Polyhedral gasifier and relative method

A gasifier and oxygen technology, applied in chemical instruments and methods, gasification technology, combustion methods, etc., can solve the problems of lack of fuel adaptability and high capital cost, and achieve high fuel adaptability, high process efficiency, and low equipment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

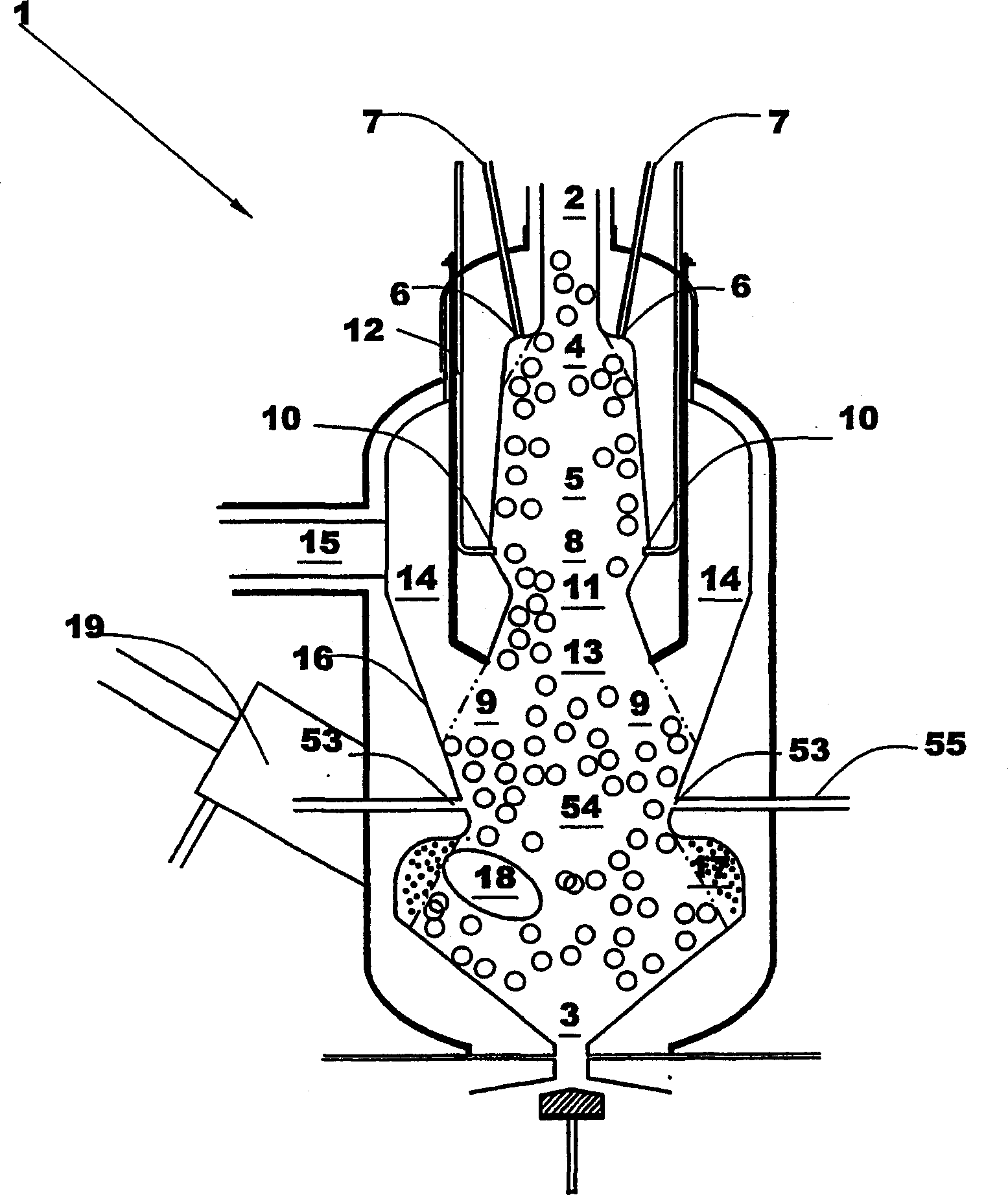

[0032] Hereinafter, presently preferred embodiments of the present invention will be described with reference to the accompanying drawings. In the illustrated preferred embodiment, figure 1 A cross-sectional view of the gasifier 1 is shown. Coarse carbonaceous feedstock enters the top of the gasifier through the coarse feed port 2 and moves down through the gasifier 1 until it becomes molten ash at the bottom 3 . Coarse feedstocks may include, but are not limited to, the following feedstocks: coal, oil coke, municipal solid waste, biomass, or combinations thereof. Below the feed port 2, the fuel enters the pyrolysis zone, number 4 is at the top of this zone and number 5 is at the bottom of this zone. In the pyrolysis zone the crude fuel is heated by the combination of combustion and gasification and causes devolatilization of the crude fuel. Combustion oxygen or air and steam required for pyrolysis enter through several ports 6 branched by tubes 7 . The amount of oxygen or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com