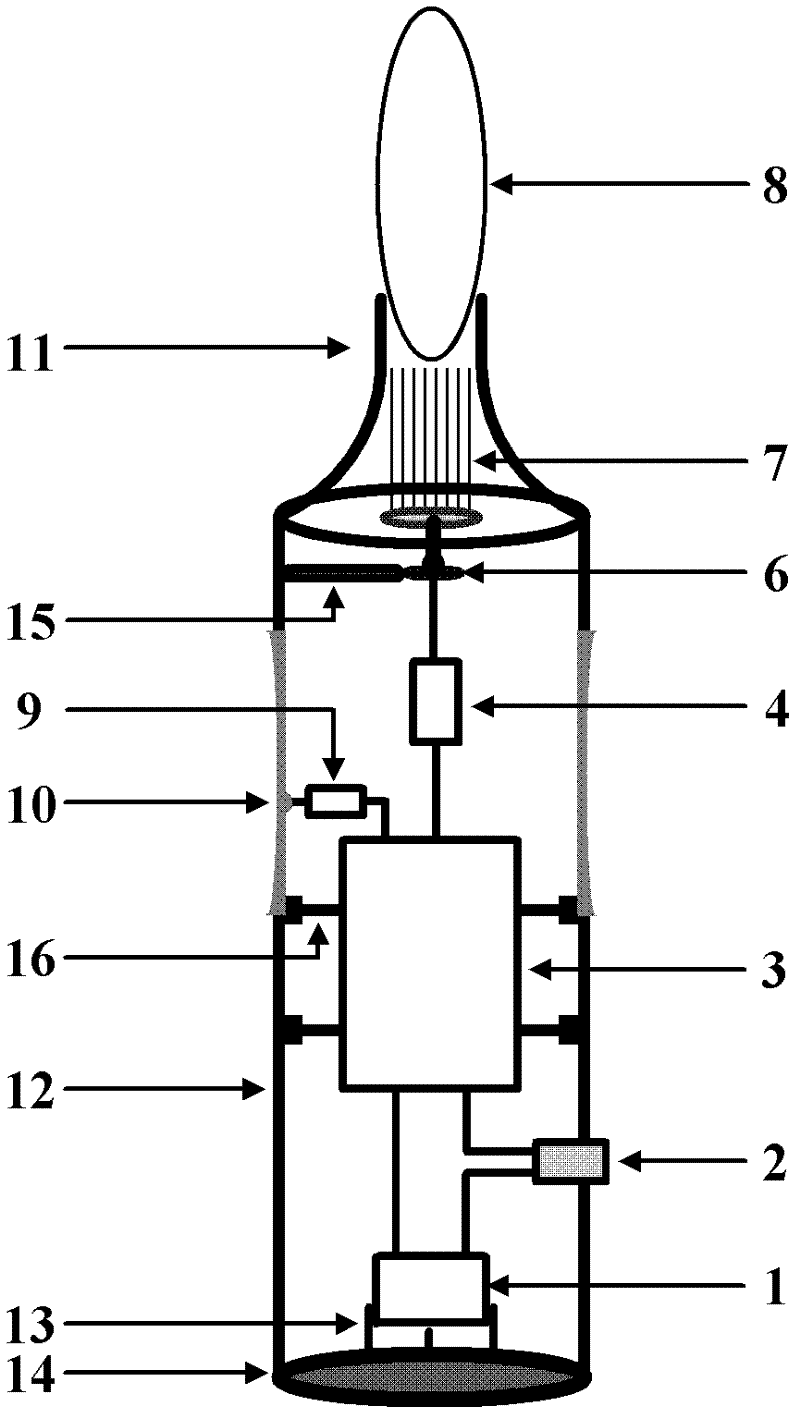

Handheld plasma electric torch

The invention relates to a handheld plasma electric torch. The handheld plasma electric torch comprises an electric torch shell, a battery rack, a rechargeable battery, a low voltage switch, a booster, a first resistor, a second resistor, an electrode interface, an electrode, a booster fixing rack and an electrode interface fixing rack, wherein the rechargeable battery is connected with the low voltage switch and the booster; the battery rack is arranged on the lower part of the electric torch shell; the rechargeable battery is arranged in the electric torch shell and fixed by the battery rack; the electric torch shell is a hollow cavity and is provided with a handheld part which is made of a conductive material; an opening for accommodating the electrode is formed at the upper end of the electric torch shell; the booster is fixed in the electric torch shell by the booster fixing rack; the high voltage output end of the booster is connected with the electrode interface by the first resistor; and the low voltage end of the booster is connected with the handheld part of the electric torch shell by the second resistor. By using the handheld plasma electric torch, the problems that a power supply is expensive, the volume is large, the power supply works only when grounded and cannot be moved, the area of generated plasmas is small and the like in the conventional atmosphere pressure plasma device has can be solved.

Owner:武汉海思普莱生命科技有限公司

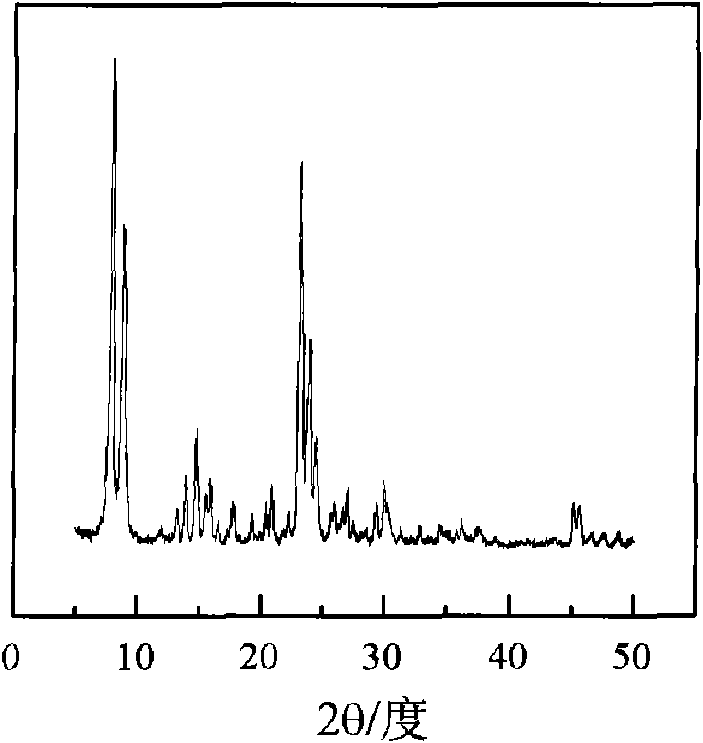

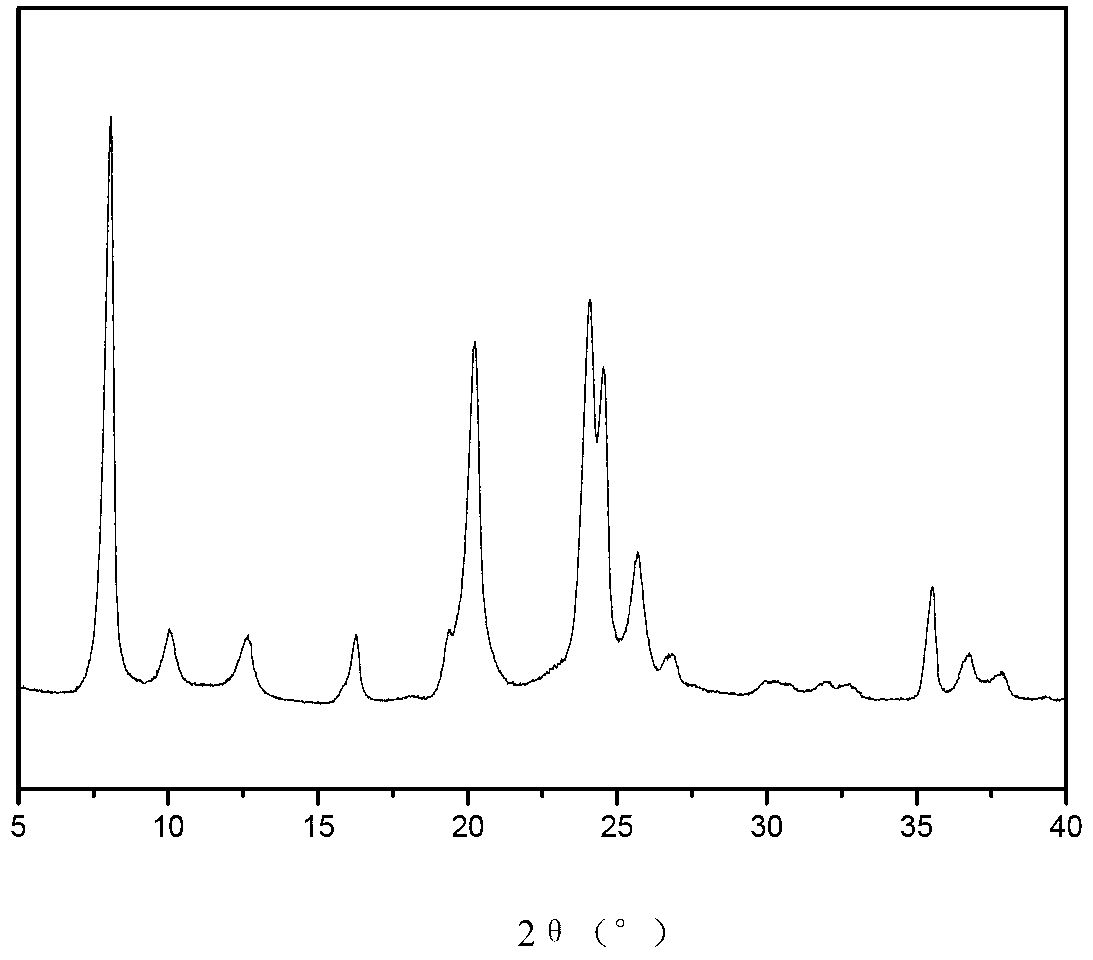

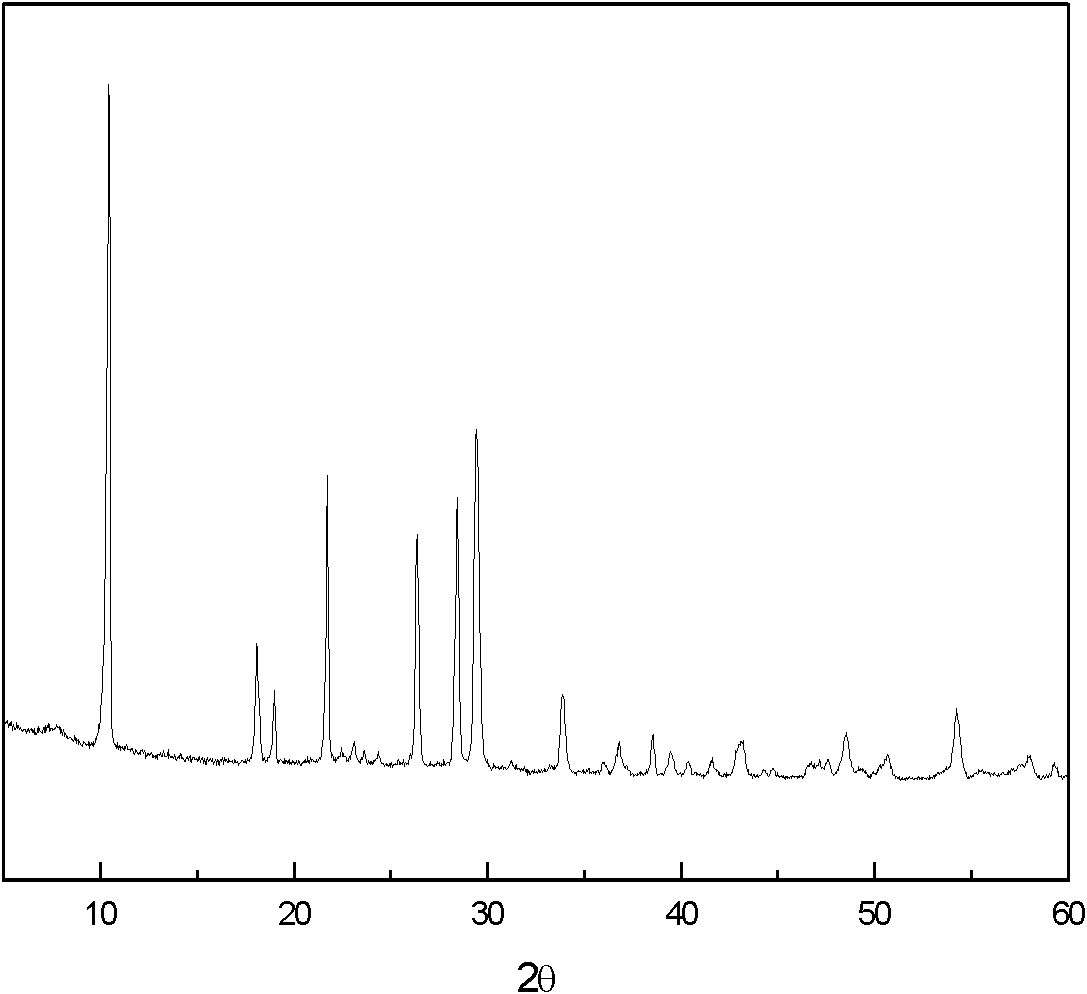

Method for preparing ZSM-22 molecular sieve by using seed crystal synthesis method

ActiveCN103101924AShorten crystallization timeLow crystallization temperatureCrystalline aluminosilicate zeolitesMolecular sieveAluminium salts

The invention relates to a preparation method of a molecular sieve, and provides a method for preparing ZSM-22 molecular sieve by using a seed crystal synthesis method. The method comprises the following steps of: uniformly mixing deionized water with aluminum sulfate; adding alkali sources into a mixture; adding tetraethoxysilane under stirring; continuously stirring until the solution is uniform to form silicon-aluminum gel; adding ZSM-22 molecular sieve crystal seed to stir; putting the mixture into a reaction kettle for crystallization reaction; and filtering and drying a product to obtain ZSM-22 molecular sieve raw powder. By using the preparation method, the application of organic template agent is eliminated, the crystallization time is shortened, the crystallization temperature is reduced, and the industrial application is facilitated; the product keeps good crystallization degree and purity and high catalytic reaction activity; the unnecessary loss during production is reduced; the product has a potential application value on some important catalytic reaction; and inorganic raw materials used in production is environmentally-friendly and low in cost.

Owner:ZHEJIANG JIRUITONG NEW MATERIAL CO LTD

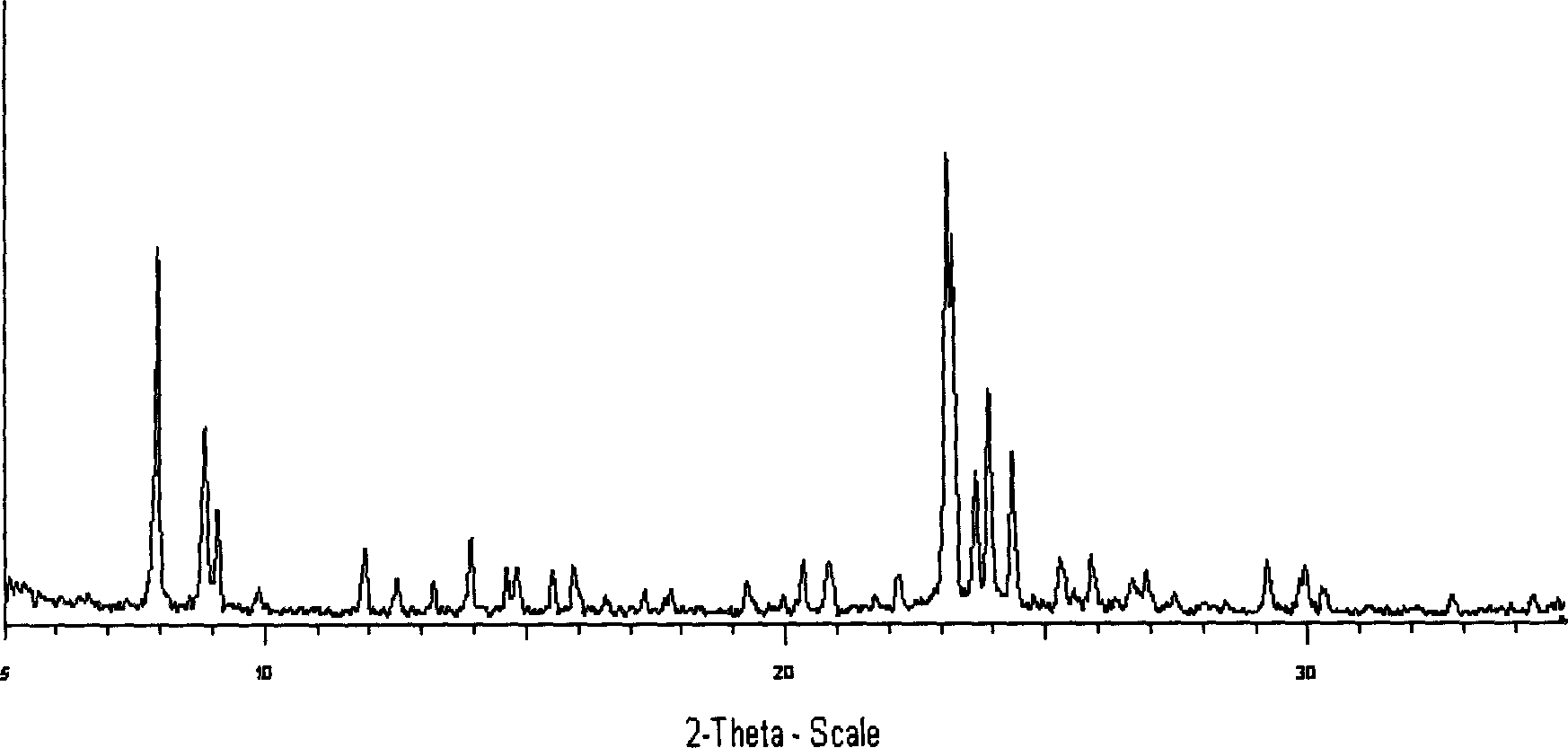

Method for preparing titanium-silicon molecular sieve

InactiveCN1488438AShorten hydrothermal crystallization timeReduce dosageMolecular sieve catalystsMolecular-sieve aluminophosphatesSolventMolecular sieve

The invention is a kind of manufacturing method for TS-1 molecular sift using organic silicon, organic titanium, organic template agent, water and and isopropanol are raw materials. The TS-1 molecular sift is produced through producing of reaction mix solvent, dydrolyse, condense, and water heat crystallizing. The character is: the organic alkali template agent TPAOH thickness are 3~15% and 15~35% in dydrolyse and crystallizing period. The producing efficiency high, the cost is low. The TS-1 molecular sift has a high catalyst and oxidizing activity.

Owner:EAST CHINA NORMAL UNIVERSITY

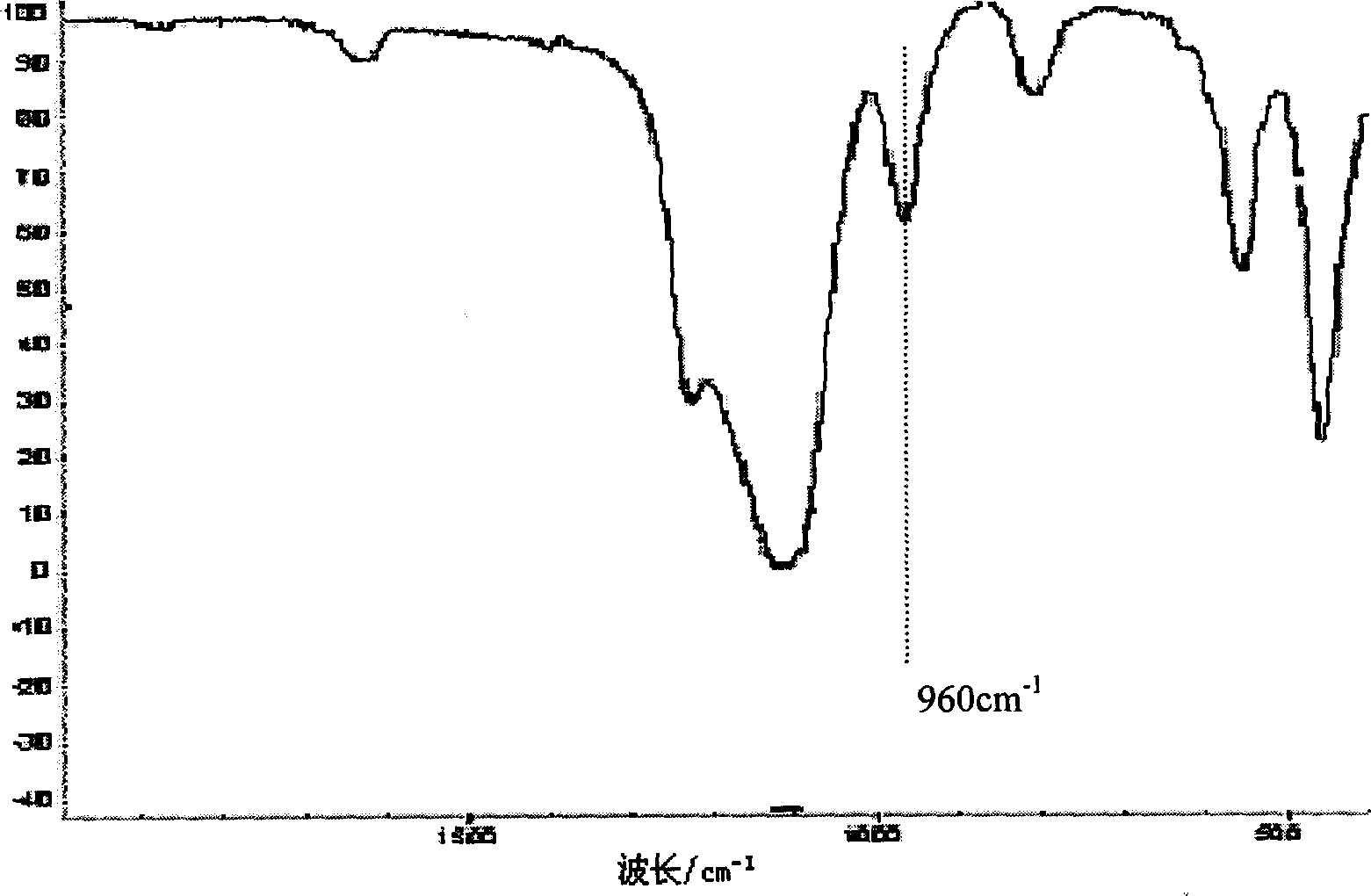

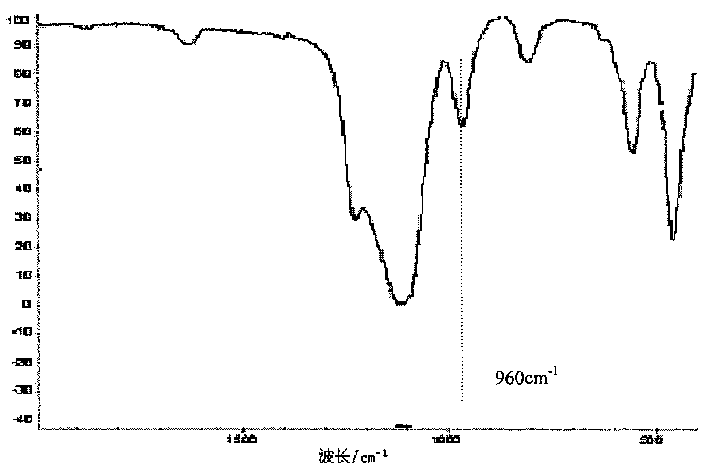

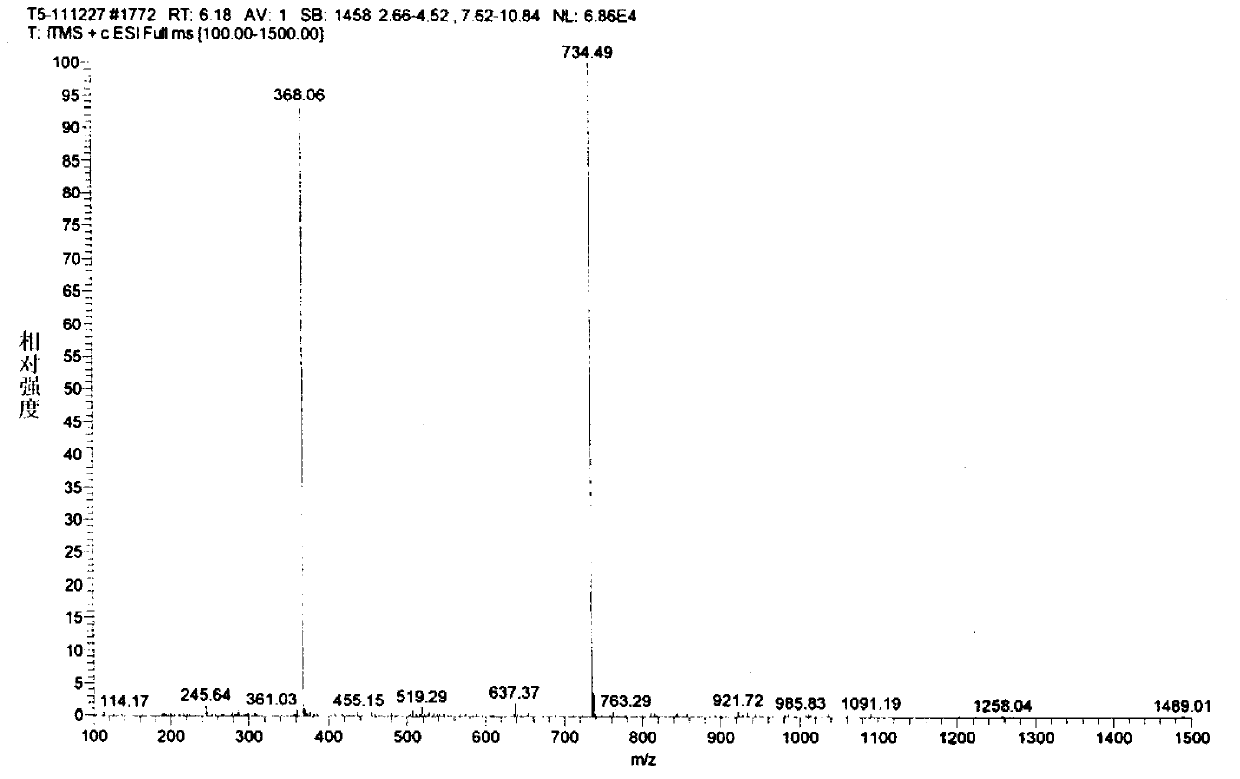

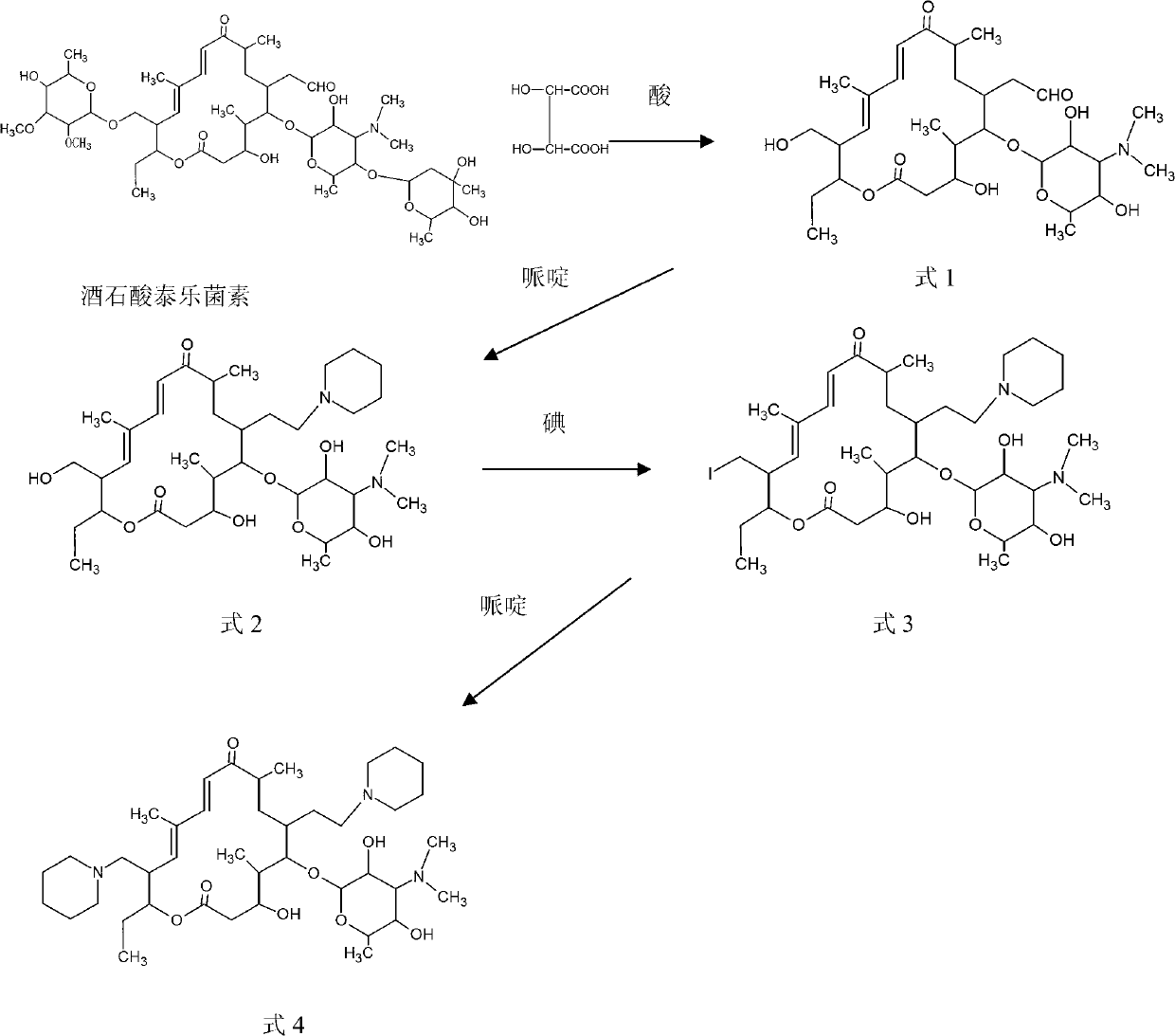

Process for preparing 20,23-bi-piperidyl-5-O-carbon mould amine glycosyl-tylosin lactone

ActiveCN102863487AOvercoming rare and expensive shortcomingsReduce manufacturing costSugar derivativesSugar derivatives preparationOrganic solventIodine

The invention relates to a process for preparing 20,23-bi-piperidyl-5-O-carbon mould amine glycosyl-tylosin lactone. Tylosin tartrate serves as a raw material, an intermediate product of 23-oxhydryl-5-O-carbon mould amine glycosyl-tylosin lactone is obtained through hydrolyzation, an organic phase is extracted through phase inversion, and an intermediate product of 20-piperidyl-23-oxhydryl-5-O-carbon mould amine glycosyl-tylosin lactone is produced through combination with piperidine under the effect of methanoic acid. A final product of the 20,23-bi-piperidyl-5-O-carbon mould amine glycosyl-tylosin lactone is formed by ammonization with the piperidine through iodination. By the aid of the process, the production technology is simplified, the dosage of auxiliary raw materials such as the piperidine, iodine and an organic solvent is greatly reduced, the purity of the obtained product is higher than 98%, the yield of the final product of the 20,23-bi-piperidyl-5-O-carbon mould amine glycosyl-tylosin lactone reaches 58.7%, and the process has good industrial application prospects.

Owner:QILU ANIMAL HEALTH PROD

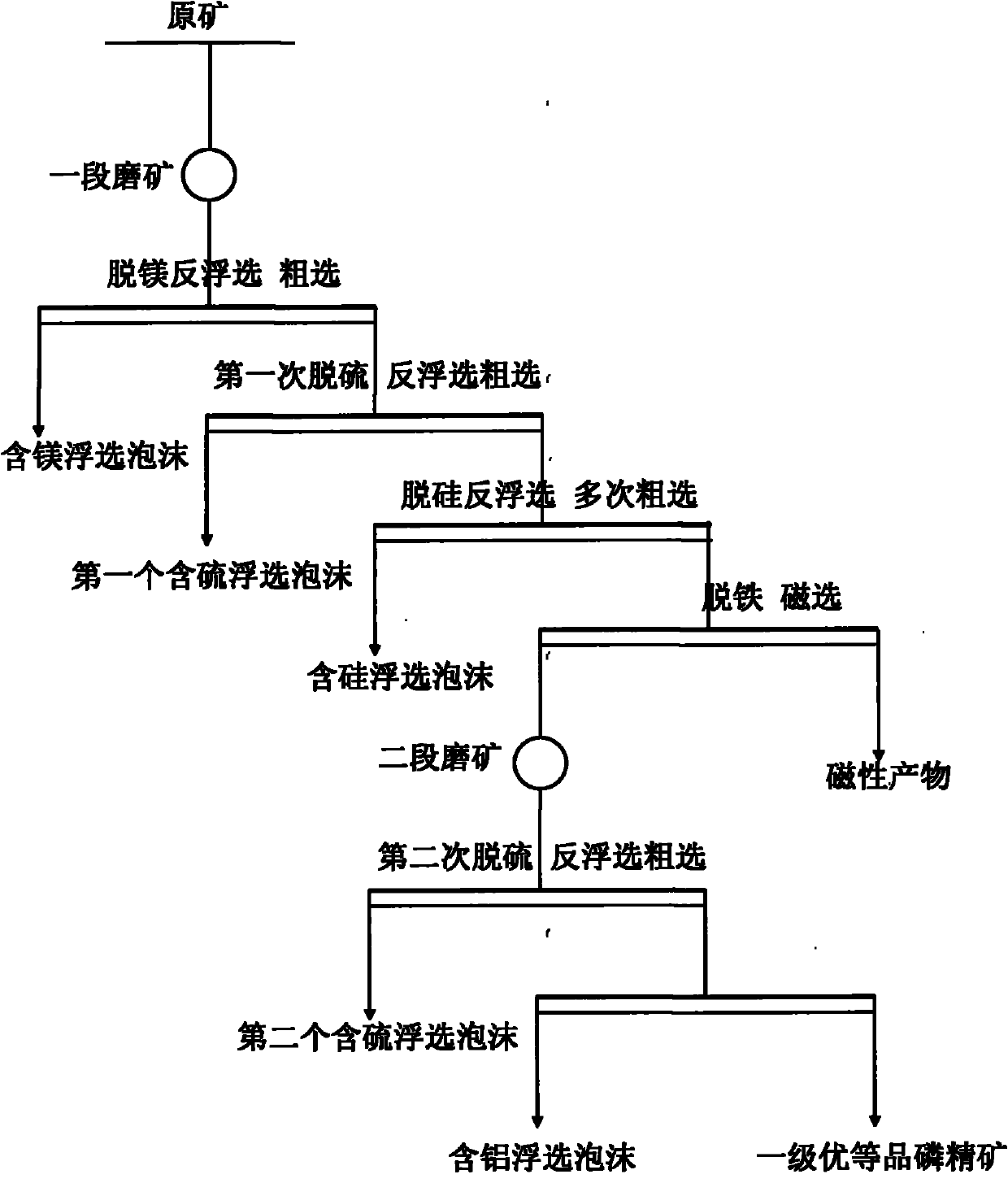

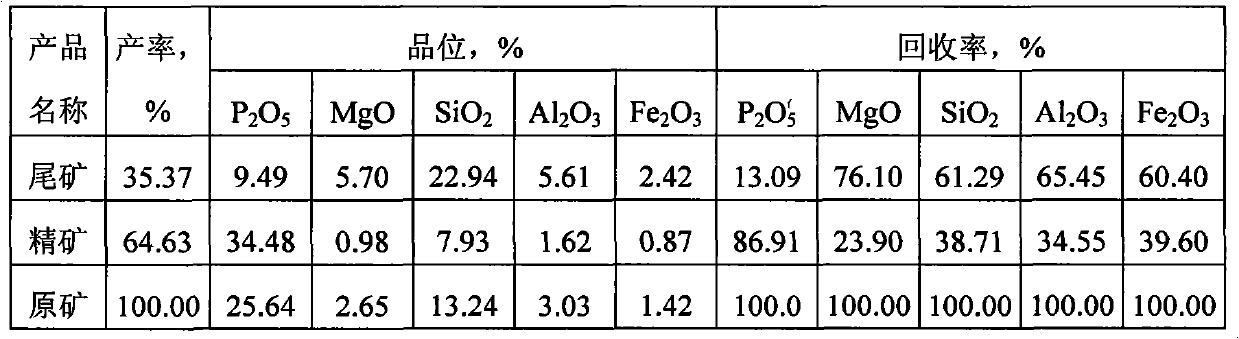

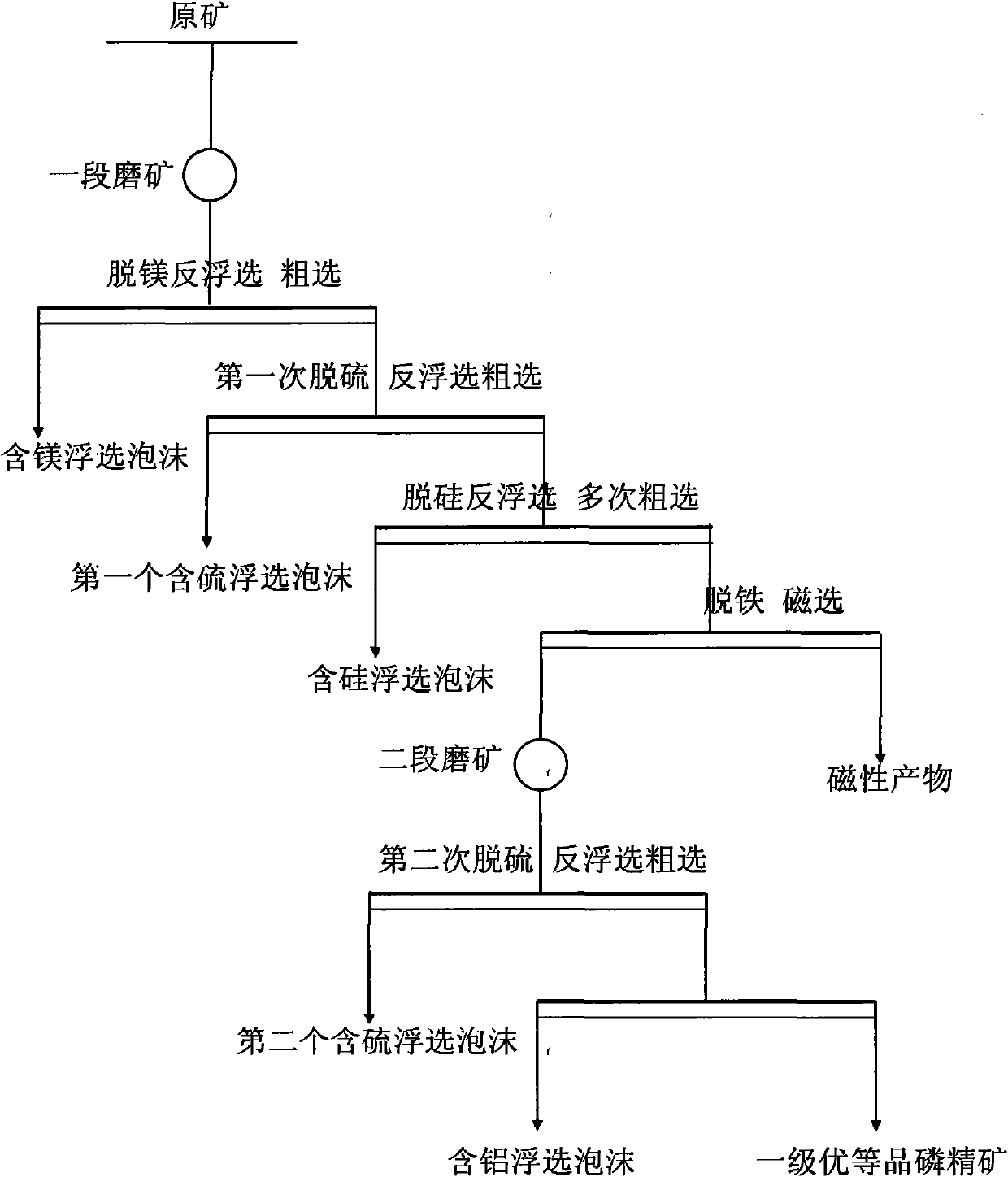

Method for separating collophanite

The invention relates to a method for separating collophanite, which is characterized by comprising the following steps of: (1) coarsely grinding raw collophanite; (2) performing reverse floatation on the grinding product to remove magnesium; (3) reacting floatation base flow of the step (2) with a desulfurization floatation medicament for reverse floatation to remove sulfur; (4) reacting the floatation base flow in the step (3) with a desilicification floatation medicament for reverse floatation to remove silicon; (5) performing intensity magnetic separation on the floatation base flow in the step (4) to remove iron; (6) regrinding a non-magnetic product in the step (5); (7) reacting the grinding product in the step (6) with a desulfurization floatation medicament for reverse floatation to remove sulfur; and (8) reacting the floatation base flow in the step (7) with a dealumnization floatation medicament for reverse floatation to remove aluminum to obtain aluminum-containing floatation foam and the floatation base flow, wherein the floatation base flow is the final phosphorus concentrate. The method can perform floatation at normal temperature and even low temperature to obtain phosphorus concentrate, and has the advantages of high separation property, low energy consumption and effective improvement of the P2O5 recovery rate.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

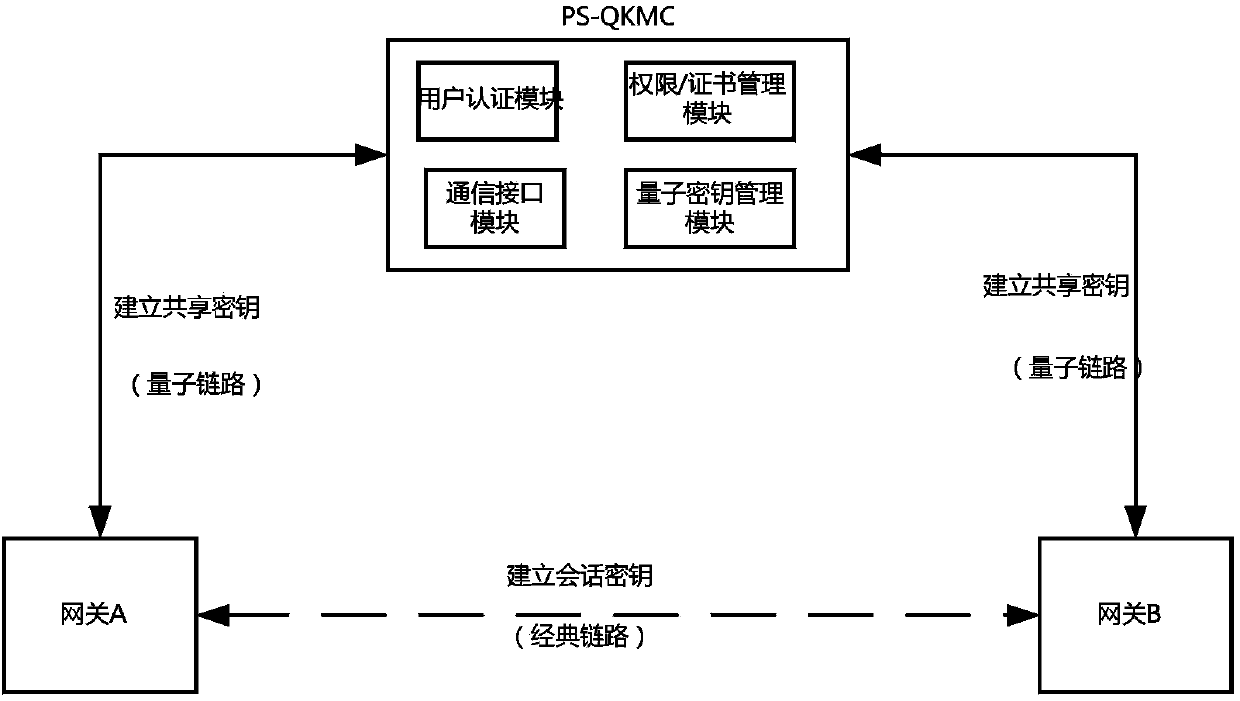

Power special quantum encryption gateway system

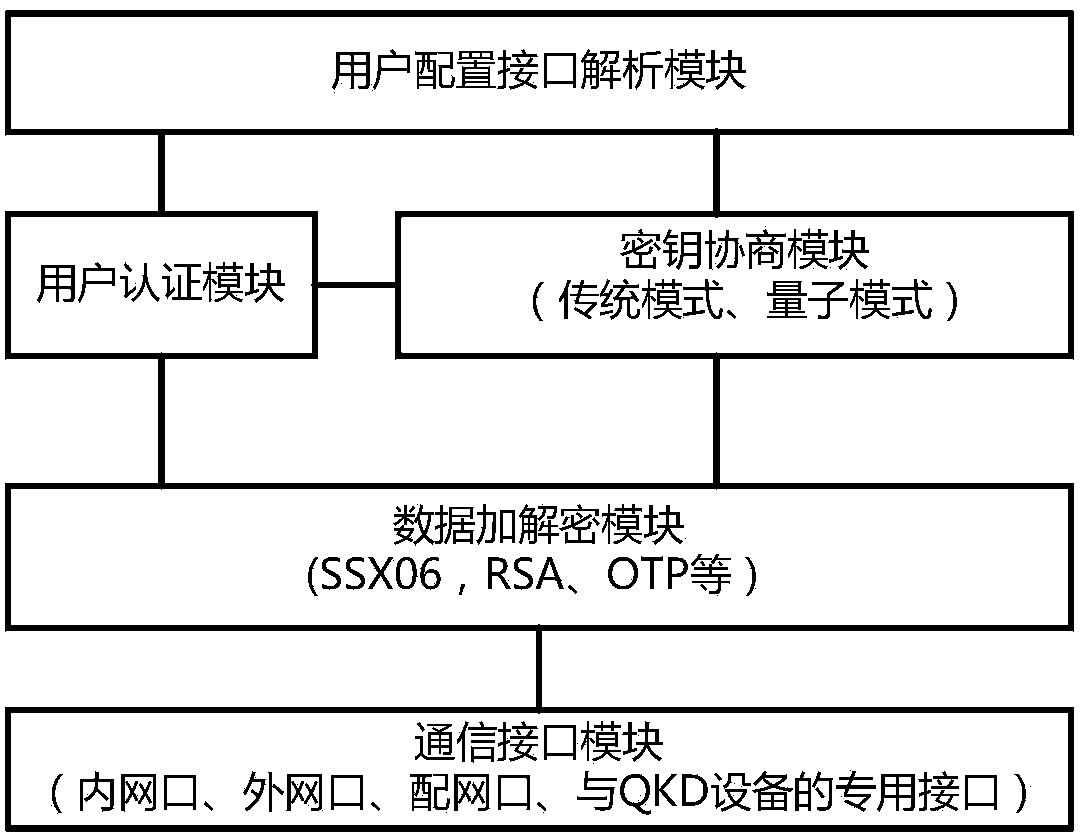

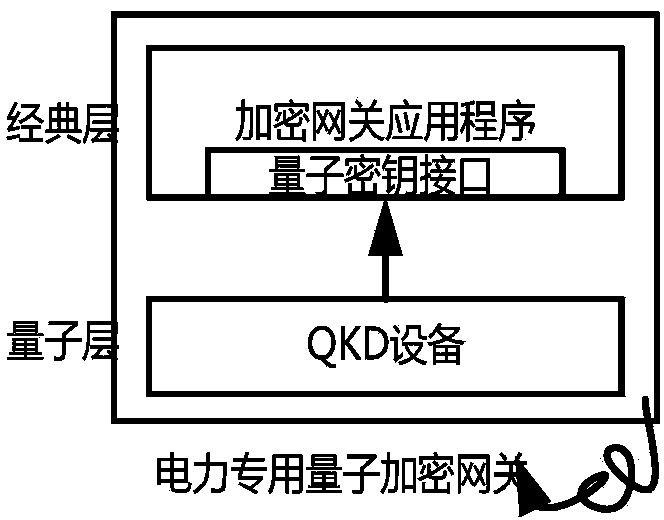

ActiveCN103475464AAdd extensionsMinor changesKey distribution for secure communicationNetwork connectionsCommunication interfaceElectric power system

The invention provides a power special quantum encryption gateway system. The system comprises a power special quantum encryption gateway communicated with a gateway management device through a quantum link; the power special quantum encryption gateway is used for performing encryption communication through the quantum link or a classic link; a quantum secret key distributing device is integrally arranged on the power special quantum encryption gateway and comprises a vertical integration model and a transverse integration mode; the quantum link comprises a quantum secret key sending device and a quantum secret key receiving device which are connected with each other through an optical fiber or a free space; the gateway management device comprises a user authentication module, a user right / certificate management module, a quantum secret key management module and a communication interface module. Compared with the prior art, the power special quantum encryption gateway system provided by the invention is capable of synchronously supporting the traditional mode encryption function and the quantum mode encryption function, and capable of providing unconditional information security assurance for the power system data transmission under the quantum mode, and convenient for the large-scale deployment and industrial practicality of the power special quantum encryption network.

Owner:STATE GRID CORP OF CHINA +3

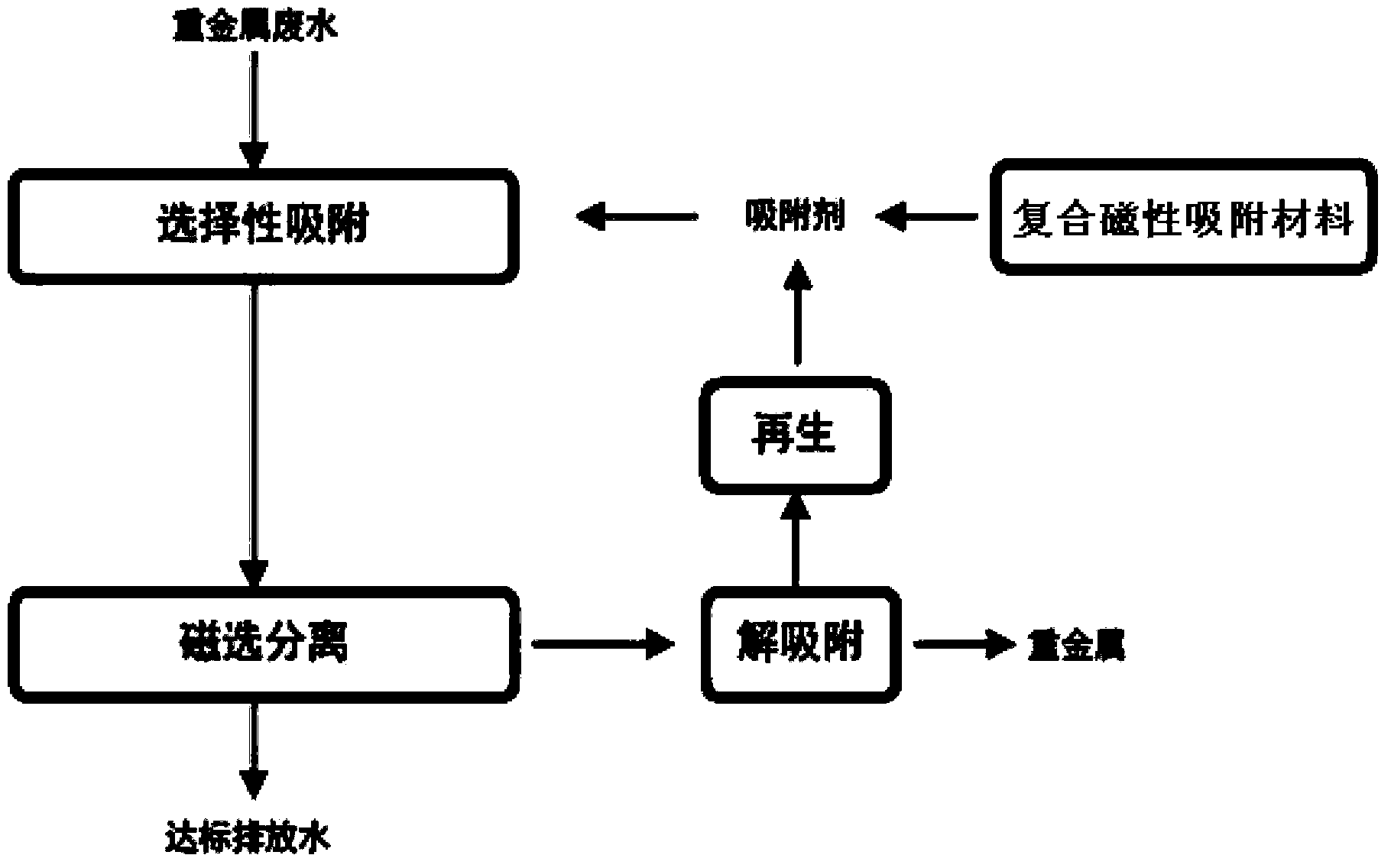

Preparation method for composite magnetic adsorption material and method for removing heavy metal ions in waste water

InactiveCN103623782ALarge adsorption capacityFast adsorptionOther chemical processesWater/sewage treatment by sorptionWastewaterSolvent

The invention relates to a preparation method for a composite magnetic adsorption material and a method for removing heavy metal ions in waste water. The preparation method comprises the following steps: (1) putting a magnetic seed in a grinding machine for fine grinding so as to obtain a submicron magnetic particle; (2) mixing the magnetic particle and a high-molecular natural material capable of absorbing heavy metals with a solvent, adding a flocculating agent and carrying out uniform mixing and a reaction so as to obtain a spherical composite magnetic product; and (3) subjecting the composite magnetic product to magnetic separation, washing and drying so as to obtain the composite magnetic adsorption material. The magnetic adsorption material is added into waste water containing heavy metal ions, then stirring, adsorption and a reaction are carried out, a magnet separator is used for magnetic separation and adsorption of magnetic material containing heavy metal ions, and heavy metals are recovered. According to the invention, the adsorption material is easy to prepare; the removal rate of the heavy metals is high; the advantages of simple process, low cost and environment friendliness are obtained; and the methods are suitable for industrial application.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

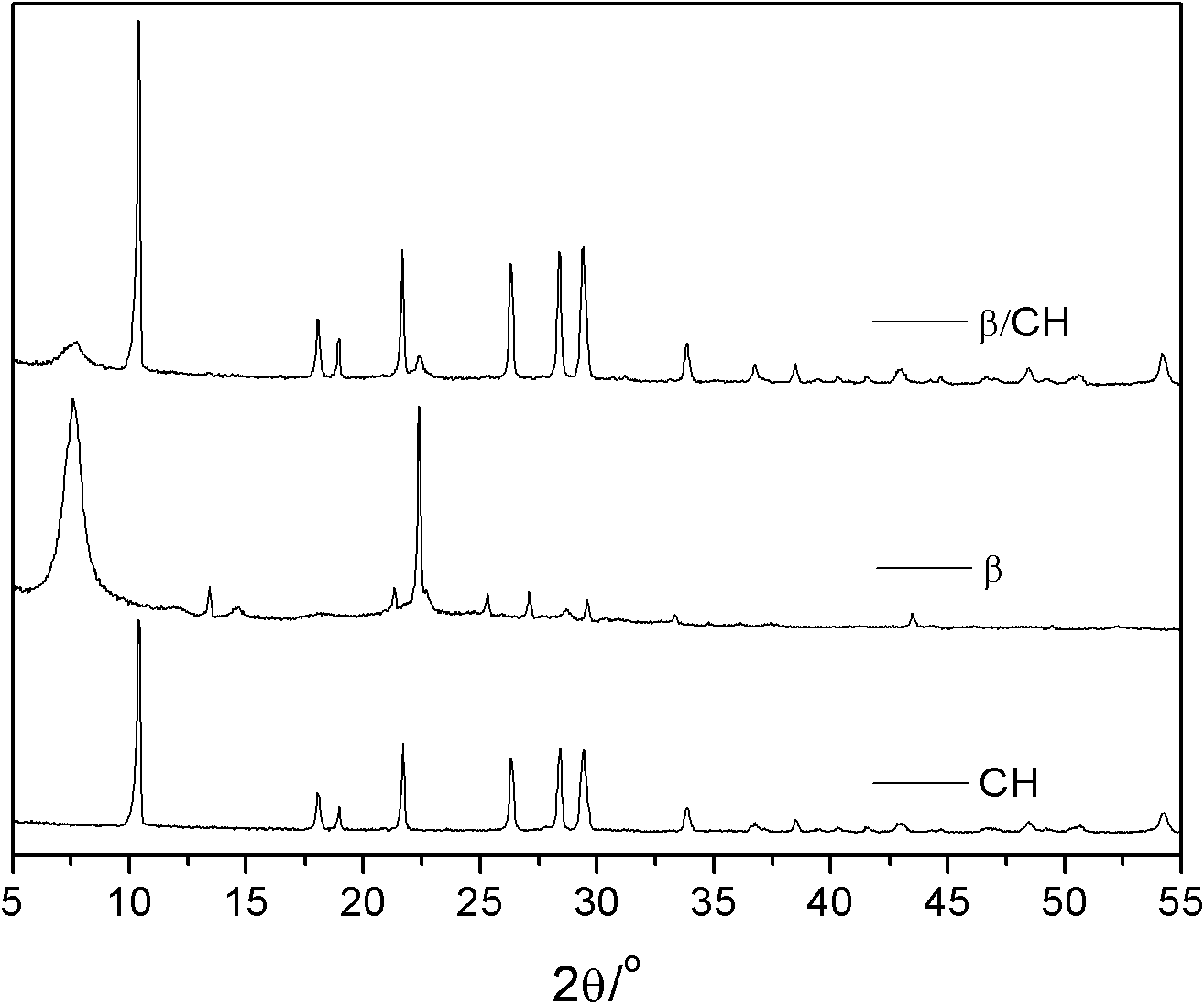

Honeycomb-ceramic-type monolithic catalyst, and preparation method and application thereof

InactiveCN102133537AIncrease roughnessPromote nucleationMolecular sieve catalystsDispersed particle separationMass ratioCordierite

The invention discloses a honeycomb-ceramic-type monolithic catalyst, and preparation method and application thereof. The monolithic catalyst takes honeycomb ceramic as a carrier, a Beta molecular sieve is coated on the surface of the honeycomb ceramic and taken as a coating layer, and then active component, namely precious metal, is loaded on the surface of Beta molecular sieve; the active component of the precious metal is one or two selected from palladium or platinum; in the honeycomb-ceramic-type monolithic catalyst, the mass ratio of the coating layer of the Beta molecular sieve to the honeycomb ceramic is 0.02-0.2:1, the mass ratio of the precious metal to the coating layer of the Beta molecular sieve is 0.02-0.2:1, the honeycomb ceramic is cordierite honeycomb ceramic; and in the invention, the high-silicon or full-silicon Beta molecular sieve is taken as the coating layer of the monolithic catalyst, and has the characteristics of good water resistance, high heat stability andthe like, and the monolithic burning catalyst taking the Beta molecular sieve as the coating layer can keep better activity and stability under high temperature, and suitable for being taken as catalytic combustion catalyst for application.

Owner:ZHEJIANG CENWAY MATERIALS CO LTD

Immobilized enzyme biological catalyst, preparation method and application

InactiveCN101058824AReduce dosageImprove distributionImmobilised enzymesChemical industryDielectricPotassium

The invention relates to an immobilized enzyme biocatalyst and the manufacturing method and application. The immobilized enzyme biocatalyst regards tubular hollow silica dioxide dielectric hole material as a carrier external surface, inner surface and micropore in the wall of which are fixed biological enzyme molecule. The method includes physical adsorption cast investment or chemical coupling / crosslinking method; the biocatalyst is provided with good enzyme dispersibility and high carrying quantity, high recovery ratio of enzymatic activity, low enzyme flow rate. The invention can fix penicillin acylating enzyme, glucose oxidase, peroxidase, cytase and so on, which also can be used for removing sugar in protein, removing sugar in total egg, removing oxygen in food , microbiological sensing device, antibiosis and disinfection reaction, wherein immobilized penicillin acylating enzyme biocatalyst can be used to hydrolyze penicillin potassium and manufacture 6-APA.

Owner:BEIJING UNIV OF CHEM TECH

Double-frequency and double-polarization antenna capable of operating in compass satellite navigation system and mobile third-generation (3G) network

InactiveCN102354809ALow return lossImproving Impedance BandwidthRadiating elements structural formsAntenna earthingsTelecommunicationsThird generation

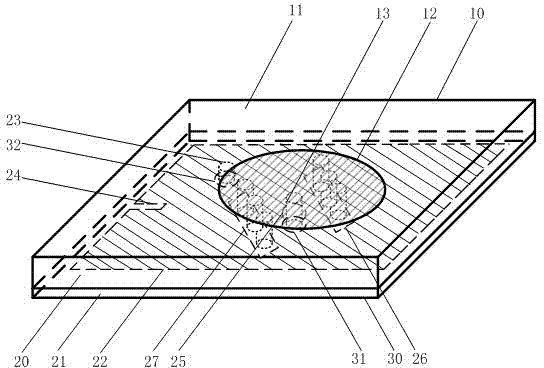

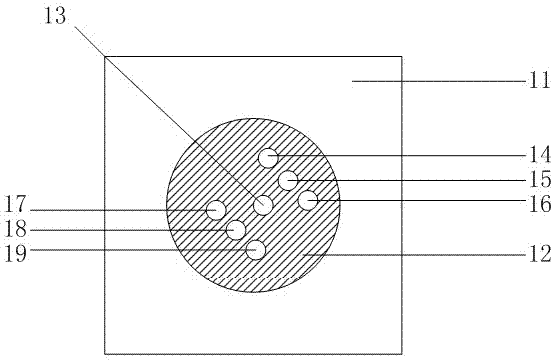

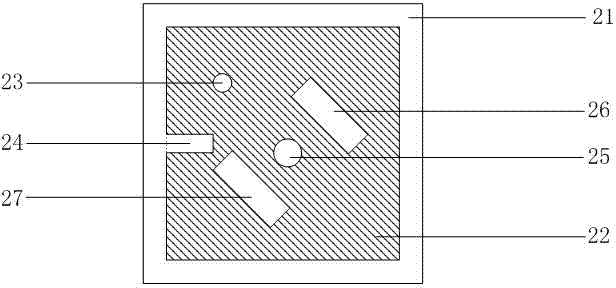

The invention discloses a double-frequency and double-polarization antenna capable of operating in a compass satellite navigation system and a mobile third-generation (3G) network and is implemented in a form of a laminated micro-strip circuit. The double-frequency and double-polarization antenna capable of operating in the compass satellite navigation system and the mobile 3G network comprises an upper-layer micro-strip antenna, a lower-layer micro-strip antenna and a metal floor layer, wherein the upper-layer micro-strip antenna has an upper-layer patch; the lower-layer micro-strip antenna has a lower-layer patch; the metal floor layer is arranged on a bottom layer; the upper-layer micro-strip antenna and the lower-layer micro-strip antenna share one metal floor layer; and the antenna is provided with six short-circuit metal columns which pass through the upper-layer micro-strip antenna and the lower-layer micro-strip antenna from the upper-layer patch and then are connected with the metal floor layer which is arranged on the bottom layer. The antenna adopts a feeding mode of dual-port coaxial feeding and has the advantages of simple and compact structure, miniaturization, convenience for processing and industrialized application, and the like.

Owner:SOUTH CHINA UNIV OF TECH

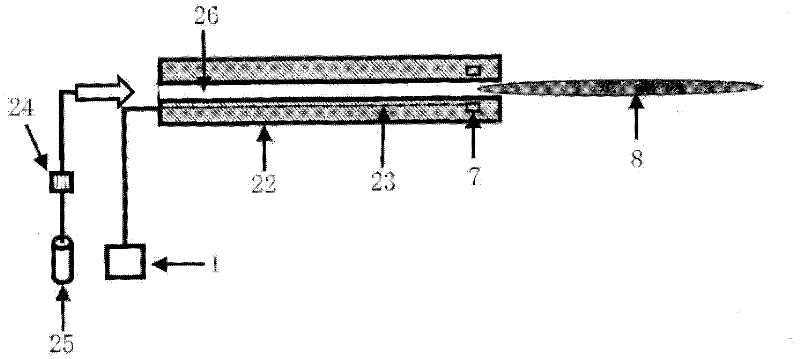

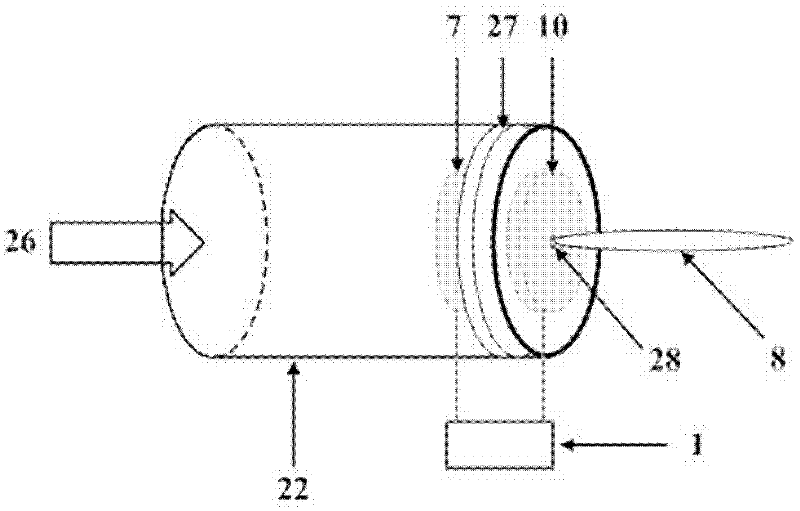

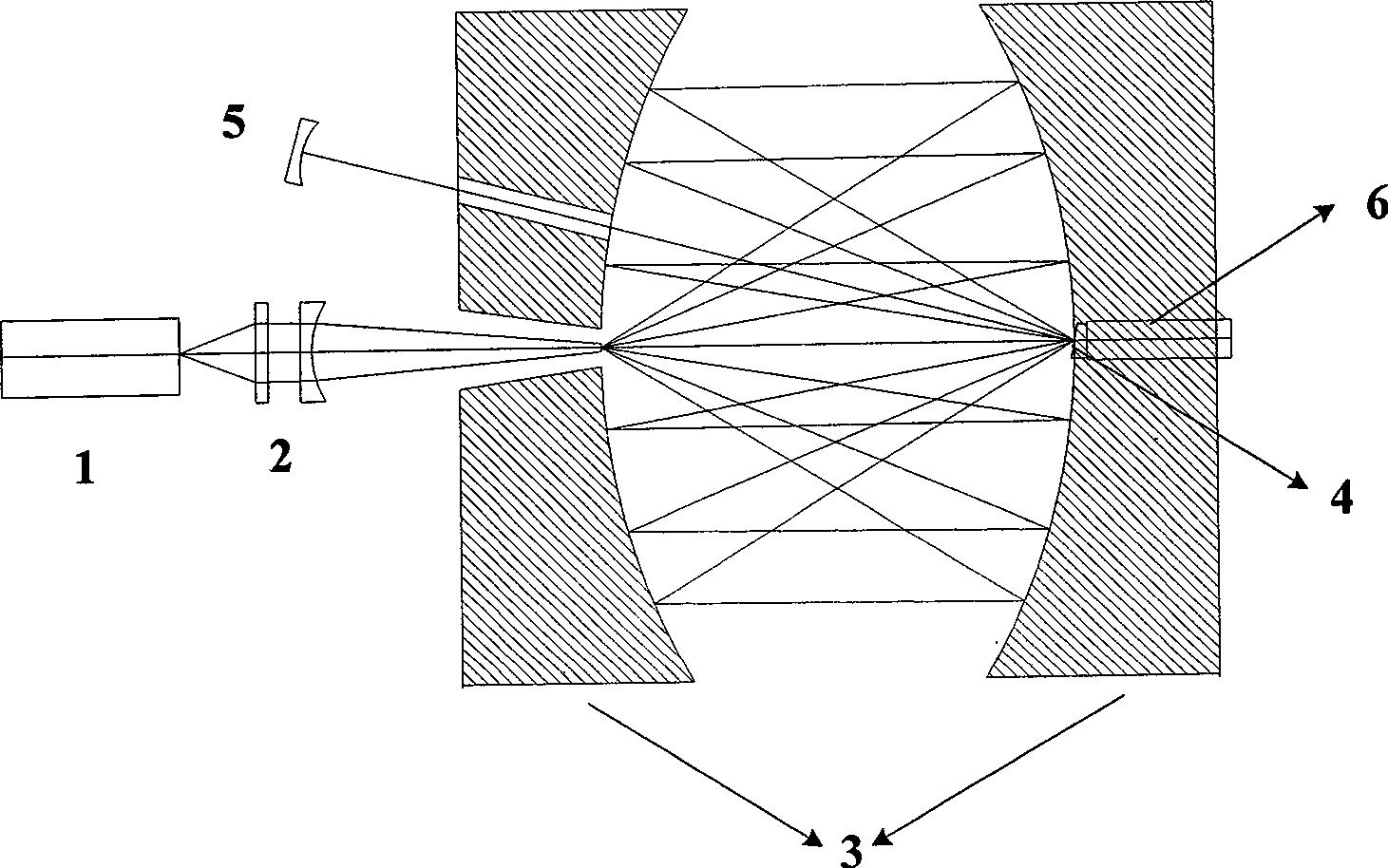

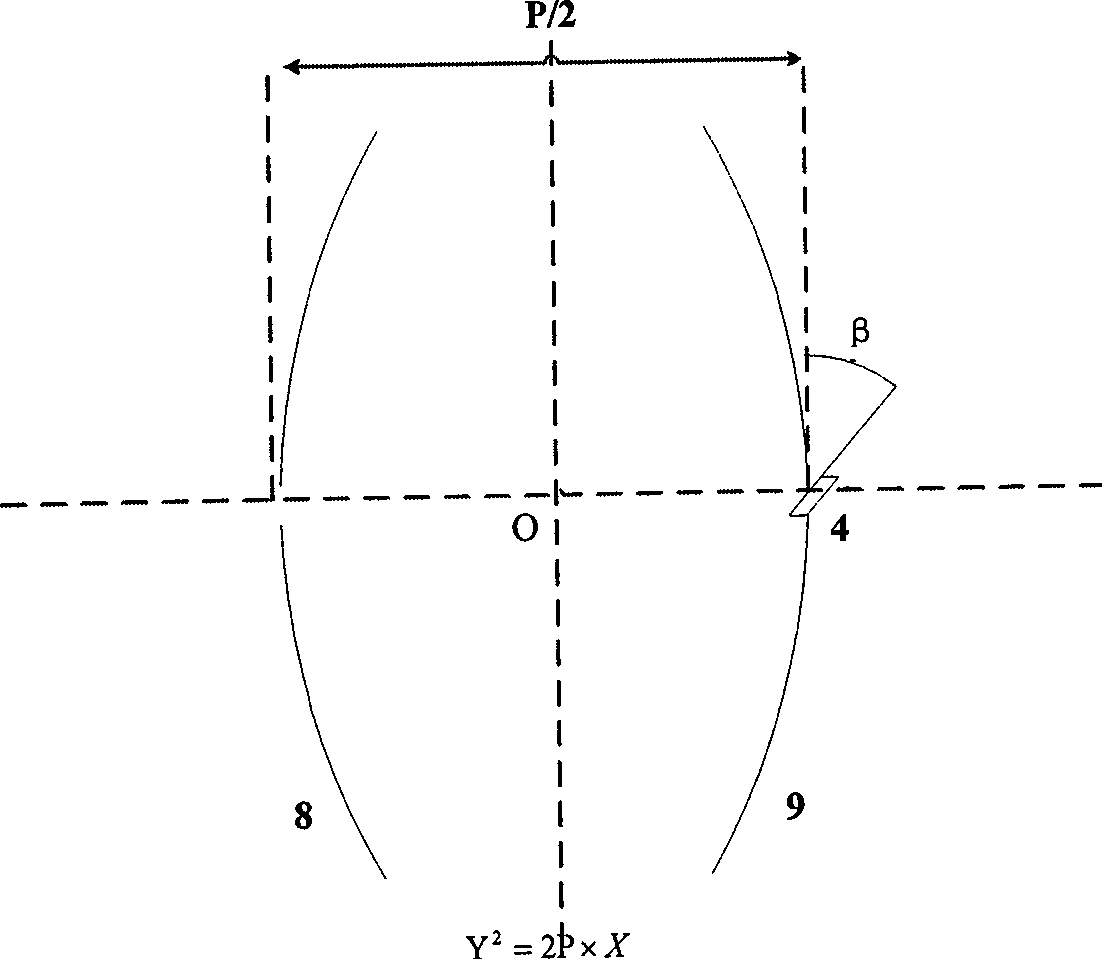

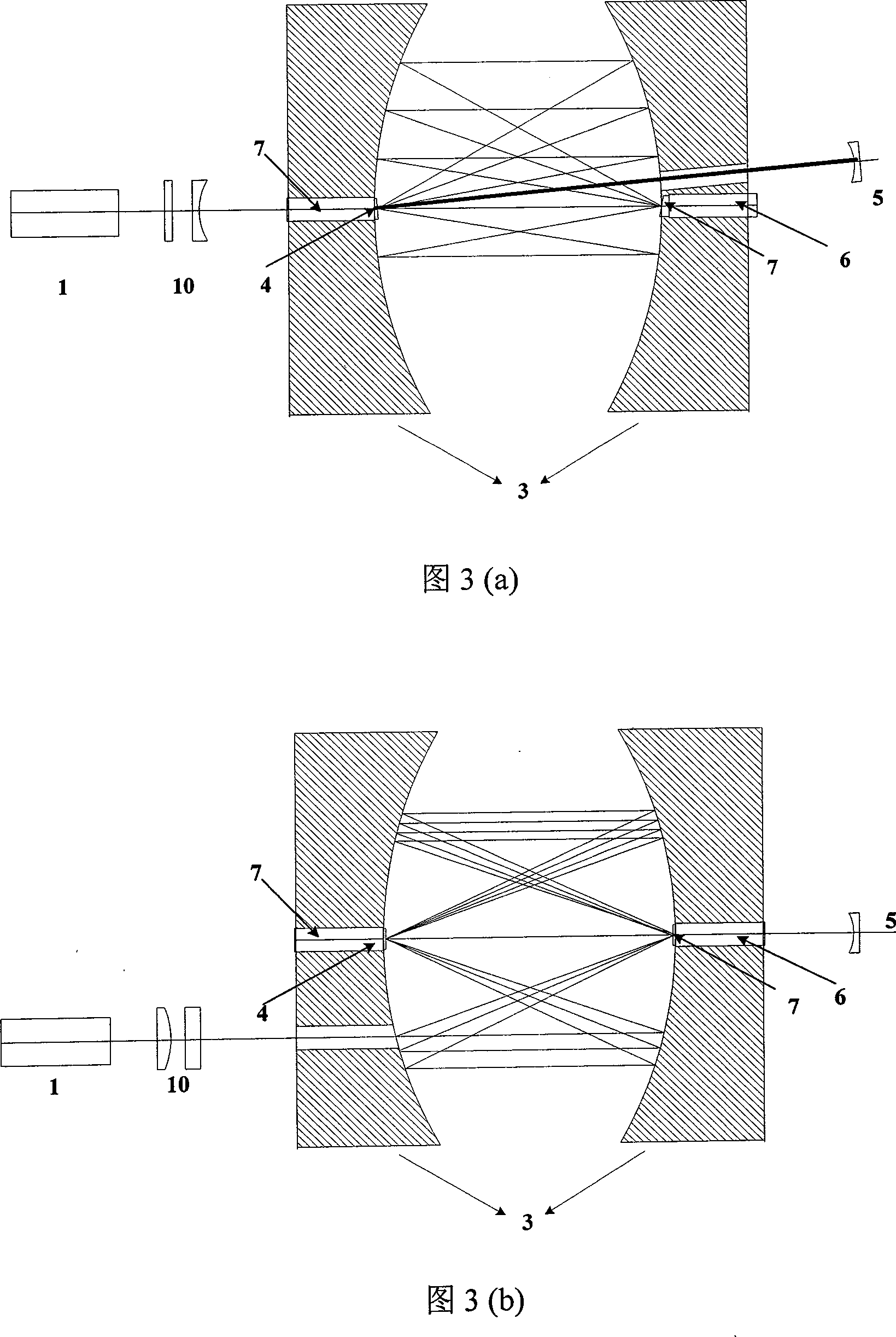

Disc piece solid laser

The invention discloses a video disc fixing laser. A video disc laser crystal and a laser cavity resonator output lens form a laser cavity resonator; the focus of one of two paraboloid reflectors positioned in a conjugating way is positioned in the video disc laser crystal; a pump light sent by a semiconductor laser stack array is firstly collimated by a pump light collimator, then is imaged on the video disc laser crystal through the two paraboloid reflectors and is output as laser formed through the laser cavity resonator at last. The invention adopts the method of semiconductor stack array and has high efficiency, long service life and convenient equipment maintenance. A double-paraboloid pump system positioned in the conjugating way reduces the requirement for the collimation degree of the pump light and realizes high-efficiency imaging of the pump light. Each secondary pump luminous spot has regular and symmetrical shape, reasonable power density distribution and small position excursion of the light luminous spots for each imaging, and high-efficiency and even pumping is realized. The equipment has smaller volume, simple mechanical structure and adjustment and lighter weight, and is convenient for industrial application.

Owner:HUAZHONG UNIV OF SCI & TECH

Positive electrode material of lithium ion battery and preparing method thereof

ActiveCN103151521AReduce the effect of tap densityImprove cycle performanceCell electrodesSodium-ion batteryIron phosphate

The invention relates to a lithium titanate-carbon co-cladded lithium manganese iron phosphate positive electrode material. According to the invention, the characteristic of zero stress of a lithium titanate material is utilized for inhibition of deformation of a positive electrode during charging and discharging so as to improve cycle performance and resistance to over-charge and over-discharge of the positive electrode material, and conductivity and electrochemical properties of the positive electrode material are improved through co-cladding of the lithium titanate material and carbon; meanwhile, tap density of lithium titanate is as high as 1.68 g / cm<3>, which enables influence of carbon cladding on the tap density of the positive electrode material to be reduced. A preparation method for the positive electrode material provided by the invention is simple, is easy to operate and can easily realize industrial application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Electroless nickel-phosphorus plating process for Nd-Fe-Bo permanent magnet material

InactiveCN1807682AAvoid bulgingPrevent peelingLiquid/solution decomposition chemical coatingCleaning using liquidsElectroless nickelPhosphor

The invention discloses a chemical plating nickel plating method of neodymium-iron- boron permanent magnet material, which is characterized by the following: adopting plugging chemical plating to plug neodymium-iron-boron and thick and block-up neutral chemical plating; carrying on chemical plating nickel phosphor method of acidic high-phosphorus chemical plating, wherein the method comprises the following steps: tumbling; chamfering; degreasing; derusting; activating; plugging chemical plating; neutering chemical plating; acidifying high-phosphorus chemical plating; inactivating. The invention simplifies the application of industry, which reduces cost of production.

Owner:鲁国强

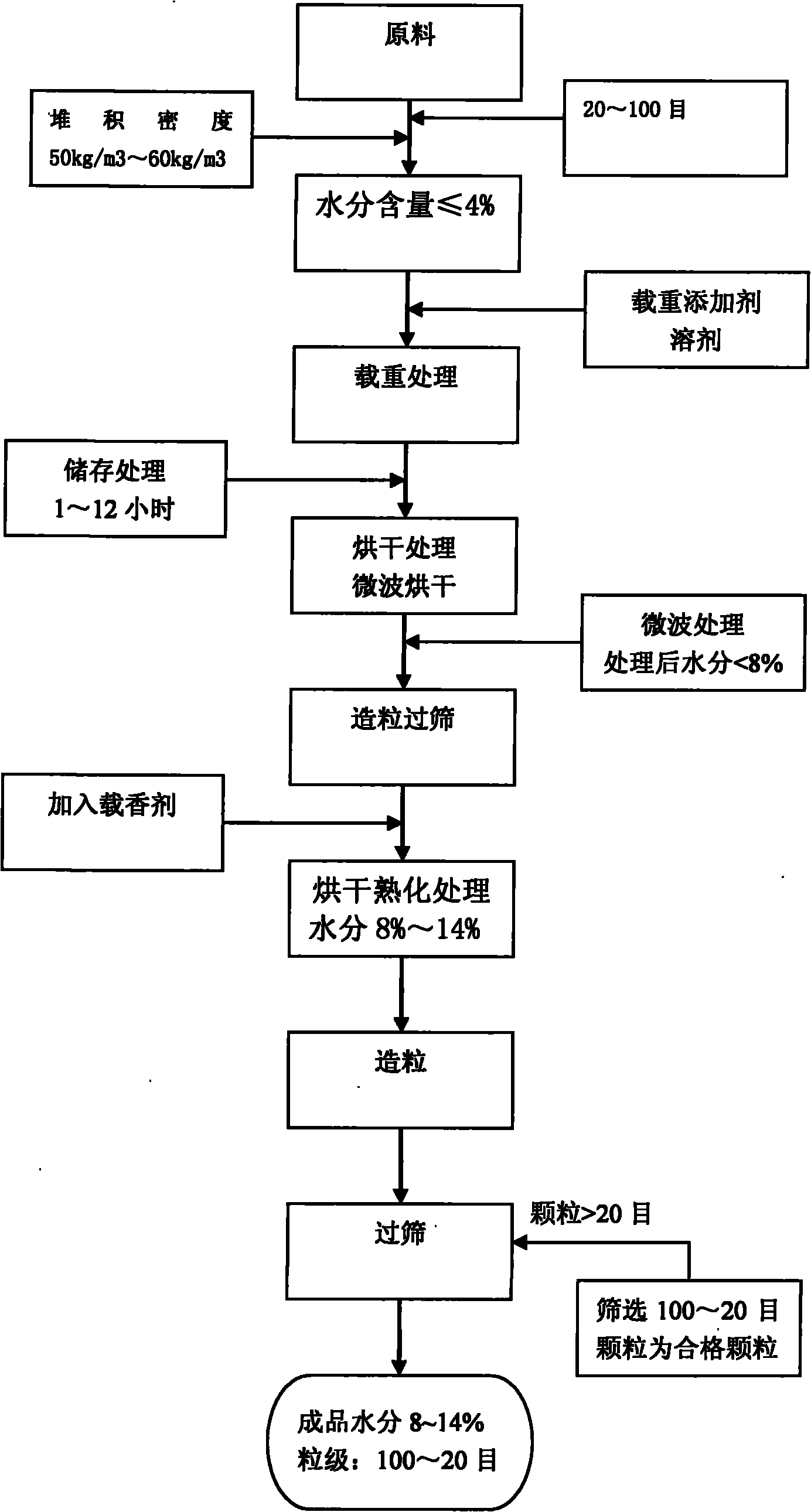

Preparation method of cigarette flavor compensating particles

The invention relates to a preparation method of cigarette flavor compensating particles, in particular to a filtering material added to a cigarette filter and the preparation method of the material, belonging to the technical field of a cigarette auxiliary material. The cigarette flavor compensating particles are mainly composed of a silicic acid rock base material and a flavor carrying agent; bulking silicic acid rock is taken as a raw material; a loading agent is added; and finally the silicic acid rock load particles are formed by loading, drying, granulating and other processes. In the preparation method, particle materials are from the silicic acid rock and a natural plant material, and the silicic acid rock has better absorption characteristics; after loading and microwave treatment, the silicic acid rock particles have no influence on cigarette flavor, and the employed loading agent has the action of synergetic harm reduction at the same time; and a formula plant extract and plant fiber loaded on the surface of the particles can effectively release quantitative flavor elements and transfers the flavor elements to sucked smoke. The silicic acid rock particles prepared by the method can be used for directly combining with the current filter tip forming process, thus achieving convenient industrialized application.

Owner:SHANGHAI HUABAO BIOLOGICAL TECH

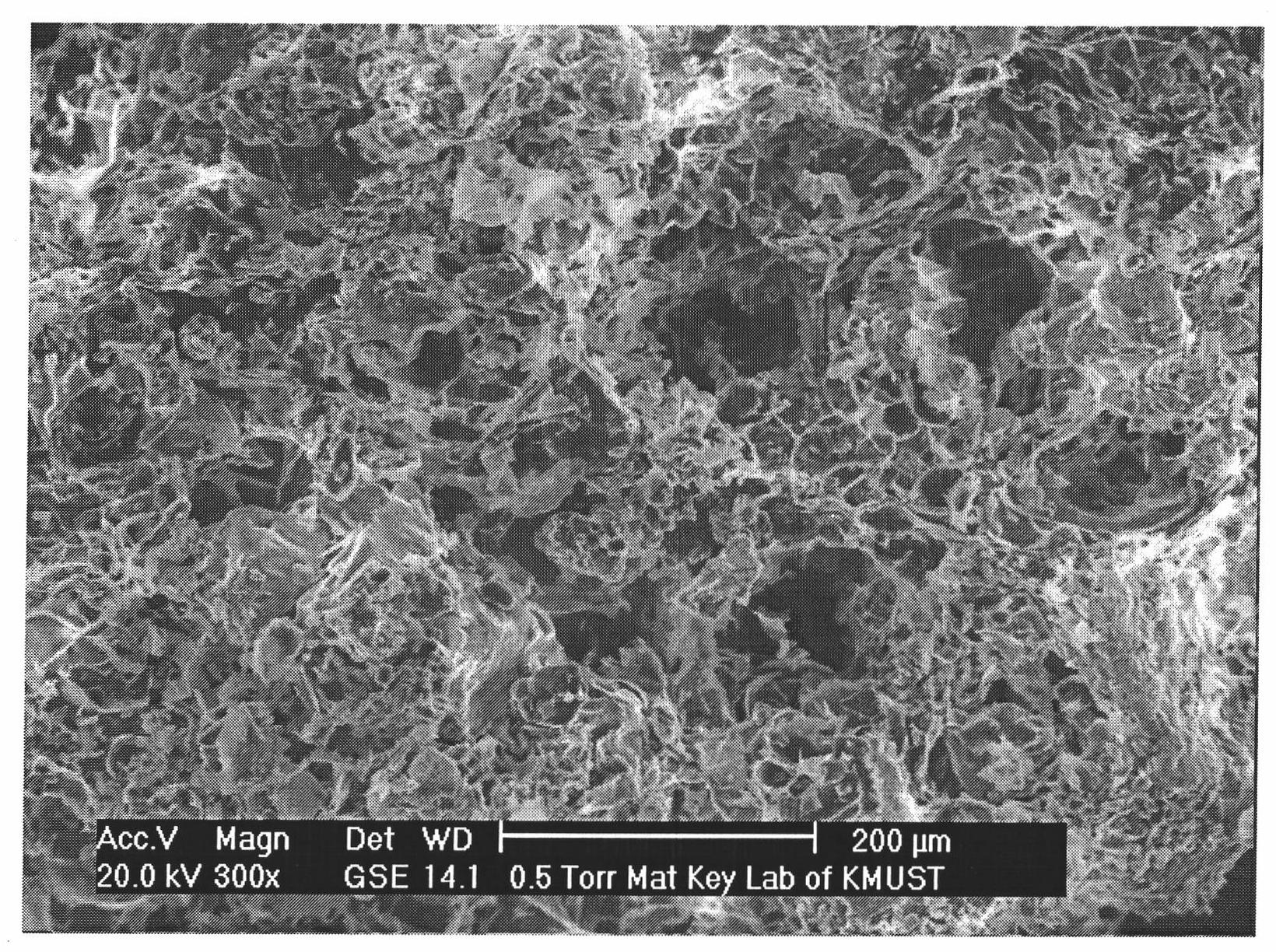

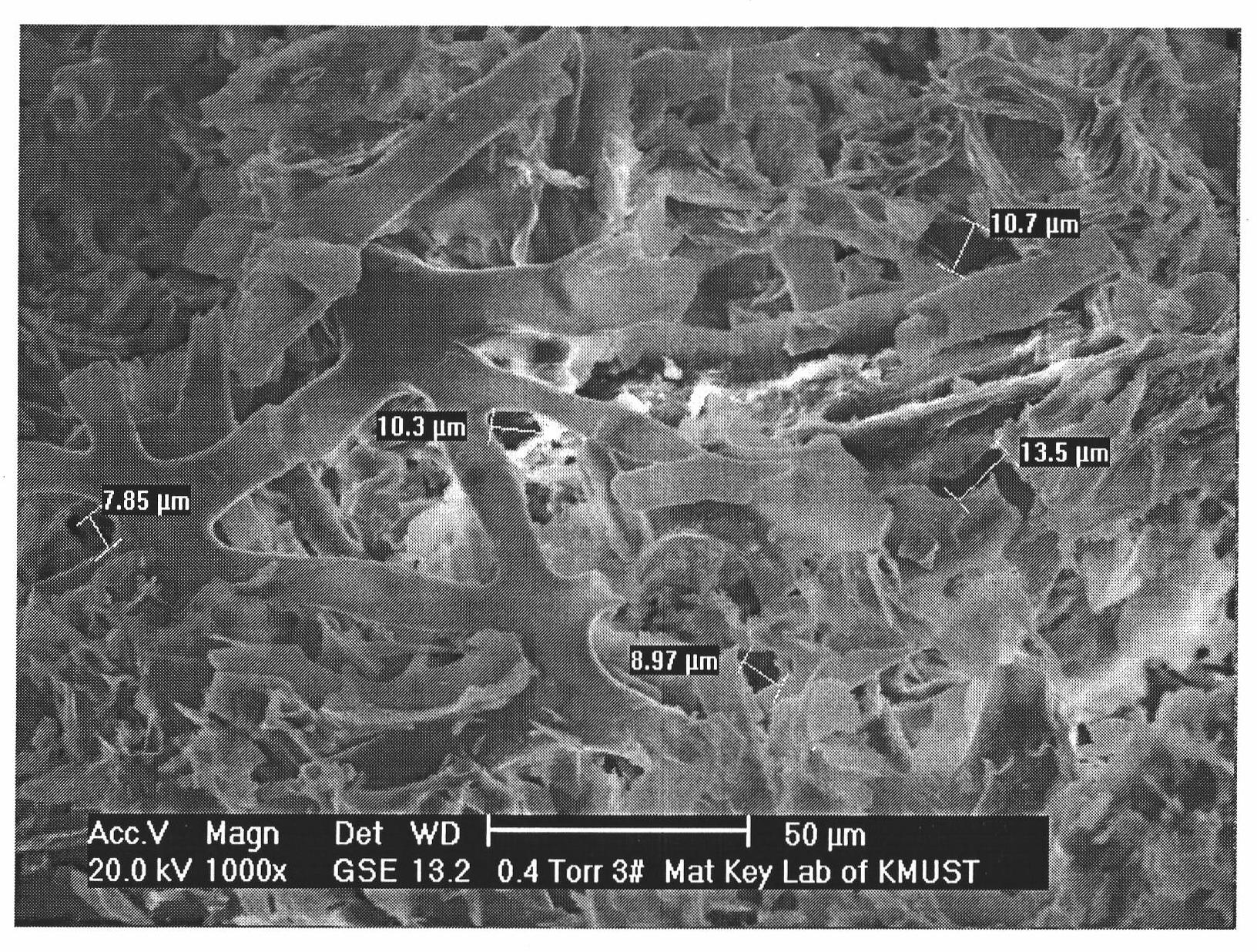

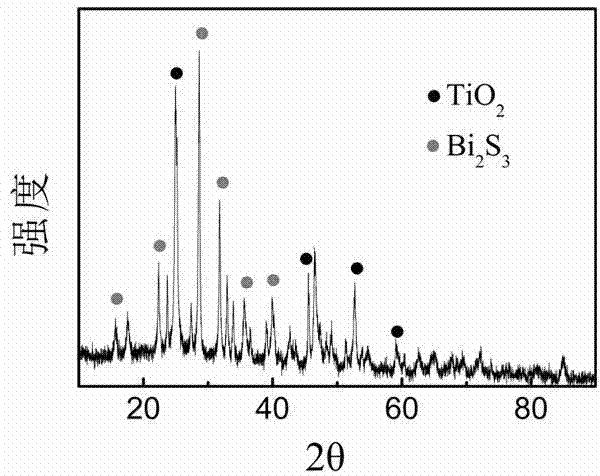

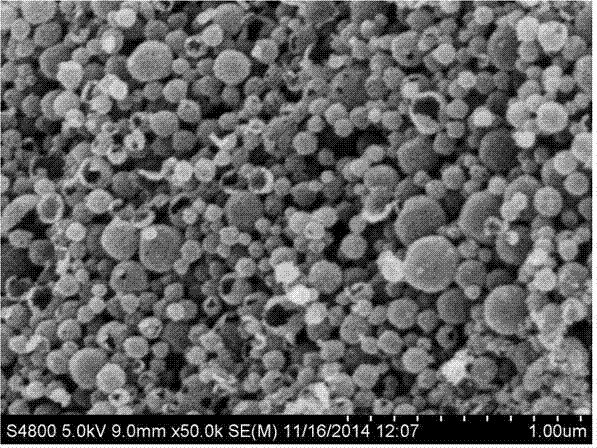

Metallic oxide/metal sulfide hollow nanospheres as well as preparation method and application thereof

ActiveCN104492460AEffective compoundAvoid recombinationPhysical/chemical process catalystsHeterojunctionPhysical chemistry

The invention discloses a metallic oxide / metal sulfide core-shell heterojunction hollow nanosphere. The inner layer of the spherical shell is a metallic oxide polycrystalline layer; the outer layer of the spherical shell is a metal sulfide polycrystalline layer; a heterojunction is formed between the metallic oxide polycrystalline layer and the metal sulfide polycrystalline layer; the thickness of each layer is 10 nanometers or below; and the diameter of the hollow sphere is 100-600 nanometers. The preparation method comprises the following steps: utilizing a template adsorption method, performing stepped adsorption and subsequent hydrothermal sulfuration, thereby preparing the metallic oxide / metal sulfide core-shell heterojunction hollow nanosphere. The metallic oxide / metal sulfide core-shell heterojunction hollow nanosphere disclosed by the invention is regular in structure, the thickness of the spherical shell is controllable, the grain size of the metallic oxide and metal sulfide is 10nm or below, the crystal quality is high, and the specific surface area is larger than 200m<2> / g. The method disclosed by the invention is simple and low in cost, has extremely wide range on selection of types of metallic oxides and selection of metal sulfides and contributes to industrialized application.

Owner:ZHEJIANG UNIV

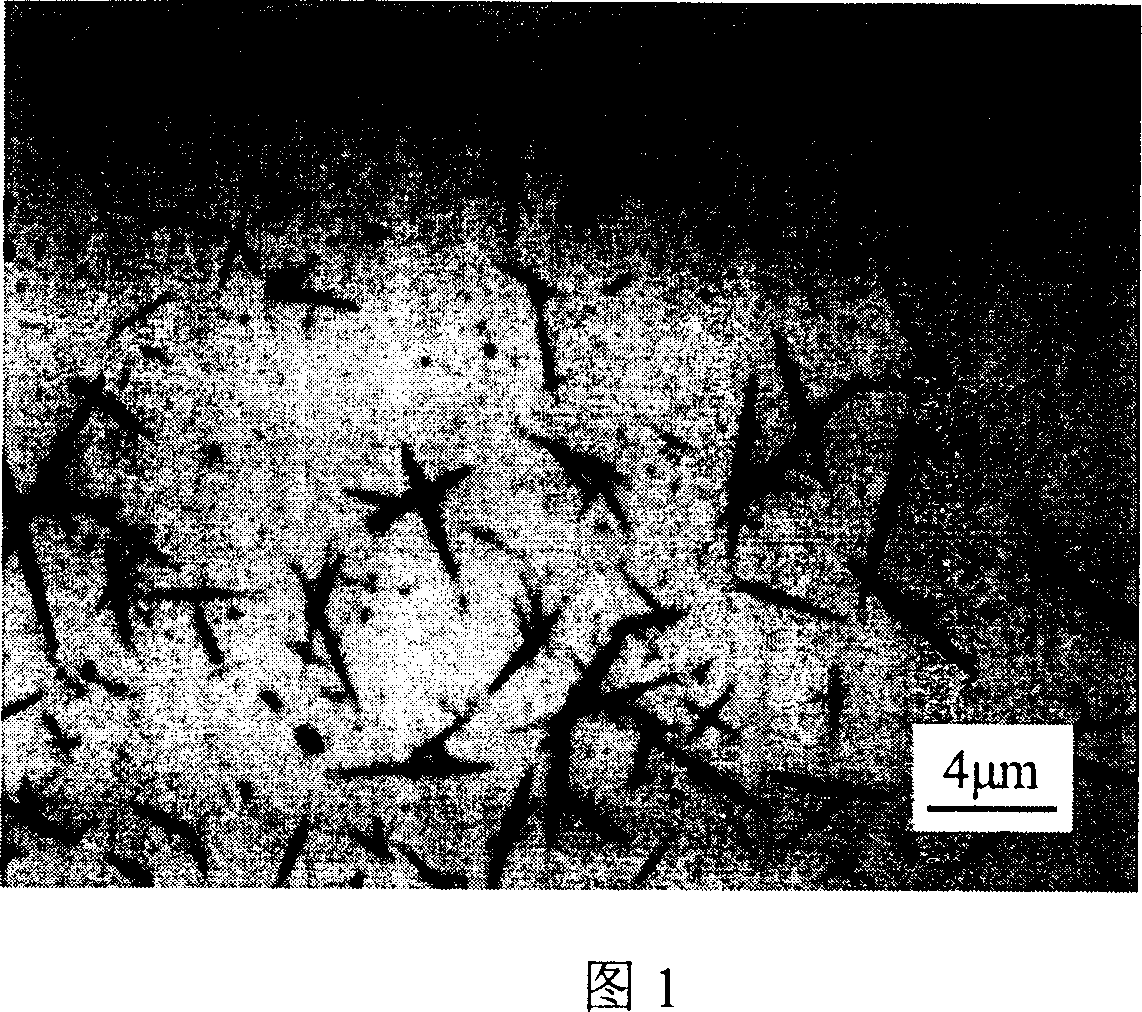

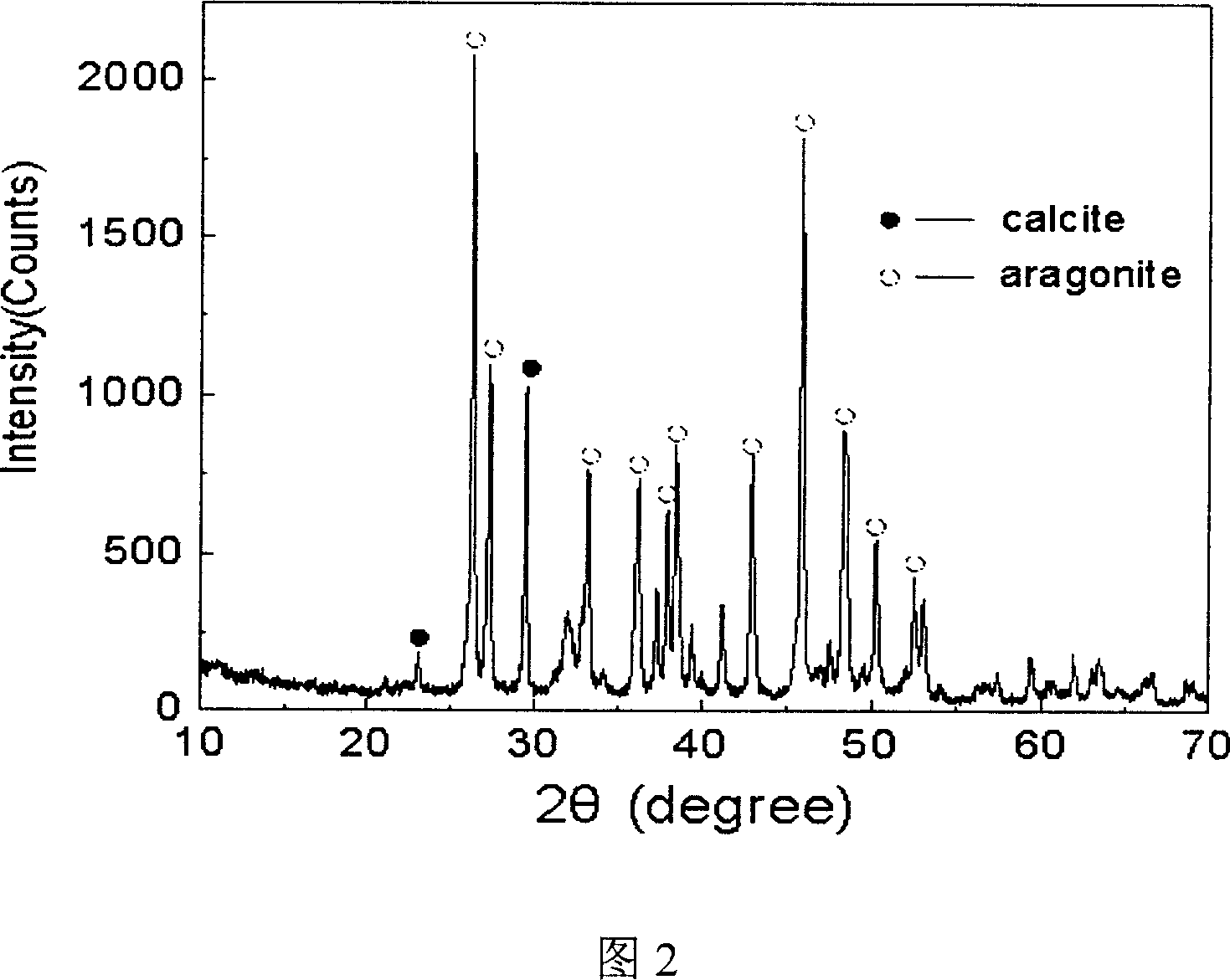

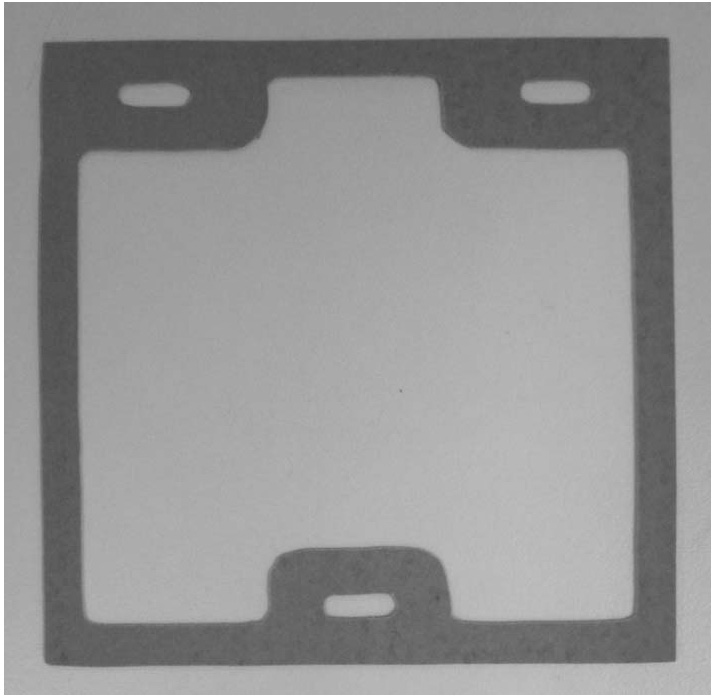

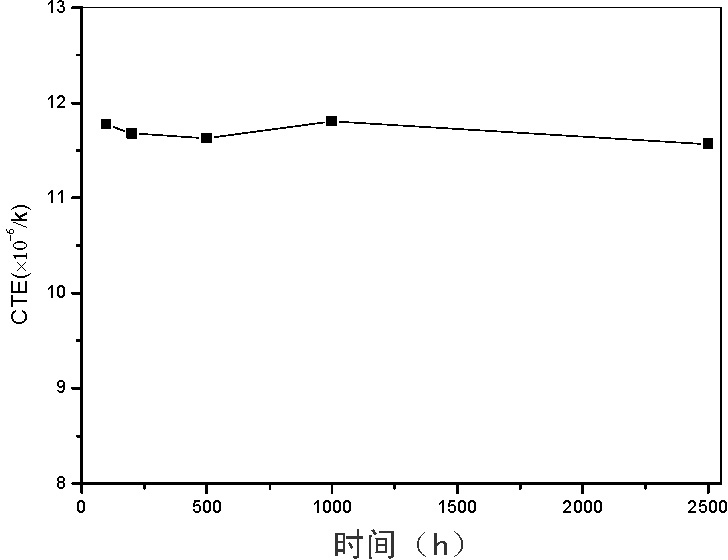

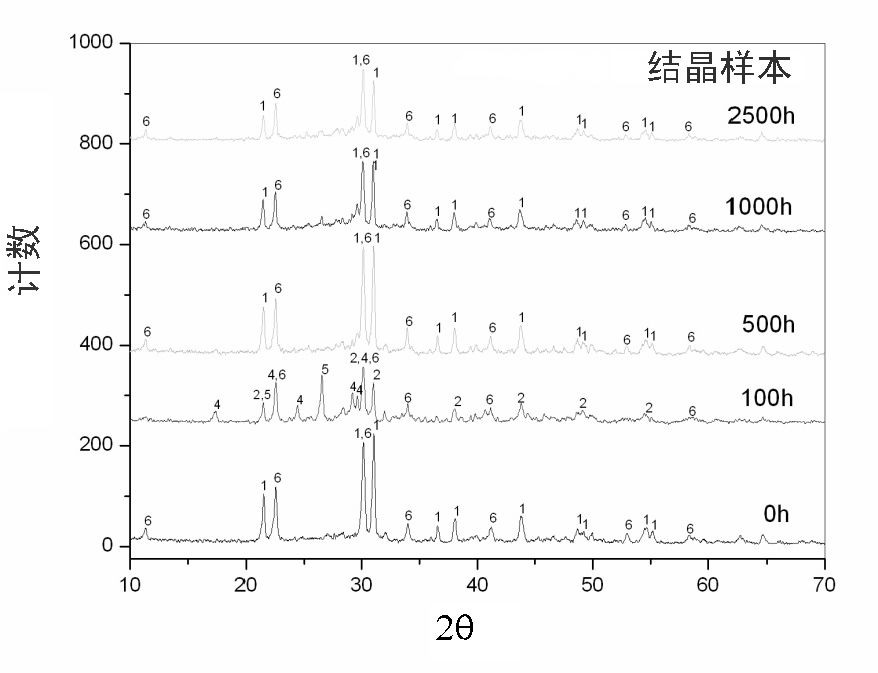

Sealing gasket for medium-and-low temperature solid oxide fuel cell, and manufacturing method and application of sealing gasket

ActiveCN102386345ASmall change in coefficient of thermal expansionStable thermal cycleCell component detailsFuel cellsPlasticizer

The invention relates to a sealing gasket for a medium-and-low temperature solid oxide fuel cell, and a manufacturing method and application of the sealing gasket. The sealing gasket comprises sealing glass powder, a dispersant, a plasticizer, a bonding agent and a solvent, and is characterized in that: the sealing glass powder comprises 28 to 38 mol percent of SiO2, 5 to 15 mol percent of B2O3, 30 to 40 mol percent of BaO, 0 to 10 mol percent of Al2O3, 0 to 5 mol percent of ZrO2, 0 to 16 mol percent of CaO, 0 to 15 mol percent of ZnO, 0 to 0.5 mol percent of NiO, 0 to 0.5 mol percent of Cr2O3 and 0 to 0.5 mol percent of Co2O3. Under the working temperature of the medium-and-low temperature solid oxide fuel cell, the coefficient of thermal expansion of the sealing gasket provided by the invention is slightly changeable in long-term thermal treatment, and is stable in the multiple thermal circulation and long-term running of a galvanic pile.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

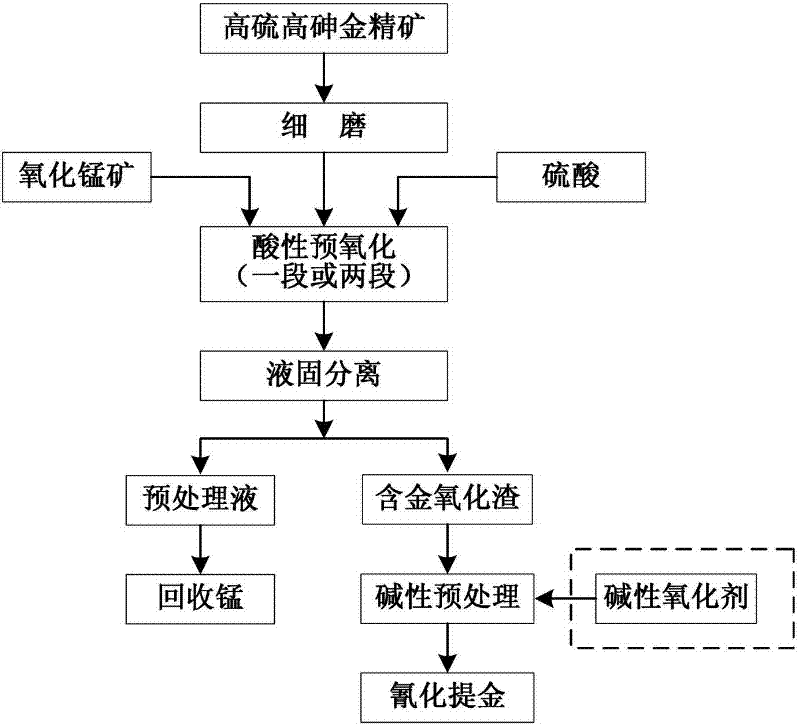

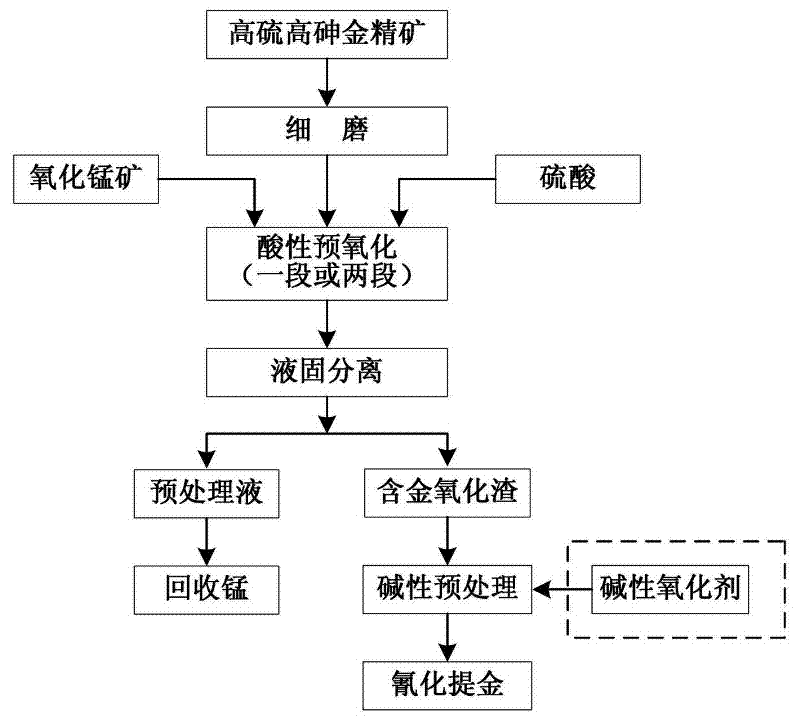

Gold extraction method by pre-oxidation and cyanide leaching of refractory gold concentrate

ActiveCN102409183AEasy to operateMild control conditionsProcess efficiency improvementSlagOre concentrate

The invention discloses a gold extraction method by pre-oxidation and cyanide leaching of refractory gold concentrate, comprising the following steps: firstly mixing the refractory gold concentrate and a dispersing agent, grinding by a grinder; then mixing the oxidant and the grinded material, size mixing; then mixing and stirring the slurry with concentrated sulfuric acid, so as to perform more than a period of acid pre-oxidation reaction, reacting for more than one hour at a constant temperature, separating the solid and the liquid; then adjusting the pH value of the gold-bearing slag afterthe pre-oxidation, performing alkaline pretreatment for more than one hour; performing cyanide gold extraction on the slurry after alkaline pretreatment, passing oxygen or air during the cyanide process. The invention has advantages of low cost, simple operation, strong adaptability of raw material, high gold recovery rate, environmental pollution-free and easy industrial application.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

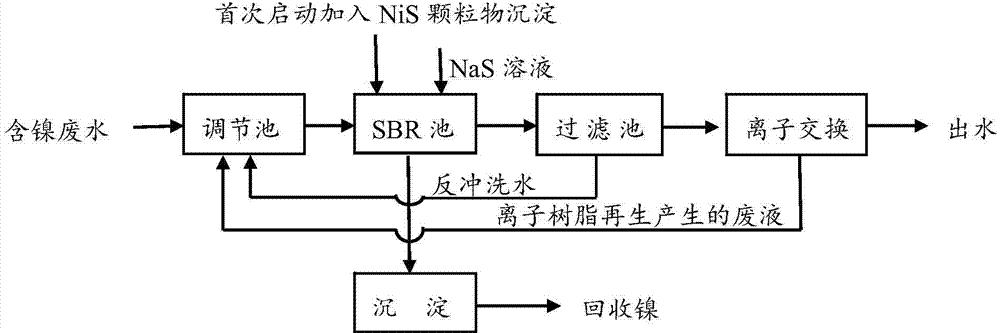

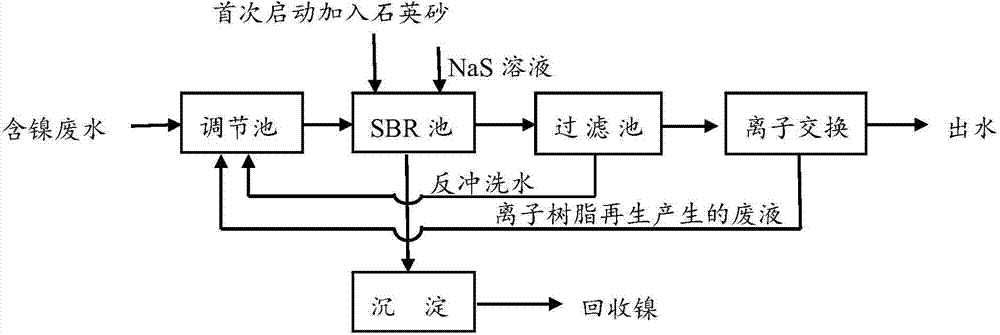

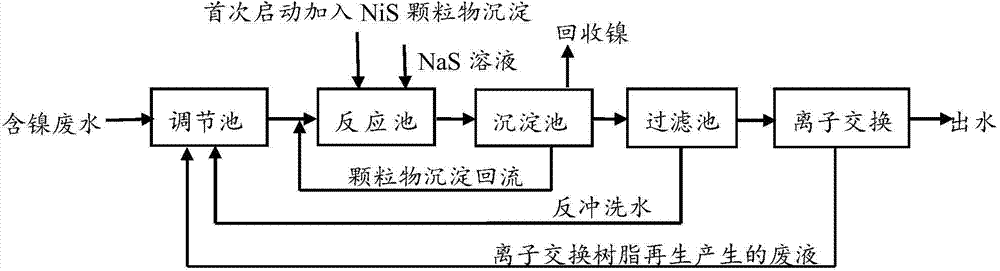

Treatment method of heavy metal wastewater

InactiveCN104261526ATo achieve the purpose of purifying wastewaterLarge particle sizeWater treatment compoundsWater contaminantsParticulatesFiltration

The invention provides a treatment method of heavy metal wastewater, and particularly relates to a method for treating heavy metal wastewater by virtue of a precipitation method. The method comprises the following steps: adding sodium sulfide in a heavy metal wastewater treatment process, reacting sulfur ions with heavy metal ions in the wastewater to generate particulate matters, further adding sulfide precipitates of heavy metal, stirring, standing, and accelerating the sedimentation of micro particulate matters and other substances by using generated particulate matter precipitates; further preferably adding quartz sand, and accelerating the rapid sedimentation of the particulate matters and other substances under the wrapping action of quartz sand; further performing subsequent process treatment including sand filtration and ion exchange on a supernatant liquor obtained after sedimentation to reach the emission standard; and periodically discharging and collecting part of the precipitates, and recycling heavy metals in the precipitates. Because the method provided by the invention is simple in working procedure, low in cost and high in efficiency, the method can be widely applied to the treatment of industrial wastewater particularly the heavy metal wastewater.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

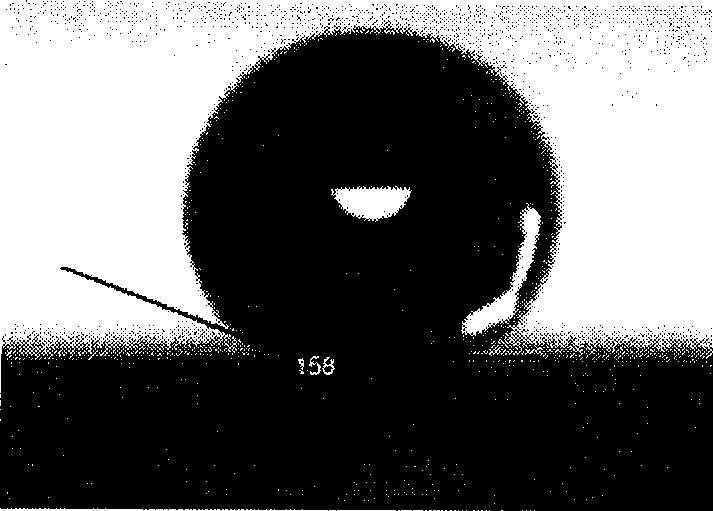

Surface processing method of super-hydrophobic ice-covering-proof aluminum and steel with rough surface

InactiveCN101705488AEase of industrial applicationWide applicabilityMetallic material coating processesRough surfaceAcetic acid

The invention relates to a surface processing method of super-hydrophobic ice-covering-proof aluminum and steel with rough surfaces. The method comprises the following steps: performing ultrasonic cleaning to aluminum and steel plates with acetone and deionized water, drying, suspending the aluminum and steel plates in a sealed container with 20vol.%-80vol.% of hydrochloric acid solution, then etching aluminum and steel plates with volatile hydrochloric acid for 15min-1h in a water bath under the temperature of boiling water, namely 100 DEG C; after the etching, placing the aluminum and steel plates in the normal hexane solution of fluorosilane to performing evaporation and modification of fluorosilane at 200-300 DEG C for 1-2h, and finally taking out the samples to keep temperature in the air at 180-300 DEG C for 1-2h; and in the fluorosilane solution, the weight ratio of fluorosilane to normal hexane is 1-5%, and the pH value of the added acetic acid aqueous solution is 3 and the content is 2-4% of the normal hexane solution of fluorosilane.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com