Material delivery task dynamic distribution method based on internet of things technology

A dynamic allocation and task technology, applied in logistics, instruments, data processing applications, etc., can solve problems such as long optimization time, difficult global optimal solution, material distribution model and method, and combined optimization of handling tasks, so as to improve material handling Efficiency, improved accuracy, and reduced material handling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Describe the present invention below in conjunction with specific embodiment:

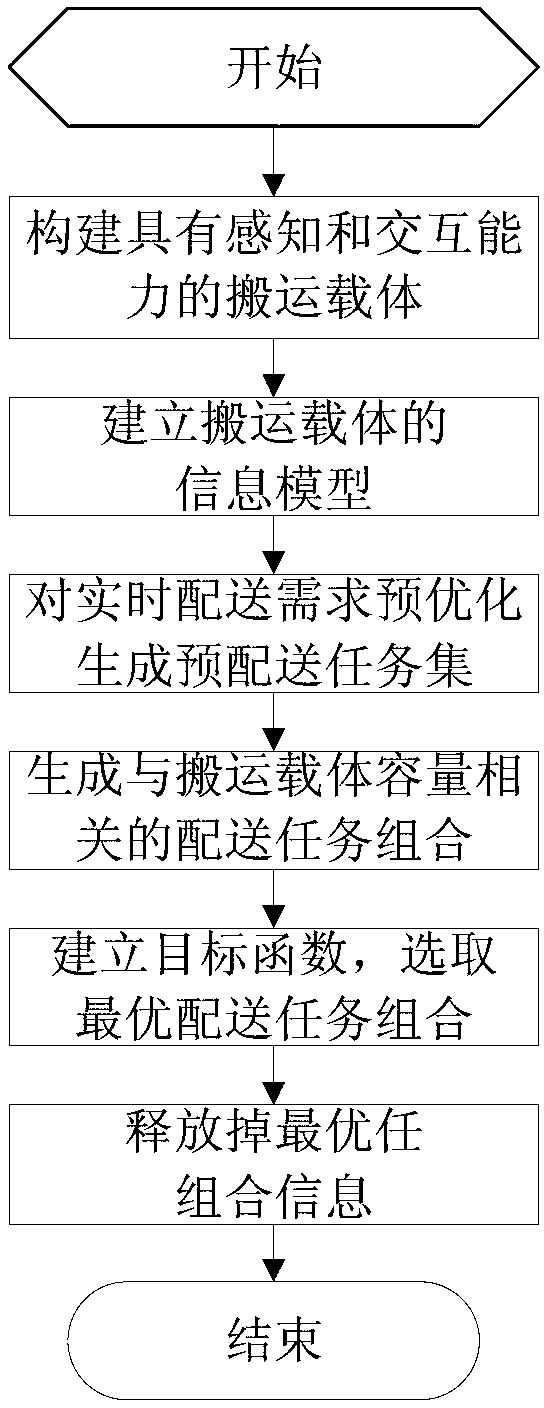

[0031] Refer to attachedfigure 1 , a method for dynamically allocating material distribution tasks based on IoT technology proposed in the present invention, adopts the following steps:

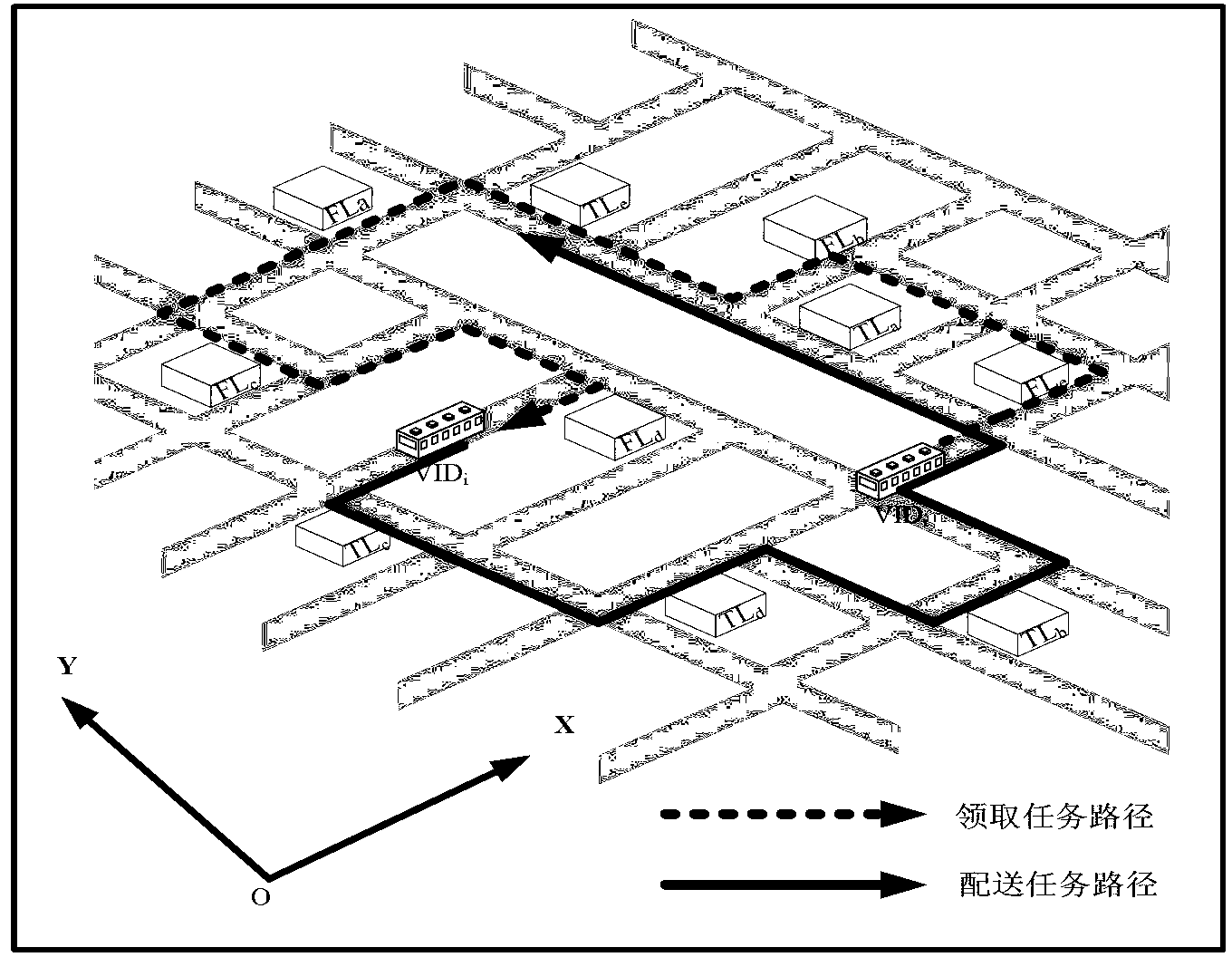

[0032] Step 1: Obtain the real-time dynamic information of the material handling carrier through the RFID automatic identification device attached to the material handling carrier, and establish the information model of the carrier; the information model of the carrier includes: the number of the carrier, the maximum carrying space of the carrier, and the The real-time position of the carrier and the real-time use space of the carrier.

[0033] In the workshop, RFID automatic identification equipment is attached to the material handling carrier, including RFID readers, software systems and display devices. The handling carrier can perceive the real-time status information of the surrounding manufacturing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com