Hydroprocessing of biocomponent feedstocks with low purity hydrogen-containing streams

a biocomponent and stream technology, applied in the direction of hydrocarbon oil treatment products, biofuels, fuels, etc., can solve the problems of modifying and/or replacing low pressure units to allow for higher processing pressure, affecting the production of diesel fuel from biocomponent sources, and requiring expensive capital investmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

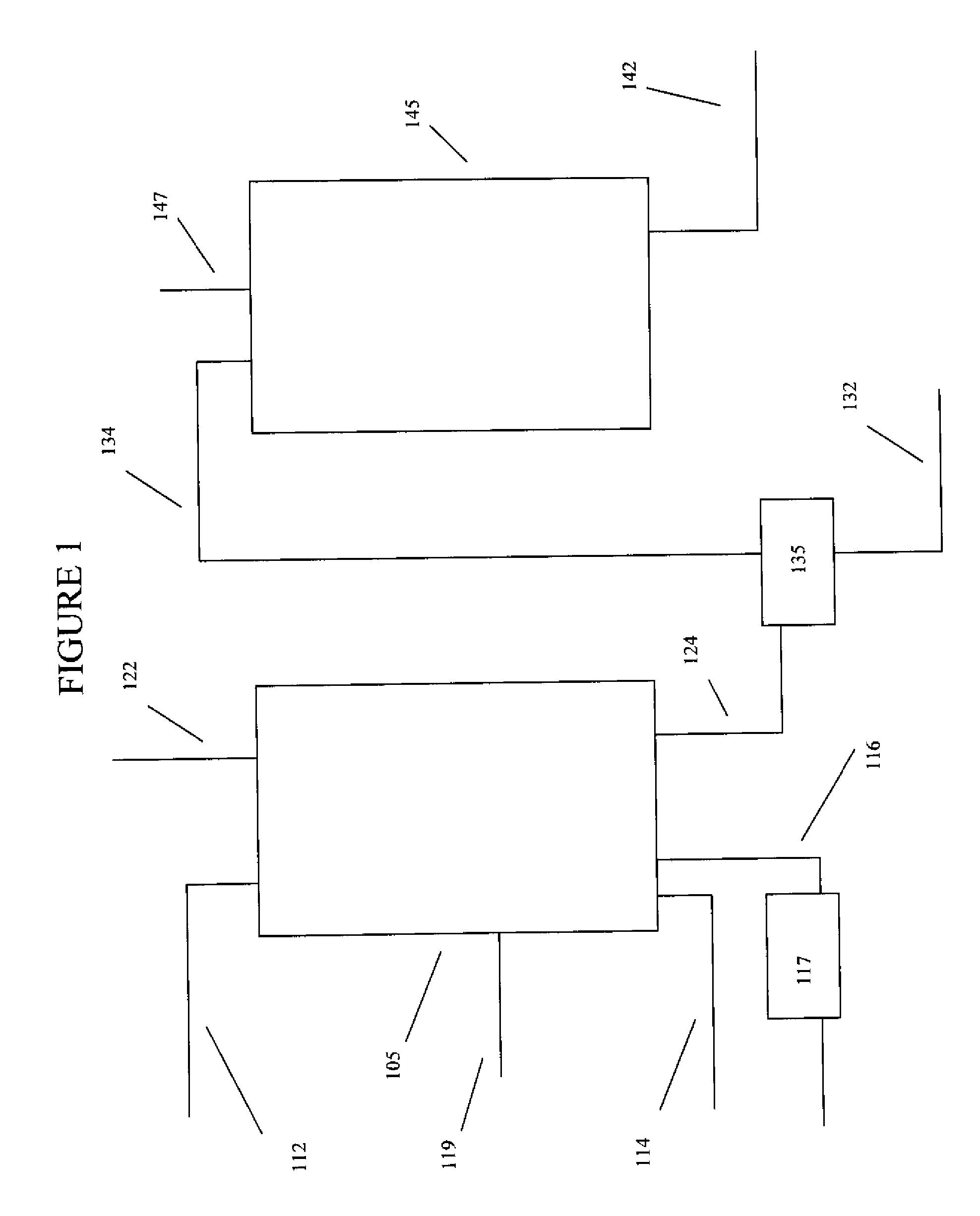

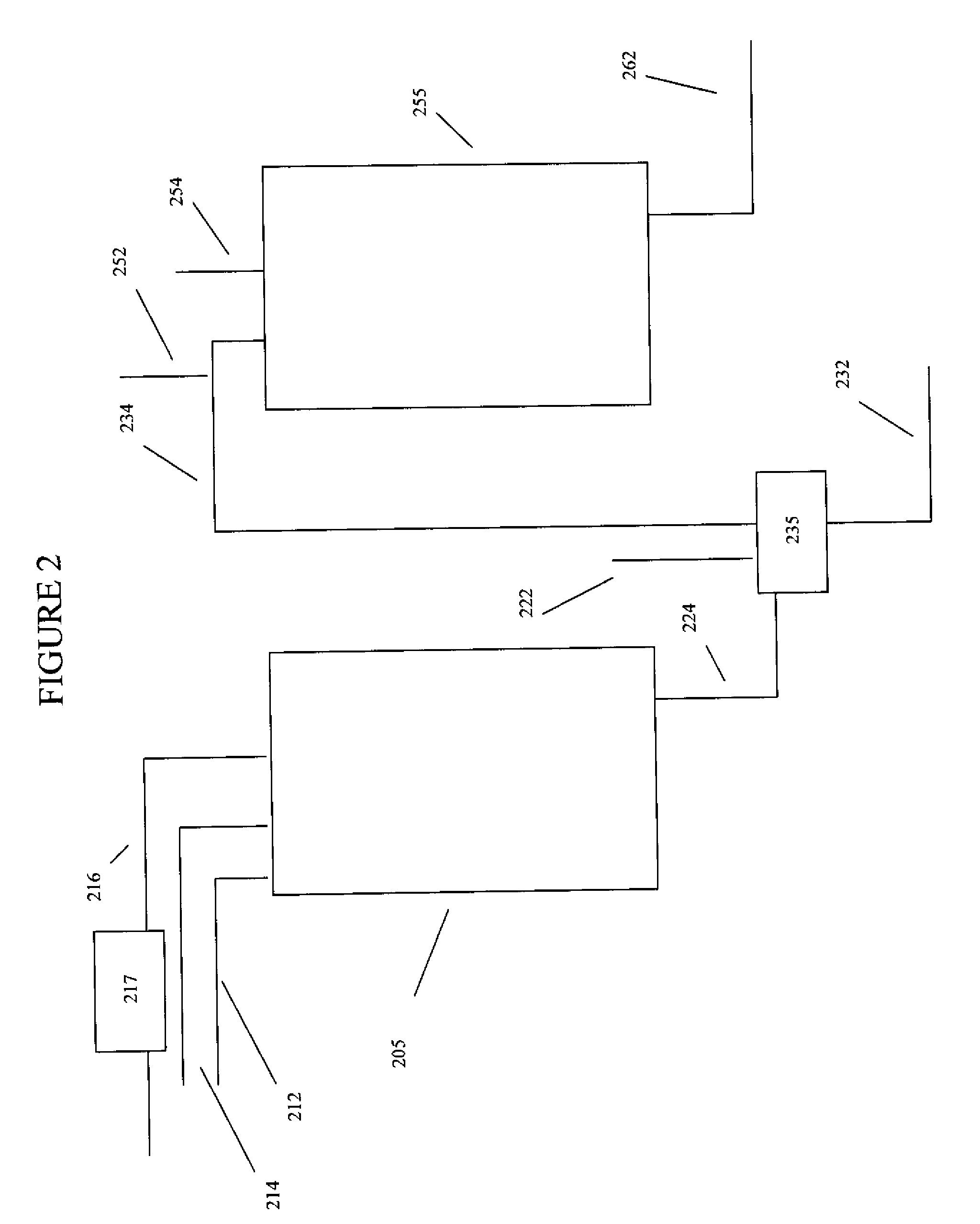

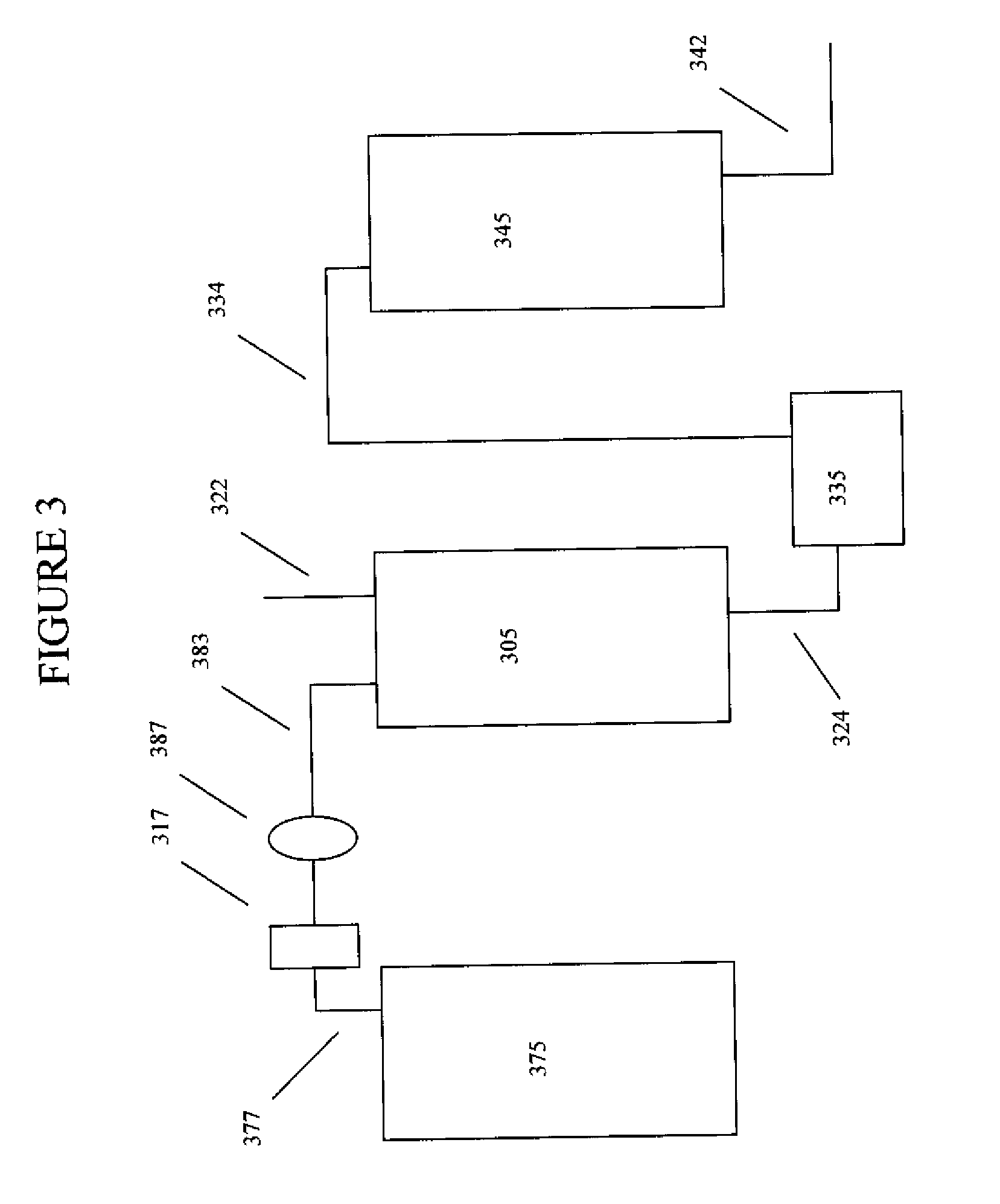

Image

Examples

example 1

[0117]A mineral ADO is hydrotreated to yield a product suitable for use in the diesel fuel pool, having a finished sulfur content of about 3 wppm or less and a finished nitrogen content of about 2 wppm or less, and exhibiting an API gravity of about 34.9 (degrees). About 70 wt % of this hydrotreated mineral ADO is added to about 30 wt % soybean oil to form a mixed feed. This mixed feed is contacted in a hydroprocessing reactor with a treat gas comprising about 40 mol % hydrogen and about 60 mol % methane in the presence of a commercial supported (alumina) NiMo hydrotreating catalyst at a temperature of about 625° F. (about 329° C.) and at a total reactor pressure of about 200 psig (about 1.4 MPag). The hydrotreating catalyst is not fresh and has been previously used to hydrotreat vacuum gas oils (VGO) to the extent that the catalyst has about a 10% activity reduction, as compared to fresh catalyst of identical composition. The treat gas is introduced at a rate of about 2250 scf / bbl ...

examples 2-4

[0119]A mixed feedstock, containing about 30 wt % of a biocomponent feed (soybean oil) and about 70 wt % of a mineral feed (bottoms from a hydrocracking unit), as described in Table 1 below, was hydrodeoxygenated in a pilot unit comprising a ˜100 cm3 HDO reactor loaded with an activated catalyst based on a commercially available supported NiMo catalyst. The HDO catalyst was activated using a DMDS spiked light gasoil. The HDO reactor EIT was thereafter brought to about 625° F. (about 329° C.), and the unit pressure was brought to between about 150 psig (about 1.0 MPag) and about 200 psig (about 1.4 MPag). This HDO reactor was run using a relatively low hydrogen content treat gas (˜40 mol % H2, with the remainder being methane) at a treat gas rate of about 2250 scf / bbl (about 380 Nm3 / m3), which corresponds to a hydrogen partial treat gas rate of about 900 scf / bbl (about 150 Nm3 / m3). The feed was run through the unit at an LHSV of between about 1.0 hr−1 and about 1.3 hr−1.

TABLE 1Base F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| hydrogen partial pressure | aaaaa | aaaaa |

| hydrogen partial pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com