Patents

Literature

65results about How to "Controlled reunion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

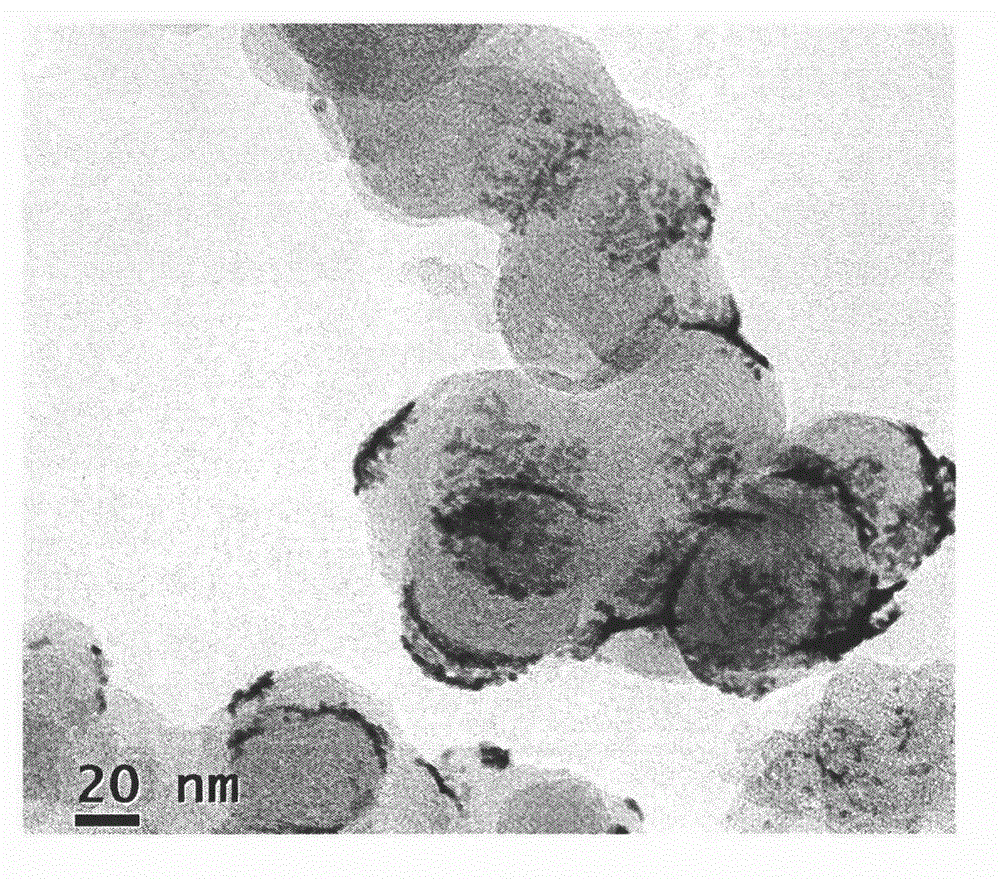

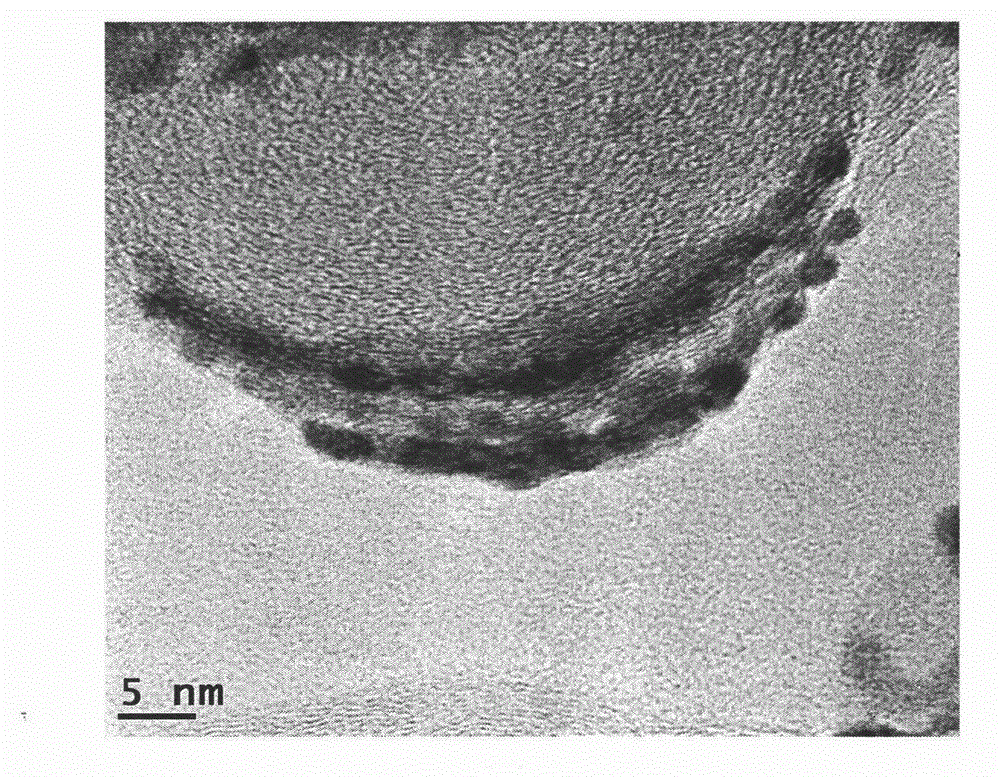

ZSM-5 type molecular sieve for catalyst for reaction for preparing propylene from methanol and/or dimethyl ether

ActiveCN101624192AImprove diffusion abilityHigh P/E ratioMolecular sieve catalystsHydrocarbon from oxygen organic compoundsDispersitySilicon

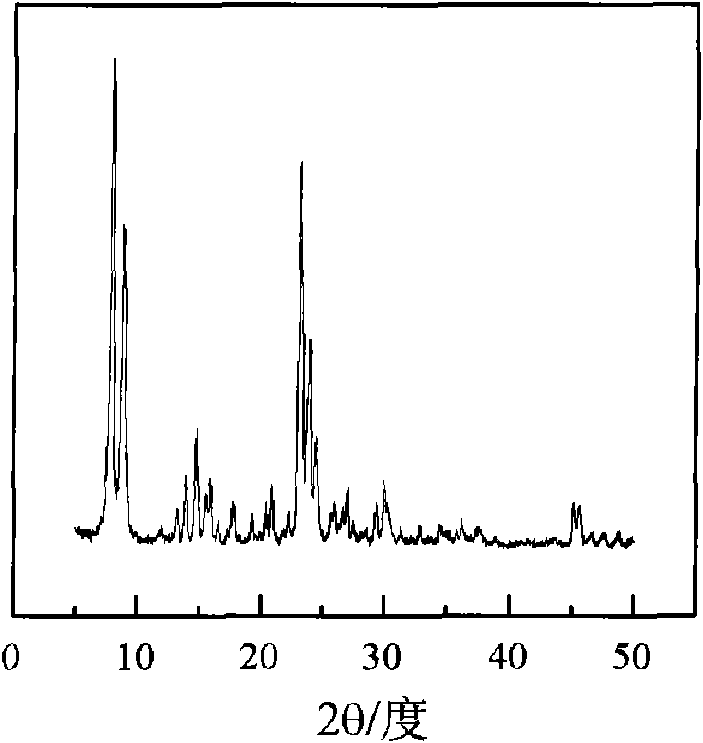

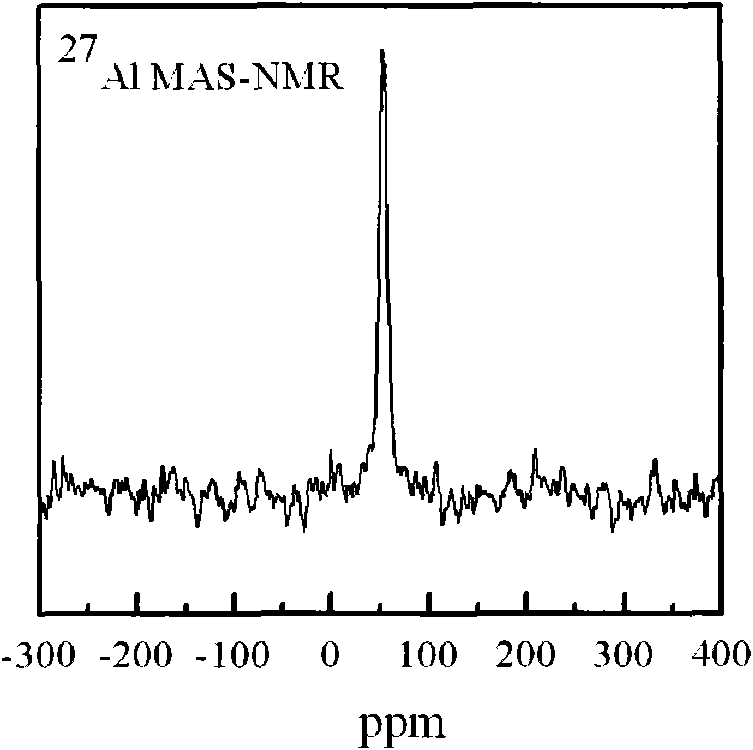

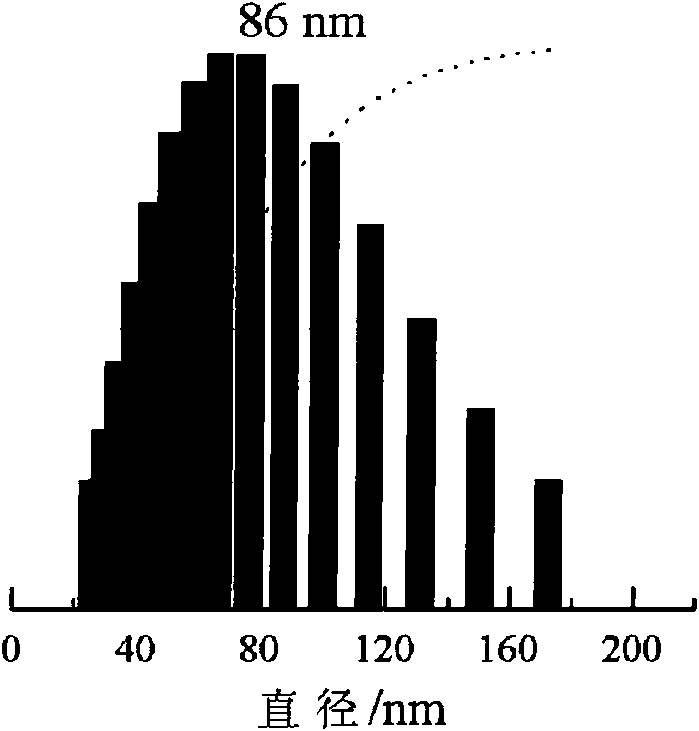

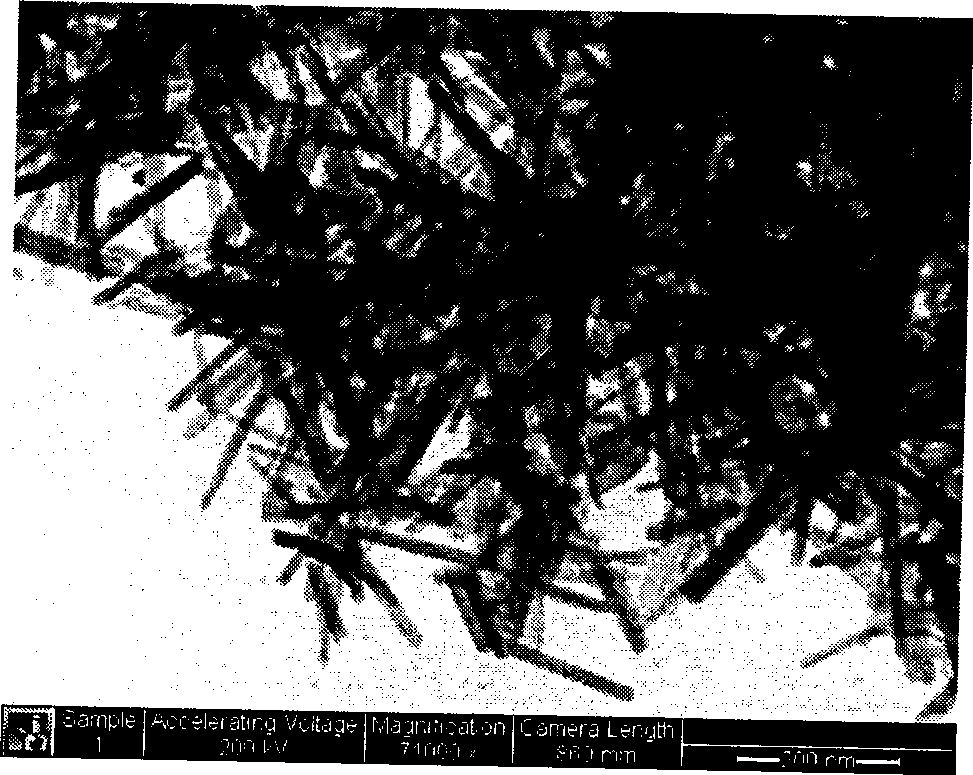

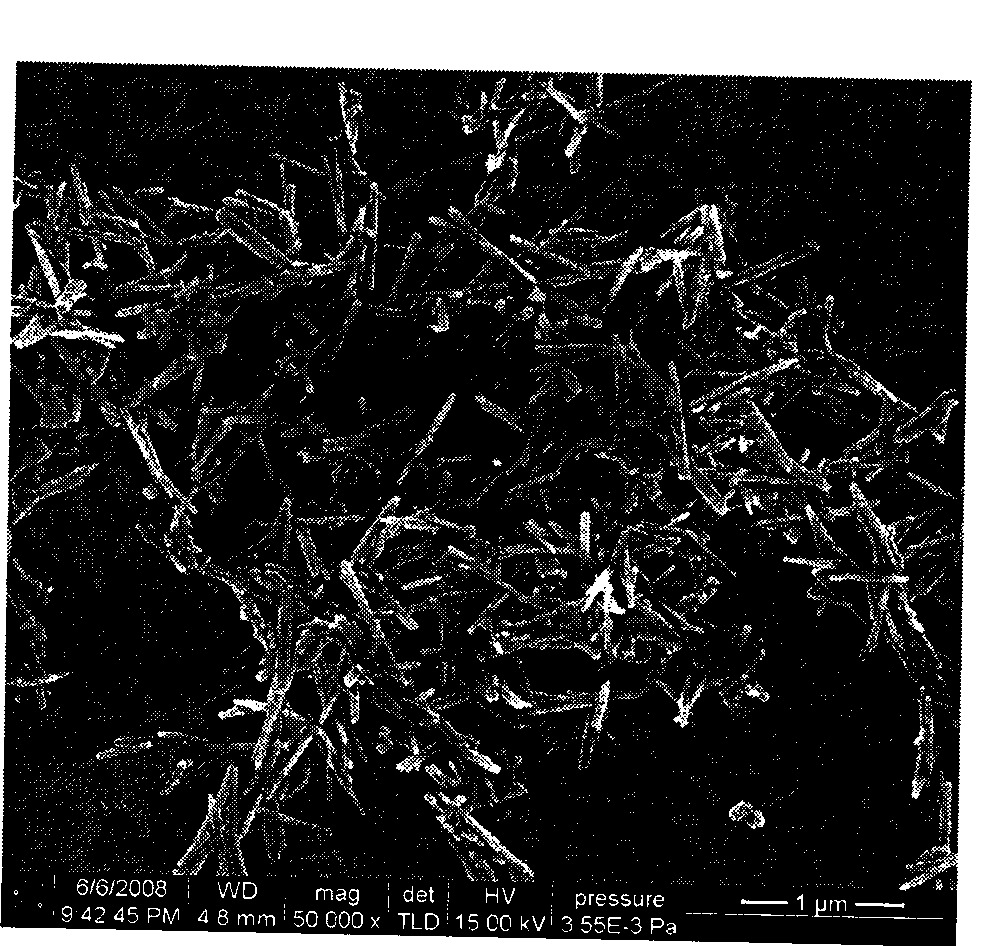

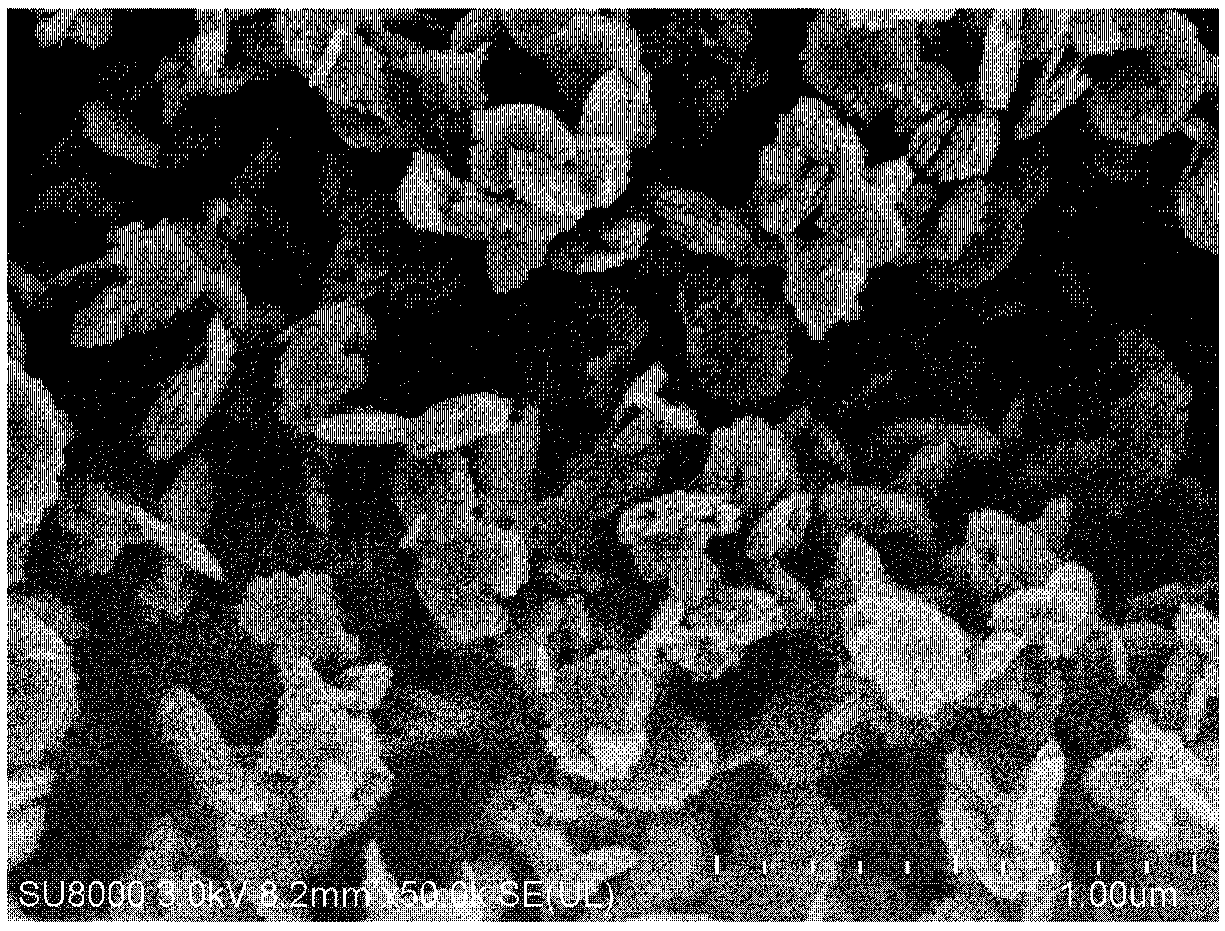

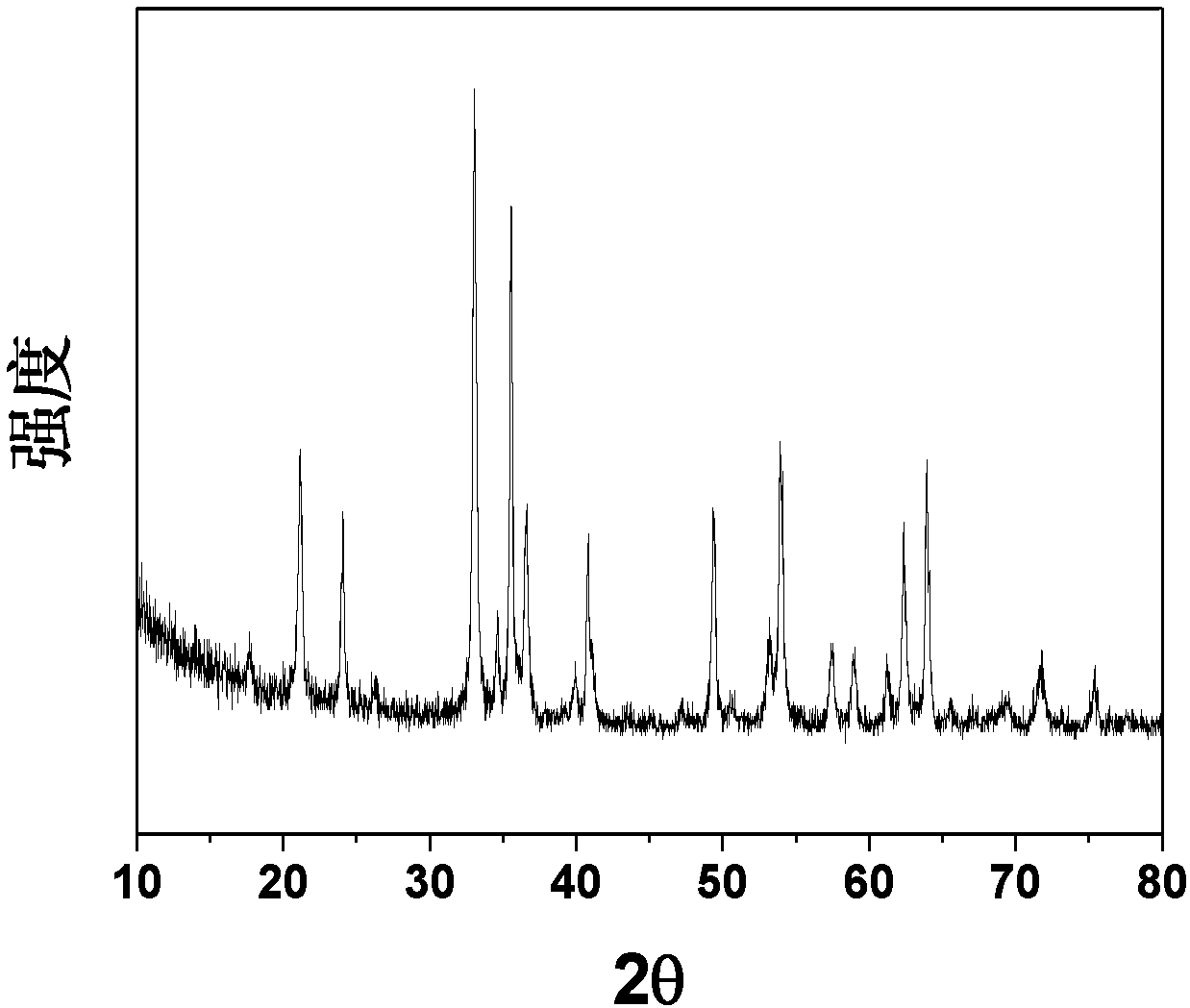

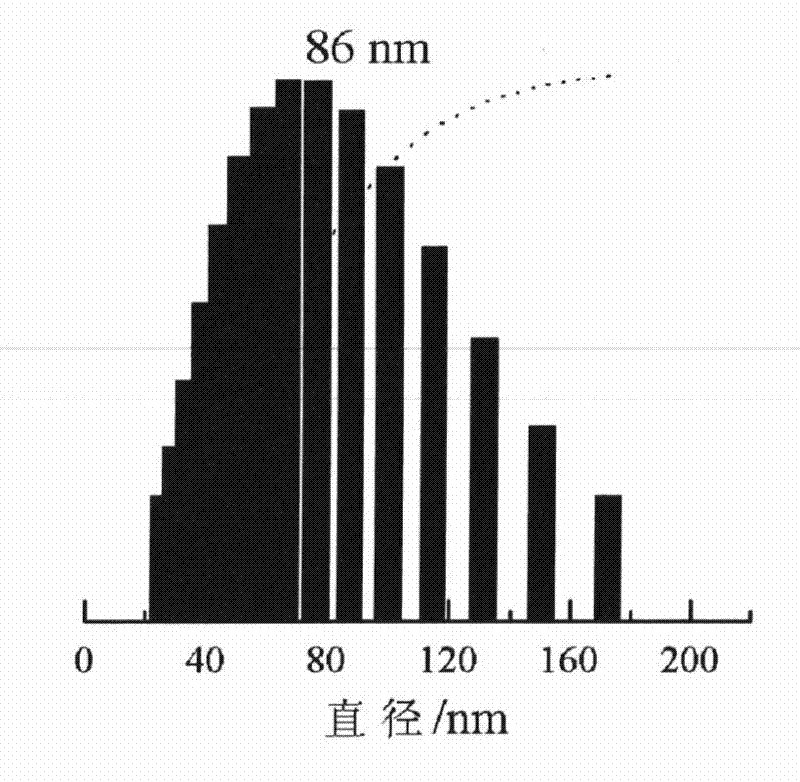

The invention provides a ZSM-5 type molecular sieve for a catalyst for a reaction for preparing propylene from methanol and / or dimethyl ether, which has a silica alumina ratio of 250-1,150 and a grain diameter of 65-250nm. A preparation method of the molecular sieve comprises the following steps: (1) mixing an aluminum source and an organic directing agent and stirring an obtained mixture at constant temperature of 0-30 DEG C for 2-24 hours; (2) adding a silicon source and an organic addition agent to the mixed solution obtained in the step (1) and continuing stirring the mixed solution to obtain gel; (3) stirring the gel obtained in the step (2) at 35-95 DEG C and then carrying out a crystallization reaction for 24-240 hours at 60-200 DEG C, wherein in the raw materials for synthesizing the molecular sieve, and the molar ratio of OH<-1> to SO2 to AL2O3 to H2O to the organic directing agent to the organic directing agent is (0.1-0.35):1:(0.0005-0.01):(10-25):(0.1-0.6):(0.5-8). The ZSM-5 type catalyst has the characteristics of controllable grain size, adjustable silica alumina ratio, high dispersity, and the like and has higher propylene selectivity and P / E ratio in the reaction for preparing low carbon olefin from the methanol and / or the dimethyl ether.

Owner:DATANG INT CHEM TECH RESINST

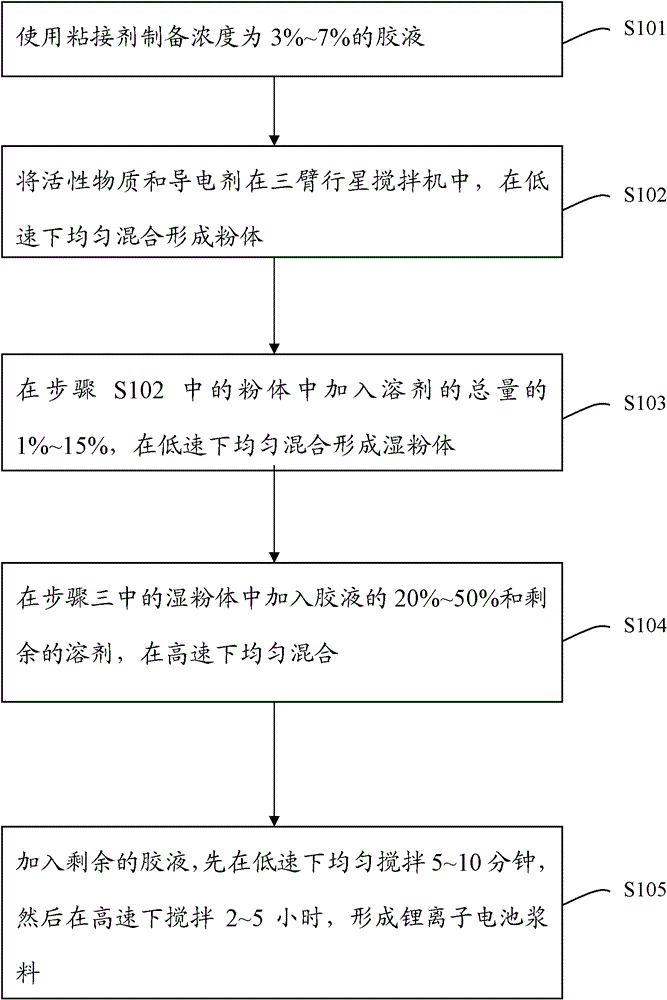

Lithium ion battery slurry, preparation method of the lithium ion battery slurry, and lithium ion battery

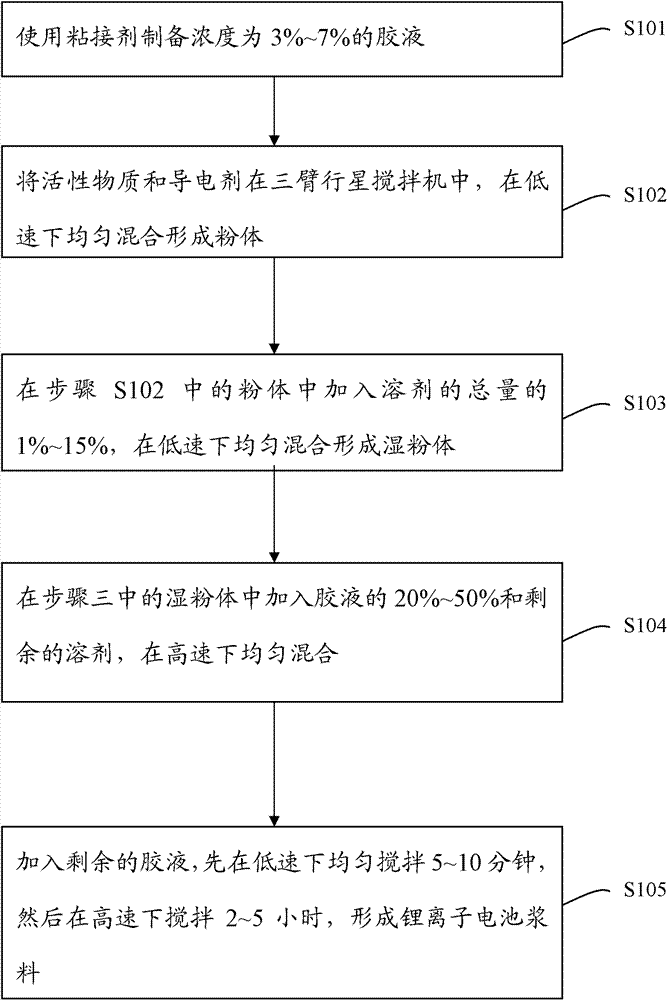

The invention discloses a preparation method of lithium ion battery slurry. The preparation method comprises the following steps of 1, preparing a glue solution having a concentration of 3 to 7% by an adhesive, 2, putting one or more active substances and one or more conducting additives into a three-arm planetary stirrer, and uniformly mixing the mixture into powder at a low speed, 3, adding 1 to 15% of a solvent into the powder obtained by the step 2, and uniformly mixing the mixture into wet powder at a low speed, wherein a ratio of the total mass of the solvent to the mass of the powder is in a range of (55: 4) to (50: 50), 4, adding 20 to 50% of the glue solution and the rest of the solvent into the wet powder, and uniformly mixing at a high speed, and 5, adding the rest of the glue solution into the mixture obtained by the step 4, uniformly stirring at a low speed for 5 to 10 minutes, and then stirring at a high speed for 2 to 5 hours to obtain the lithium ion battery slurry. The invention also discloses the lithium ion battery slurry and a battery pole piece prepared by the preparation method, and a lithium ion battery.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

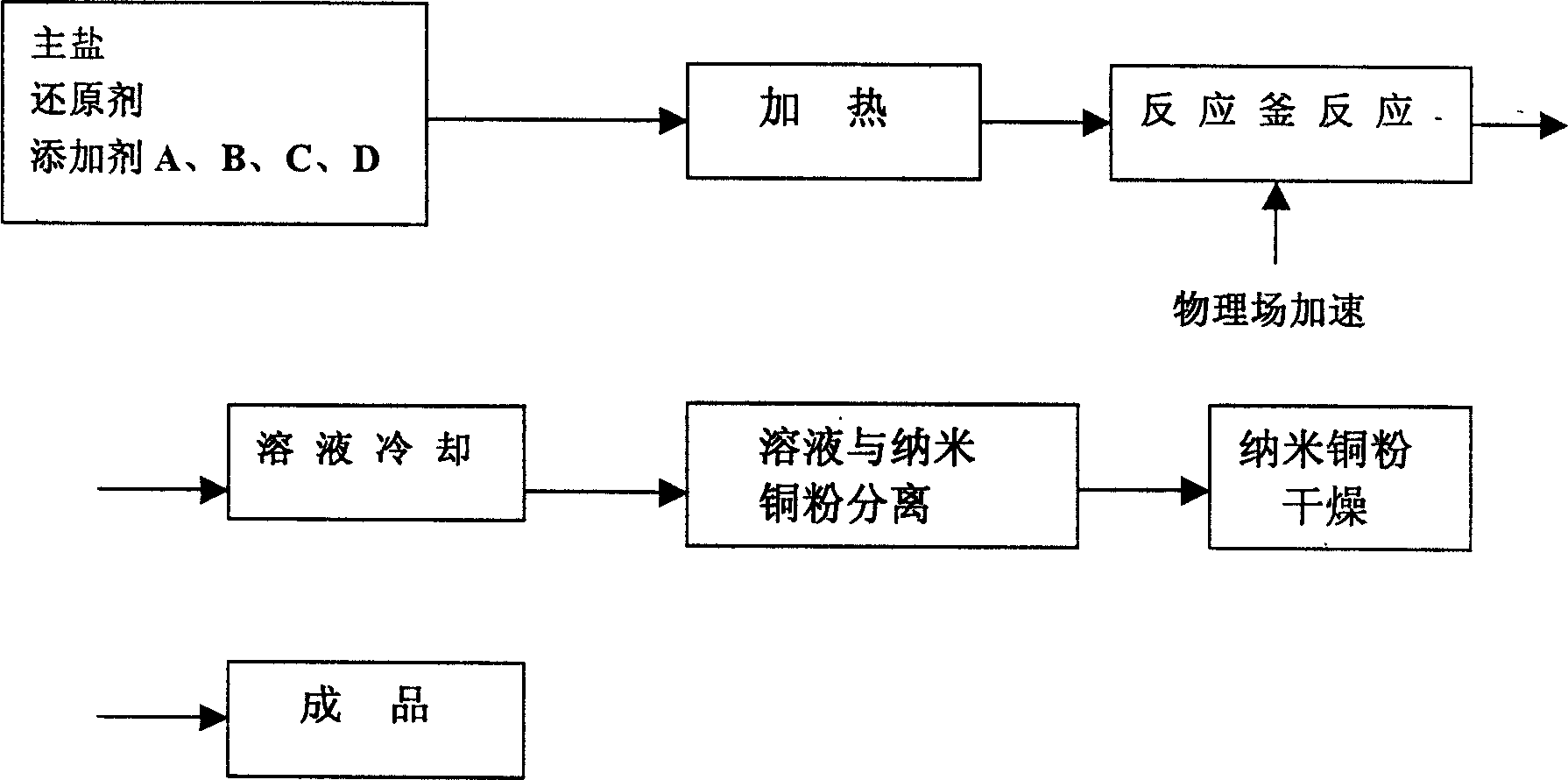

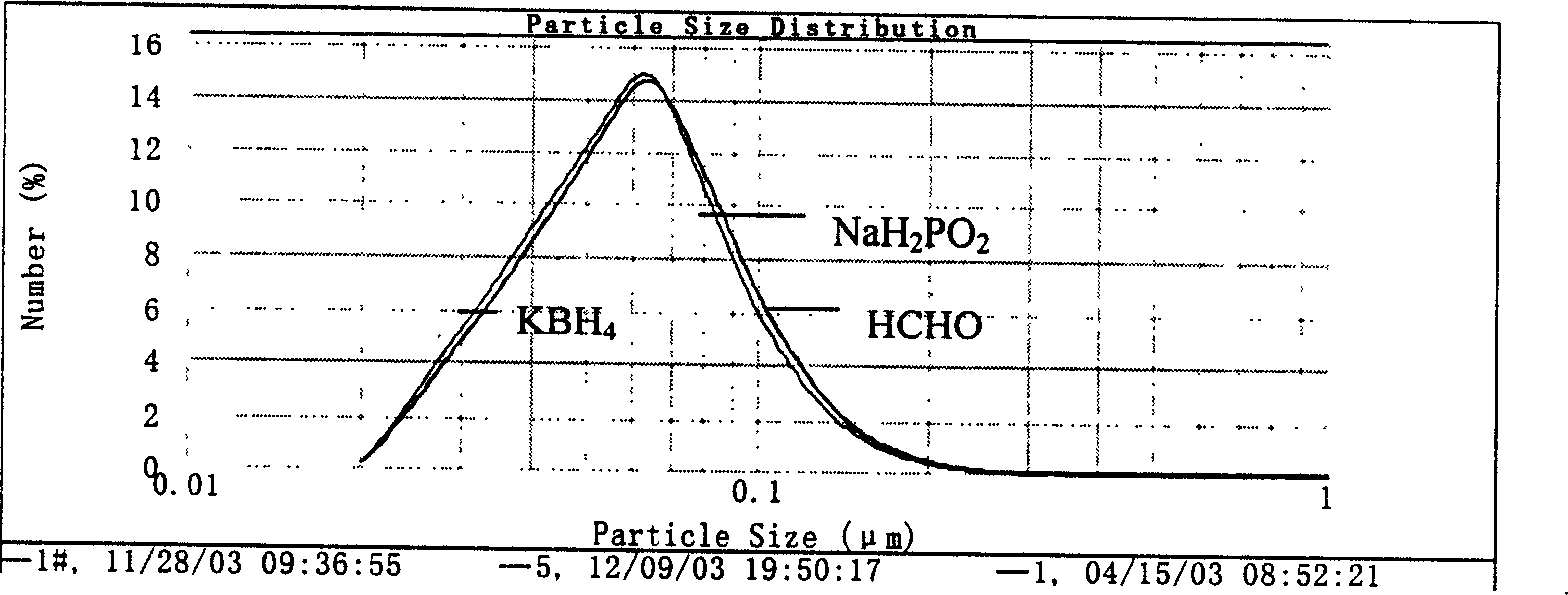

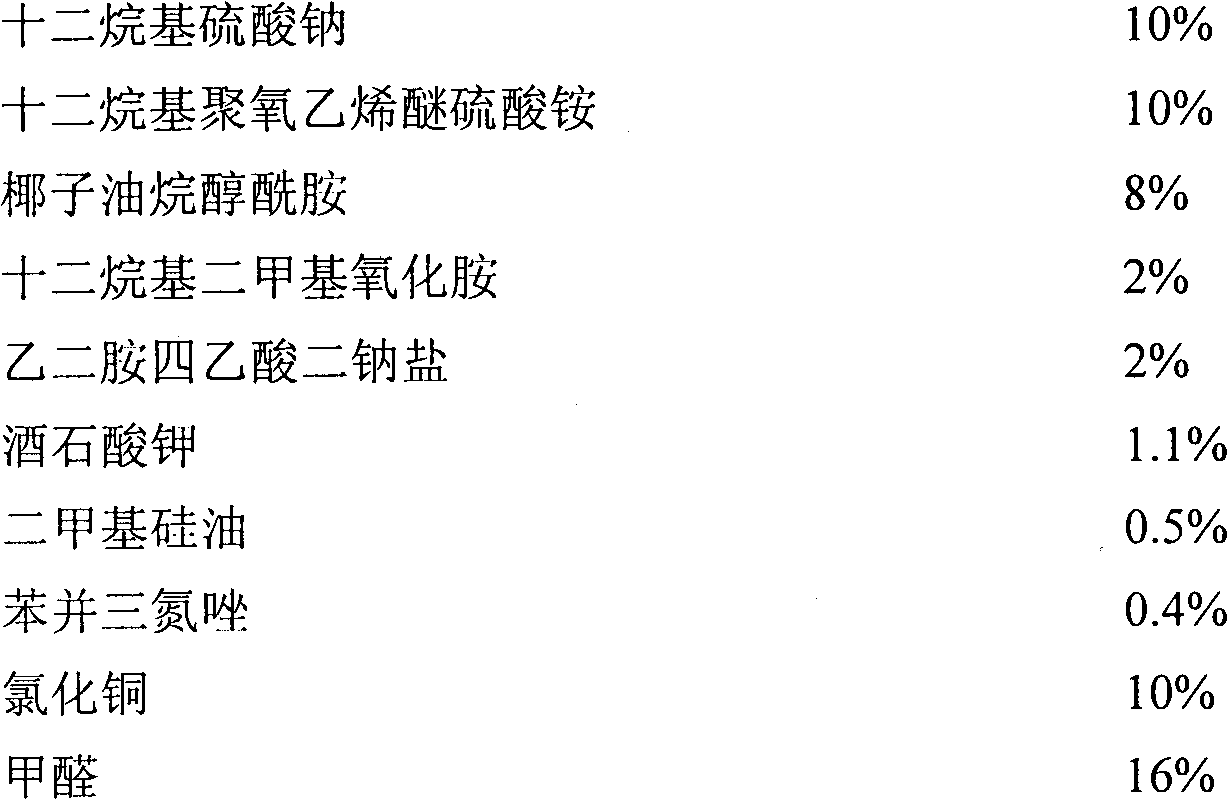

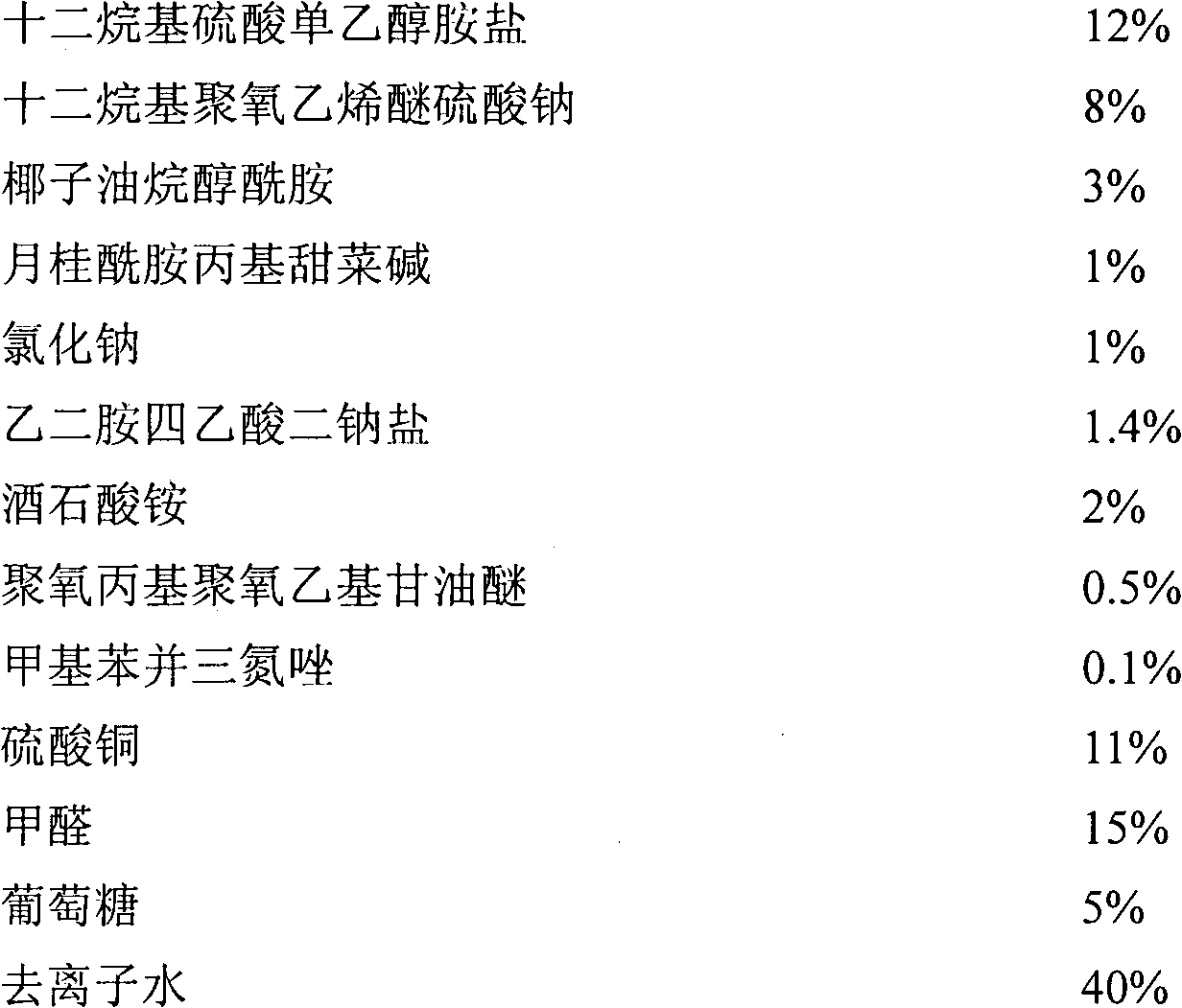

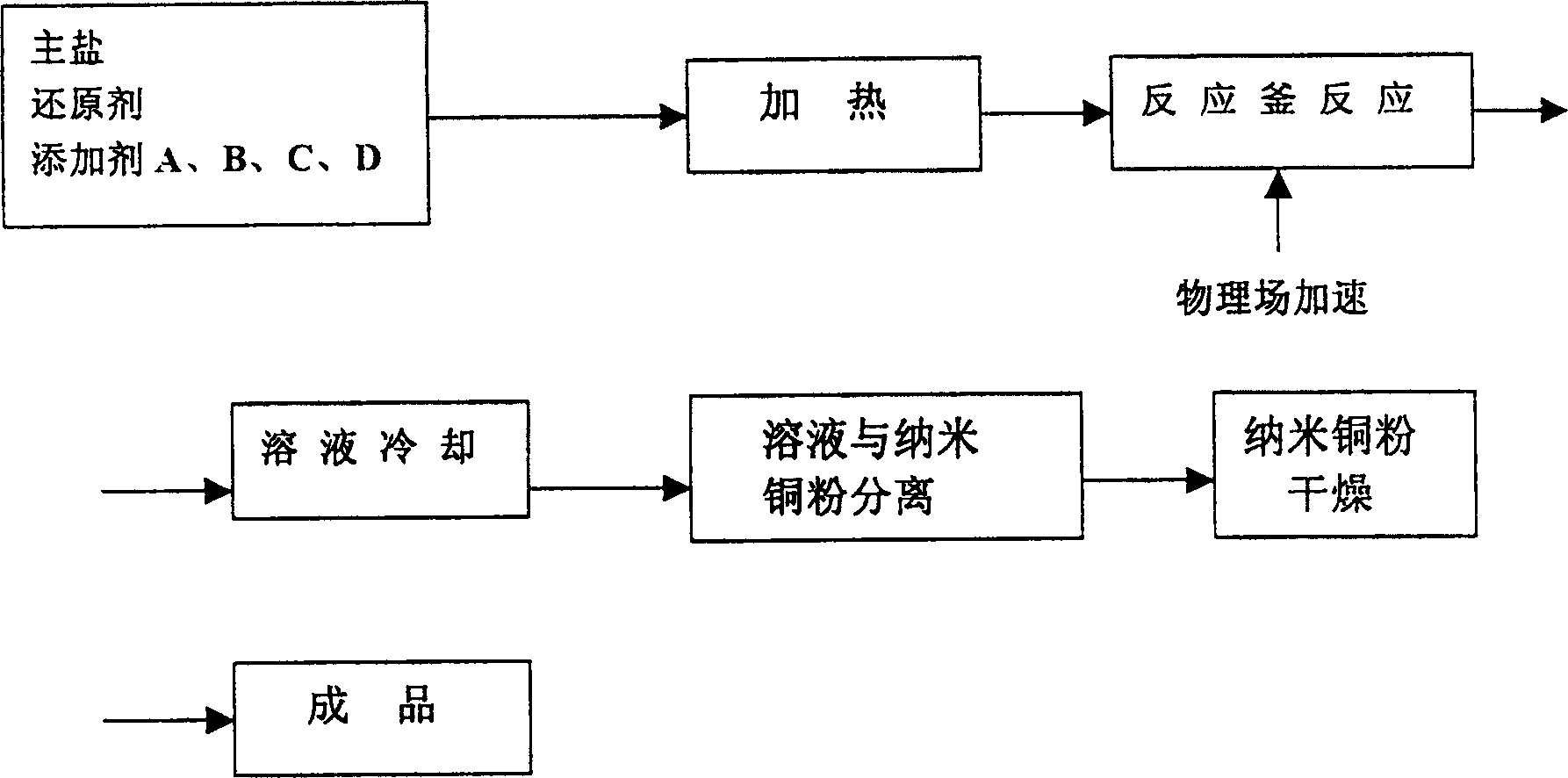

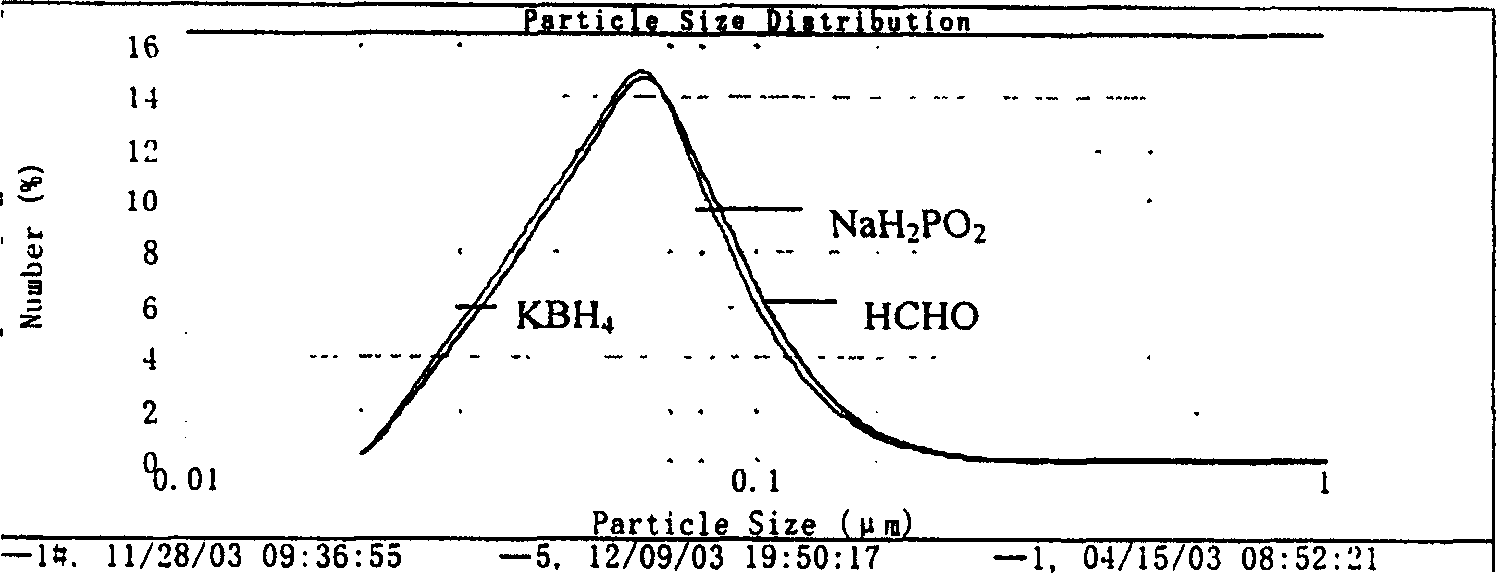

Method for preparing nanometer copper powder by chemical reduction in water solution

The present invention is chemical reduction process of preparing nanometer copper powder in water solution, and relates to electrochemical process for preparing powdered material. The preparation process adopts the proper combination of main salt, reductant and additives, the main salt is copper sulfate or copper chloride, the reductant is sodium hypophosphorate, sodium borohydride and formaldehyde, and the additives include silver nitrate or palladium chloride, gelatin or SDBS, potassium sodium tartrate or triethanolamine and sodium hydroxide or potassium hydroxide. During the preparation, outer ultrasonic field is applied. The preparation process is simple and high in preparation speed, and has no coagulation of copper powder to ensure the medium powder size smaller than 100 nm for ideal use effect of the nanometer copper powder.

Owner:UNIV OF SCI & TECH BEIJING

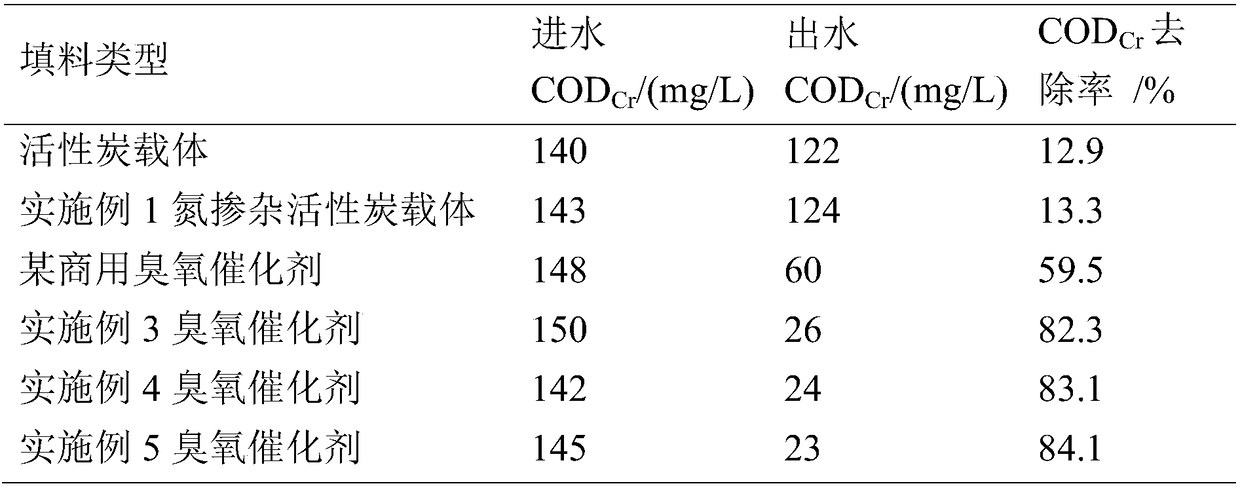

Catalyst for ozone catalytic oxidation, and preparation method thereof, and method for treating industrial wastewater by using catalyst

ActiveCN108404950AControlled sinteringControlled reunionPhysical/chemical process catalystsNature of treatment waterChemical industryCatalytic oxidation

The invention discloses a catalyst for ozone catalytic oxidation. The catalyst comprises: nitrogen-doped active carbon as a carrier, a main catalyst comprising two or a plurality of materials selectedfrom a Fe oxide, a Mo oxide, a Cu oxide, a Ni oxide and a Mn oxide, and a co-catalyst comprising one selected from a Ru oxide, a Pd oxide and a Pt oxide, wherein the mass fraction of the doped nitrogen is 1-20% relative to all the carrier, and the catalyst comprises 100 parts by weight of the carrier, 10-50 parts by weight of the main catalyst, and 1-10 parts by weight of the co-catalyst. According to the present invention, the catalyst can be used for various chemical industry sewage treatment fields, is used for reducing difficultly-degraded organic matters, cyanides and the like in sewage,is especially suitable for the field of deep treatment of coal chemical industry sewage and coking sewage, and can reduce the coking wastewater CODCr to less than 30 mg / L from 150 mg / L in the deep treatment of coking wastewater so as to achieve the circulation water reuse standard, wherein the CODCr removal rate can achieve more than 80%.

Owner:邢台旭阳科技有限公司

Prepn process of in-situ grain reinforced refractory aluminium-base composite material

The in-situ grain reinforced refractory aluminum-base composite material consists of Si 11-13 wt%, Mg 0.5-1.5 wt%, Cu 0.8-1.3 wt%, Ni 0.5-1.5 wt%, and TiB2 1-20 wt% except Al. The preparation process includes the following steps: 1. adding ZL102 alloy and Al-Si intermediate alloy or industrial pure aluminum into crucible, melting, heating and covering with covering agent; 2. mixing KFB4 and KTiF6, stoving and adding into the melt via stirring; 3. taking out the side product after reaction, adding industrial pure Mg, Al-Ni intermediate alloy and Al-Cu intermediate alloy, scumming, pumping vacuum and letting stand; and 4. low pressure casting formation. The composite material of the present invention has reinforcing TiB2 grains with clean interface and even distribution, excellent structure and performance, excellent high temperature strength, high plasticity and high modulus, and the present invention is suitable for industrial production.

Owner:SHANGHAI JIAO TONG UNIV

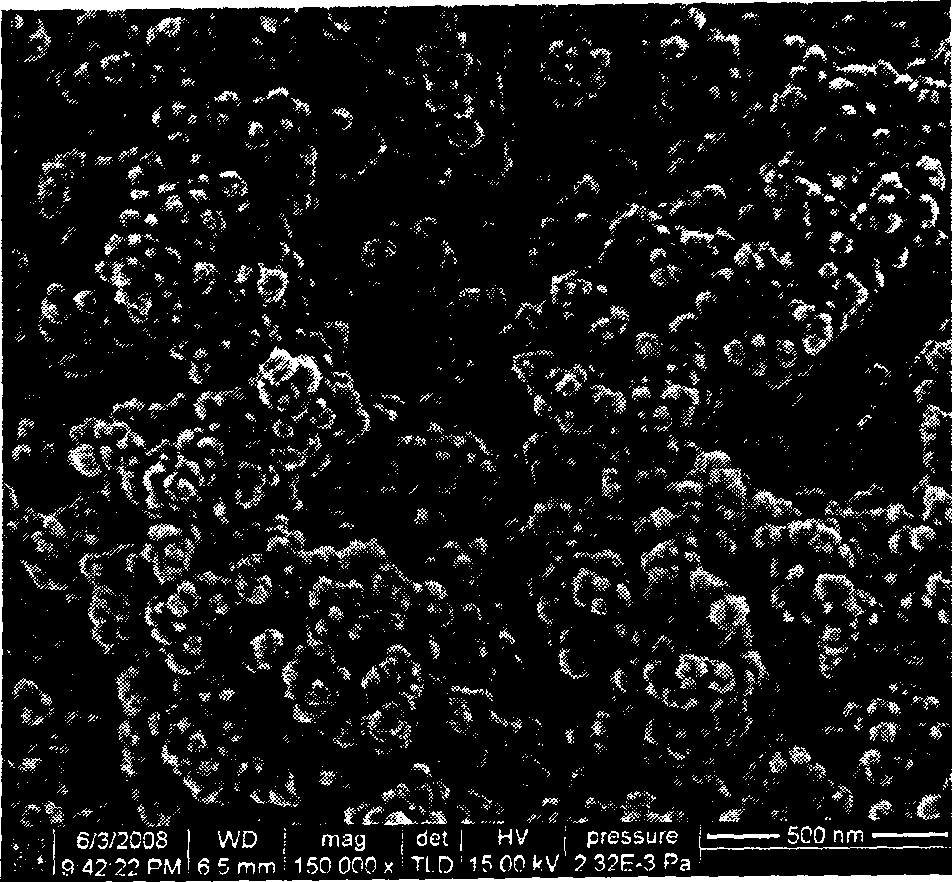

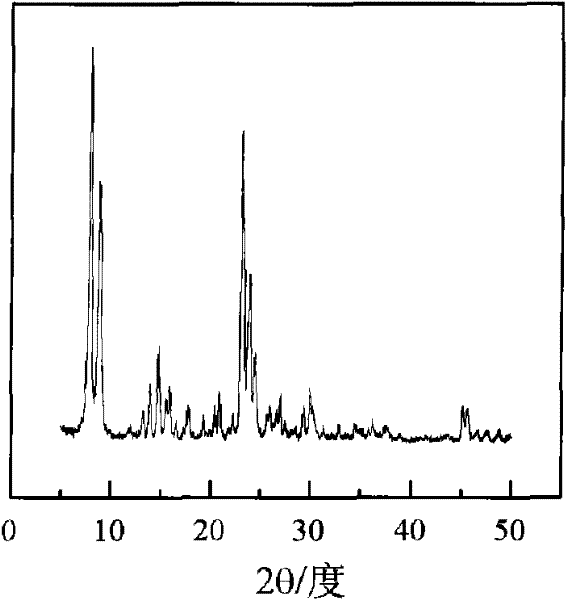

Preparation of nano hydroxylapatite powder

InactiveCN101486452AShape is easy to controlUniform particle sizePhosphorus compoundsPhosphateApatite

The invention relates to a method for preparing a nanometer hydroxyl apatite powder by utilizing hydrothermal solution, which pertains to the chemical field. Cheap calcium nitrate and phosphate which are easy to purchase in the market are taken as raw materials, the two saline solutions are mixed in accordance with certain Ca / P ratio, after adjustment and mixing by using ammonia, the pH value of the suspension comes to a certain range and then the suspension is put into a reaction kettle; under the conditions of certain stirring speed, heating temperature and holding time, reaction happens and hydroxyl apatite is generated; and the acicular or bulbiform nanometer hydroxyl apatite powder is obtained after filtration, being cleaned by a certain solvent and drying under certain conditions. The preparation method is simple and easy to be operated and has good repeatability; the obtained power has high purity and narrow particle size range and is suitable for being popularized and applied in various fields such as hard tissue repair, wastewater treatment, chromatography filler, and the like.

Owner:CHONGQING UNIV

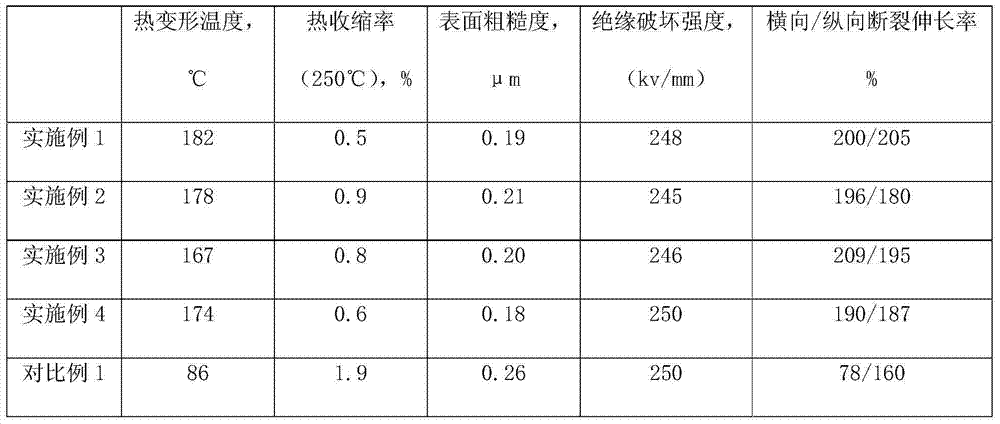

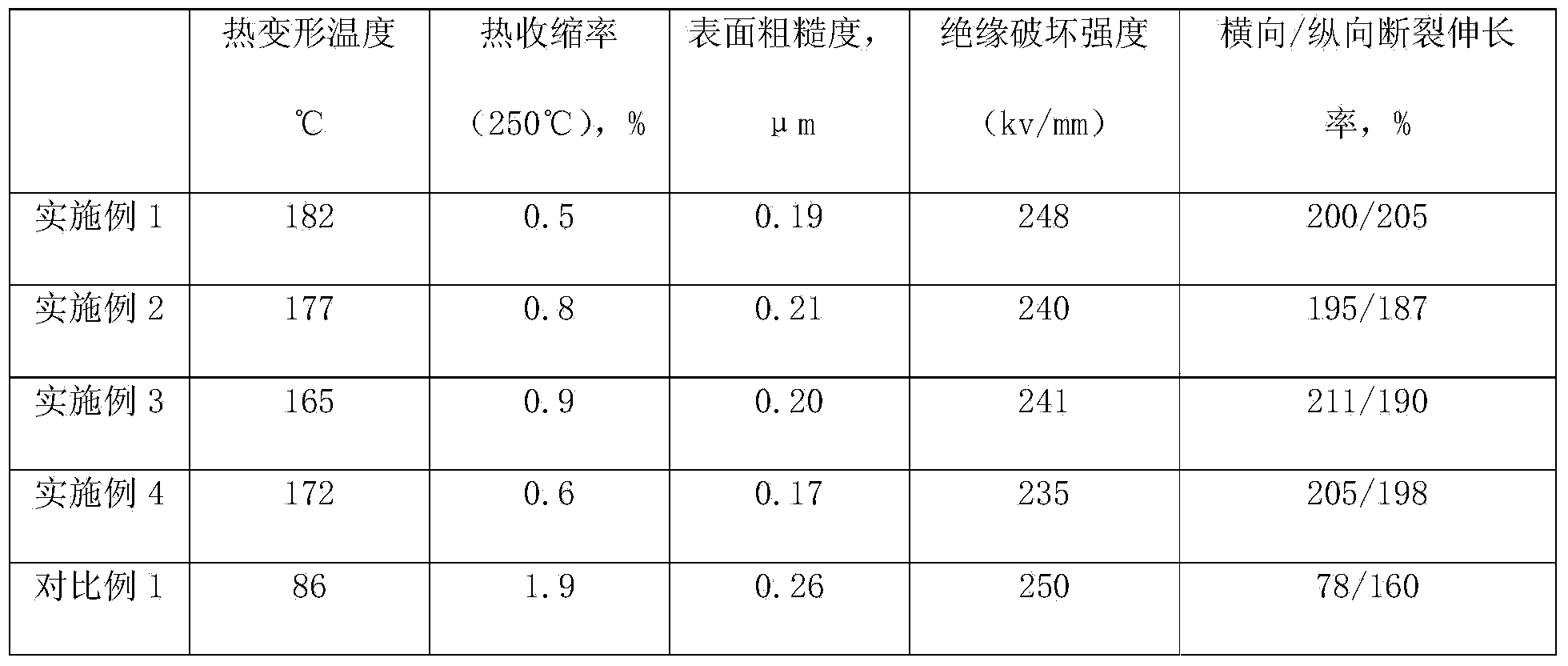

Preparation method of biaxially oriented polyphenylene sulfide composite film

The invention relates to the technical field of extraordinary film preparation, and especially relates to a preparation method of a biaxially oriented polyphenylene sulfide composite film with good toughness and excellent heat resistance. The preparation method comprises the steps of master batch preparation, sheet casting and stretching film formation. The biaxially oriented polyphenylene sulfide composite film prepared by adopting a technical scheme in the invention has the advantages of excellent heat resistance, excellent dimensional stability, excellent heat formability and excellent toughness, can be applied the fields of electric insulation materials or forming materials of motors, transformers and insulation cables, the field of circuit substrate materials, and the field of loudspeaker vibration plates for mobile phones.

Owner:常州钟恒新材料股份有限公司

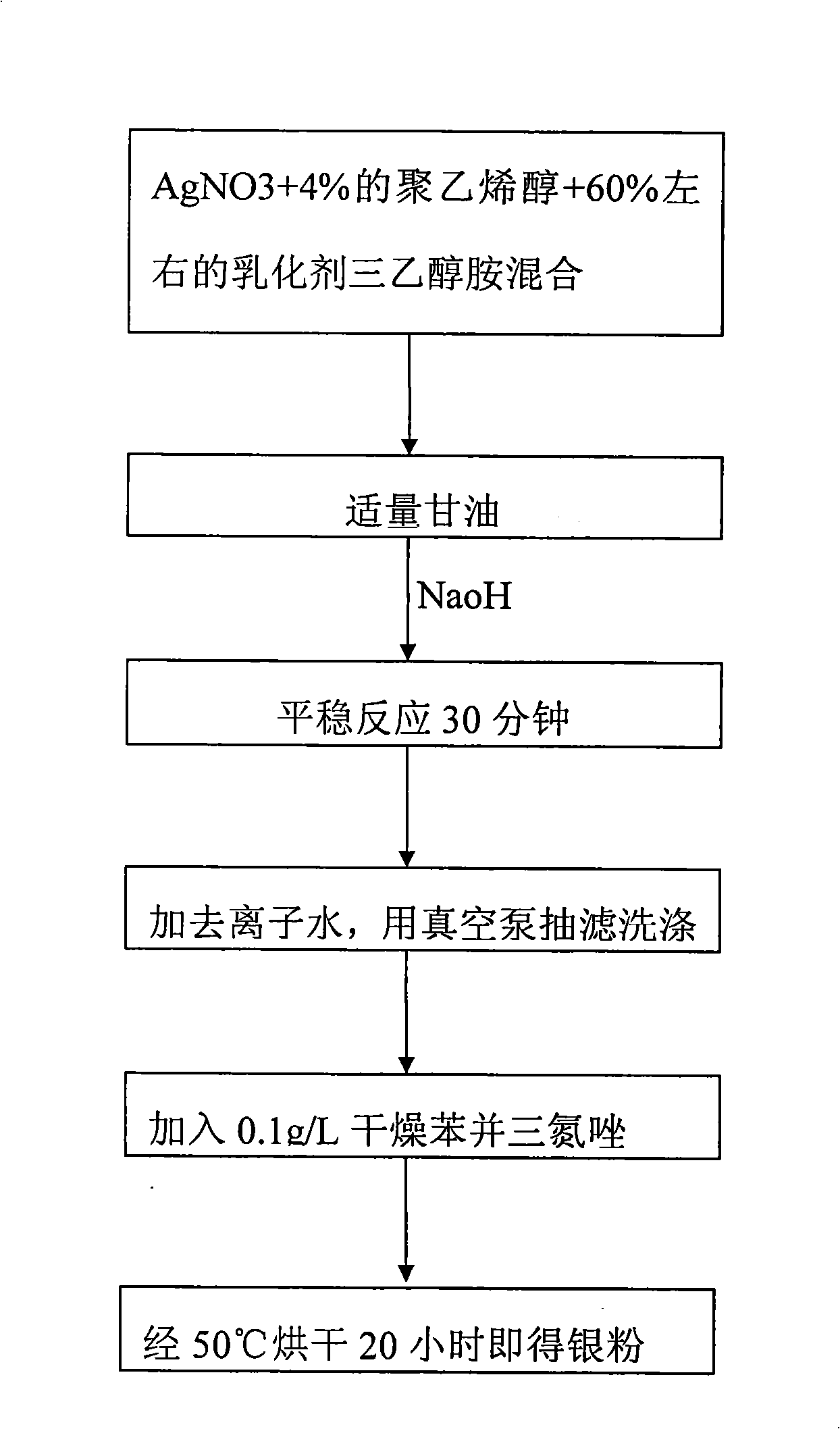

Method for preparing nano silver powder

The invention discloses a method for preparing nanometer silver powders. The method comprises the following steps: a. mixing AgNO+, 4 percent of polyvinyl alcohol and about 60 percent of emulsifier triethanolamine; b. adding proper amount of glycerol into the mixture; c. smoothly reacting the mixture for 30 minutes; d. adding deionized water into the mixture, and performing pumping filtration washing on the mixture through a vacuum pump; e. dehydrating the mixture by using anhydrous alcohol; f. adding 20 to 50 milliliters of 0.1 gram per liter dried protective agent benzotriazole after the dehydration; and g. drying the mixture for 18 to 24 hours at a temperature of 50 DEG C to obtain the nanometer silver powders of which the particle diameter is between 50 and 100 nanometers. The method for preparing the nanometer silver powders has the advantages of simple production process, low production cost, low investment of equipment, easy process control, and high yield.

Owner:桐柏鑫泓银制品有限责任公司 +1

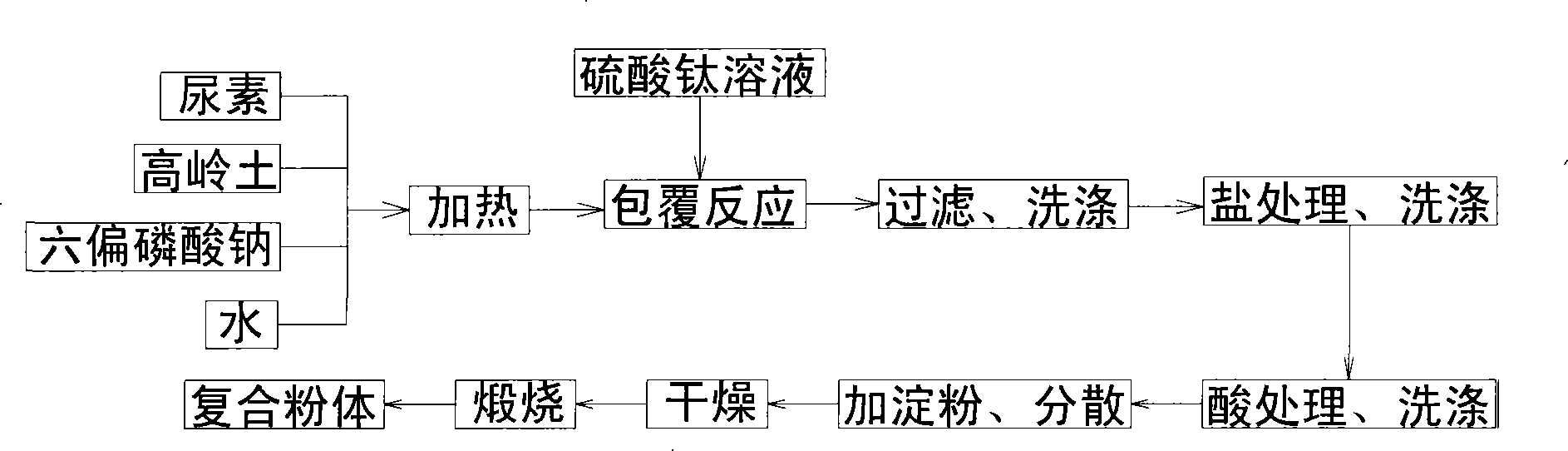

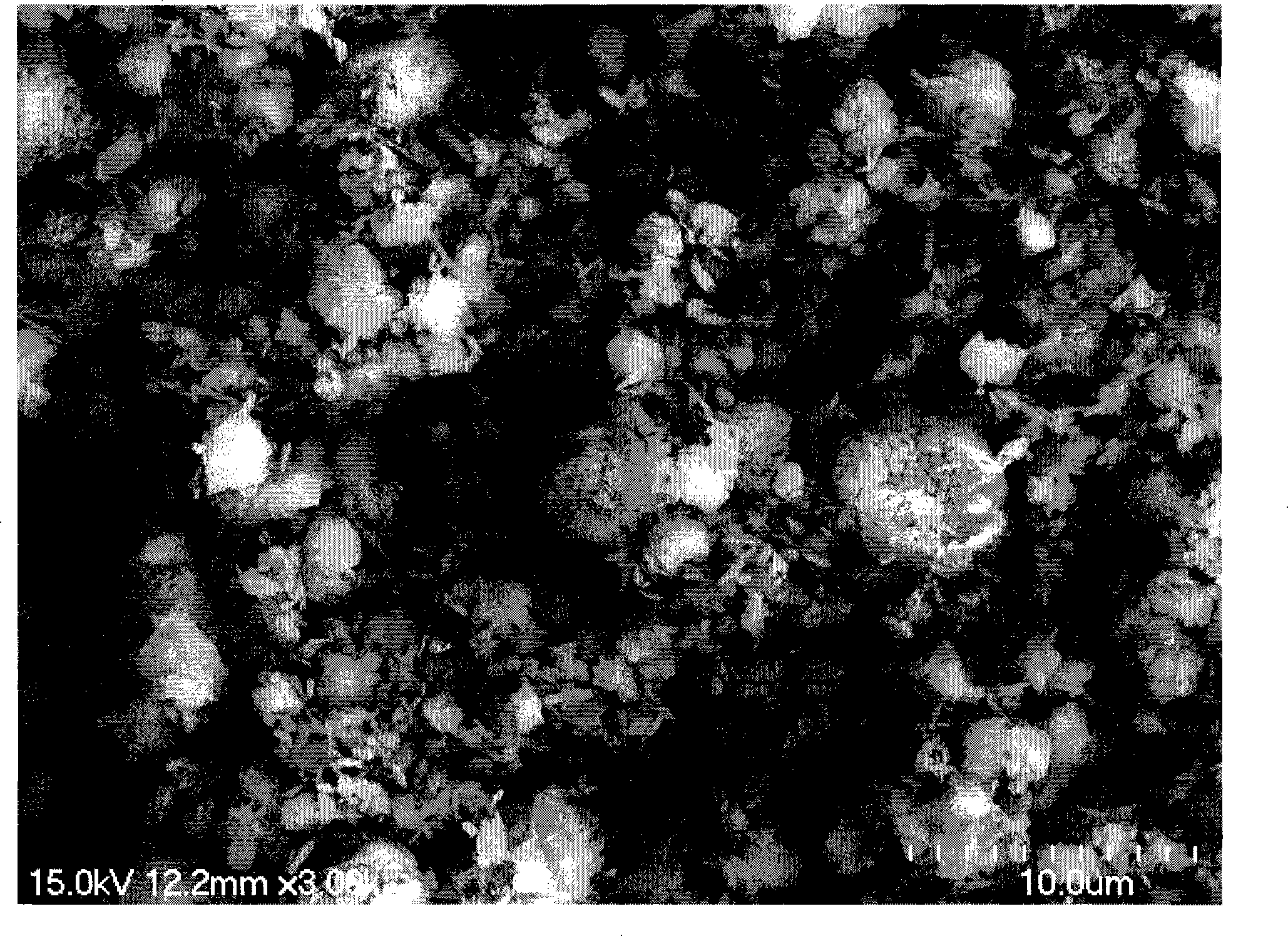

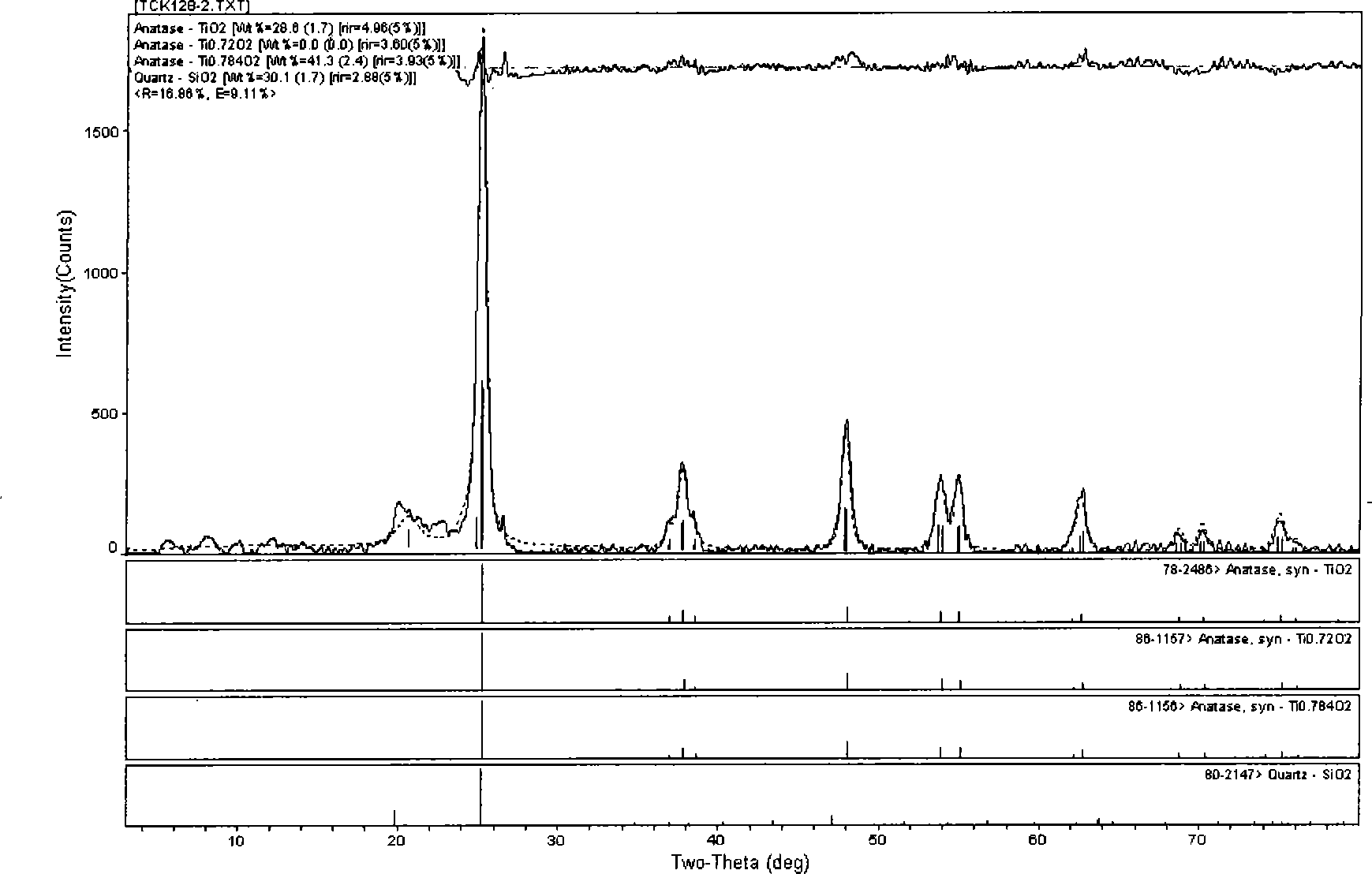

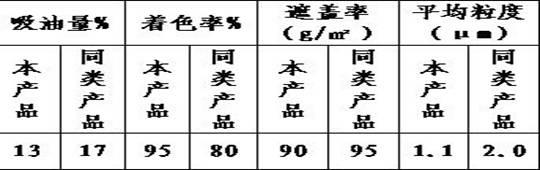

Titania coating kaolinite compound powder and method for preparing same

InactiveCN101250337AUniform whitenessSmall particle size distribution rangeInorganic pigment treatmentSODIUM METAPHOSPHATESodium phosphates

Titanium oxide coating kaolin composite powder belongs to a process for producing composite white pigment powder through the inorganic treatment method. The raw material formulation is formed by following components with percentage by weight: 12%-18% titanium sulfate, 6%-9% kaolin, 10%-19% carbamide, 0.15%-0.30% sodium hexametaphosphate, 0.5%-1.2% starch, 0.04%-0.08% water-soluble carbonate, 0.01%-0.05% phosphorus acid and rest amount of water. The preparation process comprises the steps of coating reacting, water scouring, salt treatment, acid treatment, dispersion, drying and calcination. The titanium oxide coating kaolin composite powder which is prepared through adopting the homogenous precipitation method has the advantages of even whiteness and small particle size distribution range, and each index all approximates to the index of titanium white powder.

Owner:中国高岭土有限公司

A method for preparing nanometer copper powder in a small molecule viscous medium

The invention discloses a method for preparing nano copper powder in a micromolecular viscous medium. The method comprises the steps of: by taking a surface active agent, salt, a complexing agent, an antifoaming agent, an antioxidant, cupric salt, a reducing agent and deionized water as raw materials and according to the proportion of (0.001-95 percent) : (0.001-95 percent) : (0.001-80 percent): (0.001-75 percent): (0.001-70 percent): (0.001-75 percent): (0.001-70 percent): (0.001-98 percent), preparing the micromolecular viscous medium by using the surface active agent, the salt, the complexing agent, the antifoaming agent, the antioxidant and the deionized water; adding the cupric salt and uniformly mixing; adding the reducing agent and mixing; adding the deionized water to dilute so asto reduce the degree of viscosity according to a mass ratio of 1:0.5-10 of the total quantity of all materials abovementioned to the deionized water after the reaction completes; and obtaining nano copper powder through filter-pressing, deionized water washing, acetone washing and vacuum drying. According to the method disclosed by the invention, the raw materials selected in the invention are easily available, the manufacturing technique is simple and short, the production efficiency is high, the production cost and the energy compunction are low, and powder has low possibility of agglomeration and has good dispersibility, therefore the method is suitable for large-scale production and solves the problems of easy oxidation and easy agglomeration of the nano copper powder existing in the traditional chemical preparation method.

Owner:NANJING FORESTRY UNIV

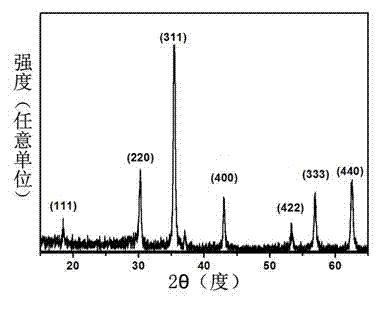

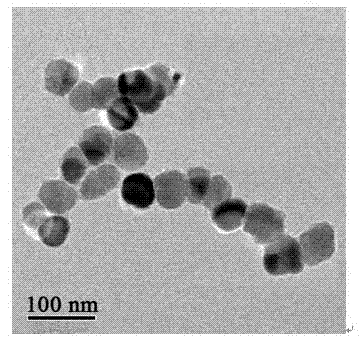

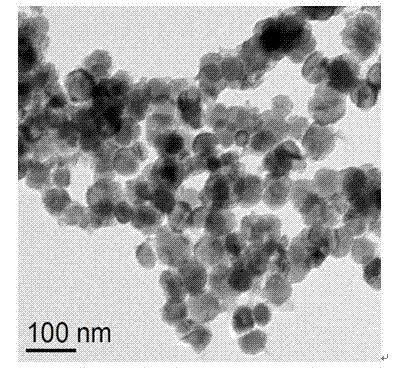

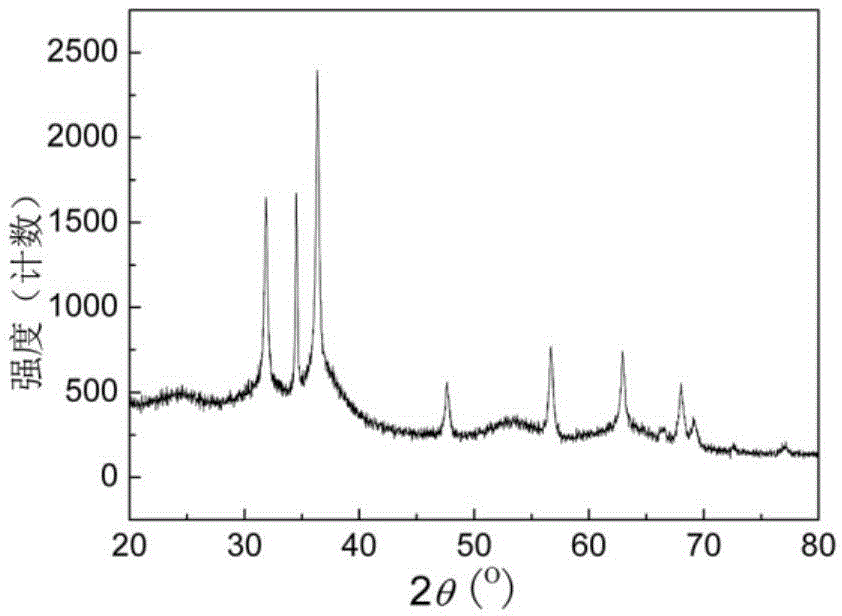

Fe3O4 nano-microsphere and preparation method thereof

InactiveCN102502879AGuaranteed decentralizationControlled reunionFerroso-ferric oxidesNanotechnologyMicrosphereActive agent

The invention discloses a Fe3O4 nano-microsphere preparation method, which includes: adding NaOH into raw materials including FeCl2 and FeCl3 to adjust pH, preparing Fe3O4 under heating reaction, and using polyethylenimine as cationic surfactant to modify surface of the Fe3O4 so as to obtain the Fe3O4 nano-microsphere. The Fe3O4 nano-microsphere preparation method is simple in synthesis process, low in cost, quick and safe in preparation and easy in implementation of industrial production, and production equipment is simple. The Fe3O4 nano-microsphere prepared by the method is excellent in magnetic performance and high in dispersity.

Owner:EAST CHINA NORMAL UNIV

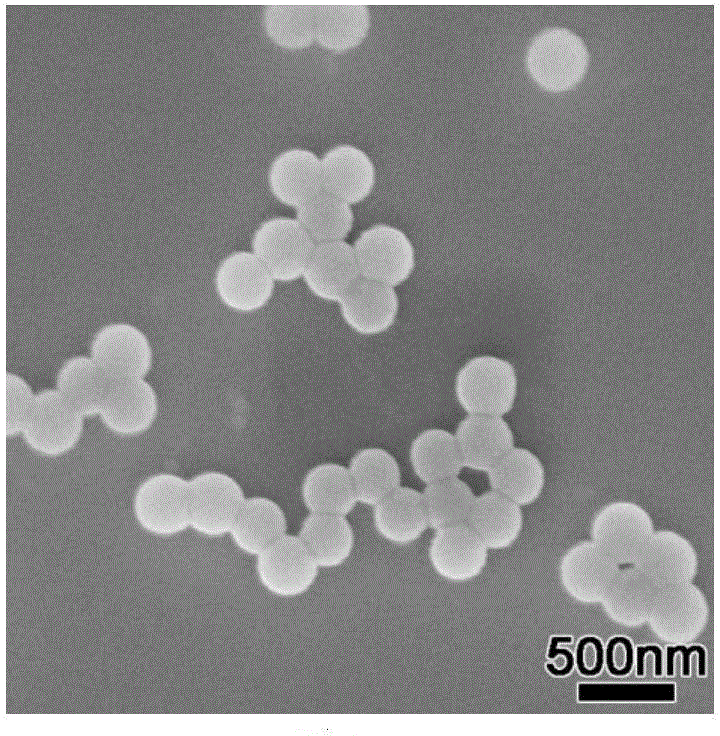

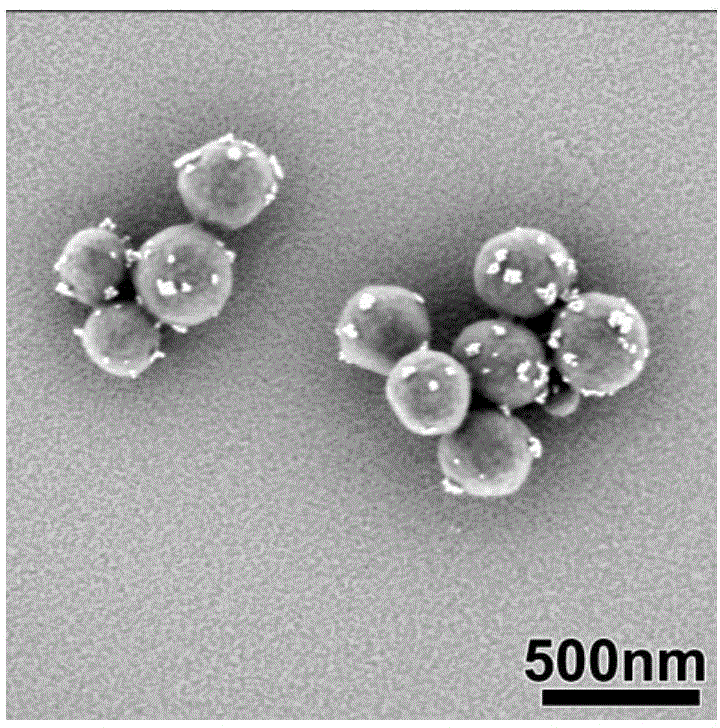

Preparation method of strawberry type organic-inorganic composite particles

The invention discloses a preparation method of strawberry type organic-inorganic composite particles. The preparation comprises the following steps: (a) preparation of template polymer particles: adding hydrophilic monomers, deionized water, an initiating agent and template monomers in a high-pressure kettle, performing a reaction under 40-70DEG C, and stopping the reaction when the pressure drops to 0.1-0.4MPa so as to obtain a template polymer emulsion; (b) preparation of the strawberry type organic-inorganic composite particles: pouring zinc acetate and a solvent in a reactor, after performing dispersion under 20 DEG C for 10 min, raising the temperature to 55DEG C, holding the temperature for 1h; adding the template polymer emulsion in the heated reactor, adding a water solution of a second reactant, performing rotary evaporation on composite particles obtained after the reaction, performing centrifugal water washing, and performing low-temperature drying till the weight of the dried materials is constant so as to obtain the strawberry type organic-inorganic composite particles of which the morphologies are controllable. According to the preparation method disclosed by the invention, the micromorphologies and sizes of ZnO particles can be effectively controlled so as to prepare the strawberry type organic-inorganic composite particles of which the morphologies are controllable.

Owner:HEBEI UNIV OF TECH

Method for printing double smooth surfaces at one time and matting agent for printing ink

ActiveCN102690553AShorten the timeShorten the production cycleInksOther printing apparatusParaffin waxSmooth surface

The invention discloses a method for printing double smooth surfaces at one time and a matting agent for printing ink. The matting agent is prepared from the following raw materials in part by weight: 90 to 95 parts of polyethylene paraffin scattered in a fluffy state, 2 to 4 parts of hydrogenated castor oil and 0.4 to 1 part of polyacrylamide. The preparation method comprises the following step of uniformly mixing the three substances in a high speed mixer. The method for printing double smooth surfaces at one time comprises the following steps: uniformly mixing gravure ink and the matting agent in a ratio of 1:(2-4); printing matted patterns on parts of a base material requiring a matting effect through gravure equipment by using the mixed matting gravure ink; and printing bright patterns on parts of the base material requiring a bright effect by using gravure ink without the matting agent, or reversing the sequence to achieve the same effect.

Owner:JIANGSU JIN JIA NEW PACKAGING MATERIALS CO LTD

Biaxial orientation type polyphenylene sulfide composite membrane

The invention relates to the technical field of preparation of specific membranes, and particularly relates to a biaxial orientation type polyphenylene sulfide composite membrane with good toughness and excellent heat resistance. The composite membrane comprises the following components: membrane-grade polyphenylene resin, an organic elastomer and an inorganic filler, wherein the membrane-grade polyphenylene resin comprises membrane-grade polyphenylene resin for a master batch and membrane-grade polyphenylene resin for casting of a sheet. The biaxial orientation type polyphenylene sulfide composite membrane prepared by adopting the technical scheme provided by the invention has excellent heat resistance, size stability, thermal formability and toughness. The biaxial orientation type polyphenylene sulfide composite membrane disclosed by the invention can be applied to fields of electric insulating materials or forming materials for a motor, a transformer, an insulating cable and the like, a circuit substrate material, a loudspeaker vibrating plate for a mobile phone and the like.

Owner:常州钟恒新材料股份有限公司

Preparing method for TiC matrix steel base steel bond hard alloy

InactiveCN106811659AUniform pore size distributionImprove uniformityTransportation and packagingMetal-working apparatusCemented carbideSolvent

The invention relates to a preparing method for a TiC matrix steel base steel bond hard alloy. The preparing method includes the following steps that titanium carbide powder and matrix steel matrix powder are weighed according to the proportion, alloy powder is put into a ball grinding machine to be mixed and smashed, added absolute ethyl alcohol is a process control agent, and the wet mixed powder is put into a vacuum drying box to be dried after ball grinding and is used for standby use after drying; an organic monomer and an initiator are added into a solvent to prepare pre-mixed liquid; an additive improving slurry fluidity and dispersity is added; a catalyst and a pH modifier are added and are evenly stirred, and slurry is obtained; and the slurry is injected into an injection and coagulation die, vacuum suction or vibration gas removing is conducted, after the slurry is cured to be formed, a blank is put into the vacuum drying box to be dried, the dried blank is subjected to integrated degumming and sintering in a vacuum sintering furnace, and the steel bond hard alloy is prepared. The preparing method has the beneficial effects that the technology is simple, the cost is relatively low, and parts large in size and complex in shape are easy to prepare on the basis that the macro performance of the steel bond hard alloy is ensured.

Owner:丹阳惠达模具材料科技有限公司

Lithium ion battery slurry, preparation method of the lithium ion battery slurry, and lithium ion battery

The invention discloses a preparation method of lithium ion battery slurry. The preparation method comprises the following steps of 1, preparing a glue solution having a concentration of 3 to 7% by an adhesive, 2, putting one or more active substances and one or more conducting additives into a three-arm planetary stirrer, and uniformly mixing the mixture into powder at a low speed, 3, adding 1 to 15% of a solvent into the powder obtained by the step 2, and uniformly mixing the mixture into wet powder at a low speed, wherein a ratio of the total mass of the solvent to the mass of the powder is in a range of (55: 4) to (50: 50), 4, adding 20 to 50% of the glue solution and the rest of the solvent into the wet powder, and uniformly mixing at a high speed, and 5, adding the rest of the glue solution into the mixture obtained by the step 4, uniformly stirring at a low speed for 5 to 10 minutes, and then stirring at a high speed for 2 to 5 hours to obtain the lithium ion battery slurry. The invention also discloses the lithium ion battery slurry and a battery pole piece prepared by the preparation method, and a lithium ion battery.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

Preparation of binary alloy nanowire direct alcohol fuel cell catalyst

InactiveCN102941085AControl dissolution growthIncrease profitCell electrodesMetal/metal-oxides/metal-hydroxide catalystsNano catalystNanowire

The invention discloses a preparation method of a binary alloy-supported nanowire direct alcohol fuel cell catalyst, relating to a preparation method of a high-stability direct alcohol fuel cell catalyst, solving the problems of poisoning of nano catalyst metal particle, blocked transport of alcohol fuels and high preparation cost in existing direct alcohol fuel cell catalysts. The method disclosed herein is characterized by: using a surfactant as a template and forming a bi-continuous micelle in solvents with different polarities, according to different charges charged on the surfactant and a metal precursor salt, forming the nanowire-supported binary alloy catalyst with different adsorption layers by static self-assembly. According to the invention, the prepared catalyst is beneficial for alcohol fuel transport, and has the advantages of low cost, strong toxicity resistance, high activity, and high stability.

Owner:TIANJIN POLYTECHNIC UNIV

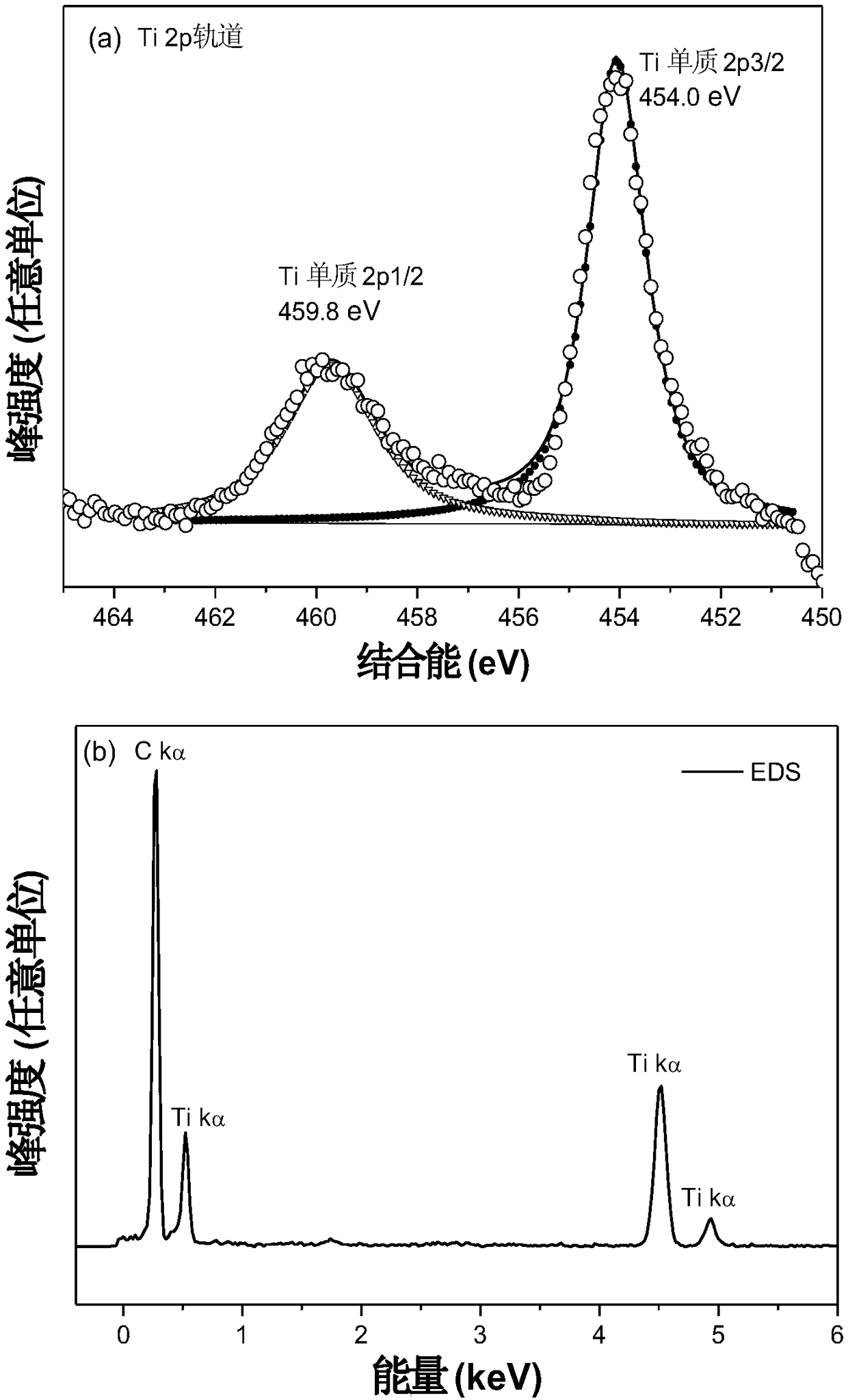

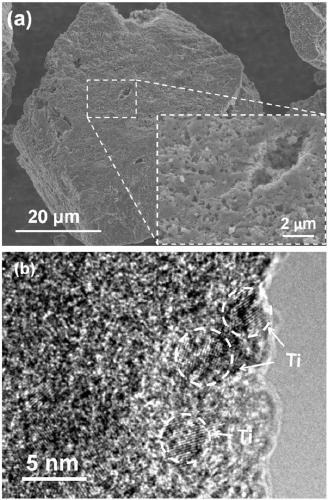

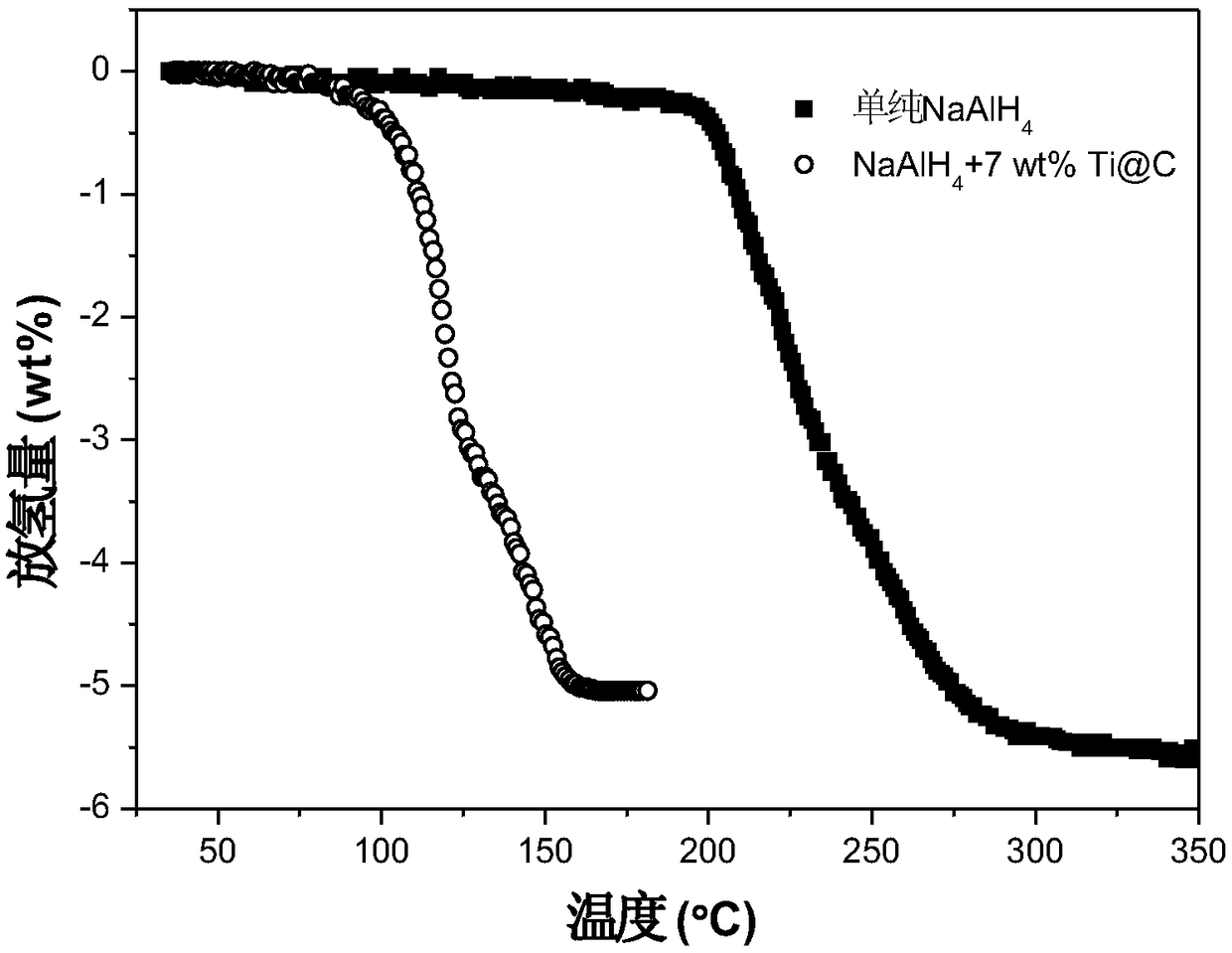

Amorphous carbon-loaded nano metal particle catalyst and preparation method and application thereof

ActiveCN109012664AControlled reunionComplete restorationReversible hydrogen uptakeMetal/metal-oxides/metal-hydroxide catalystsPtru catalystOrganosolv

The invention discloses an amorphous carbon-loaded nano metal particle catalyst and a preparation method and application thereof. The preparation method comprises the following steps: mixing metallocene dichloride and lithium hydride by ball milling under protection of an inert atmosphere to obtain a powdery mixture; heating the powdery mixture until the metallocene dichloride is completely reduced to a elemental metal and cyclopentadiene is dehydrocarburized to obtain a heated product; pulverizing the heated product to powder, and then added the powder to an organic solvent to obtain a mixture; separating a solid material from the mixture, and heating to remove the organic solvent to obtain the amorphous carbon-supported nano metal particle catalyst. The preparation method of the catalystis simple, and the NaAlH4 and MgH2 hydrogen storage materials with the added catalyst have the advantages of low hydrogen release temperature, fast hydrogen release rate and long cycle life.

Owner:ZHEJIANG UNIV

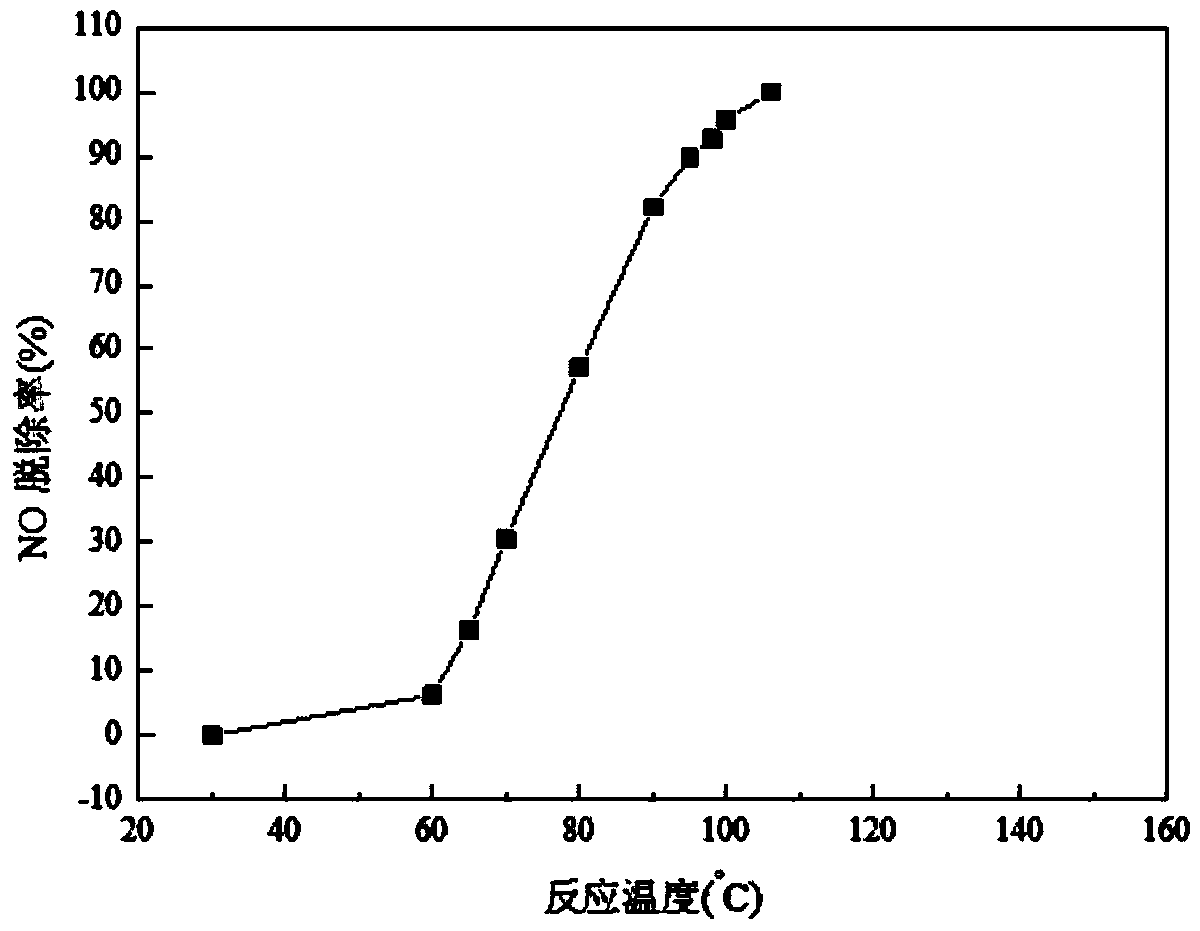

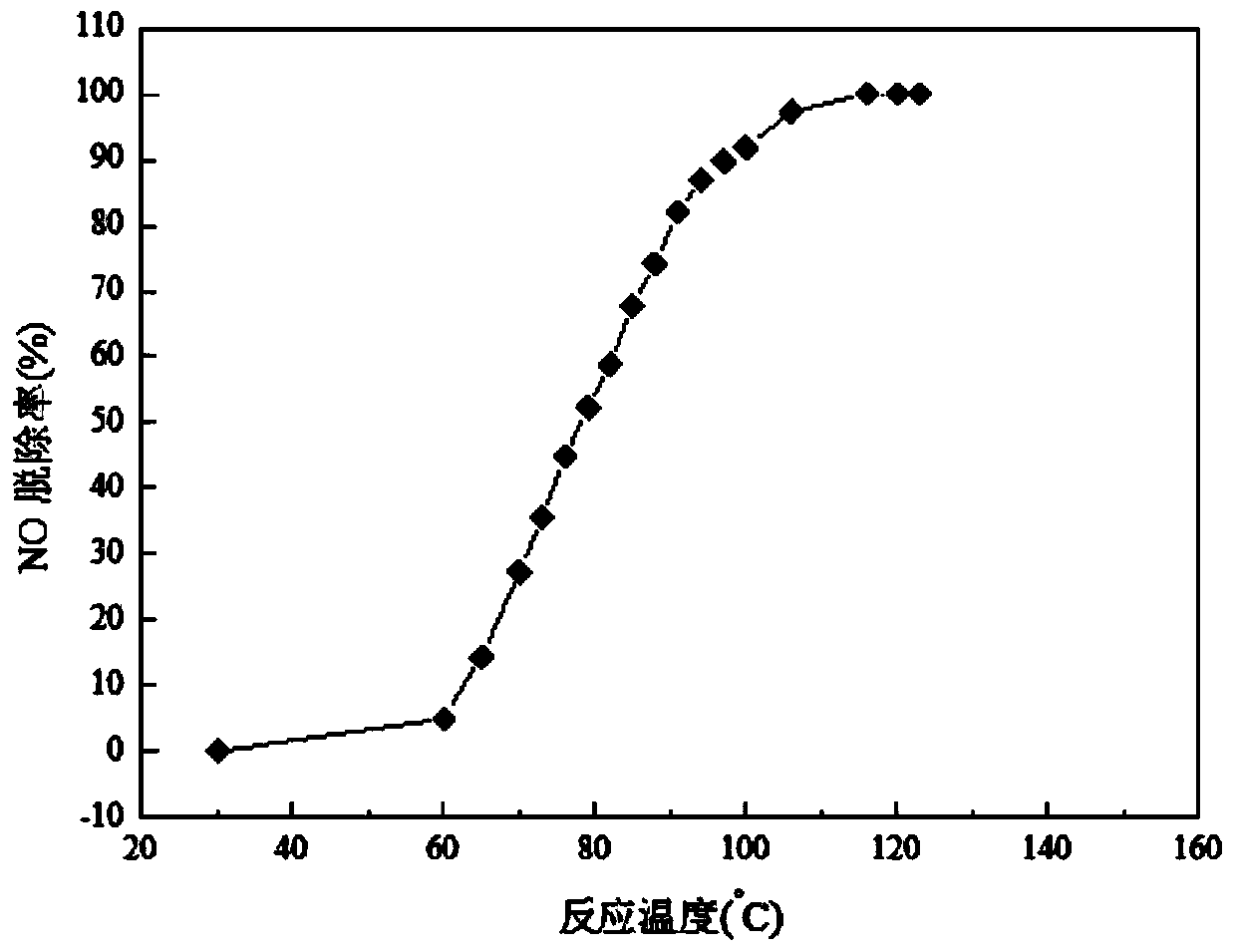

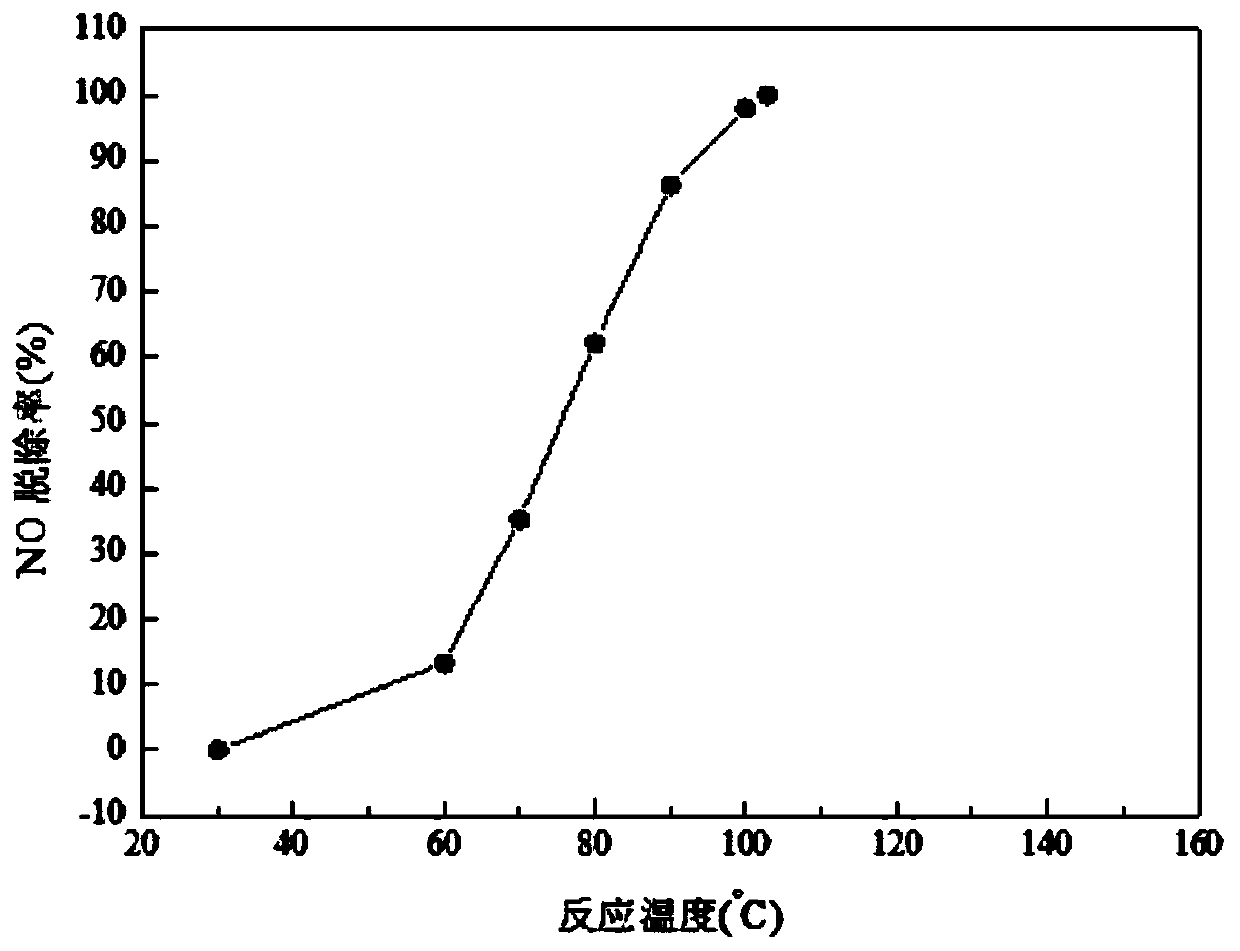

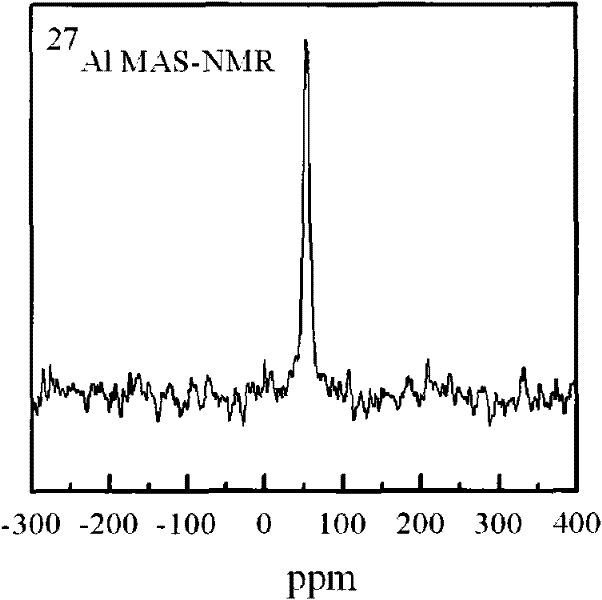

Novel low-temperature SCR (selective catalytic reduction) catalyst based on cubic-phase zirconia carrier and preparation method of novel low-temperature SCR catalyst

ActiveCN104043449AReduce loadReduce manufacturing costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentCerium

The invention belongs to the field of environmental protection and environmental catalysis, and in particular discloses a novel low-temperature SCR (selective catalytic reduction) catalyst based on a cubic-phase zirconia carrier and a preparation method of the novel low-temperature SCR catalyst. According to the catalyst, single cubic-phase zirconia serves as a carrier, load active components are manganese oxides, and aids are cerium oxides, wherein the cubic-phase zirconia accounts for 50-95 mass percent, the manganese oxides account for 2.5-25 mass percent, and the cerium oxides account for 2.5-25 mass percent. The cubic-phase zirconia serves as the carrier, so that the specific performance of the carrier can be fully utilized; by virtue of interaction between the carrier and MnOx and CeOx, the denitration activity of the catalyst is improved. The catalyst prepared by the preparation method shows good catalytic activity under the conditions that ammonia serves as a reducing agent and the temperature is 60-180 DEG C.

Owner:NANJING DONGYAO RES INST OF ARCHITECTURAL TECH CO LTD

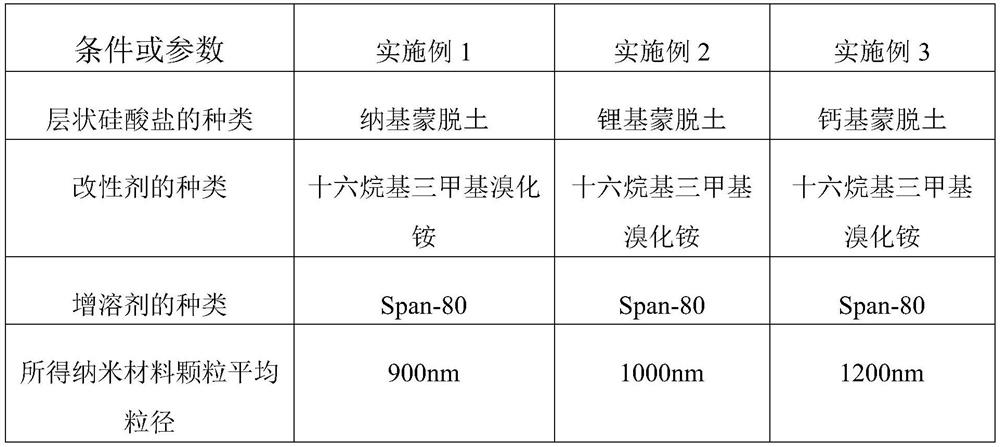

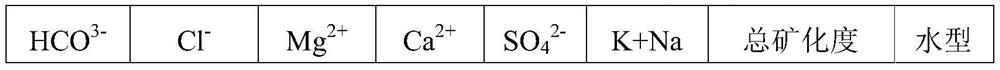

Polyacrylamide nano composite material as well as preparation method and application thereof

The invention discloses a polyacrylamide nano composite material as well as a preparation method and application thereof. The polyacrylamide nano composite material is prepared from an acrylamide monomer and a nano material in situ, wherein the content of insoluble substances in the polyacrylamide nano composite material is less than or equal to 7%. The polyacrylamide nano composite material is resistant to high temperature and salt, a complexing agent does not need to be added in the preparation process, the cost is low, and the polyacrylamide nano composite material has a good application prospect as an oil displacement agent.

Owner:NINGBO FENGCHENG ADVANCED ENERGY MATERIALS RES INST CO LTD

Metal-oxide mixed-phase titanium-chromium brown pigment and preparation process thereof

ActiveCN102532953AControlled reunionReduce the temperaturePigment physical treatmentRubidium oxideRare earth

The invention relates to a chemical raw material and a preparation process thereof, in particular to a metal-oxide mixed-phase titanium-chromium brown pigment and a preparation process thereof. The metal-oxide mixed-phase titanium-chromium brown pigment comprises the components of titanium dioxide, dichromium trioxide, diantimony trioxide, lithium fluoride, sodium tetraborate, potassium carbonate, rare earth oxide, cerium oxide and rubidium oxide. According to the metal-oxide mixed-phase titanium-chromium brown pigment and the preparation process thereof disclosed by the invention, a dispersing agent and a color fixing agent suitable for a metal-oxide mixed-phase pigment product are used, and the added quantity and the adding condition of an auxiliary agent are carefully chosen, so that the aim of complete pigment transition and uniform color and luster is fulfilled, the high-temperature transition of the product is effectively controlled, the problem of particle aggregation is solved, the aim of energy saving and consumption reduction is fulfilled, the production cost is reduced, and the equipment utilization ratio is effectively increased.

Owner:赵进军

Method for preparing silver-nickel-tin-oxide-doped electric contact material on basis of ball-milling method

InactiveCN111957980ANothing producedReduce manufacturing costTransportation and packagingMetal-working apparatusMixed oxideTin

The invention discloses a method for preparing a silver-nickel-tin-oxide-doped electric contact material on the basis of a ball-milling method. The method includes the steps of 1, weighing tin oxide powder, other oxide powder and milling balls respectively, and processing the weighed mixed powder to obtain a primarily-mixed oxide powder body A; 2, mixing silver powder, nickel powder and tin powderwith the primarily-mixed oxide powder body prepared in step 1 to form a mixed powder body B, and performing mechanical alloying surface treatment on the mixed powder body B to obtain a mixed powder body C; and 3, sequentially performing annealing, primary press-forming, sintering, re-pressing and re-sintering treatment on the mixed powder body C obtained in step 2 to finally prepare the silver-nickel-tin-oxide-doped electric contact material. The preparation method solves the problems of high cost, long production cycle and complex process in existing silver-nickel-tin-oxide-doped electric contact material and effectively improves the electrical property of the silver-nickel-tin-oxide-doped electric contact material.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Method for preparing nano- copper powder by chemical reduction in water solution

The present invention is chemical reduction process of preparing nanometer copper powder in water solution, and relates to electrochemical process for preparing powdered material. The preparation process adopts the proper combination of main salt, reductant and additives, the main salt is copper sulfate or copper chloride, the reductant is sodium hypophosphorate, sodium borohydride and formaldehyde, and the additives include silver nitrate or palladium chloride, gelatin or SDBS, potassium sodium tartrate or triethanolamine and sodium hydroxide or potassium hydroxide. During the preparation, outer ultrasonic field is applied. The preparation process is simple and high in preparation speed, and has no coagulation of copper powder to ensure the medium powder size smaller than 100 nm for ideal use effect of the nanometer copper powder.

Owner:UNIV OF SCI & TECH BEIJING

3D nano iron oxide as well as in-situ preparation method and application of 3D nano iron oxide gel

ActiveCN108439478AControlled reunionInhibition of agglomerationCatalyst carriersOther chemical processesIron saltsPolyvinyl alcohol

The invention discloses 3D nano iron oxide as well as an in-situ preparation method and an application of the 3D nano iron oxide gel. The preparation method comprises the steps as follows: a water-soluble polymer and iron salt are dissolved in water, and a mixed liquor is obtained; the mixed liquor is heated, and nano iron oxide which grows in situ and is graded orderly is obtained; the product isrepeatedly frozen and thawed, and 3D nano iron oxide composite gel which grows in situ and is fixed through gelling is obtained. The template action of water-soluble polymers such as polyvinyl alcohol is used for controlling iron oxide to grow in polyvinyl alcohol in situ, polyvinyl alcohol can form gel with a freezing-thawing method to further fix and disperse the iron oxide, agglomeration of the iron oxide can be inhibited fundamentally, the problem of difficulty in solid-liquid separation in water treatment of iron oxide powder is solved, the preparation method is simple and efficient, theobtained gel is uniform, porous and controllable in shape, has excellent adsorption property and catalytic performance, is prone to solid-liquid separation and has broad application prospects in environmental pollution control.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

ZSM-5 type molecular sieve for catalyst for reaction for preparing propylene from methanol and/or dimethyl ether

ActiveCN101624192BImprove diffusion abilityHigh P/E ratioMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sievePtru catalyst

The present invention provides a ZSM-5 type molecular sieve catalyst for a reaction for preparing propylene from methanol and / or dimethyl ether, which has a silica alumina ratio of 250-1,150 and a grain diameter of 65-250nm. A preparation method of the molecular sieve comprises the following steps: (1) mixing an aluminum source and an organic directing agent and stirring an obtained mixture at constant temperature of 0-30 DEG C for 2-24 hours; (2) adding a silicon source and an organic addition agent to the mixed solution obtained in the step (1) and continuing stirring the mixed solution to obtain gel; (3) stirring the gel obtained in the step (2) at 35-95 DEG C and then carrying out a crystallization reaction for 24-240 hours at 60-200 DEG C, wherein in the raw materials for synthesizing the molecular sieve, and the molar ratio of OH<-1> to SO2 to AL2O3 to H2O to the organic directing agent to the organic directing agent is (0.1-0.35):1:(0.0005-0.01):(10-25):(0.1-0.6):(0.5-8). The ZSM-5 type catalyst has the characteristics of controllable grain size, adjustable silica alumina ratio, high dispersity, and the like and has higher propylene selectivity and P / E ratio in the reaction for preparing low carbon olefin from the methanol and / or the dimethyl ether.

Owner:DATANG INT CHEM TECH RESINST

Preparation method of TiC high-alloy hot work die steel based steel bond hard alloy

The invention relates to a preparation method of TiC high-alloy hot work die steel based steel bond hard alloy. The preparation method comprises the following steps: weighing titanium carbide powder and high-alloy hot work die steel based body powder in proportion; mixing and pulverizing alloy powder in a ball mill, wherein added anhydrous ethanol is a process control agent; after ball-milling is finished, drying wet mixed powder in a vacuum drying box for subsequent use; adding organic monomer and an initiator in a solvent to prepare premixed liquid; adding an additive which improves fluidity and dispersibility of slurry; adding a catalyst and a pH regulator, and evenly stirring to obtain the slurry; injecting the slurry into a gel-casting mold and vacuumizing or shaking to remove air; after the slurry is solidified and formed, drying a blank in the vacuum drying box; and carrying out integral degumming and sintering on the dried blank in a vacuum sintering furnace to prepare the steel bond hard alloy. The preparation method of the TiC high-alloy hot work die steel based steel bond hard alloy has the advantages of simple process, low cost and easiness in preparation of large parts in complicated shapes on the basis of the macroscopic performance of the steel bond hard alloy.

Owner:丹阳惠达模具材料科技有限公司

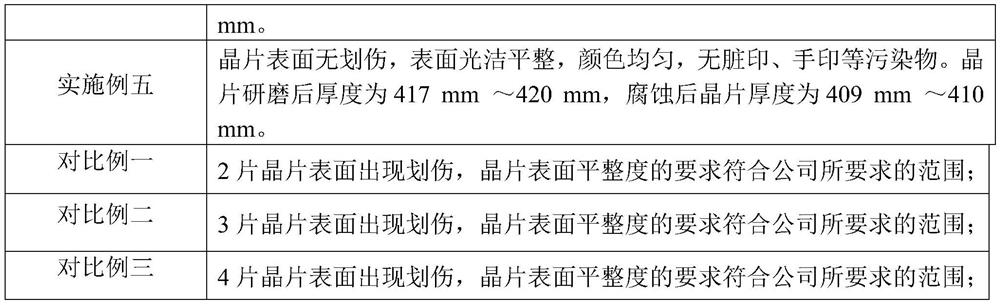

Suspension, grinding fluid and preparation method thereof

InactiveCN113698914AExtended service lifeEasy to useOther chemical processesSemiconductor materialsWafering

The invention discloses a suspension, a grinding fluid and a preparation method thereof, and relates to the technical field of semiconductor materials. The suspension liquid is prepared from the following raw materials: sodium dodecyl benzene sulfonate, sodium tripolyphosphate, an acrylamide-sodium acrylate polymer, sulfomethylated polyacrylamide, n-hydroxymethylated acrylamide, phytic acid and water, and the grinding fluid is prepared from the following raw materials: grinding powder, grinding oil, the suspension liquid and deionized water. According to the invention, the grinding liquid using the suspension liquid has high uniformity, and the suspension liquid can effectively reduce accumulation and precipitation of grinding powder in the grinding liquid in a mixture, so that the wafer grinding quality is ensured.

Owner:威科赛乐微电子股份有限公司

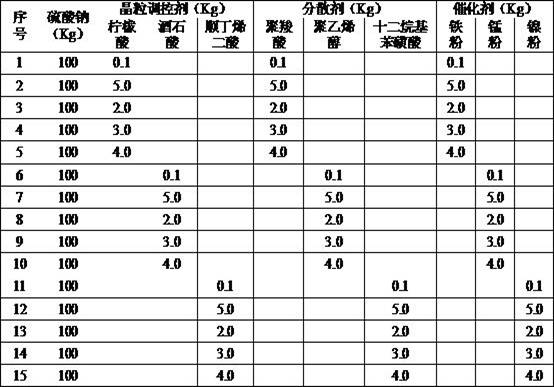

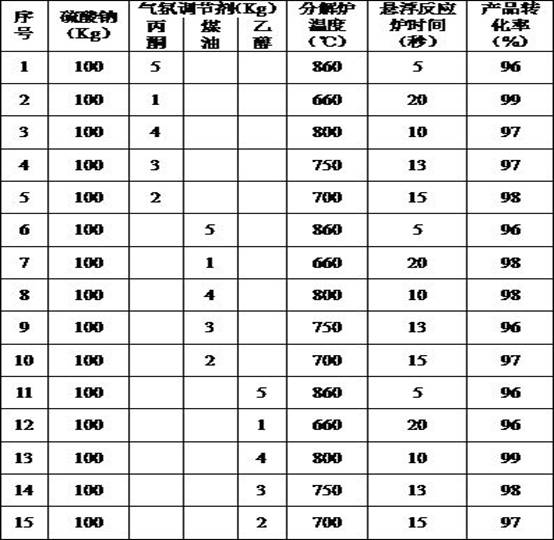

Method for producing sodium sulfide by suspending sodium sulfate

PendingCN113772632ASmall particle sizeControlled reunionAlkali metal sulfides/polysulfidesPtru catalystPhysical chemistry

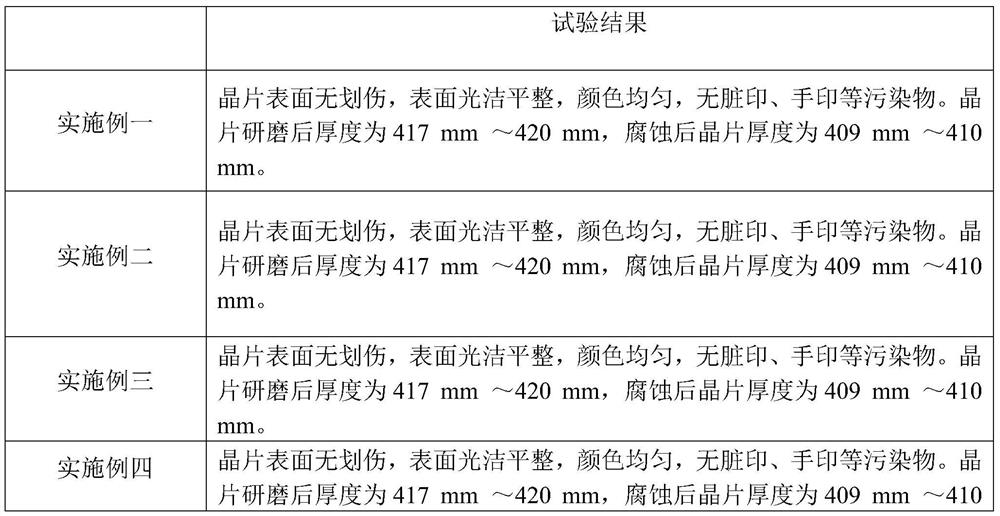

The invention discloses a method for producing sodium sulfide by suspending sodium sulfate. The method comprises the following steps: adding a crystal grain regulating agent and a dispersing agent into a saturated sodium sulfate solution, and carrying out concentrating, crystallizing and drying to obtain superfine sodium sulfate powder; and adding a catalyst into the superfine sodium sulfate powder, carrying out uniform mixing, adding the formed mixture into a suspension reaction furnace, conducting reacting to obtain a product mixture, and sorting the product mixture to obtain sodium sulfide. Compared with the prior art, the method of the invention has the characteristics of high production efficiency, simple process and low production cost.

Owner:SOUTHWEAT UNIV OF SCI & TECH

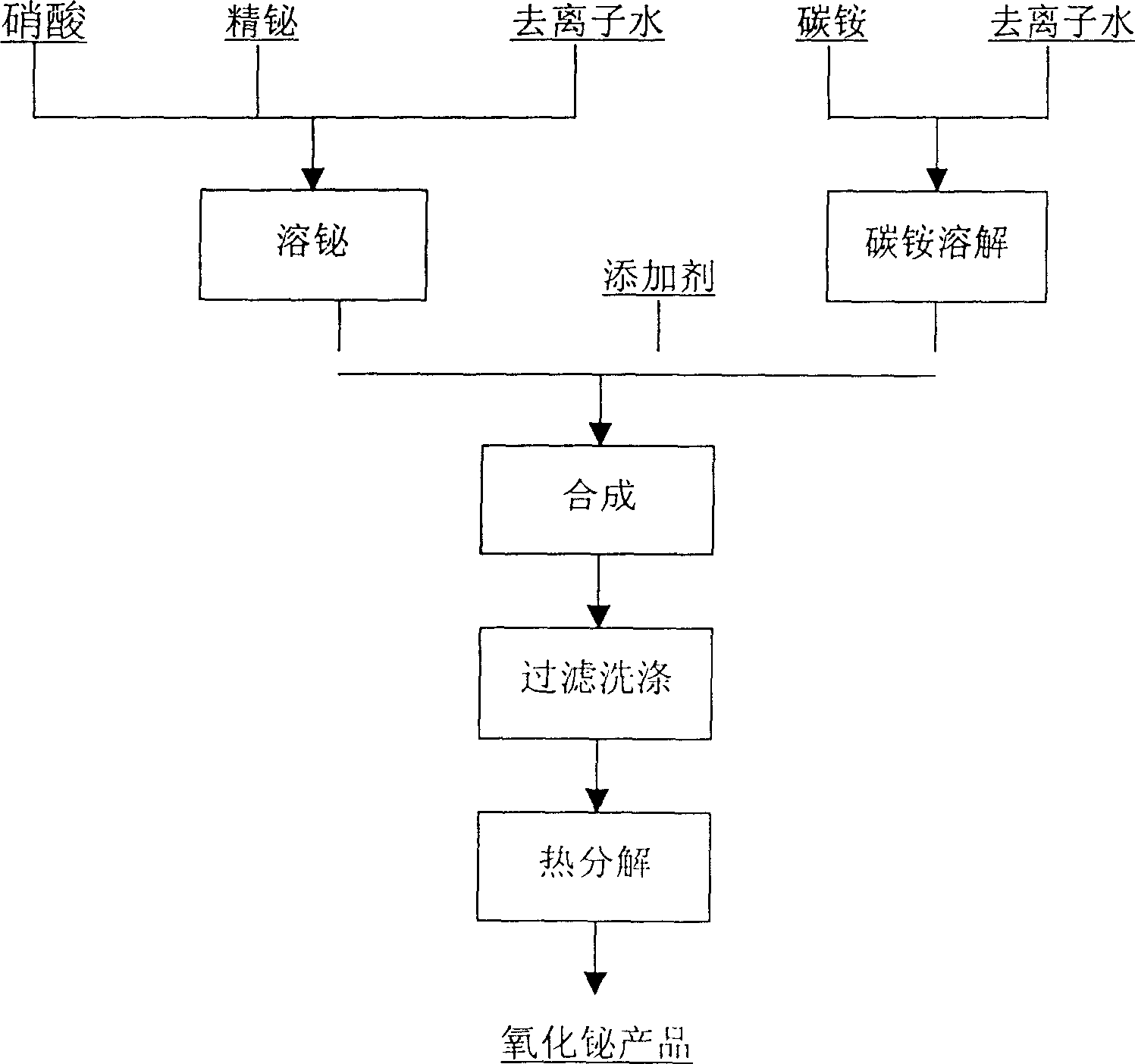

Bismuth oxide micro-powder and its preparation method

The invention discloses a bismuth oxide micro-powder and its preparation method which comprises, charging bismuth nitrate solution containing 100-350g / L of Bi 3+ into ammonium hydrogen carbonate solution with concentration of 10-25 wt%, controlling the weight ratio of charged ammonium and bismuth between 1.5-3.5, producing bismuth carbonate precipitate while agitating at normal temperature, filtering and washing, carrying out thermal treatment for the filter cake at 100-700 deg. C, thus obtaining the bismuth oxide product, dispersing agent 0.1-5 wt% of the ammonium hydrogen carbonate solution can be charged.

Owner:JIANGSU DANGSHENG MATERIAL TECH CO LTD +1

Silicon nitride-based ceramic welding sealing component and preparation method thereof

The invention discloses a silicon nitride-based ceramic welding sealing component and a preparation method thereof, and relates to the technical field of metallized ceramic processing. The invention discloses a silicon nitride-based ceramic welding sealing component which comprises a silicon nitride ceramic matrix and a metallization layer, the silicon nitride ceramic matrix is prepared from modified silicon nitride, mullite fiber, aluminum nitride, calcium oxide, titanium oxide, a binder and a dispersing agent through the steps of modified silicon nitride preparation, mixing, granulation, primary sintering, secondary sintering and the like; raw materials of the metallization layer comprise copper powder, tungsten powder, copper oxide, yttrium oxide, zinc oxide and an organic binding agent. The invention further discloses a preparation method of the silicon nitride-based ceramic welding sealing component composed of the metallization layer and the silicon nitride ceramic matrix. According to the silicon nitride-based ceramic welding sealing component, the density of the silicon nitride ceramic matrix is improved, the silicon nitride-based ceramic welding sealing component has excellent strength, hardness and fracture toughness, the tensile strength of the sealing component is improved, and the silicon nitride-based ceramic welding sealing component has excellent high-temperature resistance.

Owner:湖南省新化县鑫星电子陶瓷有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com