Patents

Literature

70208 results about "Compositermes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Absorbent articles comprising nanoparticles

Owner:NANO MET ZERO

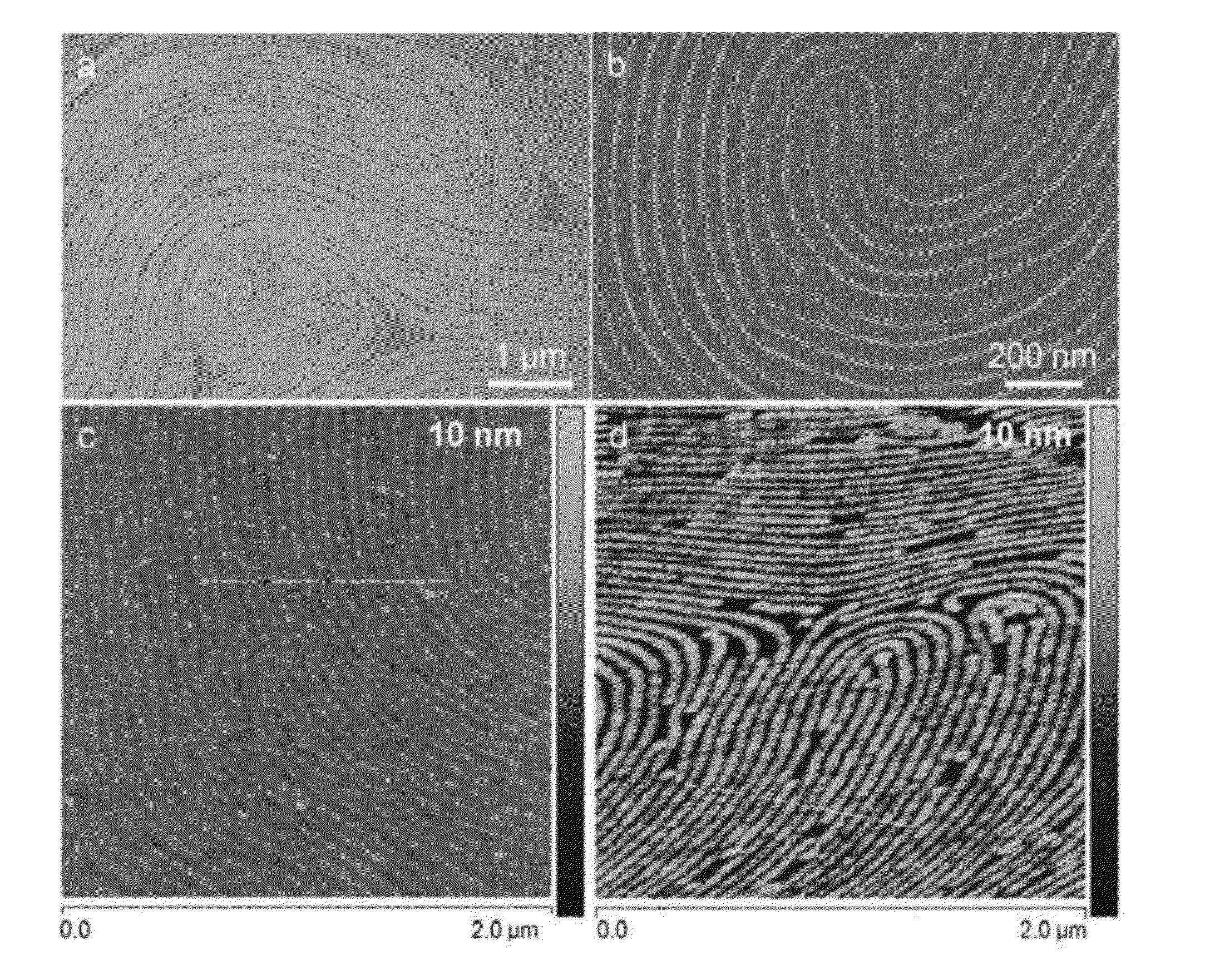

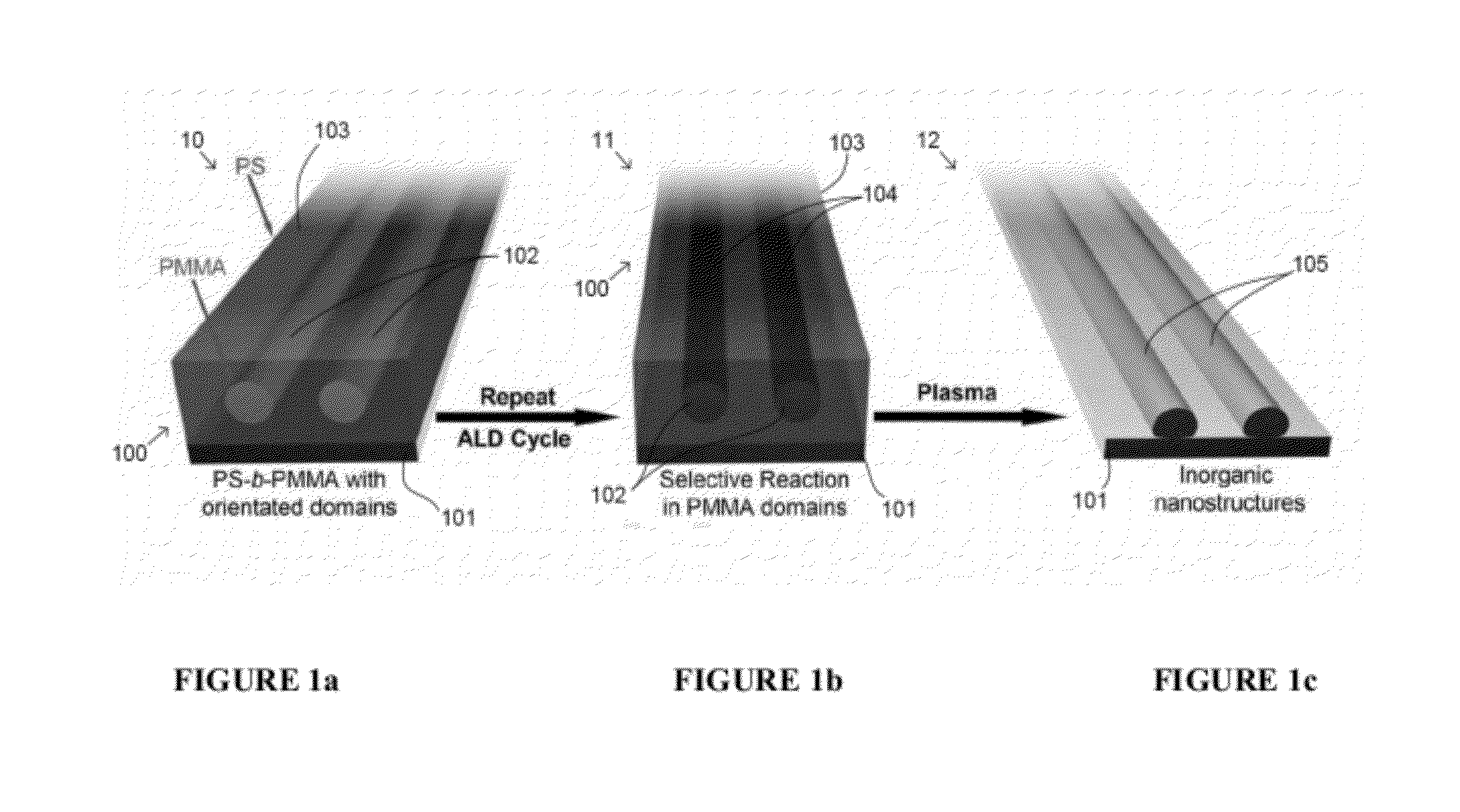

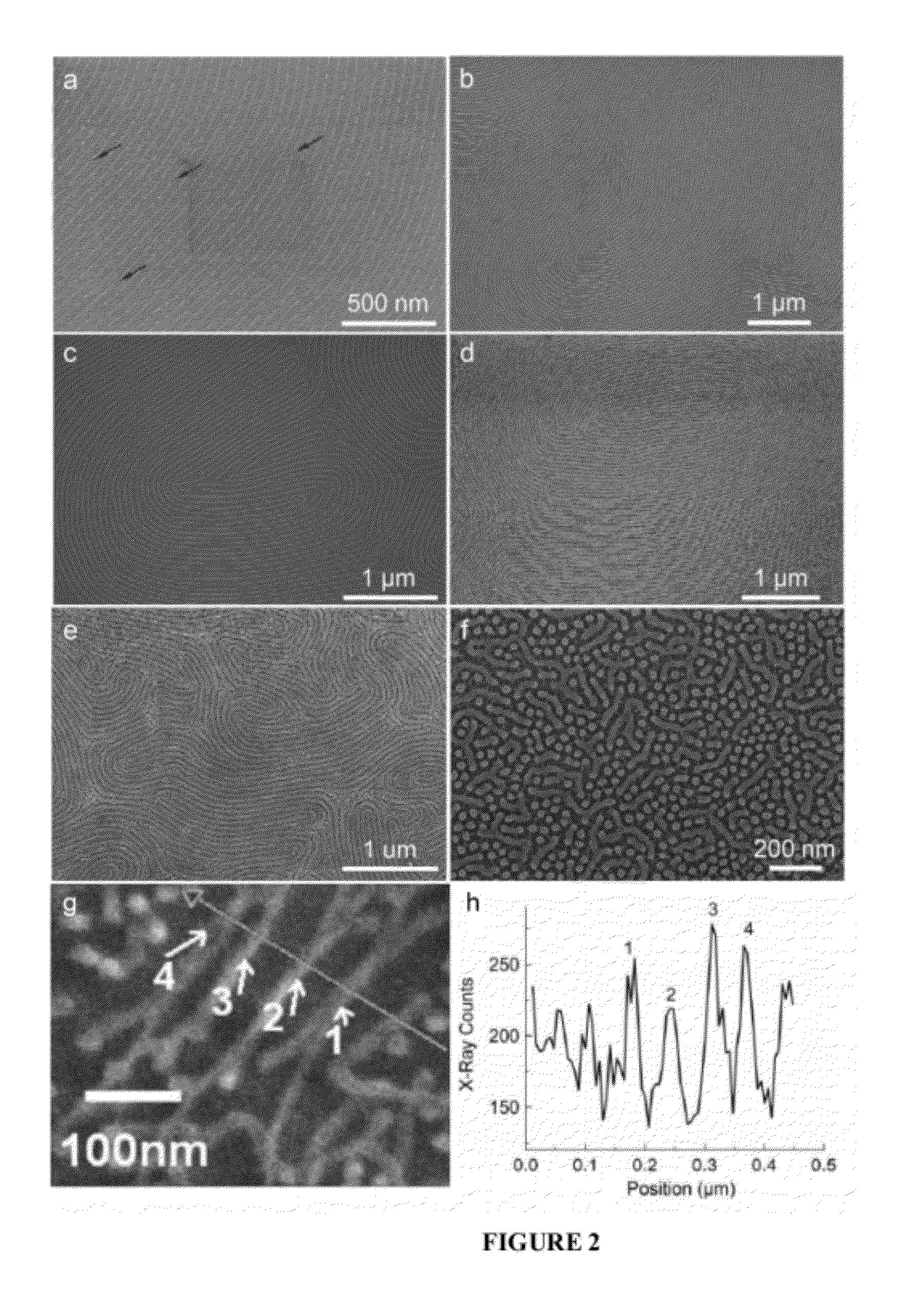

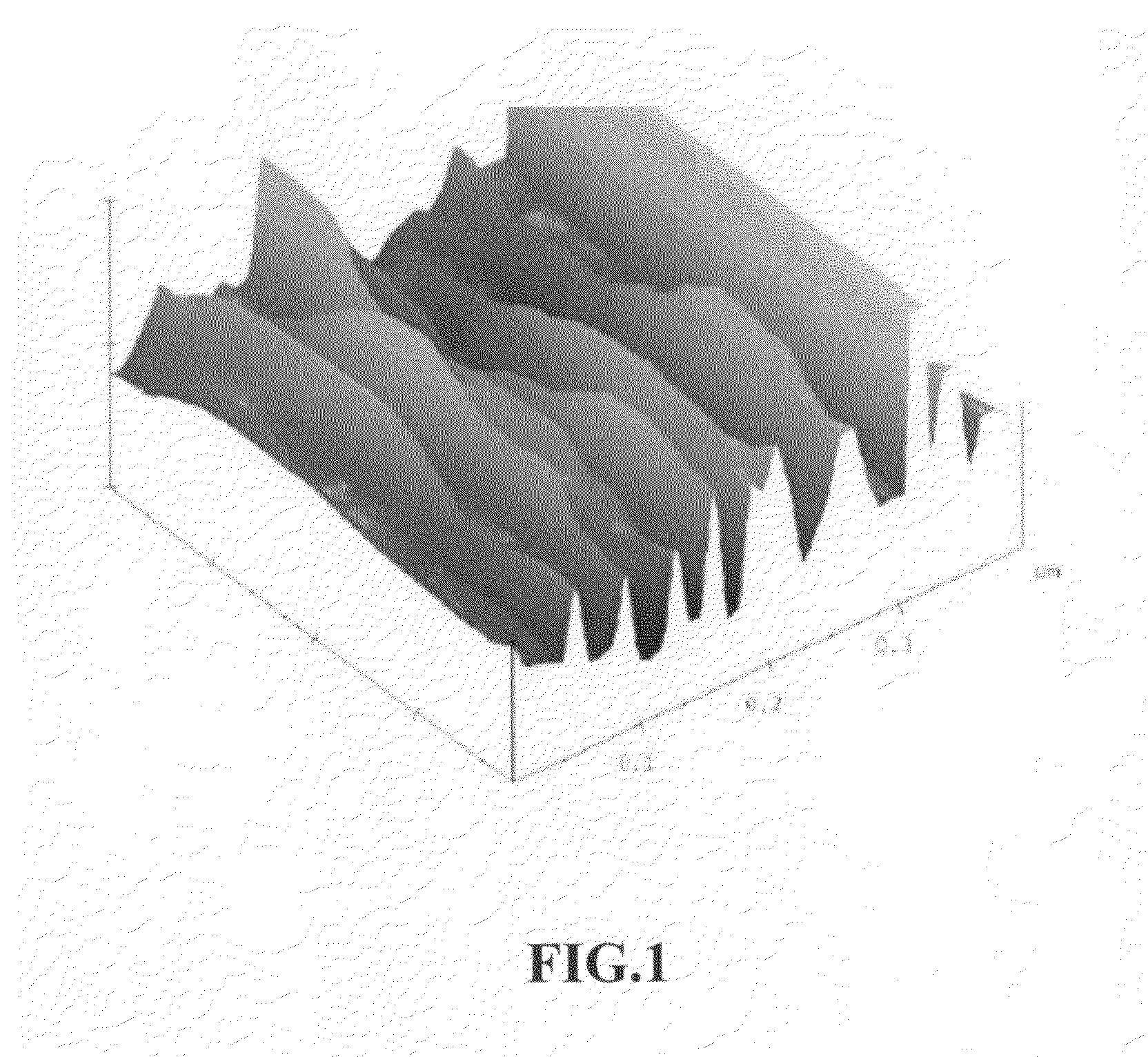

Ordered Nanoscale Domains by Infiltration of Block Copolymers

ActiveUS20120046421A1Low costHighly controllable molecularProgramme controlSolid electrolytesNanostructureAtomic layer deposition

A method of preparing tunable inorganic patterned nanofeatures by infiltration of a block copolymer scaffold having a plurality of self-assembled periodic polymer microdomains. The method may be used sequential infiltration synthesis (SIS), related to atomic layer deposition (ALD). The method includes selecting a metal precursor that is configured to selectively react with the copolymer unit defining the microdomain but is substantially non-reactive with another polymer unit of the copolymer. A tunable inorganic features is selectively formed on the microdomain to form a hybrid organic / inorganic composite material of the metal precursor and a co-reactant. The organic component may be optionally removed to obtain an inorganic feature s with patterned nanostructures defined by the configuration of the microdomain.

Owner:UCHICAGO ARGONNE LLC

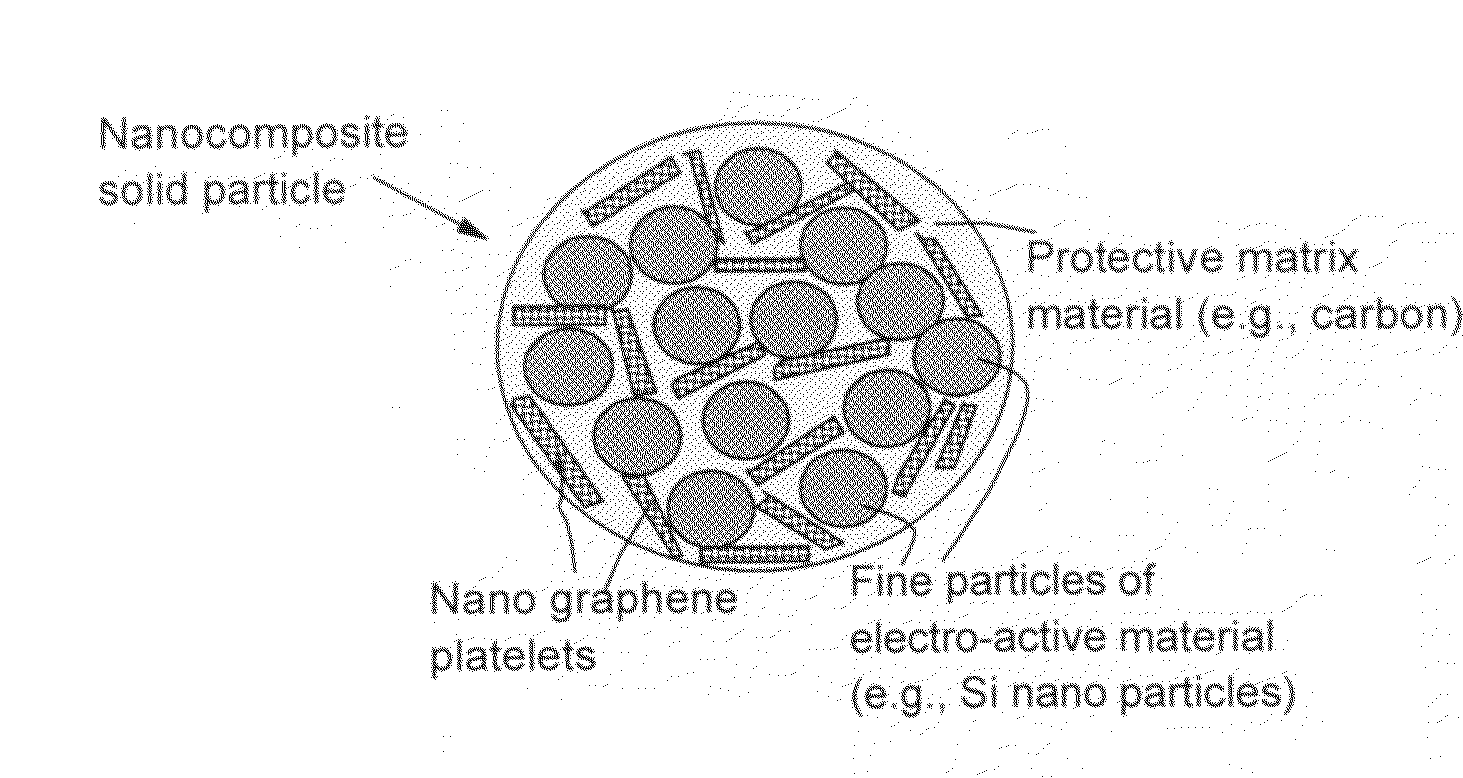

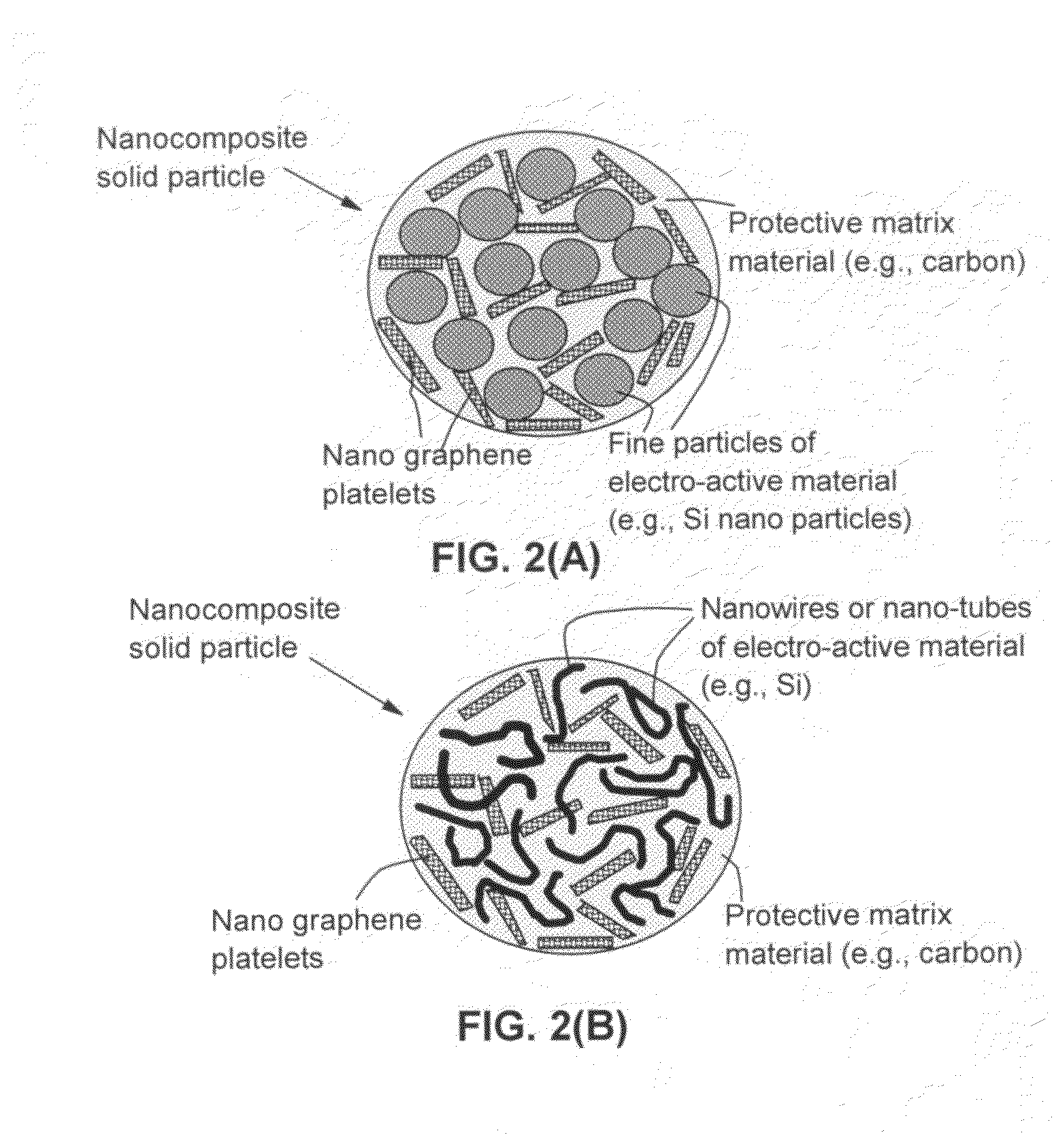

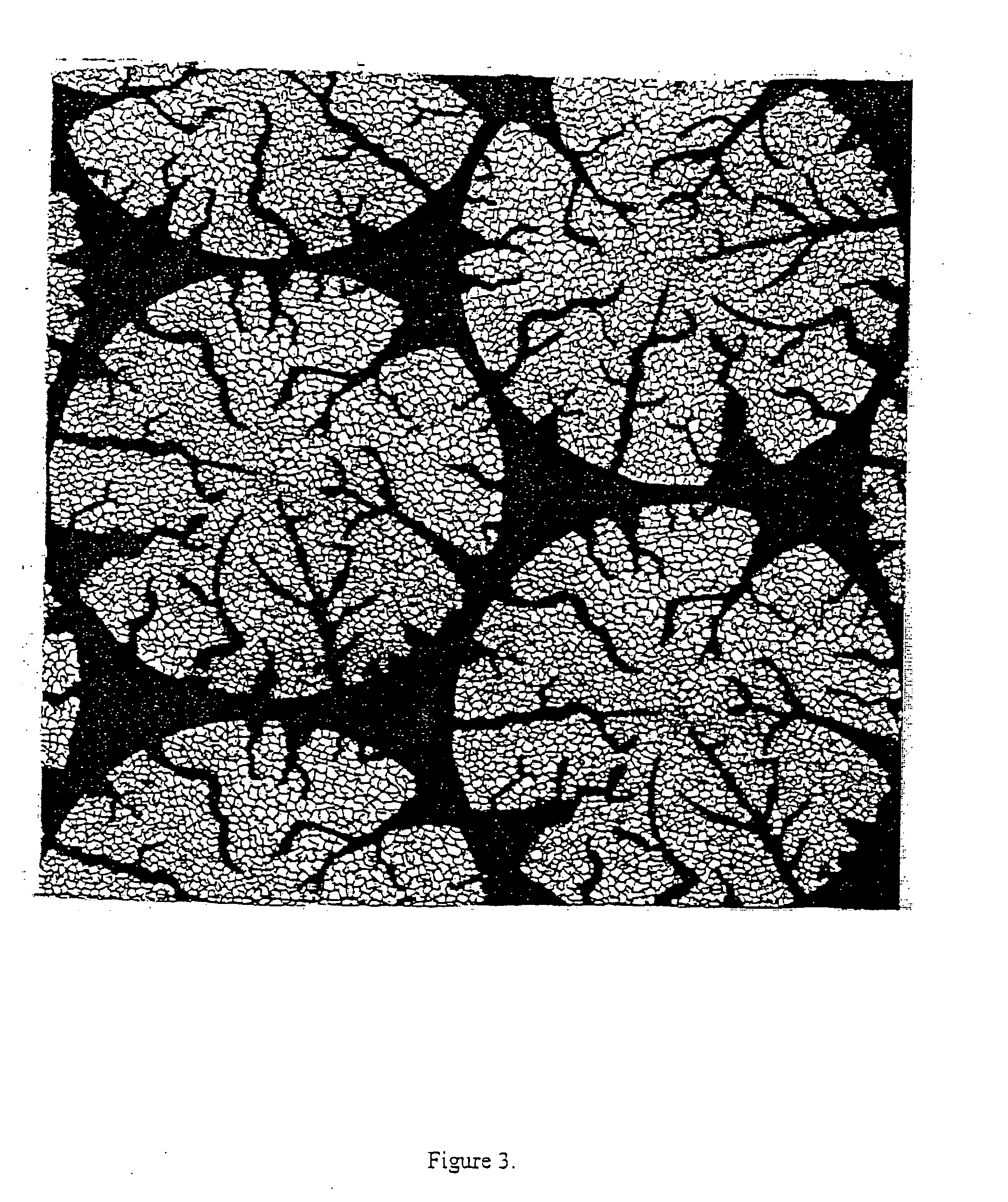

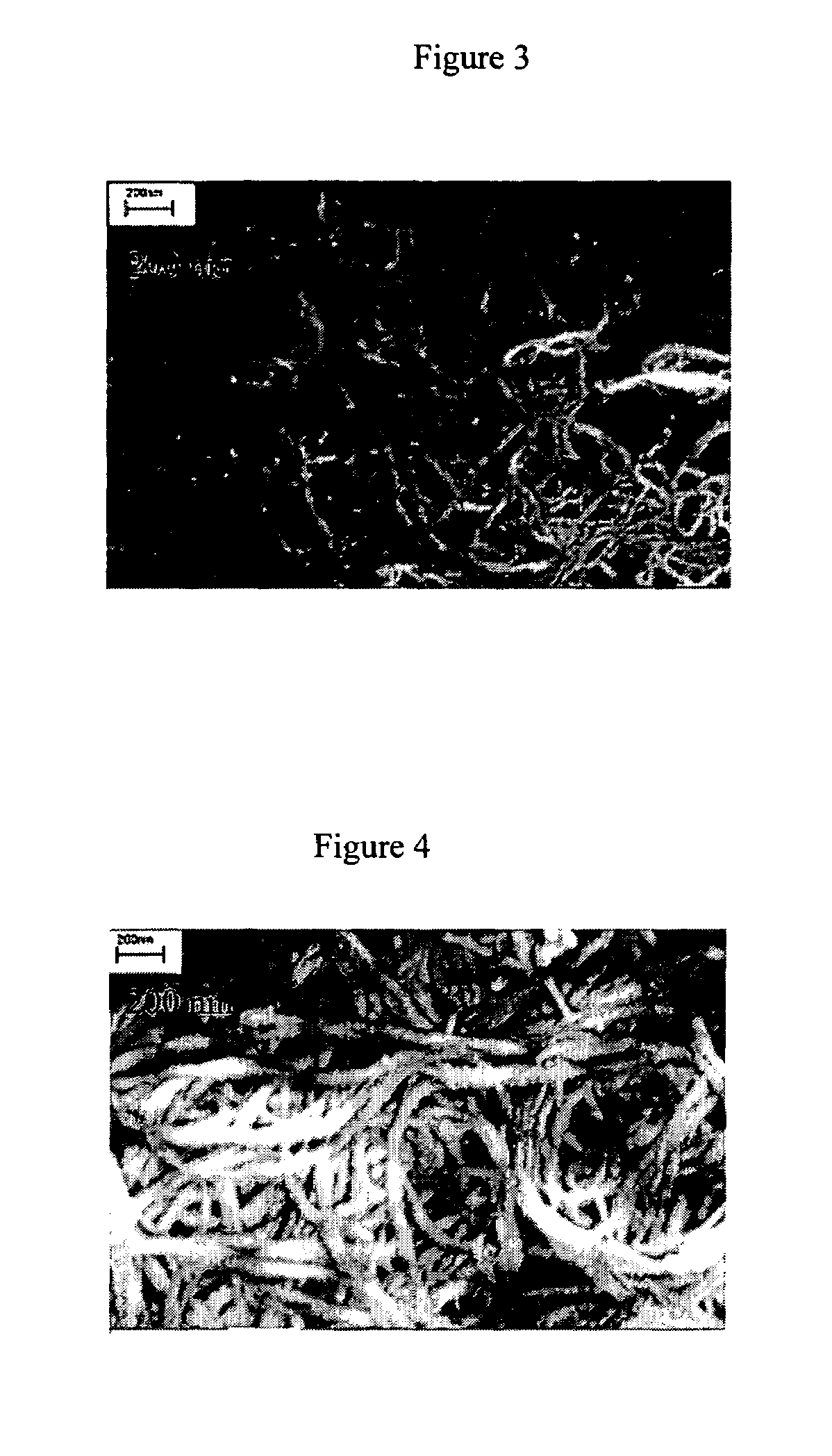

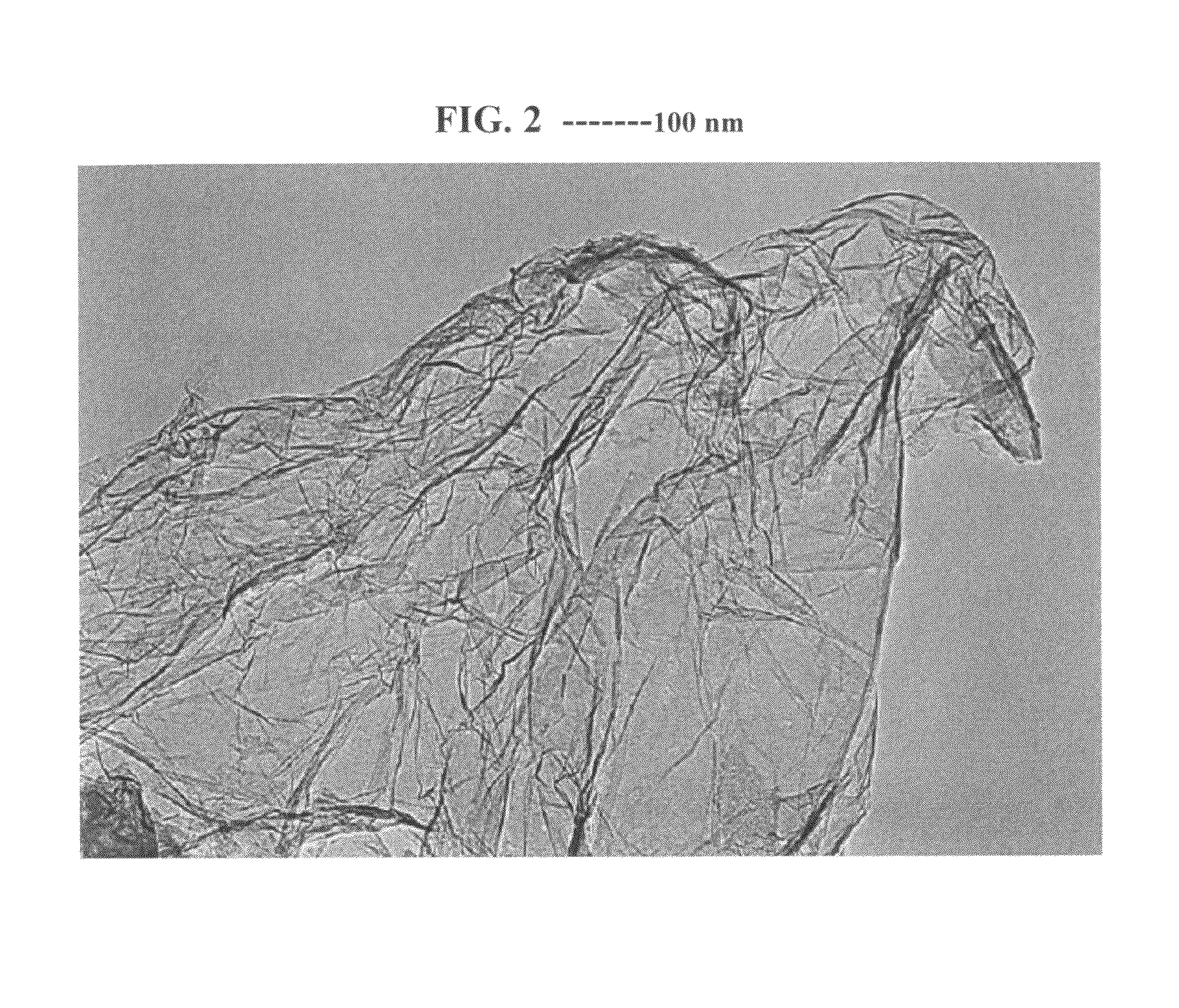

Nano graphene reinforced nanocomposite particles for lithium battery electrodes

ActiveUS20100143798A1Increase stiffnessHigh strengthActive material electrodesSecondary cellsLithium metalNanocomposite

A solid nanocomposite particle composition for lithium metal or lithium ion battery electrode applications. The composition comprises: (A) an electrode active material in a form of fine particles, rods, wires, fibers, or tubes with a dimension smaller than 1 μm; (B) nano graphene platelets (NGPs); and (C) a protective matrix material reinforced by the NGPs; wherein the graphene platelets and the electrode active material are dispersed in the matrix material and the NGPs occupy a weight fraction wg of 1% to 90% of the total nanocomposite weight, the electrode active material occupies a weight fraction wa of 1% to 90% of the total nanocomposite weight, and the matrix material occupies a weight fraction wm of at least 2% of the total nanocomposite weight with wg+wa+wm=1. For a lithium ion battery anode application, the matrix material is preferably amorphous carbon, polymeric carbon, or meso-phase carbon. Such a solid nanocomposite composition provides a high anode capacity and good cycling stability. For a cathode application, the resulting lithium metal or lithium ion battery exhibits an exceptionally high cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

Single-wall carbon nanotube-polymer composites

This invention relates to single-wall carbon nanotube / polymer composites, a process for the production of such, and their use as fibers, films and articles.

Owner:EI DU PONT DE NEMOURS & CO

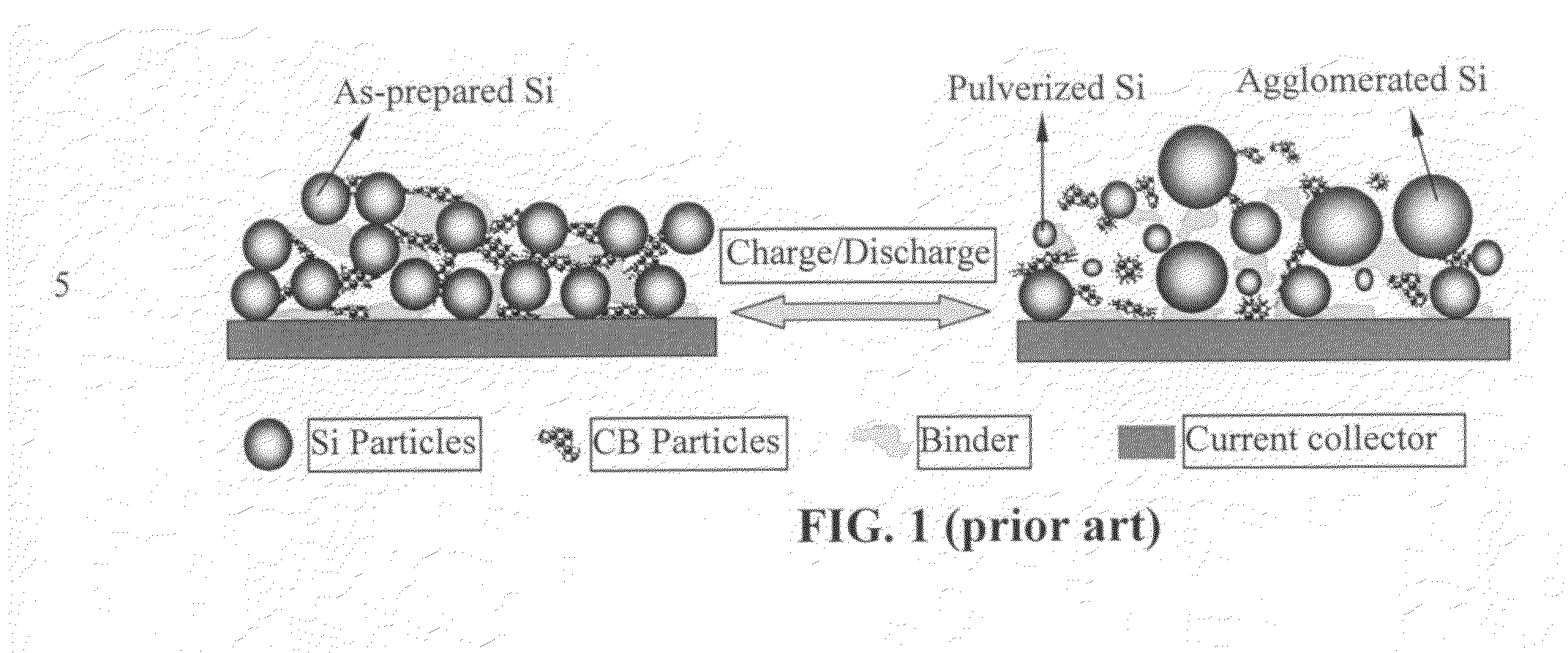

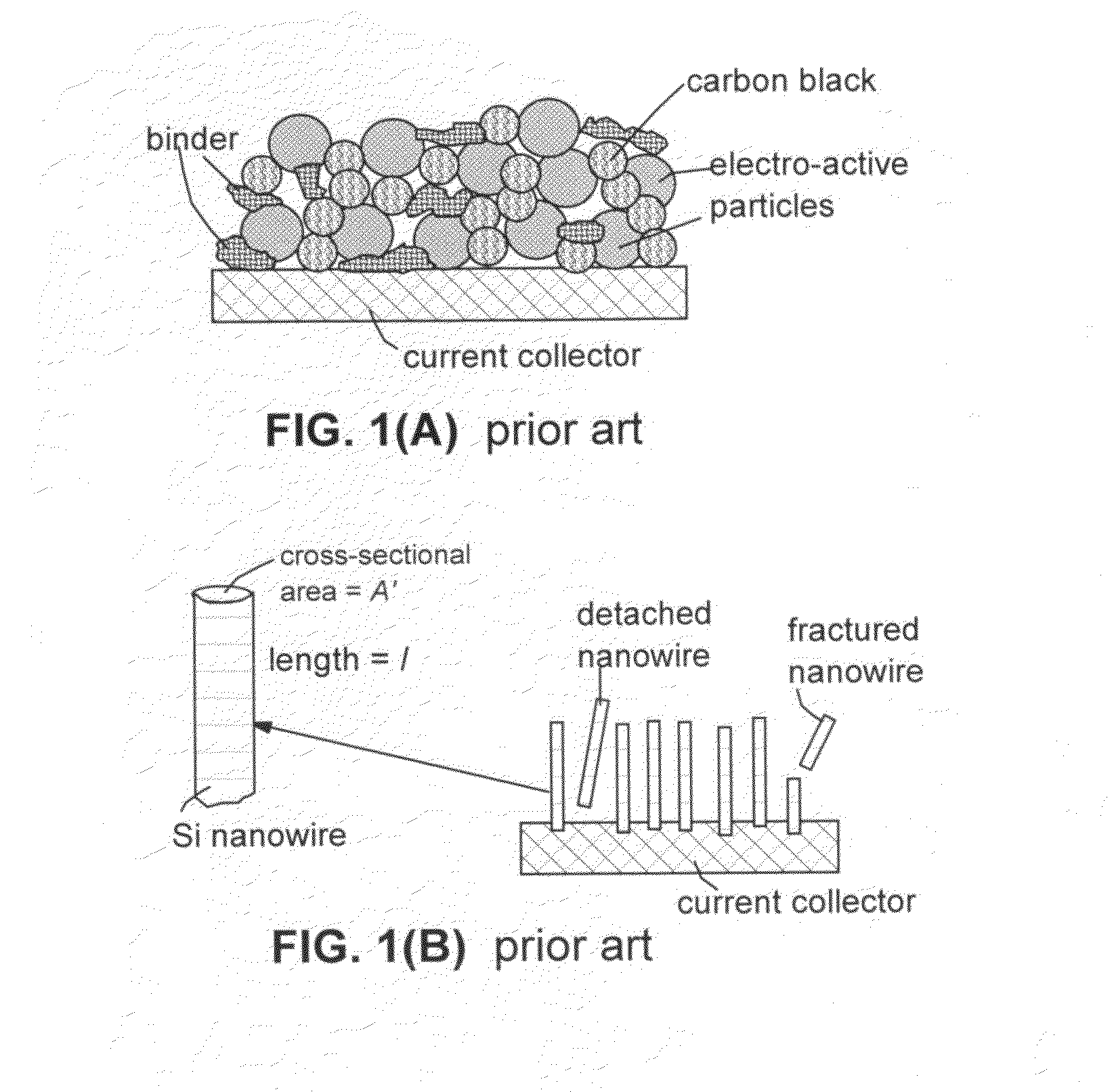

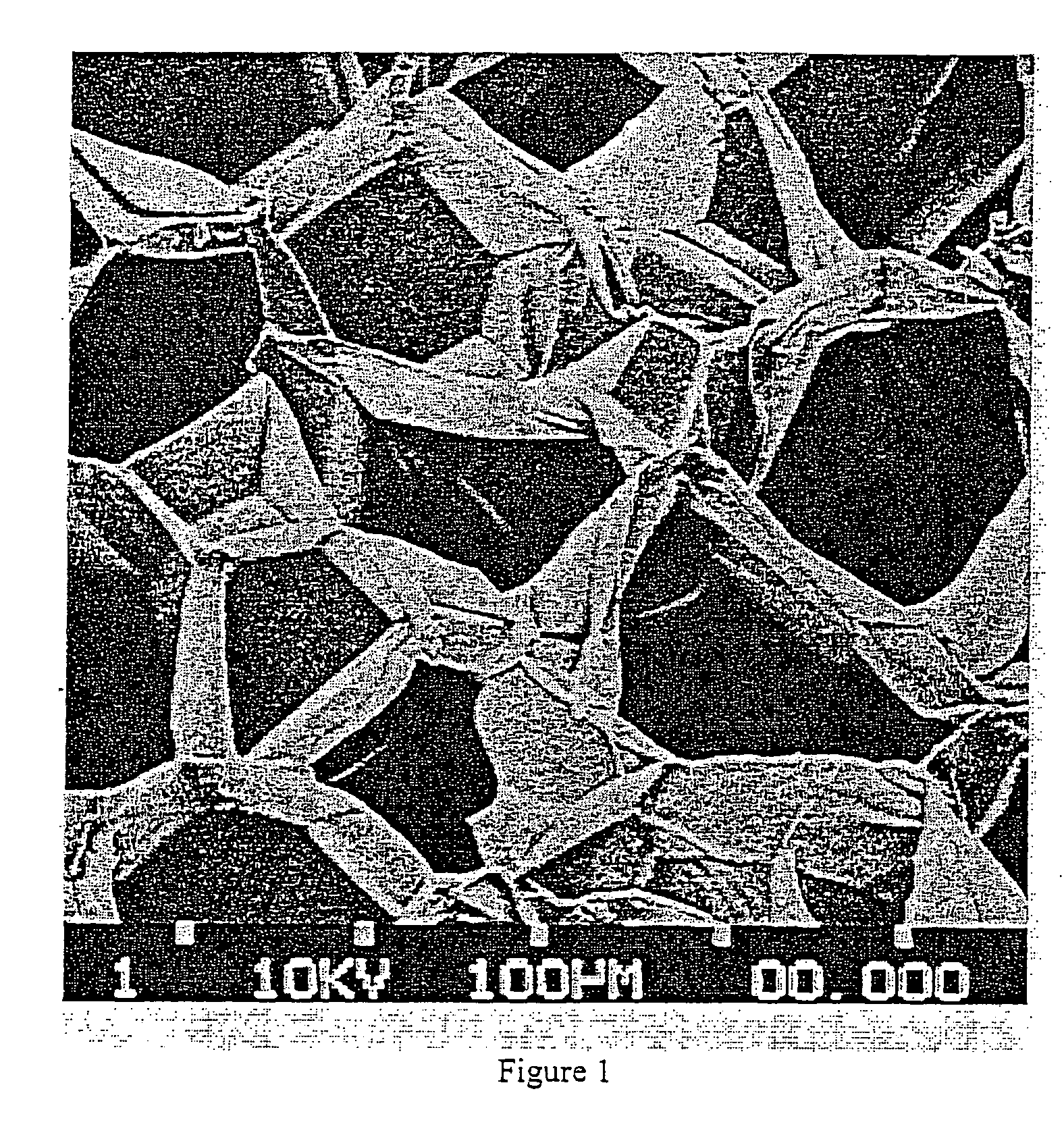

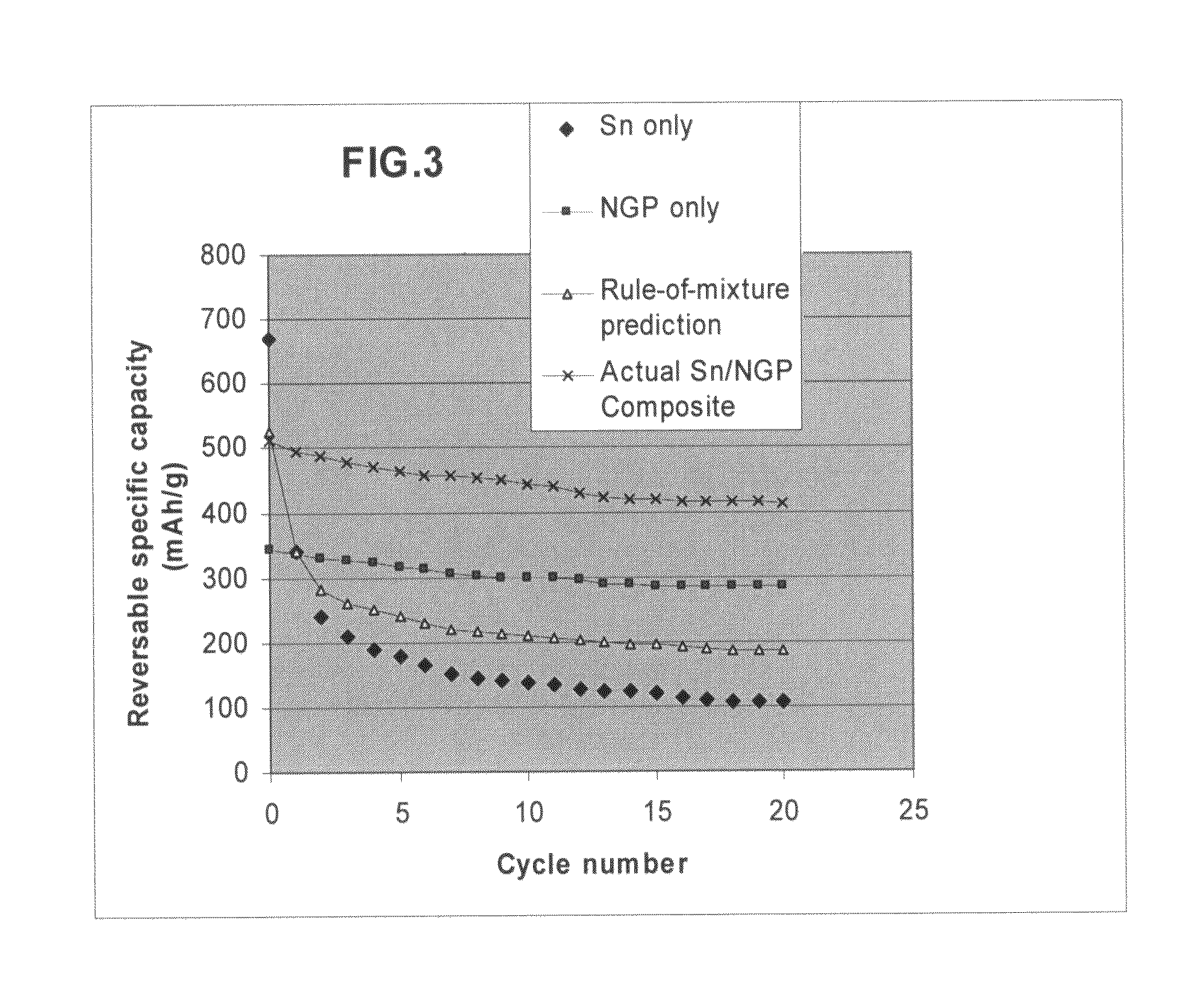

Nano graphene platelet-based composite anode compositions for lithium ion batteries

ActiveUS20090117467A1Improve conductivityLower internal resistanceElectrolytic capacitorsSecondary cellsGraphene flakeGraphite

The present invention provides a nano-scaled graphene platelet-based composite material composition for use as an electrode, particularly as an anode of a lithium ion battery. The composition comprises: (a) micron- or nanometer-scaled particles or coating which are capable of absorbing and desorbing lithium ions; and (b) a plurality of nano-scaled graphene platelets (NGPs), wherein a platelet comprises a graphene sheet or a stack of graphene sheets having a platelet thickness less than 100 nm; wherein at least one of the particles or coating is physically attached or chemically bonded to at least one of the graphene platelets and the amount of platelets is in the range of 2% to 90% by weight and the amount of particles or coating in the range of 98% to 10% by weight. Also provided is a lithium secondary battery comprising such a negative electrode (anode). The battery exhibits an exceptional specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

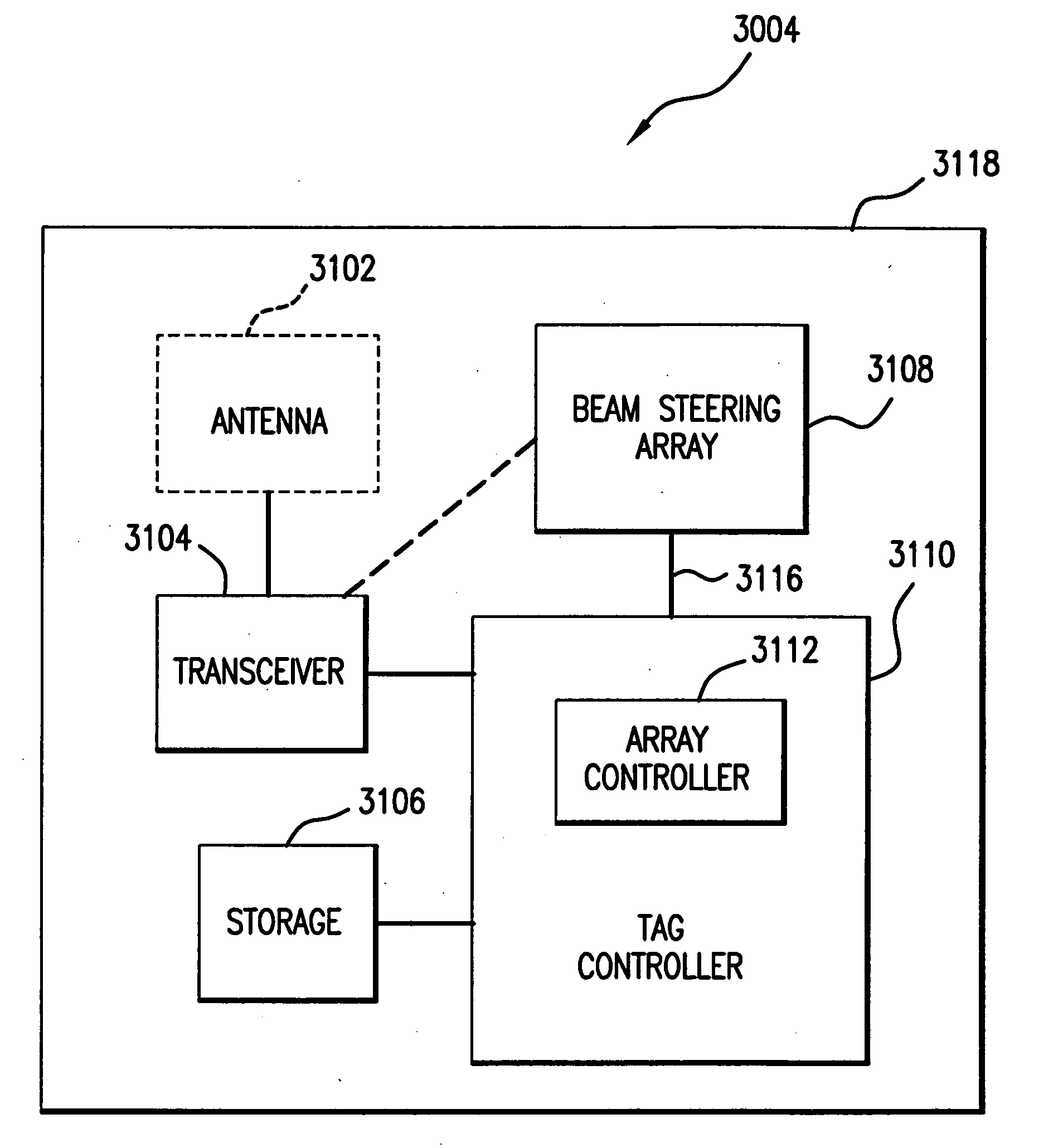

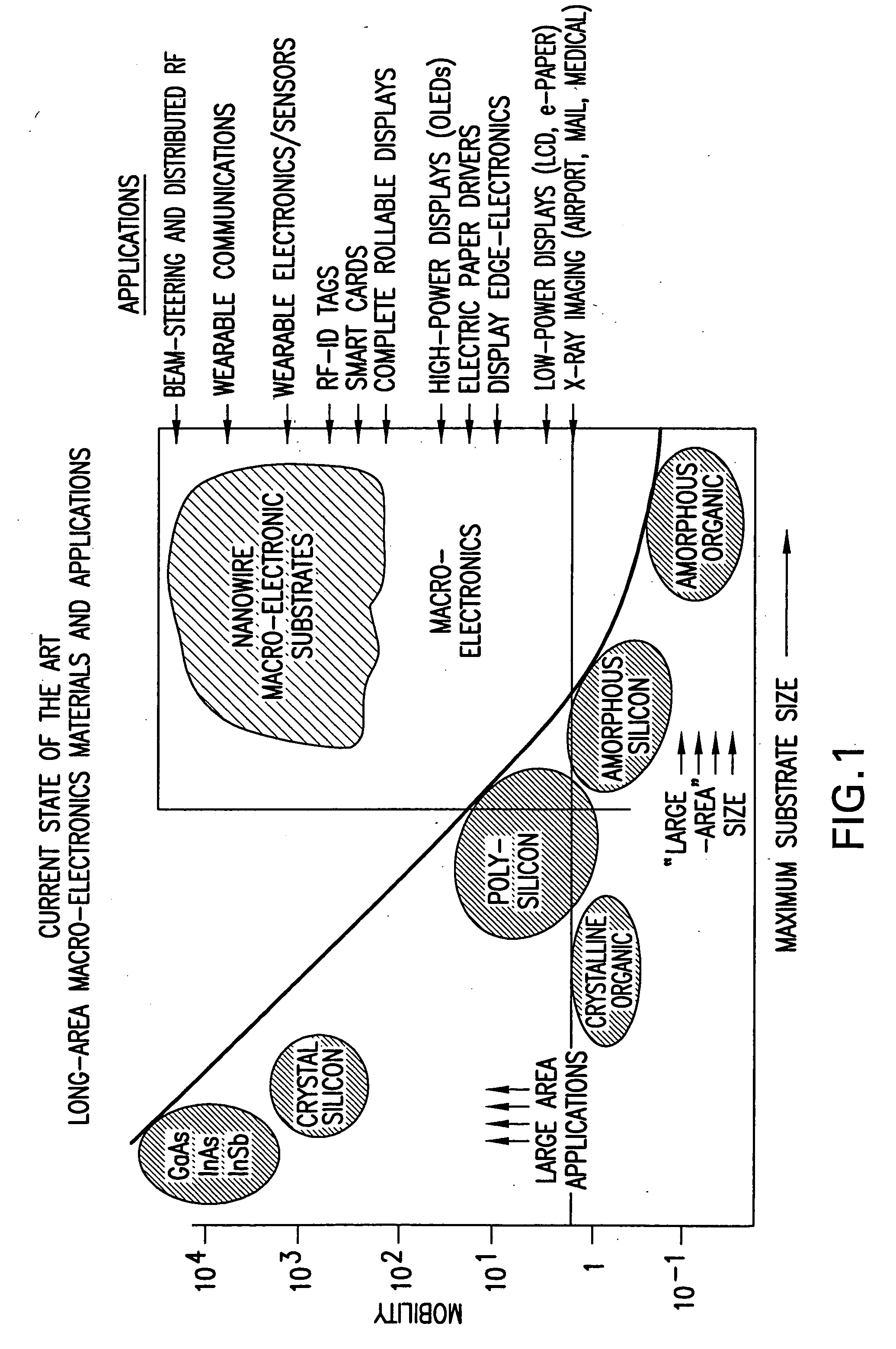

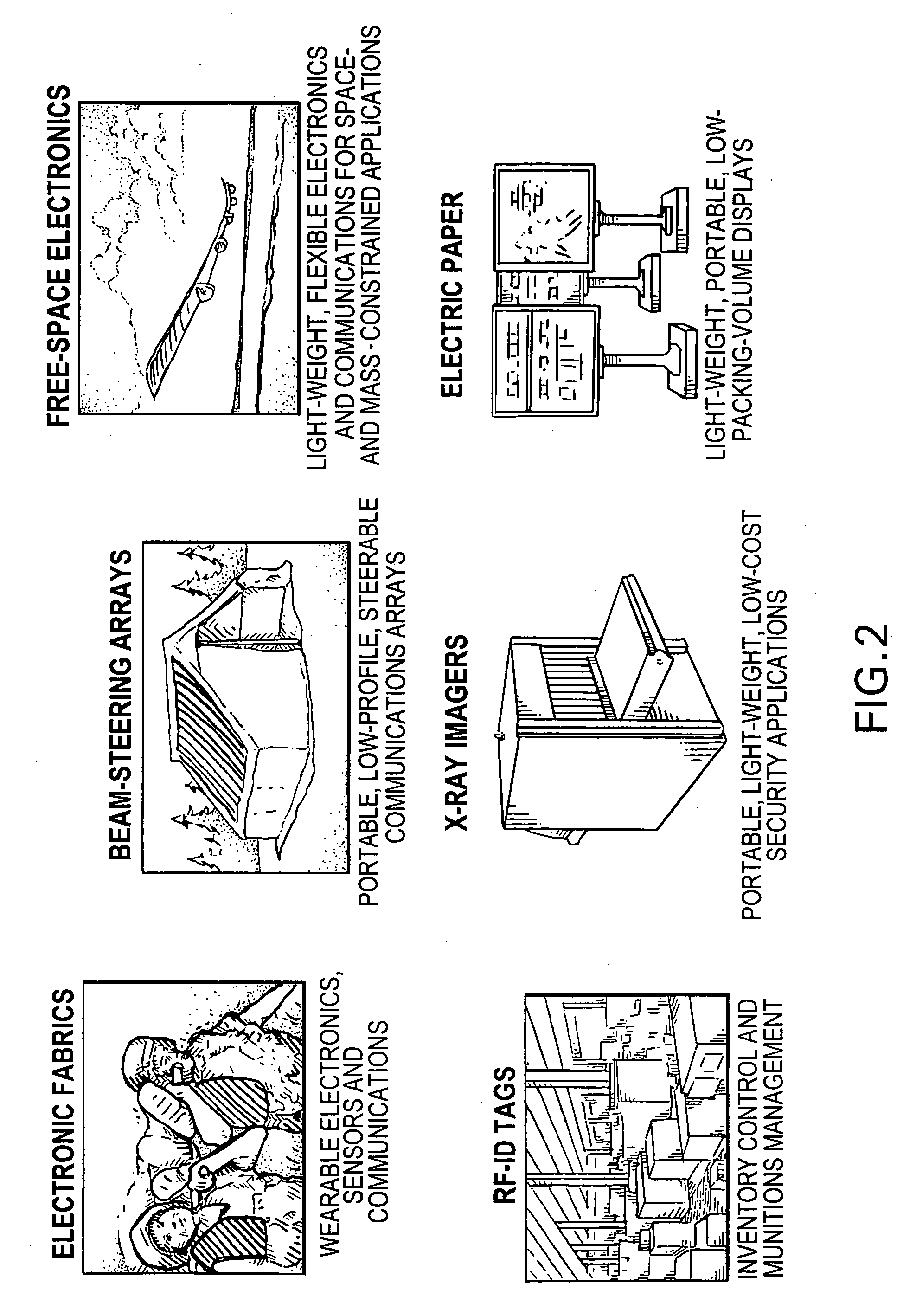

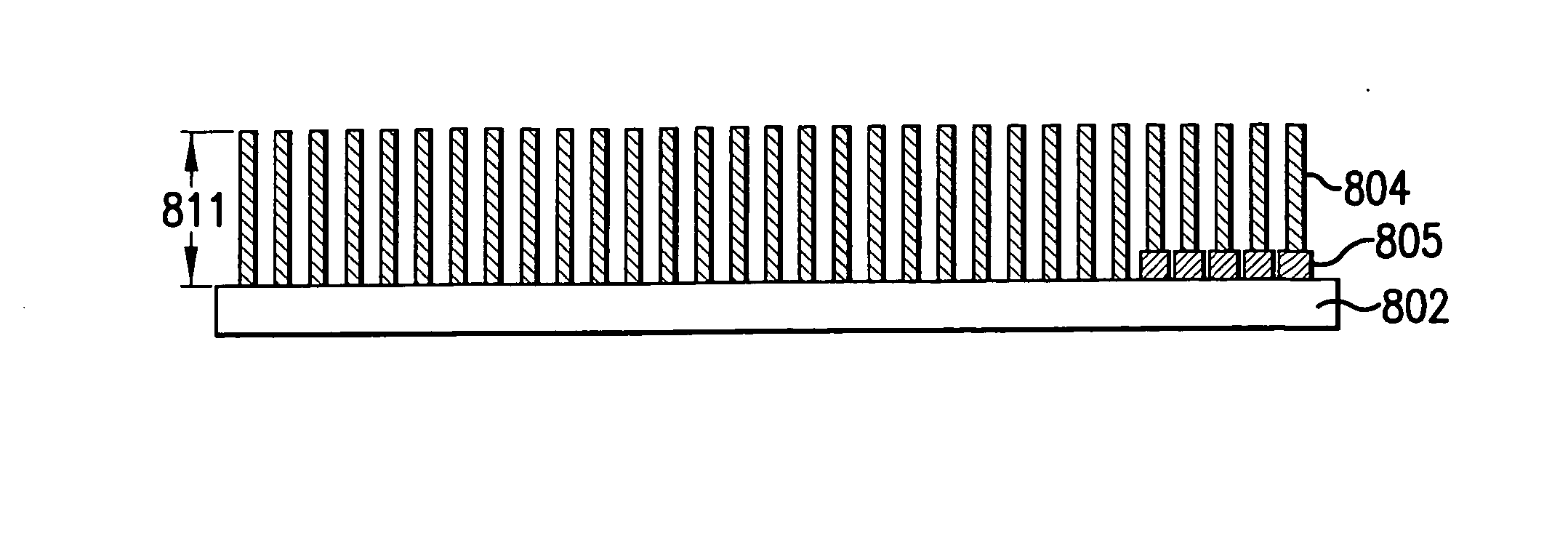

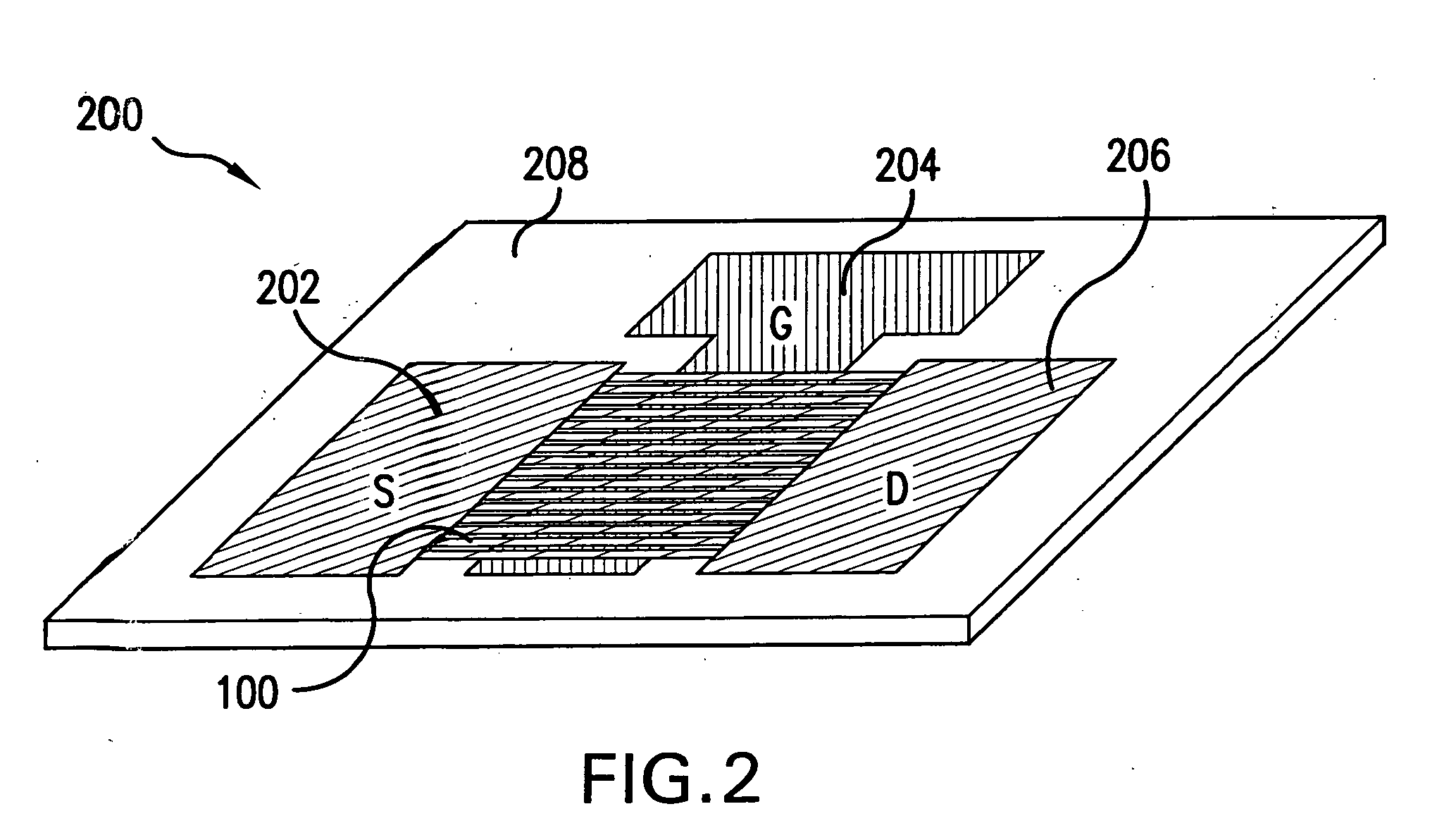

Applications of nano-enabled large area macroelectronic substrates incorporating nanowires and nanowire composites

Macroelectronic substrate materials incorporating nanowires are described. These are used to provide underlying electronic elements (e.g., transistors and the like) for a variety of different applications. Methods for making the macroelectronic substrate materials are disclosed. One application is for transmission an reception of RF signals in small, lightweight sensors. Such sensors can be configured in a distributed sensor network to provide security monitoring. Furthermore, a method and apparatus for a radio frequency identification (RFID) tag is described. The RFID tag includes an antenna and a beam-steering array. The beam-steering array includes a plurality of tunable elements. A method and apparatus for an acoustic cancellation device and for an adjustable phase shifter that are enabled by nanowires are also described.

Owner:ONED MATERIAL INC

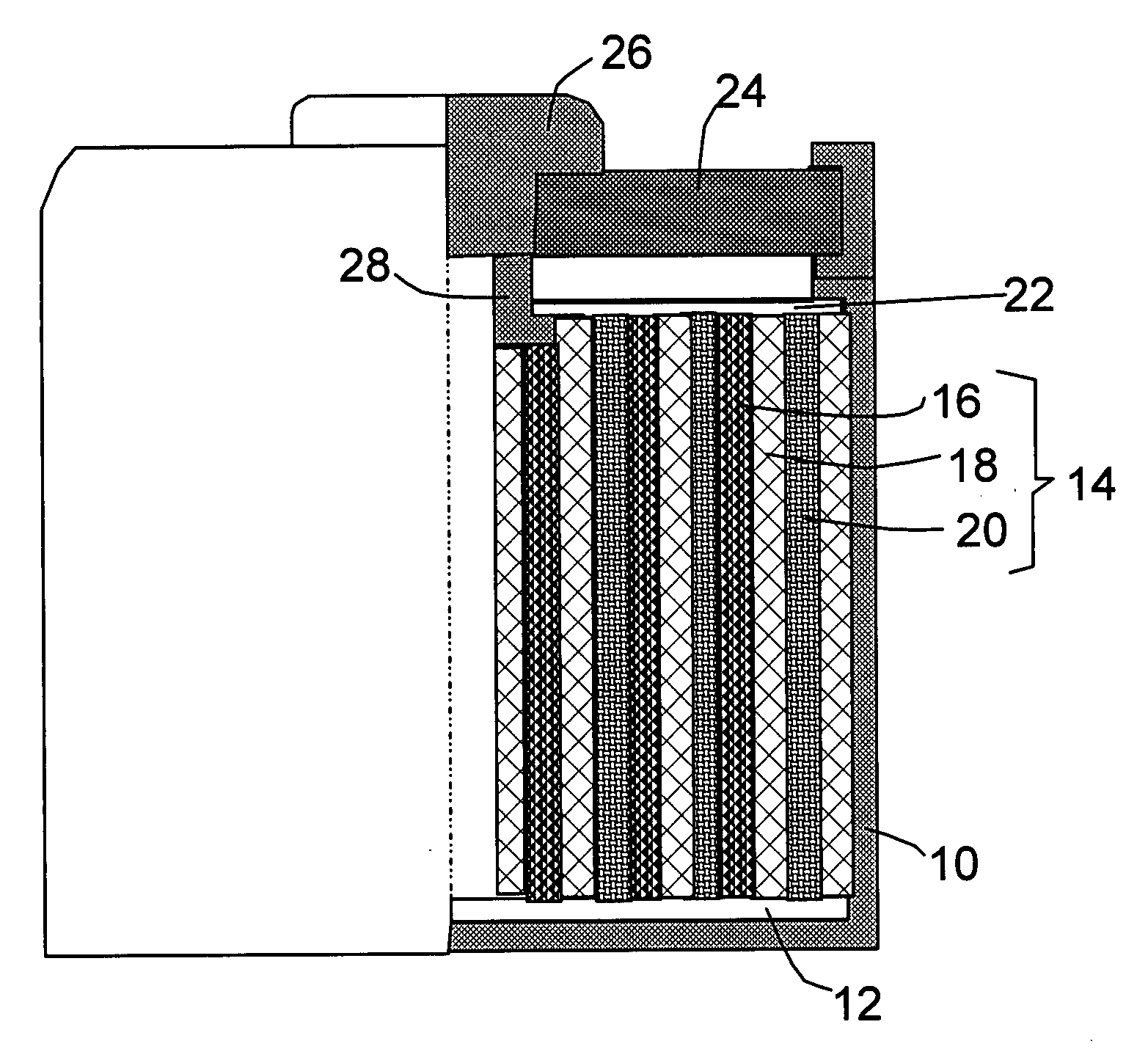

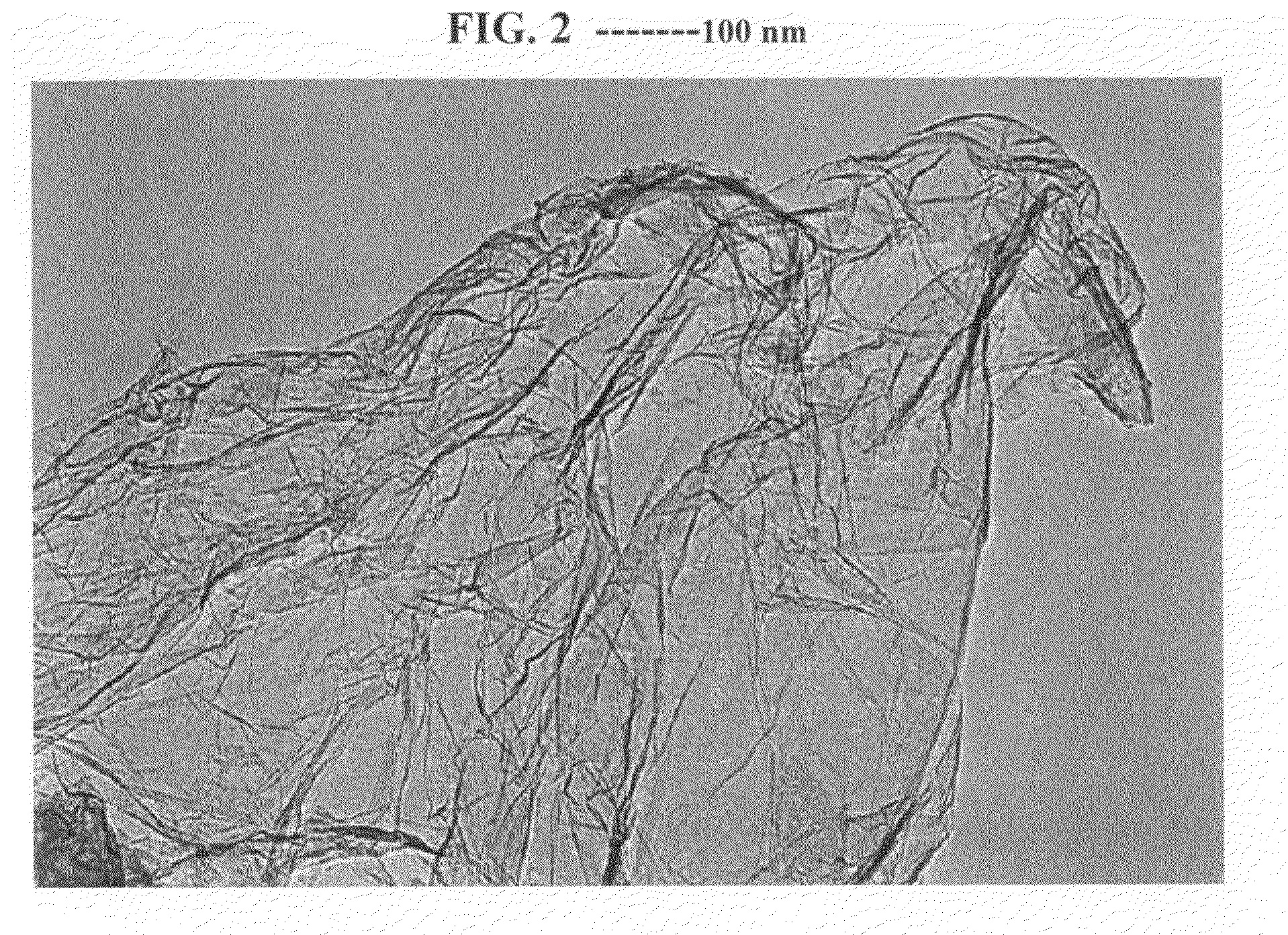

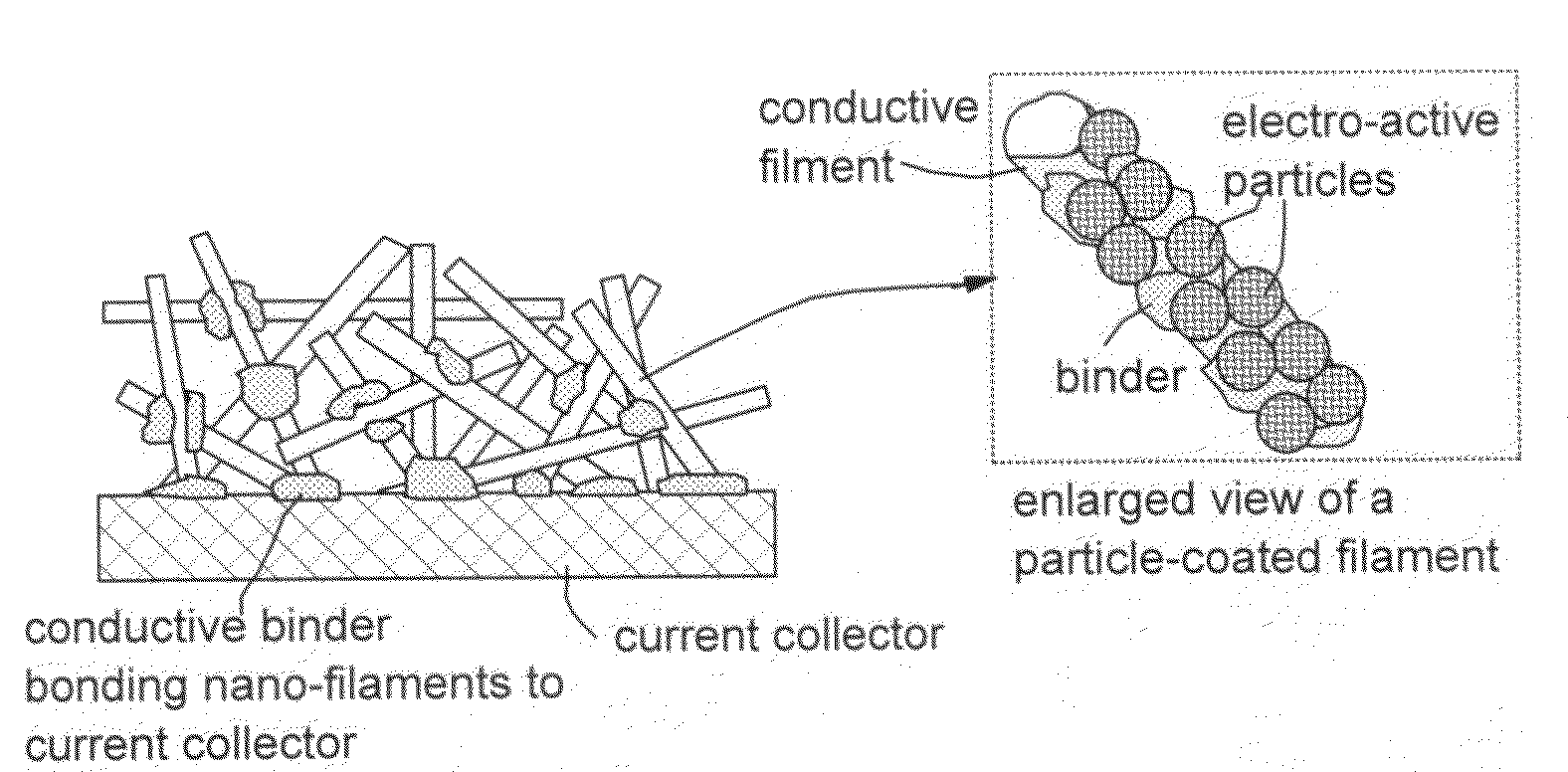

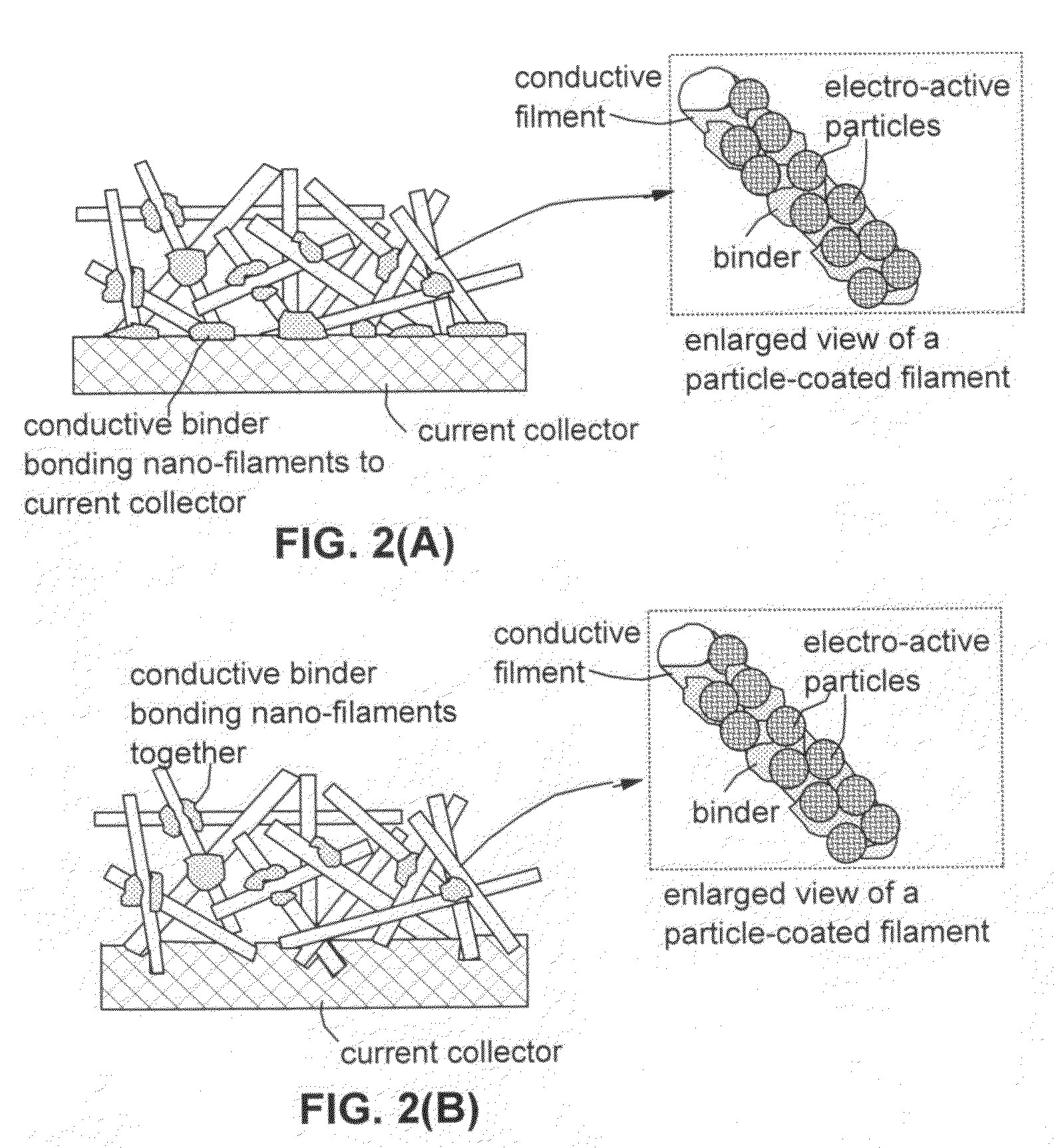

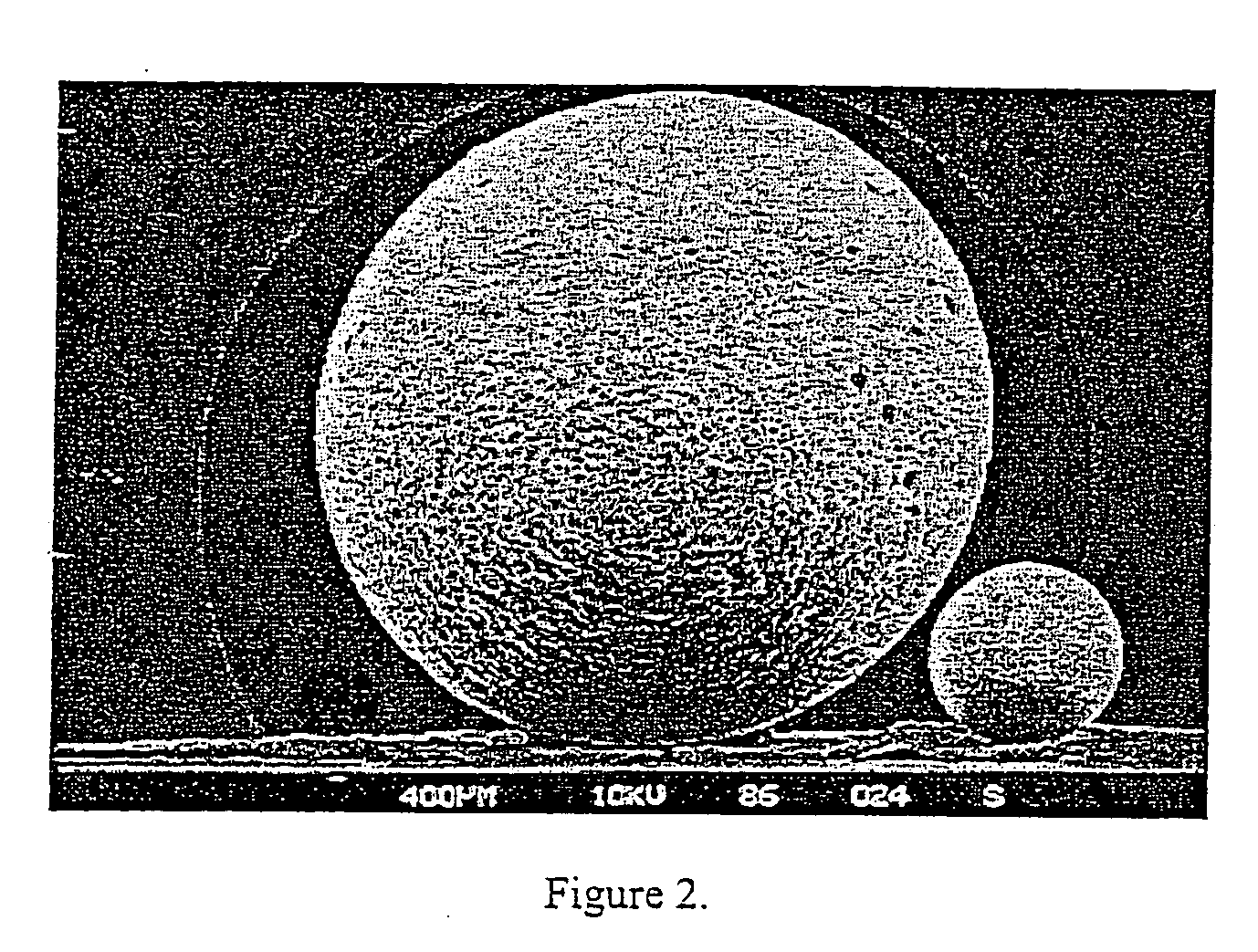

Conductive nanocomposite-based electrodes for lithium batteries

ActiveUS20090305135A1High specific capacityHigh reversible capacityMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesCarbon layerComposite electrode

This invention provides a nanocomposite-based lithium battery electrode comprising: (a) A porous aggregate of electrically conductive nano-filaments that are substantially interconnected, intersected, physically contacted, or chemically bonded to form a three-dimensional network of electron-conducting paths, wherein the nano-filaments have a diameter or thickness less than 1 μm (preferably less than 500 nm); and (b) Sub-micron or nanometer-scale electro-active particles that are bonded to a surface of the nano-filaments with a conductive binder material, wherein the particles comprise an electro-active material capable of absorbing and desorbing lithium ions and wherein the electro-active material content is no less than 25% by weight based on the total weight of the particles, the binder material, and the filaments. Preferably, these electro-active particles are coated with a thin carbon layer. This electrode can be an anode or a cathode. The battery featuring such an anode or cathode exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

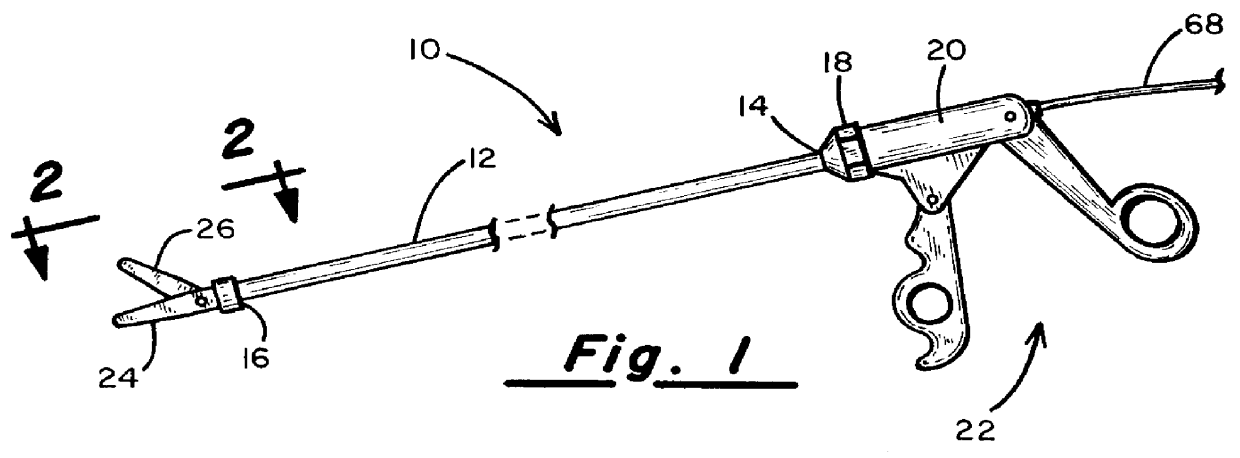

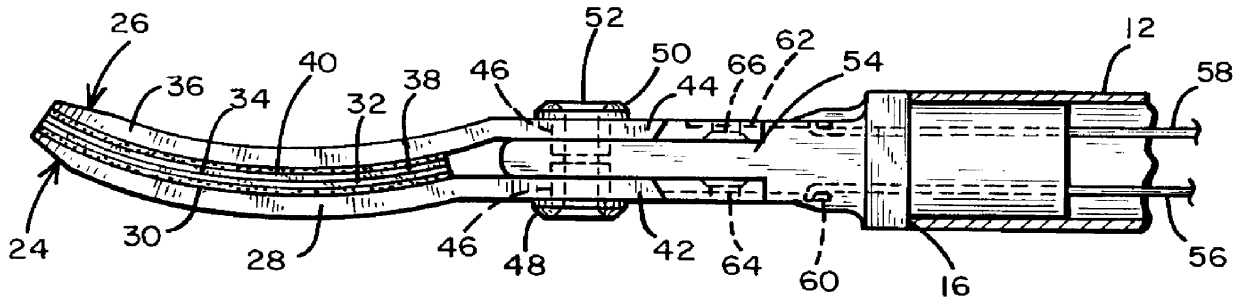

Surgical scissors with bipolar coagulation feature

A bipolar electrosurgical scissors for use in open or endoscopic surgery has a pair of opposed blade members pivotally joined to one another and to the distal end of the scissors itself by a rivet which extends through a insulated bushing member. Each of the blade members comprises a blade support and a blade itself, each fabricated from metal, such as stainless steel. The blades are affixed to their associated supports by means of a suitable adhesive or adhesive composite material such as a fiberglass reinforced epoxy exhibiting dielectric properties. Cutting is performed, steel-on-steel, without causing a short circuit between the two blade supports which themselves function as the bipolar electrodes.

Owner:THE GOVERNOR & COMPANY OF THE BANK OF SCOTLAND

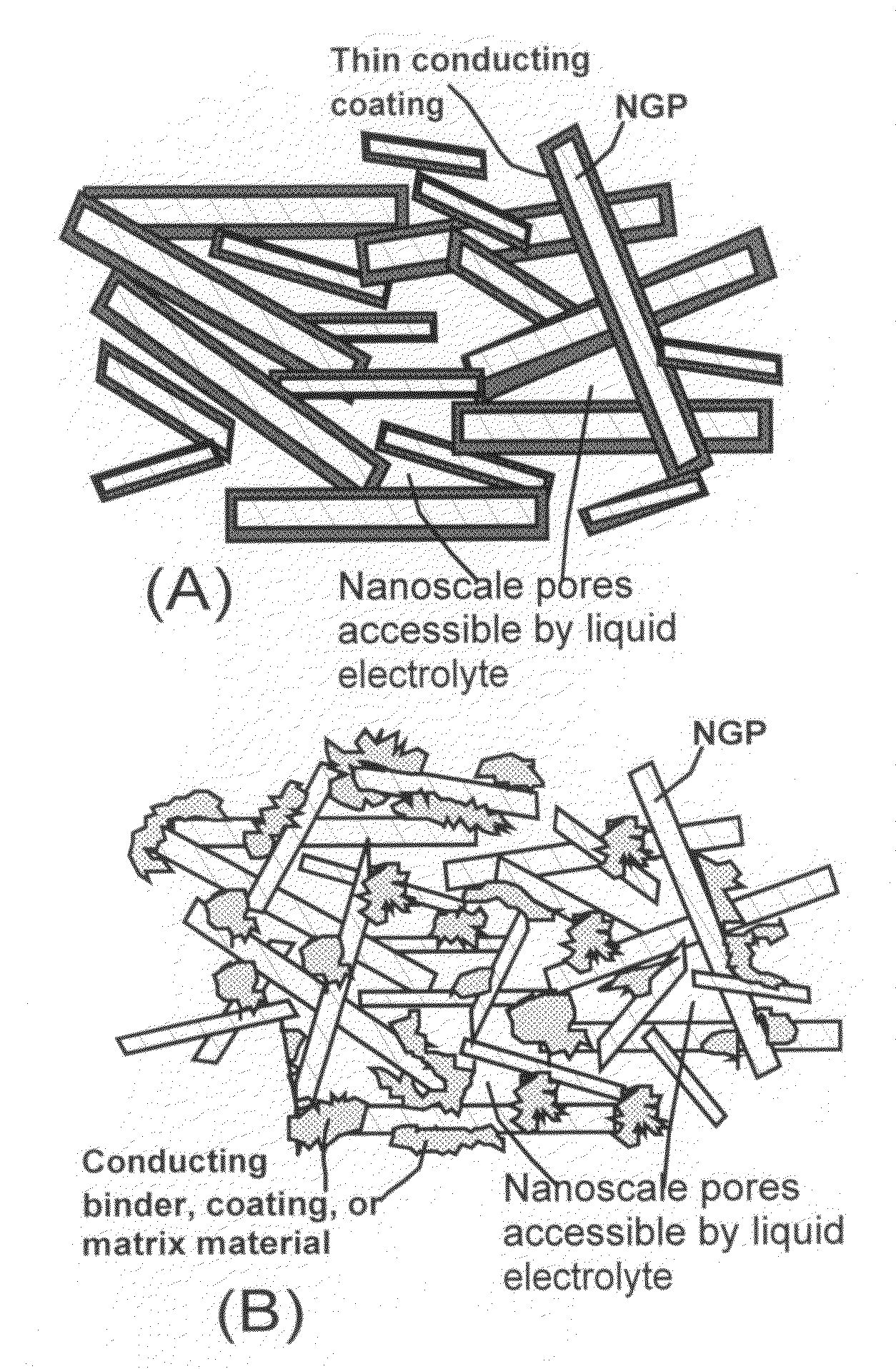

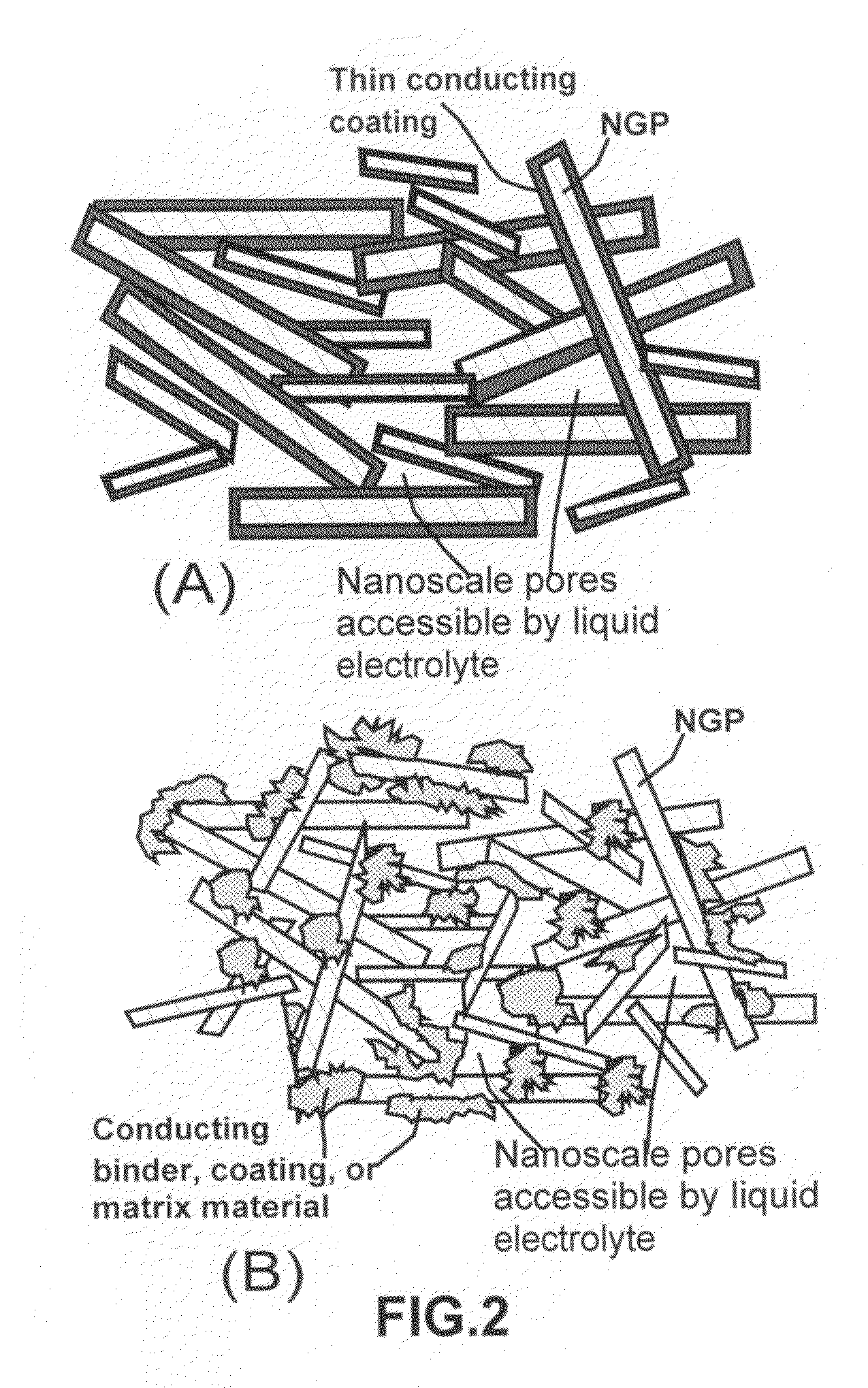

Nano-scaled graphene plate nanocomposites for supercapacitor electrodes

ActiveUS7623340B1Increase specific surface area and electrical conductivityMaterial nanotechnologyElectrolytic capacitorsCapacitancePolymer science

A preferred embodiment of the present invention is a meso-porous nanocomposite material comprising: (A) nano-scaled graphene platelets, wherein each of the platelets comprises a sheet of graphite plane or multiple sheets of graphite plane, and the platelets have a thickness no greater than 100 nm (preferably smaller than 10 nm) and an average length, width, or diameter no greater than 10 μm (preferably smaller than 500 nm); and (B) an electrically conducting binder or matrix material attached or bonded to the platelets to form the nanocomposite material having liquid accessible pores, which provide a surface area greater than about 100 m2 / gm, preferably greater than 500 m2 / gm, and most preferably greater than 1000 m2 / gm. Also disclosed is a capacitor that includes at least an electrode comprising such a meso-porous nanocomposite material. A supercapacitor featuring such a nanocomposite exhibits an exceptionally high capacitance value.

Owner:SAMSUNG ELECTRONICS CO LTD +1

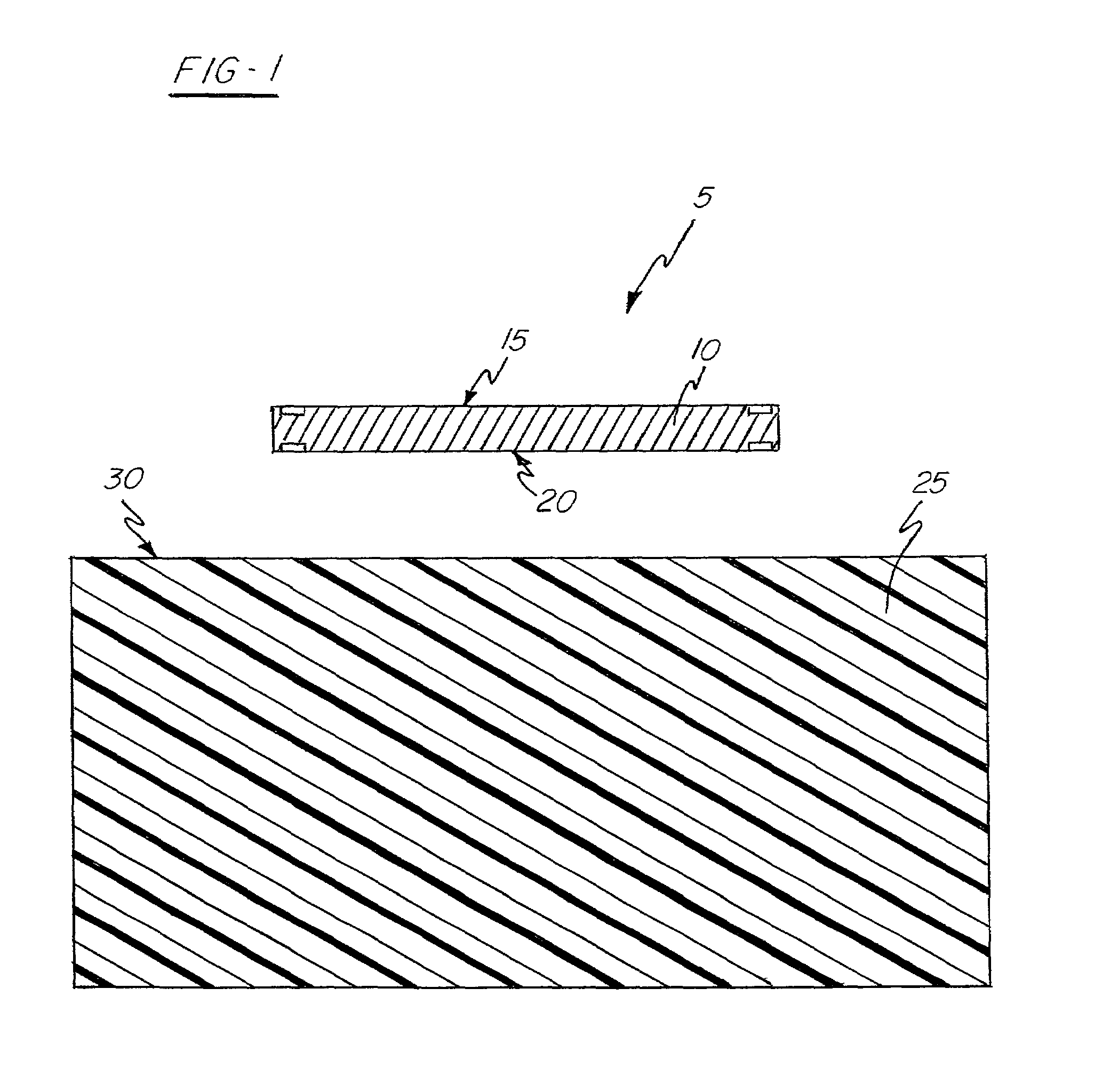

Structural and other composite materials and methods for making same

InactiveUS20050281999A1High strength-to-weight ratioEasy to manufactureSynthetic resin layered productsLaminationPolymer scienceHigh intensity

In accordance with the present invention, structural and other composite materials have been developed which have superior performance properties, including high compressive strength, high tensile strength, high shear strength, and high strength-to-weight ratio, and methods for preparing same. Invention materials have the added benefits of ease of manufacture, and are inexpensive to manufacture. The superior performance properties of invention materials render such materials suitable for a wide variety of end uses. For example, a variety of substances can be applied to invention materials without melting, dissolving or degrading the basic structure thereof. This facilitates bonding invention materials to virtually any surface or substrate. Moreover, the bond between invention materials and a variety of substrates is exceptionally strong, rendering the resulting bonded article suitable for use in a variety of demanding applications. Invention materials can be manufactured in a wide variety of sizes, shapes, densities, in multiple layers, and the like; and the performance properties thereof can be evaluated in a variety of ways.

Owner:PETRITECH

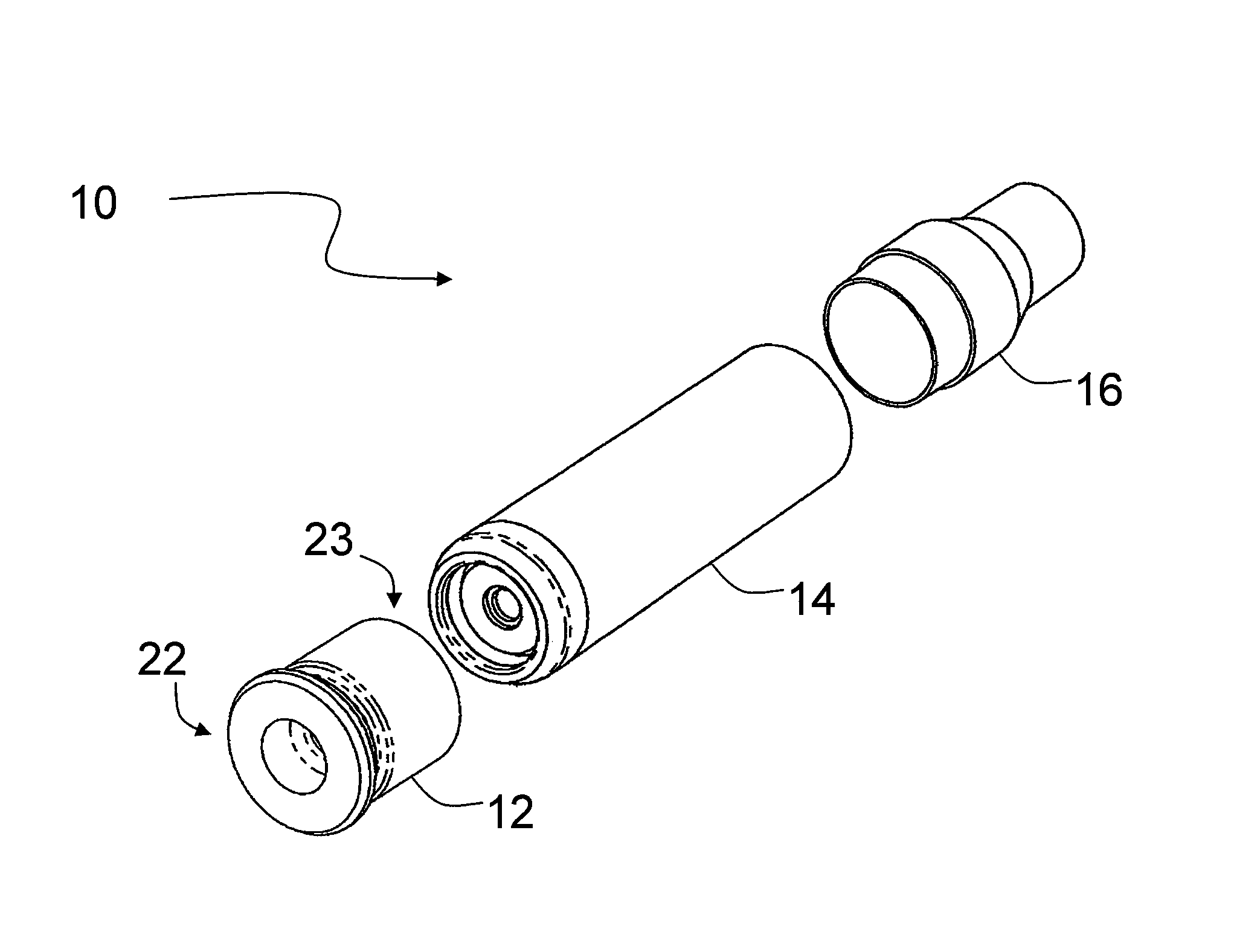

Nanotube/metal substrate composites and methods for producing such composites

InactiveUS20050238810A1Simplified and advantageous mannerReduce productionMaterial nanotechnologyIndirect heat exchangersHydrogen fuel cellChemical vapor deposition

Carbon nanotubes are grown directly on metal substrates using chemical vapor deposition. Metal substrates are comprised of catalysts which facilitate or promote the growth of carbon nanotubes. The nanotube coated metal substrates have applications including, but not limited to, heat transfer and thermal control, hydrogen storage, fuel cell catalytic reformers, electronics and semiconductors, implantable medical devices or prostheses, and tribological wear and protective coatings.

Owner:MAINSTREAM ENG

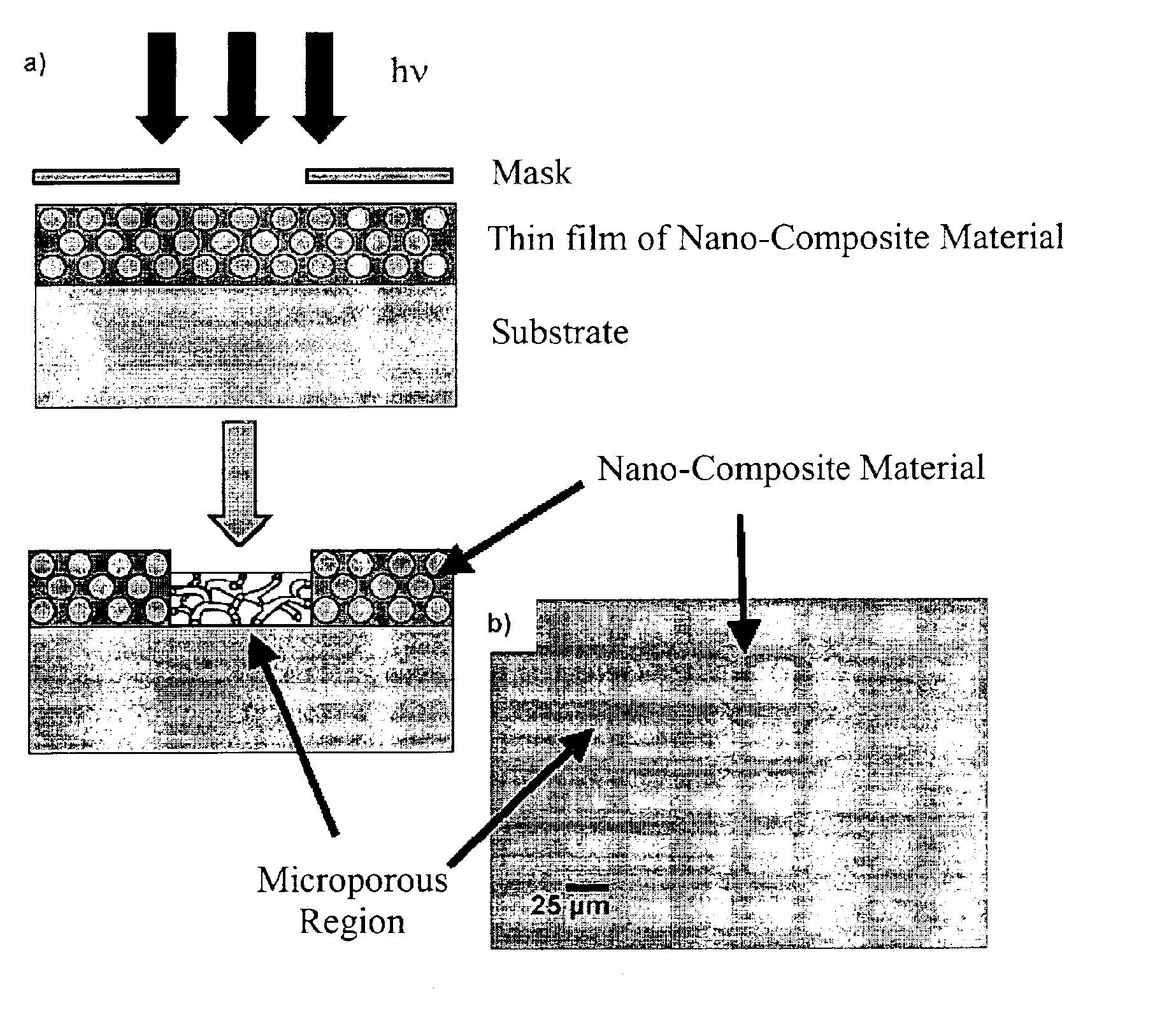

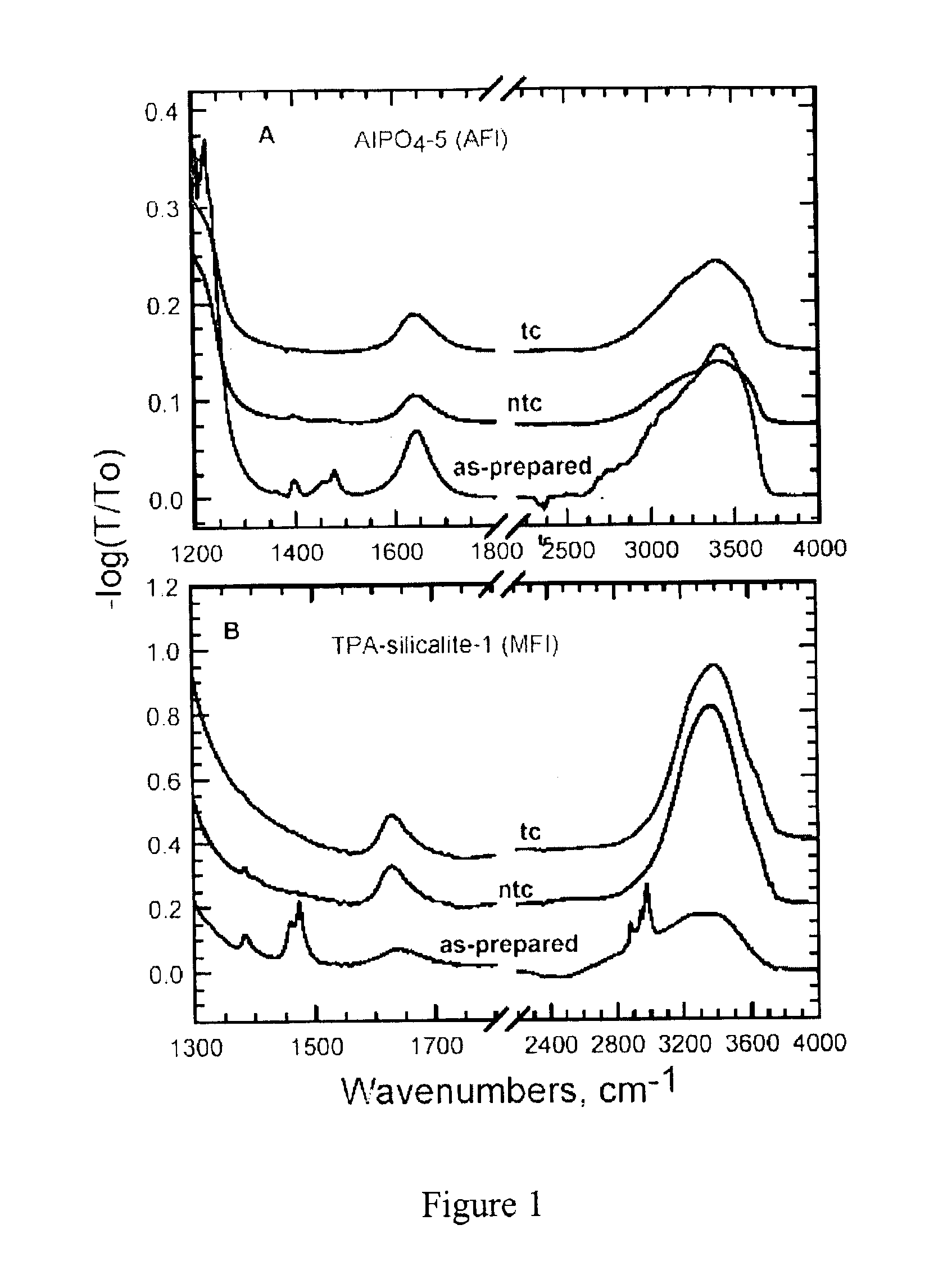

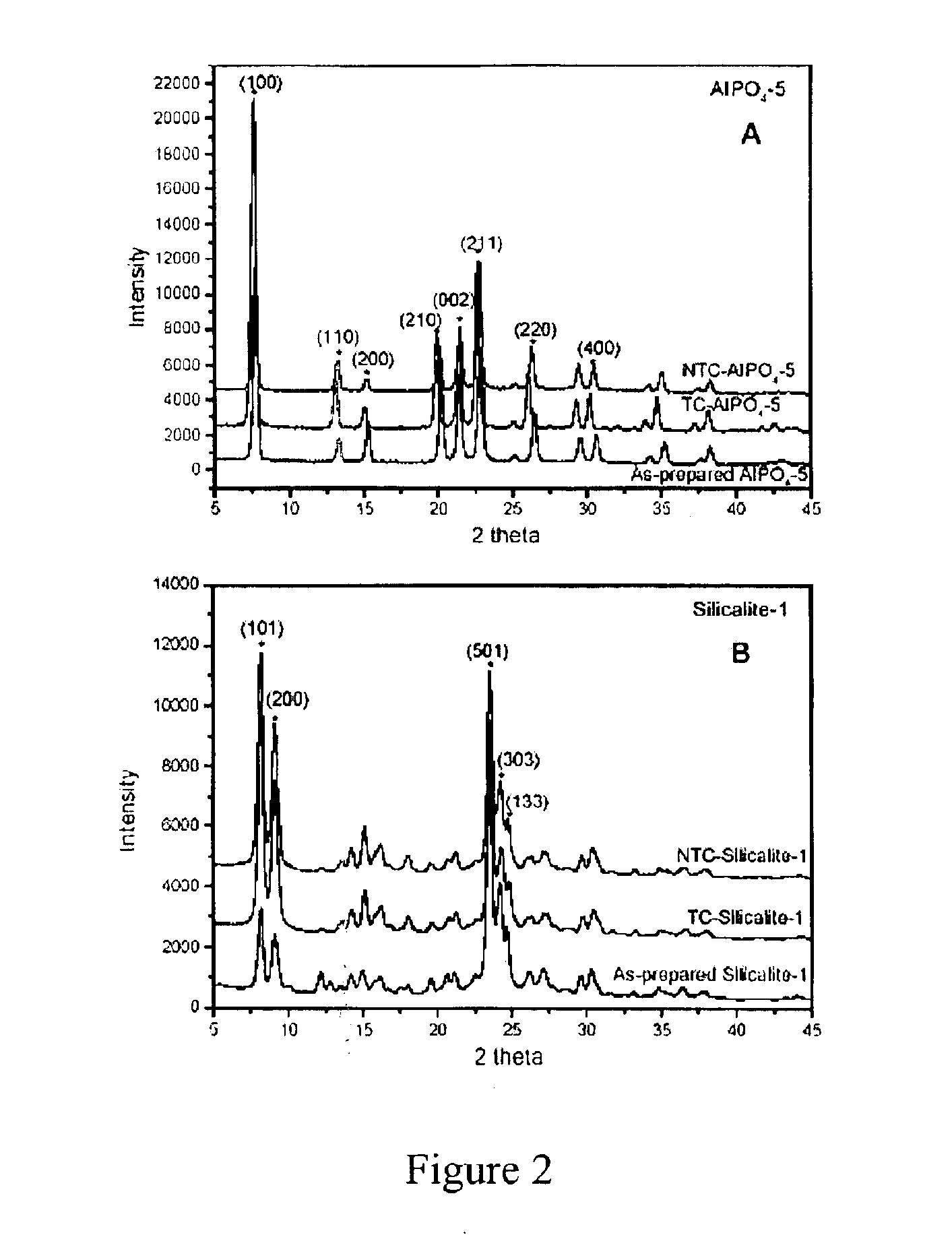

Methods for removing organic compounds from nano-composite materials

InactiveUS6960327B2Conveniently producedAvoid calcinationAluminium compoundsSilicaLight waveSimple Organic Compounds

The present invention provides methods for selectively removing organic compound from a nano-composite material which comprises the organic compound that is dispersed within a solid inorganic compound structure. In particular, methods of the present invention comprise irradiating the nano-composite material with electromagnetic radiation wavelength that is shorter than the wavelength of visible light.

Owner:RGT UNIV OF CALIFORNIA

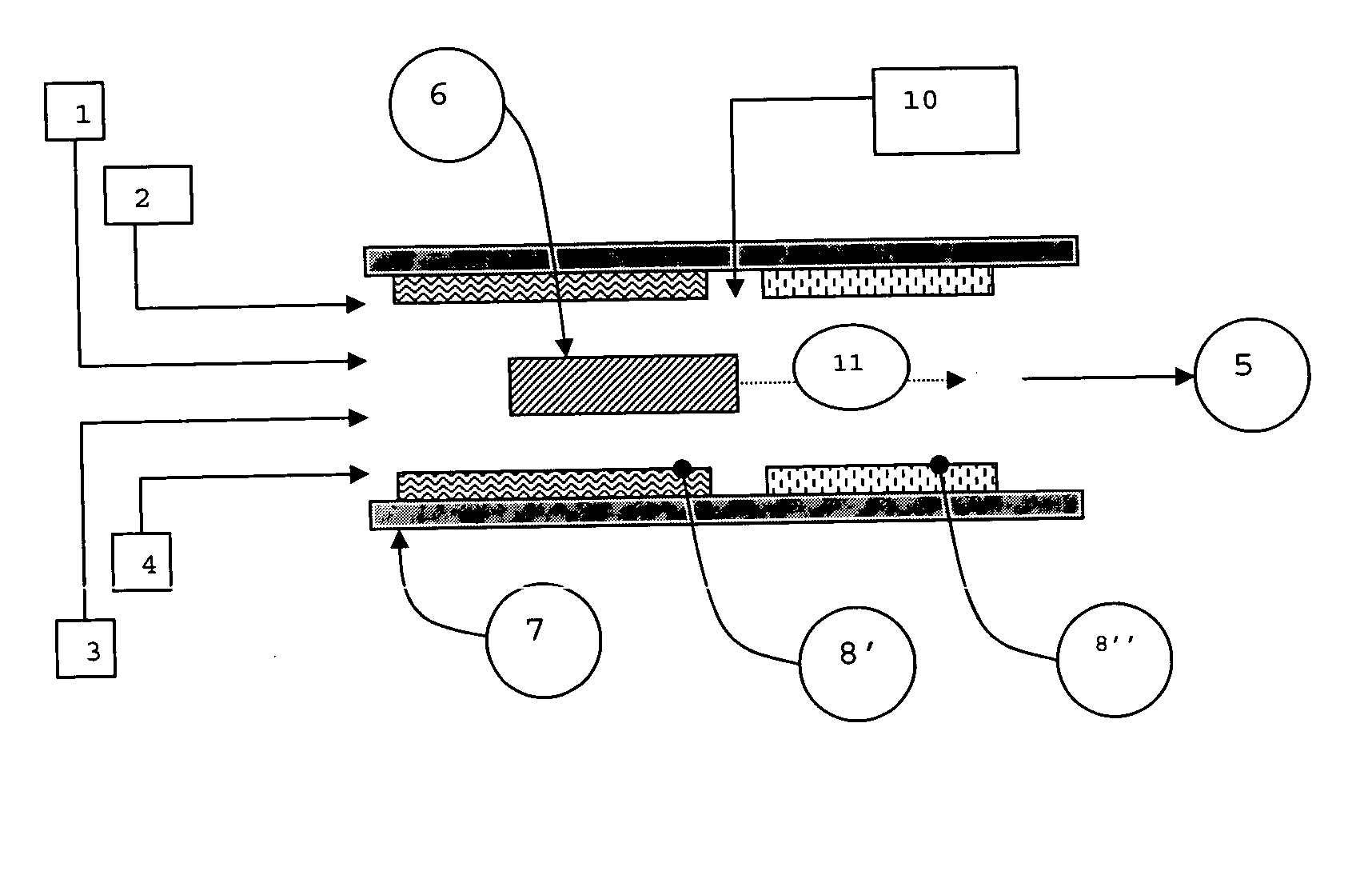

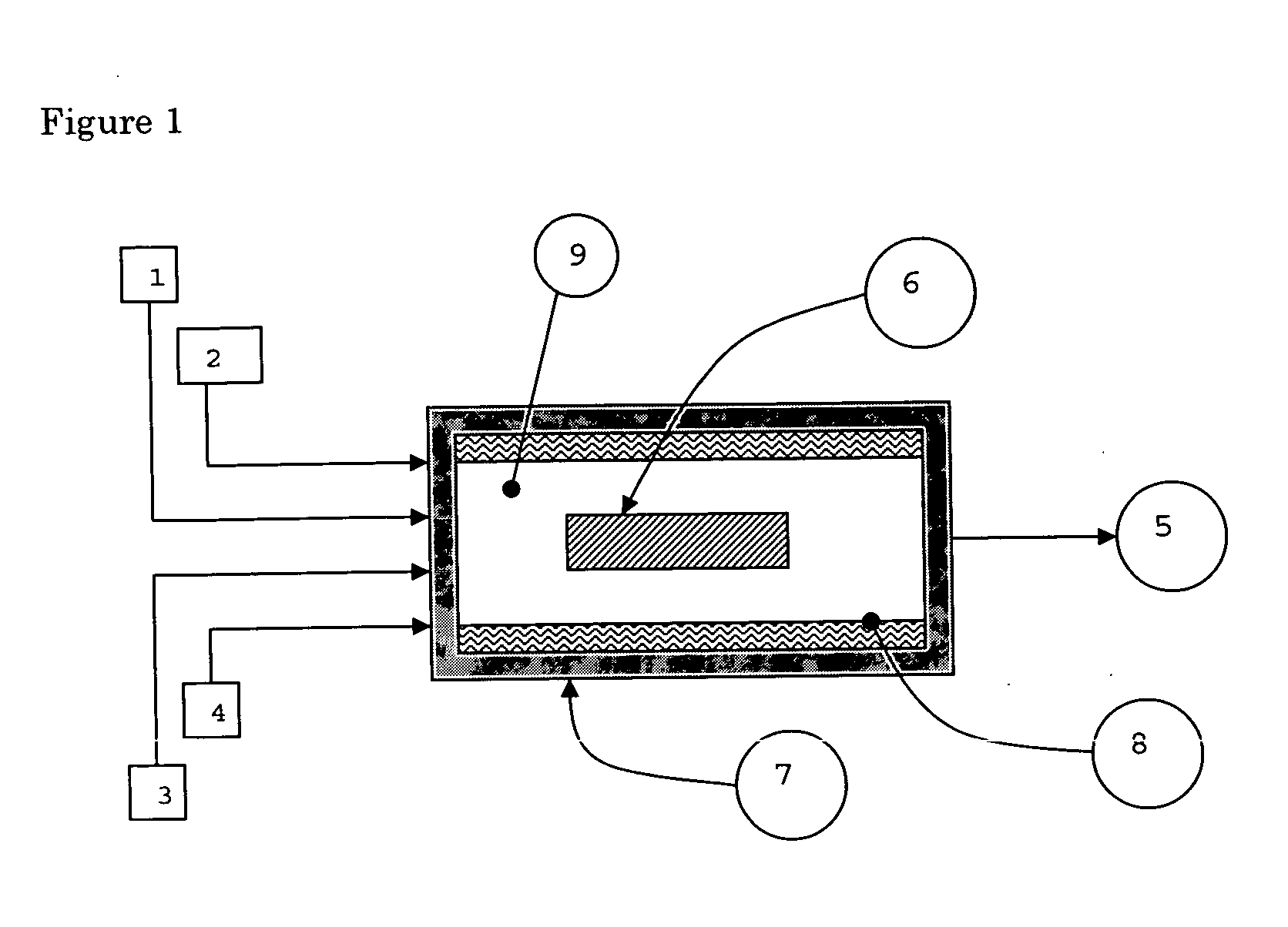

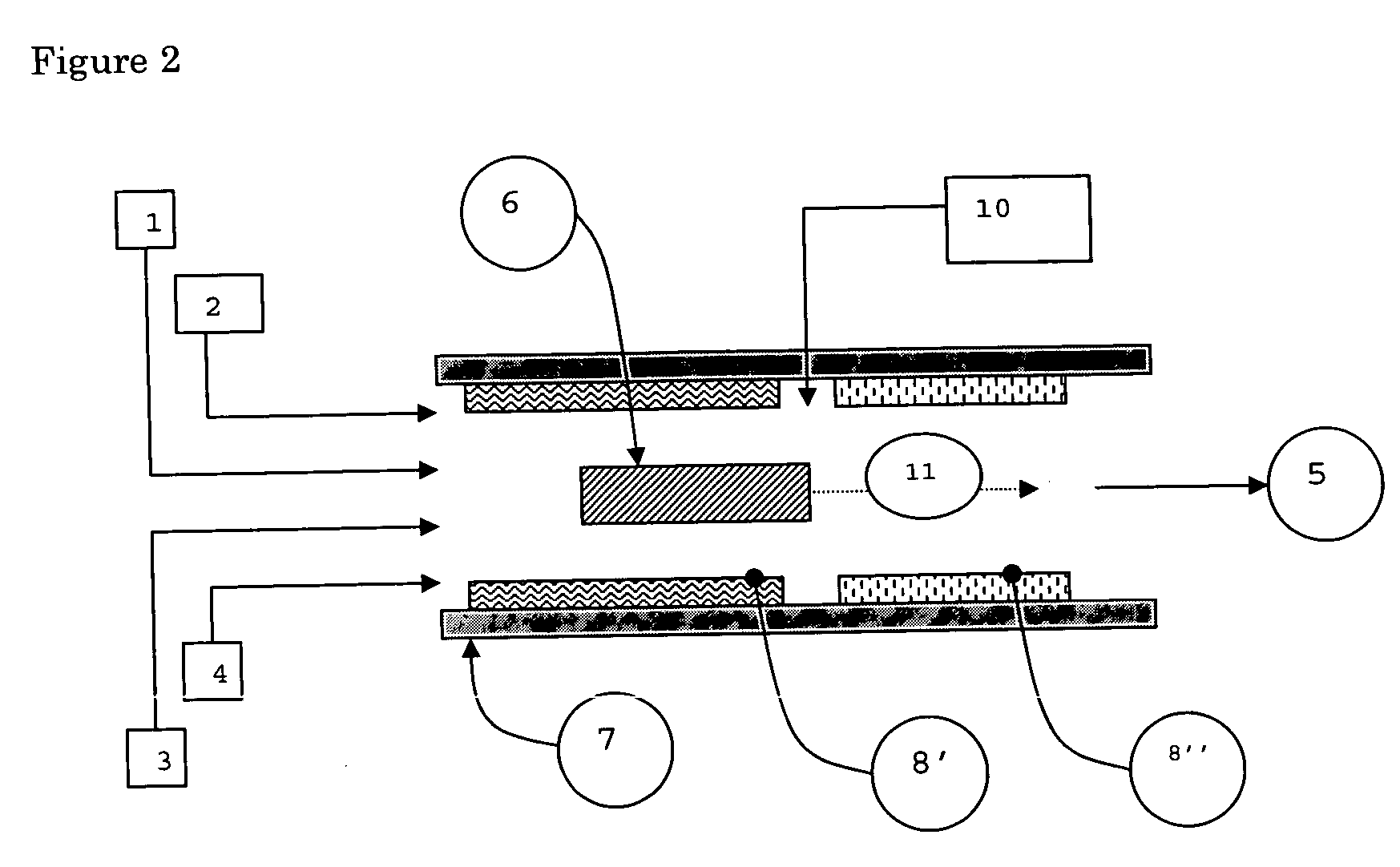

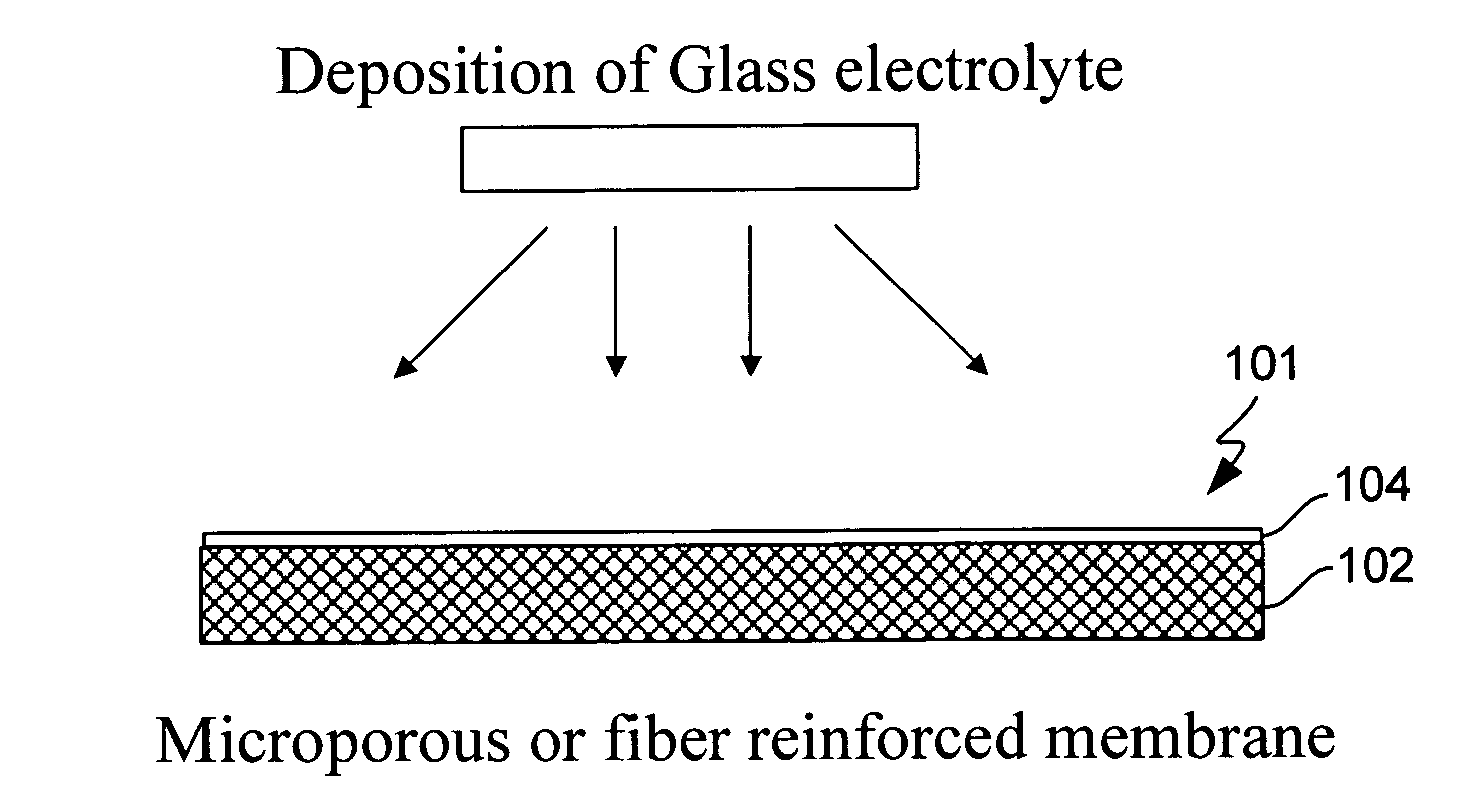

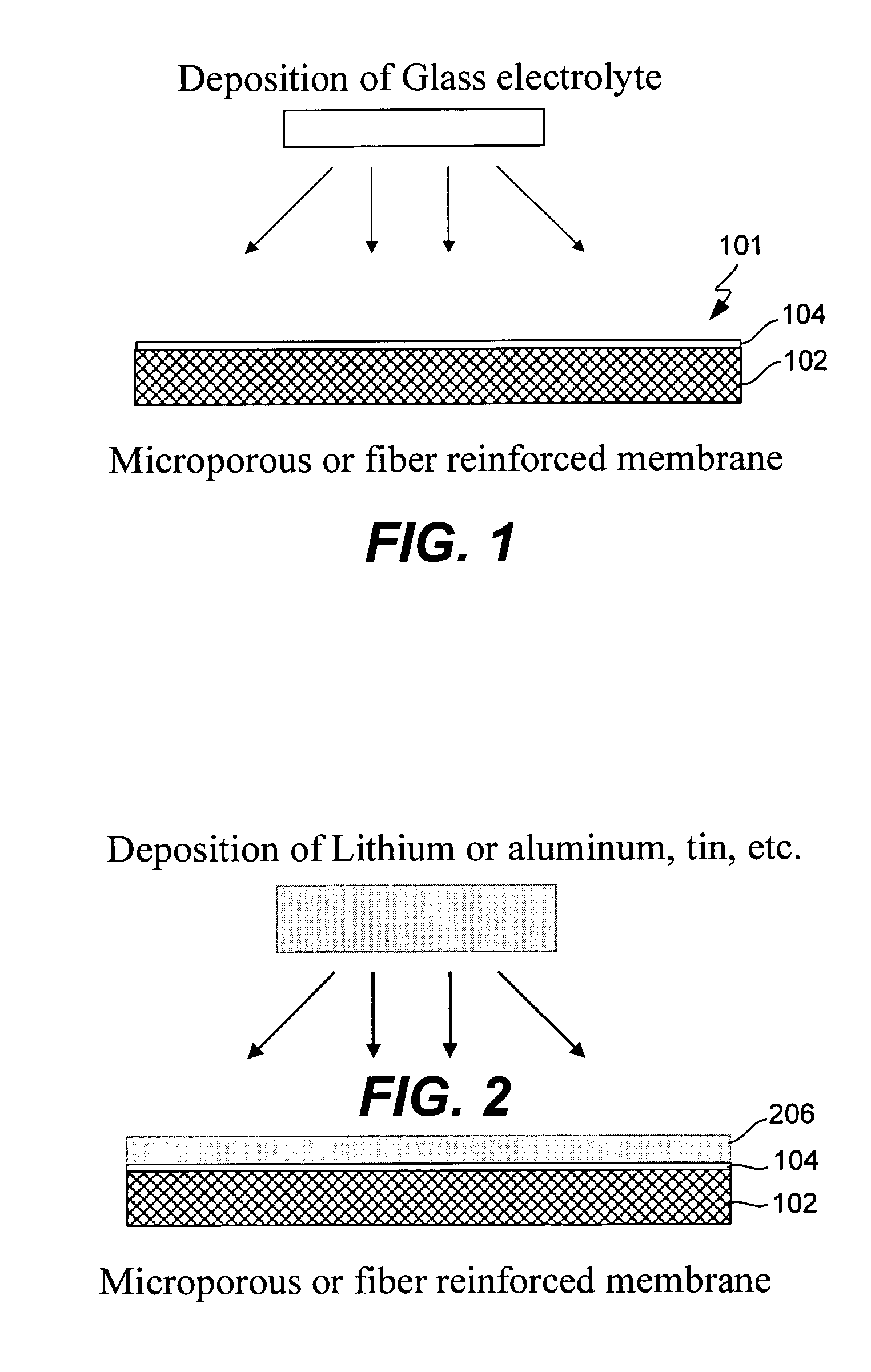

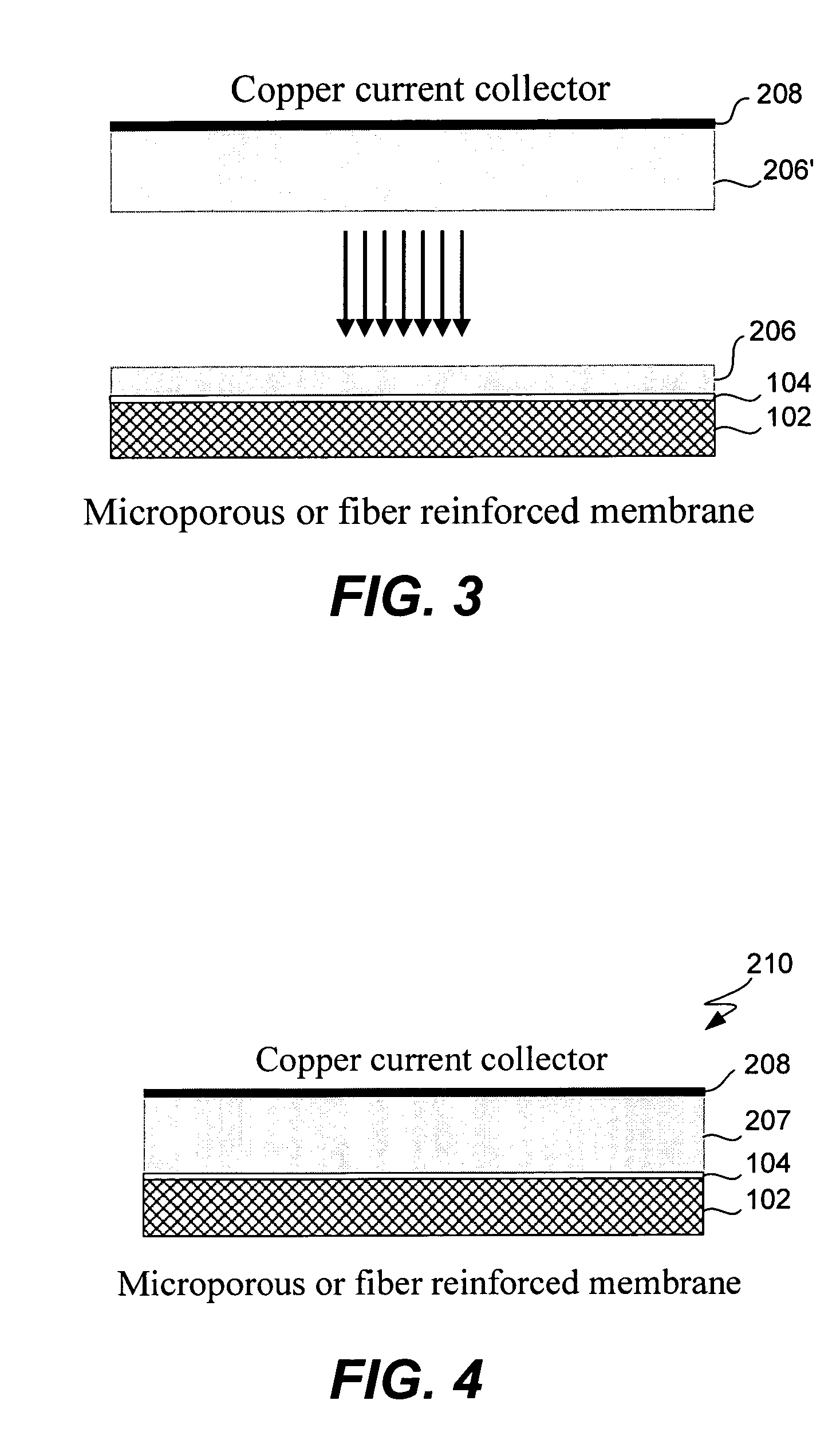

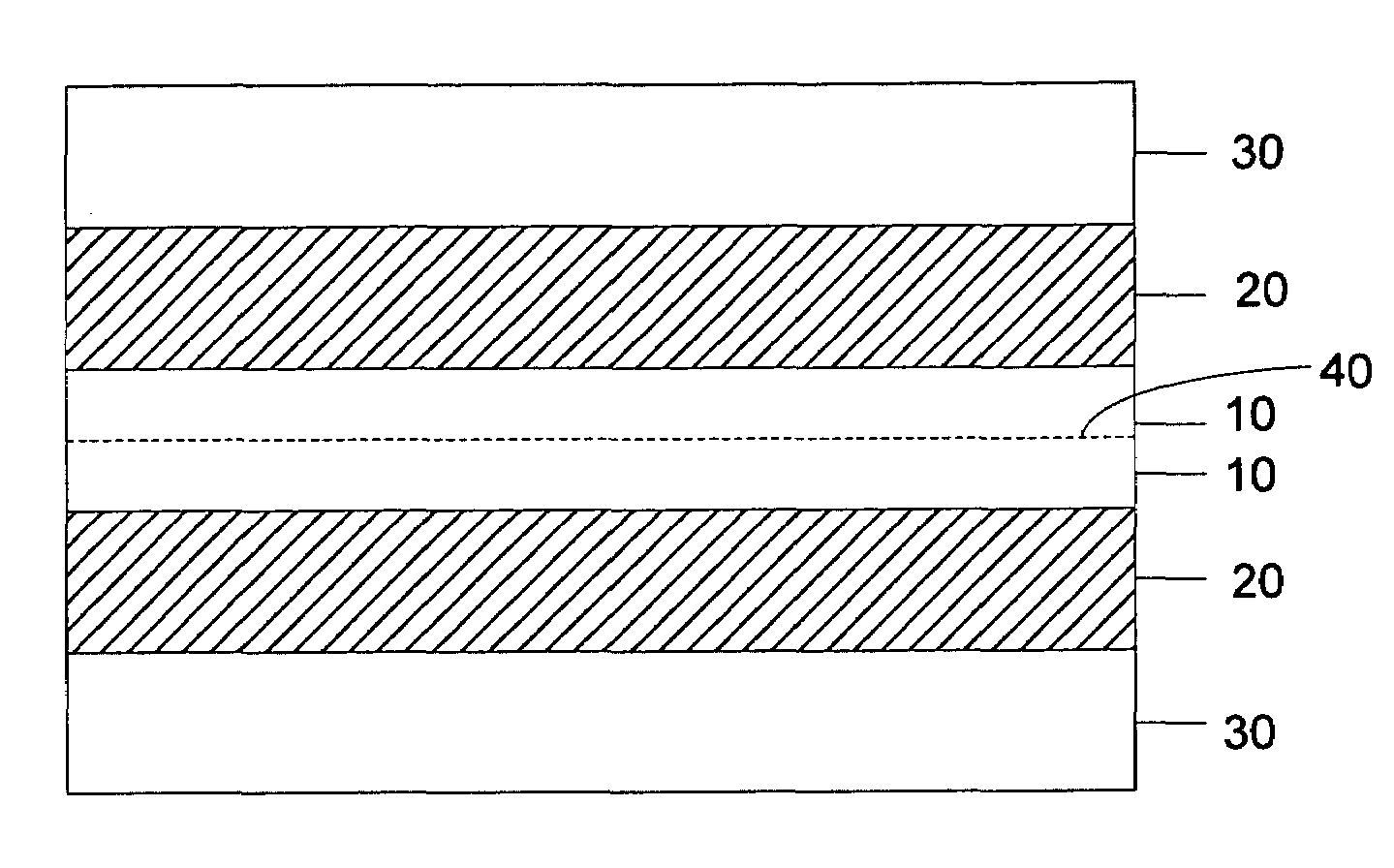

Electrochemical device separator structures with barrier layer on non-swelling membrane

InactiveUS7070632B1Avoid harmful reactionsElectrode carriers/collectorsSolid electrolyte cellsElectrochemistryFluid electrolytes

Disclosed are electrochemical device separator structures which include a substantially impervious active metal ion conducting barrier layer material, such as an ion conducting glass, is formed on an active metal ion conducting membrane in which elongation due to swelling on contact with liquid electrolyte is constrained in at least two of three orthogonal dimensions of the membrane. The non-swelling character of the membrane prevents elongation in the x-y (or lateral, relative to the layers of the composite) orthogonal dimensions of the membrane when it is contacted with liquid electrolyte that would otherwise cause the barrier layer to rupture. Substantial swelling of the membrane, if any, is limited to the z (or vertical, relative to the layers of the composite) dimension.

Owner:POLYPLUS BATTERY CO INC

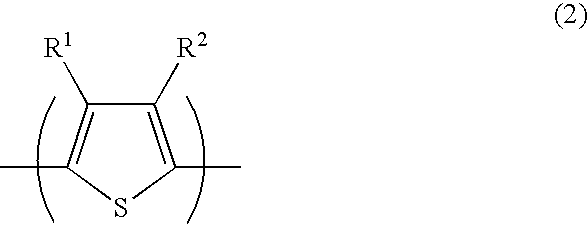

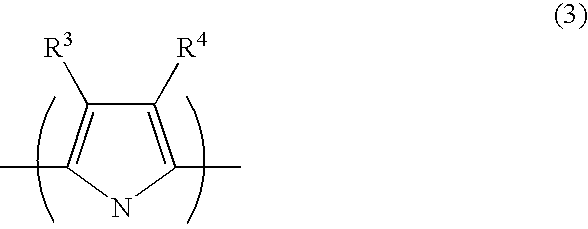

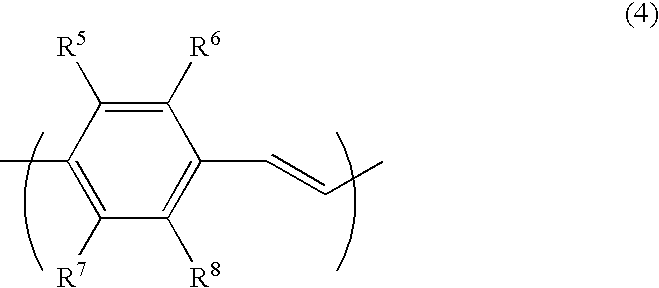

Composition containing carbon nanotubes having coating thereof and process for producing them

ActiveUS20060052509A1Not impair characteristicImprove conductivityMaterial nanotechnologySynthetic resin layered productsColloidal silicaConductive polymer

The object of the present invention is to provide a carbon nanotube composition that does not impair the characteristics of the carbon nanotubes itself, allows the carbon nanotubes to be dispersed or solubilized in a solvent, does not cause separation or aggregation of the carbon nanotubes even during long-term storage, has superior electrical conductivity, film formability and moldability, can be easily coated or covered onto a base material, and the resulting coated film has superior moisture resistance, weather resistance and hardness; a composite having a coated film composed thereof; and, their production methods. In order to achieve this object, the present invention provides a carbon nanotube composition that contains a conducting polymer (a) or heterocyclic compound trimer (i), a solvent (b) and carbon nanotubes (c), and may additionally contain a high molecular weight compound (d), a basic compound (e), a surfactant (f), a silane coupling agent (g) and colloidal silica (h) as necessary; a composite having a coated film composed of the composition; and, their production methods.

Owner:MITSUBISHI CHEM CORP

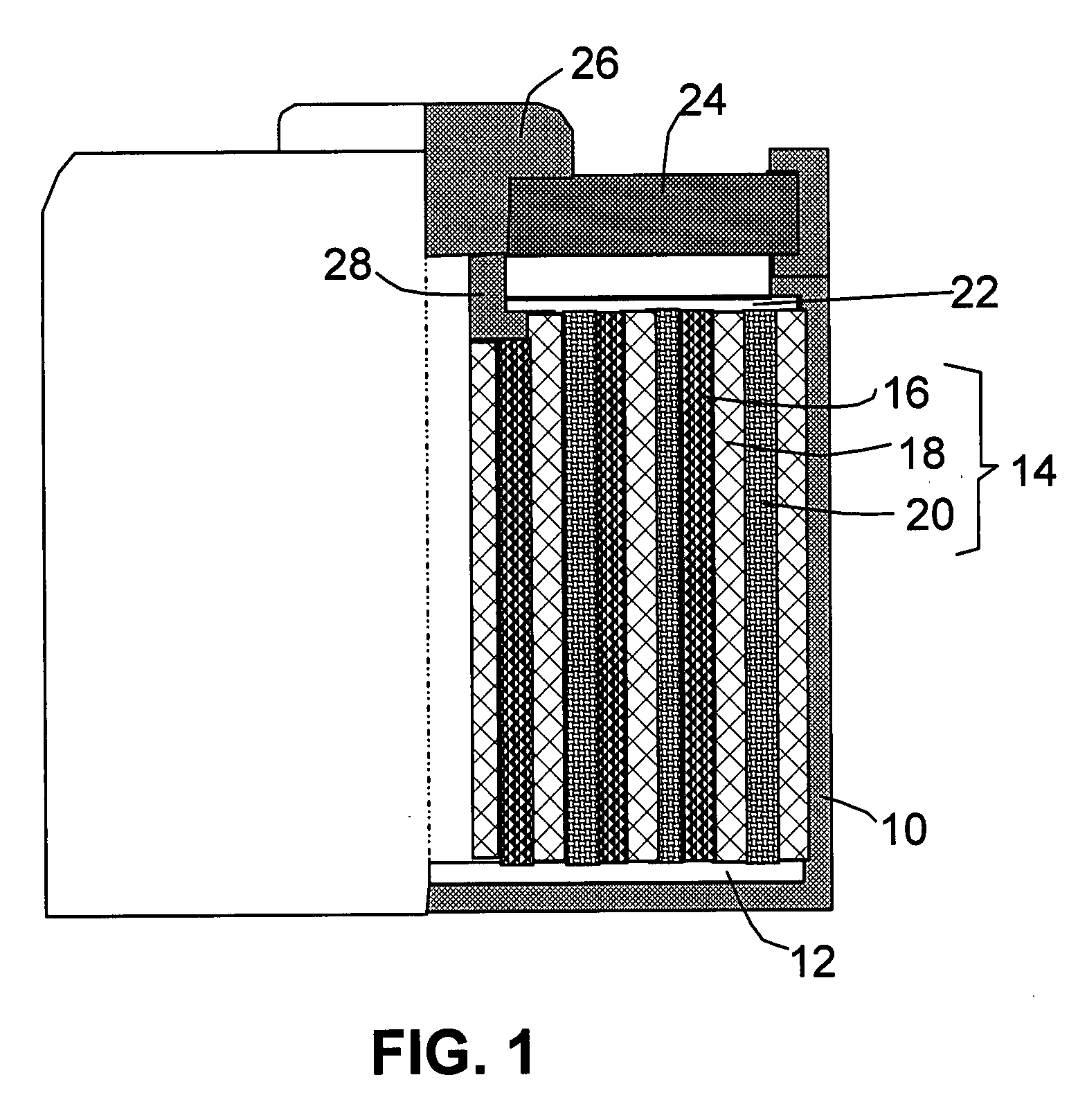

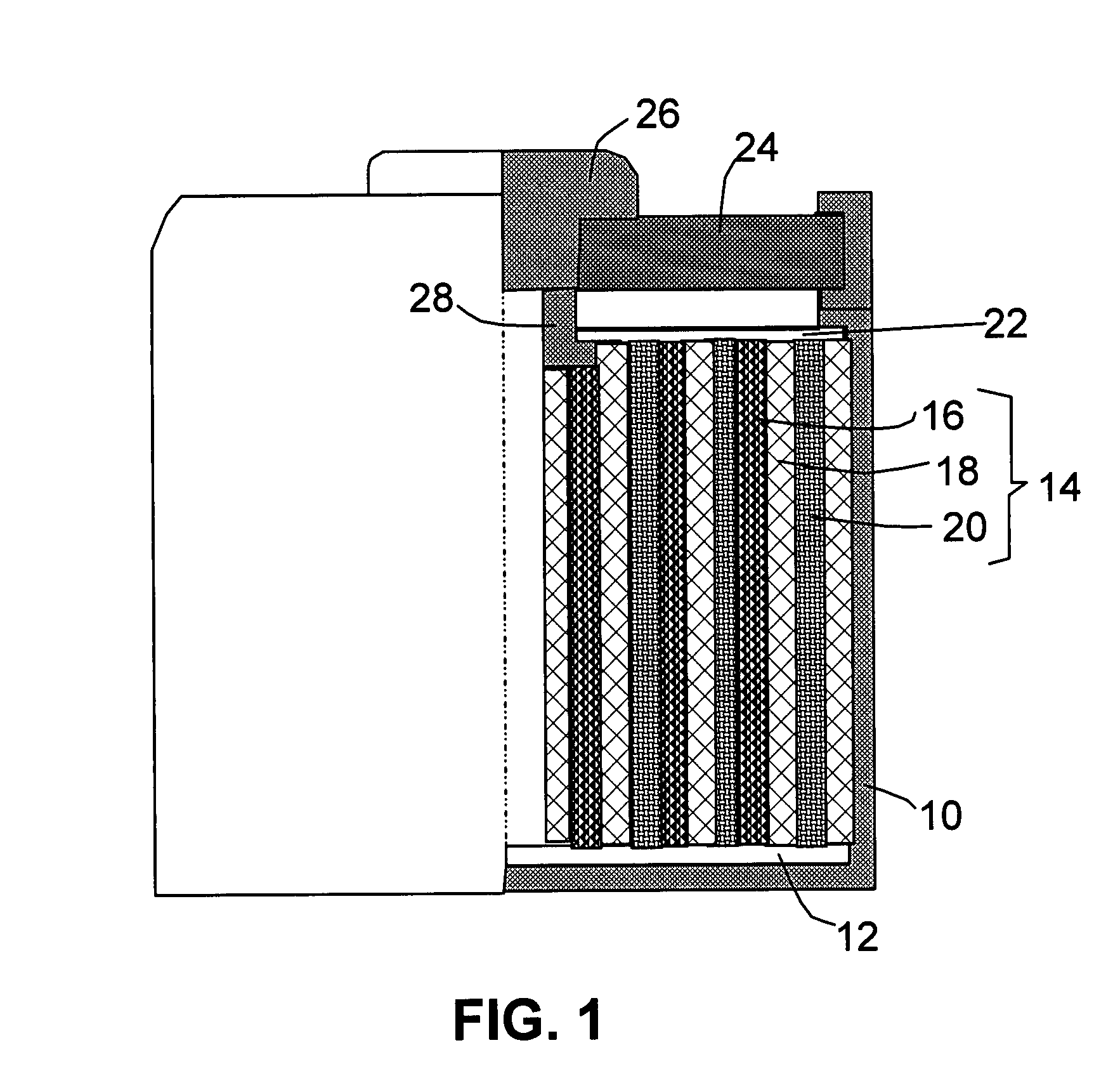

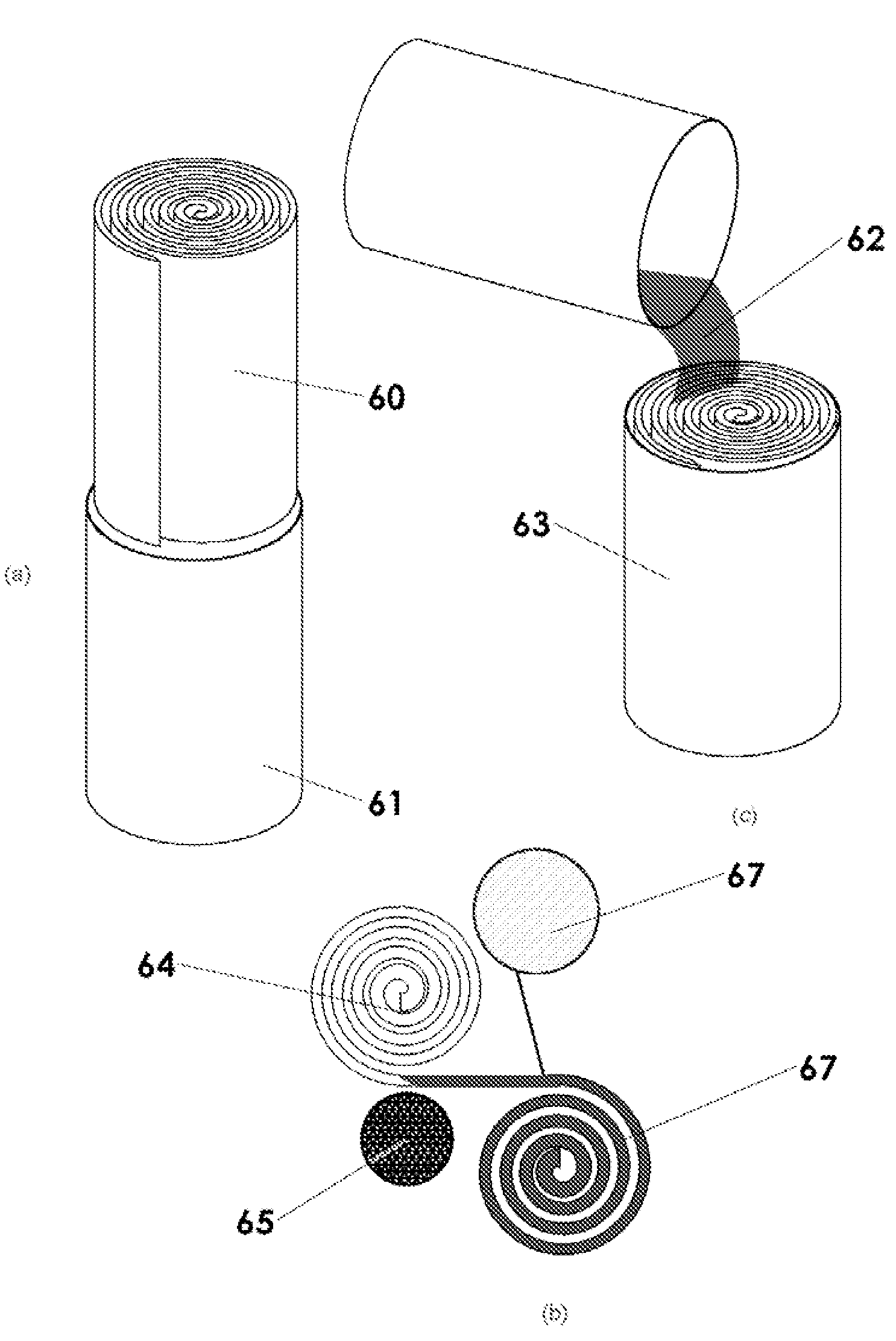

Supercapacitor having electrode material comprising single-wall carbon nanotubes and process for making the same

InactiveUS7061749B2Avoid shortingHybrid capacitor electrolytesHybrid capacitor electrodesSupercapacitorNanotube

The present invention relates to a supercapacitor, also known as an electrical double-layer capacitor or ultracapacitor, having electrode material comprising single-wall carbon nanotubes. The carbon nanotubes can be derivatized with functional groups. The electrode material is made by preparing a polymer-nanotube suspension comprising polymer and nanotubes, forming the polymer-nanotube suspension into a polymer-nanotube composite of the desired form, carbonizing the polymer-nanotube composite to form a carbonaceous polymer-nanotube material, and activating the material. The supercapacitor includes electrode material comprising activated carbonaceous polymer-nanotube material in contact with current collectors and permeated with an electrolyte, which may be either fluid or solid. In the case of a fluid or compressible electrolyte, an electrolyte-permeable separator or spacer is interposed between the electrodes to keep the electrodes from shorting. The supercapacitor made with electrodes comprising underivatized single-wall carbon nanotubes and polymer that has been carbonized and activated appears to operate as a non-Faradaic supercapacitor.

Owner:GEORGIA TECH RES CORP

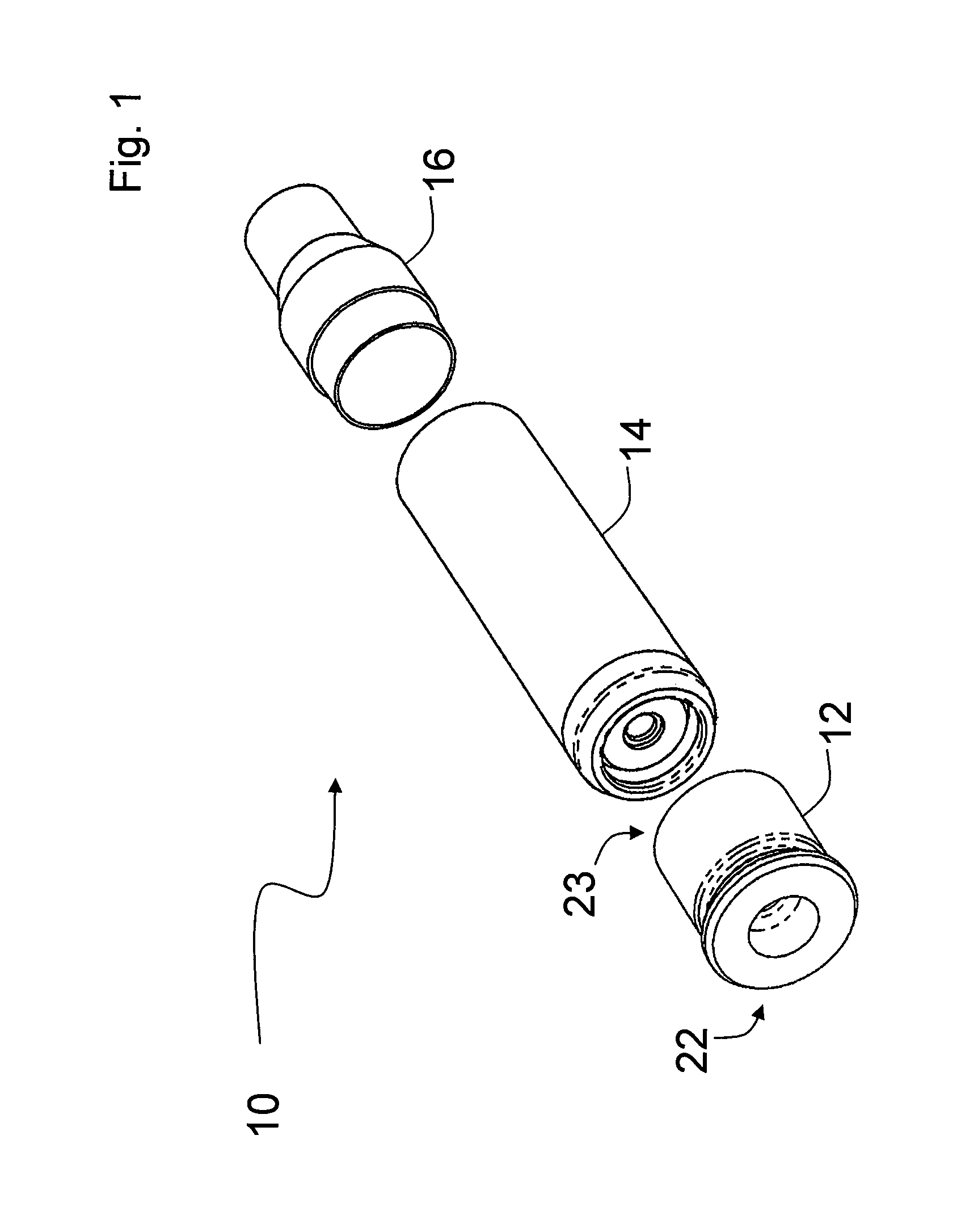

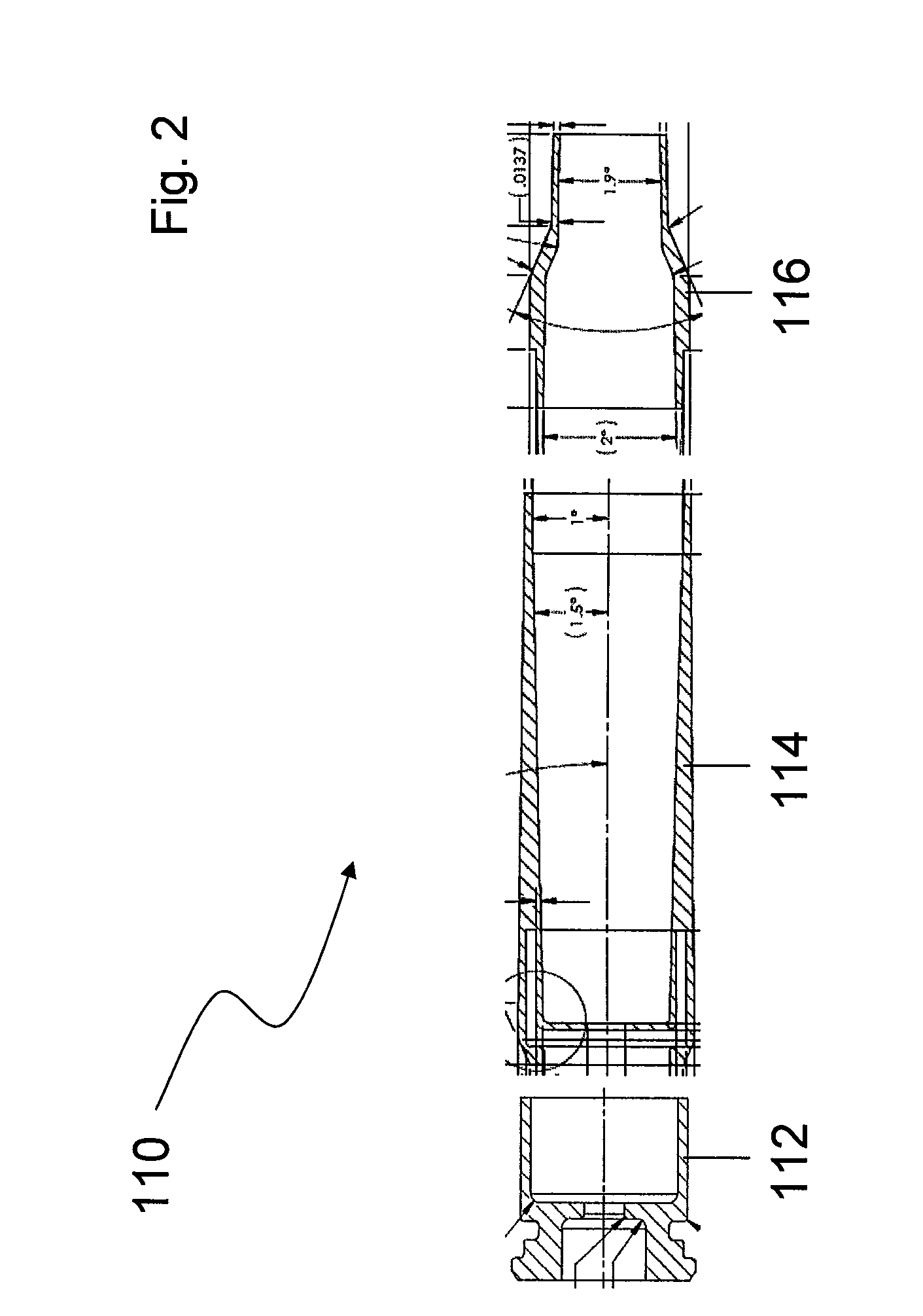

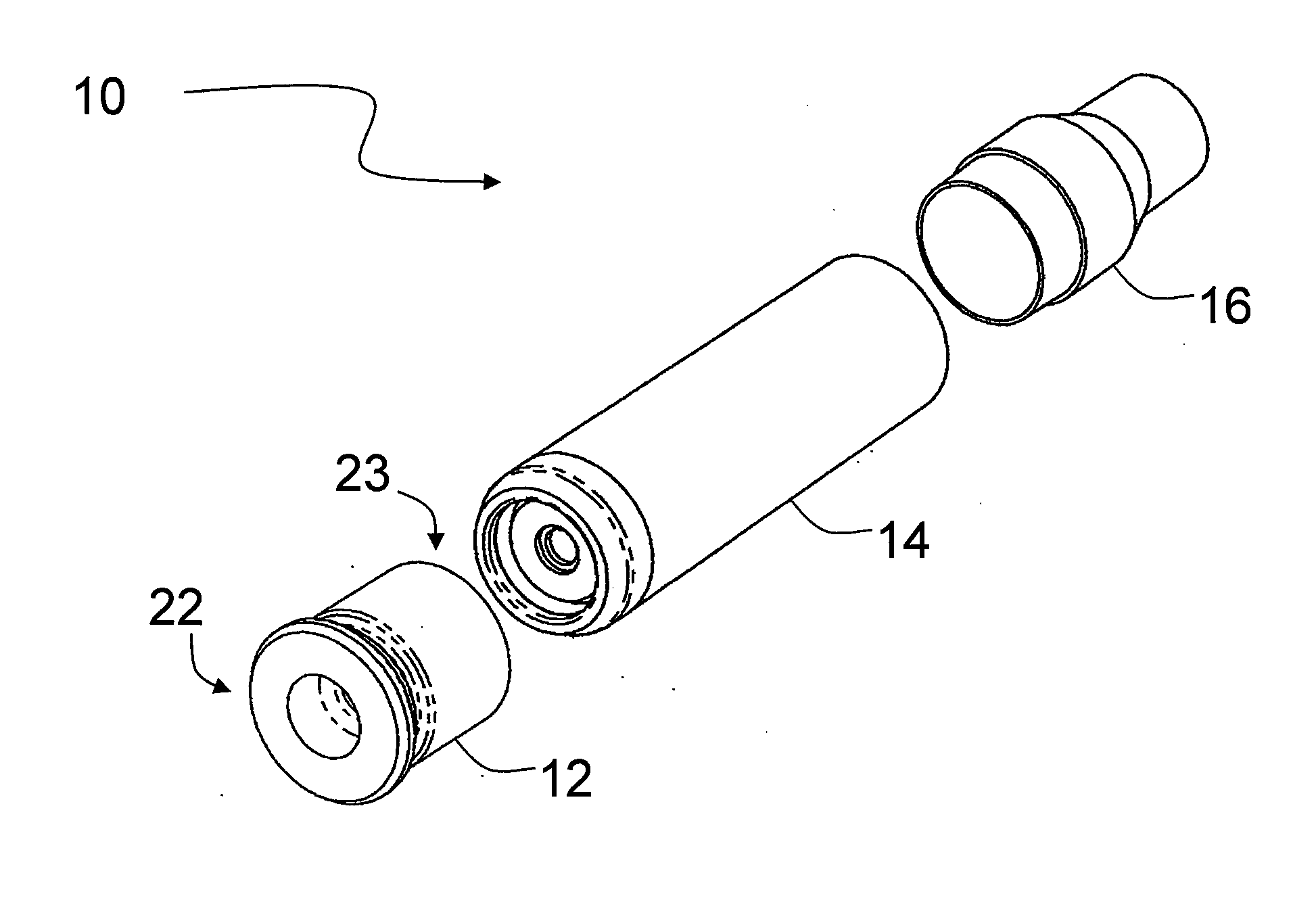

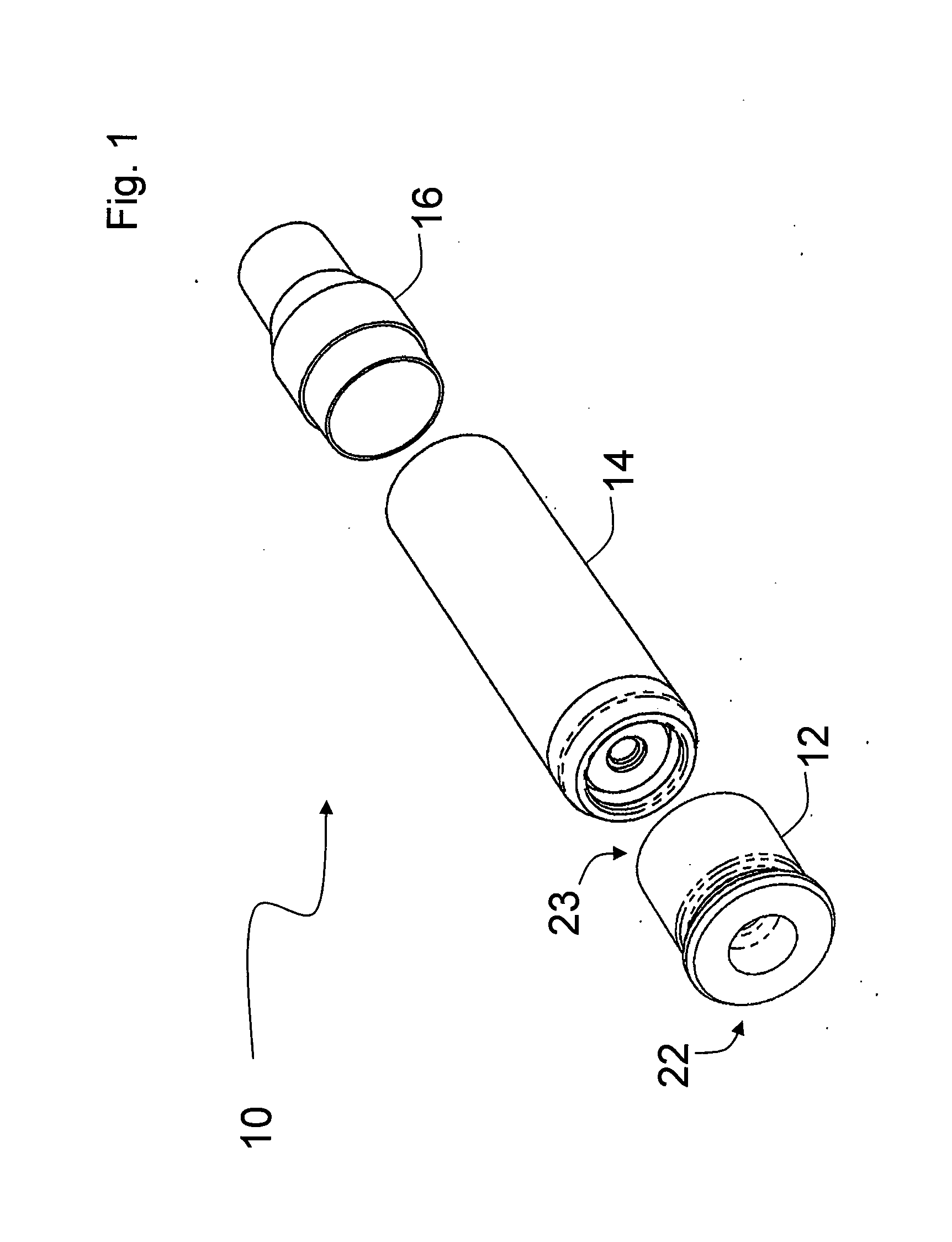

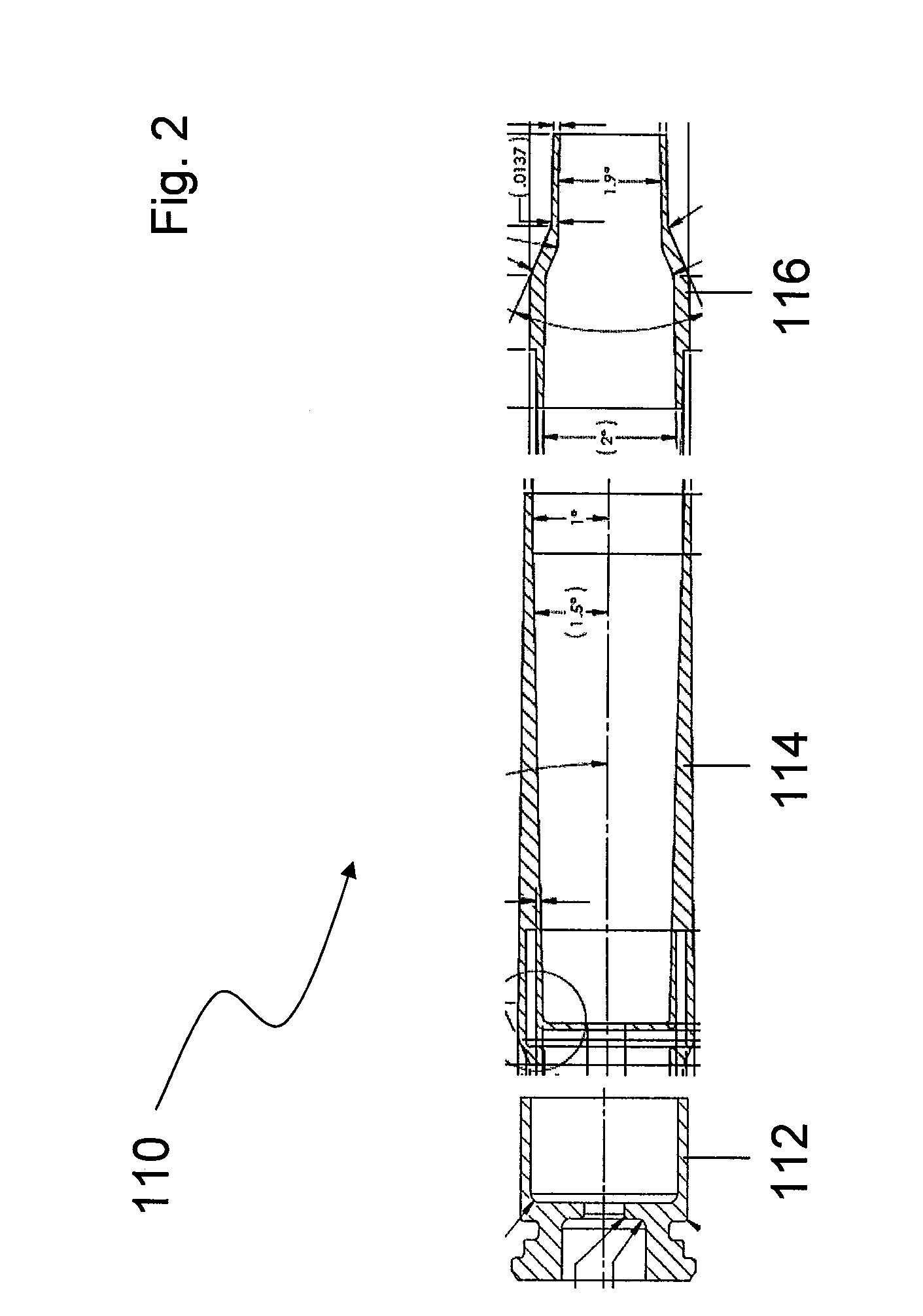

Ammunition cartridge case bodies made with polymeric nanocomposite material

The present invention is directed to a three-part ammunition cartridge casing body comprising a head or base portion, a case portion and a cap portion. The cartridge casing body further comprises: the base portion, made of metal or polymeric resin, having a closed end and an open end; a substantially cylindrical case portion, open on both ends, joined to the open end of the base portion and comprising a nanocomposite material of a nanoclay dispersed in a polyamide resin matrix; and a cap portion, made of a nanocomposite material of a nanoclay dispersed in a polyamide resin matrix and further comprising glass fibers, joined to the other end of the case portion, wherein the case portion is more ductile than the cap portion.

Owner:NYLON CORP OF AMERICA

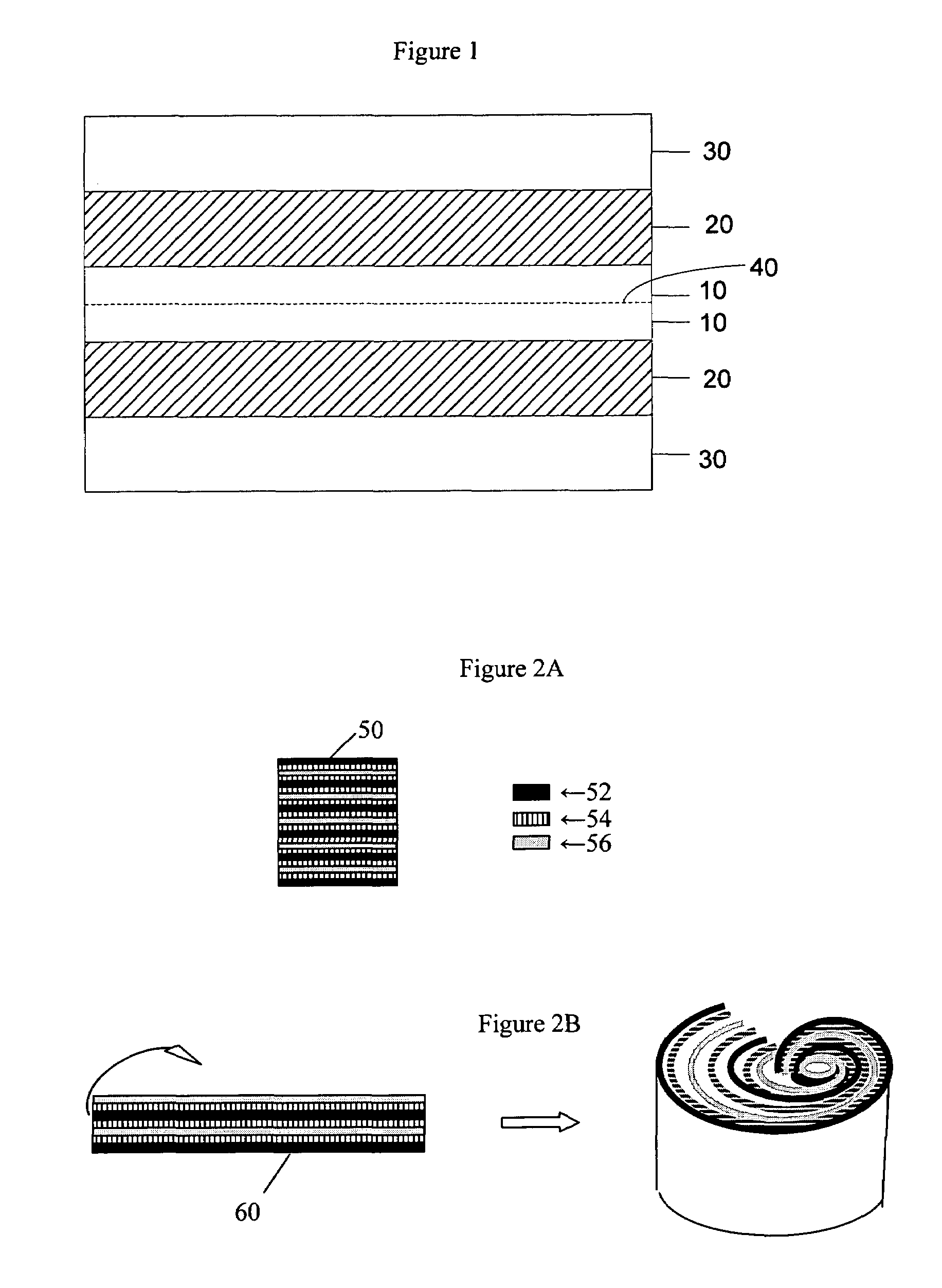

System and process for producing nanowire composites and electronic substrates therefrom

The present invention relates to a system and process for producing a nanowire-material composite. A substrate having nanowires attached to a portion of at least one surface is provided. A material is deposited over the portion to form the nanowire-material composite. The process further optionally comprises separating the nanowire-material composite from the substrate to form a freestanding nanowire-material composite. The freestanding nanowire material composite is optionally further processed into a electronic substrate. A variety of electronic substrates can be produced using the methods described herein. For example, a multi-color light-emitting diode can be produced from multiple, stacked layers of nanowire-material composites, each composite layer emitting light at a different wavelength.

Owner:ONED MATERIAL INC

Preparation method of polymer/graphene composite material through in situ reduction

ActiveCN101864098AEvenly dispersedQuality improvementSpecial tyresNon-conductive material with dispersed conductive materialElectrical conductorVulcanization

The invention relates to a preparation method of a polymer / graphene composite material through in situ reduction, which is characterized by comprising the following steps: adopting ultrasonic wave or grinding to evenly disperse the graphite oxide prepared by a Hummers method into polymer dispersion; introducing reducing agent into the polymer dispersion for in situ reduction, enabling the graphite oxide to be reduced into the grapheme so as to obtain stable polymer / graphene composite emulsion; carrying out demulsification, agglomeration and drying to obtain the composite polymer / grapheme composite master batch; adding the dried polymer / grapheme composite master batch and various assistants into the polymeric matrix according to a certain ratio; and carrying out double-roller mixing, vulcanization, melt extrusion or injection molding to obtain the polymer / graphene composite material with excellent physical and mechanical properties.

Owner:成都创威新材料有限公司

Nano graphene platelet-base composite anode compositions for lithium ion batteries

ActiveUS7745047B2Improve conductivityLower internal resistanceAlkaline accumulatorsElectrolytic capacitorsGraphiteGraphene

The present invention provides a nano-scaled graphene platelet-based composite material composition for use as an electrode, particularly as an anode of a lithium ion battery. The composition comprises: (a) micron- or nanometer-scaled particles or coating which are capable of absorbing and desorbing lithium ions; and (b) a plurality of nano-scaled graphene platelets (NGPs), wherein a platelet comprises a graphene sheet or a stack of graphene sheets having a platelet thickness less than 100 nm; wherein at least one of the particles or coating is physically attached or chemically bonded to at least one of the graphene platelets and the amount of platelets is in the range of 2% to 90% by weight and the amount of particles or coating in the range of 98% to 10% by weight. Also provided is a lithium secondary battery comprising such a negative electrode (anode). The battery exhibits an exceptional specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

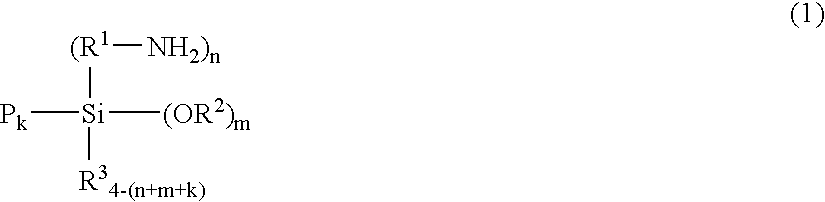

Conjugated diolefin (co)polymer rubber, process for producing (co)polymer rubber, rubber composition, composite, and tire

ActiveUS7342070B2Reduce fuel consumptionImprove performanceSpecial tyresRolling resistance optimizationHysteresisPolymer science

Disclosed are a conjugated diolefin (co) polymer rubber formed from either a conjugated diolefin or a conjugated diolefin and an aromatic vinyl compound, wherein the (co) polymer rubber has a primary amino group and an alkoxysilyl group which are bonded to a (co) polymer chain; a process for producing the same; a rubber composition; a composite; and a tire. The (co) polymer rubber has satisfactory processability, and can give an automotive tire tread having a balance among wear resistance, failure characteristics, low hysteresis loss and wet-skid characteristics.

Owner:ENEOS MATERIALS CORP

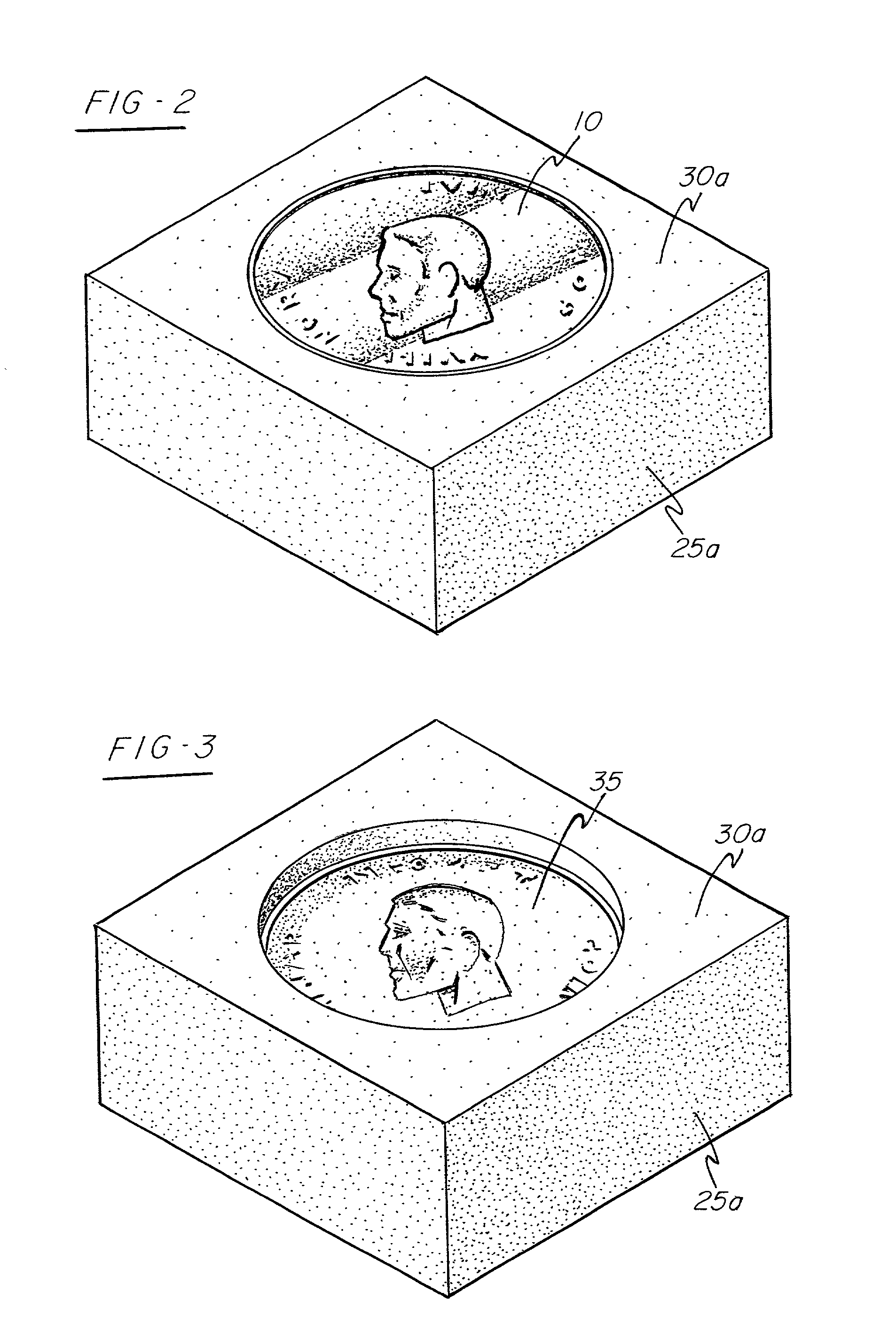

Structural and optical applications for shape memory polymers (SMP)

InactiveUS6986855B1Easy to processReduce handling costsDischarging arrangementMouldsVisual inspectionUltraviolet

The methods of manufacturing molds from shape memory materials and molds made thereby, in accordance with the present invention, provide numerous advantages for molding castable composite parts. The initial mold cost is low enough to accommodate economical production of as few as a single part incorporating high surface definition and intricate three dimensional detail. The preferred methods and molds made thereby are transparent, thereby, curing of the corresponding part by ultra-violet and infra-red light is made possible, as well as, visual inspection during injection and curing of the given resin. Removal of the cured part from within the mold is simplified.

Owner:SPINTECH LLC

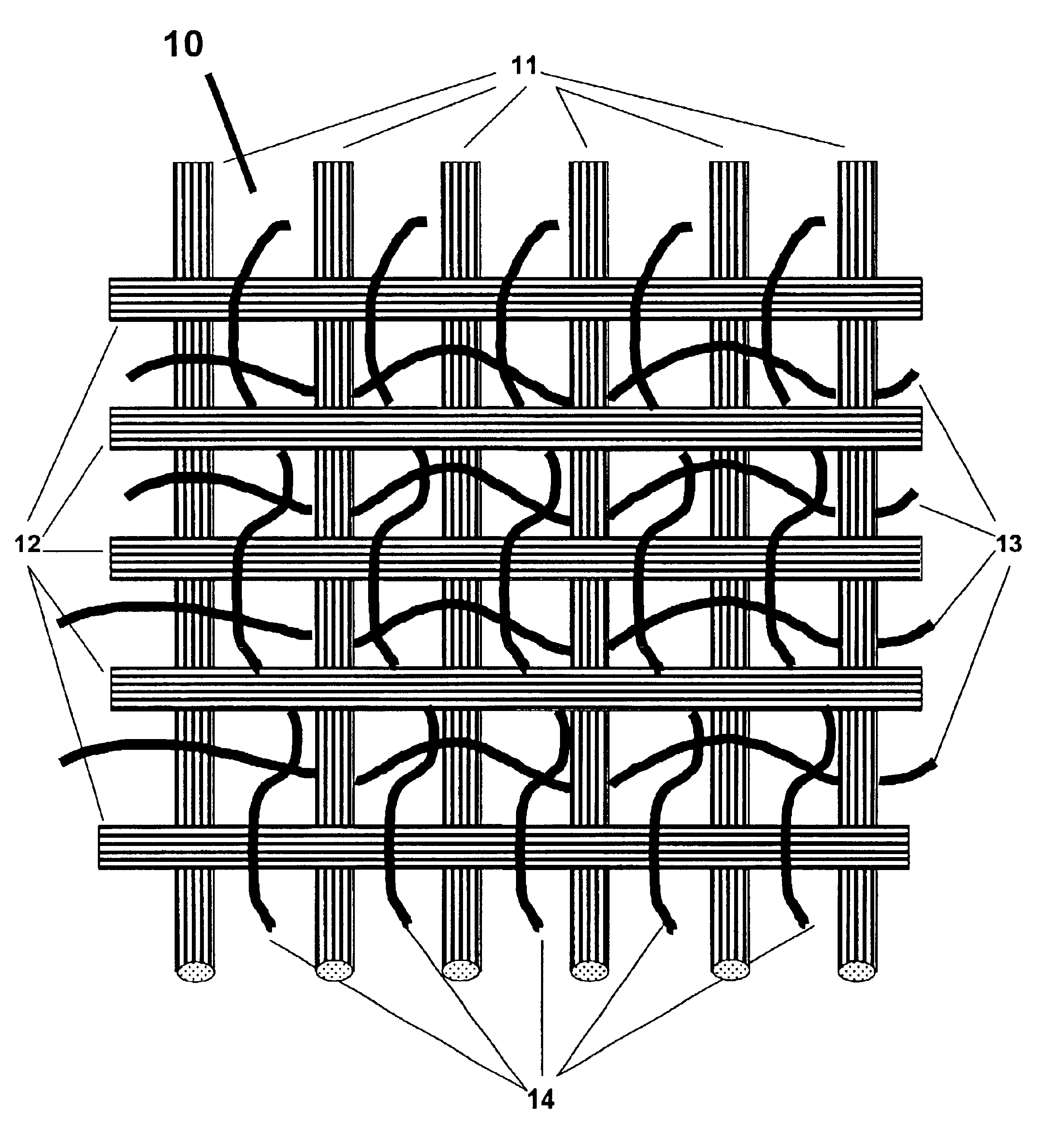

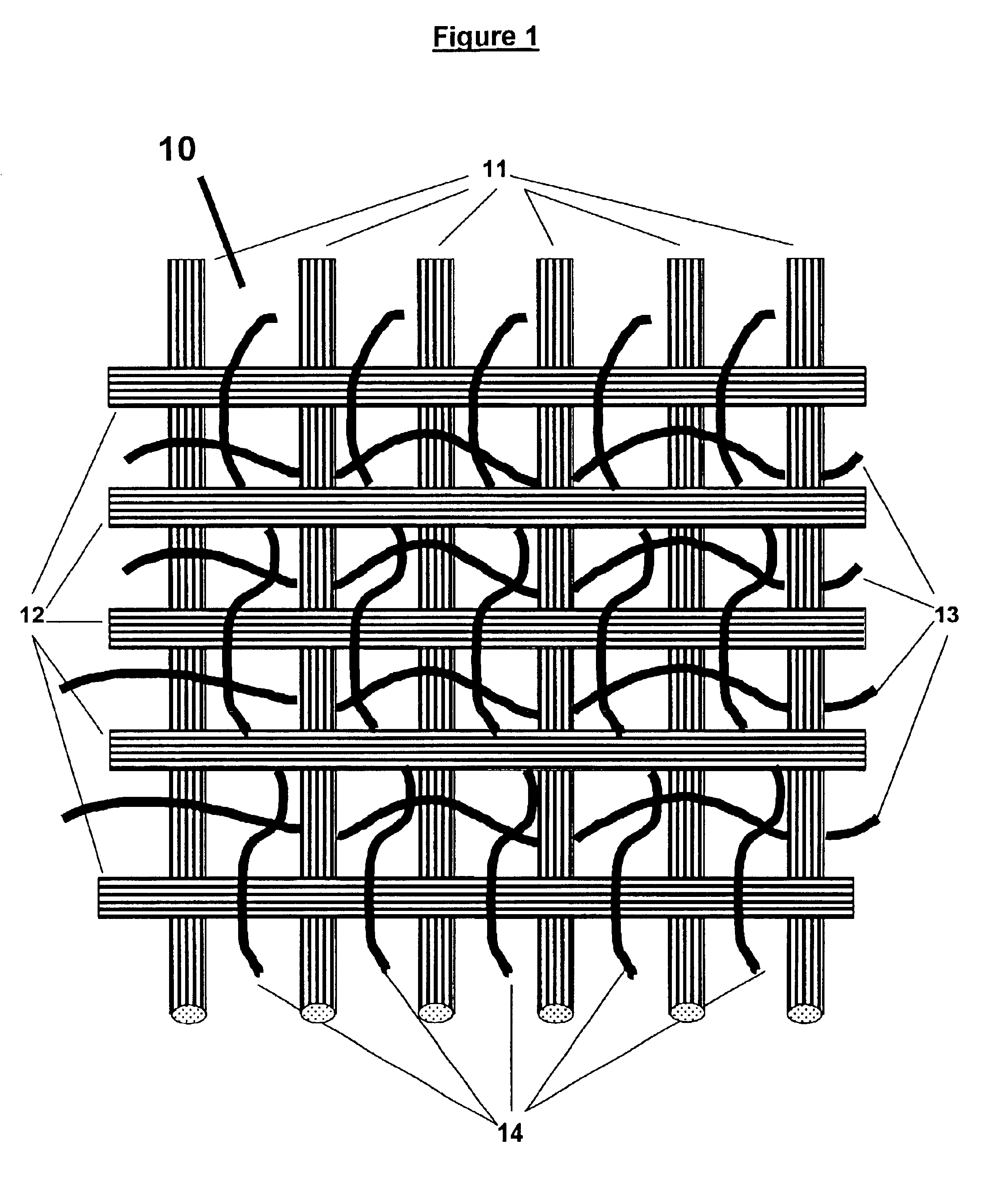

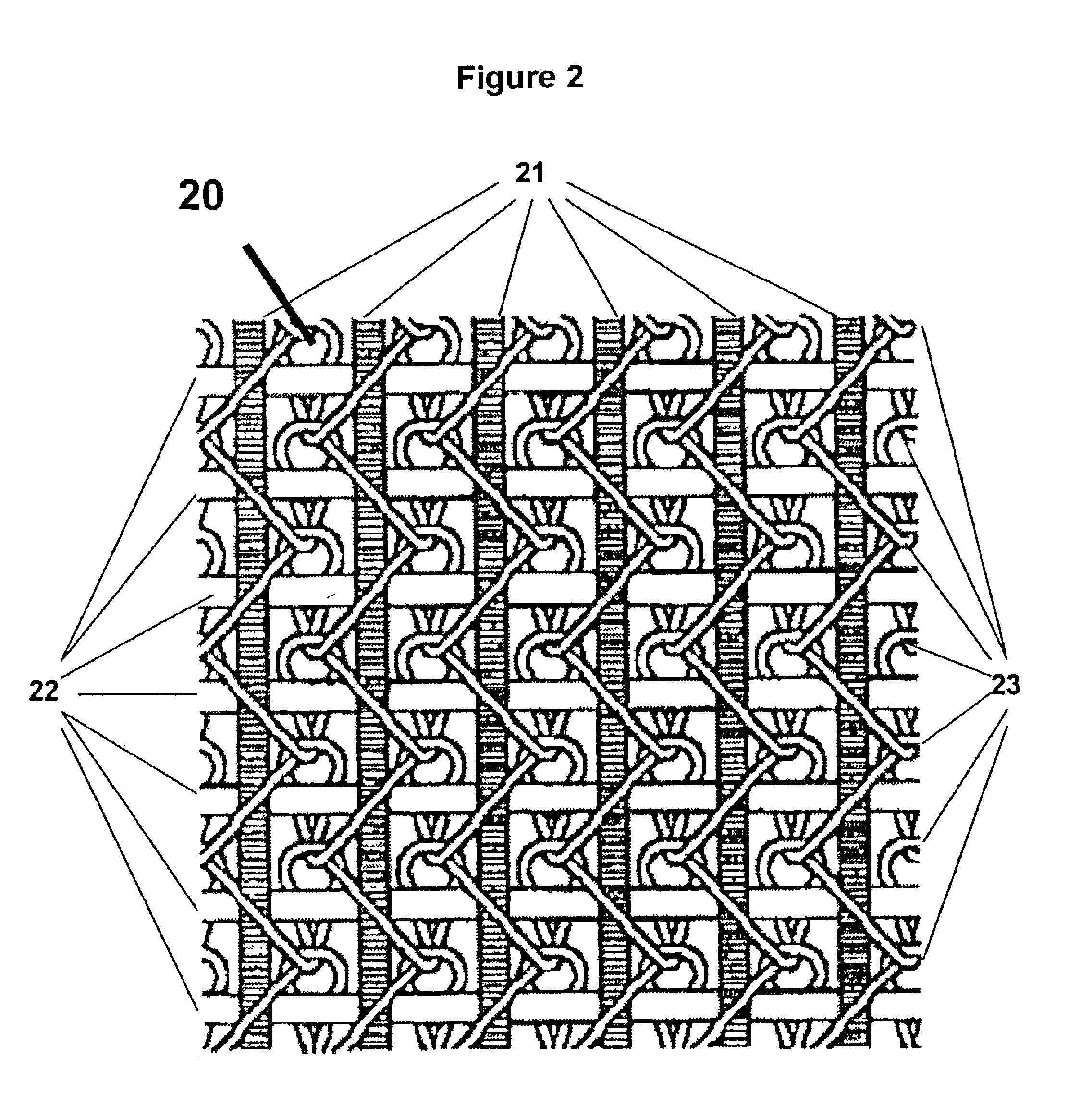

Bi-directional and multi-axial fabrics and fabric composites

InactiveUS6841492B2Increase resistanceImprove effectivenessOrnamental textile articlesProtective fabricsYarnEngineering

Bi-directional and multi-axial fabrics, fabric composites, ballistically resistant assemblies thereof, and the methods by which they are made. The fabrics are comprised of sets of strong, substantially parallel, unidirectional yarns lying in parallel planes, one above the other, with the direction of the yarns in a given plane rotated at an angle to the direction of the yarns in adjacent planes; and one or more sets of yarns having lower strength and higher elongation interleaved with the strong yarns. The fabrics of the invention provide superior ballistic effectiveness compared to ordinary woven and knitted fabrics but retain the ease of manufacture on conventional looms and knitting machines.

Owner:HONEYWELL INT INC

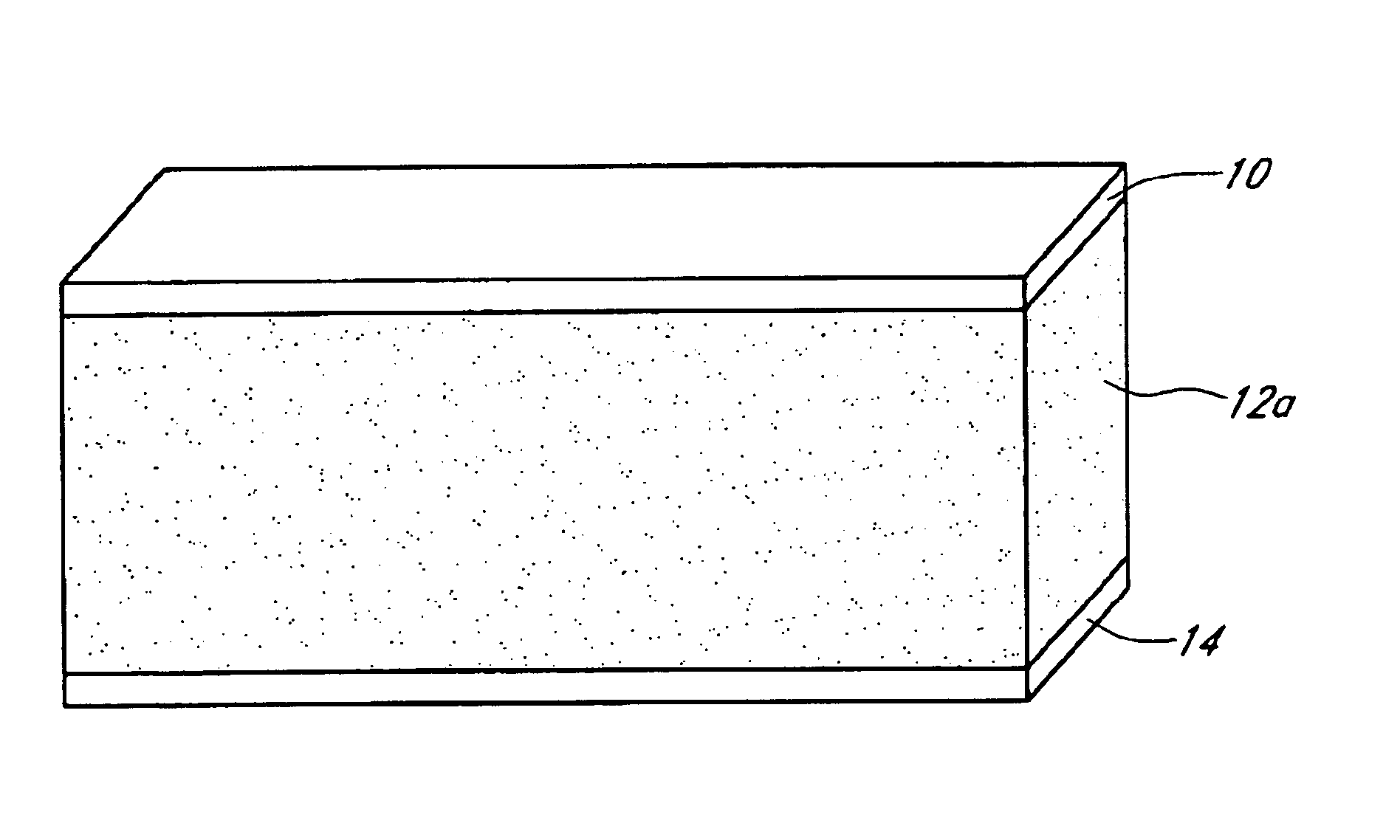

Composite building material

InactiveUS6941720B2Reduce noise transmissionLow acoustic transmissionConstruction materialSolid waste managementArchitectural engineeringPlastic property

This invention generally pertains to a composite building material comprising a lightweight core with a thin fiber cement facing on one side of the core and a second facing material on the other side. The fiber cement facing that is used on at least one of the faces of the building material is 3 / 16″ or less, more preferably ⅛″ or less. The green fiber cement facing is preferably formed by a slurry-dewatering process to form a sheet that is in a plastic, uncured, state prior to manufacture of the composite. The composite building material is assembled in an uncured state and then cured.

Owner:JAMES HARDIE TECH LTD

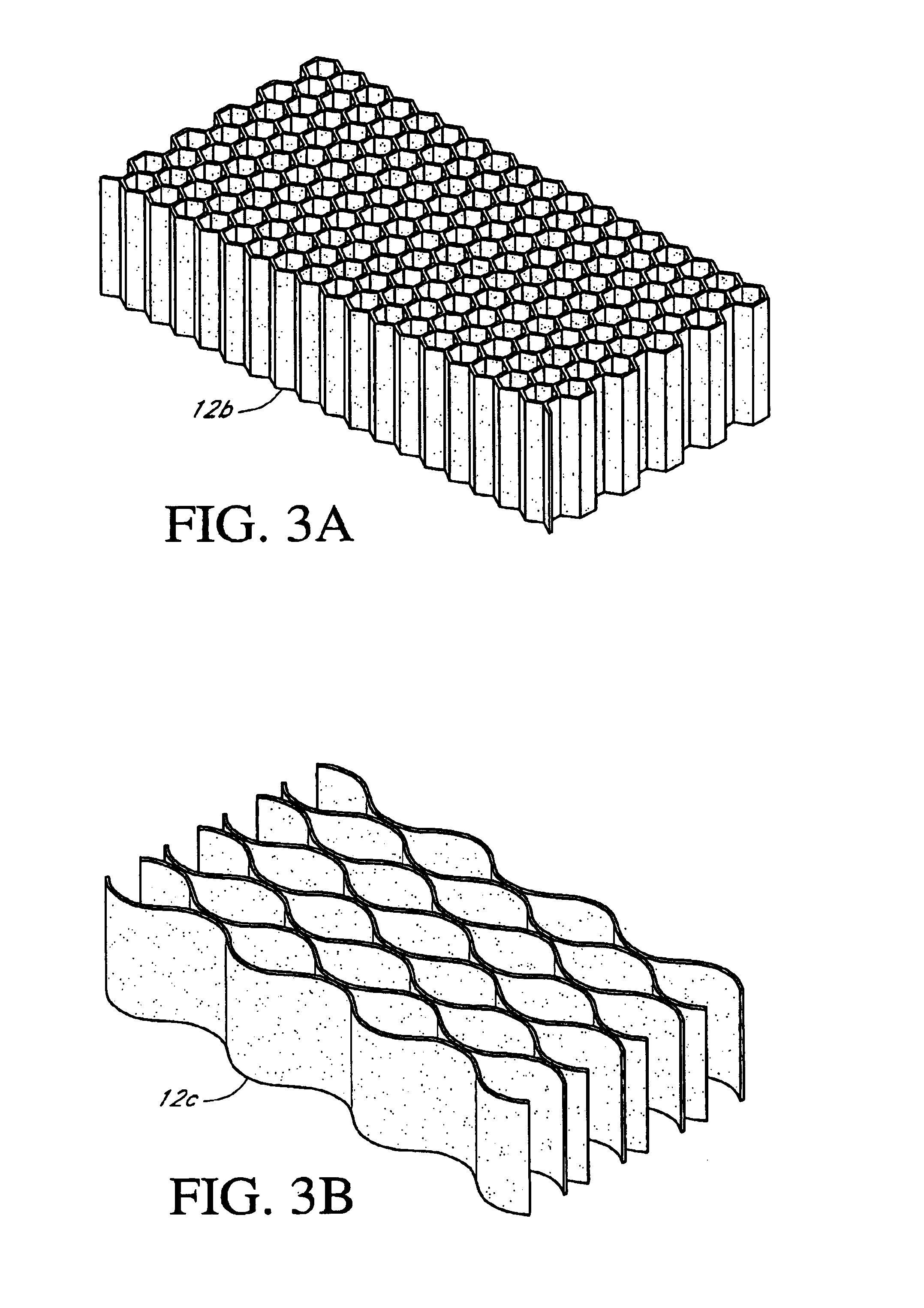

Tissue engineering composite

InactiveUS6991652B2Facilitate formationNon-invasive methodBiocideCosmetic implantsTissue engineeringDamages tissue

The invention provides a biocompatible composite for use in a living subject for purposes of repairing damaged tissues and reconstructing a new tissue. The composite includes a biodegradable or absorbable three-dimensional support construct, a liquid or viscous fluid forming a gel matrix or viscous fluid when delivered to an area of interest in a living subject. The biodegradable construct provides an ideal surface for cell or cell extract attachment, while the gel matrix or viscous fluid acts as both a carrier material and a separator for maintaining the space between the constructs as well as the structural integrity of the developing issue.

Owner:CLEMSON UNIV RES FOUND +1

Ammunition cartridge case bodies made with polymeric nanocomposite material

The present invention is directed to a three-part ammunition cartridge casing body comprising a head or base portion, a case portion and a cap portion. The cartridge casing body further comprises: the base portion, made of metal or polymeric resin, having a closed end and an open end; a substantially cylindrical case portion, open on both ends, joined to the open end of the base portion and comprising a nanocomposite material of a nanoclay dispersed in a polyamide resin matrix; and a cap portion, made of a nanocomposite material of a nanoclay dispersed in a polyamide resin matrix and further comprising glass fibers, joined to the other end of the case portion, wherein the case portion is more ductile than the cap portion.

Owner:NYLON CORP OF AMERICA

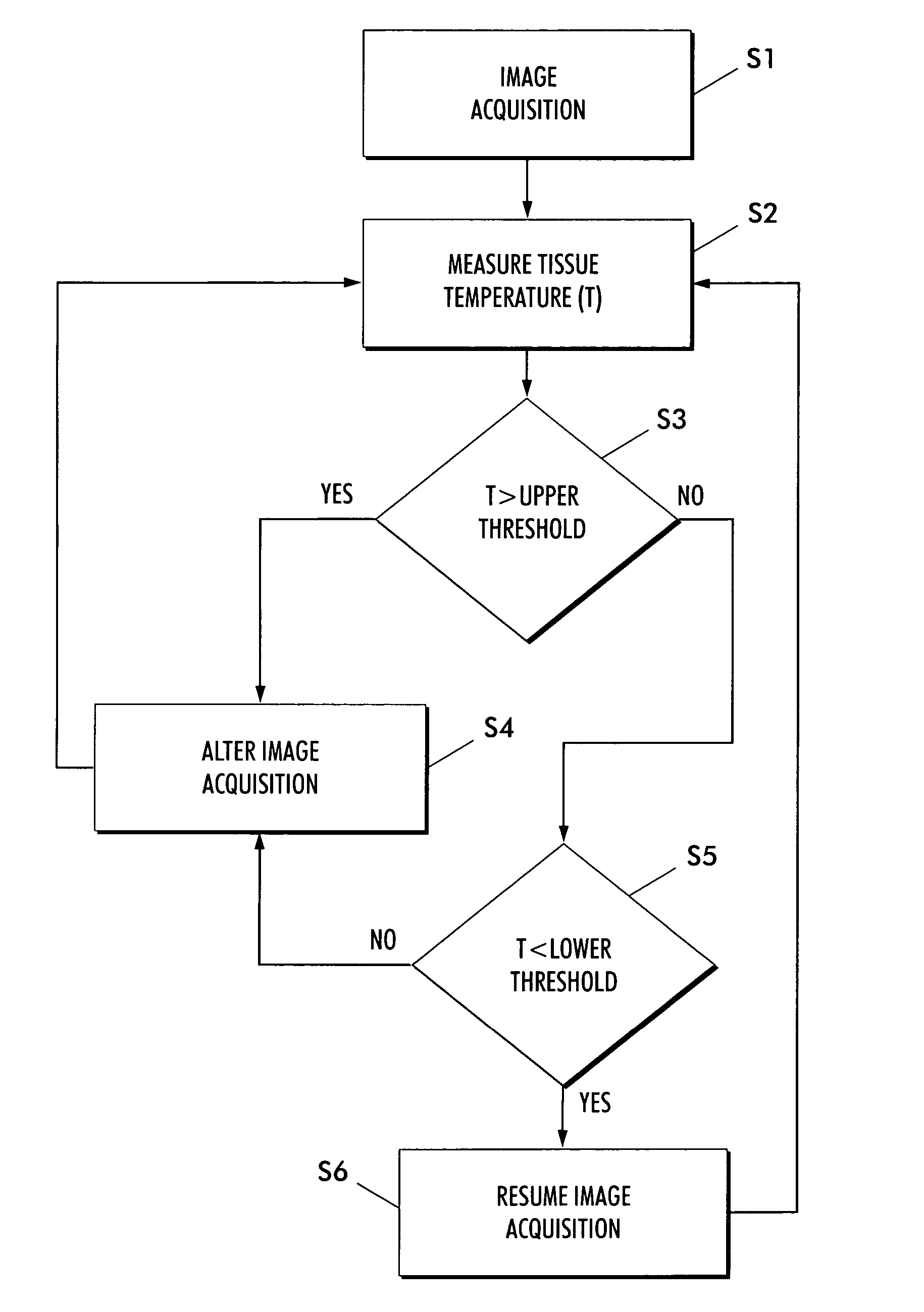

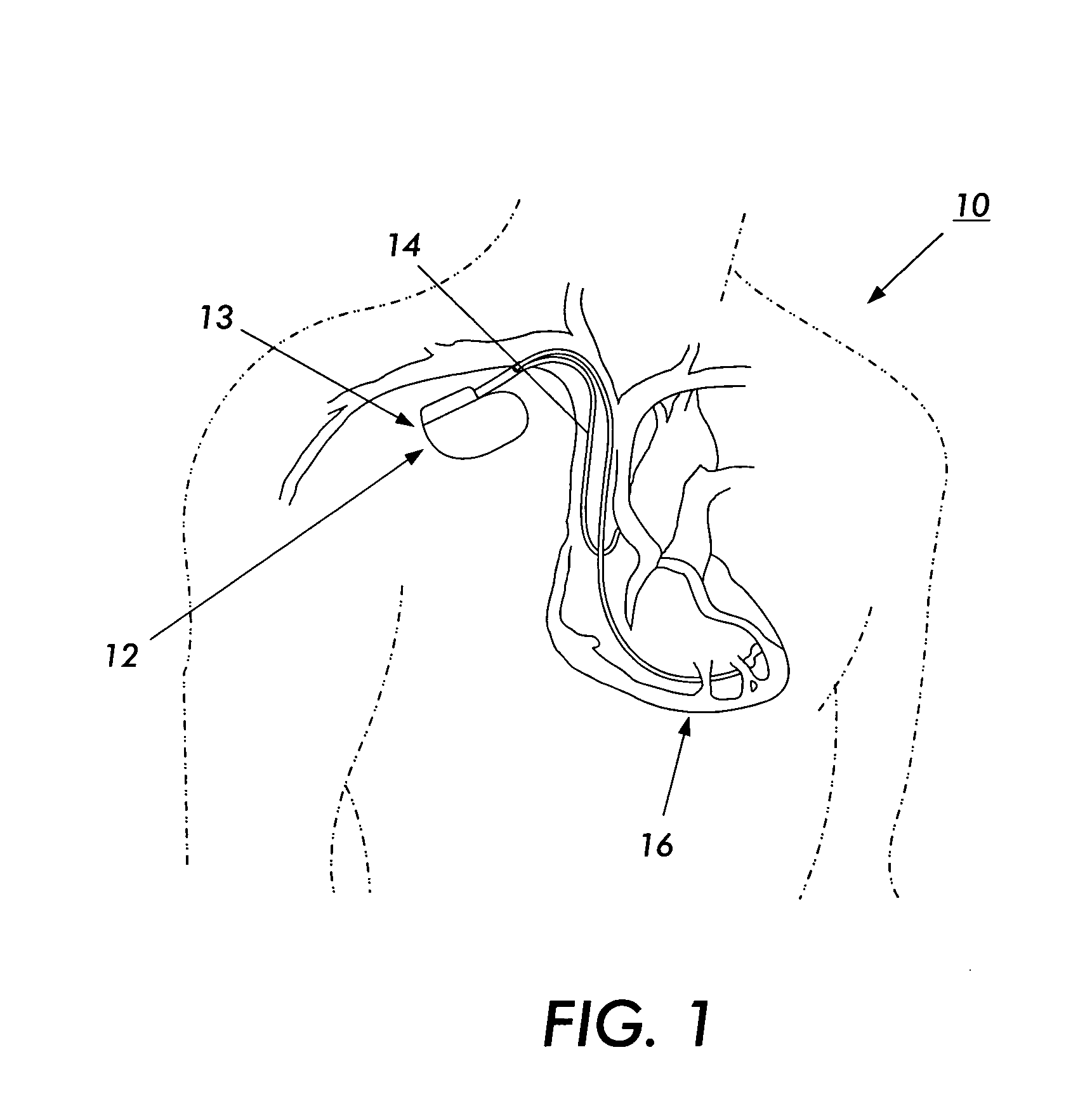

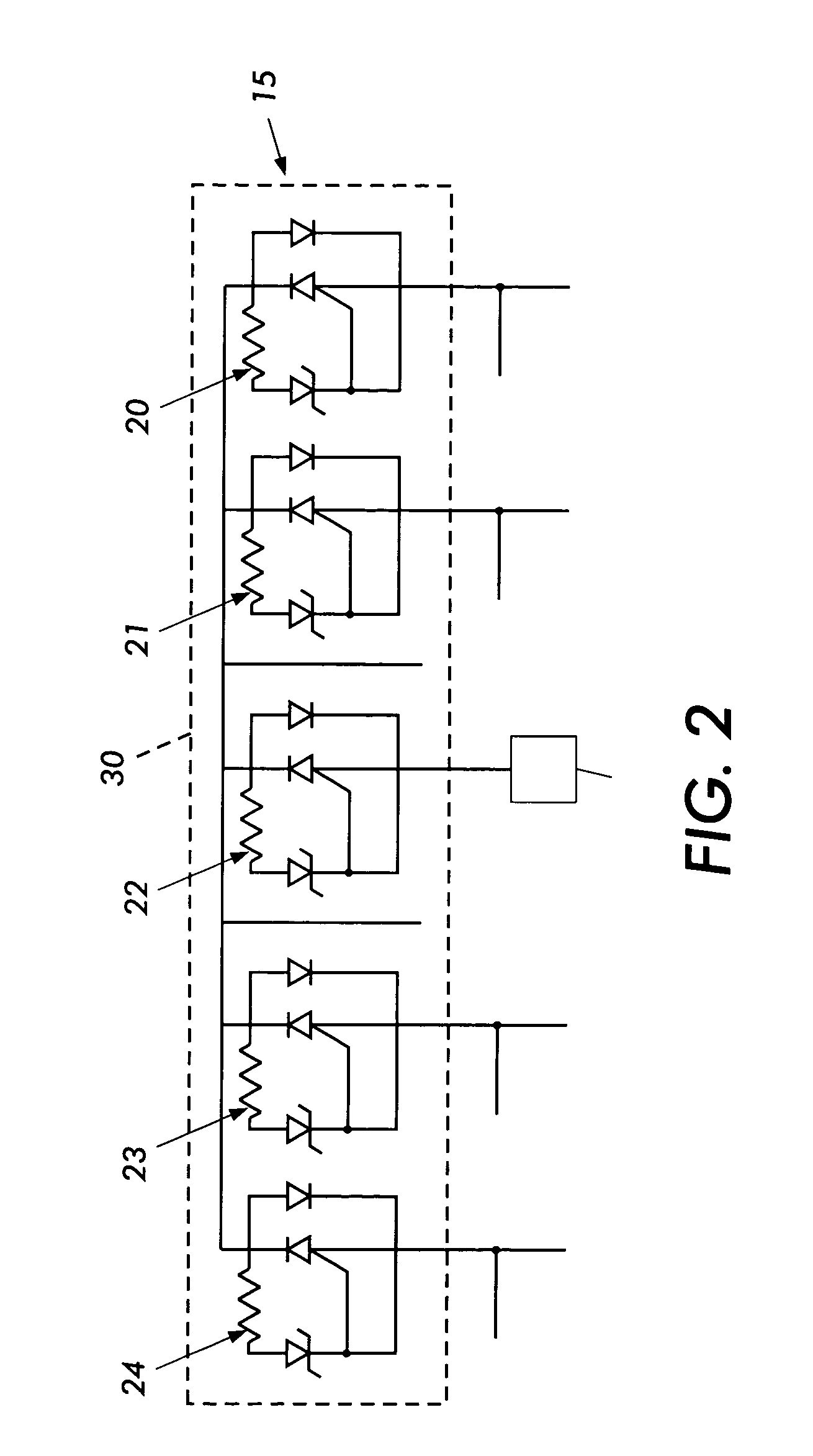

Device and method for preventing magnetic resonance imaging induced damage

An electromagnetic shield has a first patterned or apertured layer having non-conductive materials and conductive material and a second patterned or apertured layer having non-conductive materials and conductive material. The conductive material may be a metal, a carbon composite, or a polymer composite. The non-conductive materials in the first patterned or apertured layer may be randomly located or located in a predetermined segmented pattern such that the non-conductive materials in the first patterned or apertured layer are located in a predetermined segmented pattern with respect to locations of the non-conductive materials in the second patterned or apertured layer.

Owner:MEDTRONIC INC

Two-dimensional fiber cloth reinforced composite material and preparation method thereof

InactiveCN101224989AImprove fracture toughnessImprove use reliabilityMetal powderStructural stability

The invention discloses a two-dimensional fiber cloth reinforced ceramics based composite material and the preparation technique, which adopts the two-dimensional fiber cloth as the reinforcing phase and the ceramic powder or the refractory metal powder as the stuffing, and the carbon and the carborundum as the base. The process steps are following: first the sizing agent with different ceramic powder and metal powder is coated on the two-dimensional fiber cloth, and then overlapping, puncturing and repeated densification are carried out. The preparation method has the advantages of lowering preparation cost and shortening preparation cycle, and the two-dimensional fiber cloth reinforced ceramics based composite material has the advantages of high shear strength between layers, structural stability and high reliability. The types of fiber cloth and the base can be adjusted and optimized in a wider range according to the applications, so as to be applicable for different fields.

Owner:NAT UNIV OF DEFENSE TECH

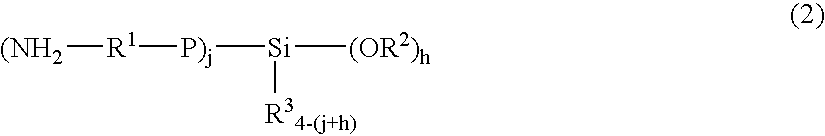

Insulating sheathing with tough three-ply facers

InactiveUS6093481AImprove insulation performanceHighly controllableSynthetic resin layered productsHeat proofingPuncture resistanceHardness

A method for continuously manufacturing an insulation board by facing a foam-forming composition with one or two facing sheets to form a singly or doubly faced composite, at least one sheet comprising either a tough polymeric layer or a laminate of a tough polymeric layer with at least one other facing material, the tough polymeric layer of at least one sheet facing to the outside of the composite, and foaming and curing the faced foam-forming mixture to produce an insulation board having an exceptional hardness and puncture resistance.

Owner:THE DOW CHEM CO

Aerogel-foam composites

InactiveUS20090029147A1Increase flexibilityMaintain good propertiesSolar heat devicesSynthetic resin layered productsPolymer scienceMonolith

The invention provides reinforced aerogel monoliths as well as reinforced composites thereof for a variety of uses. Compositions and methods of preparing the monoliths and composites are also provided. Application of these materials in transparent assemblies is also discuss.

Owner:ASPEN AEROGELS

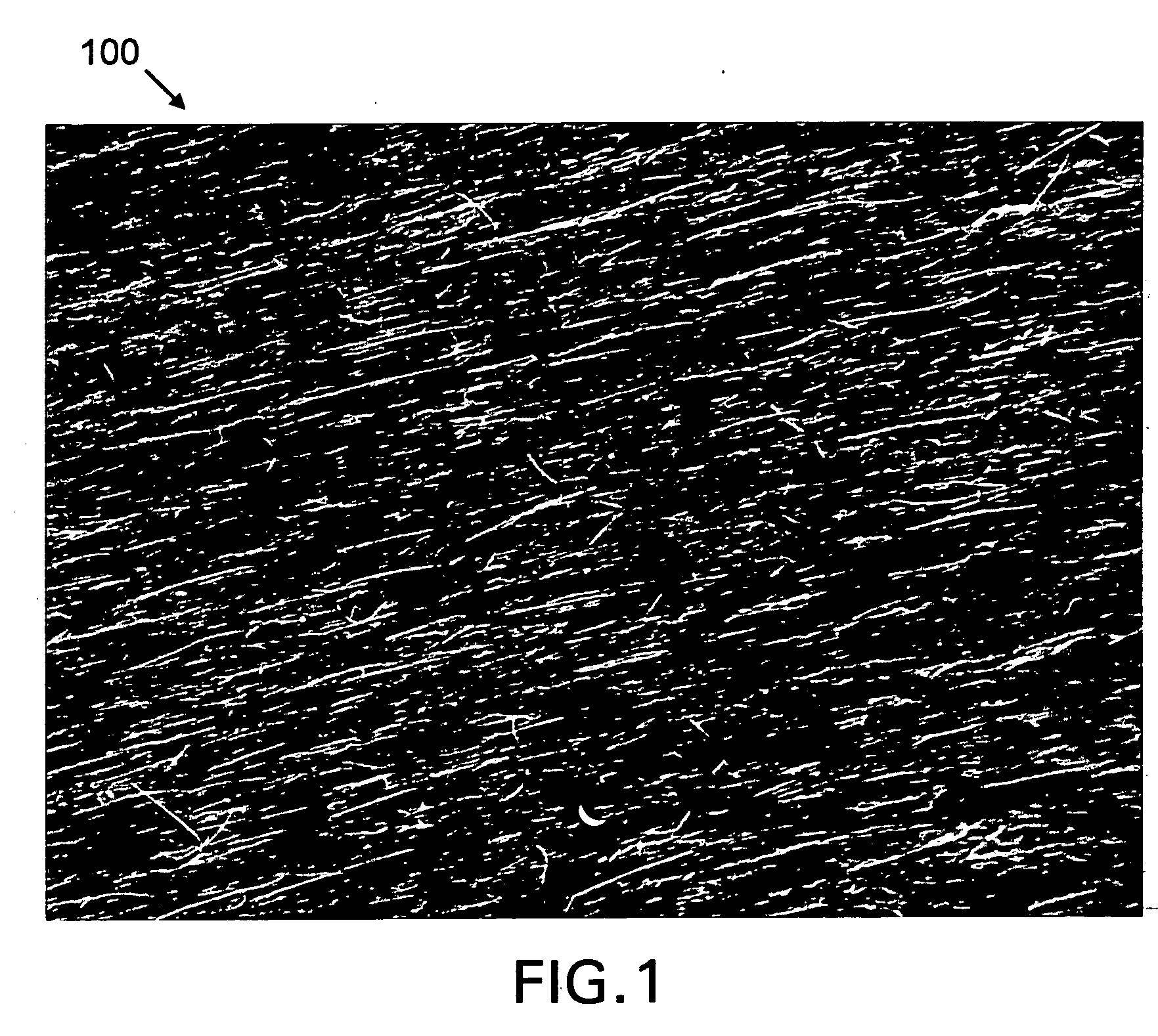

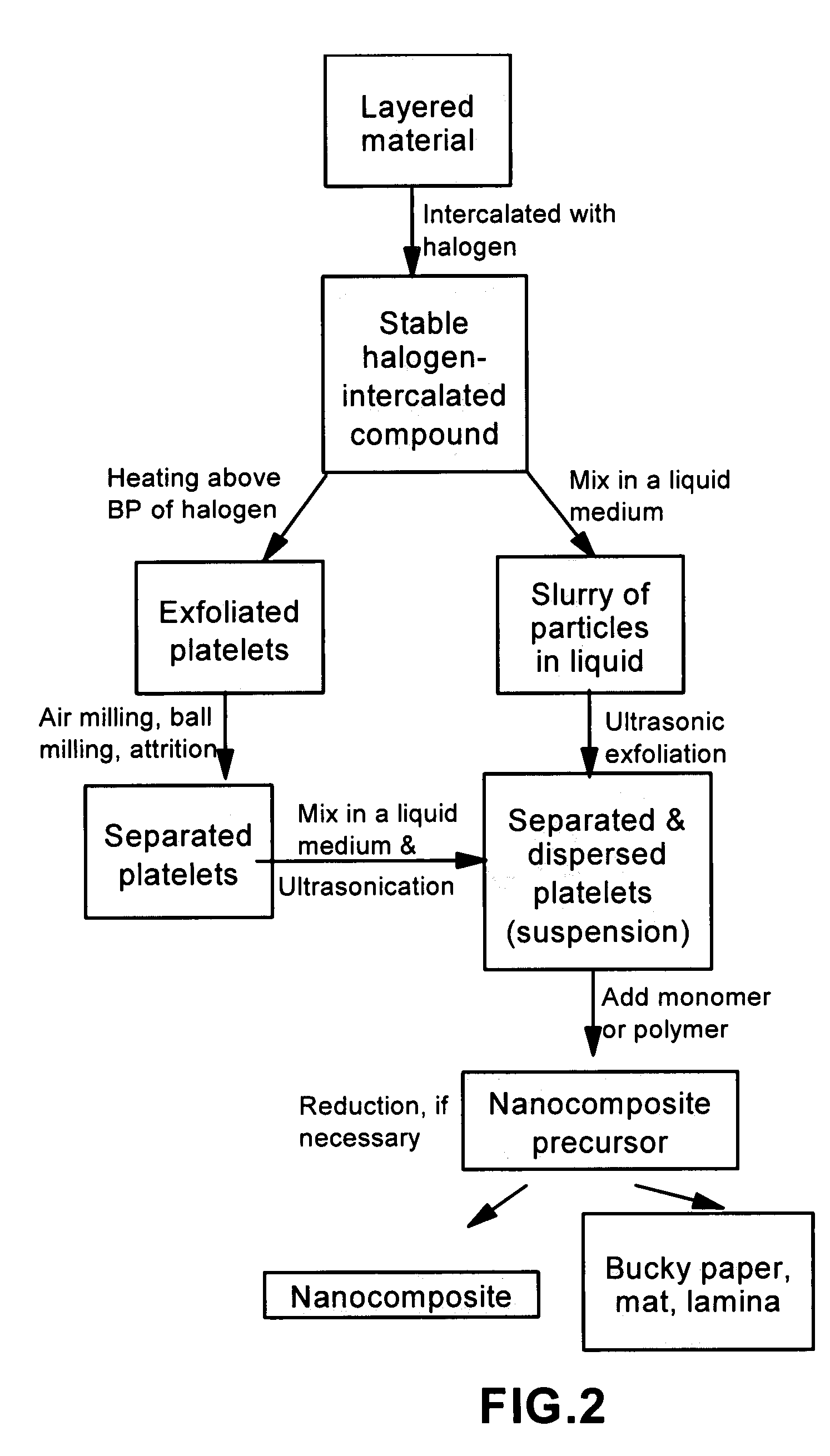

Method of producing nano-scaled graphene and inorganic platelets and their nanocomposites

ActiveUS20080206124A1Readily captured and re-usedReduce impactCarbon compoundsSelenium/tellurium compundsLiquid mediumPhysical chemistry

Disclosed is a method of exfoliating a layered material (e.g., graphite and graphite oxide) to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm, and often between 0.34 nm and 1.02 nm. The method comprises: (a) subjecting the layered material in a powder form to a halogen vapor at a first temperature above the melting point or sublimation point of the halogen at a sufficient vapor pressure and for a duration of time sufficient to cause the halogen molecules to penetrate an interlayer space of the layered material, forming a stable halogen-intercalated compound; and (b) heating the halogen-intercalated compound at a second temperature above the boiling point of the halogen, allowing halogen atoms or molecules residing in the interlayer space to exfoliate the layered material to produce the platelets. Alternatively, rather than heating, step (a) is followed by a step of dispersing the halogen-intercalated compound in a liquid medium which is subjected to ultrasonication for exfoliating the halogen-intercalated compound to produce the platelets, which are dispersed in the liquid medium. The halogen can be readily captured and re-used, thereby significantly reducing the impact of halogen to the environment. The method can further include a step of dispersing the platelets in a polymer or monomer solution or suspension as a precursor step to nanocomposite fabrication.

Owner:GLOBAL GRAPHENE GRP INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com