Patents

Literature

205 results about "Average level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Typically a women aged 20 to 29 will have an average level of 149 pg/ml (pictograms per milliliter). A female aged 30 to 39 will average a level of 210 pg/ml. And those over 40 but not in menopause will have an average level of 152 pg/ml.

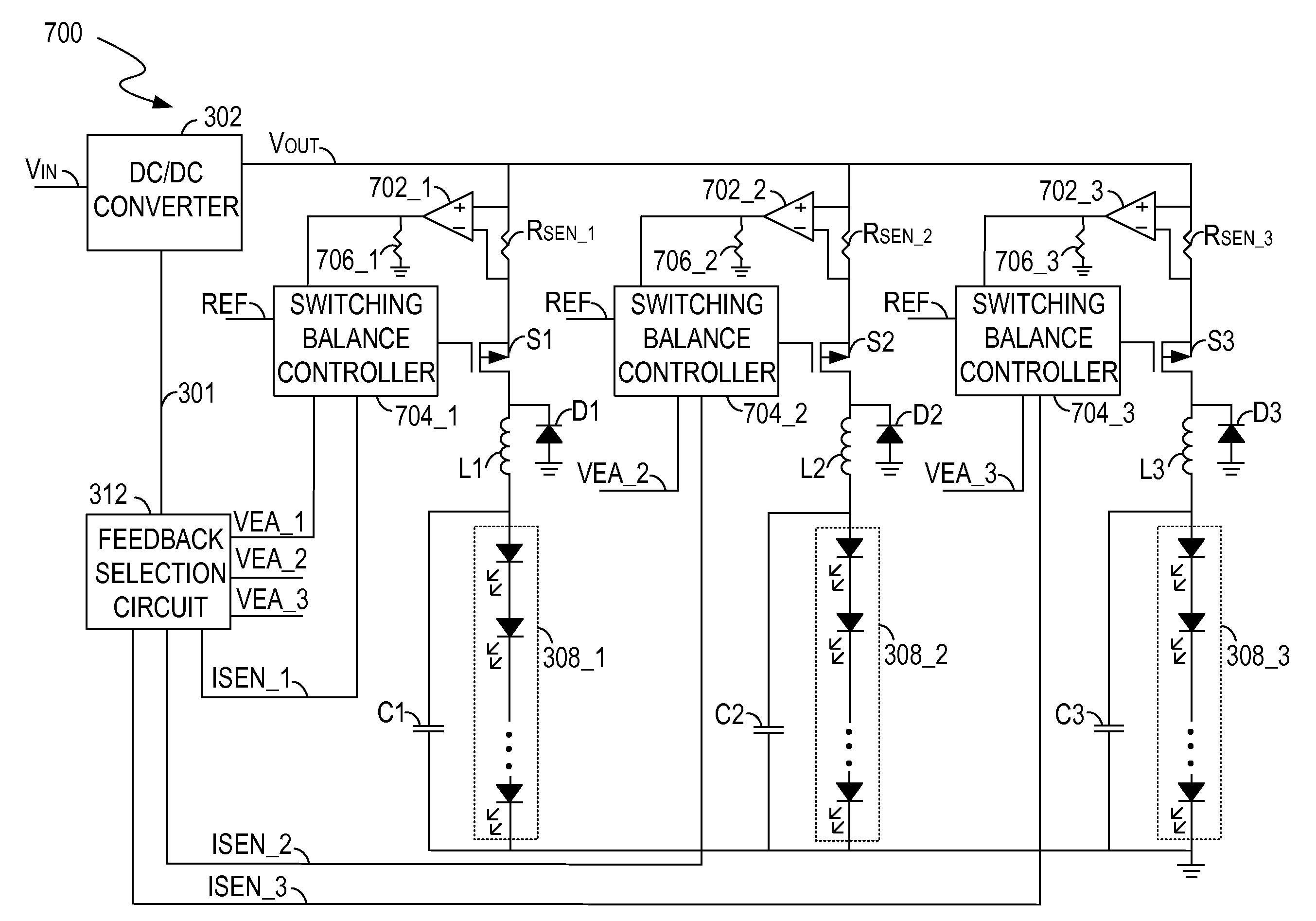

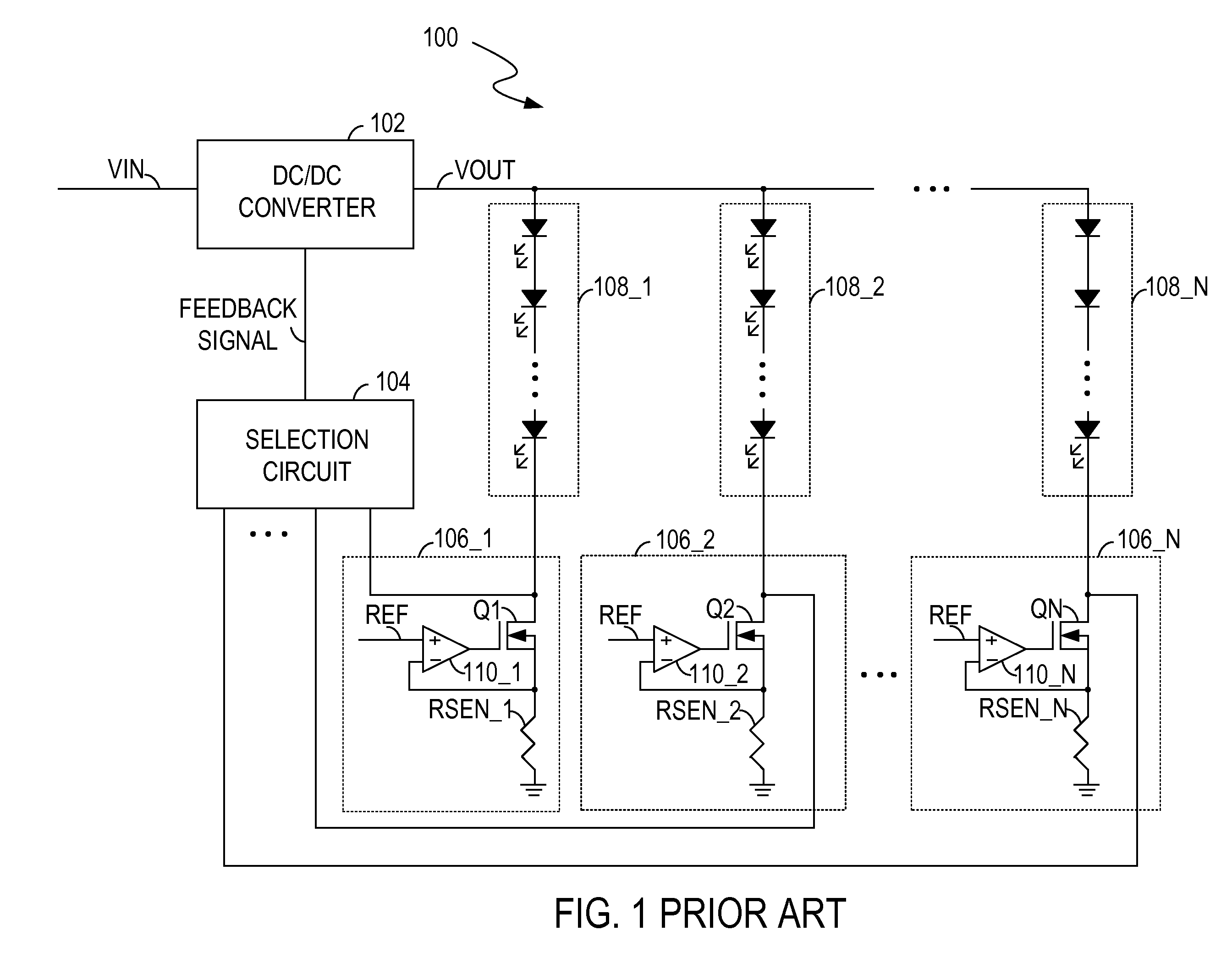

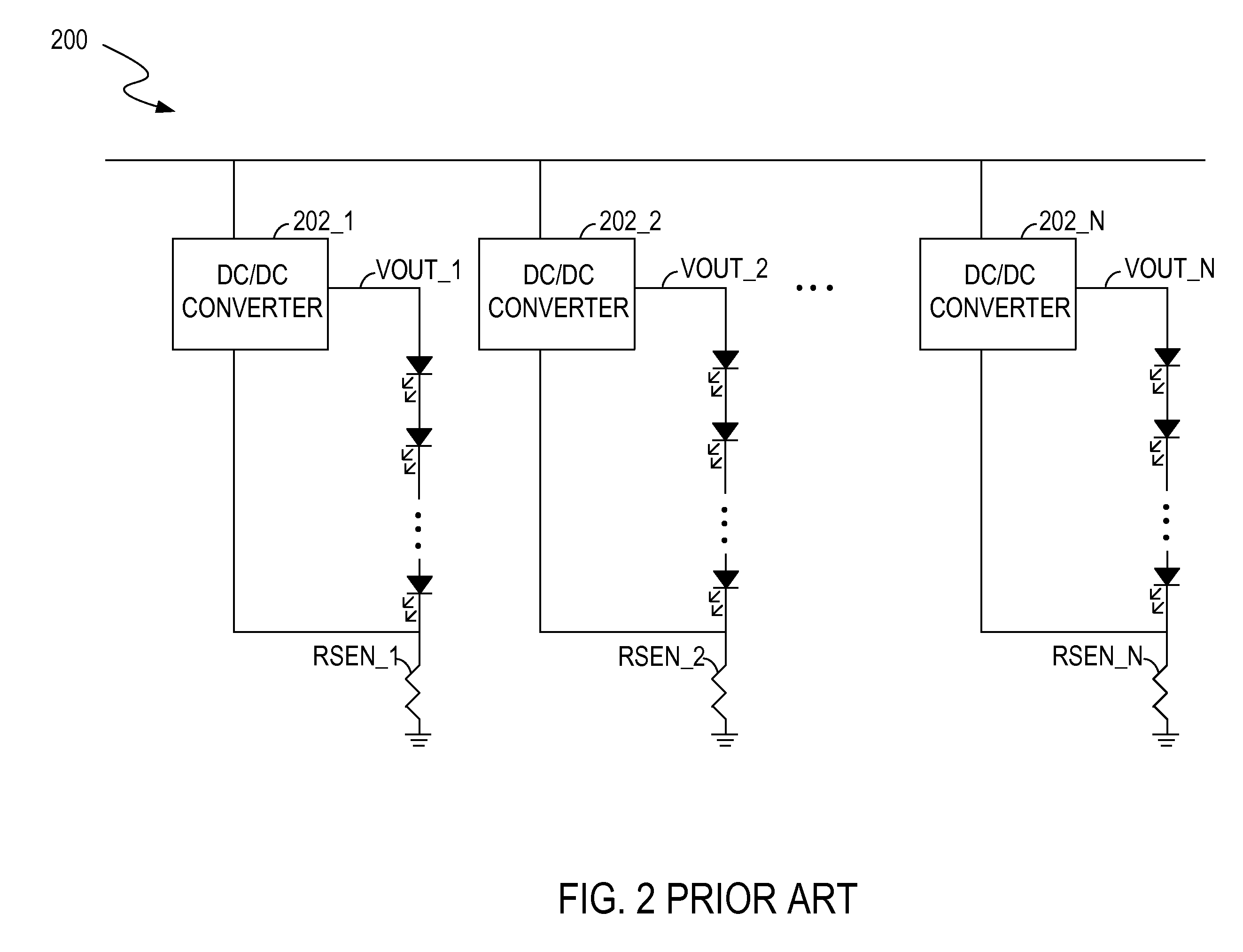

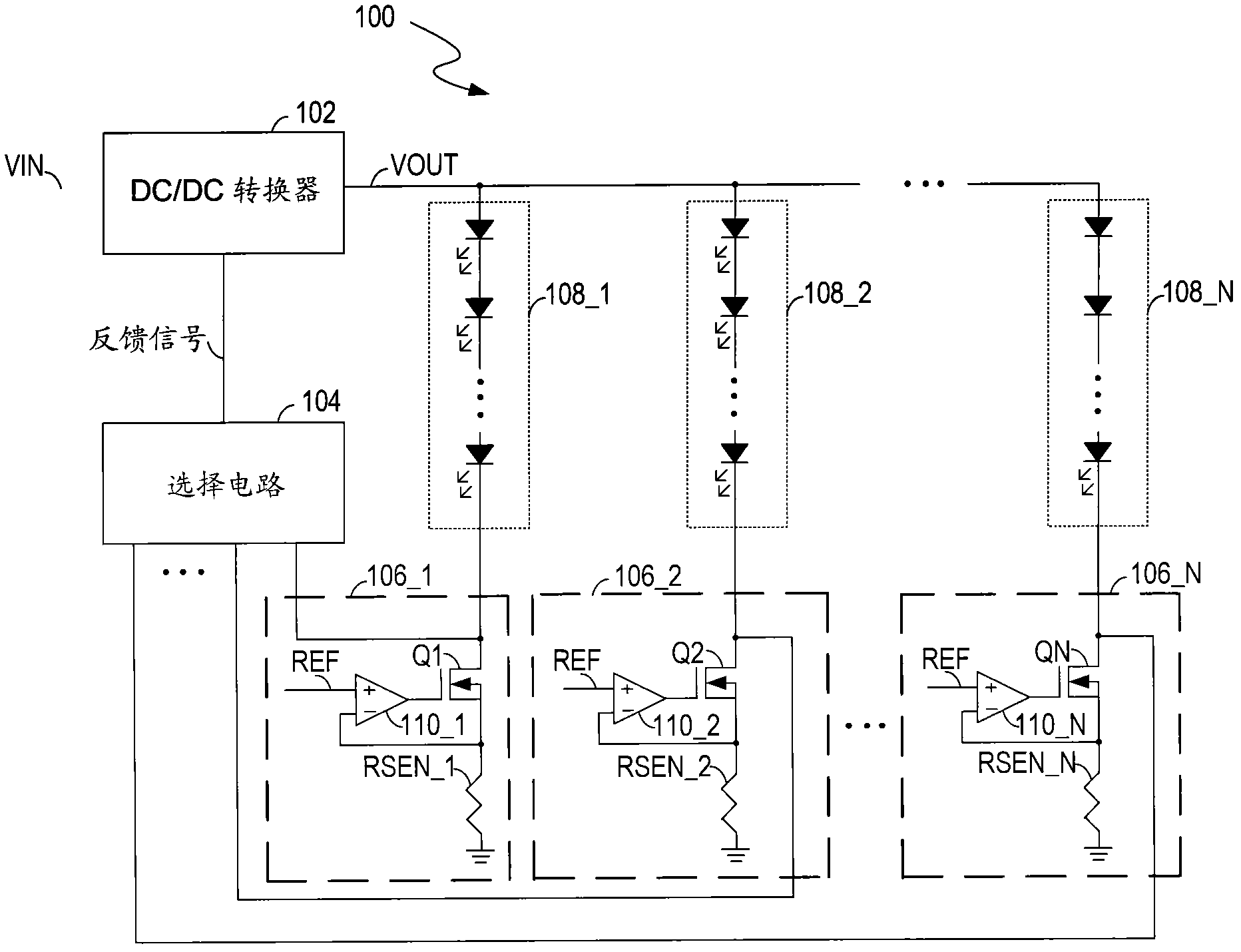

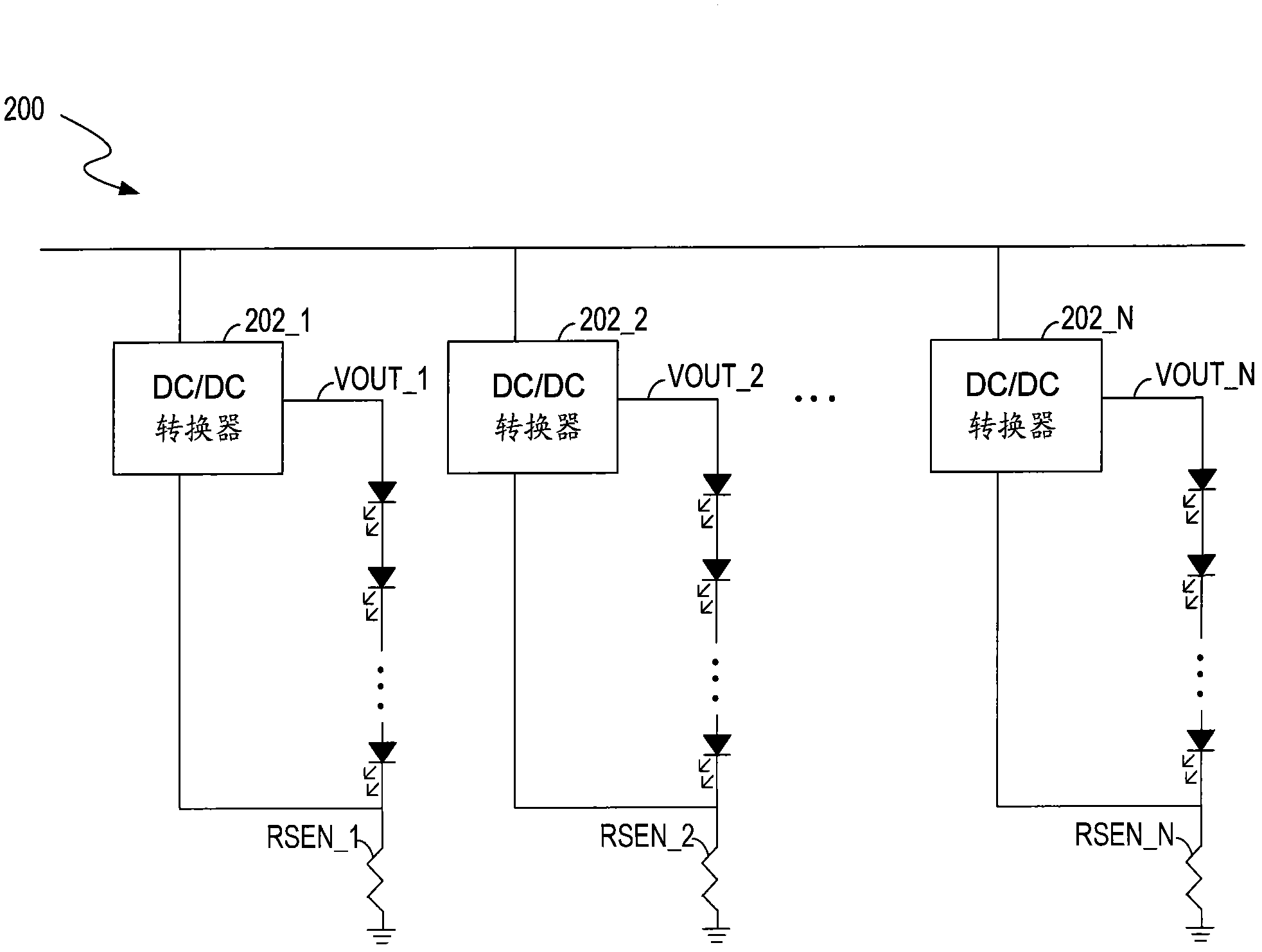

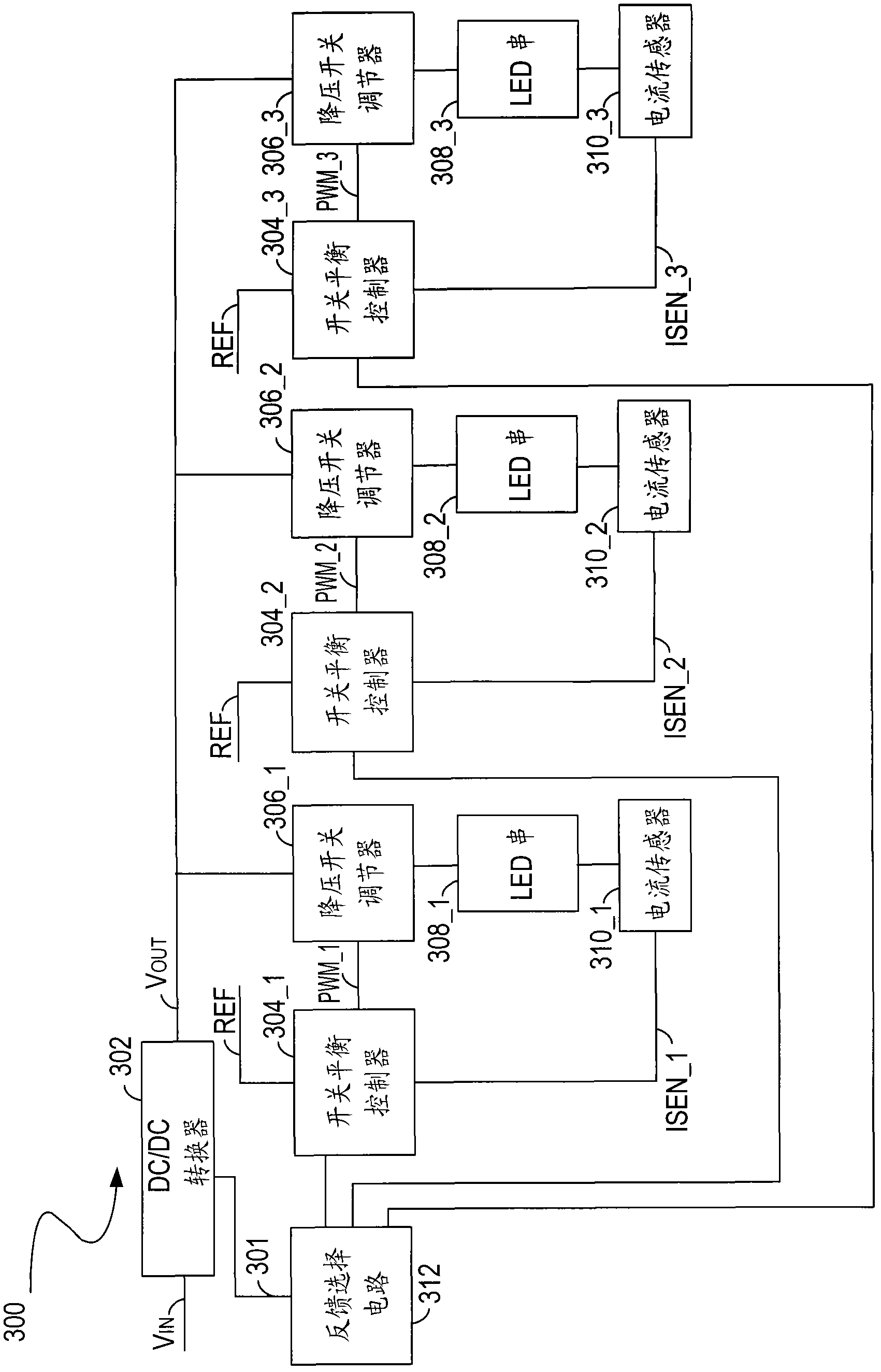

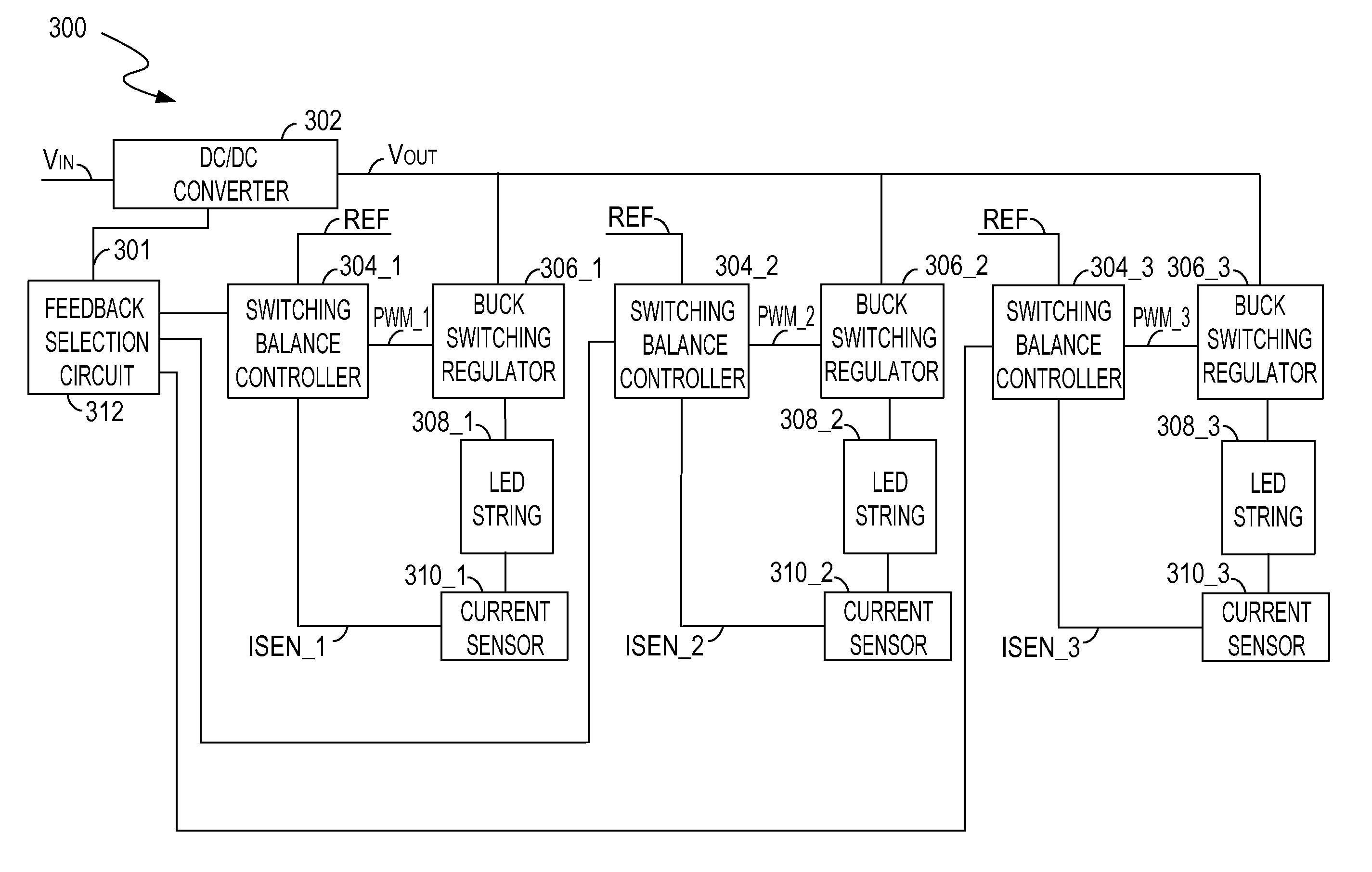

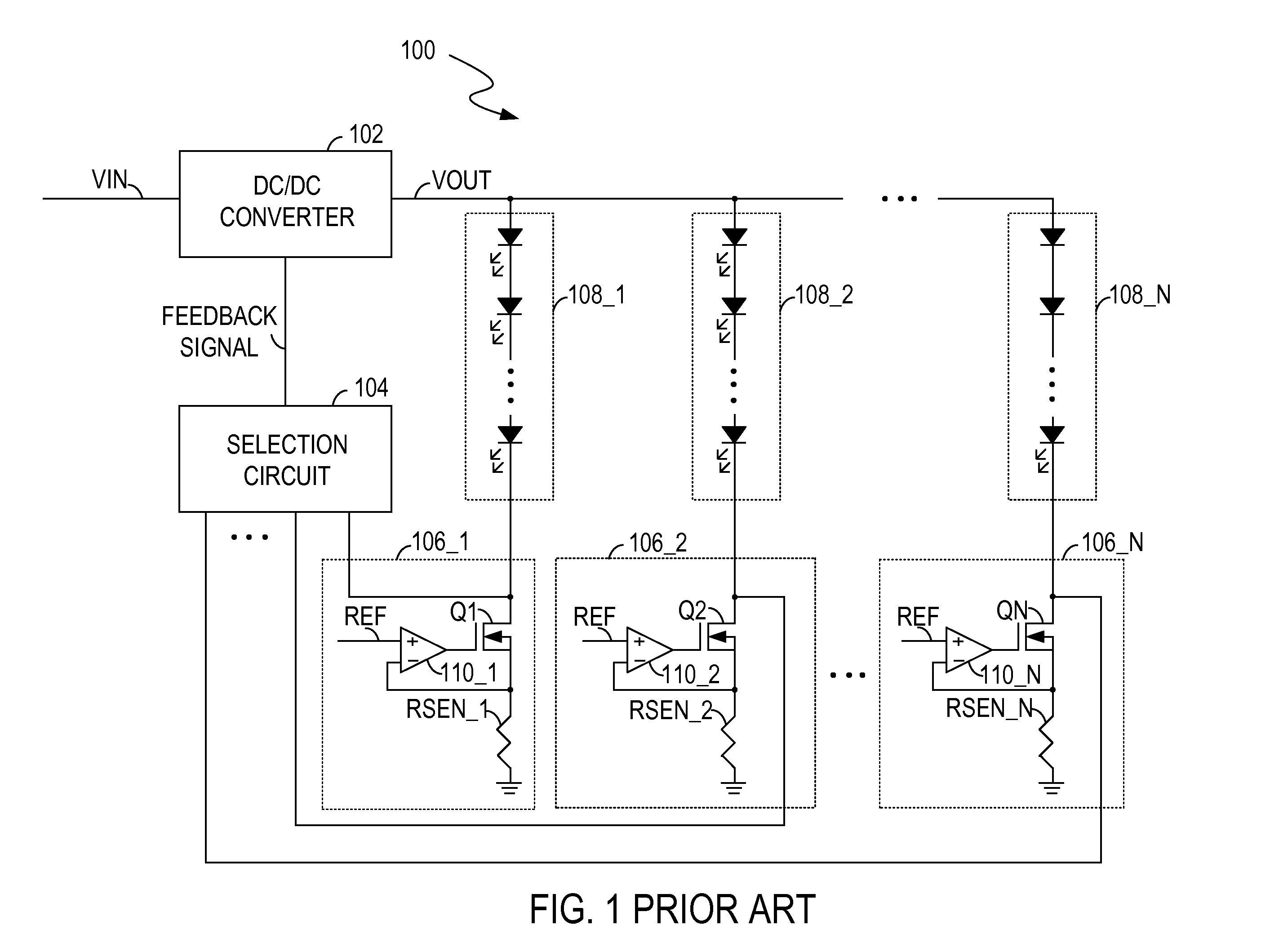

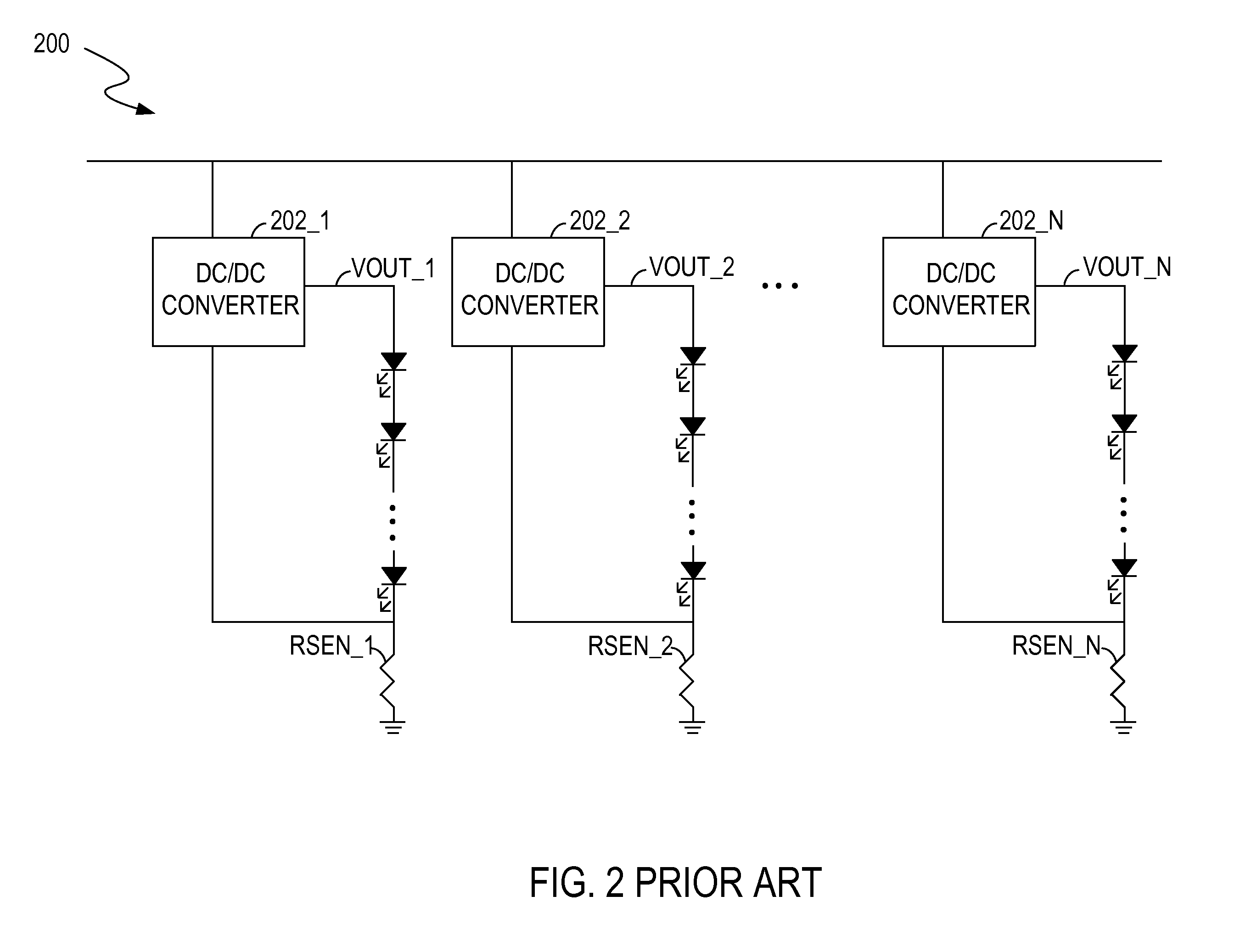

Circuits and methods for powering light sources

A driving circuit for powering a plurality of light-emitting diode (LED) light sources includes a power converter and a plurality of current balance controllers. The power converter receives an input voltage and provides a regulated voltage to the LED light sources. The current balance controllers coupled to the power converter control a plurality of currents through the LED light sources respectively. The current balance controllers receive a first reference signal indicative of a target average level and a second reference signal indicative of a maximum transient level, and regulate an average current of each of the currents to the target average level and a transient level of each of the currents within the maximum transient level.

Owner:O2 MICRO INT LTD

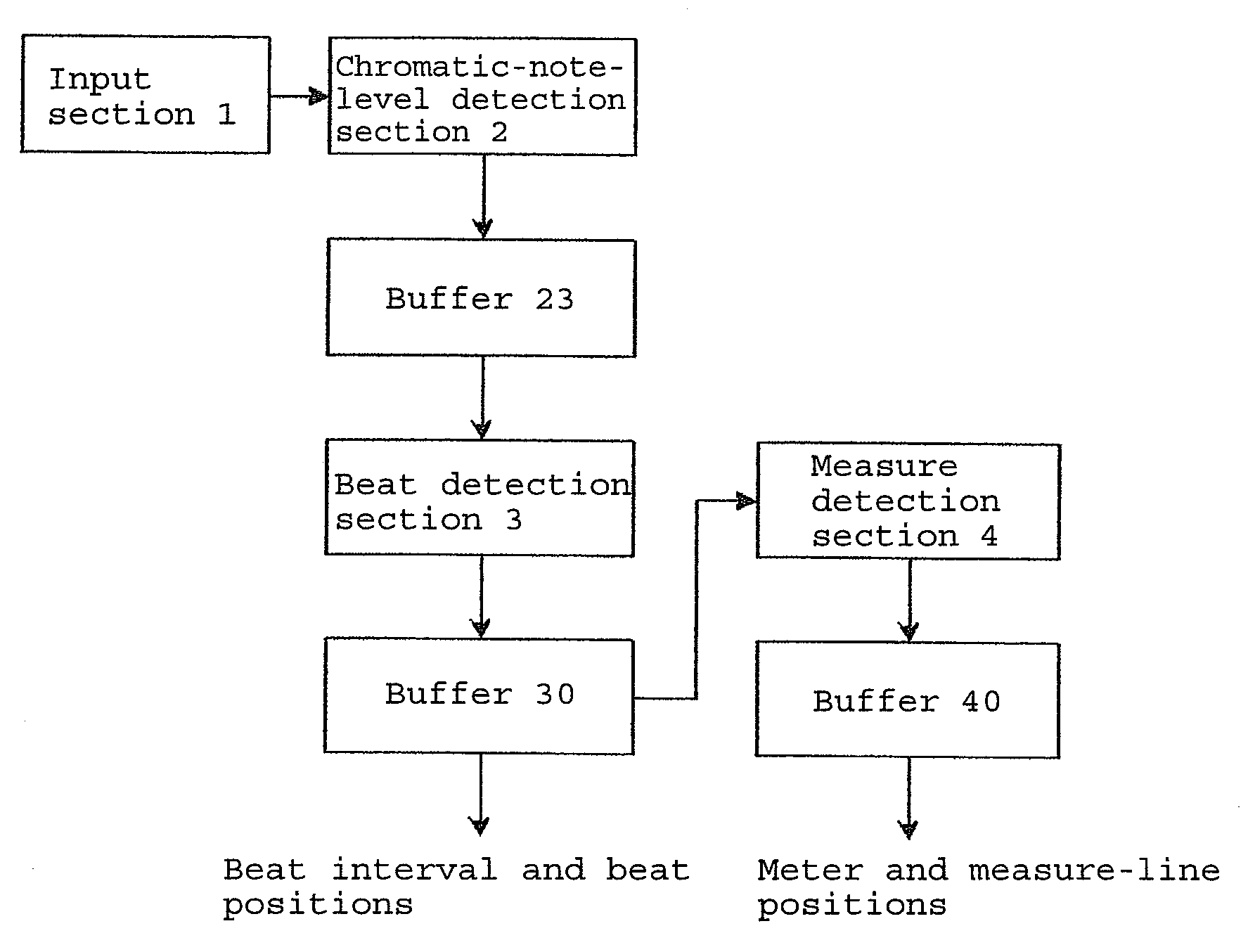

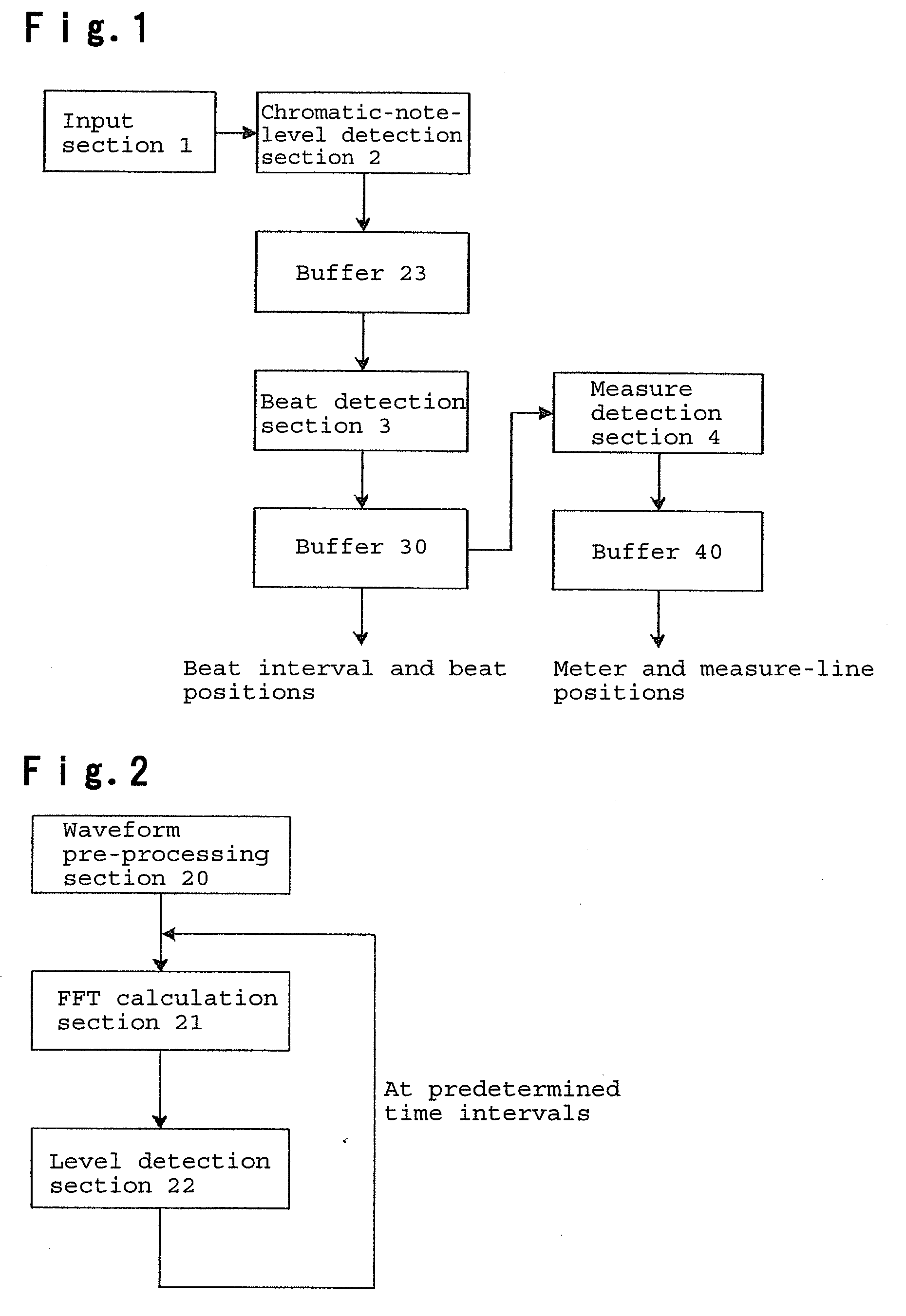

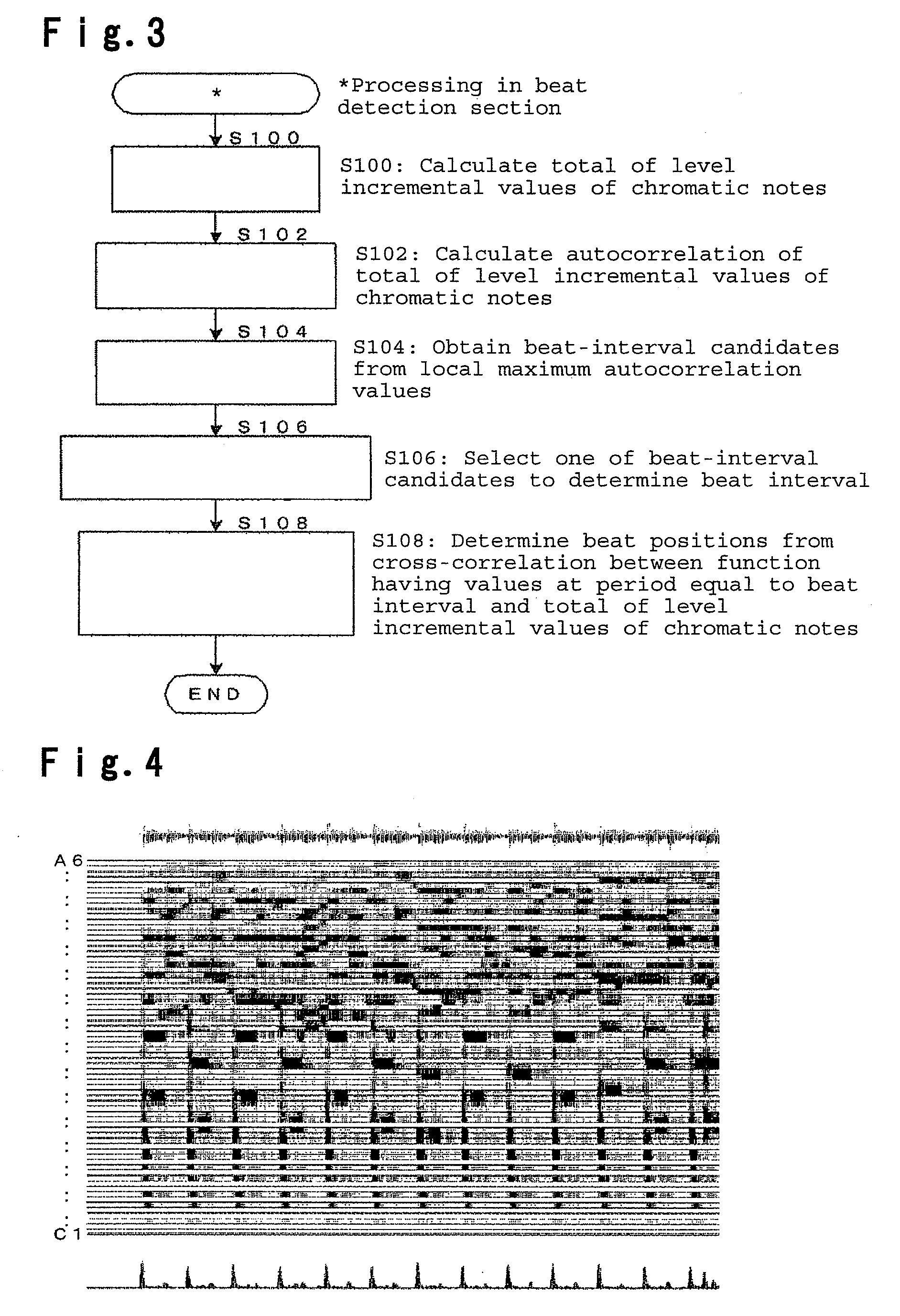

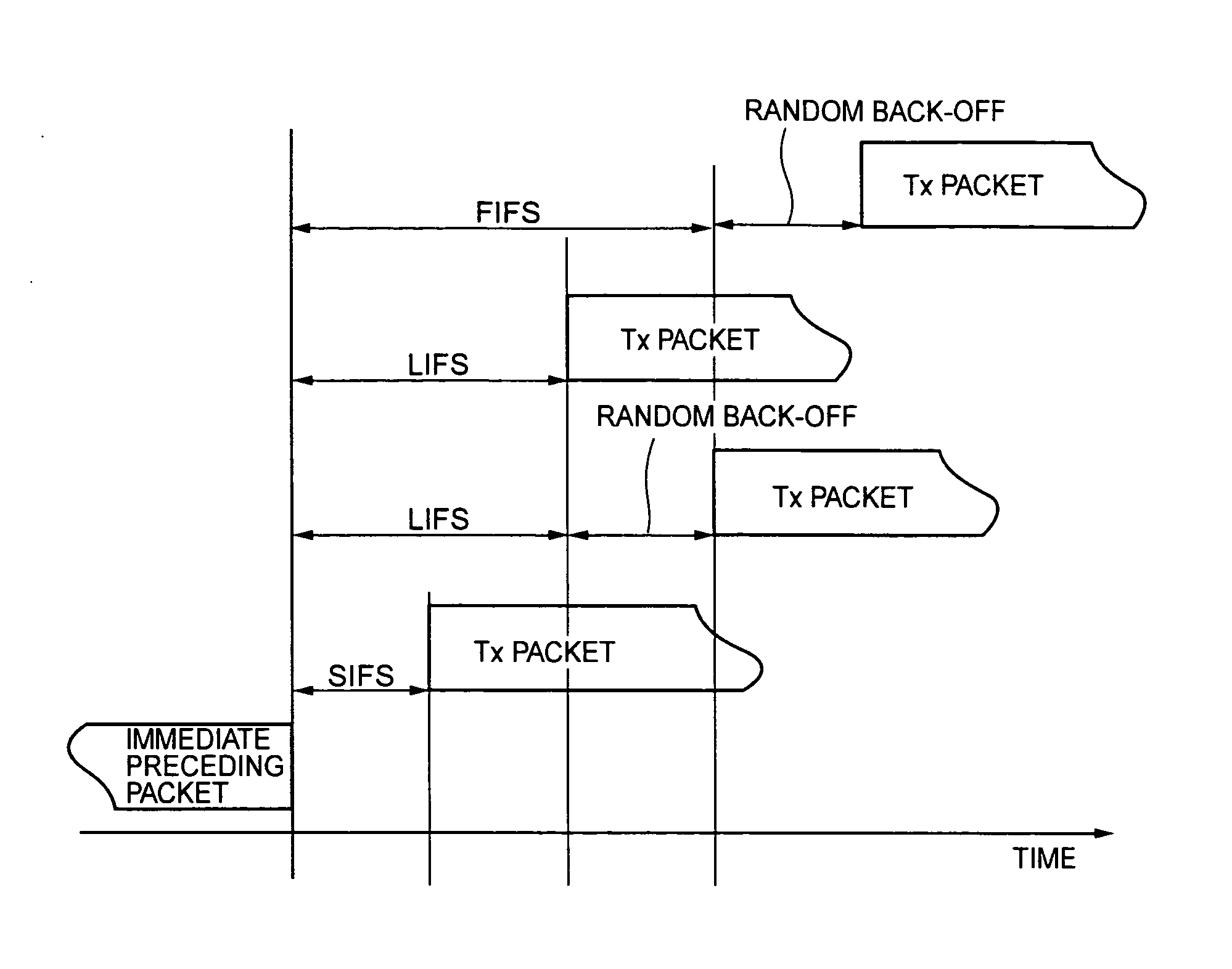

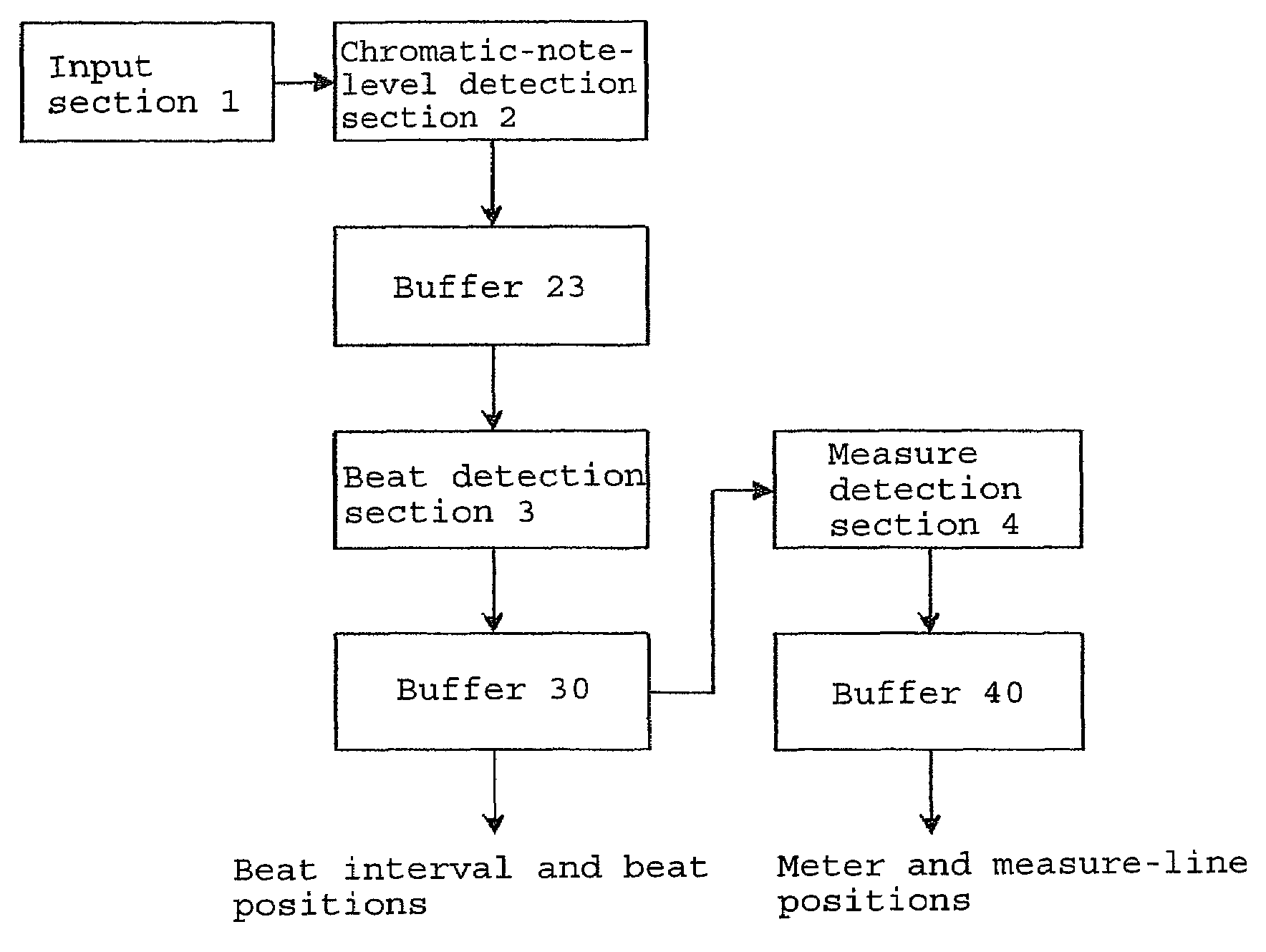

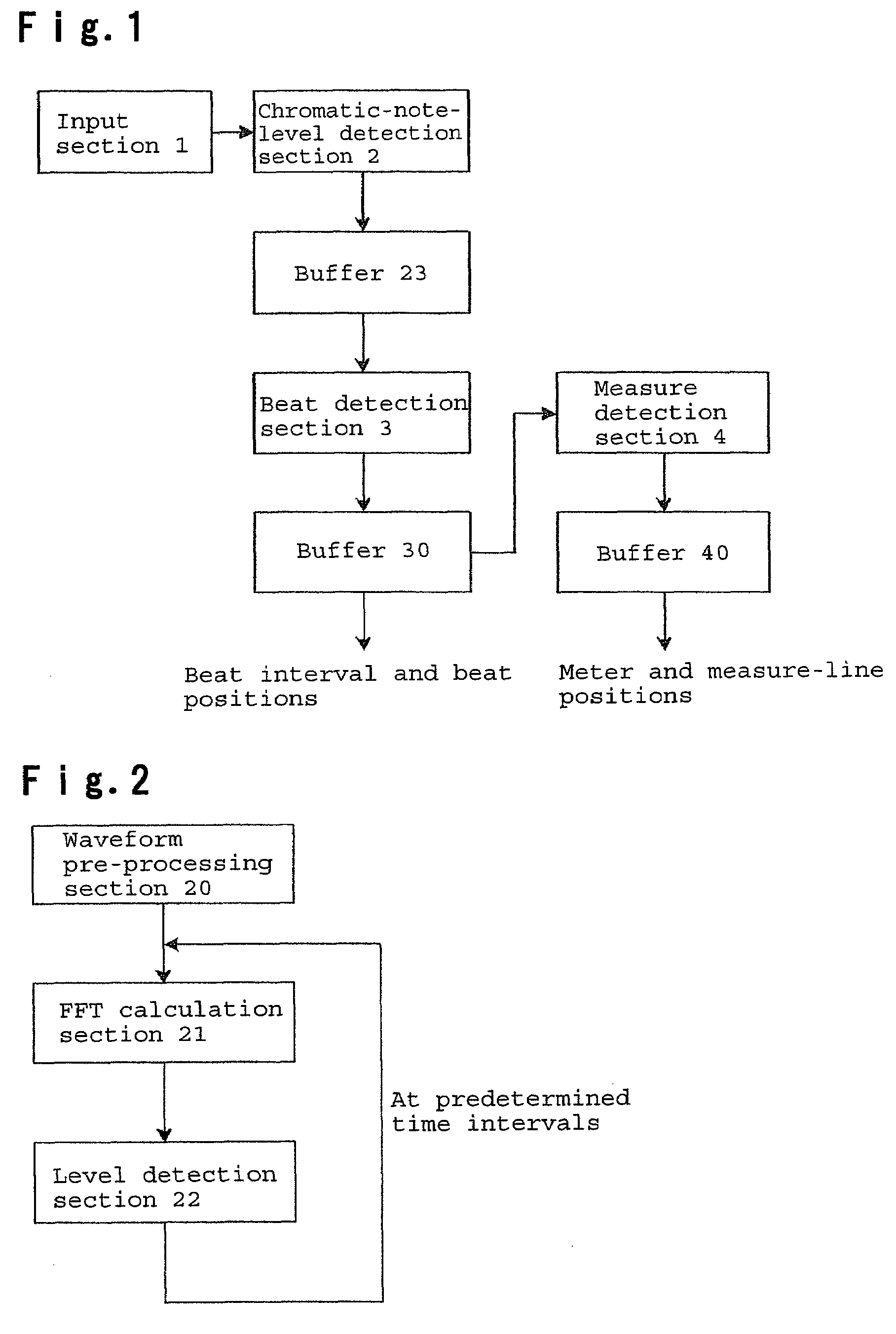

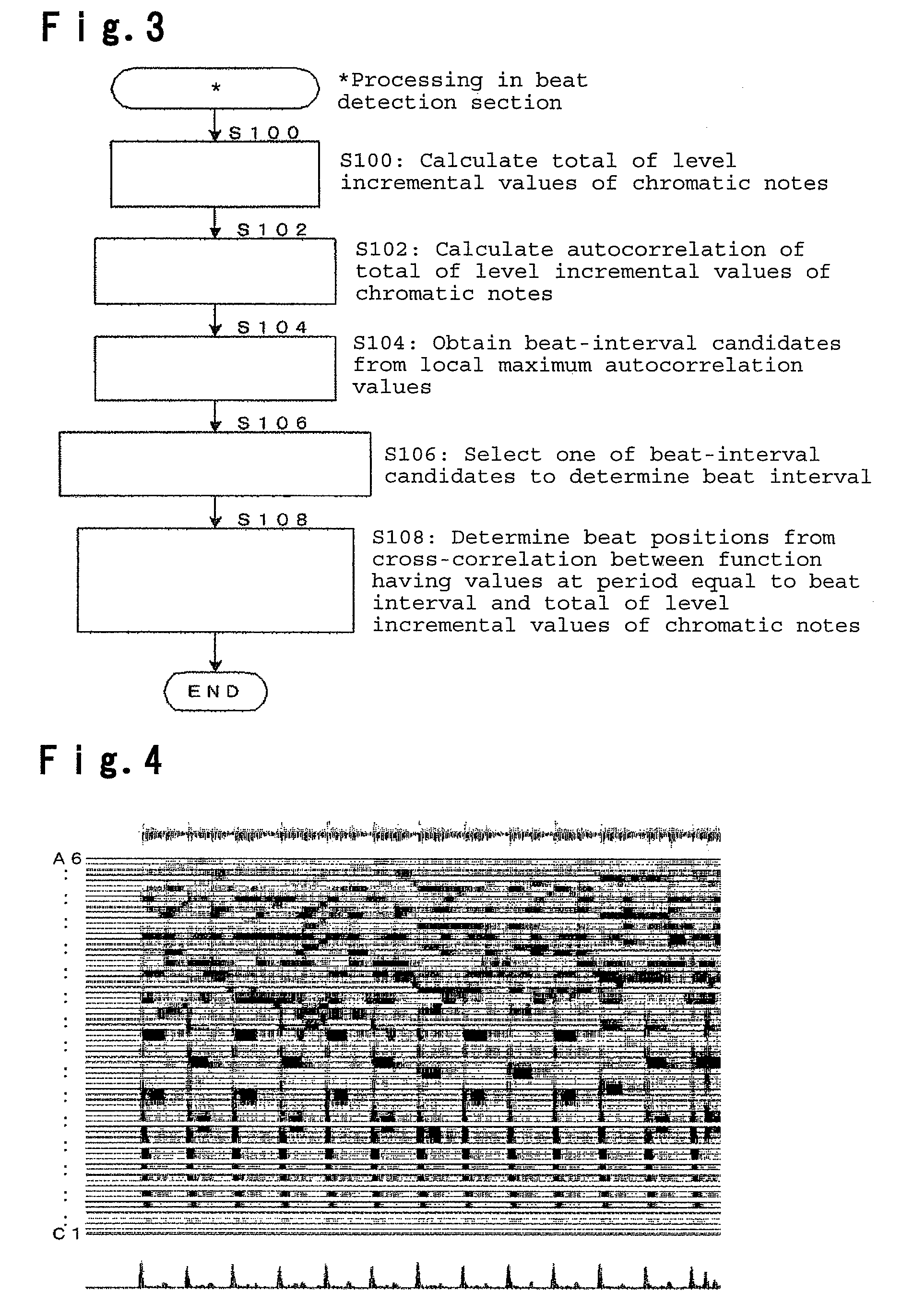

Tempo detection apparatus, chord-name detection apparatus, and programs therefor

There is provided a tempo detection apparatus capable of detecting, from the acoustic signal of a human performance of a musical piece having a fluctuating tempo, the average tempo of the entire piece of music and the correct beat positions, and further, the meter of the musical piece and the position of the first beat. The tempo detection apparatus includes an input section 1 for receiving an acoustic signal; a chromatic-note-level detection section for applying an FFT calculation to the received acoustic signal at predetermined time intervals to obtain the level of each chromatic note at each of predetermined timings; a beat detection section 2 for summing up incremental values of respective levels of all the chromatic notes at each of the predetermined timings, to obtain the total of the incremental values of the levels, indicating the degree of change of entire sound at each of the predetermined timings, and for detecting an average beat interval and the position of each beat from the total of the incremental values of the levels; and a measure detection section 3 for calculating the average level of each chromatic note for each beat, for summing up incremental values of respective average levels of all the chromatic note for each beat to obtain a value indicating the degree of change of entire sound at each beat, and for detecting a meter and the position of a measure line from the value indicating the degree of change of entire sound at each beat.

Owner:KAWAI MUSICAL INSTR MFG CO

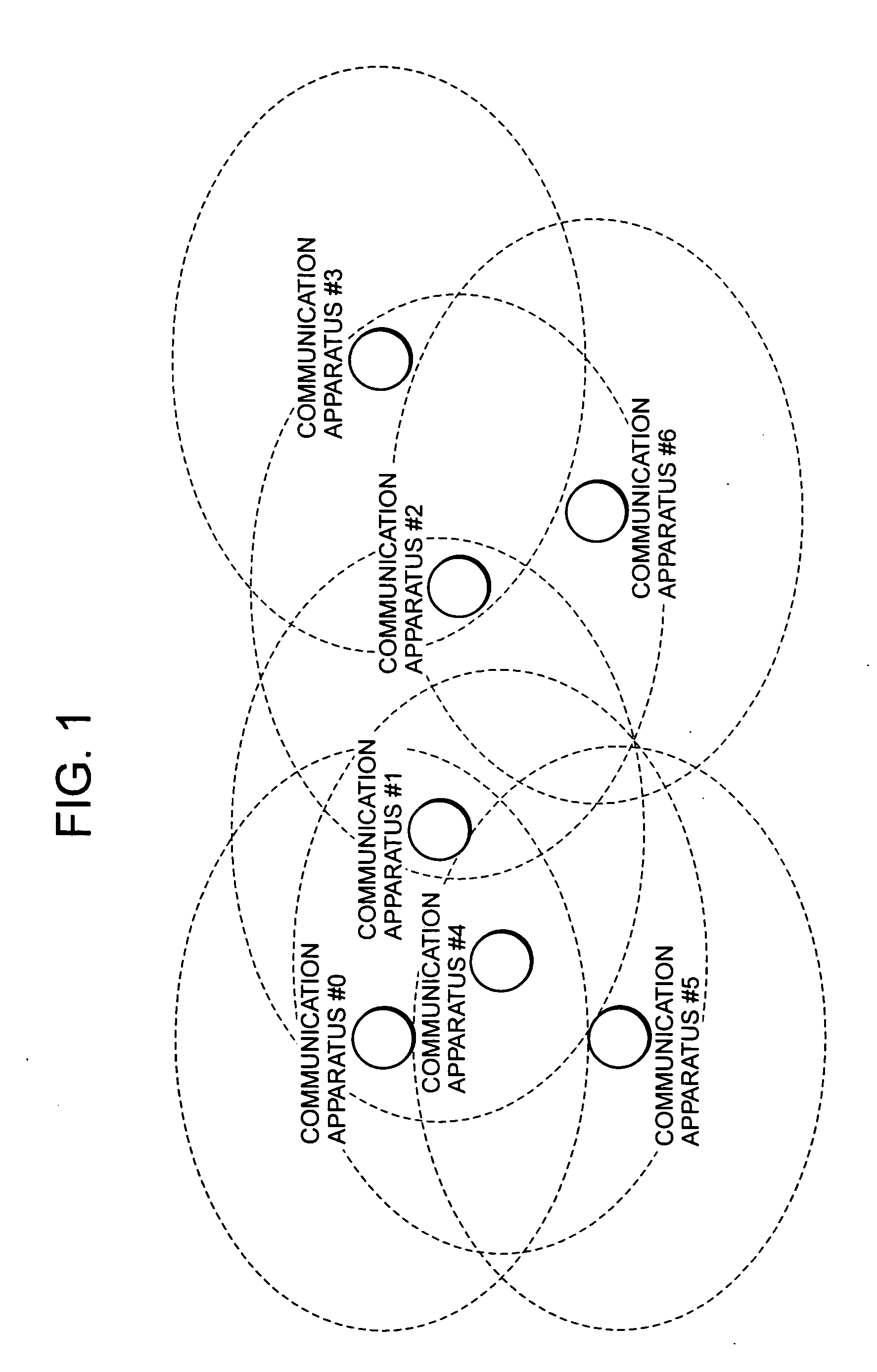

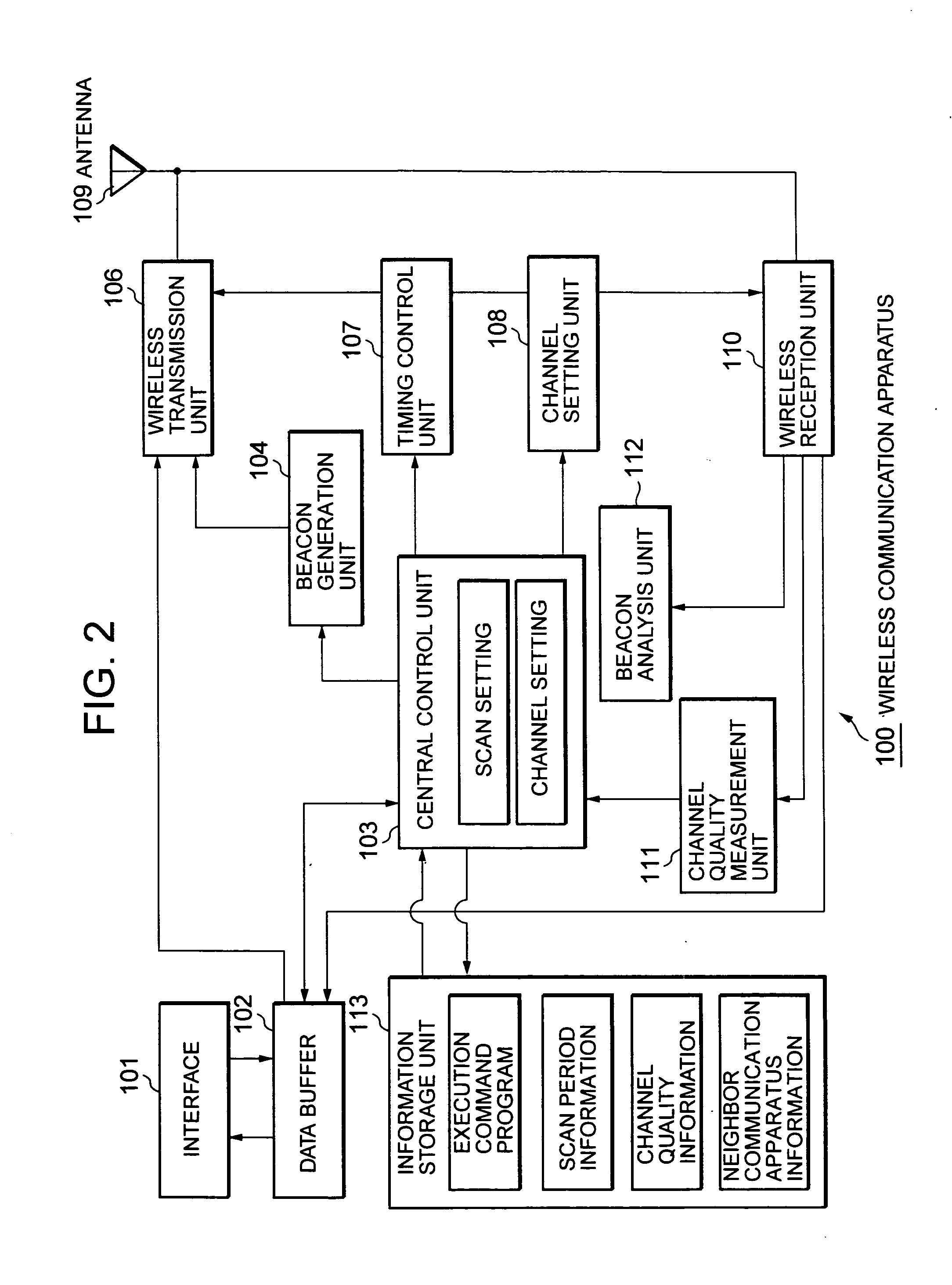

Wireless communication system, wireless communication apparatus, wireless communication method and computer program

InactiveUS20050085190A1Accurate configurationTransmission systemsFrequency-division multiplex detailsCommunications systemTransmission channel

In a wireless communication environment provided with a plurality of channels, a suitable ad hoc network is formed without mutual interference between communication stations. Each communication station acquires an average level of interference that a neighbor station receives for every channel, and a channel with the lowest average interference level is determined as a transmission channel. By weighting the interference of the neighbor station with a high priority for the local station, such as a destination station to which a large amount of packets is transmitted from the local station, to obtain a weighted average for each channel, a channel with less interference for a prioritized neighbor station for the local station is selected as the transmission channel. As a result, throughput of the entire system is improved.

Owner:SONY CORP

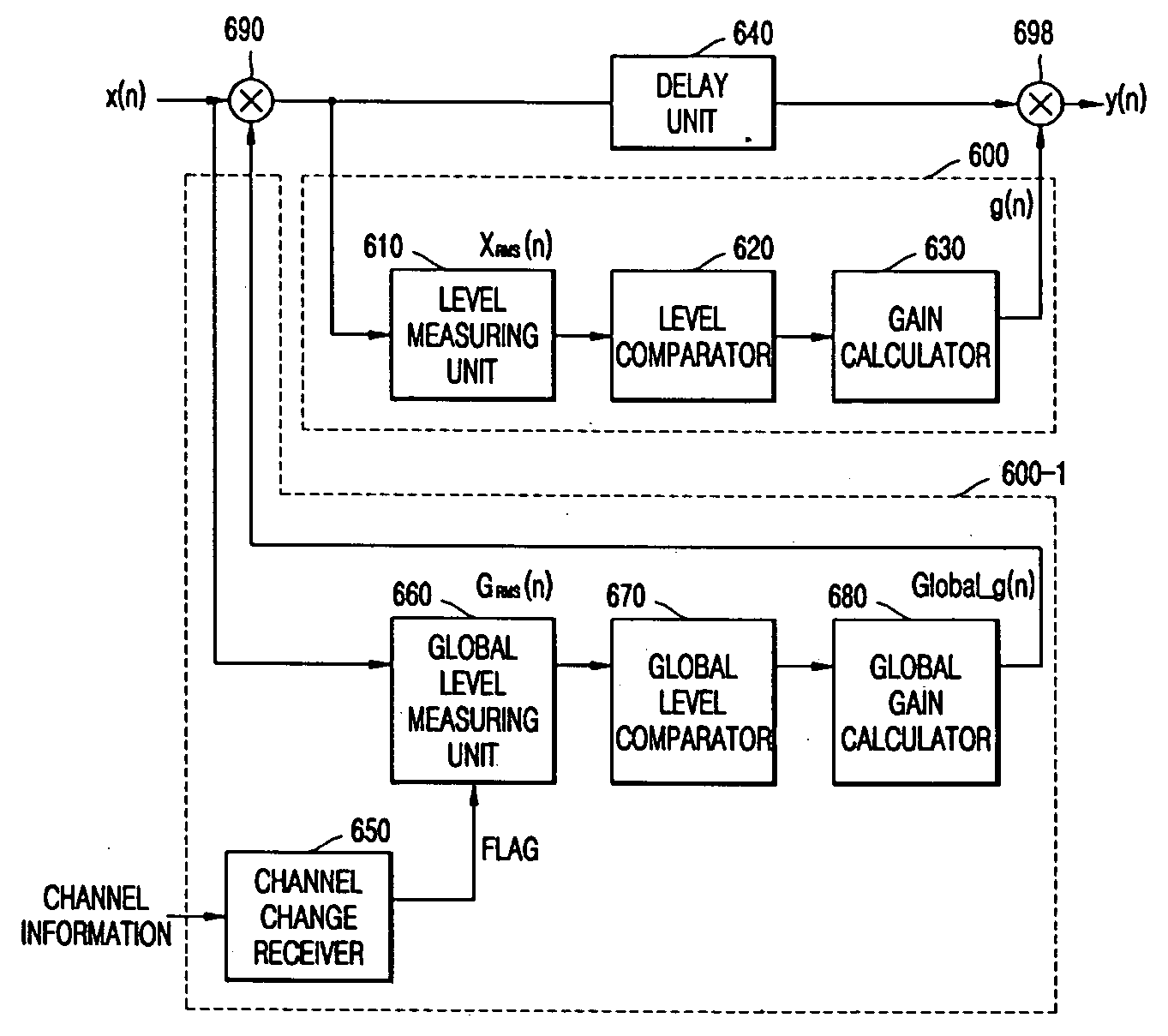

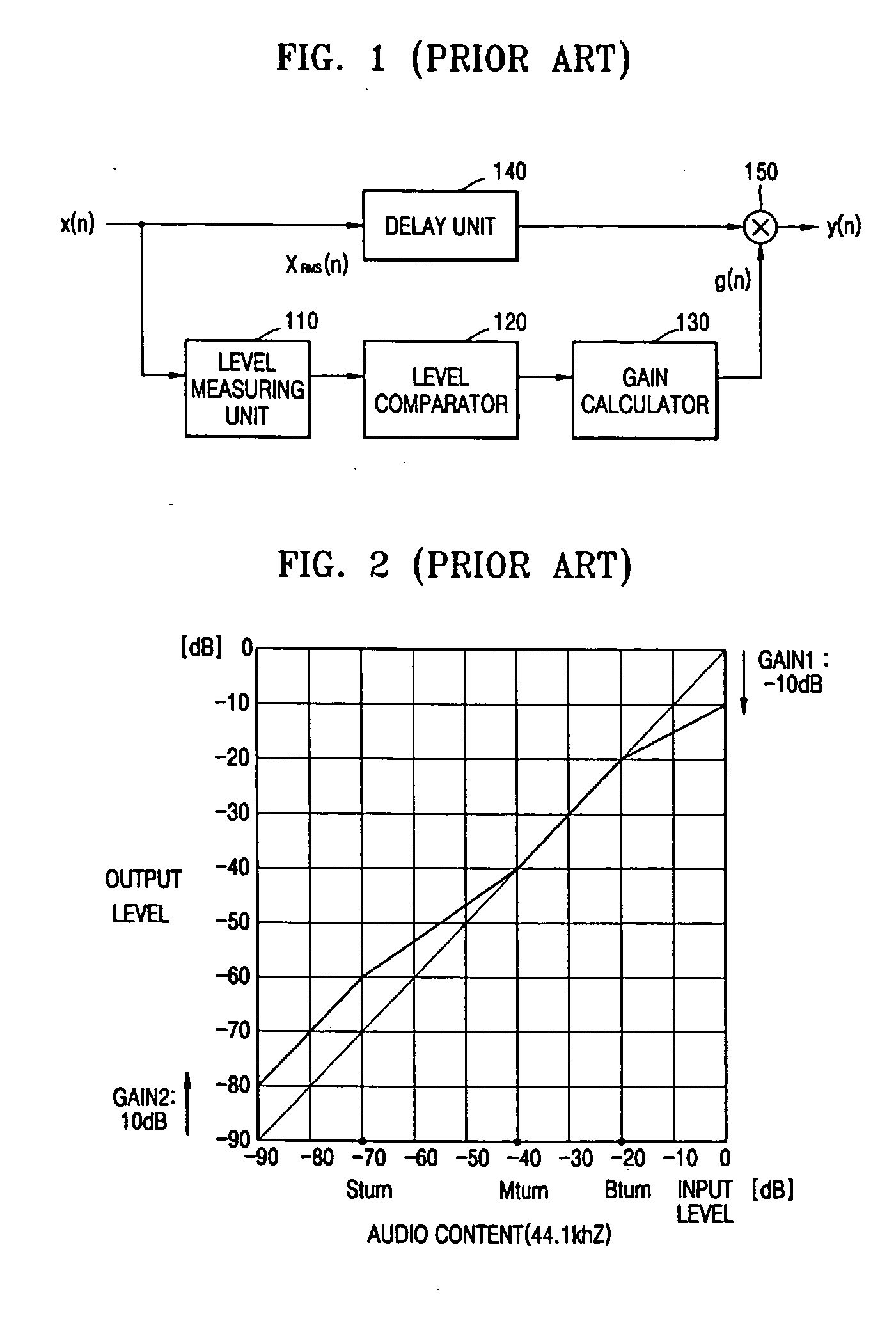

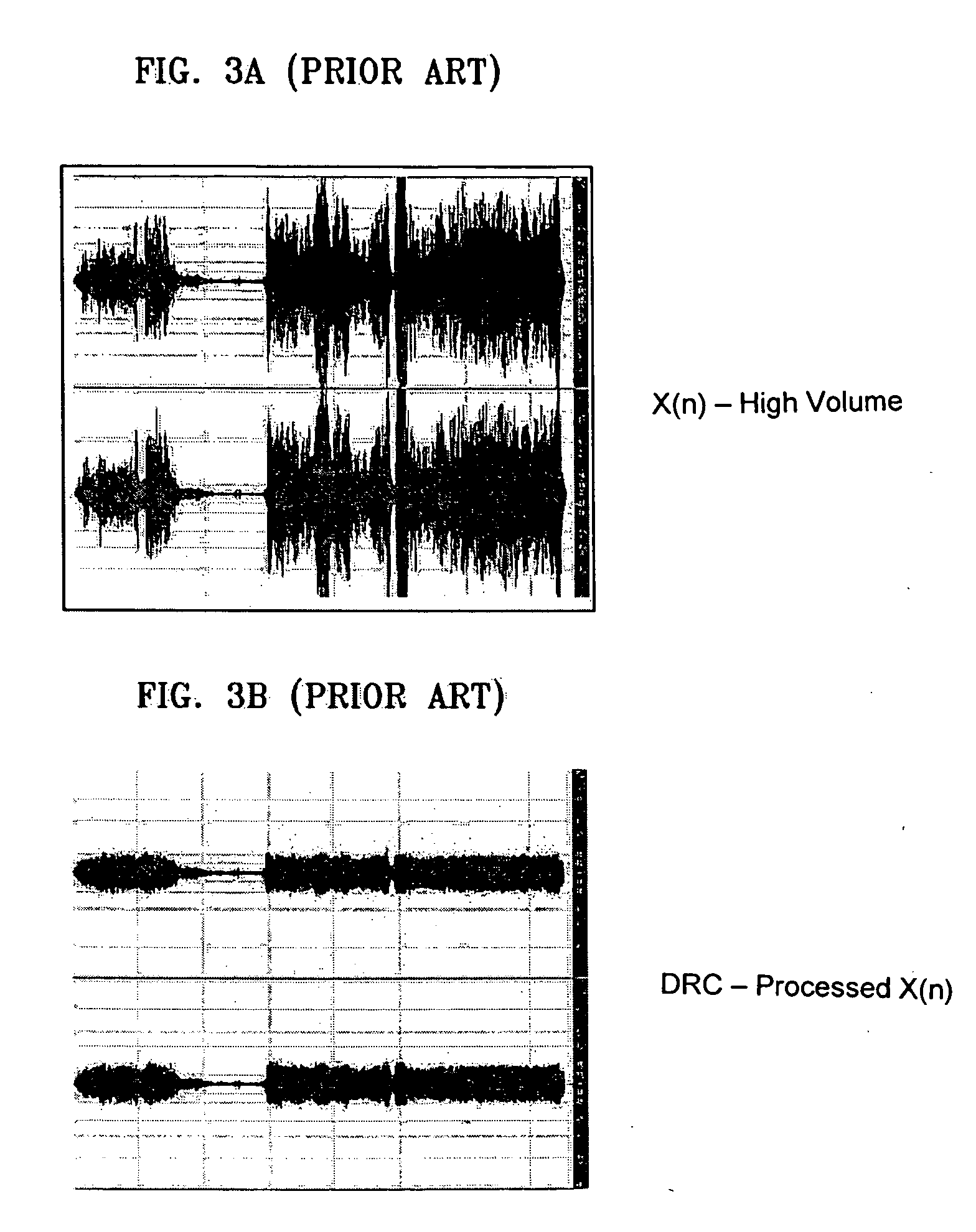

Apparatus and method of automatically compensating an audio volume in response to channel change

InactiveUS20060018493A1Television system detailsBroadcast information characterisationComputer scienceAudio frequency

An apparatus and method of automatically compensating audio volume in response to a channel change. The method includes generating a gain value to adjust a level of an input audio signal by comparing an average level of the input audio signal with a predetermined input / output level curve, adjusting an audio volume of the input audio signal by applying the generated gain value to the level of the input audio signal, and adjusting a dynamic range of the audio signal having the adjusted audio volume.

Owner:SAMSUNG ELECTRONICS CO LTD

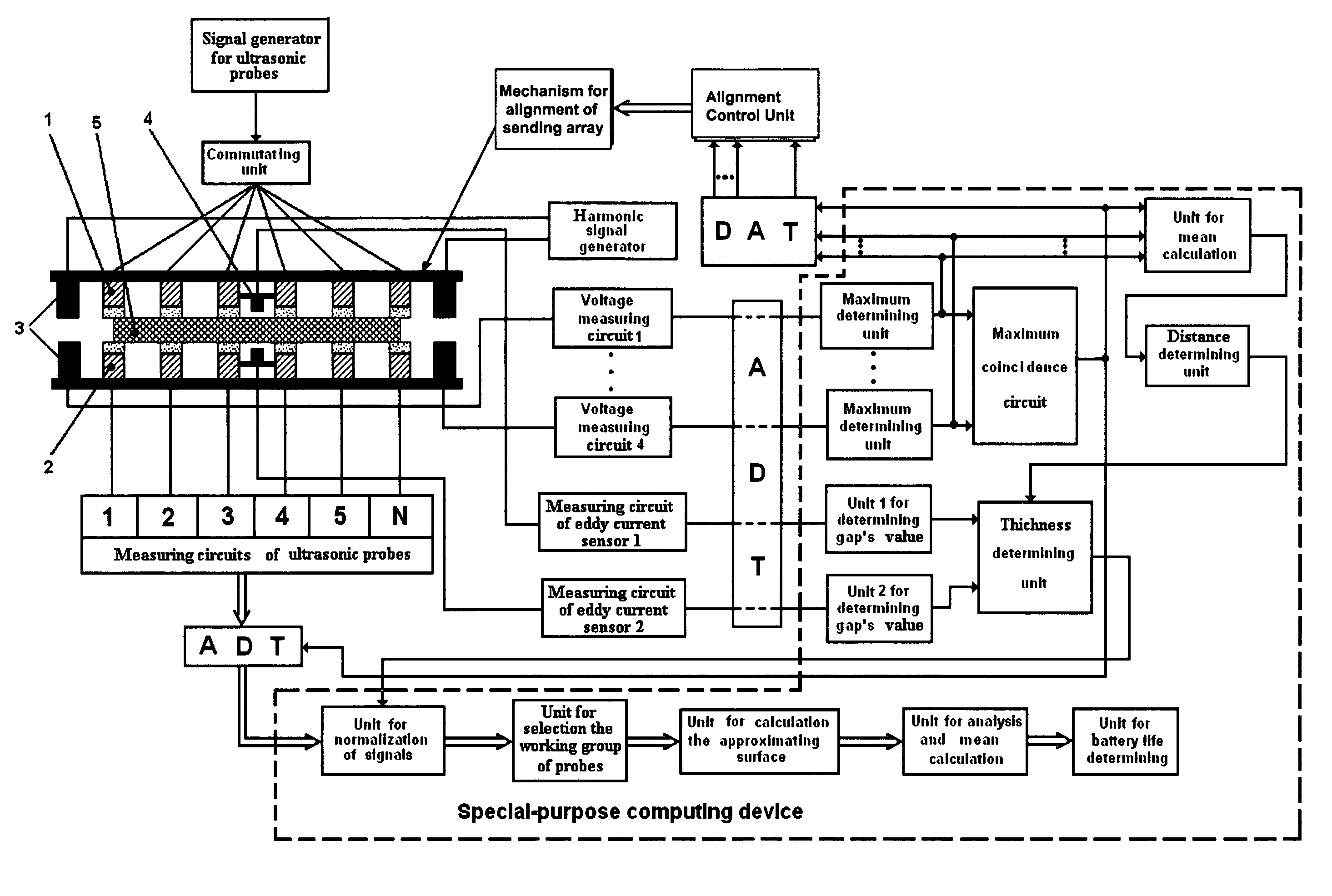

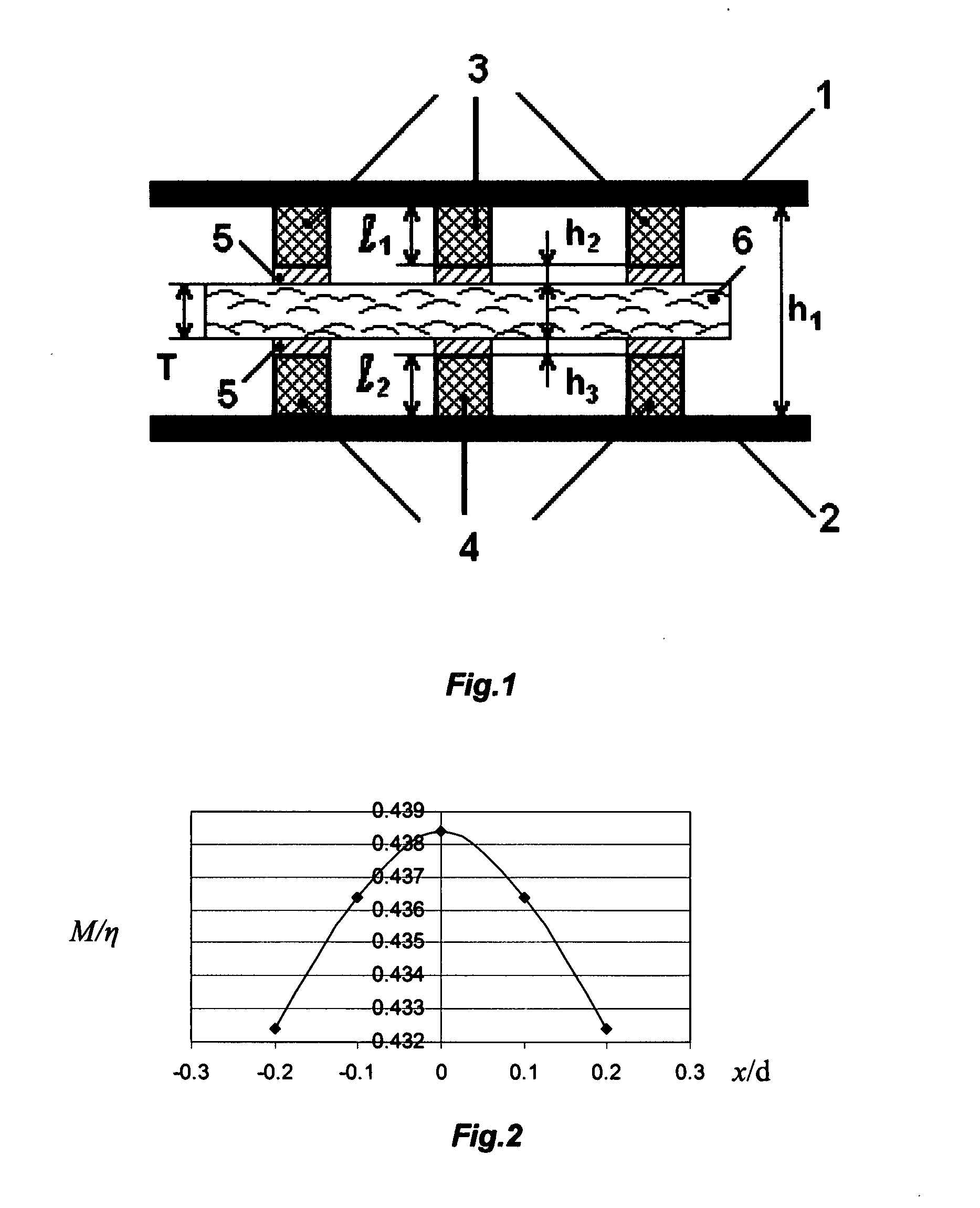

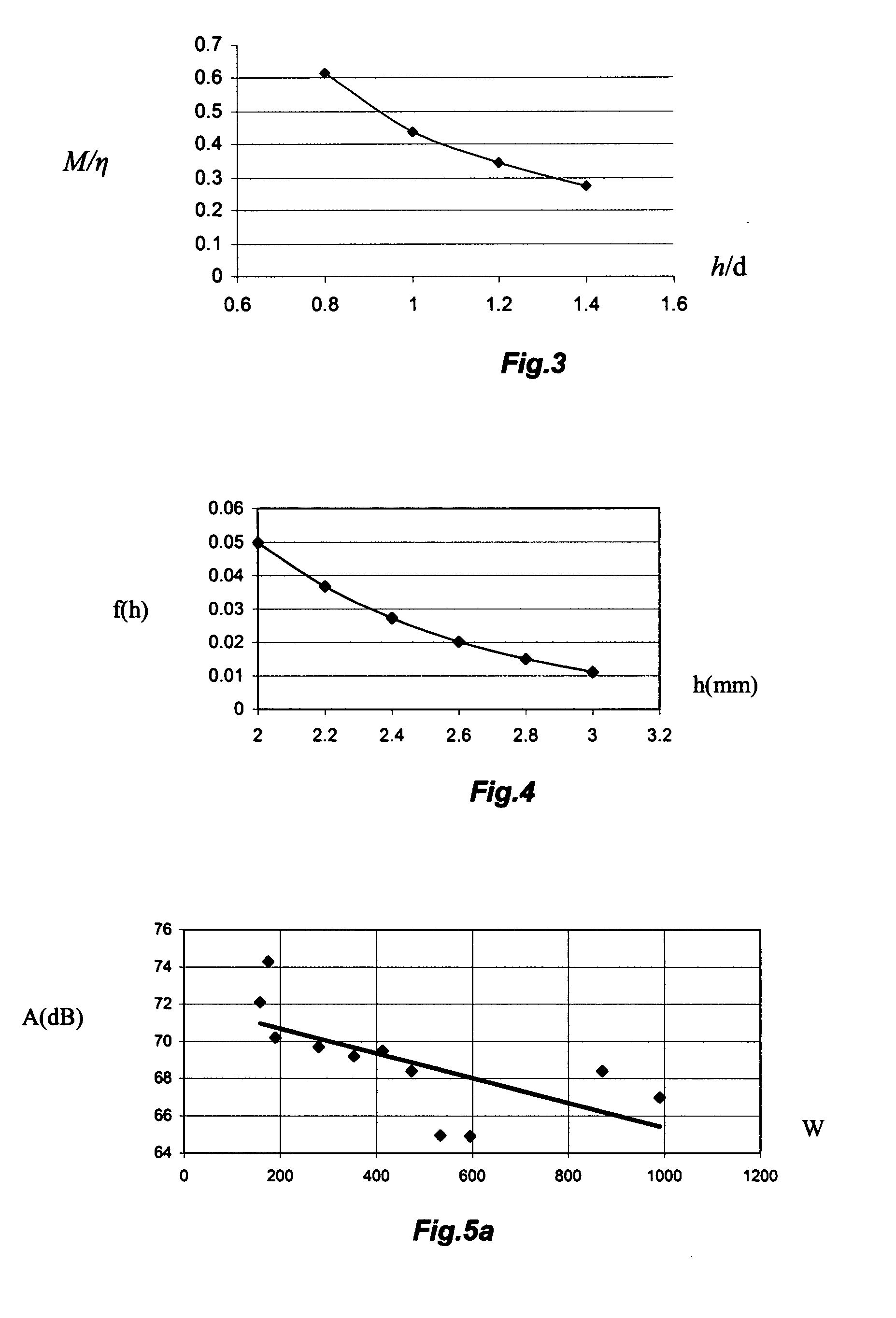

Apparatus and method for determining service life of electrochemical energy sources using combined ultrasonic and electromagnetic testing

InactiveUS20080028860A1Vibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesMeasurement testSonification

The present invention is an apparatus and method for determining the remaining service life of electrochemical energy generation and storage device including batteries, supercapacitors, DSSC solar cells and fuel cell. Measurements are performed by passing ultrasonic oscillations through the test object. The apparatus of the present invention comprises two arrays of transmitting and receiving ultrasonic probes between which the object being tested is affixed. Polyurethane tips are used for matching the acoustic resistance of the probes with the test object body. The apparatus includes means for positioning the transmitting and the receiving probe arrays relative to each other. The apparatus includes an electromagnetic means for measuring the test object thickness. The calibration characteristic for determining the remaining service life of a the test object are established from the signal values from the ultrasonic probes related to the number of charge-discharge cycles obtained at various charge values. A three-dimensional approximating dependence surface is constructed using the normalized signals from the receiving probes. The average value of this surface is determined. The remaining service life of the test object is determined using a calibration curve based on the average level of the surface

Owner:ENERIZE CORP

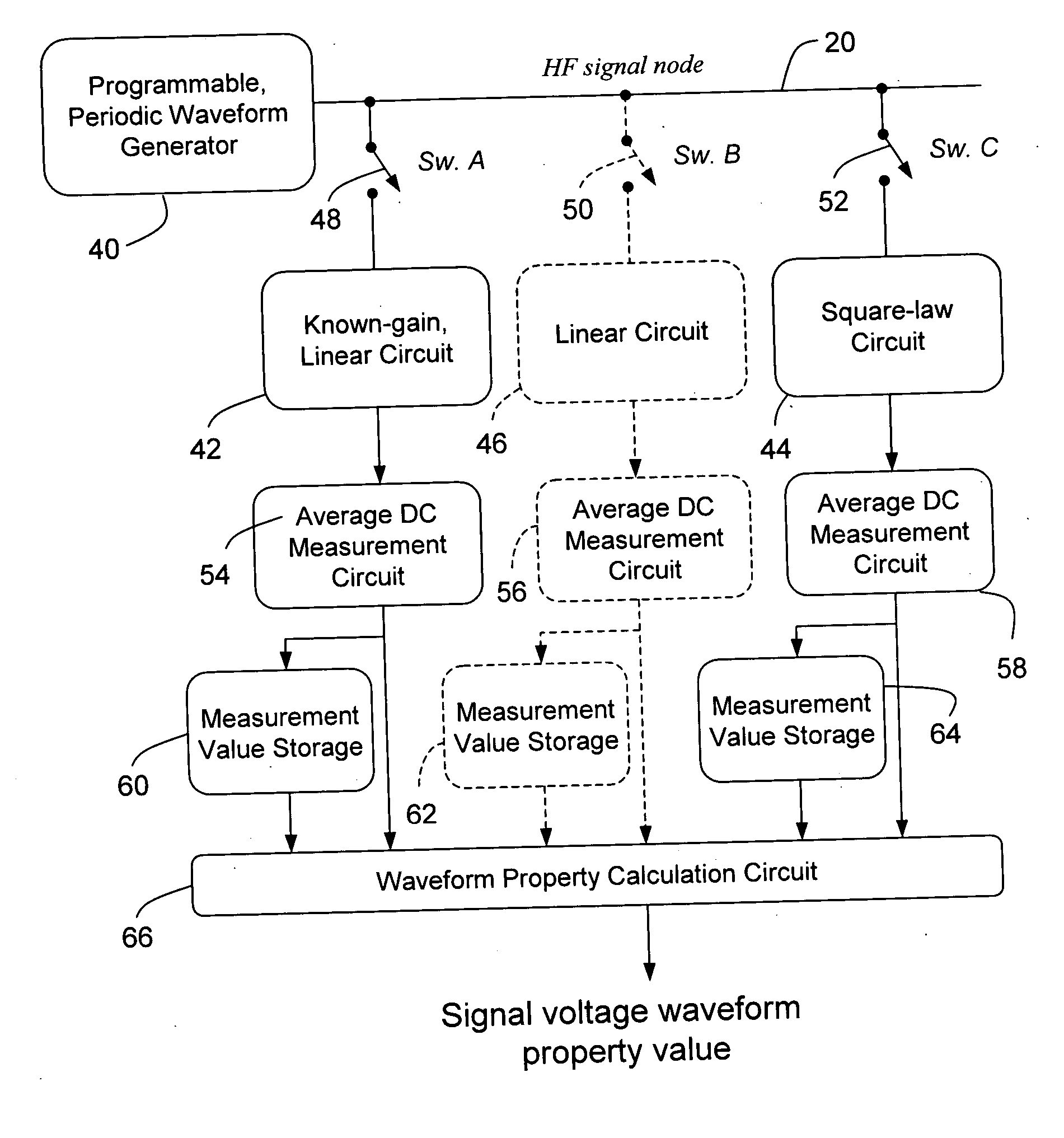

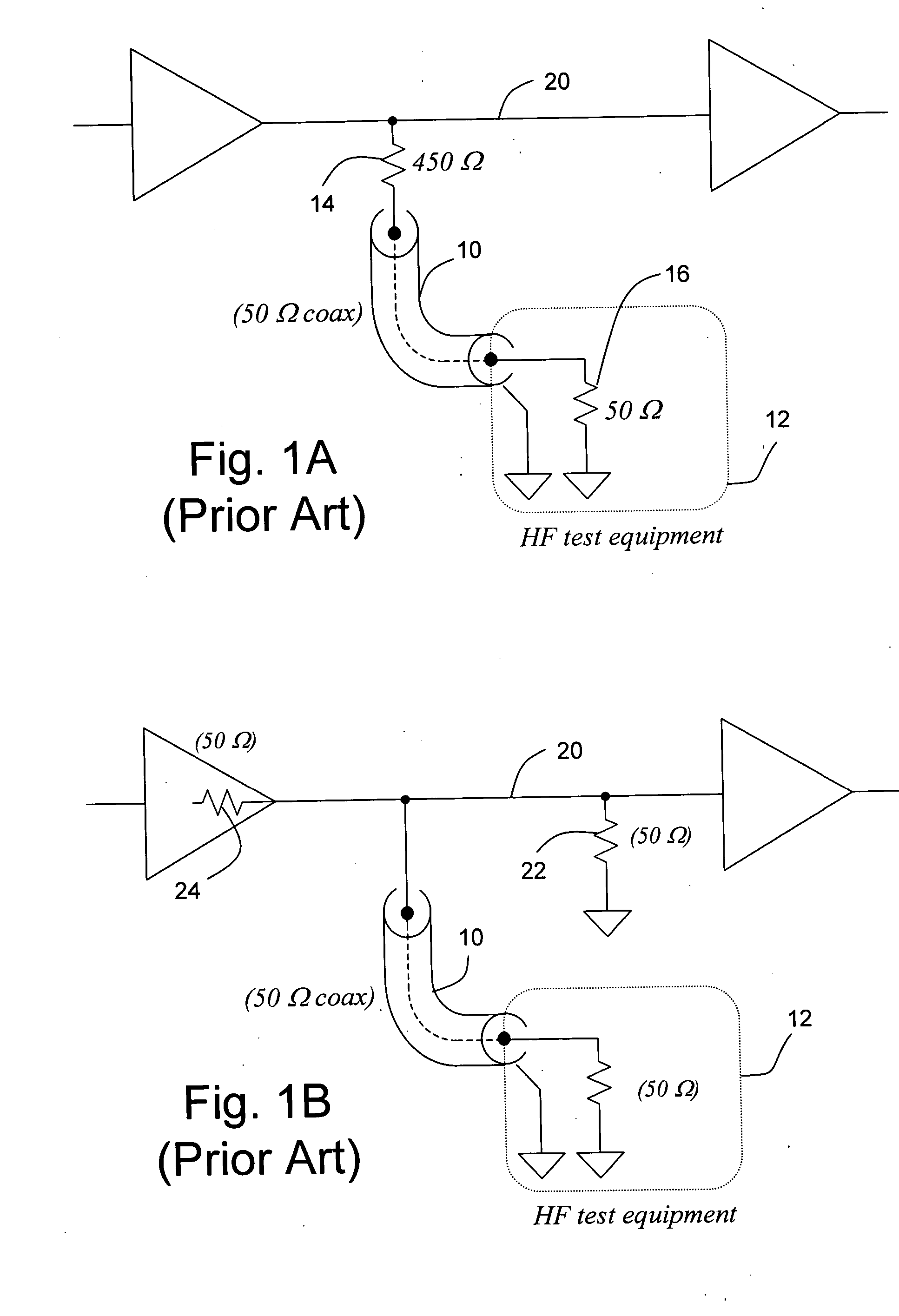

Circuit and method for low frequency testing of high frequency signal waveforms

A method of deducing properties of the shape of a waveform comprises (a) generating a signal based on a periodic pattern of logic levels; (b) measuring a DC level that is proportional to the average level of the signal and a DC level that is proportional to the average of the signal level squared; (c) repeating steps (a) and (b) one or more times; and (d) calculating a property value of the shape of the waveform based on a plurality of measurements.

Owner:LOGICVISION

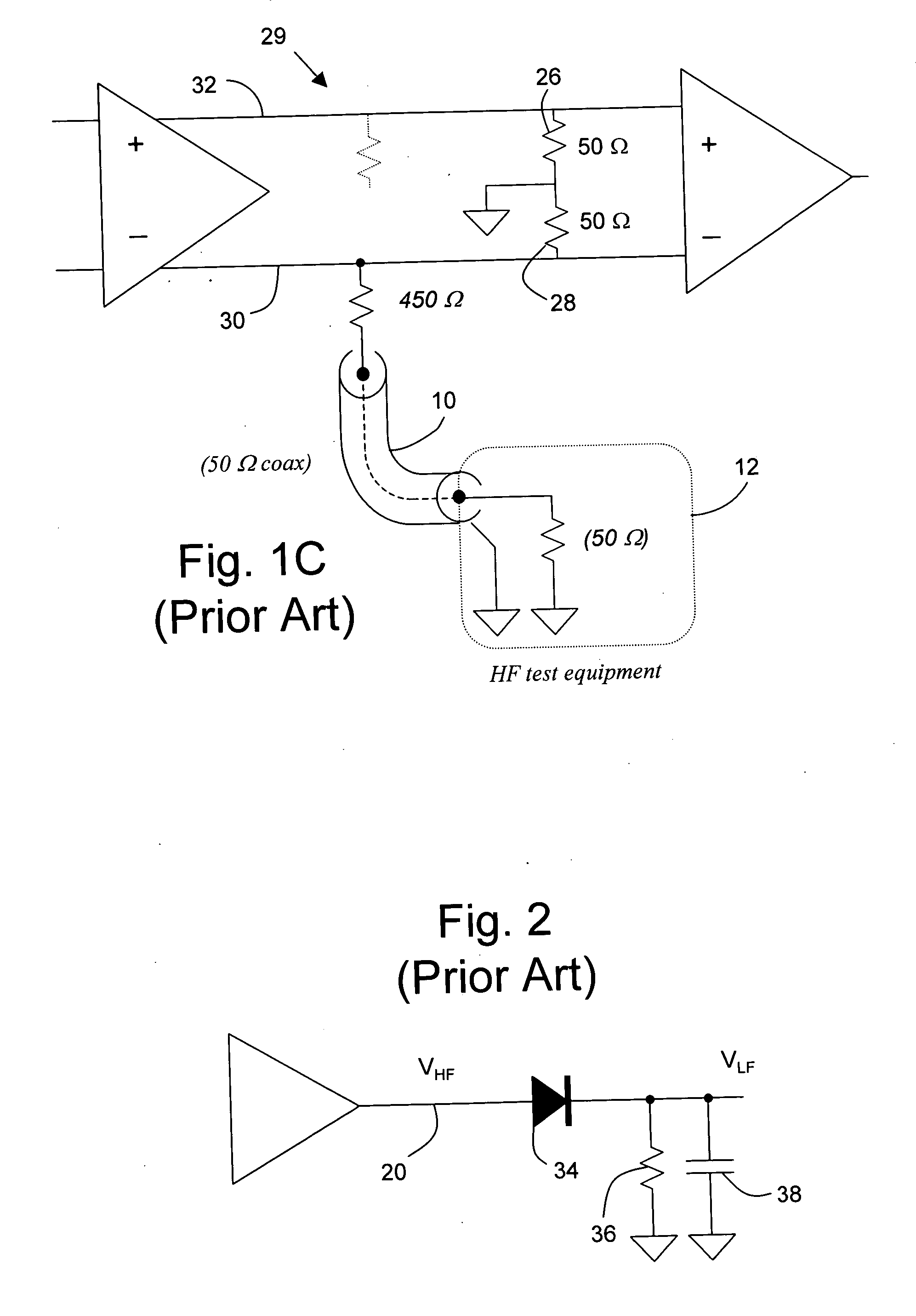

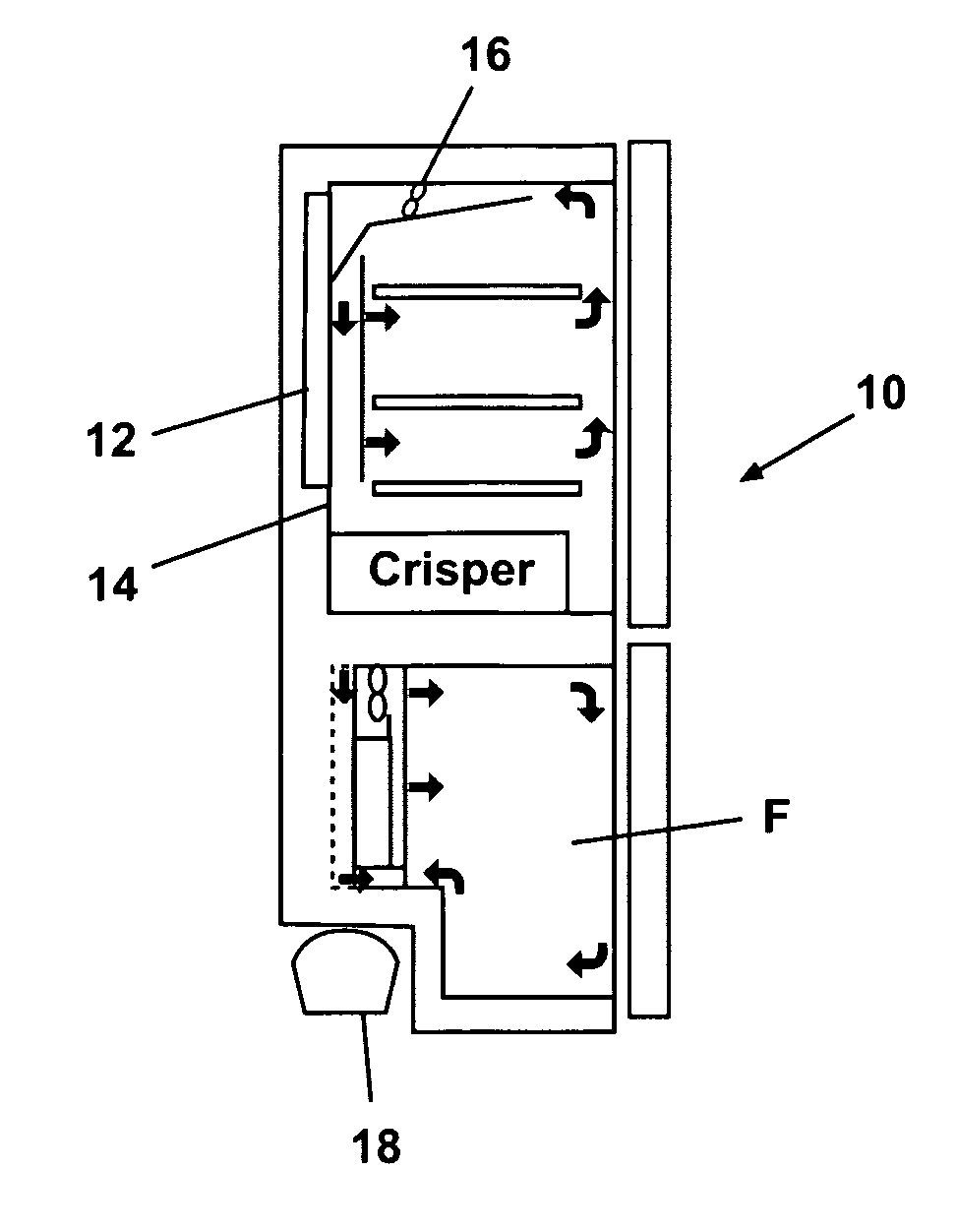

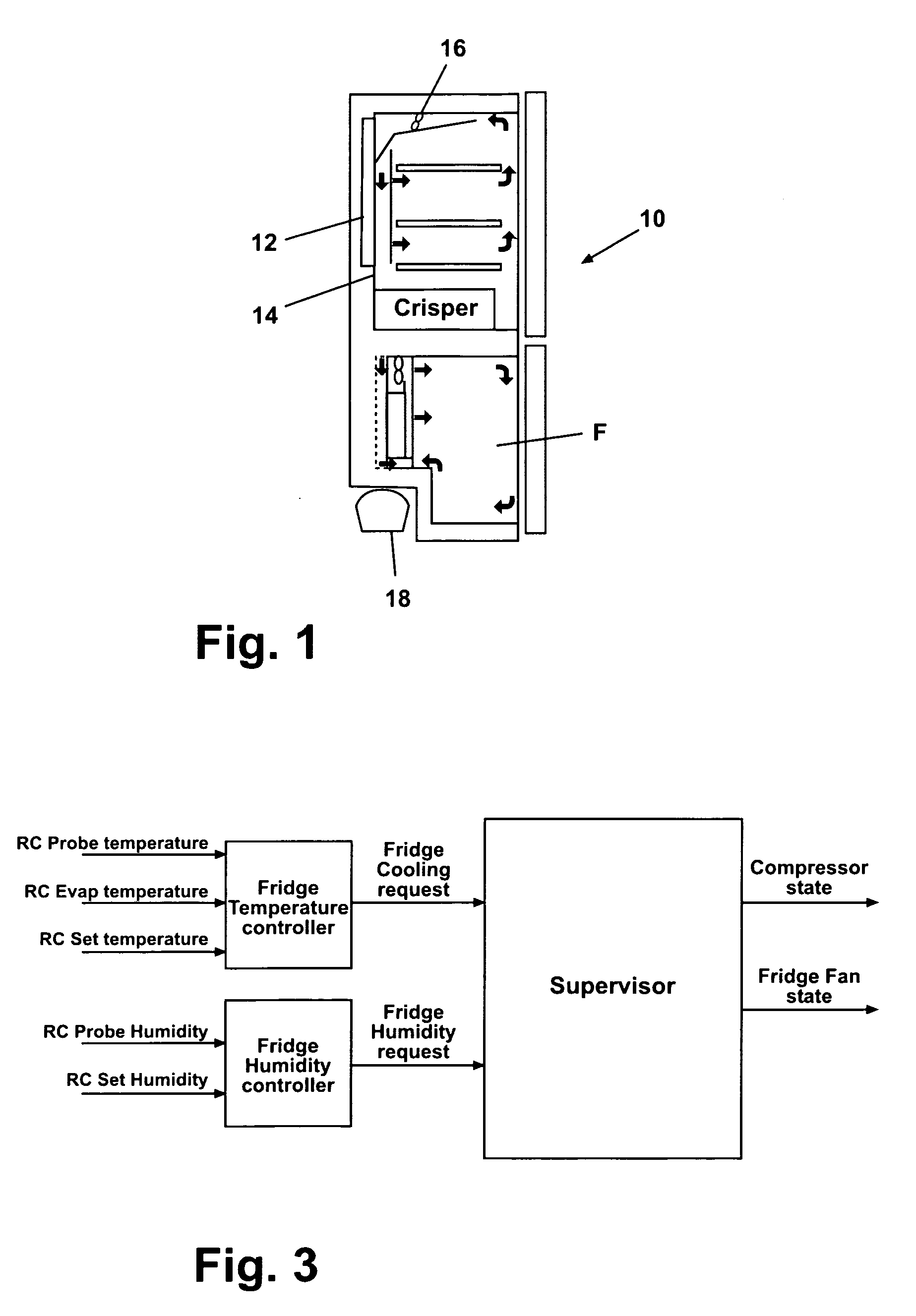

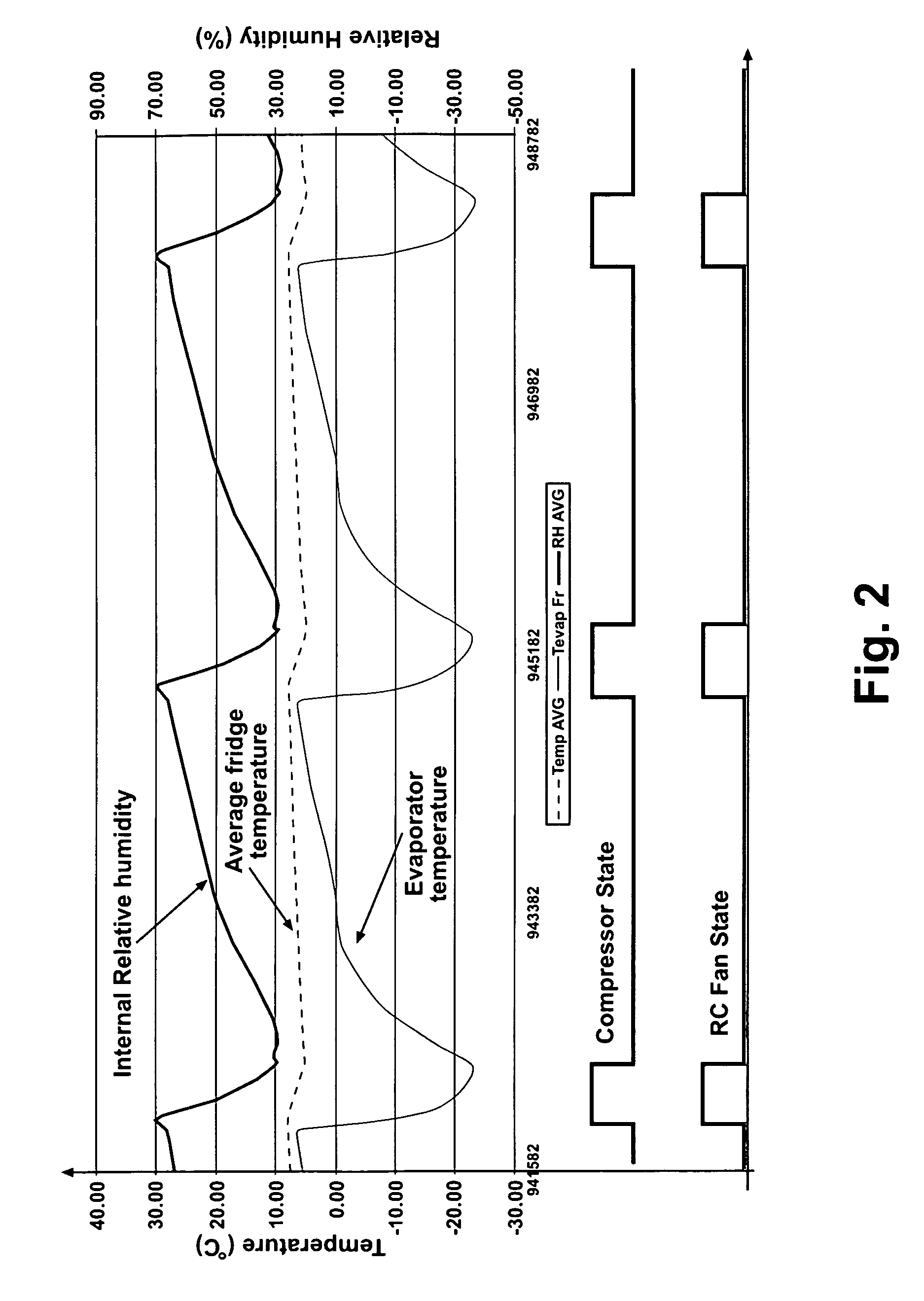

Method for controlling humidity in a domestic refrigerator, and refrigerator adapted to carry out such method

A method for controlling the humidity inside a refrigerator, having at least a cavity and a refrigeration circuit including an evaporator and a compressor, comprising the step of measuring the relative humidity level inside the cavity, measuring the temperature of the evaporator and feeding the above measured values to a control algorithm capable of driving the refrigeration circuit in order to maintain substantially constant the average level of relative humidity and corresponding to a set value.

Owner:WHIRLPOOL CORP

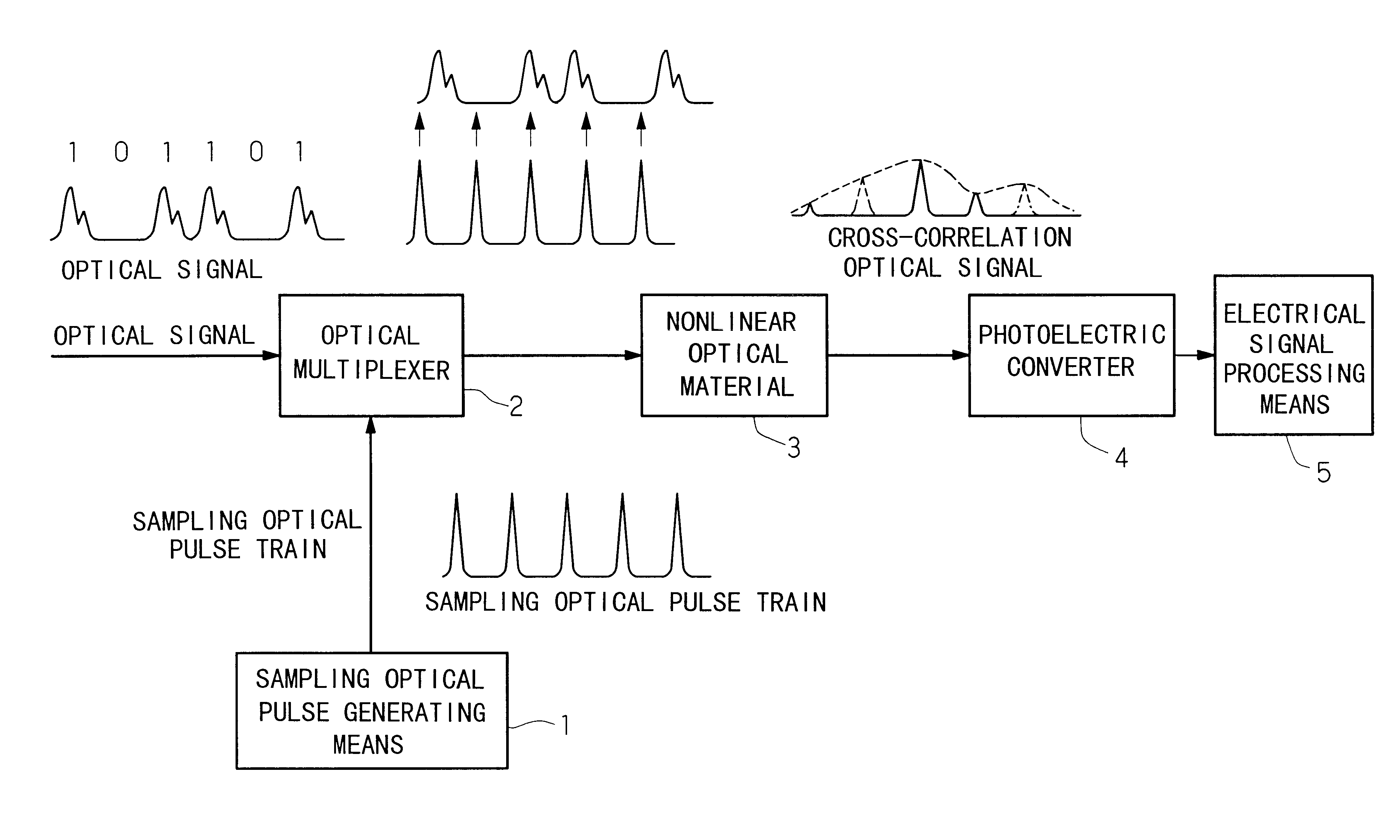

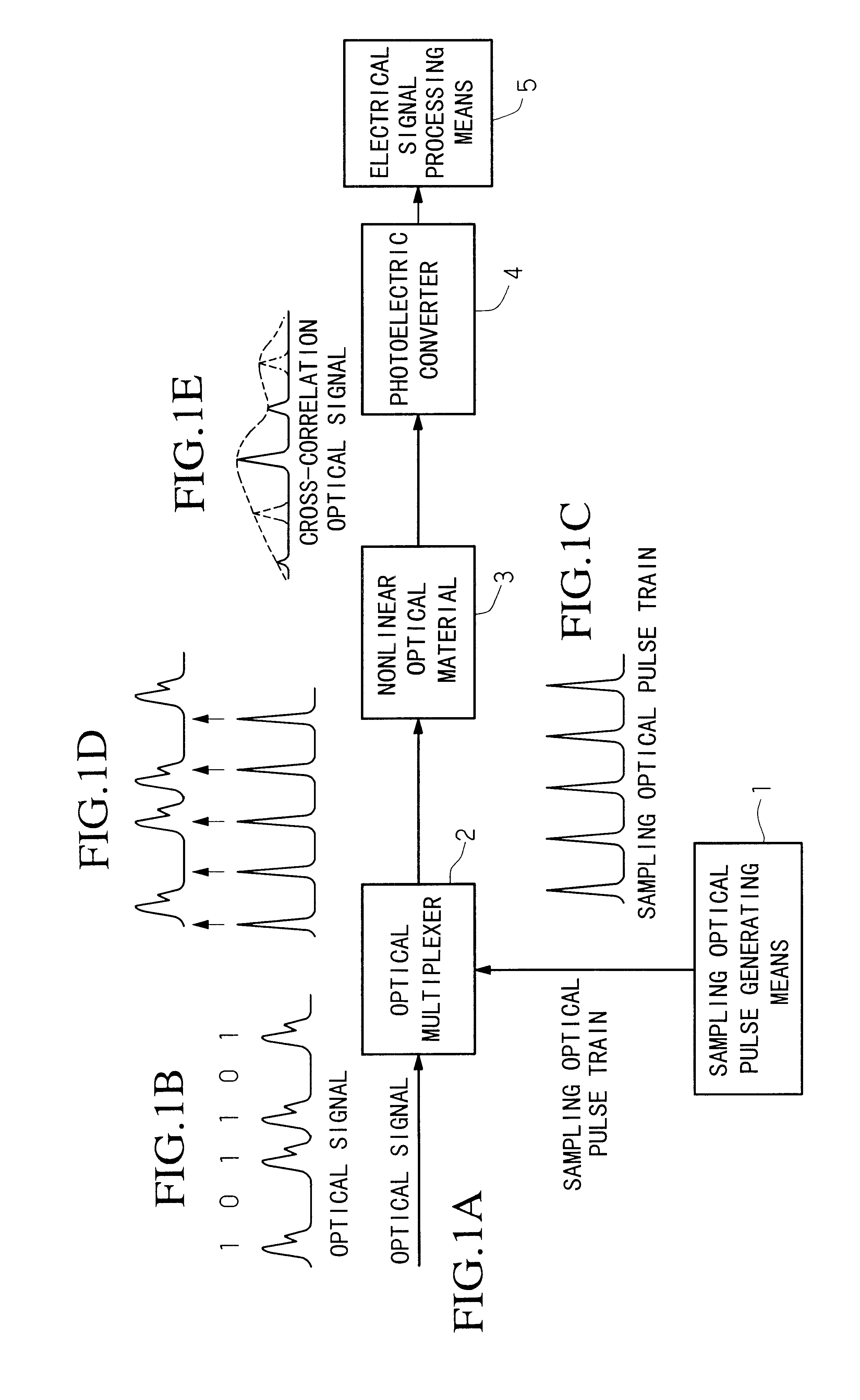

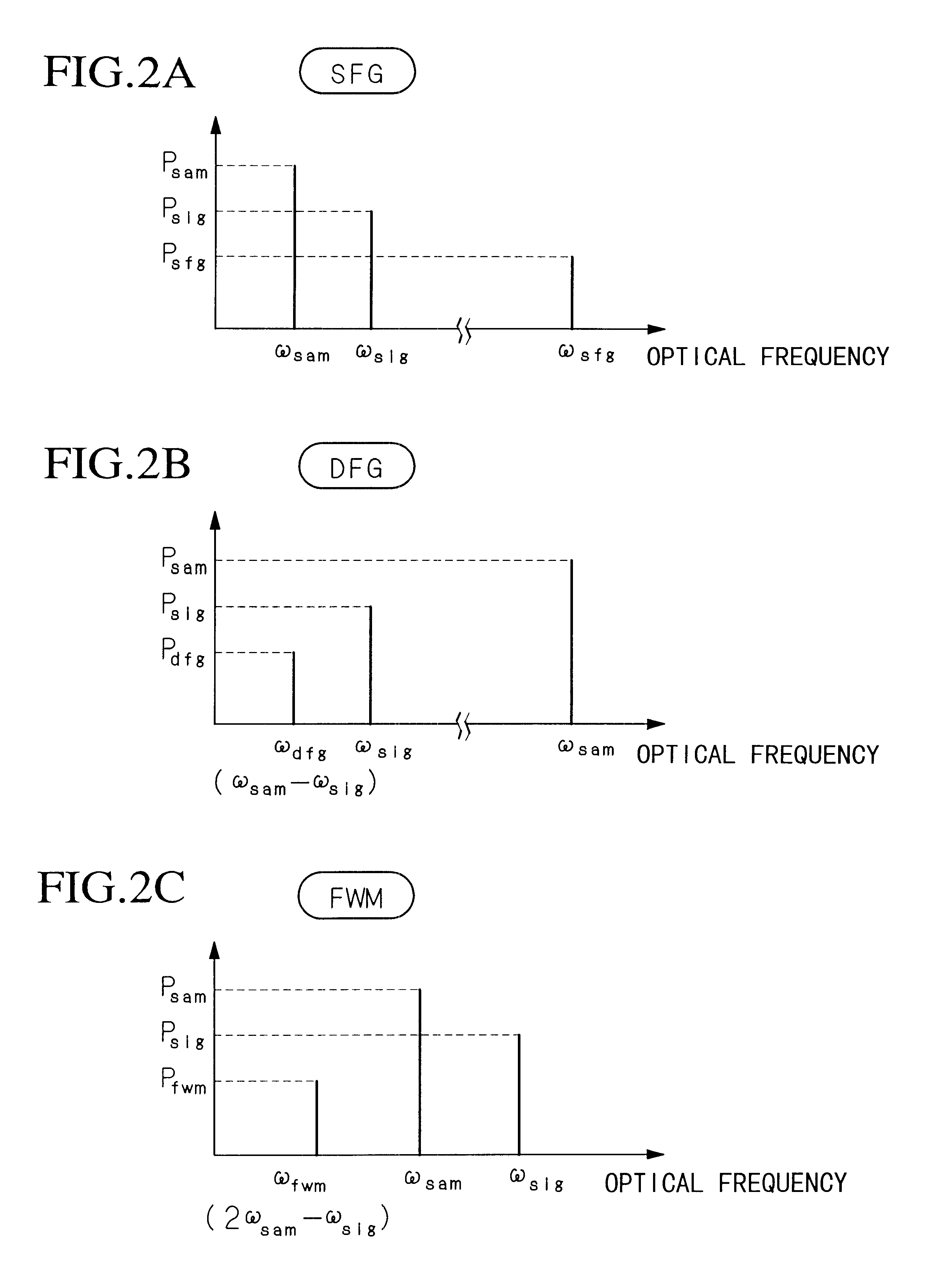

System for monitoring quality of optical signals having different bit rates

InactiveUS6396601B1Baseband system detailsWavelength-division multiplex systemsSignal qualityTime segment

An optical signal quality monitoring system is provided, by which the quality of optical signals can be examined using a single monitoring system, not depending on the bit rate of each signal. In the system, an optical signal having a bit rate N.f0, that is, N times as much as basic clock frequency f0, is sampled by using a pulse repetition frequency f0 / n1-DELTAf or f0 / n1+DELTAf where n1 is a predetermined natural number and the pulse repetition frequency slightly differs from f0 / n1 by DELTAf, and an amplitude histogram of the optical signal is determined based on results of the sampling. Regarding the sampling points which constitute the histogram, a set of higher-level points and a set of lower-level points are extracted and a ratio of a difference between an average level of the set of higher-level points within a predetermined period and an average level of the set of lower-level points within a predetermined period, to the sum of standard deviations of both sets within each predetermined period is calculated as a coefficient of the S / N, and the quality of the optical signal is examined based on the coefficient. By performing optical sampling, quality of optical signals having bit rates of a few dozen Gbit / s or more can be monitored.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

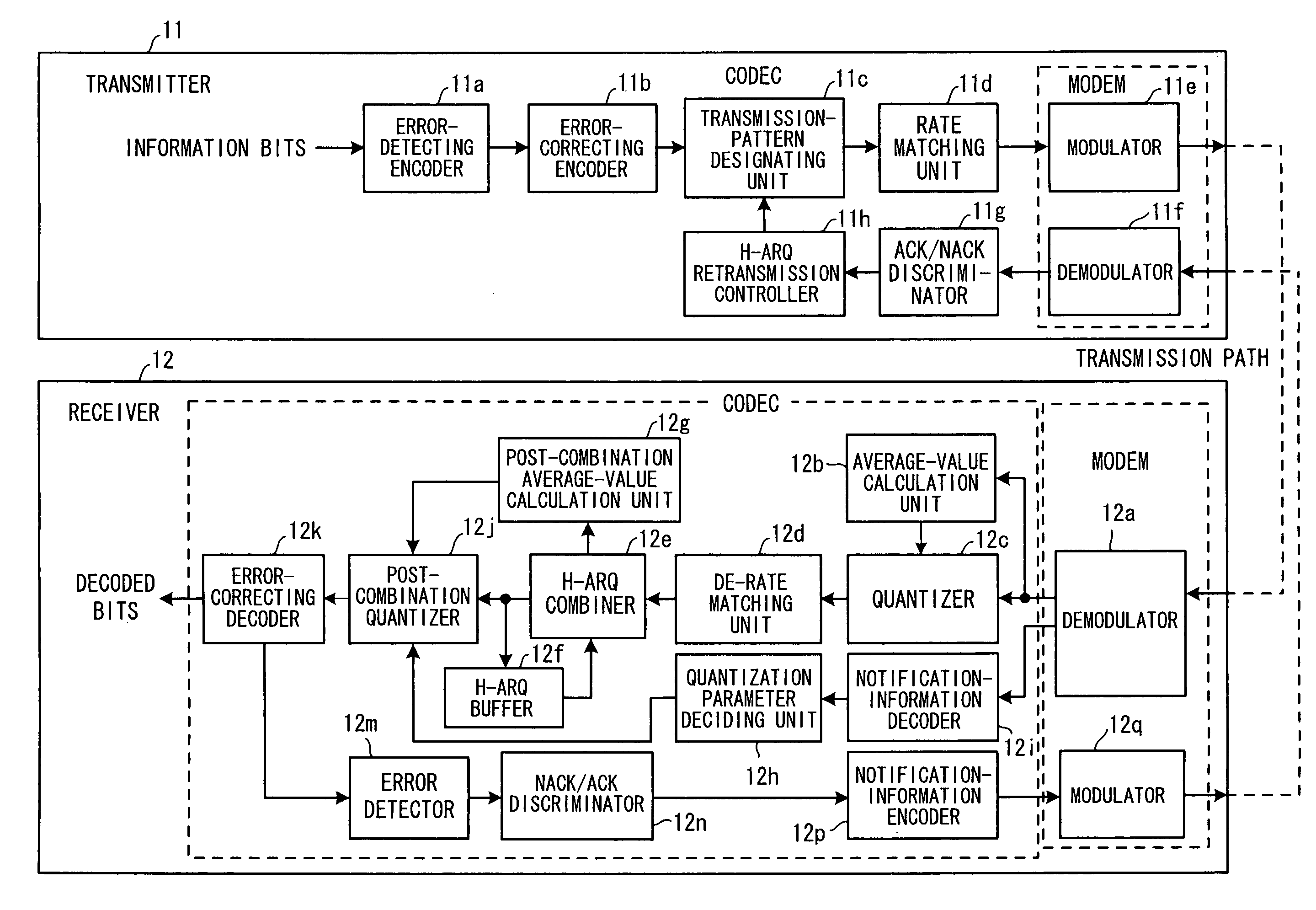

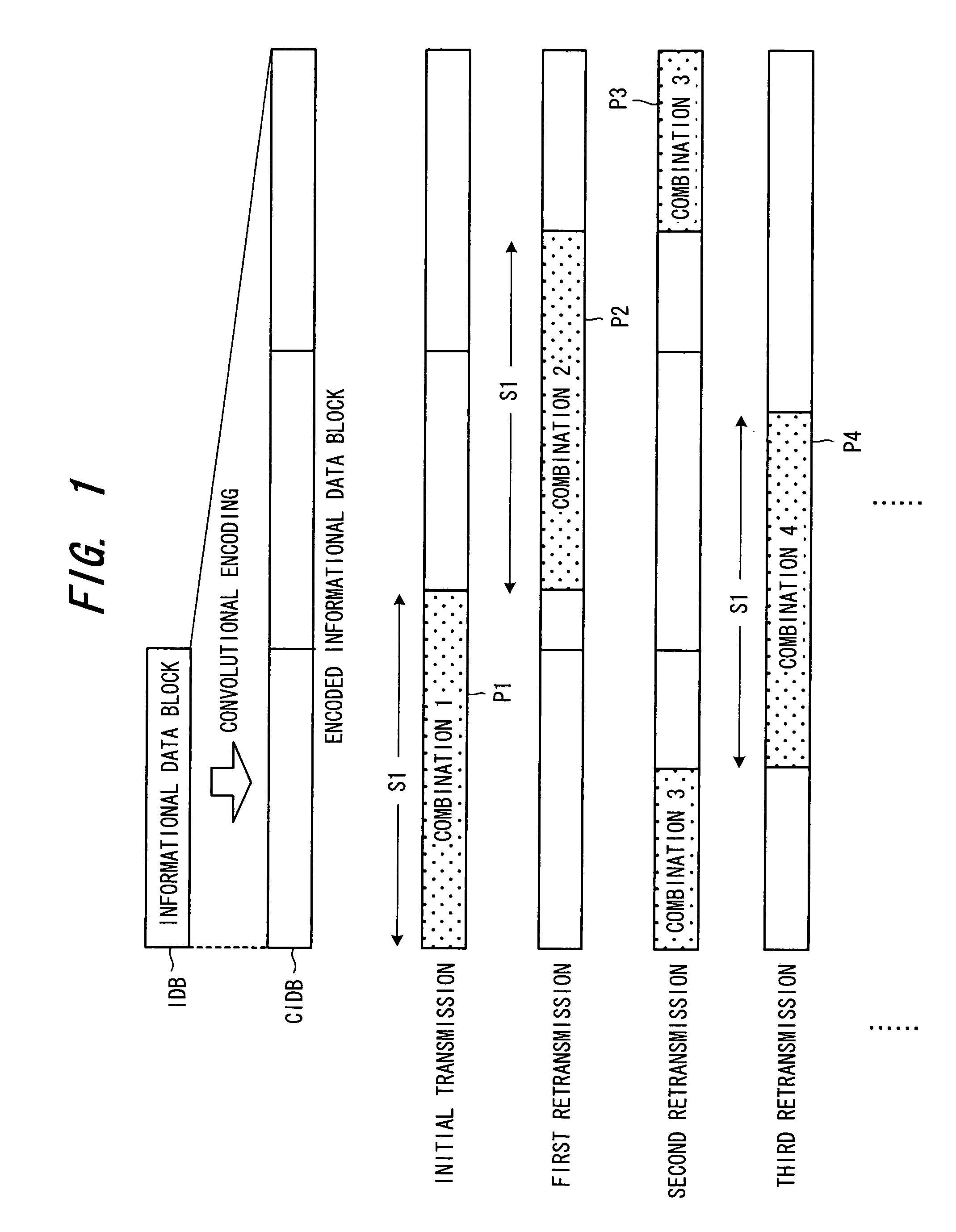

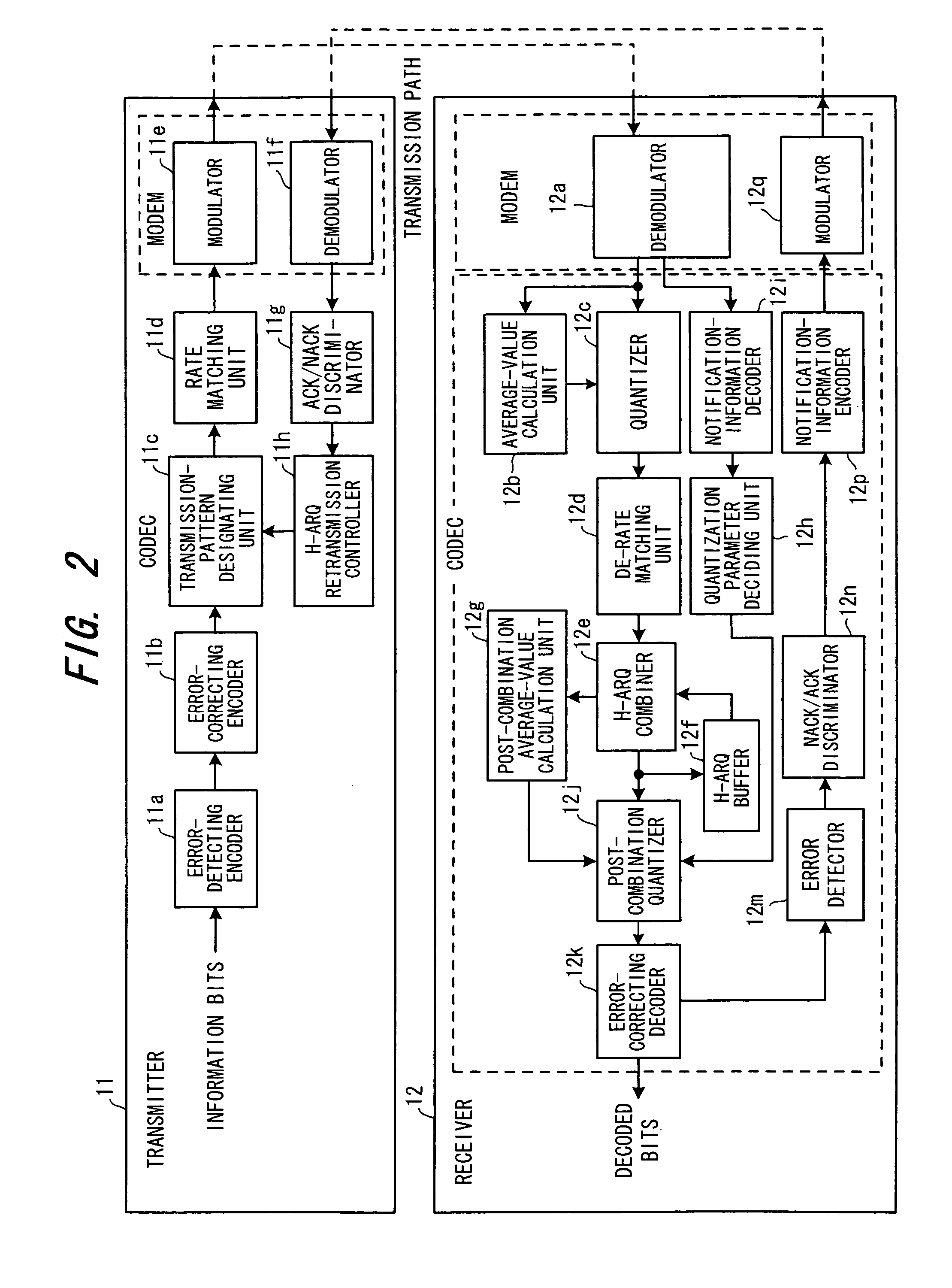

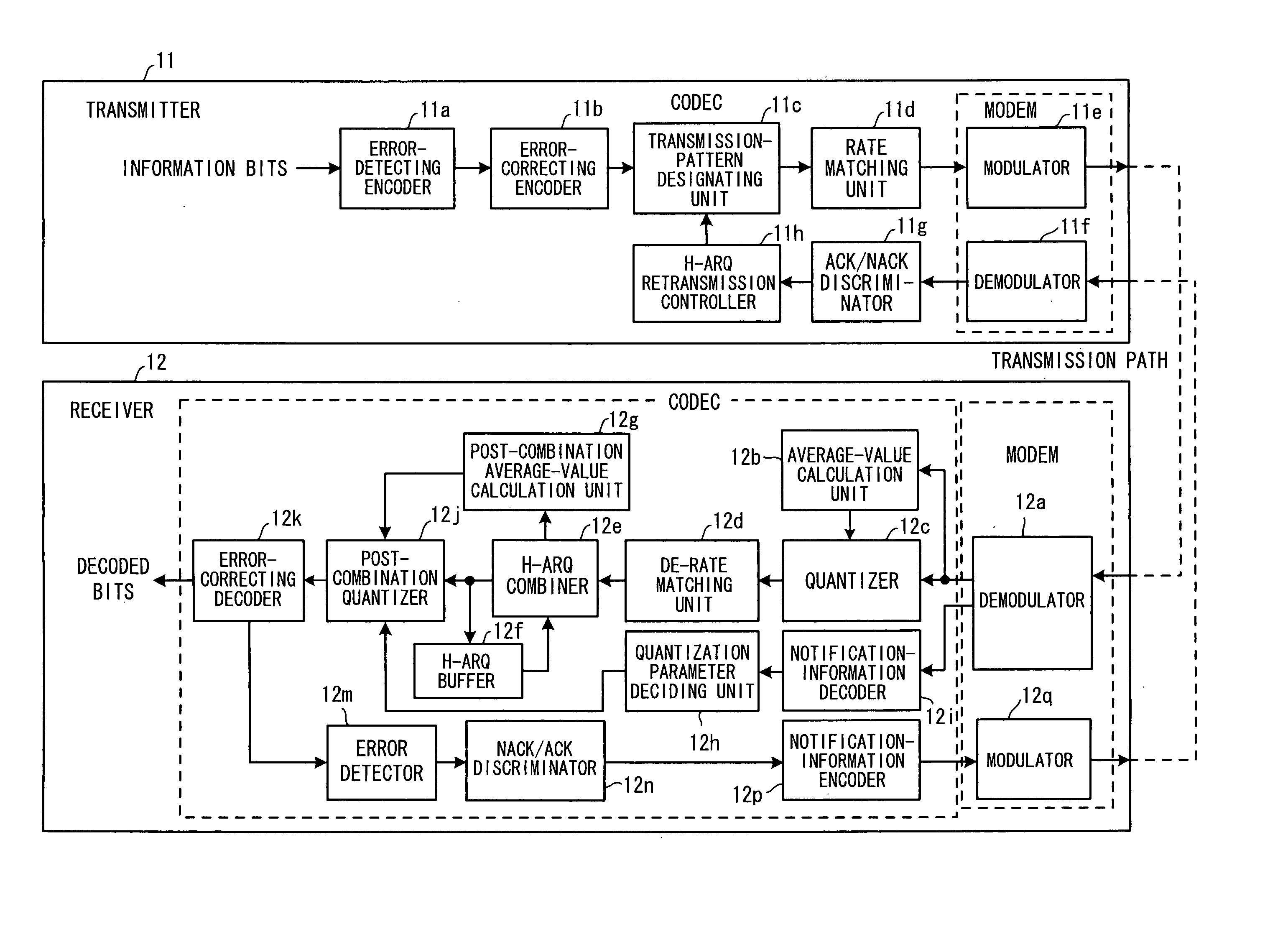

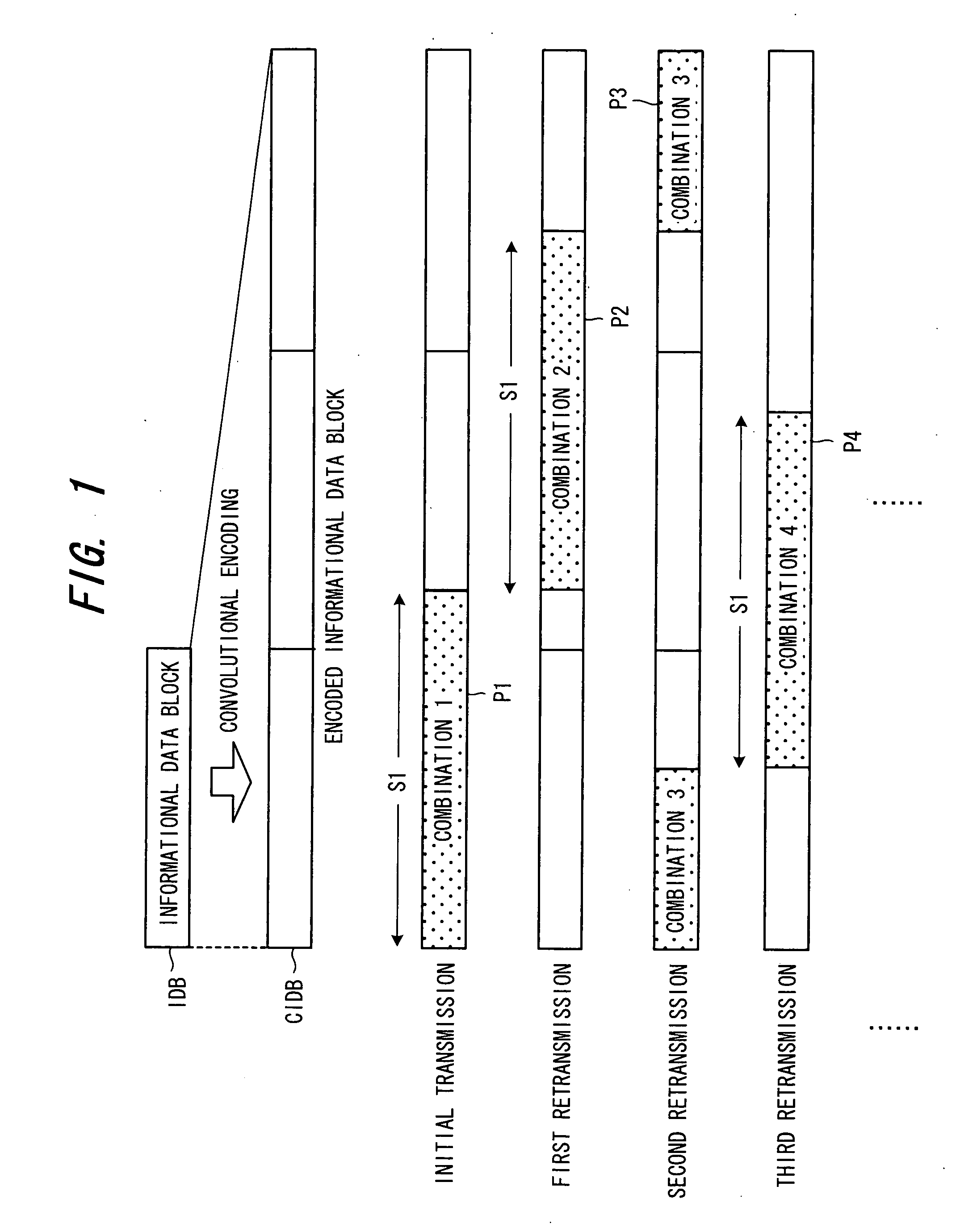

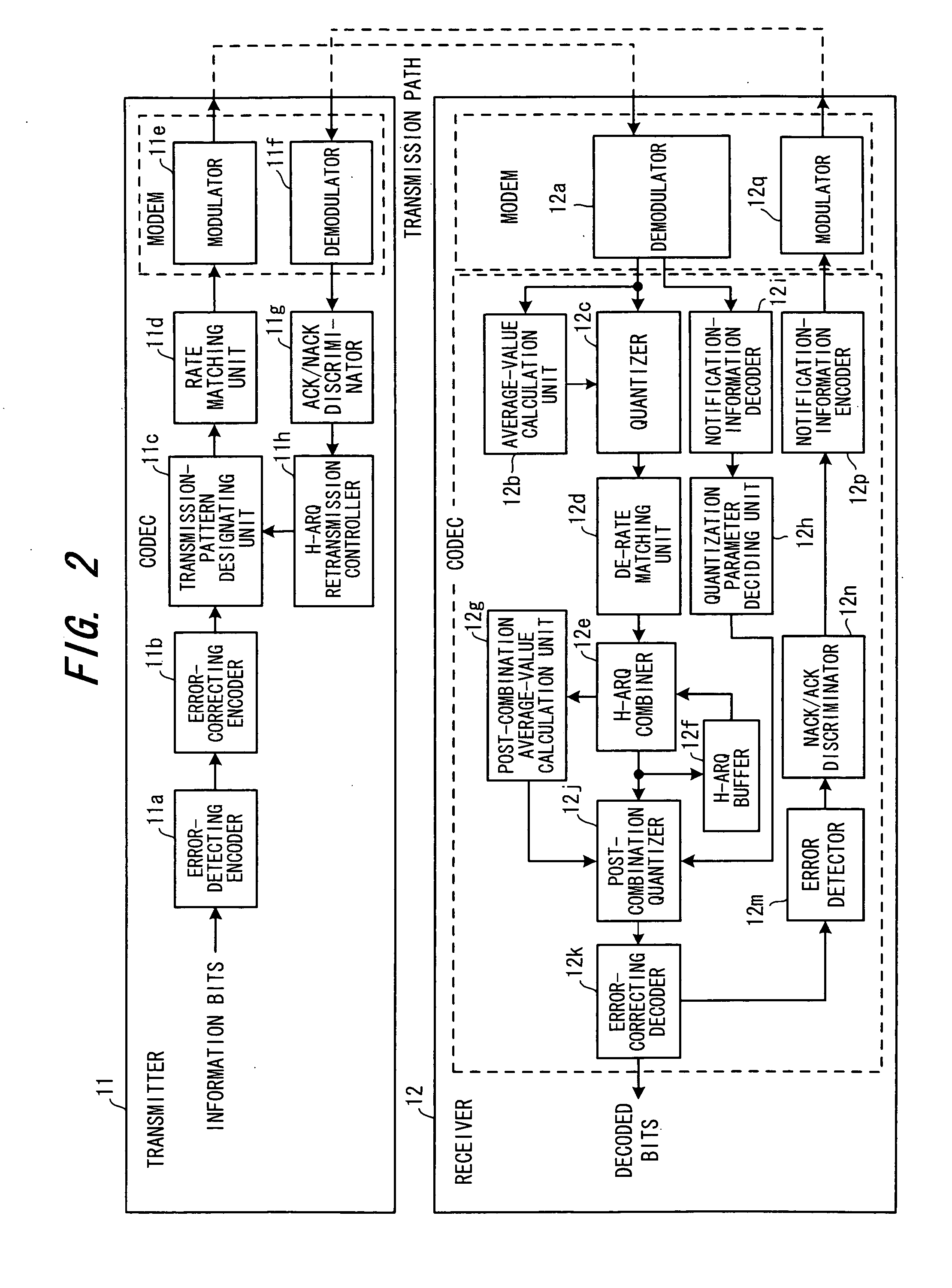

Communication system and receiving method

InactiveUS7512860B2Reduce errorsError prevention/detection by using return channelModulated-carrier systemsComputer hardwareCommunications system

A receiving apparatus in a communication system in which when a systematically encoded signal cannot be decoded correctly on a receiving side, the signal is retransmitted from a transmitting side. The receiving apparatus combines stored data, which has been generated based upon data already received, and newly received data, decides a range of quantization levels of the combined data using an average level only of systematic bits of the stored data and newly received data, quantizes the combined data based upon the range of quantization levels and number of quantization bits, applies decoding processing to the quantized data, notifies the transmitting side of whether decoding could be performed correctly, and stores the combined data as the stored data when decoding cannot be performed correctly.

Owner:FUJITSU LTD

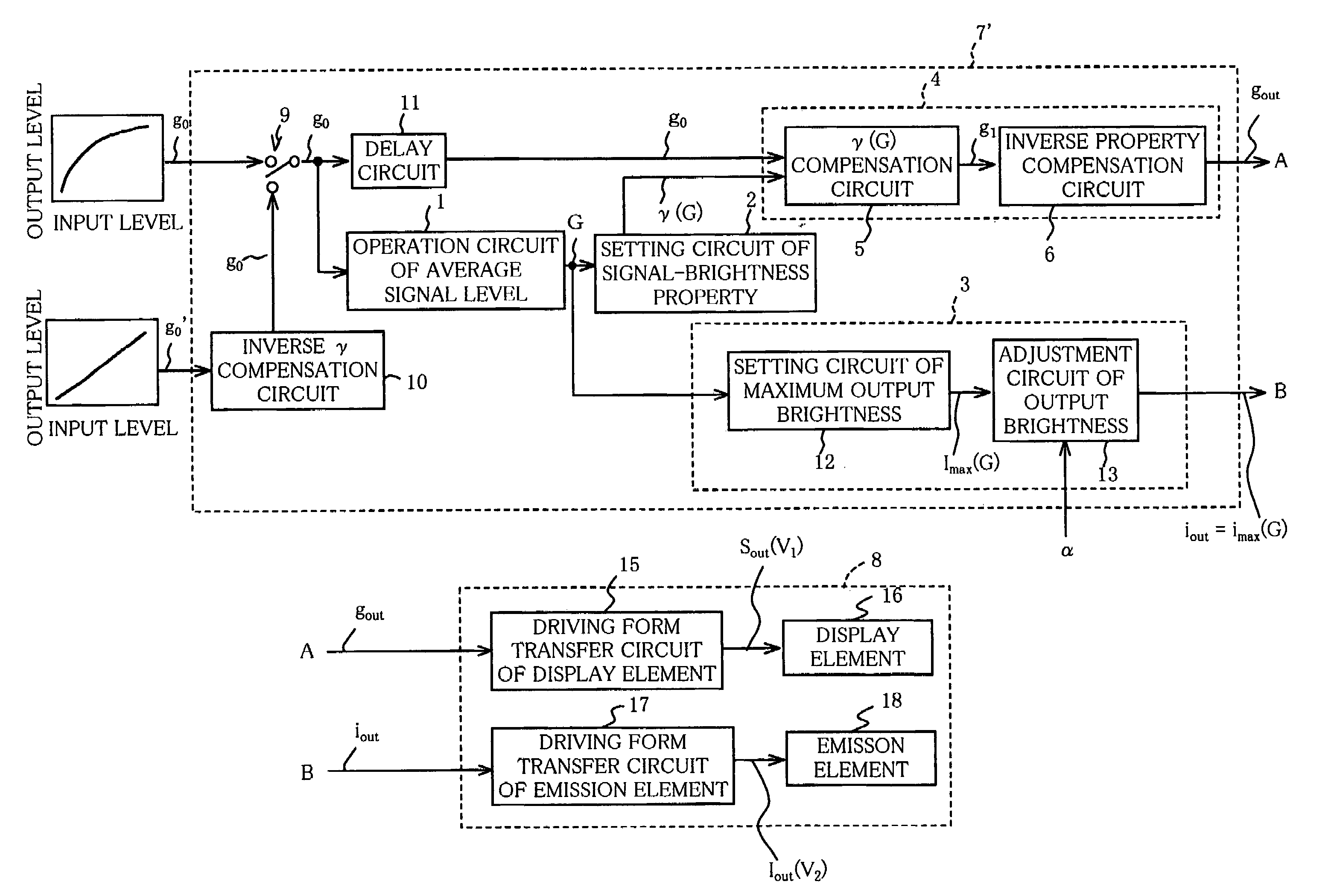

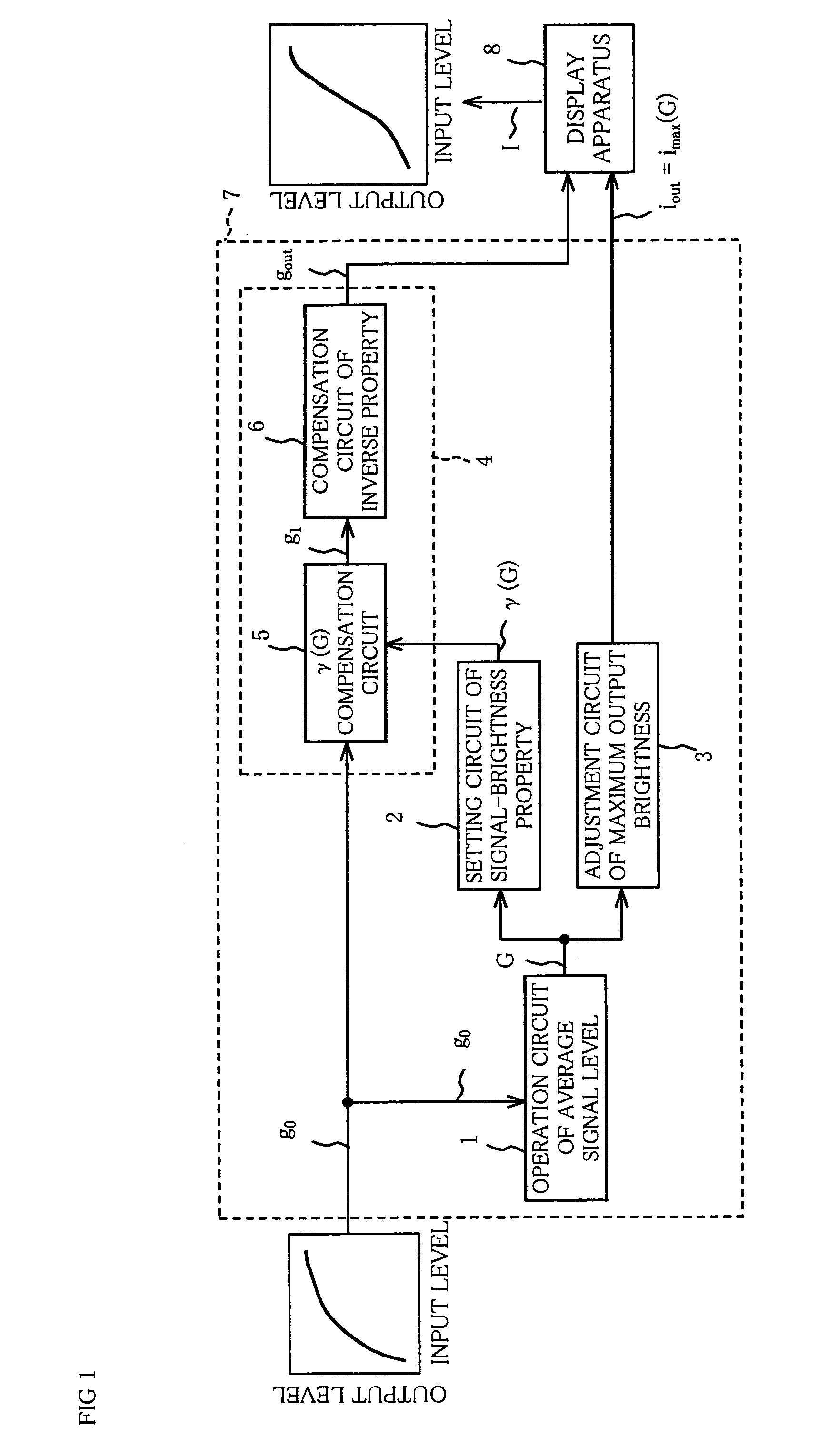

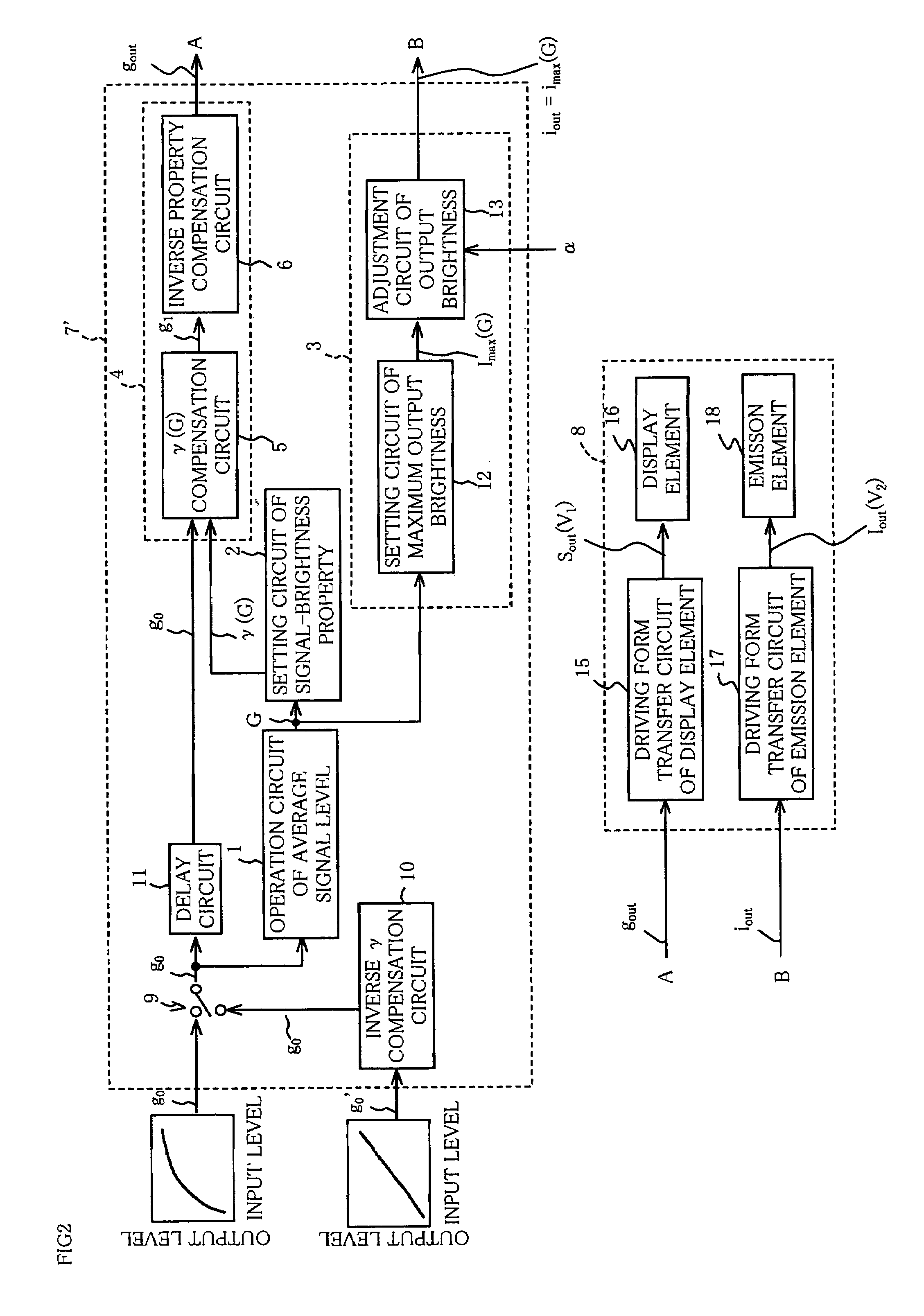

Image reproducing method, image display apparatus and picture signal compensation device

InactiveUS7170477B2Improve display qualityReduce glareCathode-ray tube indicatorsInput/output processes for data processingComputer scienceBrightness perception

When reproducing an image by a display apparatus having a plurality of pixels, in an average signal level operation circuit is performed an operation to obtain an average signal level which is an average level of all the pixel signals in a picture signal including a pixel signal representing information of a pixel, then, according to this average signal level, in an input signal-output brightness property setting circuit is set an input signal-output brightness property representing variations in brightness of a pixel with respect to a level of the pixel signal, then, the compensation of the picture signal is performed either to satisfy the input signal-output brightness property thus set in a signal compensation section or to allow variations in maximum output brightness of a pixel of the display apparatus according to the average signal level in a maximum output brightness adjustment circuit, so as to output the picture signal subject to compensation to the display apparatus.

Owner:SHARP KK

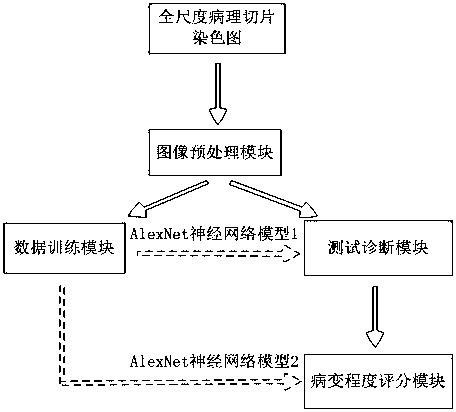

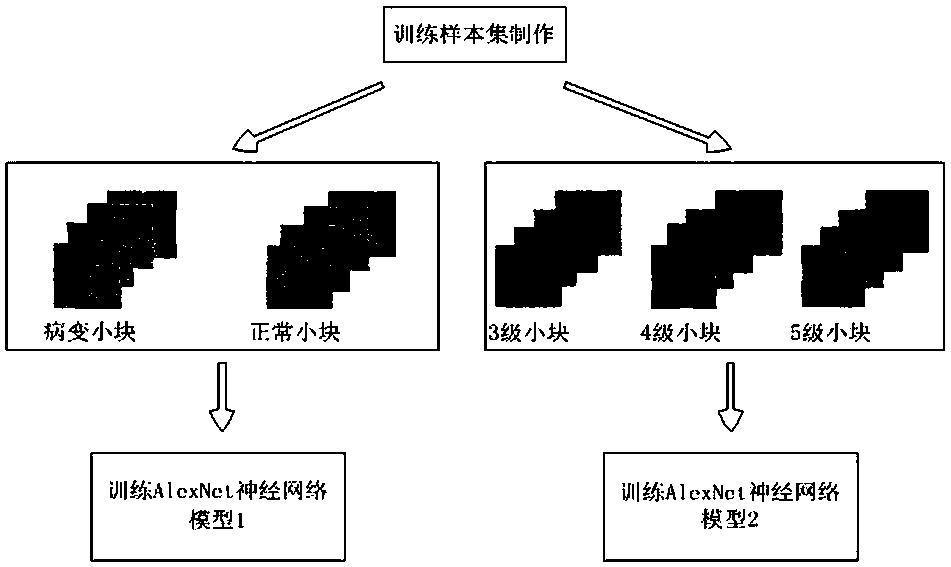

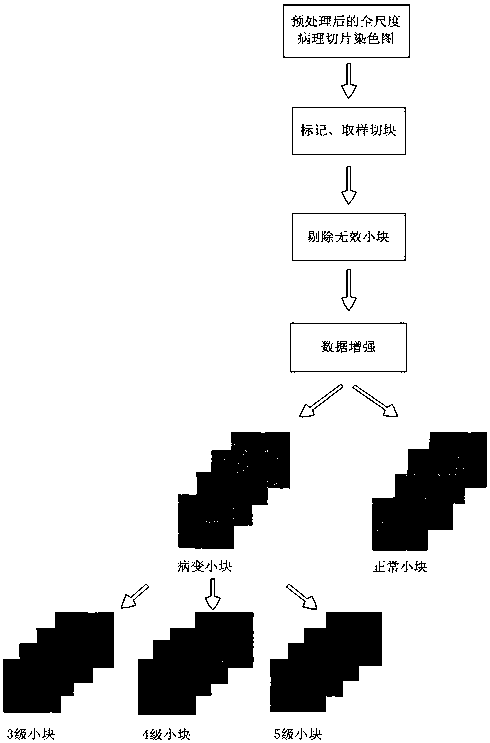

Rapid diagnosis and scoring method for full-scale pathological section based on deep learning

ActiveCN108305249ASolve the problem of size limitationImplement diagnosticsImage enhancementImage analysisNetwork modelScore method

The invention relates to a rapid diagnosis and scoring method for a full-scale pathological section based on deep learning. Preprocessing is carried out on a full-scale pathological section staining map; the node number of a full-connection layer and an output layer of a traditional AlexNet neural network is changed to meet the needs of practical problems, a marked training sample set is selectedto train two AlexNet neural network models for diagnosis and scoring, and high-dimensional feature information of a lesion area is extracted; with the two improved AlexNet neural network models aftertraining, the full-scale pathological section staining map is diagnosed and scored; and according to a diagnosis predicted probability, a probability heat map is drawn and the lesion area is identified visually, statistics of proportions of small sampling block numbers with different lesion degrees is carried out, and the lesion degree of a tissue is scored. Therefore, the diagnosis and Gleason scoring of the full-scale pprostate tissue pathological section are realized automatically; and the accuracy rate and the calculation rate exceed the average level of the artificial diagnosis substantially.

Owner:FUJIAN NORMAL UNIV

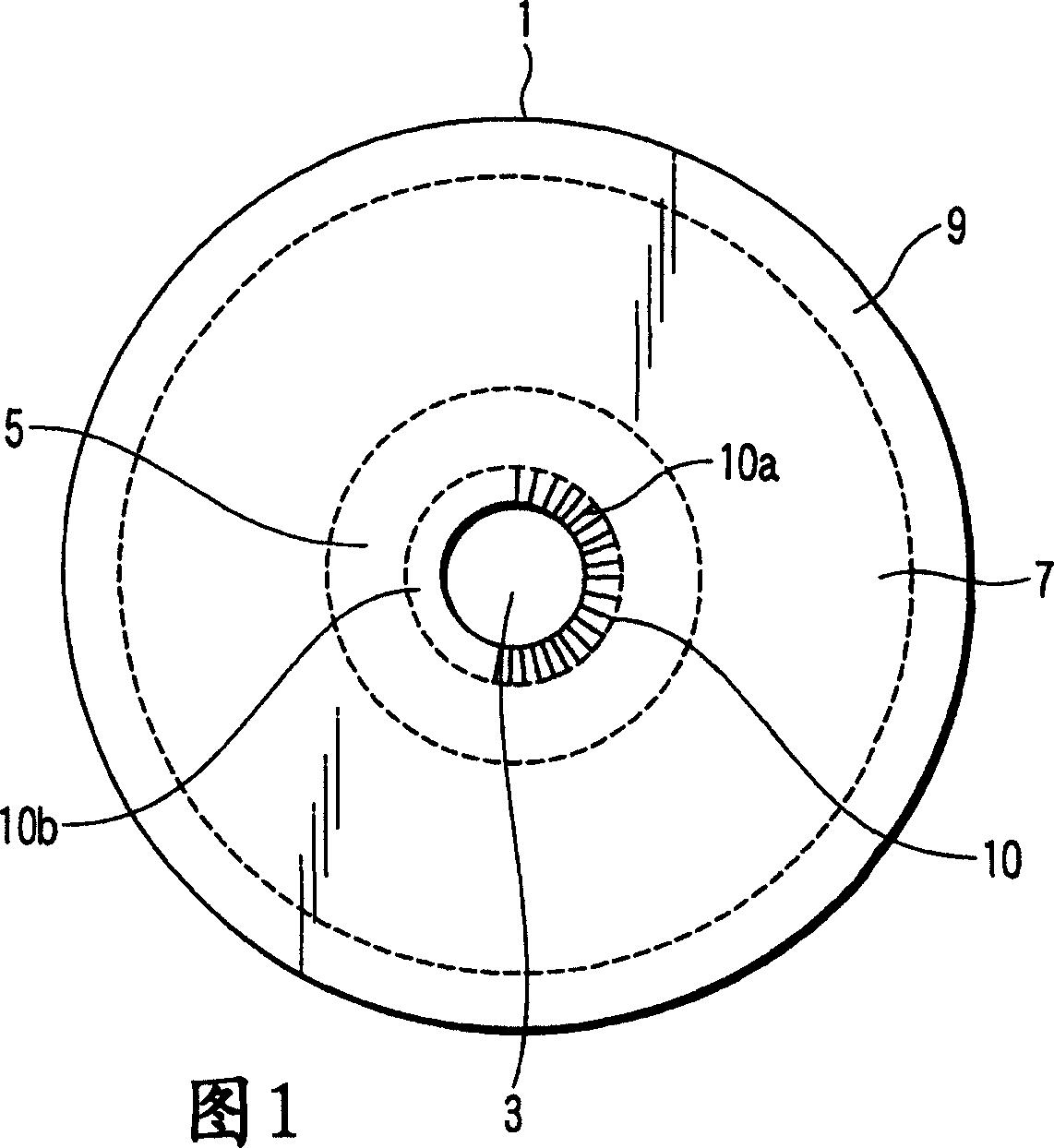

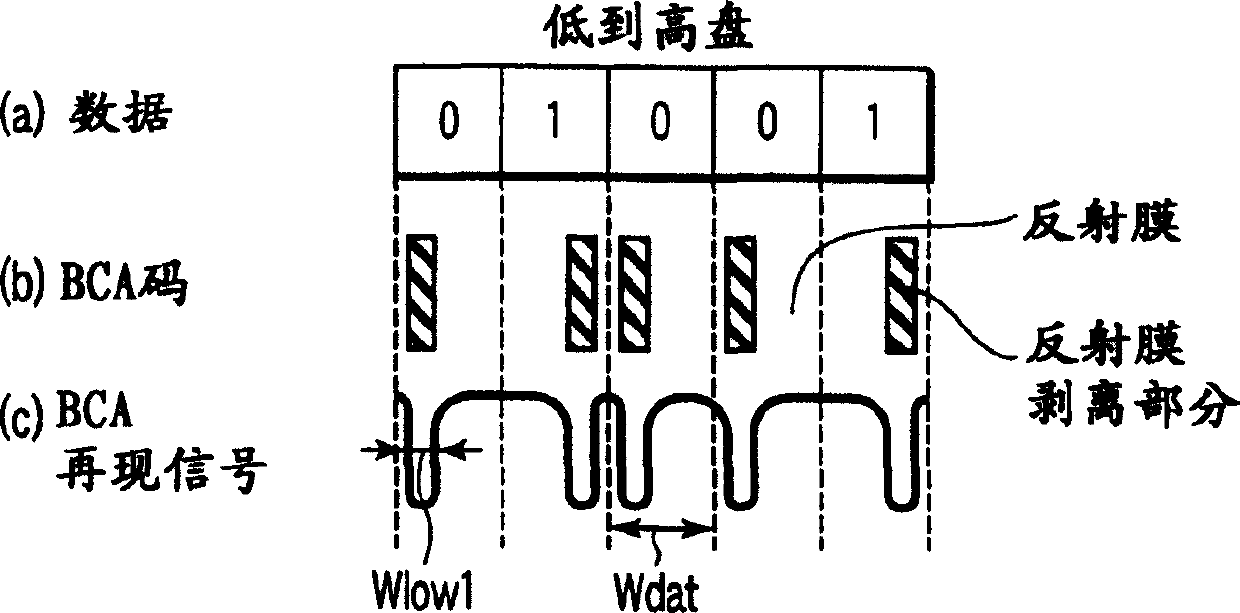

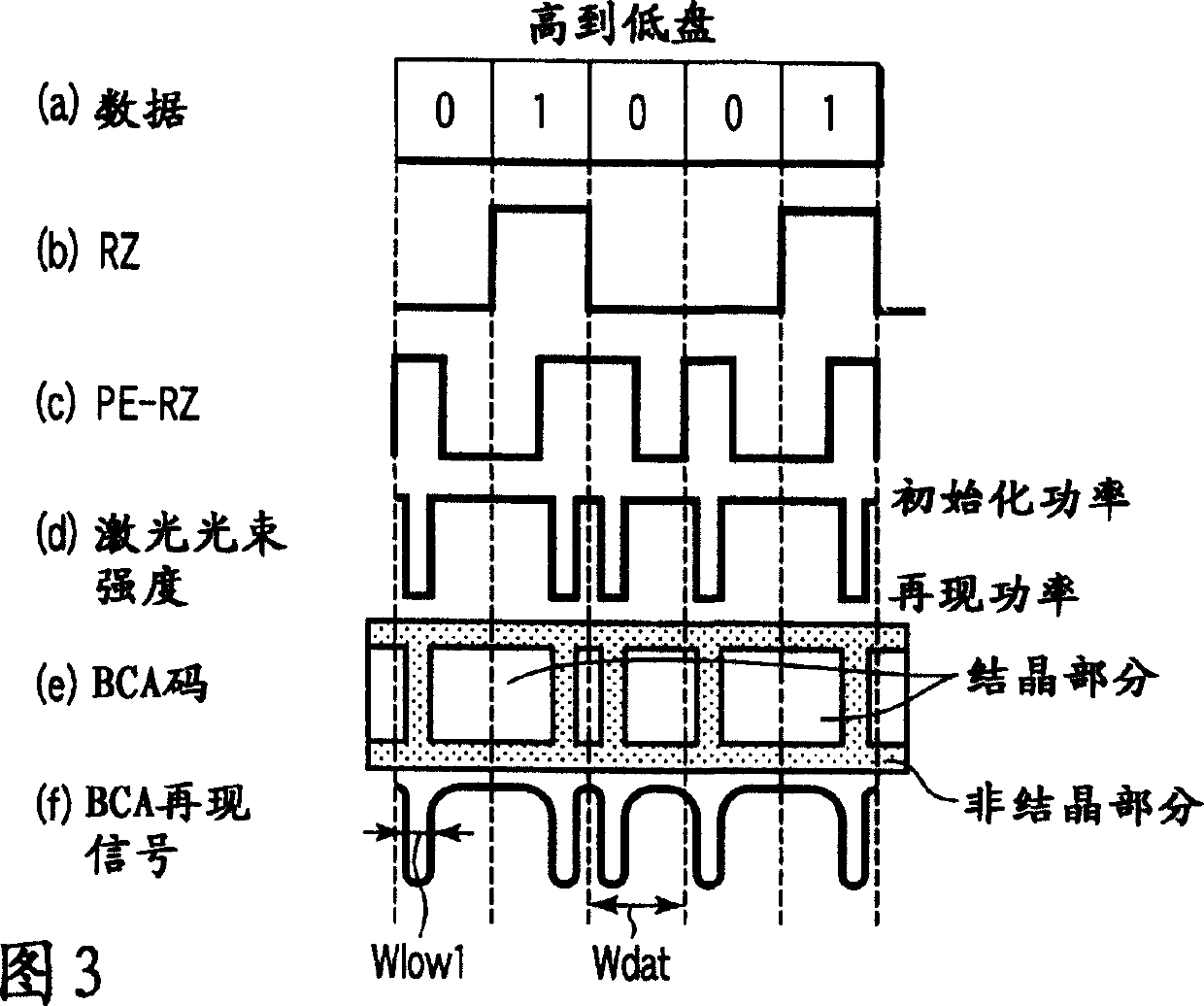

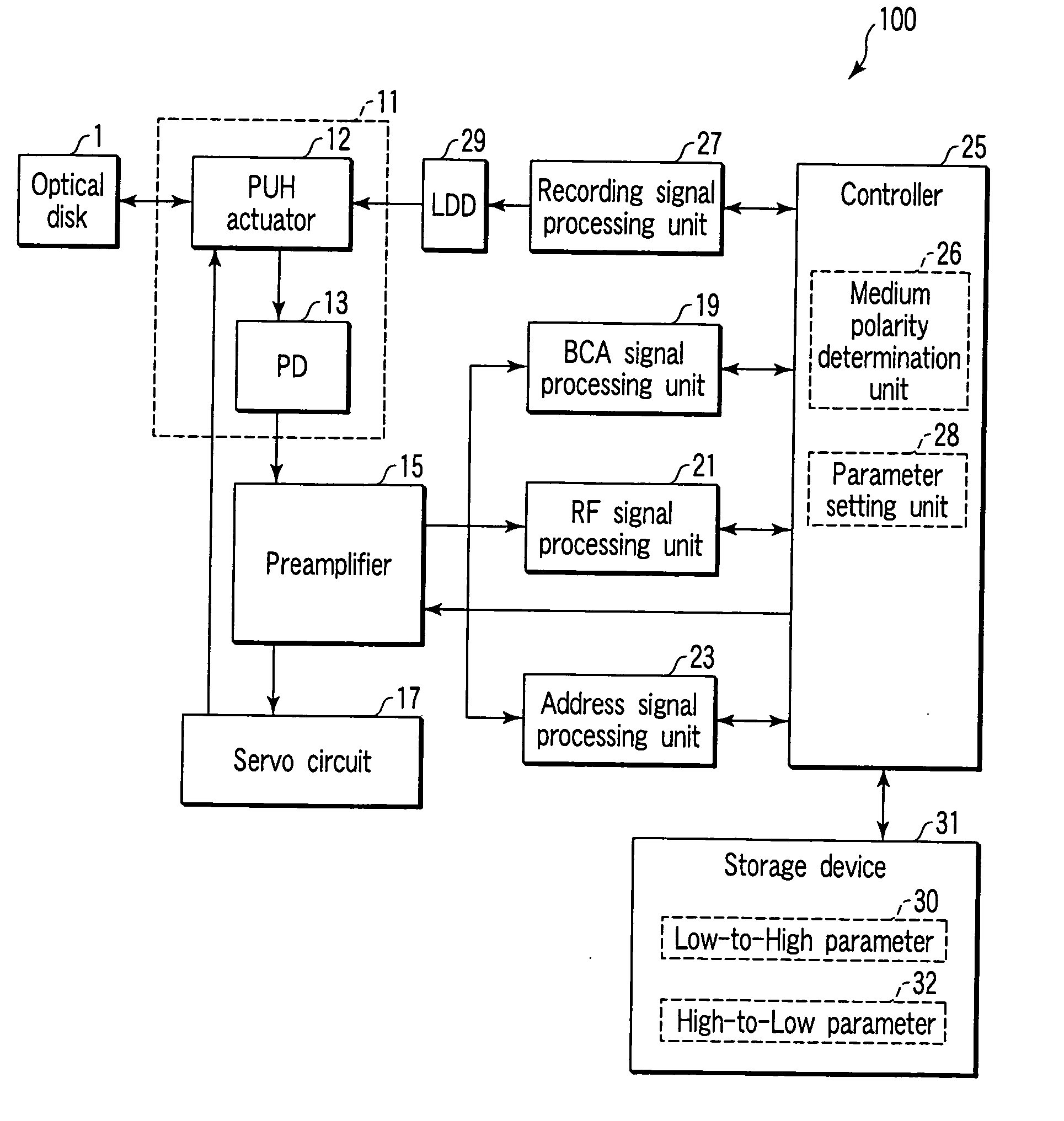

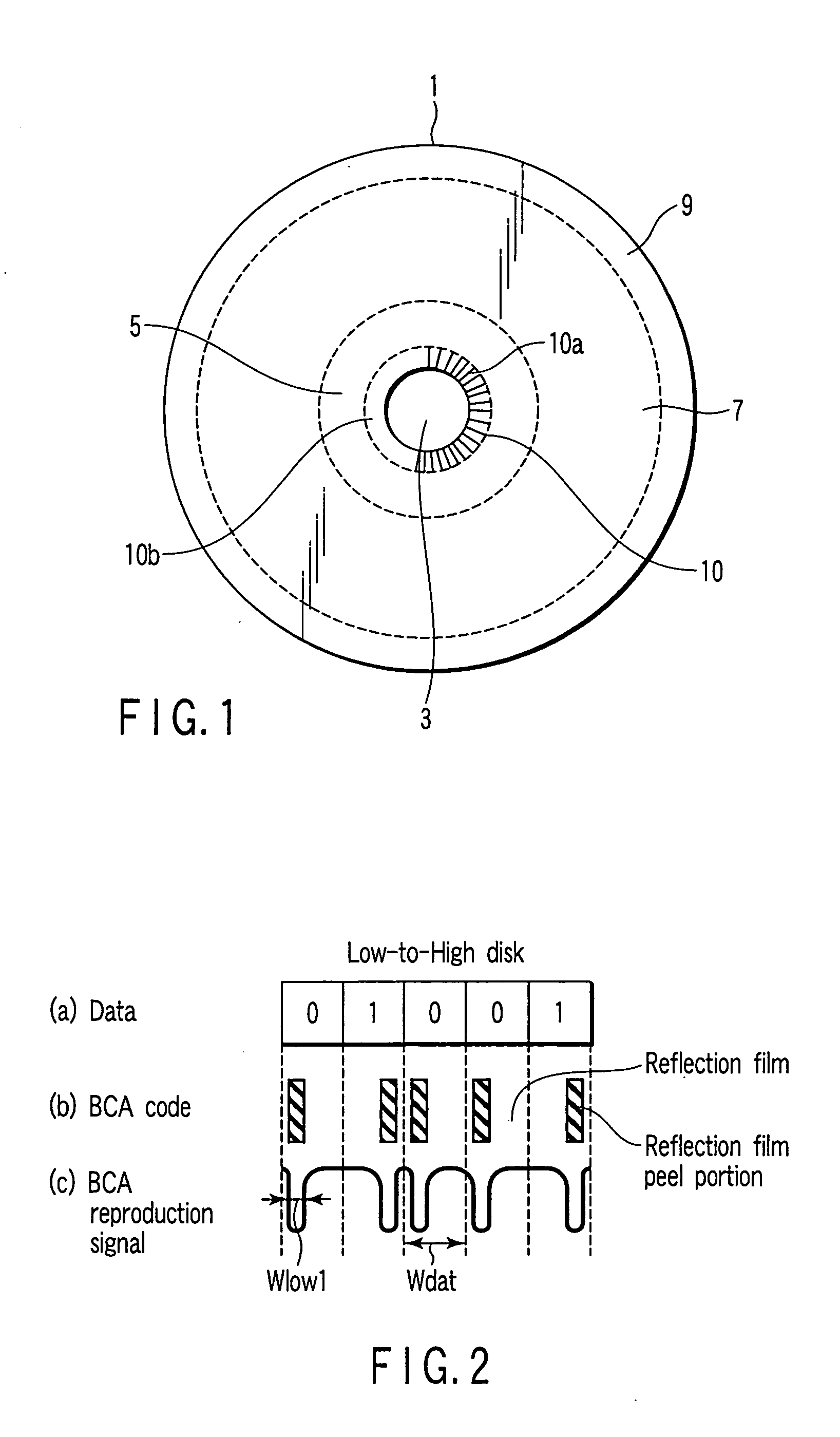

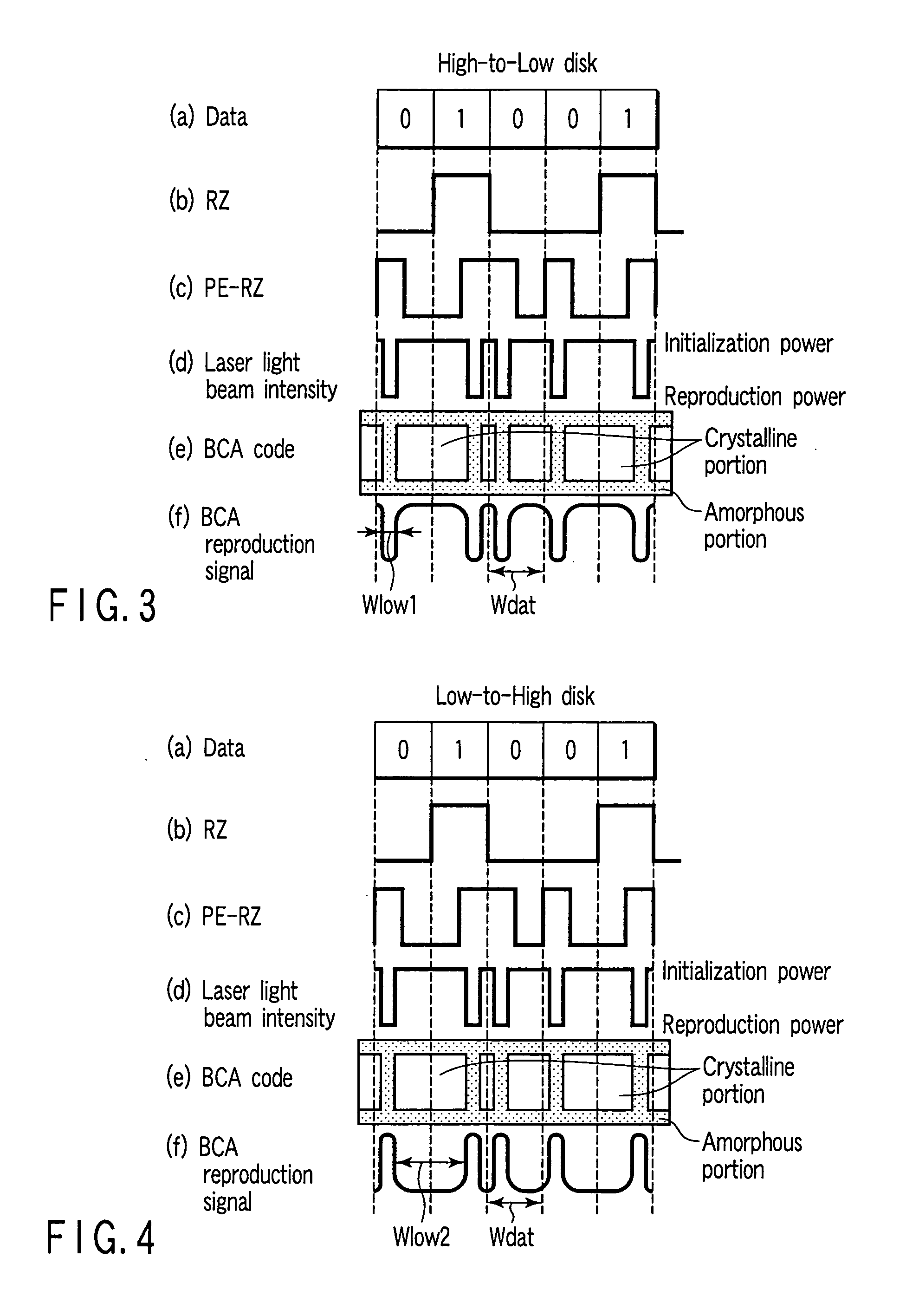

Optical disk, optical disk apparatus, optical disk recording and reproduction method, and apparatus and method for recording BCA code

InactiveCN1627375AImprove reflectivityChange reflectivityOptical beam sourcesRecord information storageOptical recordingReflectivity

A disc (1) has a burst cut area (BCA) (10) formed by a crystalline part and an amorphous part, and the disc (1) is an optical disc in which the reflectance of the crystalline part is lower than that of the amorphous part ( L-H medium). The width Wcry of the crystalline portion in the BCA(10) is less than half of the data period Wdat. Therefore, the average level of the BCA reproduction signal does not change regardless of whether the optical disc is an HL medium or an L-H medium, so that focus control and BCA code reproduction can be performed even if the circuit parameters are default values.

Owner:TOSHIBA SAMSUNG STORAGE TECH KOREA CORP

Communication system and receiving method

InactiveUS20060002484A1Reduce errorsError prevention/detection by using return channelModulated-carrier systemsComputer hardwareCommunications system

A receiving apparatus in a communication system in which when a systematically encoded signal cannot be decoded correctly on a receiving side, the signal is retransmitted from a transmitting side. The receiving apparatus combines stored data, which has been generated based upon data already received, and newly received data, decides a range of quantization levels of the combined data using an average level only of systematic bits of the stored data and newly received data, quantizes the combined data based upon the range of quantization levels and number of quantization bits, applies decoding processing to the quantized data, notifies the transmitting side of whether decoding could be performed correctly, and stores the combined data as the stored data when decoding cannot be performed correctly.

Owner:FUJITSU LTD

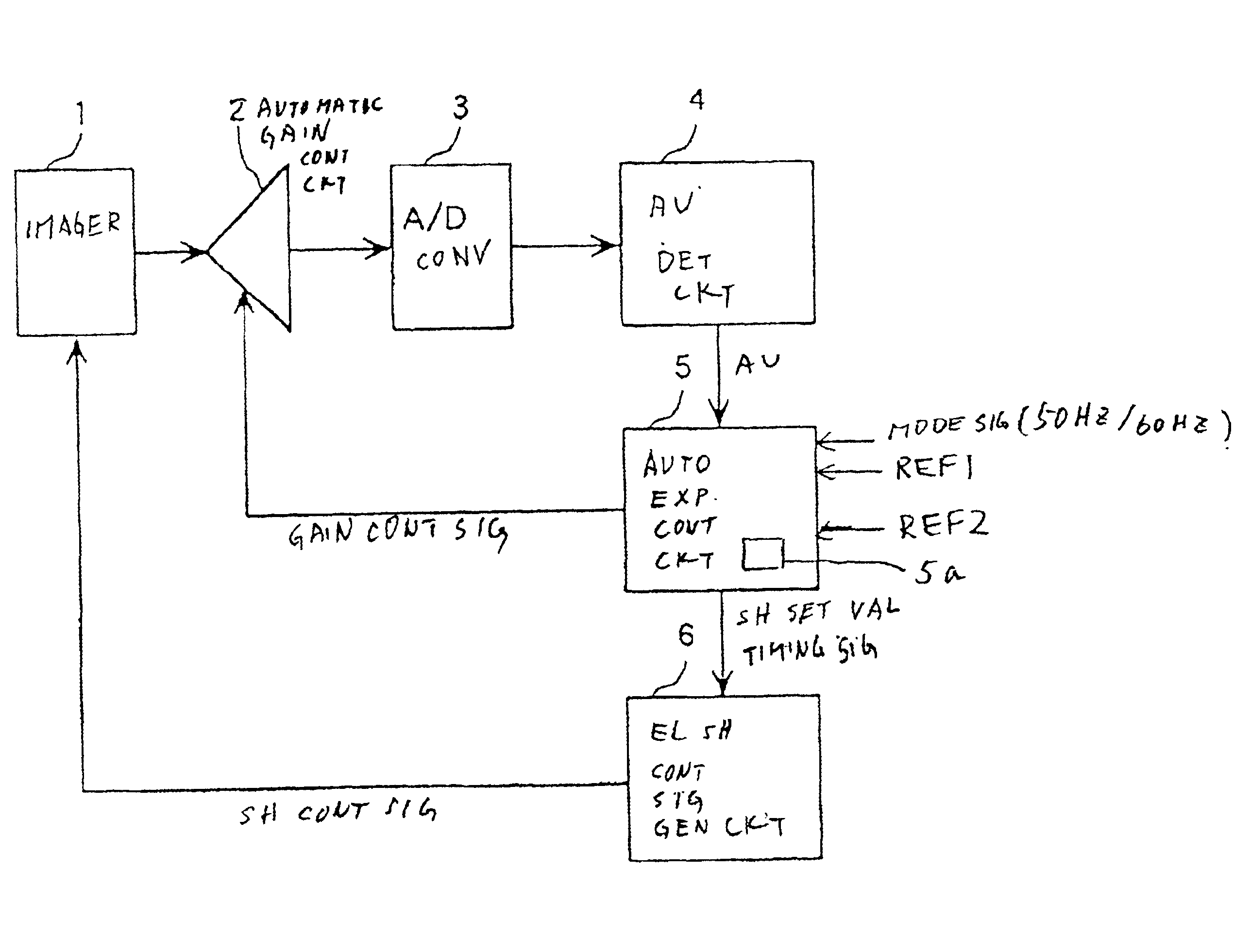

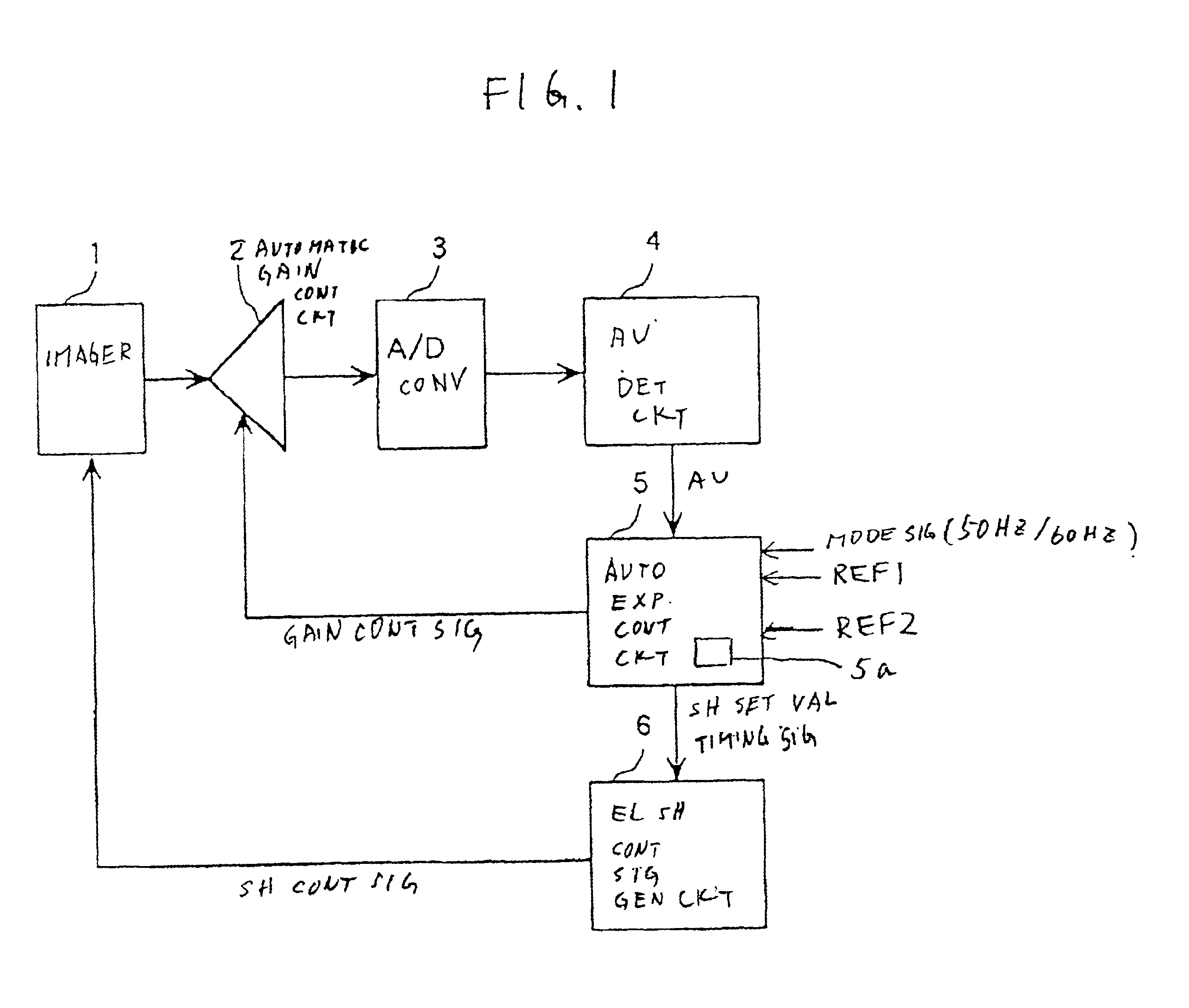

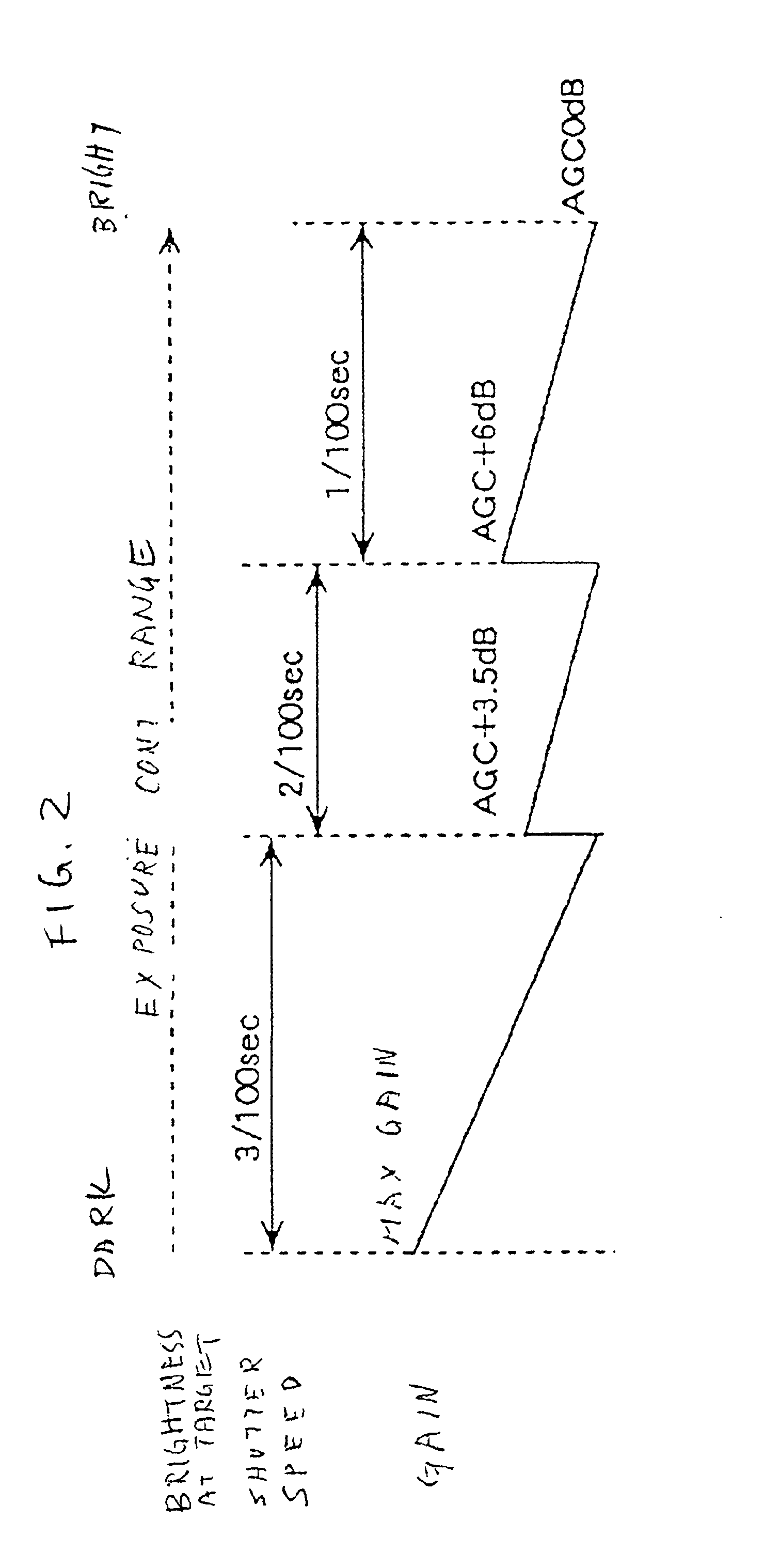

Video signal processing apparatus

InactiveUS6882363B1Easy to optimizeEasy to processTelevision system detailsColor signal processing circuitsElectronic shutterControl signal

An automatic gain controlling circuit controls a gain of a video signal from an imager having an electronic shutter function according to a gain control signal. An average detecting circuit detects an average level of a luminance signal of the video signal. An automatic exposure controlling circuit generates the gain control signal according to the luminance average level in response to a mode signal indicative of the cycles per second of the ac line and generates a timing signal corresponding to the ac line and a shutter speed control signal together with electronic shutter control signal generation circuit at a unit of the voltage variation cycle of the ac line according to the luminance average level such that a shutter interval of the imager is changed stepwise and each of the shutter intervals is an integer times the voltage variation cycle of the ac line. The automatic exposure controlling range is expanded by changing the shutter speed stepwise from {fraction (1 / 100)} sec, {fraction (2 / 100)} sec {fraction (3 / 100)} sec at 50-Hz-ac area, for example, to provide coarse exposure controlling and fine automatic gain controlling is provided every shutter interval to suppress flicker.

Owner:PANASONIC CORP

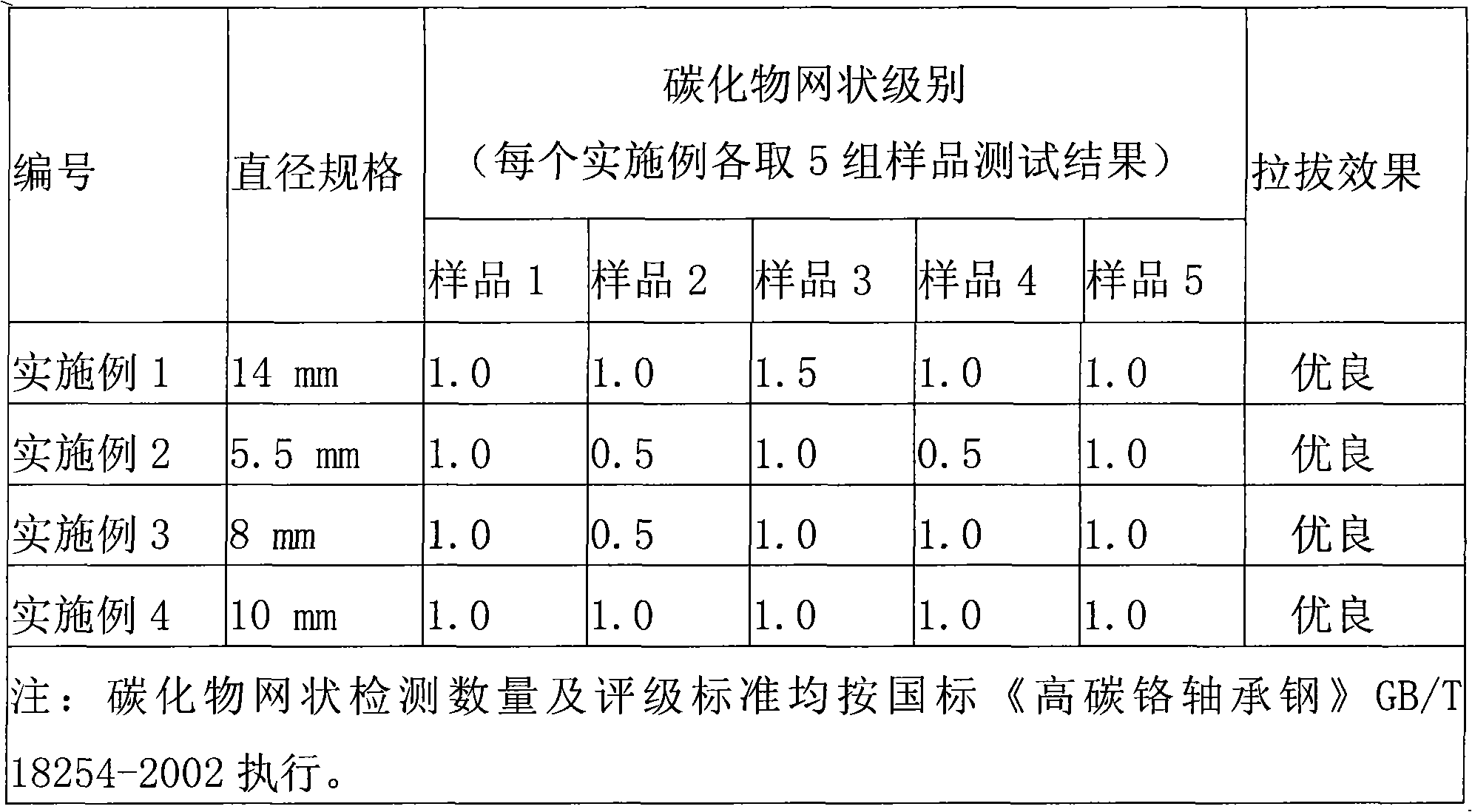

Method for reducing net level of bearing steel wire rod carbide

The invention discloses a method for reducing net level of bearing steel wire rod carbide, including the following steps: firstly, bearing steel continuous casting billet is heated and warmed up, and rough rolling, medium rolling and pre-finishing treatments are carried out at the temperature of 1030 to 1130 DEG C, so that the accumulated elongation percentage n1 of rolled pieces is 65 to 120 times; secondly, pre-hydrocooling treatment of rolled pieces is carried out, the cooling speed is controlled in the range of 10 to 40 DEG C per second, and the cooling time is controlled in the range of 0.8 to 2.2 seconds; then 4 to 10 sub-finishing treatments of rolled pieces are carried out, the start-rolling temperature is controlled in the range of 900 to 950 DEG C, and the final-rolling temperature is controlled in the range of 920 to 990 DEG C; then the rolled pieces are in hydrocooling treatment, the cooling speed is controlled in the range of 50 to 350 DEG C per second, the spinning temperature is controlled in the range of 760 to 820 DEG C, and dispersed rolls are manufactured; finally, the dispersed rolls are in air-cooled treatment, the air-cooled speed is controlled in the range of 2 to 10 DEG C per second, the roll collection temperature when the dispersed rolls come out of air-cooled roller way is controlled in the range of 330 to 450 DEG C, and the dispersed rolls are disposed in environmental air and cooled till room temperature. The products produced by using the method have 95% of carbide whose net level is less than or equal to 1.0 in which the average level is 0.95, thereby being capable of increasing abrasion resistance and service life of steel.

Owner:武钢集团有限公司

Tempo detection apparatus, chord-name detection apparatus, and programs therefor

There is provided a tempo detection apparatus capable of detecting, from the acoustic signal of a human performance of a musical piece having a fluctuating tempo, the average tempo of the entire piece of music and the correct beat positions, and further, the meter of the musical piece and the position of the first beat. The tempo detection apparatus includes an input section; a chromatic-note-level detection section for applying an FFT calculation to obtain the level of each chromatic note at each of predetermined timings; a beat detection section for summing up incremental values of respective levels of all the chromatic notes, indicating the degree of change of entire sound at each of the predetermined timings, and for detecting an average beat interval and the position of each beat from the total of the incremental values of the levels; and a measure detection section for calculating the average level of each chromatic note for each beat, for summing up incremental values of all the chromatic note for each beat to obtain a value indicating the degree of change, and for detecting a meter and the position of a measure line from the value indicating the degree of change of entire sound at each beat.

Owner:KAWAI MUSICAL INSTR MFG CO

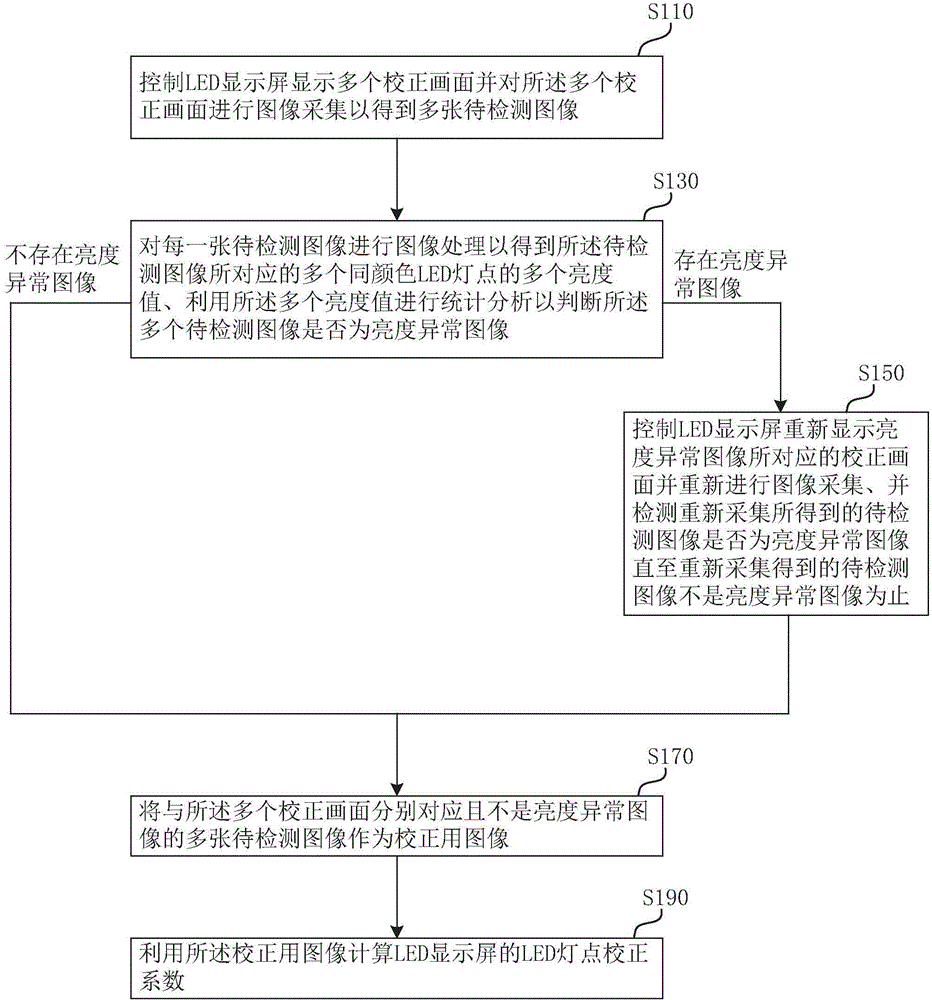

Method for detecting images with brightness abnormality and LED display screen uniformity correction method

ActiveCN104900178AEnsure safety and effectivenessAvoid Correction ArtifactsStatic indicating devicesLED displayImage detection

The invention relates to a method for detecting images with brightness abnormality and an LED display screen uniformity correction method adopting the method for detecting images with brightness abnormality. After collecting target pictures (such as correction pictures) to obtain images to be detected, the method for detecting images with brightness abnormality uses a statistical method to analyze a brightness value of each LED lamp point that the images to be detected correspond to, for example, a statistical value representing an average level of brightness distribution and a statistical value representing the dispersion degree of brightness distribution are calculated, and then in combination with a set threshold range, whether each image to be detected is an image with brightness abnormality is judged. When an image with brightness abnormality is detected to exist, image acquisition is performed again individually to replace the image with brightness abnormality, thereby overcoming the problem of a blurred screen in correction which is caused by an ambient light change, a fact that an image acquisition device (such as a camera) or a screen body is shielded, a screen display abnormality and the like which may occur in a conventional correction collection process.

Owner:XIAN NOVASTAR TECH

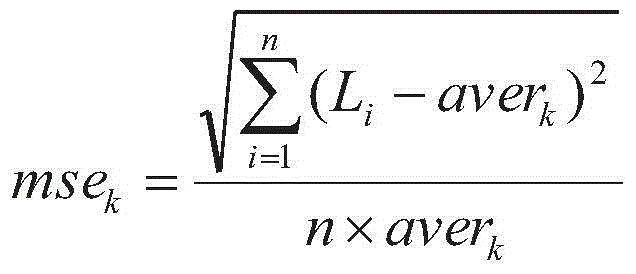

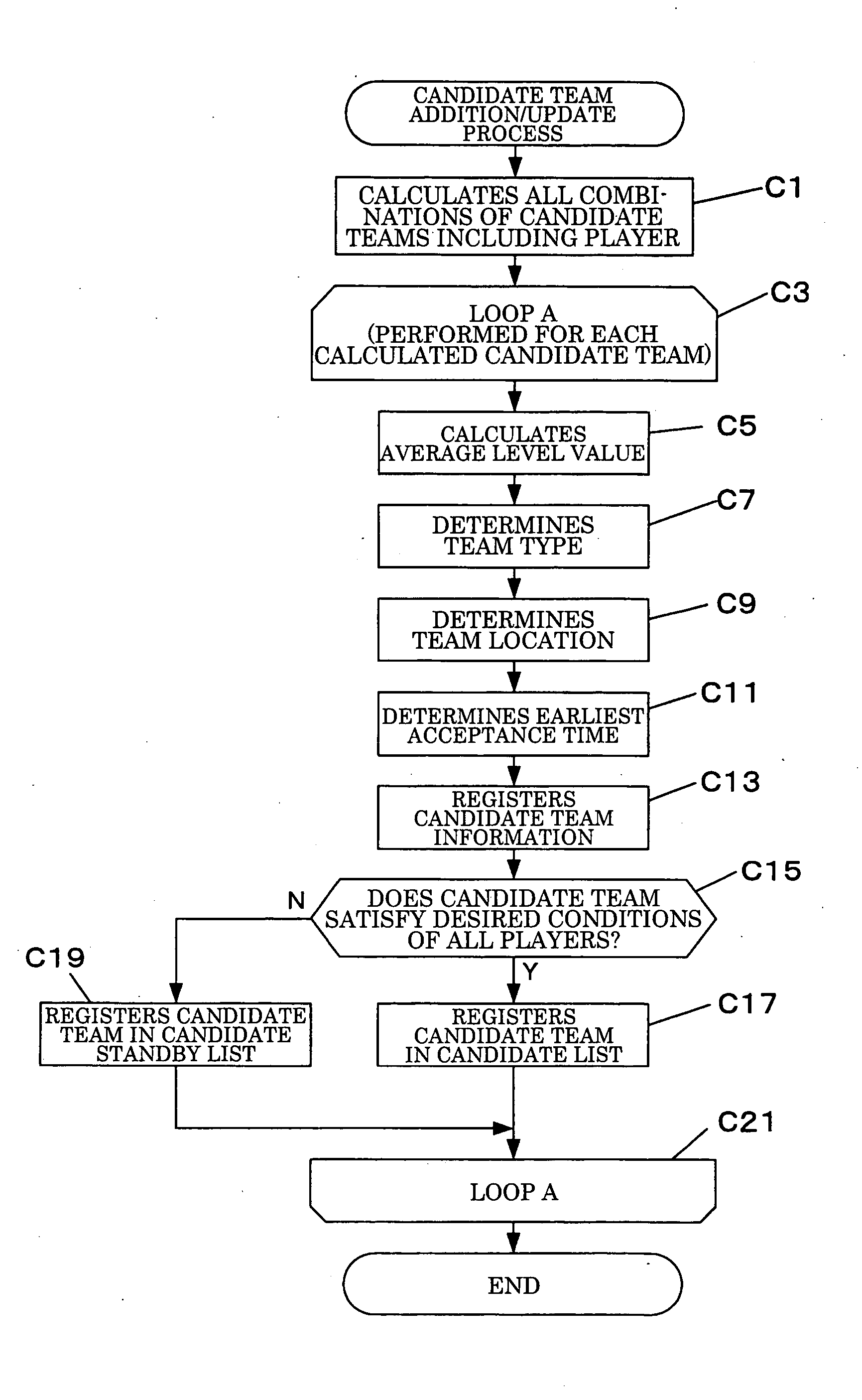

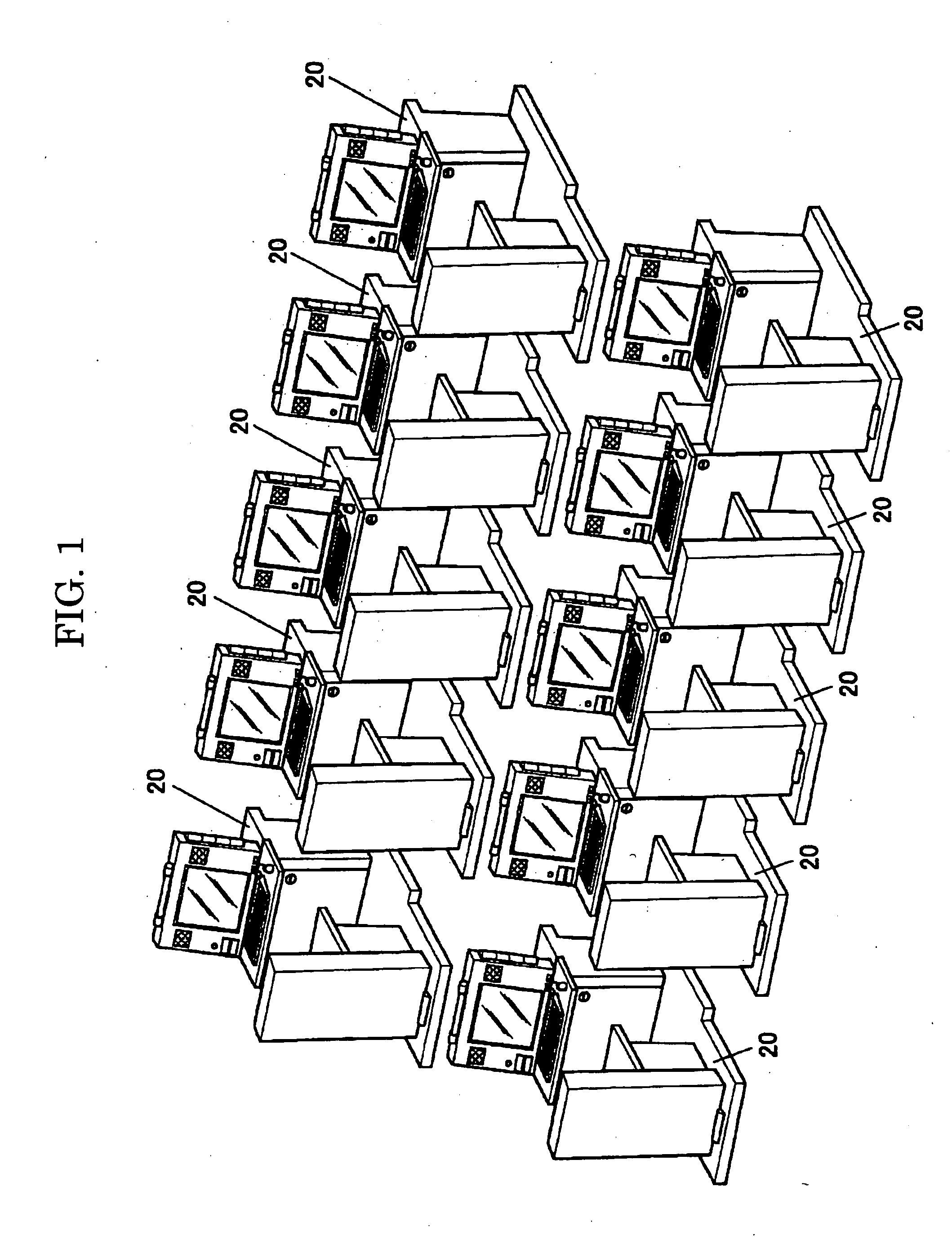

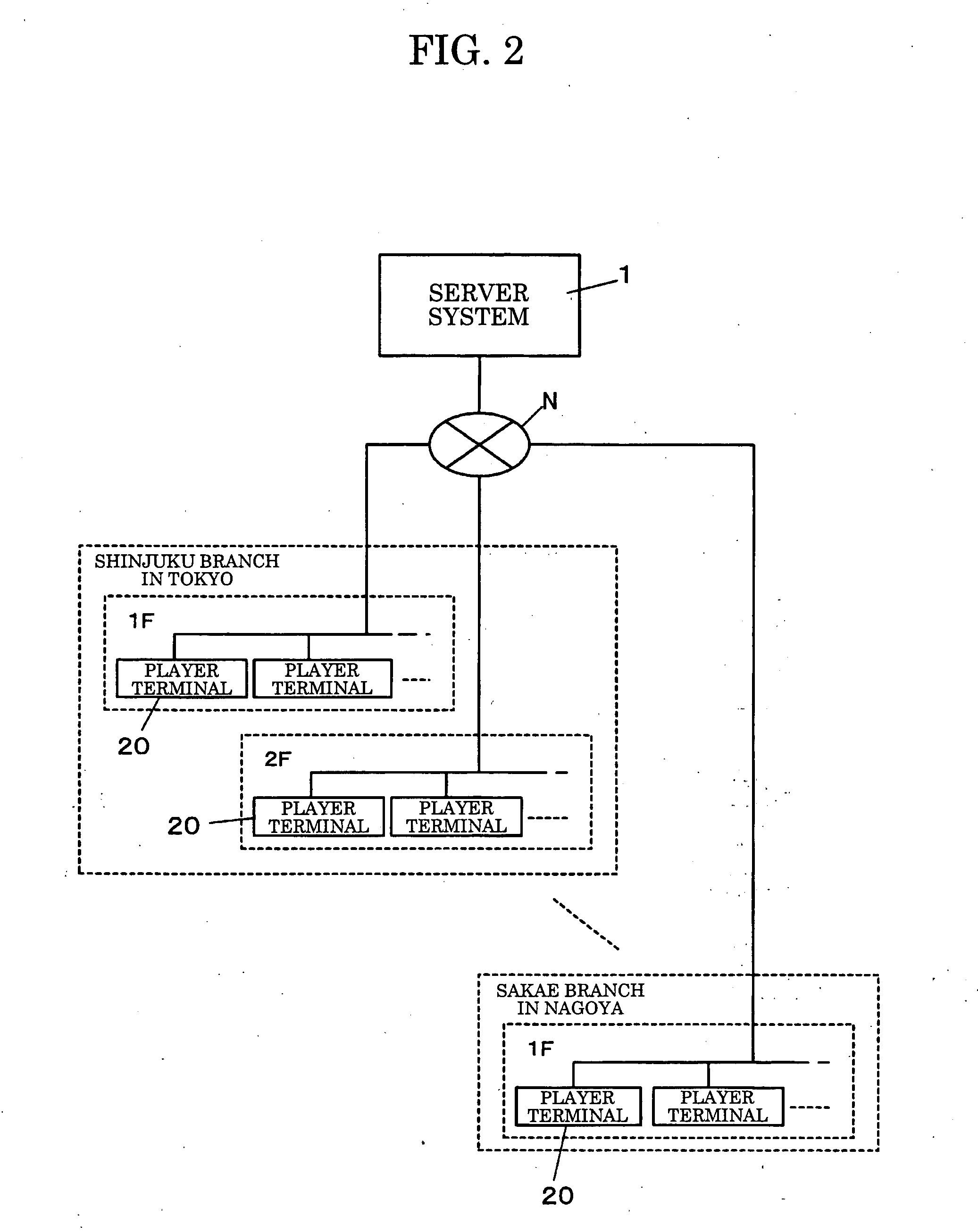

Server system, team formation method in network game, and information storage medium

InactiveUS20070202953A1Easily uniteVideo gamesSpecial data processing applicationsInformation storageAverage level

A play level value of each player which is changed depending on game results is stored in a player management DB. When accepting a matching request from a player terminal, all candidate teams including the player who has issued the matching request are calculated. Candidate teams of which the average level values are almost equal and which completely differ as to the players belonging thereto are determined as opposing teams.

Owner:BANDAI NAMCO ENTERTAINMENT INC

Optical disk, optical disk apparatus, optical disk recording and reproduction method, and apparatus and method for recording BCA code

InactiveUS20050128917A1Ensure correct executionOptimization parametersTelevision system detailsOptical beam sourcesComputer scienceReflectivity

A disk has a burst cutting area (BCA) formed by a crystalline portion and an amorphous portion, and the disk is an optical disk (L-H medium) in which the reflectance of the crystalline portion is lower than that of the amorphous portion. The width Wcry of the crystalline portion in the BCA is lower than half the data period Wdat. Therefore, the average level of a BCA reproduction signal is unchanged regardless of whether the optical disk is an H-L medium or an L-H medium, so that focus control and reproduction of a BCA code can be performed even if a parameter of a circuit is a default.

Owner:KK TOSHIBA

Circuits and methods for driving light sources

InactiveCN102427633AReduce consumptionLow costElectric light circuit arrangementDriver circuitTransverter

A driving circuit for powering light-emitting diode (LED) light sources includes an energy converter and a plurality of current balance controllers. The energy converter receives input voltage and provides modulated voltage to the LED light sources, and the current balance controllers connected with the energy converter respectively control currents flowing across the LED light sources. The current balance controllers receive a first referential signal indicating a target average level and a second referential signal indicating a maximal transient level, and modulate average level of each current into the target average level and maximal transient level of each current to a level within the maximal transient level.

Owner:AOTU ELECTRONICS WUHAN

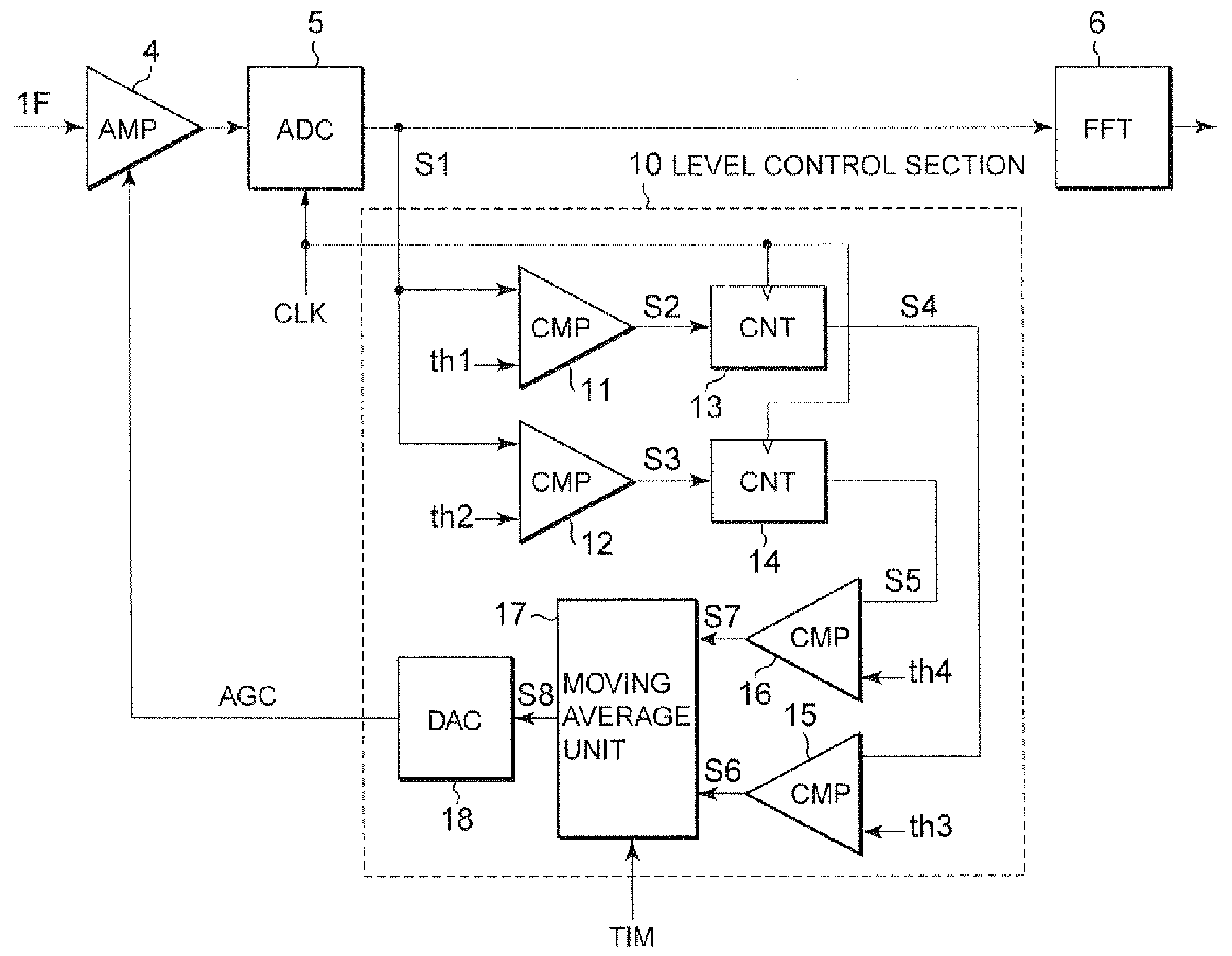

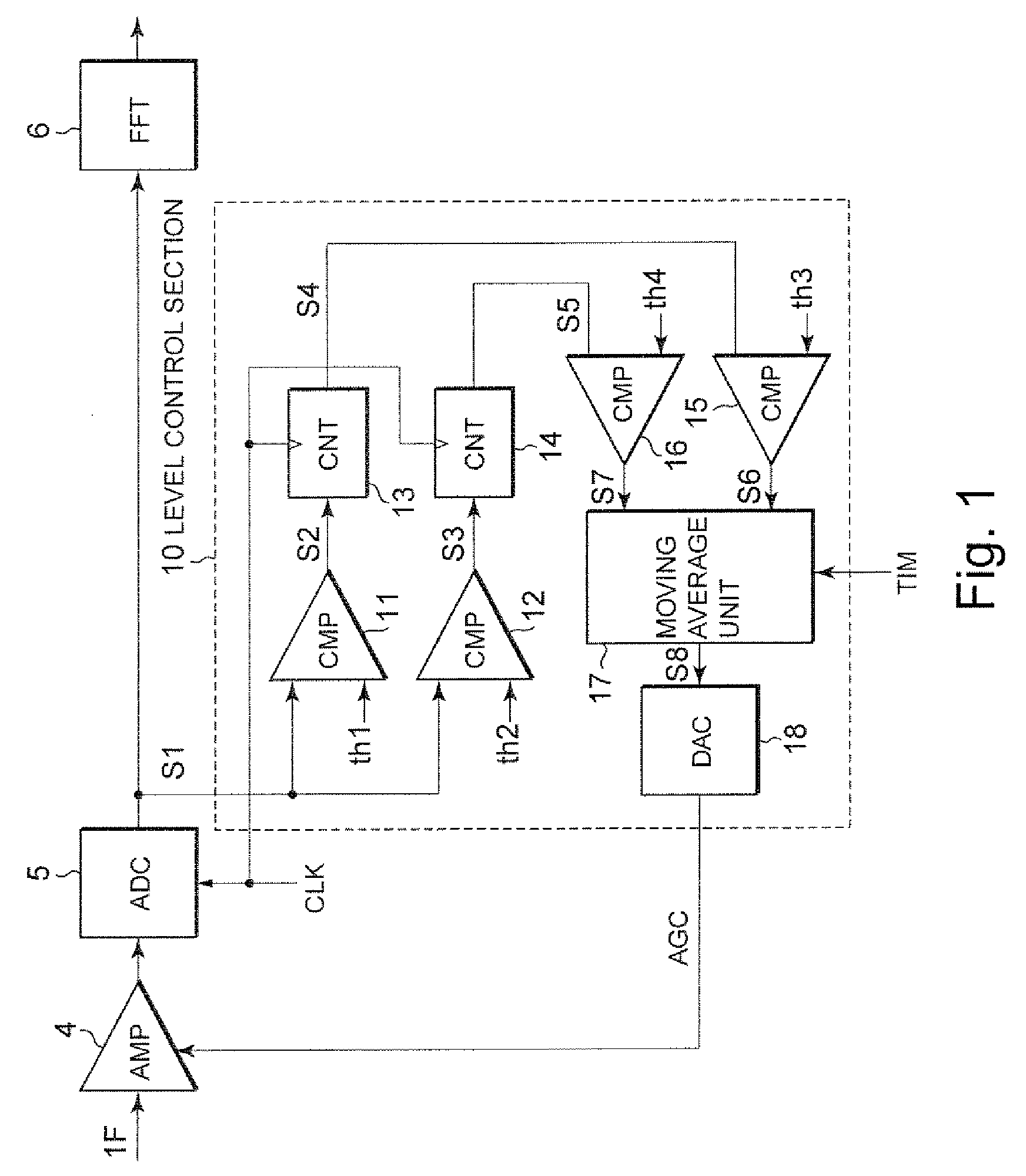

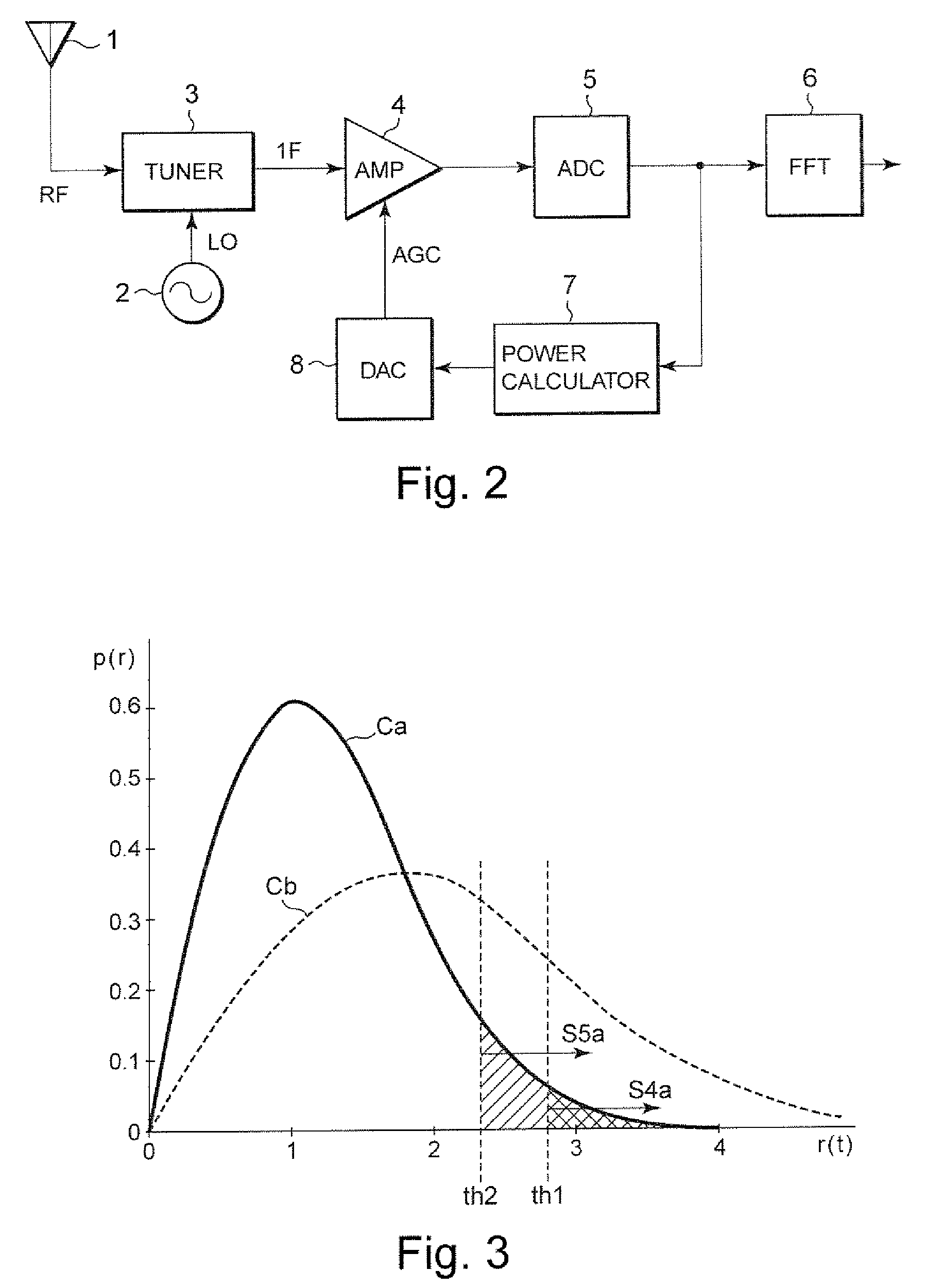

OFDM receiver

ActiveUS20080100485A1Simple circuit configurationElectric signal transmission systemsAmplitude-modulated carrier systemsMoving averageControl signal

The present invention provides an OFDM receiver having a level control section comprising comparators which respectively compare a first signal outputted from an ADC with threshold values, counters which respectively count the frequencies with which the level of the first signal exceeds the threshold values, based on second and third signals corresponding to the results of comparison by the comparators, a moving average unit which calculates an average value of the level of the first signal lying in a predetermined period, based on fourth and fifth signals corresponding to the frequencies counted by the these counters, and a DAC which generates a gain control signal for controlling an AMP in such a manner that the average level of the first signal outputted from the ADC becomes a predetermined value, according to a sixth signal calculated by the moving average unit.

Owner:LAPIS SEMICON CO LTD

Circuits and methods for powering light sources

A controller for regulating a current through a light-emitting diode (LED) light source includes a first reference pin for receiving a first reference signal indicative of a target average level, and a dimming control pin for receiving a dimming signal. The controller regulates an average level of the current to the target average level. The current is regulated according to the first reference signal and a ramp signal if the dimming signal has a first level. The ramp signal is synchronized with the dimming signal. The current is cut off if the dimming signal has a second level.

Owner:O2 MICRO INC

Artificial regulatory method for increasing female rice field eel fecundity

InactiveCN101103711AMaintain fecundityClimate change adaptationAnimal feeding stuffFinless eelNatural state

The invention belongs to the aquaculture technology field, in particular relating to an artificial control method for the improvement of female finless eel parent fecundity. The finless eel has special physiological phenomena and sex reversal characteristics with small size, large egg granules and low fecundity. Thus the scale finless eel propagation is subject to the restrictions of the female finless eel parent self-conditions. In the invention, through the artificial simulation of female finless eel culture and development environment, the rational selection of parental finless eels, the reasonable stocking density arrangement, the appropriate feeding and management methods, the pre-oviposition period intensive culture and the artificial control measures, the female finless eel fecundity in natural state can be enhanced to the fecundity up to 450 to 1300 grains each and the 680 grains average level from 170 to 650 grains each and the average 260 grains. Therefore, the average fecundity of finless eel is improved by 161%.

Owner:HUAZHONG AGRI UNIV

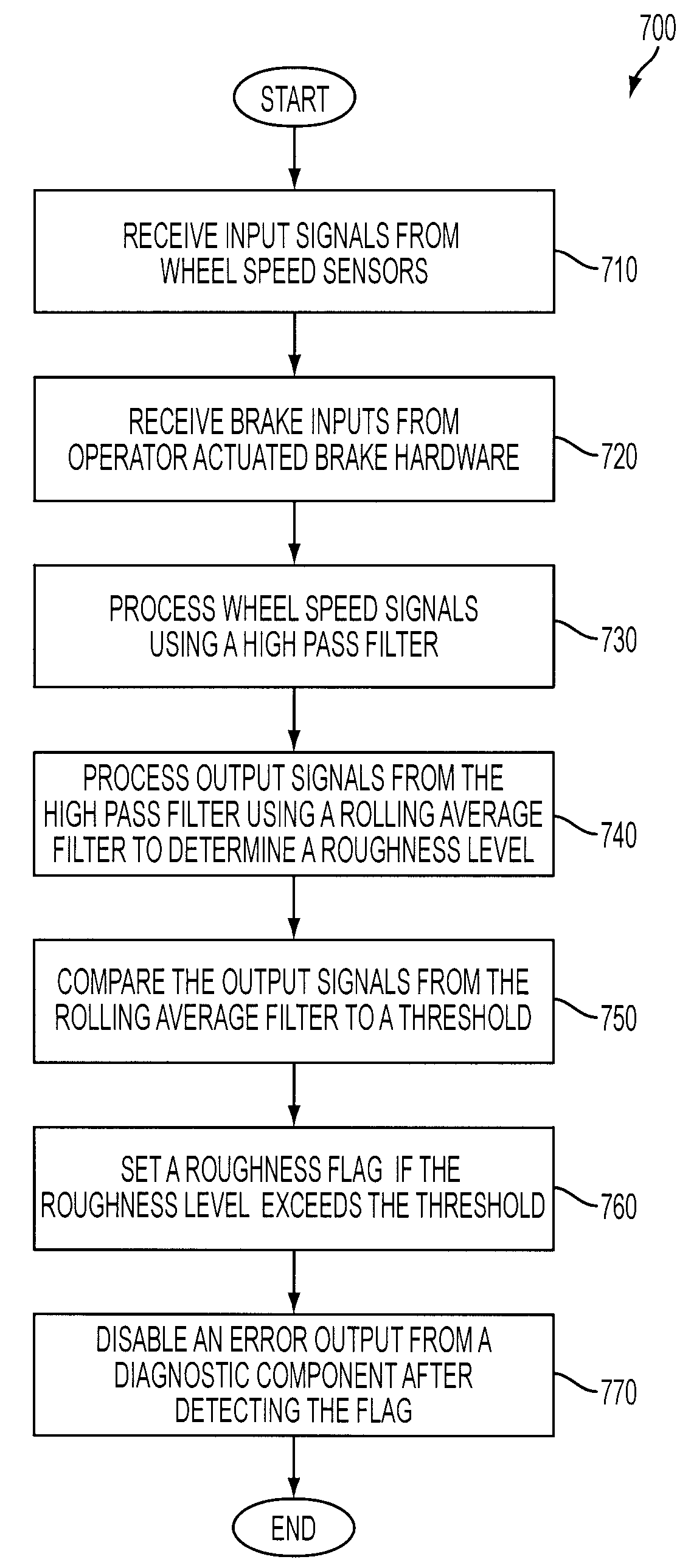

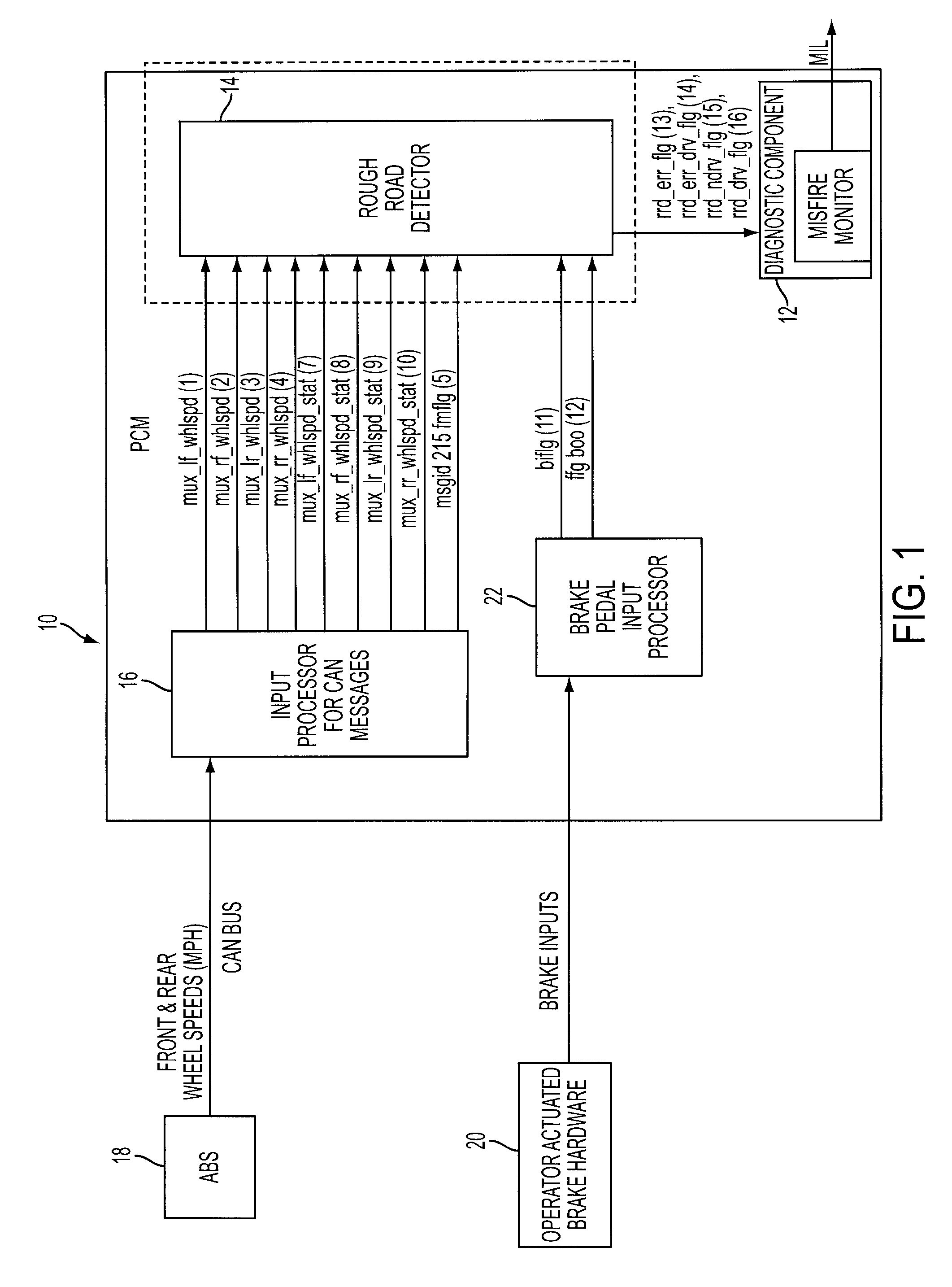

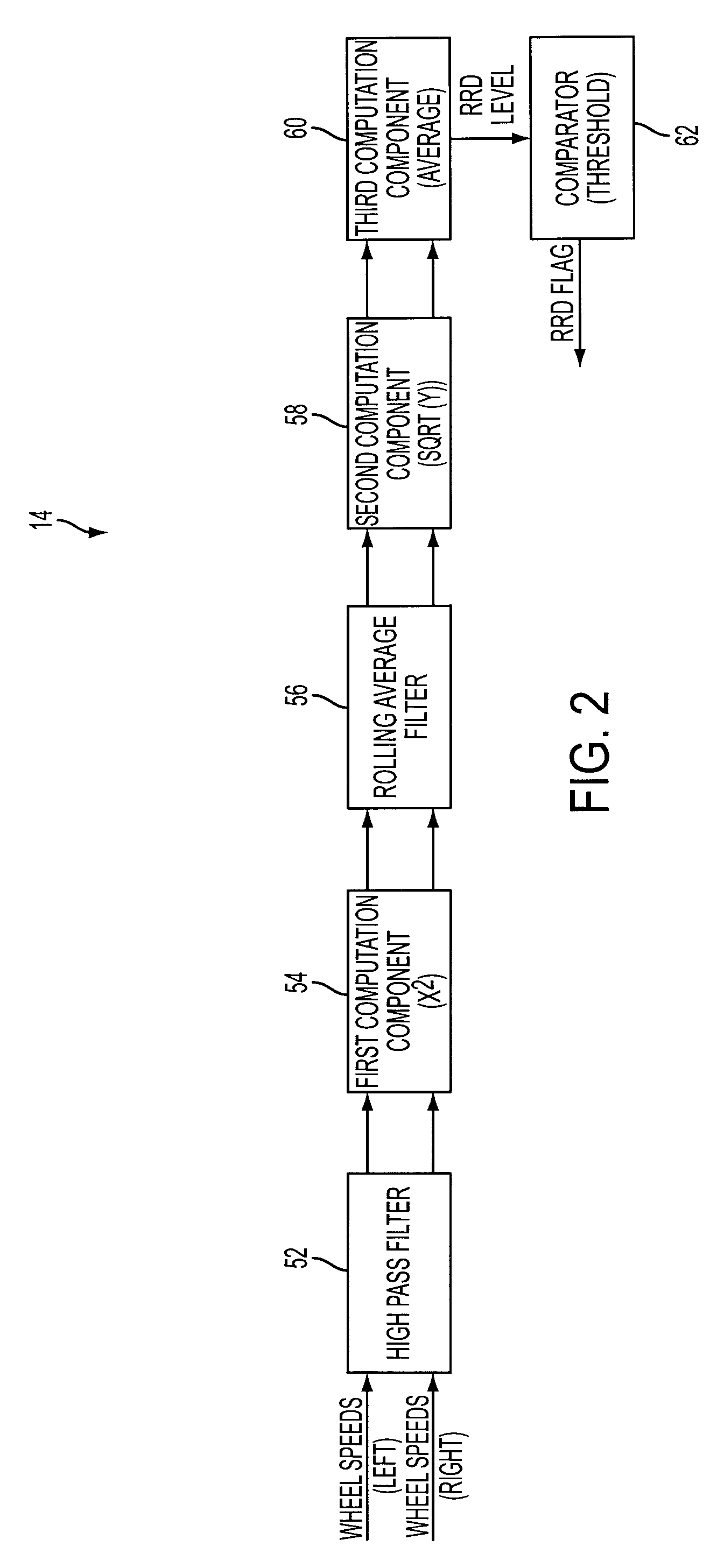

Rough Road Detection System Used in an On-Board Diagnostic System

ActiveUS20080177437A1Reduce false positiveOutput errorVehicle testingHand manipulated computer devicesWheel speed sensorRoad surface

An on-board diagnostic system of a vehicle comprises a diagnostic component configured to detect a vehicle operating condition and to produce an error output when the vehicle operating condition is determined to be abnormal; and a rough road detector configured to determine an average level of roughness of a road surface based on signals from wheel speed sensors, to compare the roughness with a predetermined threshold, and to disable the error output of the diagnostic component or switch to an alternate calibration for the diagnostic component if the roughness level has exceeded the predetermined threshold.

Owner:FORD GLOBAL TECH LLC

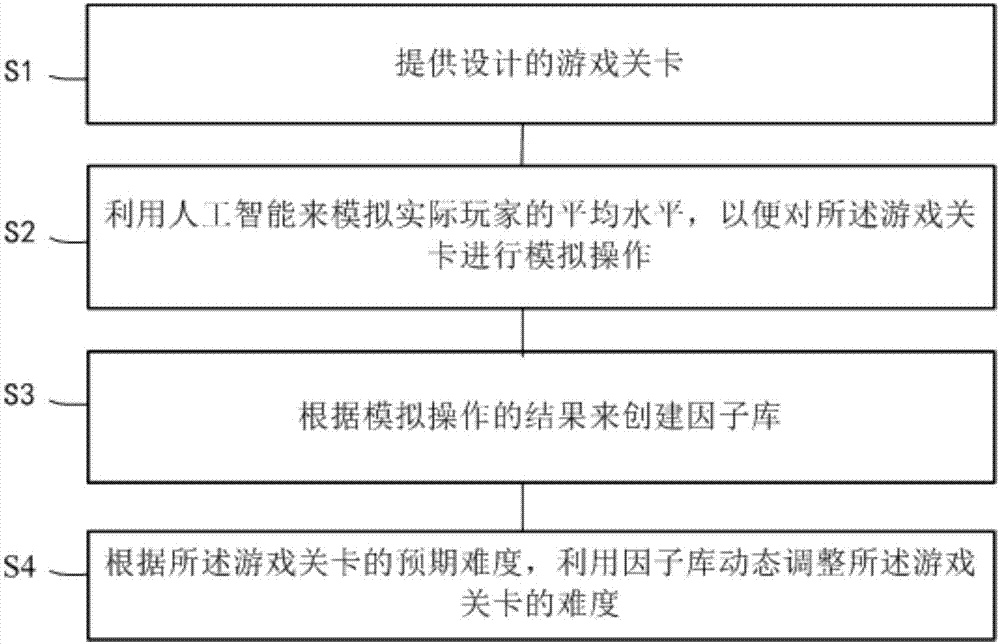

Game level refinement difficulty adjustment method

InactiveCN107982920AEliminate the disadvantages of tuningEasy to adjustVideo gamesSimulationAverage level

The invention discloses a game level refinement difficulty adjustment method. The method includes the following steps that 1, designed game levels are provided; 2, the average level of actual playersis simulated through artificial intelligence, and thus simulating operation of the game levels is facilitated; 3, according to the result of the simulating operation, a factor library is created; 4, according to the expected difficulty of the game levels, the difficulty of the game levels is dynamically adjusted through the factor library. The game level refinement difficulty adjustment method caneliminate the disadvantages of a current game with the game levels in game level adjustment, and more precise, high-precision and automatic adjustment can be achieved.

Owner:波克科技股份有限公司

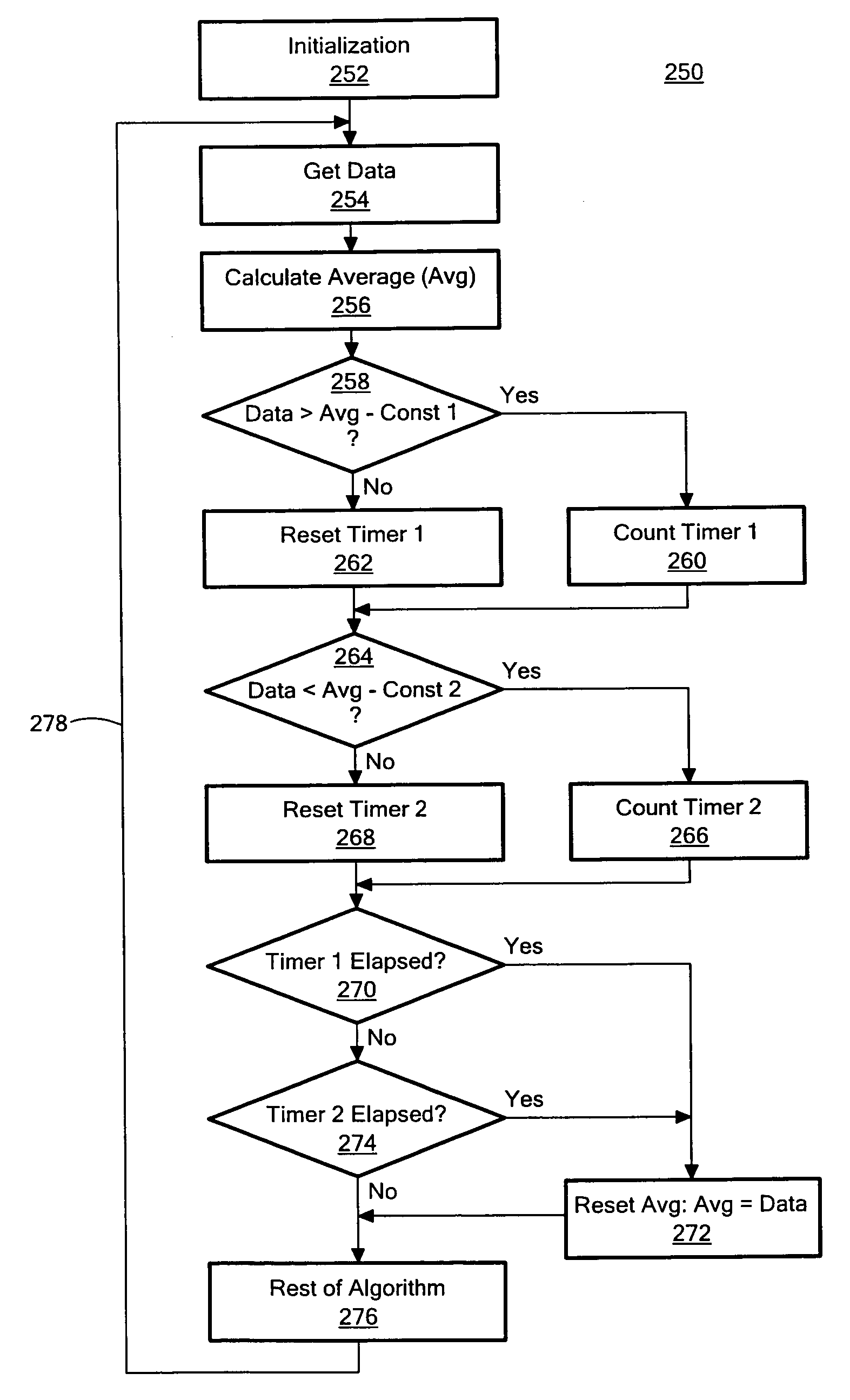

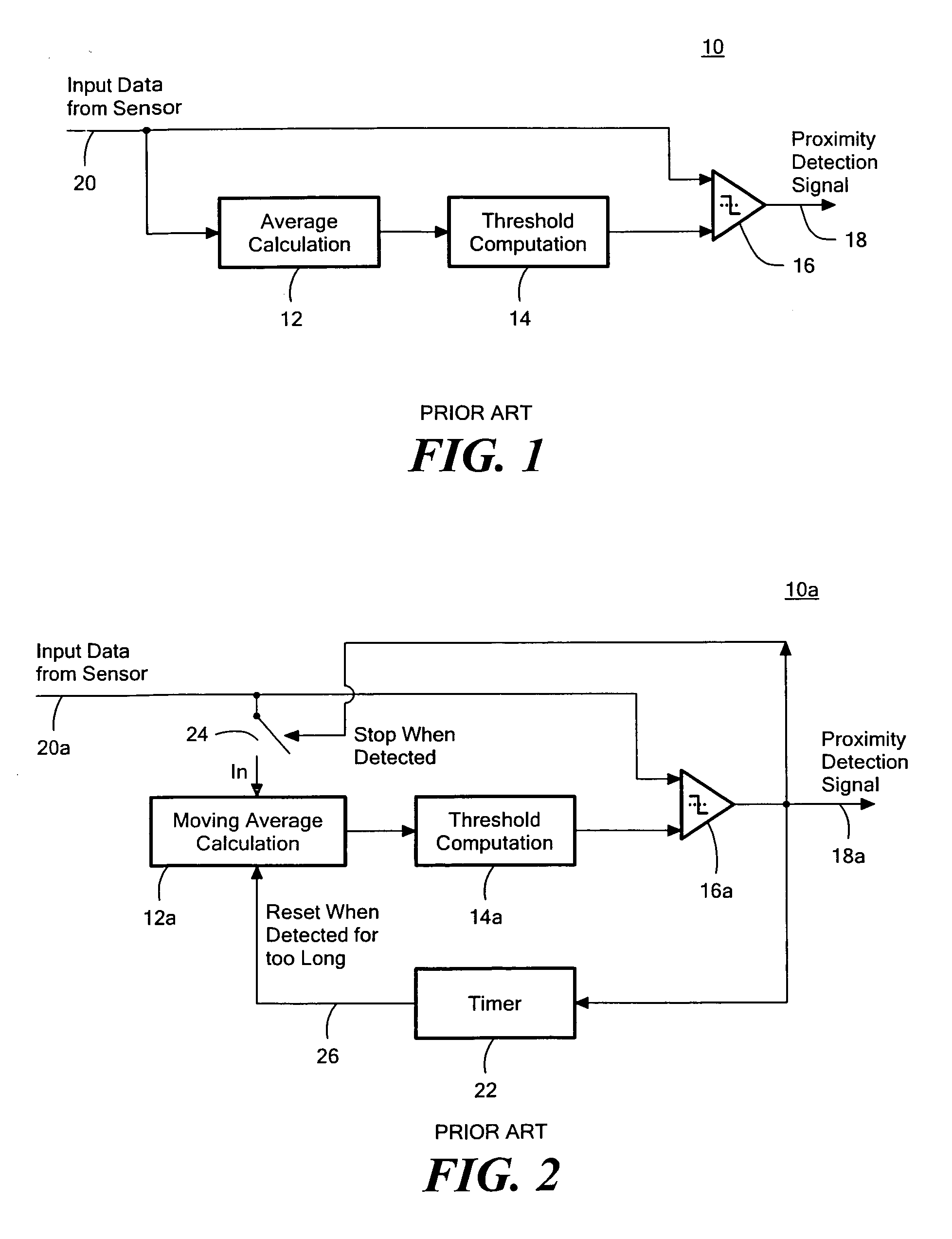

Proximity detection system and method

ActiveUS20080290929A1Easy to optimizeEasy to controlElectronic switchingAlarmsMoving averageHuman–computer interaction

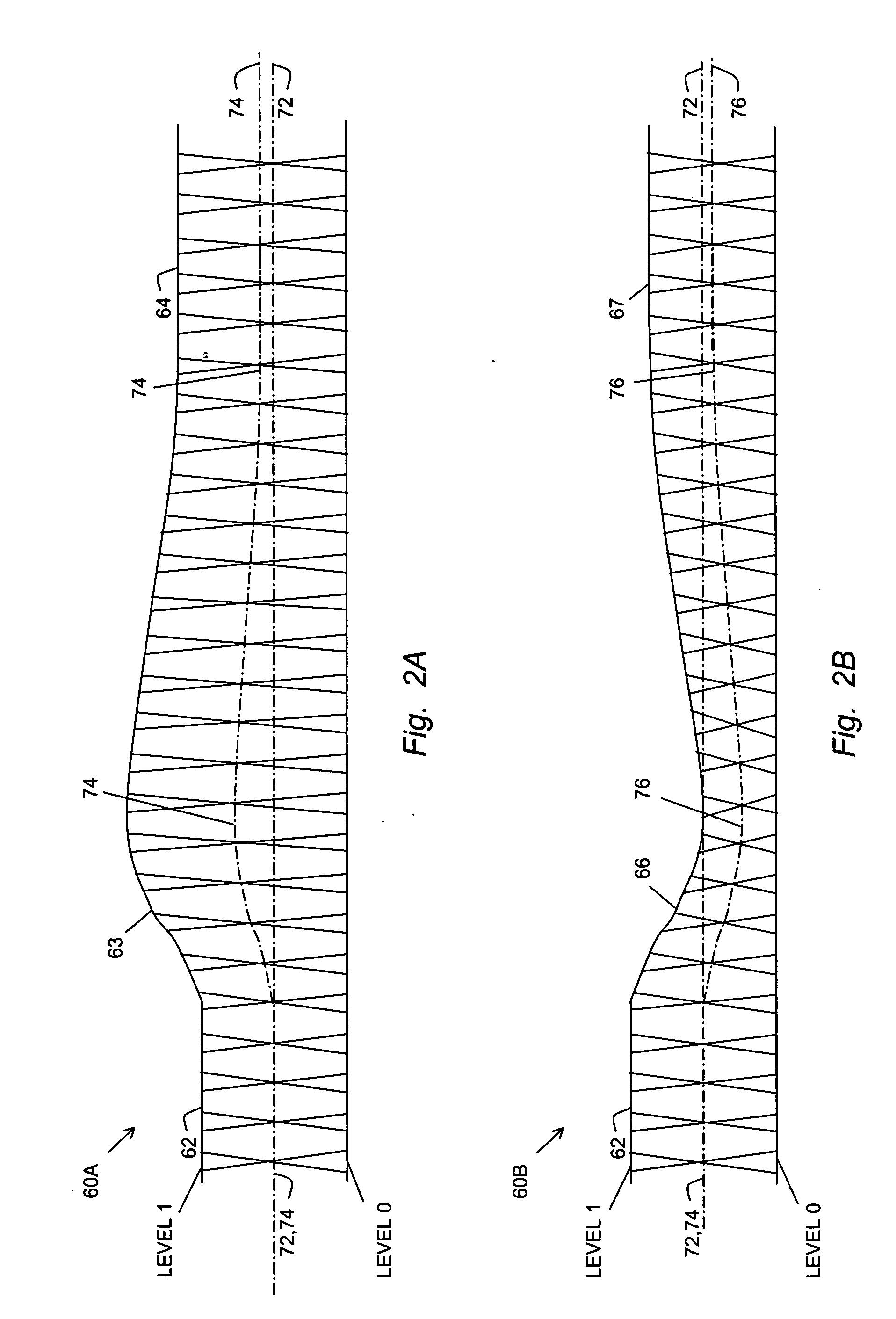

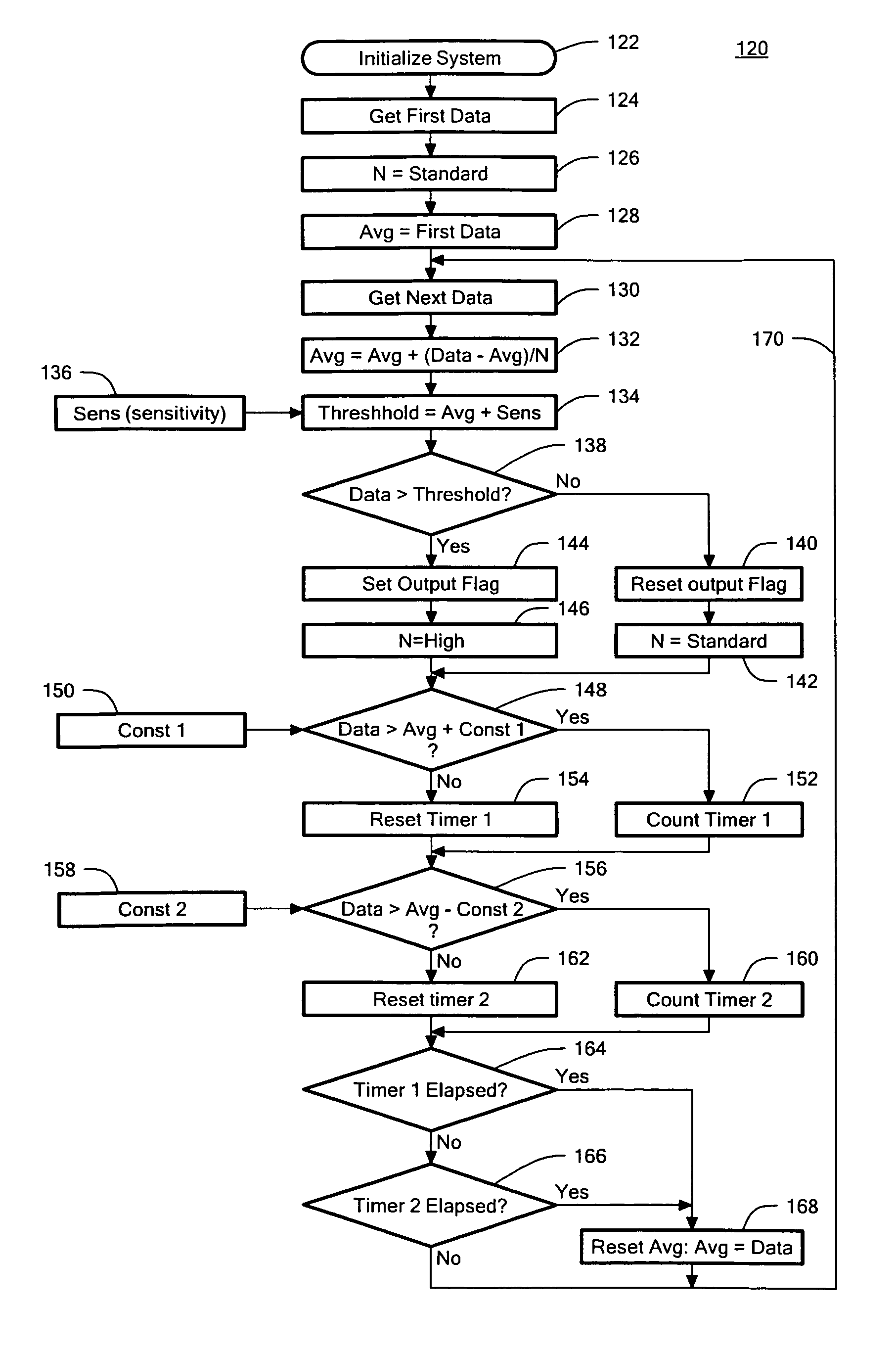

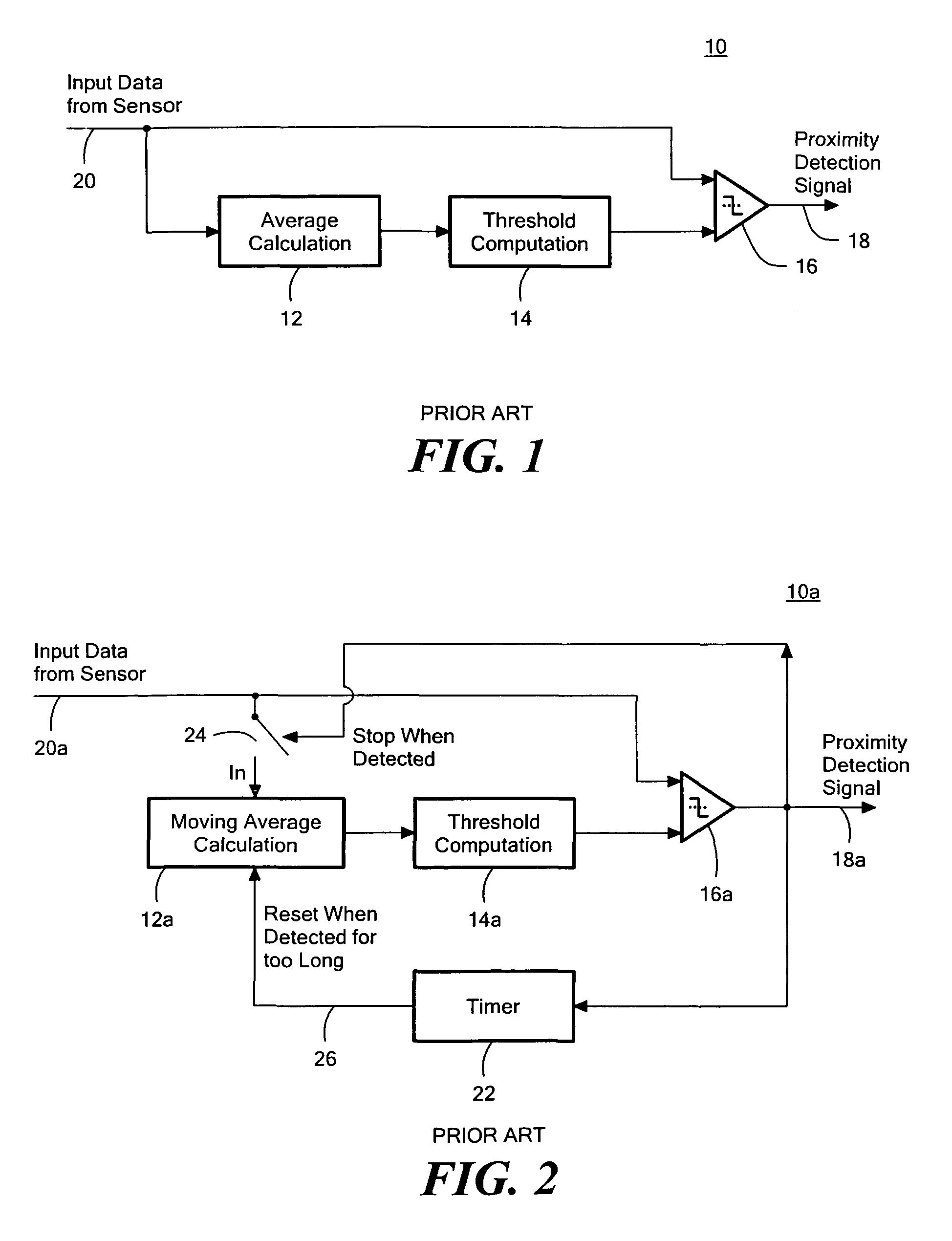

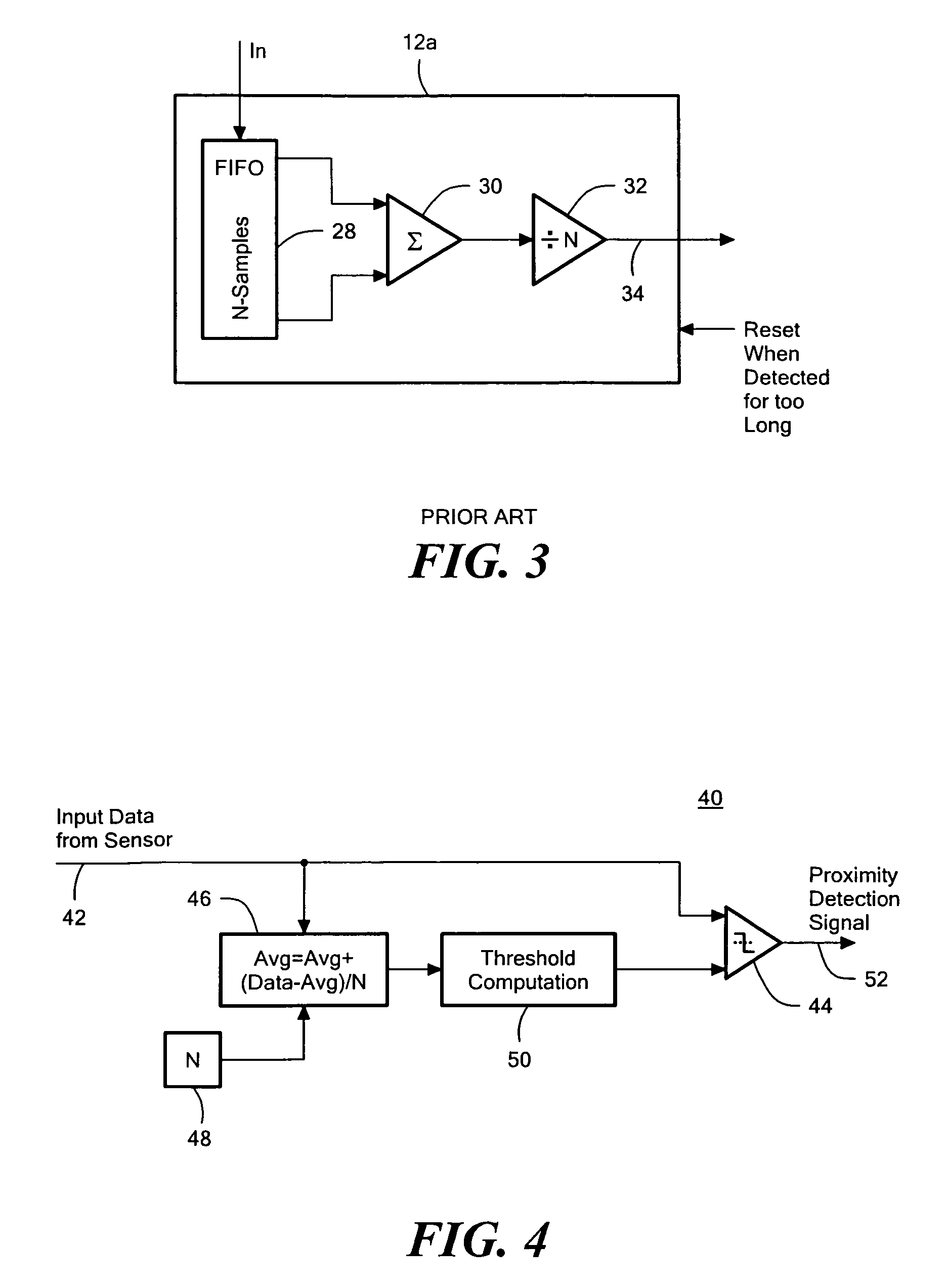

Proximity detection is accomplished by determining with a moving average calculation a moving average level of input data; setting a threshold level in response to the average level and a sensitivity factor; producing a proximity detection output when the input data meets the threshold level; and changing the weighting used by the average level calculation in response to a proximity detection output.

Owner:ANALOG DEVICES INC

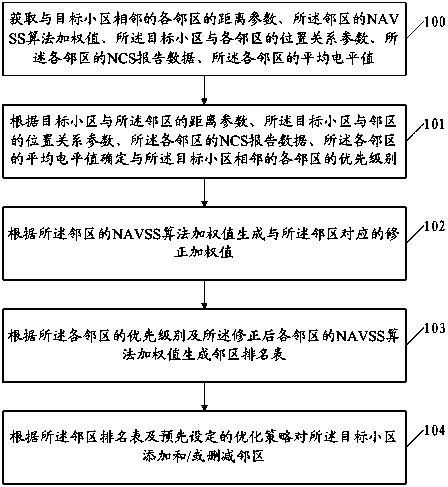

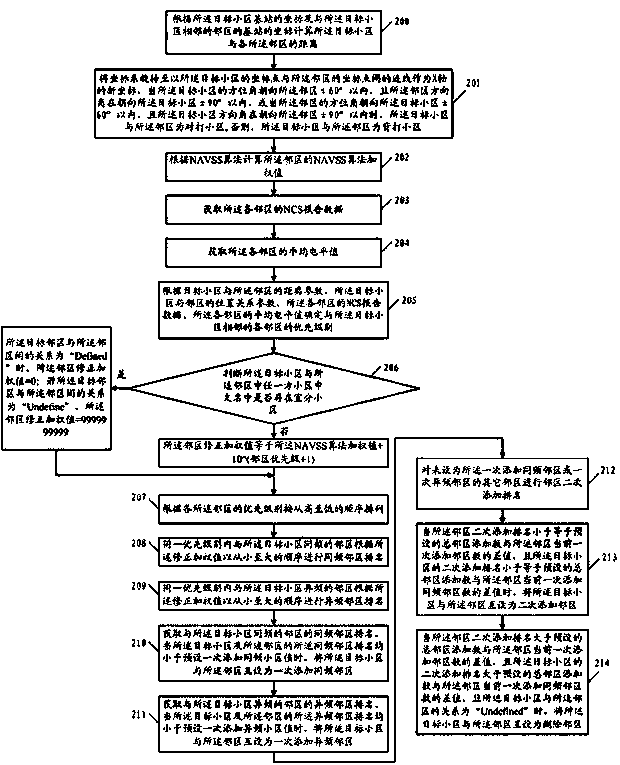

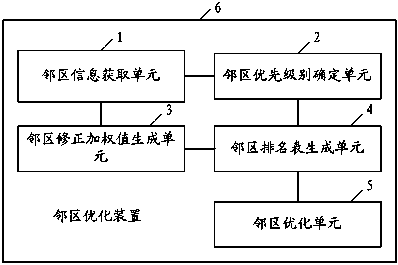

Method and device for optimizing neighbors

InactiveCN103458473ARealize two-way selectionGuaranteed success rateWireless communicationData miningAverage level

The invention discloses a method for optimizing neighbors. The method includes acquiring distance parameters of the various neighbors adjacent to a target cell, NAVSS algorithm weighted values of the neighbors, position relation parameters of the target cell and the various neighbors, NCS (neighboring cell support) report data of the various neighbors and average level values of the various neighbors; determining priority levels of the various neighbors adjacent to the target cell according to the distance parameters of the target cell and the neighbors, the position relation parameters of the target cell and the neighbors, the NCS report data of the various neighbors and the average level values of the various neighbors; generating corrected weighted values corresponding to the neighbors according to the NAVSS algorithm weighted values of the neighbors; generating a neighbor precedence table according to the priority levels and the corrected weighted values of the various neighbors; adding the certain neighbors to the target cell and / or deleting the certain neighbors from the target cell according to the neighbor precedence table and preliminarily set optimization strategies. The method has the advantage that cells can be effectively switched over in wireless communication procedures.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV +1

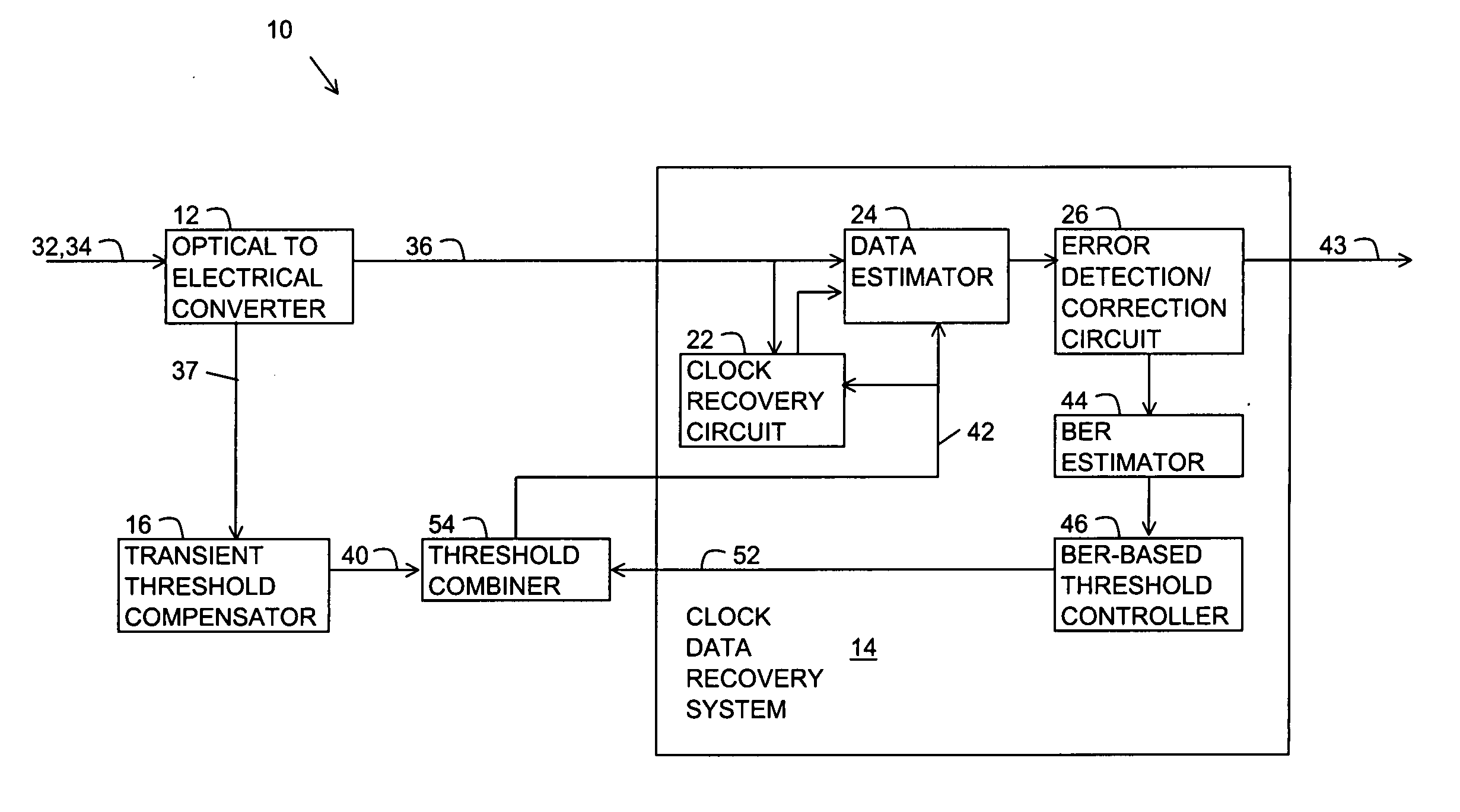

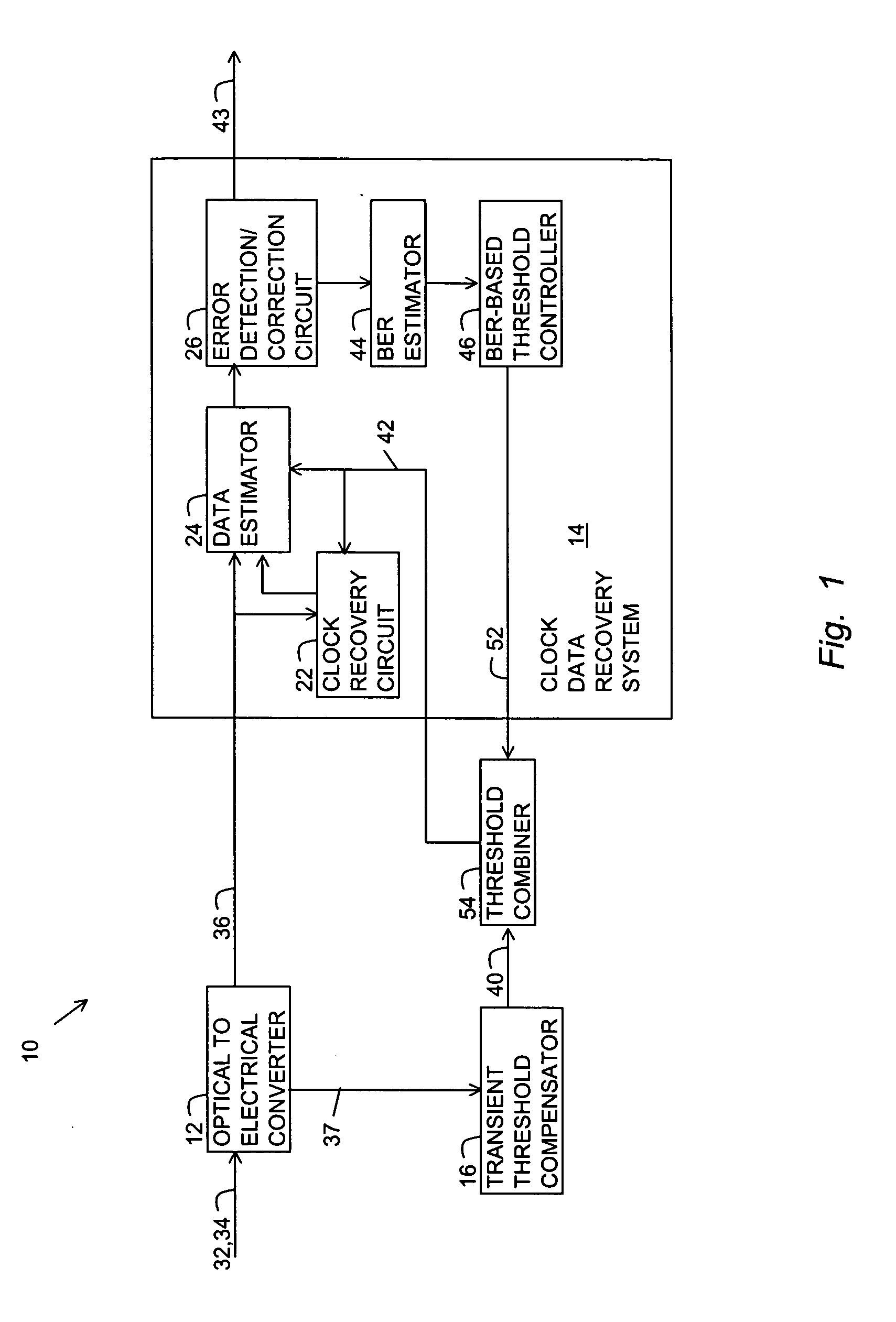

Optical receiver having transient compensation

InactiveUS20060110170A1Improving bit error rate (BER) performanceLow costTransmission monitoringElectromagnetic receiversDecision thresholdAverage level

An optical receiver having compensation for signal level transients. The receiver includes an OE converter, a transient threshold compensator, a threshold combiner and a CDR system. The OE converter receives the incoming optical signal and provides a modulated electrical signal having a high speed response for tracking the modulation on the optical signal and an averaged electrical signal having a moderate speed response for tracking changes in the average level of the optical signal. The transient threshold compensator processes the averaged electrical signal for providing a transient feedforward adjustment. The threshold combiner combines the transient feedforward adjustment with a lower speed BER feedback threshold adjustment for providing a decision threshold signal. The CDR system uses the decision threshold signal for recovering a clock, providing the BER feedback threshold adjustment, and estimating the data carried by the modulation.

Owner:LUMENTUM FIBER OPTICS INC

Proximity detection system and method

ActiveUS7884733B2Easy to controlImproved generationElectronic switchingAlarmsMoving averageHuman–computer interaction

Proximity detection is accomplished by determining with a moving average calculation a moving average level of input data; setting a threshold level in response to the average level and a sensitivity factor; producing a proximity detection output when the input data meets the threshold level; and changing the weighting used by the average level calculation in response to a proximity detection output.

Owner:ANALOG DEVICES INC

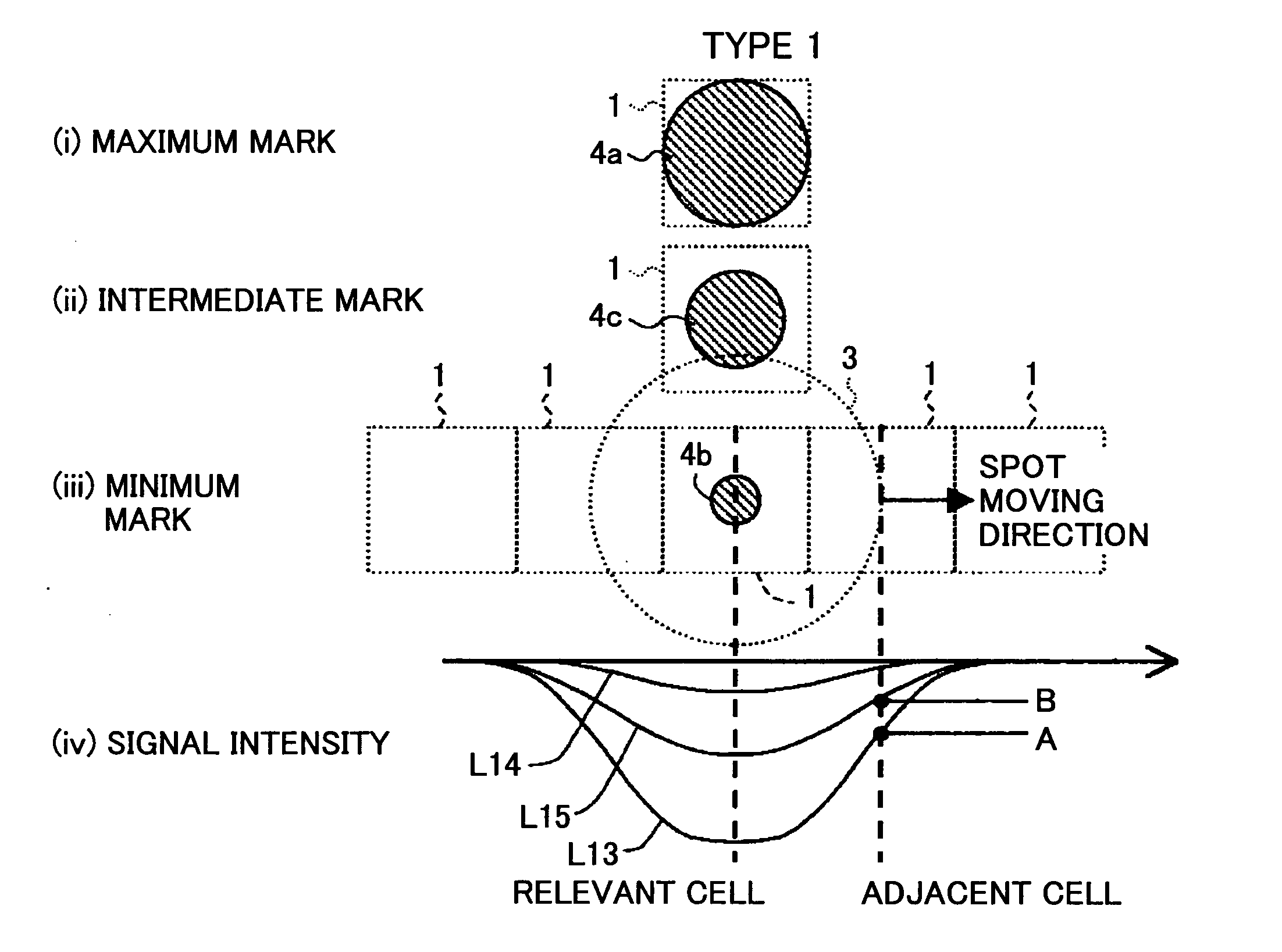

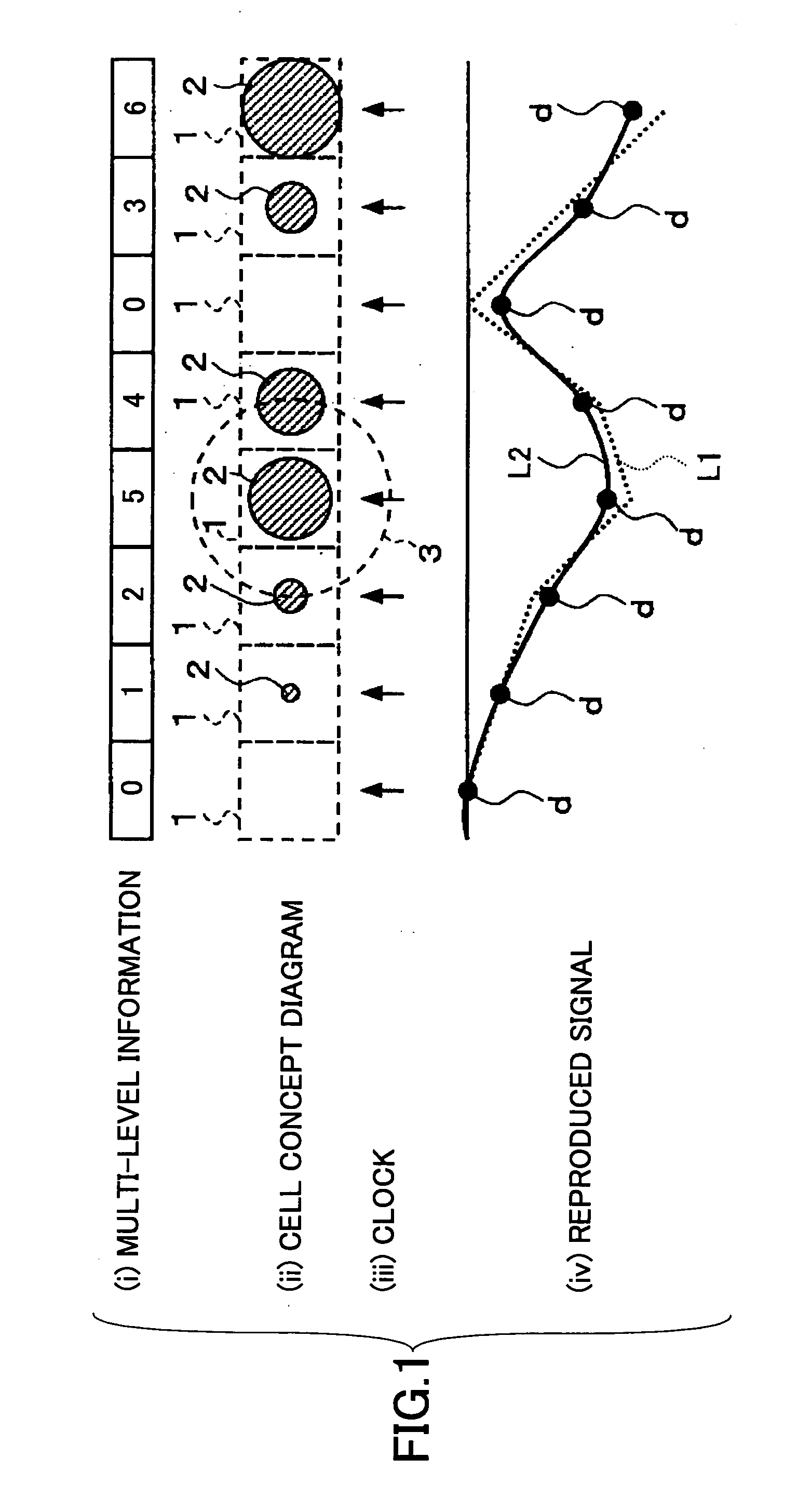

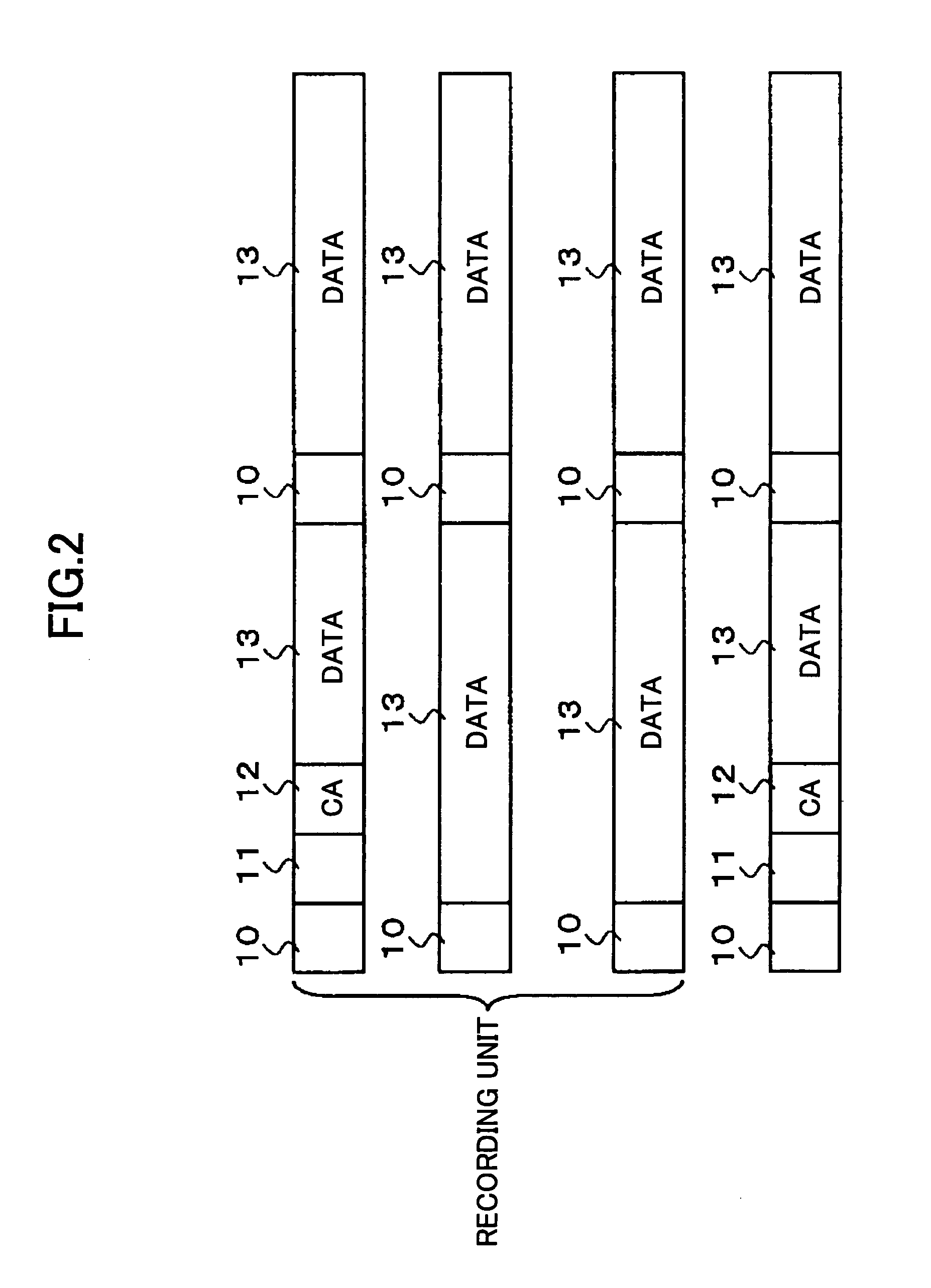

Multi-level information reproducing method, multi-level information recording medium, multi-level information waveform equalizing device, multi-level information reproducing apparatus, multi-level information recording apparatus, signal processing method, reproduced signal processing circuit and optical disk apparatus

InactiveUS20050213462A1Exact reproductionImprove accuracyTelevision system detailsFilamentary/web record carriersComputer hardwareSignal processing circuits

A multi-level information reproducing method for reproducing from a recording medium on which marks having detection signal levels different according to multi-level information are recorded in areas virtually divided uniformly, comprising the steps of: a) obtaining a reproduced signal from a series of patterns of multi-level information indicating an average level of intersymbol interference components to adjacent areas generated from marks according to all the multi-level information; and b) optimizing frequency characteristics of a reproducing part with respect to the reproduced signal.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com