Patents

Literature

5910 results about "Methods of production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production methods fall into three main categories: job (one-off production), batch (multiple items, one step at a time for all items), and flow (multiple items, all steps in process at once for separate items).

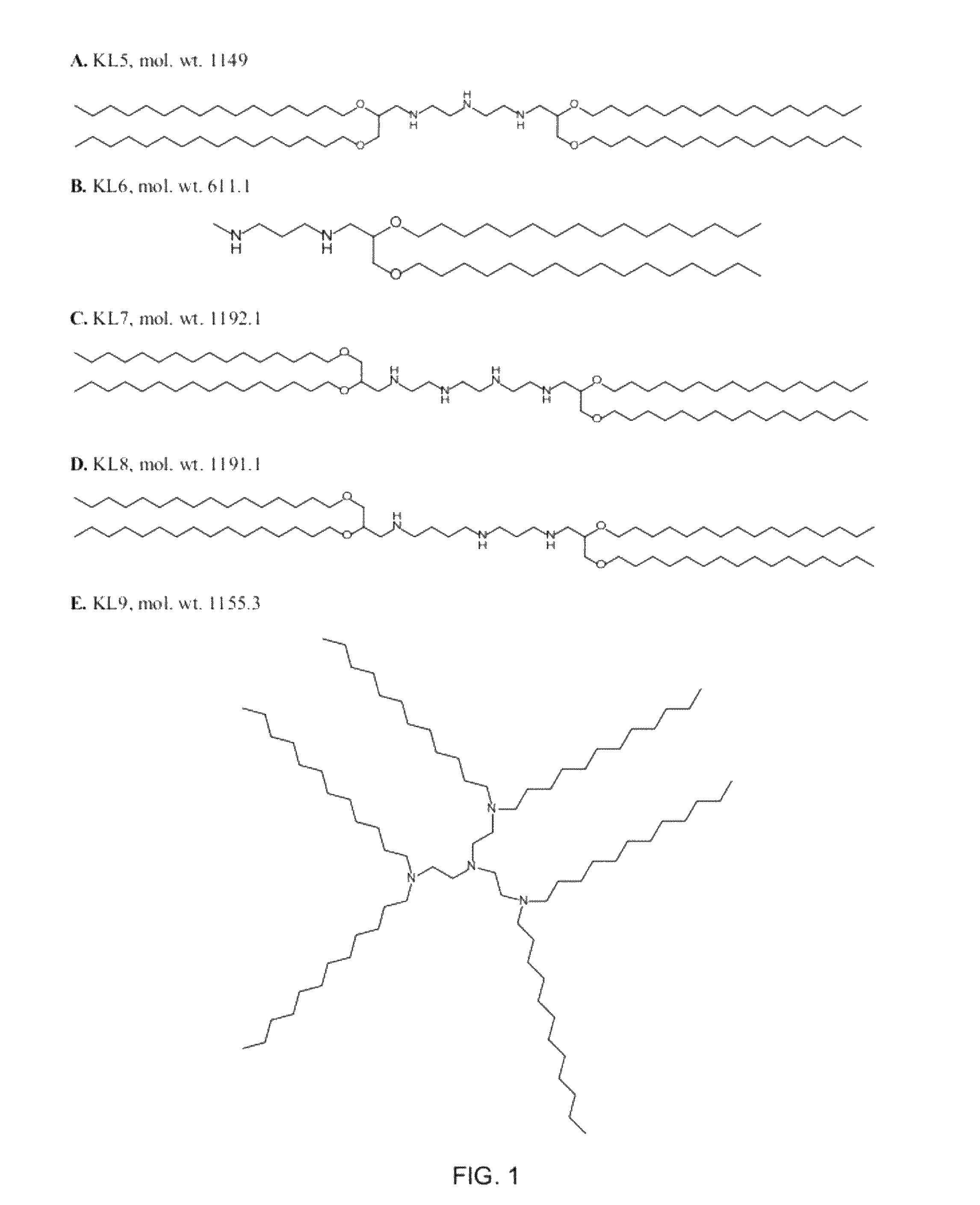

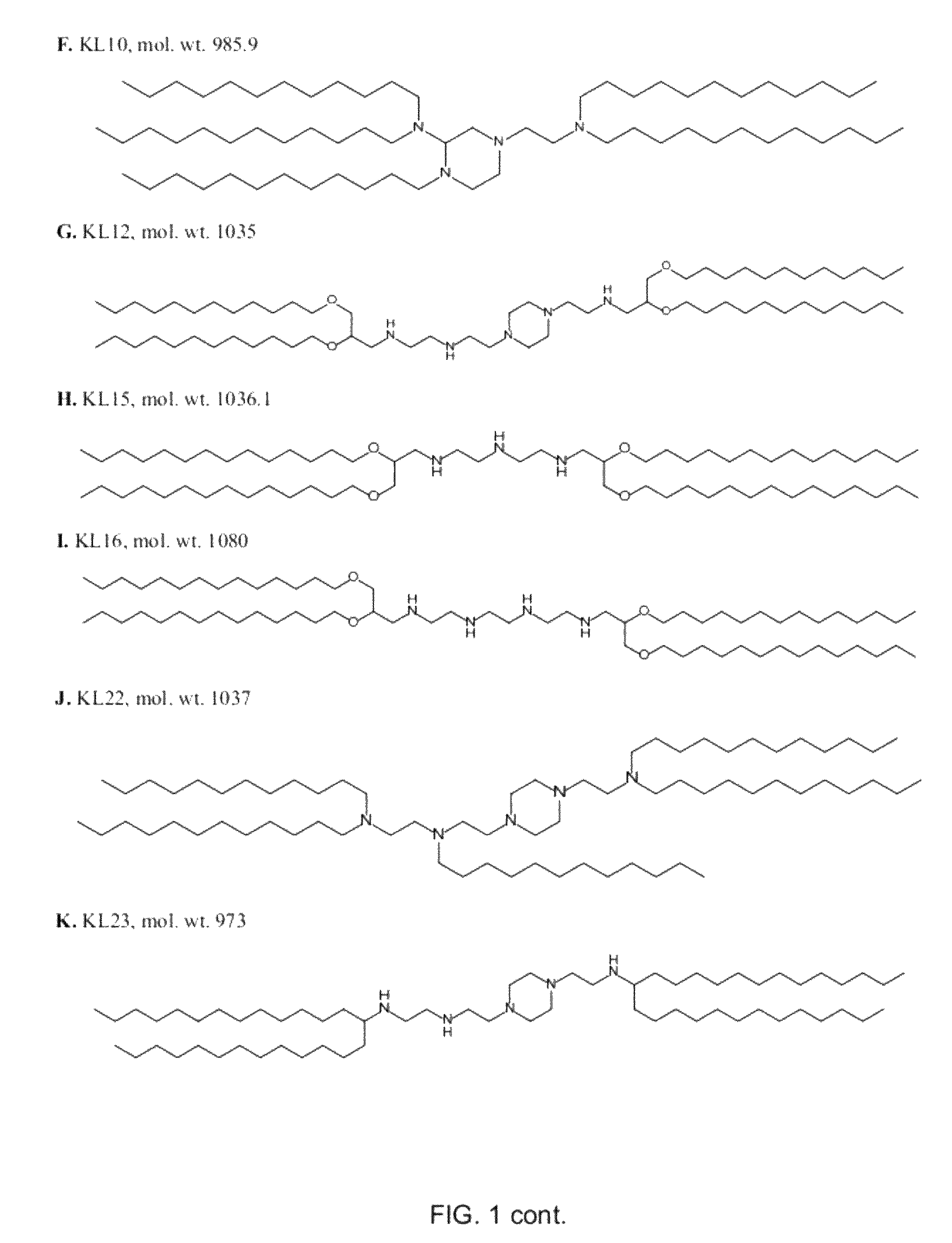

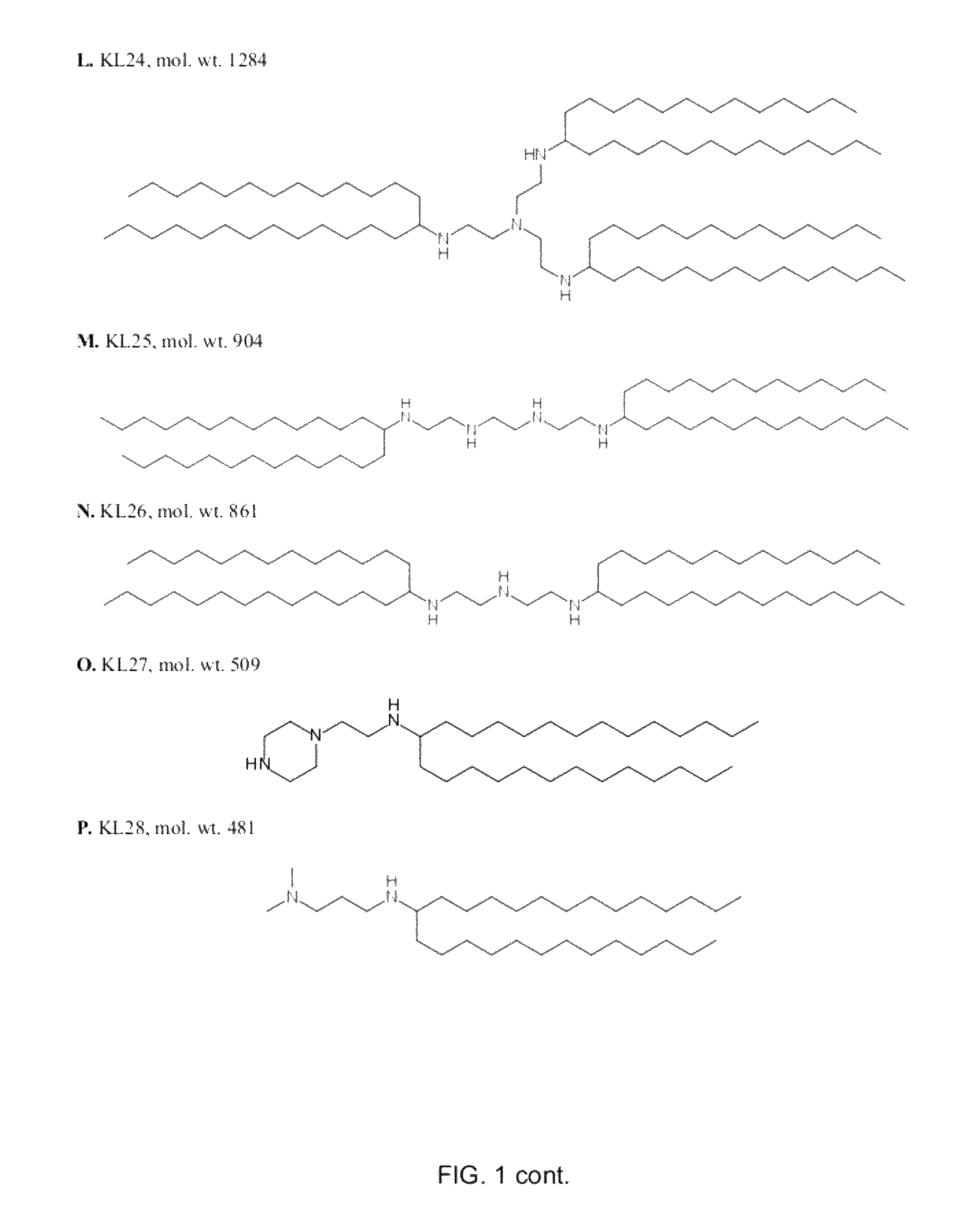

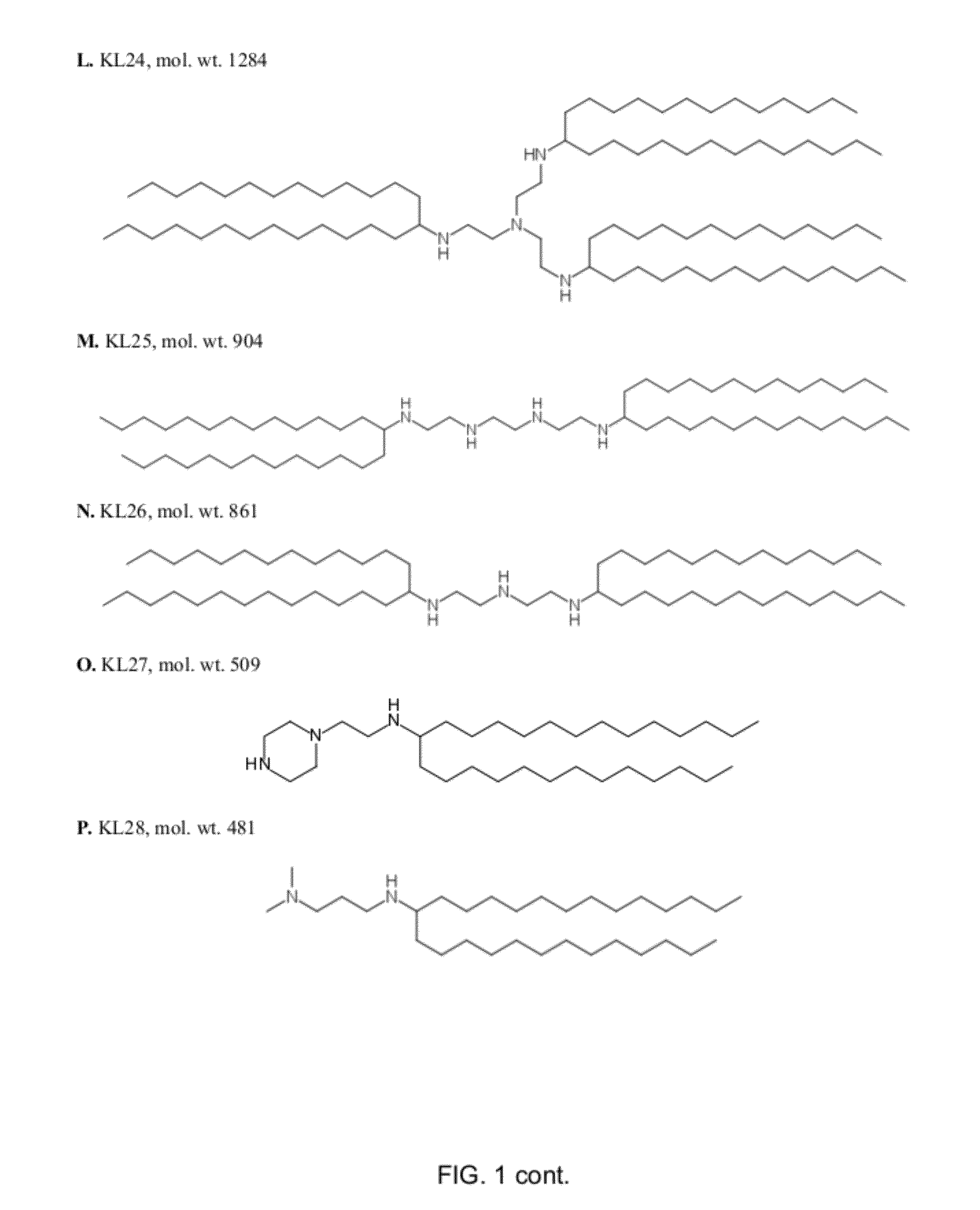

Lipids and compositions for intracellular delivery of biologically active compounds

ActiveUS8691750B2High yieldHigh purityPowder deliveryMaterial nanotechnologyLipid formationIntracellular drug delivery

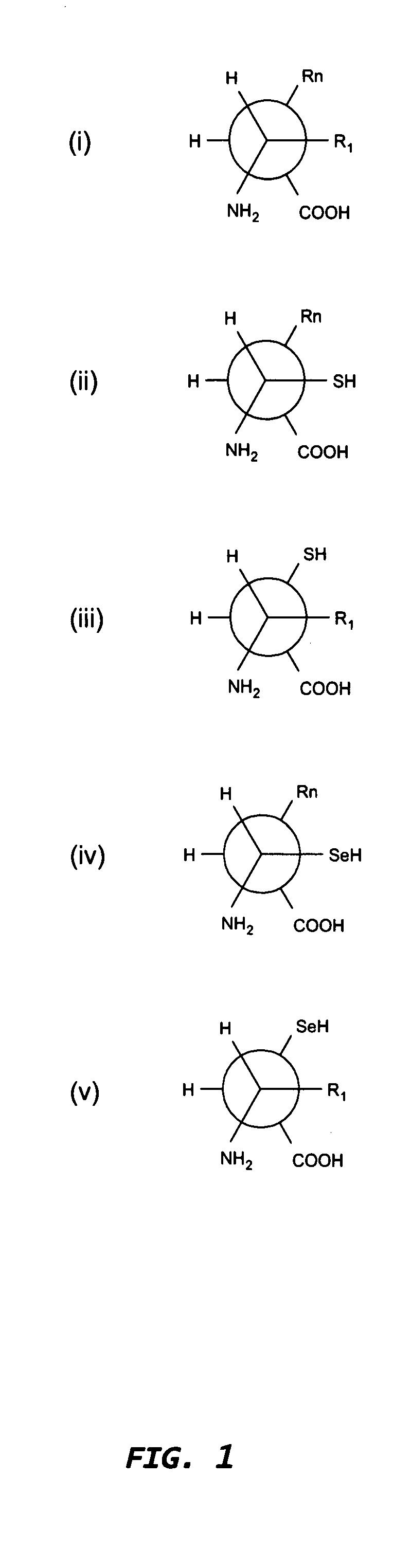

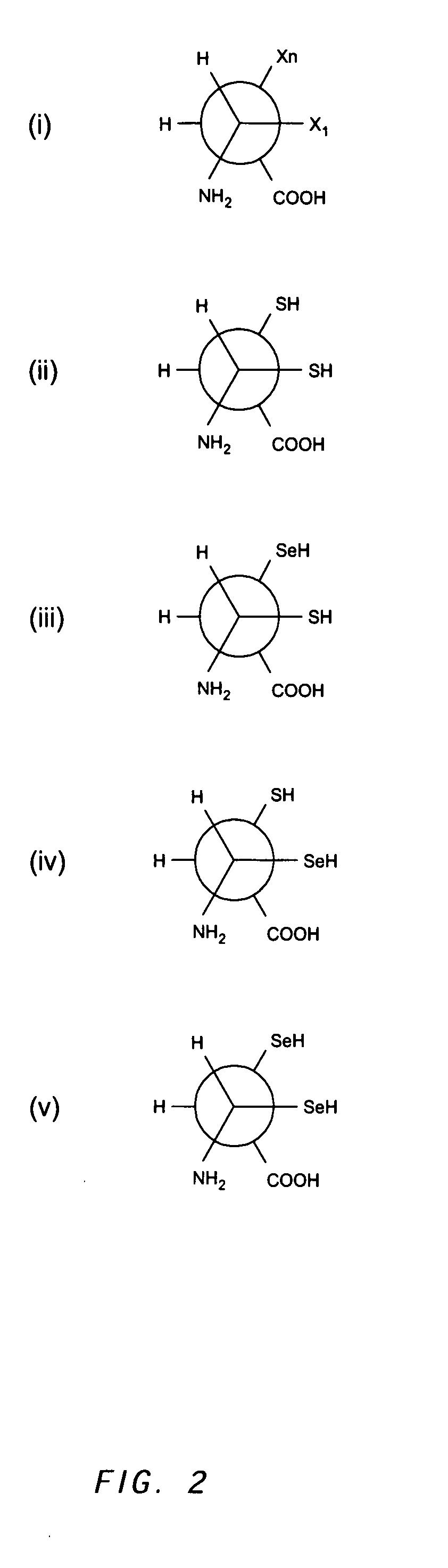

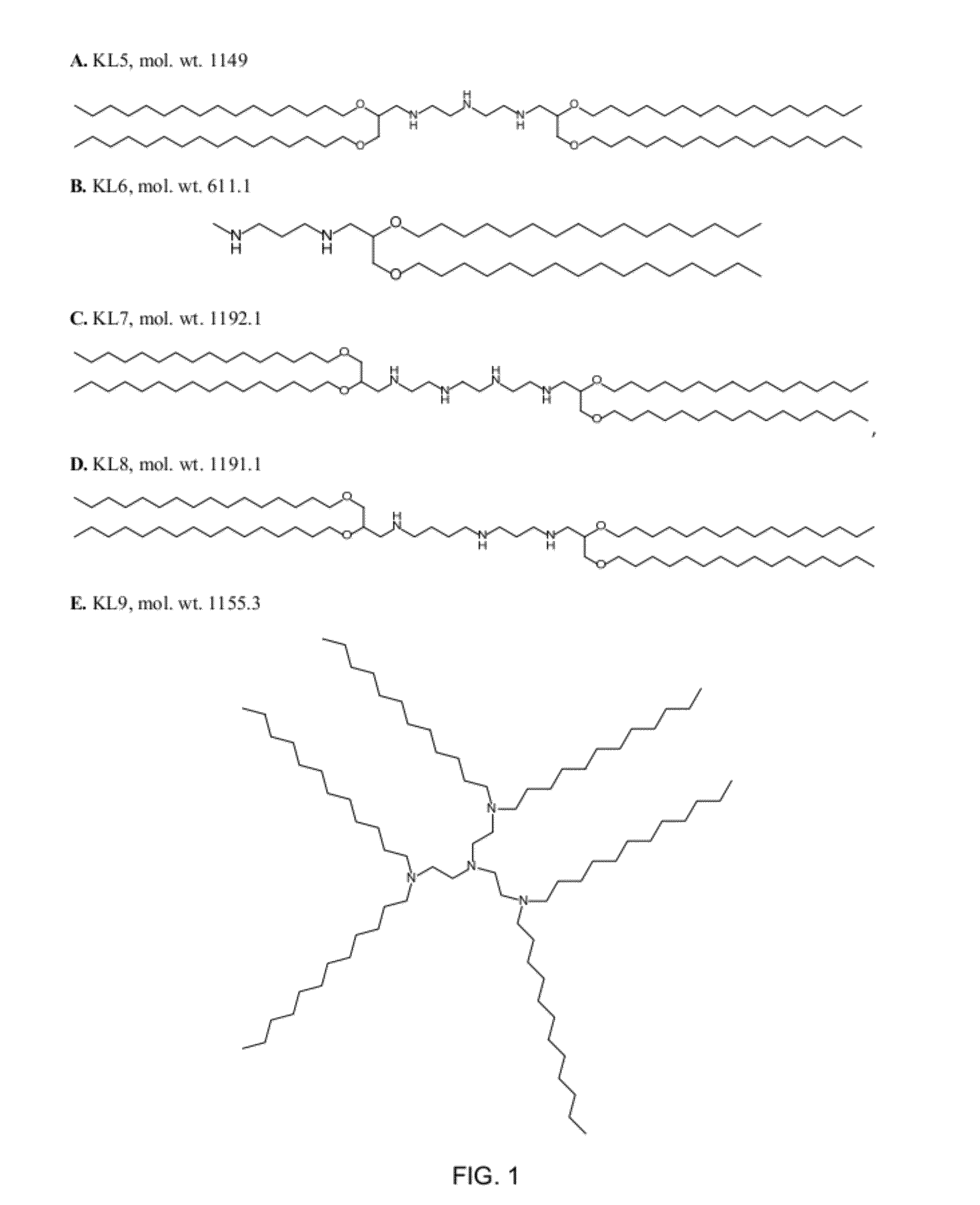

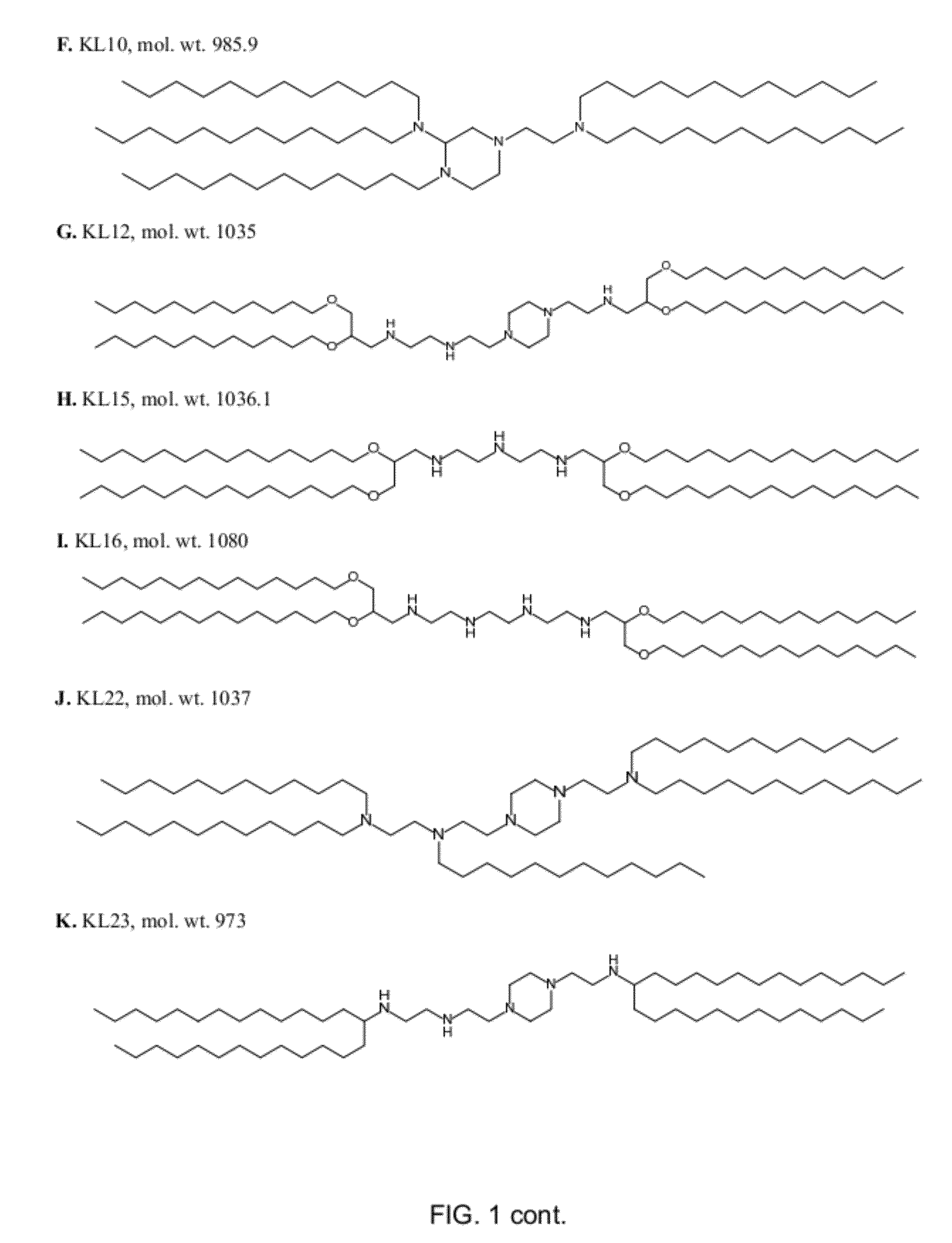

The present invention provides novel amino-lipids, compositions comprising such amino-lipids and methods of producing them. In addition, lipid nanoparticles comprising the novel amino-lipids and a biologically active compound are provided, as well as methods of production and their use for intracellular drug delivery.

Owner:AXOLABS

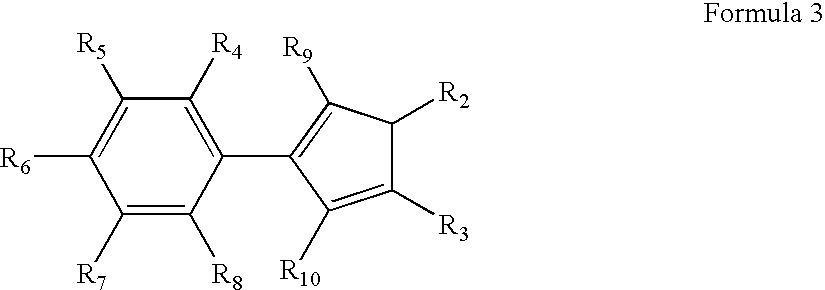

High melting thermoplastic elastomeric alpha-olefin polymers (PRE/EPE effect) and catalysts therefor

InactiveUS6559262B1Activity of fluxional unbridged metallocene polymerization catalystsHigh molecular weightGroup 4/14 element organic compoundsMetallocenesElastomerEthylene Homopolymers

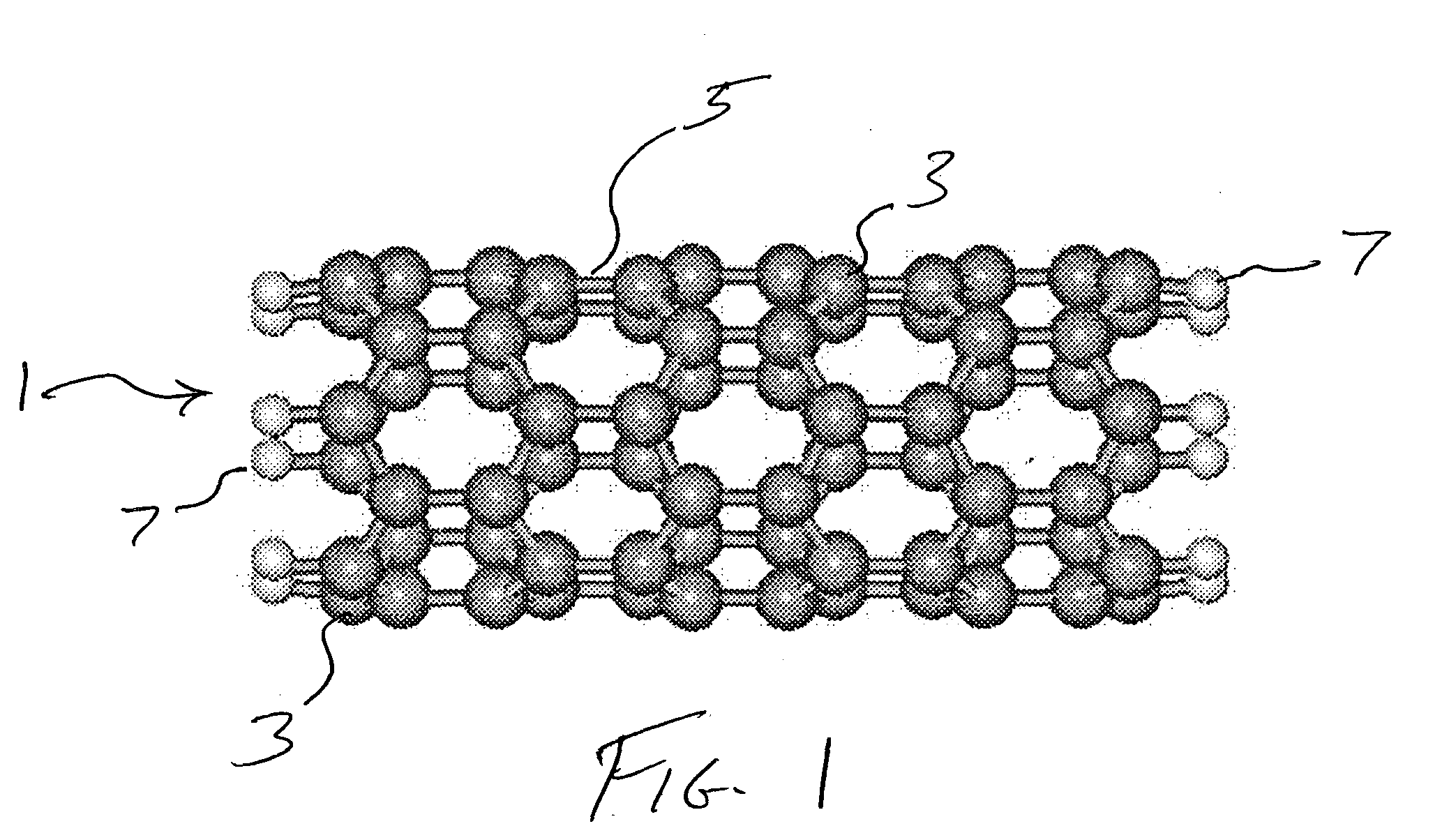

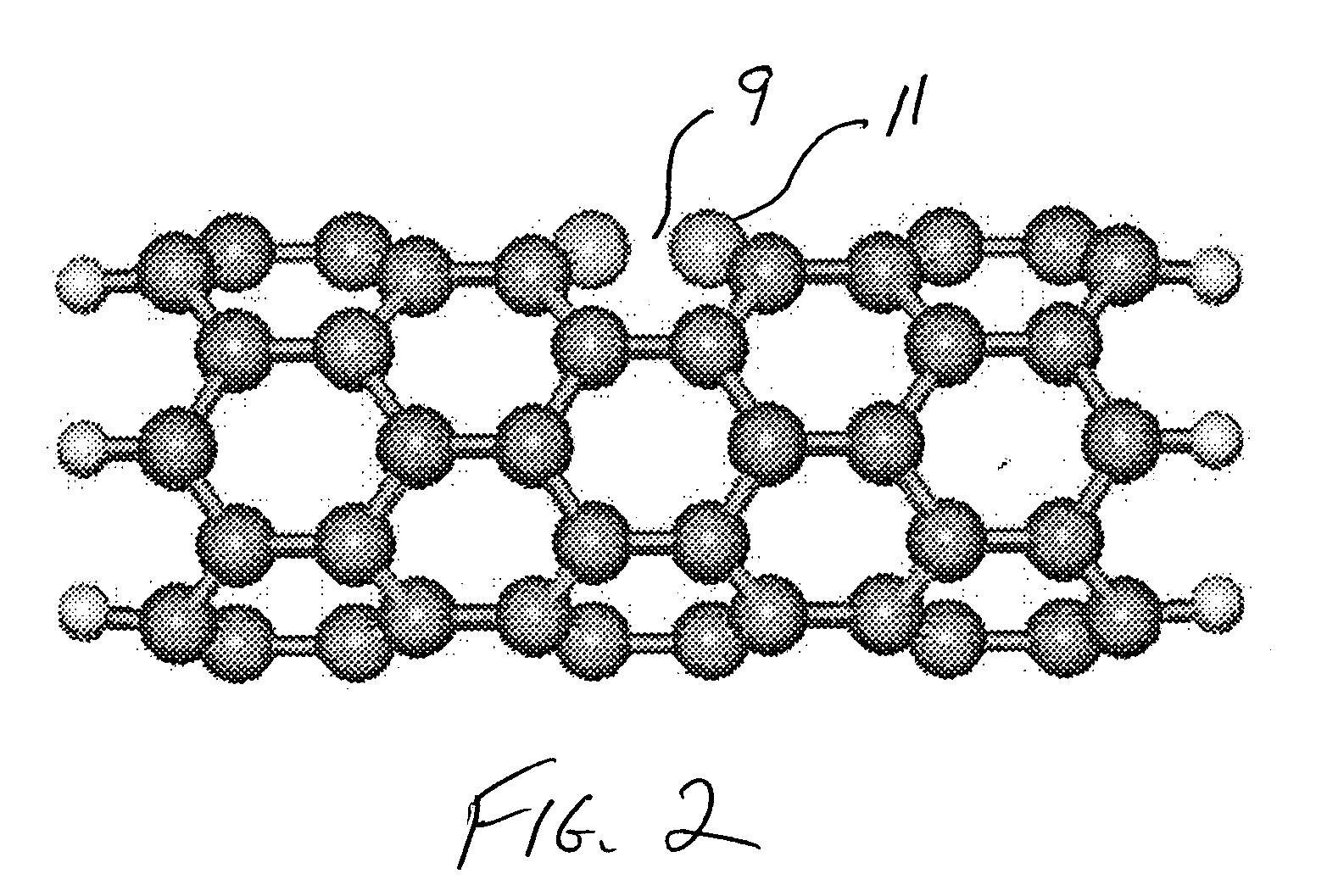

This invention relates generally to low ethylene insertions into I-olefin polymers and processes for production of such polymers using unbridged fluxional metallocenes, primarily substituted aryl indenyl metallocenes, and more particularly to use of unbridged, fluxional, cyclopentadienyl or indenyl metallocene catalyst systems in methods of production of high melting point I-olefin homo- and co-polymers, particularly elastomeric crystalline and amorphous block homo- and co-polymers of I-olefins. The activity of fluxional unbridged metallocene polymerization catalysts containing at least one 2-arylindene ligand is increased 10x or more by the addition of small (typically 0.1-10 wt. %) amounts of ethylene to the polymerization system, which increase is termed the Polymerization Rate-Enhancement effect (PRE), which is measured in terms of an Ethylene Enhancement Factor (EEF) as a dimensionless ratio in the range of from about 1.1 to about 10 or above. The amount of ethylene included in the reaction system can be selected and controlled to be so small as to result in essentially minimal (<2 mole %) incorporation of ethylene units into the resulting elastomeric polymer and the molecular weight may be increased. Amounts of ethylene to generate the PRE effect may be greater than 0.1 wt. % and preferably range up to about 2 wt. %. However, if a polymer with more ethylene is desired, additional ethylene may be incorporated into the polymerization feed, including up to 10 to about 50 mole % based on olefin units. A second important aspect of this invention is the ability to use a PRE activity-enhancing amount of ethylene in an olefin polymerization without substantially affecting the physical properties of the elastomer. In a third important aspect of this invention, I-olefin elastomers are produced through incorporation of ethylene using unbridged fluxional catalyst systems which may not otherwise produce acceptable elastomeric homopolymers. This effect is termed the EPE effect, for Elastomeric Property-Enhancing effect. The EPE amount of ethylene required to produce such elastomers typically overlaps the PRE activity-enhancing amount. Incorporation of up to about 5 mole % or more of ethylene typically will produce an elastomeric polymer using such catalyst systems. Typical useful amounts of incorporated ethylene include about 1 to 3 mole %. Preferred polymers of this invention retain sufficient crystallinity to provide a high melting point (by DSC) of about 80° C., preferably above 100° C., including in the range of from about 120° C. to about 140° C. and above. Novel flexible alpha-olefin homo and copolymers having elongation in excess of 600% and substantially no retained force are disclosed.

Owner:BP CORP NORTH AMERICA INC

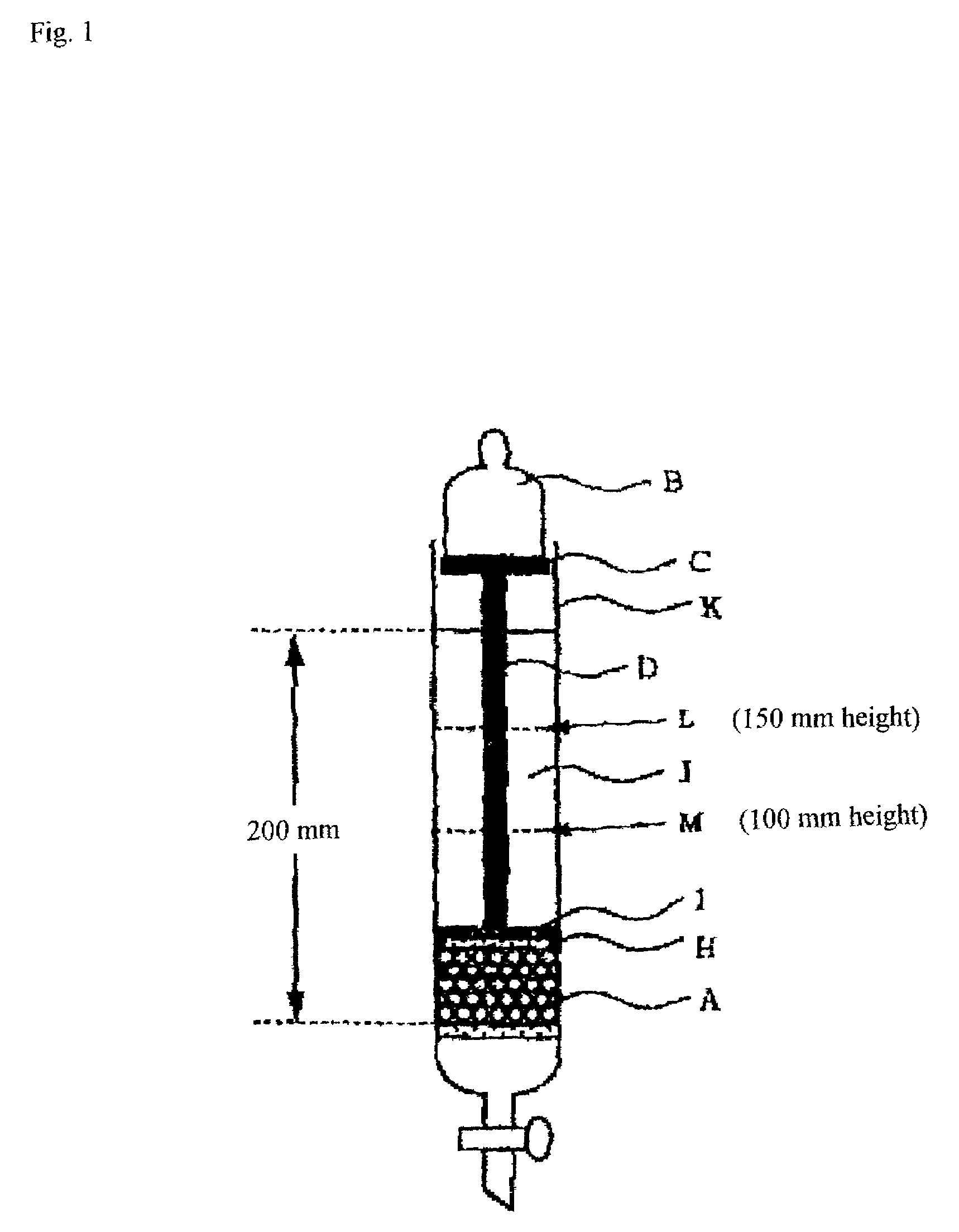

Water-absorbing agent and production process therefor, and water-absorbent structure

InactiveUS7098284B2Promote absorptionMaintain good propertiesOther chemical processesAbsorbent padsBursting strengthAbsorption capacity

The present invention provides: a novel water-absorbing agent, which exhibits an excellent absorption capacity under a load (AAP), gel layer liquid permeation rate under a load (FRUP), saline flow conductivity (SFC), and shape-maintaining property and ball burst strength (BBS) of a swollen water-absorbing agent aggregate, and excellent persistency of these effects for a long time. The water-absorbing agent, which comprises a polymer obtained by a process including the steps of polymerizing and then crosslinking a monomer including acrylic acid and / or a salt thereof, with the water-absorbing agent being characterized by: (1) exhibiting a free swelling capacity of not less than 23 g / g (GV), a gel deformation of not more than 12.5 cm under a short-time load (0.5 hrPT), and a gel deformation deterioration of not more than 3.5 cm under a load with the passage of time (ΔPT); (2) exhibiting a free swelling capacity of not less than 23 g / g (GV), a ball burst strength of not less than 80 gf (BBS), and a deterioration of ball burst strength of not more than 40% (DBBS); or (3) exhibiting a free swelling capacity of not less than 23 g / g (GV), an absorption capacity of not less than 20 g / g under a load of 4.9 kPa (AAP), and a gel deformation of not more than 12.5 cm under a load (16 hrPT).

Owner:NIPPON SHOKUBAI CO LTD

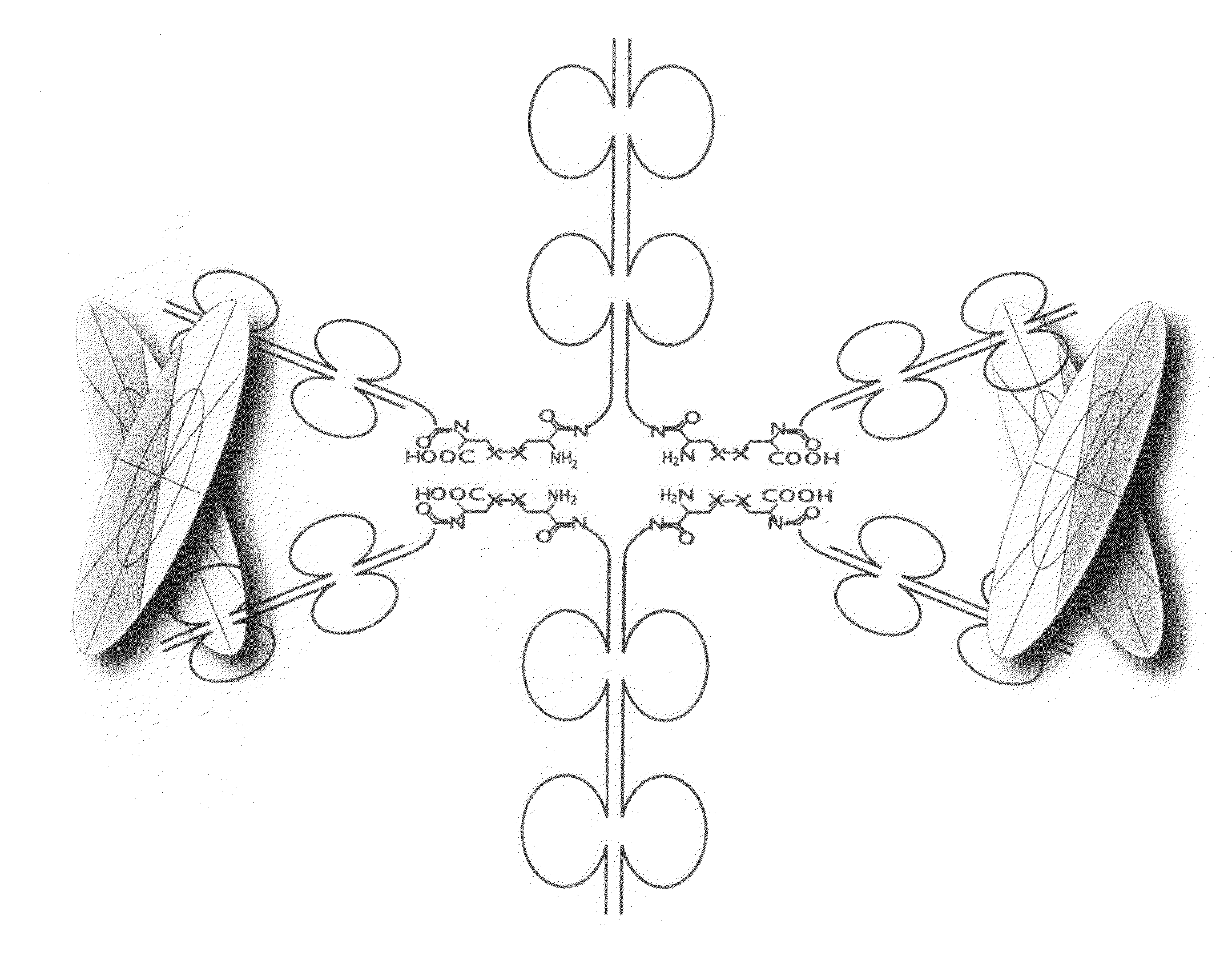

Hybrid immunoglobulins with moving parts

Hybrid immunoglobulins containing moving parts are provided as well as related compositions and methods of use and methods of production. In addition, analogous genetic devices are provided as well as related compositions and methods of use and methods of production.

Owner:BIOMOLECULAR HLDG LLC

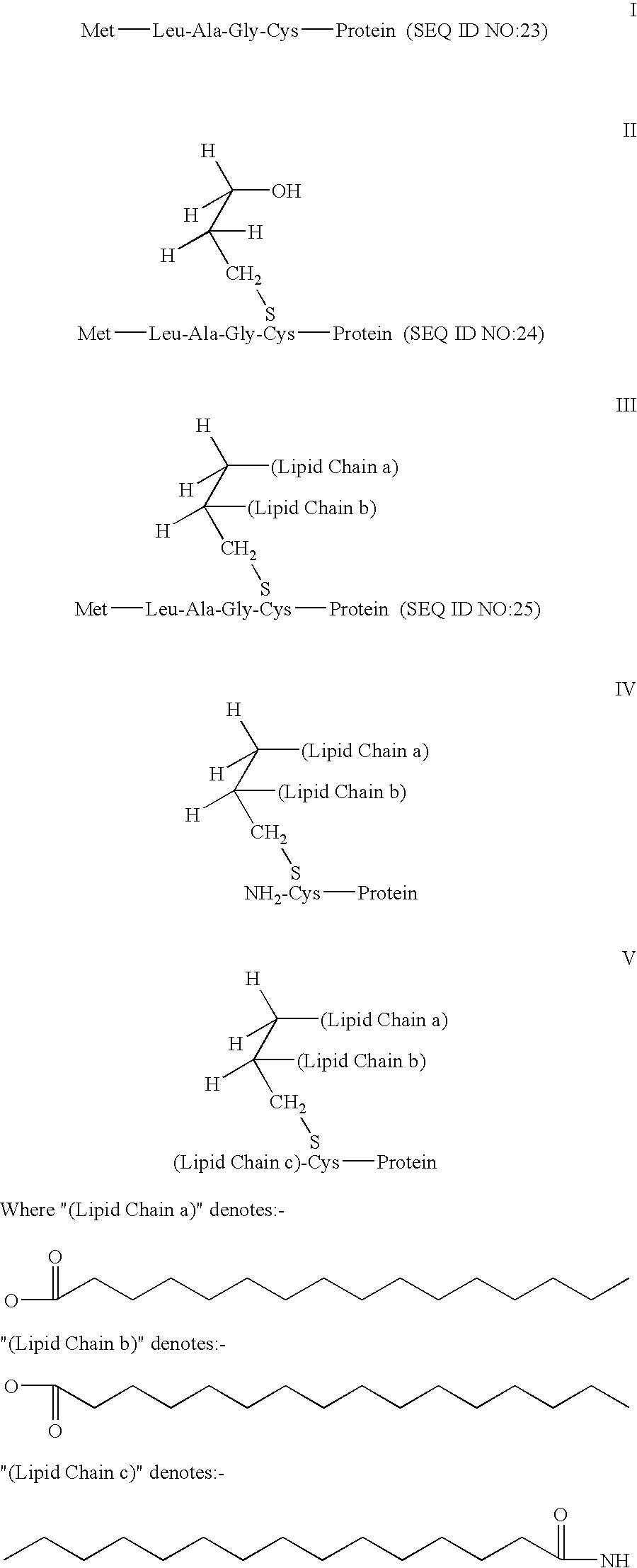

Novel Lipids and Compositions for Intracellular Delivery of Biologically Active Compounds

ActiveUS20120295832A1High yieldHigh purityPowder deliveryBiocideLipid formationIntracellular drug delivery

The present invention provides novel amino-lipids, compositions comprising such amino-lipids and methods of producing them. In addition, lipid nanoparticles comprising the novel amino-lipids and a biologically active compound are provided, as well as methods of production and their use for intracellular drug delivery.

Owner:AXOLABS

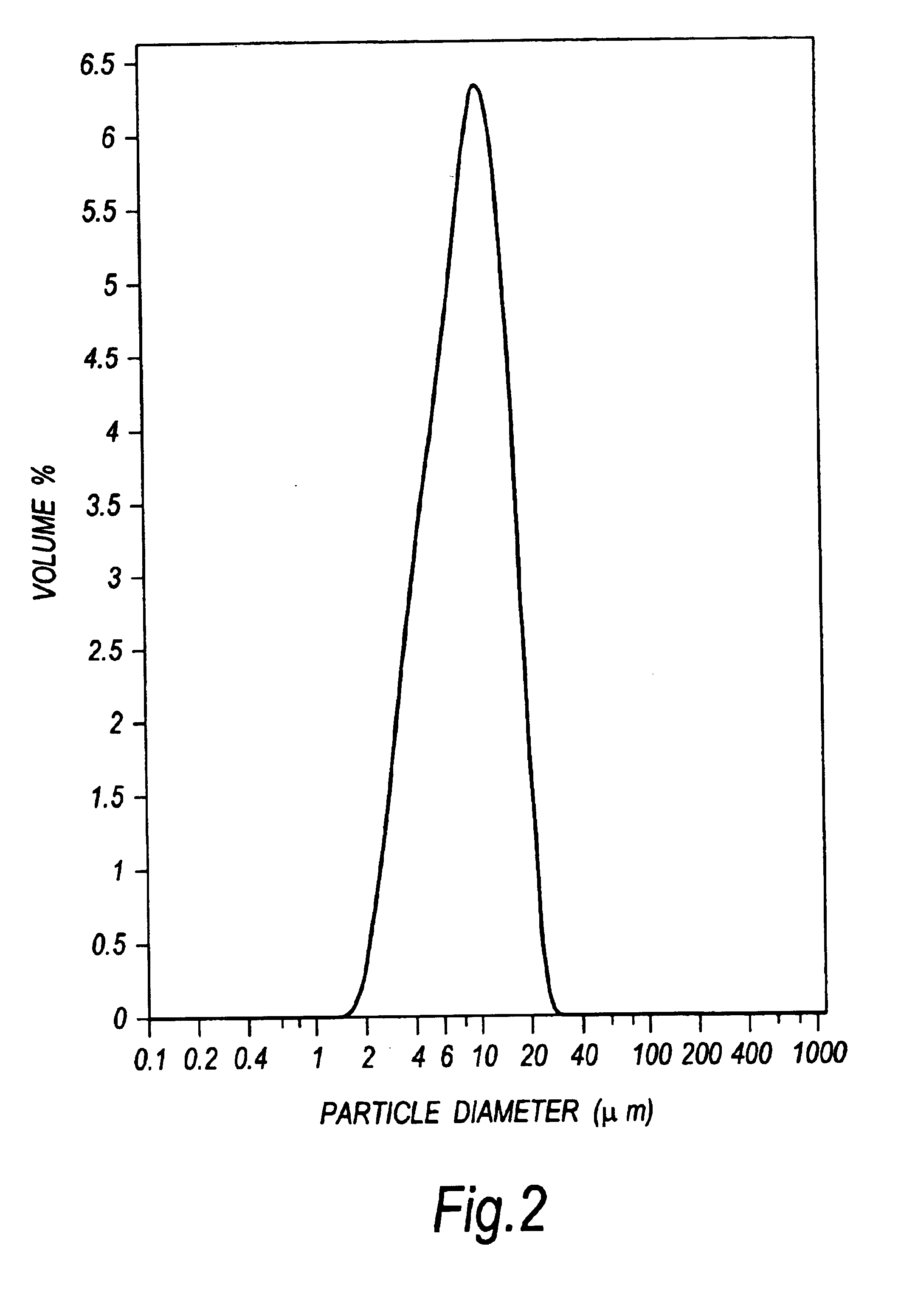

Antigen delivery system and method of production

The present invention concerns polymer particle vaccine delivery systems in which a water insoluble protein antigen, e.g. a lipidated HpaA protein, is incorporated with particles comprising a polymer matrix. The present invention also concerns a method for incorporating such a water insoluble protein antigen with a polymer matrix in order to produce a polymer particle vaccine delivery system. In addition, the invention also provides a vaccine composition comprising the polymer particle delivery system. The vaccine can be used to treat and / or reduce the risk of for example Helicobacter infection.

Owner:ASTRAZENECA AB

Water-absorbing agent and production process therefor, and sanitary material

InactiveUS20040106745A1Improve balanceMaintain stable propertiesAbsorbent padsBandagesWater solubleMethods of production

There is provided: a production process for a water-absorbing agent having stable properties in a short time; and a water-absorbing agent. The production process comprises the step of blending an acid-group-containing water-absorbent resin powder with a noncrosslinkable water-soluble inorganic base and / or an irreducible alkaline-metal-salt pH buffer and further with a dehydratable crosslinking agent reactable with the acid group, thereby subjecting the resin powder to crosslinking treatment, or comprises the step of blending an acid-group-containing water-absorbent resin powder with the above base and / or pH buffer and further with a crosslinking agent reactable with the acid group, thereby subjecting the resin powder to crosslinking treatment, wherein the resin powder has a weight-average particle diameter of 300 to 600 mum wherein the ratio of fine powders having particle diameters of not larger than 150 mum in the resin powder is not more than 10 weight %.

Owner:NIPPON SHOKUBAI CO LTD

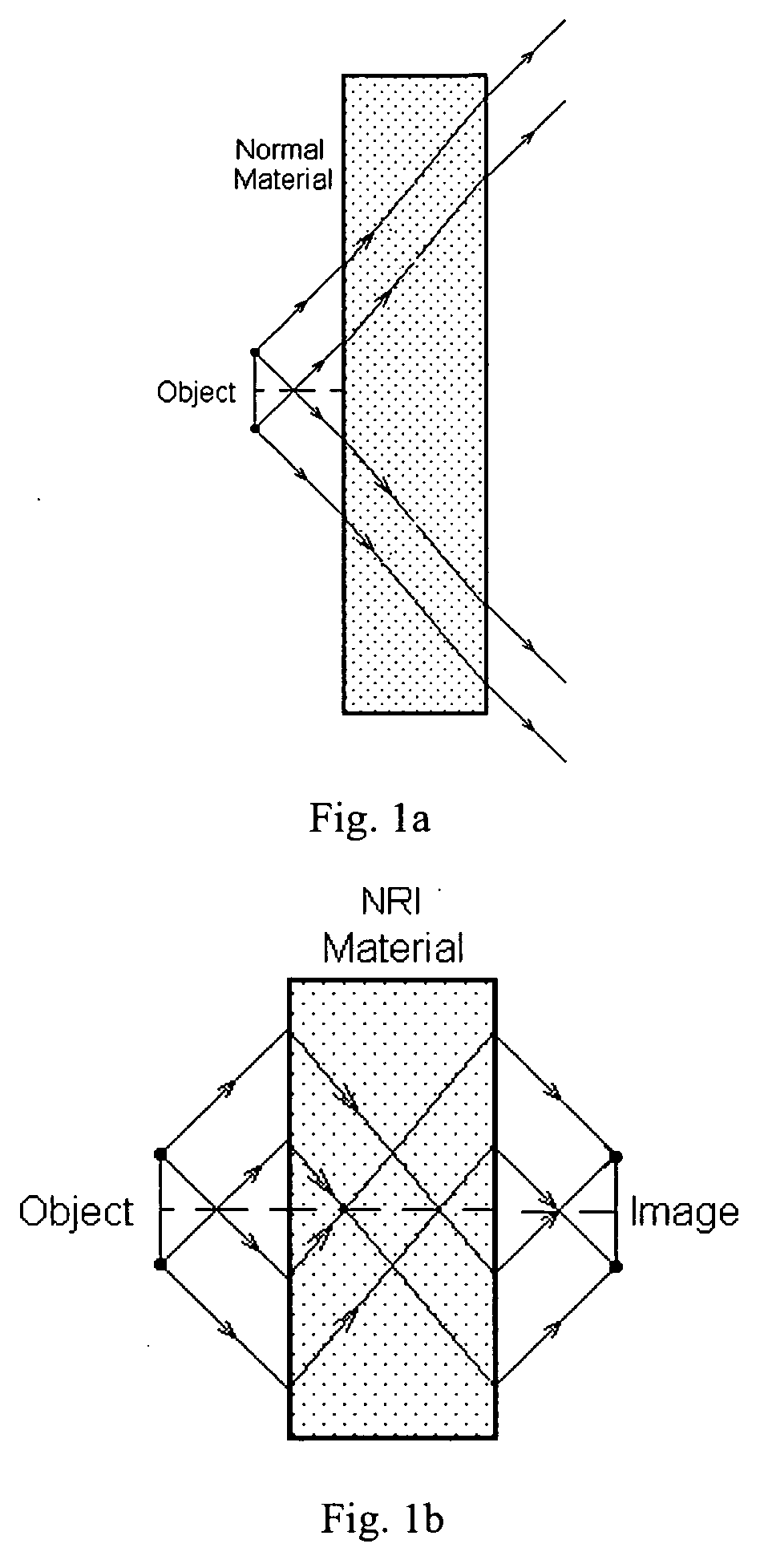

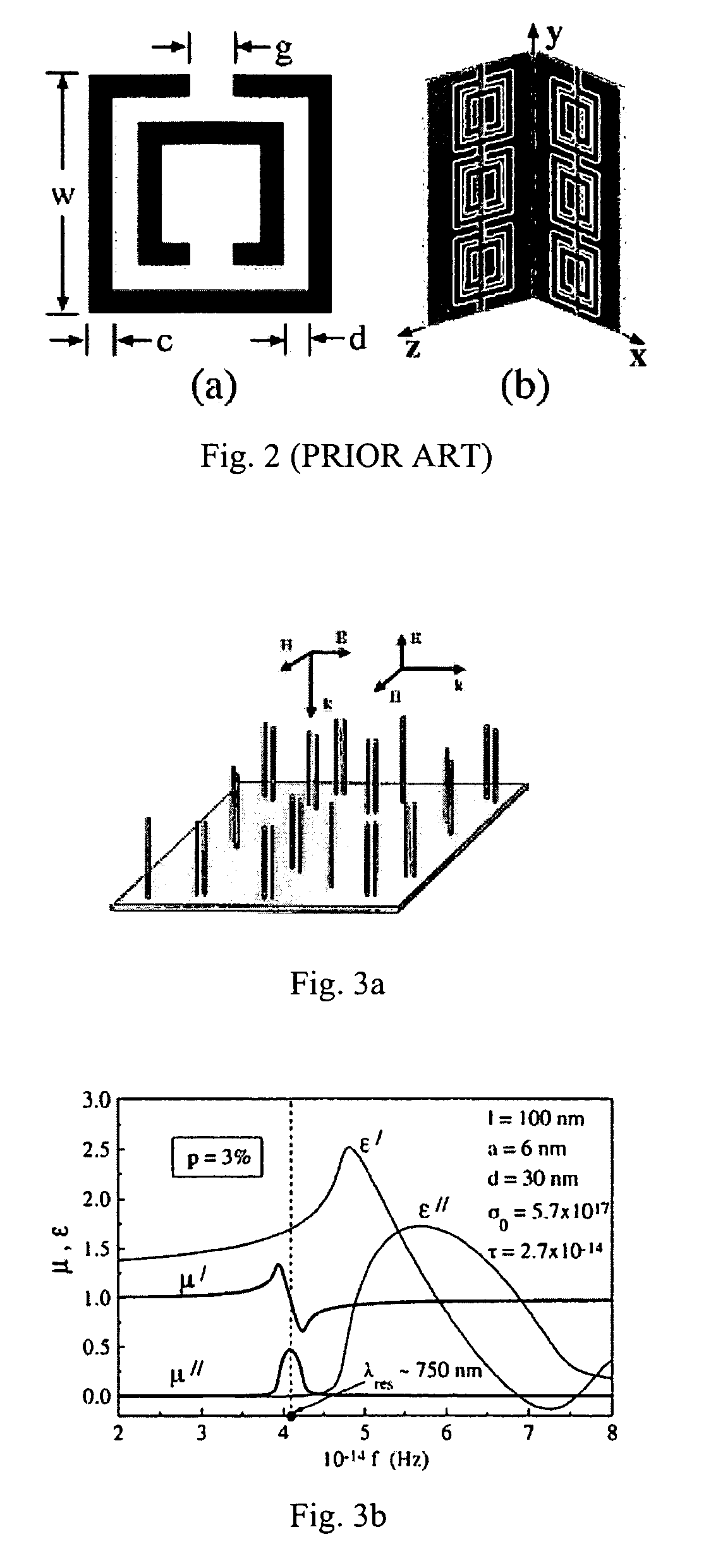

Negative refractive index and opto-magnetic materials and method of fabricating same

InactiveUS20050221128A1Reduce processing timeLow chemical consumptionNanoopticsRecord information storageCost effectivenessOptical property

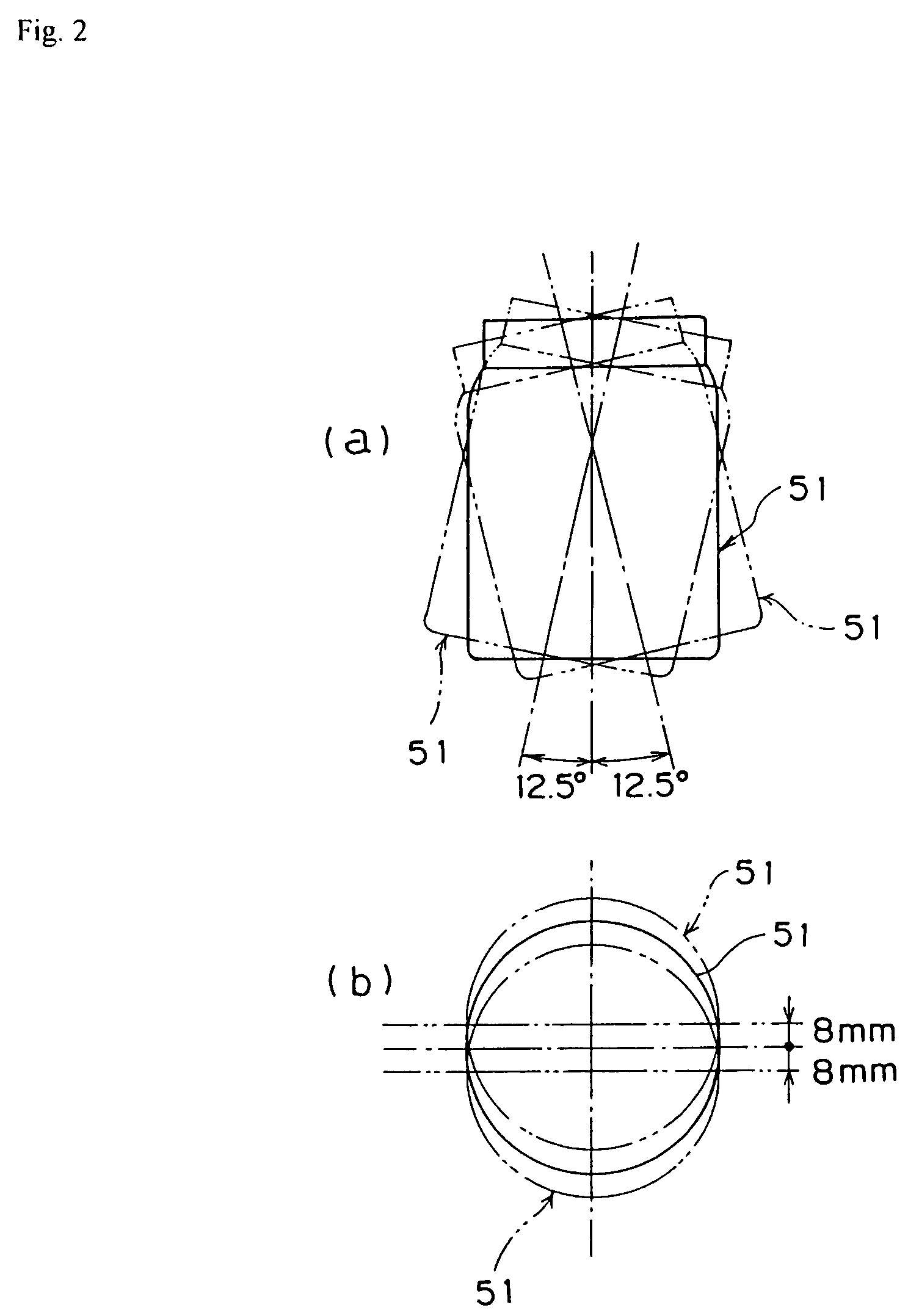

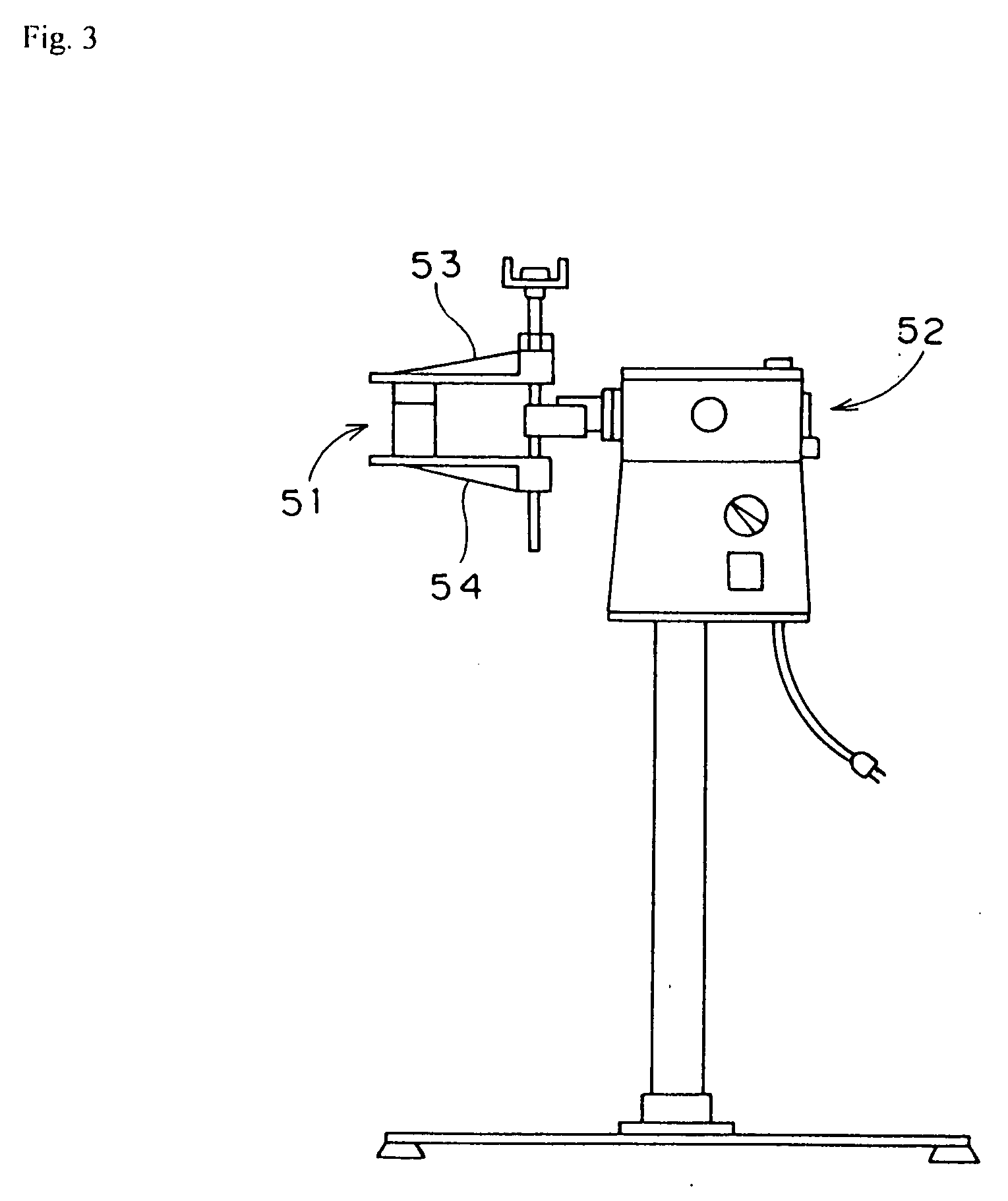

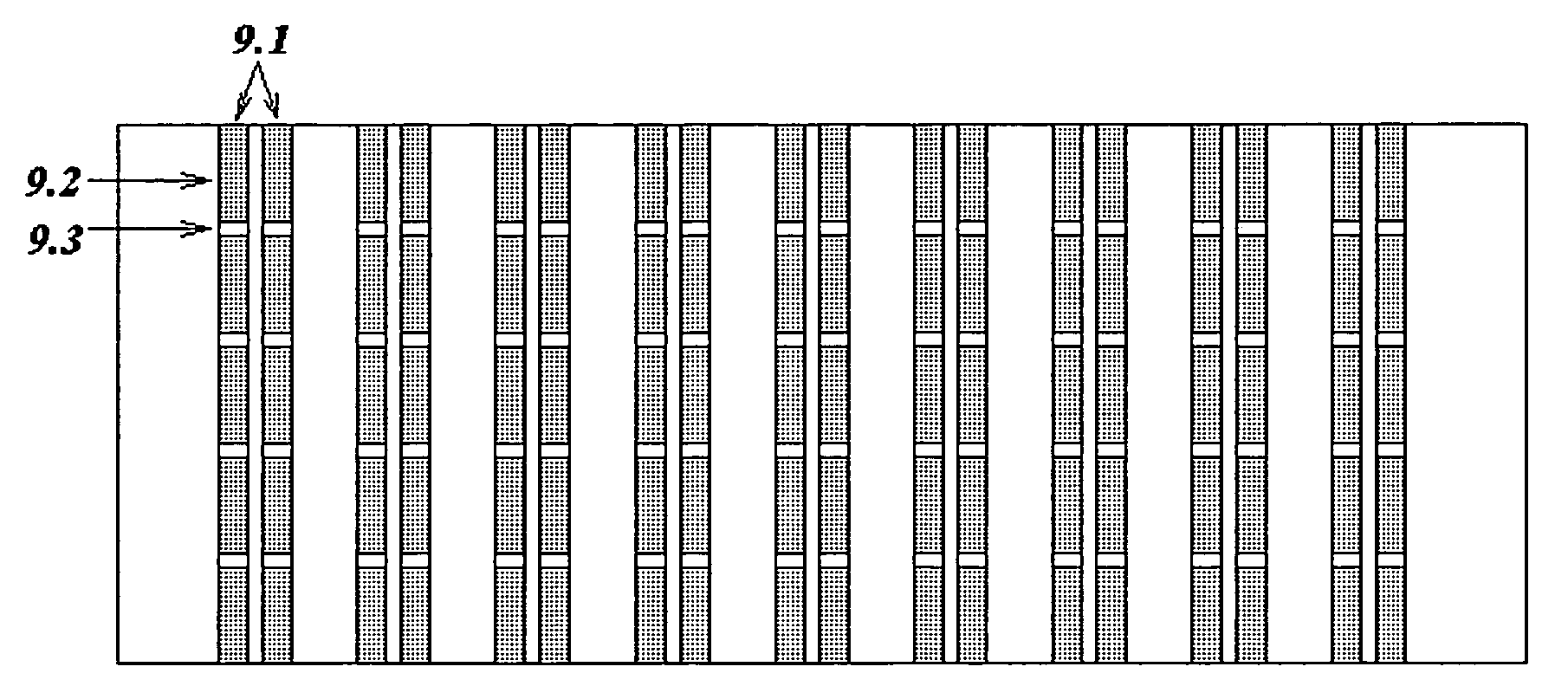

One-dimensional, two-dimensional and three-dimensional negative refractive index (NRI) and / or opto-magnetic materials operating in spectral ranges spanning from the visible to far IR wavelength ranges is disclosed. Said materials are comprised of metal or metal / dielectric wire pairs arranged in a number of sublattices (one for one dimensional material, two for two-dimensional and three or more for three dimensional material), such that in each lattice, said wire pairs are essentially parallel to each other. Such a materials are useful and practical in obtaining previously unachievable important optical functions in these spectral ranges. Such optical properties are highly desired for many applications. A practical means of manufacture that is compatible with cost-effective and large-scale production methods is also provided.

Owner:LAKE SHORE CRYOTRONICS INC

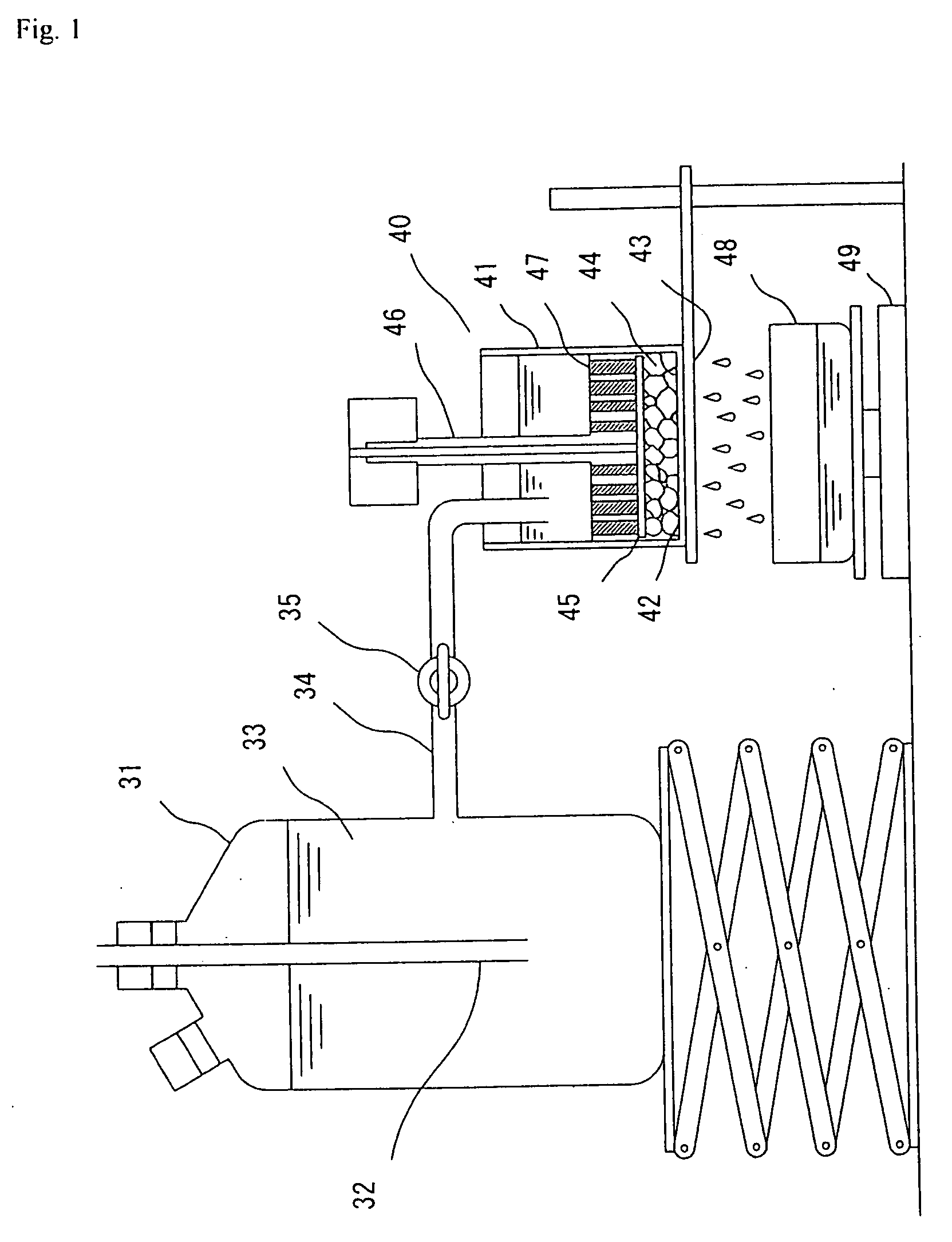

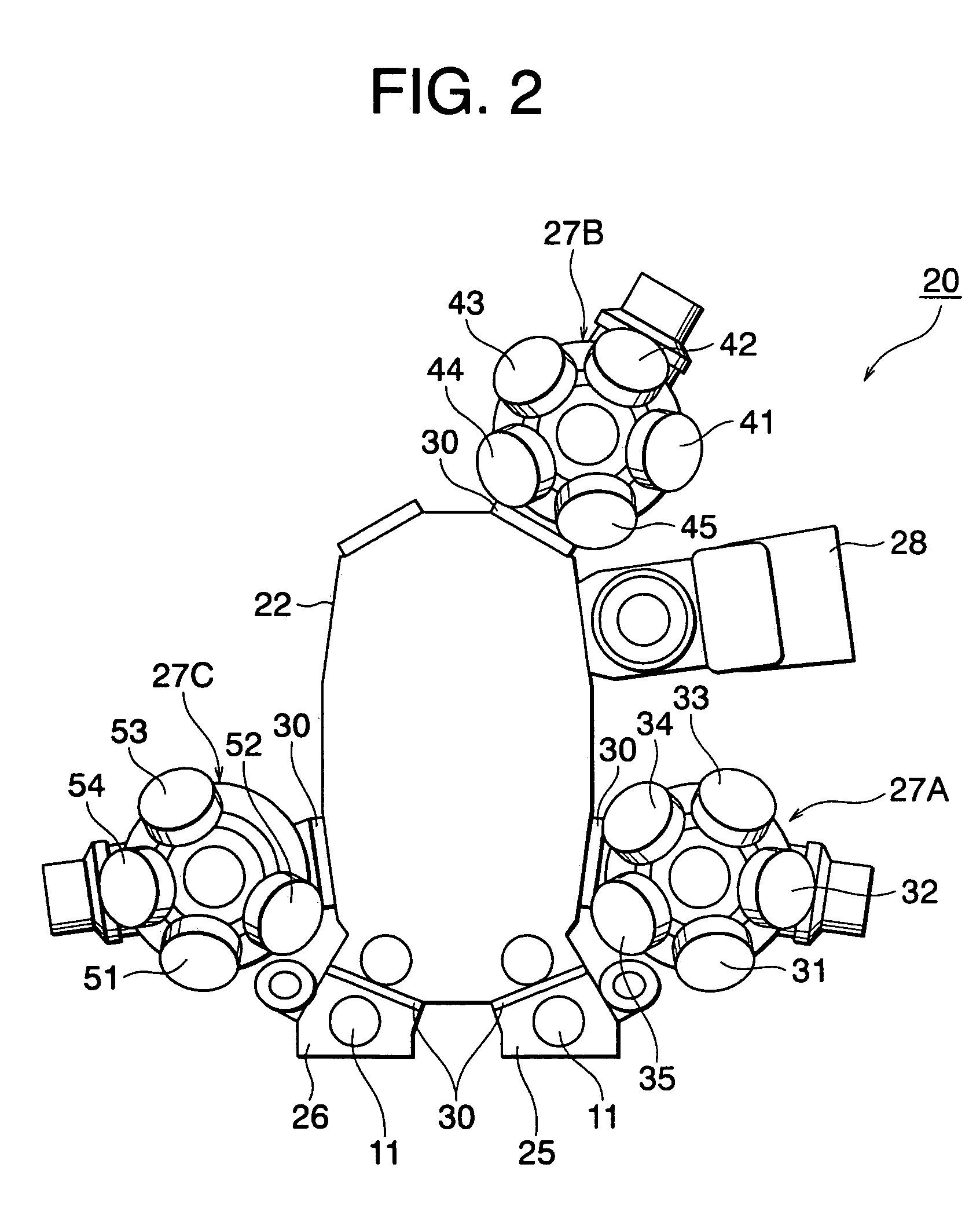

Apparatus and method of production of thin film photovoltaic modules

InactiveUS7271333B2Reduce weightSimple and cheap to manufactureCosmonautic vehiclesPV power plantsEngineeringMethods of production

Owner:ASCENT SOLAR TECH

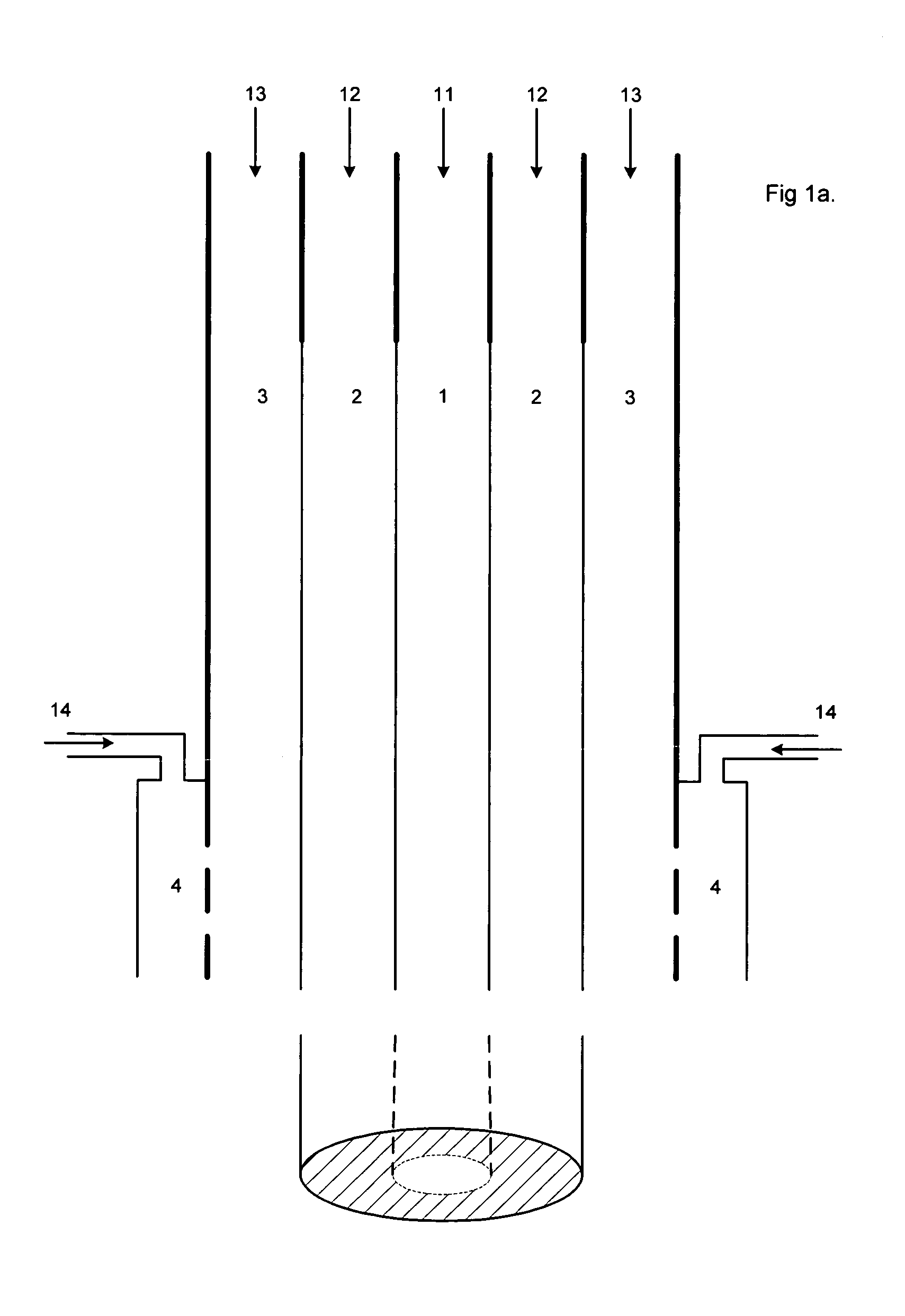

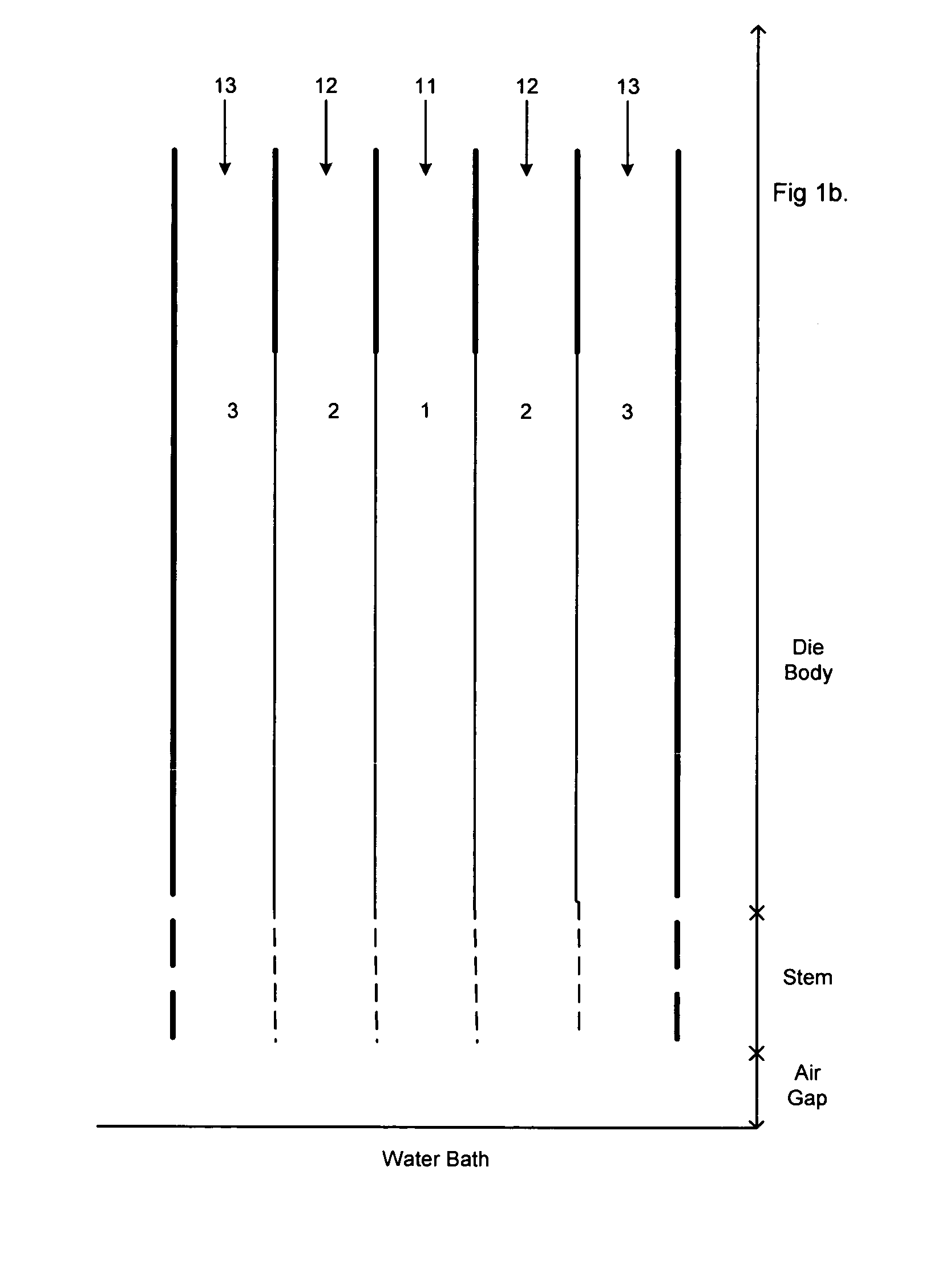

Poly(ethylene chlorotrifluoroethylene) membranes

InactiveUS7247238B2Improve permeabilityImprove integrityMembranesSemi-permeable membranesFiberGlycerol

Porous polymeric membranes including Halar (poly (ethylene chlorotrifluoroethylene)) and related compounds and the methods of production thereof which avoid the use of toxic solvents. Preferred solvents, coating agents and pore forming agents are citric acid ethyl ester or glycerol triacetate. The membranes may be in the form of a hollow fiber or flat sheet, and may include other agents to modify the properties of the membrane, such as the hydrophilic / hydrophobic balance. Leachable agents may also be incorporated into the membranes.

Owner:EVOQUA WATER TECH LLC

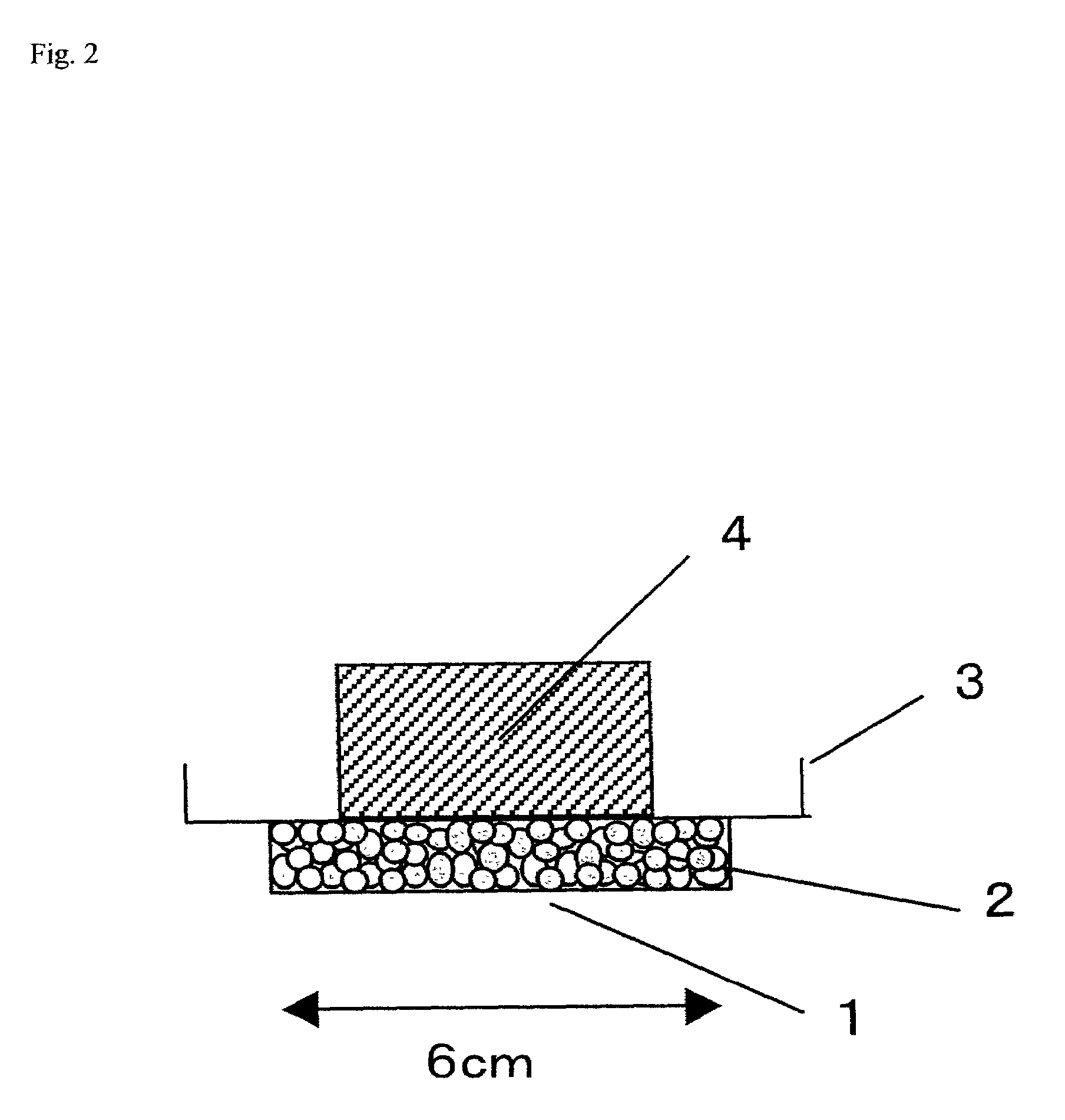

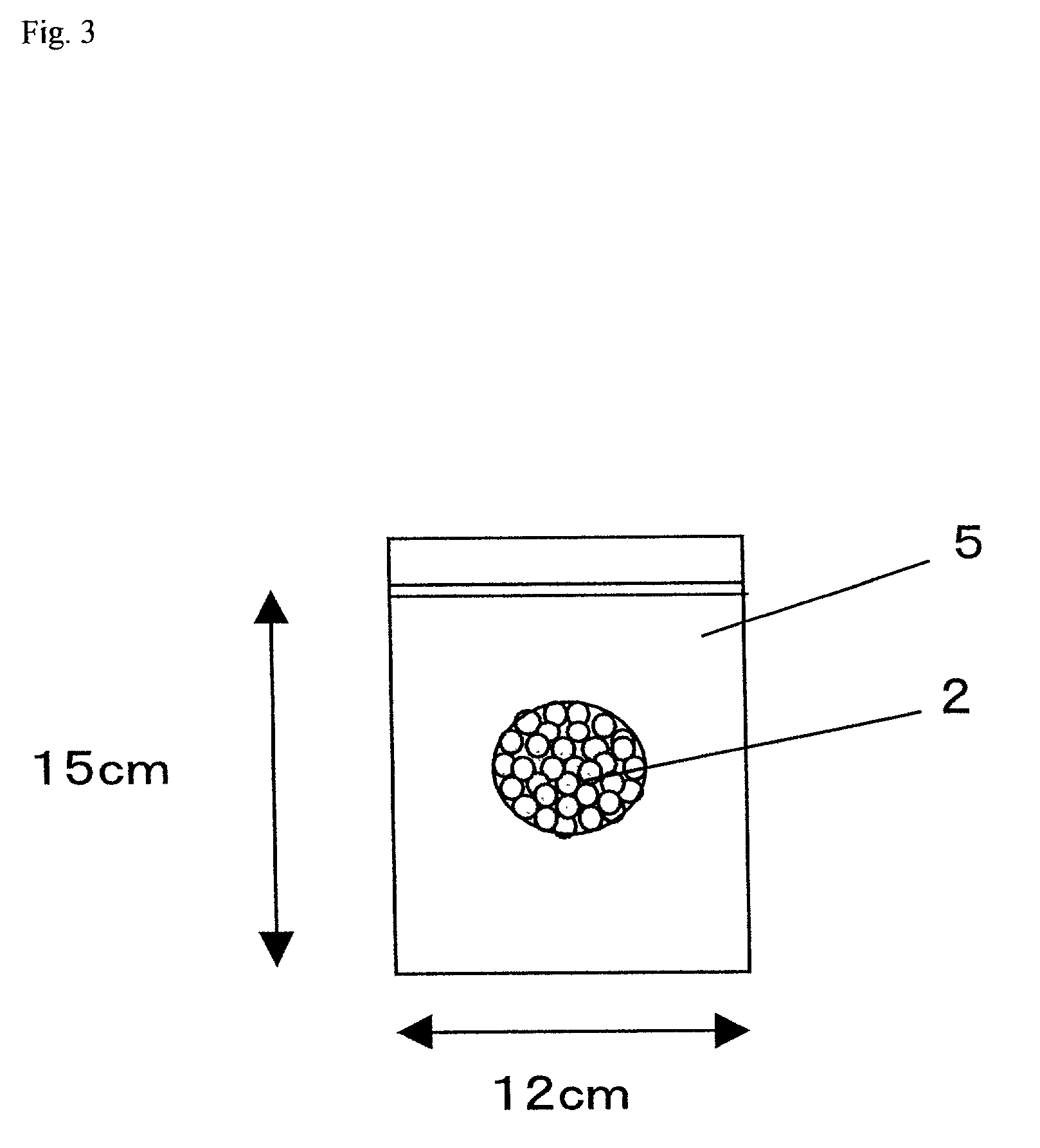

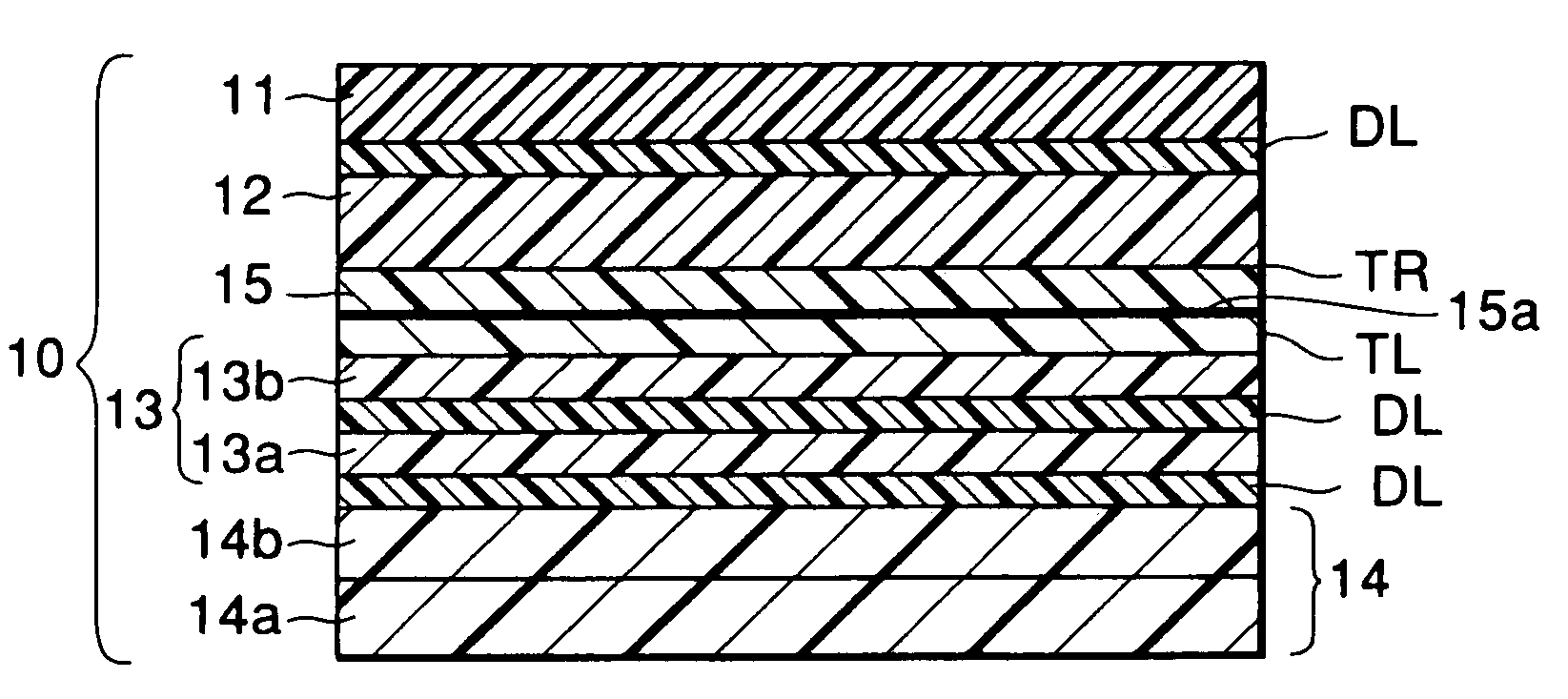

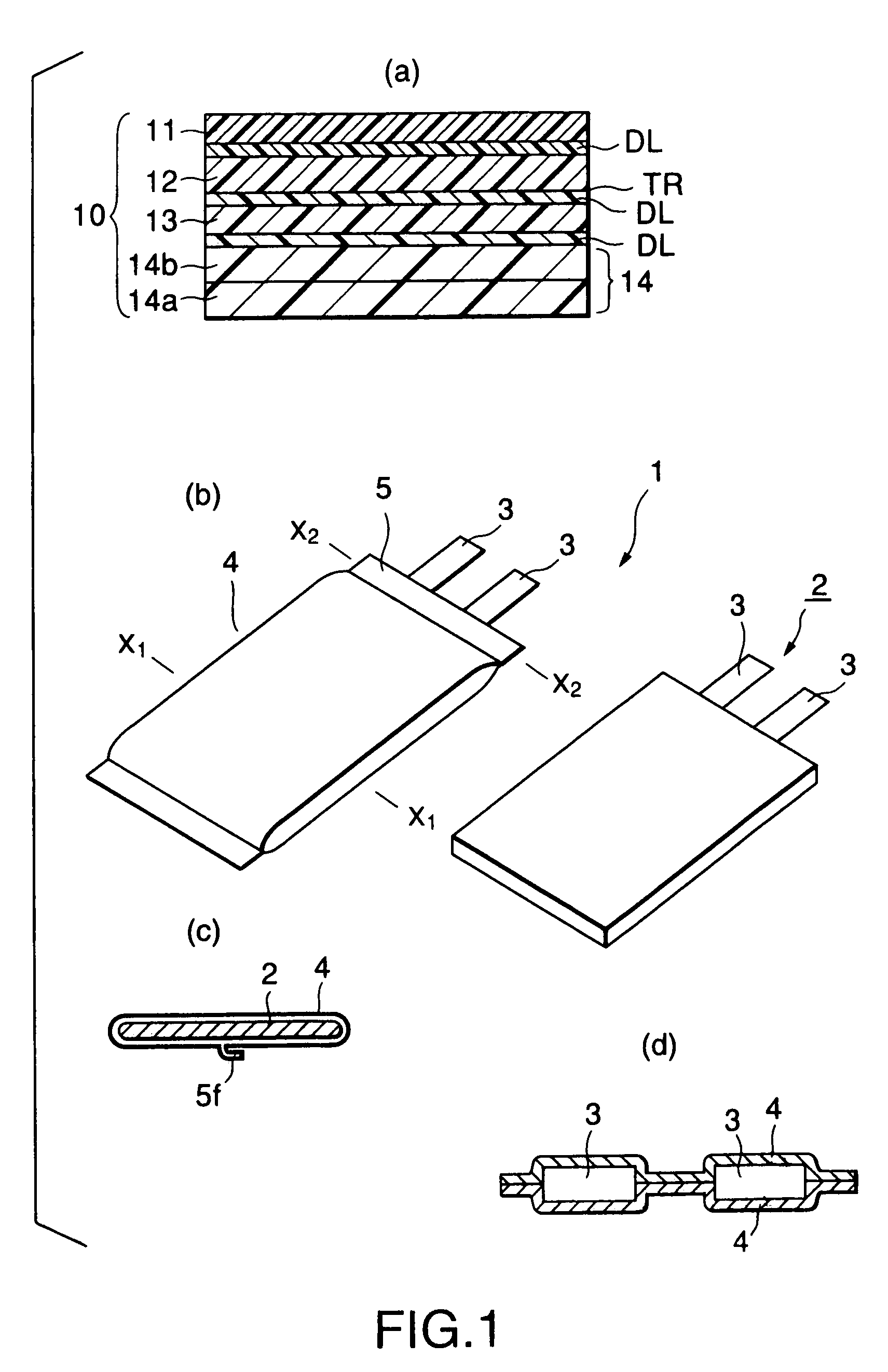

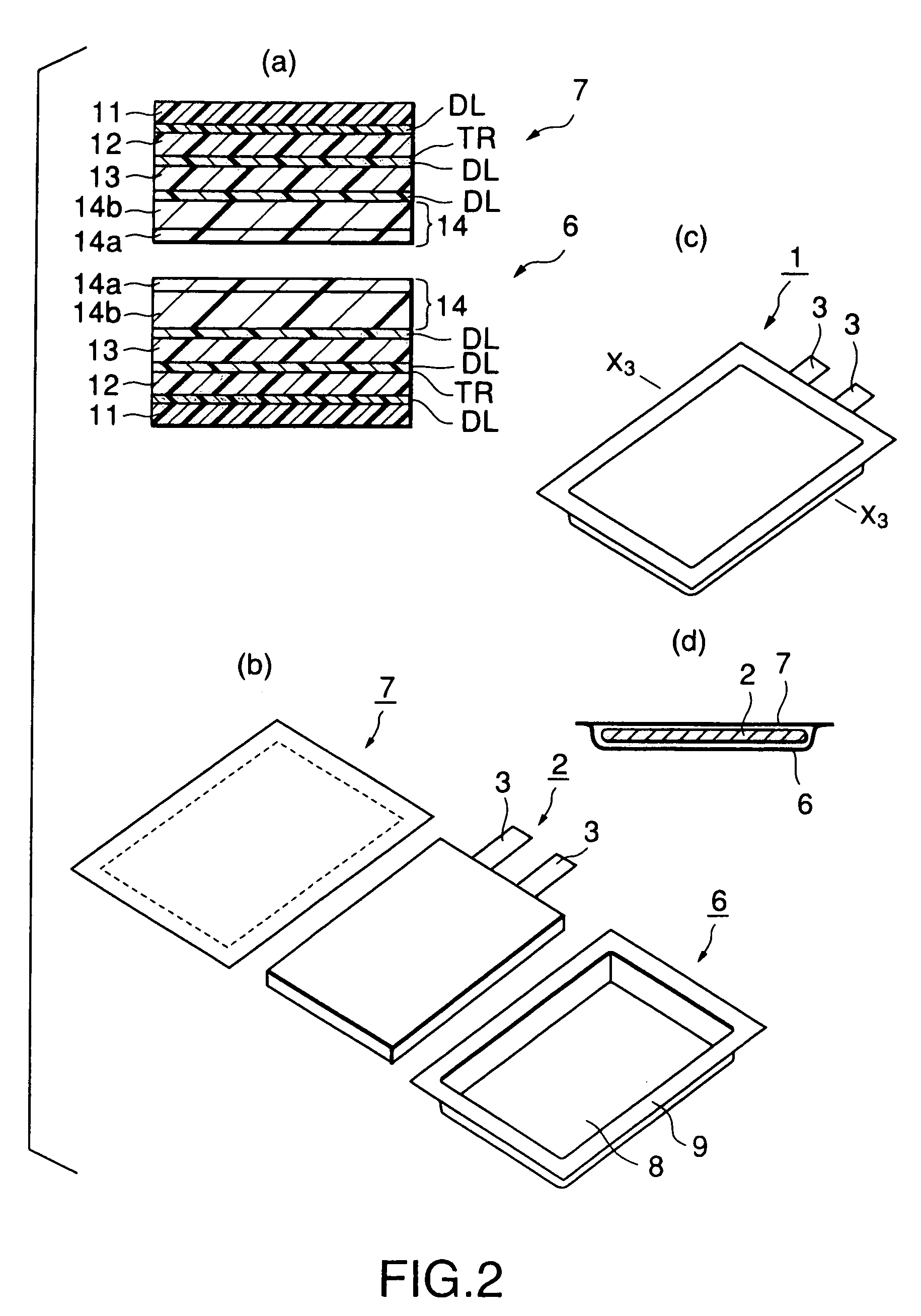

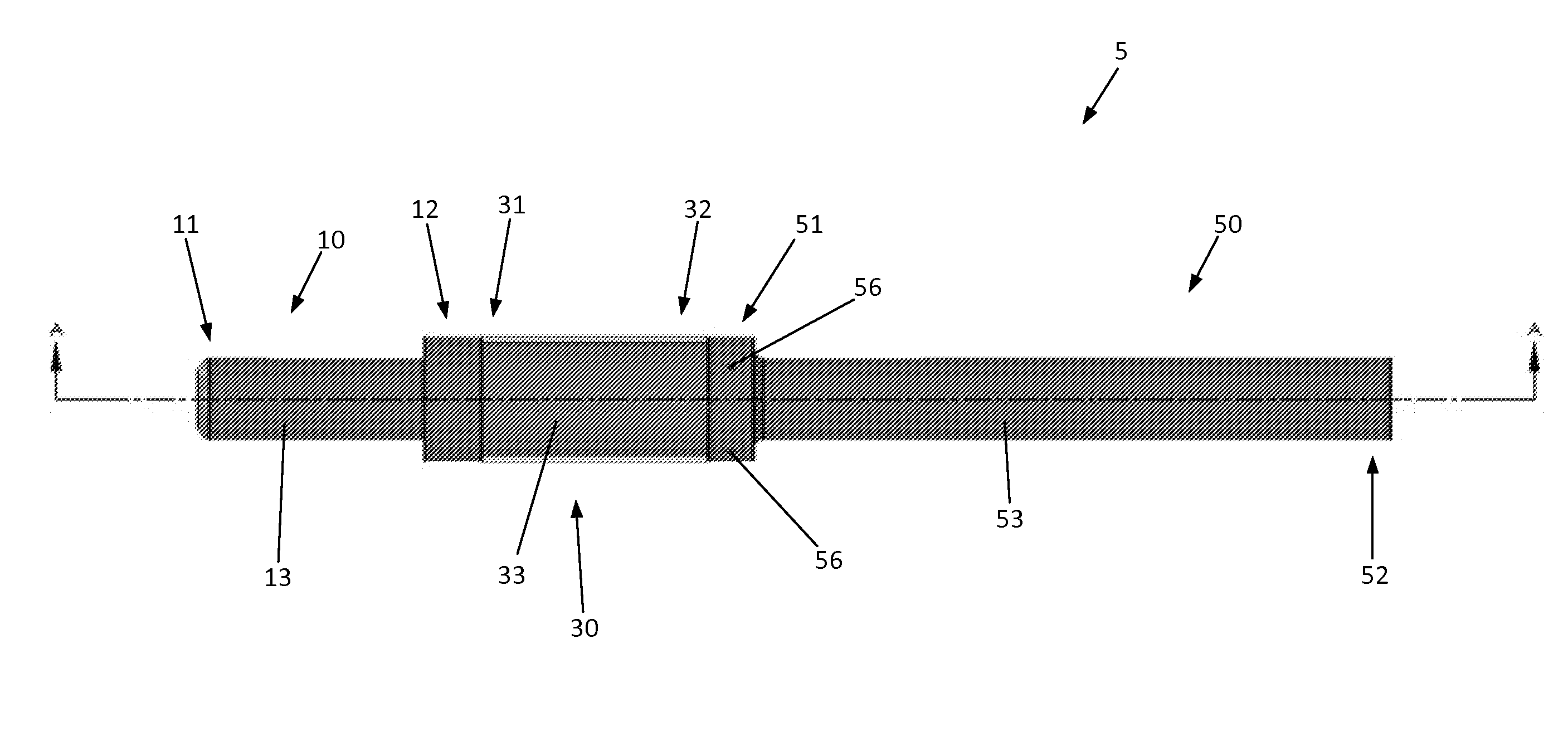

Material for packaging cell, bag for packaging cell, and its production method

InactiveUS7285334B1Excellent gas barrier performanceHigh mechanical strengthNon-aqueous electrolyte accumulatorsSynthetic resin layered productsEngineeringMethods of production

A lithium battery comprises a pouch (4) and a lithium battery module (2) packaged in the pouch (4). The pouch (4) is formed from a battery packaging laminated structure (10). The laminated structure (10) has an outermost layer (11), a barrier layer (12) and an innermost layer (14), or an outermost layer (11), a barrier layer (12), an intermediate layer (13) and an innermost layer (14) superposed in that order. The outermost layer (11) is formed of a formable base material, the barrier layer (12) is formed of a impermeable base material having a barrier property, the intermediate layer (13) is formed of a formable base material and the innermost layer (14) is formed of a heat-adhesive base material.

Owner:DAI NIPPON PRINTING CO LTD

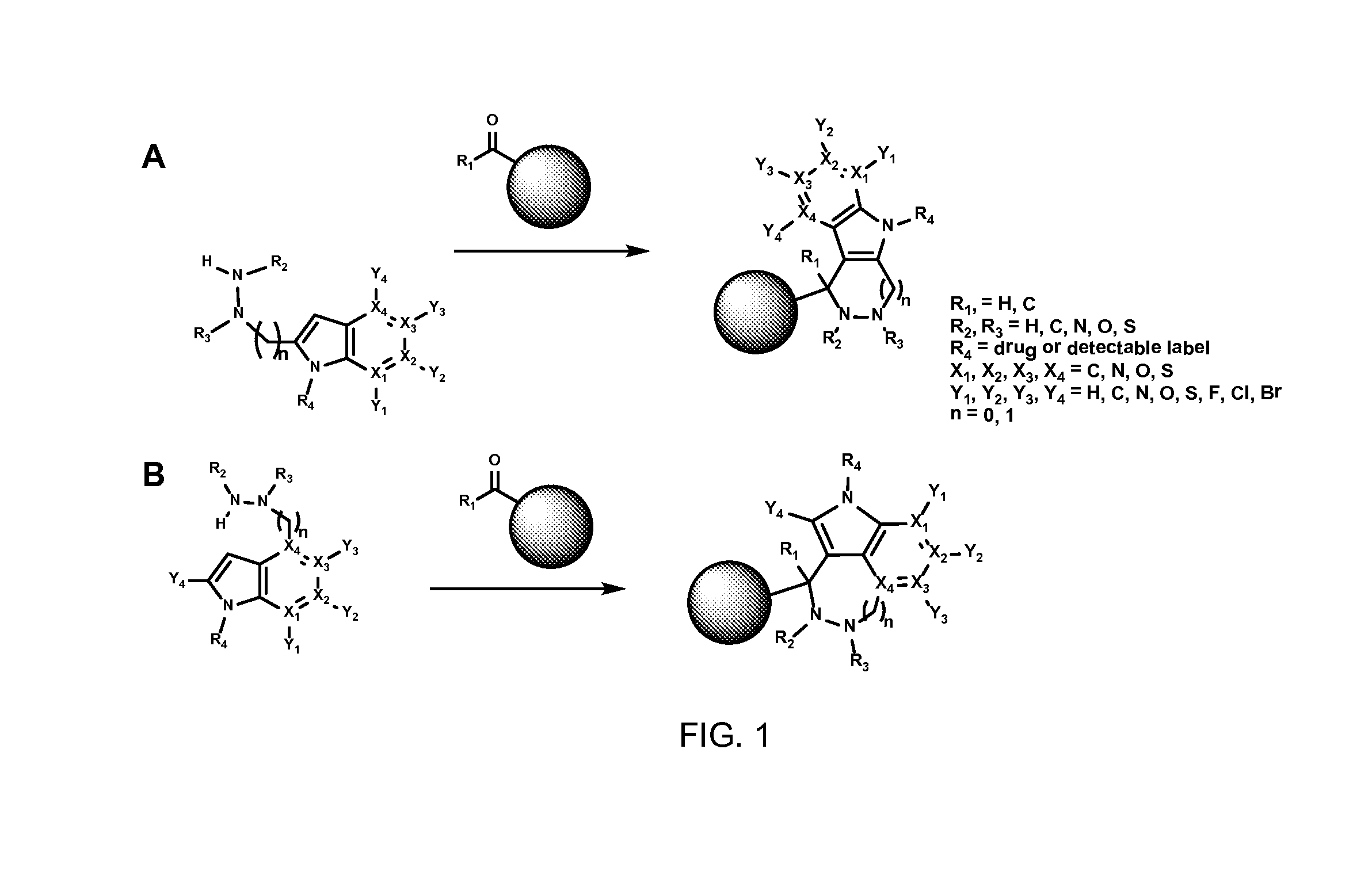

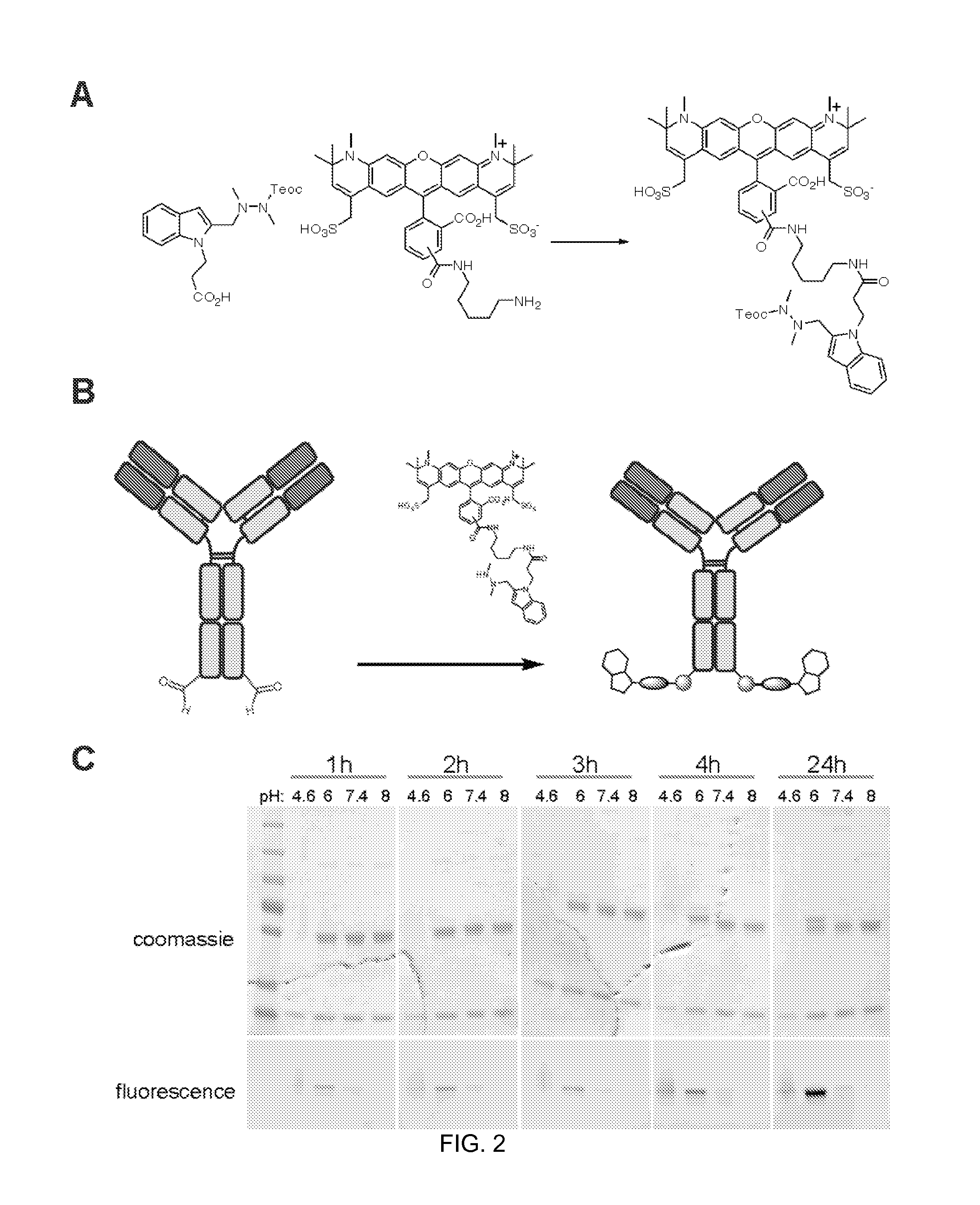

Hydrazinyl-indole compounds and methods for producing a conjugate

ActiveUS20140141025A1Effective treatmentMultiple functionsPeptide/protein ingredientsPeptide preparation methodsMethods of productionStereochemistry

The present disclosure provides conjugate structures (e.g., polypeptide conjugates) and hydrazinyl-indole compounds used to produce these conjugates. The disclosure also provides methods of production of such conjugates, as well as methods of using the same.

Owner:REDWOOD BIOSCI

Antibodies as T cell receptor mimics, methods of production and uses thereof

InactiveUS20060034850A1Aid in stabilizationAnimal cellsImmunoglobulin superfamilyHla moleculesDisease cause

The present invention relates to a methodology of producing antibodies that recognize peptides associated with a tumorigenic or disease state, wherein the peptides are displayed in the context of HLA molecules. These antibodies will mimic the specificity of a T cell receptor (TCR) but will have higher binding affinity such that the molecules may be used as therapeutic, diagnostic and research reagents. The method of producing a T-cell receptor mimic of the present invention includes identifying a peptide of interest, wherein the peptide of interest is capable of being presented by an MHC molecule. Then, an immunogen comprising at least one peptide / MHC complex is formed, wherein the peptide of the peptide / MHC complex is the peptide of interest. An effective amount of the immunogen is then administered to a host for eliciting an immune response, and serum collected from the host is assayed to determine if desired antibodies that recognize a three-dimensional presentation of the peptide in the binding groove of the MHC molecule are being produced. The desired antibodies can differentiate the peptide / MHC complex from the MHC molecule alone, the peptide alone, and a complex of MHC and irrelevant peptide. Finally, the desired antibodies are isolated.

Owner:TEXAS TECH UNIV SYST

Filter for displaying, display unit and production method therefor

InactiveUS20030156080A1High color purityGood colorMagnetic/electric field screeningStatic indicating devicesDisplay deviceCopper foil

The display filter is constituted by laminating a transparent adhesive layer (C) 31 containing dye, a polymer film (B) 20, a transparent electrically conductive layer (D) 10, a transparent adhesive layer (E) 40, and a functional transparent layer (A) 60 having an anti-reflection property, a hard coat property, a gas barrier property, an antistatic property and an anti-fouling property sequentially in this order, adhered on a display area 00; on this occasion, the transparent electrically conductive layer (D) 10 is grounded to a ground terminal of the display via an electrode 50 and an electrically conductive copper foil adhesive tape 80.

Owner:MITSUI CHEM INC

Defect controlled nanotube sensor and method of production

InactiveUS20050036905A1Avoid contactImprove defect densityMaterial nanotechnologyAnalysis using chemical indicatorsEngineeringMethods of production

Sensor for detecting a physical or chemical quantity, comprising a defect controlled nanotube. The sensor can be produced by post treating a nanotube with sufficient energy to modify at least one of density and type of defects in the nanotube, and associating the nanotube with a circuit capable of providing an output signal based upon change of electrical characteristic of the nanotube in response to stimulus of the nanotube.

Owner:MATSUSHITA ELECTRIC WORKS LTD

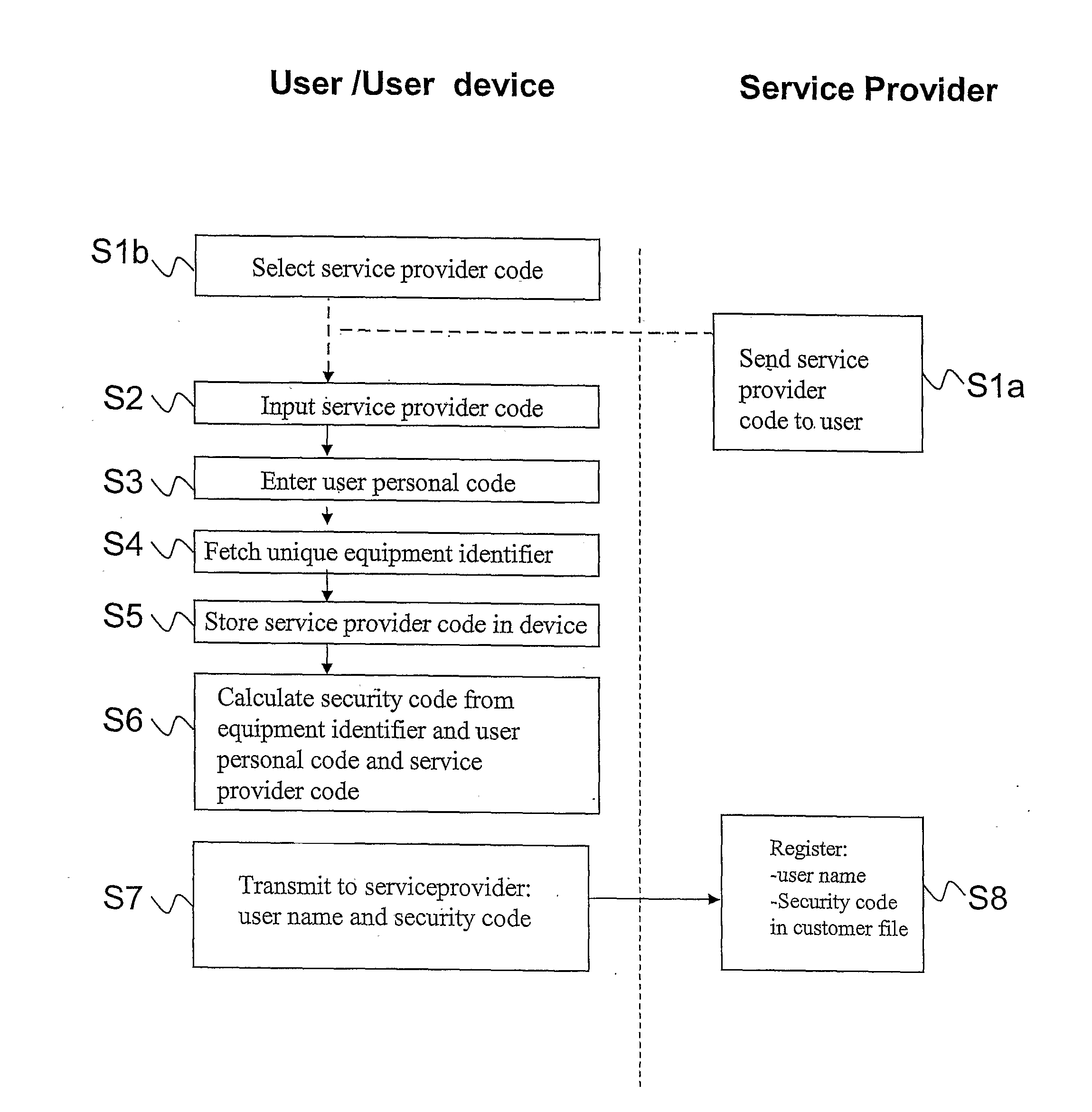

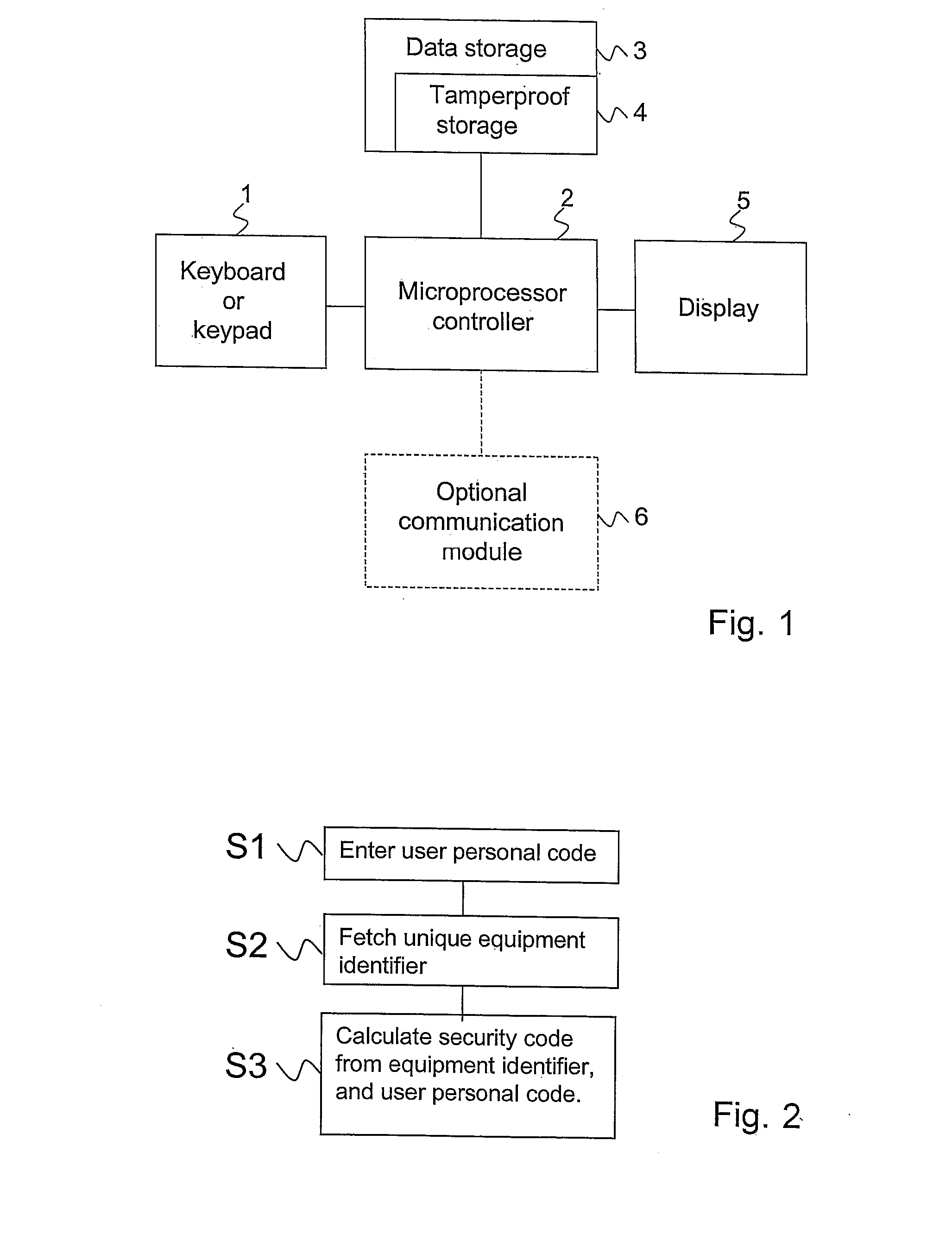

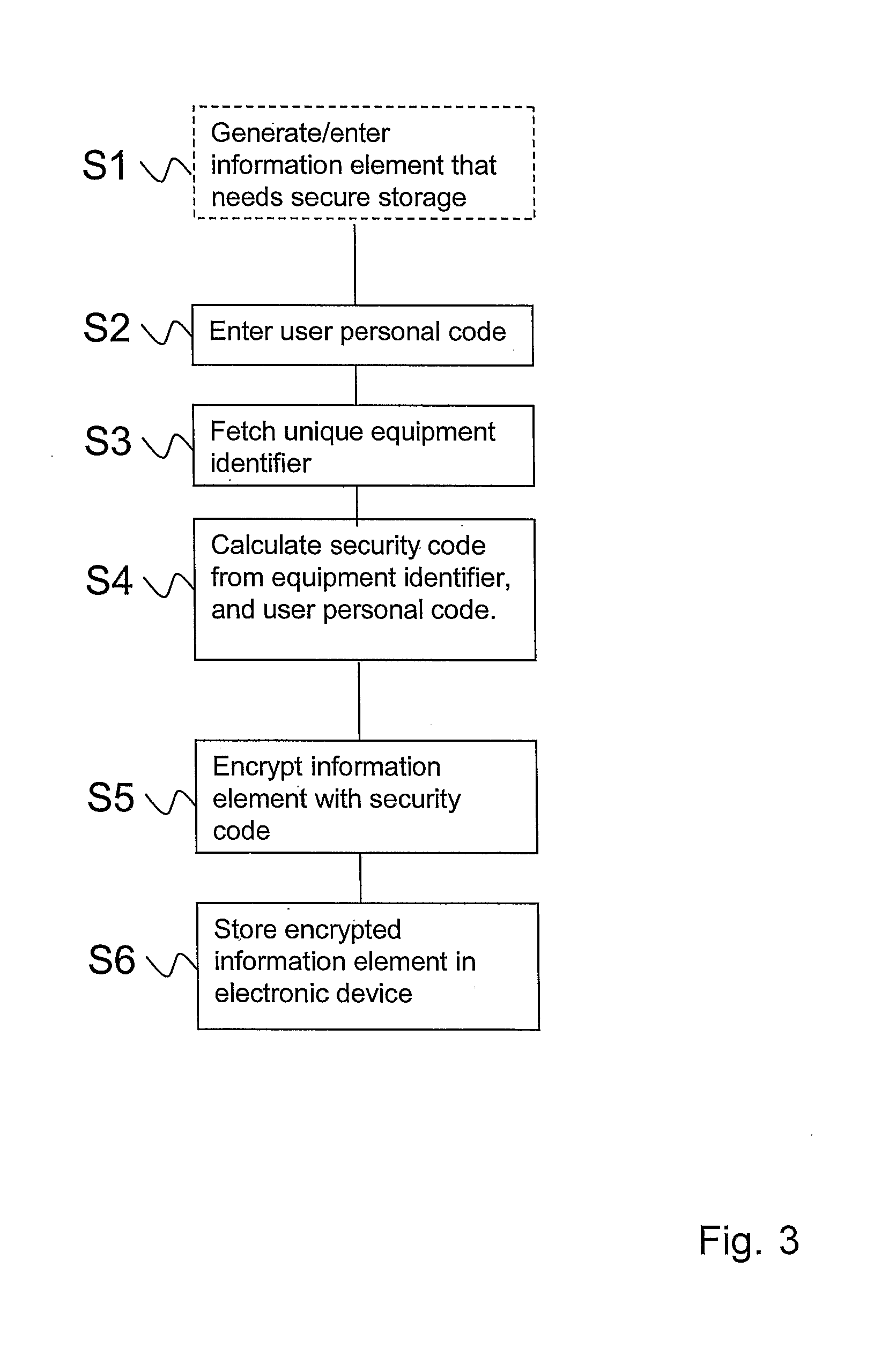

Security Code Production Method and Methods of Using the Same, and Programmable Device Thereof

InactiveUS20080137861A1User identity/authority verificationDigital data authenticationUser deviceUser authentication

A method of producing a security code by means of a programmable user device is described. The security code produced represents in itself both the user and the user device. In one embodiment, a service provider code representing a service provider by whom the user is registered with his / her user name forms an addition to the basis, on which the security code is calculated. The security code is useful for several security applications, such as for user authentication, and for local storage of information, as well as for signing and encryption / decryption of information to be exchanged between the user and a service provider, or vice versa.

Owner:ENCAP AS

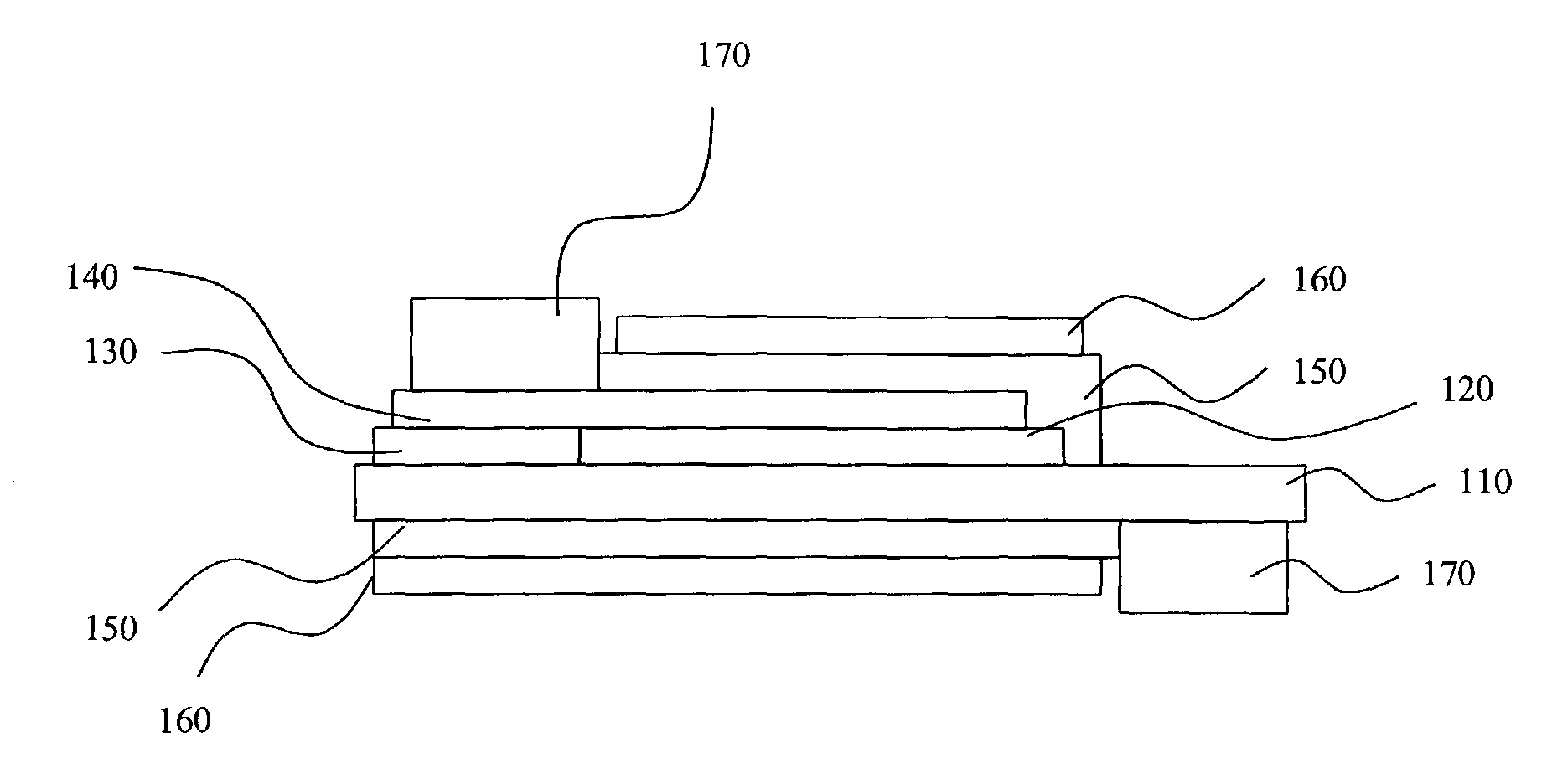

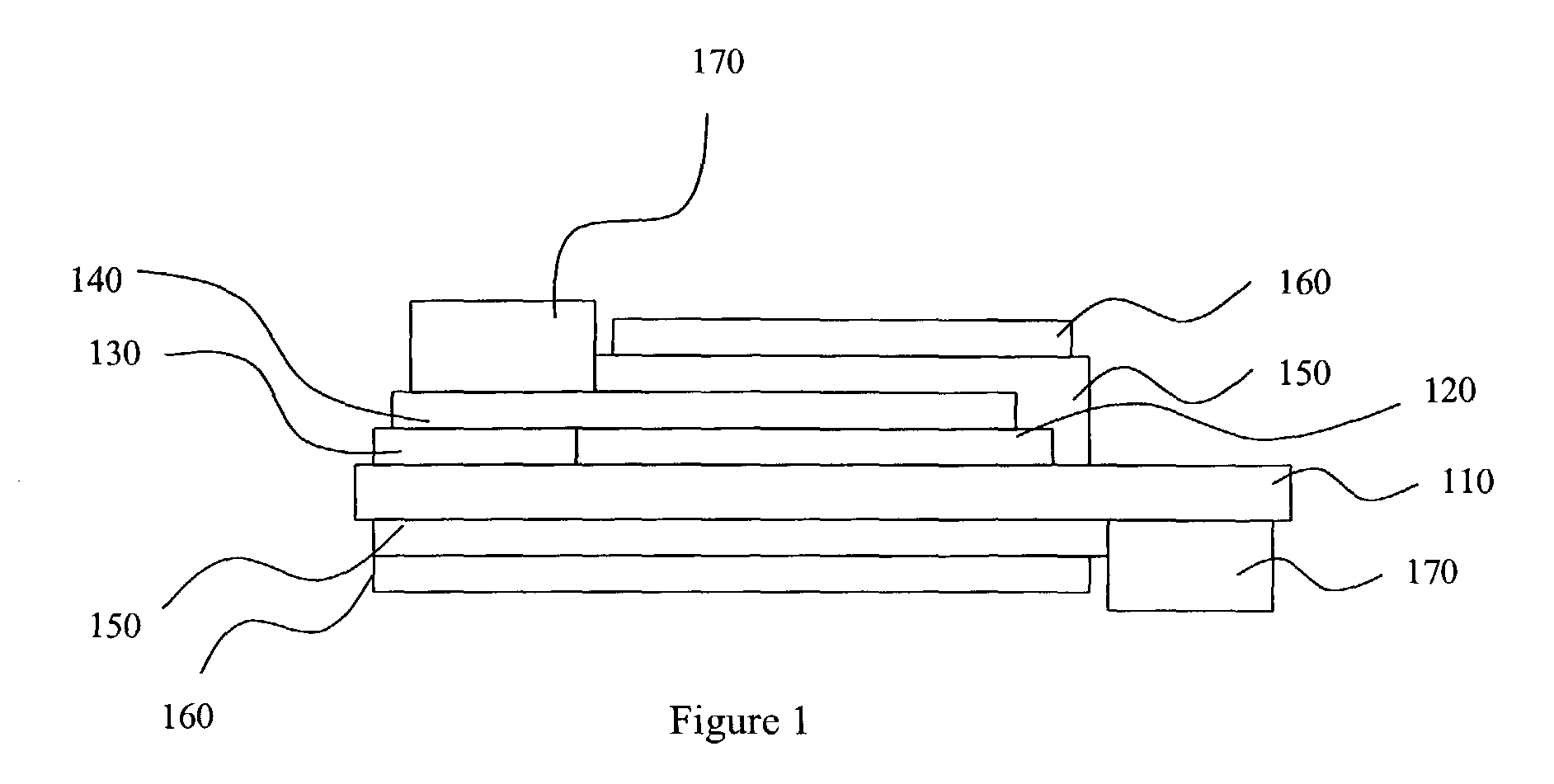

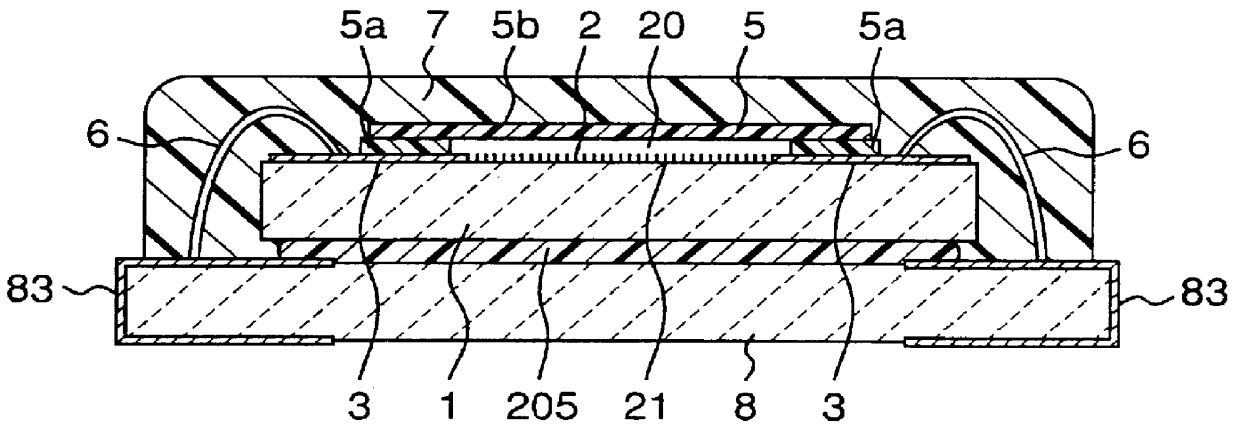

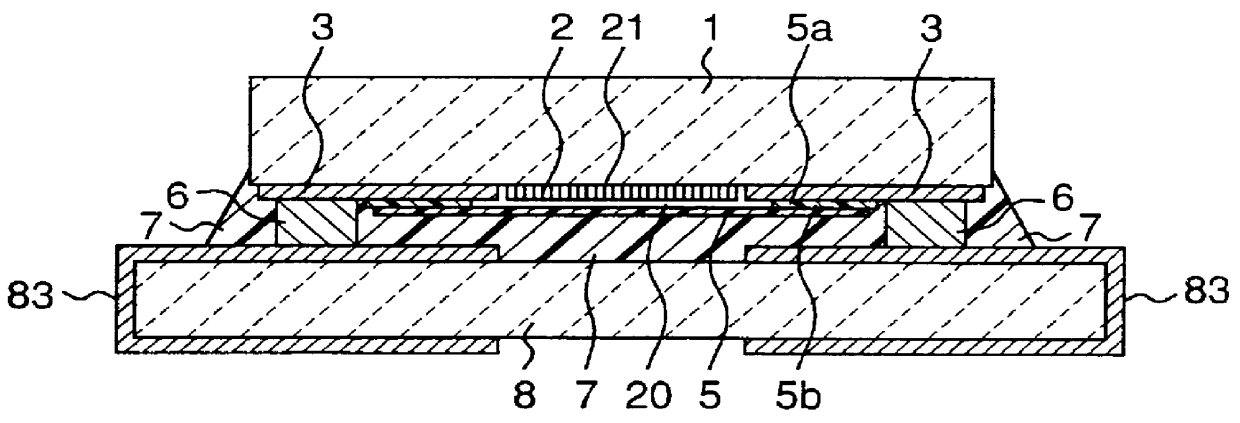

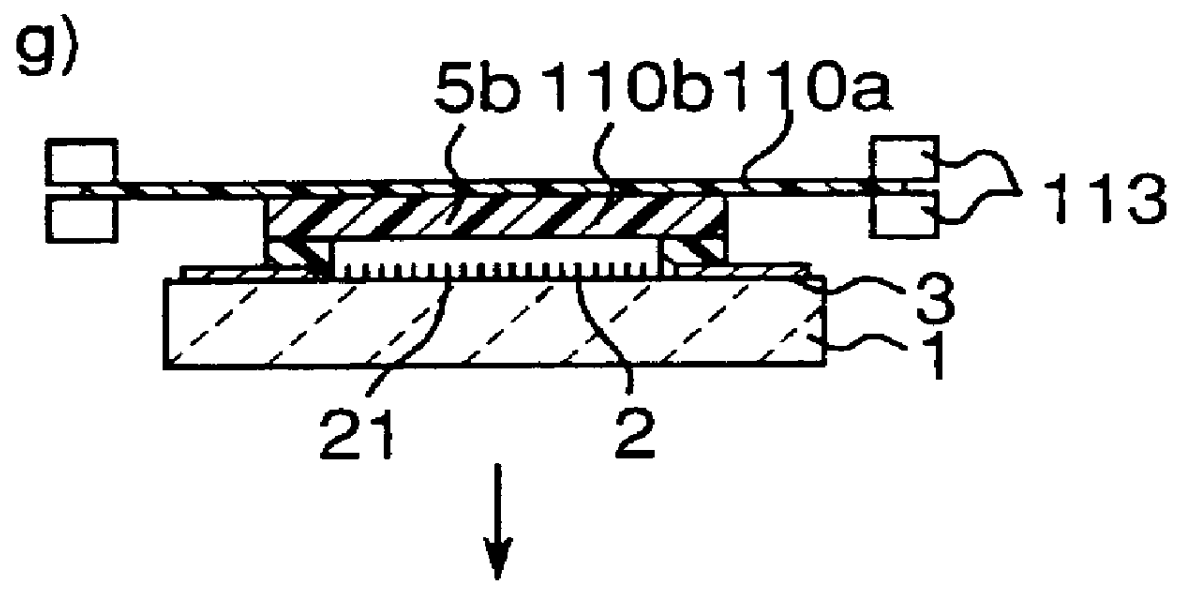

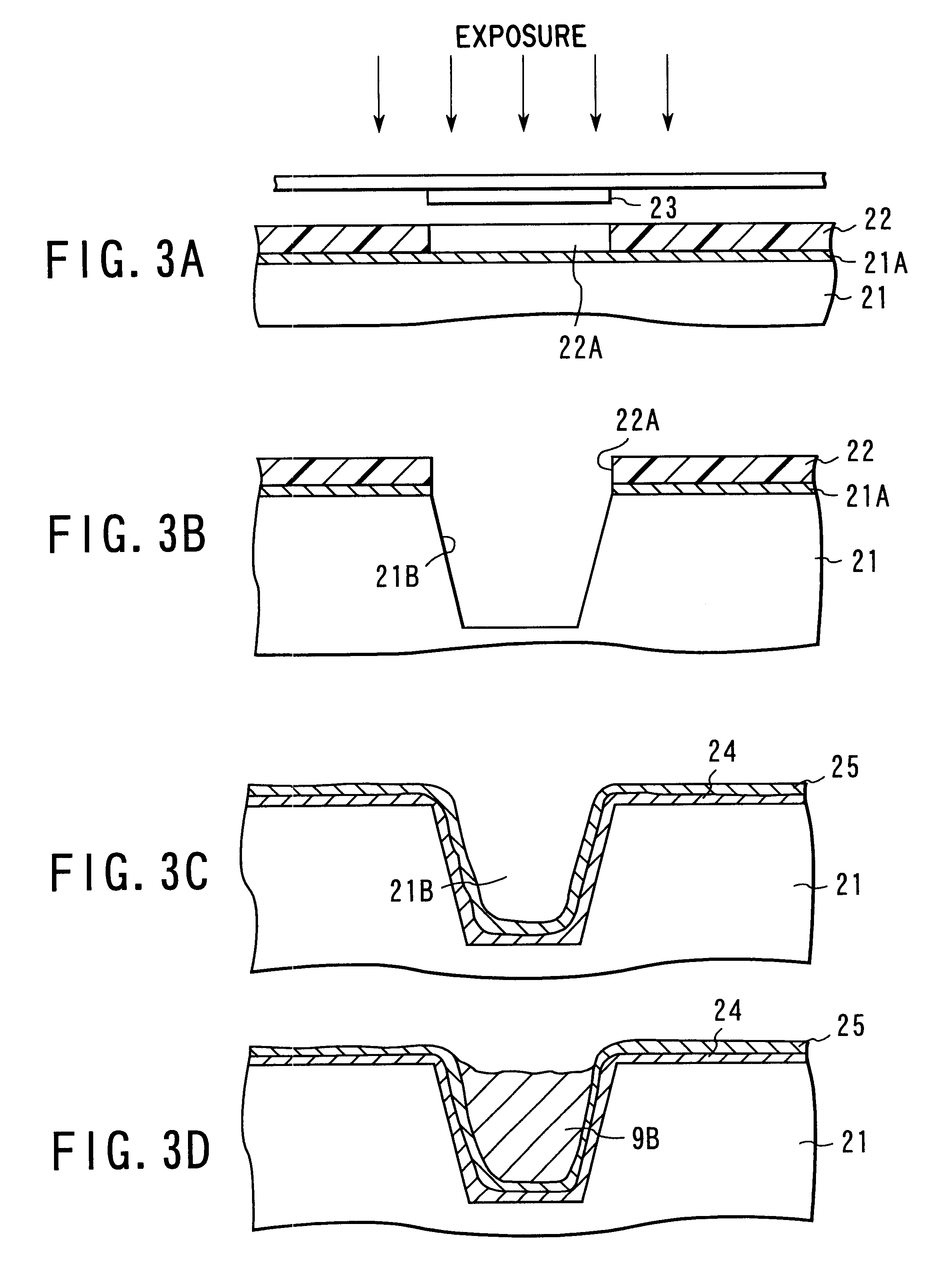

Electronic part and a method of production thereof

InactiveUS6154940APrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyHermetic sealInterconnection

The present invention relates to an electronic part used for mobile communications apparatuses and the like, and more particularly to an electronic part, such as an acoustic surface-wave device, a piezoelectric ceramic device or the like, which requires an oscillation space near the surface of the functional device chip thereof, and a method of production thereof. With this method, a space retainer for forming a sealed space at the functional portion of the chip can be hermetically sealed and have high moisture resistance, and the process of forming the space retainer can be carried out easily. The electronic part of the present invention comprises a functional device chip, a space retainer for forming a sealed space at the functional portion of the chip, a circuit substrate to which the chip is secured, electrode interconnection portions for establishing electric connection between the chip and the circuit substrate, and a sealing resin for covering and sealing at least the space retainer, wherein the space retainer comprises a support layer made of a synthetic resin film, provided with an opening enclosing the functional portion and joined onto the main surface, and a cover formed and joined onto the support layer so as to cover the functional portion and form a sealed space between the cover and the functional portion.

Owner:SKYWORKS PANASONIC FILTER SOLUTIONS JAPAN

Patterned Plexus of Filaments, Method of Producing and Articles Containing Patterned Filaments

ActiveUS20140377488A1Good flexibilityOptimize load distributionSolesLayered productsEngineeringLoad distribution

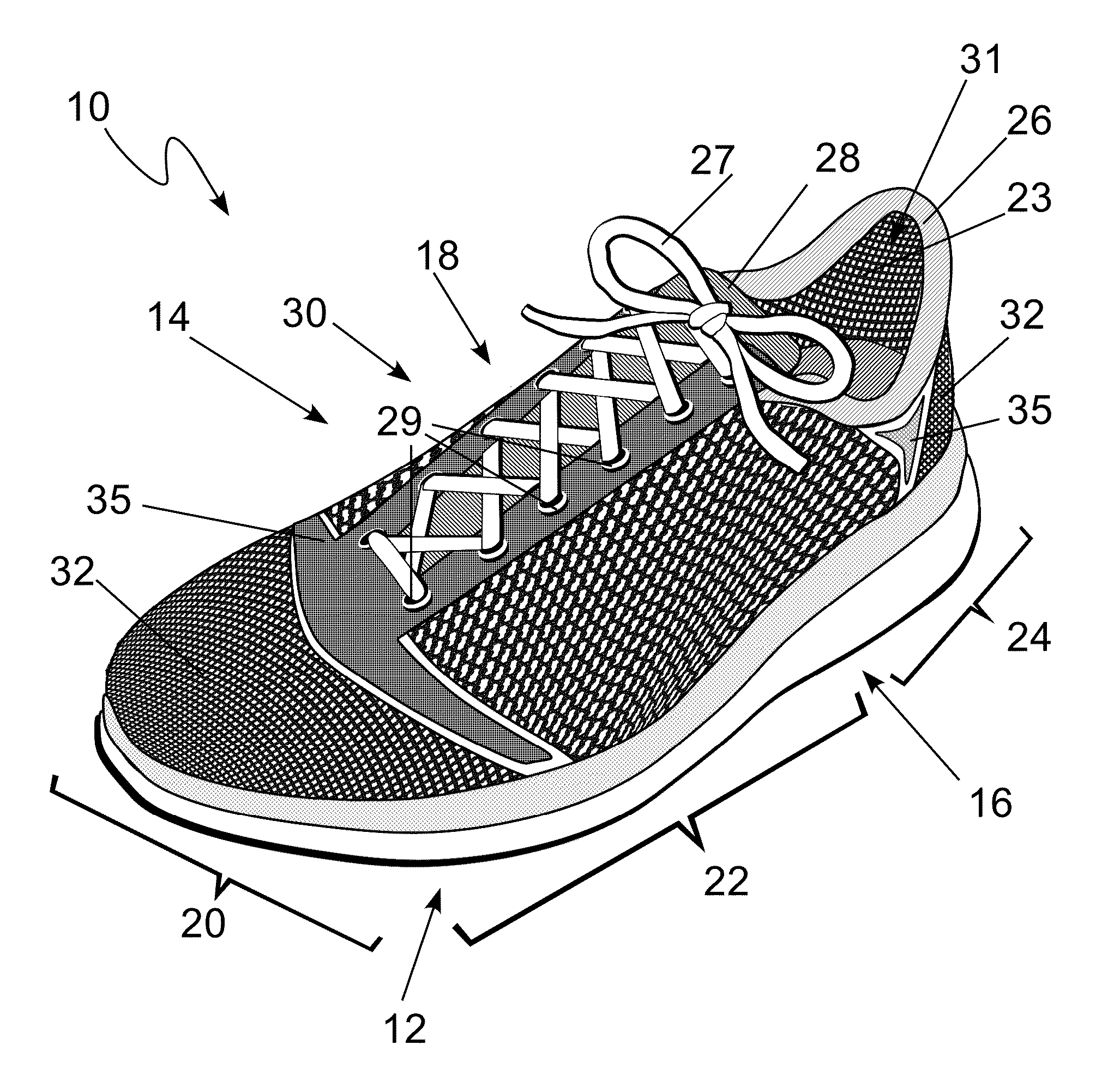

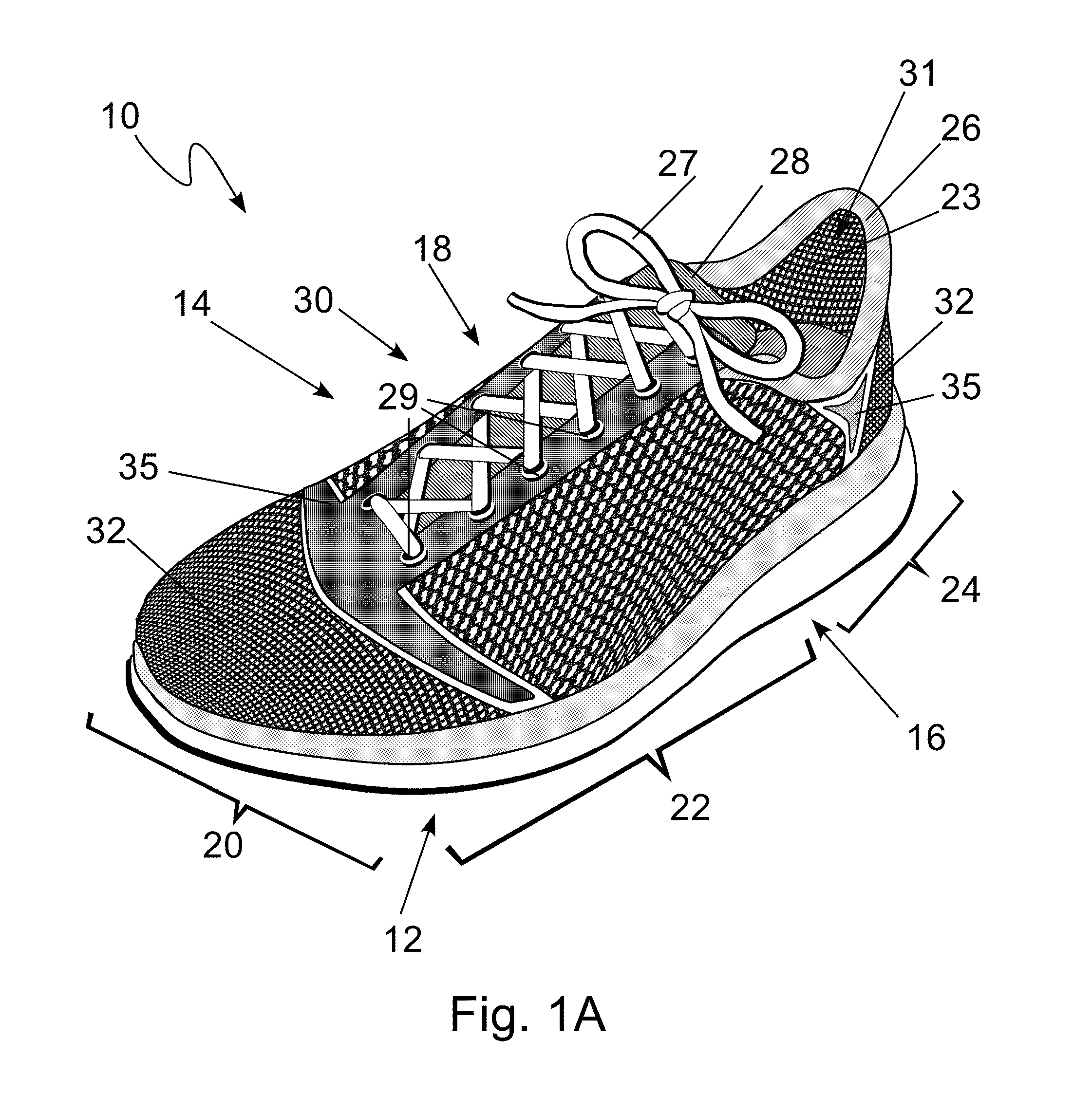

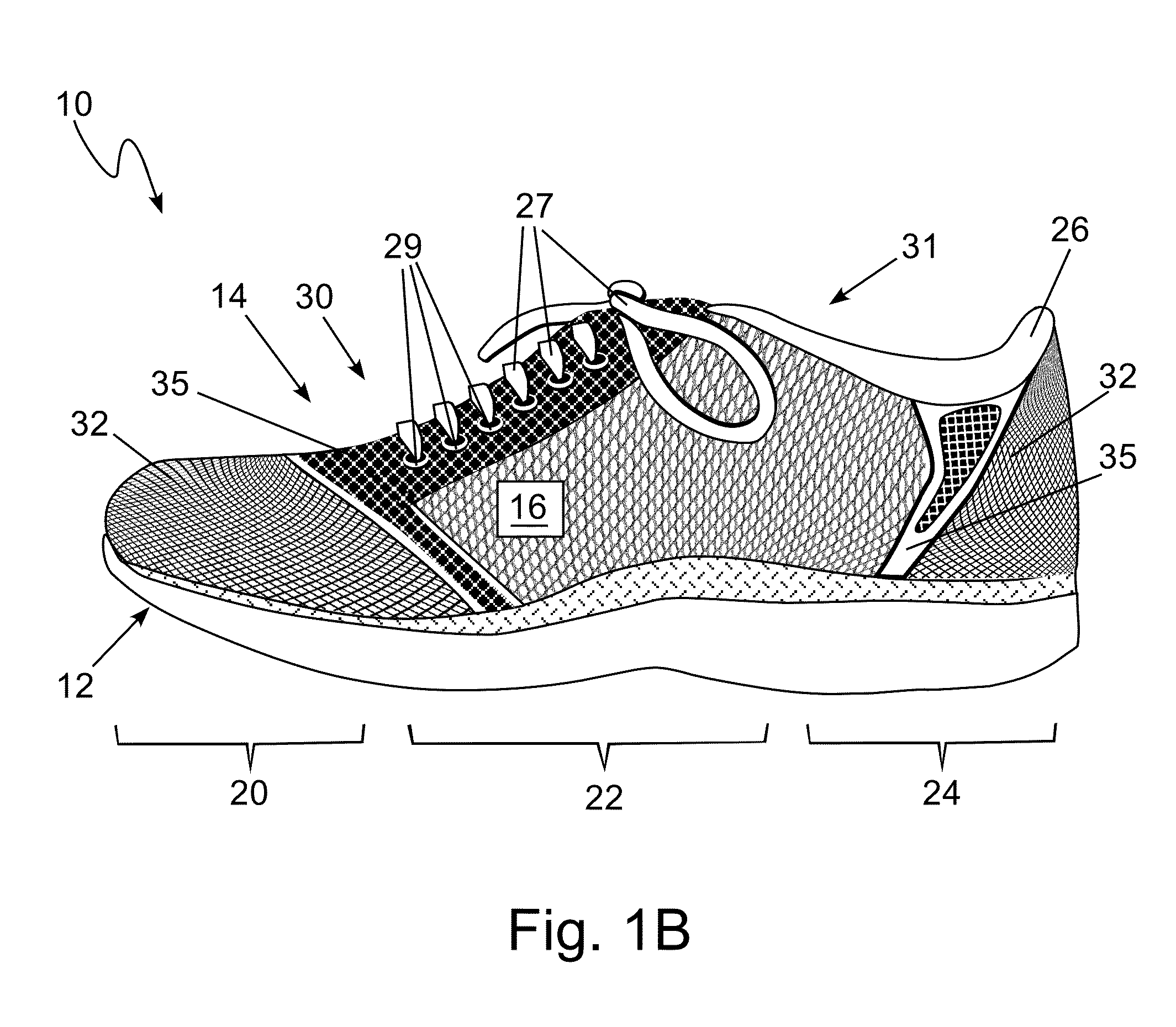

Disclosed herein is a plexus of filaments which is composed of groups of filaments, whose filament members are linked together, in a repetitious pattern, and whose filaments may be interlaced or linked to bisecting groups of filaments, creating a patterned plexus whose filament members generally follow spiraling paths, while linking with neighboring filaments, creating a group, or interlaced groups, of tension distributive filaments within a plexus of filaments; said plexus exhibiting greater conformal and constrictive qualities in comparison to the prior art. Also disclosed is a method of producing filament structures for a variety of uses including composite structures with tension displacement properties, and sporting goods requiring conformal load distribution with minimal weight; such as, running shoes.

Owner:JAMISON BRADFORD C

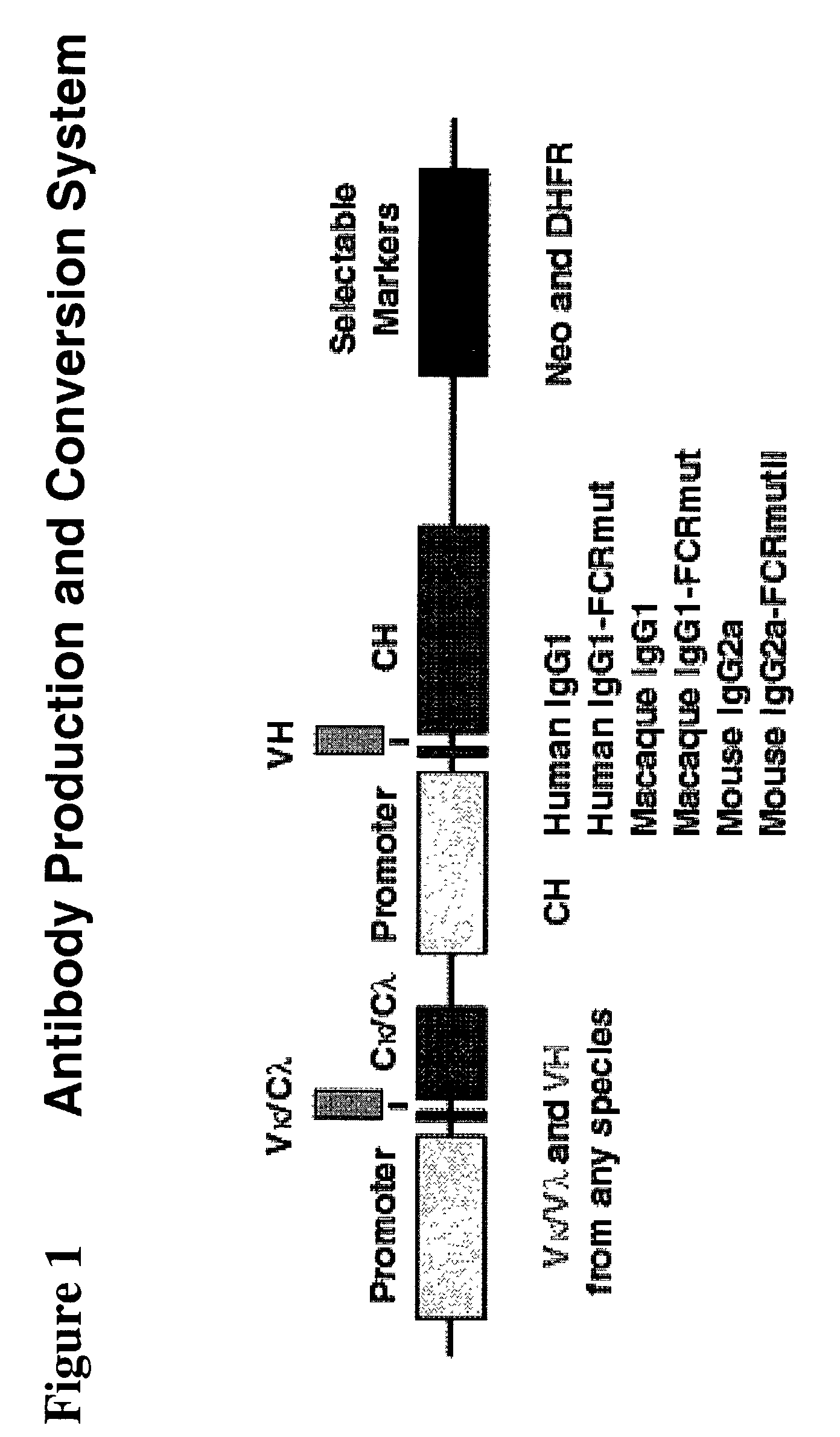

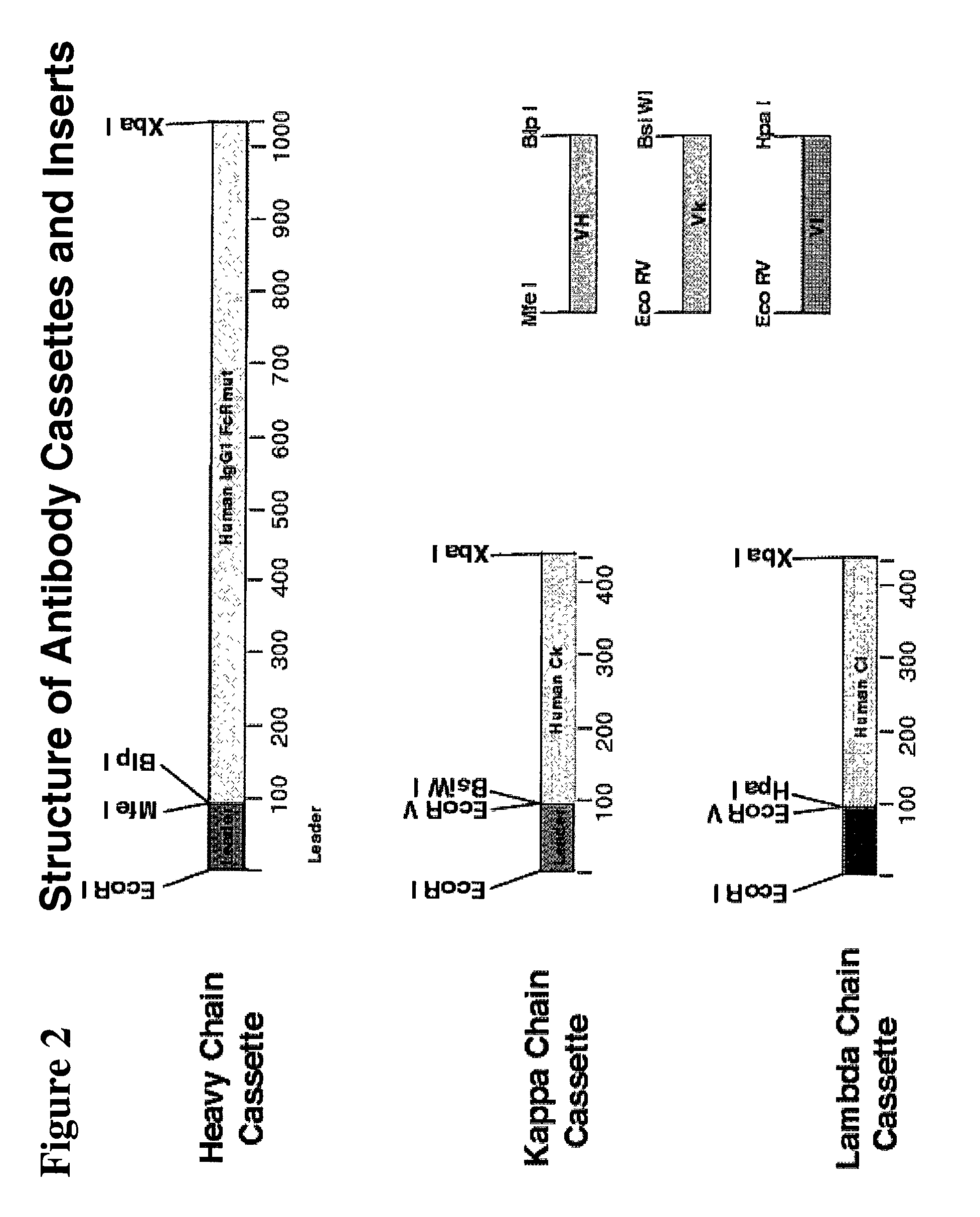

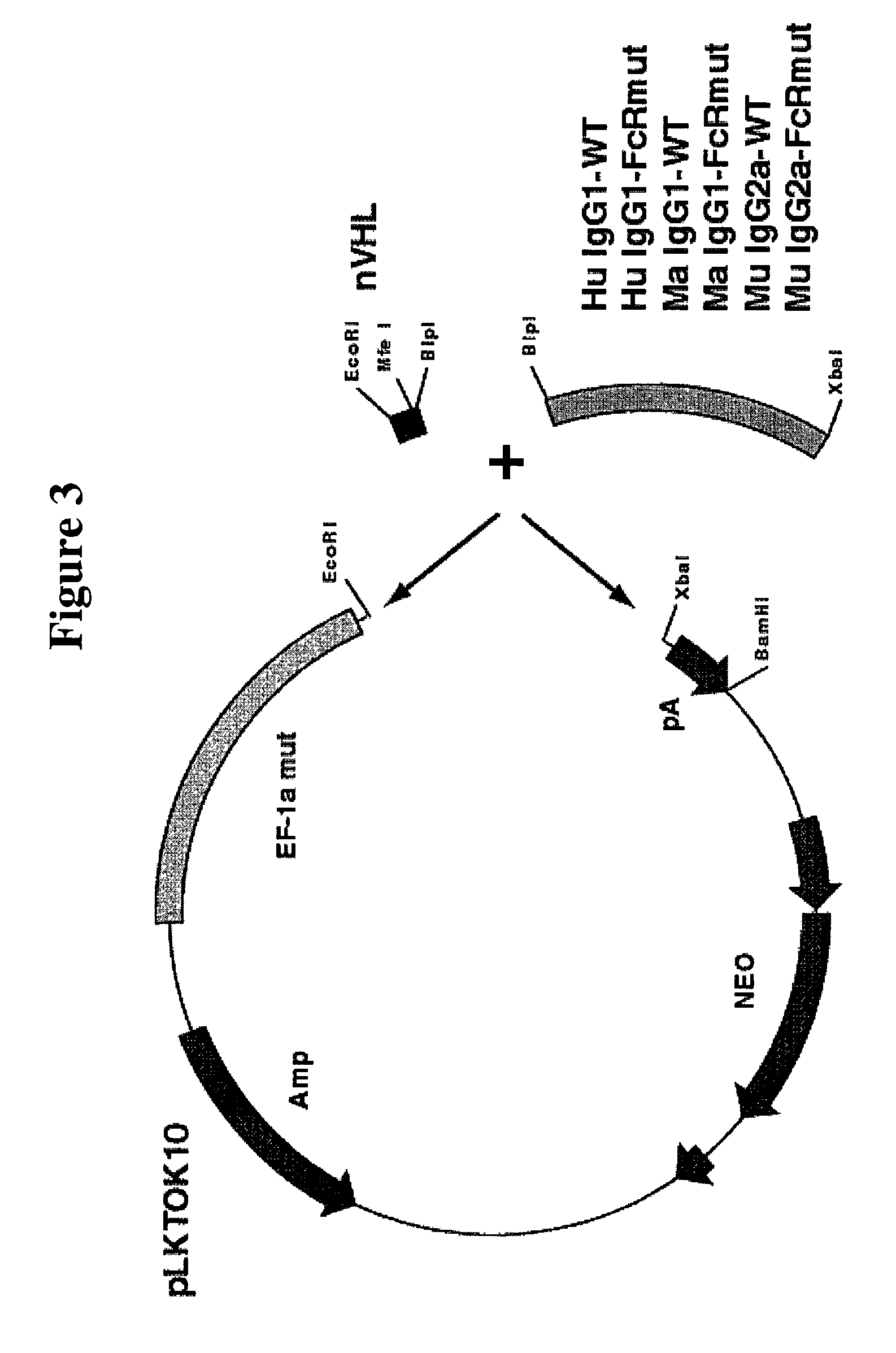

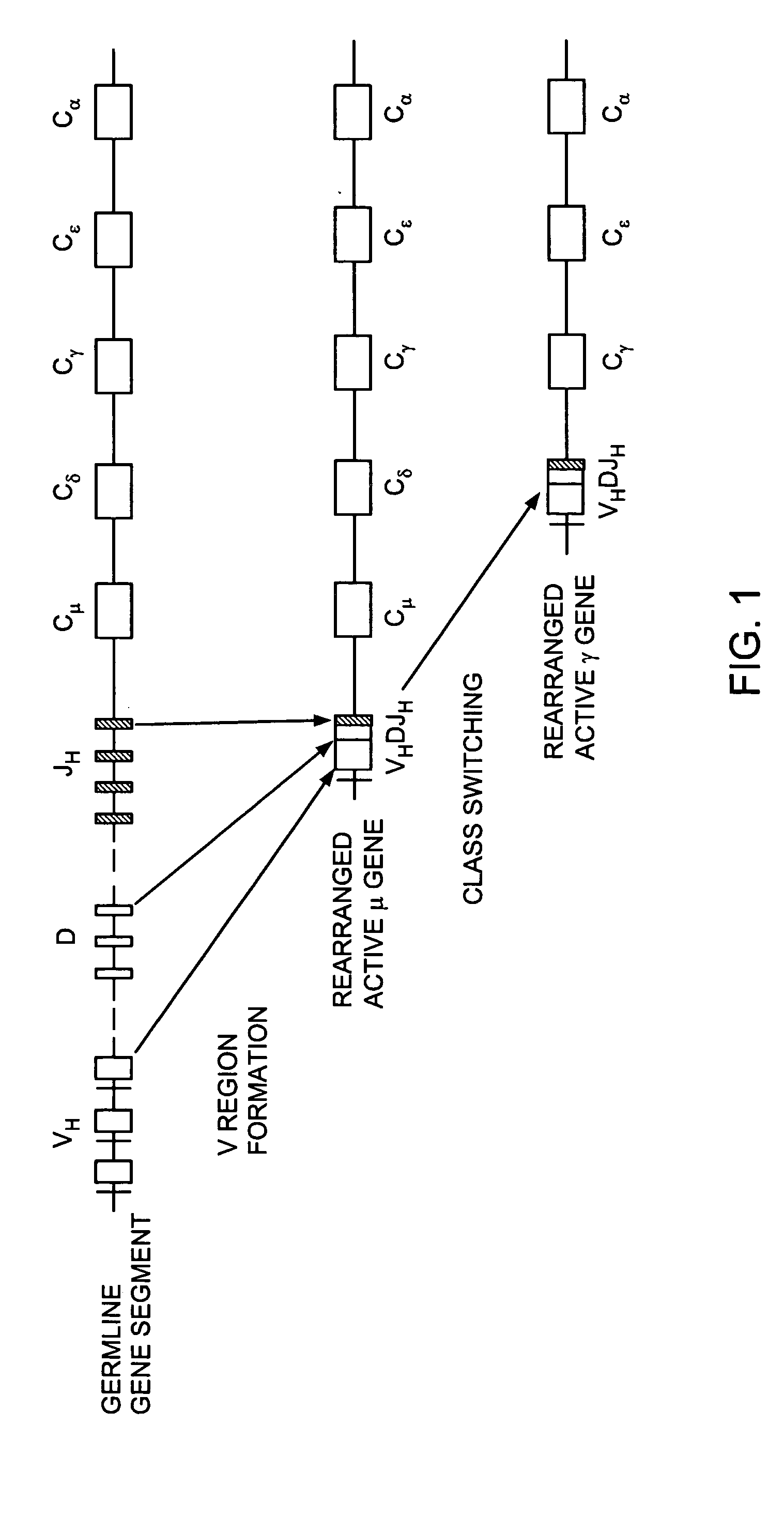

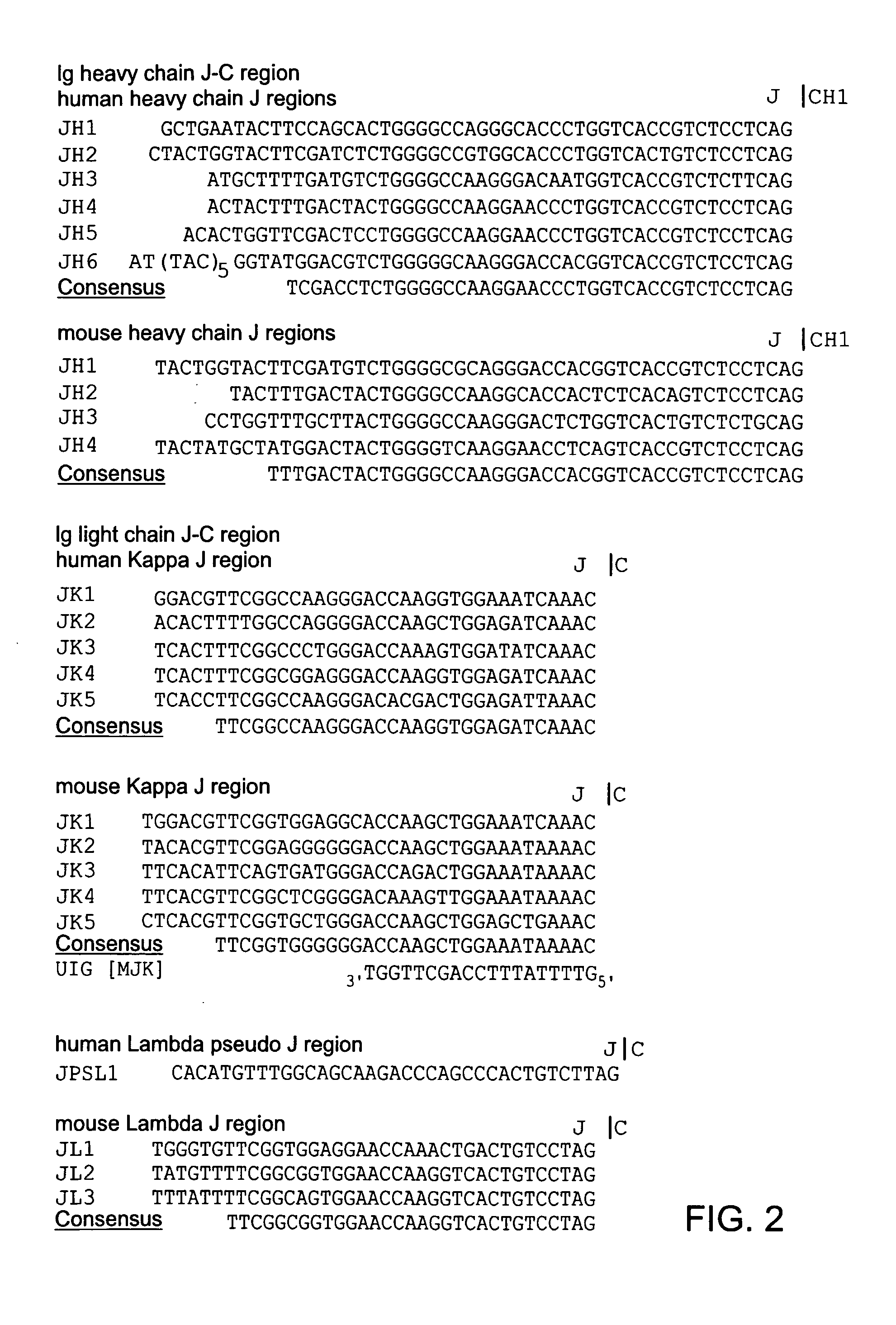

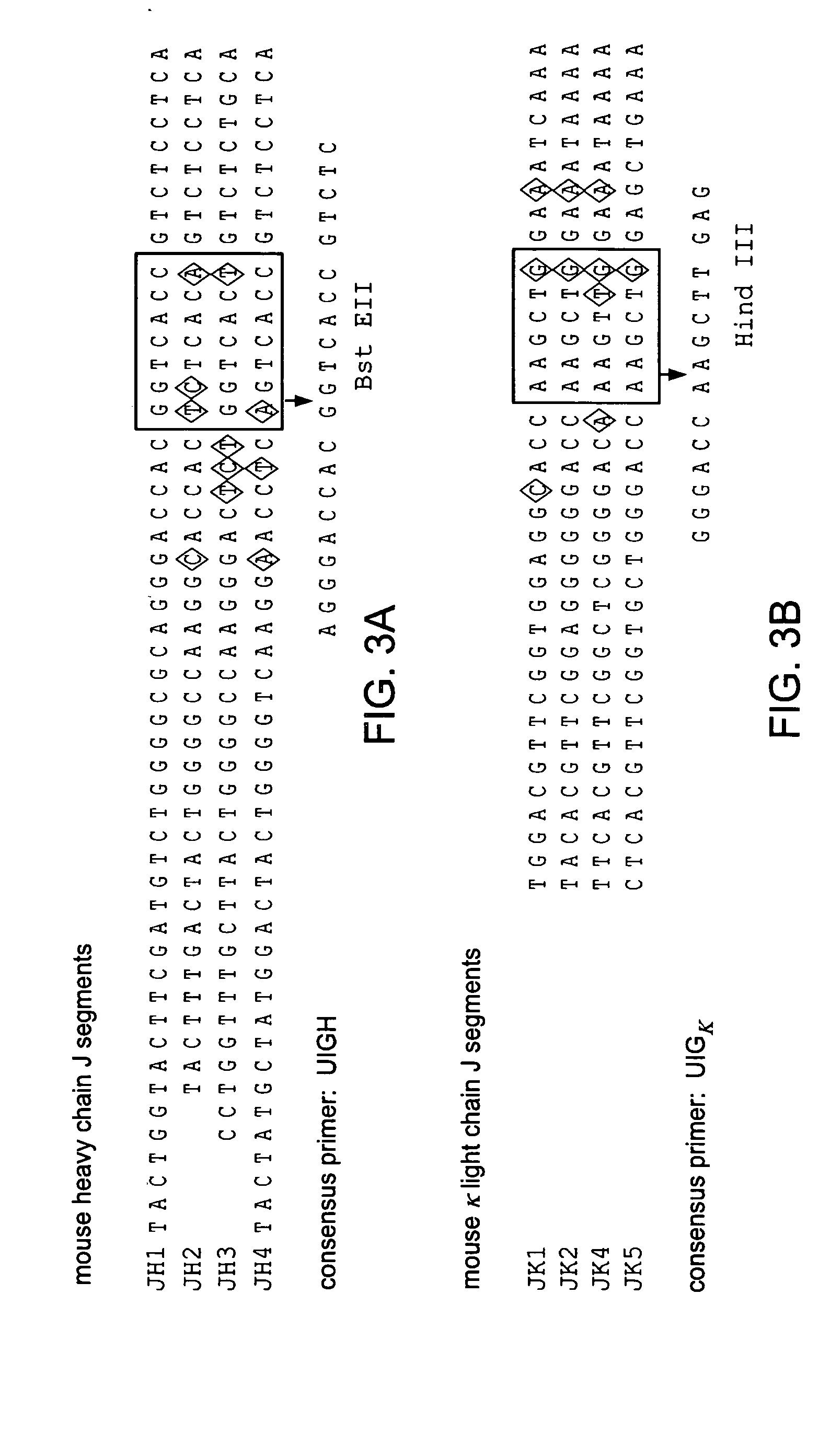

Immunoglobulin DNA cassette molecules, monobody constructs, methods of production, and methods of use therefor

InactiveUS7053202B2Rapid and simple generationAnimal cellsSugar derivativesDna encodingMethods of production

Featured are DNA molecules, expression vectors, and host cells useful for creation of immunoglobulins, as well as novel immunoglobulin molecules termed monobodies. Additionally provided are methods of production of immunoglobulins, including monobodies, as well as methods of using the disclosed immunoglobulin and monobody constructs, expression vectors and host cells containing DNA encoding molecules for production of immunoglobulin and monobody proteins.

Owner:TAKEDA PHARMA CO LTD

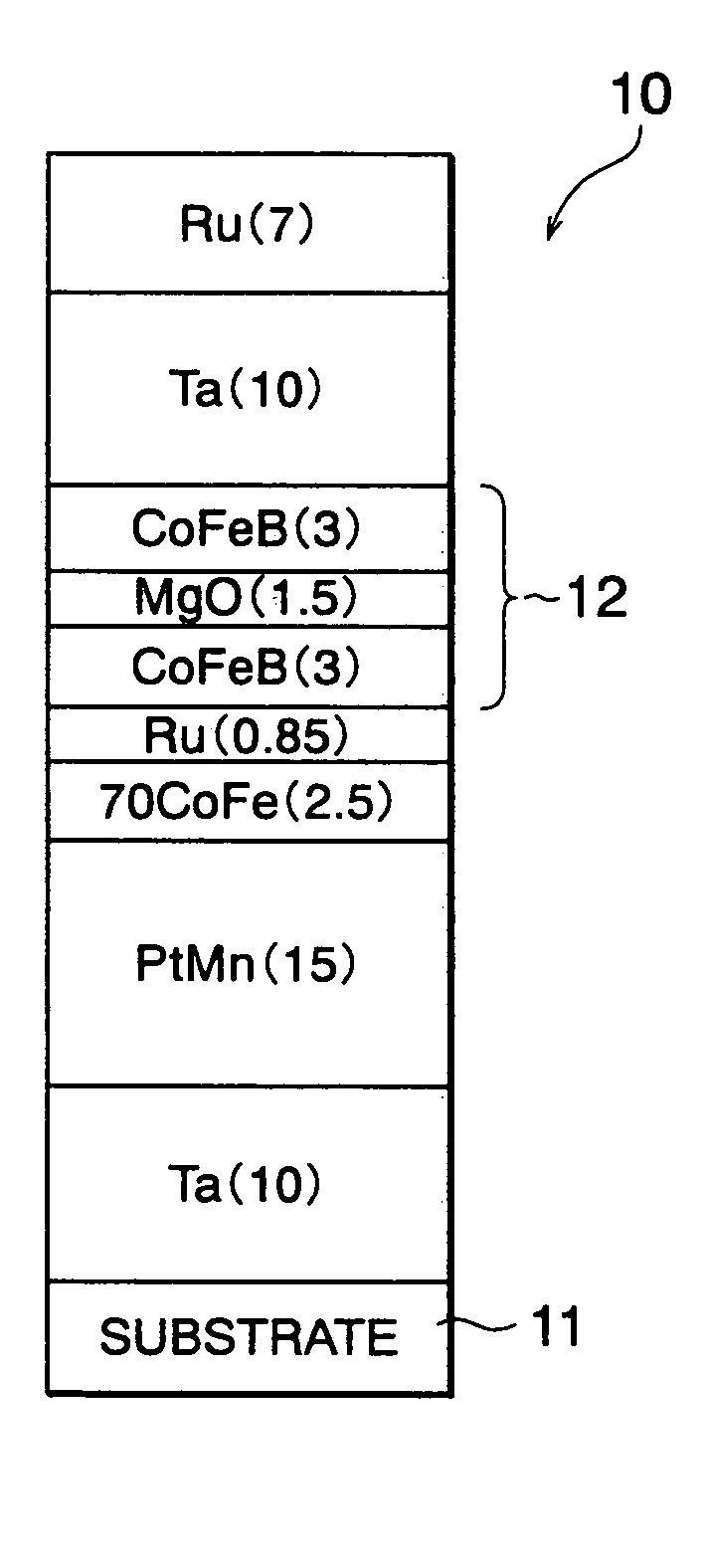

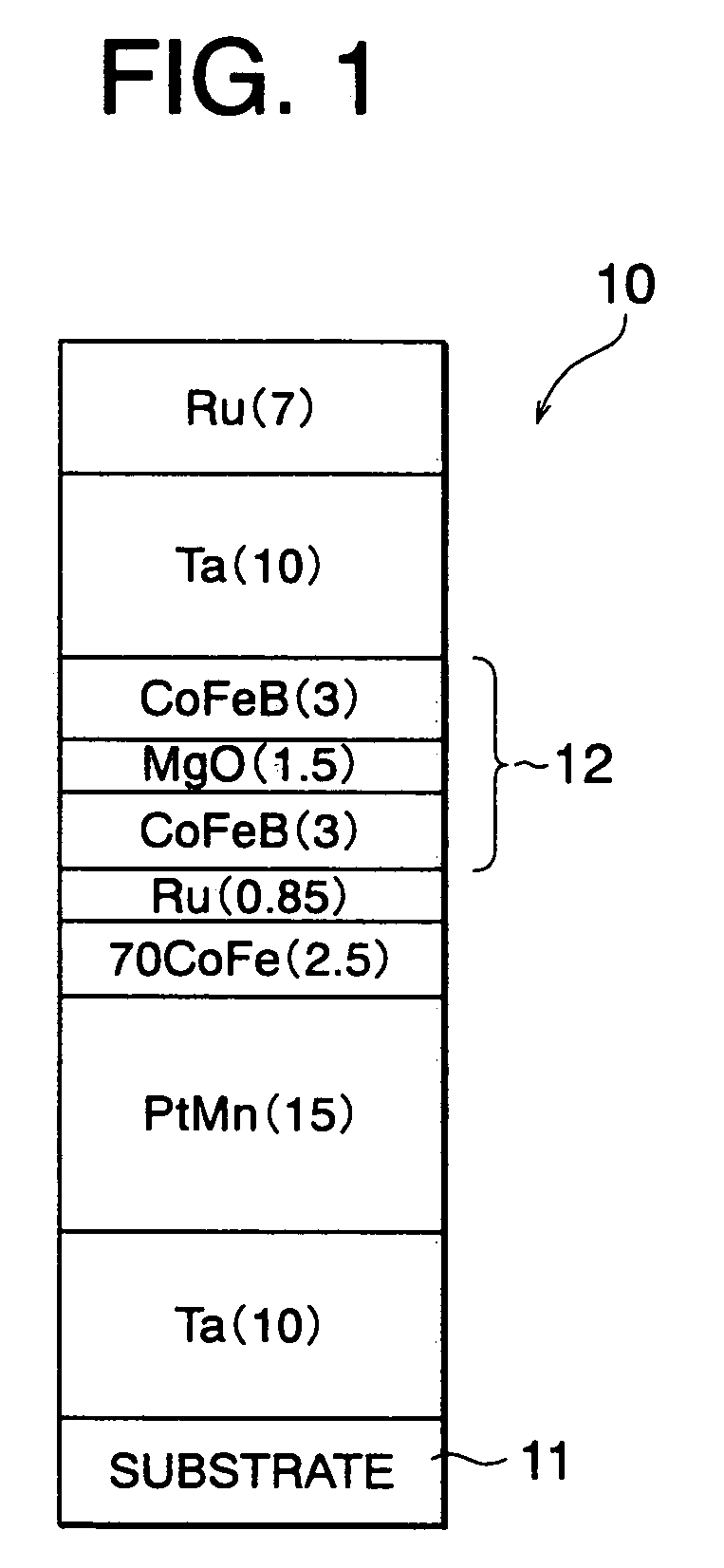

Magnetoresistance effect device and method of production of the same

InactiveUS20060056115A1Increase valueMaintain good propertiesNanomagnetismMagnetic-field-controlled resistorsMethods of productionMolecular physics

A magnetoresistance effect device including a multilayer structure having a pair of ferromagnetic layers and a barrier layer positioned between them, wherein at least one ferromagnetic layer has at least the part contacting the barrier layer made amorphous and the barrier layer is an MgO layer having a highly oriented texture structure.

Owner:CANON ANELVA CORP +1

Chimeric antibody with specificity to human B cell surface antigen

A chimeric antibody with human constant region and murine variable region, having specificity to a 35 kDA polypeptide (Bp35(CD20)) expressed on the surface of human B cells, methods of production, and uses.

Owner:ROBINSON RANDY +2

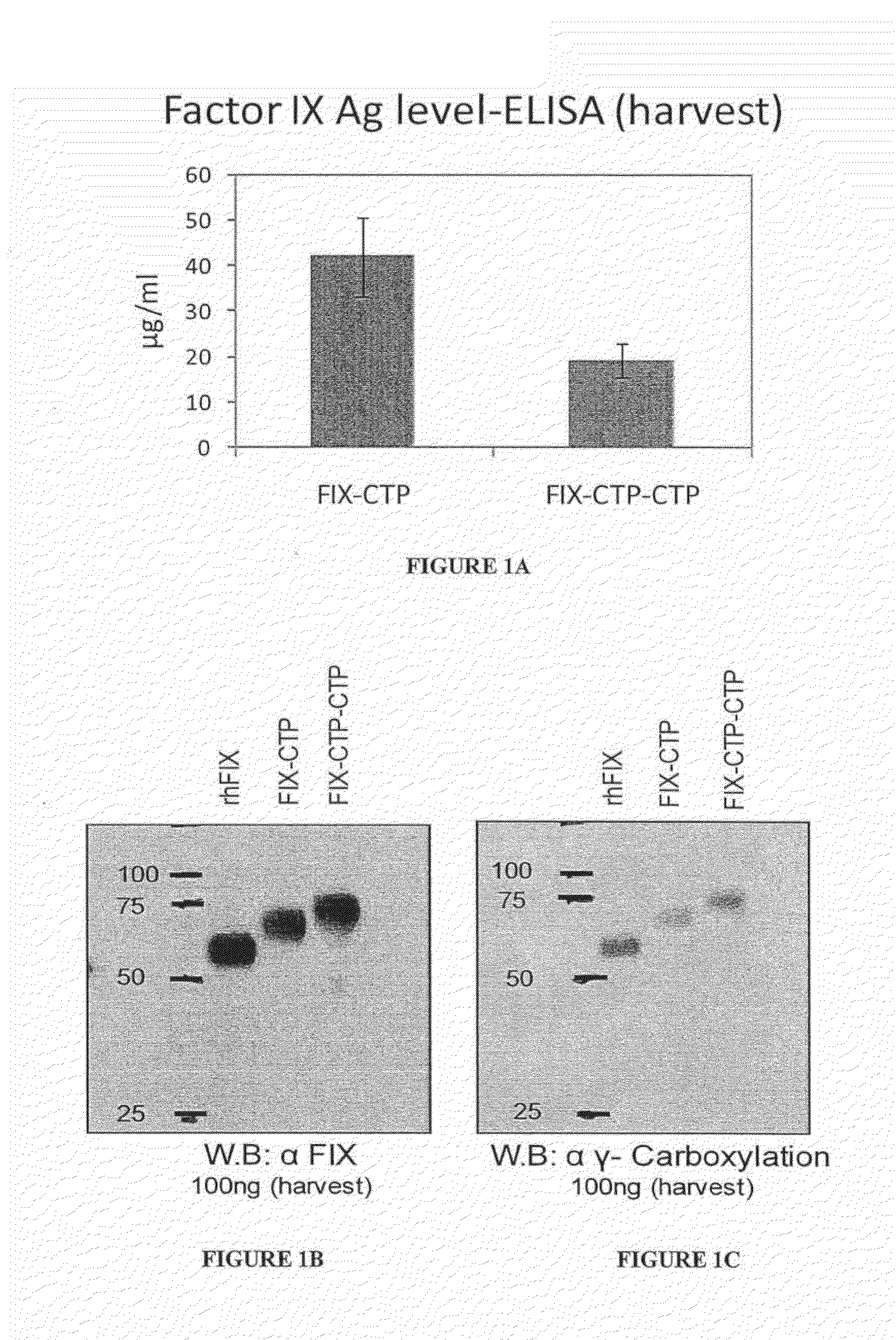

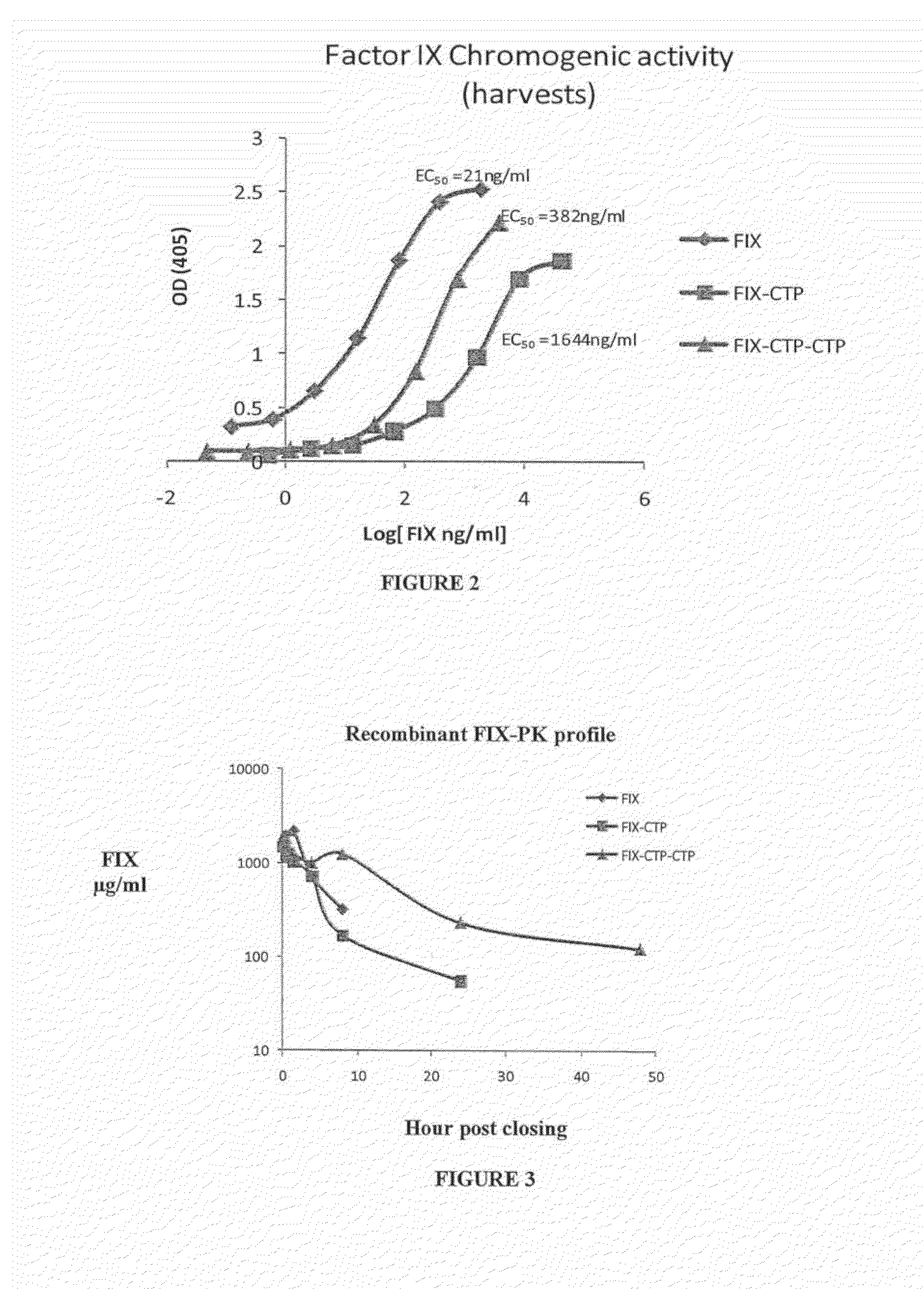

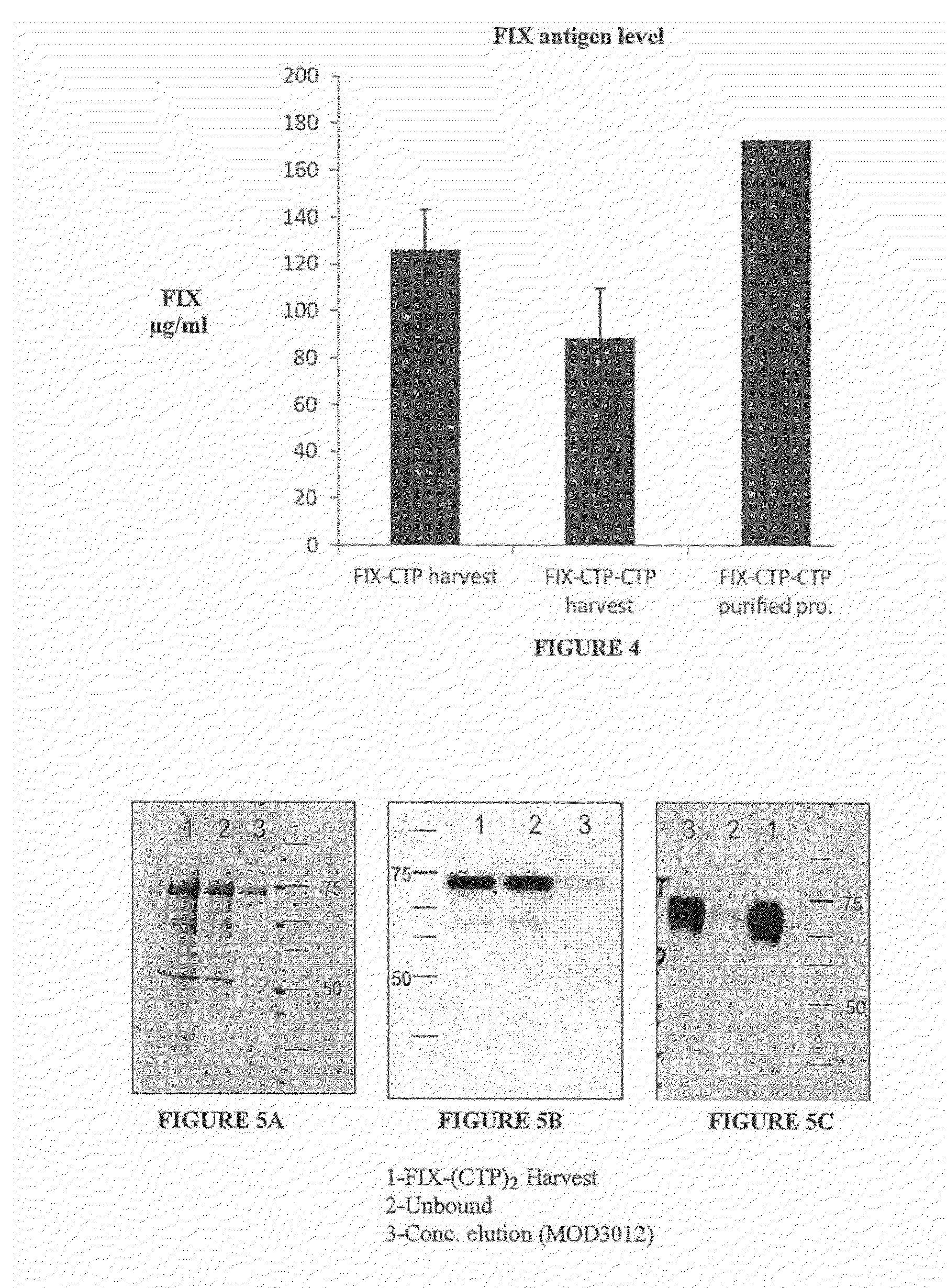

Long-acting coagulation factors and methods of producing same

ActiveUS20130243747A1Prevent coagulationPreventing hemophiliaBacteriaPeptide/protein ingredientsNucleotidePolynucleotide

Polypeptides comprising at least one carboxy-terminal peptide (CTP) of chorionic gonadotrophin attached to the carboxy terminus but not to the amino terminus of a coagulation factor and polynucleotides encoding the same are disclosed. Pharmaceutical compositions comprising the polypeptides and polynucleotides of the invention and methods of using and producing same are also disclosed.

Owner:OPKO BIOLOGICS

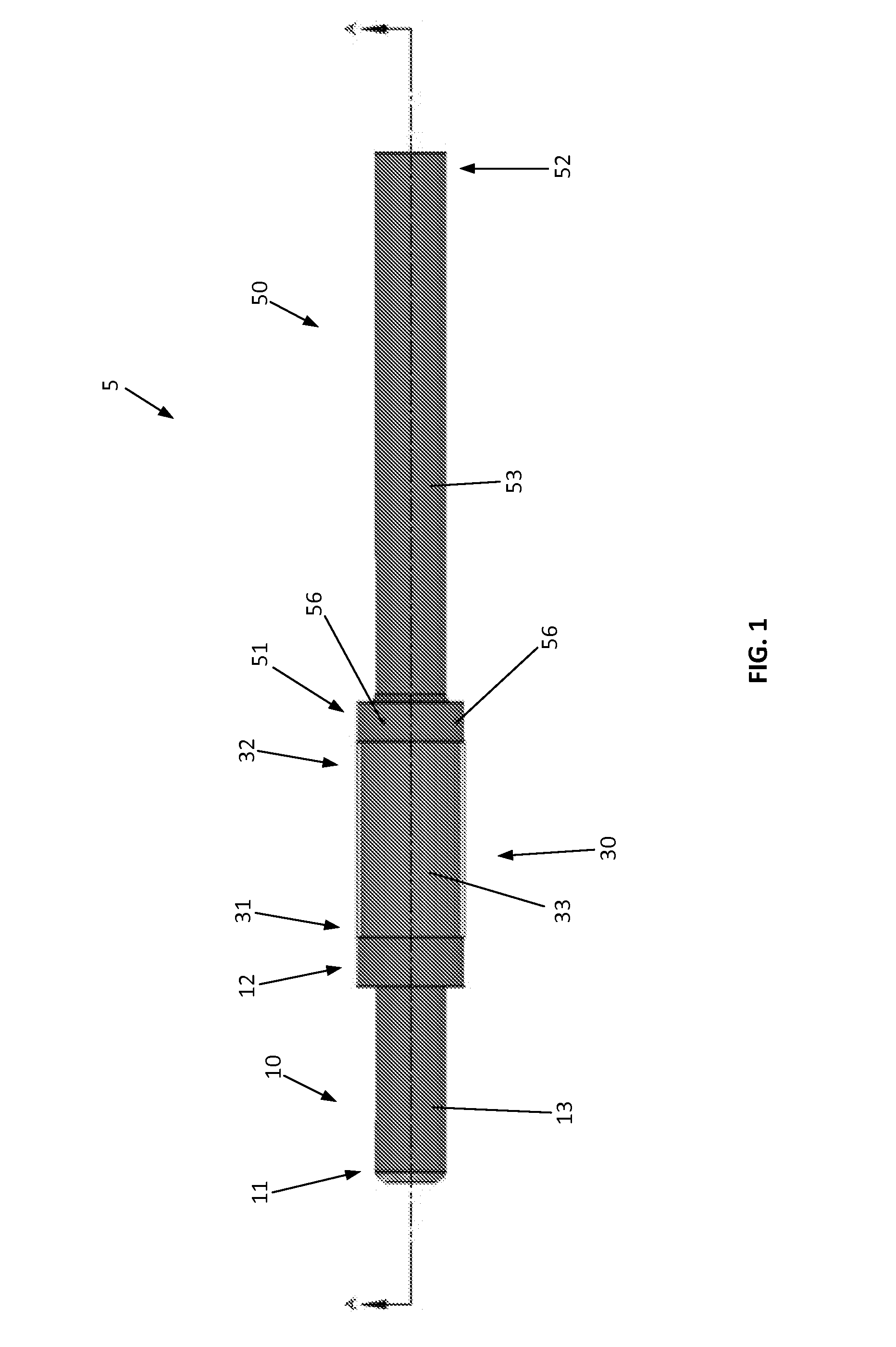

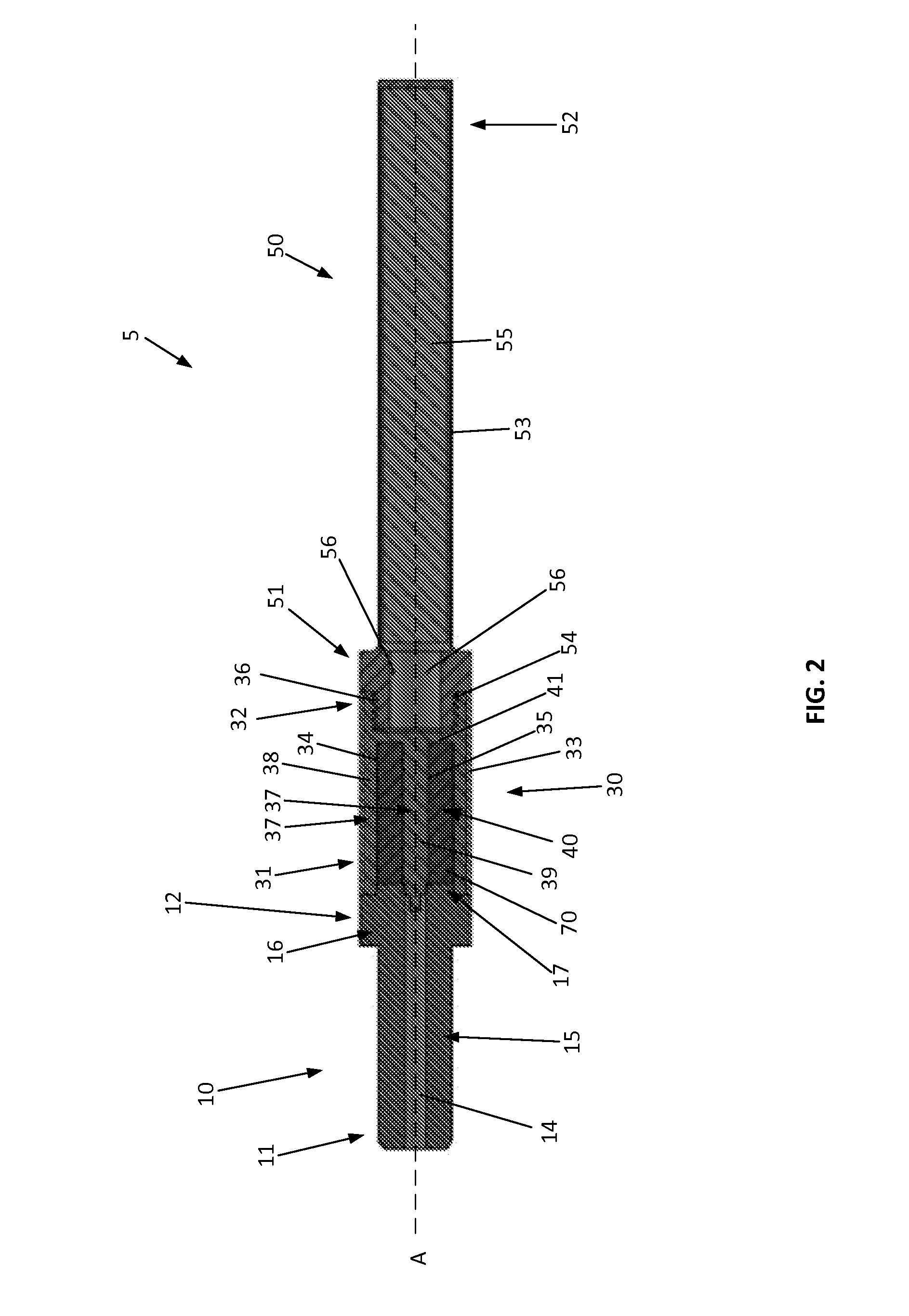

Electronic smoking article including a heating apparatus implementing a solid aerosol generating source, and associated apparatus and method

A smoking article is provided, having a component housing including a power source, and a tubular housing having a first end and a longitudinally-opposed second end, wherein the first or second end is configured to receive the component housing. The tubular housing includes an outer wall defining a cylindrical cavity. An aerosol-generating element is configured to be received within the cylindrical cavity, wherein the aerosol-generating element is configured to produce an aerosol in response to heat. An associated aerosol-generating element and related production methods are also provided.

Owner:RAI STRATEGIC HLDG INC

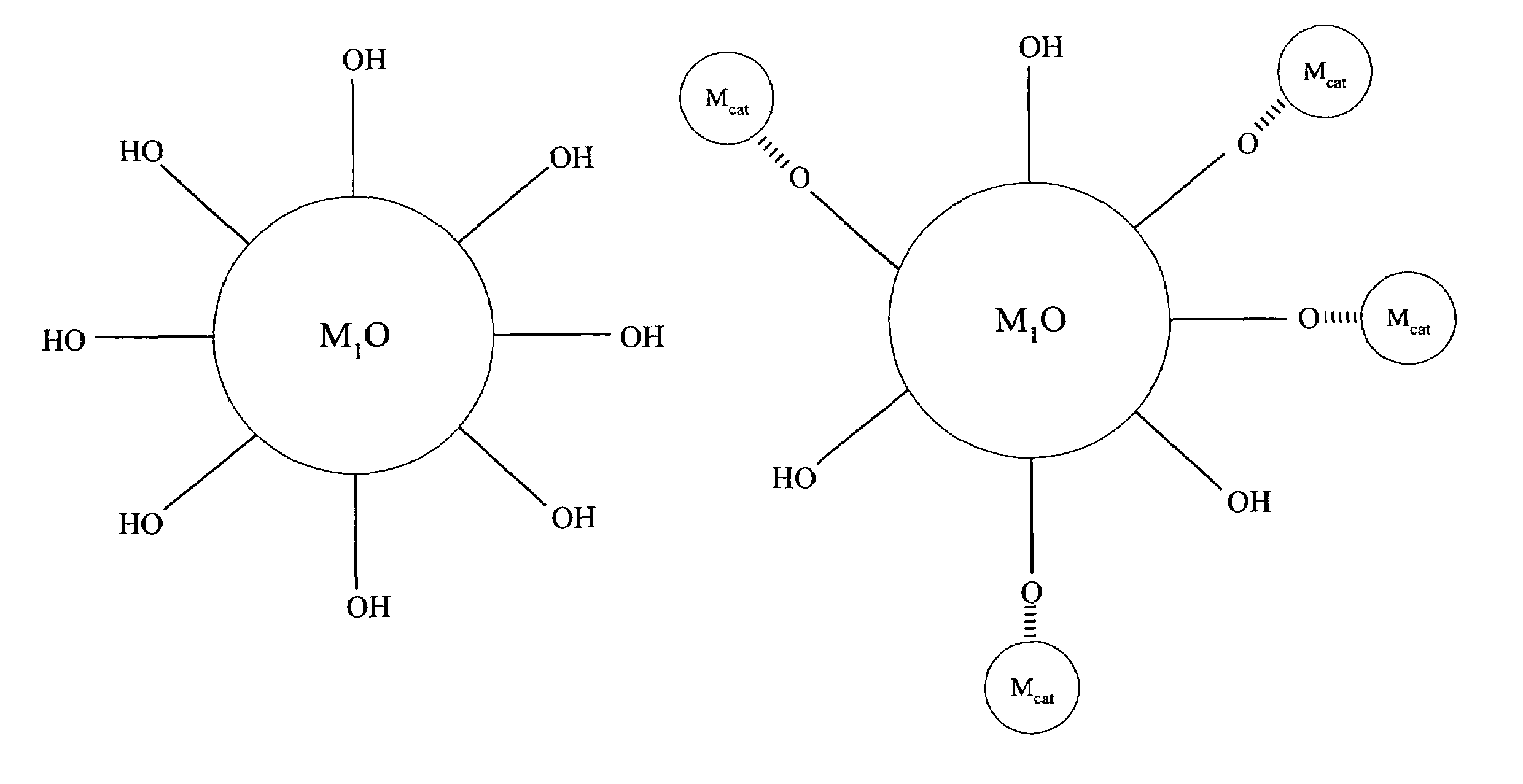

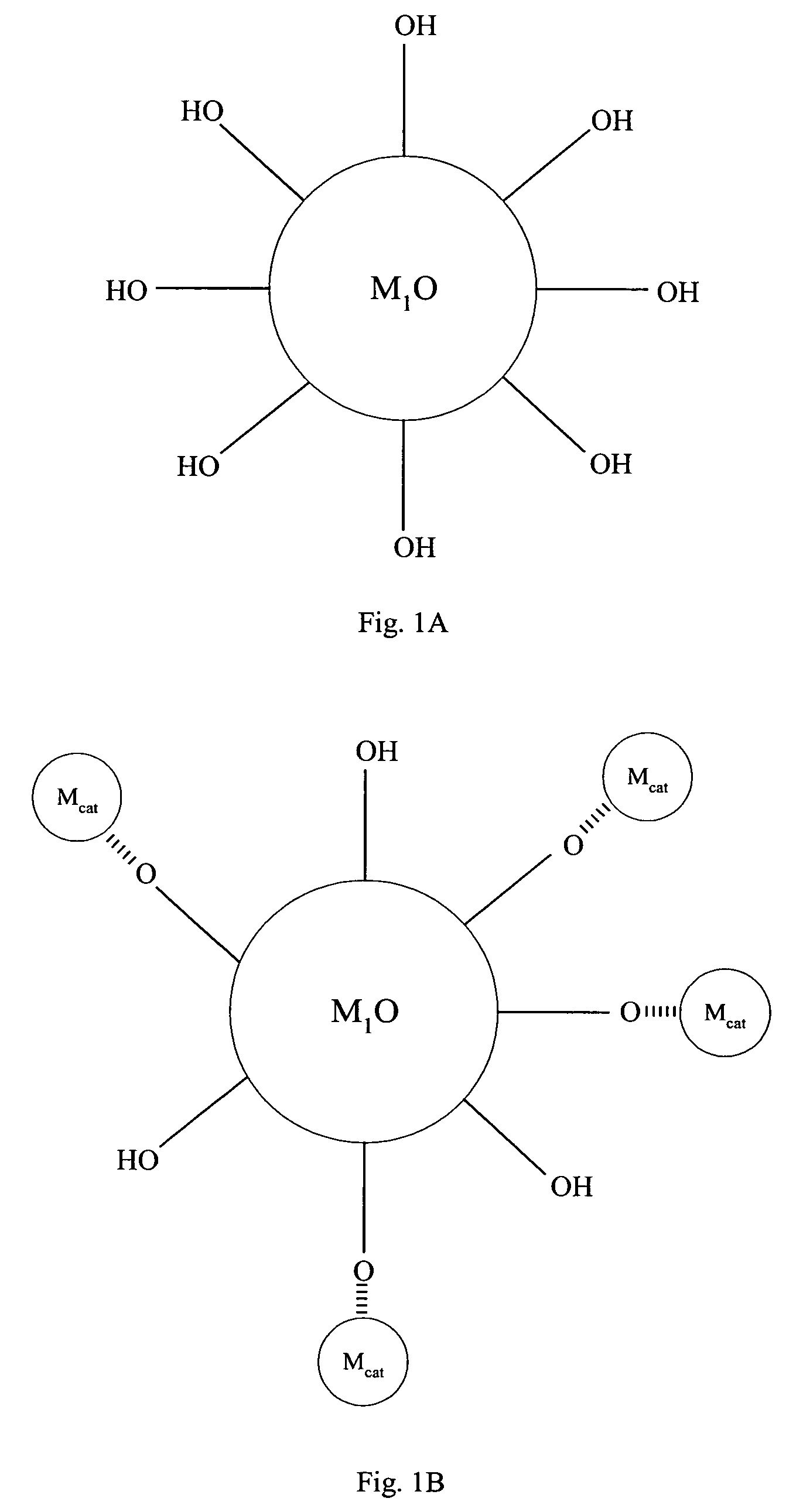

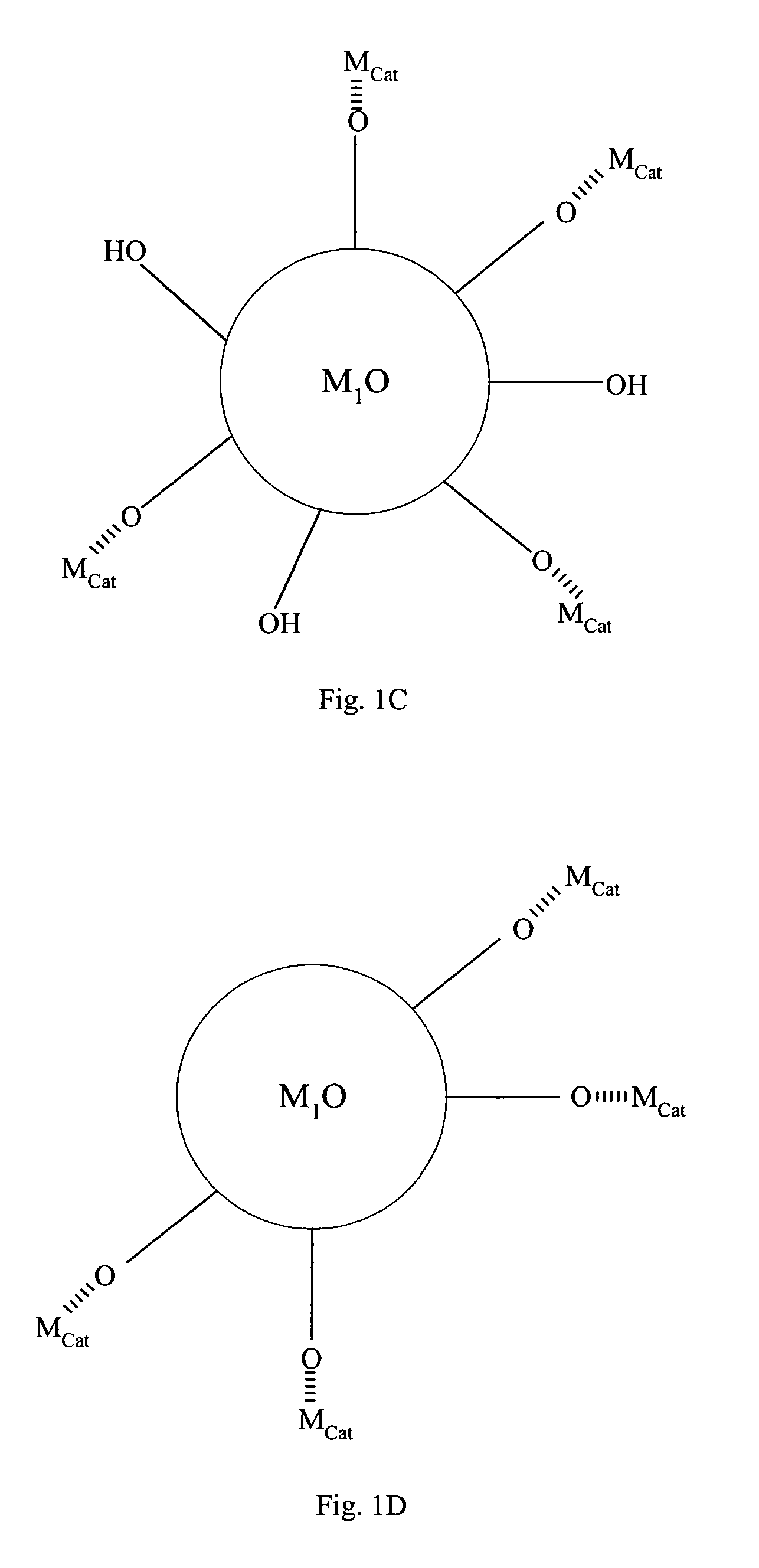

Catalytic material and method of production thereof

ActiveUS7541012B2High metal dispersionGas treatmentOrganic chemistryMetal catalystMethods of production

The present invention features a catalytic material which includes a metal catalyst anchored to a nano-sized crystal containing a metal oxide. Furthermore, the present invention features a method of producing the catalytic material described herein. Finally, the present invention features using the catalytic material for removing contaminants and for getting the desired products.

Owner:THE HONG KONG UNIV OF SCI & TECH

Oil country tubular goods excellent in collapse characteristics after expansion and method of production thereof

InactiveUS20050217768A1Excellent in collapse characteristicSmall rate of dropFurnace typesHeat treatment furnacesMethods of productionSteel belt

The present invention provides a method of production of oil country tubular goods having a small drop in collapse pressure after expansion and having a collapse pressure recovering by low temperature ageing at about 100° C. and oil country tubular goods obtained by this method of production. This method of production comprises hot rolling a steel slab having amounts of addition of C, Mn, P, S, Nb, Ti, Al, and N in specific ranges and having a balance of iron and unavoidable impurities and shaping the steel strip coiled at a temperature of not more than 300° C. as it is into a tube. Alternatively, it comprises heating steel pipe having amounts of addition of C, Mn, P, S, Nb, Ti, Al, and N in specific ranges and having a balance of iron and unavoidable impurities to a temperature of the Ac3 [° C.] to 1150° C., then cooling it in a range of 400 to 800° C. at a rate of 5 to 50° C. / second.

Owner:NIPPON STEEL CORP

Soluble salt ceramic tile and production method thereof

The invention discloses a soluble salt ceramic tile and a production method thereof. The method comprises the following steps: (1) preparing ceramic tile powder for later use by a conventional method; (2) preparing a water-soluble soluble salt ink for the soluble salt ceramic tile; (3) preparing surface paste of the soluble salt ceramic tile; (4) preparing a ceramic tile green compact; (5) drying; (6) applying the surface paste; (7) carrying out ink-jet printing; (8) drying and firing; (9) edging; and (10) sorting, packaging and warehousing. The invention solves the following problems in the soluble salt ceramic tile production process in the prior art: the pattern obtained by the soluble salt technique does not have bright and abundant colors; in the subsequent polishing process, the consumption of the grinding material, energy sources and industrial water is high, and abundant polishing waste is generated, thereby influencing and polluting the environment; and the soluble salt ceramic tile has high requirements for the green compact raw materials, thereby causing increase of production cost and great waste of resources. The production method disclosed by the invention is more environment-friendly and economic, and has more abundant decorative effects.

Owner:HANGZHOU NABEL CERAMIC

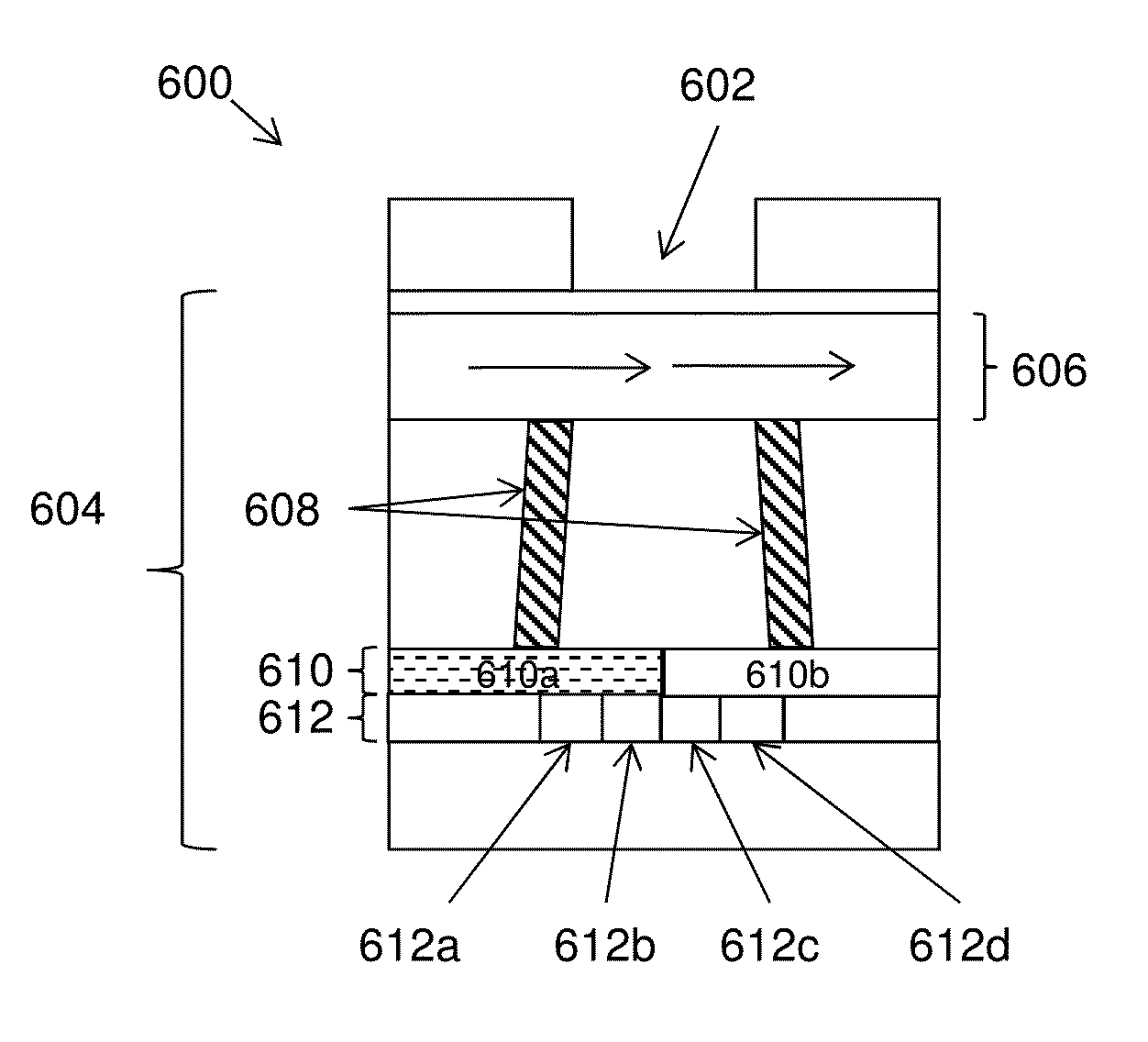

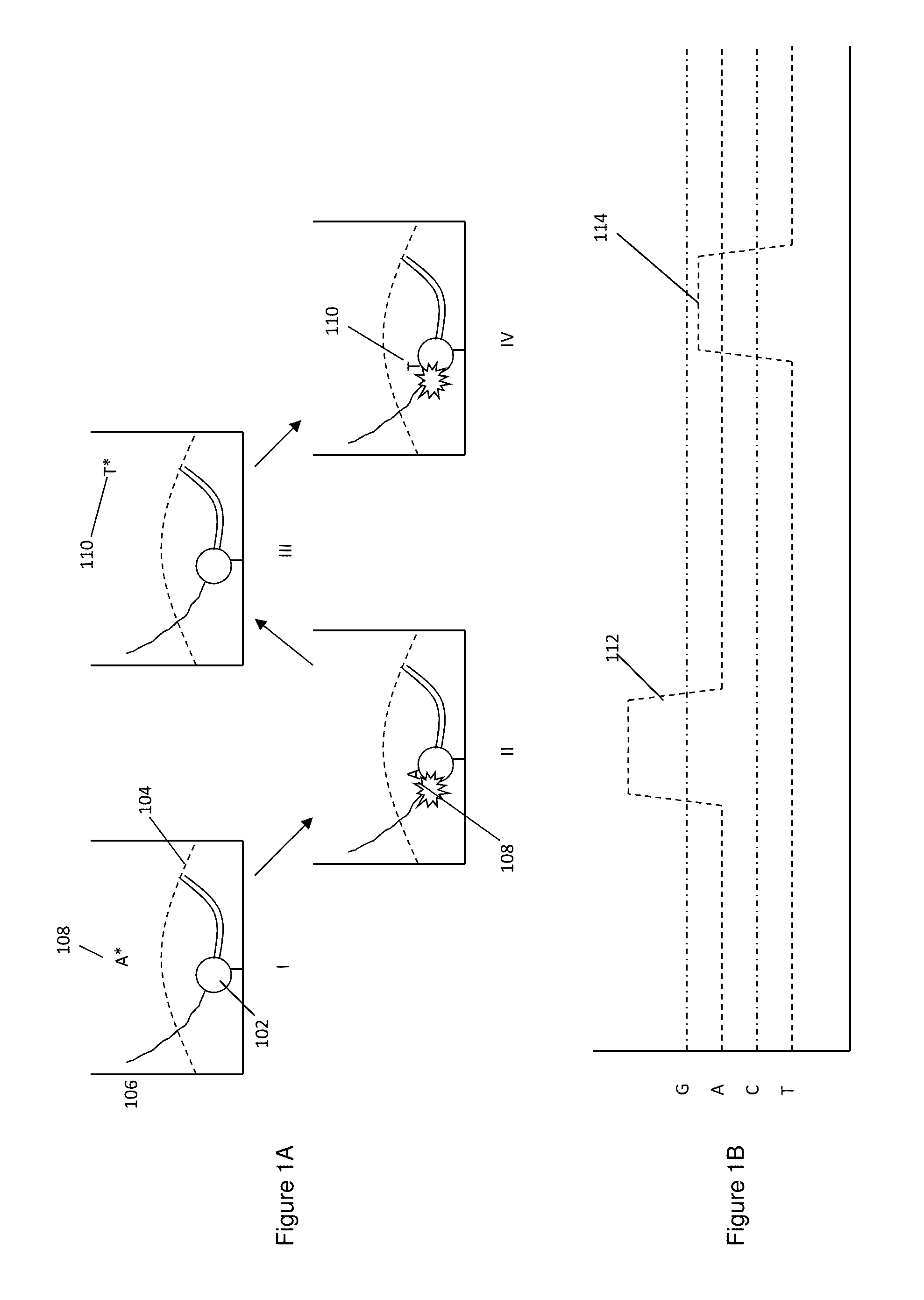

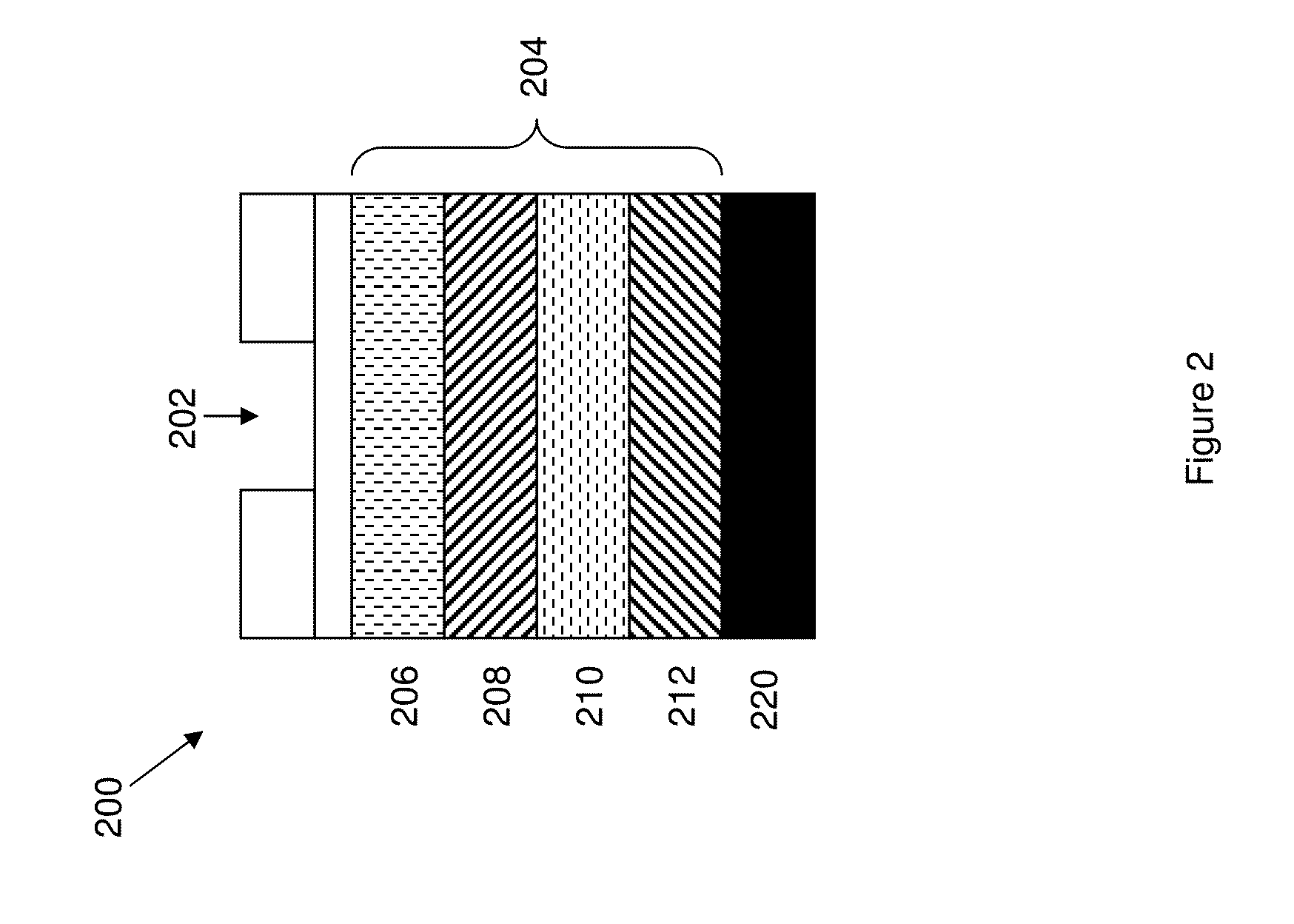

Arrays of integrated analytical devices and methods for production

Arrays of integrated analytical devices and their methods for production are provided. The arrays are useful in the analysis of highly multiplexed optical reactions in large numbers at high densities, including biochemical reactions, such as nucleic acid sequencing reactions. The integrated devices allow the highly sensitive discrimination of optical signals using features such as spectra, amplitude, and time resolution, or combinations thereof. The arrays and methods of the invention make use of silicon chip fabrication and manufacturing techniques developed for the electronics industry and highly suited for miniaturization and high throughput.

Owner:PACIFIC BIOSCIENCES

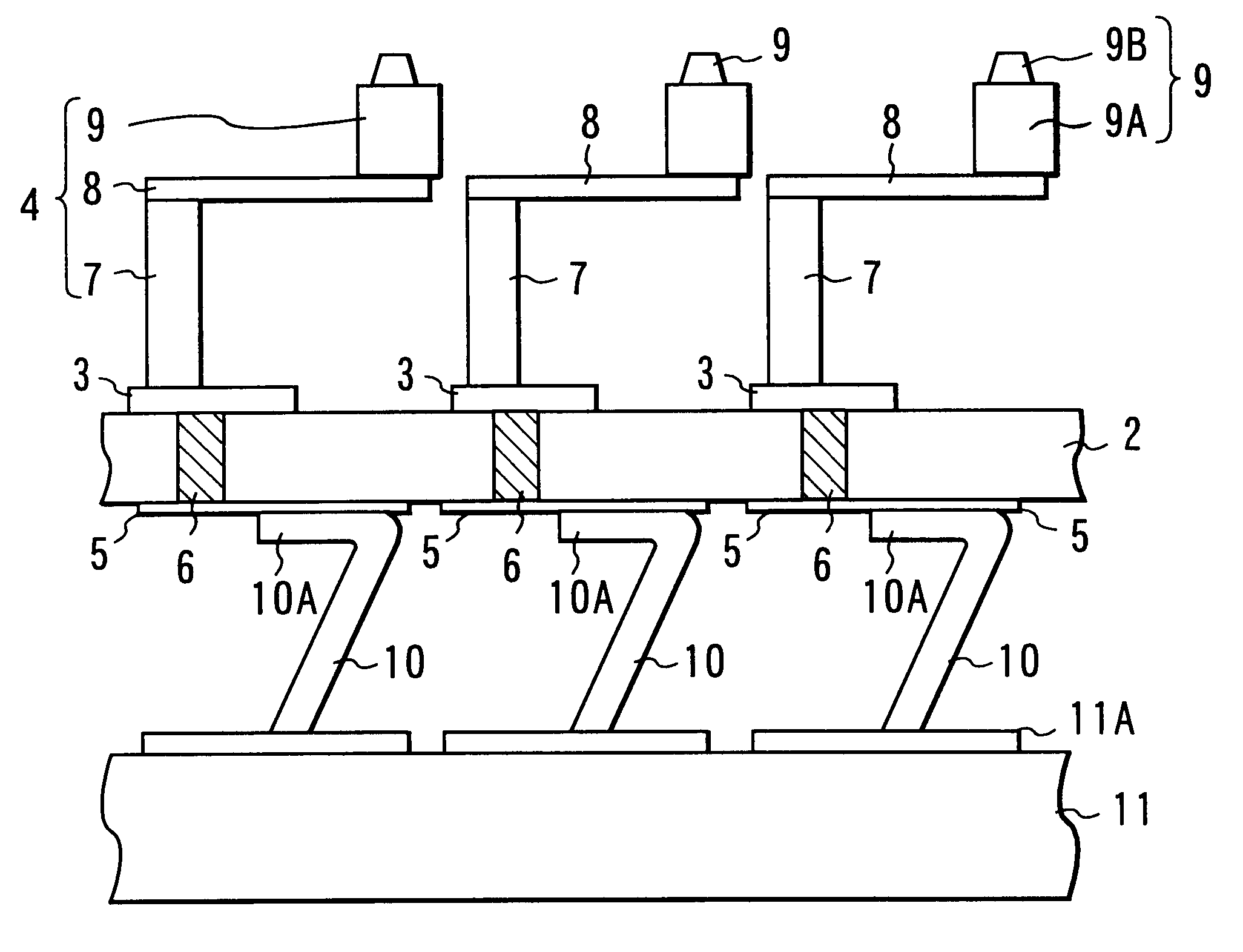

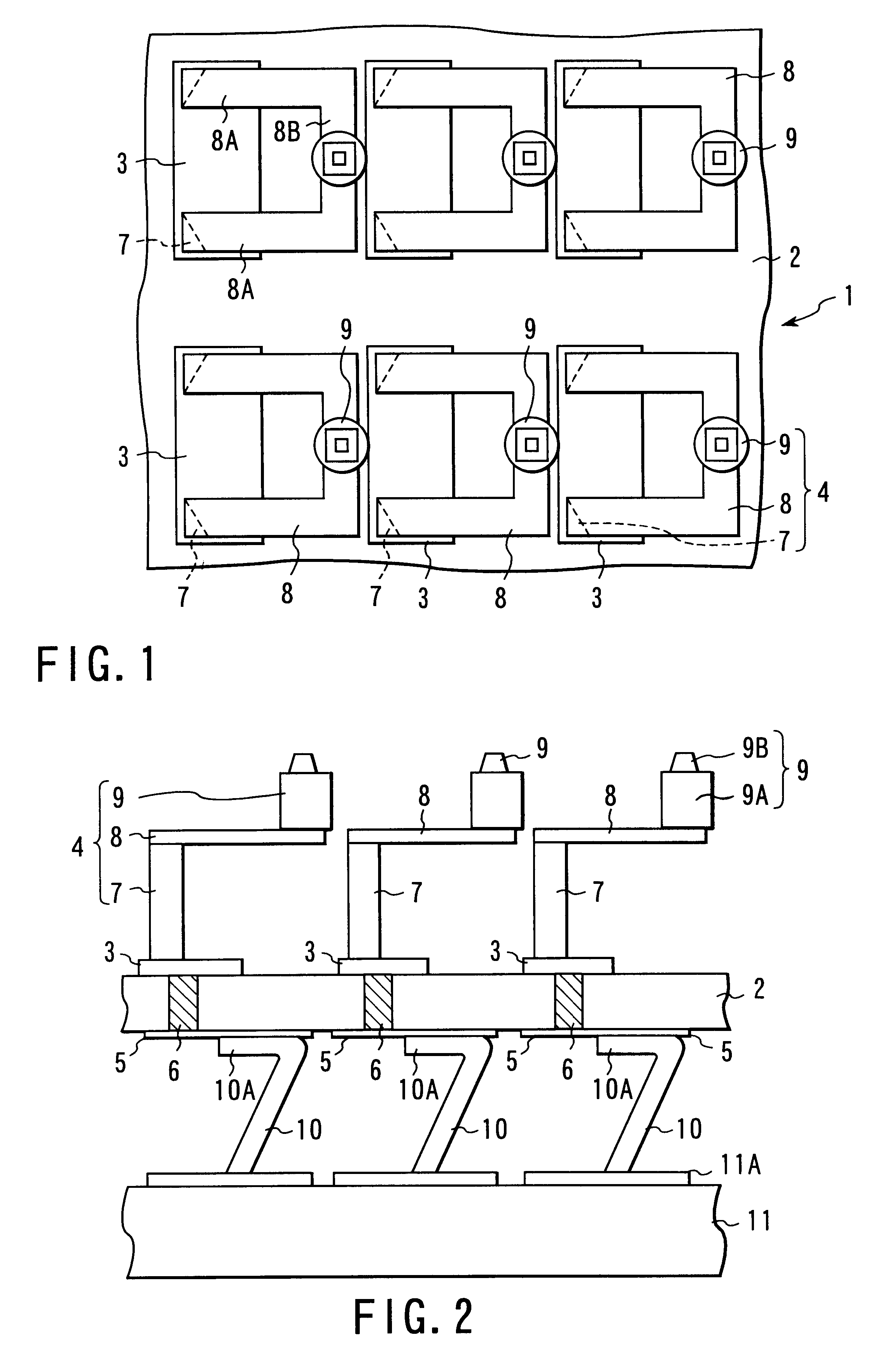

Contactor and production method for contractor

InactiveUS6344752B1Lessen thermal Ad influenceIncrease freedomElectrical measurement instrument detailsElectrical testingProbe cardMethods of production

A conventional probe card is very complex in a support structure of probe terminals and it has been difficult to change an array of the probe terminals correspondingly to various arrays of electrode pads of an object to be checked. A contactor (1) of the present invention simultaneously sets its probe terminals in contact with a plurality of electrode pads of an object to be checked and electrical checking of the object is made once or a plurality of times. It has a plurality of first electrodes (3) arranged on a first substrate (silicon substrate) (2) and probe terminals (4) respectively provided on these electrodes (3). The probe terminal (4) has a conductive support (7) provided on the first electrode, elastic support plate (8) whose one end is fixed to the upper end of the conductive support column (7), and probe terminal (bump) 9 fixed to the free end portion of the elastic support plate (8).

Owner:TOKYO ELECTRON LTD

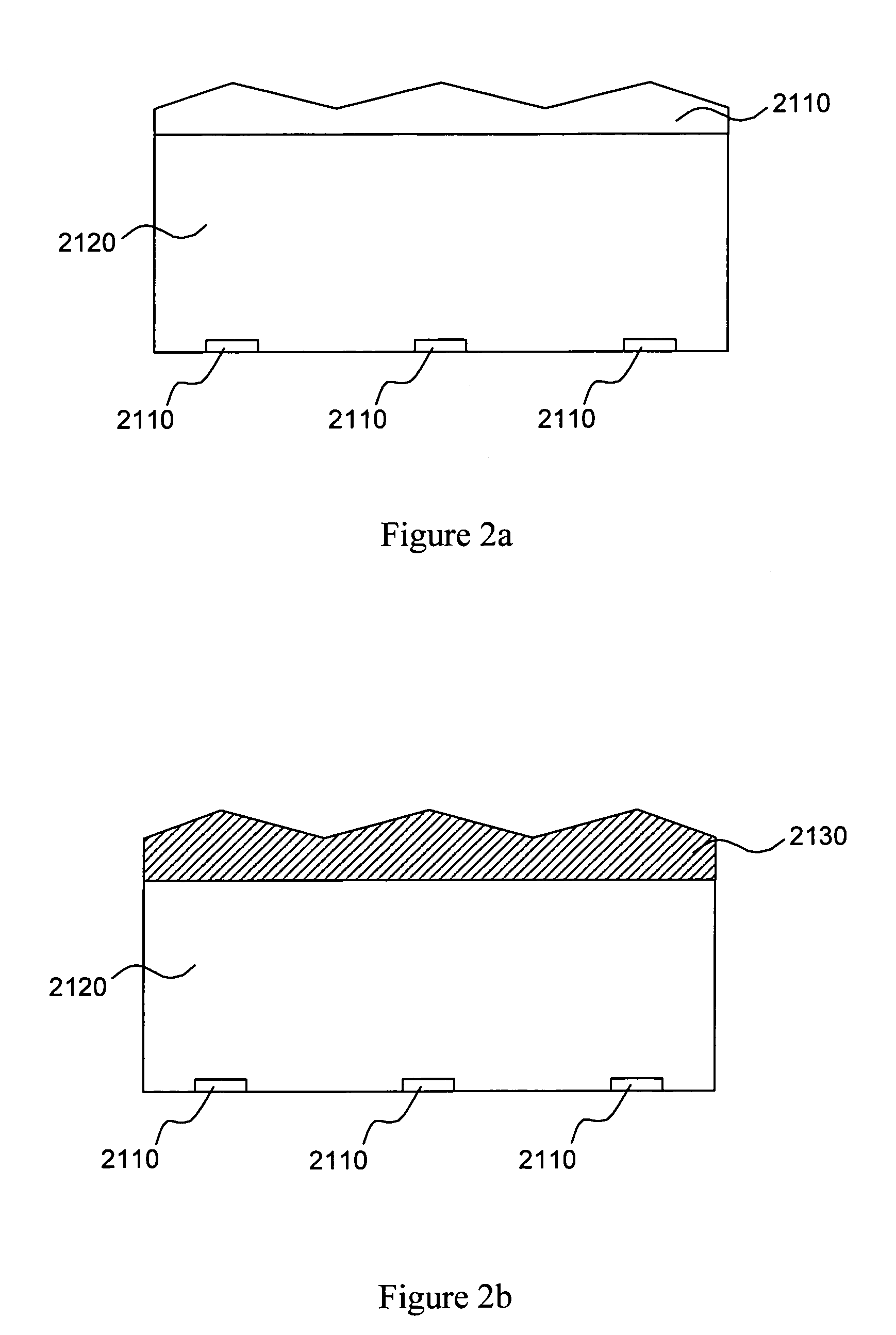

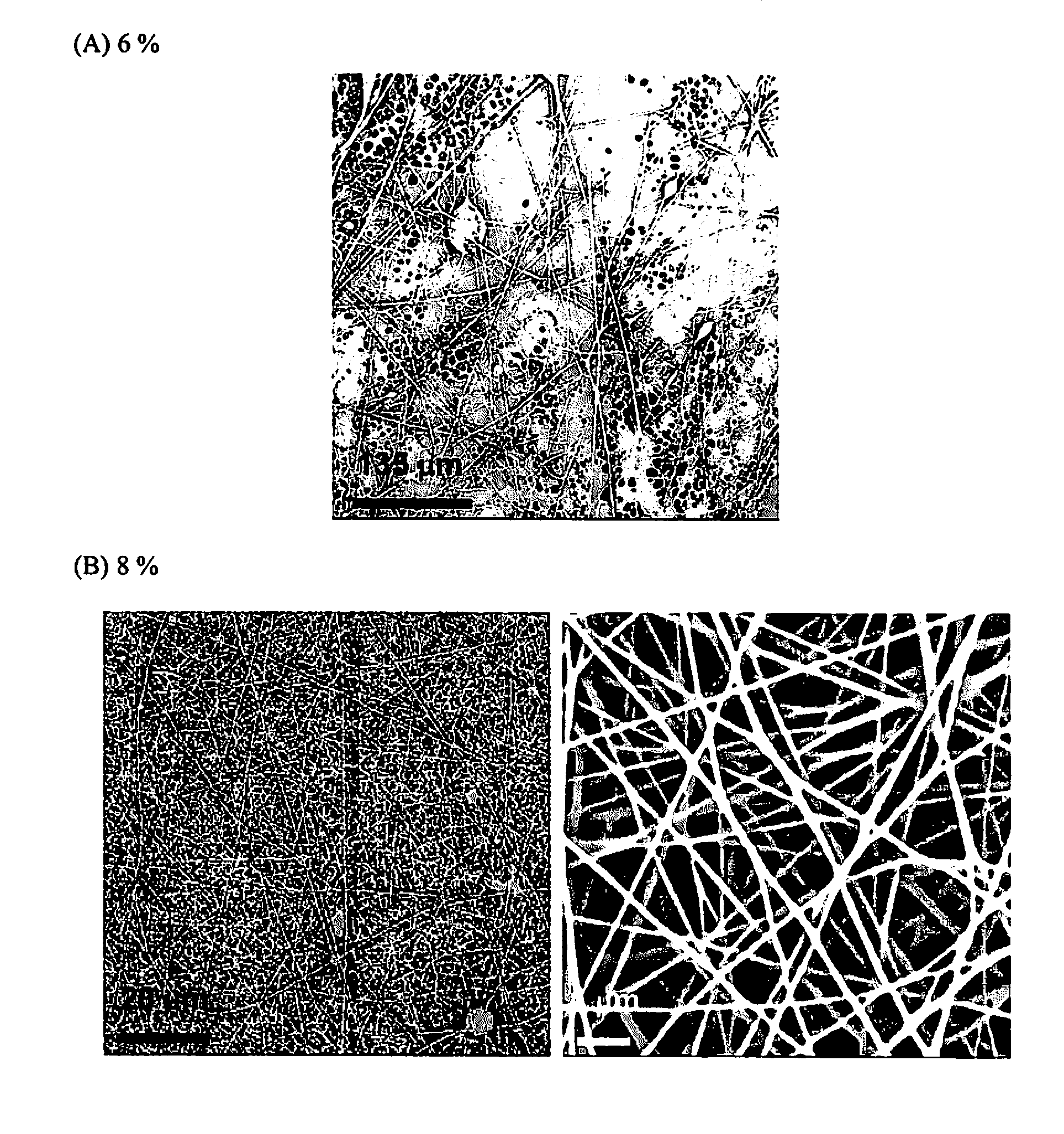

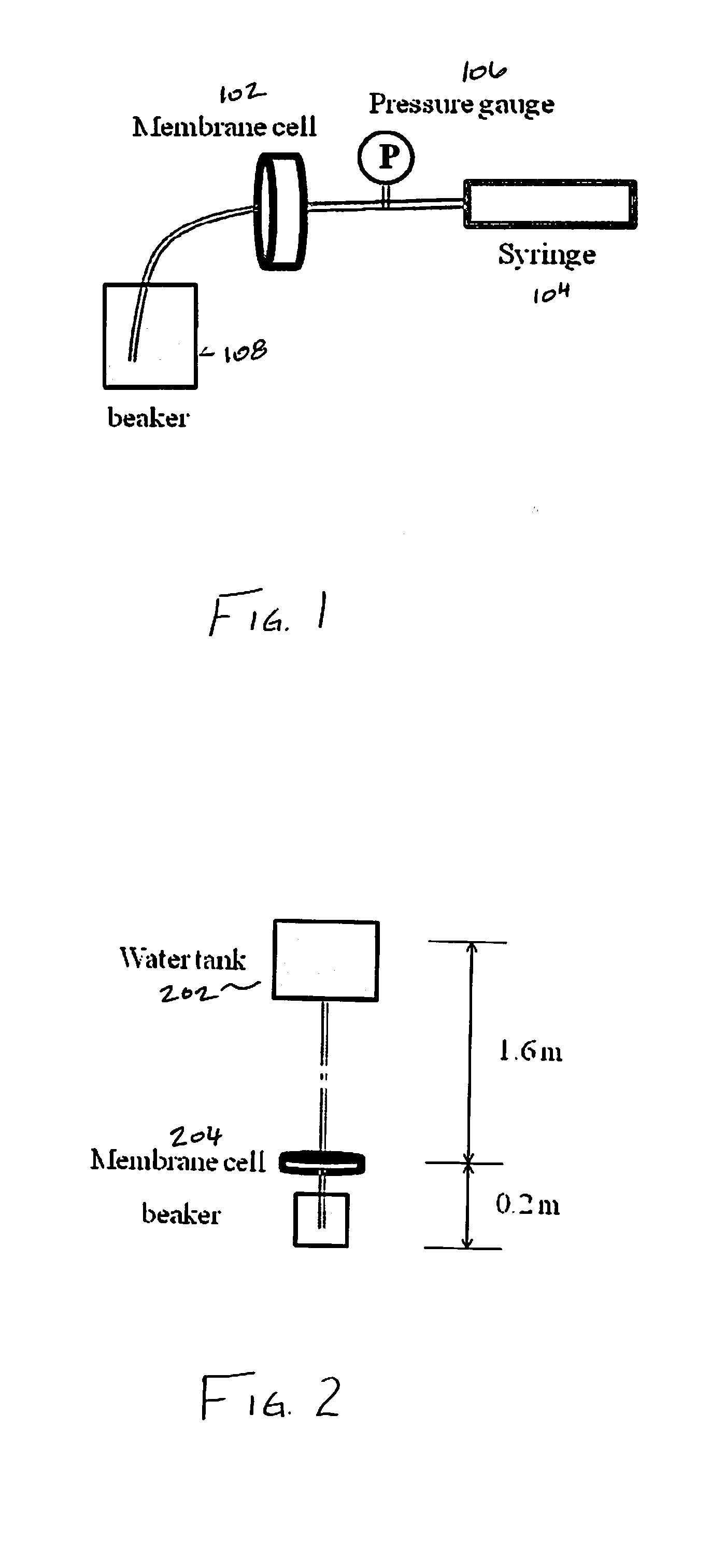

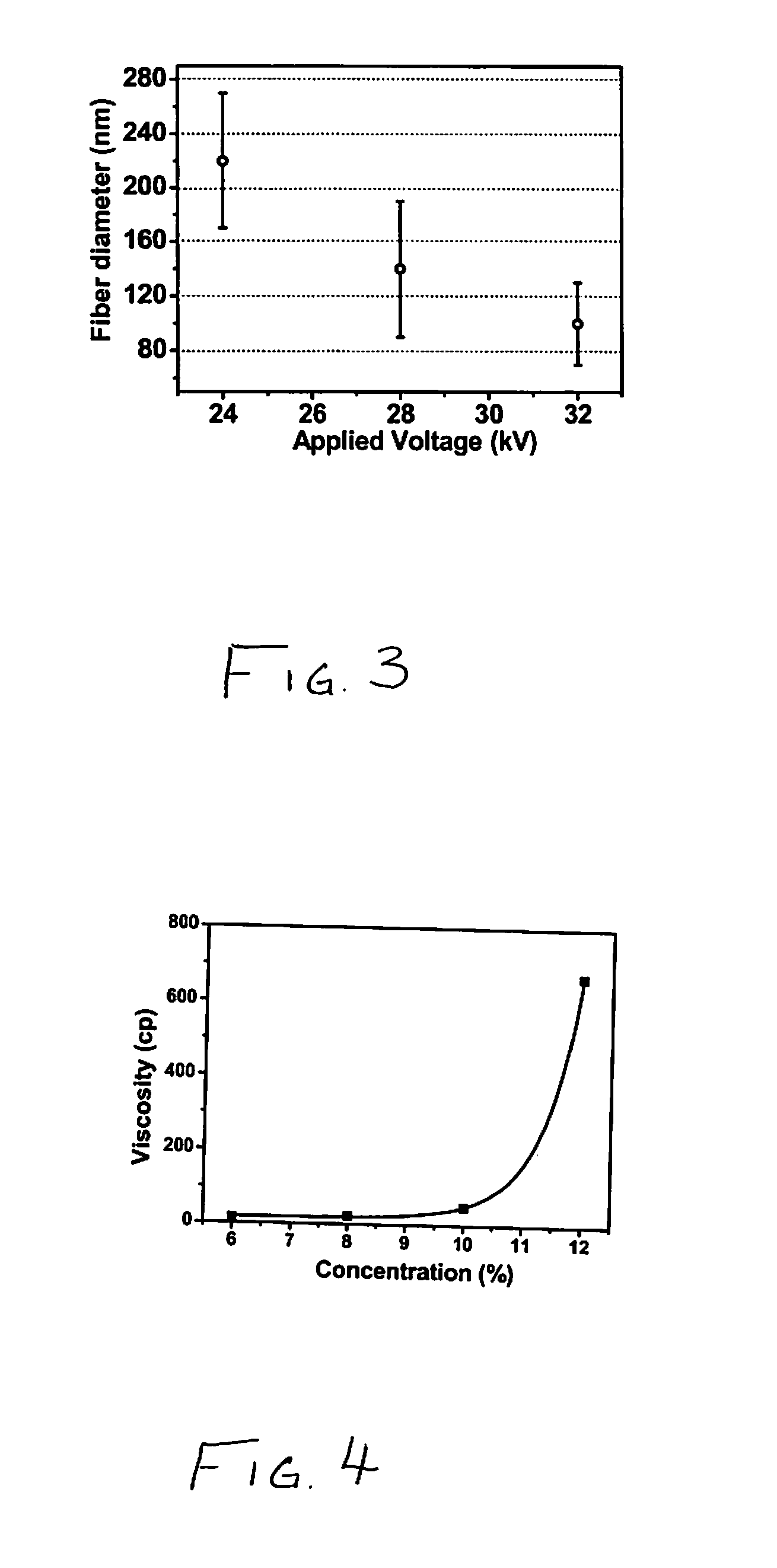

High flux high efficiency nanofiber membranes and methods of production thereof

A membrane is provided including a coating layer having cellulose nanofibers produced from oxidized cellulose microfibers and an electrospun substrate upon which the coating layer is applied. The nanofibers of the electrospun substrate have a diameter greater than that of the cellulose nanofibers. The membrane also has non-woven support upon which the electrospun substrate is disposed. Microfibers of the non-woven support have a diameter greater than that of the nanofibers of the electrospun substrate. Application of electrospun membrane is in microfiltration area, while the cellulose nanofiber membrane serves in ultra-filtration, nanofiltration, and reverse osmosis after chemical modification.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

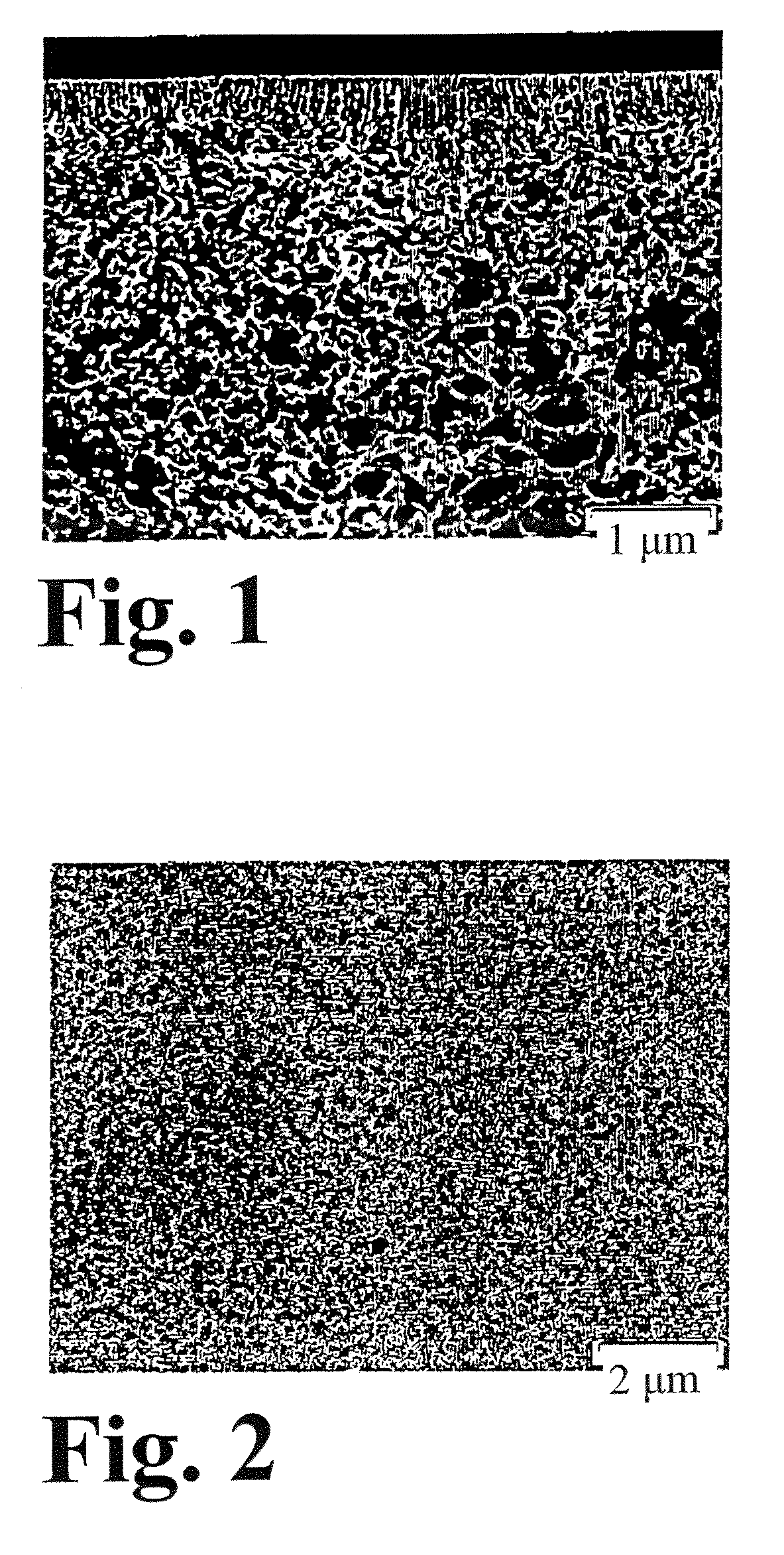

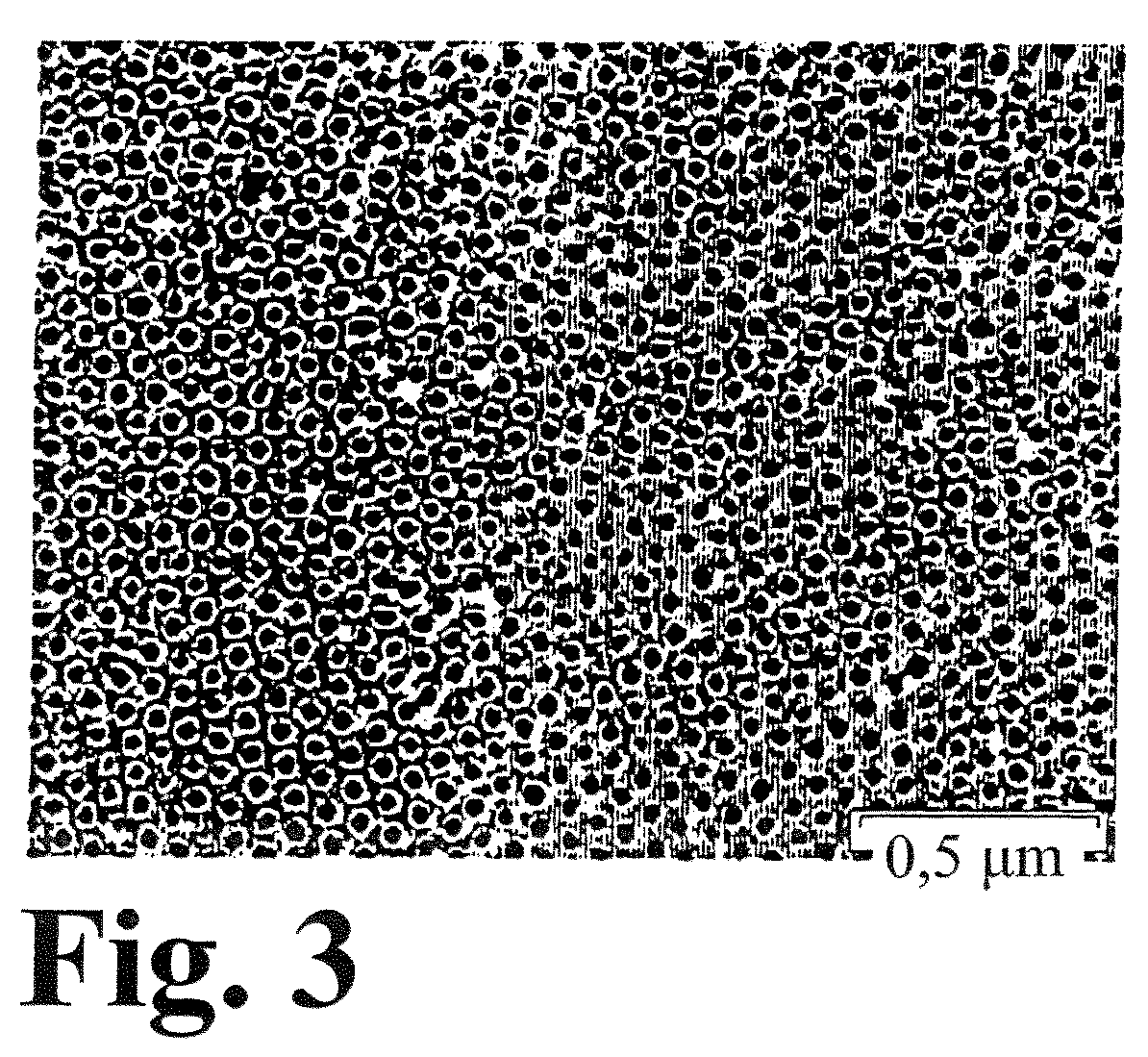

Isoporous membrane and method of production thereof

A membrane is produced by dissolving one or more polymers, at least one of which is a block copolymer, in a liquid which includes a solvent, to produce a casting solution. The casting solution is formed into film, and the film is immersed into a precipitation bath which contains at least one non-solvent for the block copolymer so that the film forms a membrane. The membrane is used for filtering a fluid that contains colloidal particles or proteins, and / or for ultrafiltration or nanofiltration, by flowing the fluid through the membrane.

Owner:GKSS FORSCHUNGSZENTRUM GEESTHACHT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com