Patents

Literature

64results about How to "Improve deoxidation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

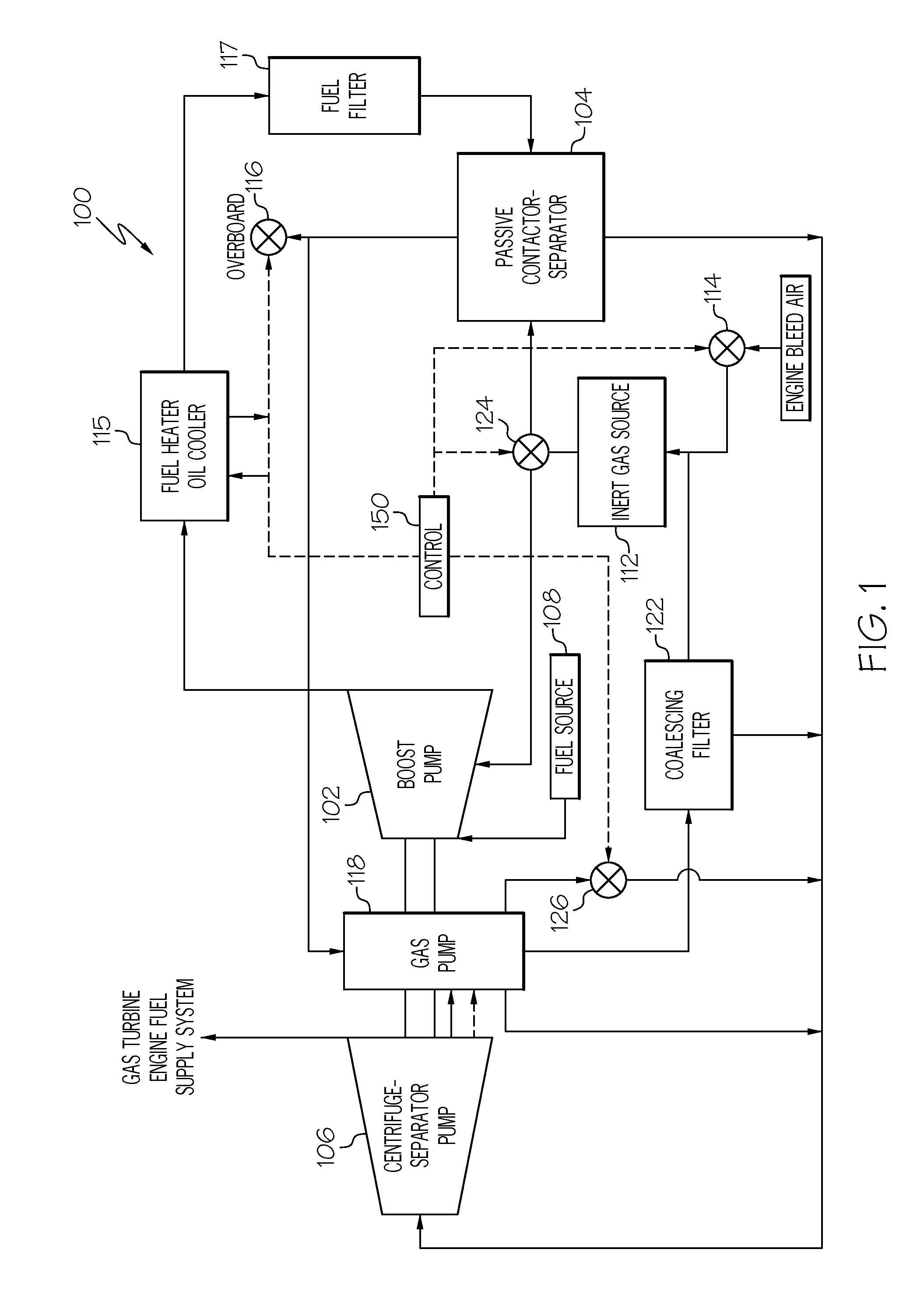

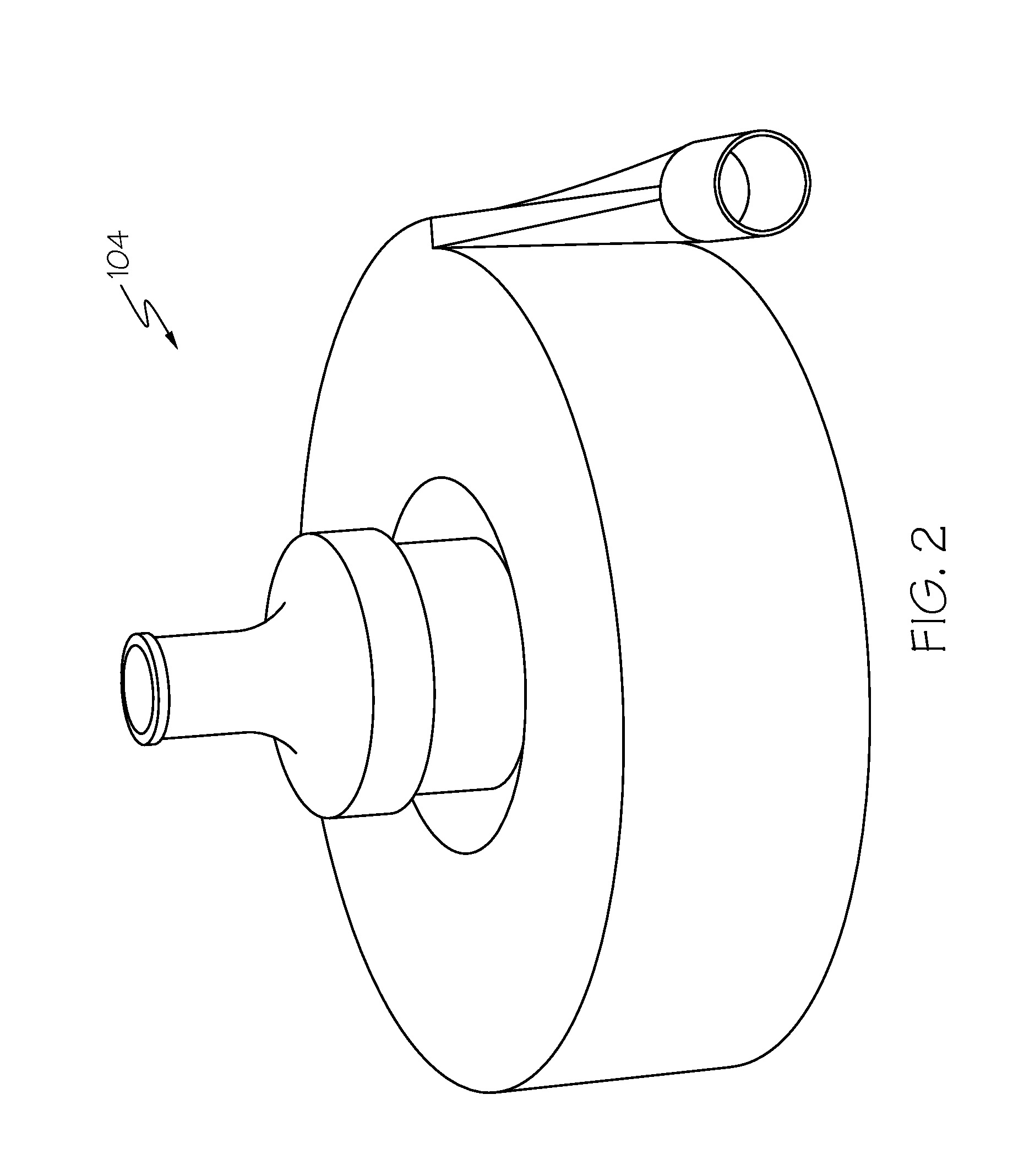

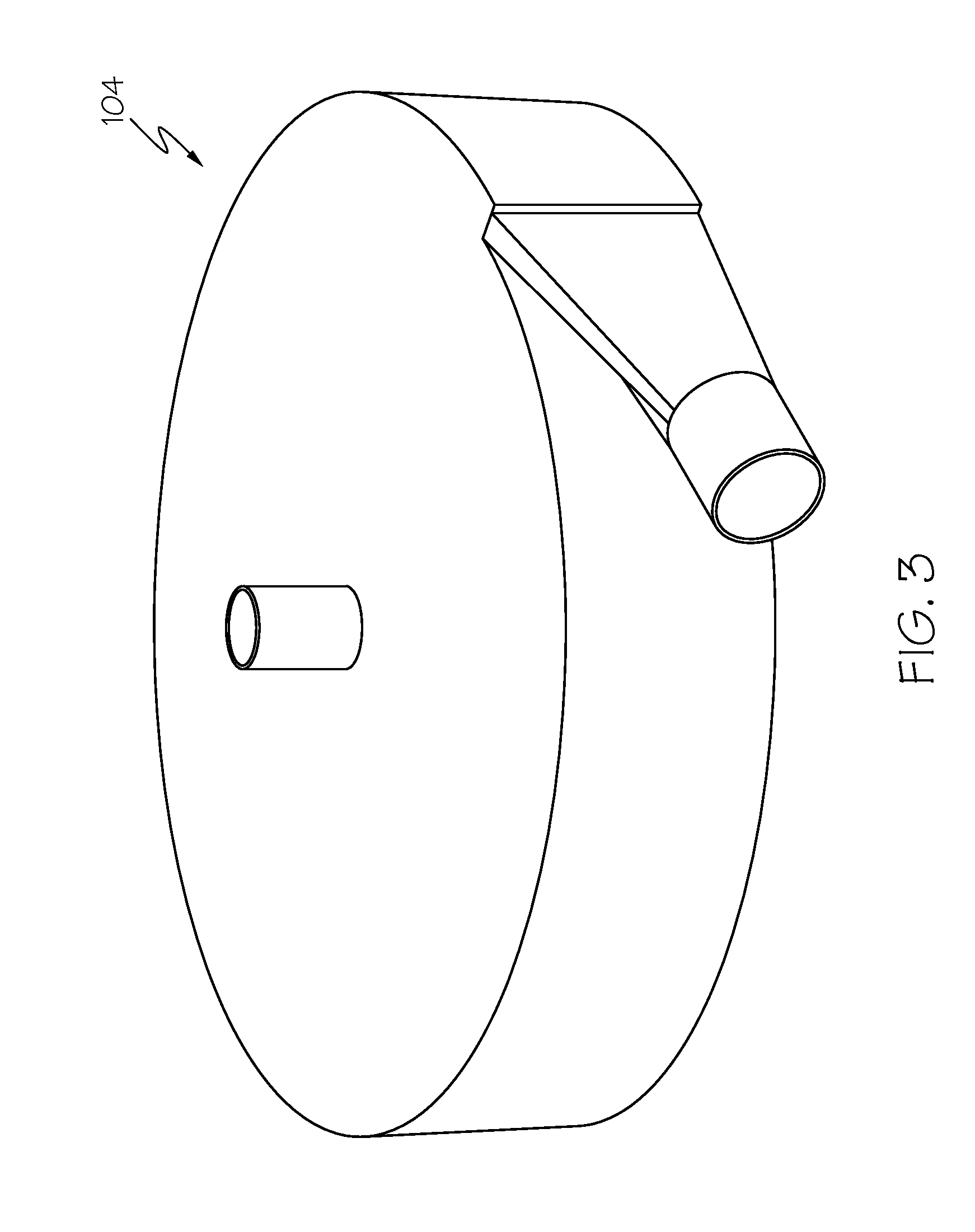

Aircraft fuel deoxygenation system

ActiveUS20160167802A1Increase fuel/gasImprove deoxidation efficiencyLiquid degasification with auxillary substancesDispersed particle filtrationOxygenDeoxygenation

An aircraft fuel deoxygenation system includes a boost pump, a contactor-separator, and a centrifuge-separator pump. The boost pump is adapted to receive fuel from a fuel source and inert gas from an inert gas source, and is configured to mix the fuel and inert gas and supply a fuel / gas mixture. The contactor-separator is coupled to receive the fuel / gas mixture and is configured to remove oxygen from the fuel and thereby generate and supply deoxygenated fuel with entrained purge gas and separated purge gas. The centrifuge-separator pump is coupled to receive the deoxygenated fuel with entrained purge gas and is configured to separate and remove the entrained purge gas from the deoxygenated fuel and supply the deoxygenated fuel and additional purge gas.

Owner:HONEYWELL INT INC

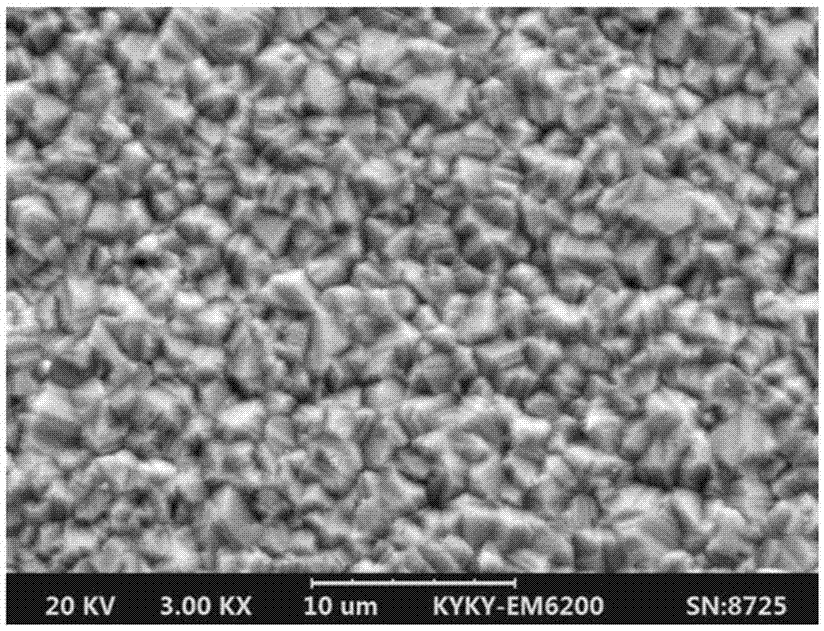

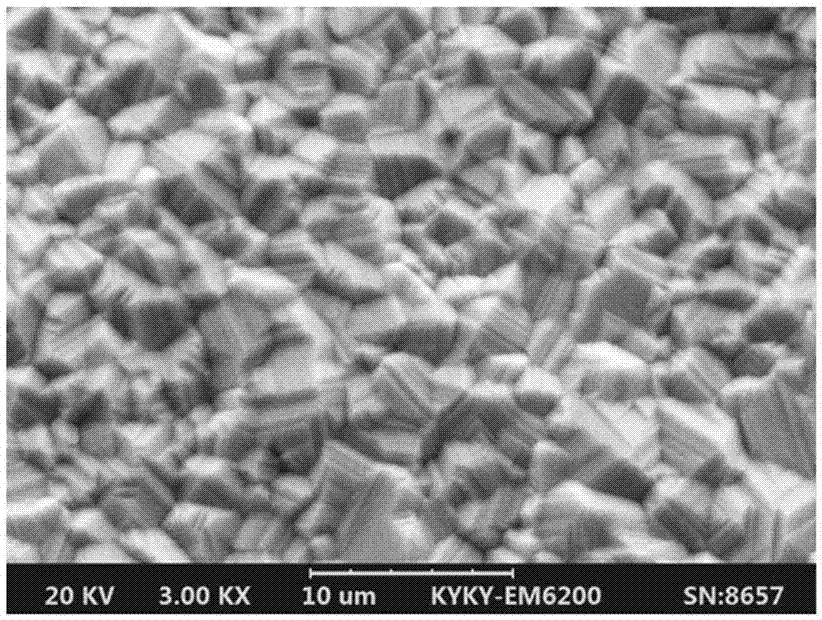

Method for preparing rare earth alloy by molten salt electrolysis

ActiveCN103572329AInhibition formationImprove deoxidation efficiencyAlkaline earth metalPresent method

Provided in the present invention are a rare earth metal and a rare earth metal alloy and a method for the preparation of these by molten salt electrolysis. In the method for the preparation of the rare earth metal alloy by molten salt electrolysis, the electrolyte is an alkali metal or the chloride-fused salt of an alkaline earth metal, the positive electrode is an inert electrode or graphite, the negative electrode is composed of a rare-earth metal oxide and the oxides of other alloy components and / or metal powders, and electrolysis is induced by the passage of a direct current. During the electrolytic process, the temperature of electrolysis is higher than the melting point of the rare earth metal alloy produced and lower than the melting point of the negative electrode; the surface layer of the positive electrode is in the first stage electrolyzed to a liquid metal film which accumulates to a certain volume before falling to the crucible at the bottom. The current density of the negative electrode is sufficient to separate out from said negative electrode the components of the rare earth metal alloy. The electrolysis voltage is lower than the decomposition potential of the electrolyte and higher than the decomposition potential of the oxides corresponding to each component of the rare earth metal alloy. A crucible is used to collect the rare earth metal and the alloy obtained through the present method. The present method is technically simple and environmentally-friendly, while featuring low energy consumption, high current efficiency, and low costs.

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

Deoxidation method for molten salt and deoxidated molten salt

ActiveCN106517097ALess corrosiveImprove deoxidation efficiencyChloride preparationFluoride preparationSulfate radicalsWater vapor

The invention discloses a deoxidation method for a molten salt and a deoxidated molten salt. The method comprises the following steps: introducing carbon into the molten salt, carrying out first-time heating under vacuum conditions until the molten salt is molten, carrying out first-time heat preservation, carrying out first-time cooling, then, carrying out second-time heating until the molten salt is molten, carrying out second-time heat preservation, and carrying out second-time cooling, thereby obtaining the deoxidated molten salt, wherein the molten salt is a fluoride molten salt and / or chloride molten salt. The deoxidation method disclosed by the invention is high in deoxidation efficiency and simple and easy in operation and is safe, reliable and controllable, the carbon-reduction product is removed in the form of gas and does not deposit, and nitrate radicals, sulfate radicals, free oxygen and oxygen-derived free radicals are removed from the molten salt, so that industrial production is facilitated; and in case of later-stage molten-salt treatment by HF-H2, phenomena that pipelines are blocked up by the molten salt and the molten salt is lost due to acute boiling of the molten salt caused by water vapor expansion are absent.

Owner:上海联和日环能源科技有限公司

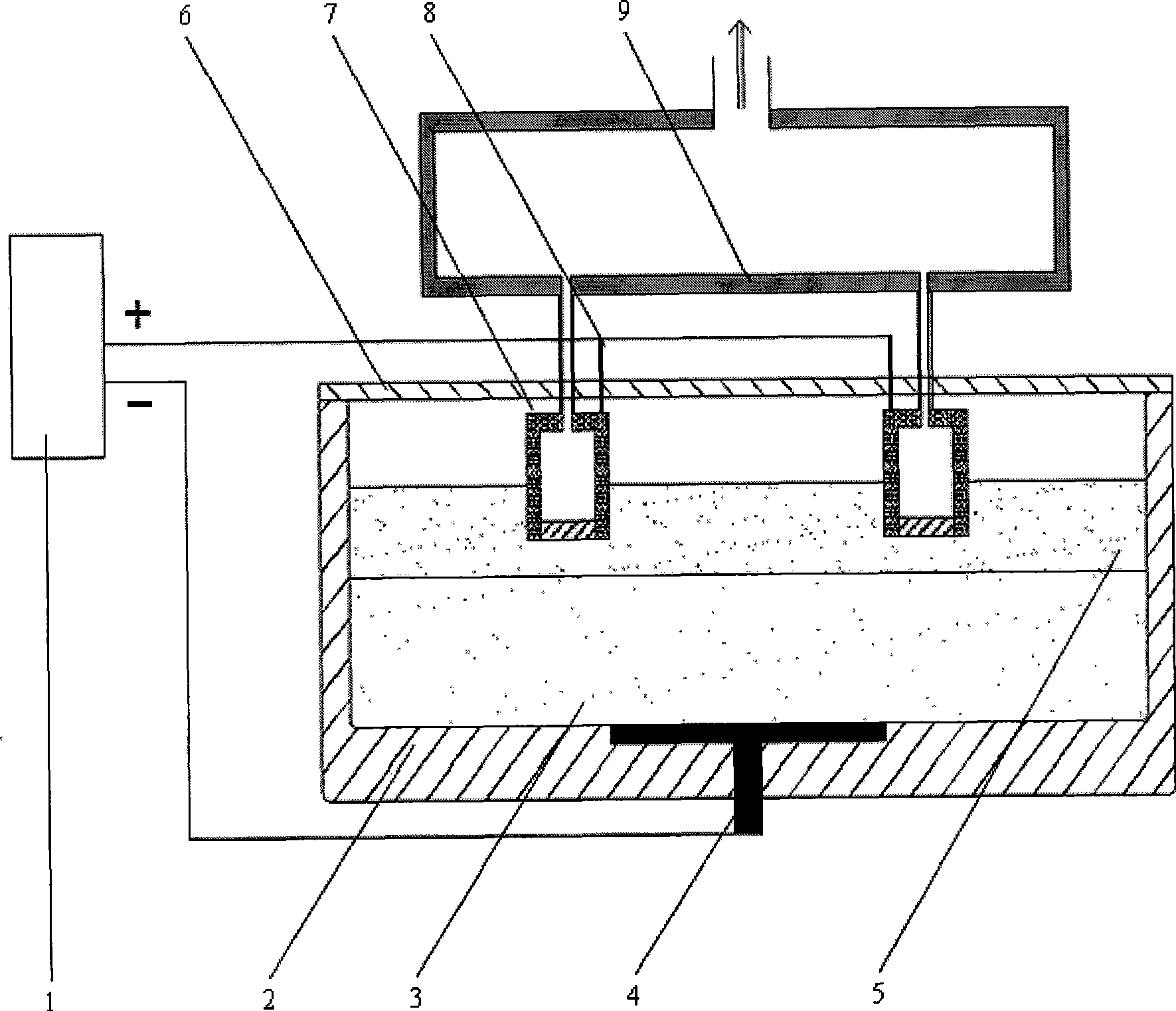

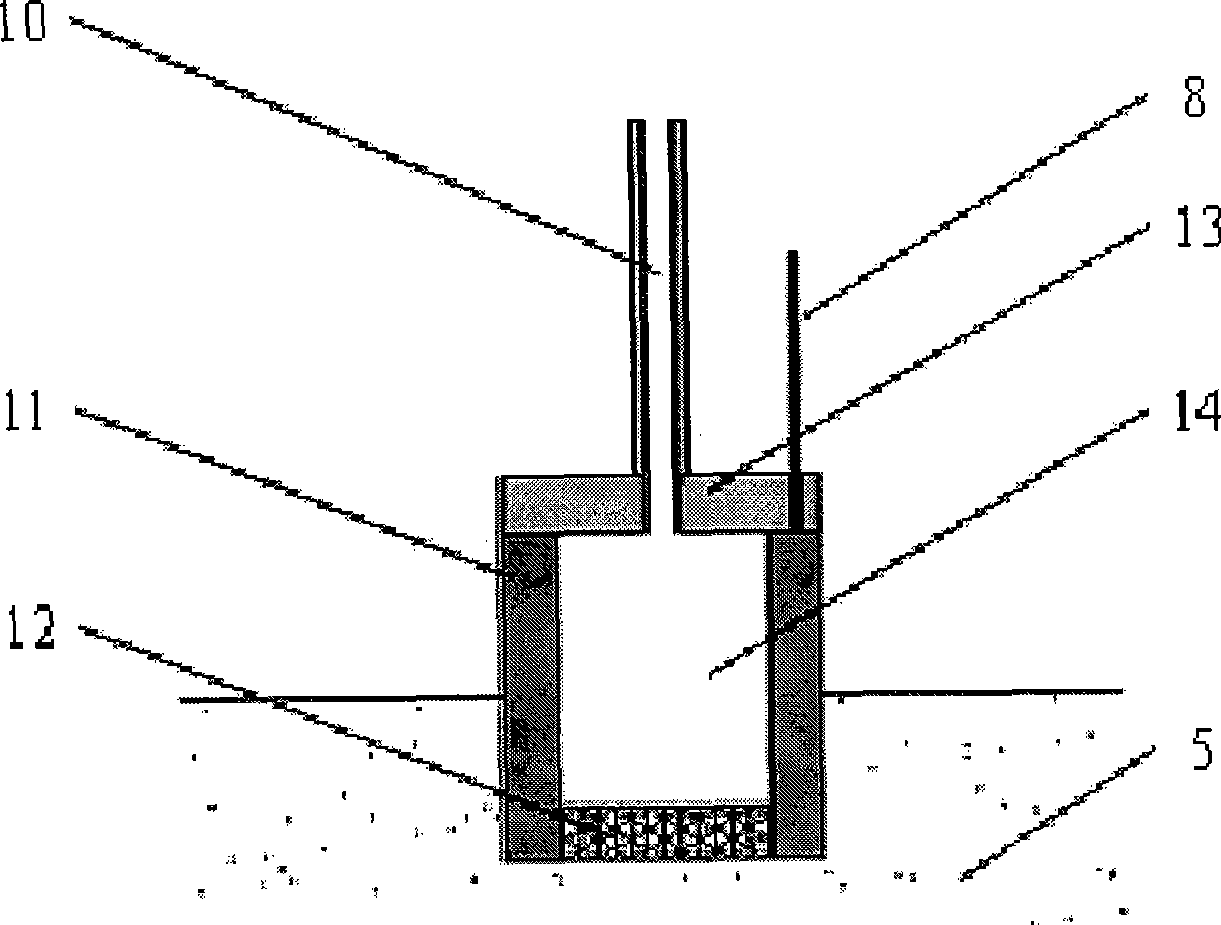

Slag nonpollution deoxygenation method capable of regulating anode oxygen partial pressure and device thereof

InactiveCN101457276AImprove pollutionAccelerated exclusionGas emission reductionOxygen ionsVacuum chamber

The invention relates to a pollution-free molten slag deoxidization method capable of adjusting anode oxygen partial pressure and a device thereof, and belongs to the technical field of metallurgical refining process. In the method, molten steel or molten metal is deoxidized and purified by the special device. In the method, the molten slag is taken as electrolyte, a deaeration cavity electrode inserted into the molten slag is taken as an anode, and the molten steel or the molten metal is taken as a cathode; the deaeration electrode is provided with an electrode cavity and is communicated with a vacuum chamber by a conduit; an applied DC power supply exerts direct current impulse voltage so that an electric field is formed between the molten steel or the molten metal and an oxygen electrode of the molten slag, and the conduction of oxygen ions in a molten slag system and mass transfer of dissolved oxygen in the molten steel are controlled by controlling a current value and a voltage value of the DC power supply as well as components of the molten slag. The oxygen is diffused from the molten slag to the electrode cavity and discharged by an air exhaust system by controlling the oxygen partial pressure of the electrode cavity.

Owner:SHANGHAI UNIV

Electroless tin plating formula for printed circuit board

ActiveCN106939417AComplexation effectiveStrong complexationLiquid/solution decomposition chemical coatingThioureaTin plating

The invention discloses an electroless tin plating formula for a printed circuit board. The formula comprises the following components with the following concentrations: 10-30g / L of stannous ions, 70-130g / L of thiourea, 30-70g / L of methanesulfonic acid, 30-60g / L of citric acid, 20-50g / L of tetrasodium iminodisuccinate, 10-30g / L of carbohydrazide, 10-50mg / L of interfacial agent, 0.05-0.15g / L of bismuth acetate and 20-40g / L of polyamino polyether methylene phosphonate, wherein the component solutions are uniformly mixed and then prepared into an electroless tin plating solution; and the electroless tin plating solution has the following characteristics: tin is stable in tin deposition rate, bivalent tin is not liable to be oxidized into tetravalent tin, and the solution is high in stability. The formula disclosed by the invention contains many complexing agents, the stannous ions are not liable to be oxidized into tetravalent tin, the oxidization of oxygen dissolved in the plating solution can be cancelled by virtue of a reducing agent, the plating solution contains bismuth acetate, a plating layer is a tin-bismuth alloy, and the alloyed plating layer is not liable to grow tin whiskers; and moreover, the electroless tin plating solution has the following characteristics: tin is stable in tin deposition rate, bivalent tin is not liable to be oxidized into tetravalent tin, and the solution is high in stability.

Owner:SHENZHEN CHENGGONG CHEM

Process of preparing titanium sponge by fusion electrolysis of titanium dioxide

InactiveCN1664173AImprove conductivityImprove the efficiency of electrochemical deoxidationElectrolysisLithium chloride

The invention relates to a method for preparing the titanium sponge through electrolyzing the titania by fused salt. The titania applied in the cathode is formed by roasting 1-3h in the carbon reducing atmosphere and 1200-1300 Deg.c. The cathode has two forms: one is plate-like titania, which is formed through roasting the shaped titania combined with PVA adhensive in high temperature and carbon reducing atmosphere; the second is titania particles, which is formed through roasting the rectangle mesh cathode made up of non-corrosive steel or metallic titanium netting in high temperature and carbon reducing atmosphere. The electrolyte is the mixing molten salt system of calcii chloridum and lithium chloride, and the anode uses carbite or inert materials. The cathode and anode are arranged vertically, and the electrode surfaces are parallel, and the electrolyser has at least one group of anode-cathode-anode electrode, and it can set many electrodes in one electrolyser. The voltage of the controlling electrolyzer is 2.8-3.2V, the electrolyzing temperature is 850-900 Deg.c. Cleaning the cathode with the dilute hydrochloric acid and drying it, and getting the titanium sponge, which contains oxygen below 600ppm and the current efficiency is between 70-80%.

Owner:UNIV OF SCI & TECH BEIJING

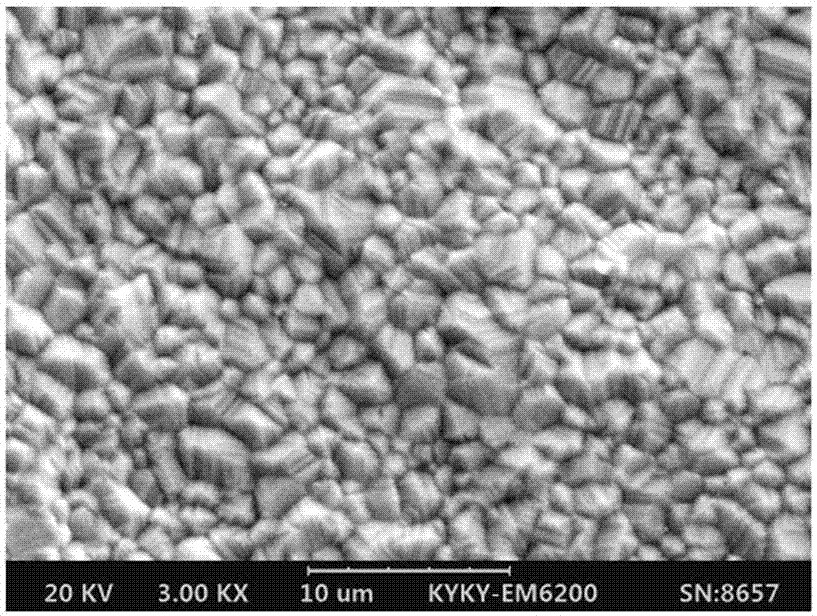

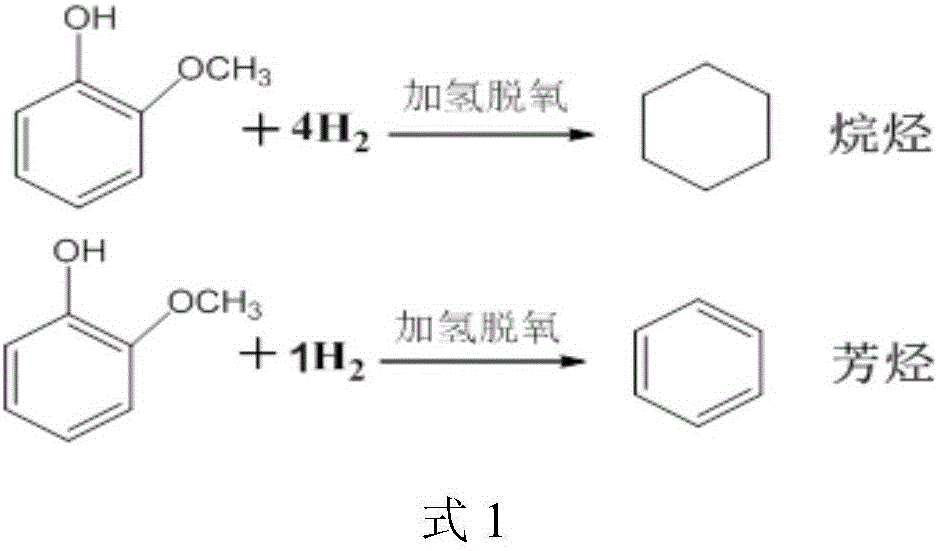

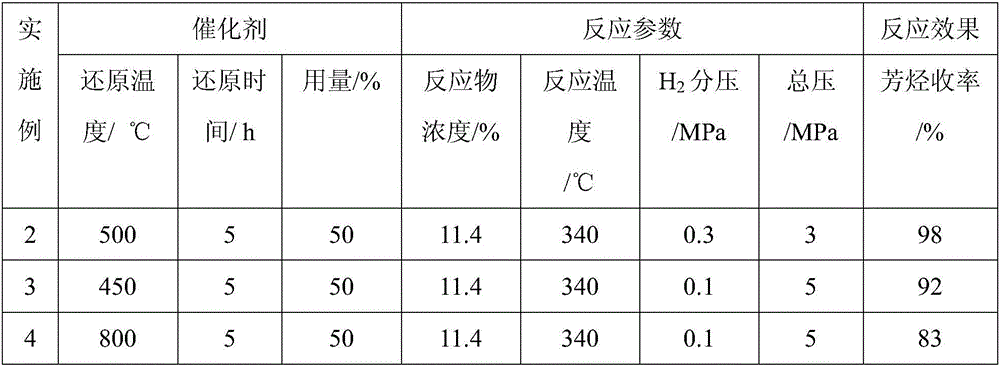

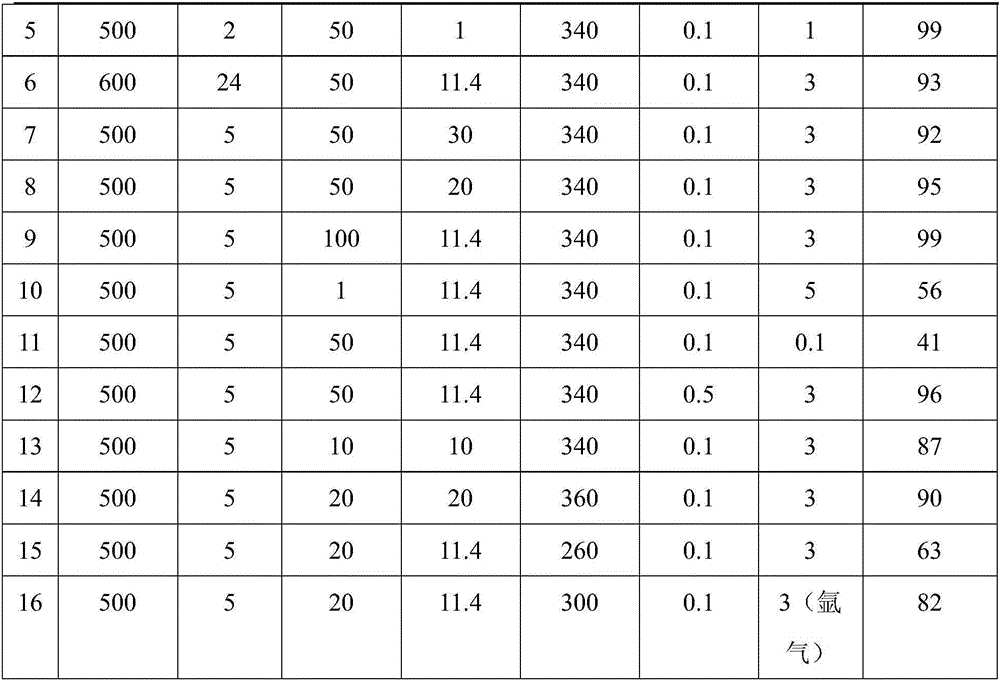

Method for preparation of aromatic hydrocarbon by catalyzing hydrodeoxygenation of monocyclic phenolic platform compound under low hydrogen partial pressure

InactiveCN106495974AEasy to makeHigh catalytic activityCatalystsHydrocarbon preparation catalystsHydrogen pressureHydrodeoxygenation

The invention discloses a method for preparation of aromatic hydrocarbon by catalyzing hydrodeoxygenation of a monocyclic phenolic platform compound under low hydrogen partial pressure. MoO3 is adopted as the catalyst to catalyze hydrogenolysis fracture of C-O bond in the monocyclic phenolic platform compound so as to realize transformation of the monocyclic phenolic platform compound to an aromatic hydrocarbon product, the catalytic activity is high, and the deoxygenation efficiency is high, thus being conducive to improving the selectivity of aromatic hydrocarbon in the product, and reducing hydrogen consumption of the hydrodeoxygenation process, the needed hydrogen partial pressure is low, and the catalyst is cheap and renewable, thereby solving the problems of need for high hydrogen pressure in the reaction process, high hydrogen consumption, and suppressed large-scale application caused by easy carbon deposit deactivation during reaction and high price of the loaded noble metal catalyst in the prior art.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Production technology of steel used for pipe line steel electrode

InactiveCN101705327AControl oxygen contentIncrease the refining rateManufacturing convertersProcess efficiency improvementSlagOxygen

The invention relates to a production technology of steel used for a pipe line steel electrode, which sequentially comprises converter steel making technology, argon station refining technology and continuous casting technology; specific technological parameters of the converter steel making technology are as follows: (1) in molten iron in a converter, the weight percentage content of S is less that or equal to 0.003 percent; (2) converter finishing point control is as follow: steel tapping temperature is 1680 to 1690 DEG C, and in tapped molten steel, the weight percentage content of C is 0.04 to 0.06 percent; (3) converter finishing point slag-thickening operation is as follows: magnesium balls and lime dry slag are added at the converter finishing point to lead final slag in the steel tapping course to be thickened; and (4) final deoxidation technology is as follows: when steel tapping reaches 1 / 3, final deoxidizer and refining slag are added, and stirring is conducted with heavy argon; at the interval between 4 / 5 of the steel tapping and finish of the steel tapping, argon blowing is conducted for 25 to 35 seconds; and the refining slag consists of the lime and fluorite, and weight ratio of the lime to the fluorite is 2:0.4 to 0.6. The production technology well controls contents of carbon, silicon and oxygen in the production process, thus improving the steel-making success rate of the steel used for the pipe line steel electrode.

Owner:武钢集团有限公司

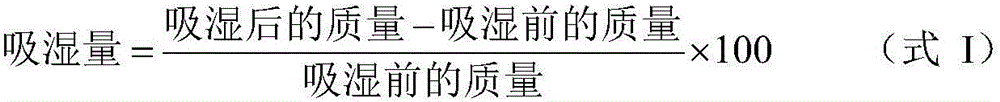

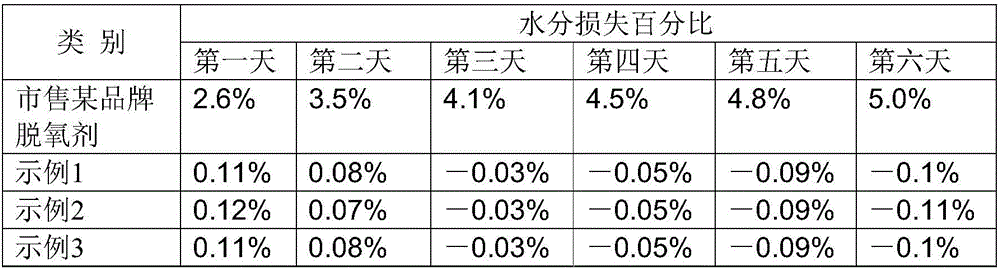

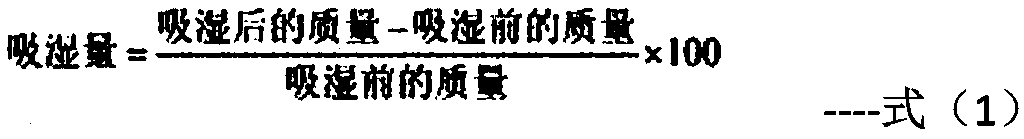

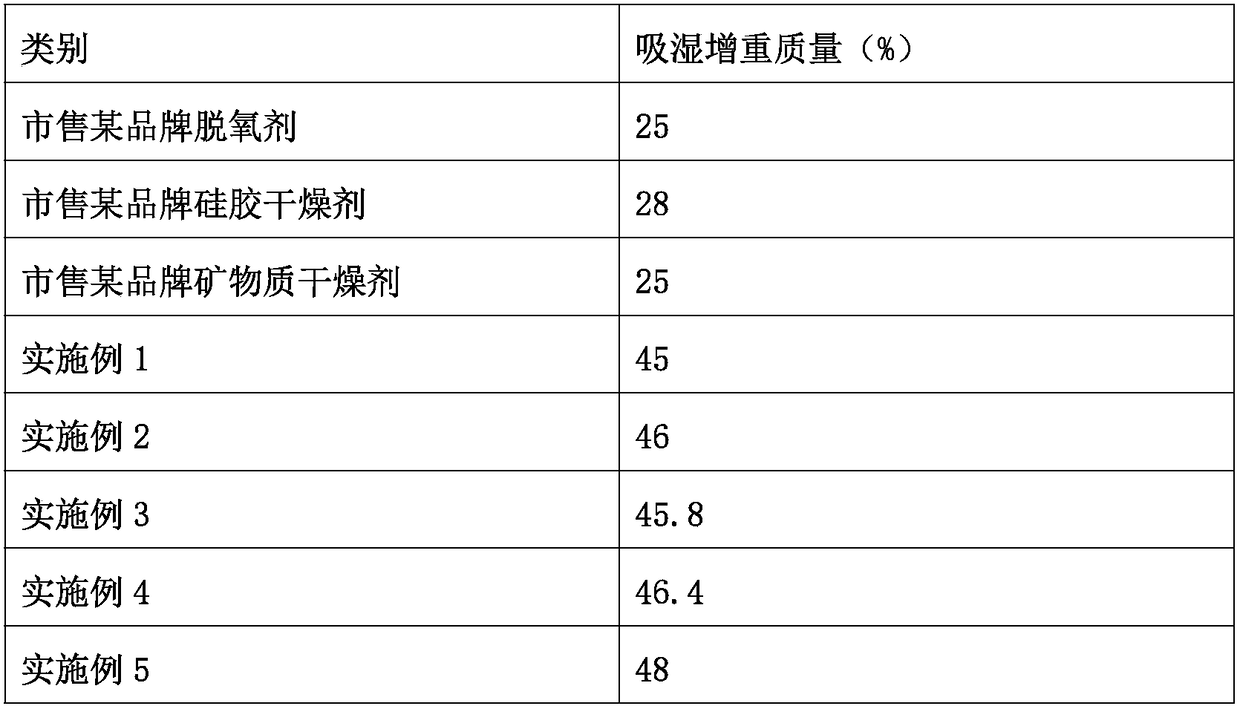

Deoxidizing agent for foods and method for preparing deoxidizing agent

InactiveCN106490440AExcellent water absorption and drying propertiesAvoid diversionFood preservationIron powderChloride

The invention discloses a deoxidizing agent for foods. The deoxidizing agent comprises, by weight, 40-60% of iron powder, 1-6% of electrolytes, 5-15% o calcium chloride, 13-25% of silicon dioxide, 1-5% of macromolecule water absorbing resin, 10-23% of fillers and 5-10% of water. The invention further discloses a method for preparing the deoxidizing agent. The method includes preparation steps of 1), dissolving the electrolytes by the aid of the water, adding the calcium chloride into the electrolytes and uniformly stirring the electrolytes, the calcium chloride and the water to obtain mixed liquid; 2), adding the macromolecule water absorbing resin into the mixed liquid obtained at the step 1), uniformly stirring the macromolecule water absorbing resin and the mixed liquid to obtain first mixtures, then allowing the first mixtures to stand still for 10-20 minutes, adding the fillers and the silicon dioxide into the first mixtures, uniformly mixing and stirring the fillers, the silicon dioxide and the first mixtures to obtain second mixtures, adding the reductive iron powder into the second mixtures, mixing the second mixtures and the reductive iron powder with one another under closed conditions for 10-30 minutes, sieving mixed materials by the aid of sieves with 30-80 meshes and sealing the mixed materials for standby application; 3), cooling materials obtained at the step 2), then quantitatively bagging and packaging and vacuumizing the materials to obtain the deoxidizing agent. The deoxidizing agent for the foods and the method have the advantages that the method includes simple preparation processes, excellent deoxidizing and drying effects can be realized, and moisture regaining of existing foods due to the fact that moisture carried by contents in existing deoxidizing agents is permeated into the existing foods can be effectively prevented.

Owner:东莞市欣荣天丽科技实业有限公司

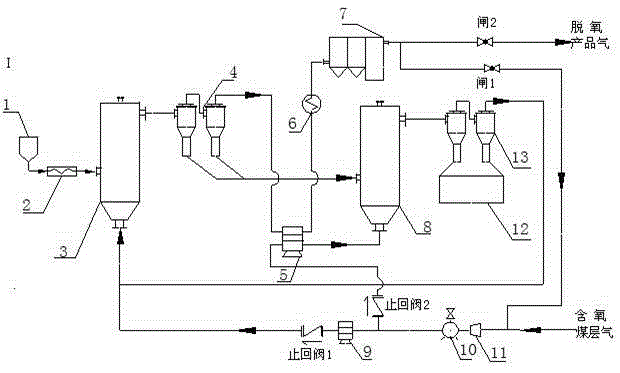

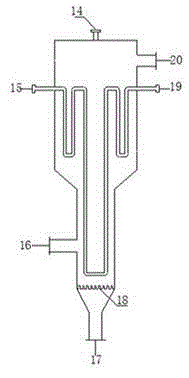

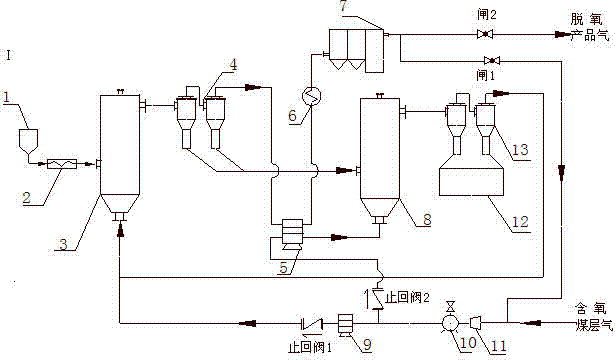

Two-stage fluidized bed coal bed gas non-catalytic deoxidation technology

The invention provides a two-stage fluidized bed coal bed gas non-catalytic deoxidation technology. The technology comprises that after passing through a heat exchanger, a raw material coal bed gas is introduced into a second fluidized bed reactor from the bottom part of the second fluidized bed reactor to be subjected to a first stage deoxidation reaction with a deoxidizer II, a gas-solid mixture after the deoxidation is introduced into a second gas-solid separator from the top lateral part of the second fluidized bed, and a separated solid is discharged from an ash bucket; a separated primary product gas is introduced into the bottom part of a first fluidized bed to be subjected to a second stage deoxidation reaction with a deoxidizer introduced from the bottom lateral part of the first fluidized bed, a gas-solid mixture after the reaction is introduced into a first gas-solid separator from the top lateral part of the first fluidized bed, and a deoxidation product gas which has an oxygen content less than 1.5% is finally acquired after a separated product gas passes through a heat exchanger, a cooler and a deduster. The deoxidation technology avoids the combustion and cracking reaction of methane and reduces the loss of methane, and at the same time the deoxidizers can be fully used.

Owner:TAIYUAN UNIV OF TECH

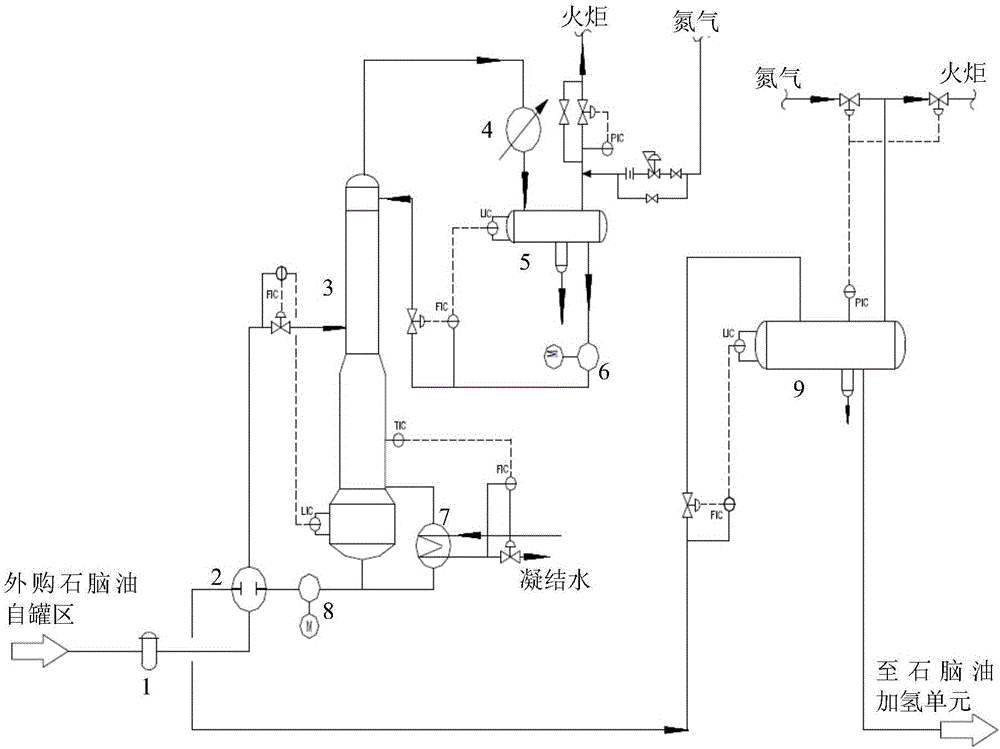

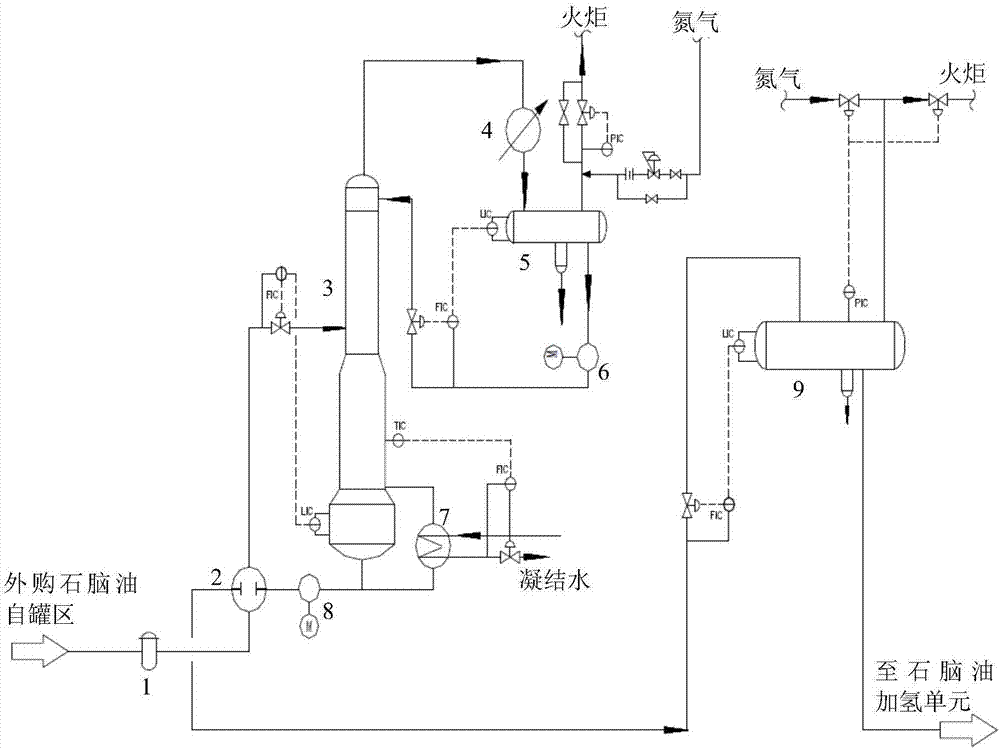

Method and system for optimizing hydrorefining low-pressure deoxygenation and feeding heat exchange for naphtha

ActiveCN105969421AReduce textureLower requirementTreatment with plural serial refining stagesTreatment with hydrotreatment processesNaphthaReboiler

The invention method and a system for optimizing hydrorefining low-pressure deoxygenation and feeding heat exchange for naphtha. The method includes that the naphtha is filtered and is subjected to heat exchange, then is fed into a deoxygenation tower to be subjected to deoxygenation treatment, the tower top pressures are flexibly controlled so that different working conditions can be adapted, tower-top gas phases are cooled and then are fed into a tower-top return tank, liquid phases completely return a tower top, and non-condensable gas on the top of the return tank is exhausted into a torch pipe network; a part of deoxygenated naphtha distilled at a tower bottom is fed into a reboiler at the bottom of the deoxygenation tower and is heated to obtain partial gas phases and partial liquid phases, and then the partial gas phases and the partial liquid phases return a tower kettle; heat is exchanged between another part of deoxygenated naphtha distilled at the tower bottom and filtered naphtha, and deoxygenated naphtha is used as a naphtha hydrogenation material after being subjected to heat exchange. The system comprises a naphtha feeding filter, a deoxygenation tower feeding and deoxygenated naphtha heat exchanger, the deoxygenation tower, a deoxygenation tower-top cooler, the deoxygenation tower-top return tank and the deoxygenation tower-bottom reboiler. The method and the system have the advantage that hydrorefining low-pressure deoxygenation and feeding heat exchange for the naphtha can be optimized by the aid of the method and the system.

Owner:BEIJING PETROCHEM ENG

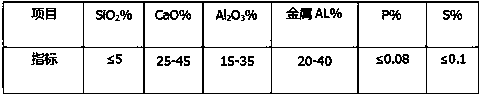

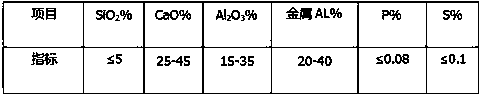

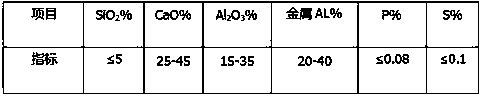

Method for controlling residual aluminum in electroslag remelting steel

The invention relates to the electroslag remelting technology, in particular to a method for controlling residual aluminum in electroslag remelting steel, and aims to overcome the disadvantages of the prior electroslag remelting technology, such as poor stability of remelting slag system, poor efficiency in controlling aluminum increase in metal melting pond in remelting process, high difficulty in controlling residual aluminum in electroslag remelting steel, and poor quality of electroslag remelting steel. The control method is realized by the electroslag remelting process in the existing electroslag furnace, wherein the remelting slag consists of, by weight, CaO 28% to 40%, Al2O3 10% to 15%, MnO 0.2% to 0.5%, CaF2 15% to 25%, and the balance of Al2(SiO3)3. In the remelting process, the content of FeO in the remelting slag is controlled to be not larger than 0.5% by deoxidization. The method provided by the invention is effective in controlling aluminum increase in the metal melting pond, and easy in controlling residual aluminum in the electroslag remelting steel, and has the advantages of high stability of the remelting slag system and high quality of electroslag remelting steel.

Owner:ZHEJIANG ELECTROSLAG NUCLEAR MATERIAL

Method and system for naphtha hydrofining low-pressure deoxidation and feed heat exchange optimization

ActiveCN105969421BLower requirementPromote escapeTreatment with plural serial refining stagesTreatment with hydrotreatment processesNaphthaGas phase

The invention method and a system for optimizing hydrorefining low-pressure deoxygenation and feeding heat exchange for naphtha. The method includes that the naphtha is filtered and is subjected to heat exchange, then is fed into a deoxygenation tower to be subjected to deoxygenation treatment, the tower top pressures are flexibly controlled so that different working conditions can be adapted, tower-top gas phases are cooled and then are fed into a tower-top return tank, liquid phases completely return a tower top, and non-condensable gas on the top of the return tank is exhausted into a torch pipe network; a part of deoxygenated naphtha distilled at a tower bottom is fed into a reboiler at the bottom of the deoxygenation tower and is heated to obtain partial gas phases and partial liquid phases, and then the partial gas phases and the partial liquid phases return a tower kettle; heat is exchanged between another part of deoxygenated naphtha distilled at the tower bottom and filtered naphtha, and deoxygenated naphtha is used as a naphtha hydrogenation material after being subjected to heat exchange. The system comprises a naphtha feeding filter, a deoxygenation tower feeding and deoxygenated naphtha heat exchanger, the deoxygenation tower, a deoxygenation tower-top cooler, the deoxygenation tower-top return tank and the deoxygenation tower-bottom reboiler. The method and the system have the advantage that hydrorefining low-pressure deoxygenation and feeding heat exchange for the naphtha can be optimized by the aid of the method and the system.

Owner:BEIJING PETROCHEM ENG

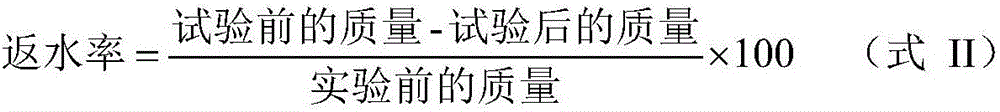

Deoxidant for foods and with moisture-absorption function and preparation method of deoxidant

InactiveCN108271991ASimple compositionAvoid diversionFood preservationFood ingredientsMetal chlorideIron powder

The invention provides a deoxidant for foods and with a moisture-absorption function and a preparation method of the deoxidant. The deoxidant comprises iron powder, metal chloride, a water-retaining agent and a gas adsorbent. The content of the iron powder is 40-80%; the content of the metal chloride is 4-45%; the content of the water-retaining agent is 10-35%; and the content of the gas adsorbentis 0-5%. In the invention, based on a traditional iron oxidant (iron powder), the use of the metal chloride can absorb moisture in the packaging bag of the deoxidant, and maintain a dry environment in the packaging bag of the deoxidant. In the invention, the dosage of the water-retaining agent is controlled so as to ensure the moisture required by the reaction of the iron deoxidant, and the synergistic action of a plurality of ingredients can effectively avoid that the moisture generated in the use process of the deoxidant is transferred to foods so as to ensure that the deoxidant has a moisture-absorption effect, and the use of the water-retaining agent can be used for regulating the moisture in the deoxidant so as to effectively control the speed of reaction between the deoxidant and oxygen.

Owner:JIANGSU OUK PACKAGING TECH

Low-carbon aluminum-containing steel and smelting control method thereof

PendingCN112322958AImprove pourabilityReduce erosionManufacturing convertersProcess efficiency improvementAluminateSlag

The invention relates to the field of steel smelting, in particular to low-carbon aluminum-containing steel and a smelting control method thereof. The method comprises the following steps of controlling the endpoint carbon content in molten steel to range from 0.08 percent to 0.12 percent during converter tapping; carrying out decarburization treatment on the molten steel by adopting a vacuum degassing process; adding aluminum into the molten steel for carrying out deoxidation; and after refining is finished, conducting calcium treatment on the molten steel. The carbon content in the converterendpoint molten steel is controlled to range from 0.08 percent to 0.12 percent , so that the oxidability of the molten steel and the erosion of the high-temperature molten steel to a furnace lining are reduced, and the service life of a converter is prolonged. Meanwhile, an oxygen source can be brought to natural decarburization under the subsequent vacuum degassing condition, and conditions arecreated for VD natural decarburization. A VD treatment process is adopted for decarburization, so that carbon is lower after decarburization is finished. The aluminum is added for deoxidation, so thatthe deoxidation efficiency can be improved, and the deoxidation speed is high. The deoxygenation of refining slag is facilitated. After LF treatment is finished, the molten steel is subjected to calcium treatment, inclusions can be subjected to denaturation treatment, so that low-melting-point calcium aluminate is formed, and the castability of the molten steel is improved.

Owner:SGIS SONGSHAN CO LTD

Steel ladle magnesium-containing deoxidizing slag

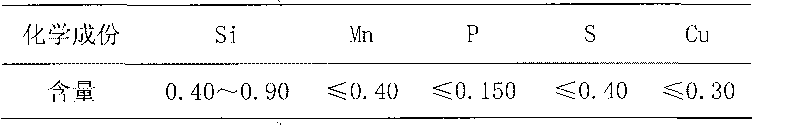

InactiveCN102041354AGood for hitImprove reducibilityProcess efficiency improvementChemical compositionSmelting process

The invention discloses steel ladle magnesium-containing deoxidizing slag which is characterized by comprising the following chemical compositions by weight percent: 10-40% of Mg, 30-60% of CaO, 12-30% of SiO2 and Al2O3, more than 0 and less than or equal to 10% of MgO, 0-5% of C and the balance of impurities, wherein the sum of the contents of Mg and CaO is no less than 60wt% of the total weight. According to the invention, the problems of the prior art that for the steel grade with lower aluminium silicate and narrow content range of aluminium silicate, such as on the condition that the target aluminium content of the finished steel is 0.0100wt% or less than 0.0100wt% and the tolerance is only 0.0020-0.0080wt%, the aluminum components can not satisfy the demand in the smelting process or the degree of purity is low so as to affect the yield of smelting and the performances of the final product, can be solved. Therefore, the invention has good popularizing prospect and application prospect.

Owner:BAOSHAN IRON & STEEL CO LTD

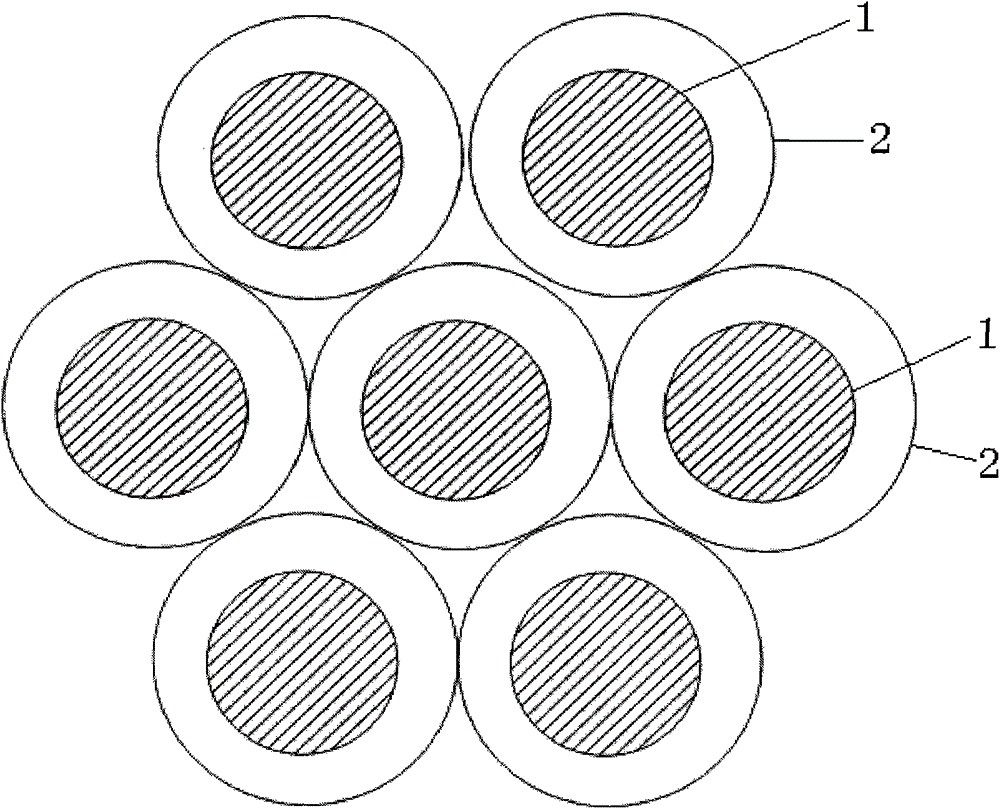

Chemical gas regulating agent and preparation method thereof

InactiveCN104415658AReduce cakingExtended service lifeDispersed particle separationMicroballoon preparationPhysical chemistryChemistry

The invention discloses a chemical gas regulating agent and a preparation method thereof. The chemical gas regulating agent comprises inner cores and outer shells arranged outside the inner cores, wherein each inner core is deoxidizing agent, each outer shell comprises a catalyst capable of catalyzing the deoxidizing agent to carry out deoxidation reaction and a binder. No direct contact is caused among different inner cores constituting the chemical gas regulating agent due to the chemical gas regulating agent with the structure; one part of inner cores are reacted firstly when the chemical gas regulating agent is subjected to deoxidation, the inner core deoxidizing agents which are subjected to deoxidation reaction firstly cannot contact the inner core deoxidizing agents which are not subjected to deoxidation reaction due to the protection effect of the outer shells, the chemical gas regulating agent can be prevented from caking, the service life of the chemical gas regulating agent is prolonged and the deoxidation efficiency is improved.

Owner:湖南华望熏蒸消毒有限公司

Two-stage fluidized bed coal bed gas non-catalytic deoxidation technology

The invention provides a two-stage fluidized bed coal bed gas non-catalytic deoxidation technology. The technology comprises that after passing through a heat exchanger, a raw material coal bed gas is introduced into a second fluidized bed reactor from the bottom part of the second fluidized bed reactor to be subjected to a first stage deoxidation reaction with a deoxidizer II, a gas-solid mixture after the deoxidation is introduced into a second gas-solid separator from the top lateral part of the second fluidized bed, and a separated solid is discharged from an ash bucket; a separated primary product gas is introduced into the bottom part of a first fluidized bed to be subjected to a second stage deoxidation reaction with a deoxidizer introduced from the bottom lateral part of the first fluidized bed, a gas-solid mixture after the reaction is introduced into a first gas-solid separator from the top lateral part of the first fluidized bed, and a deoxidation product gas which has an oxygen content less than 1.5% is finally acquired after a separated product gas passes through a heat exchanger, a cooler and a deduster. The deoxidation technology avoids the combustion and cracking reaction of methane and reduces the loss of methane, and at the same time the deoxidizers can be fully used.

Owner:TAIYUAN UNIV OF TECH

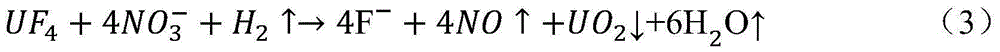

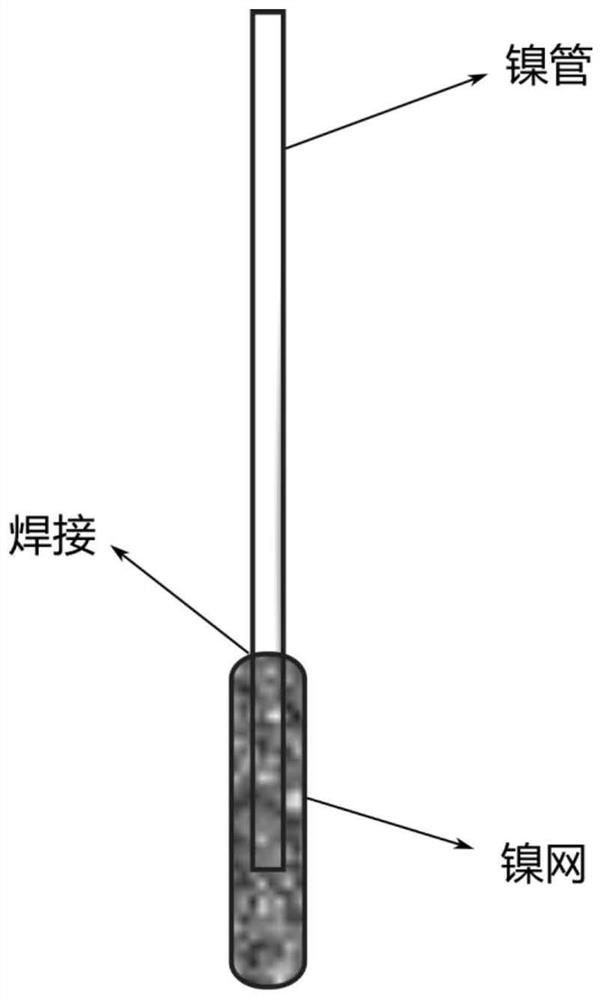

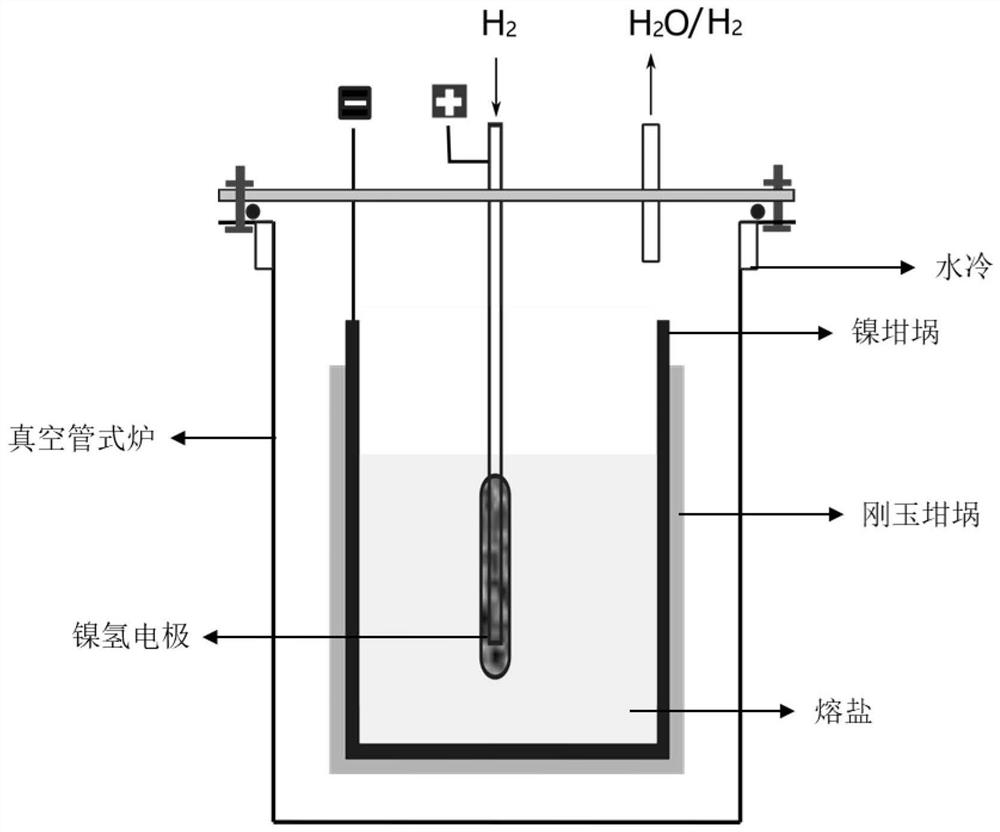

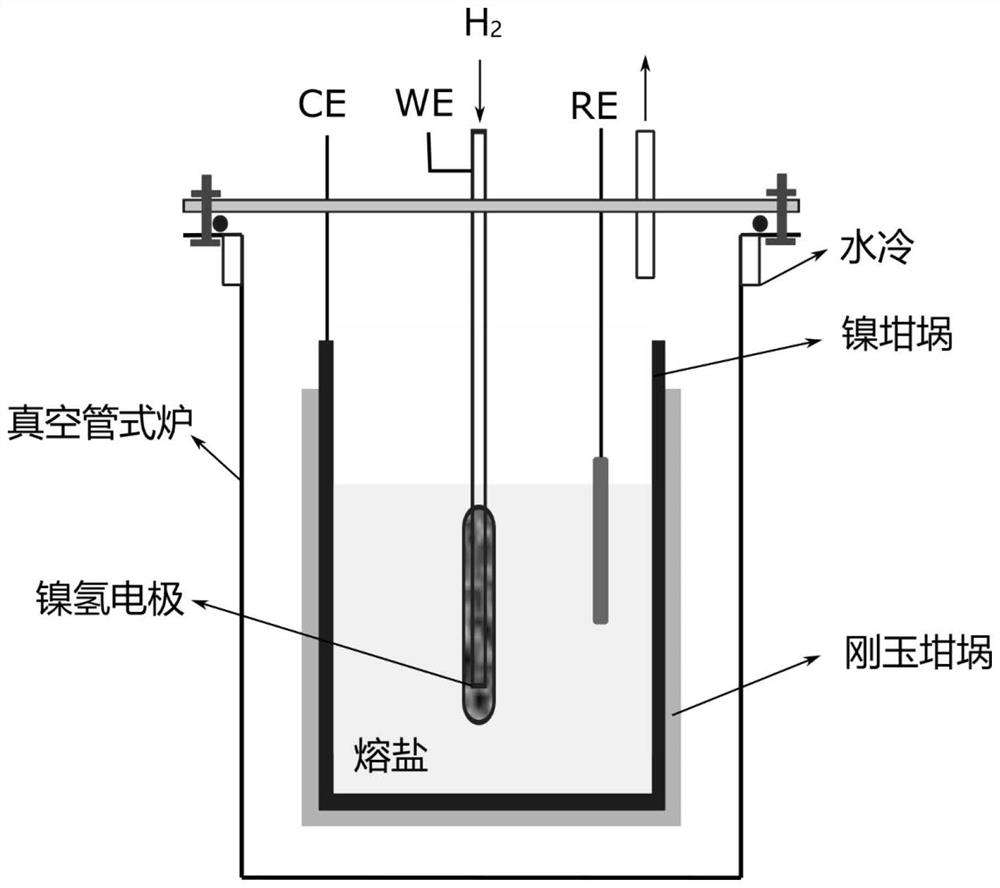

Molten salt, electrochemical purification method of molten salt and electrochemical device

ActiveCN113603059ARandom combinationImprove deoxidation efficiencyChloride preparationFluoride preparationElectrolysisMolten salt

The invention discloses molten salt, an electrochemical purification method of the molten salt and an electrochemical device. The electrochemical purification method of the molten salt comprises the step that: in the molten salt in a molten state, with a hydrogen electrode taken as an anode, and H2 is electrolyzed into H < + > on the surface of the hydrogen electrode, in the anode, an electrode reaction described in the specifications is carried out, in the molten salt, the oxygen content is less than or equal to 230ppm, the sulfur content is less than or equal to 5ppm, and the transition metal element content is less than or equal to 8ppm, and the oxygen content can be less than or equal to 80ppm. According to the method, the molten salt is purified by adopting a process based on a hydrogen electrode electrolysis method, the purification purposes of deoxidation, desulfurization, removal of transition metal ions (such as iron and nickel) and the like can be achieved by only adopting H2 instead of using highly toxic HF or highly corrosive HCl, and the deoxidation purification efficiency and the deoxidation purification level of the method are comprehensively superior to those of a traditional HF / HCl-H2 method and an electrochemical method.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

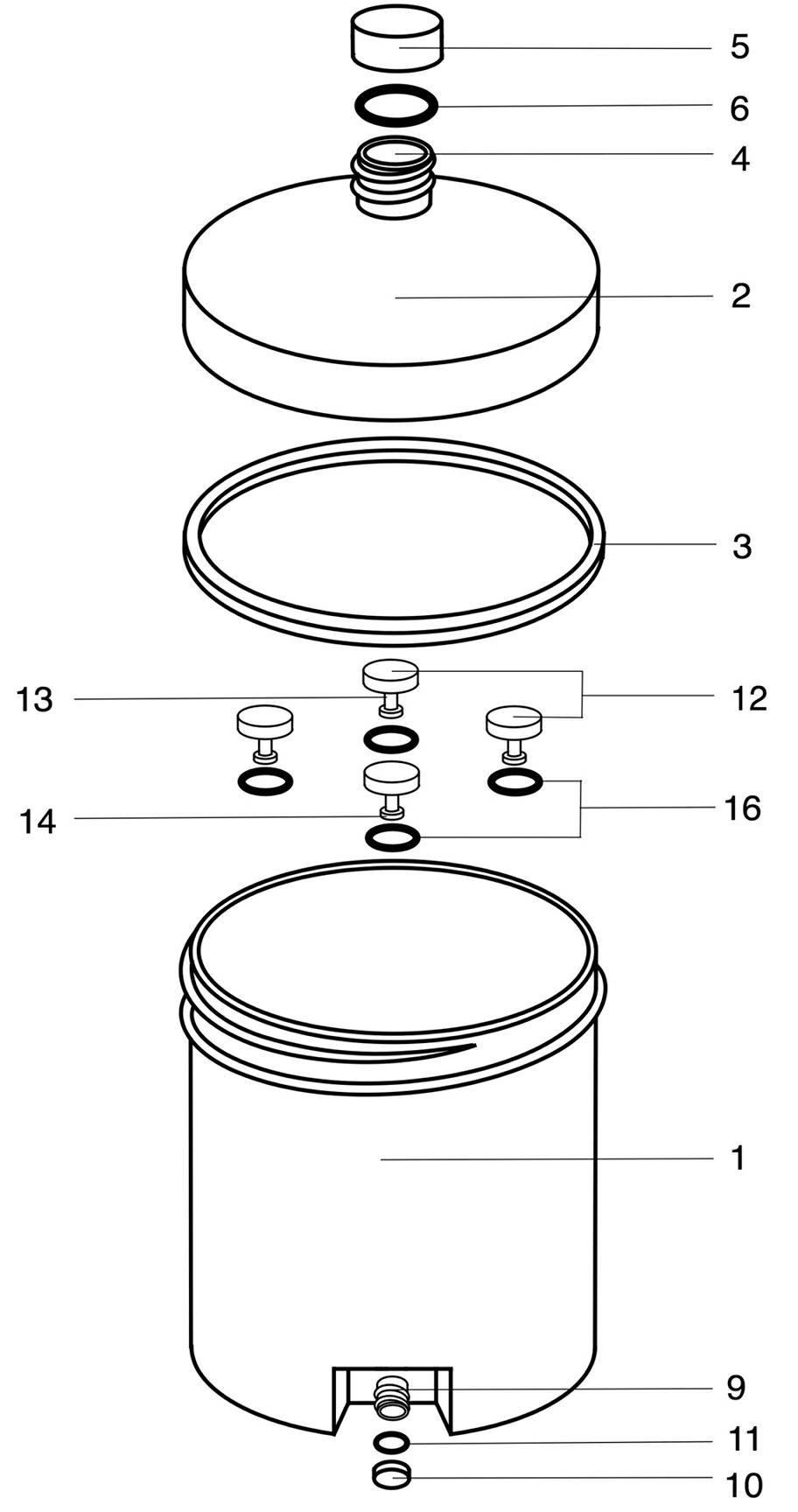

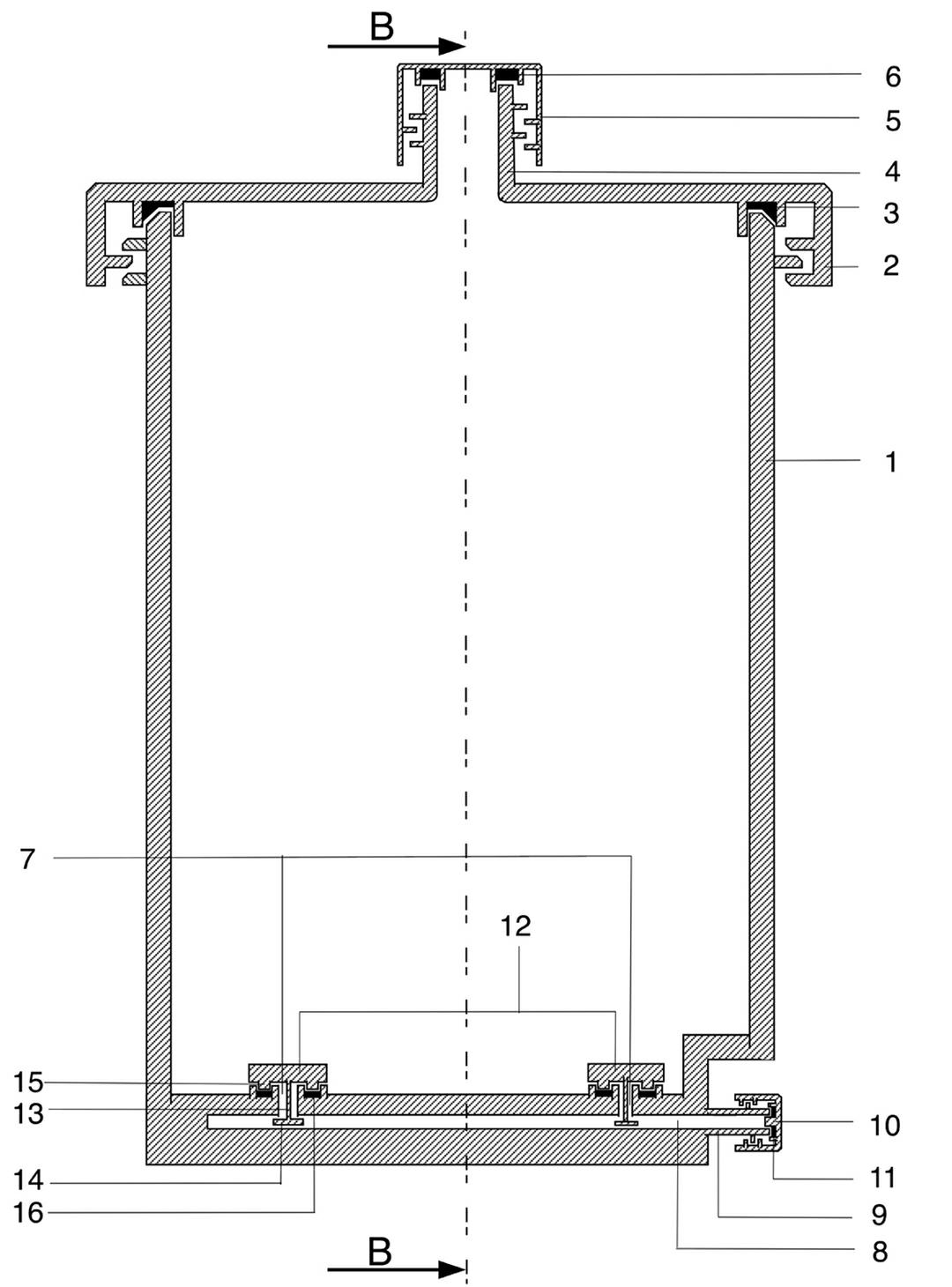

Dialysis vessel

InactiveCN102101063AImprove deoxidation efficiencyGood sealing effectLiquid degasificationLaboratory glasswaresUrologyDialysis

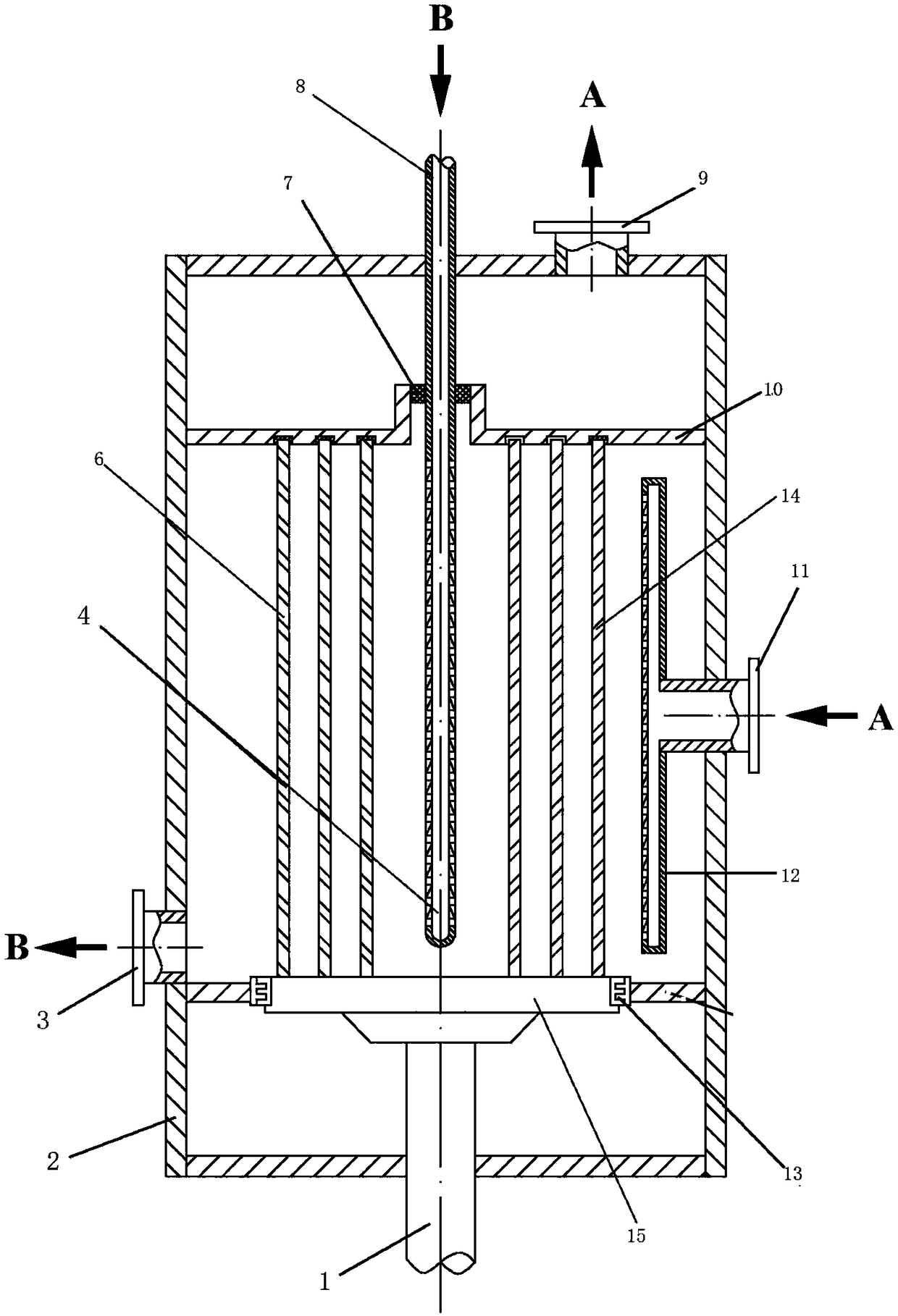

The invention provides a dialysis vessel. The dialysis vessel comprises a dialysis vessel body and a dialysis vessel cover, wherein the dialysis vessel body is a hollow column; the dialysis vessel cover is closely connected with the upper end of the dialysis vessel body; an air outlet and an air outlet cover are arranged on the dialysis vessel cover; at least two air inlet holes distributed uniformly along the circumferential direction are formed on the inner bottom surface of the dialysis vessel body; the air inlet holes are communicated with an air channel at the bottom of the dialysis vessel body; floating valve plugs are arranged in the air inlet holes; a sealing cover is arranged on an air conduit port at the outer end of the air channel; and at least two supports with wedge-shaped clamping grooves are arranged on the inner bottom surface of the dialysis vessel body along the circumferential direction. By the technical scheme, air bubbling and deoxidizing efficiency can be obviously improved and sealing effect is good, so that oxygen-sensitive samples are protected from oxidative damage in the dialysis process.

Owner:INST OF FIELD OPERATION SURGERY NO 3 MILITARY MEDICL UNIV PLA

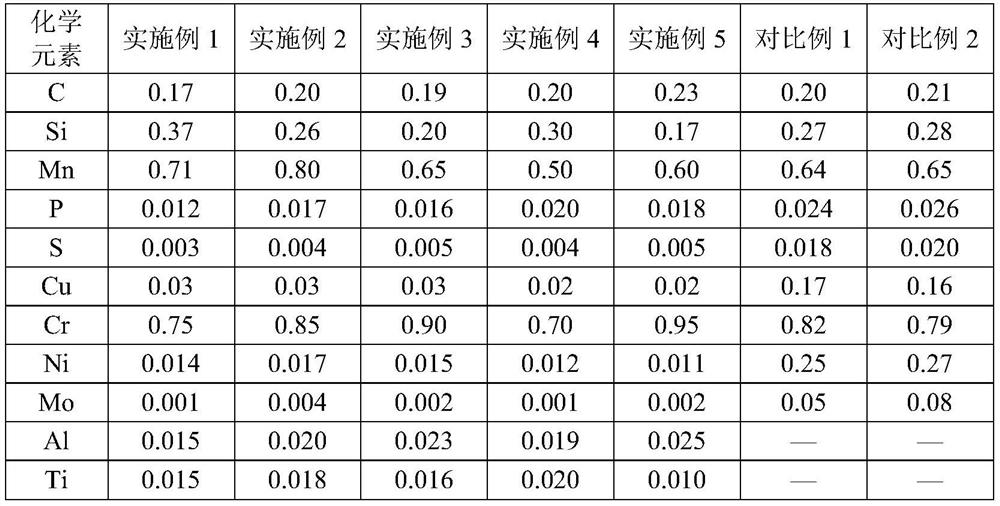

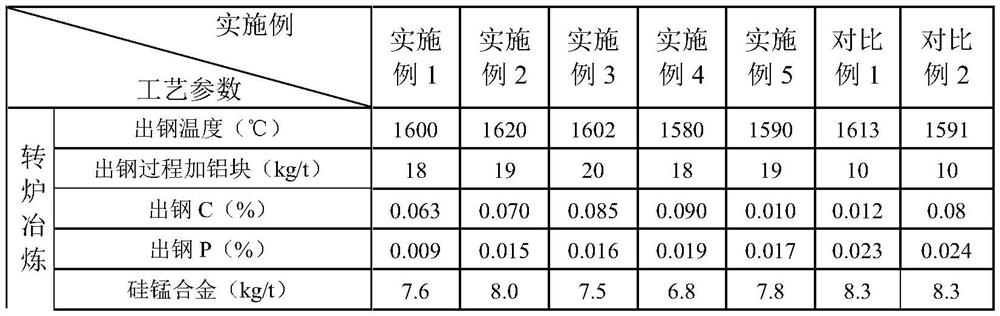

High-plasticity dual-phase steel and production method thereof

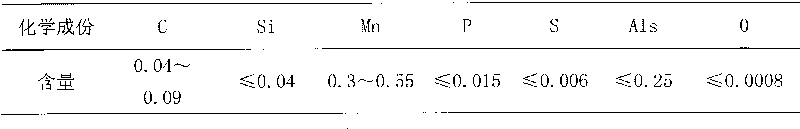

ActiveCN113106345AImprove deoxidation efficiency and alloy melting speedReduce refining timeTemperature control deviceManufacturing convertersDuctilityPlasticity

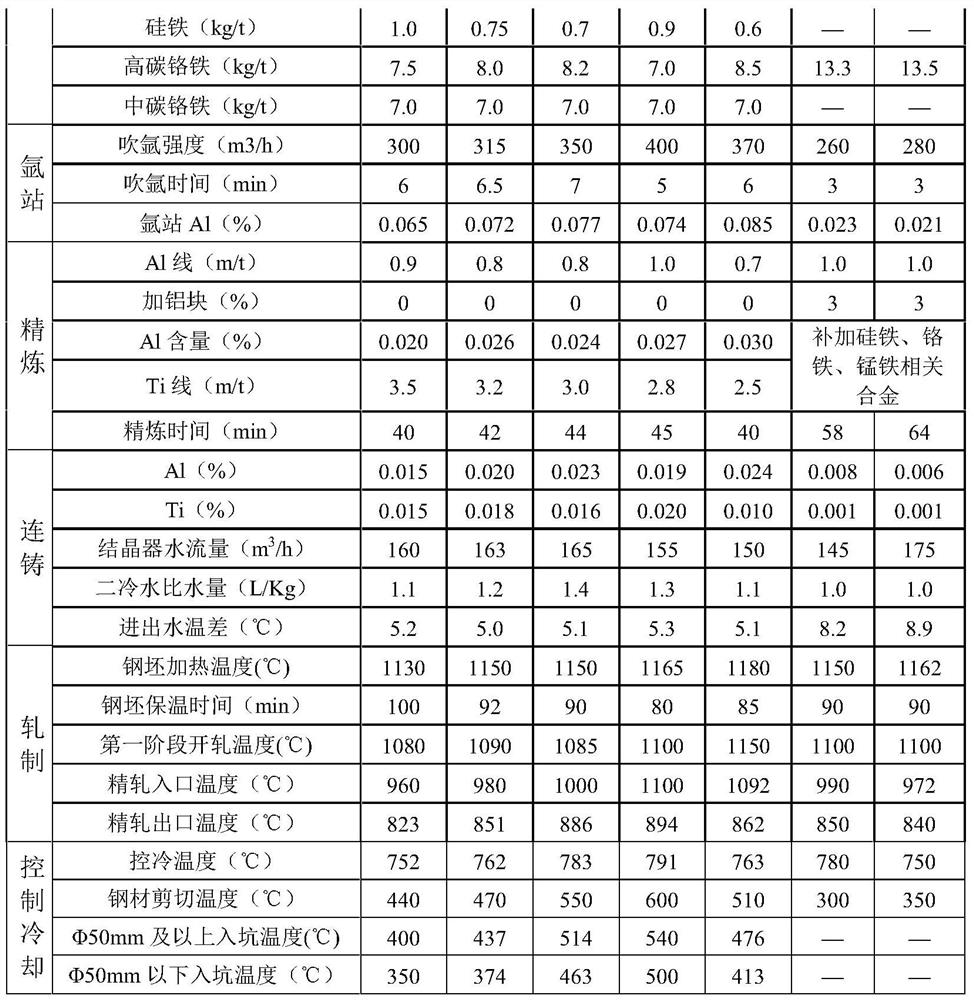

The invention discloses high-plasticity dual-phase steel and a production method thereof. The high-plasticity dual-phase steel comprises the following chemical components in percentage by mass: 0.17 to 0.23 percent of C, 0.17 to 0.37 percent of Si, 0.50 to 0.80 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.005 percent of S, 0.70 to 0.95 percent of Cr, 0.015 to 0.025 percent of Al, 0.010 to 0.020 percent of Ti, less than or equal to 0.02 percent of Ni, less than or equal to 0.05 percent of Cu, less than or equal to 0.005 percent of Mo, 0.0015 to 0.0018 percent of O and the balance Fe and inevitable impurities. The production method of the high-plasticity dual-phase steel comprises the following steps of converter smelting, argon station treatment, LF refining, continuous casting, rolling and cooling. According to the steel, a proper amount of Ti and Al alloy is added to conduct microalloying on the steel, the quality of molten steel is further purified, and by means of the characteristics of the Ti alloy and the characteristic that a separated Ti-containing compound can effectively hinder grain coarsening, the prepared steel has the diameter phi of 24-100 mm, the yield strength of 850-1000 MPa, the tensile strength of 1000-1150 MPa, the ductility of 14-17.5%, the percentage reduction of area of 44.5-48% and the impact energy of 60-75 J; and the hardenability and plasticity index of the steel are greatly improved.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

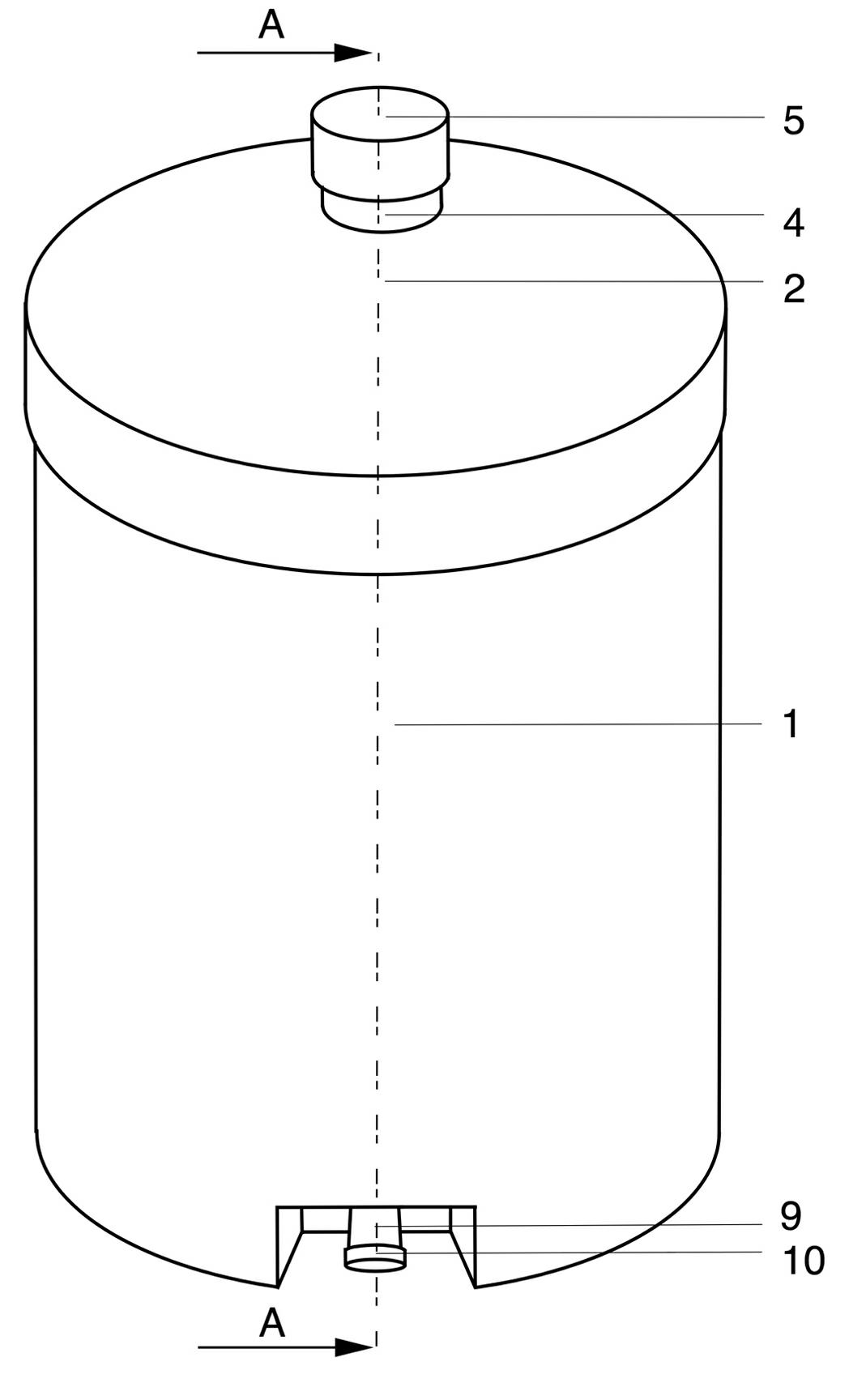

Device and method for continuously removing dissolved oxygen in fuel oil

ActiveCN108531214ANo heating requiredImprove continuityLiquid degasification with auxillary substancesHydrocarbon oils refiningRoom temperatureFuel oil

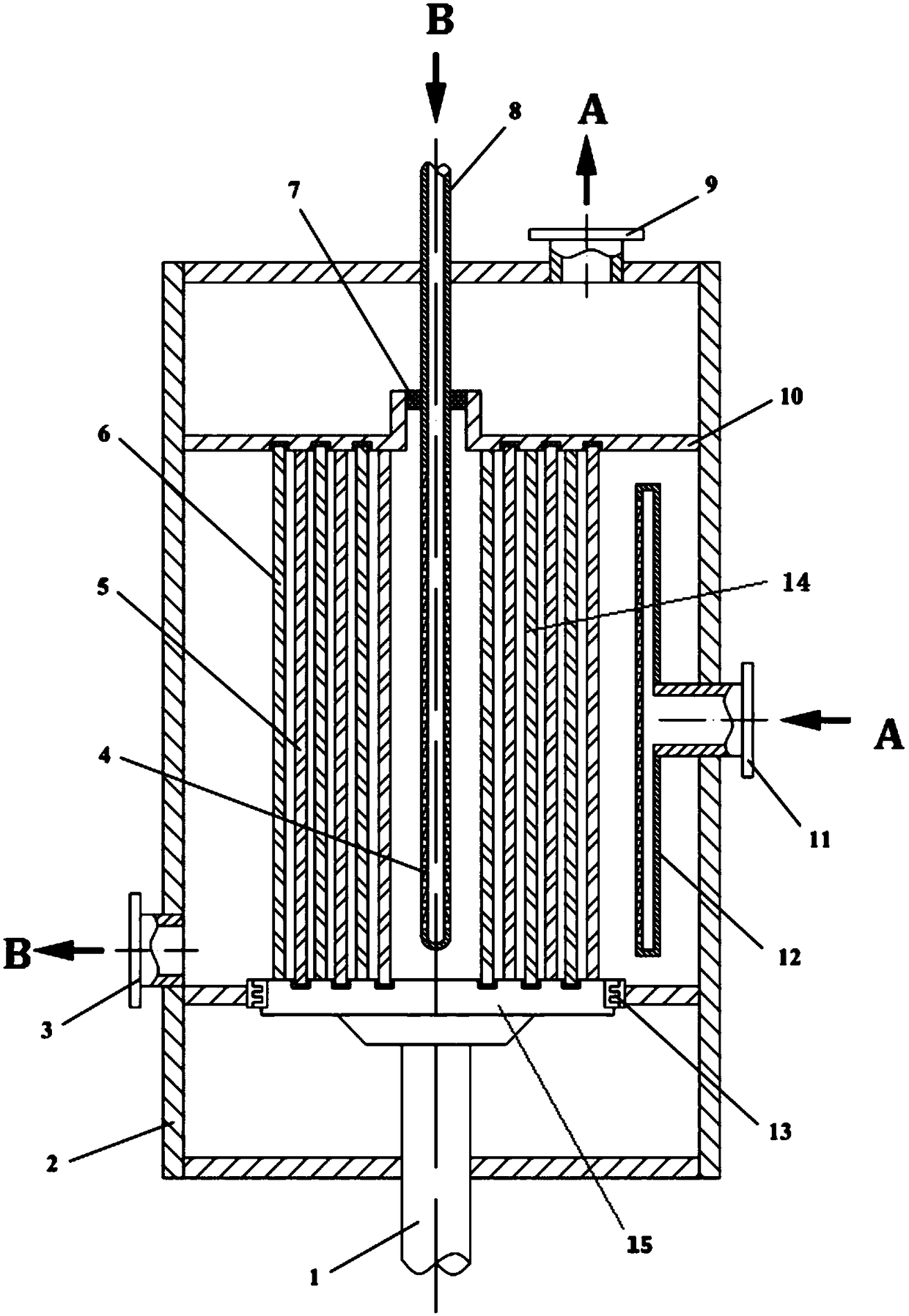

The invention discloses a device for continuously removing dissolved oxygen in fuel oil. The device comprises an outer shell (2), a liquid inlet (8), a liquid outlet (3), a gas inlet (11), an exhaustport (9), a rotating shaft (1), a disc (15) and a liquid redistribution pipe (4). A plurality of moving annulus barrels (6) with holes in side walls are axially and fixedly arranged on the upper end face of the disc (15) and filled with lipophilic dispersion filler (14). The invention further discloses a method for continuously removing dissolved oxygen in fuel oil by use of the device. The devicefor continuously removing dissolved oxygen in fuel oil has advantages of high continuity, low treatment cost and great removal effects, and the dissolved oxygen in fuel oil at the room temperature can be removed to 10ppb or below.

Owner:TIANJIN UNIV

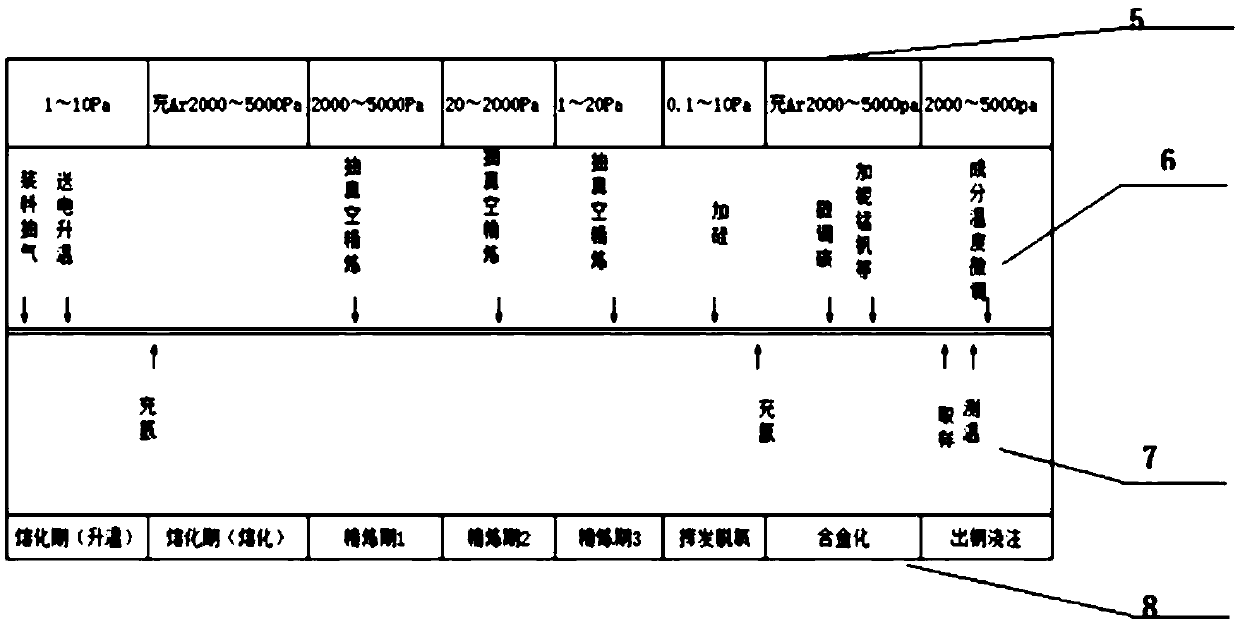

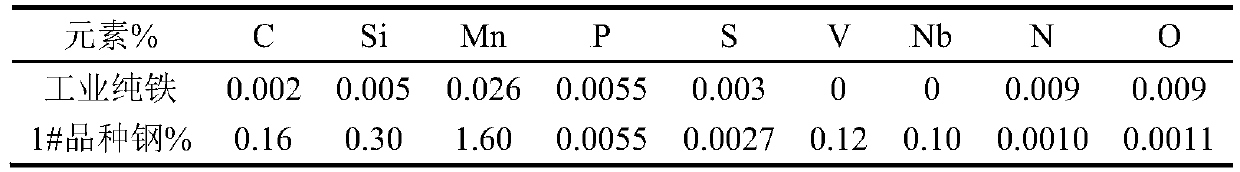

Vacuum melting process of aluminum-free low-oxygen steel

ActiveCN109628696AImprove applicabilityImprove technical problems in smelting metal materials, etc.Three stageMolten steel

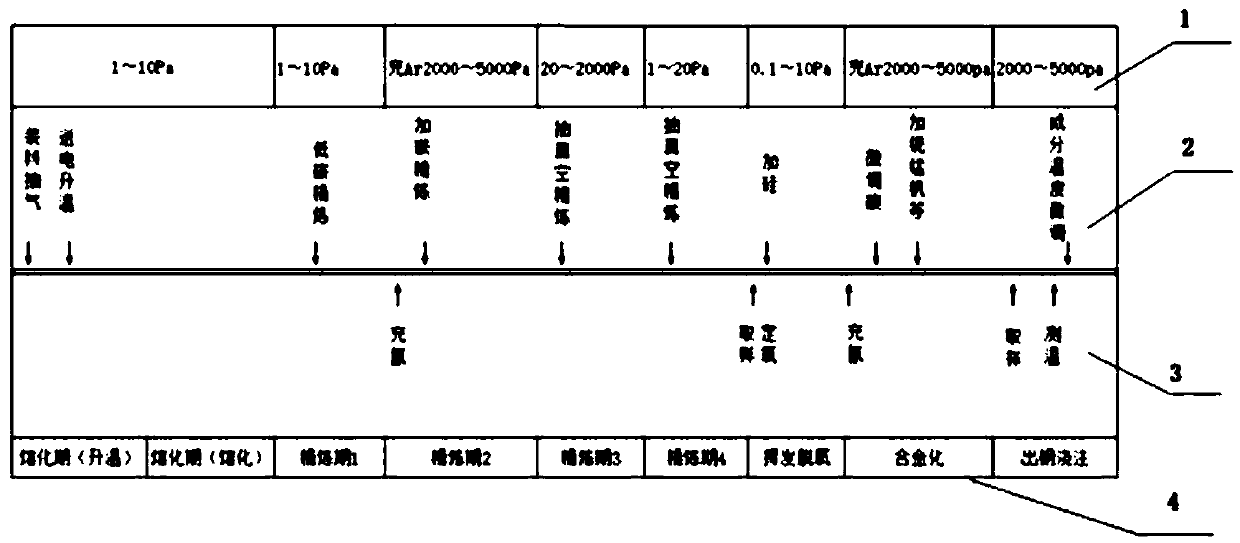

The invention discloses a vacuum melting process of aluminum-free low-oxygen steel. The vacuum melting process comprises three stages: a melting stage, a refining stage and an alloying stage, whereina carbon deoxidation process is adopted during the melting stage, a step deoxidation process is adopted during the refining stage, a rapid alloying process is adopted during the alloying stage, and then the steel is rapidly cast and solidified. By using the rapid alloying process, the steel is rapidly cast and solidified. By pre-matching carbon or using the carbon in the raw material to participate in vacuum deoxidation in the melting process, the deoxidation efficiency can be improved significantly, the refining deoxidation can be further performed, the process can fully utilize the advantages of high vacuum deoxidation of carbon, and the deoxidation product discharge molten steel in the form of gas, so that the purity of the molten steel is greatly improved; the melting loss of the alloyin the alloying stage is reduced, and the impurities and the like are avoided; the entire melting process does not require the introduction of a deoxidizing agent such as aluminum or others which arenot easily removed, and the process can provide a brand new idea for the smelting production of steels with no aluminum or very low aluminum content.

Owner:武汉钢铁有限公司

Deoxidizing agent for steelmaking and preparation method thereof

InactiveCN107419060AHigh organic contentLarge oxygen absorption capacitySteelmakingCompression molding

The invention discloses a deoxidizing agent for steelmaking and a preparation method thereof and belongs to the technical field of steelmaking additive preparation. The deoxidizing agent for steelmaking is prepared from, by weight, 30-40 parts of calcium oxide, 20-30 parts of calcium carbide, 20-30 parts of magnesium oxide, 10-20 parts of barium carbonate, 20-30 parts of a carbonized material and 40-50 parts of products. According to the deoxidizing agent for steelmaking and the preparation method thereof, after being pulverized and molten, the calcium oxide, the calcium carbide, the magnesium oxide and barium sulfate are put into a mold, and compression molding is conducted, so that a cast ingot is obtained; and after pulverized, cast ingot powder is mixed with the carbonization material and the products and stirred, so that the deoxidizing agent for steelmaking is obtained. The deoxidizing agent for steelmaking has the beneficial effects of being high in deoxidizing efficiency and good in deoxidizing effect.

Owner:常州莱尚纺织品有限公司

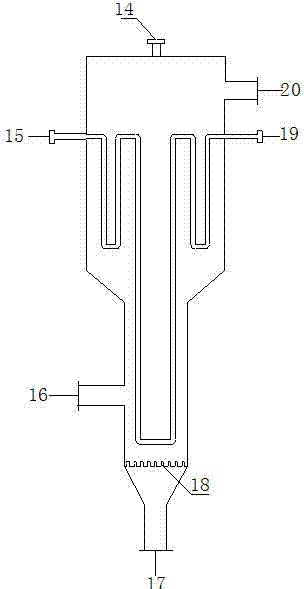

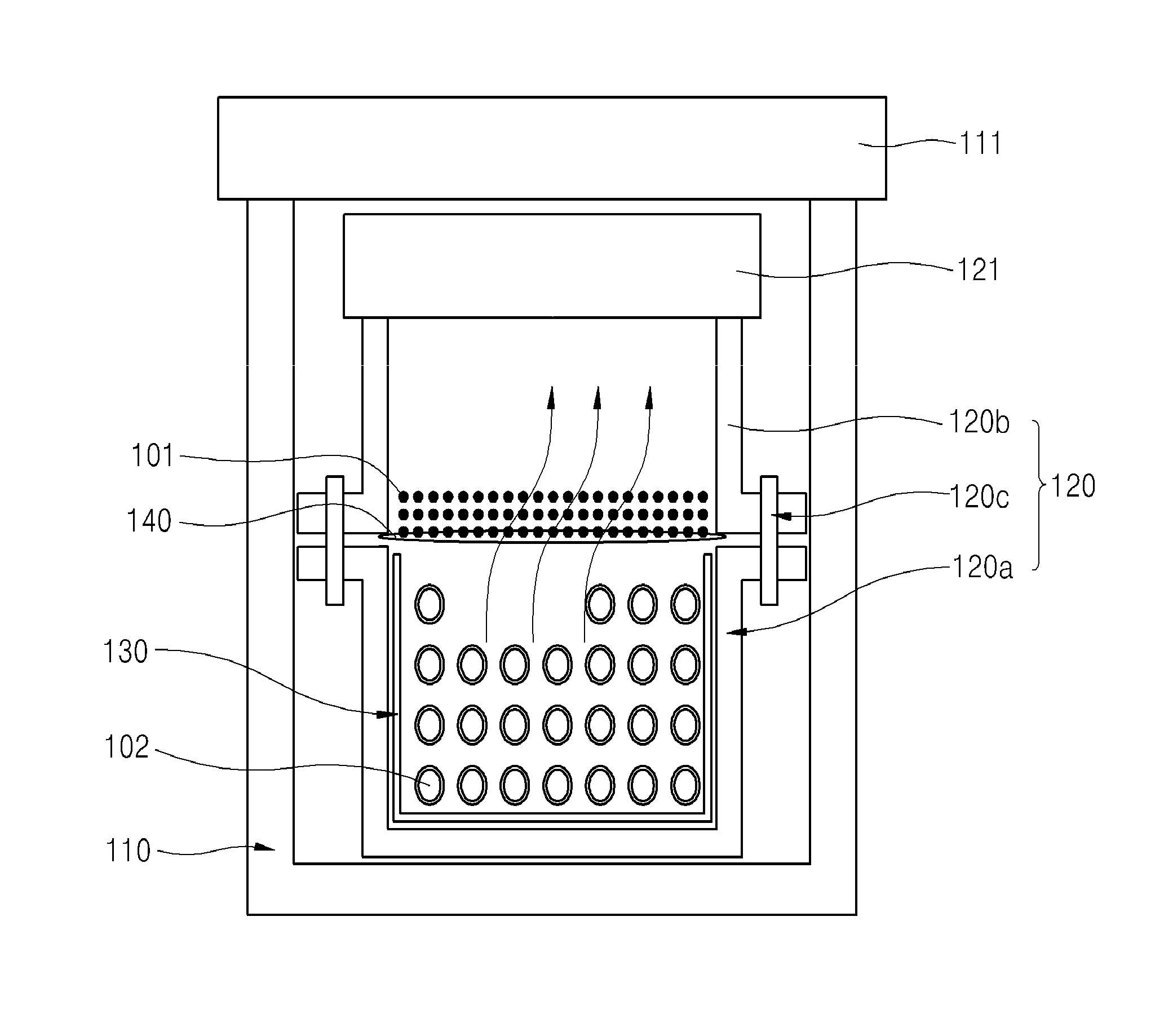

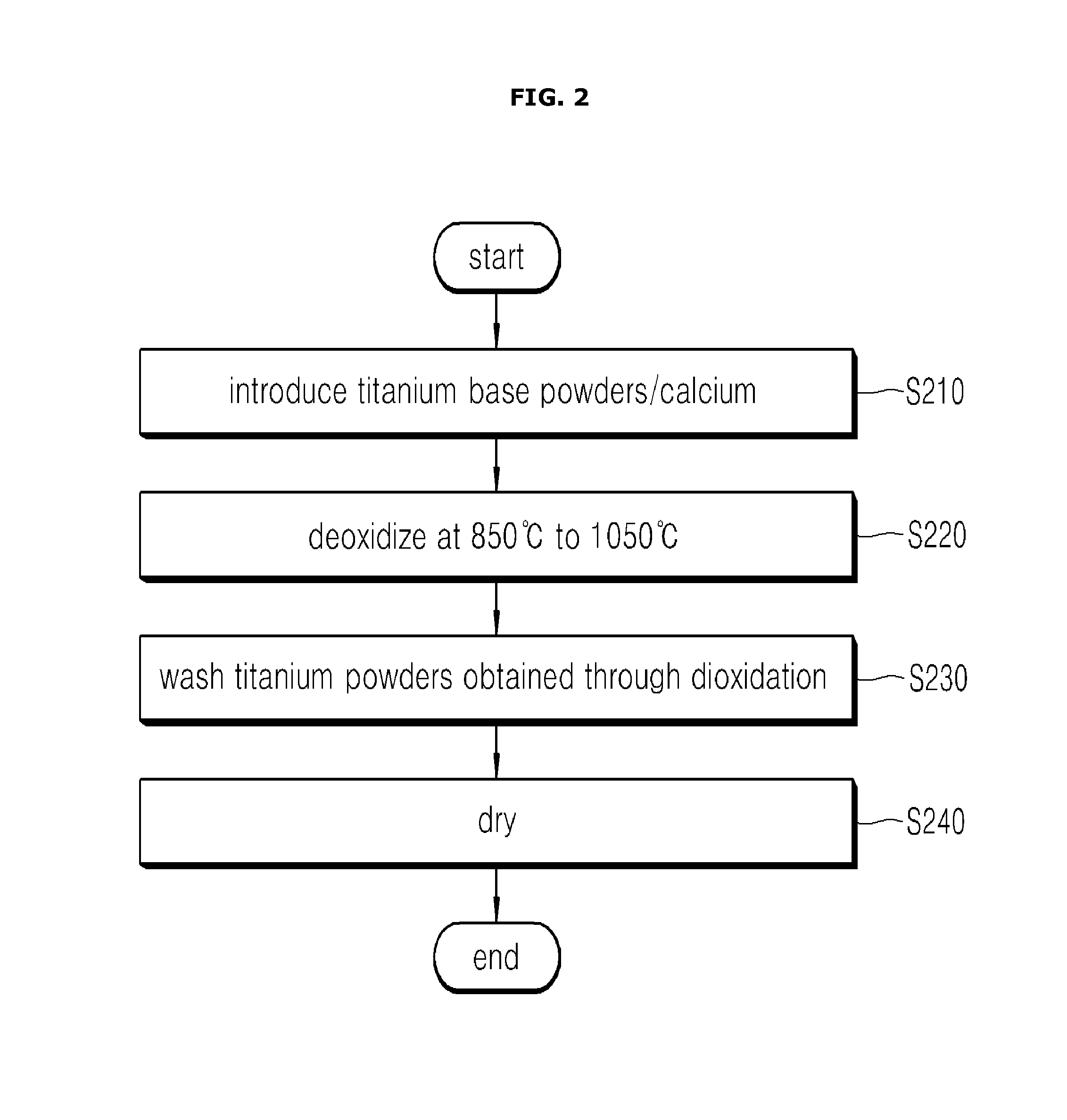

Deoxidation apparatus for preparing titanium powder with low oxygen concentration

ActiveUS8449813B1Reduce oxygen concentrationImprove deoxidation efficiencyTransportation and packagingBlast furnace componentsTitanium powderMelt temperature

Disclosed is a deoxidation apparatus for preparing low-oxygen titanium powders. The deoxidation apparatus includes a lower container having an open upper portion and storing an deoxidizer representing an oxygen degree higher than an oxygen degree of titanium and a melting temperature lower than a melting temperature of titanium, and an upper container coupled with the lower container on the lower container and storing titanium base powders. The upper container is provided at a lower surface thereof with a sieve, and allows the deoxidizer, which is evaporated due to heating, to make contact with the titanium base powders so that the titanium base powders are deoxidized.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

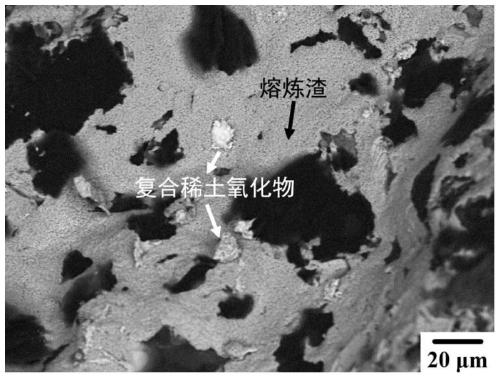

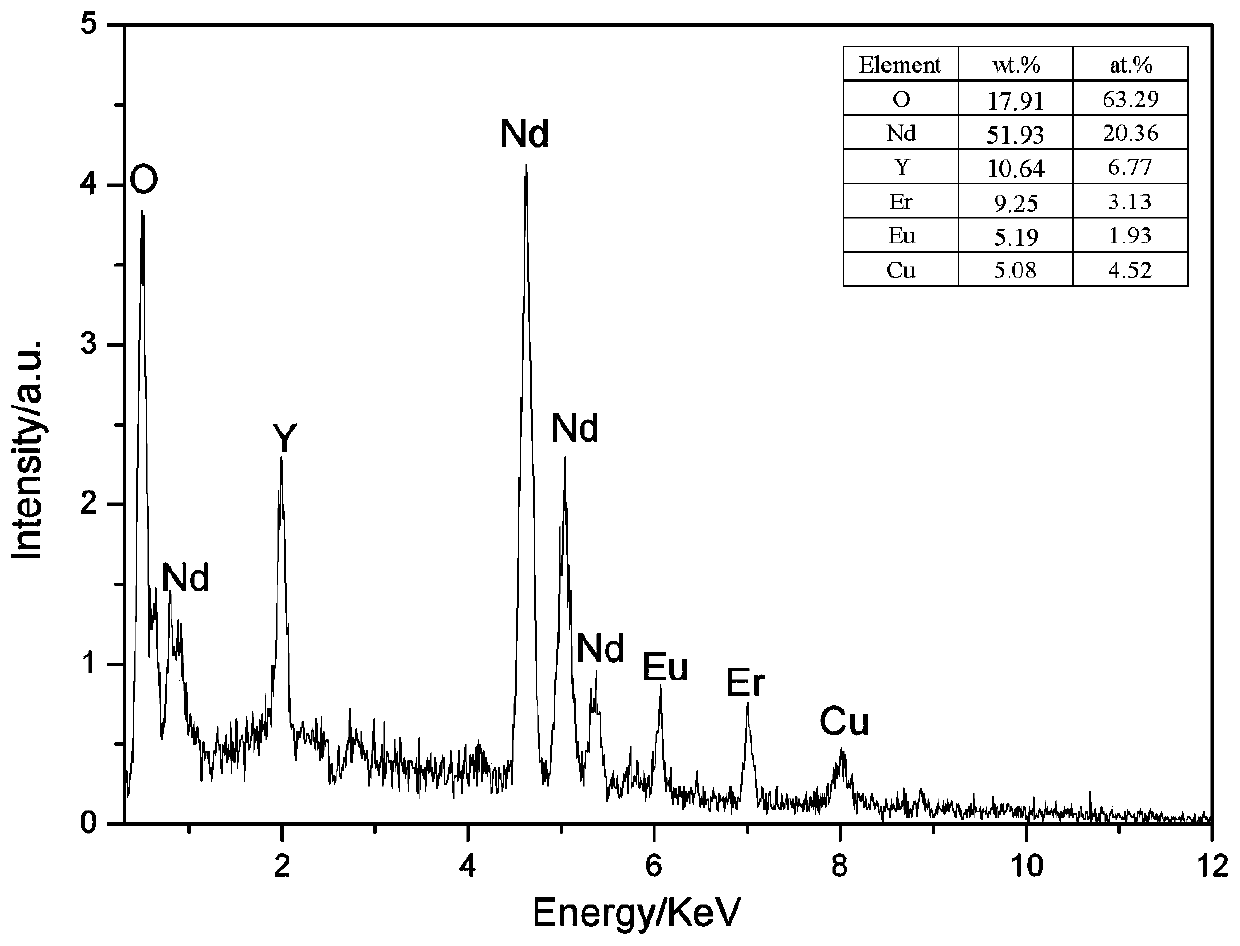

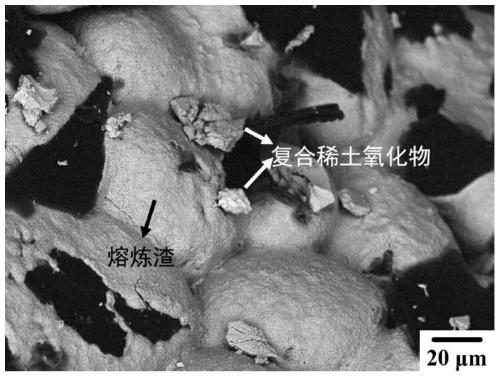

Deep deoxidizing agent and method for copper melt

The invention relates to a deep deoxidizing agent and method for copper melt, in particular to a deep deoxidizing agent and method for oxygen-free copper. The technological method is characterized inthat a cathode electrolytic copper plate is melted in a vacuum melting furnace at 1,100-1,250 DEG C, firstly, a phosphor copper intermediate alloy is added for preliminary deoxidization, then the deoxidizing agent is added for deep deoxidization, and finally, the oxygen content of the copper material can be lower than 20 ppm. The deoxidizing agent is prepared from chemical components including, byweight, 3%-10.5% of neodymium, 0.5%-3% of yttrium, 0.5%-4.5% of erbium, 0.15%-1.5% of europium and the balance copper. The deoxidizing agent is required to be mechanically crushed firstly before being used, then is ball-milled by the aid of a ball mill to be in the particle size ranging from 100 mu m to 300 mu m and is added to the copper melt after being coated by copper foil, after addition, the deoxidizing agent is quickly stirred for 20-30 min by the aid of a graphite rod, and a copper material is cast after slag fishing. Compared with traditional deoxidizing agents and methods for the oxygen-free copper, the method has the advantages that the method is high in deoxidizing efficiency, easy to operate and low in labor cost, and the deep deoxidizing purpose can be achieved.

Owner:YANTAI UNIV

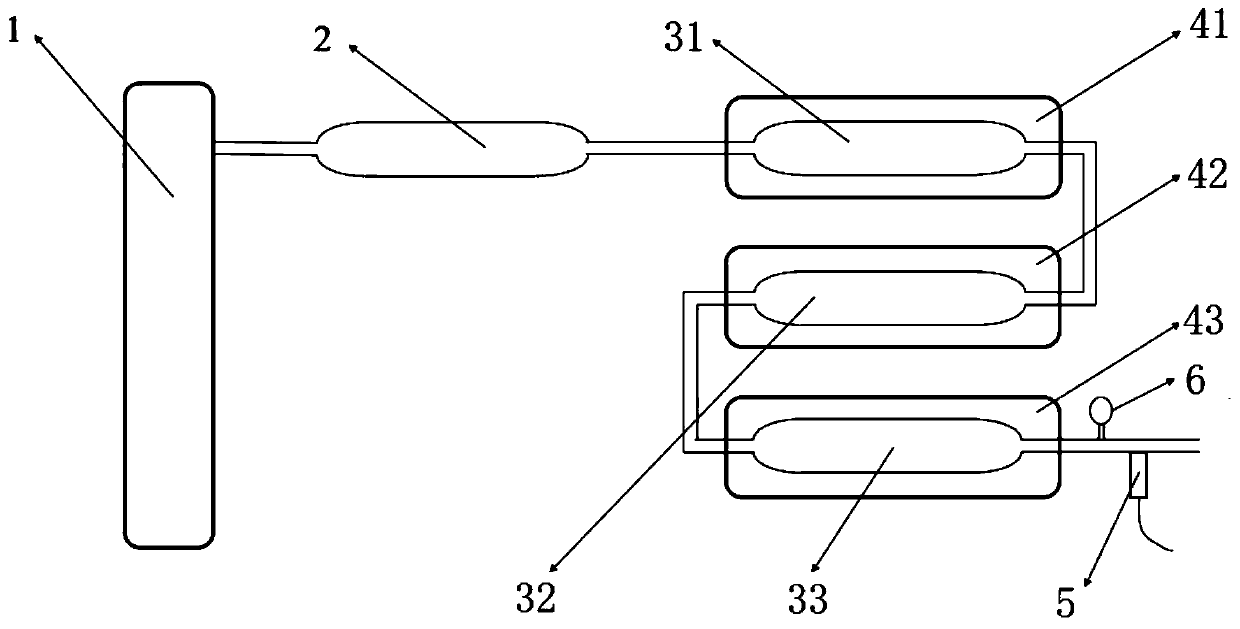

A gas purification device and its application

InactiveCN107362661BReduce humidityImprove purification qualityDispersed particle separationWater vaporShielding gas

The invention discloses a gas purifying device and an application thereof. The gas purifying device comprises a dehumidifying purifying chamber, a first deoxidizing purifying chamber, a second deoxidizing purifying chamber and a third deoxidizing purifying chamber which are serially connected by a pipeline. The inlet of the dehumidifying purifying chamber is connected with a gas bottle of a protective gas. The interior of the dehumidifying purifying chamber is filled with a silica gel dehumidizer. The interior of the first deoxidizing purifying chamber is filled with one of simple substance copper or copper-based alloy as a deoxidizing purifier. The interior of the second deoxidizing purifying chamber is filled with one of simple substance molybdenum or molybdenum-based alloy as the deoxidizing purifier. The interior of the third deoxidizing purifying chamber is filled with one of simple substance titanium, titanium sponge or titanium-based alloy as the deoxidizing purifier. The first deoxidizing purifying chamber, the second deoxidizing purifying chamber and the third deoxidizing purifying chamber are provided with heating units. The gas purifying device is capable of executing the adsorption removal to water vapor and oxygen in the gas, and satisfying various requirements in the experiment and production for the atmosphere environment, and has the characteristics of simple operation, rapid purifying speed, long service time of the purifier, and low cost.

Owner:CENT SOUTH UNIV

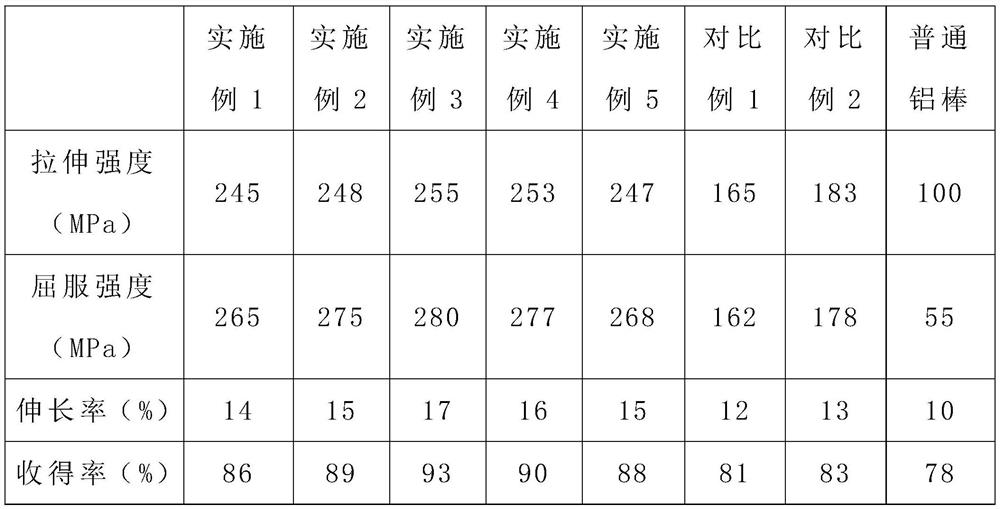

High-yield and high-strength cold-drawn deoxidized aluminum bar and processing technology thereof

The invention discloses a high-yield and high-strength cold-drawn deoxidized aluminum bar and a processing technology thereof. The aluminum bar comprises a core material, a first shell layer and a second shell layer, the first shell layer and the second shell layer are sequentially arranged on the surface of the core material outwards, and the core material comprises the following components of, by mass, 9%-12% of silicon, 10%-13% of calcium, 5%-6% of magnesium and 1%-5% of niobium. Through the structure and the components of the aluminum bar, the strength and the yield of the aluminum bar areimproved, the first shell layer and the second shell layer wrap the core material, the core material is prevented from being interfered by air, aluminum oxidation is prevented from affecting the deoxidation efficiency of molten steel, the additive amount of elements difficult to obtain is reduced, the first shell layer and the second shell layer are rapidly oxidized, products float upwards, and the surface of the molten steel is shielded; and after molten steel is deoxidized, secondary oxidation of the molten steel can be avoided, sputtering of aluminum is prevented, excessive use is not needed, the utilization rate of the aluminum bar is increased, residues of the aluminum bar in the molten steel are reduced, the yield of the aluminum bar is increased, and the technology is suitable forwide application and popularization.

Owner:江苏戴美特医疗科技有限公司

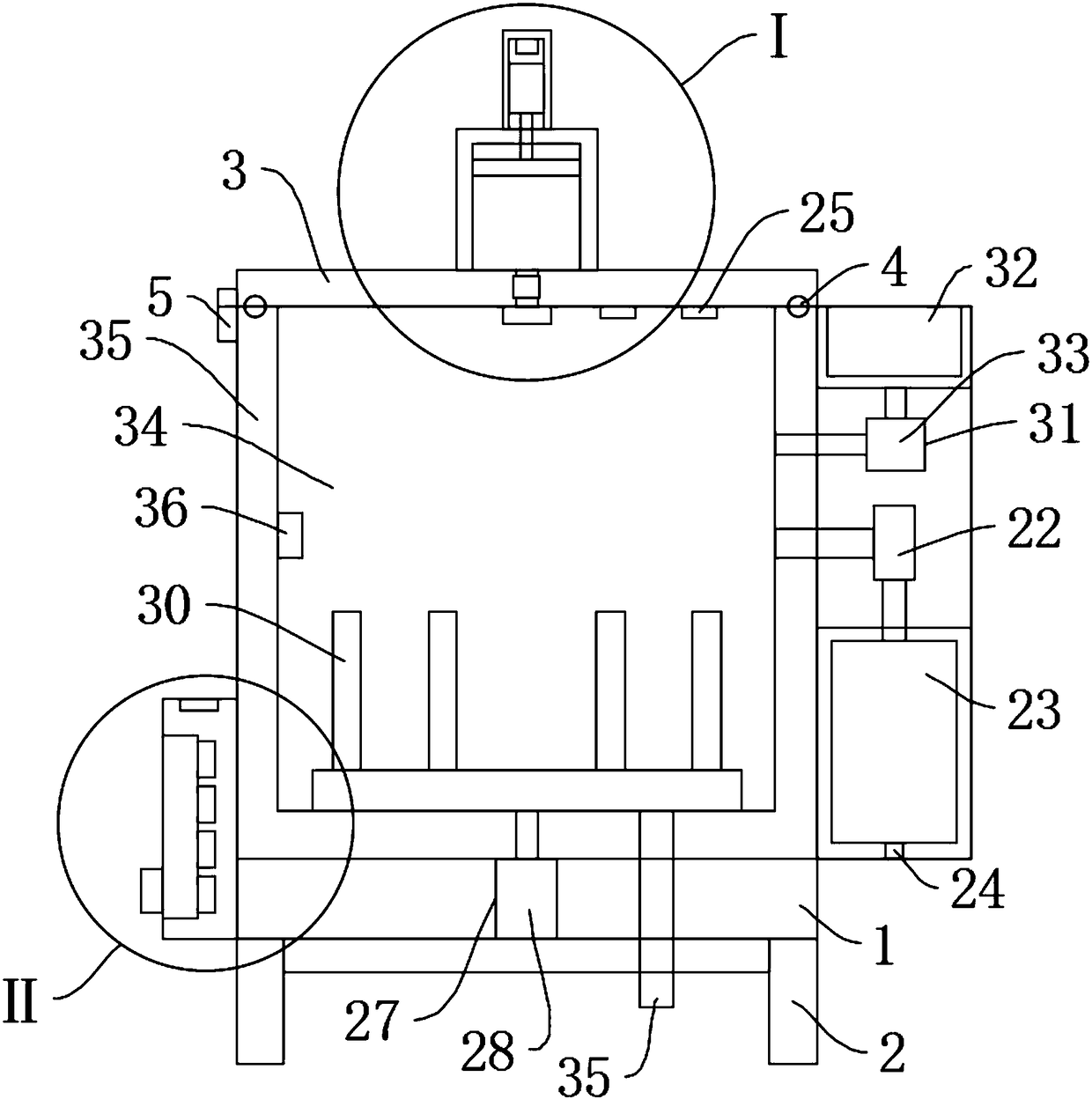

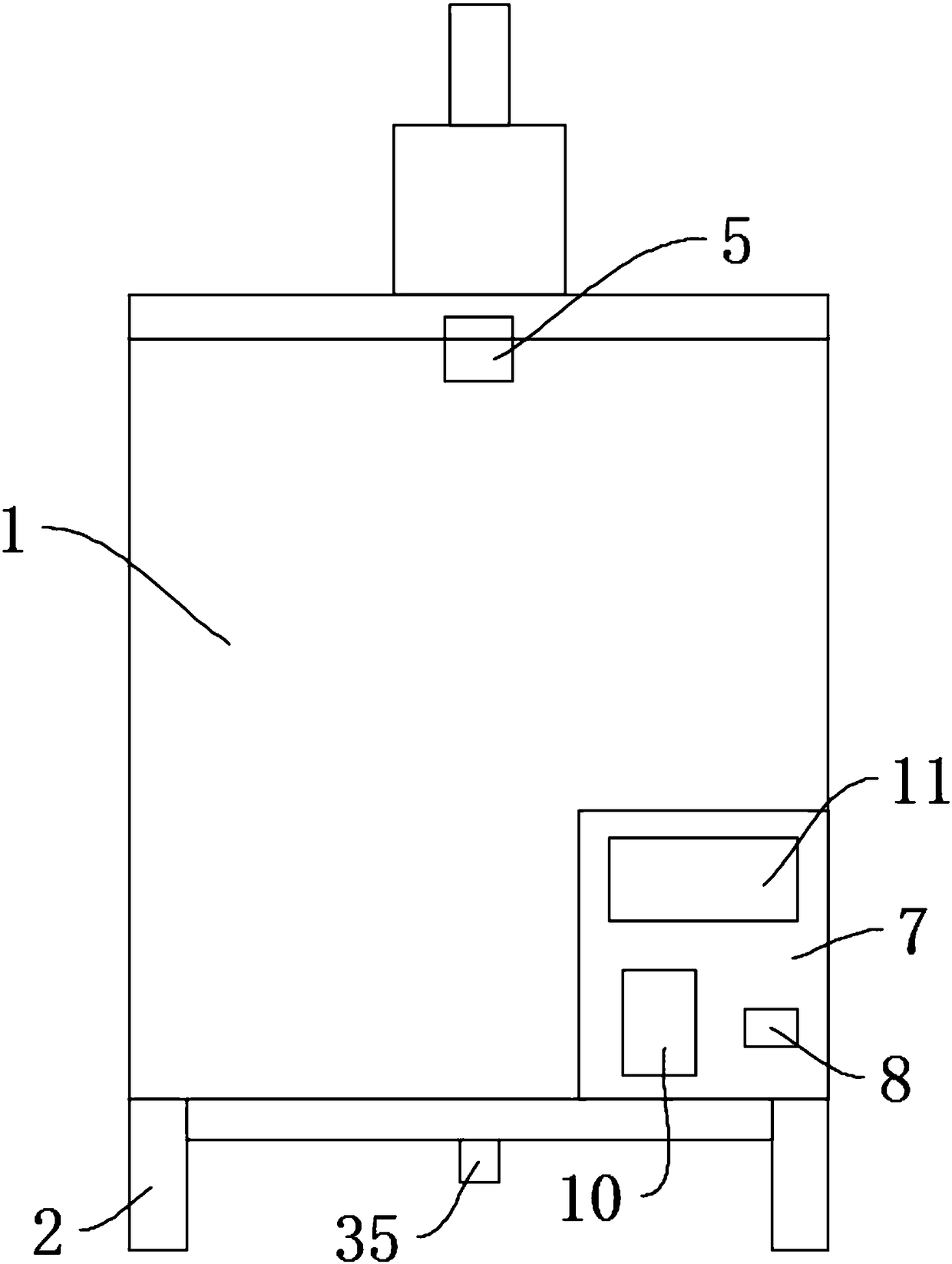

Salt making system vacuum deoxidation device and method

InactiveCN108584985AEasy dischargeImprove deoxidation efficiencyLiquid degasificationAlkali metal chloridesRubber ringElectromagnetic lock

The invention discloses a salt making system vacuum deoxidation device and method. The device comprises a deoxidation machine shell, a deoxidation machine base, a deoxidation machine upper cover, a sealing rubber ring, an electromagnetic lock, a control device, a gas device, a stirring device and a delivering device, the control device is arranged on one side of the deoxidation machine shell, thedeoxidation machine upper cover is arranged on the upper side of the deoxidation machine shell, the deoxidation machine base is arranged on the lower side of the deoxidation machine shell, the electromagnetic lock is arranged on the upper side of the control device, the gas device is arranged on the upper side of the deoxidation machine upper cover, and the sealing rubber ring is arranged on the lower surface of the inside of the deoxidation machine upper cover. The salt making system vacuum deoxidation device has the advantages that oxygen discharging can be accelerated by feeding inert gas in the process of vacuum deoxidation, full-automatic sensing of oxygen content, liquid information and air pressure information can be realized to realize full-automatic vacuum deoxidation processing operation of a salt making system, deoxidation efficiency is high, and operation is simple.

Owner:新疆盐湖制盐有限责任公司

Preparation method of environment-friendly smokeless (acidic) molten steel refining agent

The invention discloses a preparation method of an environment-friendly smokeless (acidic) molten steel refining agent. The refining agent is composed of a component A and a component B, the componentA is a silicon-based deoxidizer, the dosage is 40% by mass, the component B is prepared from one or any composition of silicate, carbonate and passivated lime, the dosage is 50-60% by mass, in the refining agent, alkalinity R is larger than or equal to 2.0 (CaO / SiO2), N is smaller than or equal to 0.06%, and silicate, carbonate and passivated lime are all made by mechanical ball pressing. The environment-friendly smokeless (acidic) molten steel refining agent is safe and environmentally friendly, has no toxic or harmful impurity element, is convenient to store and transport, not likely to beoxidized by air when used at high temperature, high in yield, high in deoxidation efficiency in slag and high in speed, and is the most ideal molten steel refining agent.

Owner:西峡县耀辉冶金材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com