Maintenance equipment site selection and inventory method and system under multistage supply chain and inventory warehouse

A maintenance equipment and supply chain technology, applied in the field of maintenance equipment inventory data processing, can solve problems such as less consideration of warehouse location and inventory control collaborative optimization, high total operating costs, and less research, so as to solve warehouse location and inventory control Collaborative optimization problems, improving optimization efficiency, and ensuring the effect of service levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0079] 1. Site selection-inventory integration model

[0080] 1.1 Problem description

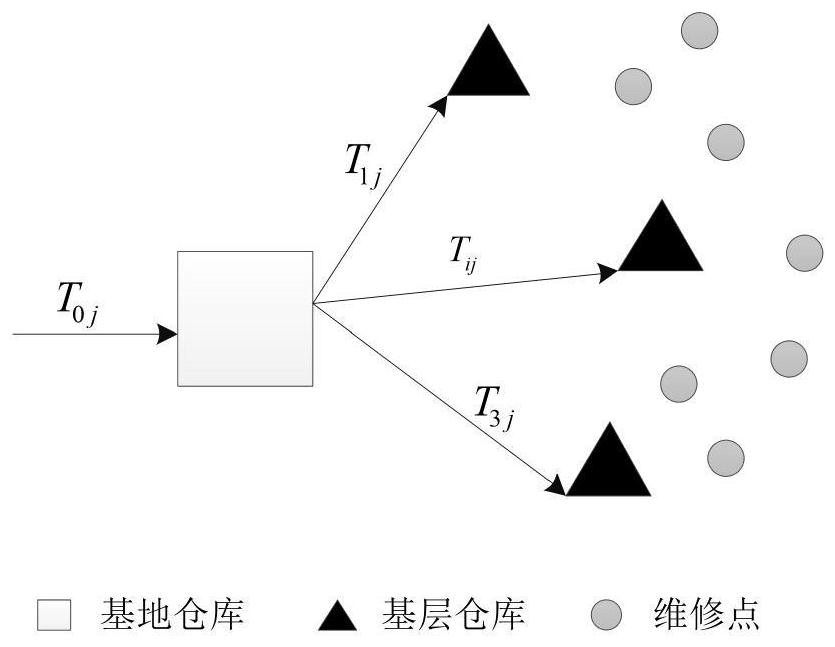

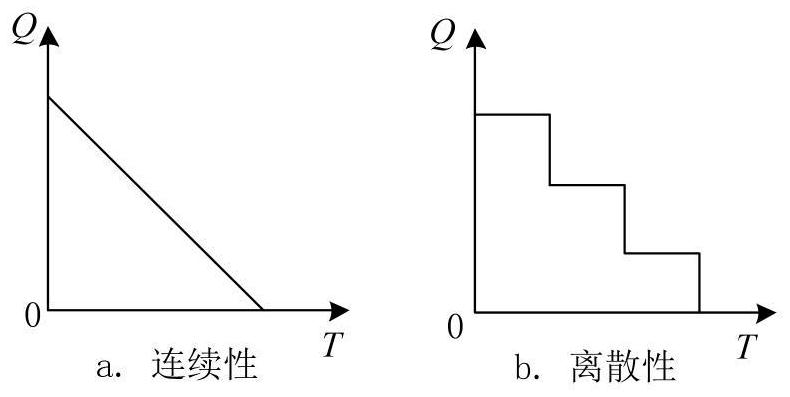

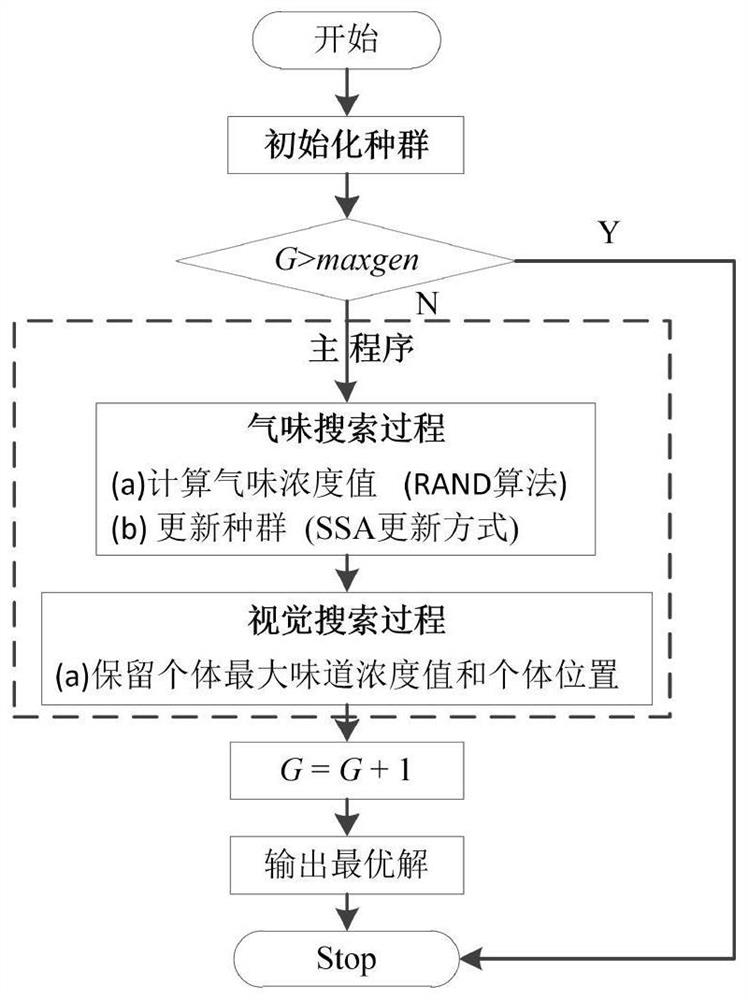

[0081] The present invention provides an inventory system consisting of a base warehouse, multiple grassroots warehouses with undetermined locations, N maintenance points and M types of maintenance equipment, such as figure 1 shown. Knowing the demand for equipment generated by each maintenance point, the base warehouse regularly replenishes itself according to the consumption of equipment and distributes equipment to the established grass-roots warehouse. The goal is to formulate a suitable warehouse location and inventory control plan under the premise of ensuring a certain service level of each warehouse, so that the total cost of the system is minimized. The plan needs to include the following points: (1) Determine the opening location of the grass-roots warehouse; (2) Determine the distribution of maintenance points to the grass-roots warehouse; (3) Determine the order cycle, order b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com