Polyacrylamide nano composite material as well as preparation method and application thereof

A nanocomposite material, polyacrylamide technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high energy consumption and increased cost of polyacrylamide, and achieve low insoluble content, low cost, Appropriate molecular weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0091] Embodiment 1~3 nano material preparation

[0092] (1) Mix 10 g of phyllosilicate with 200 ml of water in a 1 cubic meter multifunctional reaction kettle, and swell for 25 minutes under stirring;

[0093] (2) The reaction system obtained above was heated up to 80°C, 16g of modifier was added, and stirred for 12 hours;

[0094] (3) Add 4 g of solubilizer to the reaction system obtained above, and react for 4 hours.

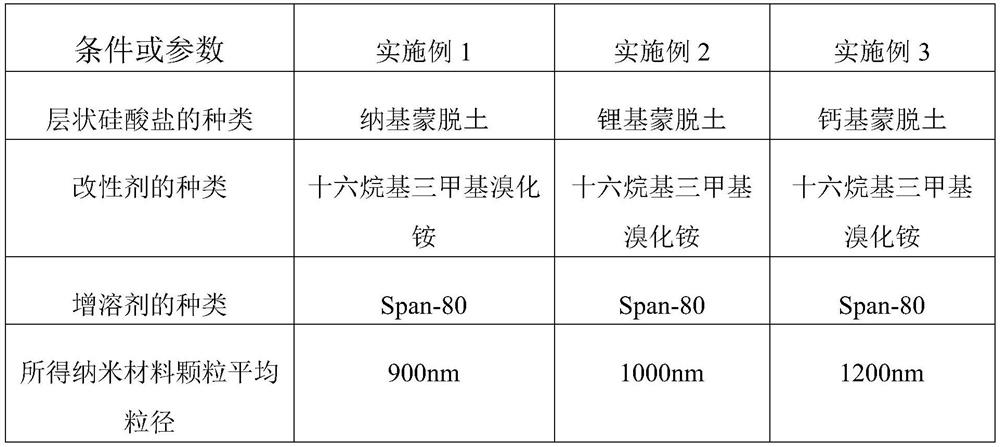

[0095] Different conditions or parameters between embodiments 1~3 are as shown in table 1:

[0096] Table 1, the concrete parameter that embodiment 1~3 nano material prepares

[0097]

Embodiment 4

[0098] The preparation of embodiment 4 polyacrylamide nanocomposites

[0099] (1) Mix 40g of acrylamide monomer and 100g of pure water in a preparation kettle, add 0.5g of urea and 0.2g of ammonia water, and stir for 25min;

[0100] (2) Adjust the pH value of the above reaction system to 8, add 0.4 g of the nanomaterial prepared in Example 1, and stir for 15 min;

[0101] (3) Transfer the mixed system obtained above to a polymerization kettle, pass nitrogen gas for 20 minutes, add 0.32 g of sodium persulfate, add 0.32 g of potassium bisulfite, react at 70°C for 60 minutes, keep warm at 50°C for 3 hours, and polymerize to form polyacrylamide nanocomposites;

[0102] (4) Extrude the polyacrylamide nanocomposite obtained above into pieces from the polymerization kettle, put it into a coarse granulator for coarse granulation, and then enter a fine granulator for fine granulation to obtain 4mm polyacrylamide Nanocomposite particles;

[0103] (5) The polyacrylamide nanocomposite ...

Embodiment 5

[0107] The preparation of embodiment 5 polyacrylamide nanocomposites

[0108] (1) Mix 40g of acrylamide monomer and 100g of pure water in a preparation kettle, add 0.5g of urea and 0.2g of ammonia water, and stir for 25min;

[0109] (2) Adjust the pH value of the above reaction system to 8, add 0.2 g of the nanomaterial prepared in Example 1, and stir for 15 min;

[0110] (3) Transfer the mixed system obtained above to a polymerization kettle, pass nitrogen gas for 20 minutes, add 0.32 g of sodium persulfate, add 0.32 g of potassium bisulfite, react at 70 ° C for 60 min, keep at 50 ° C for 3 h, and polymerize to form polyacrylamide nano composite materials;

[0111] (4) Extrude the polyacrylamide nanocomposite obtained above into pieces from the polymerization kettle, put it into a coarse granulator for coarse granulation, and then enter a fine granulator for fine granulation to obtain 5mm polyacrylamide Nanocomposite particles;

[0112] (5) The polyacrylamide nanocomposite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com