Patents

Literature

72 results about "Carrying cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In marketing, carrying cost, carrying cost of inventory or holding cost refers to the total cost of holding inventory. This includes warehousing costs such as rent, utilities and salaries, financial costs such as opportunity cost, and inventory costs related to perishability, shrinkage (leakage) and insurance. Carrying cost also includes the opportunity cost of reduced responsiveness to customers' changing requirements, slowed introduction of improved items, and the inventory's value and direct expenses, since that money could be used for other purposes. When there are no transaction costs for shipment, carrying costs are minimized when no excess inventory is held at all, as in a Just In Time production system.

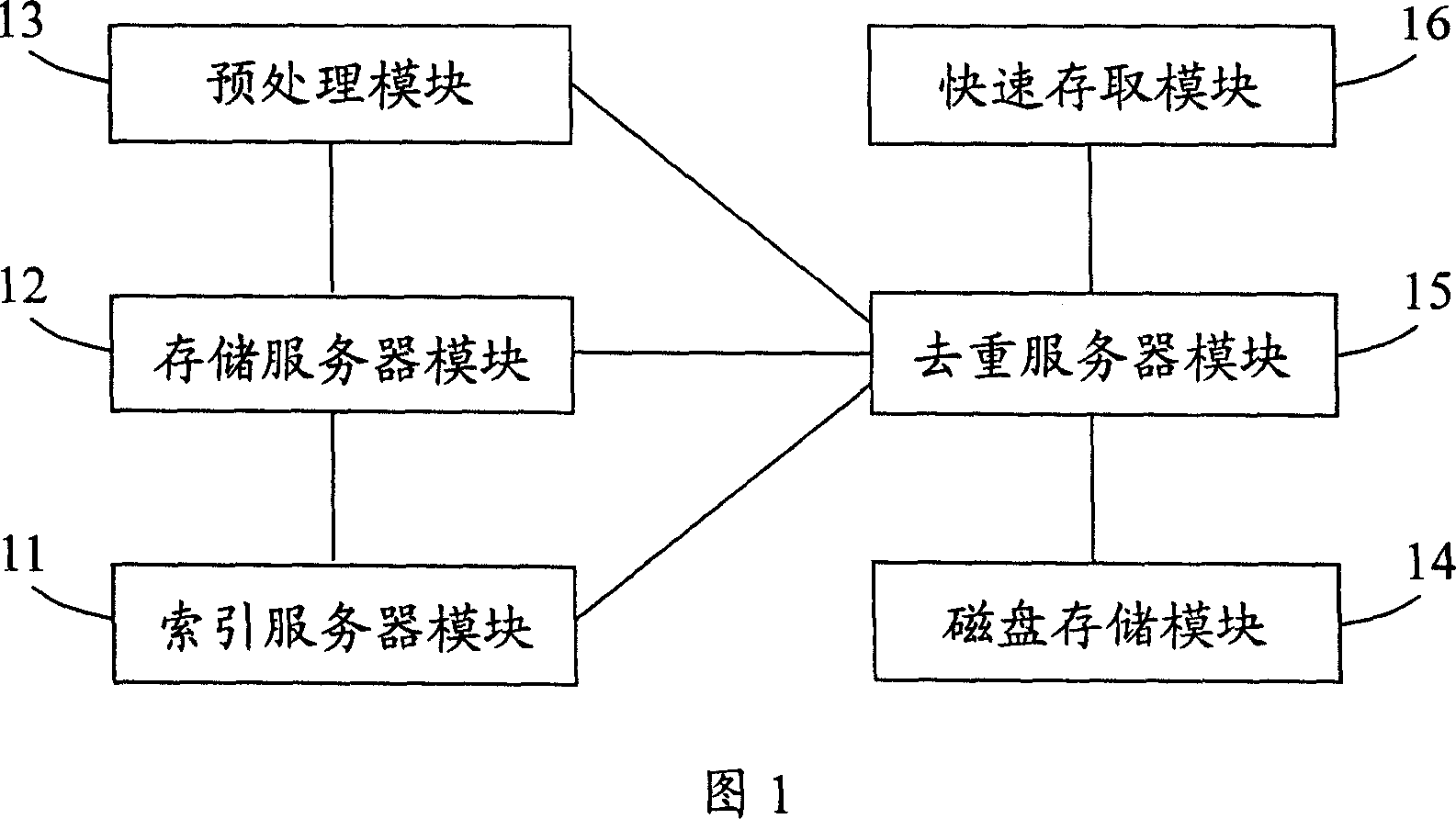

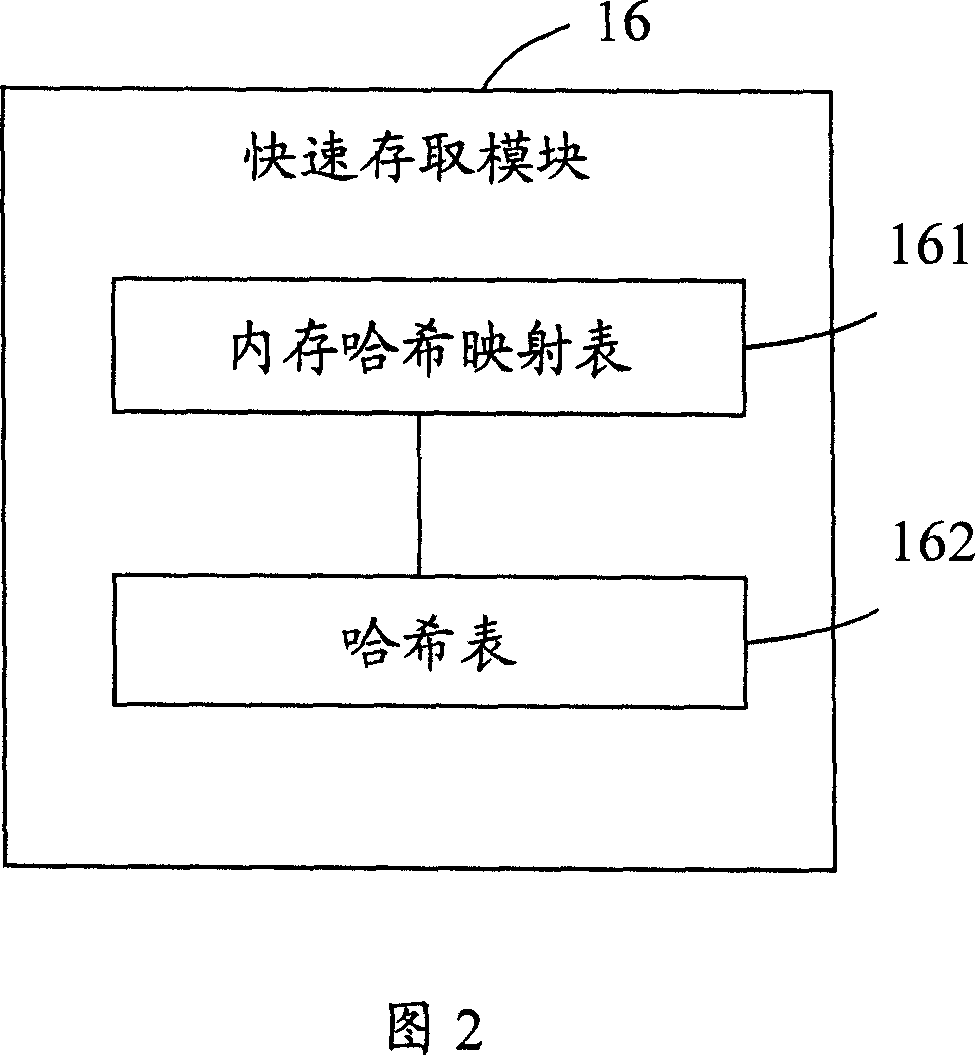

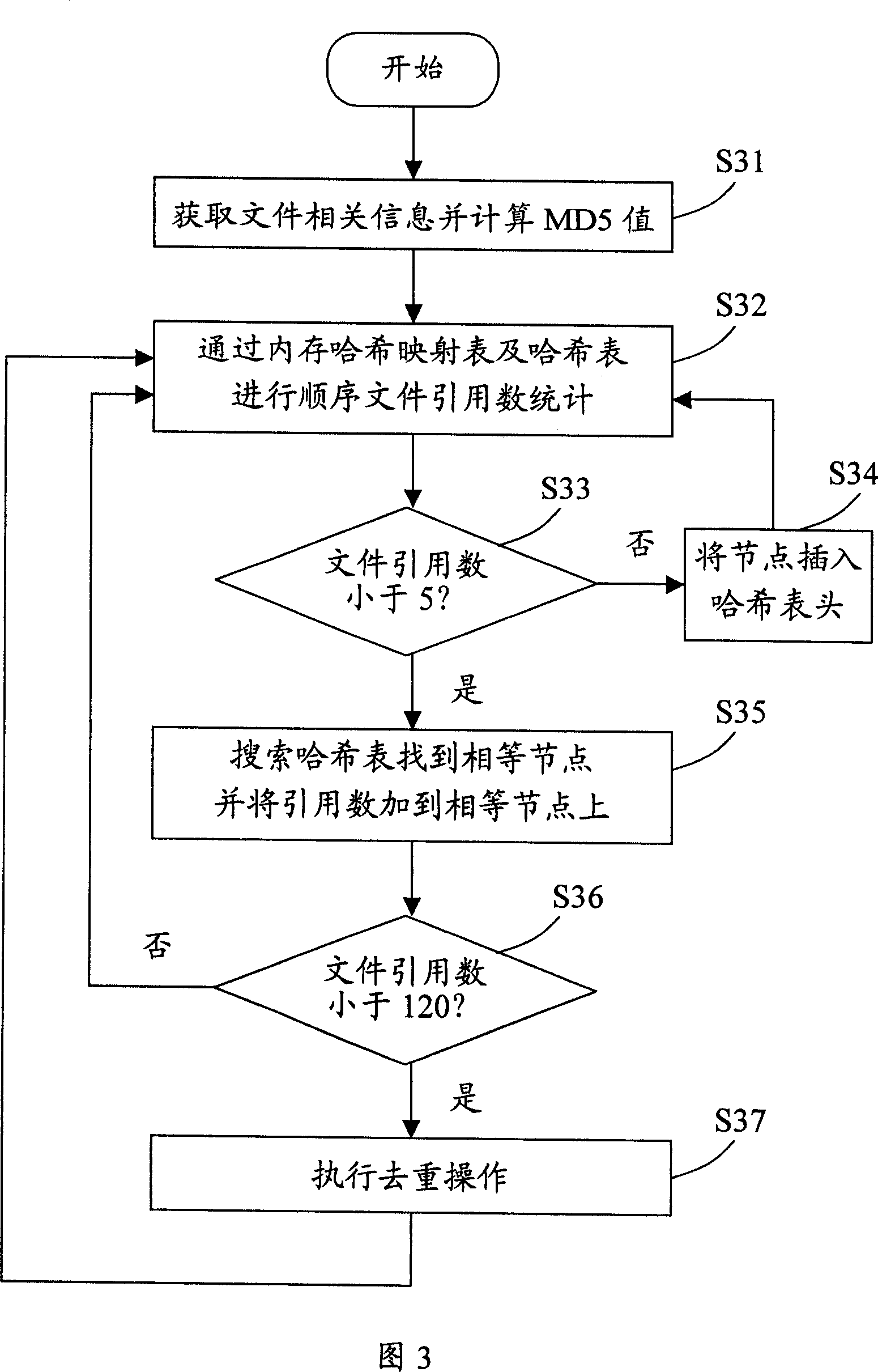

System and method for eliminating redundancy file of file storage system

ActiveCN101079034AReduce storage costsEnsure safetySpecial data processing applicationsFile sizeCarrying cost

The invention discloses a system to remove redundant file in file storing system, which is characterized by the following: comprising sea quantity memory system; constructing with the memory server module and index server module; also comprising pre-treating module, quick storing module and removing repeat server module; getting file MD5 value and file size with the pre-treating module; proceeding file quoting number statistic with the quick storing module; deleting repeated file when the file quoting number reach intended value with the removing repeat server module; connecting the index server module, the storing server module and the pre-treating module consecutively; connecting the quick access module, index server module, storing server module and the pre-treating module to the removing repeat server module. This invention also discloses a corresponding method to remove redundant file in accessing system. This invention can control carrying cost effectively.

Owner:SHENZHEN TENCENT COMP SYST CO LTD

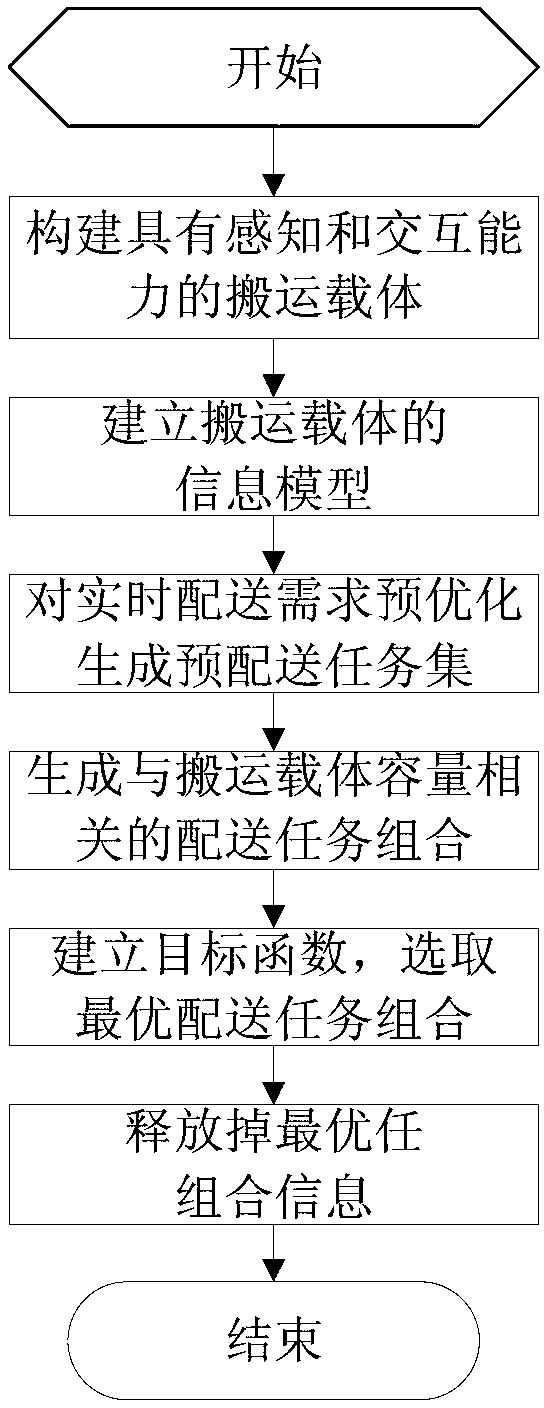

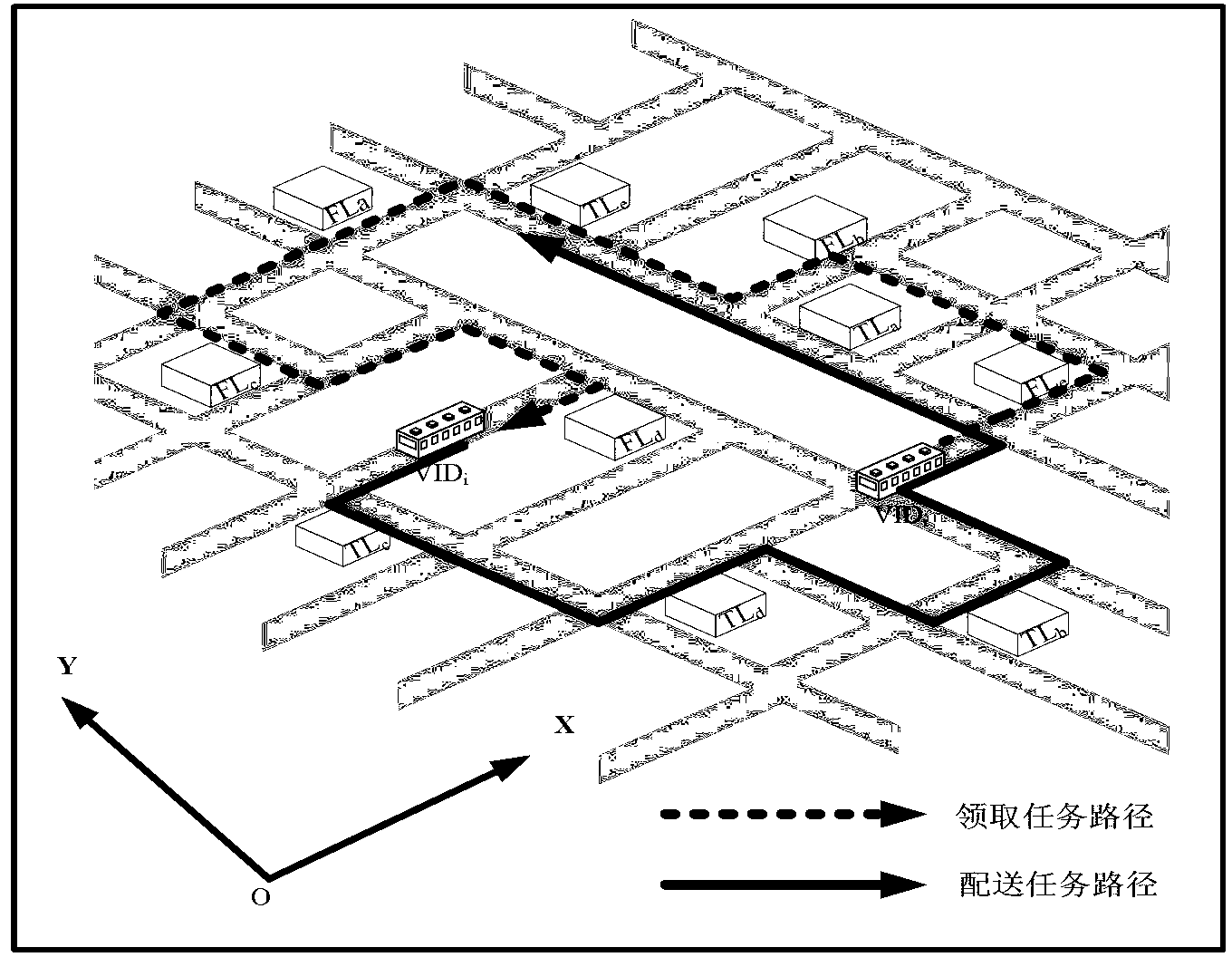

Material delivery task dynamic distribution method based on internet of things technology

InactiveCN103310321AAdapt to task dynamic optimizationAdapt to the delivery situationLogisticsComputation complexityDistribution method

The invention provides a material delivery task dynamic distribution method based on an internet of things technology. Based on the real-time state information of carrying carriers and the work mode that the carrying carriers scramble for tasks, the most suitable material carrying task set is actively obtained, and an efficient and feasible task distribution model and method are provided for the timely distribution of production materials from the three aspects of the dynamic distribution strategy of the tasks, the task dynamic distribution method based on the real-time state of the carrying carriers and the combinatorial optimization of the tasks,. As the real-time position information after the carrying carriers unload, the task dynamic combinatorial optimization facing to the capacity of the carrying carriers and the like are fully considered in the method, compared with the traditional material delivery task optimization method, the method has the advantages that the defects that the computation complexity of an original distribution strategy is high, the optimization time is long, and the change of material delivery tasks is difficultly dynamically responded are overcome, the efficiency of workshop distribution is improved, the carrying cost is saved, and the digital precise distribution and the intellectualization of material distribution management are better realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

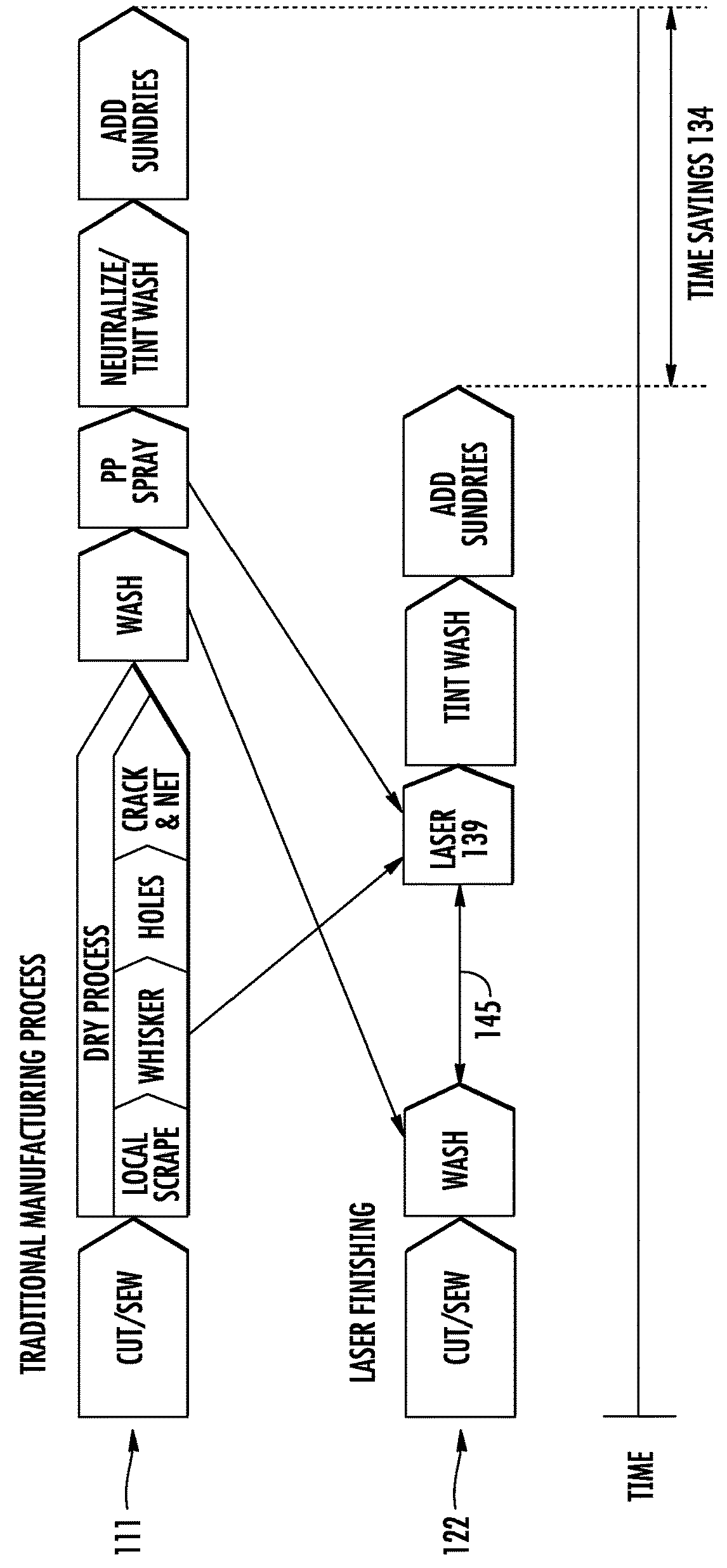

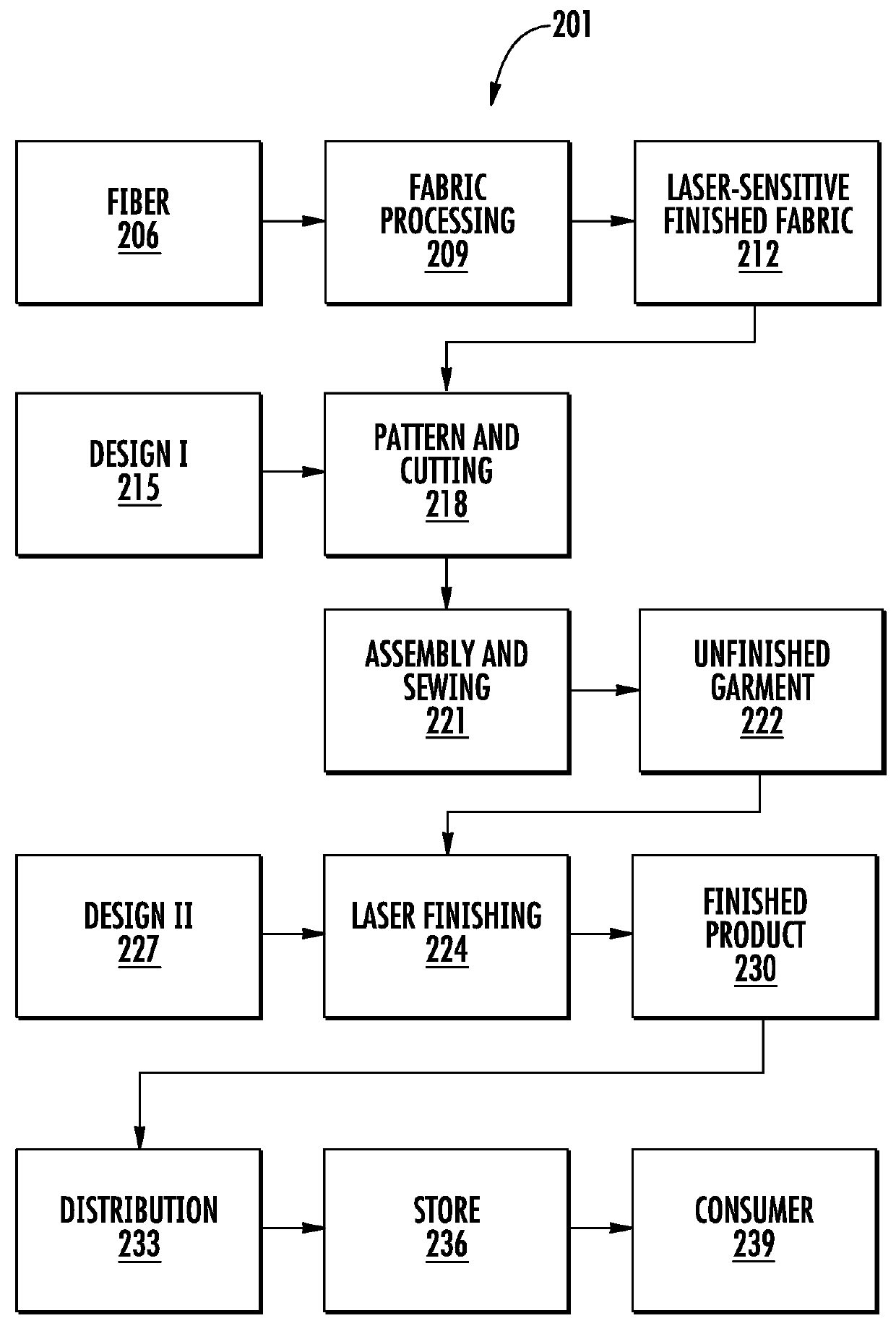

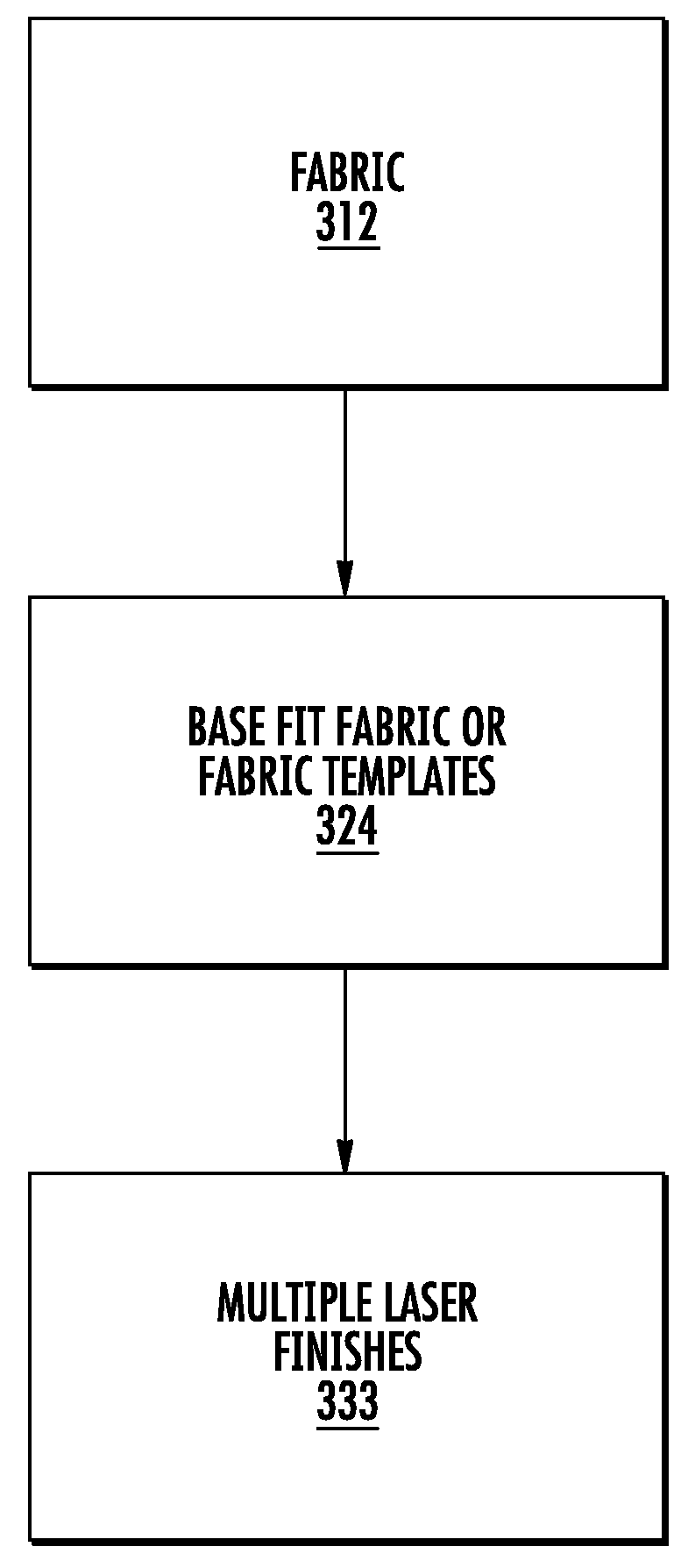

Using Fabric Templates to Obtain Multiple Finishes by Laser Finishing

ActiveUS20180165736A1Reduce finishing costsLow costPattern makingSewing apparatusLost salesTime to market

Laser finishing of apparel products allows an operating model that reduces finishing cost, lowers carrying costs, increases productivity, shortens time to market, be more reactive to trends, reduce product constraints, reduces lost sales and dilution, and more. Improved aspects include design, development, planning, merchandising, selling, making, and delivering. The model uses fabric templates, each of which can be used to produce a multitude of laser finishes. Operational efficiency is improved.

Owner:LEVI STRAUSS & CO

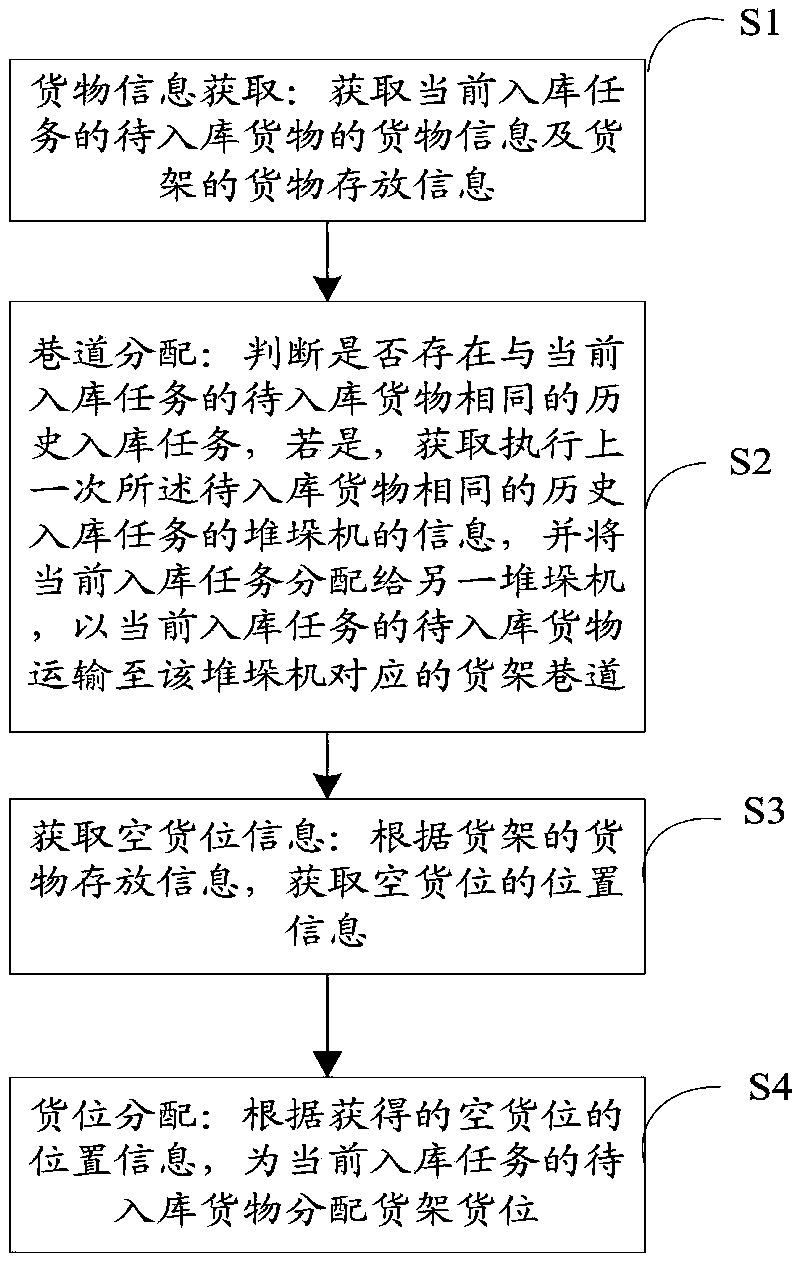

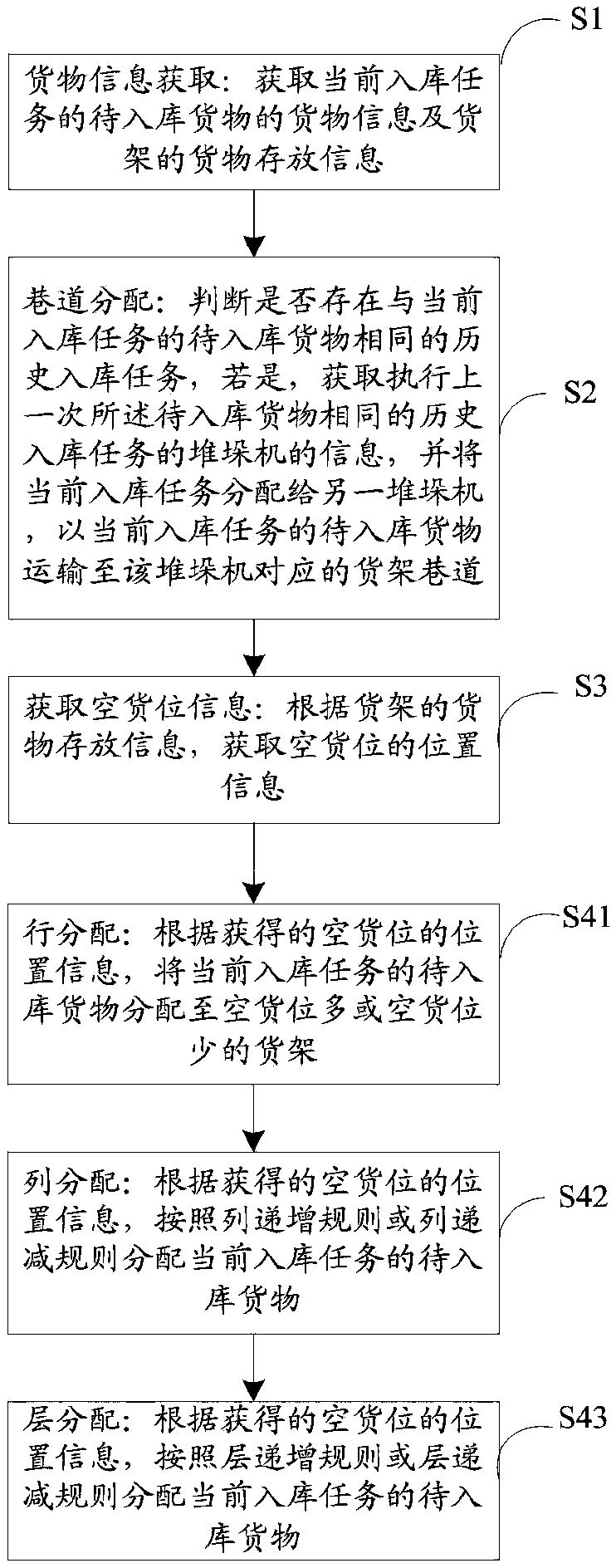

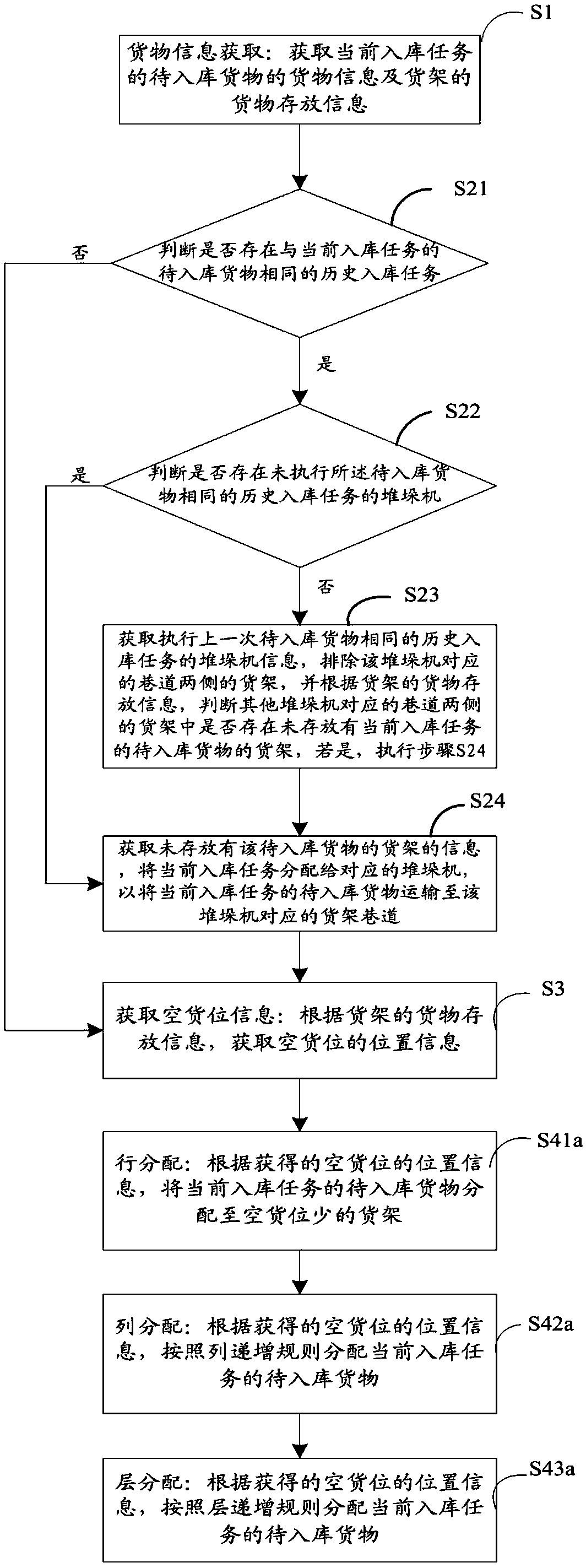

Automatic high rack warehouse goods space allocation method

ActiveCN109677831AImprove work efficiencyImprove space utilizationConveyorsStorage devicesStack machineCarrying cost

The invention discloses an automatic high rack warehouse goods space allocation method. The automatic high rack warehouse storage space allocation method includes the following steps that firstly, goods information is obtained; secondly, whether a historical warehousing task for to-be-warehoused goods the same with to-be-warehoused goods of the current warehousing task exists or not is judged, ifthe historical warehousing task for the to-be-warehoused goods the same with the to-be-warehoused goods of the current warehousing task exists, the information of a stacking machine executing the lasttime of historical warehousing task for the same to-be-warehoused goods is obtained, the current warehousing task is allocated to the other stacking machine, and therefore the to-be-warehoused goodsof the current warehousing task are transported into a goods rack roadway corresponding to the stacking machine; thirdly, empty goods space information is obtained; and fourthly, goods space allocation is conducted. By means of the automatic high rack warehouse goods space allocation method, goods identification and classification are achieved, average goods space allocation is achieved accordingto the goods, the work efficiency and the space utilization rate of an automatic high rack warehouse are effectively improved, automatic high rack warehouse management is facilitated, and the goods carrying cost is reduced.

Owner:深圳市今天国际软件技术有限公司

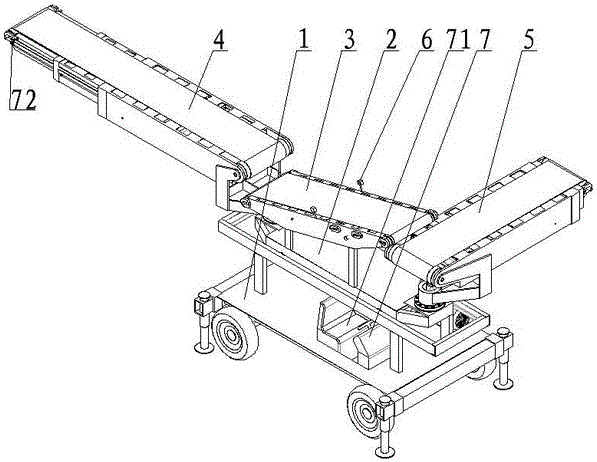

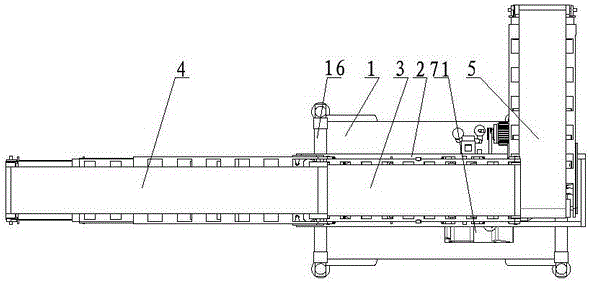

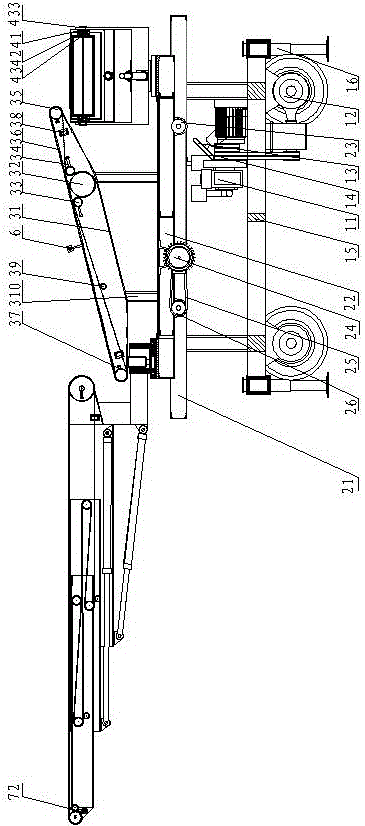

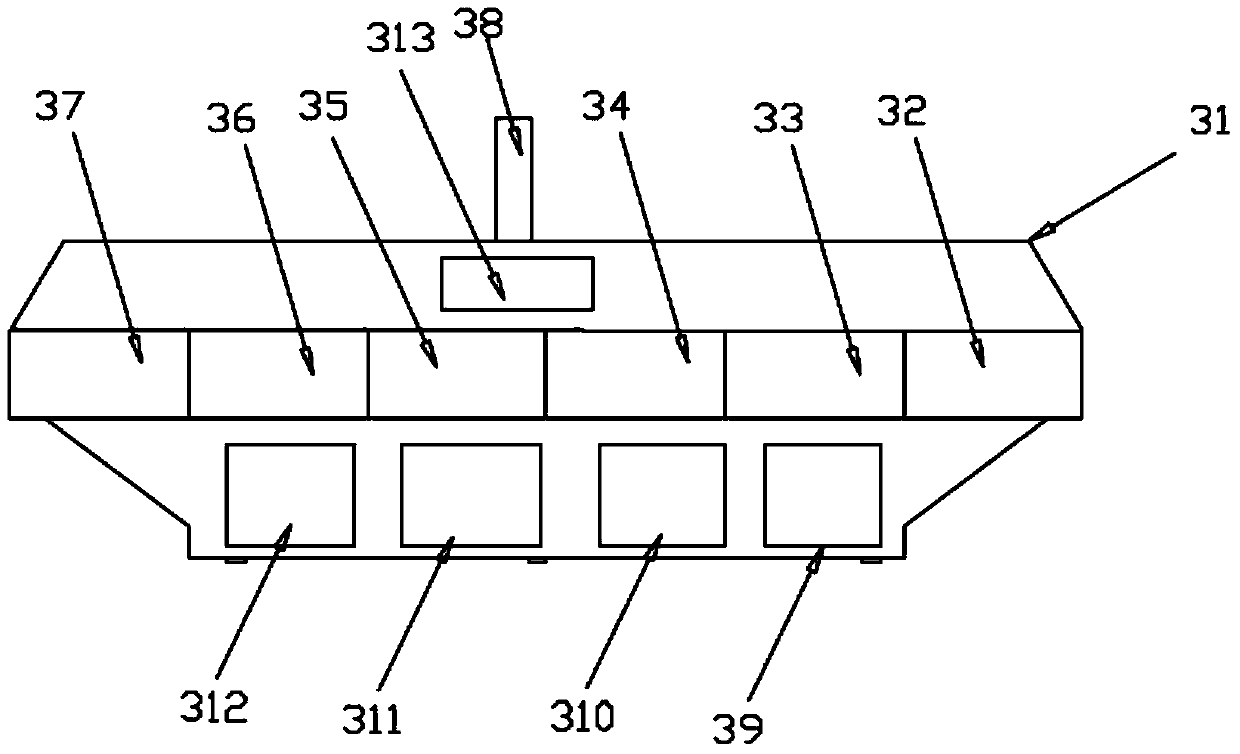

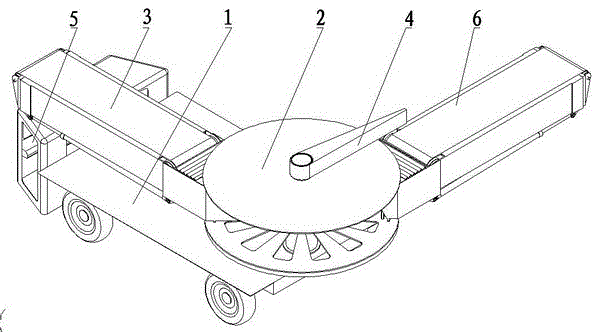

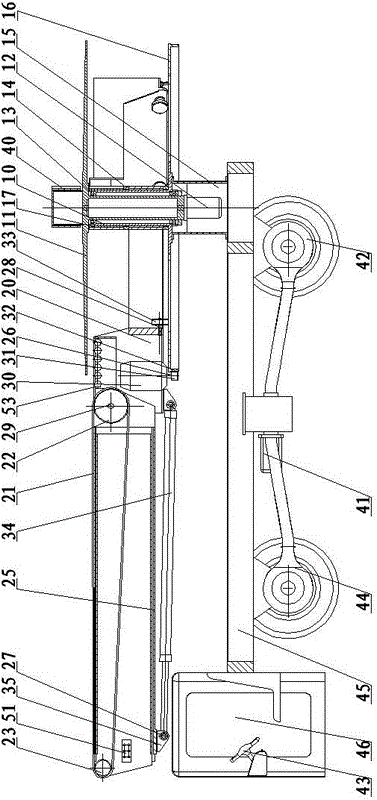

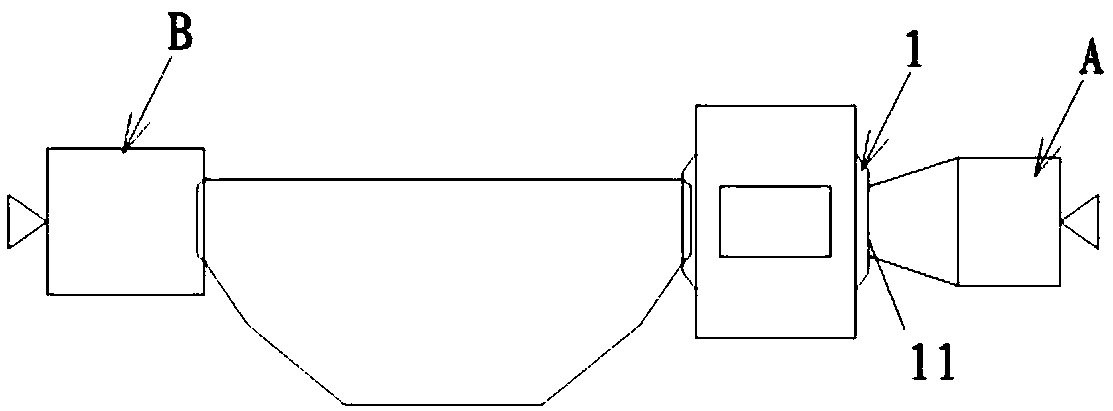

Amplitude-variable extensible belt turning conveying bidirectional loading-unloading machine

InactiveCN106629092AAdjustable workAdjustable postureConveyorsRollersWorking environmentMechanical equipment

The invention discloses an amplitude-variable extensible belt turning conveying bidirectional loading-unloading machine and relates to the field of logistics transportation cargo loading-unloading mechanical equipment. The loading-unloading machine is composed of a vehicle, a sliding platform, a middle transition conveyor, a first belt conveyor, a second belt conveyor, a metering device and an operation control system, wherein the vehicle has bearing and walking functions, the sliding platform has a sliding function, the middle transition conveyor is capable of achieving inclined conveying, the first belt conveyor and the second belt conveyor have amplitude changing, swing rotation and extending functions, the metering device has metering, display, storage and printing functions, and the operation control system is used for operation of the whole loading-unloading machine. According to the amplitude-variable extensible belt turning conveying bidirectional loading-unloading machine, the structure is simple, work is reliable, movement and place transfer are convenient and fast, the operation range is large, manual auxiliary carrying can be reduced, the labor intensity is lowered, operation time is shortened, the loading-unloading work efficiency is improved, the loading-unloading carrying cost is reduced, the working environment and labor conditions are improved, it is ensured that loading-unloading transportation is economical, fast, convenient and safe, the logistics transportation direction can be changed, forward and reverse bidirectional loading and unloading are achieved, and the loading-unloading number and weight can be automatically counted, recorded, displayed and stored.

Owner:襄阳忠良工程机械有限责任公司

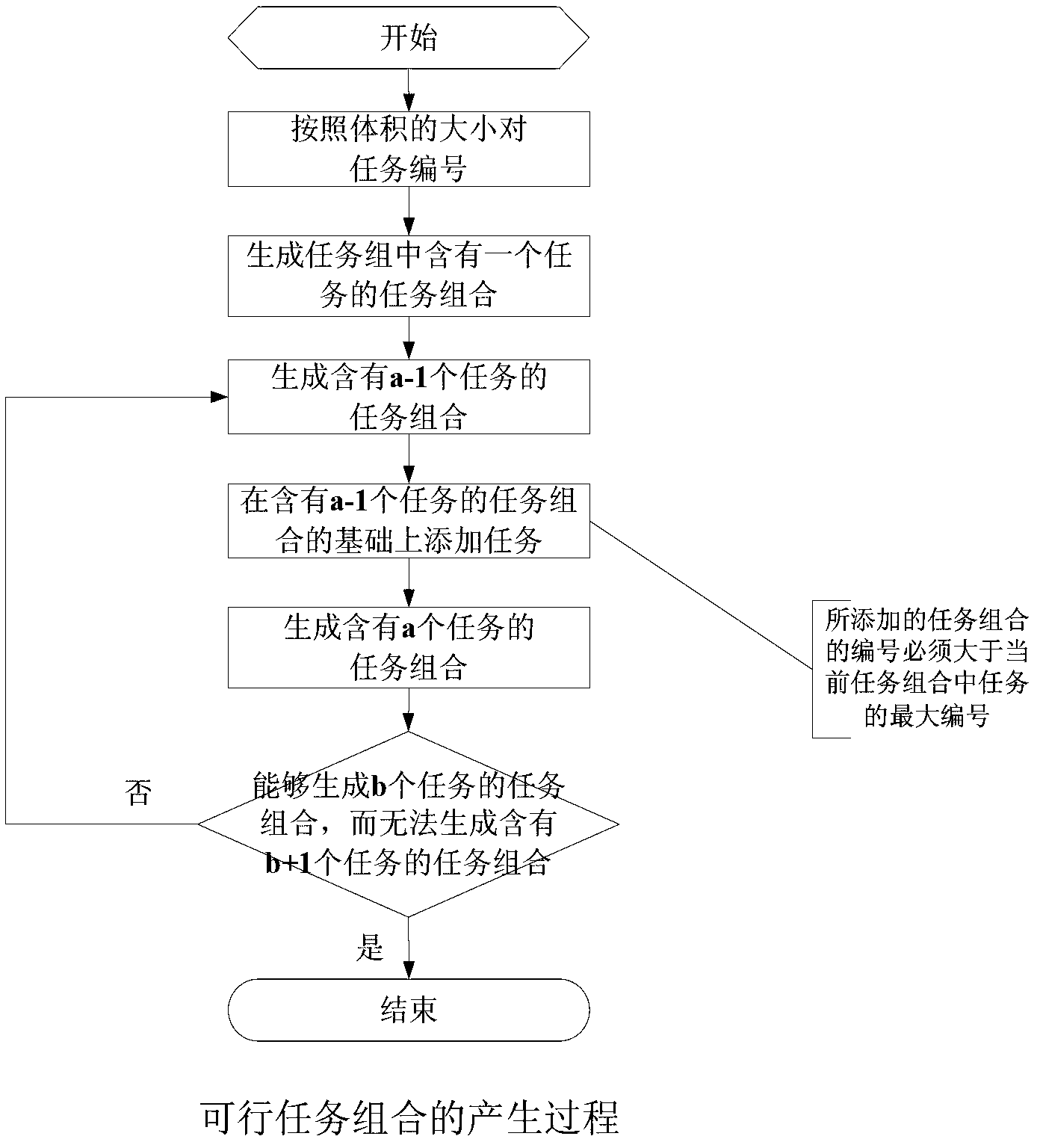

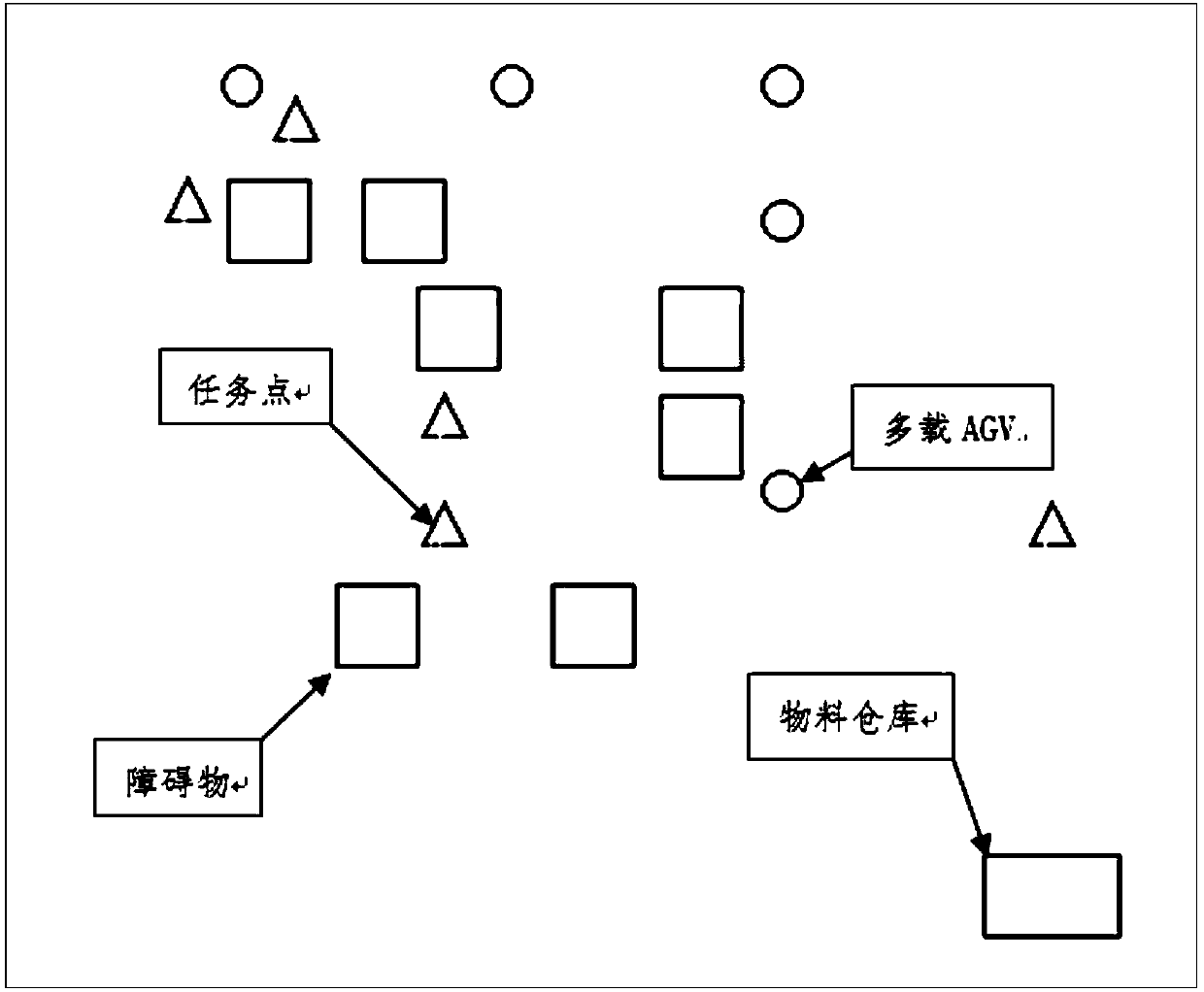

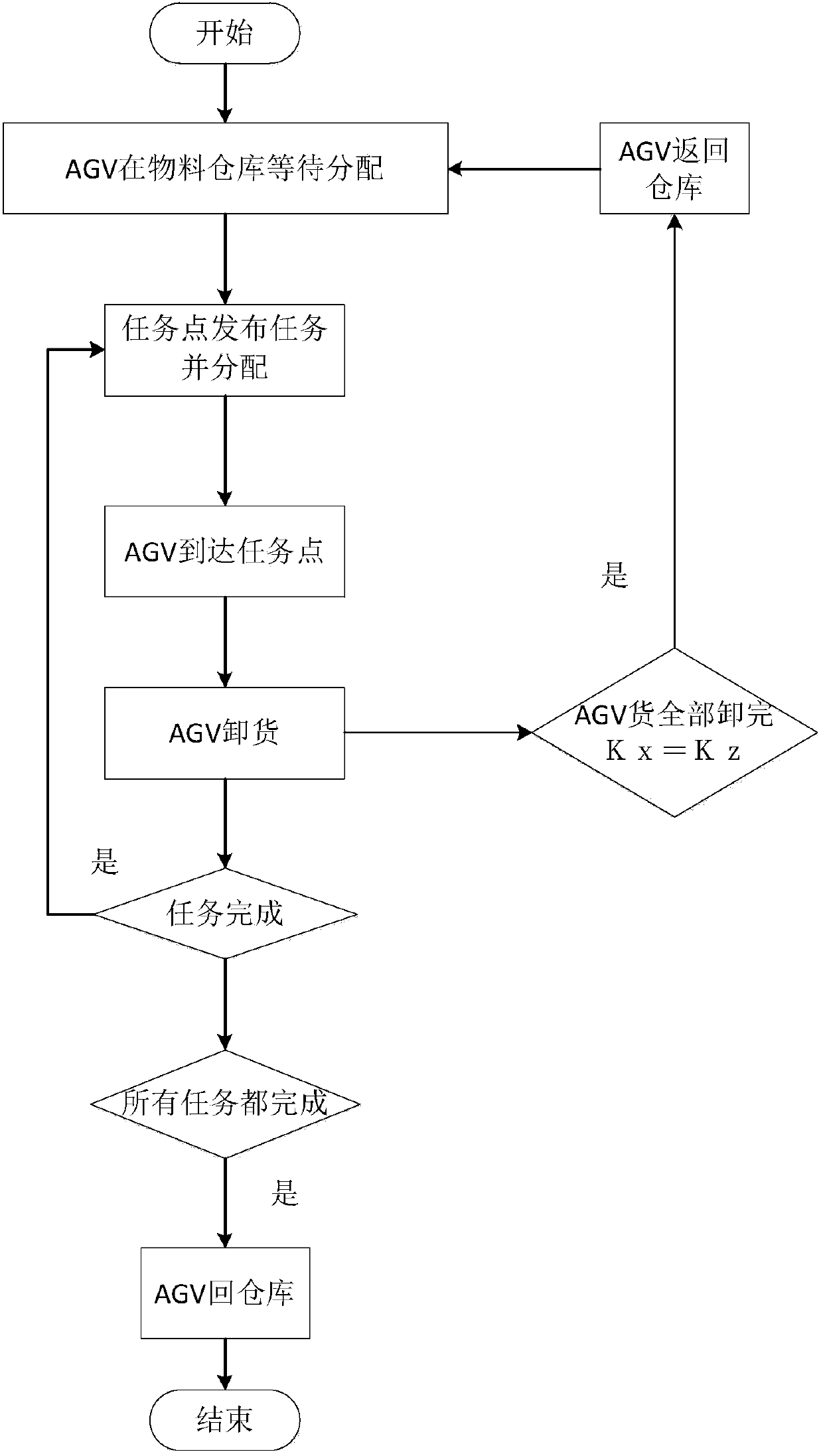

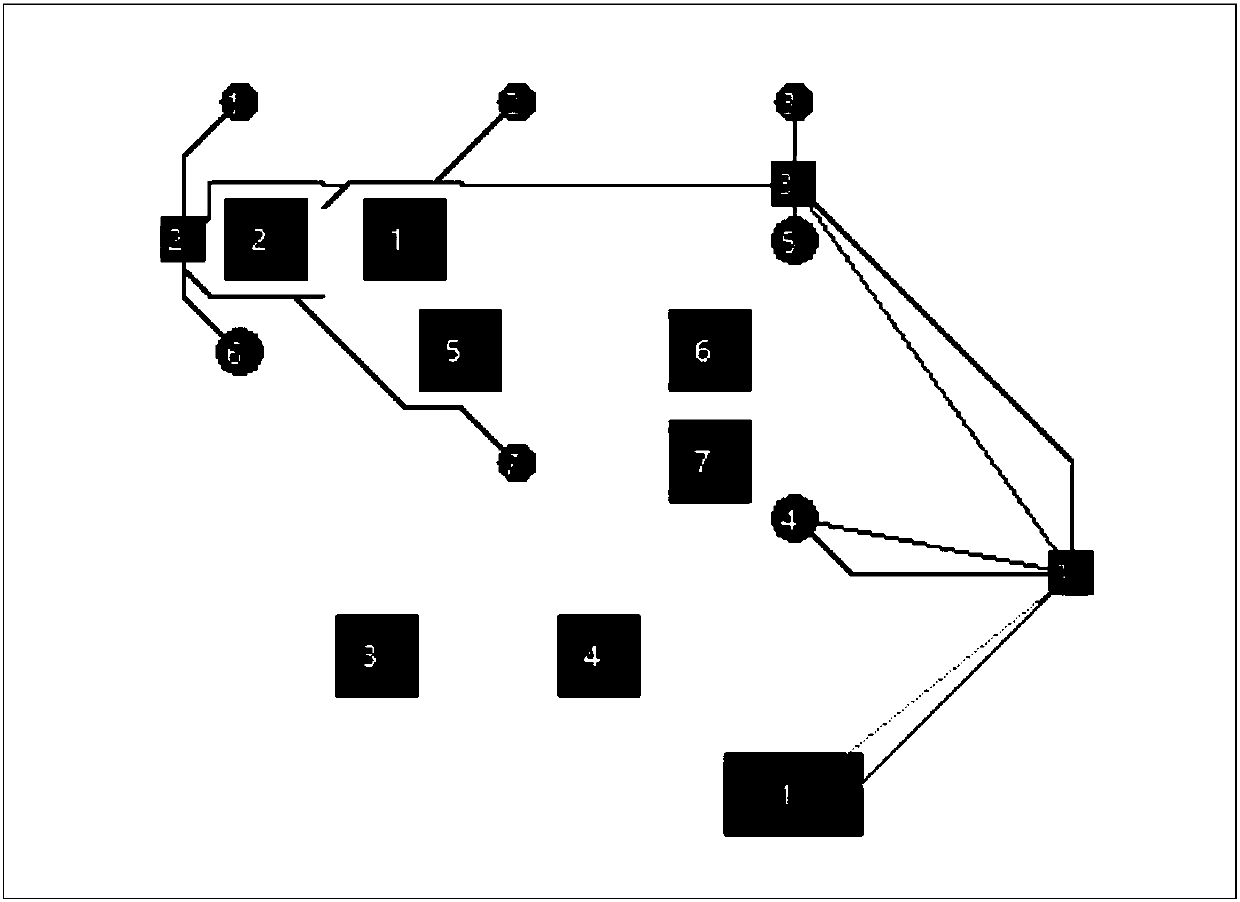

Multi-load AGV task assignment forming method for tobacco factory material transport

InactiveCN107657364AImprove handling efficiencyReduce handling costsResourcesLogisticsTask completionCarrying cost

The invention provides a multi-load AGV task assignment forming method for tobacco factory material transport. The method comprises the following steps: machine unit material demand information is obtained, tasks to be completed are generated, task information is released, the task information is received via an AGV, task income is calculated based on an income function, and bidding operation is performed; according to task auction rules, a task assignment solution is generated, and the tasks are executed via the AGV according to the task assignment solution. According to the method, the AGV is used for transporting materials of machine units in a tobacco factory, the materials is transported from a material warehouse to a material stacking part for the machine units; the method is appliedto a multi-load AGV; compared with a single load AGV, the multi-load AGV is advantageous in that a large quantity of tobacco can be carried in a single time and high carrying efficiency can be realized; but the multi-load AGV is high in complexity of task decision making, and therefore an auction algorithm is adopted in the method to improve task assigning efficiency, lower zero load rates of themulti-load AGV and lower material carrying costs; task completion time is taken into account in task completion income, and real time demand can be satisfied while an aim is set to optimize task completion income.

Owner:CENT SOUTH UNIV

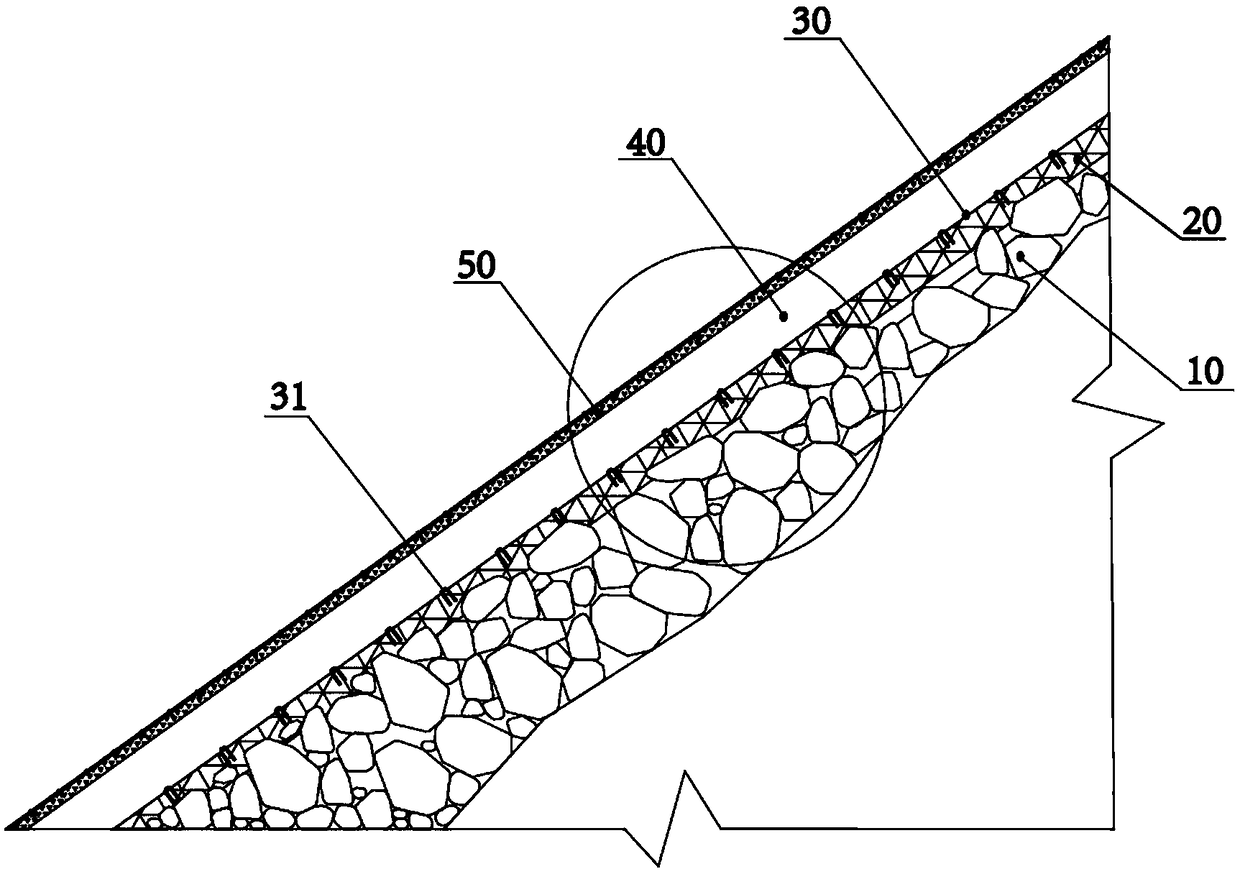

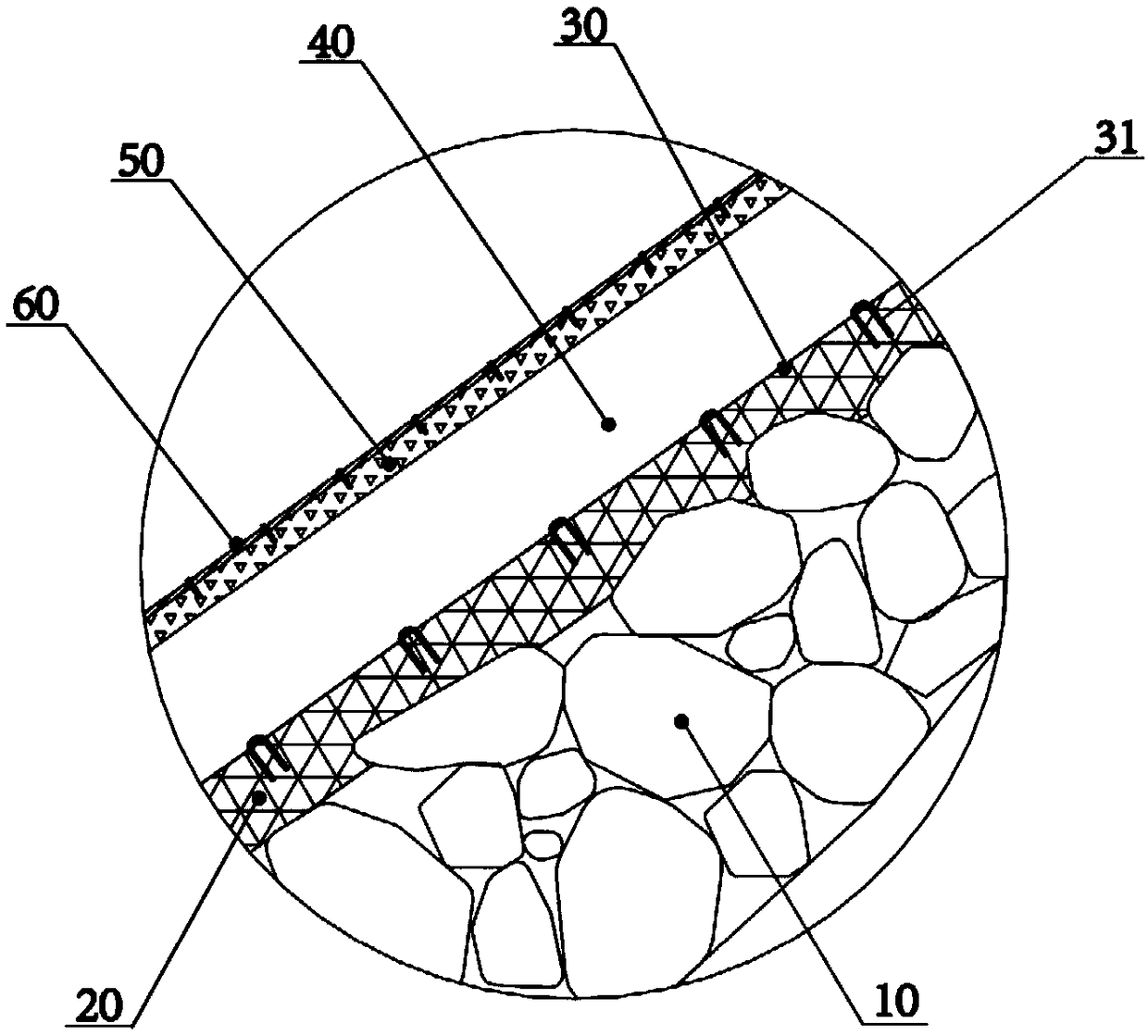

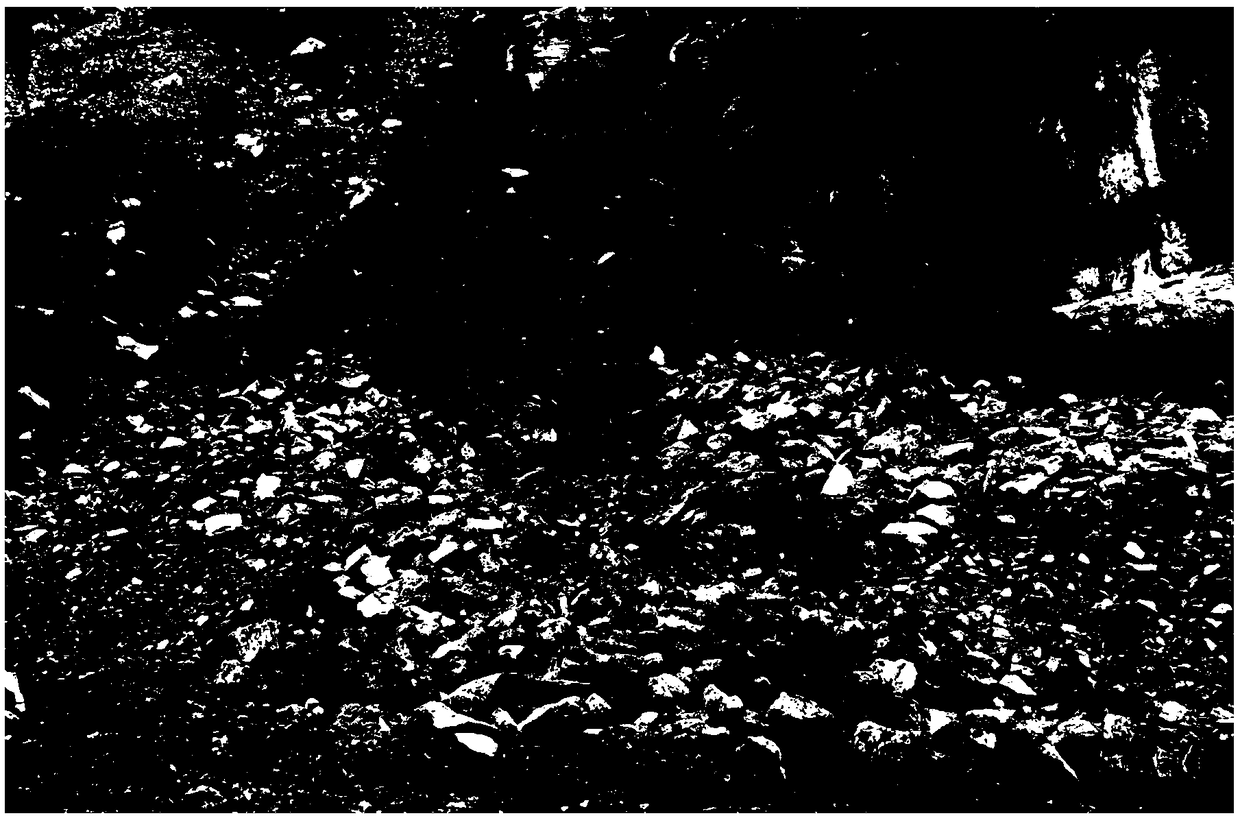

Macadam slope vegetation recovery structure and construction method

PendingCN108684245AAdvantage structureAdvantages of construction methodFlowers cultivationHops/wine cultivationRevegetationStructure of the Earth

The invention provides a macadam slope vegetation recovery structure and a construction method, and relates to the technical field of slope restoration. According to the macadam slope vegetation recovery structure, by means of matched arrangement of a covering soil layer, a first protection layer, a base layer, a planting layer and other specific structures, the slope stability can be effectivelyenhanced, ecological restoration on a macadam slope is achieved, the needed covering soil is greatly reduced, and the technical problem that the covering soil layer is large in thickness, the soil volume is large, and a soil source cannot be guaranteed due to the fact that direct soil covering is adopted for plant cultivation in the prior art is relieved. In addition, the macadam slope vegetationrecovery structure can control the macadam slope locally, macadam clearing and carrying expenses are saved, the cost is greatly reduced, and the technical problem that due to the fact that in the prior art, a machine is adopted for clearing and carrying the macadam slope in the prior art, the stacking place is limited, the transportation distance is long, and the clearing and carrying cost is highis relieved. The construction method of the macadam slope vegetation recovery structure is further provided.

Owner:MEILIGUOTU BEIJING ECOLOGICAL ENVIRONMENT ENG TECH RES INST CO LTD

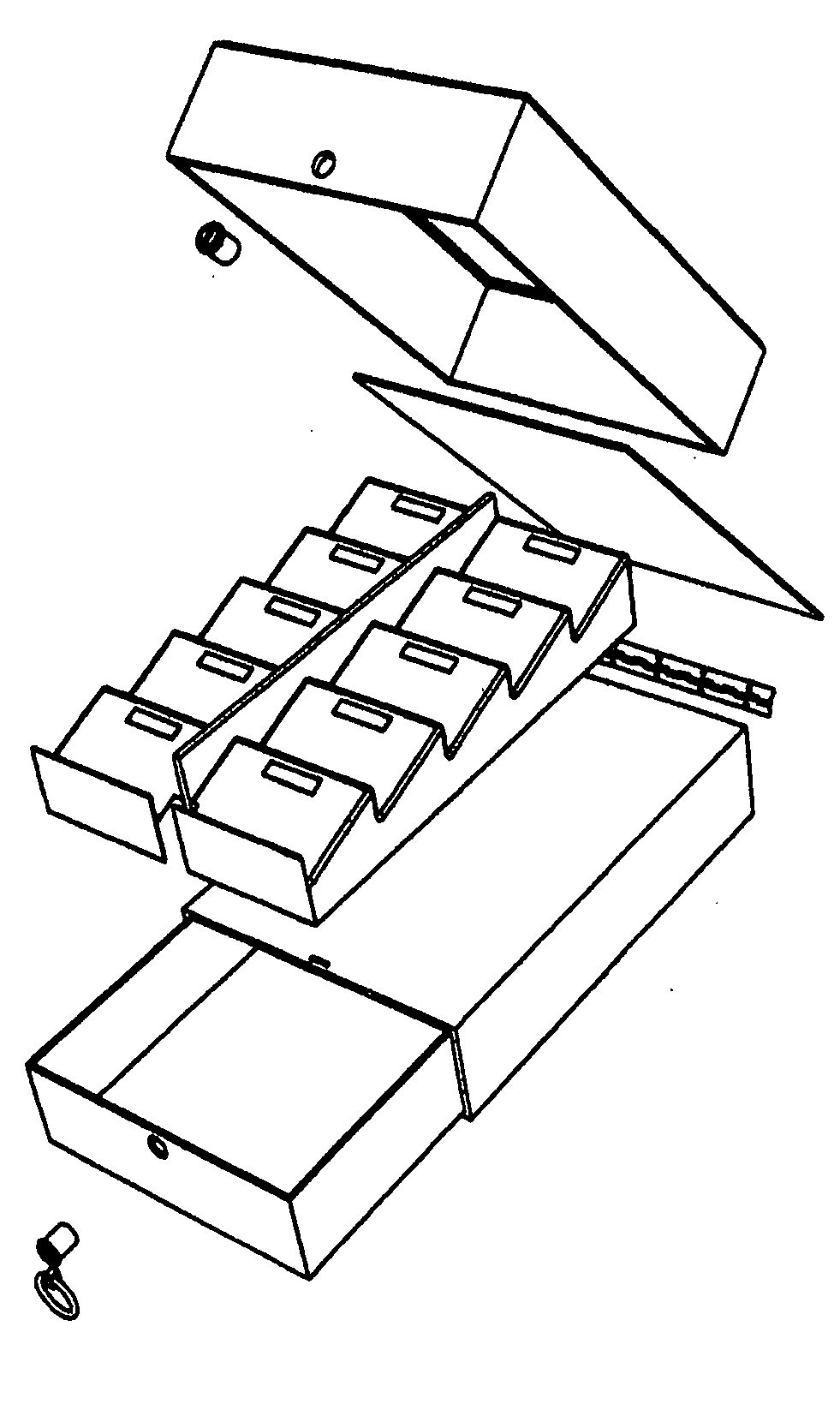

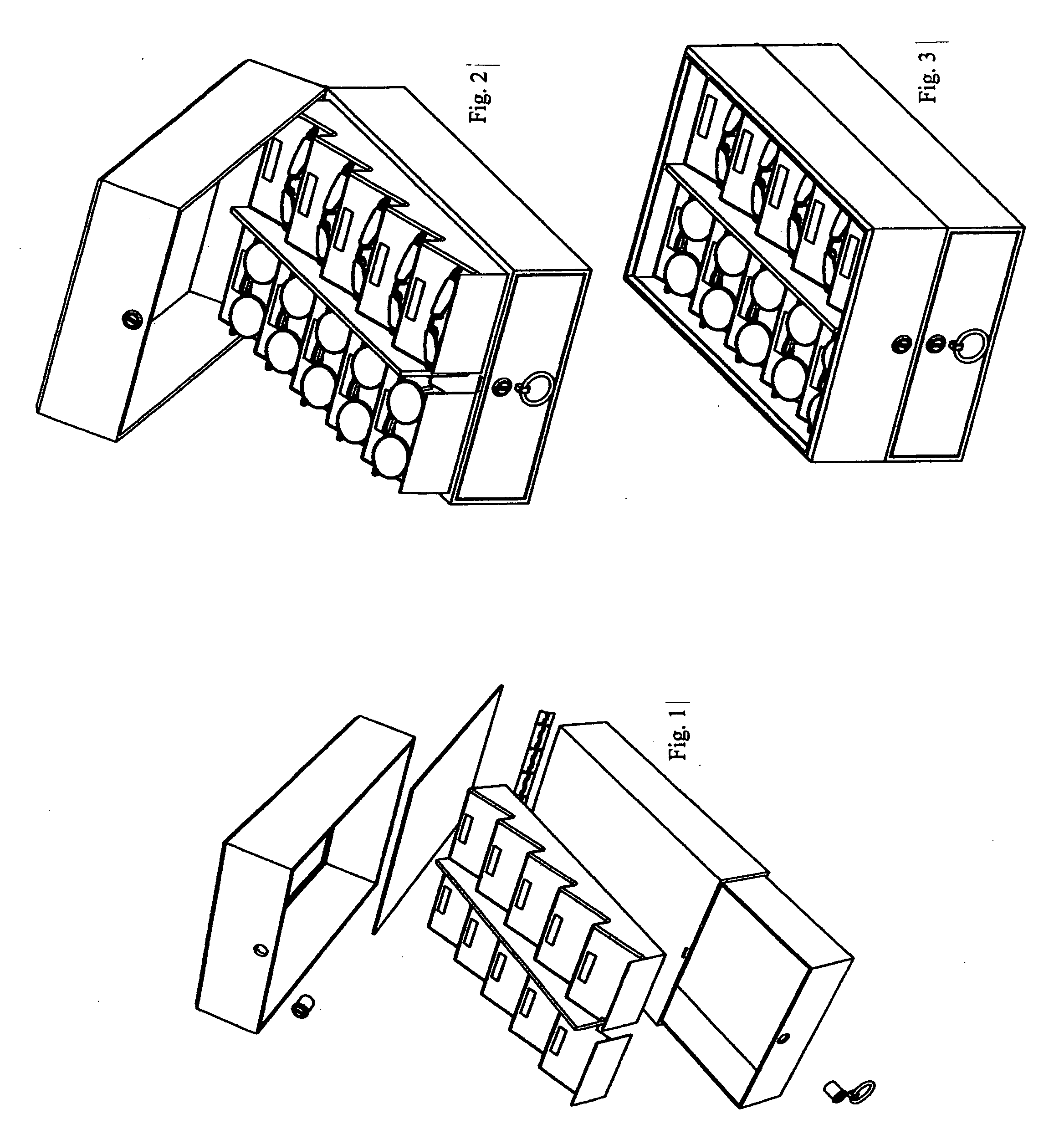

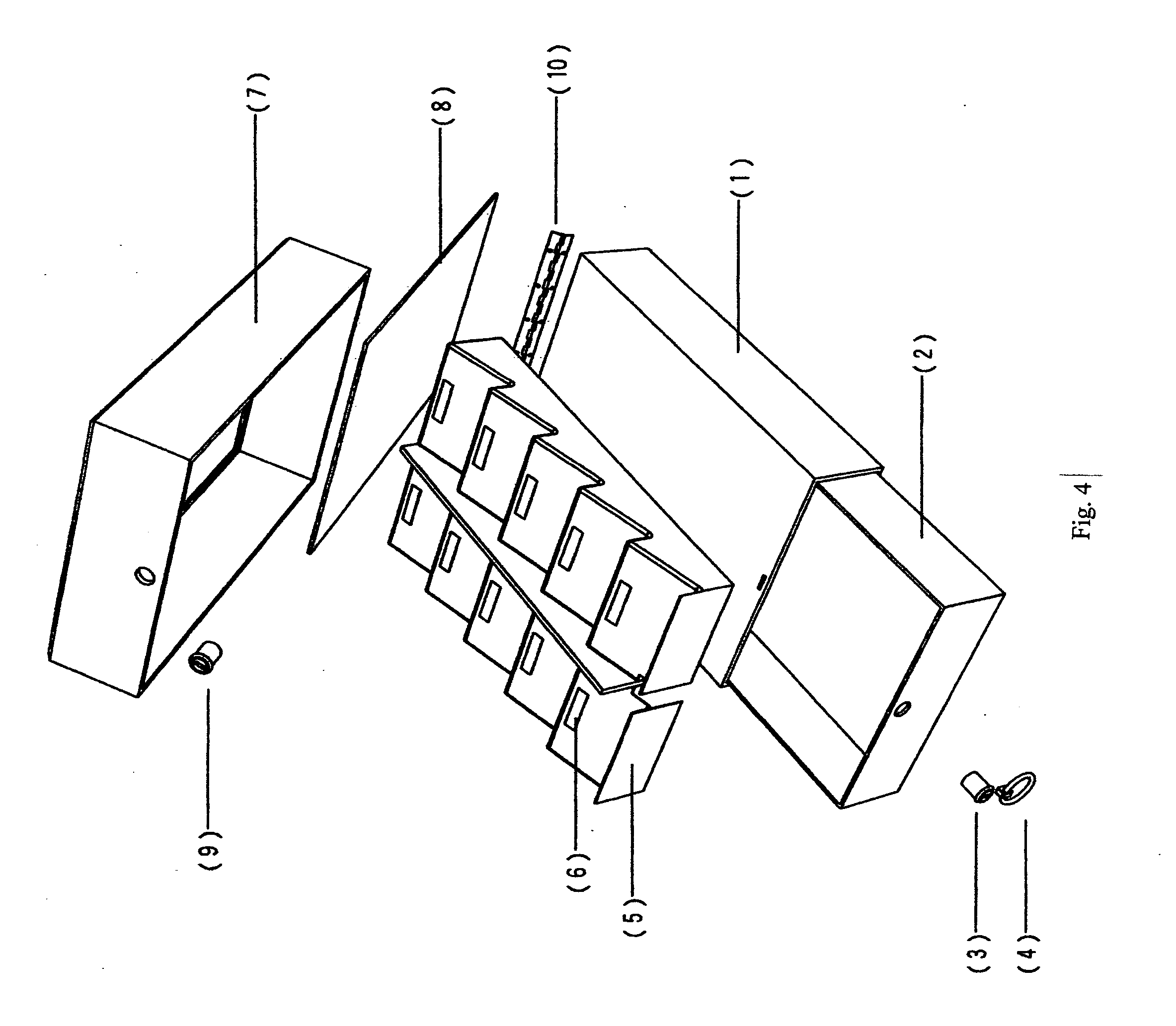

Eyeglass and sunglass display and carrying case

InactiveUS20120012502A1Avoid damageDisplay clearOther accessoriesRigid containersLong term durabilityEyewear

Owner:YOUNG DENNIS MICHAEL

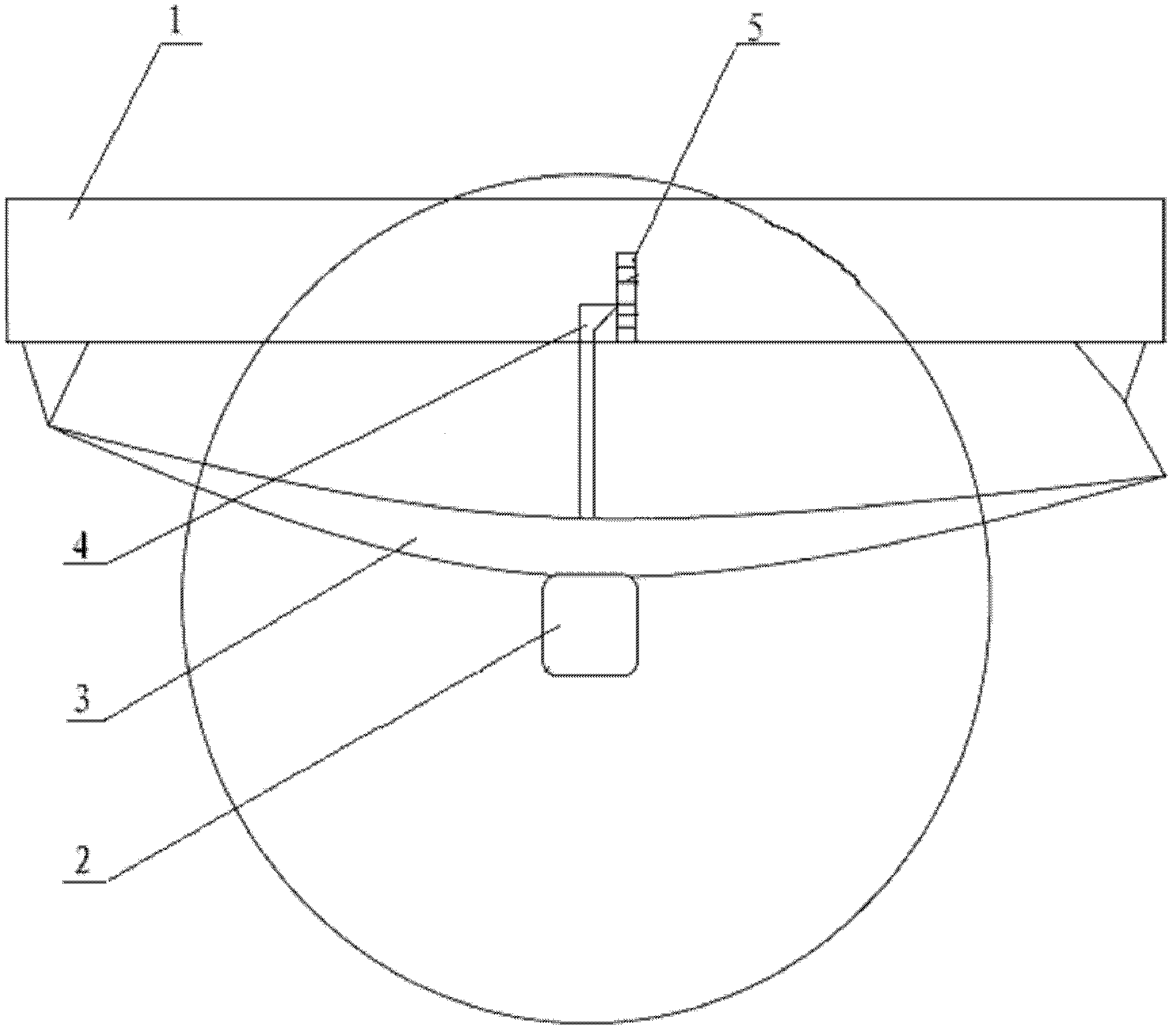

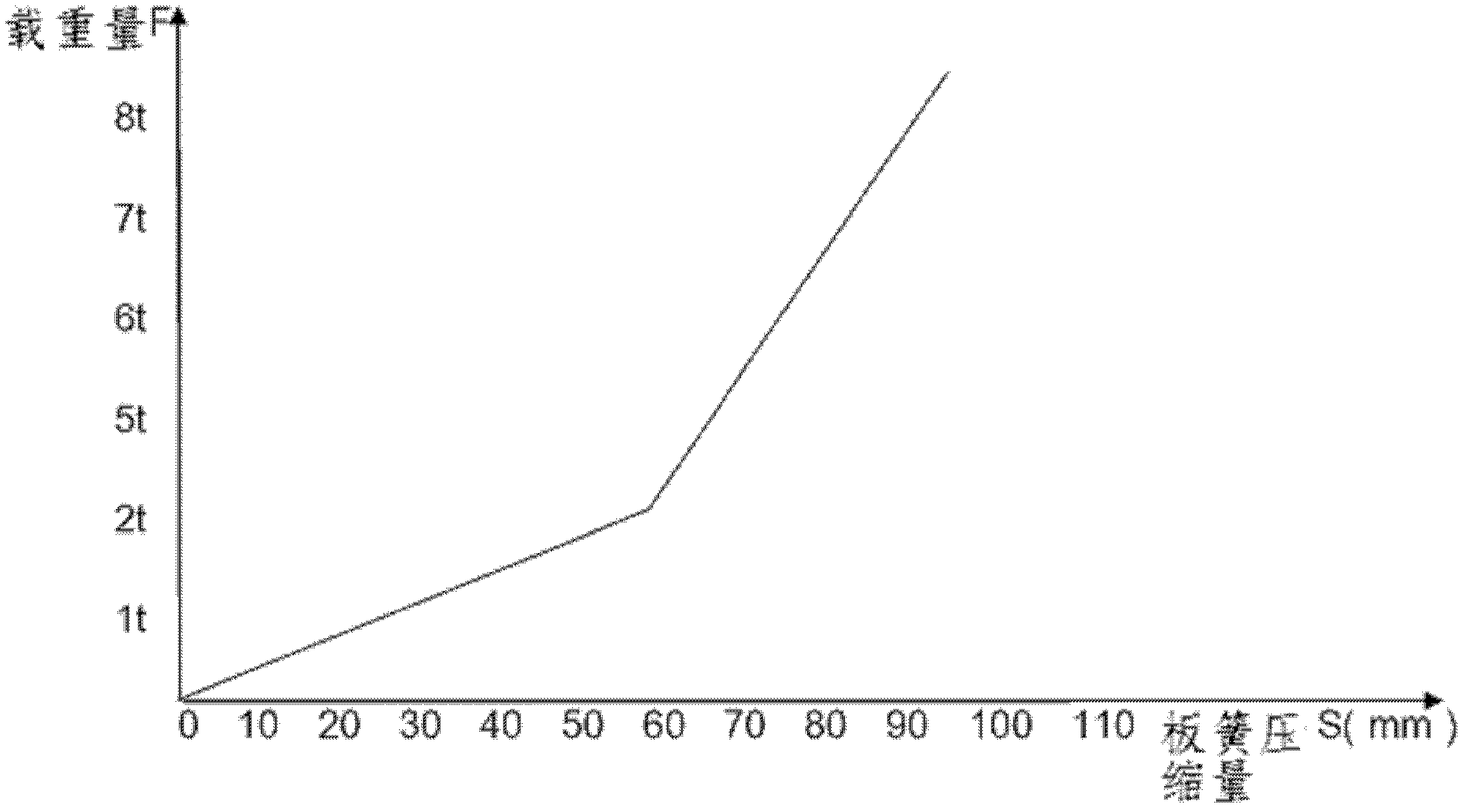

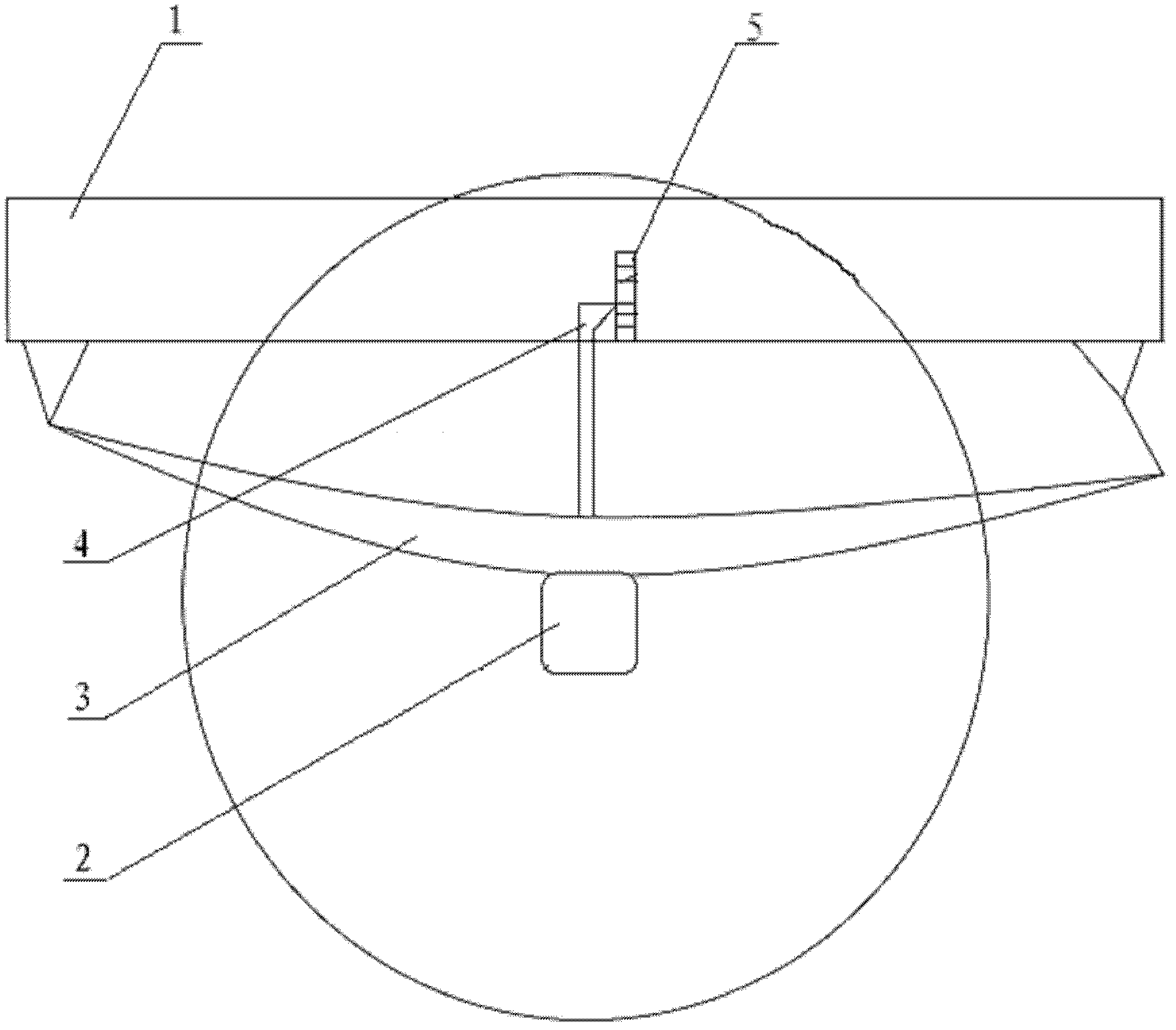

Vehicle load detecting device and engineering vehicle

The invention discloses a vehicle load detecting device comprising an elastic component, wherein the elastic component is arranged between a vehicle frame (1) and a vehicle bridge (2) of the engineering vehicle, the telescopic direction of the elastic component is in parallel with the up-and-down direction of the engineering vehicle, and the vehicle load detecting device further comprises a detecting part for detecting the compression quantity of the elastic piece; and operators can directly compute or obtain the carrying capacity of the engineering vehicle of the current status according to the compression quantity of the elastic component detected by the detecting device. Compared with the carrying capacity computing mode in the prior art, the carrying capacity computing mode is higher in accuracy, suitable for various operators with different experiences, and simpler to operate, so that the work efficiency can be improved, the labor force can be saved, and the material carrying cost can be further saved. Furthermore, the invention further discloses the engineering vehicle with the engineering vehicle load detecting device.

Owner:WEICHAI POWER CO LTD

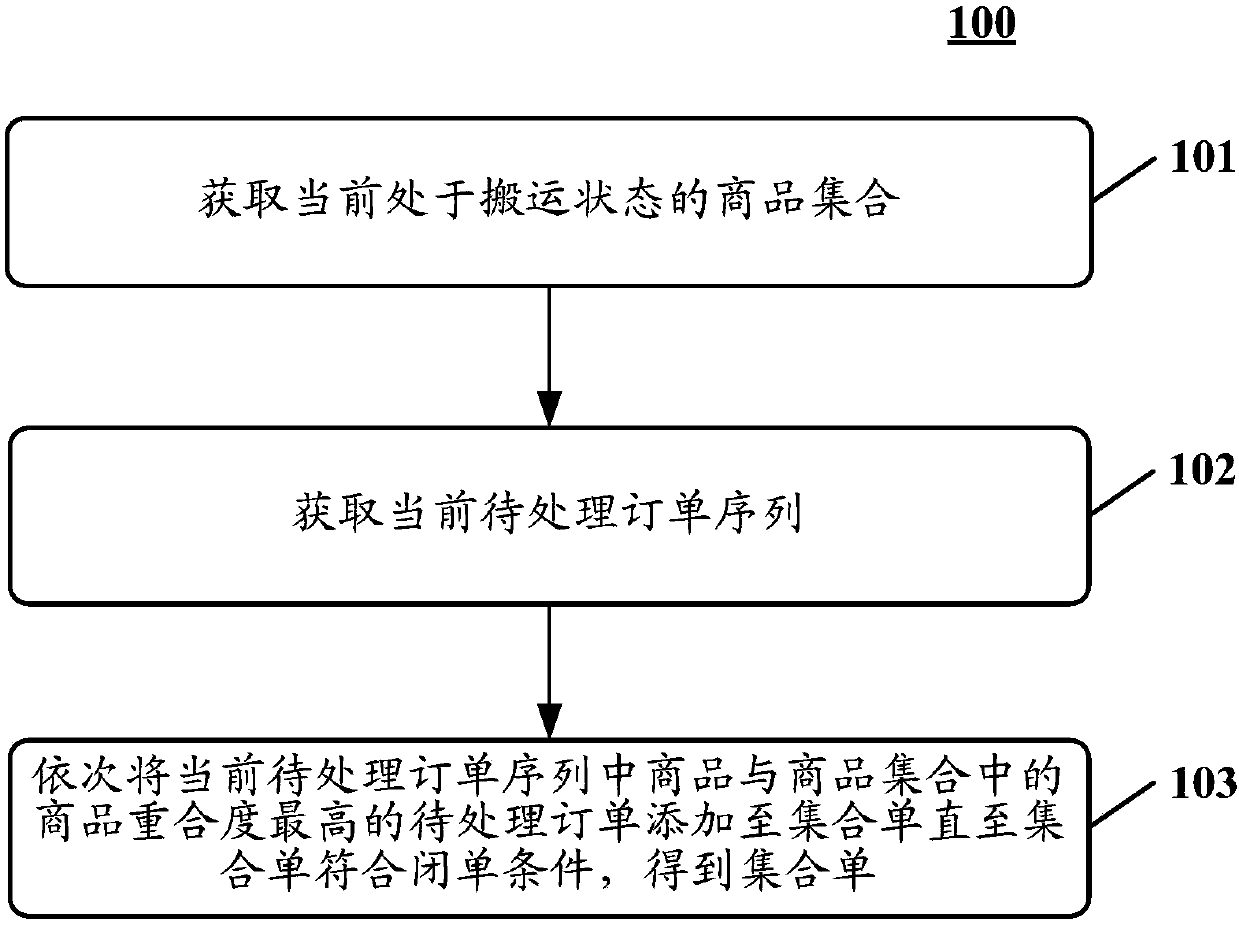

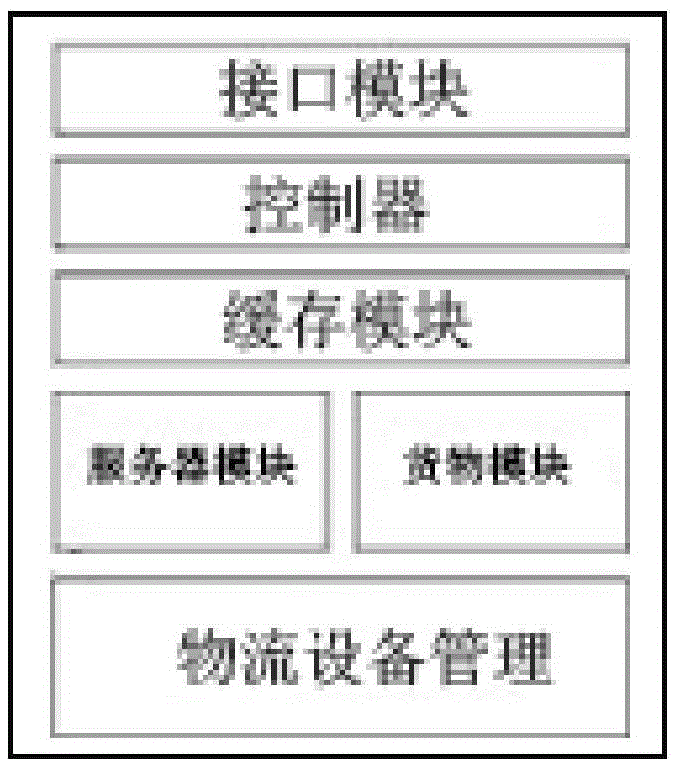

A method and device for improving warehouse-out efficiency

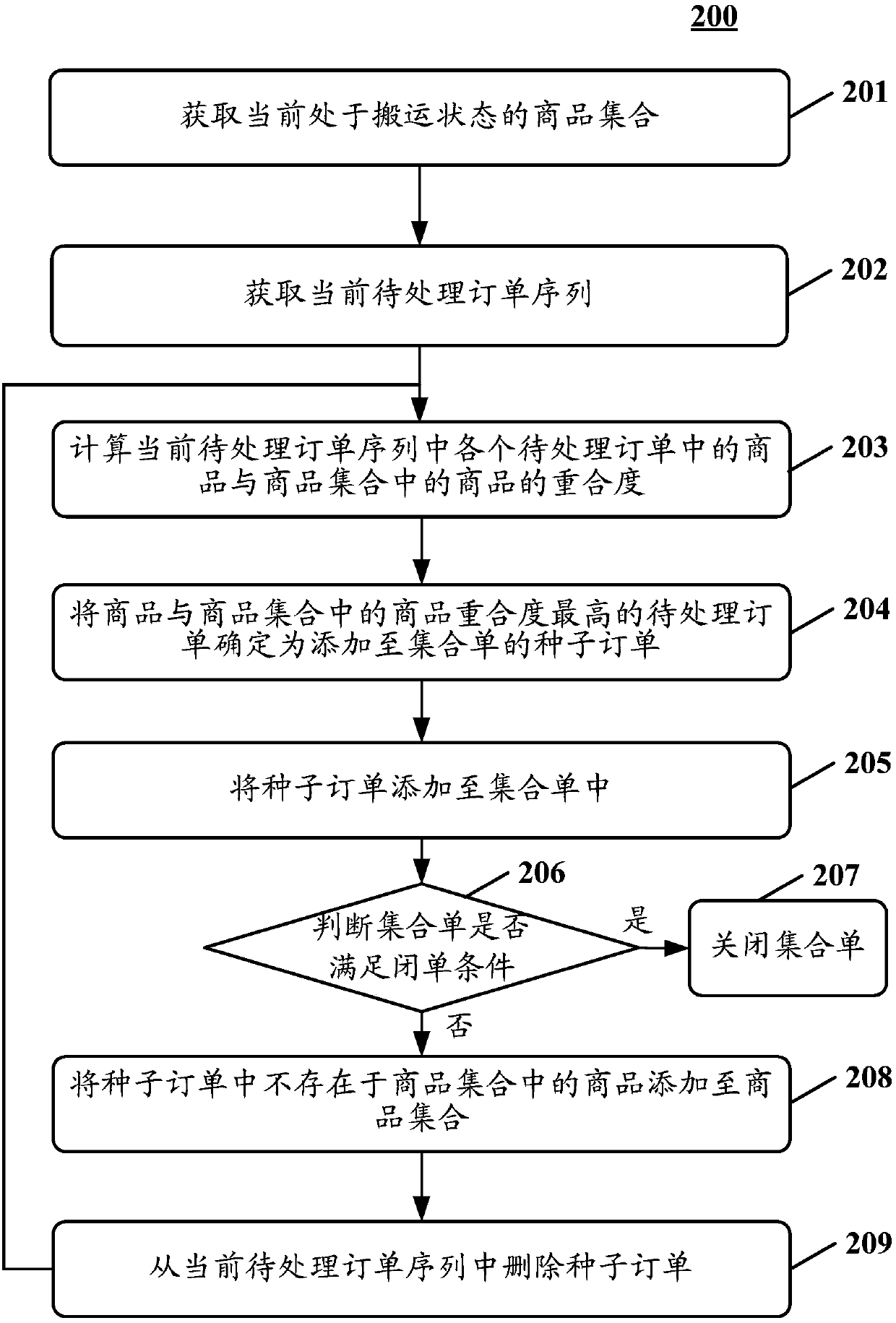

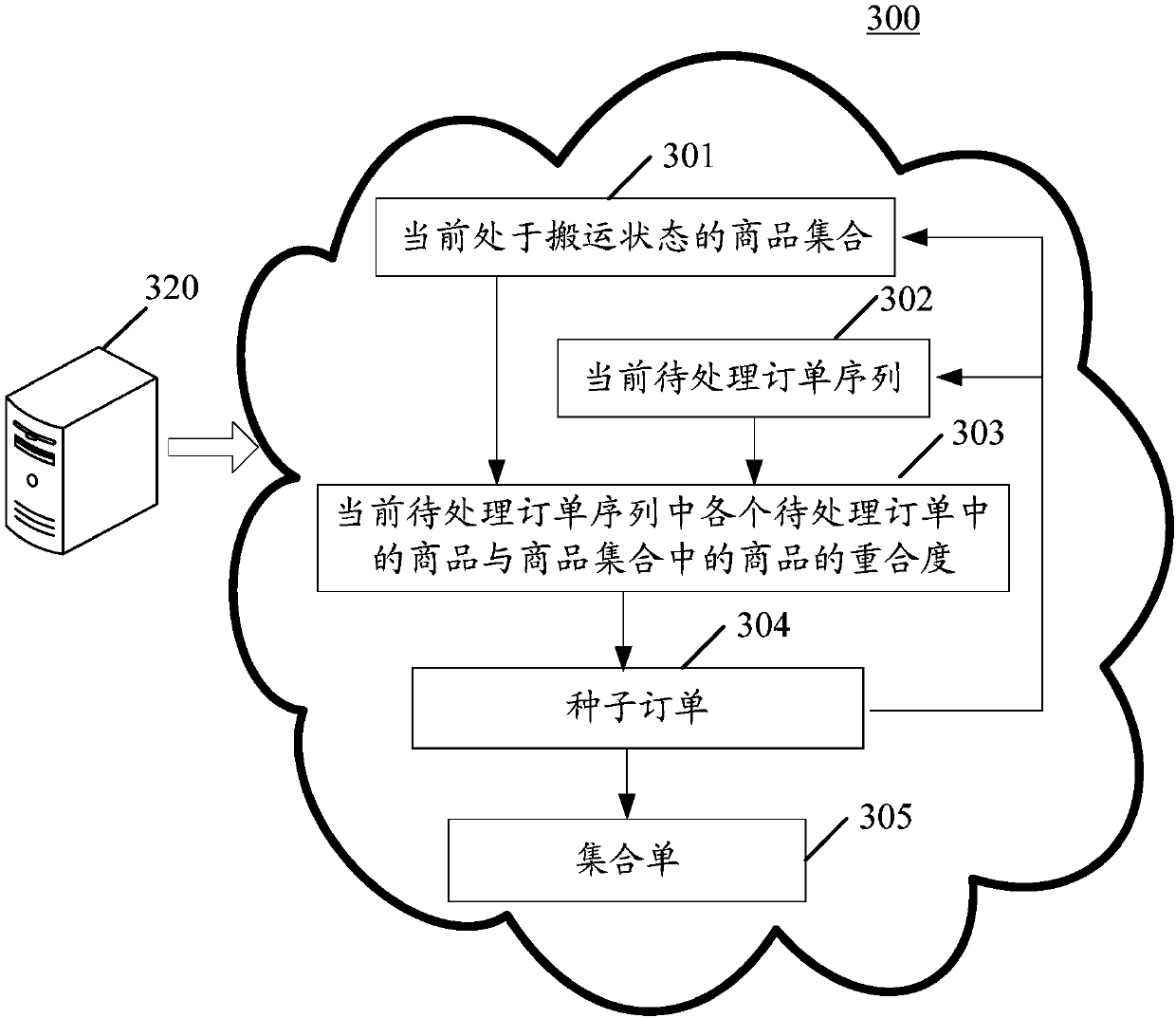

ActiveCN109658018AImprove processing efficiencyFully consider the distanceResourcesLogisticsAlgorithmCarrying cost

The invention discloses a method and device for improving warehouse-out efficiency. A specific embodiment of the method comprises the steps of obtaining a commodity set which is currently in a carrying state; Obtaining a current to-be-processed order sequence; And sequentially adding the to-be-processed order with the highest commodity coincidence degree in the current to-be-processed order sequence and the commodity set to the set order until the set order meets an order closing condition to obtain a set order. According to the embodiment, the picking distance and the carrying cost of the commodities in the established collection list during picking are fully considered, and the processing efficiency of the collection list is improved.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

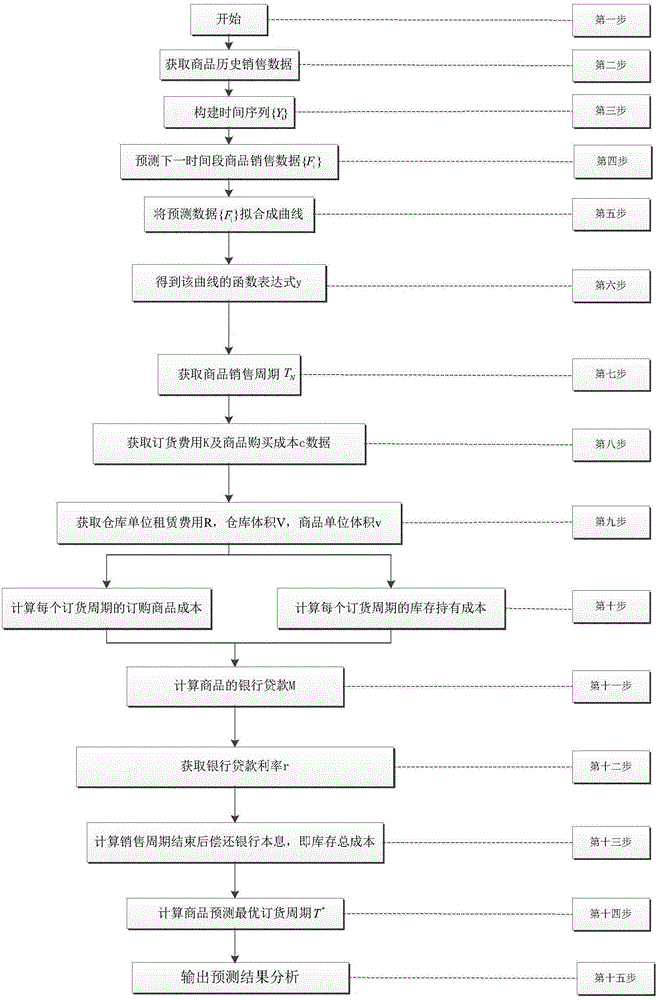

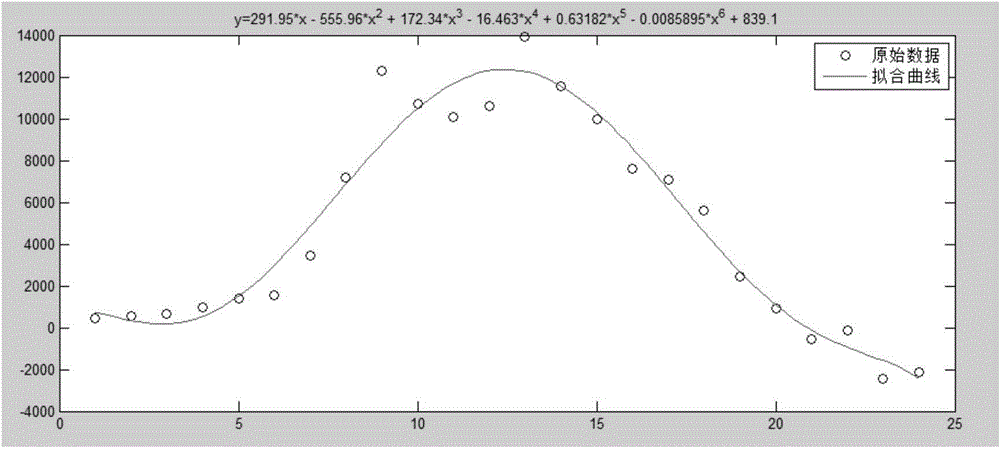

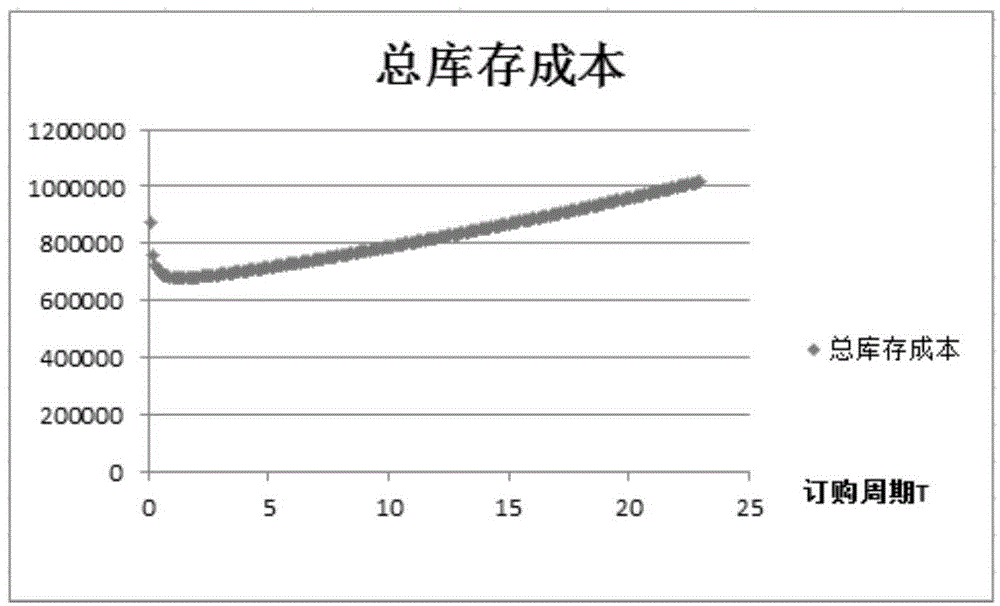

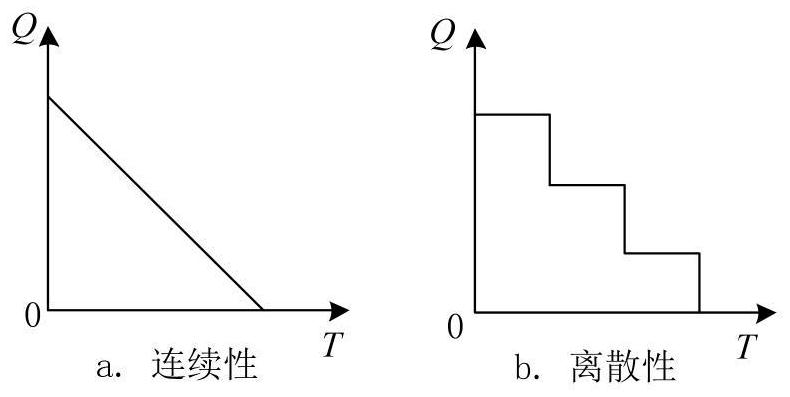

Optimal ordering period prediction method for seasonal and periodic goods

The invention discloses an optimal ordering period prediction method for seasonal and periodic goods, and the method is suitable for the goods which is periodic and is sensitive to seasons, wherein the sales volume of the goods increases at first and then decreases. The method comprises the steps: predicting the sales demands of the goods in the current period based on the history sales data of the goods; considering the ordering cost of the goods, the stock cost and the interest cost of a bank loan; and calculating the optimal ordering period of the goods through a quantitative method. Output results enable the decision facilitating the ordering period of the current goods of an enterprise to be made in advance, thereby providing accurate and scientific judgment for the decisions of the requirements for stock capacity, the stock cost control and the amount of bank load of the enterprise.

Owner:NANJING UNIV

Mobile phone camera integrated assembling equipment

InactiveCN103747122AAvoid secondary pollutionIncrease productivityTelephone set constructionsEngineeringCarrying cost

The invention discloses mobile phone camera integrated assembling equipment . The equipment comprises an automatic cleaning machine, a glue dispensing mounting machine and an infrared tunnel drying furnace, wherein the automatic cleaning machine is connected with the output end of a paster reflow soldering through a feeder machine; the output end of the automatic cleaning machine is connected with the glue dispensing mounting machine through the feeder machine; a fixture stitching workbench is connected between the output end of the glue dispensing mounting machine and the input end of the infrared tunnel drying furnace; and the fixture stitching workbench covers a general fixture toward a product outputted by the glue dispensing mounting machine. According to the invention, the circuit board of the reflow soldering enters the integrated assembling equipment provided by the invention immediately through the feeder machine, so that the automatic cleaning machine, and the glue dispensing mounting machine and the infrared tunnel drying furnace in the integrated equipment are designed to be of enclosed structures so that secondary pollution such as oil stain, dust and the like, caused by station type operation, is solved, the production efficiency is improved, and the labor carrying cost is reduced; and besides, the paster mounting precision is high.

Owner:惠州市桑莱士智能科技股份有限公司

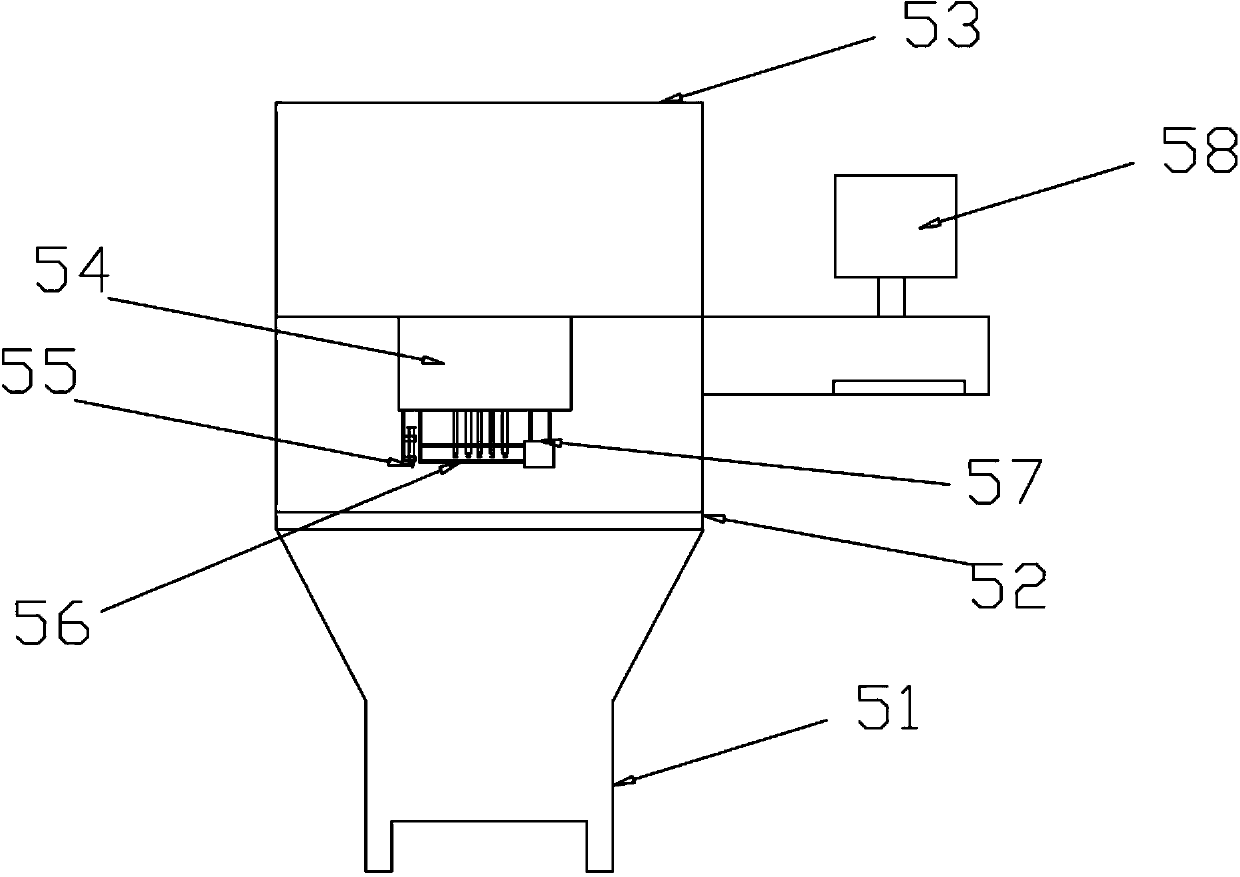

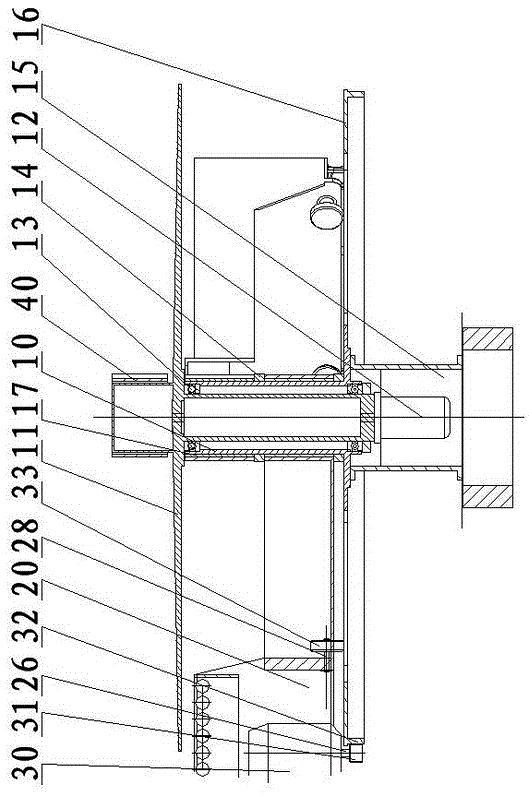

Rotating disk transition type bidirectional loading and unloading machine

ActiveCN105905581AReduce dropPrevent falling damageSupporting framesControl systemWorking environment

The invention provides a rotating disk transition type bidirectional loading and unloading machine, and relates to the field of logistics transportation cargo handling machinery. The loading and unloading machine is formed by a load-bearing trolley, two belt conveyors, an intermediate conveyer, a stop gauge, and an operating control system. The loading and unloading machine is simple in structure, reliable in operation, and is economical and practical, and energy saving and environmentally friendly. The loading and unloading machine is folded when travelling, and appearance dimension is small, so moving and transition are convenient and fast. When the loading and unloading machine operates, the machine is unfolded, and operation range is large, and the machine can guide and change logistics directions, and realizes positive and negative double-direction loading and unloading. Operation directions and postures of the belt conveyors can be adjusted, so as to adapt to changes of cargo loading and unloading positions. Cargoes directly arrive in one-time loading and unloading. The machine can directly enter a carriage, a counter, and a container to operate, thereby reducing manual auxiliary carrying, reducing labor intensity of workers, shortening operation time, improving loading and unloading efficiency, and reducing loading and unloading and carrying cost. In loading and unloading and conveying processes, drop height of objects is low, transition is stable without impact, and dust discharge is reduced, working environment is improved, and objects are prevented from falling and being damaged in transition conveying, so as to ensure safety of cargo loading and unloading.

Owner:襄阳忠良工程机械有限责任公司

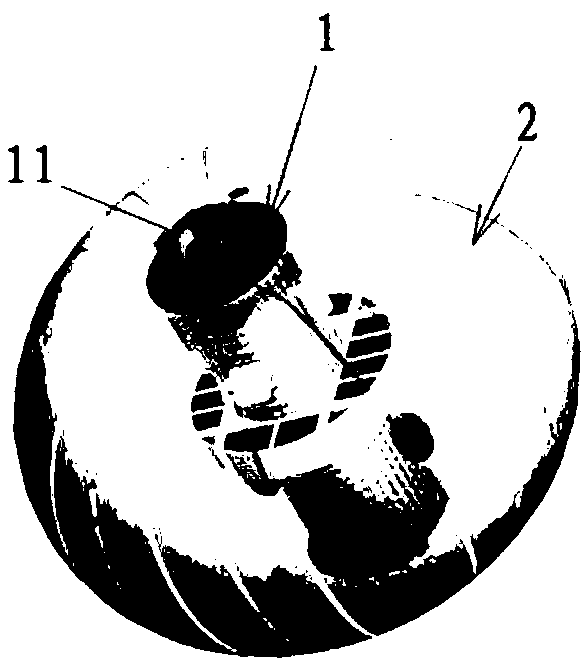

Manned habitation cabin for space exploration

ActiveCN108622439ASmall footprintReduce weightCosmonautic environmental control arrangementArtificial satellitesCarrying capacityEngineering

The invention relates to a manned habitation cabin for space detection. The manned habitation cabin comprises a rigid cabin (1) and a flexible cabin (2), wherein the rigid cabin (1) is arranged at a central position, and the flexible cabin (2) is arranged surrounding the rigid cabin (1). In the initial state, the flexible cabin (2) is in a retracted state, and in the working state, the flexible cabin (2) is in an unfolded state. By adopting the combined structure of the rigid cabin and the flexible cabin, the advantages of the two structural forms are integrated, and the rigid cabin in the central position is used as a bearing structure and fully satisfies the bearing requirements in the process of carrying launch or orbital maneuvering. The flexible cabin is in a retracted state during the carrying launch or orbital maneuvering process, the occupied space is small, and mass characteristics are relatively definite, so that the flexible cabin in a retracted state is beneficial to the carrying launch or orbital maneuvering process; and the flexible cabin is light in weight, thus the carrying capacity of a carrier is less required, the limitation of the carrying capacity is met, and the carrying cost is further reduced.

Owner:BEIJING SPACE TECH RES & TEST CENT

Warehouse-out condition-based goods setting display optimization system

The invention provides a warehouse-out condition-based goods setting display optimization system. According to the system, the optimal display mode of goods is calculated through analysis according to historic data, weight, volume and storage conditions of the goods and category attribute data, which are allocated from a warehouse; and the goods are transported to an appointed goods shelf for placement, so that the goods circulation efficiency is improved; the utilization rate of the warehouse is improved; and the carrying cost is reduced. Based on recently used LRU principle, the factors comprising the allocation quantity, the volume and the weight of the goods and product attributes are accurately calculated to obtain the optimal display position.

Owner:TIANJIN SHENGGOU TECH DEV CO LTD

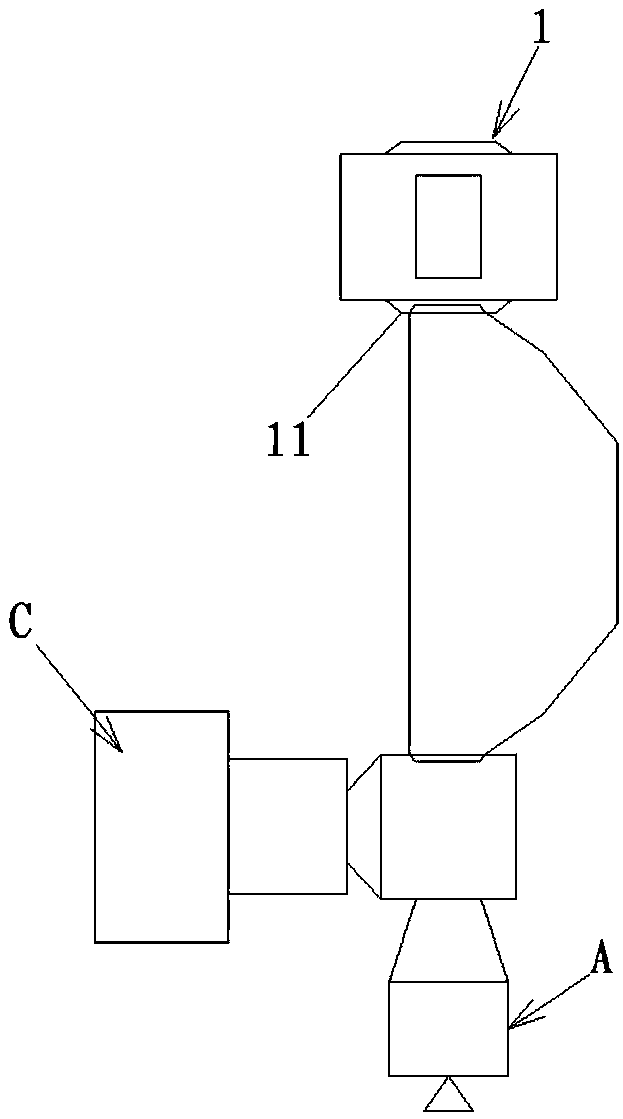

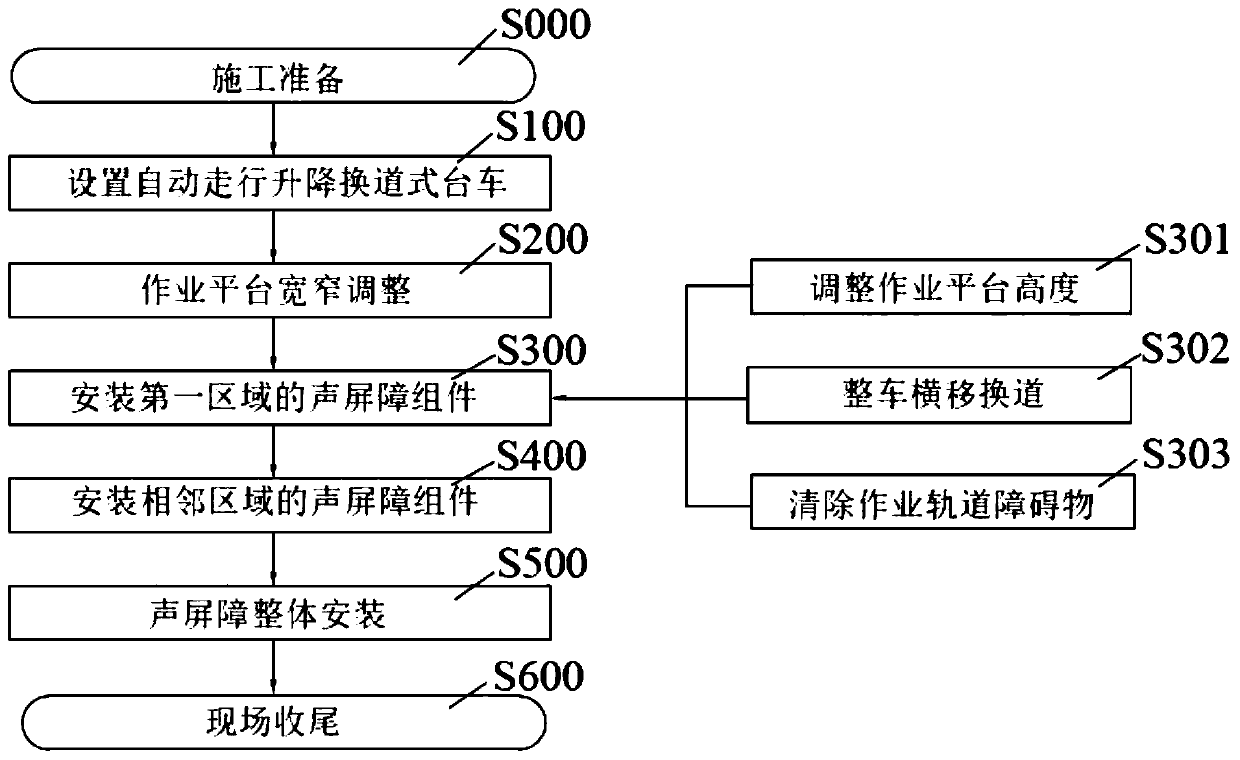

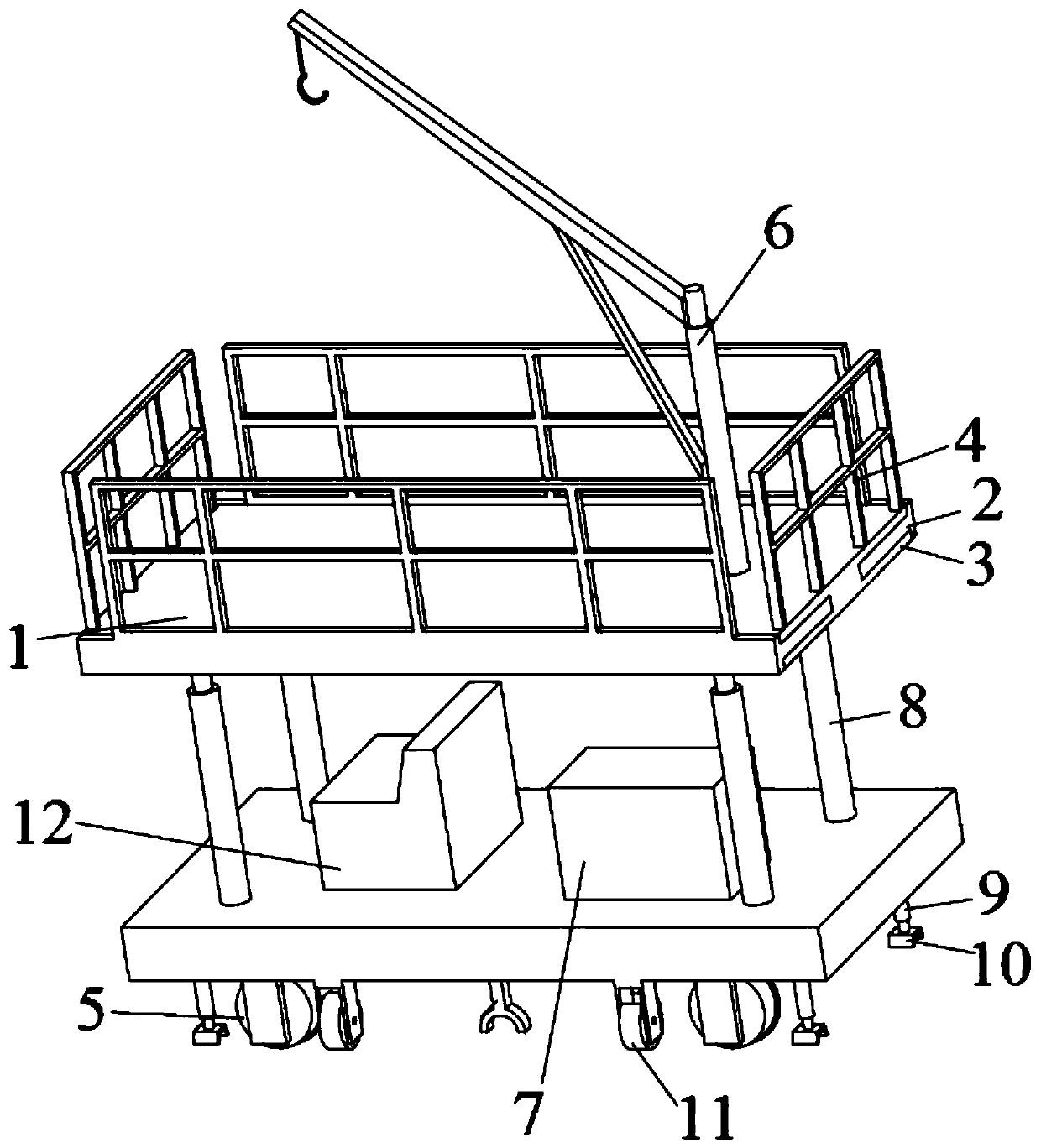

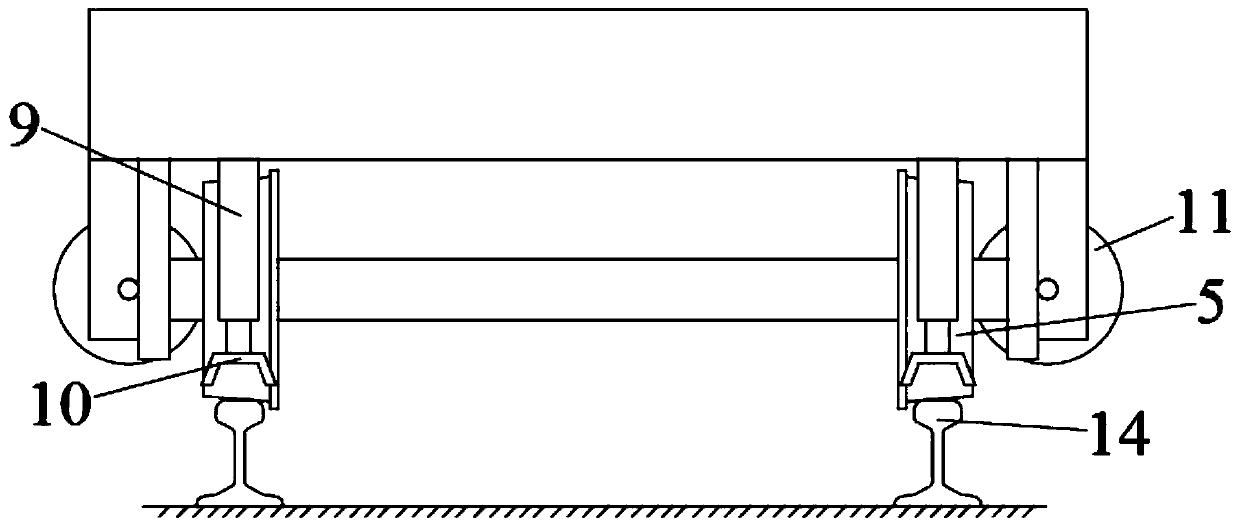

Installing sound barrier construction method of automatic walking lifting lane-changing trolley

ActiveCN110130230ALow costSolve the problem of frequent dismantling and modificationNoise reduction constructionBridge erection/assemblySound barrierBridge deck

The invention discloses the technical field of sound barrier installation, and particularly relates to an installing sound barrier construction method of an automatic walking lifting lane-changing trolley. The installing sound barrier construction method comprises the steps of arranging the automatic walking lifting lane-changing trolley, adjusting the work platform width, installing a sound barrier assembly of a first area, arranging sound barrier assemblies of adjacent areas, and overall installing sound barriers. According to the installing sound barrier construction method, the problems that when a traditional lorry-mounted crane lifts the sound barrier assemblies to match with a scaffold to construct, to set up a temporary platform wastes time and labor, in different bridge width construction, the temporary platform needs detaching and modifying frequently; and when a lorry-mounted crane lifts the sound barrier assemblies to match with a rail-mounted gantry crane and a platform lorry to construct, the braking effect of relying on artificial external force on a braking device is low, and safety accidents are prone tooccurring are solved, operators can install sound barriers normatively and effectively, the cost of scaffold materials, carrying cost and the time cost of repeatedly disassembly and installation are reduced, effects of work platform reliability, safety and efficiency, and less time andlabor are improved.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

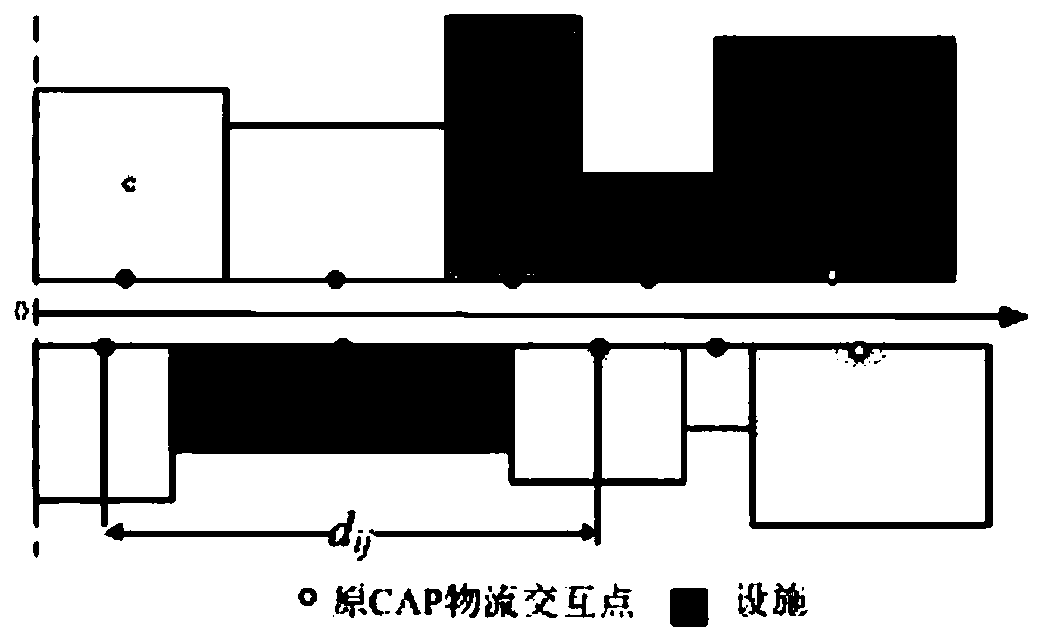

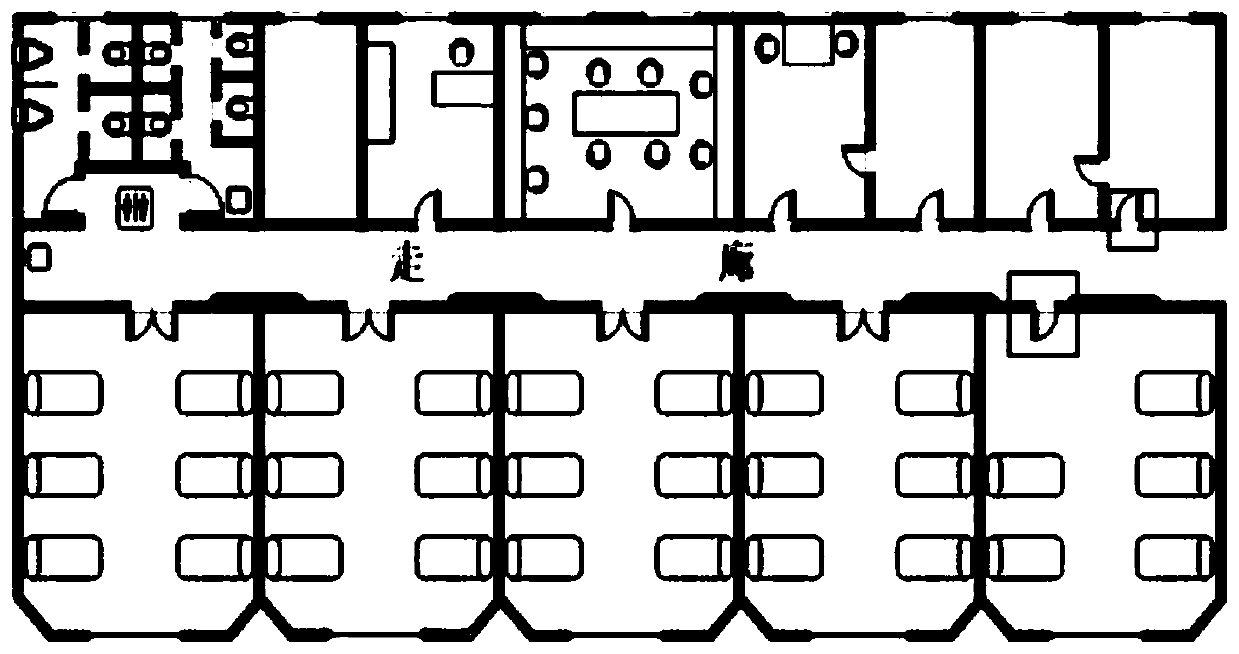

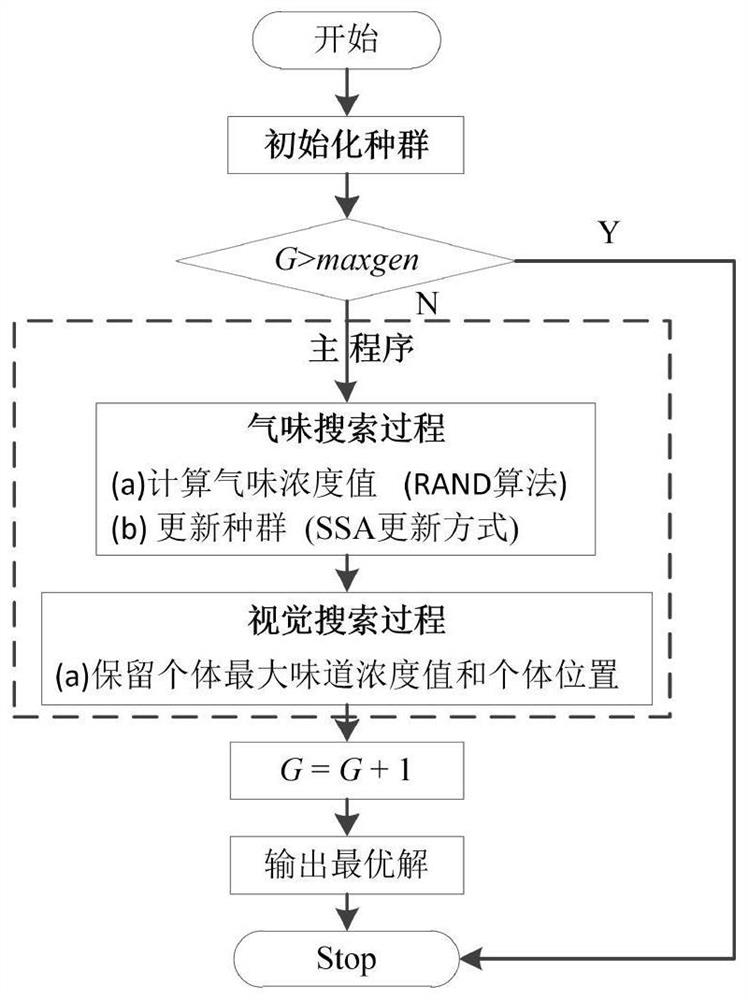

Aisle arrangement method

ActiveCN110569589AAccurate Multi-Objective SolvingReduce handling costsArtificial lifeSpecial data processing applicationsMathematical modelAlgorithm

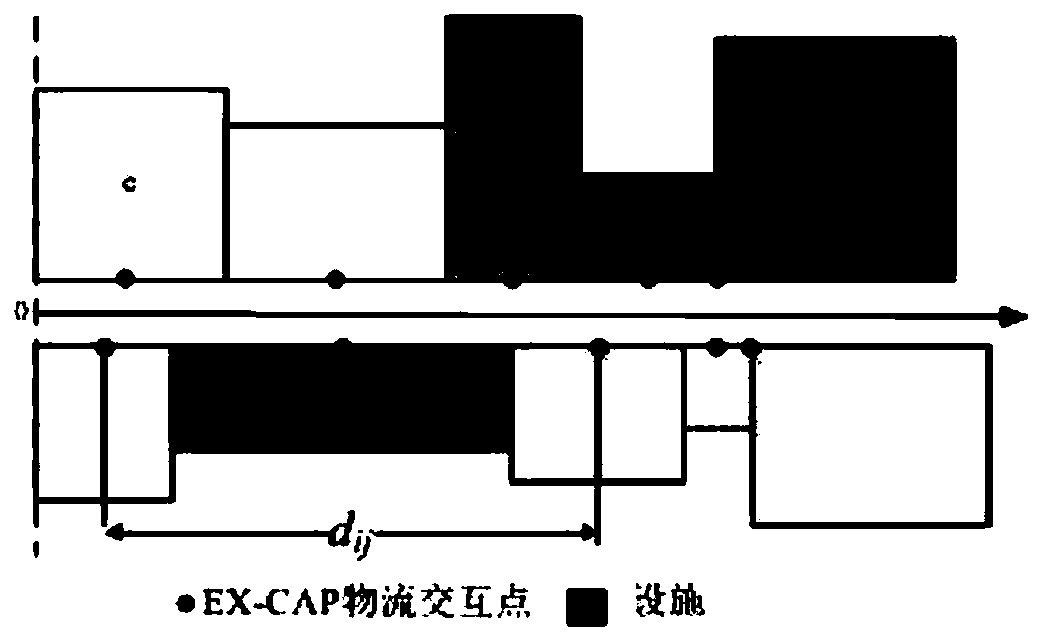

The invention provides an aisle arrangement method. The aisle arrangement method comprises the following steps: (1) establishing a mathematical model aiming at minimizing material handling cost; (2) obtaining an initial population; (3) updating the population by adopting a hybrid algorithm formed by compounding a chicken swarm algorithm and a genetic algorithm; (4) updating the population; (5) repeating the steps (3)-(4) according to the set number of times; and (6) outputting the population individual with the highest objective function value in the population as the optimal solution. According to the method, the genetic algorithm and the chicken swarm algorithm are fused under the condition of fully considering field actual constraint conditions, multi-target solution of the accurate layout model is realized on the basis of establishing the more accurate workshop overall layout mathematical model, and the solution precision is improved. According to the method, the influence of the change of logistics interaction points in the horizontal direction of aisle sidelines on aisle arrangement and total cost is considered, a mixed integer programming model conforming to the characteristics is constructed according to the problem characteristics, and the total logistics carrying cost of a workshop is effectively reduced.

Owner:SOUTHWEST JIAOTONG UNIV

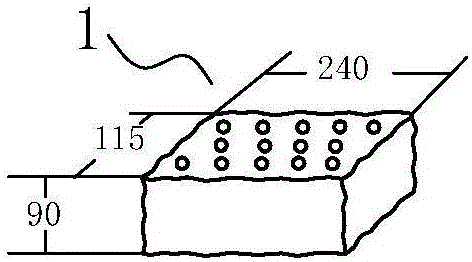

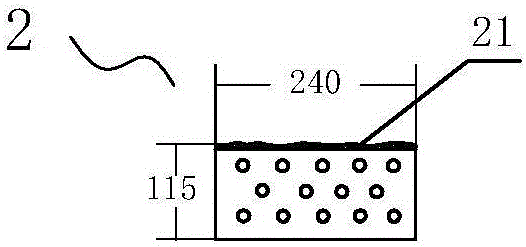

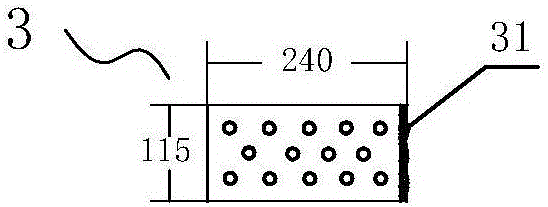

Construction method for in-situ processing and polishing bricks and constructing plain brick wall

InactiveCN106592812AImprove appearance qualityFulfil requirementsWallsBuilding material handlingBrickCarrying cost

The invention relates to a construction method for in-situ processing and polishing bricks and constructing a plain brick wall. The construction method comprises the following steps: 1) preparing for construction; 2) surveying and setting out; 3) in-situ processing and polishing the bricks; 4) constructing the plain brick wall; 5) maintaining. According to the construction method, the advantages of sufficient local common brick resources and low cost are fully utilized, the local common bricks are secondarily processed and polished at the construction site, the outer vertical surfaces of the common bricks are cut and polished, the indexes, including physical dimension, flatness, appearance quality, and the like, of the outer vertical surfaces of the common bricks can meet the plain brick requirements, the standard common bricks are cut and processed into specially shaped bricks for the supporting masonry engineering, and then the plain brick wall is manually constructed, so that the design requirements of 'clean and tidy architectural appearance and merging with the local environment' can be met, the cost is lowered and a new method is supplied for treating the similar engineering. The construction method has the advantages of simple process, high processing efficiency, high practicability, capability of lowering the repeated transportation and carrying cost and capability of lowering cost.

Owner:广西建工第五建筑工程集团有限公司

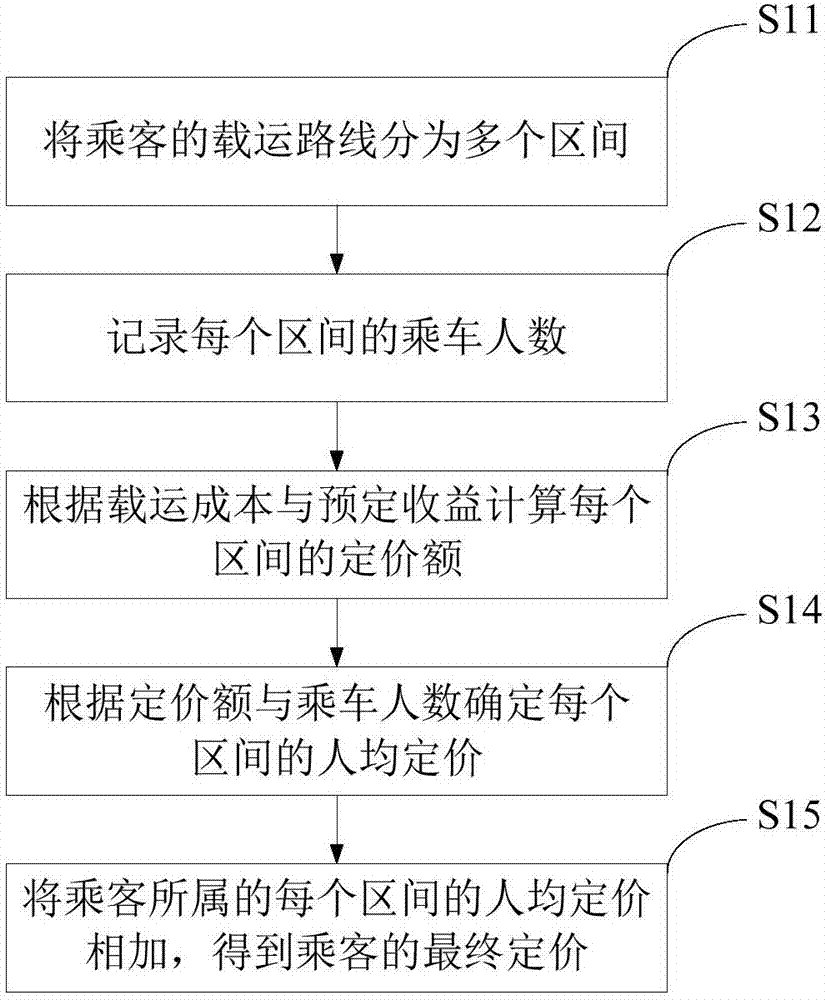

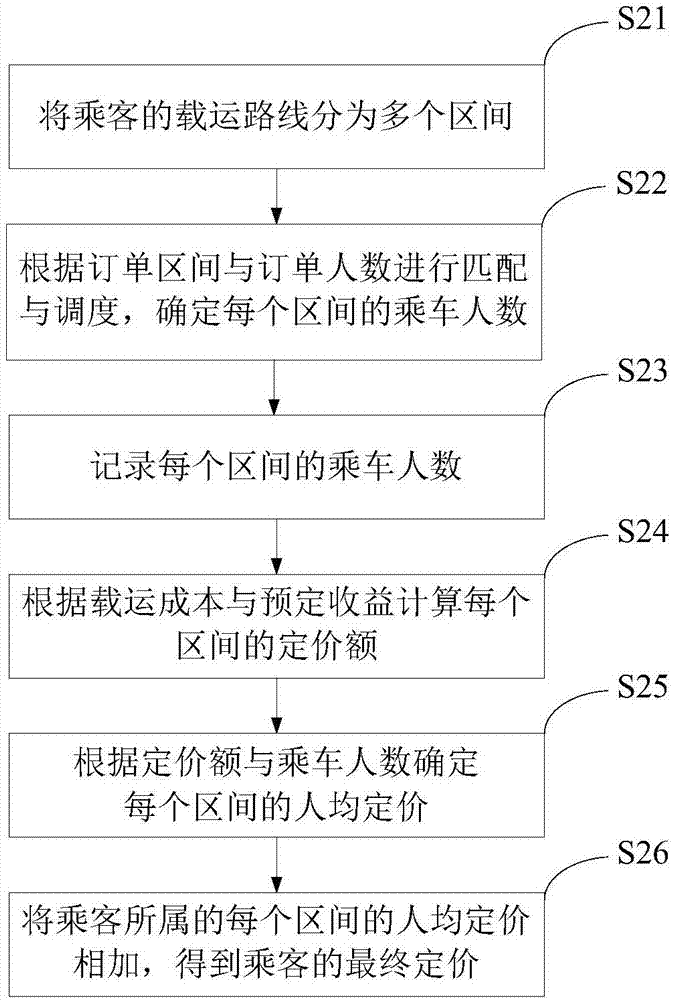

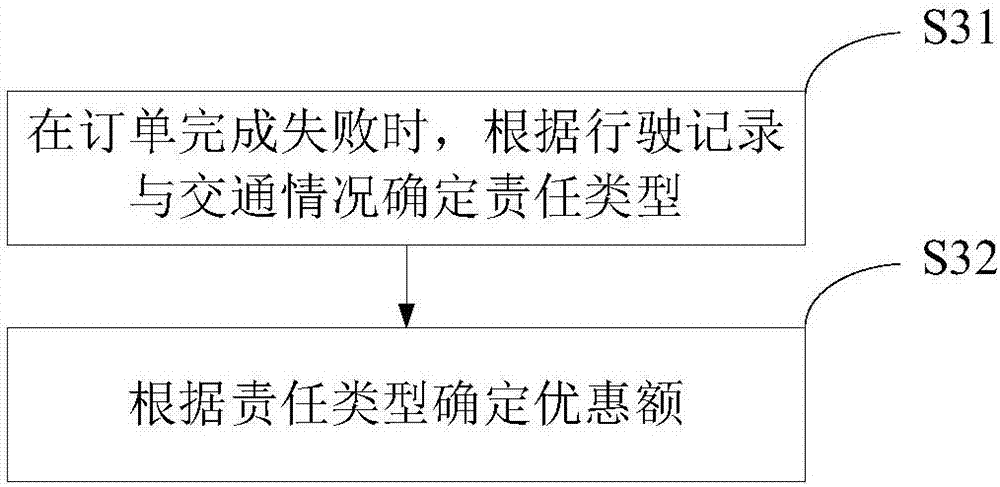

Carrying pricing method and system

The invention provides a carrying pricing method and a system, and relates to the technical field of intelligent transportation. The carrying pricing method comprises the following steps: dividing the carrying route of passengers into a plurality of sections; recording the number of passengers in each section; calculating the total price of each section according to the carrying cost and predetermined income; determining the price per passenger of each section according to the total price and the number of passengers; and adding the prices per passenger of all sections to which passengers belong together to get the final price of passengers. The technical problem in the prior art that there is no systematic method for managing the pricing for each carpooling person and it is impossible to determine the use price of transportation according to unified, rational and precise standards and rules is solved.

Owner:HANGZHOU NAJIE TECH CO LTD

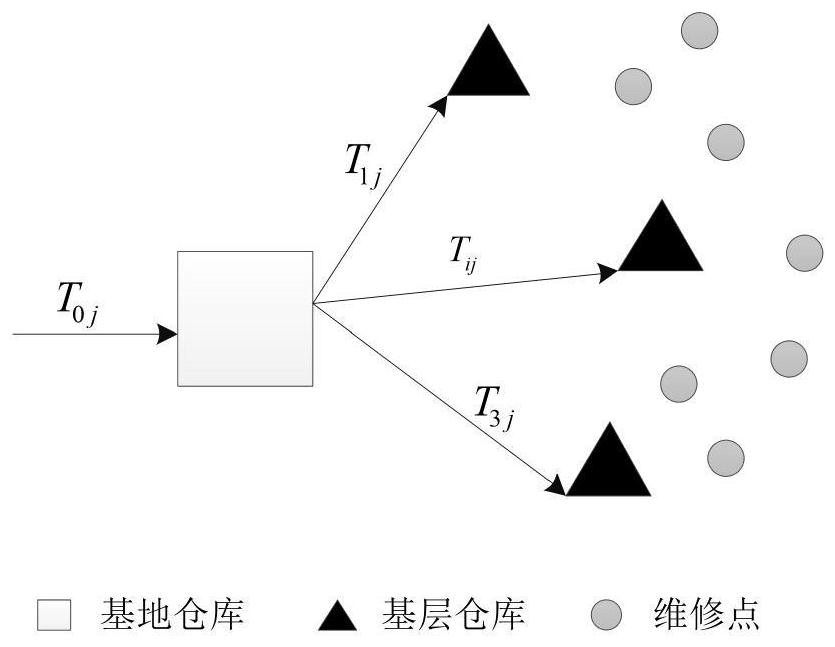

Maintenance equipment site selection and inventory method and system under multistage supply chain and inventory warehouse

ActiveCN112288138ASite selection cost is smallLow costForecastingArtificial lifeLocal optimumApproximation algorithm

The invention belongs to the technical field of maintenance equipment inventory data processing, and discloses a maintenance equipment site selection and inventory method under a multi-stage supply chain and an inventory warehouse, and the method comprises the steps of carrying out the optimization and updating of a constructed warehouse site selection and inventory collaborative optimization system of maintenance equipment under the multi-stage supply chain through employing a hybrid fruit fly optimization algorithm; and determining the opening position of the base warehouse, assigning a maintenance point to the base warehouse, and making an inventory control decision, so that the sum of the base warehouse site selection cost, the ordering cost and the storage cost is minimum. According to the invention, the opening position of the base warehouse can be determined, and the sum of the site selection cost, the ordering cost and the storage cost is minimized through the assignment from the maintenance point to the base warehouse and the inventory control decision. According to the invention, the JRD model structure based on the RAND approximation algorithm is derived and arranged again, so that the HFOA algorithm is designed to be very suitable for solving the model, the algorithm is not prone to falling into local optimum and is stable in convergence, and the invention has higher solving efficiency for the large-scale site selection inventory problem.

Owner:XIDIAN UNIV

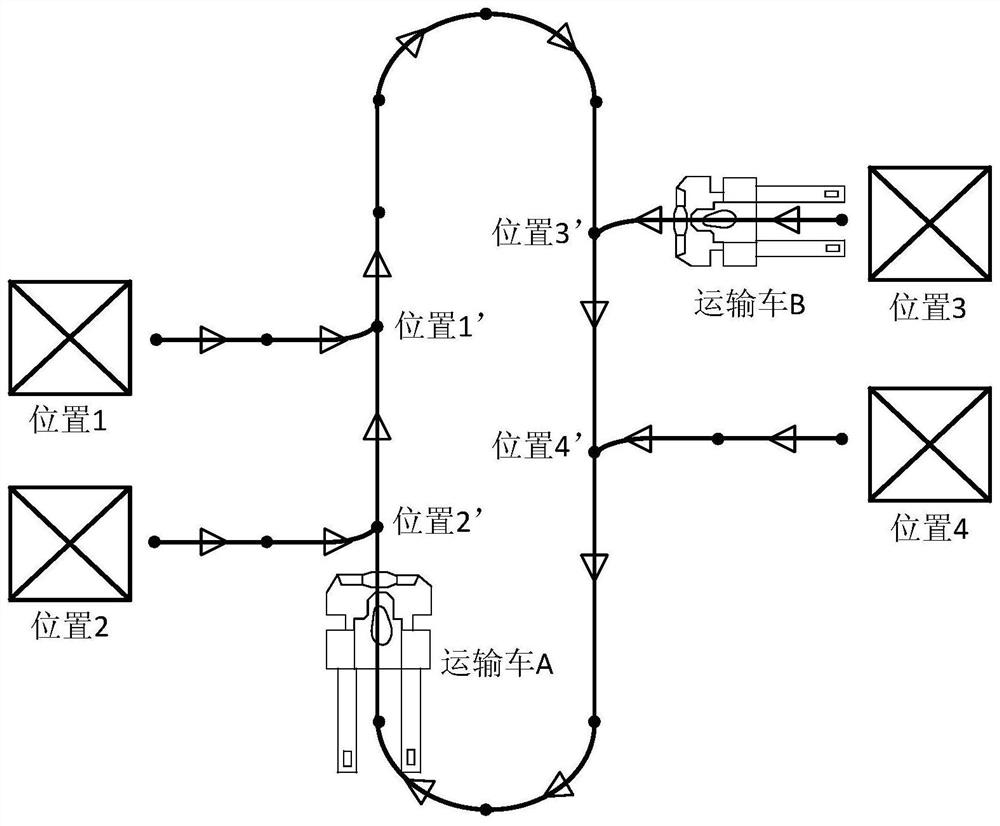

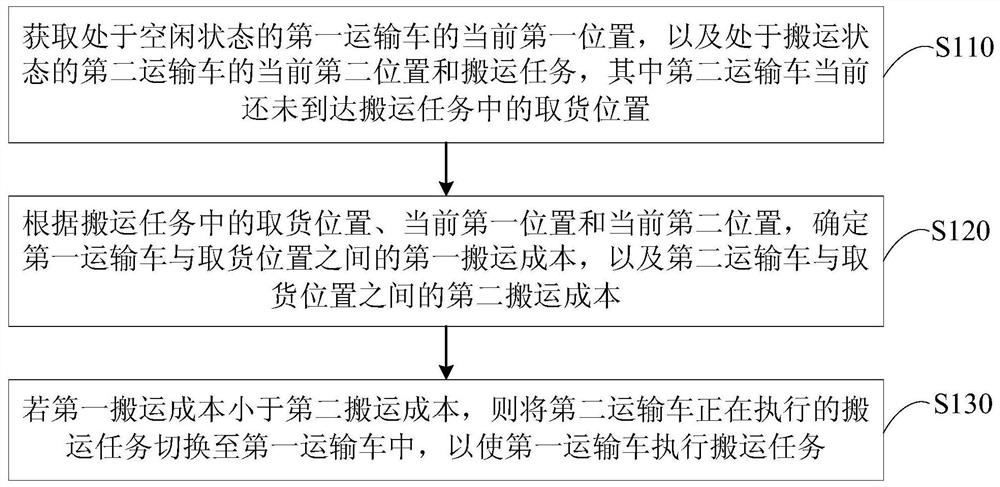

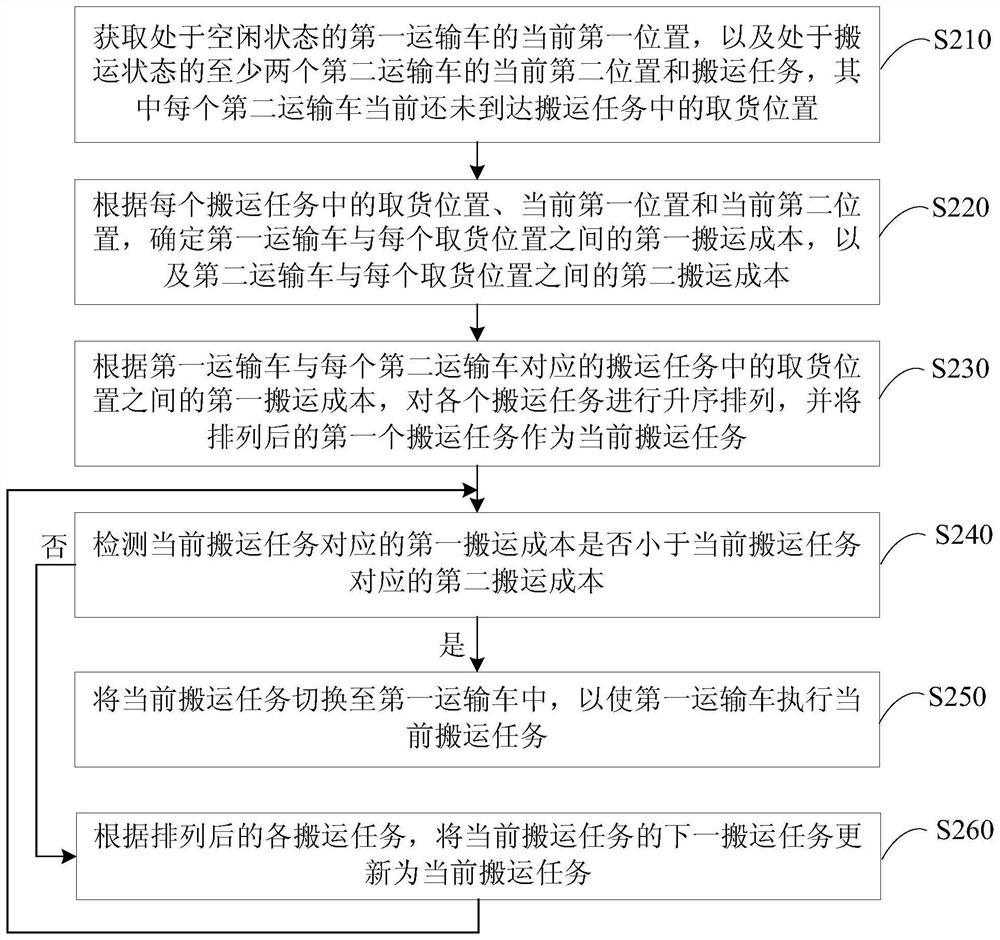

Carrying task switching method, device, equipment and storage medium

ActiveCN111724015ACarrying costs realizedReduce handling costsResourcesCarrying costComputer science

The embodiment of the invention discloses a carrying task switching method, a device, equipment and a storage medium. The method comprises the steps of acquiring the current first position of a firsttransport vehicle in an idle state, the current second position of a second transport vehicle in a carrying state and a carrying task, and the second transport vehicle does not reach a goods taking position in the carrying task at present; determining a first carrying cost between the first transport vehicle and the goods taking position and a second carrying cost between the second transport vehicle and the goods taking position according to the goods taking position, the current first position and the current second position in the carrying task; and if the first carrying cost is smaller than the second carrying cost, switching the carrying task executed by the second transport vehicle into the first transport vehicle so as to enable the first transport vehicle to execute the carrying task. According to the method, the carrying tasks can be reasonably distributed, the carrying cost of the transport vehicle is reduced, and the carrying efficiency is improved.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

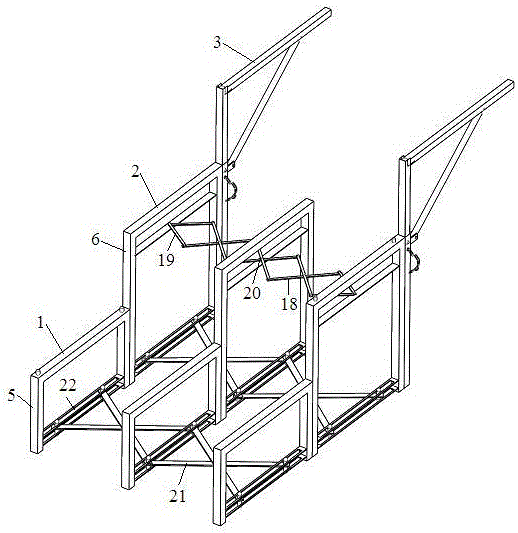

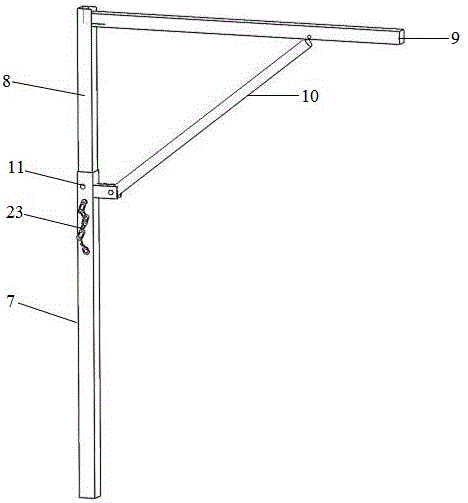

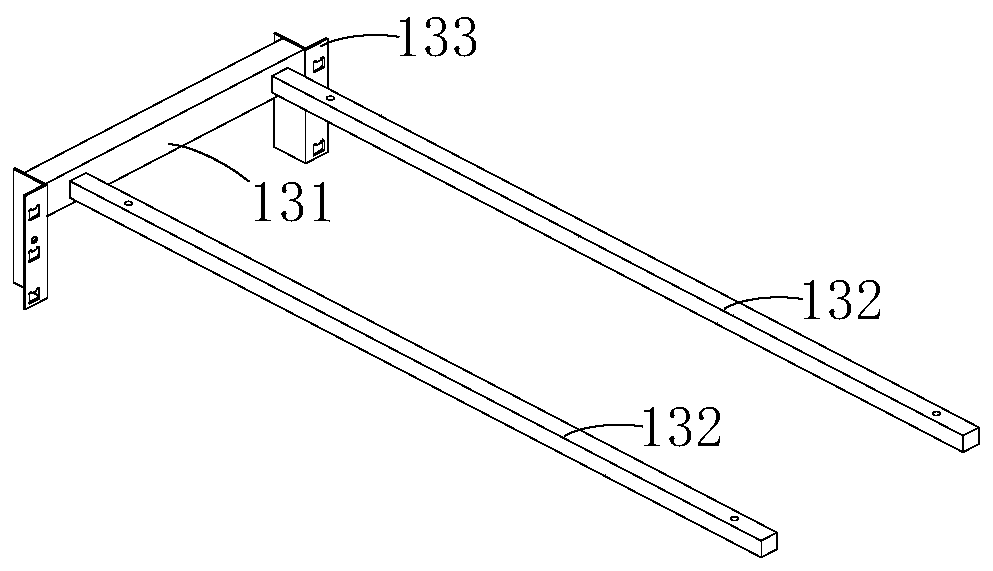

Expansible chorus/group shooting platform

The invention discloses an expansible chorus / group shooting platform, comprising a first supporting unit, a second supporting unit and a third supporting unit in terrace distribution, and folding plates spread on the three supporting units, wherein the first supporting unit and the third supporting unit are fixed respectively at two sides of the second supporting unit, the first supporting unit is composed of a plurality of short support frames and cross links connecting the short support frames, the second supporting unit is composed of a plurality of long support frames and cross links connecting the long support frames, and the third supporting unit is composed of supporting rods, expansible rods, bent rods and bracing rods. The expansible chorus / group shooting platform may expand in a horizontal direction, can save storage space and can also save carrying cost.

Owner:HENAN NORMAL UNIV

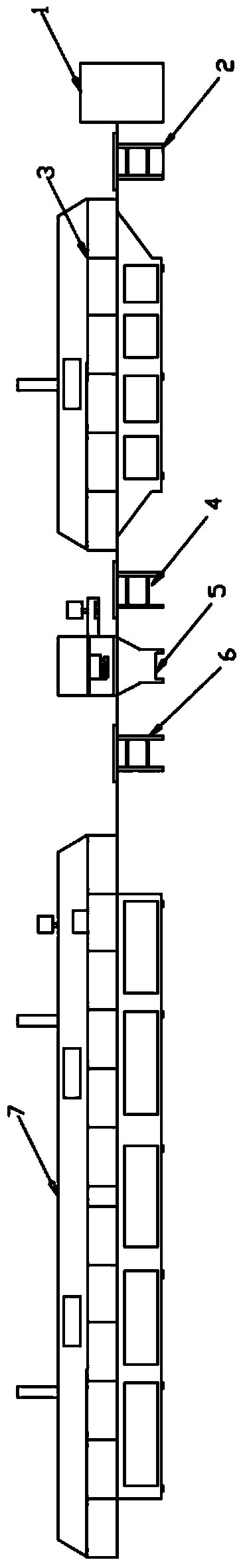

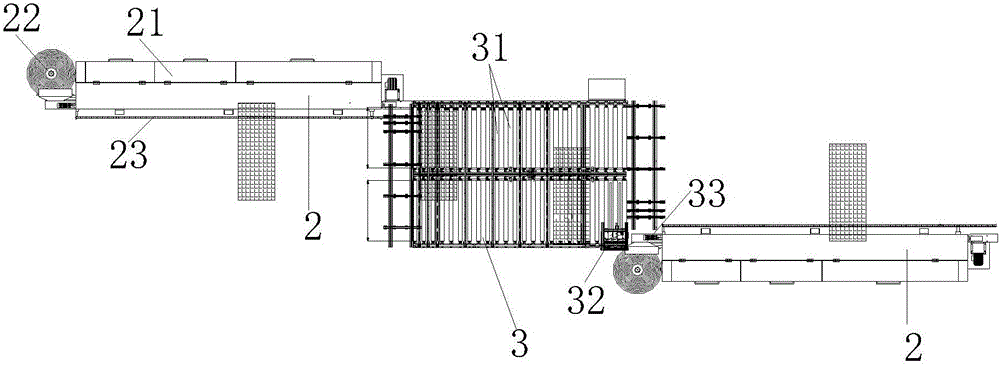

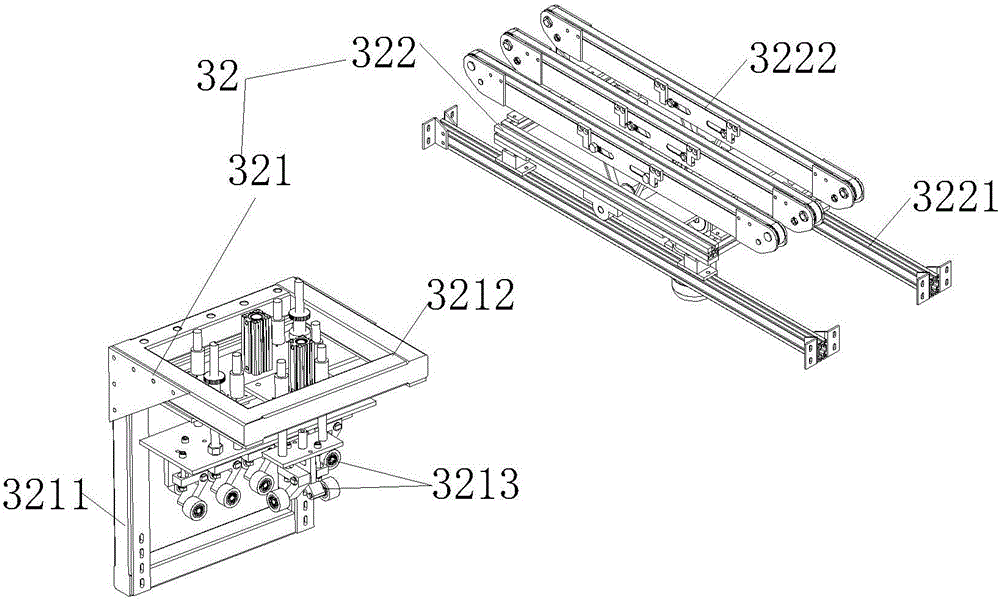

Intelligent panel type custom furniture conveying production line

InactiveCN106144469ARealize automatic connectionRelaxed and comfortable working environmentMulti-purpose machinesDomestic articlesProduction lineCarrying cost

The invention relates to the technical field of furniture production, and discloses an intelligent panel-type customized furniture conveying production line, including an automatic material preparation conveying system, an edge banding system and a double-row power translation system. The power translation system is connected; the edge banding system is arranged on both sides of the double-row power translation system, and the edge banding system can move along the side of the double-row power translation system; the present invention has the advantages of direct reduction in manual handling costs , The stacking of workpieces on the roller line is conducive to management and convenient transportation, and the advantages of realizing automatic connection of processing equipment and improving production efficiency.

Owner:广东友力智能科技有限公司

Two-component ceramic tile adhesive

The invention discloses a two-component ceramic tile adhesive composed of a powder adhesive and a back adhesive; the powder adhesive is composed of the raw materials in parts by mass: 200-400 kg of cellulose ether, 30-70 kg of starch ether, 50-150 kg of calcium formate, 60-130 kg of a water reducing agent and 30-70 kg of a water repellent; the back adhesive is composed of the raw materials in parts by mass: 250-450 kg of an acrylic emulsion, 30-70 kg of water, 0.8-1.6 kg of a defoaming agent, 0.3-0.7 kg of a preservative, and a thickening agent, wherein the part amount of the thickening agent is used for adjusting the viscosity of the back adhesive to 5000-50000 MPa*s. The powder adhesive does not contain cement and quartz sand, and saves a lot of transportation and carrying costs; the back adhesive is mainly used for cooperating with heavy tiles, marble, vitrified tiles and other tiles with relatively low water absorption rate for back surface treatment, makes the tiles more fitted with the powder adhesive, and avoids generation of hollowing and other phenomena.

Owner:蒋其同

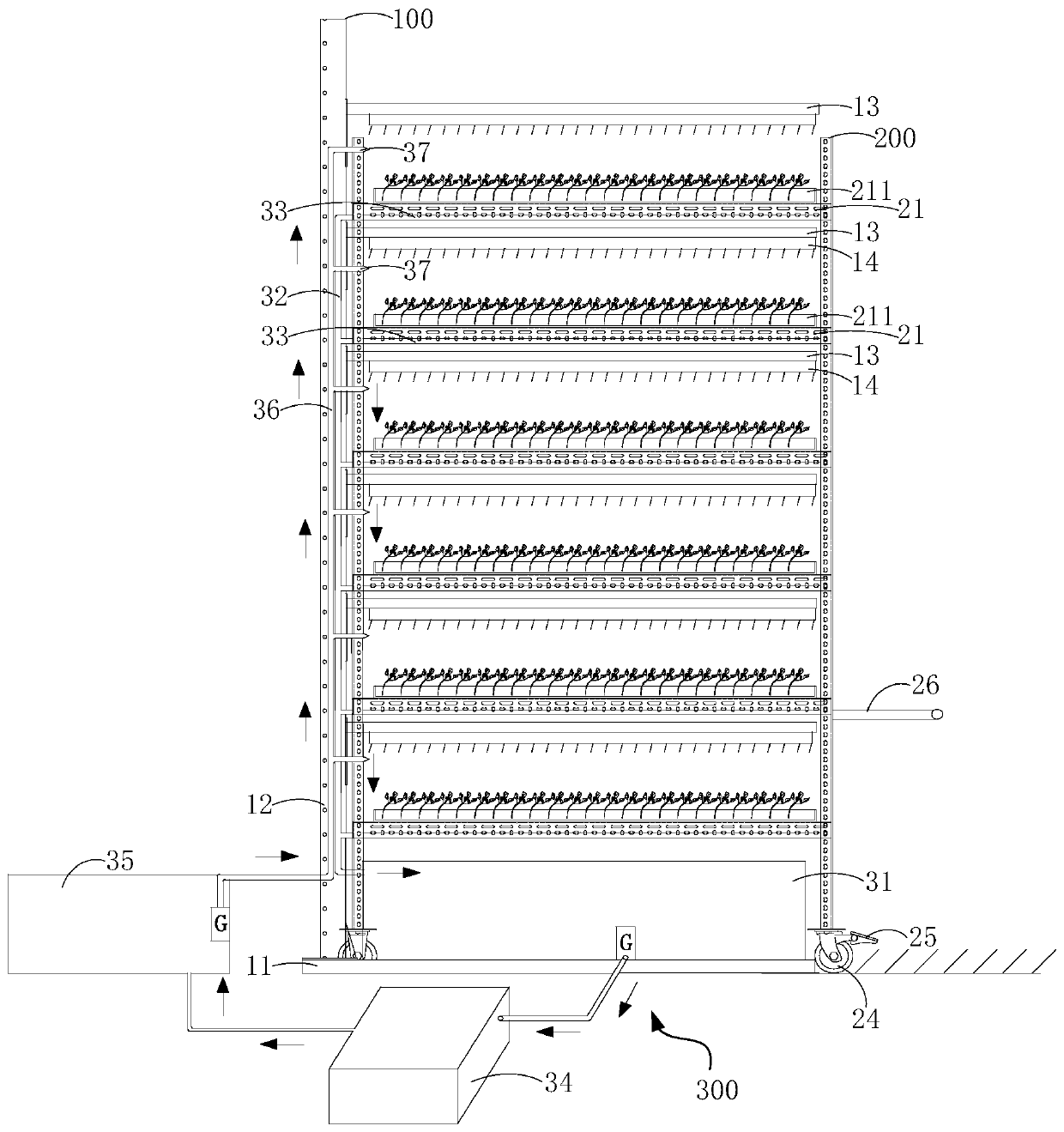

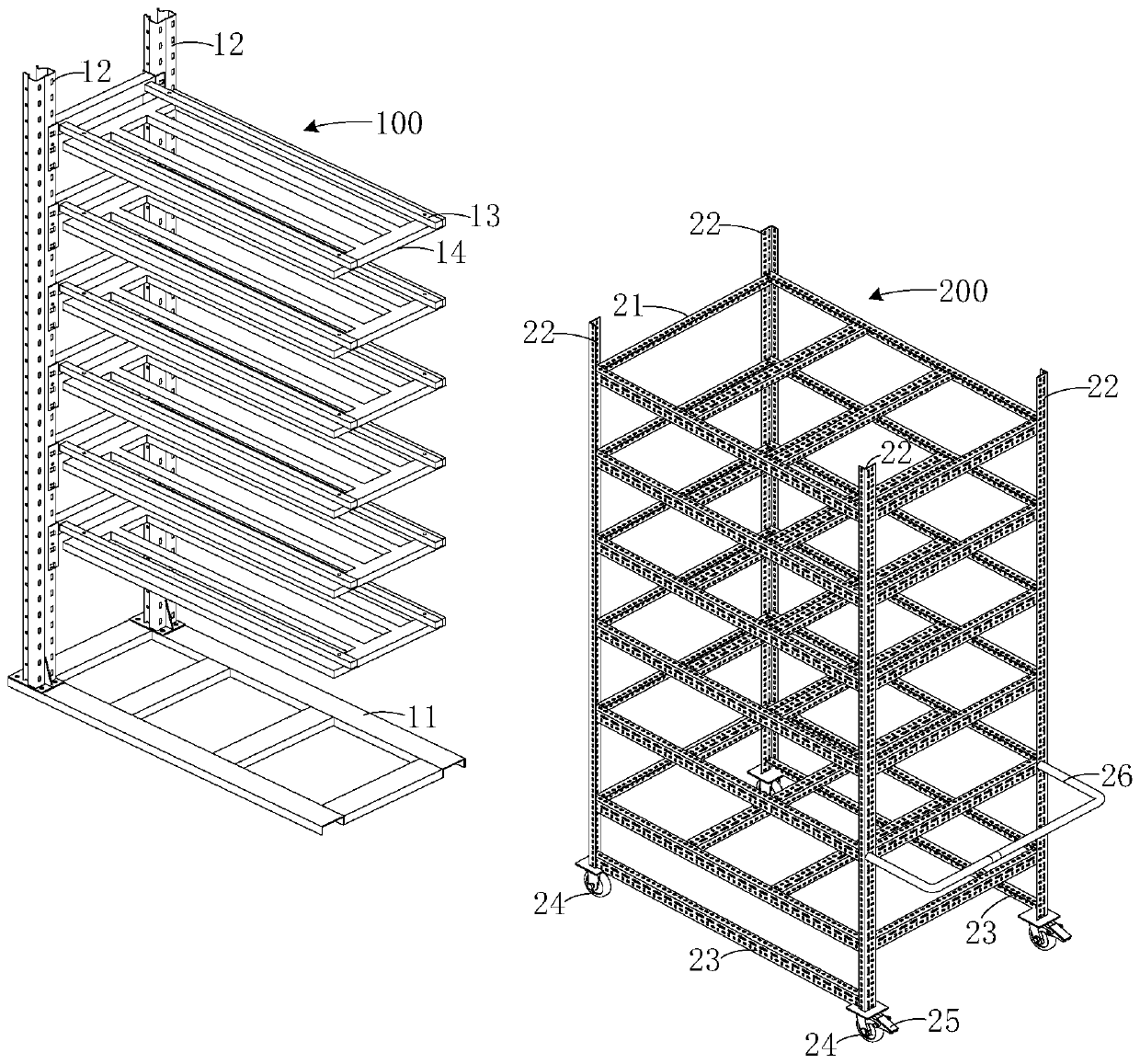

Split-type multilayer seedling raising device capable of recycling nutrient liquid

InactiveCN110432043AImprove rotation efficiencyEfficient recyclingClimate change adaptationPressurised distribution of liquid fertiliserNutrient solutionCarrying cost

The invention discloses a split-type multilayer seedling raising device capable of recycling nutrient liquid. The split-type multilayer seedling raising device comprises an environment frame, a seedling raising rack and a nutrient liquid recycling system. The environment frame is provided with a plurality of layers of horizontal beams, and the seedling raising rack is provided with a plurality oflayers of horizontal racks. The horizontal racks are used for carrying seedling trays, and are in staggered arrangement with the horizontal beams. The nutrient liquid recycling system arranged on theenvironment frame comprises a recycling water tank, a return pipeline and a plurality of collection pipelines. The collection pipelines are communicated with the return pipeline, and the return pipeline is communicated with the recycling water tank. The collection pipelines are arranged on the horizontal beams respectively to collect the nutrient liquid flowing from drain holes. The split-type multilayer seedling raising device has the advantages that the manual carrying cost can be reduced, the spatial rotation efficiency is improved, the nutrient liquid can be effectively recycled, and resources can be saved.

Owner:张允楠

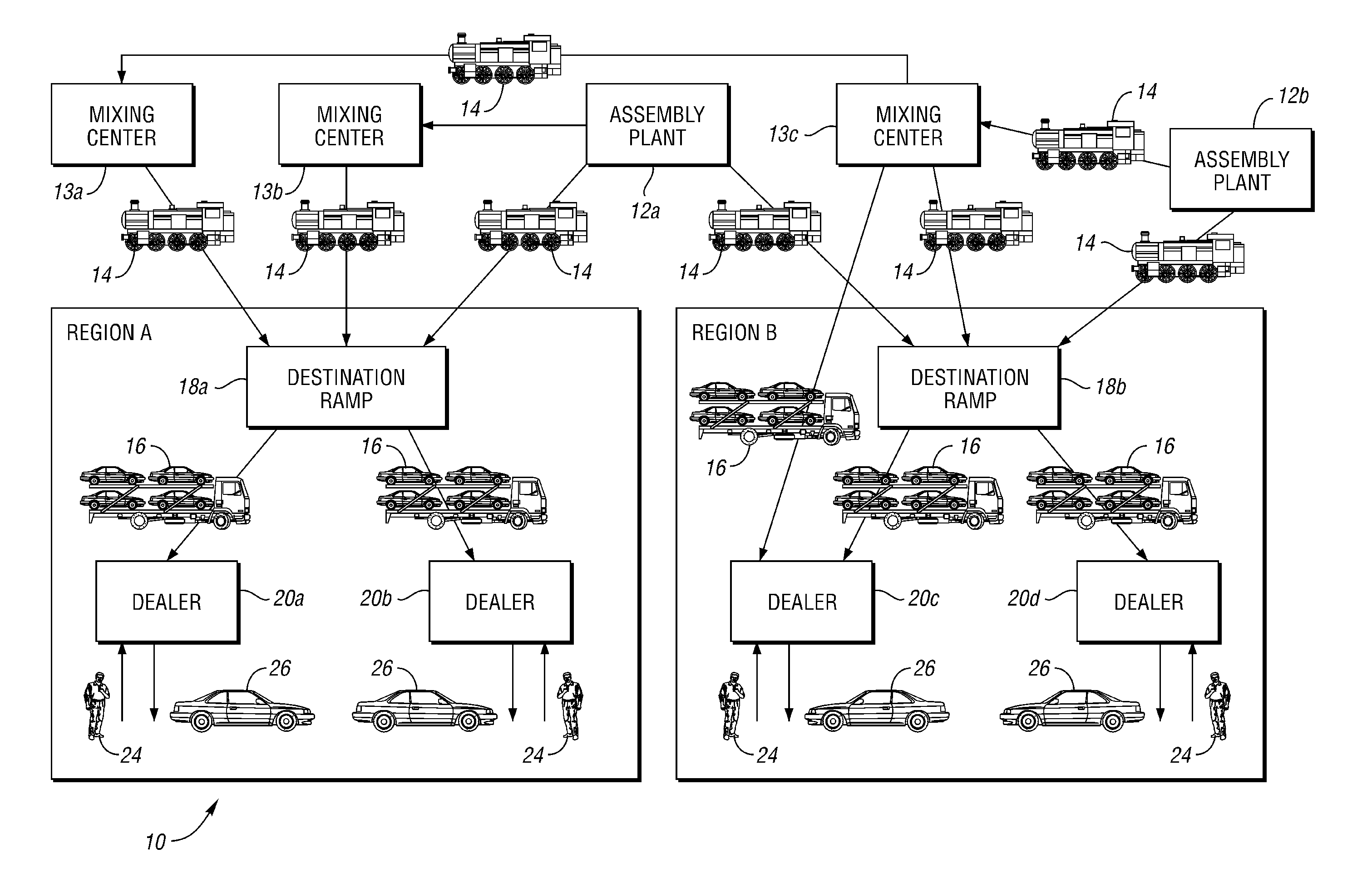

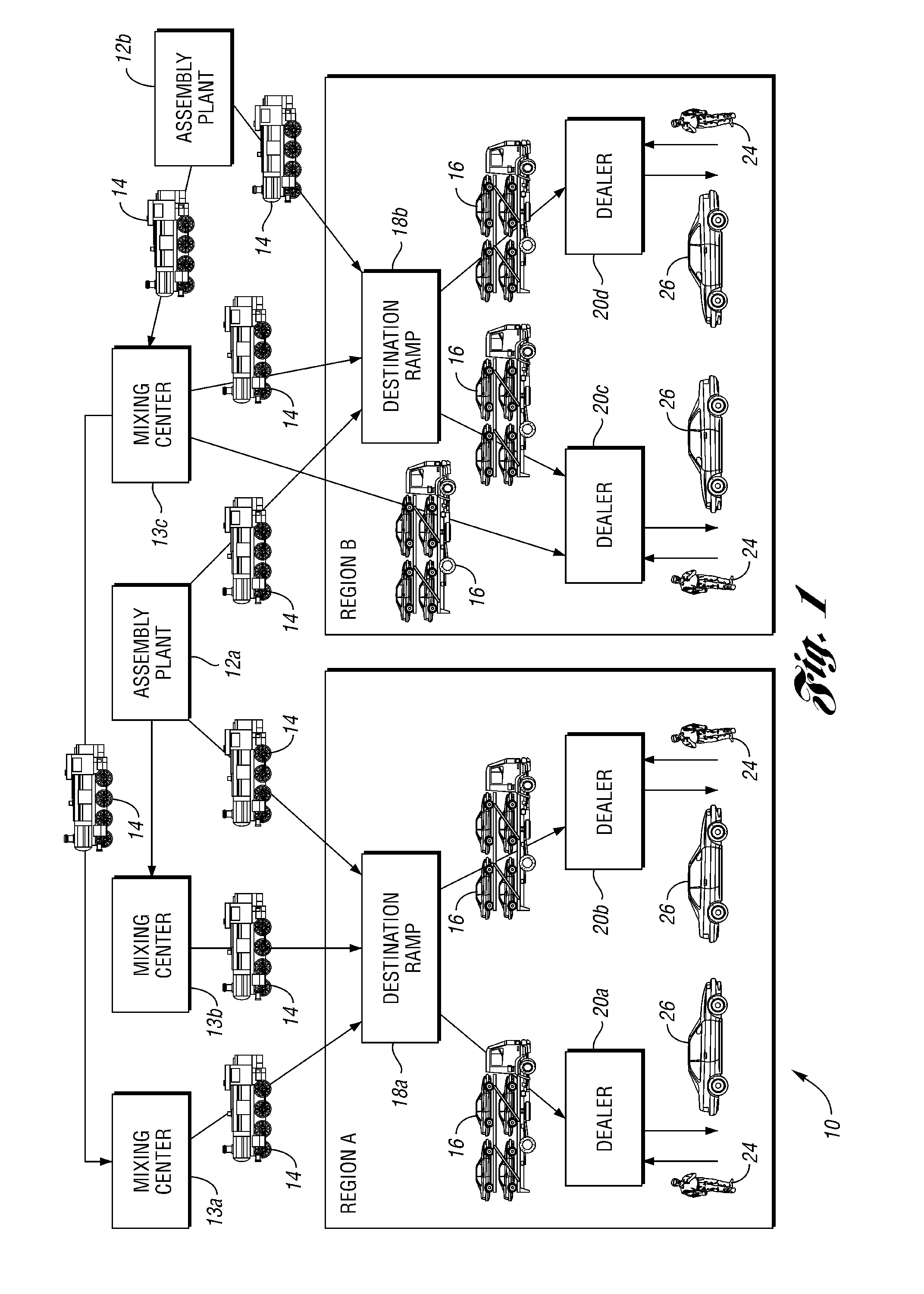

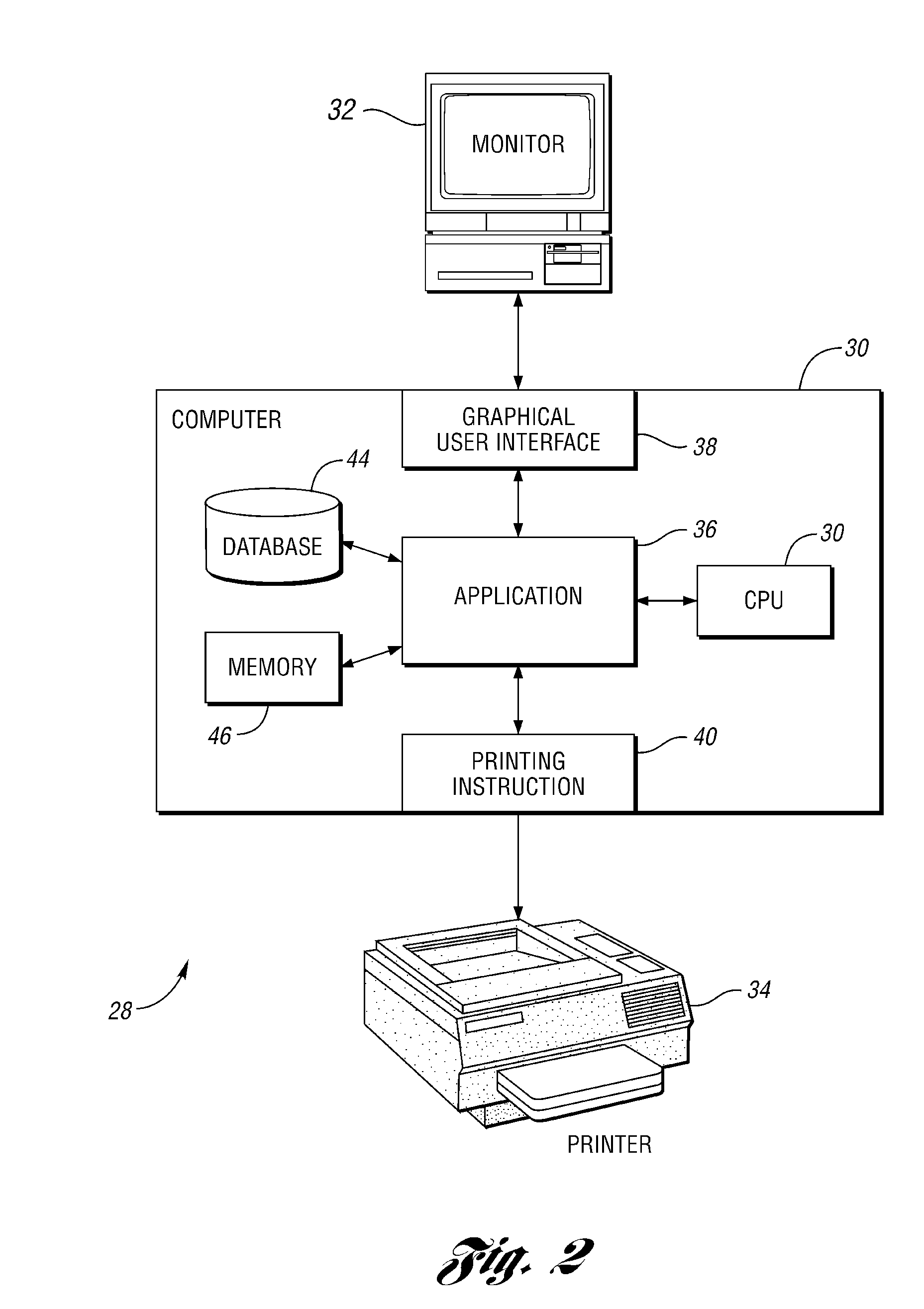

Electronic method and system for monitoring distribution facilities

InactiveUS20070208580A1Effectively financial impactEffective meanResourcesLogisticsCarrying costComputer science

An electronic method for monitoring one or more distribution facilities in a manufacturing enterprise which manufactures a number of products for purchase through a number of dealers. The method includes the steps of receiving distribution facility profile information for one or more distribution facilities and daily activity information for the one or more distribution facilities; and calculating a carrying cost for each of the one or more distribution facilities based on the profile and daily activity information. The one or more distribution facilities can be one or more mixing centers.

Owner:FORD MOTOR CO

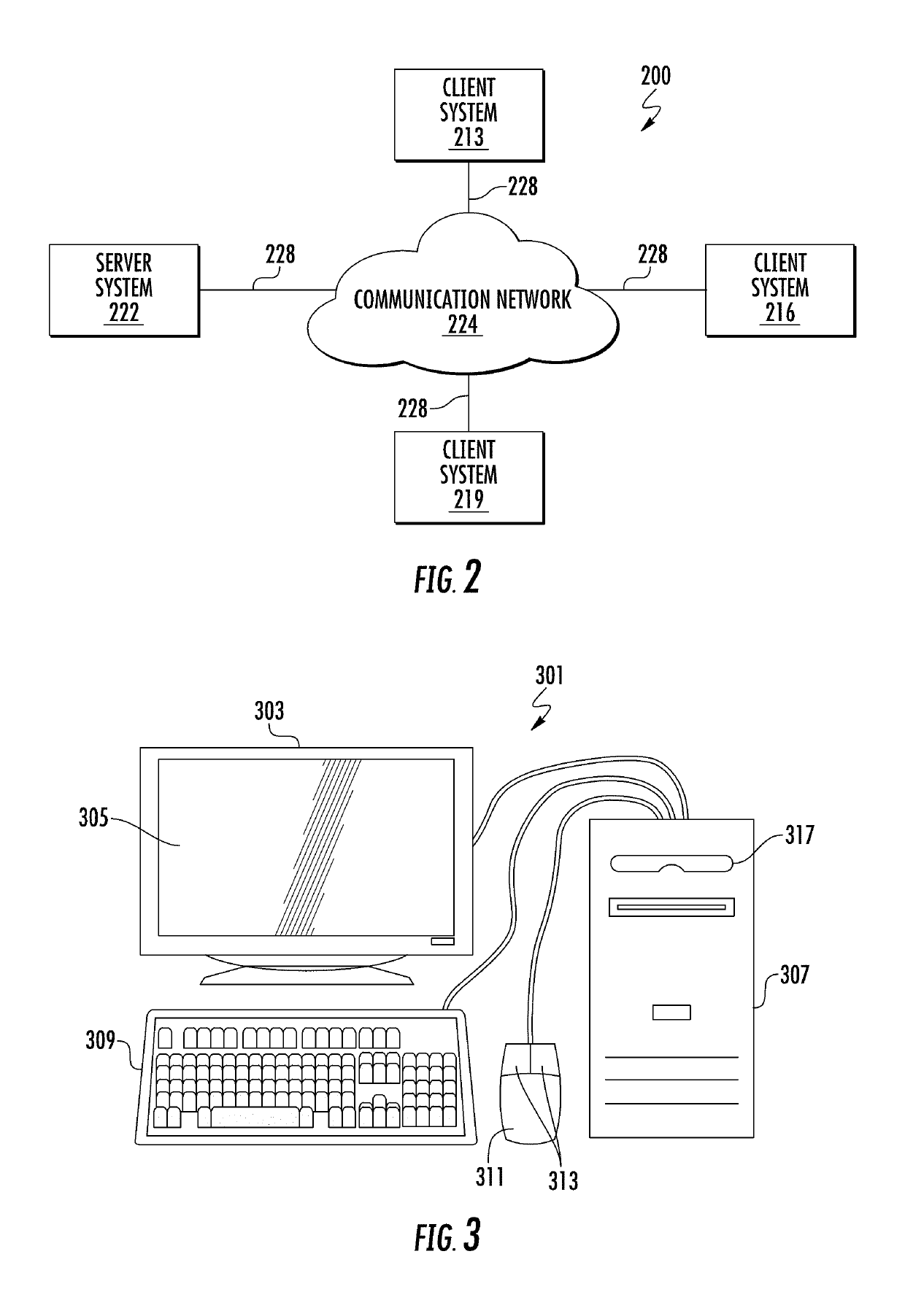

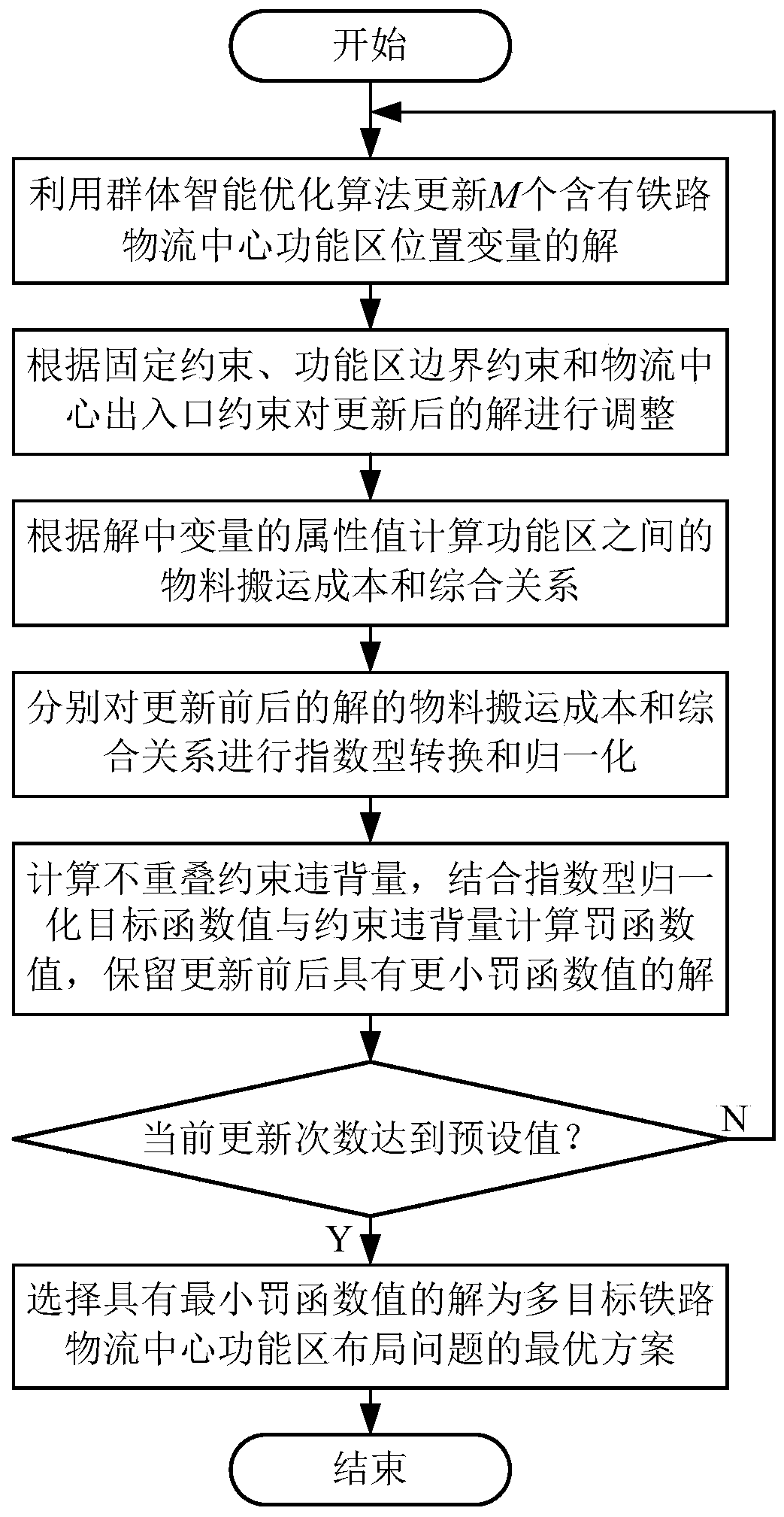

On-Demand Manufacturing of Laser-Finished Apparel

ActiveUS20190264380A1Reduce finishing costsLower carrying costPattern makingLaser beam fibre treatmentLost salesProduction rate

An on-demand manufacturing of apparel system includes online customization and ordering of garments, previewing of the garments, manufacturing including laser finishing of garments, and delivery to the customer. Laser finishing of apparel products reduces finishing cost, lowers carrying costs, increases productivity, shortens time to market, be more reactive to trends, reduces product constraints, reduces lost sales and dilution, and more. Fabric templates can be used to produce a multitude of laser finishes. Operational efficiency is improved.

Owner:LEVI STRAUSS & CO

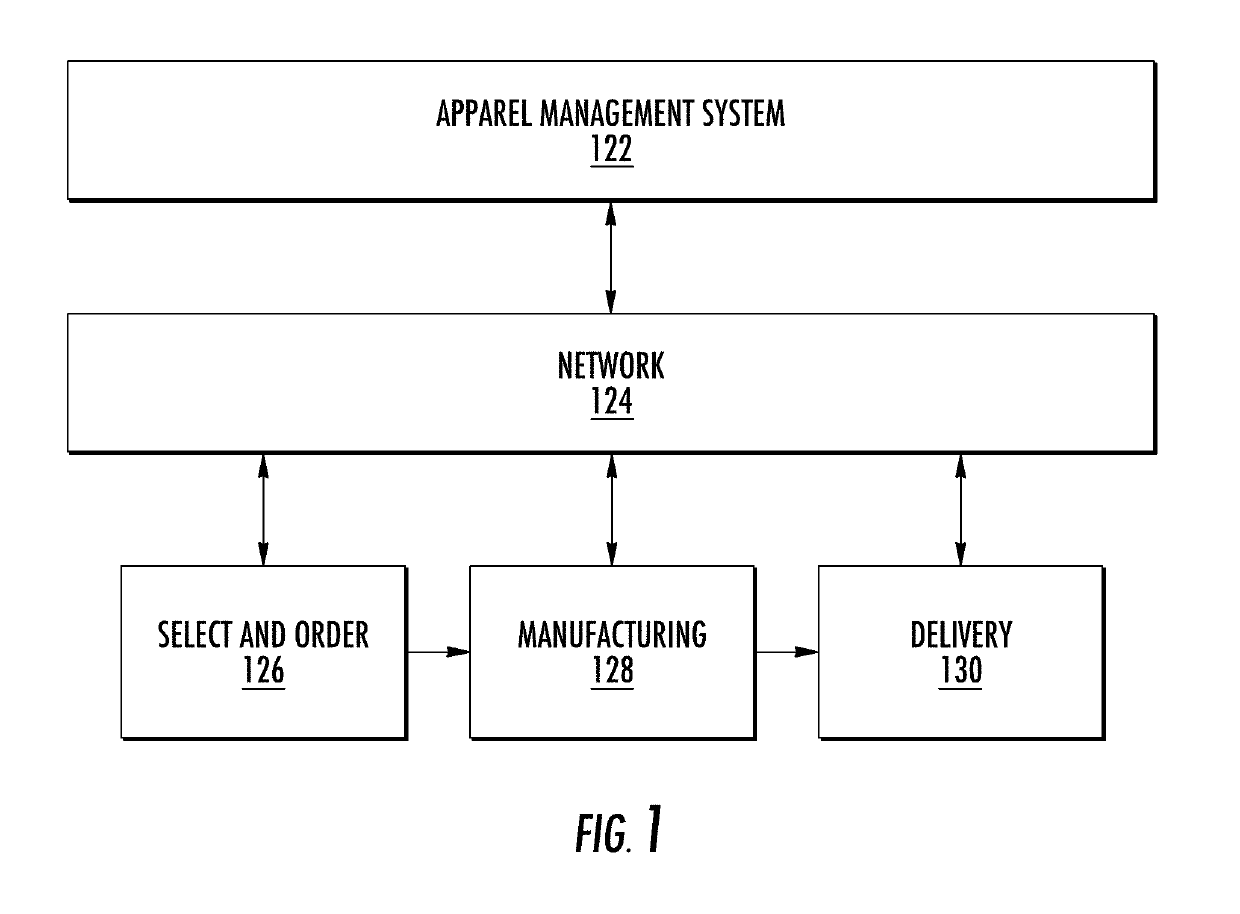

Multi-target railway logistics center function area layout method based on exponential normalization

InactiveCN109919388AGuaranteed feasibilityMeet the constraintsGenetic modelsForecastingLogistics managementCarrying cost

A multi-target railway logistics center function area layout method based on exponential normalization comprises the steps that A, generatingM solutions and corresponding each solution to a multi-target railway logistics center function area layout scheme; B, adjusting the solution according to the fixed constraint, the functional region boundary constraint and the logistics center entrance and exit constraint; C, performing exponential conversion and normalization on the material carrying cost and the comprehensive relation of the solution before and after updating, constructing a penalty function by combining the normalized objective function and the minimum distance constraint violation quantity, and reserving the solution with a lower penalty function value before and after updating; and D, if the current updating frequency reaches a preset value, selecting a solution with a minimum penalty function value as an optimal scheme, and if not, repeating the steps A to C. Through the exponential normalization method, the problem that in the multi-objective optimization process, the material carrying cost and the comprehensive mutual relation between functional areas of the railway logistics center are difficult to balance is successfully solved, and the operation efficiency of the railway logistics center is improved.

Owner:XUZHOU NORMAL UNIVERSITY

Method for creating new peanut specie in space breeding

InactiveCN102246693AHigh rate of beneficial mutations for mutagenesisIncrease mutation rateHorticulture methodsPlant tissue cultureRootstockGermplasm

The invention belongs to the technical field of the peanut genetic breeding method and relates to a method for creating a new peanut specie in space breeding. The method is characterized by comprising the following steps: the growing point of the mature peanut seed embryo is used as the carrying material to be carried in a returnable spacecraft for space mutation; and after the mutation, the mutated embryo growing point is used to perform tissue culture and obtain a tissue culture regeneration seedling, the tissue culture regeneration seedling is used as the scion, an unmutated seedling of the same variety is used as the rootstock to perform grafting treatment and form a grafted seedling, the grafted seedling is transplanted in a field and a new and beneficial mutated specie is obtained after harvesting. The method has the following beneficial effects: the mutagenic beneficial mutation rate is high, the carrying cost is low, the selection difficulty is small, and the method is simple and is easy to master.

Owner:SHANDONG PEANUT RES INST

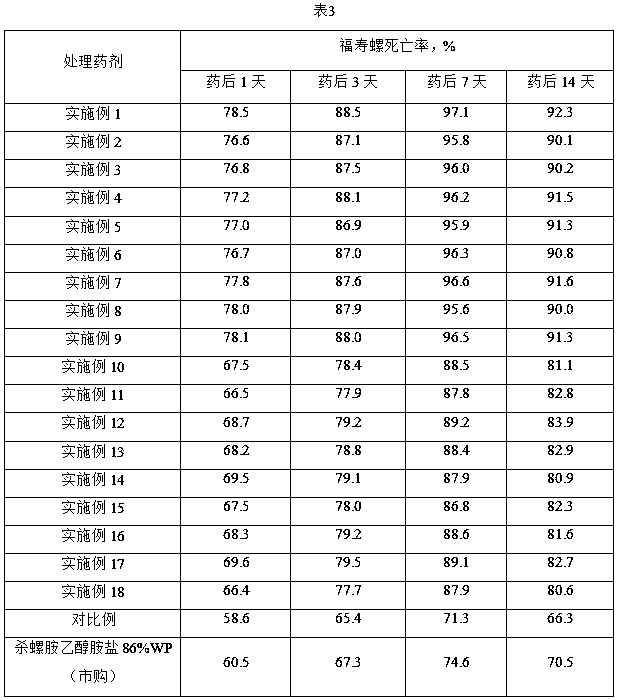

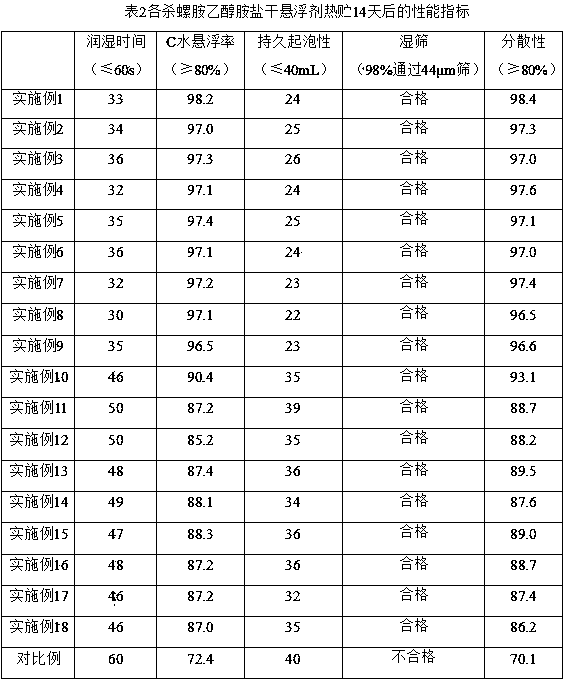

Niclosamide ethanolamine dry flowable and preparation method thereof

The invention discloses a niclosamide ethanolamine dry flowable and a preparation method thereof. The dry flowable comprises an effective component and additives, wherein the effective component is niclosamide ethanolamine; the additives include a dispersing agent, a wetting agent, a disintegrating agent, a defoaming agent and a filler. According to the dry flowable, the effective component content is high and up to 90%; the dry flowable is small in particle size, outstanding in performance, high in storing stability and low in storing and carrying cost, has high activity to mollusc pests suchas ampullaria gigas, oncomelania and snail, and is fast to disinfect insects, long-lasting in effect, and convenient to use.

Owner:QINGDAO RAINBOW CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com