Prep. of high-load bi-and multi-component precious metallic catalyst

A precious metal catalyst and loading capacity technology, which is used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. and other problems, to achieve the effect of improving metal utilization rate, reducing preparation cost, and high metal utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

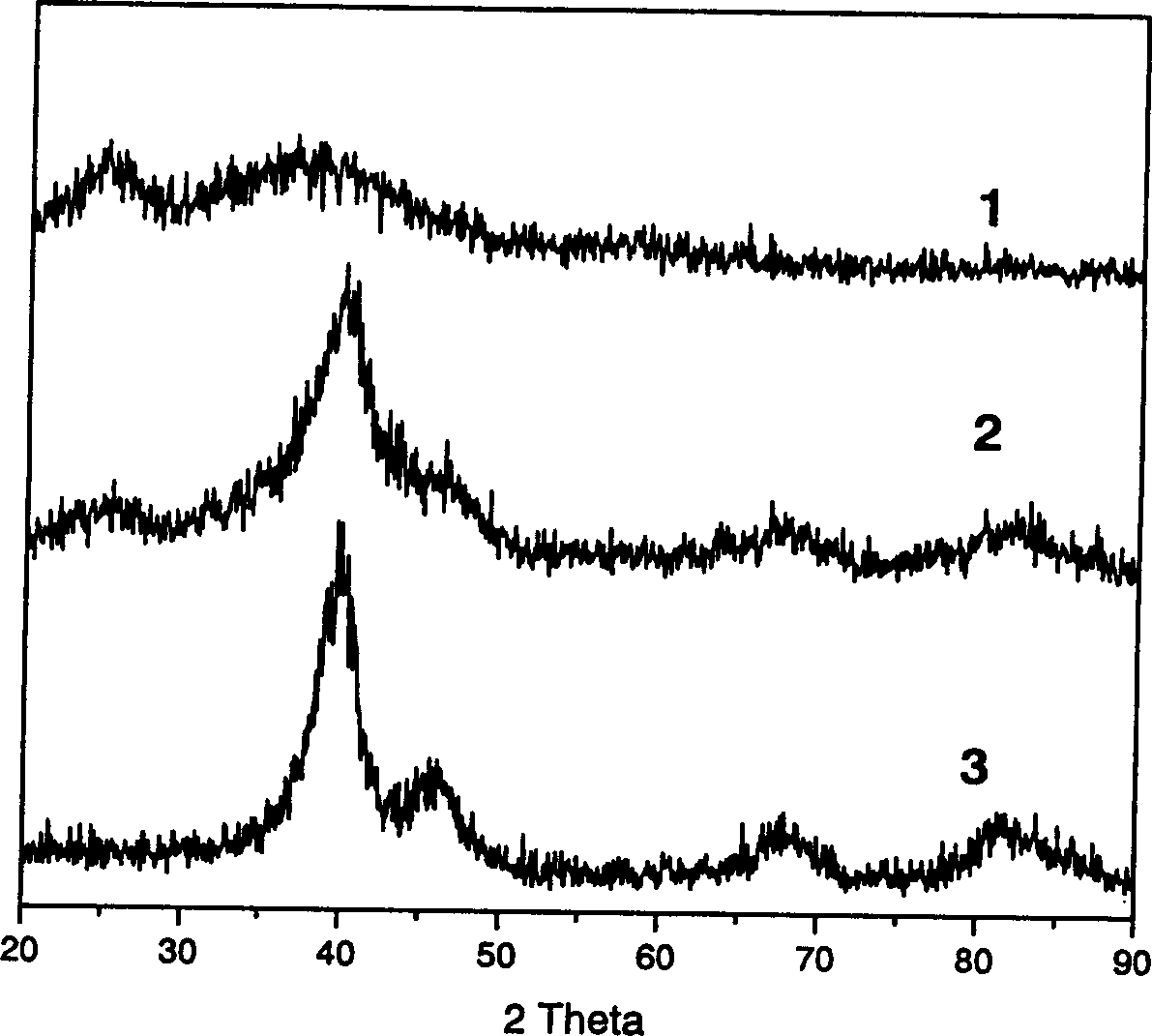

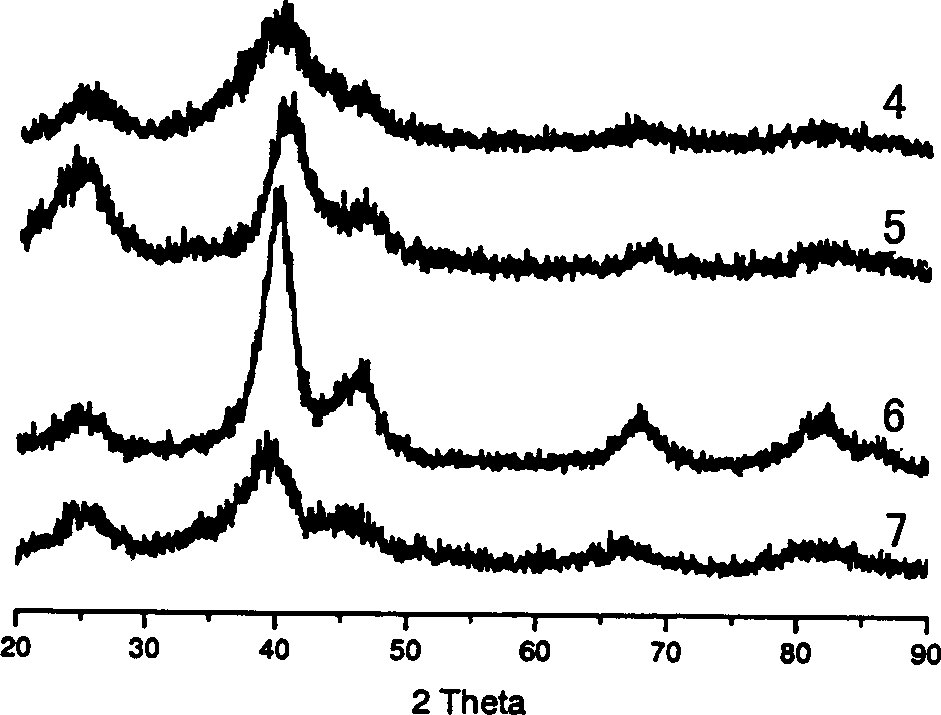

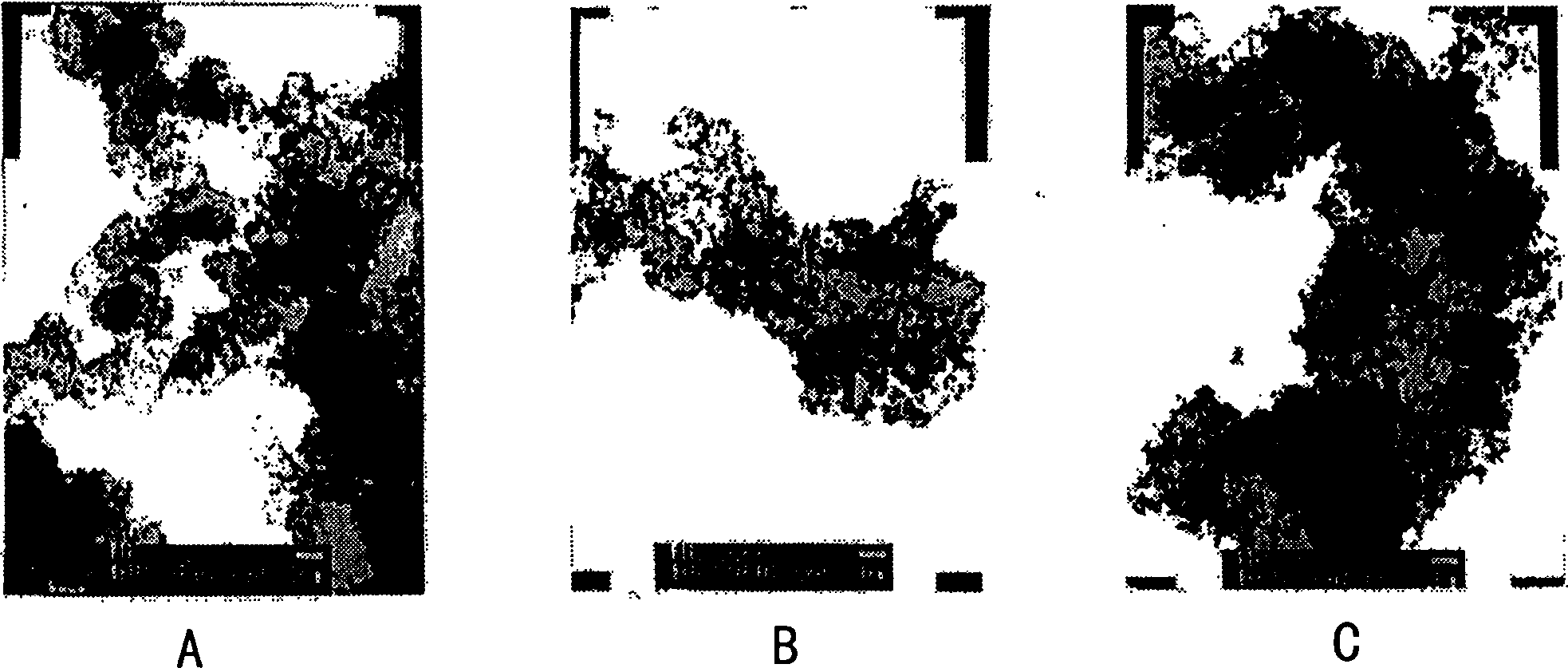

[0043] Embodiment 1: Preparation of PtRu / C (30PtRu%, Pt / Ru=1) electrode catalyst

[0044] Activated carbon XC-72R was pre-treated with 5 mol / L nitric acid solution, dried at 200°C for 4 hours, weighed 5 grams and dispersed with 400 ml of ethylene glycol for 30 minutes by ultrasonic oscillation to prepare carbon slurry. 3.9 gram of chloroplatinic acid (containing 1.44 gram of platinum) and 1.94 gram of ruthenium trichloride (containing 0.72 gram of ruthenium) were dissolved in 50 milliliters of deionized water to prepare a mixed solution of platinum and ruthenium, which was transferred to the carbon slurry after ultrasonic oscillation for 20 minutes, and passed After argon deoxygenation and stirring for 4 hours, add 50 ml of 1 mol / L sodium hydroxide / ethylene glycol solution, continue stirring for 4 hours, then raise the temperature to 185°C and keep it for 4 hours, then cool down to 25°C, adjust with dilute hydrochloric acid solution The pH value reached 3, and after stirring f...

Embodiment 2

[0045] Embodiment 2: Preparation of PtRu / C (60PtRu%, Pt / Ru=1) anode catalyst

[0046] Activated carbon XC-72R was pre-treated with 5 mol / L nitric acid solution, dried at 200°C for 4 hours, weighed 2 grams and dispersed with 150 ml of ethylene glycol aqueous solution (95% ethylene glycol content) for 30 minutes by ultrasonic oscillation to prepare carbon slurry. Measure 40 milliliters of chloroplatinic acid / ethylene glycol solution (50 milligrams of platinum / ml), measure 25 milliliters of ruthenium trichloride aqueous solution (40 milligrams of ruthenium / ml) and mix, and add dropwise in the carbon slurry after 20 minutes of ultrasonic oscillation, After stirring for 4 hours with argon deoxygenation, add 15 ml of 1.5 mol / L sodium hydroxide / ethylene glycol solution dropwise, continue stirring for 4 hours, then raise the temperature to 180°C and keep it for 4 hours, then cool down to 25°C, and use 1.5 mol 1 / liter of dilute hydrochloric acid solution to adjust the pH value to 2.5, ...

Embodiment 3

[0047] Embodiment 3: the preparation of PtRu / C (90PtRu%, Pt / Ru=1) catalyst

[0048] Activated carbon XC-72R was pre-treated with 5 mol / L nitric acid solution, dried at 200°C for 4 hours, weighed 1 gram and dispersed with 60 ml of ethylene glycol for 30 minutes by ultrasonic oscillation to prepare carbon slurry. Measure 120 ml of chloroplatinic acid / ethylene glycol solution (50 mg platinum / ml), measure 60 ml of ruthenium trichloride / ethylene glycol (50 mg ruthenium / ml) and mix, and mix with carbon slurry after ultrasonic oscillation for 50 minutes After stirring for 10 hours with argon deoxygenation, add 10 ml of 2.5 mol / L sodium hydroxide solution dropwise, continue stirring for 5 hours, then raise the temperature to 180°C and keep it for 6 hours, then cool down to 25°C, and use 1.5 mol / L Adjust the pH value of the dilute hydrochloric acid solution to 2.5, stir for 5 hours, filter, and the filtrate is clear and transparent. The solid was vacuum-dried at 70°C for 8 hours to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com