Patents

Literature

998 results about "Vaporizer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

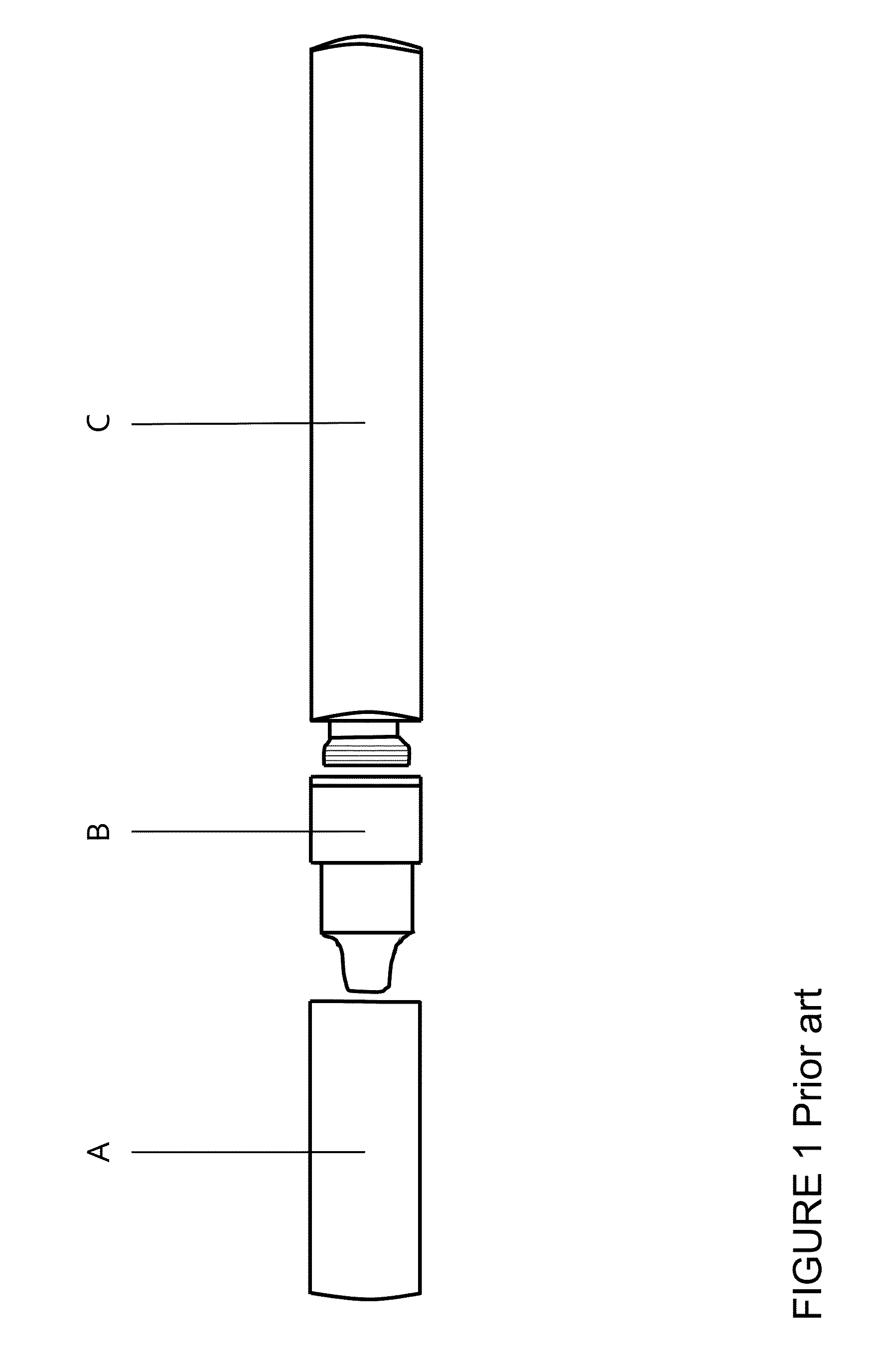

A vaporizer or vaporiser, colloquially known as a vape, is a device used to vaporize substances for inhalation. Plant substances can be used, commonly cannabis, tobacco, or other herbs or blends of essential oil. However, they can also be filled with a combination propylene glycol, glycerin, and drugs such as nicotine (e.g. extract from tobacco) or tetrahydrocannabinol as a liquid solution.

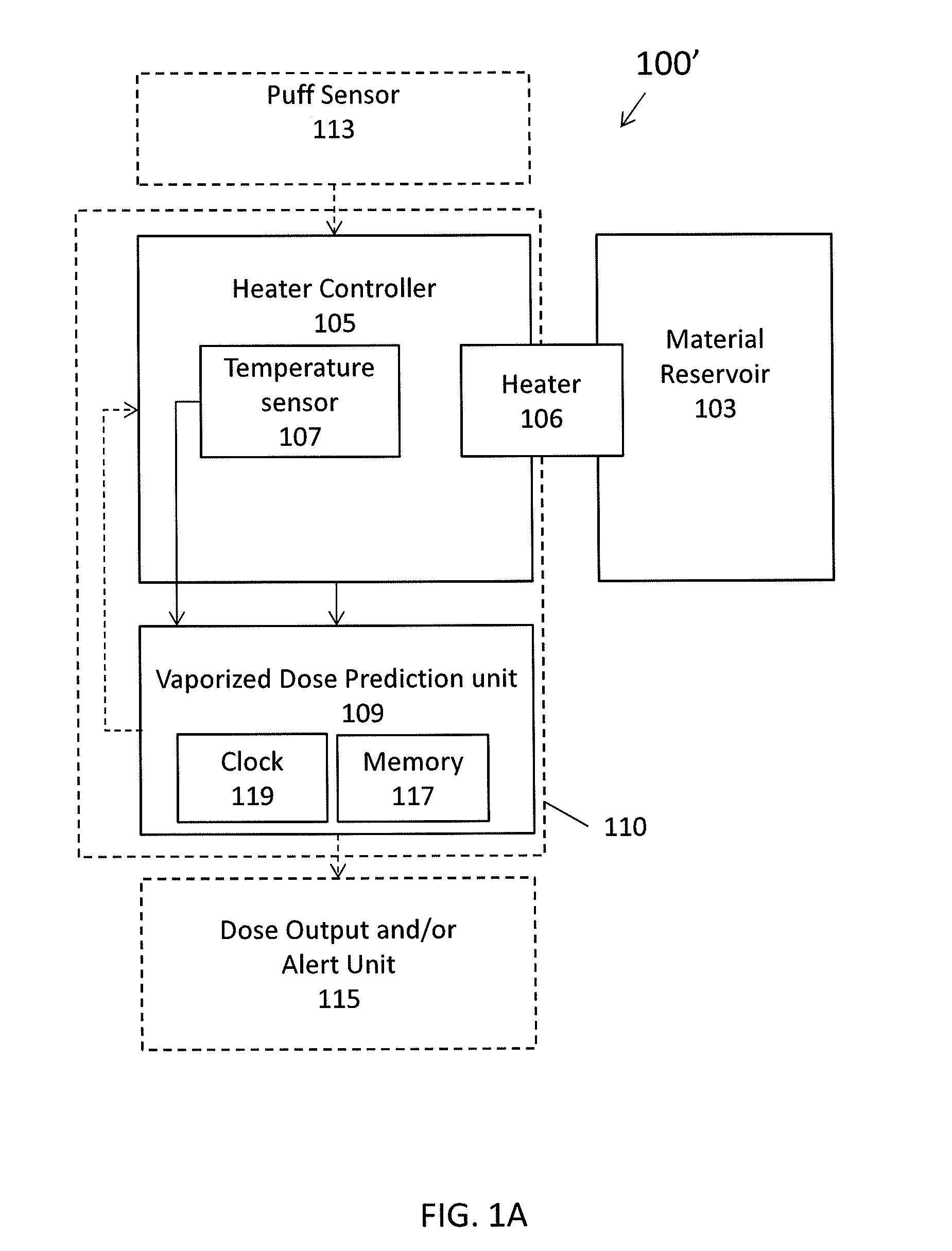

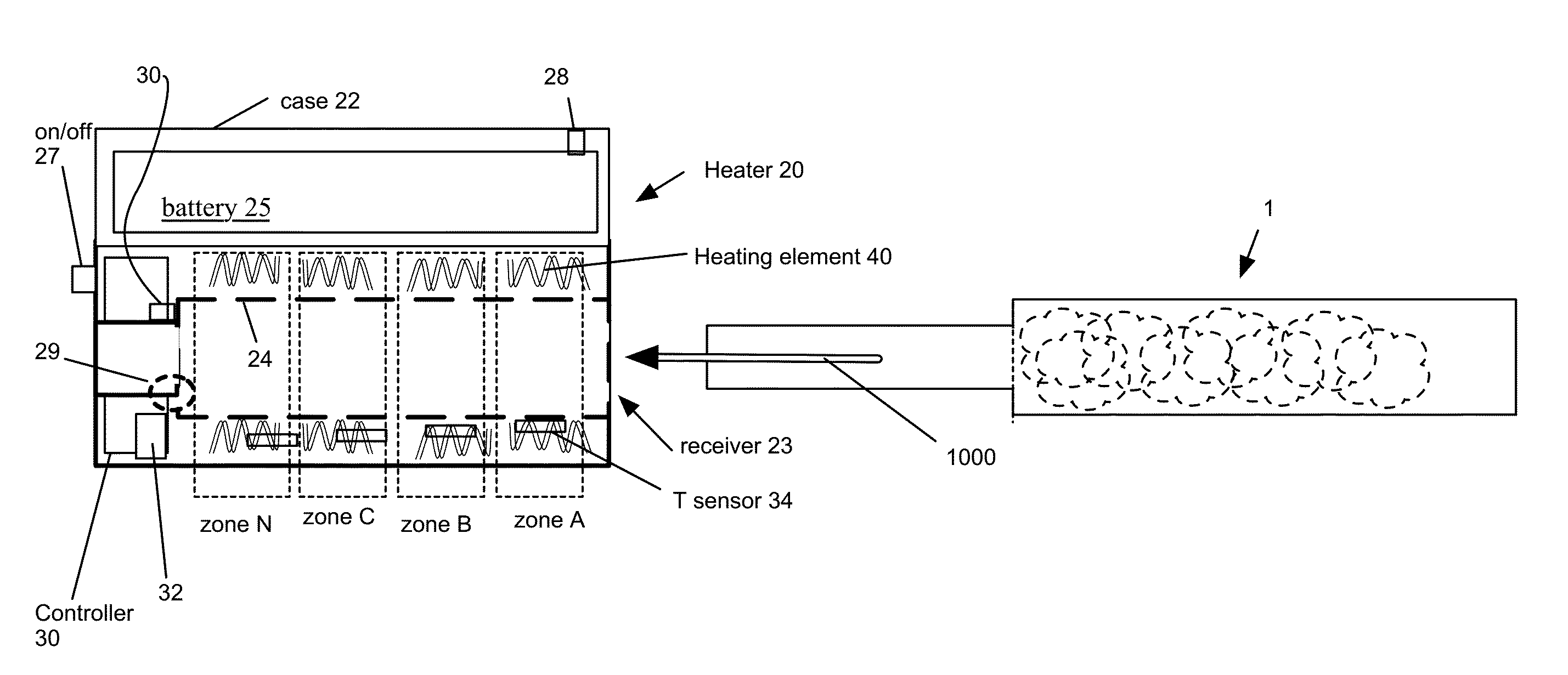

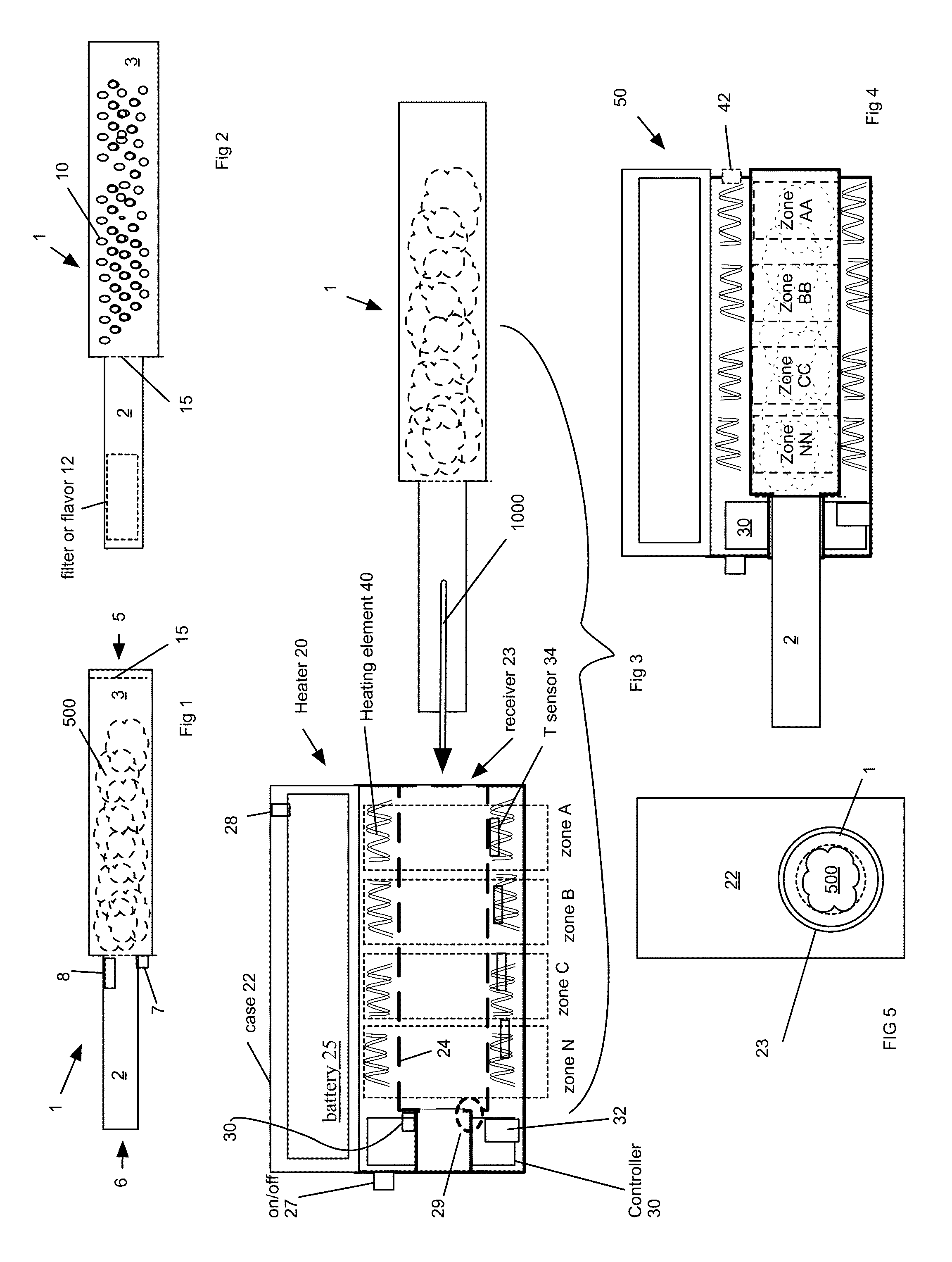

Calibrated dose control

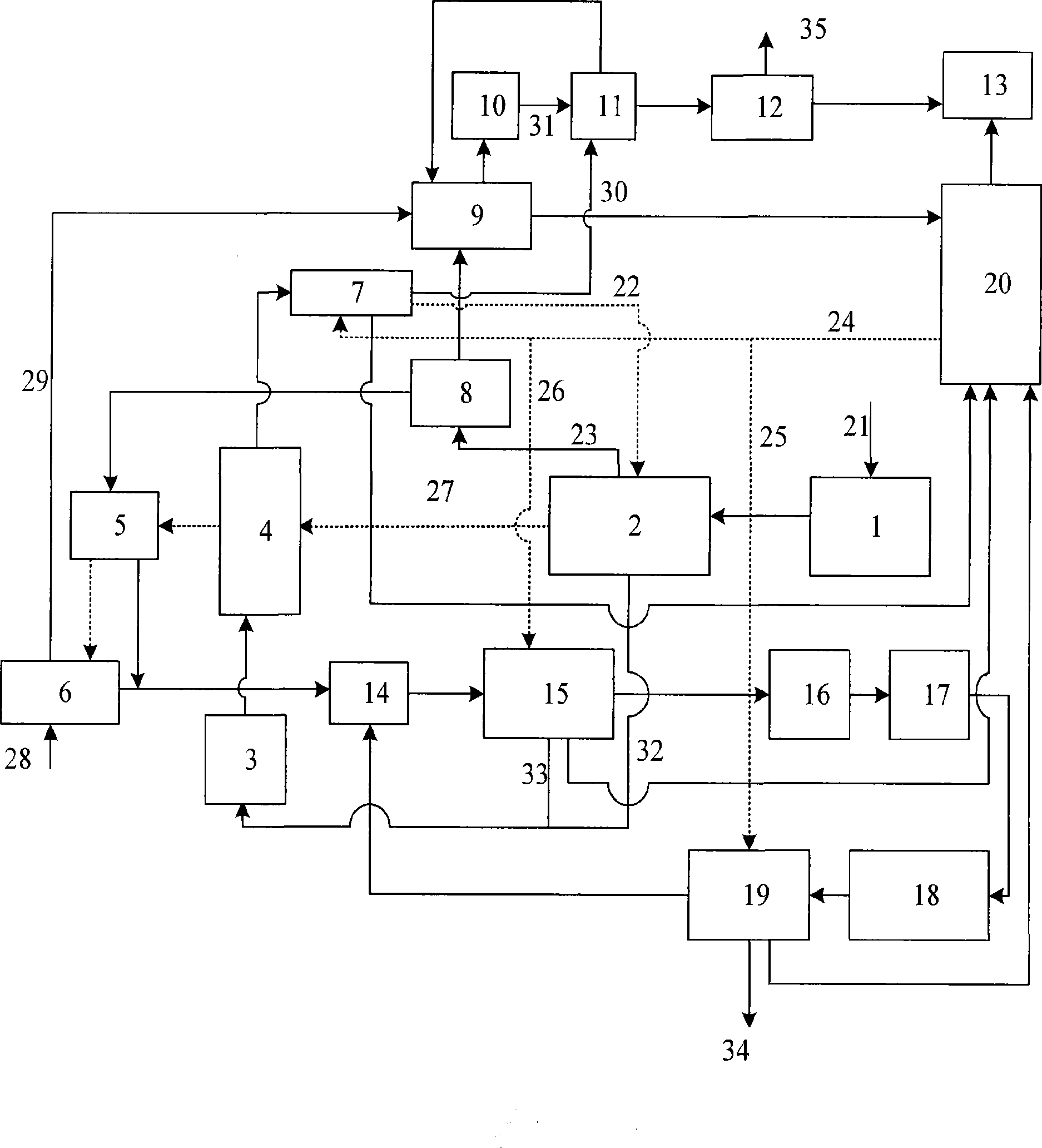

Methods and vaporizer apparatuses that estimate, measure and / or predict the amount of vapor and / or material (including active ingredients) released by the vaporizer apparatus. In particular, described herein are electronic vaporizers and methods of using them that determine a dose / amount of vapor and / or a material in the vapor based primarily or exclusively on the electrical and thermal properties, e.g., power or energy applied to the vaporizing element (e.g., heating coil) and the temperature of the material immediately before and as it is vaporized. Dose information may be used to control operation of the device and / or reported to the user.

Owner:JLI NAT SETTLEMENT TRUST

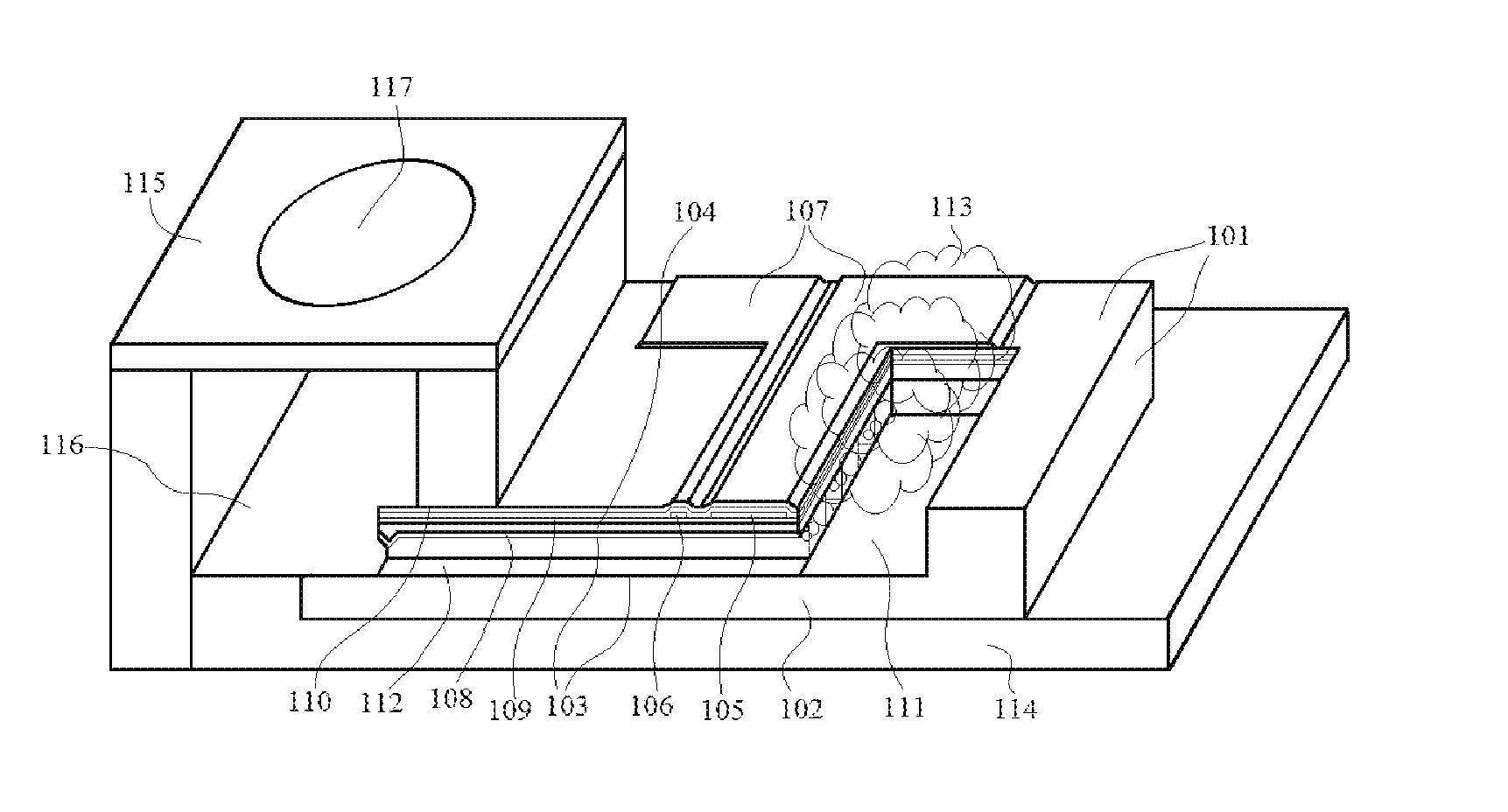

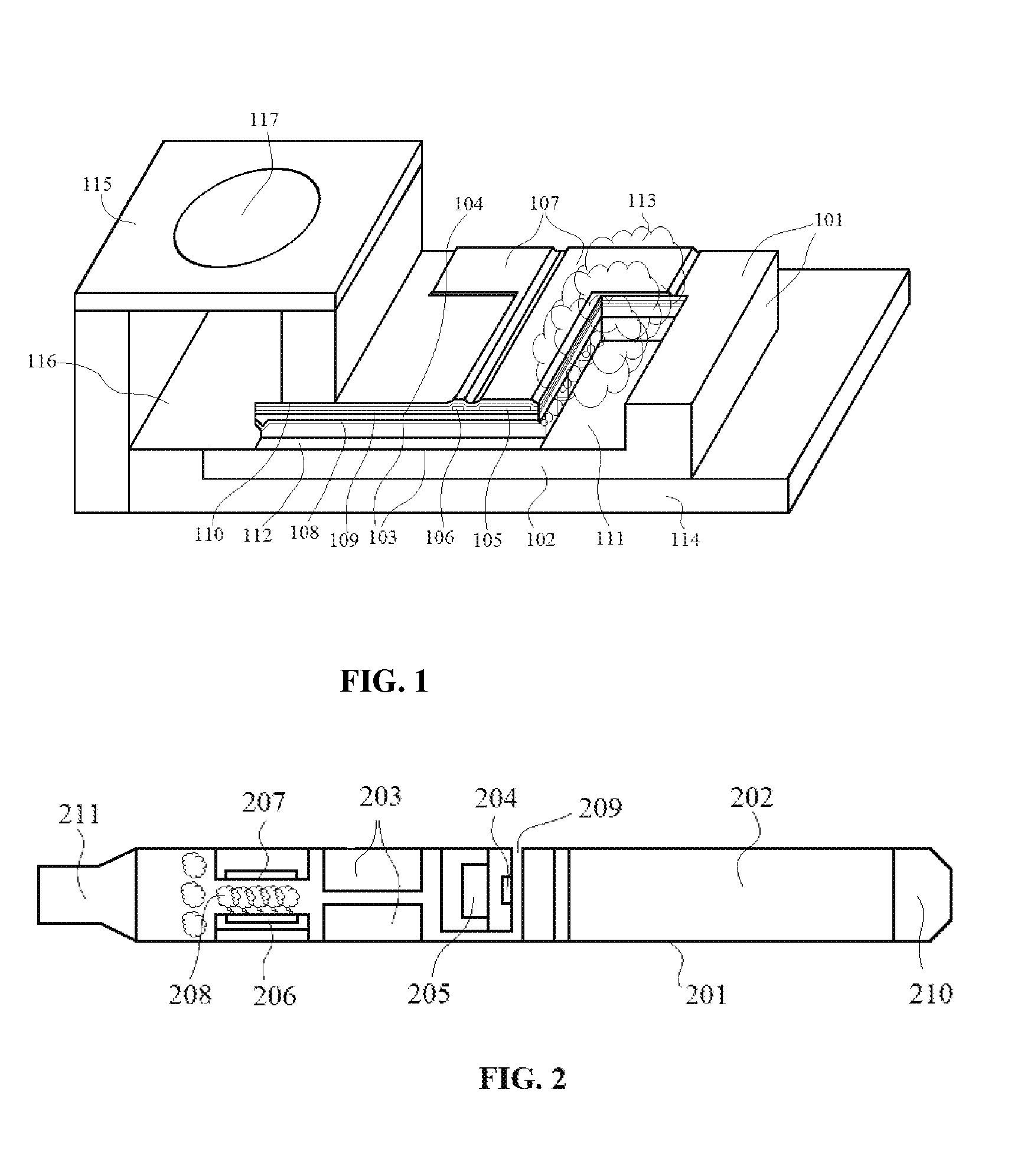

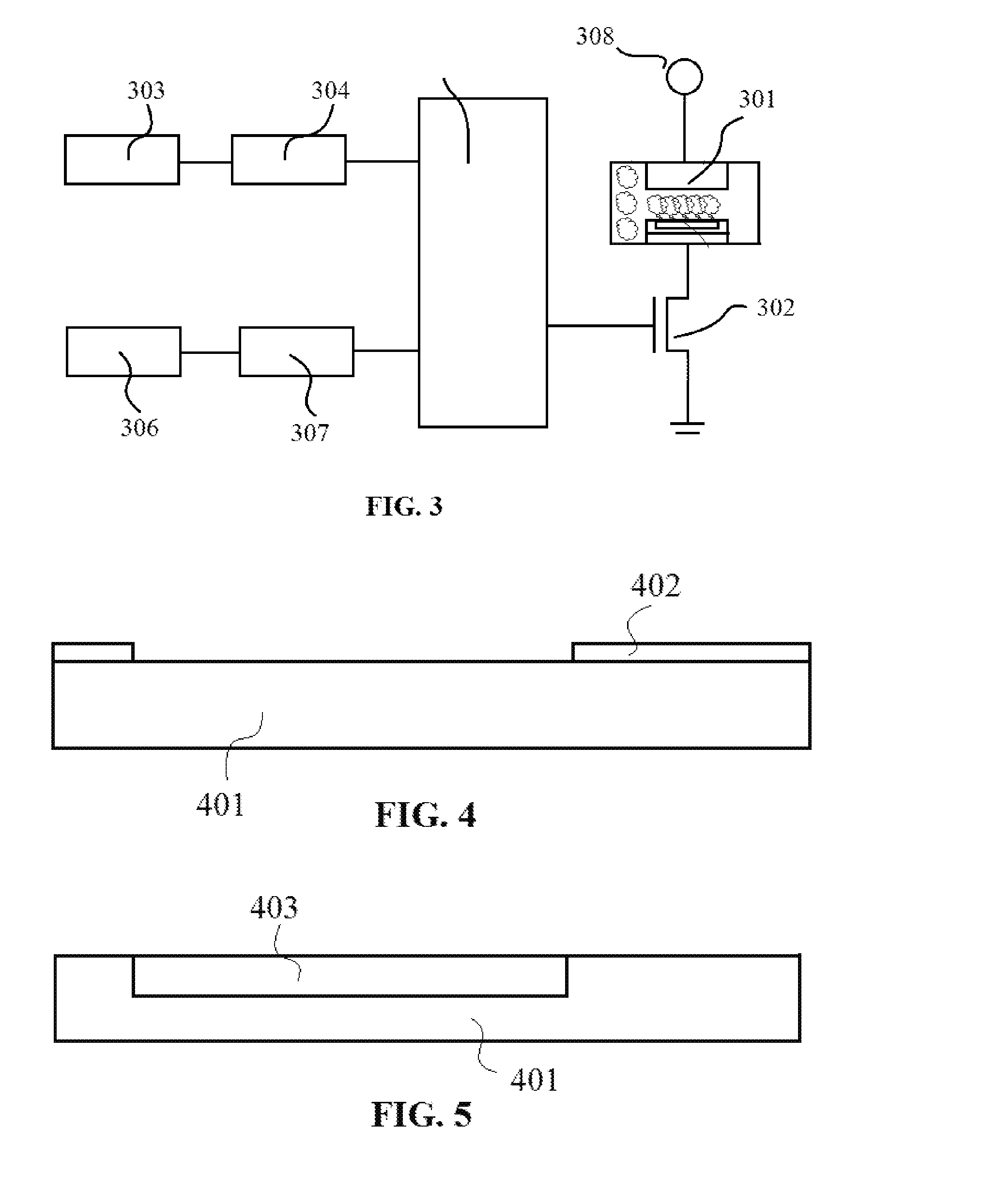

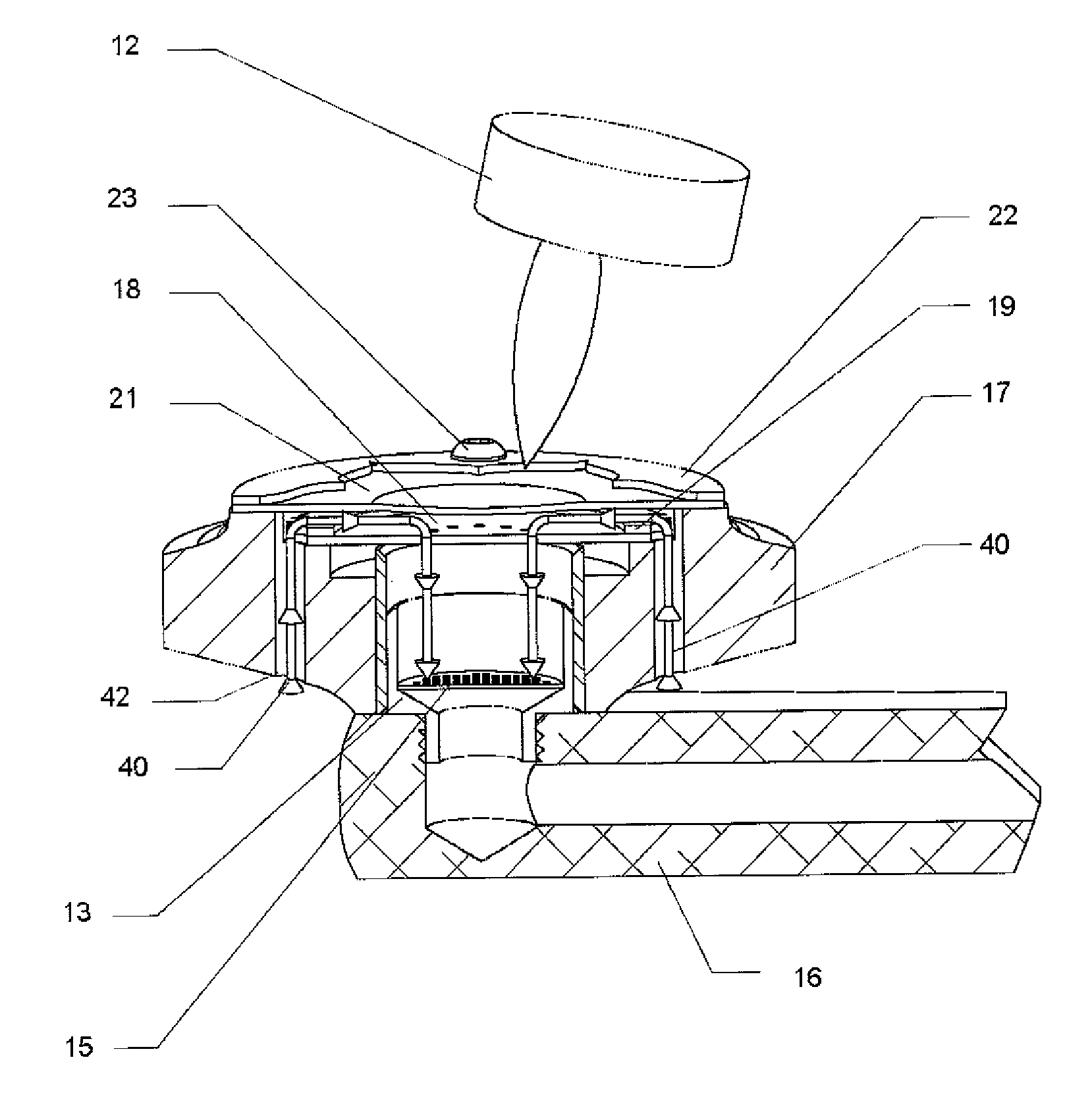

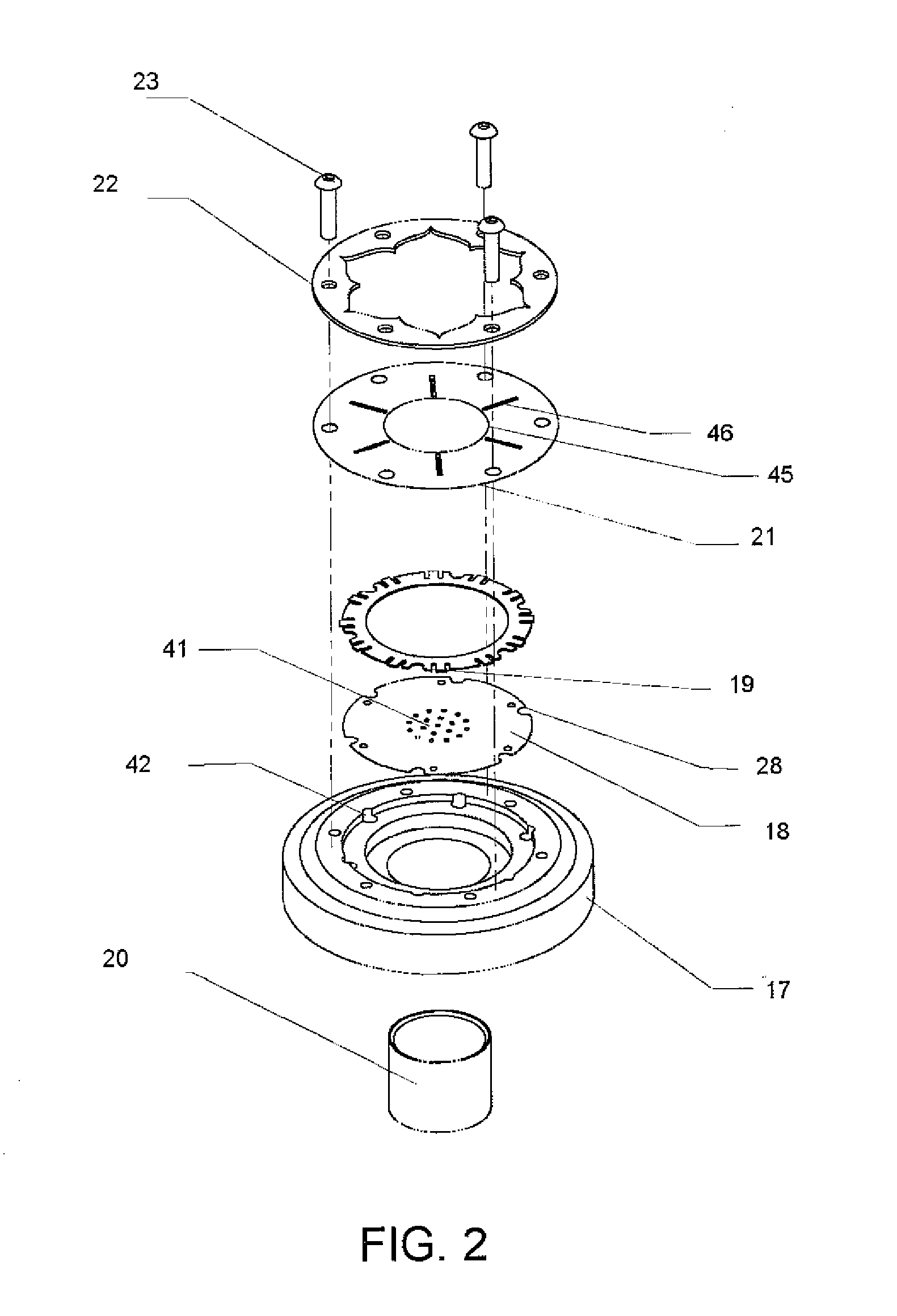

MEMS Vaporizer

ActiveUS20160007653A1Low costImprove reliabilityExhaust apparatusSemiconductor/solid-state device manufacturingEngineeringElectronic cigarette

A MEMS vaporizer is described which can be used for electronic cigarettes. The vaporizer mainly composes: a silicon substrate, a micro-channel array, a membrane suspending over the micro-channel array and supported by the silicon substrate, a resistance heater and a resistance temperature sensor are disposed on the membrane. Since the vaporizer is a silicon-based integrated actuator which provides advantages including small size, compact structure, lower power consumption, lower cost, increased reliability, higher precision, and more environmental friendliness.

Owner:POSIFA TECH LTD

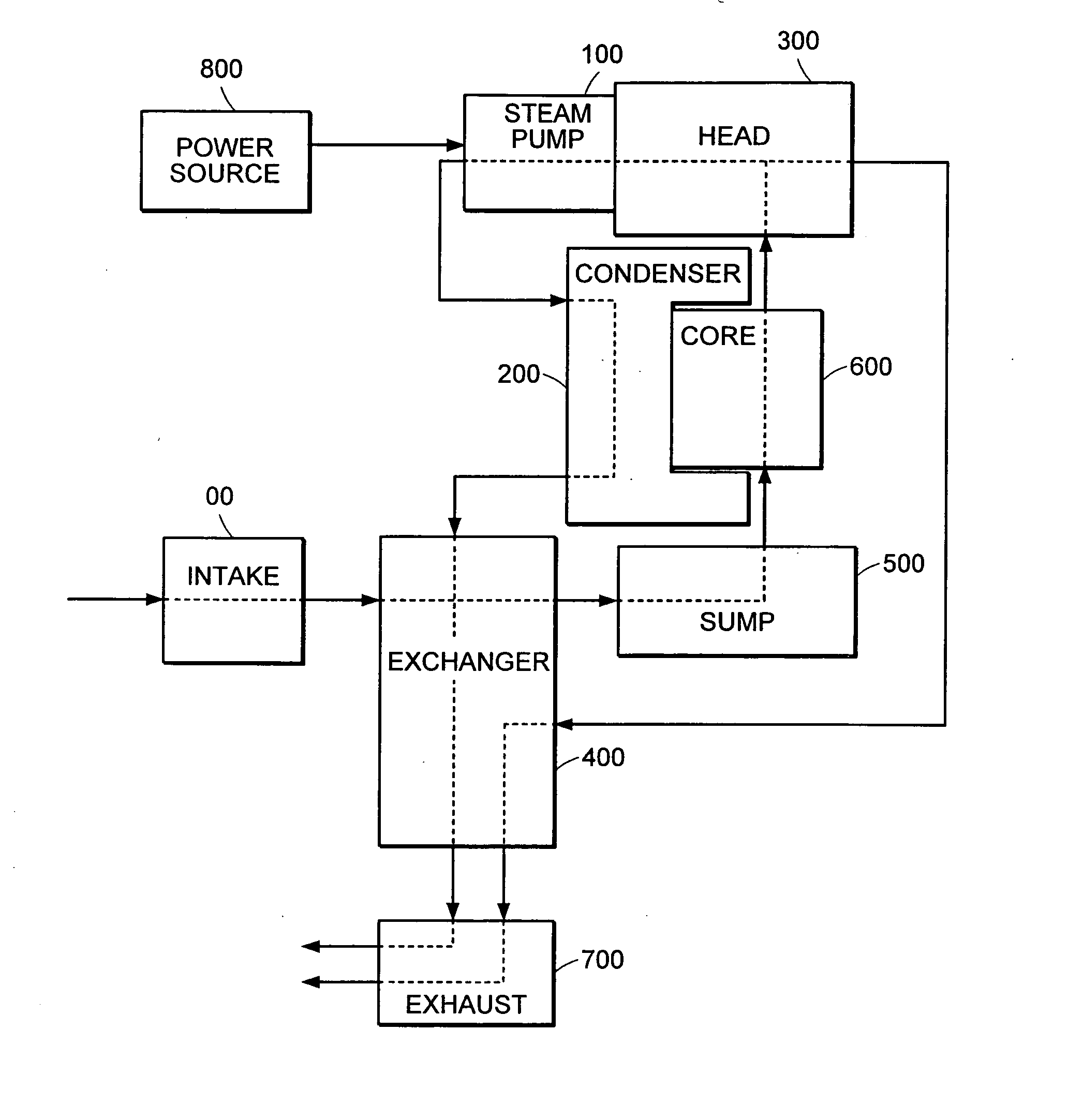

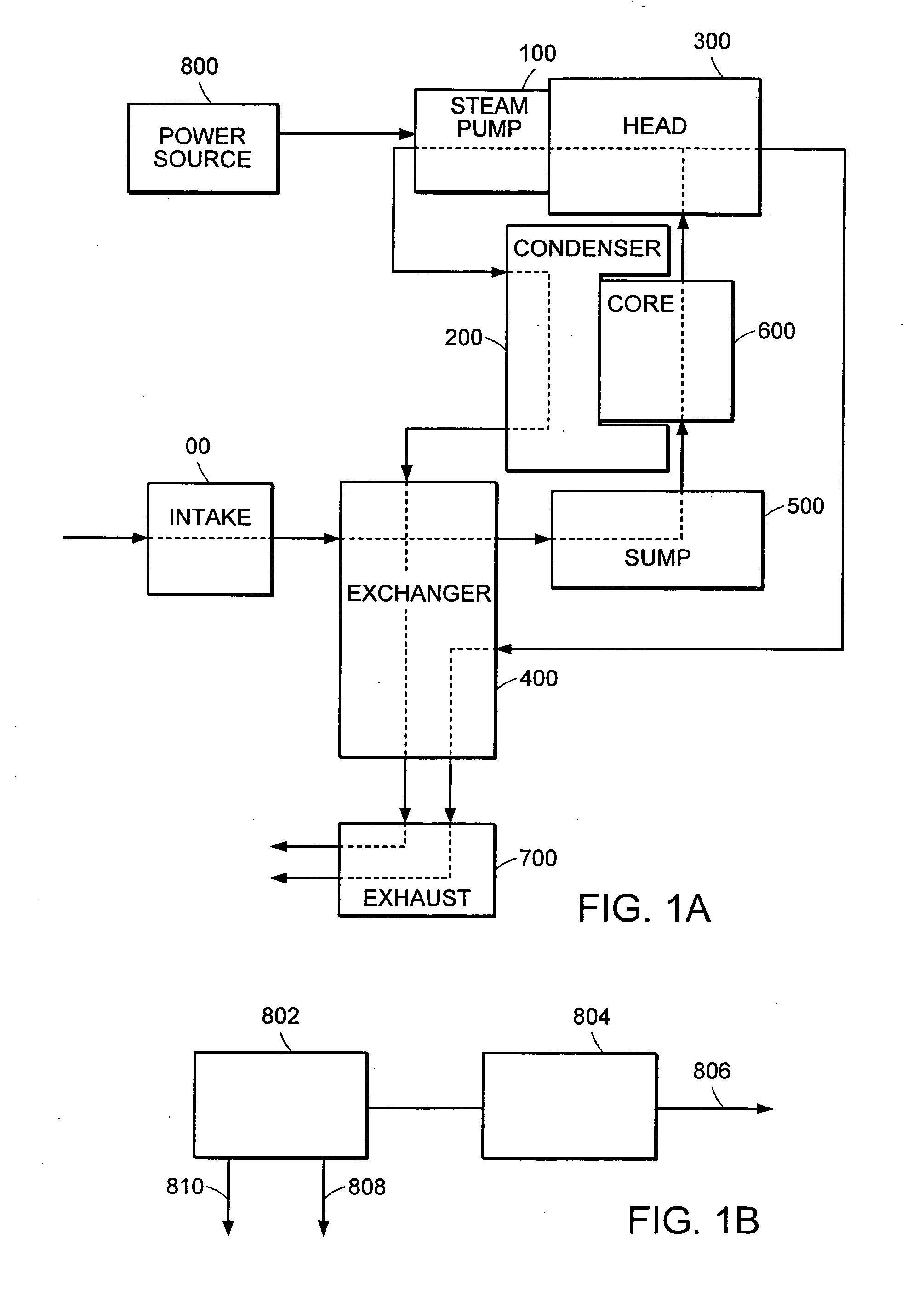

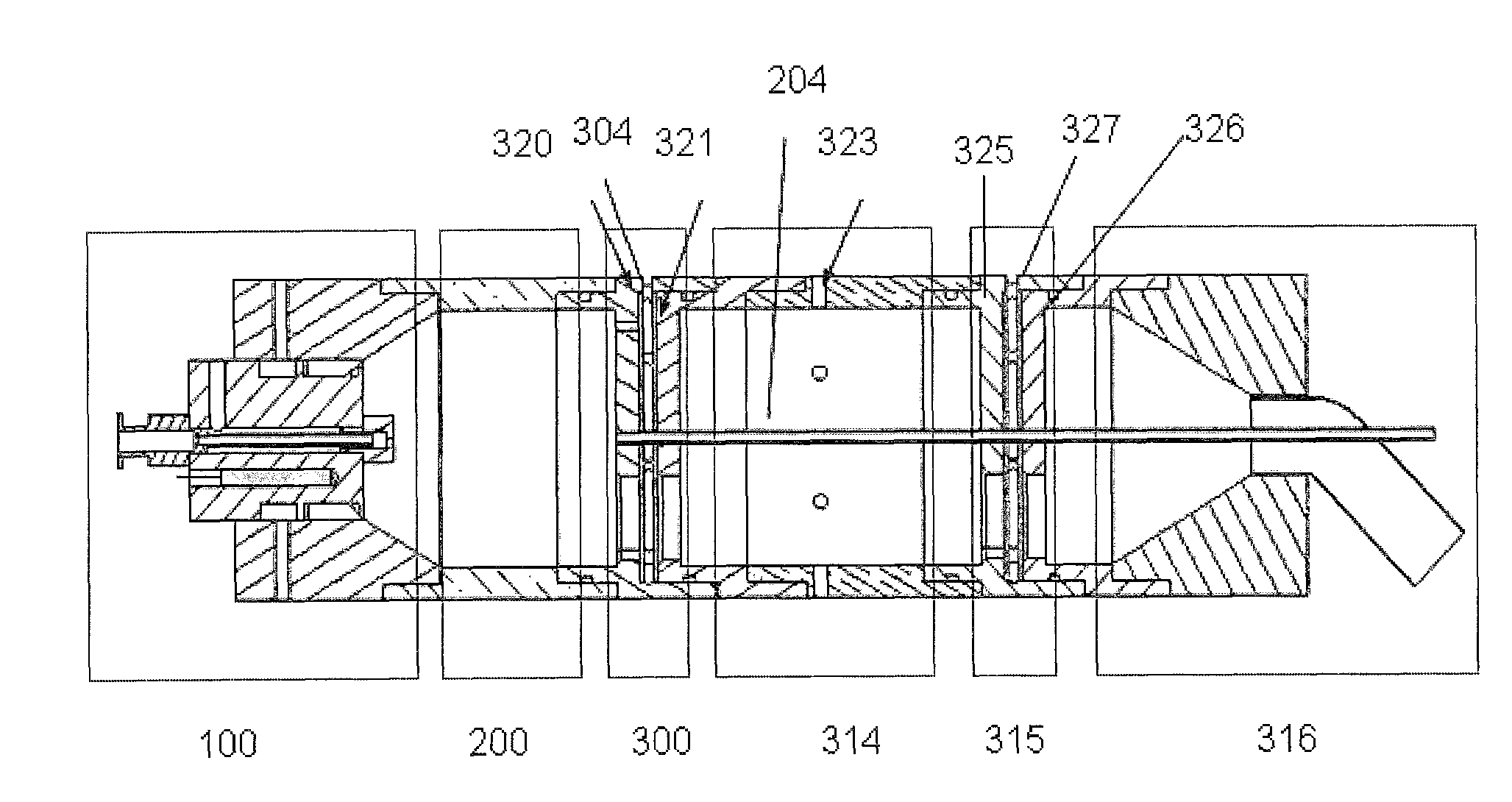

Pressurized vapor cycle liquid distillation

ActiveUS20050016828A1Easy maintenanceMaximize energy efficiencyDistillation regulation/controlUsing liquid separation agentHeat managementDrive shaft

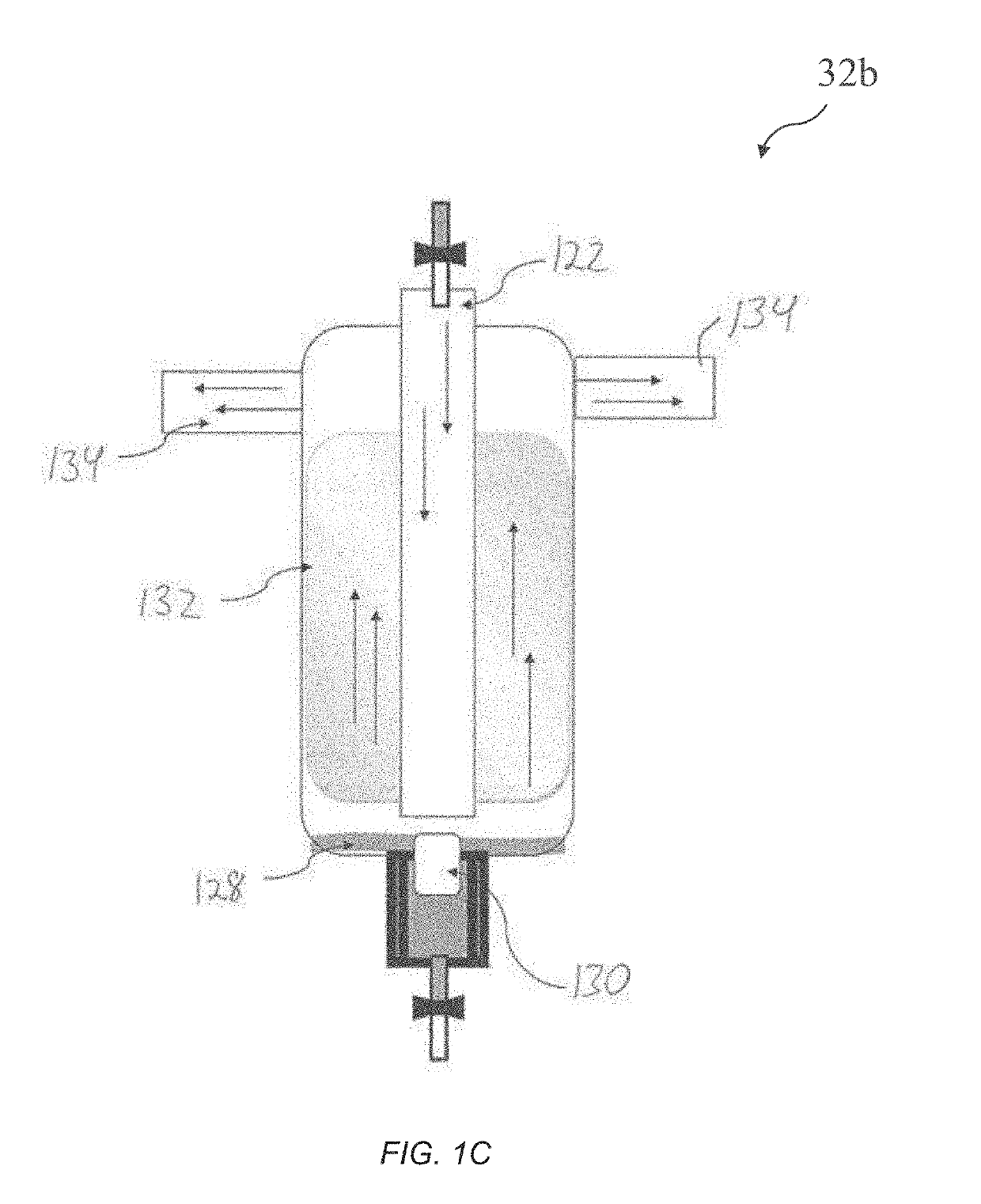

Embodiments of the invention are directed toward a novel pressurized vapor cycle for distilling liquids. In some embodiments of the invention, a liquid purification system is revealed, including the elements of an input for receiving untreated liquid, a vaporizer coupled to the input for transforming the liquid to vapor, a head chamber for collecting the vapor, a vapor pump with an internal drive shaft and an eccentric rotor with a rotatable housing for compressing vapor, and a condenser in communication with the vapor pump for transforming the compressed vapor into a distilled product. Other embodiments of the invention are directed toward heat management, and other process enhancements for making the system especially efficient.

Owner:DEKA PROD LLP

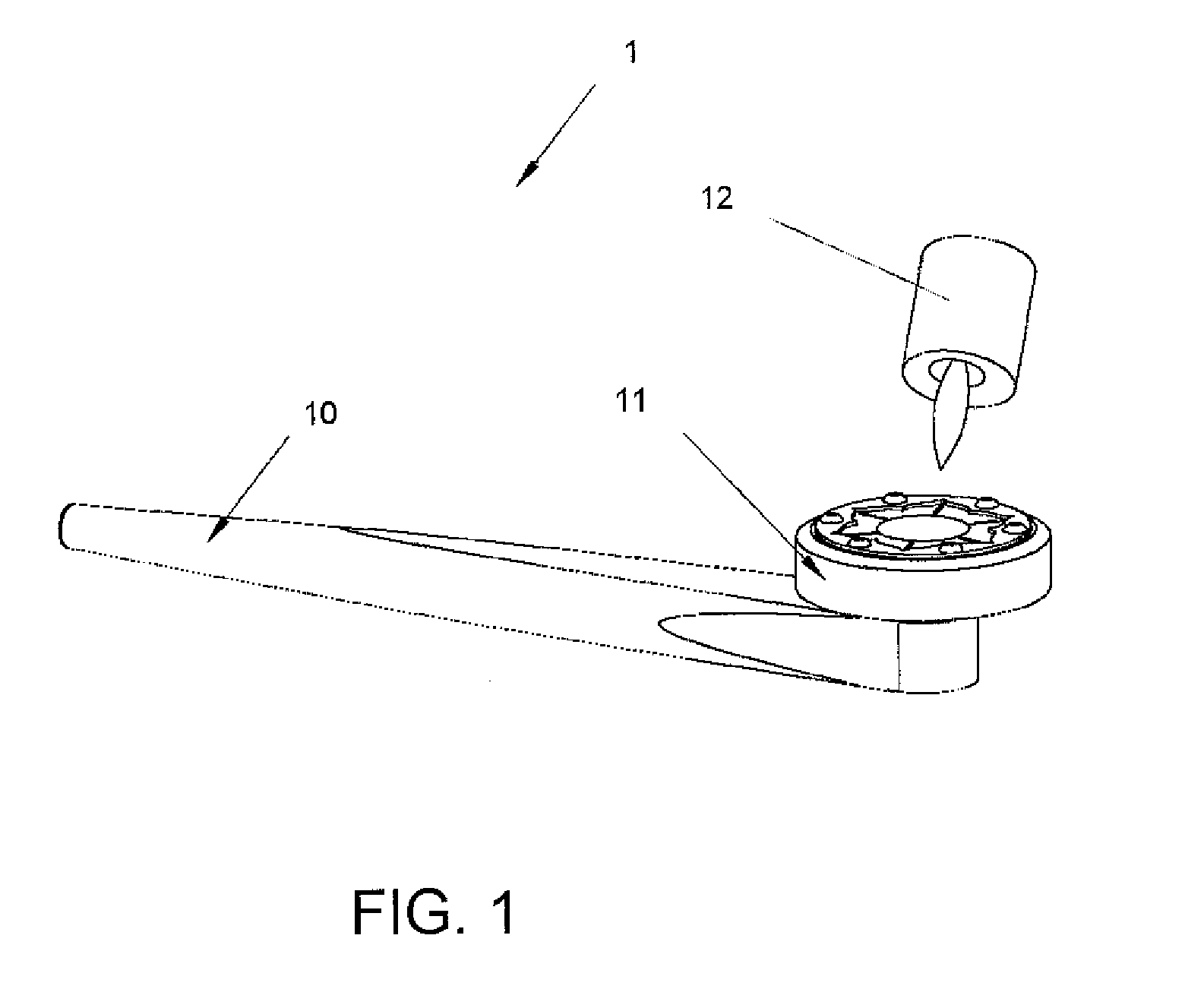

Vaporizer with foil heat exchanger

ActiveUS20110073121A1Minimize expansionMinimize flexTobacco pipesTobacco devicesPlate heat exchangerCombustion

This invention vaporizes a botanical substance for inhalation using a combustion generated heat source. A substantially planar non-porous heat exchanger transfers heat to the inhalation air and keeps combustion byproducts separated from the inhalation air. In use, air is drawn past the heat exchanger and then through a reservoir holding the botanical substance, vaporizing any volatiles in the substance. The heat exchanger assembly can be magnetically attached to the pipe assembly.

Owner:VAPMAN GMBH SRL

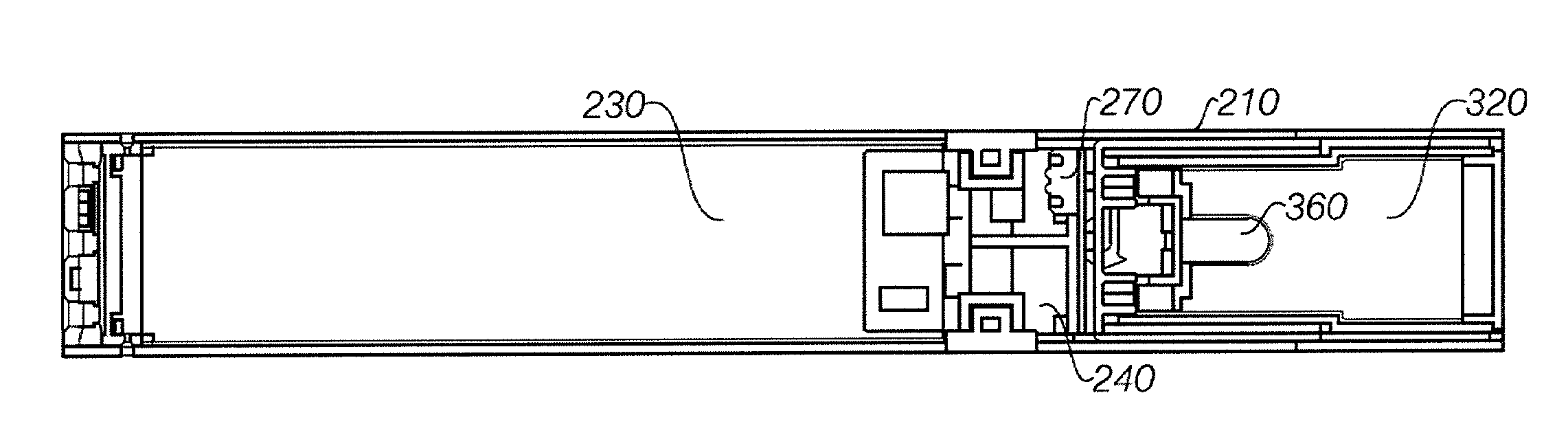

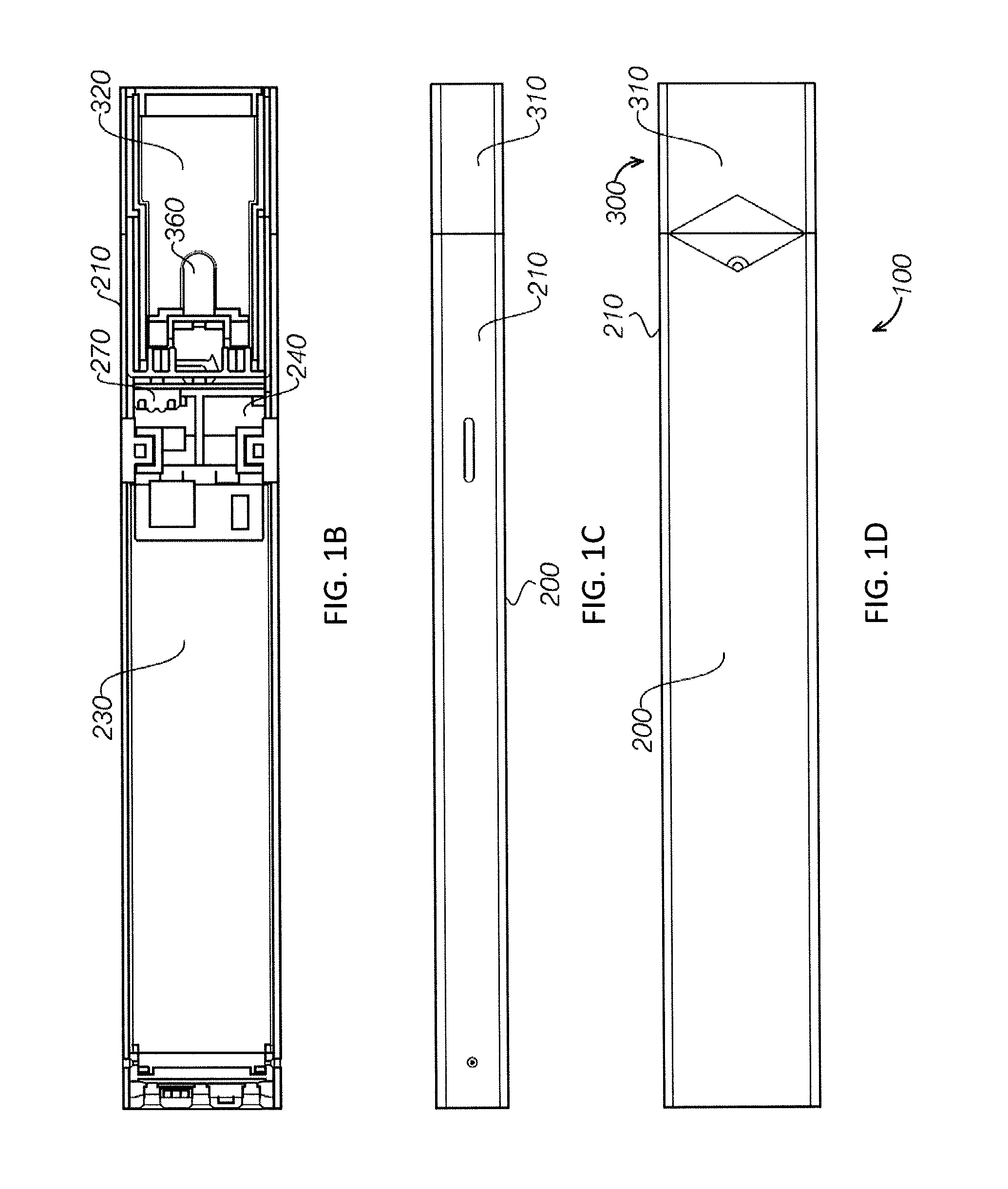

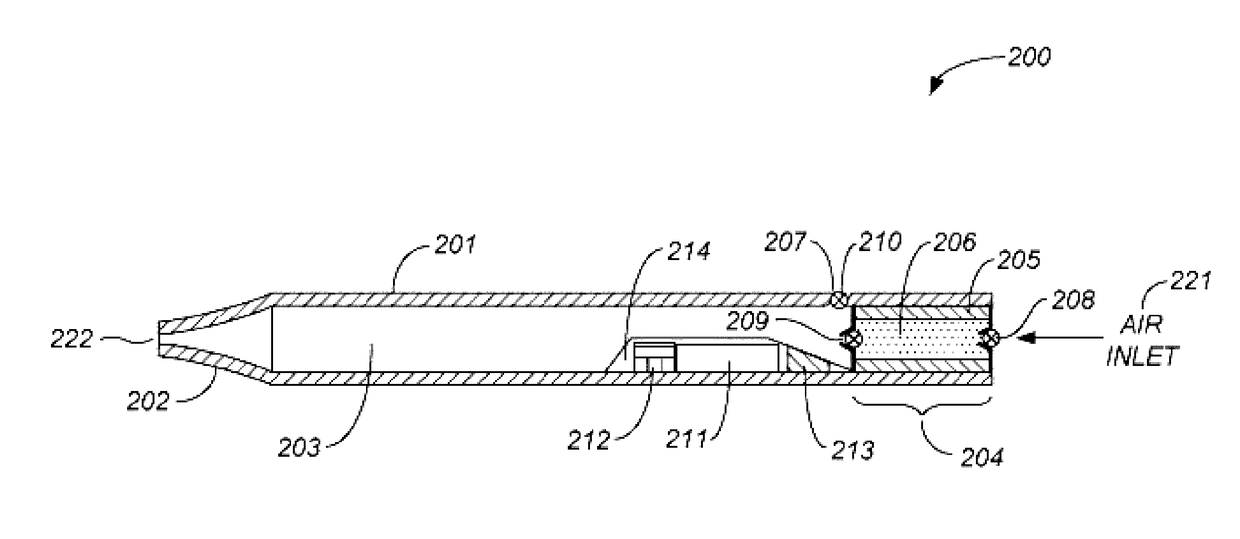

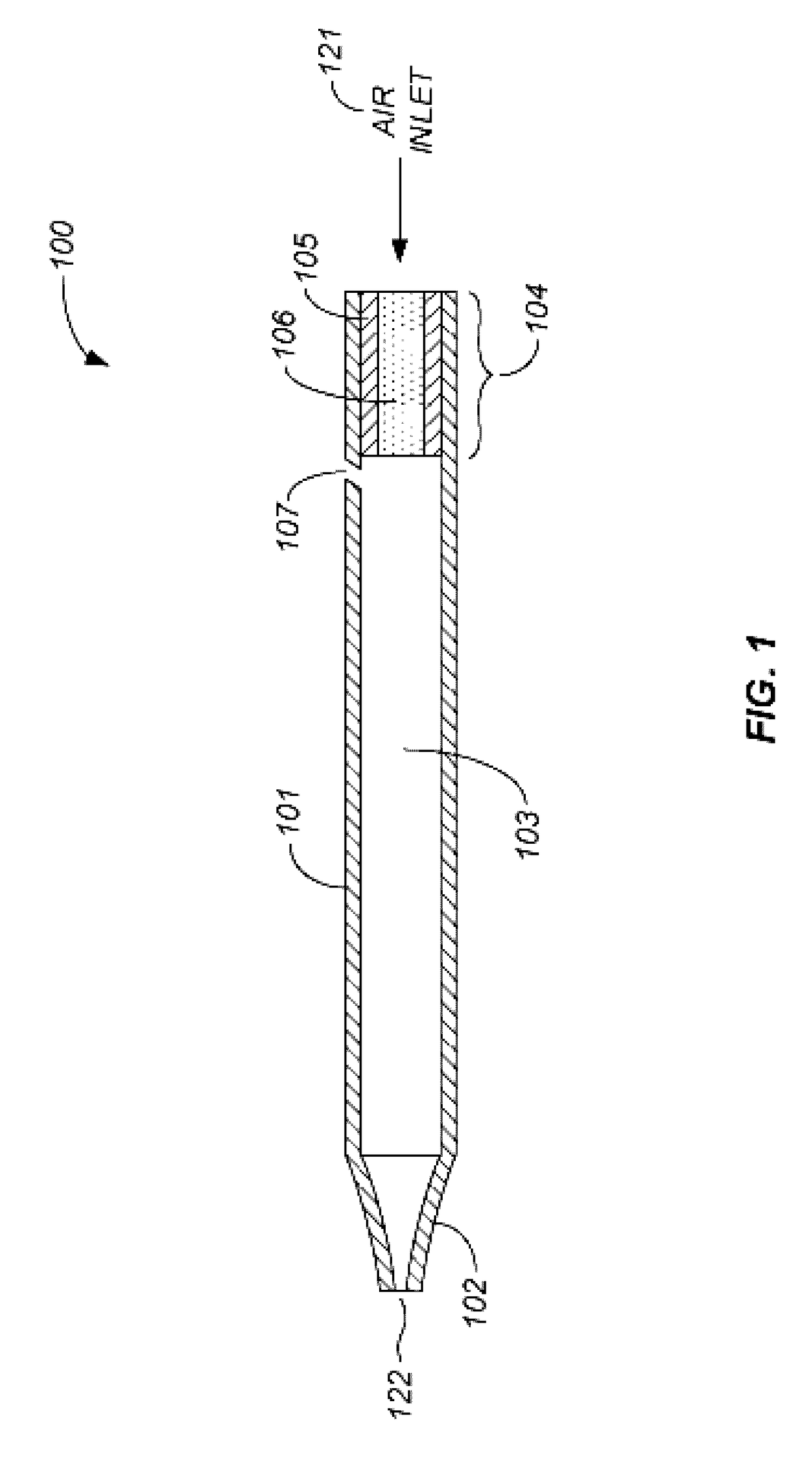

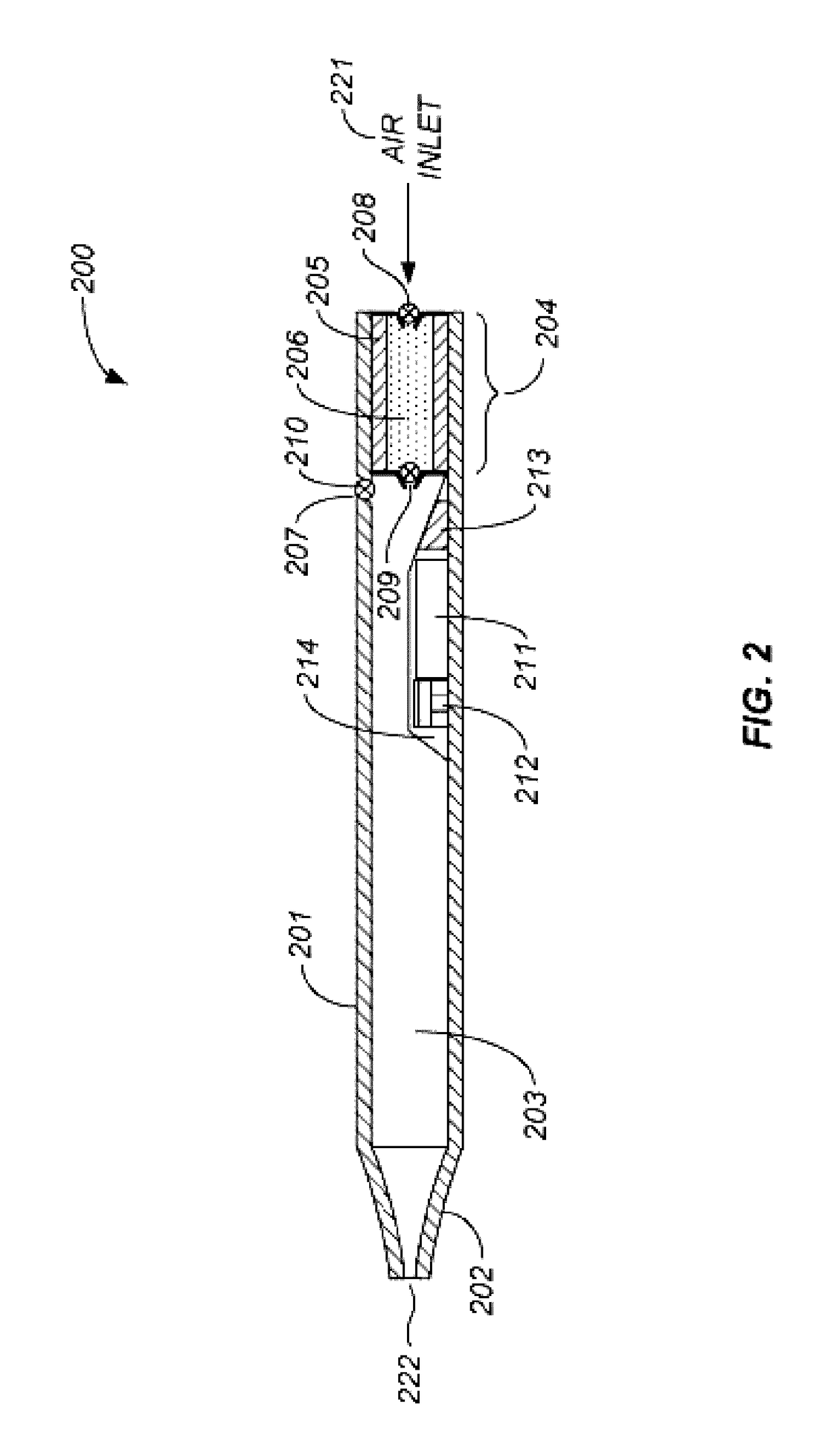

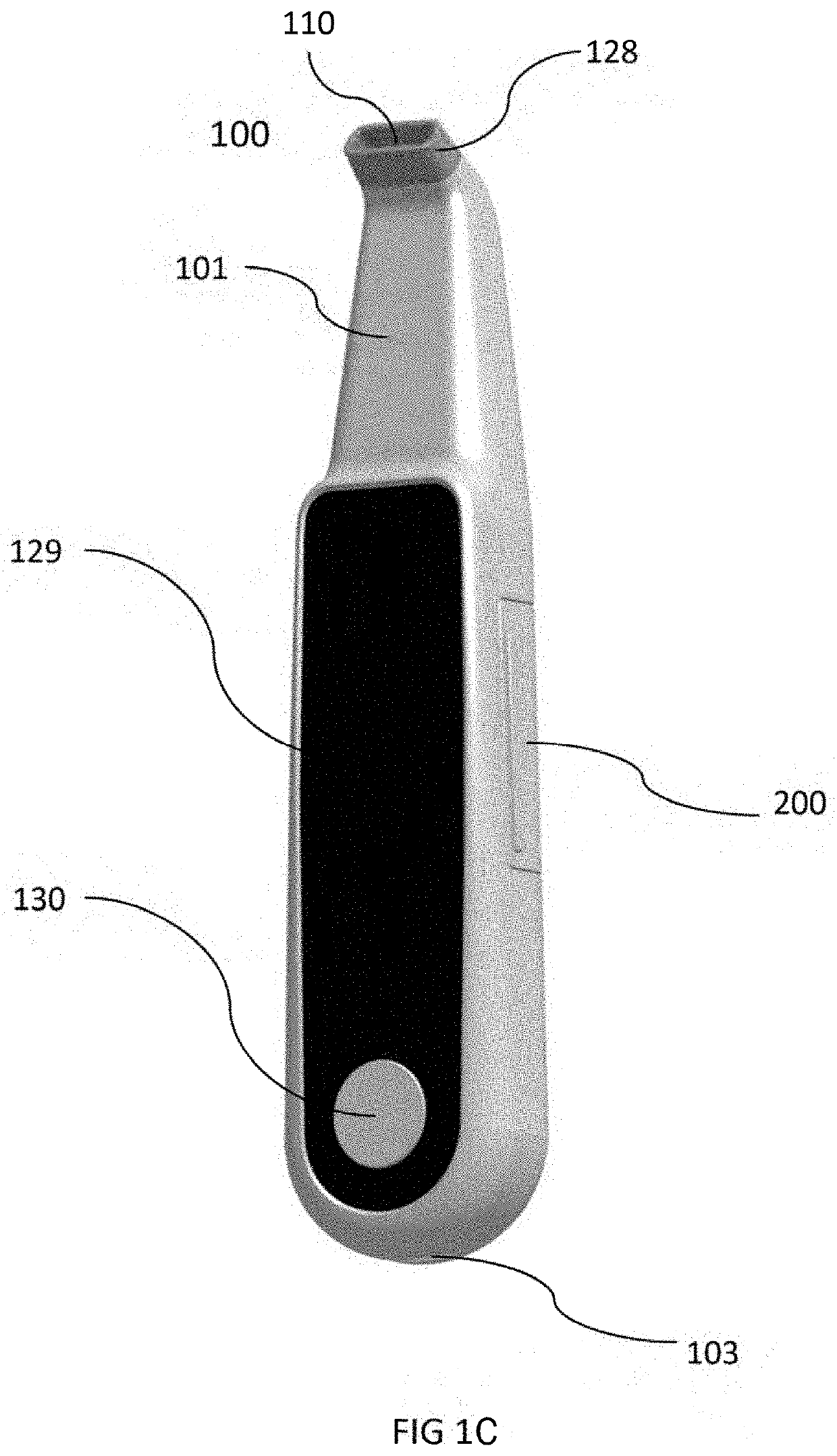

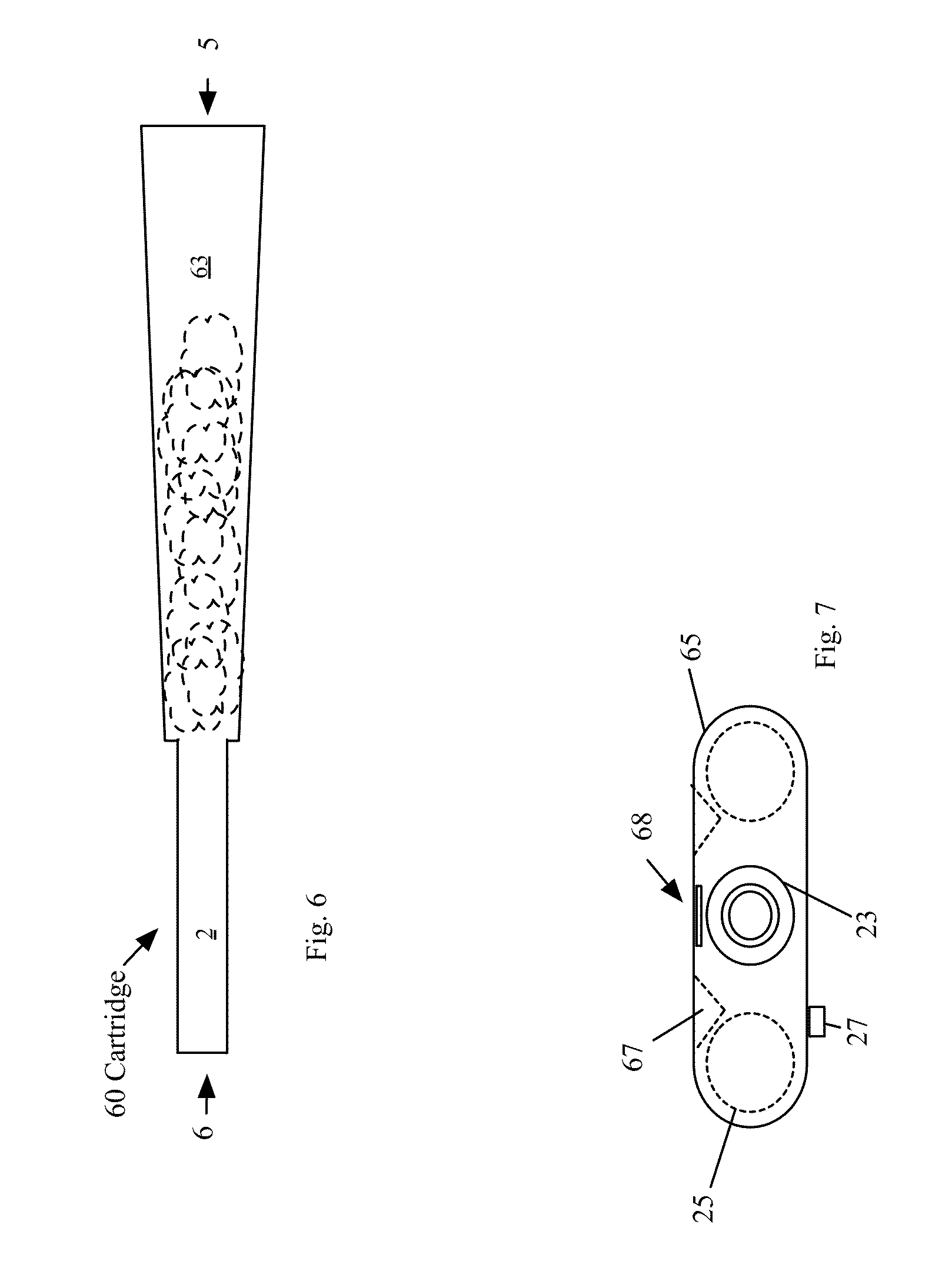

Vaporization device systems and methods

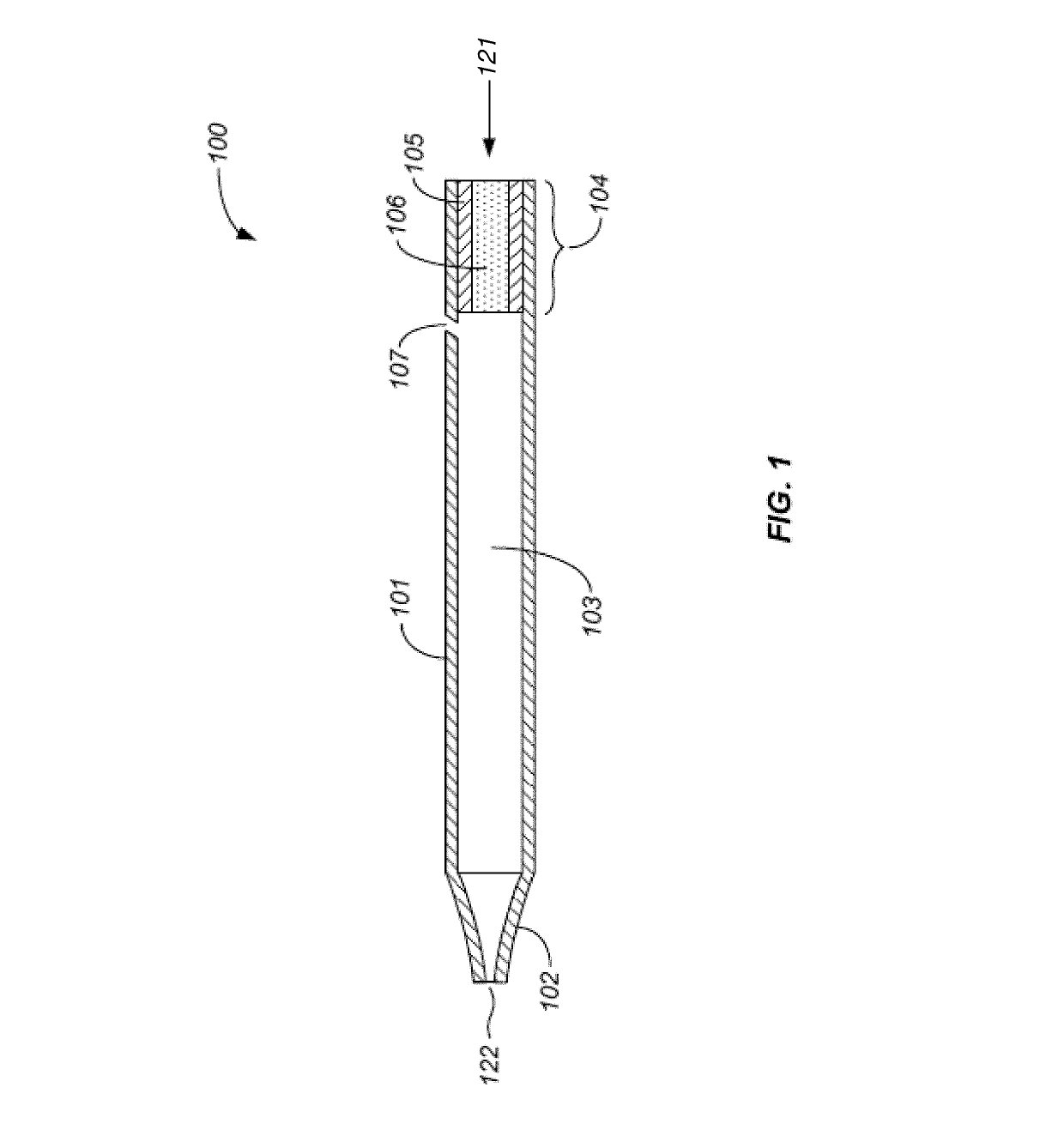

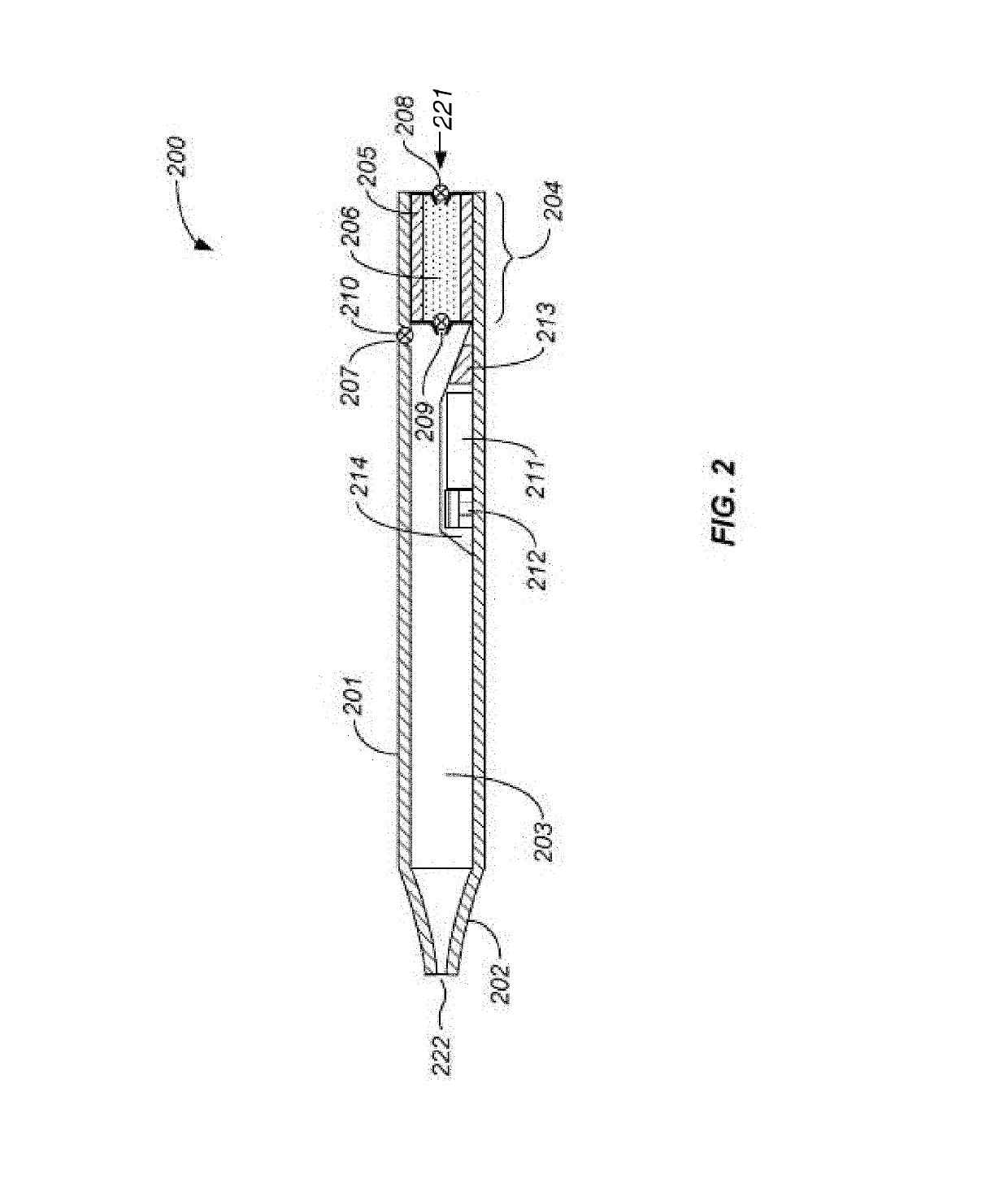

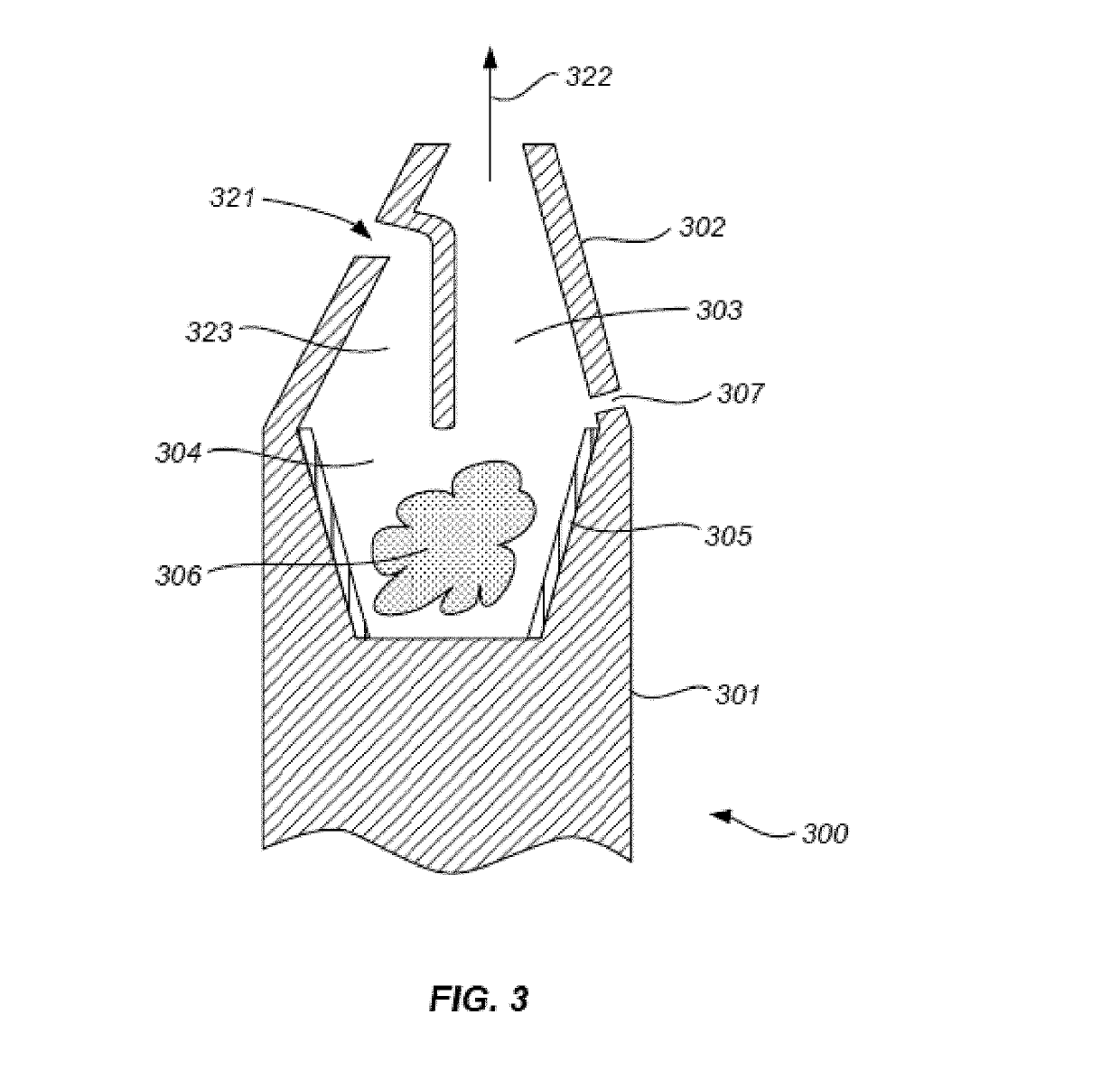

ActiveUS20170095005A1Resist of electrical contactImprove stabilityOhmic-resistance electrodesOhmic-resistance waterproof/air-tight sealsEngineeringMechanical engineering

Vaporization devices and methods of operating them. In particular, described herein are vaporizer cartridges for controlling the power applied to a resistive heater.

Owner:JLI NAT SETTLEMENT TRUST

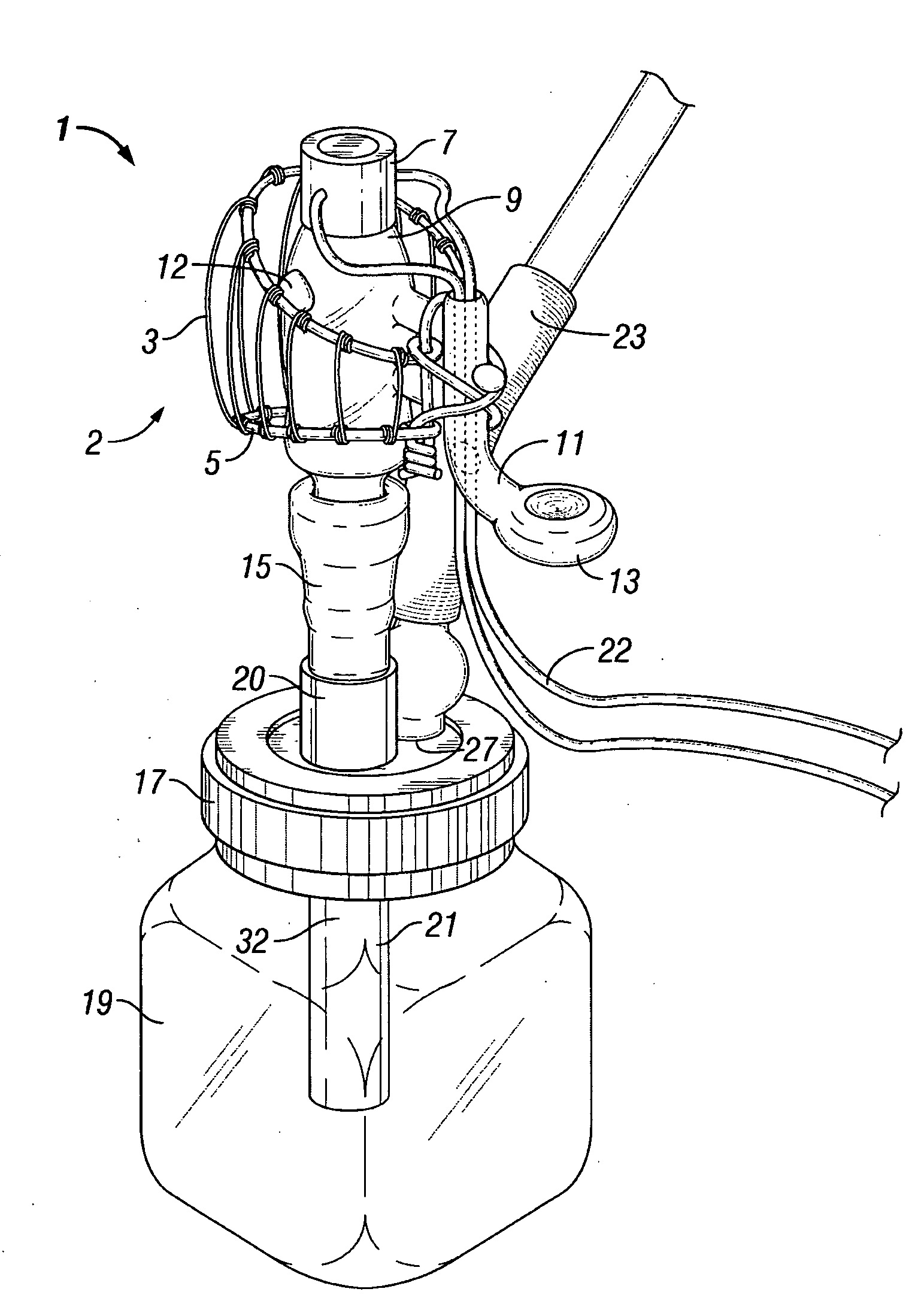

Tobacco vaporizer and related water pipe system

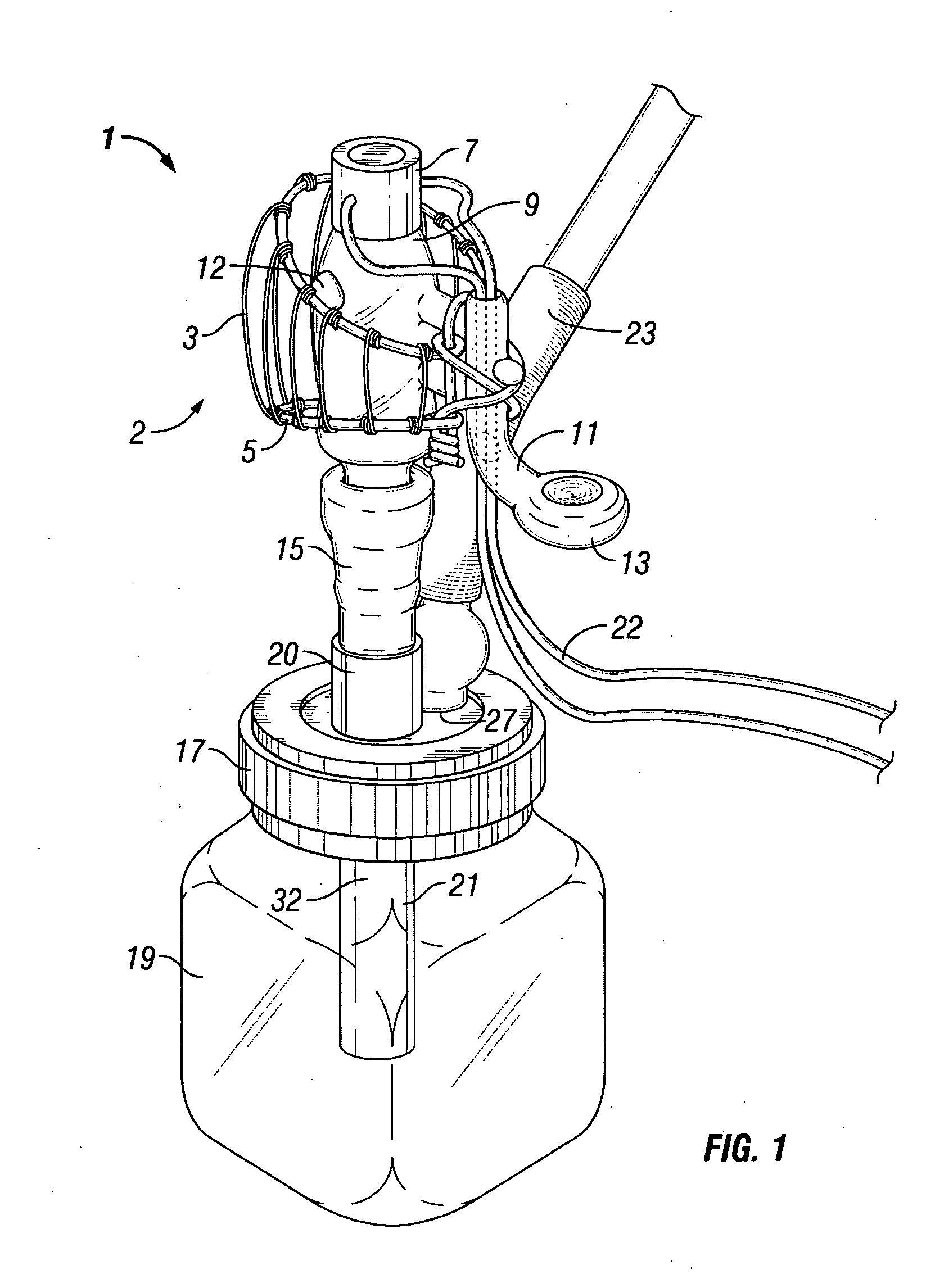

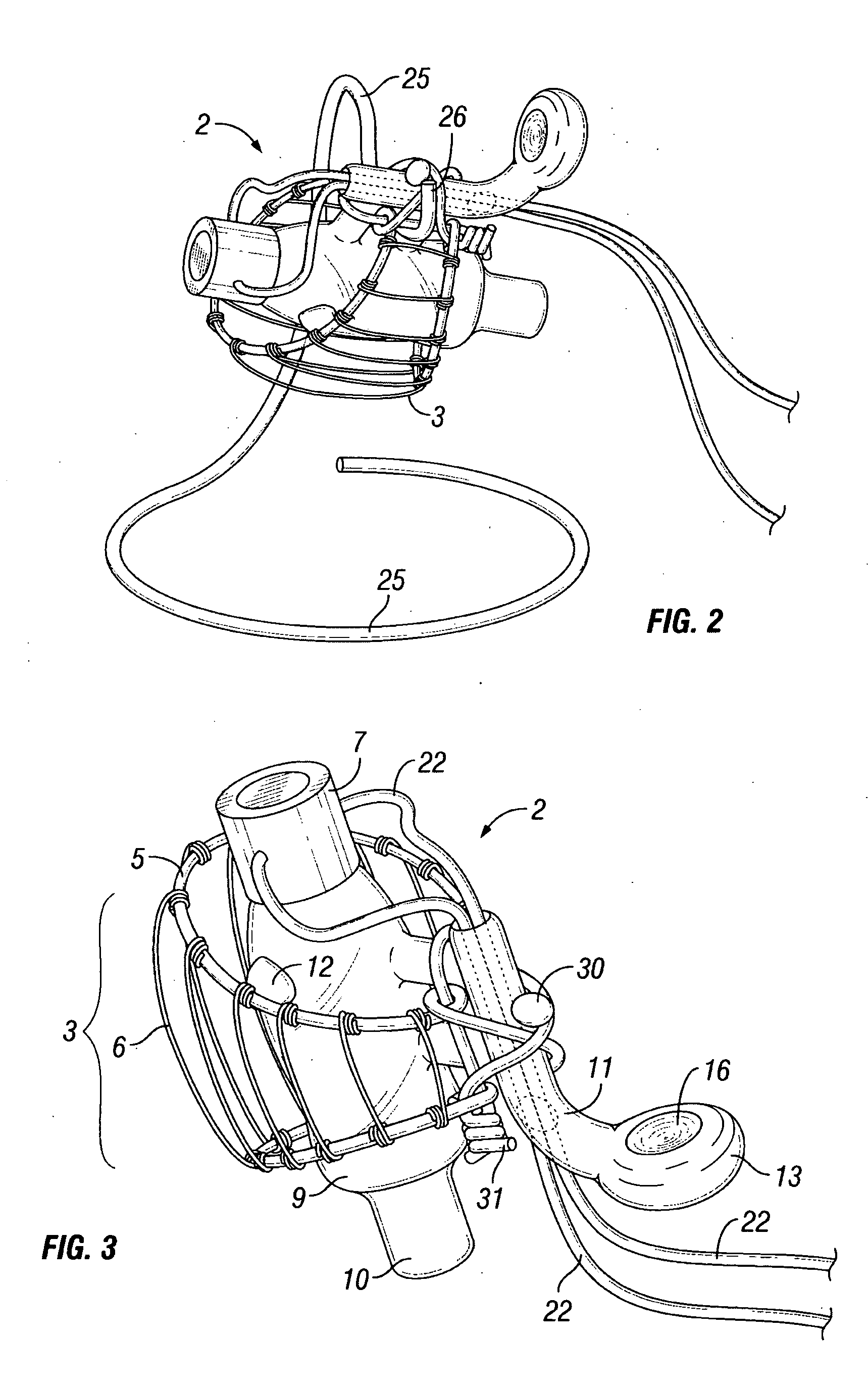

InactiveUS20070280652A1Increase airflowProducing thick vapor cloudsSpace heating and ventilationTobacco pipesEngineeringWater pipe

An improved vaporizer unit and water pipe assembly for extracting ingestible vapors from tobacco and herbs. Preferable embodiments of said assembly may comprise blown glass, colored glass, and adaptations for the safety of the user and to protect against breakability of said assembly. Other preferred features and embodiments include but are not limited to a cage secured to protect a central vessel housing a heating means, a hanger for storing, enhanced airflow, enhanced draw, and portability.

Owner:WILLIAMS CLAYTON J

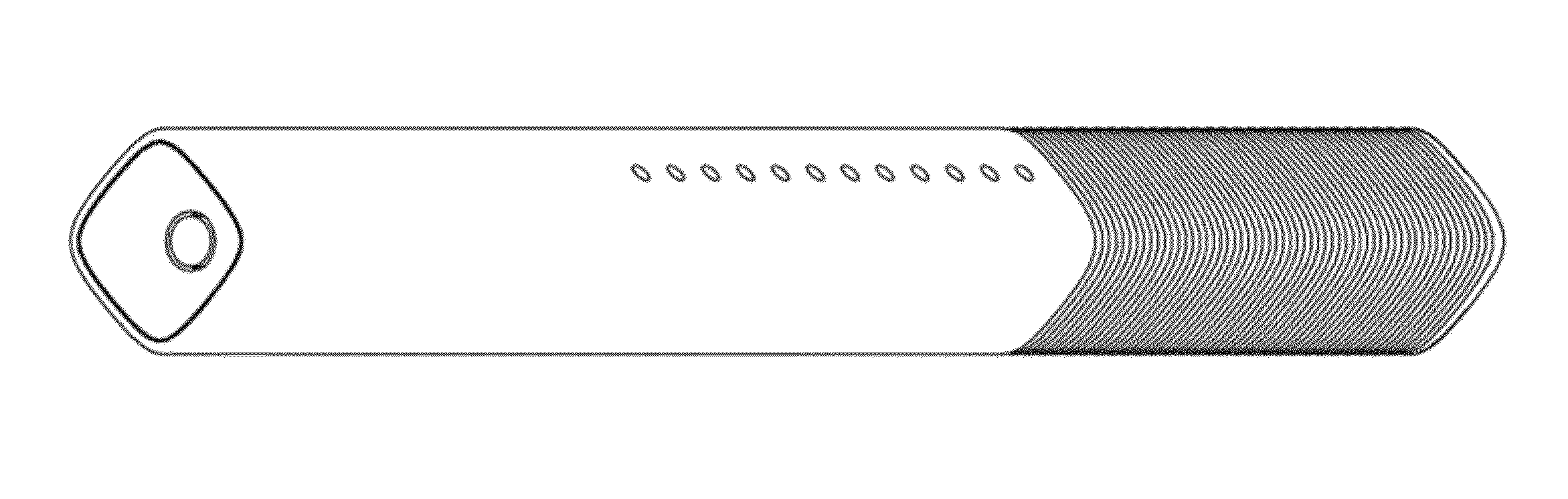

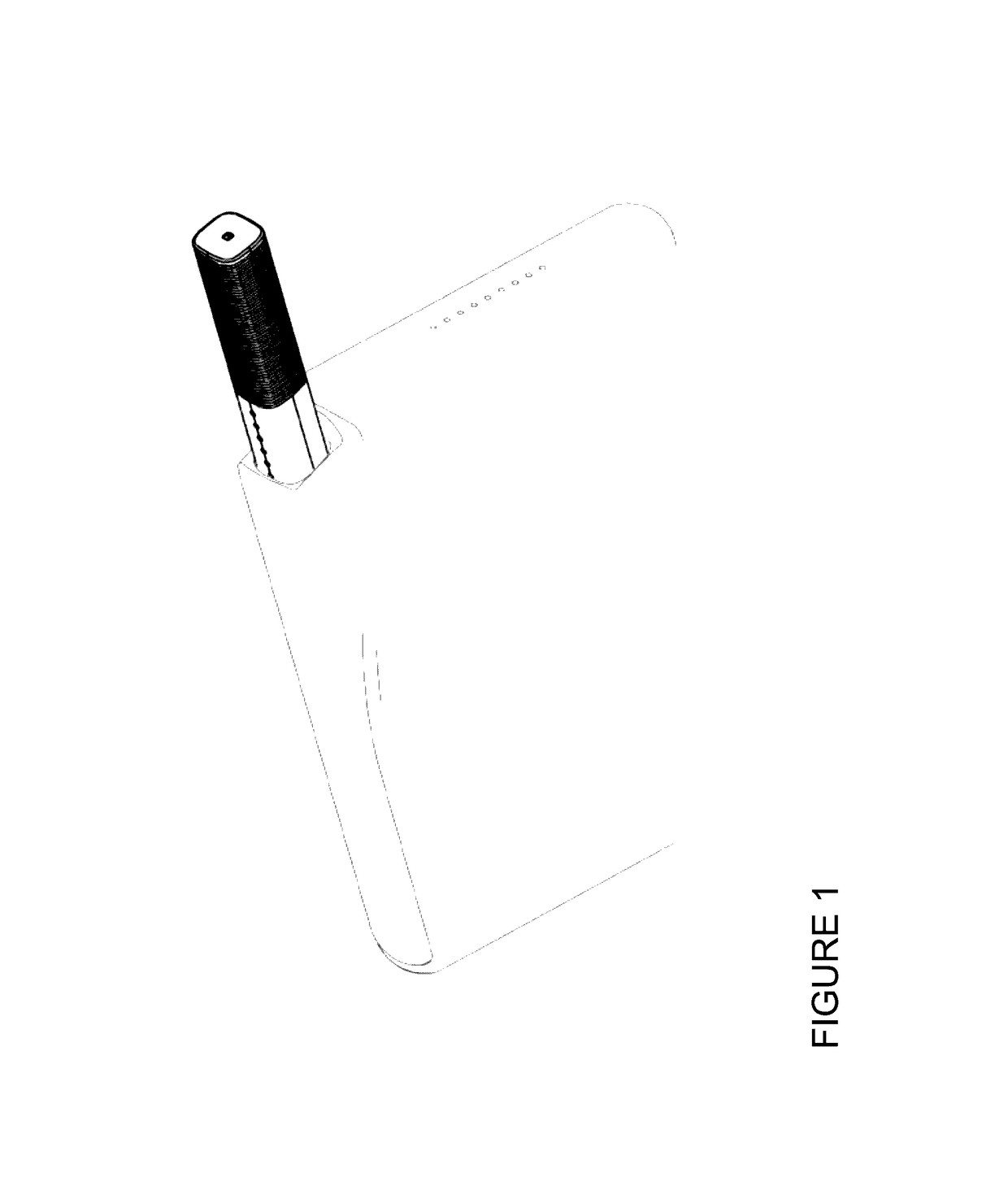

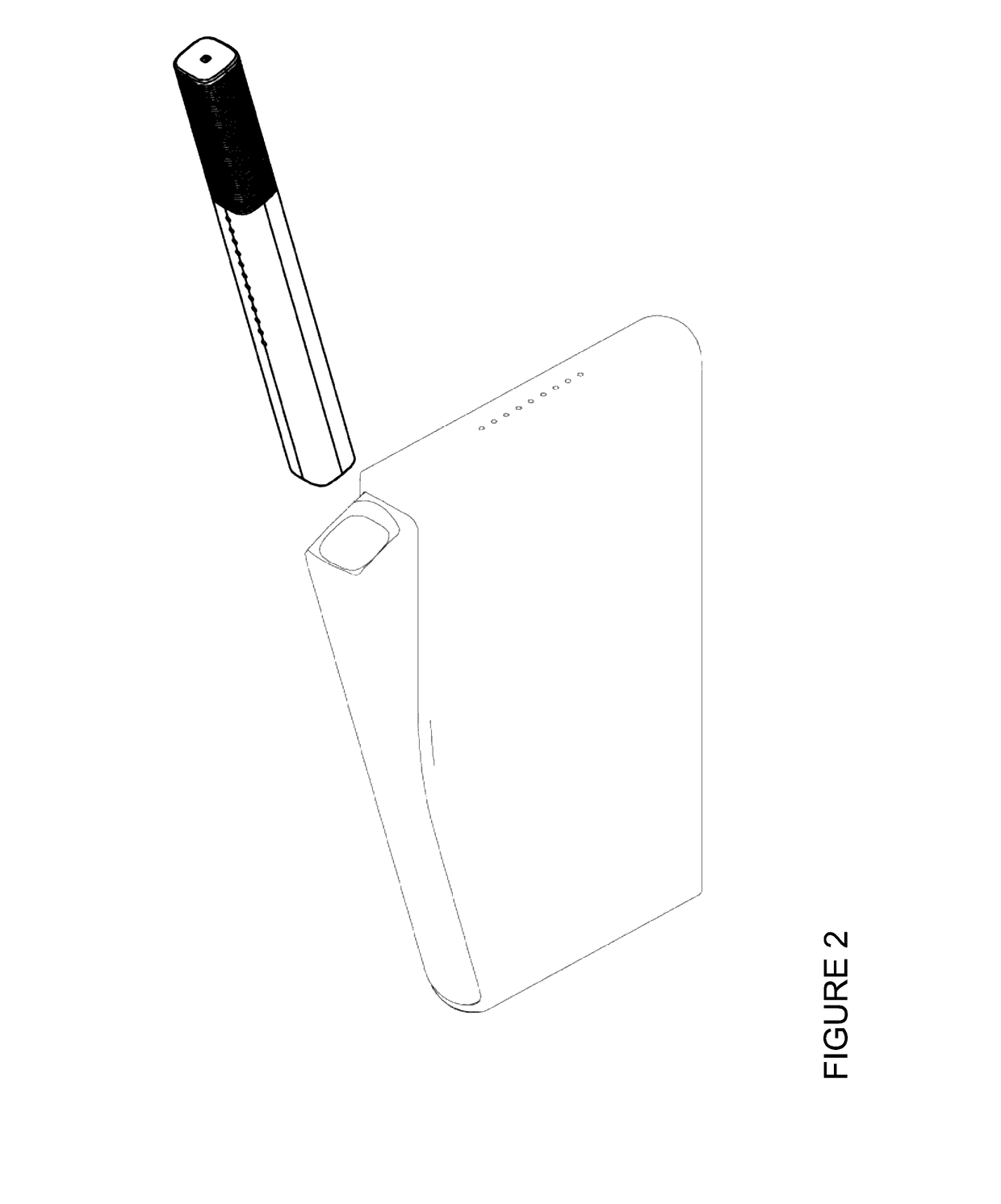

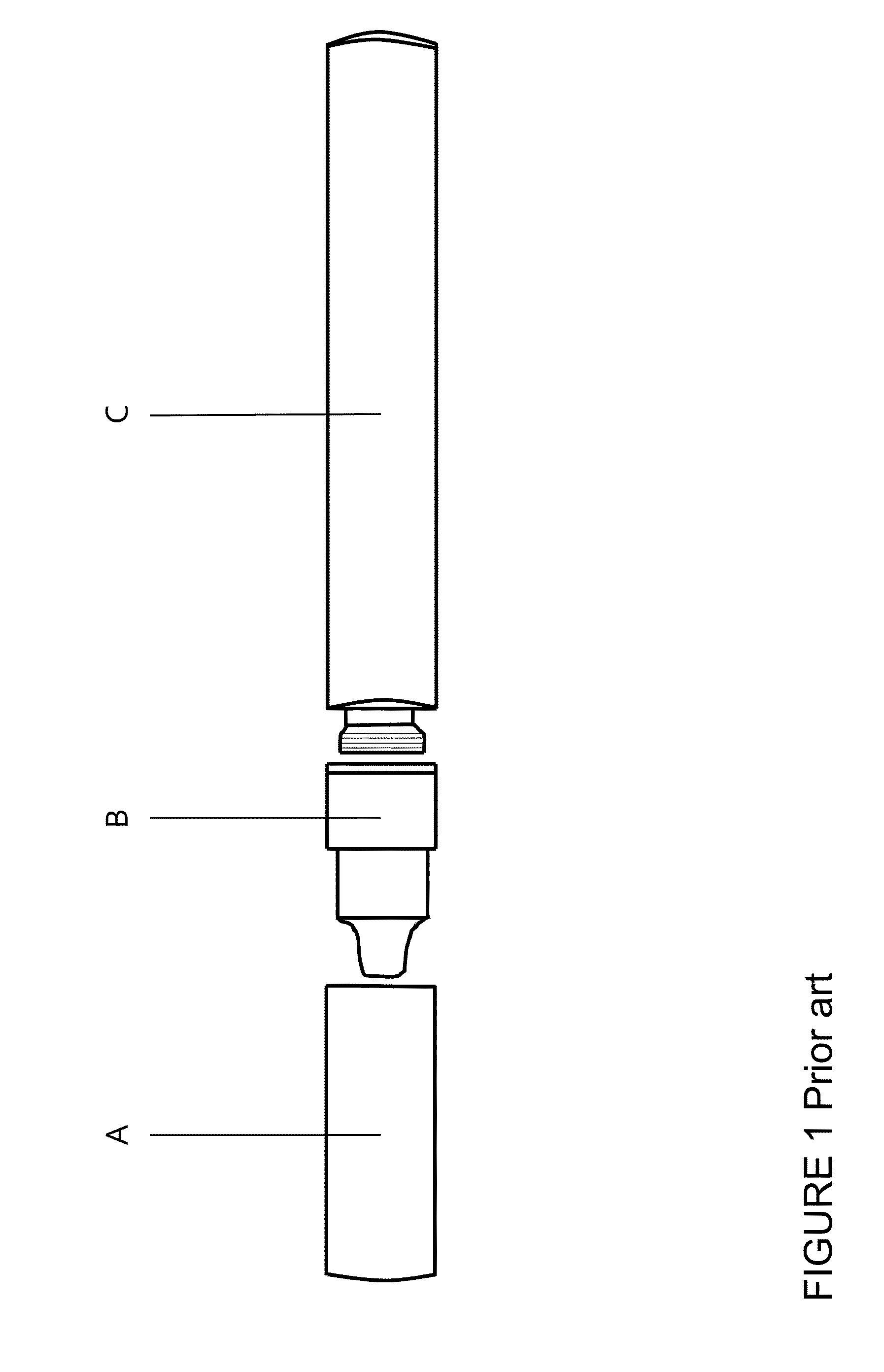

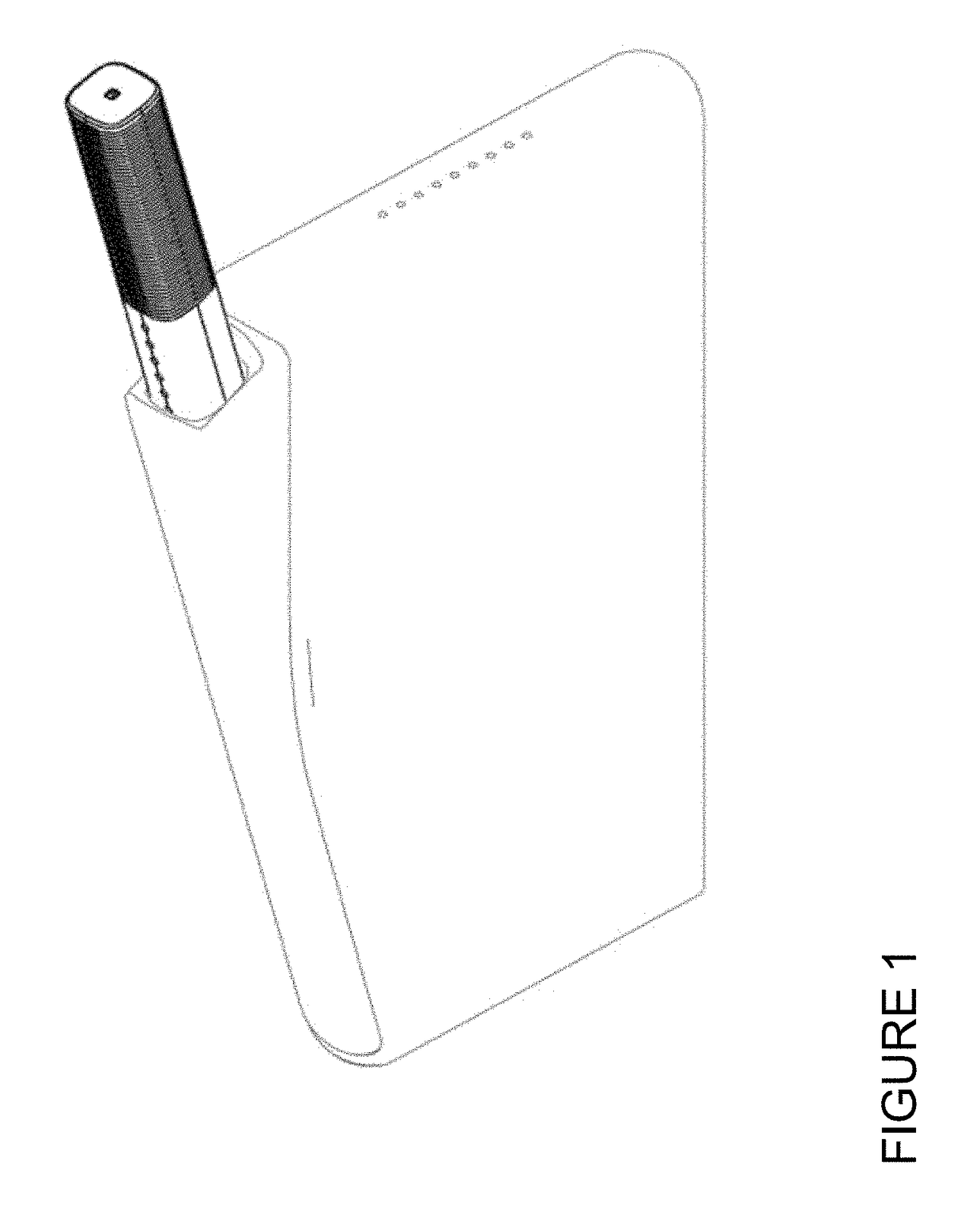

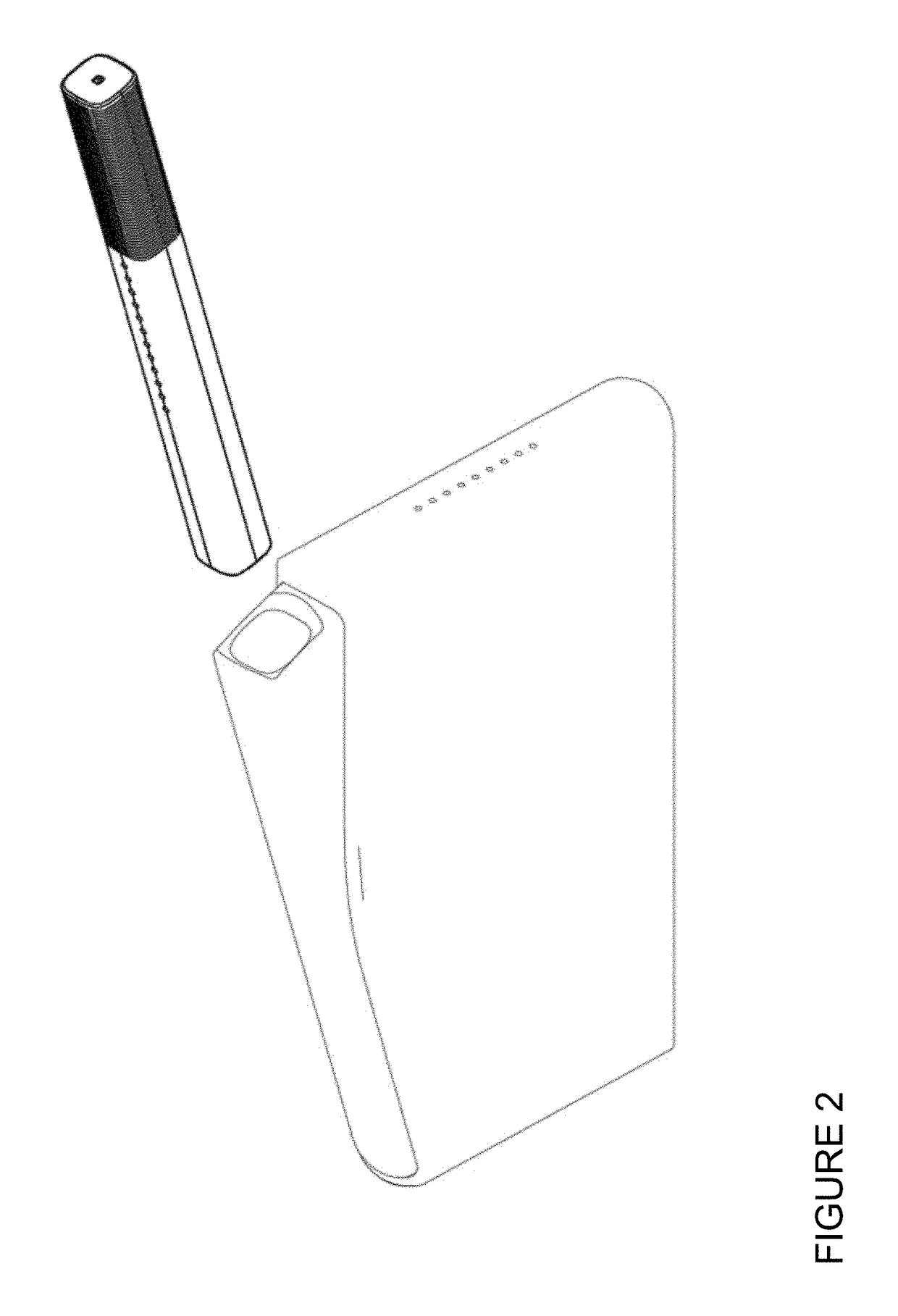

E-cigarette personal vaporizer

InactiveUS20150245662A1Tobacco treatmentPackaging cigaretteElectronic cigaretteMechanical engineering

A user-replaceable e-liquid cartridge adapted to be inserted into or attached to a portable, personal storage and carrying case for an e-liquid e-cigarette PV. The combination of cartridge and case forms in normal use a portable, personal device for the storage and carrying of the PV and its re-filling with e-liquid.

Owner:AYR LTD

Aerosol processing and inhalation method and system for high dose rate aerosol drug delivery

ActiveUS7802569B2Risk minimizationIncrease dose rateRespiratorsDispersed particle separationCounter flowSolvent vapor

Owner:KAER BIOTHERAPEUTICS CORP

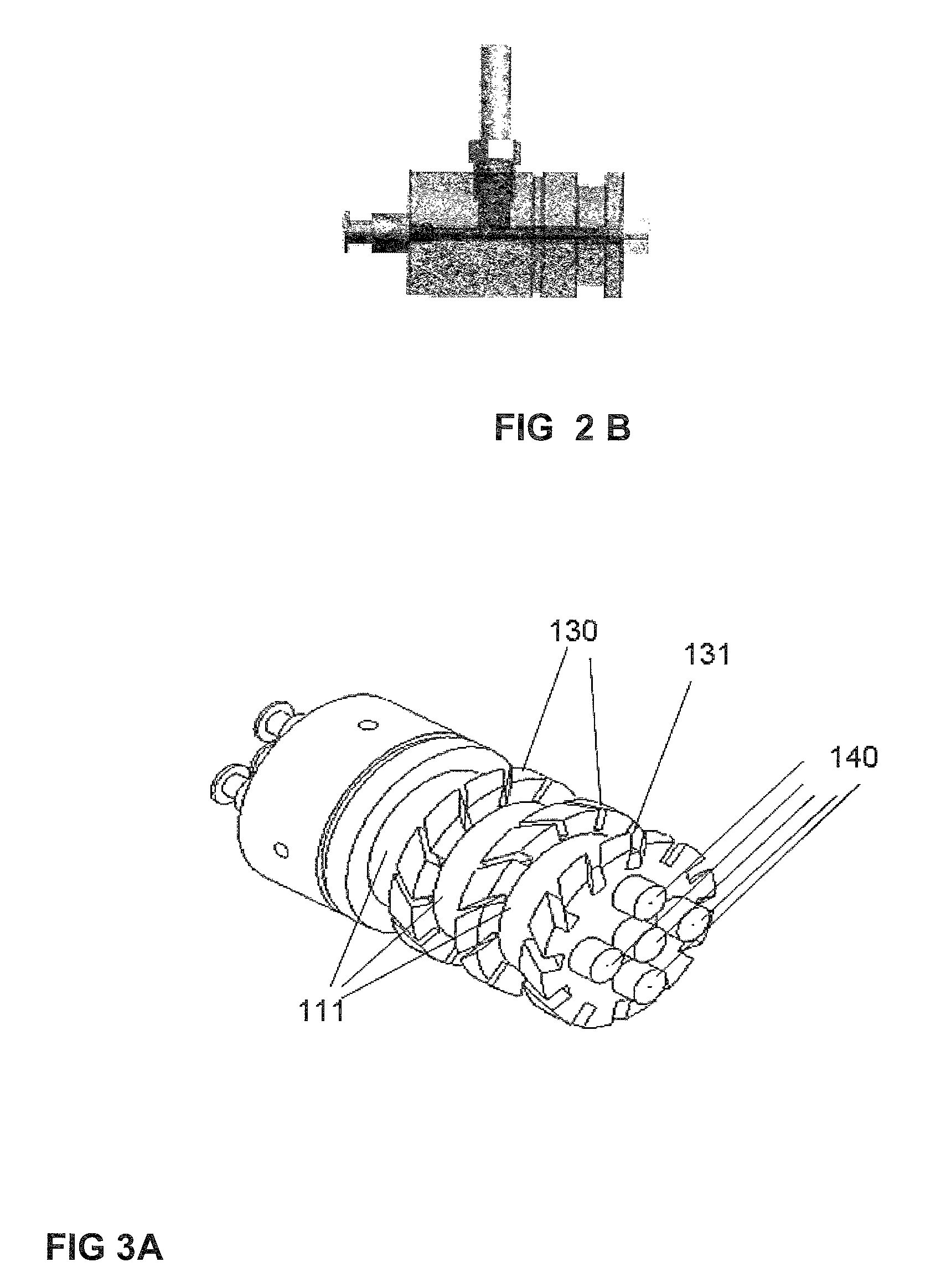

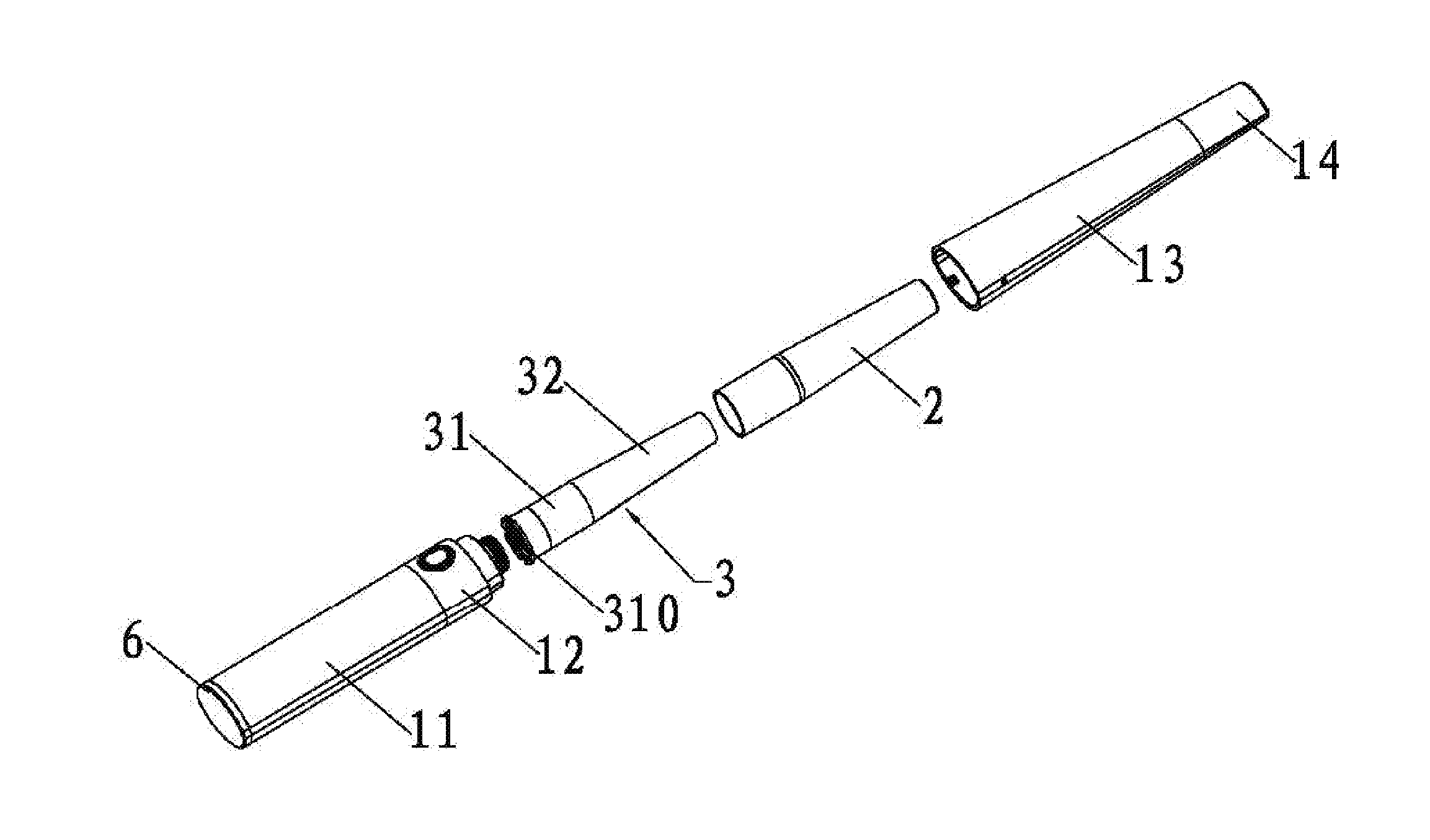

Smokeless cigarette substitute product

ActiveUS20120111346A1Big ratioLower overall flow resistanceRespiratorsTobacco smoke filtersThermal energyChemistry

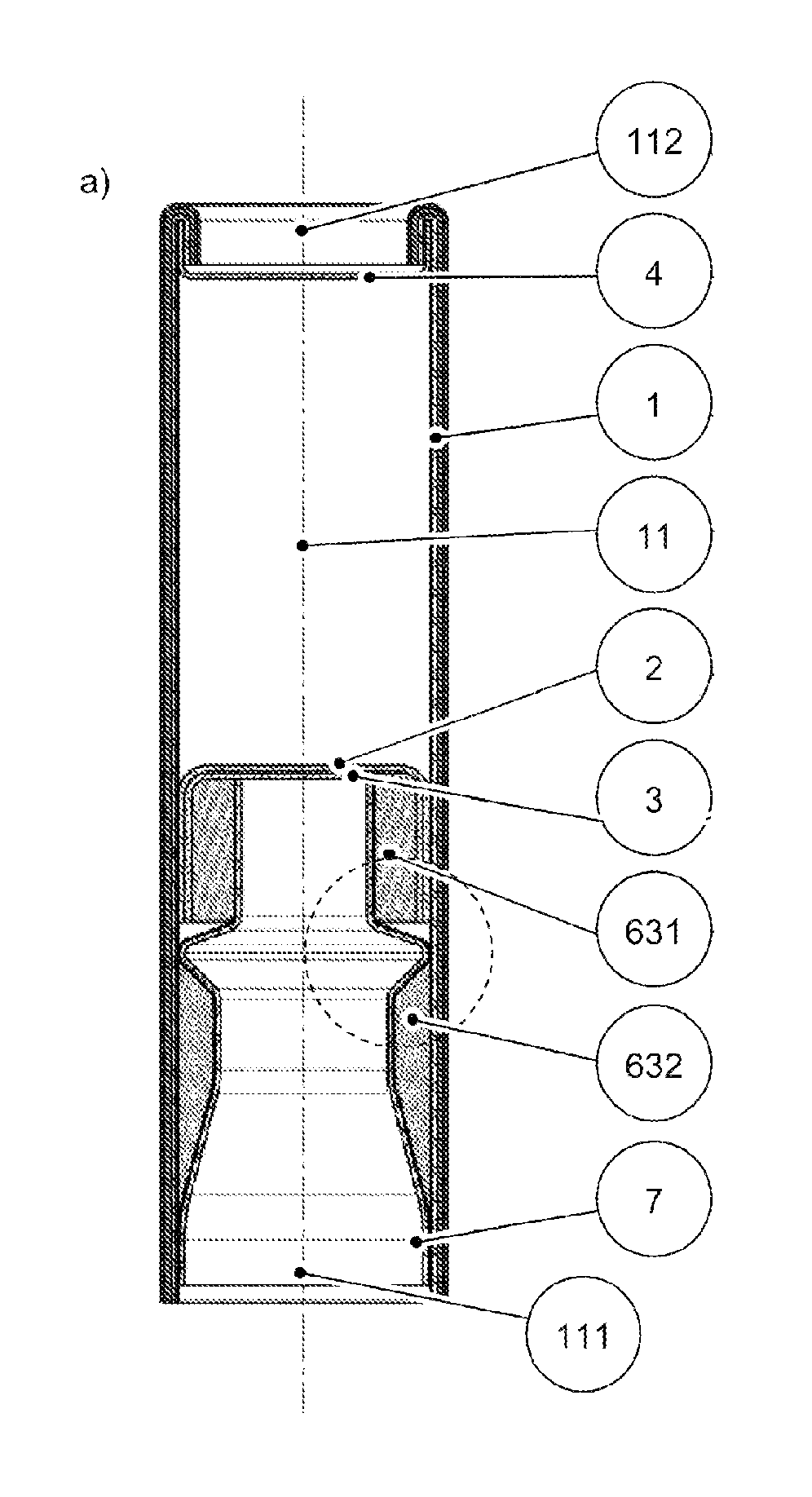

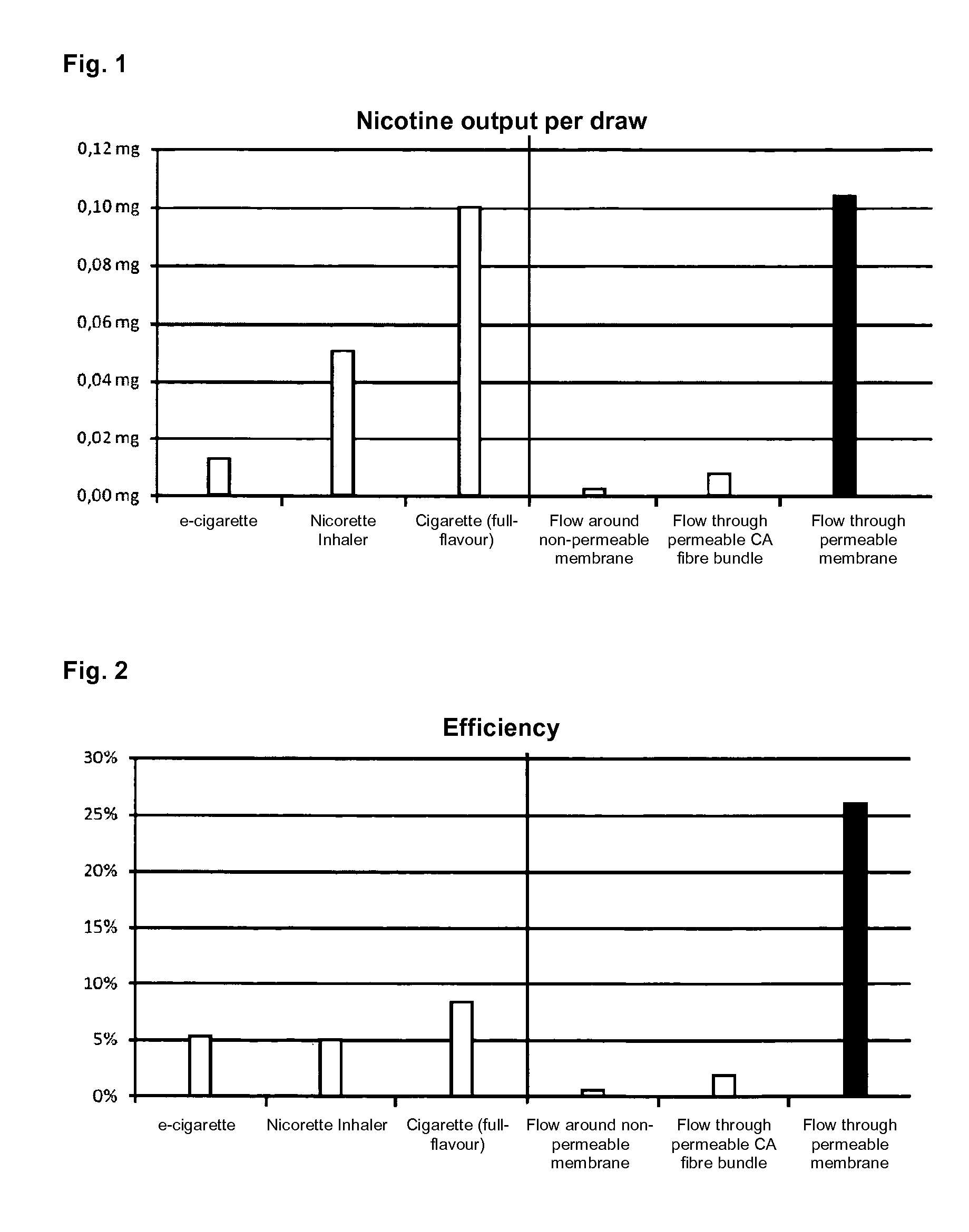

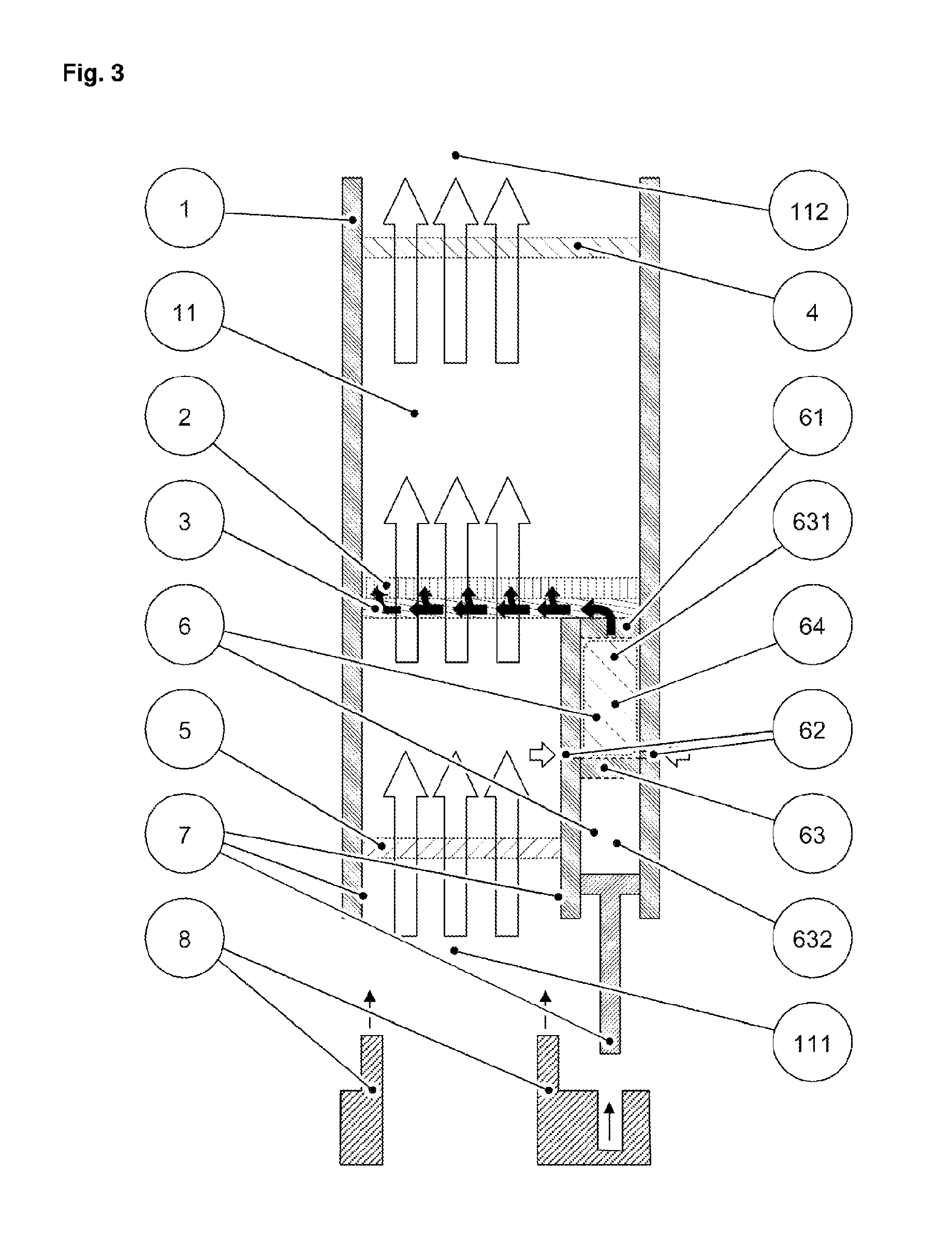

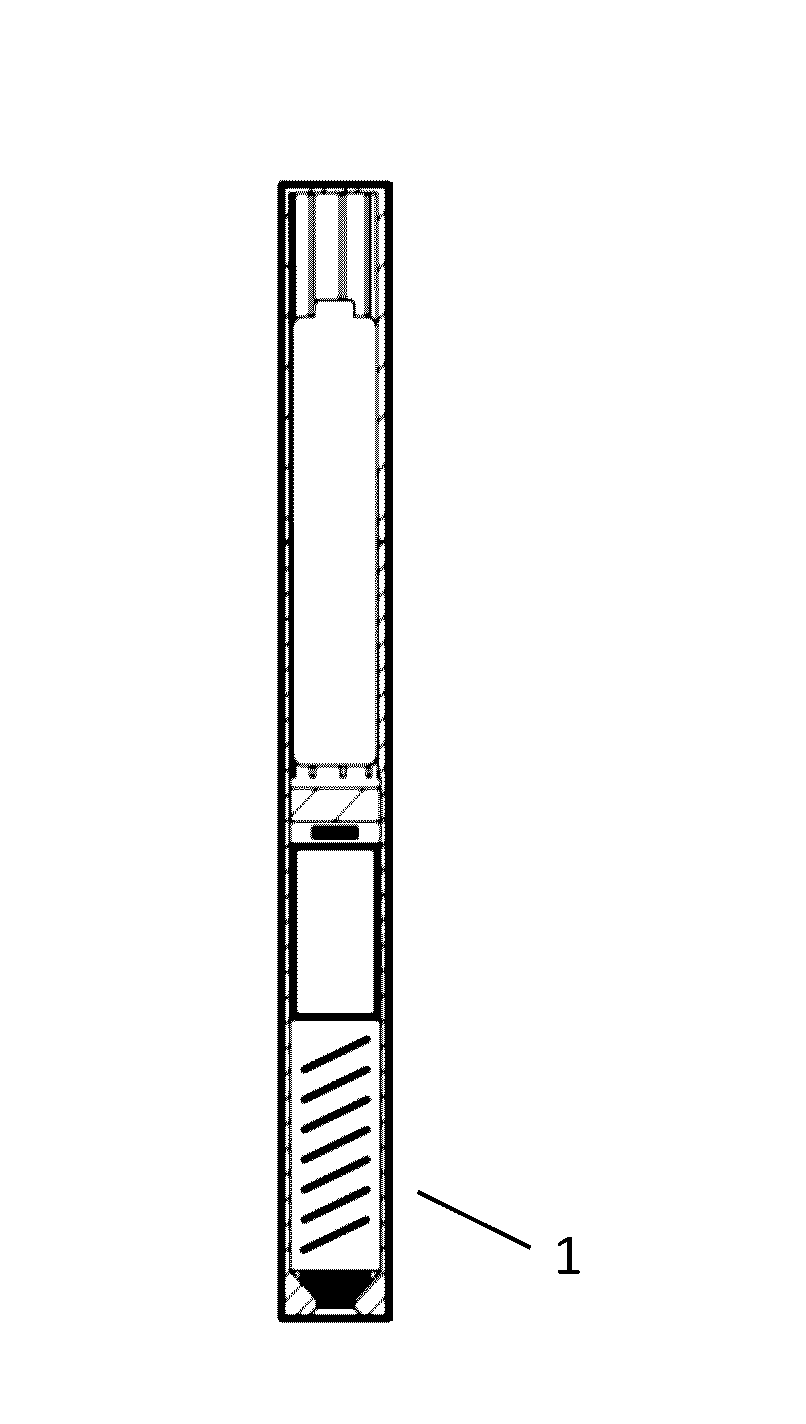

Method and device for volatilising active and / or aroma materials for the purpose of releasing an inhalable aerosol, wherein a fluid flows through a flow channel (11) in a preferably cylindrical hollow body (1) and wherein the fluid in this flow channel entirely or in part flows through at least one vaporiser membrane (2), wherein the at least one vaporiser membrane has been and / or is wetted with a substance containing an active and / or aroma material to be vaporised and wherein the fluid additionally containing thermal energy vaporises this substance on flowing through the vaporiser membrane and supplies it to the fluid stream.

Owner:PHILIP MORRIS PROD SA

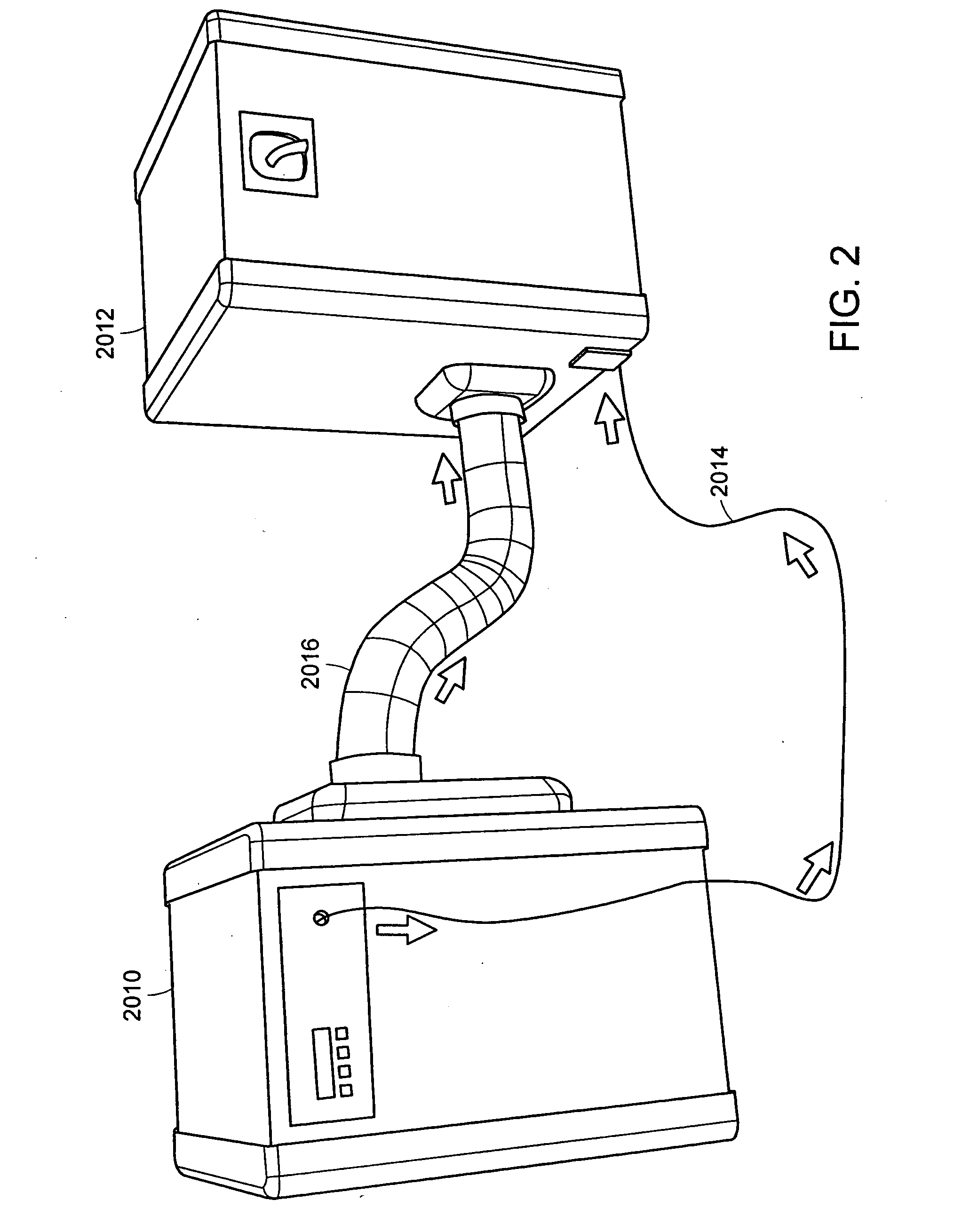

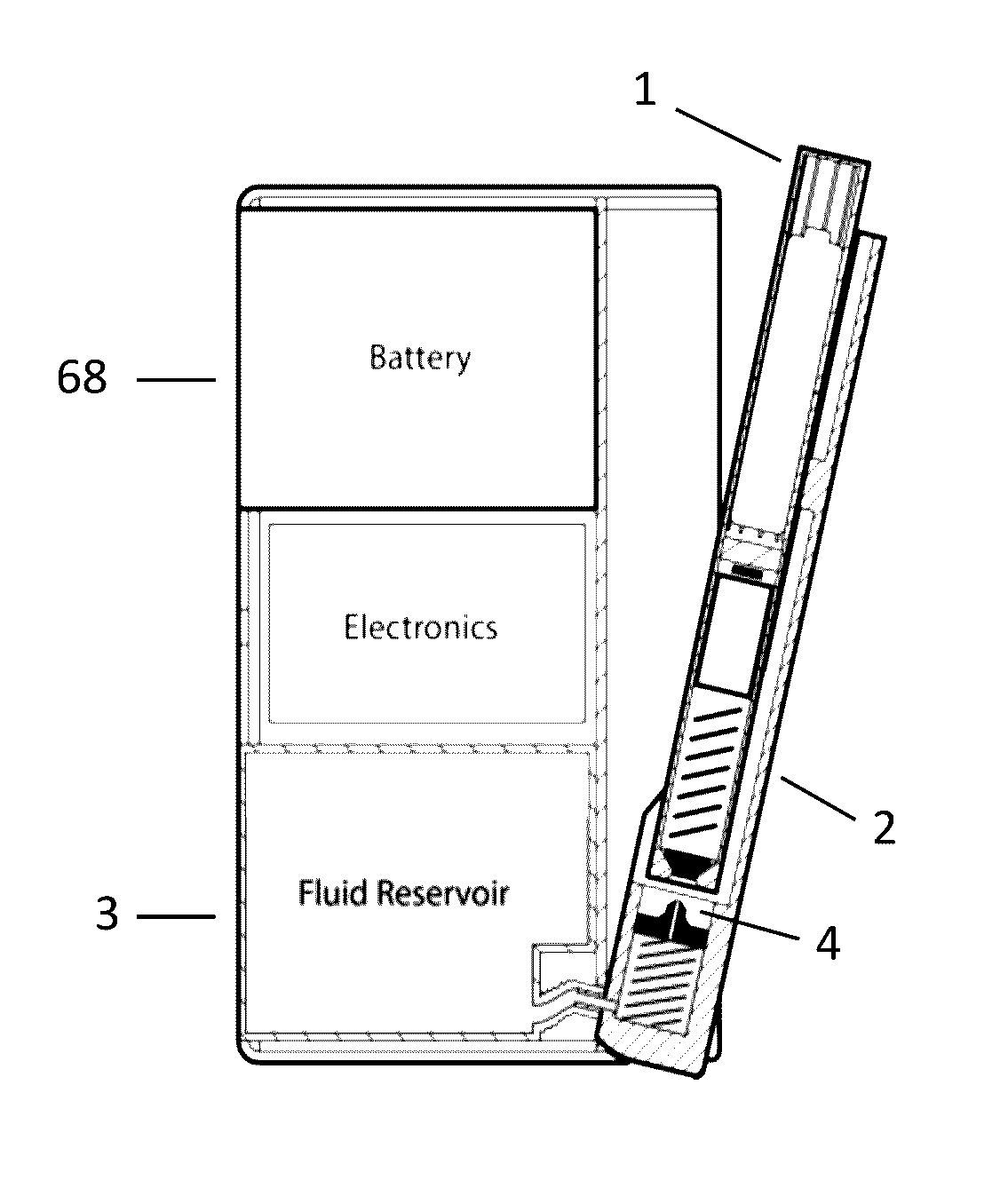

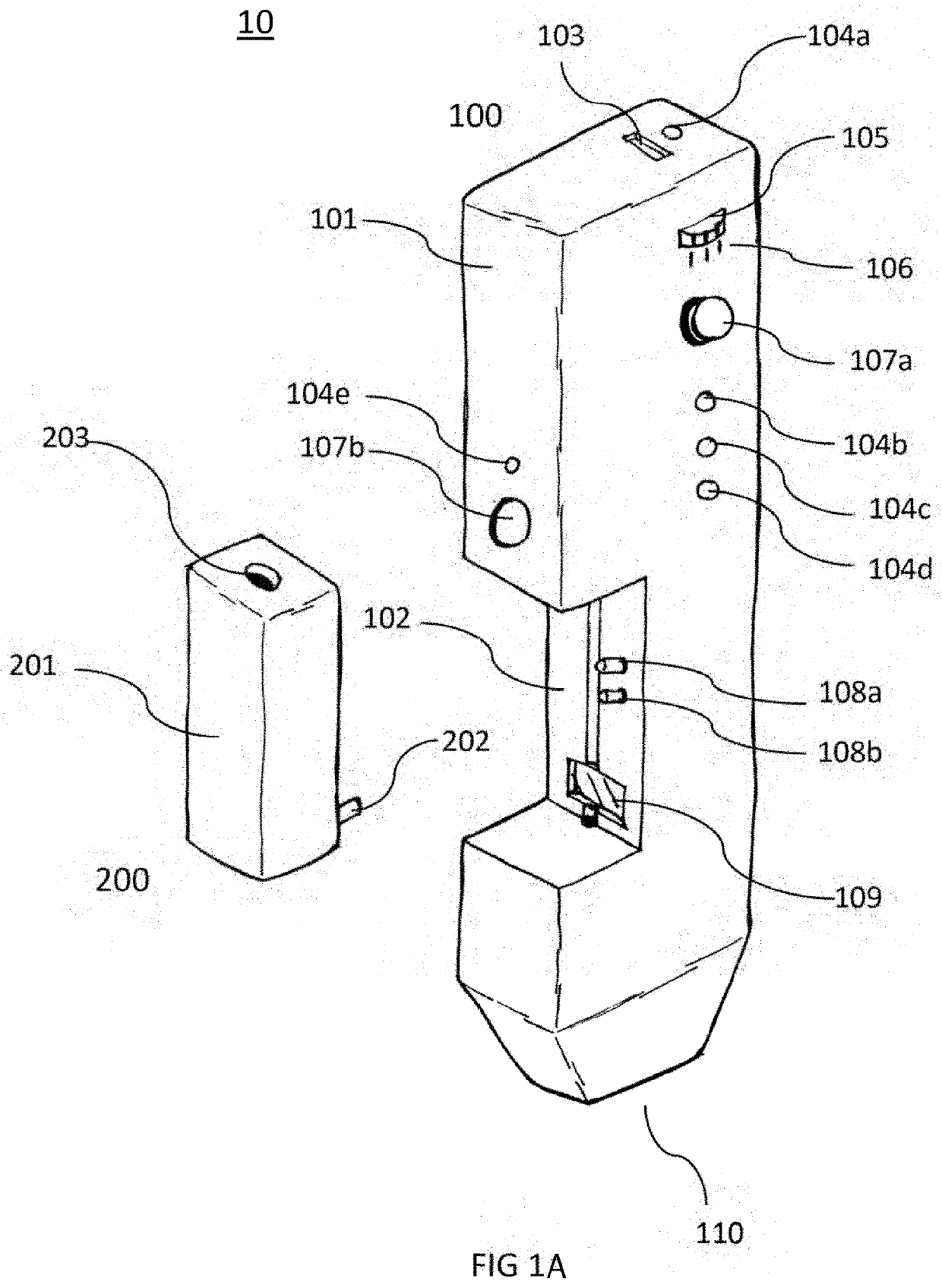

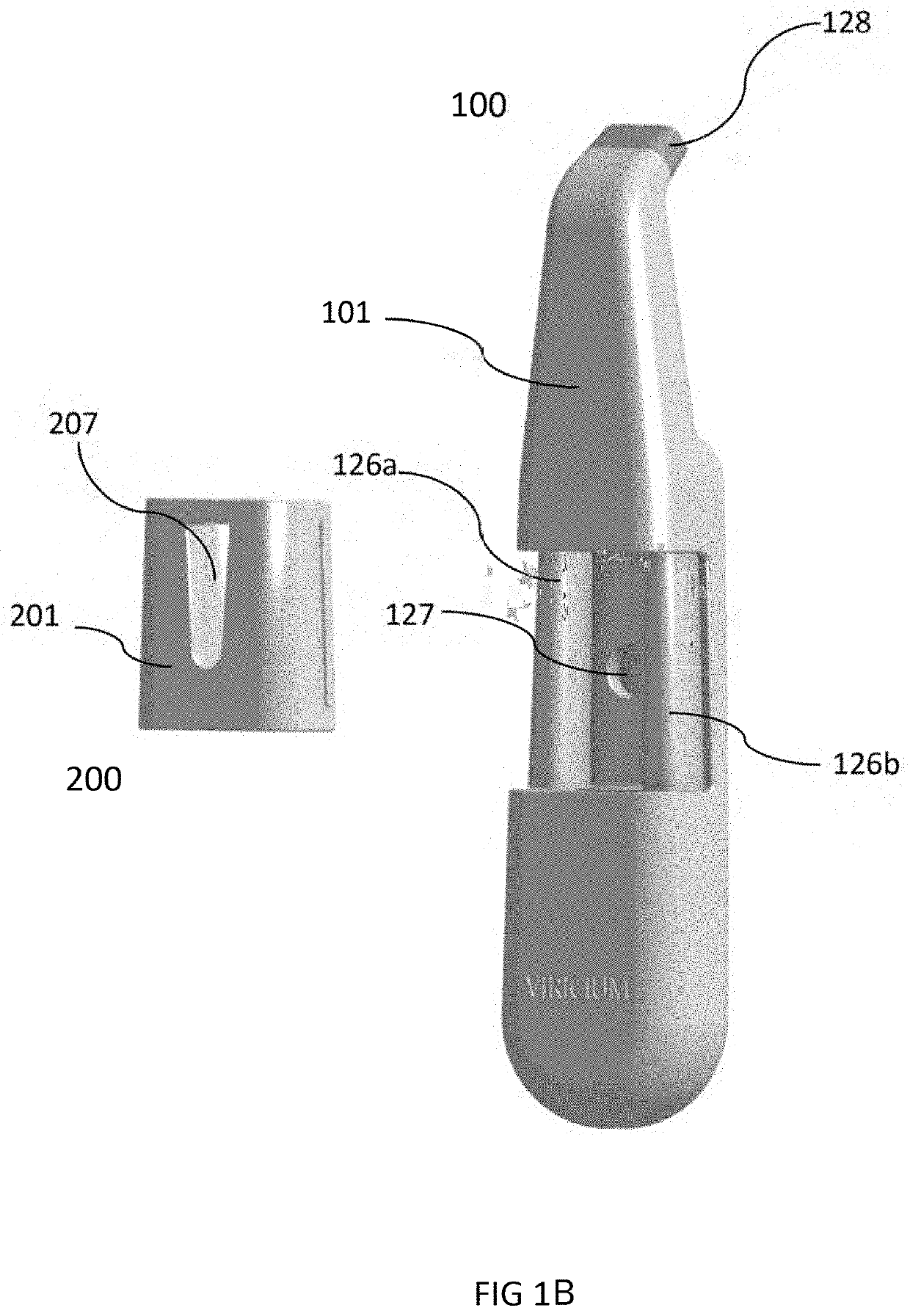

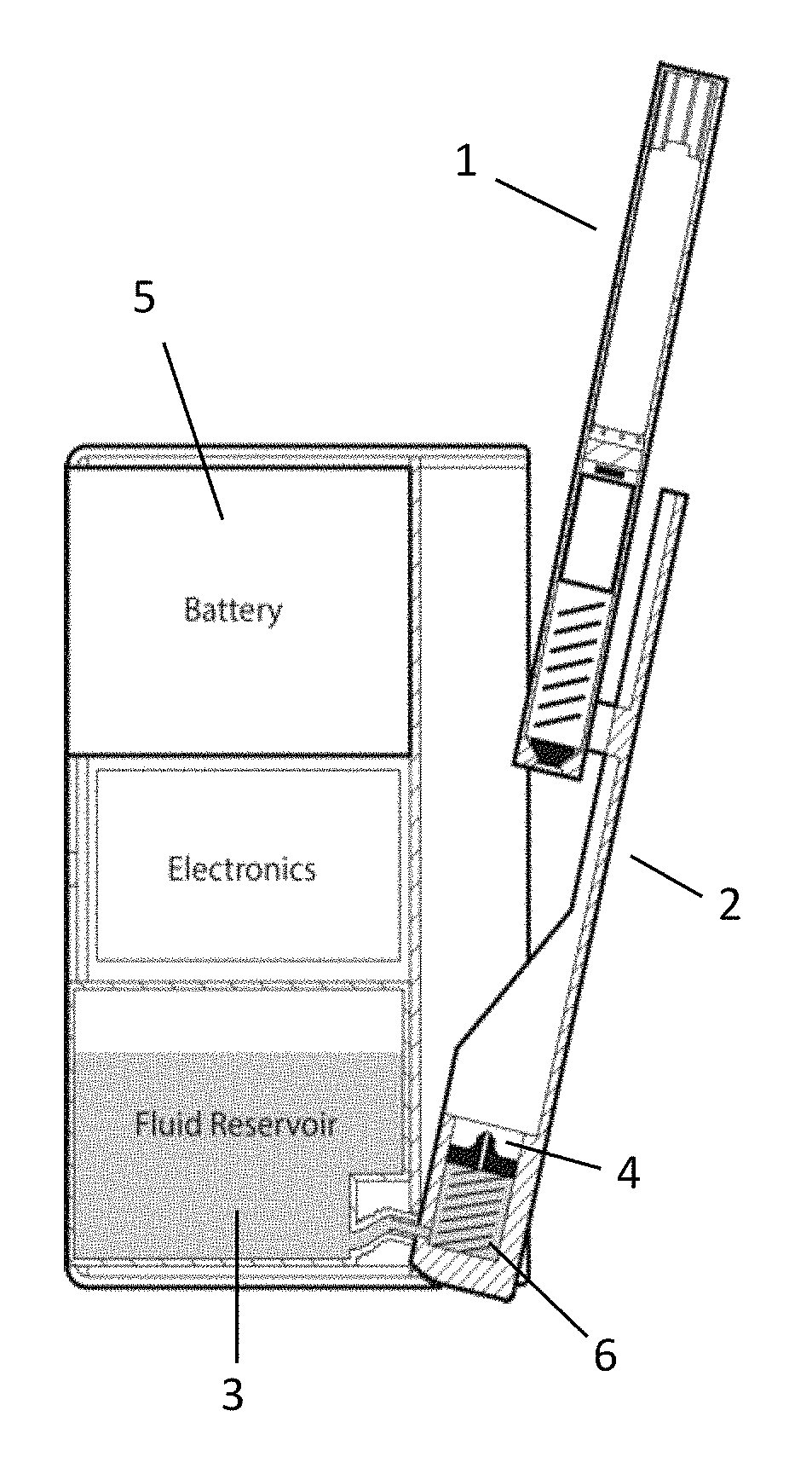

Electronic vaporiser system

An electronic cigarette vaporiser system including a vaporiser and a single piezo-electric pump that both withdraws liquid from a cartridge and also pumps controlled amounts of liquid into a reservoir in the vaporizer. The piezo-pump can be in a case that enables the vapouriser to be stored, and the cartridge is attached to or inserted into the case. The case both re-fills the vapouriser with liquid and re-charges a battery in the vapouriser.

Owner:AYR LTD

E-cigarette personal vaporizer

Owner:AYR LTD

E-cigarette personal vaporizer

A user-replaceable e-liquid cartridge adapted to be inserted into or attached to a portable, personal storage and carrying case for an e-liquid e-cigarette PV. The combination of cartridge and case forms in normal use a portable, personal device for the storage and carrying of the PV and its re-filling with e-liquid.

Owner:AYR LTD

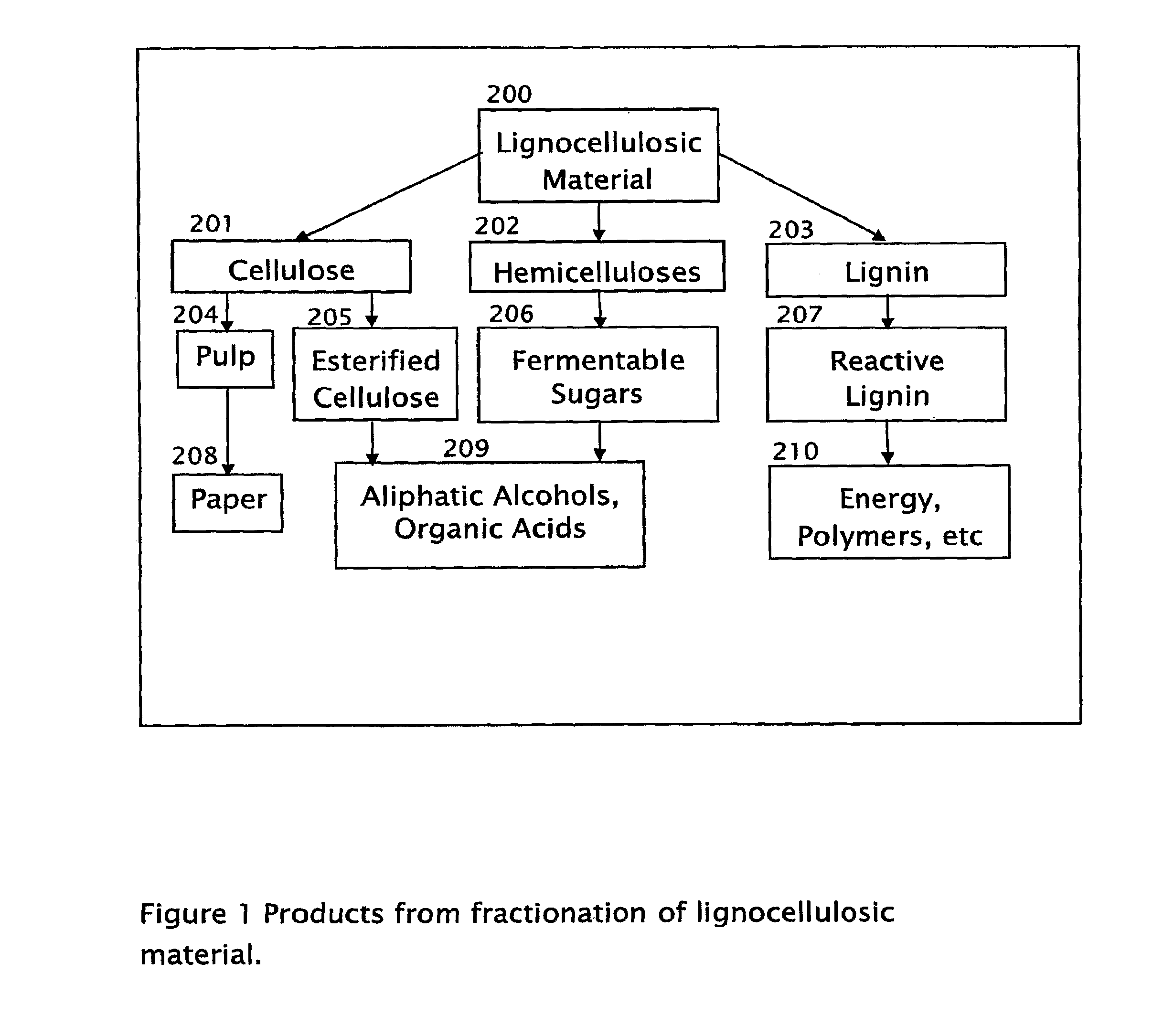

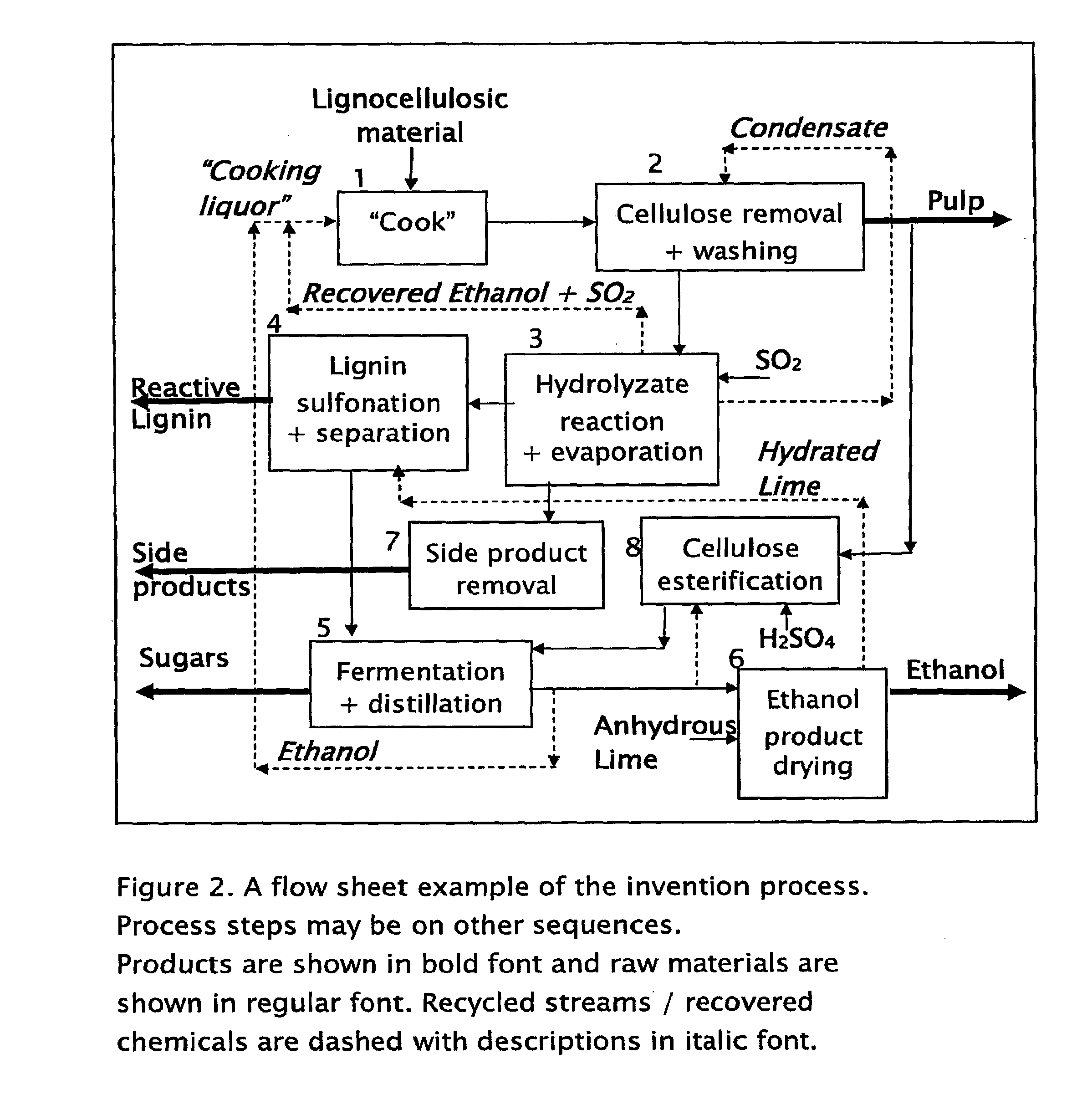

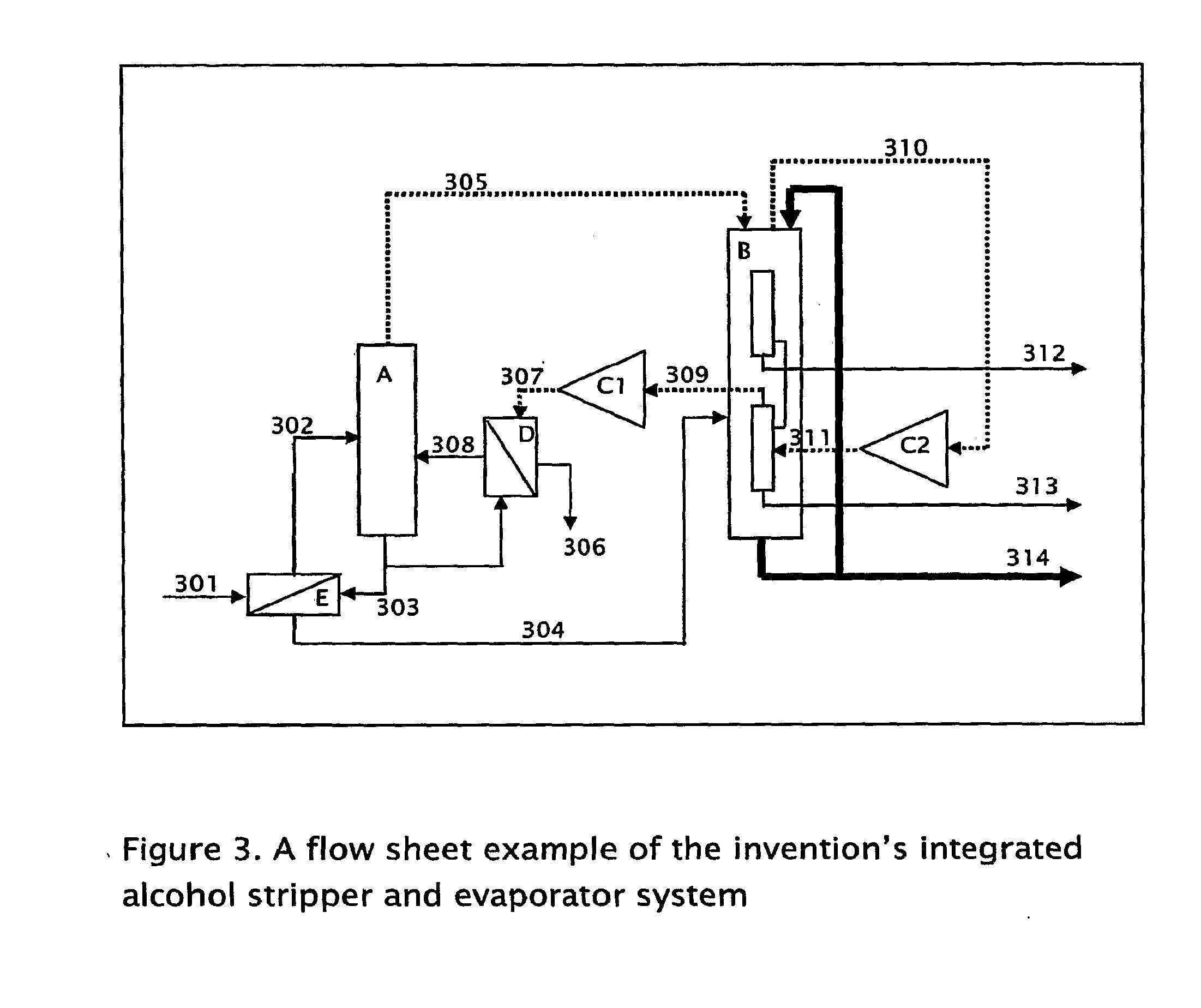

Process for the stepwise treatment of lignocellulosic material to produce reactive chemical feedstocks

InactiveUS20110003352A1Using liquid separation agentCalcium/strontium/barium sulfatesSulfonateLignosulfonates

A method for the fractionation of lignocellulosic materials into reactive chemical feedstock in a batch or semi continuous process by the stepwise treatment with aqueous aliphatic alcohols in the presence of sulfur dioxide or acid. Lignocellulosic material is fractionated in a fashion that cellulose is removed as pulp, or converted to esterified cellulose, cooking chemicals are reused, lignin is separated in the forms of reactive native lignin and reactive lignosulfonates and hemicelluloses are converted into fermentable sugars, while fermentation inhibitors are removed. In an integrated vapor compression stripper and evaporator system, aliphatic alcohol is removed from a liquid stream and the resulting stream is concentrated for further processing.

Owner:API INTELLECTUAL PROPERTY HOLDINGS LLC +1

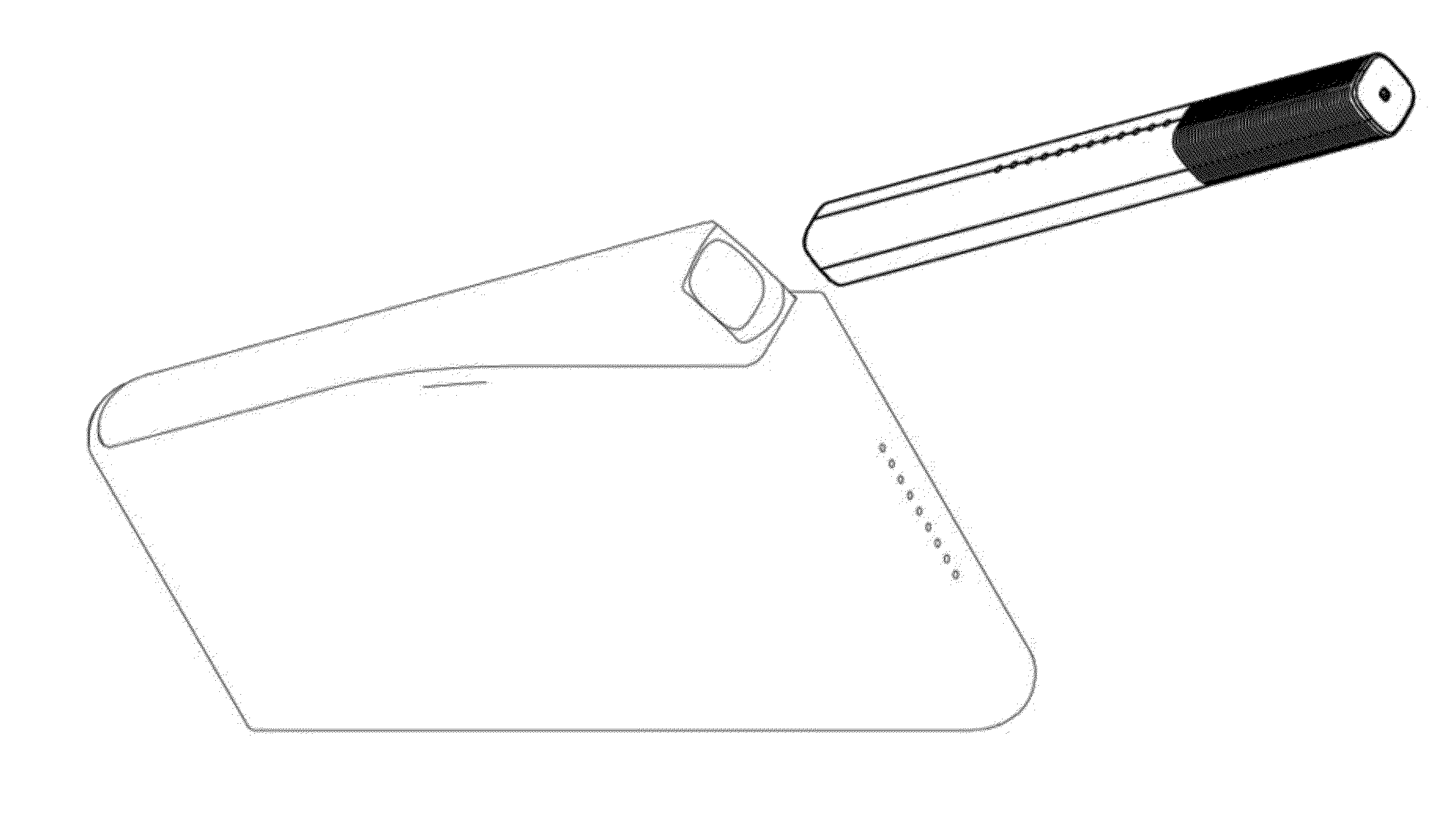

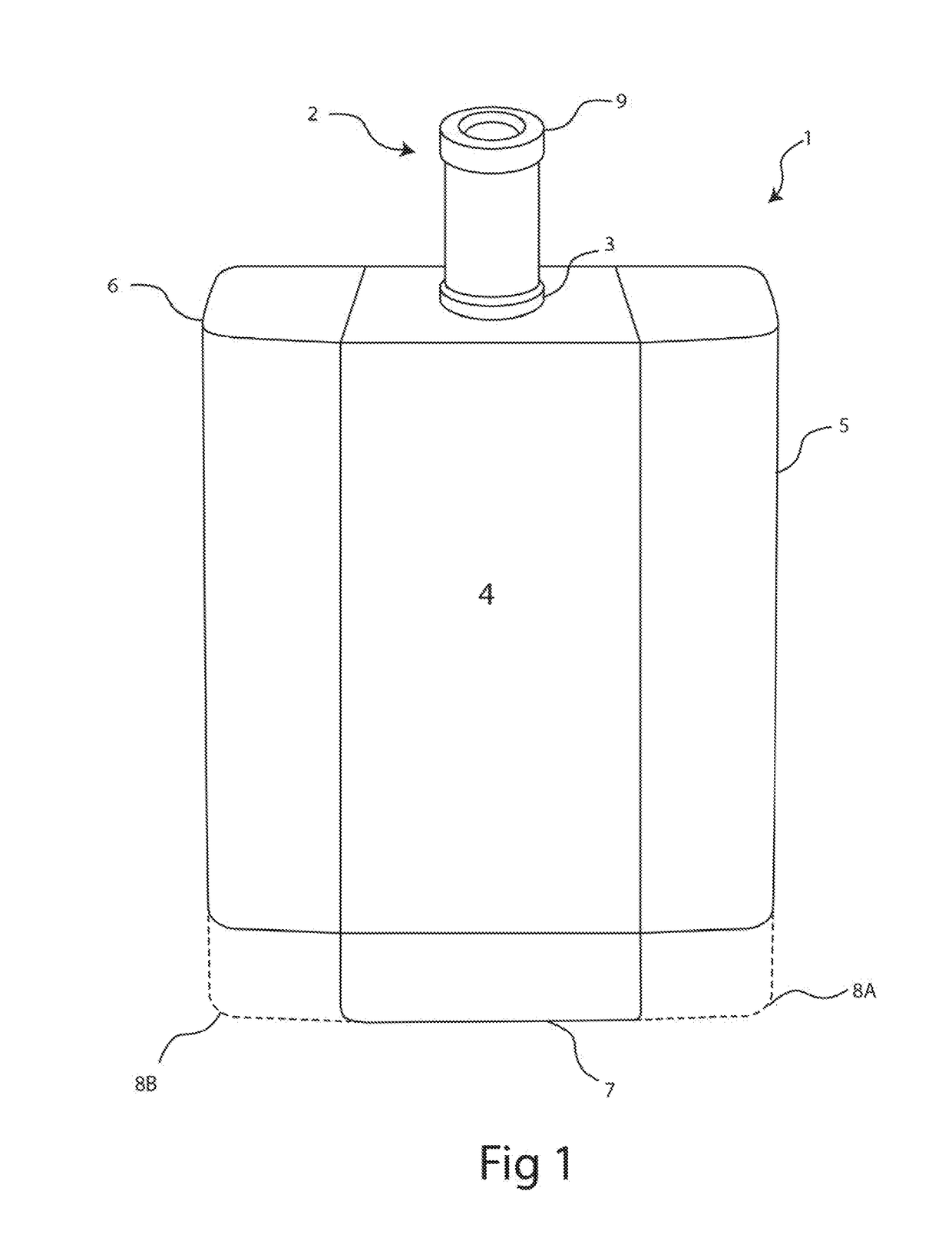

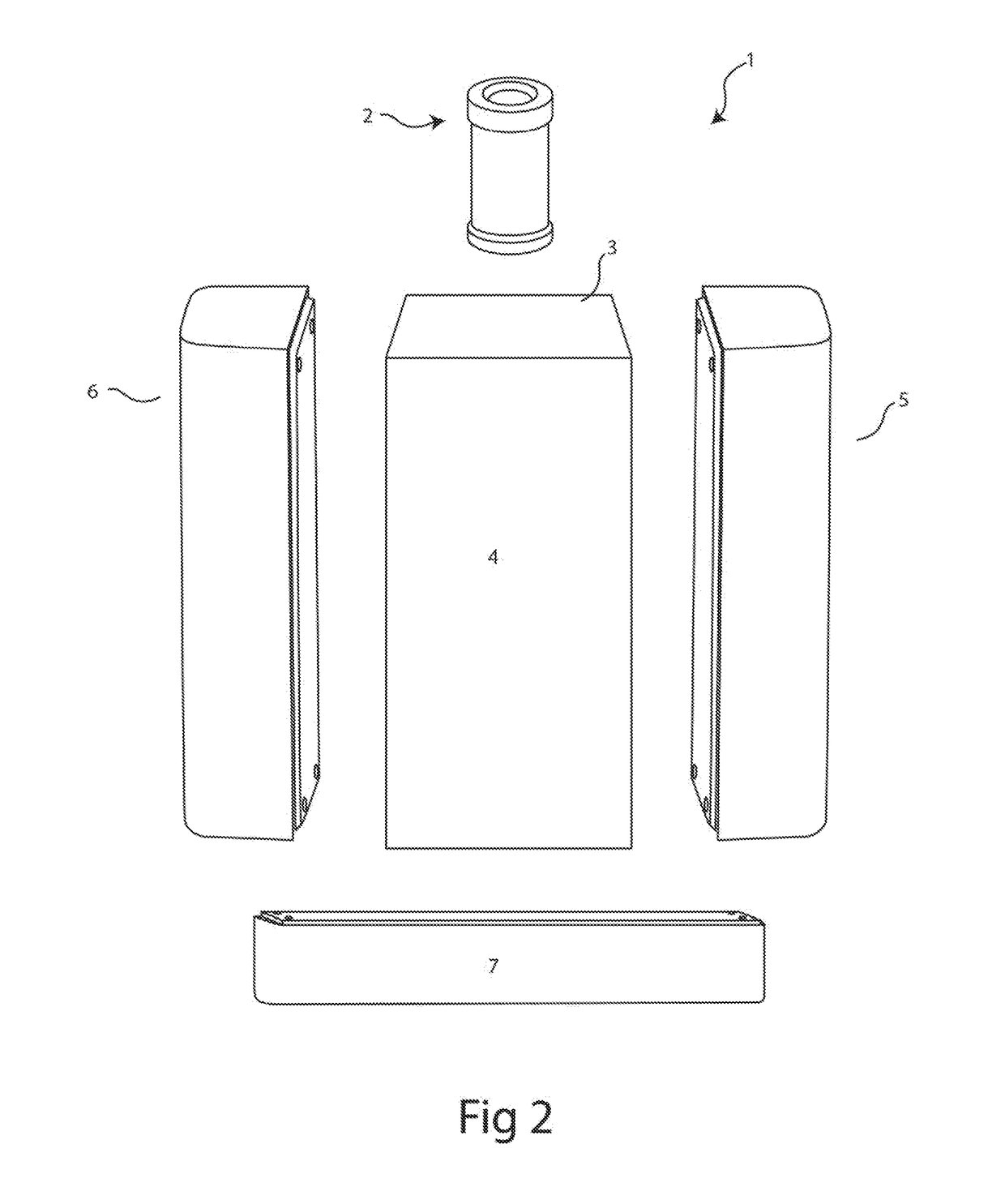

Portable vaporizer and storage systems

InactiveUS20170215479A1Easy accessSteam generation heating methodsTobacco pipesHybrid storage systemBiomedical engineering

A portable vaporizer with at least one detachable storage compartment for storing a significant amount of smokable materials. The storage compartment is accessed by opening a door so smokable material can be conveniently poured from a spout into the vaporizer's heating chamber. A tool designed for specific purposes is integrated into the detachable storage for use with scooping, loading, stirring, packing, cleaning, or extracting the smokable materials into, from, or within the heating chamber. The detachable storage compartment having an extended surface to fit partially inside the heating chamber tightly packs the smokable material. In instances where a tool is used to scoop the smokable materials, the heating chamber has a nub to aid in the transfer of the smokable material from the tool onto the nub within the heating chamber. A heating chamber is constructed of glass, and a heating element is embedded in the glass base and / or walls.

Owner:KIES NATHAN R

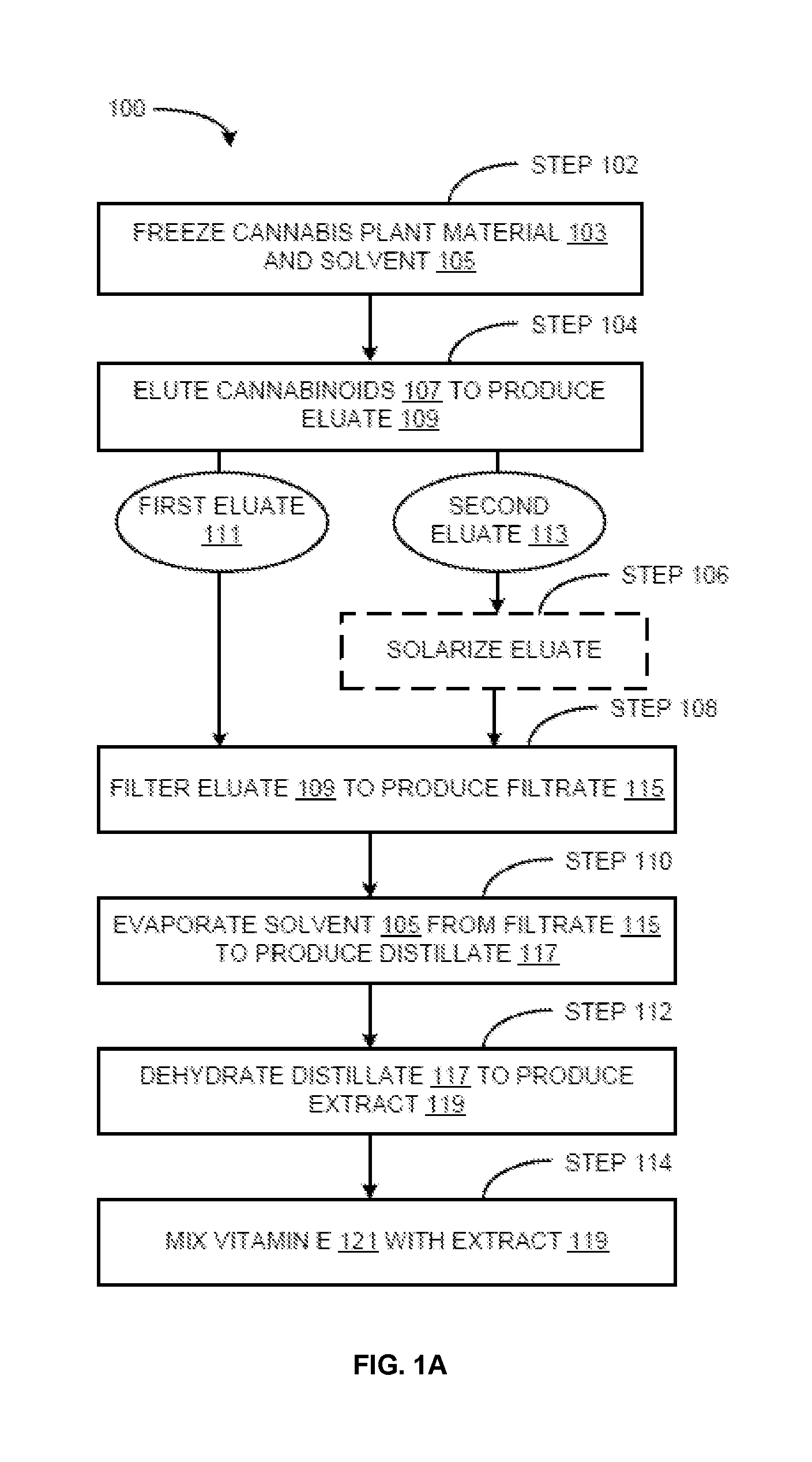

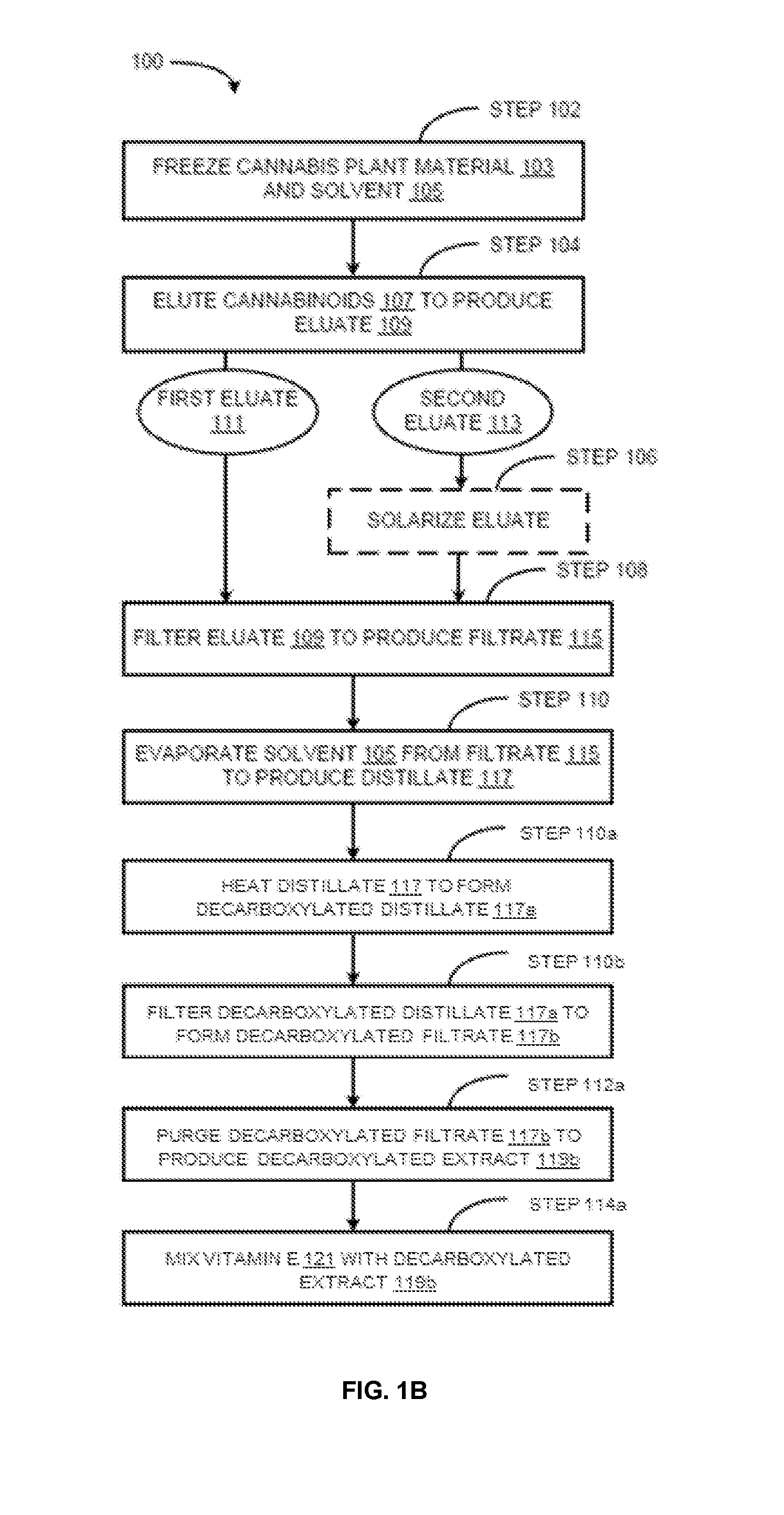

Methods for preparation of cannabis oil extracts and compositions

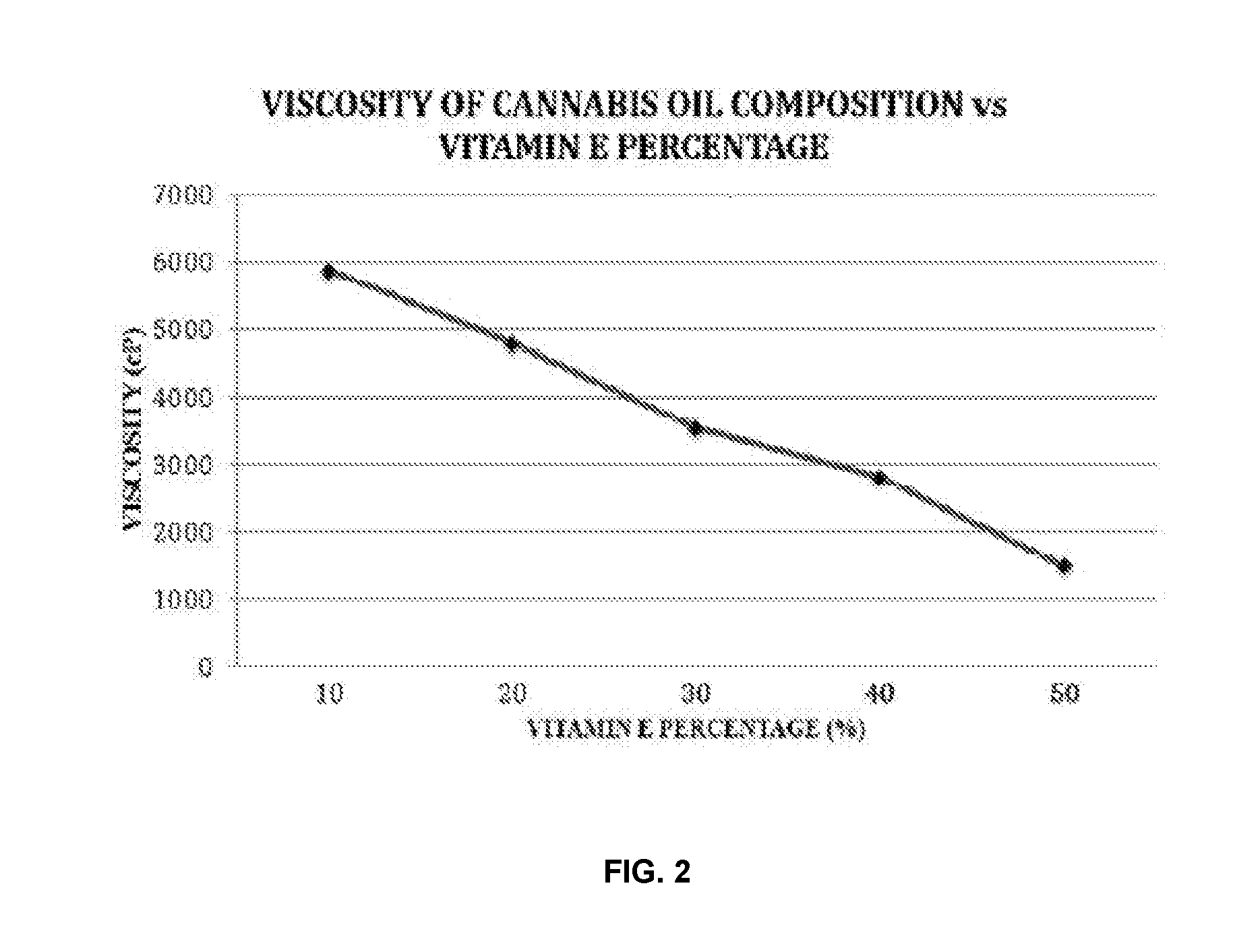

The present invention provides cannabis oil extracts and compositions thereof, including cannabis oil compositions containing vitamin E, and methods for preparing the extracts and compositions. In some embodiments, the present invention provides a method for preparing a cannabis oil extract comprising eluting cannabinoids from cannabis plant material with a solvent to produce an eluate, filtering the eluate with a filter to produce a filtrate, evaporating the solvent from the filtrate with a distiller to produce a distillate, and purging the distillate under conditions sufficient to remove residual solvent, thereby preparing the extract. In some embodiments, the method further includes mixing a quantity of vitamin E with the extract to produce a cannabis oil composition.

Owner:CONSTANCE THERAPEUTICS INC

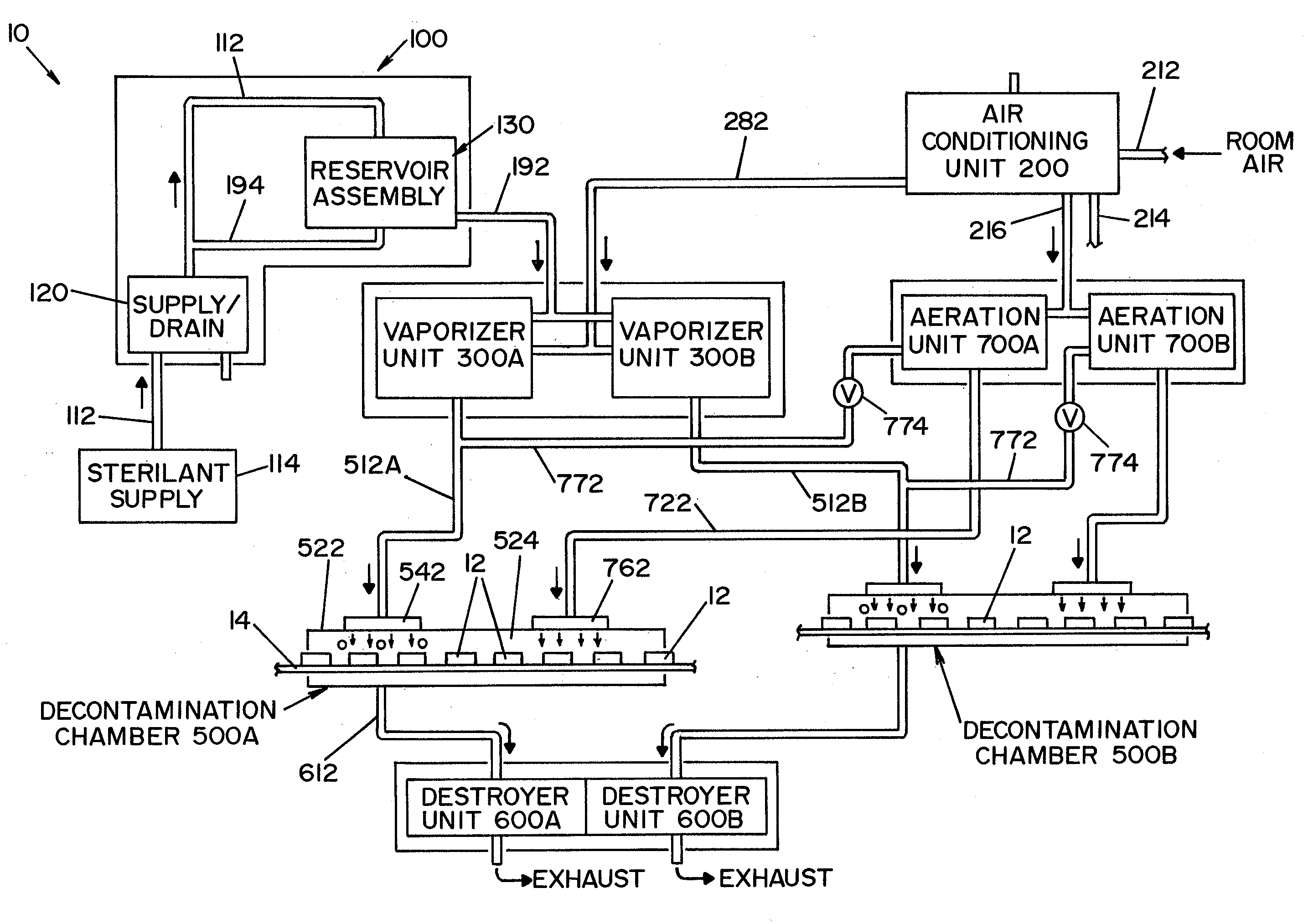

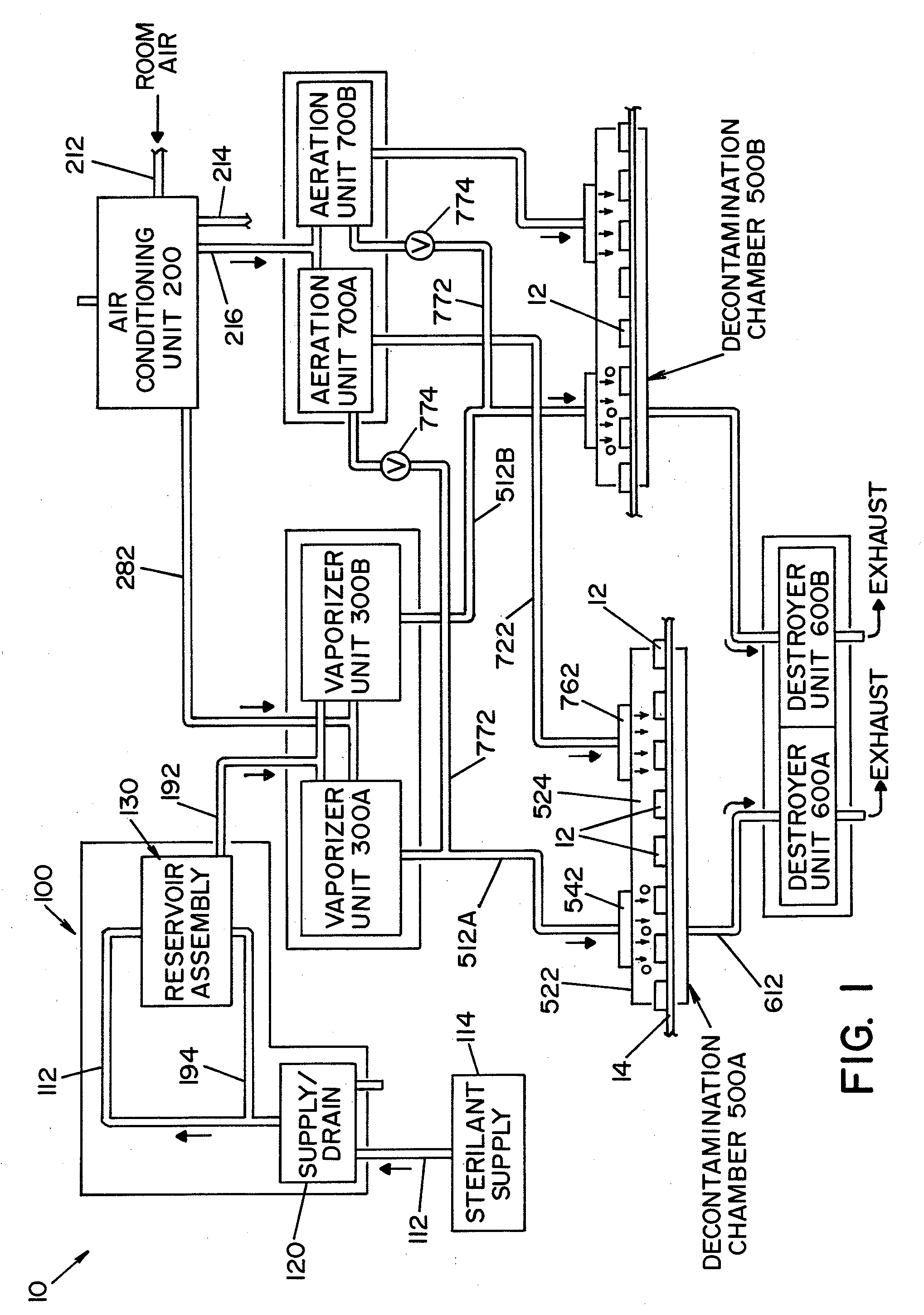

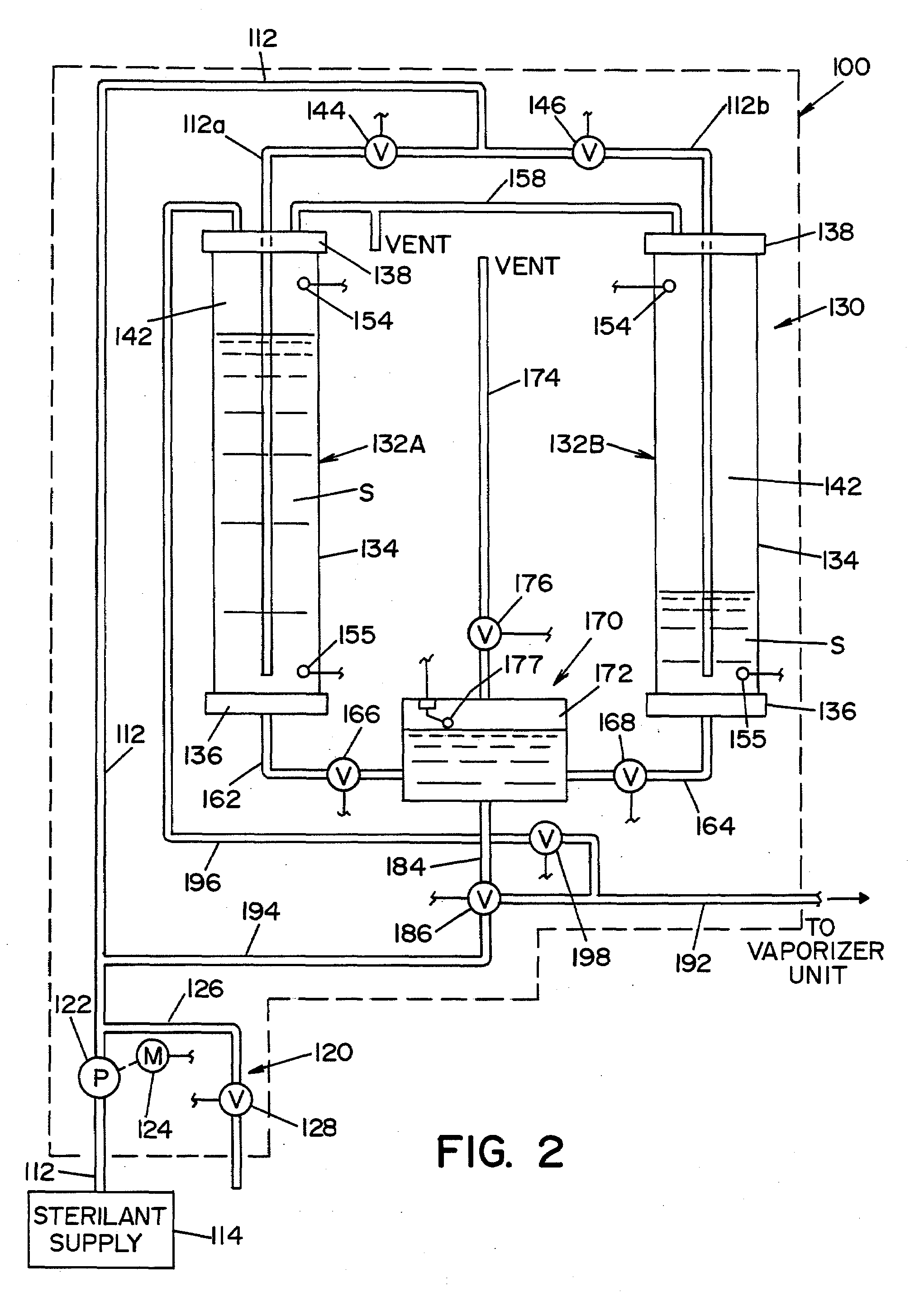

Hydrogen peroxide vaporizer

ActiveUS20070253859A1Modifies flowModifies temperatureLavatory sanitoryDeodrantsLiquid hydrogenEngineering

A method of decontaminating articles, comprising the steps of:(a) moving a plurality of articles having a known temperature along a first path;(b) conveying a carrier gas along a second path that includes an elongated plenum, the second path intersecting the first path downstream from the plenum;(c) heating the carrier gas to a temperature of at least about 105° C. at a location upstream of the plenum;(d) introducing into the carrier gas in the plenum an atomized mist of a liquid hydrogen peroxide of known concentration; and(e) controlling the following:(1) the volumetric flow of carrier gas along the second path;(2) the volume of hydrogen peroxide introduced into the carrier gas; and(3) the temperature of the carrier gas introduced into the plenum, such that the concentration of the vaporized hydrogen peroxide in the carrier gas where the first path intersects the second path has a dew point temperature below the known temperature of the articles.

Owner:AMERICAN STERILIZER CO

Electronic vaporiser system

A electronic cigarette vaporiser that includes a mechanical valve that is (i) pushed up from its seat to enable automatic filling of the vaporiser with e-liquid from a fluid transfer mechanism and (ii) returns to seal against its seat at other times when the vaporiser is being vaped or inhaled from (e.g. when filling is complete).

Owner:AYR LTD

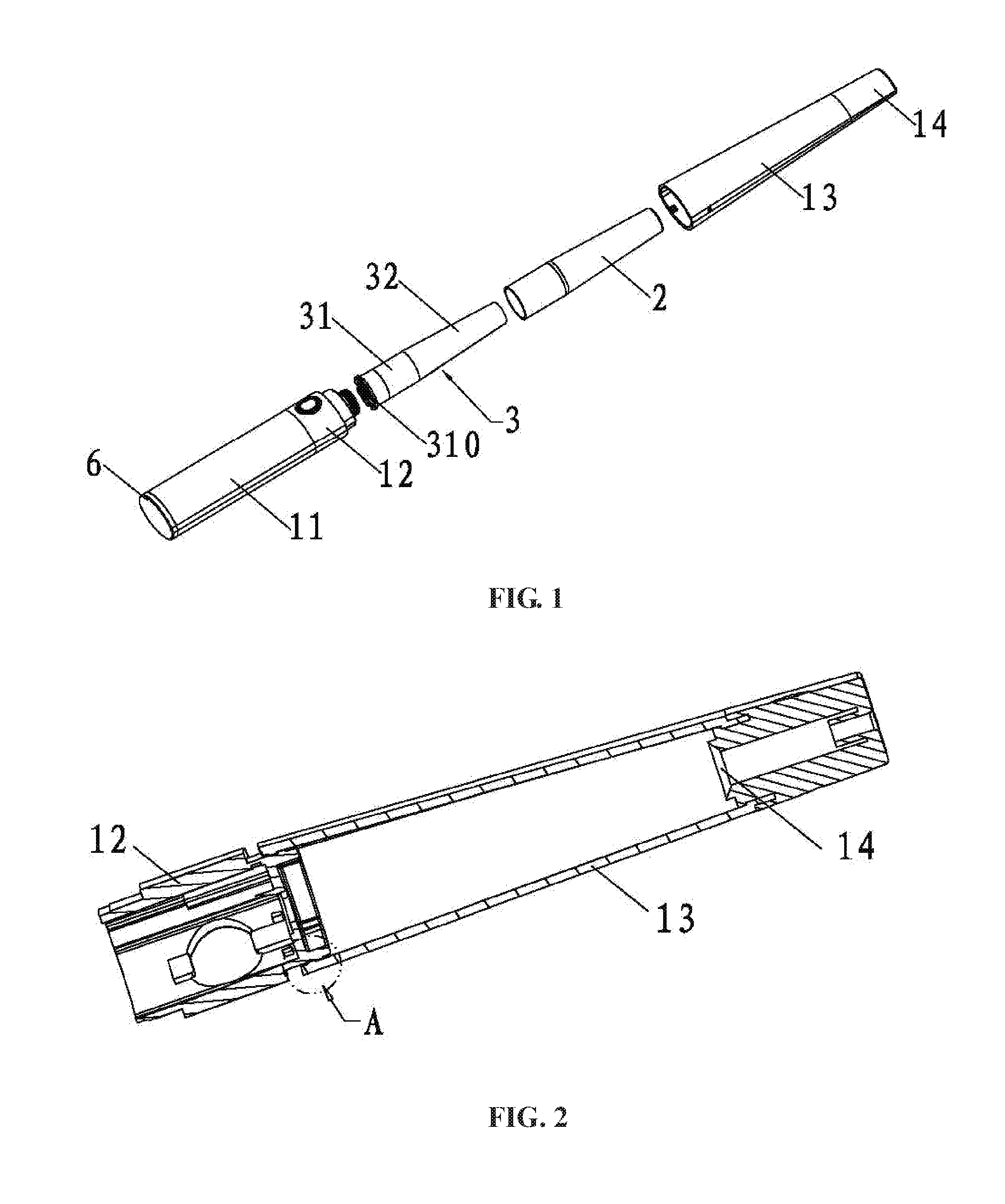

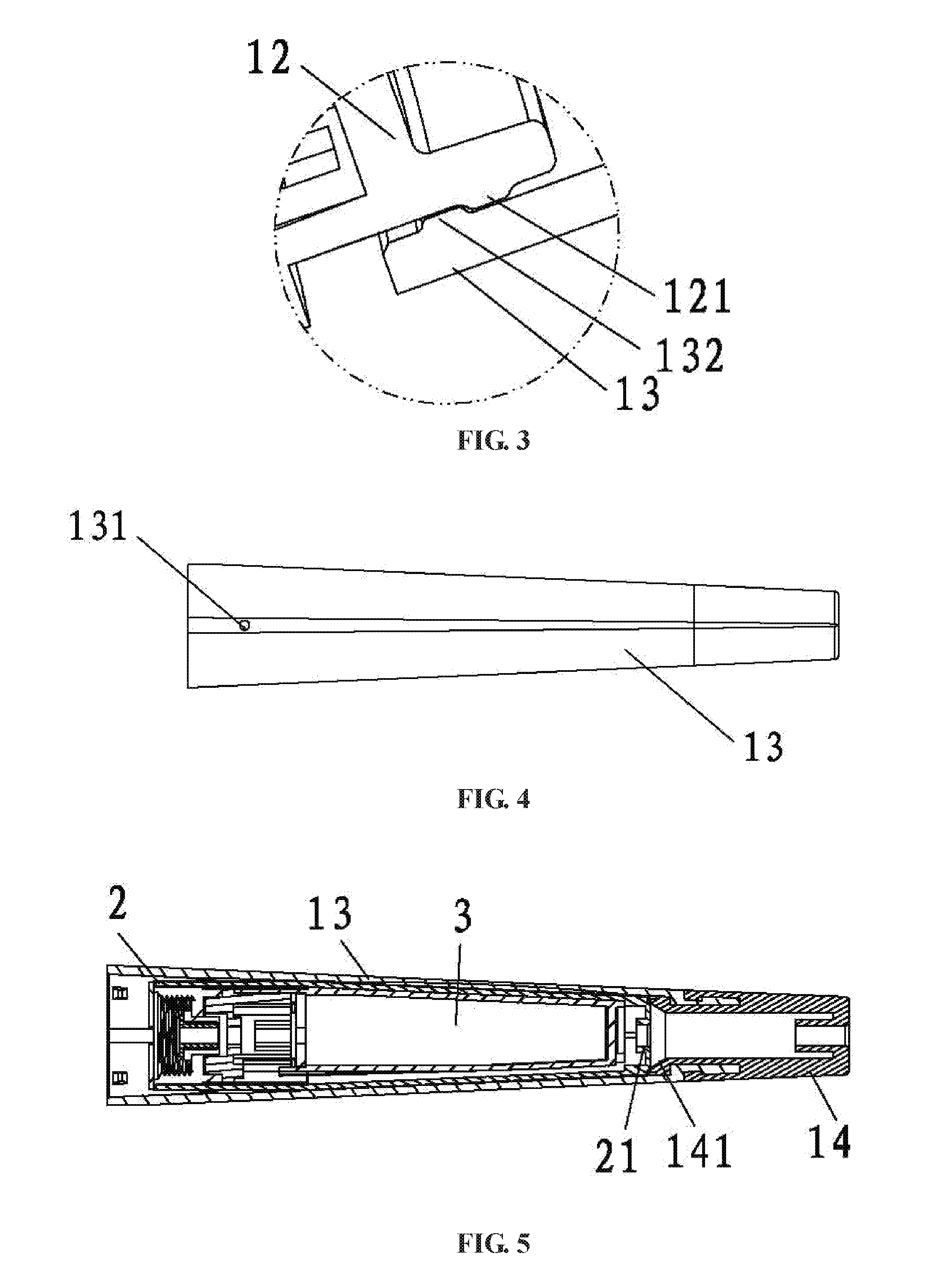

Electronic cigarette with oval shaped cross section and manufacturing process thereof

ActiveUS20160366941A1Easy to separateAvoid burnsSnap-action fastenersTobacco pipesVaporizationEngineering

The invention discloses an oval-shaped electronic cigarette and manufacturing process thereof. Inner housing of vaporization assembly is arranged inside outer housing of vaporization assembly and sleeved on vaporization assembly which comprises e-cigarette liquid cup and vaporizer having an outer wall in close fit with inner wall of the inner housing of vaporization assembly. A space is formed between outer wall of the e-cigarette liquid cup and inner wall of the inner housing of vaporization assembly to serve as a vapor flow channel. The inner housing of vaporization assembly is arranged at one end with vapor flow outlet, the outer edge of which is hermetically connected with and pressed against bell-mouth structure formed on the mouthpiece.

Owner:LIN GUANGRONG

System for analyzing and controlling consumable media dosing information

A vaporizing article, comprises a vaporizer drive circuit; one or more memories configured to store a percentage of at least one constituent in an inhalation media, one or more compensation values for at least one compensation category for the at least one constituent, and instructions; and a control circuit comprising a processor coupled with the one or more memories configured to run the instructions, the instructions configured to cause the processor to: receive a dose target for a constituent; determine whether to perform compensation for an inhalation media dose in order to ensure the dose target is met; when compensation is to be performed, determine the properly compensated inhalation media dose based on an associated compensation value for the constituent; and control the vaporizer drive circuit so as to dispense a compensated dose of the inhalation media.

Owner:WELLNESS INSIGHT TECH INC

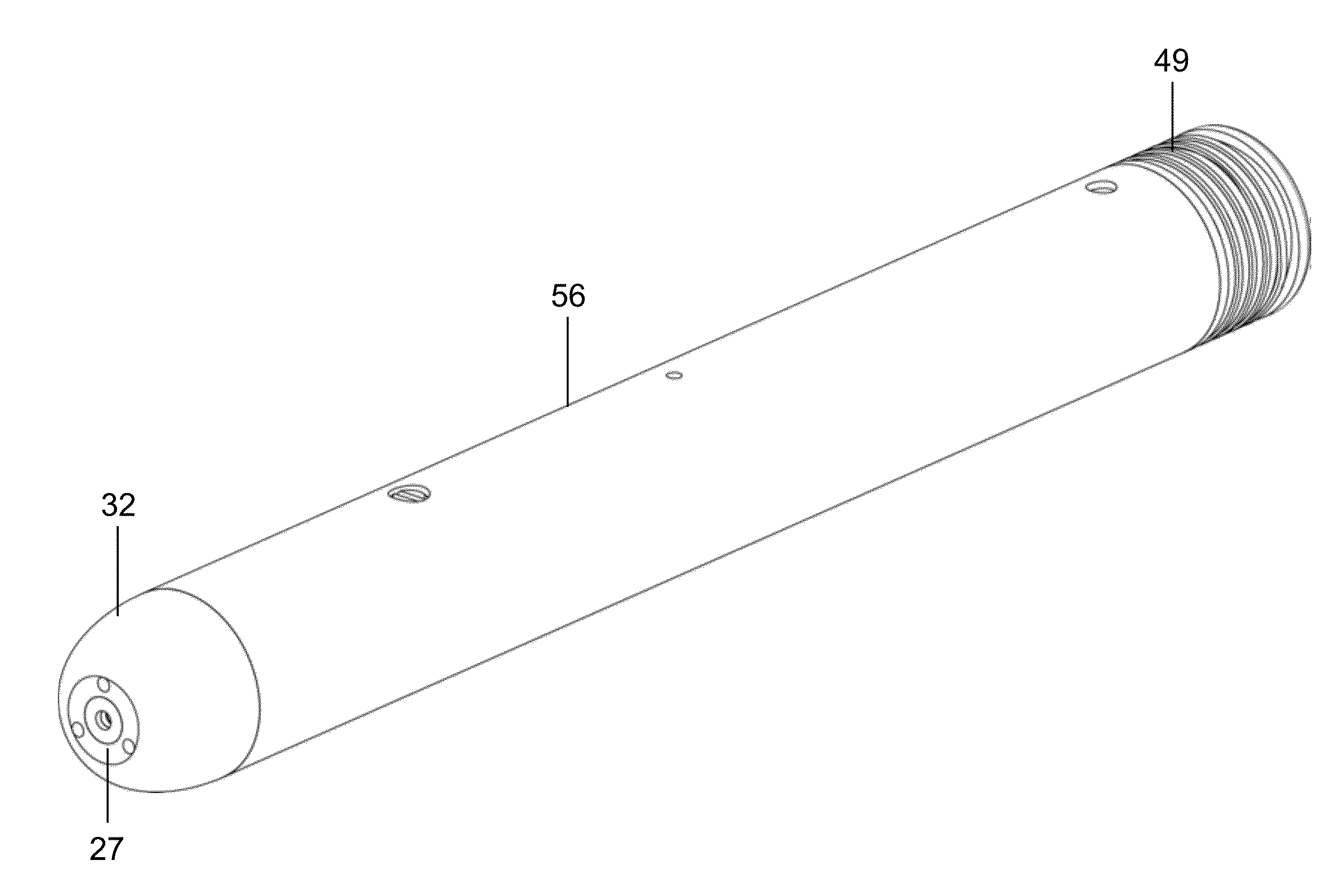

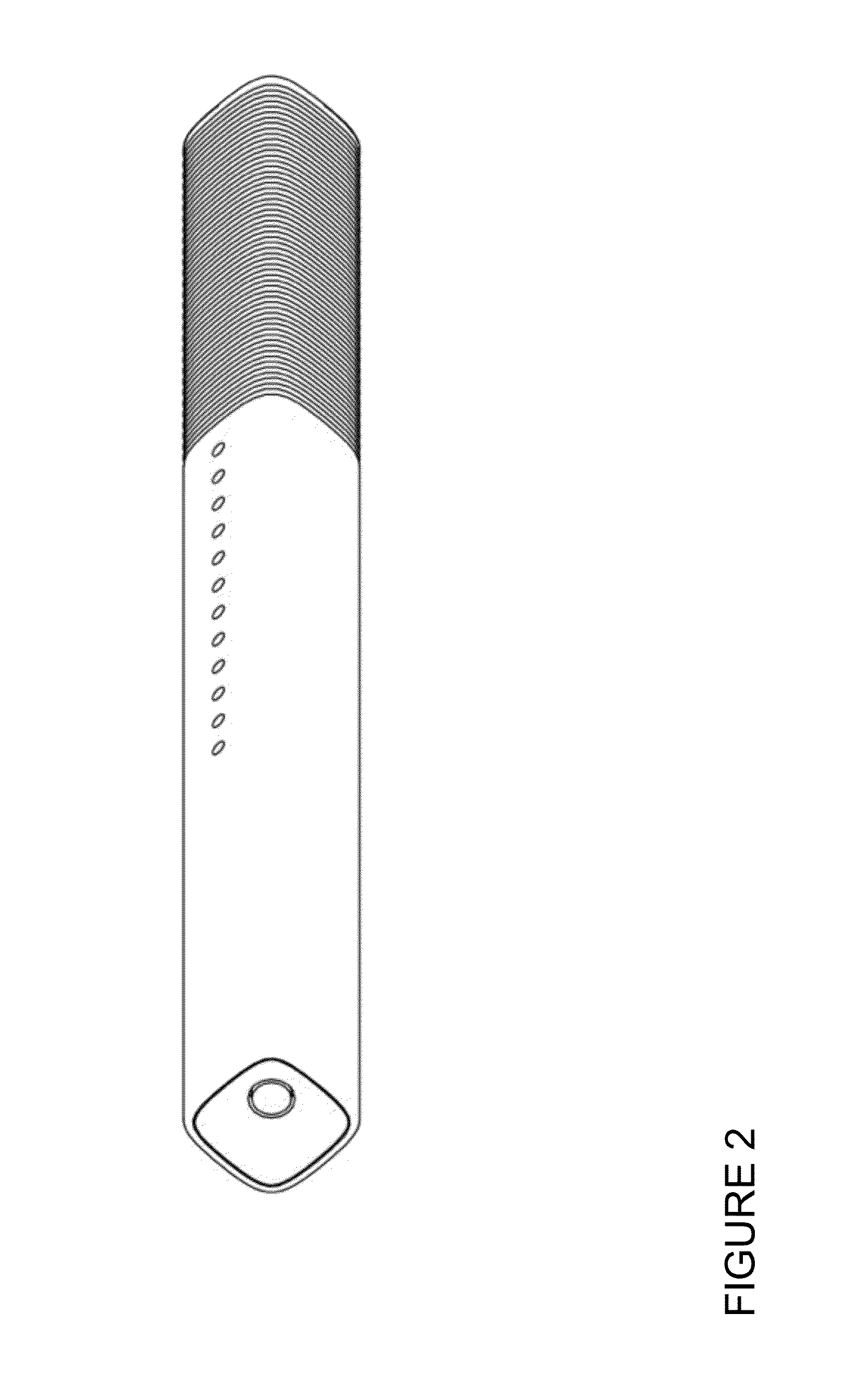

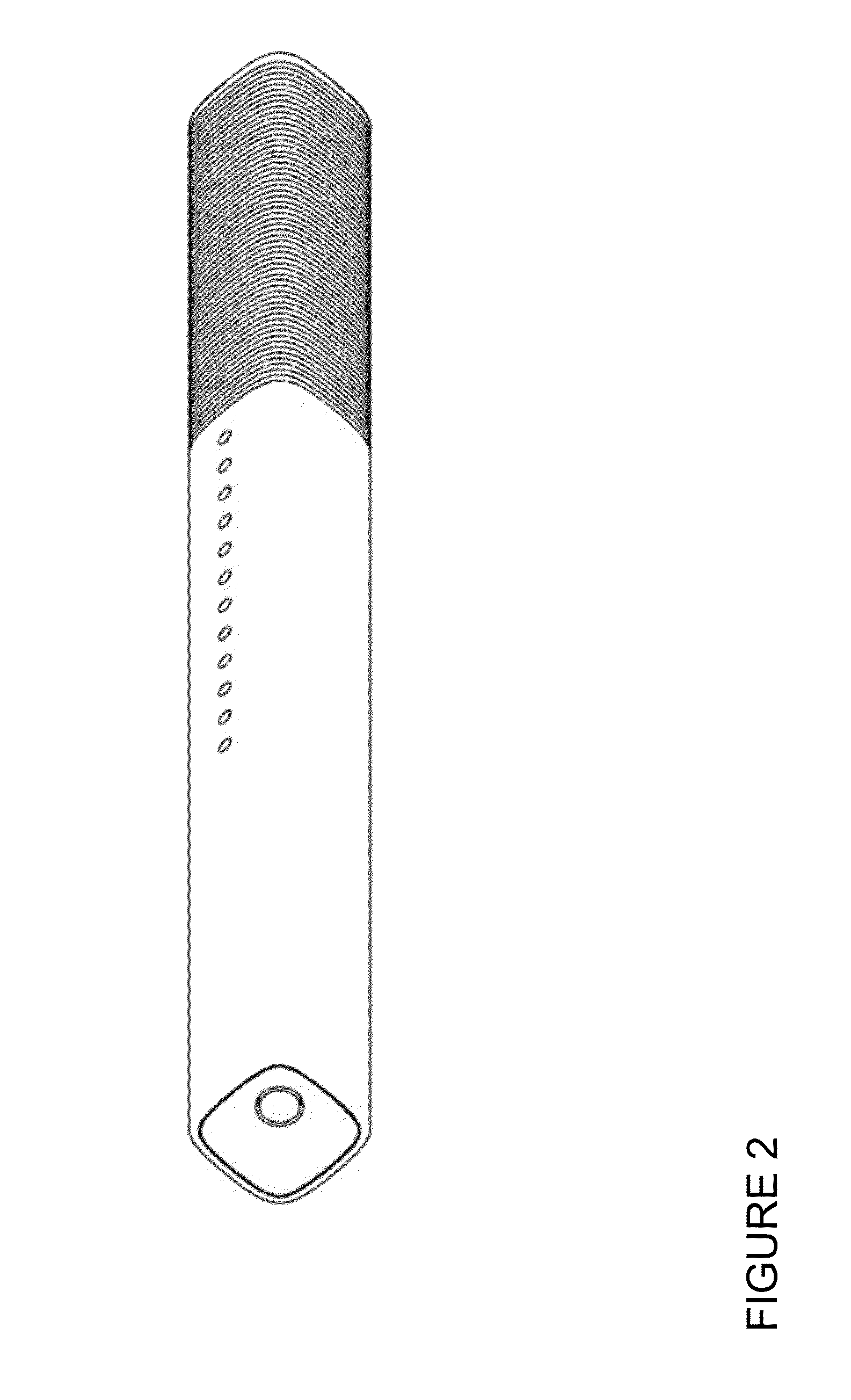

Vaporizer and vaporizer cartridges

ActiveUS20160235122A1Reduce and eliminate cloggingReduce odorTobacco treatmentTobacco devicesEvaporatorEngineering

Owner:KRIETZMAN MARK

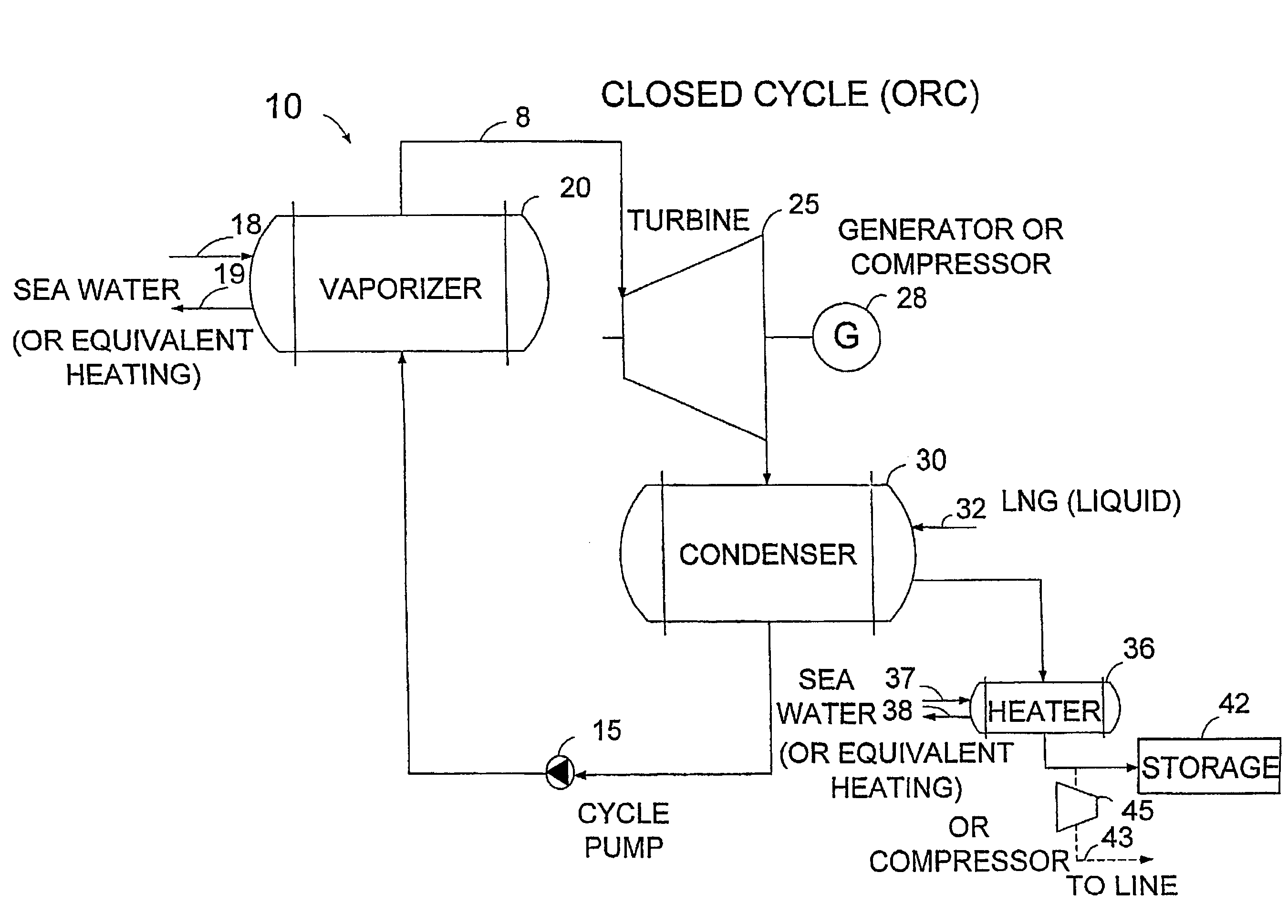

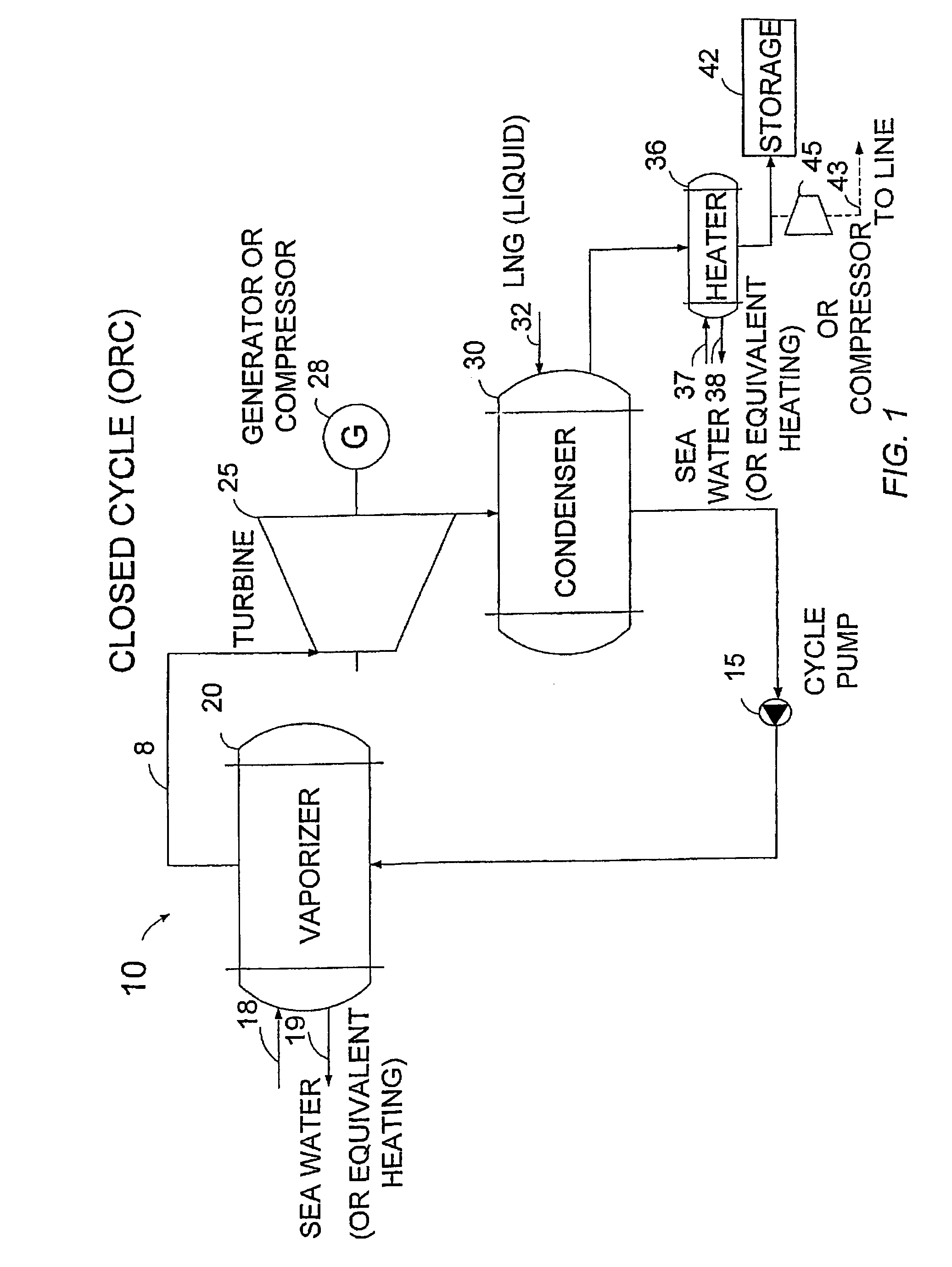

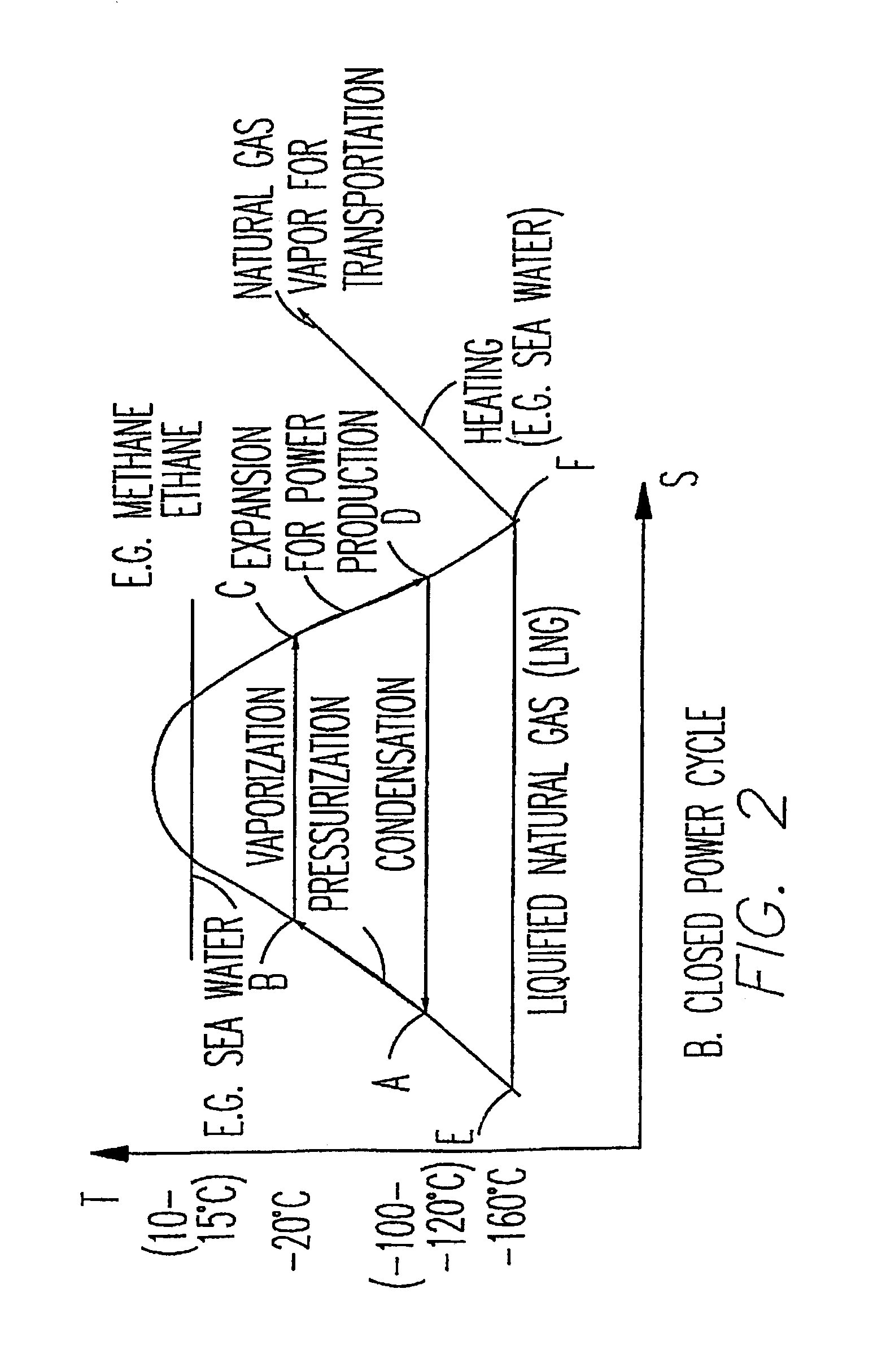

Power and regasification system for LNG

ActiveUS20090100845A1Power generationLarge temperature differenceSteam useGas handling/storage effectsEngineeringTurbine

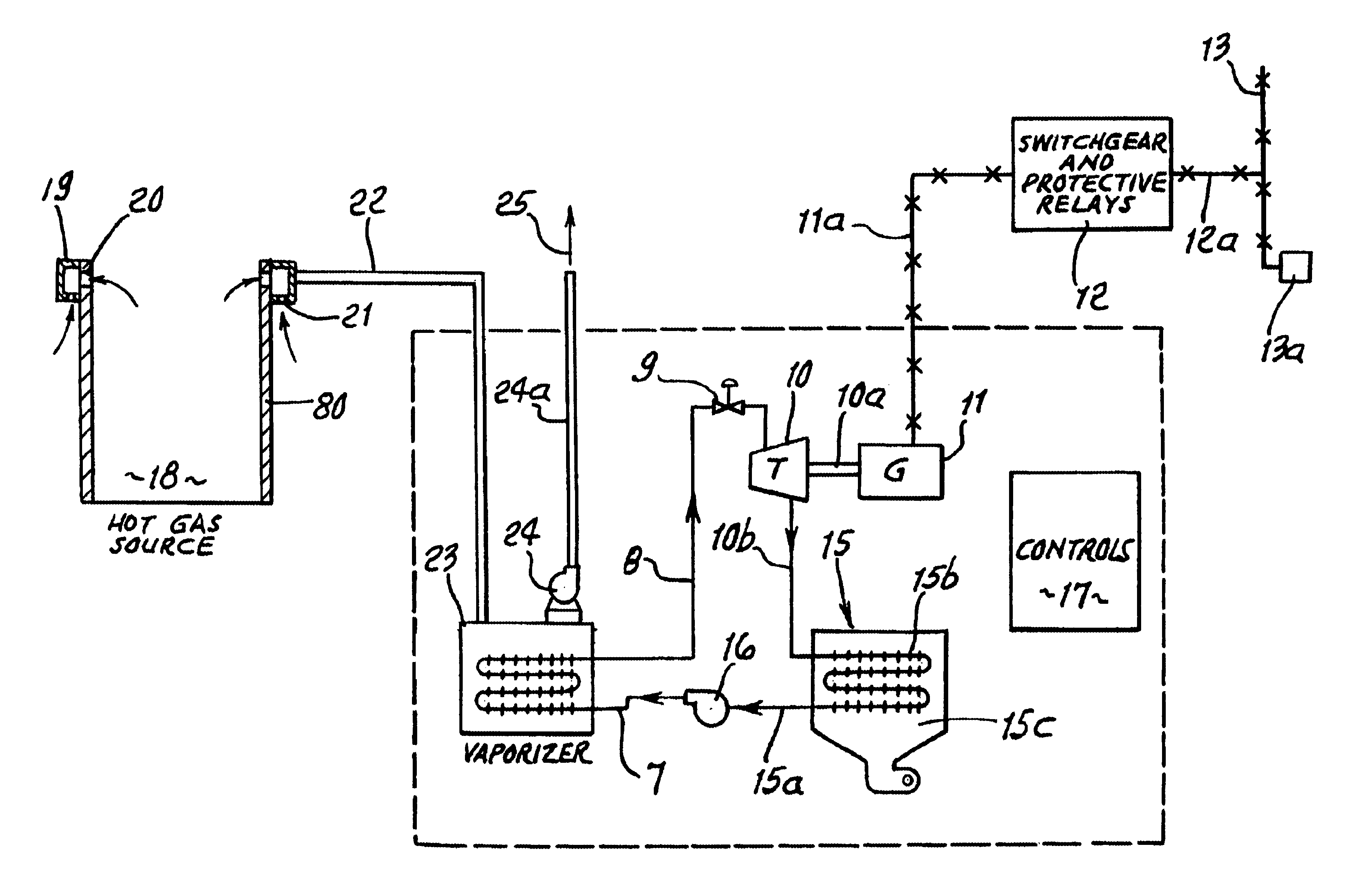

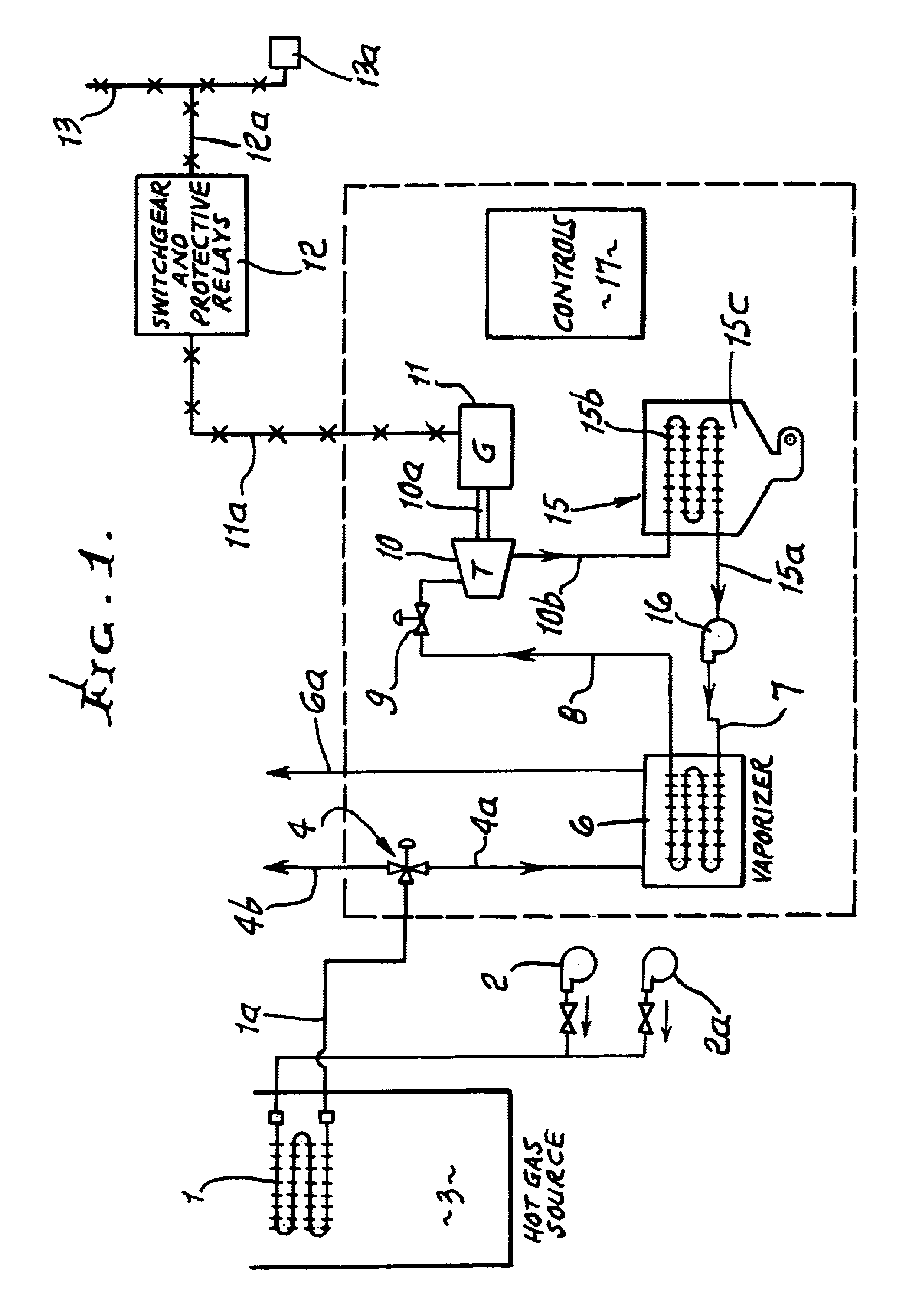

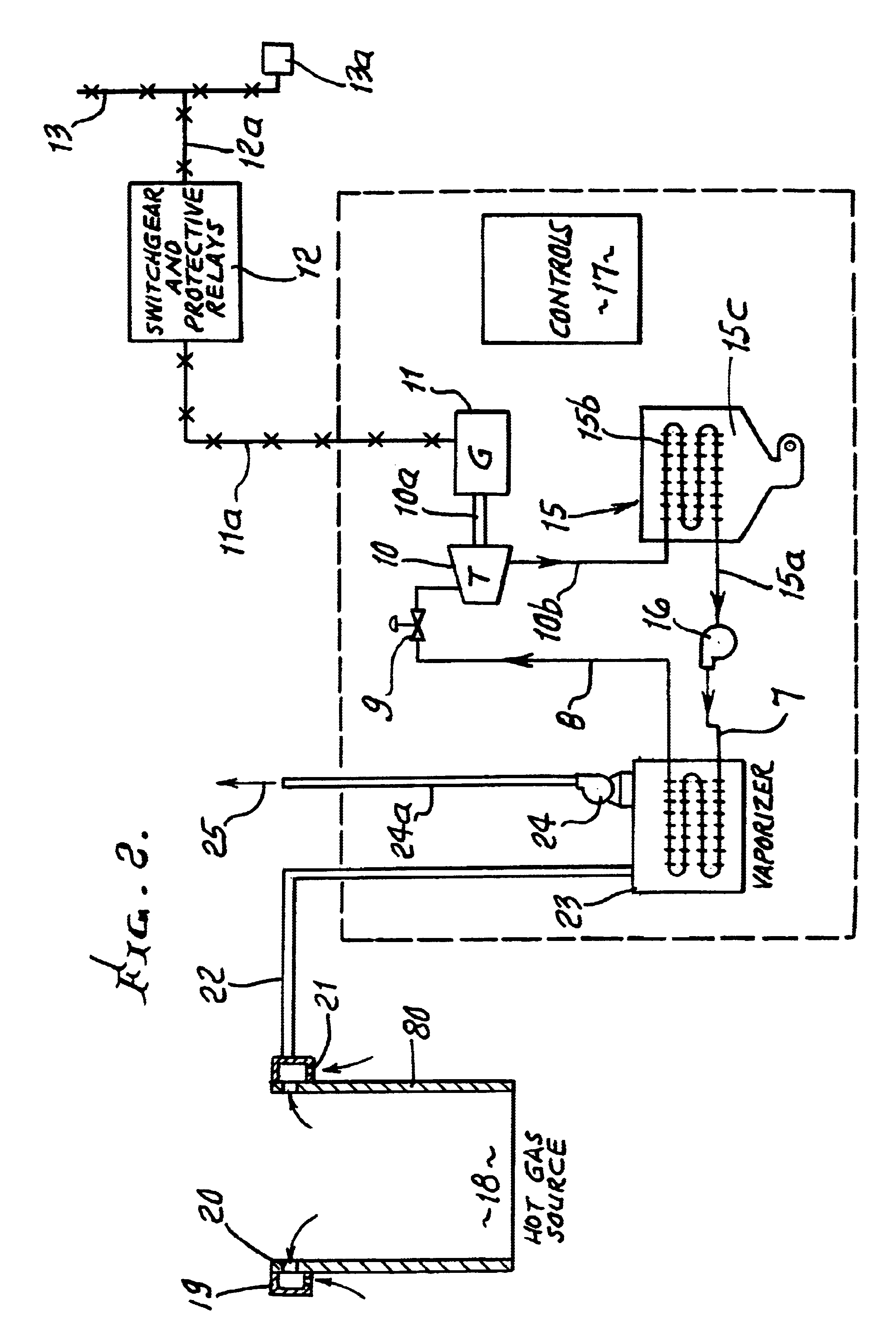

The present invention provides a power and regasification system based on liquefied natural gas (LNG), comprising a vaporizer by which liquid motive fluid is vaporized, said liquid motive fluid being LNG or a motive fluid liquefied by means of LNG; a turbine for expanding the vaporized motive fluid and producing power; heat exchanger means to which expanded motive fluid vapor is supplied, said heat exchanger means also being supplied with LNG for receiving heat from said expanded fluid vapor, whereby the temperature of the LNG increases as it flows through the heat exchanger means; a conduit through which said motive fluid is circulated from at least the inlet of said vaporizer to the outlet of said heat exchanger means; and a line for transmitting regasified LNG.

Owner:ORMAT TECH INC

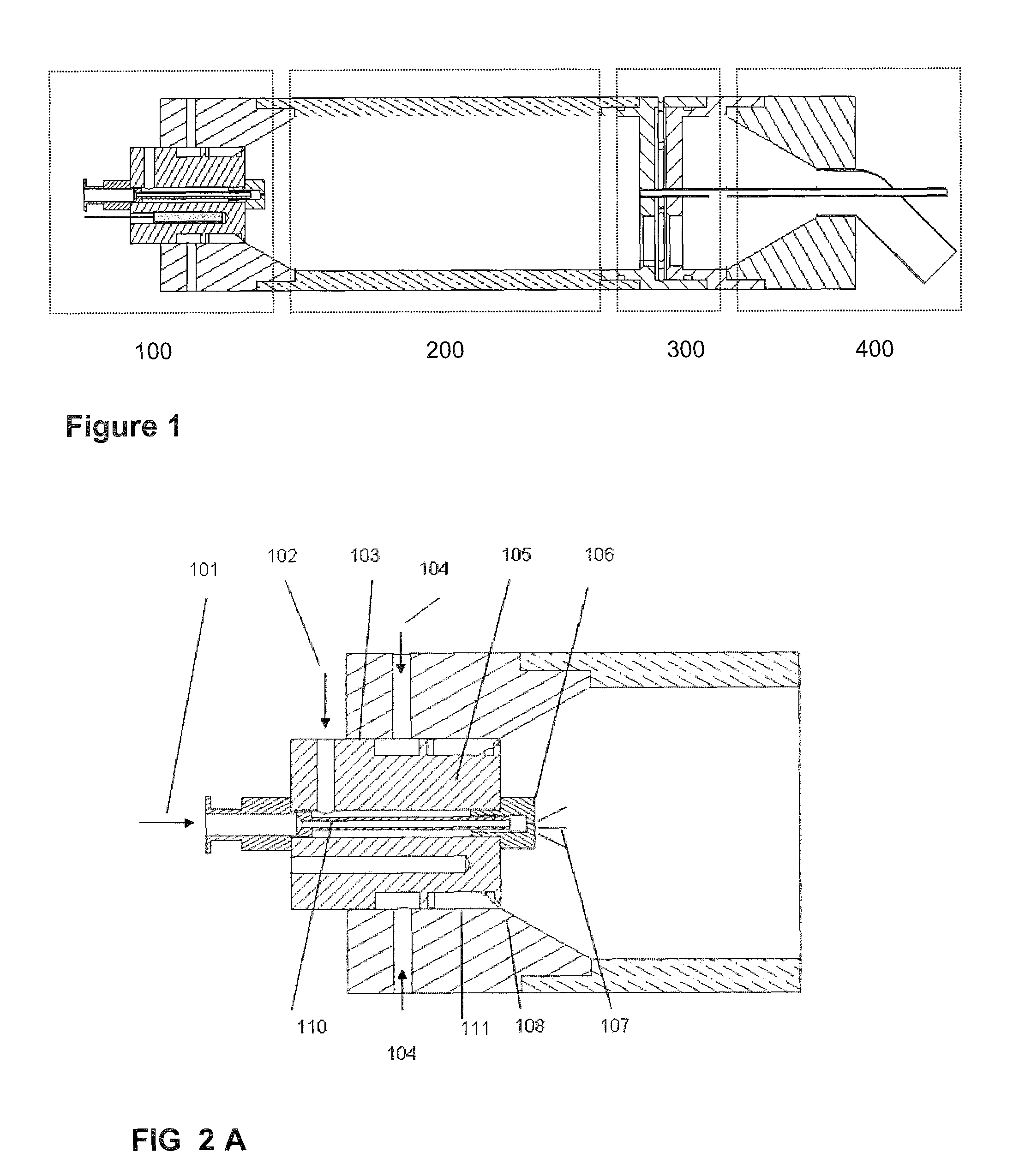

Interphase device for the direct coupling of liquid chromatography and gas chromatography

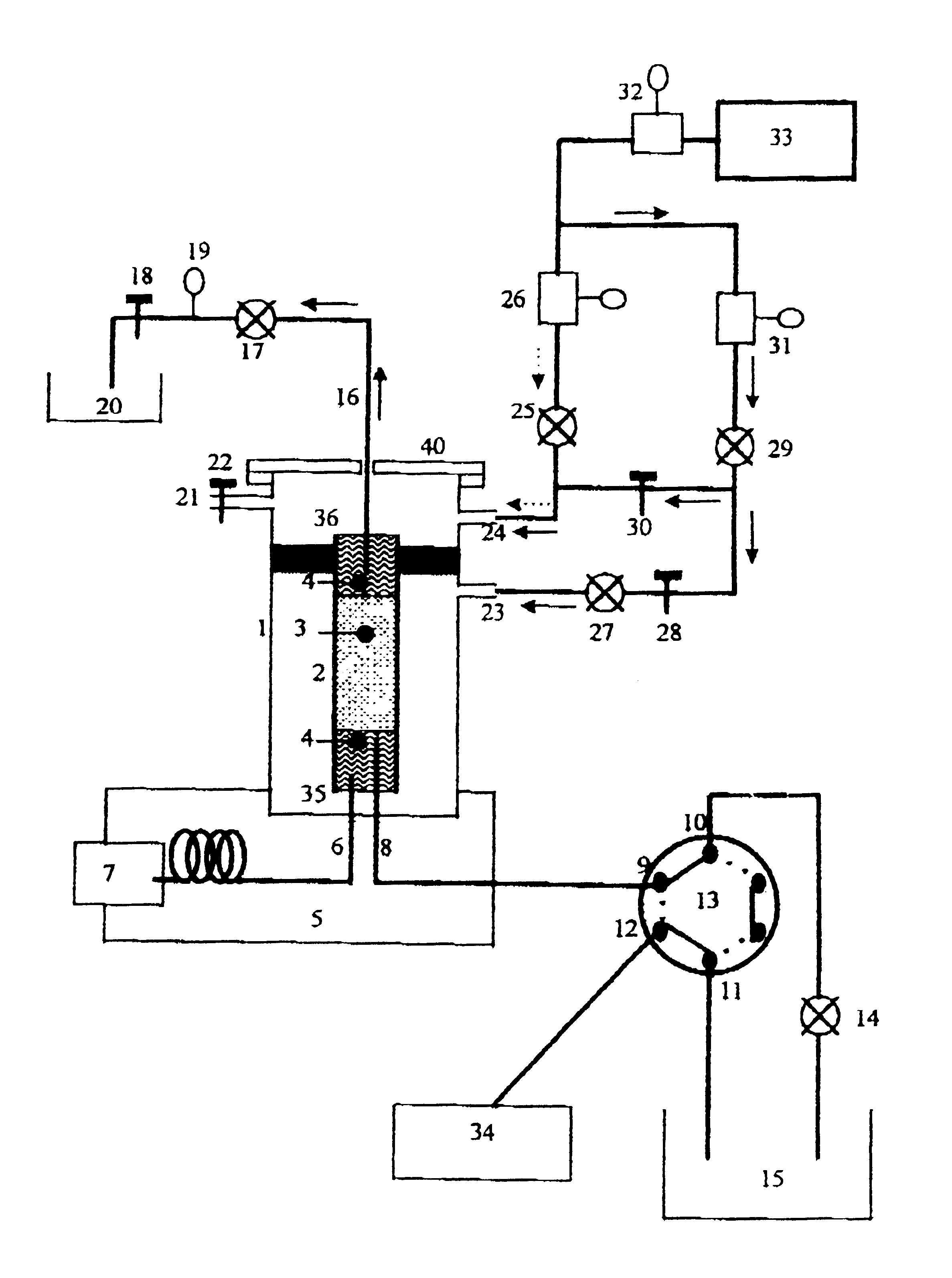

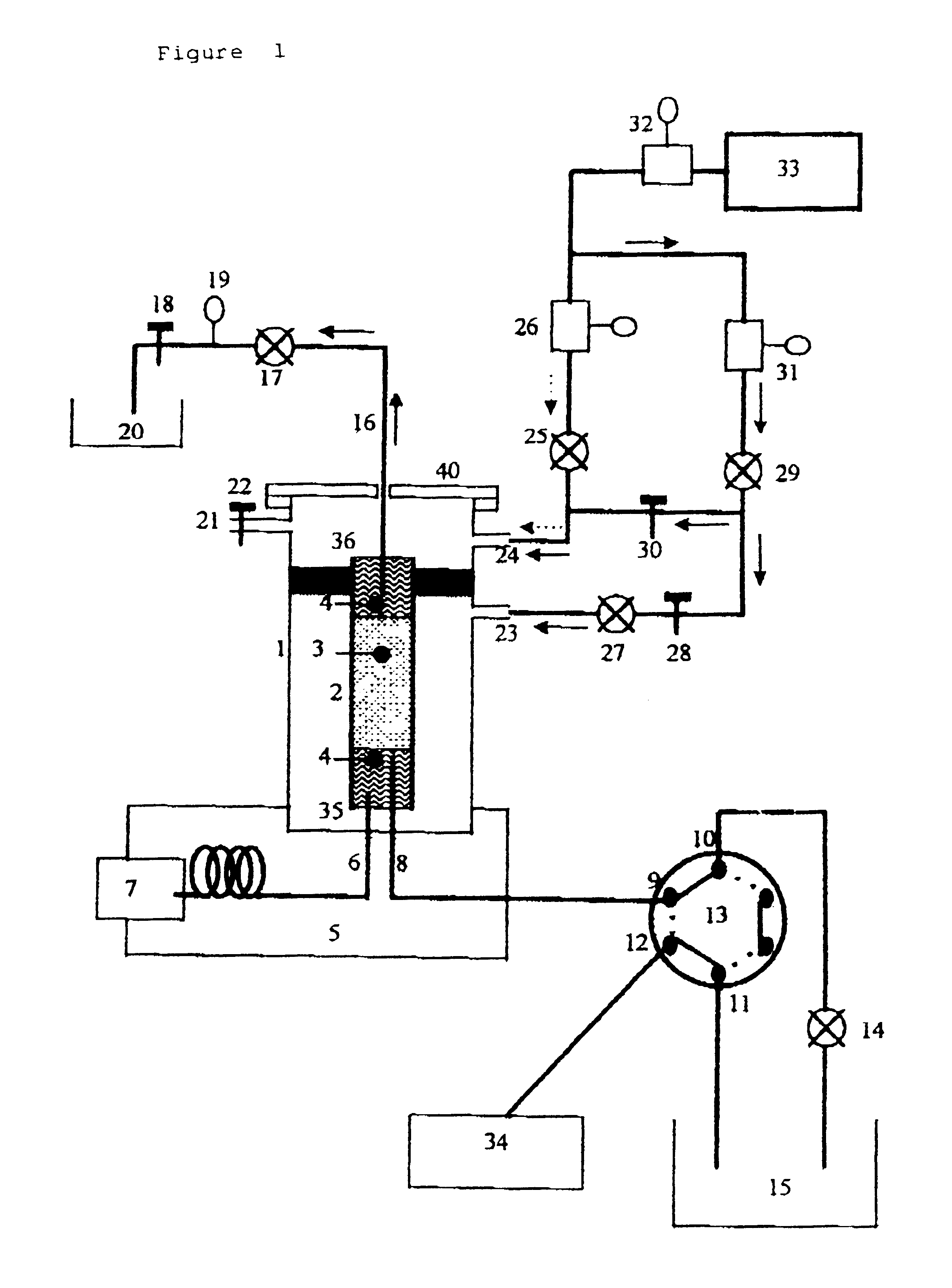

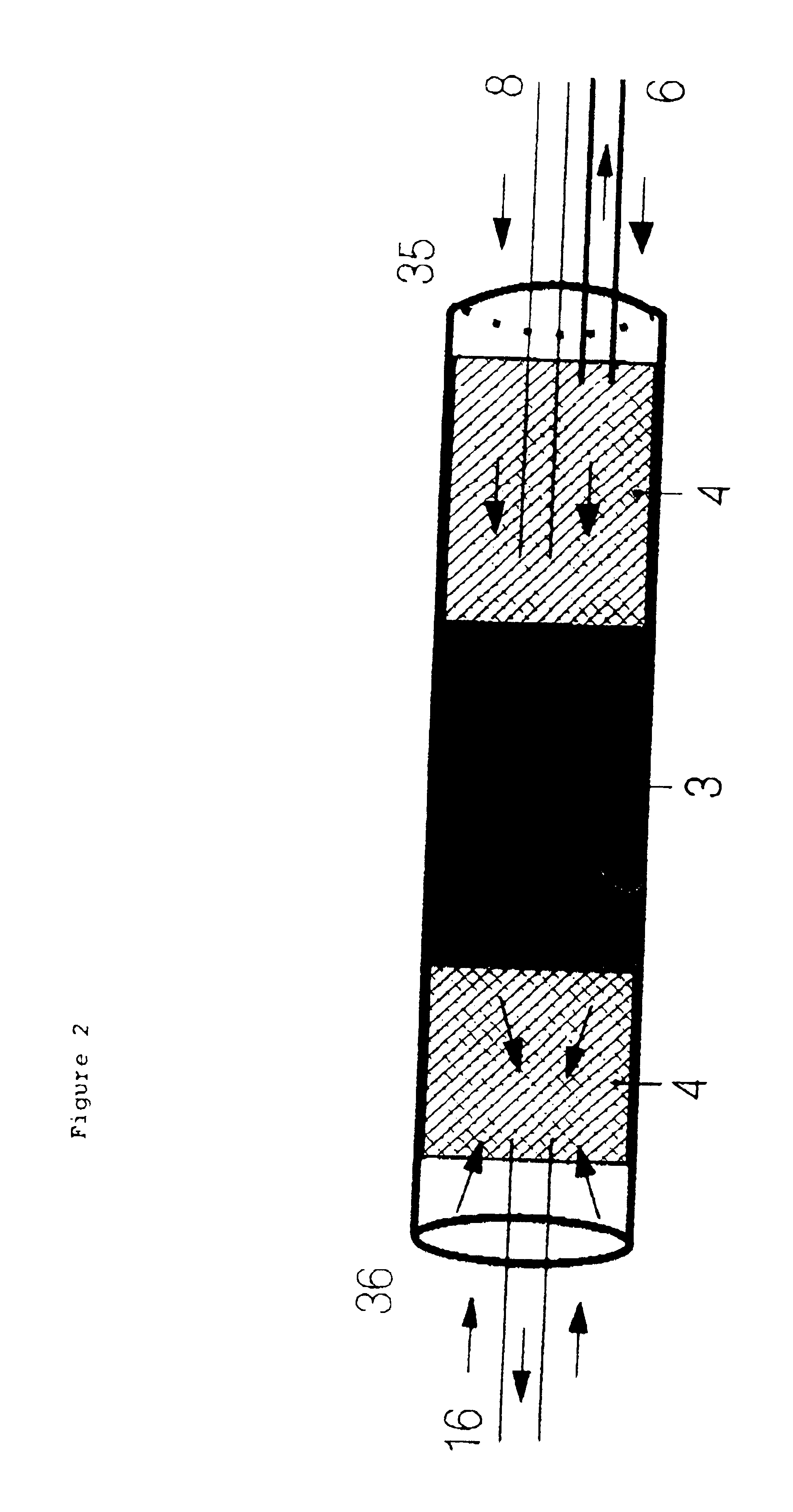

InactiveUS6402947B1Prevent floodingIncrease flow rateIon-exchange process apparatusComponent separationFluid phaseGas liquid chromatographic

The basic structure of a PTV (programmed temperature vaporizer) injector has been considerably modified so that is can be used for the direct coupling of liquid chromatography in normal phase or reverse phase, and gas chromatography and also for the introduction of high volumes in gas chromatography. The glass tube of the injector is filled with an adsorbent. By means of a system of valves and tubes or capillary tubes, the previously selected fraction of liquid chromatography is transferred to the injector, said fraction coming in through the same extremity for introducing the gas chromatography column. The eluent is entrained by a gas stream through the adsorbent, wherein are retained the solutes, and the solvent is removed through a tube or capillary tube introduced in the injector through the opposite extremity. Thereafter, the solutes are desorbed thermally passing to the chromatography column.

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC) +2

Recycled flue gas desulfurization and denitration method

The invention relates to a recycled flue gas desulfurization and denitration method, which sequentially comprises the following steps of: introducing flue gas of SO2 and NOx into a desulfurizing tower, and absorbing the SO2 with a desulfurizing agent (barren liquor) in the desulfurizing tower; desorbing the desulfurizing agent (rich liquor) which absorbs the SO2 through a multi-effect evaporator,releasing the SO2 gas, and concentrating the SO2 gas into liquid SO2 through condensation drying; making the desulfurized flue gas enter a denitration tower, injecting gaseous ozone from an ozone generator, oxidizing the NO in the flue gas, absorbing the oxidized NO by using a denitrifier to form nitrate; crystallizing and separating out the nitrate in the solution after the nitrate reaches certain concentration, and filtering and drying to obtain the nitrate product. The method turns the wastes into wealth, and the SO2 and NOx in the flue gas are recycled by higher-additional value liquid SO2 and nitrate products, so that the recycling and value maximization in the desulfurization and denitration process is realized. Due to the adoption of the technical scheme, the high desulfurization and denitration rate can be achieved, the desulfurization rate is over 96 percent, the denitration rate is more than 90 percent, and the purity of the nitrate product is over 96 percent. The method hasthe advantages of simple desulfurization and denitration process, low investment, and low operation cost for desulfurization and denitration, and solves the problems that the conventional desulfurization and denitration process has high cost, generates a side product of a mixture of sulfuric acid (sulfate) and nitric acid (nitrate), and has low additional value.

Owner:EAST CHINA UNIV OF SCI & TECH

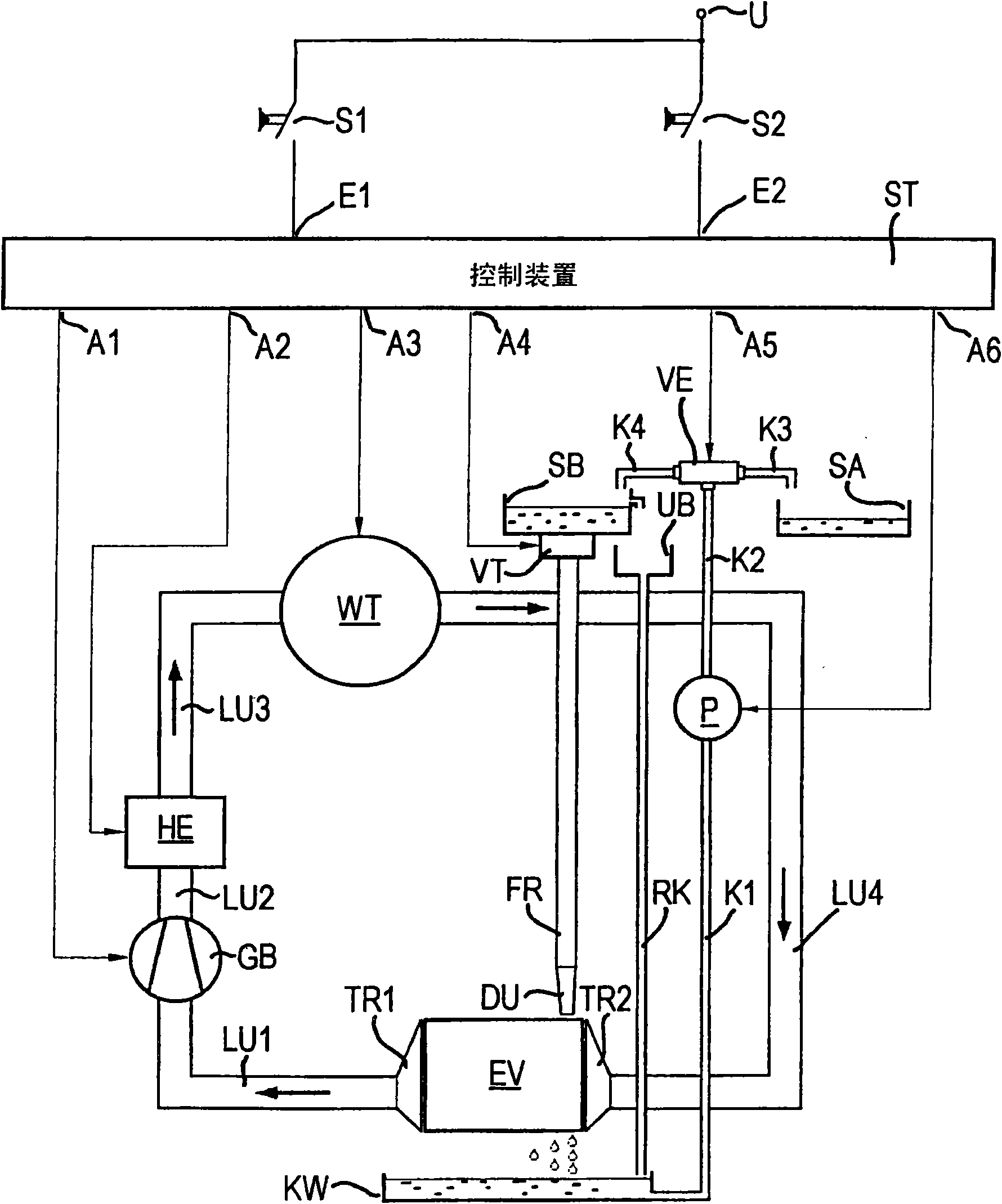

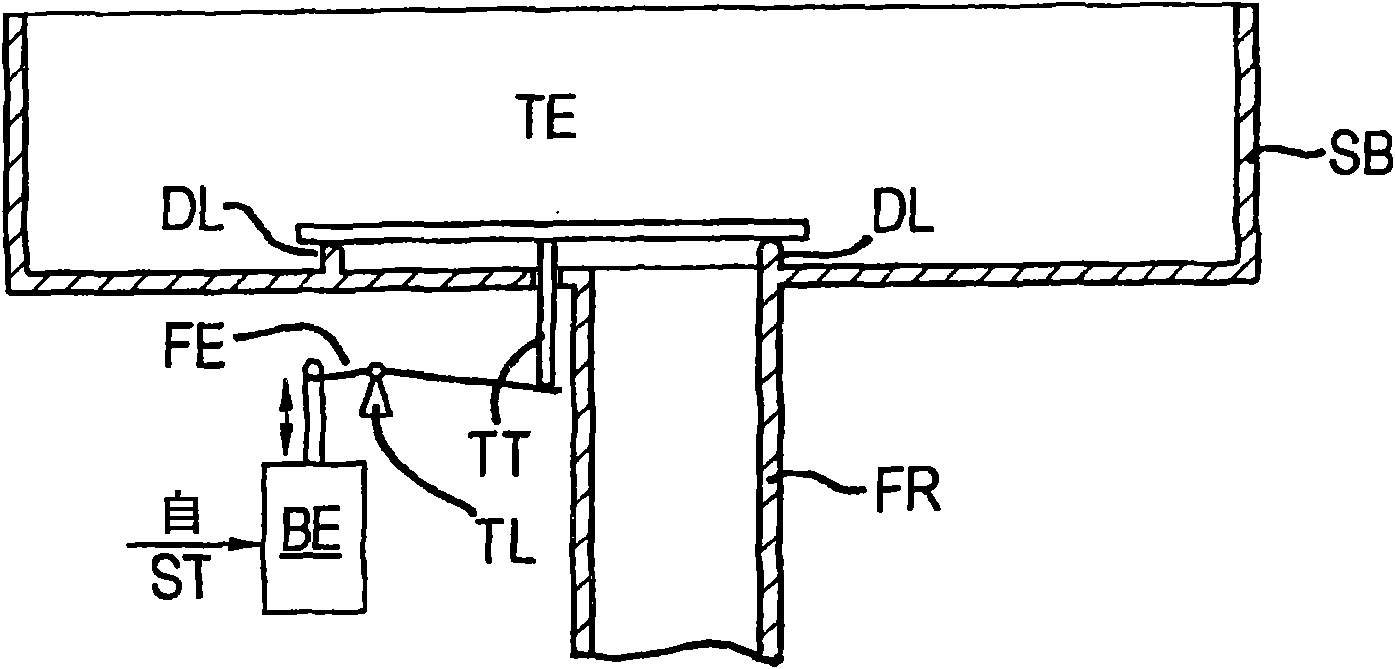

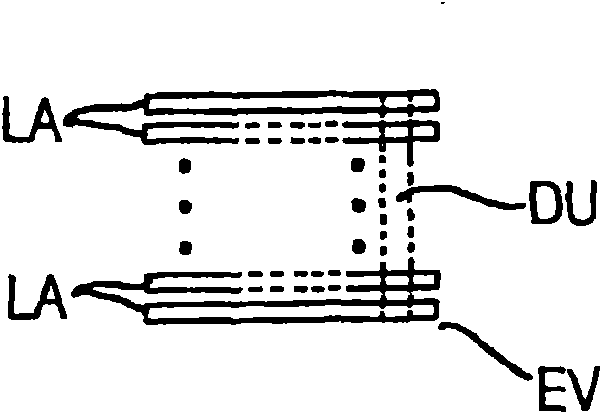

Method and device for cleaning a component, particularly of a vaporizer of a condenser device and a washer or washer/dryer comprising such a device

ActiveCN101652514AEasy to cleanThe method steps are simpleTextiles and paperHome appliance efficiency improvementThermodynamicsLaundry washing machine

In order to clean a component disposed inside a process air circuit of a washer or washer / dryer, particularly a vaporizer (EV) of a condenser device, condensation water acquired in the process air circuit from the drying of wet laundry and collected in a condensation water tank (KW) is conducted to a rinsing container (SB) provided above the condenser and dispensed to the component (EV) in question as a gush of water by the sudden opening of said rinsing container on the outlet side.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Electronic vaporiser system

An electronic cigarette vaporizer system includes a case and a vaporizer that is stored in the case; the system includes a non-contact sensor that detects release or withdrawal of the vaporizer from the case. When withdrawal of the vaporizer is detected, then the vaporizer electronic circuitry changes state, e.g. to a ready mode, or a pre-heating mode in which an inhalation detector is activated or to a heating mode, where an atomizing unit in the vaporizer is at least partly activated so that the vaporizer is fully heated when the first inhalation is taken.

Owner:AYR LTD

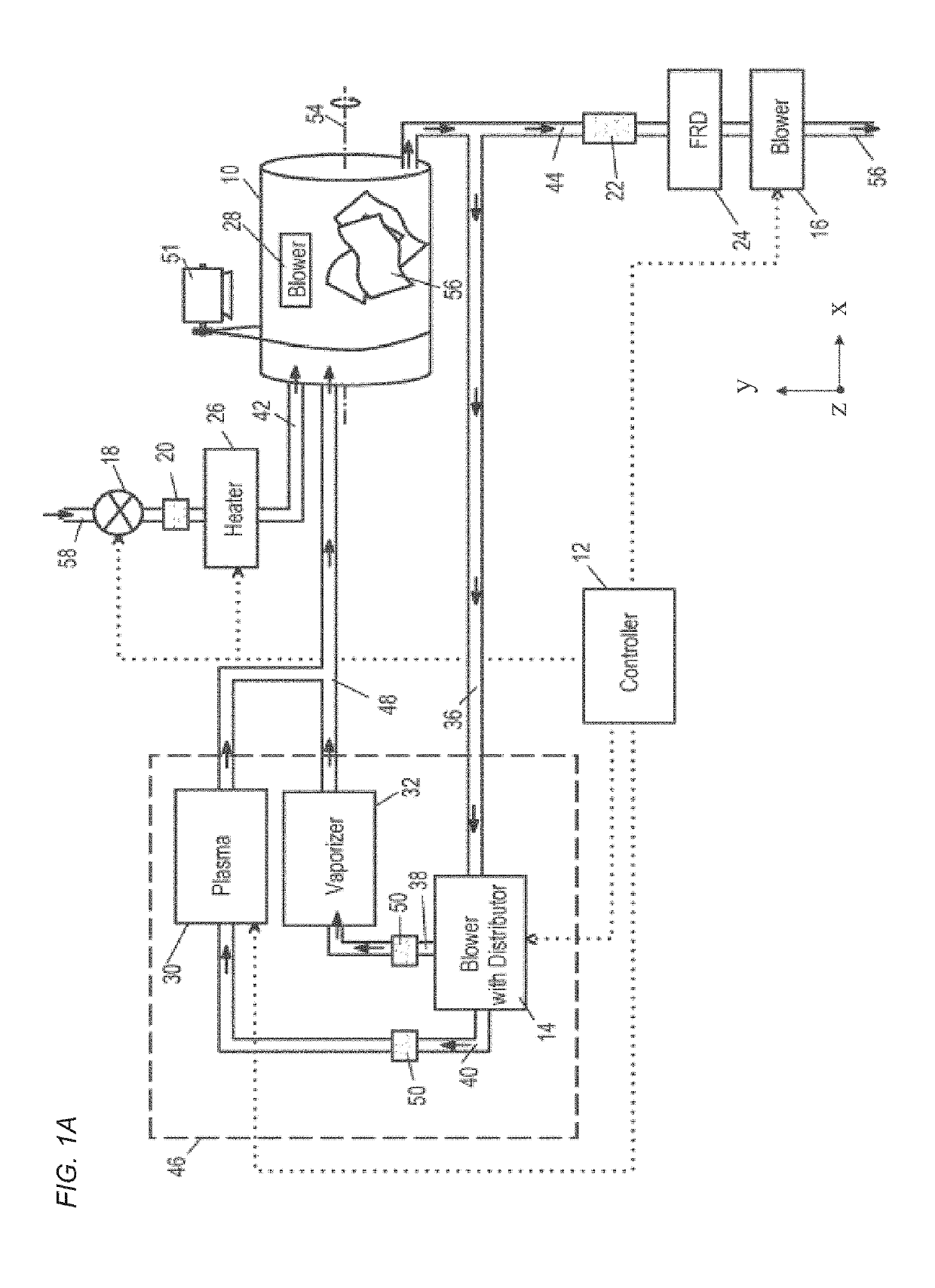

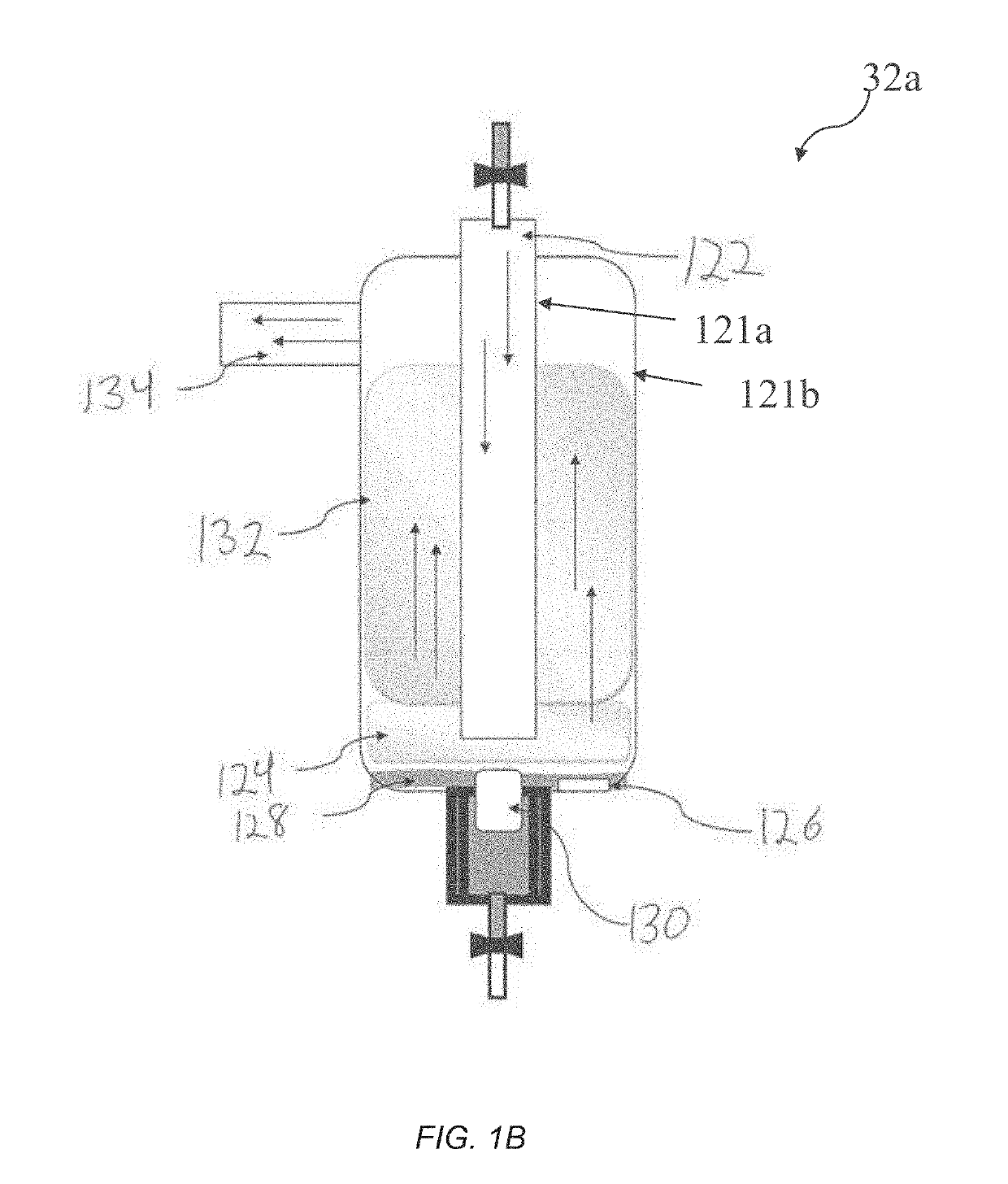

Sterilization, disinfection, sanitization, decontamination, and therapeutic devices, systems, and methods

ActiveUS20190314535A1Reducing removing build-upPromote formationAntibacterial agentsLavatory sanitoryTherapeutic DevicesNitrogen

A sterilization, disinfection, sanitization, or decontamination system having a chamber defining a region, and a generator for creating a free radical effluent with reactive oxygen, nitrogen, and other species and / or a vaporizer. A closed loop circulating system without a free-radical destroyer is provided for supplying the mixture of free radicals from the generator mixed with the hydrogen peroxide solution in the form of the effluent to the chamber. The system is used in sterilizing, disinfecting, sanitizing, or decontaminating items in the chamber or room and, with a wound chamber, in treating wounds on a body. The wound chamber may be designed to maintain separation from wounds being treated. Various embodiments can control moisture to reduce or avoid unwanted condensation. Some embodiments can be incorporated into an appliance having a closed space, such as a washing machine. Some embodiments may include a residual coating device that deposits a bactericidal coating on sterilized items.

Owner:STERIFRE MEDICAL INC

Waste heat recovery system

InactiveUS6742337B1Efficient systemPrevent heat lossGas turbine plantsSteam engine plantsWorking fluidDiluent

A waste heat recovery system comprising ducting to which hot gas is communicated, means to supply lower temperature diluent gas to the ducting, to mix with the hot gas, and produce a reduced temperature mixed gas stream, a vaporizer in communication with the ducting, to receive the stream and to transfer heat from the stream to a working fluid in the vaporizer to vaporize said fluid, and a blower operating to displace the stream through the vaporizer.

Owner:ENERGENT CORP

Vaporizer devices with blow discrimination

PendingUS20190104767A1Absorbs excessive heatDissipates excessive heatCigar manufactureFluid pressure measurement by electric/magnetic elementsEngineeringVaporization

Methods and apparatuses for discriminating between user blowing and drawing (sucking) in an electronic vaporization device. Described herein are electronic aerosol devices and methods of controlling or operating them which can accurately differentiate between blowing and drawing (sucking) through the mouthpiece and adjust the control of the vaporizer accordingly.

Owner:JUUL LABS INC

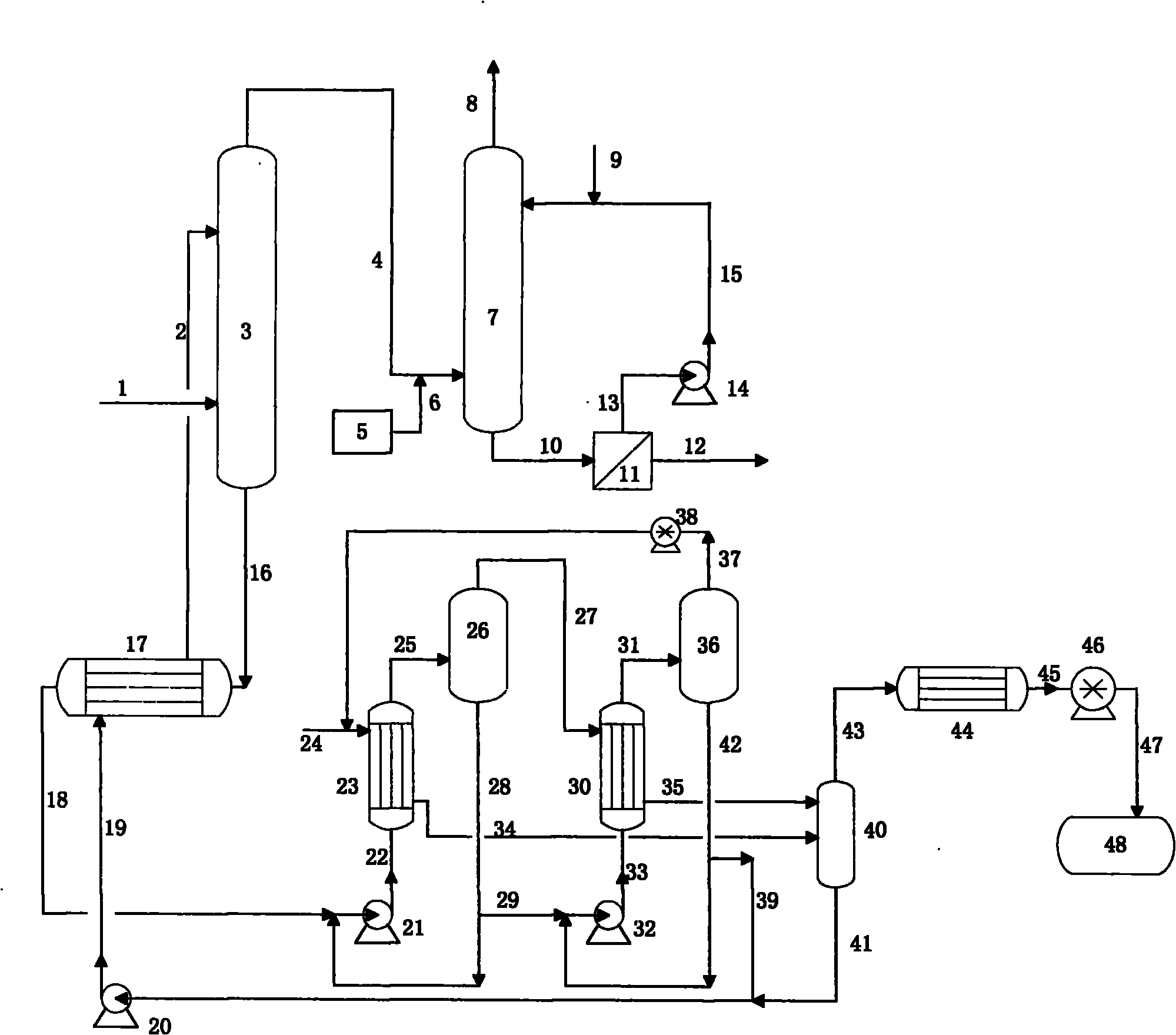

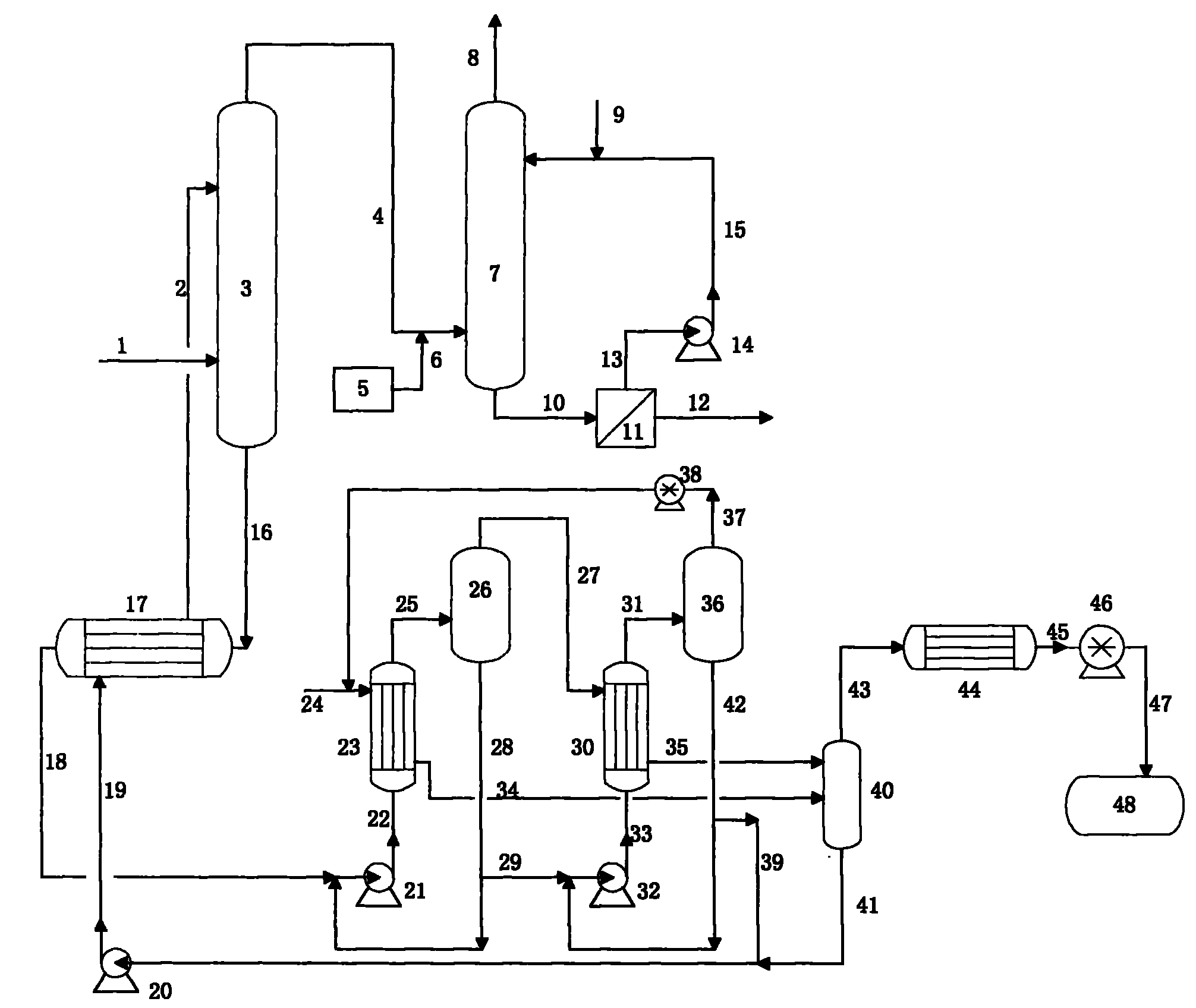

Integrated process of furfural production as well as wastewater, waste slag and waste gas treatment

InactiveCN101481189ACurb emissionsPollution suppressionOrganic chemistryEnergy inputWater vaporDistillation

The invention belongs to the technical field of the chemical production, and relates to a technology for optimizing energy saving and integrating treatment of waste water, waste slag and waste gas in a furfural production process, which is suitable for the energy saving and the three-waste treatment and reformation of furfural production enterprises. The technology is characterized in that limestone and dolomite are used for neutralizing furfural waste water to convert acetic acid into calcium magnesium acetate, and then the water exchanges heat with high-temperature aldehyde gas generated by a hydrolysis kettle to enter an evaporator; high-temperature vapor generated by the vaporization of the waste water enters the hydrolysis kettle to be used as a reaction medium, the residual concentrated liquid is decolorized for extracting calcium magnesium acetate salt, and the residual liquid is used for smoke desulfurization and denitration. After the low-pressure automatic heating and vaporization of high-temperature aldehyde slag for furfural recovery, the high-temperature aldehyde slag is dried at a low temperature to reduce the water content of the aldehyde slag to be lower than 20 percent. The invention has the advantages that the utilization rates of materials and energy are greatly increased, the zero discharge of three wastes is realized without additional energy consumption, and the calcium magnesium acetate salt of high value is also prepared. After the automatic heating distillation and low-temperature drying of the aldehyde slag, the aldehyde slag is used for active carbon and is effectively and cleanly burnt.

Owner:DALIAN UNIV OF TECH

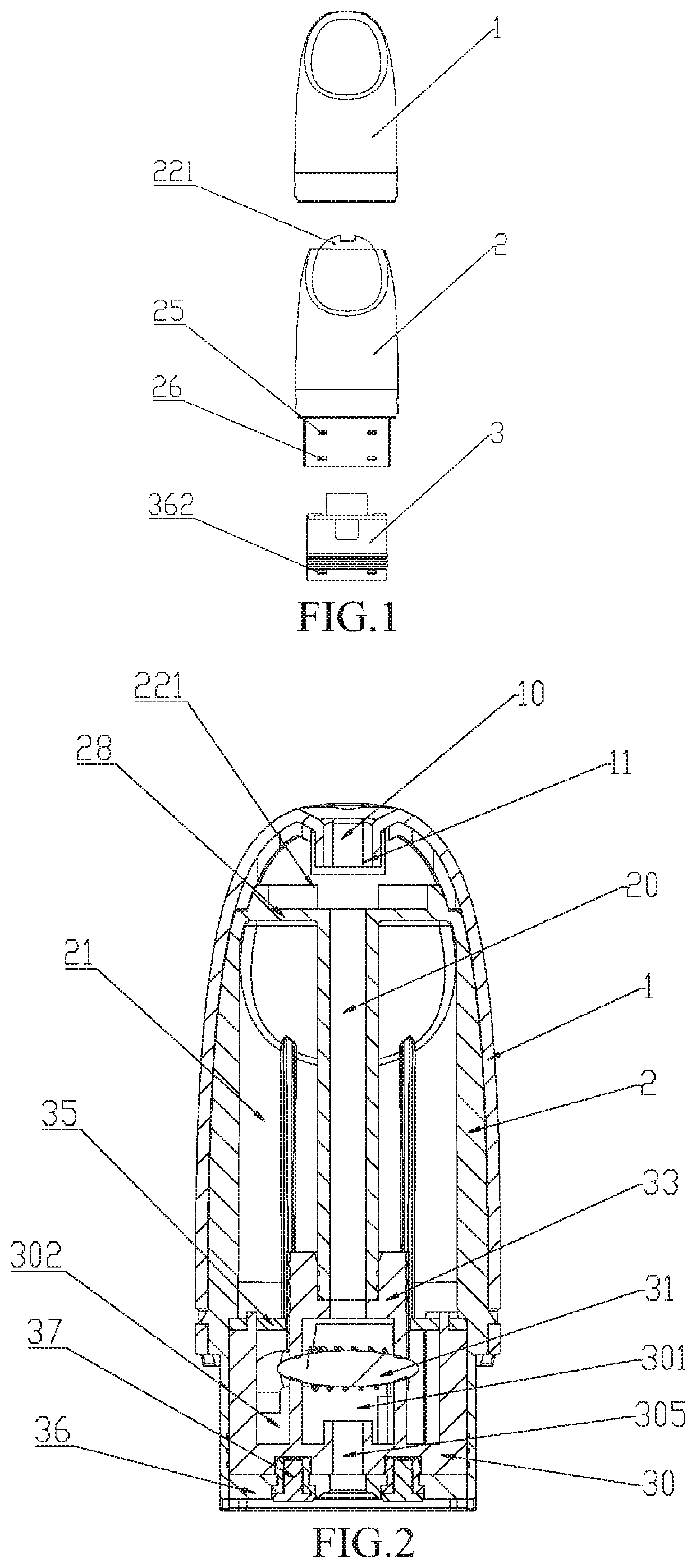

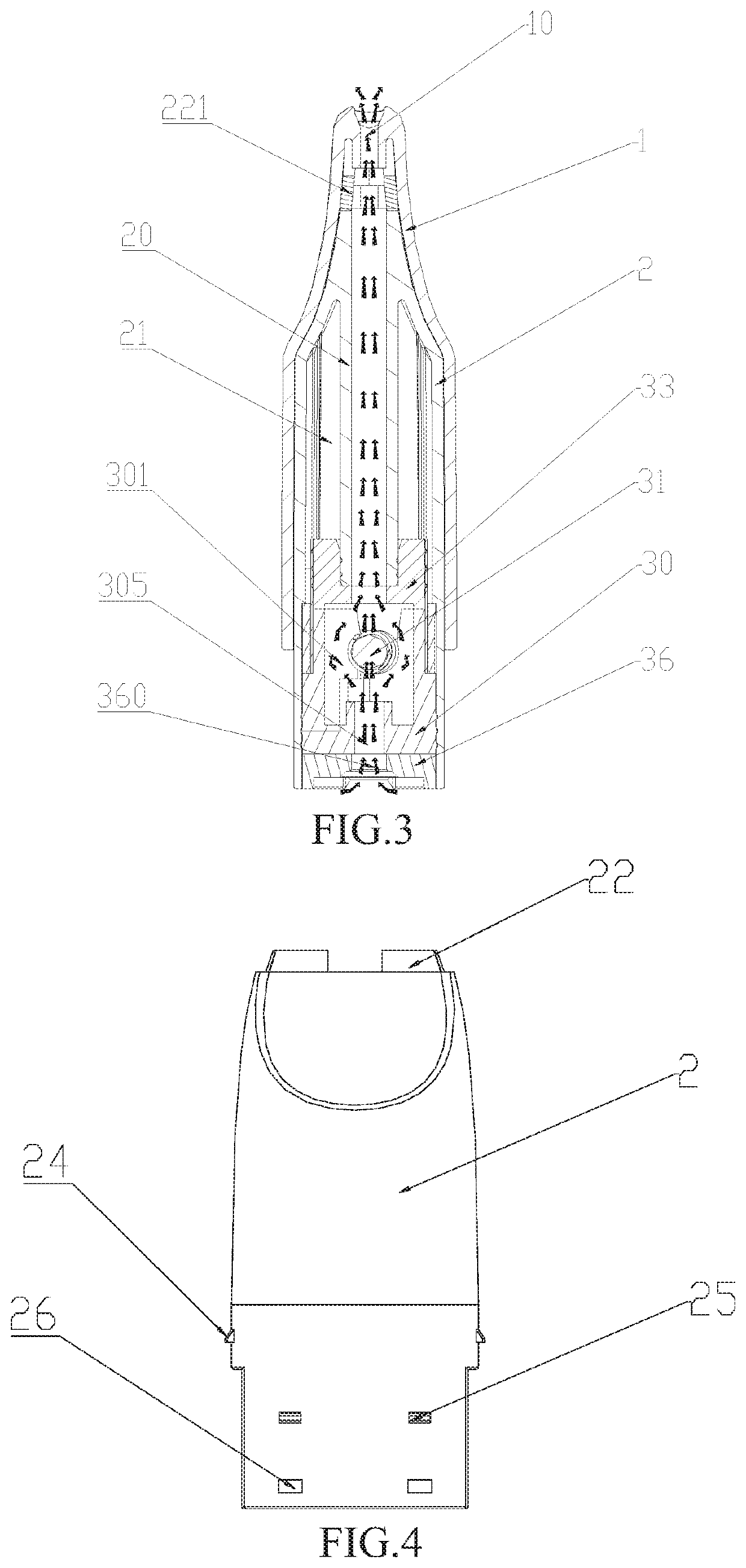

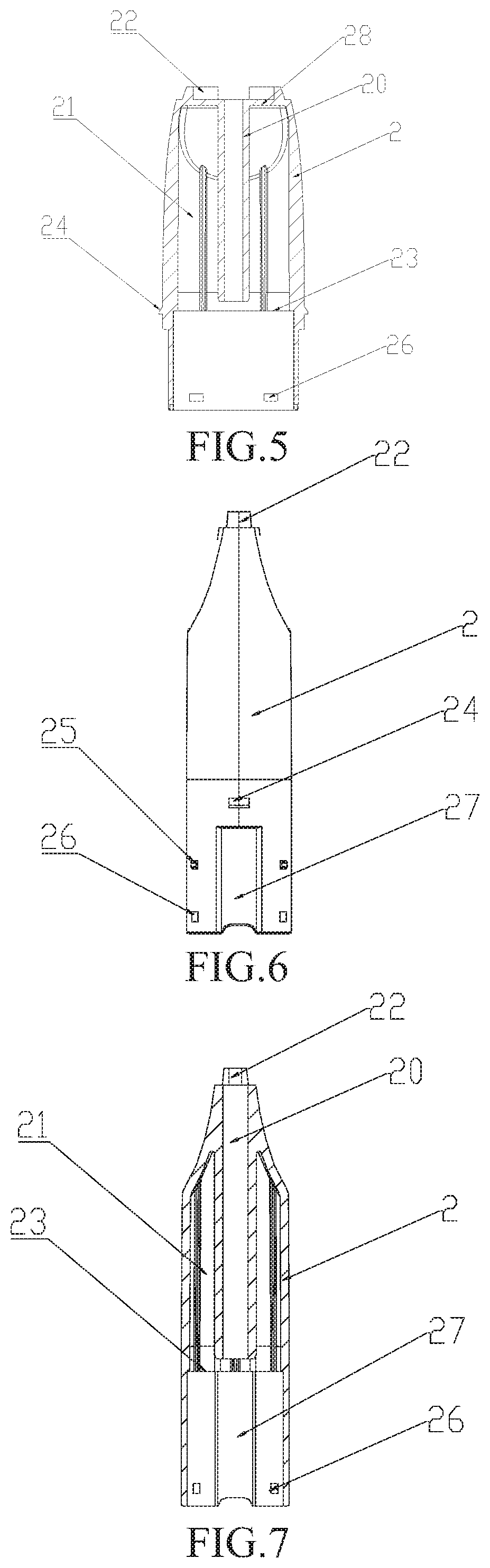

Electronic cigarette vaporizer with liquid storage transition chamber

ActiveUS11051550B2Great tastePrevent liquid leakageTobacco pipesTobacco devicesEngineeringElectronic cigarette

An electronic cigarette vaporizer with a liquid storage transition chamber comprises a liquid reservoir comprising an upper wall at its top end and a vapor outlet tube extends downwards from the center of the upper wall, and a vaporizing device comprising a vaporizing base sleeved in the lower part of the liquid reservoir, and a liquid storage chamber is defined above the vaporizing device between the liquid reservoir and the vapor outlet tube; and inner and outer chambers sealed from each other are formed inside the vaporizing base, the inner chamber mounted with a vaporizing unit serves as a vaporizing chamber, and the outer chamber filled with liquid storage medium serves as a liquid storage transition chamber, wherein the vaporizing chamber communicates with the vapor outlet tube, and the liquid storage transition chamber communicates with the liquid storage chamber so as to supply liquid for the vaporizing unit.

Owner:LIN GUANGRONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com