Patents

Literature

215results about How to "Reduce handling costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

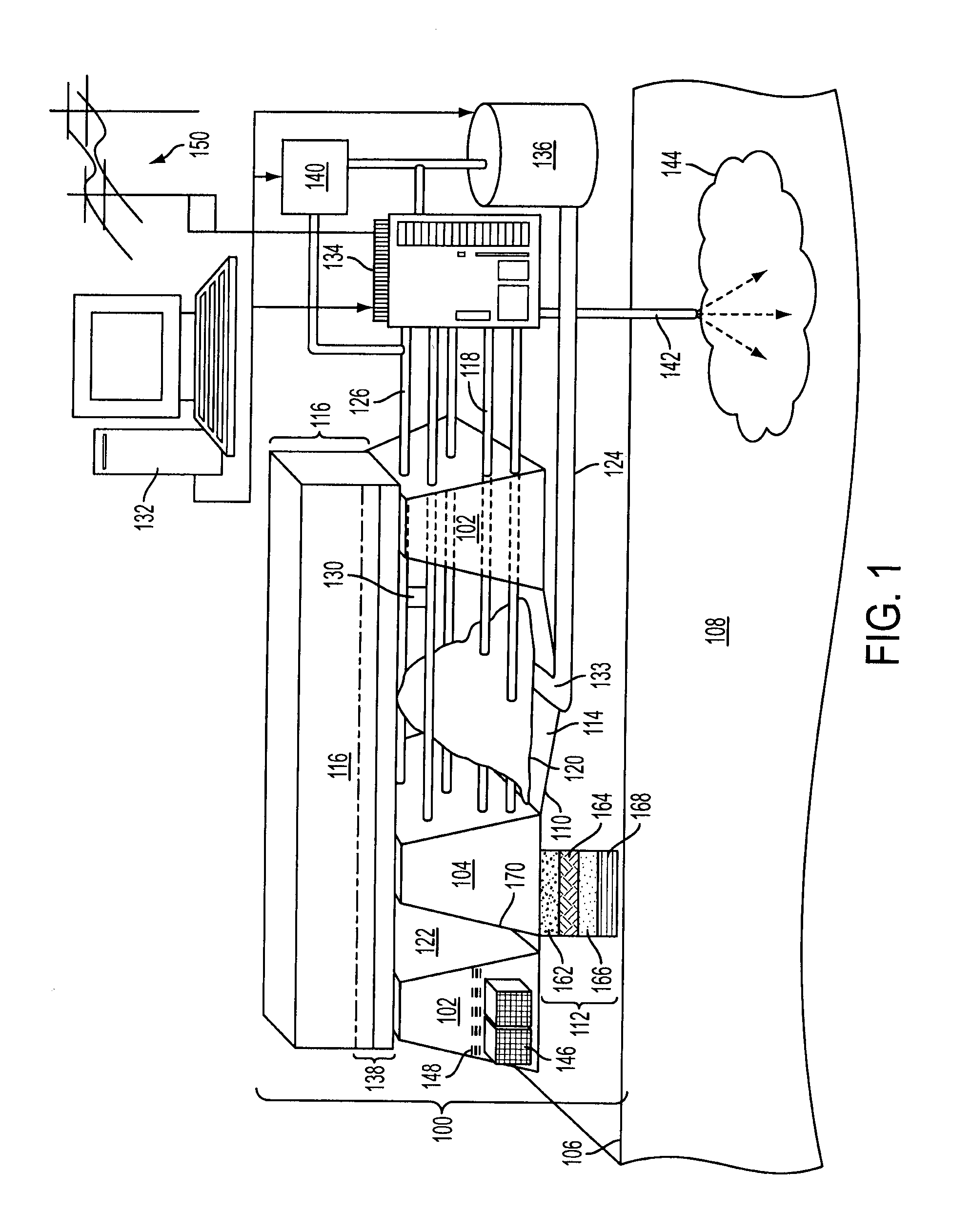

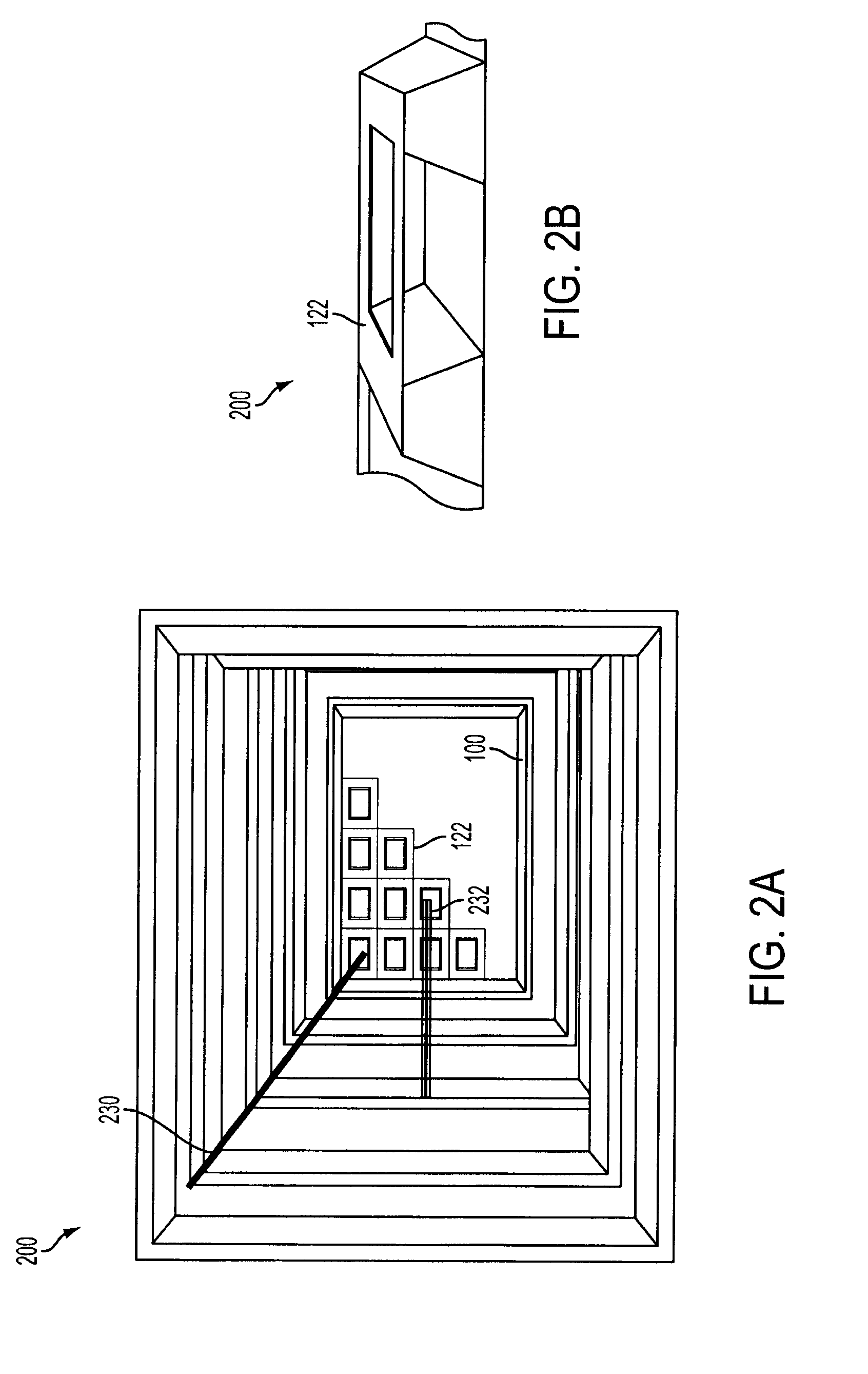

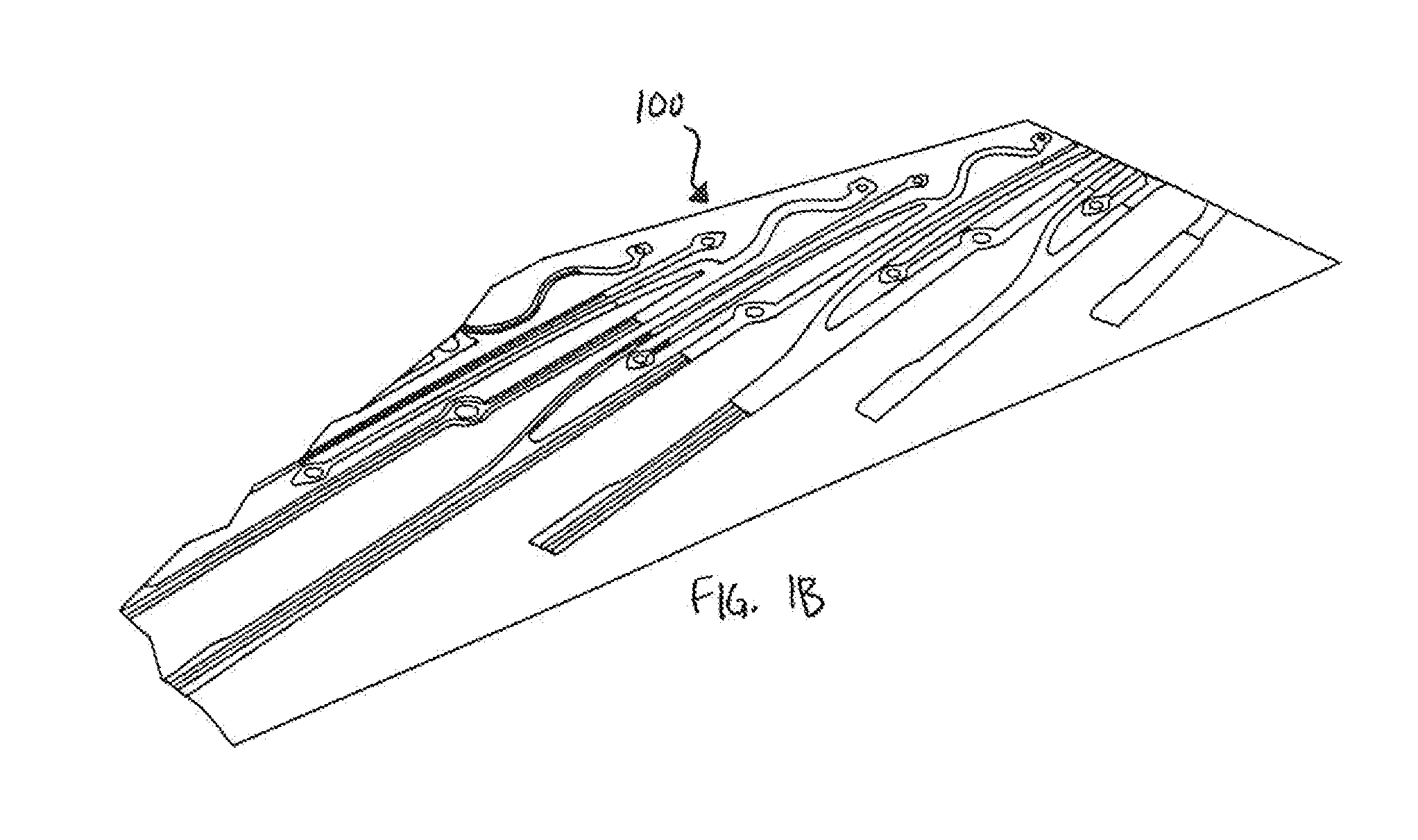

Shoreline erosion and flood control system and method

ActiveUS20070140598A1Reduce shippingReduce handling costsBagsCoastlines protectionEngineeringFlood control

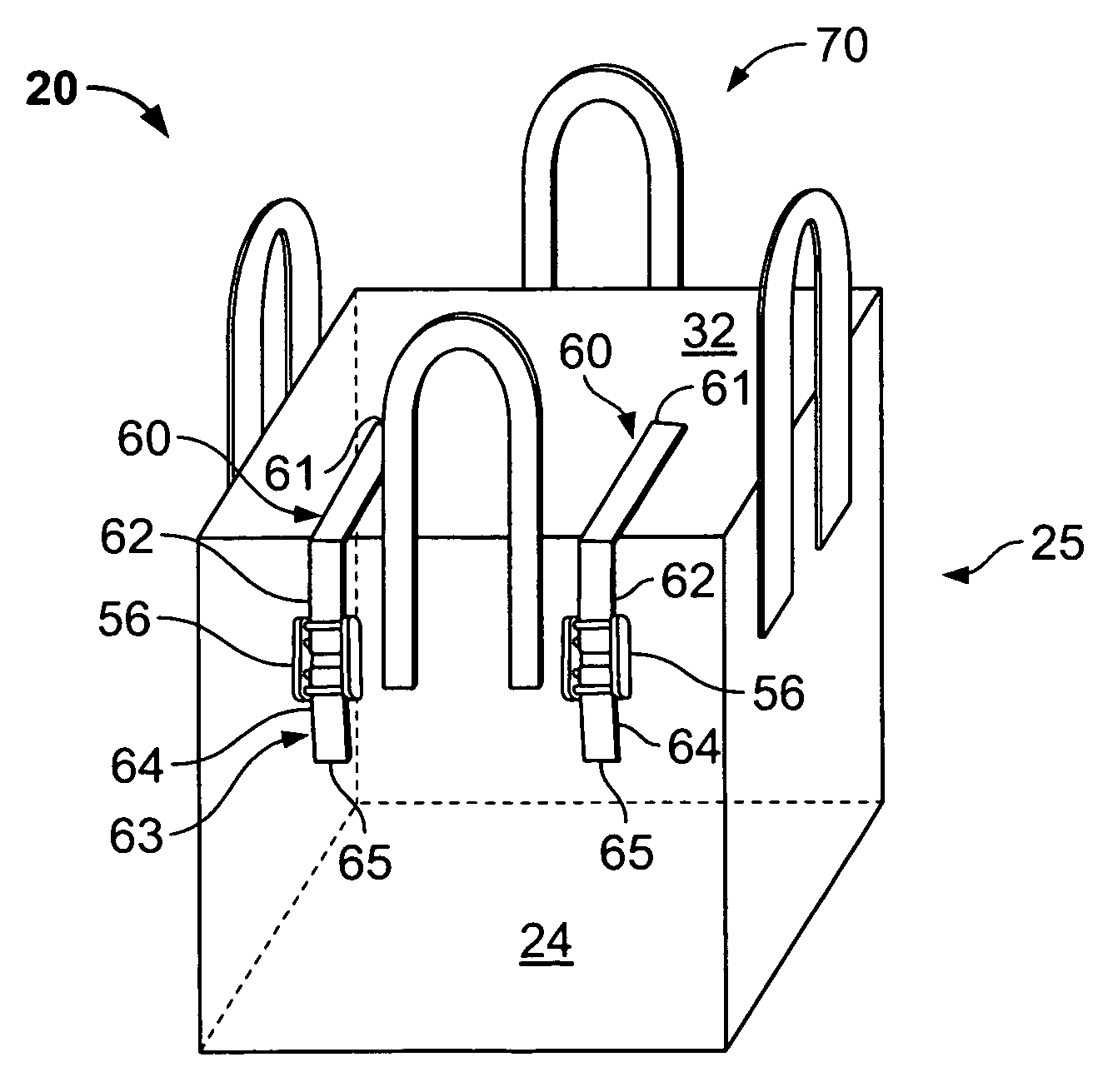

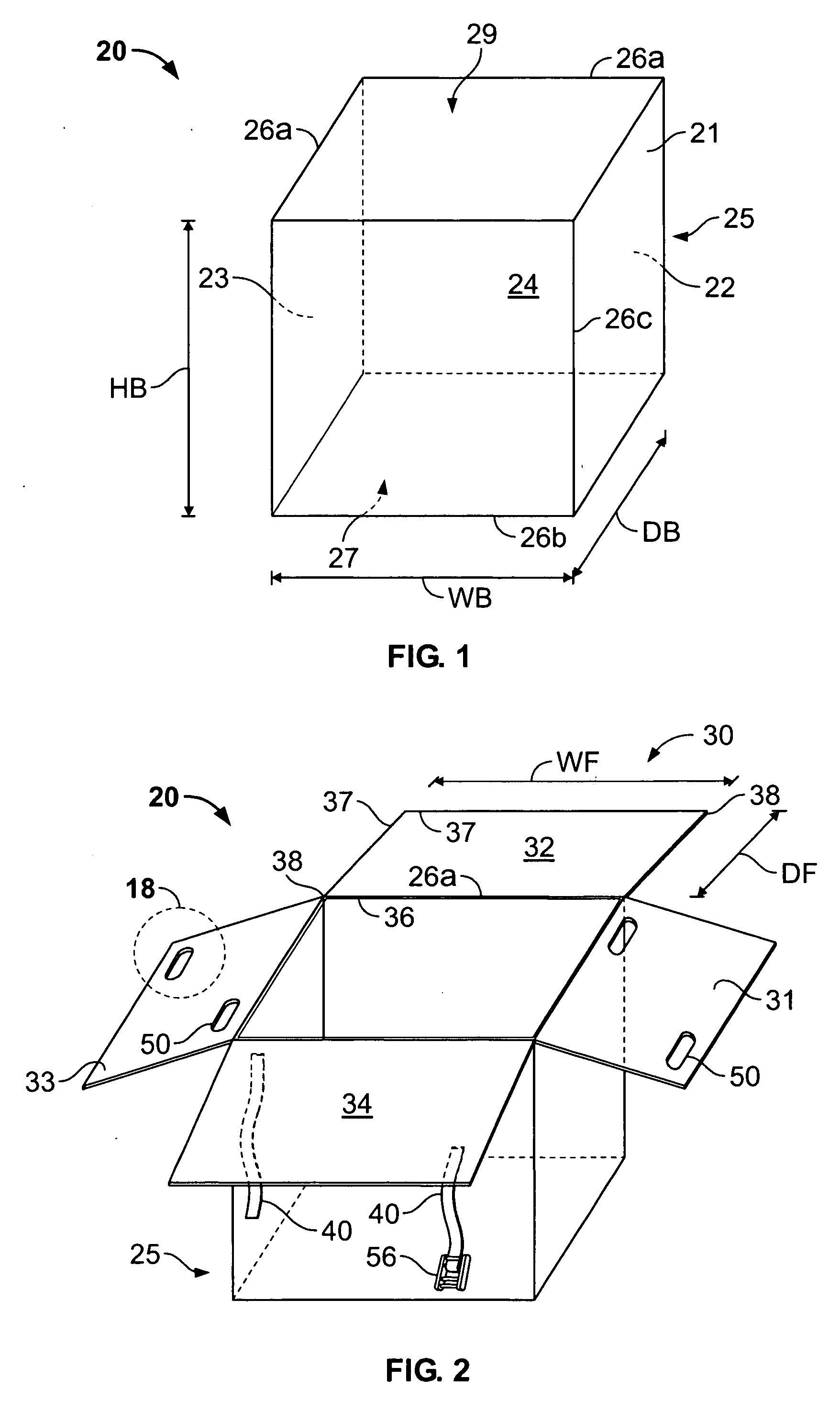

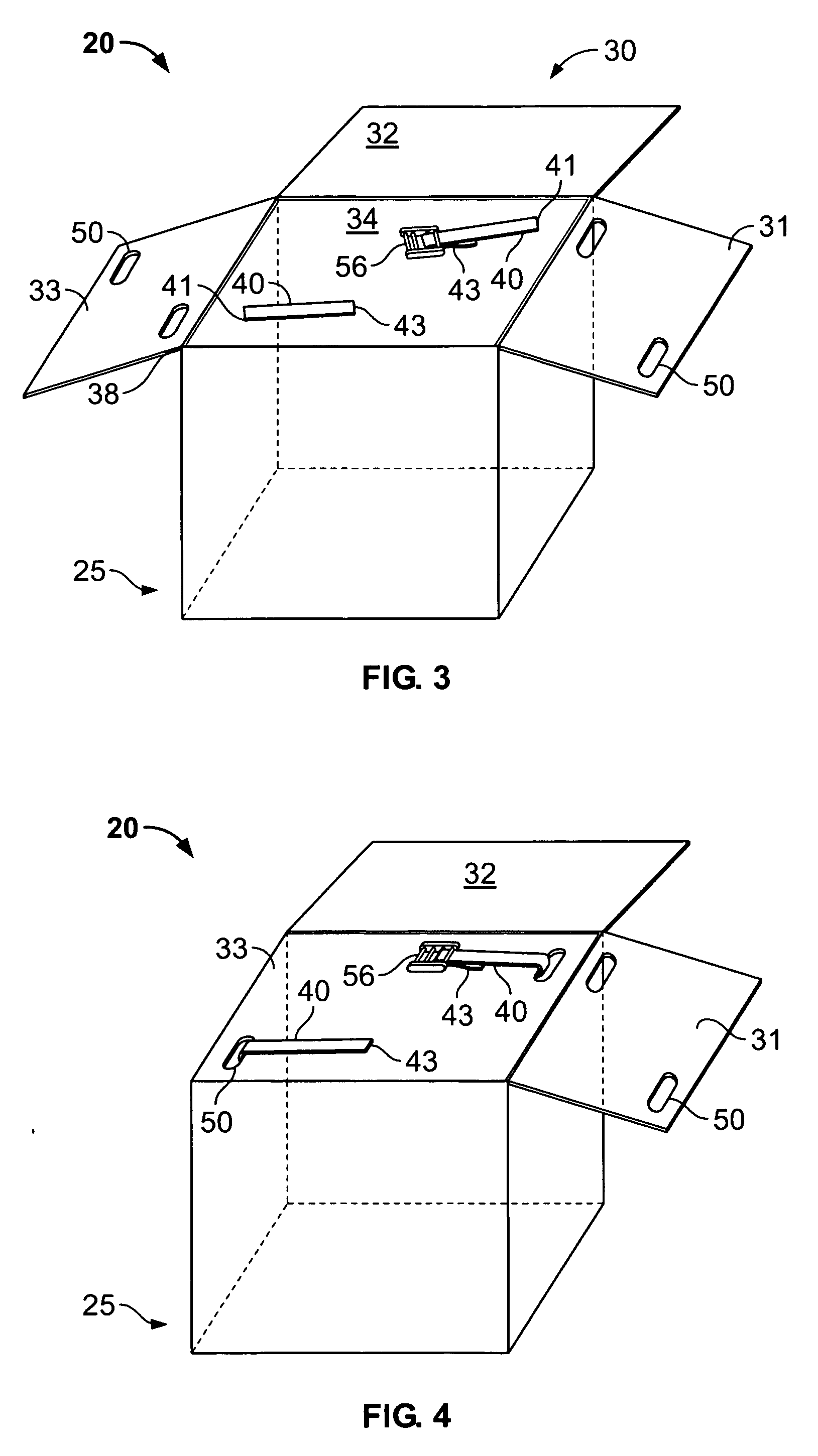

A bulk container and method suitable for forming an interlinked wall. In one embodiment, the bulk container may generally include sidewalls, lifting straps for transporting the container, and a closeable top. Linking loops may be provided on at least one sidewall which are each configured to be engaged by connecting members to link adjacent bulk containers together for forming an interlinked wall. In one embodiment, the connecting member is a belt which may be tensioned. Another possible embodiment includes a linking strap affixed to the sidewall panel and to which the linking loops may be attached or formed as an integral part thereof. A barrier wall system and method of forming the same from interlinked bulk containers is also provided. The barrier wall system is suitable for use in, but not limited to, shoreline erosion protection and flood control applications.

Owner:URBAN ENVIRONMENTAL CORP

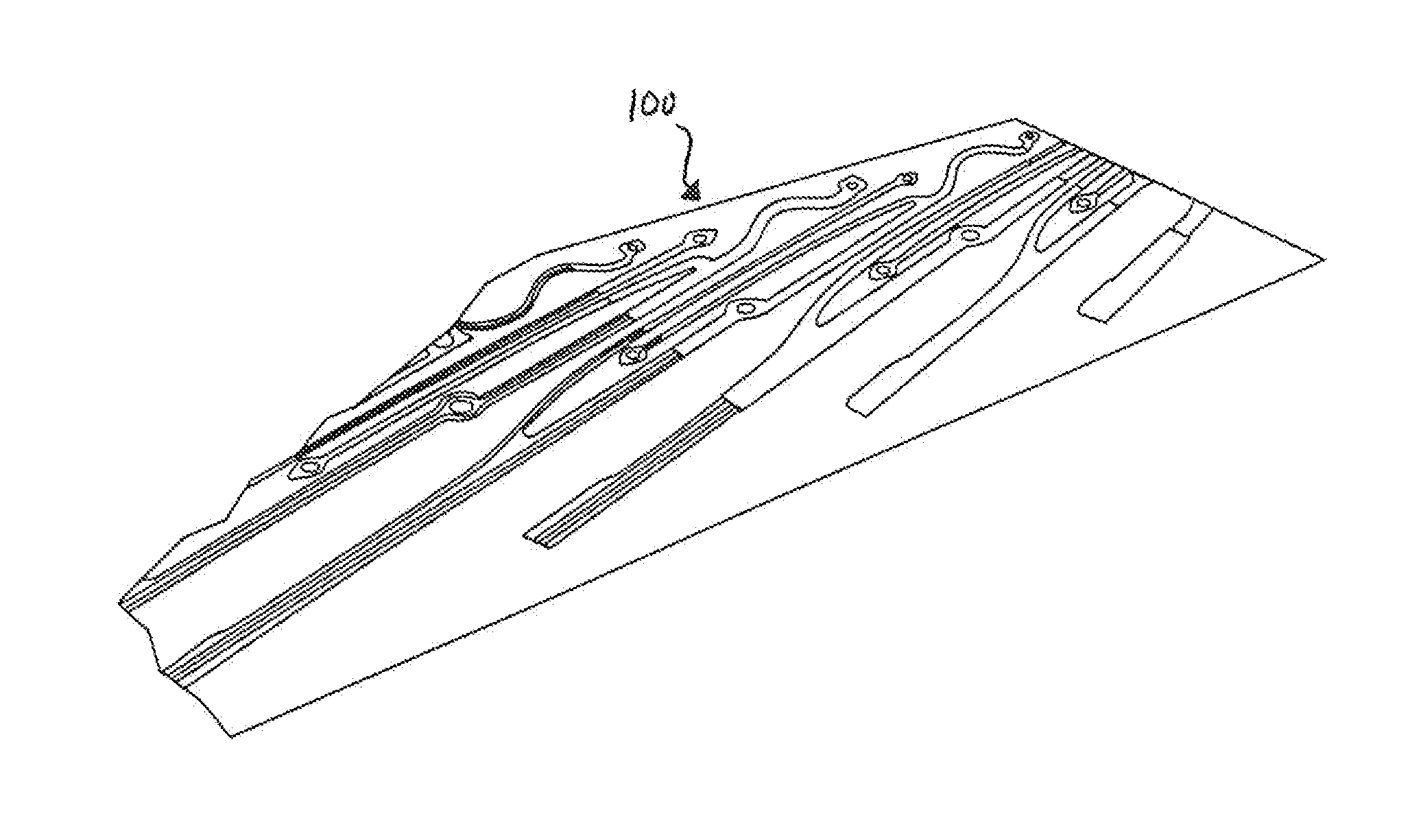

Methods of recovering hydrocarbons from water-containing hydrocarbonaceous material using a constructed infrastructure and associated systems

ActiveUS20080190813A1Reduce processing costsIncrease volume outputThermal non-catalytic crackingUnderground chambersEngineeringHydrocarbon

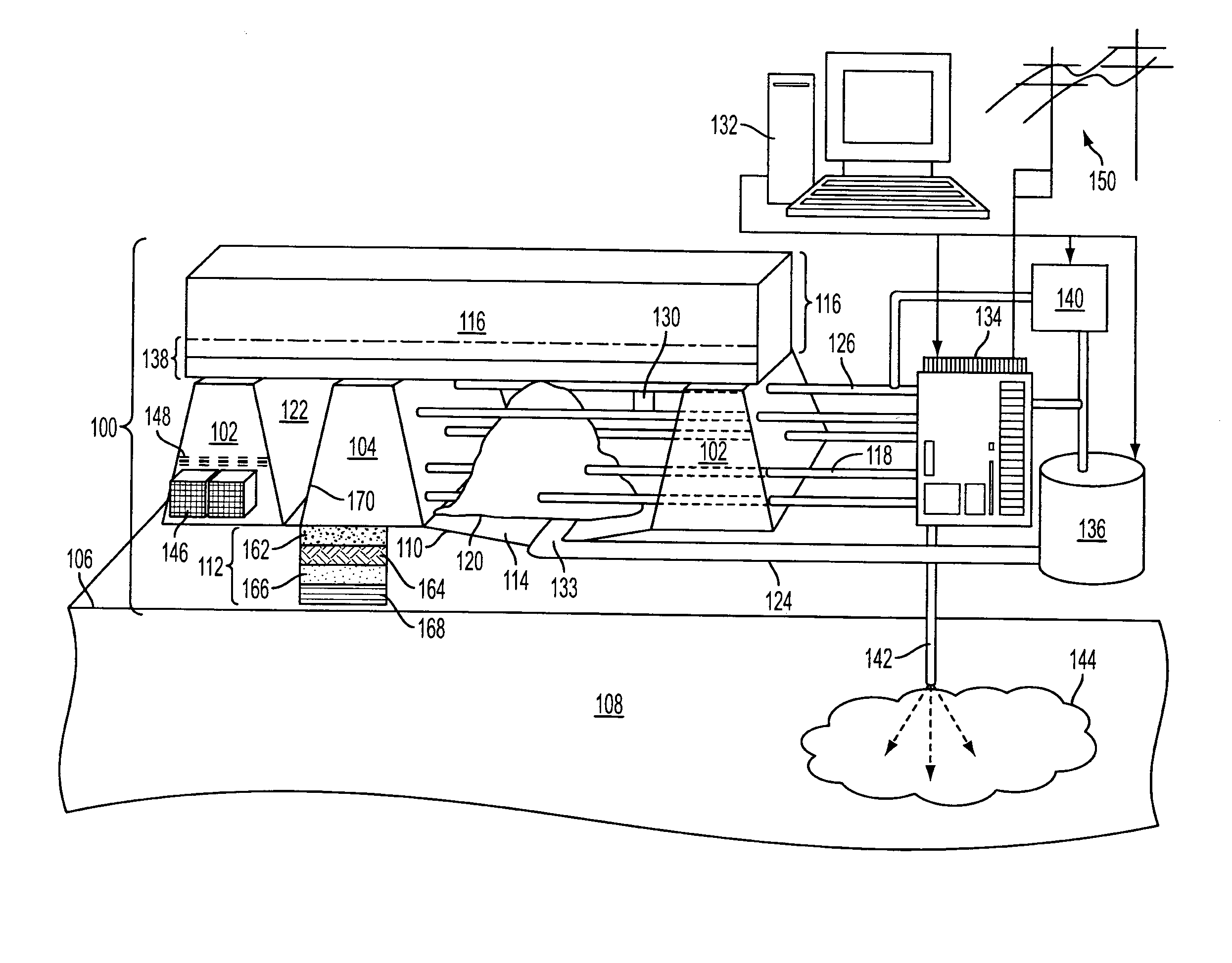

A method of recovering hydrocarbons from water-containing hydrocarbonaceous materials can include forming a constructed permeability control infrastructure. This constructed infrastructure defines a substantially encapsulated volume. A mined or separately collected water-containing hydrocarbonaceous material can be introduced into the control infrastructure to form a permeable body of hydrocarbonaceous material. The permeable body can be heated sufficient to initially remove water therefrom as a water vapor. The water vapor can be removed from the infrastructure via an outlet which can be controlled or shut off when the permeable body is sufficiently dewatered. The dewatered permeable body can be heated sufficient to remove hydrocarbons therefrom. During heating the hydrocarbonaceous material is substantially stationary as the constructed infrastructure is a fixed structure. Removed hydrocarbons can be collected for further processing, use in the process, and / or use as recovered.

Owner:RED LEAF RESOURCES

Restoration method of polluted soil

ActiveCN105598144AEasy to implementReduce handling costsContaminated soil reclamationNutrientGrowing season

The invention relates to a restoration method of polluted soil. The restoration method comprises the following steps: adding an extracting solution into the polluted soil to extract heavy metals in the polluted soil, planting wetland plants in the polluted soil, and obtaining the plants with enrichment of the heavy metals after one growing season. The restoration method has the advantages that the heavy metals in the soil are extracted in situ, and aquatic plants are used for absorbing the heavy metals enriched in the extracting solution, so that the aftertreatment problem of the leached liquid from soil extraction and the problem of loss of nutrient components such as nitrogen, phosphorus and potassium and the like in the soil after soil extraction are solved; and an innovative idea and an innovative path are provided for restoring the soil polluted by the heavy metals.

Owner:柳州市龙江水电建设有限公司

Physical contact layer for body-worn leadware using selective deposition

ActiveUS20130248226A1Reduce material costsAvoid partialElectrotherapyBioelectric signal measurementConductive materialsContact layer

A printed electrical circuit and methods for additively printing electrical circuits. Patterned layers of conductive, insulating, semi-conductive materials, and other materials are print deposited on a flexible or rigid substrate to form electrical circuits. A buffering layer is selectively deposited to cover or encapsulate these materials to comprise a comfort layer that provides a soft and comfortable interface to the skin of a wearer. The comfort layer can be selectively deposited on the same press that the conductive, insulating, semi-conductive materials, and other materials are deposited. Further, the comfort layer is selectively deposited only where it is desired and exactly where it is desired.

Owner:MOLEX INC

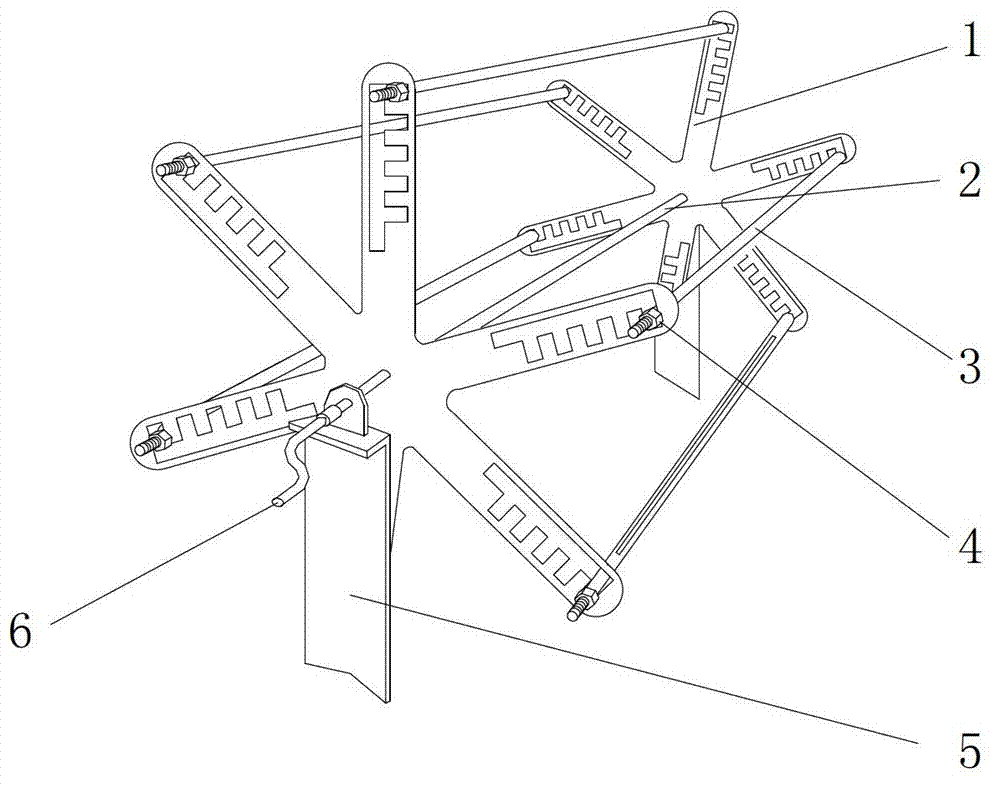

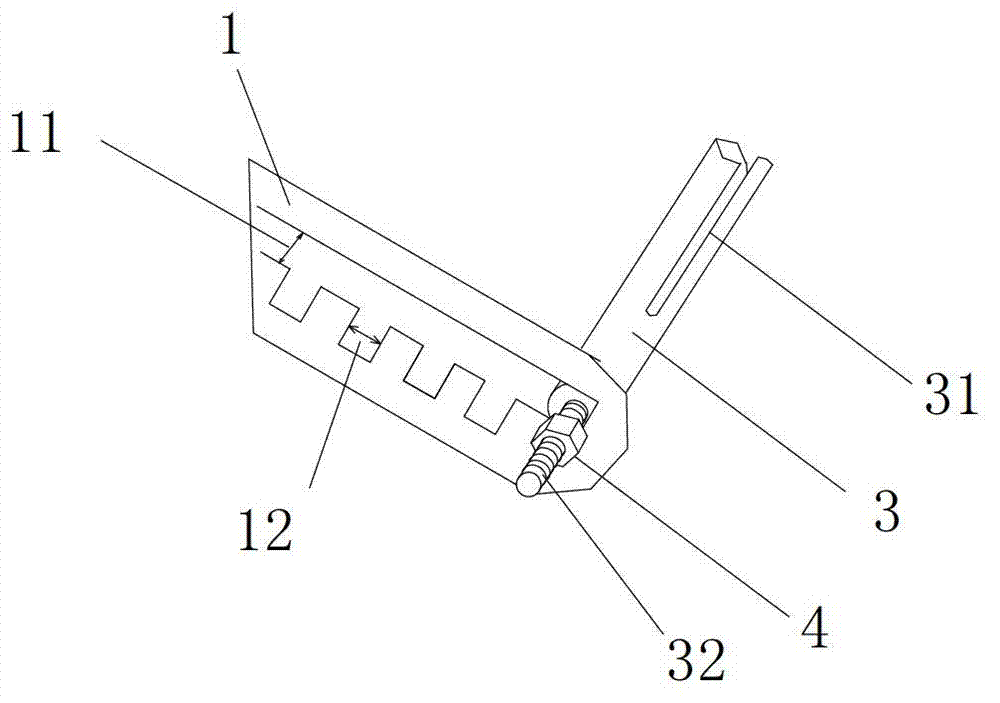

Outside-diameter-variable paper drum

The invention discloses an outside-diameter-variable paper drum which comprises a central shaft, at least two radial fixed mounts and circumferential fixed bars, wherein the radial fixed mounts are fixedly and uniformly distributed at the two end heads of the central shaft, and the number of the circumferential fixed bars is the same as that of the radial fixed mounts. A radial slot and a plurality of tangential slots with unequal radiuses are formed in each radial fixed mount, and the tangential slots are communicated with the radial slot. Threaded ends are arranged at two ends of each circumferential fixed bar, and the diameters of the threaded ends are smaller than the width of the radial slot and the tangential slots. The circumferential fixed bars are fixedly arranged on the preset tangential slots through nuts, and an axial opening slot for clamping a paper head is arranged in at least one circumferential fixed bar. The circumferential fixed bars comprise hollow tubes of which the diameters are larger than the width of the tangential slots, and threaded ends of which the diameters are smaller than the width of the radial slot and the tangential slots are arranged at two ends of the hollow tubes. An axial opening slot for clamping the paper head is arranged in at least one hollow tube. The outside-diameter-variable paper drum has multiple purposes, and the outside diameter of the paper drum can be adjusted in a step mode. The outside-diameter-variable paper drum has the beneficial effects that the storage and carrying cost is reduced, and the use ratio of a product is increased.

Owner:XIANHE CO LTD

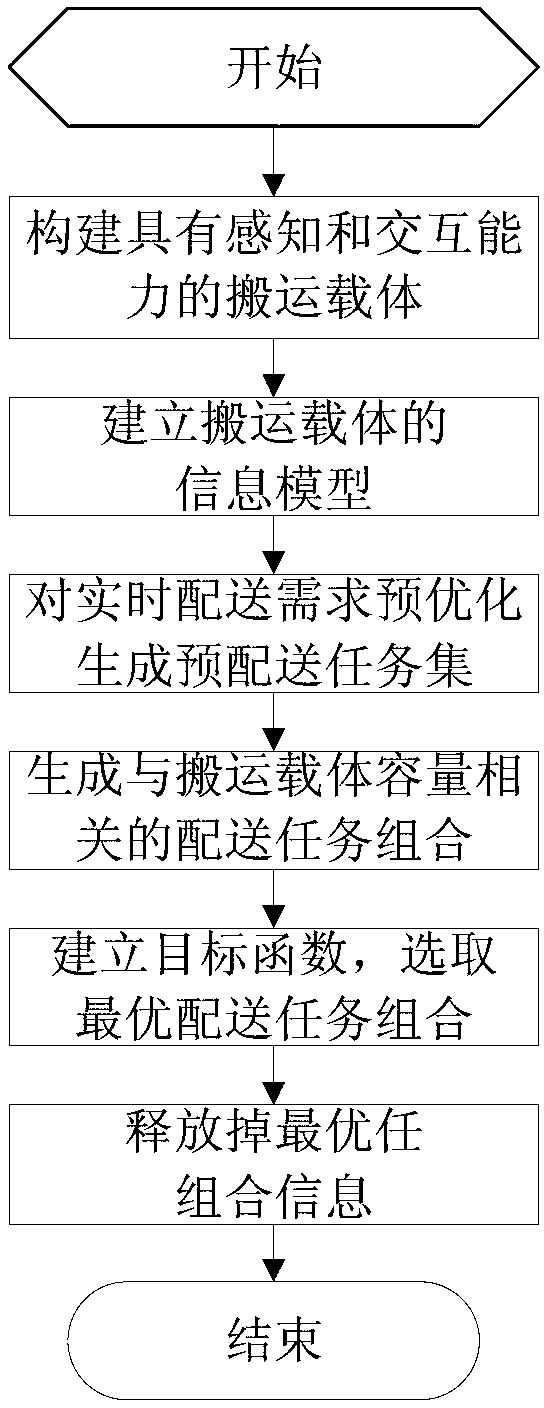

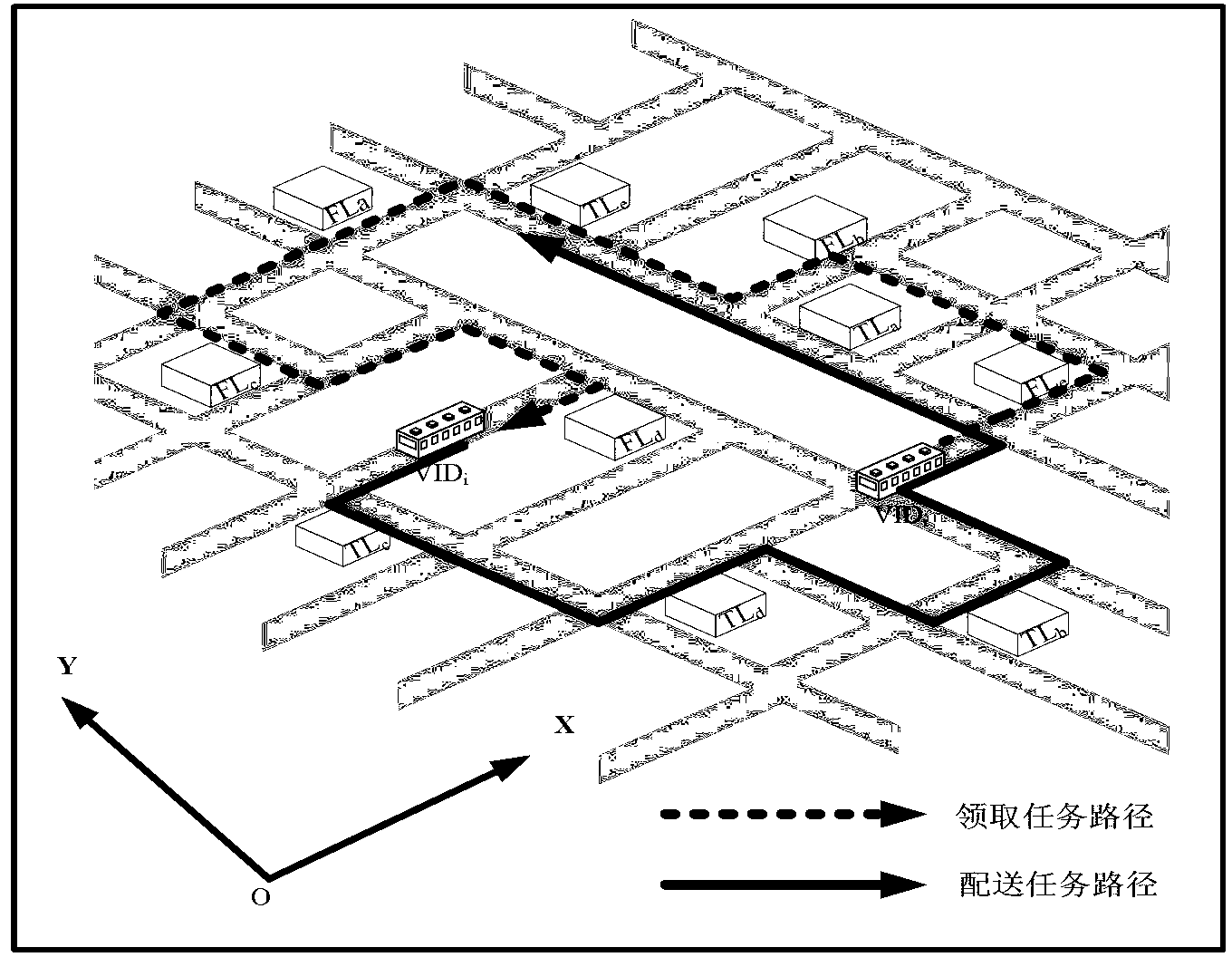

Material delivery task dynamic distribution method based on internet of things technology

InactiveCN103310321AAdapt to task dynamic optimizationAdapt to the delivery situationLogisticsComputation complexityDistribution method

The invention provides a material delivery task dynamic distribution method based on an internet of things technology. Based on the real-time state information of carrying carriers and the work mode that the carrying carriers scramble for tasks, the most suitable material carrying task set is actively obtained, and an efficient and feasible task distribution model and method are provided for the timely distribution of production materials from the three aspects of the dynamic distribution strategy of the tasks, the task dynamic distribution method based on the real-time state of the carrying carriers and the combinatorial optimization of the tasks,. As the real-time position information after the carrying carriers unload, the task dynamic combinatorial optimization facing to the capacity of the carrying carriers and the like are fully considered in the method, compared with the traditional material delivery task optimization method, the method has the advantages that the defects that the computation complexity of an original distribution strategy is high, the optimization time is long, and the change of material delivery tasks is difficultly dynamically responded are overcome, the efficiency of workshop distribution is improved, the carrying cost is saved, and the digital precise distribution and the intellectualization of material distribution management are better realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

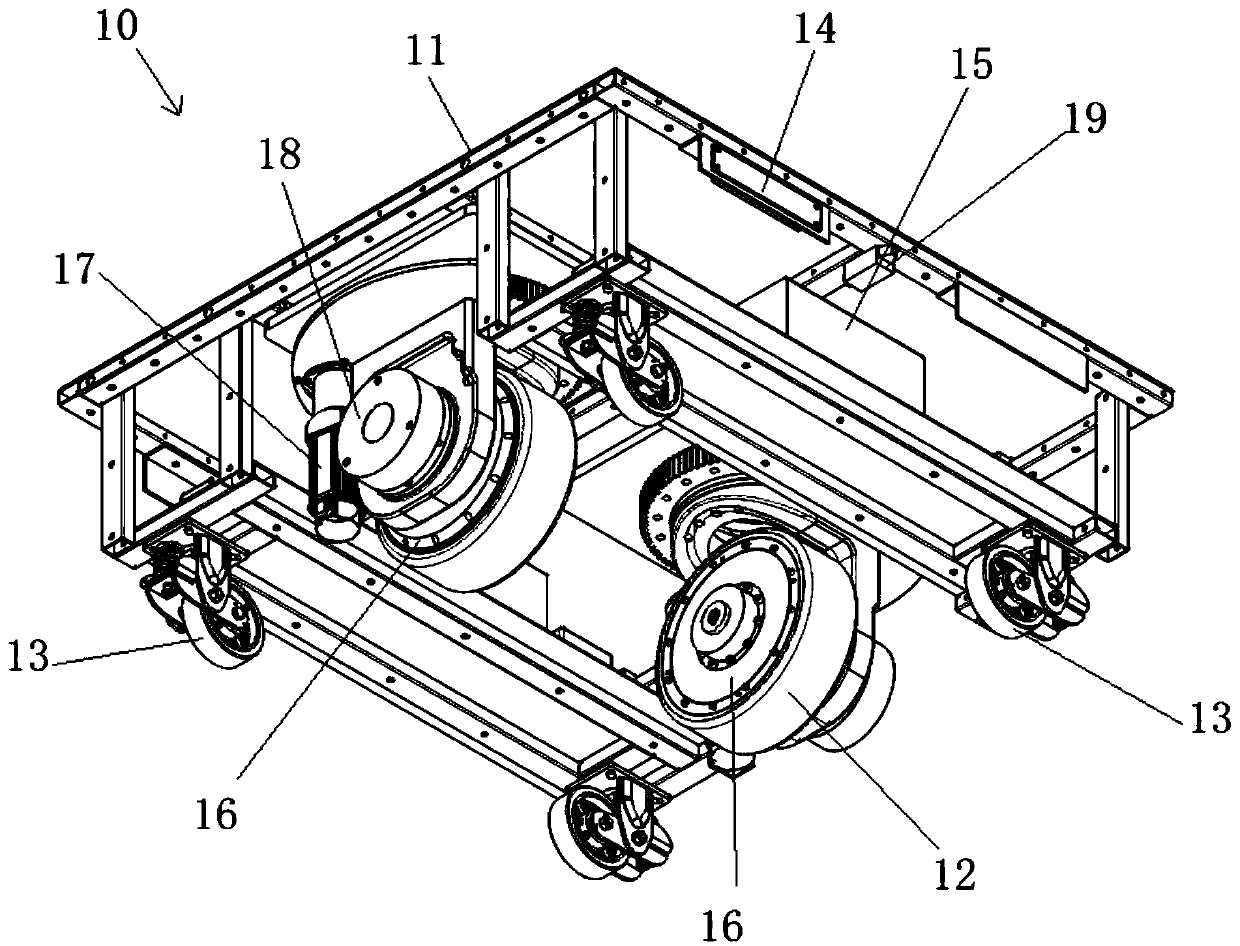

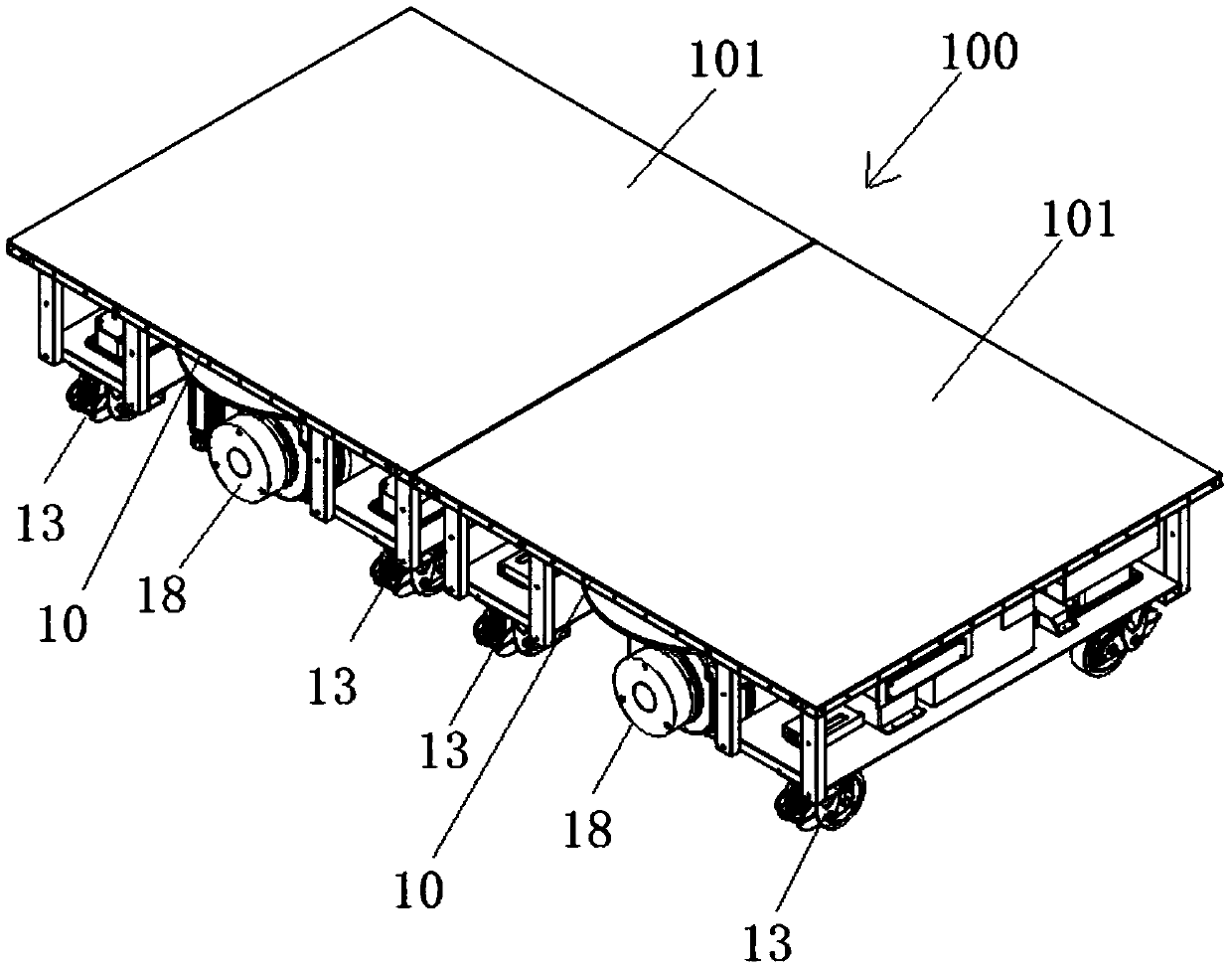

Spliced carrying vehicle and carrying system and carrying method

ActiveCN109625123AHeavy loadTime stableElectric devicesPropulsion by batteries/cellsVehicle frameDrive wheel

The invention is suitable for the technical field of AGVs, and discloses a spliced carrying vehicle and carrying system and a carrying method. The spliced carrying vehicle comprises a vehicle body, the vehicle can independently work and work synergistically with another vehicle after being spliced, and comprises a frame assembly, driving wheels, supporting wheels, a navigation device, a butt jointdevice, a battery and a complete-vehicle controller. The two or more driving wheels and / or supporting wheels are connected with electric steering components respectively. The spliced carrying systemcomprises a scheduling system and two or more spliced carrying vehicles. The spliced carrying system is adopted for the carrying method. According to the embodiment of the spliced carrying vehicle andcarrying system and the carrying method, the spliced carrying vehicle can be used as a heavy spliced carrying vehicle, can be spliced and separated, and can improve carrying efficiency and lower carrying costs.

Owner:SHANDONG INST OF ADVANCED TECH CHINESE ACAD OF SCI CO LTD

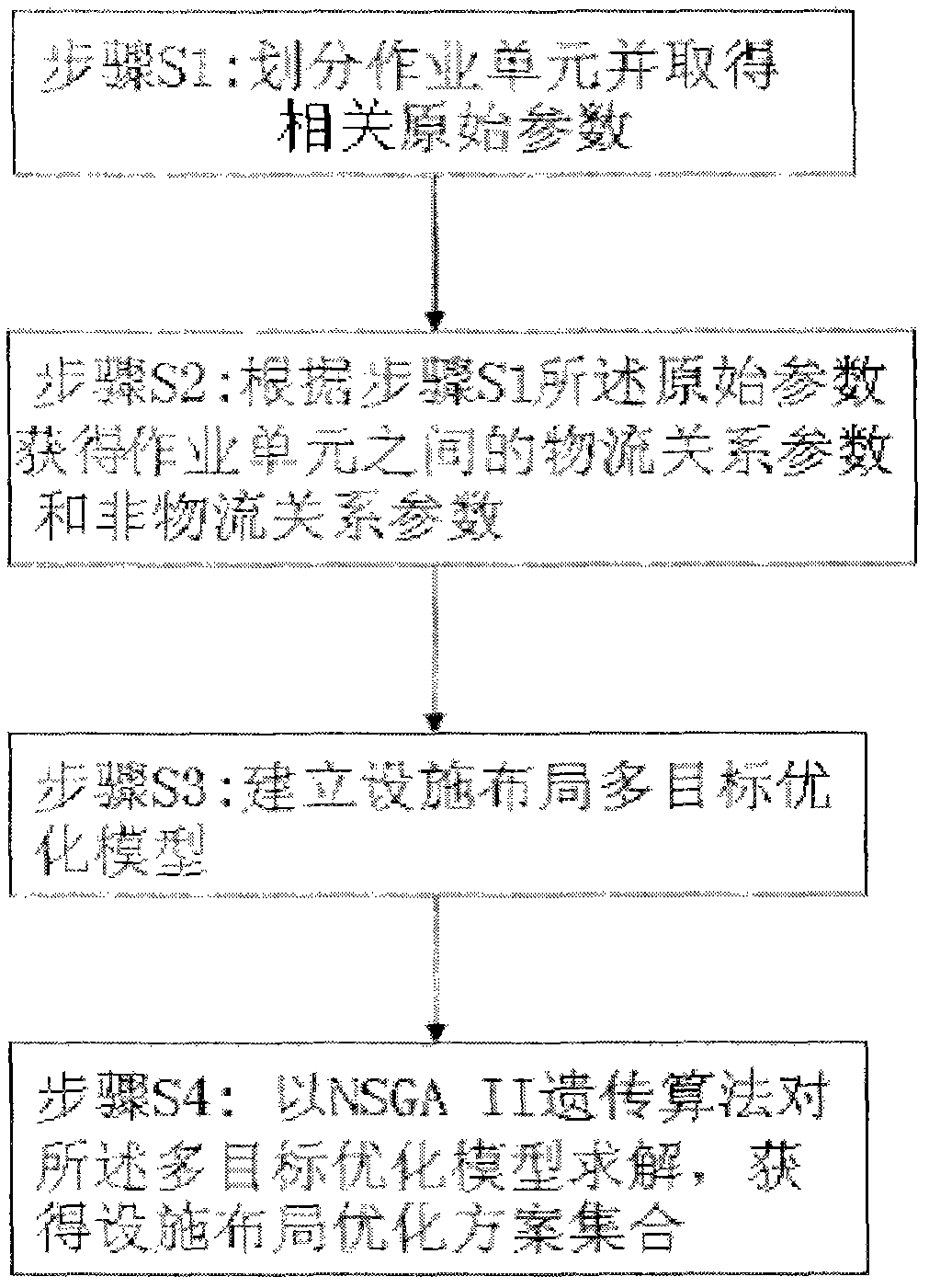

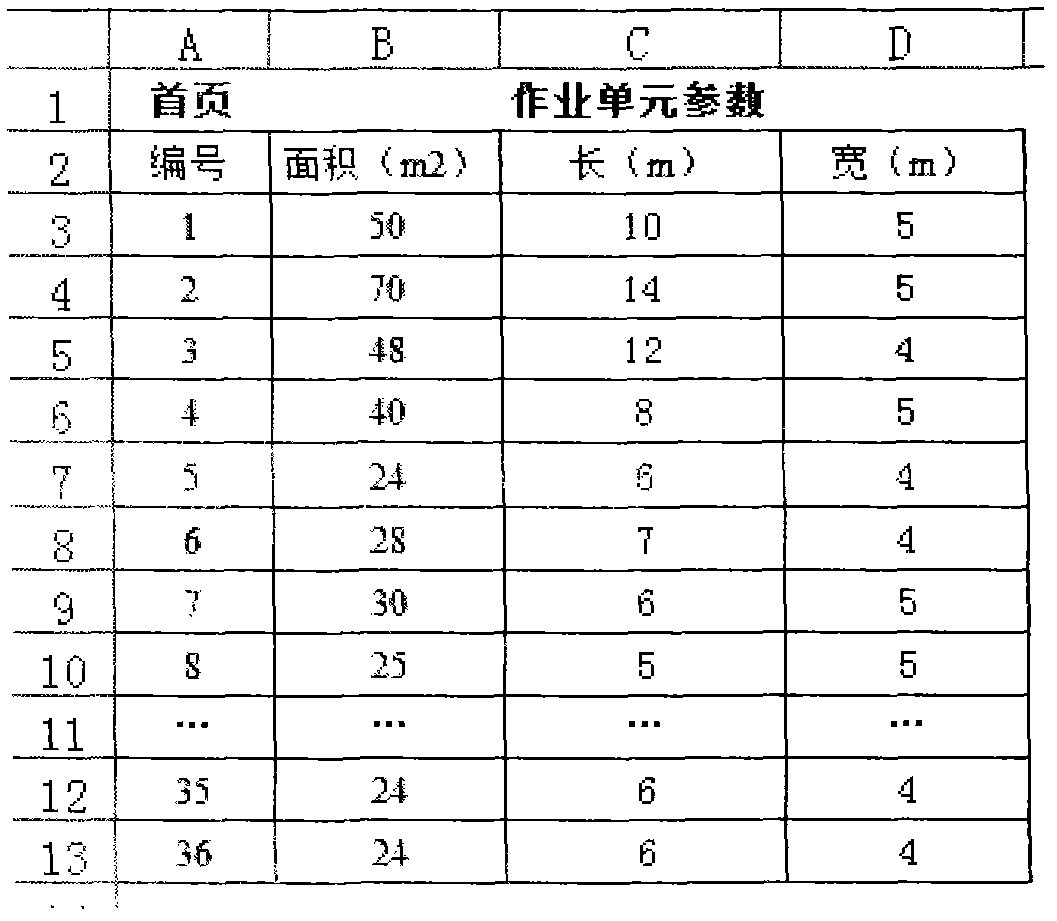

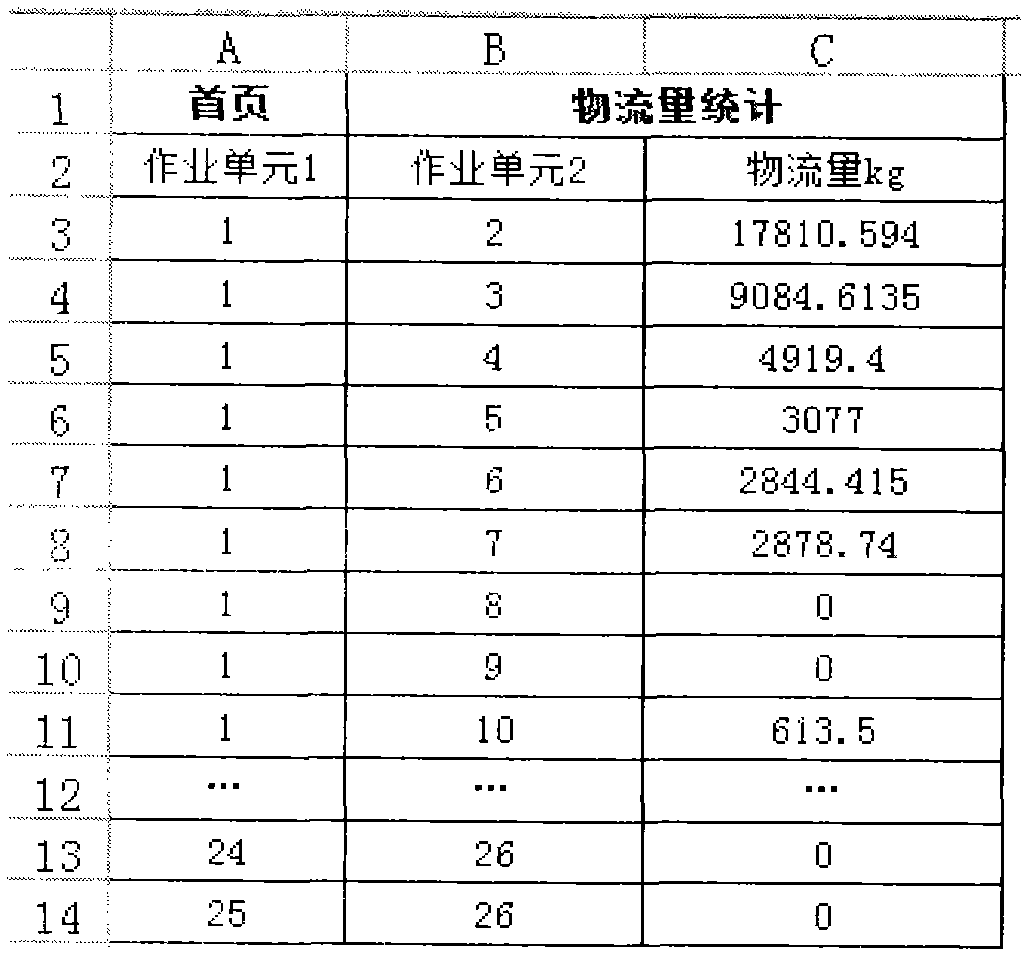

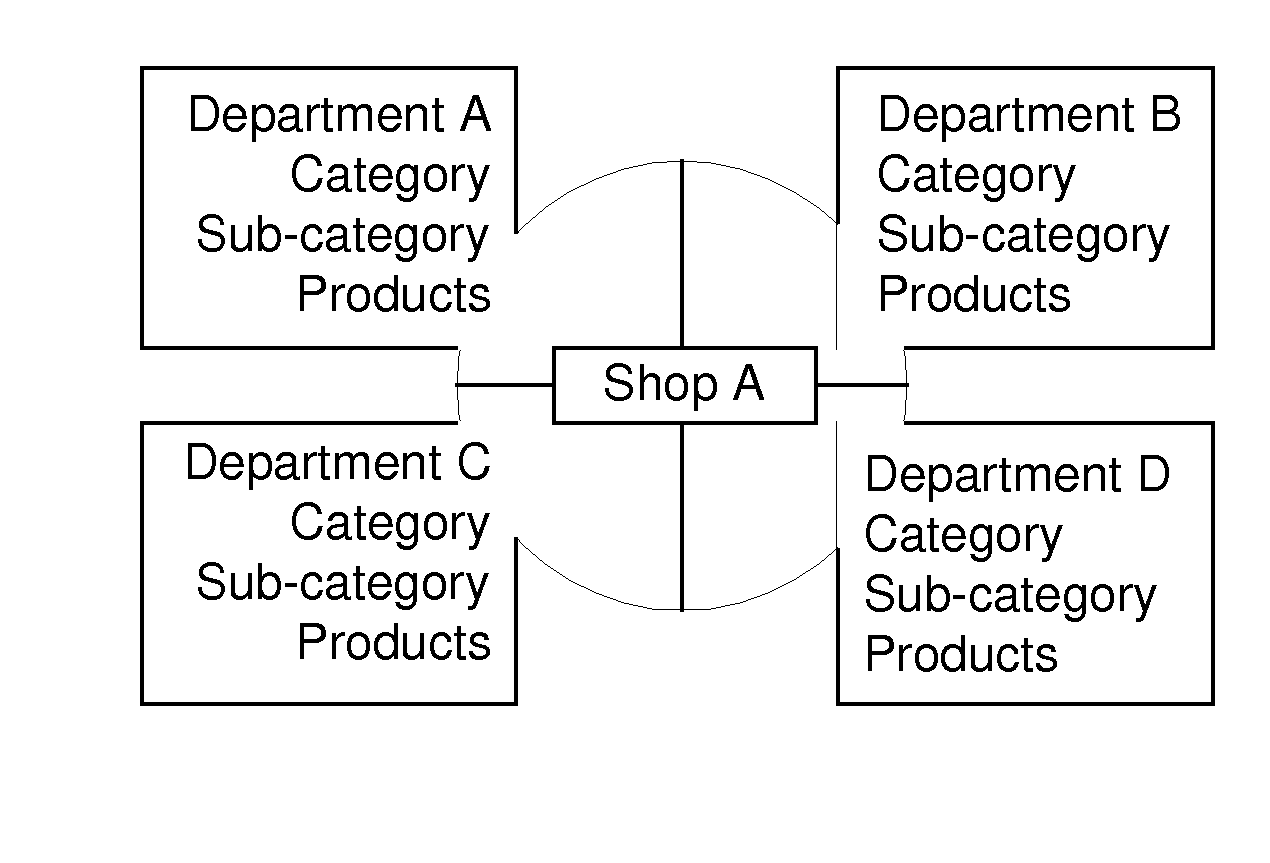

Multipurpose optimization method for distribution of facilities in plant

InactiveCN102214333AReduce Handling CrossoversIncrease intimacyInstrumentsComputer sciencePareto solution

The invention provides a multipurpose optimization method for distribution of facilities in a plant, which comprises the steps of: 1. dividing distribution areas of facilities in the plant into operation units and obtaining related original parameters; 2. obtaining logistic relation parameters and non-logistic relation parameters of the operation units according to the original parameters obtained from the step 1; 3. building a multipurpose facility distribution optimization model; and 4. solving the multipurpose optimization model by using an NSGA (non-dominated sorting genetic algorithm) II, thus obtaining a Pareto solution set as a facility distribution optimization scheme set. With the method, the technical problem that multipurpose optimization distribution is carried out on the facilities in a building of the plant is solved, and the use of the method has the advantages of high distribution efficiency, high operation vision degree, good optimization effect, low use cost and strong university.

Owner:HENAN POLYTECHNIC UNIV

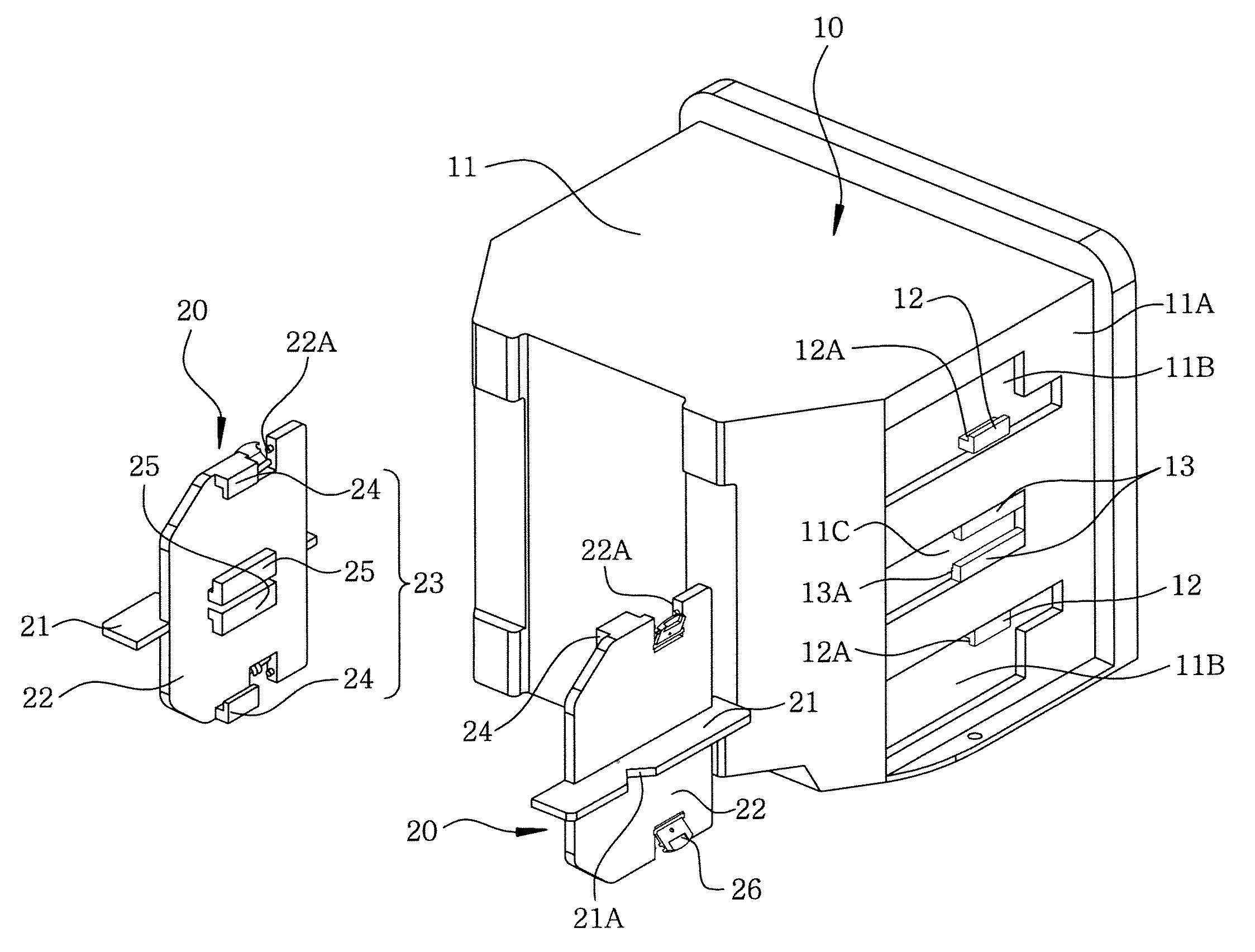

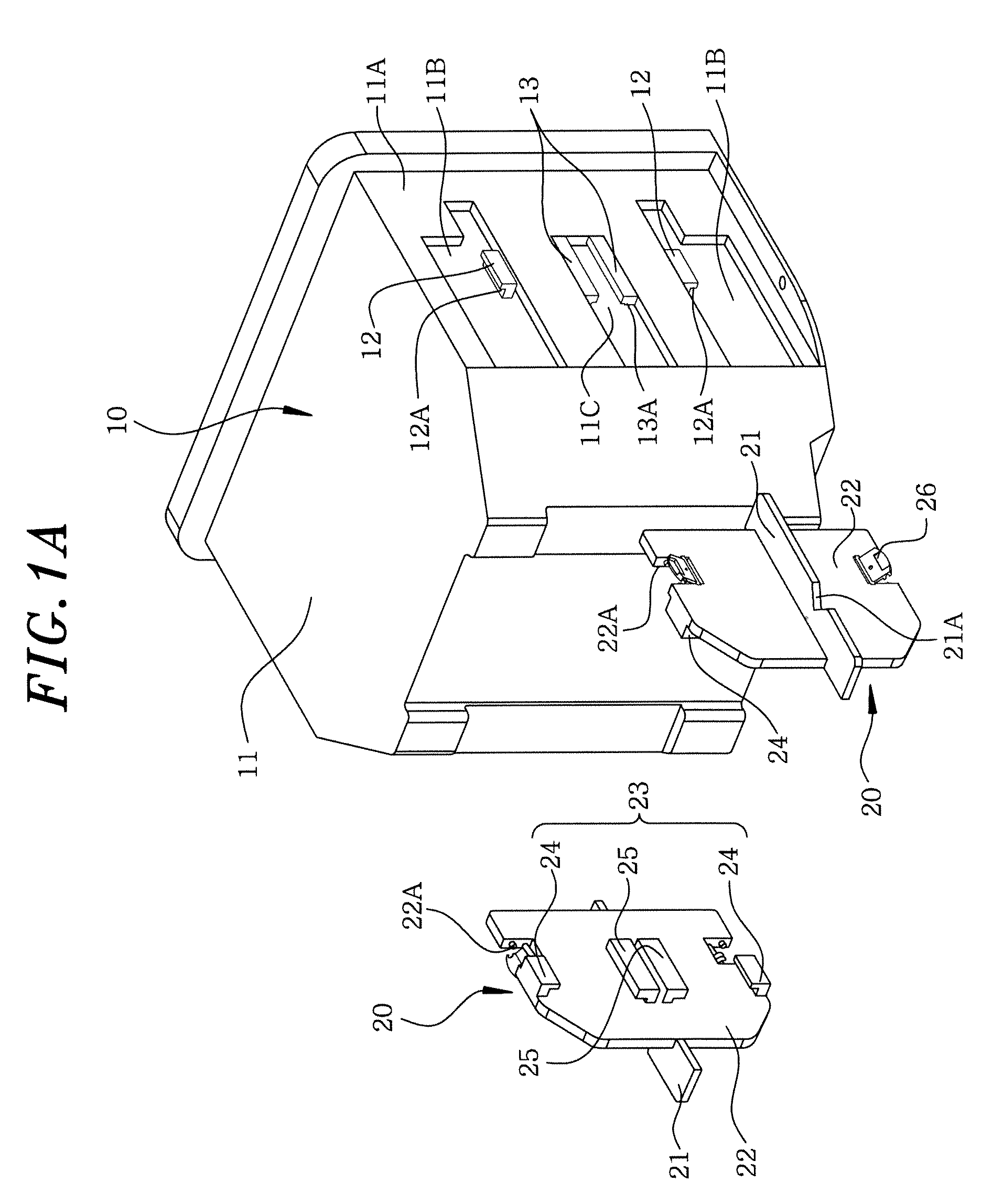

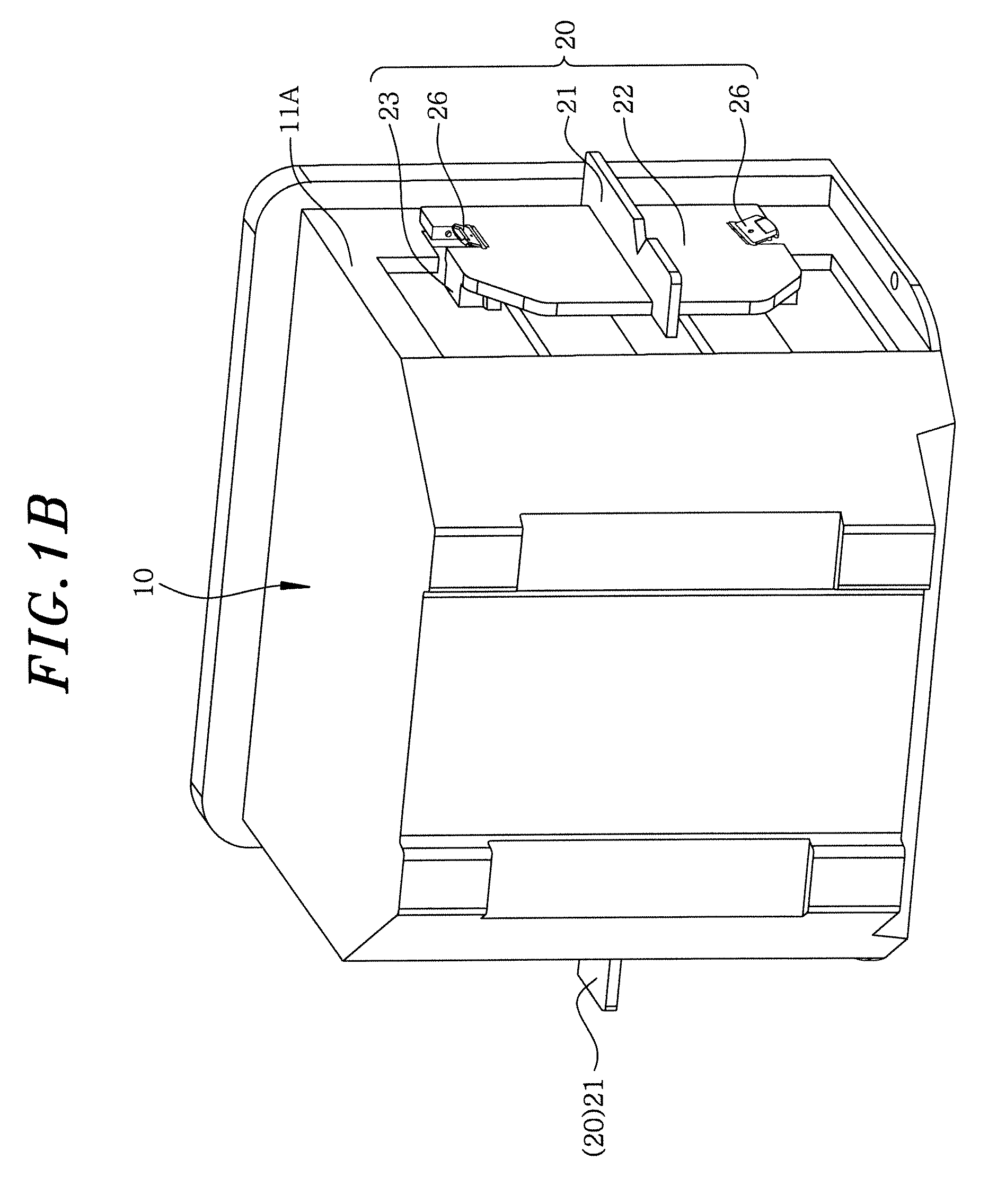

Method for handling and transferring a wafer case, and holding part used therefor

InactiveUS20070231110A1Reduce processing costsEasy to operateSemiconductor/solid-state device manufacturingConveyor partsEngineeringTransfer line

In a method for handling a wafer case having attachable and detachable grips, the wafer case is handled in an automatic transfer line while the grips are detached from the wafer case and holding parts are attached to portions of the wafer case from which the grips have been detached. The holding parts allow an automatic transfer unit to hold the wafer case.

Owner:TOKYO ELECTRON LTD

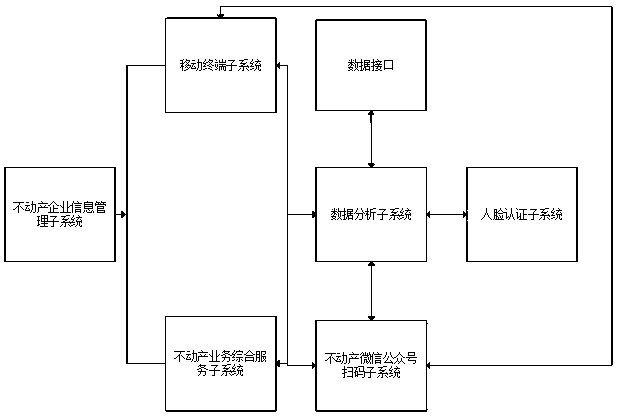

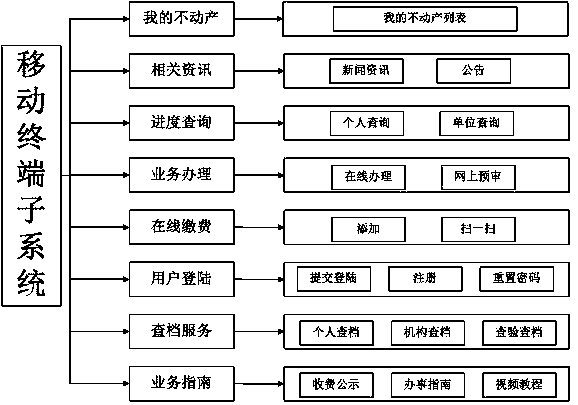

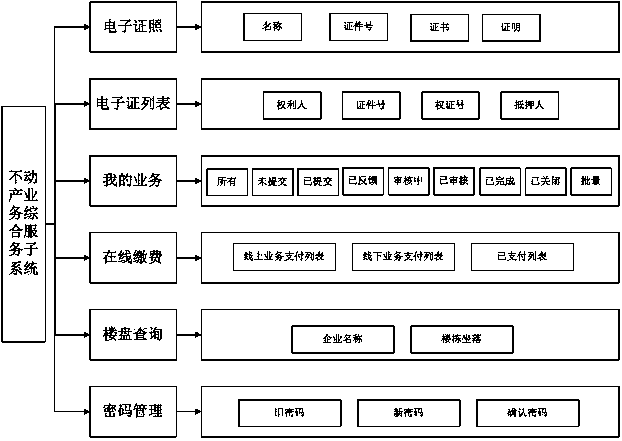

Real estate registration system and real estate registration method

ActiveCN109636318AReduce handling costsAvoid inconvenienceOffice automationAuthentication systemData interface

The invention relates to the technical field of real estate registration systems, and specifically relates to a real estate registration system and a real estate registration method. The system comprises a mobile terminal subsystem, a real estate business integrated service subsystem, a real estate enterprise management subsystem, a data analysis subsystem, a face authentication system and a datainterface. User through mobile terminal subsystem, the real estate business integrated service subsystem provides a real estate registration application; the data analysis subsystem reads data of eachdepartment through a data interface; including a residential building department, Data of a local tax department, a civil government department, an industrial and commercial department, a public security department and the like automatically handle related real estate registration services, mechanisms of real estate registration service online acceptance, online audit, offline registration, online reservation, immediate access and the like are achieved, real estate registration services do not need to be melted for 24 hours, the working efficiency is improved, and the service handling cost isreduced.

Owner:南宁市自然资源信息集团有限公司

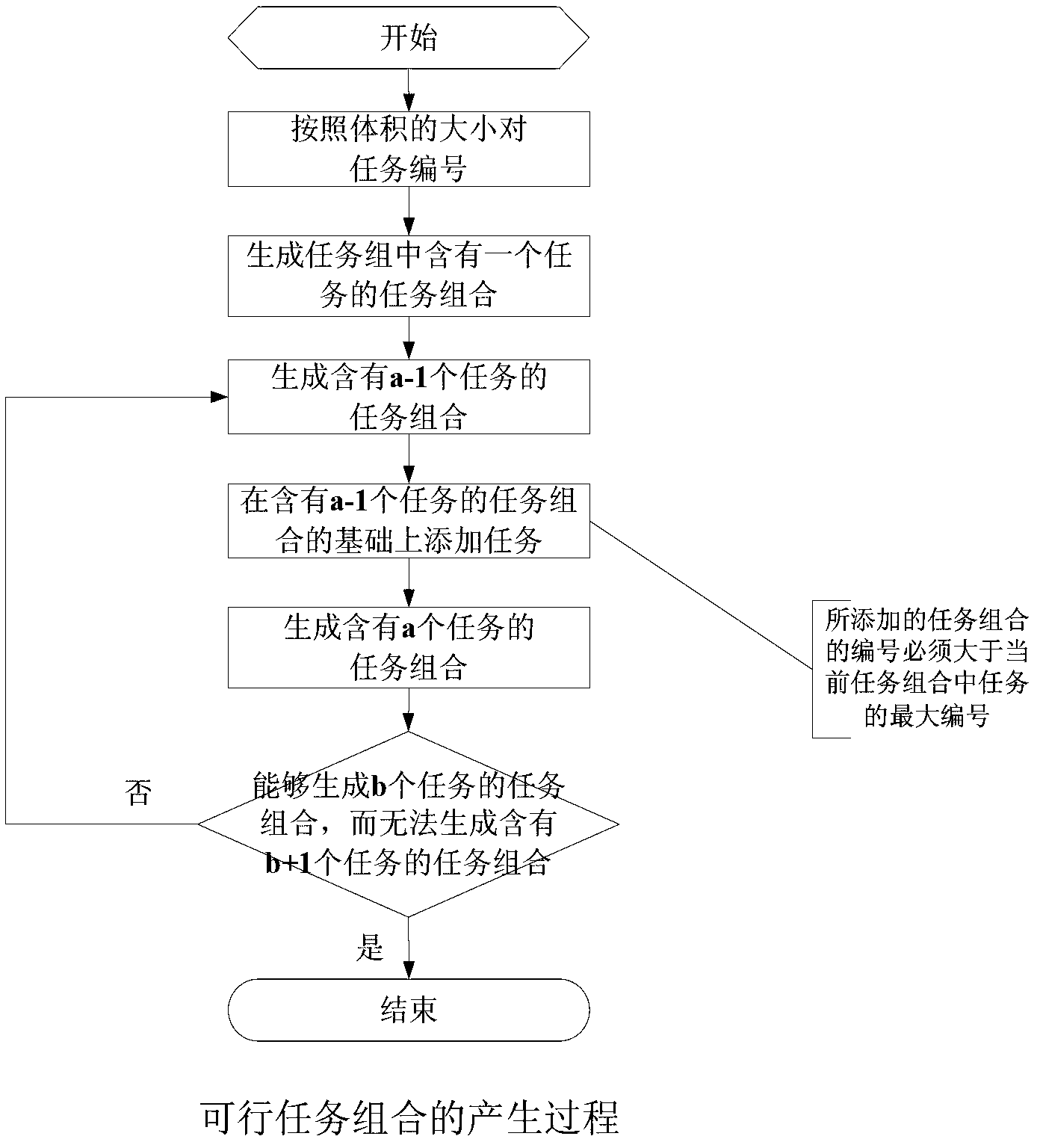

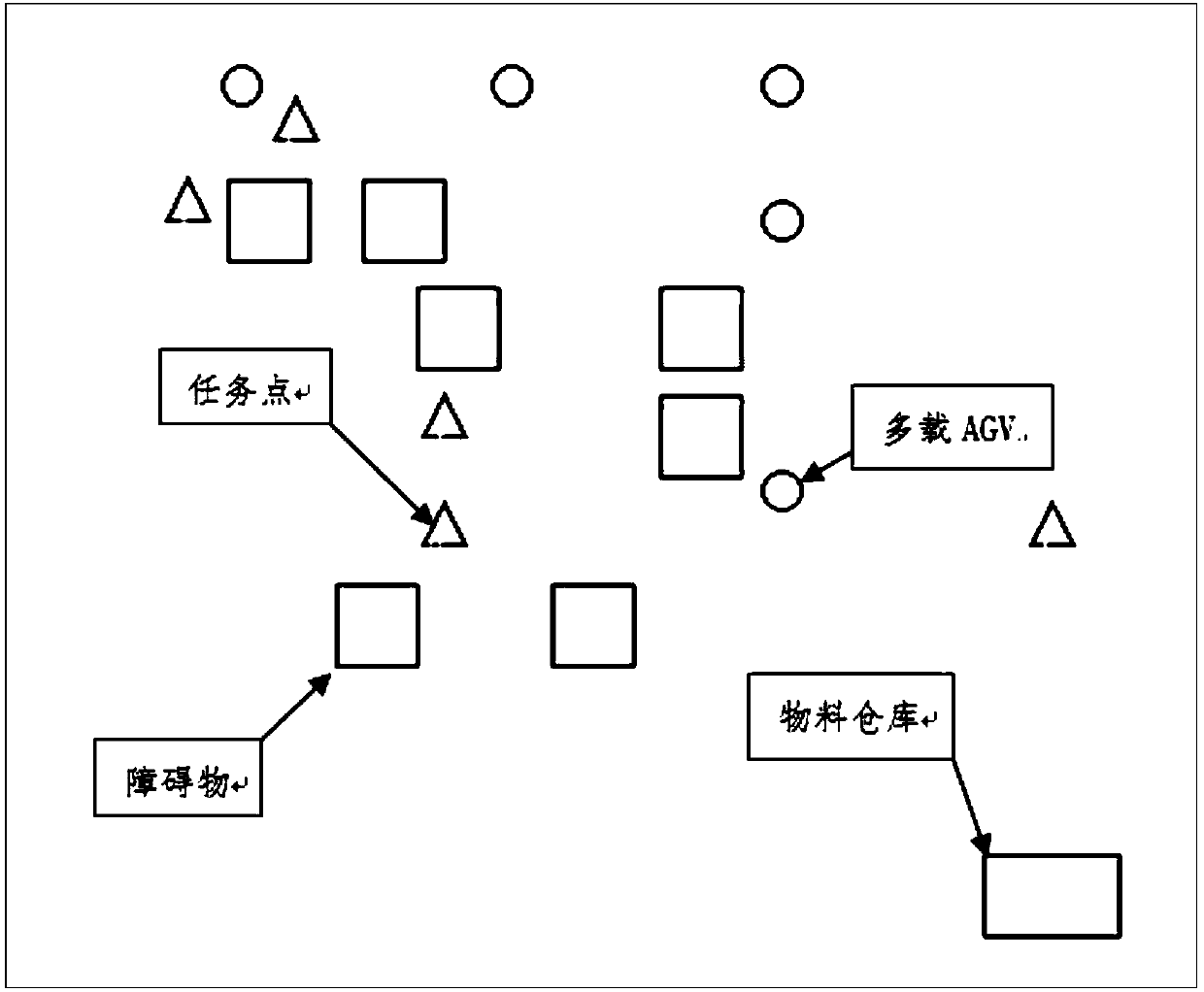

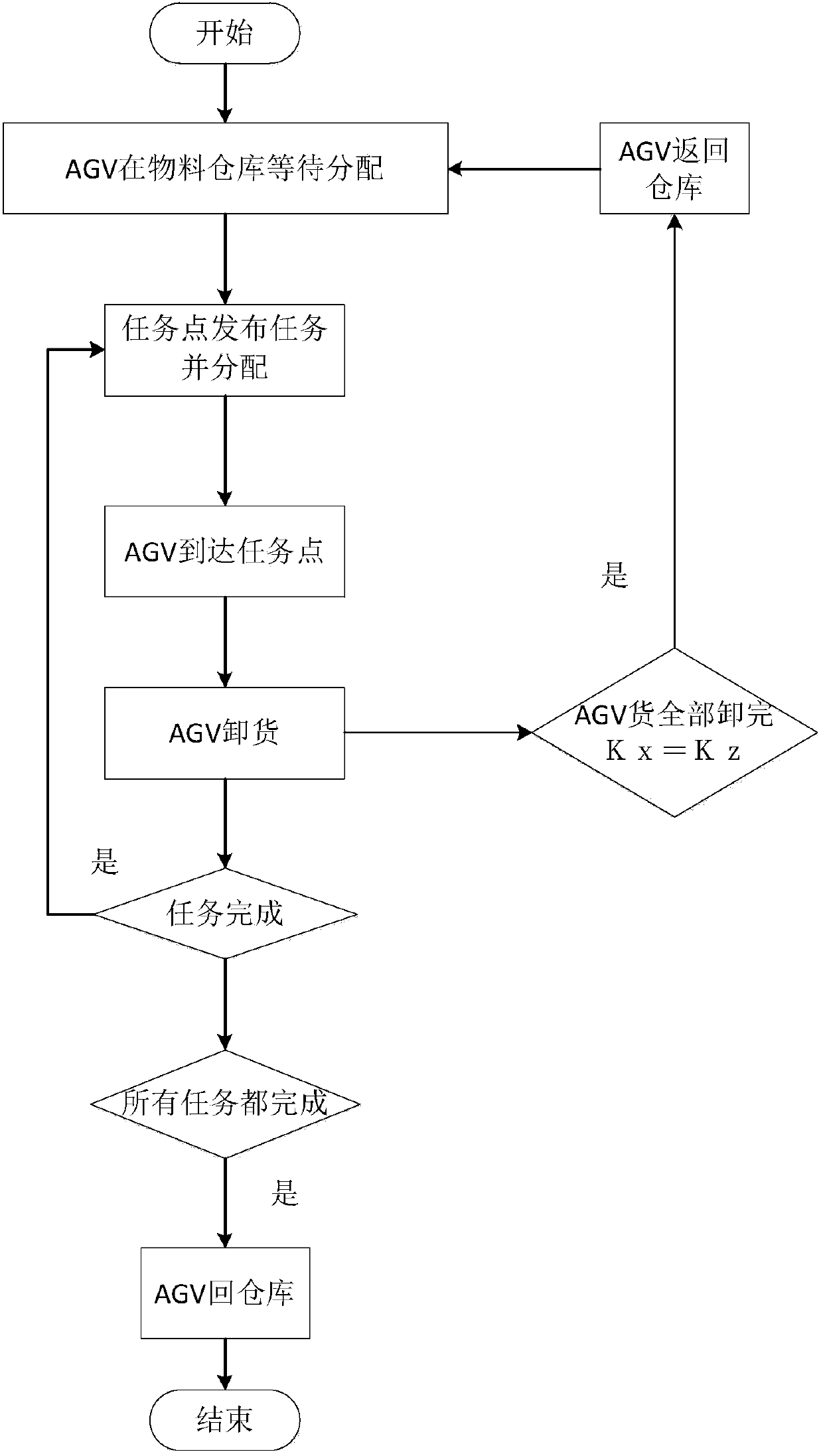

Multi-load AGV task assignment forming method for tobacco factory material transport

InactiveCN107657364AImprove handling efficiencyReduce handling costsResourcesLogisticsTask completionCarrying cost

The invention provides a multi-load AGV task assignment forming method for tobacco factory material transport. The method comprises the following steps: machine unit material demand information is obtained, tasks to be completed are generated, task information is released, the task information is received via an AGV, task income is calculated based on an income function, and bidding operation is performed; according to task auction rules, a task assignment solution is generated, and the tasks are executed via the AGV according to the task assignment solution. According to the method, the AGV is used for transporting materials of machine units in a tobacco factory, the materials is transported from a material warehouse to a material stacking part for the machine units; the method is appliedto a multi-load AGV; compared with a single load AGV, the multi-load AGV is advantageous in that a large quantity of tobacco can be carried in a single time and high carrying efficiency can be realized; but the multi-load AGV is high in complexity of task decision making, and therefore an auction algorithm is adopted in the method to improve task assigning efficiency, lower zero load rates of themulti-load AGV and lower material carrying costs; task completion time is taken into account in task completion income, and real time demand can be satisfied while an aim is set to optimize task completion income.

Owner:CENT SOUTH UNIV

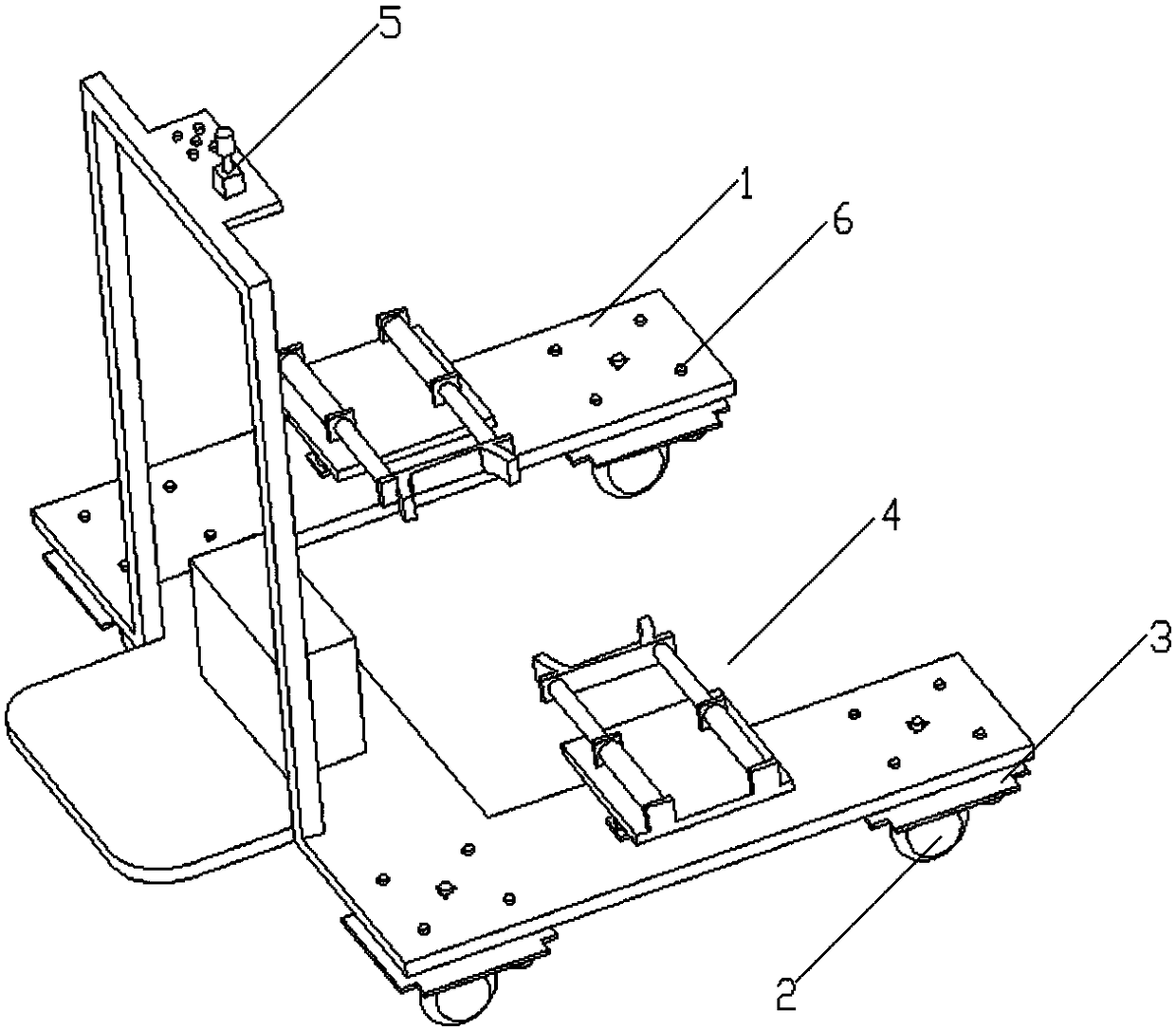

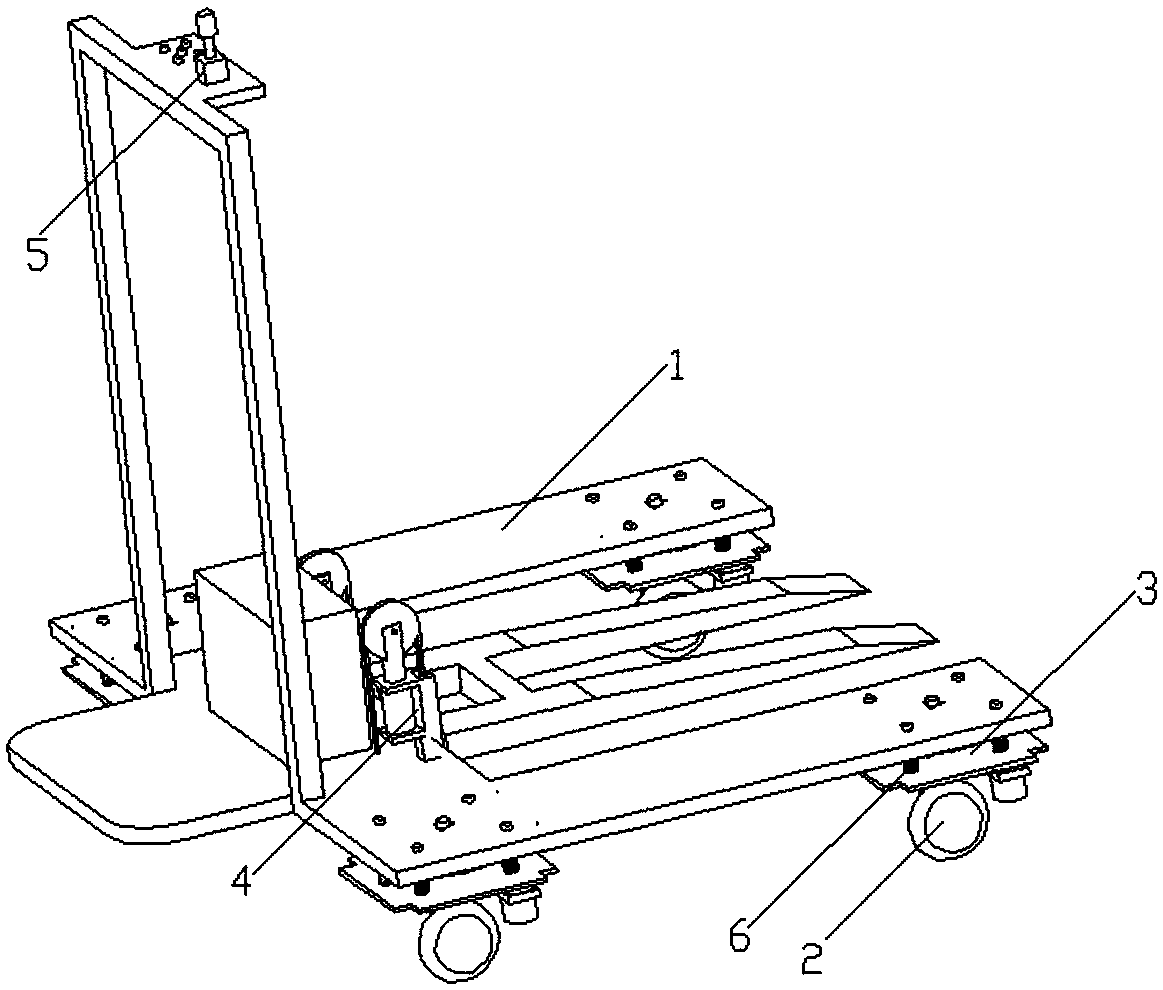

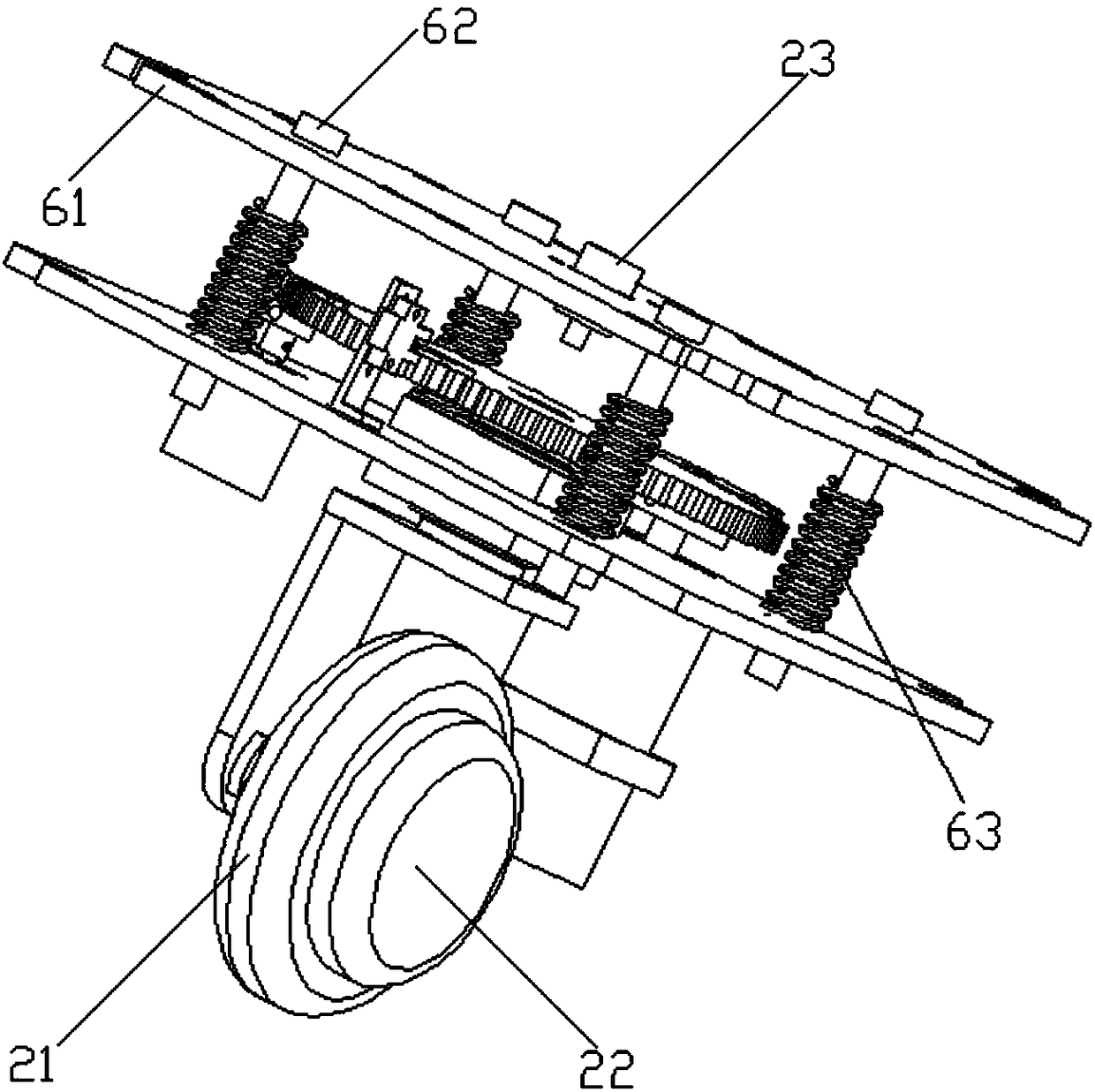

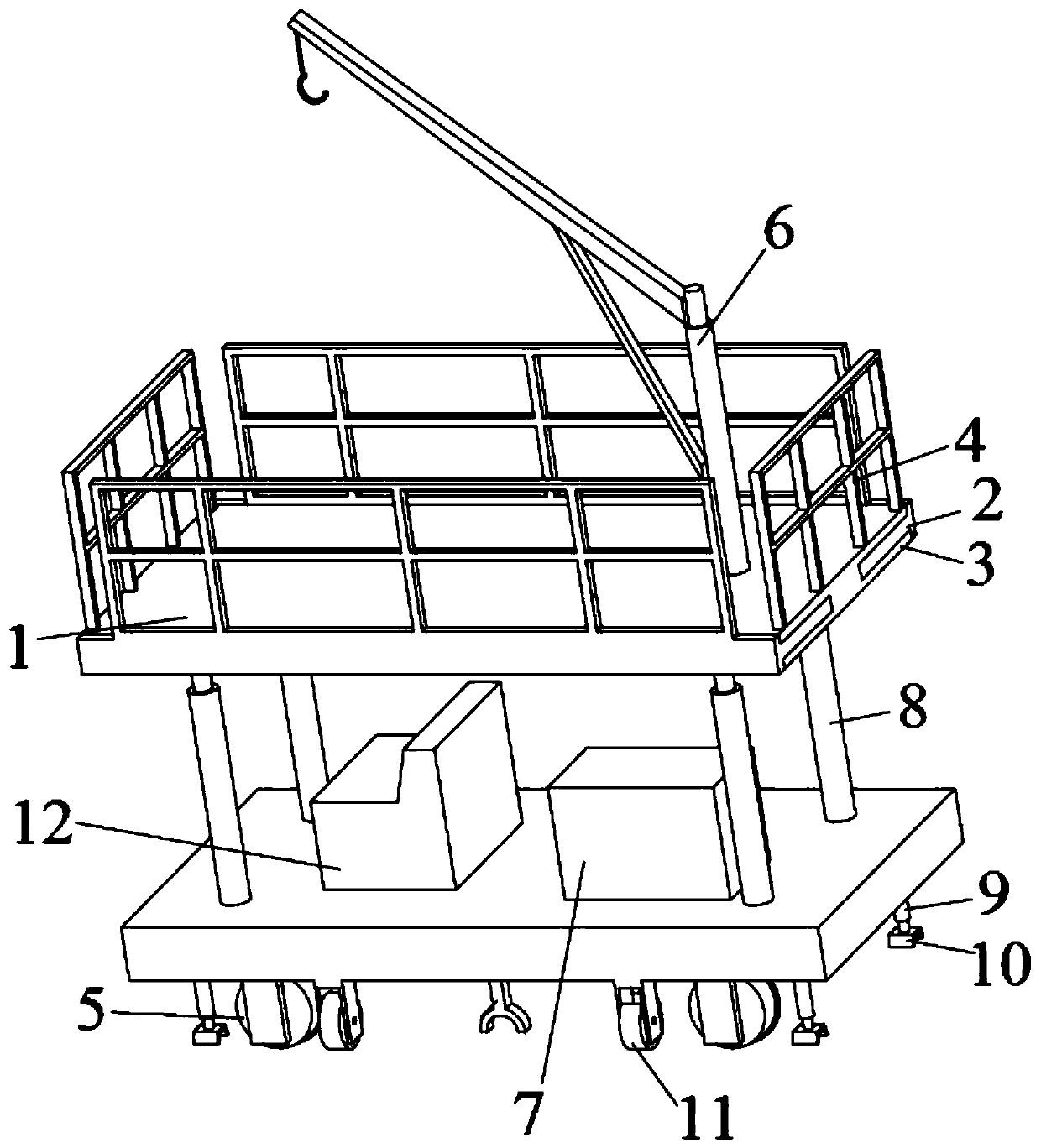

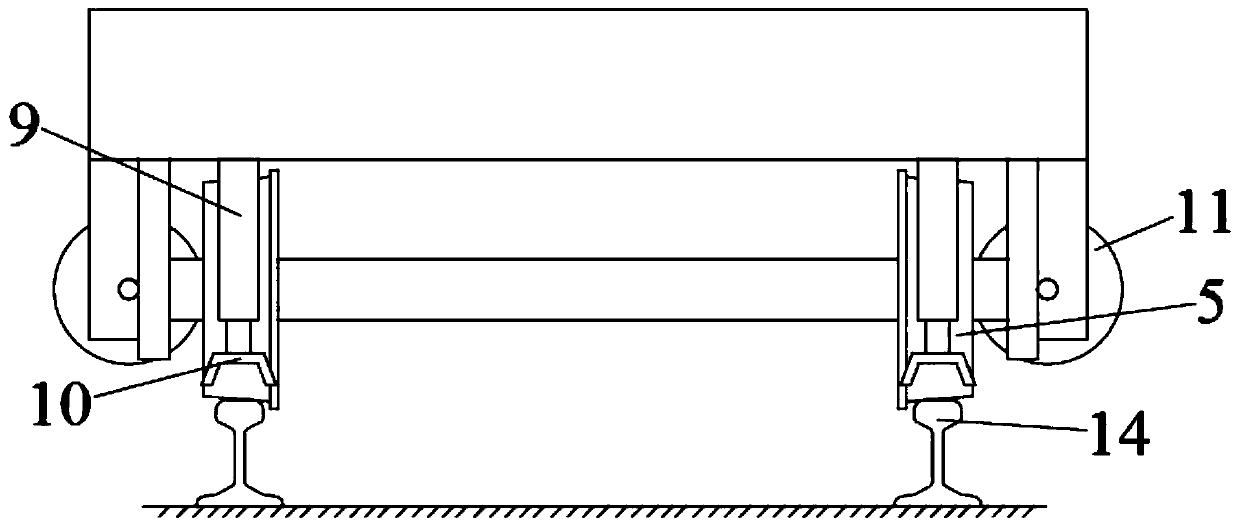

Conveying device with 360-degree steering function

PendingCN108275619AEasy to operateIncrease diversitySledge wheelsLifting devicesVehicle frameEngineering

The invention relates to a conveying device with the 360-degree steering function. The conveying device comprises a frame, a plurality of moving mechanisms, a plurality of steering mechanisms, dampingmechanisms, clamping mechanisms, an operation handle and a controller, wherein the moving mechanisms, the steering mechanisms, the damping mechanisms, the clamping mechanisms, the operation handle and the controller are arranged on the frame; and the controller is electrically connected to the multiple moving mechanisms, the multiple steering mechanisms, the clamping mechanisms and the operationhandle. According to the conveying device, by means of the moving mechanisms and the steering mechanisms, the 360-degree steering function of the conveying device can be achieved, in addition, back-and-forth movement, oblique-direction translation, oblique-direction steering and in-situ spinning motion of the conveying device can be realized, and therefore the flexibility of movement can be greatly improved; the conveying device is further provided with the damping mechanisms so that a conveying trolley can move stably, and therefore the impact caused by bad road conditions can be reduced, thediversity of goods by conveyed by the conveying device can be greatly increased, and the application range of the device can be further improved; and in addition, moving and steering of the conveyingdevice can be accurately controlled through the operation handle, and therefore the operation performance of the conveying device can be further improved, the conveying efficiency can be further improved, and the conveying cost can be lowered.

Owner:惠州城市职业学院 +1

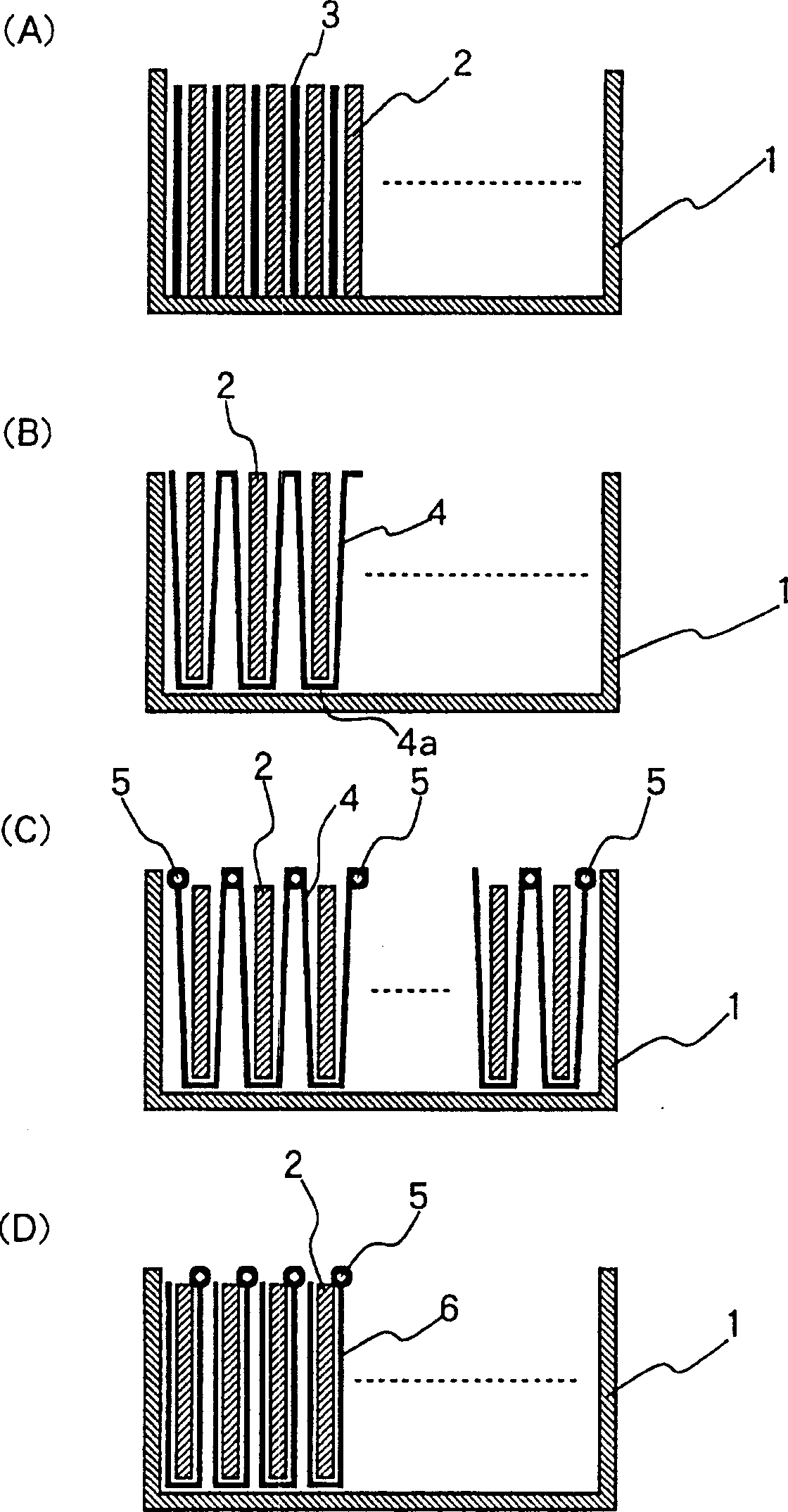

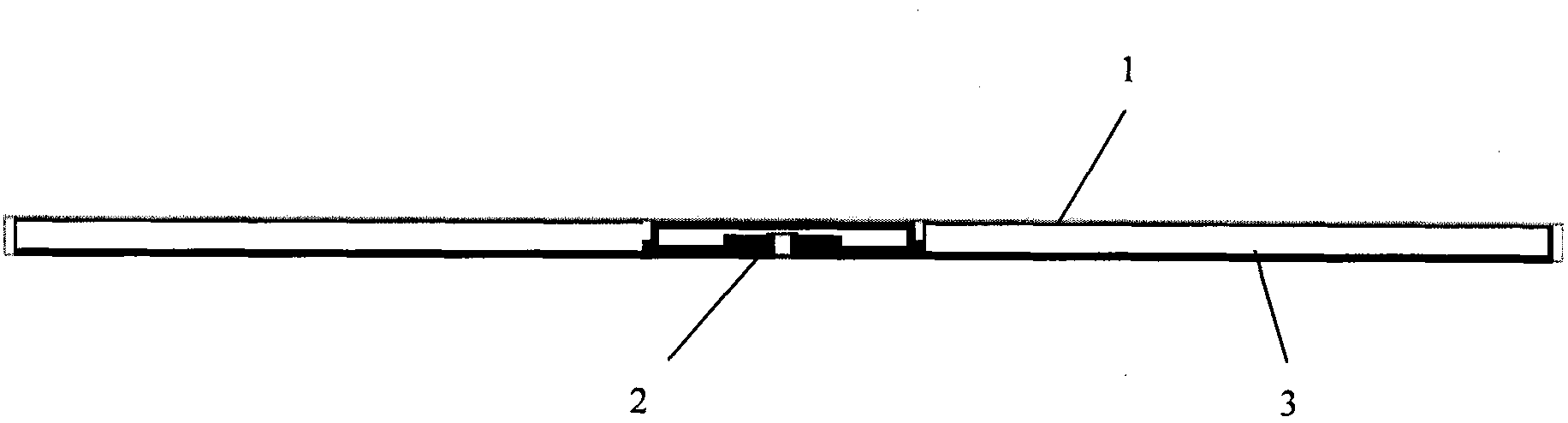

Glass plate packing method and packing structure

InactiveCN1436703AImprove protectionReduce handling costsPackage recyclingInternal framesCushioningPolypropylene

The invention provides a transporting method and structure thereof. A plurality of glass plates 2 are received vertically side by side in a box-formed container 1 with an upper surface opened, and cushioning sheets 3 made of a polypropylene or a polyethylene are put between the respective adjacent glass plates 2.

Owner:ASAHI GLASS CO LTD

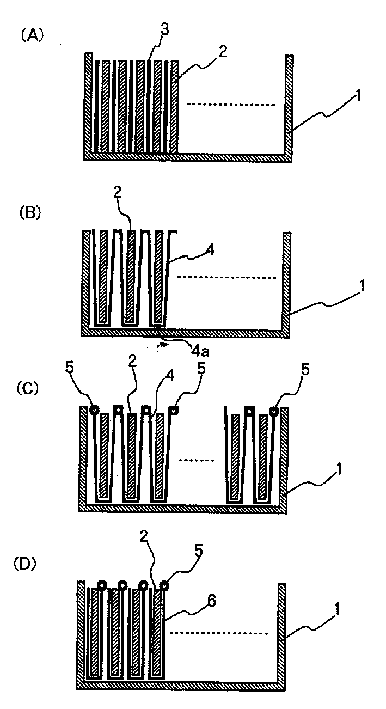

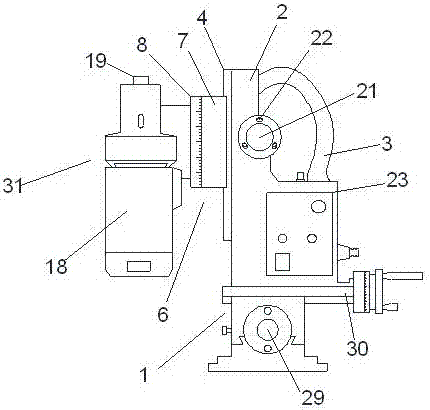

Handheld side tie rod positioning and rotating universal milling machine

PendingCN107262788AEasy to installEasy to disassembleMilling machinesMilling equipment detailsEngineeringMechanical engineering

The invention discloses a handheld side tie rod positioning and rotating universal milling machine. The milling machine comprises a base. A stand column is arranged on the base. One side of the stand column is provided with a lifting handle. The other side of the stand column is provided with a sliding block. A rotary milling head device is arranged on the sliding block. The rotary milling head device comprises a side tie rod positioning disk and a milling head which are arranged on the sliding block. The milling head is connected with the sliding block through the side tie rod positioning disk. The handheld side tie rod positioning and rotating universal milling machine is small in size and convenient to carry. The machining angle can be adjusted on the circumference by 360 degrees; machining angle positioning is fast, and operation is easy; moreover, the milling head is stable in installation, convenient to dismantle and convenient to maintain and replace, and the working efficiency is improved.

Owner:罗甸县金泰模具机械制造有限公司

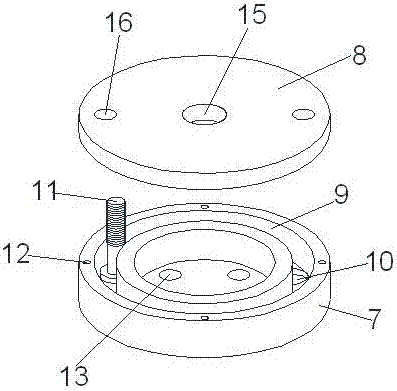

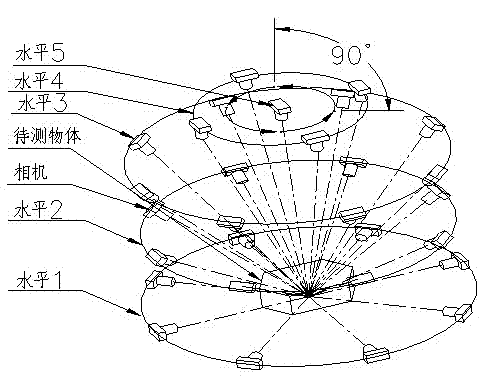

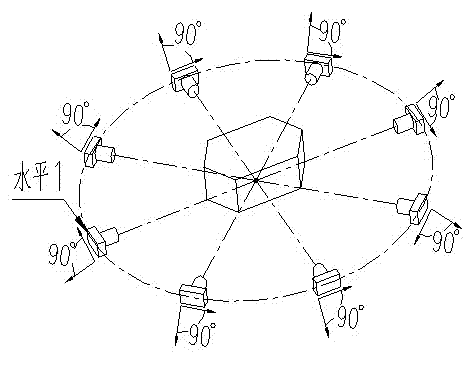

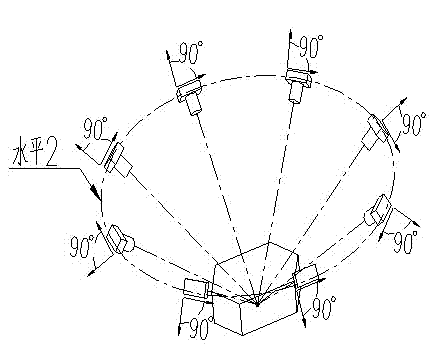

Optical detection method for plate material forming and springback

ActiveCN103191958ARealize the display effectReduce handling costsUsing optical meansMetal working apparatusComputer Aided DesignSurface scanning

The invention discloses an optical detection method for plate material forming and springback. A photographical measurement and surface scanning combined method is adopted to realize the detection for the springback amount of a workpiece;the shape after the springback is expressed by a point cloud form, and the shape before the springback is expressed by a computer aided design (CAD) numerical simulation; the later shape and the previous shape are compared through inversion software; and a springback three-dimensional direction value and a visible digital expression mode of the springback can be determined at any position of the workpiece. A photographical measurement technology and a surface scanning technology are combined for measurement, so that the problems of low point cloud processing speed and low fusion precision of the pure surface scanning technology are solved; and by using the three-dimensional optical detection method, the definite advantages on large-size, ultra-large-size, ultra-small-size and A-level curved surface products or workpieces which can not be detected by using a contact measurement method are realized.

Owner:GUANGZHOU WANBAO GRP MINQUAN ELECTRICAL APPLIANCE CO LTD

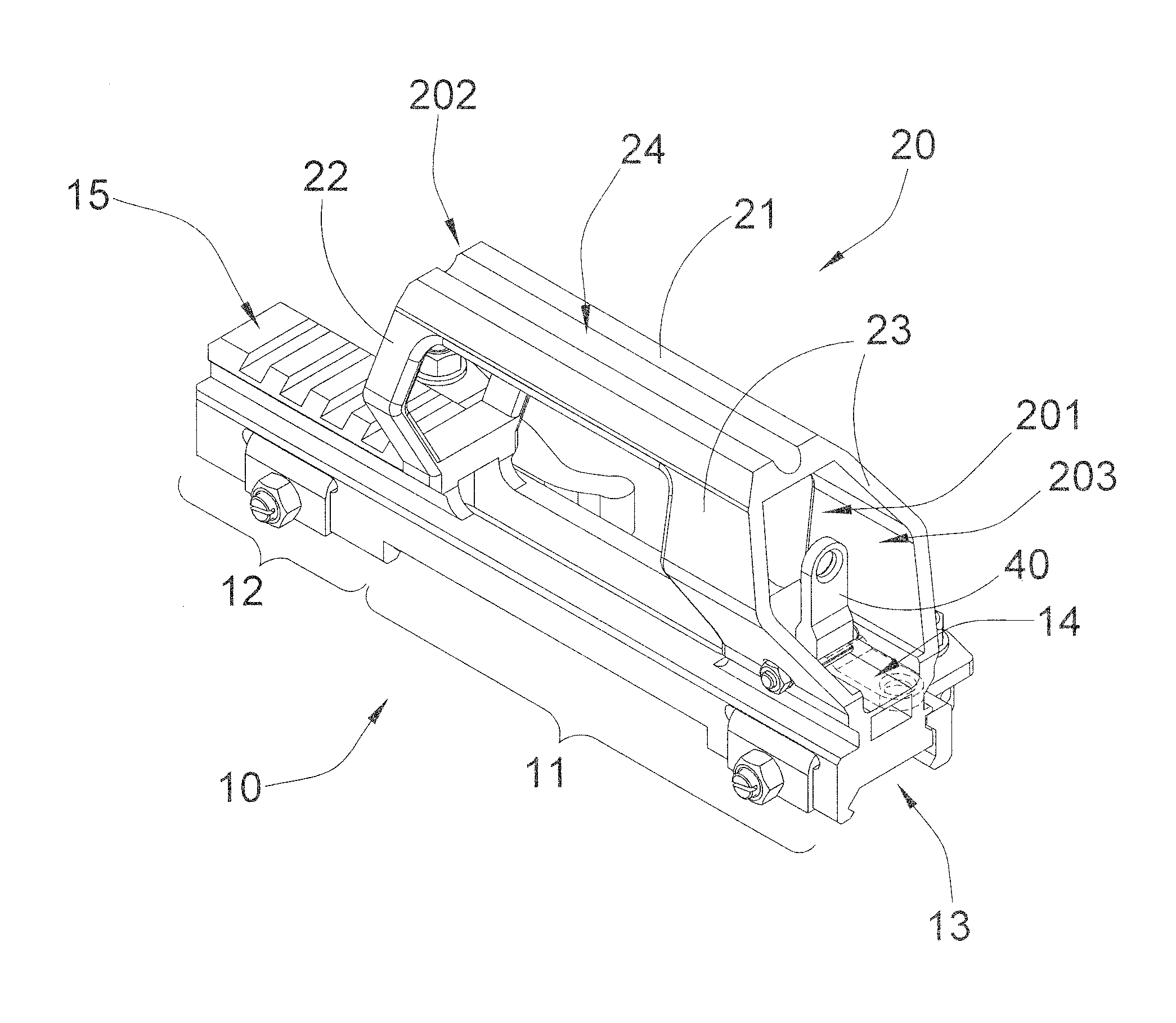

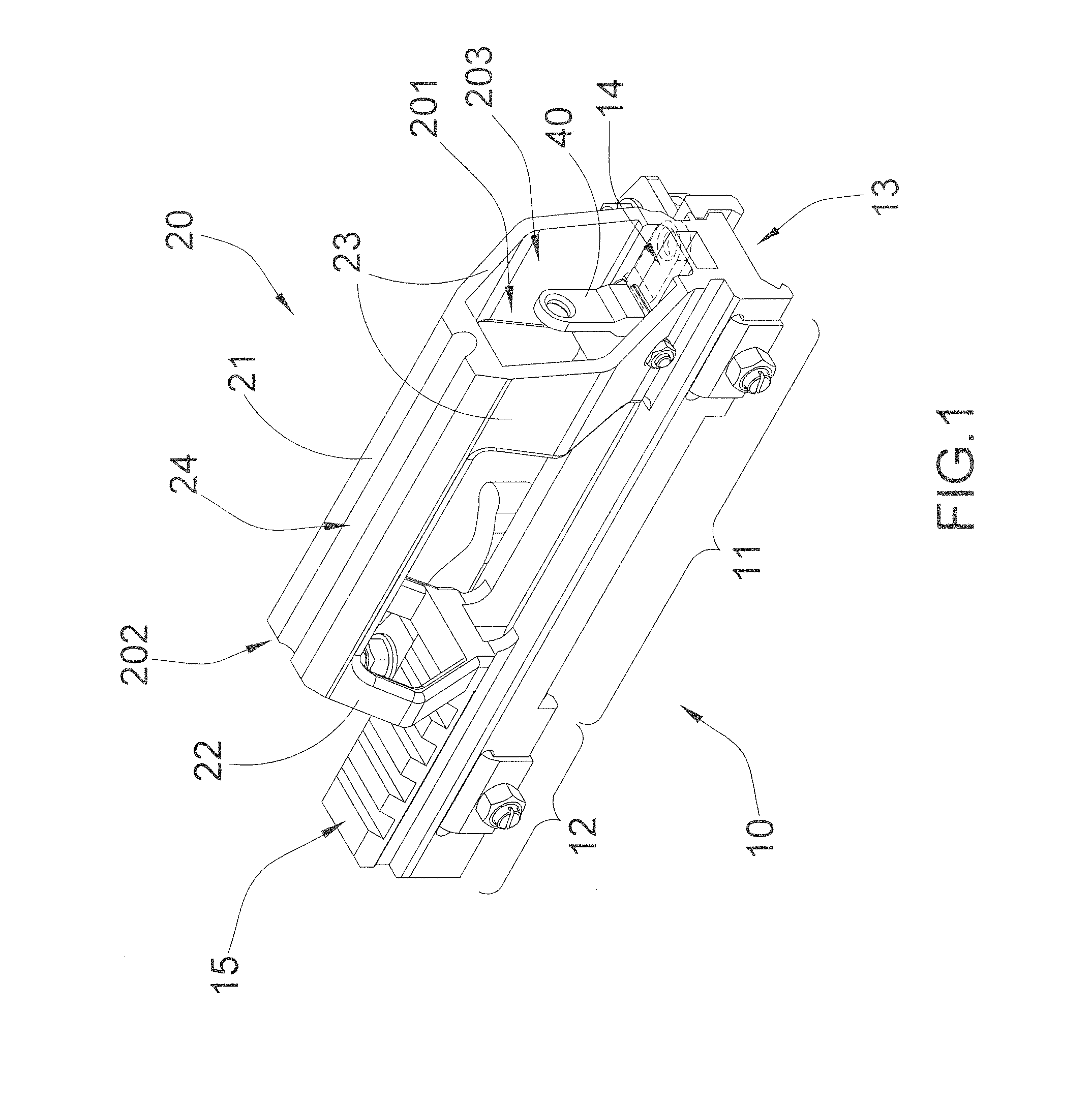

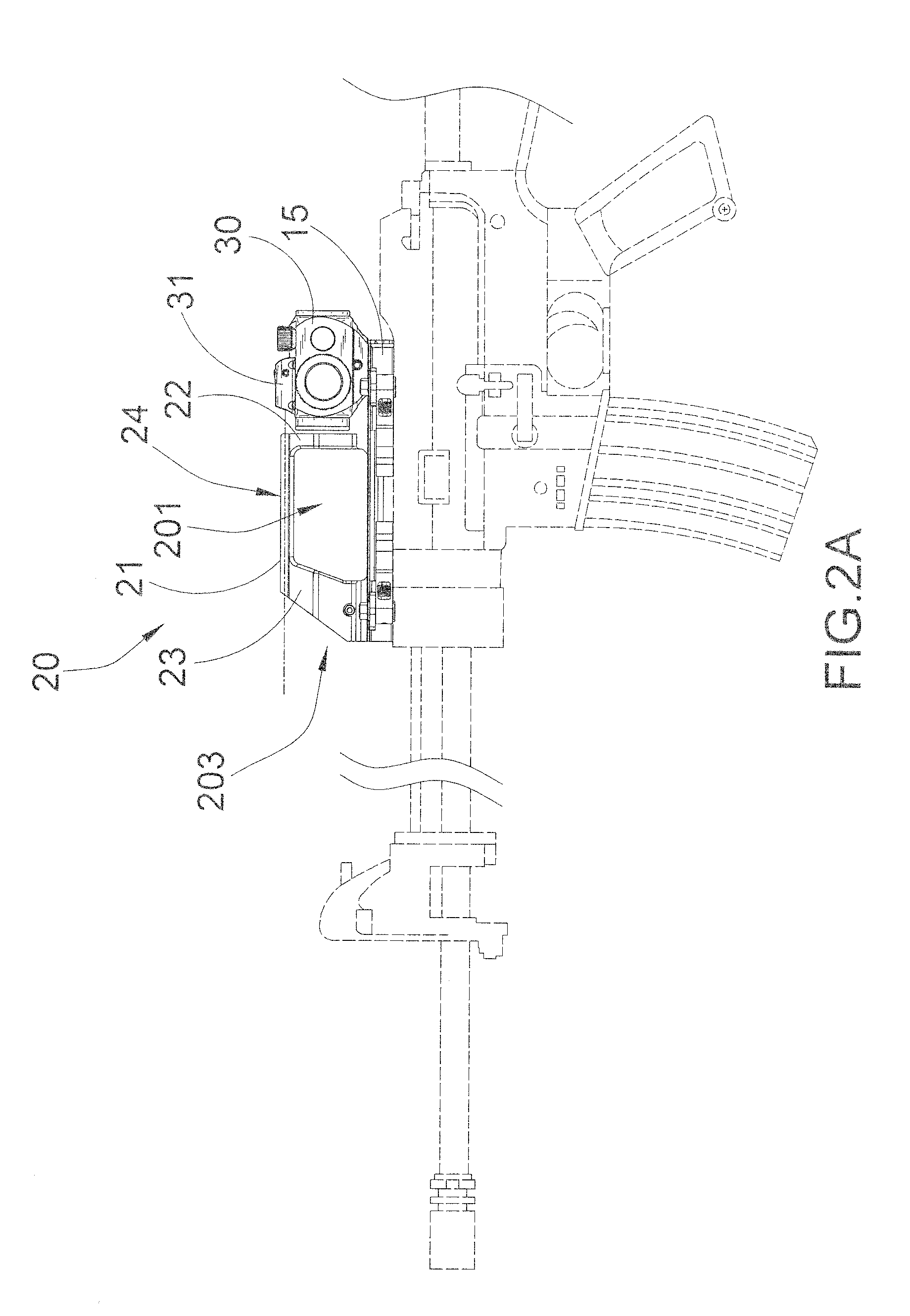

Handle Sight

ActiveUS20150345901A1Reduce handling costsReduce manufacturing costSighting devicesArms wearablesEngineeringMechanical engineering

A handle sight for a firearm includes a mounting base and a carrying handle. The mounting base has an elongated shape and defining a first end portion and an opposed second end portion, wherein the mounting base is adapted for detachably mounting on the firearm in a reversible orientation to locate the first end portion of the mounting base one of a forward direction and a rearward direction of the firearm. The carrying handle is upwardly extended from the first end portion of the mounting base at a top side thereof, wherein the carrying handle has a hollow structure to define a sight channel for parallelly align with a barrel axis of the firearm so as to enable an operator to aim at a front iron sight of the firearm through the sight channel.

Owner:NCSTAR

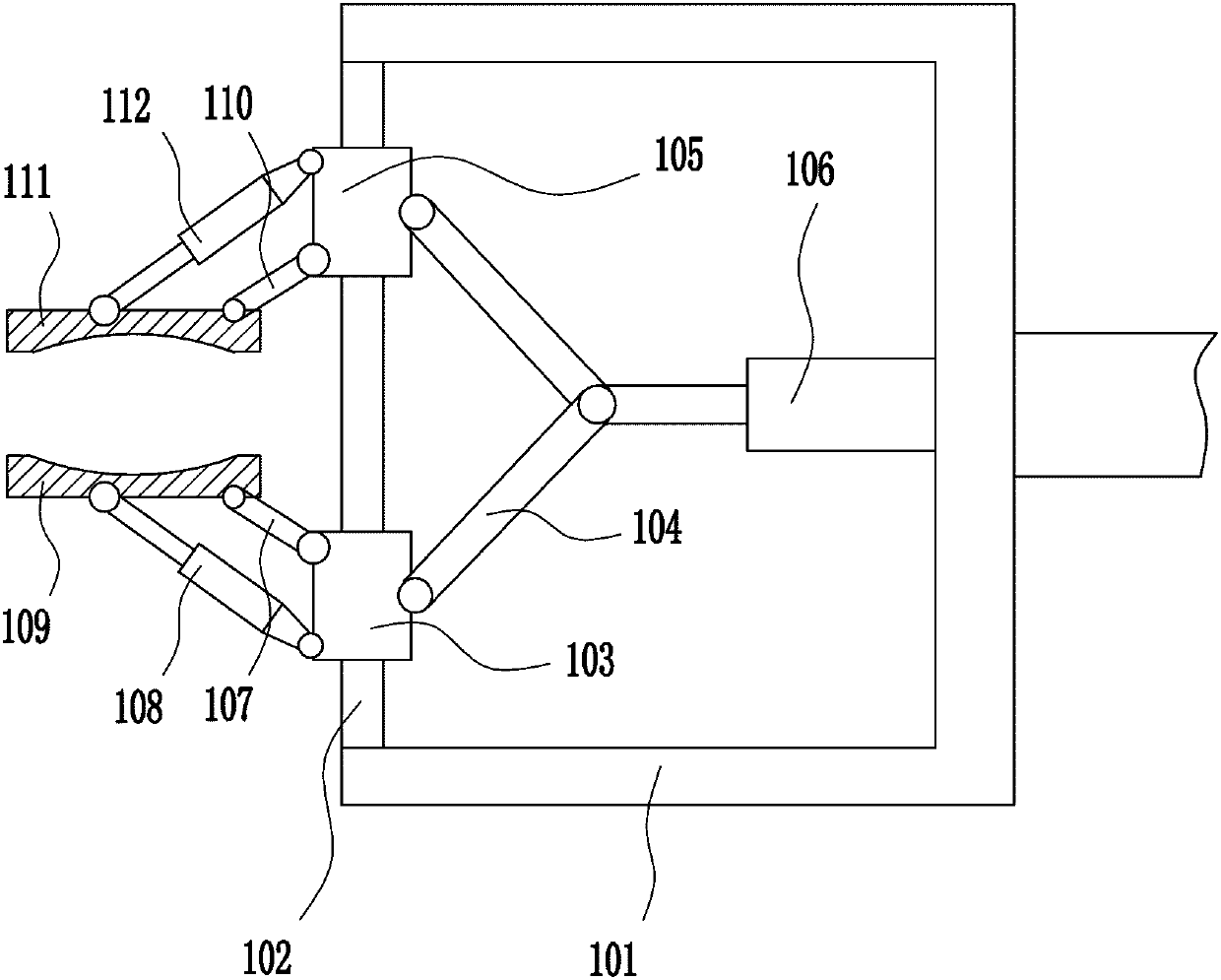

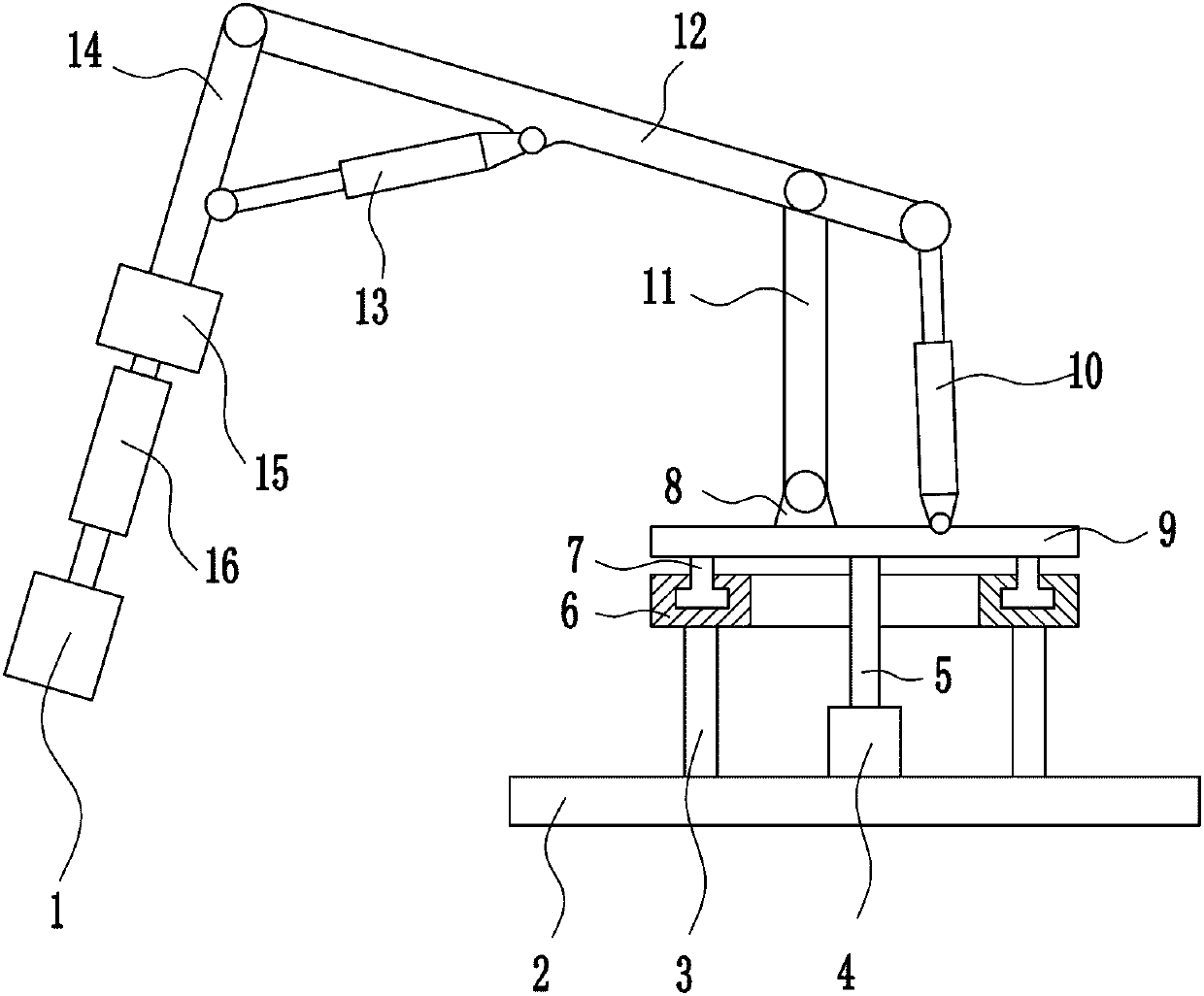

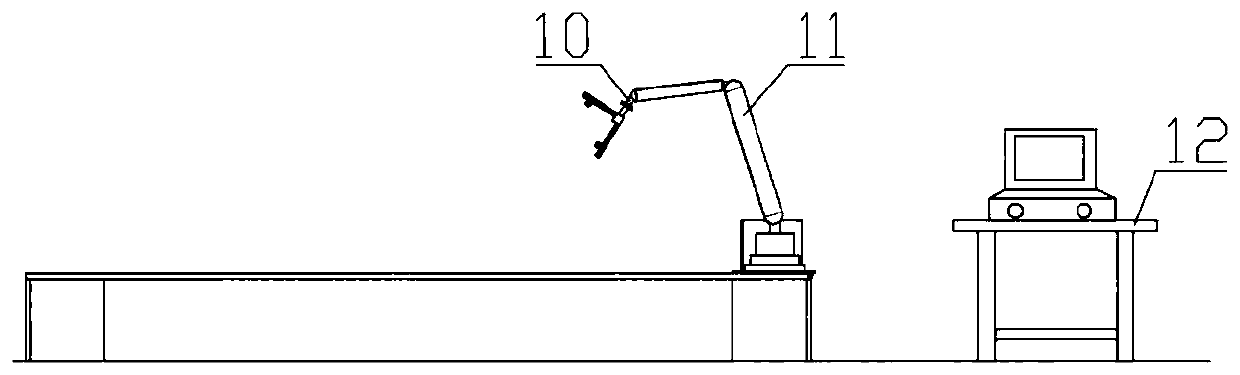

Warehouse goods carrying robot

ActiveCN105945940AFast handlingReduce handling costsProgramme-controlled manipulatorGripping headsControl engineeringElectric machinery

The invention relates to a robot, in particular to a warehouse goods carrying robot. The technical problem to be solved by the invention is to provide the warehouse goods carrying robot with time and labor saving, fast carrying speed and low carrying cost. In order to solve the technical problem, the invention provides the warehouse goods carrying robot; the warehouse goods carrying robot comprises a clamping device, a baseplate, support rods, a rotating motor I, a rotating shaft, an annular slide rail, a slide block, a bracket, a rotating plate, a cylinder I, a connecting rod I, a connecting rod II, a cylinder II, a connecting rod III, a rotating motor II and a cylinder III; the support rods are symmetrically arranged at the top of the baseplate; the annular slide rail is arranged at the upper ends of the support rods; the slide block is arranged on the annular slide rail; the rotating plate is arranged at the top of the slide block; the rotating motor I is arranged in middle of the top of the baseplate, and is positioned between the support rods; and the rotating shaft is arranged at the top of the rotating motor I. The warehouse goods carrying robot achieves the effects of time and labor saving, fast carrying speed and low carrying cost.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

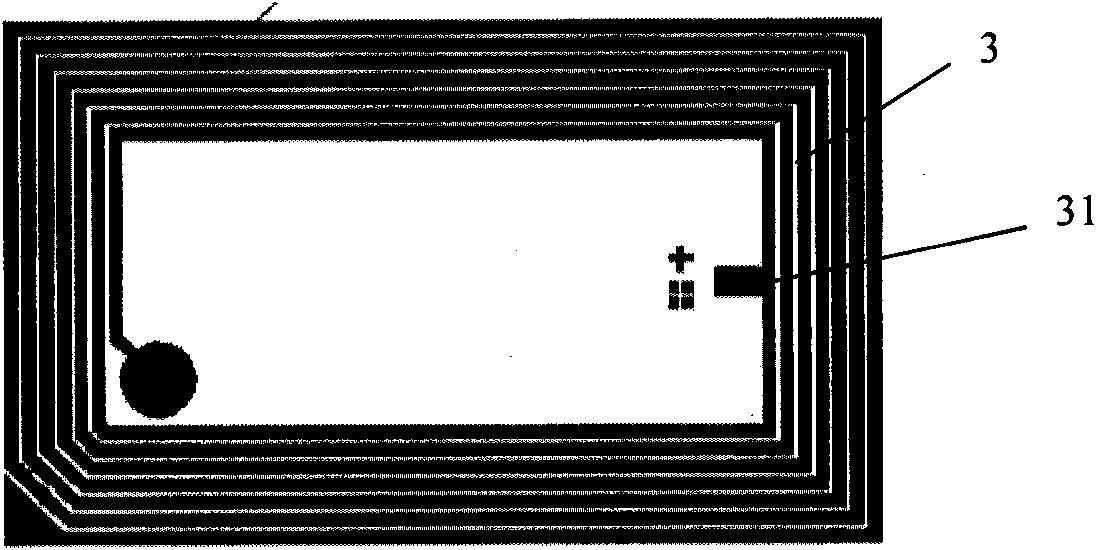

Printed circuit board with radio frequency identification and production method thereof

InactiveCN102014573AReduce labor costsImprove accuracyAntenna supports/mountingsPrinted electric component incorporationAdhesiveEngineering

The invention discloses a printed circuit board with a radio frequency identification, comprising a printed circuit board, a radio frequency identification chip, a radio frequency identification antenna and conductive adhesive, wherein the radio frequency identification chip is arranged on the printed circuit board; the radio frequency identification antenna is printed on the printed circuit board; an antenna pin is arranged at one side of the radio frequency identification antenna; and the pin antenna is closely connected with a connecting port of the radio frequency identification chip by the conductive adhesive. The production method comprises the following steps of: firstly, printing the radio frequency identification antenna on the printed circuit board; secondly, coating an insulating layer at the part of the radio frequency identification antenna, which corresponds to a jumper wire; thirdly, printing the jumper wire and respectively connecting two ends of the jumper wire with the head and the tail of the radio frequency identification antenna; fourthly, coating the conductive adhesive on the antenna pin by adhesive dispensing equipment; fifthly, turning over the radio frequency identification chip to be connected with the antenna pin; sixthly, hot pressing the conductive adhesive and curing the conductive adhesive; and seventhly, testing the qualified rate. By using the invention, the labor cost can be saved, the work accuracy can be improved, the quality of products can be ensured, the processing can be accelerated and the logistics dynamic can be effectively tracked.

Owner:上海中京电子标签集成技术有限公司 +5

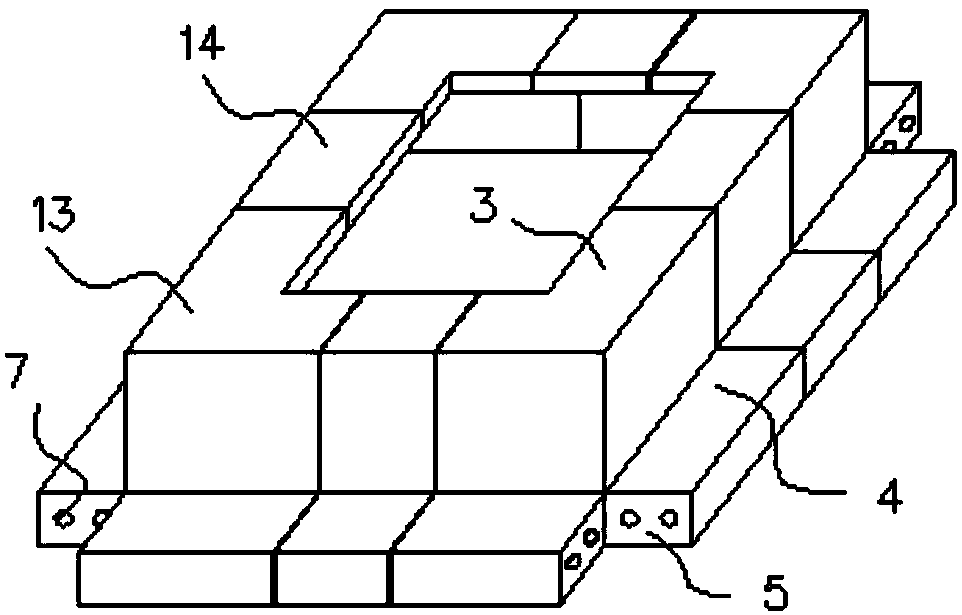

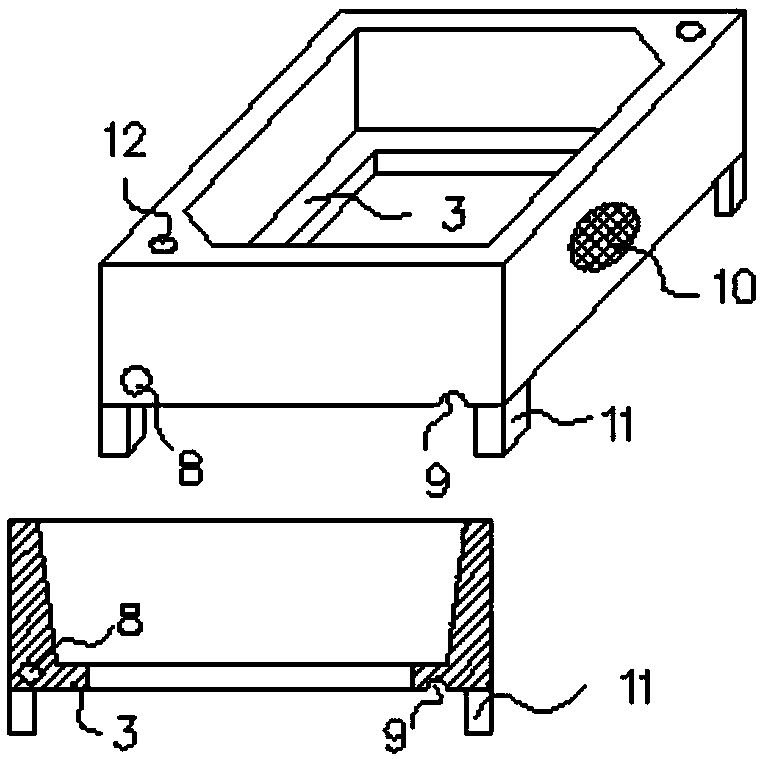

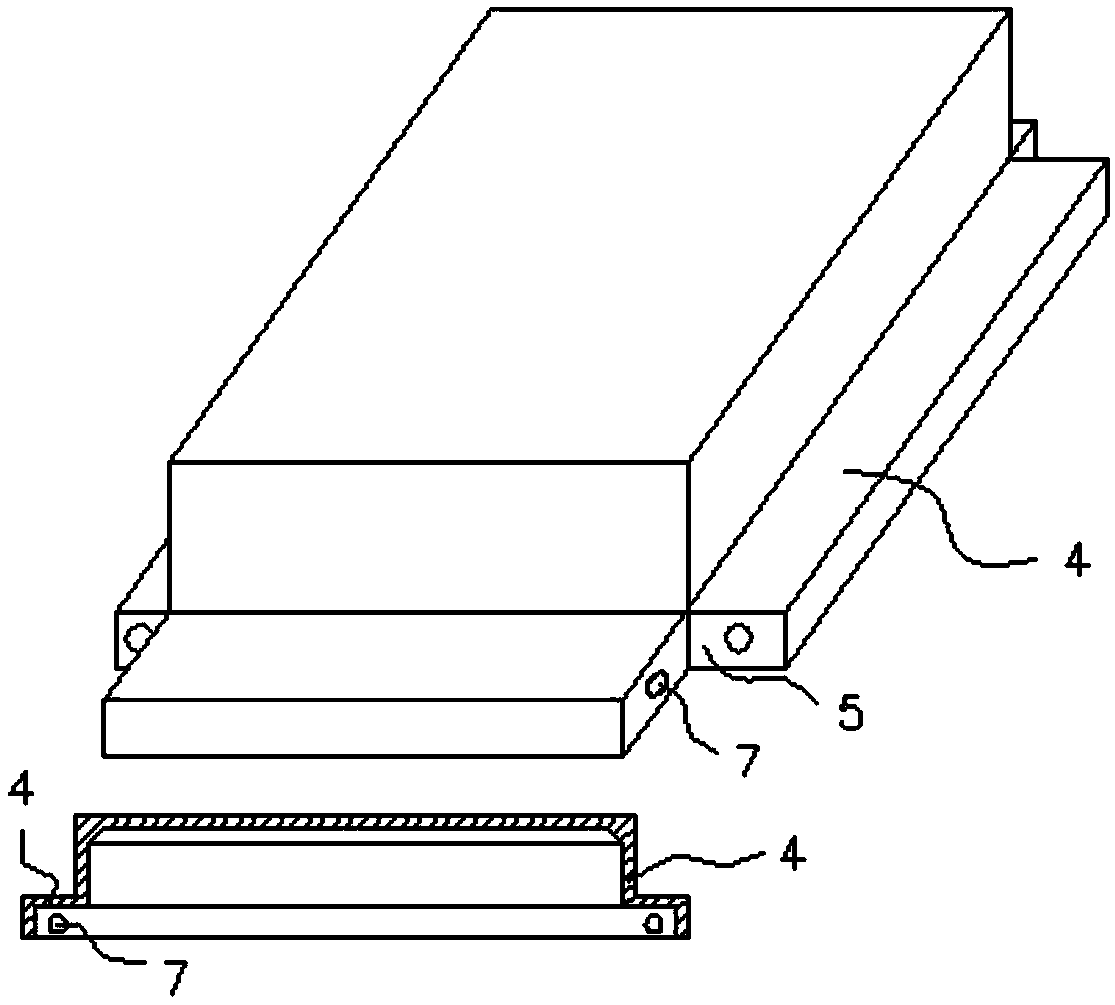

Cover die for construction of composite-section ribbed floor and construction method thereof

ActiveCN109680929ASolve mold problemsReduce production processForms/shuttering/falseworksReinforced concreteEngineering

The invention discloses a cover die for construction of a composite-section ribbed floor and a construction method thereof. The cover die comprises two cylinders or one cylinder and one box or two boxes, wherein each cylinder is of a cylindrical surrounding body structure of which the upper part and lower part are communicated; the cylinders comprise a cylinder I and / or a cylinder II; each box isof a cavity body structure of which one end is opened and the other end is sealed; the boxes comprise a box I and / or a box II; the cylinder I is sheathed above the exterior of the cylinder II, and / orthe box I is sheathed above the exterior of the cylinder II, and / or the box I is sheathed above the exterior of the box II; a lower flange die cavity of a cast-in-situ concrete rib is formed between the cylinder and / or the box; a web plate die cavity of a cast-in-situ concrete dense rib is formed between the adjacent cylinders and / or the boxes. One of the cover die is reserved in a reinforced concrete prefabricated rib cylinder or box, and the other one is a detachable and repeatedly used cylinder die, or is a prefabricated concrete cylinder reserved in the floor. The cover die is a construction die with the advantages that the production is simple; the construction is convenient; the construction period is short; the manufacturing cost is low; the good use effect is obtained.

Owner:贵州皆盈科技开发有限公司

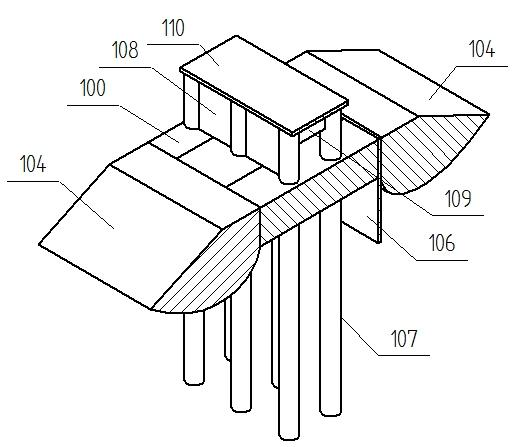

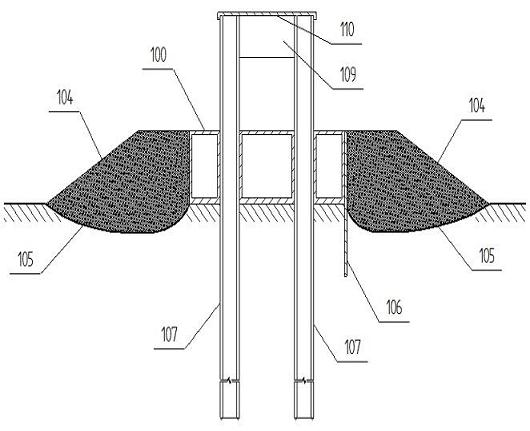

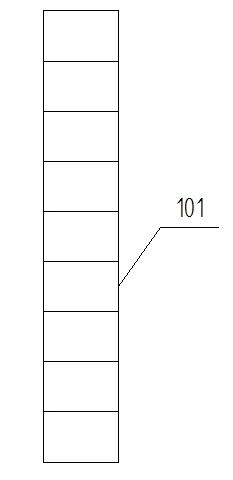

Caisson type high-pile seawall and construction method thereof

InactiveCN102587316AImprove carrying capacityImprove stabilityBreakwatersQuaysOcean bottomCarrying capacity

The invention relates to a seawall and a construction method thereof. Reinforced concrete caissons are sequentially connected, tubular piles penetrate through the reinforced concrete caissons, and accordingly a foundation of the seawall is formed. The caisson type high-pile seawall comprises a caisson platform positioned on a seabed soft soil foundation in coastal engineering, carrying piles which penetrate through the caisson platform and are implanted into a seabed are arranged on the caisson platform, and pressing layers are arranged on a sea-adjacent side and a land-adjacent side of the caisson platform. The caisson type high-pile seawall and the construction method thereof have the advantages that carrying capacity and stability of the seawall are improved, the caisson platform can be used as a construction platform, construction can be carried out according to a land construction method after construction machinery is placed on the caisson platform, offshore operation of ships is reduced, construction cost is lowered, and the construction method can be widely applied to constructing costal seawalls.

Owner:浙江海桐高新工程技术有限公司

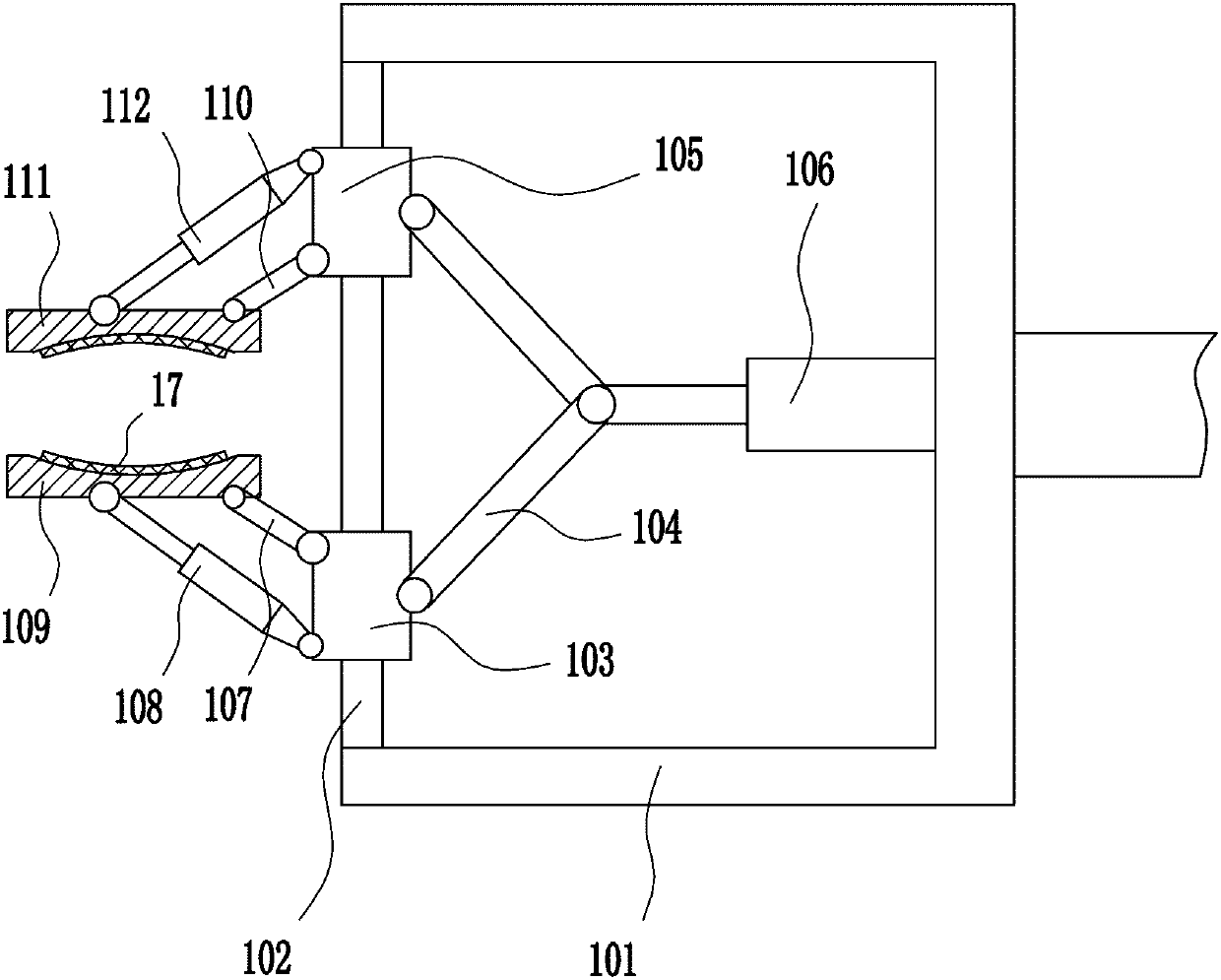

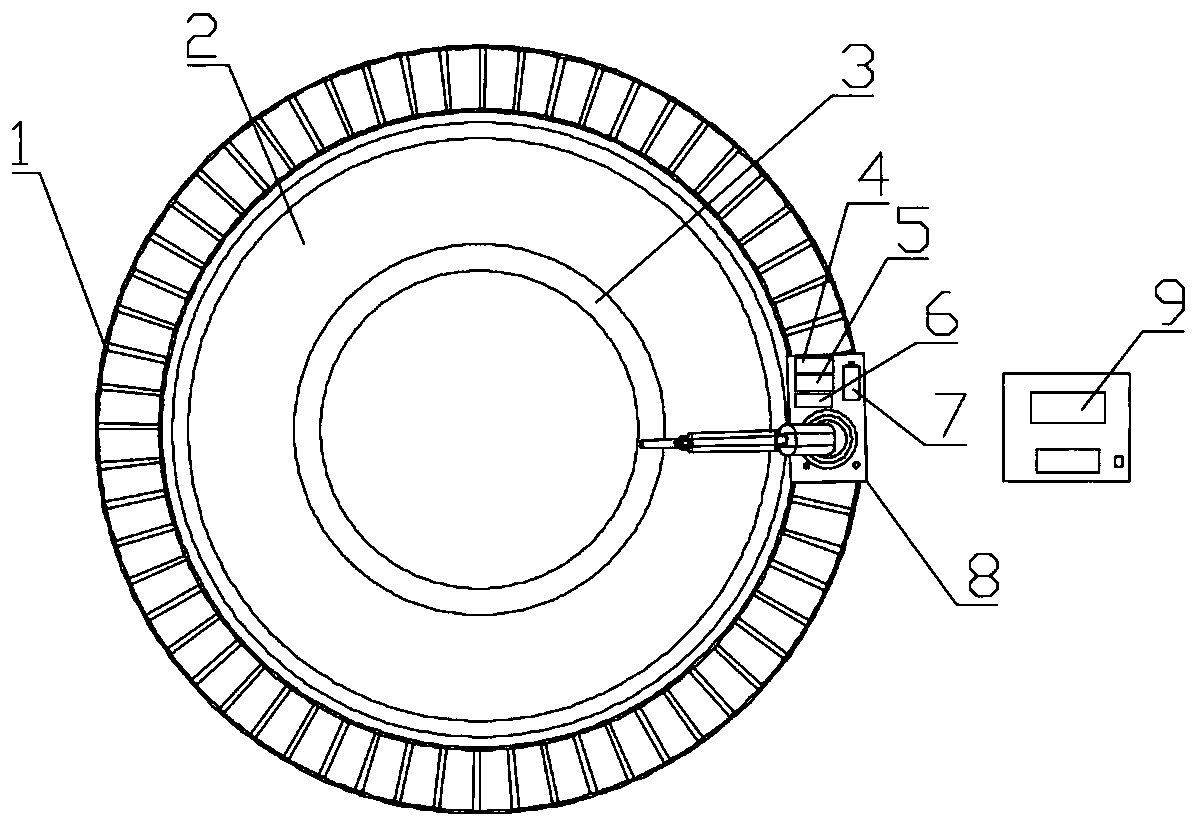

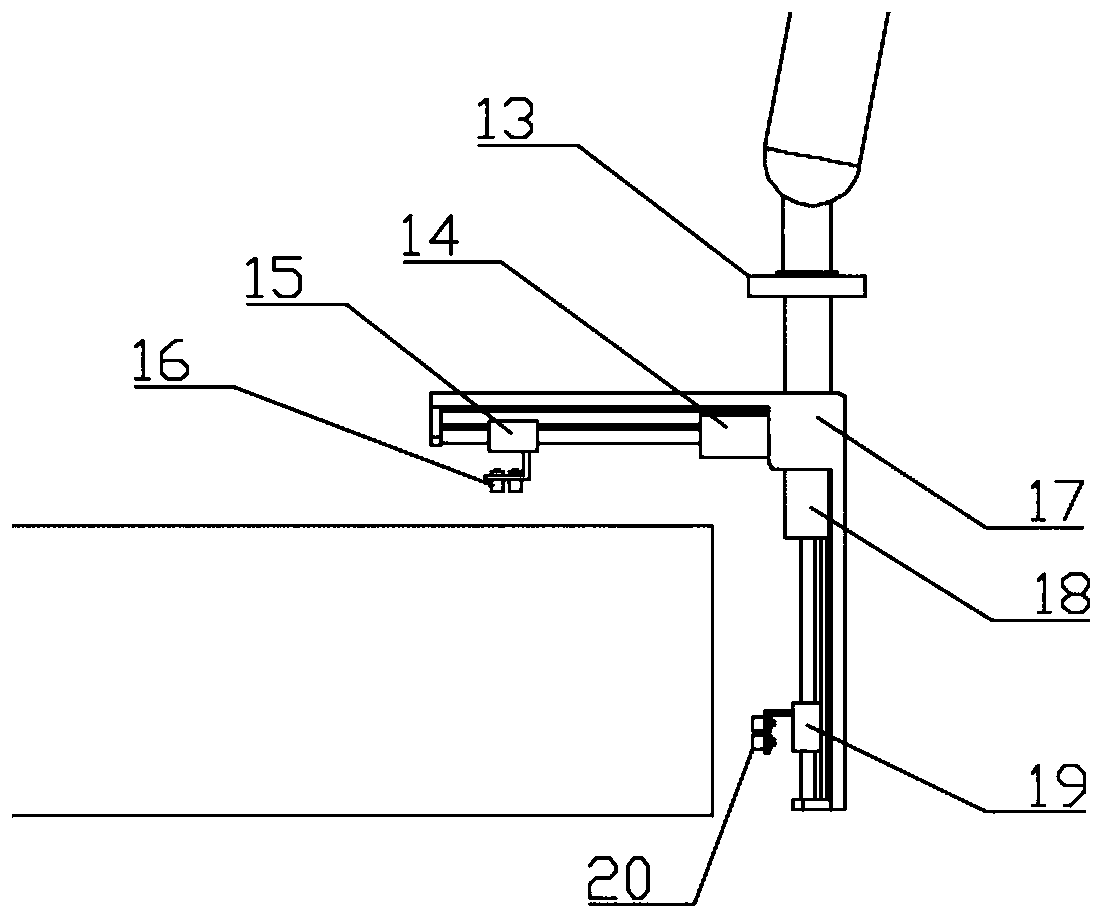

Track type ultrasonic detecting device for large ring member and ring member detecting method

InactiveCN110441392AExpand the scope of detectionImprove loading and unloading efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringNondestructive testing

The application provides a track type ultrasonic detecting device for a large ring member and a ring member detecting method, and belongs to the technical field of ultrasonic nondestructive testing. The track type ultrasonic detecting device comprises: a pool containing a coupling agent, wherein a large ring member is arranged in the pool; a circular track arranged at the outer periphery of the pool; an industrial robot movably installed on the circular track; a driving component in transmission connection with the industrial robot and used for driving the industrial robot to move on the circular track; and an ultrasonic scanning mechanism movably mounted on the industrial robot for detecting internal defects of the large ring member. The detecting device can accurately and comprehensivelytest the large ring member, and can adapt to the detection of ring members with different sizes, thereby improving the detection efficiency of the ring members and the accuracy of detecting data.

Owner:WUHAN UNIV OF TECH

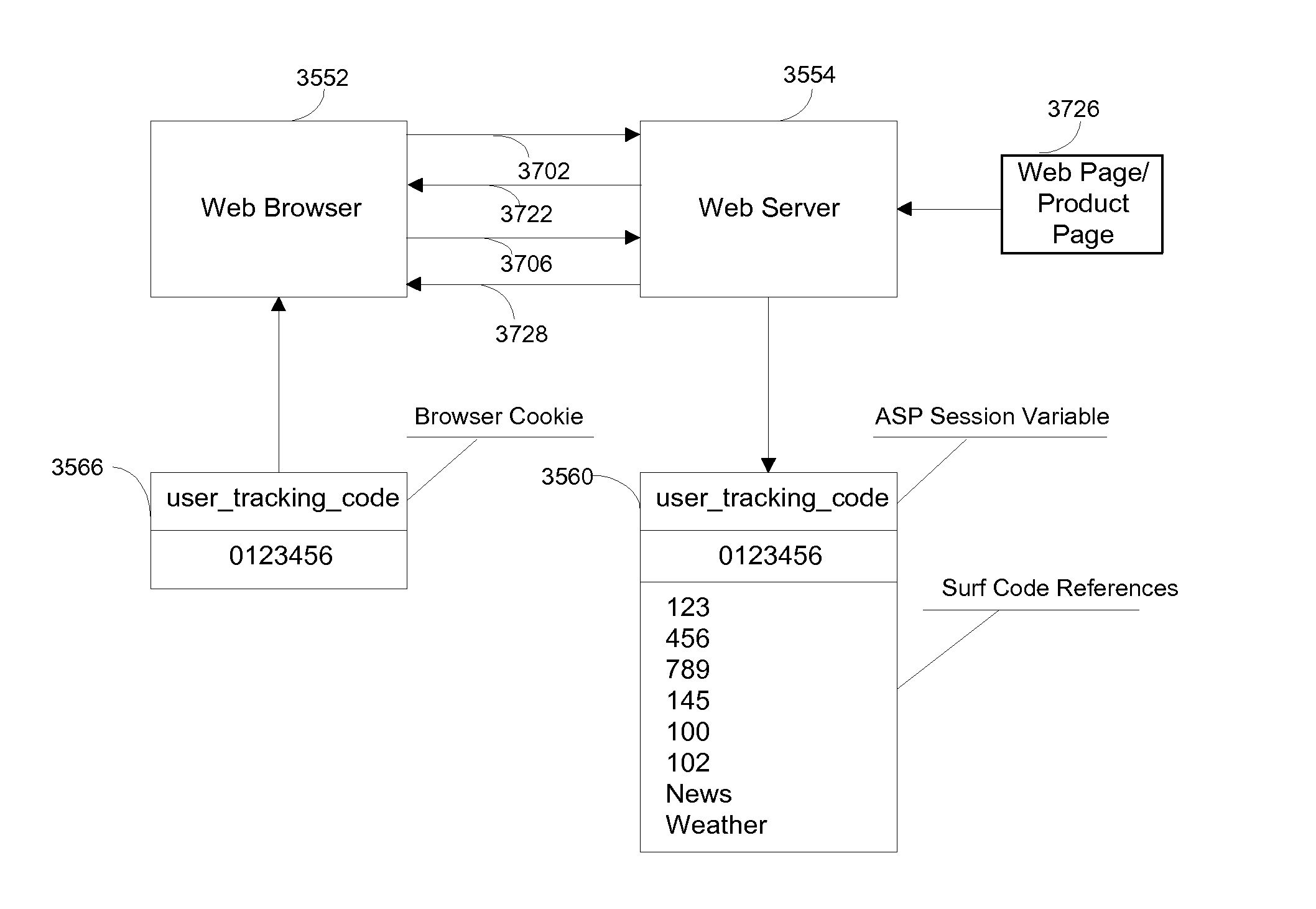

Method of using a code to track user access to content

InactiveUS20100223290A1Way of increaseSimplify buyer ' decisionDigital data processing detailsMultiple digital computer combinationsThe InternetClient-side

A method for tracking user internet surfing involving steps of providing a computer hosting a plurality of contents stored on a computer storage medium; storing on the computer storage medium a surf code reference for each content in the plurality of contents; storing on the computer storage medium an identification of the user to enable the user to log in to the computer; enabling a logged-in user to access the computer through the requesting client to view a content in the plurality of contents; maintaining a user list comprising the surf-code reference of the content viewed by the logged-in user; enabling the logged-in user to access the user list to identify the content viewed by the logged-in user; and, presenting the content viewed by the logged-in user to the requesting client based on the user list.

Owner:PILOANDIA LLC

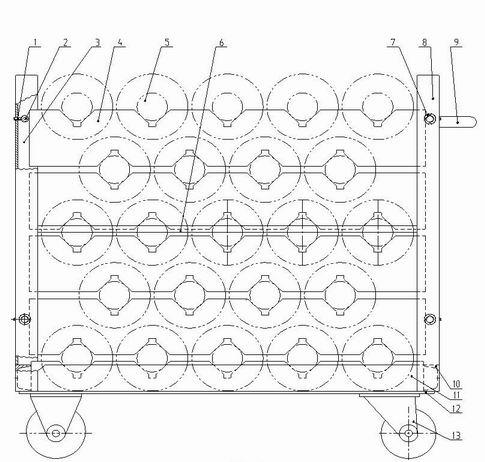

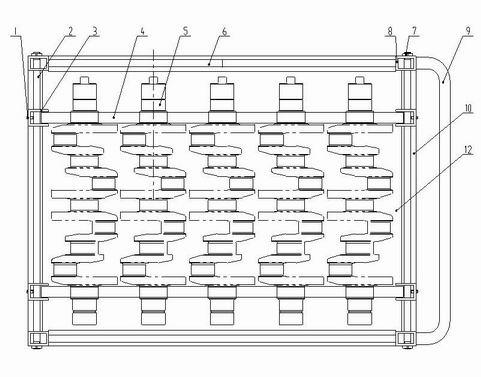

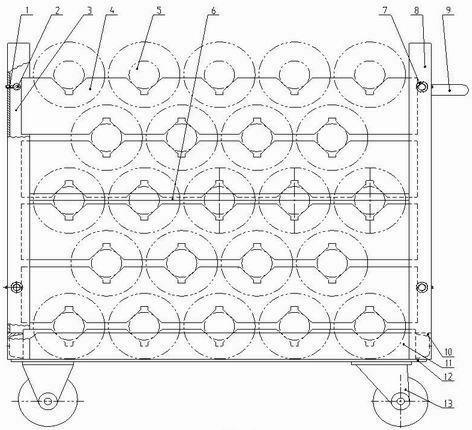

Transfer cart with crankshafts

InactiveCN102582671AAchieve turnoverReasonable structureHand carts with multiple axesArchitectural engineeringCrankshaft

The invention relates to a transfer cart with crankshafts, which is provided with a bottom plate and wheel sets. Four vertical columns and a frame are welded on the bottom plate, two guide connecting rods are respectively arranged between the two front vertical columns and between the two rear vertical columns, the two guide connecting rods on the front side and the two guide connecting rods on the rear side are perpendicularly connected with two limit groove plates respectively, and a bottom bearing plate and a plurality of middle bearing partitions are sequentially mounted between the frontlimit groove plate and the rear groove plate layer by layer. V-shaped grooves of the upper end face of the lower middle bearing partition are arranged oppositely to V-shaped grooves of the lower end face of the upper middle bearing partition, and V-shaped grooves of the lower end face and V-shaped grooves of the upper end face of the same middle bearing partition are arranged at intervals in a staggered manner. When in use, the crankshafts and the middle bearing partitions are sequentially mounted layer by layer, the crankshafts in layers are disposed in a staggered manner so that space can be utilized sufficiently and more crankshafts can be disposed. The transfer cart with the crankshafts is reasonable in structure, simple in operation, high in transferring efficiency, low in transferring cost and wide in application.

Owner:TIANRUN IND TECH CO LTD

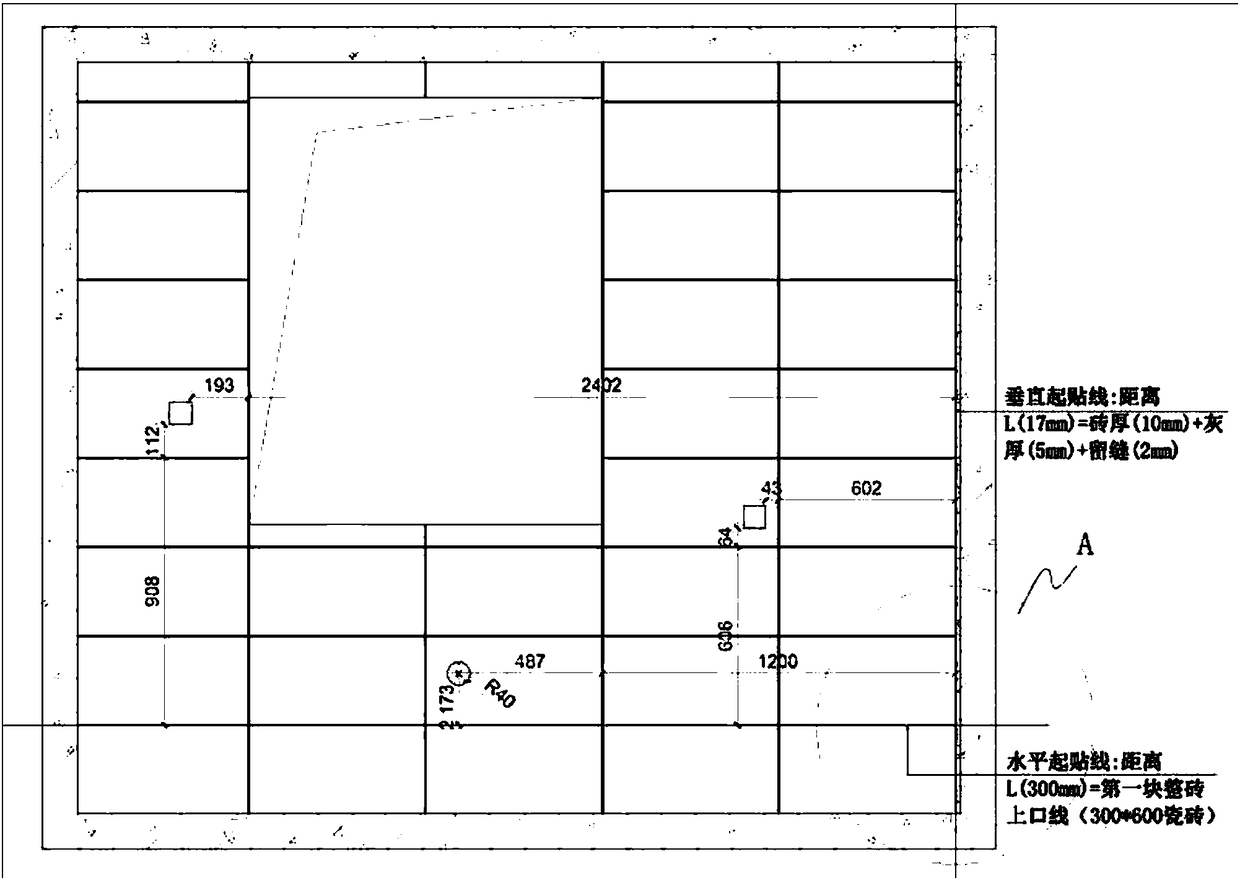

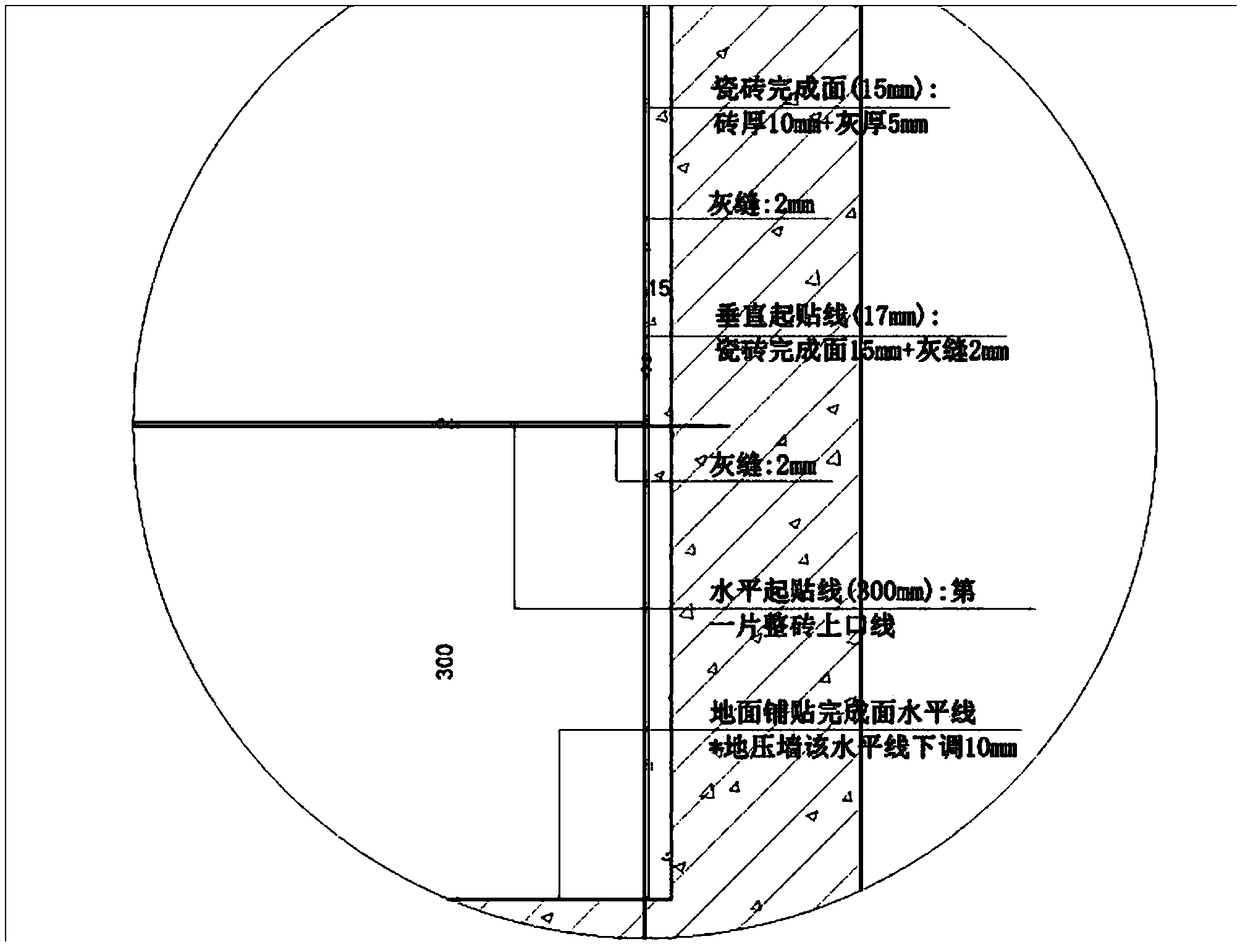

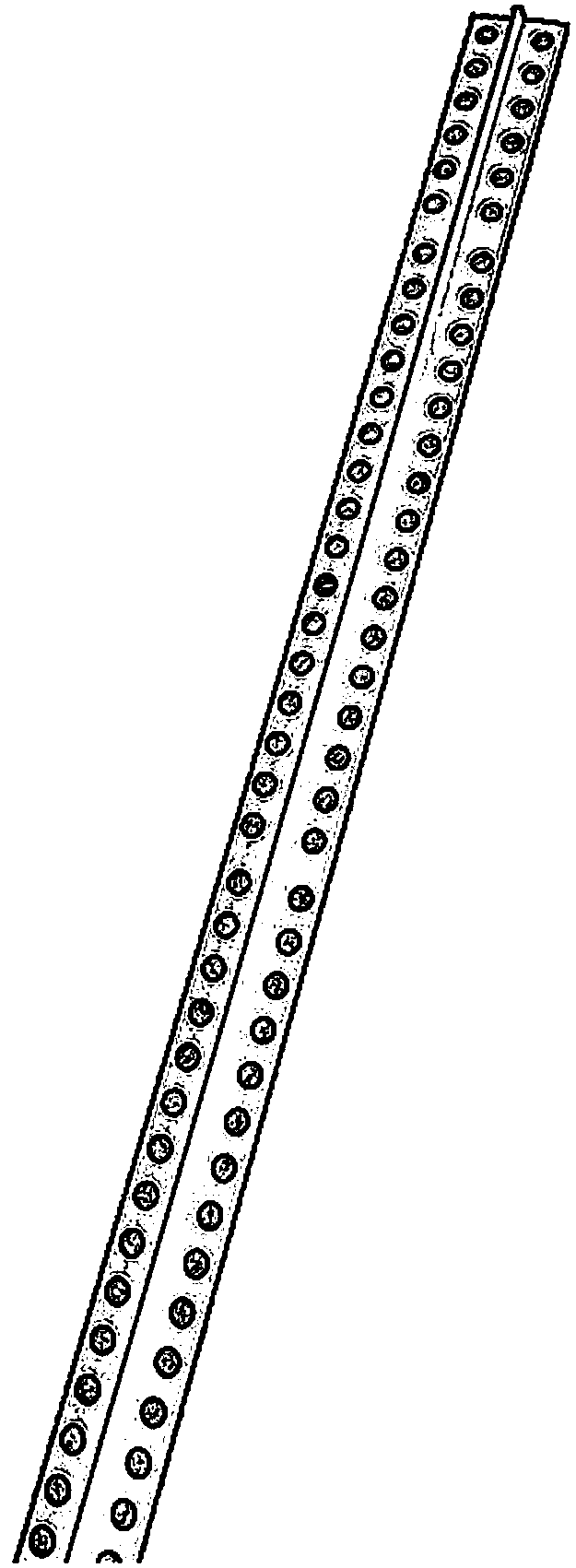

Method and tool for mounting assembly type ceramic tiles

InactiveCN108571154AImprove construction efficiencyPaste firmlyBuilding constructionsAdhesiveSurvey result

The invention relates to a method and a tool for mounting assembly type ceramic tiles. The mounting method comprises the following steps: carrying out a survey by a surveyor on a site where tiles arepre-tiled to obtain a survey result, wherein indexes of the survey include the flatness, verticality and squareness of internal and external corners of a base layer; according to the survey result, leveling a substandard wall or ground base by a leveling bricklayer; according to a preset tiling plan, sticking a start tiling line for positioning a tiling position of a single tile on the leveled base by the surveyor, and determining a processing size of the single tile according to the start tiling line; processing the ceramic tile in a factory according to the processing size, wherein the processing comprises cutting and punching the ceramic tile; and according to a construction drawing, scraping an adhesive on the base and the processed tile by a tiling bricklayer along the start tiling line with a tiling tool to tile the tiles. The method and tool provided by the invention improve the construction efficiency and ensure the construction quality.

Owner:上海相品家居建材有限公司

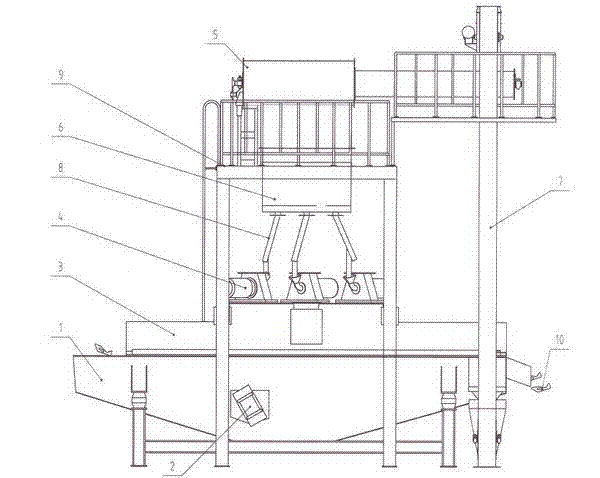

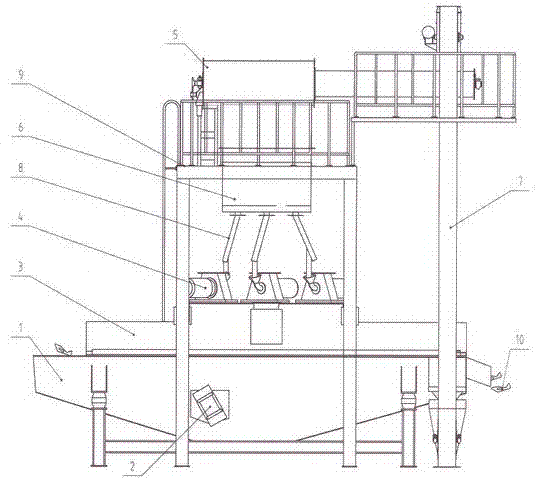

Continuous shot-blasting cleaner

InactiveCN102240979APlay a role in surface strengtheningIncrease productivityAbrasive blasting machinesEngineeringMechanical engineering

The invention discloses a continuous shot-blasting cleaner which comprises a vibration bed, a shot-blasting chamber, a shot-blasting device, a shot warehouse, a lifting machine and a shot separator, wherein the vibration bed is fixedly mounted with the help of elastic support legs; a latticed support wall is arranged on top side of the vibration bed; a lateral inclined slope is arranged under the support wall; a shot outlet is formed at bottom of the slope; the shot-blasting chamber is arranged above the vibration bed; a lower opening of the shot-blasting chamber is hermetically butted with an upper opening of the vibration bed; at least one shot-blasting device, the interior of which is communicated with an outlet, is arranged above the shot-blasting chamber; the shot warehouse is horizontally arranged right above the shot-blasting chamber with the help of a bracket; and the outlet, which is communicated with the shot-blasting device with the help of a shot pipe, is arranged at the bottom of the shot warehouse. The continuous shot-blasting cleaner has the advantages that a casting gradually moves toward right end under the effect of the vibration of the vibration bed; the surface of the casting is attacked by the shots blasted from the shot-blasting device, thereby clearing away the impurities on the surface of the casting as well as strengthening the surface of the casting; the whole production process is continuously processed; a workpiece need not be turned over; and the production efficiency is greatly promoted and the carrying cost is lowered.

Owner:永红保定铸造机械有限公司

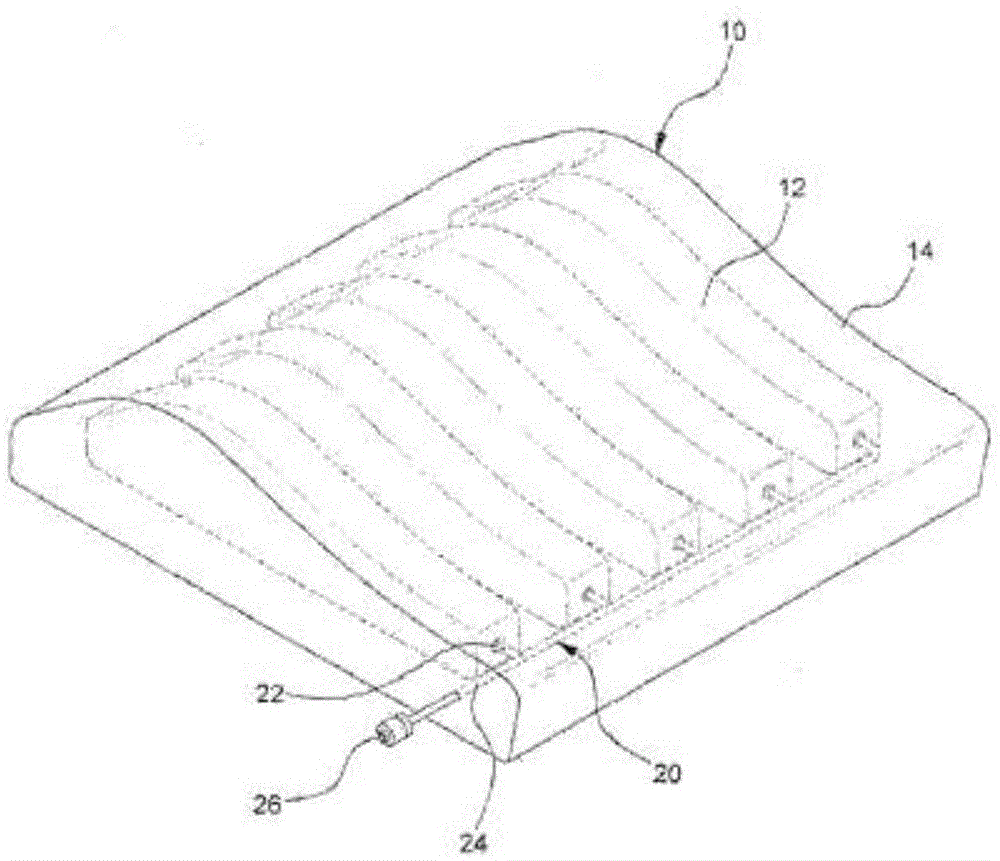

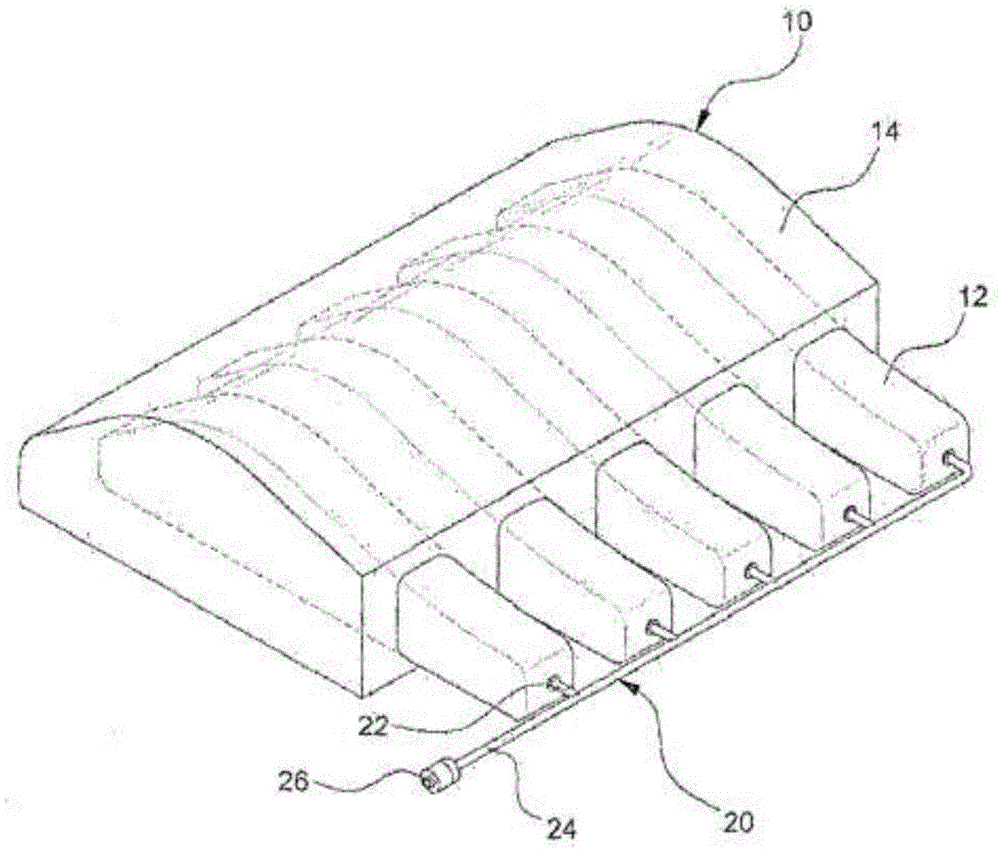

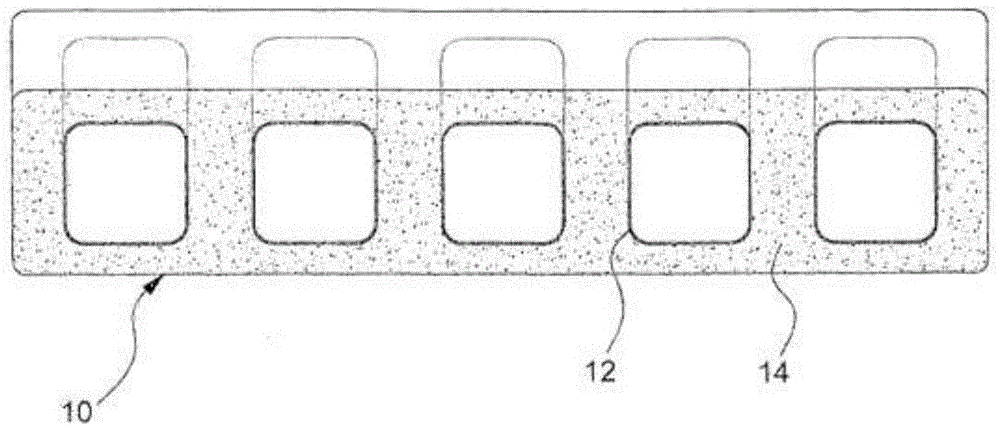

Cushion having embedded automatically-charging air tubes and method for manufacturing same

The present invention relates to a cushion having embedded automatically-charging air tubes and a method for manufacturing same, and more specifically, to a cushion having embedded automatically-charging air tubes usable as cushioning material in bedding including beds and pillows, and various seats, and to a method for manufacturing the cushion having embedded automatically-charging air tubes. The present invention intends to provide the cushion having embedded automatically-charging air tubes and the method for manufacturing same, by arranging air tubes uniformly spaced apart inside a cavity of a mold for manufacturing a cushion, and foam-molding by injecting a cushion material inside the cavity in the mold, so that the cushion material surrounds the air tubes while integrally adhering to the outer surface of the air tubes. As a result, air can be automatically charged inside the air tubes and cushioning force with high elasticity can be provided, while enabling even distribution of a load by integrally forming the air tubes and the cushion material.

Owner:咸义信 +1

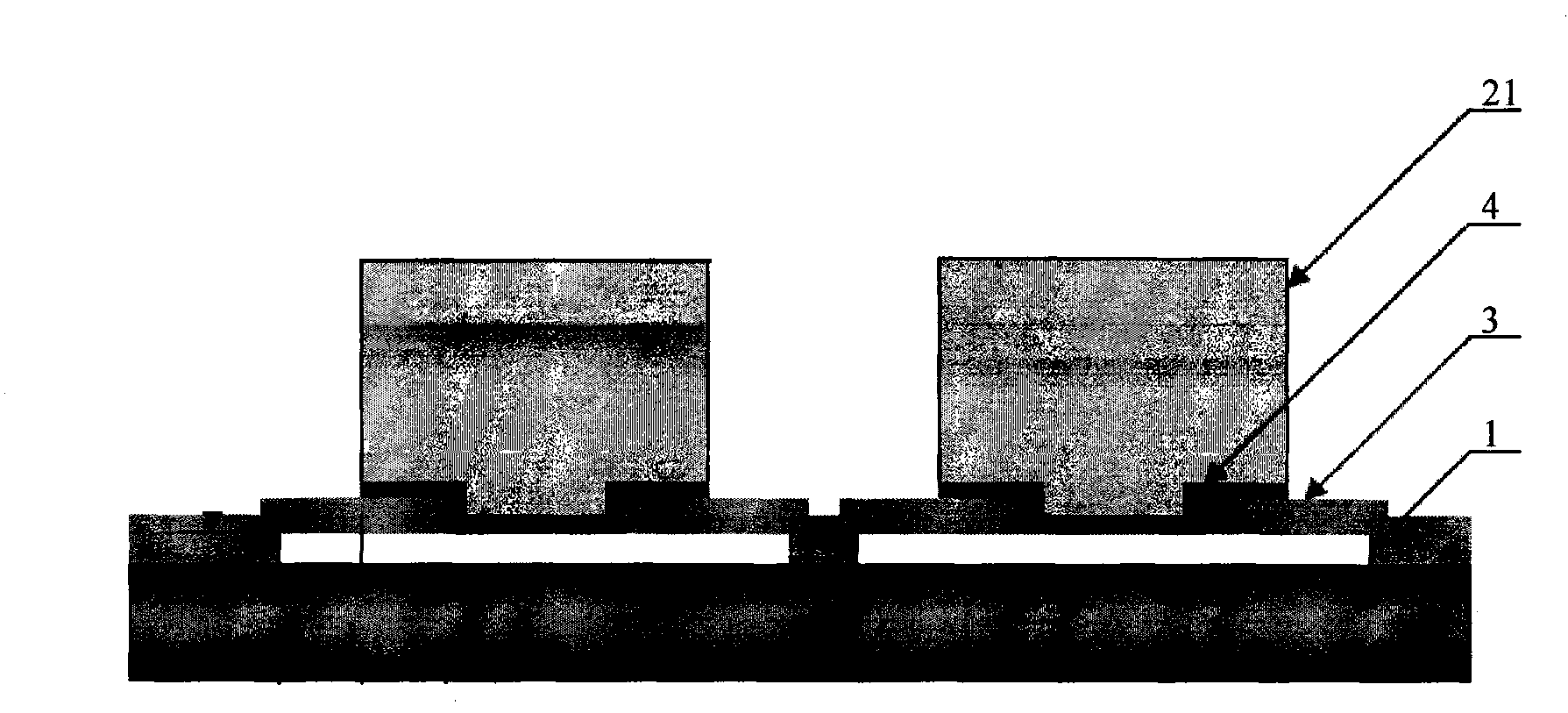

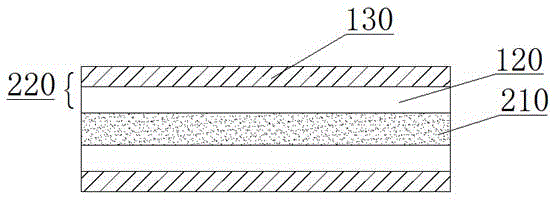

Making method of anti-static lamination type support pad for protecting LCD panel

ActiveCN104589769AReduce pollutionReduce incidenceSynthetic resin layered productsLaminationForeign matterPolyolefin

The invention relates to a making method of an anti-static lamination type support pad for protecting an LCD panel. According to the making method, a polyolefin film of an anti-static layer is at least formed on one surface or two surfaces of a polyolefin or polyurethane foam sheet by virtue of lamination. The lamination type support pad made by using the making method can be used as a panel lamination type support pad which is used for preventing the surface from being scraped, polluted and impacted and is especially sensitive to static electricity when a liquid crystal display panel is stored and conveyed, and can be used for effectively preventing the edge of the lamination type support pad from fluffing, further effectively reducing the dust generation rate and preventing foreign matters from permeating between the lamination type support pads.

Owner:纳诺化学技术株式会社 +2

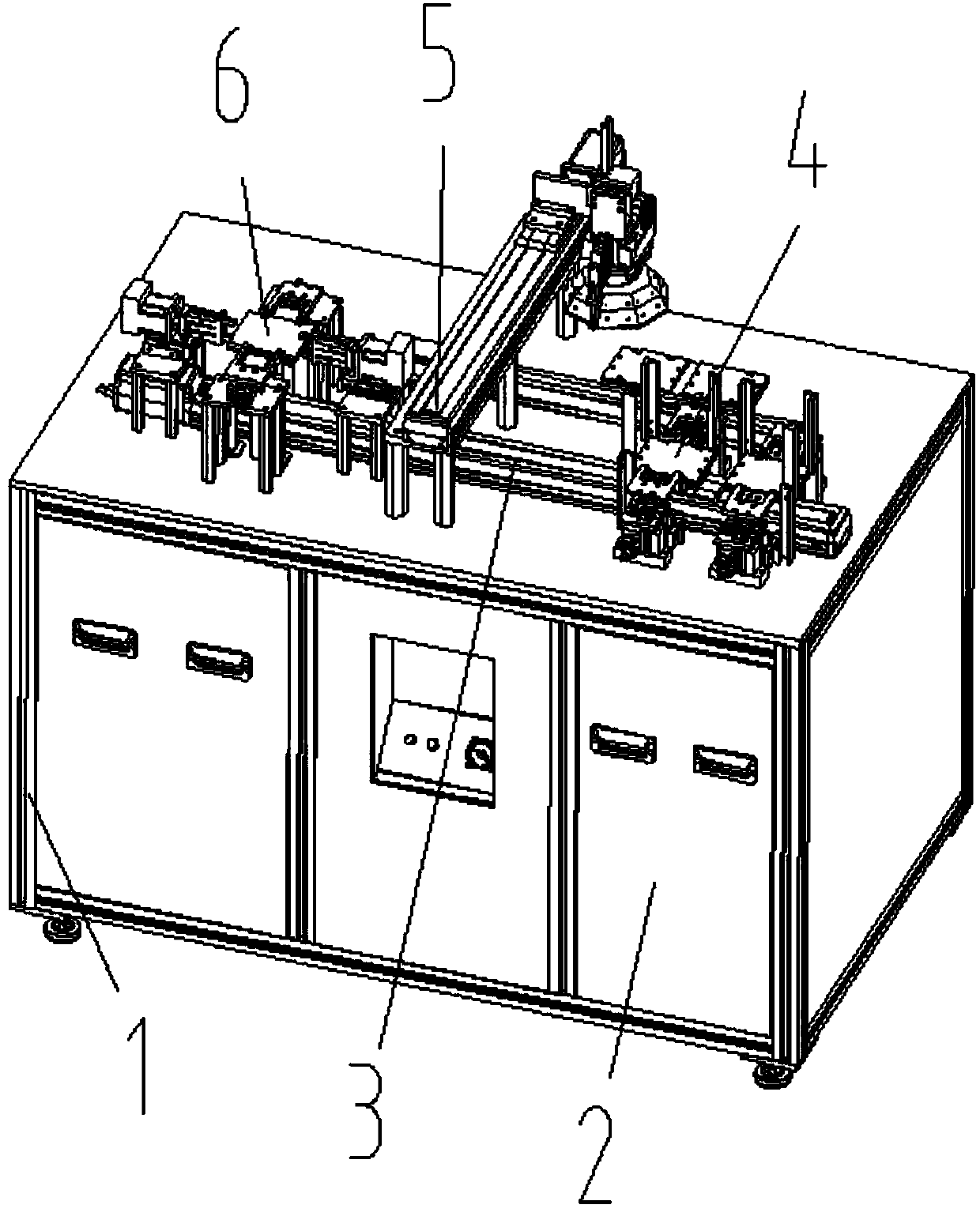

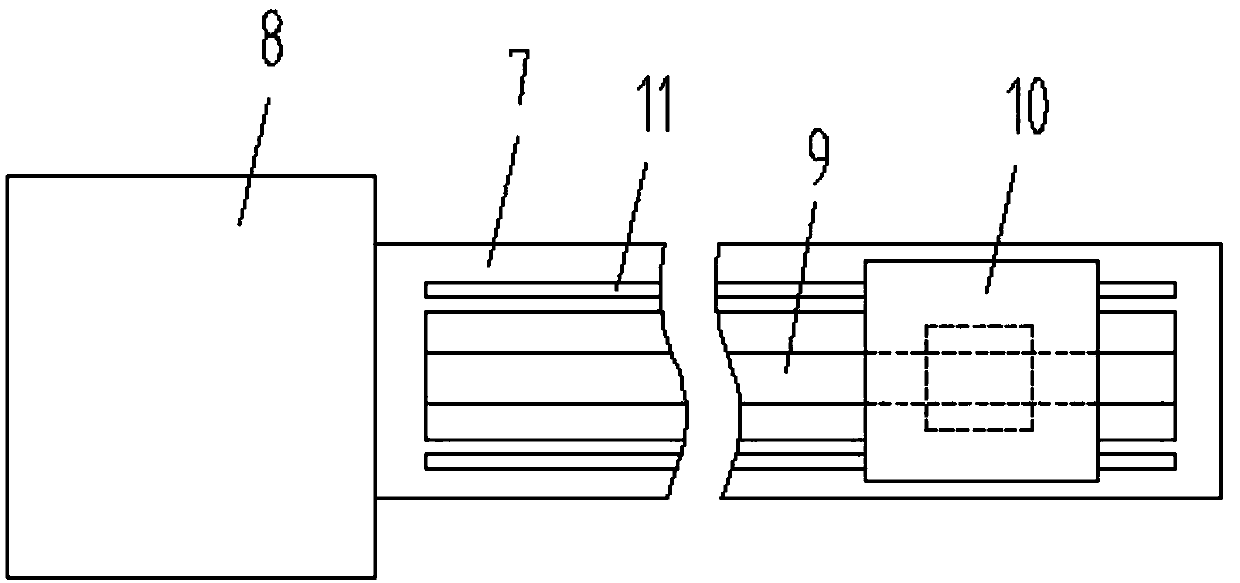

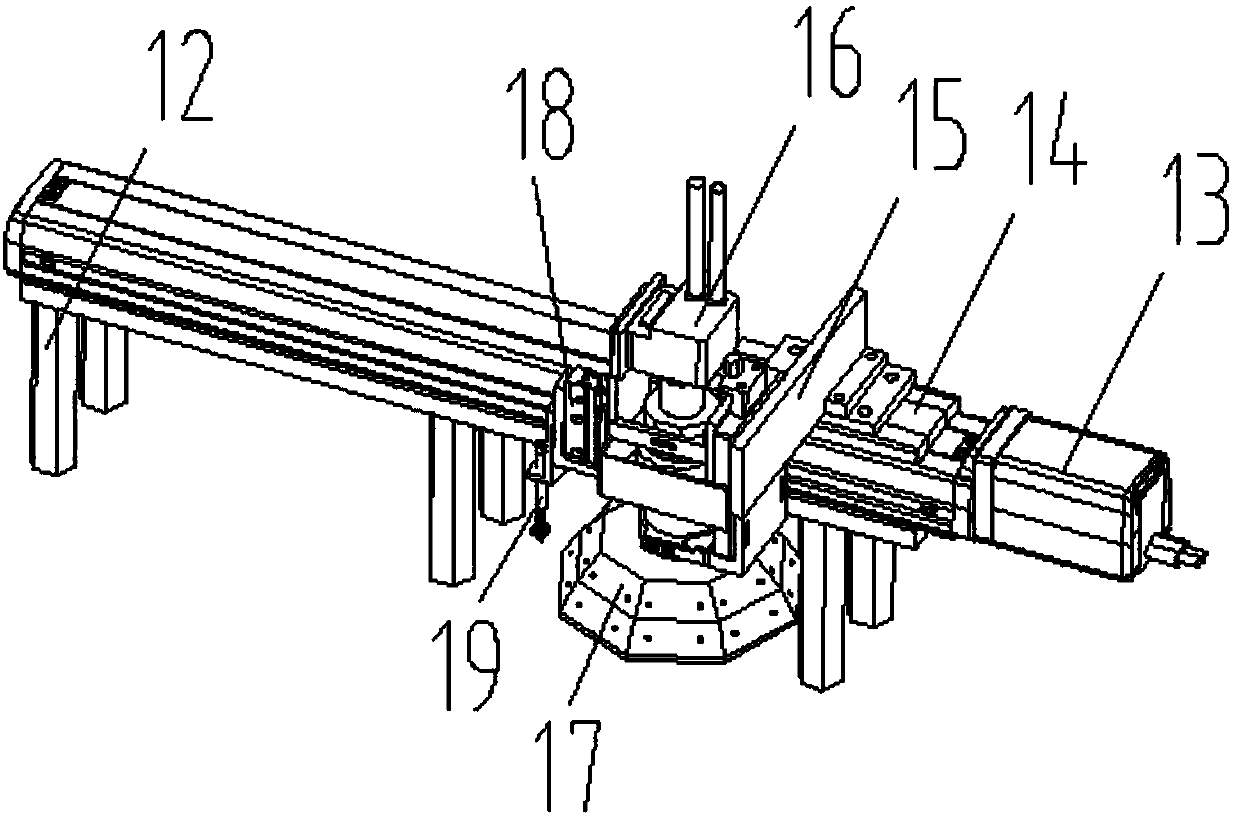

Full-automatic optical detection machine for LED substrate

InactiveCN107826688AReduce handling costsImprove detection efficiencyOptically investigating flaws/contaminationConveyor partsDistribution controlEngineering

The invention relates to a full-automatic optical detection machine for an LED substrate. The full-automatic optical detection machine for the LED substrate comprises a machine frame and a power distribution control cabinet. A conveying device is arranged on the machine frame, a detection device which is matched with the substrate (30) is arranged above the middle of the conveying device, and a turnover device is arranged on the left side of the detection device. The turnover device comprises a material obtaining and lifting device. Turnover bases are arranged on the portions, located on the left side and the right side of the material obtaining and lifting device, of the machine frame, turnover moving cylinders are arranged on the turnover bases and connected with turnover motors, the turnover motors are connected with turnover clamping cylinders, and the turnover clamping cylinders are connected with the turnover clamping blocks. According to the full-automatic optical detection machine for the LED substrate, the conveying device which can conduct reciprocating movement is adopted to conduct conveying, the detection device is arranged in the middle of the conveying device, the turnover device which is matched with the substrate on the conveying device is arranged on the left side of the detection device, and therefore turnover of the substrate is achieved through the turnoverdevice, then the detection efficiency is greatly improved, the detected substrate can return to the position where the substrate is placed, and the handling cost of the substrate is greatly reduced.

Owner:DONGGUAN UNIV OF TECH

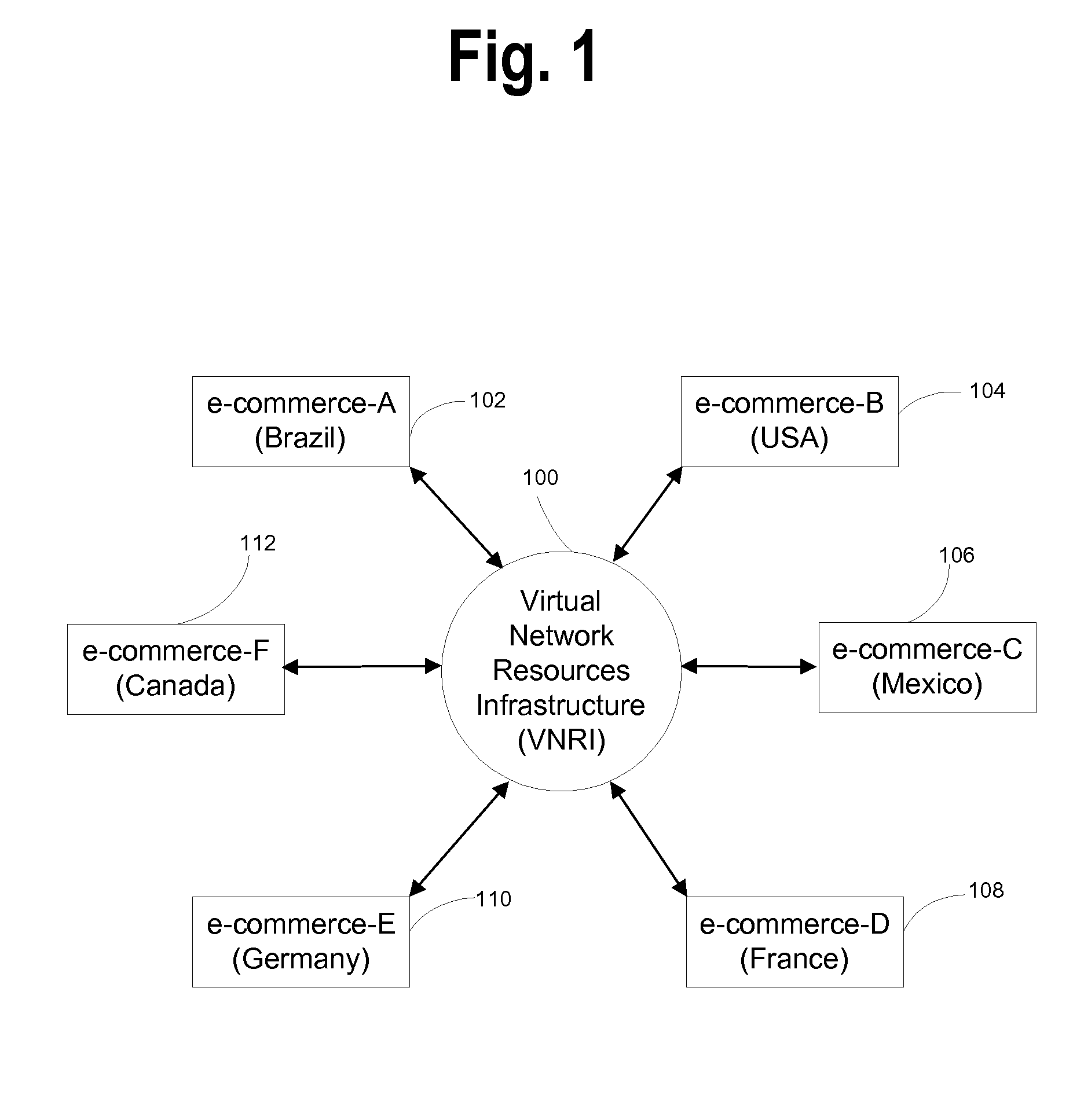

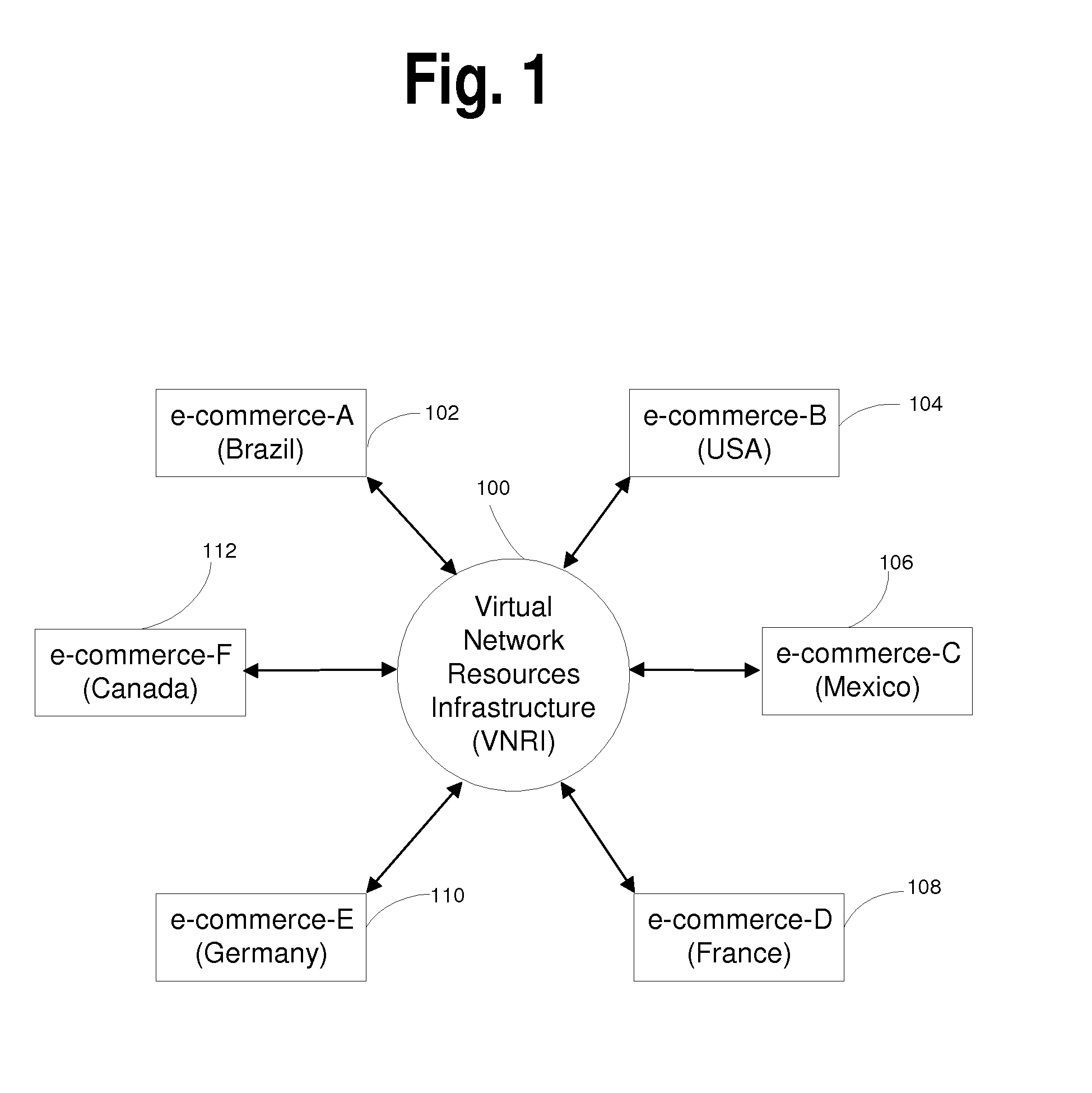

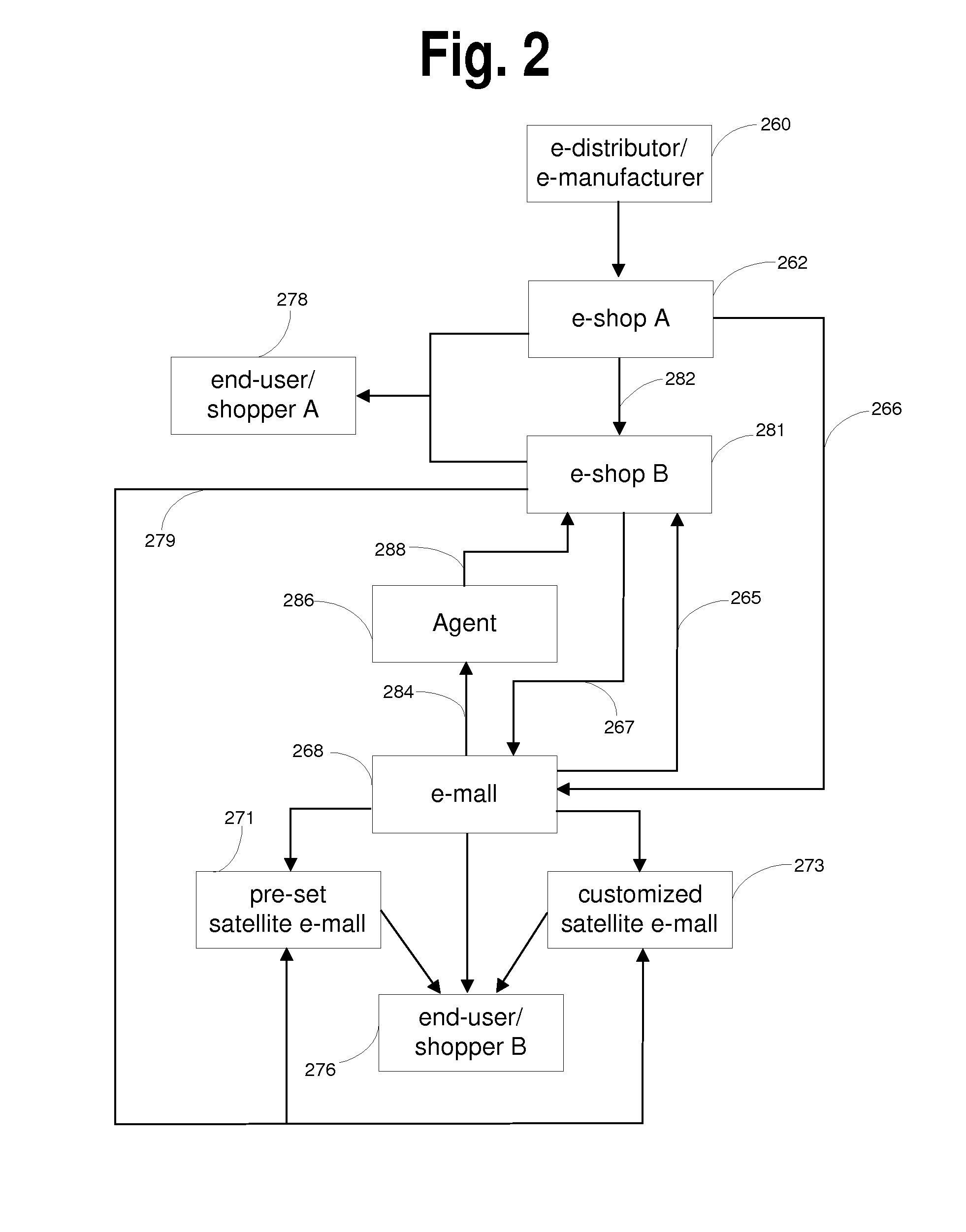

Method of plug-in content hosting

ActiveUS20080052615A1Reduce storageReduce shippingDigital computer detailsNatural language data processingWeb siteE-commerce

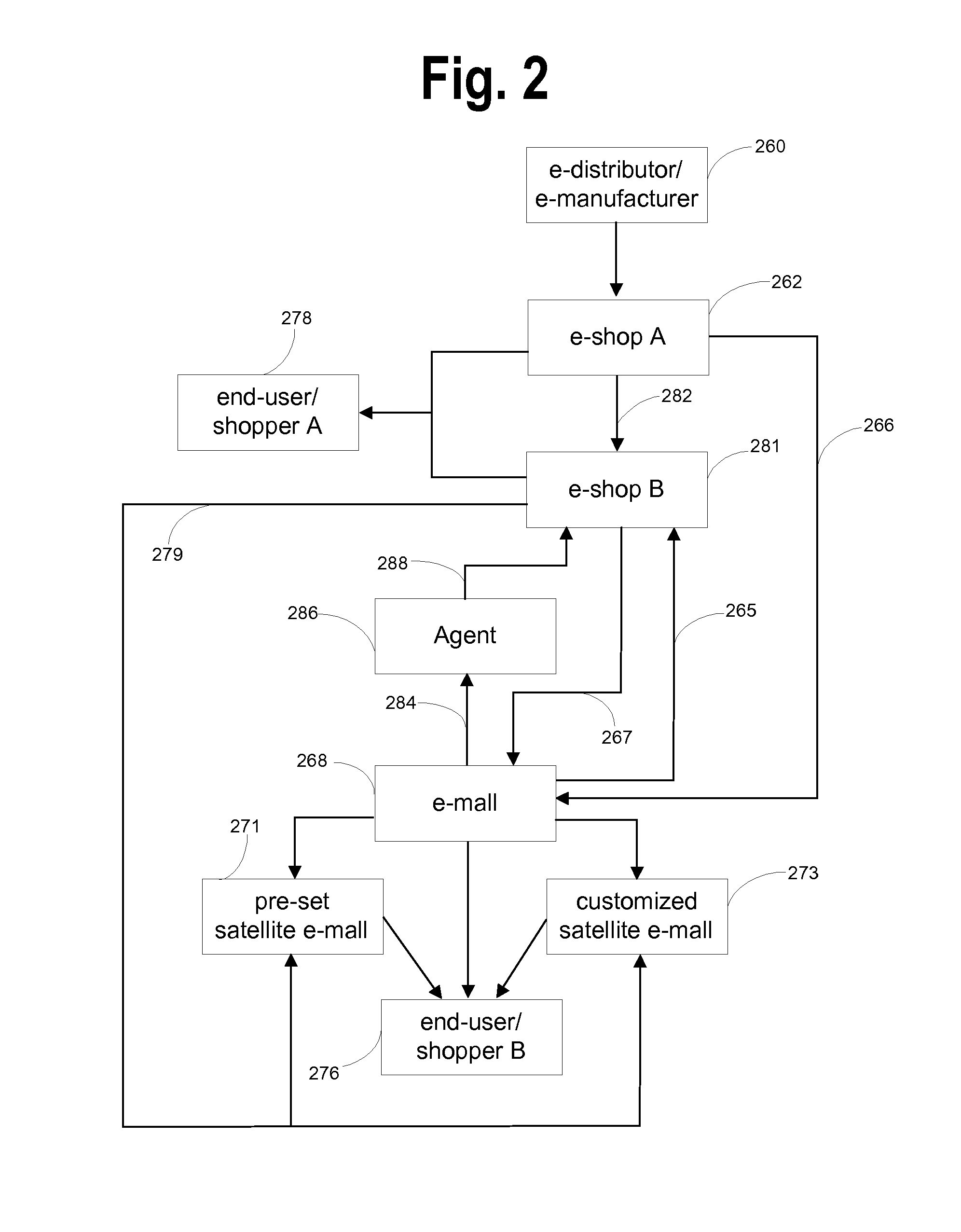

A virtual network resource infrastructure for hosting and managing a plurality of e-malls and each e-mall uses the virtual network resource infrastructure for offering e-commerce solution and the hosting of: e-shops, e-distributors and web sites. Also, on-line foreign language interface translation and interface exchange. Further having satellite e-malls with e-services and e-mall using satellite e-malls' e-services; user surfing tracking means and multiple sales channel where e-shops, e-malls, satellite e-malls and e-distributors sell their products directly or cross-sell each others products.

Owner:PILOANDIA LLC

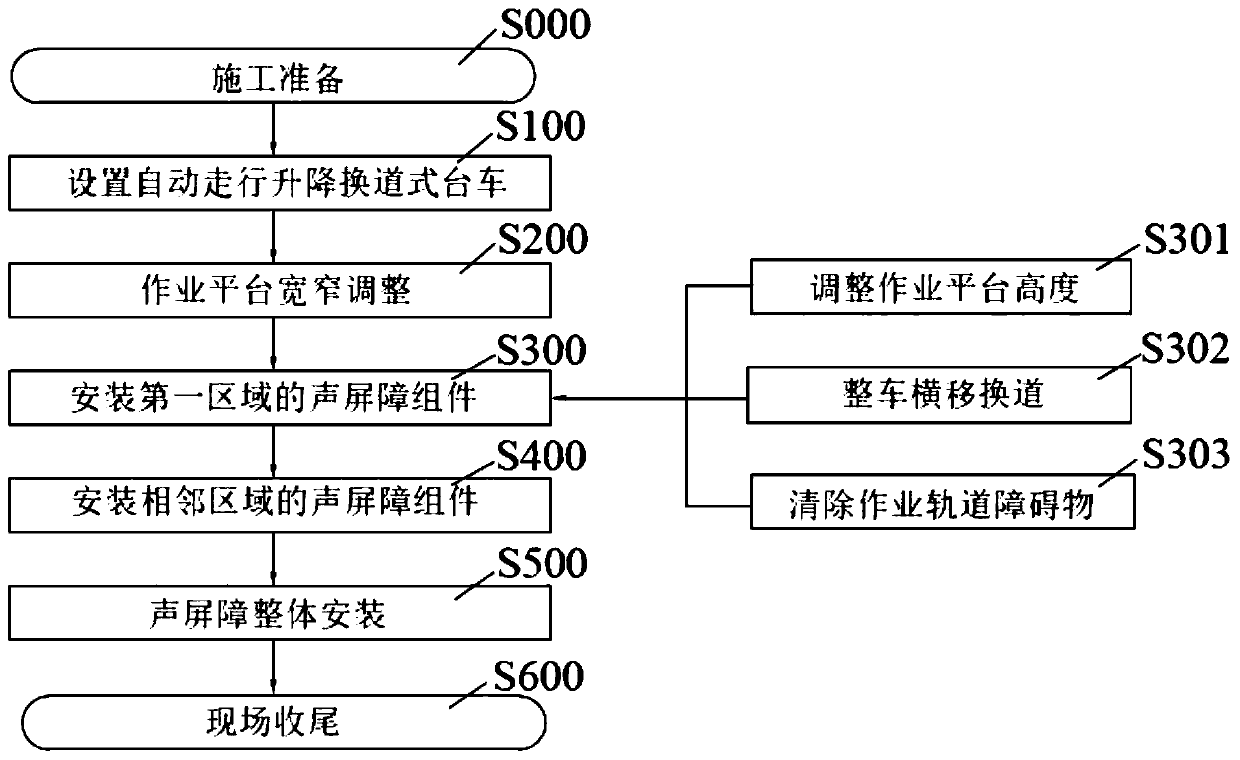

Installing sound barrier construction method of automatic walking lifting lane-changing trolley

ActiveCN110130230ALow costSolve the problem of frequent dismantling and modificationNoise reduction constructionBridge erection/assemblySound barrierBridge deck

The invention discloses the technical field of sound barrier installation, and particularly relates to an installing sound barrier construction method of an automatic walking lifting lane-changing trolley. The installing sound barrier construction method comprises the steps of arranging the automatic walking lifting lane-changing trolley, adjusting the work platform width, installing a sound barrier assembly of a first area, arranging sound barrier assemblies of adjacent areas, and overall installing sound barriers. According to the installing sound barrier construction method, the problems that when a traditional lorry-mounted crane lifts the sound barrier assemblies to match with a scaffold to construct, to set up a temporary platform wastes time and labor, in different bridge width construction, the temporary platform needs detaching and modifying frequently; and when a lorry-mounted crane lifts the sound barrier assemblies to match with a rail-mounted gantry crane and a platform lorry to construct, the braking effect of relying on artificial external force on a braking device is low, and safety accidents are prone tooccurring are solved, operators can install sound barriers normatively and effectively, the cost of scaffold materials, carrying cost and the time cost of repeatedly disassembly and installation are reduced, effects of work platform reliability, safety and efficiency, and less time andlabor are improved.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com