Patents

Literature

35results about How to "High metal dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

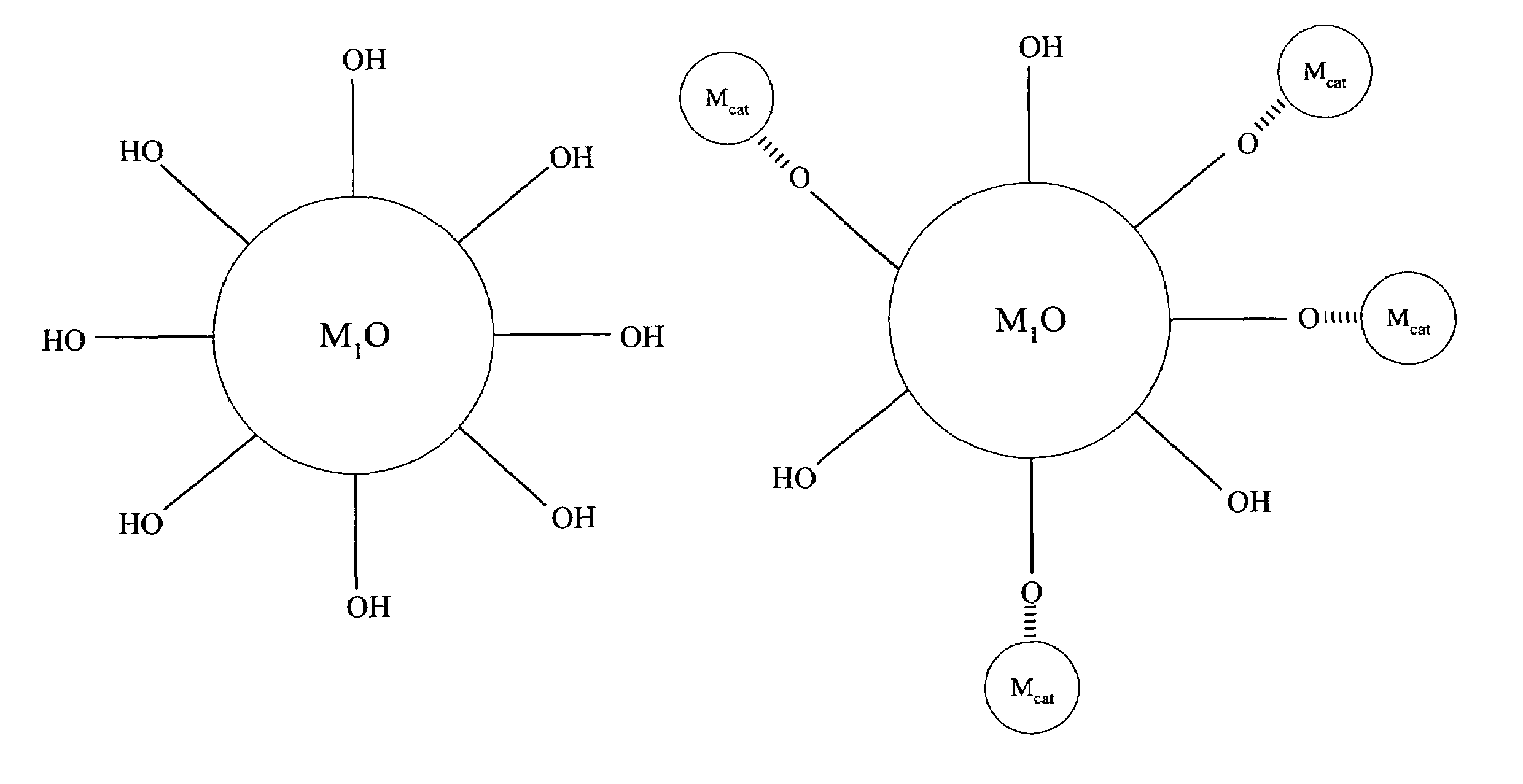

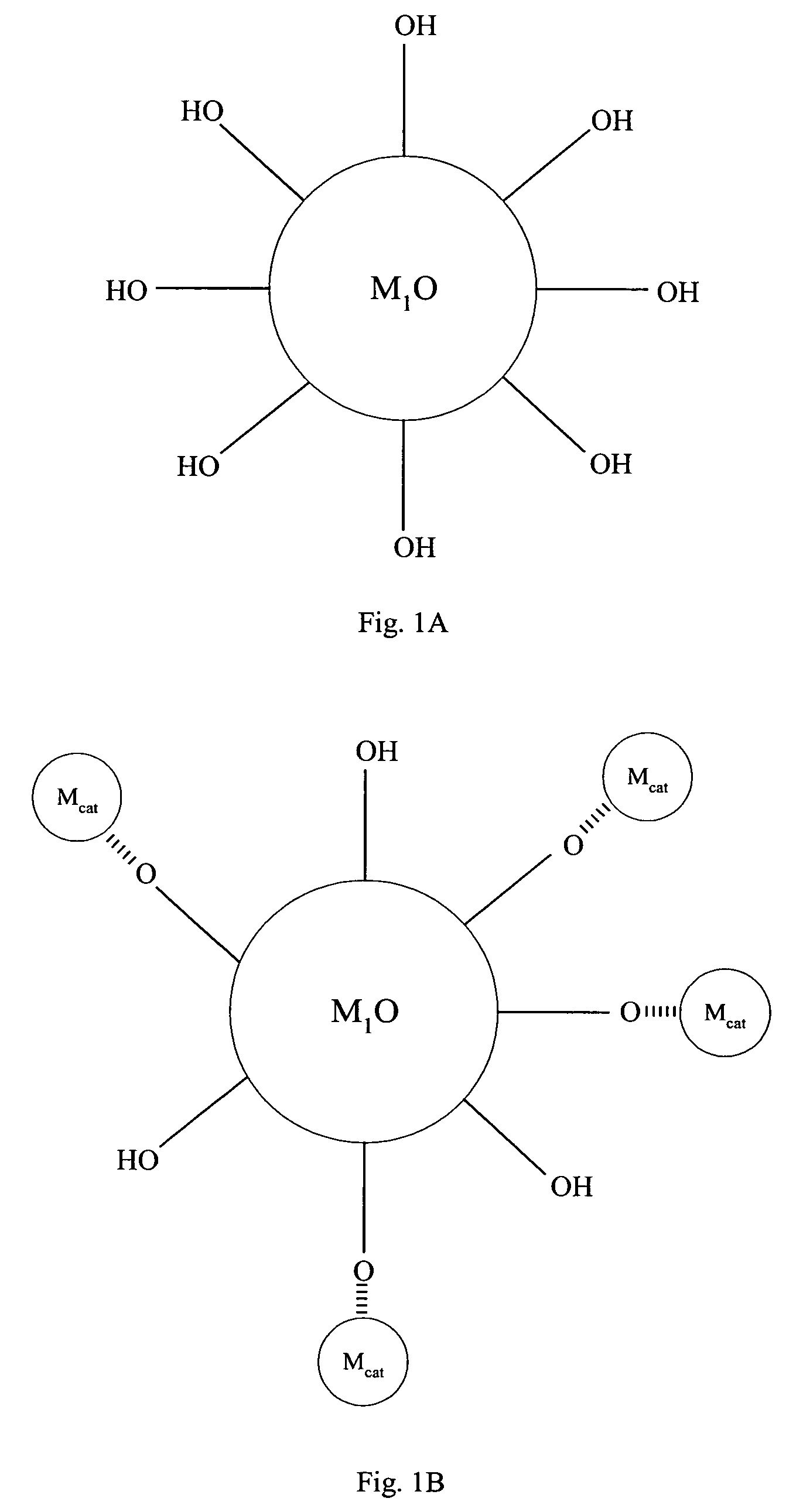

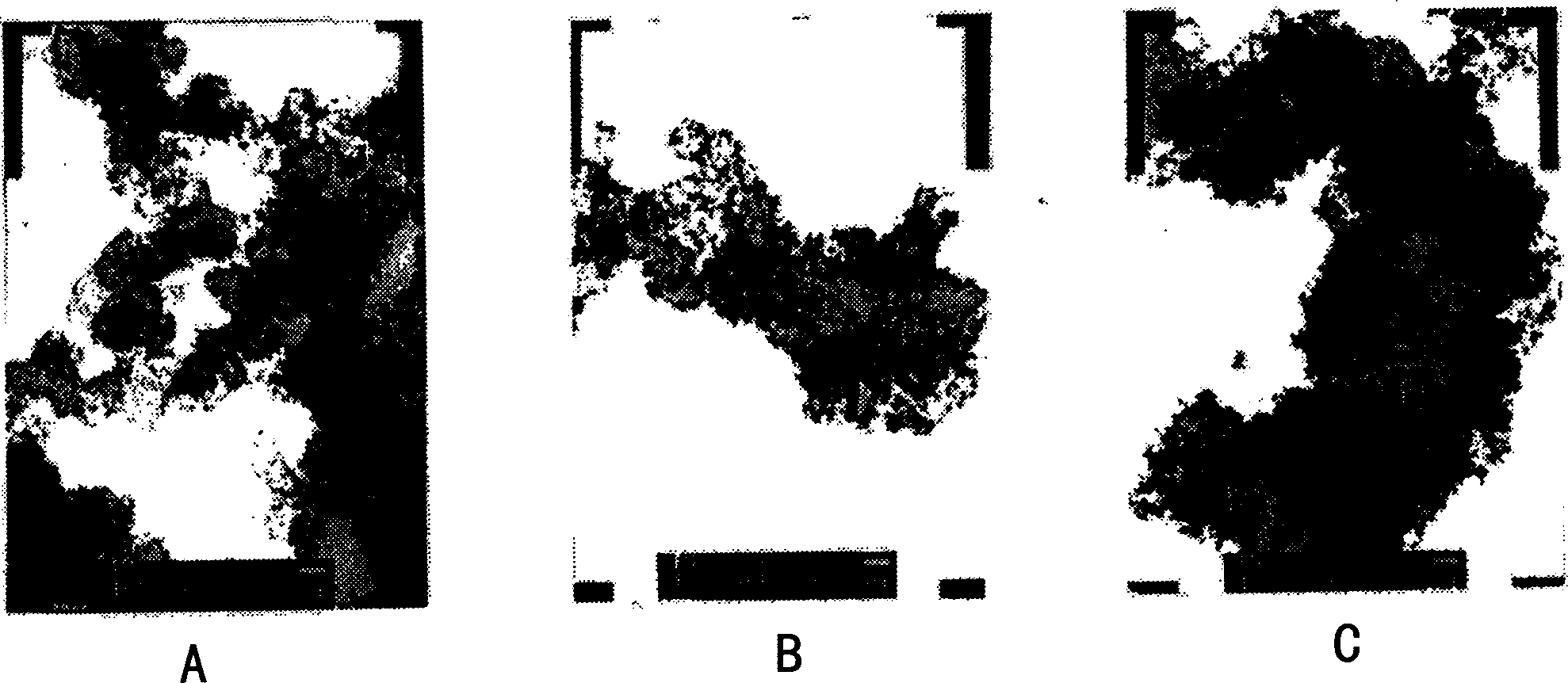

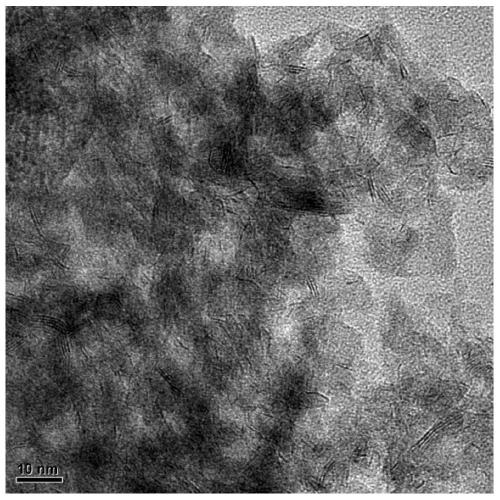

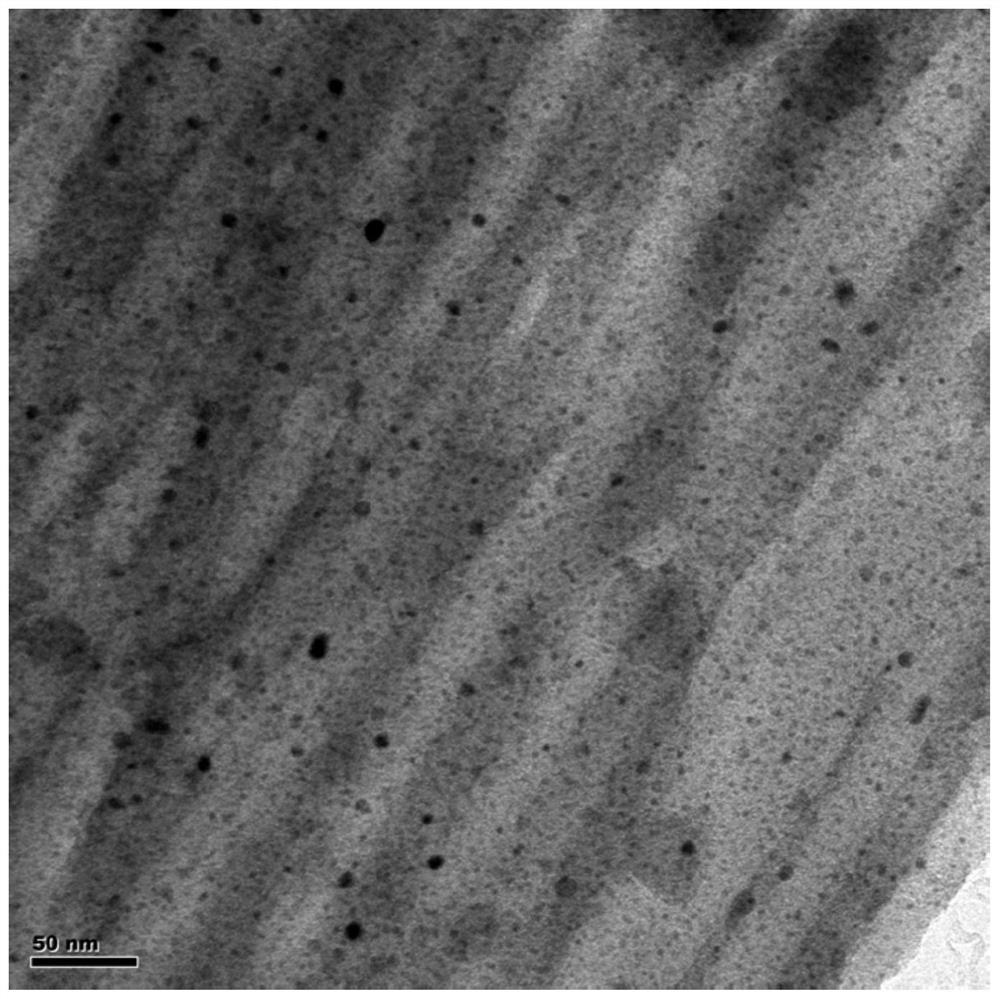

Catalytic material and method of production thereof

ActiveUS7541012B2High metal dispersionGas treatmentOrganic chemistryMetal catalystMethods of production

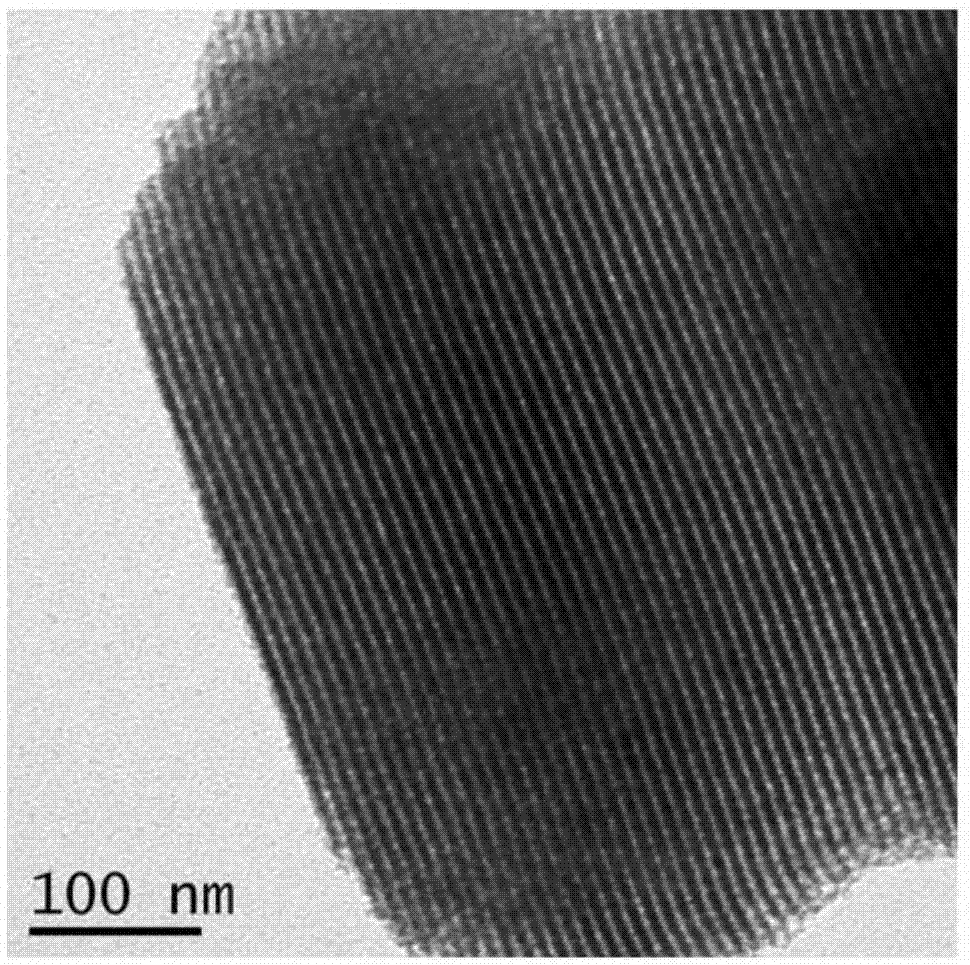

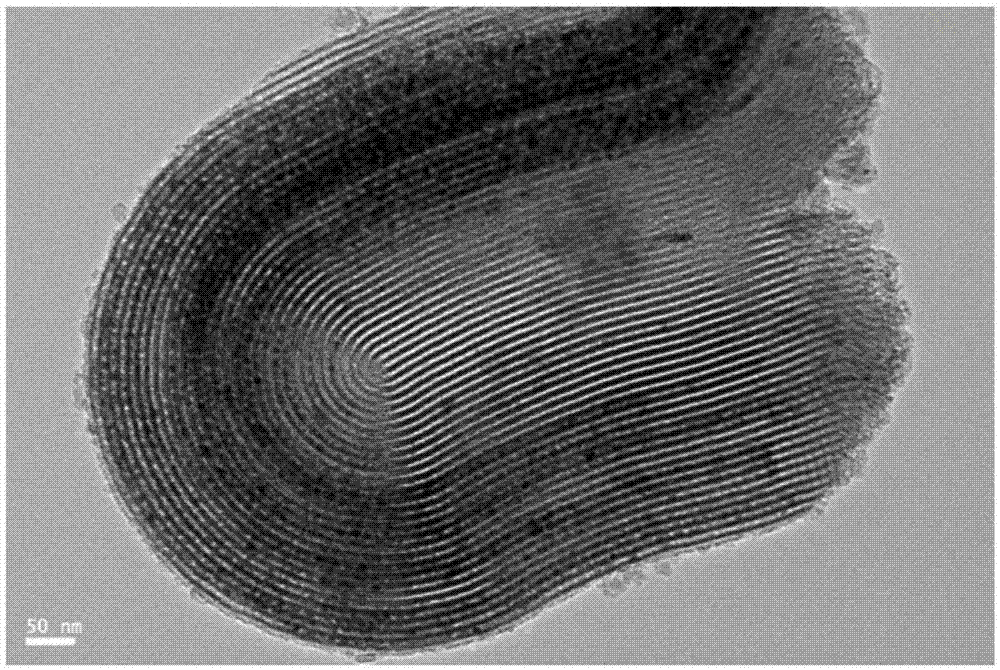

The present invention features a catalytic material which includes a metal catalyst anchored to a nano-sized crystal containing a metal oxide. Furthermore, the present invention features a method of producing the catalytic material described herein. Finally, the present invention features using the catalytic material for removing contaminants and for getting the desired products.

Owner:THE HONG KONG UNIV OF SCI & TECH

Catalyst used for synthesizing middle distillate from synthetic gas, its preparation method and application

InactiveCN1785515AHigh thermal and hydrothermal stabilityGood stabilityLiquid hydrocarbon mixture recoveryCatalyst activation/preparationCOBALTOUS NITRATENon noble metal

A catalyst for synthesizing the intermediate oil from synthetic gas by Fischer-Tropsch reaction contains Co (5-35 Wt%), mesoporous ZrO2 as carrier (53-93), noble metal (0-2) and oxide of non-noble metal. Its preparing process includes such steps as impregnating said carrier in the aqueous solution of nitrate containing the oxide of non-noble metal or the alcohol solution of organic alkydester, and impregnating it in the equeous solution of cobalt nitrate and the nitrate (or chloride) or noble metal. It has high activity, stability, selectivity and mechanical performance.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

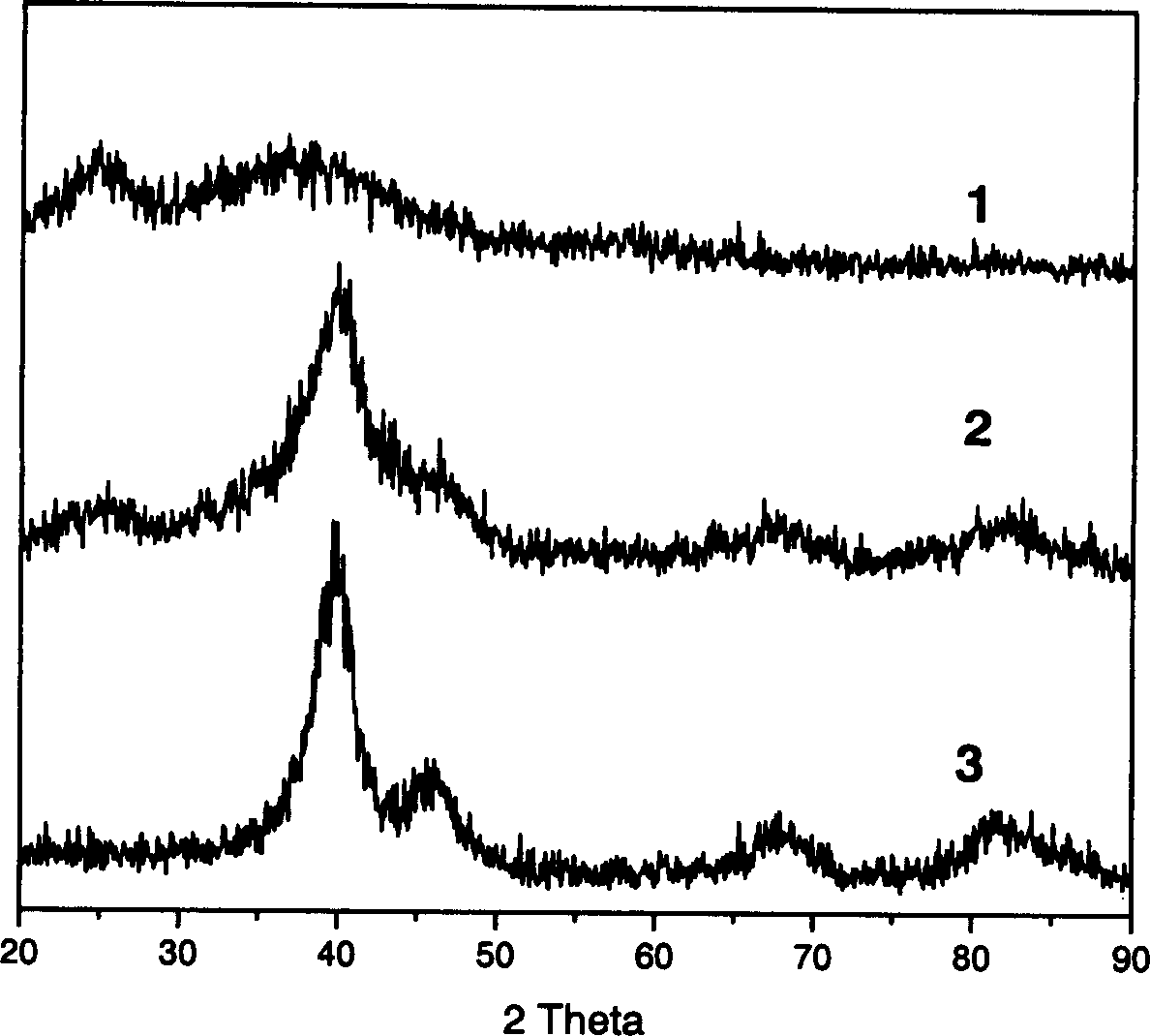

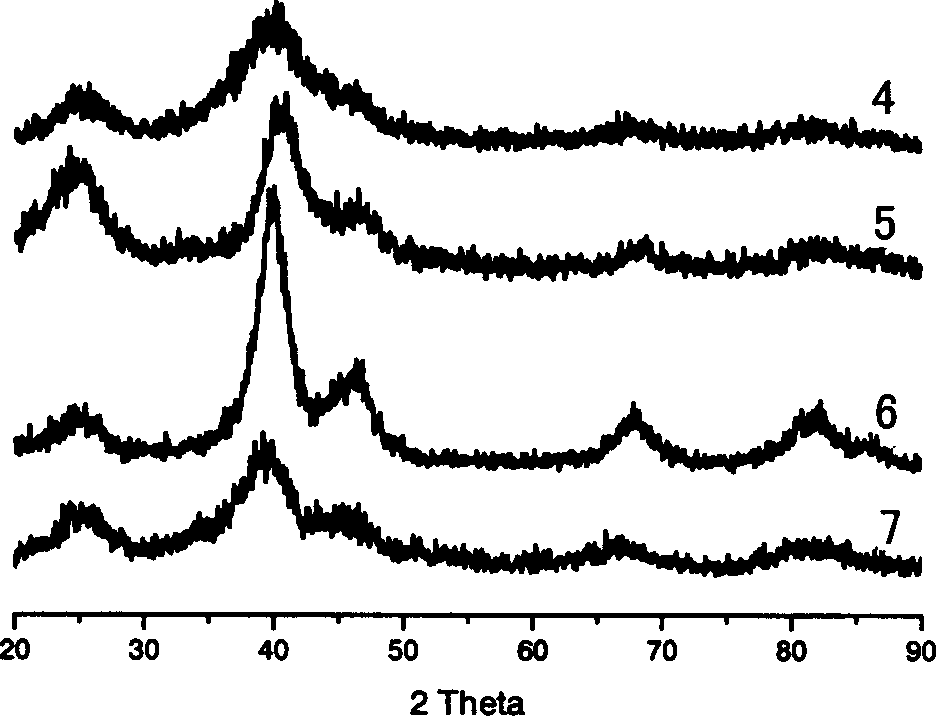

Co-Zr catalyst for Fischer-Tropsch synthesis and its prepn and application

InactiveCN1398669AImprove stabilityReduced inactivation rateCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsMetalChemistry

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Hydrocracking catalyst containing compound molecular sieve and preparing method thereof

InactiveCN1488726AImprove nitrogen resistanceHigh hydrocracking activityHydrocarbon oil crackingMolecular sieveNitrogen

The present invention relates to a hydrocracking catalyst containing compound molecular sieve and its preparation method. Said catalyst composition uses amorphous aluminosilicate and a compound molecular sieve as carrier, in which the amorphous aluminosilicate content is 30-60% of catalyst weight, compound molecular sieve content is 1-20% of catalyst weight, and is the mixture of modified Y molecular sieve and SAPO molecular sieve, VIB group metal oxide content is 10-40%, VIII group metal oxide content is 1-20% of IVB group metal oxide content is 1-10%. Said invented catalyst is prepared by adopting co-precipitation method, and its strength and performance can be raised and improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

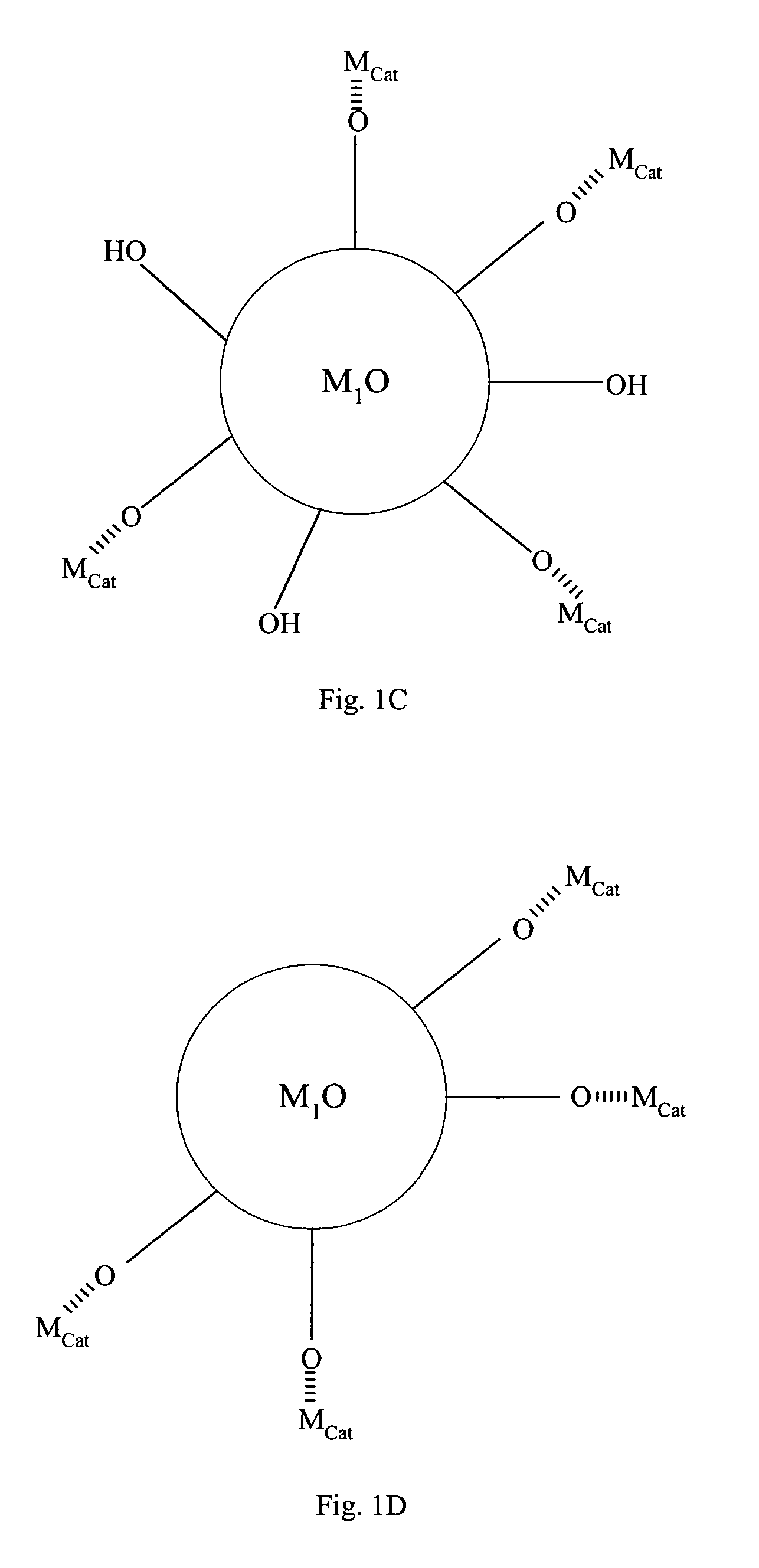

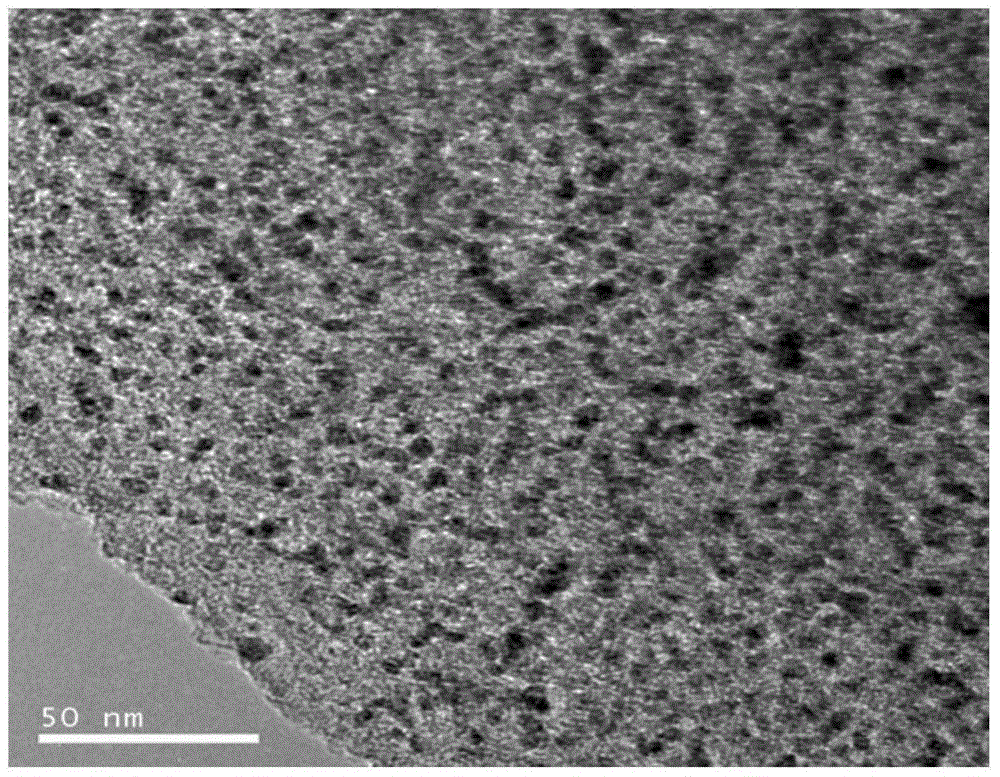

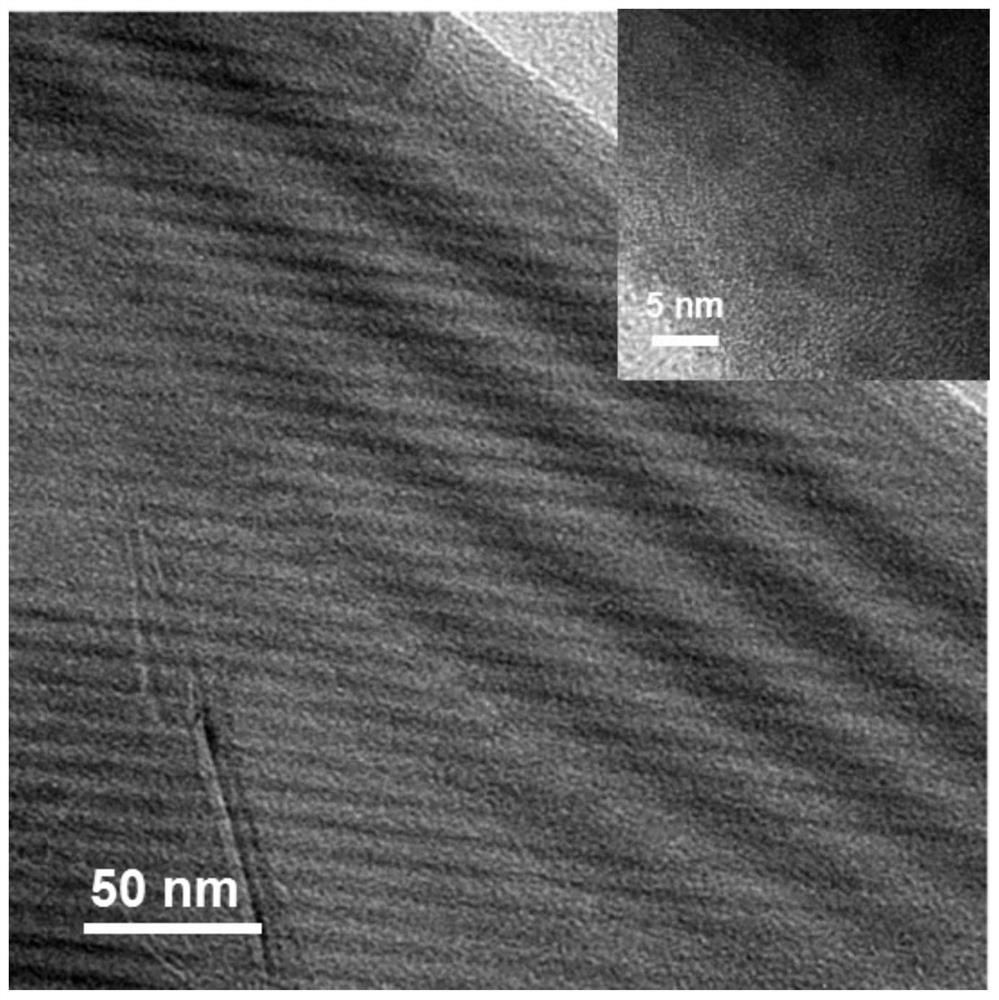

Nickel-based methanation catalyst dispersive in SBA-15 ducts and preparation and application thereof

ActiveCN107199047AHigh activityGood choiceMolecular sieve catalystsGaseous fuelsNickel saltMethanation

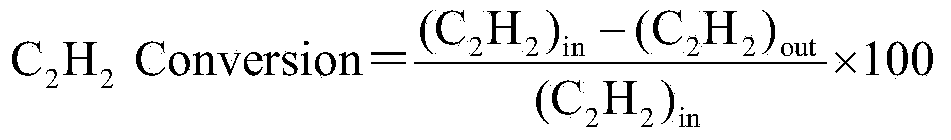

The invention relates to a nickel-based methanation catalyst dispersive in SBA-15 ducts and preparation and application thereof; the nickel-based methanation catalyst comprises, by 100 parts by weight, 5-20 parts of metallic nickel, 10-40 parts of an additive, and the balance of mesoporous molecular sieve SBA-15. The preparation comprises: preparing nickel salt solution, and adding an additive; in the nickel salt solution, soaking the SBA-15 in mixed liquid prepared in step A at room temperature, and calcining in vacuum after soaking to obtain the nickel-based methanation catalyst. By adding the additive and using the mesoporous molecular sieve SBA-15 with stable chemical properties, good thermal conductivity and large specific surface area as a support, the nickel-based metal catalyst with the active component dispersive in support ducts is prepared; the catalyst has the advantages of high catalytic activity, good methane selectivity, good thermal selectivity, long catalyst life and the like. Under optimal conditions, the catalyst may reach 100% in CO conversion rate, 99.9% in methane selectivity and 99.9% in methane yield, and has a promising industrial prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

Catalysts for feedstock-flexible and process-flexible hydrogen production

InactiveUS20130058861A1Highly active andEasy to switchHeterogenous catalyst chemical elementsCatalyst activation/preparationSyngasPtru catalyst

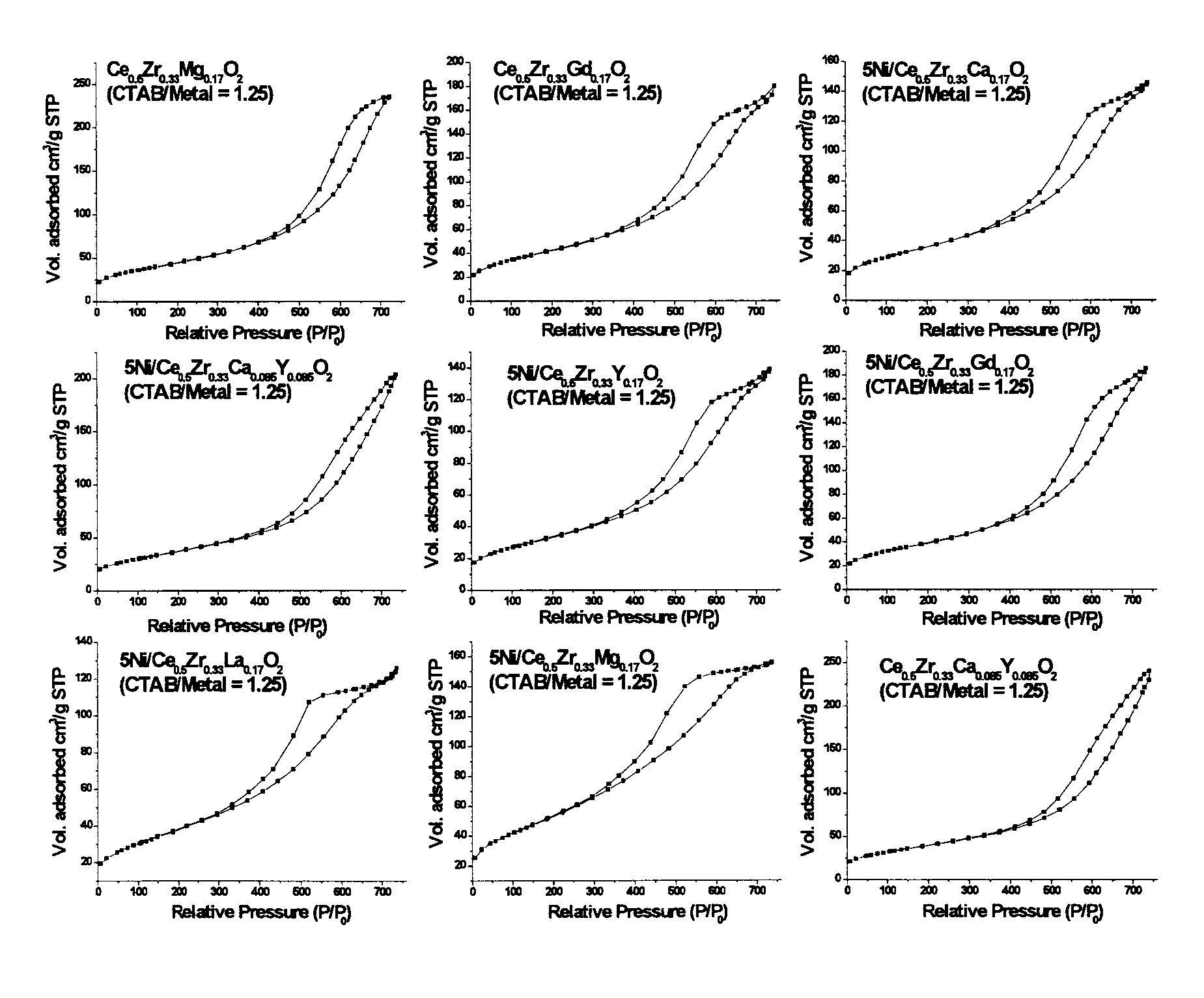

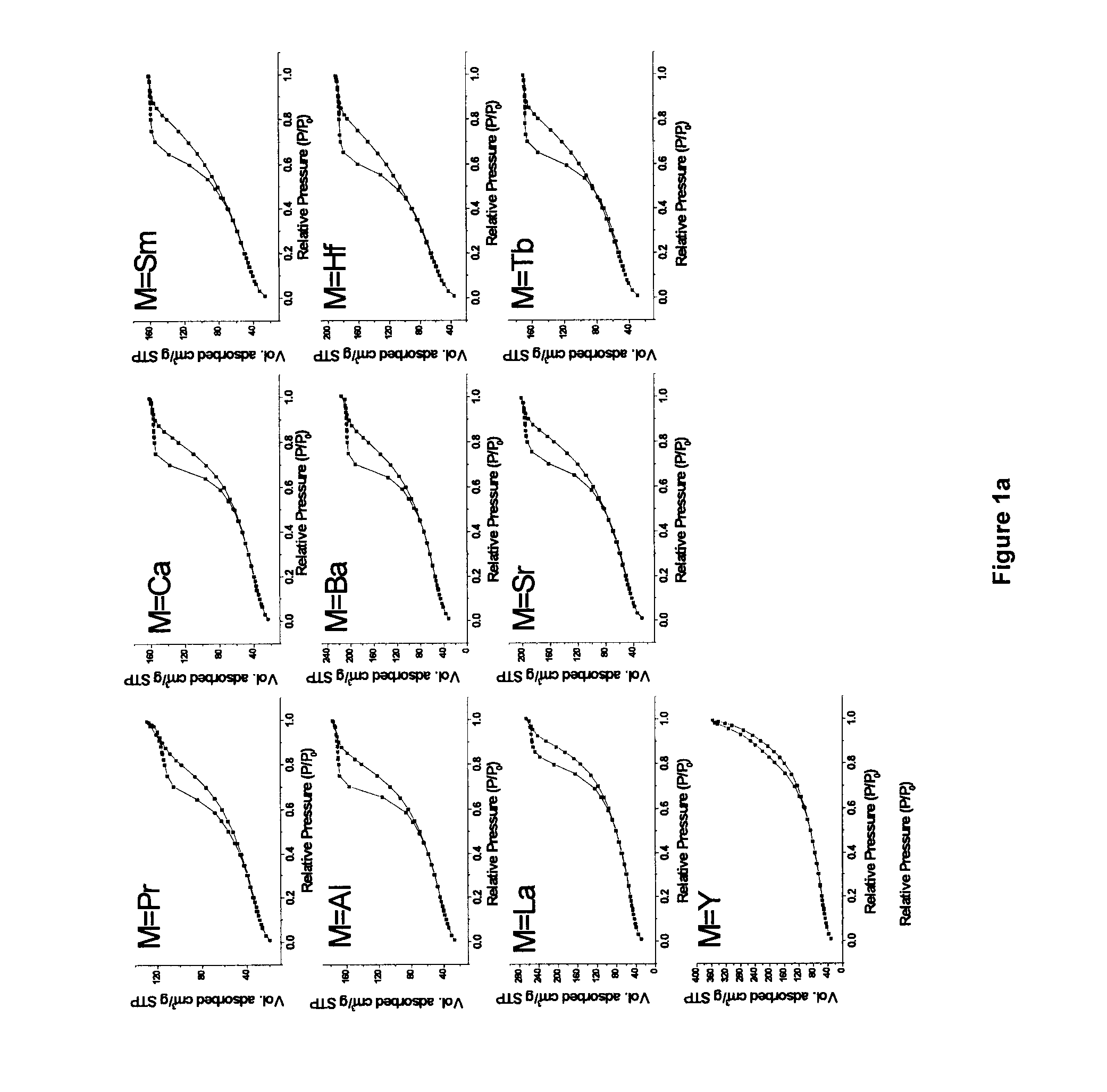

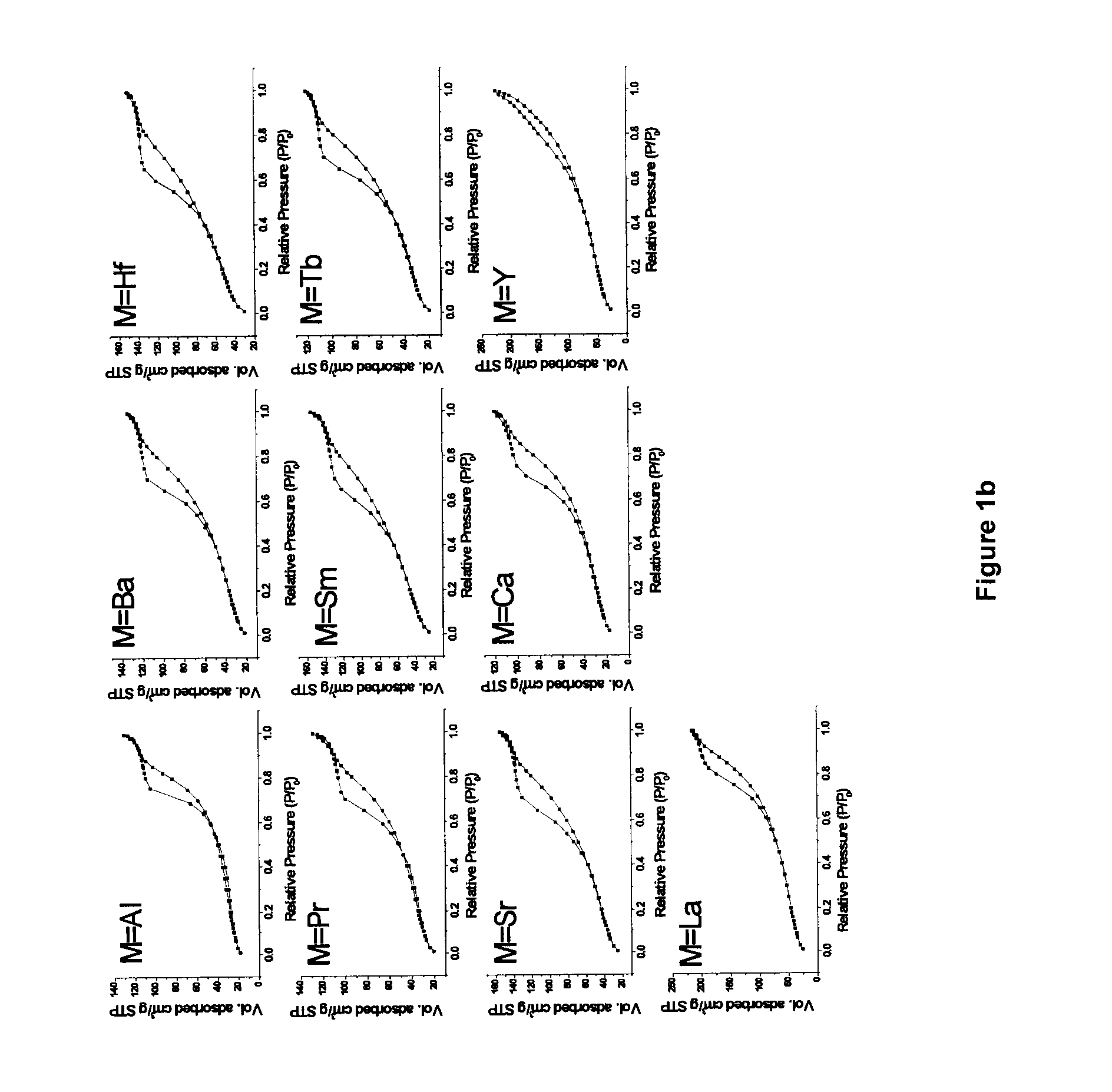

A series of ternary oxide and quaternary oxide catalysts were prepared and evaluated for various reforming processes. Representative examples of these catalysts were found to be active and stable for all the processes tested verifying the “feedstock and process flexible” nature of these catalysts. Thus, feedstock- and process-flexible reforming catalysts for hydrogen and / or syngas production have been developed.

Owner:UNIVERSITY OF REGINA

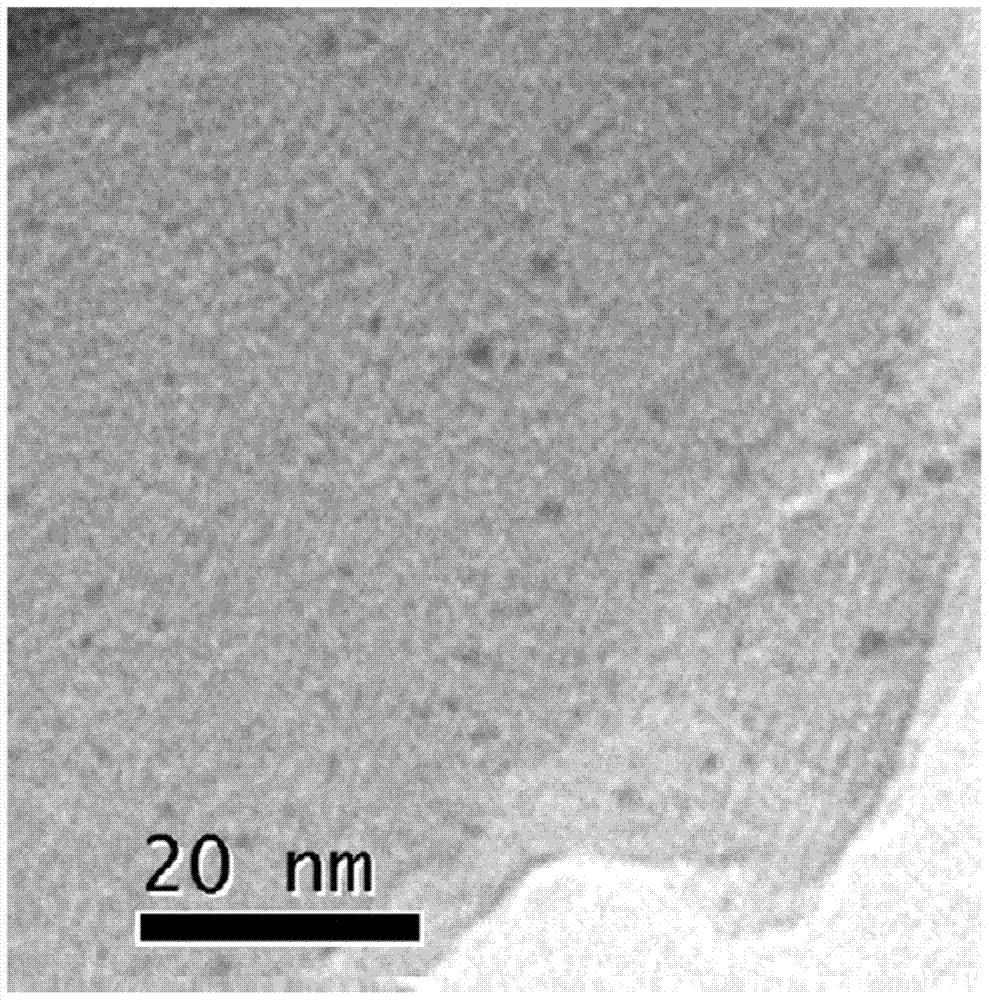

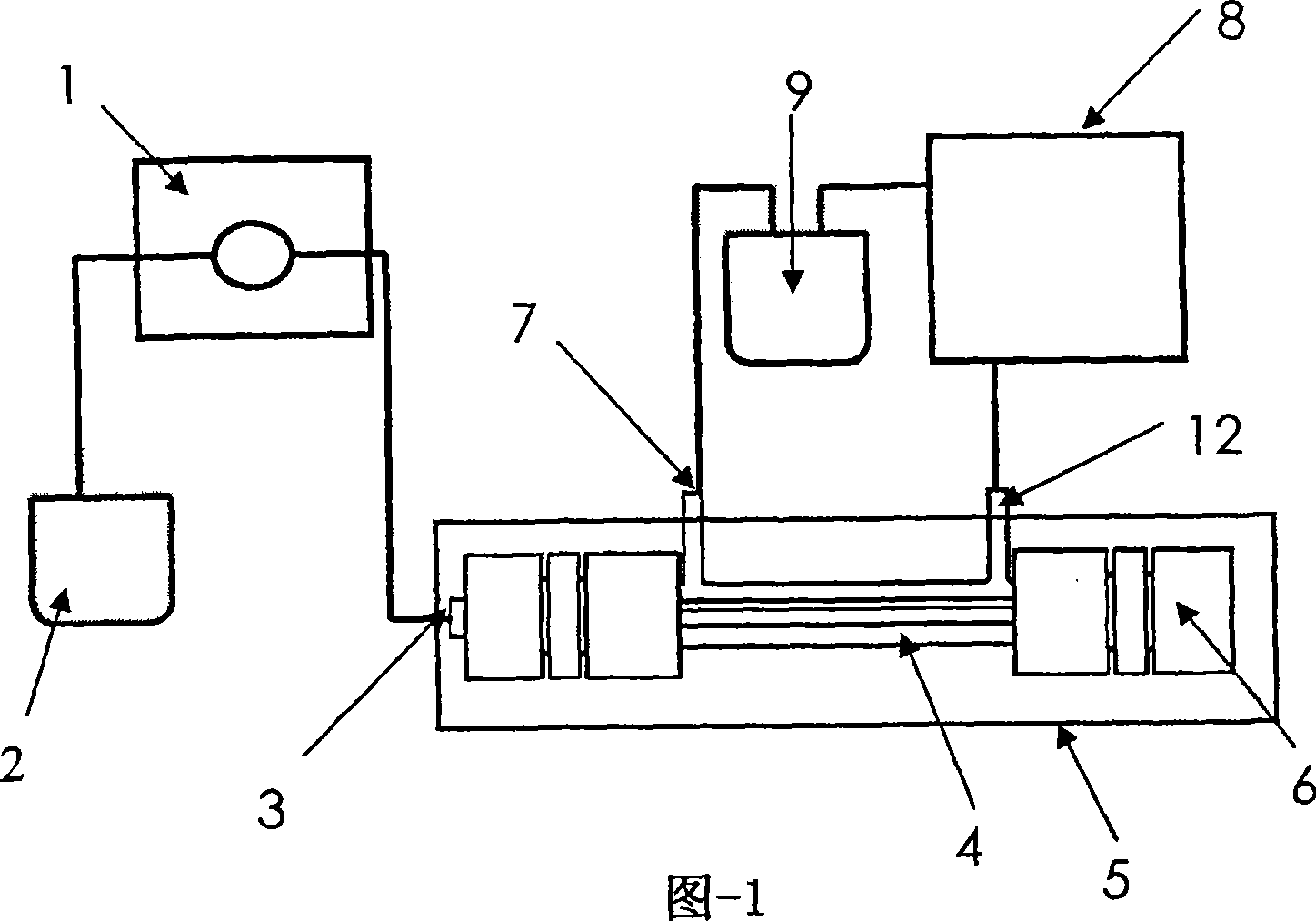

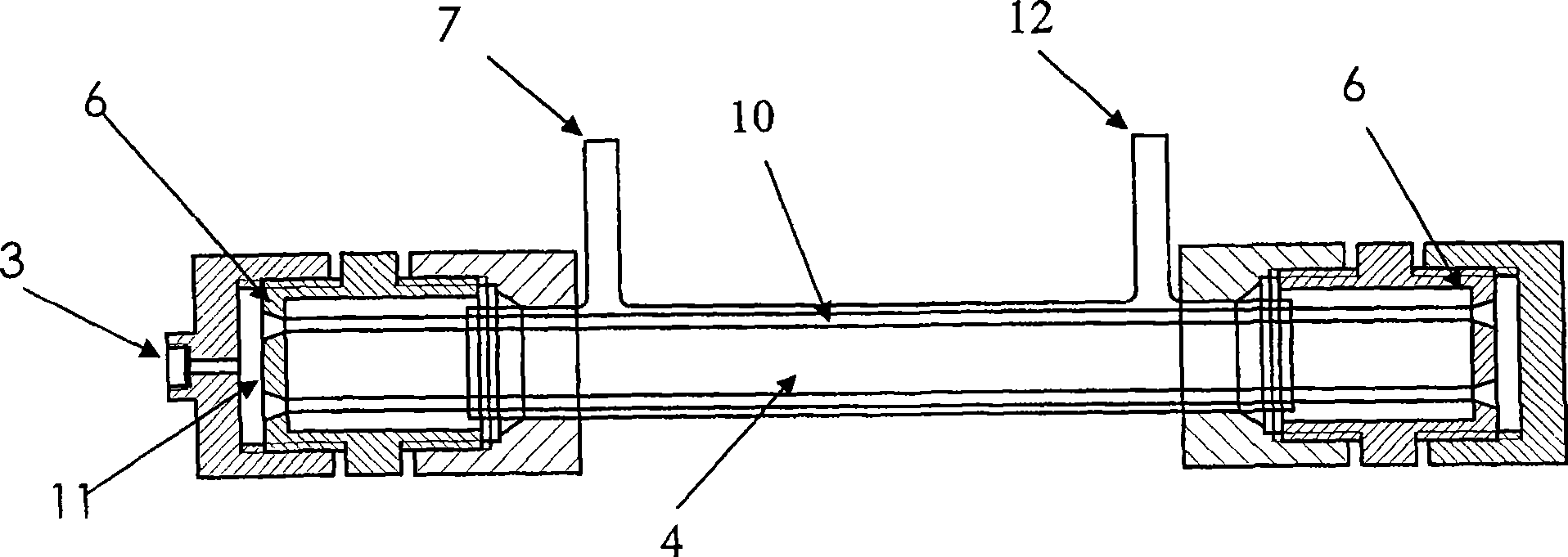

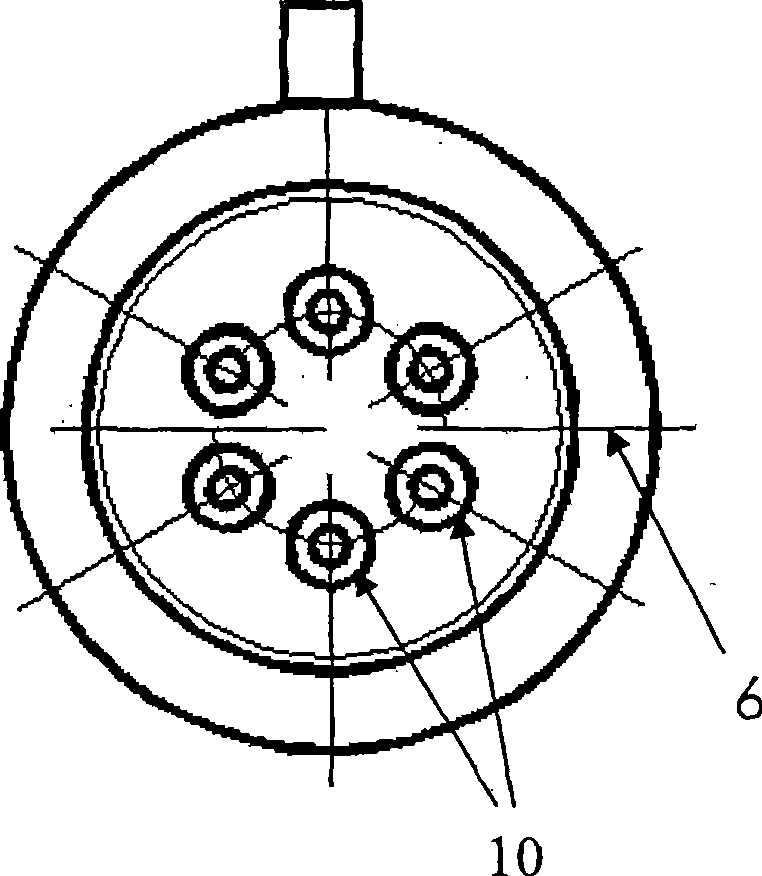

Method for preparation of load type metallic catalyst and equipment thereof

InactiveCN101081364ALow costHigh metal dispersionMetal/metal-oxides/metal-hydroxide catalystsNano catalystIon

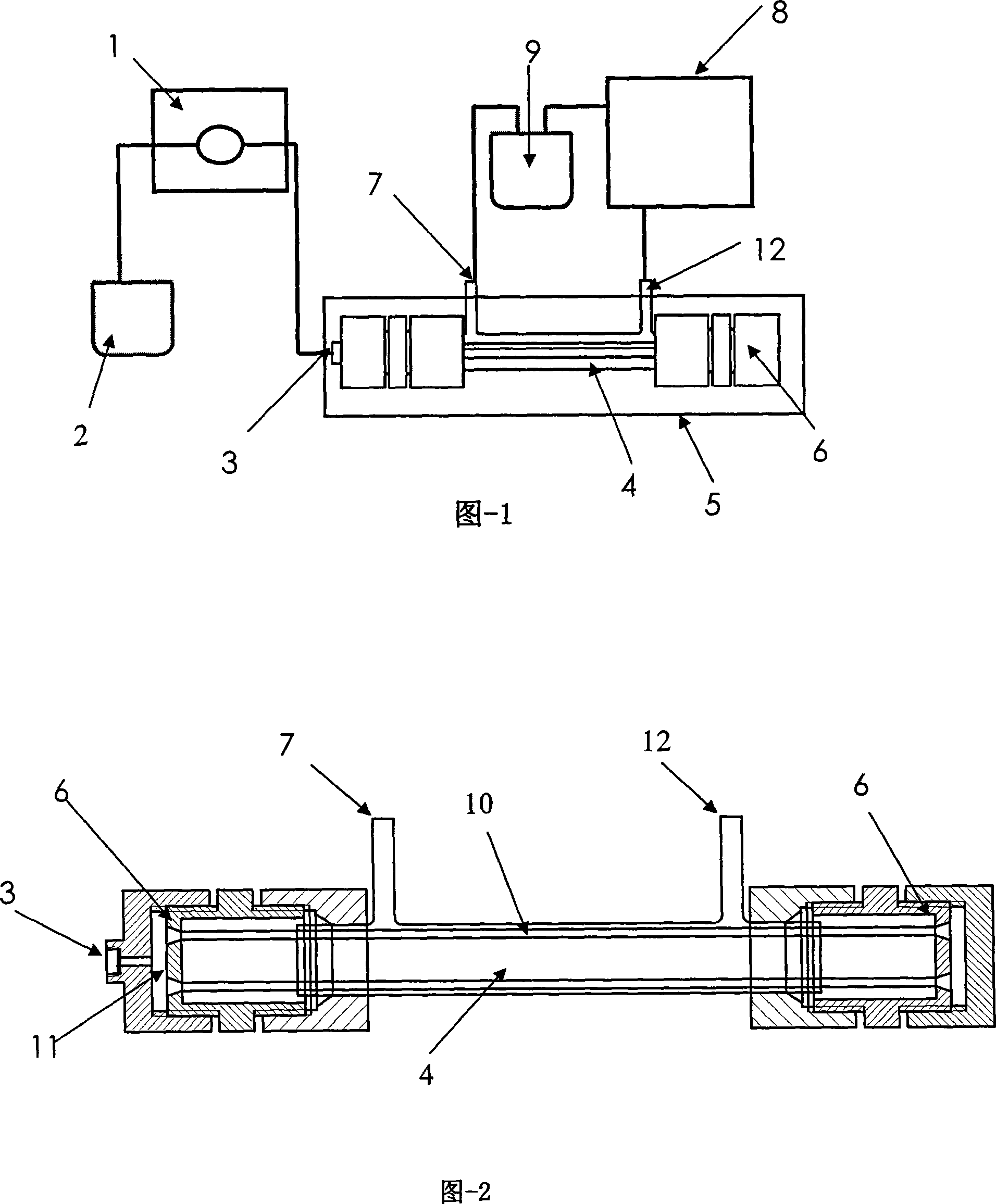

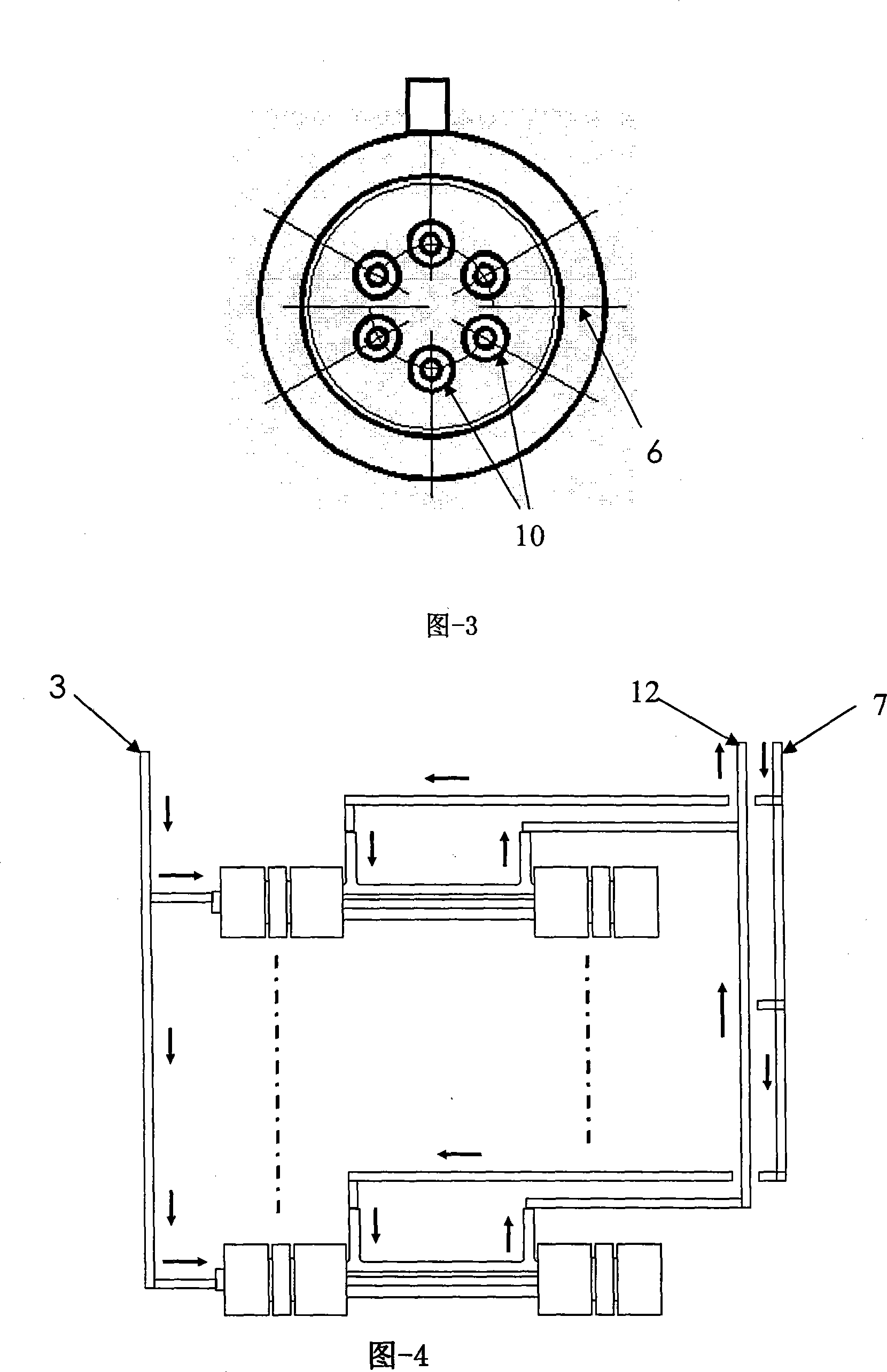

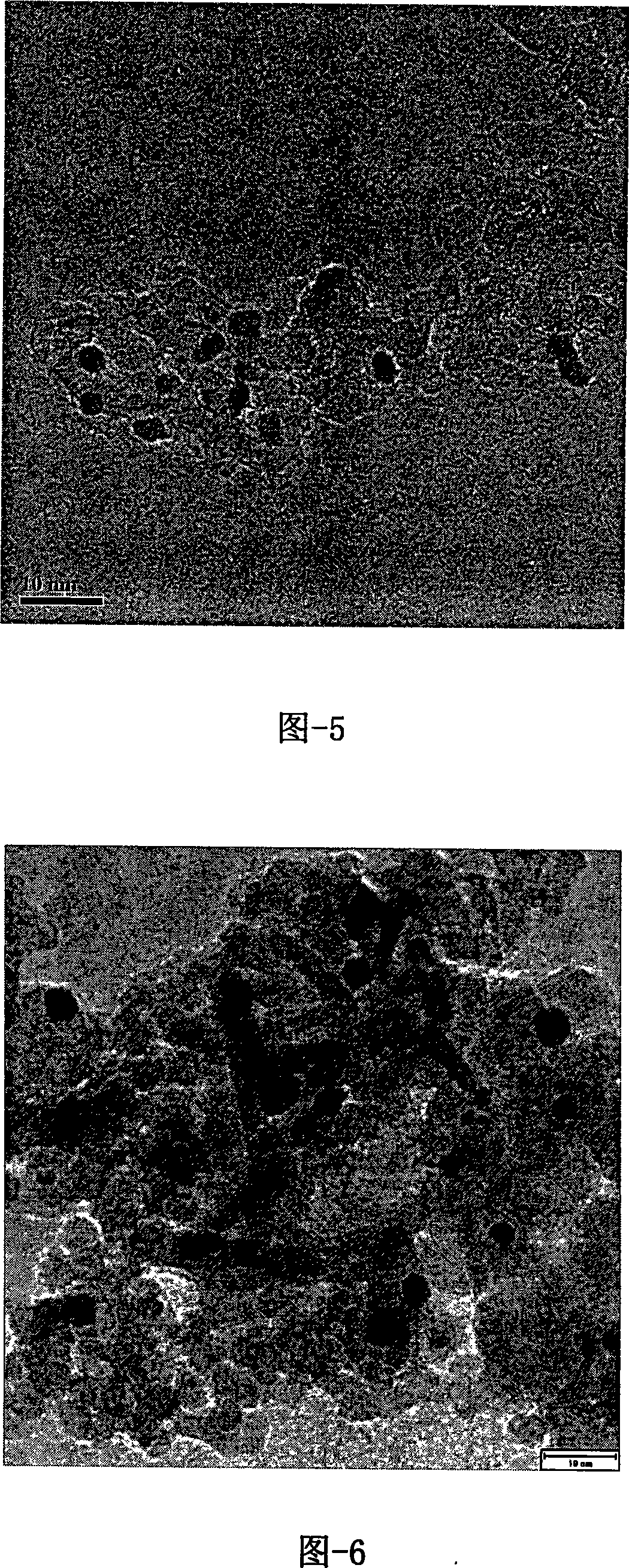

The present invention belongs to the field of catalyst preparing technology, and is especially supported nanometer metal catalyst preparing process and apparatus. The process includes diffusing metal salt solution from metering pump to mixed slurry solution comprising reductant and carrier material through the micropores in the ceramic film pipe under ultrasonic introduction for metal ion to be adsorbed and reduced in the surface of catalyst carrier, the subsequent centrifugal separation, washing the precipitant with deionized water, stoving and burning to form the supported nanometer metal catalyst. The present invention has the advantages of homogeneous distribution of active catalyst component, small size, high metal dispersion, etc.

Owner:BEIJING UNIV OF TECH

Prep. of high-load bi-and multi-component precious metallic catalyst

InactiveCN1448216AHigh metal utilizationEasy to operateCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsChemistryPrecious metal

The present invention is preparation process of two-component and multiple-component loaded catalyst with relatively high loaded amount and containing noble metal(s) of Pt, Pd, Ru, Os, Ir, Rh, Re, etc. and other transition metal(s). By means of altering the solvent composition in dispersion system, raising the viscosity of solvent and lowering the diffusion rate of metal particles inside the solution effectively, it is possible to prevent the mutual polymerization and enlarging of metal particles without adopting macro molecule surfactant in preparing two-component and multiple-component loaded nanometer-level noble metal-based catalyst with high dispersivity and great loaded amount. Several kinds of metal may be loaded onto the carrier in once process while ensuring high metal dispersivity even in case of high metal loading amount.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Carbon-supported multi-component catalyst and preparation method and application thereof

ActiveCN105214686AEasy to prepareHigh metal dispersionOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsPlatinumActivated carbon

The invention provides a carbon-supported multi-component catalyst and a preparation method thereof. The catalyst is prepared from a carrier and metal active components loaded on the carrier. The carrier is activated carbon. The metal active components comprise palladium, platinum and a transition metal element assistant. Based on the mass of the carrier, namely, the activated carbon, the capacity of palladium ranges from 0.5 wt% to 5.0 wt%, the capacity of platinum ranges from 0.5 wt% to 5.0 wt%, and the capacity of the transition metal element assistant ranges from 0.1 wt% to 2.5 wt%. Meanwhile, the mass ratio of palladium to platinum is 1:0.5-2.0. The catalyst can be applied to catalytic hydrogenation for synthesis of benzotriazole ultraviolet absorbent. The preparation method of the catalyst is easy and convenient, the catalytic activity is high, the selectivity and yield of target products are high, good stability is achieved, and meanwhile three wastes generated in the hydrogenation process are fewer.

Owner:ZHEJIANG UNIV OF TECH +1

Synthesis method for zeolite-coated precious metal particles and application of zelite-coated precious metal particles in light paraffin isomerization

ActiveCN105413742AHigh metal dispersionReduce loadMolecular sieve catalystsHydrocarbon oils refiningAlkaneAir atmosphere

The invention provides a synthesis method for zeolite-coated precious metal particles. The synthesis method comprises the steps that 1, a metal salt solution of platinum-containing soluble salt and / or palladium-containing soluble salt is taken to be mixed with a silicon source and / or an aluminum source, a template agent, a pH value regulating agent and water, gel is obtained through stirring, and dry gel is obtained through drying; 2, crystallization is performed by adopting a dry gel steam assisting method; 3, a product obtained through crystallization is calcined for 5-8 hours in an air atmosphere and then reduced for 2-4 hours in a hydrogen atmosphere. According to the method, by learning from the characteristics of synthesizing Silicate-1-coated precious metal through a steam assisting converting method, a precursor of solid superacid is introduced in the synthesizing process of mordenite and Beta zeolite, synthesis of a zeolite molecular sieve of which pore channels contain precious metal is successfully achieved, and the catalytic property of the catalyst in a light paraffin isomerization reaction is further improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Composite catalyst for hydrodeoxygenation reaction and preparation method thereof

ActiveCN109675589AHigh metal dispersionAvoid reunionPhysical/chemical process catalystsHydrocarbonsHydrogenSulfur

The invention discloses a composite catalyst for hydrodeoxygenation reaction and a preparation method thereof. The catalyst comprises metal and MoS2-x, wherein the mass content of the metal is 0.5 to10 percent. The preparation method of the catalyst comprises the following steps: regulating reaction conditions through a hydrothermal method or a solvothermal method, firstly preparing the MoS2-x containing sulphur vacancy, dispersing the MoS2-x into a solvent, adding a metal salt solution, performing dispersing and mixing, reducing metal ion into metal through in-situ reduction, and anchoring the metal to the surface of the MoS2-x. The method is simple in preparation processes, and avoids high-temperature hydrogen reduction, and the formed catalyst has the advantages of high dispersion degree of metal, large specific surface area and high hydrodeoxygenation activity.

Owner:XIANGTAN UNIV

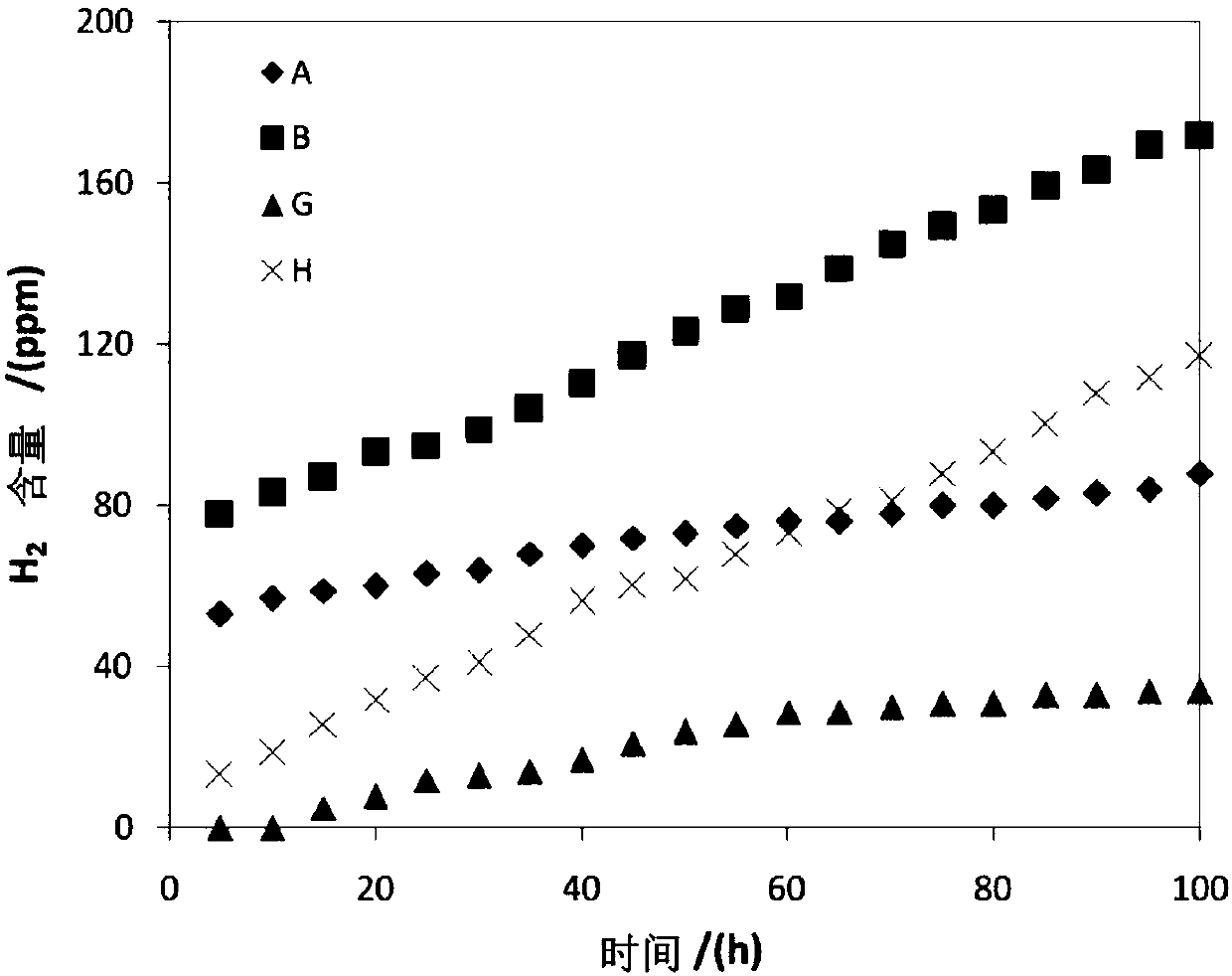

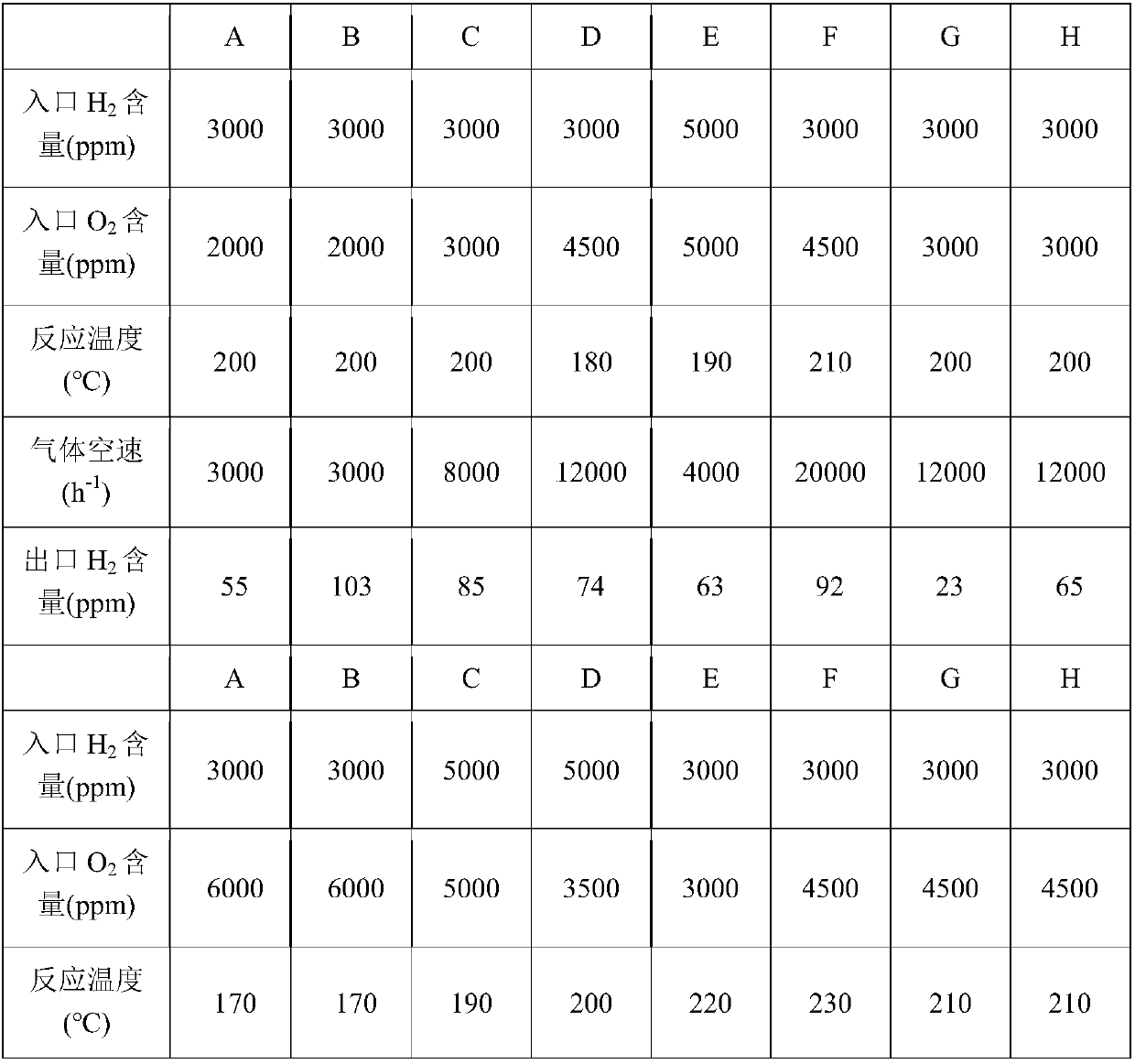

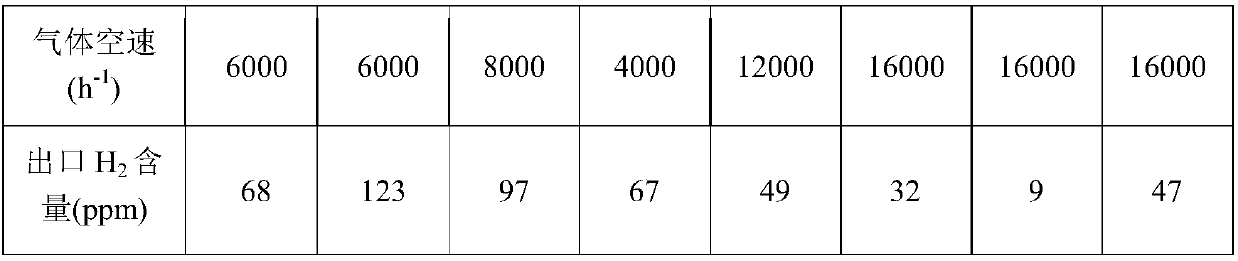

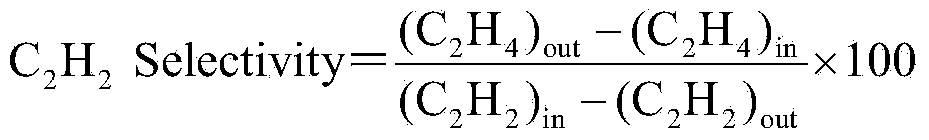

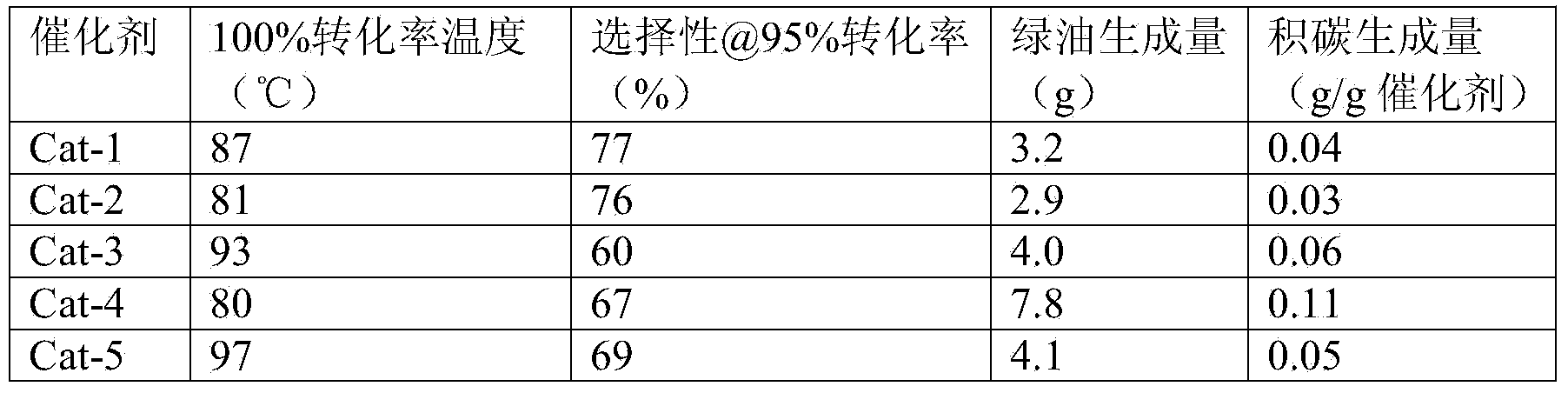

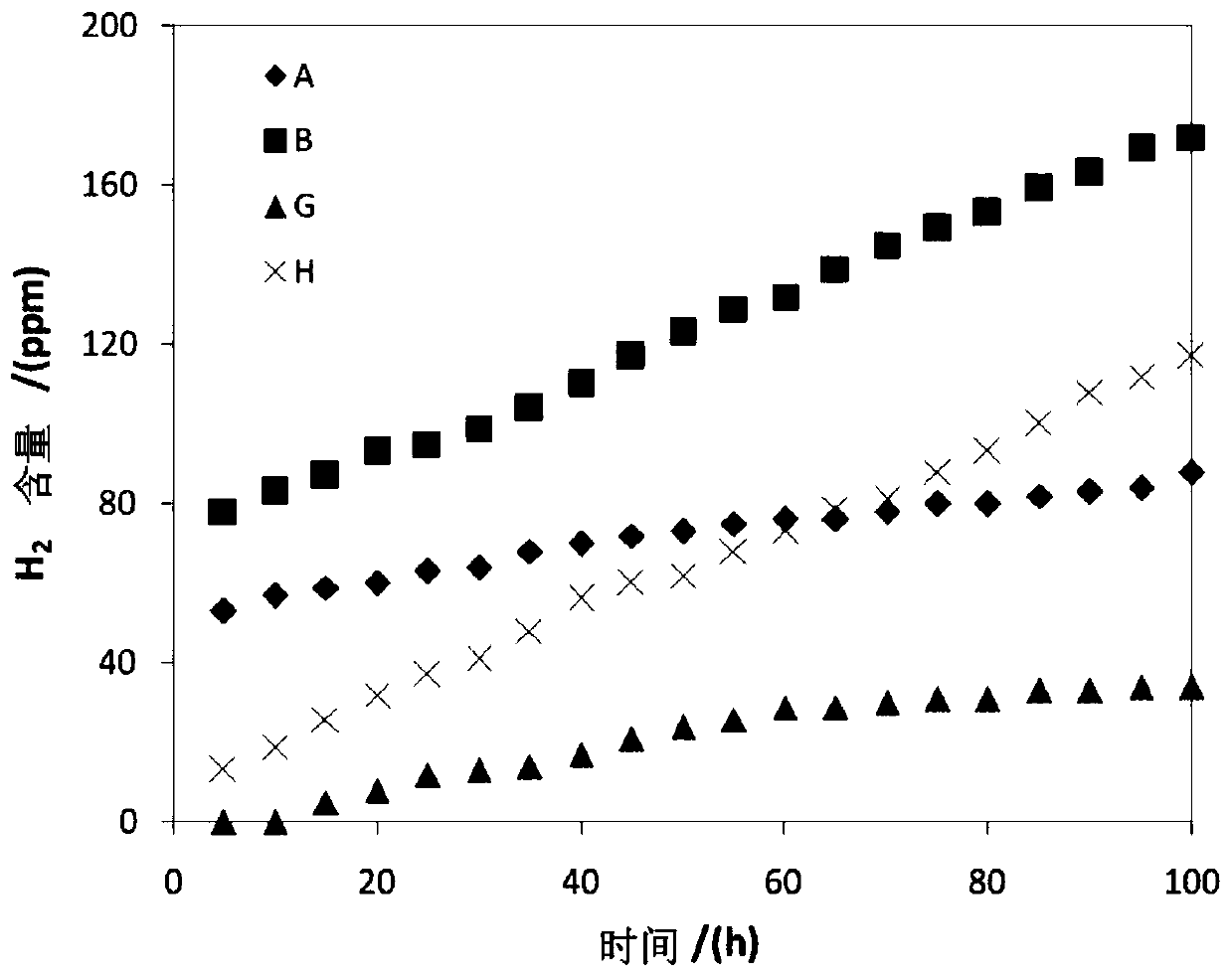

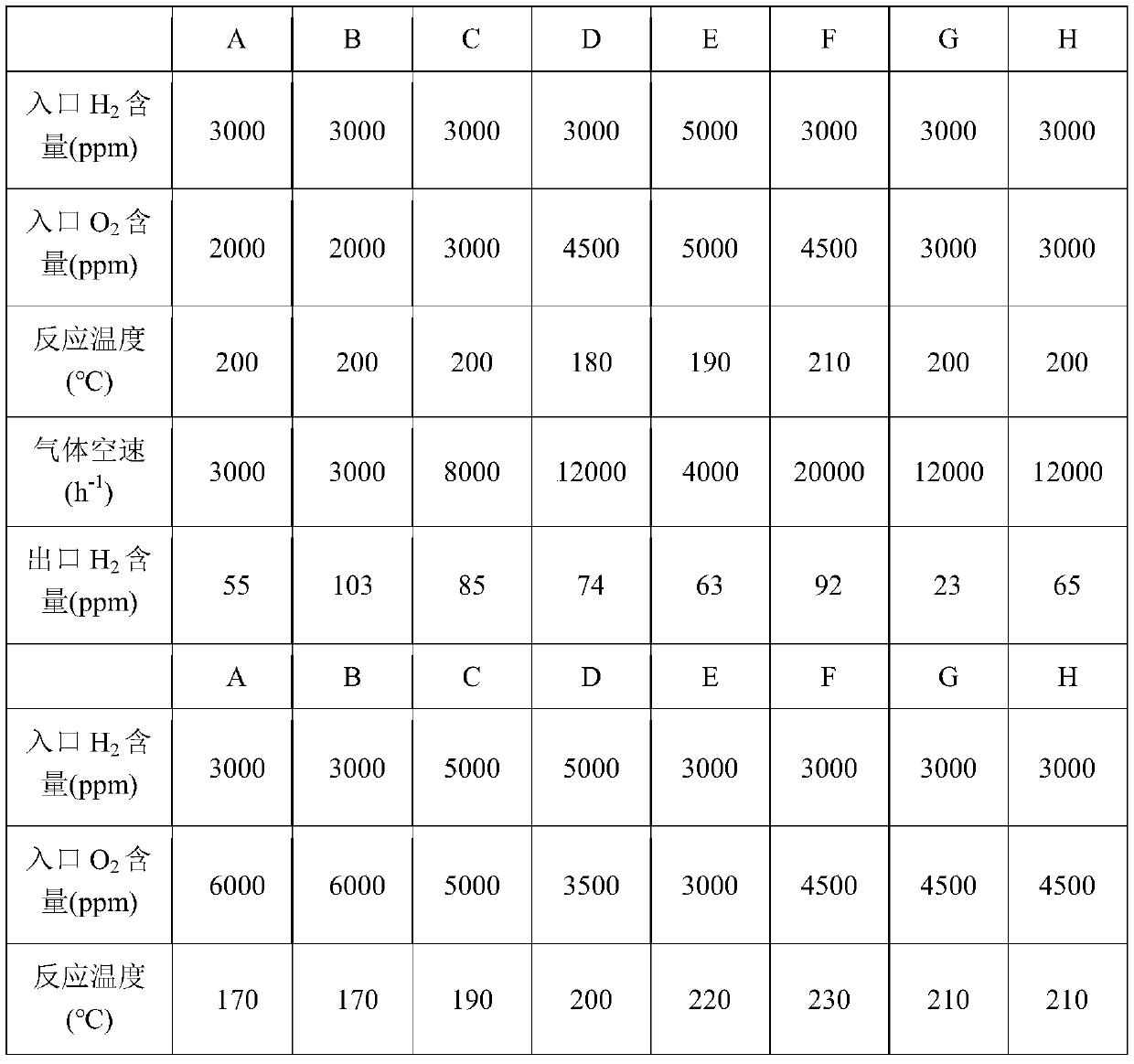

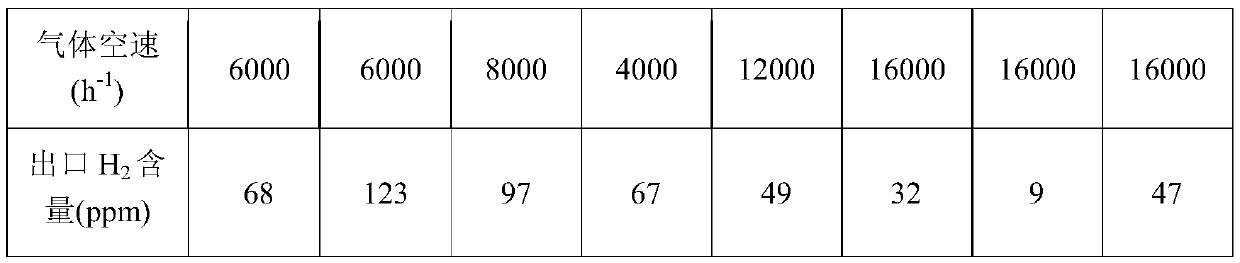

Monolithic catalyst and preparation and application thereof

ActiveCN107694562AHigh metal dispersionImprove hydrogenation activityMolecular sieve catalystsCatalyst activation/preparationOxalateHigh concentration

The invention provides a high-dispersion monolithic catalyst for selectively catalytic oxidization of H2 in the atmosphere of high-concentration CO and a preparation method and application of the high-dispersion monolithic catalyst. The catalyst is suitable for a fixed bed reactor and has a multilayer structure, wherein the multilayer structure includes but not limited to a shell layer, an activecomponent layer, a carrier coating and a honeycomb carrier layer. The catalyst can be applied to the process of the selectively catalytic oxidization of H2 in the atmosphere of the high-concentrationCO, wherein the ratio of H2 to O2 in feed gas is 1:1 to 1:3, the reaction temperature is 150-250 DEG C, and the pressure is 0.3-0.6 MPa; besides, when the airspeed is 3000-20000h<-1>, the content of output H2 is less than 100 ppm, so that the reaction requirements of subsequent vapor catalytic coupling synthesis of oxalate by using CO are met.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Hydrogenation catalyst with large specific surface and low acid amount, and application thereof

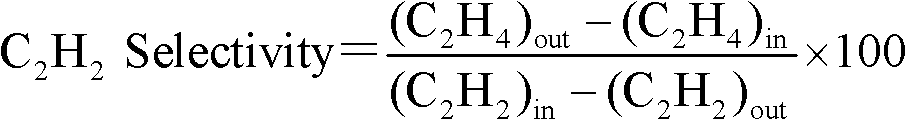

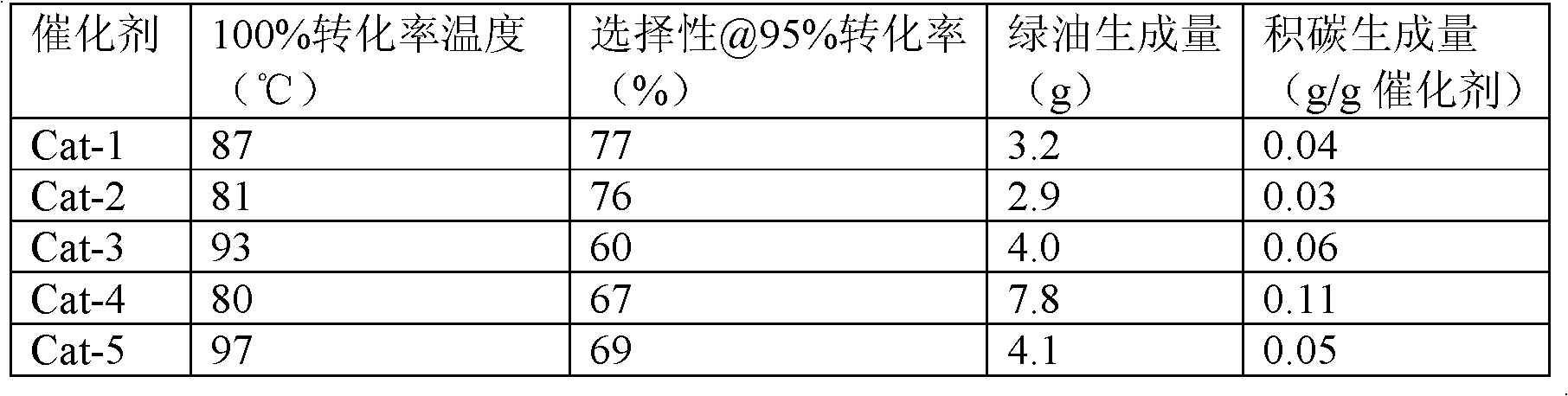

ActiveCN103071491AHigh metal dispersionHigh activityHydrocarbon from carbon oxidesHydrocarbon purification/separationGas phaseUnsaturated hydrocarbon

The invention discloses a palladium metal hydrogenation catalyst used in unsaturated hydrocarbon hydrogenation. The catalyst comprises a metal active component palladium, a carrier alumina and a silica auxiliary agent. The catalyst provided by the invention has a relatively large specific surface (a specific surface area is 140-330cm<2> / g), and relatively low surface acid content (lower than 0.15mmol / g). The content of the auxiliary agent silica is 0.5-10wt%. Silica is added into the catalyst through a gas-phase silylation treatment upon alumina. Preferably, the catalyst provided by the invention also comprises a plurality of auxiliary agents. When the catalyst provided by the invention is used in an unsaturated hydrocarbon hydrogenation reaction, the catalyst has the advantages of high activity and low yield of green oil and carbon deposit.

Owner:CHINA PETROLEUM & CHEM CORP +1

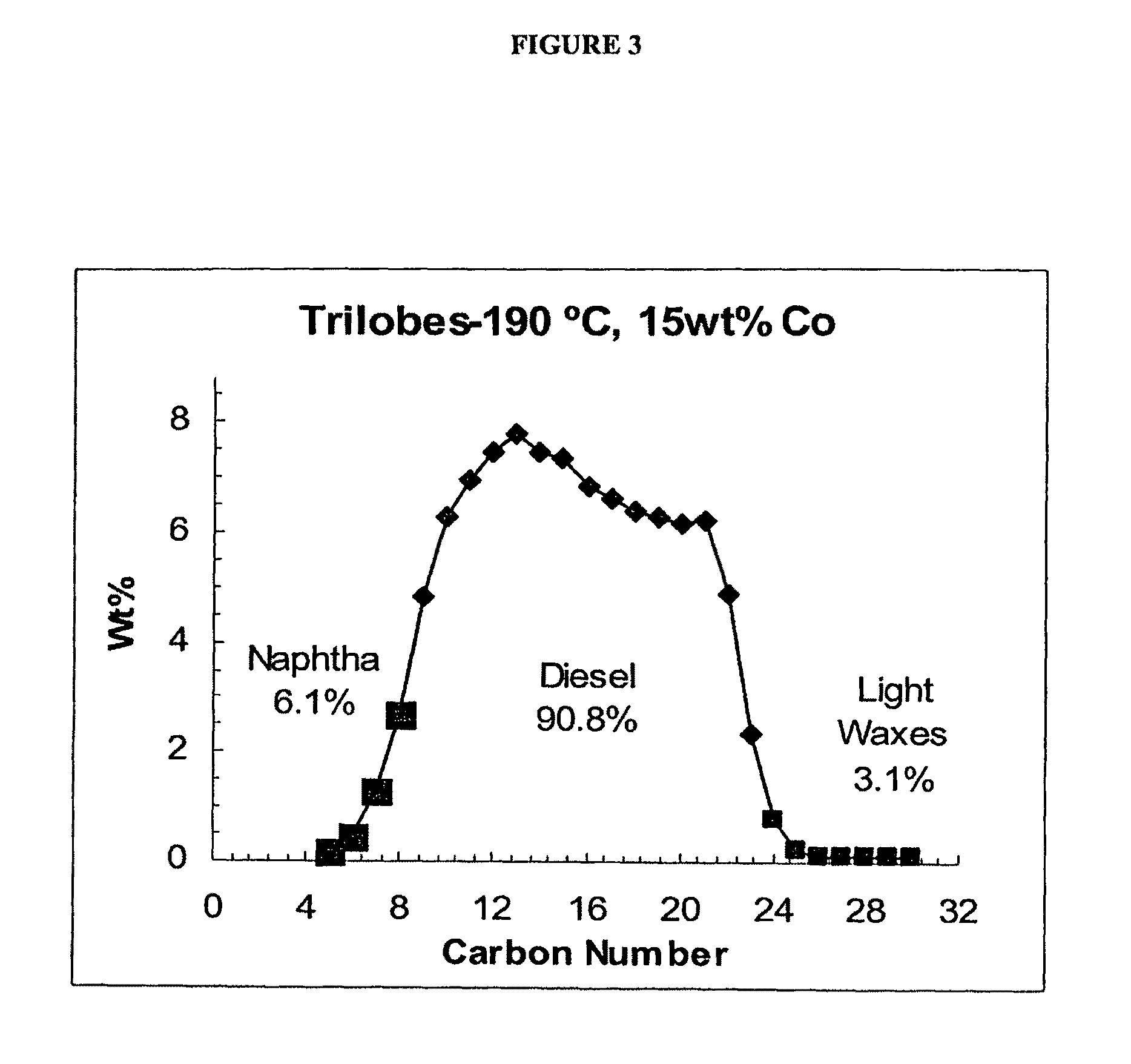

Low-pressure Fischer-Tropsch process

ActiveUS8053481B2Reduce the temperatureReduce metal contentHydrogenOrganic compound preparationWaxRhenium

A Fischer-Tropsch process for producing diesel fuel or diesel blending stock with a high cetane number, in a concentration of 65-90 wt % at pressures below 200 psia, using a cobalt catalyst with a rhenium and / or ruthenium promoter. The catalyst is a cobalt catalyst with crystallites having an average diameter greater than 16 nanometers, and the resulting hydrocarbon product after a rough flash, contains less than 10 wt % waxes (>C23).

Owner:CANADA CHEM CORP

Method for comprehensive treatment of volatile organic waste gas

InactiveCN109876657AHigh metal dispersionReduce carbon depositionDispersed particle separationIncinerator apparatusDispersityCarbon deposit

The invention provides a method for comprehensive treatment of volatile organic waste gas. The method mainly includes the steps that microwave radiation is introduced into a catalytic combustion treatment process of the volatile organic waste gas, radiation energy of 3000-4000 MHz is the most appropriate, if the radiation energy is too low, the activation degree of a catalyst is not enough, and nocatalyst with the excellent catalytic activity can be obtained; and if the microwave radiation energy is too high, the changes of the physical and chemical properties of the catalyst cannot be controlled due to the too high catalyst temperature, and meanwhile, energy consumption is large and the production cost is too high. In addition, microwave radiation is conducted during continuous introduction of the waste gas, the high activity of the catalyst is further maintained for a long time advantageously, and the reason is that energy of microwave radiation promotes metal ions in the catalyst to complete an oxidation-reduction cycle in the process of oxidation of adsorbed state VOCs; and after the action of microwave irradiation, the metal dispersity of the catalyst is increased, carbon deposits on the surface of the catalyst are reduced, and thus the catalyst can maintain the high activity for a long time.

Owner:PINGXIANG HUAXING ENVIRONMENTAL PROTECTION ENG TECH CO LTD

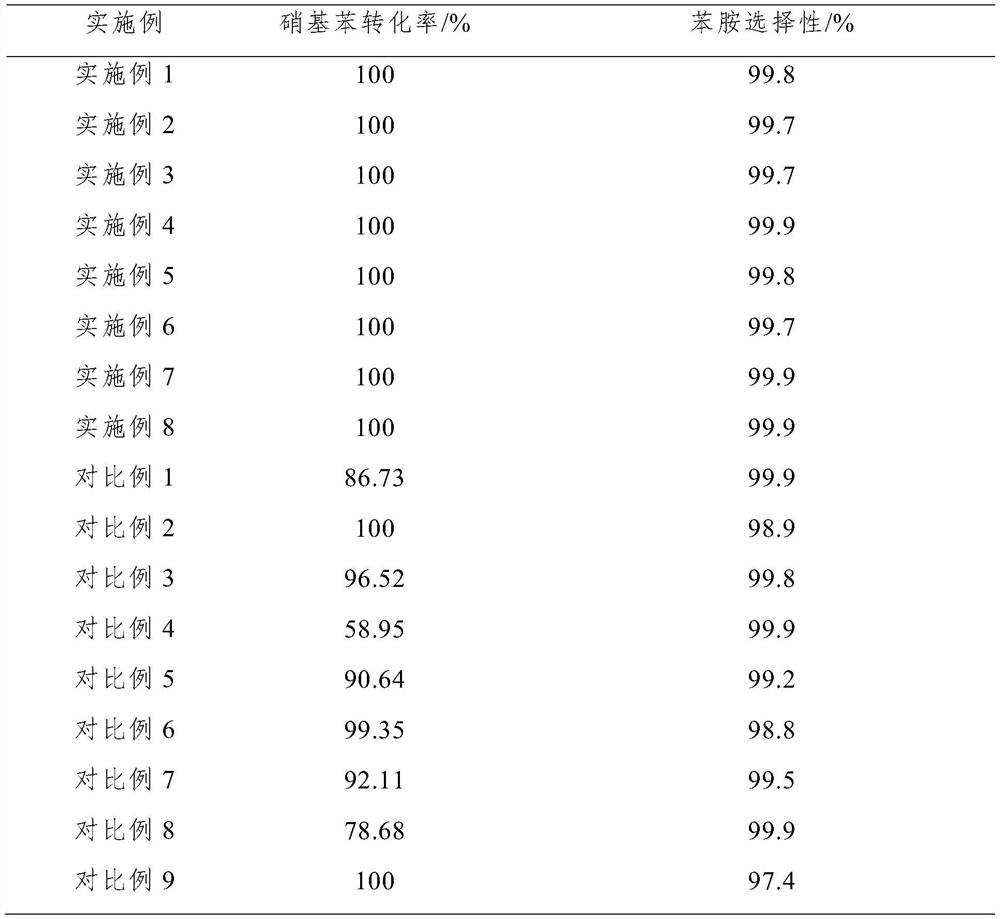

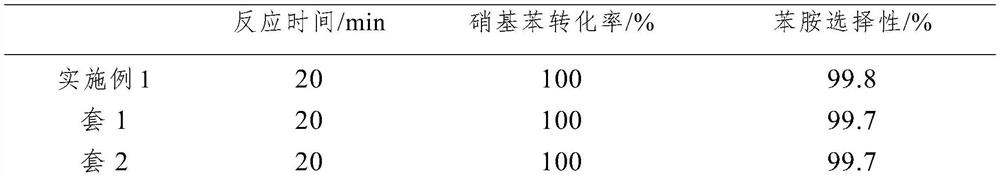

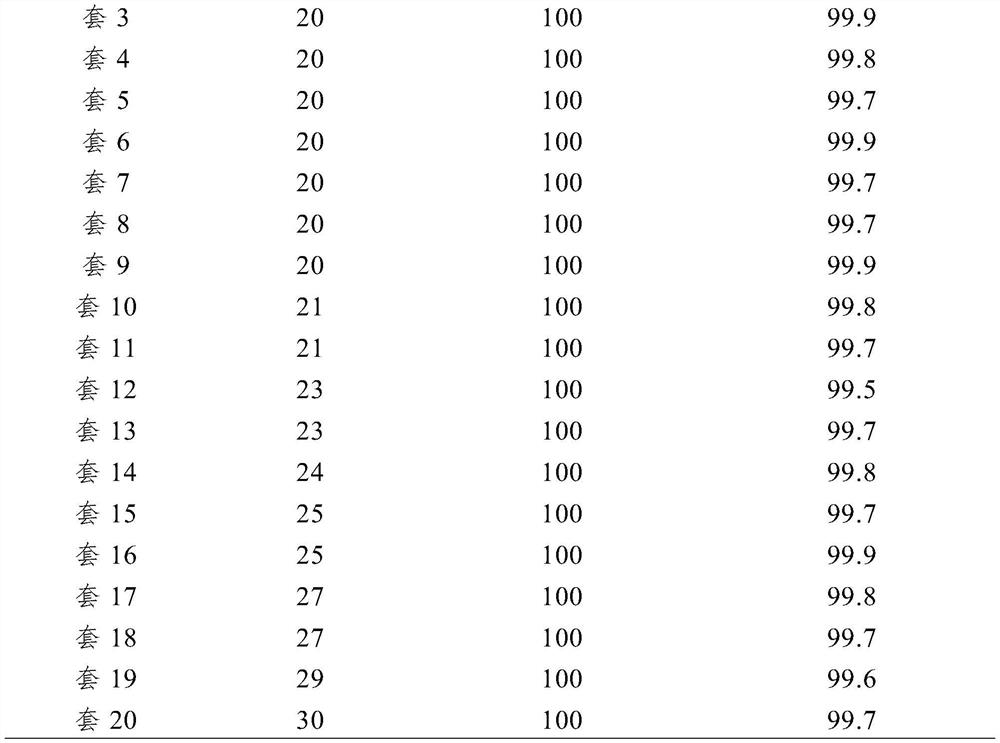

Catalyst for synthesizing aniline through nitrobenzene liquid phase hydrogenation and preparation method thereof

PendingCN112108139AHigh activityExtended service lifeCatalyst carriersOrganic compound preparationSide productNitrobenzene

The invention discloses a catalyst for synthesizing aniline through nitrobenzene liquid phase hydrogenation. The catalyst raw material comprises surface-modified carbon nanotubes and precursor atomized particles containing an active component and auxiliary agents, the active component is Pt, the auxiliary agents are more than two of Ru, Ni, Cr, La and W, and the mass of each assistant is 0.05-1.0%of the mass of the catalyst. In addition, the invention also provides a method for preparing the catalyst. Raw materials of the catalyst comprise surface-modified carbon nanotubes and precursor atomized particles containing the active component and the auxiliary agents, the active component is Pt, and the auxiliary agents are more than two of Ru, Ni, Cr, La and W. The catalyst is applied to catalytic nitrobenzene liquid phase hydrogenation aniline synthesis reaction, and has the advantages of high initial activity, long service life, few tar byproducts, and easy industrial popularization.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

Prep. of high-load bi-and multi-component precious metallic catalyst

InactiveCN1171670CImprove carrying capacityHigh metal utilizationCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsMetal particleHigh load

The present invention is preparation process of two-component and multiple-component loaded catalyst with relatively high loaded amount and containing noble metal(s) of Pt, Pd, Ru, Os, Ir, Rh, Re, etc. and other transition metal(s). By means of altering the solvent composition in dispersion system, raising the viscosity of solvent and lowering the diffusion rate of metal particles inside the solution effectively, it is possible to prevent the mutual polymerization and enlarging of metal particles without adopting macro molecule surfactant in preparing two-component and multiple-component loaded nanometer-level noble metal-based catalyst with high dispersivity and great loaded amount. Several kinds of metal may be loaded onto the carrier in once process while ensuring high metal dispersivity even in case of high metal loading amount.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

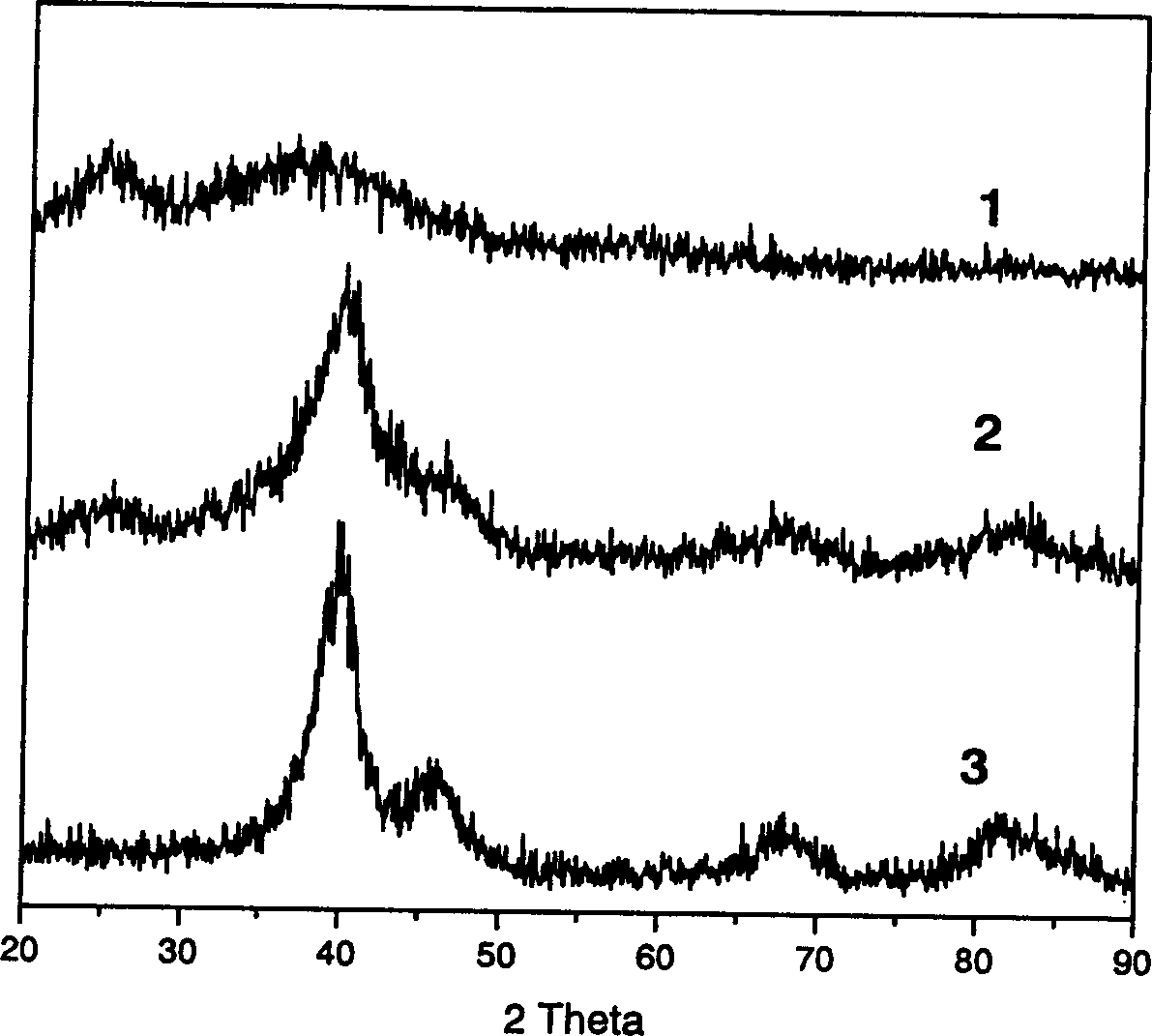

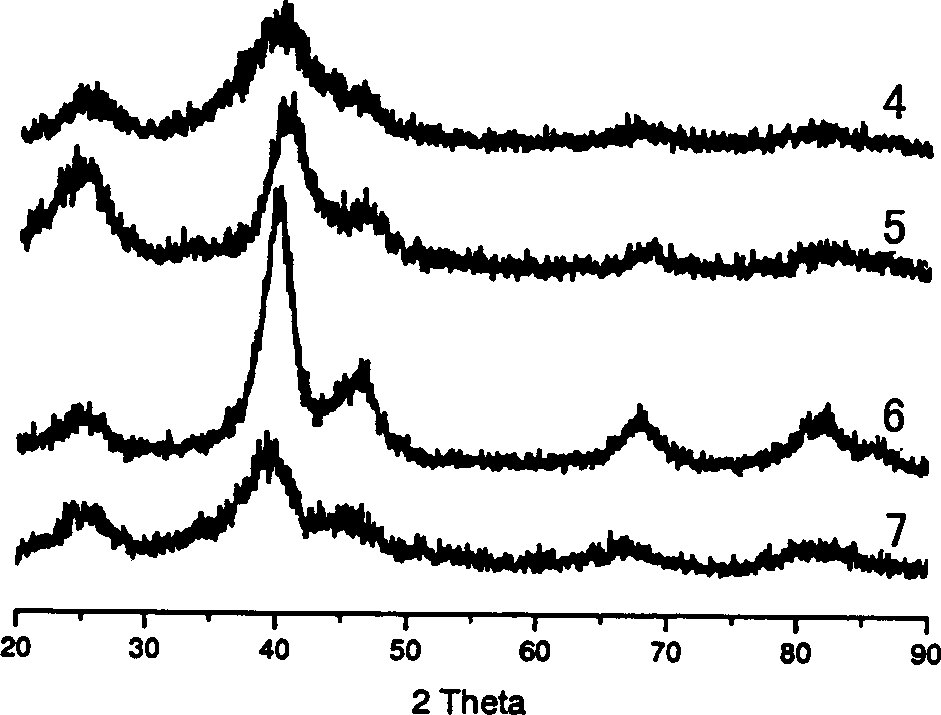

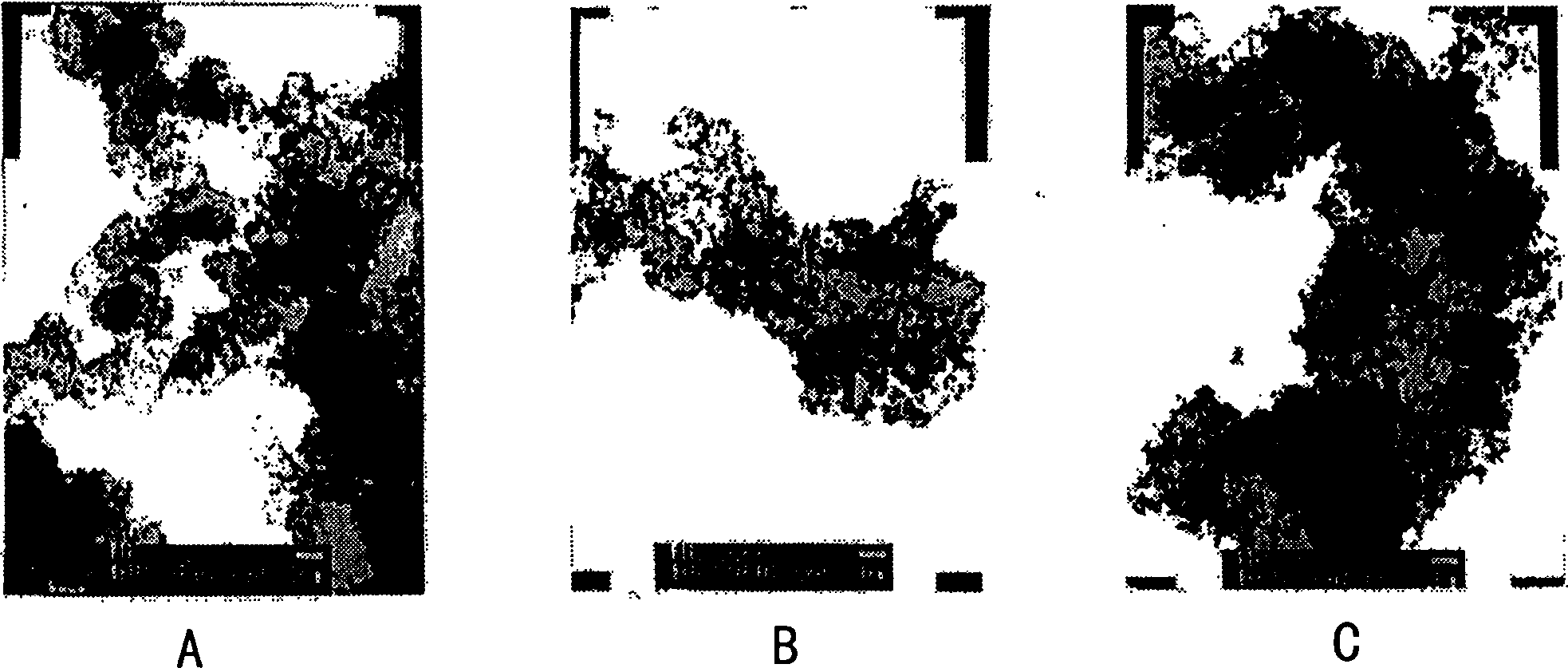

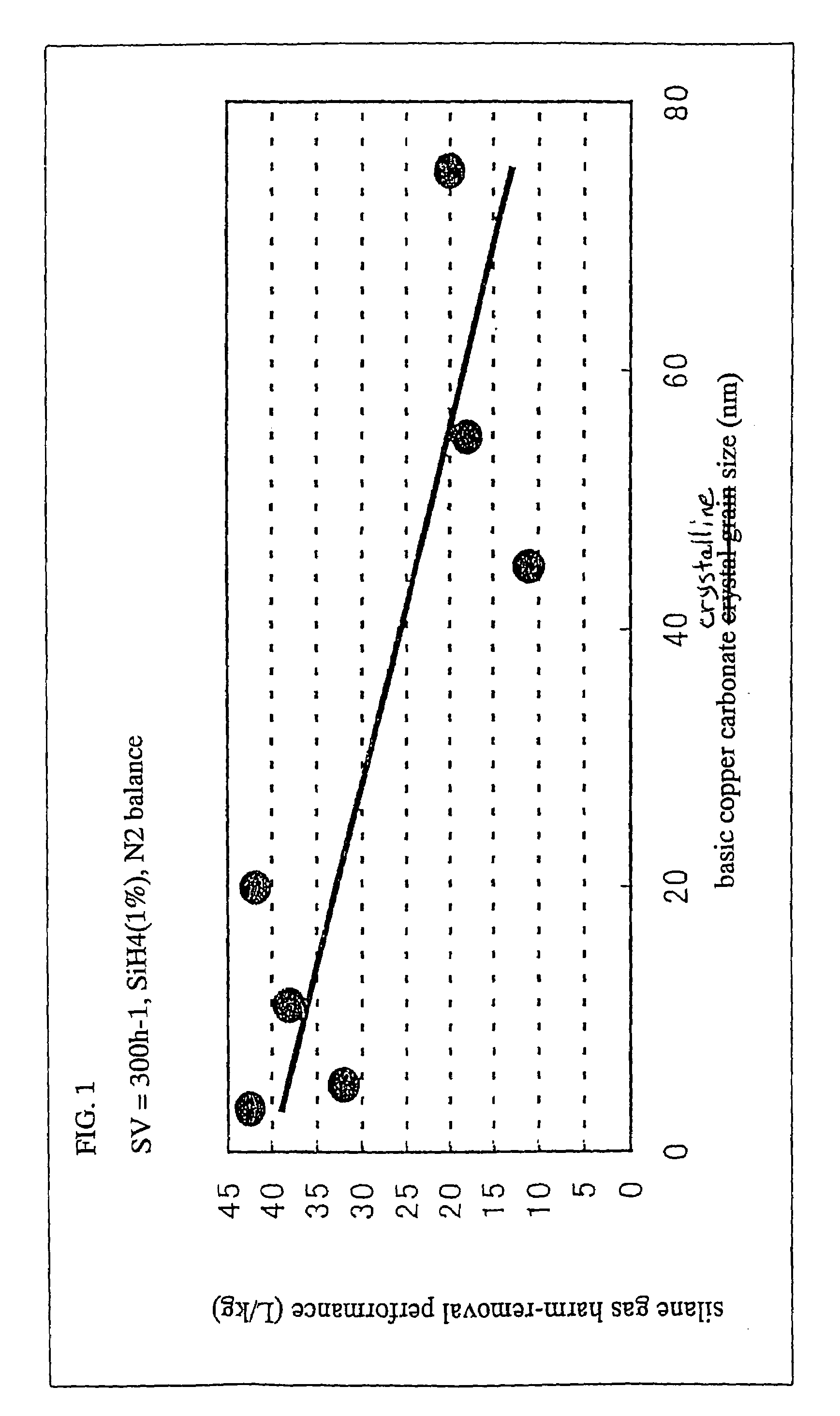

Treating agent for metal-hydride-containing exhaust gas and method of preparing the same as well as method of treating metal-hydride-containing exhaust gas

InactiveUS7067091B2Superior in performance of removing metal hydride gasImprove performanceOther chemical processesUsing liquid separation agentCopper saltPrecipitation

An object of the present invention is to provide a treatment agent superior in harm-removing performance to metal hydride containing exhaust gas, and its production method as well as a treatment method. It is a mixture of either copper hydroxide or basic copper carbonate and silicon compound or a mixture, wherein parts of said copper compound and said silicon compound form a complex. A preparation of the treatment agent is made by a precipitation method, wherein a copper salts solution serves as a precipitation mother solution, and a mixture solution of either alkali hydroxide or alkali carbonate and alkali silicate serves as a precipitating agent. A treatment agent obtained as its result shows a high harm-removing performance to the metal hydride gas and a low heat generation, for which reason the agent is useful for treatment of the metal hydride containing exhaust gas generated in semiconductor manufacturing.

Owner:SUD CHEM CATALYSTS JAPAN

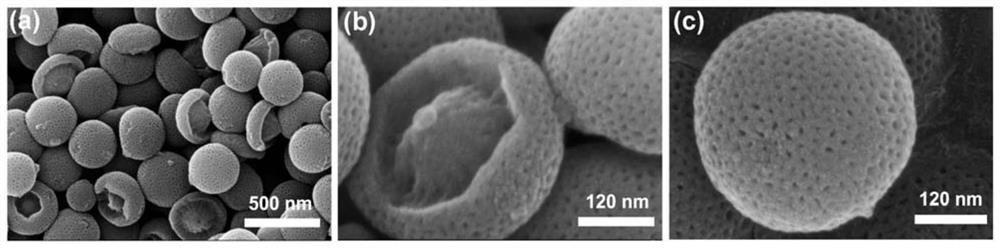

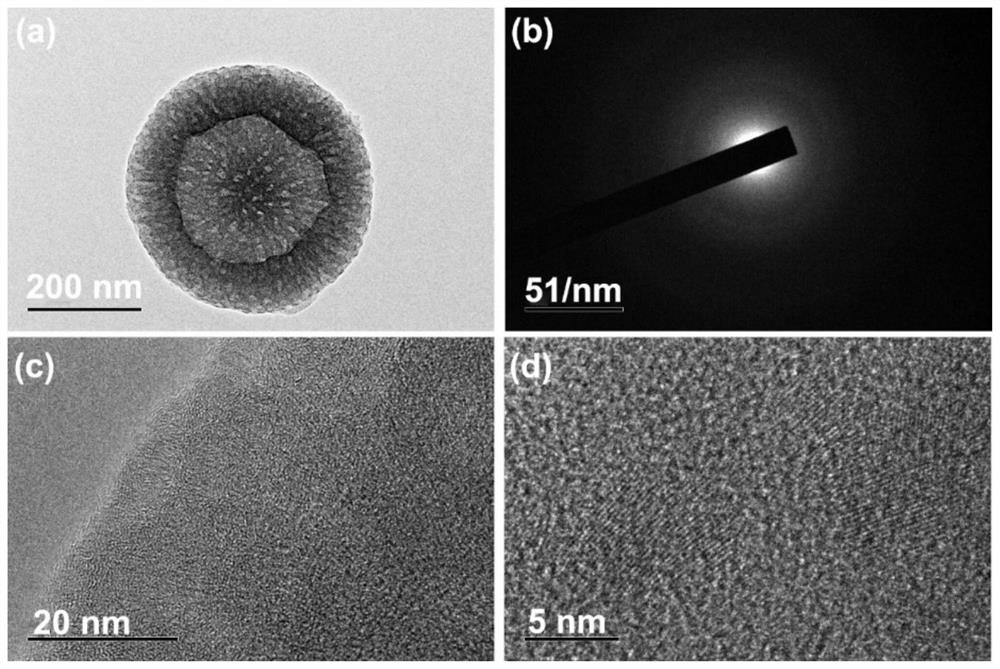

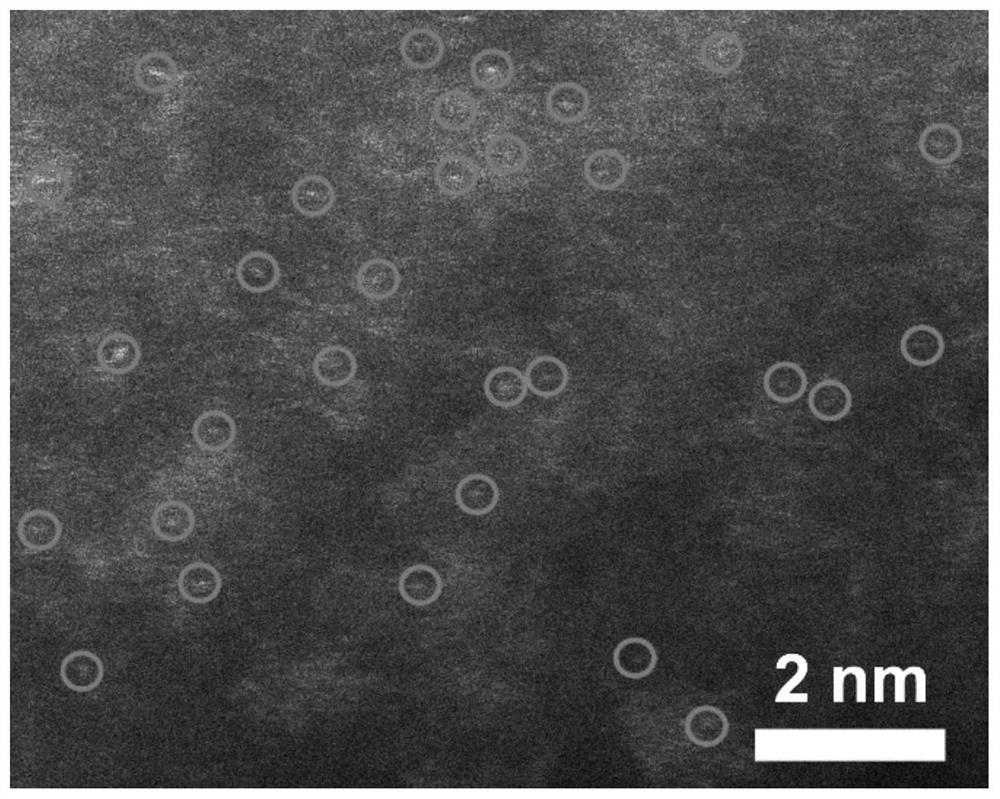

Atomic-scale metal manganese-loaded nitrogen-doped mesoporous carbon nano-microsphere and application of atomic-scale metal manganese-loaded nitrogen-doped mesoporous carbon nano-microsphere

PendingCN114737219AHigh metal dispersionHigh selectivityFuel and primary cellsCell electrodesPolyethylene oxidePtru catalyst

The invention relates to an atomic-scale manganese metal loaded nitrogen-doped mesoporous carbon nano-microsphere and application thereof, and belongs to the technical field of porous carbon material preparation. The preparation method comprises the following steps: preparing two kinds of polyethylene oxide-polypropylene oxide-polyethylene oxide with different molecular weights, dopamine hydrochloride and a mixed solvent of water and ethanol into a monomer solution; the preparation method comprises the following steps: firstly, preparing 1, 3, 5-trimethylbenzene and a monomer solution into a milky nano microemulsion system, and then adding ammonia water for stirring reaction to obtain a dopamine polymer; stirring the dopamine polymer and a manganese salt aqueous solution for reaction to obtain a polymer loaded with a metal precursor; and calcining the polymer loaded with the metal precursor in a nitrogen or inert gas protective atmosphere to obtain the mesoporous carbon nano-microspheres. The preparation method of the mesoporous carbon nano-microspheres is simple, conditions are mild, and the mesoporous carbon nano-microspheres can be used as a high-efficiency catalyst for preparing CO by reducing CO2 and a high-efficiency positive electrode catalyst of a Li-CO2 battery, and have a wide application prospect.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

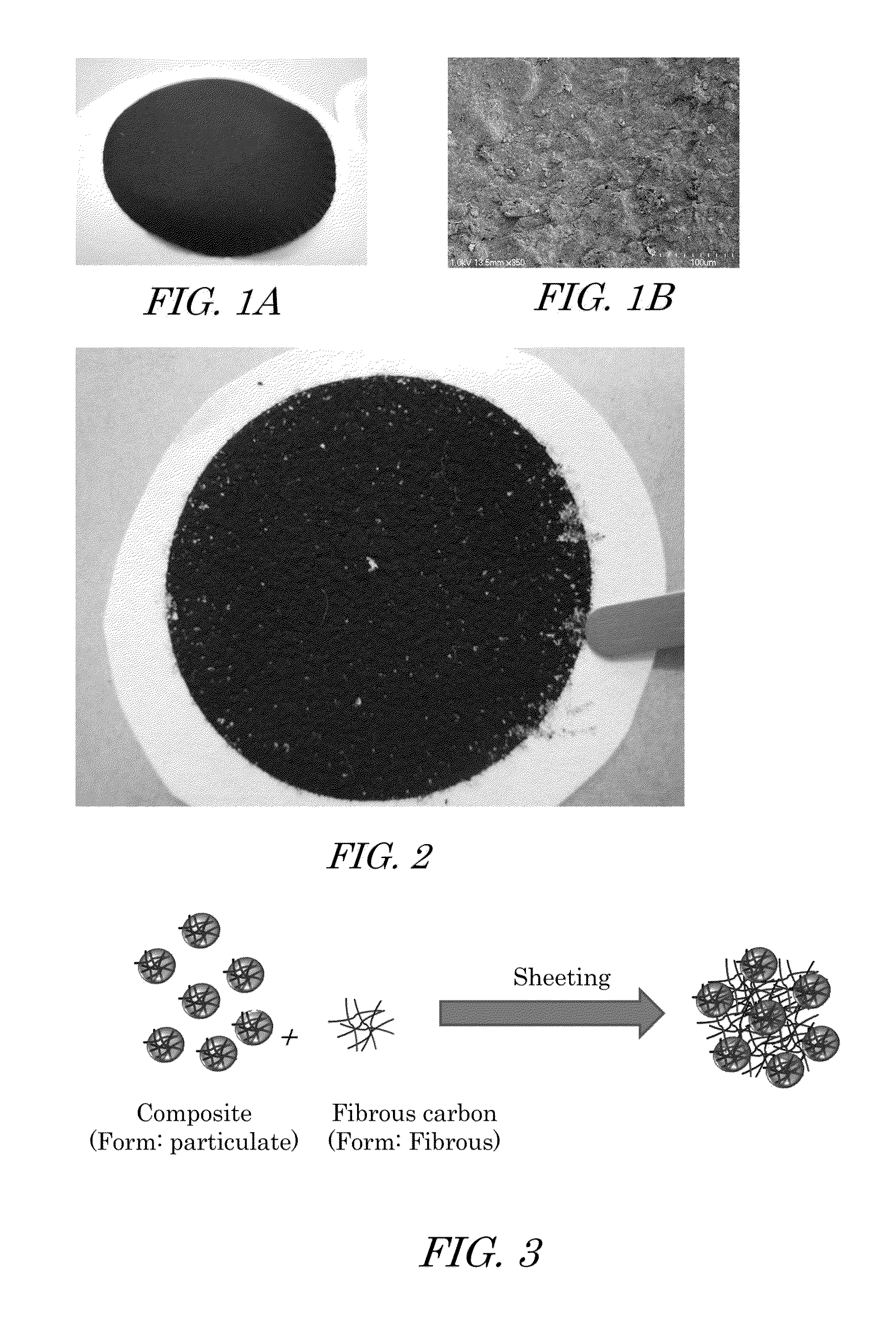

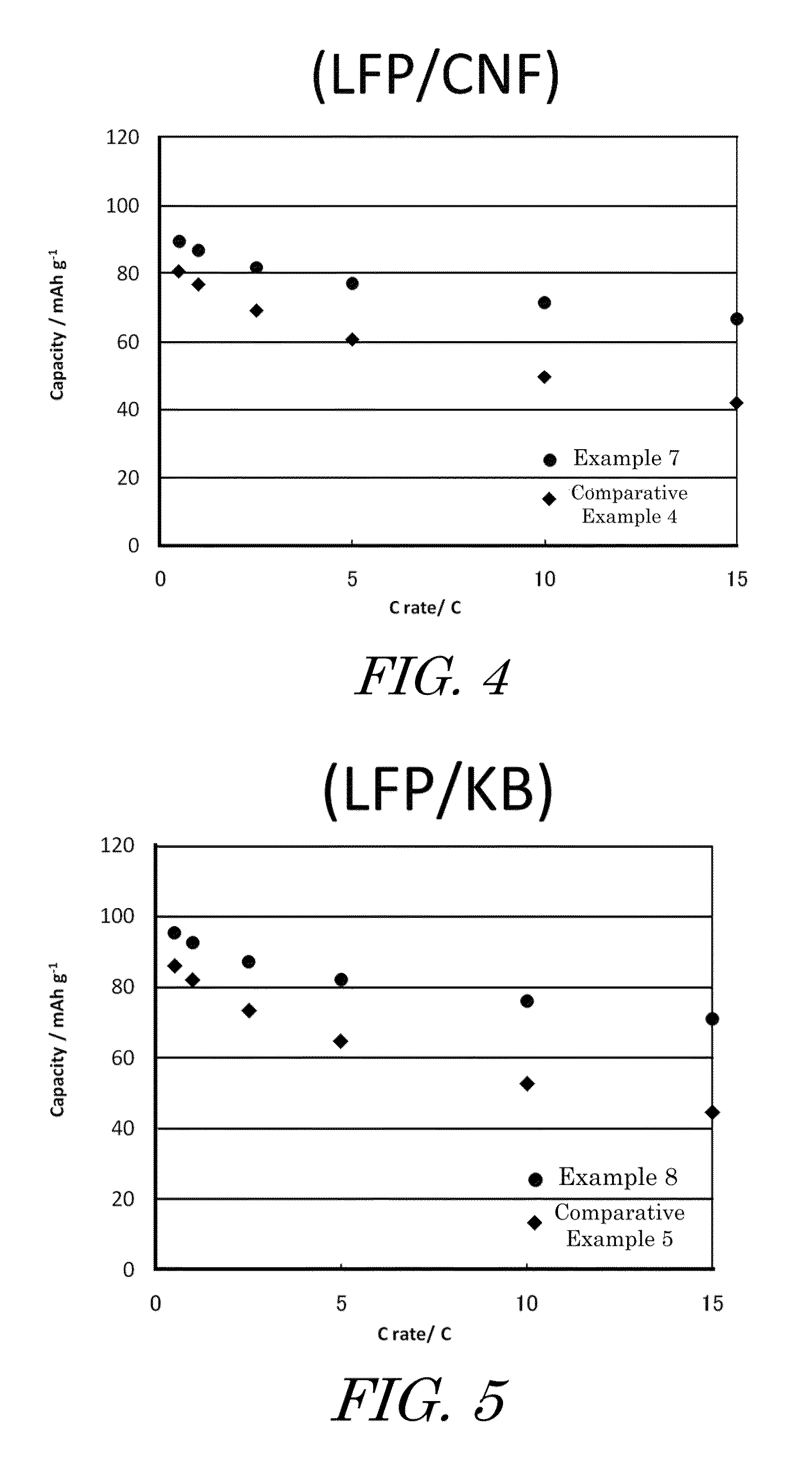

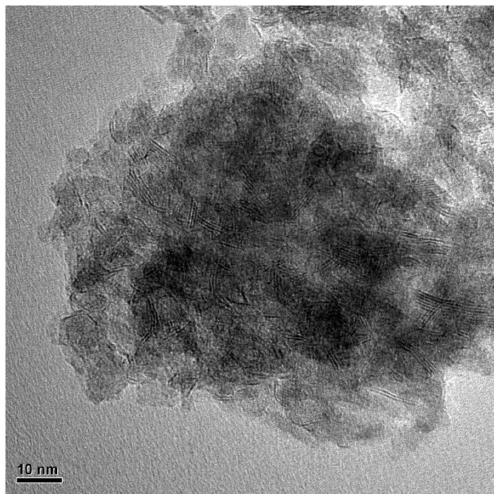

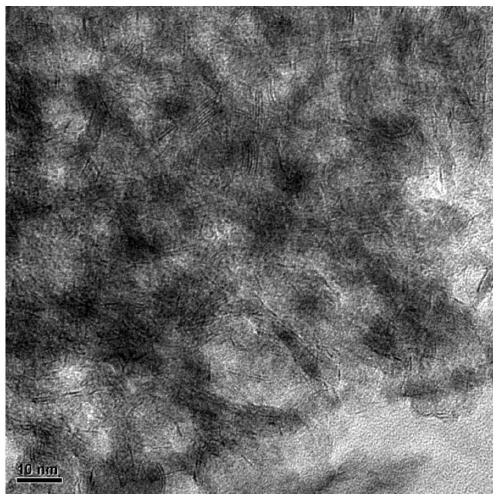

Manufacturing method of electrode material

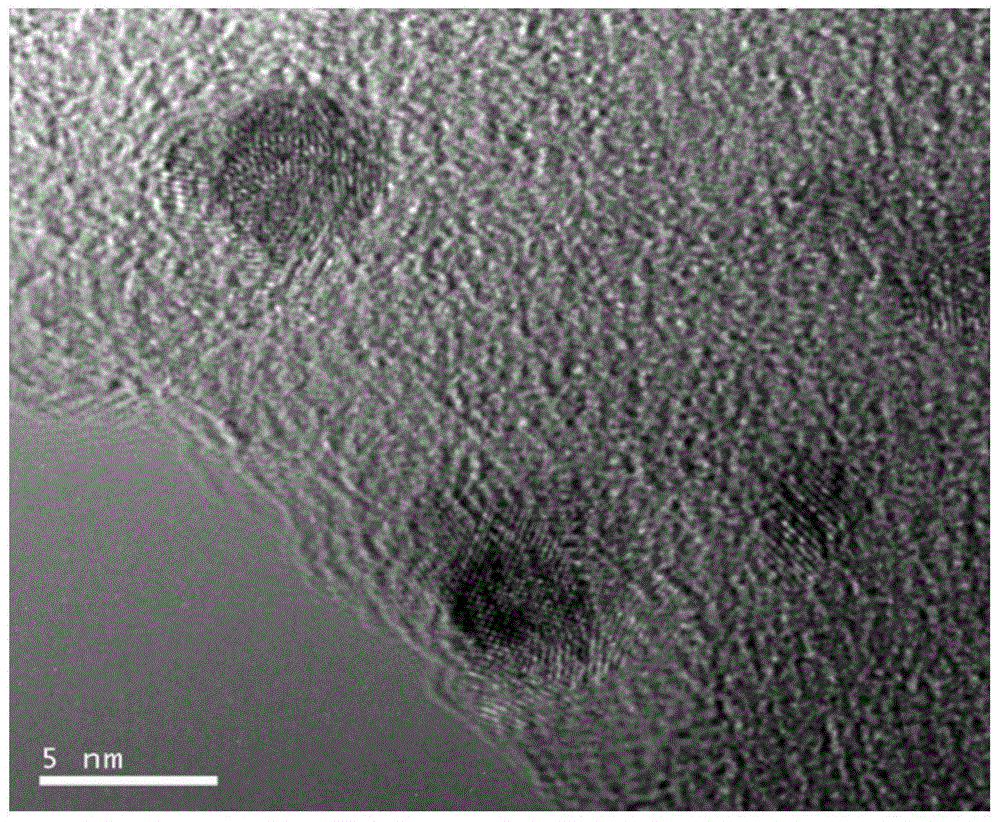

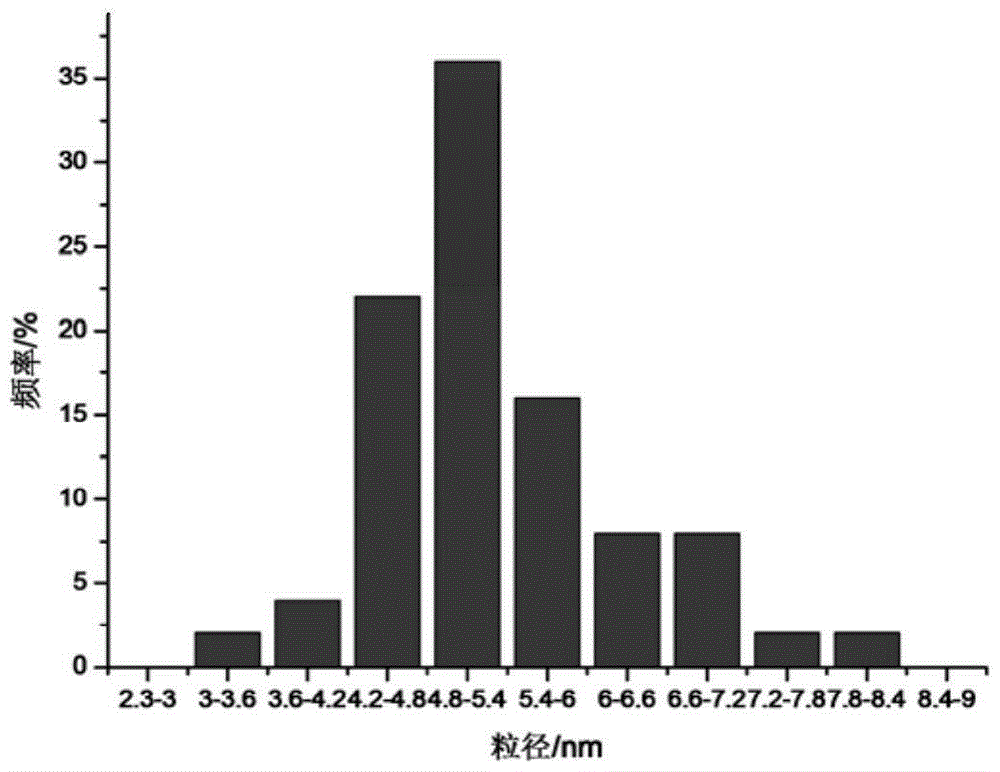

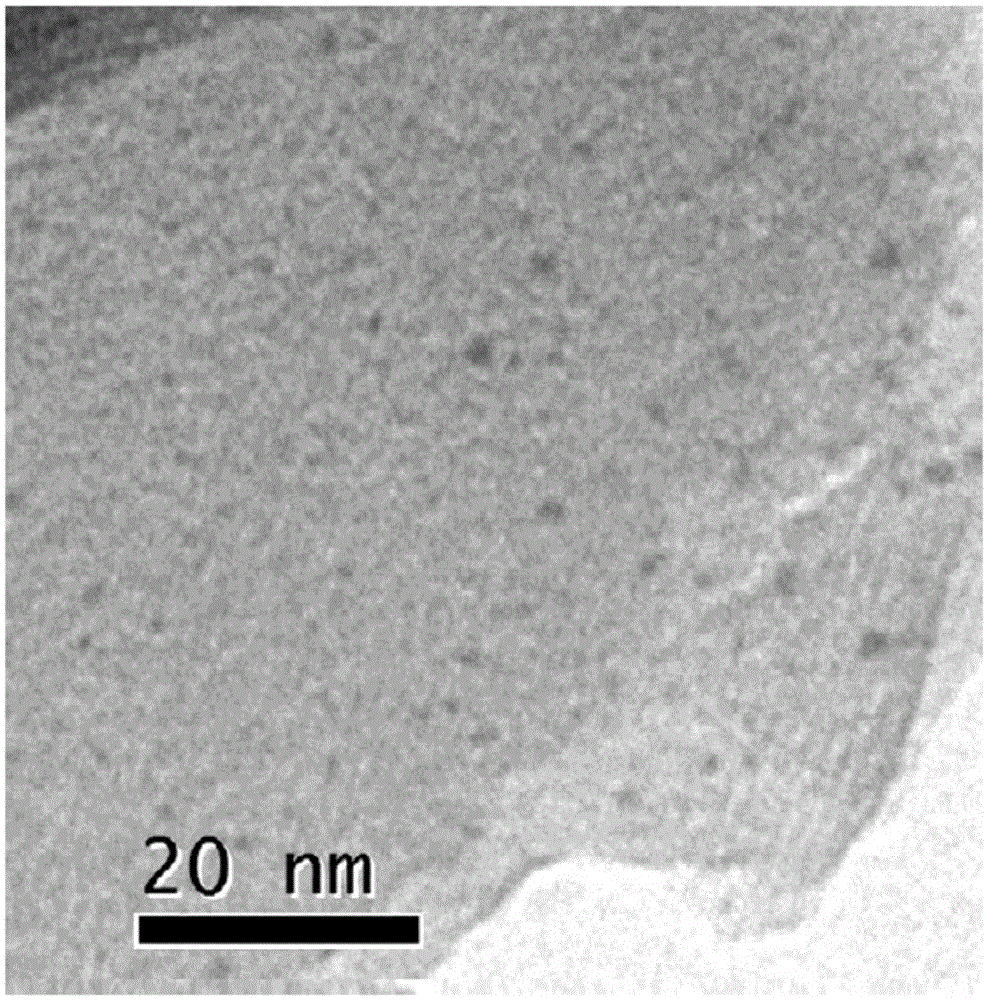

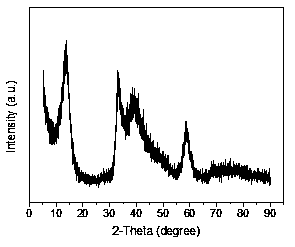

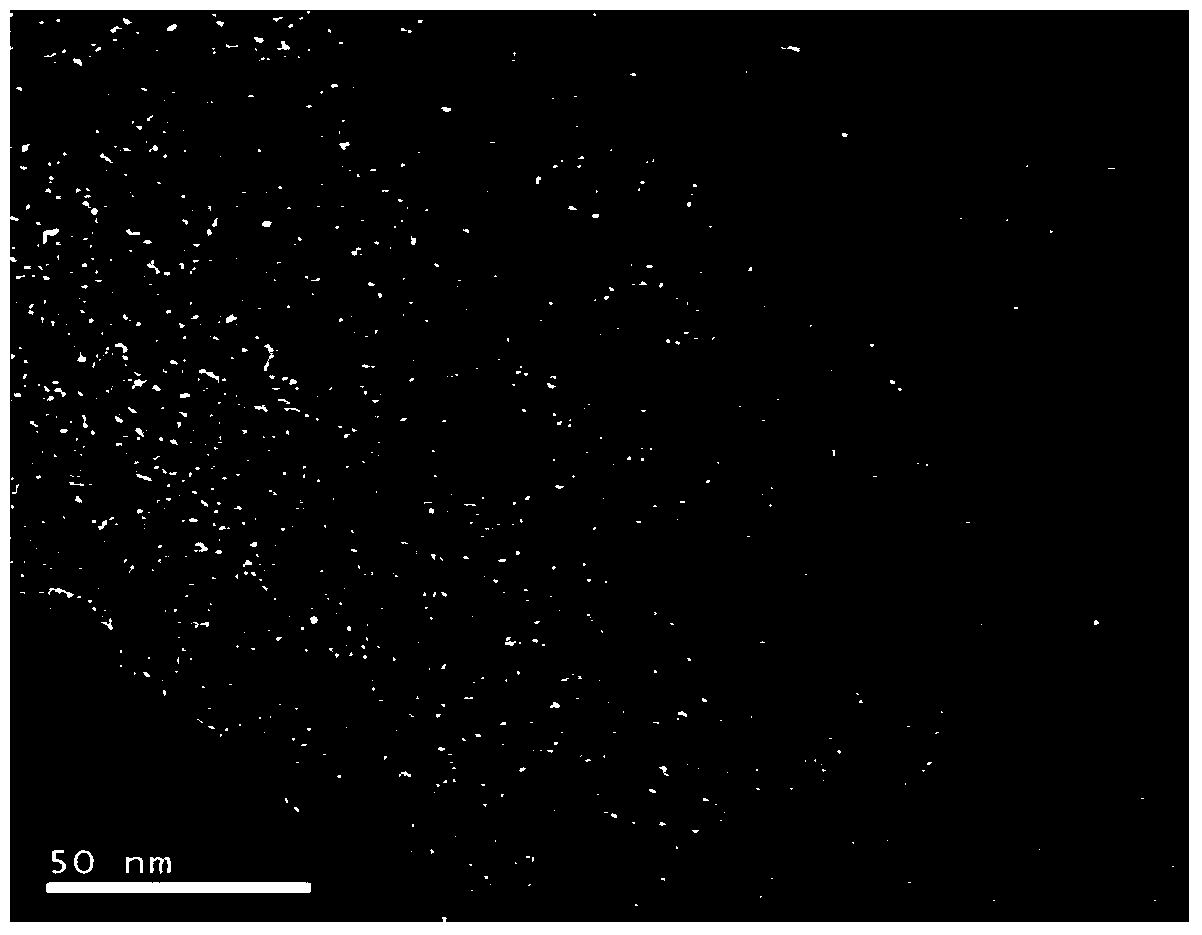

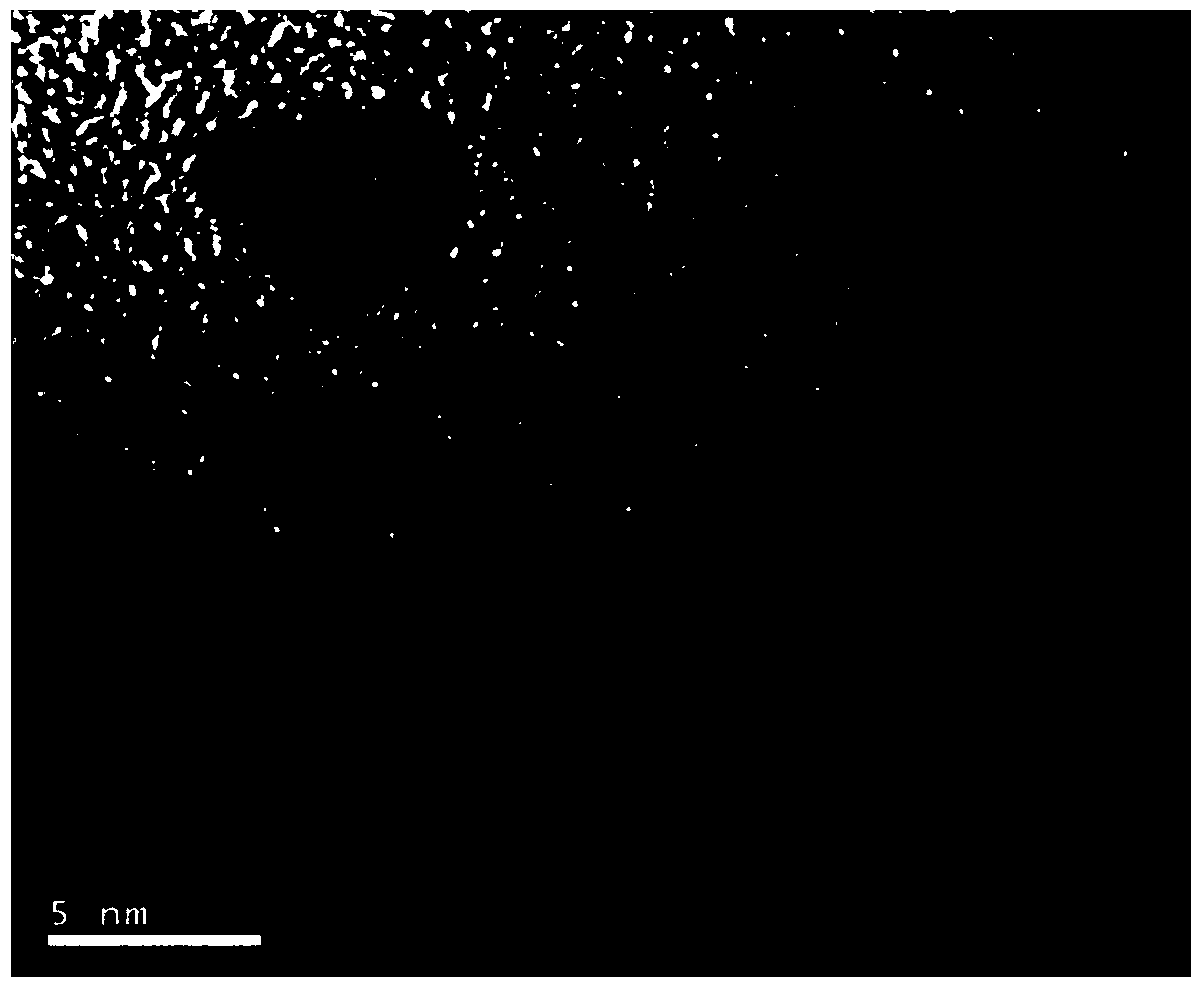

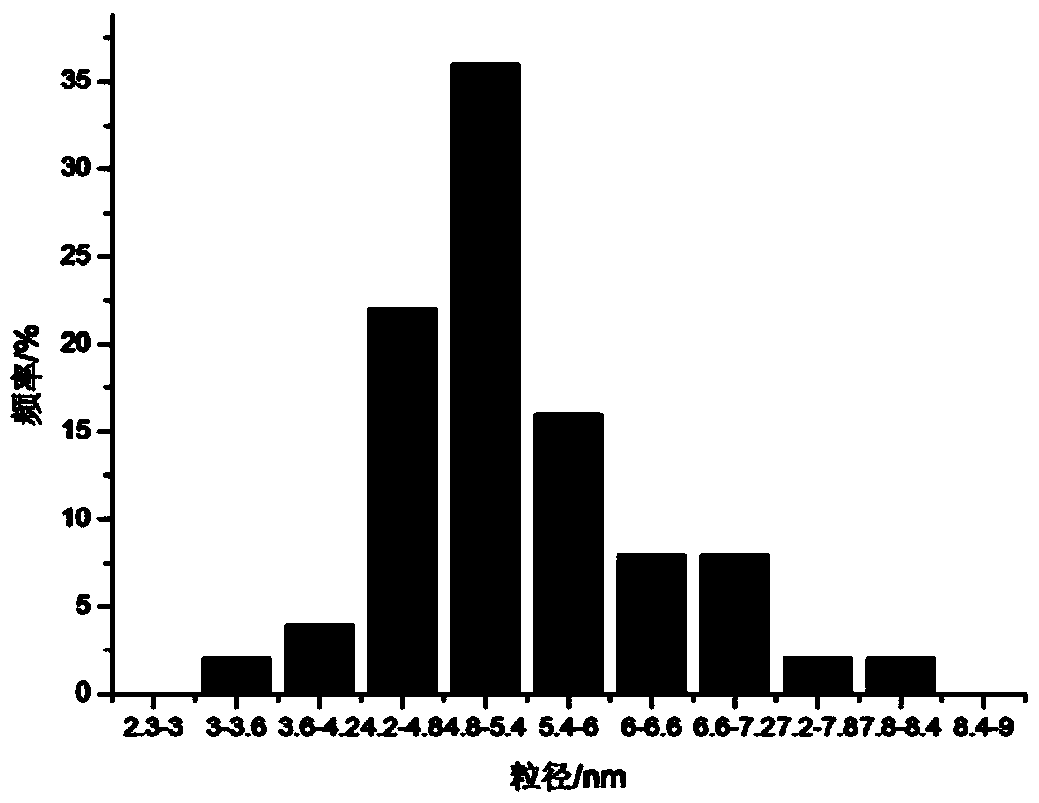

ActiveUS9299977B2Small sizeAvoid regroupingElectrode thermal treatmentHybrid capacitor electrodesNanometreMetal

A method of manufacturing a composite materials in which a carbon material and a metal compound can maintain a nanosized form as a final product is realized, and a method for manufacturing a superior electrode material is provided. A metal compound precursor is formed from a metal compound material source, and a mixture of the metal compound precursor and a carbon material is calcinated. In the treatment to form the precursor, a treatment of absorbing one of the metal compound material sources to the functional group of the carbon material and a treatment of producing on the carbon material a treatment of reacting the remaining material source of the adsorbed metal compound material source on the carbon material to produce a metal compound precursor are performed in separate steps.

Owner:NIPPON CHIMI CON CORP

Environment-friendly pre-vulcanization reforming pre-hydrogenation catalyst, preparation method and application thereof

ActiveCN111298811AHigh metal dispersionHighly active metal sulfideHydrotreatment operations starting-upCatalyst activation/preparationPtru catalystExhaust fumes

The invention discloses an environment-friendly pre-vulcanization reforming pre-hydrogenation catalyst, a preparation method and application thereof. The preparation method comprises the following steps: 1, impregnating a catalyst carrier with an active component, drying, and roasting at 480-520 DEG C; 2, cooling the catalyst roasted in the step 1 to 250-280 DEG C; and 3, heating a pre-vulcanizingagent to 250-280 DEG C, dipping and mixing the pre-vulcanizing agent with the catalyst cooled to 250-280 DEG C in the step 2, keeping the temperature constant for 1-2 hours, cooling to 40-60 DEG C, spraying an accelerant, keeping the temperature constant for 1-2 hours, and cooling to room temperature to obtain the pre-vulcanization reforming pre-hydrogenation catalyst. According to the method, the preparation process and the pre-vulcanization process of the catalyst are fully combined, so that the prepared pre-vulcanization type reforming pre-hydrogenation catalyst is high in metal dispersityand high in active metal vulcanization degree, NH3 and waste gas emission are avoided in the preparation process, direct starting of the catalyst can be achieved, and a secondary vulcanization or activation process is not needed.

Owner:PETROCHINA CO LTD

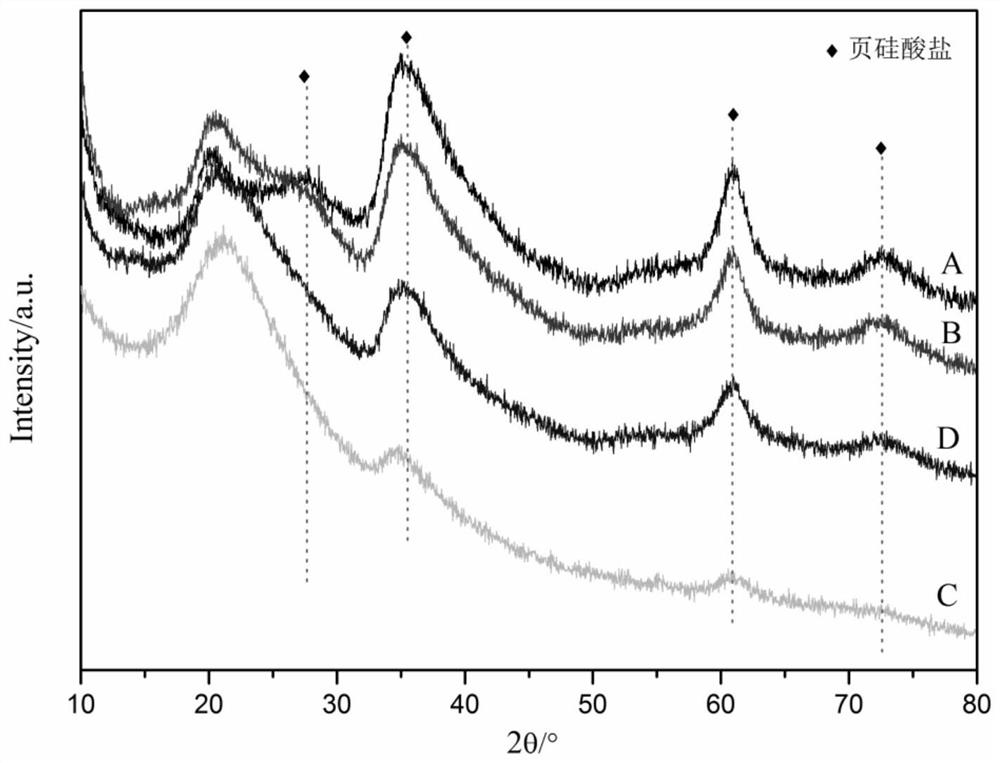

Nickel silicate-derived catalyst for producing xylitol by hydrogenation of xylose as well as preparation and application of nickel silicate-derived catalyst

InactiveCN112916011AEasy to prepareHigh metal loadingMolecular sieve catalystsOrganic compound preparationPtru catalystSilicic acid

The invention relates to a nickel silicate-derived catalyst for producing xylitol by hydrogenation of xylose as well as preparation and application of the nickel silicate-derived catalyst. The catalyst is composed of a metal nickel component and a carrier, wherein the metal nickel exists in the form of layered nickel silicate; and the carrier is a silicon oxide-containing inorganic carrier such as SiO2, HMS, MCM-41, SBA-15, ZSM-5, silicon oxide aerosol or the like. The catalyst is prepared through a uniform deposition-precipitation method which is an ammonia evaporation induced deposition-precipitation method, a urea decomposition induced deposition-precipitation method or a deposition-precipitation method using carbonate as a precipitant specifically, wherein the carbonate comprises sodium carbonate, potassium carbonate, sodium bicarbonate and potassium bicarbonate. The catalyst disclosed by the invention is used for catalyzing a reaction for producing xylitol through hydrogenation of xylose, and the catalyst has high xylose conversion activity and high xylitol selectivity; the preparation method of the catalyst is simple and convenient; requirements on equipment required by raw material storage and catalyst preparation are low; large-scale amplification application is easy; and the catalyst has a good industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

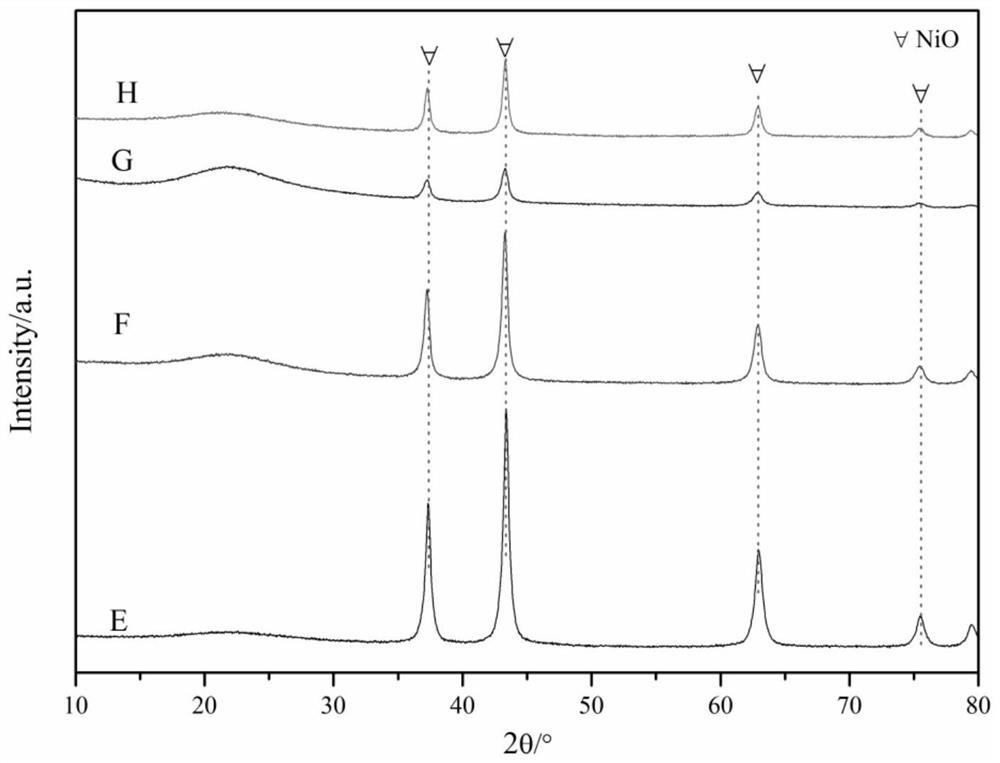

Nickel-based pure silicon type molecular sieve catalyst as well as preparation method and application thereof

InactiveCN113351239ALarge specific surface areaEvenly dispersedHydrocarbon from carbon oxidesMolecular sieve catalystsPtru catalystSilicic acid

The invention discloses a nickel-based pure silicon type molecular sieve catalyst. The specific surface area of the molecular sieve catalyst is 200-500m < 2 > / g, the size of the molecular sieve catalyst is 2-5nm, and the metal loading capacity of the molecular sieve catalyst is 5-10wt%. The preparation method of the nickel-based pure silicon type molecular sieve catalyst comprises the following steps of: mixing tetraethoxysilane, ethanol, diluted hydrochloric acid and a template agent; carrying out reflux condensation; making an obtained mixture stand still; adding a polymer spinning auxiliary solution and a metal salt solution, performing uniform stirring to obtain a spinning precursor solution; and carrying out electrostatic spinning, drying and roasting to finally obtain the pure silicon type molecular sieve catalyst. According to the nickel-based pure silicon type molecular sieve catalyst prepared by the electrostatic spinning method, the specific surface area of the catalyst is large; the active metal is uniformly dispersed on the carrier, the utilization rate of the active metal is high, the dispersity of the metal is high, the particle size is small, and the active metal is not easy to sinter in a strong exothermic reaction of synthesis gas methanation.

Owner:EAST CHINA UNIV OF SCI & TECH

Synthesis of Zeolite-coated Noble Metal Particles and Its Application in Isomerization of Light Alkanes

ActiveCN105413742BAchieve synthesisImprove catalytic performanceMolecular sieve catalystsHydrocarbon oils refiningAlkaneAir atmosphere

The invention provides a synthesis method for zeolite-coated precious metal particles. The synthesis method comprises the steps that 1, a metal salt solution of platinum-containing soluble salt and / or palladium-containing soluble salt is taken to be mixed with a silicon source and / or an aluminum source, a template agent, a pH value regulating agent and water, gel is obtained through stirring, and dry gel is obtained through drying; 2, crystallization is performed by adopting a dry gel steam assisting method; 3, a product obtained through crystallization is calcined for 5-8 hours in an air atmosphere and then reduced for 2-4 hours in a hydrogen atmosphere. According to the method, by learning from the characteristics of synthesizing Silicate-1-coated precious metal through a steam assisting converting method, a precursor of solid superacid is introduced in the synthesizing process of mordenite and Beta zeolite, synthesis of a zeolite molecular sieve of which pore channels contain precious metal is successfully achieved, and the catalytic property of the catalyst in a light paraffin isomerization reaction is further improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Hydrocracking catalyst containing compound molecular sieve and preparing method thereof

InactiveCN1211465CImprove nitrogen resistanceHigh hydrocracking activityHydrocarbon oil crackingMolecular sievePtru catalyst

The present invention relates to a hydrocracking catalyst containing compound molecular sieve and its preparation method. Said catalyst composition uses amorphous aluminosilicate and a compound molecular sieve as carrier, in which the amorphous aluminosilicate content is 30-60% of catalyst weight, compound molecular sieve content is 1-20% of catalyst weight, and is the mixture of modified Y molecular sieve and SAPO molecular sieve, VIB group metal oxide content is 10-40%, VIII group metal oxide content is 1-20% of IVB group metal oxide content is 1-10%. Said invented catalyst is prepared by adopting co-precipitation method, and its strength and performance can be raised and improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparation of load type nano metallic catalyst

InactiveCN100496700CLow costHigh metal dispersionEnergy based chemical/physical/physico-chemical processesLiquid-liquid reaction processesNano catalystSlurry

The present invention belongs to the field of catalyst preparing technology, and is especially supported nanometer metal catalyst preparing process and apparatus. The process includes diffusing metal salt solution from metering pump to mixed slurry solution comprising reductant and carrier material through the micropores in the ceramic film pipe under ultrasonic introduction for metal ion to be adsorbed and reduced in the surface of catalyst carrier, the subsequent centrifugal separation, washing the precipitant with deionized water, stoving and burning to form the supported nanometer metal catalyst. The present invention has the advantages of homogeneous distribution of active catalyst component, small size, high metal dispersion, etc.

Owner:BEIJING UNIV OF TECH

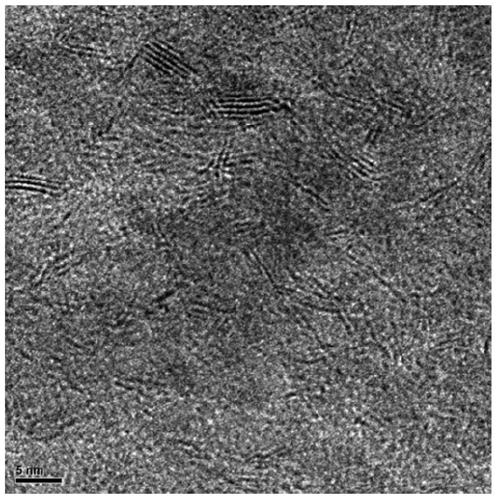

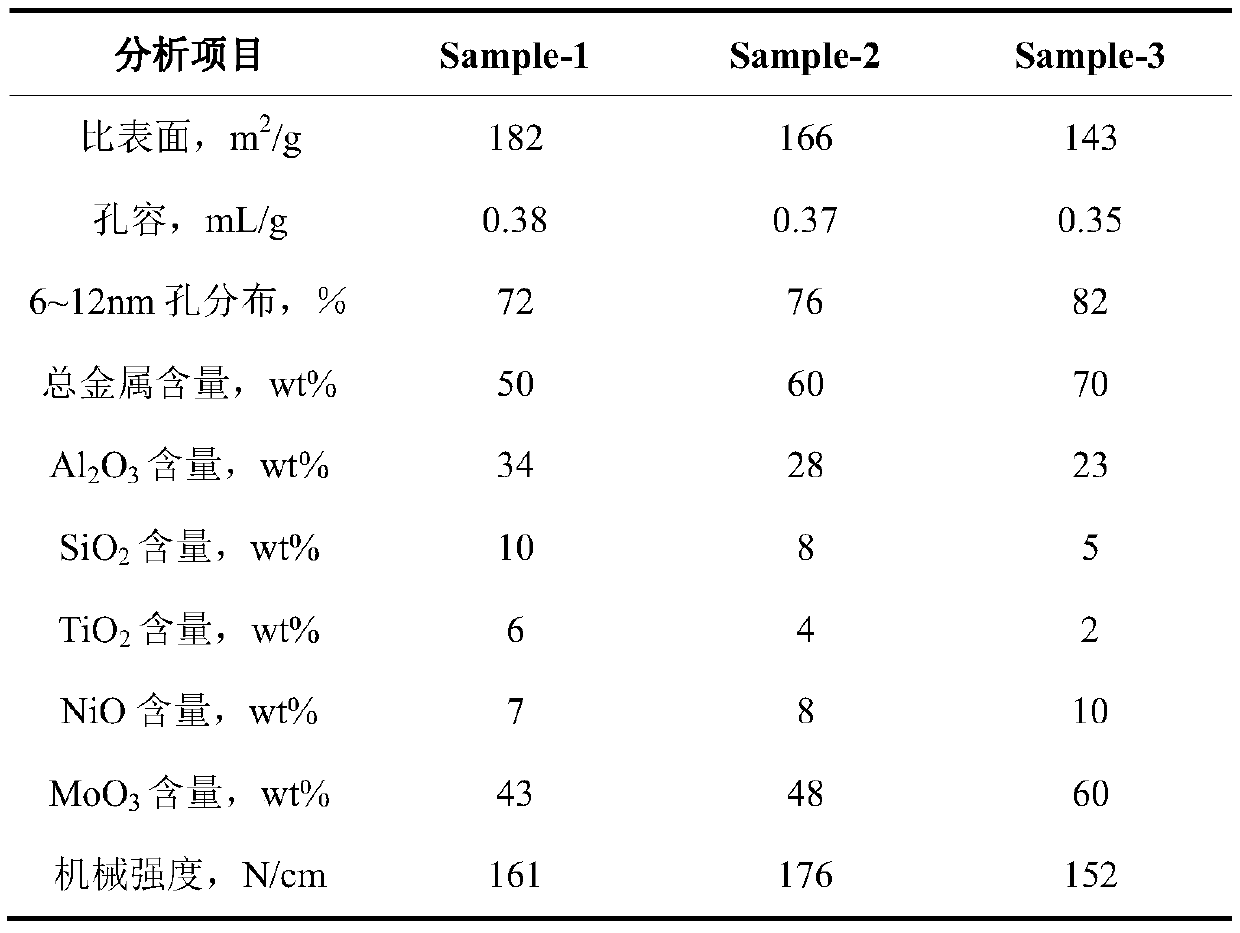

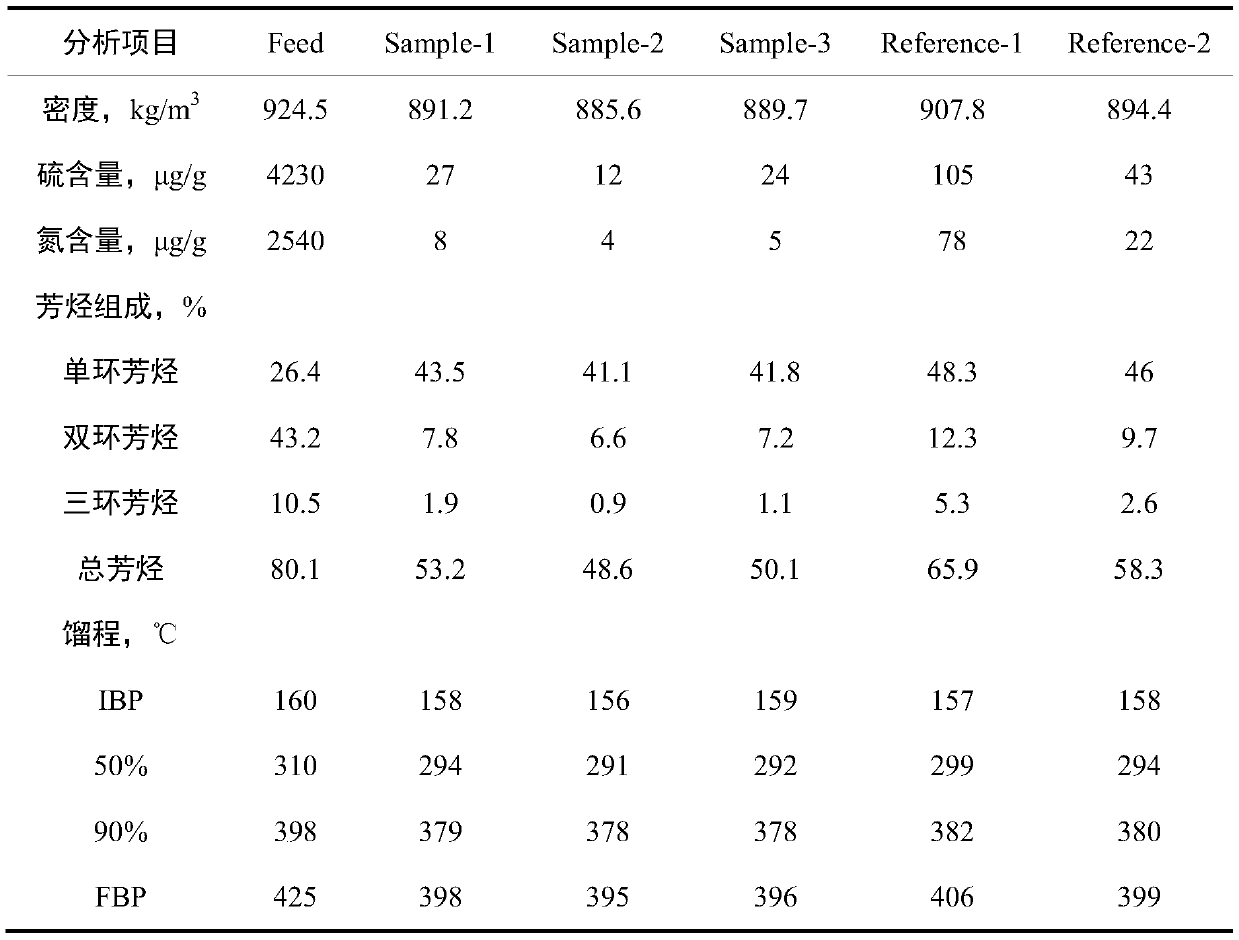

A kind of preparation method of high activity heavy distillate hydrotreating catalyst

ActiveCN106179376BHigh metal loadingHigh catalytic activityHeterogenous catalyst chemical elementsCatalyst activation/preparationDispersitySlurry

The invention is a preparation method of a highly active heavy distillate oil hydrotreating catalyst, which includes: selecting a soluble salt of Group VIII metal nickel and a polyhydroxy acid complexing agent to prepare an acidic solution; selecting a soluble salt of Group VIB metal molybdenum Salt and alkaline precipitant are used together to form an alkaline solution; a suspension slurry mixed with macroporous pseudo-boehmite, nanometer titanium dioxide powder and silica sol is used as the base, and acidic solution and alkaline solution are added in parallel to seal. The reaction causes the metal components to be evenly dispersed in the titanium-silicon-aluminum medium. After the reaction, the catalyst precursor filter cake is obtained through filtration and washing, and the finished catalyst is obtained through maturation, shaping, drying and roasting. Compared with bulk hydrogenation catalysts prepared by existing methods, the catalyst prepared by this method has the advantages of high mechanical strength, low wear, large pore volume, high metal dispersion, good hydrogenation activity, and long service life, and is particularly suitable for Hydrotreating of inferior heavy distillate oil with high sulfur and nitrogen content and a large proportion of condensed aromatic hydrocarbons, which is difficult to process.

Owner:CHINA NAT OFFSHORE OIL CORP +2

A kind of carbon supported multi-component catalyst and its preparation method and application

ActiveCN105214686BEasy to prepareHigh metal dispersionOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsMass ratioUltraviolet

The invention provides a carbon-supported multi-component catalyst and a preparation method thereof. The catalyst is composed of a carrier and a metal active component loaded on the carrier, the carrier is activated carbon, and the metal active component is palladium and platinum. and a transition metal additive; based on the quality of the carrier activated carbon, the palladium loading is 0.5wt% to 5.0wt%, the platinum loading is 0.5wt% to 5.0wt%, and the transition metal additive loading is 0.1wt% ~2.5wt%; Simultaneously, the mass ratio of palladium and platinum is 1:0.5~2.0; Catalyst of the present invention can be used in catalytic hydrogenation synthesis benzotriazole ultraviolet absorber; High activity, high selectivity and yield of the target product, good stability, and less waste generated during the hydrogenation process.

Owner:ZHEJIANG UNIV OF TECH +1

Hydrogenation catalyst with large specific surface and low acid amount, and application thereof

ActiveCN103071491BHigh metal dispersionHigh activityHydrocarbon from carbon oxidesHydrocarbon purification/separationPtru catalystUnsaturated hydrocarbon

The invention discloses a palladium metal hydrogenation catalyst used in unsaturated hydrocarbon hydrogenation. The catalyst comprises a metal active component palladium, a carrier alumina and a silica auxiliary agent. The catalyst provided by the invention has a relatively large specific surface (a specific surface area is 140-330cm<2> / g), and relatively low surface acid content (lower than 0.15mmol / g). The content of the auxiliary agent silica is 0.5-10wt%. Silica is added into the catalyst through a gas-phase silylation treatment upon alumina. Preferably, the catalyst provided by the invention also comprises a plurality of auxiliary agents. When the catalyst provided by the invention is used in an unsaturated hydrocarbon hydrogenation reaction, the catalyst has the advantages of high activity and low yield of green oil and carbon deposit.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of integral catalyst and its preparation and application

ActiveCN107694562BHigh metal dispersionImprove hydrogenation activityMolecular sieve catalystsCatalyst activation/preparationPtru catalystPhysical chemistry

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com