Patents

Literature

5179 results about "Electronic tags" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An electronic tag is a device that is firmly attached to someone or something and sets off an alarm if that person or thing moves away or is removed. A hospital is to fit new-born babies with electronic tags to foil kidnappers. Sometimes, they've snapped off the security tag and just taken the one shoe.

Smart electronic label employing electronic ink

InactiveUS6924781B1StampsElectric/electromagnetic visible signallingFlexible electronicsComputer science

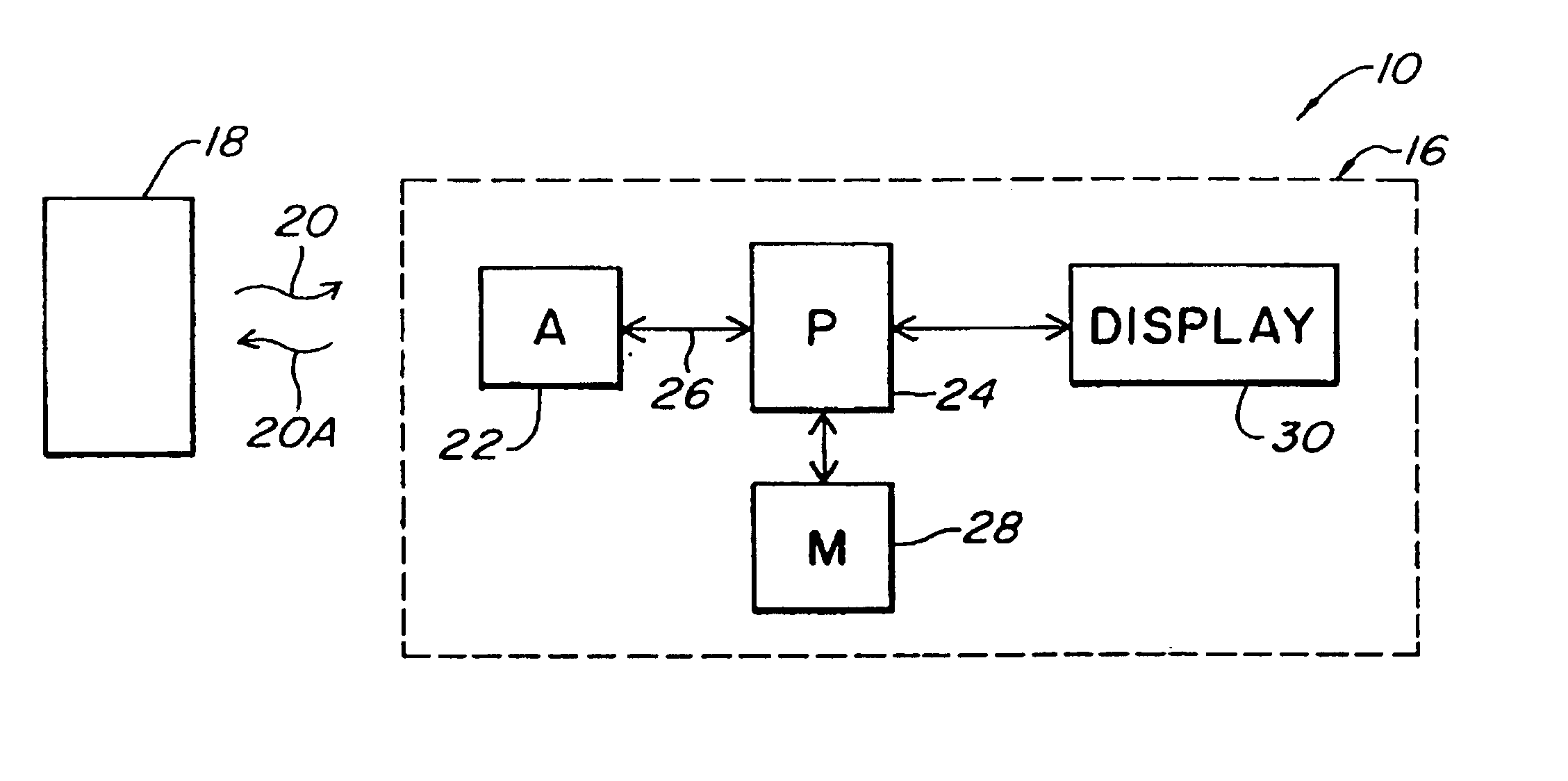

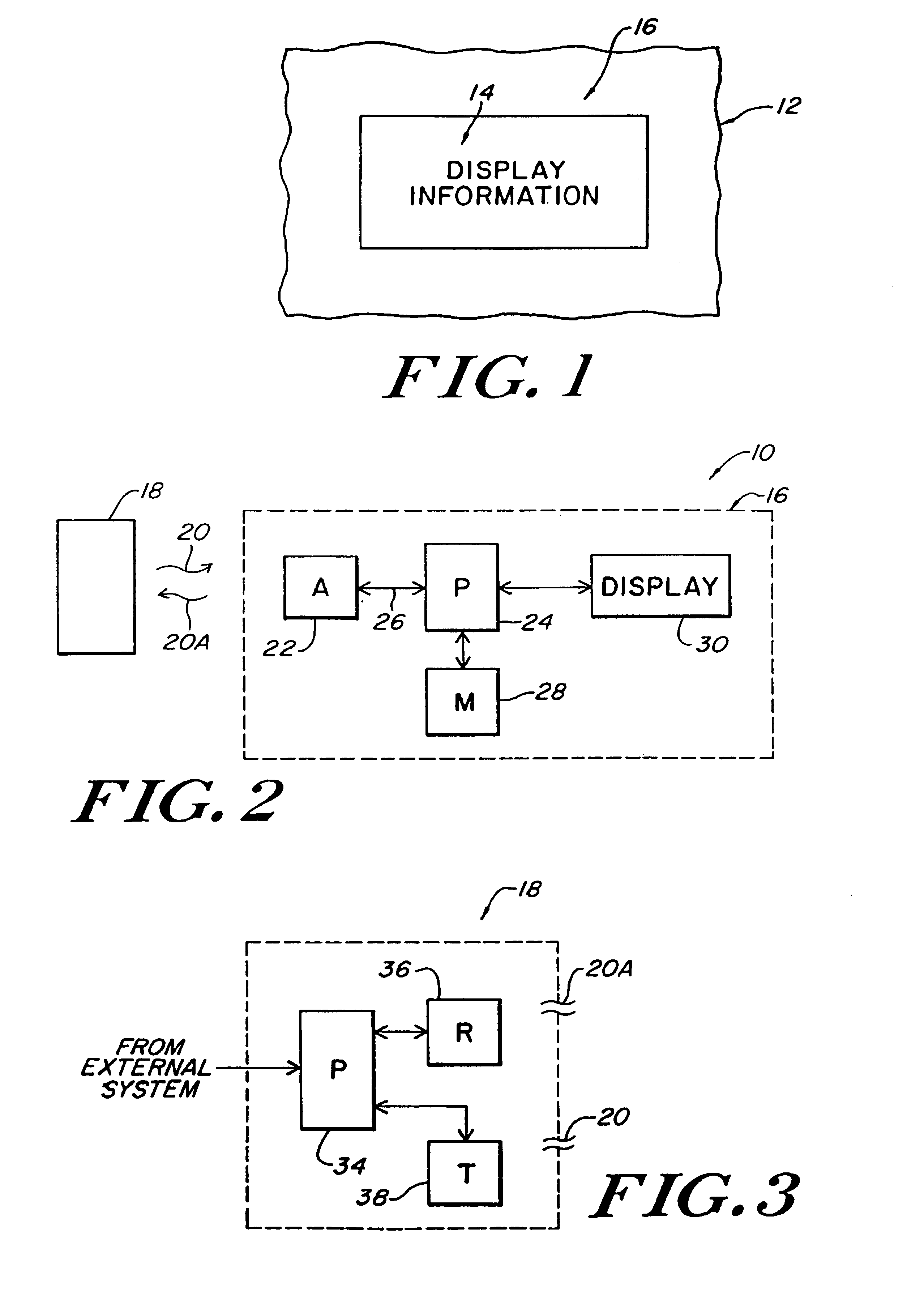

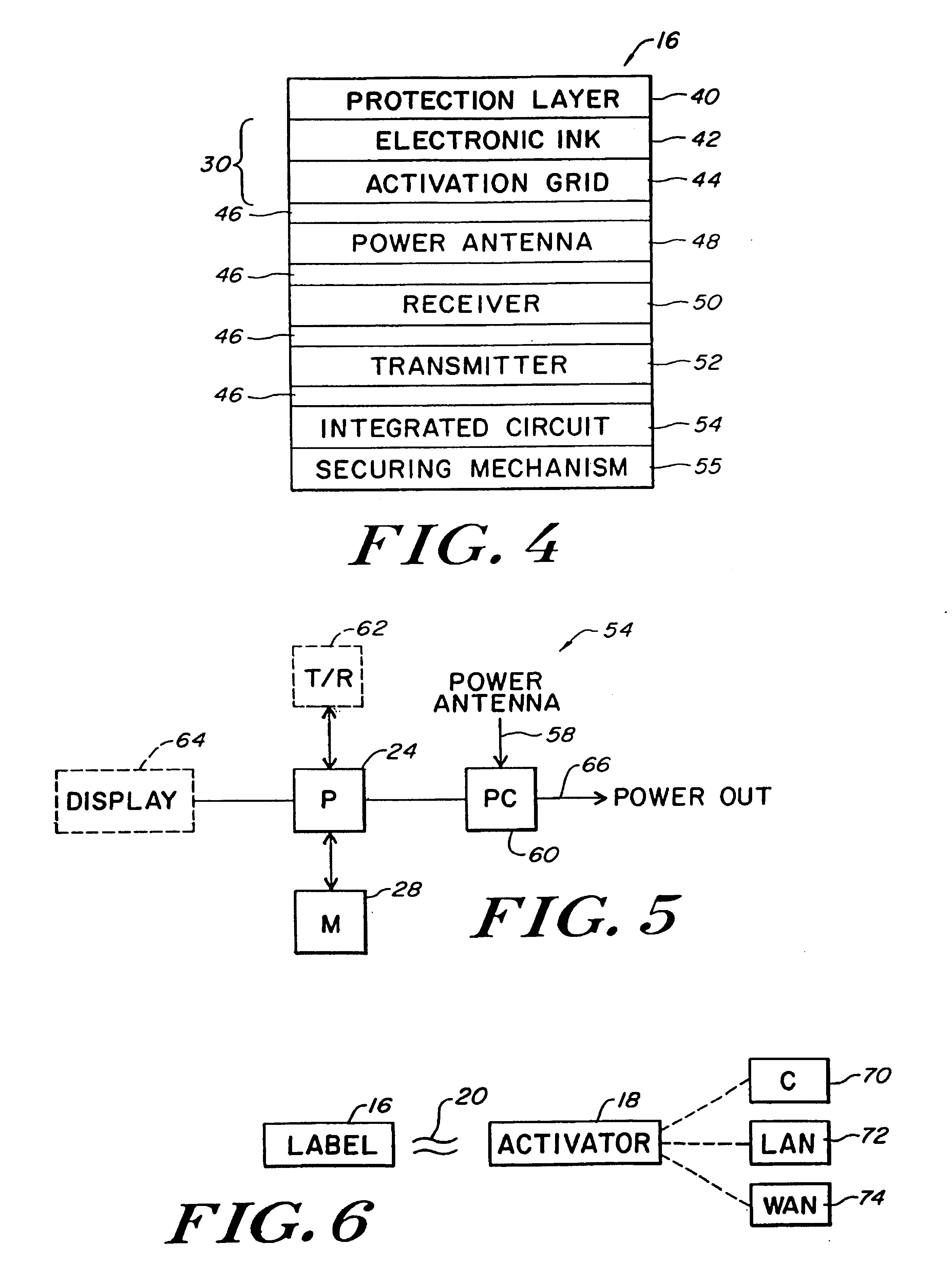

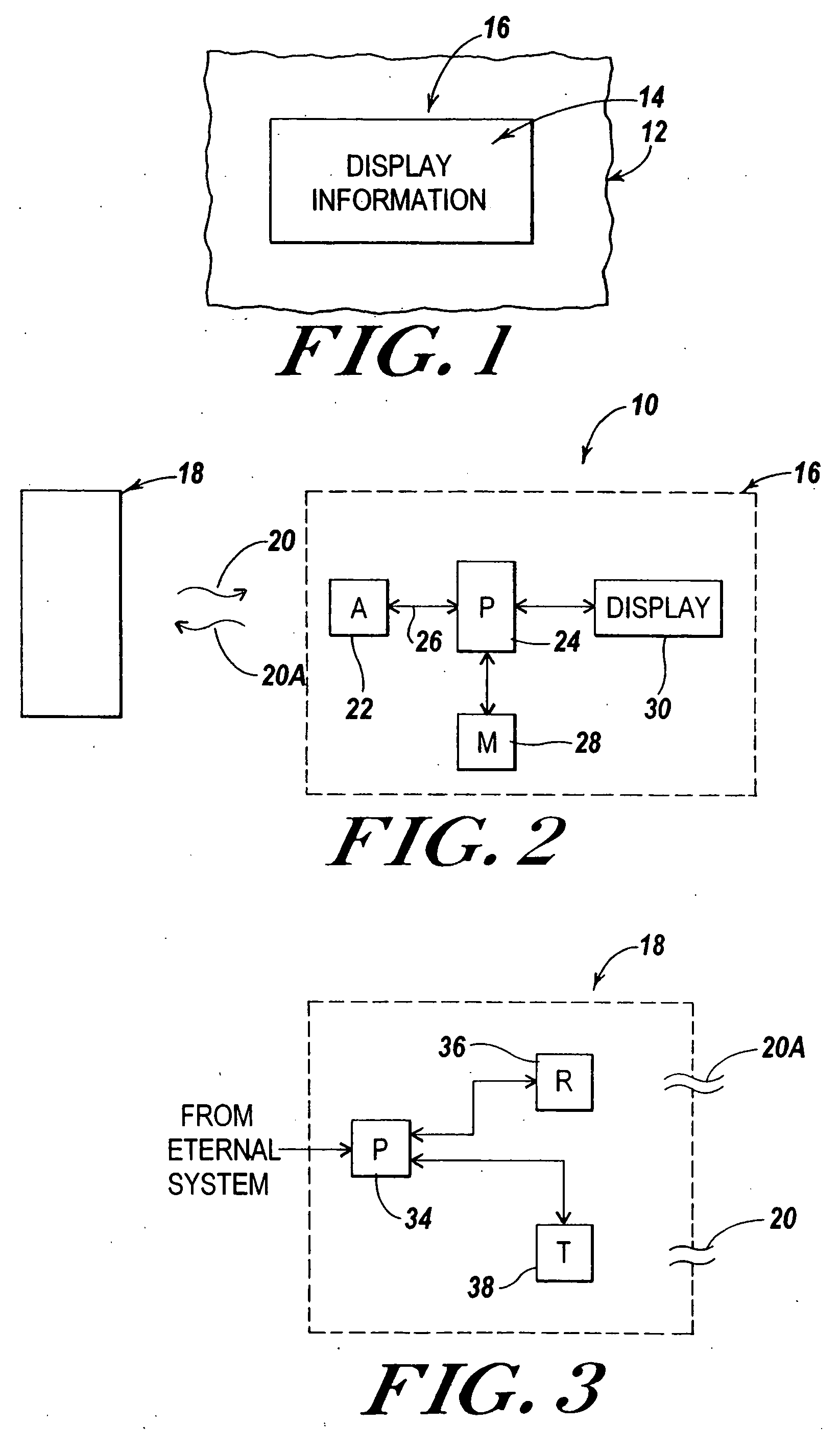

The present invention provides for smart and dumb implementations of a stand-alone, remotely updateable, remotely alterable, flexible electronic label. The electronic label provides for displaying information in connection with a mammal, non-mammal, an item or location. The label includes a display assembly having electronic ink disposed on a support, one or more antennas for sending or receiving signals corresponding to one of instructions, programs, data or selected indicia to be displayed by said display assembly, a storage element in circuit with the antenna for storing the instructions, programs, data and indicia, and one or more processors for intelligently determining the indicia to be displayed by the display assembly, for controlling and coordinating operation of the label, and for generating output signals for instructing the display assembly to display the indicia.

Owner:METROLOGIC INSTR +1

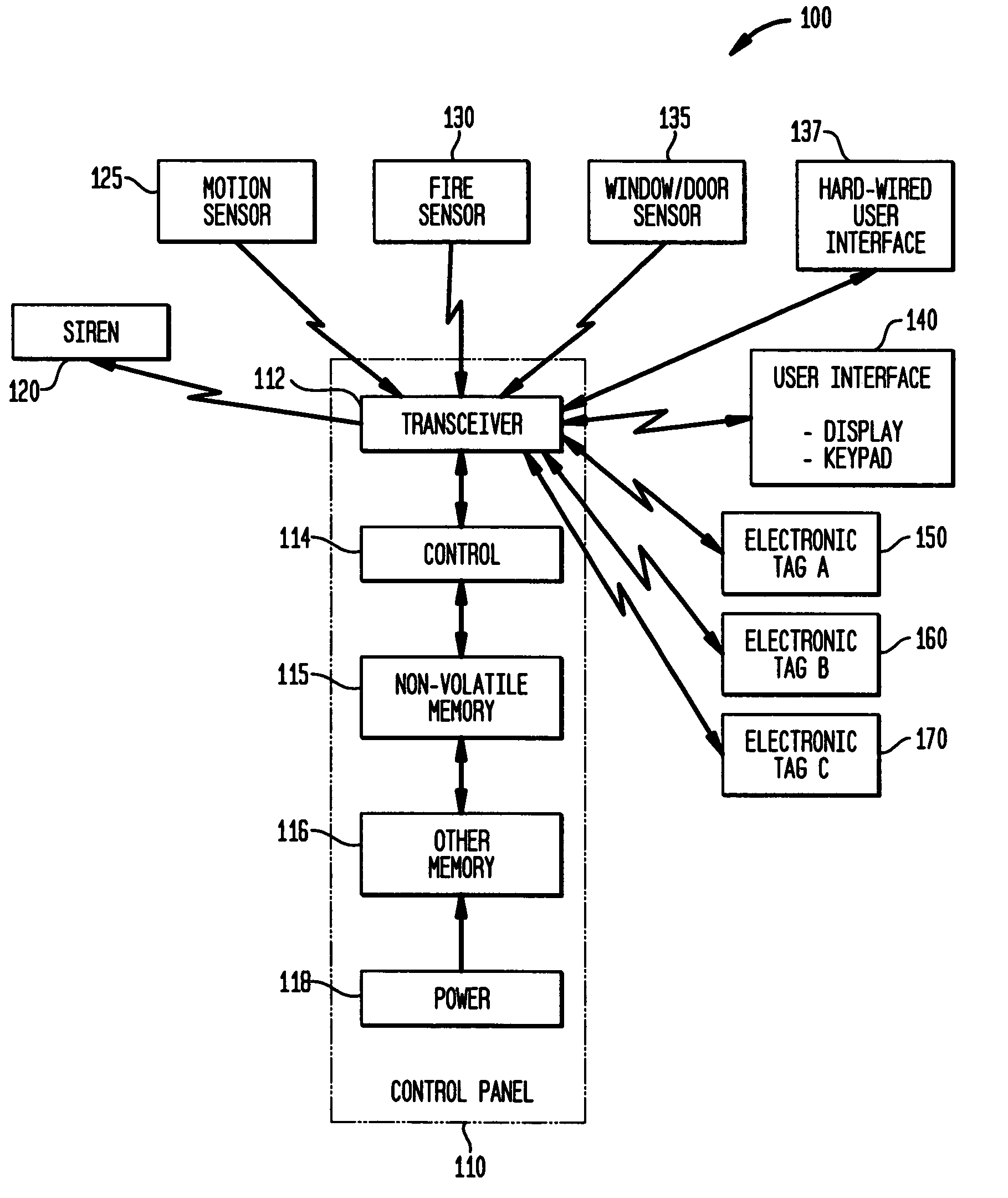

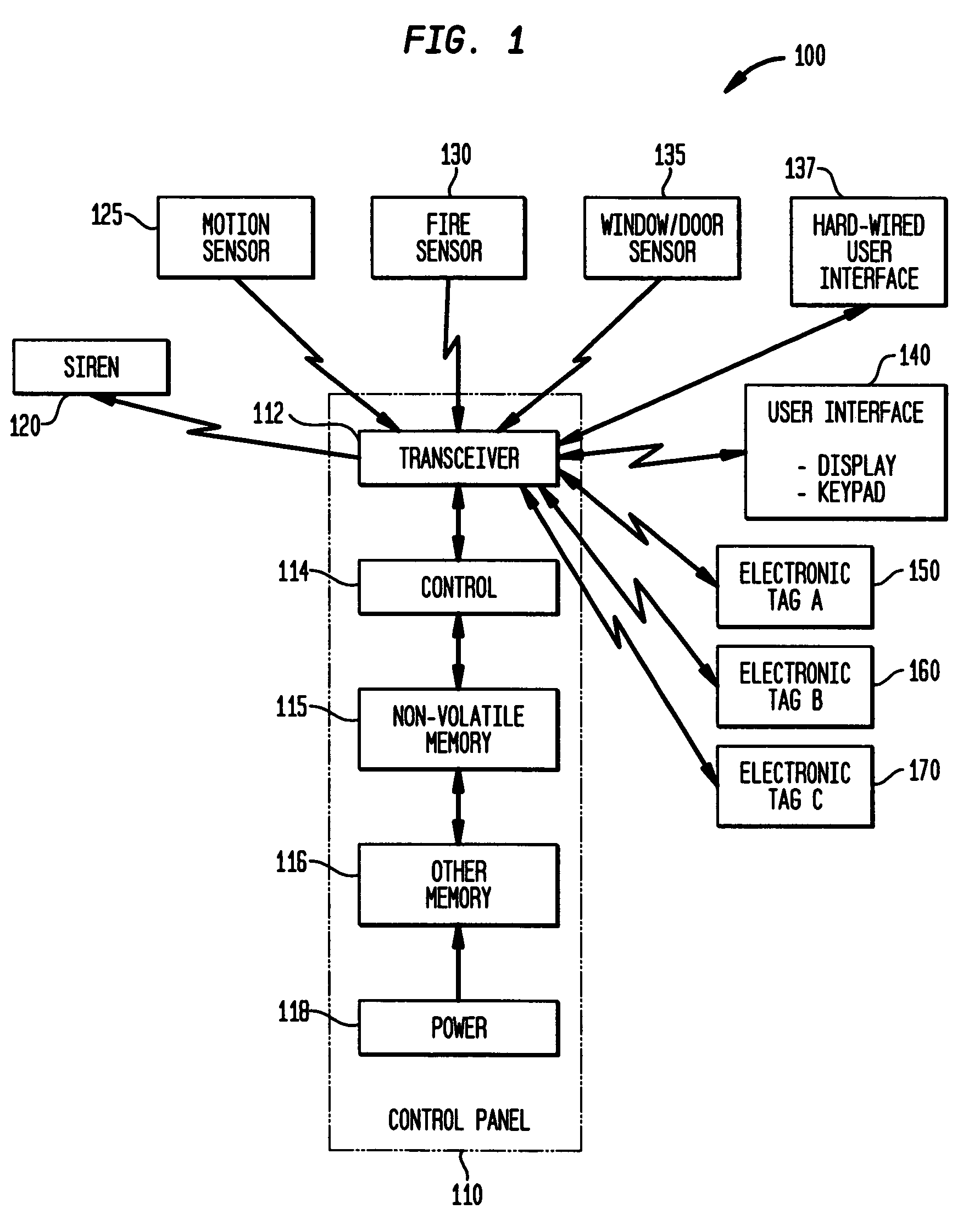

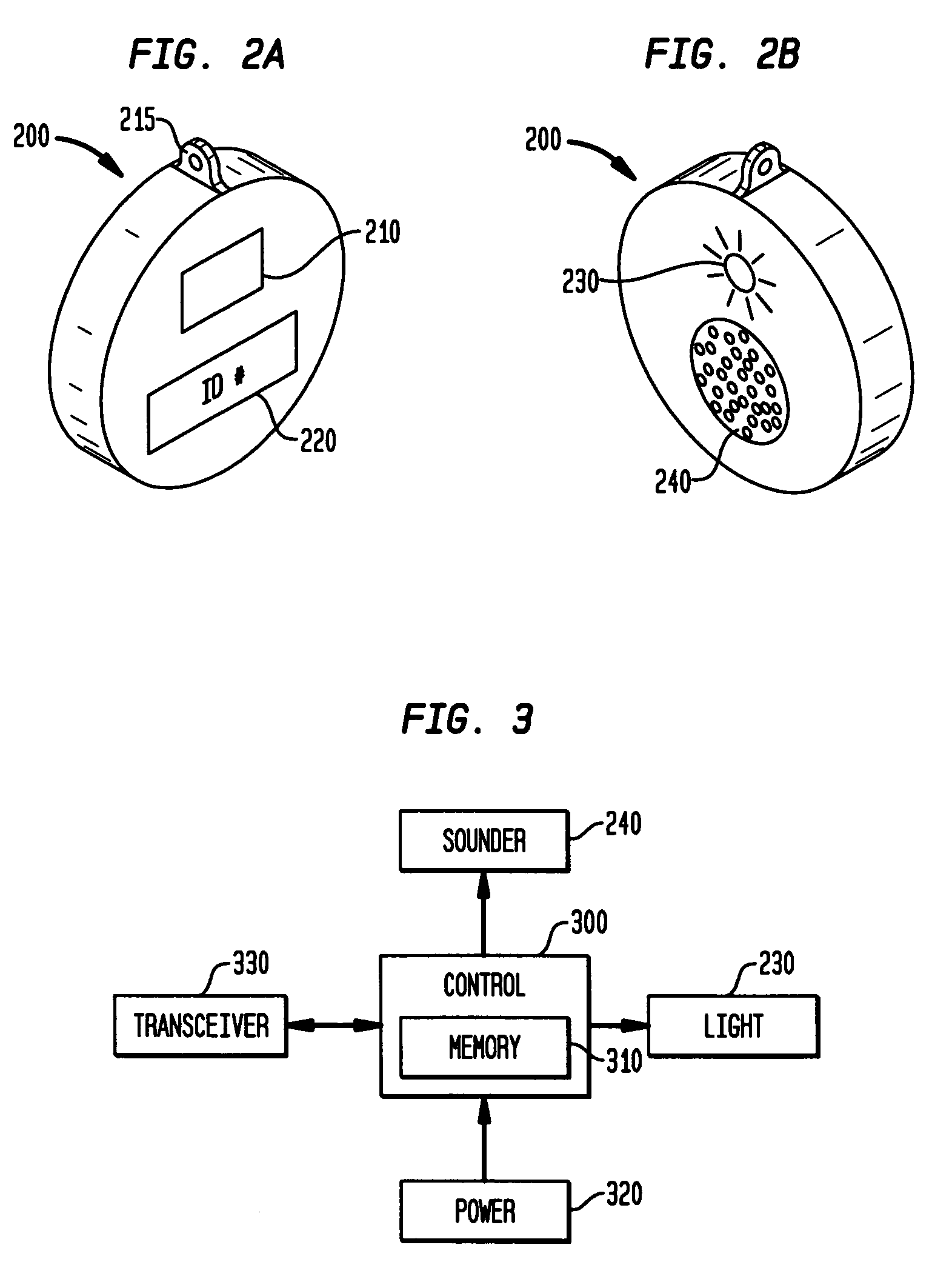

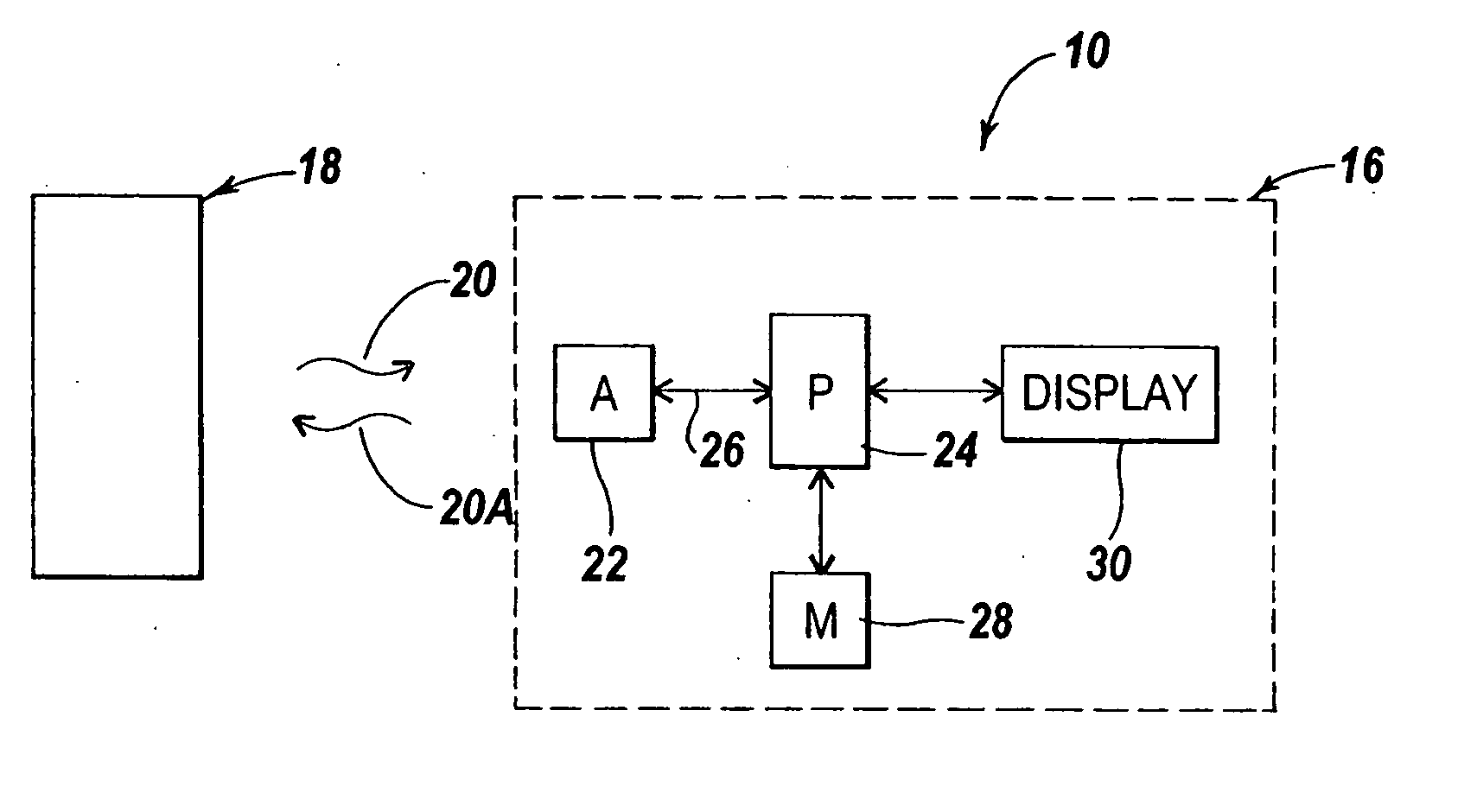

Tracking, presence verification and locating features as part of a security system

ActiveUS7113099B2More user-friendlyElectric/electromagnetic visible signallingSensing record carriersTransceiverDisplay device

Tracking, presence verification, and locating features are incorporated into a security system that includes a user interface device with a display, keypad and associated transceiver. Wireless RF electronic tags are attached to different objects, e.g., an inanimate object, or a living being such as a child or pet. To verify the presence of an object associated with a tag, the user instructs the user interface device to transmit a wireless signal to the tag. The tag responds, when within range, by returning a wireless signal. In another aspect, a person is detected such as at the entry to a home, and a low-power transmitter at the entry sends a signal to the electronic tag. The electronic tag responds by transmitting data to the security system to cause it to take a desired action. The presence of a person, such as a child, in an unauthorized area can trigger an alarm.

Owner:ADEMCO INC

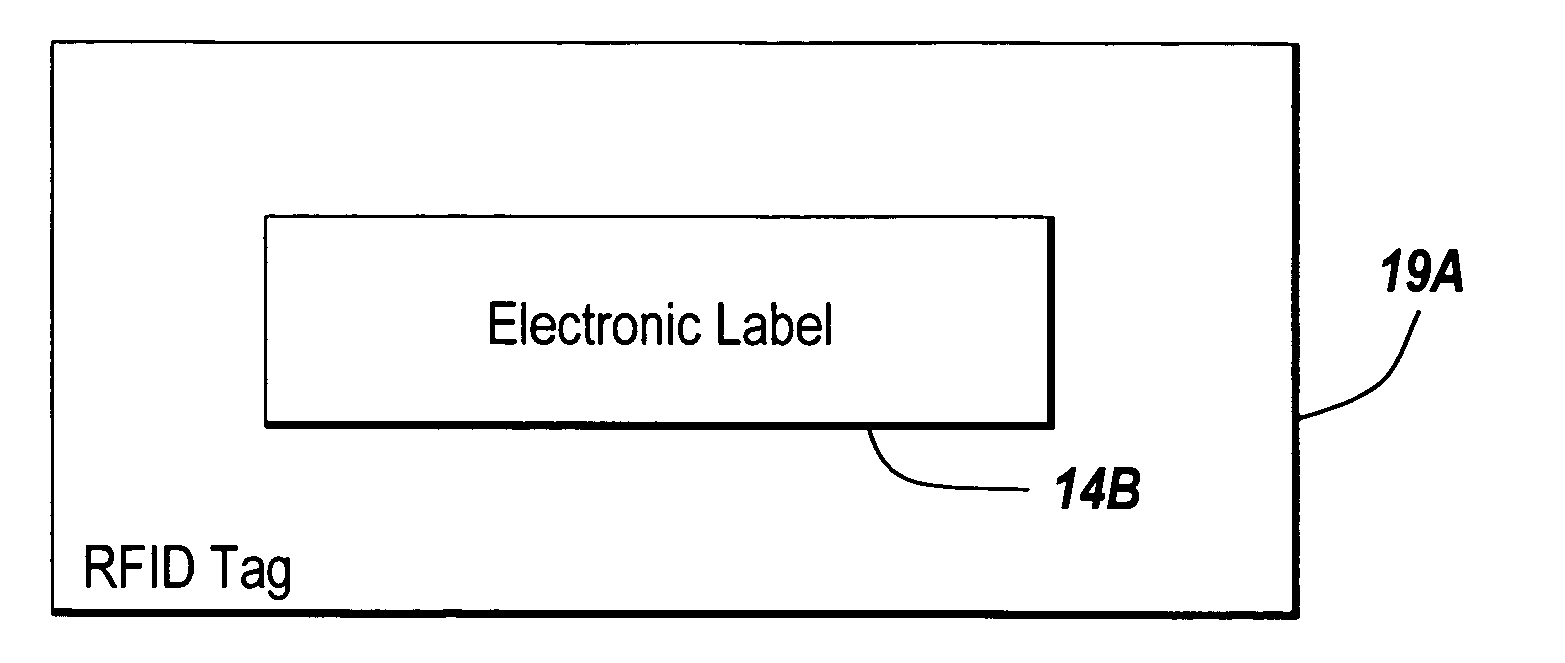

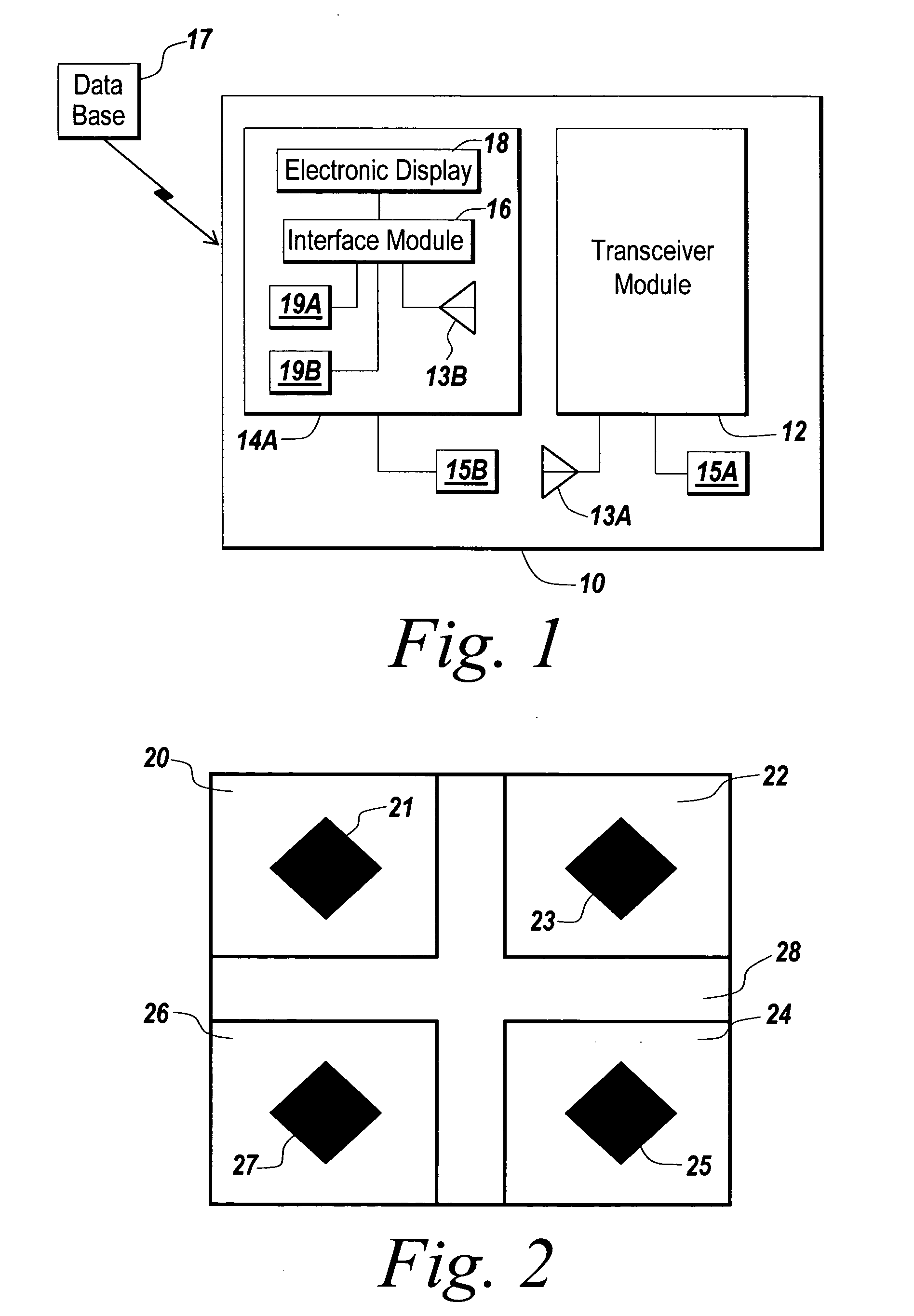

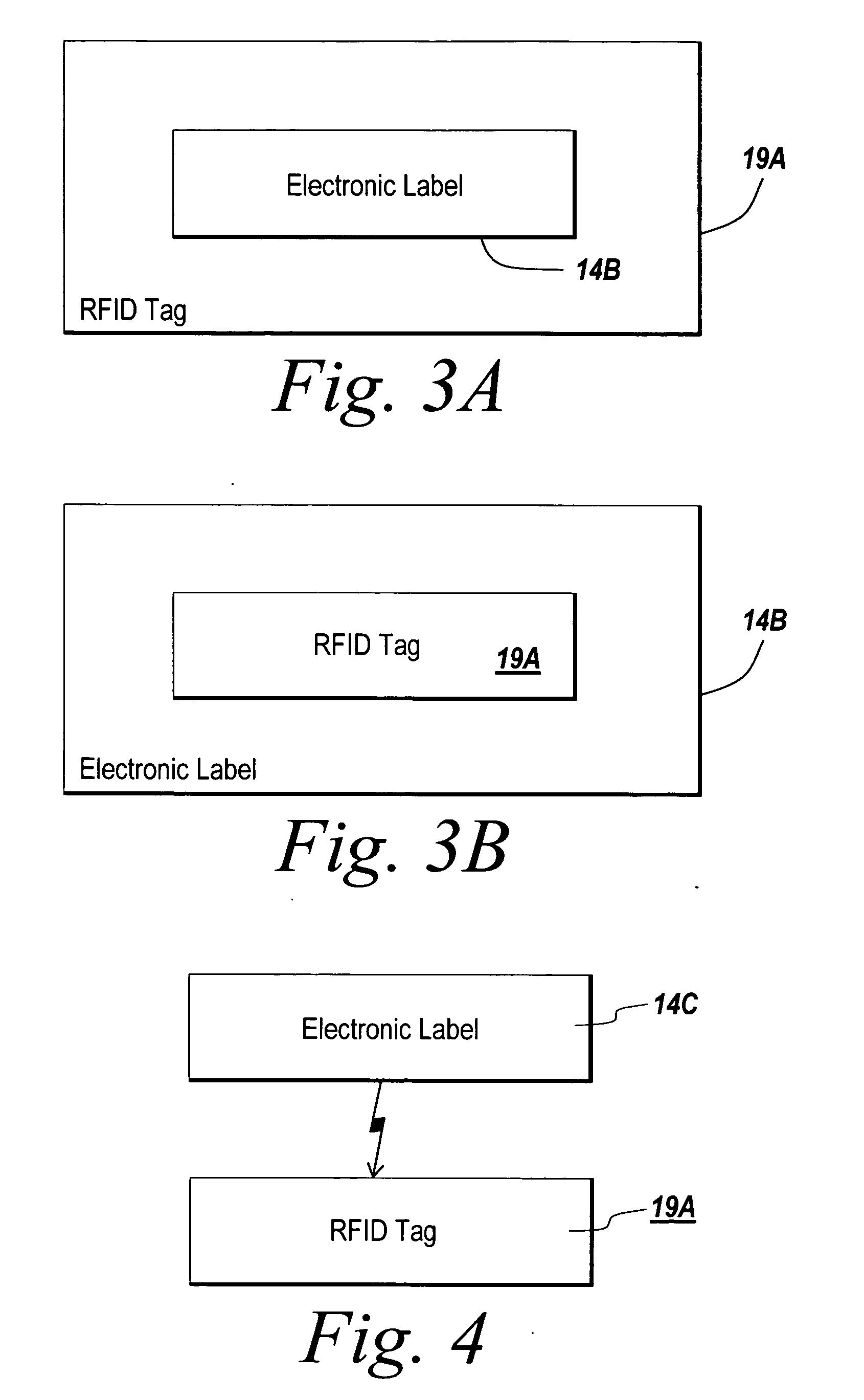

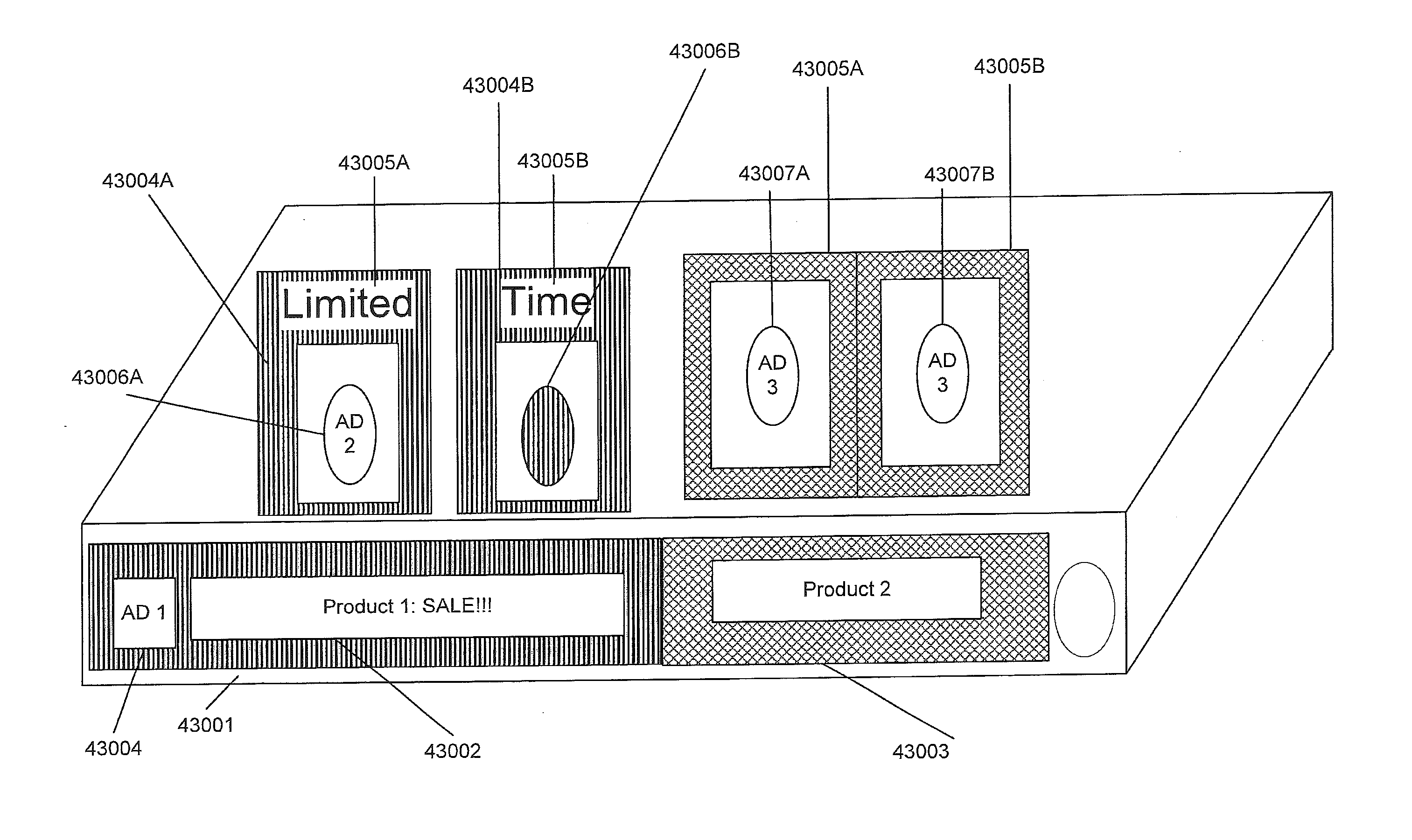

Electronically updateable label and display

InactiveUS20050134461A1Sure easyCo-operative working arrangementsVisible signalling systemsGraphicsComputer science

The present invention provides for an electronic label associated with a transponder. The electronic label displays at least one graphical element to provide a visual indication representative of information associated with the transponder. Representable information can include a result of a communication with the transponder, a location of the transponder or an item associated with the transponder, a state of the transponder, or an item associated with the transponder, a status of the transponder or an item associated with the transponder, or any combination of information. The display of the graphical element can further indicate if a read operation has failed or has not yet taken place. The graphical element is alterable and updateable. The graphical element can indicate if the RFID tag is activate or has been deactivated allowing a consumer to readily determine the state of an RFID tag associated with a consumer item.

Owner:VISIBLE TECH KNOWLEDGY +1

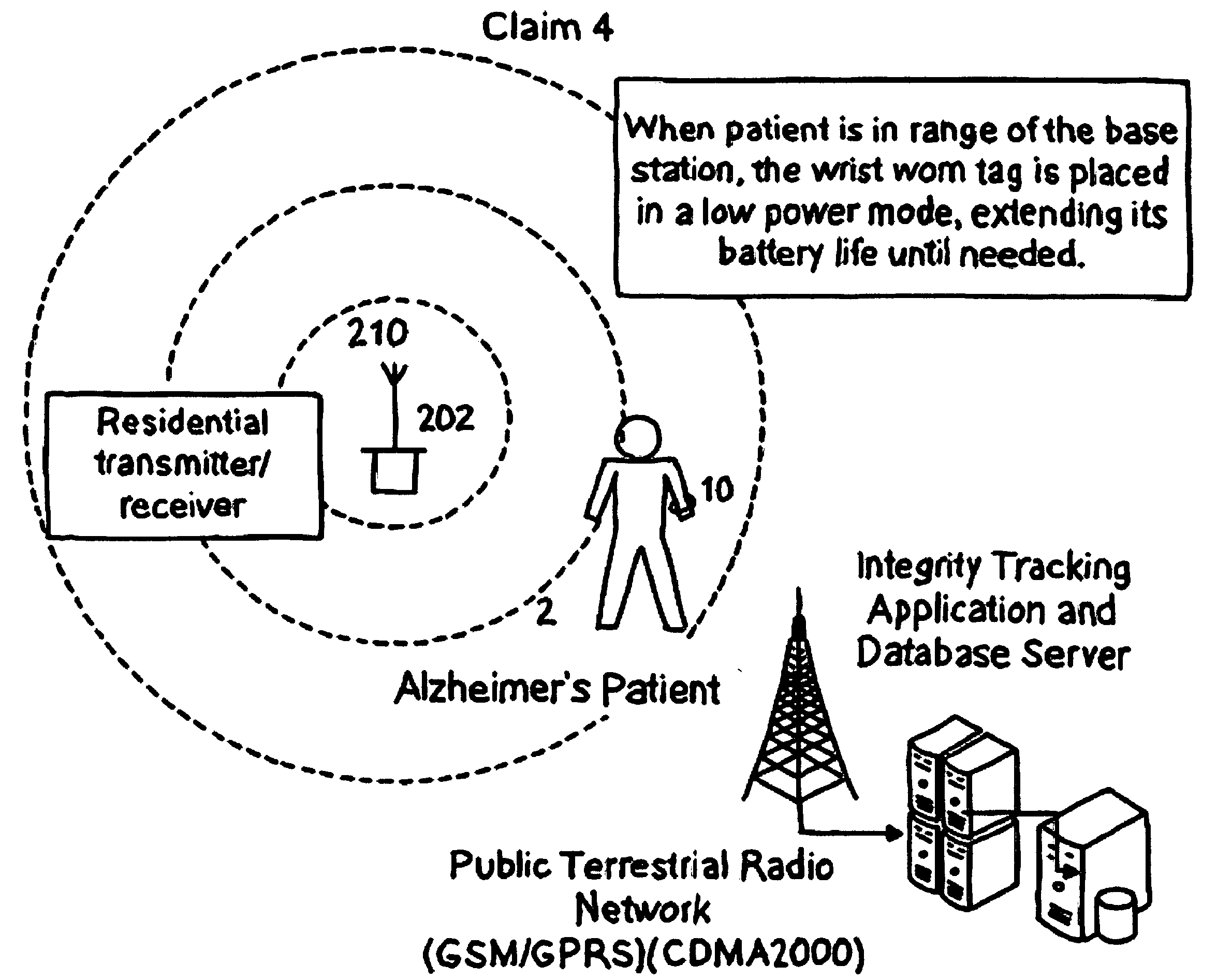

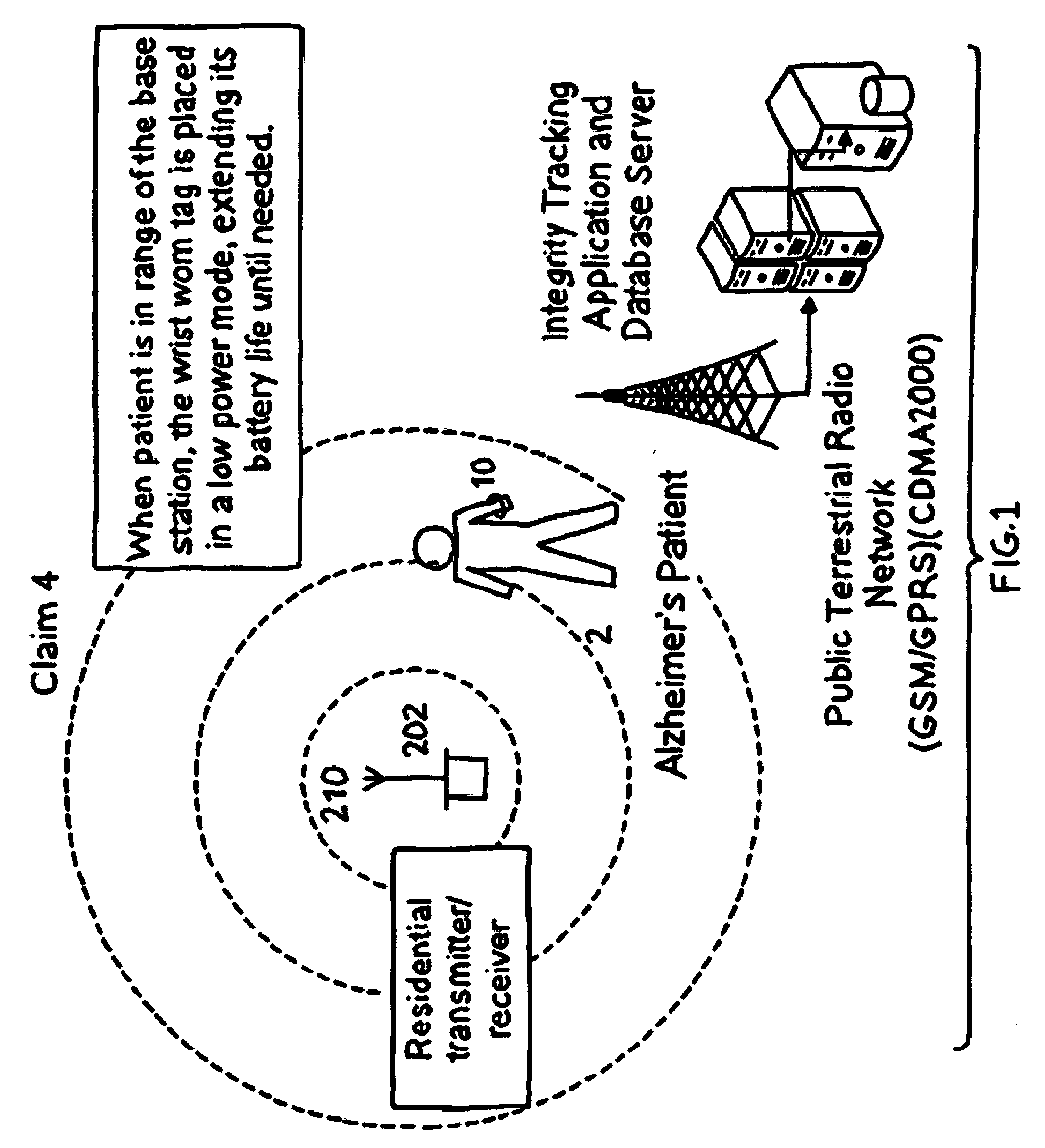

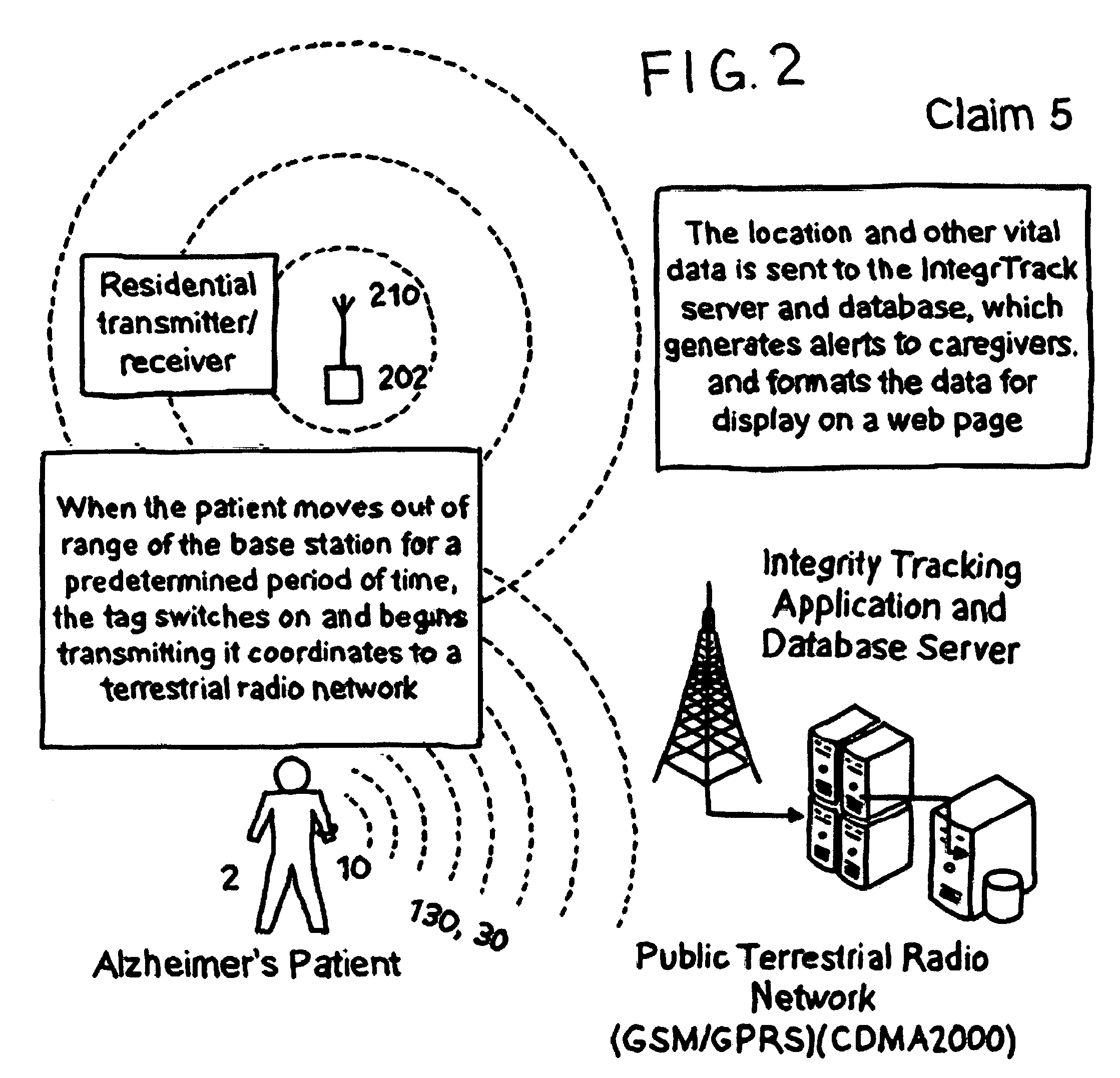

Alzheimer's patient tracking system

ActiveUS20090040041A1Reduce power consumptionLow costPower managementRoad vehicles traffic controlCaregiver personElectronic tagging

The computerized system provides a method to track Alzheimer's patients and other diseases that affect the patient's ability to contact and communicate their location or vital information to their caregivers. The system applies an electronic tag to each patient of a multiplicity of patients or only to non-confined patients and employs a computer to maintain information about their location and well being. Use is made of a global positioning system to locate a lost patient as well as to track movements of the patient. A history of the movement of the patient may also be plotted on a map. Additional components of the tag gather and relay information about the patient's condition and other environmental data. In addition, the use of a an additional external transmitter keeps the wearable tag in a low power “sleep” mode when it is in range, preserving the internal battery and only consuming power when the tag moves out of range of the external transmitter.

Owner:MOBILEHELP LLC

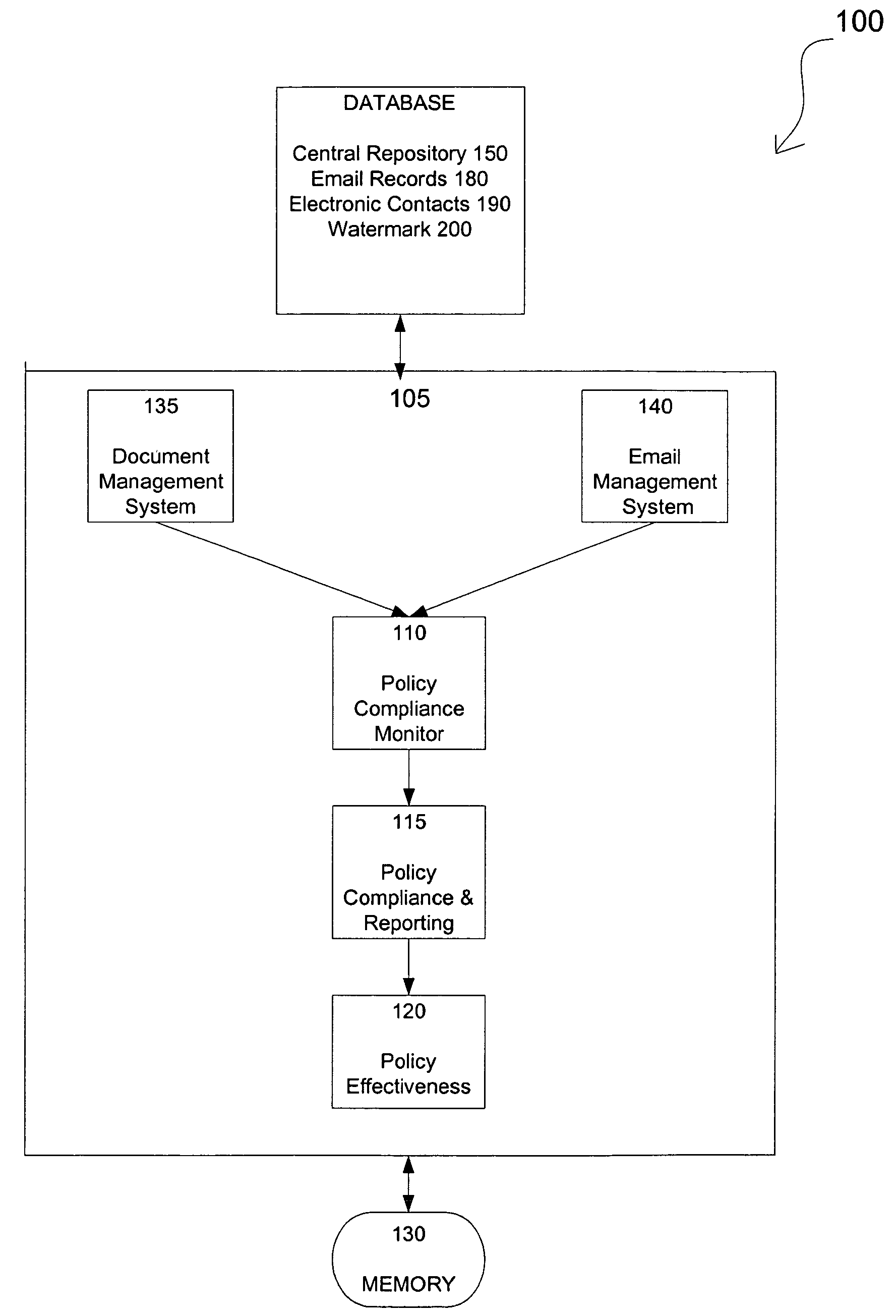

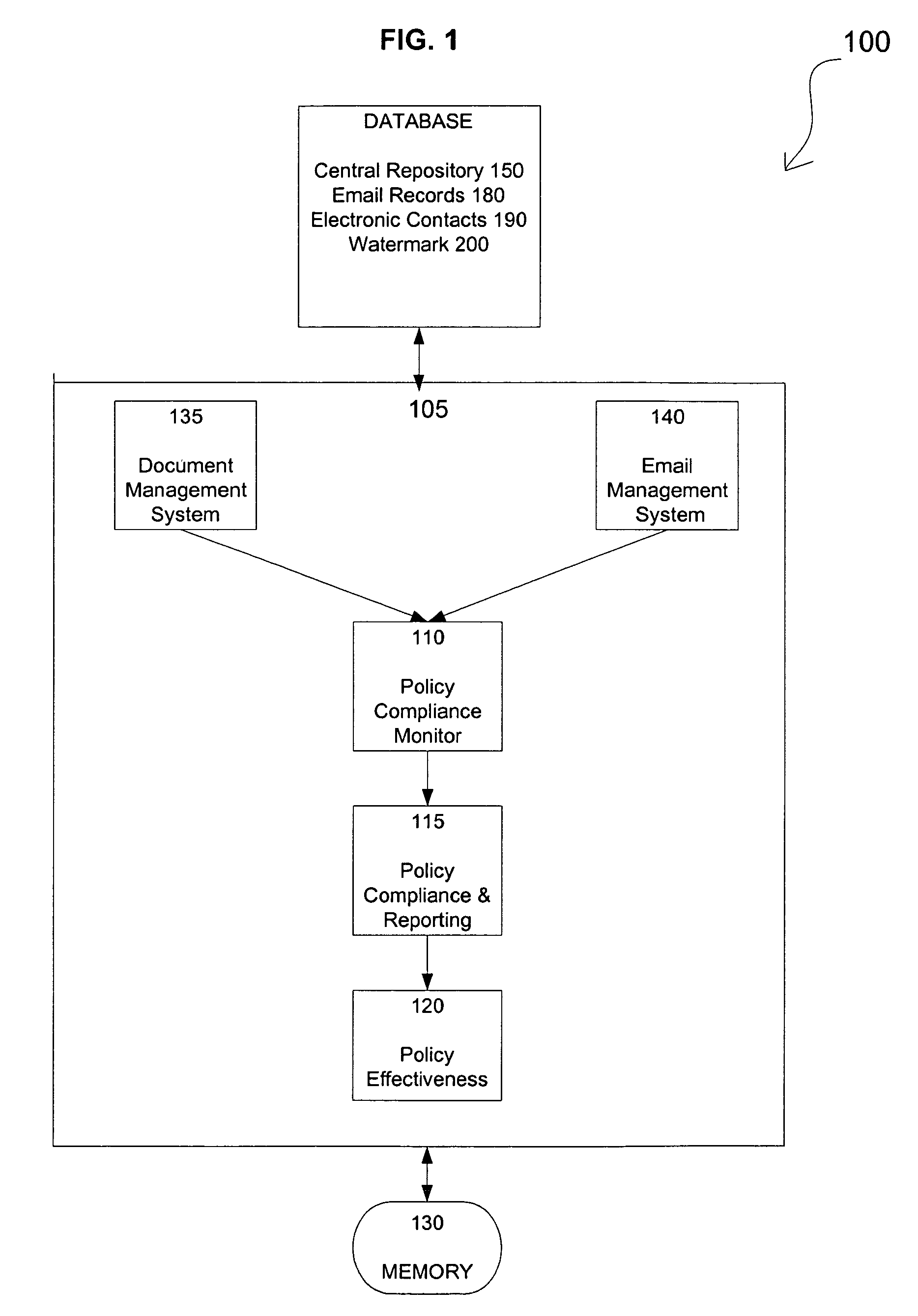

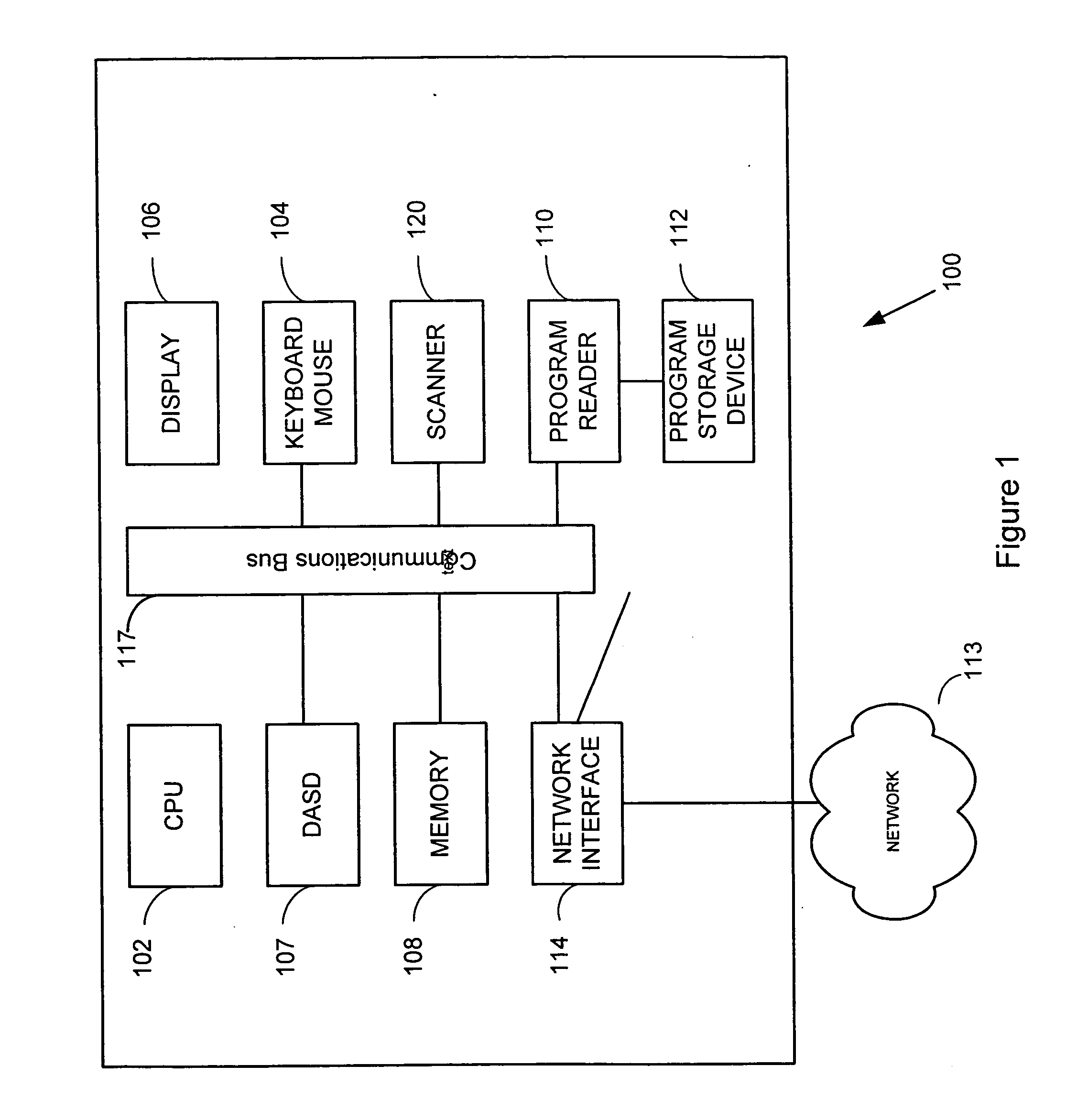

Electronic record management system

A method, apparatus, and article of manufacture for managing electronic records on a computer network is provided. The method provides the steps of creating an electronic tag that uniquely identifies an electronic record, storing the electronic tag, and distributing the electronic record. The method further performs the steps of analyzing a network user's workstation specifications, analyzing a network user's user profile, and generating a reference code, wherein the electronic tag is generated from information analyzed in the network user's workstation specification, the network user's user profile and the reference code.

Owner:HANGER SOLUTIONS LLC

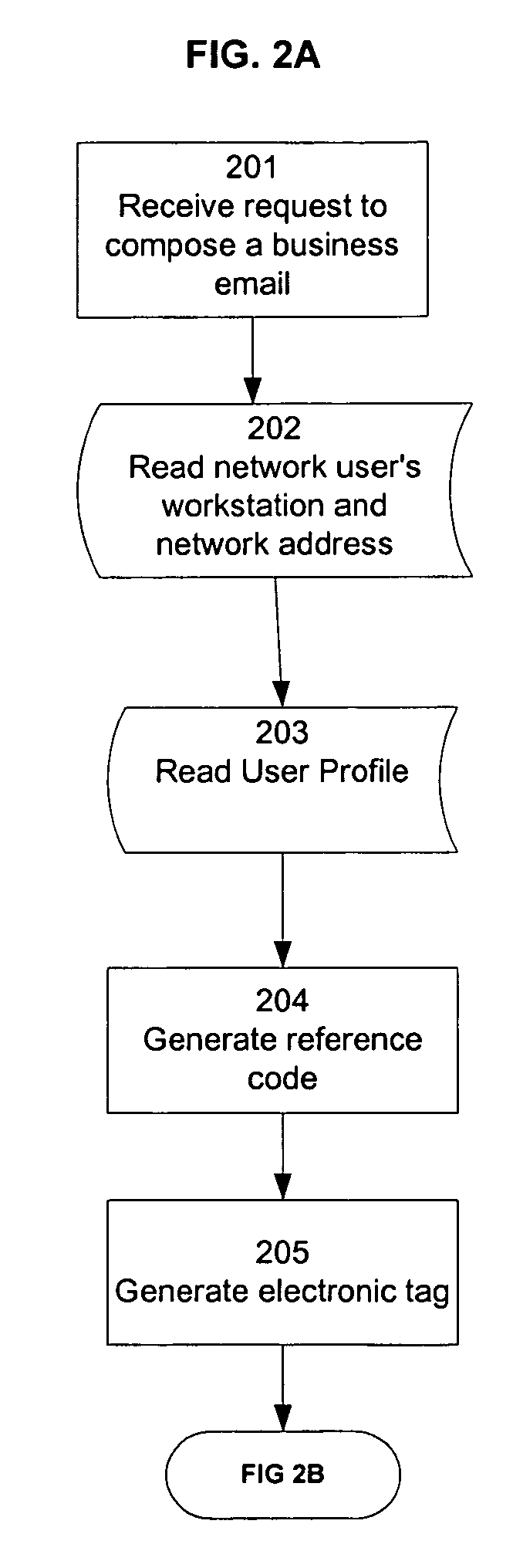

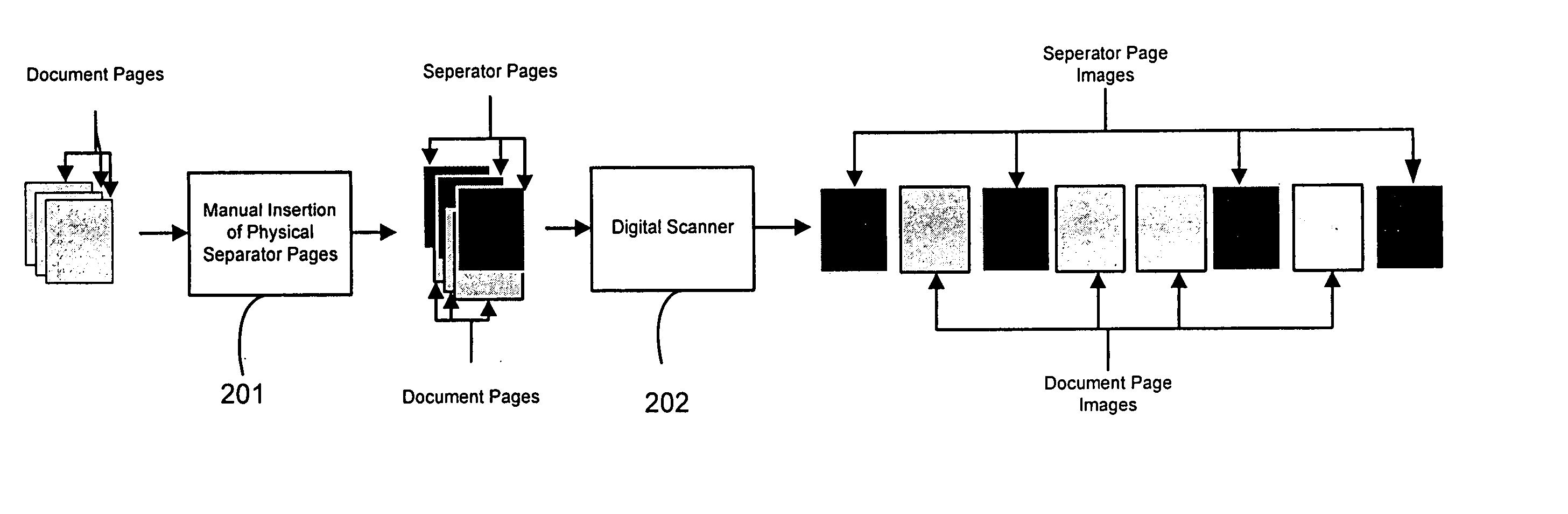

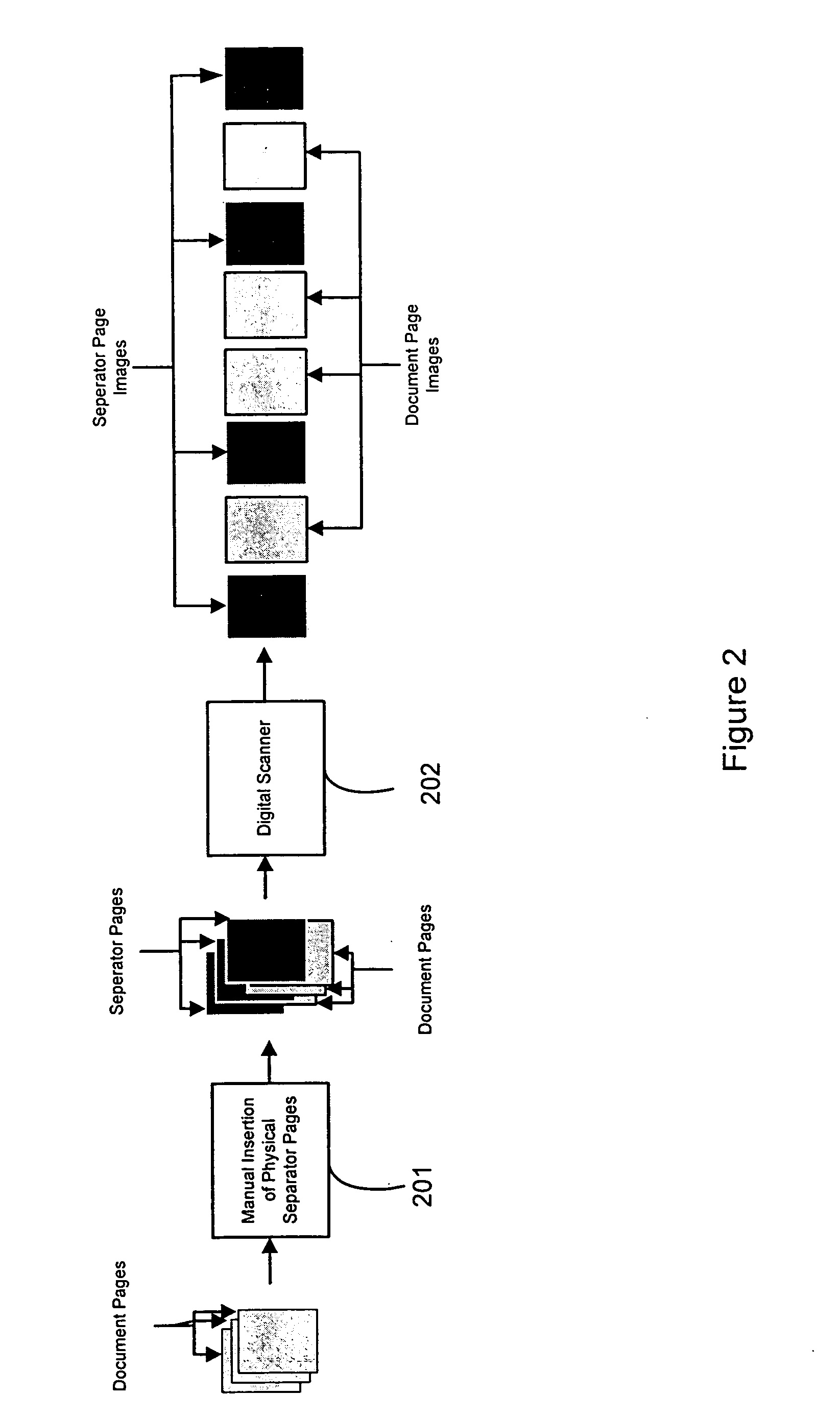

Automatic document separation

ActiveUS20050134935A1Easy maintenanceConfigurabilityImage analysisText processingPaper documentDigital image

A method and system for delineating document boundaries and identifying document types by analyzing digital images of one or more documents, automatically categorizing one or more pages or subdocuments within the one or more documents and automatically generating delineation identifiers, such as computer-generated images of separation pages inserted between digital images belonging to different categories, a description of the categorization sequence of the digital images, or a computer-generated electronic label affixed or associated with said digital images.

Owner:KOFAX

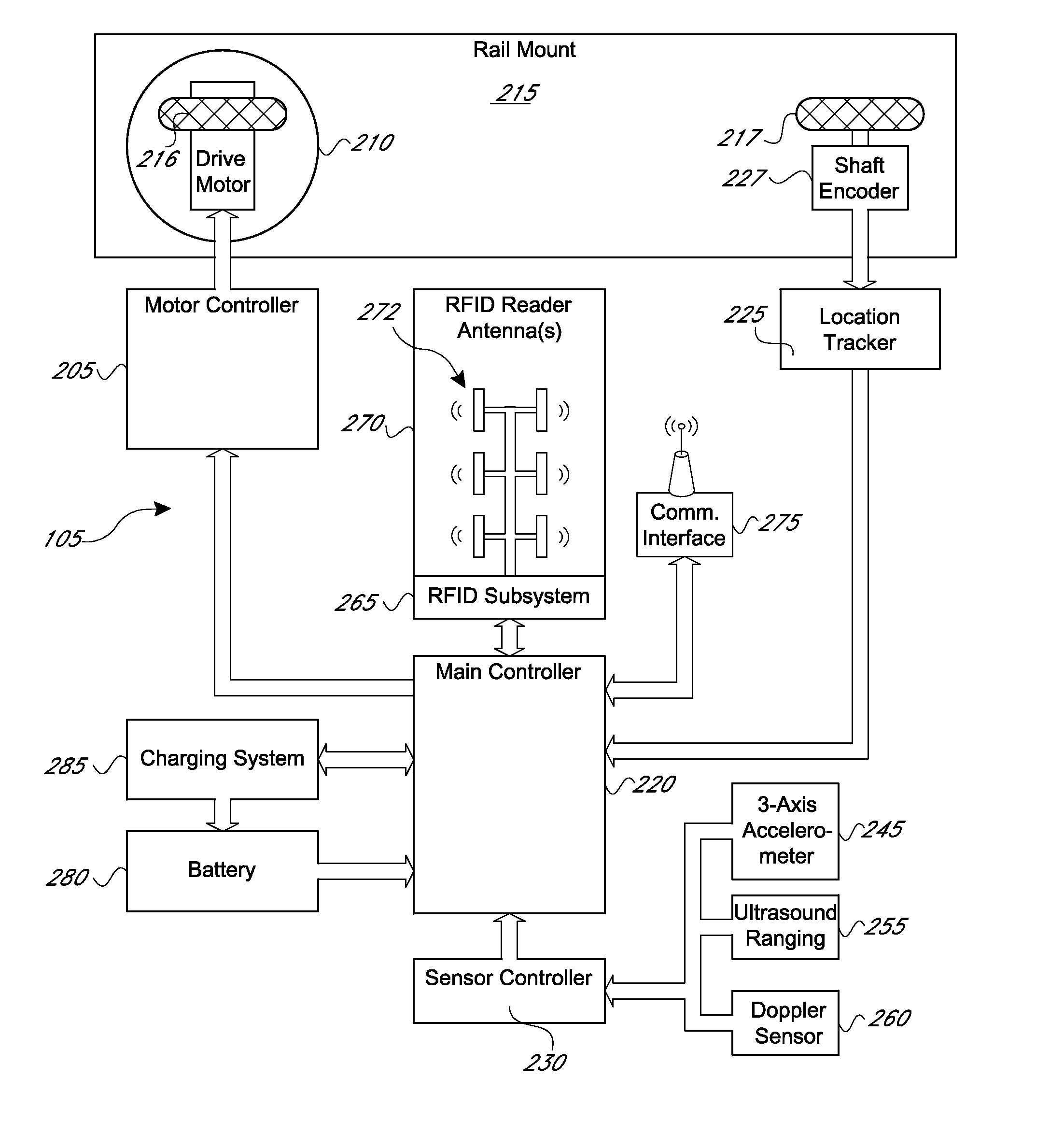

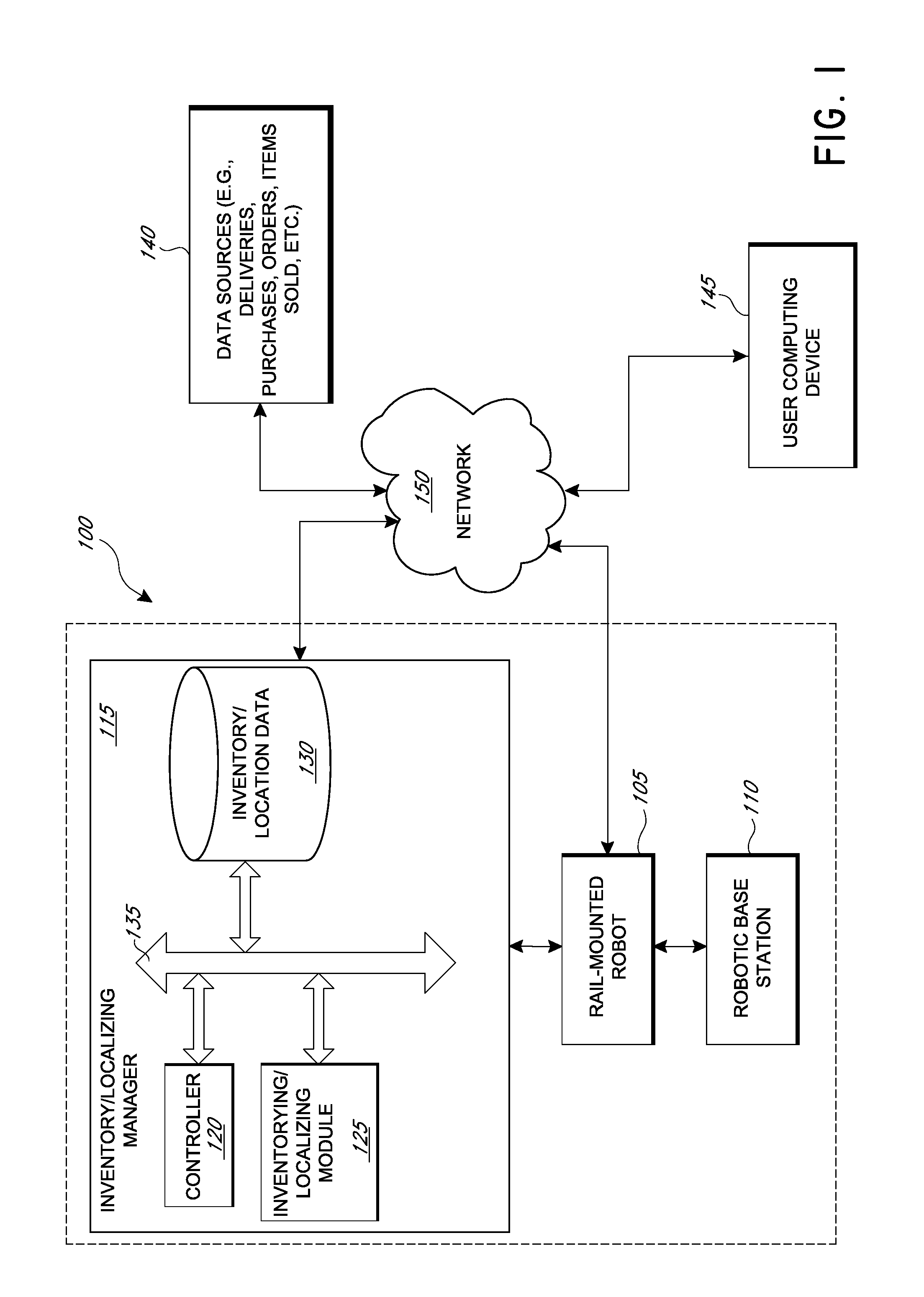

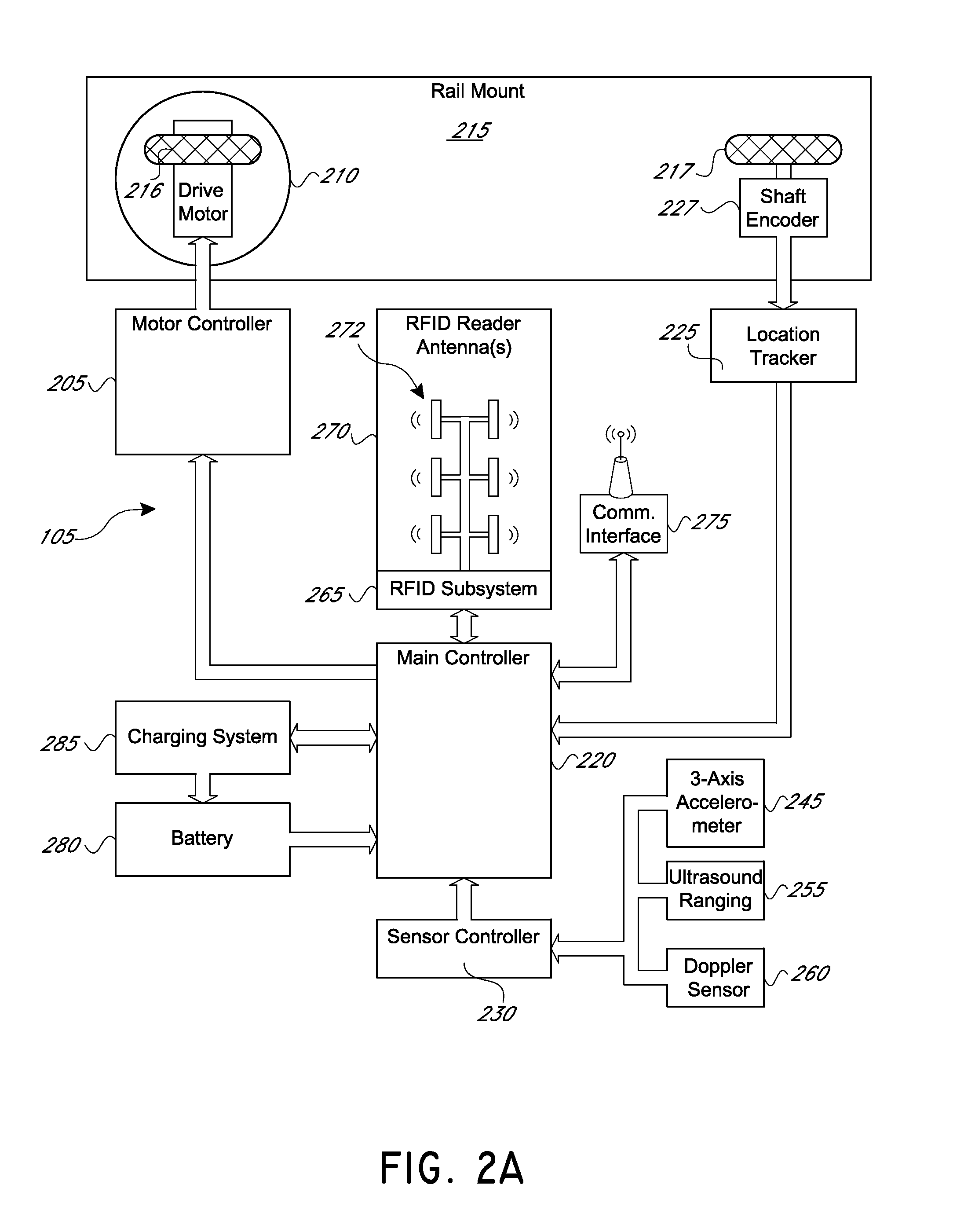

Rail-mounted robotic inventory system

Examples of a rail-mounted robotic inventory system are provided. The system includes a rail-mounted robot having an electronic tag reader configured to receive electronic tag data from electronic tags associated with inventory items. The system can include a navigation module configured to direct the rail-mounted robot along a rail through an inventory area, detect obstacles, and determine a position of the rail-mounted robot within the inventory area. The system can include an inventory identification module configured to receive the electronic tag data from the rail-mounted robot and identify and / or locate the inventory items in the inventory area based at least partly on the electronic tag data.

Owner:RFID RESOLUTION TEAM

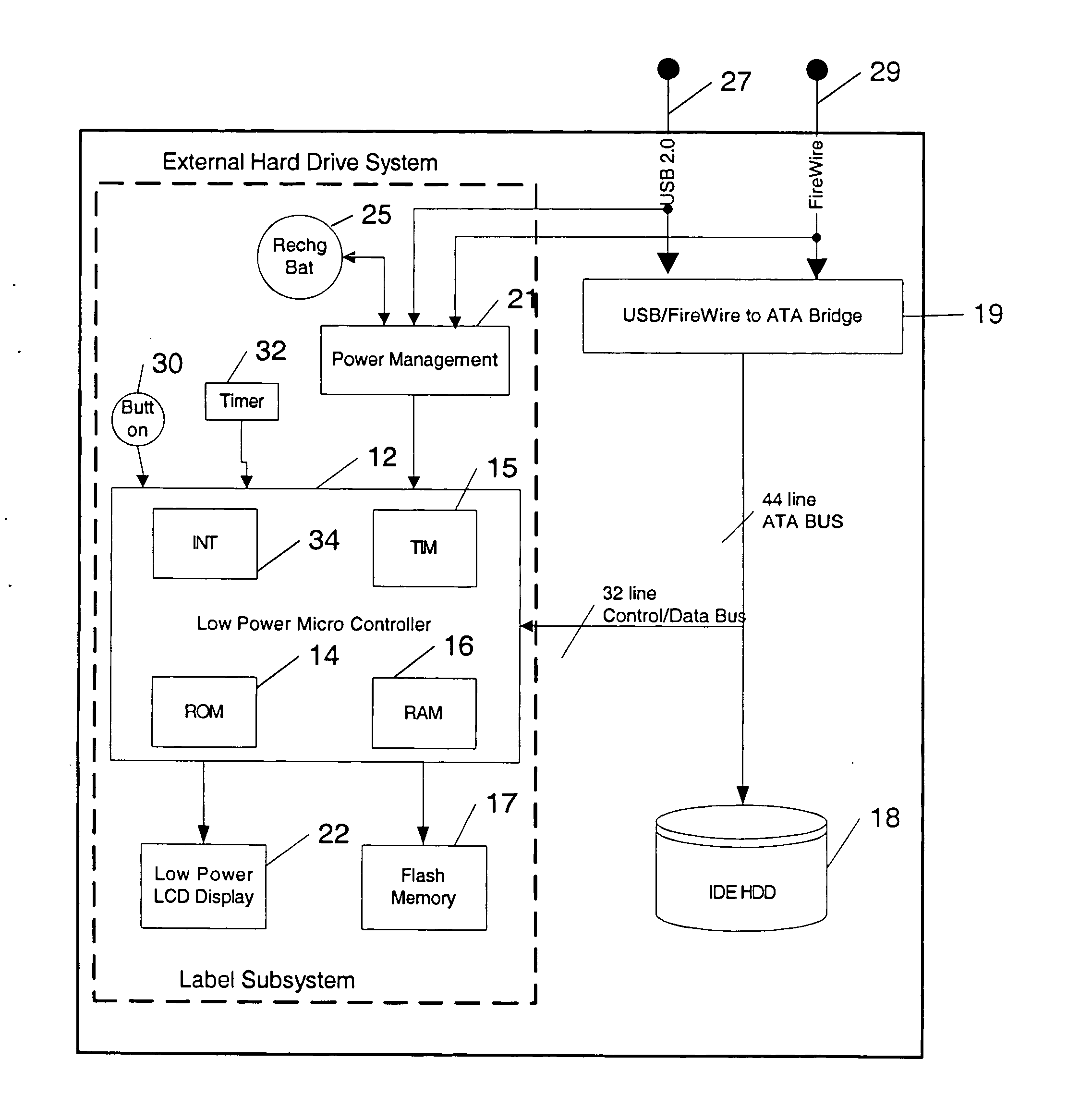

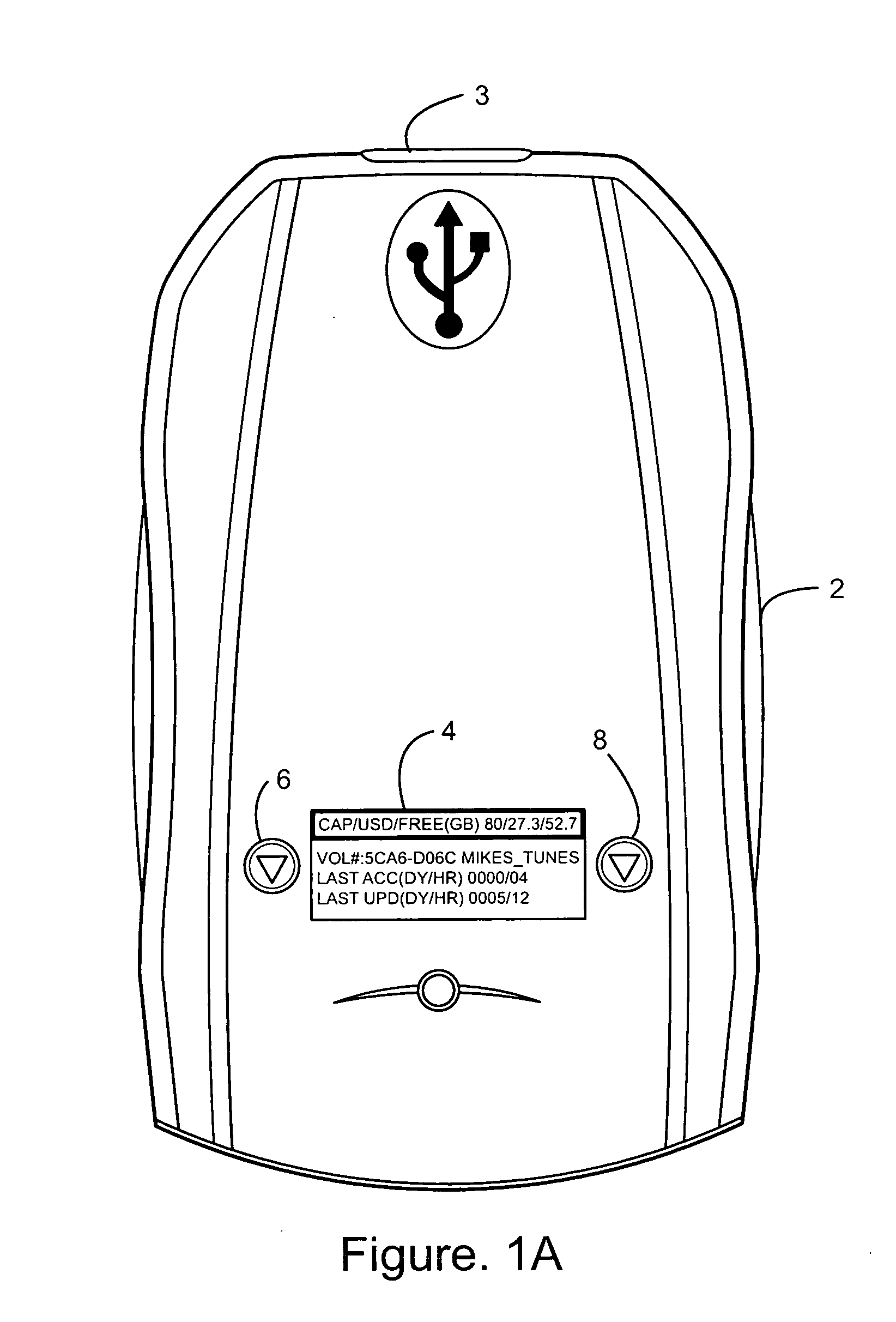

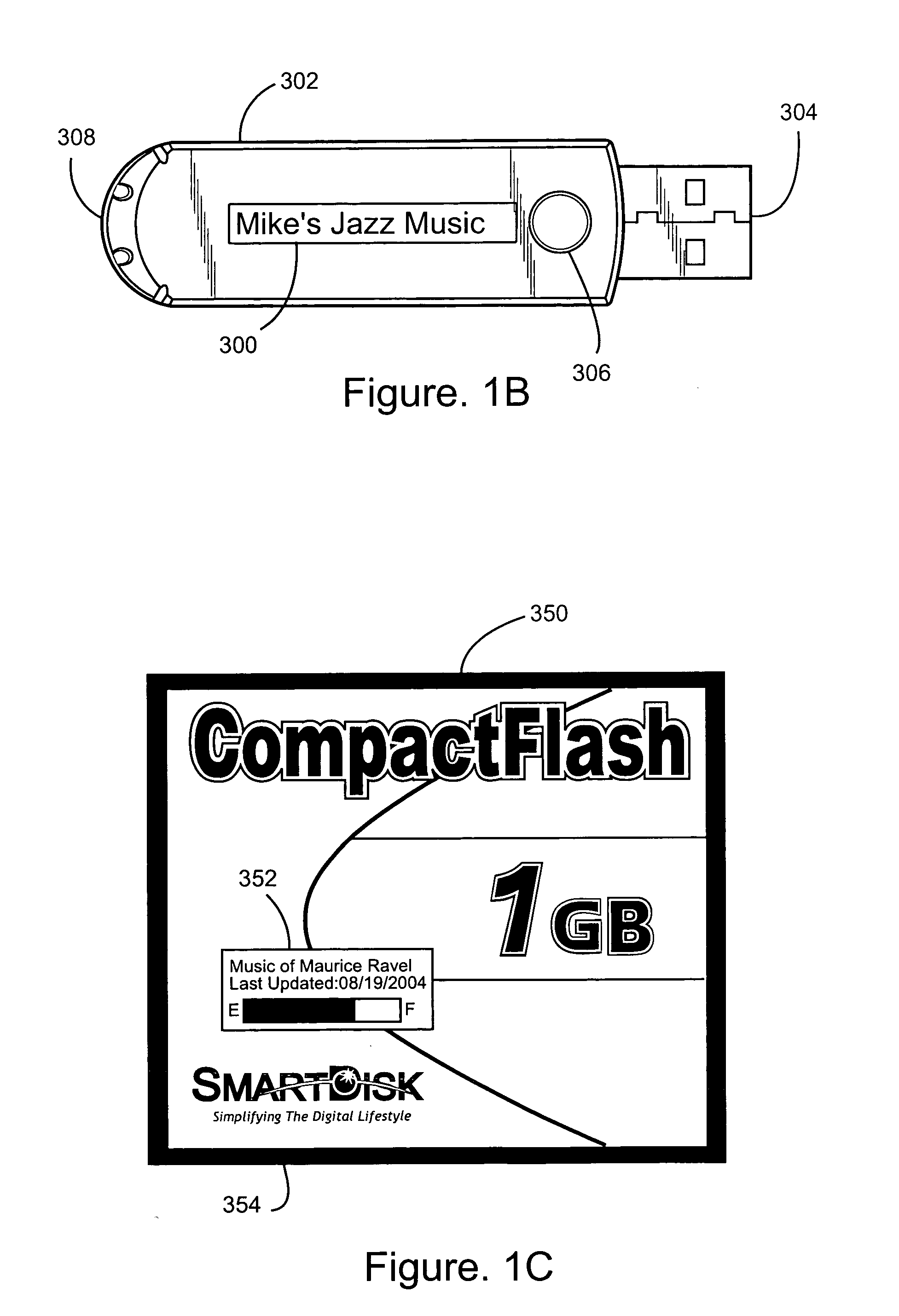

Self-labeling digital storage unit

InactiveUS20060095647A1Good adhesionEasy detachmentCarrier indicating/warning arrangementsCarrier casesDigital storageDirectory structure

Portable storage units are equipped with human readable electronic displays that contain information pertaining to the content and state of the storage units. The information displayed changes as the contents of the storage unit change. Such electronic labels can contain a variety of useful information. Some information would be static, such as owner identification, while other information will be dynamic such as the amount of free space. Still other information will be browseable such as the directory structure, file contents, storage unit total capacity, storage unit available space, storage unit directory structure, storage unit file names. storage unit file contents and device reliability statistics.

Owner:CMC MAGNETICS CORPORATION

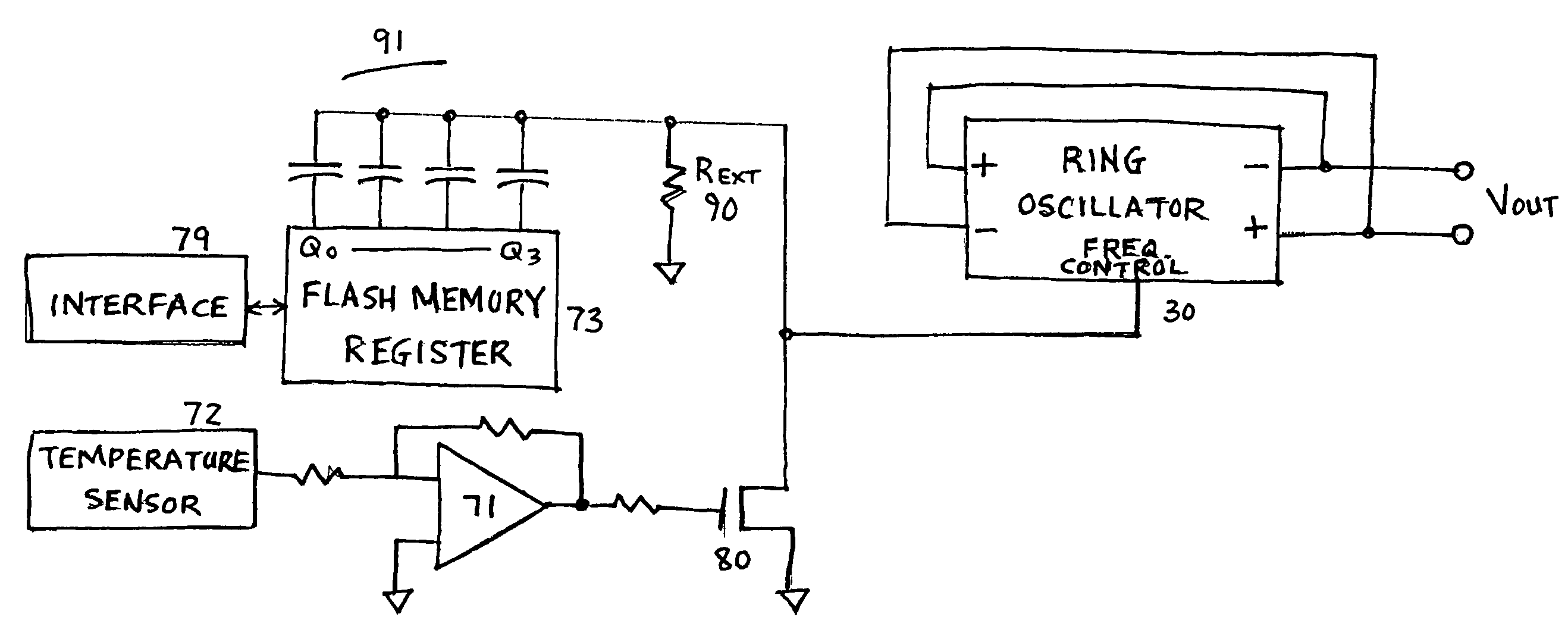

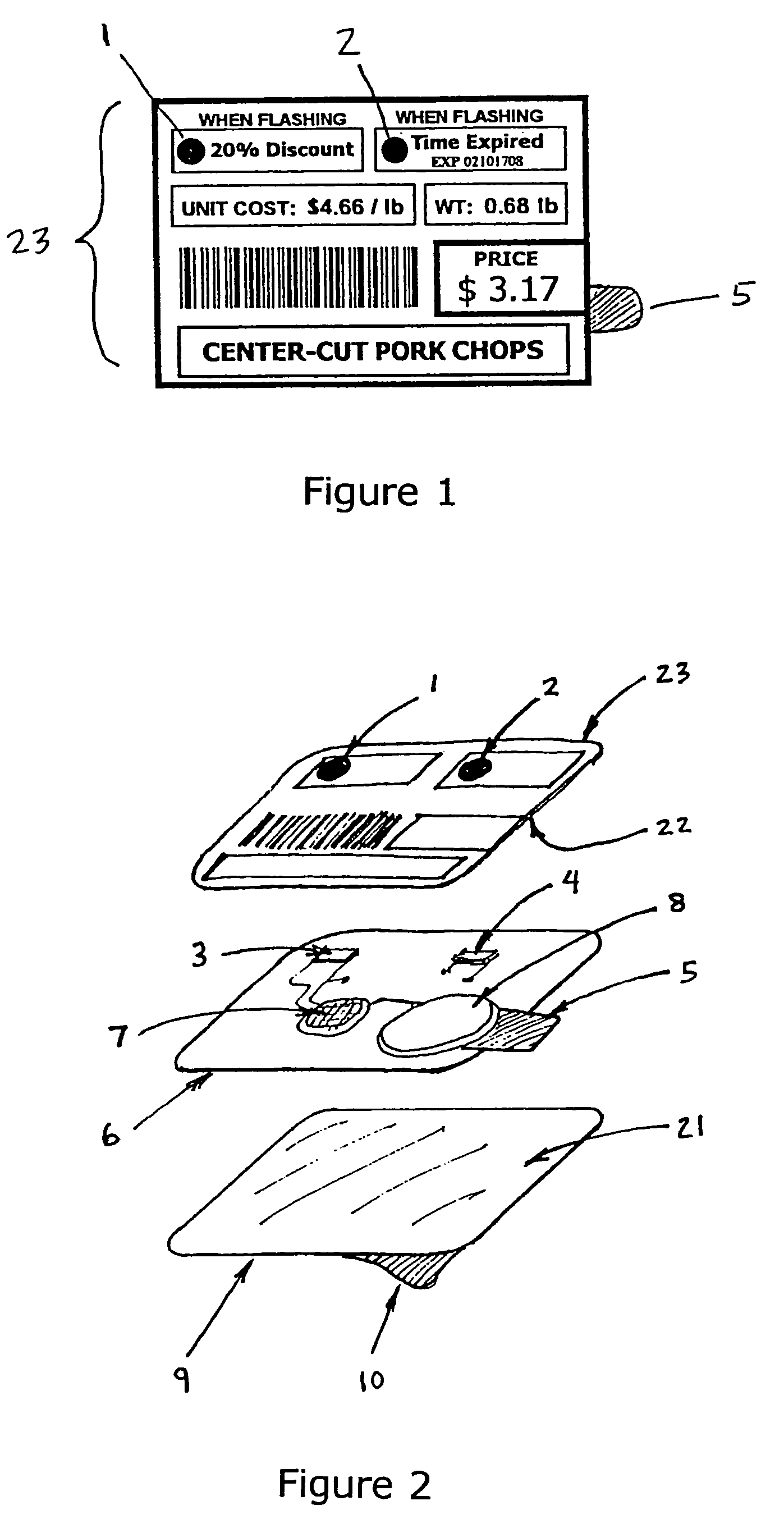

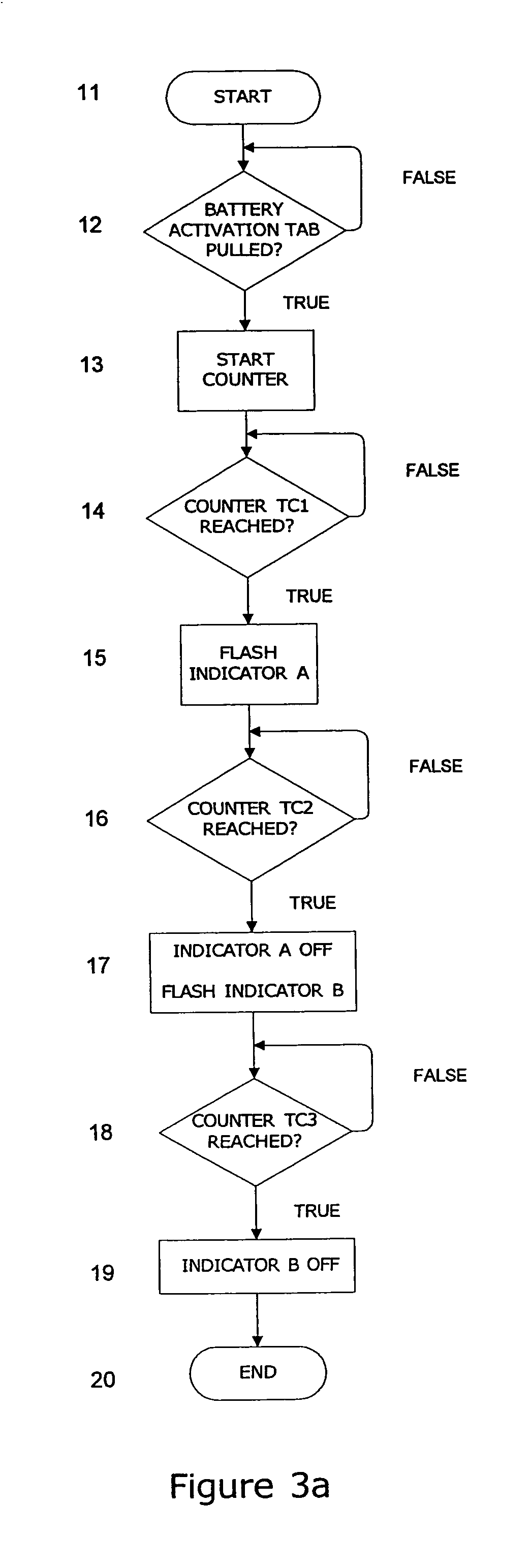

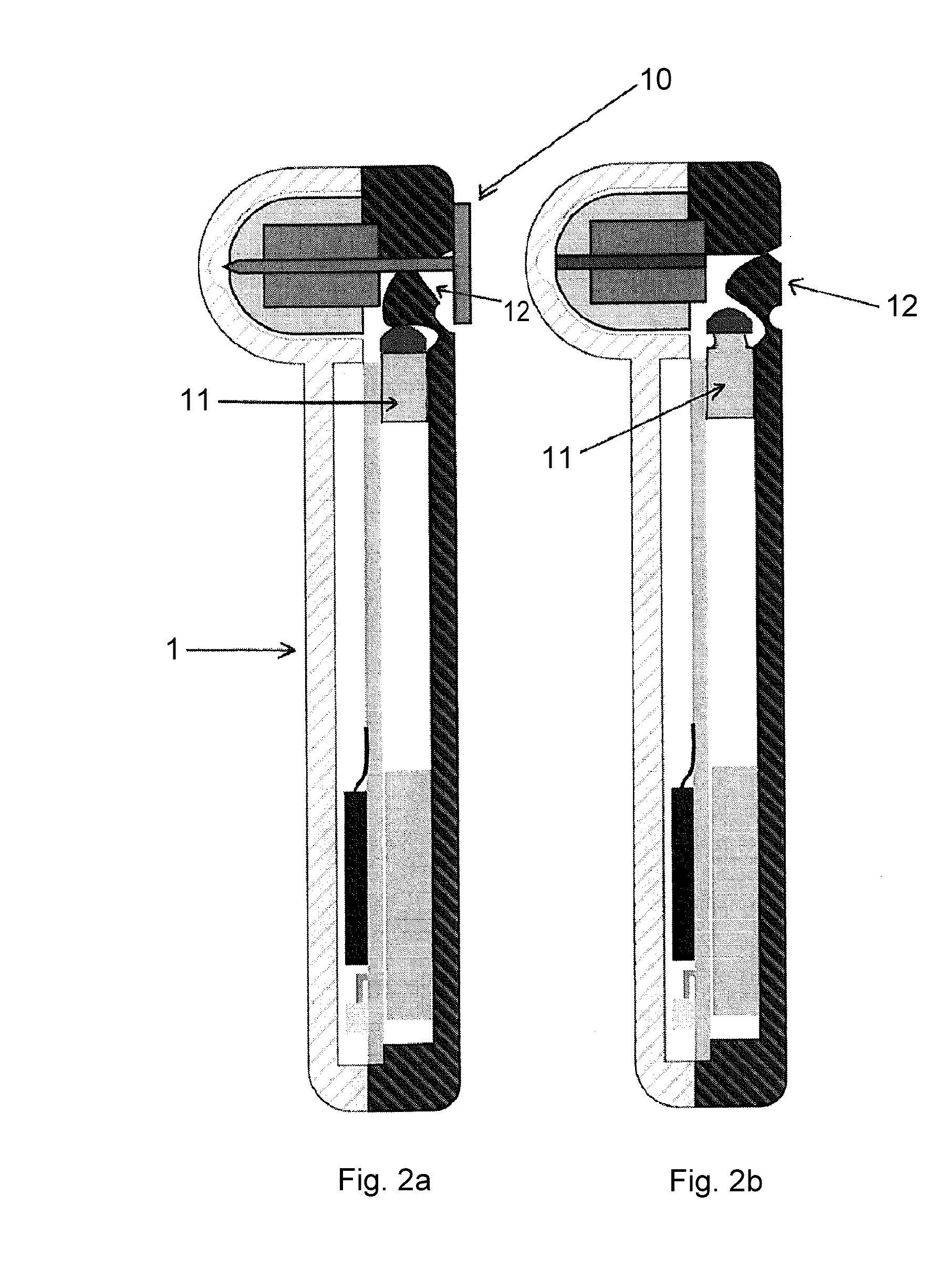

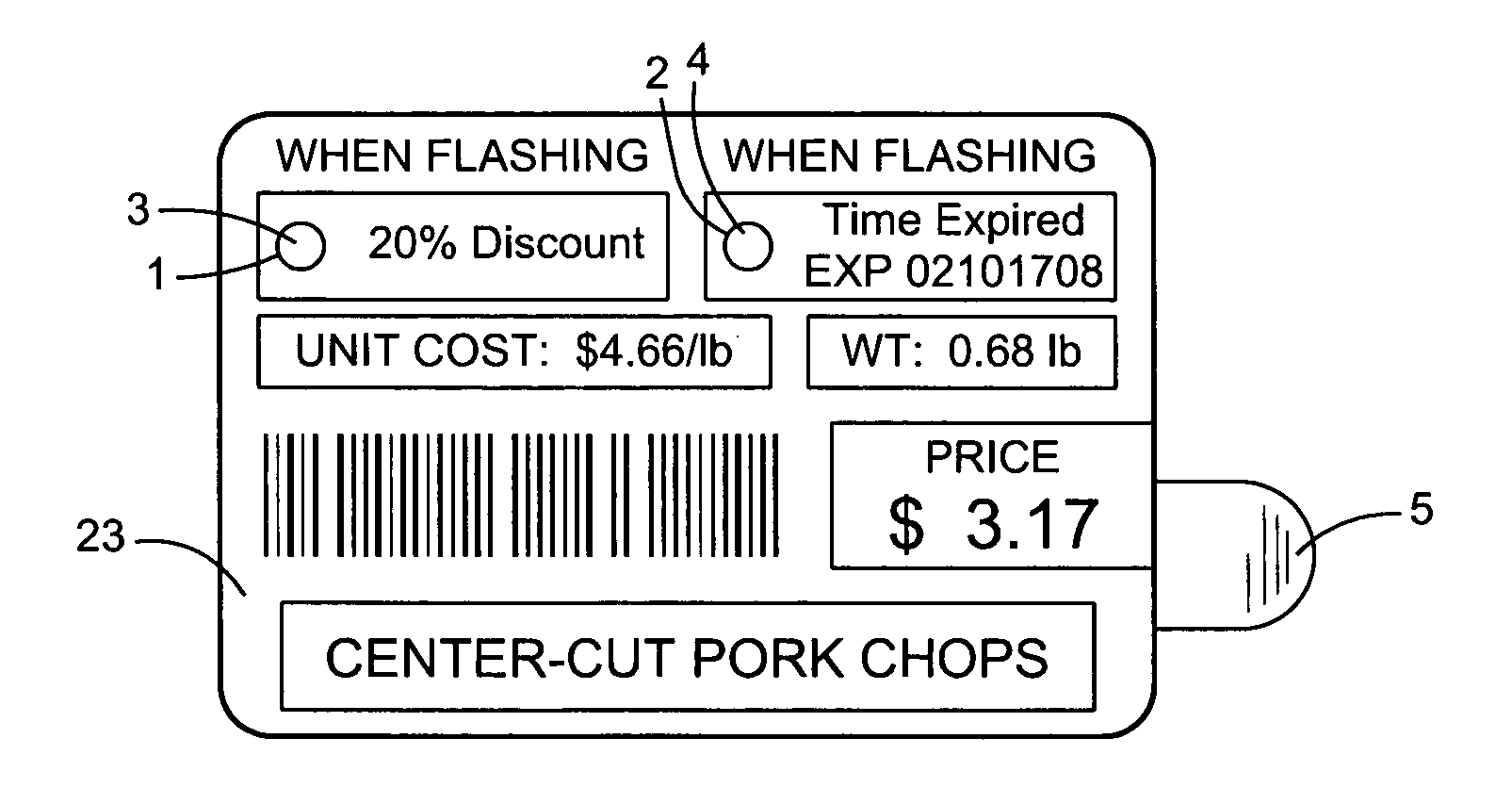

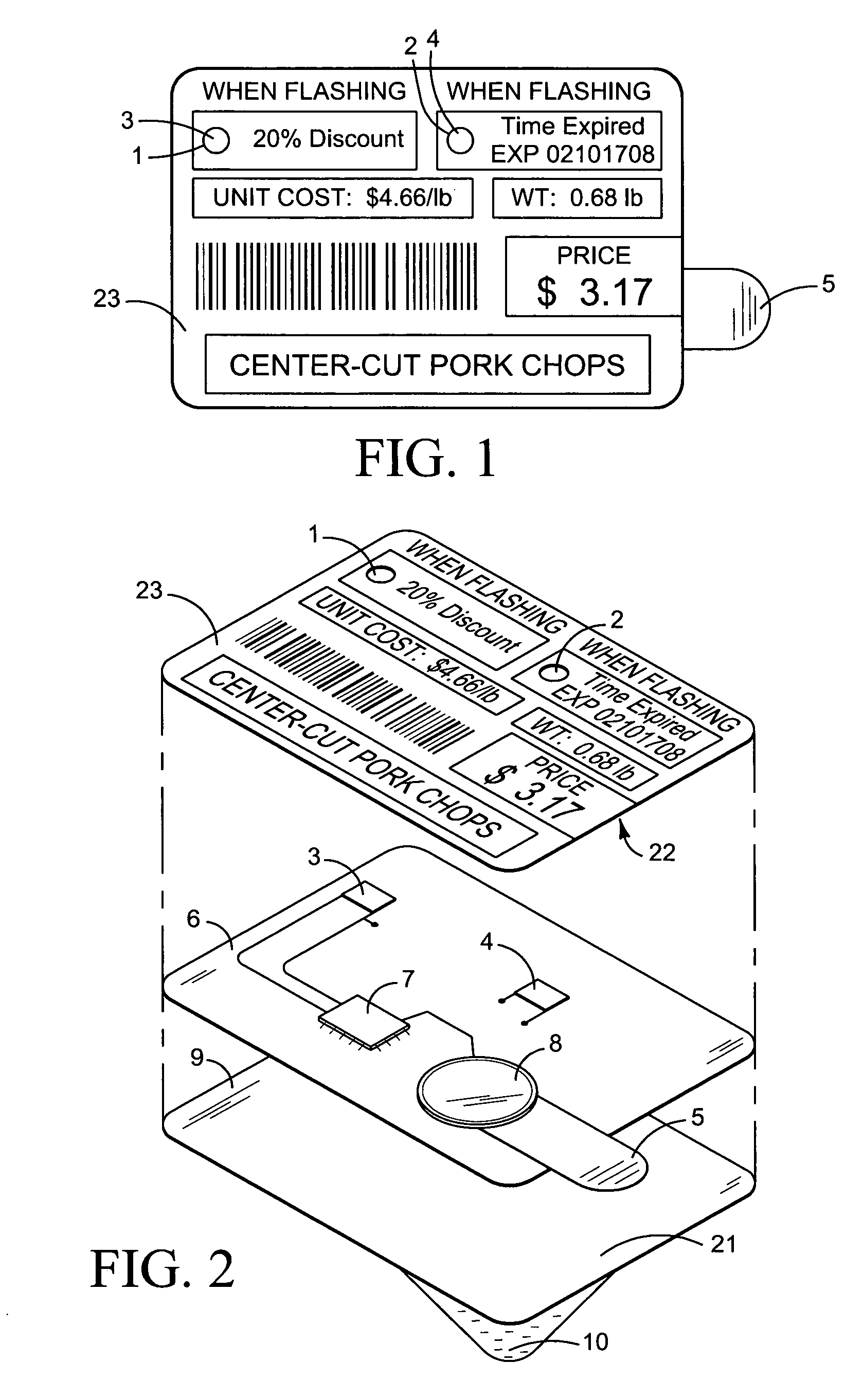

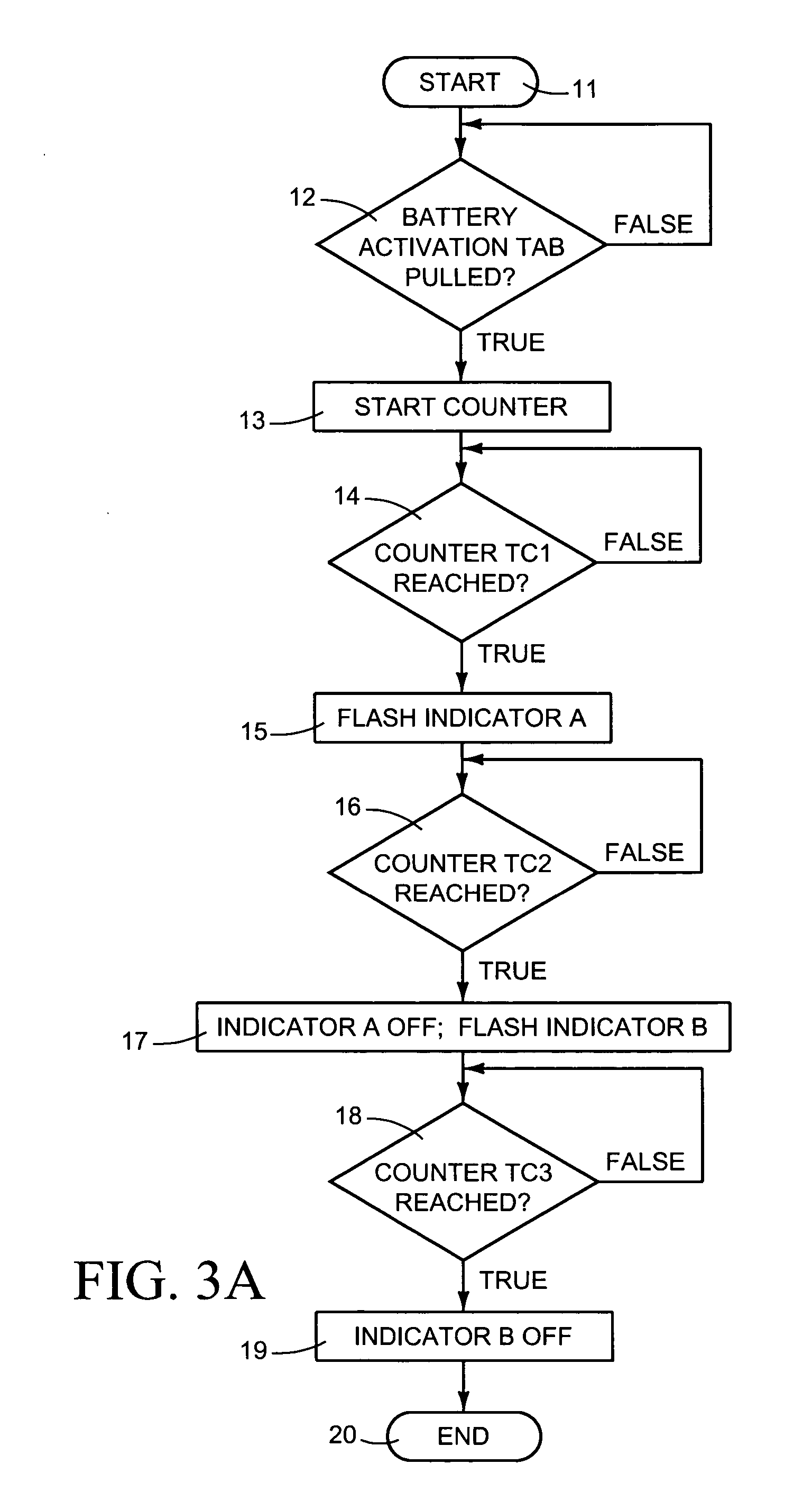

Perishable product electronic label including time and temperature measurement

ActiveUS7057495B2Informed decisionSimpler and more complex calculationStampsElectric signal transmission systemsEngineeringElectronic assemblies

An electronic assembly may be contained in a label that performs time-temperature integration (TTI) and indicates that time and / or temperature levels have been reached that may compromise the quality, shelf life, or safety of the item to which the label is affixed. The label may be used on a wide variety of objects that require careful handling in terms of temperature and / or time elapsed before use. The labeling system includes circuitry that measures and calculates, and indictor(s) that signal that the time has come for discounted sale, and, later, that the time has come for disposal rather than sale. Optionally, the circuitry may act as an “over-temperature alarm” system, to measure, calculate, and indicate when a one-time temperature violation has occurred that is of such a magnitude that the item is immediately considered compromised or spoiled. The label may take the form of a flexible, disposable label that is typically powered by a small battery. Methods may include providing a temperature-variable oscillator or time-base, counting cycles of said oscillator within a logic circuit to determine when one or more preset total cycle counts is / are reached, and signaling when said total cycle count(s) is / are reached.

Owner:COPELAND COLD CHAIN LP

Smart electronic label employing electronic ink

The present invention provides for smart and dumb implementations of a standalone, remotely updateable, remotely alterable, flexible electronic label. The electronic label provides for displaying information, such as prices, bar codes, advertising messages and restocking information, in connection with a mammal, non-mammal, an item or location. The flexibility and form factor of the electronic label allow the label to fit into and conform to the shape of the molding used in retail store shelving to display merchandize and warehouse shelving. The label can be of various sizes, shapes and lengths to allow for multiple applications. The flexible, thin label includes a flexible display assembly having electronic ink disposed on a support, one or more antennas for sending or receiving signals corresponding to one of instructions, programs, data or selected indicia to be displayed by said display assembly, a storage element in circuit with the antenna for storing the instructions, programs, data and indicia, and one or more processors for intelligently determining the indicia to be displayed by the display assembly, for controlling and coordinating operation of the label, and for generating output signals for instructing the display assembly to display the indicia.

Owner:METROLOGIC INSTR

Systems and Methods for Merchandizing Electronic Displays

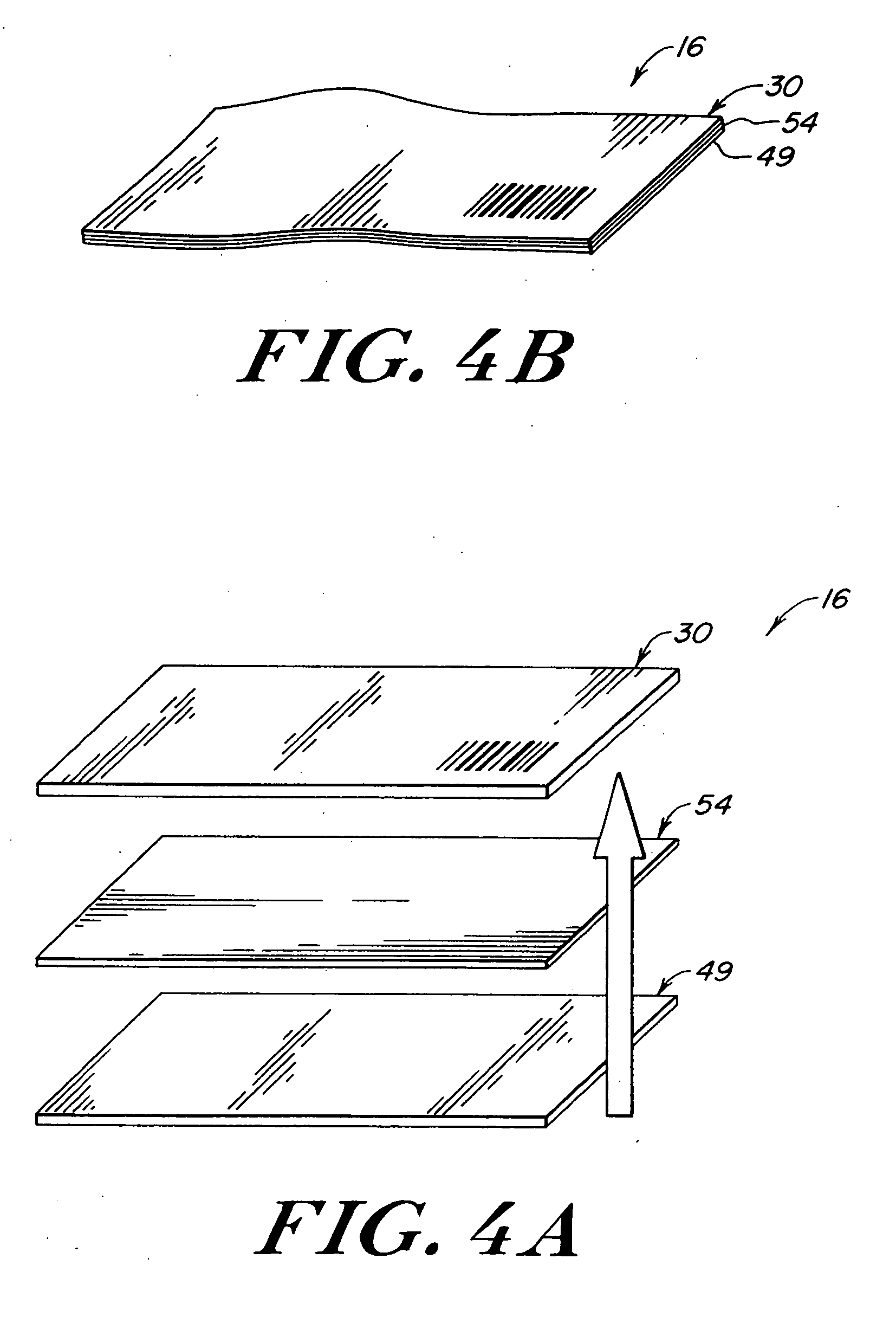

ActiveUS20160134930A1Well formedClosed circuit television systemsSelective content distributionDisplay devicePackage store

Systems and methods for a merchandizing display related to a continuous display formed by electronic displays embedded along product shelves and on the packages stored on the product shelves. An electronic label device may detect the presence of a consumer and send a trigger to the packages on its product shelf. The electronic label device may also send a trigger to surrounding electronic label devices. A streaming video may then be apportioned among displays on electronic label devices and the packages. Each of the displays may simultaneously output a different portion of the streaming video.

Owner:RTC IND

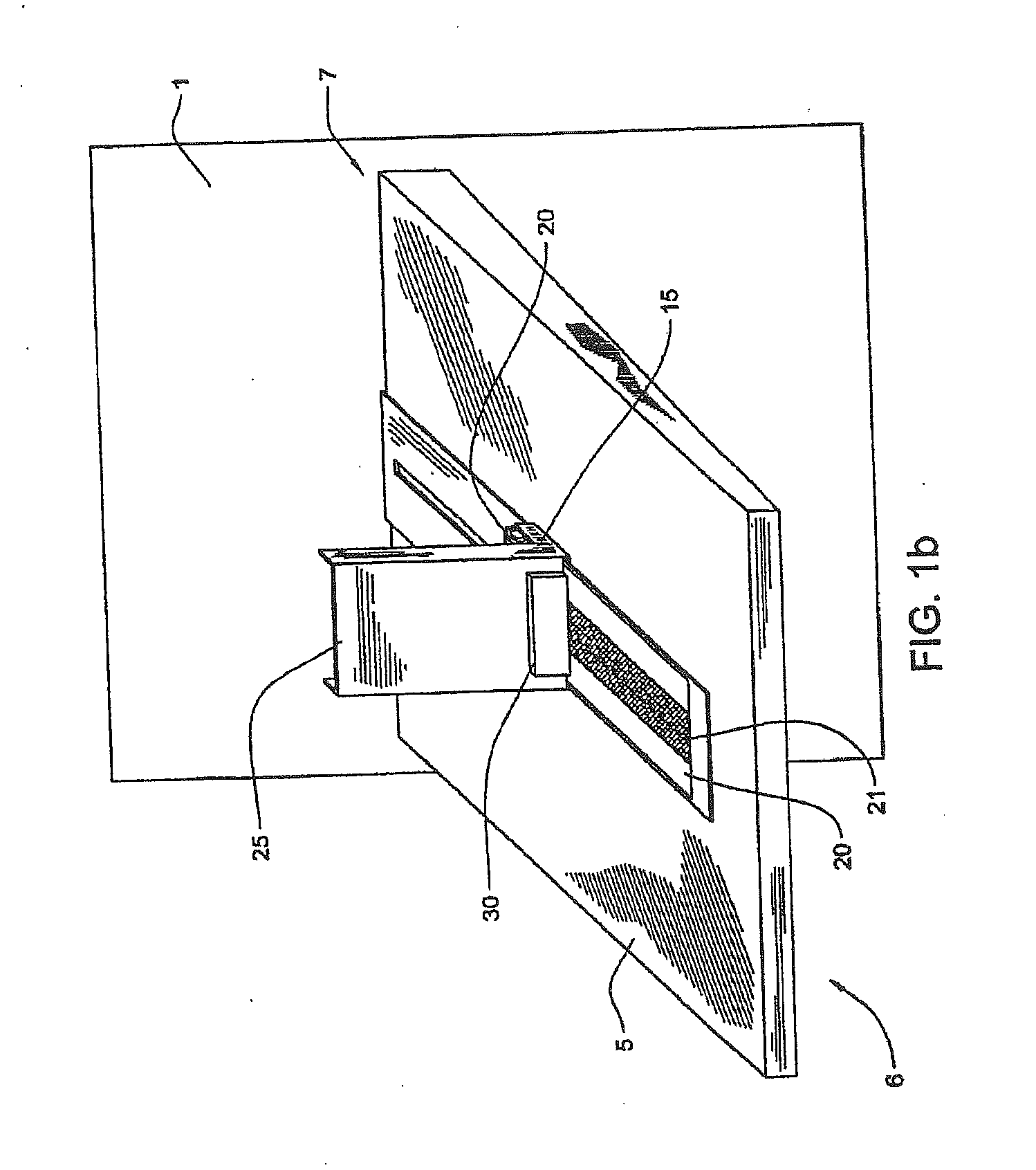

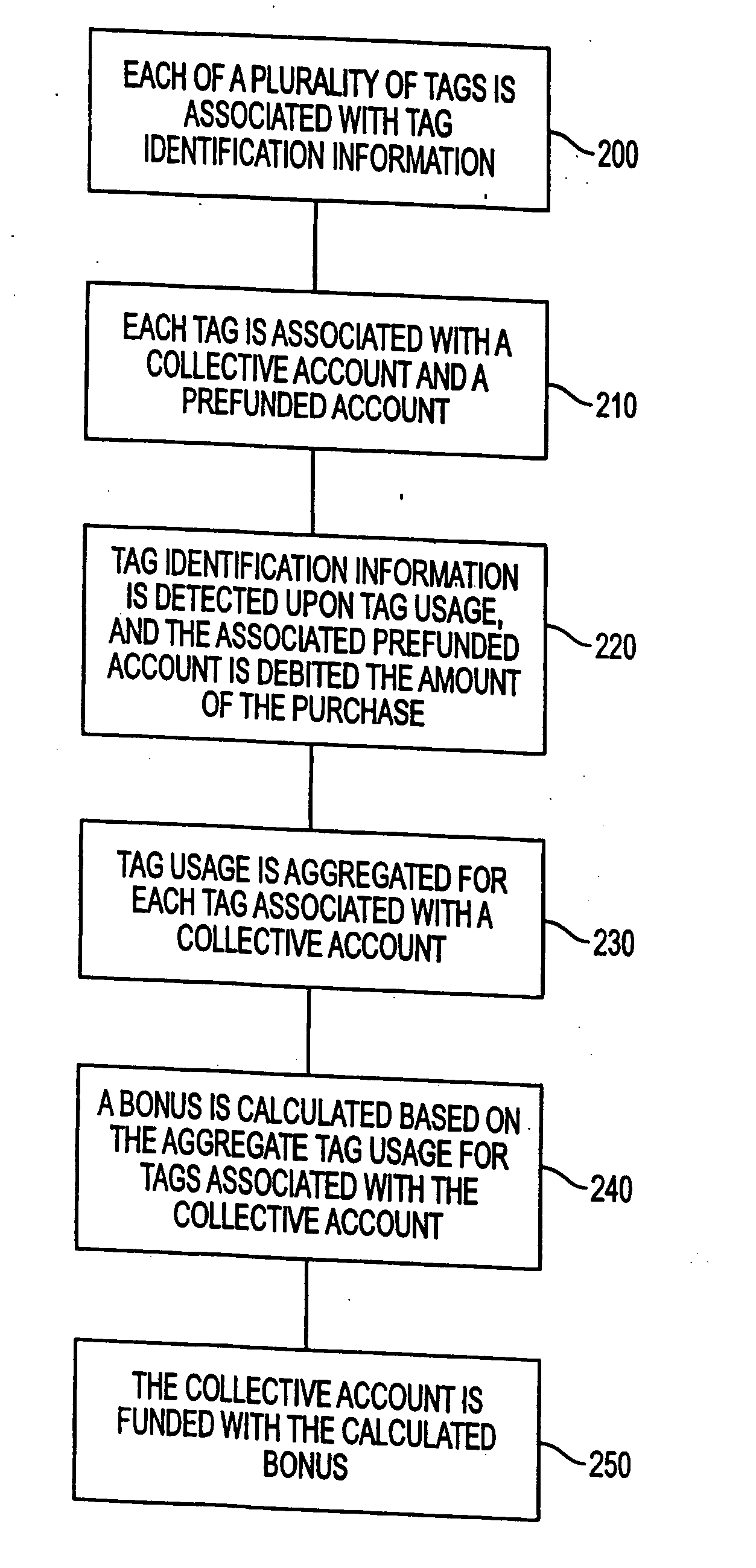

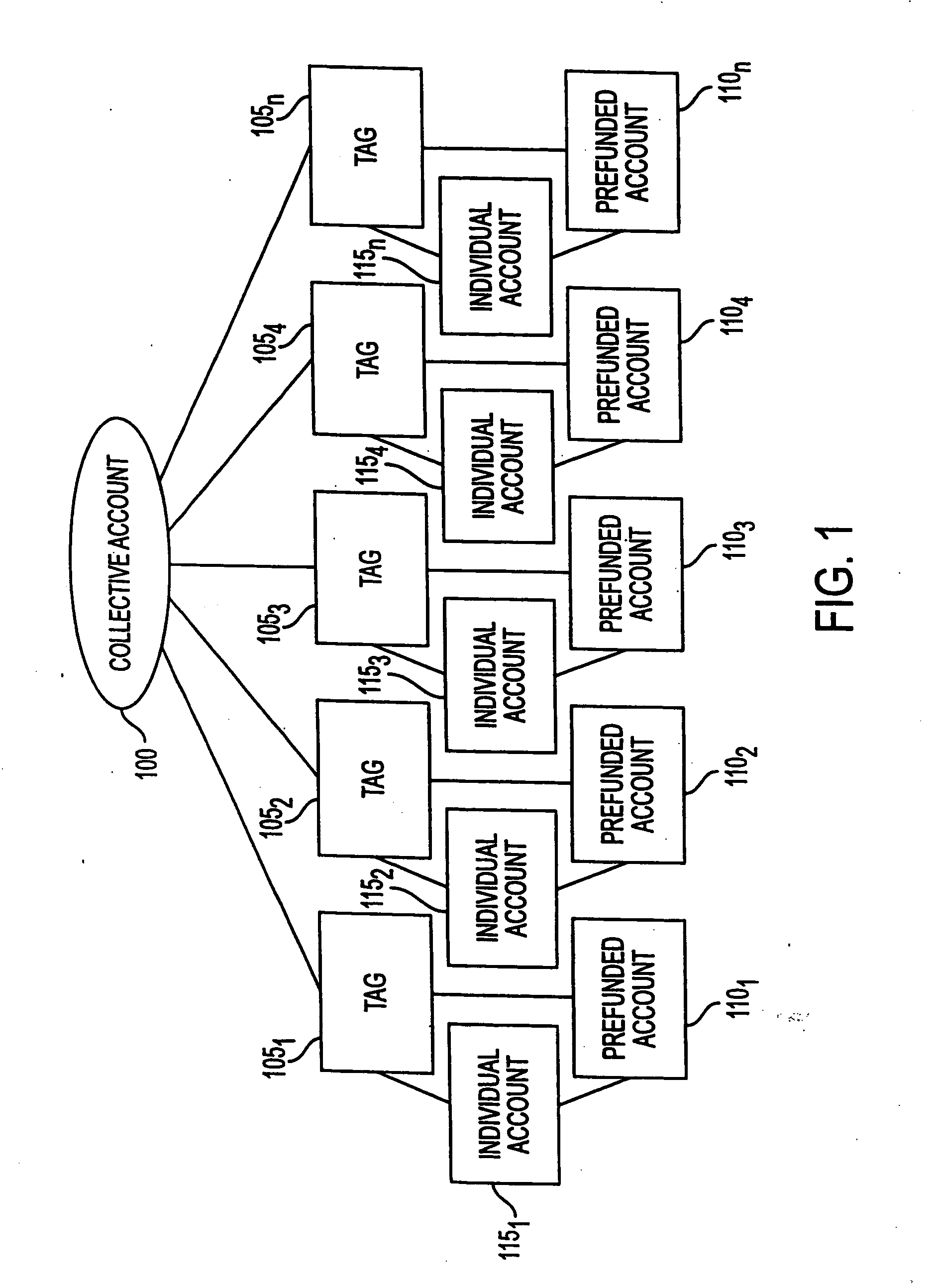

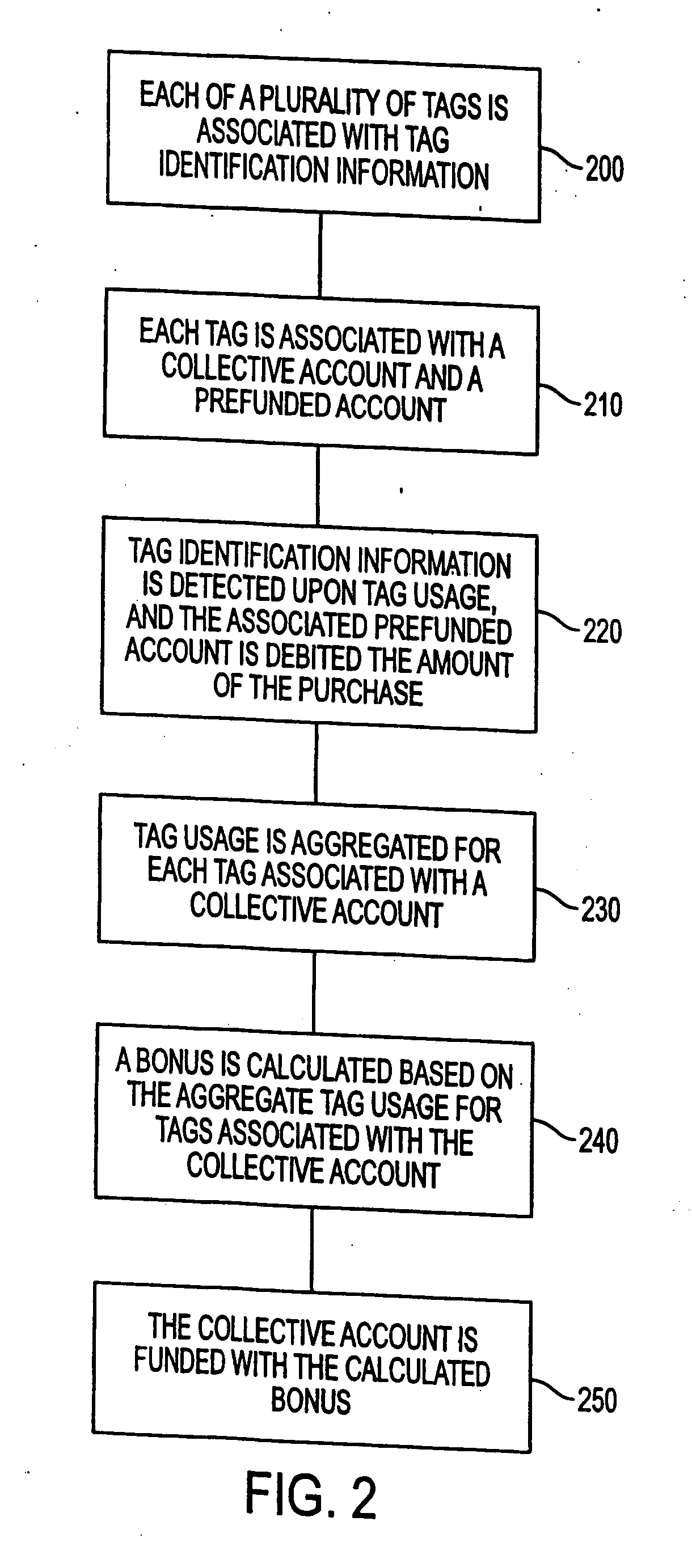

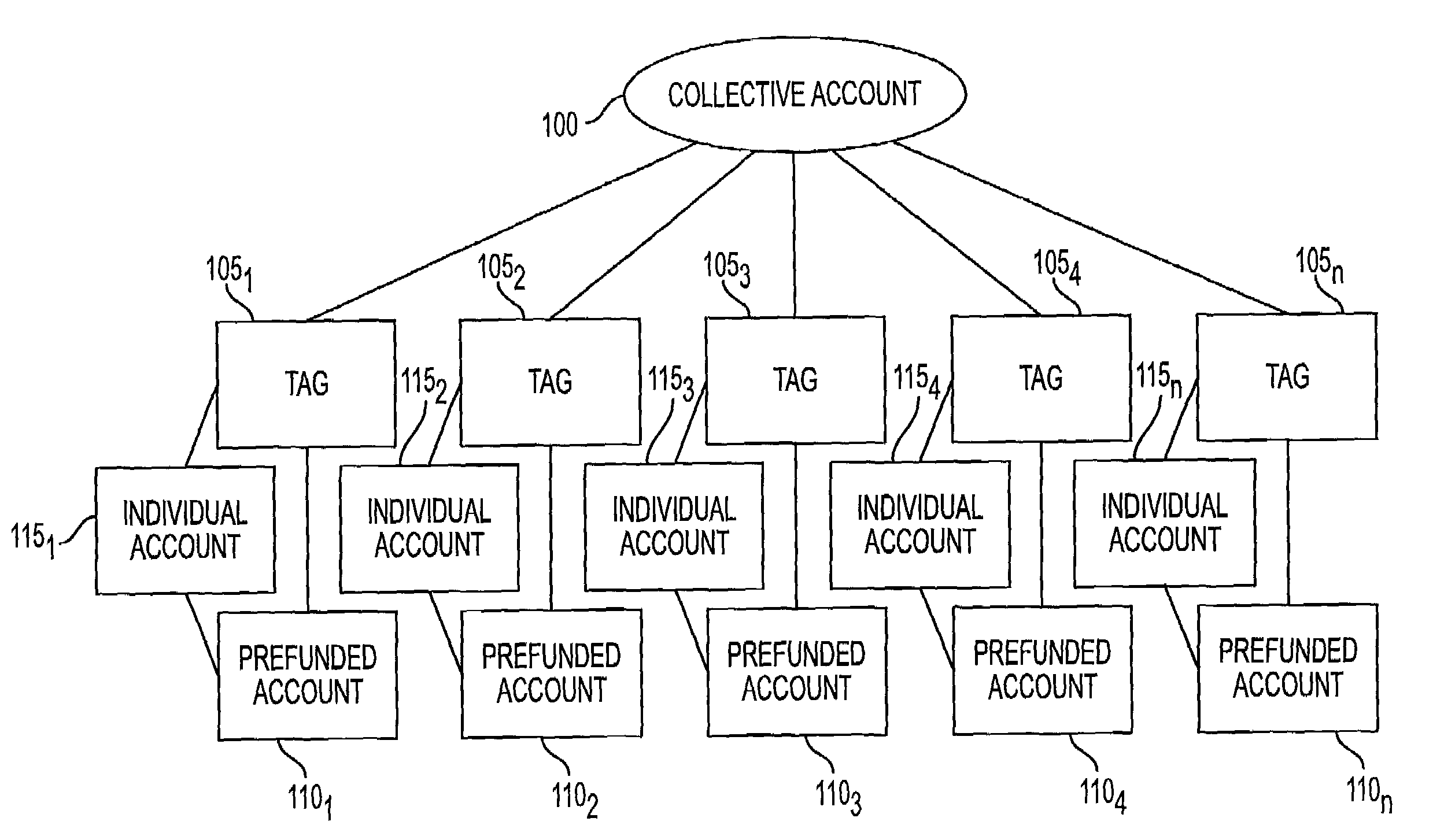

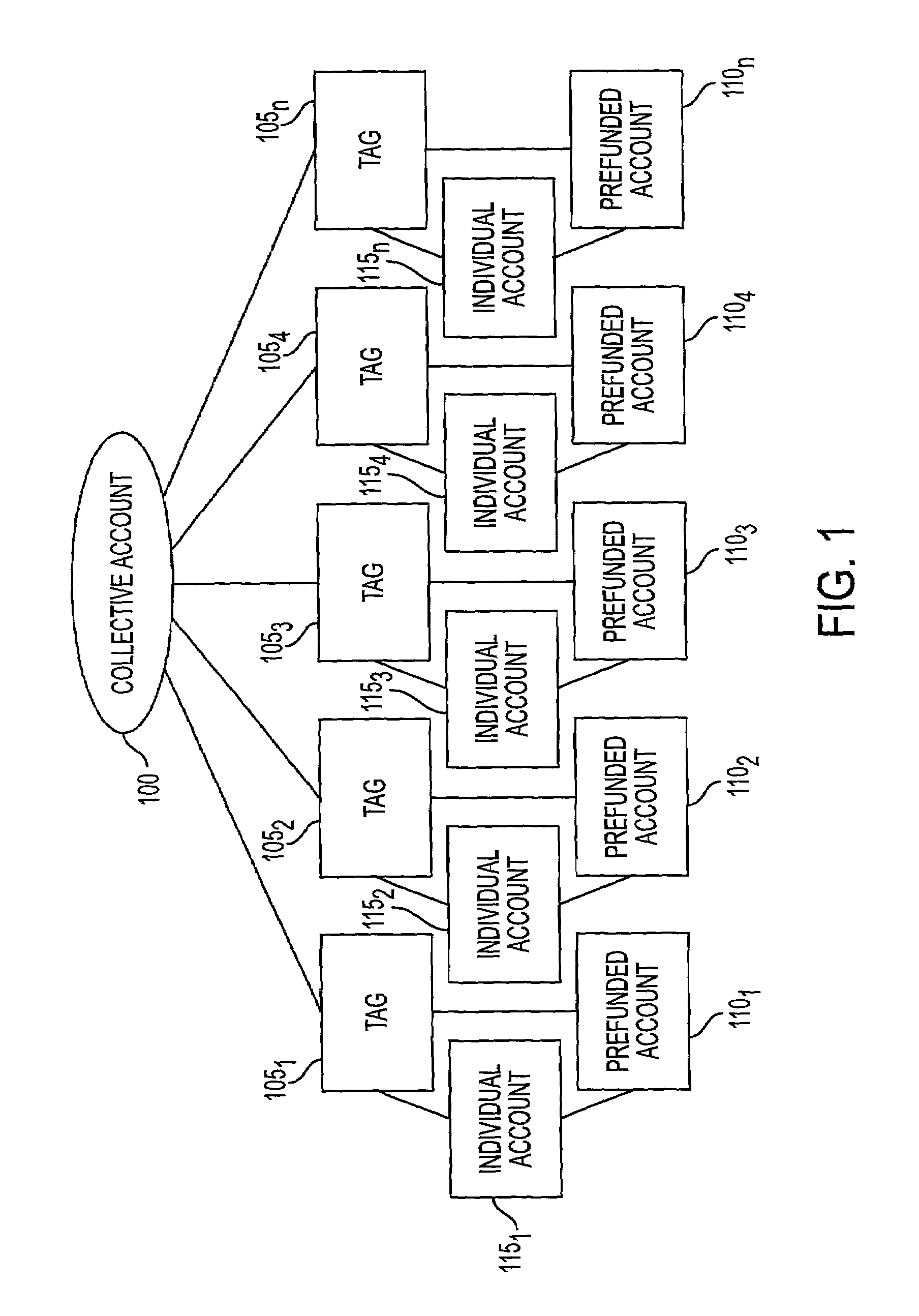

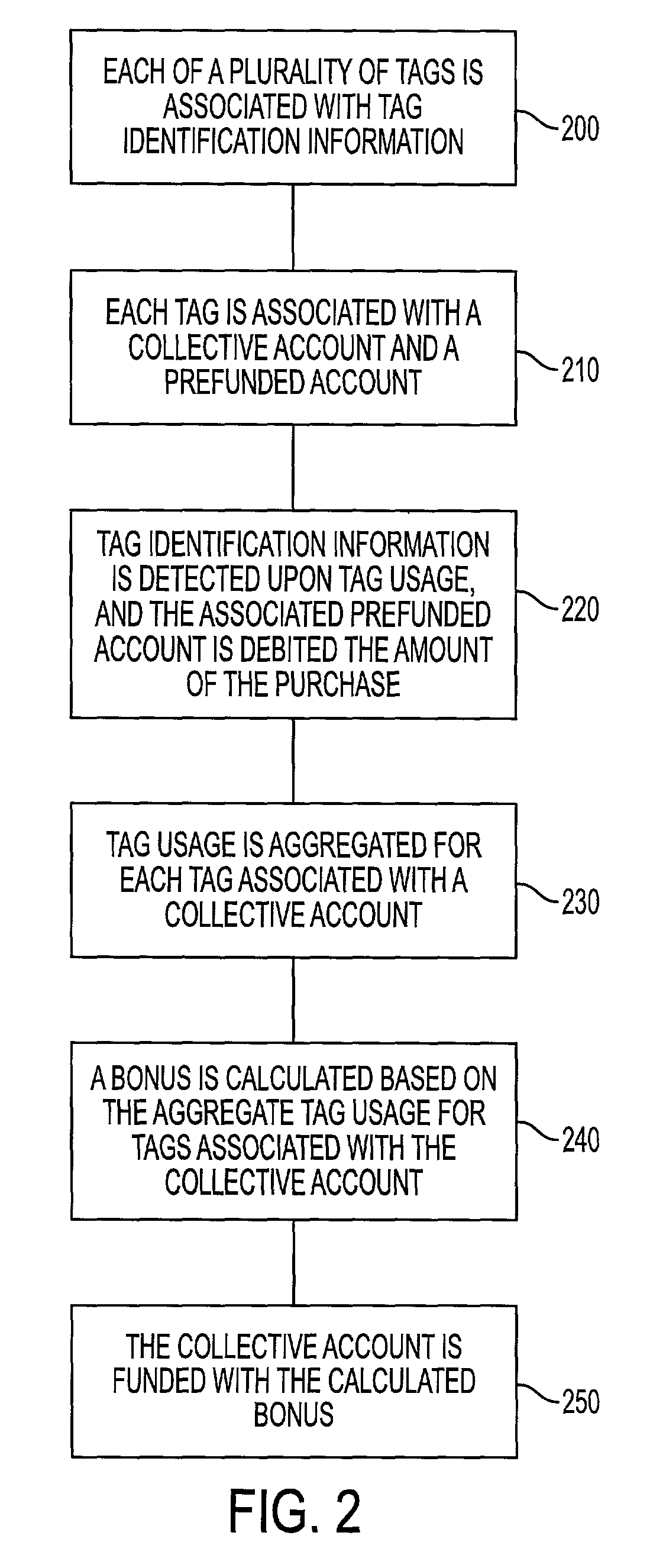

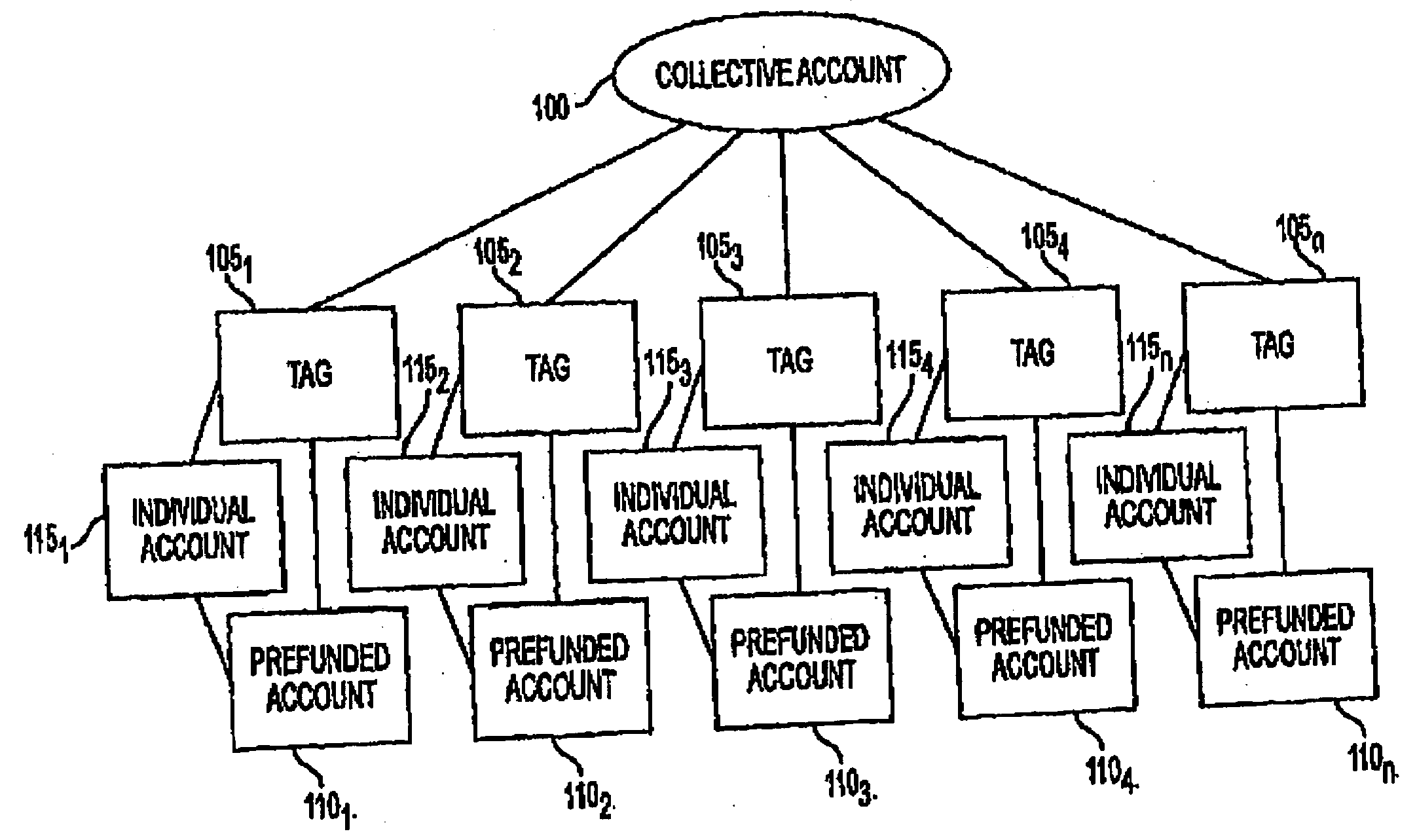

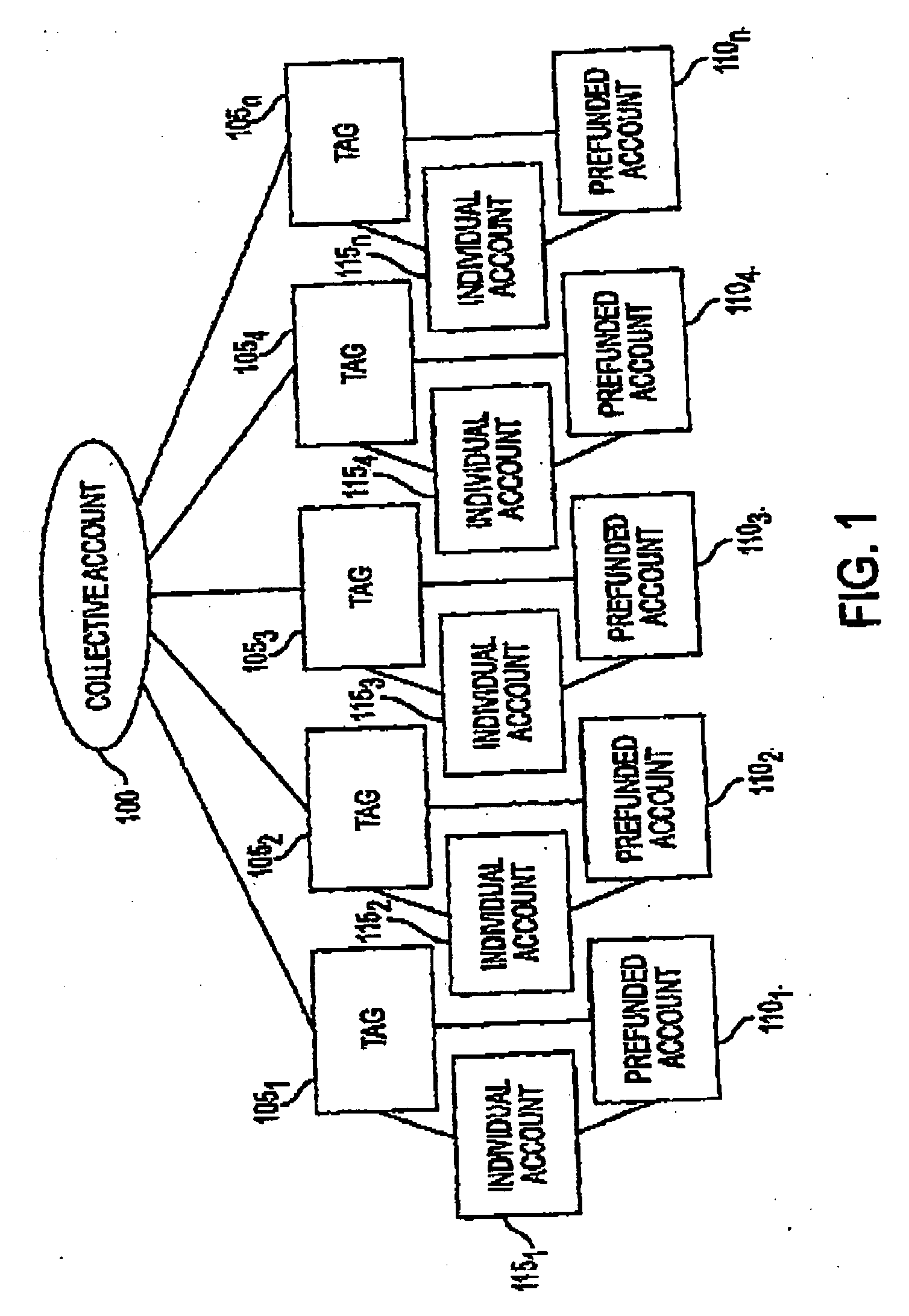

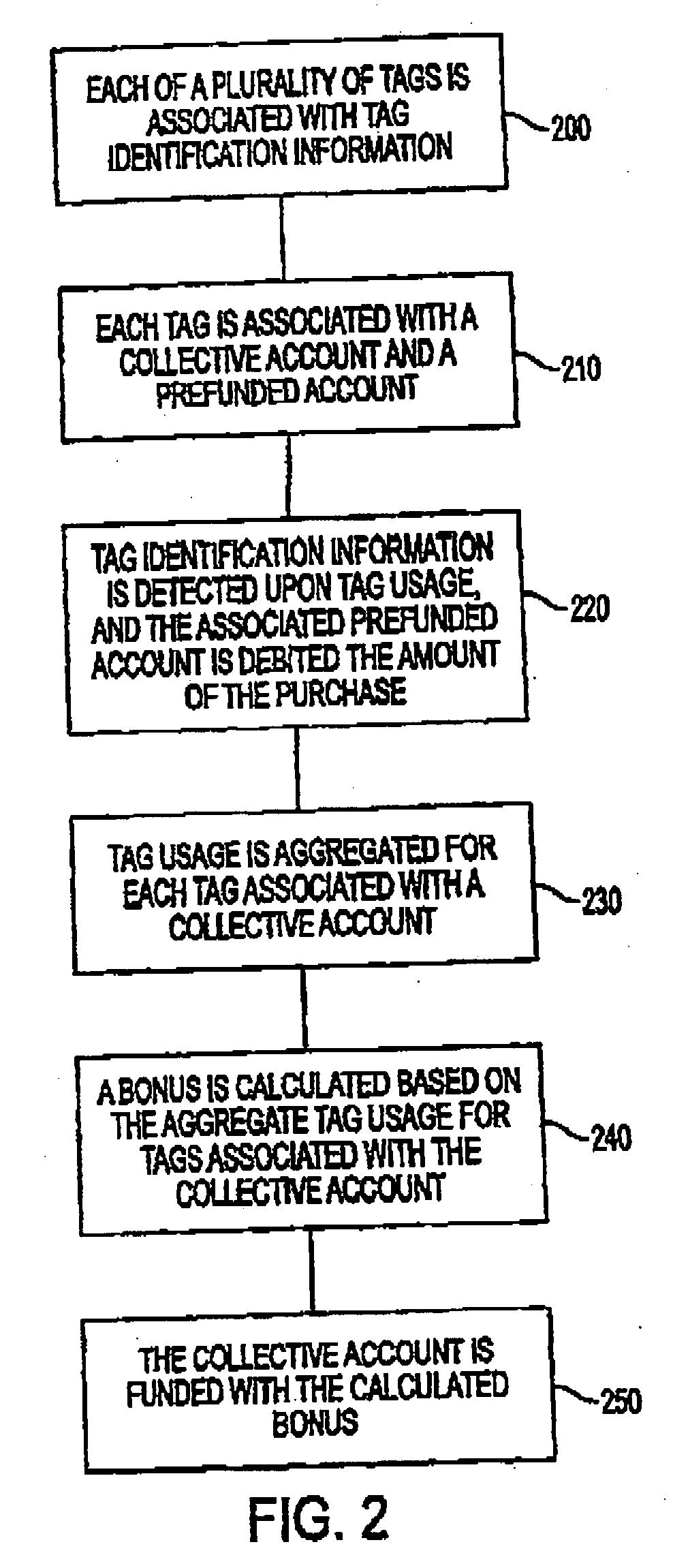

System and method for funding a collective account by use of an electronic tag

InactiveUS20050040221A1Raise the possibilityReducing motorist distractionTicket-issuing apparatusRoad vehicles traffic controlData scienceElectronic tags

A system and method for funding a collective account via aggregating usage of electronic tags is disclosed. The system and method promotes the use of electronic tags, and the funding of collective accounts that may be associated with charitable or other philanthropic causes. Further benefits may be realized by replenishing the prefunded account that serves as the source of funds for the electronic tag to an affinity account that also benefits the charitable or other philanthropic cause.

Owner:BANK ONE DELAWARE NAT ASSOC

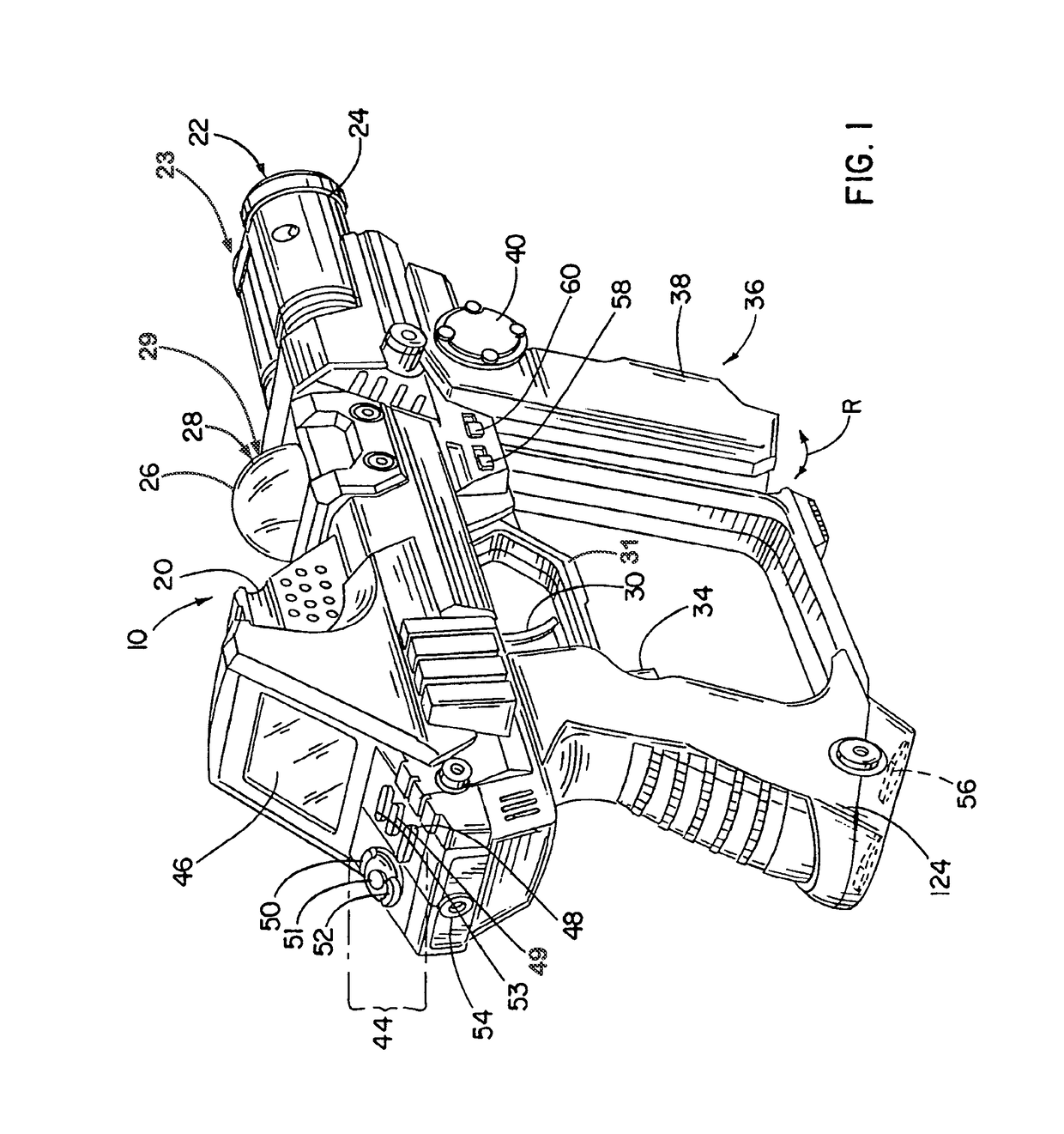

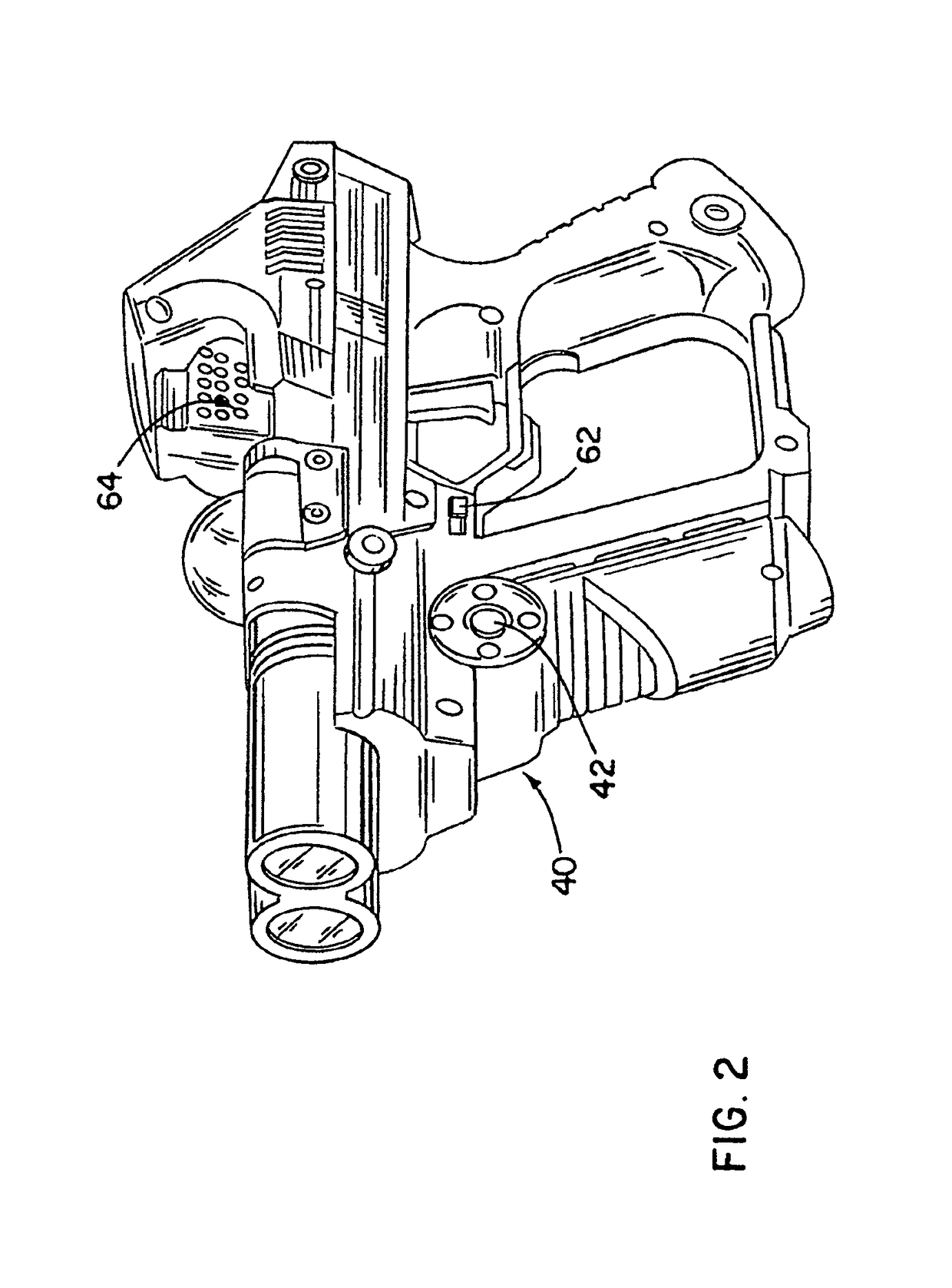

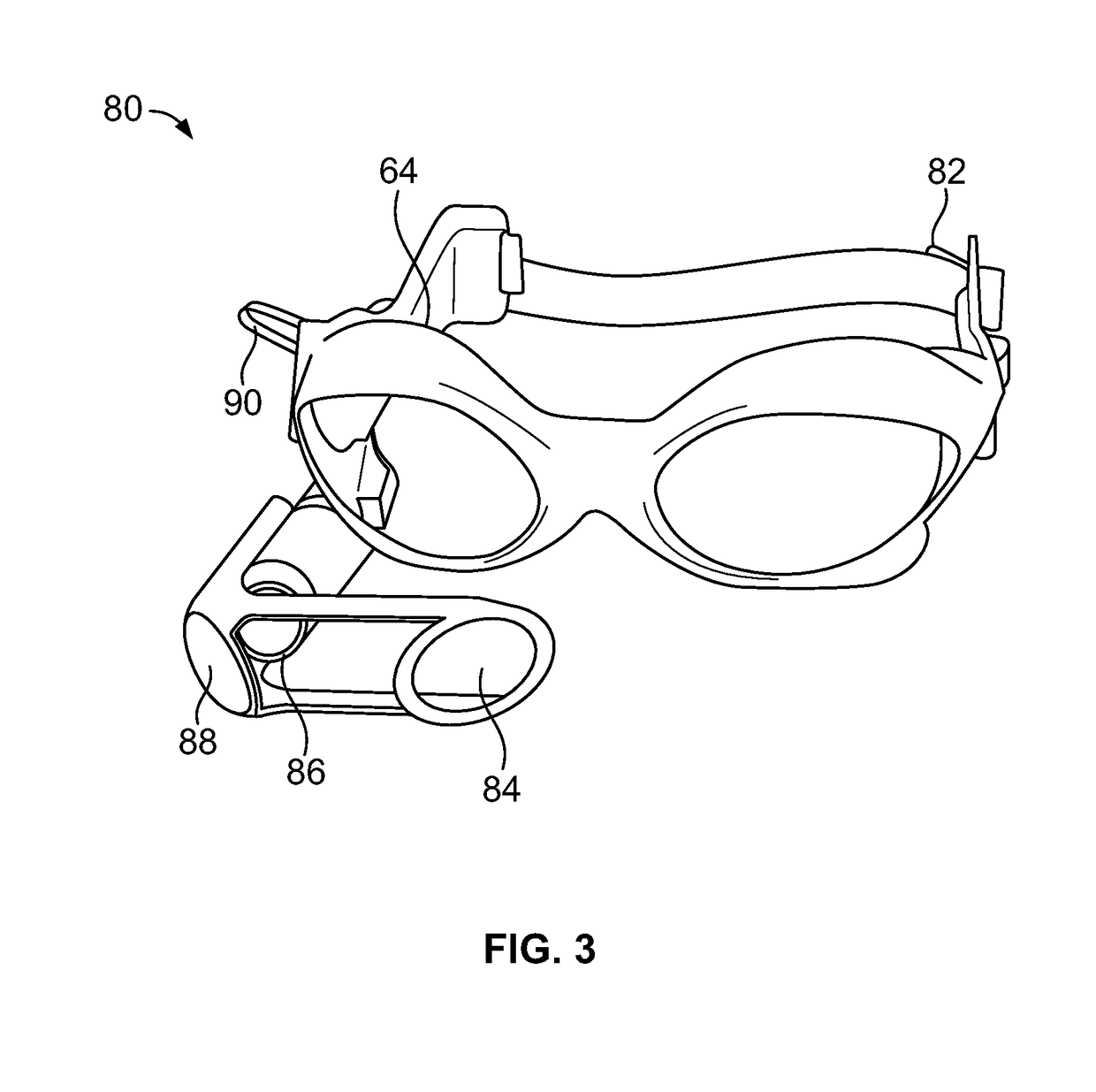

Device and method for an electronic tag game

A device combining a gun and target for facilitating a game of tag using infrared light communications and augmented reality with one or more players is provided. The device includes infrared transmitters and infrared receivers to facilitate omni-directional two-way communication between two or more devices and a shaped housing facilitating handling of the device by a user. The housing includes a grip portion with a finger-operable trigger and a barrel portion. A mobile electronic device is used as an accessory to provide single player and multiplayer augmented reality game play and a user-interface including a display and a touch screen for programming the device and controlling various game and device functions.

Owner:HASBRO INC

System and method for funding a collective account by use of an electronic tag

InactiveUS6945453B1Increase awarenessImprove efficiencyElectric signal transmission systemsTicket-issuing apparatusData scienceElectronic tags

A system and method for funding a collective account via aggregating usage of electronic tags is disclosed. The system and method promotes the use of electronic tags, and the funding of collective accounts that may be associated with charitable or other philanthropic causes. Further benefits may be realized by replenishing the prefunded account that serves as the source of funds for the electronic tag to an affinity account that also benefits the charitable or other philanthropic cause.

Owner:JPMORGAN CHASE BANK NA +1

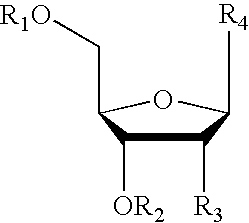

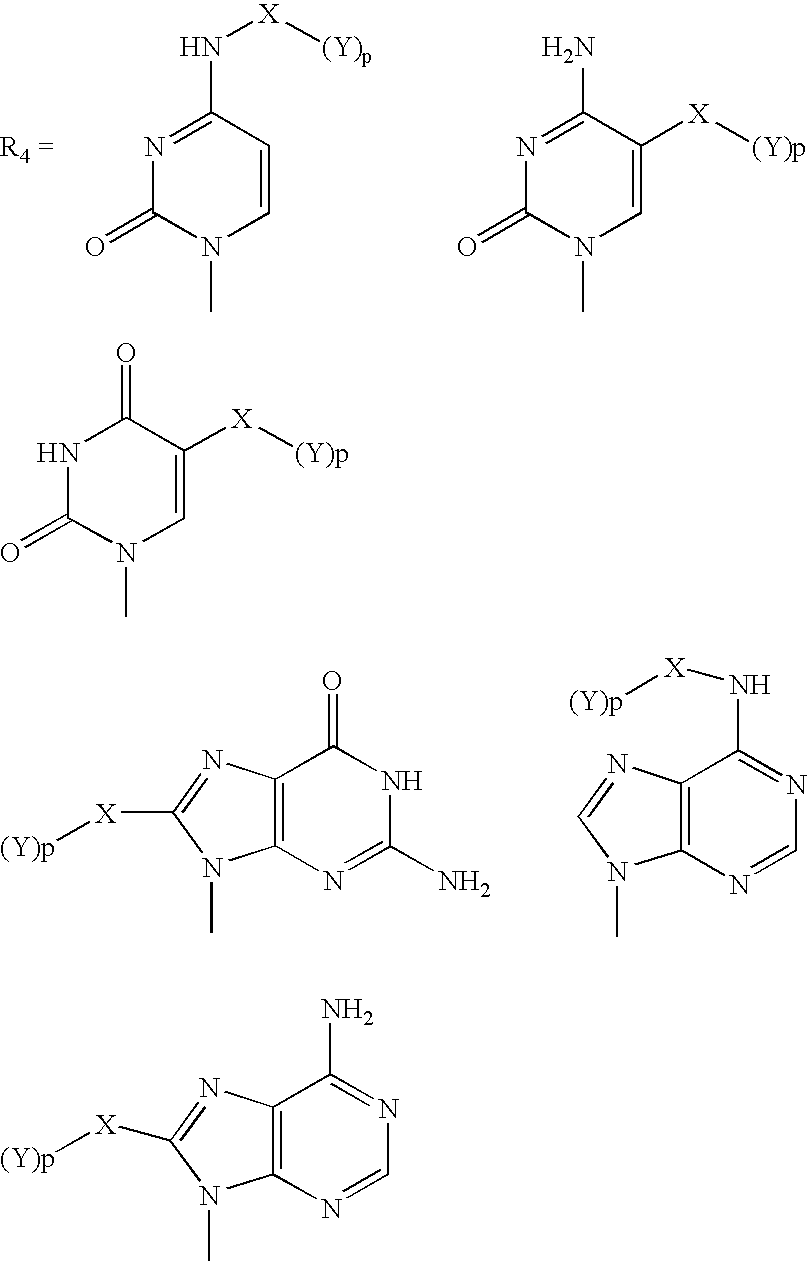

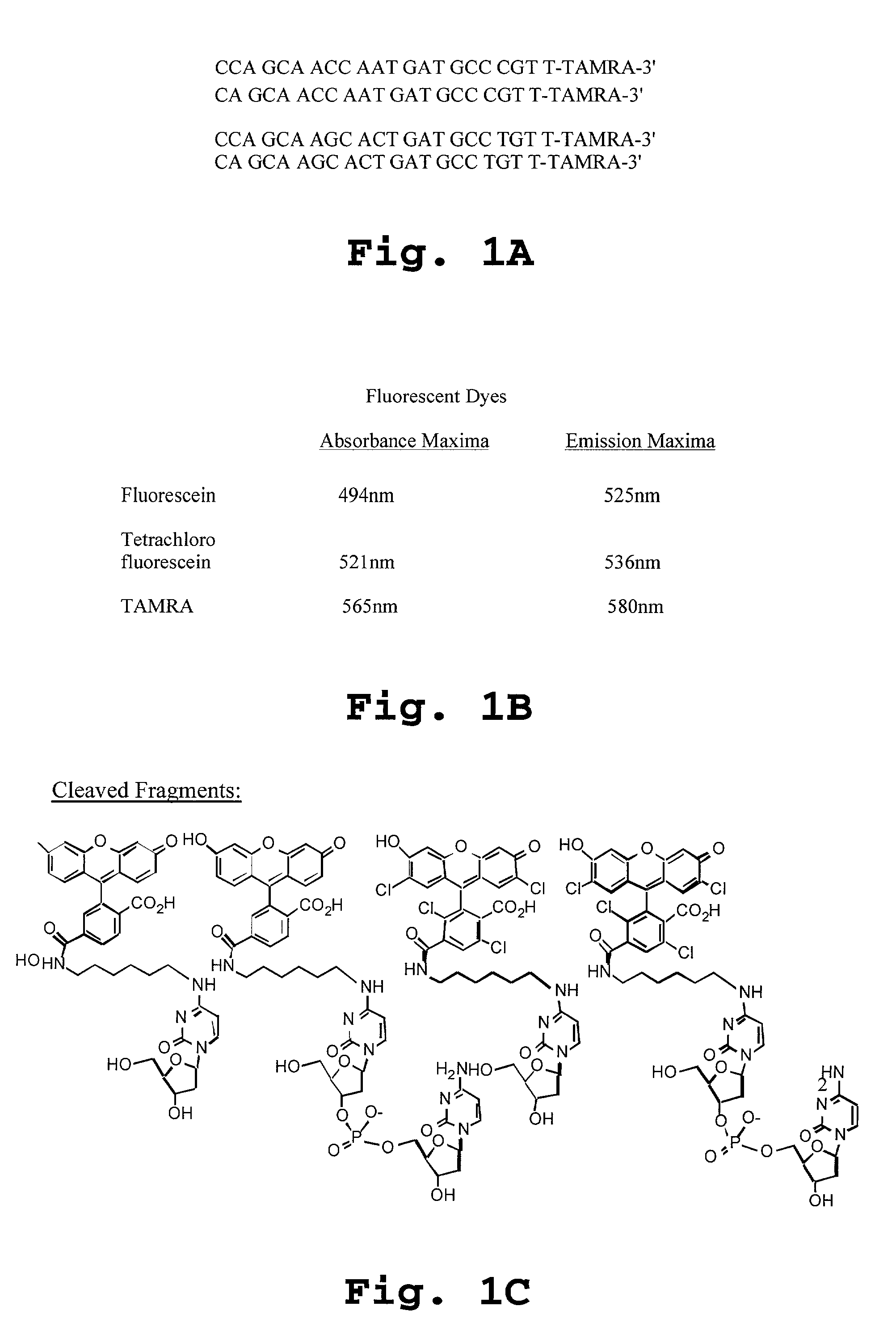

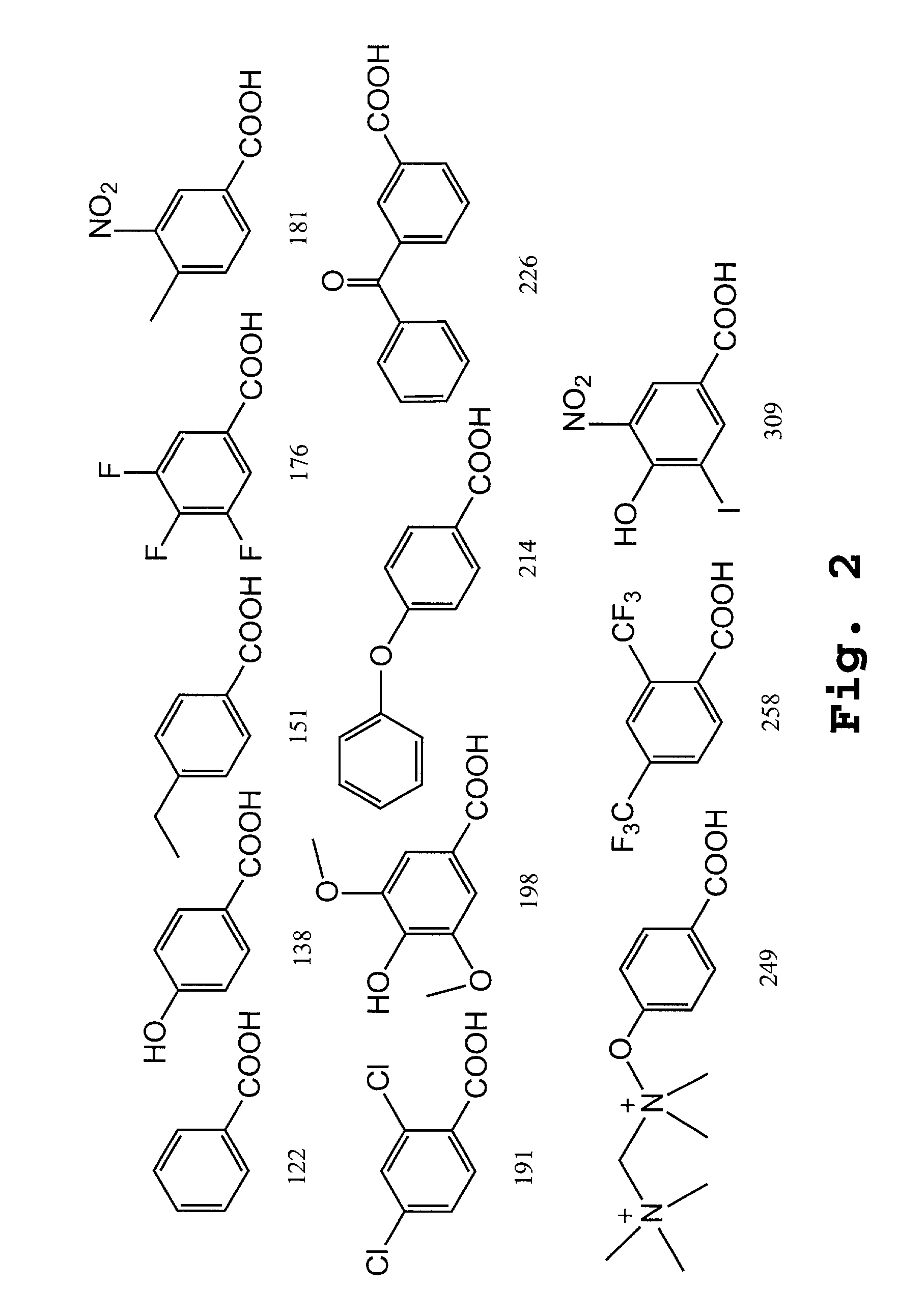

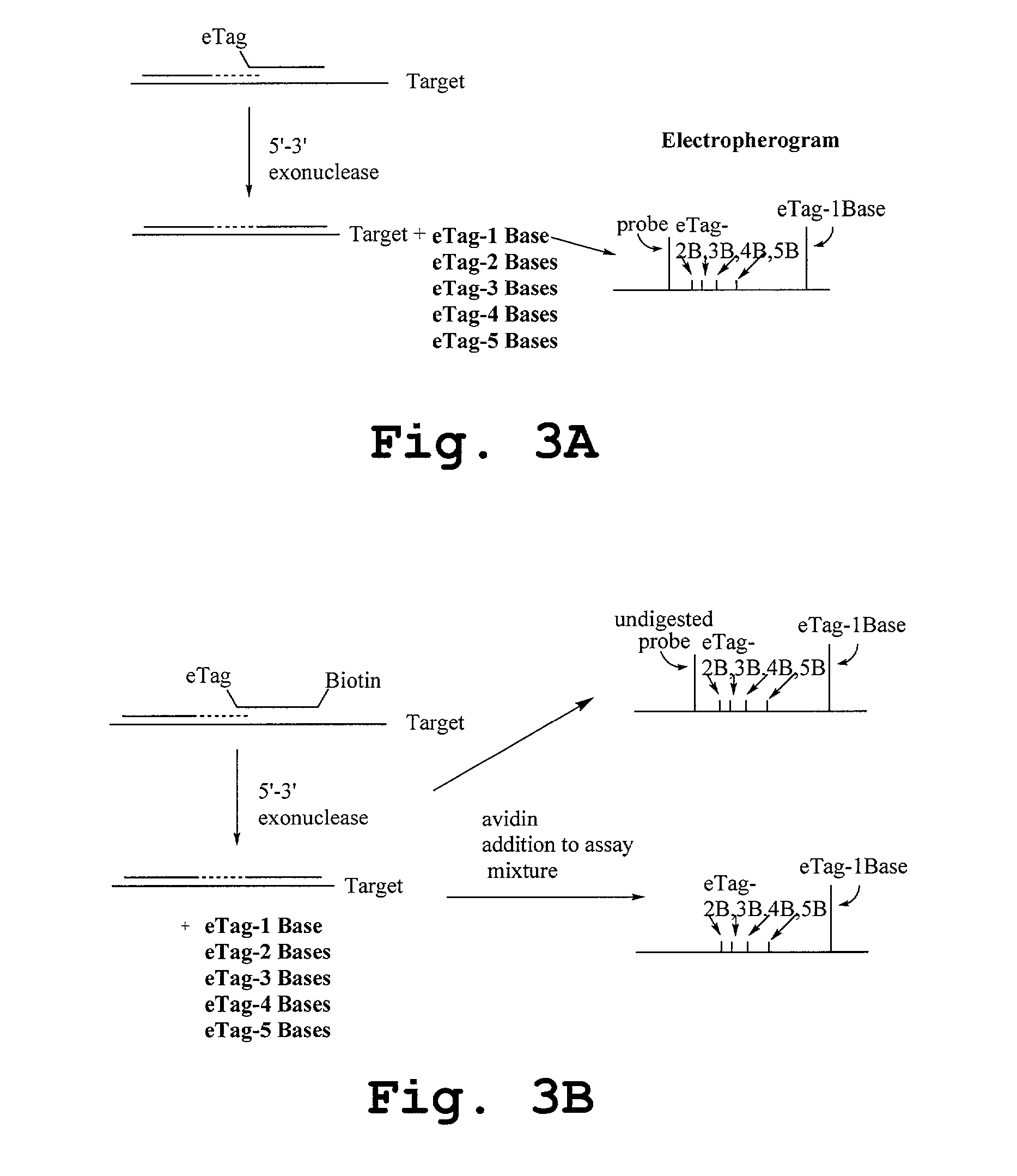

Methods and compositions for enhancing detection in determinations employing cleavable electrophoretic tag reagents

InactiveUS20040096825A1Accurate detectionDifferent massPeptide/protein ingredientsOrganic chemistry methodsElectrophoresisBiology

Probe sets for the multiplexed detection of the binding of, or interaction between, one or more ligands and target antiligands are provided. Detection involves the release of identifying tags as a consequence of target recognition. The probe sets include electrophoretic tag probes or e-tag probes, comprising a detection region and a mobility-defining region called the mobility modifier, both linked to a target-binding moiety. The probes comprise interactive functionalities adjacent the cleaved portion positioned in the probes such that the interactive functionality does not form part of the e-tag reporters. Target antiligands are contacted with a set of e-tag probes and the contacted antiligands are treated with a selected cleaving agent resulting in a mixture of e-tag reporters and uncleaved and / or partially cleaved e-tag probes. The mixture is exposed to a capture agent effective to bind to uncleaved or partially cleaved e-tag probes, followed by electrophoretic separation. In a multiplexed assay, different released e-tag reporters may be separated and detected providing for target identification.

Owner:MONOGRAM BIOSCIENCES

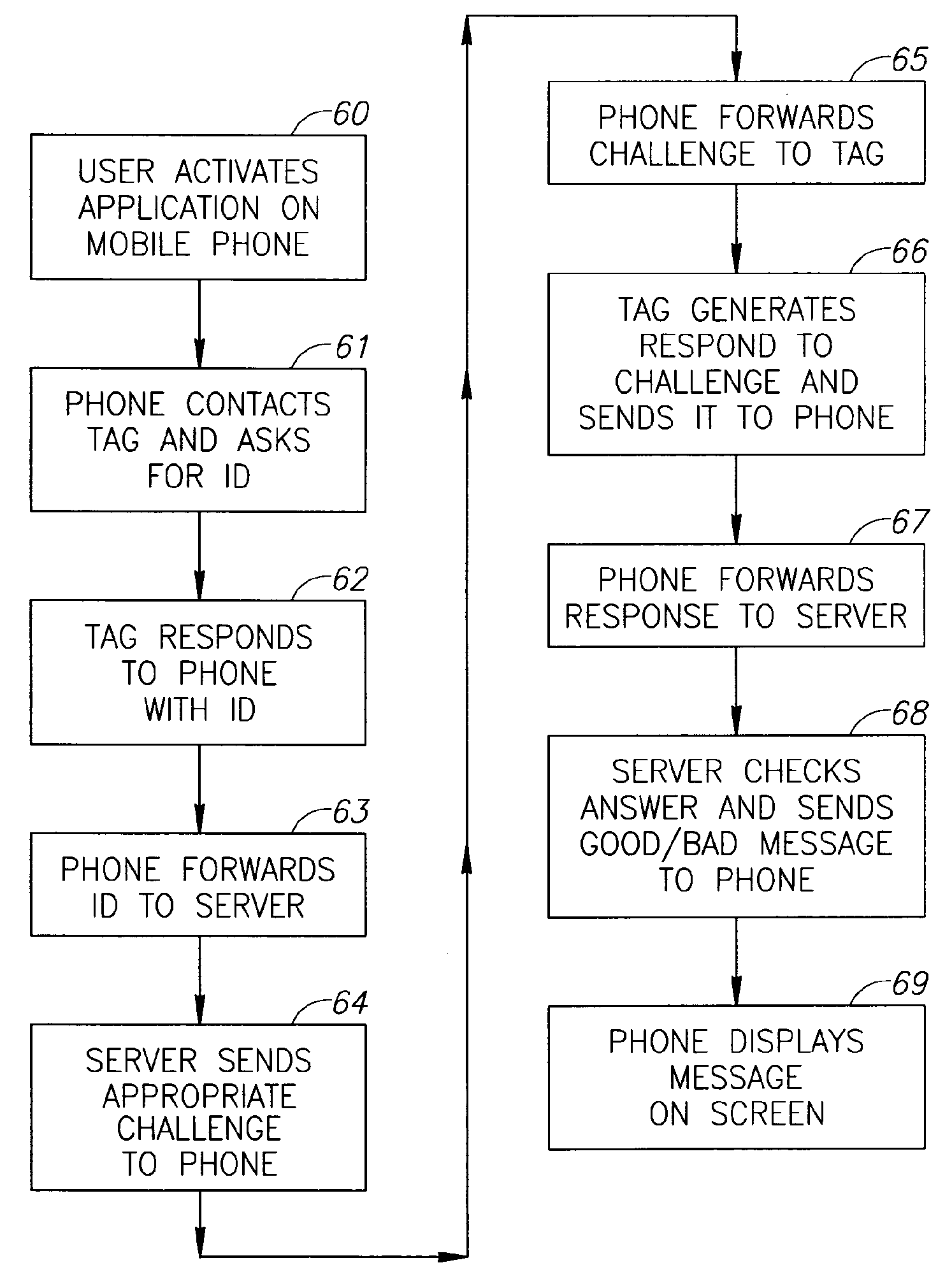

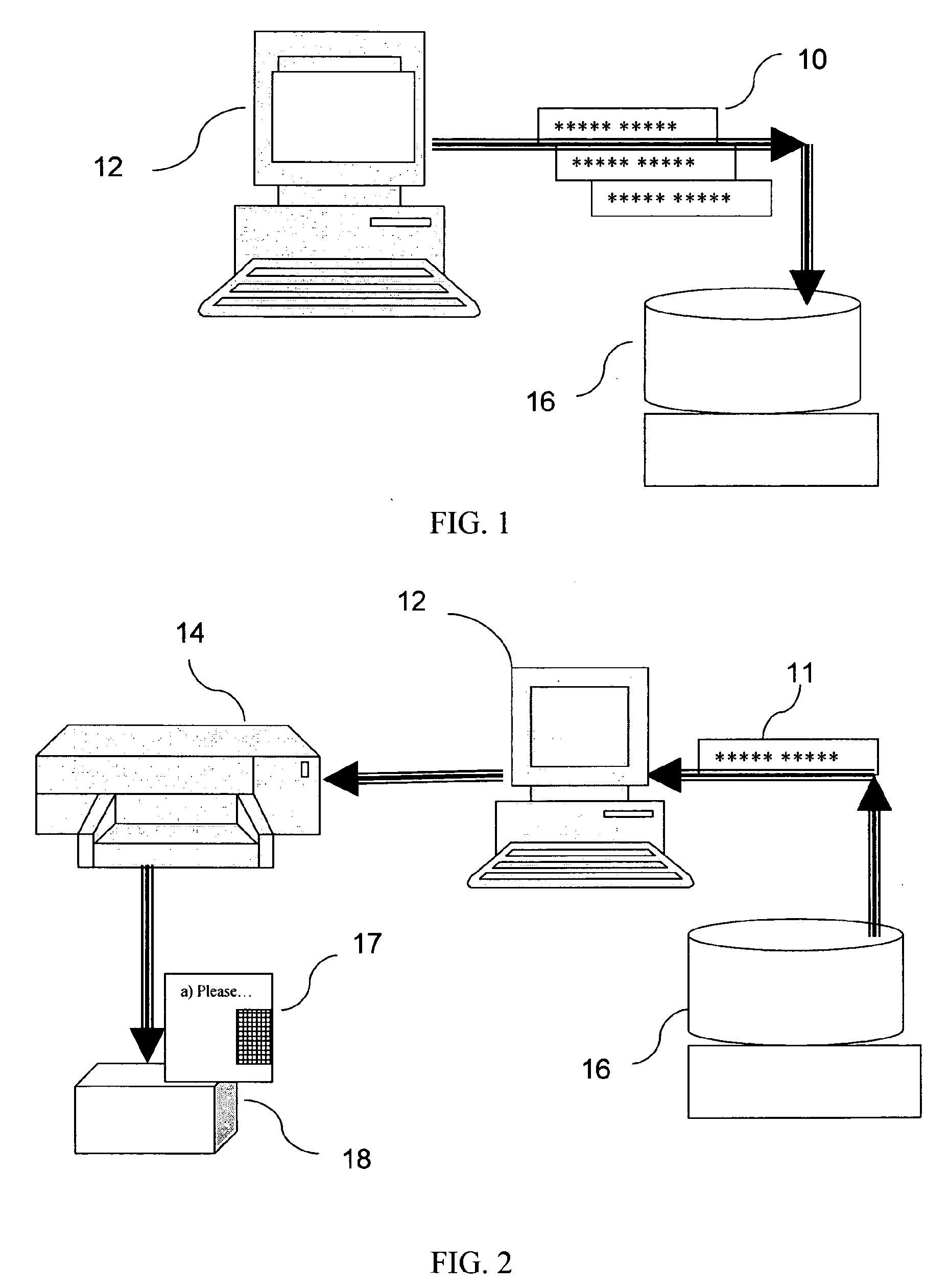

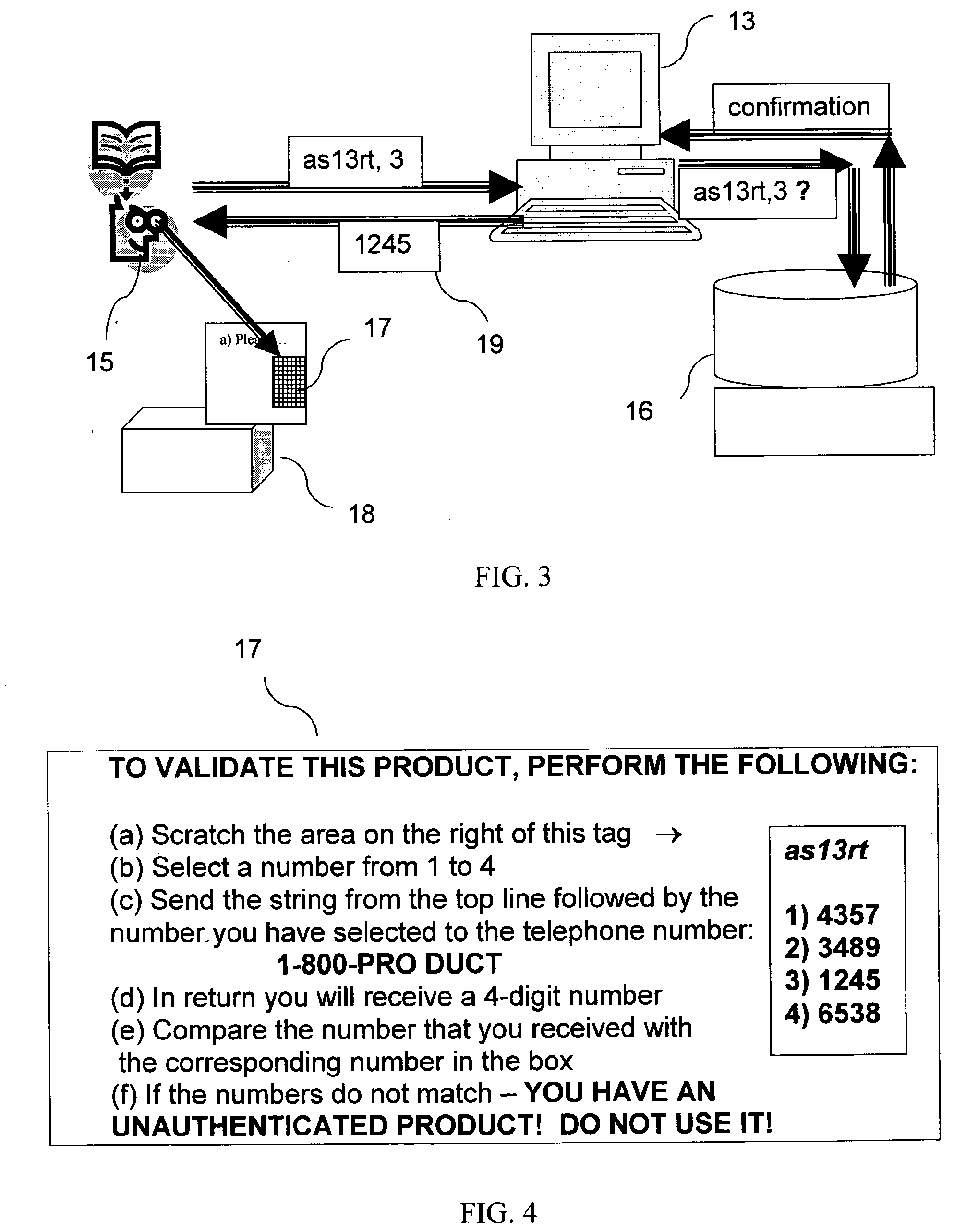

System for product authentication by mobile phone

InactiveUS20090106042A1Overcome disadvantagesIncrease probabilitySubstation equipmentBuying/selling/leasing transactionsAuthentication systemMobile phone

An authentication system enabling a customer to verify the authenticity of a product in a foolproof, secure and simple manner. plurality of secret sets of numbers is generated, each set comprising a challenge portion and a response portion. These sets are stored on a remote server. Each set is associated with a different product. The customer sends a challenge portion to the server, and prompts the server to provide a response. If the response matches that of the product in hand, the product is known to be authentic. In another embodiment of the system, cellular transmission is used to power an electronic tag attached to the product and carrying authentication data. In a third embodiment, the full manufacturer database is divided into separate databases, possibly related to product vendor, such that an authentication process can be performed without the need to access the manufacturer's entire database of products.

Owner:AUTHIX TECH LTD

System and method for funding a collective account by use of an electronic tag

InactiveUS20080010202A1Raise the possibilityReducing motorist distractionFinancePayment circuitsData scienceElectronic tags

A system and method for funding a collective account via aggregating usage of electronic tags is disclosed. The system and method promotes the use of electronic tags, and the funding of collective accounts that may be associated with charitable or other philanthropic causes. Further benefits may be realized by replenishing the prefunded account that serves as the source of funds for the electronic tag to an affinity account that also benefits the charitable or other philanthropic cause.

Owner:JPMORGAN CHASE BANK NA

Methods employing generalized target-binding e-tag probes

Methods for the multiplexed detection of the binding of, or interaction between, one or more ligands and target antiligands are provided. Detection involves the release of identifying tags as a consequence of target recognition. The methods include the use of electrophoretic tag probes or e-tag probes, comprising a detection region and a mobility-defining region called the mobility modifier, both linked to a target-binding moiety. In practicing the methods, target antiligands are contacted with a set of e-tag probes and the contacted antiligands are treated with a selected cleaving agent resulting in a mixture of e-tag reporters and uncleaved and / or partially cleaved e-tag probes. The mixture is exposed to a capture agent effective to bind to uncleaved or partially cleaved e-tag probes, followed by electrophoretic separation. In a multiplexed assay, different released e-tag reporters may be separated and detected providing for target identification.

Owner:MONOGRAM BIOSCIENCES

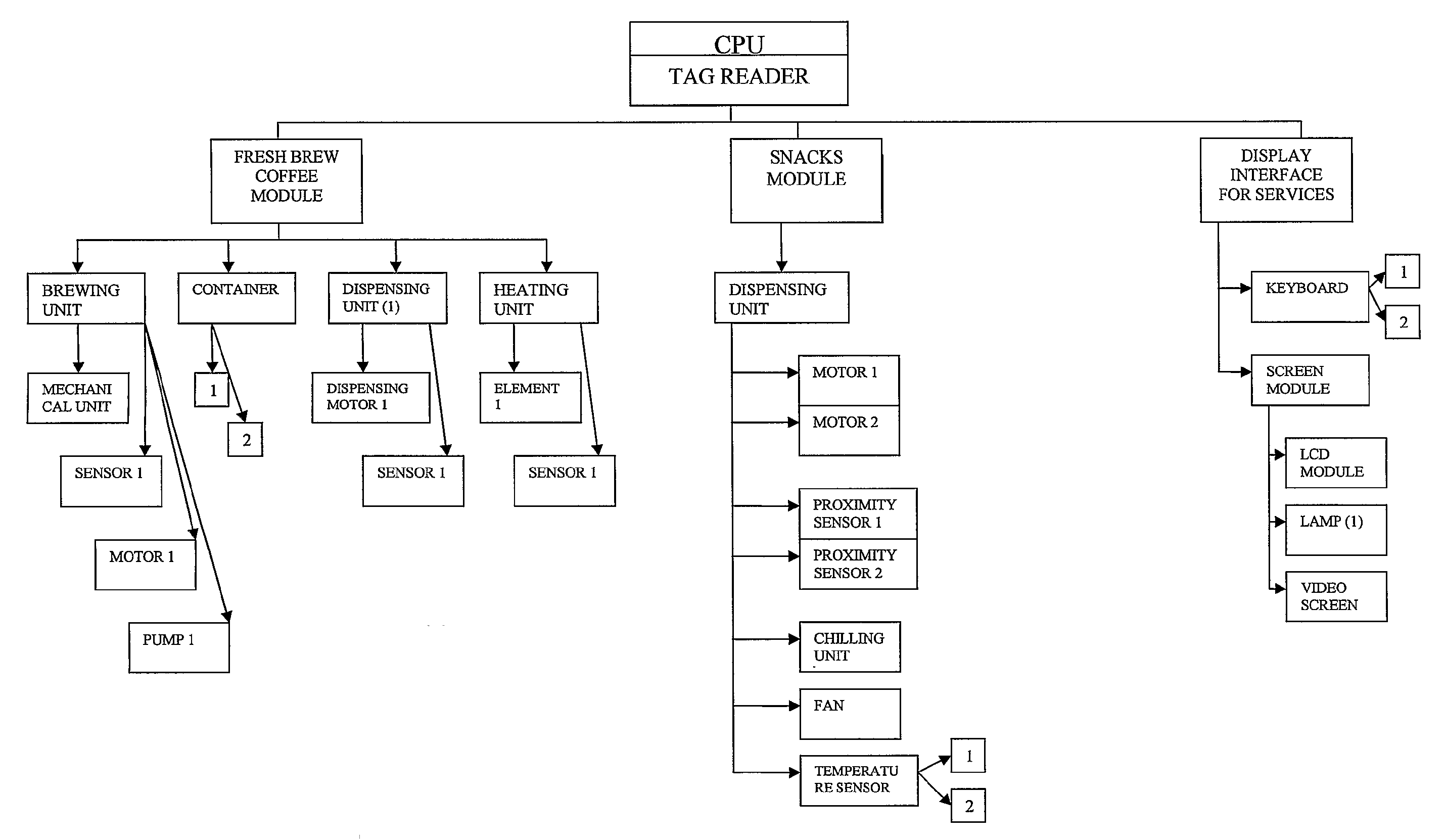

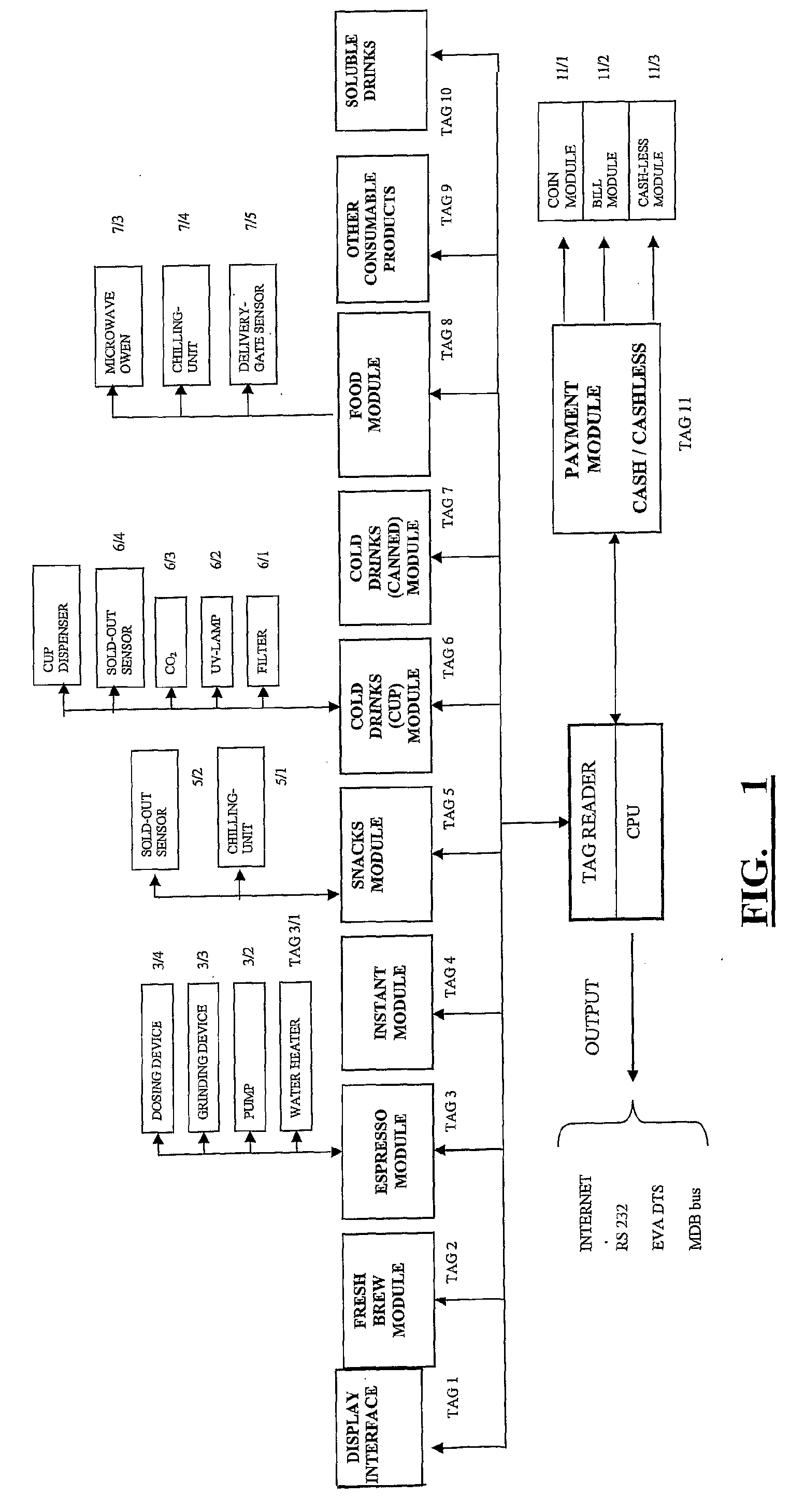

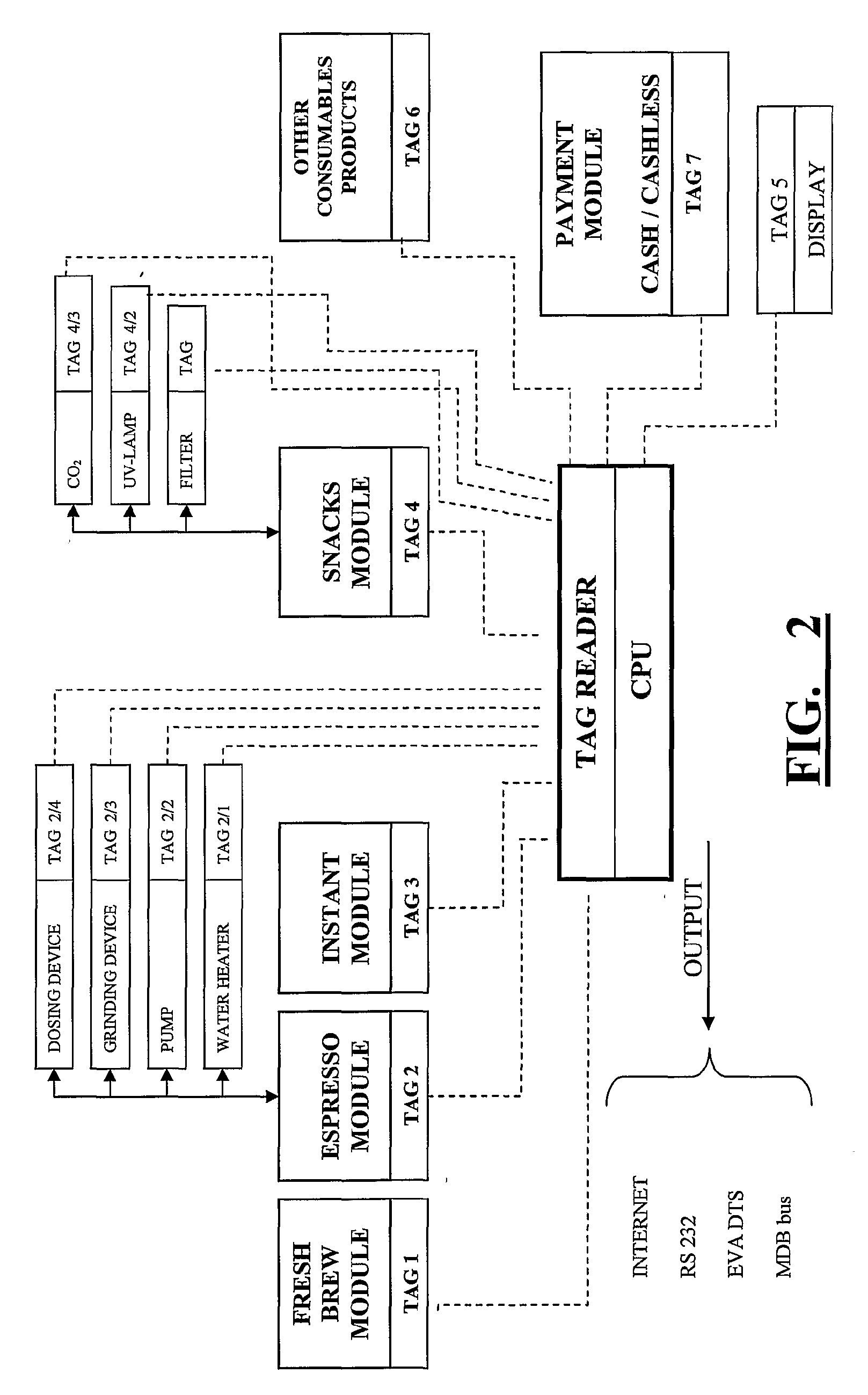

Apparatus and method for dispensing machine control

InactiveUS20080116262A1Improve quality controlReduce usageControlling coin-freed apparatusRegistering coin as creditMachine controlEngineering

In order to control the status and the operation of a dispensing machine assembly comprising one or more modules or sub-assemblies, at least one of modules or sub-modules is provided with an electronic tag and the machine is provided with a tag controller device for interacting with said tag by reading, writing and transmitting information data on or through said tag and operating said dispensing machine according to the information gathered from said tag or tags.

Owner:TUTTOESPRESSO SRL

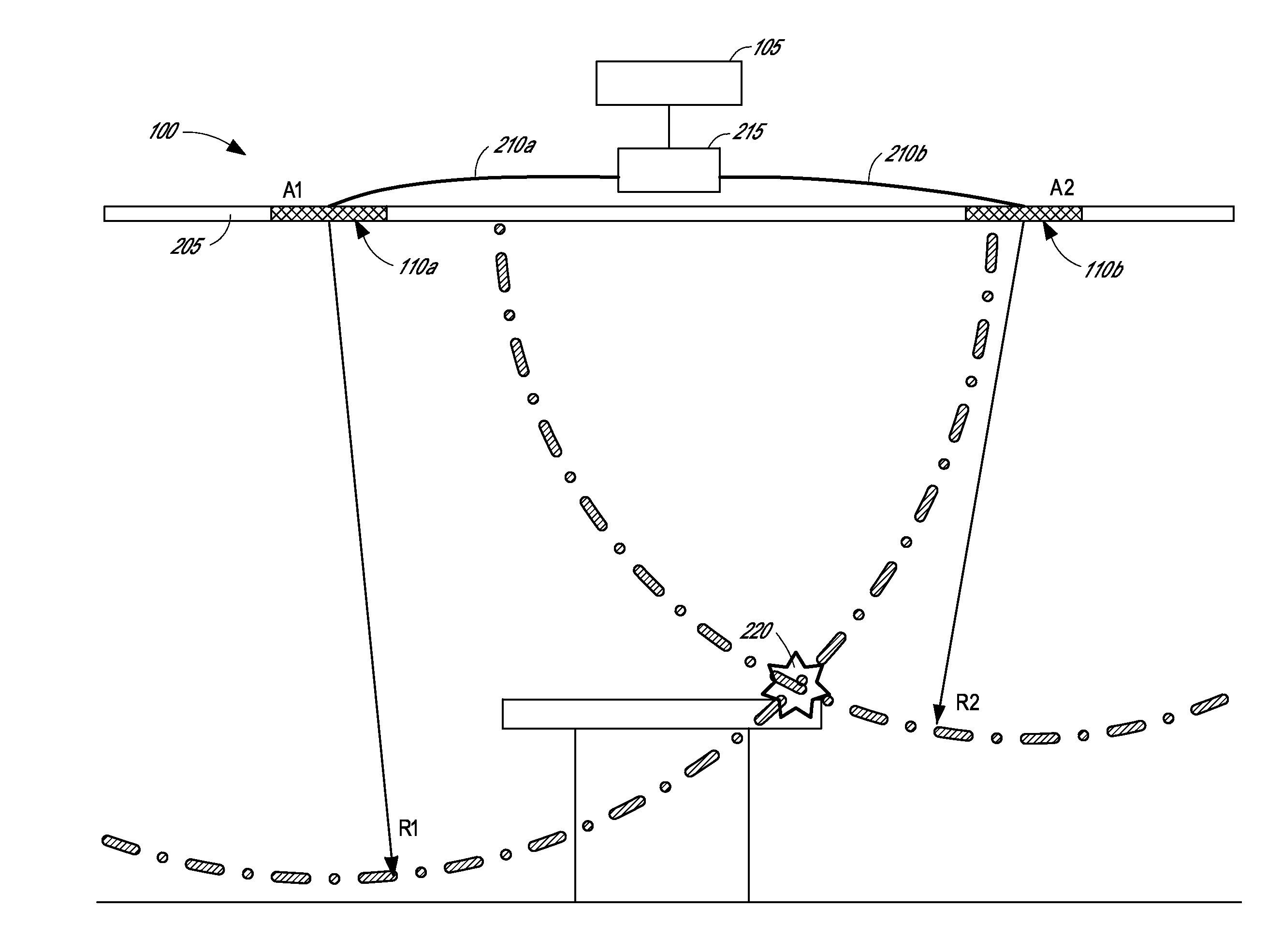

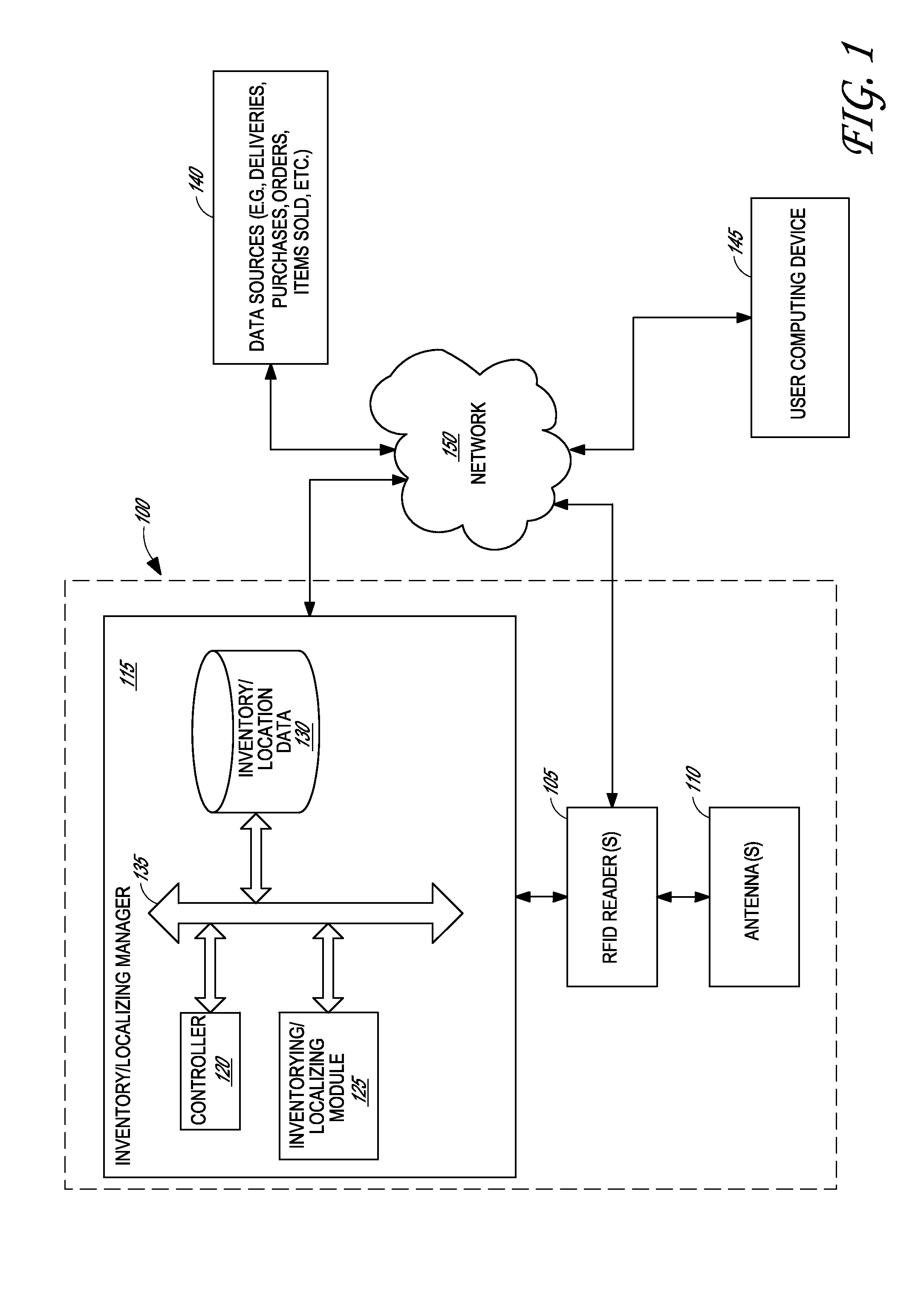

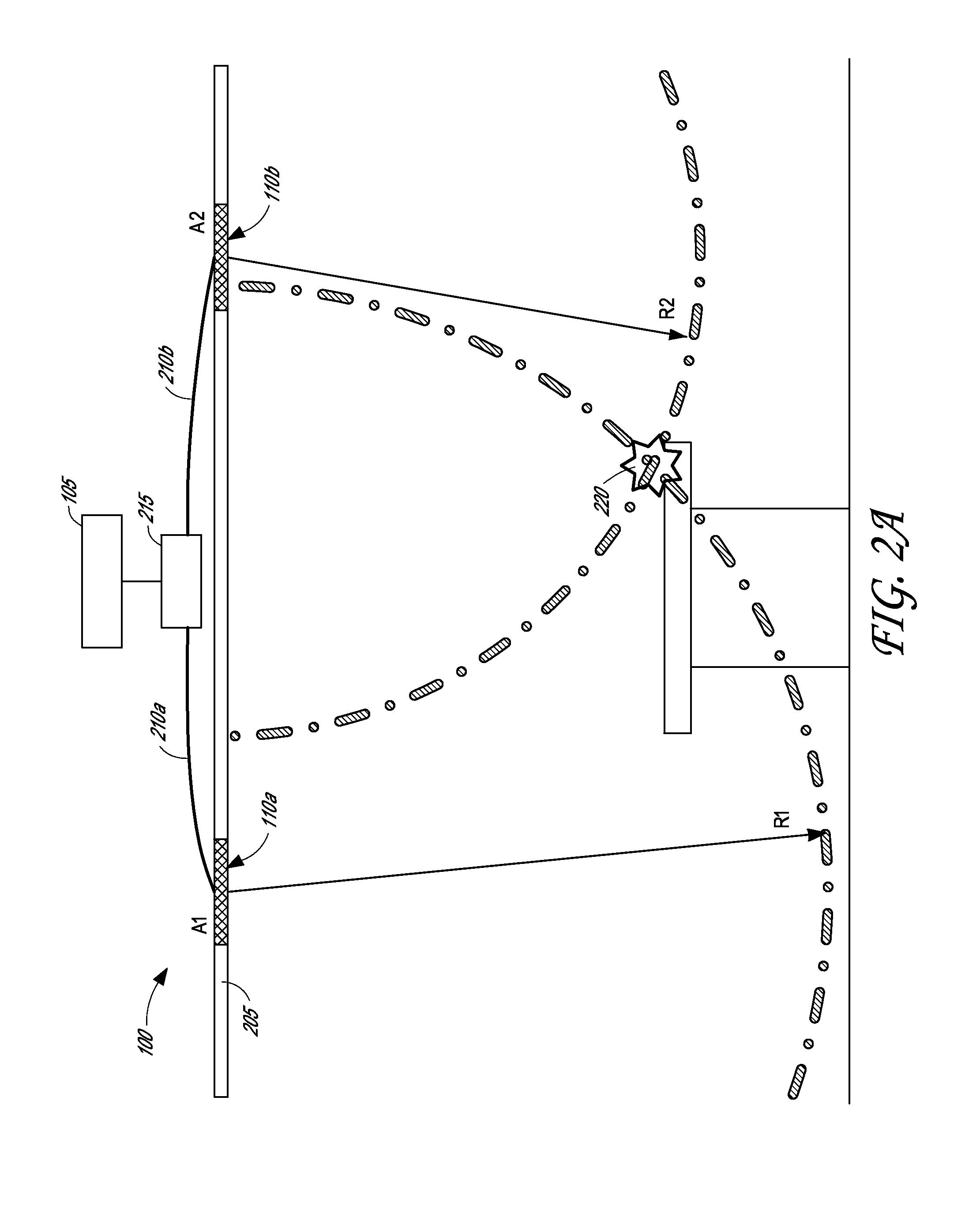

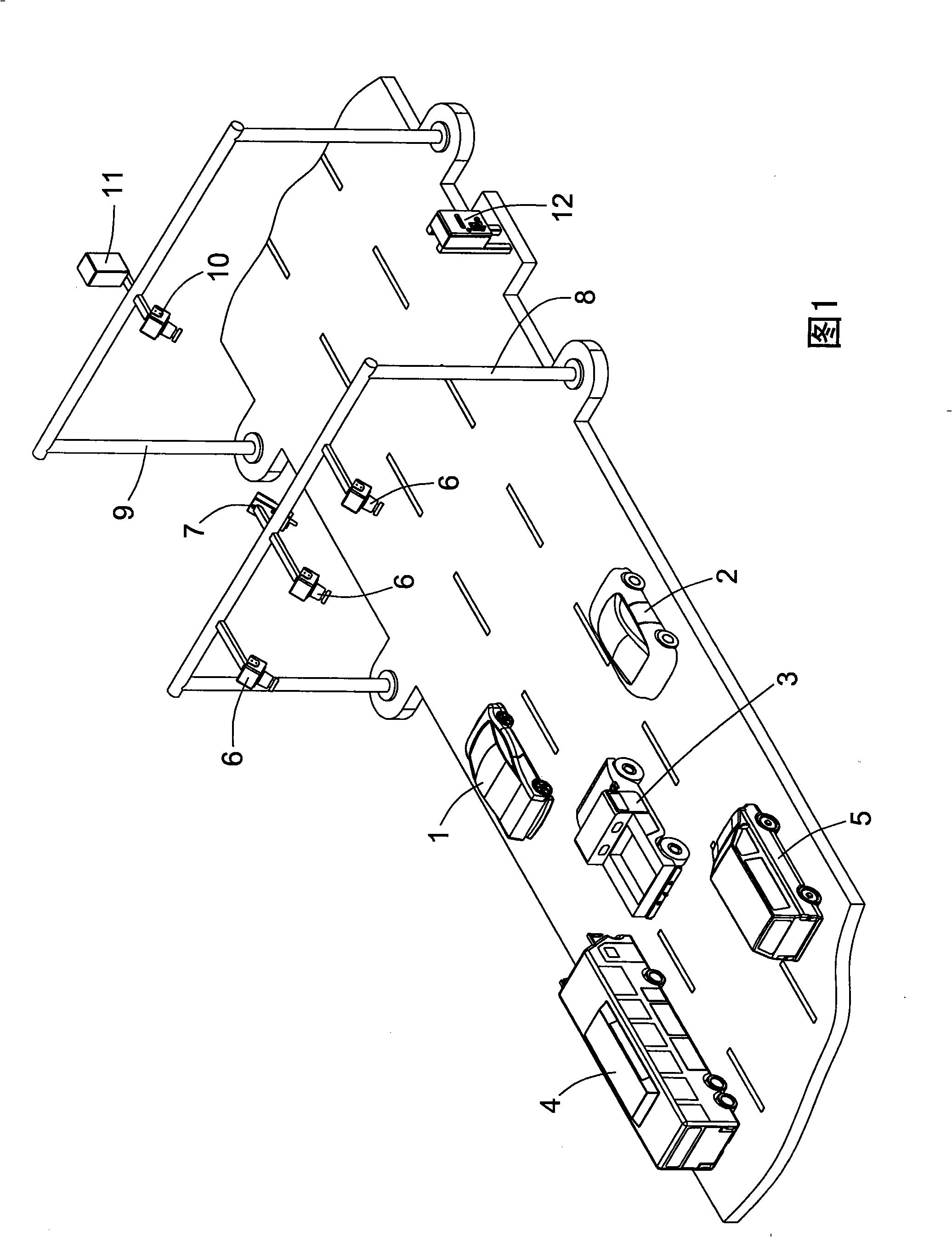

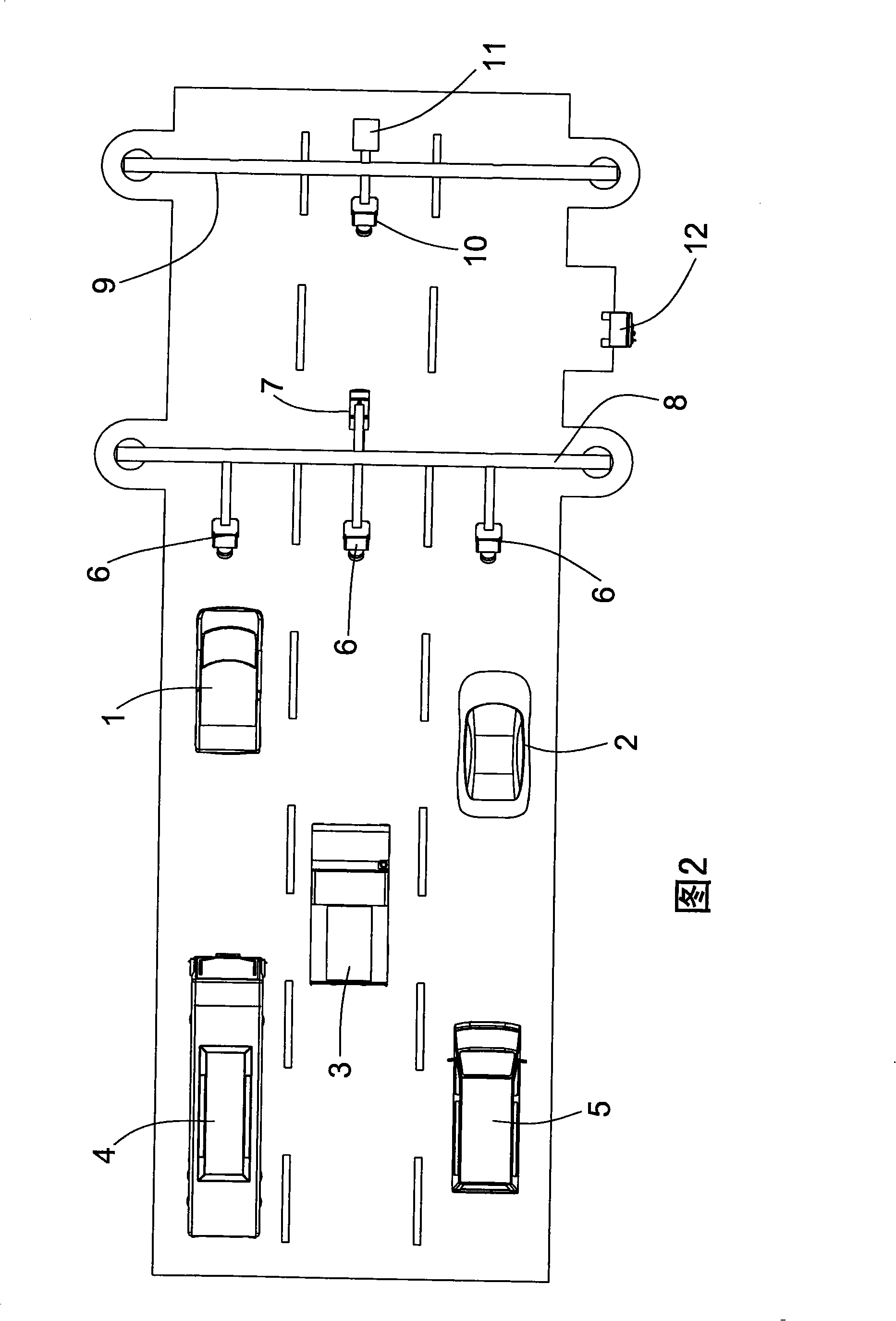

Overhead antenna live inventory locating system

InactiveUS20140361078A1Reduce stepsReduce distanceLogisticsCommerceEmbedded systemPositioning system

Overhead antenna live inventory locating systems and methods are provided. The overhead antenna inventory / locating system can include a plurality of antennas mounted in an elevated support structure. The antennas can be coupled to RFID readers that interrogate electronic tags. The inventory system can analyze the information received from the detected electronic tags and produce inventory data and location information for the tags. The antennas can be patch antennas mounted to ceiling tiles such that they can be positioned in the ceiling of a facility. The antennas can be configured to provide broad coverage from a relatively low ceiling height. The low-cost antennas can be configured in such a way as to provide accurate location information for detected tags. The inventory system can be configured to provide near real-time inventory and location information.

Owner:RFID RESOLUTION TEAM

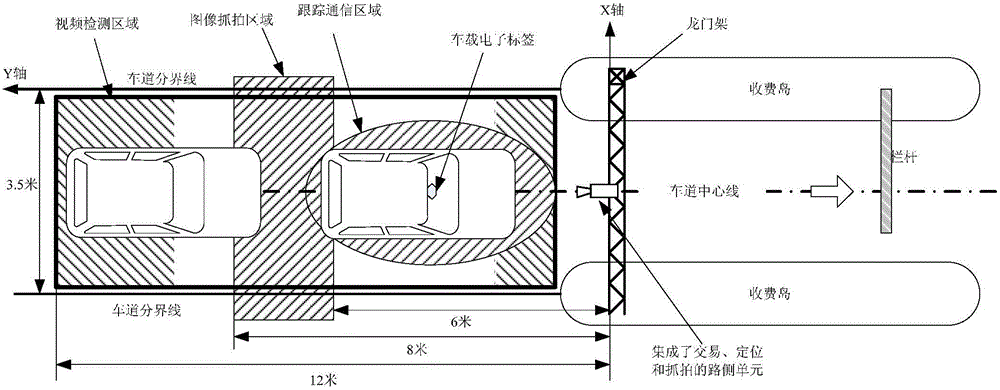

Method for locating and controlling multilane free flow video vehicle

InactiveCN101350109AReduce the numberAvoid stickingTicket-issuing apparatusDetection of traffic movementElectronic toll collectionRecognition system

The invention relates to a multi-lane free flow video vehicle position and control method, the processes thereof are that: step 1, virtual coils are arranged in the visual field of a panoramic camera to form a detection area. Step 2, when a vehicle enters the detection area, a video detector starts an algorithm program to obtain the position of the vehicle. Step 3, a central processing unit starts a microwave communication system and an image snapshot system. Step 4, a logical comparison system judges whether the vehicle has electronic label information, if without, executing step 8. Step 5, the logical comparison system judges whether a vehicle license plate number in the electronic label information and the vehicle license plate number which is identified by a license plate recognition system are consistent, if not consistent, executing step 8 is. Step 6, the images of the vehicle which are snapshot are deleted. Step 7, toll transaction is done, and a transaction record is formed after the transaction. Step 8, the transaction record which is transferred to a background billing system is further treated. Step 9, returning to a main process. The method can achieve an electronic toll collection function in a multi-lane free flow mode through the accurate location for the vehicle and the coordination control for a system.

Owner:RES INST OF HIGHWAY MIN OF COMM

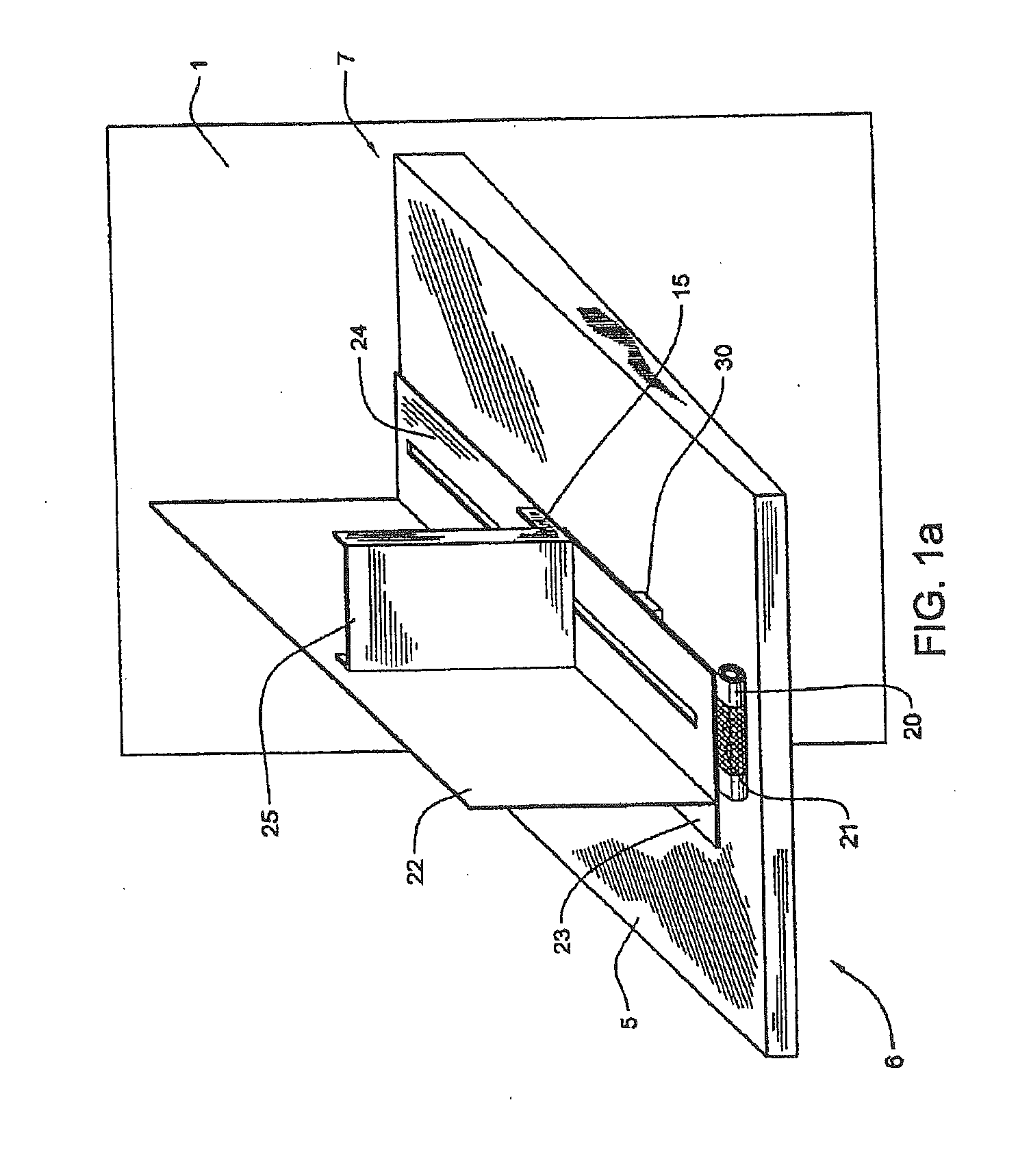

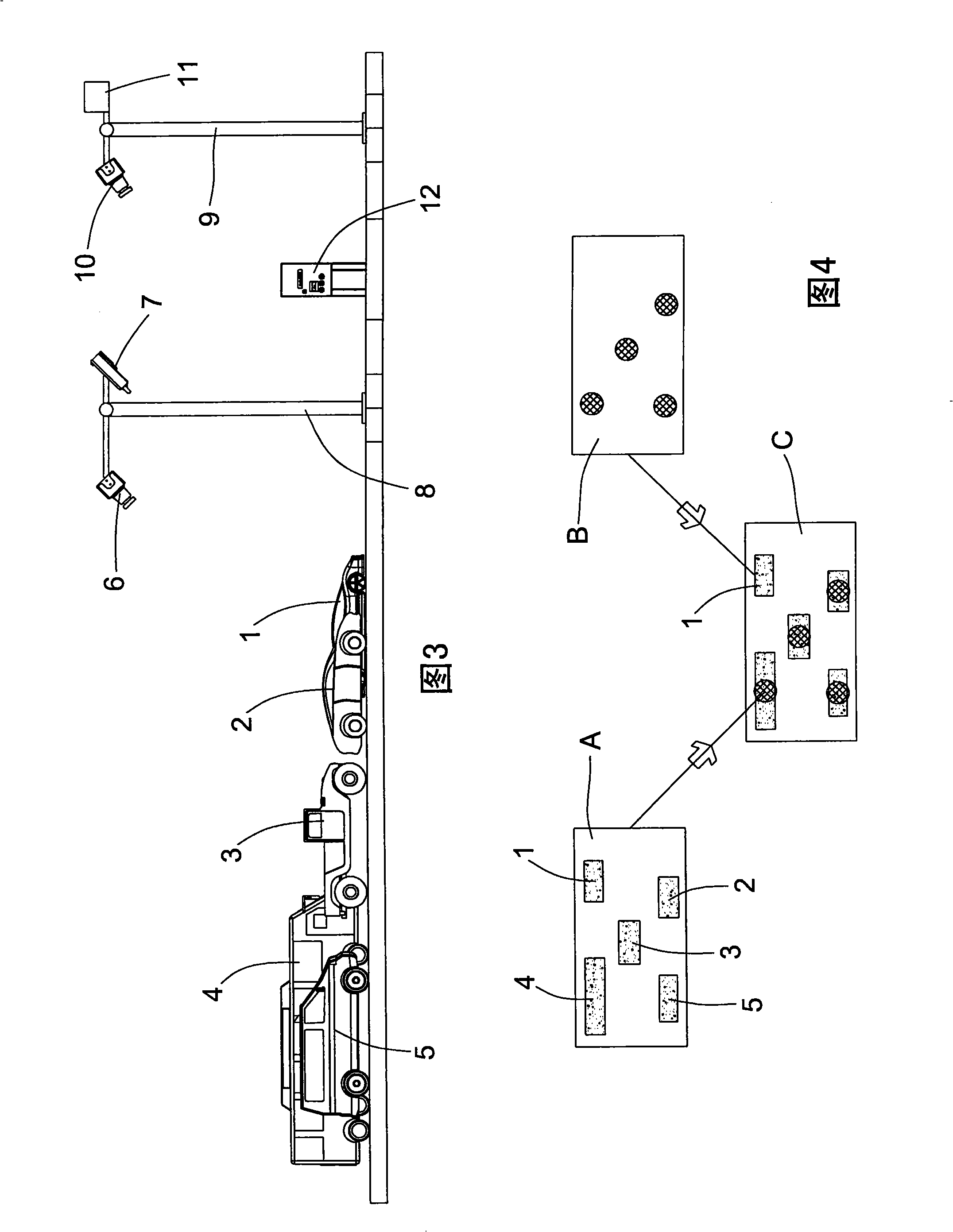

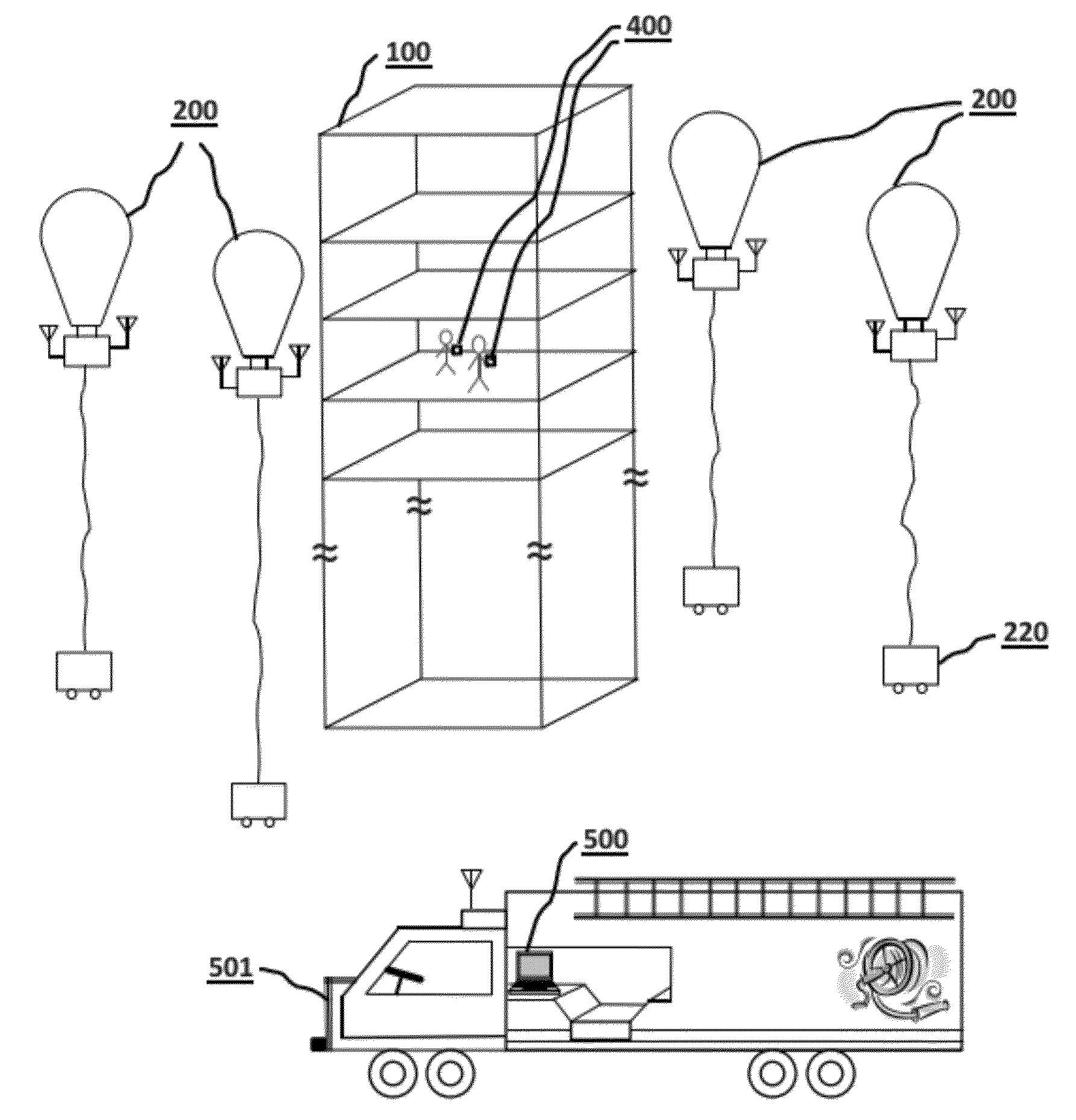

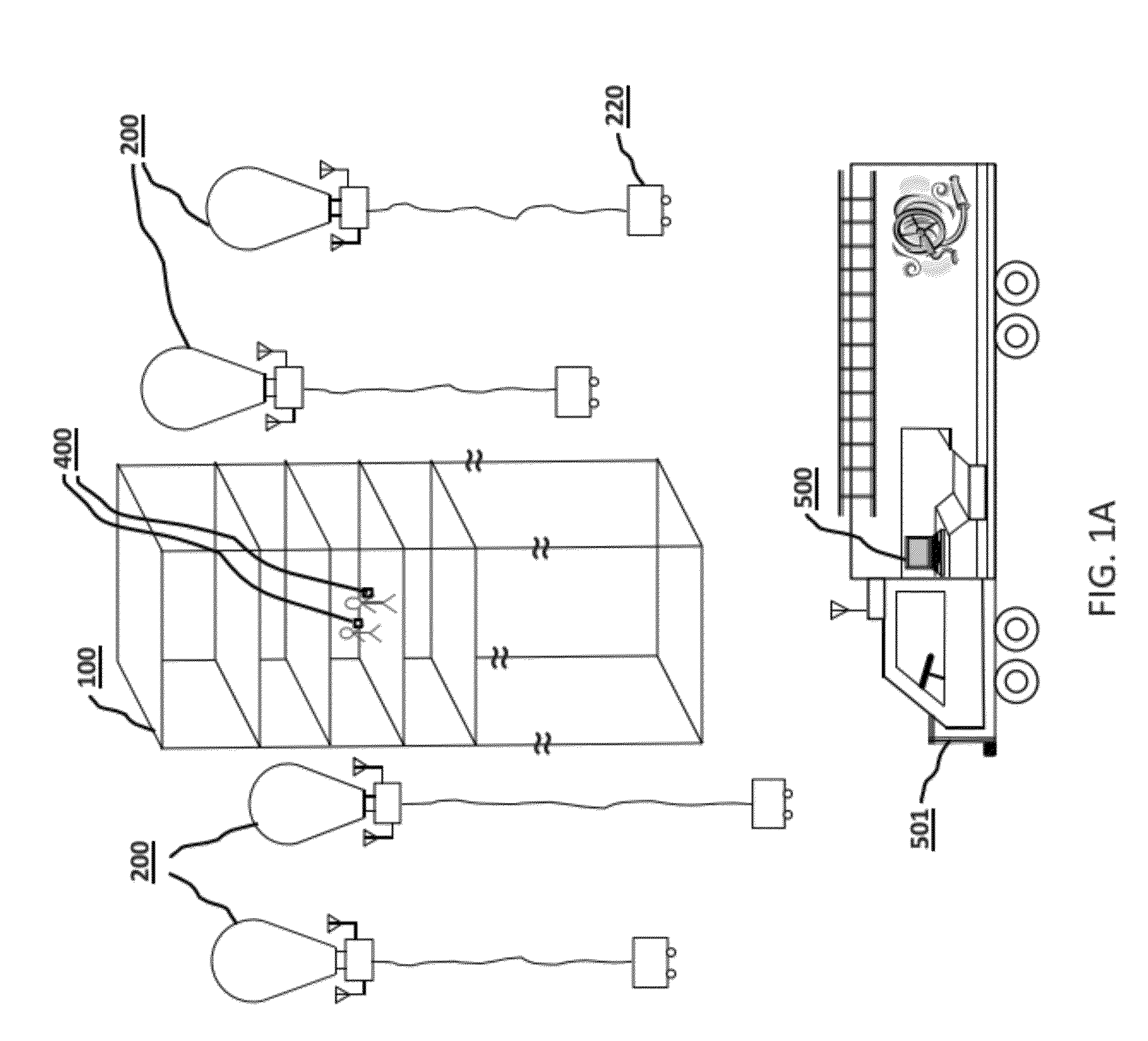

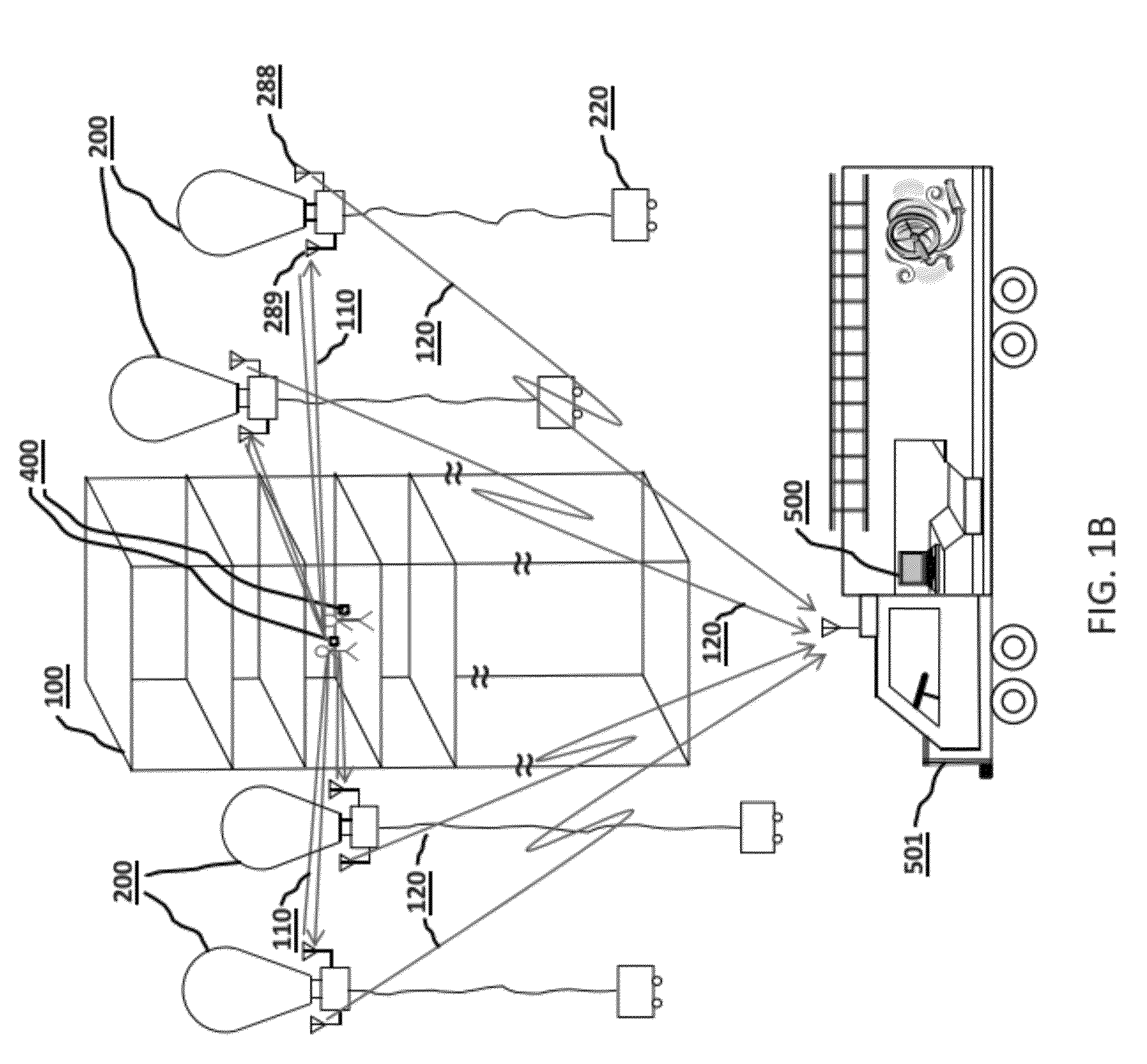

First responder team tracking system and method

InactiveUS20120286933A1Sensing detailsElectric/electromagnetic visible signallingTransceiverLocation tracking

A position tracking system for responders to an emergency is presented. The position tracking system includes a unique electronic tag attached to each responder and comprising a transceiver, the unique electronic tag configured to receive information and transmit a unique identifier via the transceiver, at least one moveable base station, and a command post comprising the command post transceiver configured to send and receive information.

Owner:KNOWLEDGE ACCESS

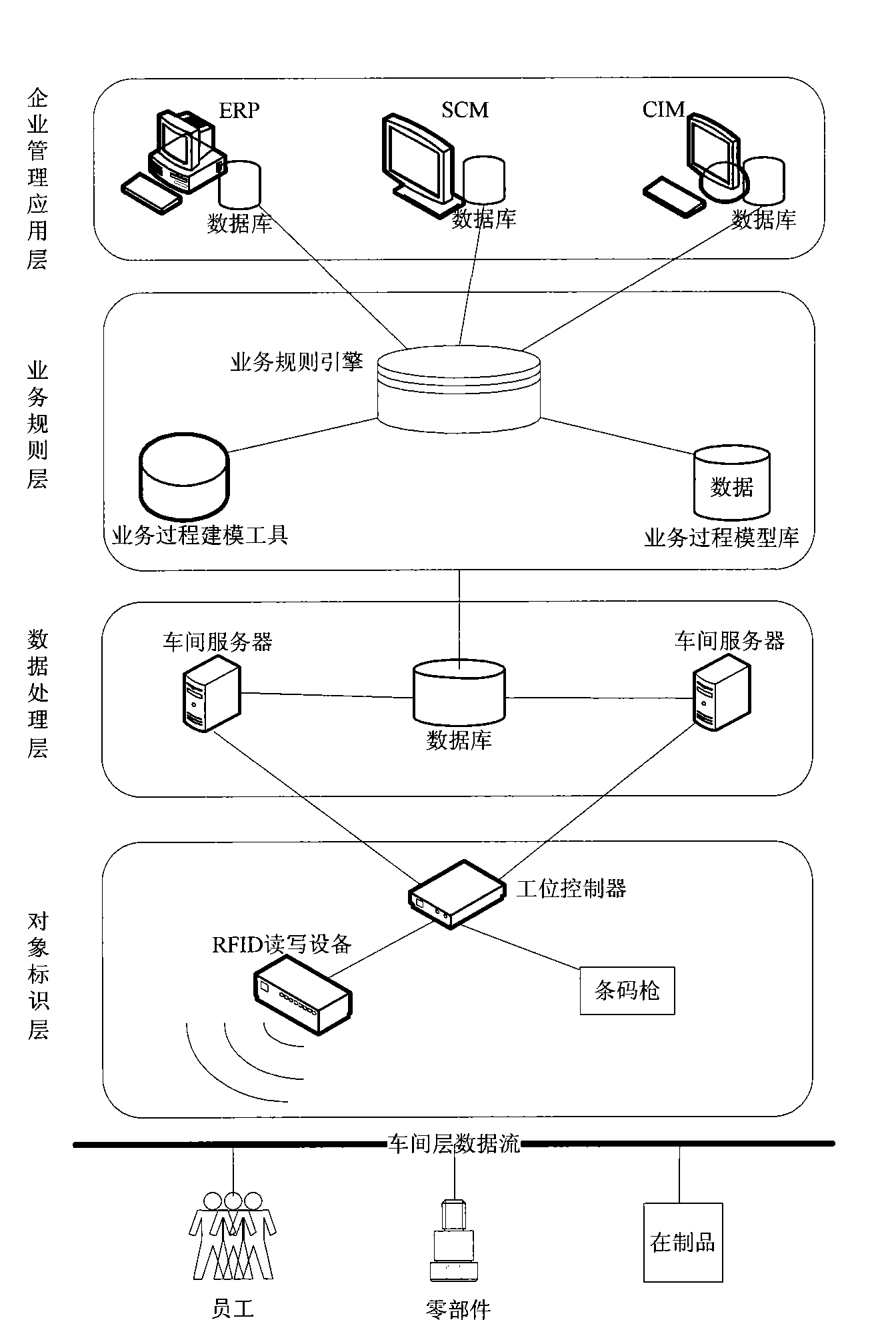

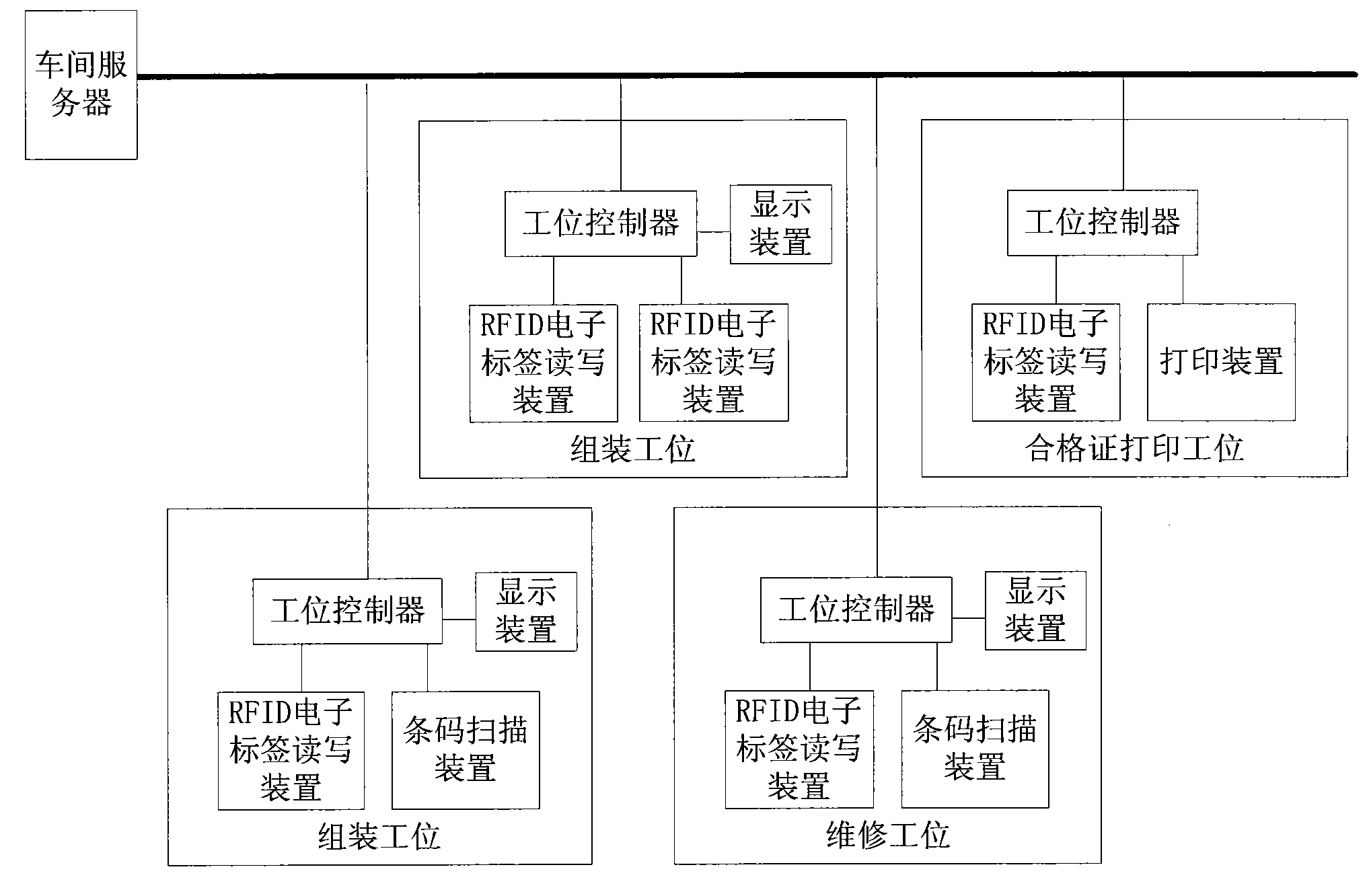

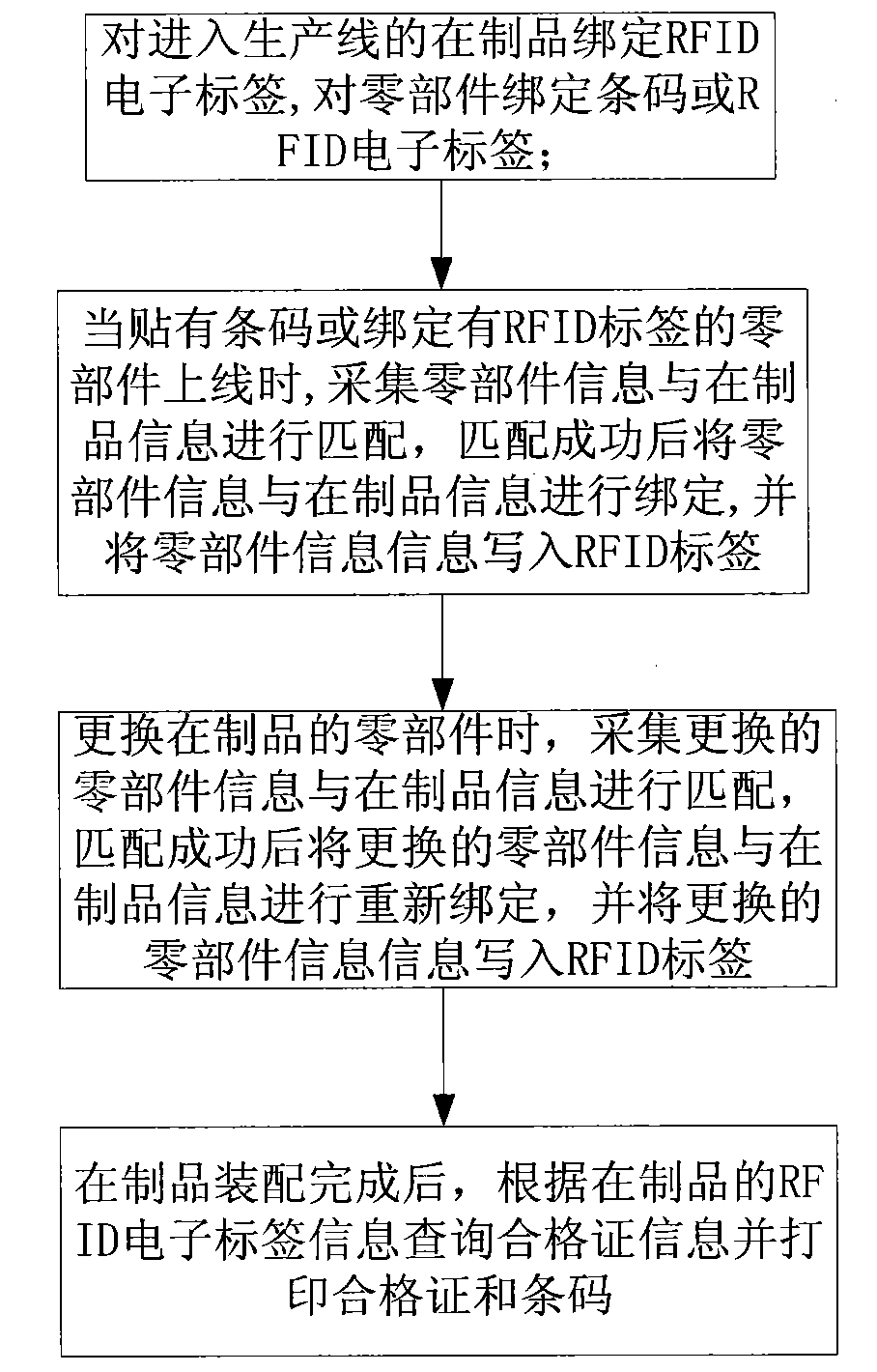

Refinement production system and production method based on RFID and bar code fusion

InactiveCN101655918AEffective cost controlLow costCo-operative working arrangementsRecord carriers used with machinesProduction lineMethods of production

The invention provides a refinement production system and a production method based on RFID and bar code fusion, wherein an RFID electronic tag is bound on the goods in process, the RFID electronic tag or a bar code can be selected randomly to be bound on the components and parts, thus being capable of effectively controlling production cost, being beneficial to carry out real time and effective collection on the information of goods in process and components and parts simultaneously, realizing accurate synchronization of material flow and information flow, and providing a possibility for therealization of refinement production for enterprises. The production method in the invention comprises the following steps: 1) binding the RFID electronic tags on the goods in process which enter a production line, and binding the bar codes or the RFID electronic tags on the components and parts; 2) when the components and parts which are pasted with bar codes or bound with the RFID electronic tags are on the production line, collecting the information of the components and parts to match with the information of the goods in process, and binding the information of components and parts with theinformation of the goods in process after matching successively; and 3) when the products are finally off the line, collecting the RFID electronic tag information which is bound on the goods in process and printing manufacturer certificates and bar codes.

Owner:CHONGQING UNIV

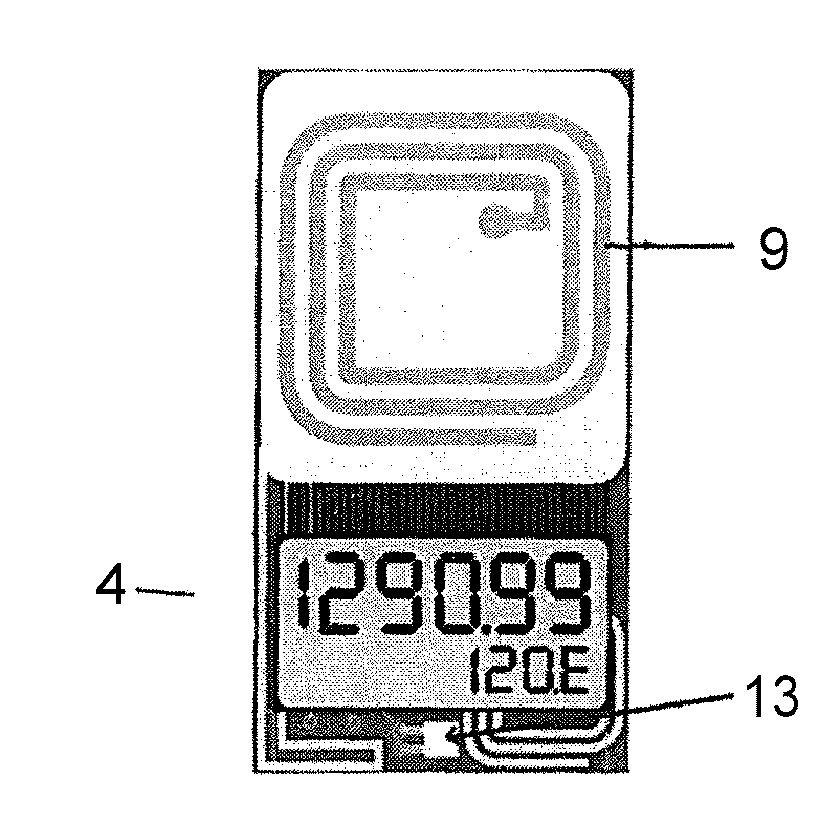

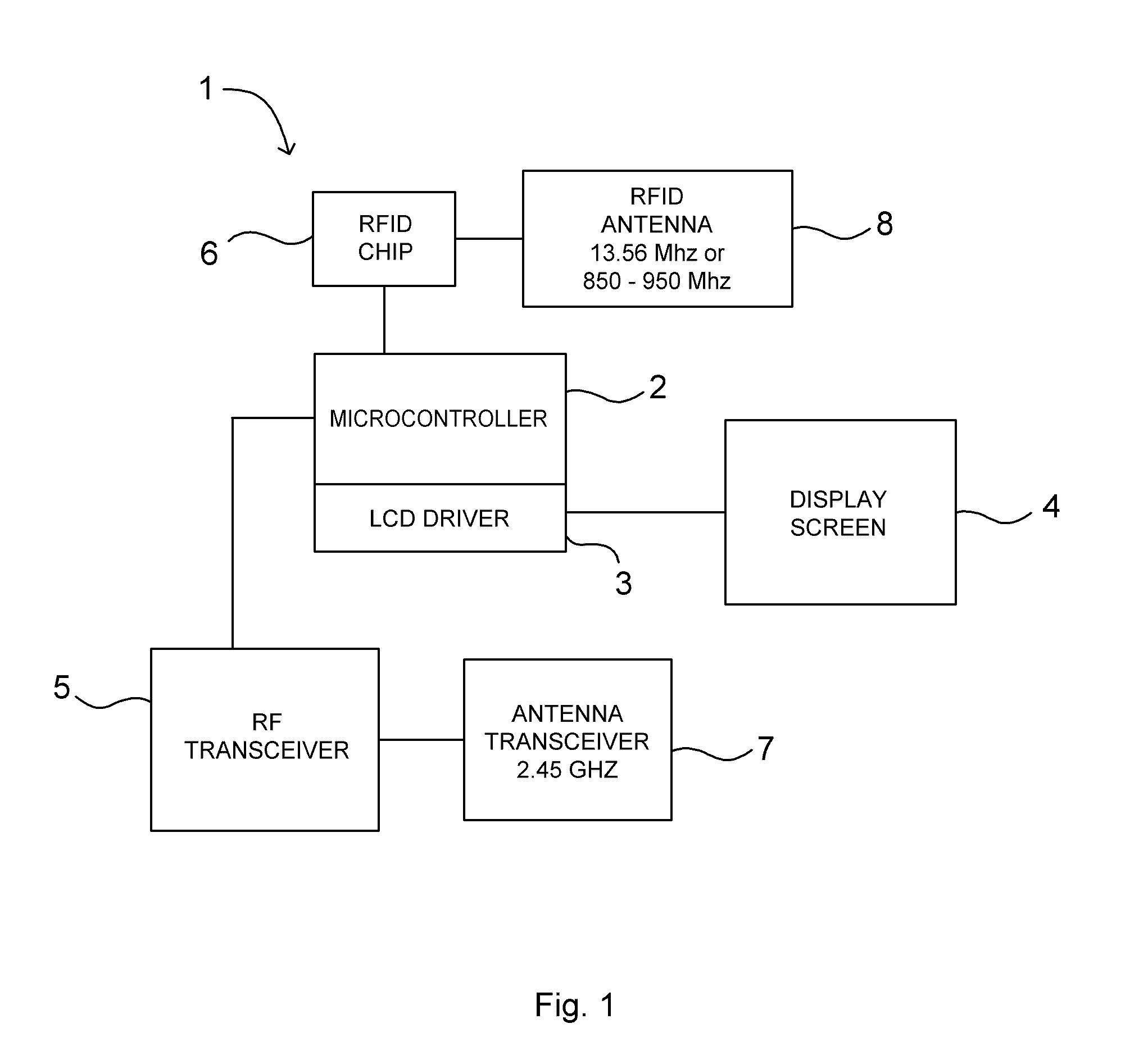

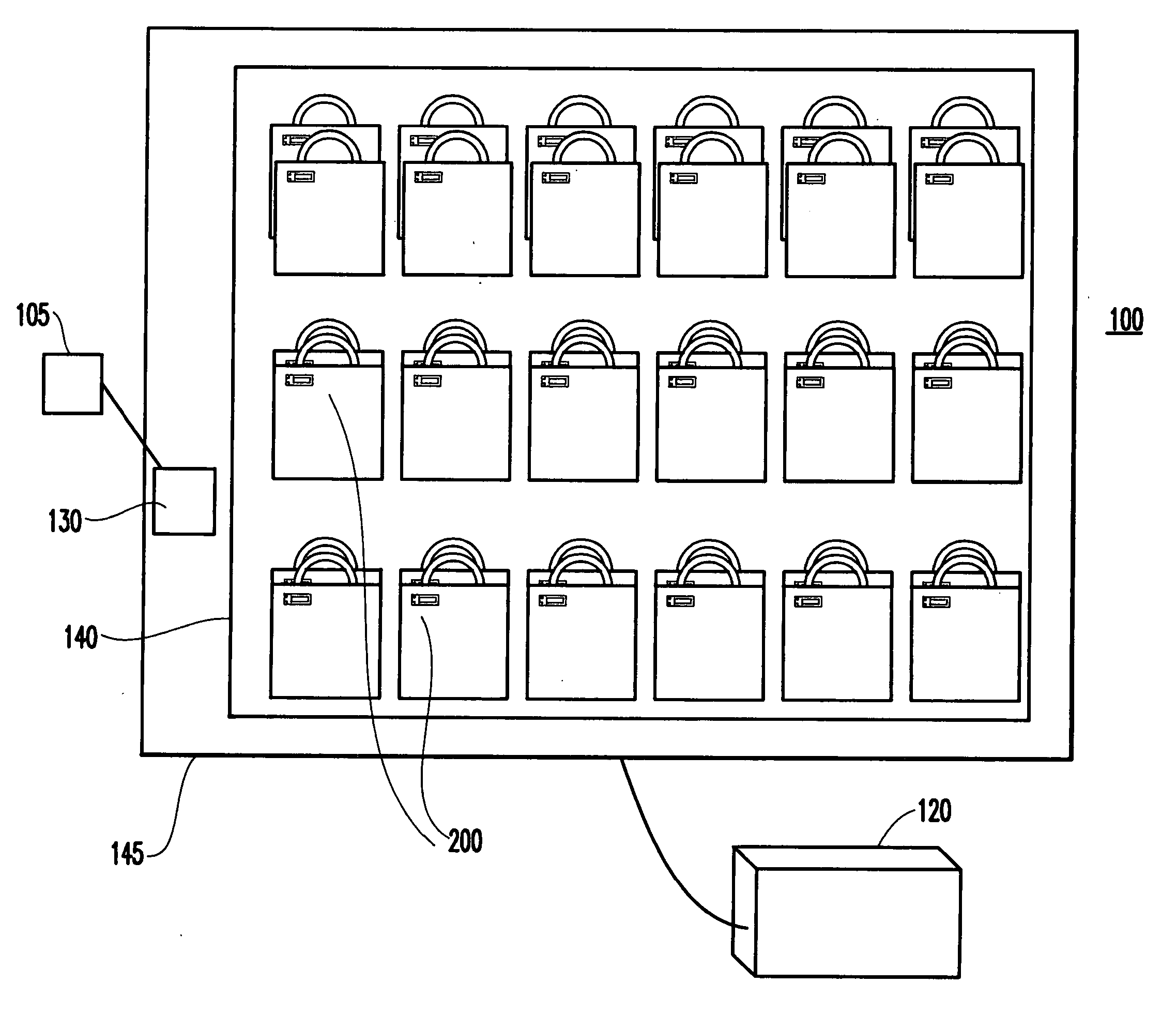

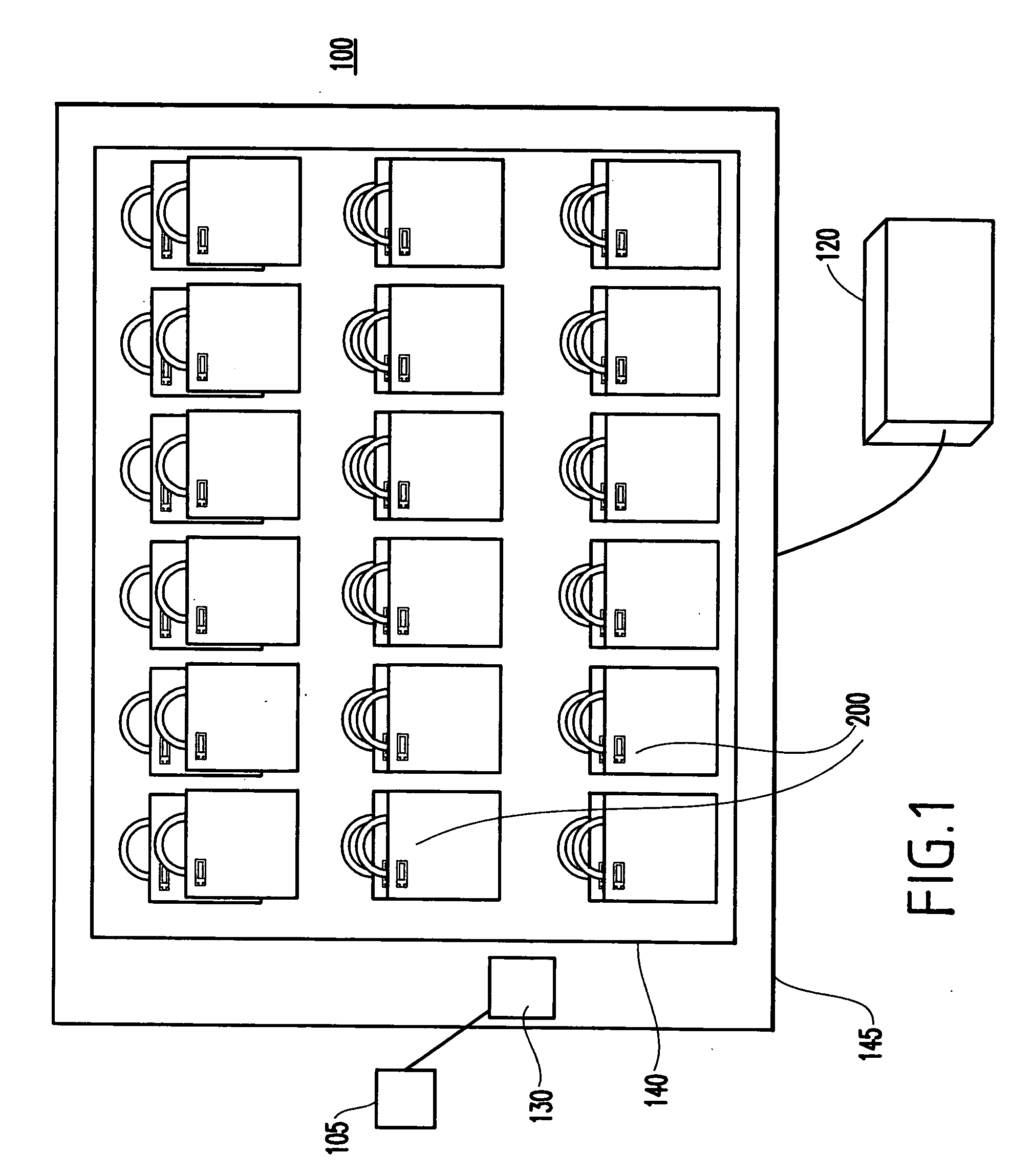

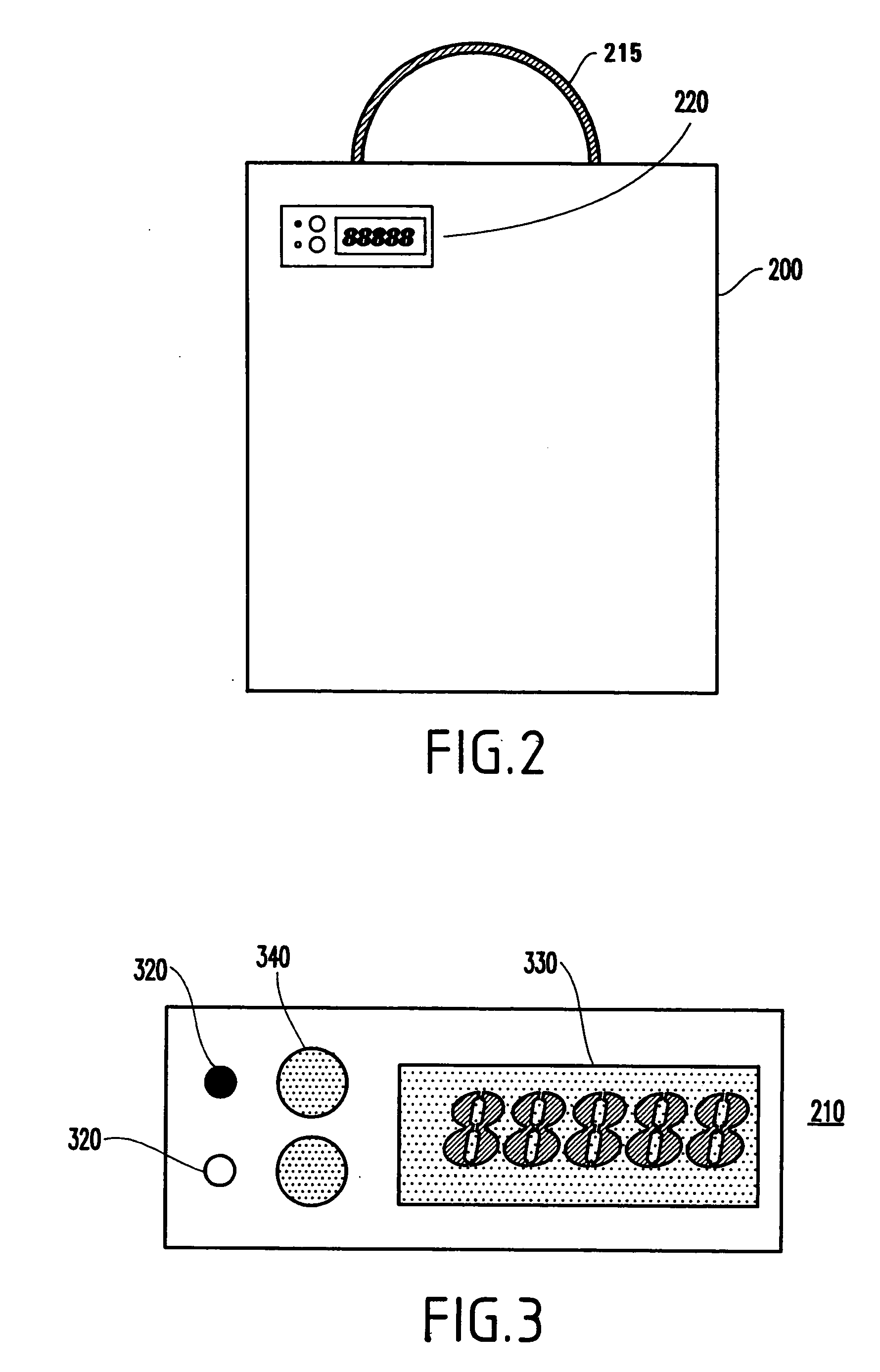

Multifunction contactless electronic tag for goods

A system for managing the inventory of articles in a sales outlet, warehouse or production center. The system includes a computer and radioelectric network including a plurality of tags, each attached to an article and comprising a transceiver, an RFID chip and three antennae. The network also includes a computerized machine, a cash desk connected to the computerized machine, transmitter-receivers connected to the computerized machine, an anti-theft terminal comprising an alternating magnetic field transmitter, and an RFID transmitter capable of transmitting a signal received by the RFID chips of the tags. Each tag is also remote-controllable and provides an anti-theft function for the article to which it is attached. The tag is also able to display the price of the article and other information relating to the article.

Owner:MPE TECH

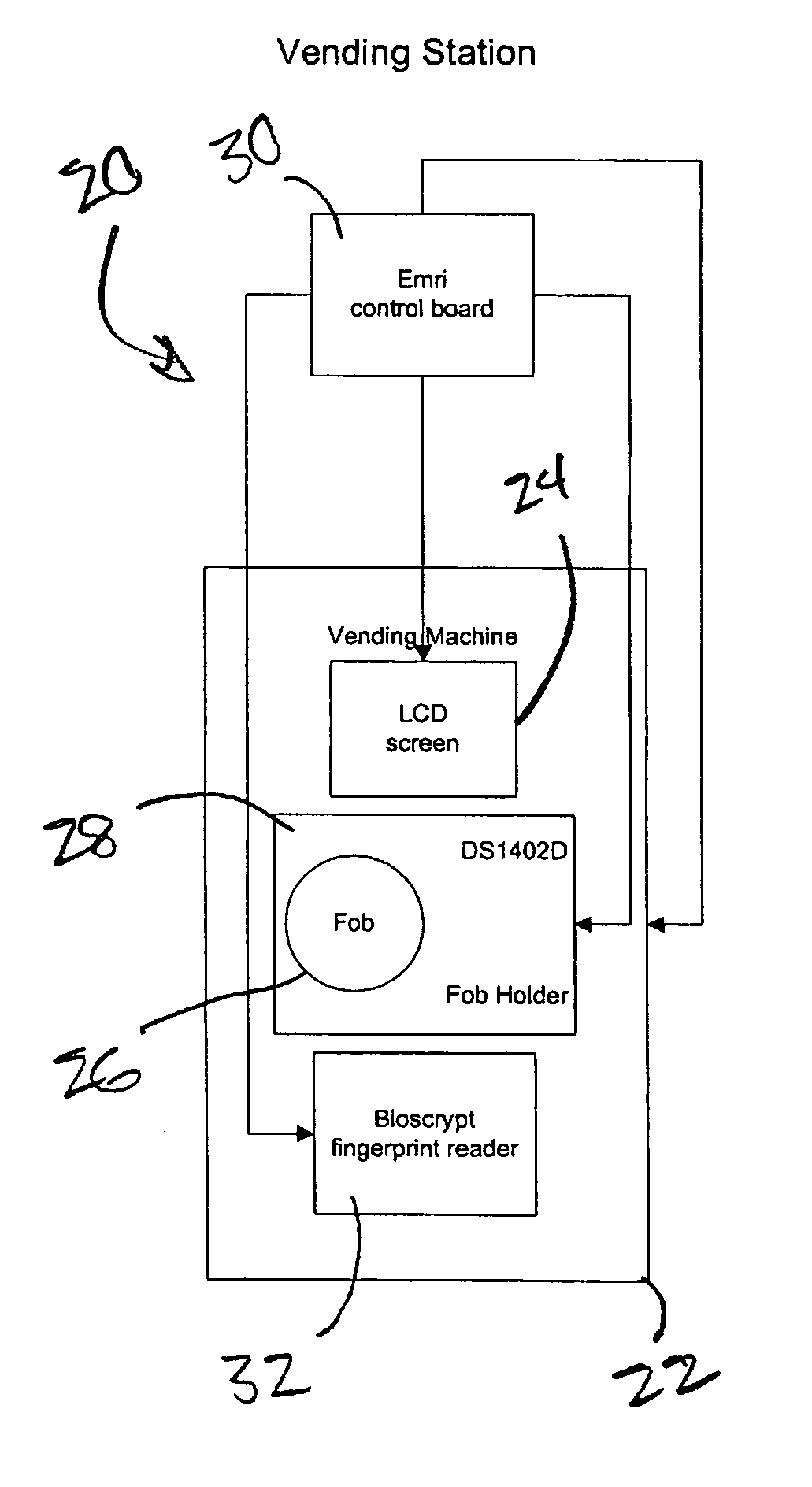

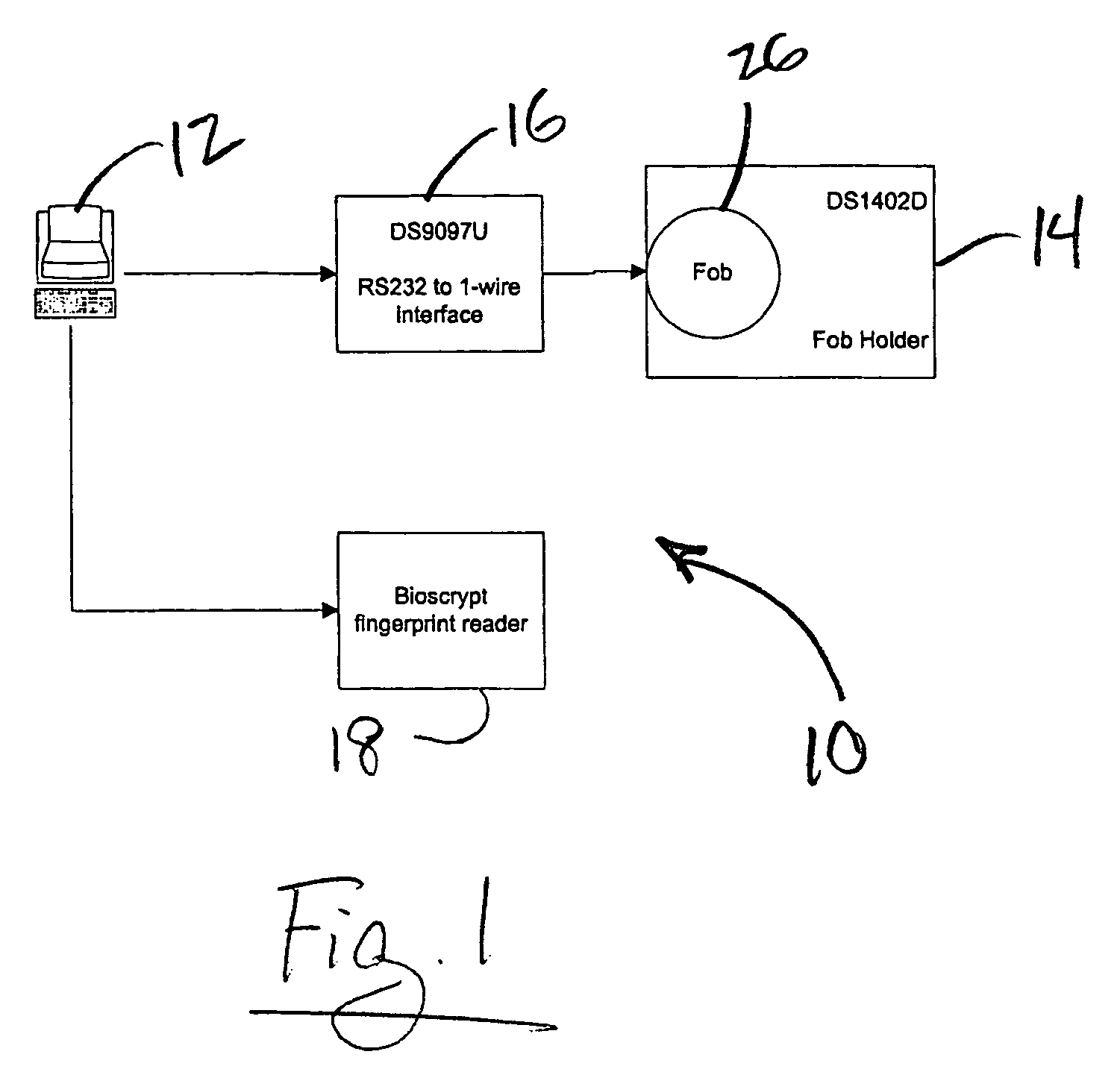

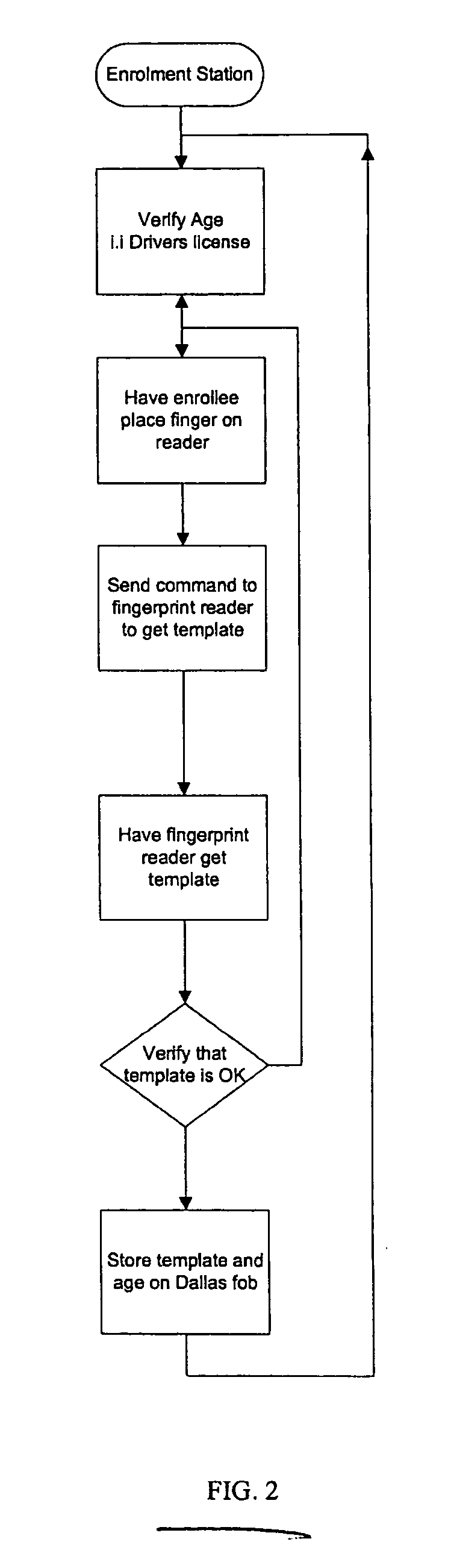

Authentication method and system for use in vending a restricted product or service

InactiveUS20060266823A1Efficient collectionEfficiently conveniently storeIndividual entry/exit registersData sortingCredit cardCentral database

An identity authentication method authenticates valid purchases of restricted products or services such as alcoholic beverages from unattended vending machines. The authentication method is designed to comply with all 50 States' requirements, as the equipment includes a field-programmable age requirement verification mechanism. The process consists of two primary steps: 1) Registration, a one-time procedure where a Patron's age is verified, fingerprint enrolled and information entered into an electronic tag, as well as a central database (if applicable); and 2) Purchase, which occurs each time a product is purchased, where the Patron presents the electronic tag to a tag reader (located on the front of the vending machine), authenticates his / her Identification by placing the appropriate finger onto a fingerprint scanner (also located on the front of the vending machine), then proceeds to purchase the product via cash, credit card, or whatever other method is applicable to that particular location.

Owner:PASSEN SELVIN +2

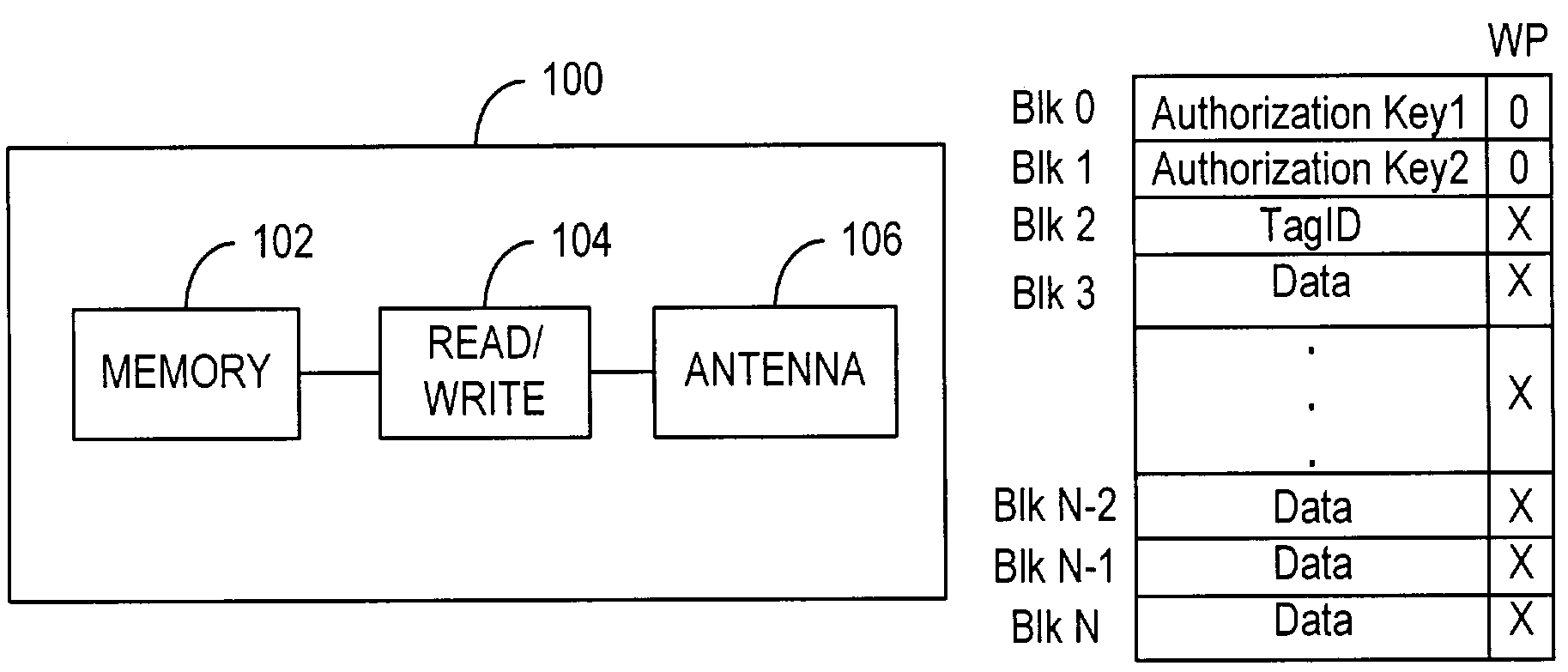

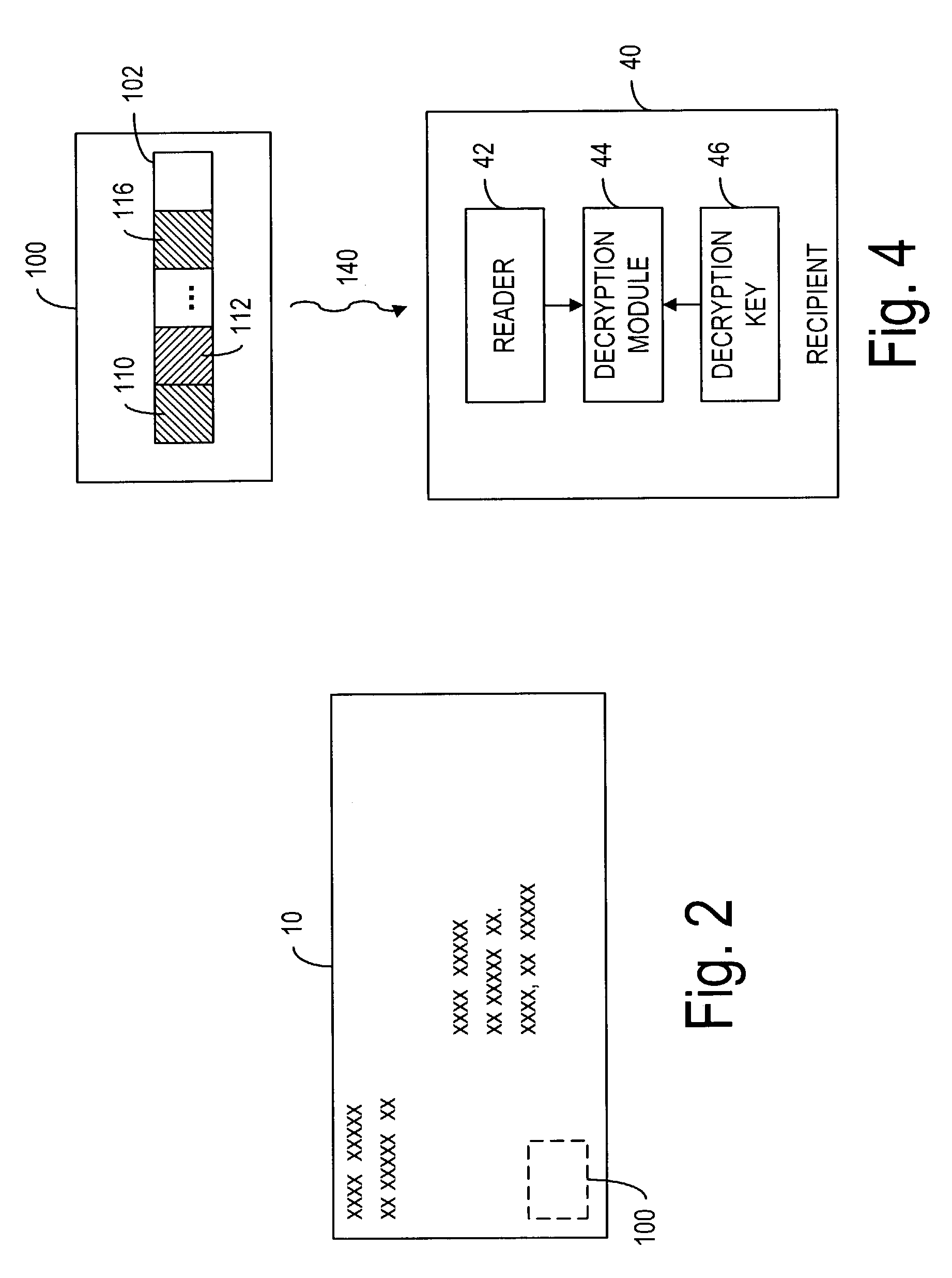

Reusable electronic tag for secure data accumulation

InactiveUS6980087B2Electric signal transmission systemsMultiple keys/algorithms usagePasswordElectronic tags

A reusable electronic tag having a plurality of memory locations to allow a user to write information onto the tag. After a memory location is written, it becomes write-protected, preventing the written content from being altered or deleted by an unauthorized user. By granting a user access right to certain memory locations, it is possible to restrict the user's ability to access the memory location depending on the granted access type and the level of restriction set for the memory location. A user with a valid password is allowed to read and write a memory location. Such a user may be allowed to clear the memory locations so that the tag can be reused.

Owner:PITNEY BOWES INC

Perishable product electronic label including time and temperature measurement

ActiveUS20060061454A1Facilitate inter communication of dataFacilitates wireless radio frequency communicationStampsElectric signal transmission systemsCommunication interfaceInterface circuits

An electronic assembly may be contained in a label that performs time-temperature integration (TTI) and indicates that time and / or temperature levels have been reached that may compromise the quality, shelf life, or safety of the item to which the label is affixed. The label may be used on a wide variety of objects that require careful handling in terms of temperature and / or time elapsed before use. The labeling system includes circuitry that measures and calculates, and indictor(s) that signal that the time has come for discounted sale, and, later, that the time has come for disposal rather than sale. Optionally, the circuitry may act as an “over-temperature alarm” system, to measure, calculate, and indicate when a one-time temperature violation has occurred that is of such a magnitude that the item is immediately considered compromised or spoiled. The label may take the form of a flexible, disposable label that is typically powered by a small battery. Methods may include providing a temperature-variable oscillator or time-base, counting cycles of said oscillator within a logic circuit to determine when one or more preset total cycle counts is / are reached, and signaling when said total cycle count(s) is / are reached. Extra sensing, time-keeping, memory storage, and / or communication interface circuits may be incorporated to augment the electronic assembly's and method's capabilities.

Owner:COPELAND COLD CHAIN LP

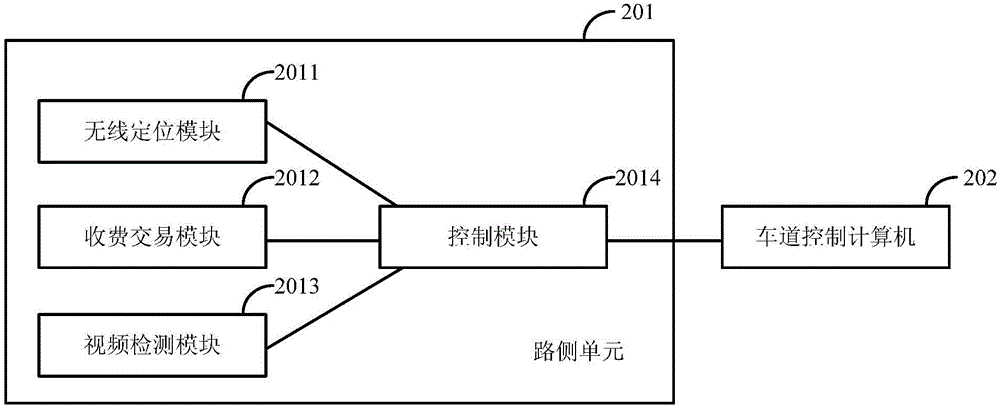

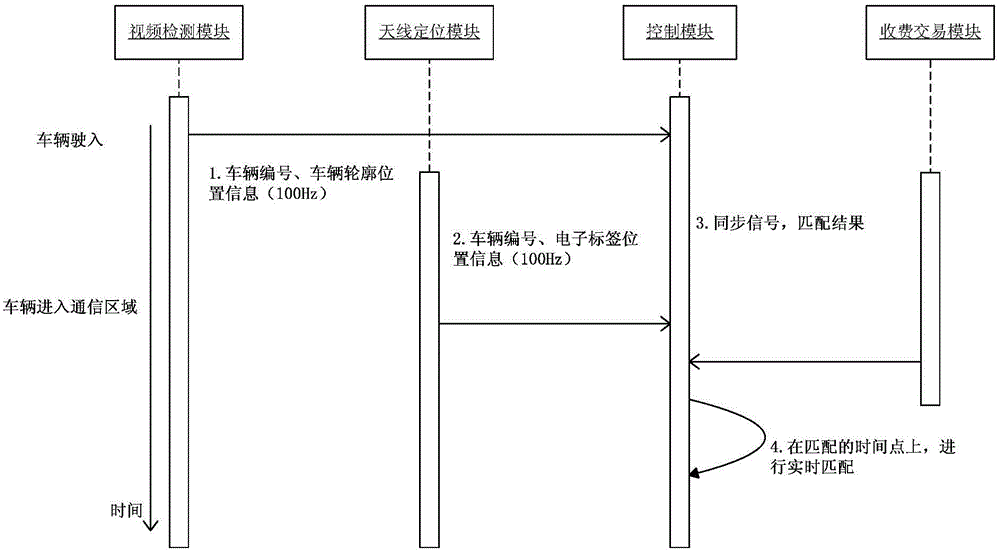

Electronic toll collection system and method

InactiveCN104574540AAccurate identificationImprove reliabilityTicket-issuing apparatusElectronic toll collection systemCar following

The invention discloses an electronic toll collection system and method. The system consists of a lane control computer and a road side unit, wherein the lane control computer is used for receiving information of the road side unit and performing corresponding treatment on the information; the road side unit comprises a wireless location module used for locating a vehicle-mounted e-tag, a toll transaction module used for communicating with the vehicle-mounted e-tag, acquiring billing and vehicle information of the vehicle-mounted e-tag and completing toll transaction, a video detection module used for detecting vehicle positions, capturing vehicle images and recognizing vehicle registration plates, and a control module used for realizing real-time position matching between position information, acquired by the wireless location module, of the vehicle-mounted e-tag and the vehicle position information detected by the video detection module and achieving corresponding process control. According to the invention, the toll transaction success rate can be effectively improved, car-following interference is reduced and toll dodging is prevented.

Owner:北京速通科技有限公司

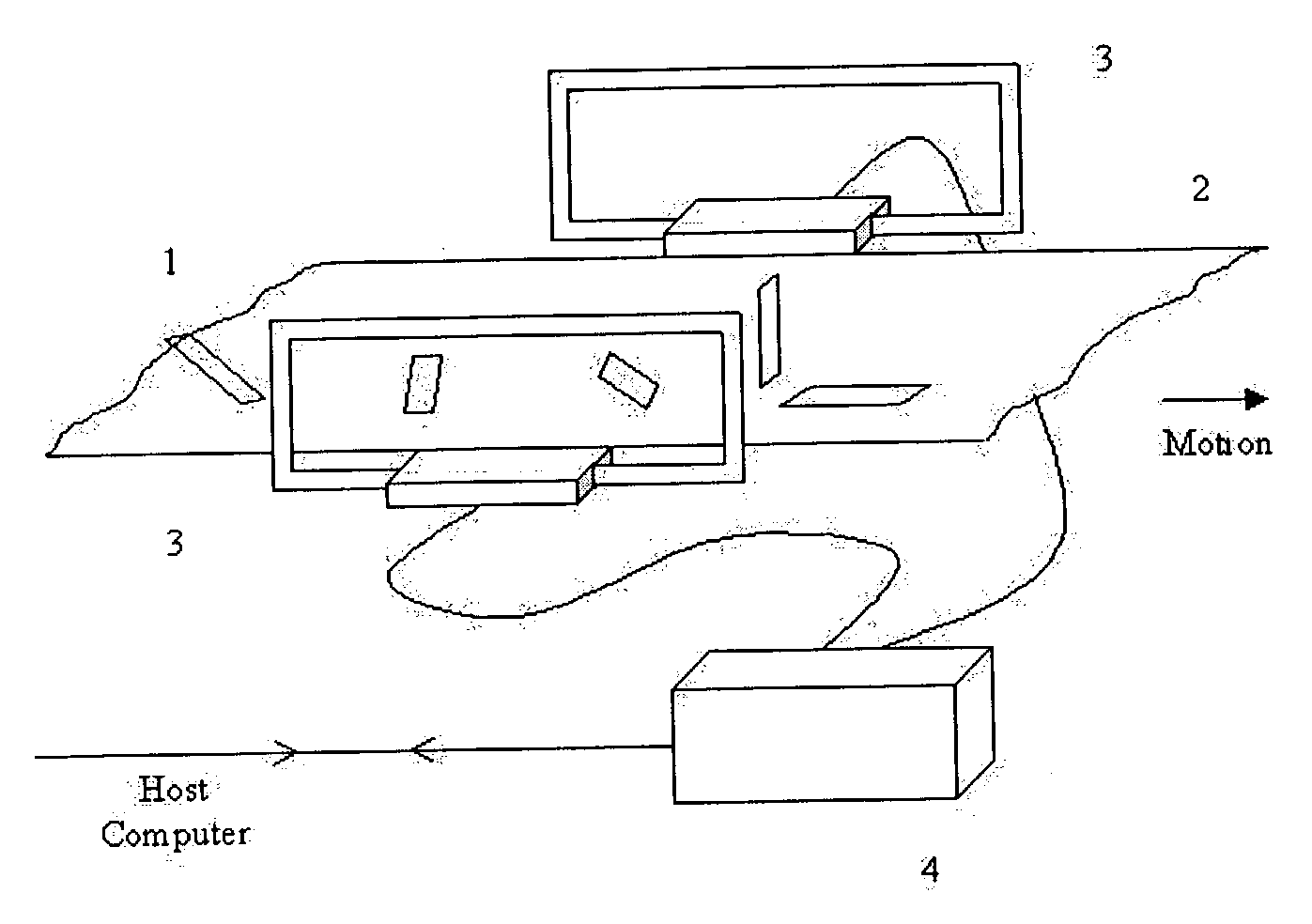

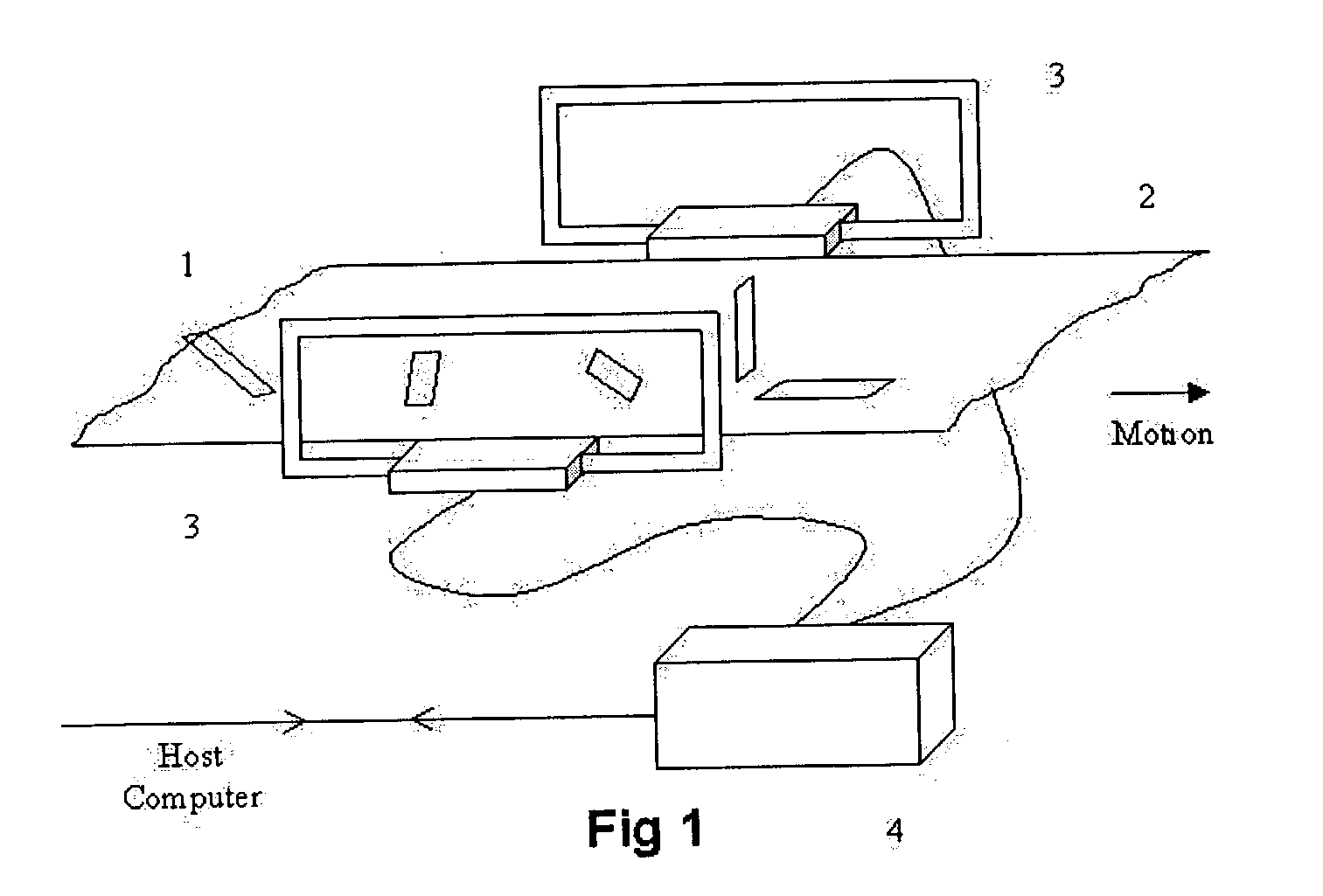

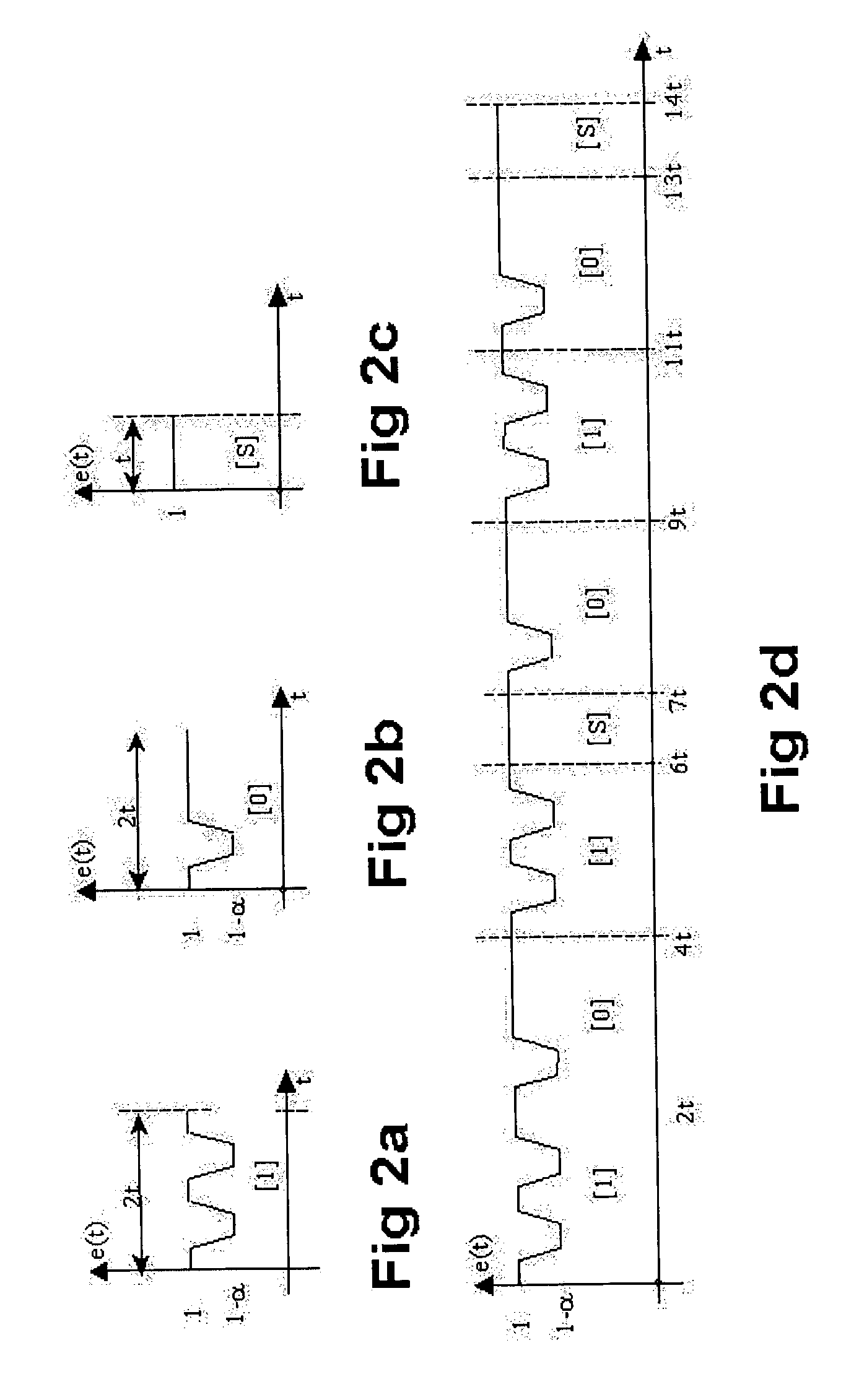

Electronic label reading system

InactiveUS6992567B2Improve efficiencyHighly flexibleResonant long antennasMemory record carrier reading problemsElectromagnetic fieldElectronic tags

An electronic label reading system includes an interrogator including a transmitter and a receiver. The system also has a transmitter antenna connected to the transmitter for generating an interrogation electromagnetic field through which objects possessing code responding labels may pass. The code responding labels include label receiving antennas for receiving from the interrogation field a label interrogation signal, and generate label reply signals, and, from the label reply signals, reply electromagnetic fields. The system also has a receiver antenna connected to the receiver for receiving the reply signals from the label reply fields. The interrogation field and label reply fields provide a communication channel from the labels to the interrogator, and the interrogator signals to the labels condition information indicative of the condition of the communication channel.

Owner:TAGSYS

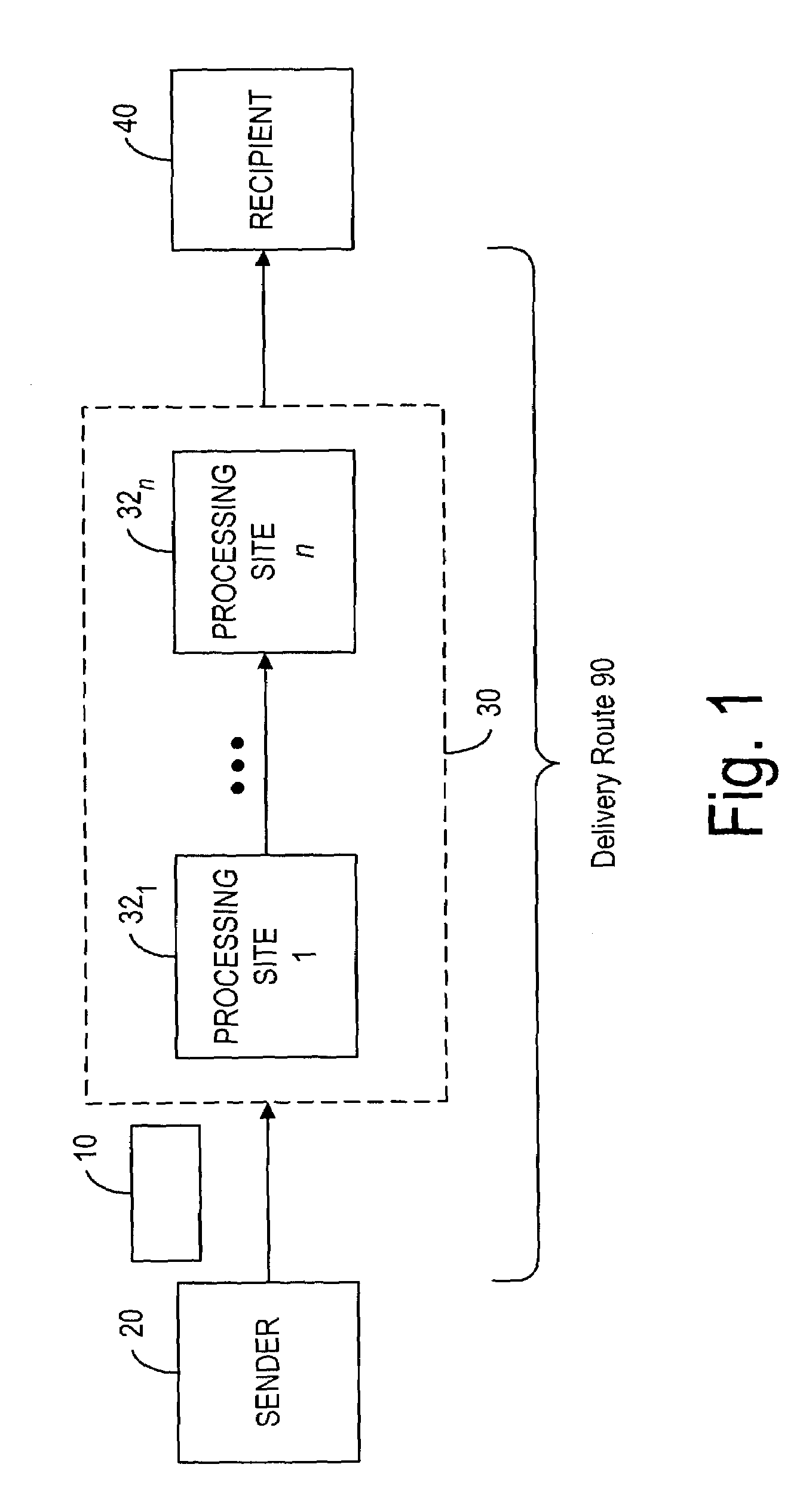

System and method for minimizing package delivery time

InactiveUS20050083213A1Timely deliveryReduce decreaseInstruments for road network navigationRoad vehicles traffic controlTransceiverOptimum route

An inventive system for delivering packages includes a computer system for determining an optimum route for delivering the package, an electronic tag associated with the package including a first transceiver, and a signaling device. The inventive system also includes a base station having a second transceiver for wirelessly communicating with the first transceiver.

Owner:VISIBLE ASSET INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com