Patents

Literature

442 results about "Inventory system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An inventory control system is a process for managing and locating objects or materials. In common usage, the term may also refer to just the software components. Modern inventory control systems often rely upon barcodes and radio-frequency identification tags to provide automatic identification of inventory objects. Inventory objects could include any kind of physical asset: merchandise, consumables, fixed assets, circulating tools, library books, or capital equipment. To record an inventory transaction, the system uses a barcode scanner or RFID reader to automatically identify the inventory object, and then collects additional information from the operators via fixed terminals, or mobile computers. The new trend in inventory management is to label inventory and assets with QR Code, and use smartphones to keep track of inventory count and movement. These new systems are especially useful for field service operations, where an employee needs to record inventory transaction or look up inventory stock in the field, away from the computers and hand-held scanners.

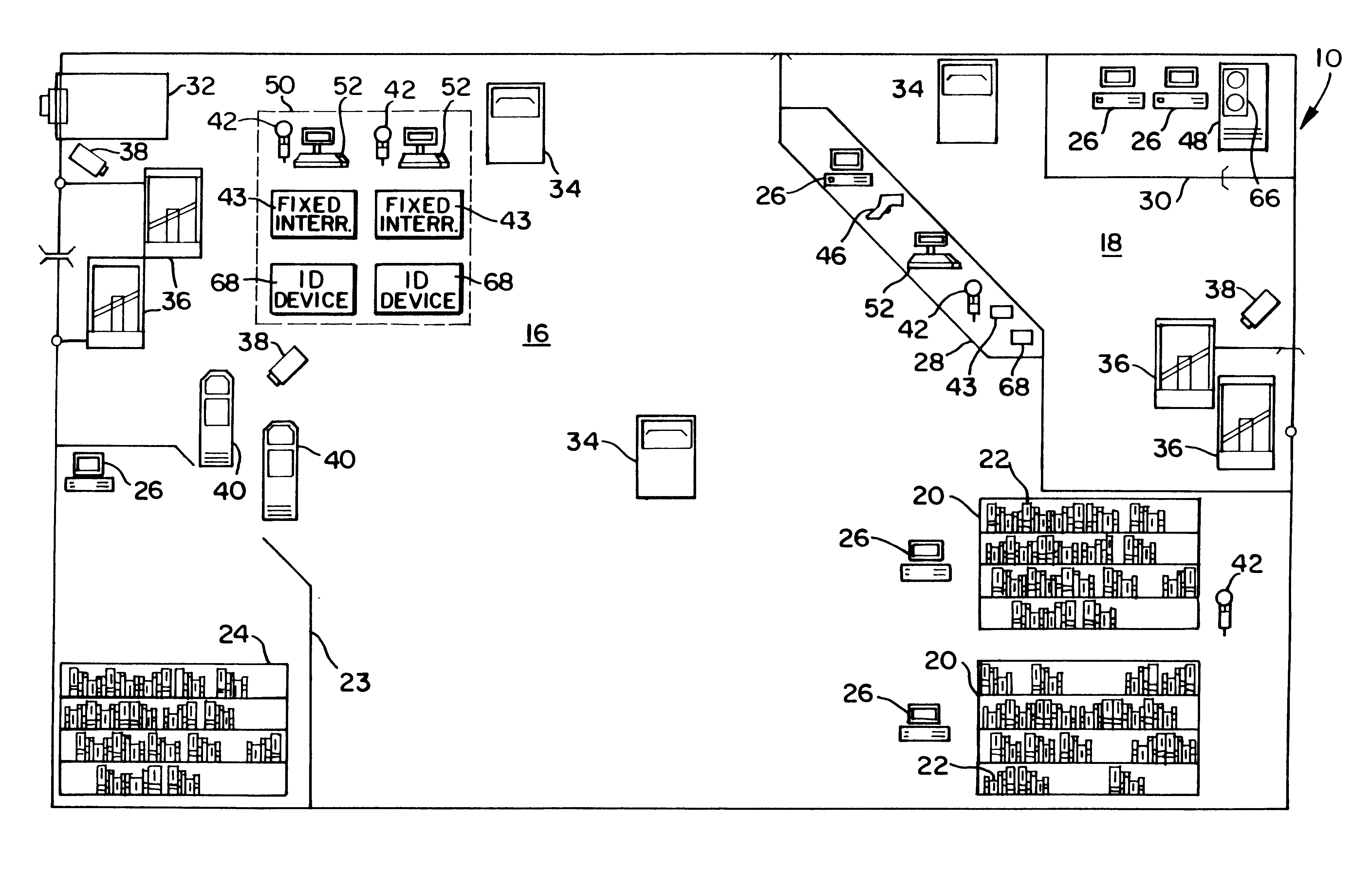

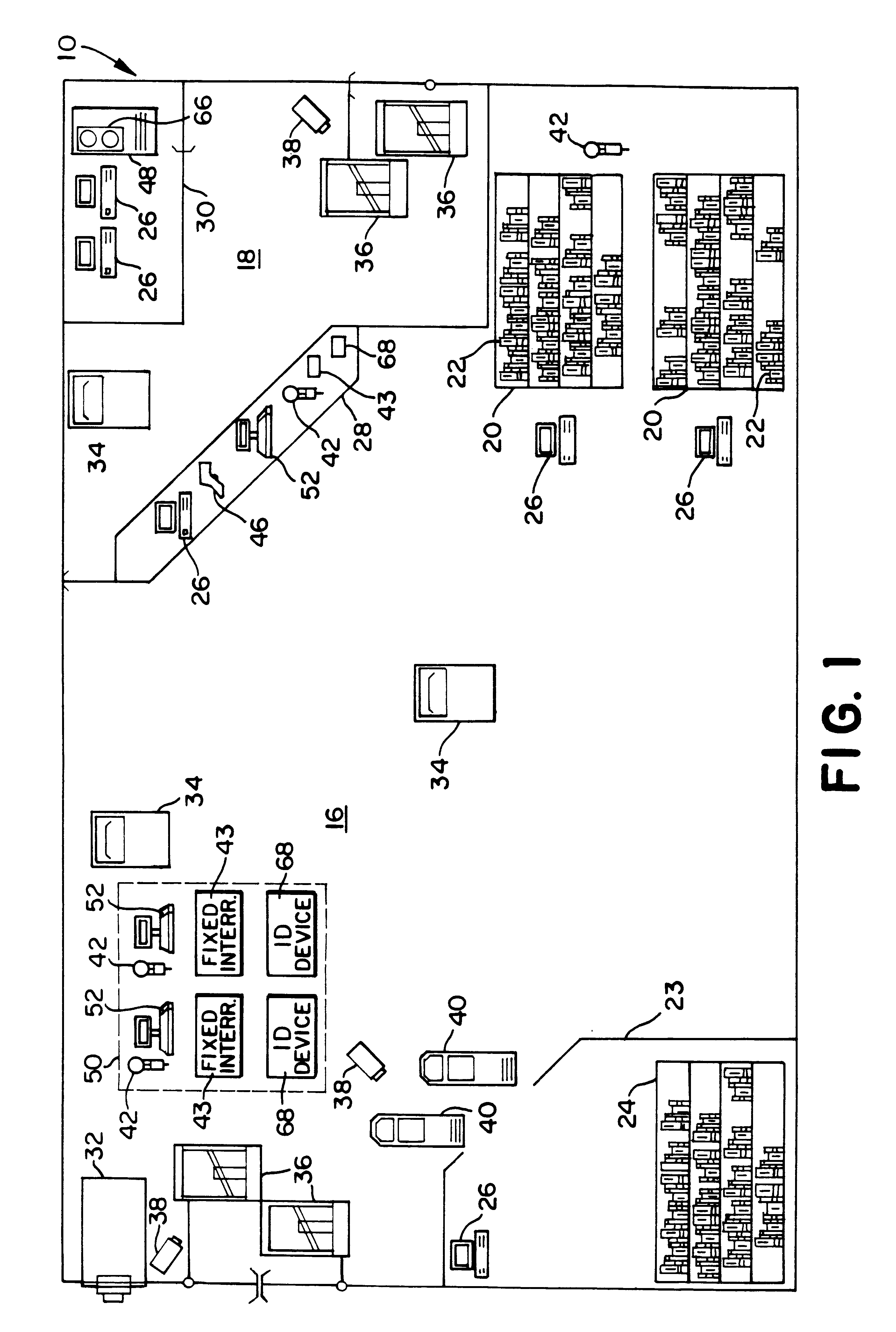

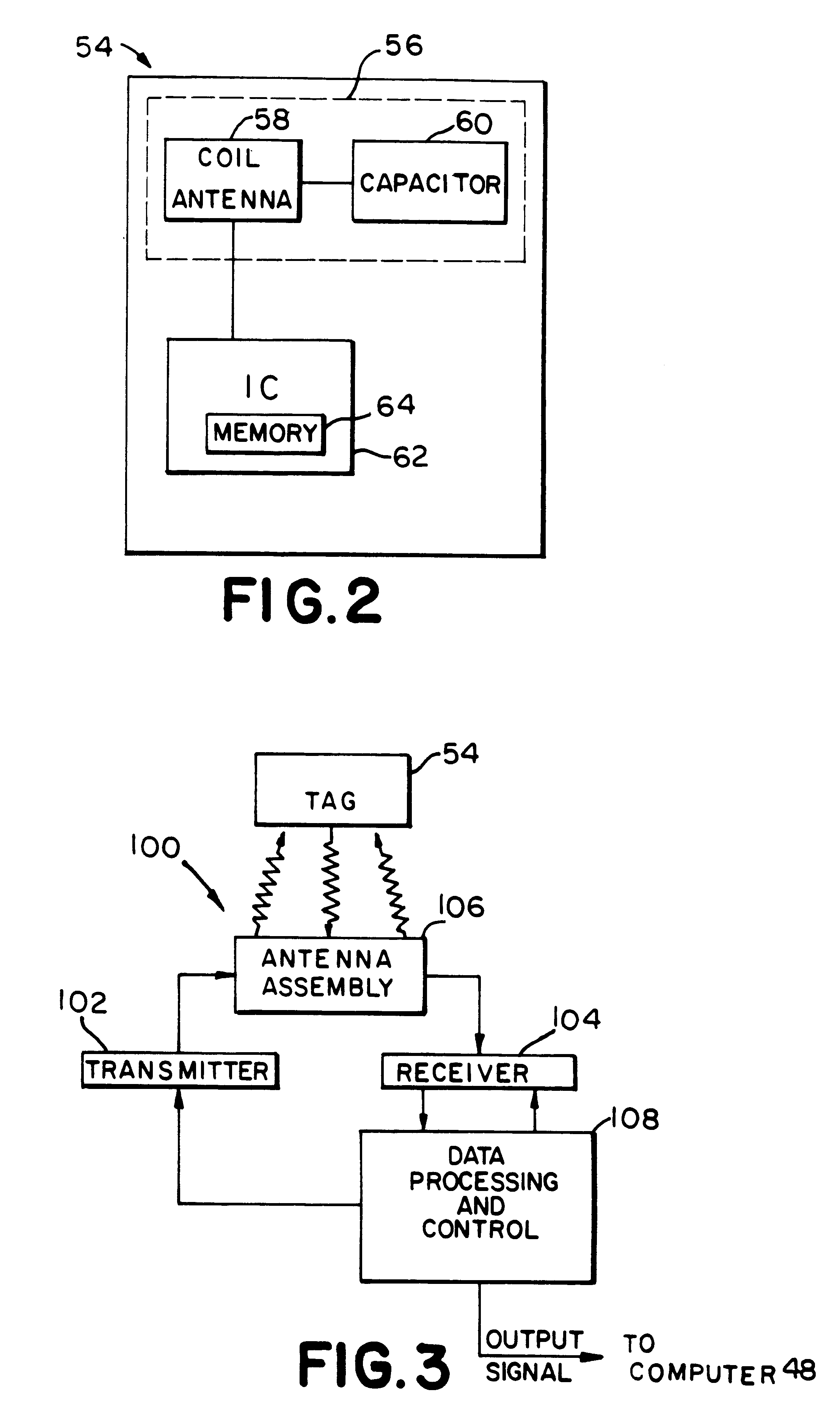

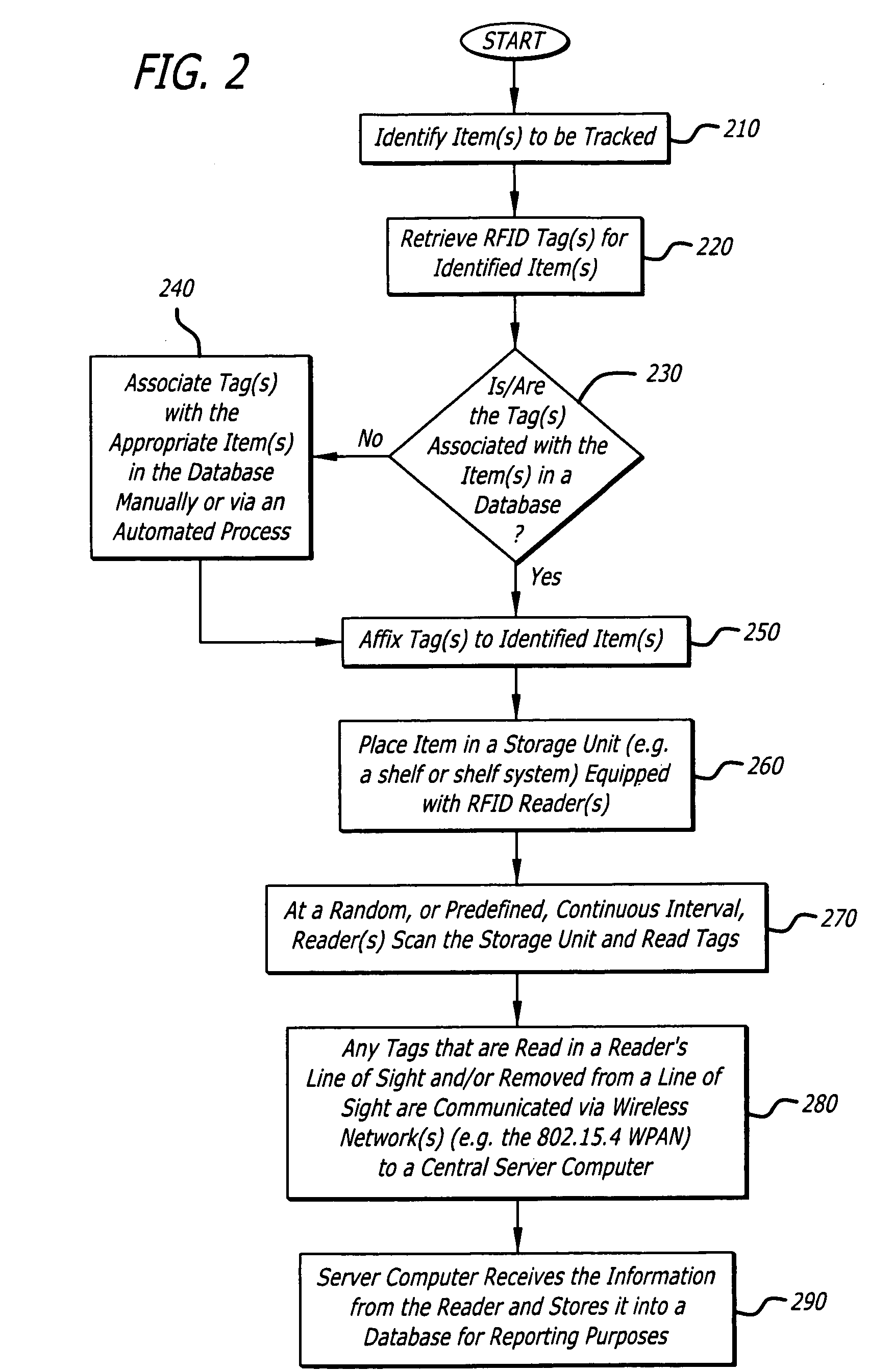

Inventory system using articles with RFID tags

InactiveUS6195006B1Electric signal transmission systemsDigital data processing detailsControl systemMobile RFID

An article inventory control system for articles, such as books, uses RFID tags attached to each article. Each tag has a unique identification or serial number for identifying the individual article. An inventory database tracks all of the tagged articles and maintains circulation status information for each article. Articles are checked out of the library using a patron self-checkout system. Checked out articles are returned to the library via patron self-check in devices. The shelves are periodically scanned with a mobile RFID scanner for updating inventory status.

Owner:CHECKPOINT SYST INC

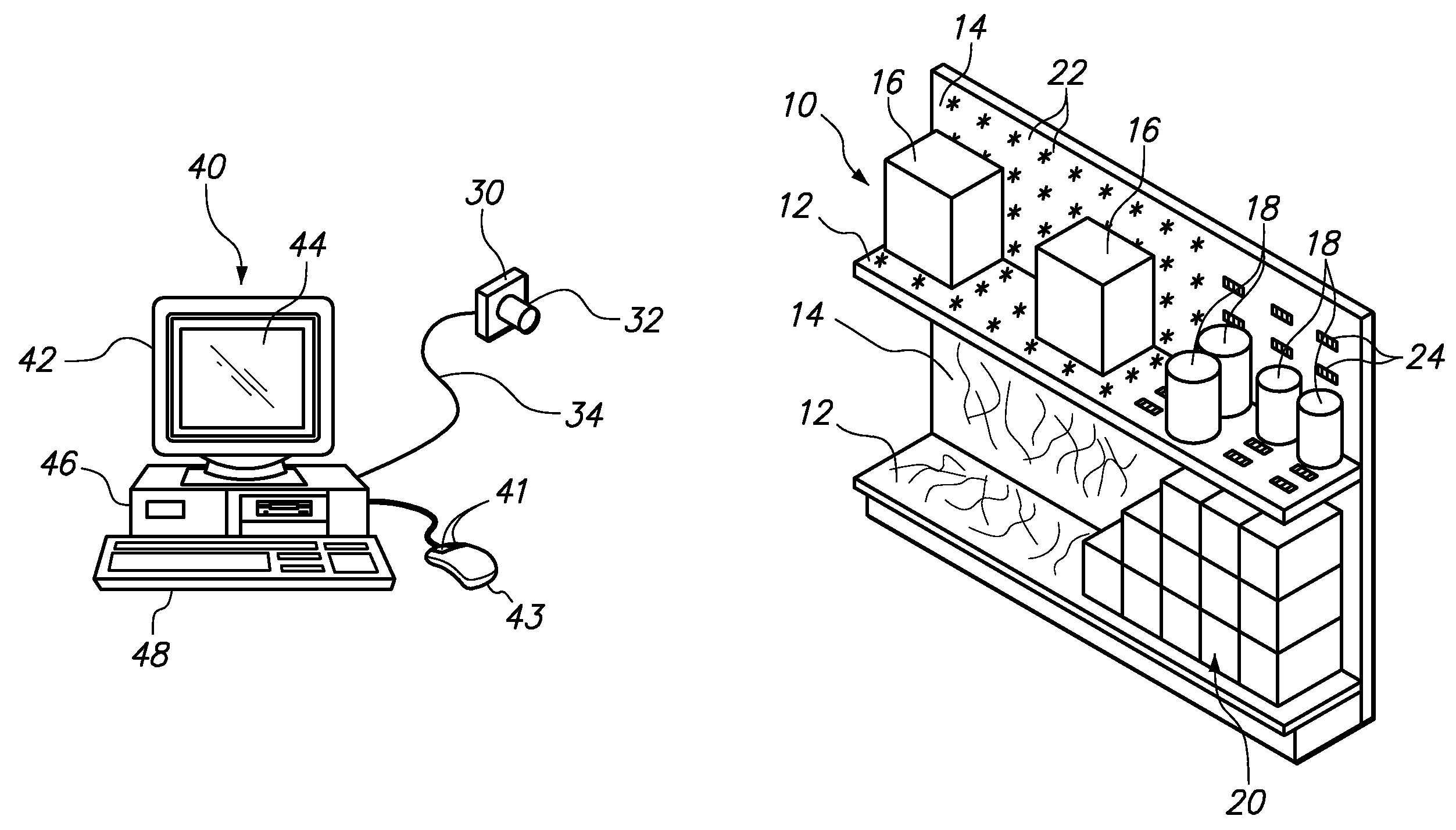

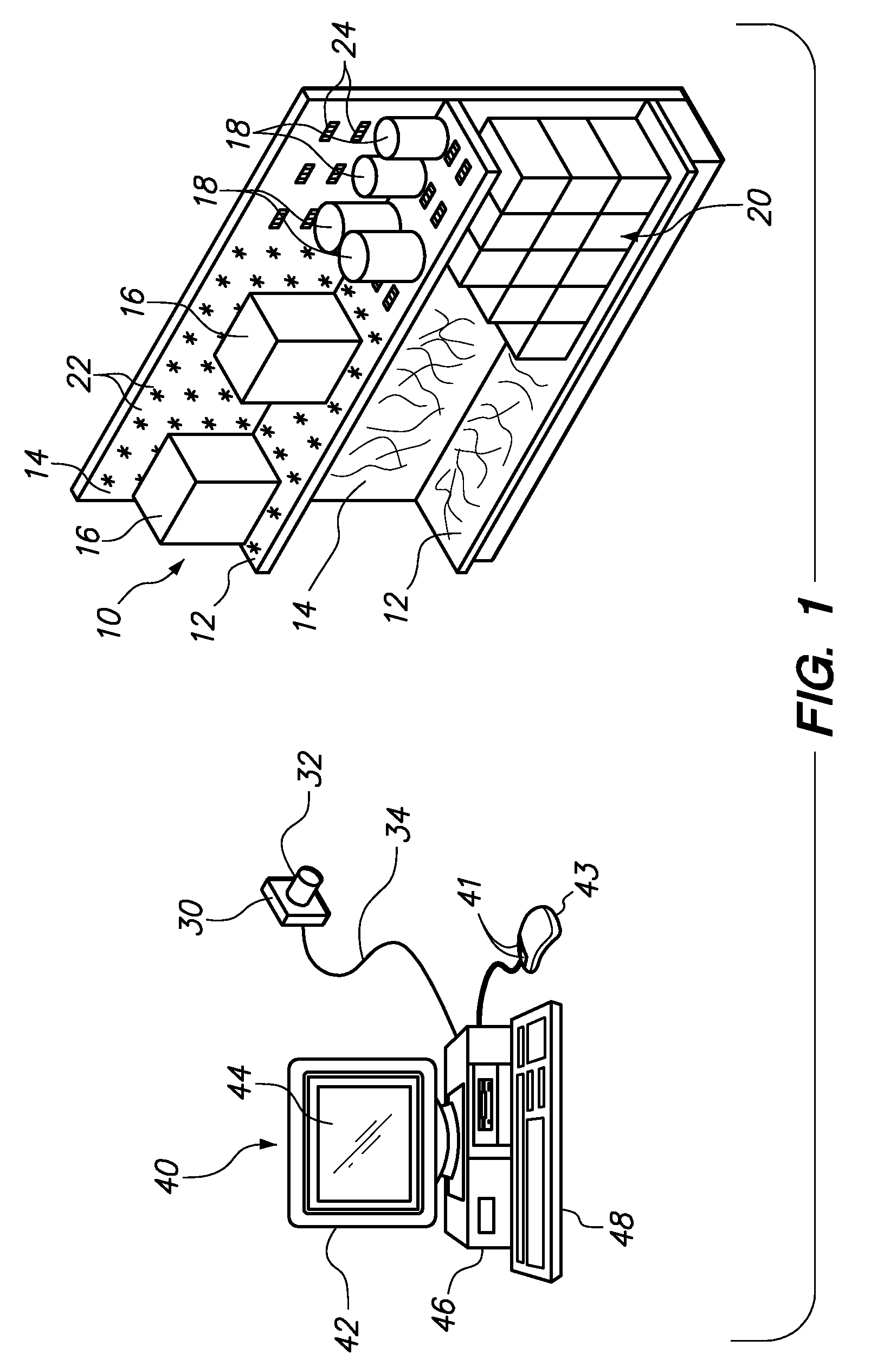

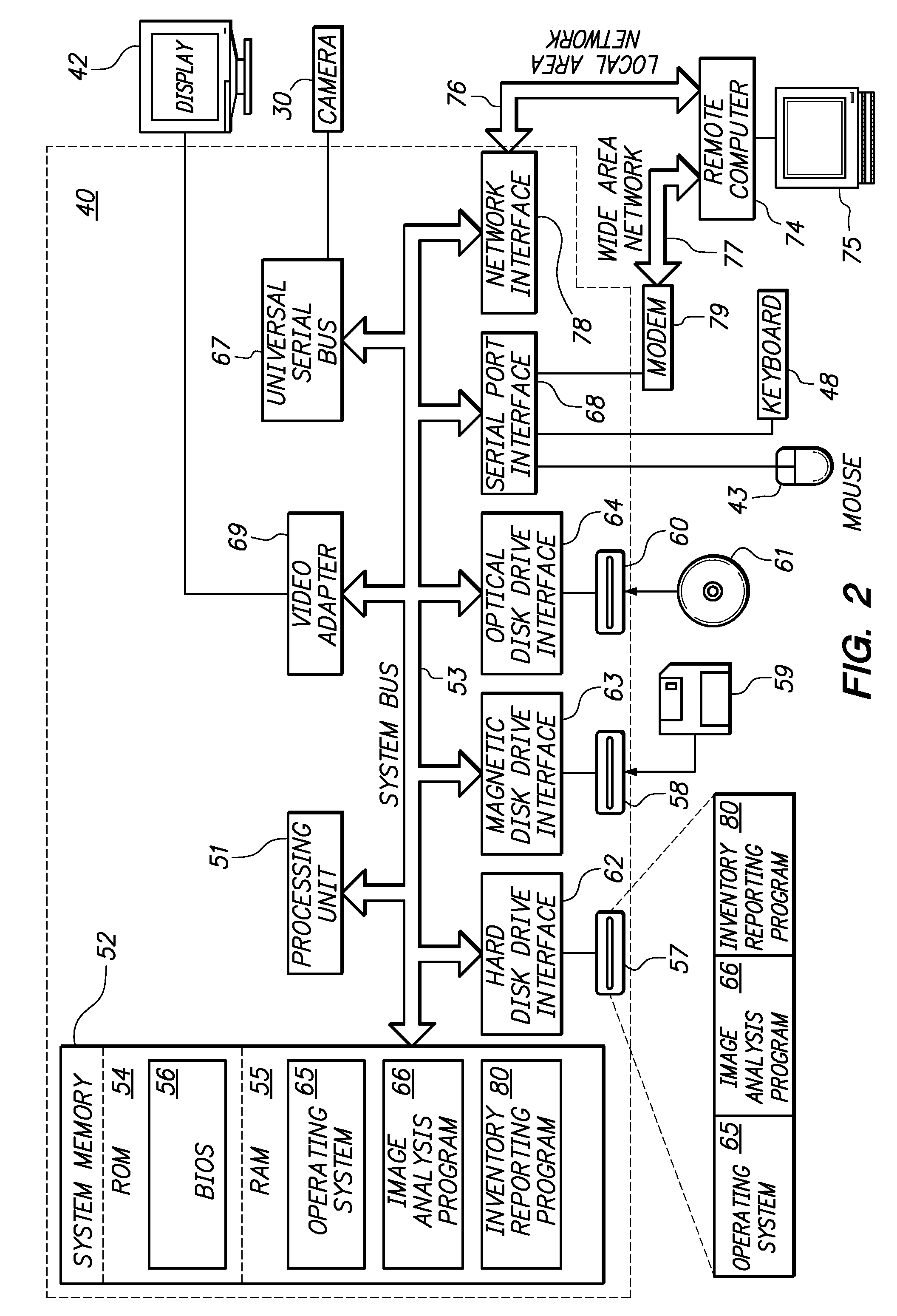

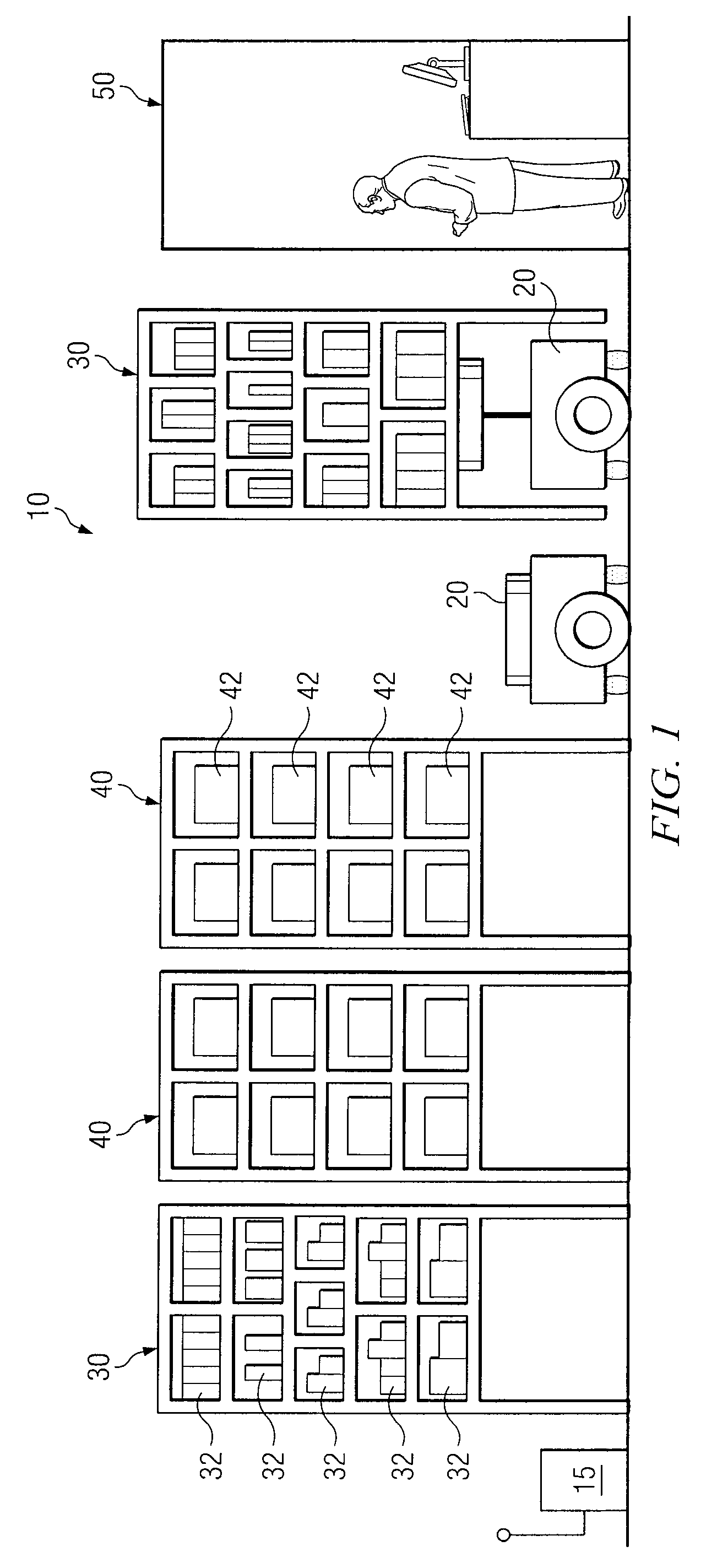

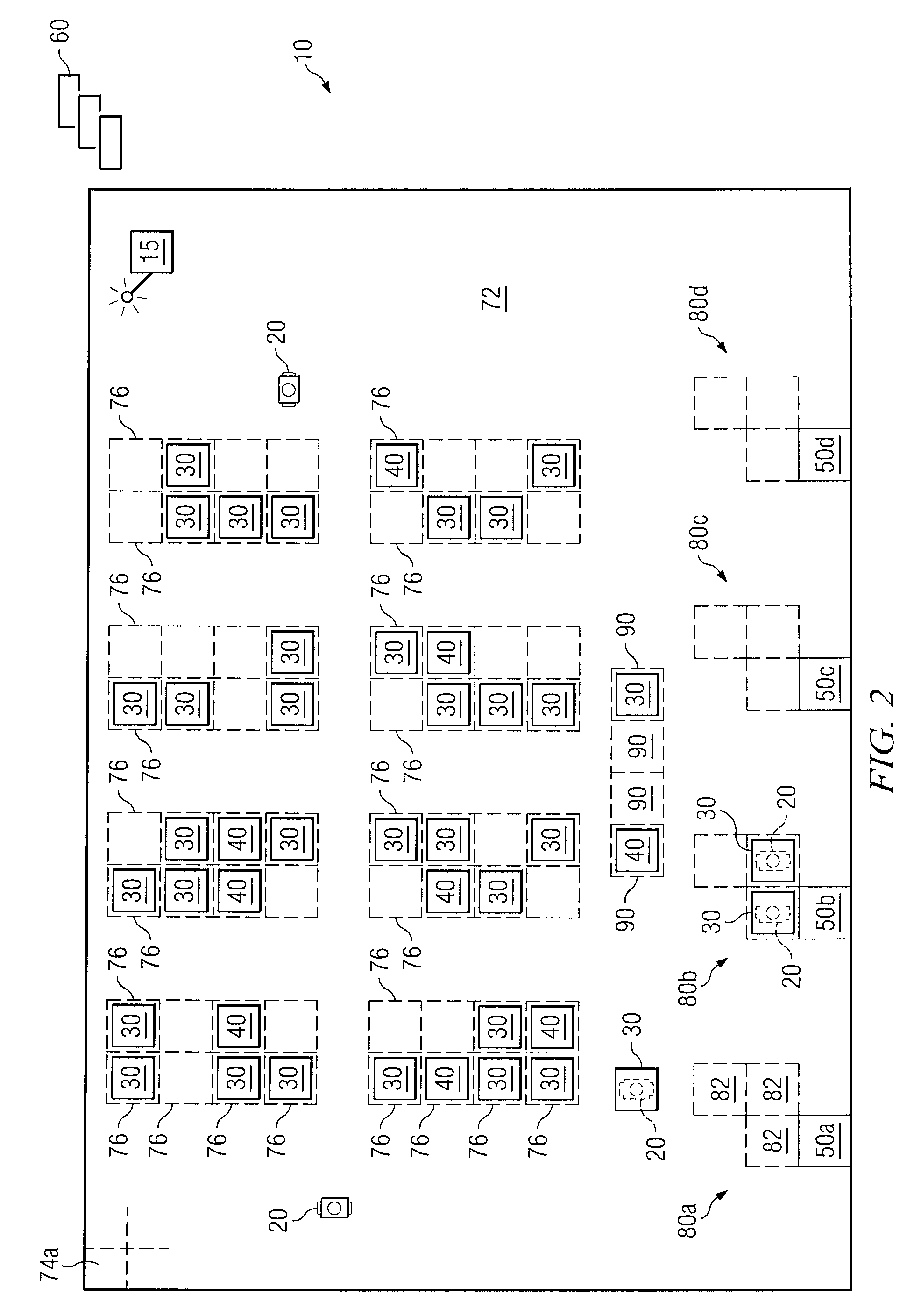

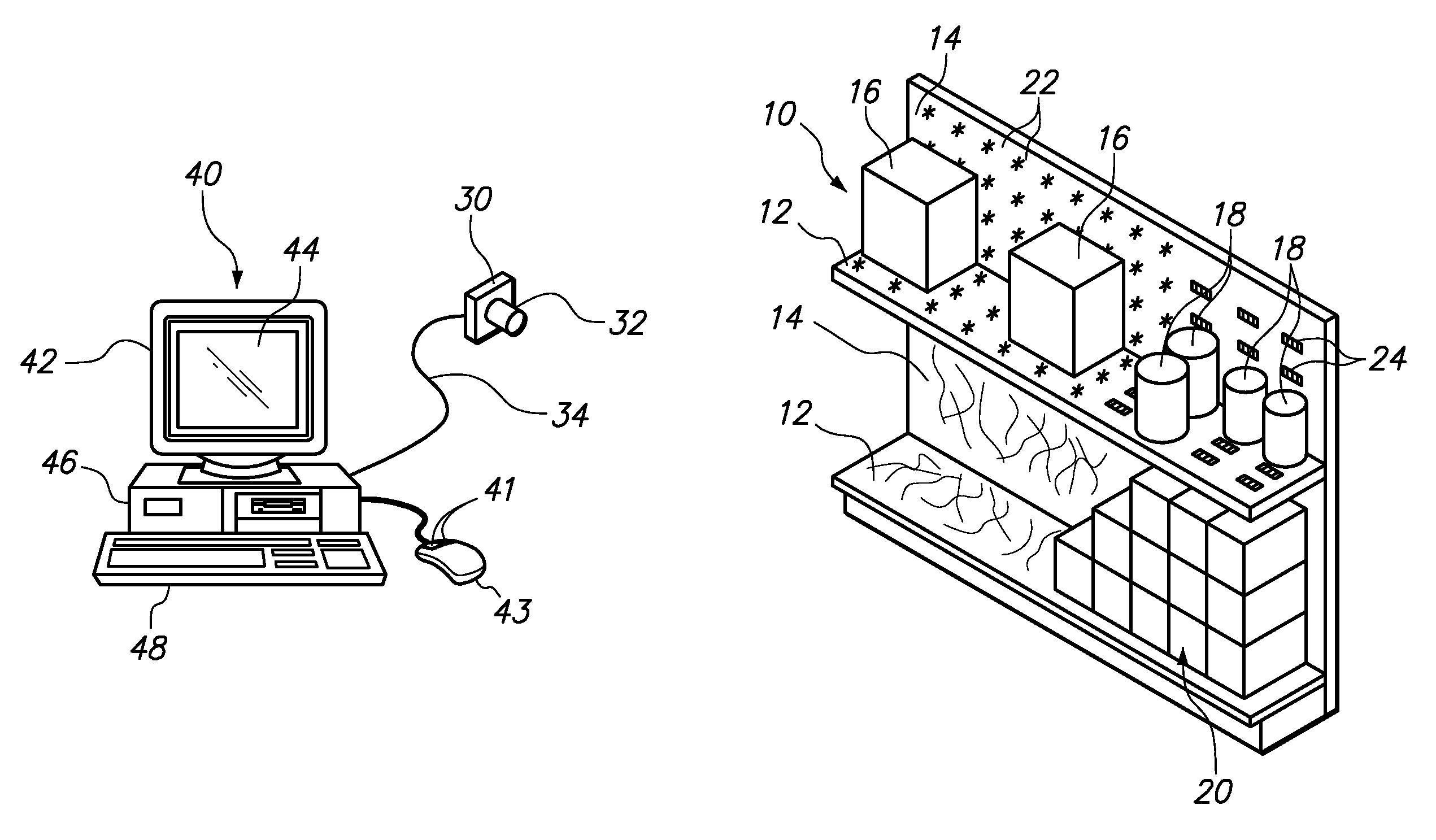

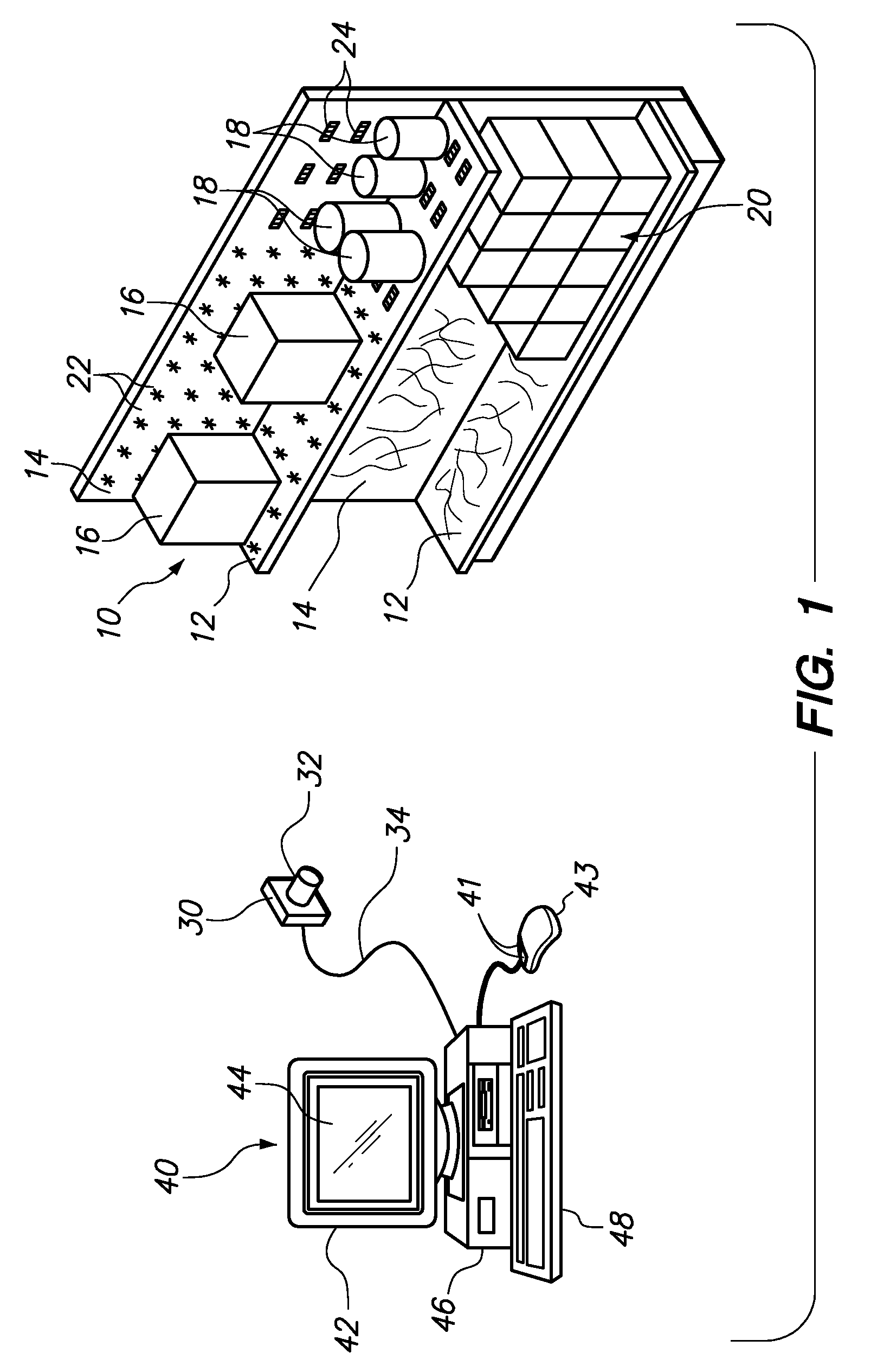

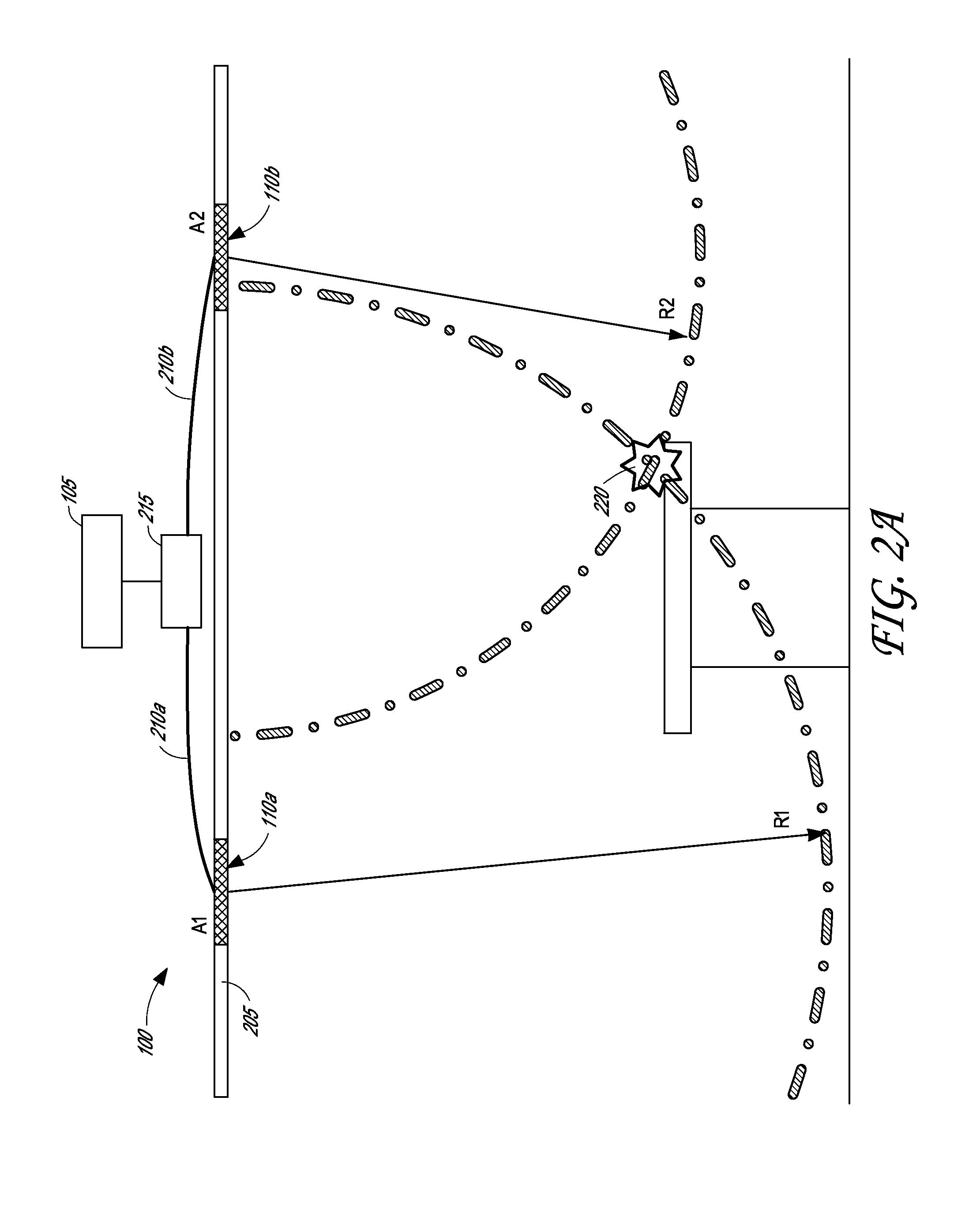

Using Cameras to Monitor Actual Inventory

System and method for monitoring inventory. Inventory items are positioned between a camera and a surface having an optically identifiable and distinct characteristic. The camera obtains an image of the inventory items present, any exposed portion of the surface, or both. The amount of the exposed surface is used to determine an amount of the inventory items that are present or missing. Furthermore, the optically identifiable characteristic may be a uniform characteristic, such as color or texture, or a set of discrete elements, such as stickers, barcodes, structural features of the shelf, a pattern of lines or shapes, or combinations thereof. Optionally, the optically identifiable characteristic is unique to the location of the shelf associated with the inventory items. Inventory or non-inventory items incorrectly positioned over the exposed surface may be excluded from the amount of the expected inventory item being determined if the item does not match the visual attributes of the expected inventory item. The camera may be fixed or movable and preferably provides digital images to a computer system having a computer readable medium with program products for analyzing the image and providing inventory reports.

Owner:TOSHIBA GLOBAL COMMERCE SOLUTIONS HLDG

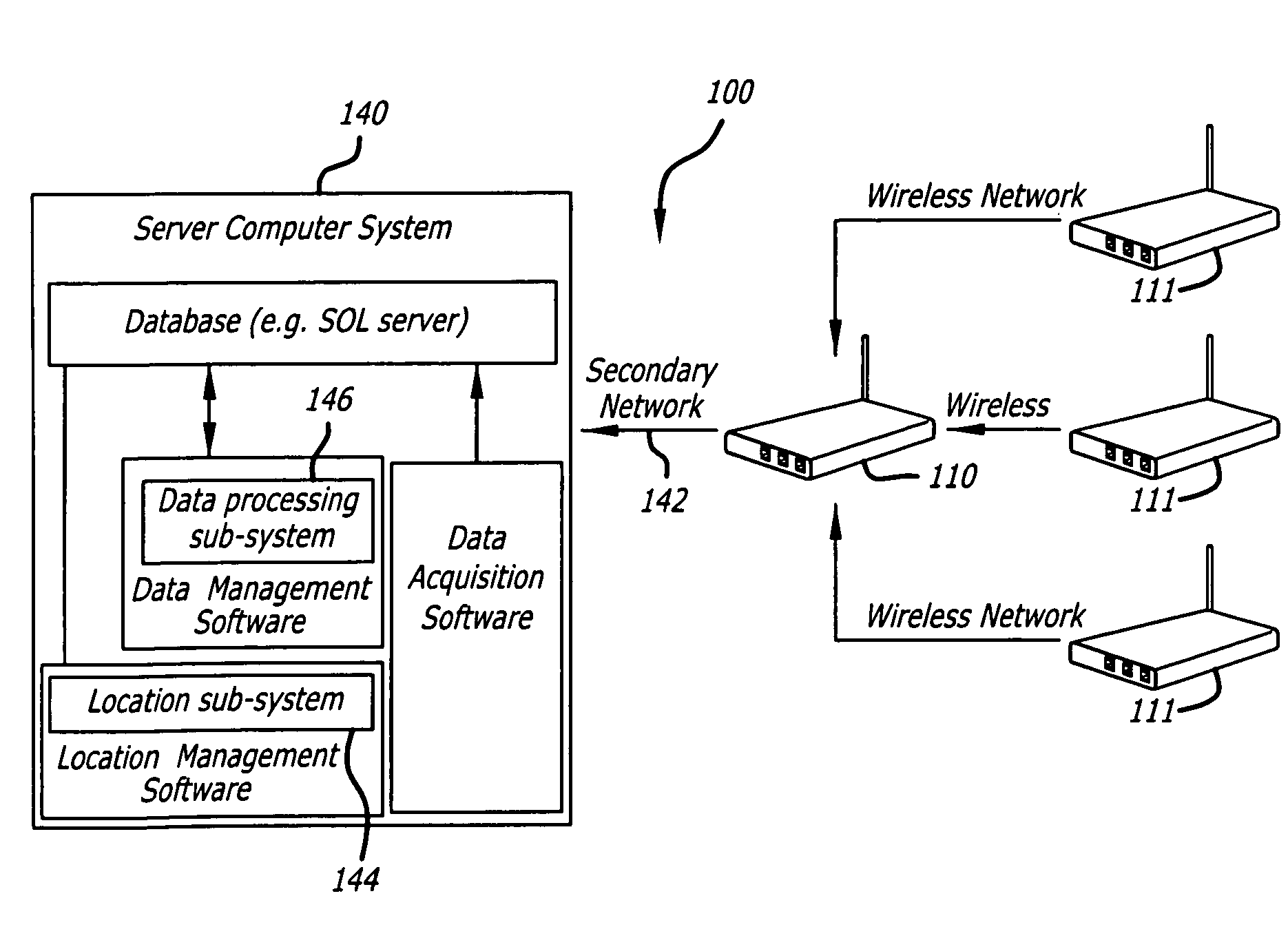

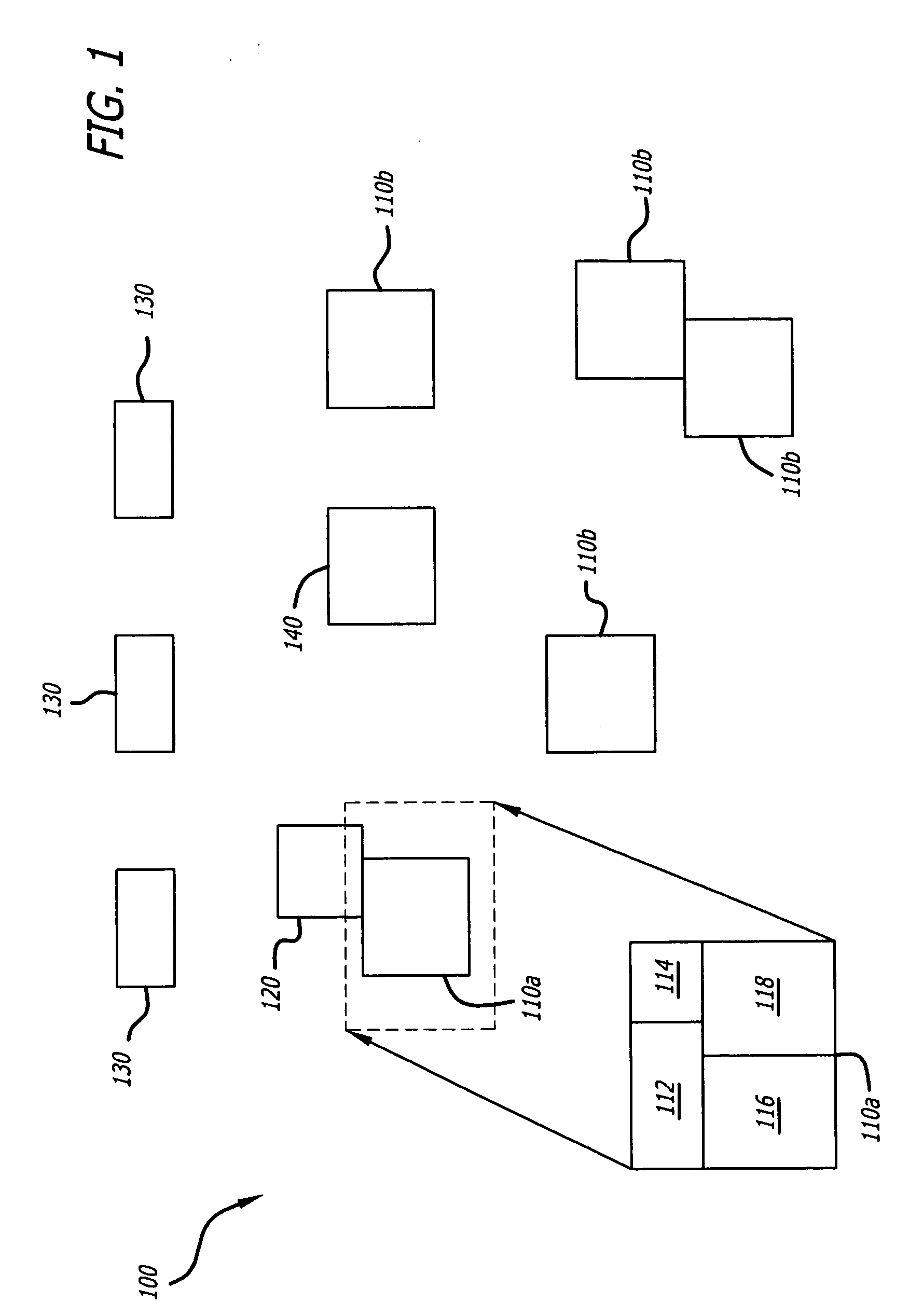

Wireless network inventory system

InactiveUS20090219170A1Position fixationElectric/electromagnetic visible signallingComputer scienceWireless network

A wireless location system is provided. The system includes network tags that emit a signal containing tag data, network readers that continuously receive data from the tags, a communication motes to receive the tag data from the readers and to calculate a network signal strength of the signal between the reader and the mote, and a server. The server receives the tag data and network signal strength data from the communication mote, performs calculations on the data, and determines the location of the reader that received the tag data based in part on the received network signal strength data.

Owner:CLARK RYAN +3

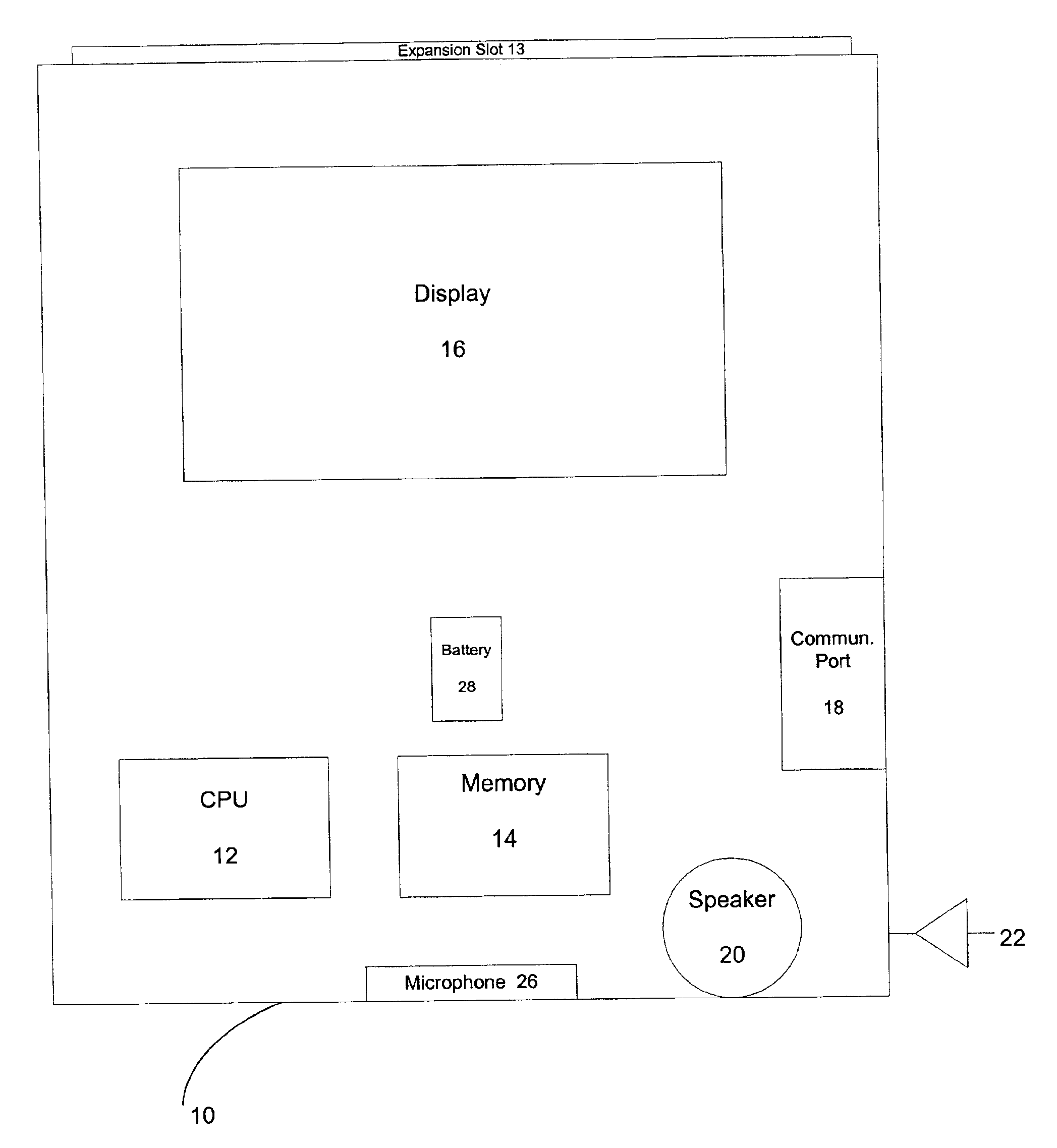

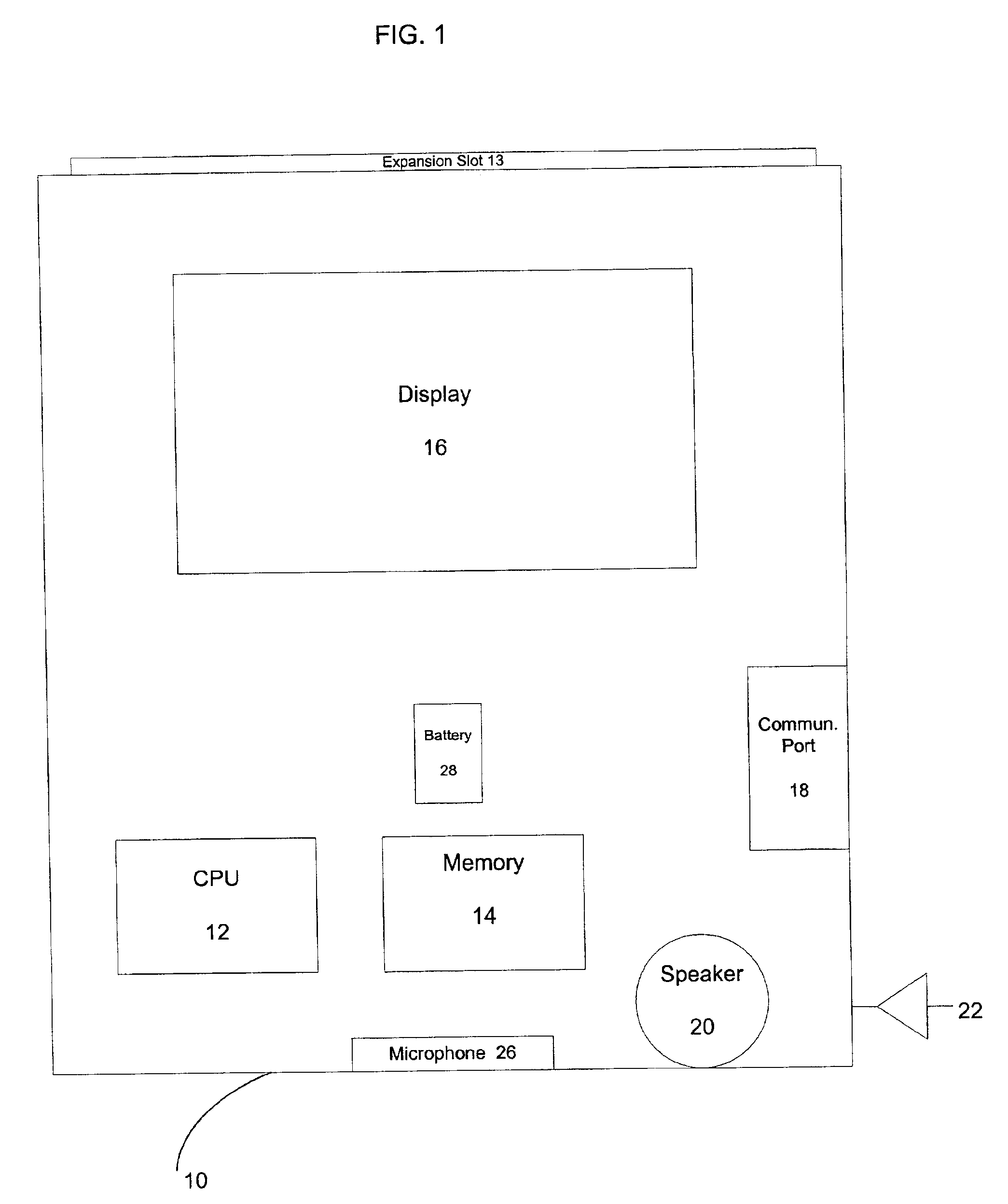

Digital watermarking apparatus and methods

InactiveUS7024016B2Improve computing powerReduced portabilitySpeech analysisCharacter and pattern recognitionDisplay deviceInventory management

The present invention relates to various digital watermarking methods and systems. In one embodiment, a handheld device displays a digitally watermarked ticket image at an event center. At the event center, a watermark decoder extracts the watermark to determine authorized entry. In another embodiment, a plurality of microlenses can provide a polarized luminance pattern on a display. The pattern corresponds to (or conveys) a unique device identifier. In yet another embodiment, monetary objects are watermarked with payload information to signify currency denomination. The payload information, once extracted, is used to provide feedback regarding the currency denomination. An audio signal or Braille output can be provided as feedback. In still another embodiment, a document management system is based on watermarks. Embedded watermarks are used to track document history, determine document version information, and enhance overall security. In still another embodiment, an inventory system reads watermarks that have been directly applied to inventory items. Inventory management is greatly enhanced. Handheld computing devices are advantageously employed with these embodiments.

Owner:DIGIMARC CORP

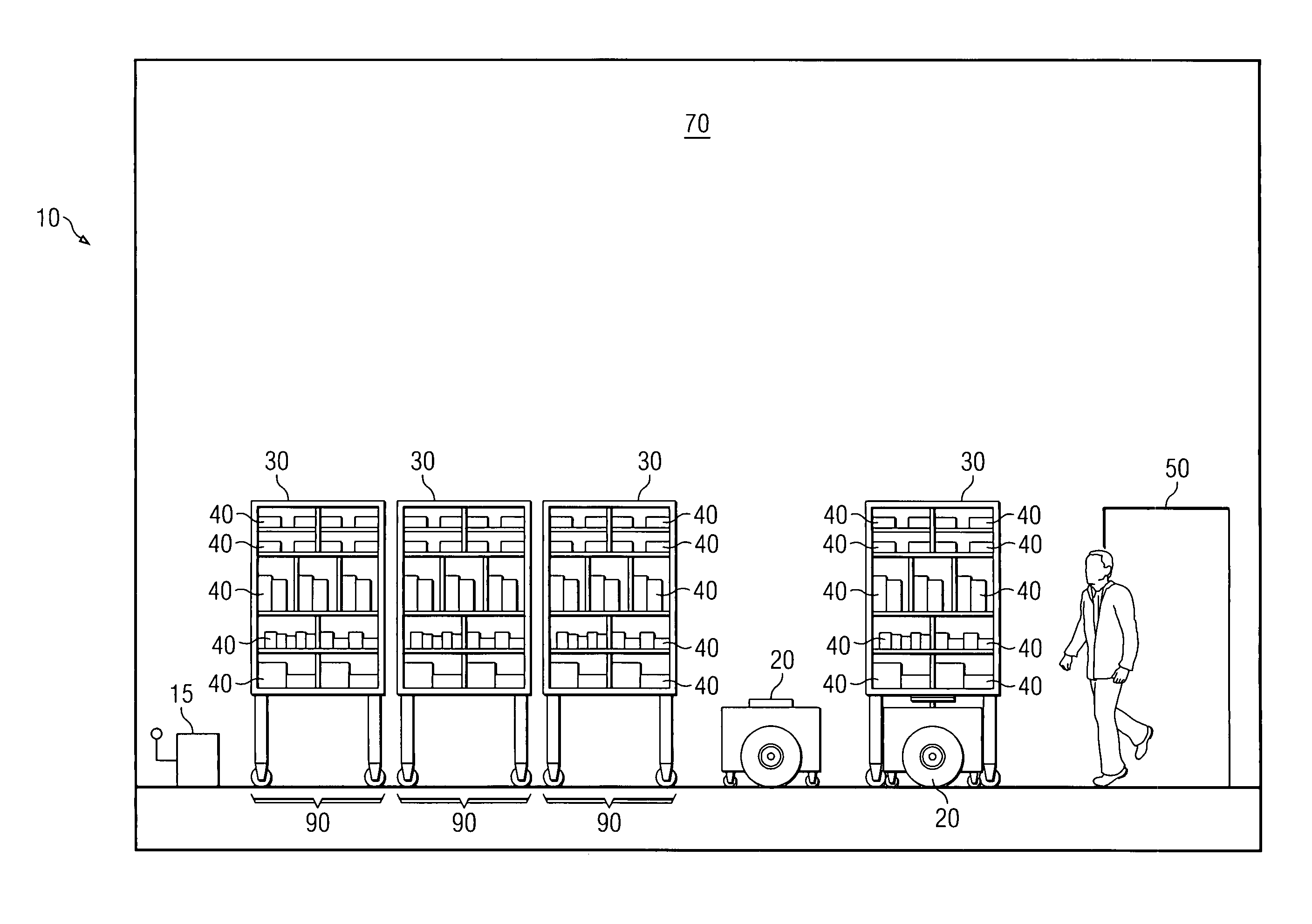

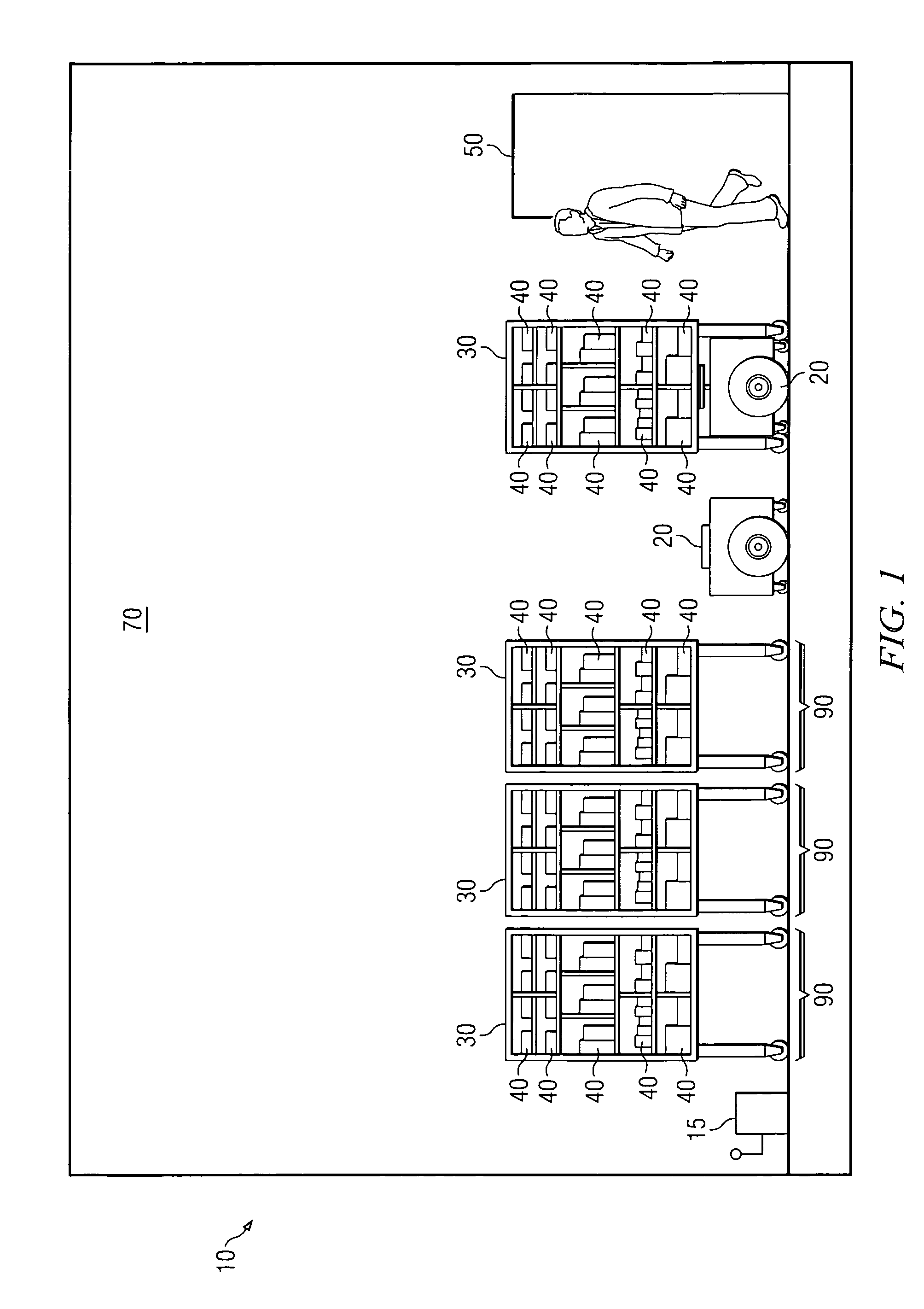

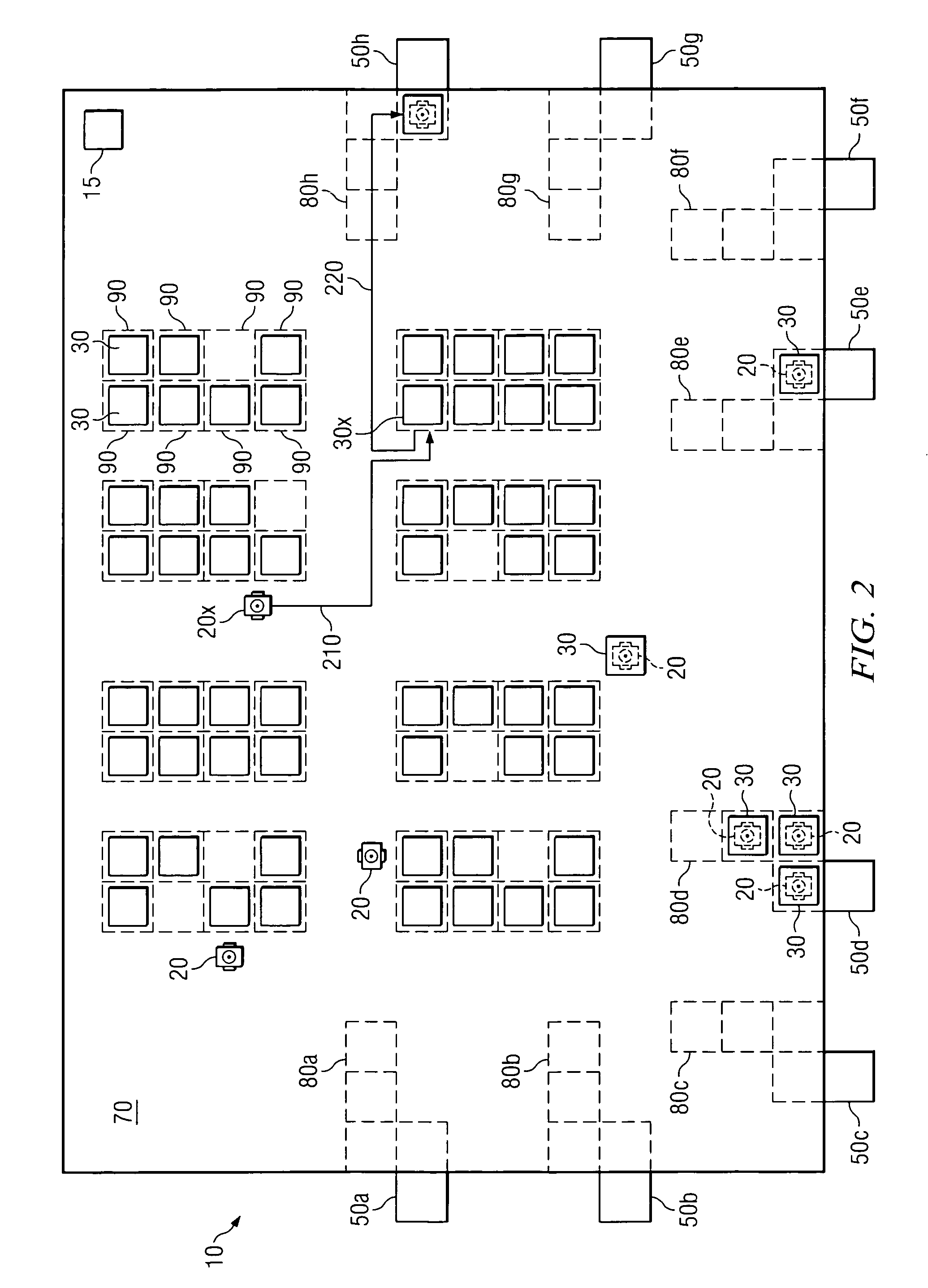

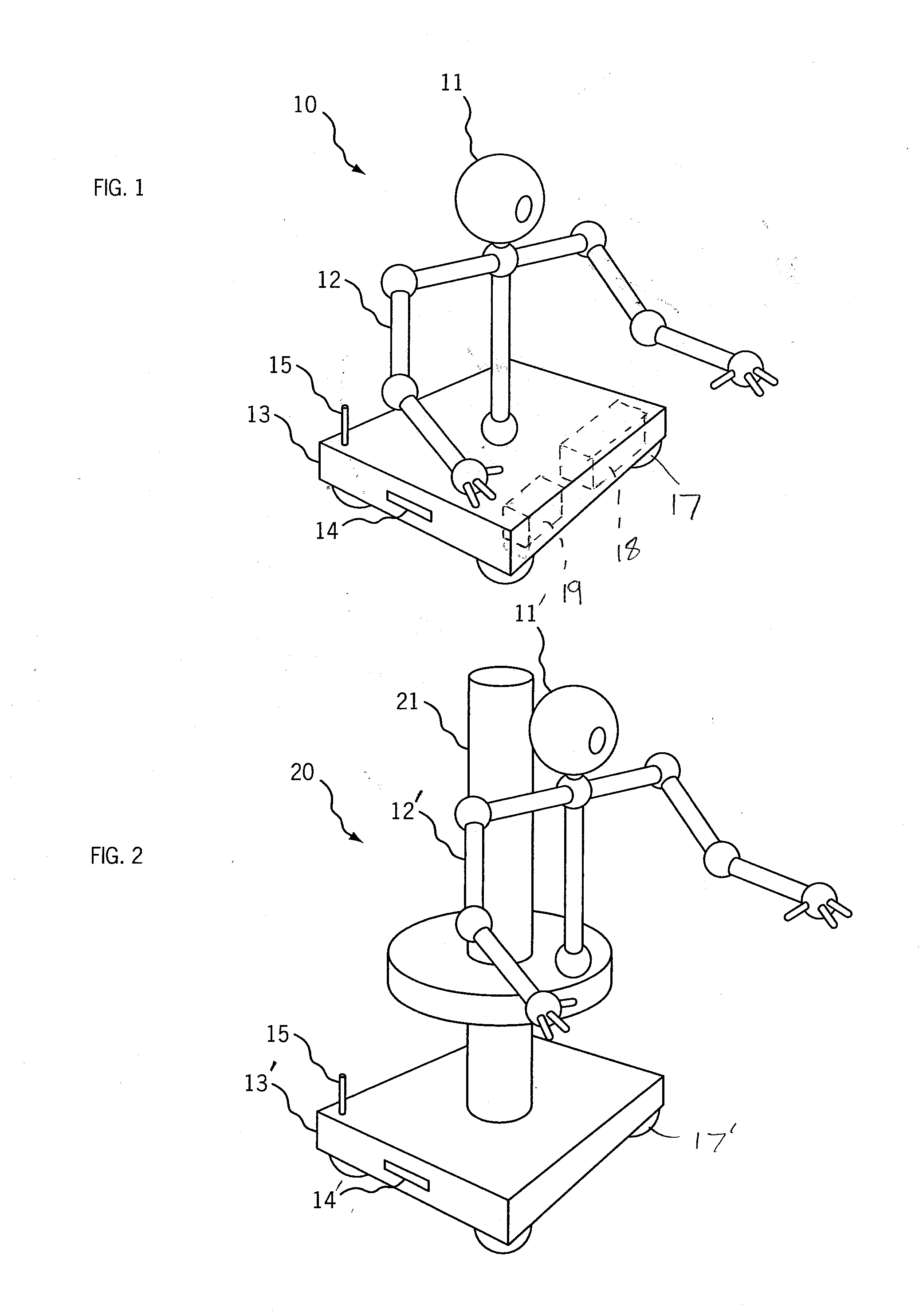

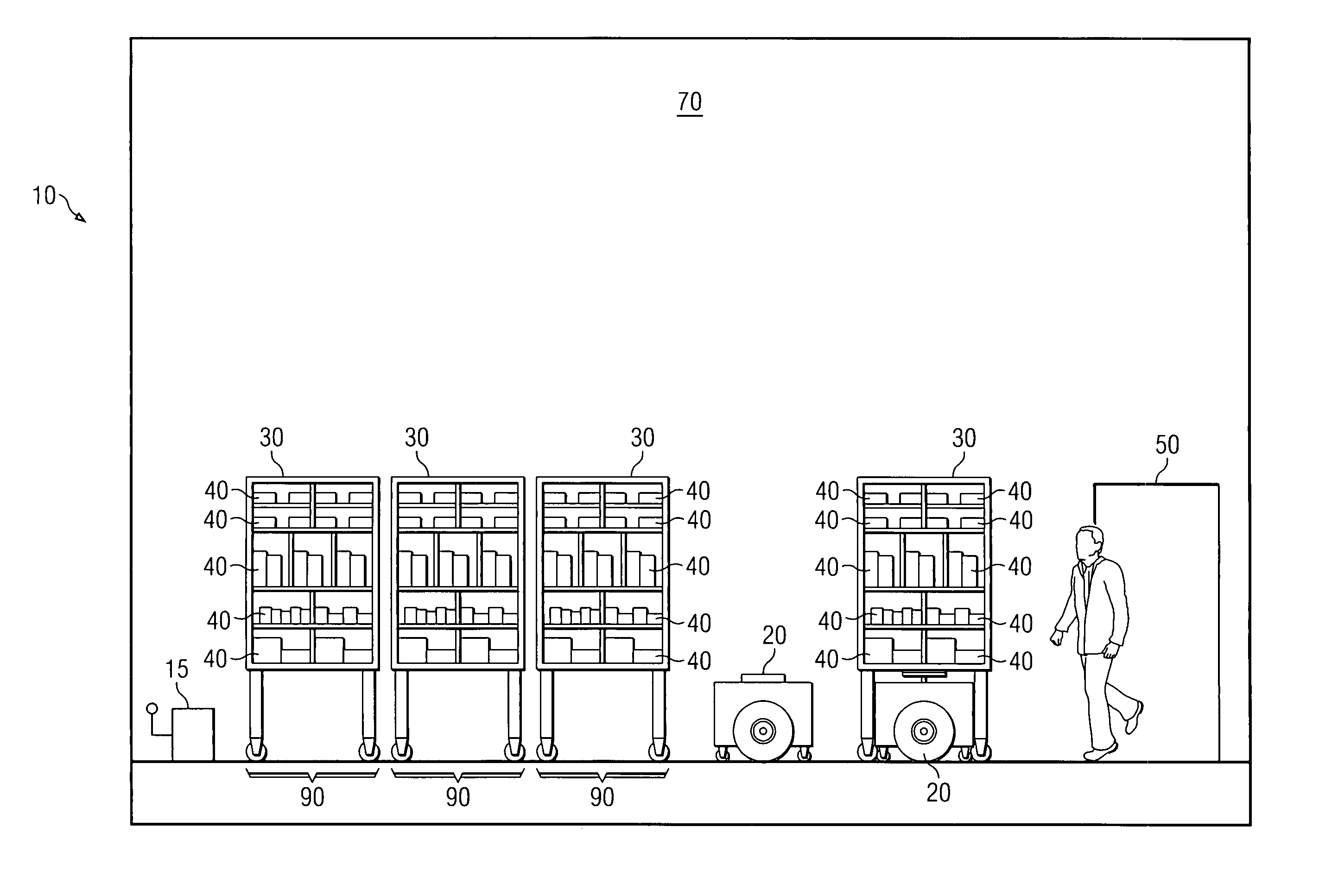

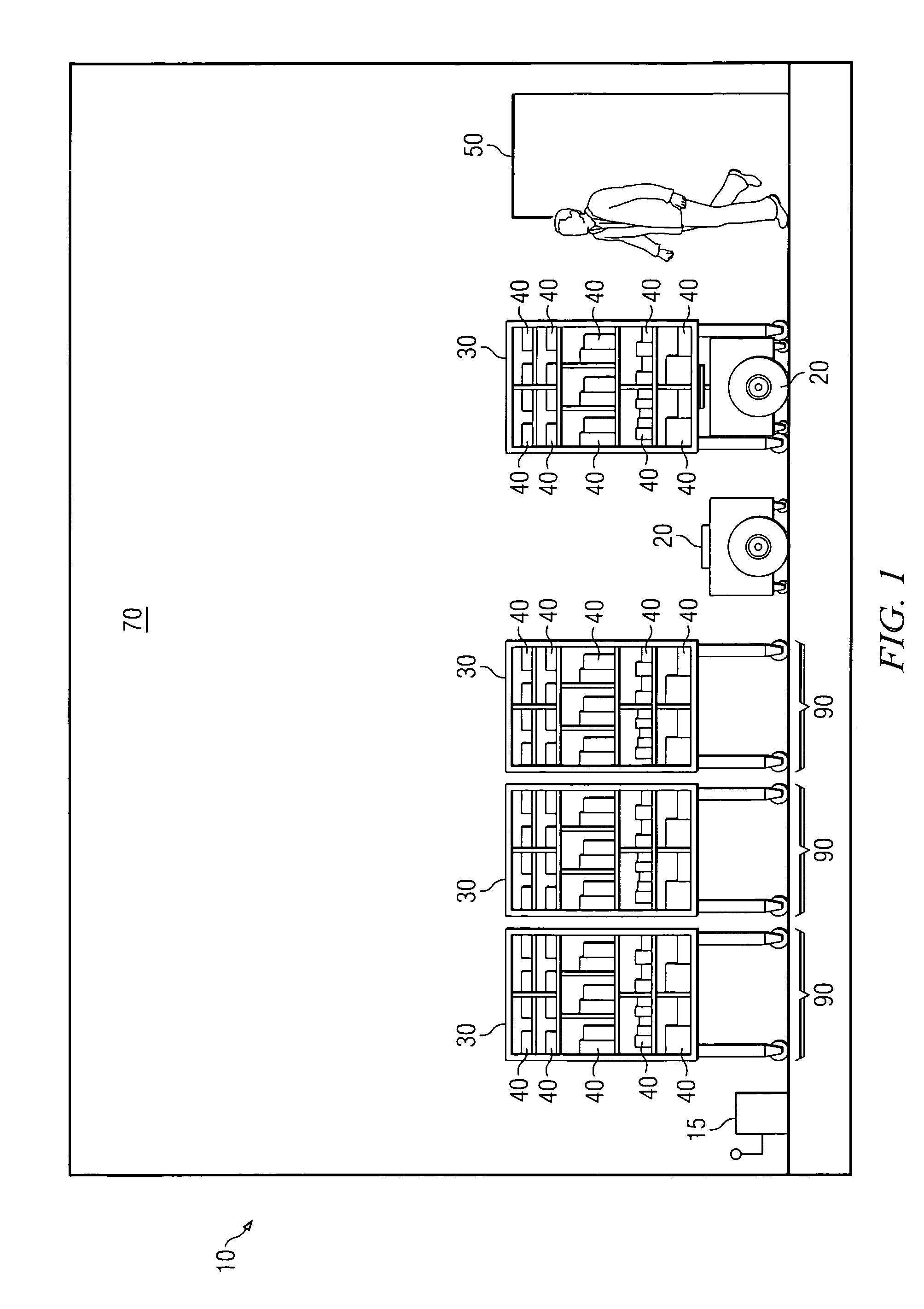

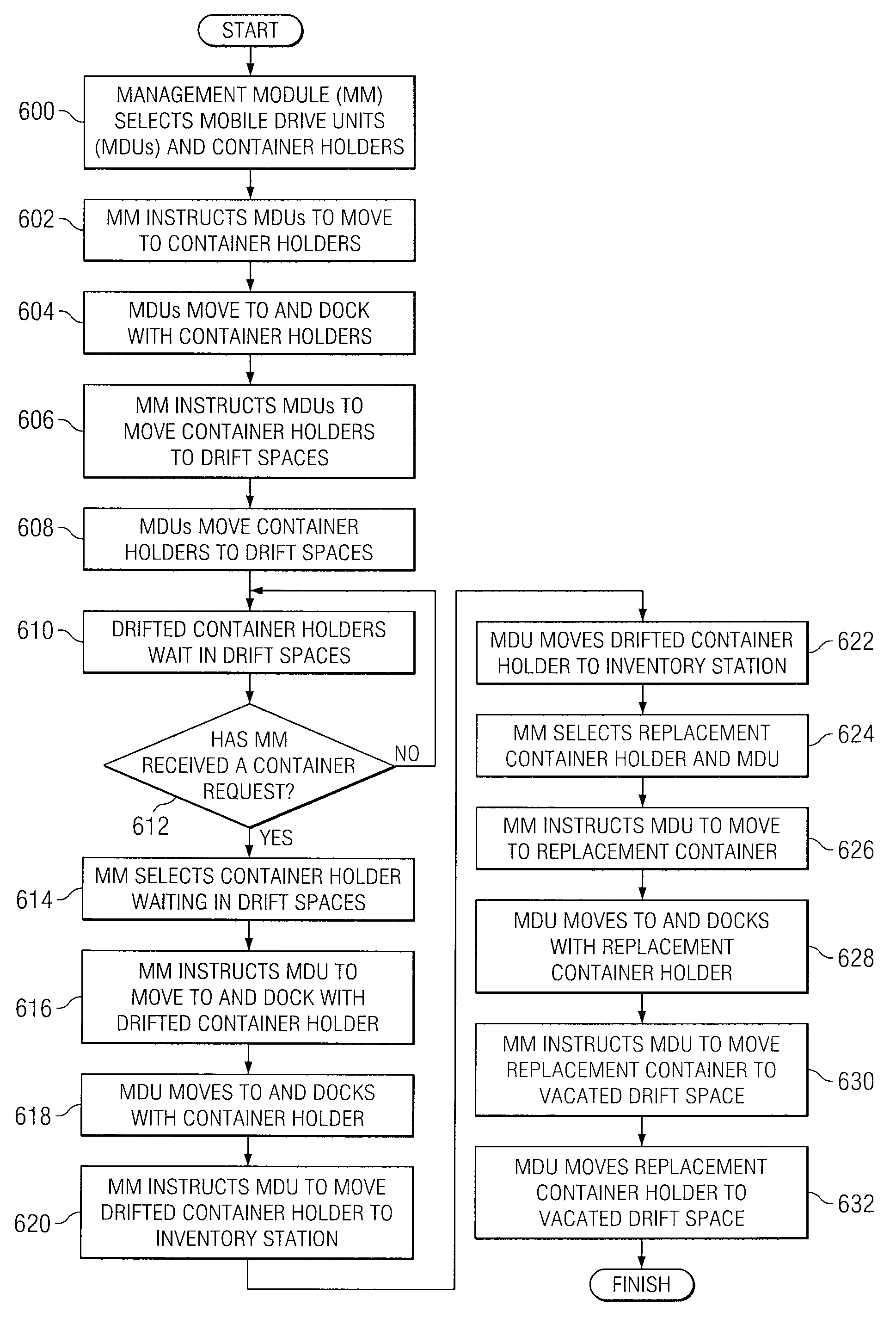

Inventory system with mobile drive unit and inventory holder

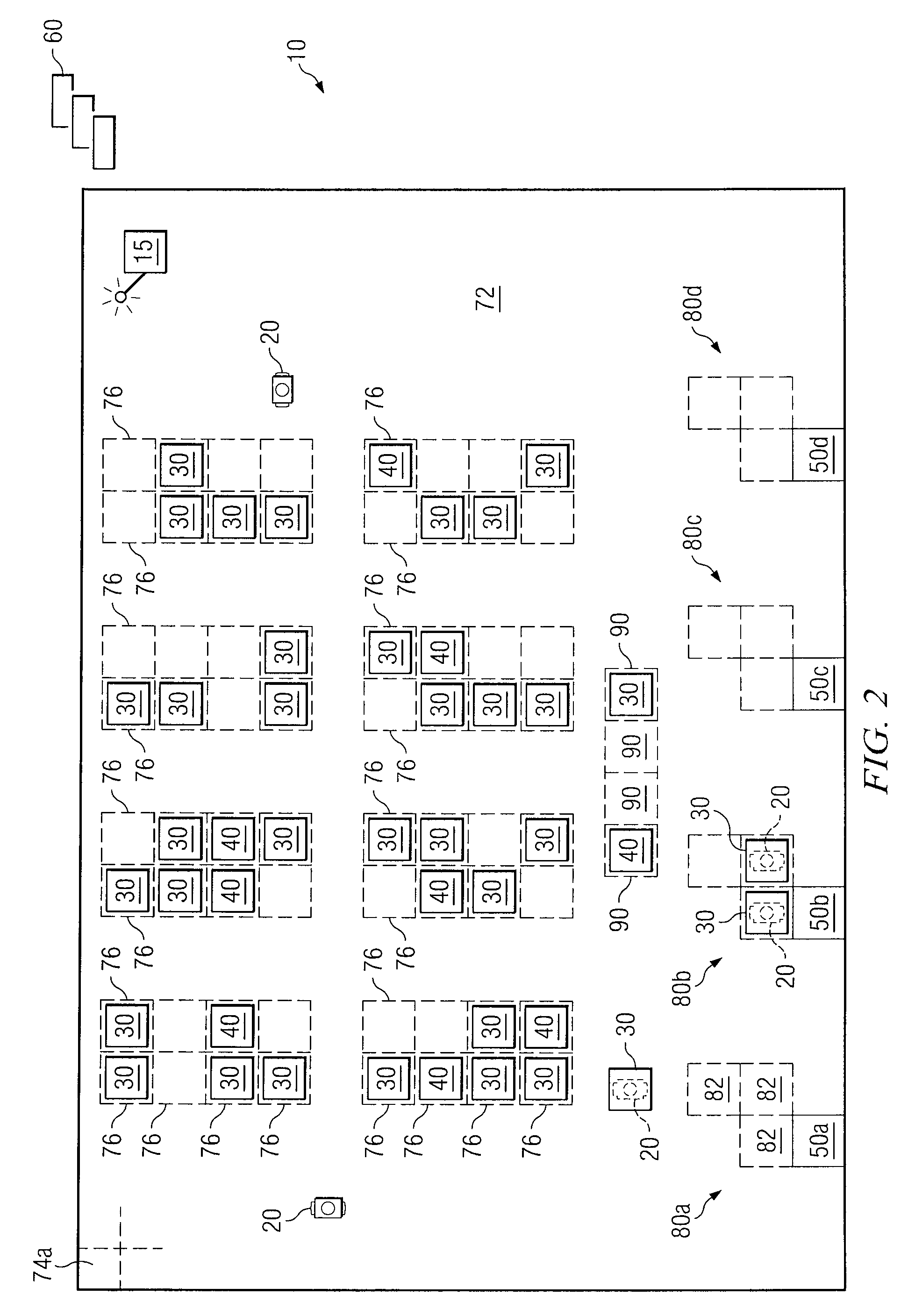

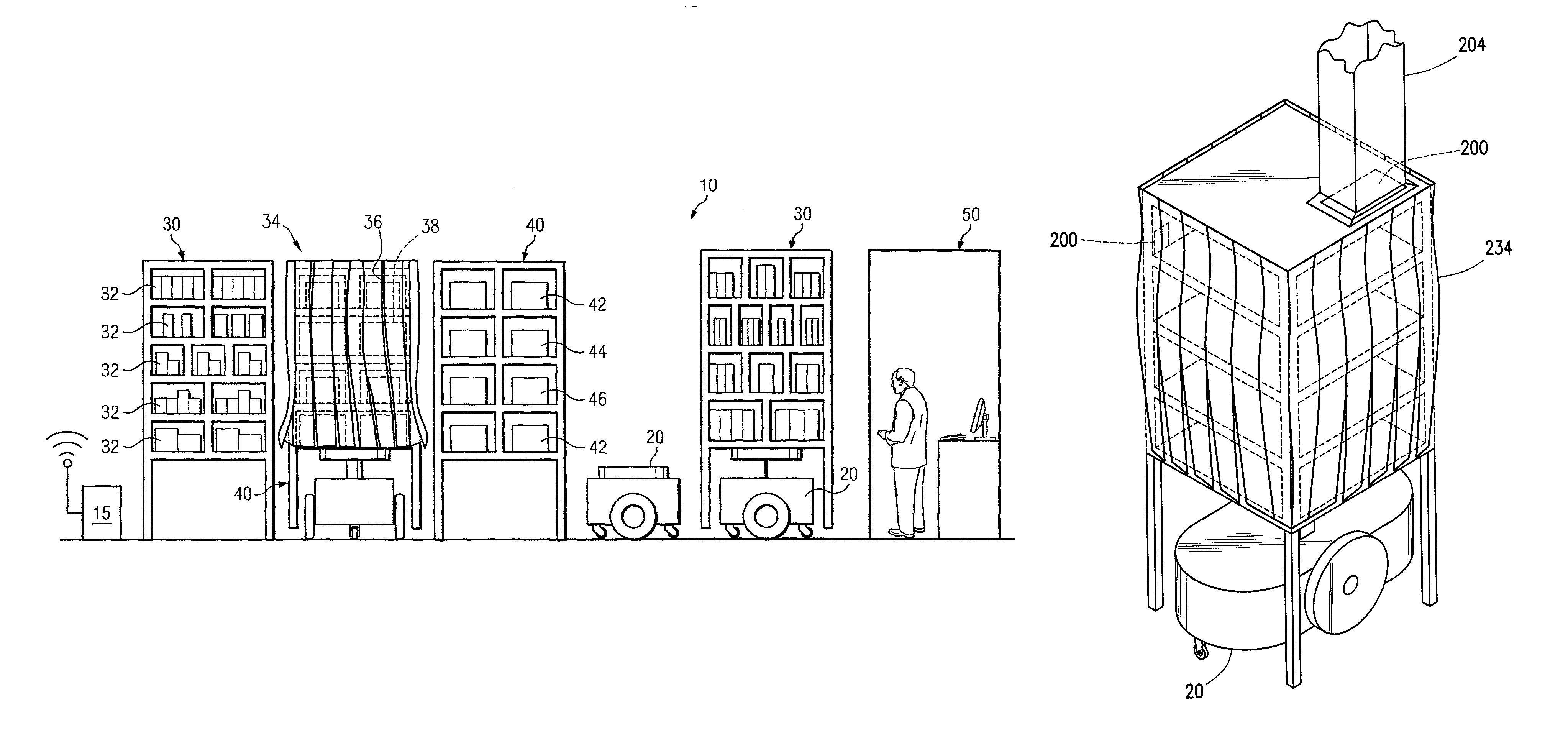

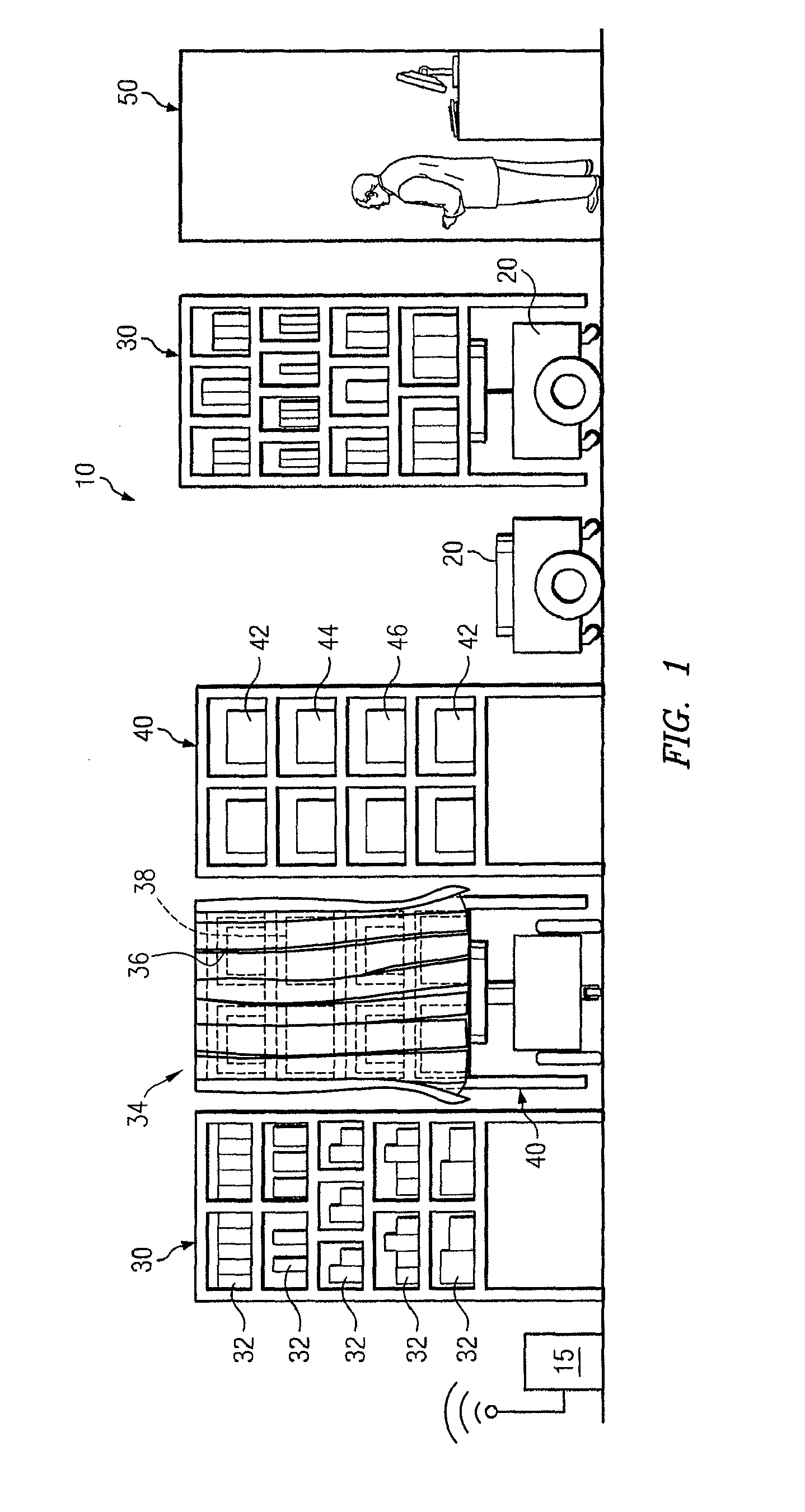

ActiveUS7402018B2Disadvantages and reduced eliminatedInventory reduced eliminatedCurtain suspension devicesVehicle with removable loadingMechanical engineeringInventory system

Owner:AMAZON TECH INC

Method and system for fulfilling requests in an inventory system

ActiveUS20090185884A1Easy to useMinimizing task-completion timeStorage devicesLoading/unloadingReal-time computingInventory system

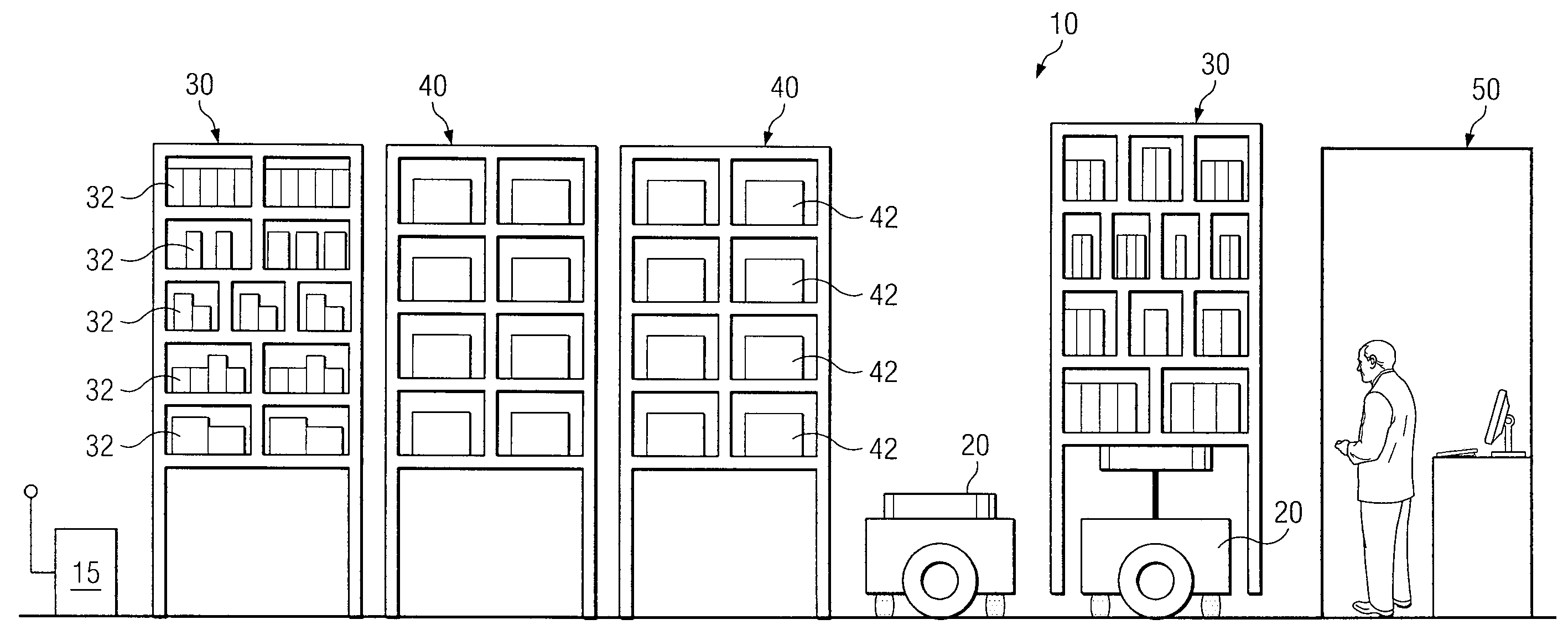

A method for fulfilling requests in an inventory system includes receiving a request indicating an activity to be completed. The method also includes selecting a holder to fulfill the request and an inventory station at which to fulfill the request. The inventory station is associated with a queue that includes a plurality of queue spaces. The method further includes moving the selected holder from a first location to a second location remote from the selected inventory station. Additionally, the method also includes determining that a trigger event has occurred and, in response to determining that the trigger event has occurred, moving the selected holder from the second location to a queue space of a queue associated with the selected inventory station.

Owner:AMAZON TECH INC

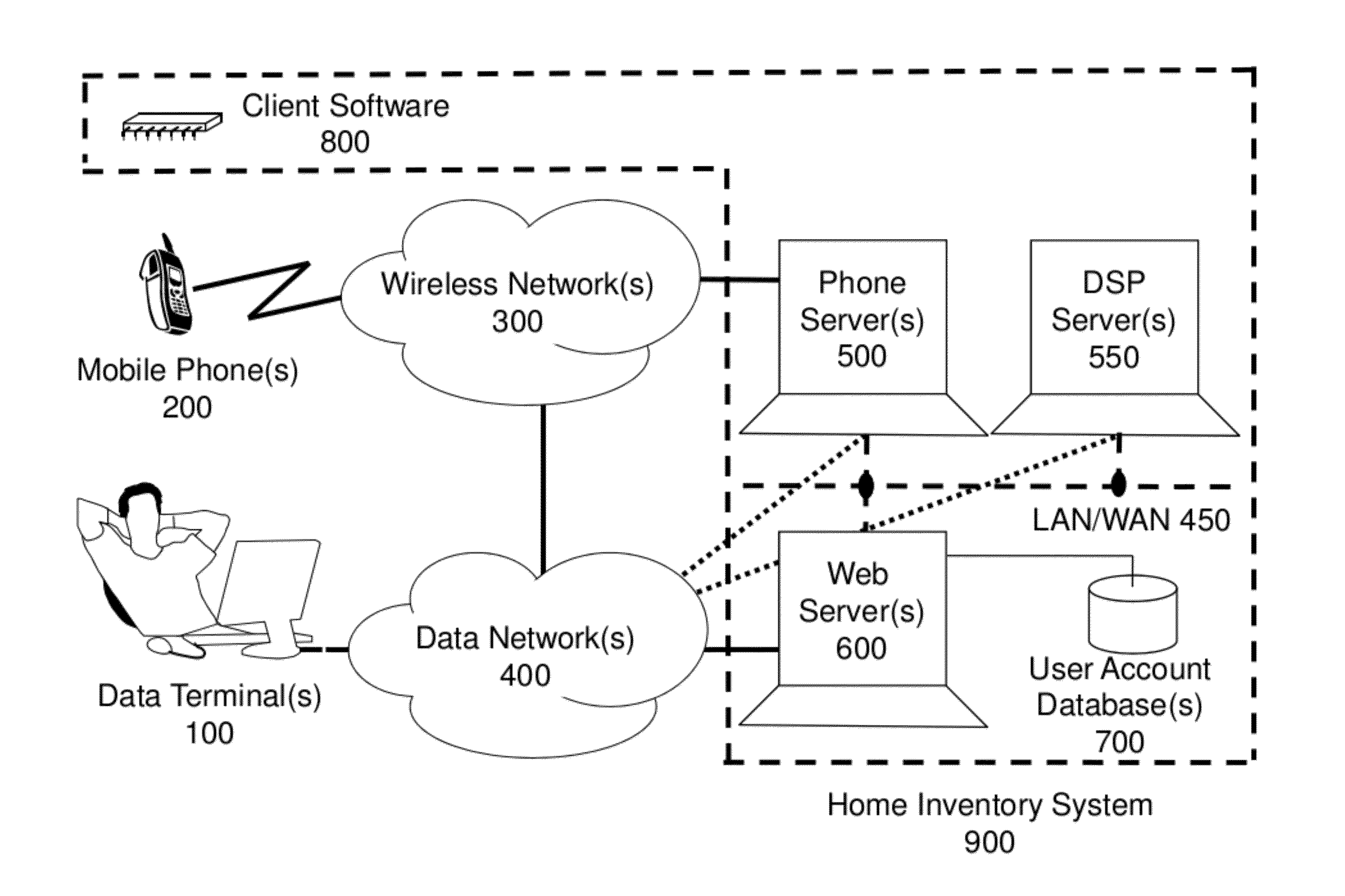

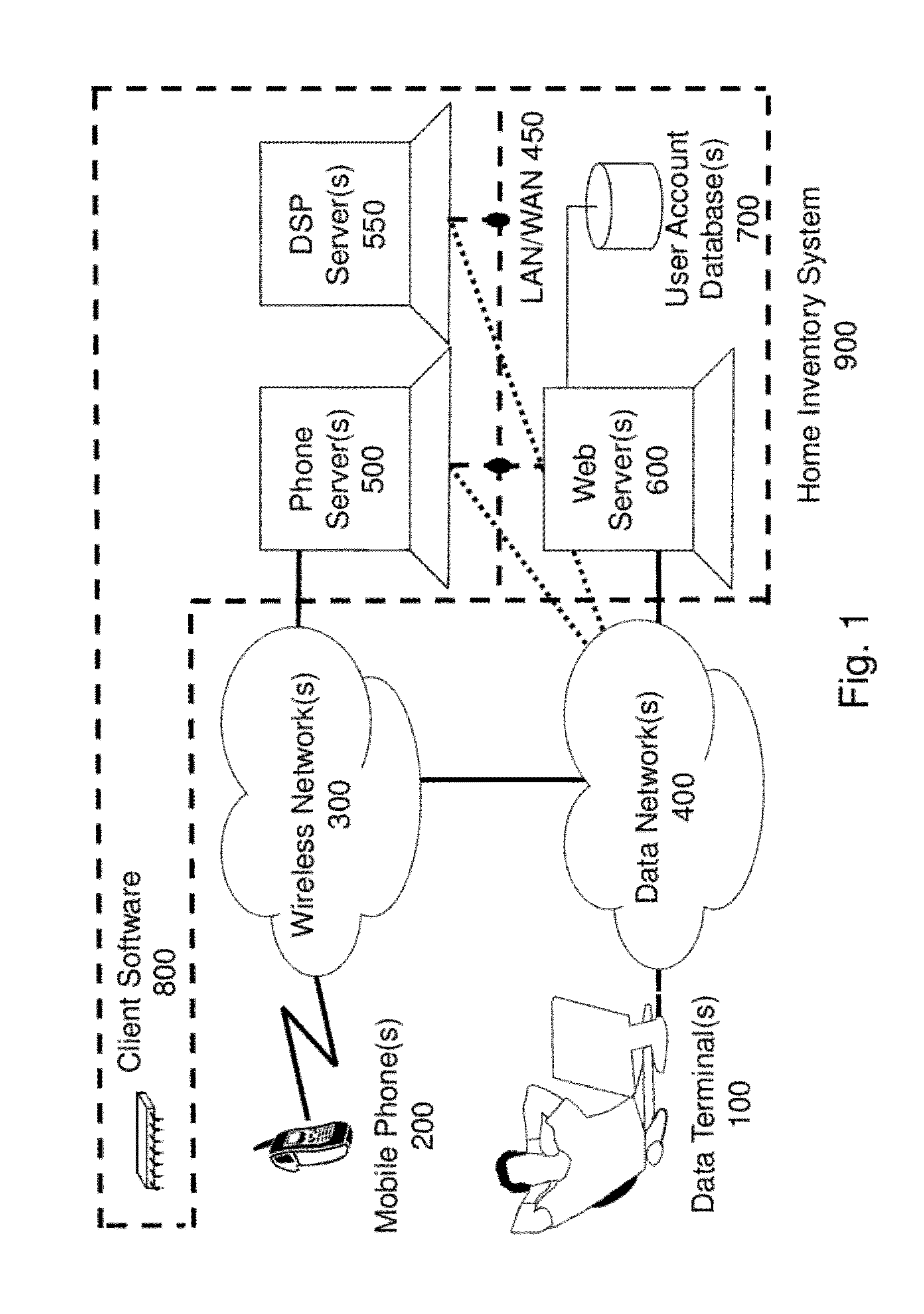

Methods and systems for inventory management

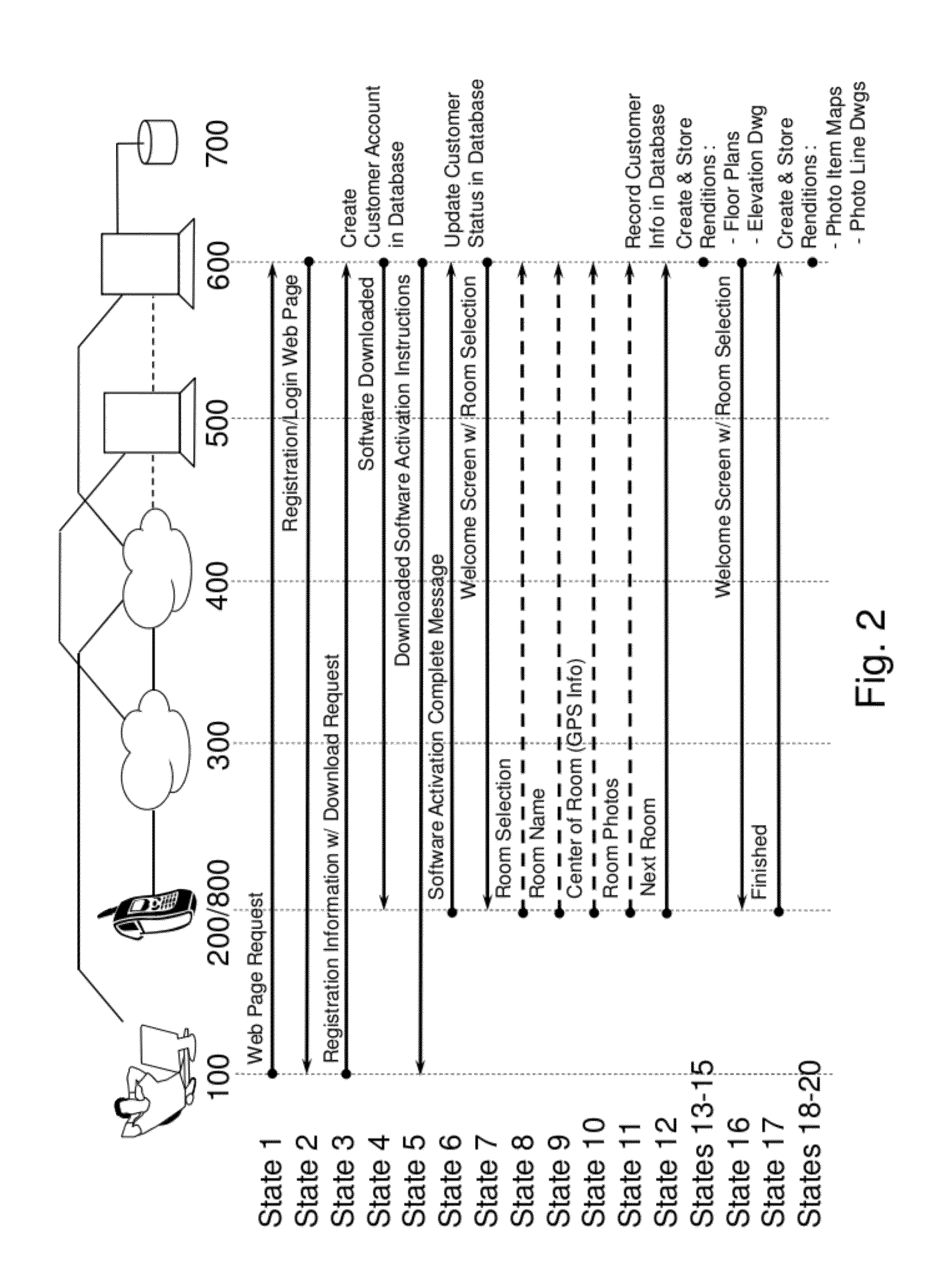

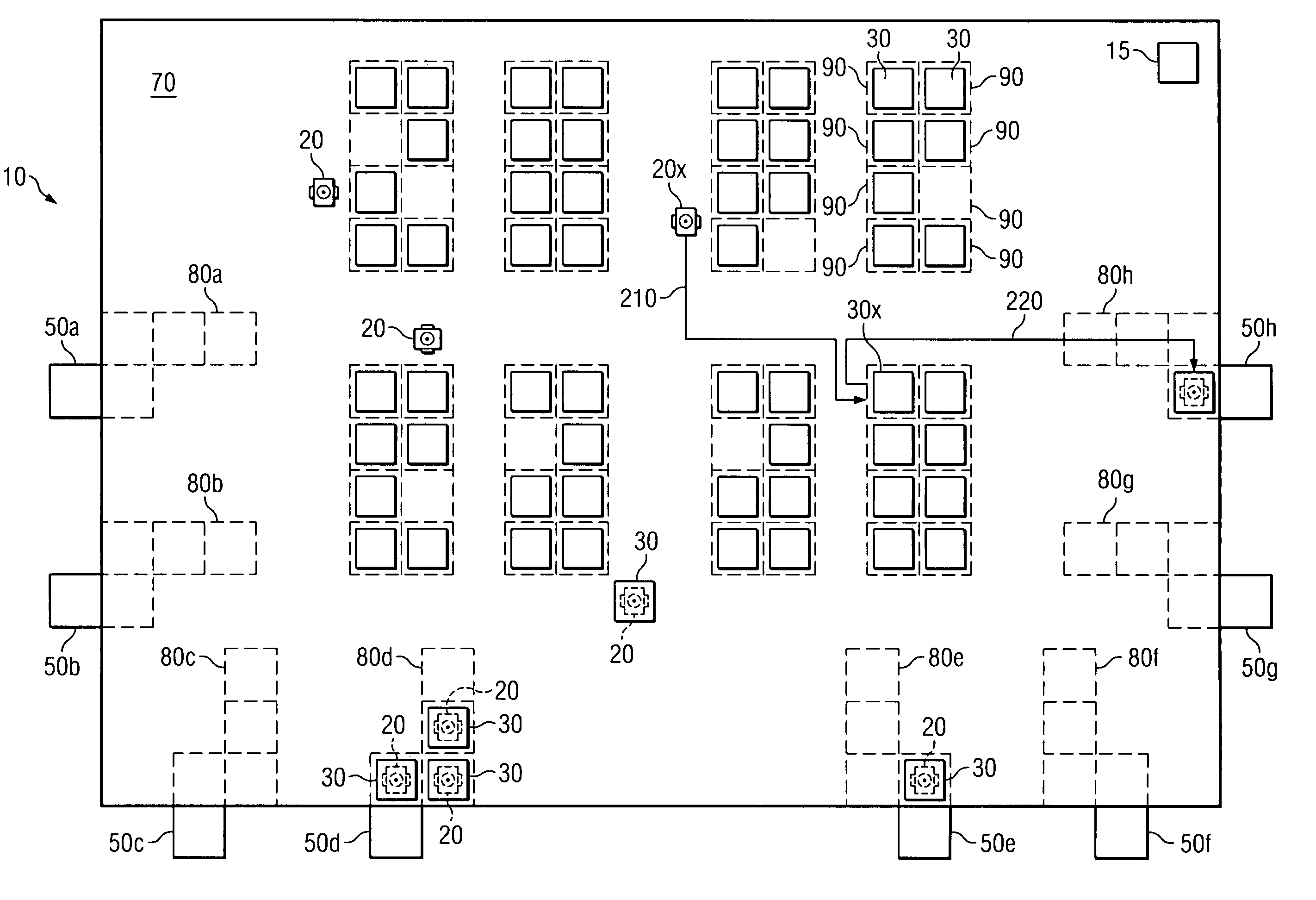

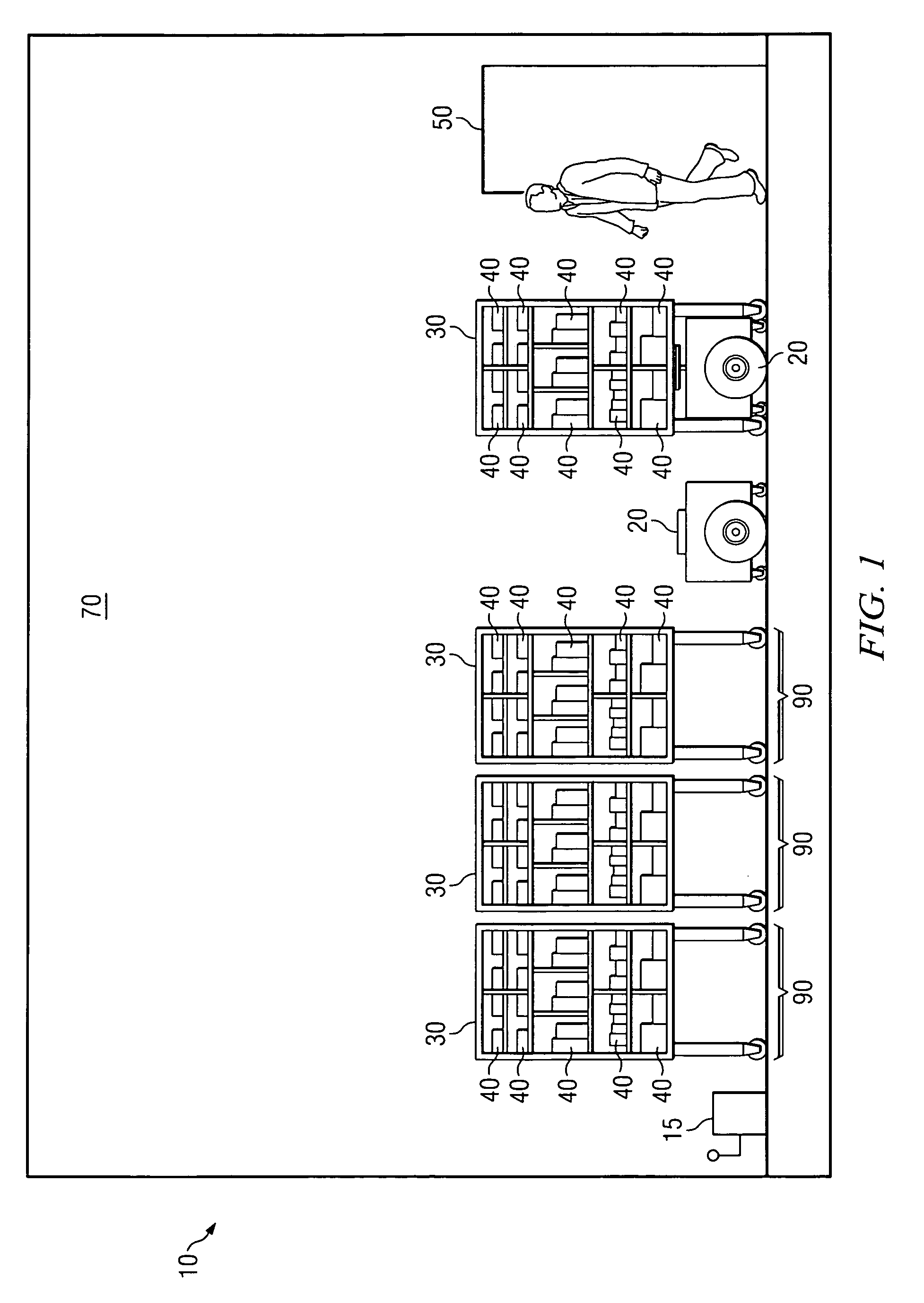

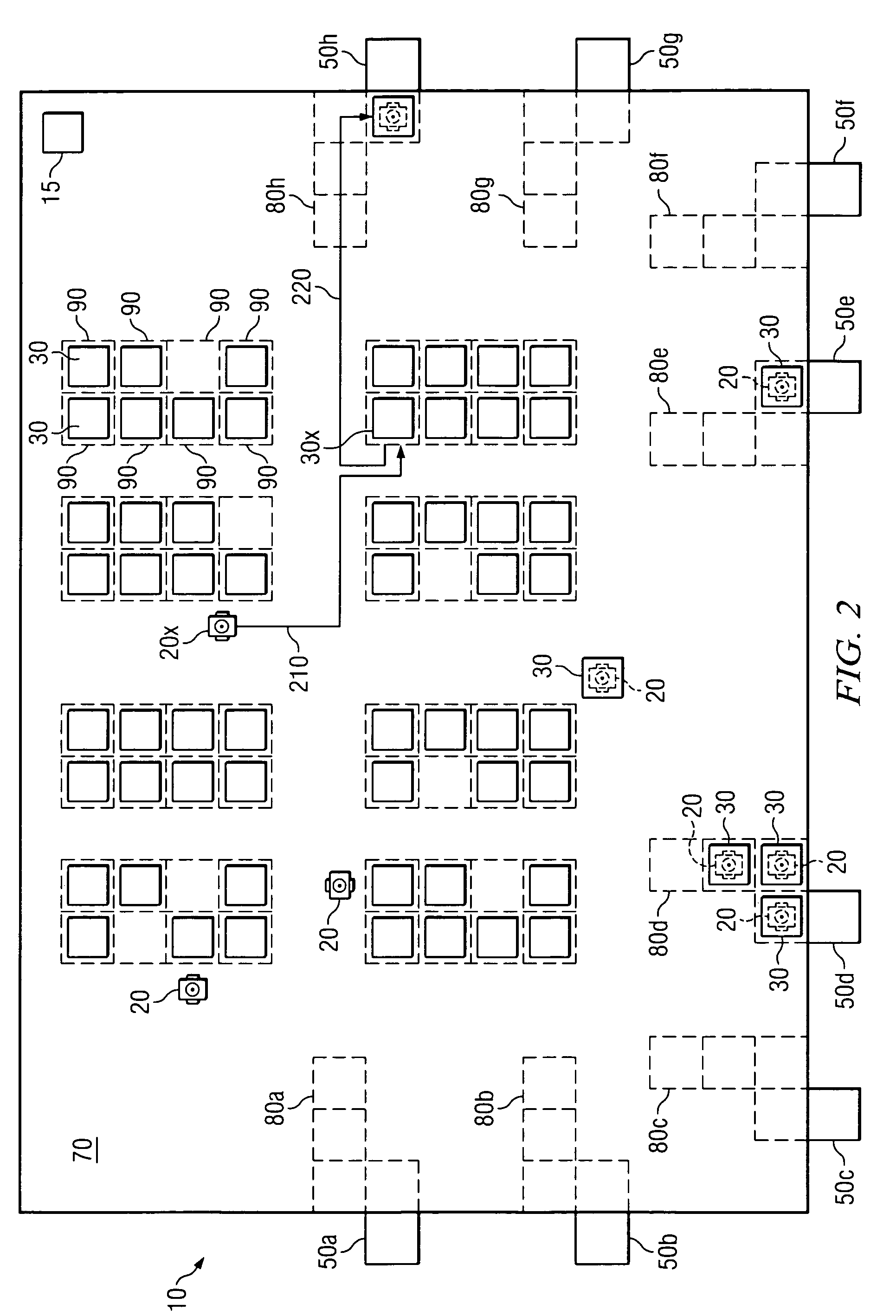

InactiveUS8219558B1Simplify the data capture, organization, and secure storage of a listLow costData processing applicationsDigital data processing detailsDigital imagingComputer terminal

The present invention relates to inventory management solutions, and in particular, to methods and systems for inventorying items and property over wireless and data networks, using digital imaging, positioning, RFID, and data terminals. The user experience in performing inventory management is simplified and enhanced over existing methods.

Owner:TRANDAL DAVID SCOTT +1

Method and system for retrieving inventory items

ActiveUS7894933B2Disadvantages and reduced eliminatedInventory reduced eliminatedDigital data processing detailsIndustrial engineeringInventory system

A method for retrieving inventory items within an inventory system includes receiving a retrieval request that identifies an inventory item and selecting, from a plurality of inventory stations, an inventory station to fulfill an order associated with the retrieval request. The method also includes selecting an inventory holder from a plurality of inventory holders that store the inventory item and selecting, from a plurality of mobile drive units, a mobile drive unit to move the selected inventory holder to the selected inventory station.

Owner:AMAZON TECH INC

Method and system for replenishing inventory items

ActiveUS7894932B2Disadvantages and reduced eliminatedInventory reduced eliminatedDigital data processing detailsLibrary scienceInventory system

A method for storing inventory items in an inventory system includes receiving a replenish request identifying an inventory item to be stored in an inventory system and determining a classification of the inventory item to be stored. The method also includes selecting an inventory holder from a plurality of inventory holders based, at least in part, on the classification of the inventory item to be stored and a classification of one or more other inventory items currently stored in the selected inventory holder. Additionally, the method includes transmitting information identifying the selected inventory holder to a mobile drive unit.

Owner:AMAZON TECH INC

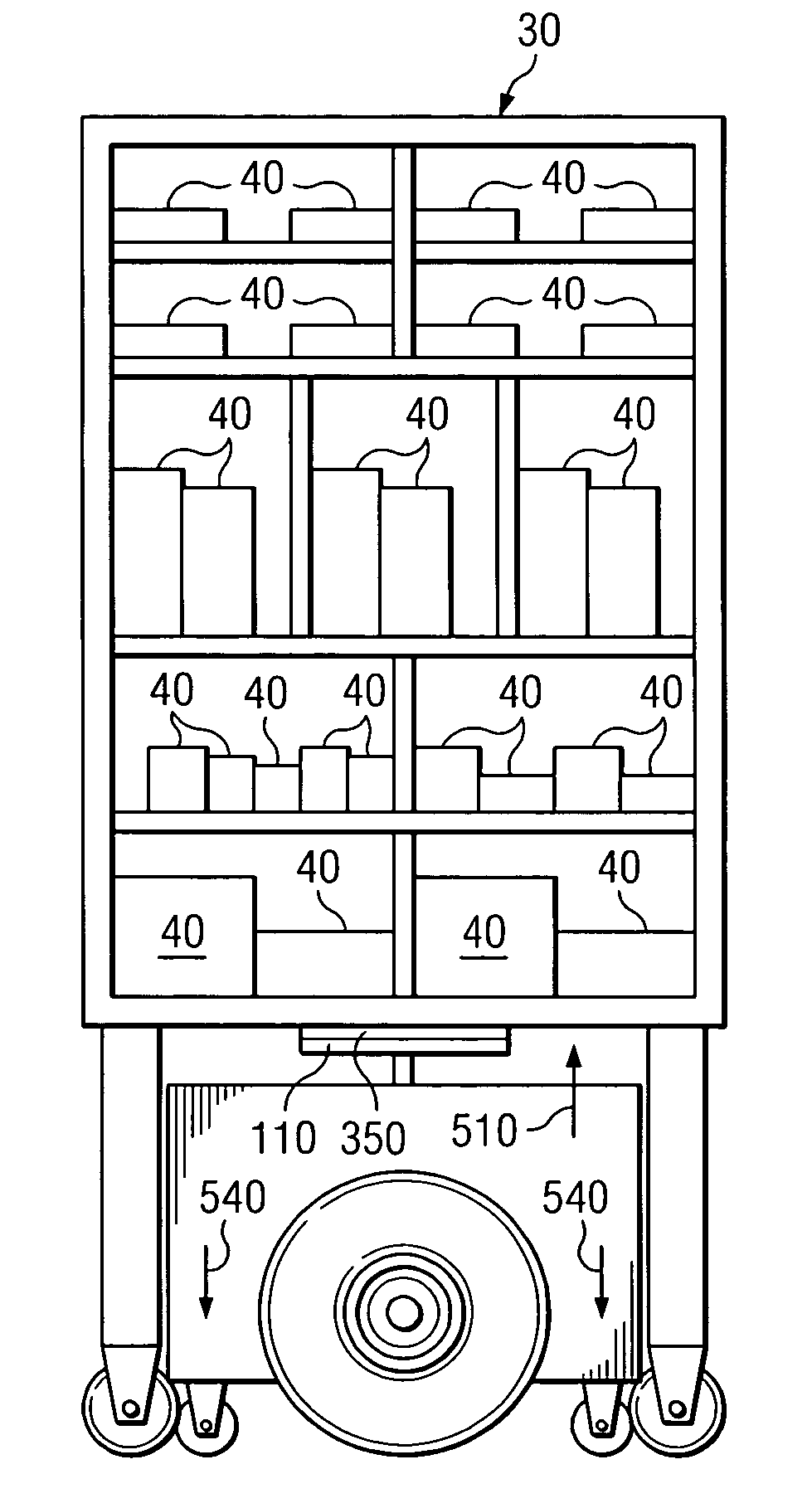

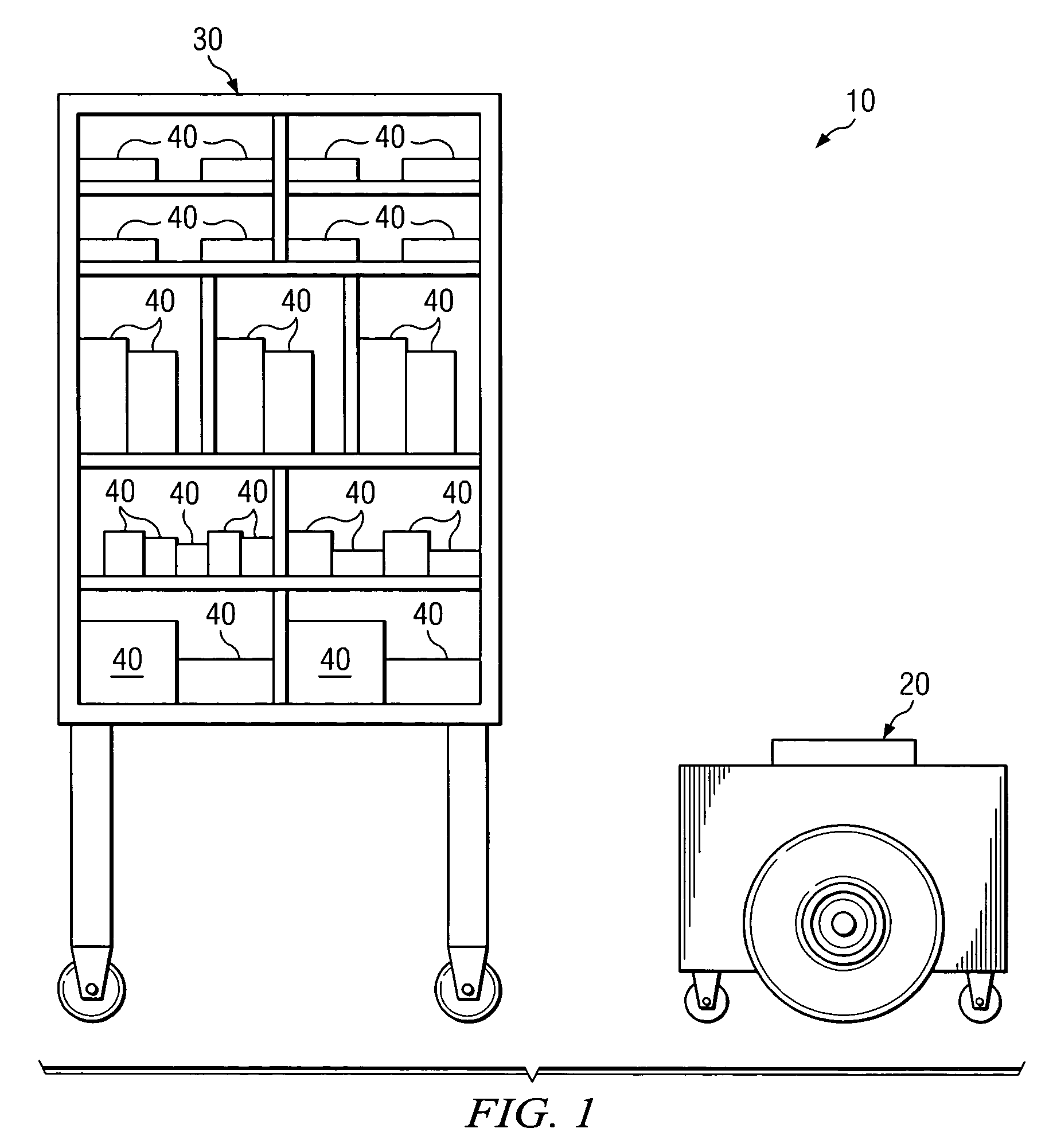

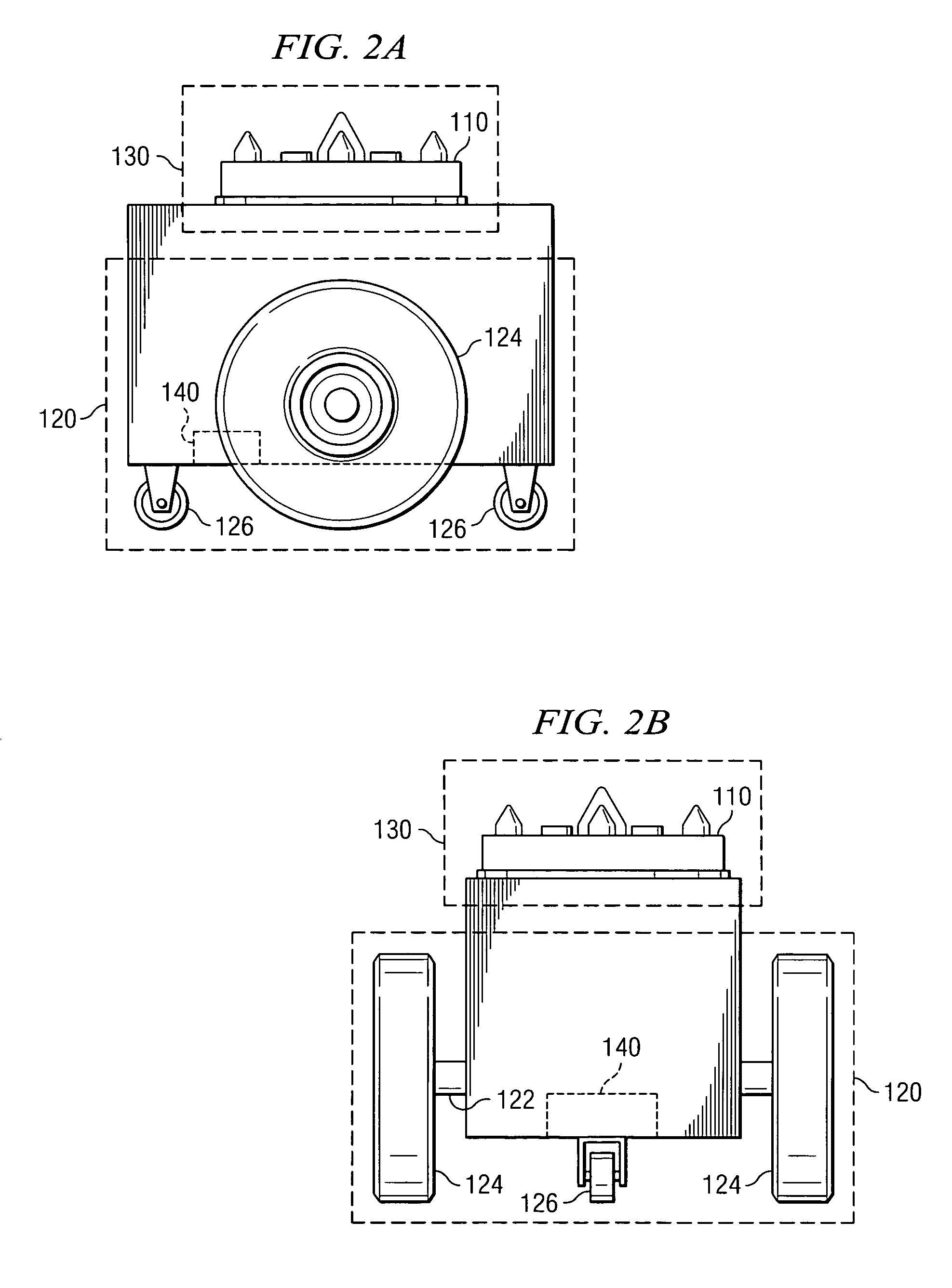

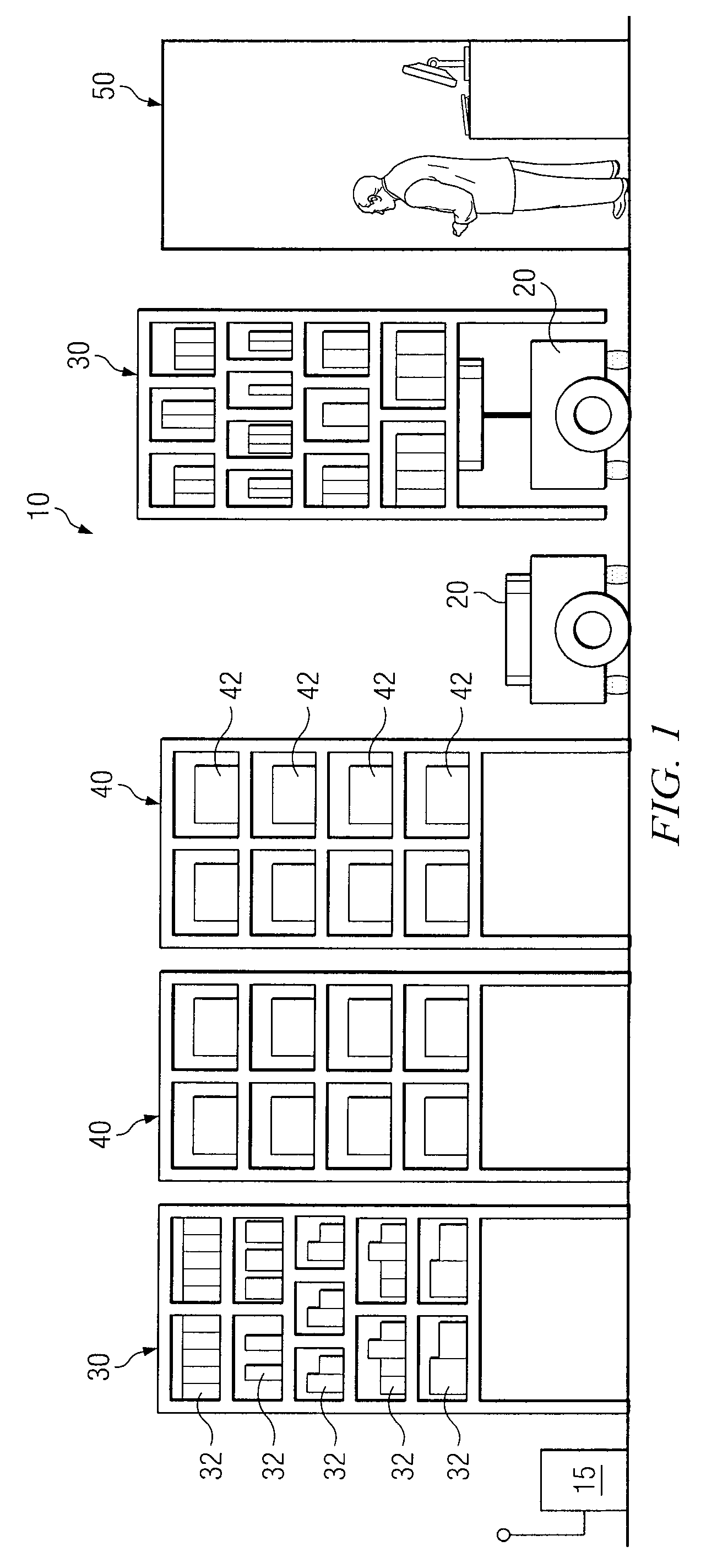

Inventory system with mobile drive unit and inventory holder

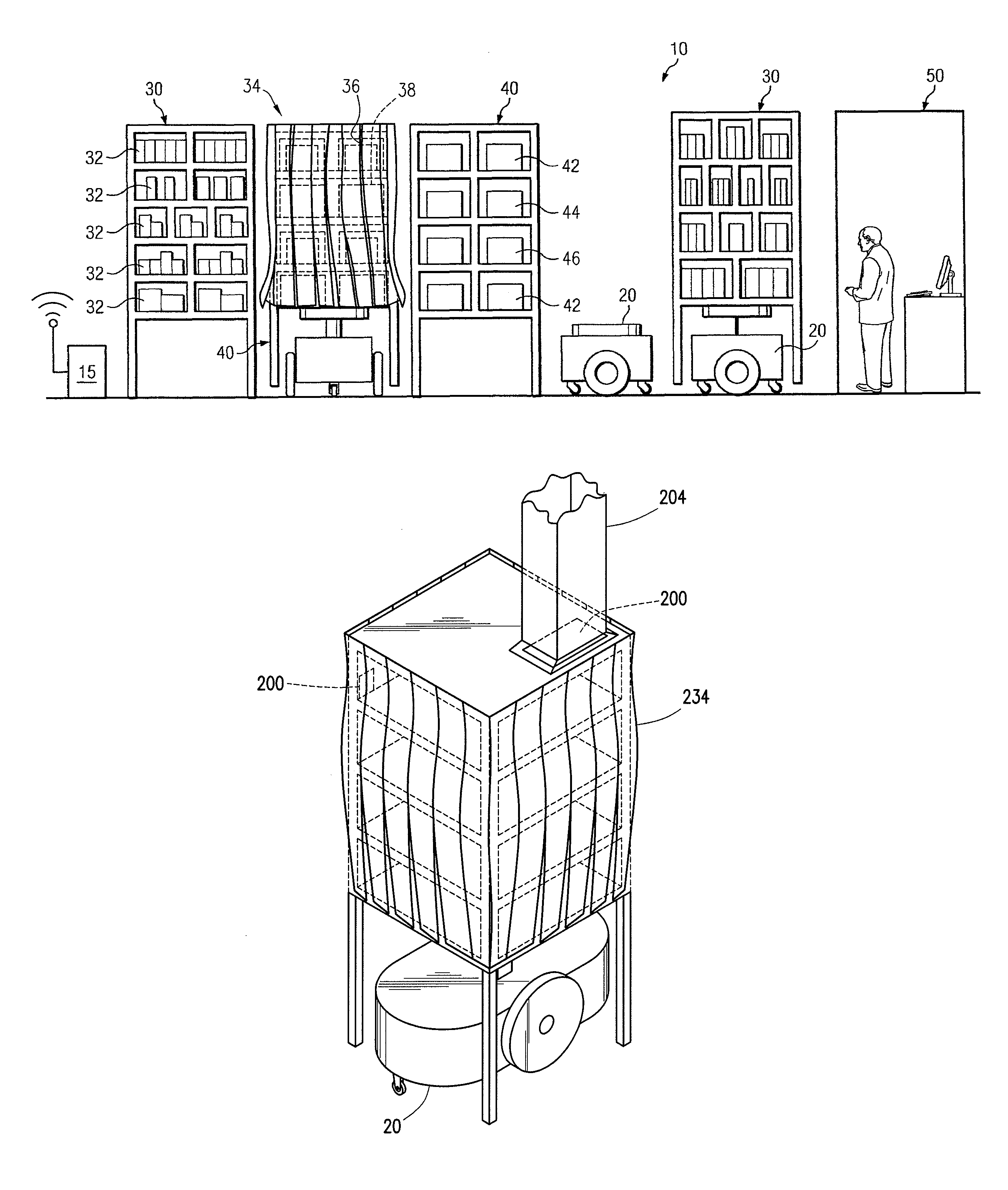

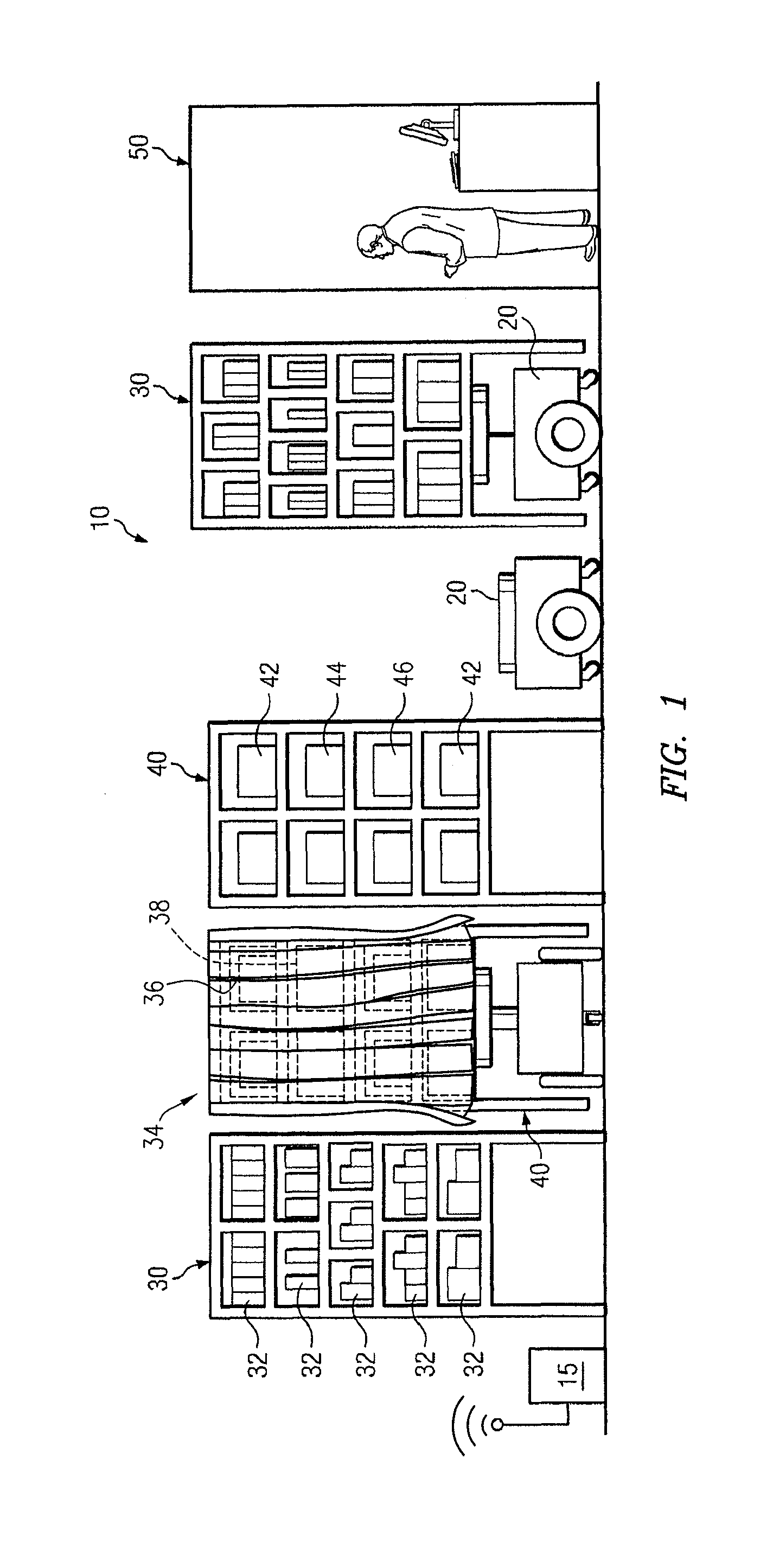

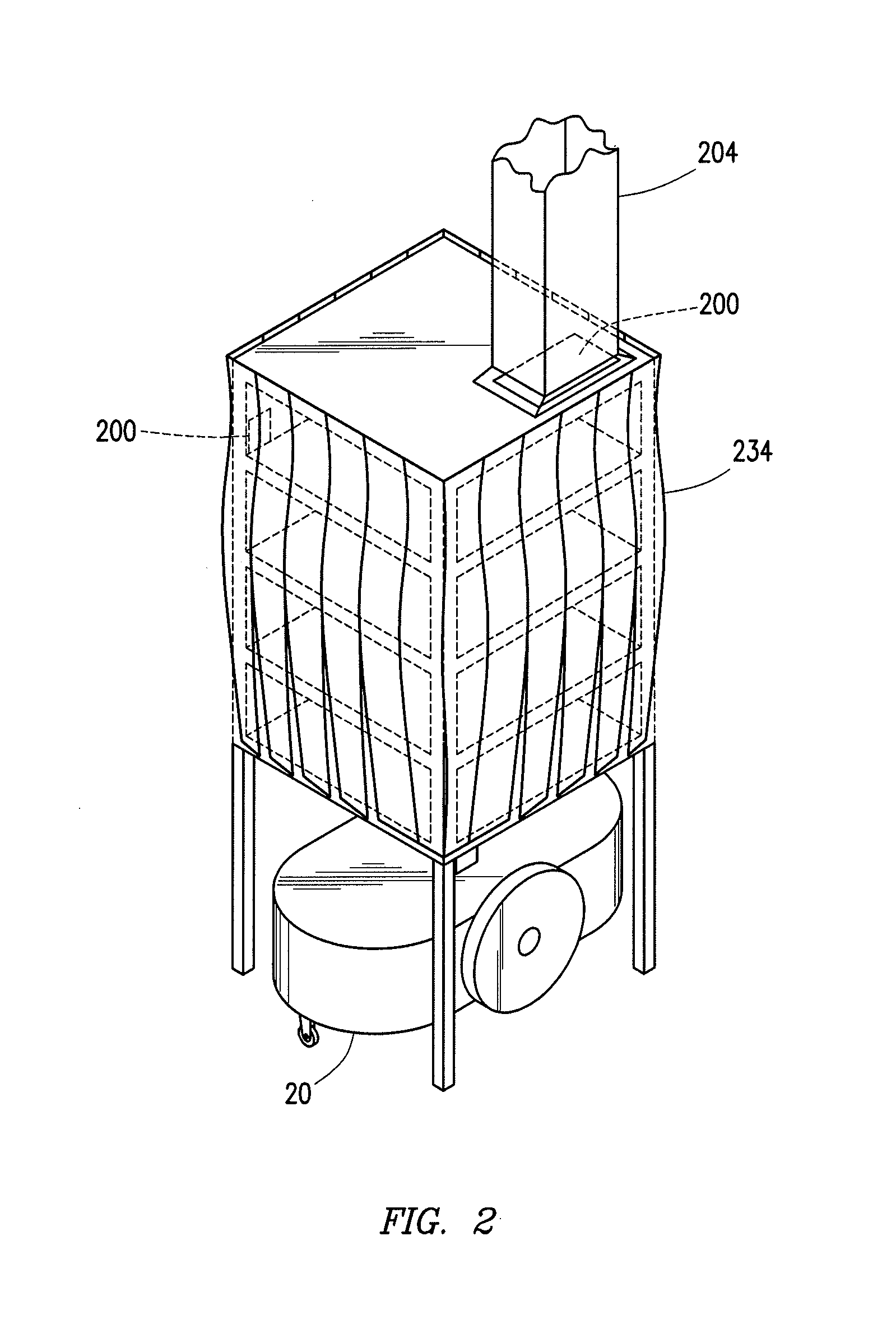

ActiveUS20060210382A1Disadvantages and reduced eliminatedInventory reduced eliminatedCurtain suspension devicesVehicle with removable loadingMechanical engineeringInventory system

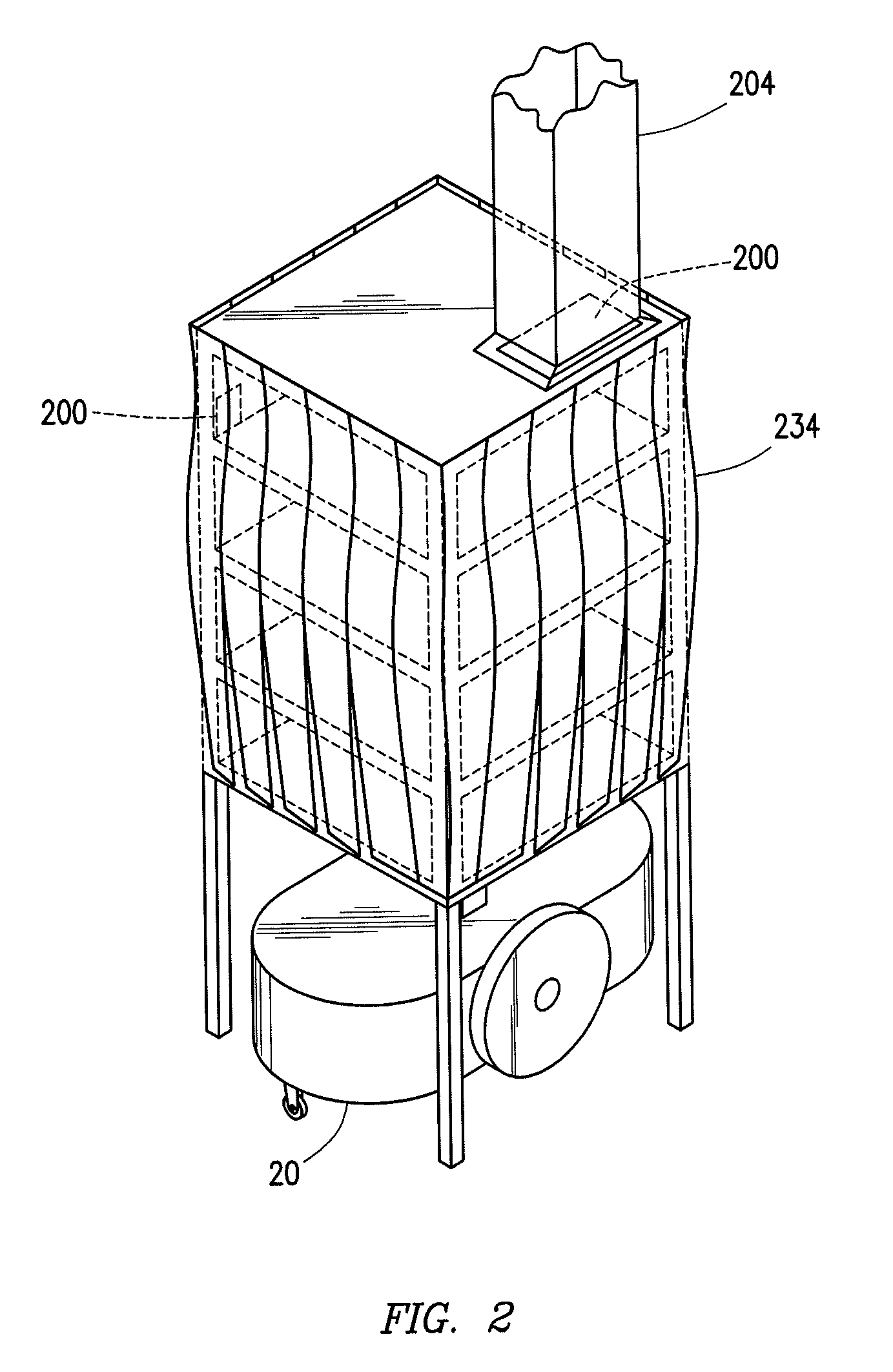

A system for transporting inventory includes an inventory holder and a mobile drive unit. The inventory holder includes a frame capable of storing inventory items and a docking plate capable of receiving a docking head from underneath. The mobile drive unit, includes a docking head capable of coupling to the docking plate and a drive module capable of propelling the mobile drive unit. The mobile drive unit is further capable to move the inventory holder when the docking head is coupled to the inventory holder.

Owner:AMAZON TECH INC

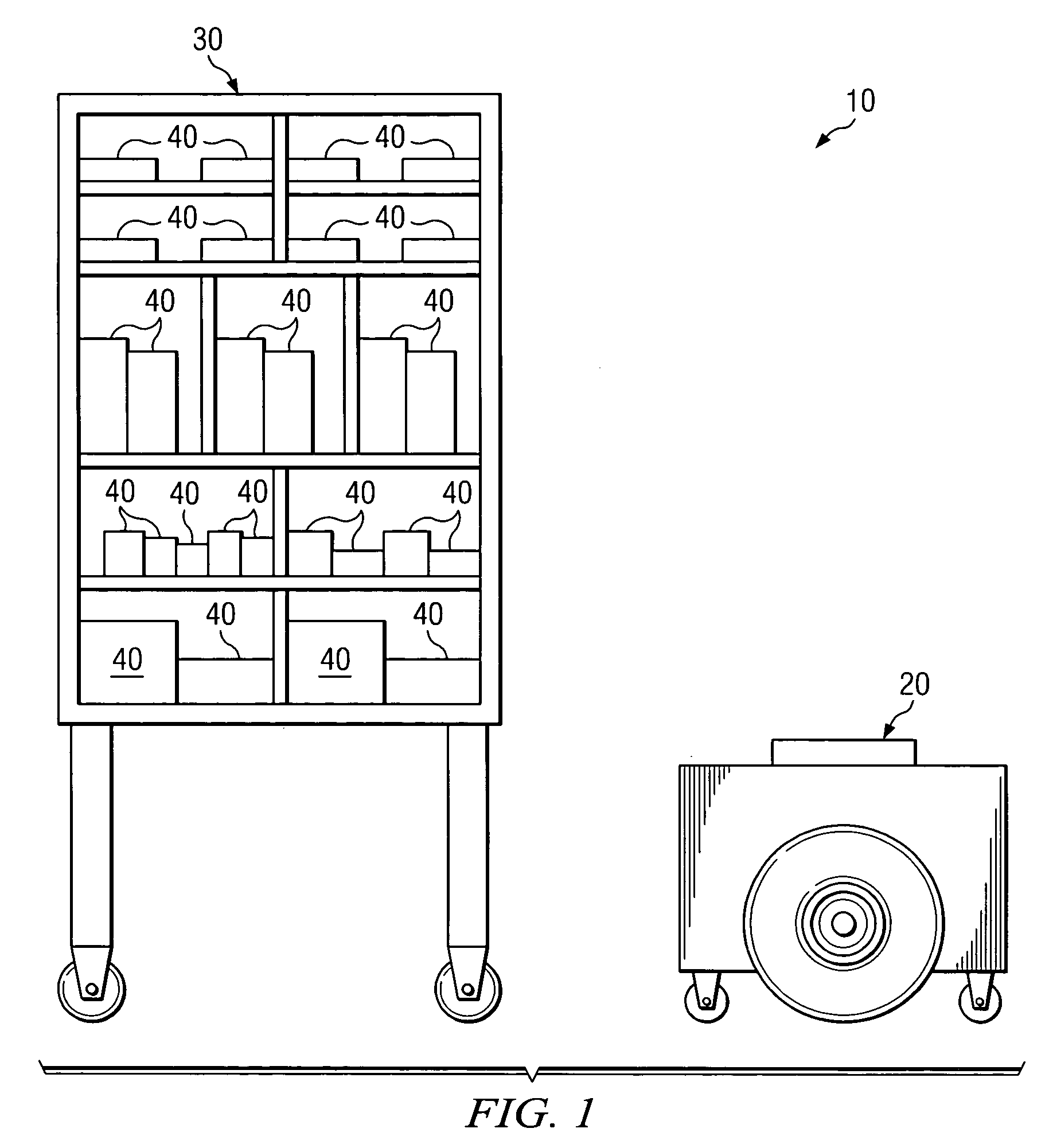

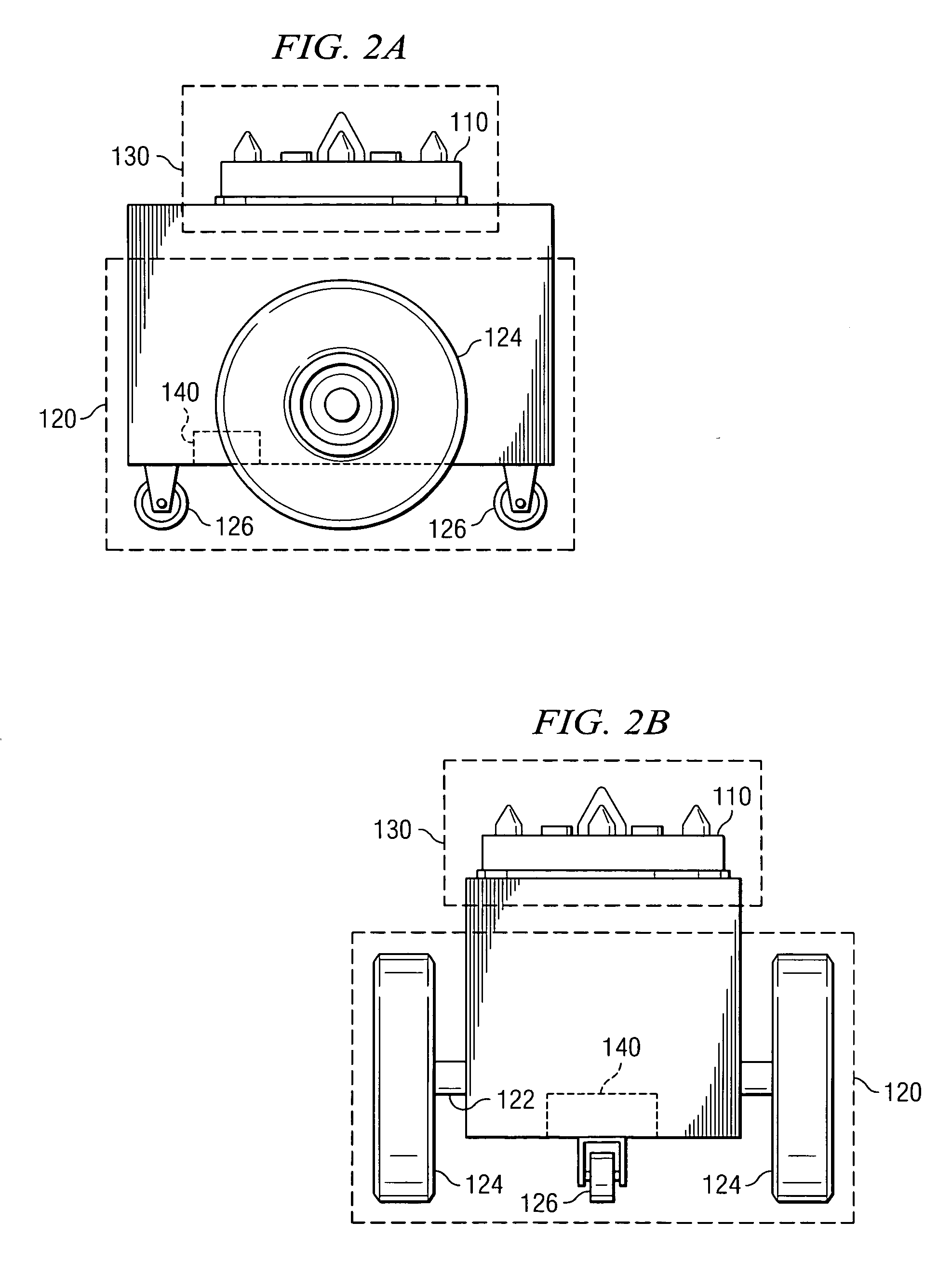

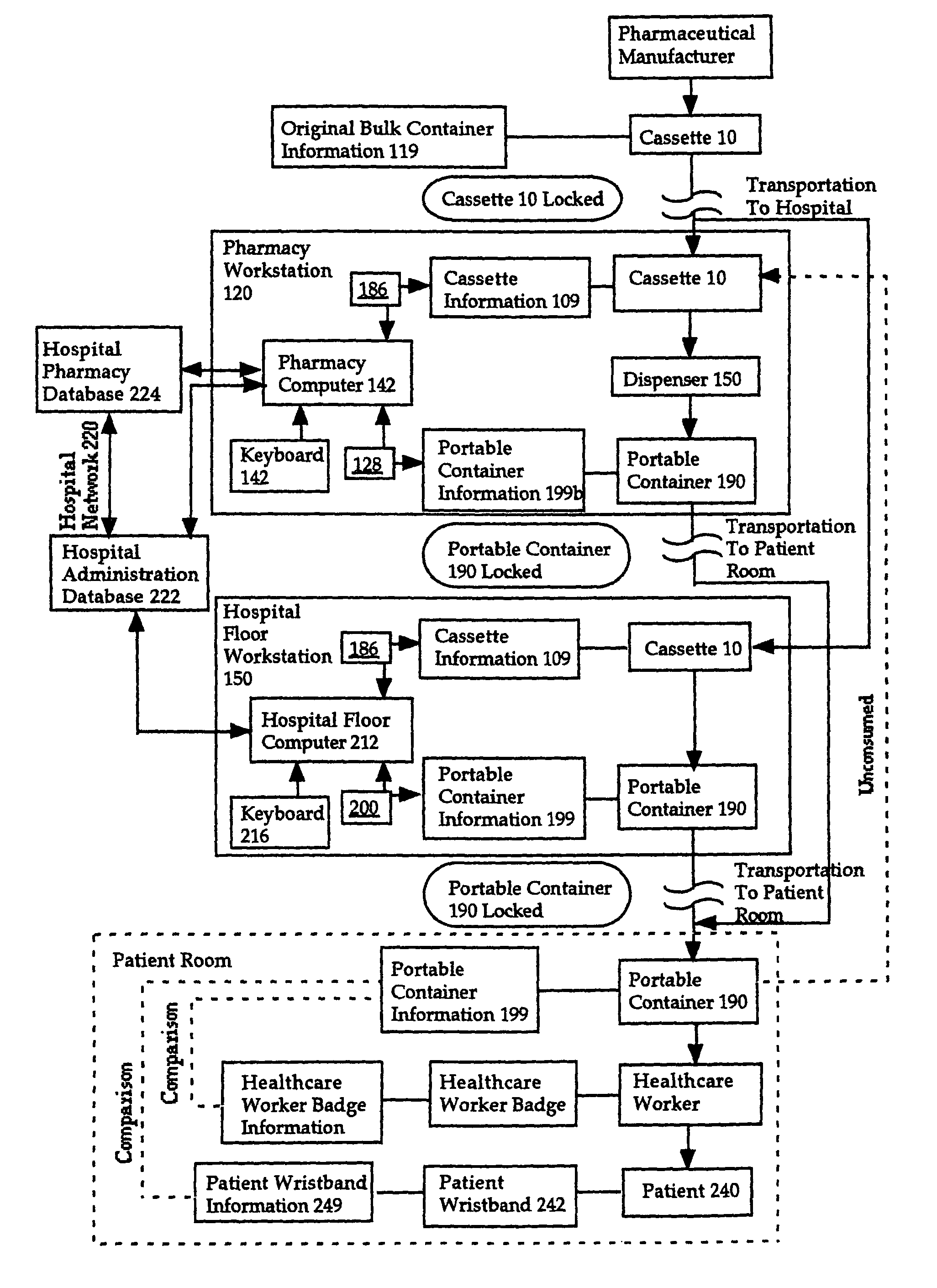

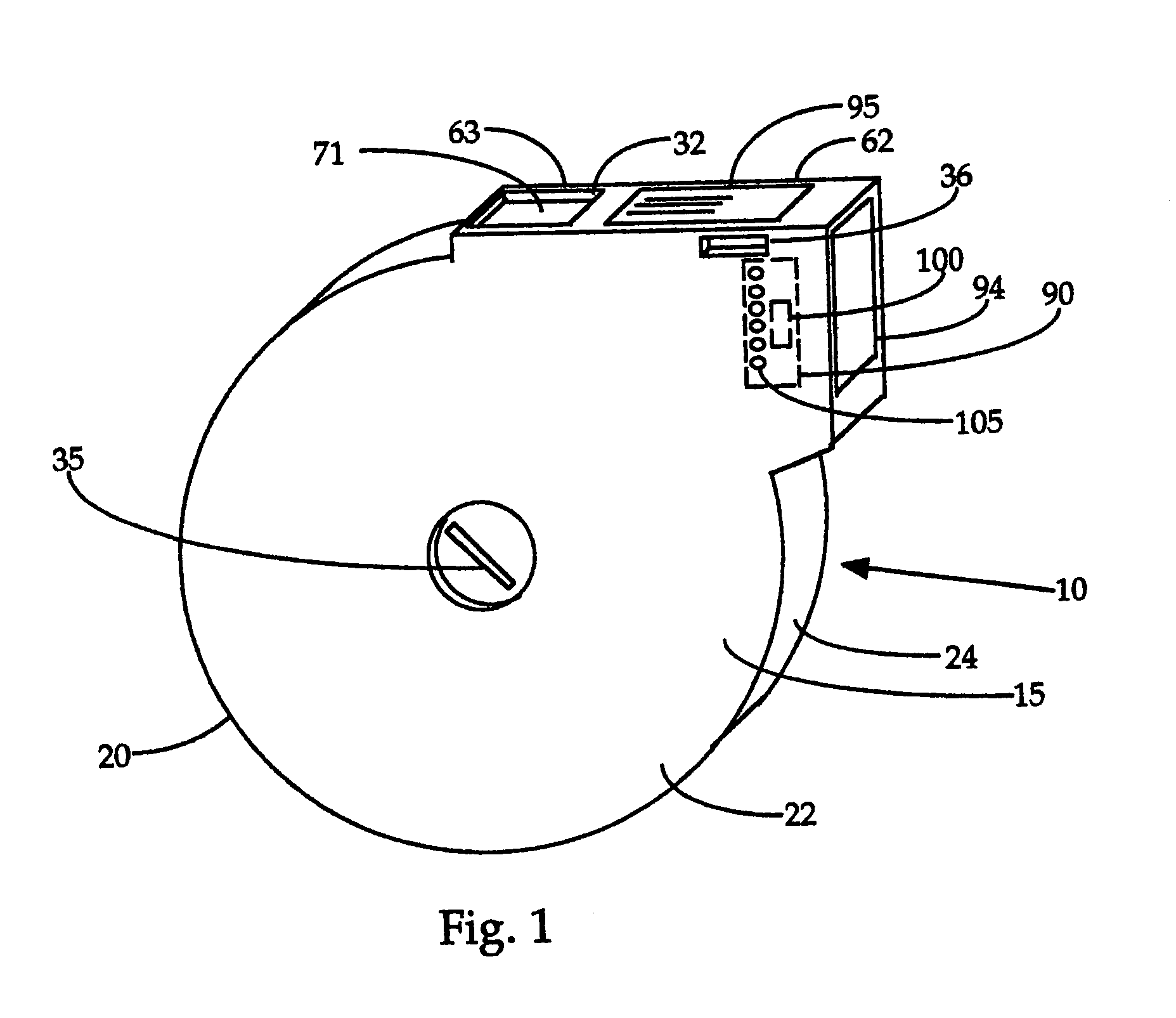

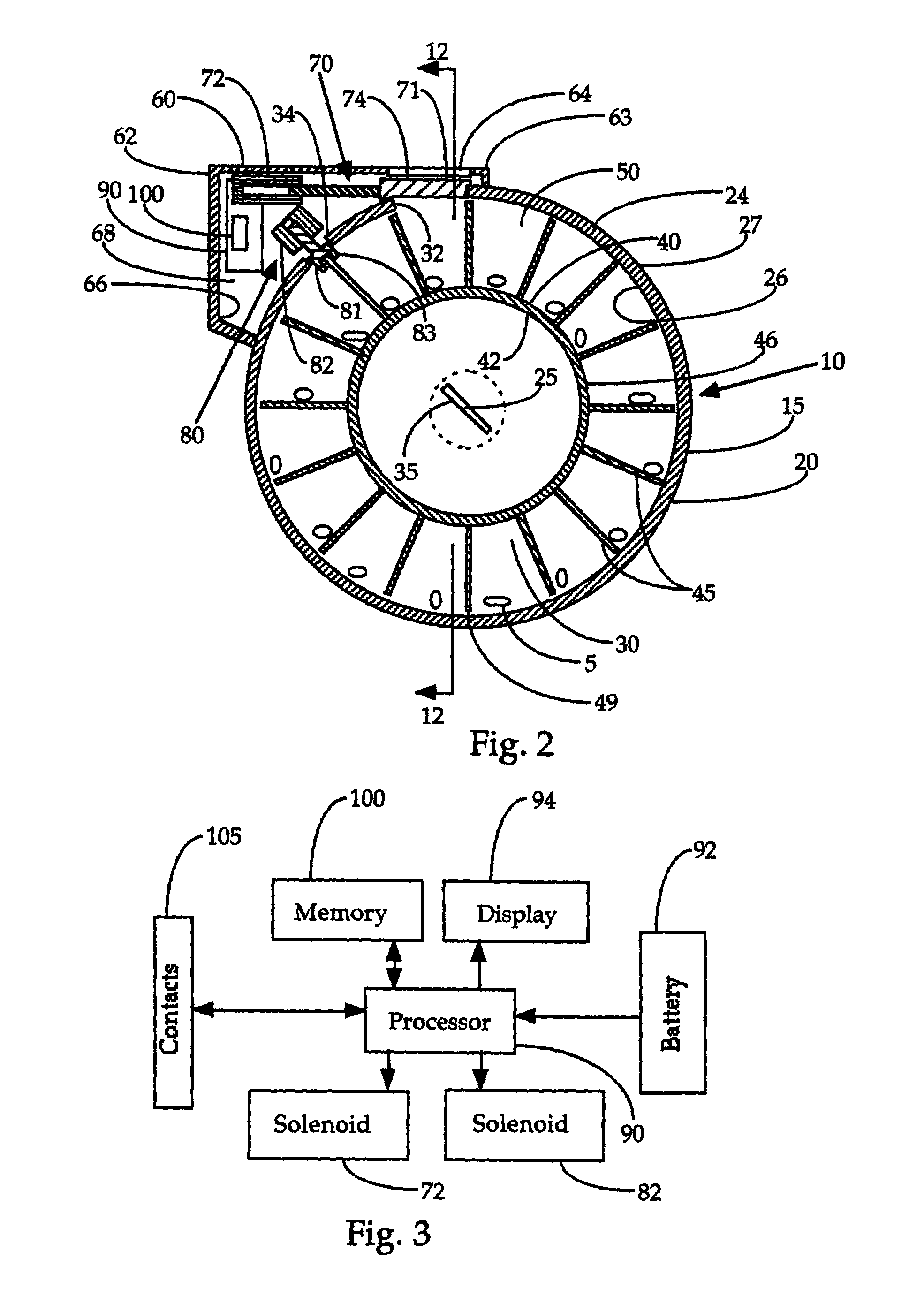

Interactive medication cassette

InactiveUS7006894B2Easy to distinguishIncrease the number ofDrug and medicationsPharmaceutical containersMagnetic tapeMedicine

This invention relates to an interactive medication cassette with a machine readable and writable information strip that contains information corresponding to the medication in the cassette. The interactive medication cassette holds the medication and couples the corresponding information to the medication. The cassette is designed for use in a medication distribution and inventory system that includes at least one medication dispensing machine having a sensor for reading the information in the strip and updating or altering this information when medication is added to or removed from the cassette. The cassette travels with the medication during the distribution of the medication to a patient, and its information is reported to one or more memory devices or hospital or pharmacy data base during this process. The cassette is filled by a pharmacy dispensing machine holding a bulk container filled with a particular type of medication and a singulator for counting the quantity of medication added to the cassette. The pharmacy dispensing machine alters the information strip to include medication and quantity information corresponding to the dispensed medication. The cassette is closed and locked to prevent unauthorized access during transport to a hospital floor workstation. A hospital floor dispensing machine incrementally dispense the medication from the cassette, and updates the information strip with additional information including the quantity of medication dispensed from the cassette. When the cassette is returned to the pharmacy and its unused contents is emptied into the bulk container, the information strip on the cassette automatically updates an information strip on the bulk container to indicate the number of doses of medication added to the bulk container. In this manner, a reliable medication distribution and inventory system is achieved while maintaining improved control over the access to the medication on the hospital floor.

Owner:SOUTHWEST TECH INNOVATIONS

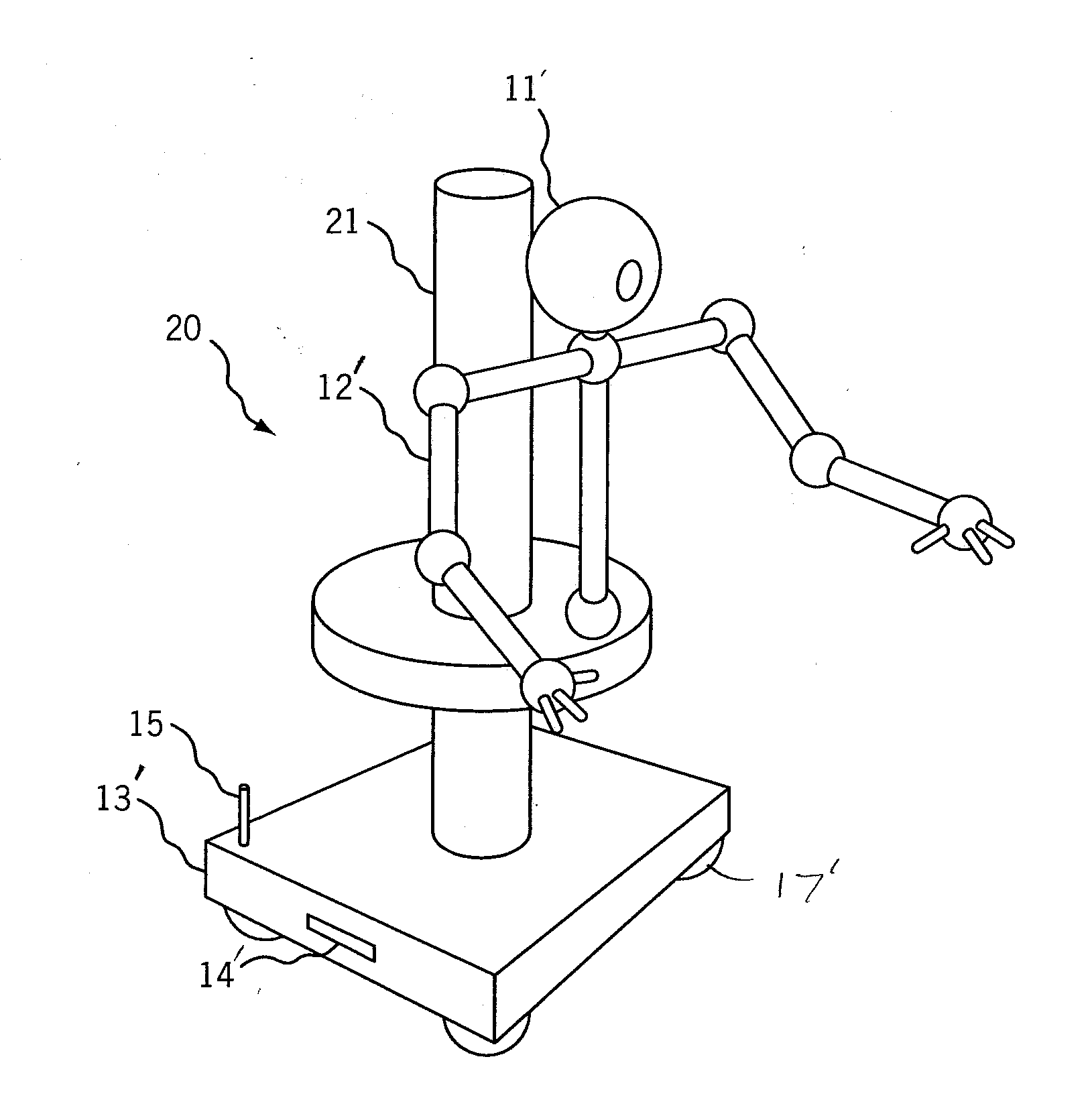

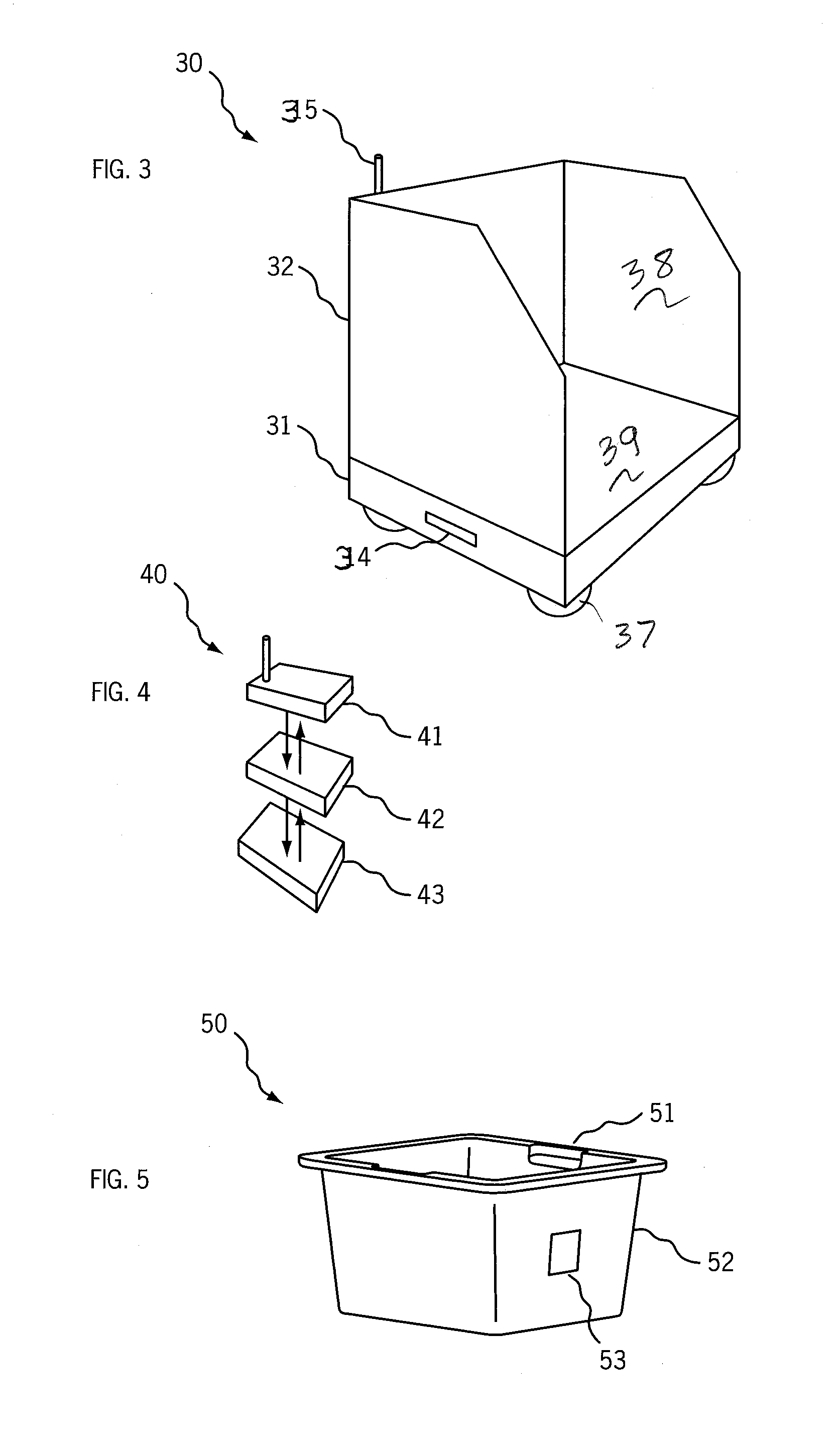

Robotic manipulator for warehouses

InactiveUS20150360865A1Programme-controlled manipulatorStorage devicesRobotic systemsCommunications system

A warehouse robotic system includes a picker robot, including a mobile base, an environment sensing system, a communications system and at least one manipulator. The picker robot can also include an object sensing system. The robotic system also includes a control system, including a communications system and a robot controller which communicates with the picker robot and is connected to an associated warehouse inventory system. The picker robot is adapted to maneuver to a first location, retrieve at least one associated object from the first location, transport the at least one associated object to a second location and place the at least one associated object at the second location. The system can also include a carrier robot and a storage container.

Owner:HDT EXPEDITIONARY SYST

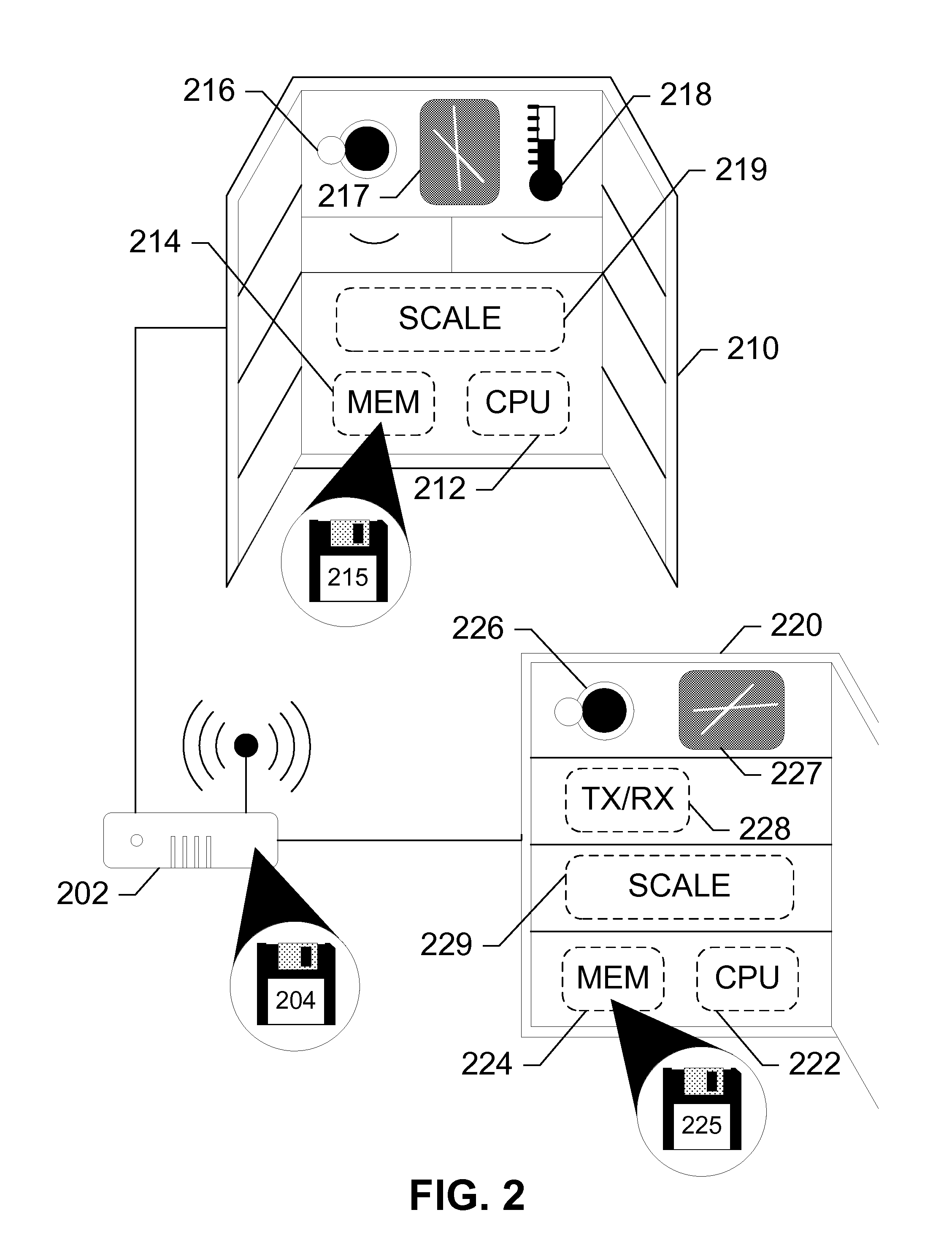

Inventory system with climate-controlled inventory

An inventory system includes a first inventory holder positioned in a first climate-controlled zone of a workspace that is at a below-freezing temperature. The system also includes a second inventory holder positioned in a second climate-controlled zone that is at an above-freezing refrigerated temperature. The system also includes a third inventory holder positioned in a third climate-controlled zone that is at ambient conditions. The system also includes a management module operable to receive an order for the first inventory item, an order for the second inventory item, and an order for the third inventory item. The management module instructs a first mobile drive unit to transport the first inventory holder to an inventory station, instructs a second mobile drive unit to transport the second inventory holder to the inventory station, and instructs a third mobile drive unit to transport the third inventory holder to the inventory station.

Owner:AMAZON TECH INC

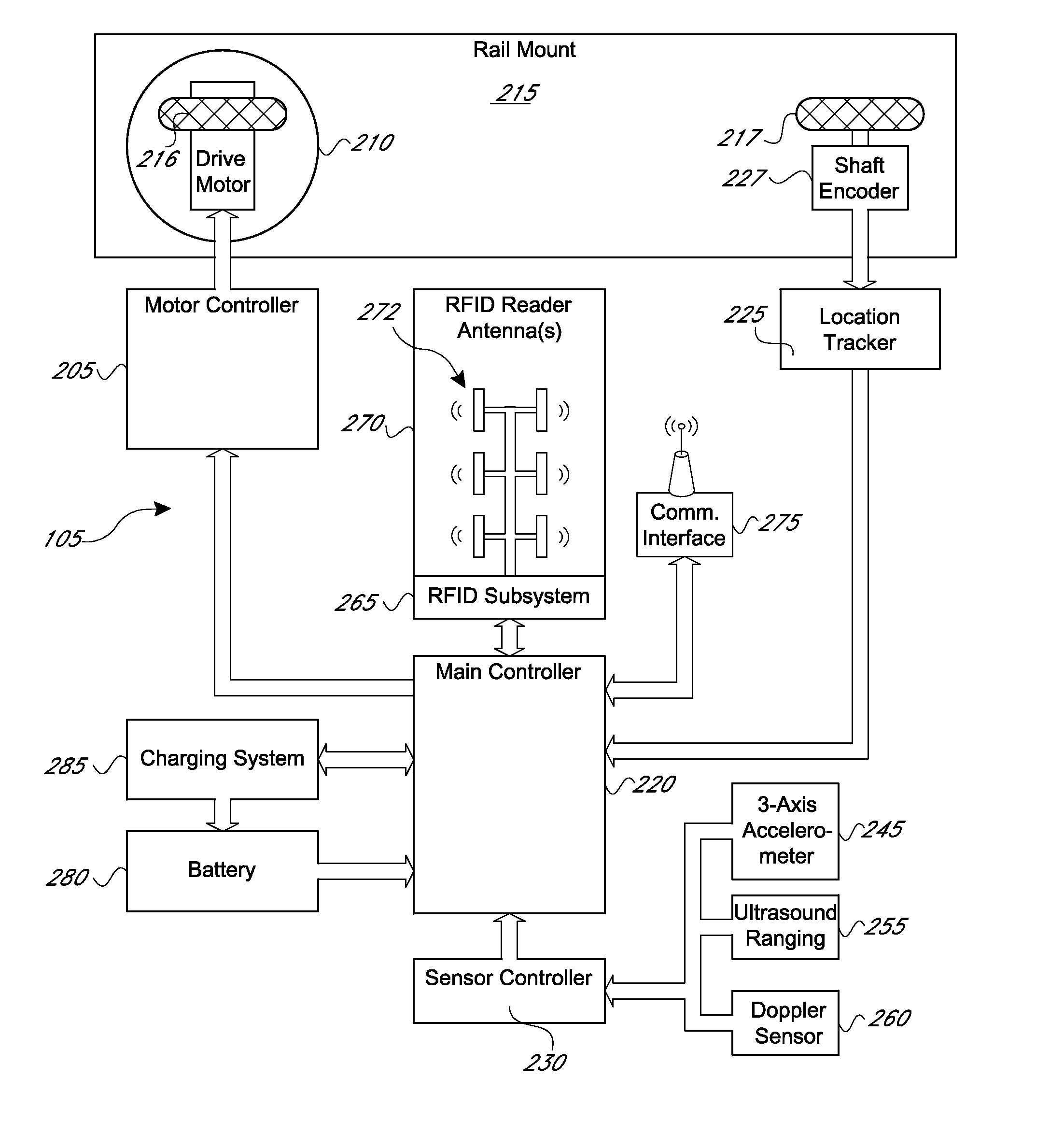

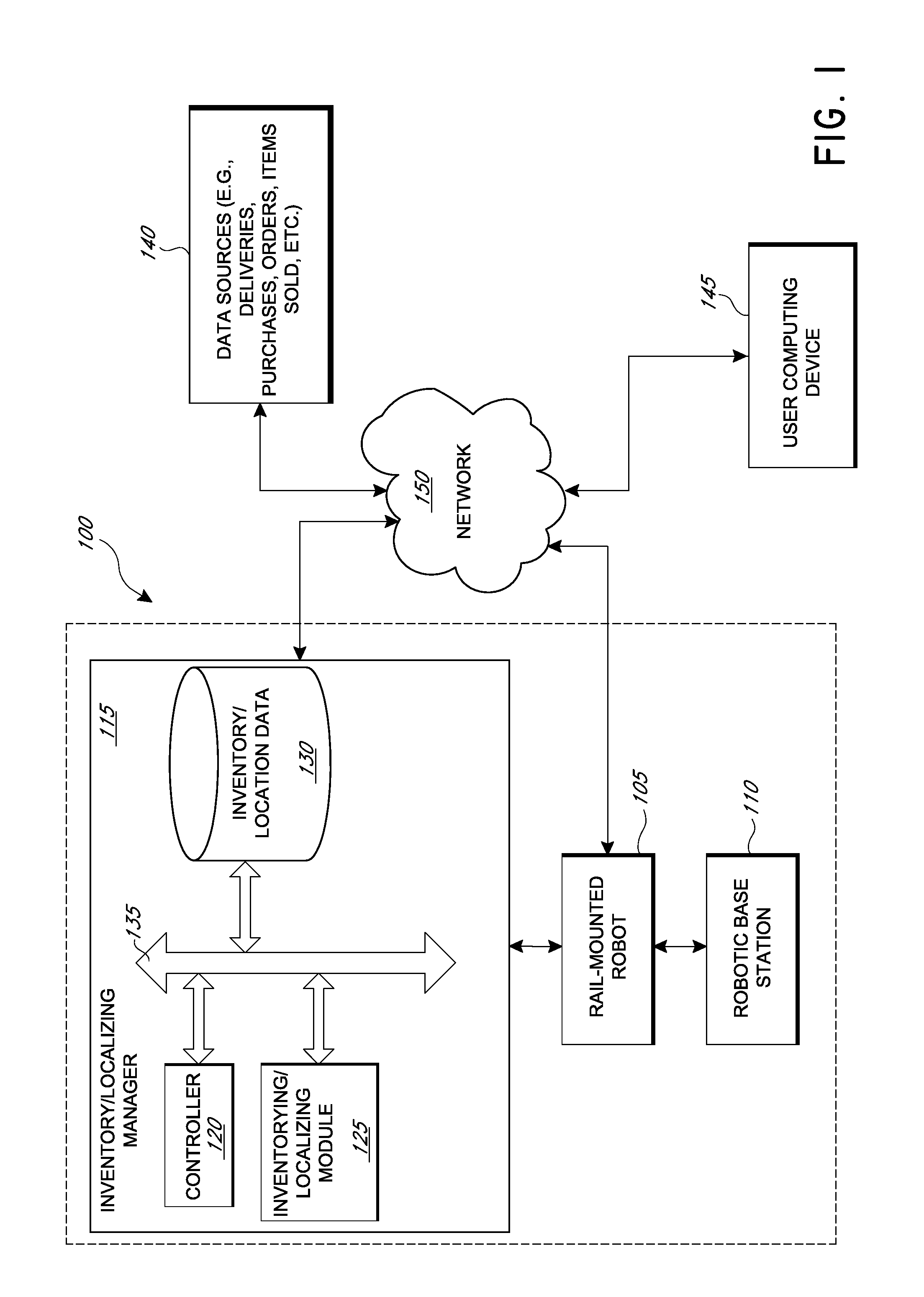

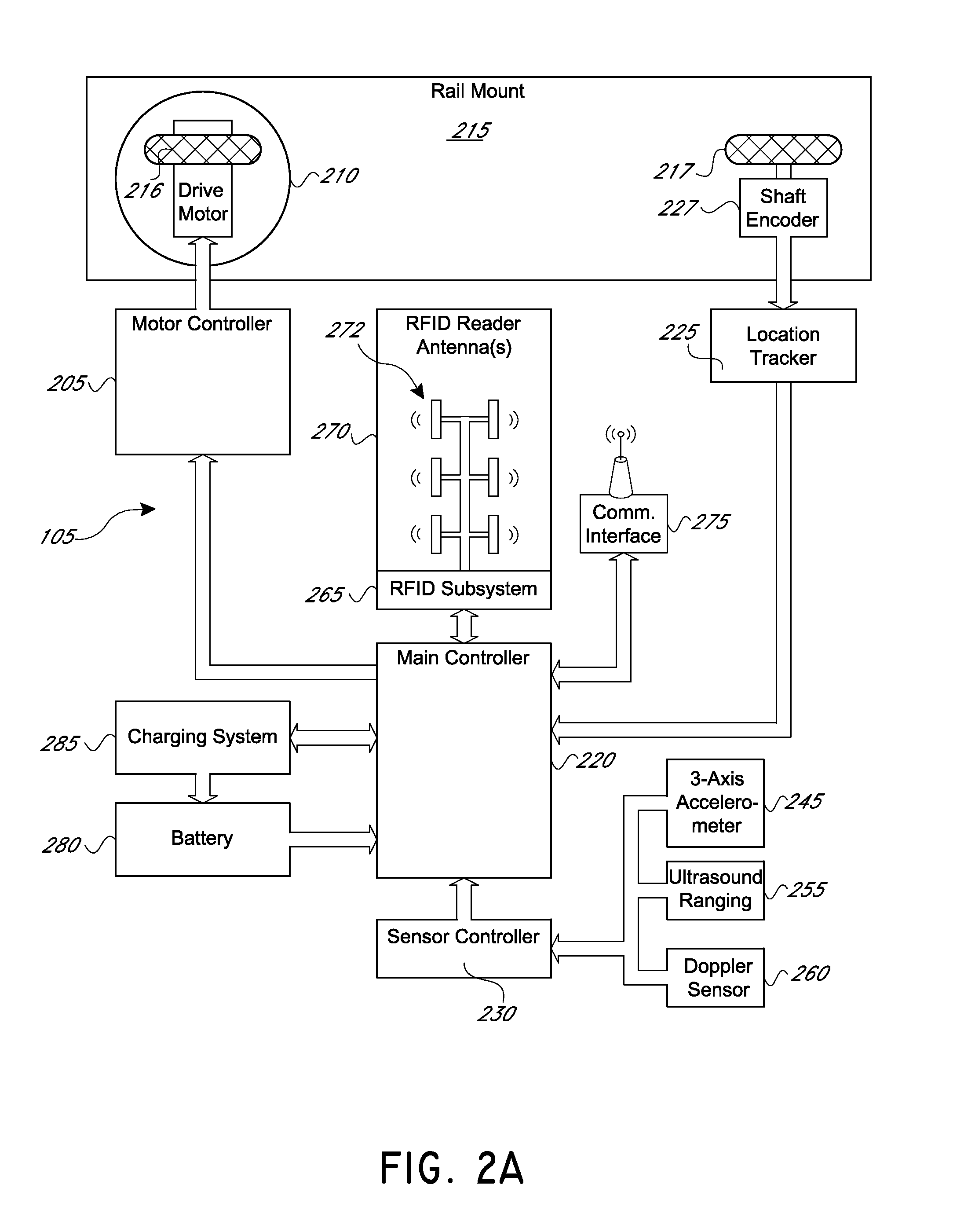

Rail-mounted robotic inventory system

Examples of a rail-mounted robotic inventory system are provided. The system includes a rail-mounted robot having an electronic tag reader configured to receive electronic tag data from electronic tags associated with inventory items. The system can include a navigation module configured to direct the rail-mounted robot along a rail through an inventory area, detect obstacles, and determine a position of the rail-mounted robot within the inventory area. The system can include an inventory identification module configured to receive the electronic tag data from the rail-mounted robot and identify and / or locate the inventory items in the inventory area based at least partly on the electronic tag data.

Owner:RFID RESOLUTION TEAM

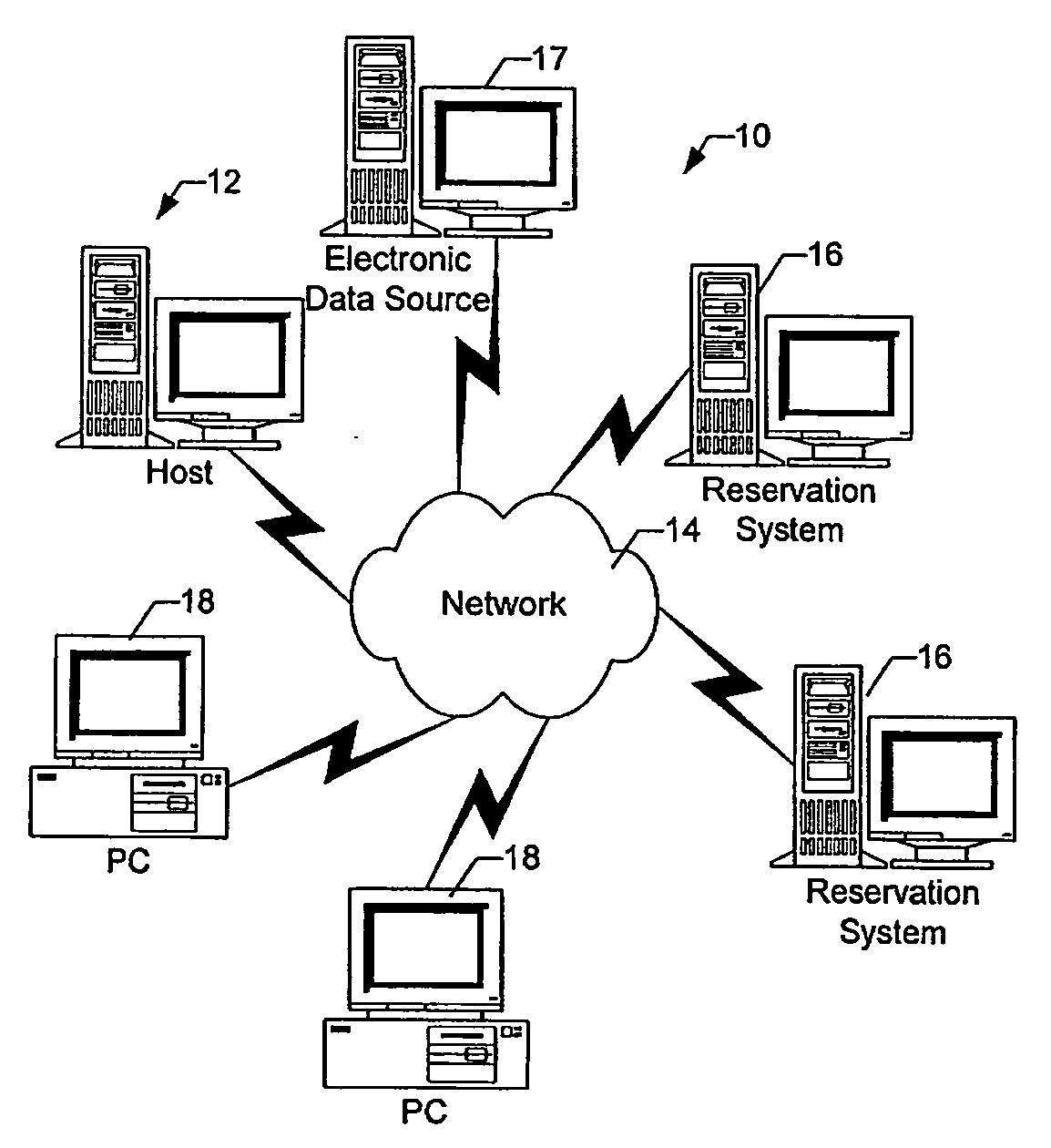

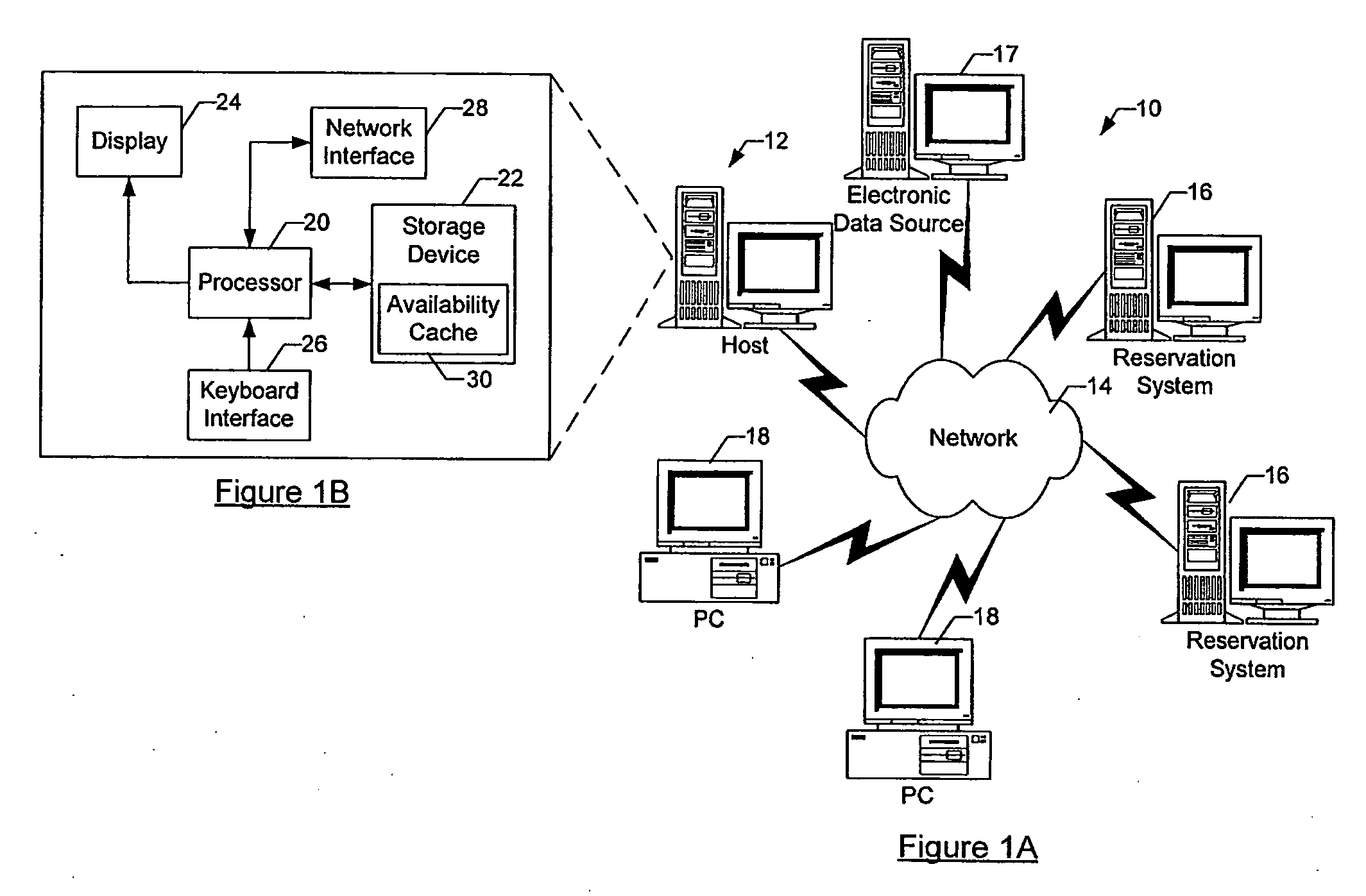

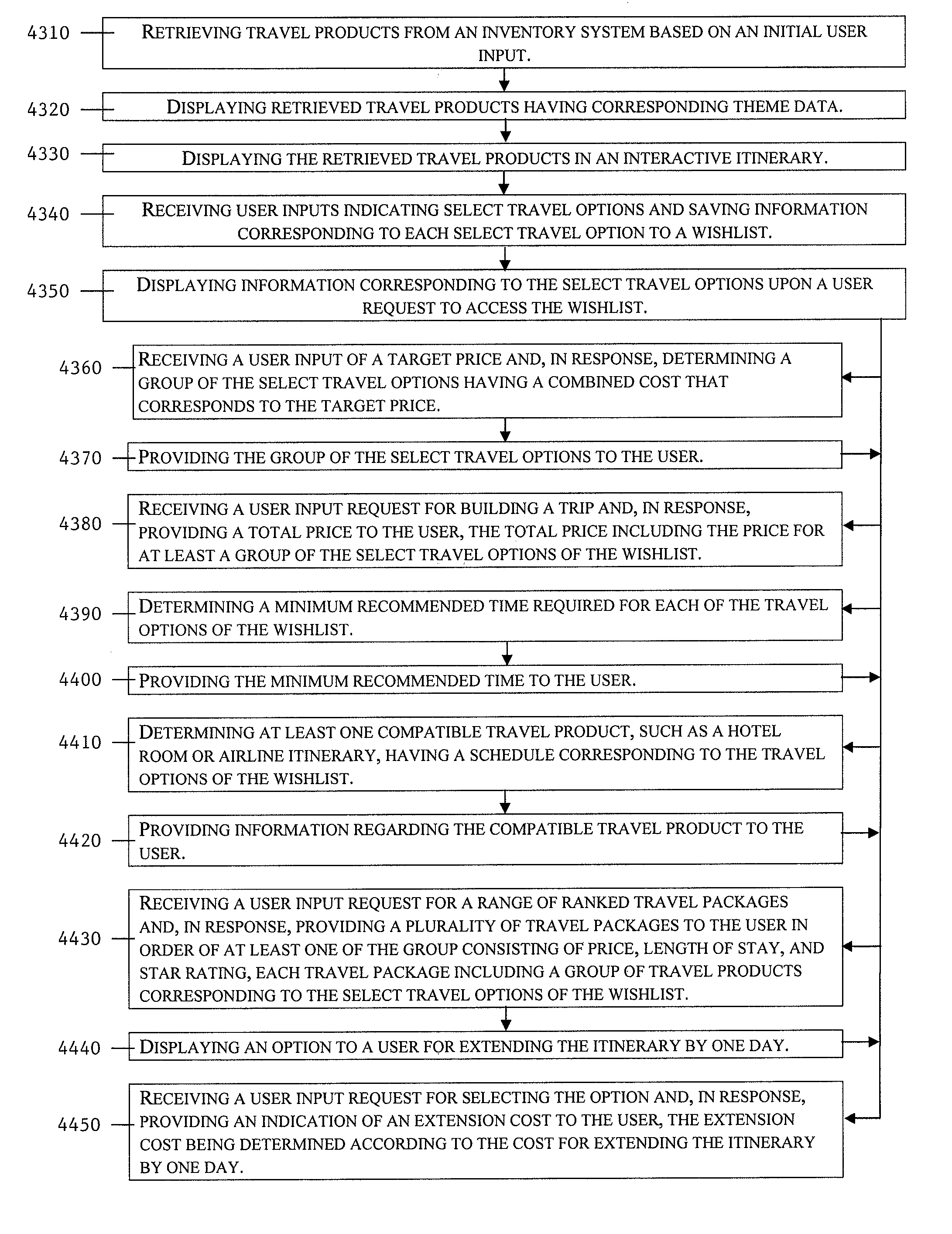

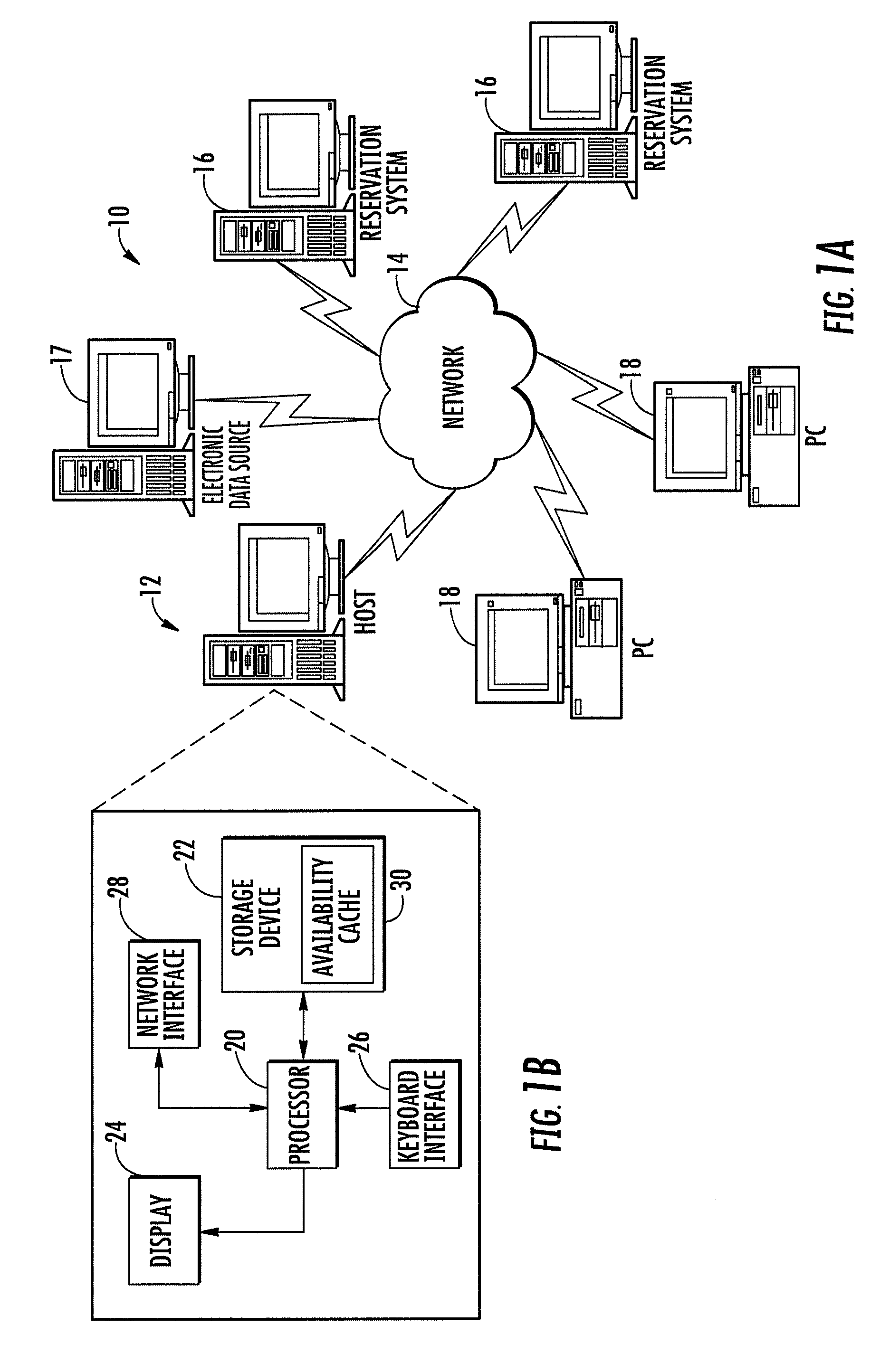

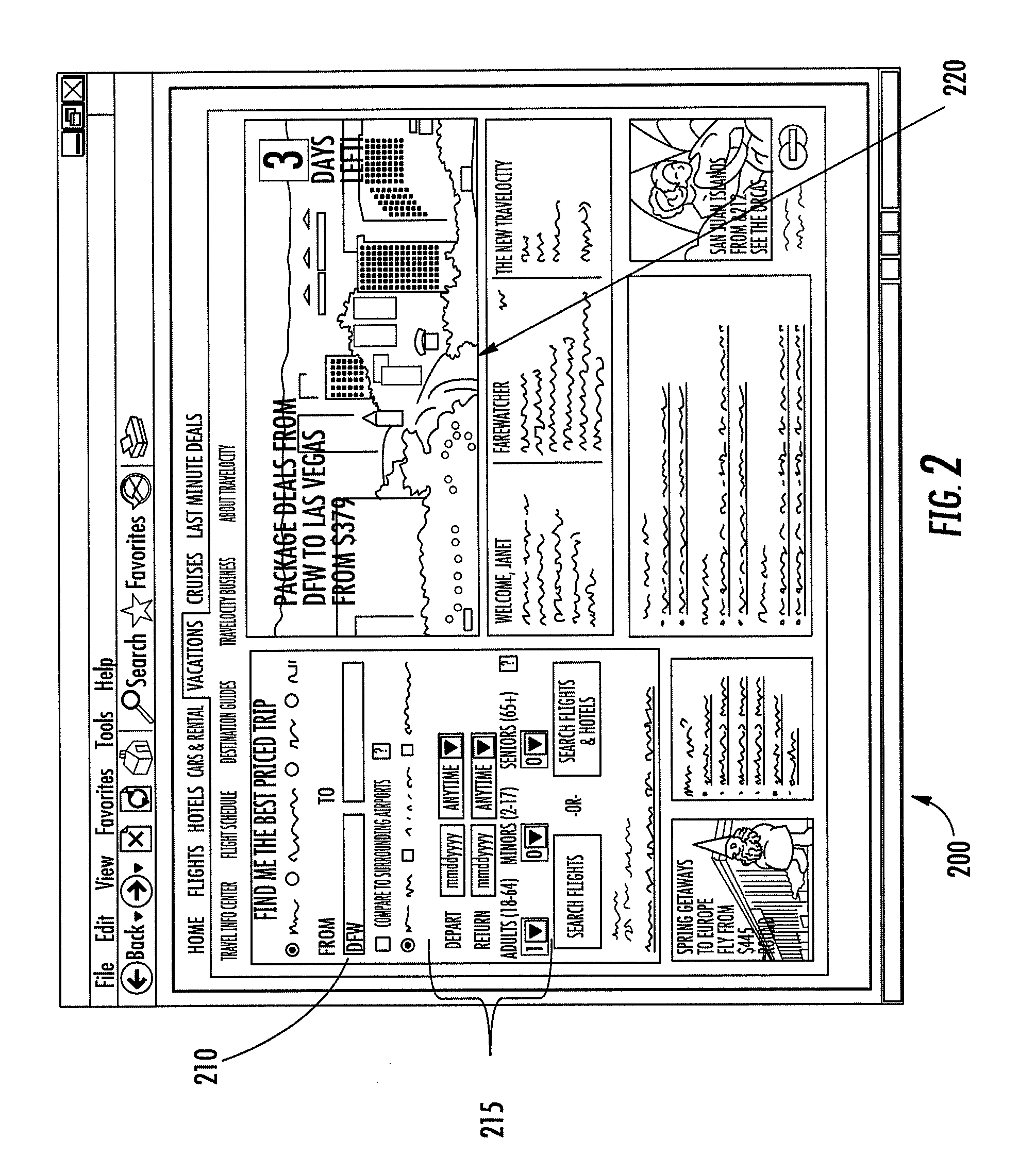

System, method, and computer program product for reducing the burden on an inventory system by assembling a suggested themed travel itinerary in response to minimal user input

InactiveUS20070143155A1Reduce the burden onOvercome problemsReservationsForecastingUser inputSystems approaches

The present invention generates a concise listing of low-priced travel products in an interactive itinerary format in response to a simplified user input that may include specification of a selected travel theme. The interactive itinerary generated by the invention may allow the user to revise the itinerary to add, remove, and / or amend details related to the various travel products listed therein such that the user may be made aware of the cost and / or scheduling effects of making a particular revision to the itinerary. The invention may also provide a concise display of supplemental information related to the selected theme and / or a selected destination for the itinerary such that the user may be better informed when making revisions to the interactive itinerary. For example, the invention may provide interactive maps, reviews, photos, and / or other supplemental information related to the selected theme and / or one or more of the listed travel products.

Owner:TRAVELOCITY COM LP

Method and system for replenishing inventory items

ActiveUS20070021863A1Disadvantages and reduced eliminatedInventory reduced eliminatedDigital data processing detailsLibrary scienceInformation transfer

A method for storing inventory items in an inventory system includes receiving a replenish request identifying an inventory item to be stored in an inventory system and determining a classification of the inventory item to be stored. The method also includes selecting an inventory holder from a plurality of inventory holders based, at least in part, on the classification of the inventory item to be stored and a classification of one or more other inventory items currently stored in the selected inventory holder. Additionally, the method includes transmitting information identifying the selected inventory holder to a mobile drive unit.

Owner:AMAZON TECH INC

Using cameras to monitor actual inventory

System and method for monitoring inventory. Inventory items are positioned between a camera and a surface having an optically identifiable and distinct characteristic. The camera obtains an image of the inventory items present, any exposed portion of the surface, or both. The amount of the exposed surface is used to determine an amount of the inventory items that are present or missing. Furthermore, the optically identifiable characteristic may be a uniform characteristic, such as color or texture, or a set of discrete elements, such as stickers, barcodes, structural features of the shelf, a pattern of lines or shapes, or combinations thereof. Optionally, the optically identifiable characteristic is unique to the location of the shelf associated with the inventory items. Inventory or non-inventory items incorrectly positioned over the exposed surface may be excluded from the amount of the expected inventory item being determined if the item does not match the visual attributes of the expected inventory item. The camera may be fixed or movable and preferably provides digital images to a computer system having a computer readable medium with program products for analyzing the image and providing inventory reports.

Owner:TOSHIBA GLOBAL COMMERCE SOLUTIONS HLDG

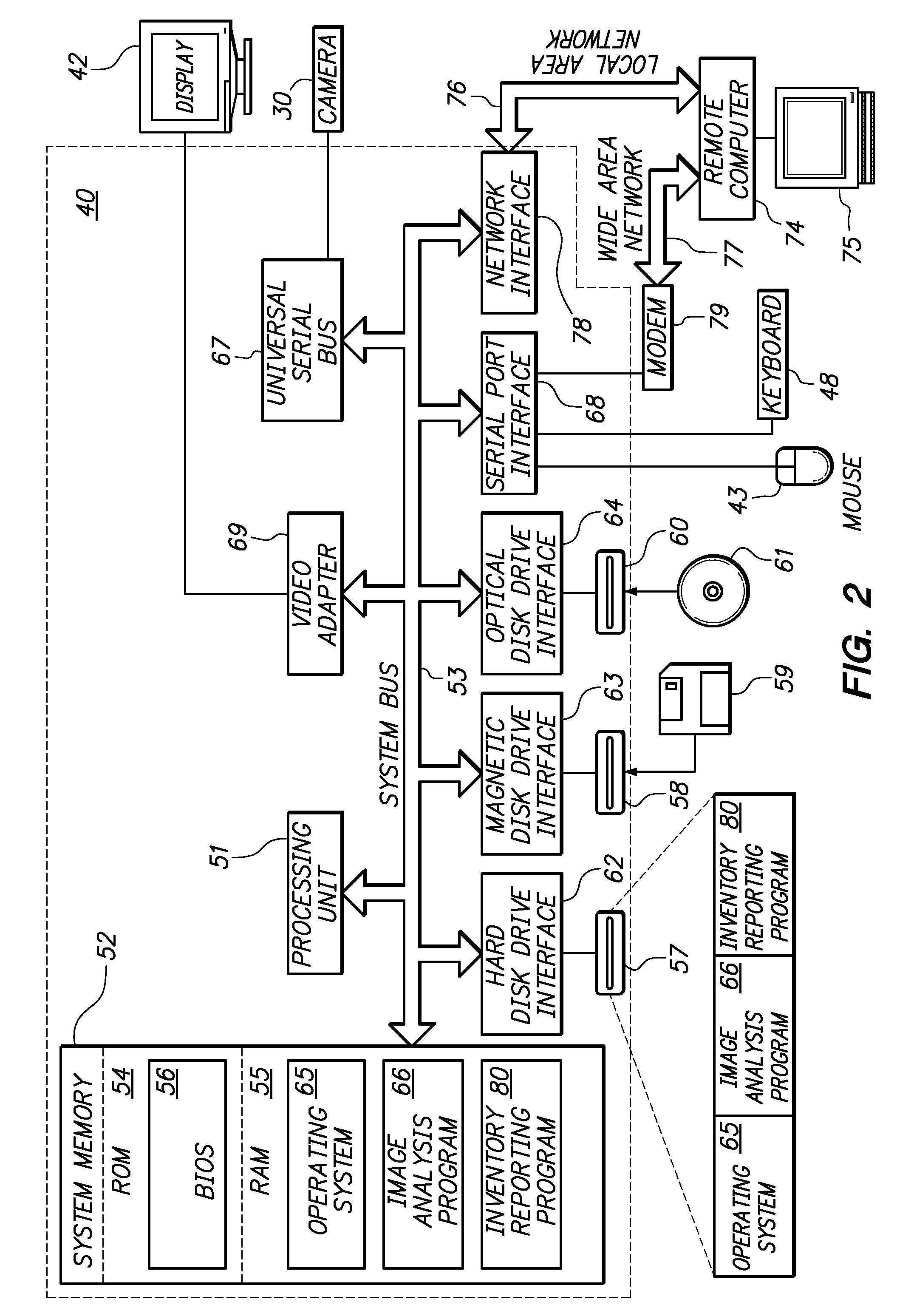

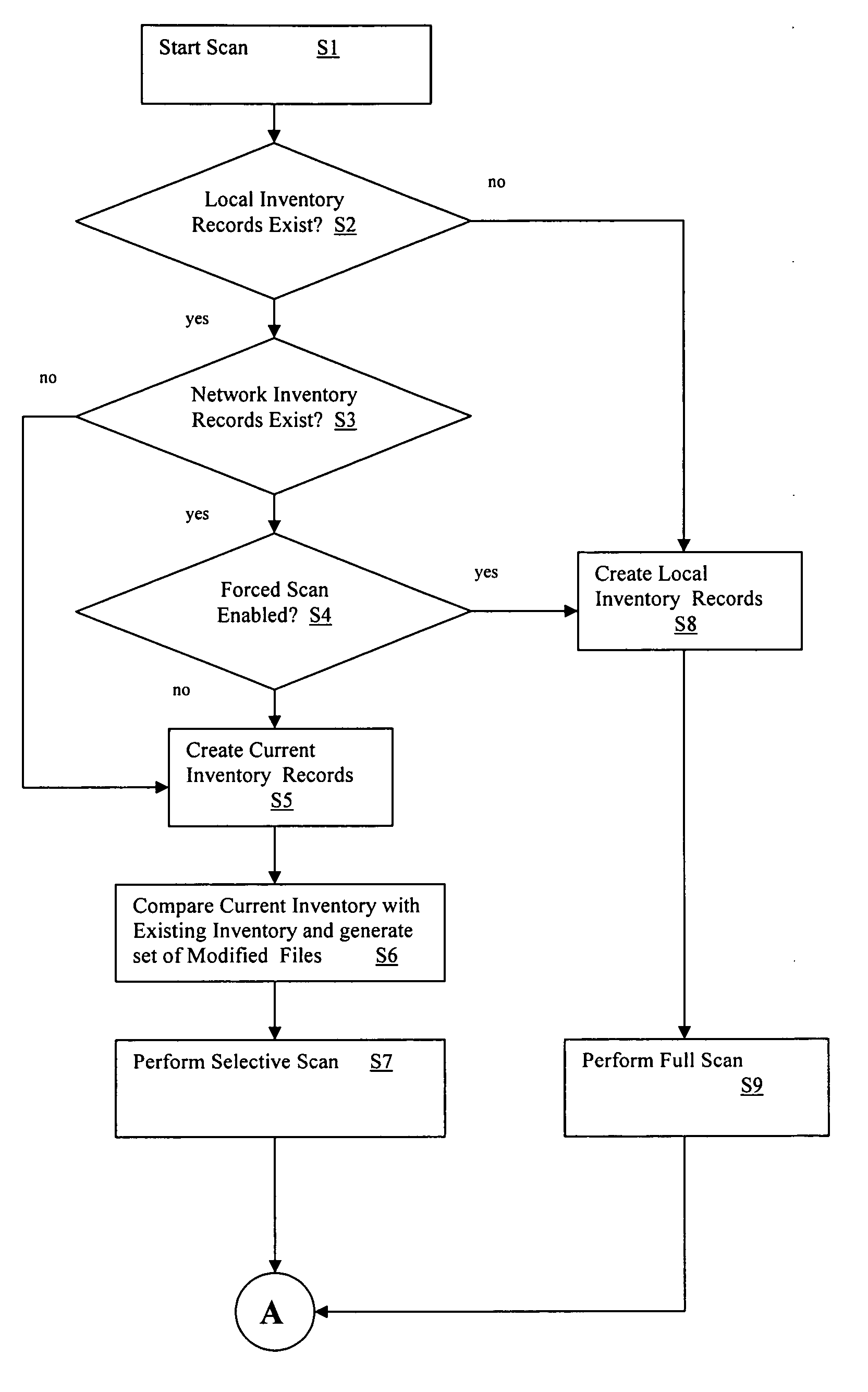

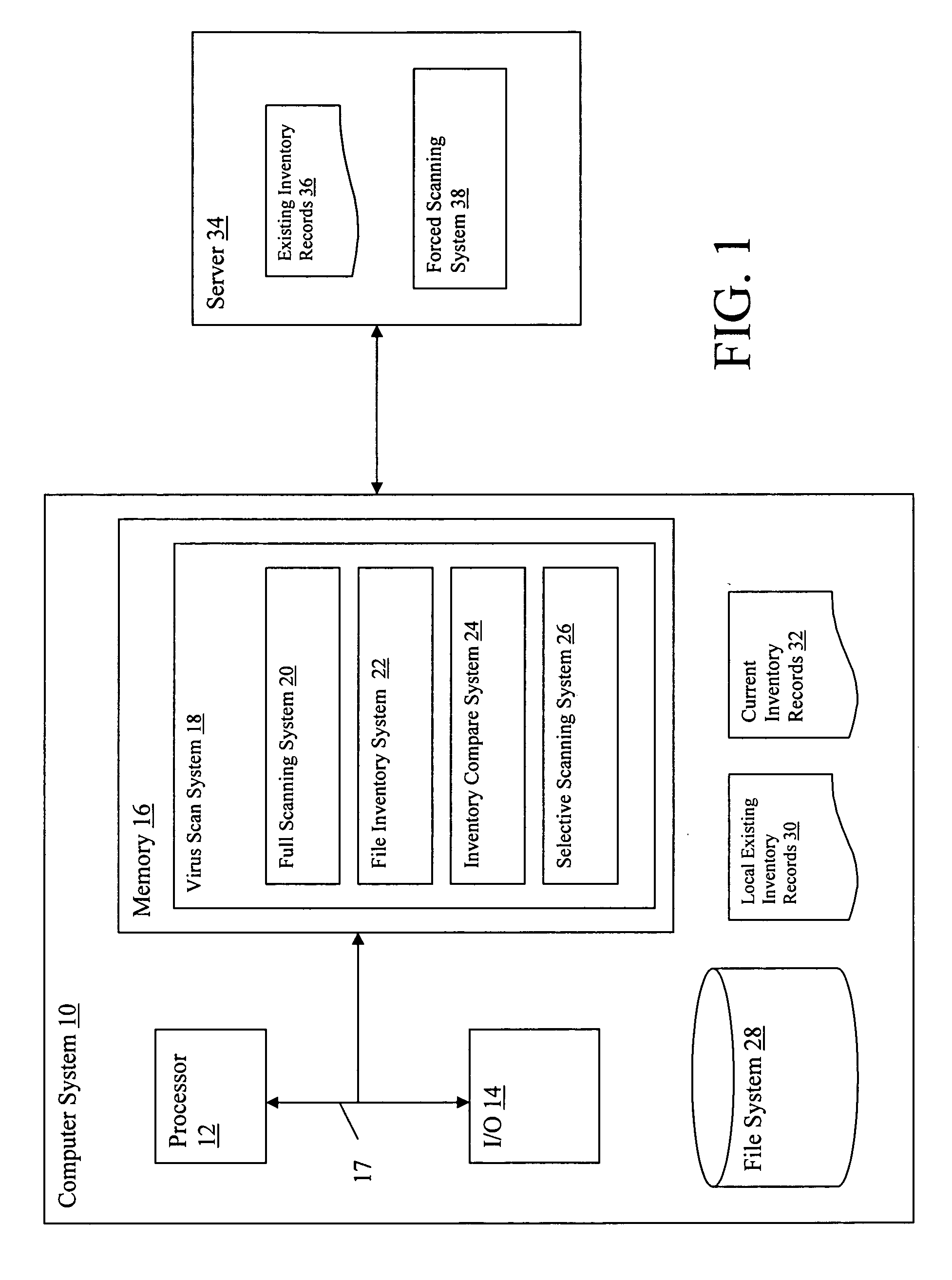

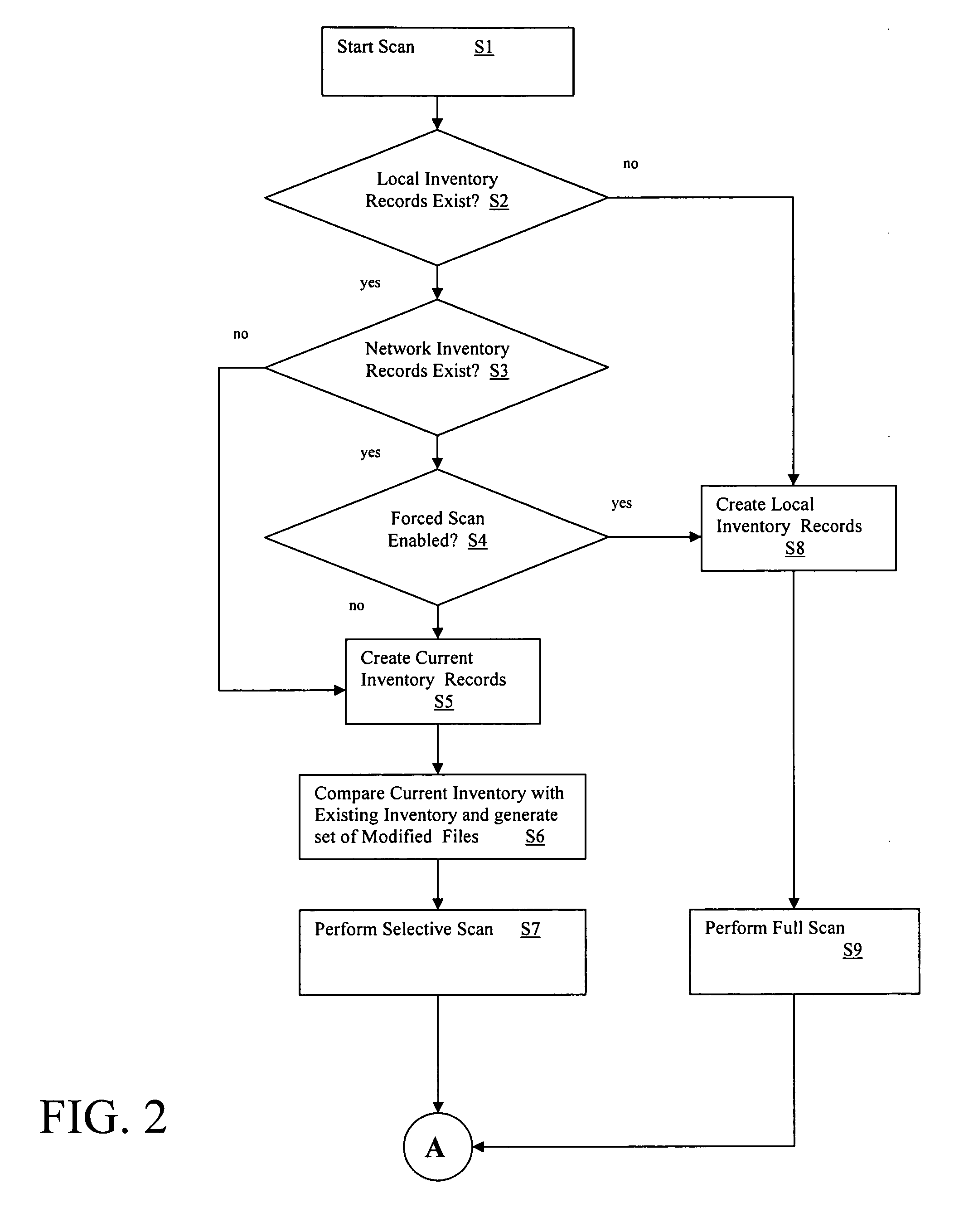

Selective virus scanning system and method

InactiveUS20060236398A1Reduce computational overheadMemory loss protectionUnauthorized memory use protectionRecordsetFile system

A virus scanning system and method. A system is provide that includes: a full scanning system for performing a full scan of each file in a file system; a file inventory system for inventorying each file in the file system and generating a set of inventory records, wherein each inventory record includes a unique key associated with each file in the file system; an inventory compare system for comparing a current set of inventory records with an existing set of inventory records to identify files in the file system that were modified since the existing set of inventory records was generated; and a selective scanning system for selectively scanning only files in the file system that were identified as modified by the inventory compare system.

Owner:SERVICENOW INC +1

Method and system for fulfilling requests in an inventory system

ActiveUS8483869B2Disadvantages and reduced eliminatedInventory reduced eliminatedLoading/unloadingStorage devicesReal-time computingInventory system

A method for fulfilling requests in an inventory system includes receiving a request indicating an activity to be completed. The method also includes selecting a holder to fulfill the request and an inventory station at which to fulfill the request. The inventory station is associated with a queue that includes a plurality of queue spaces. The method further includes moving the selected holder from a first location to a second location remote from the selected inventory station. Additionally, the method also includes determining that a trigger event has occurred and, in response to determining that the trigger event has occurred, moving the selected holder from the second location to a queue space of a queue associated with the selected inventory station.

Owner:AMAZON TECH INC

Inventory system with climate-controlled inventory

A system includes a climate-controlled inventory holder, a mobile drive unit, and a management module. The climate-controlled inventory holder is configured to control a climate of one or more inventory items stored by the inventory holder. The mobile drive unit is operable to transport the climate-controlled inventory holder from a first location to a second location based at least in part upon one or more instructions received from a management module. The management module is operable to receive an order for an inventory item, determine that the inventory holder stores the inventory item, and instruct the mobile drive unit to transport the climate-controlled inventory holder from the first location to the second location.

Owner:AMAZON TECH INC

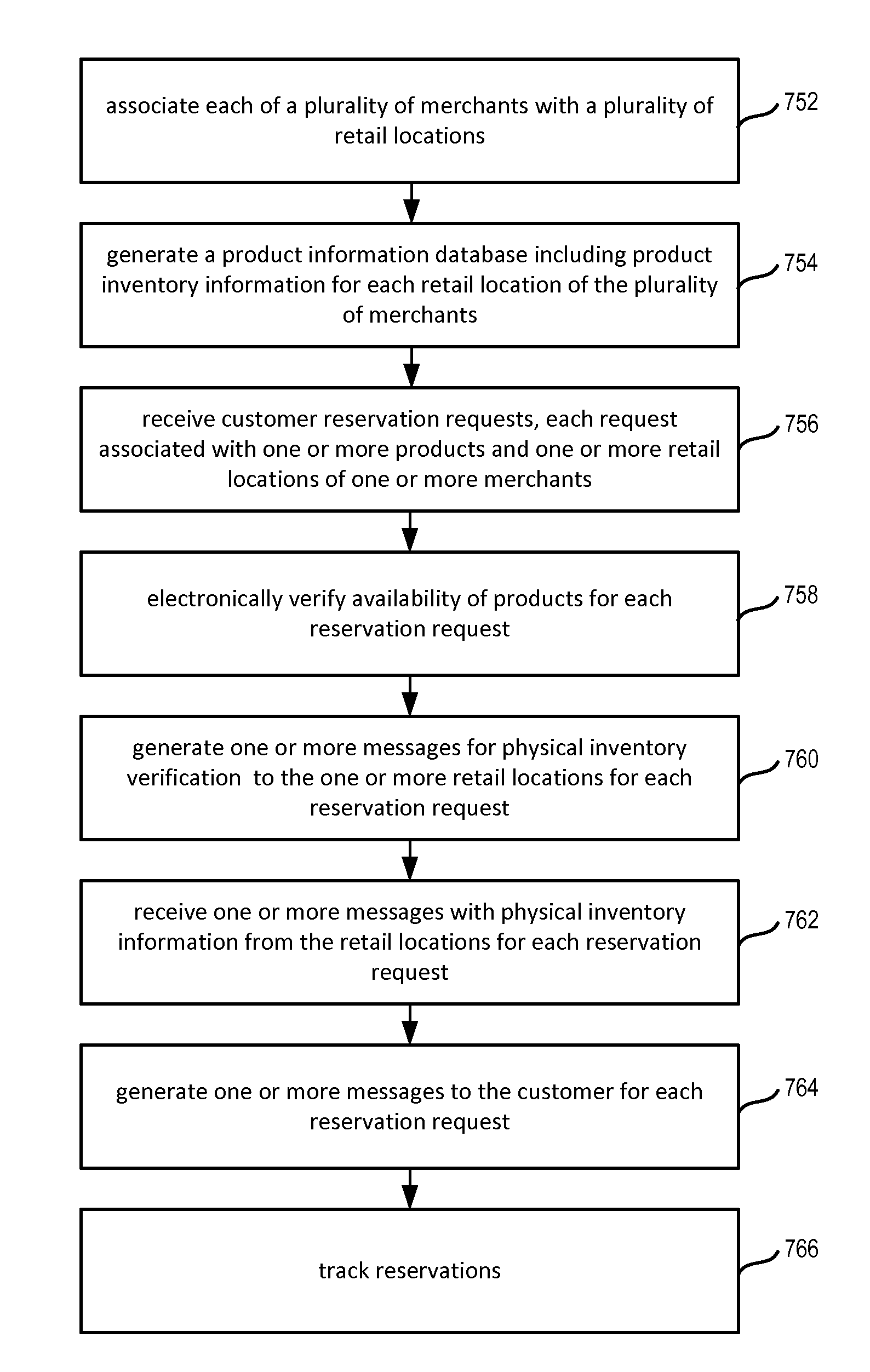

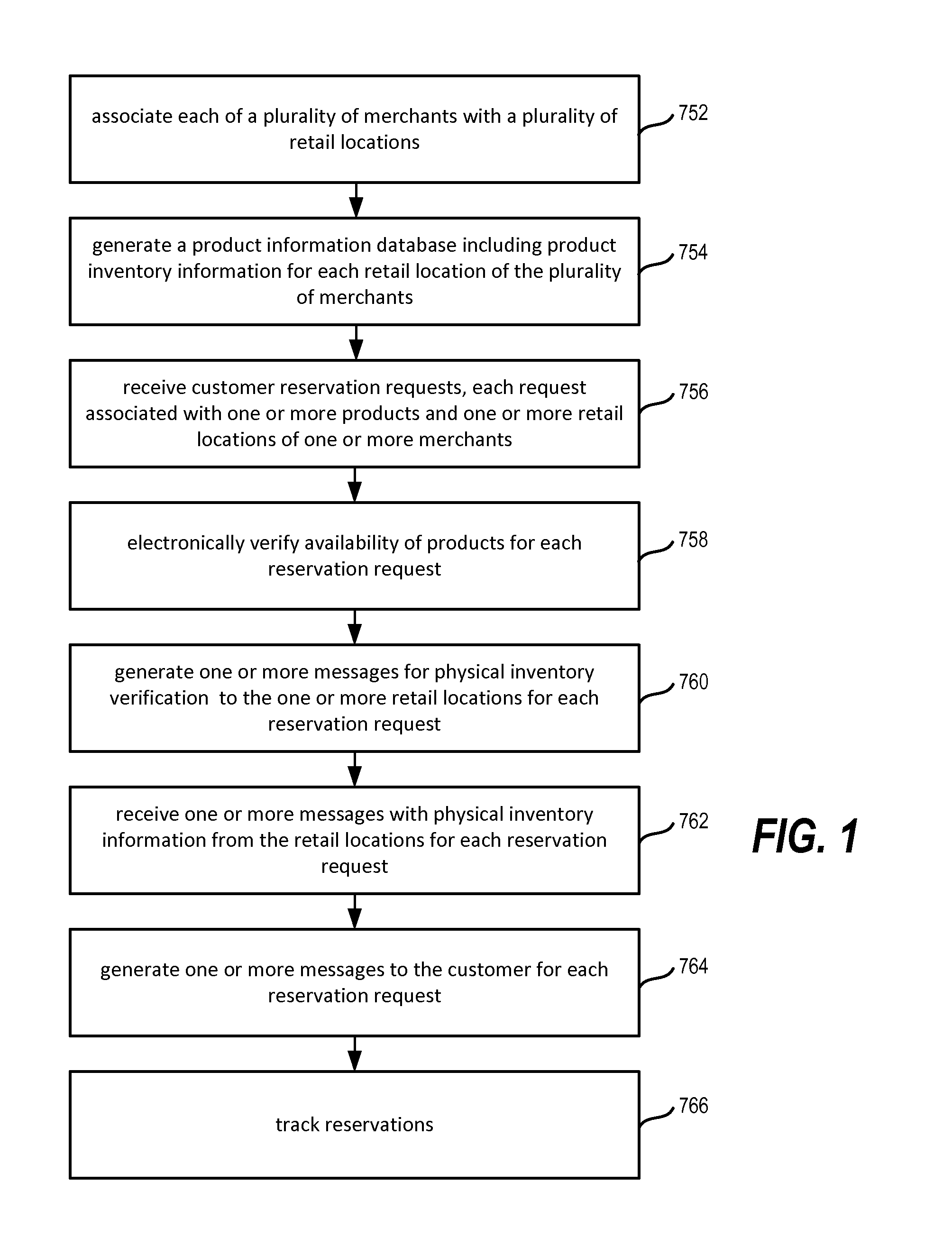

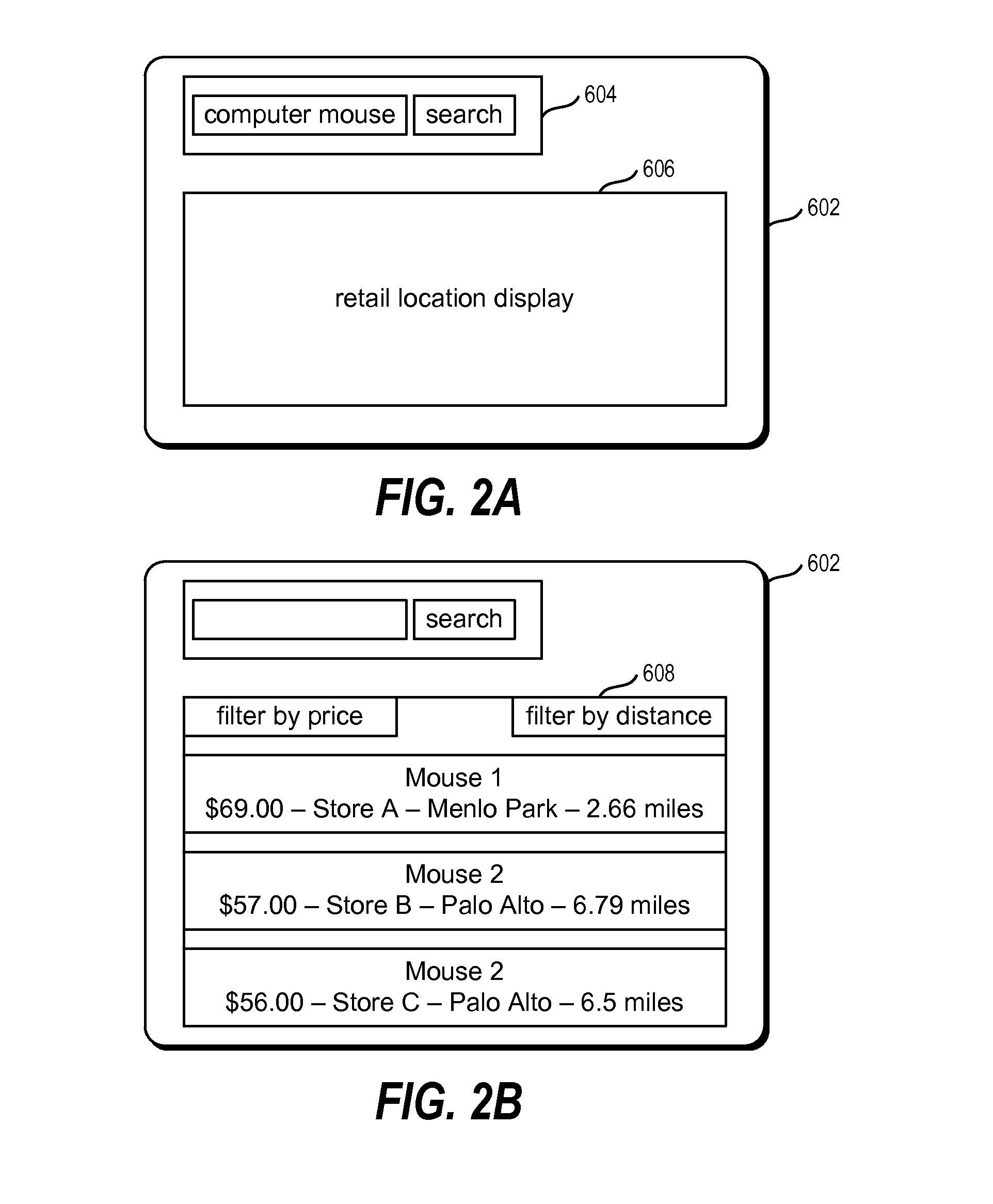

Online Reservation System For Local Pickup Of Products Across Multiple Retailers

Systems and related methods are disclosed that provide an electronic commerce and communication system that includes real-time product inventory information to enable a customer-driven experience for reservation of products. An electronic commerce exchange is provided that permits customers to browse, search, and reserve products for in-store pickup across multiple merchants, each potentially with multiple retail locations. The exchange includes a real-time product inventory database that maintains real-time product inventory information for the retail locations of the merchants. The product inventory database includes ingest engines that permit an interface to different inventory transfer protocols so that product inventory information can be maintained across disparate inventory systems maintained by different merchants.

Owner:RETAILIGENCE

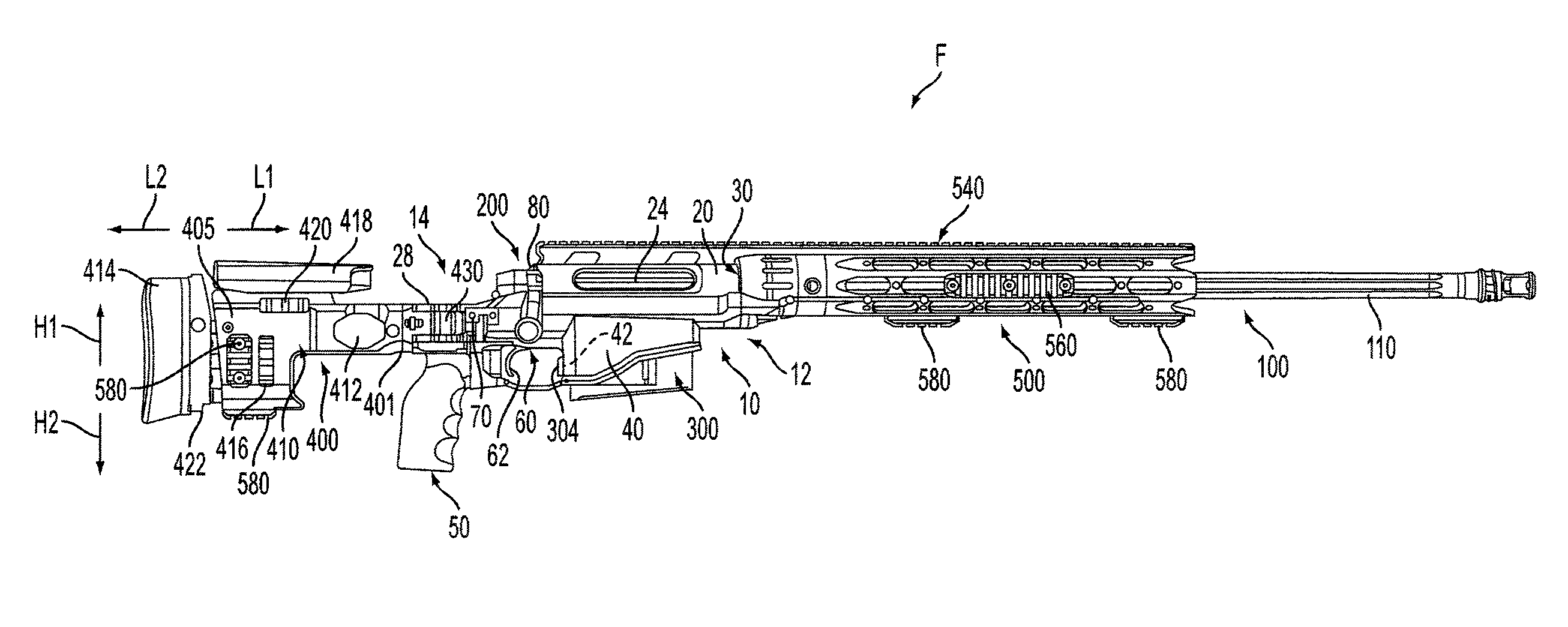

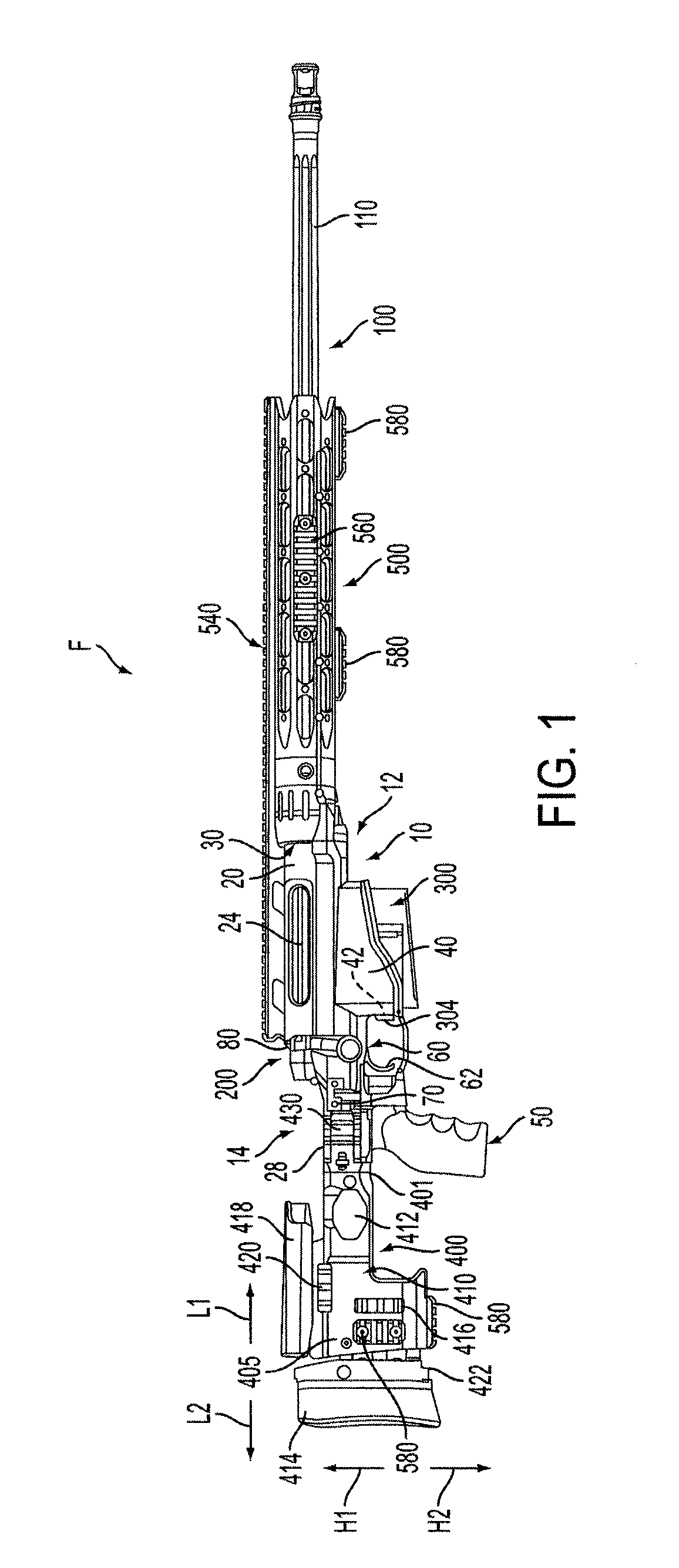

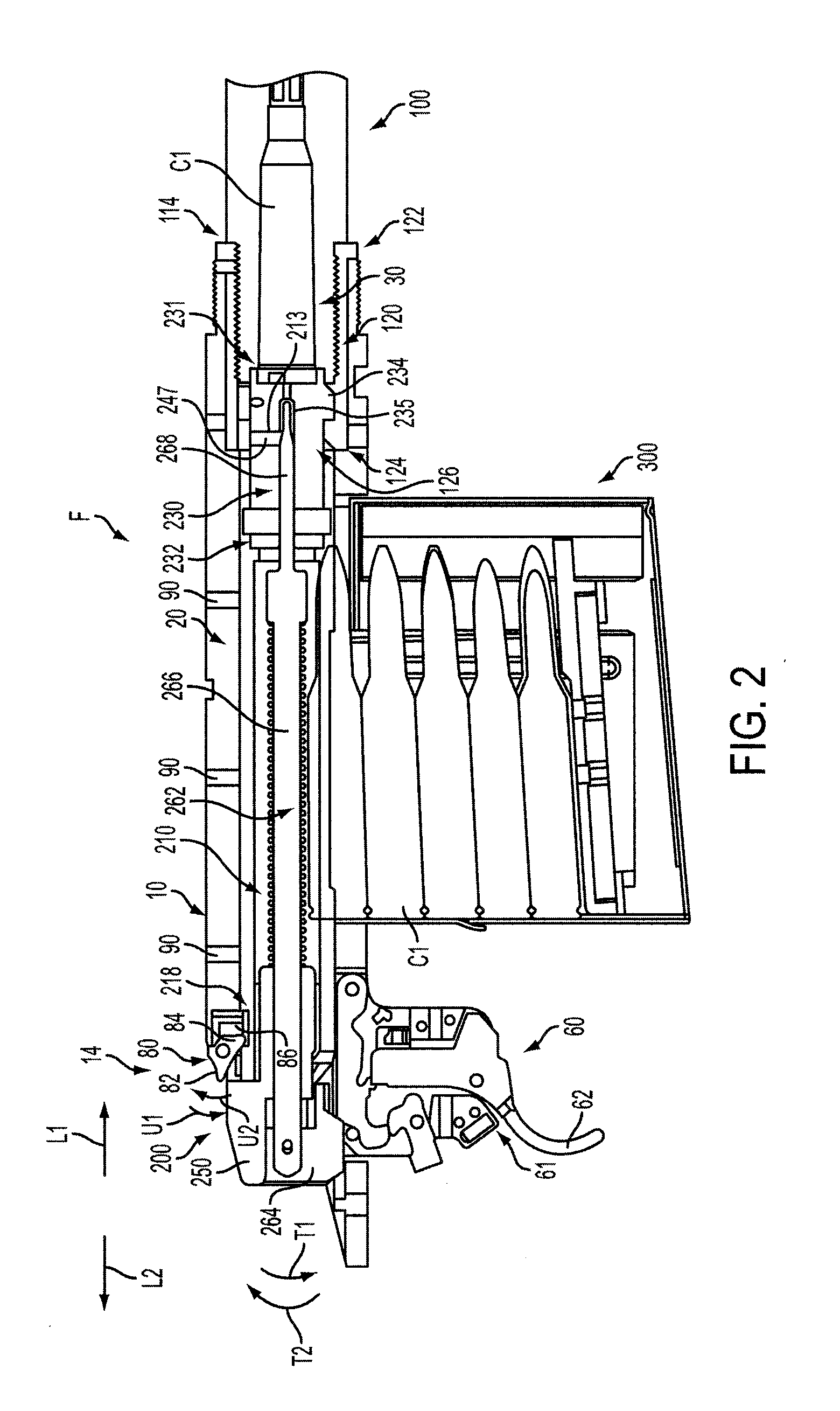

Modular firearm stock system

InactiveUS20100307042A1Ease of actuationEase of engagementCartridge extractorsWeapon assembly/disassemblyModularityEngineering

A modular firearm is disclosed. The firearm that can be configured to operate using ammunition of different calibers via interchangeability of only a few parts. The firearm includes a foldable butt stock assembly for quickly and easily converting the firearm from an extended operating configuration to a compact transport configuration, and vice-versa. Additionally, the firearm includes a modular hand guard assembly having multiple mounting platforms for accommodating a variety of different accessories.

Owner:RA BRANDS

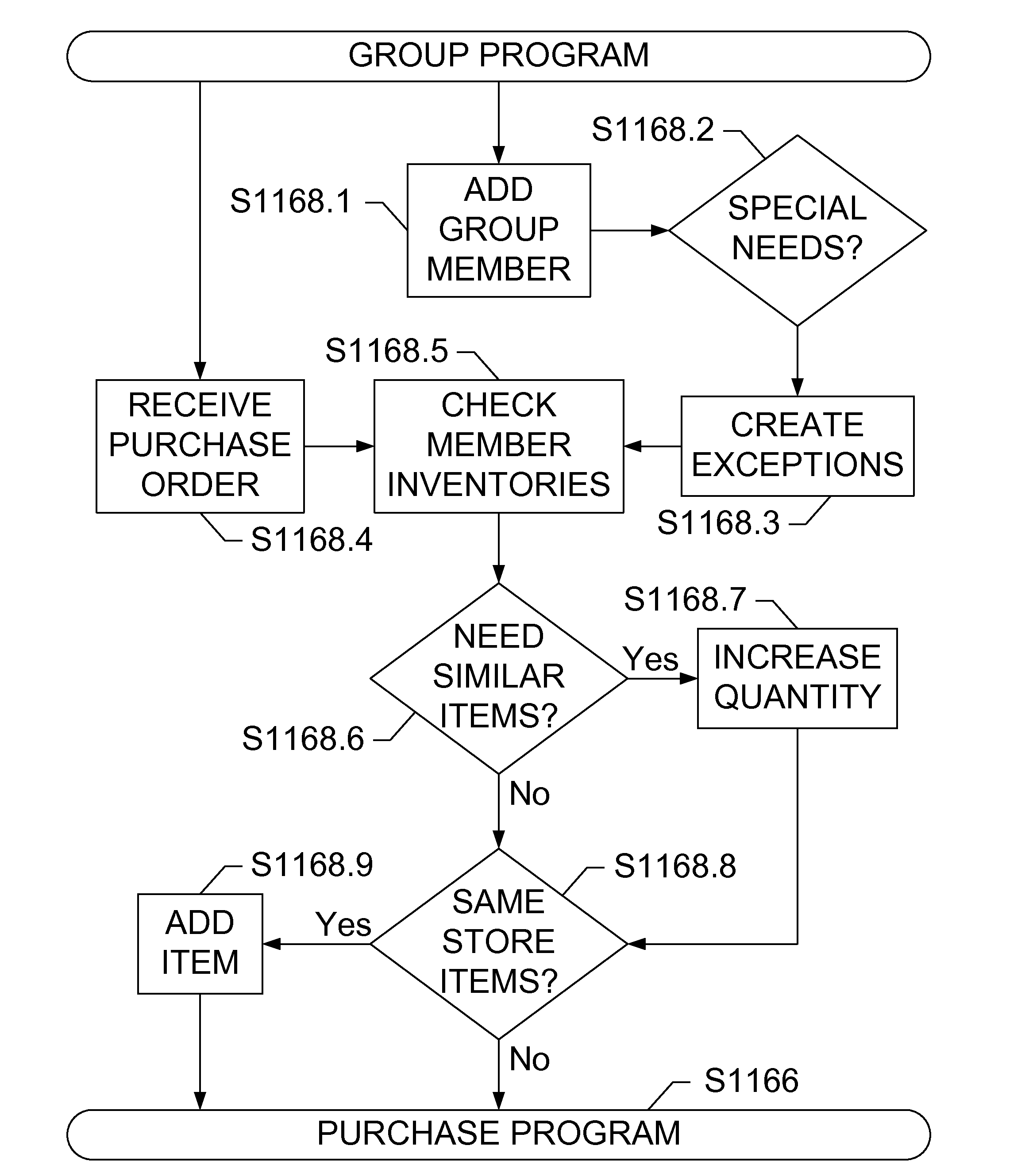

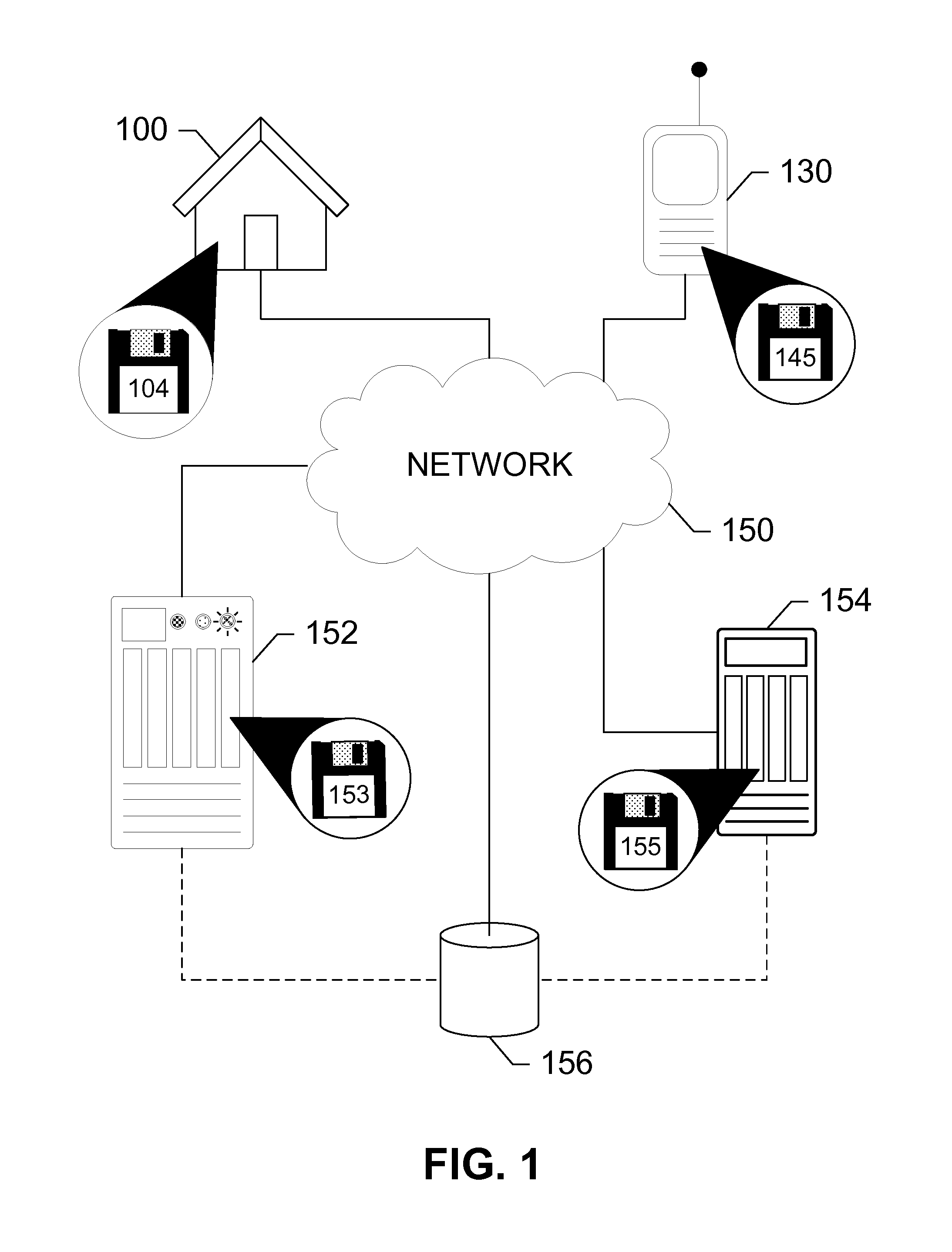

Interactive Inventory Systems and Methods

The subject disclosure provides devices, systems, and methods for interacting with a home inventory system. Home inventory systems may include appliances and storages which take inventory of their contents. Home inventory systems may interact with mobile devices to alert users of necessary or desired products. Using location information, users may be alerted when their mobile device is within proximity of a necessary or desired product.

Owner:AT&T INTPROP I L P +1

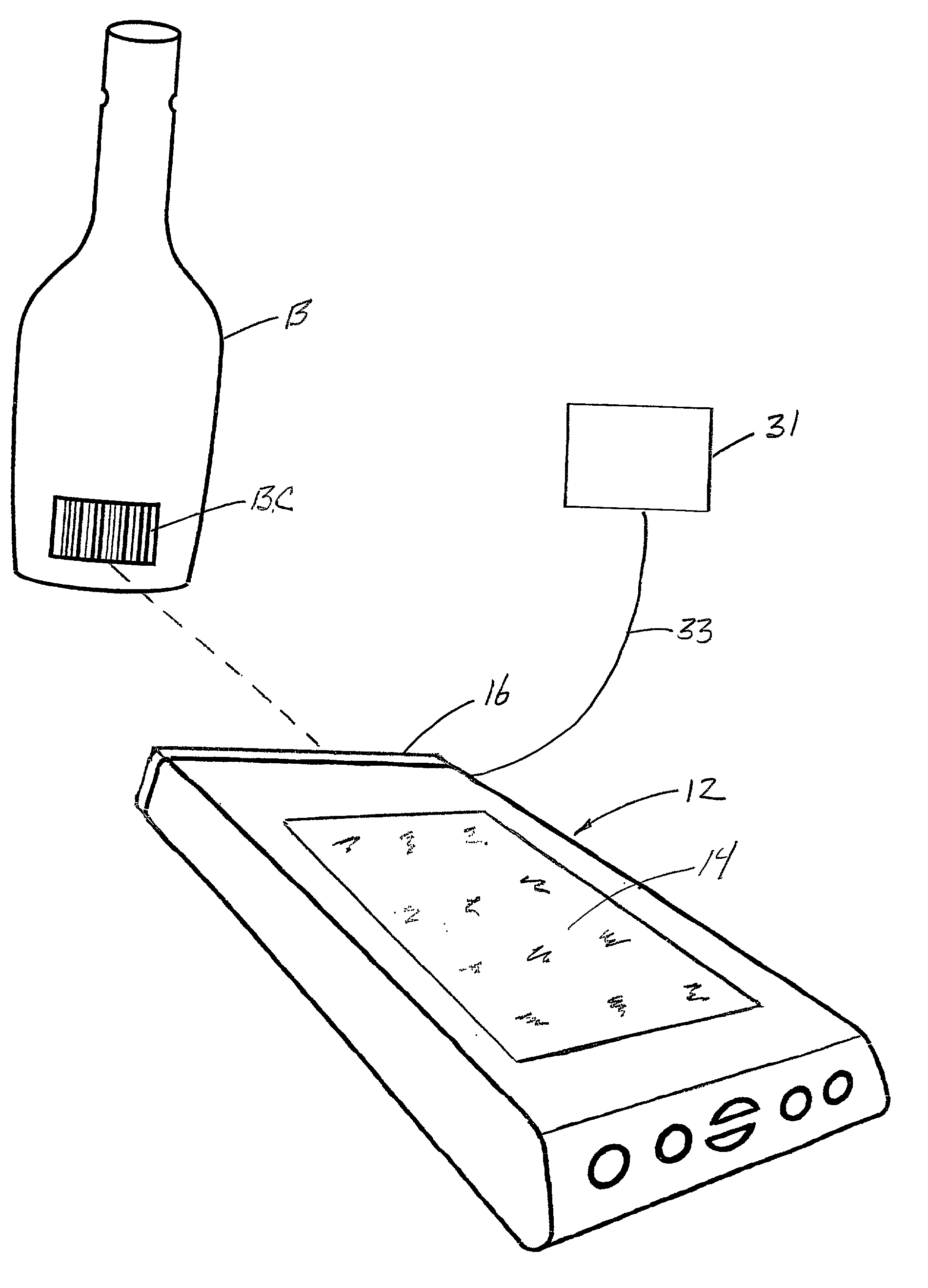

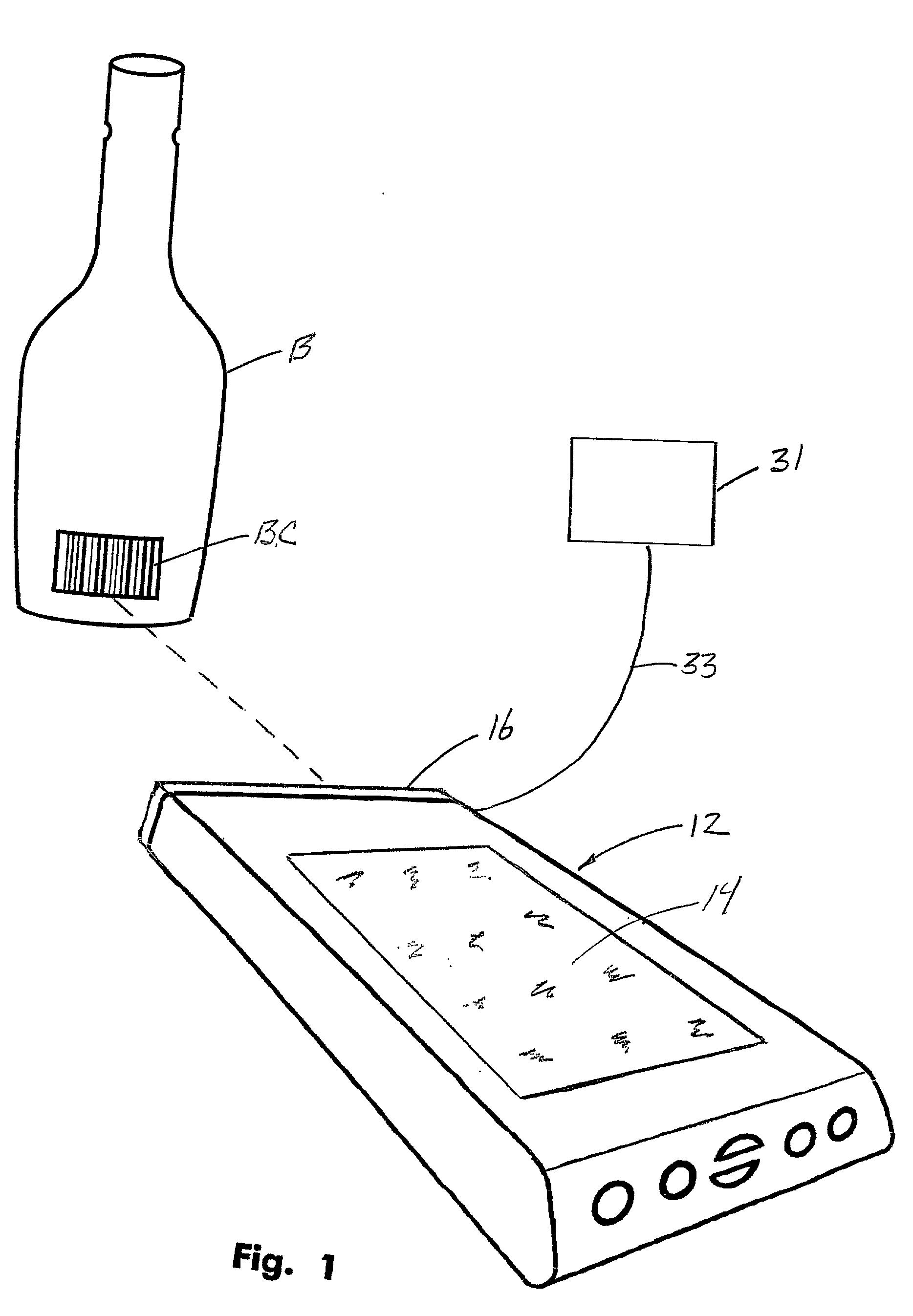

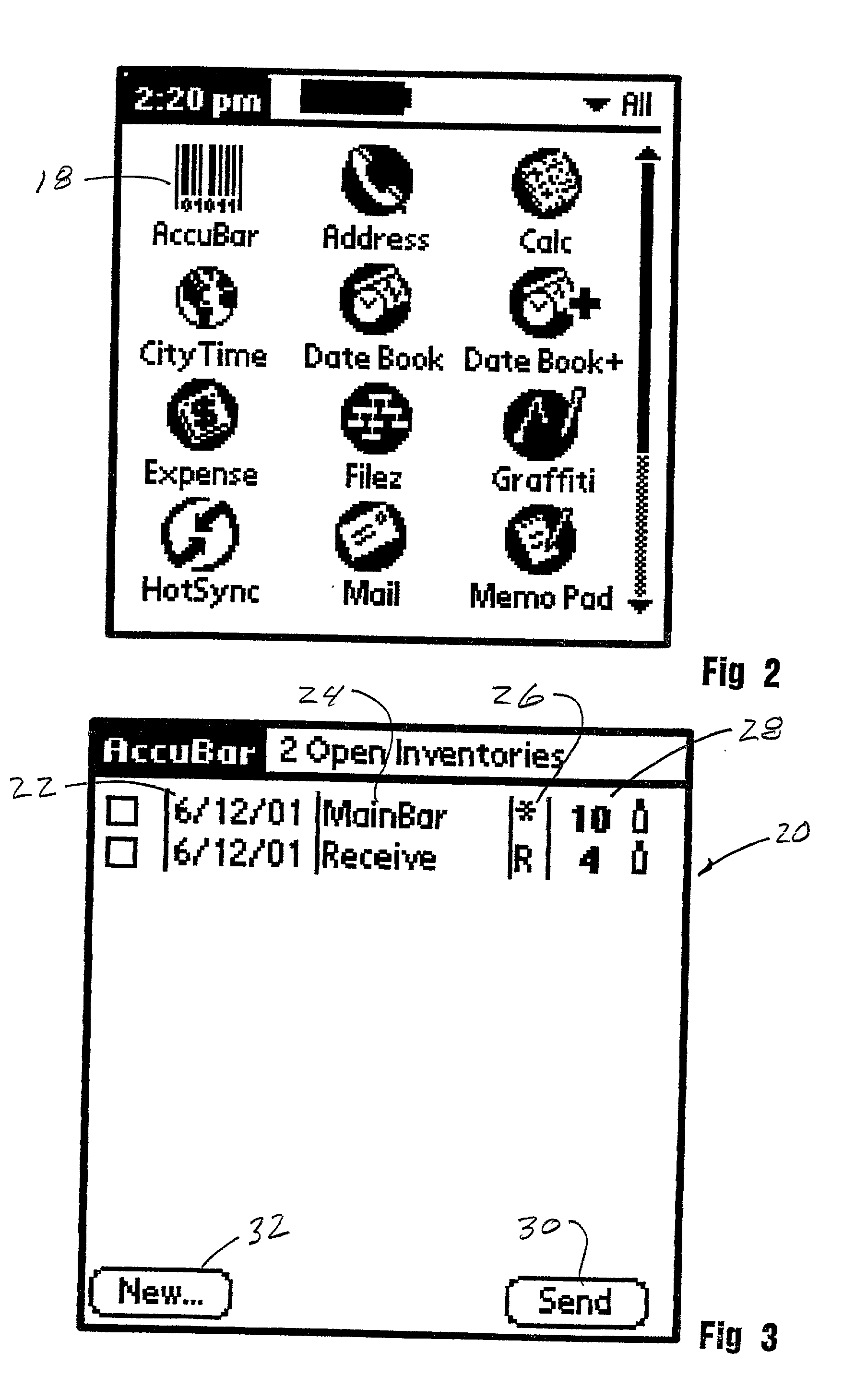

Inventory system

InactiveUS20030034392A1Accurately determinedDigital data processing detailsCo-operative working arrangementsData memoryTouchscreen

A computer-based system for taking the physical inventory of beverages dispensed in full and partially full containers so as to effectively control the theft and overpouring. The products to be inventoried, such as liquor bottles are identified by conventional barcodes that can be scanned by a scanner that is operably interconnected with a hand-held computer. The step of scanning the barcodes produces, on the touch-sensitive screen of the hand-held computer, product information concerning the product contained within the scanned bottle including a silhouette of the bottle. In accomplishing the inventory, the user indicates by touching on the silhouette of the bottle the fluid level within the bottle. This information is inputted in the computer data storage and is used to calculate the volume of beverage remaining in the bottle.

Owner:BIRCH STREET SYST LLC

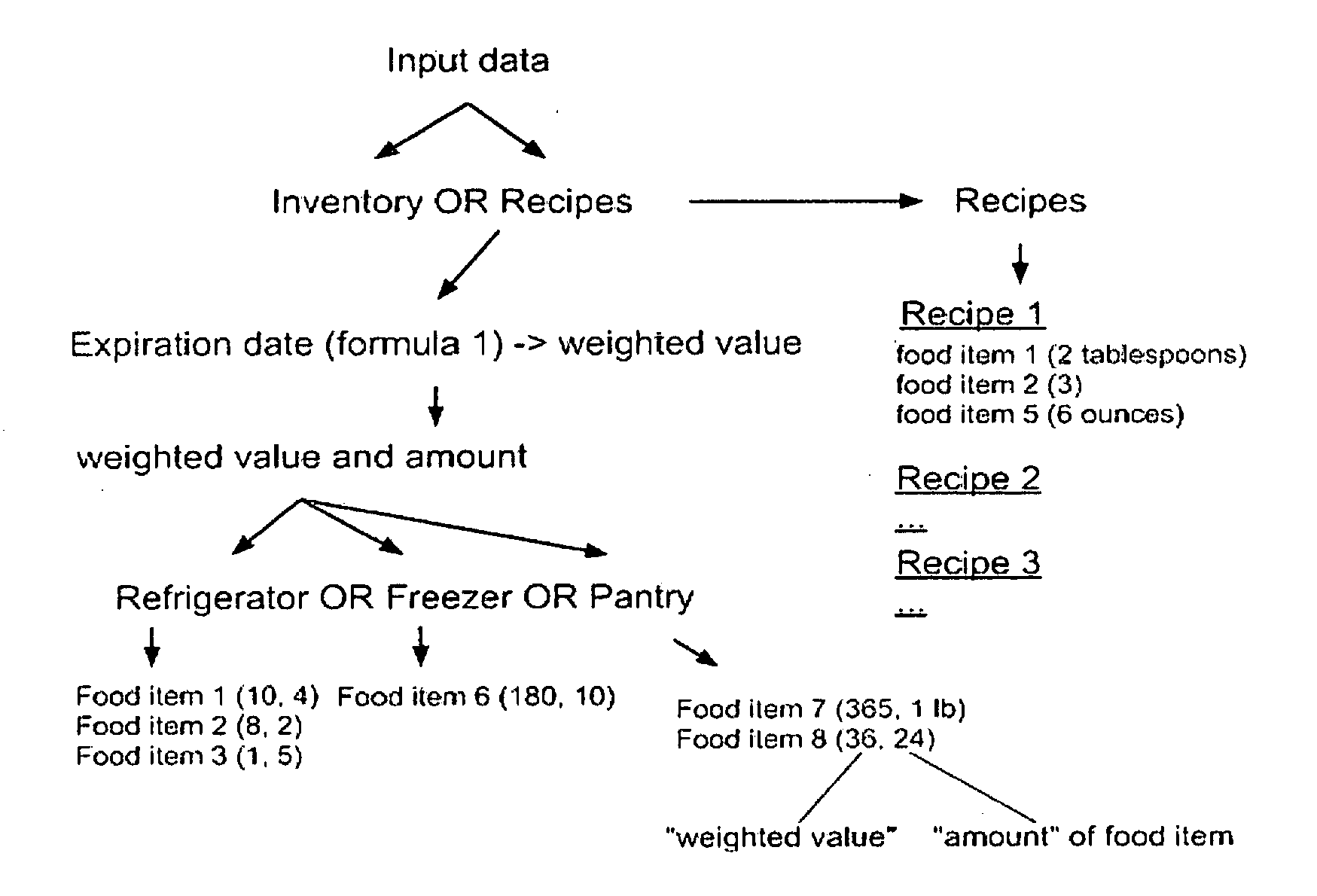

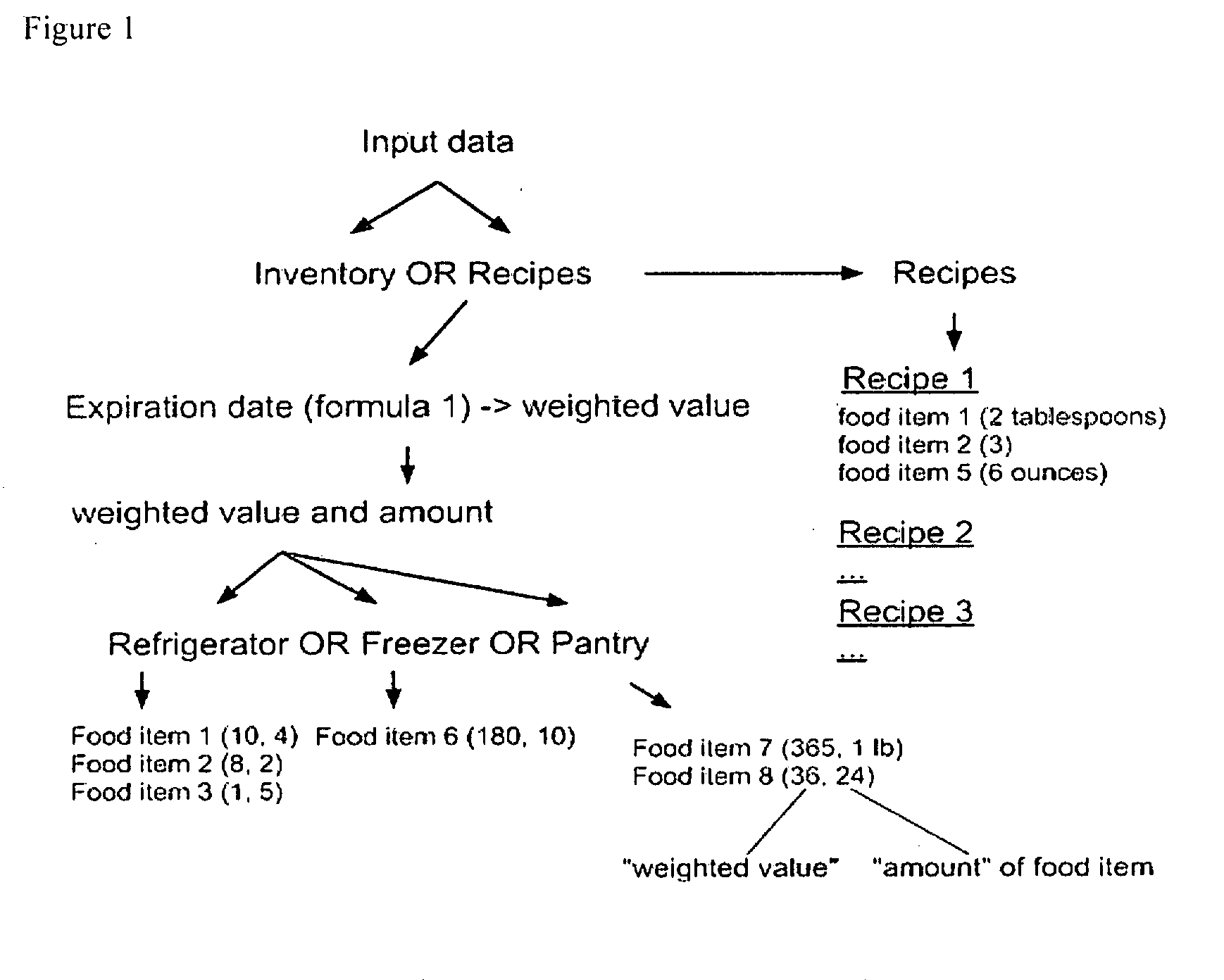

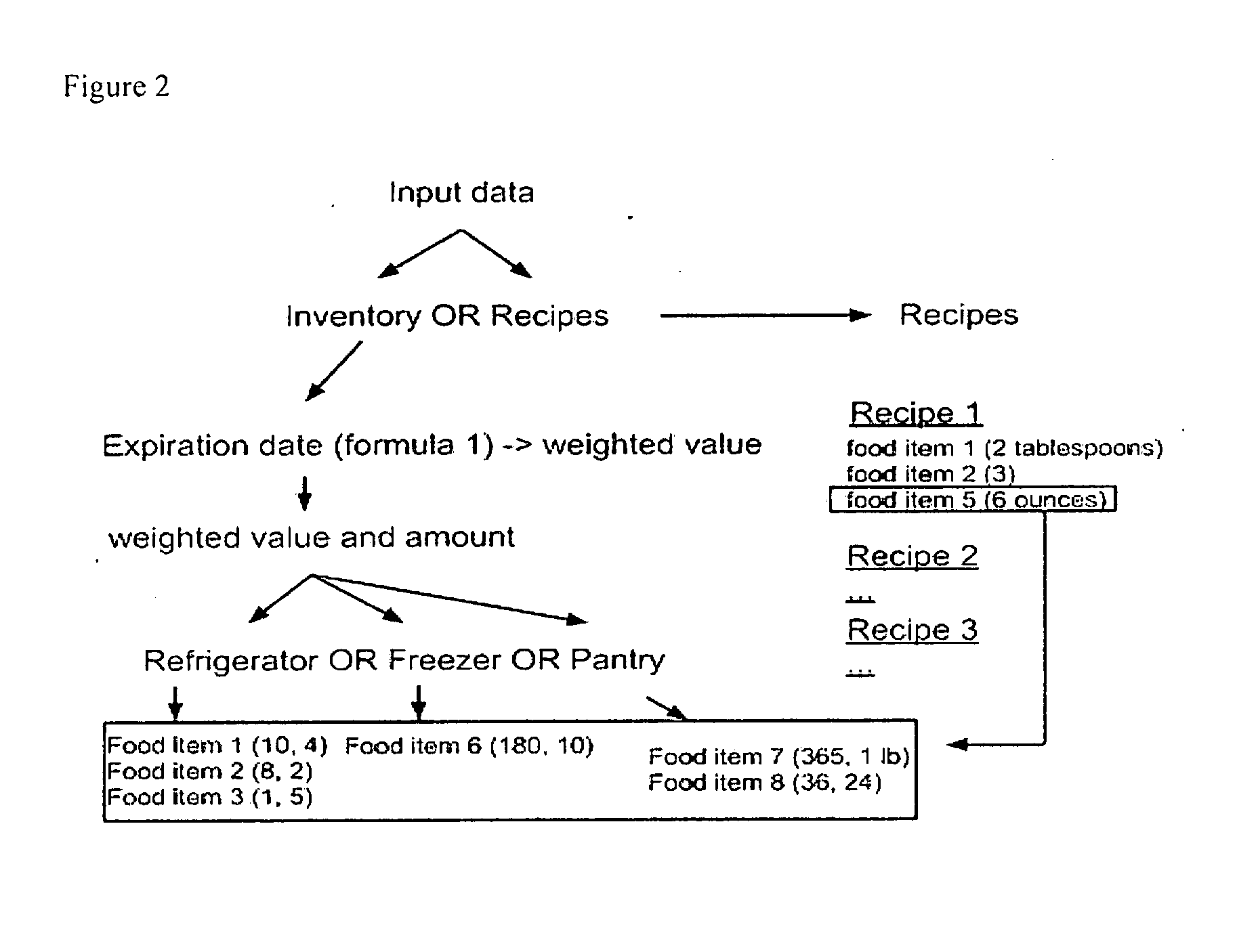

Method and Device for Expiration Date Weighted Food Inventory System and Meal Planner

InactiveUS20130138656A1Easily and accurately maintainingPrevent spoilageDigital data processing detailsMultiple digital computer combinationsEngineeringStore food

A method and device comprising a food inventory system that enables food inventory control as well as meal planning Food items are entered into a software controlled means for storing food inventory data and meal recipes. Meal planning is enabled whereby recipes are proposed based on inventory levels and / or food expiration or spoilage times, as well as nutrient and dietary information. Shopping lists are created that reflect inventory levels, recipe needs, and / or food expiration or spoilage dates.

Owner:WHEATON WENDI

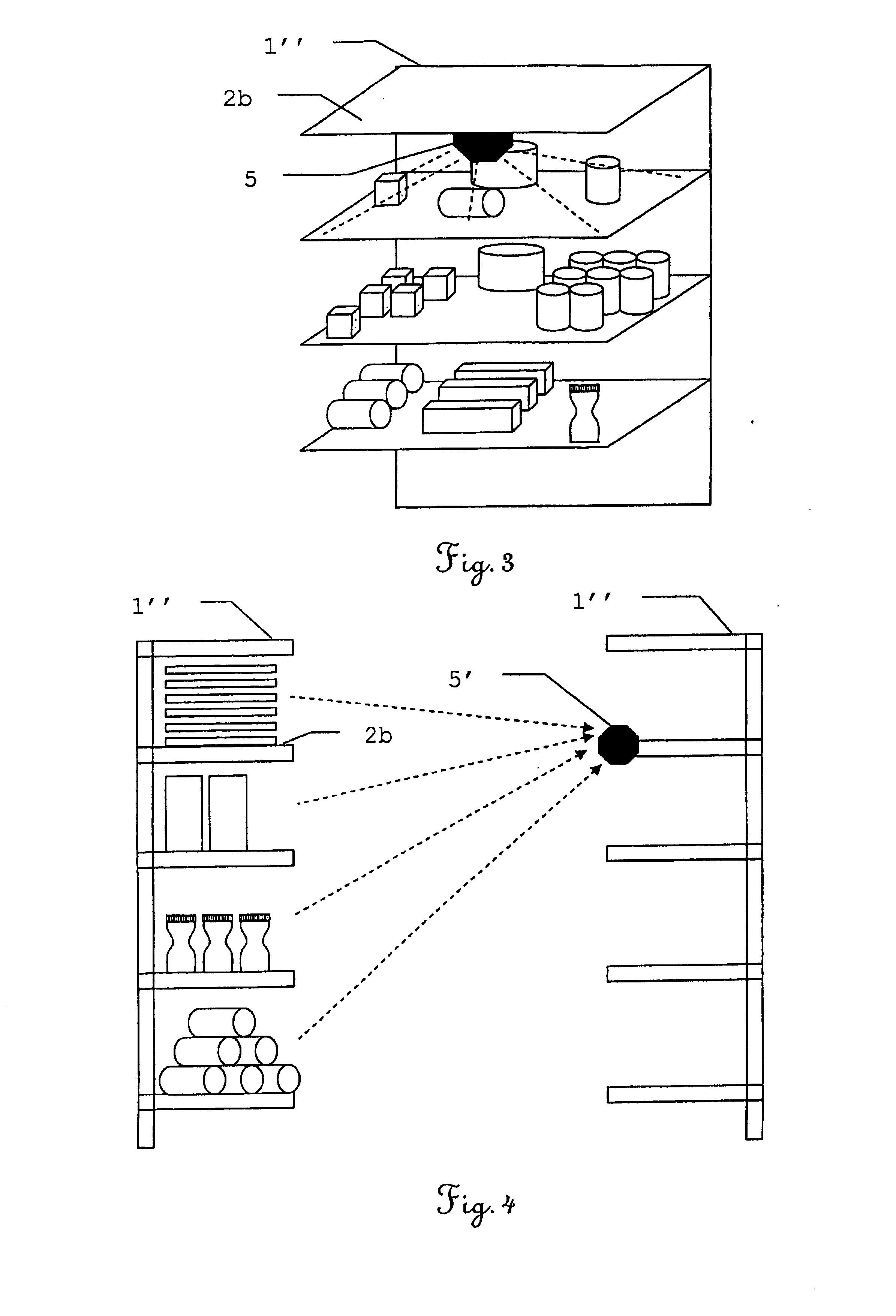

Stocking system and method for managing stocking

InactiveUS20070069867A1Improve bindingIncrease flexibilitySignalling system detailsStorage devicesSensor arrayElectrical and Electronics engineering

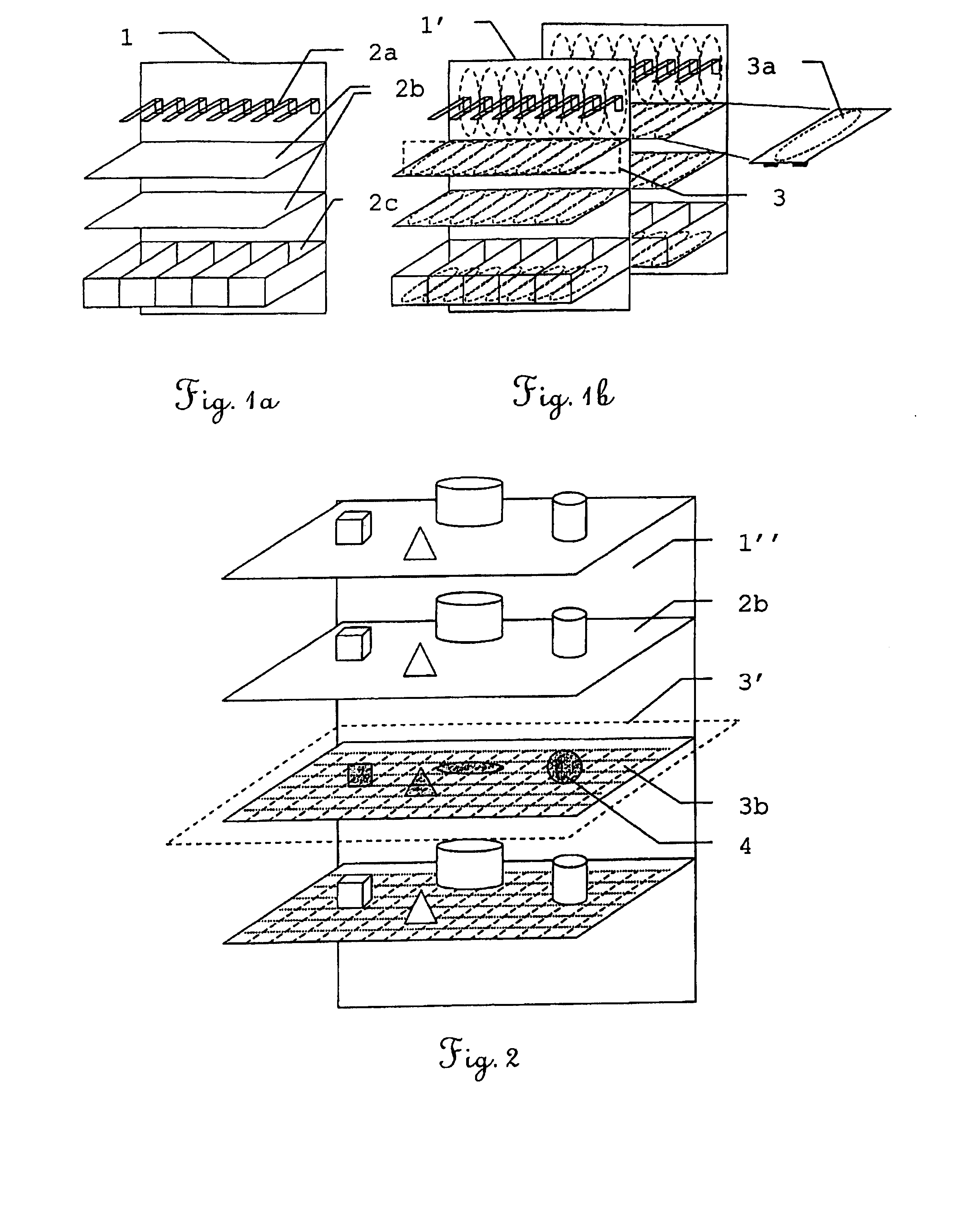

A stocking system including at least one support for goods to be stocked, a communications network, and a computing unit for deriving inventory data. The stocking system has a gravimetric sensor element that, for detecting the goods, is in the form of a sensor array or sensor matrix. This sensor element can also be supplemented with an optical sensor element. By recording a multitude of measured values of the goods, the entire stocking system can be in the form of a sensor network and, with regard to the model, is configured for deriving inventory data whereby enabling both an identification of the type of the stocked goods as well as the determination of the quantity thereof.

Owner:UNIV ST GALLEN HOCHSCHULE FUR WIRTSCHAFTS RECHTS UND SOZIALWISSENSCHAFTEN +1

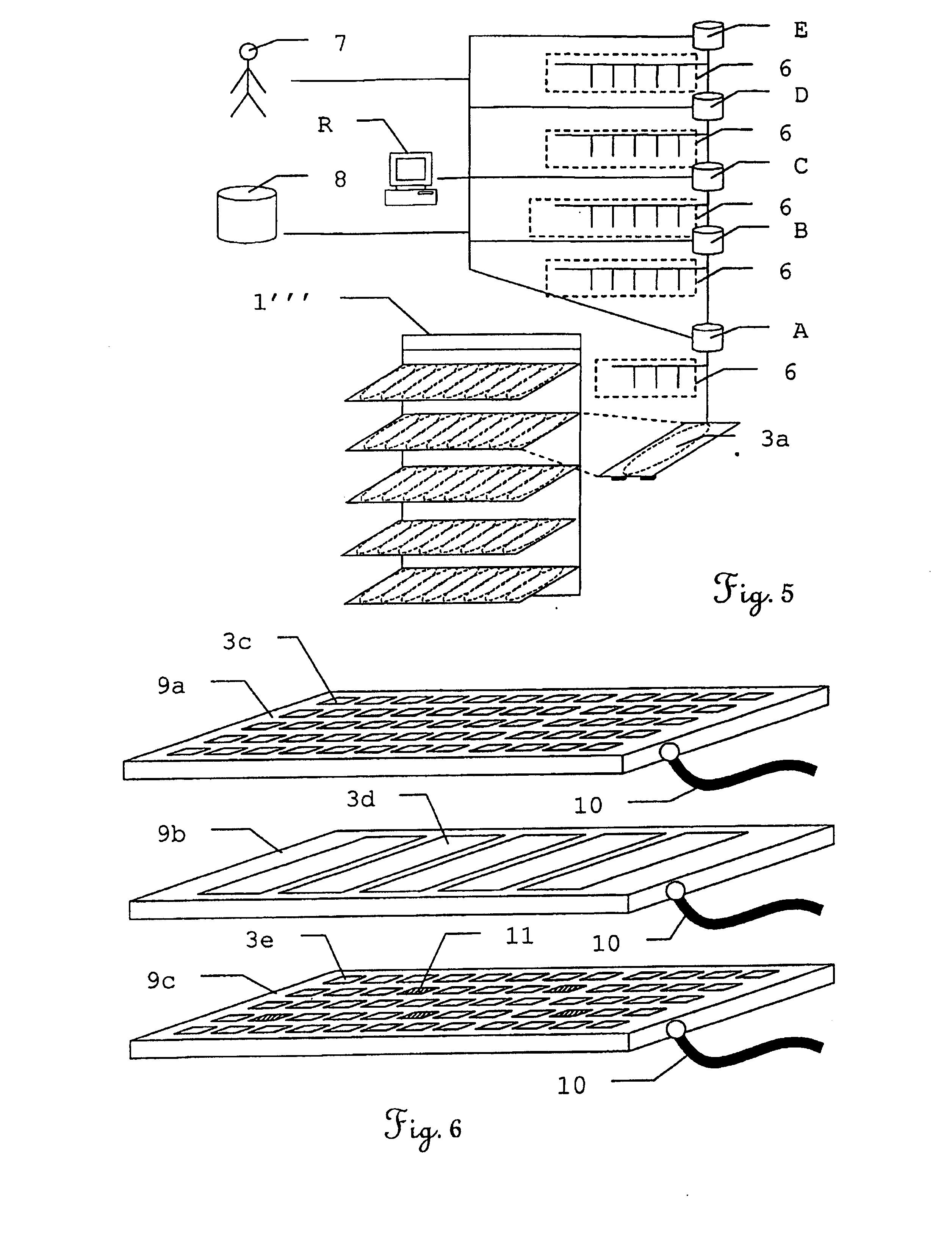

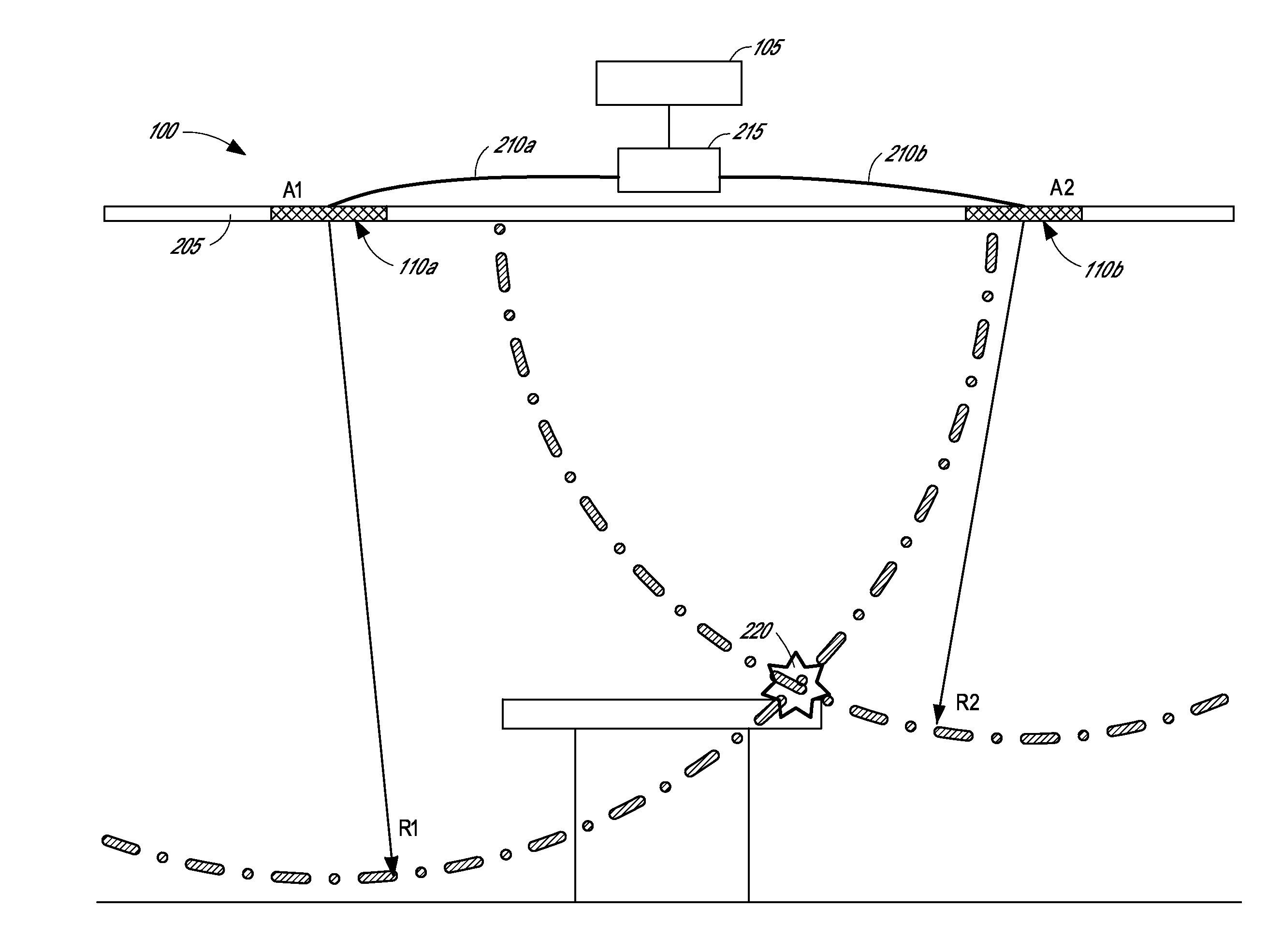

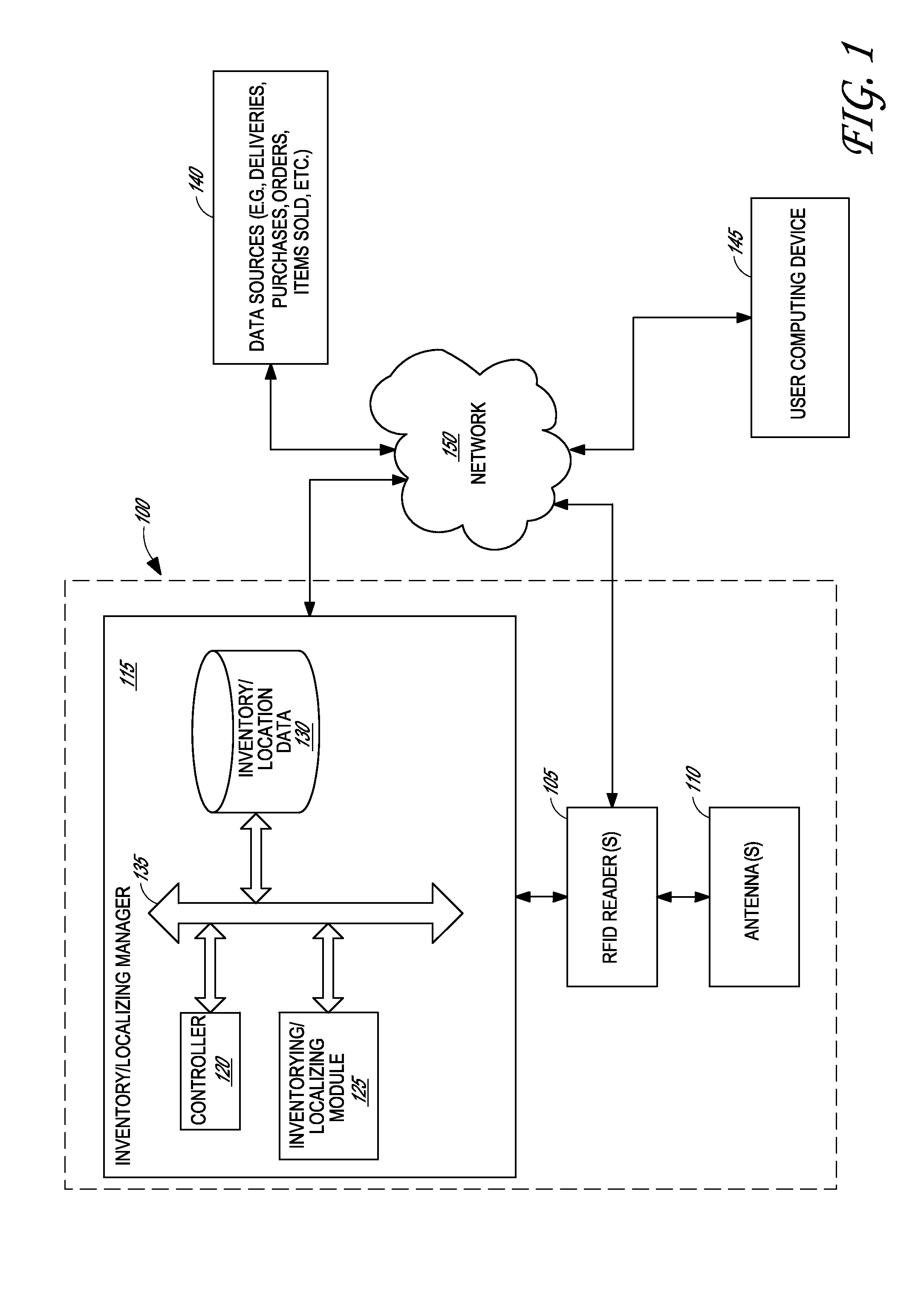

Overhead antenna live inventory locating system

InactiveUS20140361078A1Reduce stepsReduce distanceLogisticsCommerceEmbedded systemPositioning system

Overhead antenna live inventory locating systems and methods are provided. The overhead antenna inventory / locating system can include a plurality of antennas mounted in an elevated support structure. The antennas can be coupled to RFID readers that interrogate electronic tags. The inventory system can analyze the information received from the detected electronic tags and produce inventory data and location information for the tags. The antennas can be patch antennas mounted to ceiling tiles such that they can be positioned in the ceiling of a facility. The antennas can be configured to provide broad coverage from a relatively low ceiling height. The low-cost antennas can be configured in such a way as to provide accurate location information for detected tags. The inventory system can be configured to provide near real-time inventory and location information.

Owner:RFID RESOLUTION TEAM

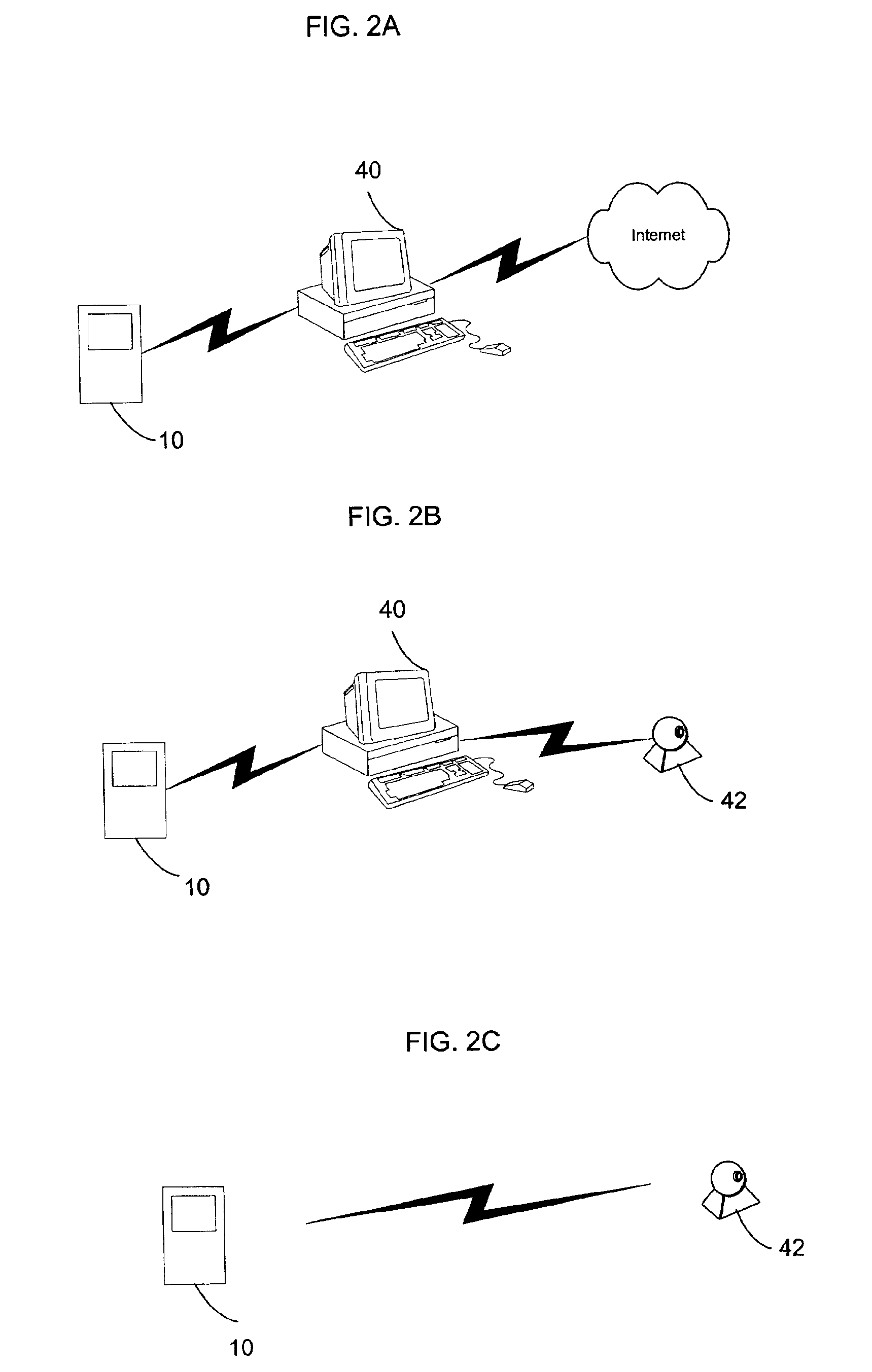

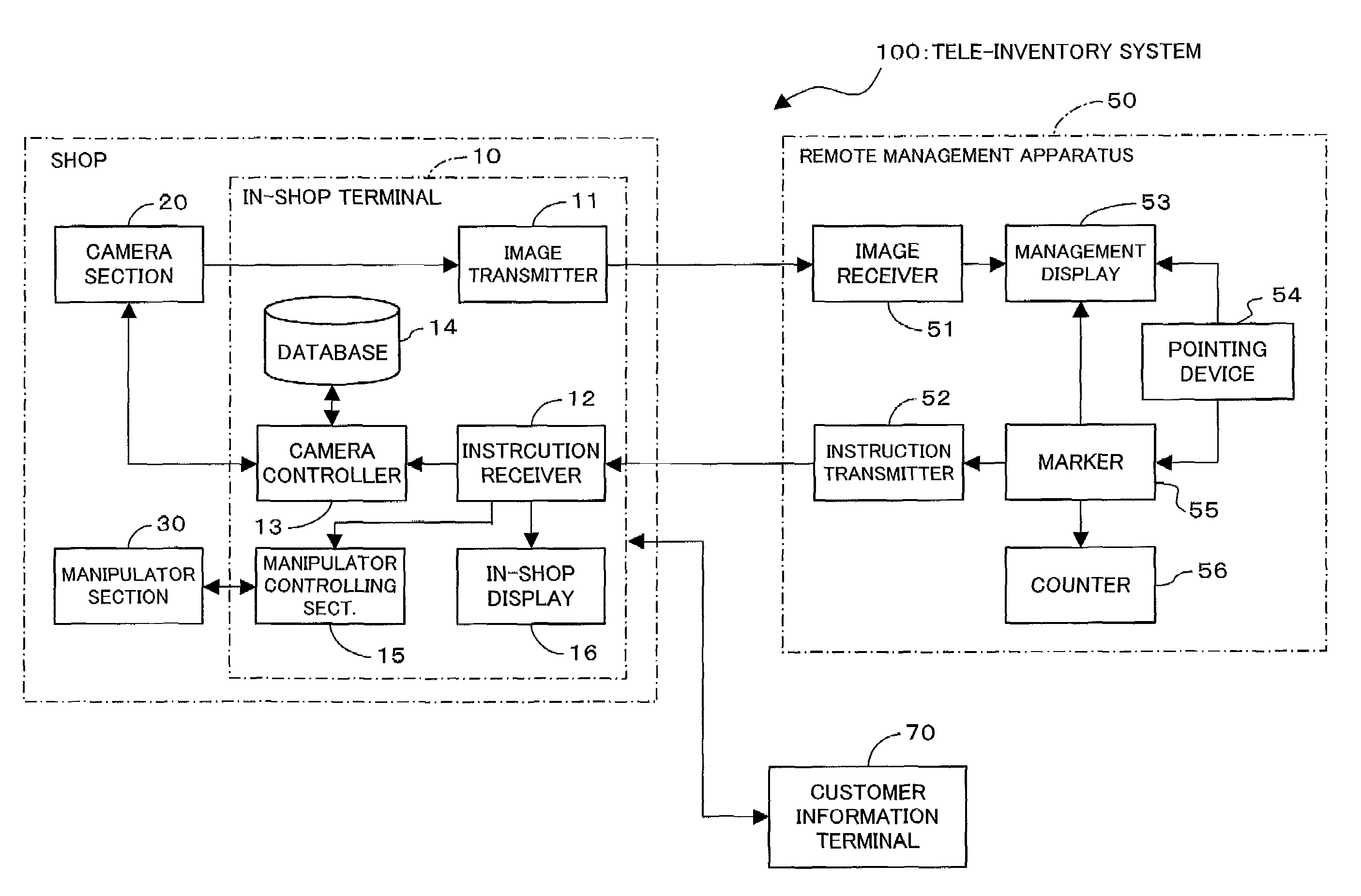

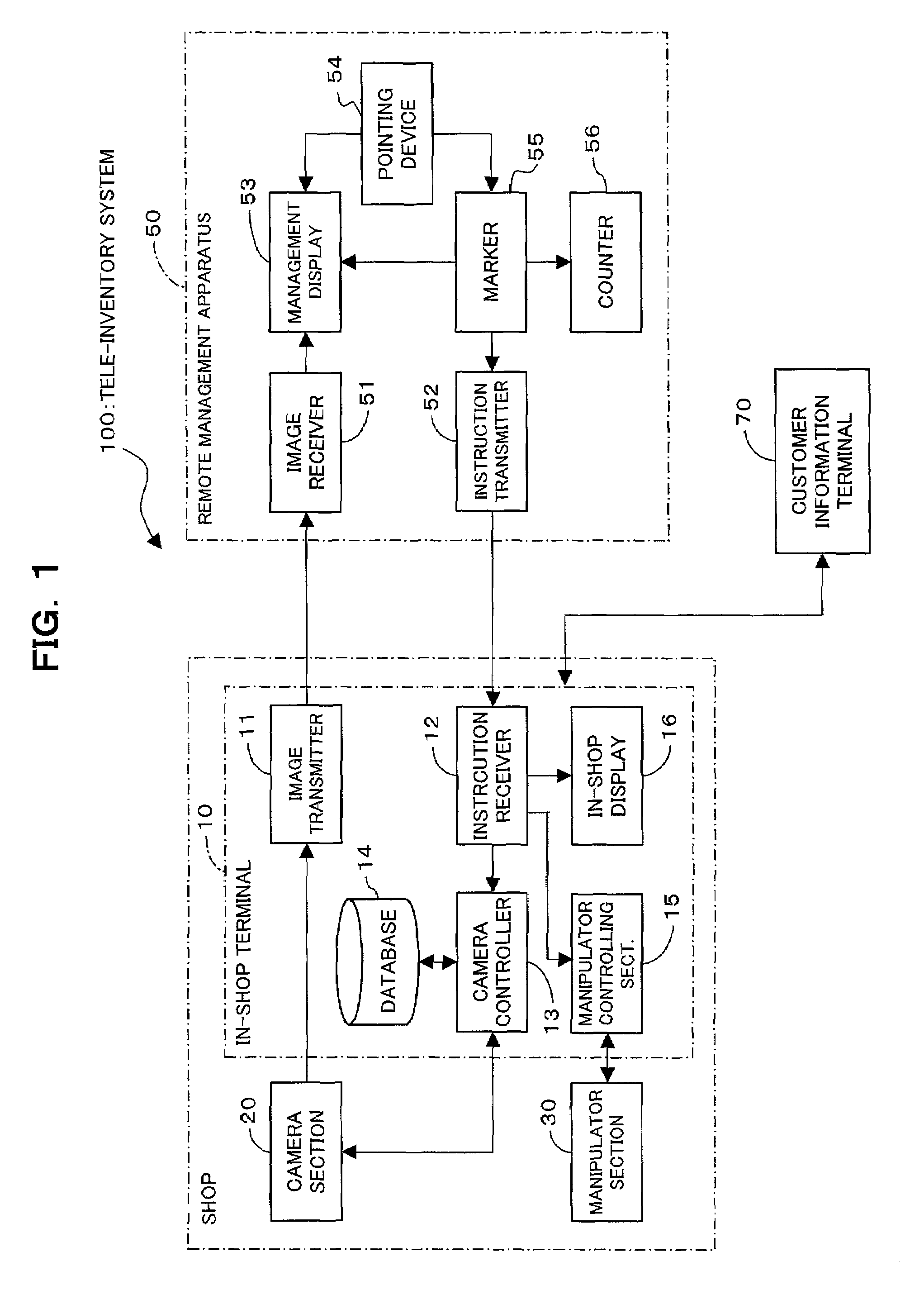

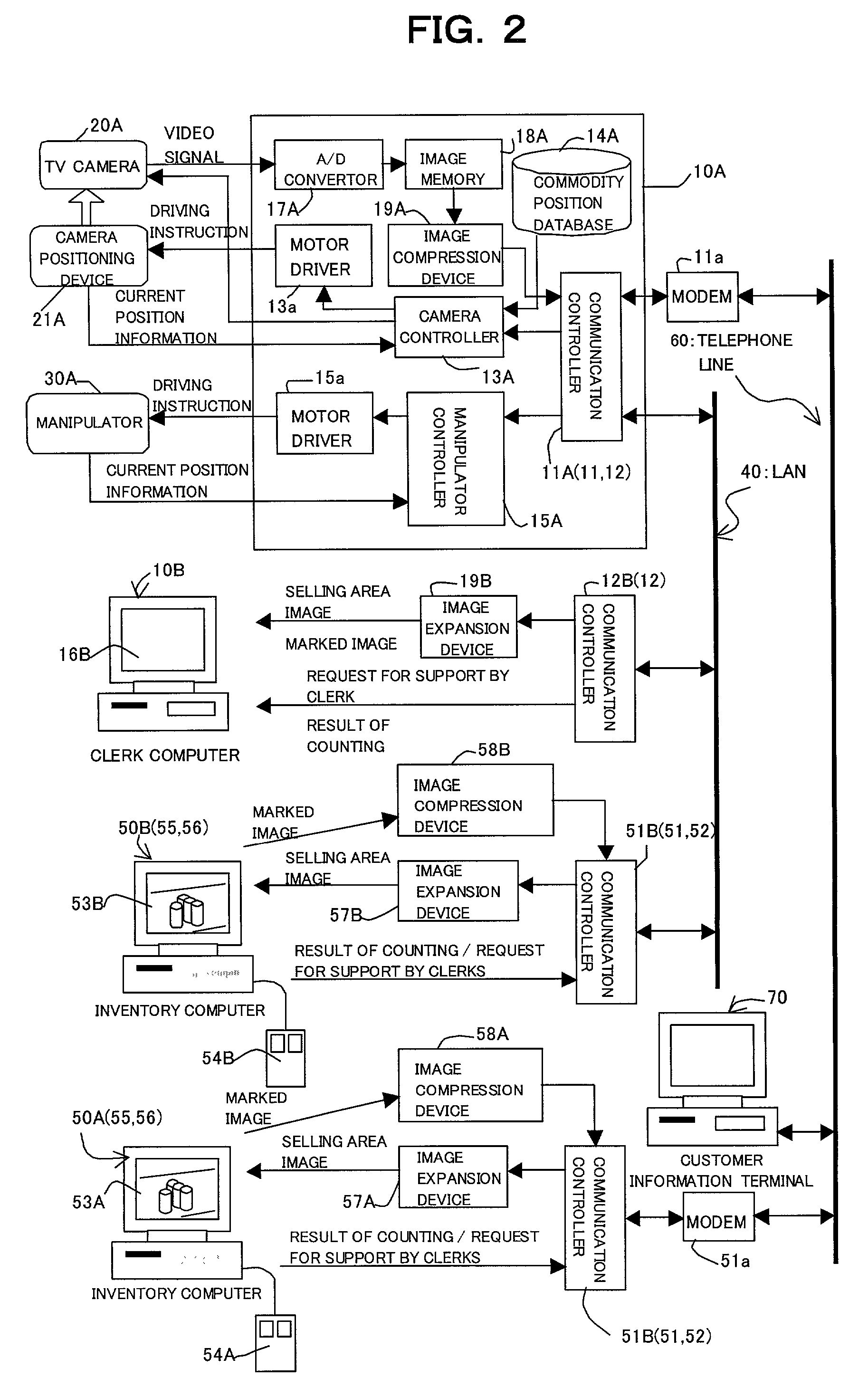

Tele-inventory system, and in-shop terminal and remote management apparatus for the system

InactiveUS7290707B2Reduce the burden onReduce in quantityAnimal feeding devicesCharacter and pattern recognitionDisplay deviceComputer terminal

A tele-inventory system for inventorying various kinds of commodities in a shop by an operator from a remote management apparatus installed remotely from the shop, includes, at shop, a camera for taking images of object commodities to be inventoried, a image-transmitter for transmitting the taken images of the object commodities to the remote management apparatus, and, at the remote management apparatus, an image-receiver for receiving the taken images of the object commodities from the image-transmitter and display for displaying the taken images of the object commodities, whereby the operator can make an inventory of the object commodities at the remote management apparatus with consulting the taken images of the object commodities which images have been displayed on the display. With this system, it is possible to inventory commodities sold and stocked in a department store or a convenience store from a remote place.

Owner:FUJITSU LTD

Asset inventory system

InactiveUS20080033847A1Maintain securityClimate change adaptationInstrumentsFlood insuranceSecurity Measure

The present invention is for a system that delivers to owners of real and personal property a service to photographically inventory assets for a variety of purposes, including specifically to document the property for insurance claim purposes following damage or destruction or other loss resulting from hurricanes, tornadoes, floods, earthquakes, theft and / or fire. Other purposes include to document the condition of property after a catastrophic event, to show before and after comparisons regarding such events, to facilitate architect and homeowner communications on various issues, to allow an absentee owner to monitor reconstruction after damage or loss has occurred, to allow an absentee owner to make design or remodeling changes during repair, to view landscaping to make similar decisions, for a contractor to document building stages completion for draws, for use by governmental agencies such as local building and zoning departments or FEMA showing compliance with building codes or flood insurance restrictions, to show security measures, and the like.

Owner:MCINTOSH ANNE PELL

System, method, and computer program product for reducing the burden on an inventory system by assembling a suggested themed travel itinerary in response to minimal user input

InactiveUS20080091482A1Reduce the burden onOvercome problemsReservationsData acquisition and loggingUser inputComputer science

The present invention generates a concise listing of low-priced travel products in an interactive itinerary format in response to a simplified user input that may include specification of a selected travel theme. The interactive itinerary generated by the invention may allow the user to revise the itinerary to add, remove, and / or amend details related to the various travel products listed therein such that the user may be made aware of the cost and / or scheduling effects of making a particular revision to the itinerary. The invention may also provide a concise display of supplemental information related to the selected theme and / or a selected destination for the itinerary such that the user may be better informed when making revisions to the interactive itinerary. For example, the invention may provide interactive maps, reviews, photos, and / or other supplemental information related to the selected theme and / or one or more of the listed travel products.

Owner:TRAVELOCITY COM LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com