Patents

Literature

297results about How to "Reduce caking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

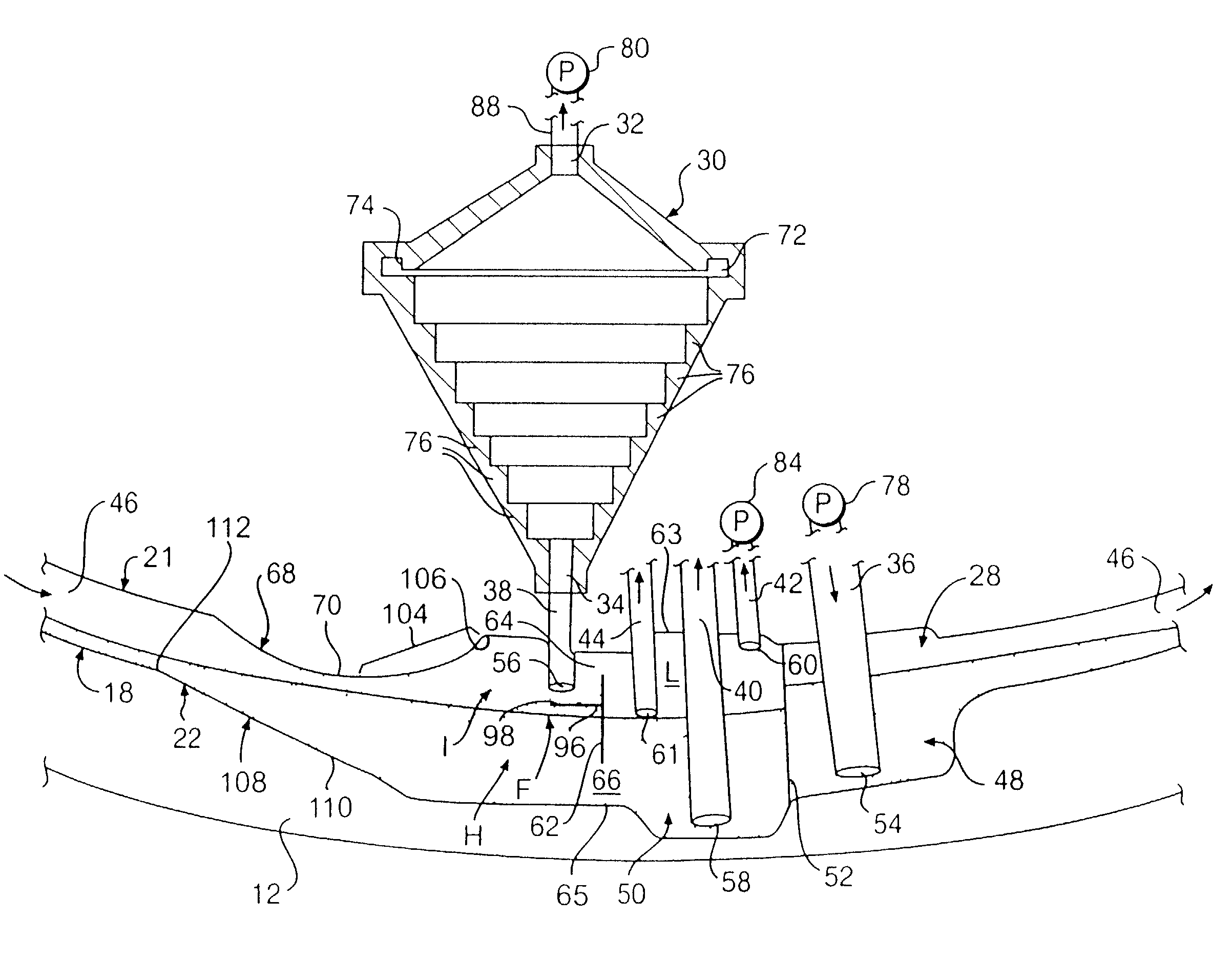

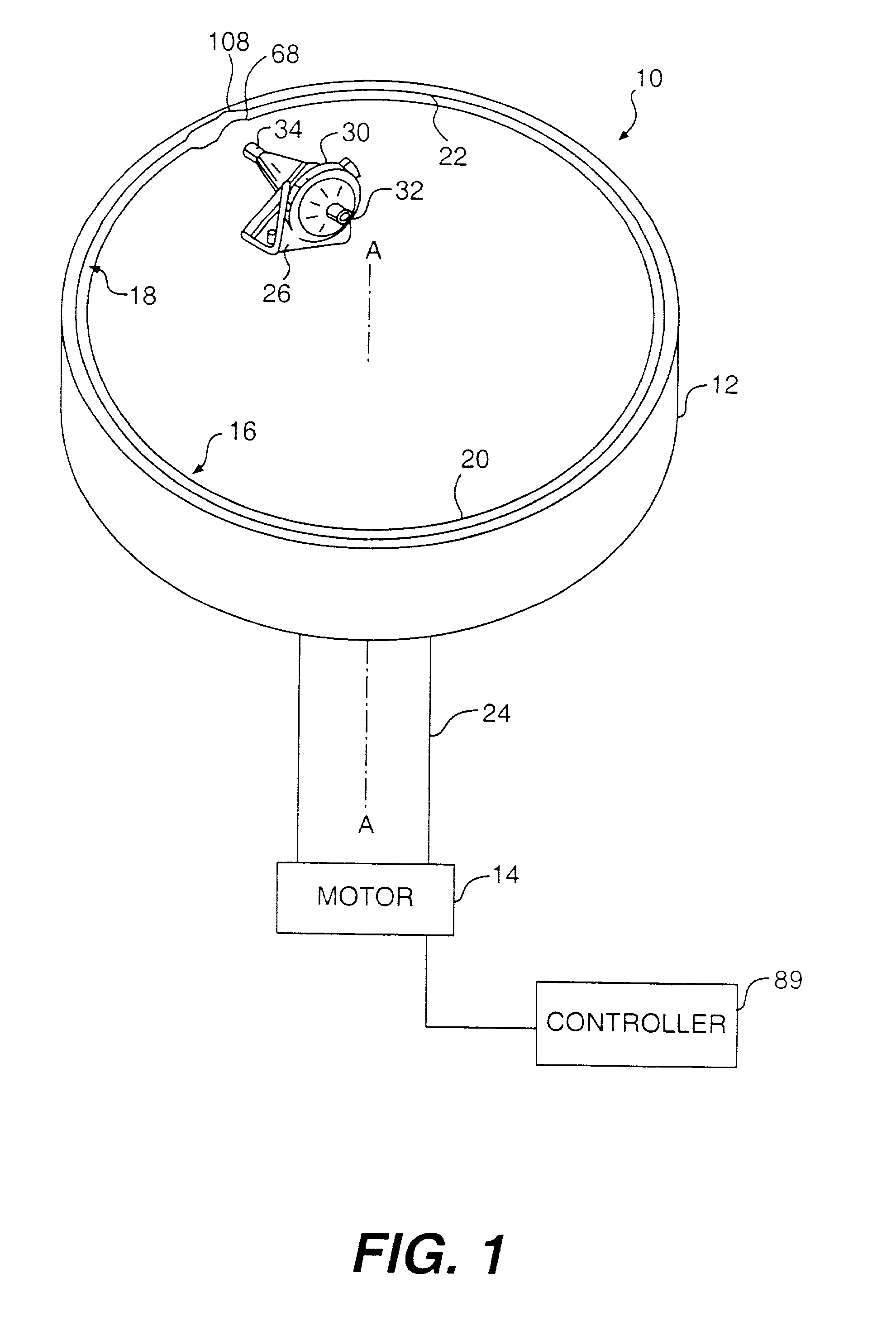

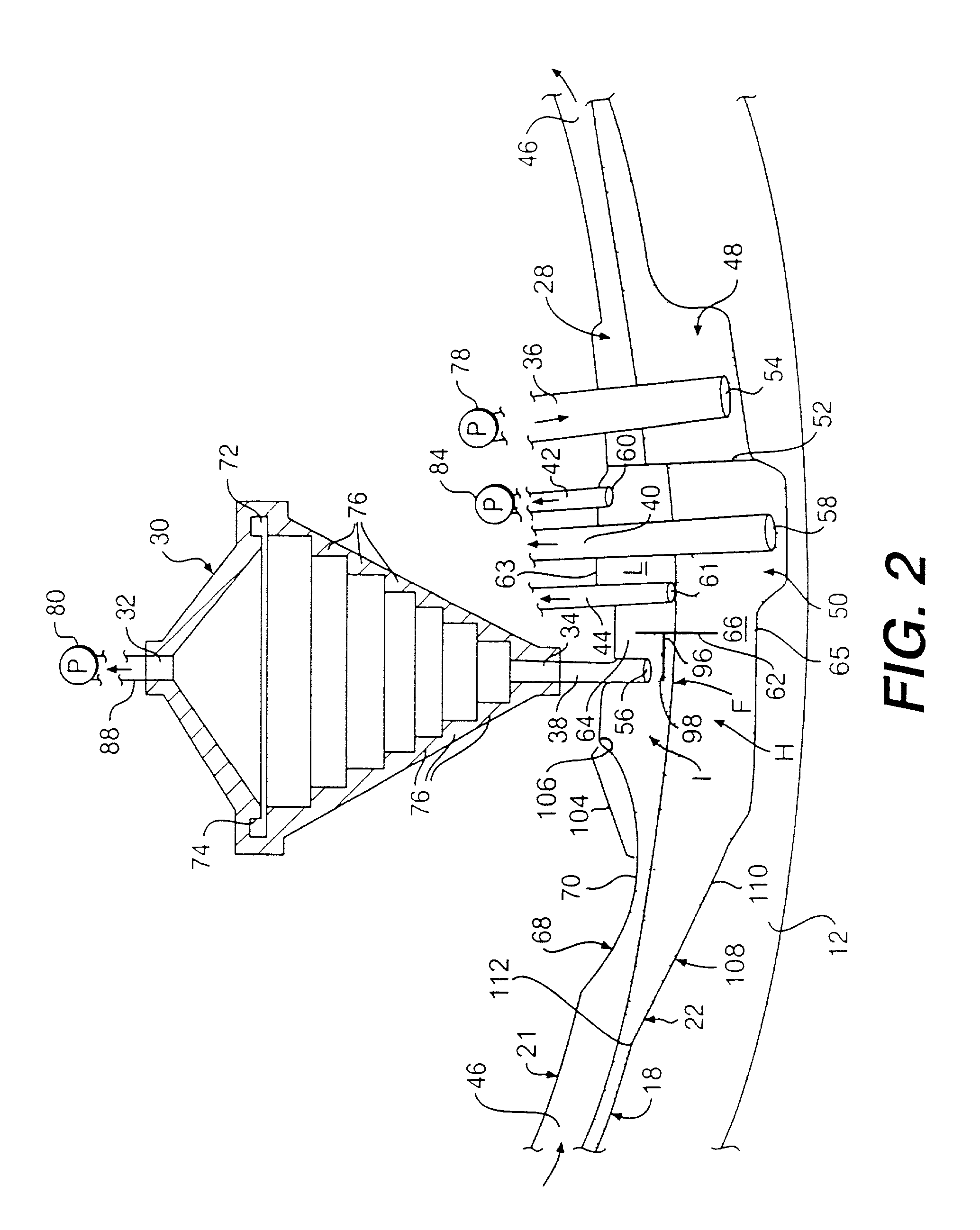

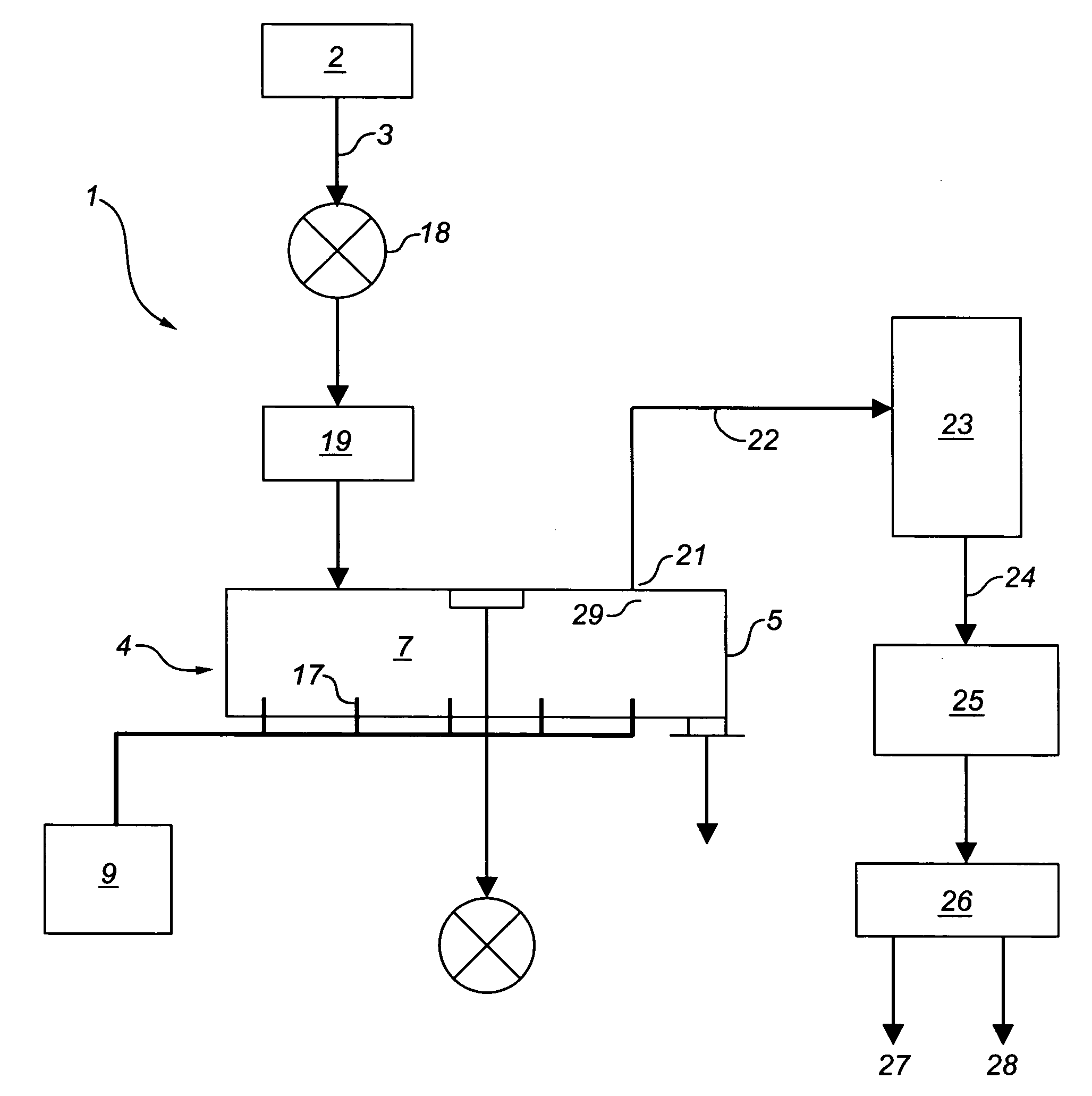

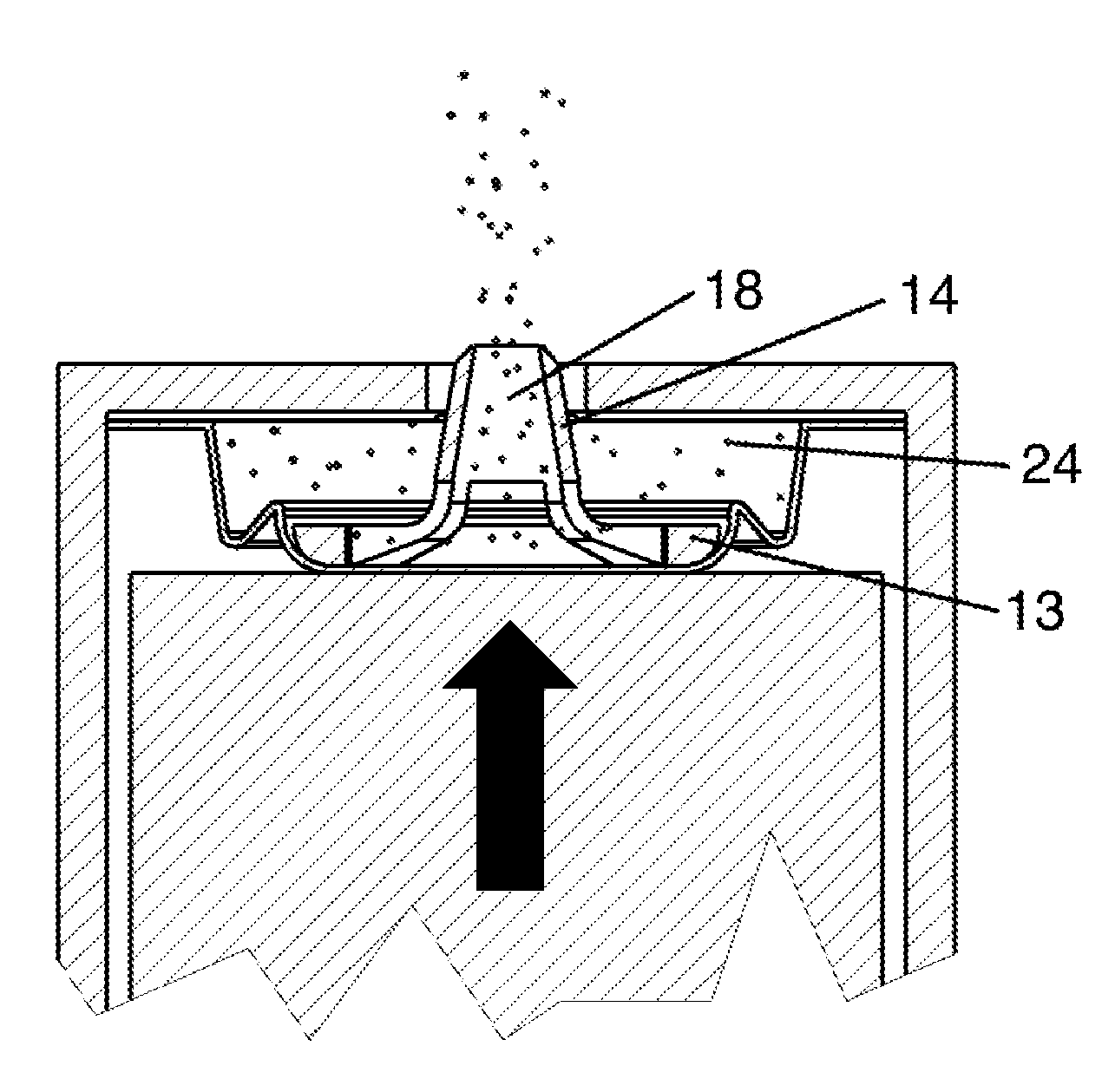

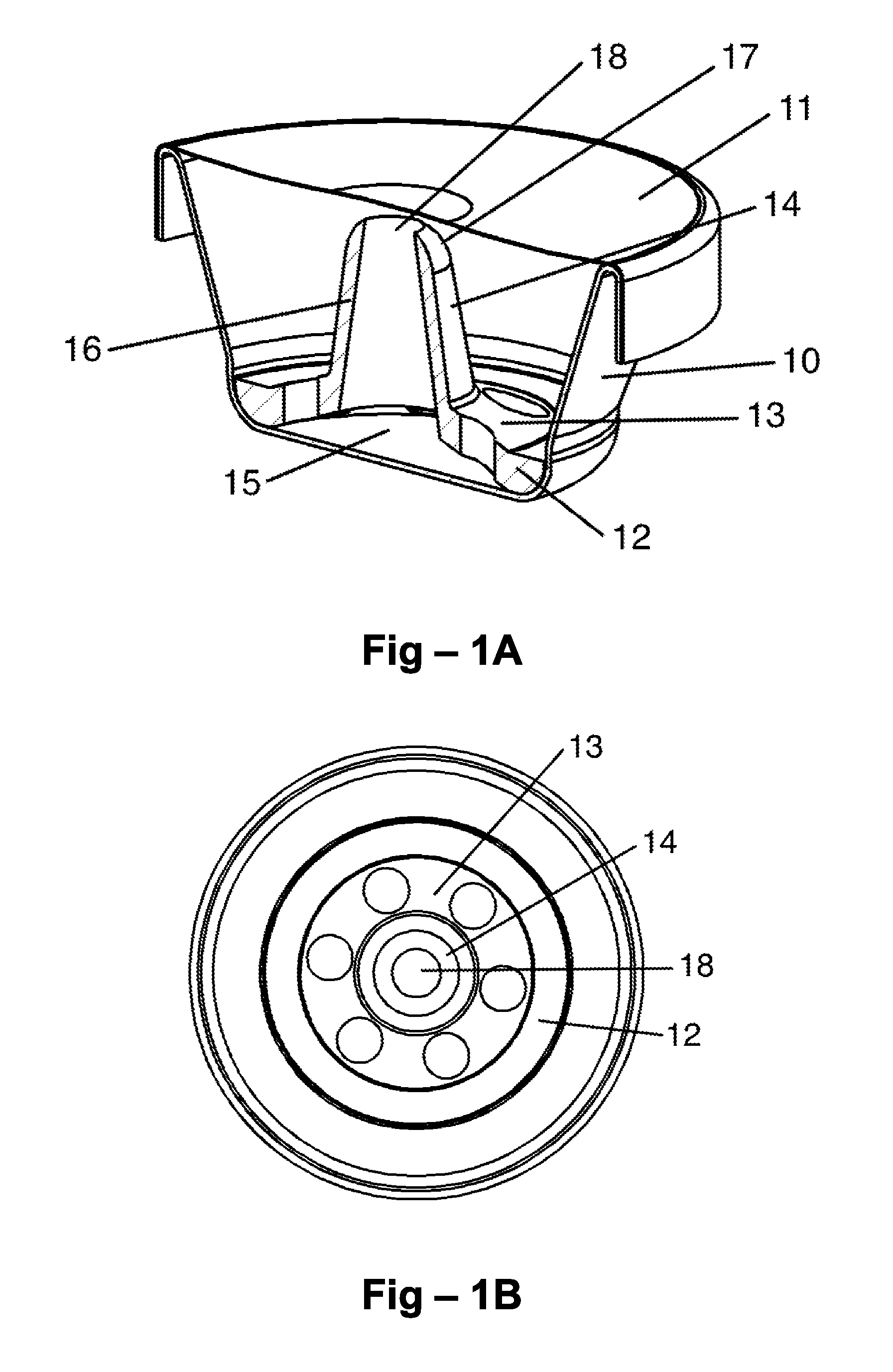

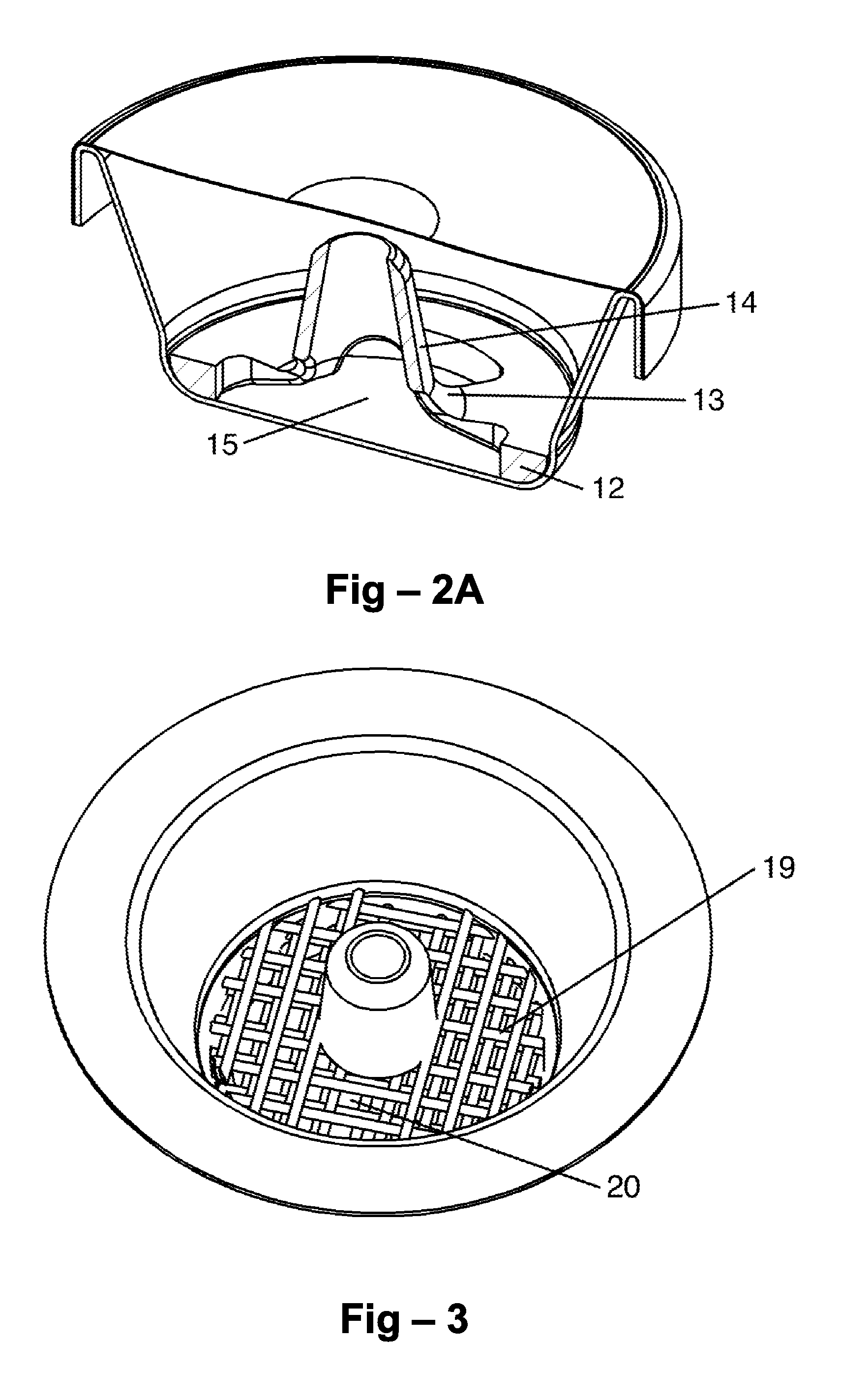

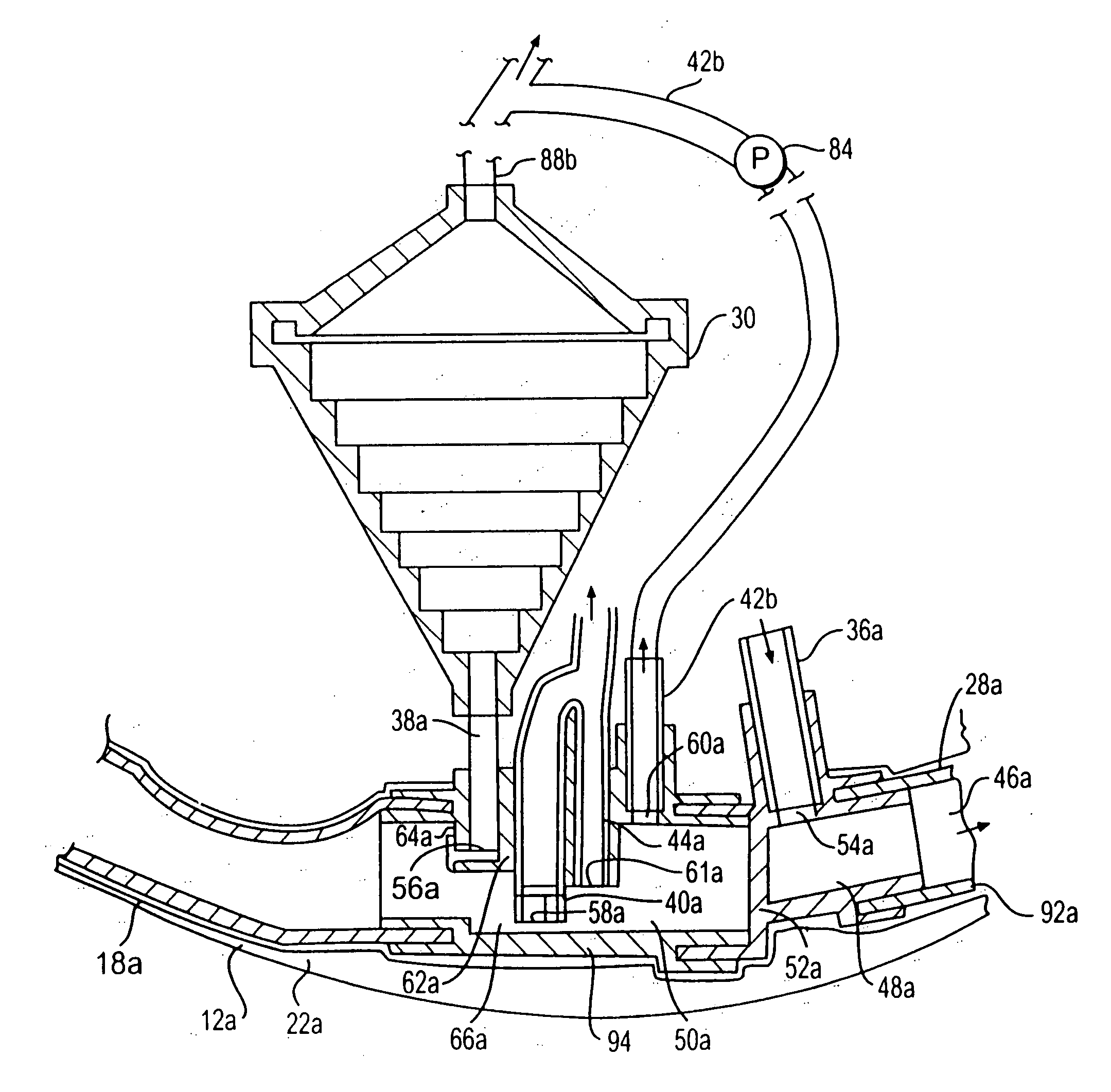

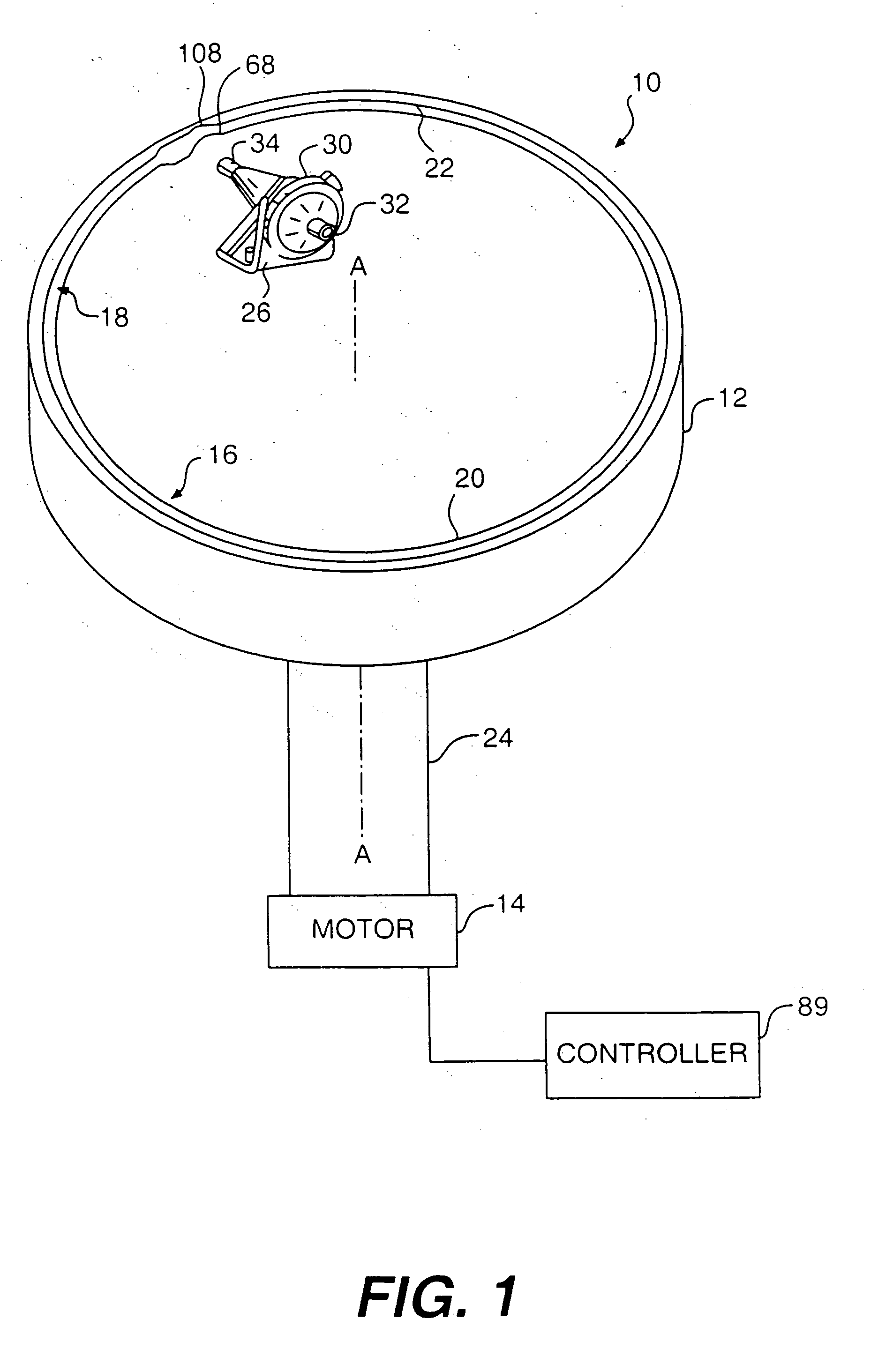

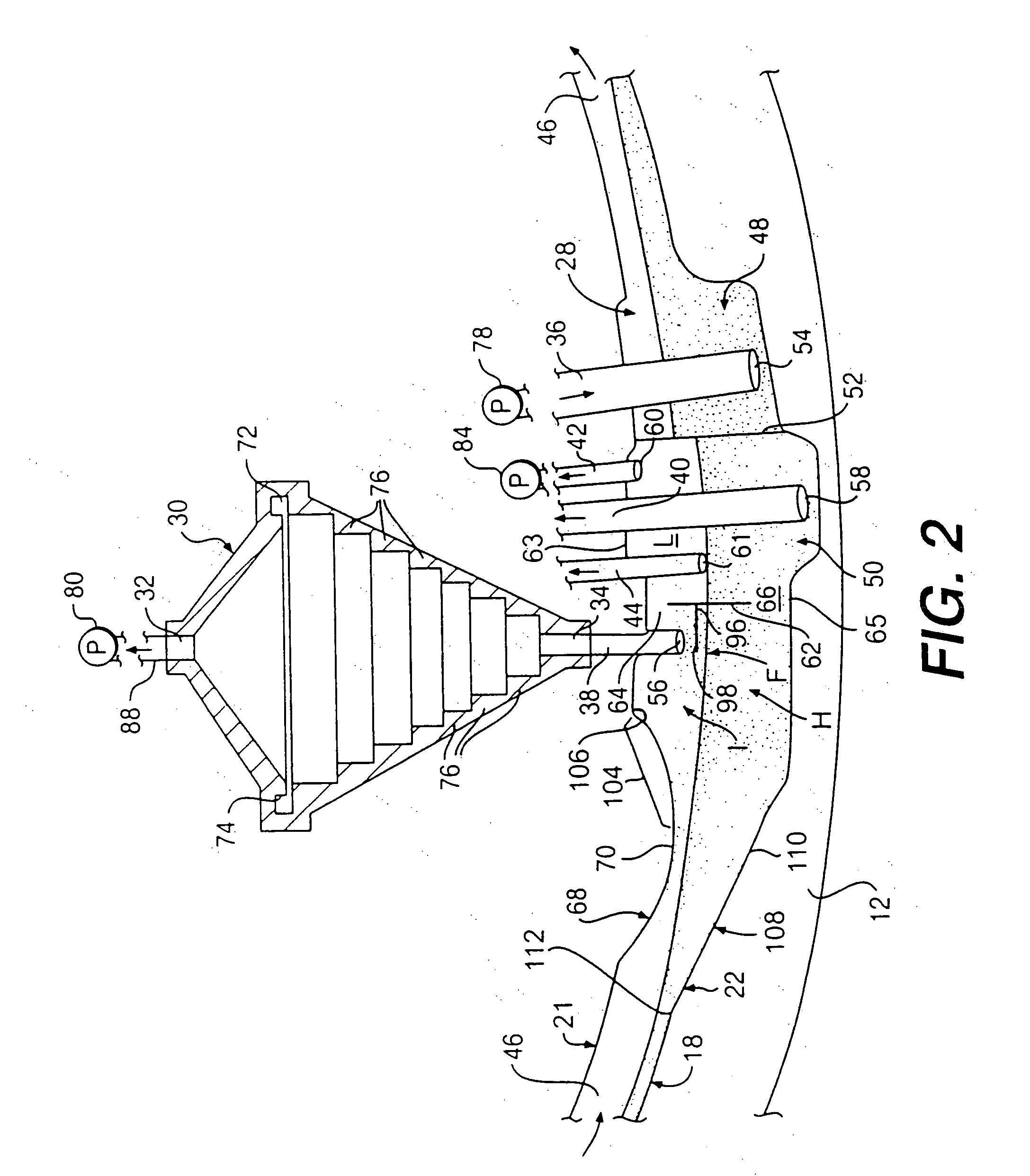

Centrifugal separation apparatus and method for separating fluid components

InactiveUS7029430B2Reduce cakingReduces platelet clumpingOther blood circulation devicesWithdrawing sample devicesHigh densityRed blood cell

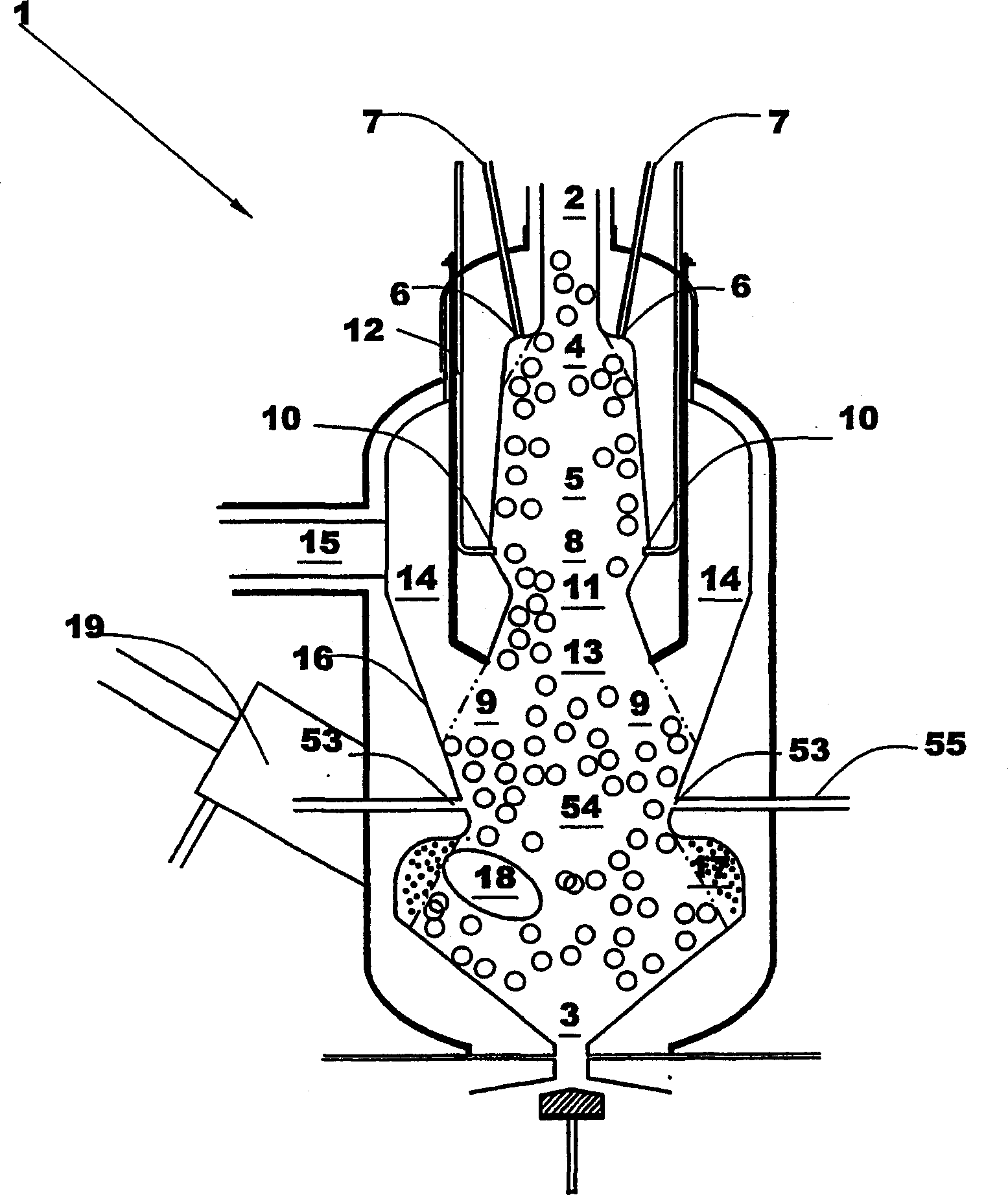

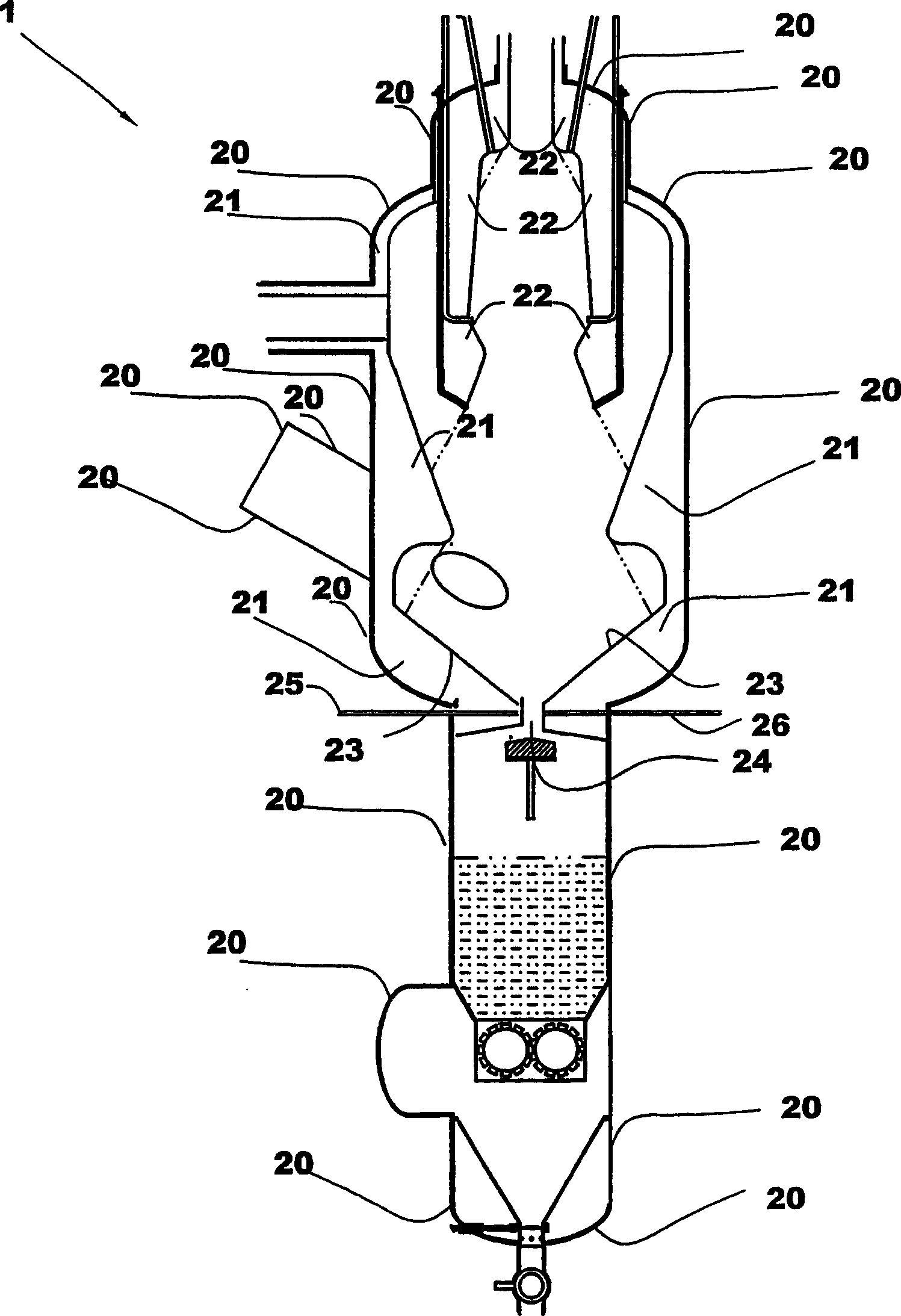

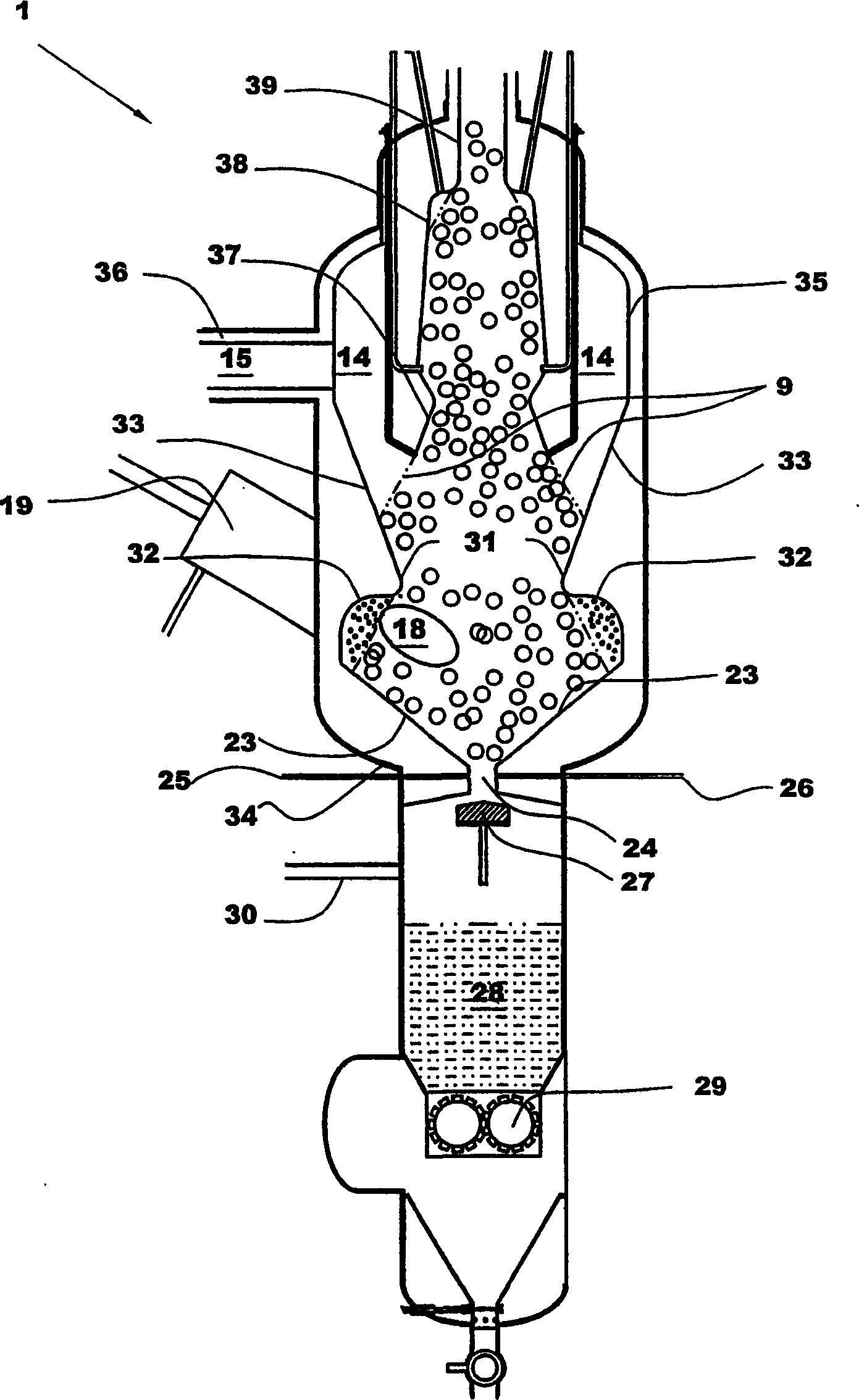

An apparatus and method are provided for separating components of a fluid or particles. A separation vessel having a barrier dam is provided to initially separate an intermediate density components of a fluid, and a fluid chamber is provided to further separate these intermediate density components by forming an elutriative field or saturated fluidized particle bed. The separation vessel includes a shield for limiting flow into the fluid chamber of relatively high density substances, such as red blood cells. The separation vessel also includes a trap dam with a smooth, gradually sloped downstream section for reducing mixing of substances. Structure is also provided for adding additional plasma to platelets and plasma flowing from the fluid chamber. The system reduces clumping of platelets by limiting contact between the platelets and walls of the separation vessel.

Owner:TERUMO BCT

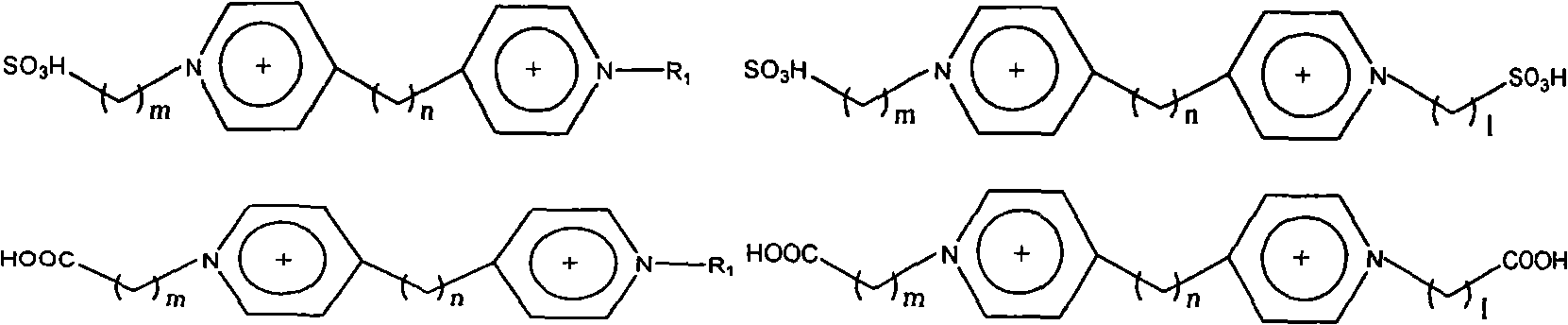

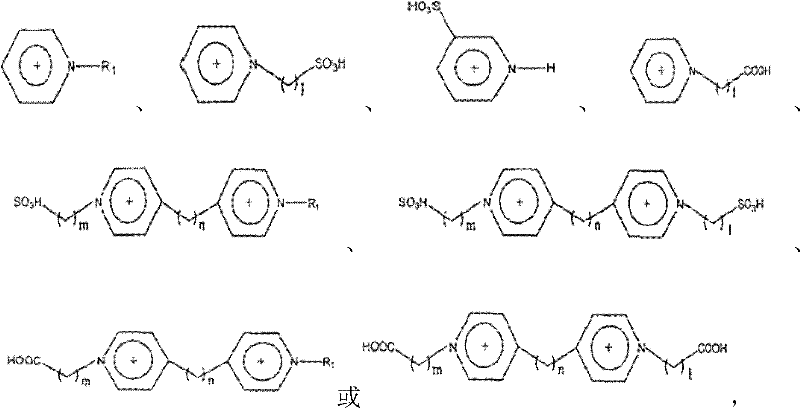

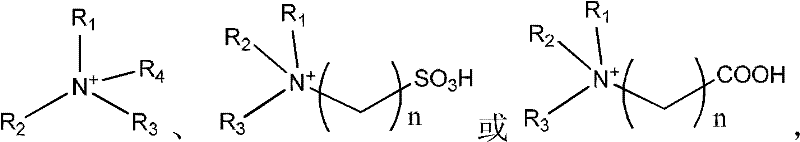

Liquid anti-caking agent for compound fertilizer

InactiveCN101654387AReduce cakingImprove anti-caking effectFertilizer mixturesFertilizerDefoaming Agents

The invention relates to a liquid anti-caking agent for a compound fertilizer, which consists of 1 to 50 weight percent of aqueous polymer, 1 to 50 weight percent of surfactant, and the balance of water. The surfactant is one or combination of any of an anionic surfactant, a non-ionic surfactant, a cationic surfactant and an amphoteric surfactant. Optionally, one ore more additives which are selected from a defoaming agent, a preservative, a dye and a pigment can also be added into the liquid anti-caking agent for the compound fertilizer; and the consumption of the defoaming agent is 0 to 5 weight percent, the consumption of the preservative is 0 to 5 weight percent and the total consumption of the dye and the pigment is 0 to 50 weight percent. The liquid anti-caking agent for the compound fertilizer can effectively solve the caking problem of a compound fertilizer product, particularly the caking problem of a compound fertilizer with high nutrient content such as a high nitrogen compound fertilizer which is difficult to solve by present enterprises producing compound fertilizers, and ensures that the compound fertilizer product has the characteristics of green fertilizers.

Owner:北京科普基业精细化工科技有限公司

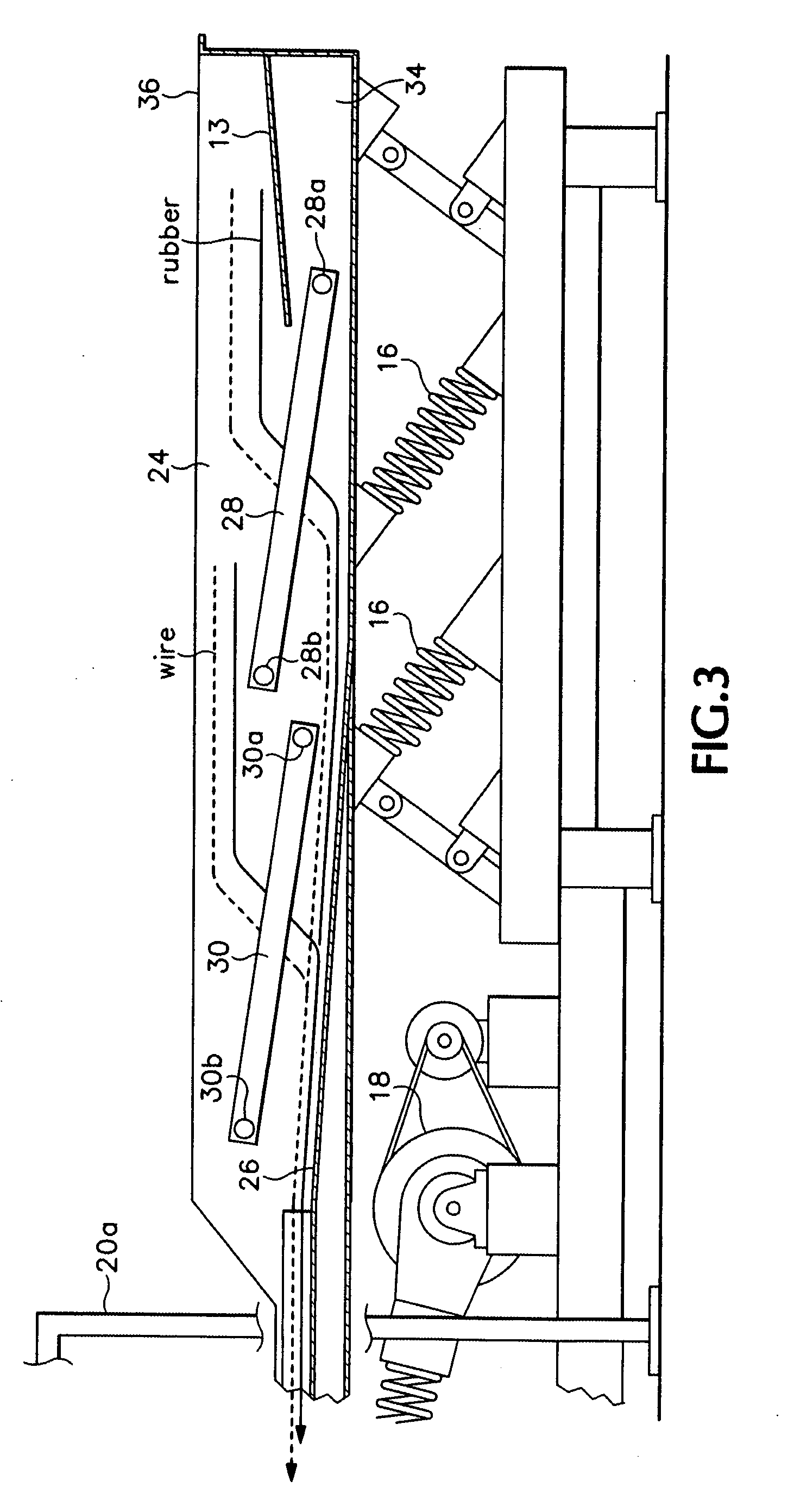

Reinforced elastomer preparation, elastomer composite and tire having component thereof

InactiveUS6172138B1Reduction of mix energyImprove processingSpecial tyresWheelsEngineeringElastomer composites

Preparation of an elastomer which contains a dispersion of filler reinforcement by forming a filler reinforcement in-situ within the elastomer host, the resulting elastomer / filler composite and tire having component which contains such reinforced elastomer. The invention includes a rubber composition of at least two elastomers wherein one of said elastomers is a pre-formed composite of elastomer and in-situ formed filler reinforcement. A tire having a component of such rubber composition, particularly a tire tread, is specifically contemplated.

Owner:THE GOODYEAR TIRE & RUBBER CO

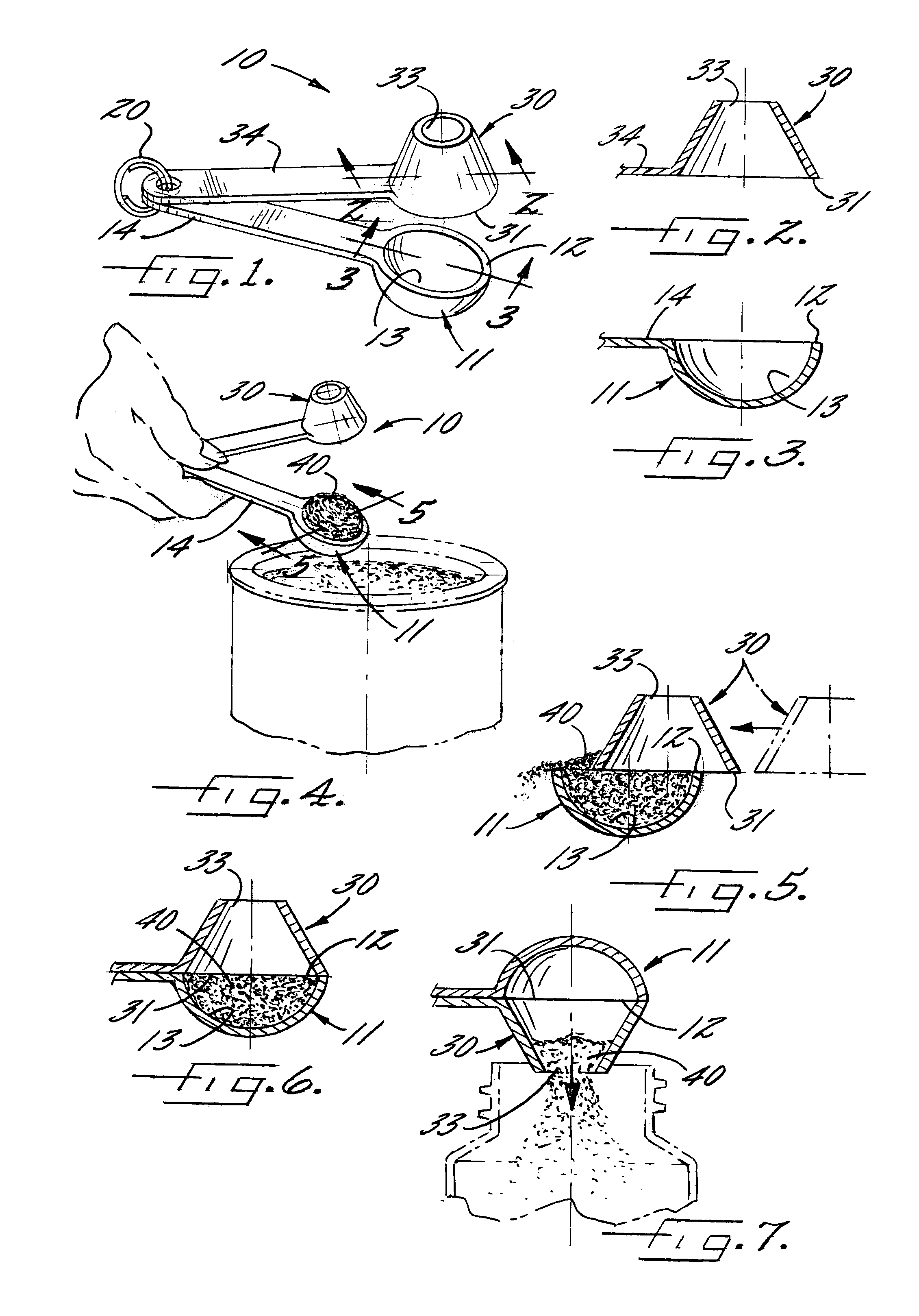

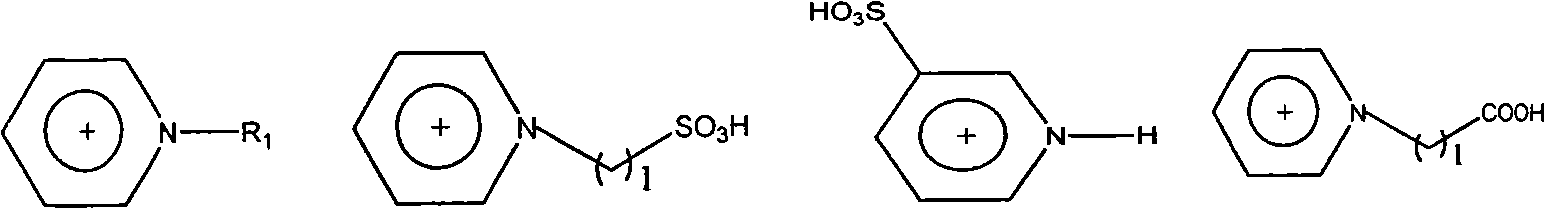

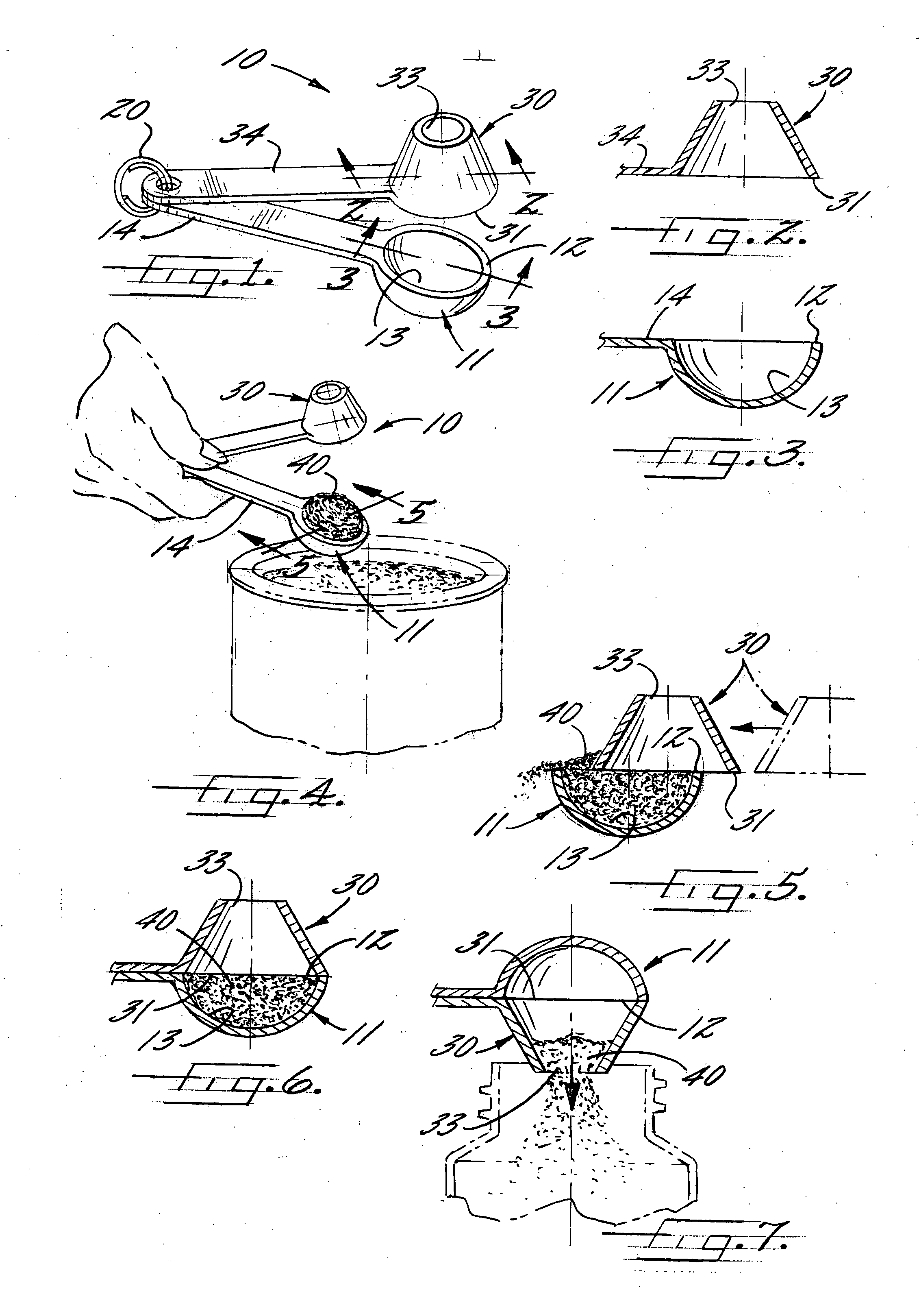

Cup for measuring and dispensing powdered product

InactiveUS6974056B2Facilitates accurate and uniform transferAccurate measurementLarge containersStationary measuring chambersAdditive ingredientEngineering

Owner:SONOCO DEV INC

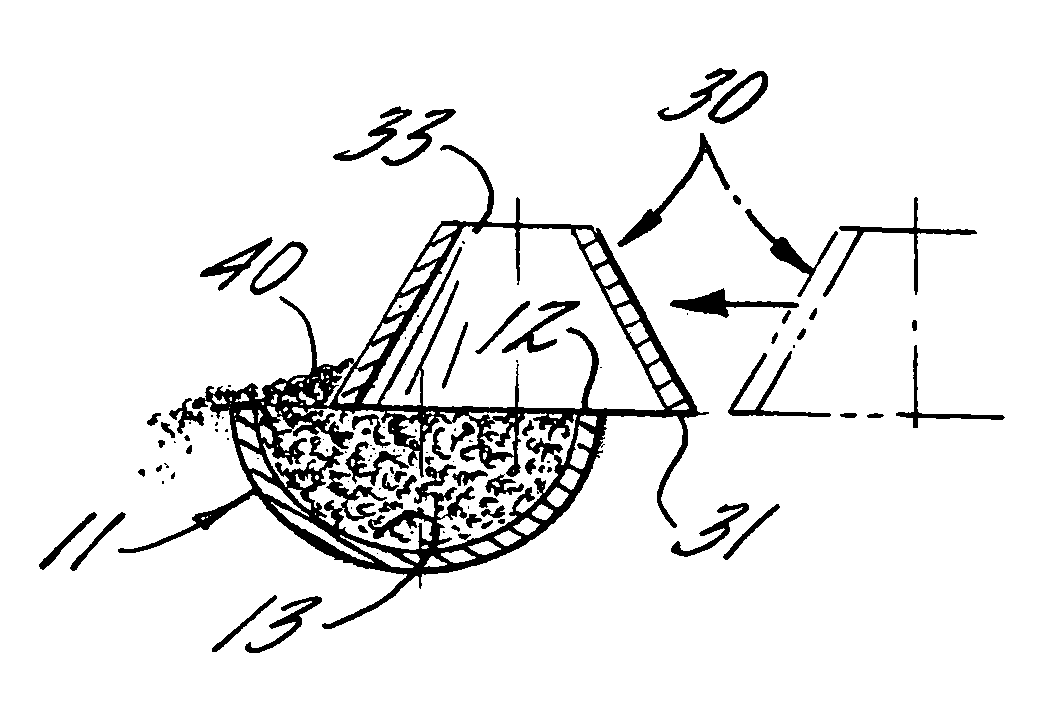

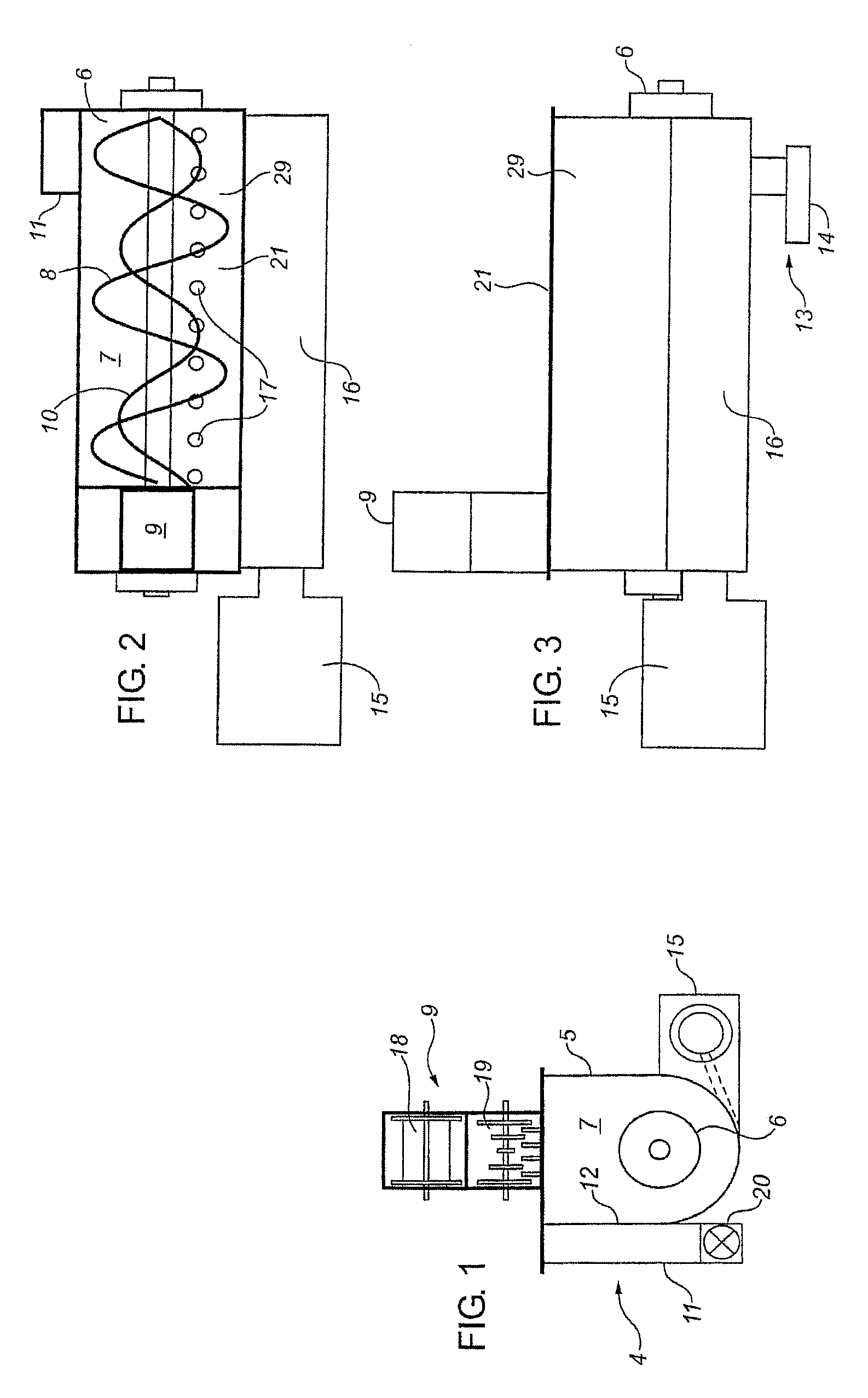

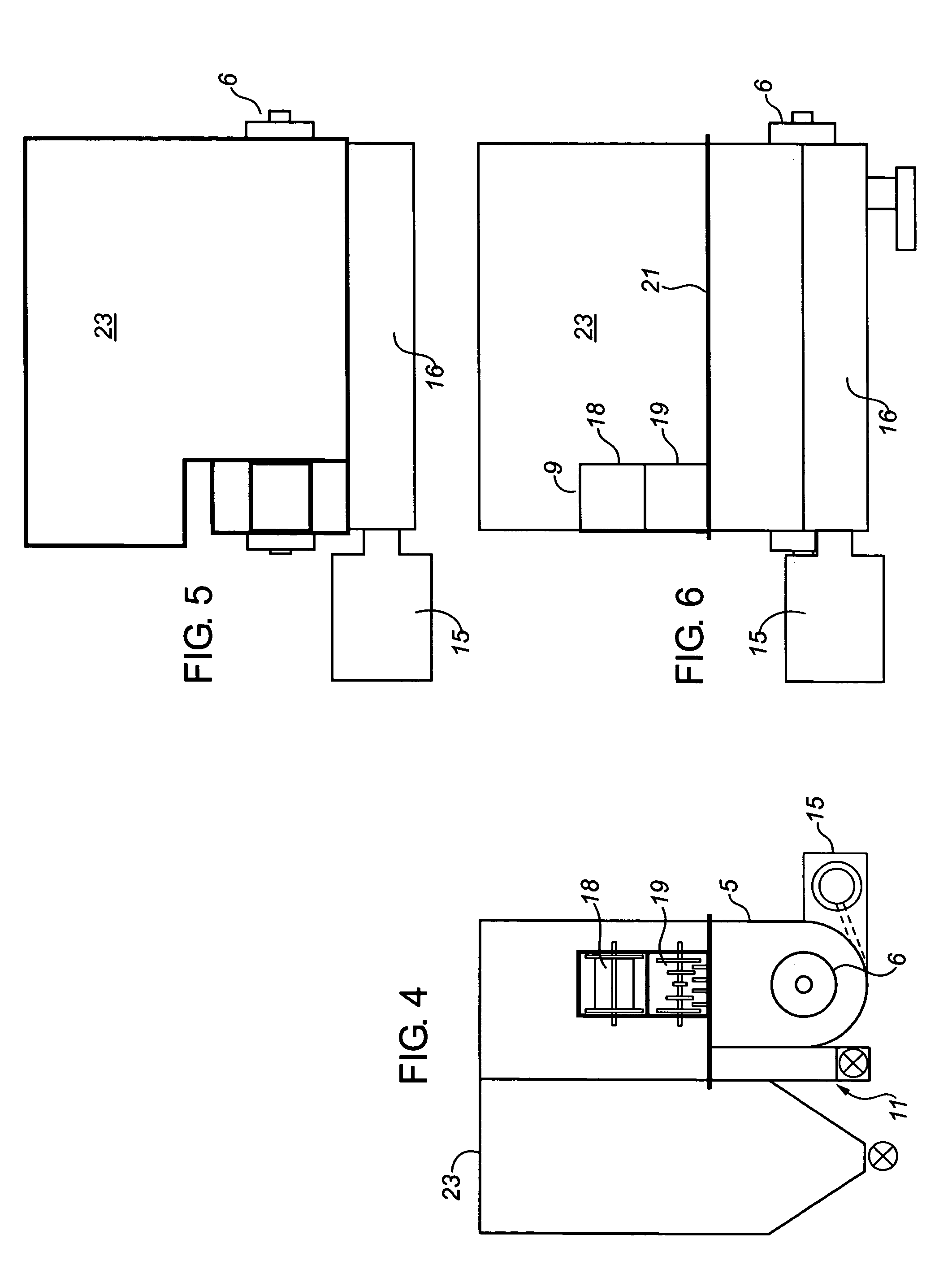

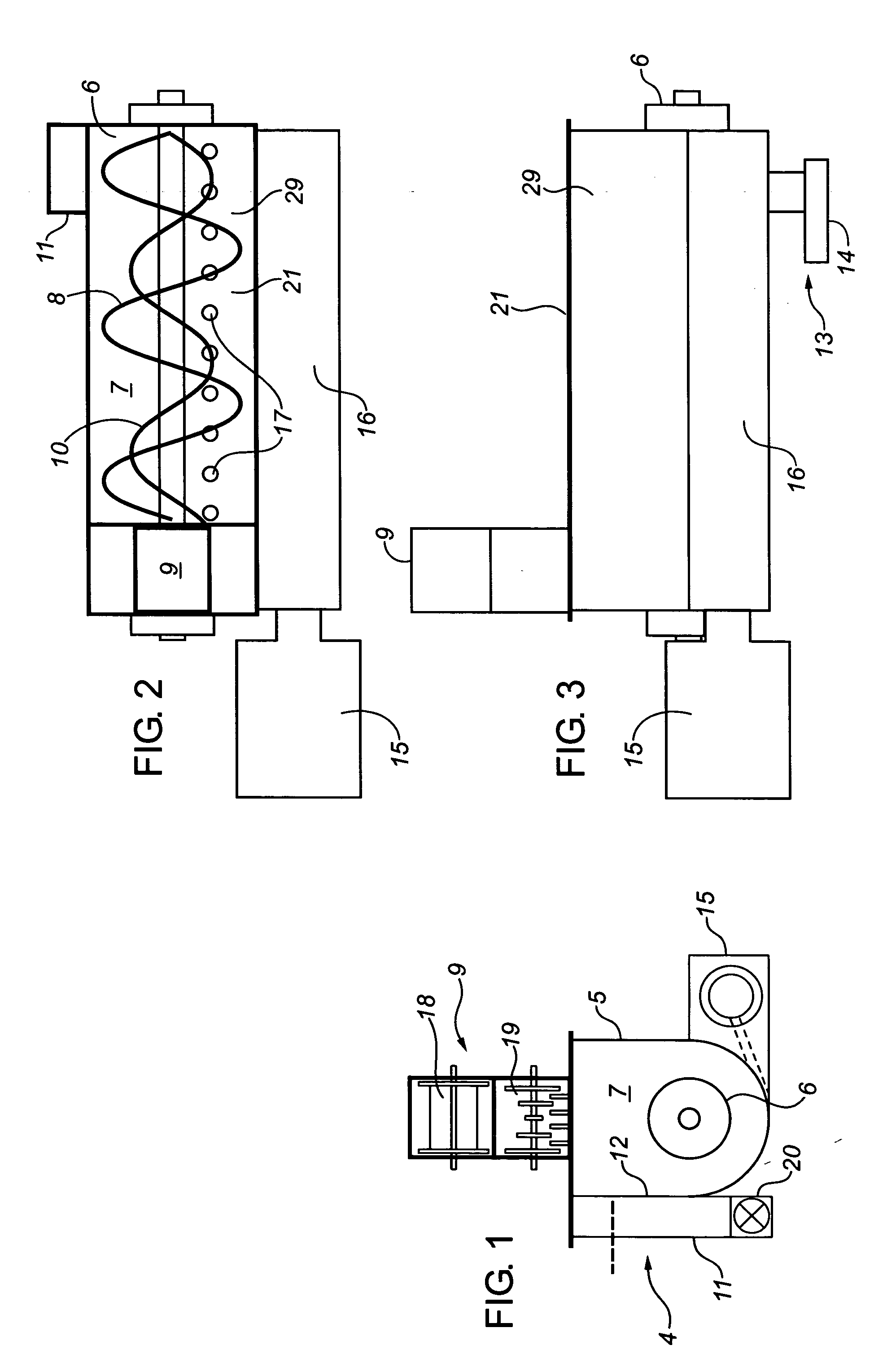

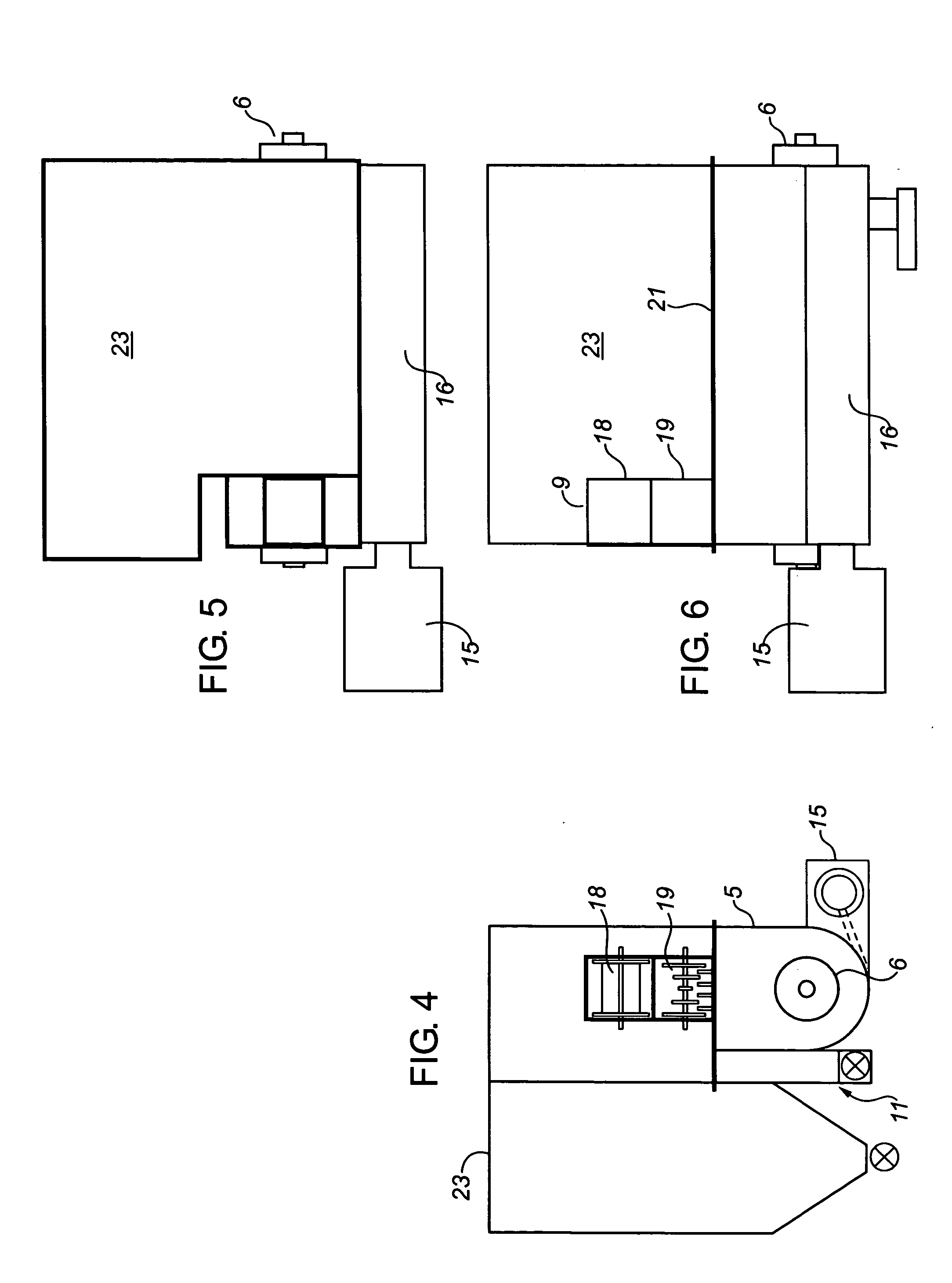

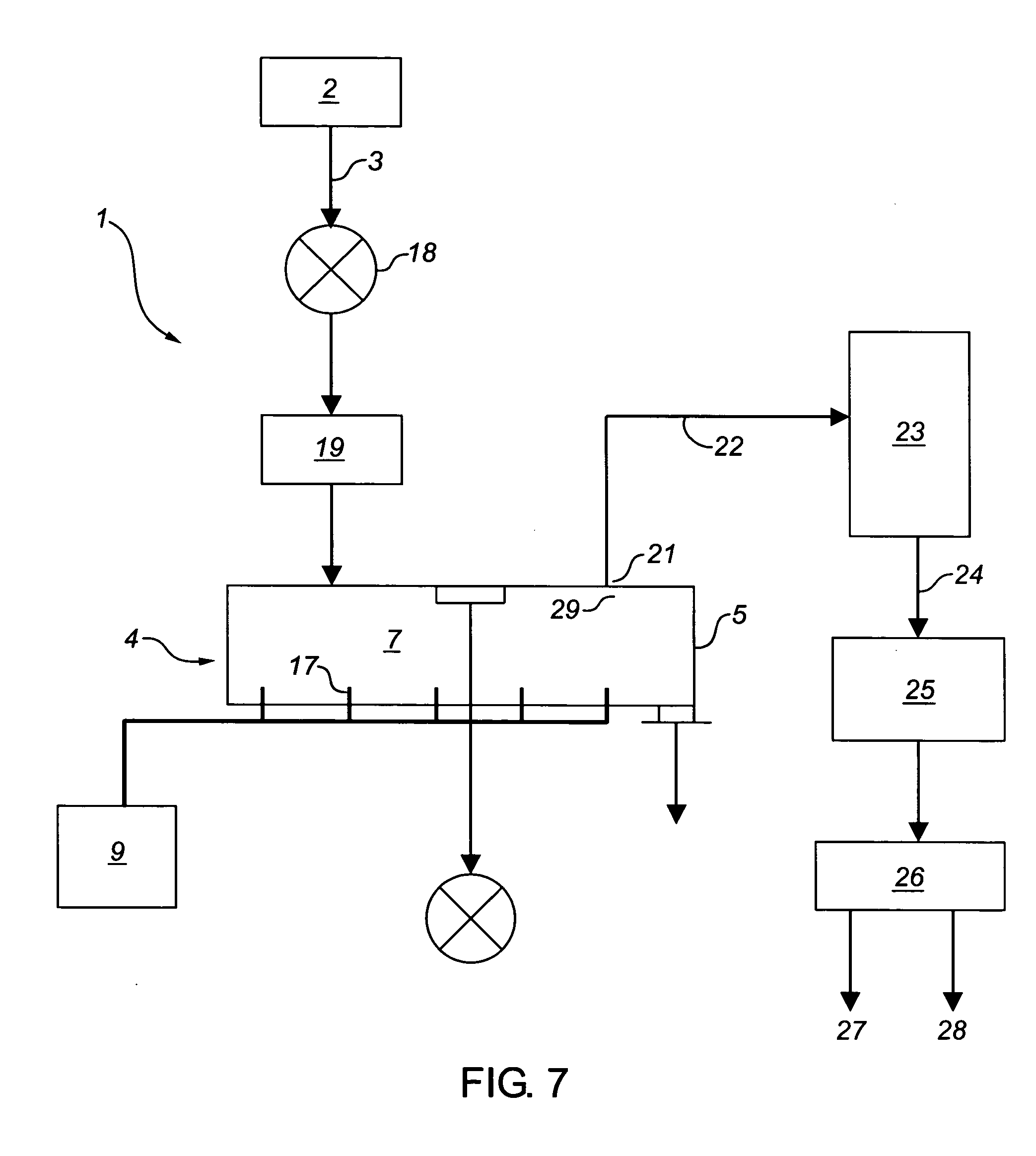

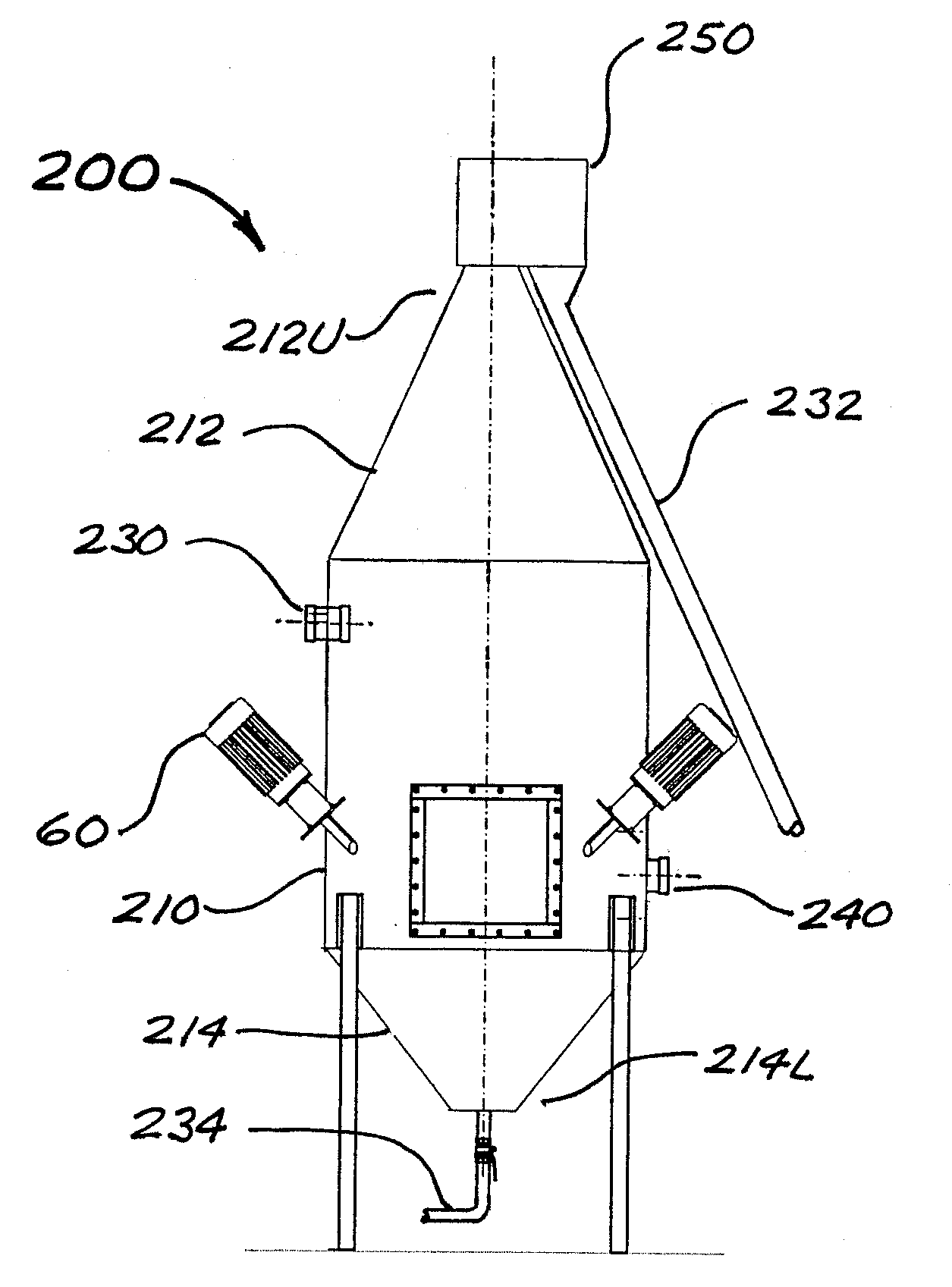

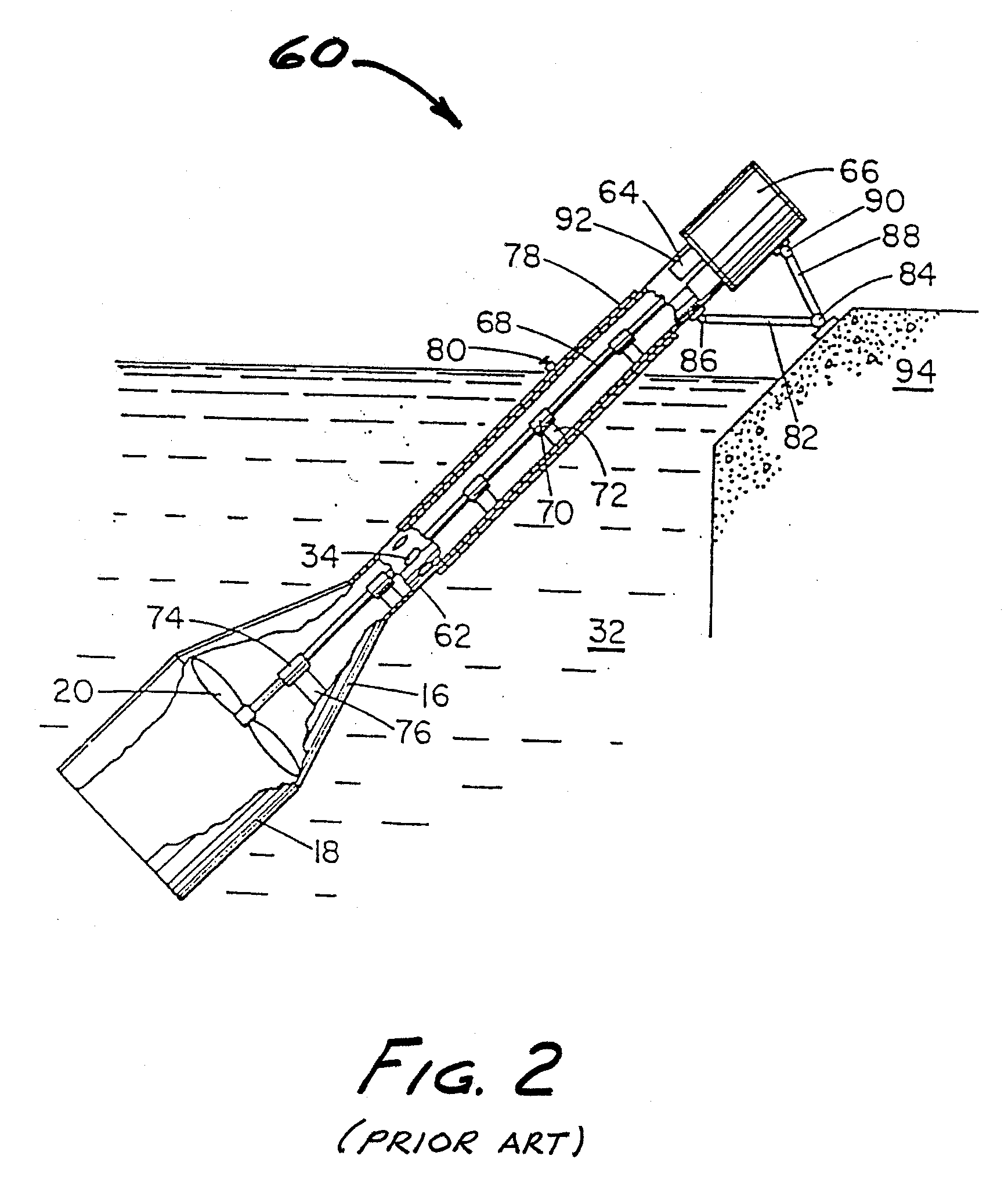

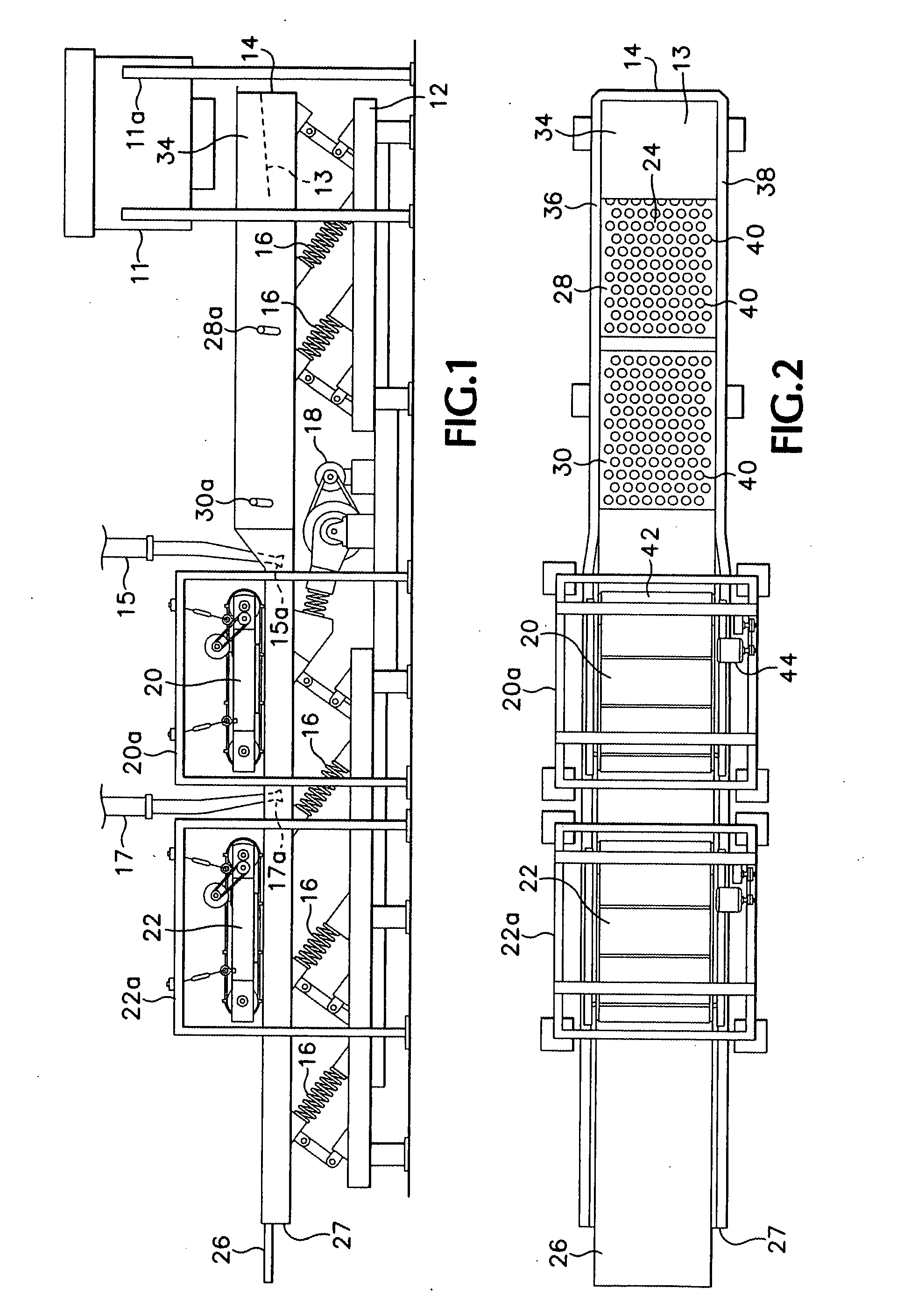

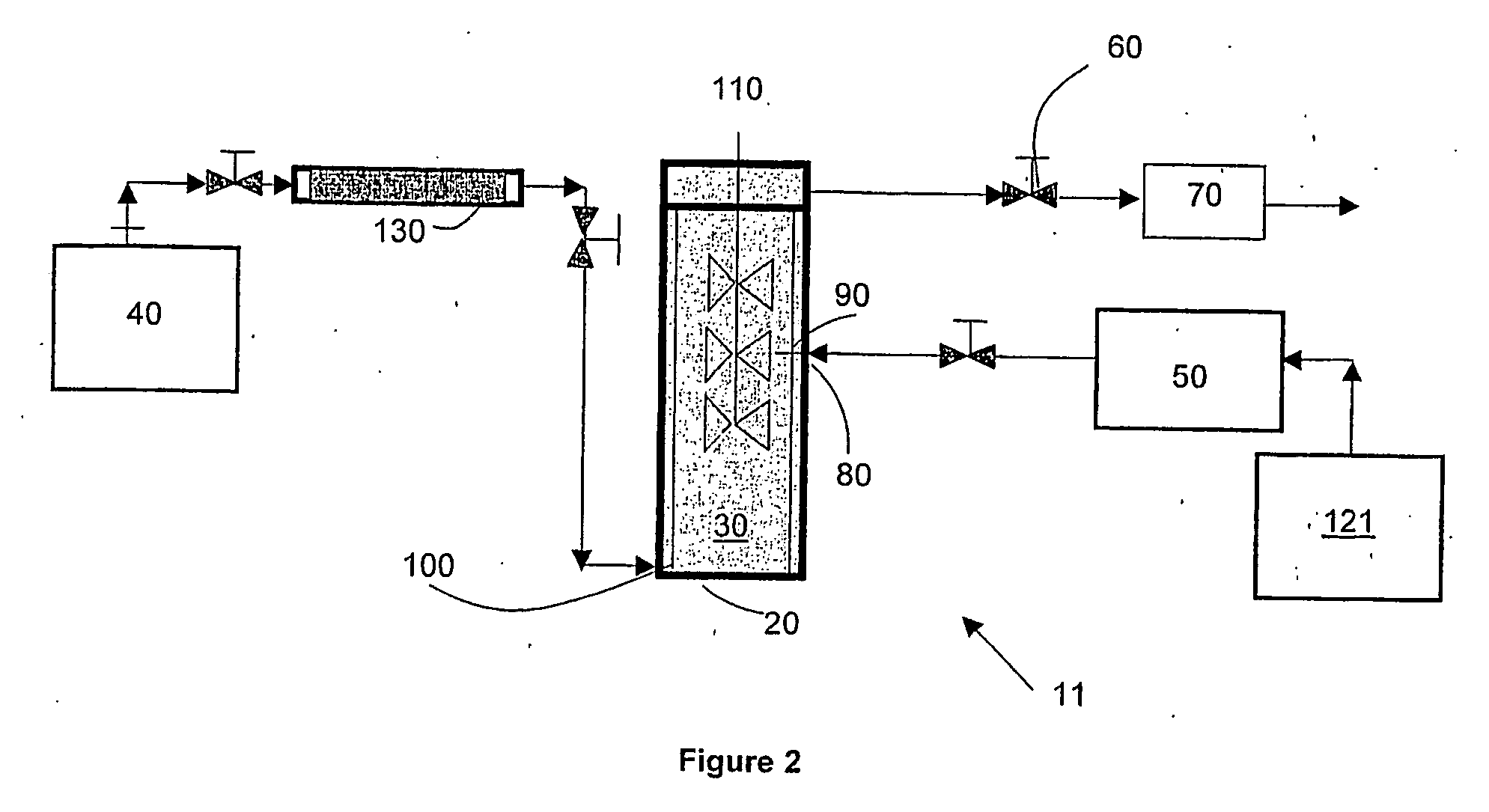

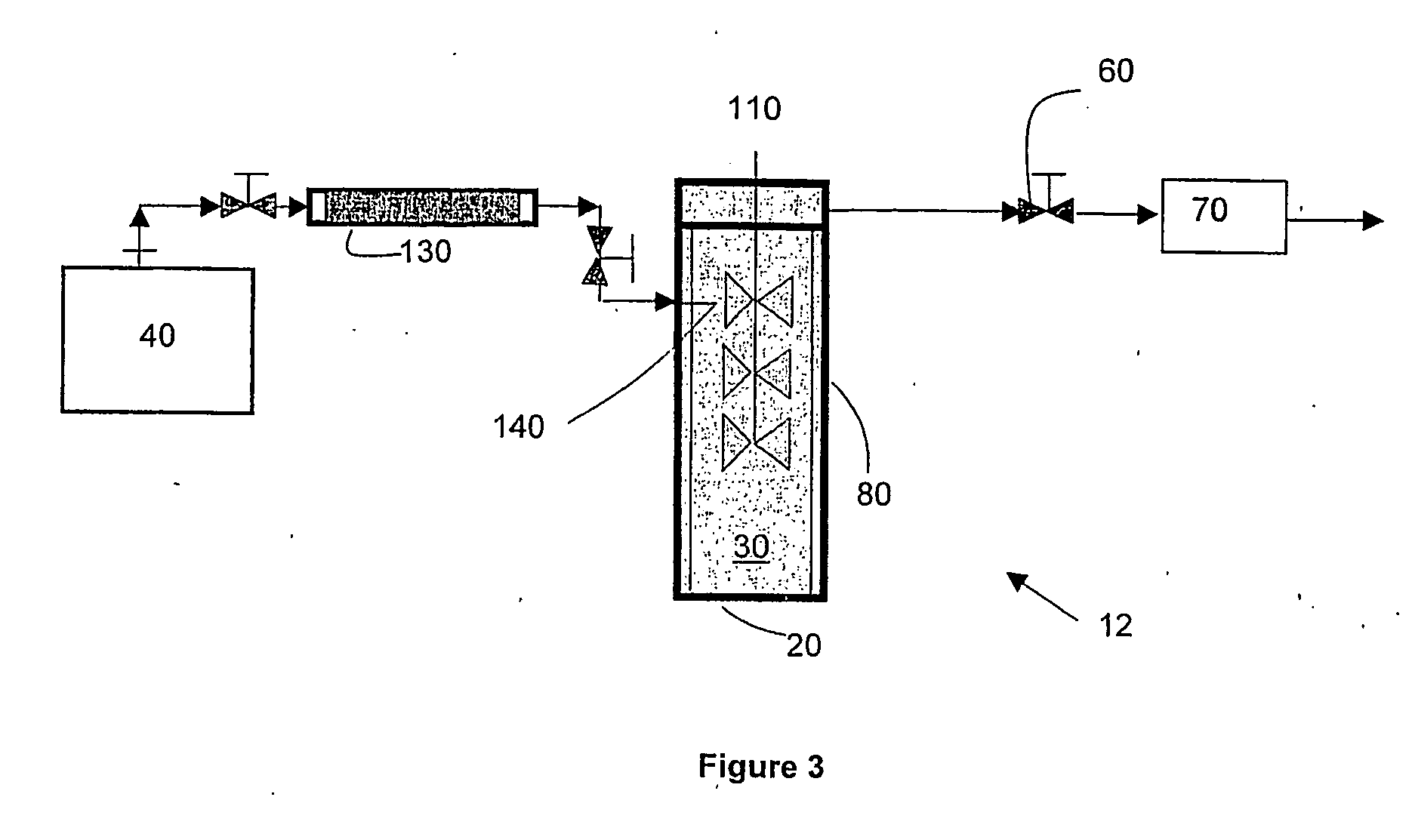

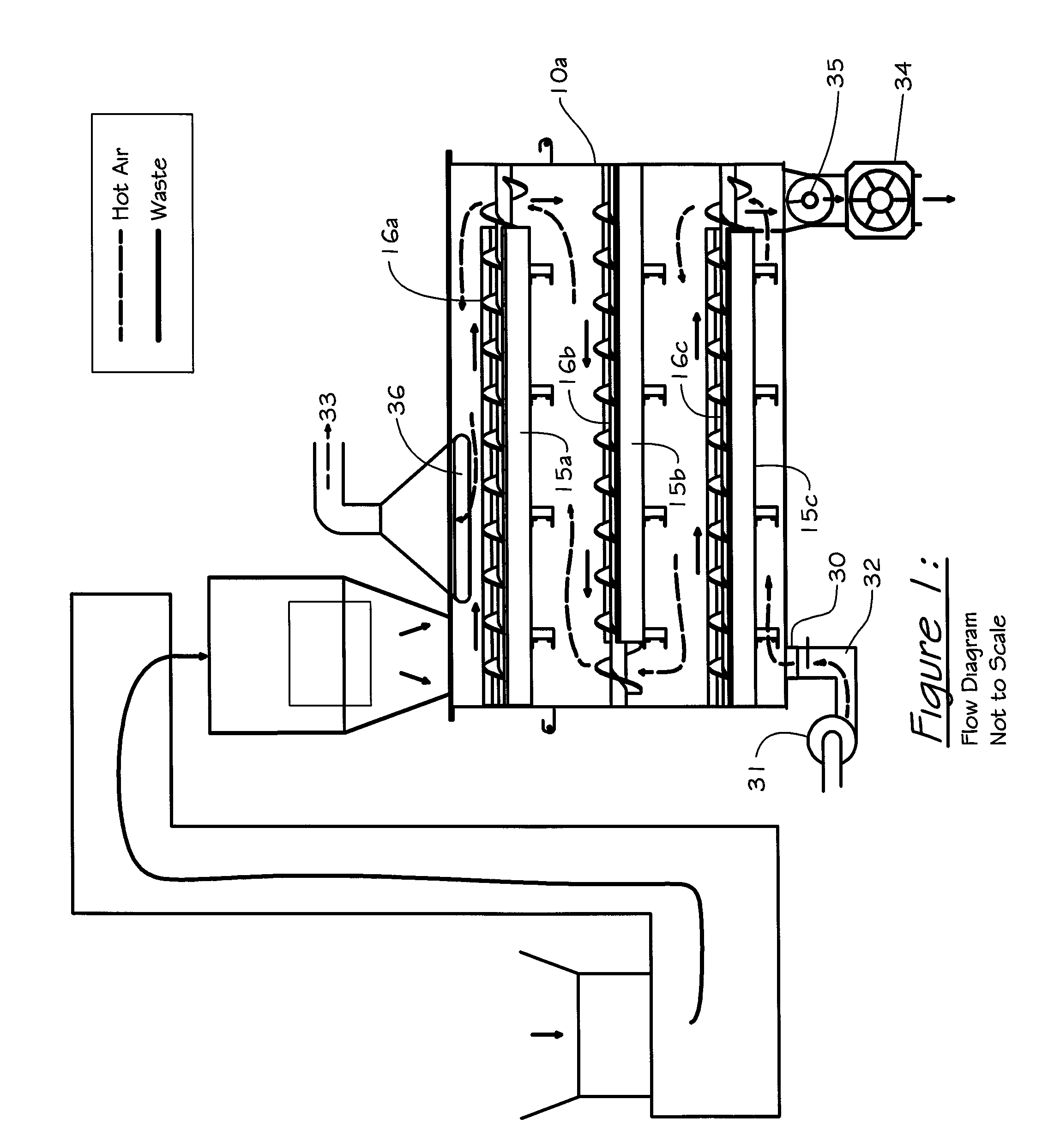

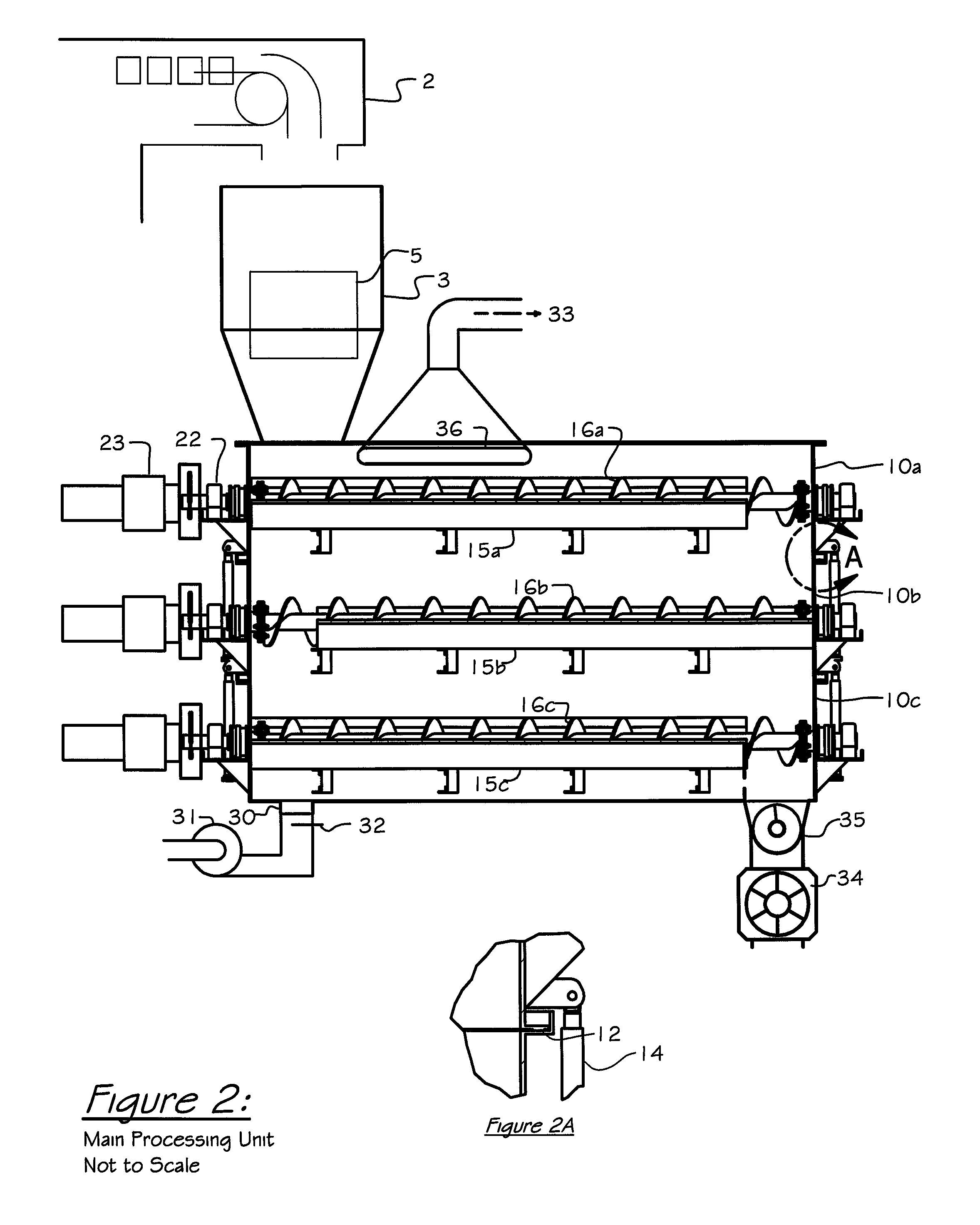

Apparatus and process for removing liquids from drill cuttings

InactiveUS7337860B2Reduce cakingReduce resultSolid waste disposalHollow article cleaningCombustionProduct gas

Owner:CLEANCUT TECH LTD

Apparatus and process for removing liquids from drill cuttings

InactiveUS20050153844A1Reduce cakingReduce resultSolid waste disposalHollow article cleaningCombustionEngineering

Drill cuttings associated with drilling fluid are thermally cleaned. The wet cuttings are fed into a vessel chamber having mechanical mixers, such as ribbon blenders, extending lengthwise of the chamber. Direct heating is applied to the chamber contents by introducing hot combustion gas from a heater. A combination of direct heating and mechanical back mixing of wet colder cuttings with drier hotter cuttings results in conditioning and conduction heating of the wet cuttings. The drilling fluid is evaporated and removed as gas. Dried cuttings are separately recovered. Caking and agglomeration of the solids is reduced.

Owner:CLEANCUT TECH LTD

Prepared reinforced elastomer, elastomer composite and tire having component thereof

InactiveUS6156822AReduction of mixing energySpeed up the processSpecial tyresWheelsPolymer scienceElastomer composites

Preparation of an elastomer which contains a dispersion of filler reinforcement by forming a filler reinforcement in-situ within the elastomer host, the resulting elastomer / filler composite and tire having component which contains such reinforced elastomer. The invention includes a rubber composition of at least two elastomers wherein one of said elastomers is a pre-formed composite of elastomer and in-situ formed filler reinforcement. A tire having a component of such rubber composition, particularly a tire tread, is specifically contemplated.

Owner:THE GOODYEAR TIRE & RUBBER CO

Medical devices for dispensing powders

A medical device for topical, intranasal or oral administration of dry powder medical compositions includes a unit dose blister form containing an internal piercing device that provides for agitation, dispersion and dispensation of the powder to a user.

Owner:MYSTIC PHARMA INC

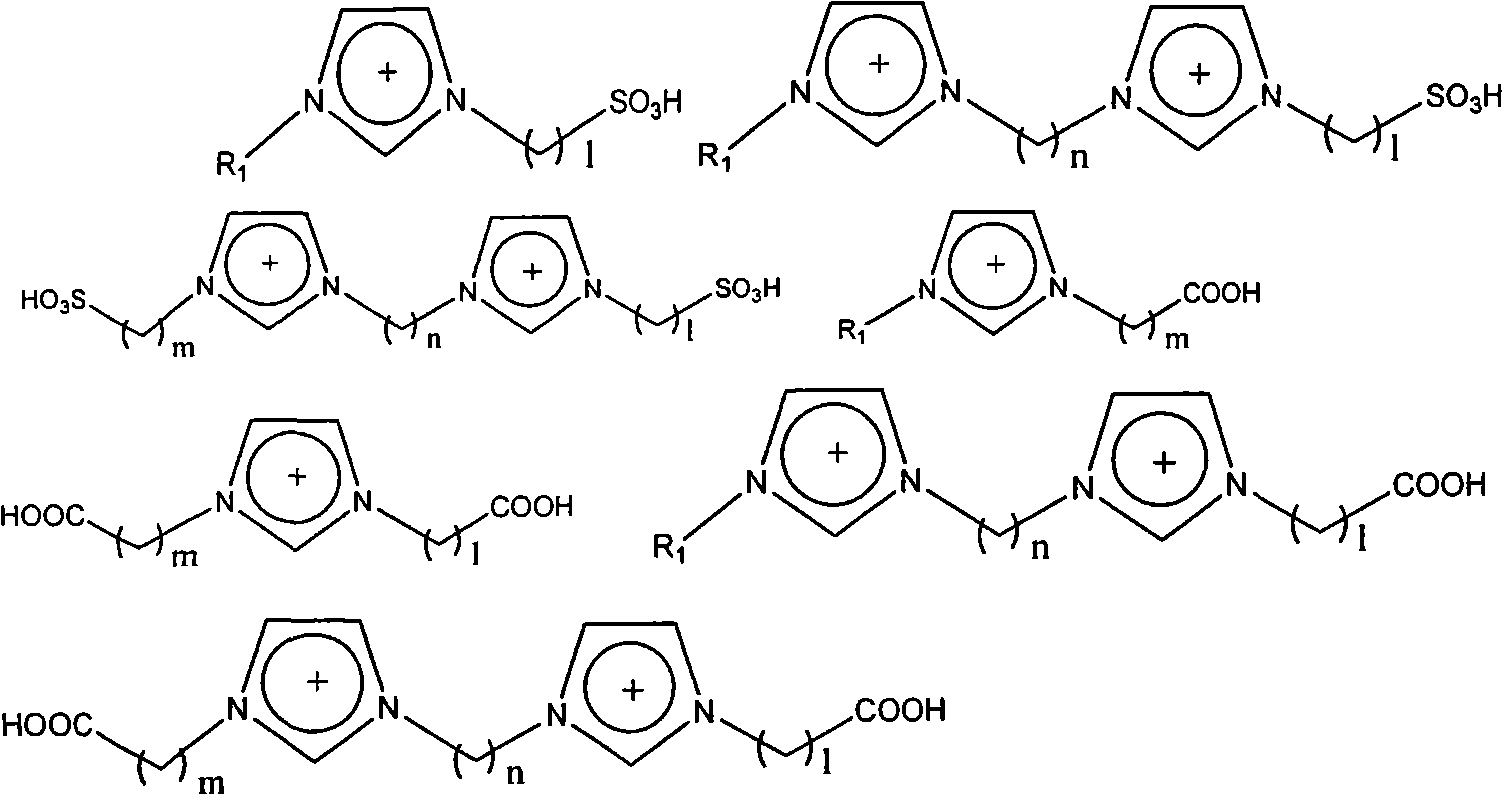

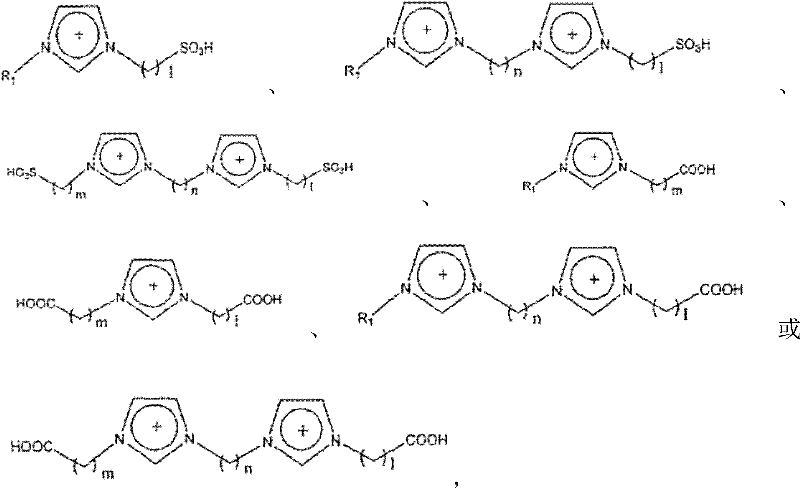

Process for synthesizing triformol using ionic liquid

InactiveCN101311154AEasy to manufactureHigh catalytic activityOrganic chemistryOrganic compound preparationAqueous solutionIonic liquid

The invention discloses a method for synthesizing trioxymethylene, wherein, formalin solution is taken as reactant and acidic ionic liquid is taken as a catalyst, and the dosage of the catalyst is 0.01-10% by weight.

Owner:富艺国际工程有限公司 +1

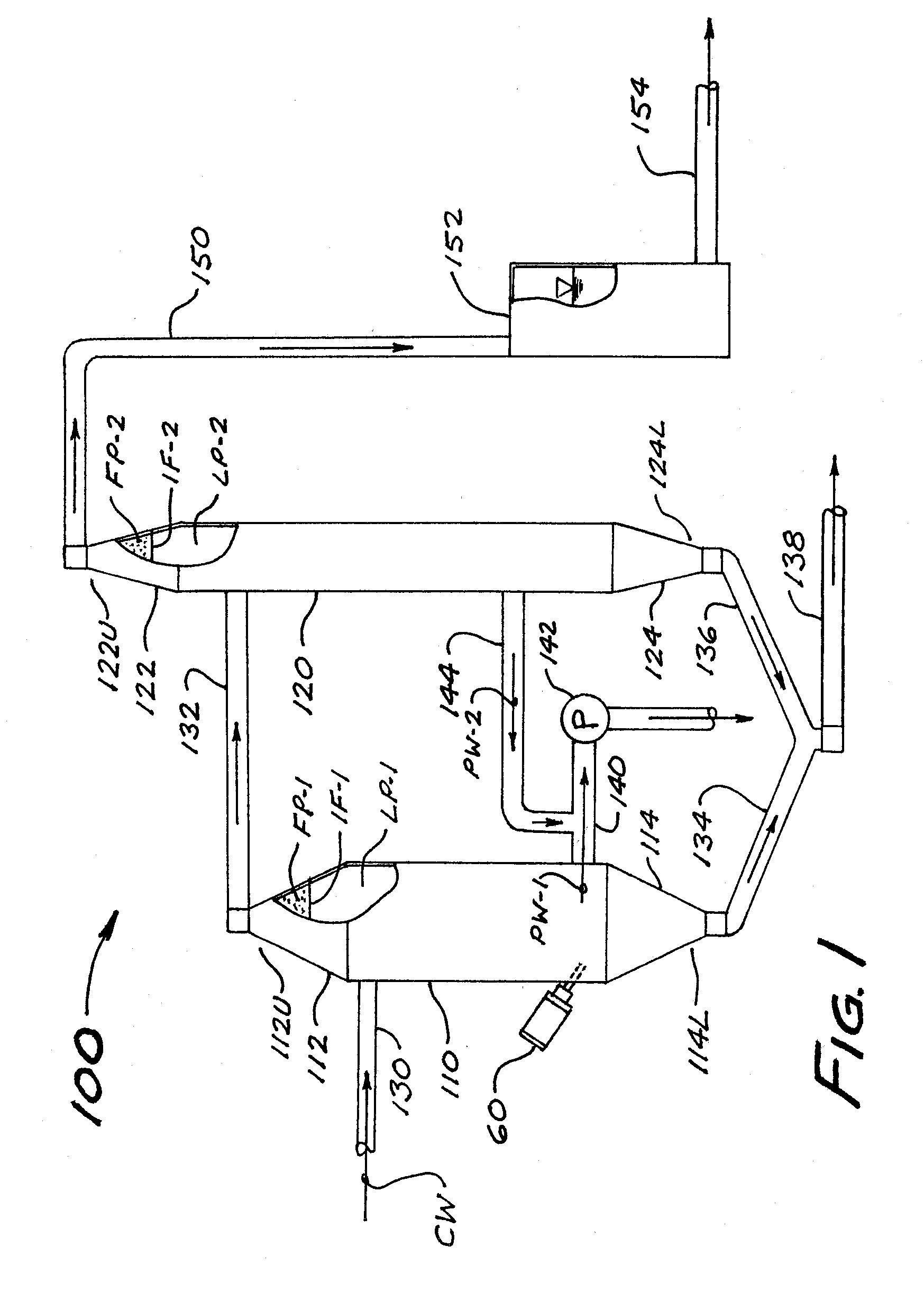

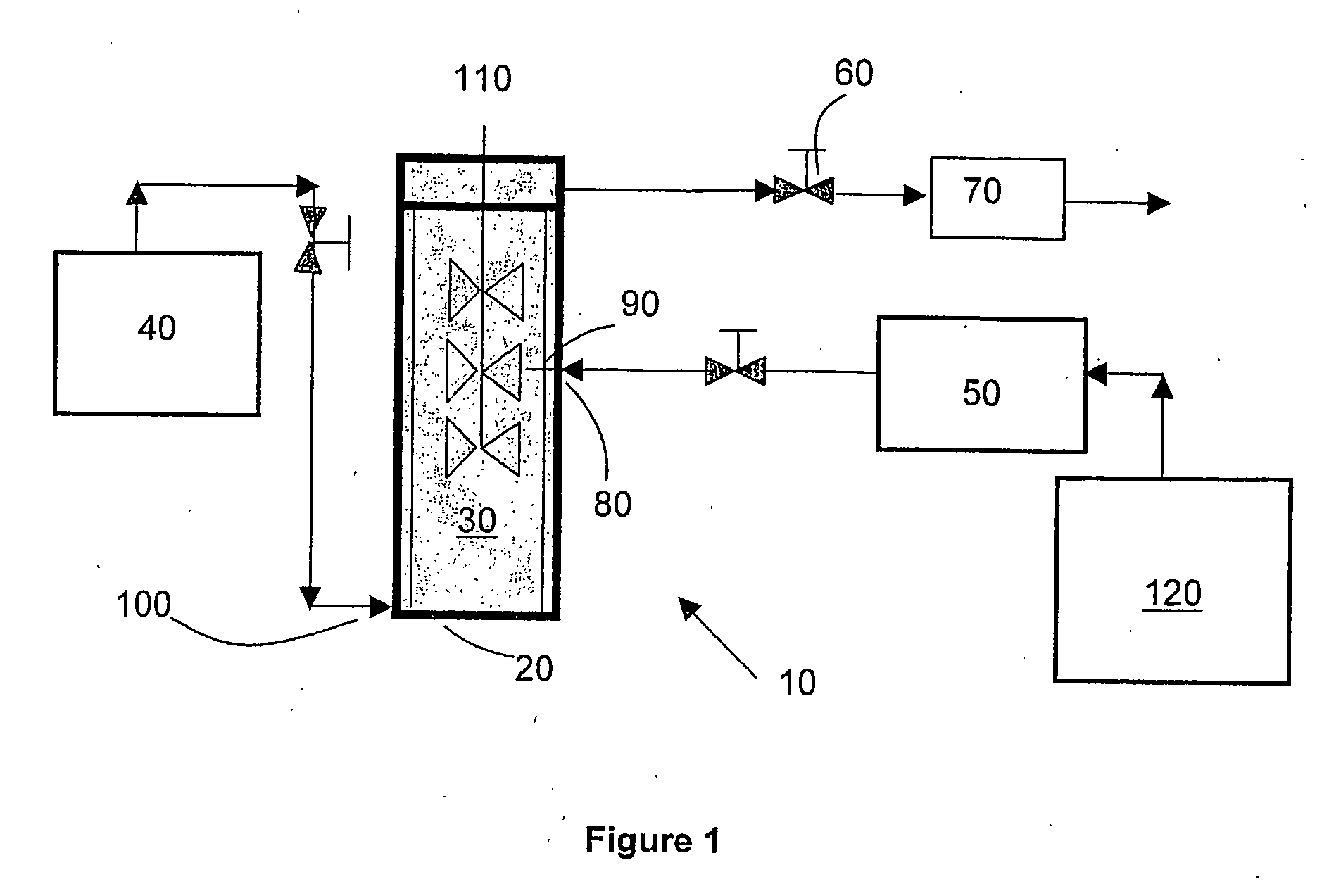

Process and apparatus for separating hydrocarbons from produced water

InactiveUS20110114566A1Improve uniformityMaximize effectivenessFatty/oily/floating substances removal devicesWater contaminantsHigh concentrationTreated water

A process for removing hydrocarbons such as oil from produced water entrains high concentrations of very small gas bubbles within produced water inside a vertically-oriented primary separation tank by means of aerators immersed in the water inside the tank. Oil droplets coat the gas bubbles which form a buoyant oil-rich froth phase overlying a gas-rich liquid phase. The froth phase flows out through a discharge port in a preferably conical upper section of the primary tank, for disposal or recovery of oil as appropriate. Solid contaminants not borne by the froth phase may be intermittently settled out of the liquid phase and removed for treatment or disposal through a discharge port in a preferably conical lower section of the primary tank. Clean processed water is drawn a medial region of the primary tank for re-use as appropriate. In a preferred embodiment, the froth phase passes into a secondary separation tank for further separation of contaminants by means of gravity and / or supplemental aeration.

Owner:1139076 ALBERTA

Powder trace element fertilizer as well as preparation method and application method thereof

InactiveCN104163709AImprove uniformityReduce deficiencyFertilizer mixturesMinor elementCITRATE ESTER

The invention discloses a powder element fertilizer as well as a preparation method and application method thereof. The method is characterized by comprising the following steps: uniformly mixing a soluble trace element fertilizer, a citrate-soluble trace element fertilizer, an acidifier and an anticaking agent to obtain a mixture, grinding and screening the mixture until the particle size is less than 150 meshes, thereby obtaining the powder trace element fertilizer; and coating seeds or other granular fertilizers with the powder trace element fertilizer. Compared with the prior art, the technique enhances the dispersion uniformity of the minor elements in soil and the absorption and utilization efficiency of the seeds for the minor elements, implements unification of the short-term fertilizer efficiency and long-term fertilizer efficiency, and reduces the problem of caking of the powder product in the use process.

Owner:HUBEI FORBON TECH

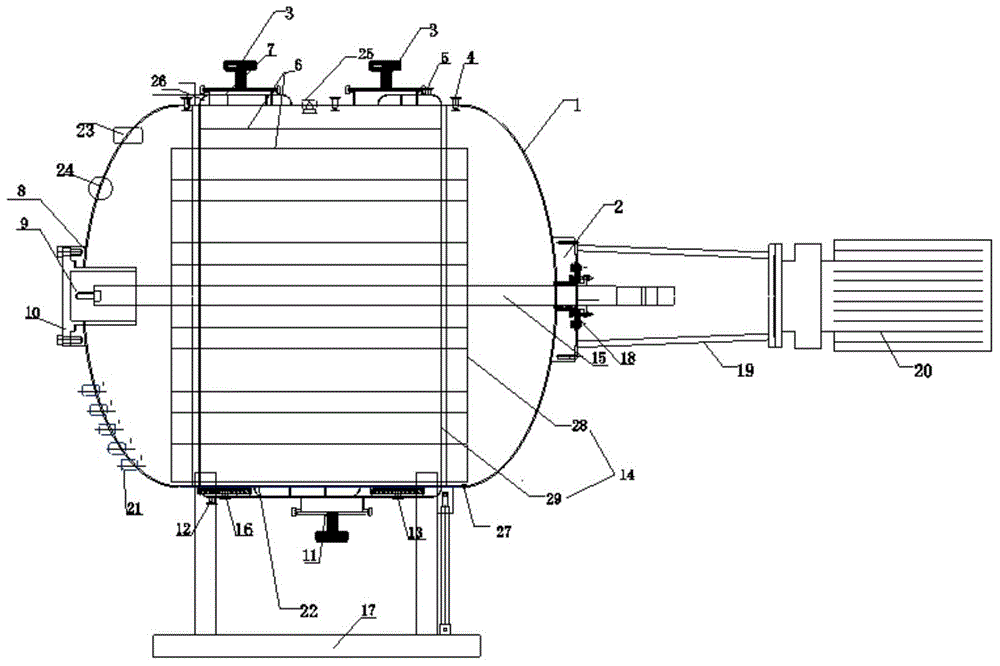

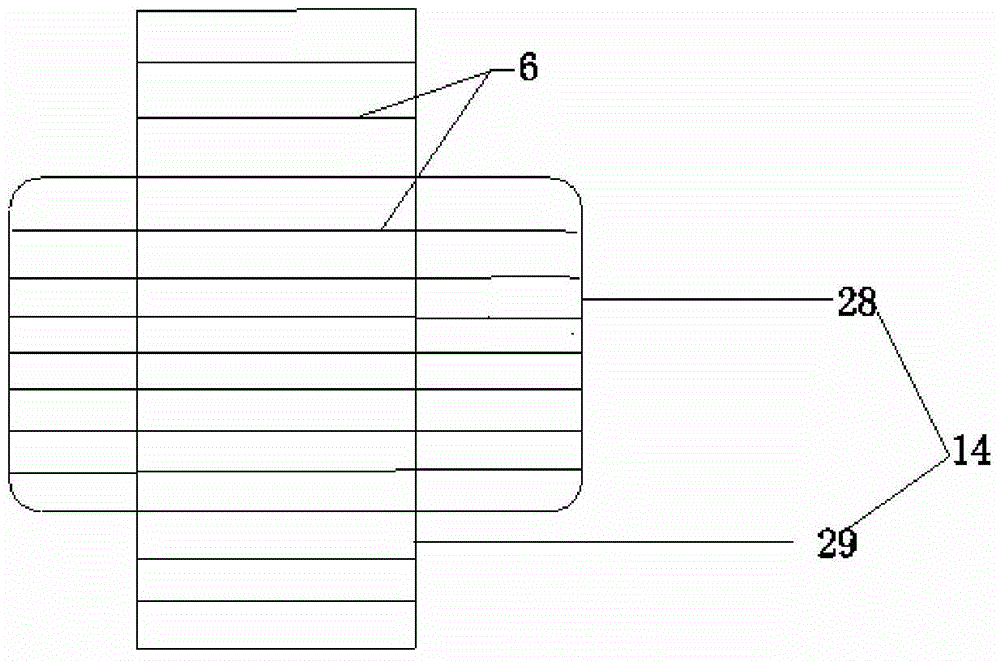

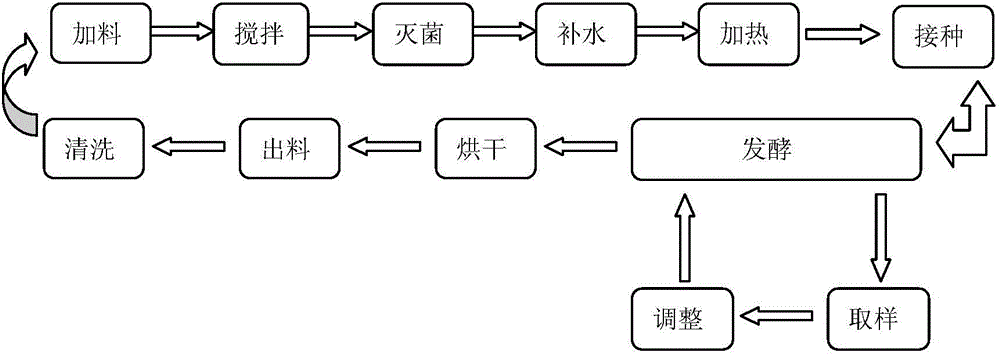

Horizontal-type solid fermentation tank and fermentation method for Pu-erh tea

PendingCN106135503AReduce lossStable productionPre-extraction tea treatmentMicroorganismEnvironmental engineering

The invention discloses a horizontal-type solid fermentation tank and fermentation method for Pu-erh tea. The fermentation tank comprises a tank body supported by a tank body support, and a clamp jacket is installed outside the tank body; the top of the tank body is provided with feed inlets, exhaust ports, diversion plates connected with heating wires, a water inlet and a water replenishing and inoculation opening; the bottom of the tank body is provided with a discharge outlet, a water vapor inlet, a sterile air inlet, a carbon dioxide inlet, a drying ventilation opening and a water outlet, and a stirring system is further arranged in the tank body. According to the fermentation method, a traditional Pu-erh tea pile-fermentation technology is changed, production standardization and specification rationalization of the Pu-erh tea are achieved on the condition that fermentation conditions such as microorganism species, tidal prism, temperature, fermentation time, inoculated-pathogen quantities and oxygen and carbon dioxide content of the Pu-erh tea are comprehensively considered, the fermentation process of the Pu-erh tea is artificially controllable, and the quality of the Pu-erh tea is more stable, safer and more controllable.

Owner:MENGHAI TEA IND +1

Preparation method of methyl propionate

InactiveCN102336661AEasy to manufactureHigh catalytic activityOrganic compound preparationCarboxylic acid esters preparationPropanoic acidMethyl propionate

The invention discloses a preparation method of methyl propionate. The method is characterized in that: propionic acid and methanol are reacted under the action of an acidic ion liquid catalyst to synthesize the methyl propionate. By the method, equipment corrosion can be reduced, and low-cost and large-scale production of the methyl propionate is realized.

Owner:BEIJING RISUN TECH CO LTD

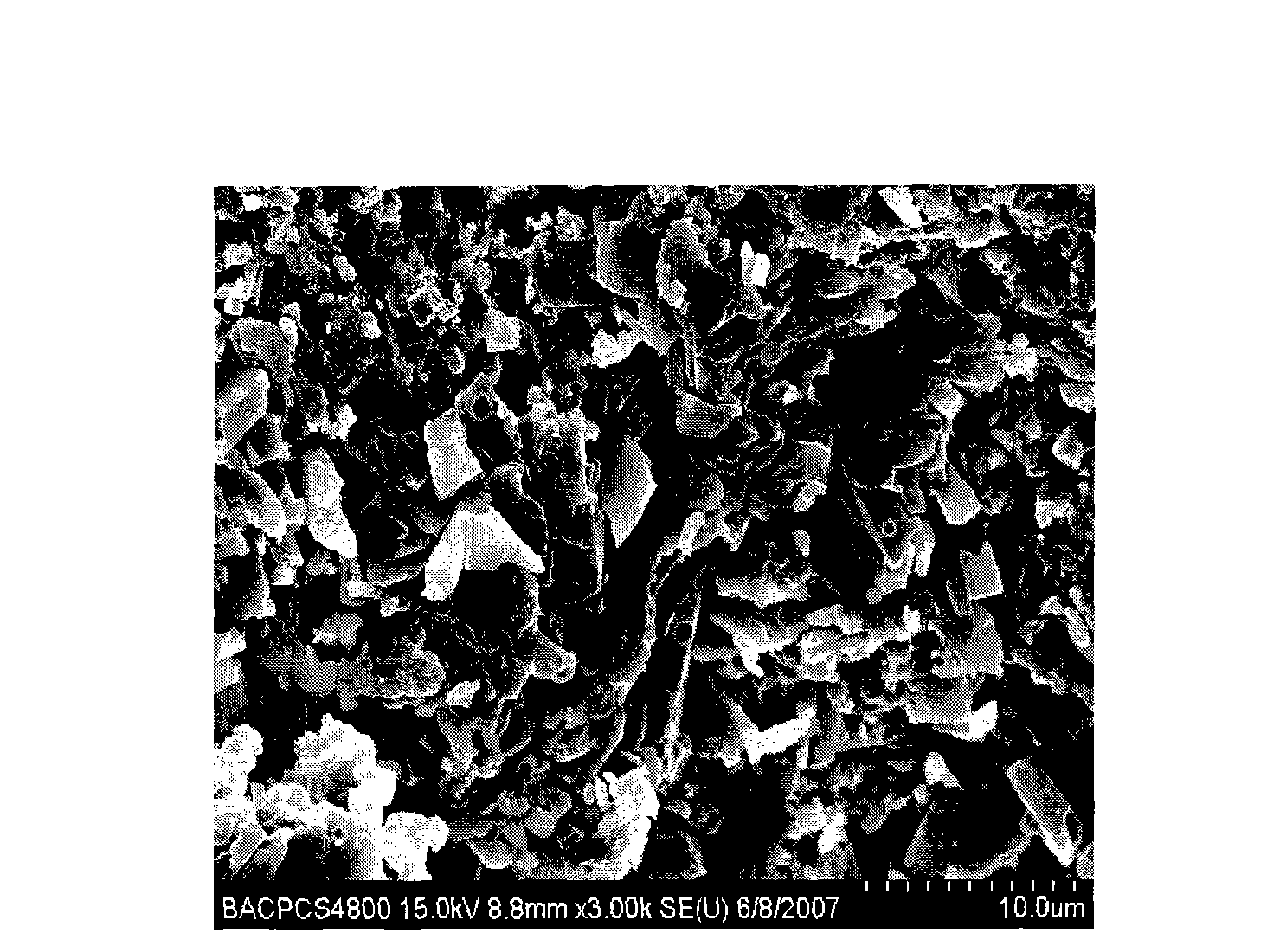

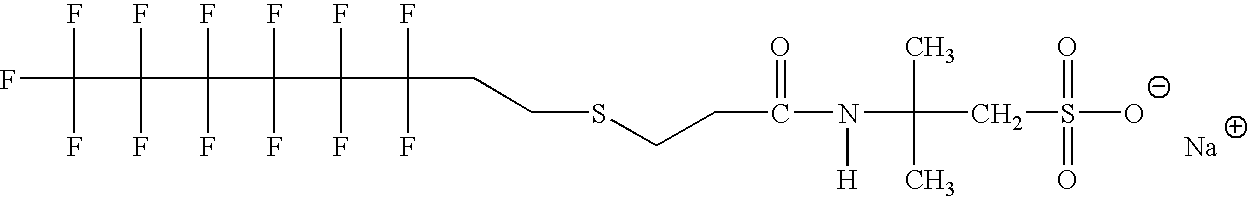

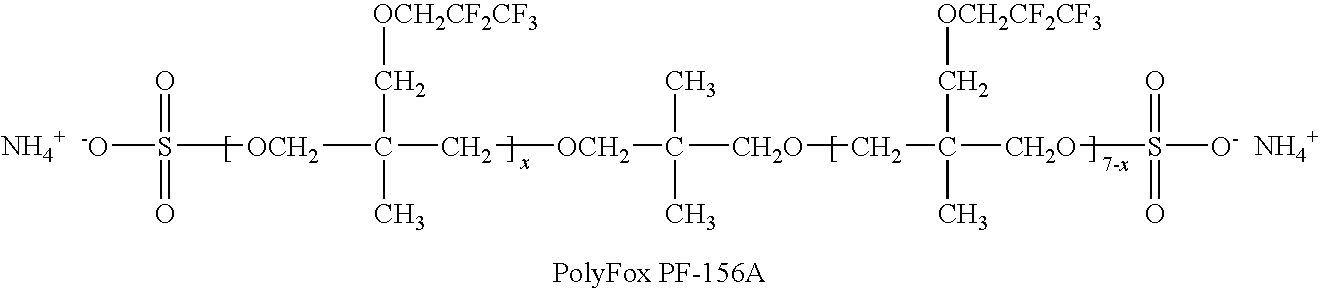

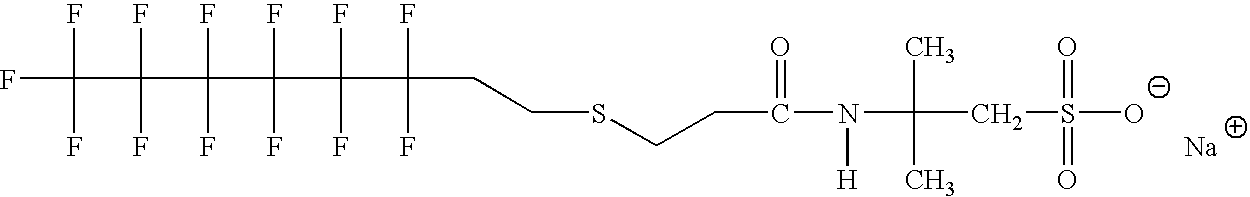

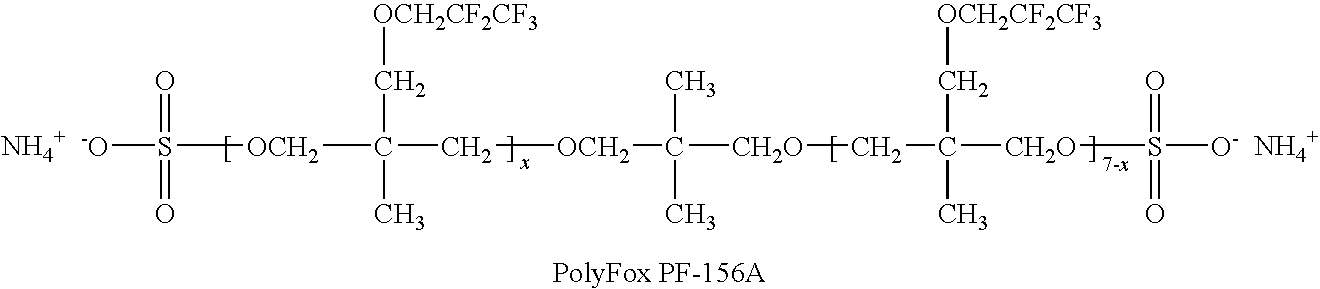

Production of silver sulfate grains using a fluorinated additive

InactiveUS20090258984A1Uniform morphologyUniform sizePigmenting treatmentCosmetic preparationsMicrometerWater soluble

An aqueous precipitation process for the preparation of particles comprising primarily silver sulfate, comprising reacting an aqueous soluble silver salt and an aqueous soluble source of inorganic sulfate ion in an agitated precipitation reactor vessel and precipitating particles comprising primarily silver sulfate, wherein the reaction and precipitation are performed in the presence of an aqueous soluble fluorinated additive, the amount of additive being a minor molar percentage, relative to the molar amount of silver sulfate precipitated, and effective to result in precipitation of particles comprising primarily silver sulfate having a mean grain-size of less than 50 micrometers.

Owner:EASTMAN KODAK CO

Centrifugal separation apparatus and method for separating fluid components

InactiveUS20060191857A1Reduce cakingReduces platelet clumpingWater/sewage treatment by centrifugal separationOther blood circulation devicesHigh densityRed blood cell

An apparatus and method are provided for separating components of a fluid or particles. A separation vessel having a barrier dam is provided to initially separate an intermediate density components of a fluid, and a fluid chamber is provided to further separate these intermediate density components by forming an elutriative field or saturated fluidized particle bed. The separation vessel includes a shield for limiting flow into the fluid chamber of relatively high density substances, such as red blood cells. The separation vessel also includes a trap dam with a smooth, gradually sloped downstream section for reducing mixing of substances. Structure is also provided for adding additional plasma to platelets and plasma flowing from the fluid chamber. The system reduces clumping of platelets by limiting contact between the platelets and walls of the separation vessel.

Owner:TERUMO BCT

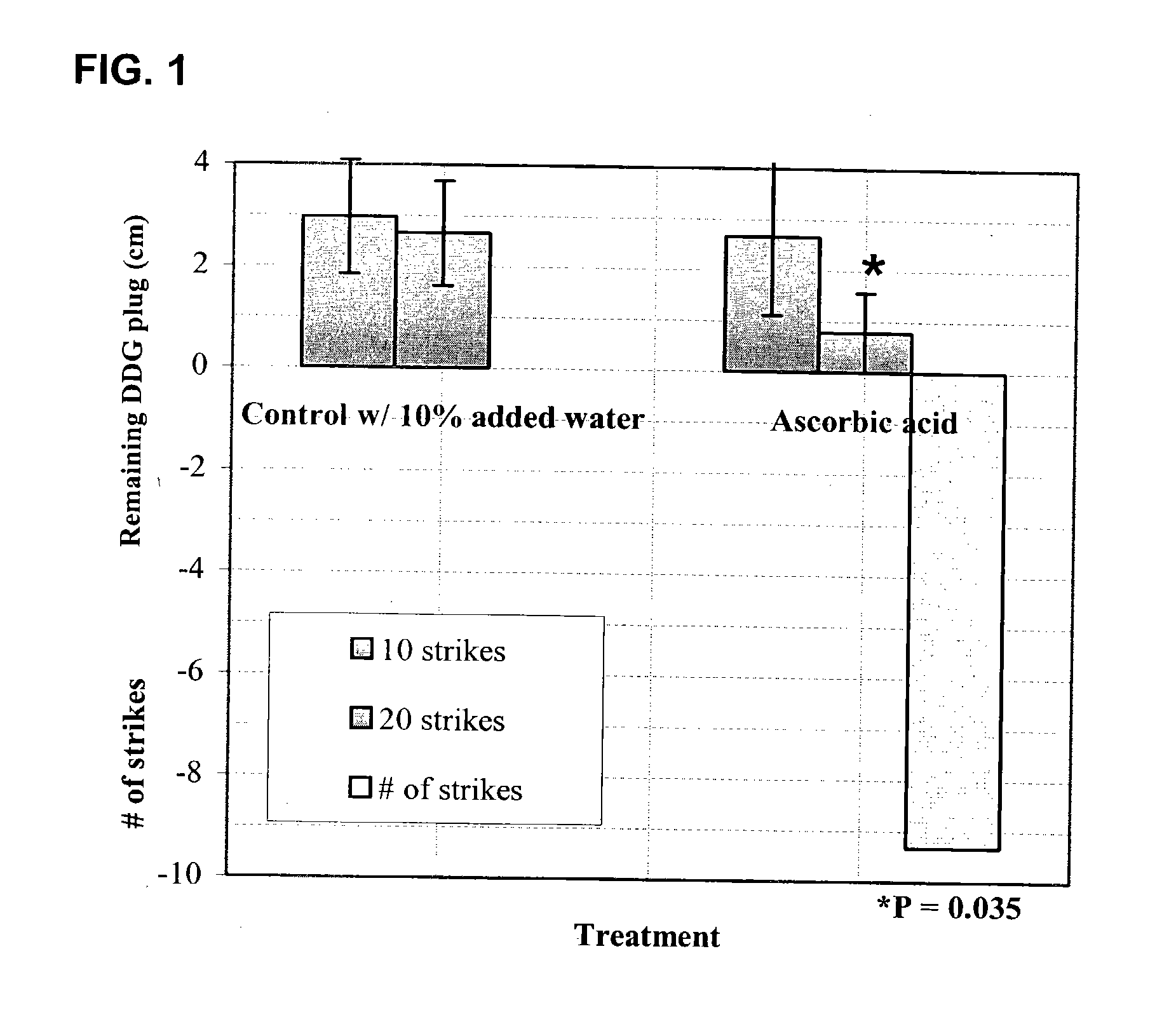

Composition and method for reducing caking and proteinaceous products

InactiveUS20050003043A1Reduce and eliminate hardeningReduce and eliminate and cakingDough treatmentWort preparationGlutenFeather meal

A method and composition for reducing caking of proteinaceous products such as dried distiller's grains, corn gluten feed, fish meal, feather meal, soybean meal and other oilseed meals, and the like, particularly during transport and storage. The composition may include a reducing agent either alone or in combination with a chaotroph. Optionally, the composition includes an enzyme which may be added to the composition or substituted for all or part of the reducing agent. The composition also optionally includes a material which assists in maintaining a reducing condition in the proteinaceous product, and optionally a material which assists in blocking of free sulfhydryl groups.

Owner:KEMIN IND INC

Coated sand with long shelf life, and production method of coated sand

InactiveCN102688979AHigh melting pointReduce cakingFoundry mouldsFoundry coresHexamethylenetetramineBoric acid

The invention provides coated sand with long shelf life and a production method of the coated sand. The coated sand is formed by silica sand, phenolic resin, a curing agent, a lubricant and boric acid, wherein 1-3 parts by weight of phenolic resin and 0.1-0.8 part by weight of boric acid are added in each 100 parts by weight of silica sand; the curing agent is urotropin, wherein 0.12-0.18 part by weight of urotropin is added in each one part by weight of phenolic resin; and the lubricant is calcium stearate, wherein 0.06-0.12 part by weight of calcium stearate is added in each one part by weight of phenolic resin. The production method comprises steps of heating silica sand to 100-130 DEG C; adding phenolic resin and boric acid into the obtained silica sand according to the proportion and mixing uniformly; adding urotropin into the obtained product according to the proportion and mixing uniformly; and adding calcium stearate into the obtained product according to the proportion and mixing uniformly.

Owner:CHANGSHA NANTUO SHAPE MATERIALS

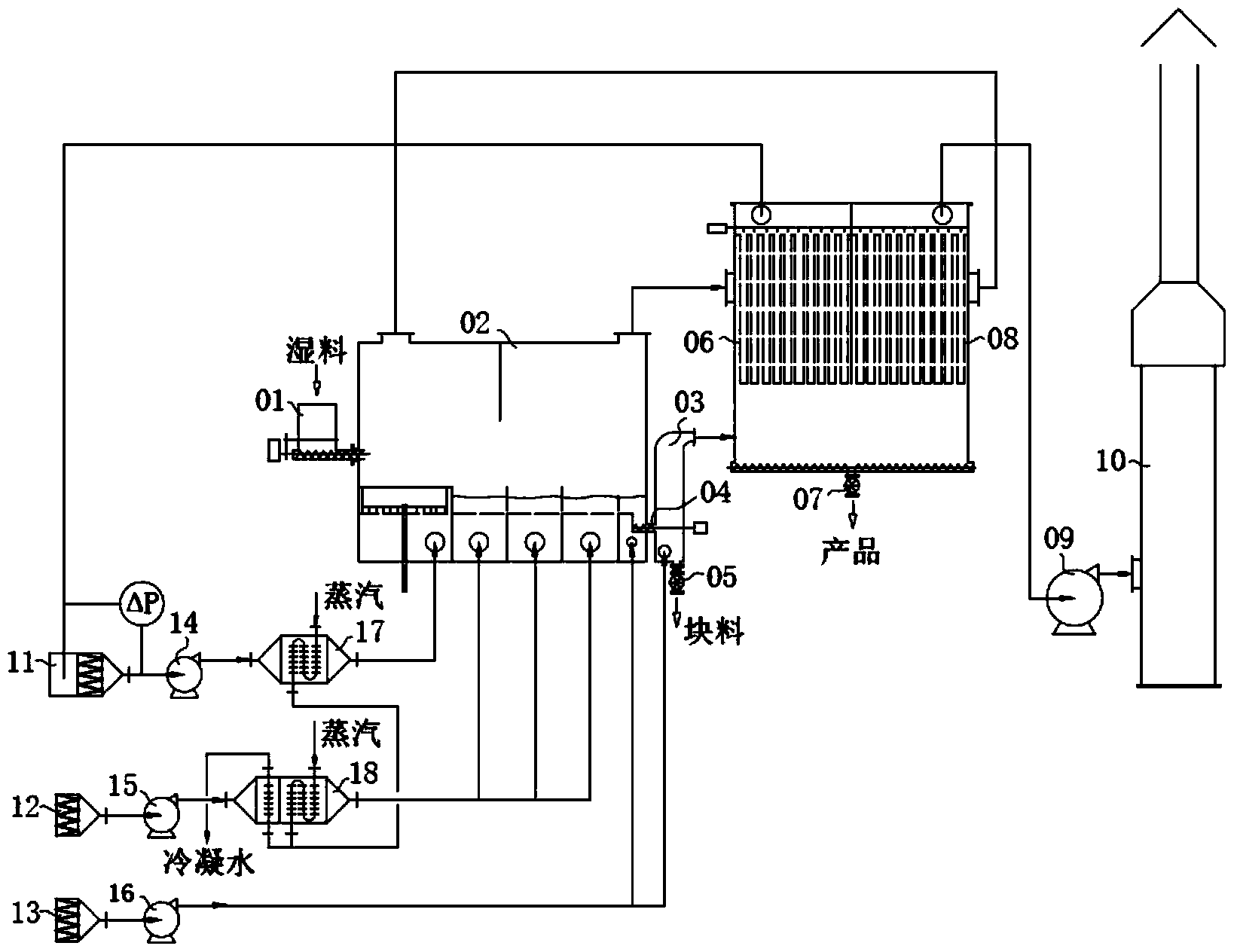

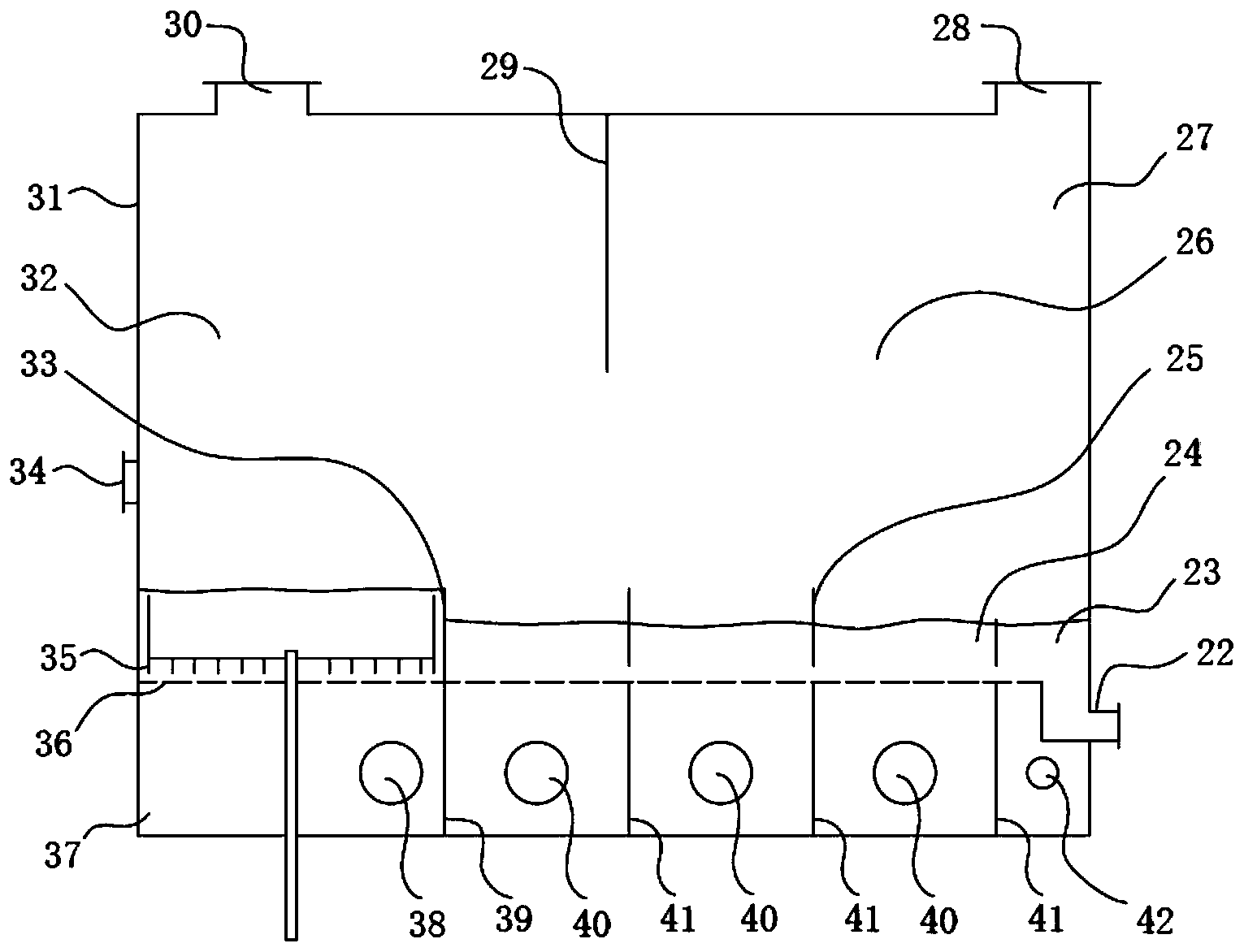

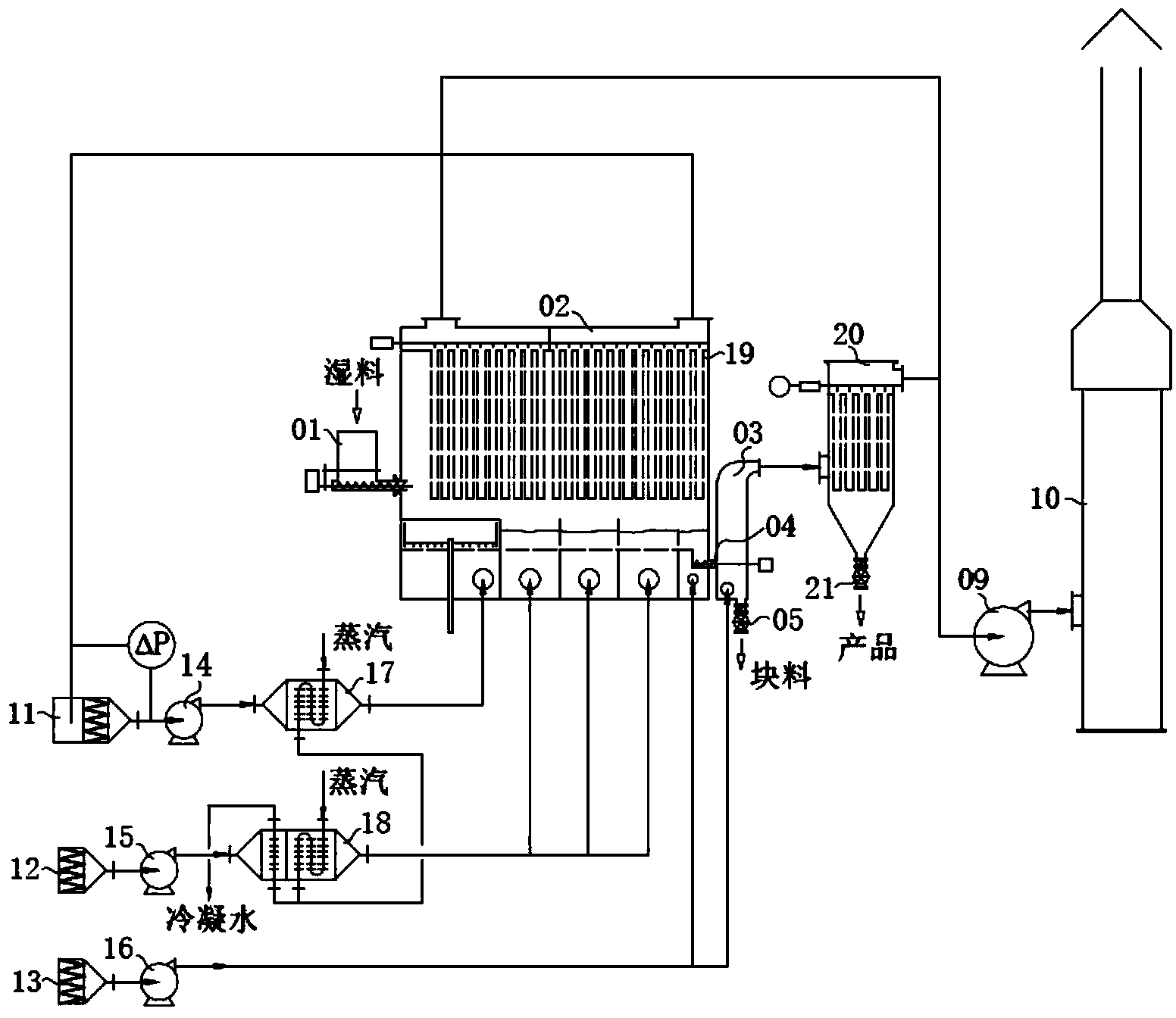

Partial tail gas circulation fluid bed drying method and equipment

ActiveCN104110941AAvoid contactAvoid problems such as blockingDrying solid materials with heatDrying gas arrangementsThermal energyFluidized bed drying

The invention provides a partial tail gas circulation fluid bed drying method and equipment. The method comprises the following steps of (1) material drying, (2) tail gas circulating, (3) tail gas discharging, (4) material cooling and (5) lump material separating. Air is filtered, pressurized and heated to be at the needed temperature and enters a deep drying section of a fluid bed drying machine to conduct deep material drying, tail gas which is discharged from the deep drying section of the fluid bed drying machine and is high in temperature and low in moisture content is dedusted, pressurized and heated and then enters a primary drying section of the fluid bed drying machine to conduct primary drying, and the tail gas which is discharged from the primary drying section of the fluid bed drying machine and is low in temperature and high in moisture content is dedusted and then discharged into the atmosphere. The equipment constructed based on the partial tail gas circulation fluid bed drying method comprises a fluid bed drying machine body, a first heating device, a second heating device, a cooling device and a dedusting device. The partial tail gas circulation fluid bed drying method and equipment have the advantages that the heat energy of drying media is fully used, drying heat efficiency is high, consecutive operation is reliable, energy is save, and emission is reduced.

Owner:ZHEJIANG UNIV OF TECH +1

Polyhedral gasifier and relative method

InactiveCN1483068AReduce manufacturing costGood operating characteristicsHydrogenVertical chamber coke ovensActivated carbonInjection port

A gasifier is disclosed combining a fixed bed gasification section where coarse fuel is gasified and an entrained flow gasification section where fine fuel is gasified. The fixed bed section includes upper and lower sections. Coarse fuel is devolatilized in the upper fixed bed section and subjected to elevated temperatures sufficient to crack and destroy tars and oils in the effluent gases. The entrained flow gasification section is disposed in a lower plenum adjacent the lower fixed bed section. A plurality of injection ports are configured to introduce oxygen, steam, or air into different sections of the gasifier to control temperature and operating conditions. Activated carbon may be formed in the upper fixed bed section and in the entrained flow section. The activated carbon may be used as a sorbent to remove pollutants from the effluent gases. The gasifier may be used with various coarse and fine fuel feedstocks.

Owner:EMERY ENERGY

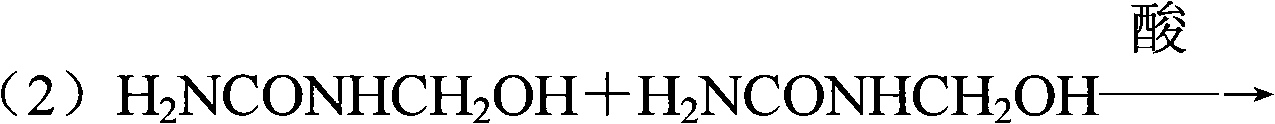

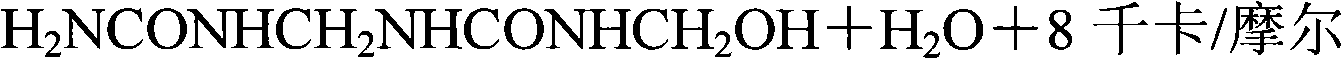

Method for preparing long-acting slow-release compound fertilizers by one-step pulp spraying granulation

InactiveCN101857513AIncrease temperatureReduce moistureFertilizer mixturesMixed materialsFORMALDEHYDE SOLUTION

The invention relates to a method for preparing long-acting slow-release compound fertilizers by one-step pulp spraying granulation, which comprises the following steps: heating and mixing urea and formaldehyde solution according to a mol ratio of (2 to 7) / 1 to be prepared into mixed material pulp with the temperature between 40 and 90 DEG C; introducing N, P and K fertilizers or filling materials and the like into a granulation device; after the mixed material pulp and ammonium sulphate are mixed in a pipeline according to a weight ratio of (5 to 30) / 1, spraying the mixture on solid materials in the granulation device for mixed granulation; simultaneously introducing ammonia for neutralization during the granulation; and obtaining the grain compound fertilizers, wherein the weight ratio of the mixed material pulp to the sulphuric acid is (5 to 30) / 1, the addition of the mixed material pulp sprayed on the solid materials accounts for 10 weight percent to 50 weight percent of the total material weight, and the quantity of the introduced ammonia accounts for 1 weight percent to 5 weight percent of the total material weight.

Owner:SHANGHAI RES INST OF CHEM IND

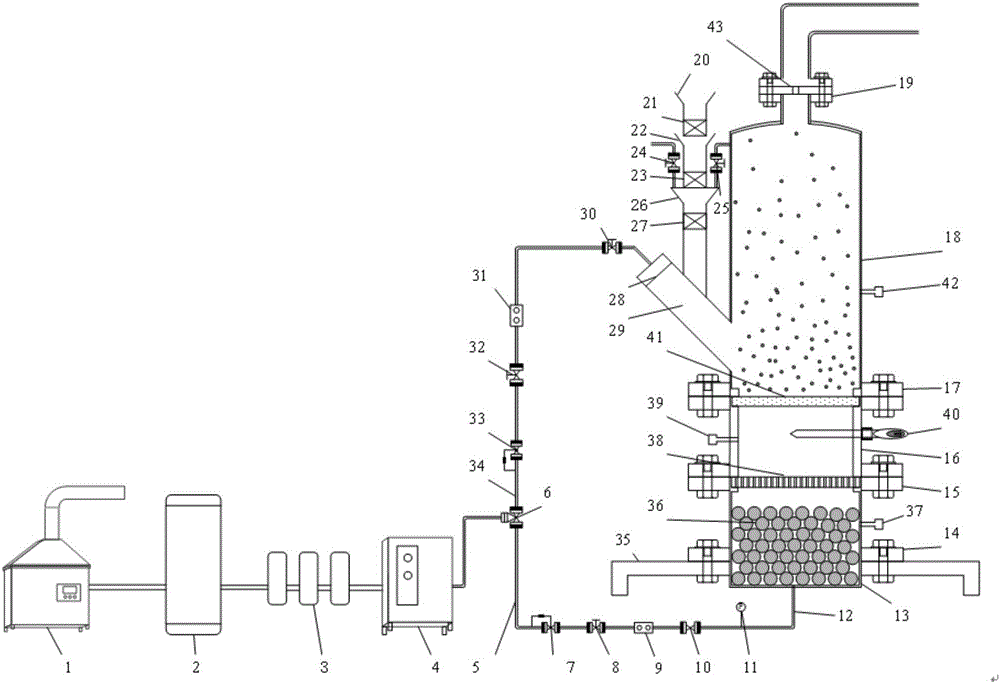

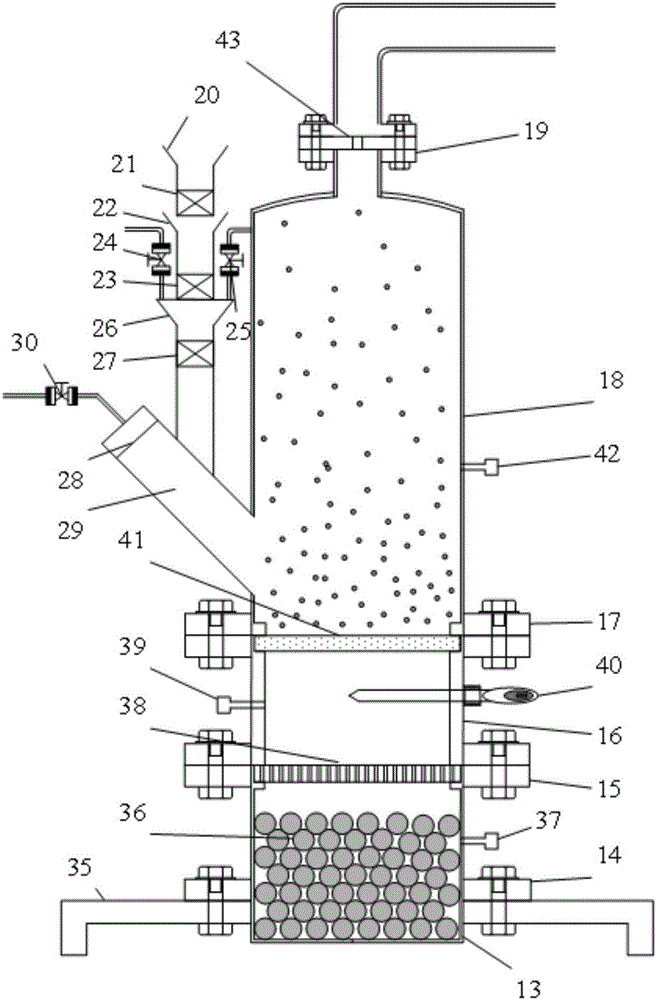

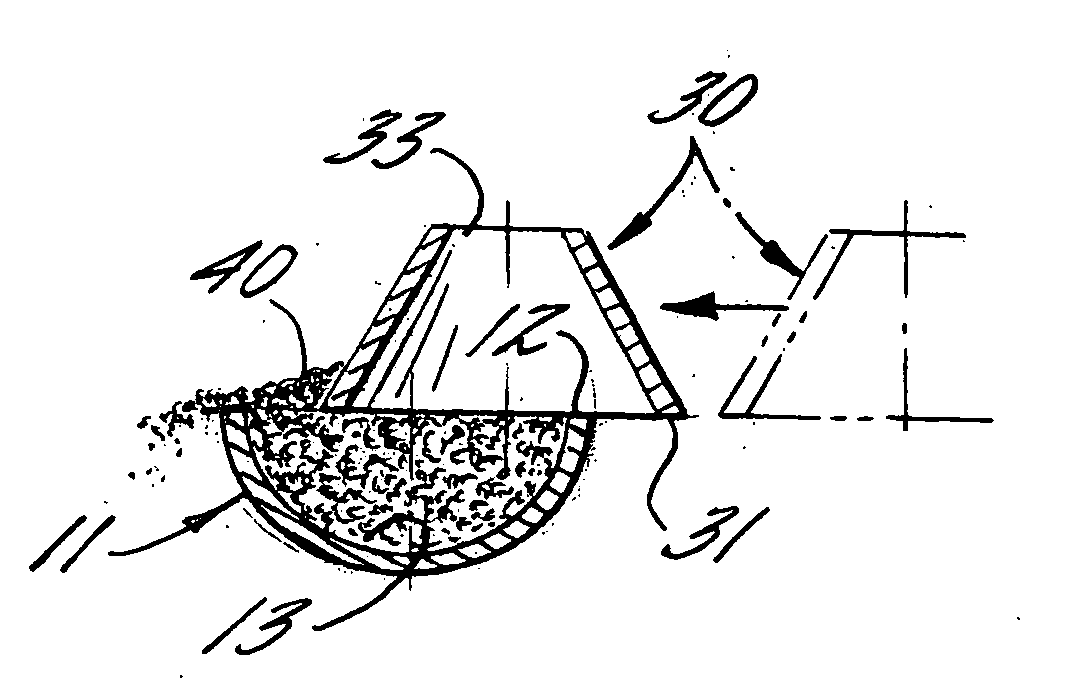

Long-term fluidized aerosol generating device with self-dispersing function

ActiveCN106512872AImprove uniformityAvoid cloggingColloidal chemistry detailsAerosol preparationEngineeringAerosol powder

The invention provides a long-term fluidized aerosol generating device with a self-dispersing function. The long-term fluidized aerosol generating device consists of an airflow supply part, an airflow drying part, a powder ebullition fluidizing part, a powder self-dispersing part and a powder online continuous supply part. Due to the unique design of the airflow drying section and an ebullition fluidizing plate, powder can be in a fluidized state under the action of the bubbling airflow of the fluidizing plate. In the self-dispersing section, part of lumpy powder is further dispersed under the action of high-speed airflow, so that the problems of viscous powder aggregation, clustering, vibrating caking and water absorbing deliquescence are effectively solved, the problems of particle unevenness and powder discharging discontinuity, which occur in the aerosol powder supply process, are effectively avoided, and the even and continuous supply of aerosol powder is ensured.

Owner:HARBIN ENG UNIV

Cup for measuring and dispensing powdered product

InactiveUS20050017028A1Facilitates accurate and uniform transferAccurate measurementLarge containersStationary measuring chambersAdditive ingredientEngineering

The present invention provides an improved apparatus for measuring and dispensing powdered products. The apparatus includes a cup portion and a funnel-shaped dispenser. The cup holds the powdered material to be measured is sized to contain a desired volume of the powder when filled to its upper edge. The upper edge of the cup has a flat surface to accommodate leveling of the powdered ingredients. The funnel-shaped dispenser serves as a leveler and aids in accurately dispensing the measured powder into a mixing area. The funnel-shaped dispenser thus defines a flat edge at its receiving opening for engaging the upper edge of the cup.

Owner:SONOCO DEV INC

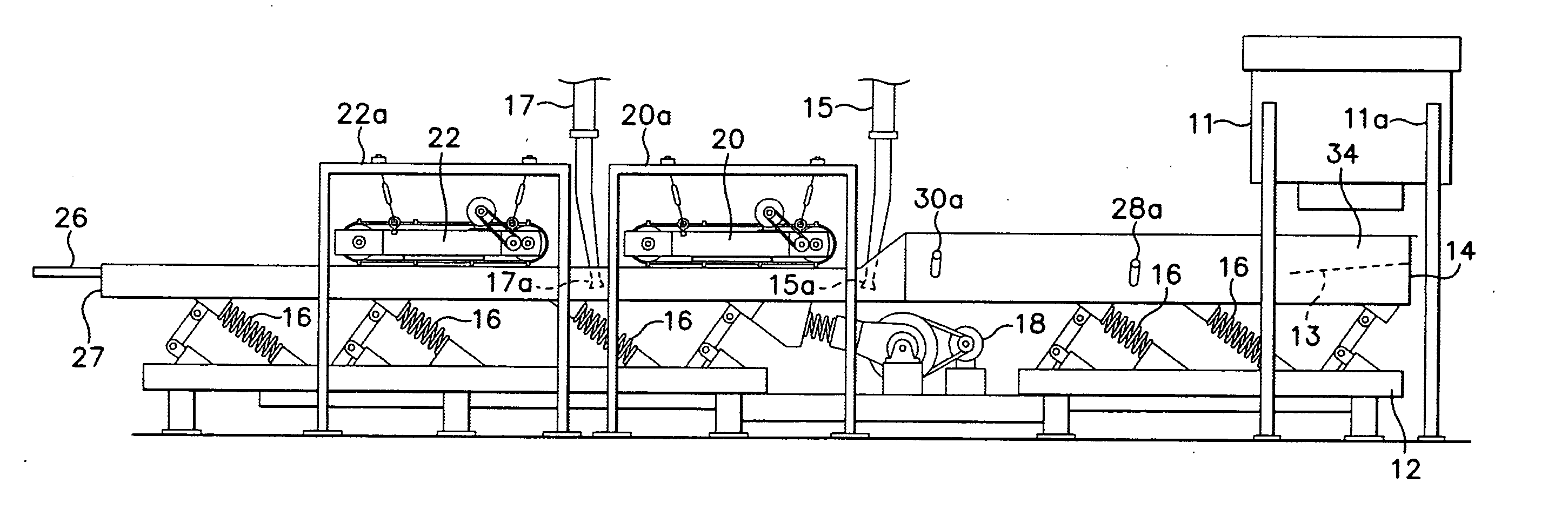

Free wire reclaimer with improved magnetic separation

ActiveUS20060070922A1Reduce cakingEfficient separationGas current separationPlastic recyclingMagnetic separatorReclaimer

A magnetic separation apparatus for separating metallic material from a granulated stream of mixed metallic and nonmetallic material comprises a vibratory conveyor having a trough assembly mounted on a suspension system and coupled to a motor for causing the suspension system to vibrate. The trough assembly includes an upper trough having at least two sections aligned in a predetermined direction of material flow and a lower trough extending in the same direction as and beneath the upper. The upper trough includes one or more gaps of a predetermined width so as to permit material to fall onto the lower trough. Each trough is arranged so as to feed a different output collection point. At least one of the gaps between a downstream section of the upper trough and an upstream section of the upper trough includes the downstream section positioned at a height lower than the upstream section thereby forming a vertical drop between the two sections with the gap positioned therebetween. For each gap, an adjustable gate may be used for adjusting the width of the gap. A magnetic separator may be arranged above the gap in the upper trough so as to pick up free metal. Rubber granules fall through the gap and are deposited in a receptacle, while metal is deposited on the upper trough which feeds a separate receptacle. A declumping zone comprising at least one perforated deck may be situated in-line with the upper and lower troughs.

Owner:ACTION EQUIP CO INC

Technical method for associated producing carbonic allyl ester, methyl carbonate, and propylene glycol

InactiveCN101092365AReduce cakingEliminate the safety hazard of overpressureProductsReagentsMethyl carbonatePropanediol

This invention discloses a process for combined production of propylene carbonate, dimethyl carbonate and propylene glycol. The method utilizes propylene oxide, CO2 and methanol as the raw materials, and adopts two-step reaction to produce propylene carbonate, dimethyl carbonate and propylene glycol. The method avoids propylene carbonate refinery process; catalyst recovery process and propylene carbonate storage apparatus. The method utilizes a novel thin film evaporator to separate and refine crude propylene carbonate and catalyst, and thus increase the separation precision and productivity. The method utilizes a set of platform framework and a DCS control chamber to realze continuous operation of the whole process, and is stable and reliable. The produced propylene carbonate, dimethyl carbonate and propylene glycol can reach pharmaceutical grade purity.

Owner:SHANDONG SHIDA SHENGHUA CHEM GROUP

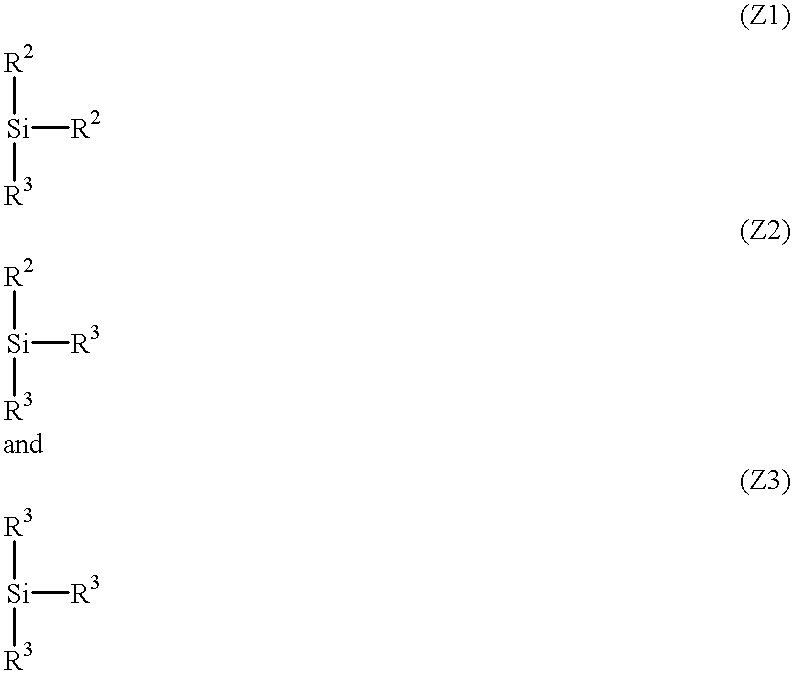

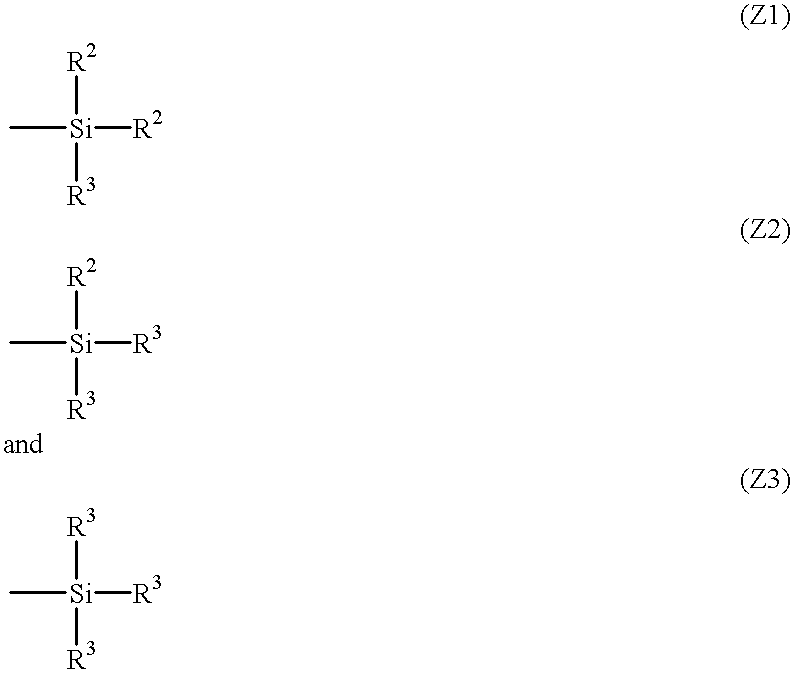

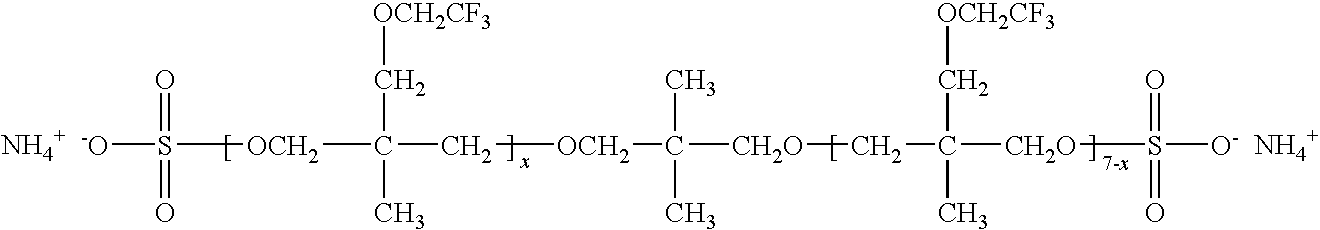

Nanoparticles from supercritical fluid antisolvent process using particle growth and agglomeration retardants

InactiveUS20060039983A1Maintain good propertiesOvercome limitationsPowder deliveryGranular deliveryGrowth retardantFluorocarbon

The present invention provides a method of forming particles using supercritical fluid (SCF). In accordance with the method, one or more growth retardant compounds having both SCF-philic and SCF-phobic groups are present when one or more solute materials reach a supersaturation point and begin to form particle nuclei. The growth retardant compounds can reduce the particle growth rate, increase the nucleation rate and also prevent particle agglomeration. Preferred growth retardant compounds include sugar acetates and fluorocarbons.

Owner:FERRO CORP

Infant multi-grain rice flour and preparation method thereof

InactiveCN103535599AImprove immunityPromote gastrointestinal digestionSugar food ingredientsVitamin food ingredientsMultivitaminLactose

The invention discloses infant multi-grain rice flour and a preparation method thereof. The infant multi-grain rice flour is prepared from the following raw materials in parts by weight: 20-40 parts of rice, 15-20 parts of oat, 15-20 parts of corn, 0.5-1.5 parts of galactooligosaccharide and glucose, 0.4-2 parts of soybean protein, 6-10 parts of hawthorn powder and 0.3-0.8 part of compound vitamin and mineral substance. Grains and hawthorn powder are added into the rice flour, so that the nutritive materials are enriched, the immunity of infants can be obviously improved, the gastrointestinal digestion function of the infants is favorably improved, and the enzymatically decomposed rice flour can be more easily absorbed and digested by the infants, can reduce the situations such as inflammation, diarrhea and dyspepsia after being eaten and is safe and reliable.

Owner:SUZHOU WILDER IND & TRADE

Precoated sand and burn-free regeneration technology thereof

ActiveCN103341587AHigh heat tensile strengthLow gasFoundry mouldsMould handling/dressing devicesHexamethylenetetramineDolomite

The invention belongs to the field of new materials and discloses precoated sand. The precoated sand is prepared from silica sand, pyrite powder, phenolic resin, bisphenol-A epoxy resin, phenolsulfonic acid, short peptide, boric acid, molybdenum disulfide, a methenamine solution, zinc stearate, dolomite powder, talcum powder and graphite powder. The invention also discloses a burn-free regeneration technology of the used precoated sand. The precoated sand prepared by the technoloyg has relatively high hot tensile strength, low gas-forming property and stable storage property; and the rejection rate of castings is relatively low.

Owner:LINYI ZHUBAO WATER METER

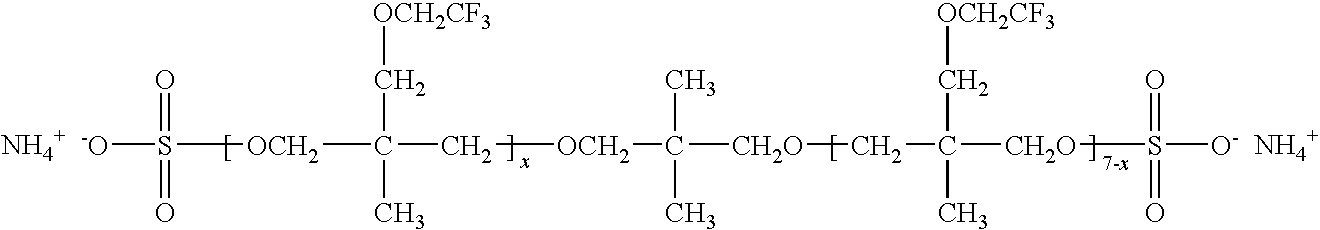

Production of silver sulfate grains using inorganic additives

ActiveUS20080241511A1Uniform sizeReadily disperseCosmetic preparationsLayered productsInorganic sulfateIon

An aqueous precipitation process for the preparation of particles comprising primarily silver sulfate, comprising reacting an aqueous soluble silver salt and an aqueous soluble source of inorganic sulfate ion in an agitated precipitation reactor vessel and precipitating particles comprising primarily silver sulfate, wherein the reaction and precipitation are performed in the presence of an aqueous soluble inorganic additive compound containing a cation capable of forming a sulfate salt that is less soluble than silver sulfate or a halide anion or an oxyanion capable of forming a silver salt that is less soluble than silver sulfate, the amount of additive being a minor molar percentage, relative to the molar amount of silver sulfate precipitated, and effective to result in precipitation of particles comprising primarily silver sulfate having a mean grain-size of less than 70 micrometers.

Owner:EASTMAN KODAK CO

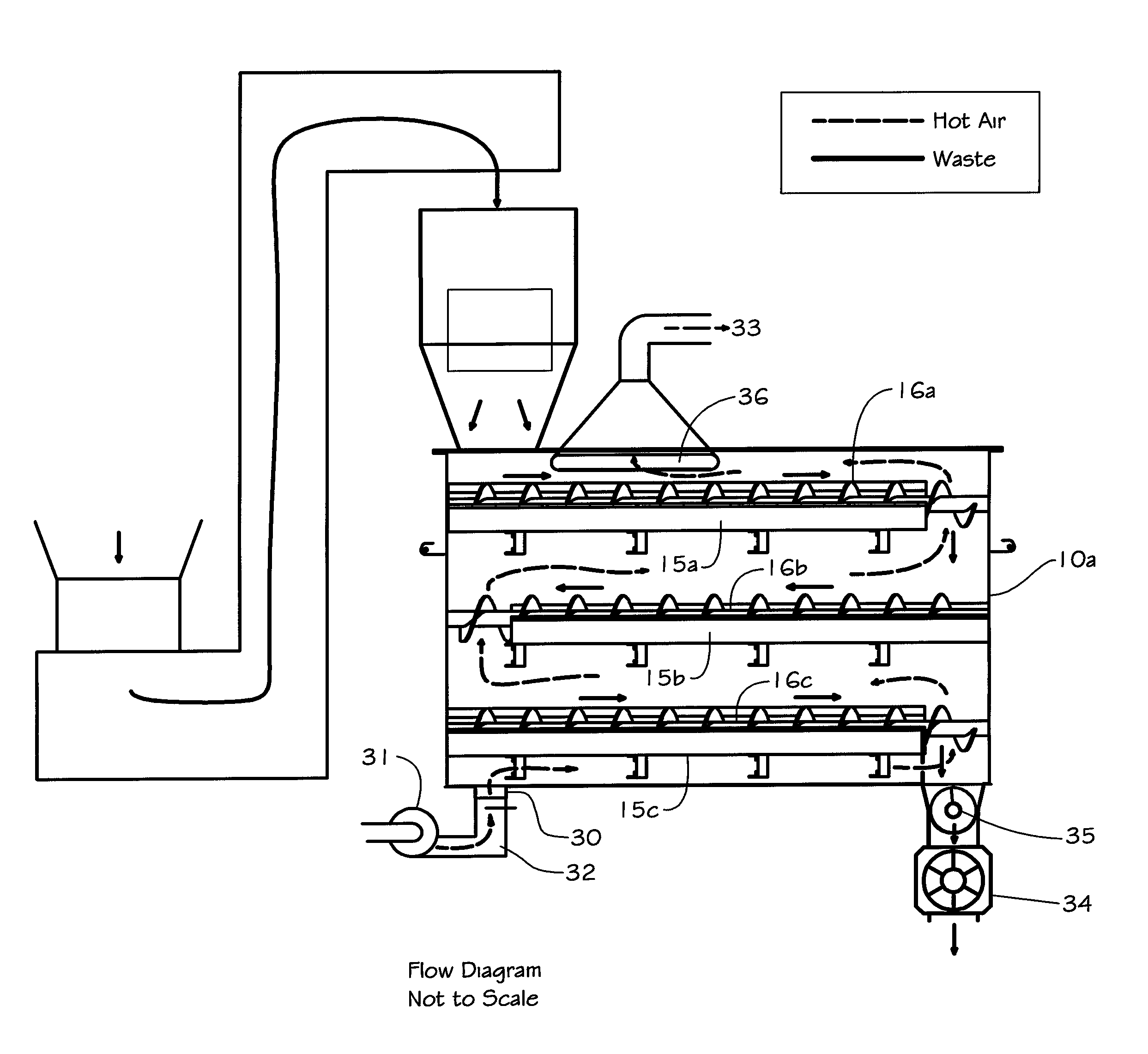

Animal waste processing

InactiveUS8147772B2Efficient dryingSave spaceManure dryingSolid waste disposalMold sporesEquine Species

A method and apparatus for eliminating mold spores, pathogens and odor from material like equine bedding. The apparatus includes two or more pairs of augers including blades to control the size of the material and to move it in a zigzag fashion through heat.

Owner:WILFORD PHILIP GRAHAM

Production of silver sulfate grains using a fluorinated additive

InactiveUS7655212B2Uniform morphologyUniform sizePigmenting treatmentCosmetic preparationsWater solubleSULFATE ION

An aqueous precipitation process for the preparation of particles comprising primarily silver sulfate, comprising reacting an aqueous soluble silver salt and an aqueous soluble source of inorganic sulfate ion in an agitated precipitation reactor vessel and precipitating particles comprising primarily silver sulfate, wherein the reaction and precipitation are performed in the presence of an aqueous soluble fluorinated additive, the amount of additive being a minor molar percentage, relative to the molar amount of silver sulfate precipitated, and effective to result in precipitation of particles comprising primarily silver sulfate having a mean grain-size of less than 50 micrometers.

Owner:EASTMAN KODAK CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com