Patents

Literature

1400 results about "Deoxygenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deoxygenation is a chemical reaction involving the removal of oxygen atoms from a molecule. The term also refers to the removal molecular oxygen (O₂) from gases and solvents, a step in air-free technique and gas purifiers. As applied to organic compounds, deoxygenation is a component of fuels production as well a type of reaction employed in organic synthesis, e.g. of pharmaceuticals.

Process for producing a saturated hydrocarbon component

ActiveUS20070131579A1Reduce carbon dioxide emissionsIncrease carbon dioxide loadProductsReagentsCarboxylic acidBase oil

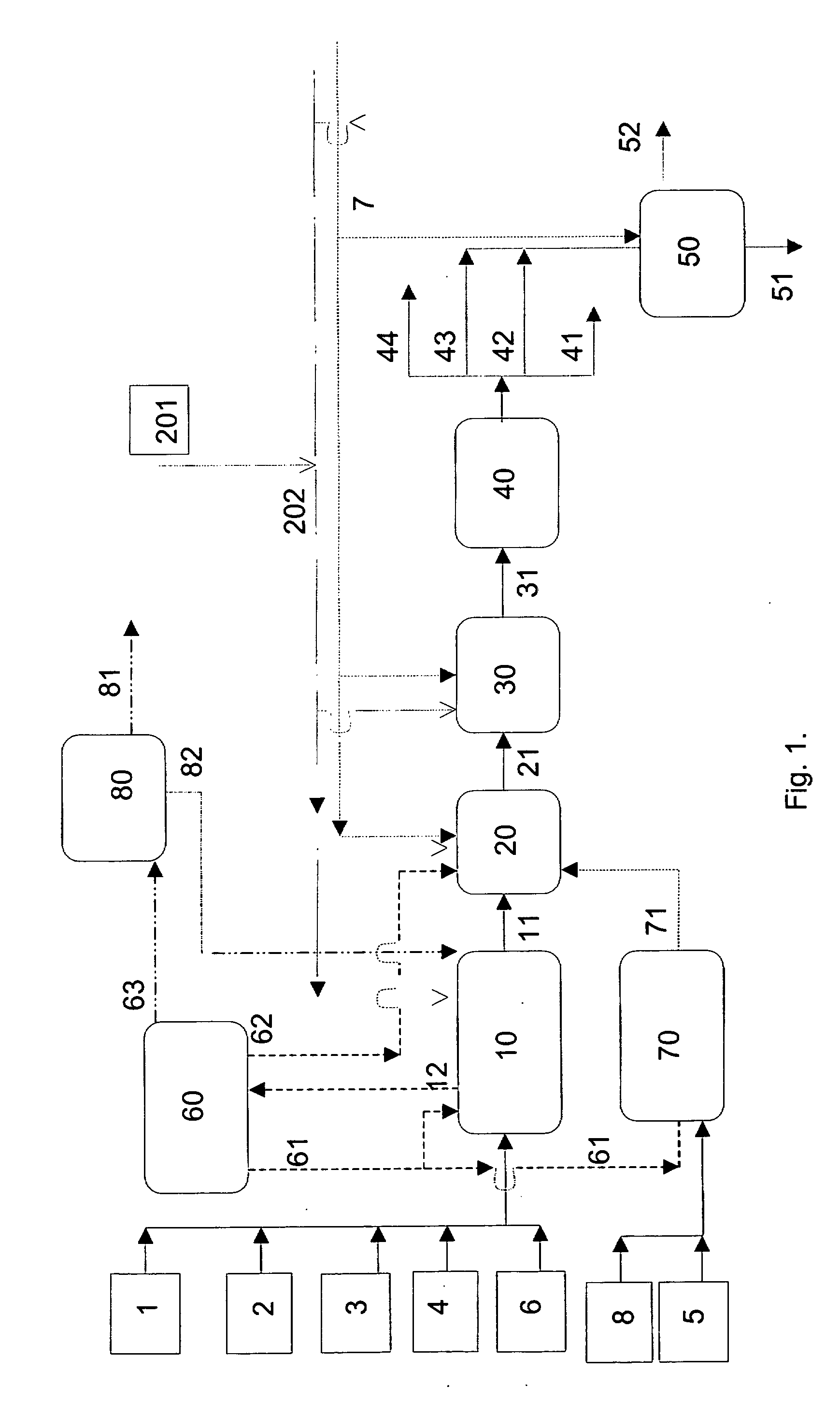

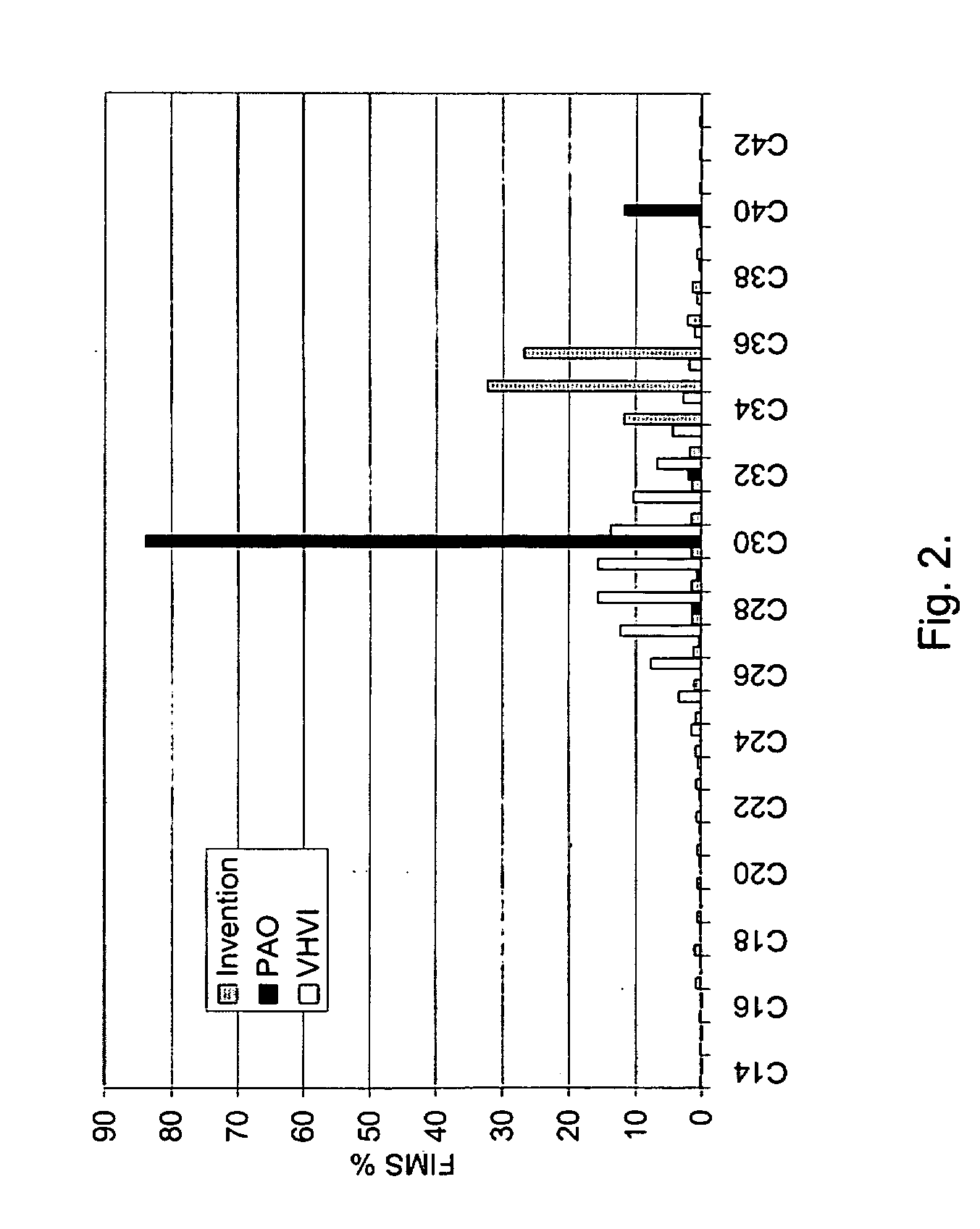

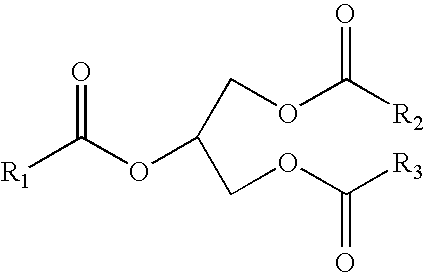

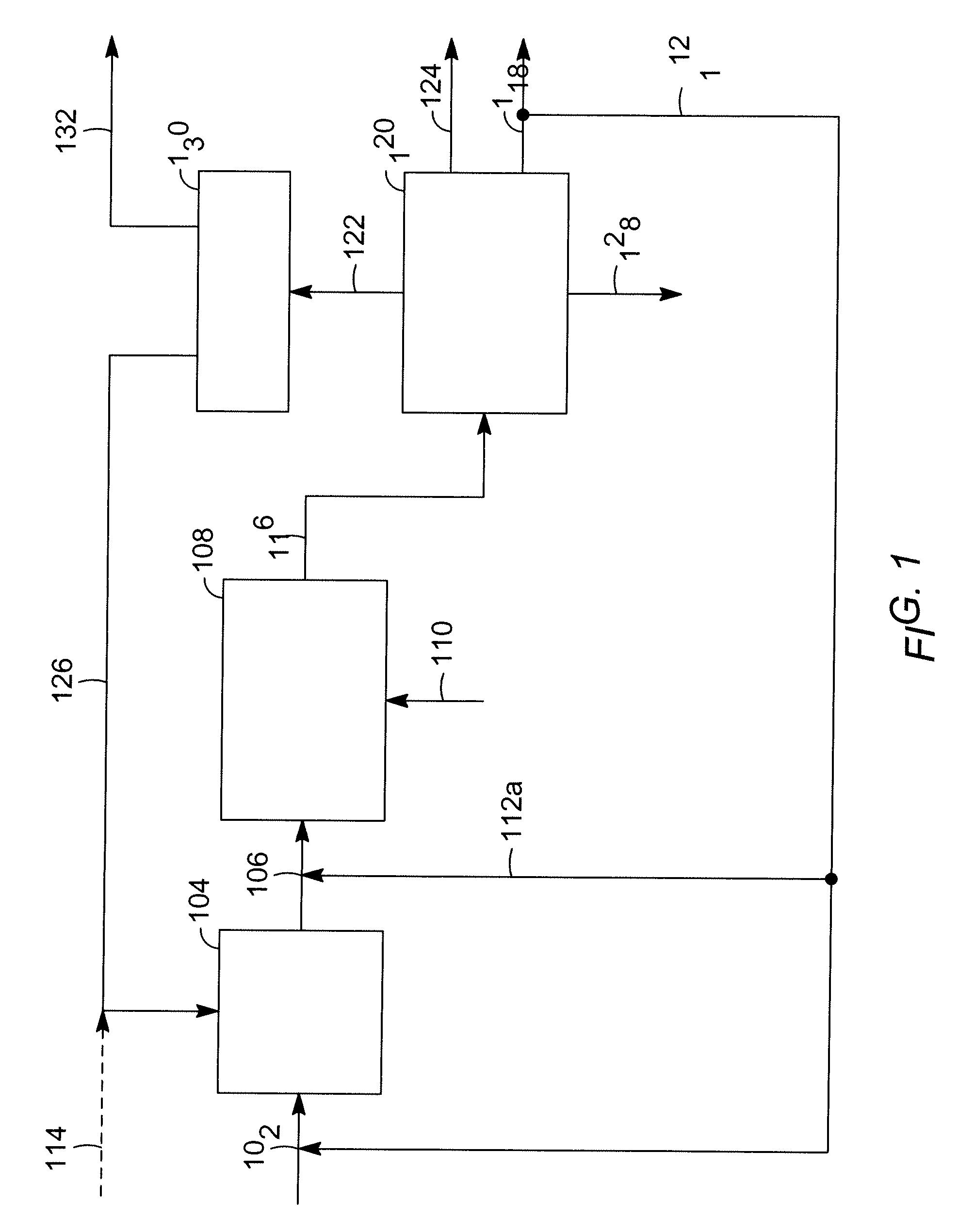

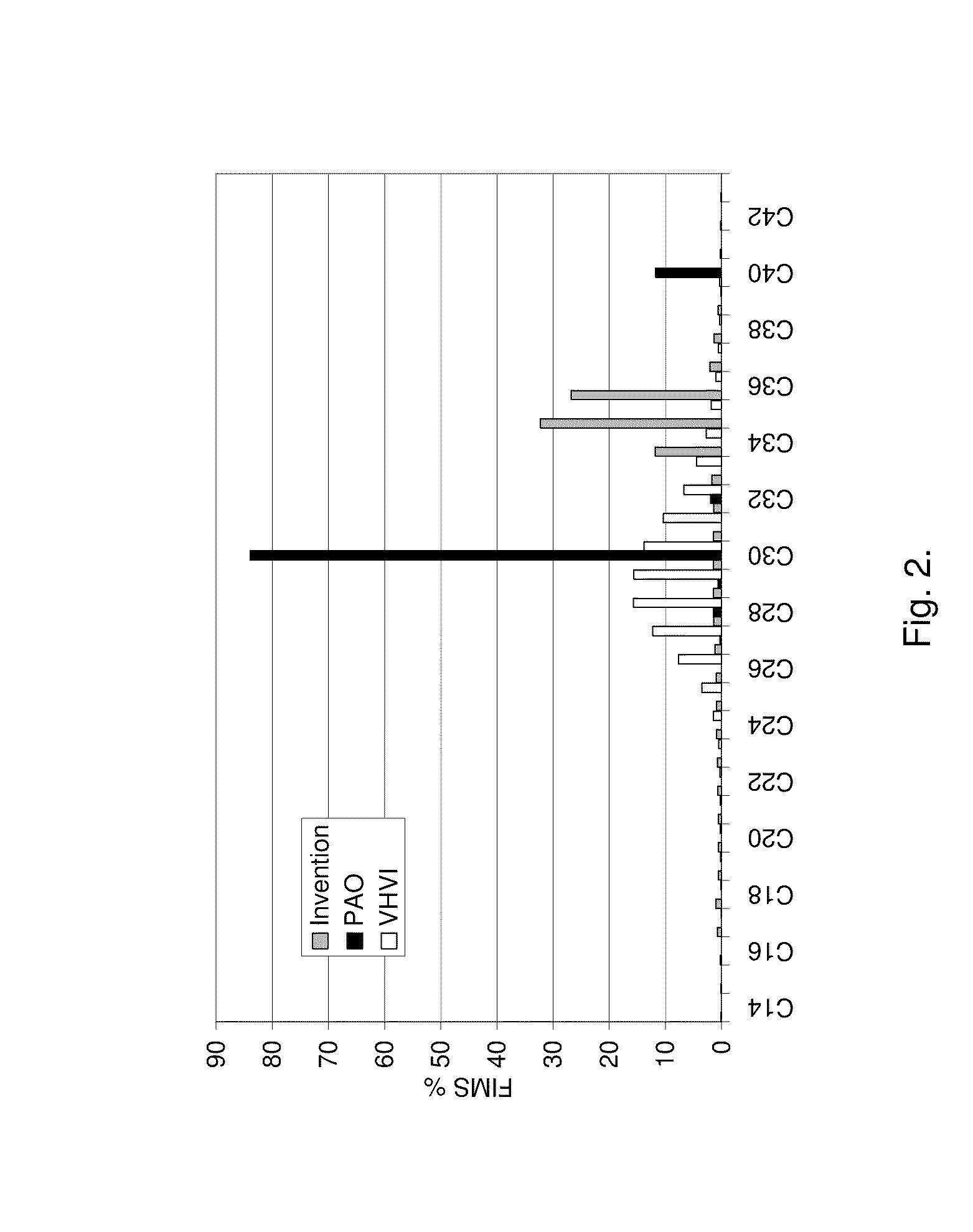

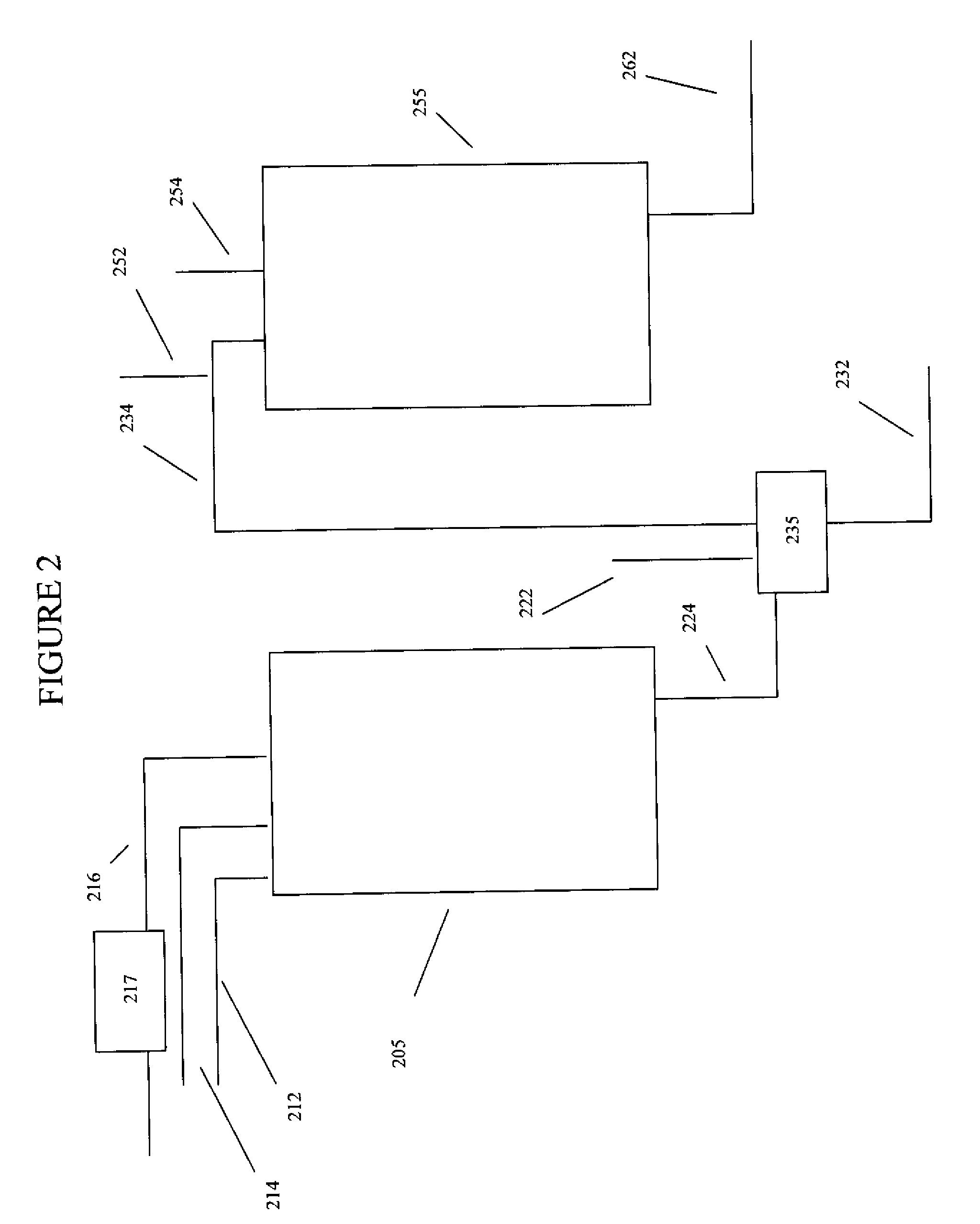

The invention relates to a process for producing high-quality saturated base oil or a base oil component based on hydrocarbons. The process of the invention comprises two main steps, the oligomerization and deoxygenation. A biological starting material containing unsaturated carboxylic acids and / or esters of carboxylic acids is preferably used as the feedstock.

Owner:NESTE OIL OY

Process for the manufacture of hydrocarbons

ActiveUS20070135669A1Quality improvementImprove low temperature performanceFatty acid chemical modificationBiofuelsDeoxygenationDistillation

A feedstock originating from renewable sources is converted to branched and saturated hydrocarbons without heteroatoms in the diesel fuel distillation range by skeletal isomerisation and deoxygenation carried out by hydrodeoxygenation or alternatively by combined decarboxylation and decarbonylation reactions, whereby the consumption of hydrogen is decreased.

Owner:NESTE OIL OY

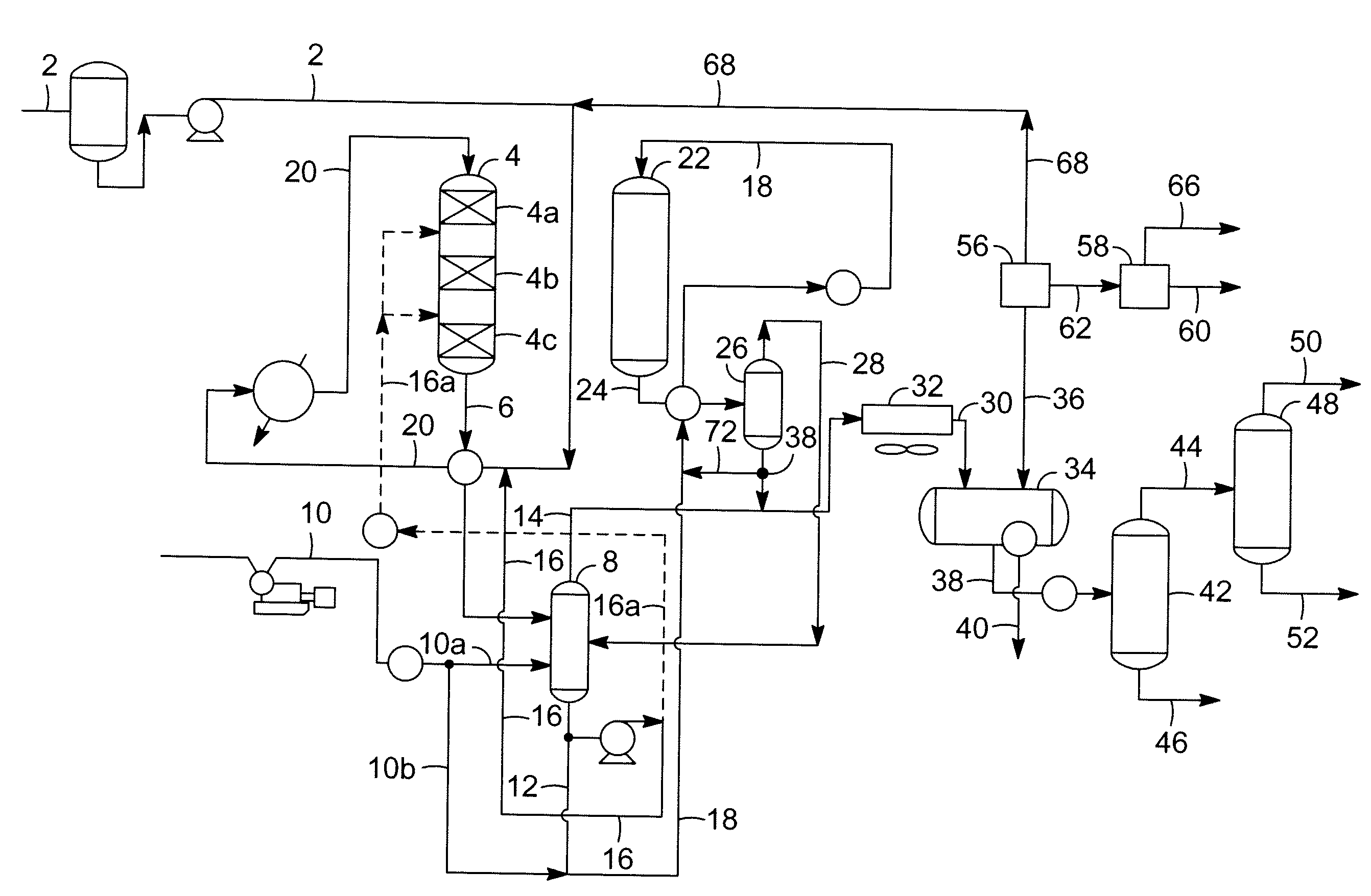

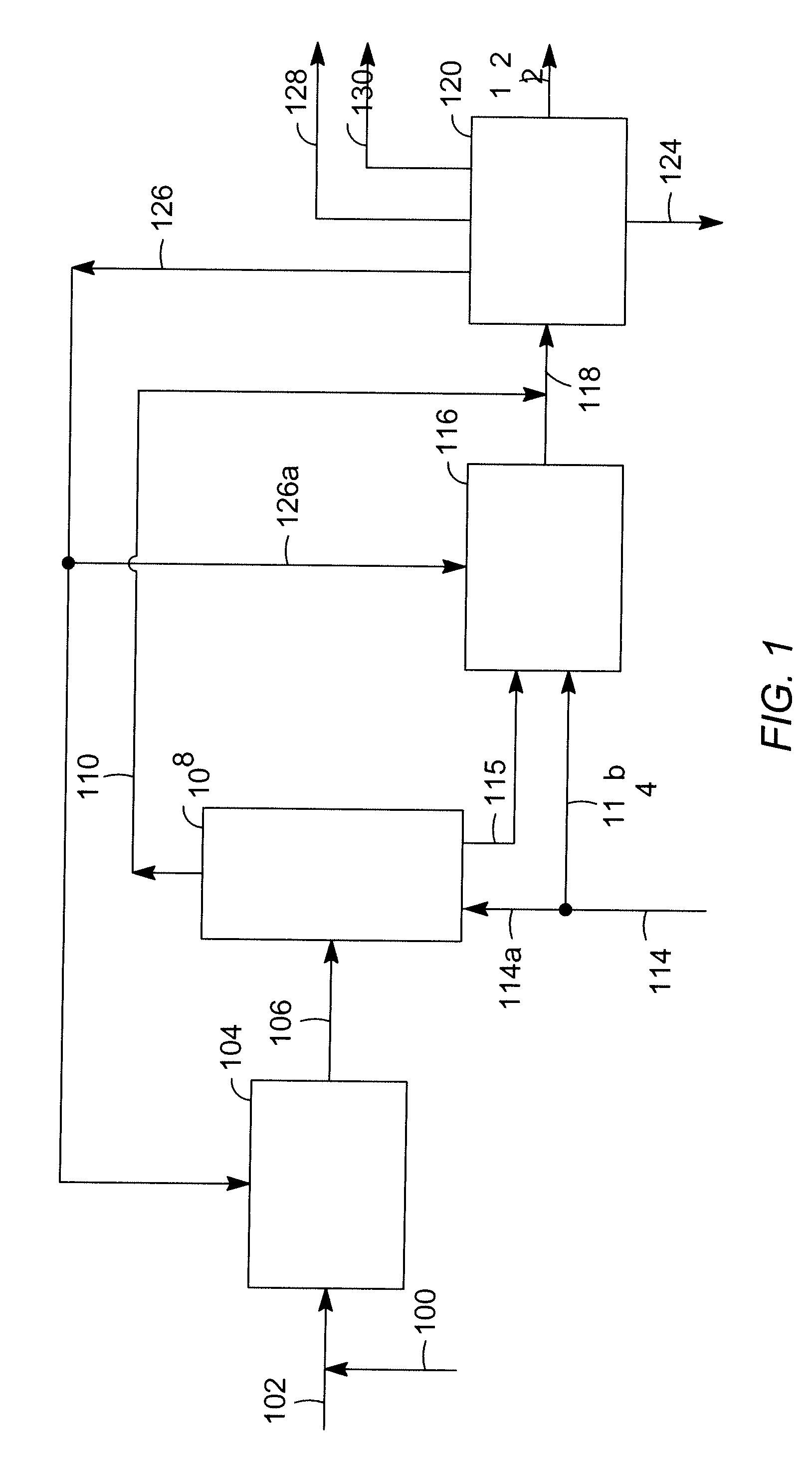

Production of Aviation Fuel from Renewable Feedstocks

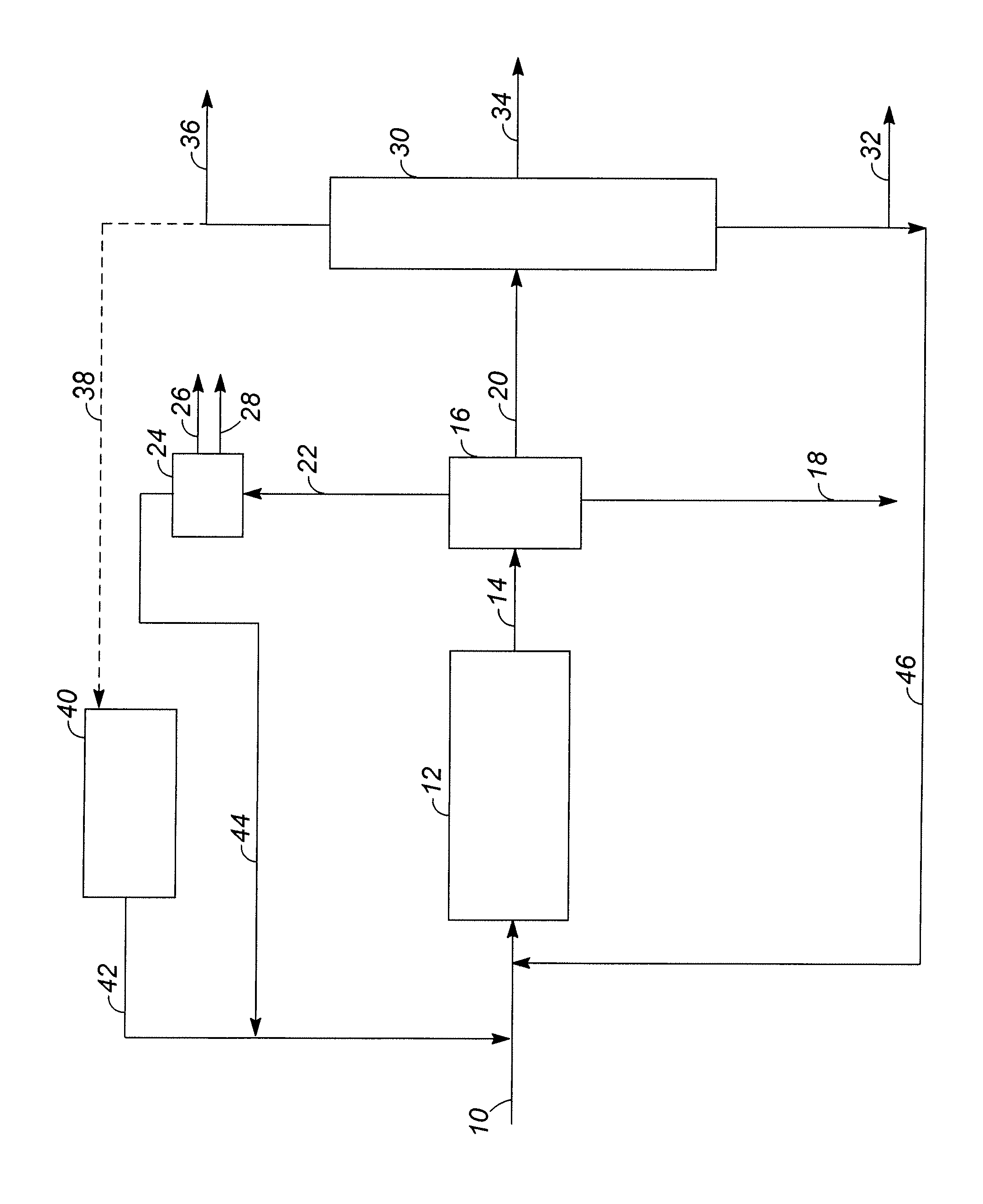

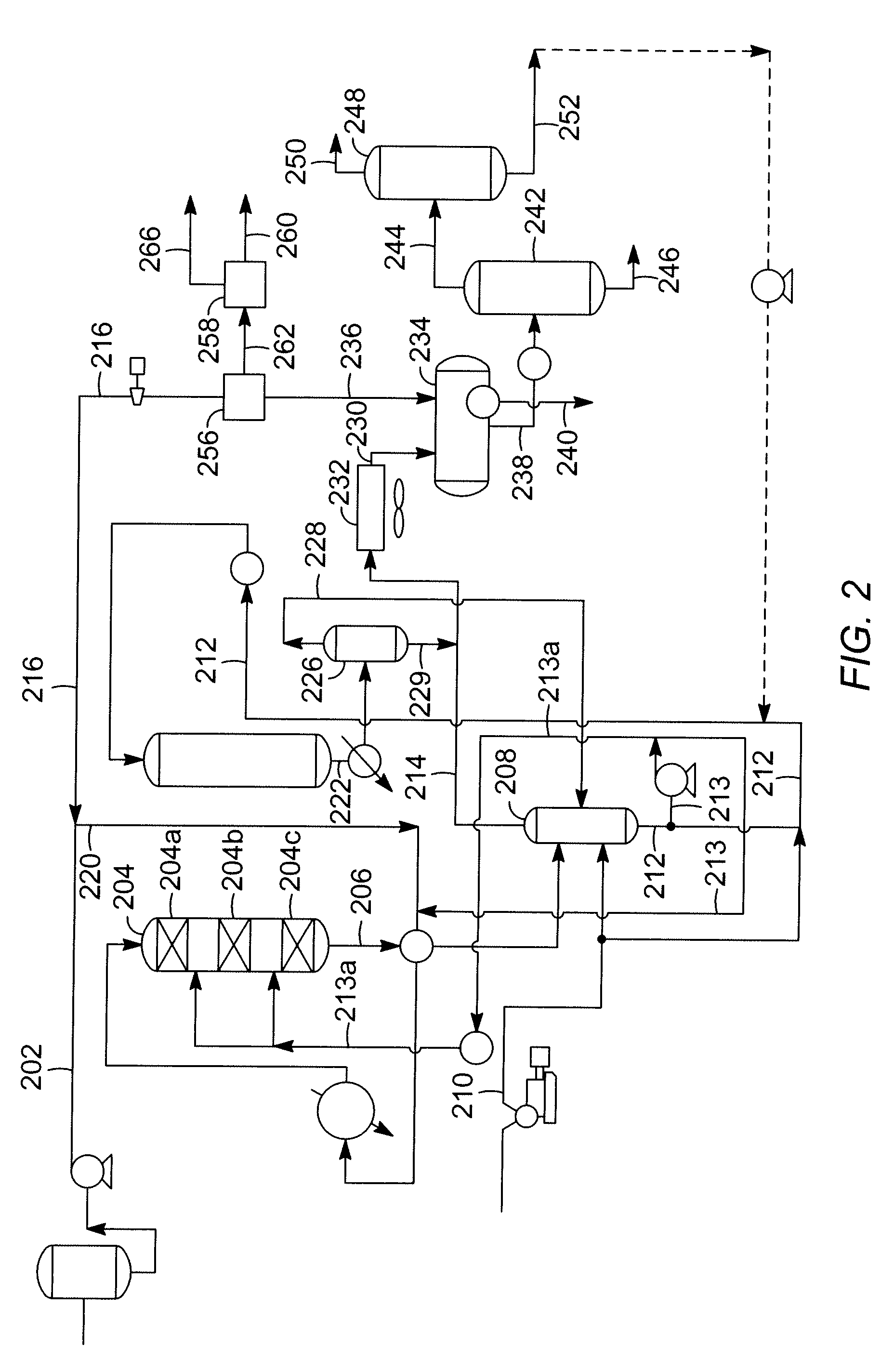

ActiveUS20090283442A1Improve solubilityMinimize severityTreatment with plural serial cracking stages onlyRefining to change hydrocarbon structural skeletonIsomerizationBoiling point

A hydrocarbon product stream having hydrocarbons with boiling points in the aviation fuel range is produced from renewable feedstocks such as plant and animal oils. The process involves treating a renewable feedstock by hydrogenating, deoxygenating, isomerization, and selectively hydrocracking the feedstock to produce paraffinic hydrocarbons having from about 9 to about 16 carbon atoms and a high iso / normal ratio in a single reaction zone containing a multifunctional catalyst, or set of catalysts, having hydrogenation, deoxygenation, isomerization and selective hydrocracking functions.

Owner:UOP LLC

Process for the manufacture of hydrocarbons

A feedstock originating from renewable sources is converted to branched and saturated hydrocarbons without heteroatoms in the diesel fuel distillation range by skeletal isomerisation and deoxygenation carried out by hydrodeoxygenation or alternatively by combined decarboxylation and decarbonylation reactions, whereby the consumption of hydrogen is decreased.

Owner:NESTE OIL OY

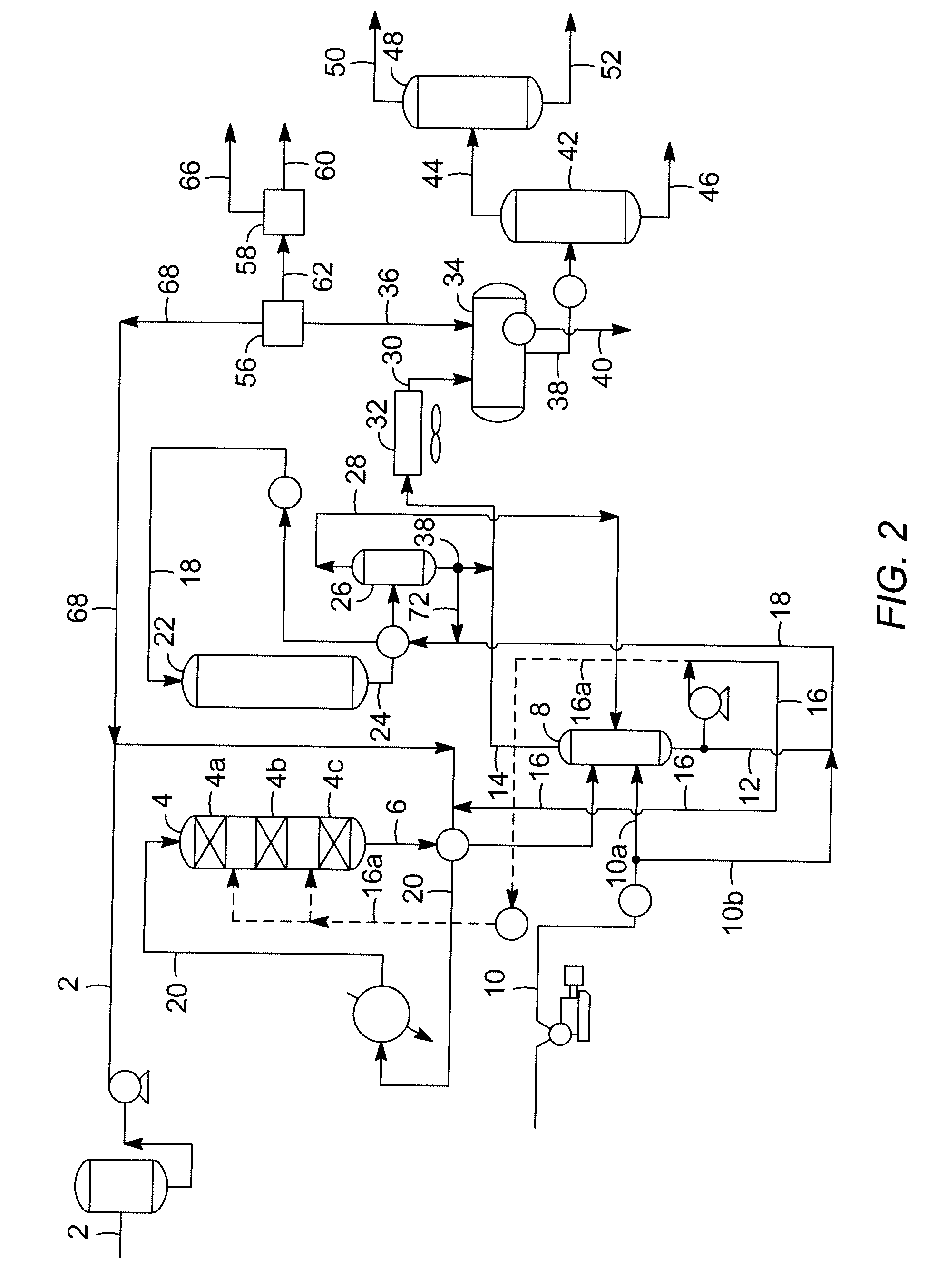

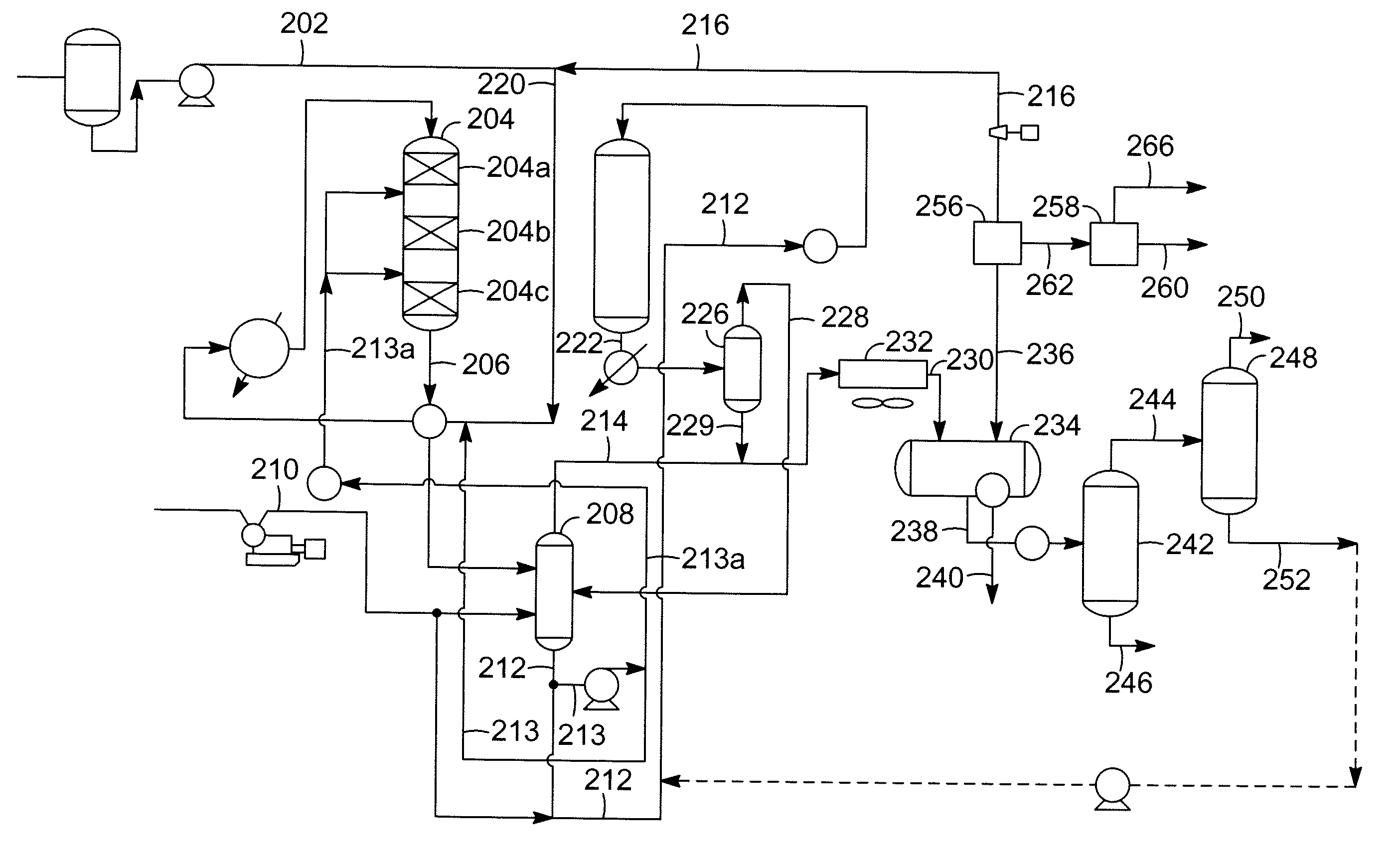

Production of Diesel Fuel from Renewable Feedstocks with Reduced Hydrogen Consumption

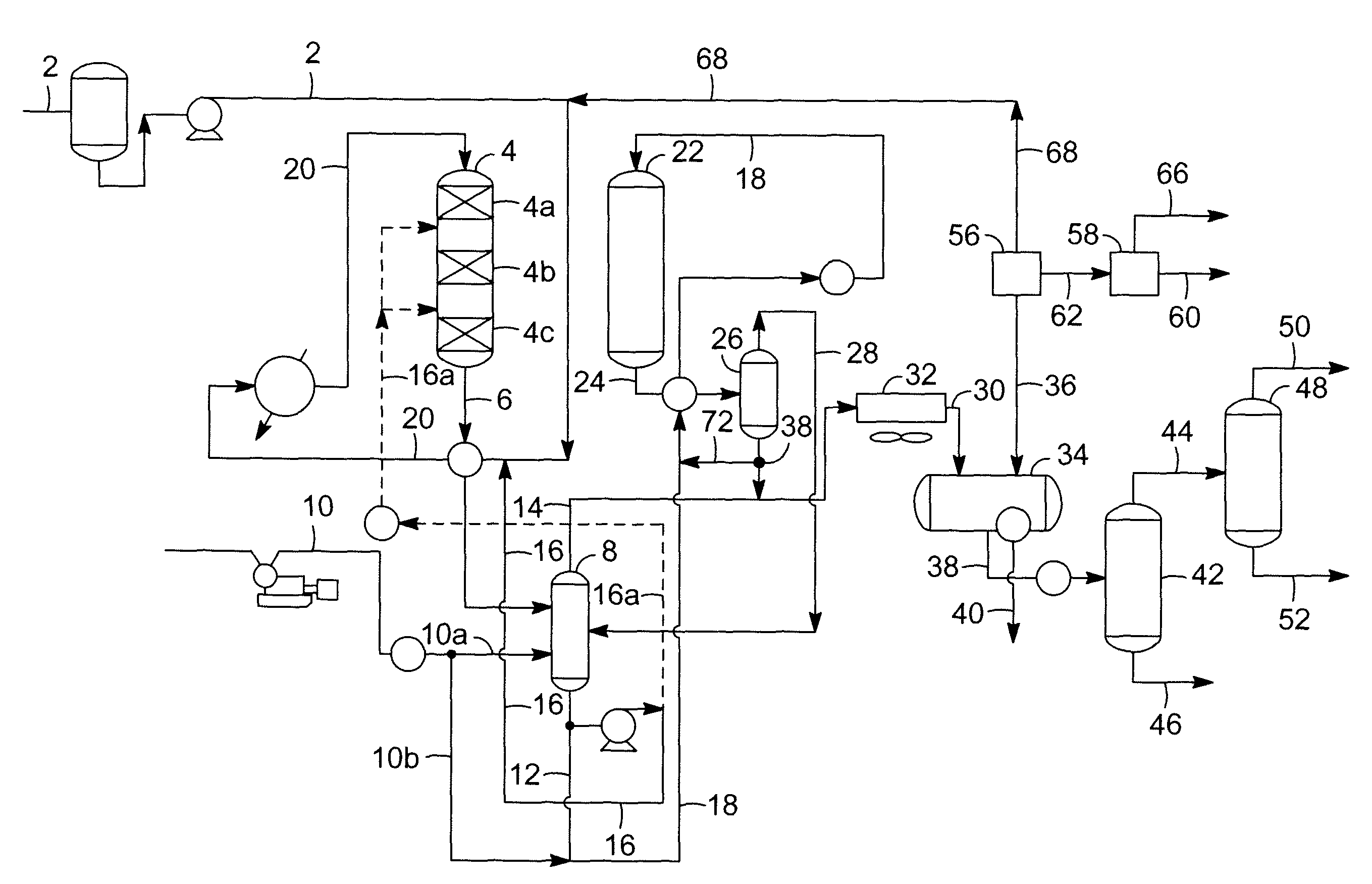

A process has been developed for producing diesel boiling range fuel from renewable feedstocks such as plant and animal fats and oils. The process involves treating a renewable feedstock by hydrogenating and deoxygenating to provide a hydrocarbon fraction useful as a diesel boiling range fuel. Water is added to the deoxygenation reaction to drive carbon monoxide and water to react to form hydrogen and carbon dioxide. The hydrogen is then consumed by the reactions. If desired, the hydrocarbon fraction can be isomerized to improve cold flow properties.

Owner:UOP LLC

Production of Diesel Fuel from Biorenewable Feedstocks with Selective Separation of Converted Oxygen

A process has been developed for producing diesel boiling range fuel from renewable feedstocks such as plant and animal fats and oils, the process providing for sulfur management. The process involves catalytically treating a renewable feedstock by hydrogenating and deoxygenating to provide a hydrocarbon fraction useful as a diesel boiling range fuel. The hydrocarbon fraction is isomerized to improve cold flow properties. A selective separation such as a hot high pressure hydrogen stripper is used to remove at least the carbon oxides from the first zone effluent before entering the isomerization zone, and to provide liquid recycle to the treating zone at pressure and temperature. A vapor stream is separated from the isomerization effluent and at least carbon dioxide is removed using at least one selective or flexible amine solution absorber. The resulting hydrogen-rich stream is recycled to the deoxygenation reaction zone

Owner:UOP LLC

Production of diesel fuel from renewable feedstocks with reduced hydrogen consumption

A process has been developed for producing diesel boiling range fuel from renewable feedstocks such as plant and animal fats and oils. The process involves treating a renewable feedstock by hydrogenating and deoxygenating to provide a hydrocarbon fraction useful as a diesel boiling range fuel. Water is added to the deoxygenation reaction to drive carbon monoxide and water to react to form hydrogen and carbon dioxide. The hydrogen is then consumed by the reactions. If desired, the hydrocarbon fraction can be isomerized to improve cold flow properties.

Owner:UOP LLC

Liquid fuel compositions

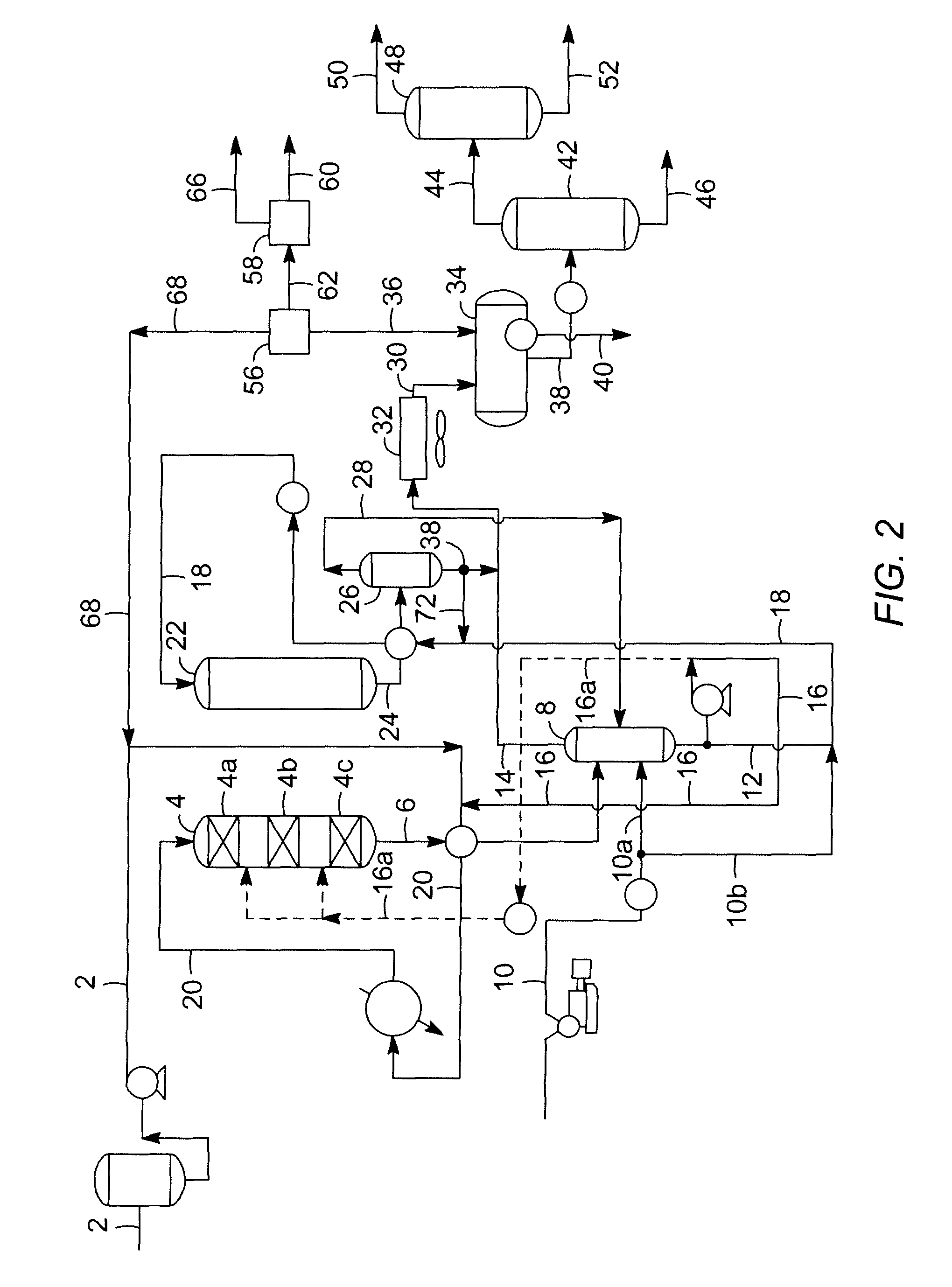

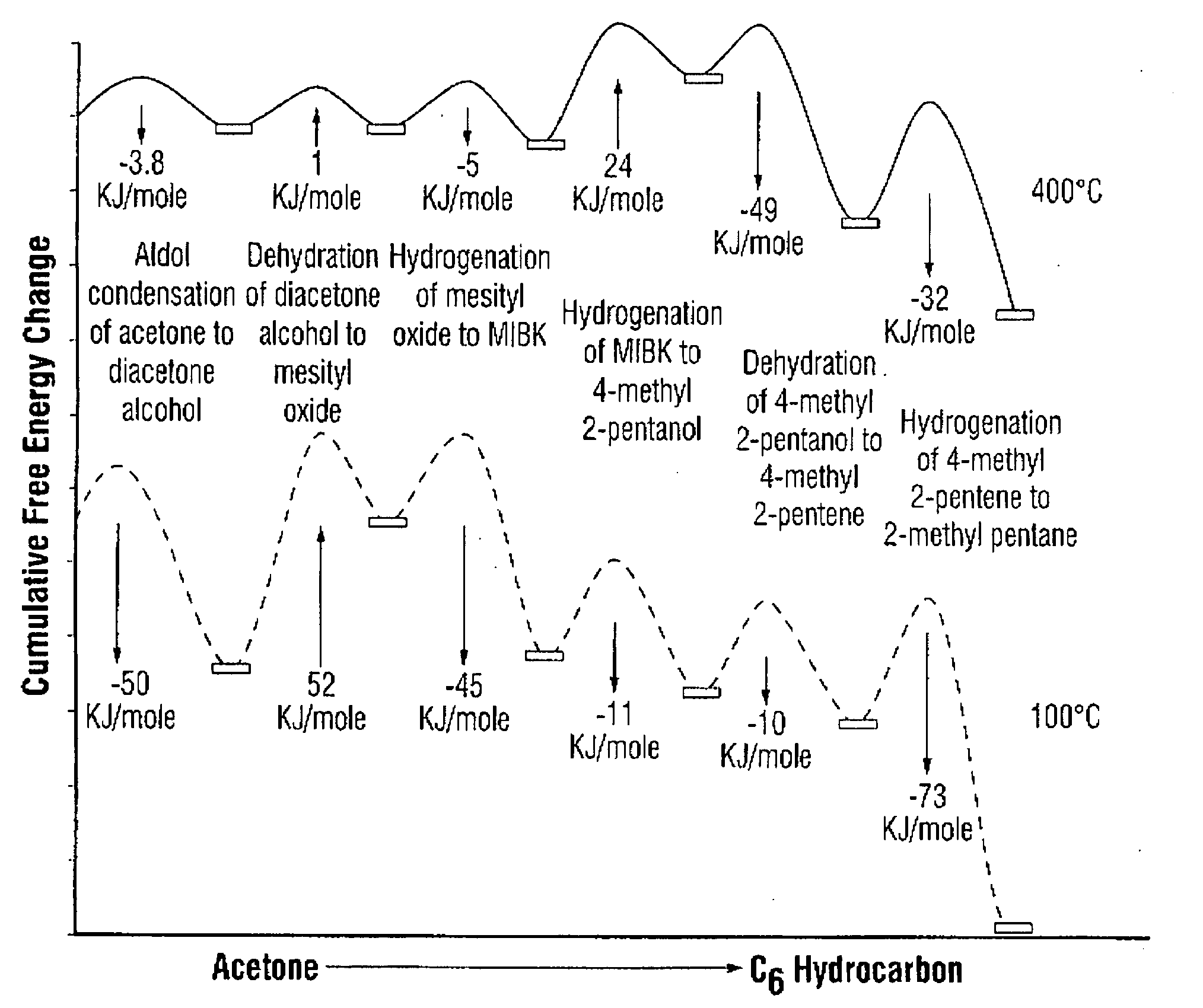

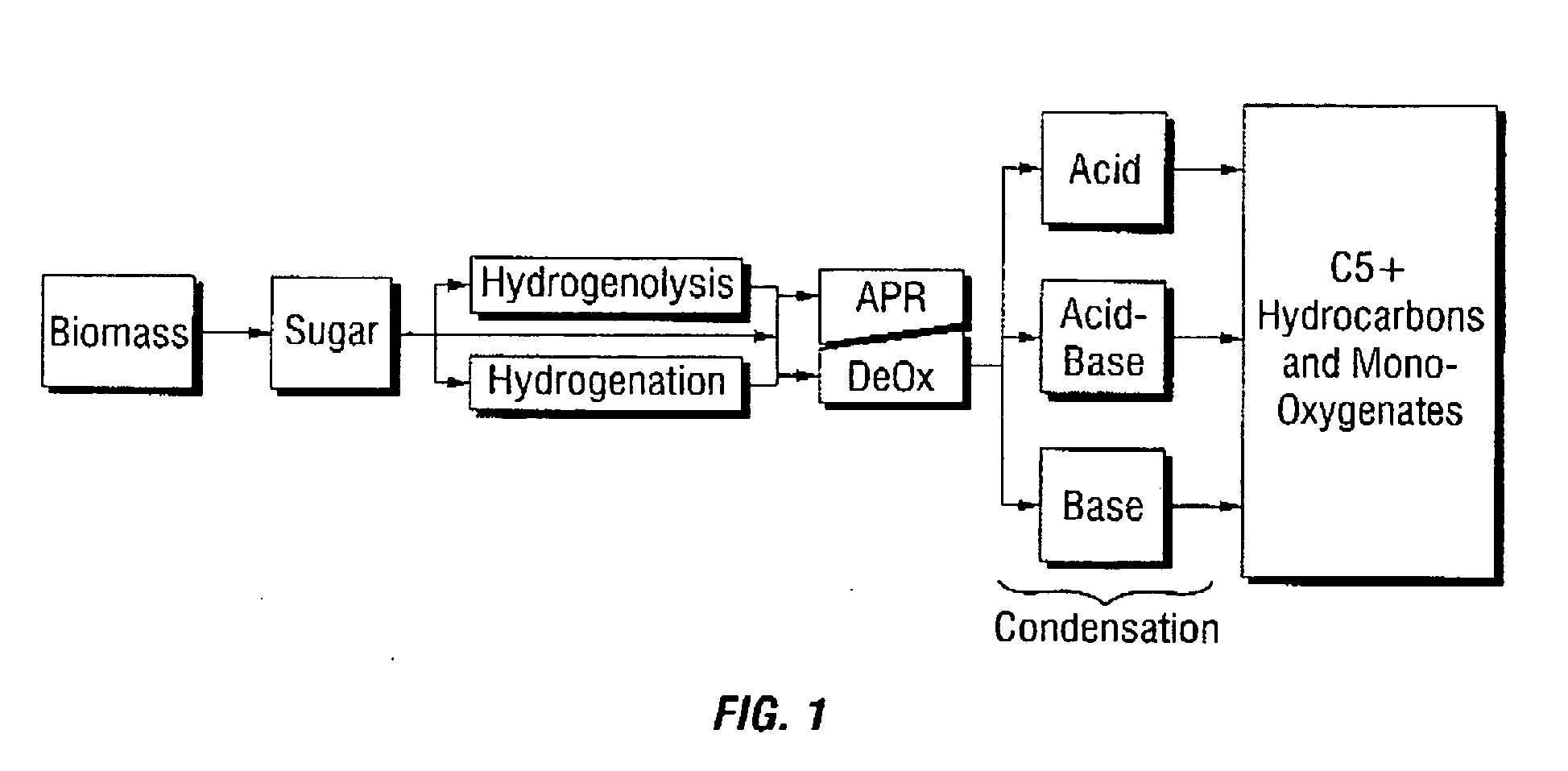

The present invention provides a liquid fuel composition comprising a distillation fraction of a component having at least one C4+ compound derived from a water-soluble oxygenated hydrocarbon prepared by a method comprising:providing water and a water-soluble oxygenated hydrocarbon comprising a C1+O1+ hydrocarbon in an aqueous liquid phase and / or a vapor phase;providing H2;catalytically reacting in the liquid and / or vapor phase the oxygenated hydrocarbon with the H2 in the presence of a deoxygenation catalyst at a deoxygenation temperature and deoxygenation pressure to produce an oxygenate comprising a C1+O1-3 hydrocarbon in a reaction stream; andcatalytically reacting in the liquid and / or vapor phase the oxygenate in the presence of a condensation catalyst at a condensation temperature and condensation pressure to produce the C4+ compound,wherein the C4+ compound comprises a member selected from the group consisting of C4+ alcohol, C4+ ketone, C4+ alkane, C4+ alkene, C5+ cycloalkane, C5+ cycloalkene, aryl, fused aryl, and a mixture thereof;wherein the liquid fuel composition is selected from:a gasoline composition having an initial boiling point in the range of from 15° C. to 70° C. (IP123), a final boiling point of at most 230° C. (IP123), a RON in the range of from 85 to 110 (ASTM D2699) and a MON in the range of from 75 to 100 (ASTM D2700);a diesel fuel composition having an initial boiling point in the range of from 130° C. to 230° C. (IP123), a final boiling point of at most 410° C. (IP123) and a cetane number in the range of from 35 to 120 (ASTM D613); anda kerosene composition having an initial boiling point in the range of from 80 to 150° C., a final boiling point in the range of from 200 to 320° C. and a viscosity at −20° C. in the range of from 0.8 to 10 mm2 / s (ASTM D445).

Owner:SHELL USA INC

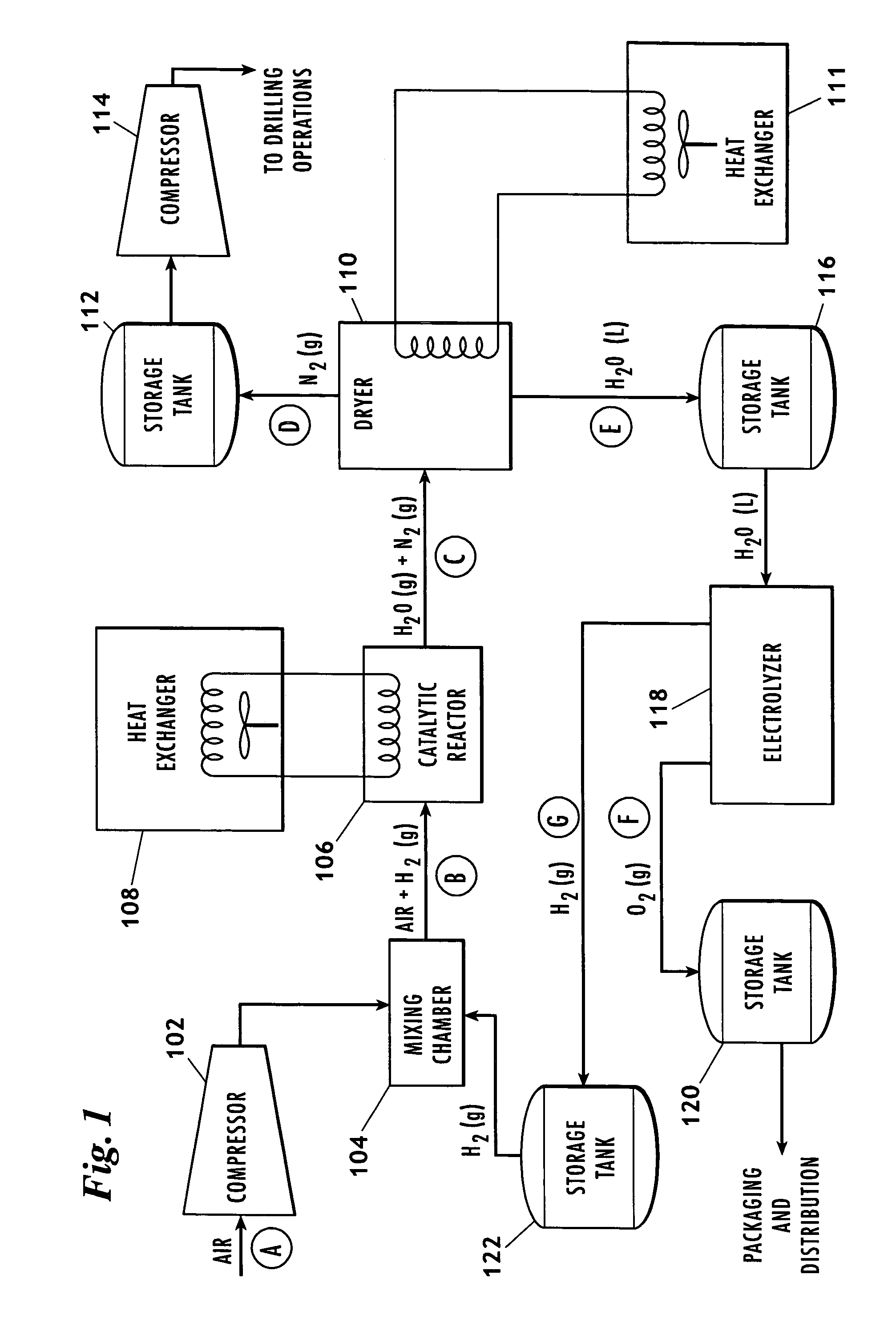

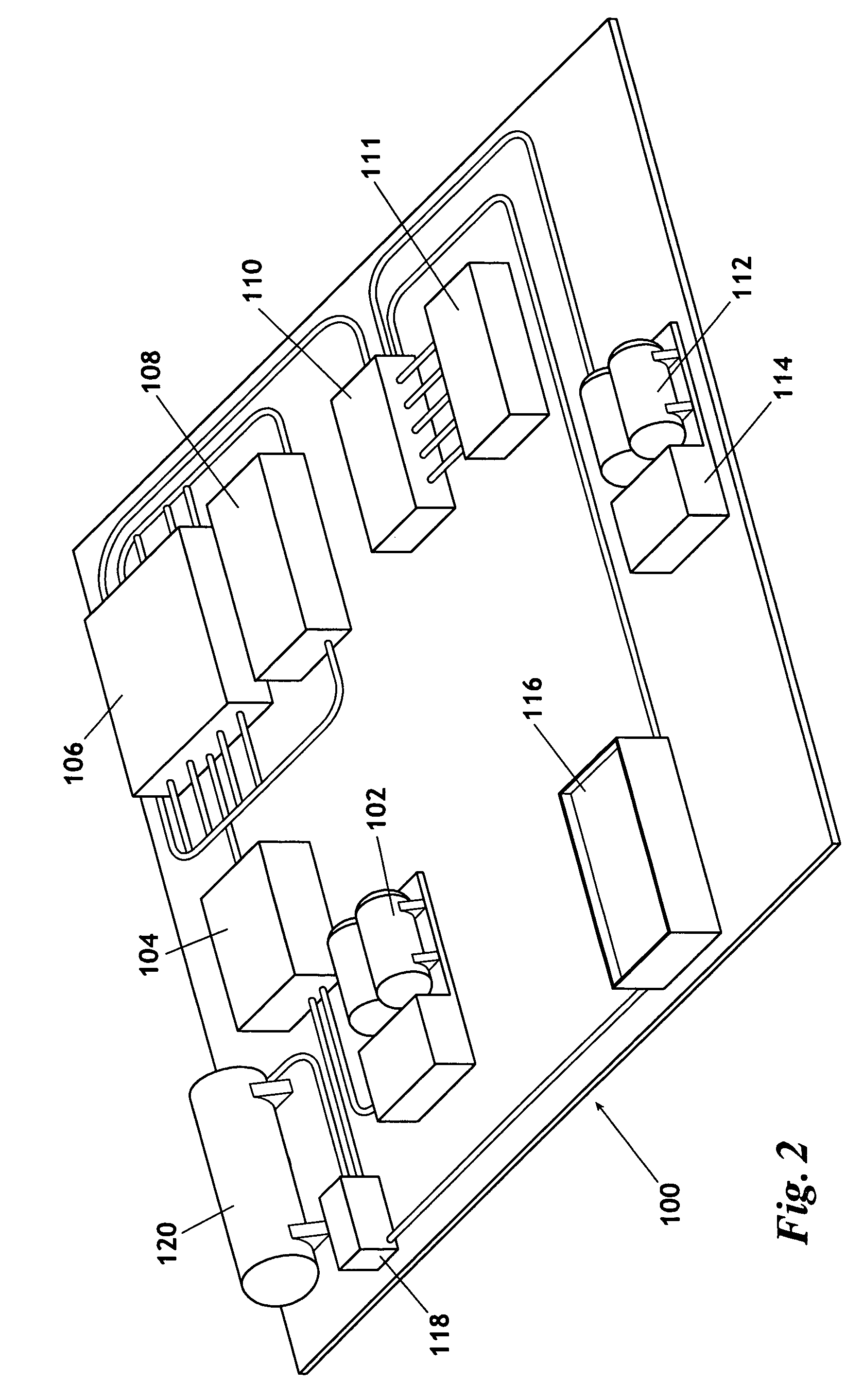

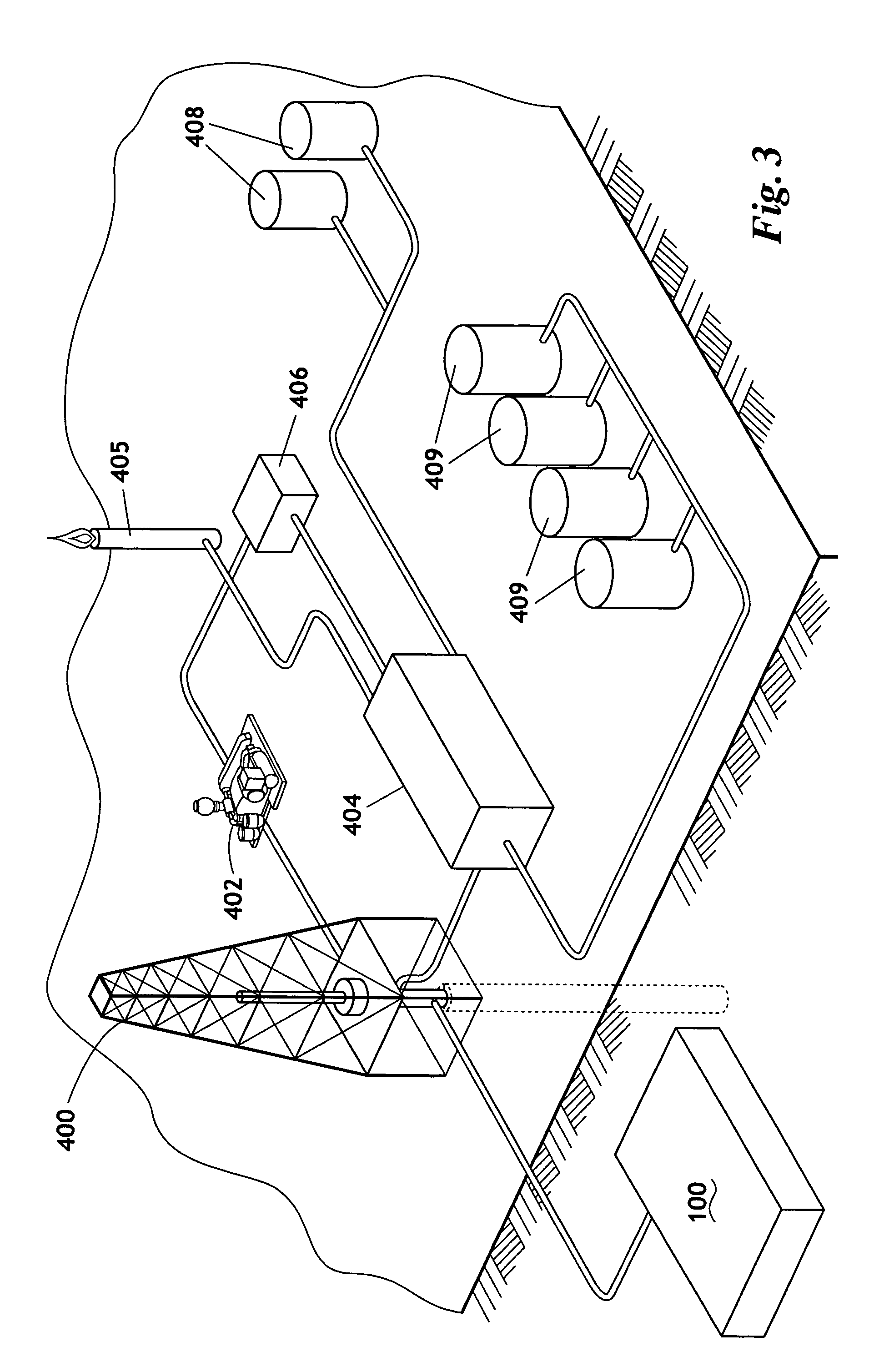

Method for producing nitrogen to use in under balanced drilling, secondary recovery production operations and pipeline maintenance

InactiveUS7468173B2Offsetting costsNitrogen purification/separationDispersed particle separationElectrolysisAtmospheric air

The invention uses a feed of atmospheric air and mixes the air with hydrogen. The hydrogen and air mixture is fed into a catalytic reactor where a deoxygenation reaction occurs. The deoxygenation reaction uses a platinum catalyst to produce water from oxygen and hydrogen. The nitrogen passes through the catalytic reactor without reacting with the hydrogen, the oxygen, or the water. The water is separated from the nitrogen in a dryer. The nitrogen may then be used in drilling and production operations. The water is fed into an electrolyzer where an electrolysis reaction occurs. The electrolyzer passes an electrical current through the water to produce gaseous oxygen and hydrogen. The hydrogen is recycled back to the catalytic reactor and the oxygen may be vented or sold.

Owner:SUNSTONE TECH

Process for producing a saturated hydrocarbon component

The invention relates to a process for producing high-quality saturated base oil or a base oil component based on hydrocarbons. The process of the invention comprises two main steps, the oligomerization and deoxygenation. A biological starting material containing unsaturated carboxylic acids and / or esters of carboxylic acids is preferably used as the feedstock.

Owner:NESTE OIL OY

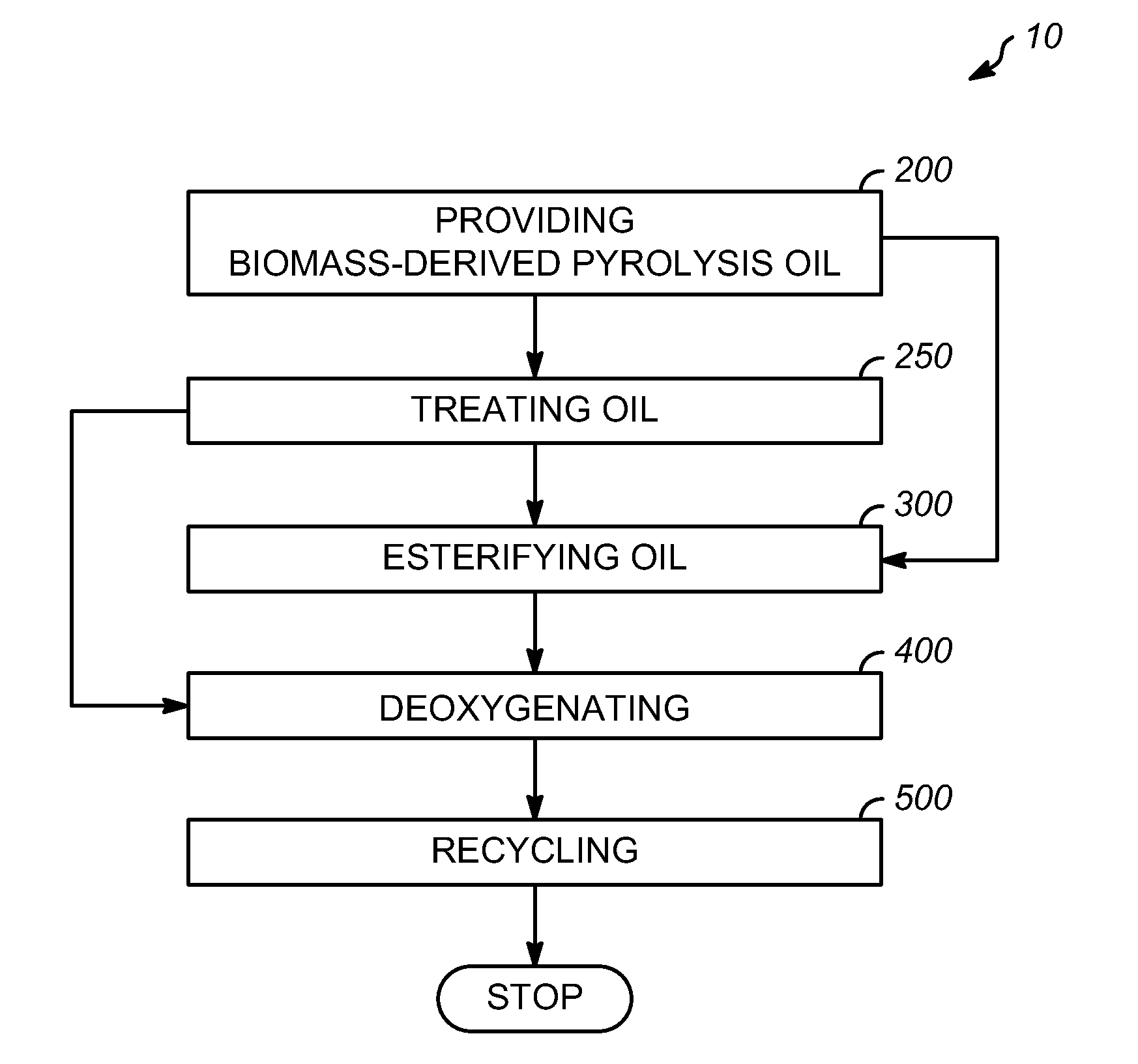

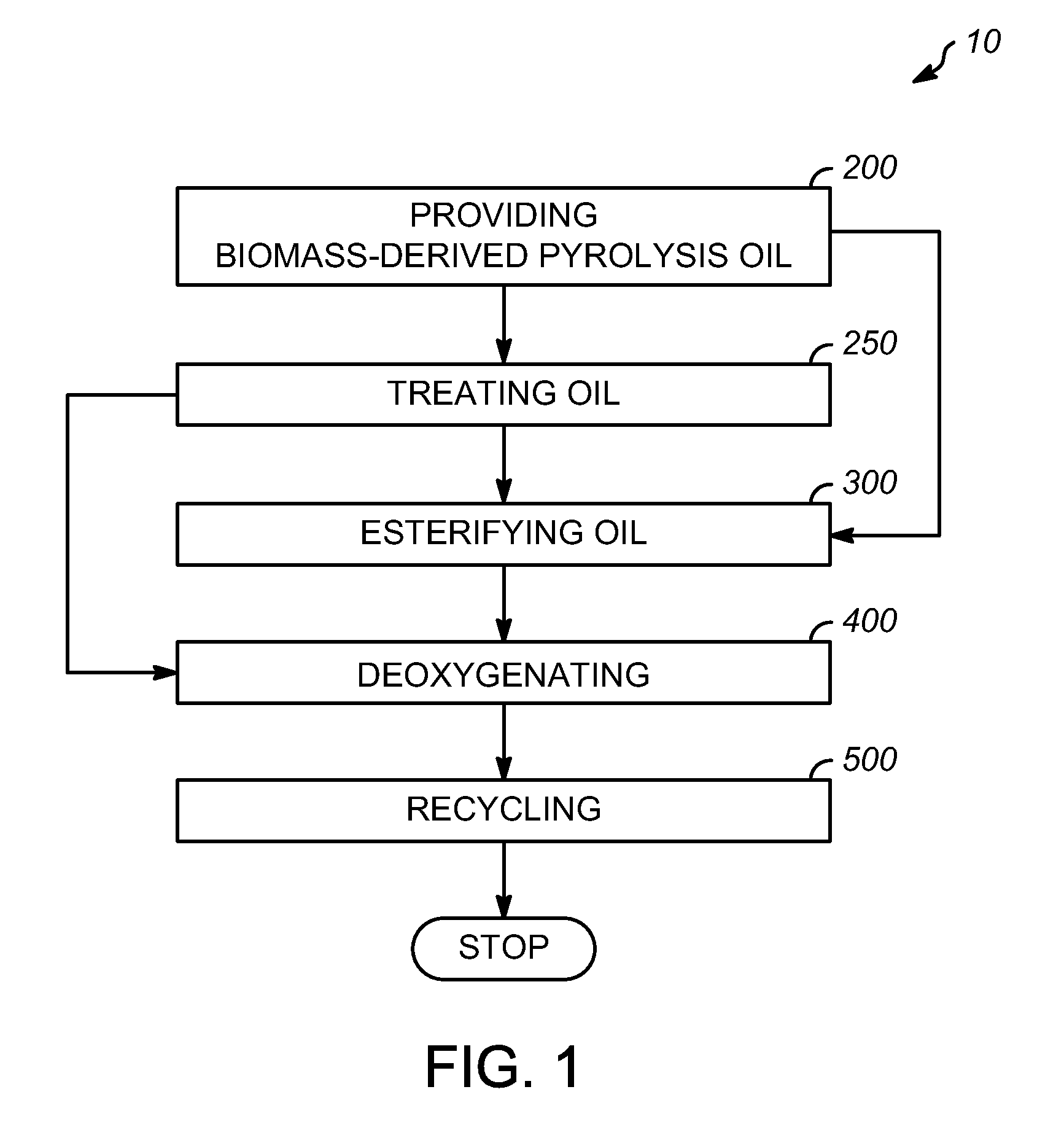

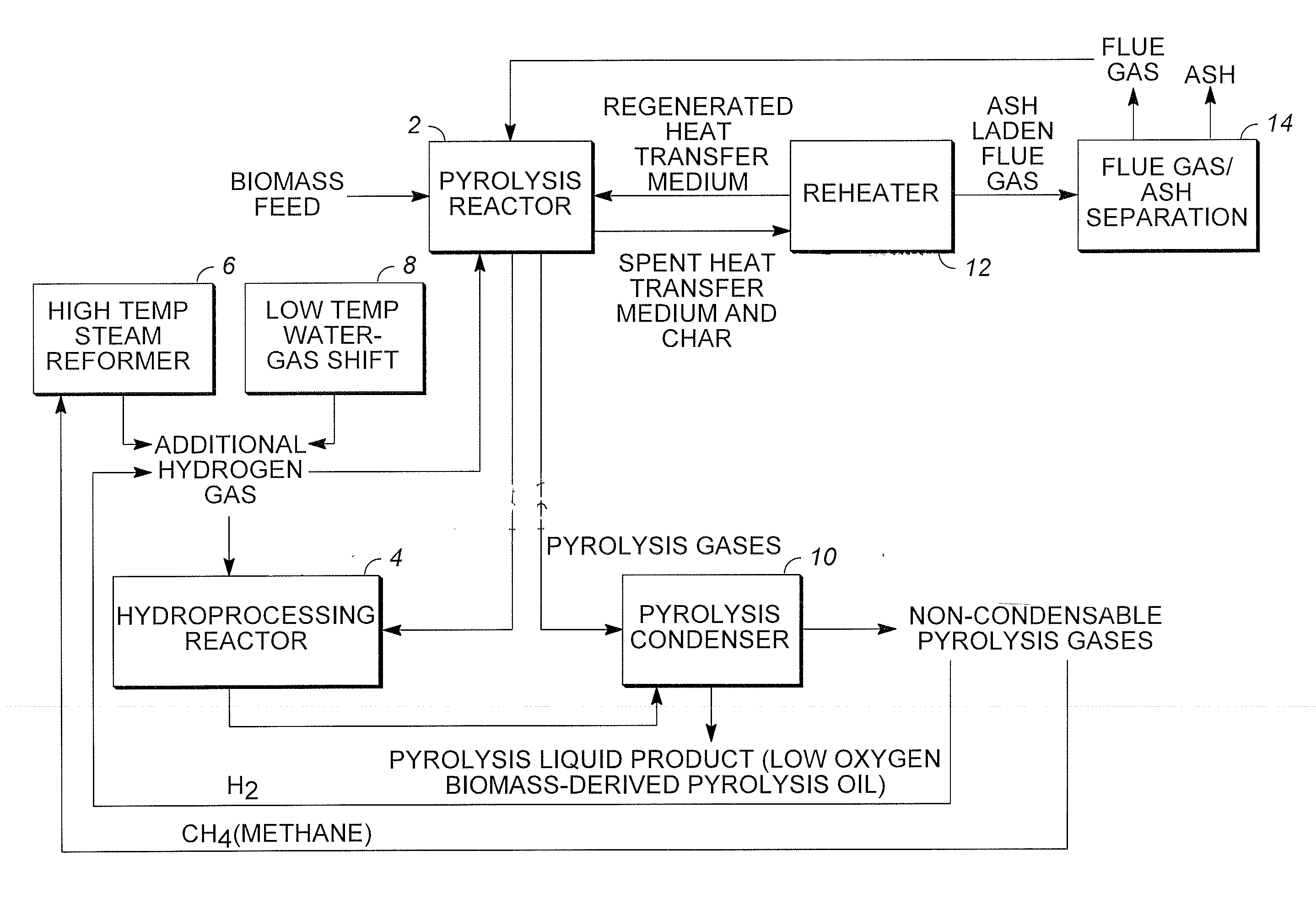

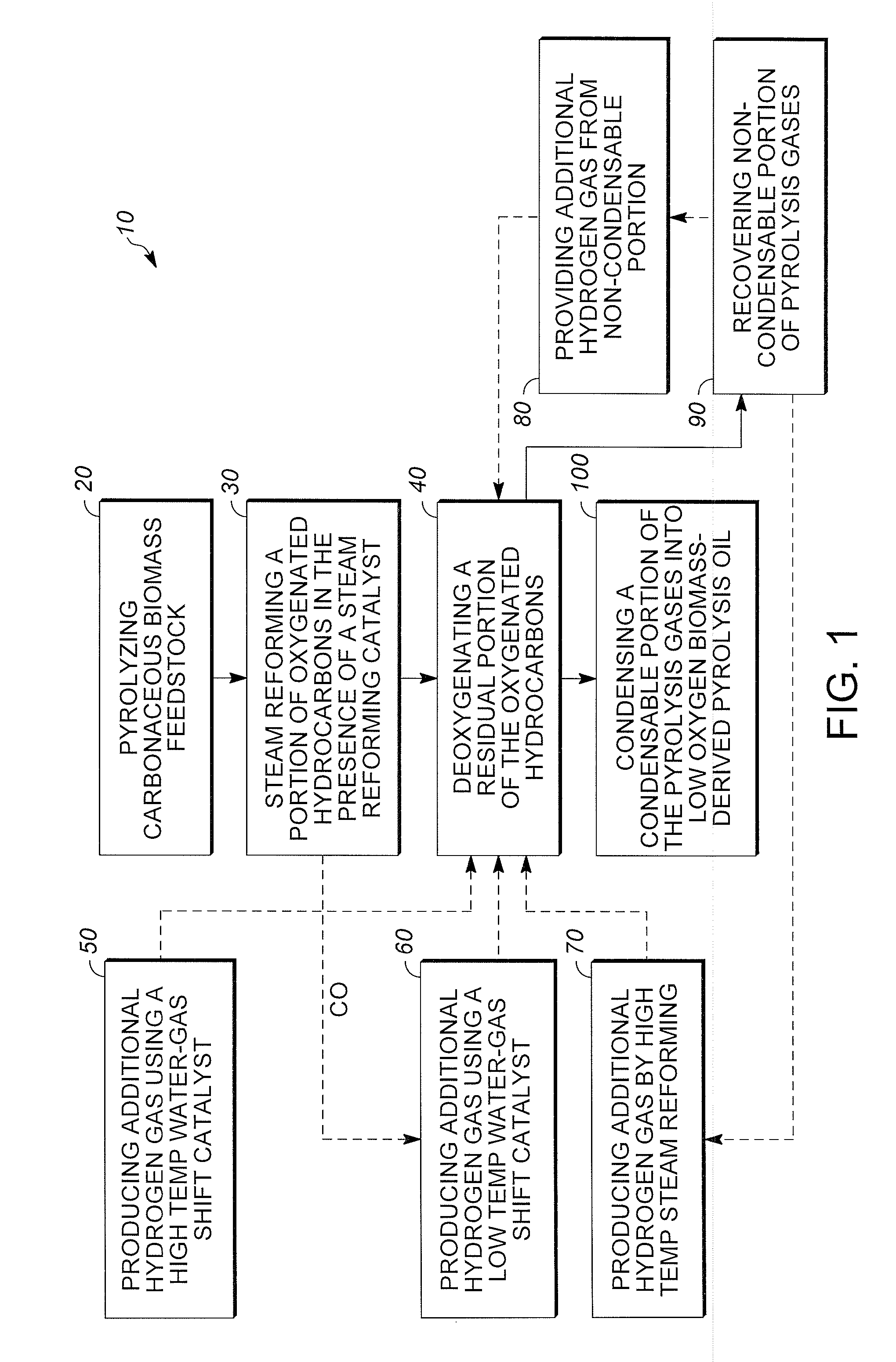

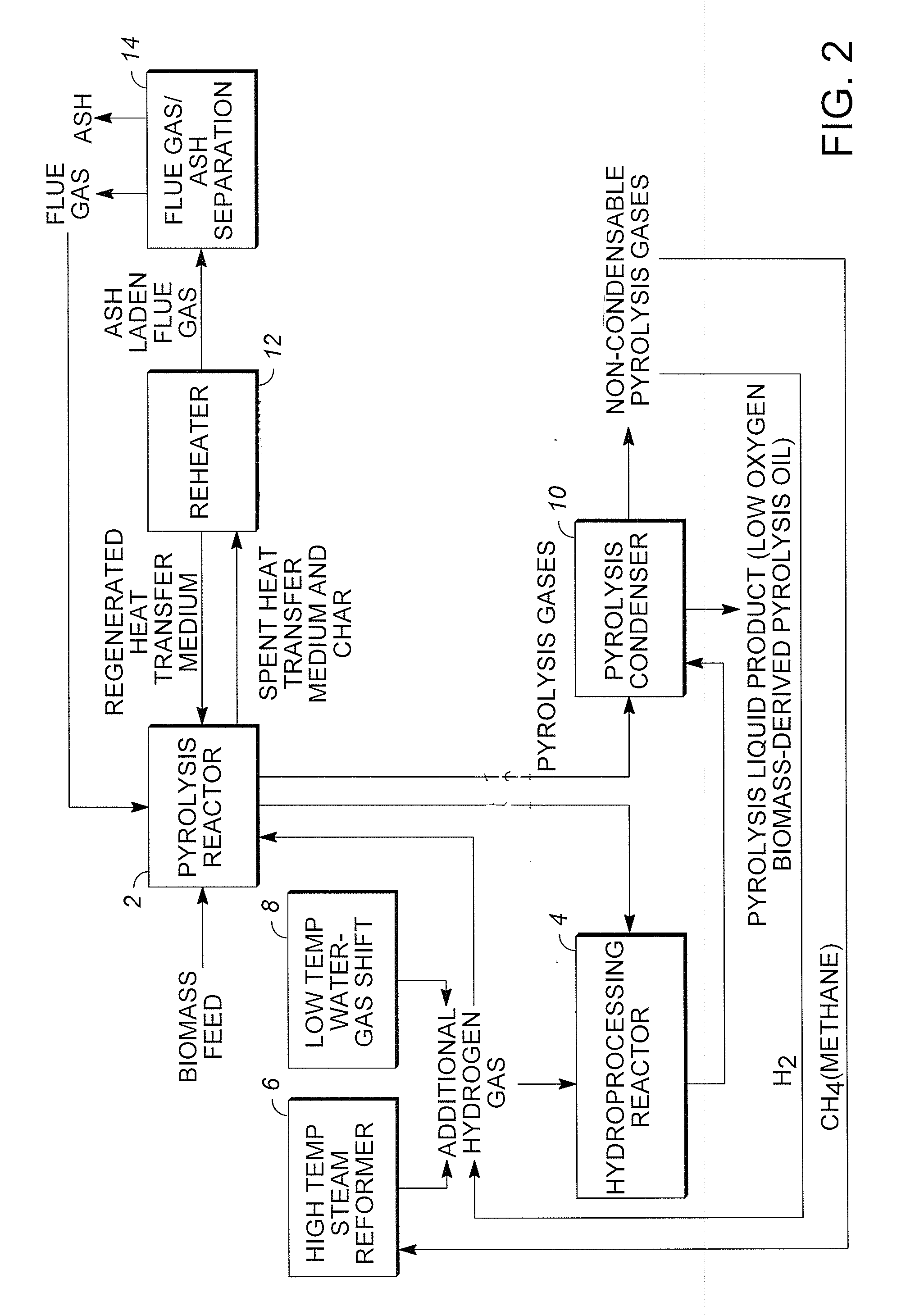

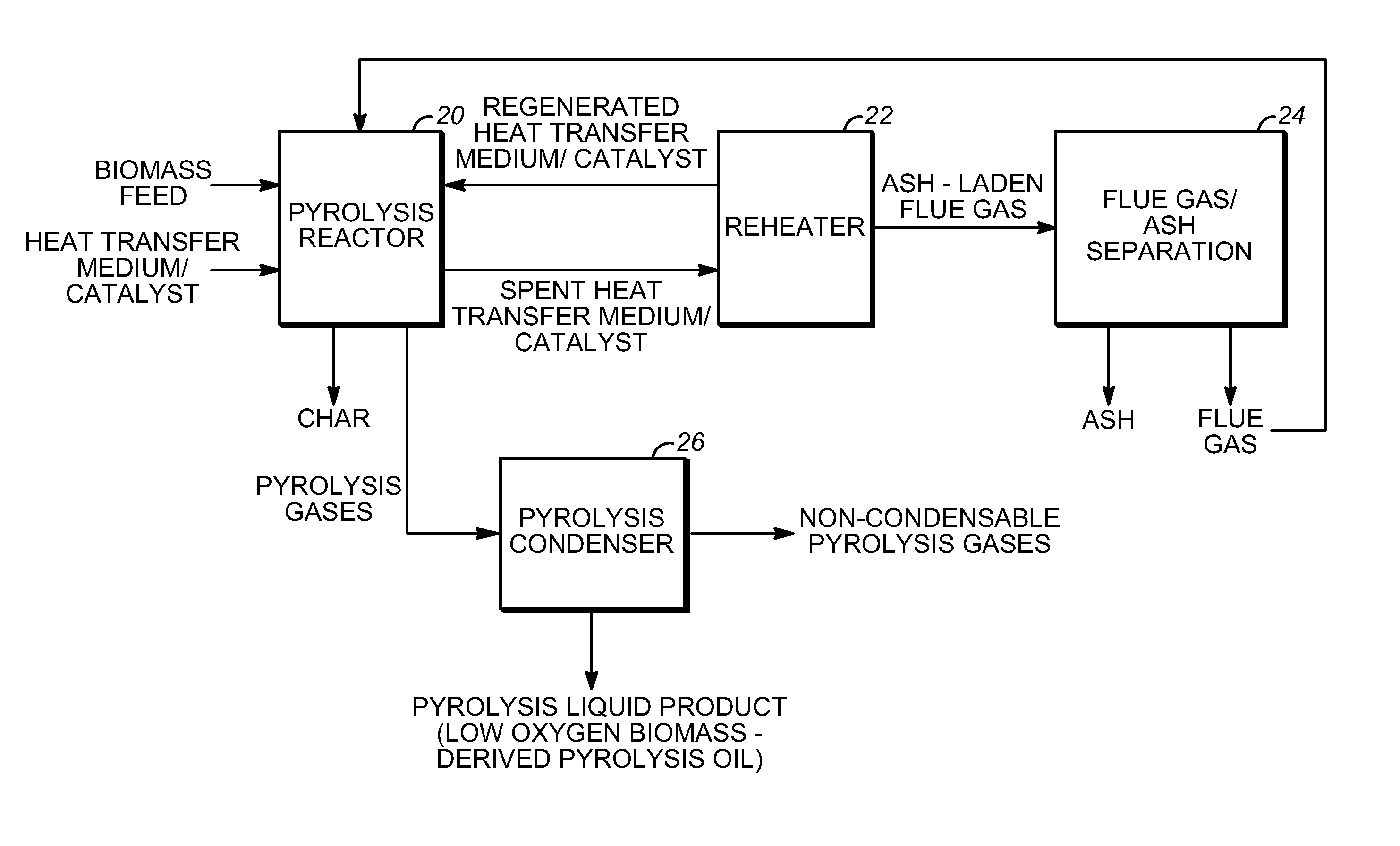

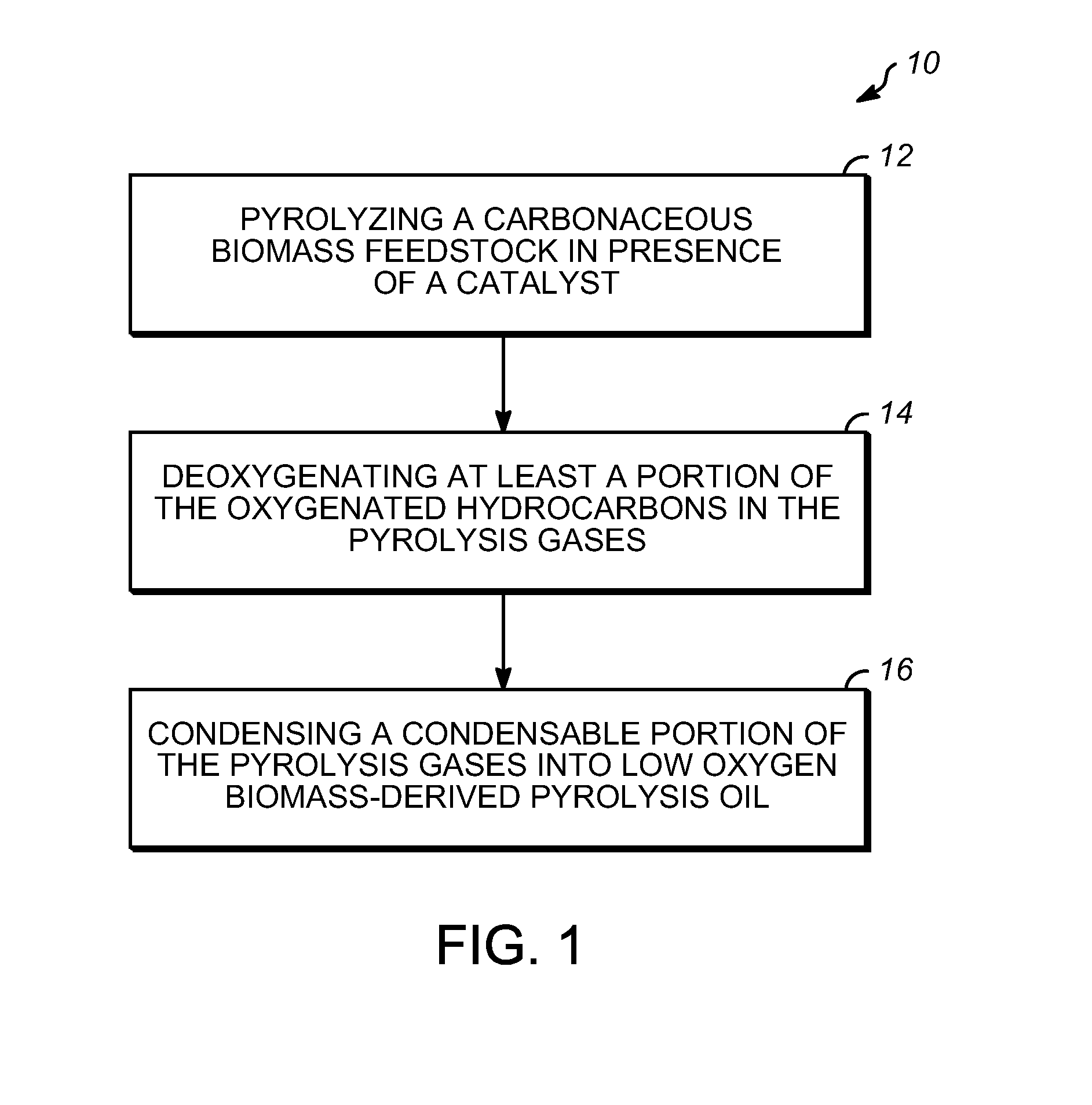

Low oxygen biomass-derived pyrolysis oils and methods for producing the same

InactiveUS20110201854A1Direct heating destructive distillationBiofuelsSteam reformingPartial oxidation

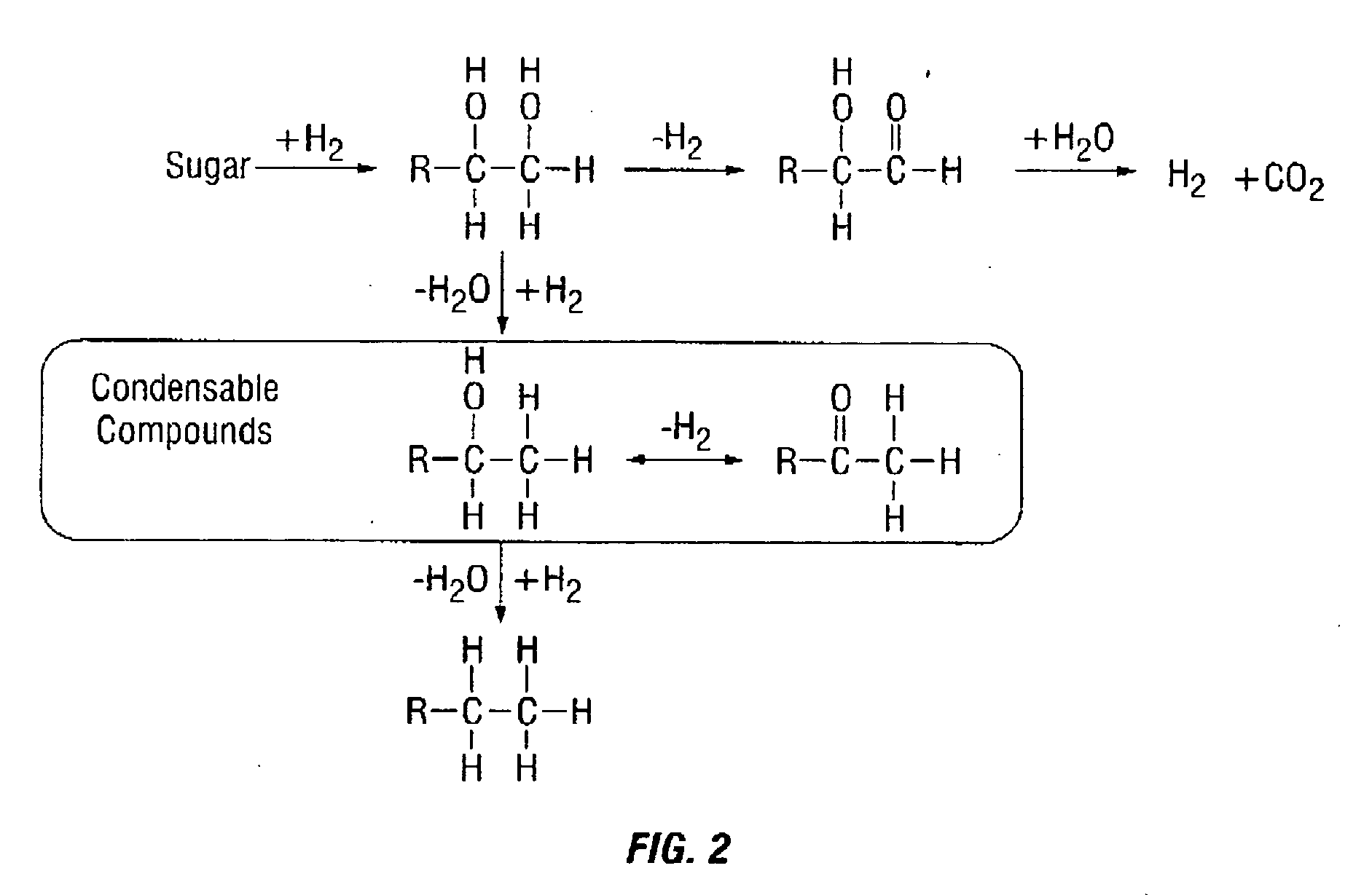

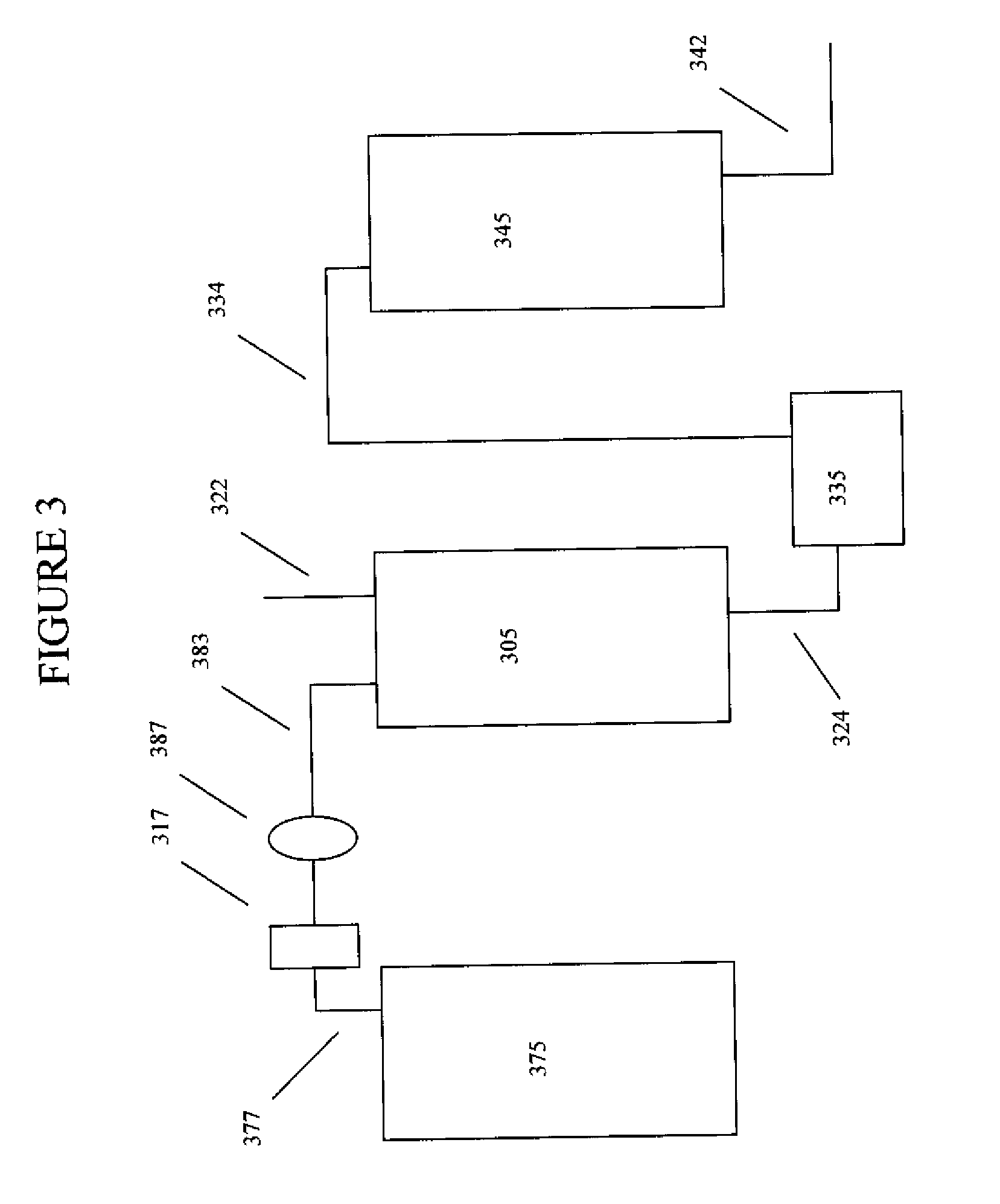

Methods are provided for producing low oxygen biomass-derived pyrolysis oil from carbonaceous biomass feedstock. The carbonaceous biomass feedstock is pyrolyzed in the presence of a steam reforming catalyst to produce char and pyrolysis gases. During pyrolysis, a portion of the oxygenated hydrocarbons in the pyrolysis gases is converted into hydrocarbons by steam reforming also yielding carbon oxides and hydrogen gas. The hydrogen gas at least partially deoxygenates a residual portion of the oxygenated hydrocarbons. Additional hydrogen gas may also be produced by water-gas shift reactions to deoxygenate the residual portion of the oxygenated hydrocarbons in the pyrolysis gases. Deoxygenation may occur in the presence of a hydroprocessing catalyst. A condensable portion of the pyrolysis gases is condensed to form low oxygen biomass-derived pyrolysis oil.

Owner:UOP LLC

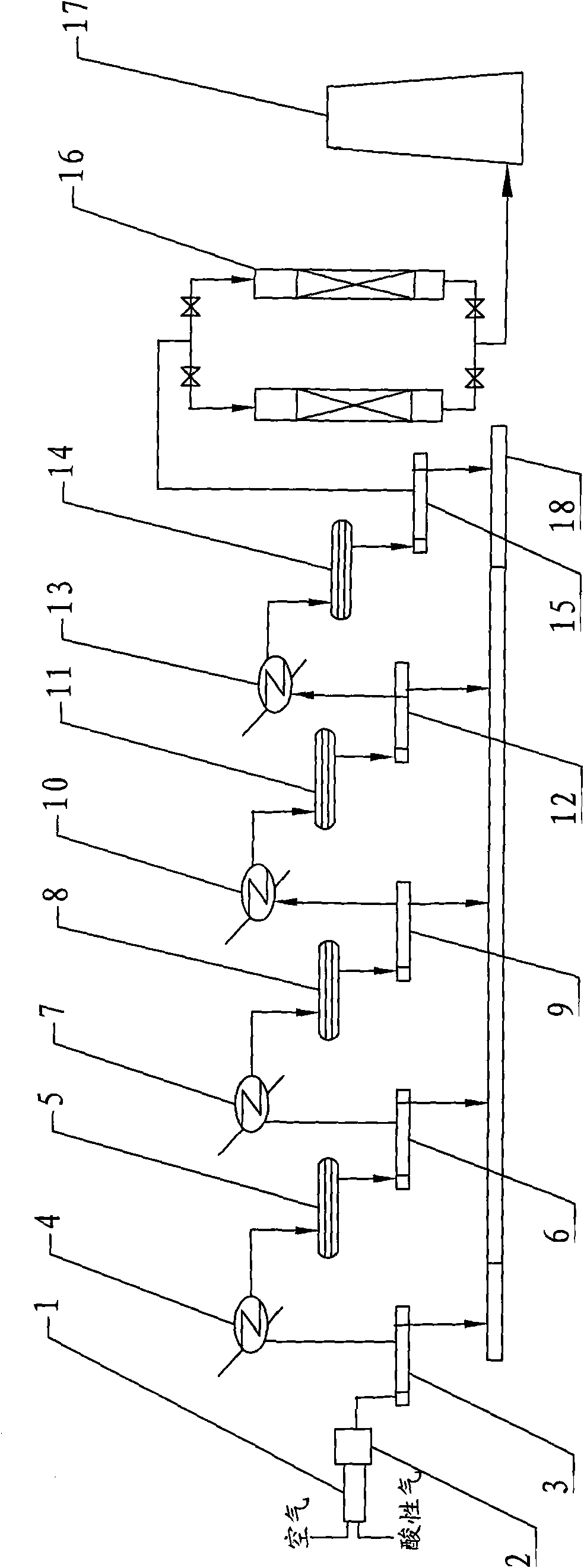

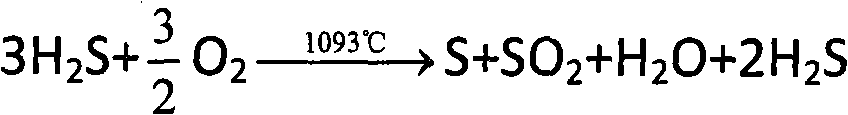

Catalyst combination process of sulfur recovering device

ActiveCN101659400AMeet the requirements of total sulfur recoveryAchieve complete hydrolysisPhysical/chemical process catalystsSulfur preparation/purificationCombustionSulfur

The invention relates to a catalyst combination process of a sulfur recovering device, belonging to the technical field of sulfur recovery, and comprising a combustion furnace, a primary clotz reactorand a secondary clotz reactor connected in series with each other. The catalyst combination process is characterized in that: behind the secondary clotz reactor, a selective hydrogenation reduction reactor, a selective oxidation reactor and two absorption desulfurizing towers connected in parallel are connected in series; a deoxygenation protection-type sulfur recovery catalyst is filled in the upper part of the primary clotz reactor, and a TiO2 sulfur recovery catalyst is filled in the lower part; an auxiliary agent type sulfur recovery catalyst is filled in the secondary clotz reactor; a SO2 selective reduction catalyst is filled in the selective hydrogenation reduction reactor and selectively reduces the SO2 into elemental sulfur; H2S selective oxidation catalyst is filled in the selective oxidation reactor and selectively oxidizes the H2S into elemental sulfur. In the invention, the recovery rate of sulfur is high, and the tail gas after desulfuration can completely reach the national discharge requirement of GB16297-1996.

Owner:山东迅达化工集团有限公司

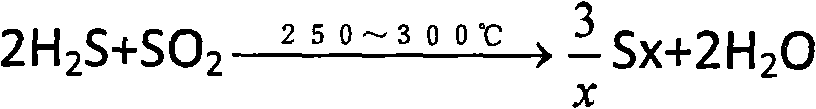

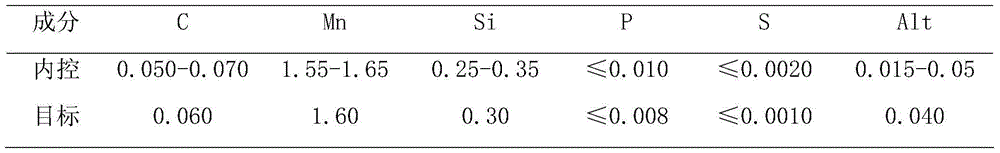

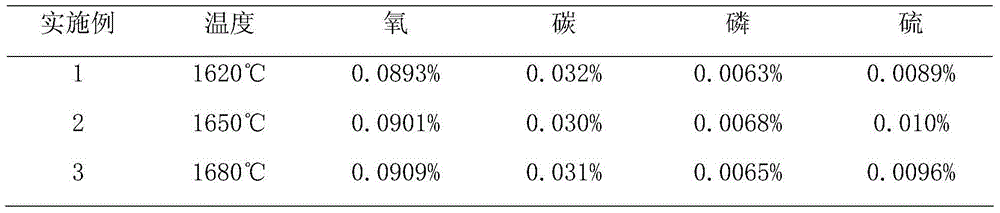

High-cleanliness pipeline steel smelting process

ActiveCN104630418ASolve the difficulty of cleanliness controlQuality improvementManufacturing convertersSulfurNon-metallic inclusions

The invention discloses a high-cleanliness pipeline steel smelting process. The process route comprises molten iron pouring, molten iron pretreatment, converter smelting, tapping, deoxidizing, alloying, LF refining furnace, treating with calcium, RH vacuum furnace and continuous casting and is characterized by comprising the following specific steps: firstly, converter smelting process; secondly, refining furnace smelting process; and thirdly, continuous casting process. The invention belongs to a steel-making process in the field of metallurgy and relates to a method for smelting and controlling a high-cleanliness pipeline steel. By molten iron desulphurization pretreatment, optimizing a converter tapping and deoxidizing system and a slagging system, LF refining furnace deep deoxygenation and reducing slag manufacturing processes, RH high-vacuum-degree degassing and inclusion removal process, the pouring is protected by the continuous casting in the whole process so that the composition of a casting billet is uniform, the contents of harmful elements such as S, P, O, N and H are low, the non-metallic inclusions are effectively controlled, the casting billet is good in internal quality and the production of high value-added ultra-low sulfur steel is ensured.

Owner:NANJING IRON & STEEL CO LTD

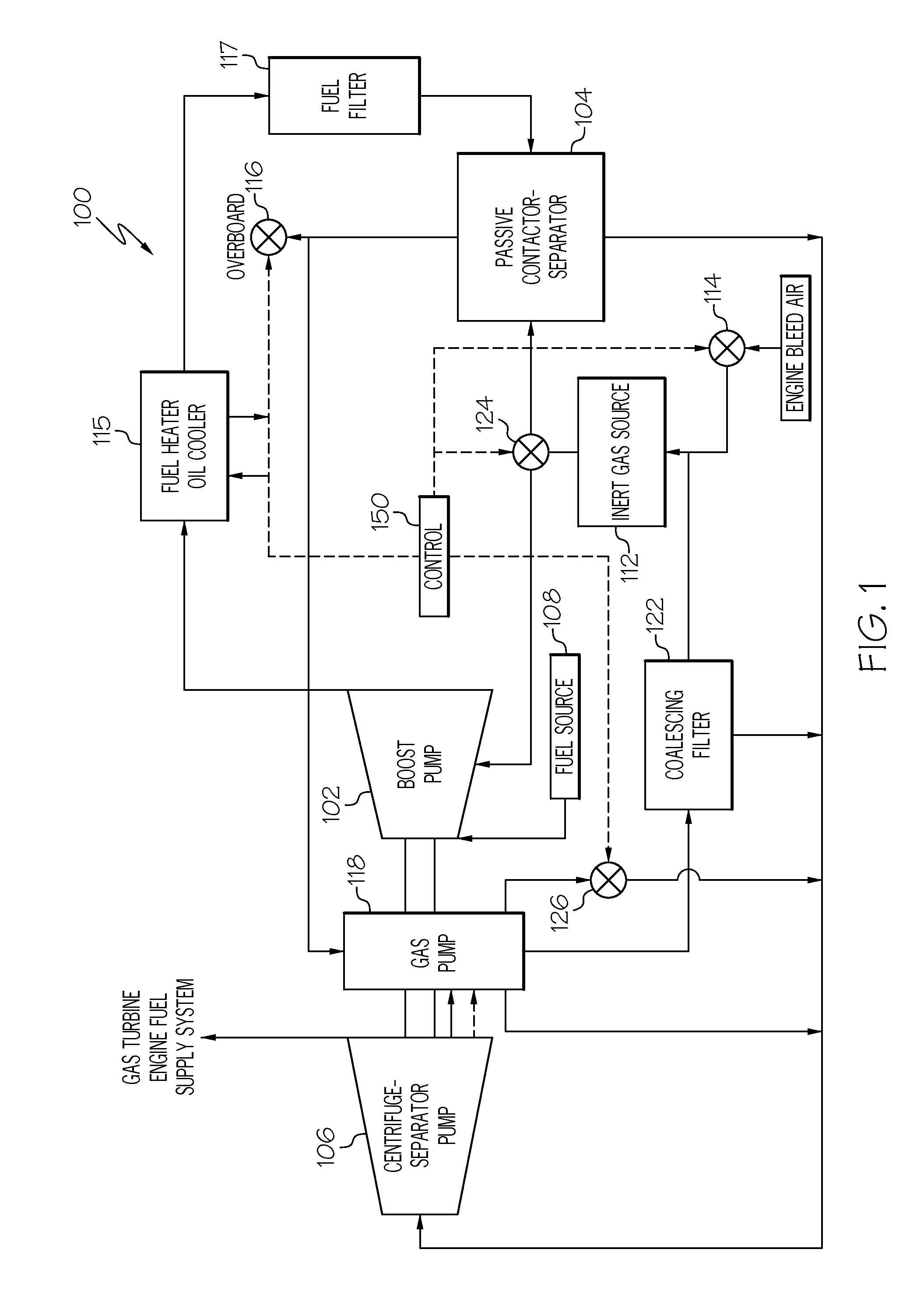

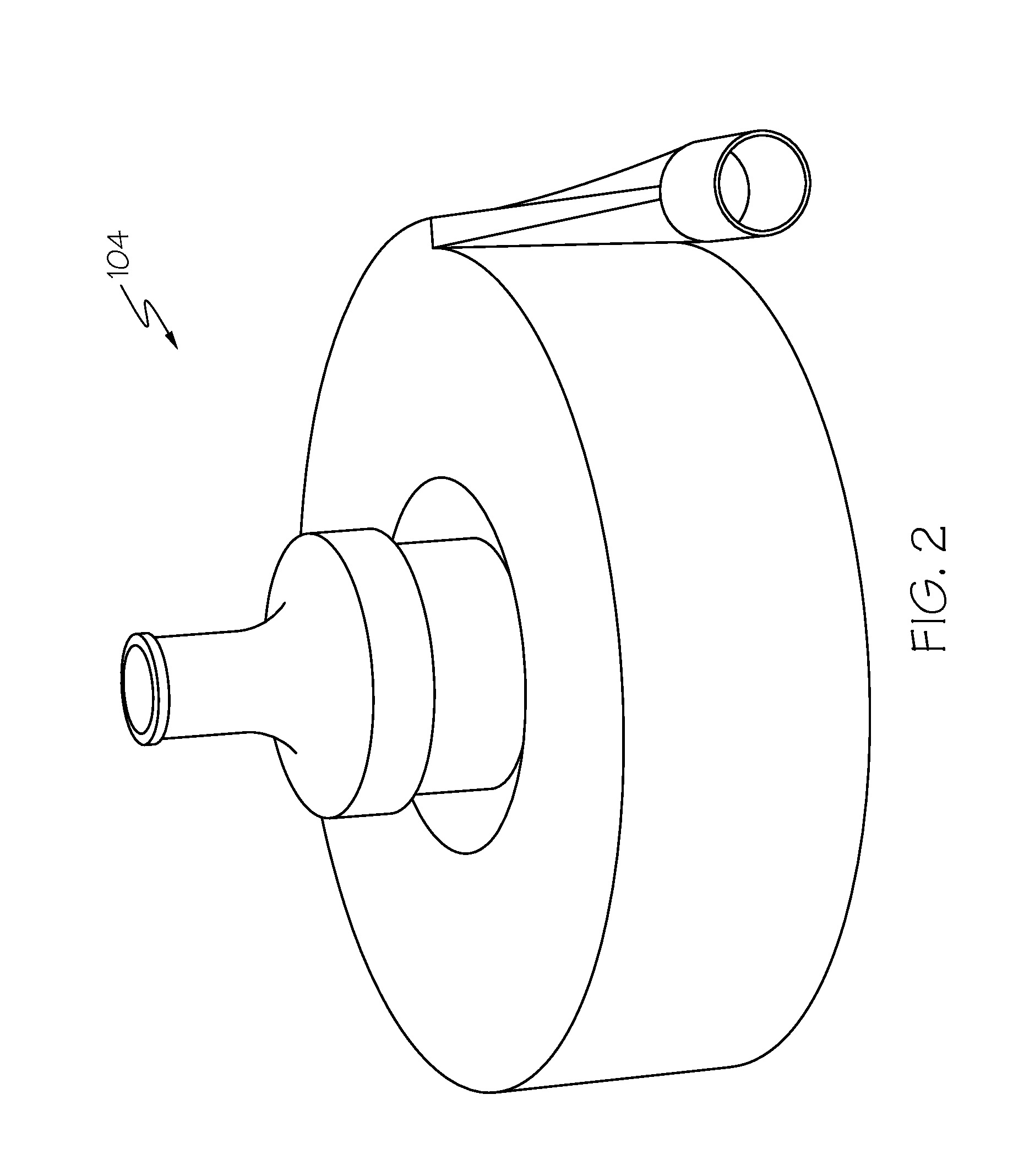

Aircraft fuel deoxygenation system

ActiveUS20160167802A1Increase fuel/gasImprove deoxidation efficiencyLiquid degasification with auxillary substancesDispersed particle filtrationOxygenDeoxygenation

An aircraft fuel deoxygenation system includes a boost pump, a contactor-separator, and a centrifuge-separator pump. The boost pump is adapted to receive fuel from a fuel source and inert gas from an inert gas source, and is configured to mix the fuel and inert gas and supply a fuel / gas mixture. The contactor-separator is coupled to receive the fuel / gas mixture and is configured to remove oxygen from the fuel and thereby generate and supply deoxygenated fuel with entrained purge gas and separated purge gas. The centrifuge-separator pump is coupled to receive the deoxygenated fuel with entrained purge gas and is configured to separate and remove the entrained purge gas from the deoxygenated fuel and supply the deoxygenated fuel and additional purge gas.

Owner:HONEYWELL INT INC

Functionalized materials and methods of using same

InactiveUS20060040280A1Reduce concentrationPrevent disengagementBioreactor/fermenter combinationsBiological substance pretreatmentsCompound (substance)Hydrolysis

Owner:LEE WILLIAM +1

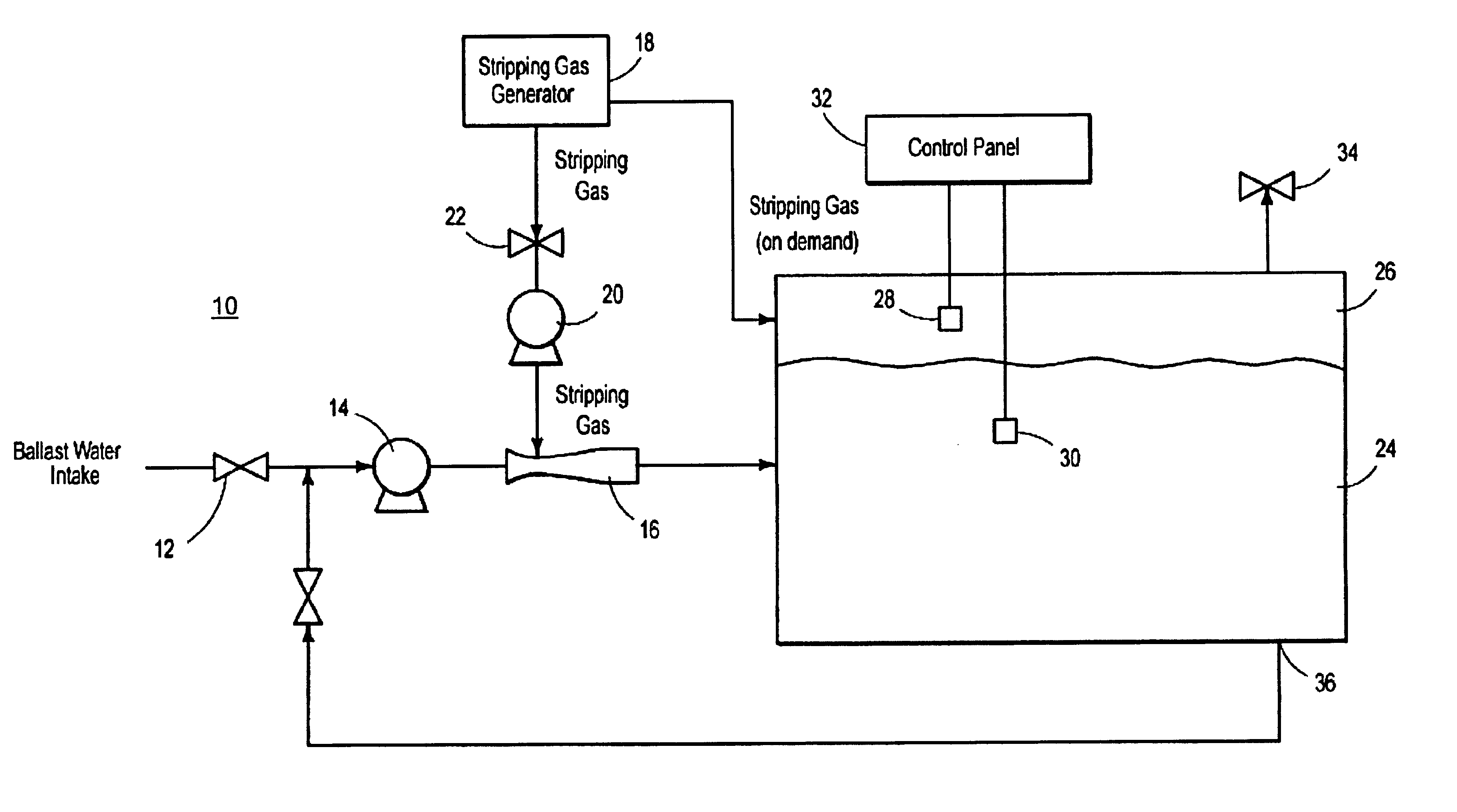

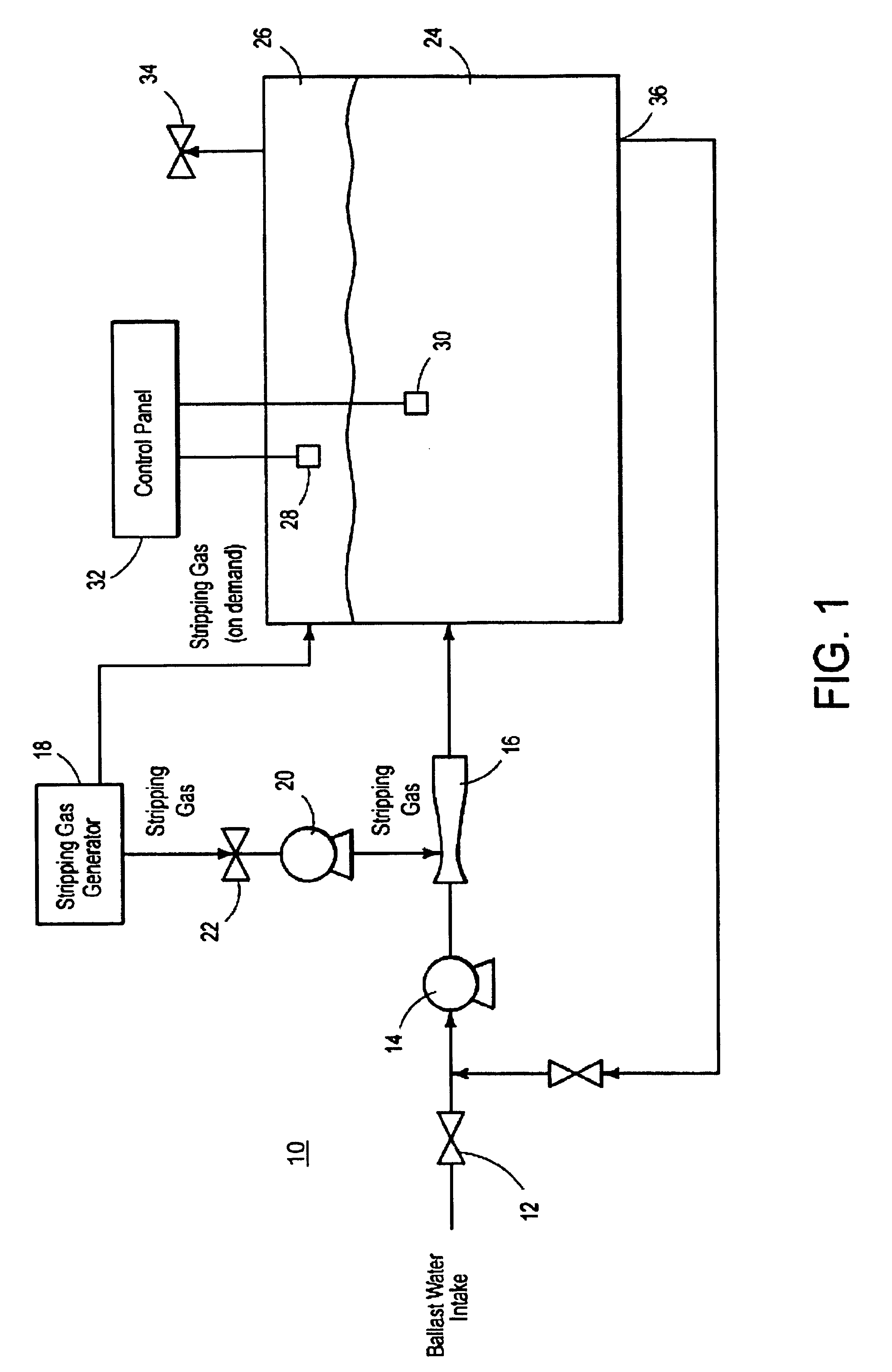

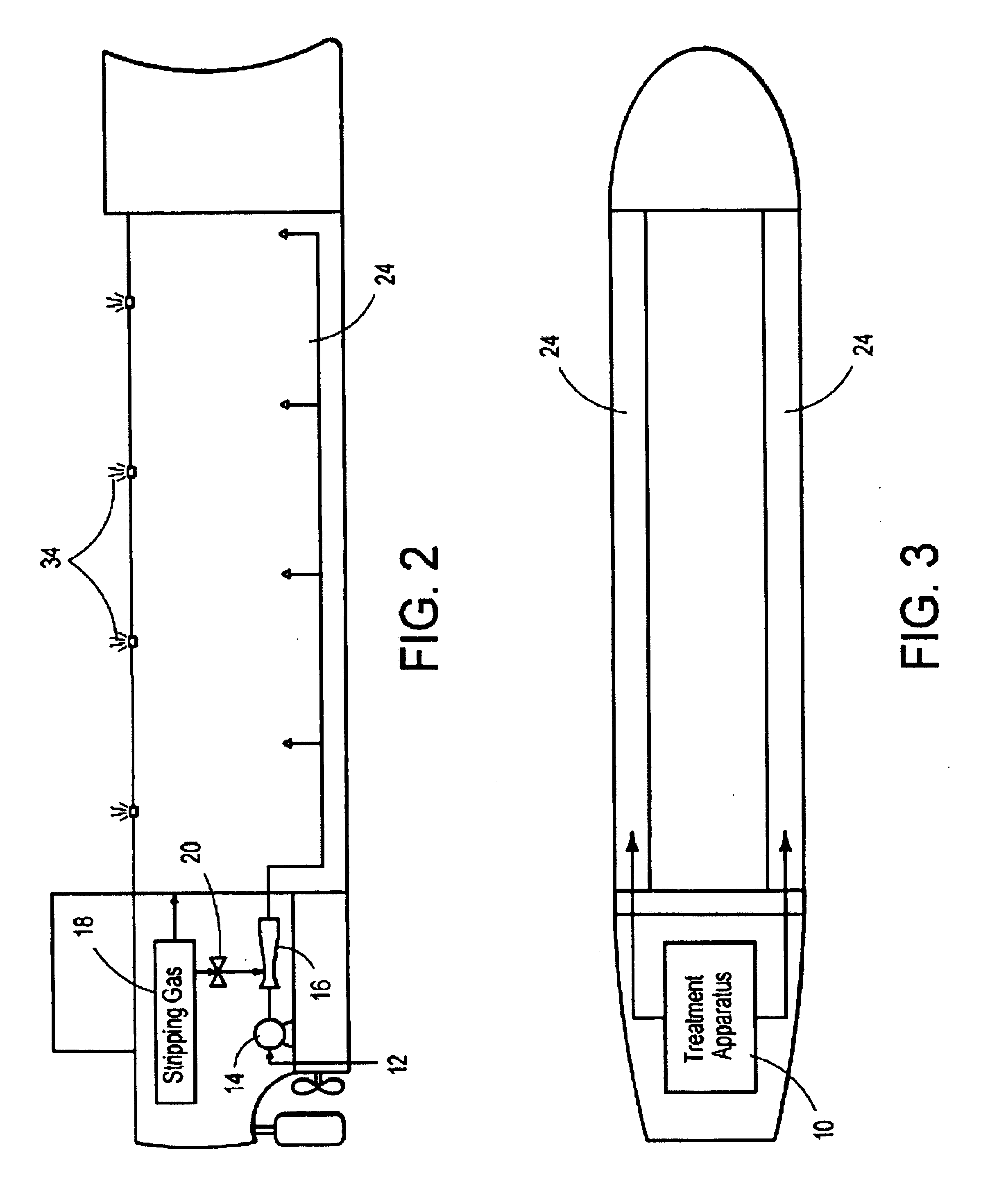

System and method of water treatment

InactiveUS6840983B2Low priceLiquid degasification with auxillary substancesSpecific water treatment objectivesWater treatment systemProduct gas

The present invention generally offers a system and a method that allows a vessel to treat water while providing corrosion inhibition. An oxygen stripping gas source produces oxygen stripping gas that may be pumped directly to, preferably but optionally, a venturi injector, or may first be pumped into an empty tank and then delivered to the injector means. Water being pumped through the injector via a transfer piping means comes into contact with the oxygen stripping gas, and dissolved oxygen in the water transfers to micro-fine stripping gas bubbles generated by the injector. The water and the micro-fine bubbles are pumped from the injector and into the tank, where the micro-fine bubbles float to the surface, and the oxygen is released into the tank's headspace. The deoxygenated water may be re-circulated through the system for additional deoxygenation or released from the tank into the surrounding waterways.

Owner:HRL LAB +1

Aromatic hydrocarbons from depolymerization and deoxygenation of lignin

ActiveUS20130025191A1Speed up the conversion processEconomically beneficialSolid fuelsLiquid carbonaceous fuelsProcess economicsDepolymerization

Processes are disclosed that achieve a high conversion of lignin to aromatic hydrocarbons, and that may be carried out without the addition of a base. Depolymerization and deoxygenation, the desired lignin convention steps to yield aromatic hydrocarbons, are carried by contacting a mixture of lignin and a solvent (e.g., a lignin slurry) with hydrogen in the presence of a catalyst. A preferred solvent is a hydrogen transfer solvent such as a single-ring or fused-ring aromatic compound that beneficially facilitates depolymerization and hinders coke formation. These advantages result in favorable overall process economics for obtaining fuel components and / or chemicals from renewable sources.

Owner:UOP LLC

Hydroprocessing of biocomponent feedstocks with low purity hydrogen-containing streams

ActiveUS20110155636A1Reduce expensesLittle or no significant impact on other refinery resourcesRefining to change hydrocarbon structural skeletonBiofuelsHydrogenDeoxygenation

A biocomponent feedstock can be hydroprocessed using a hydrogen-containing refinery as a source of hydrogen gas. A relatively low cost catalyst, such as a water gas shift catalyst and / or spent hydrotreating catalyst, can be used as a hydrogenation catalyst for the process. The hydroprocessing can allow for olefin saturation and / or deoxygenation of the biocomponent feed by using a relatively low value refinery stream, e.g., containing from about 20 mol % to about 60 mol % hydrogen.

Owner:EXXON RES & ENG CO

Method of Converting a Polyol to an Olefin

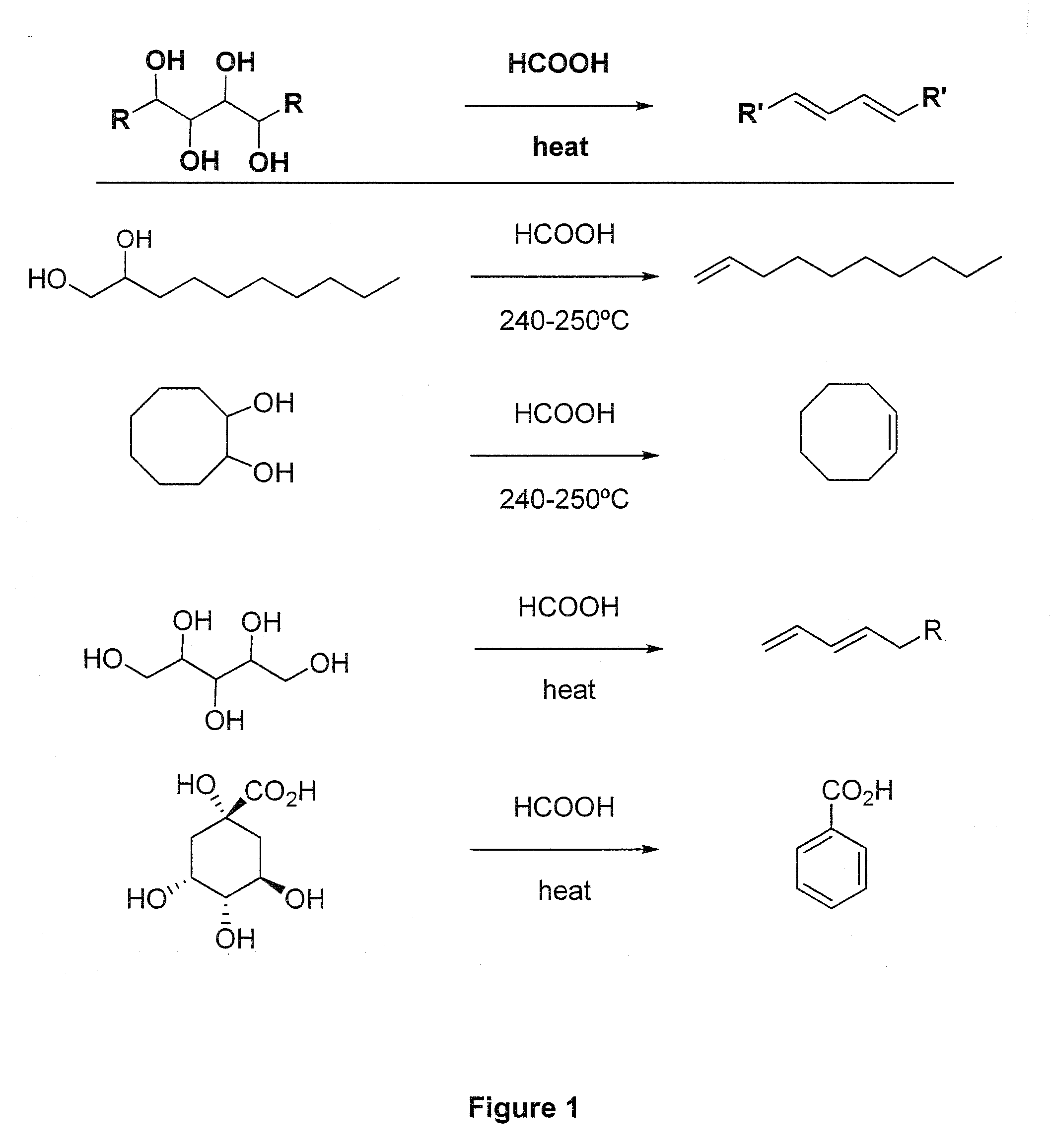

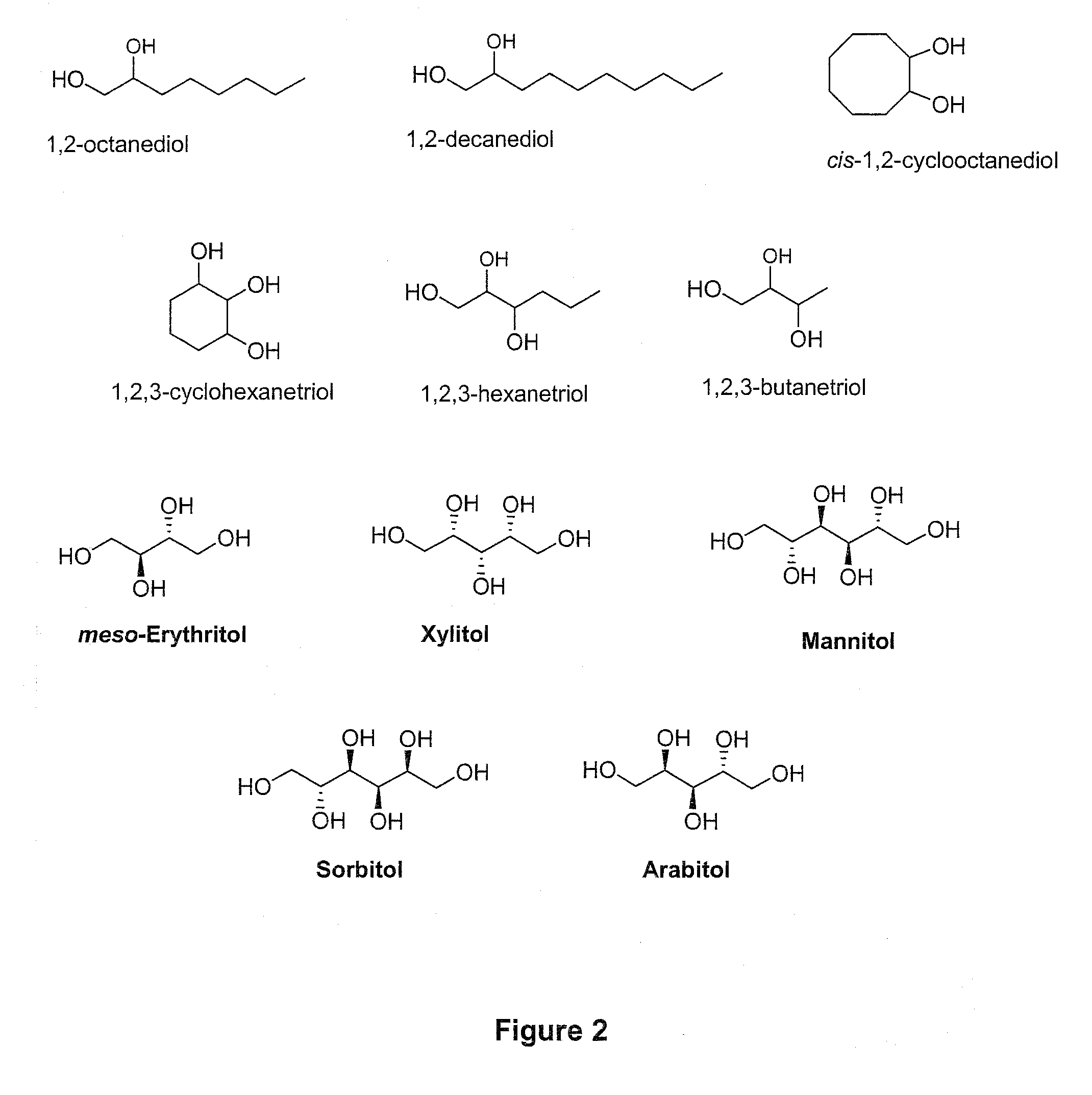

ActiveUS20090287004A1High purityHigh yieldOxygen-containing compound preparationOrganic compound preparationPolyolCarboxylic acid

A method of preparing an olefin comprising: reacting a polyol in the presence of a carboxylic acid, such that an olefin is produced by the deoxygenation of the polyol. The reacting step can comprise (a) providing a composition comprising the polyol, (b) heating the composition, and (c) introducing the carboxylic acid to the composition wherein the introducing step occurs prior to, at the same time as, or subsequent to the heating step. In one embodiment, the polyol is glycerol, the carboxylic acid is formic acid, and the olefin is allyl alcohol, which is produced at a yield of about 80% or greater.

Owner:RGT UNIV OF CALIFORNIA

Low oxygen biomass-derived pyrolysis oils and methods for producing the same

Low oxygen biomass-derived pyrolysis oils and methods for producing them from carbonaceous biomass feedstock are provided. The carbonaceous biomass feedstock is pyrolyzed in the presence of a catalyst comprising base metal-based catalysts, noble metal-based catalysts, treated zeolitic catalysts, or combinations thereof to produce pyrolysis gases. During pyrolysis, the catalyst catalyzes a deoxygenation reaction whereby at least a portion of the oxygenated hydrocarbons in the pyrolysis gases are converted into hydrocarbons. The oxygen is removed as carbon oxides and water. A condensable portion (the vapors) of the pyrolysis gases is condensed to low oxygen biomass-derived pyrolysis oil.

Owner:UOP LLC

Process for producing paraffinic hydrocarbons

ActiveUS20100076236A1Carry-outIncrease temperatureFatty acid chemical modificationBiofuelsAlkaneMonoglyceride

Process for producing paraffinic hydrocarbons, the process comprising the following steps: (a) contacting hydrogen and a feedstock comprising triglycerides, diglycerides, monoglycerides and / or fatty acids with a hydrogenation catalyst under hydro-deoxygenation conditions; and (b) contacting the whole effluent of step (a) with a hydroprocessing catalyst comprising sulphided Ni and sulphided W or Mo as hydrogenation components on a carrier comprising amorphous silica-alumina and / or a zeolitic compound under hydro-isomerisation conditions.

Owner:SHELL USA INC

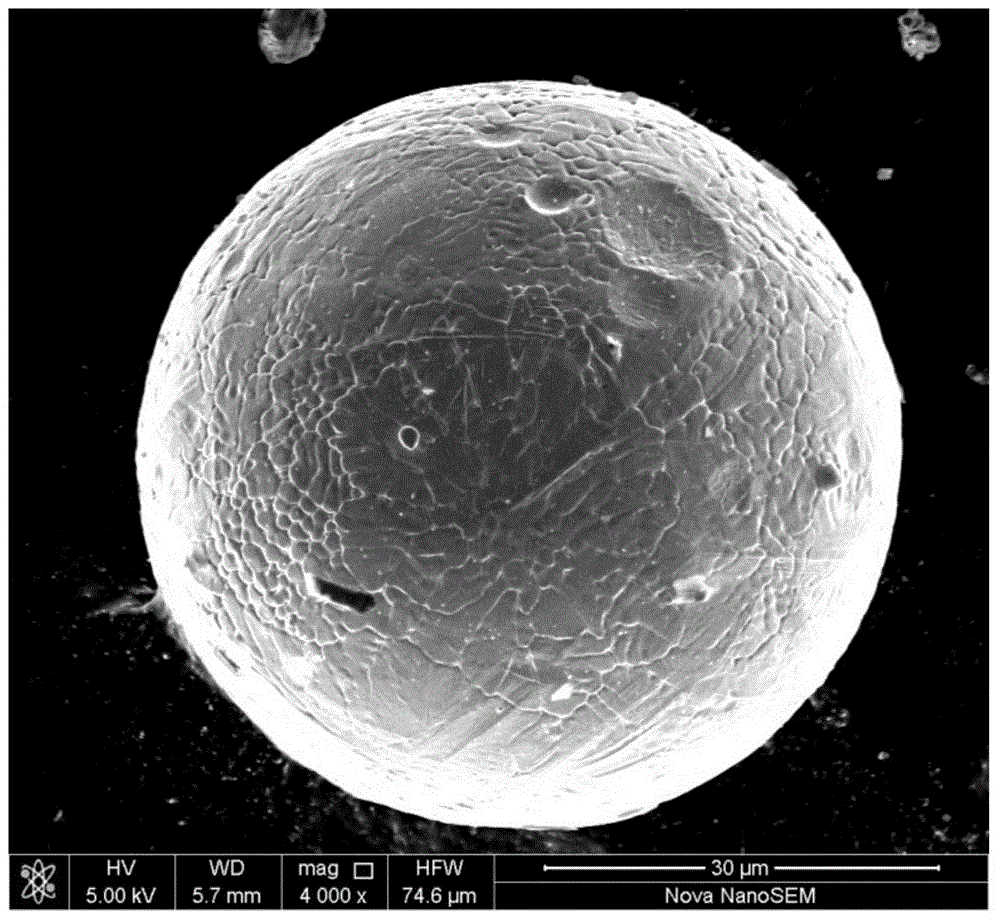

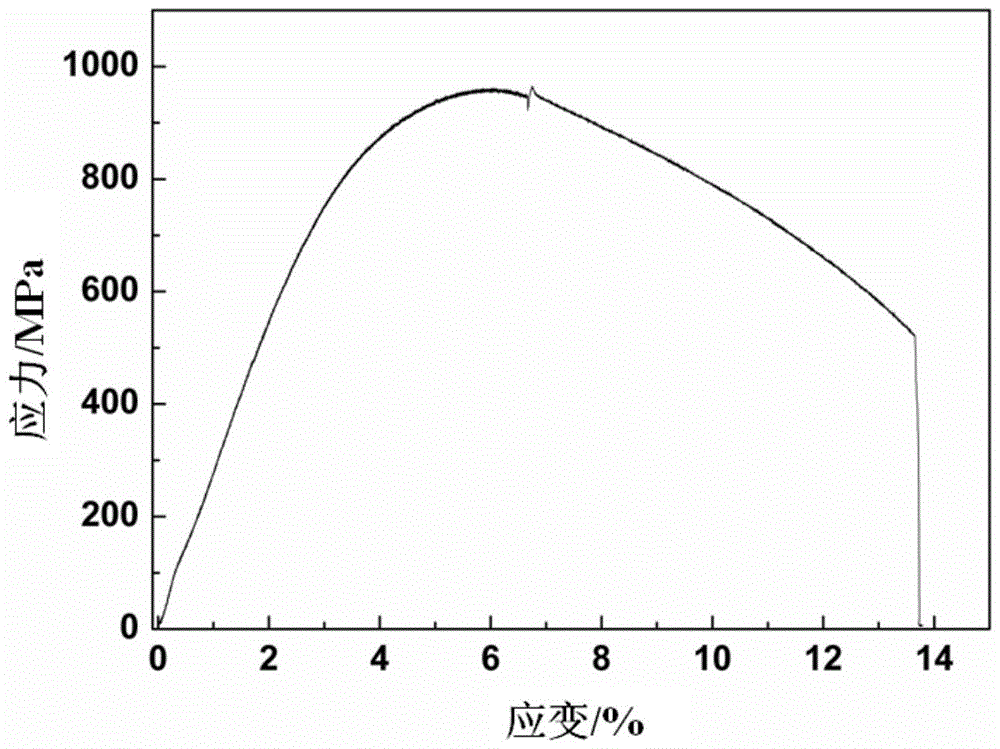

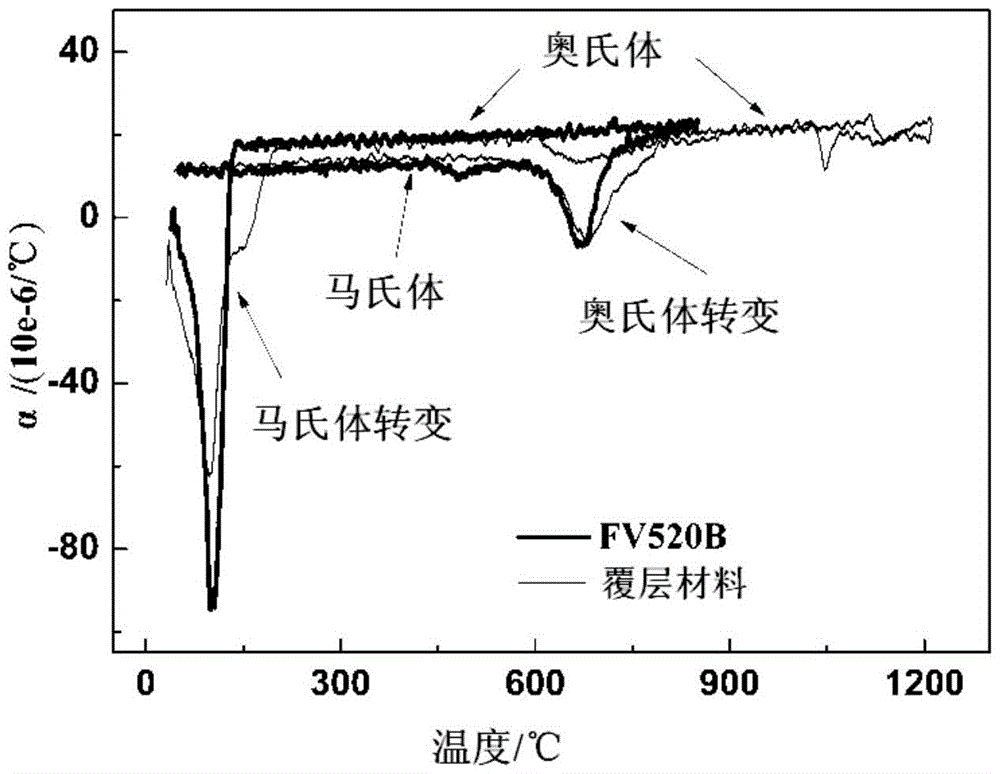

Alloy powder used for laser remanufacturing of martensitic stainless steel parts and preparation method

ActiveCN105039869ASolve and improve formabilitySolve and improve crack resistanceMetallic material coating processesSlagMartensitic stainless steel

The invention provides alloy powder used for laser remanufacturing of FV520B martensitic stainless steel parts and a preparation method. The chemical components of the alloy powder include, by weight percentage, 0.01-0.3% of C, 12-17% of Cr, 3-7% of Ni, 0.4-2% of Mo, 0.1-2% of Mn, 0.15-0.55% of Nb, 0-3% of Cu, 0.05-2% of Si, 0-1.6% of B and the balance Fe. The preparation method of the alloy powder is a vacuum melting-high pressure gas atomization method. The alloy powder can have the density and the thermal expansion coefficient which are similar to those of FV520B materials when precipitation hardening elements, deoxygenation slag forming elements and elements used for lowering the martensite phase transformation point are added and the weight percent content of all the elements are regulated; the residual stress level is lowered through the martensite phase transformation accompanying effect; and therefore the problems of cracks, deformation and the like are greatly relieved, and the forming property, the anti-cracking property and the process stability are achieved and improved when the FV520B parts are subjected to laser remanufacturing through the alloy powder.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Process for macromolecularizing phenolic compounds etc. and use thereof

InactiveUS20010007762A1Prevent rustLoss of strengthAntibacterial agentsOrganic active ingredientsPoulticeAdhesive

A process for macromolecularizing phenolic compounds or aromatic amine compounds by the action of a catalyst comprising an enzyme having a polyphenol oxidizing activity in the alkali region; applications of the compounds obtained by the above process to thickeners, stabilizers, coagulants, emulsifiers, dispersants, water retainers, antioxidants, adhesives, concrete admixtures, dyes, coating materials, petroleum recovering agent, soil conditioner, a blow-applied seed bearing surface soil stabilizer, deodorants, smell eliminators, agricultural chemical spreaders, feeding stuff binders, bactericides, antimicrobial agents, viral infection inhibitors, bioadhesion preventives, biotic repellents, insecticides, poultices, ink bases or wood treating agents; and method of waste water disposal, a method of deoxygenation and a method of treating wood, concrete or soil in which use is made of the above reaction.

Owner:SDS BIOTECH CO LTD

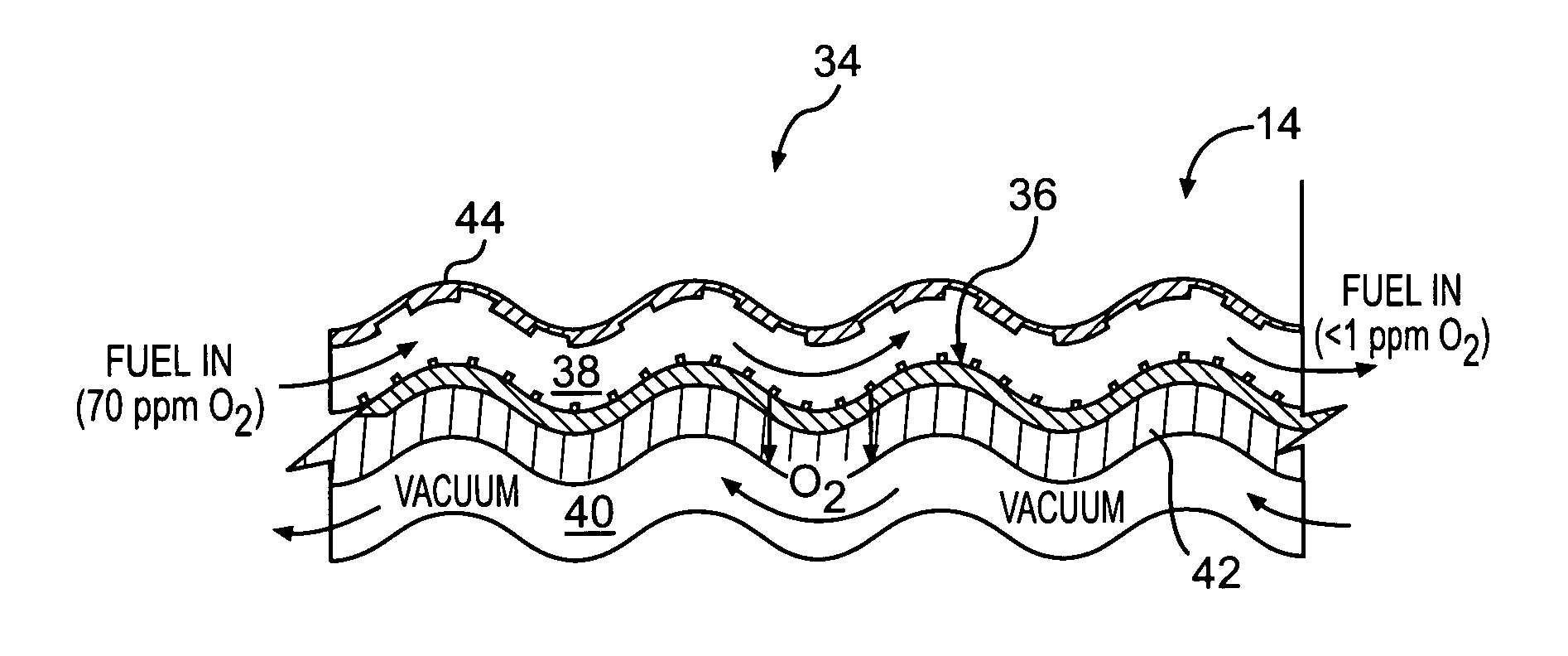

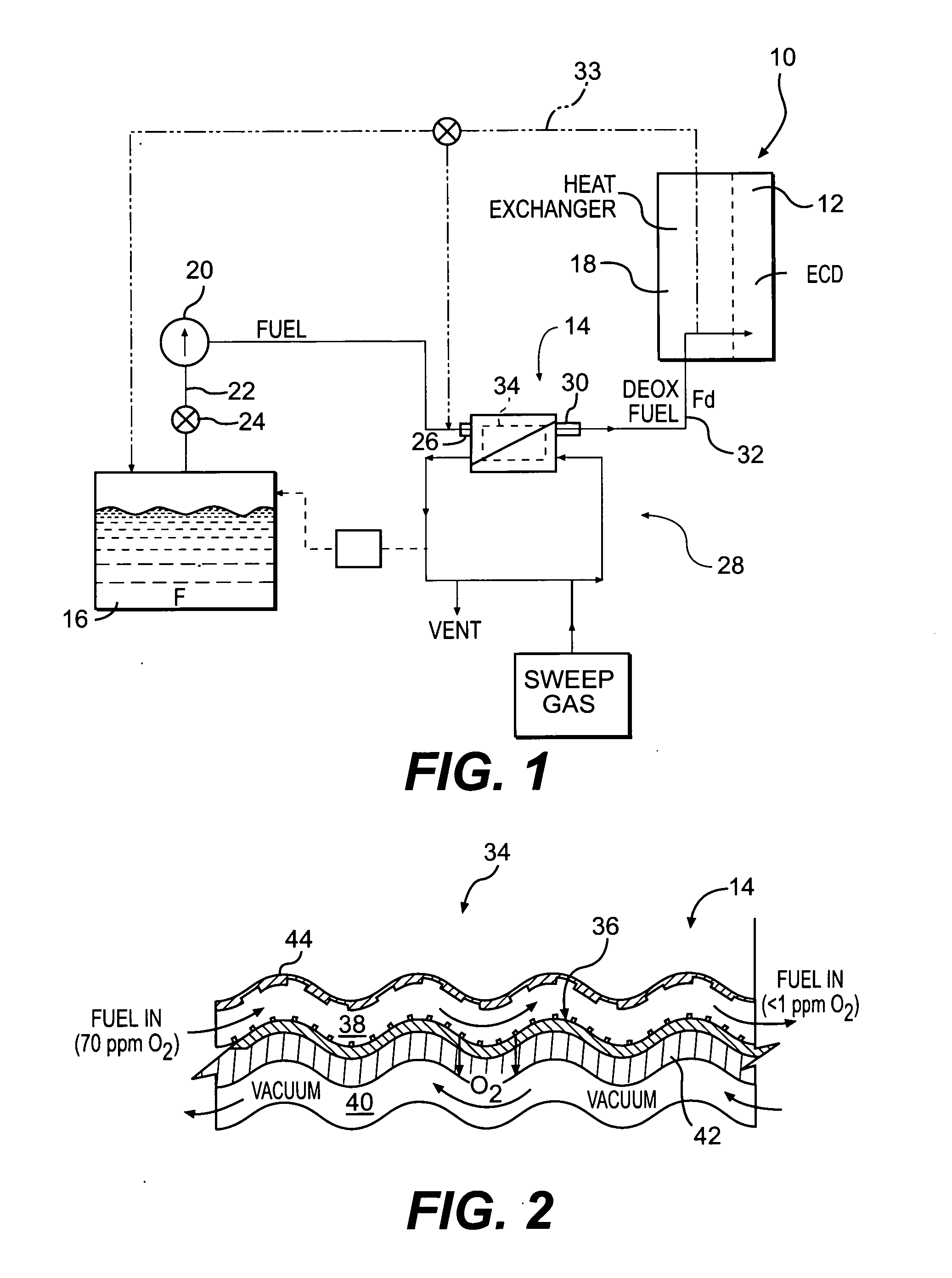

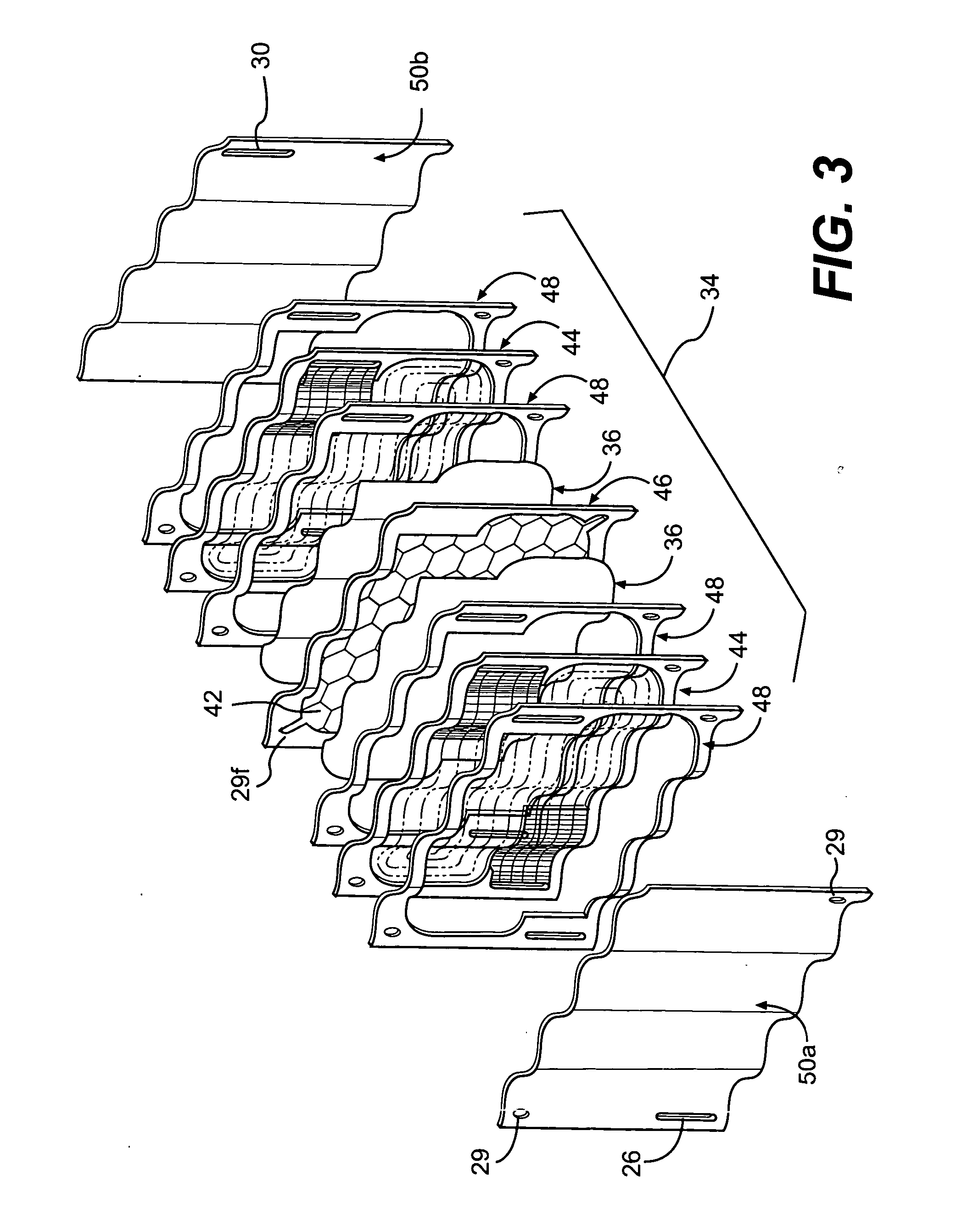

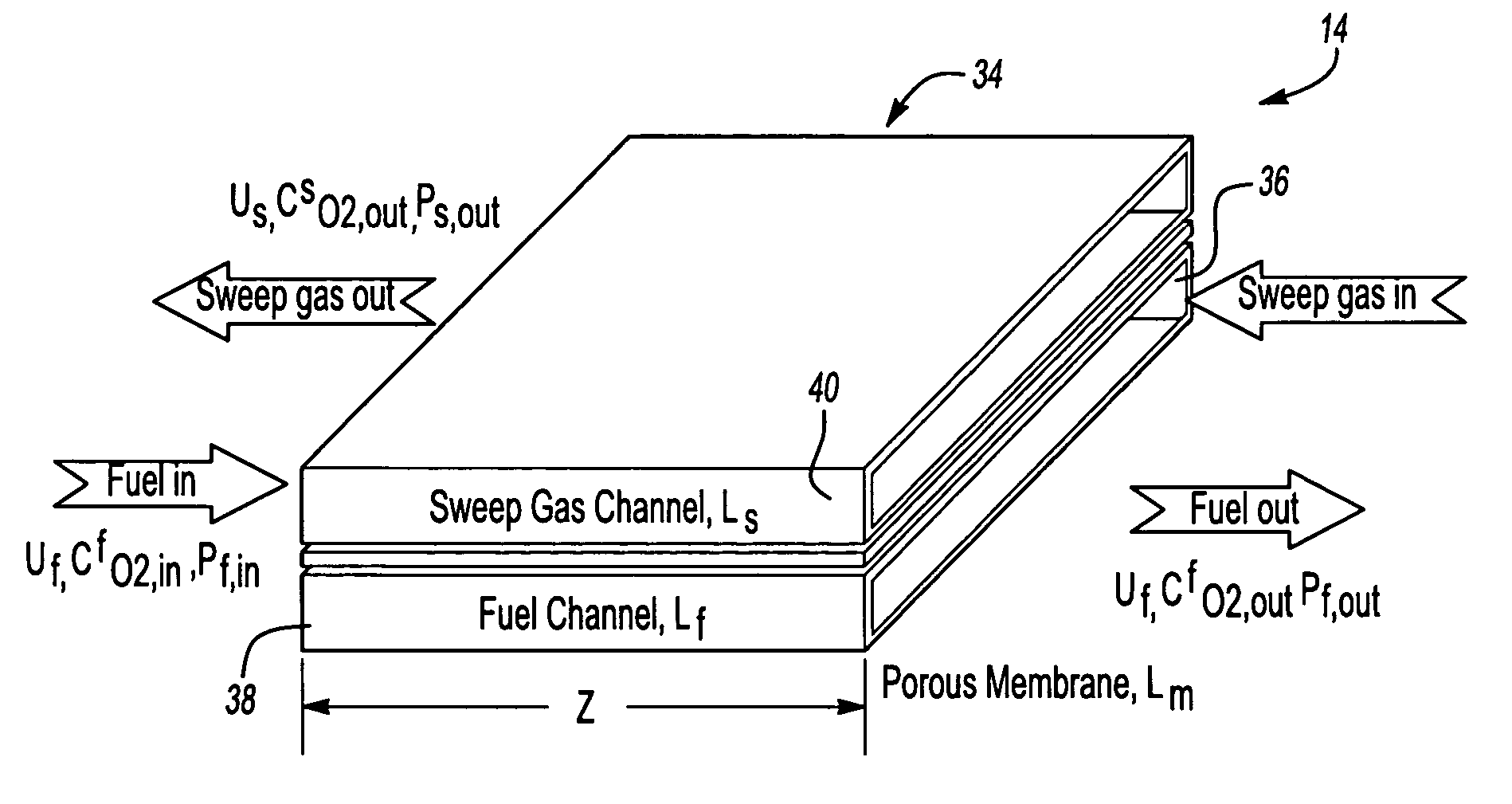

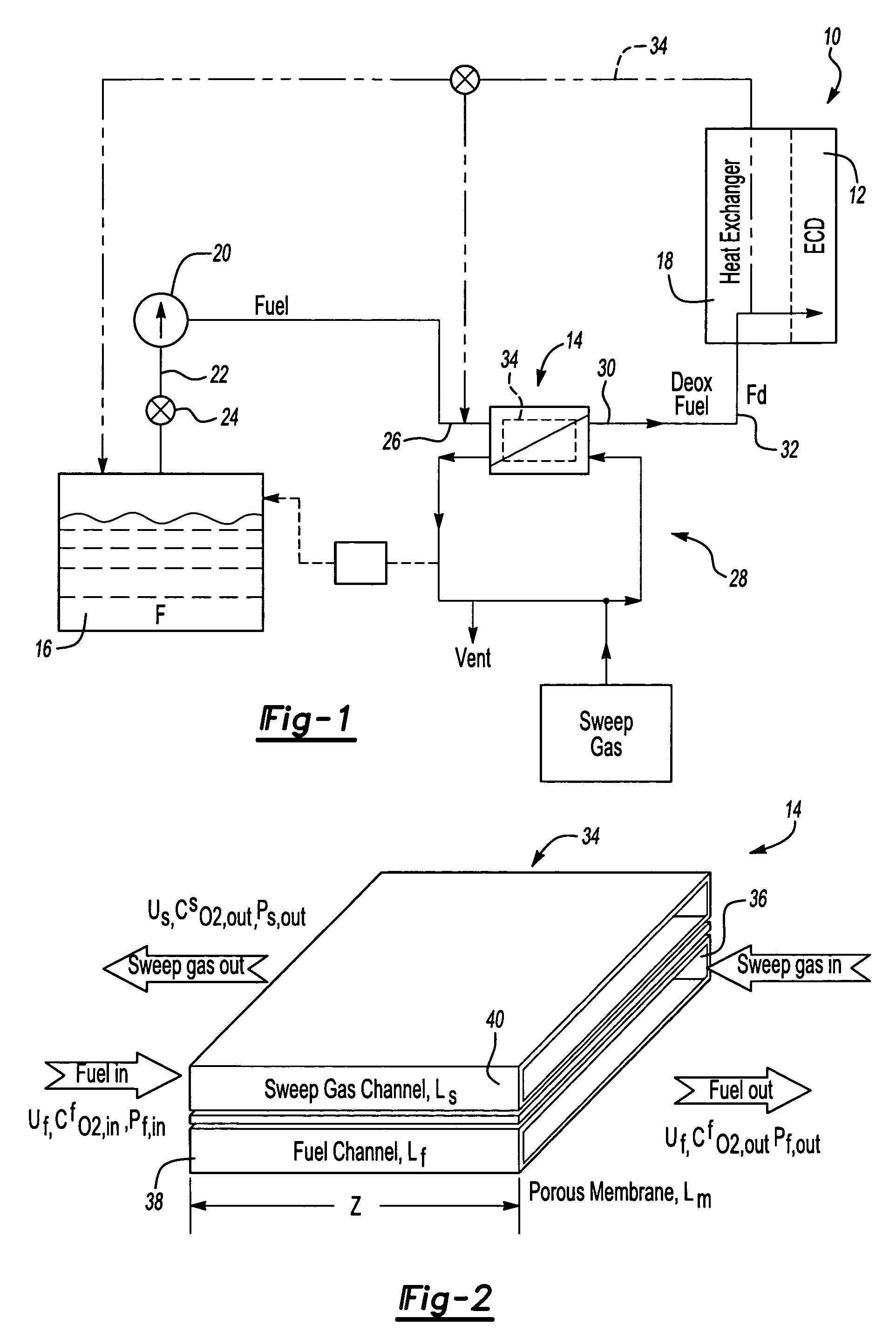

Fuel deoxygenation system with non-planar plate members

ActiveUS20060278073A1Enhances deoxygenationImprove efficiencyPower plant fuel tanksIsotope separationPorous substrateEngineering

A fuel system for an energy conversion device includes a multiple of fuel plates, oxygen permeable membranes, porous substrate plates, and vacuum frame plates which define a wave pattern configuration. The wave configuration enhances deoxygenation by increasing the efficiency and integrality due to higher surface volume ration, increase of flow turbulence, and minimal sharp edges which may otherwise damage the oxygen permeable membranes compared to other configurations.

Owner:RAYTHEON TECH CORP

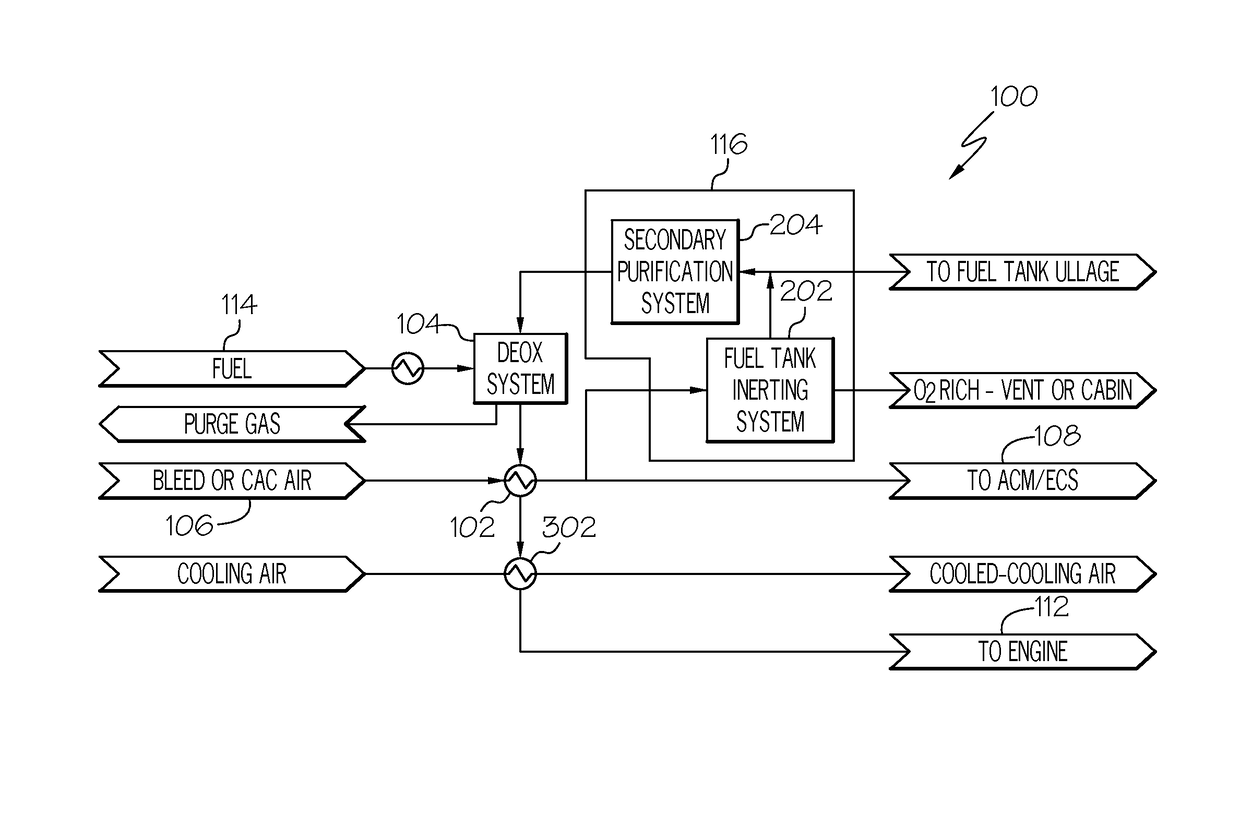

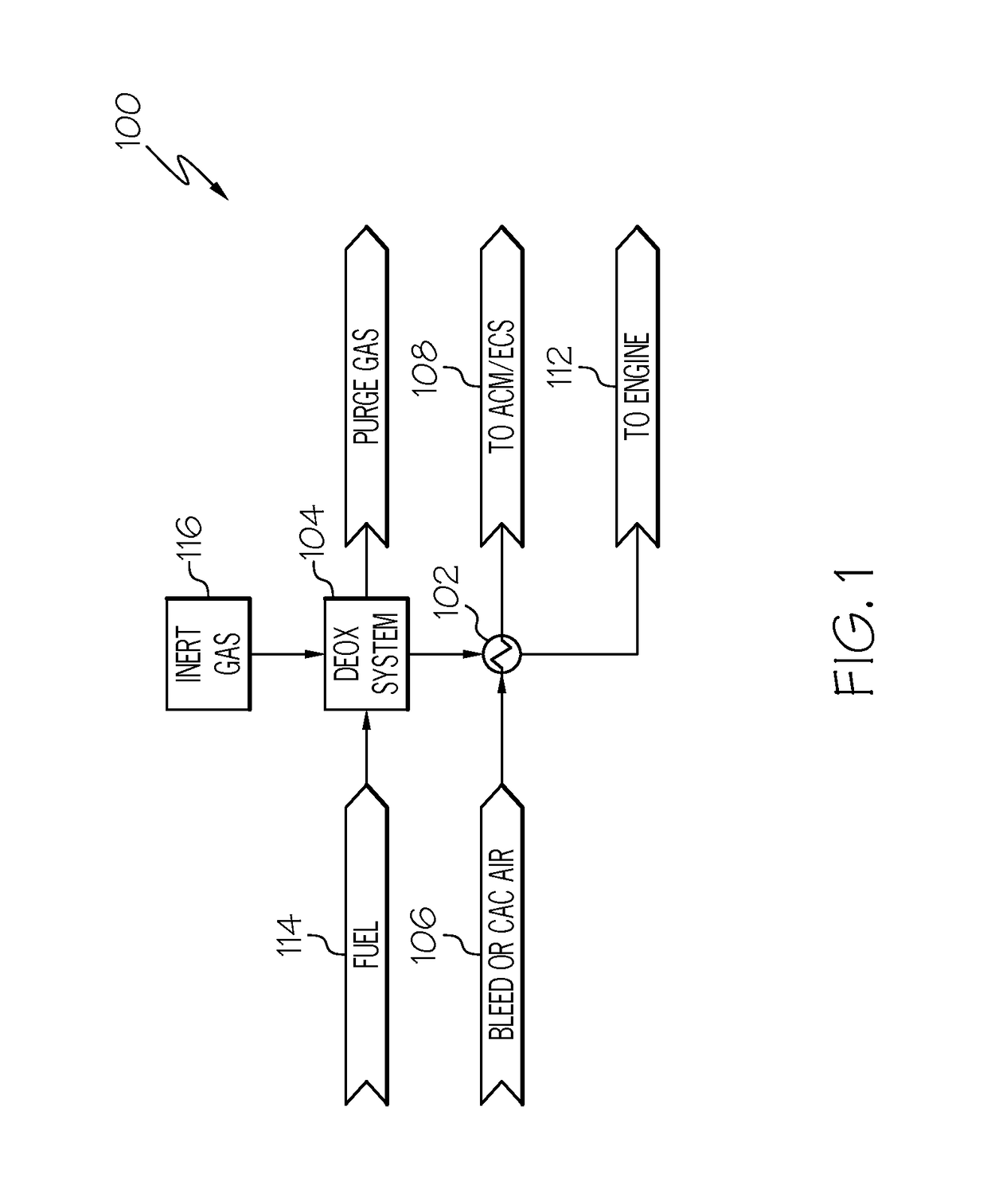

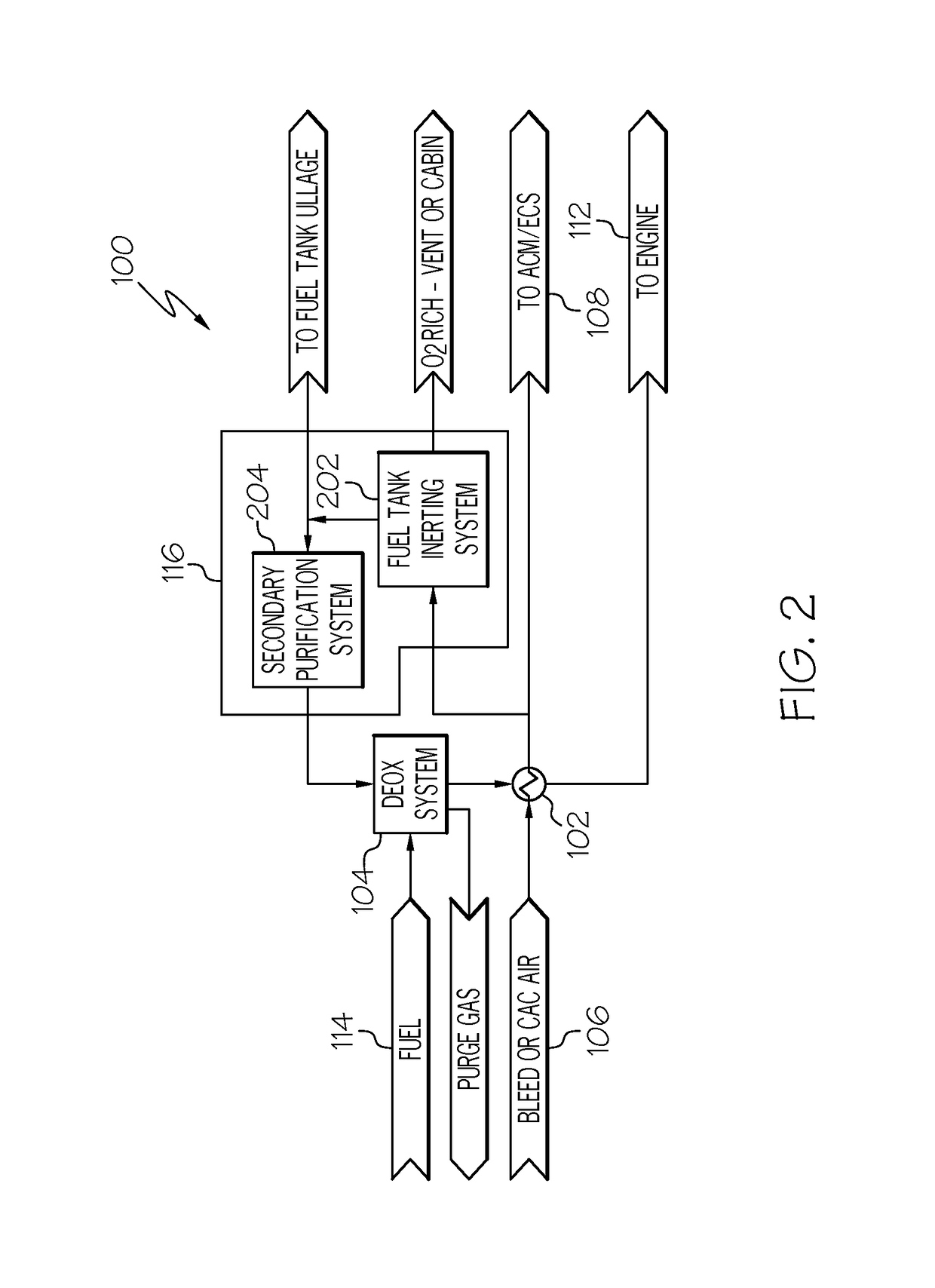

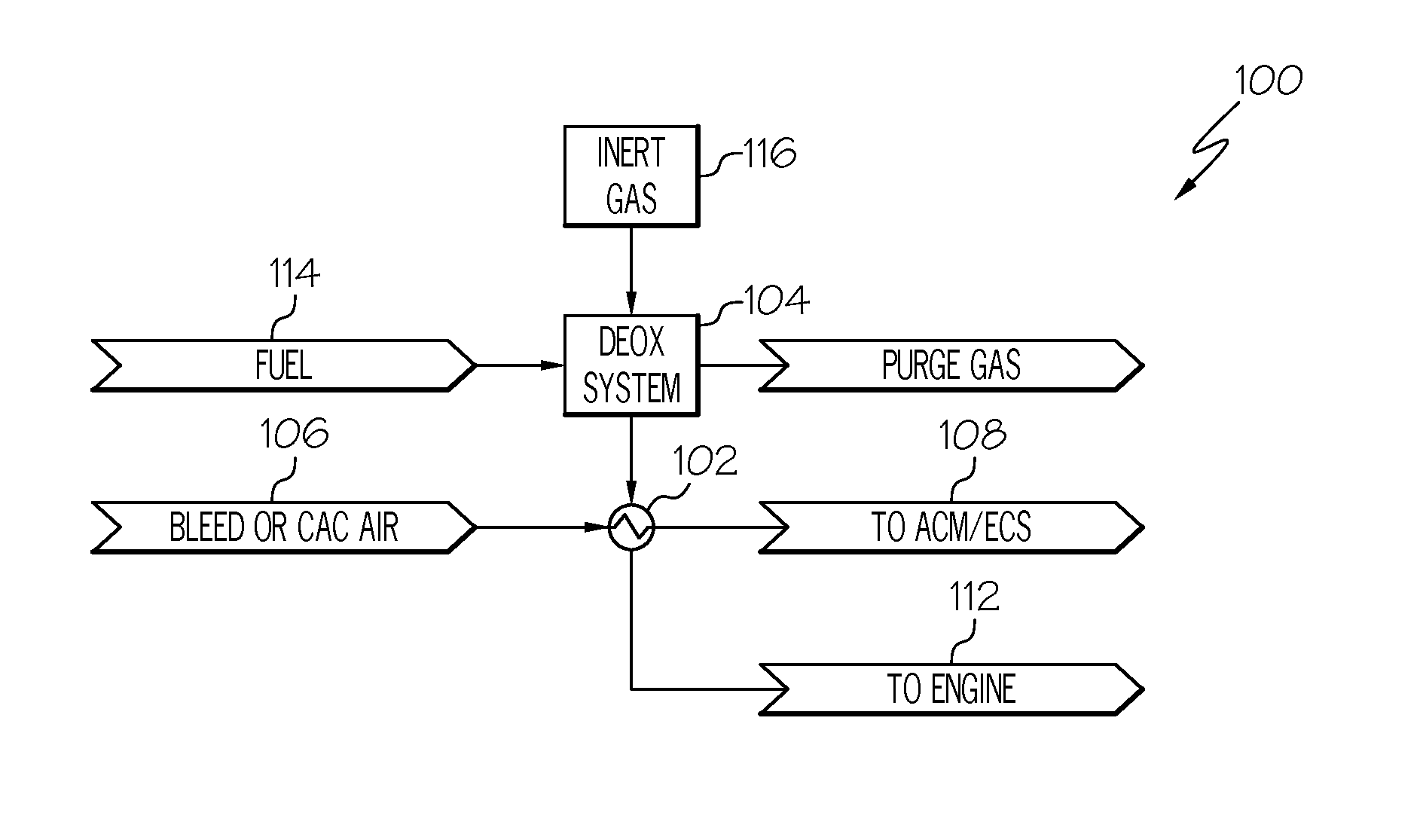

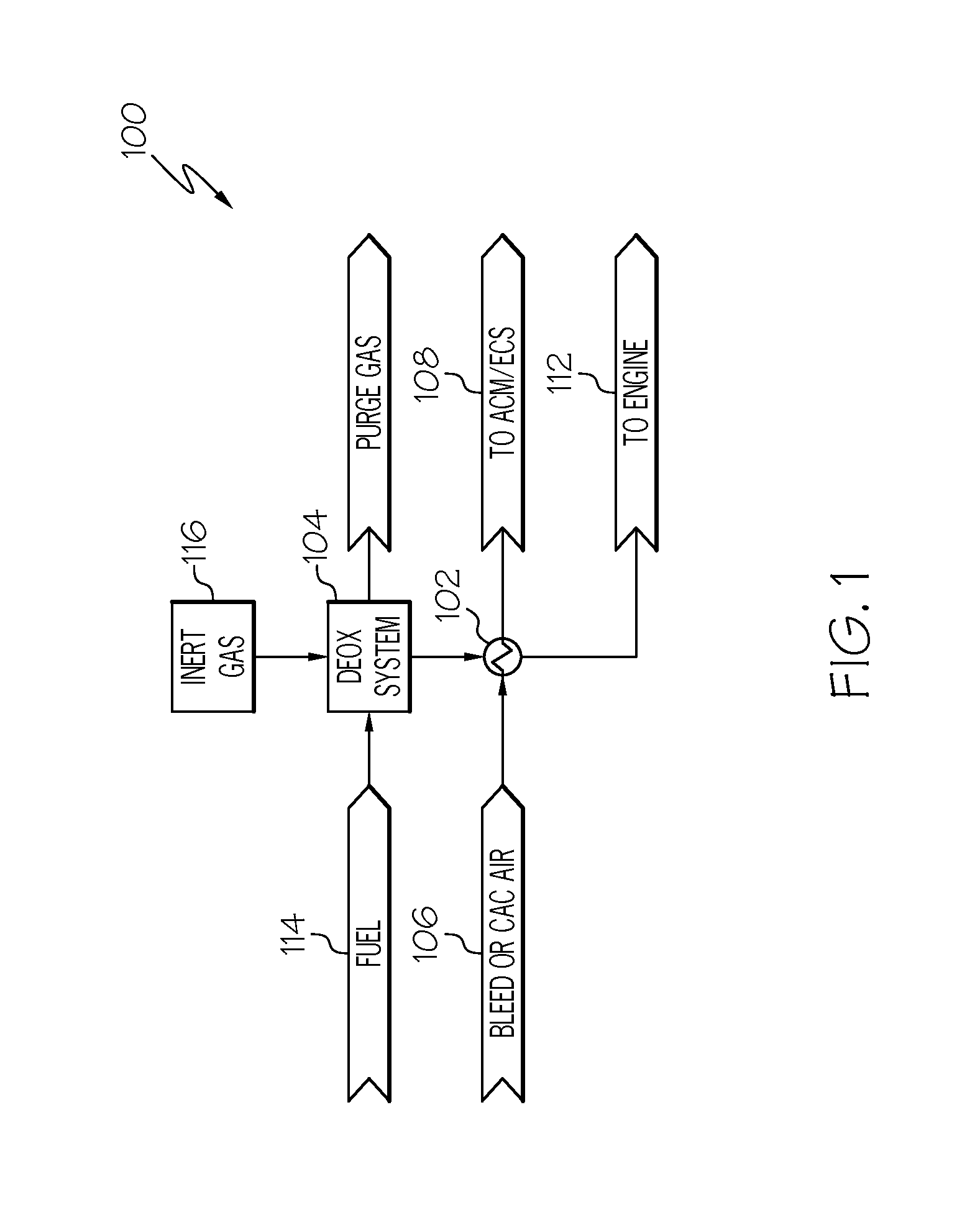

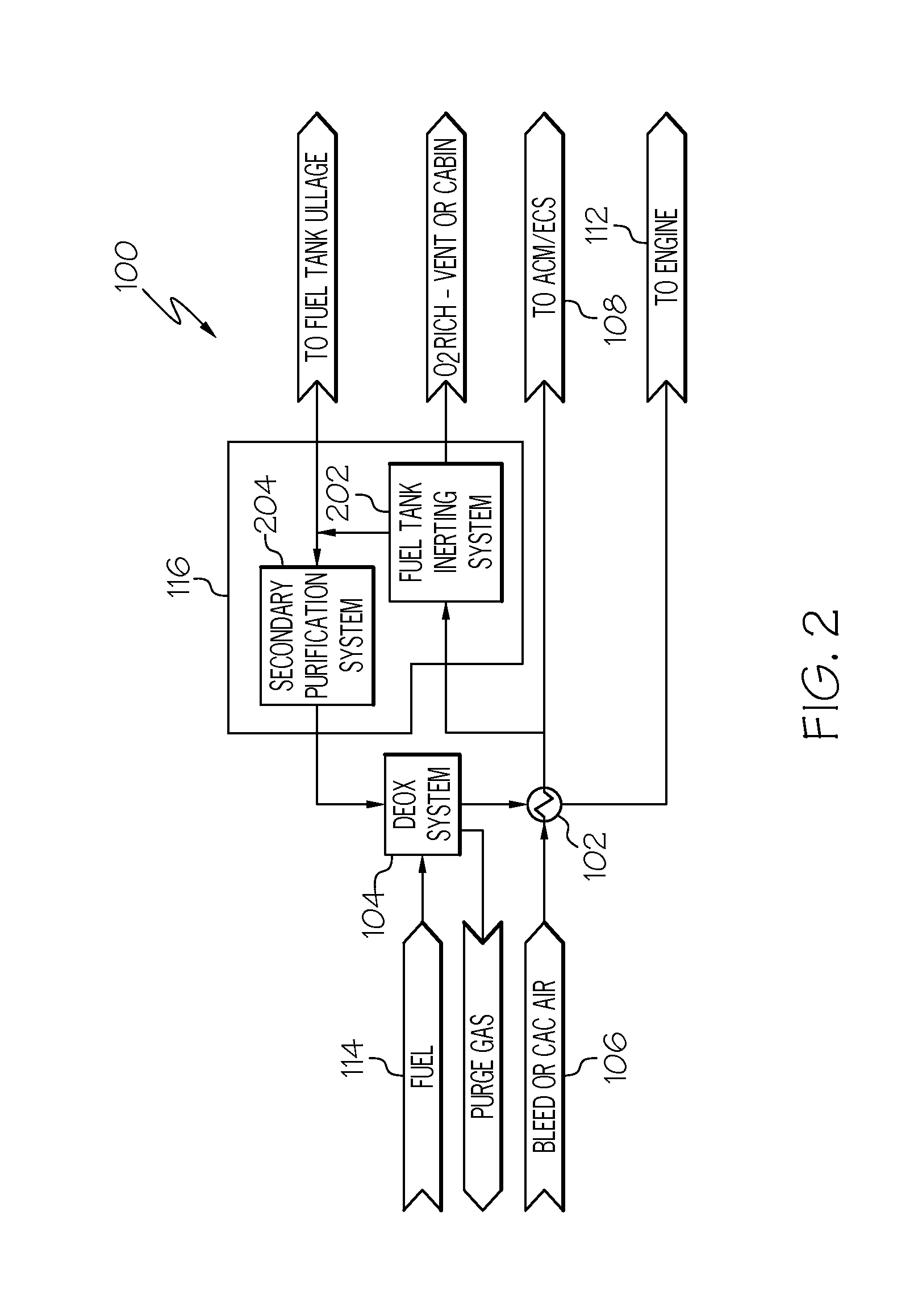

Fuel deoxygenation and fuel tank inerting system and method

ActiveUS9687773B2Gas treatmentLiquid degasification with auxillary substancesInerting systemEngineering

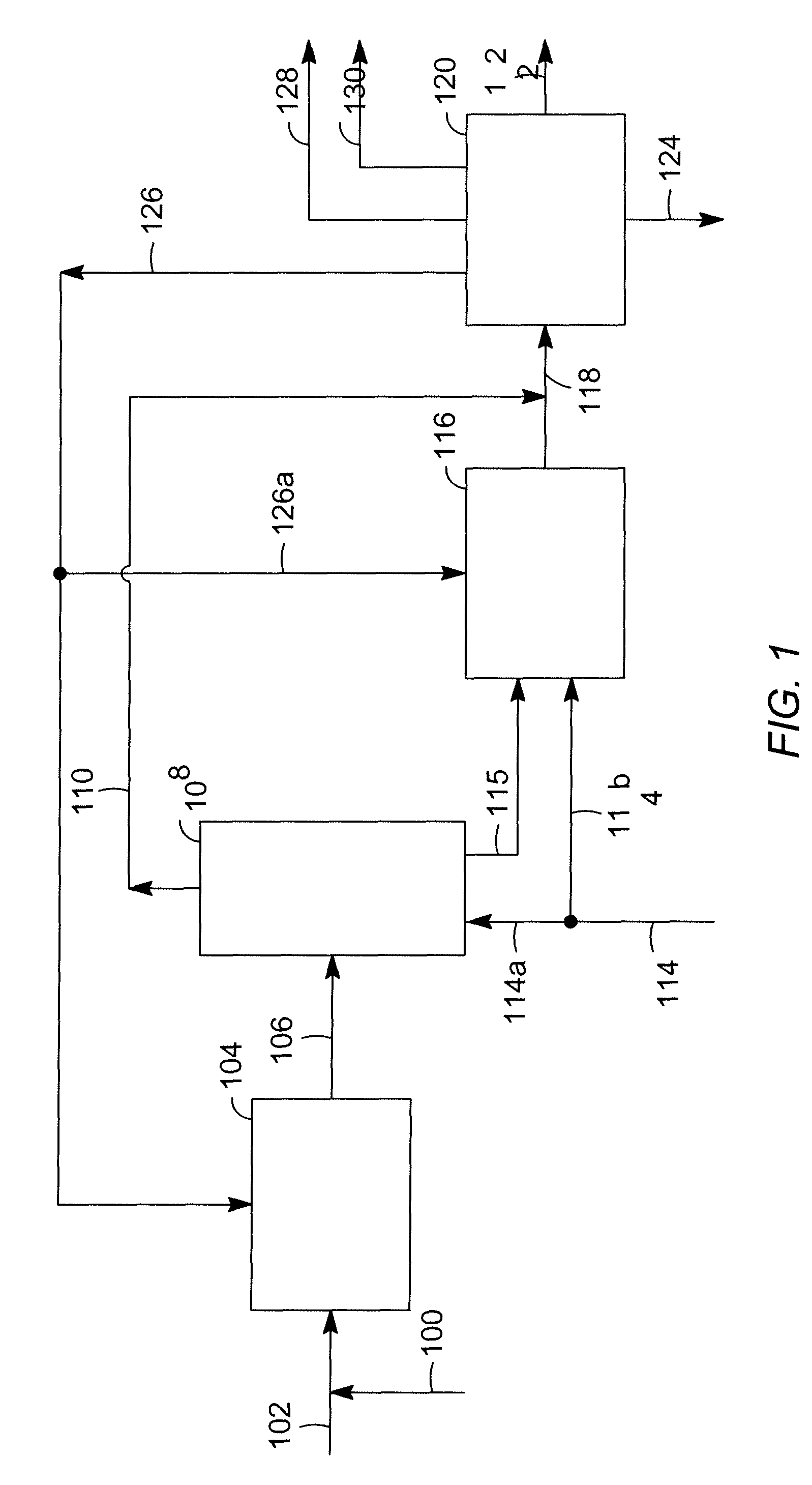

An aircraft fuel deoxygenation and tank inerting system includes an inert gas source, a fuel deoxygenation system, and an air / fuel heat exchanger. The inert gas source is configured to supply inert gas having an oxygen concentration of less than 3%. The fuel deoxygenation system is adapted to receive fuel from a fuel source and the inert gas from the inert gas source. The fuel deoxygenation system is configured to remove oxygen from the fuel and thereby generate and supply deoxygenated fuel and oxygen-rich purge gas. The air / fuel heat exchanger is adapted to receive compressed air from a compressed air source and the deoxygenated fuel from the fuel deoxygenation system. The air / fuel heat exchanger is configured to transfer heat from the compressed air to the deoxygenated fuel, to thereby supply cooled compressed air and heated deoxygenated fuel.

Owner:HONEYWELL INT INC

Smelting process for production of super-low sulphur steel

InactiveCN102534120AStable controlFast and stable controlManufacturing convertersSteelmakingAlkalinity

A smelting process for the production of super-low sulphur steel belongs to the technical field of steelmaking, and adopts the process route of molten iron magnesium jetting desulfuration pretreatment-converter smelting-ladle dusting-LF Furnace refining-RH refining-continuous casting. The smelting process is characterized in that the molten iron pretreatment adopts magnesium particle jetting for desulfuration; the converter smelting adopts high-grade steel scrap and lime; during tapping, ferro-aluminum is used for strong deoxygenation and slag surface deoxygenation is conducted; the ladle dusting is used for controlling reasonable jetting speed and dust consumption; the LF Furnace refining is used for controlling the feeding quantity of high-alkalinity refining slag and the bottom jetting flow rate of a ladle; and after refining, the oxidizing property and the alkalinity of steel slag are guaranteed. The invention has the advantages that super-low sulphur steel making can be realized fast on the condition that the sulphur content at the end point of the converter cannot be controlled stably; the dusting desulfuration jetting of the ladle lasts for 10 to 15 min; the desulfuration during the LF Furnace refining lasts for 15 to 30 min; the content of sulphur in steel can be controlled within 0.0010 percent fast and stably; and the batch stable control of super-low sulphur steel can be realized.

Owner:SHOUGANG CORPORATION

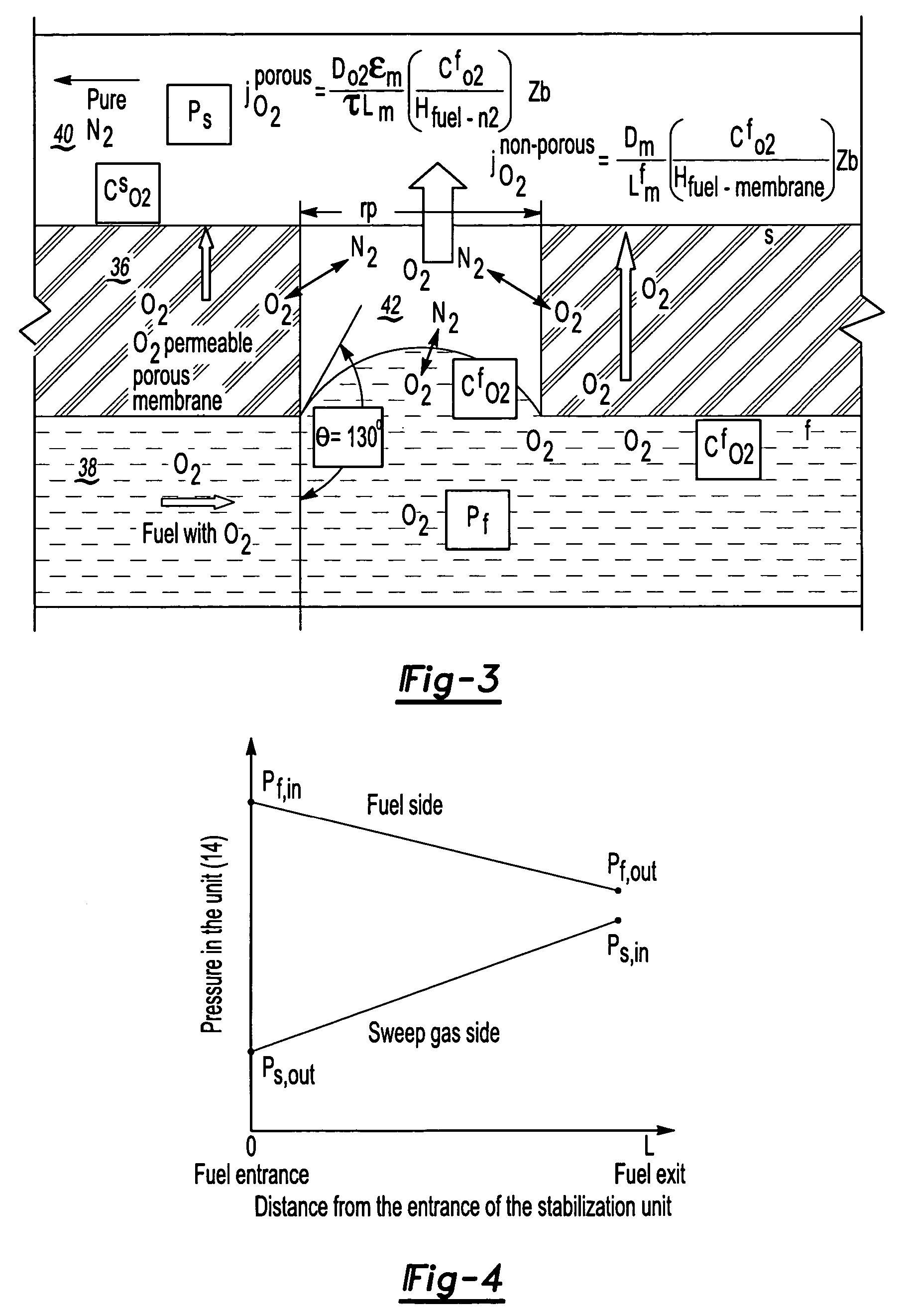

Fuel deoxygenation system

ActiveUS7153343B2Inexpensive sizeInexpensive weightLiquid fuel feeder/distributionSemi-permeable membranesPorous membraneEngineering

A fuel system for an energy conversion device includes a deoxygenator system with a porous membrane. The deoxygenator includes an oxygen receiving channel separated from the fuel channel by the porous membrane. The capillary forces counteract the pressure differential across the membrane, preventing any leakage of the fuel, while the oxygen concentration differential across the membrane allows for deoxygenation of the fuel through the porous membrane.

Owner:RTX CORP

Fuel deoxygenation and fuel tank inerting system and method

ActiveUS20150314229A1Increase fuel consumptionGas treatmentLiquid degasification with auxillary substancesInerting systemDeoxygenation

An aircraft fuel deoxygenation and tank inerting system includes an inert gas source, a fuel deoxygenation system, and an air / fuel heat exchanger. The inert gas source is configured to supply inert gas having an oxygen concentration of less than 3%. The fuel deoxygenation system is adapted to receive fuel from a fuel source and the inert gas from the inert gas source. The fuel deoxygenation system is configured to remove oxygen from the fuel and thereby generate and supply deoxygenated fuel and oxygen-rich purge gas. The air / fuel heat exchanger is adapted to receive compressed air from a compressed air source and the deoxygenated fuel from the fuel deoxygenation system. The air / fuel heat exchanger is configured to transfer heat from the compressed air to the deoxygenated fuel, to thereby supply cooled compressed air and heated deoxygenated fuel.

Owner:HONEYWELL INT INC

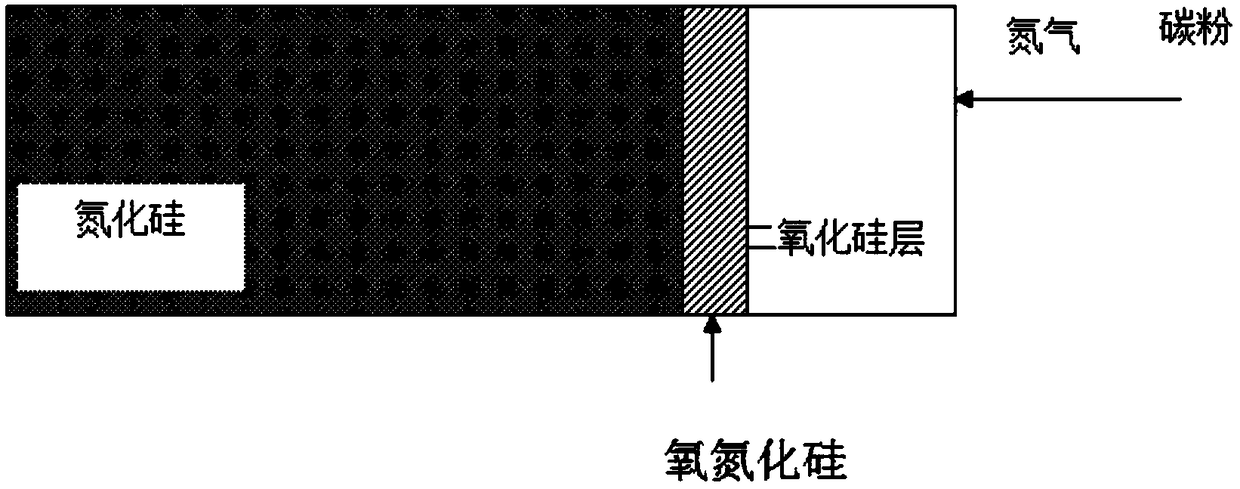

High-heat-conductivity silicon nitride ceramic and preparation method thereof

The invention provides high-heat-conductivity silicon nitride ceramic and a preparation method thereof, which are used for solving the technical problem that the existing heat conductivity is low. Thepreparation method comprises the following steps: performing deoxygenation treatment on silicon nitride powder, naturally cooling the silicon nitride powder, and grinding and sieving the obtained silicon nitride powder; mixing the powder and a sintering aid under the action of a mixed medium, and drying and sieving after mixing to obtain powder; performing pressing formation to obtain a silicon nitride ceramic green body; and performing gas pressure sintering to obtain the silicon nitride ceramic material. Compared with the prior art, the high-heat-conductivity silicon nitride ceramic and thepreparation method thereof have the following advantages: the silicon nitride powder is subjected to deoxygenation treatment, the oxygen content of the original powder is low, the degree of reducingthe lattice oxygen content in the sintering process is higher, and phonon scattering is avoided, so that the heat conductivity of the silicon nitride ceramic is improved; and the prepared silicon nitride ceramic has high heat conductivity, high thermal shock resistance and high-temperature resistance, is safe to use and is a silicon nitride ceramic substrate material with excellent mechanical, thermal and electric comprehensive performance.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com