Patents

Literature

973 results about "Liquid hydrogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

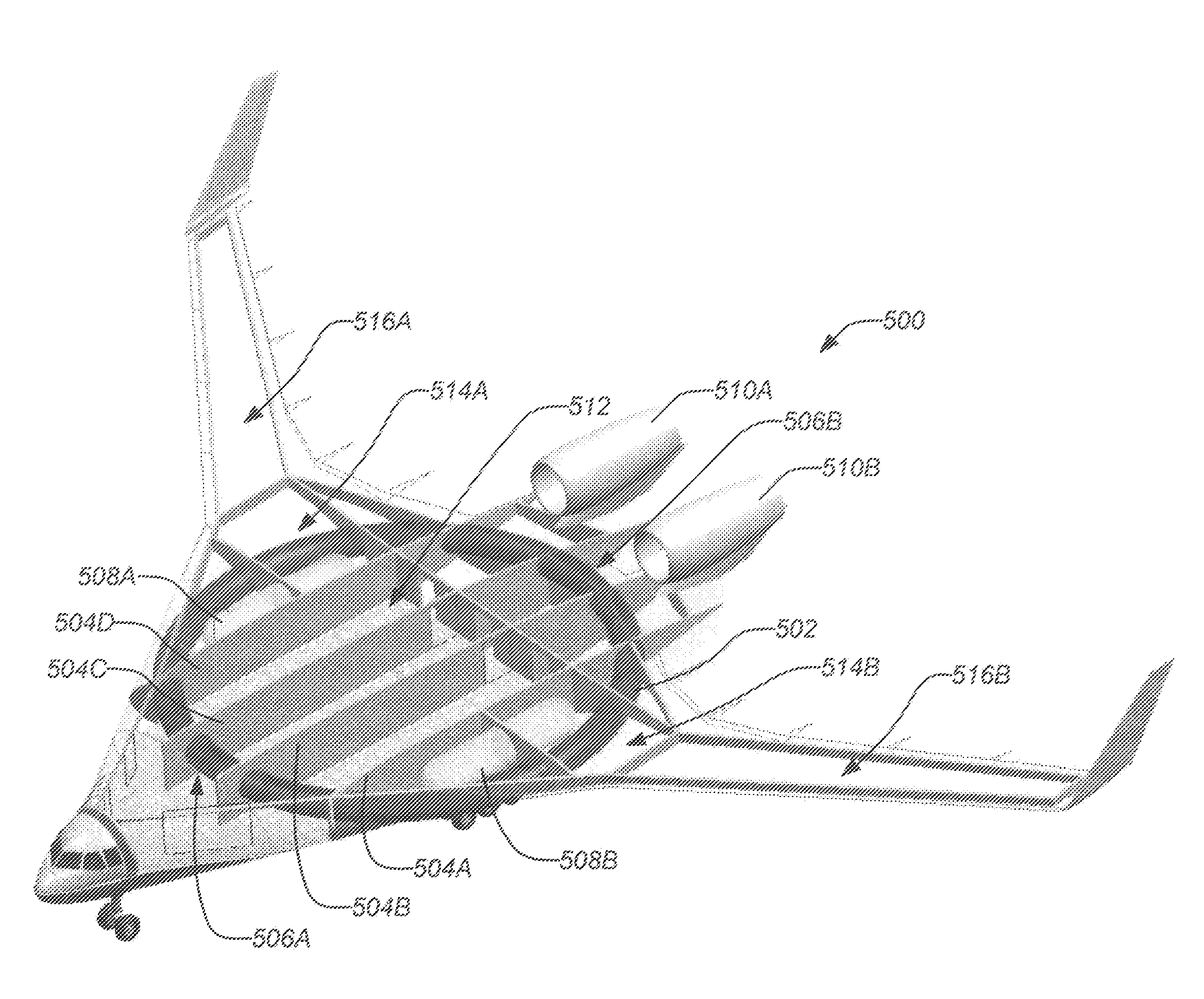

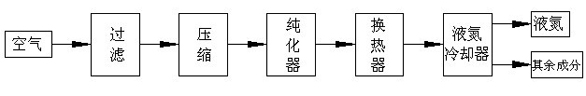

Liquid hydrogen (LH2 or LH₂) is the liquid state of the element hydrogen. Hydrogen is found naturally in the molecular H₂ form. To exist as a liquid, H₂ must be cooled below its critical point of 33 K. However, for it to be in a fully liquid state without boiling at atmospheric pressure, H₂ needs to be cooled to 20.28 K (−423.17 °F; −252.87 °C). One common method of obtaining liquid hydrogen involves a compressor resembling a jet engine in both appearance and principle. Liquid hydrogen is typically used as a concentrated form of hydrogen storage. As for any gas, storing it as liquid takes less space than storing it as a gas at normal temperature and pressure. However, the liquid density is very low compared to other common fuels. Once liquefied, it can be maintained as a liquid in pressurized and thermally insulated containers.

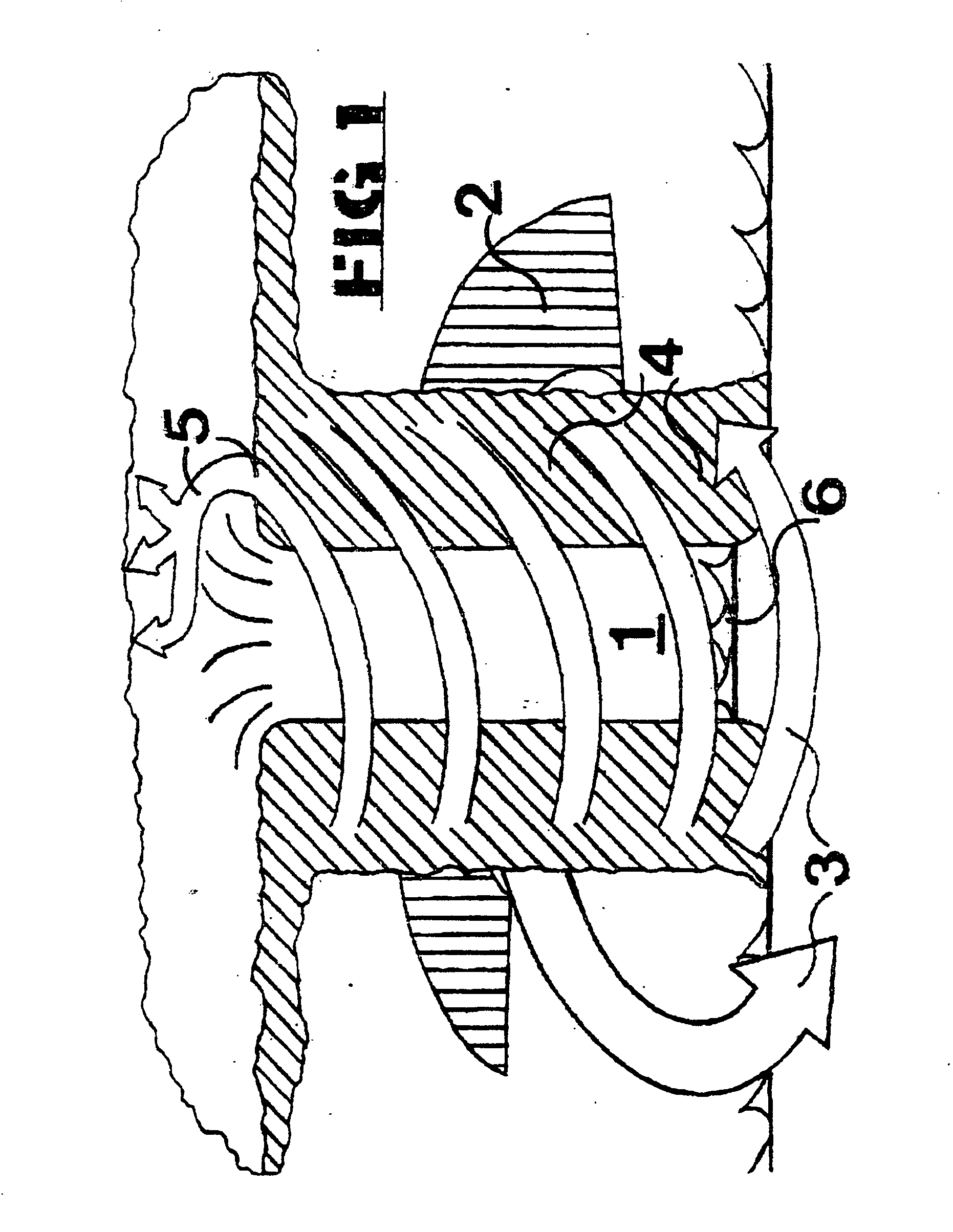

Dynamic heat sink engine

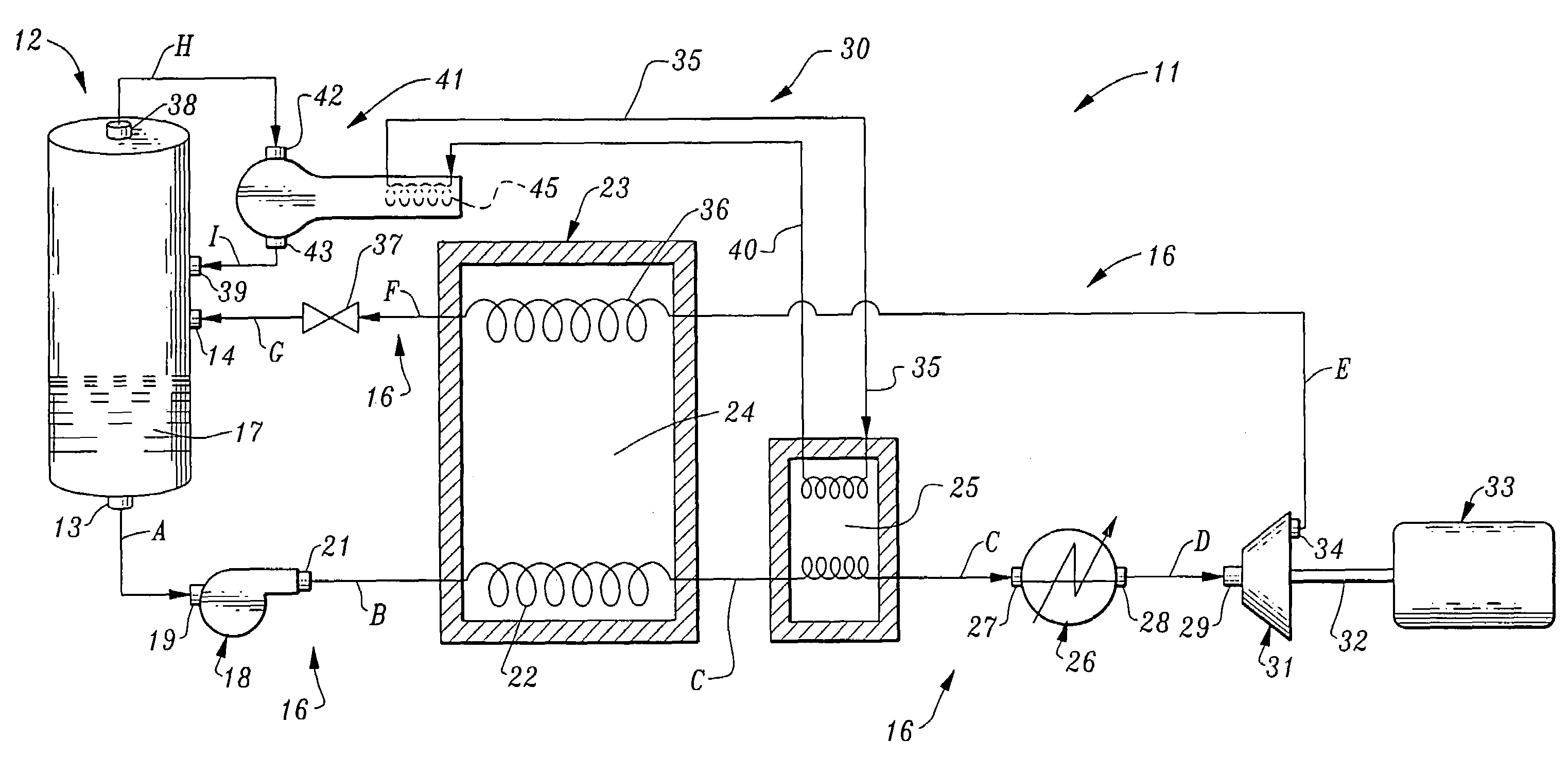

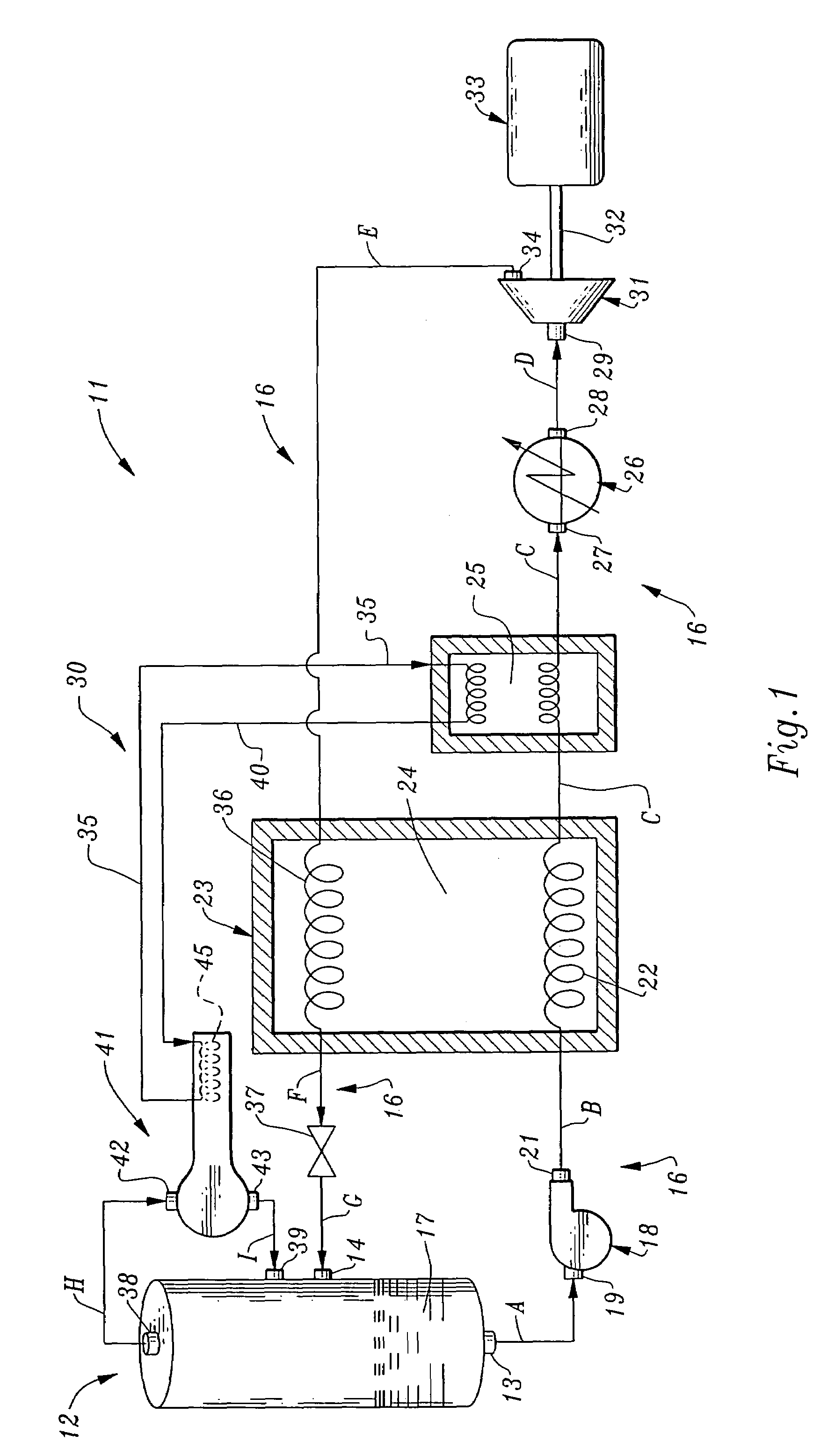

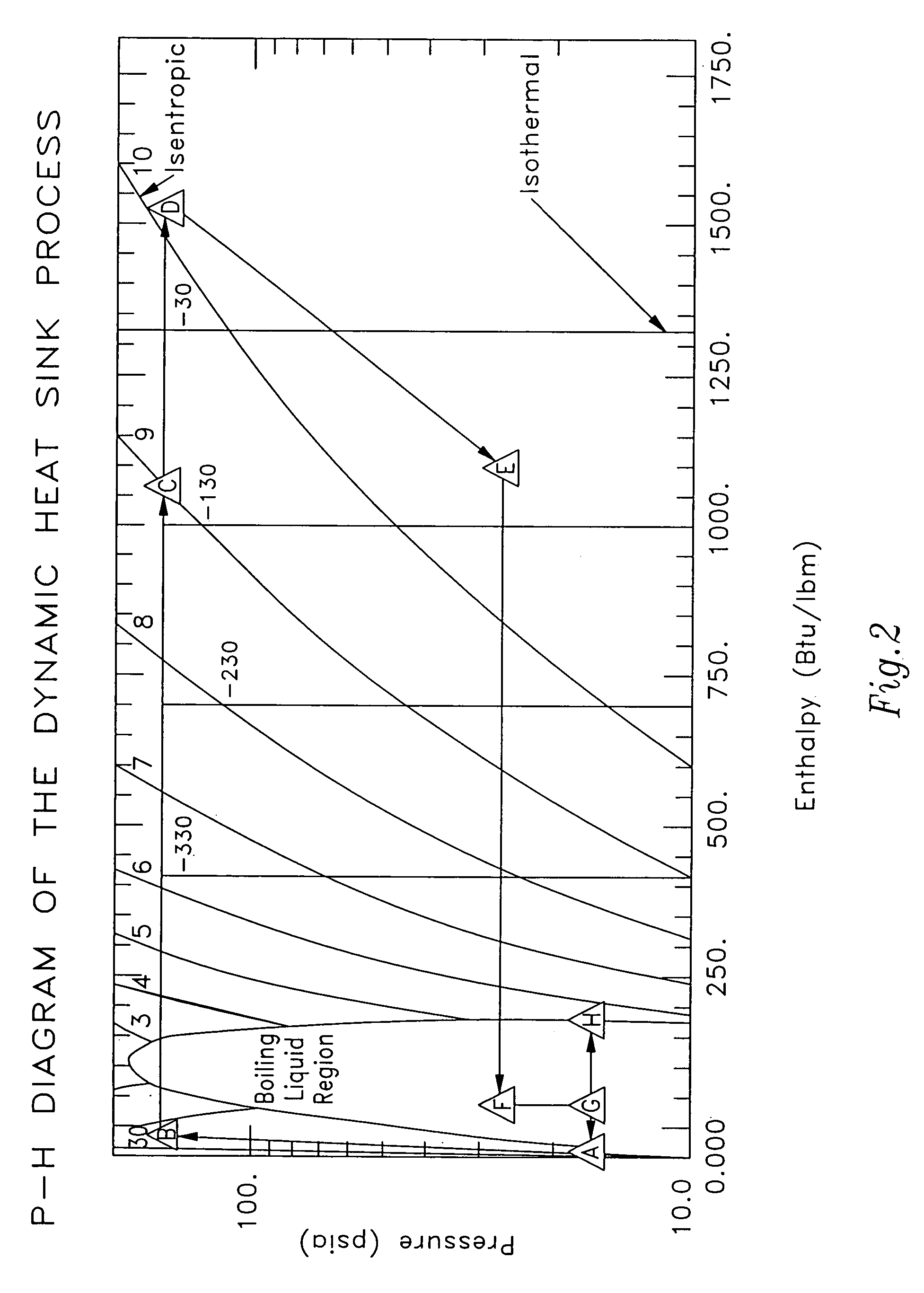

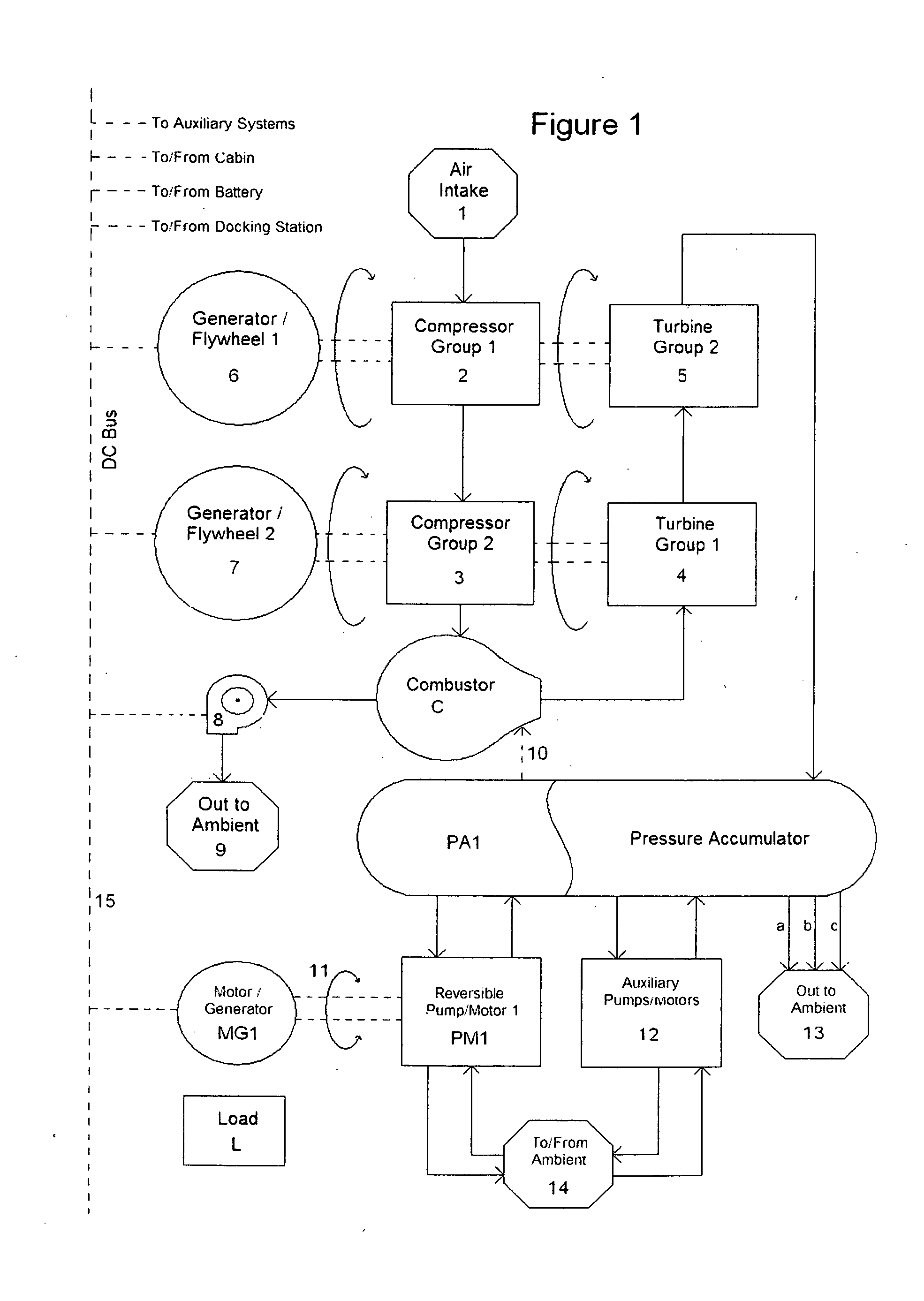

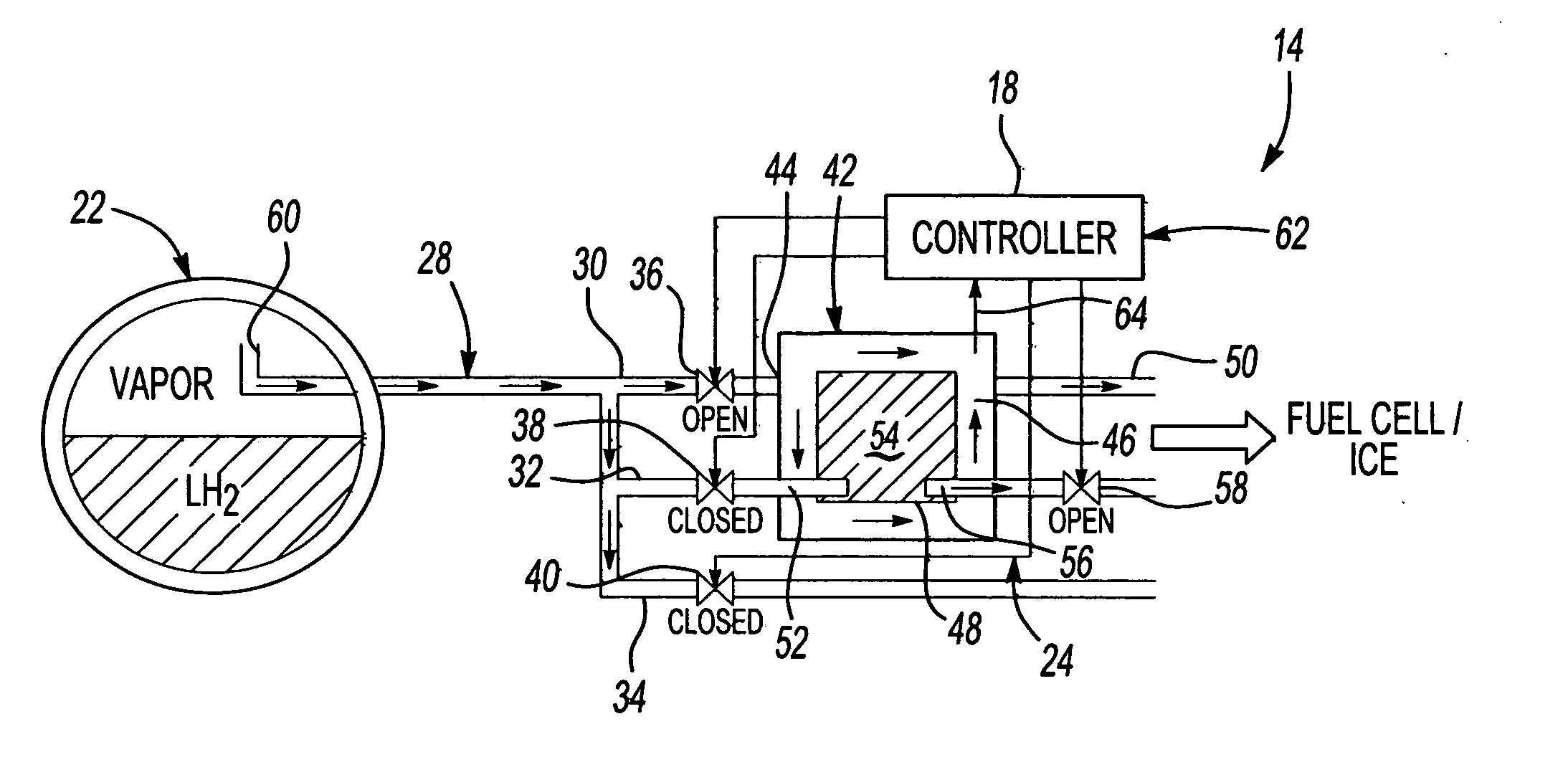

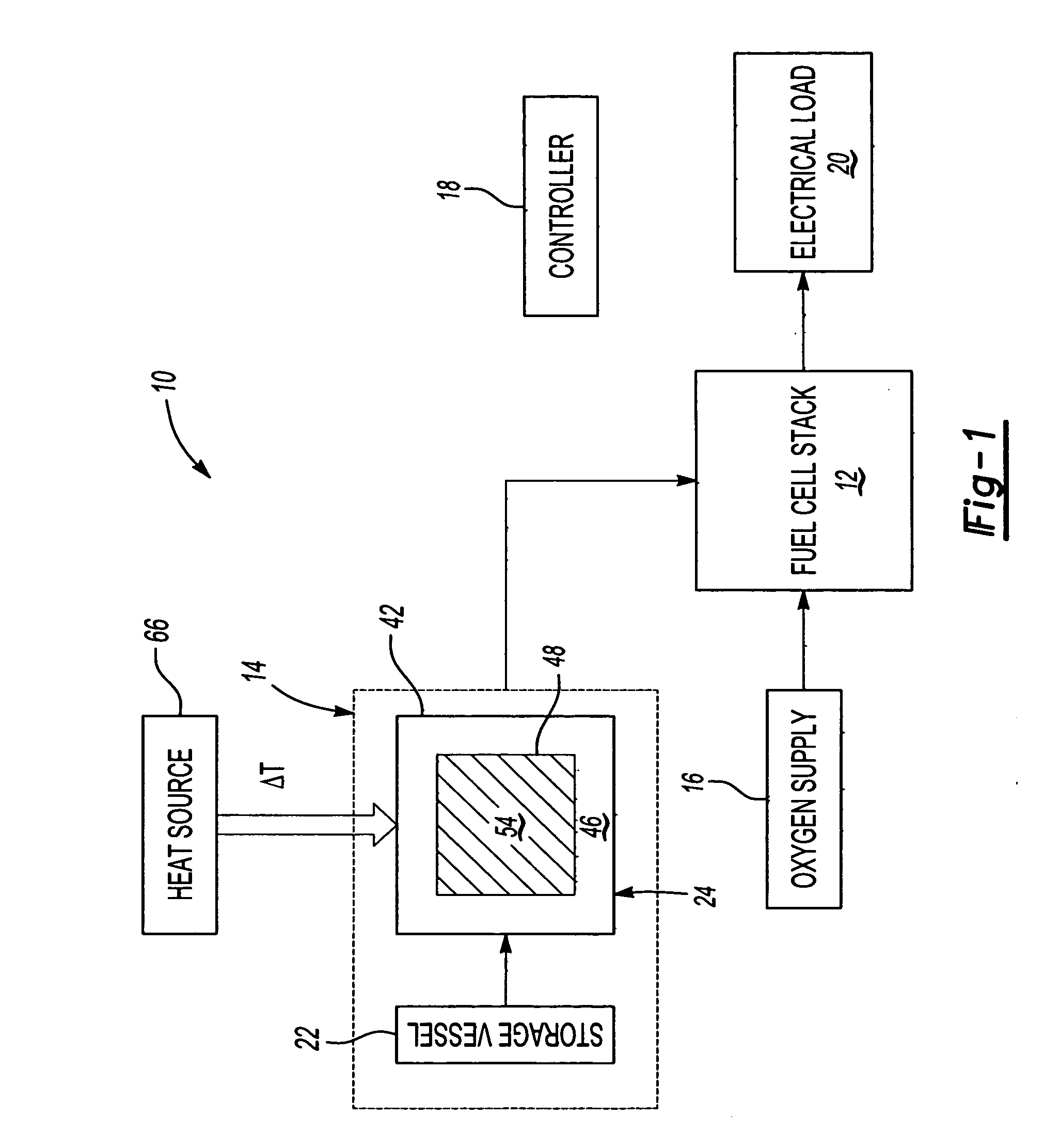

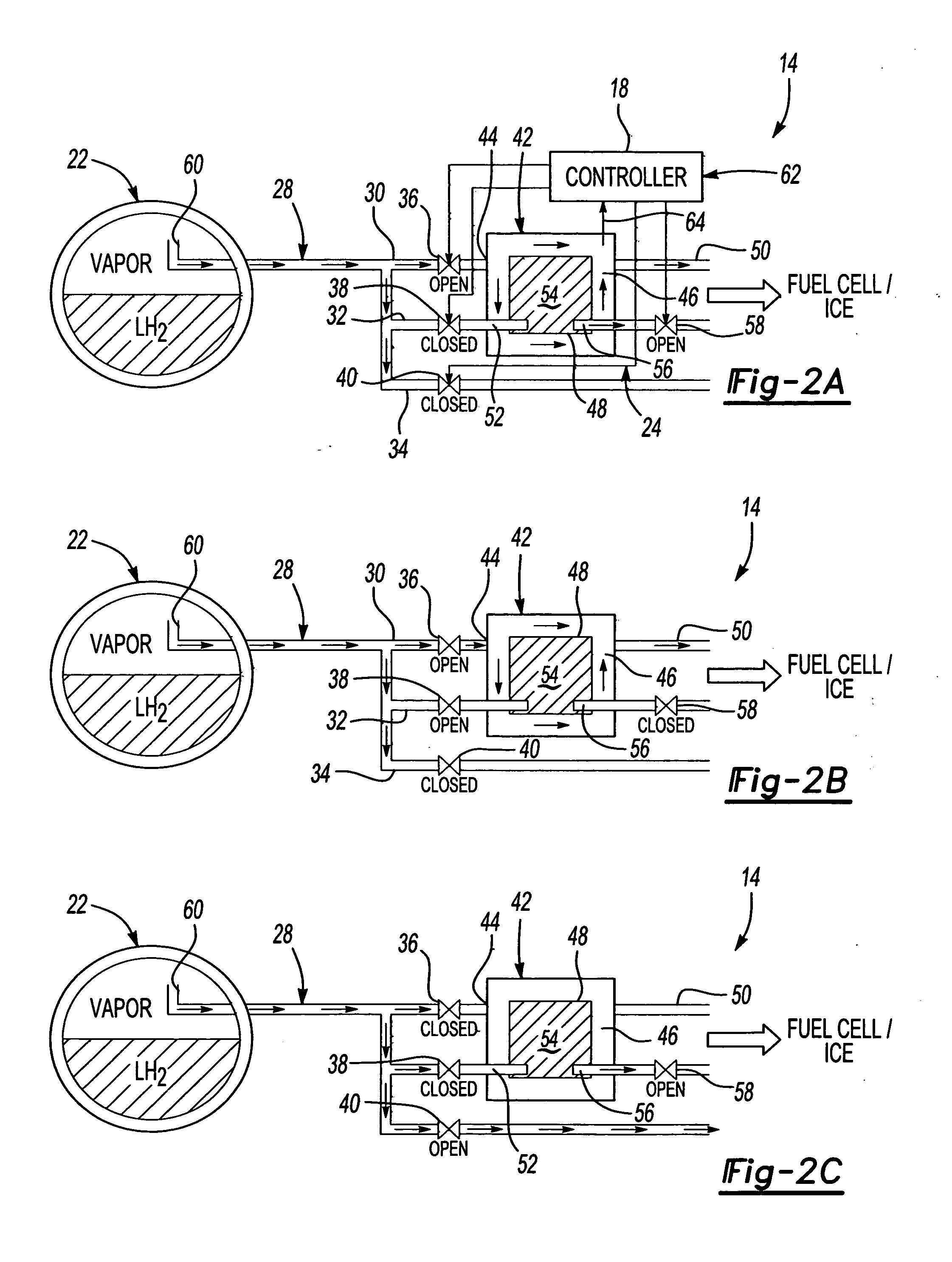

InactiveUS7047744B1Decrease in overall heat dutyImprove the coefficient of performanceFrom solar energySteam accumulatorsLiquid lineWorking fluid

A dynamic heat sink engine including a storage vessel having a working fluid outlet and a working fluid inlet. The lower portion of the storage vessel contains a cryogenic working fluid, such as liquid hydrogen, at a temperature at near its boiling point. The engine further includes a working fluid circuit extending between the working fluid outlet and the working fluid inlet of the storage vessel. The working fluid circuit includes the serial connection of the following components from the working fluid outlet to the working fluid inlet: a fluid pump; a vaporizer having a liquid line passing therethrough; a heater; an expansion engine having a rotary output shaft; an electrical generator connected to the rotary output shaft of the expansion engine; a vapor line passing through the vaporizer, the vaporizer including a heat exchanger providing thermal communication between the liquid line and the vapor line.

Owner:ROBERTSON STUART J +1

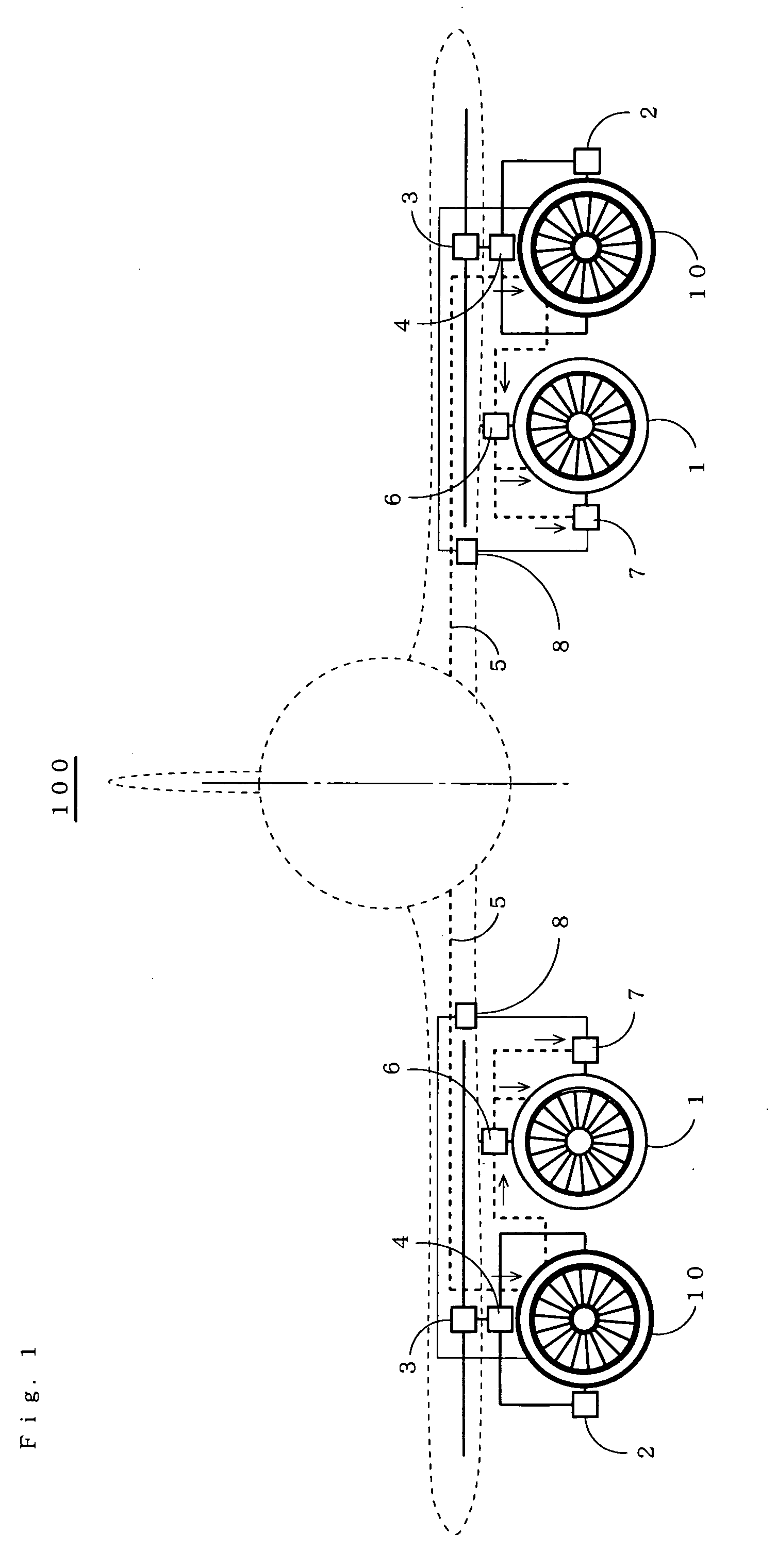

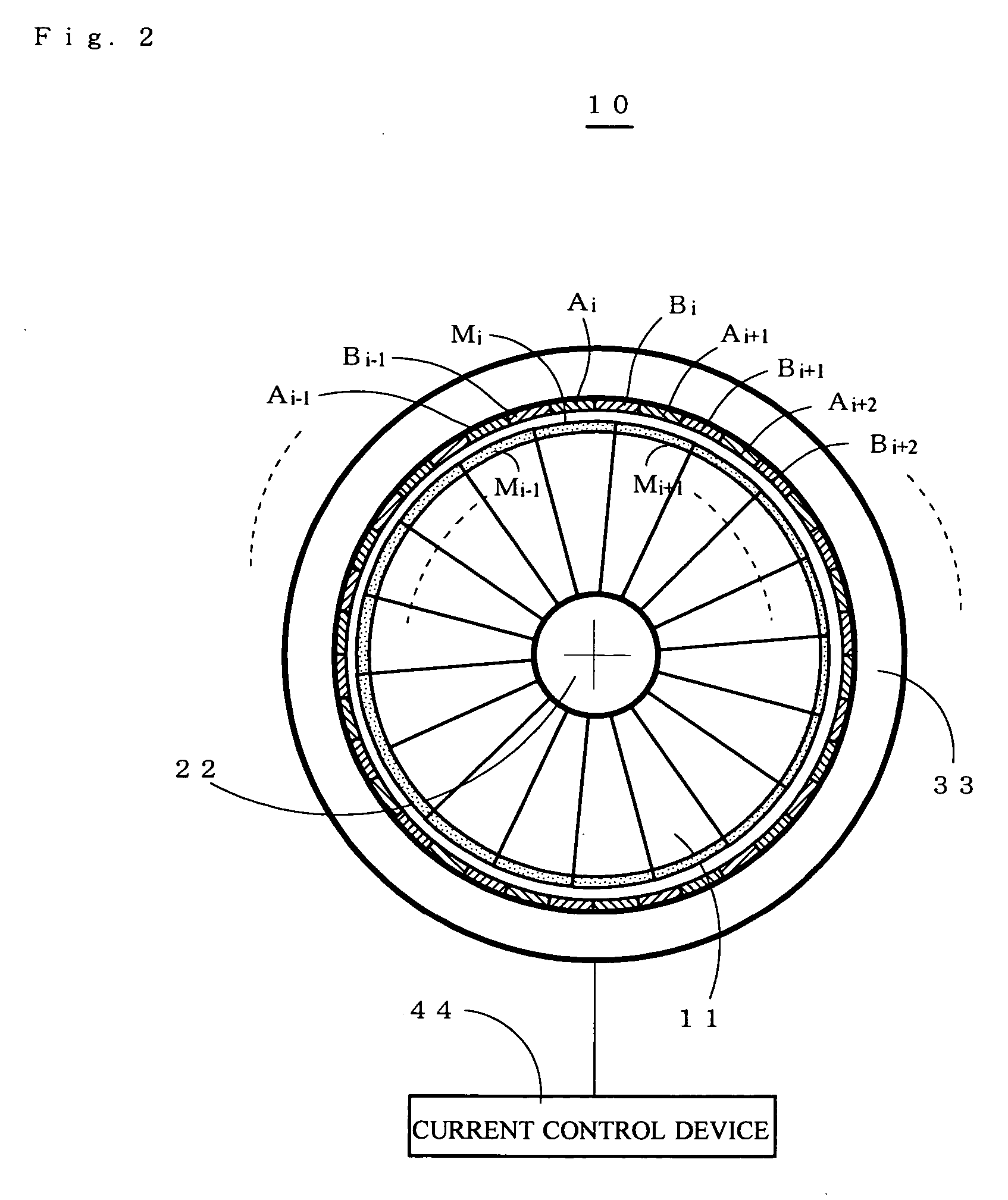

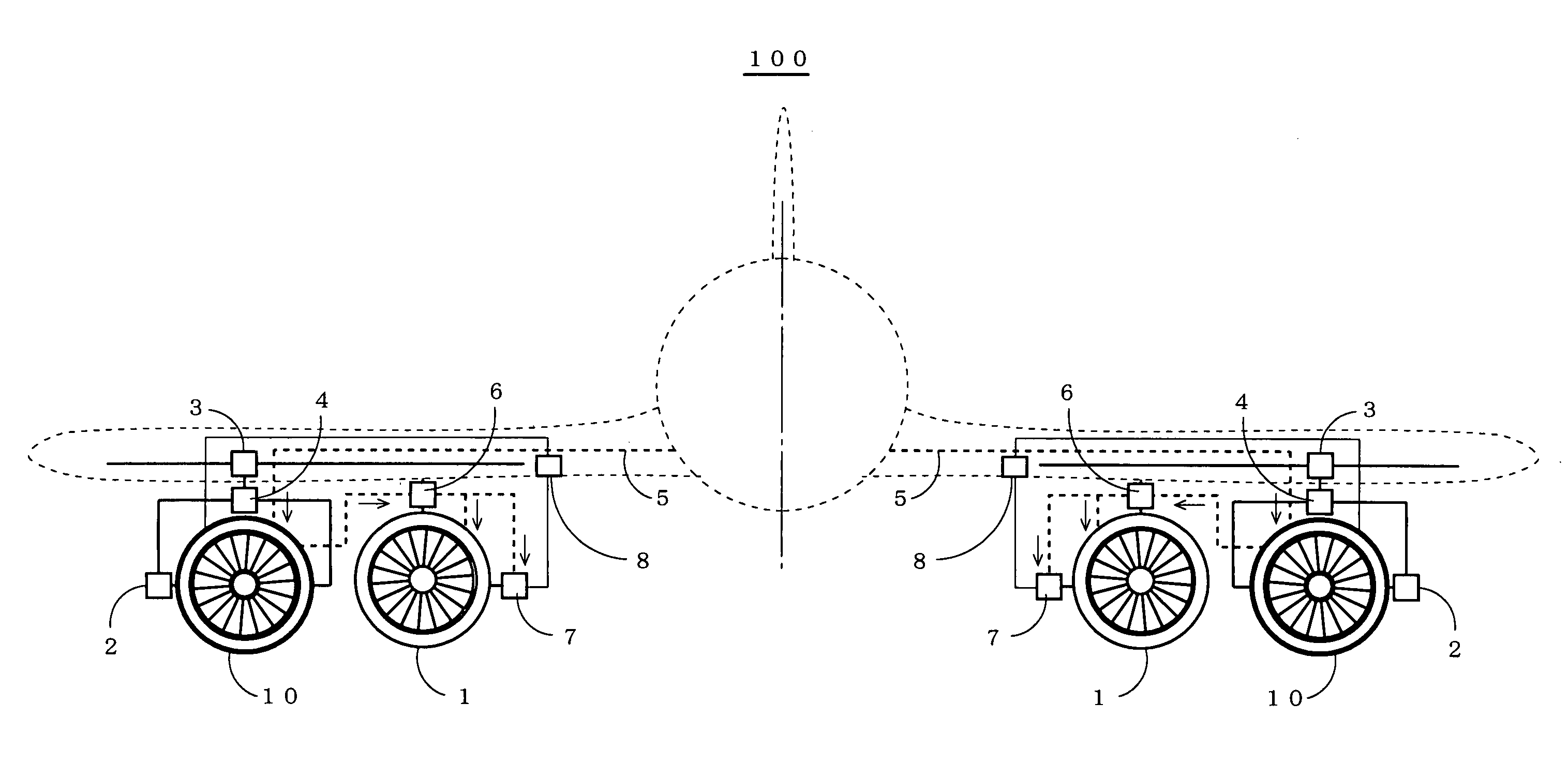

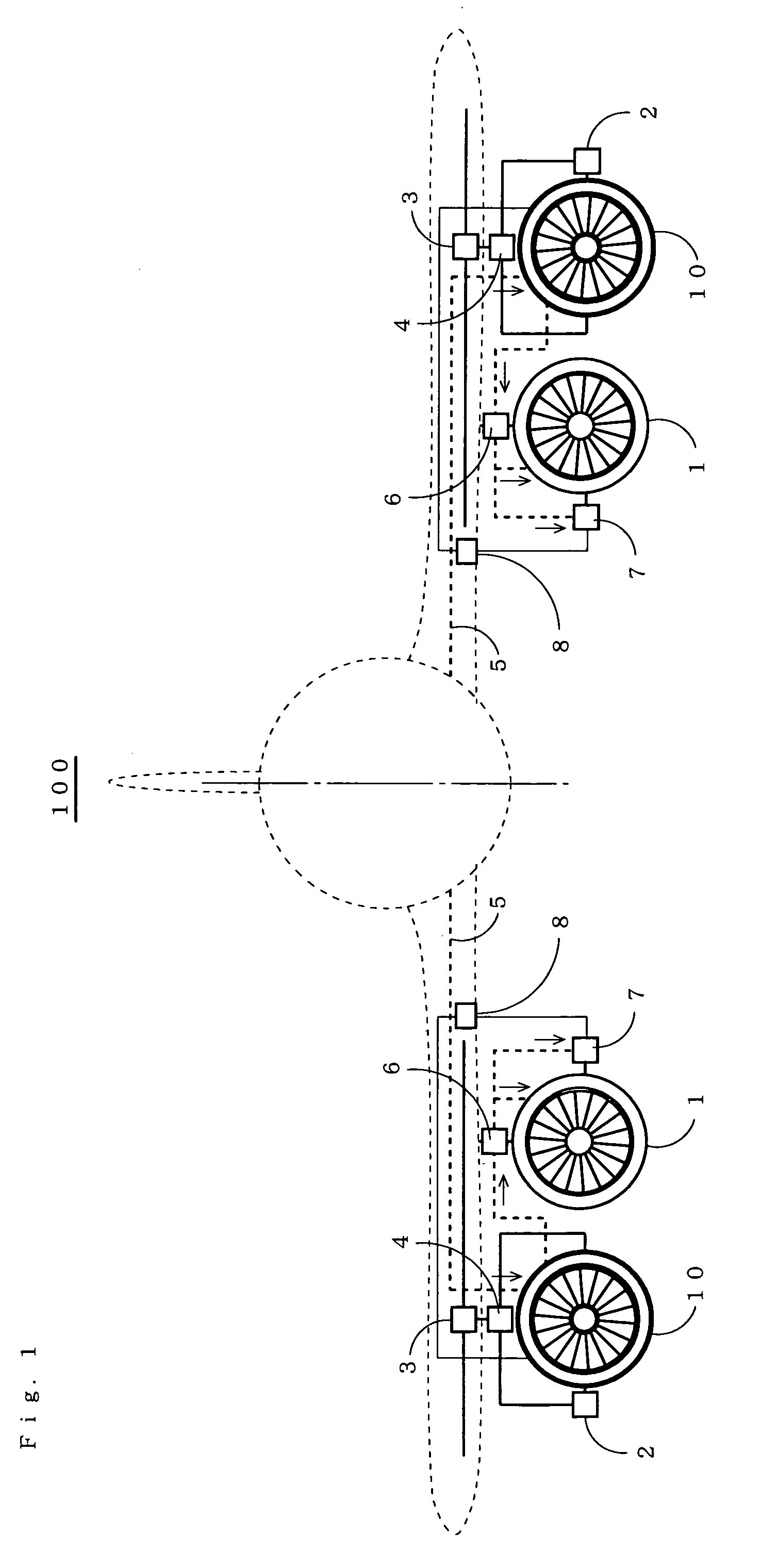

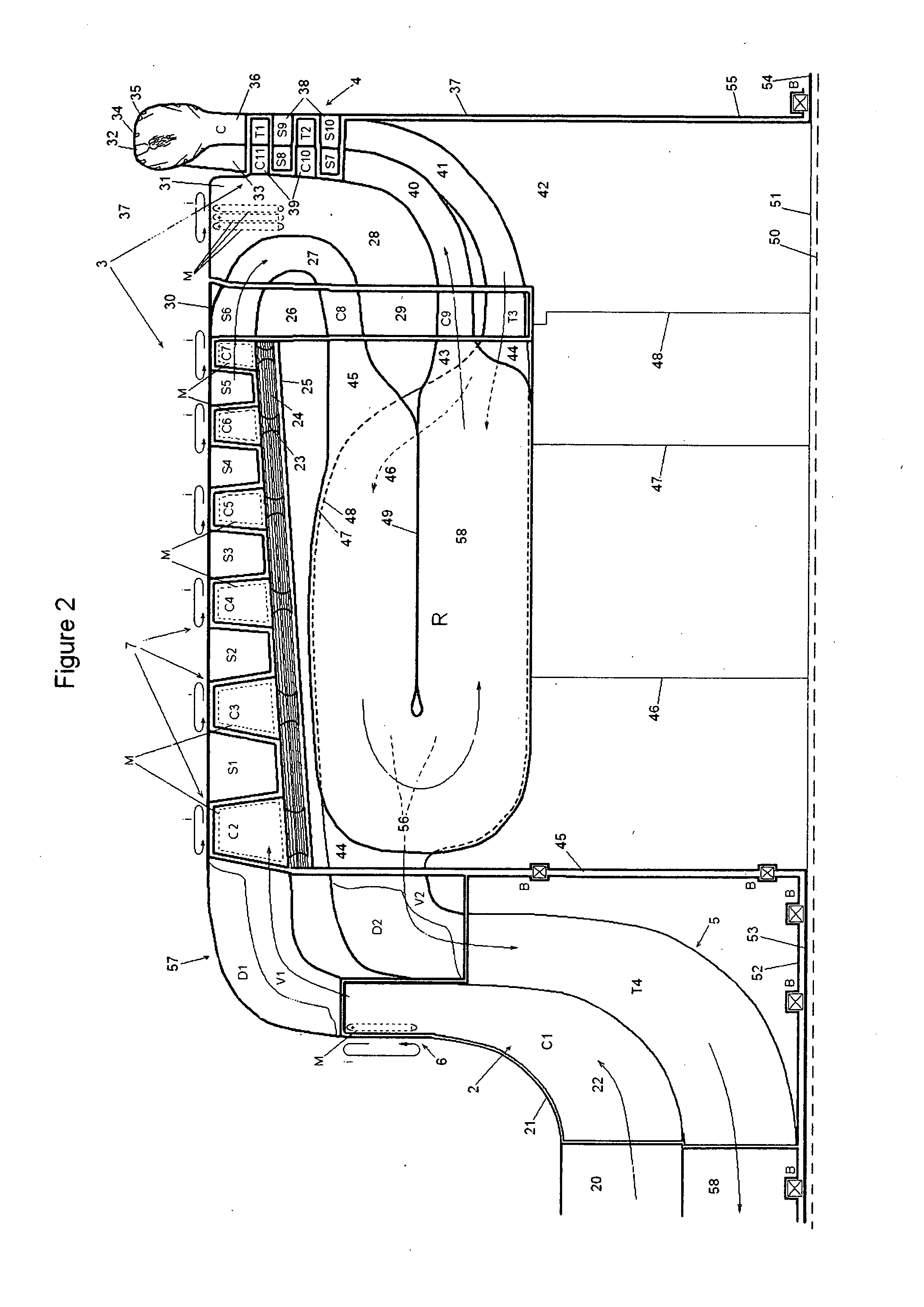

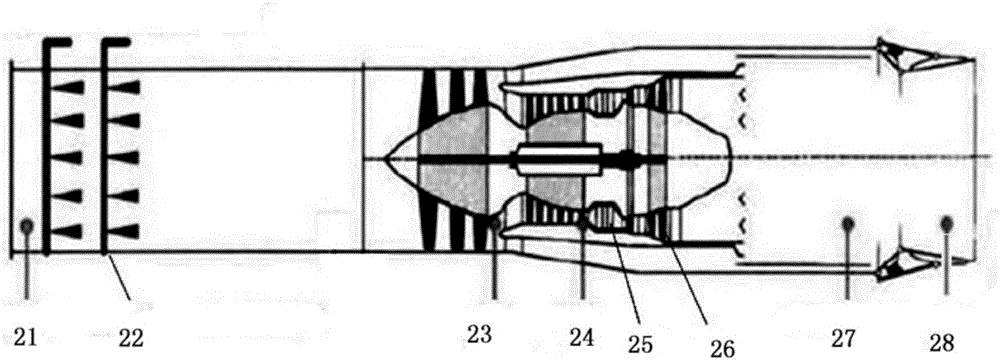

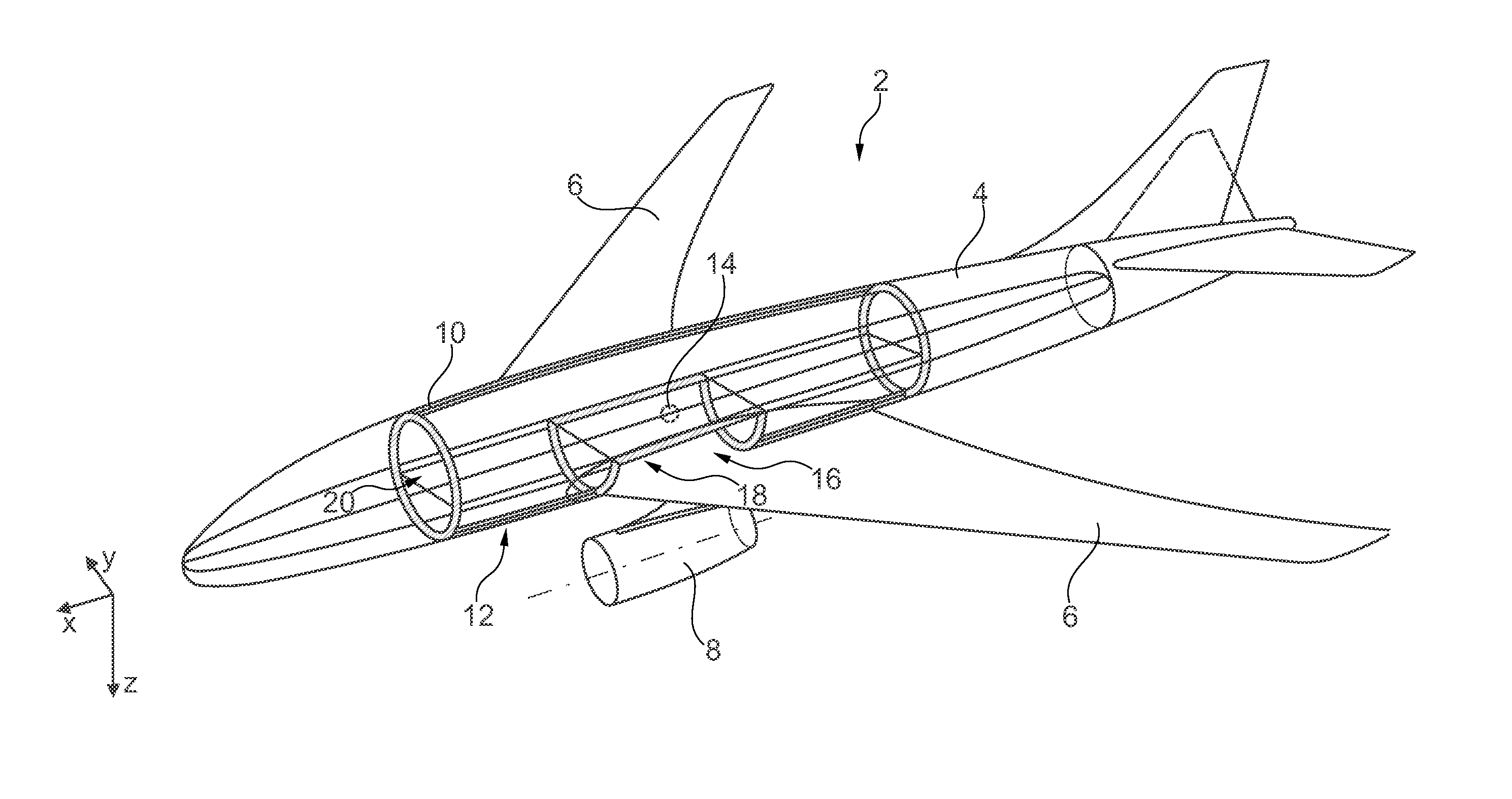

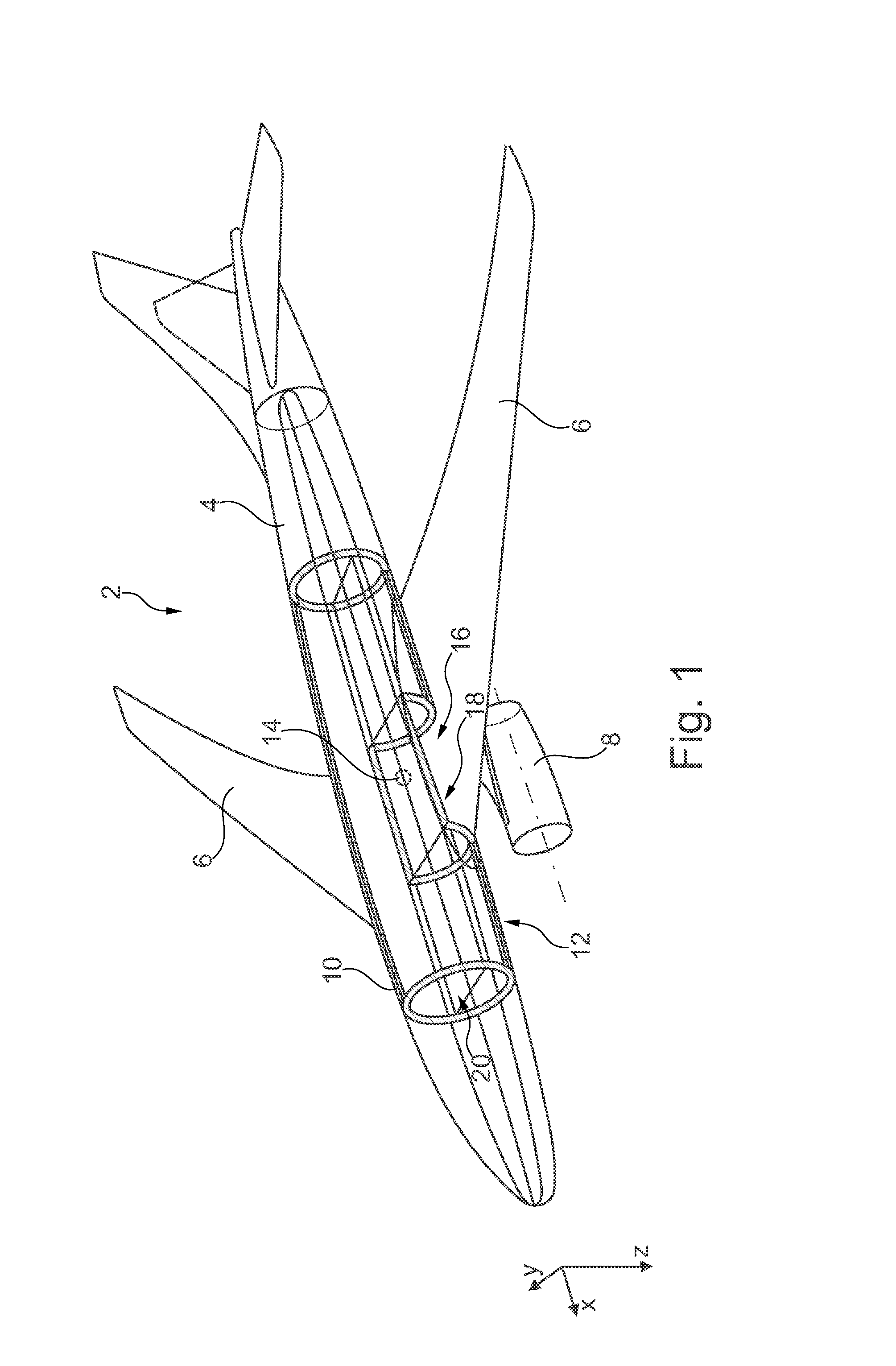

Aircraft propulsion system

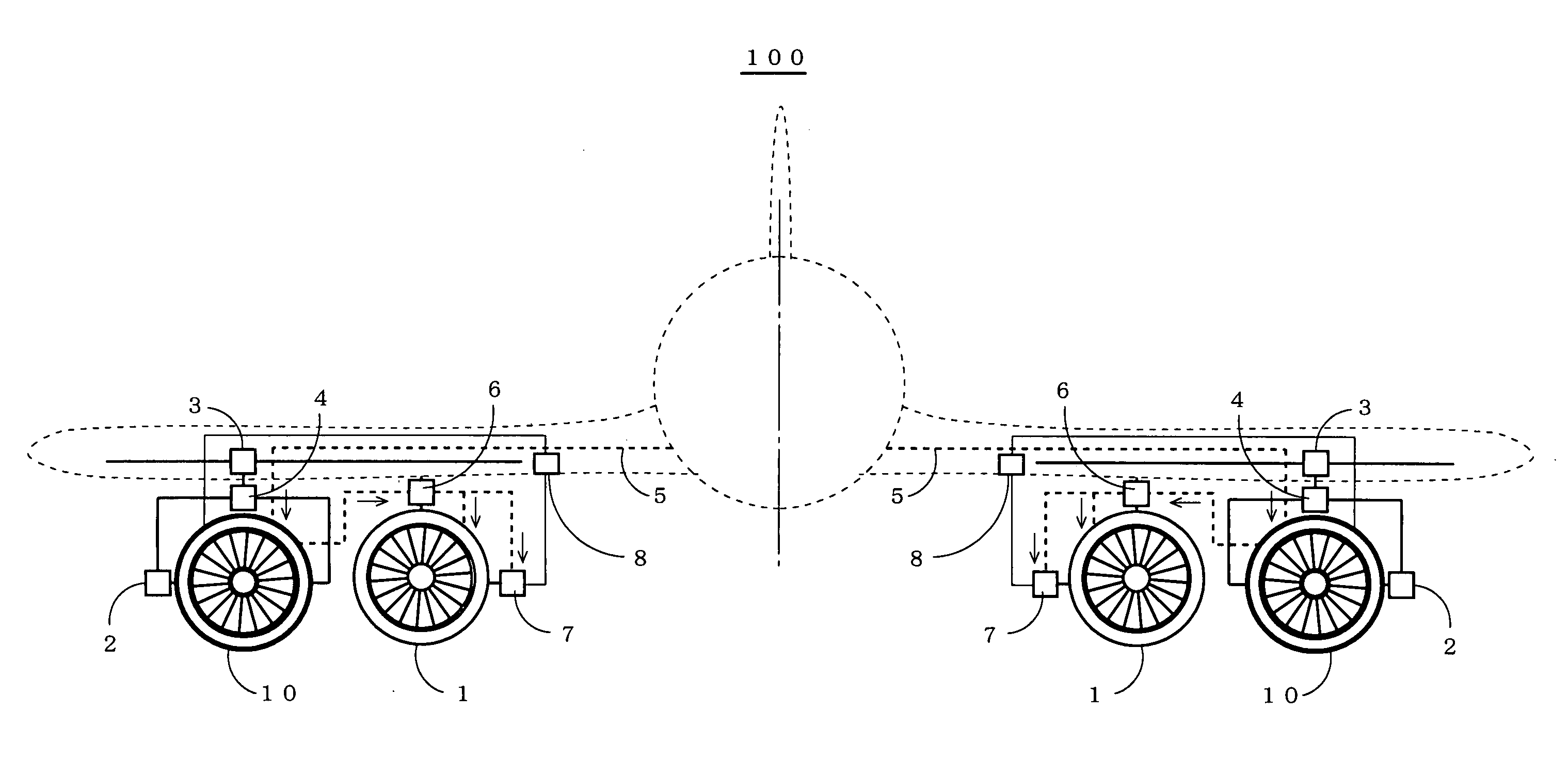

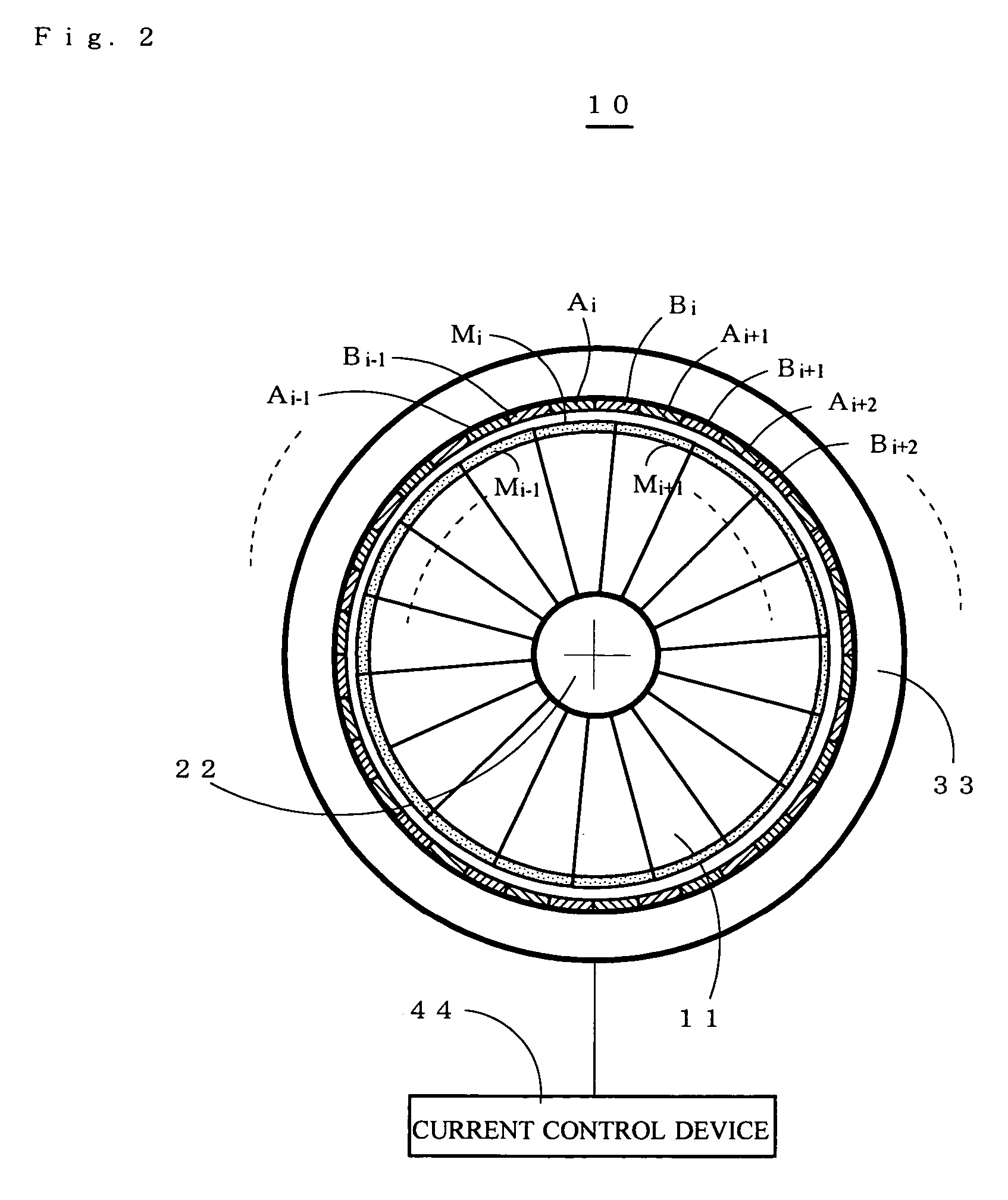

InactiveUS20060254255A1Highly compatible with environmentSynchronous generatorsMagnetic circuitCombustion chamberLiquid hydrogen

To provide an aircraft propulsion system which can secure the optimum thrust and thrust vector for flight conditions, as well as the optimum sectional area for the engine, and which is highly compatible with the environment. An electrical generator is coupled to a turbofan engine, the electrical generator is driven by output power of the turbofan engine to output electric power, and an electromagnetic driving fan is driven by the electric power. On the other hand, after bringing each of coils in the electromagnetic driving fan to a superconductive state, liquid hydrogen is introduced to a heat exchanger, collects the energy of exhaust as heat, is then vaporized, and thereafter supplied to a combustor and to a fuel cell. Further, the electromagnetic driving fan is changed in its rotational phase by a rotating mechanism portion, is made movable in a width direction of a wing and a wing chord direction by a slide mechanism portion, and can be stored inside or outside the wing by a storage mechanism portion.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY +1

Aircraft propulsion system

InactiveUS7555893B2Highly compatible with environmentMagnetic circuitAircraft power plant componentsSpacecraft propulsionFuel cells

Owner:JAPAN AEROSPACE EXPLORATION AGENCY +1

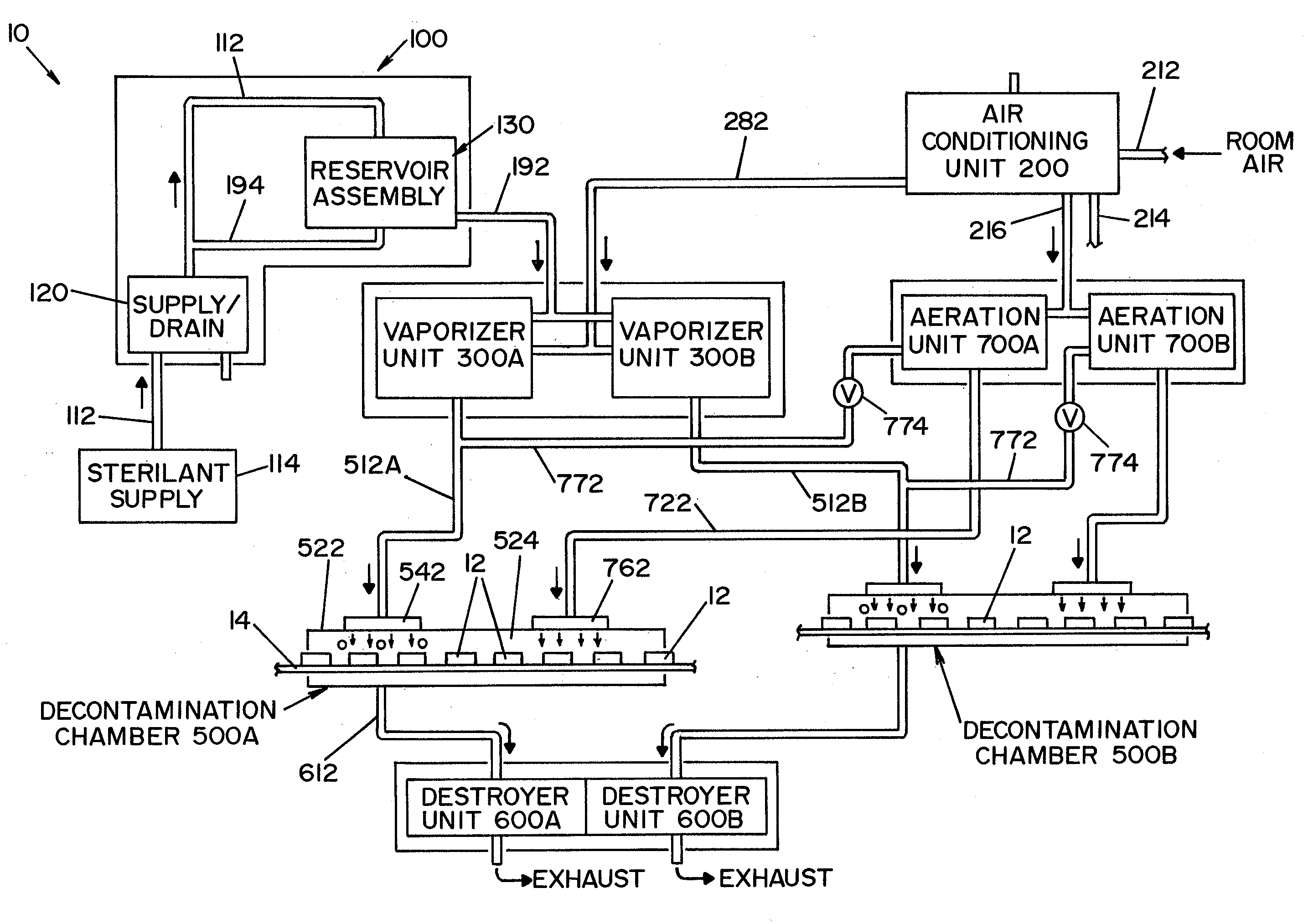

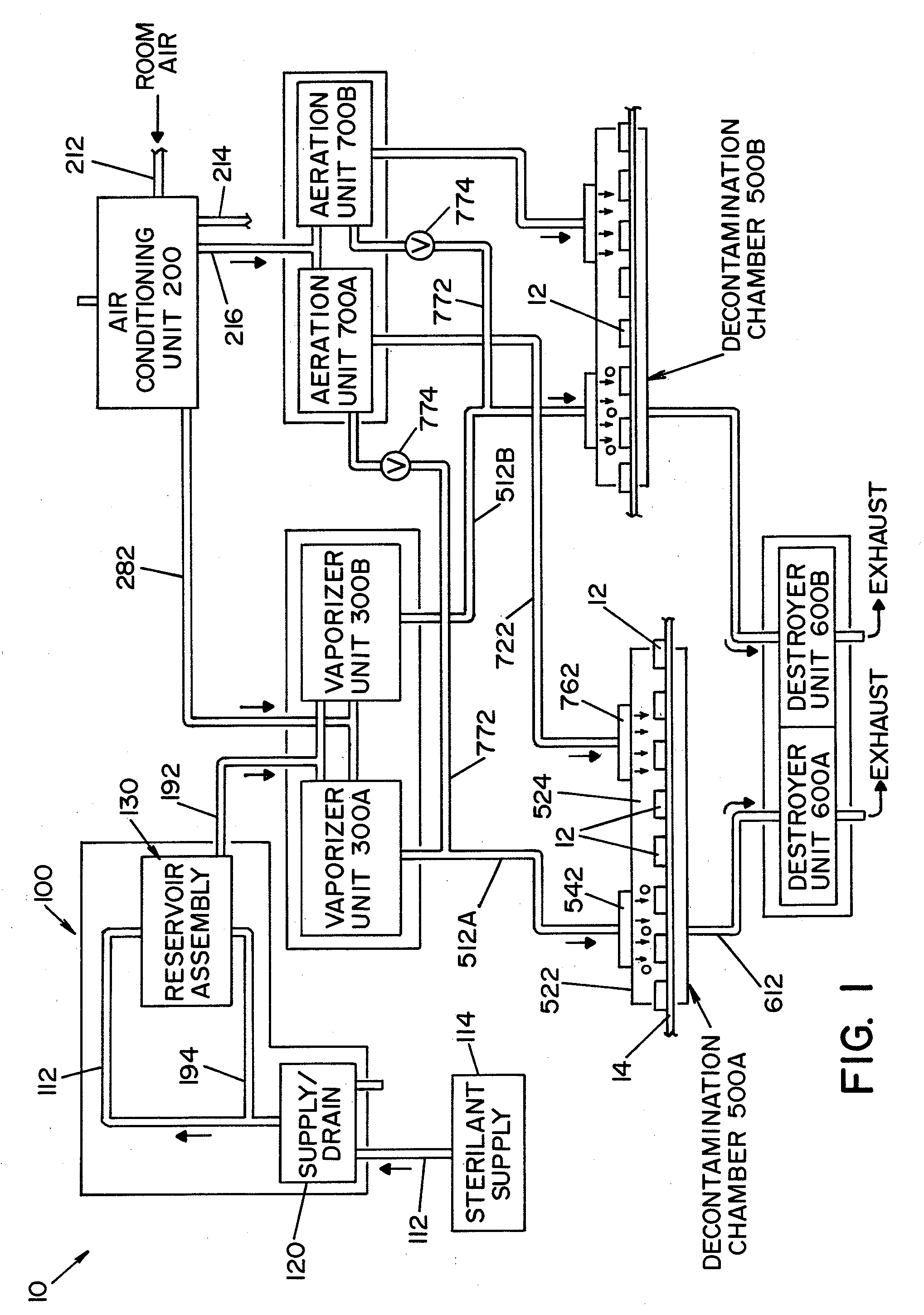

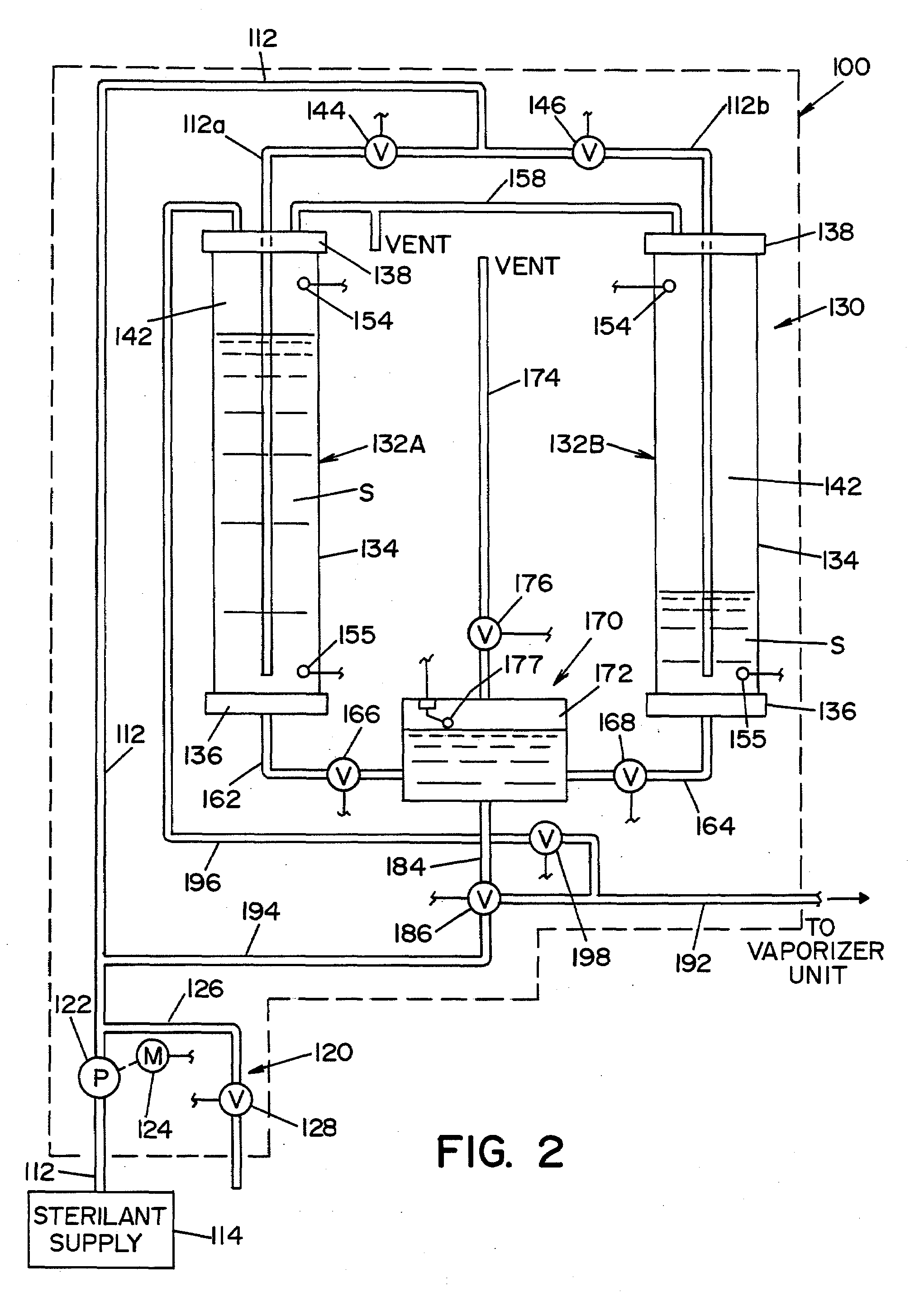

Hydrogen peroxide vaporizer

ActiveUS20070253859A1Modifies flowModifies temperatureLavatory sanitoryDeodrantsLiquid hydrogenEngineering

A method of decontaminating articles, comprising the steps of:(a) moving a plurality of articles having a known temperature along a first path;(b) conveying a carrier gas along a second path that includes an elongated plenum, the second path intersecting the first path downstream from the plenum;(c) heating the carrier gas to a temperature of at least about 105° C. at a location upstream of the plenum;(d) introducing into the carrier gas in the plenum an atomized mist of a liquid hydrogen peroxide of known concentration; and(e) controlling the following:(1) the volumetric flow of carrier gas along the second path;(2) the volume of hydrogen peroxide introduced into the carrier gas; and(3) the temperature of the carrier gas introduced into the plenum, such that the concentration of the vaporized hydrogen peroxide in the carrier gas where the first path intersects the second path has a dew point temperature below the known temperature of the articles.

Owner:AMERICAN STERILIZER CO

Multi-mode multi-propellant liquid rocket engine

InactiveUS6619031B1Cosmonautic vehiclesCosmonautic propulsion system apparatusCombustion chamberLiquid fluorine

A multi-mode multi-propellant rocket engine capable of operating in a plurality of selected modes.Propellant components may include liquid hydrogen, liquid hydrocarbon, liquid oxygen, liquid fluorine, and liquid air. The liquid oxygen and the liquid air are stored in separate tanks are mixed in a dedicated mixer prior to their injection into the combustion chamber.

Owner:MSE TECH APPL

Sky condenser with vertical tube compression and pressurized water utilization

InactiveUS20150128597A1Reducing overall weight and volumeReciprocating combination enginesPower plant arrangements/mountingVertical tubeElectrolysis

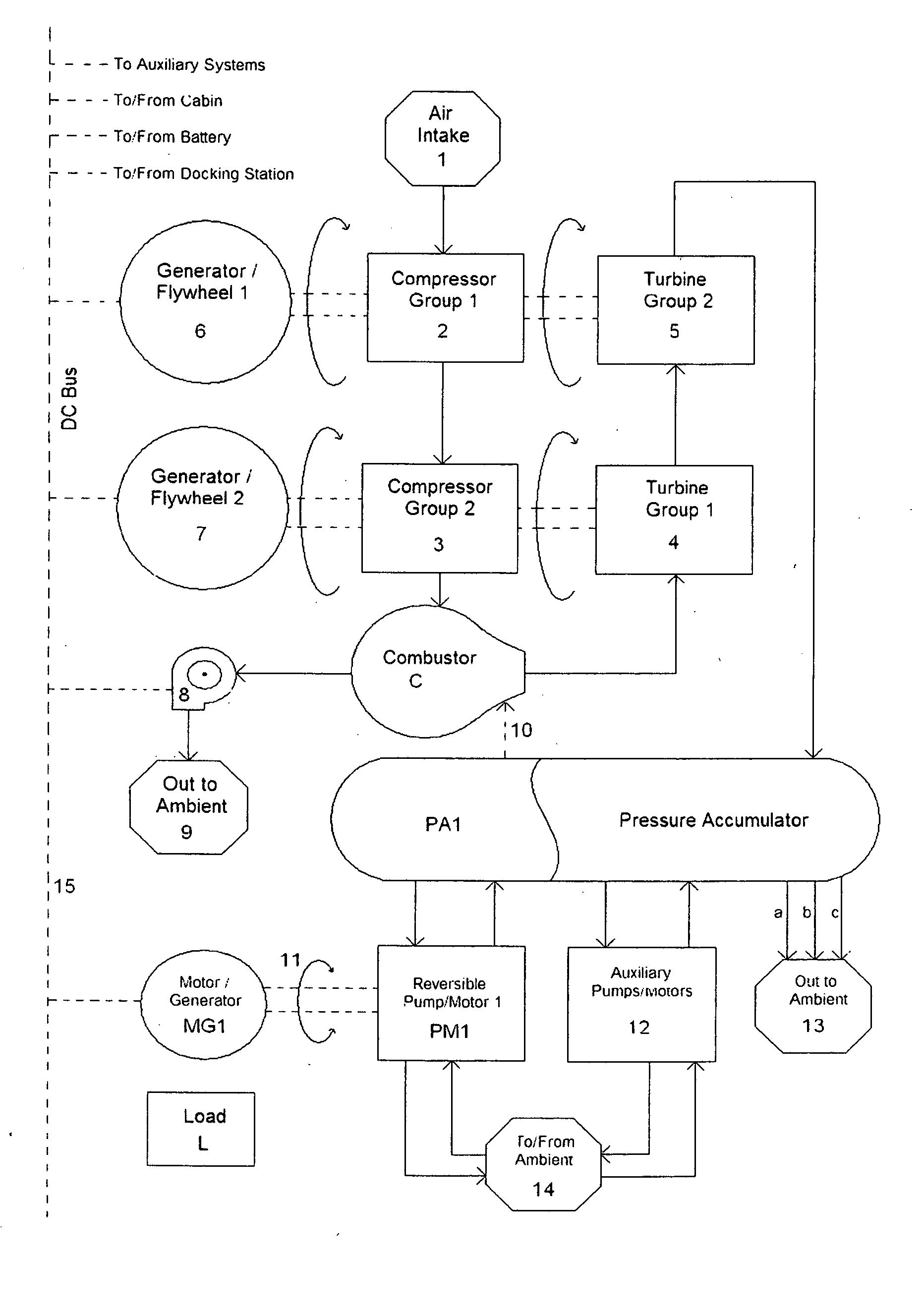

A floated condenser extracts water from the sky. The condenser is part of or supplemental to a typical buoyed wind turbine set, comprising lift element, wind turbine, retention cable, electrical output, and base. The cable is hollow or coextensive with a lumen, the inner diameter thereof is water impermeable. The hollow / lumen stacks water over an accumulator, effecting a static base pressure p=ρgh. This pressure makes the water utilizable. After pressure multiplication—via a hydrostatic piston—or not, a first stream of water electrolyzes into liquid hydrogen and oxygen, one or both stored / sold directly. Another stream of water drives a turbine / motor or series hydroelectric turbines / motors, powering electrolysis and / or grid, the water then stored at moderate pressure for water utilities. Excess power from the wind turbine also supplements electrical output. A conductor runs along the cable. Gasified hydrogen is routed via the cable, lifting the condenser / turbine / kite.

Owner:SCHLAK DANIEL KEITH

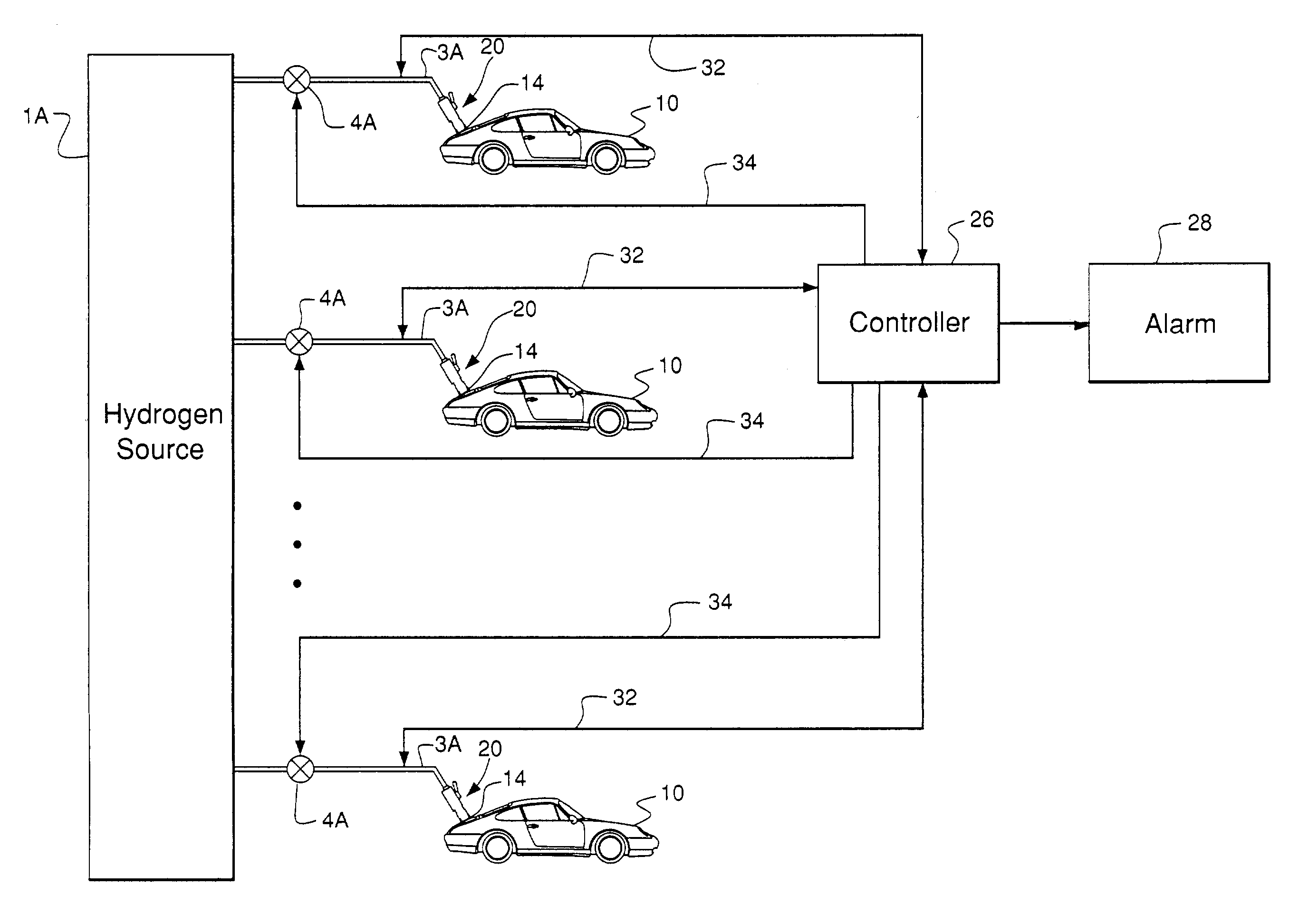

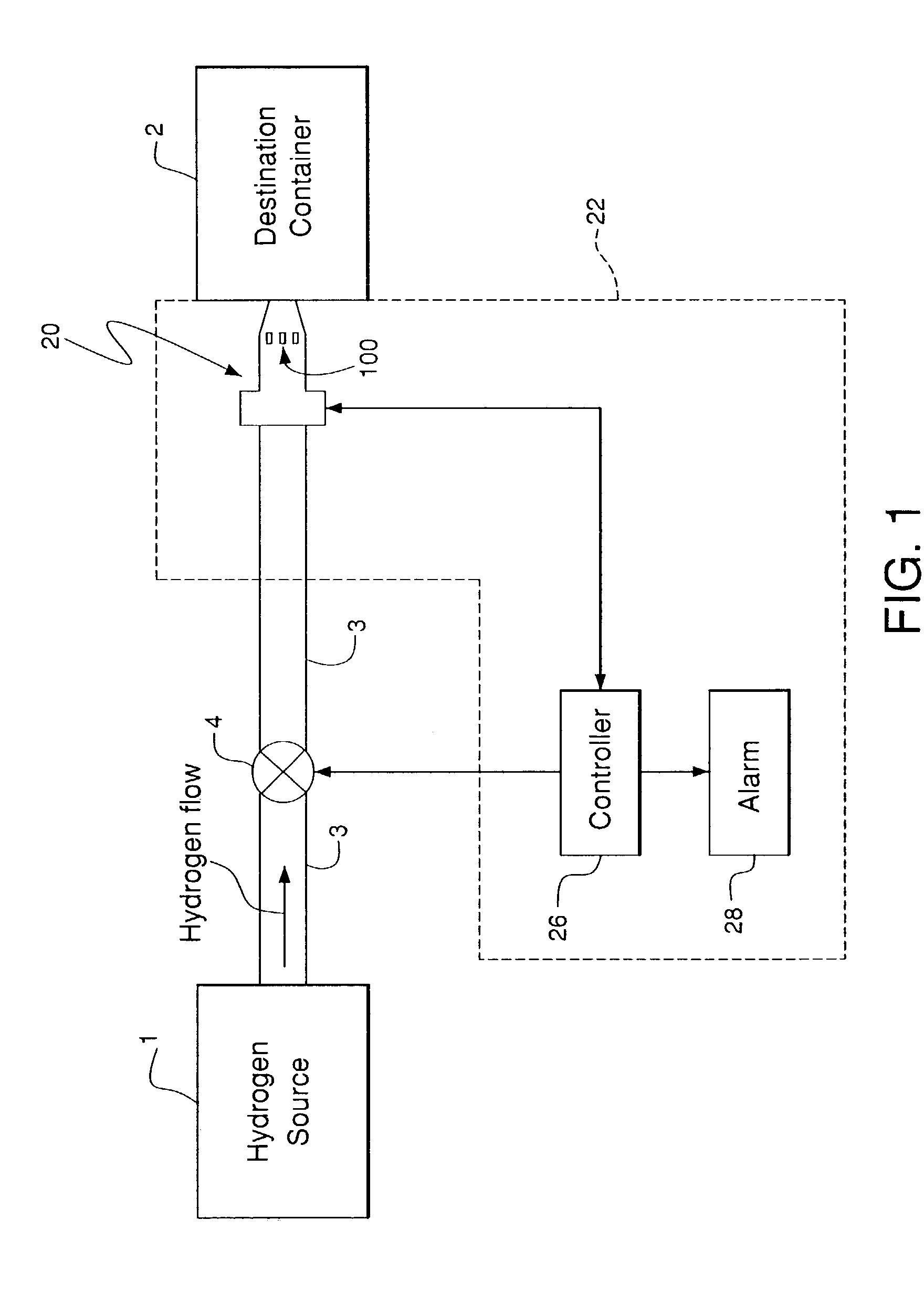

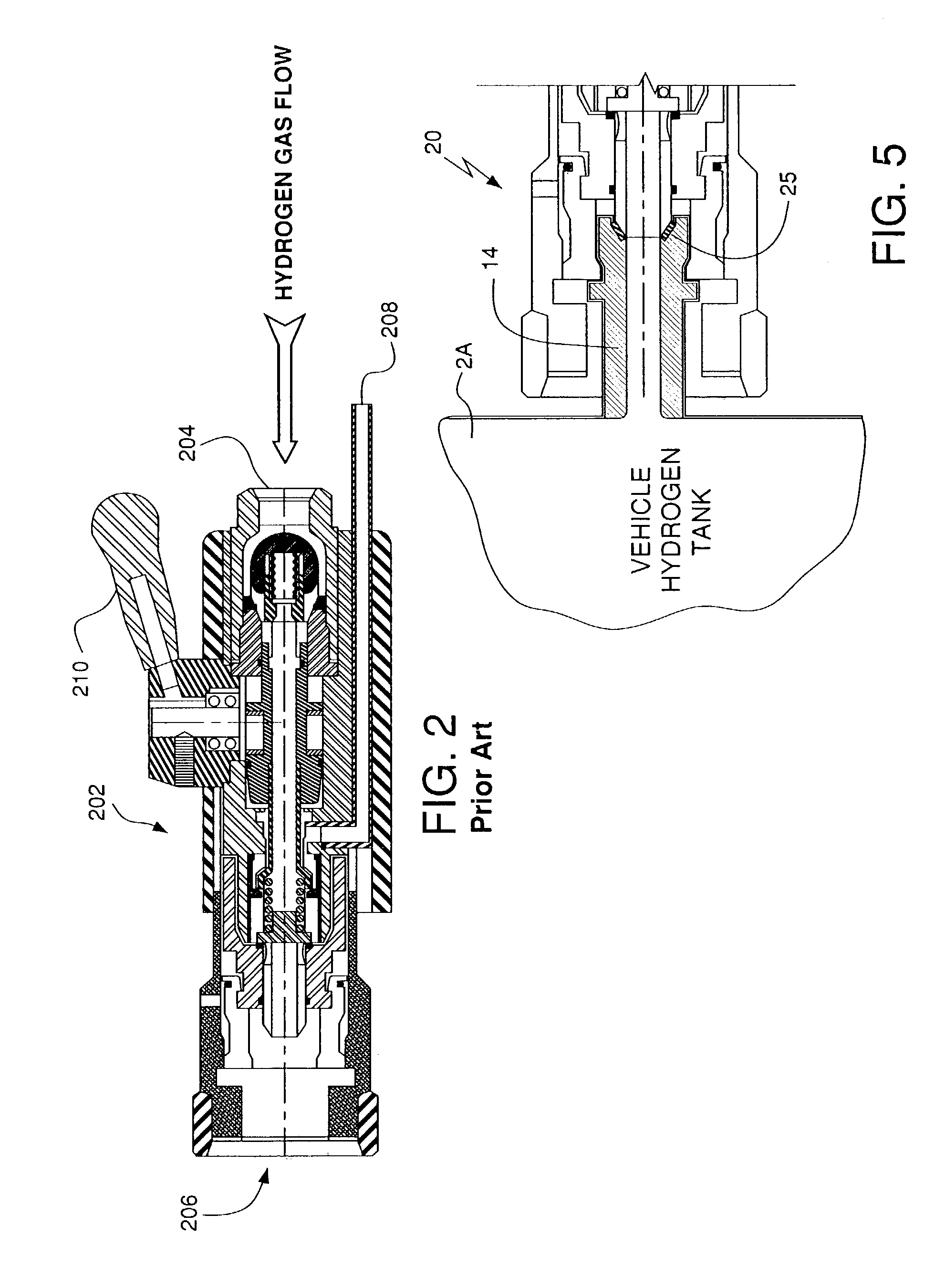

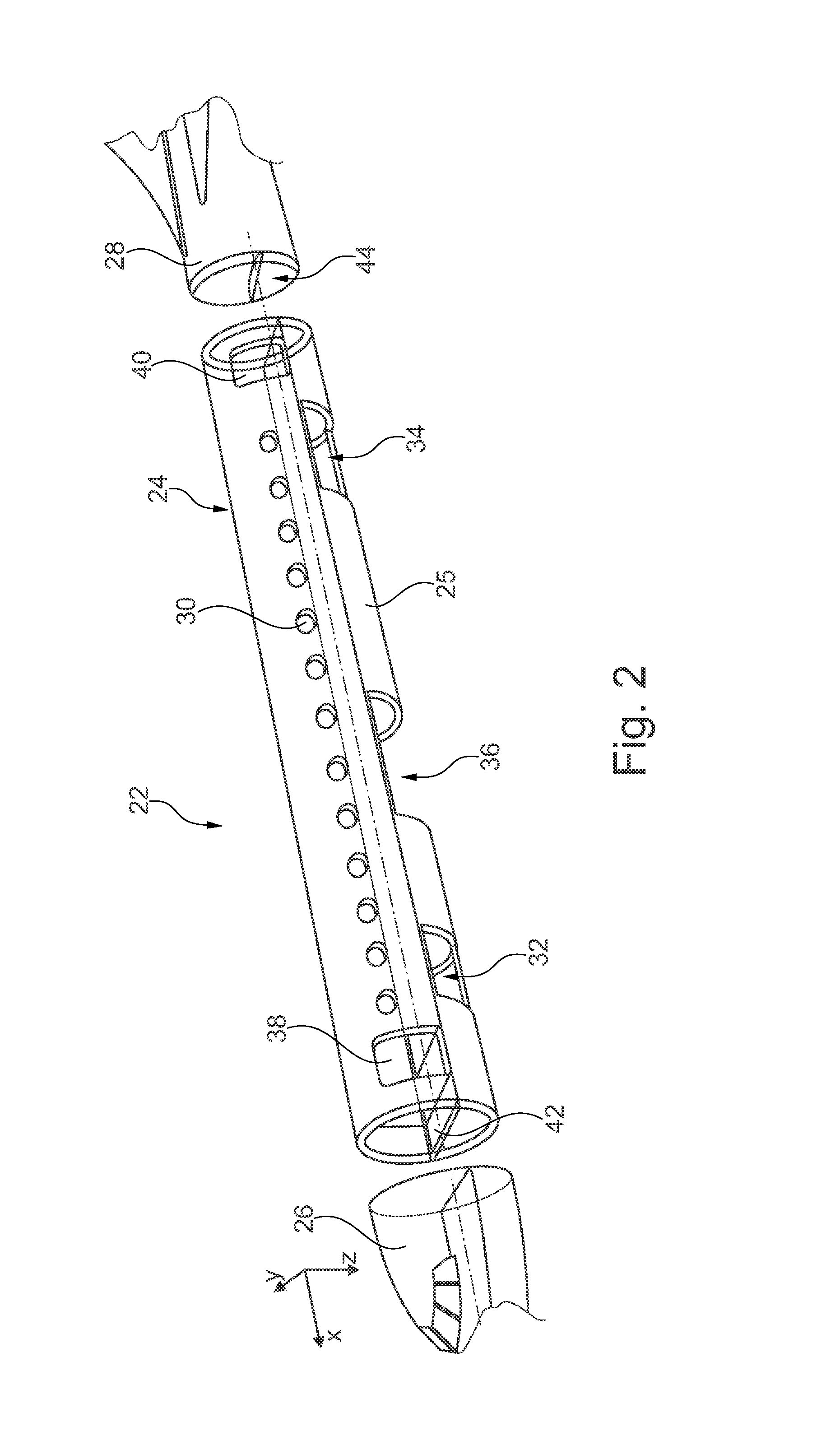

Fueling nozzle with integral molecular leak sensor

An apparatus and process for measuring the concentration of hydrogen gas being transferred through a nozzle from a source container to a destination container and for providing an alert and / or taking action where hydrogen gas leaks may create an unsafe condition. The invention can accurately and reproducibly respond to and measure the absolute hydrogen gas concentration within the nozzle housing using hydrogen gas sensors that are selective only to hydrogen, which do not require the presence of oxygen to operate and which do not saturate when hydrogen safety levels are reached. These sensors are positioned inside the nozzle housing to allow for the direct and immediate knowledge of the presence of hydrogen gas that cannot be safely determined by other means. An apparatus and process for detecting leaks of liquid hydrogen through a nozzle during transfer of liquid hydrogen from a source container to a destination container are also discussed.

Owner:AIR PROD & CHEM INC

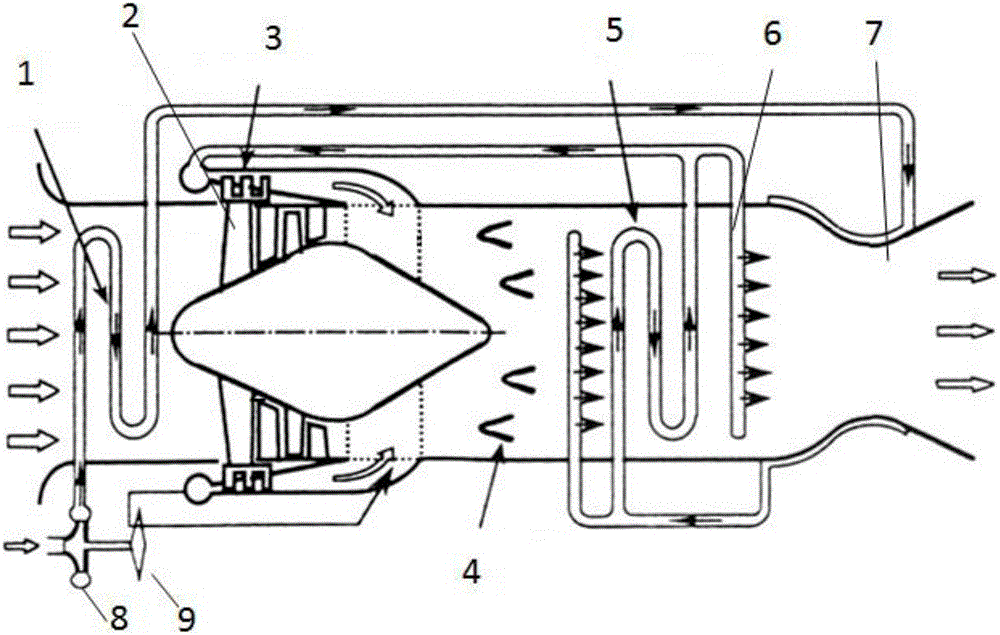

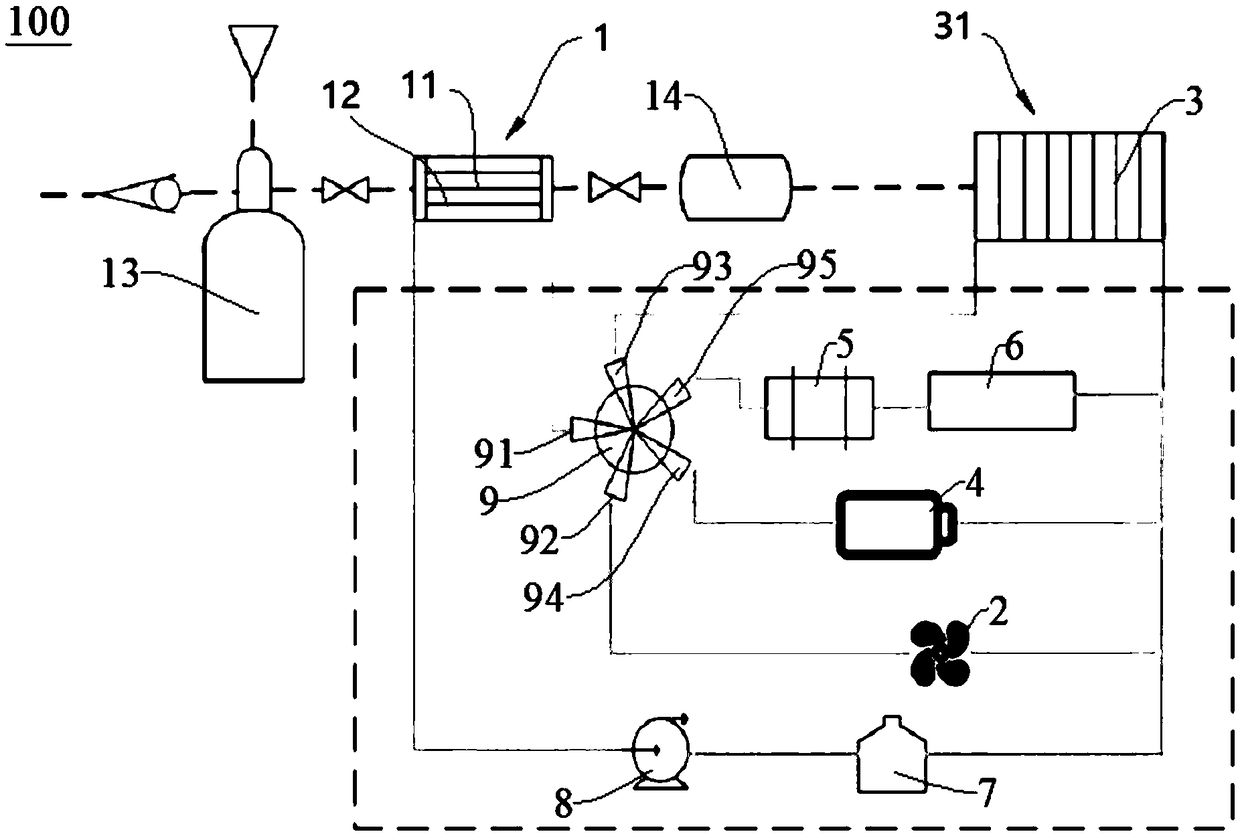

Air precooling compression aircraft engine and hypersonic velocity aircraft

ActiveCN106014637AHigh fuel specific impulseImprove economyTurbine/propulsion engine coolingGas turbine plantsCombustion chamberHydrogen exchange

The invention discloses an air precooling compression aircraft engine and a hypersonic velocity aircraft. The air precooling compression aircraft engine comprises an intake way, an air compressor, a combustion chamber and a spraying pipe arranged in sequence; and the air compressor is provided with a turbine for providing driving force. The air precooling compression aircraft engine further comprises a first heat exchanger for adopting a circular cooling agent to cool air introduced by the intake way, a cooling agent pump provided with a cooling agent outlet communicated with the first heat exchanger and a cooling agent recovery port communicated with a second heat exchanger for recovering the cooling agent, the second heat exchanger for using liquid hydrogen output by a liquid hydrogen pump as a cold source to cool the heated cooling agent and leading out the cooled cooling agent to the cooling agent pump for recycling, the liquid hydrogen pump connected with an inlet of the second heat exchanger for supplying liquid hydrogen as a fuel, and an injector positioned between the air compressor and the combustion chamber and communicated with the second heat exchanger for injecting air compressed by the air compressor and hydrogen exchanged heat by the second heat exchanger into the combustion chamber.

Owner:NAT UNIV OF DEFENSE TECH

Process for synthesizing propylene glycol ether

ActiveCN1944365AEasy to separateEliminate the purification processEther preparation from oxiranesEpoxyAlcohol

The present invention discloses process of synthesizing propylene glycol ether. Alcohol, propylene and hydrogen peroxide in the molar ratio of (1-60) to (0.5-10) to 1 are set inside a reactor with catalyst, propylene and hydrogen peroxide produce epoxidation reaction to produce epoxy propane, and the produced epoxy propane and alcohol produce etherification reaction to produce propylene glycol ether. The reaction conditions include reaction temperature of 0-200 deg.c, reaction pressure of 0.5-8.5 MPa, and space velocity of liquid hydrogen peroxide and alcohol of 0.1-65 / hr. The present invention has simple process, environment friendship and propylene glycol ether selectivity up to 90 %.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD +1

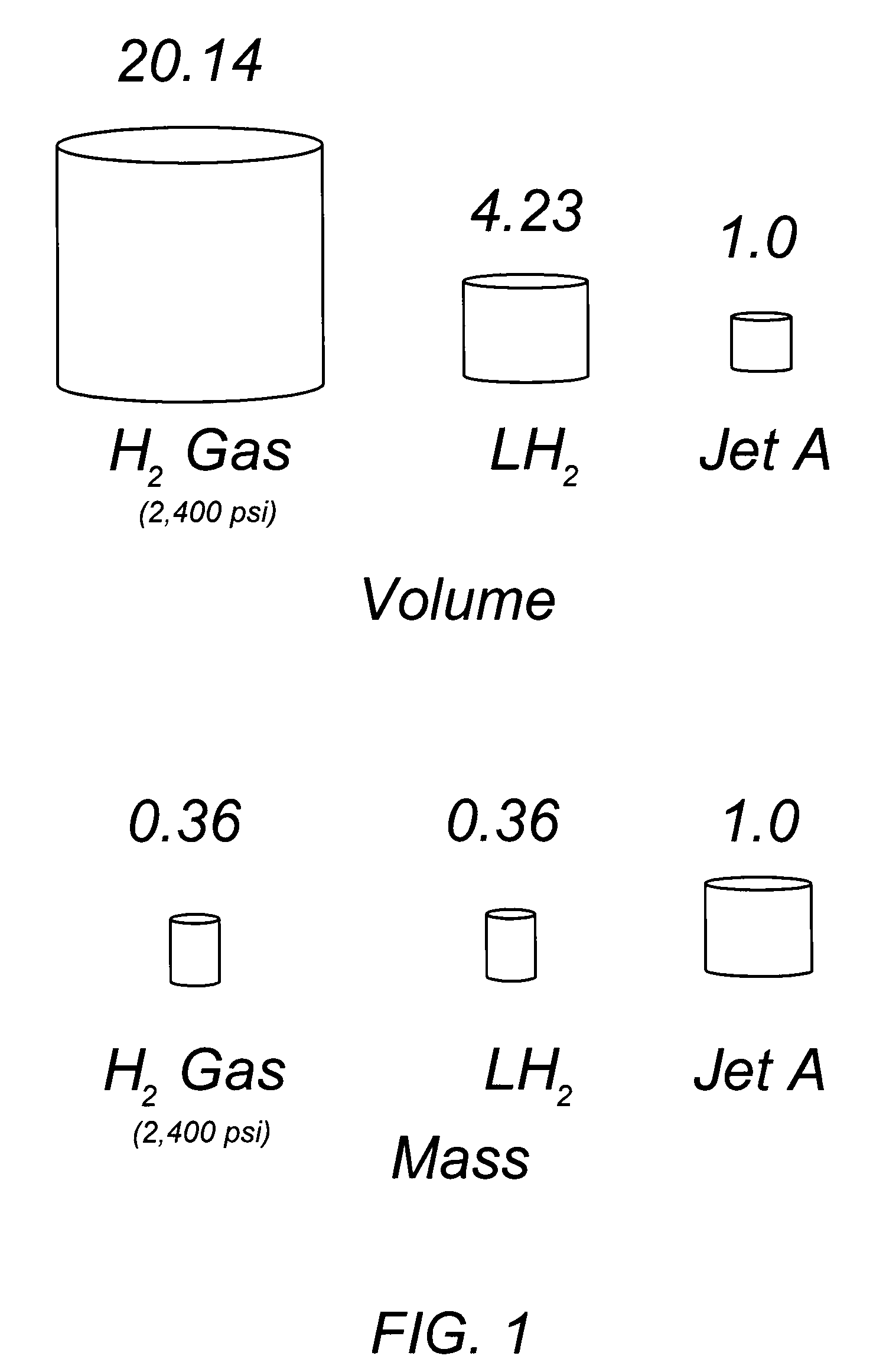

Method for recycling hydrogen chloride in tail gas of polysilicon production

ActiveCN101791487AHigh purityLarge storage capacityChlorine/hydrogen-chloride purificationSiliconDistillationChloride

The invention discloses a method for recycling hydrogen chloride in tail gas of polysilicon production. In the method, tail gas is cooled and condensed, so that most of chlorosilane is liquefied; compressed gas enters a hydrogen chloride absorption tower and absorbed by chlorosilane solution, and hydrogen gas is exhausted from the hydrogen chloride absorption tower and collected; liquid hydrogen-chloride-rich chlorosilane discharged from the bottom of the hydrogen chloride absorption tower is introduced into a hydrogen chloride distillation tower, and chlorosilane solution is discharged form the bottom of the hydrogen chloride distillation tower; and hydrogen chloride containing trace hydrogen gas is exhausted from the top of the hydrogen chloride distillation tower and enters a full condenser on the top of the distillation tower, condensate of the full condenser on the top of the distillation tower enters a return tank of the distillation tower, the trace hydrogen is exhausted from the top of the return tank of the distillation tower and collected, a part of the condensate of the return tank of the distillation tower is introduced into the hydrogen chloride distillation tower and used as return liquid, and the other part of the condensate enters a liquid hydrogen chloride reservoir for storage. The method improves the purity of recycled hydrogen chloride and the storage amount of hydrogen chloride and saves the investment of equipment.

Owner:CHINA TIANCHEN ENG

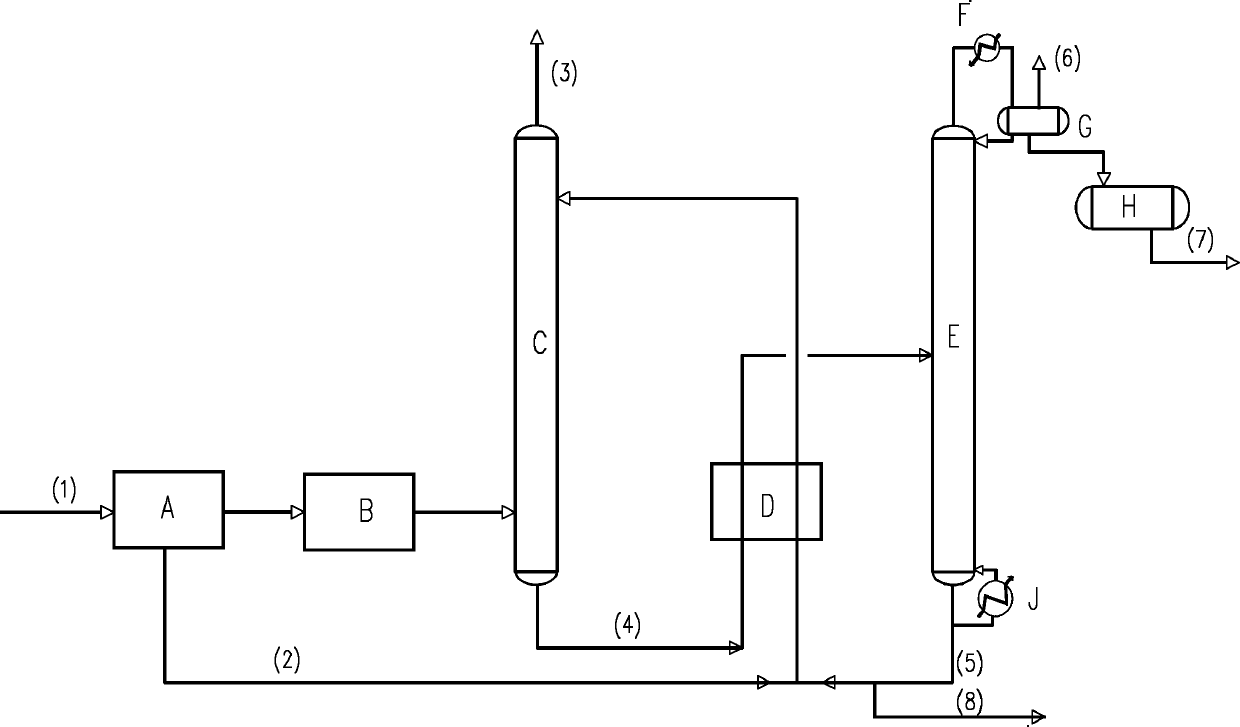

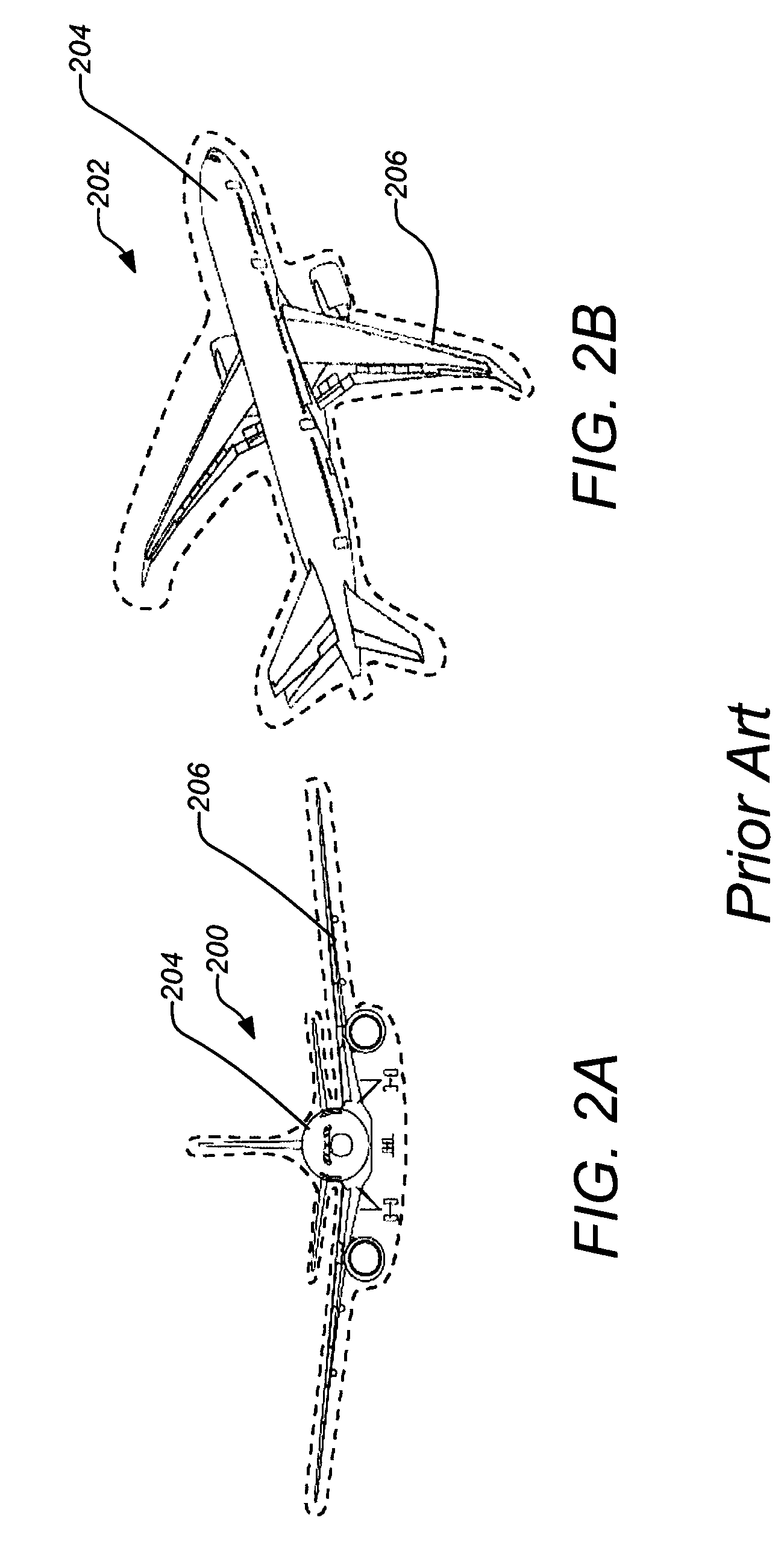

Hydrogen fueled blended wing body ring tank

InactiveUS20080230654A1Reduced tank weightReducing tank weightPower plant fuel tanksWeight reductionFuel tankLiquid hydrogen

A toroidal shaped or ring fuel tank located within the loft line of a blended wing body aircraft is disclosed. The ring tank may be used in an aircraft to store liquid hydrogen fuel with a reduced tank weight. The ring tank may be continuous with no tank end domes typically found on cylindrical pressure tanks, reducing tank weight for a given fuel volume. The ring tank configuration avoids increasing the aerodynamic shape of the aircraft and does not encroach on usable passenger or payload areas of the aircraft. In one example the ring tank may be configured in a nose down position such that the forward portion of the ring tank is outside the pressurized cabin area.

Owner:THE BOEING CO

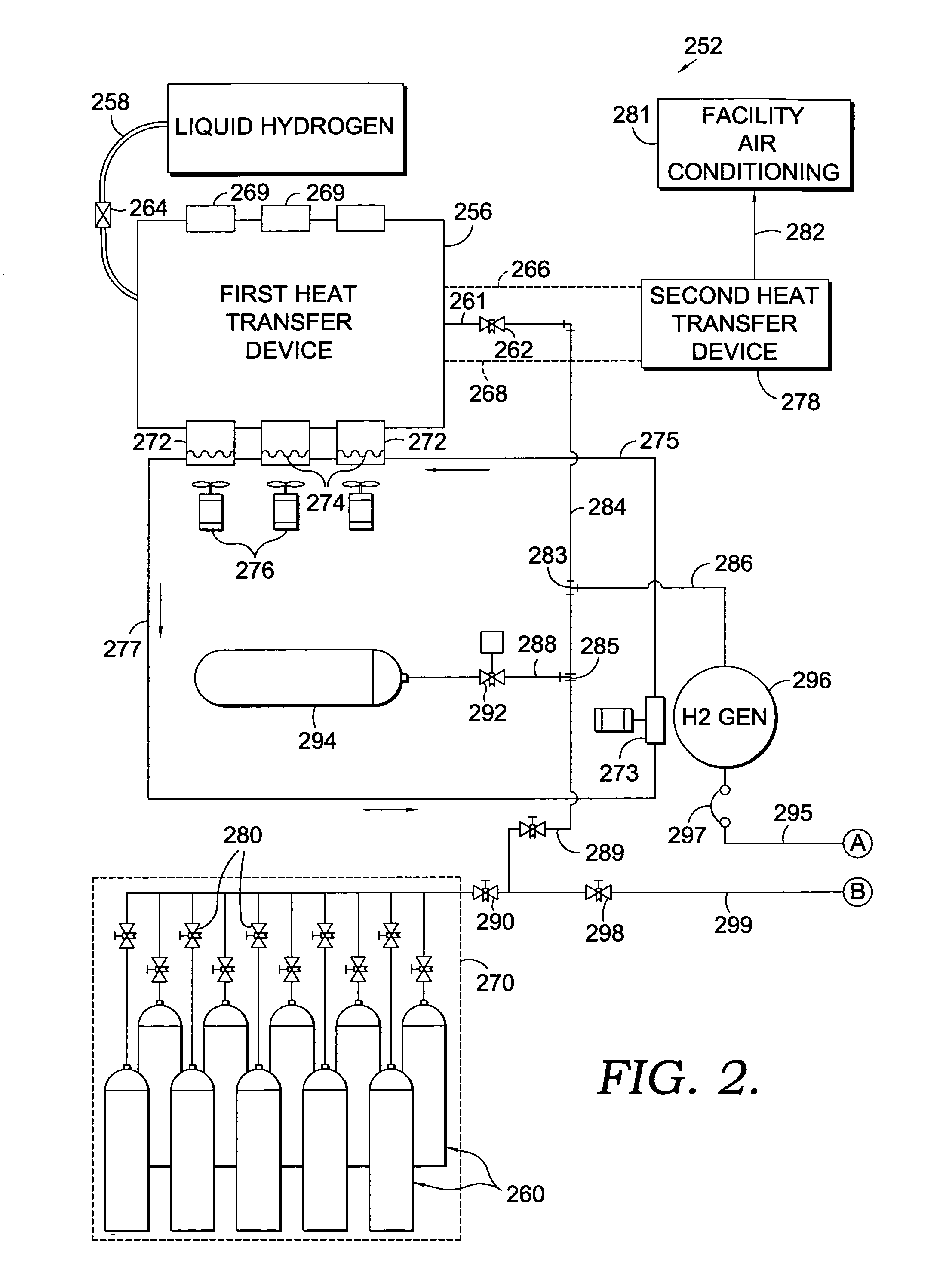

Hydrogen fueled electrical generator system and method thereof

A system and method are provided for generating electricity for use with liquid hydrogen storage facility. The system includes a liquid hydrogen storage tank with a pressure relief. An energy conversion device is connected to the pressure relief valve an converts the hydrogen into rotational energy to operate an electrical generator. Electricity created by the generator can be fed back to operate ancillary loads in the facility, or sold for use in a main electrical grid.

Owner:PROTON ENERGY SYST

Fuel system used for cooling purposes

ActiveUS20060016189A1Liquid fuel feeder/distributionSteam engine plantsNuclear engineeringHydrogen fuel

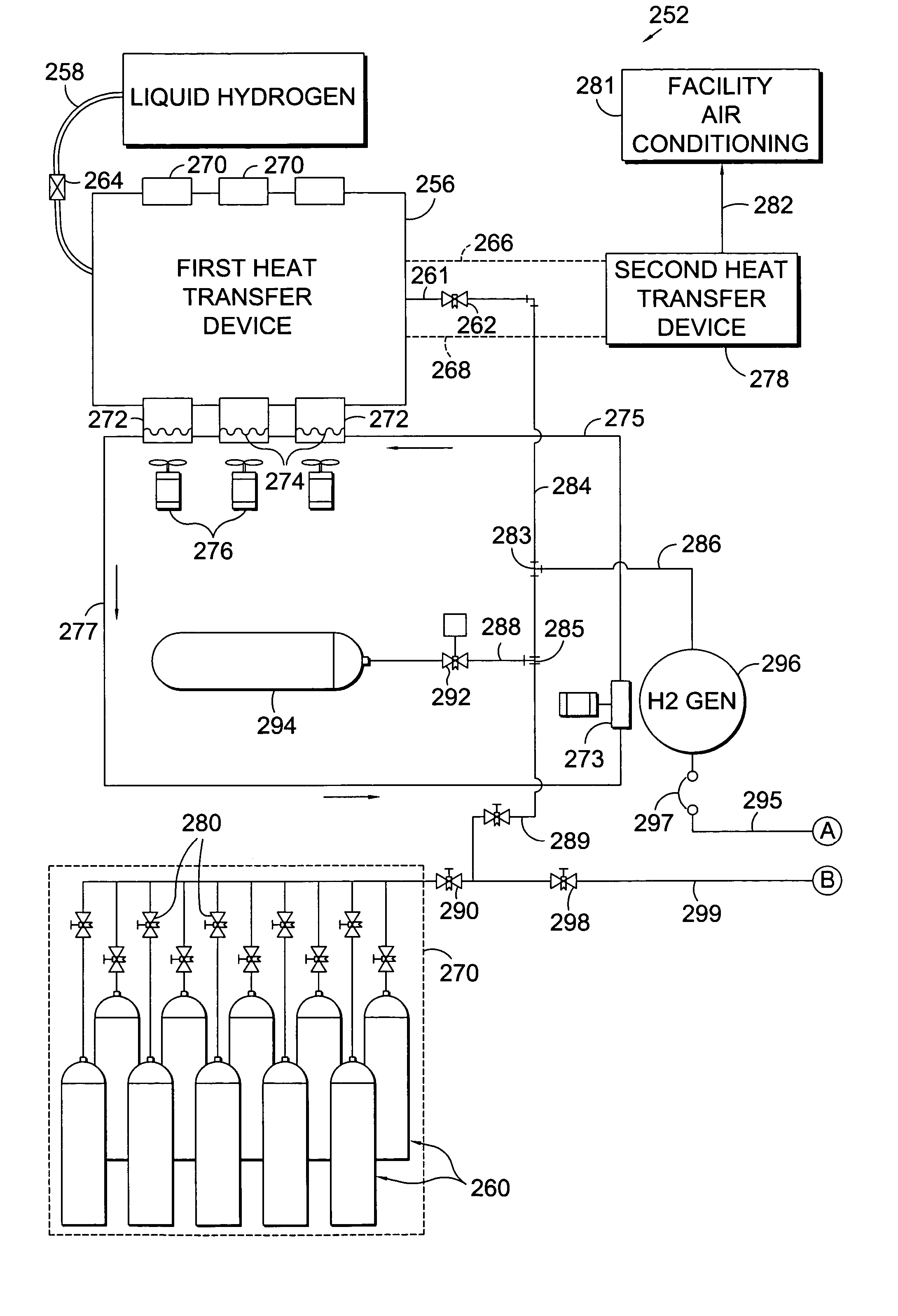

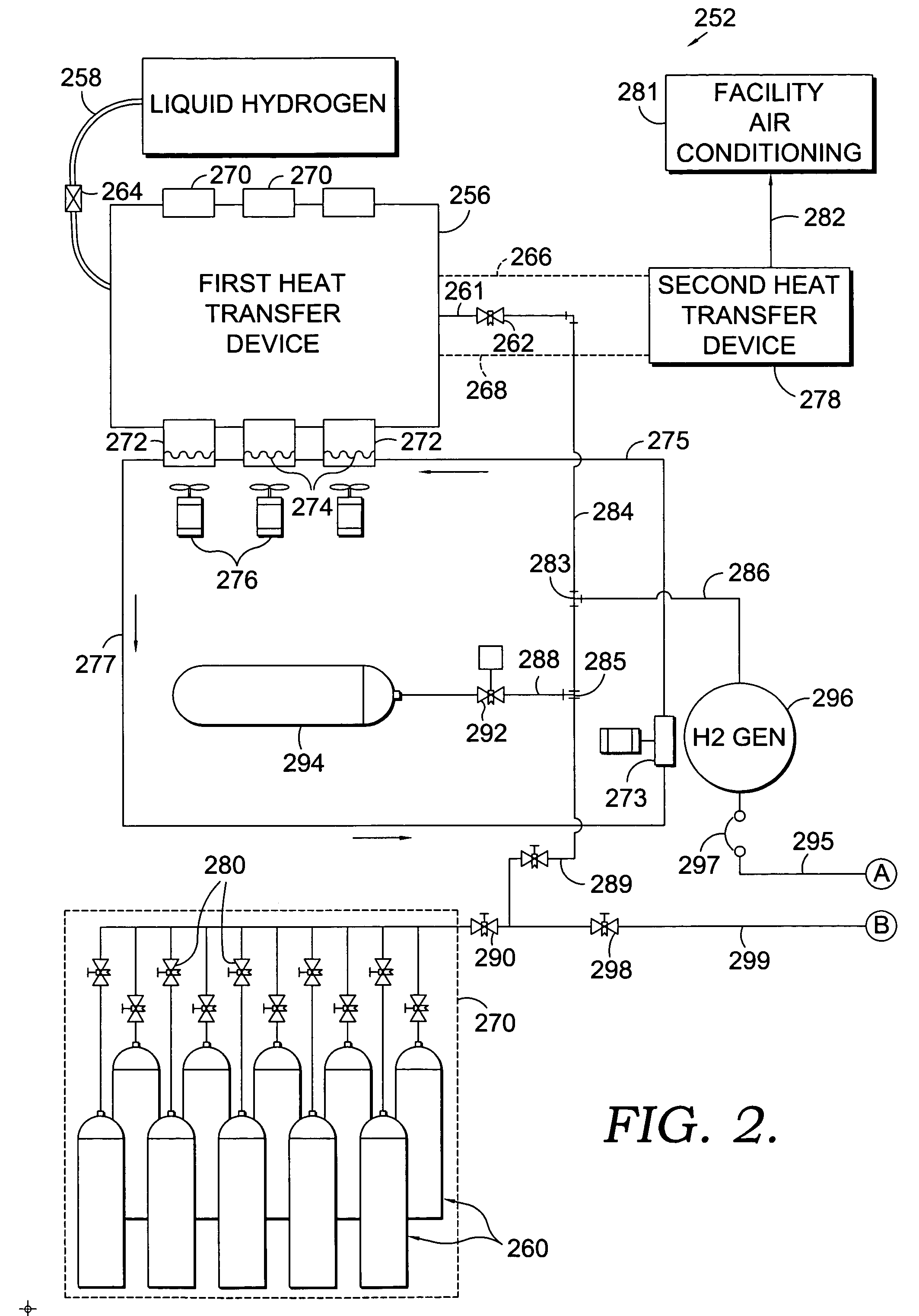

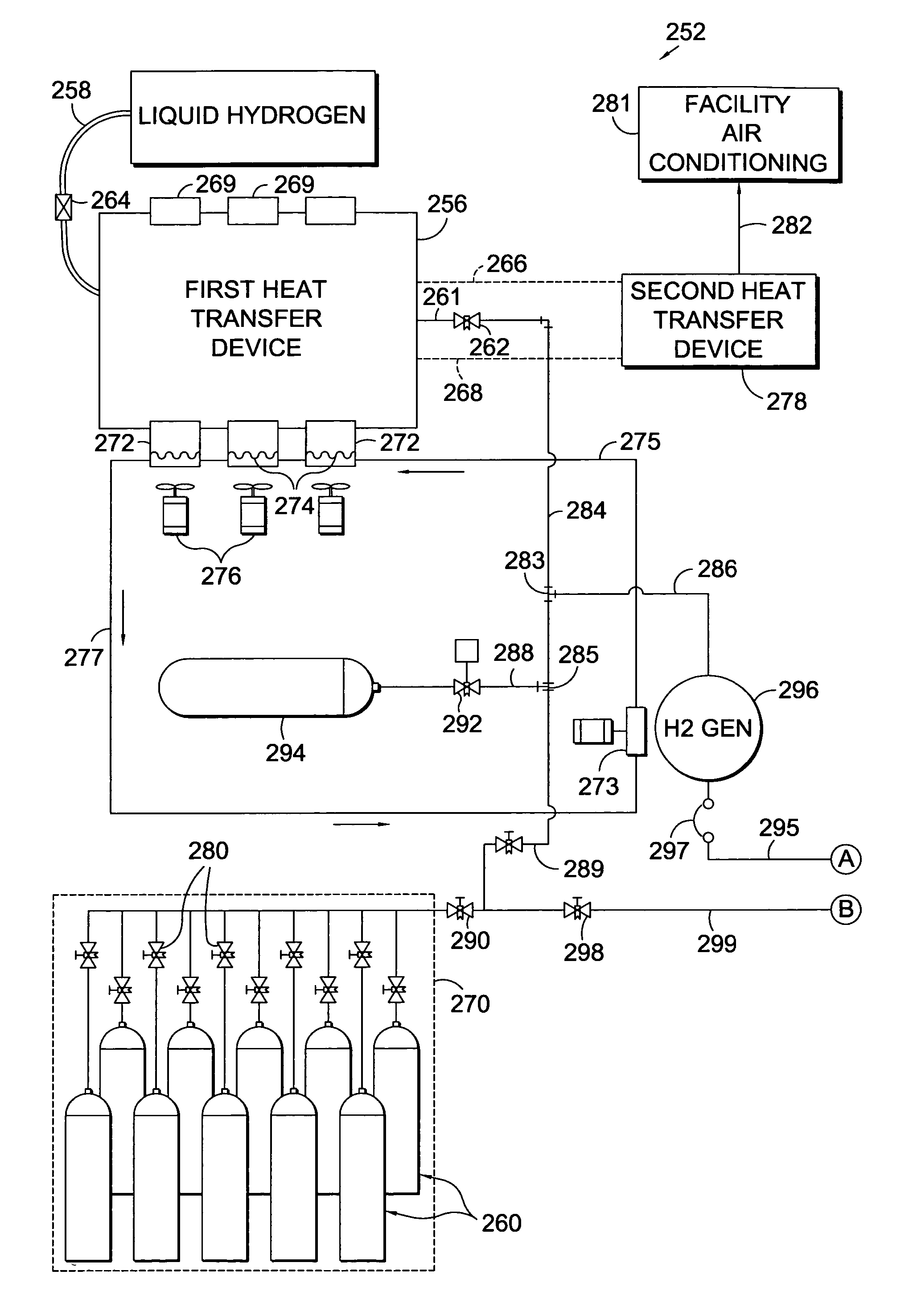

A hydrogen fuel system in which the fuel is transformed from liquid to gas is used to administer cooling, e.g., air conditioning. The system incorporates first and second stage heat exchangers. The first stage exchanger is used to benefit from the endothermic reaction created when liquid hydrogen transforms into gas. The cooling provided from this state change is transferred into a second medium which is delivered into a second stage heat transfer device and then used for cooling purposes.

Owner:T MOBILE INNOVATIONS LLC

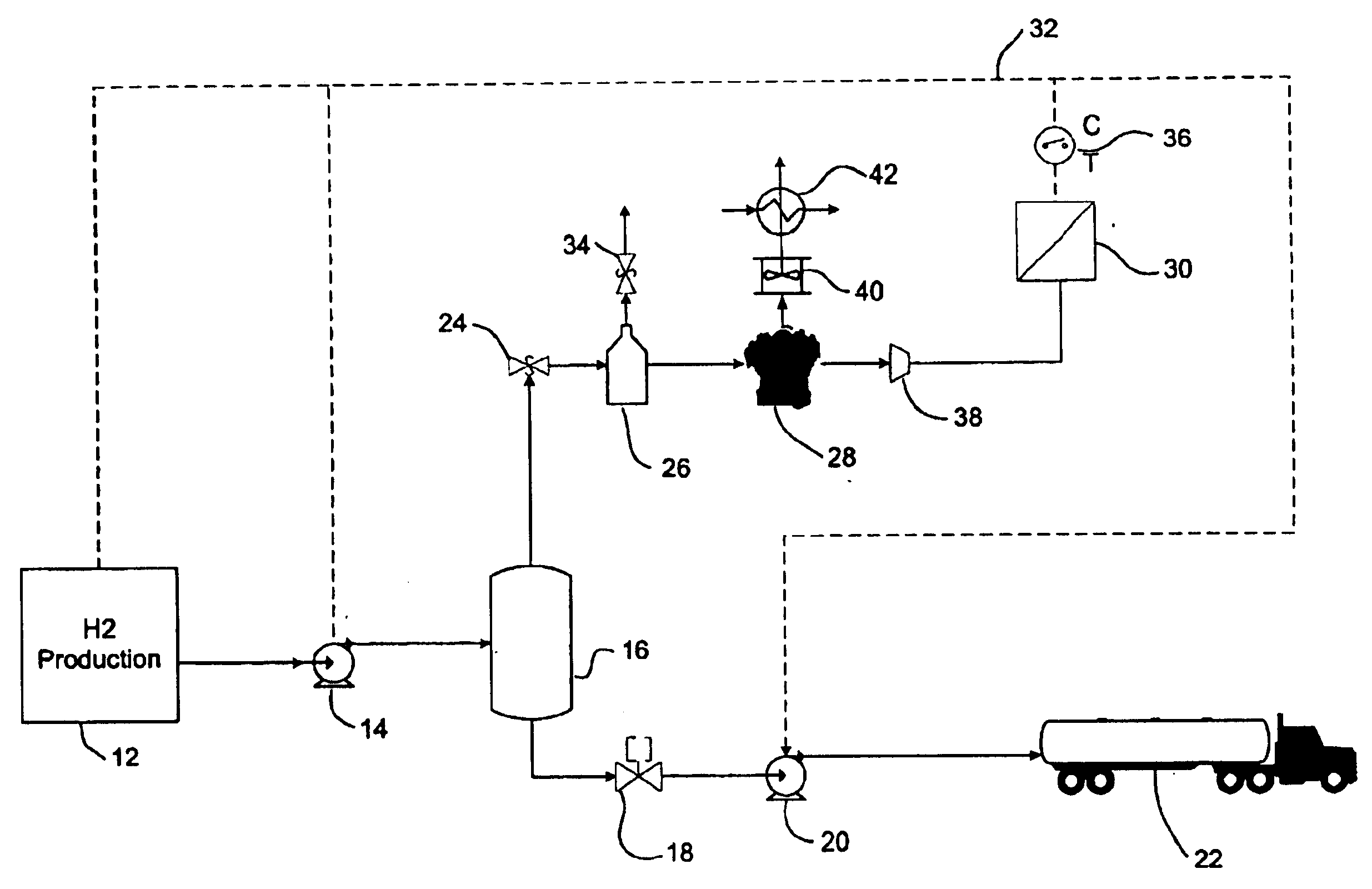

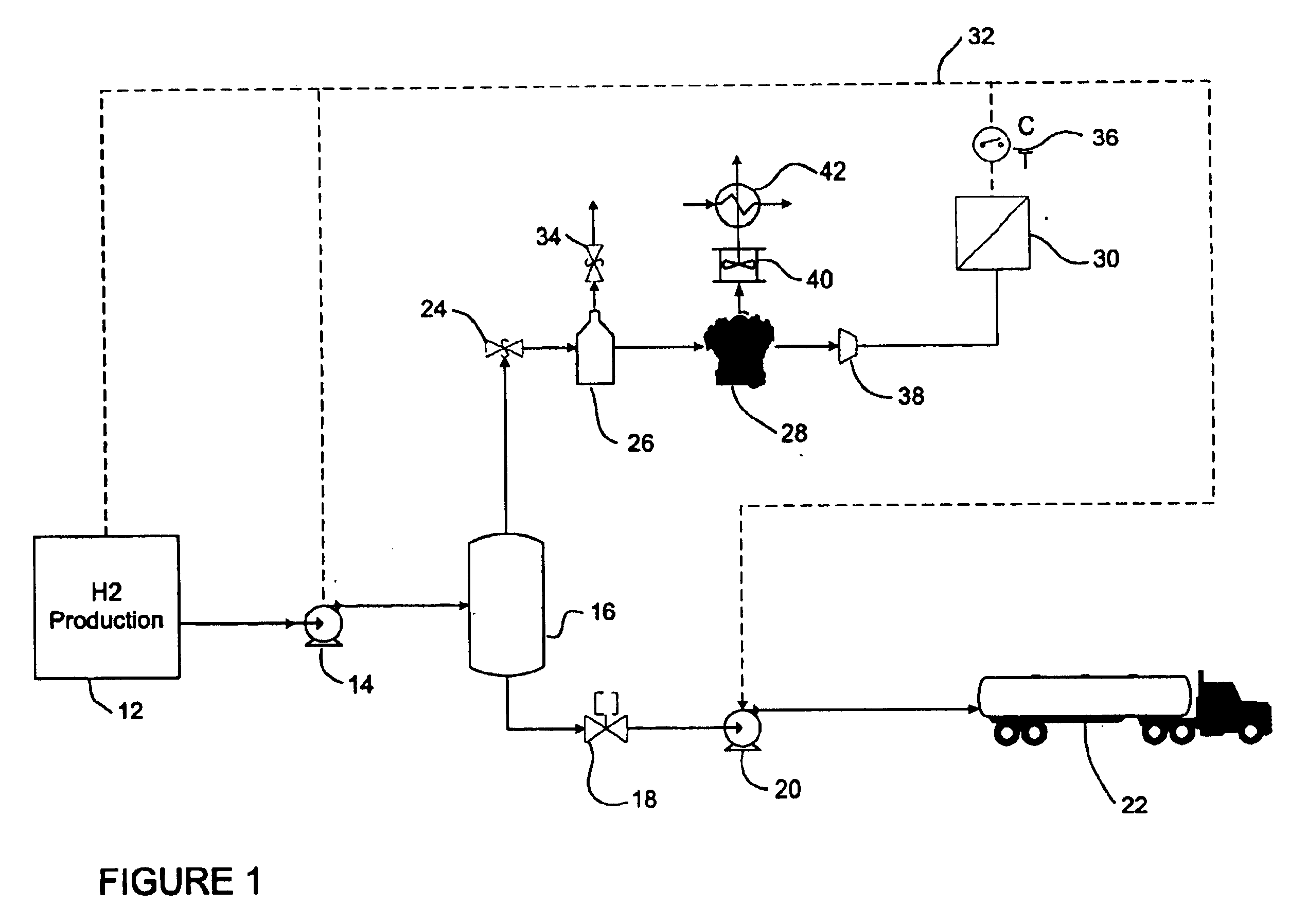

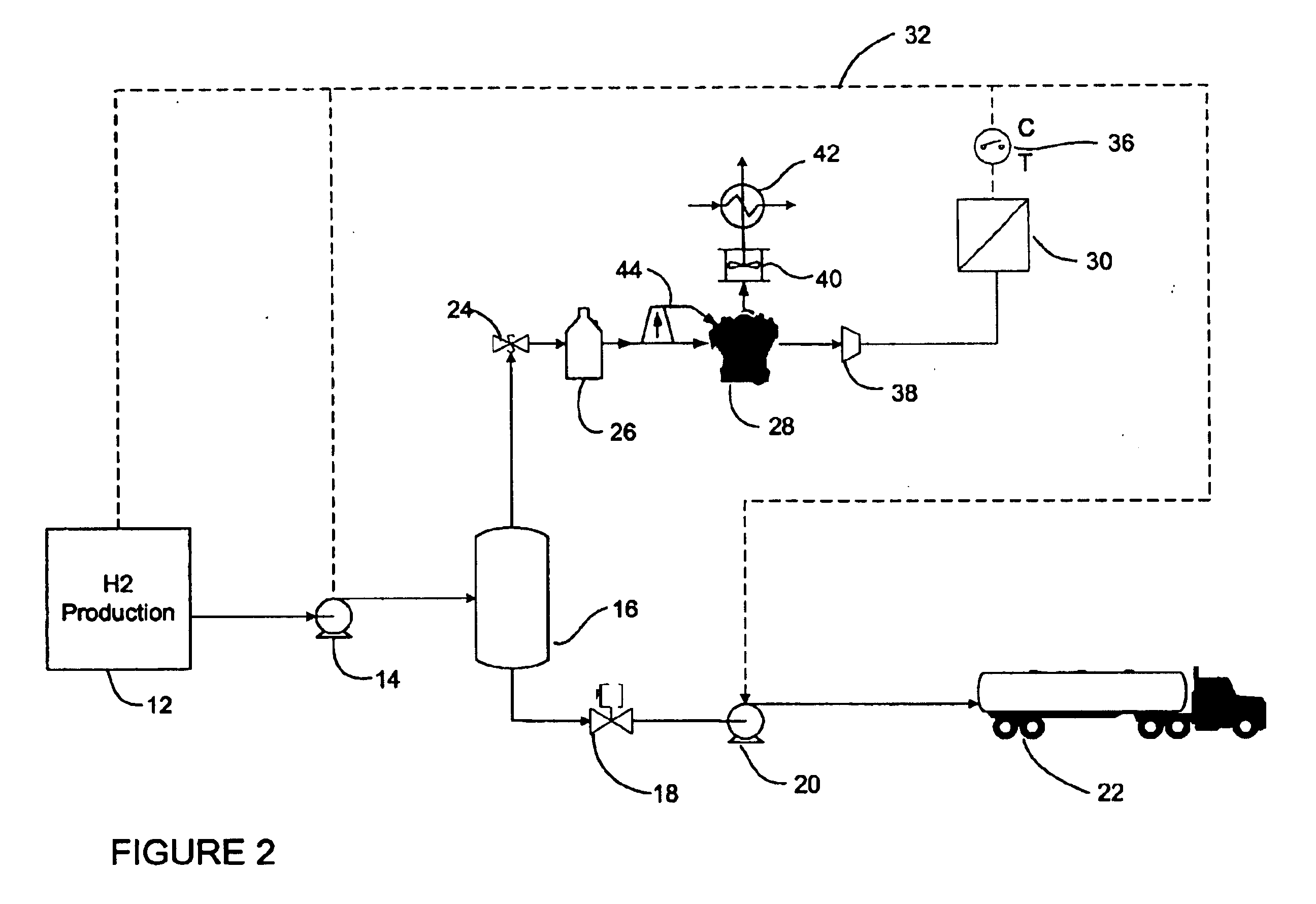

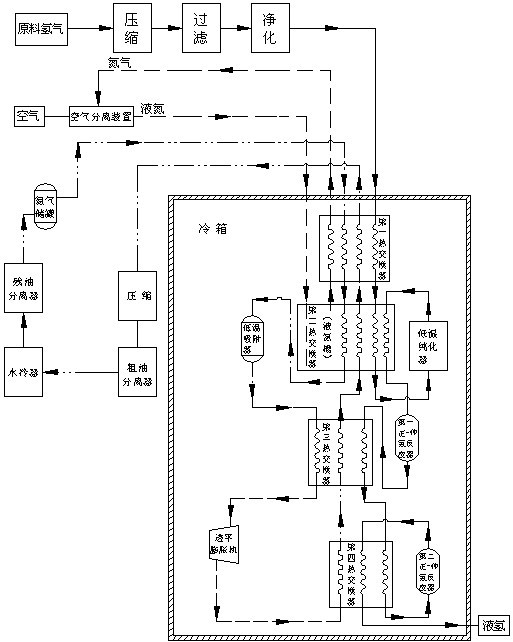

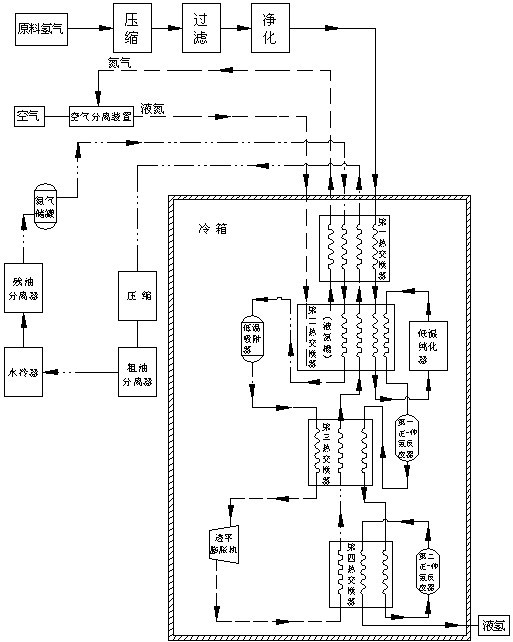

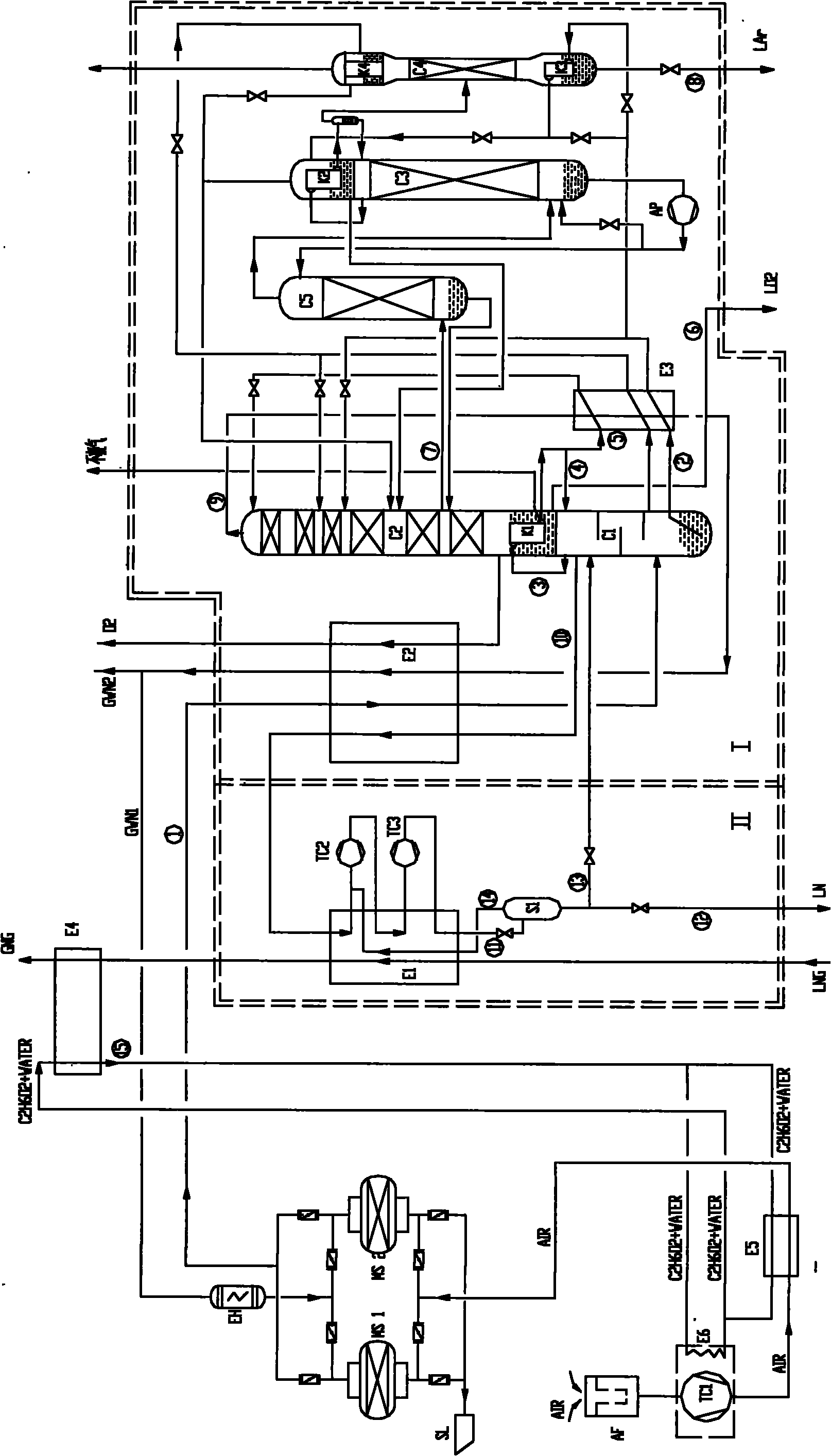

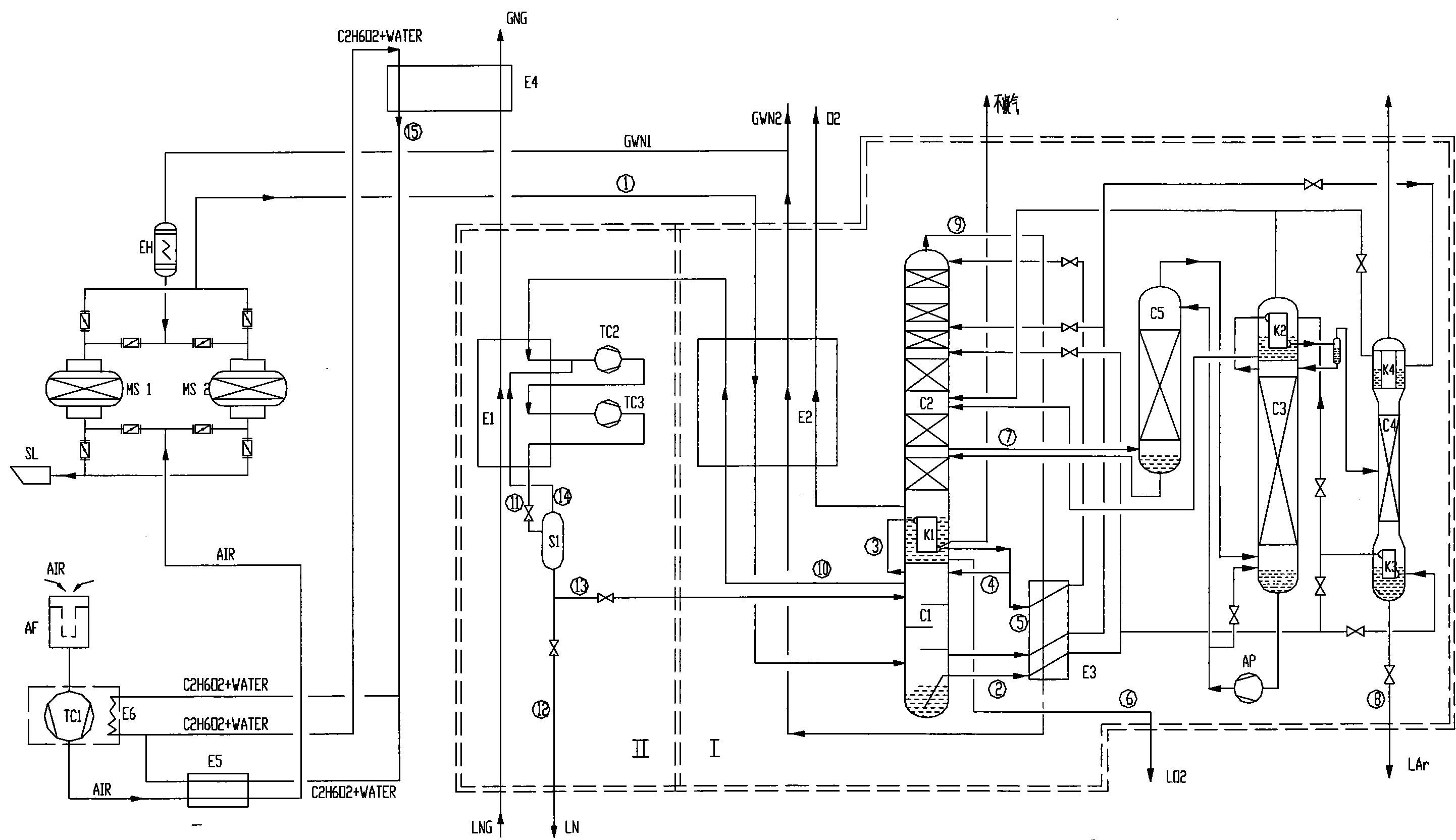

Hydrogen liquefaction process

The invention discloses a hydrogen liquefaction process comprising a nitrogen refrigeration cycle, a helium refrigeration cycle and a hydrogen refrigeration cycle. In the technical scheme, liquid helium generated by a liquid helium and air separating device is used as a refrigeration working medium, refrigerating capacity required by hydrogen condensation and liquefaction is provided by the liquid helium, rewarmed helium gas and nitrogen gas are respectively recycled and can be turned into the liquid helium and liquid nitrogen after being processed correspondingly when the refrigerating capacity is provided for the hydrogen liquefaction by the liquid helium and the liquid nitrogen, thus the continuous refrigerating capacity is provided for the hydrogen refrigeration cycle by the helium refrigeration cycle and the nitrogen refrigeration cycle, waste caused by directly discharging the helium gas or the nitrogen gas is avoided, and energy sources are saved. In the intention, operation that any one of the three refrigeration cycles is independent of the other two refrigeration cycles is realized, and heat quantity exchange is carried out among the three refrigeration cycles, thus liquid hydrogen generation is finally completed, and the liquefaction of hydrogen gas is realized by sequentially utilizing the refrigerating capacity of the liquid helium and the liquid nitrogen in the hydrogen refrigeration cycle.

Owner:ALLY HI TECH CO LTD

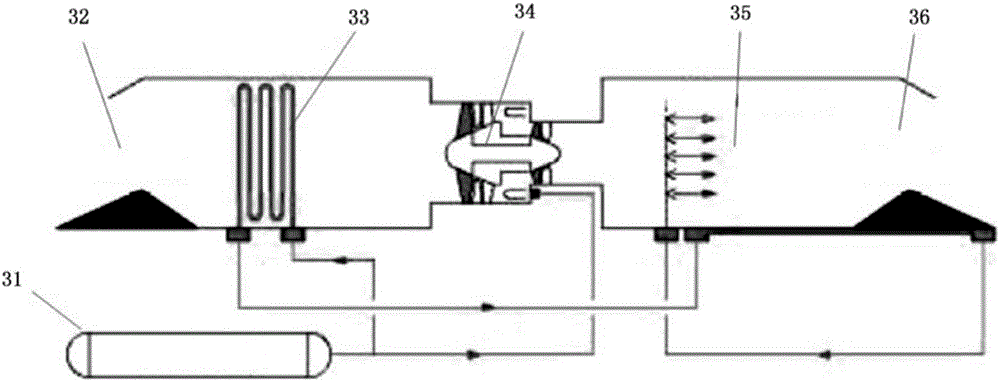

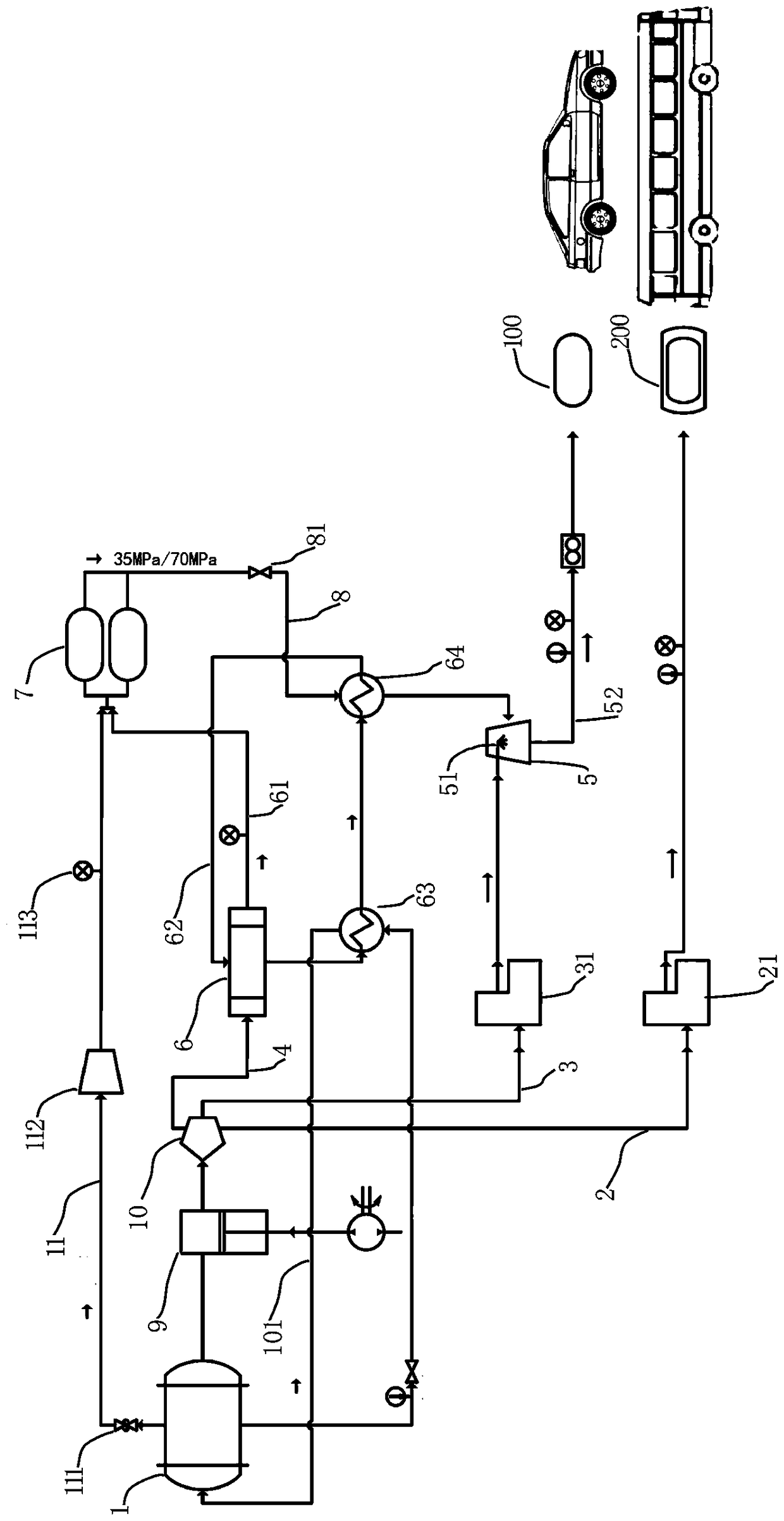

Mixed filling system applied to hydrogen filling station of liquid hydrogen

PendingCN108561749AIncreased hydrogen storage capacityIncreased fill volume requirementsGas handling/storage effectsFluid transferredHigh pressure hydrogenLiquid hydrogen

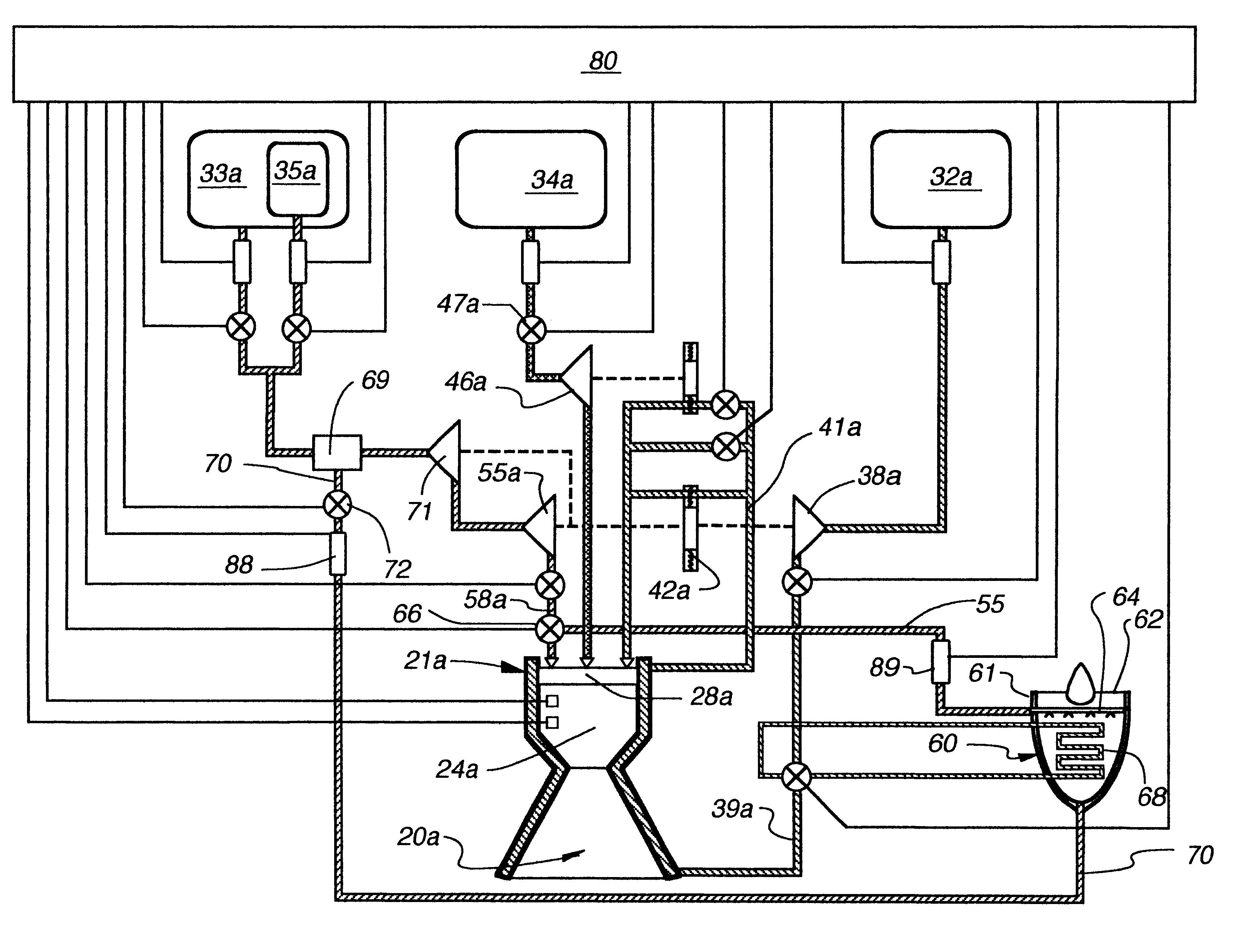

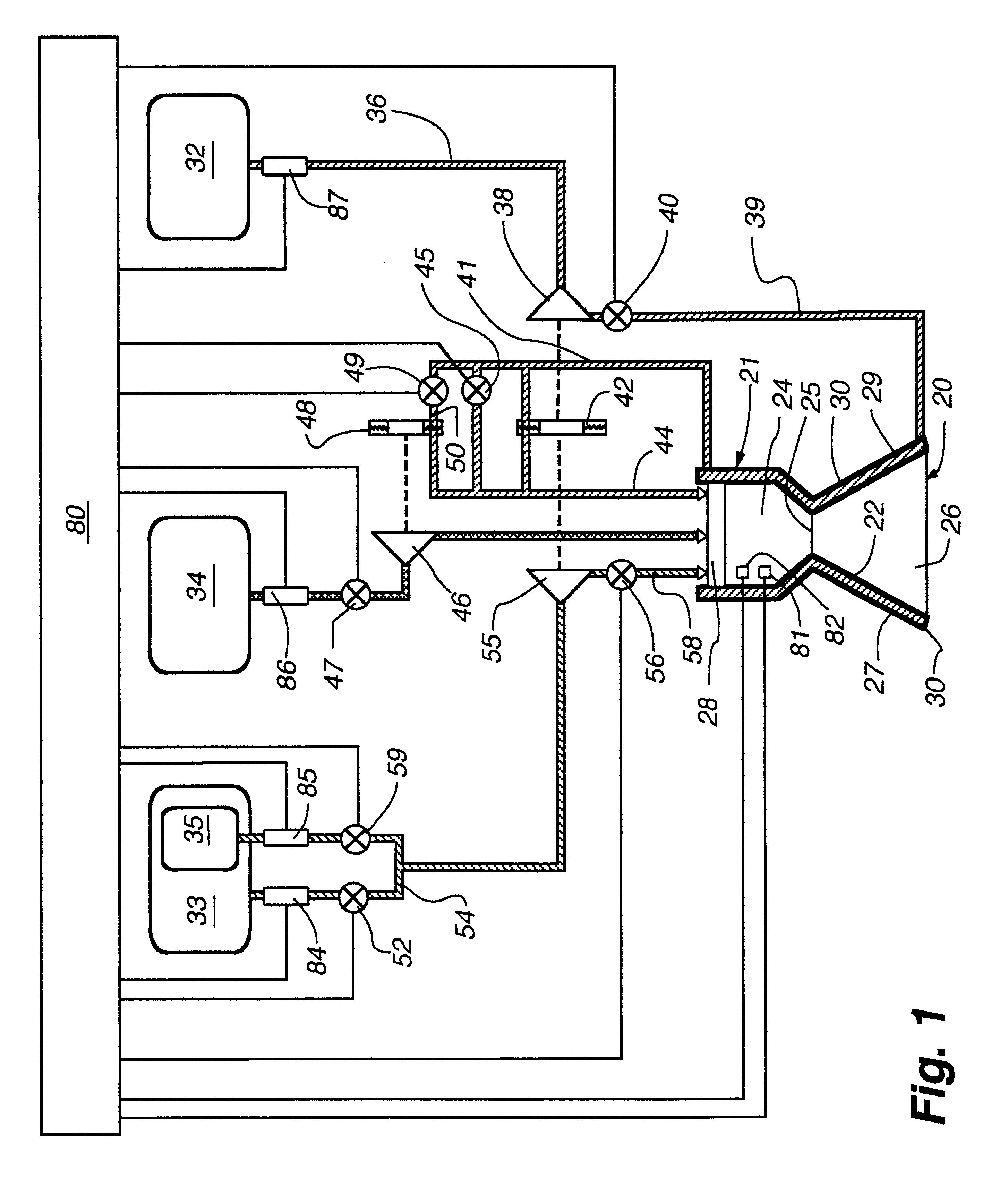

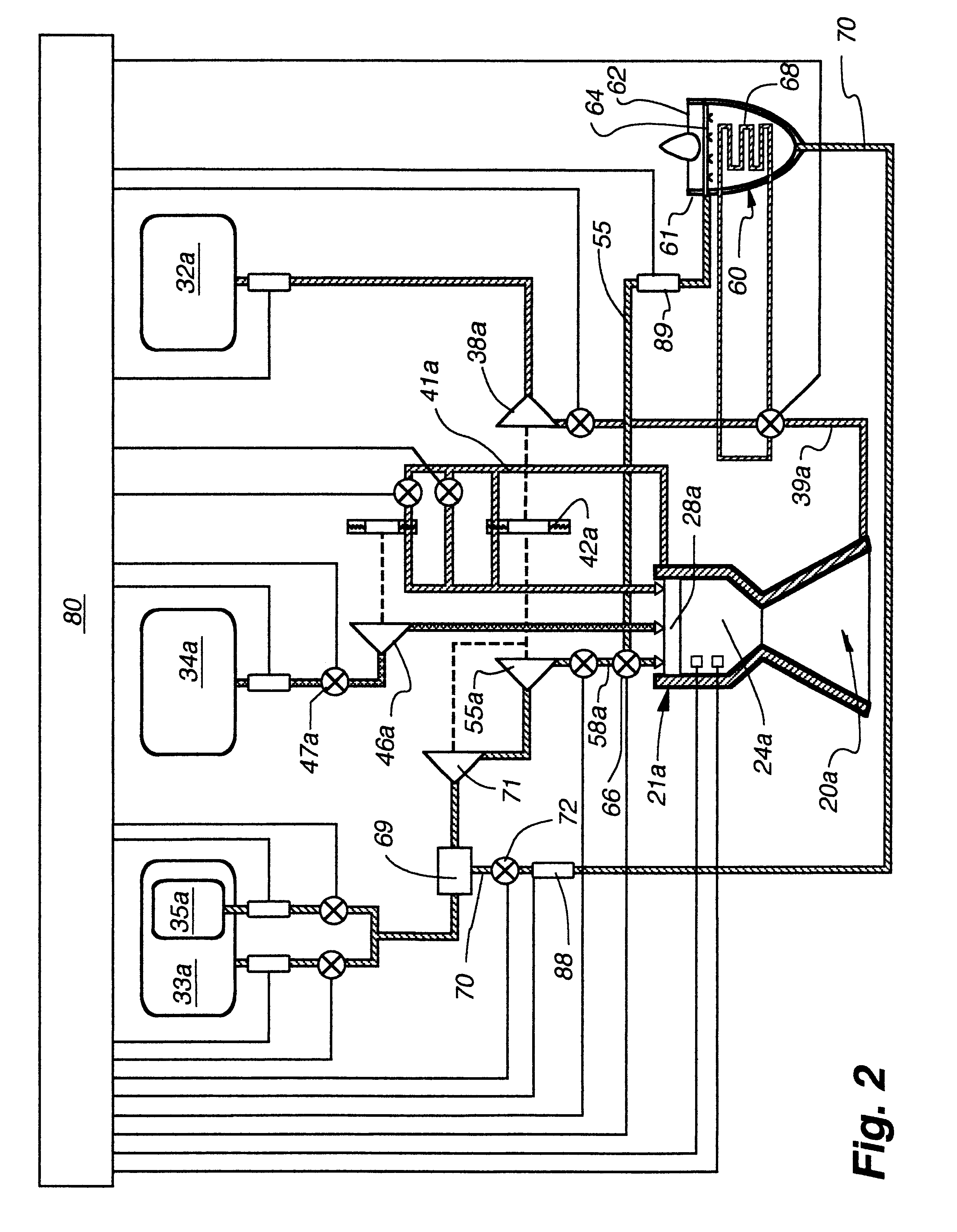

The invention discloses a mixed filling system applied to a hydrogen filling station of liquid hydrogen. The mixed filling system comprises a liquid hydrogen filling unit and a high-pressure hydrogengas filling unit which are connected with a liquid hydrogen storage pot for the station, wherein a first liquid hydrogen conveying pipe in the liquid hydrogen filling unit can be communicated with theliquid hydrogen storage pot for the station through a liquid hydrogen pump; an output end of the first liquid hydrogen conveying pipe is used for connecting a liquid hydrogen filling gun; the high-pressure hydrogen gas filling unit comprises a second liquid hydrogen conveying pipe and a third liquid hydrogen conveying pipe which can be communicated with the liquid hydrogen storage pot for the station through the liquid hydrogen pump; the second liquid hydrogen conveying pipe is communicated with a spraying nozzle in a gas-liquid mixer; the third liquid hydrogen conveying pipe is communicatedwith a vaporizer; a gas output pipe on the vaporizer is communicated with a high-pressure hydrogen gas hydrogen storage bottle; a storage bottle output pipeline of an output end of the high-pressure hydrogen gas hydrogen storage bottle is communicated to the gas-liquid mixer; a hydrogen gas output pipe of the output end of the gas-liquid mixer is used for being connected with a high-pressure hydrogen gas filling gun. The mixed filling system has the advantages that a hydrogen filling form is effectively increased and the liquid hydrogen capability is greatly improved.

Owner:ZHANGJIAGANG RES INST OF HYDROGEN ENERGY CO LTD

Method and apparatus for handling small quantities of fluids

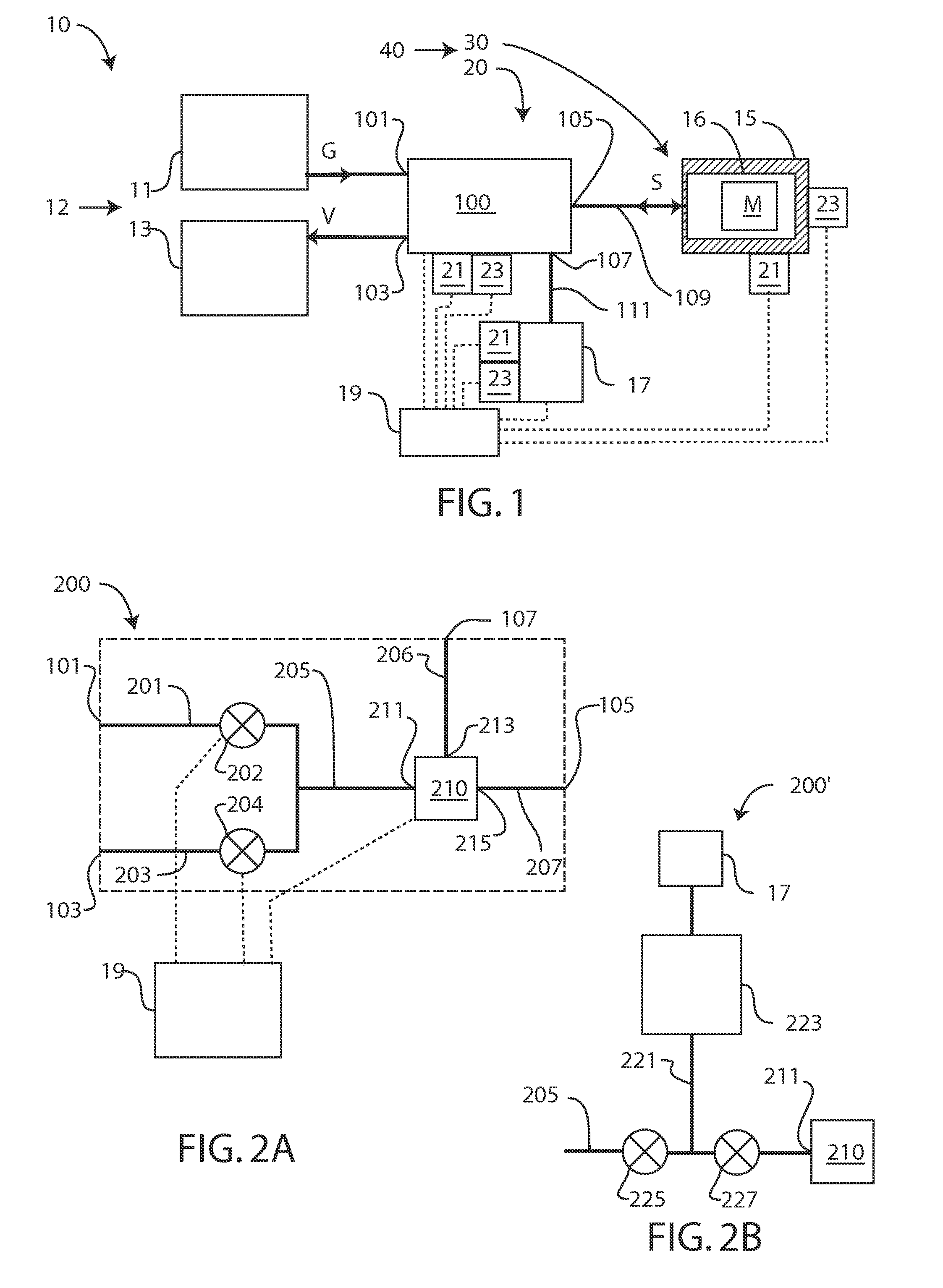

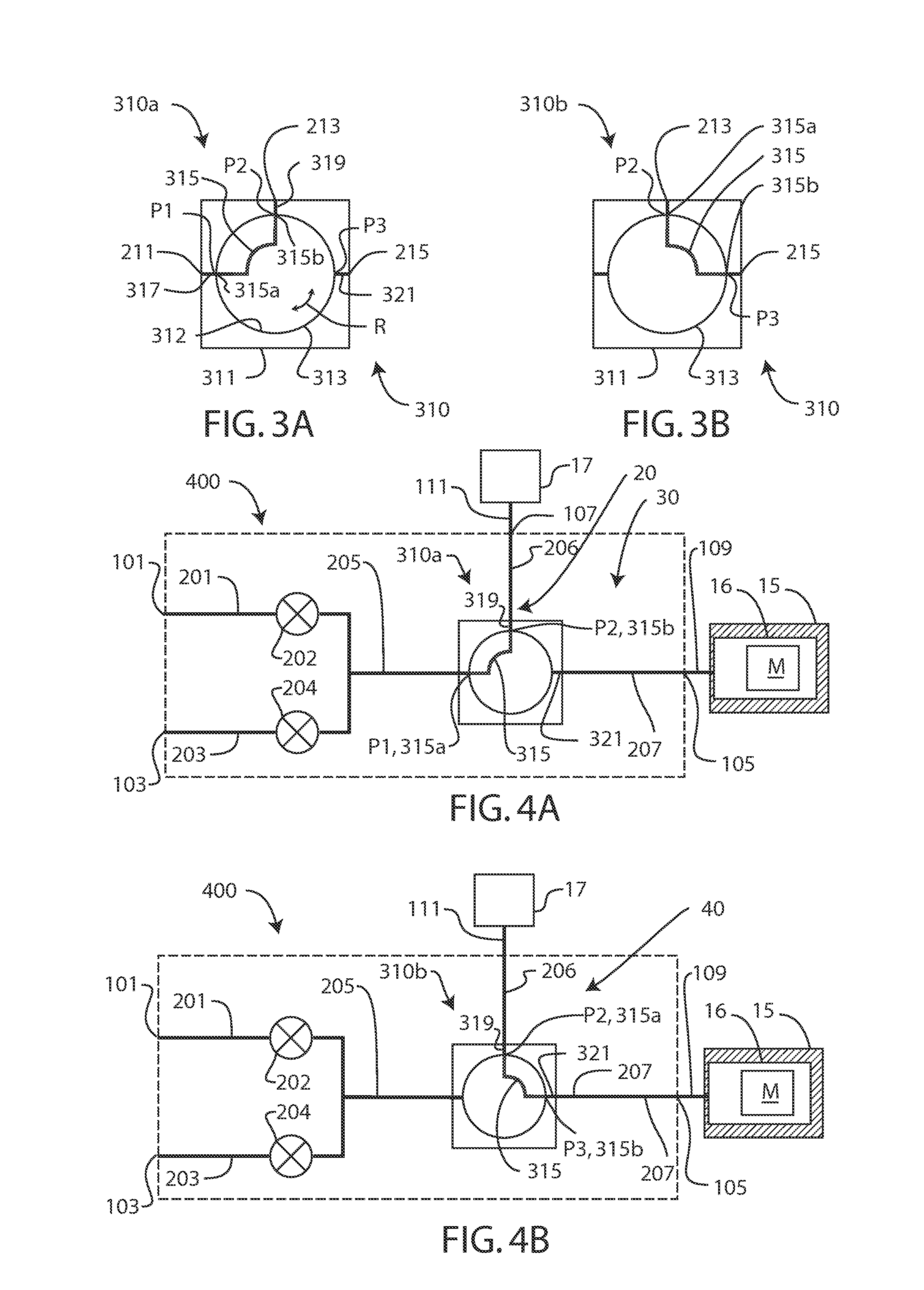

ActiveUS20070000337A1Apparatus becomes greatImprove accuracyWithdrawing sample devicesRotary valveEngineering

The invention relates to a method and an apparatus for handling small quantities of fluids useful, for example, in measuring the gas and / or liquid sorption and desorption properties of substances such as hydrogen sorption by solid or liquid hydrogen storage materials. In one embodiment, low-volume rotary valves are used to dose samples in a sample holder. In another embodiment, a rotary valve is used as a dosing / bypass valve to both condition and measure samples. The invention also relates to an actuator for a rotary valve that has a manual override feature.

Owner:HY ENERGY

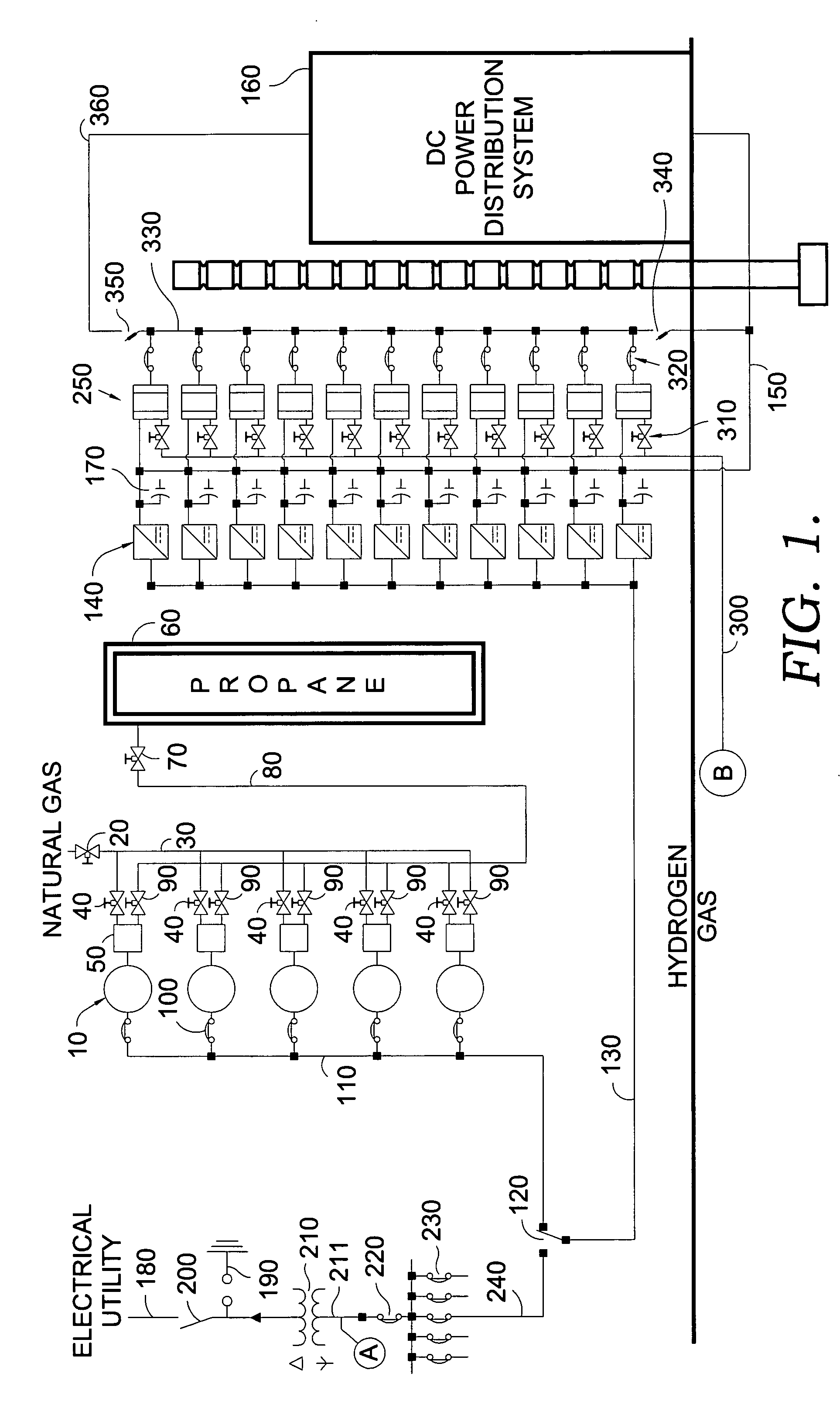

Power system for a telecommunications facility

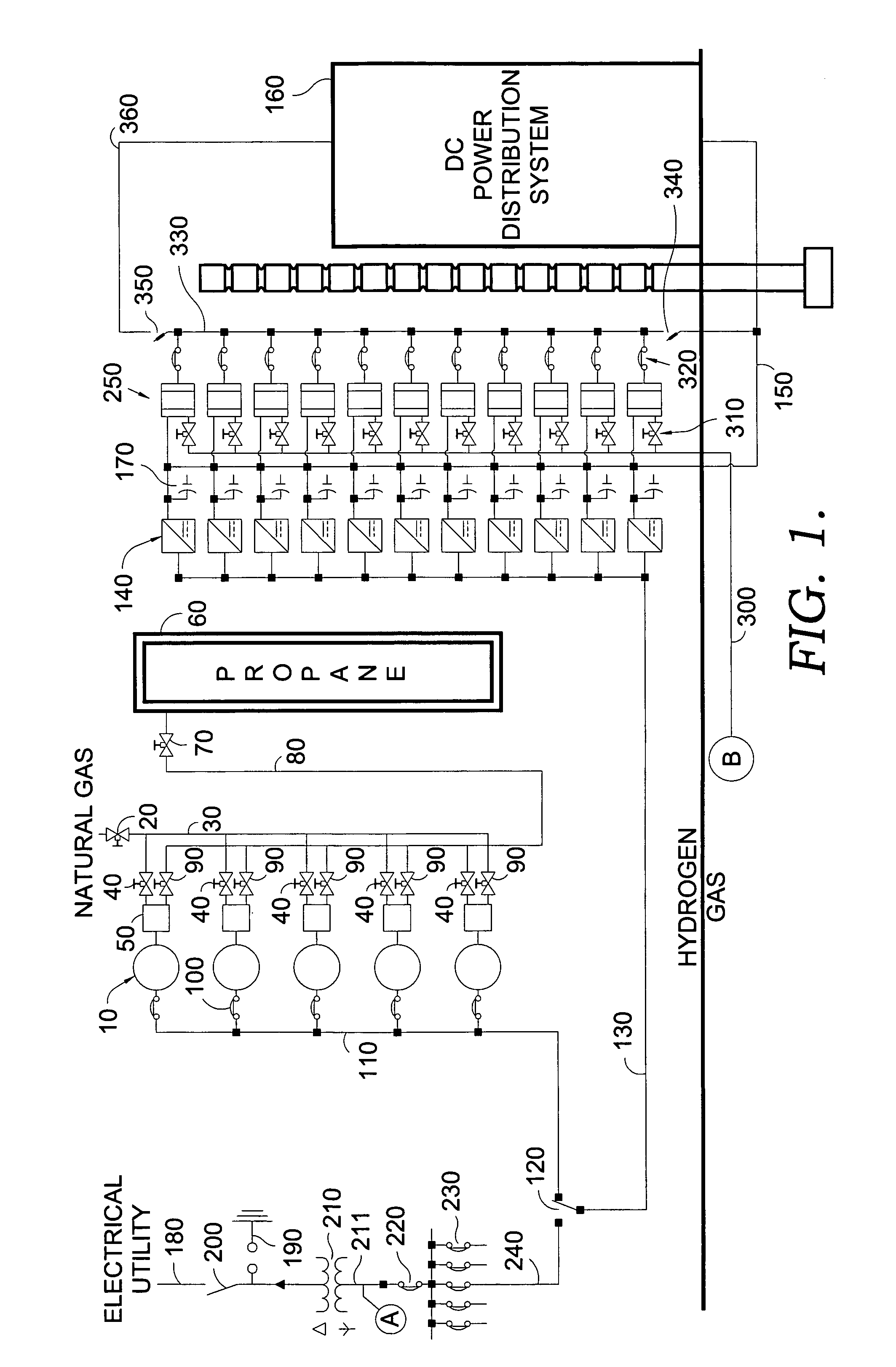

ActiveUS7081687B2Internal combustion piston enginesFuel supply apparatusExpansion tankTelecommunications link

An energy generating system for a telecommunications facility includes a hydrogen fuel supply system. The hydrogen fuel supply system includes a source of liquid hydrogen which uses a high pressure expansion tank along with additional storage tanks. The system also incorporates first and second stage heat exchangers. The first stage exchanger is used to benefit from the endothermic reaction created when liquid hydrogen transforms into vapor. The cooling provided from this state change is transferred into a second medium which is delivered into a second stage heat transfer device and then used for air conditioning purposes. The system also includes a hydrogen generator which may be used to create AC power by combusting vaporous hydrogen.

Owner:T MOBILE INNOVATIONS LLC

Full-liquid air separation device using cold energy of liquefied natural gas (LNG)

InactiveCN101846436ACompact structureImprove heat transfer efficiencySolidificationLiquefactionComing outAir cleaning

The invention disclose a full-liquid air separation device using the cold energy of the liquefied natural gas (LNG), comprising an air compressing and pre-cooling system, an air purifying system, an air separating system and a nitrogen circulating system capable of recycling the cold energy of the LNG which has the pressure of 8.0MPa or higher. The nitrogen circulating system capable of recycling the cold energy of the LNG comprises a nitrogen compressor, a wound tube heat exchanger and a gas-liquid separator; the gaseous nitrogen coming out of the gas separating system is made to enter the wound tube heat exchanger to exchange heat with the LNG and then is compressed by the nitrogen compressor to have higher pressure; the liquid nitrogen coming out of the wound tube heat exchanger is separated into gaseous nitrogen and liquid hydrogen; the liquid nitrogen coming out of the gas-liquid separator is separated into two branches, wherein one branch of the liquid nitrogen is fed in the air separating system to be used as the return liquid of a lower tower to involve in the rectification of the lower tower and to be made to carry the cold energy in the air separating system, and the other branch of the liquid nitrogen is discharged as the liquid nitrogen product; the gaseous nitrogen coming out of the gas-liquid separator is made to enter the wound tube heat exchanger and reheated to the temperature of the inlet of the nitrogen compressor and then made to enter the nitrogen compressor to circulate. Compared with the prior air separation device of the same scale, the full-liquid air separation device can save the electric energy of more than 50 percent and the consumed water of more than 90 percent.

Owner:CHINA NAT OFFSHORE OIL CORP +1

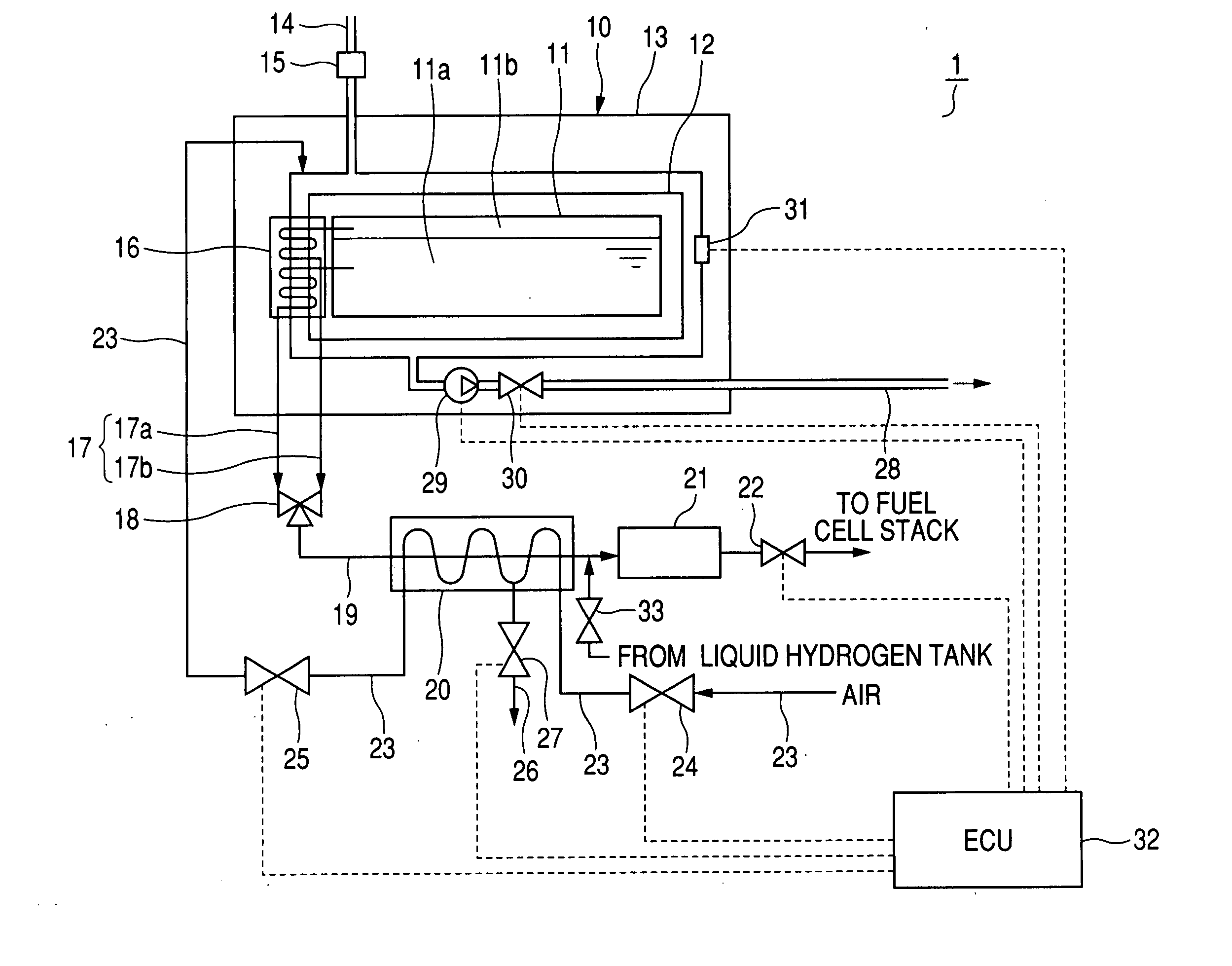

Liquid fuel storage system

Owner:DENSO CORP

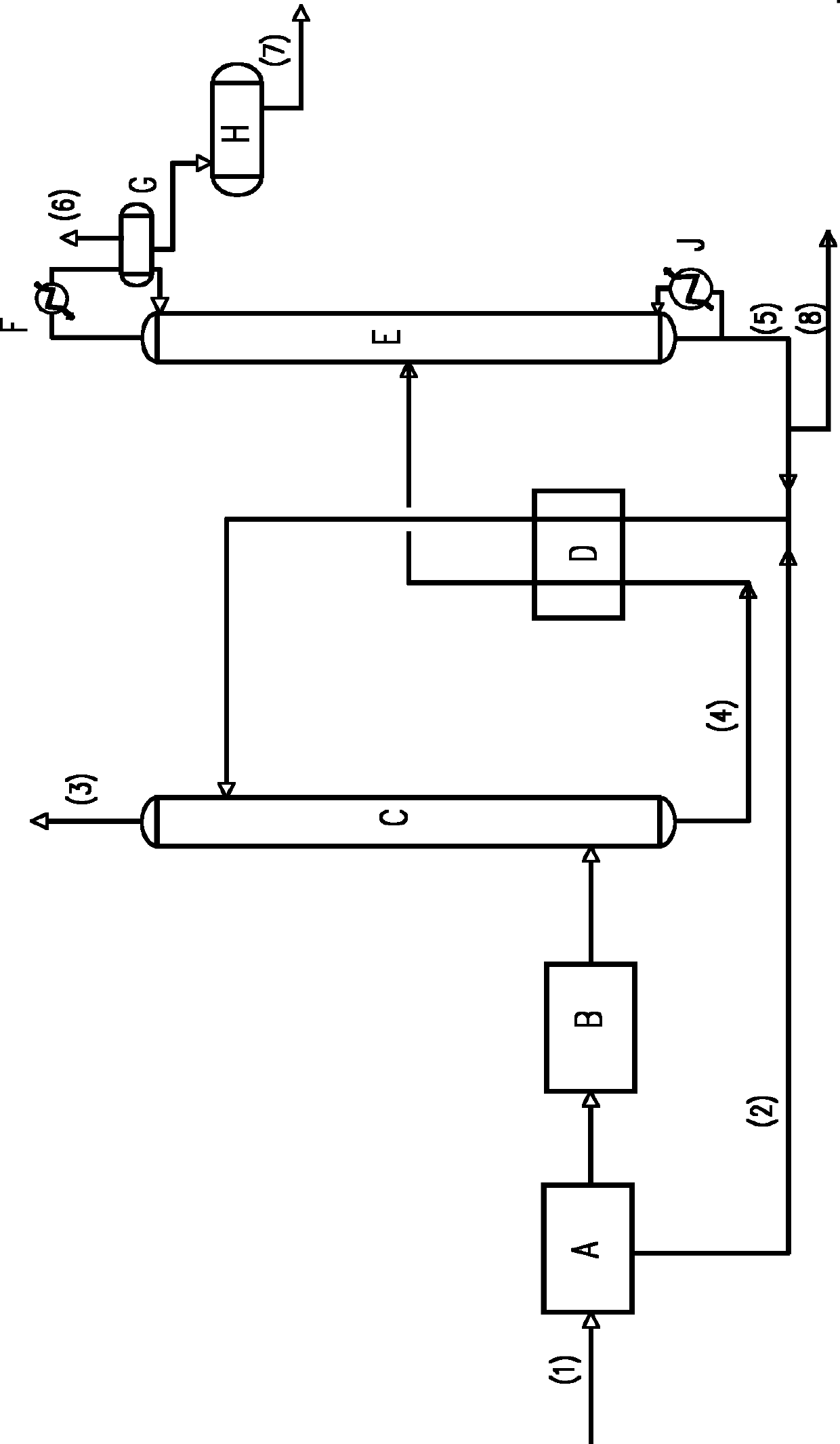

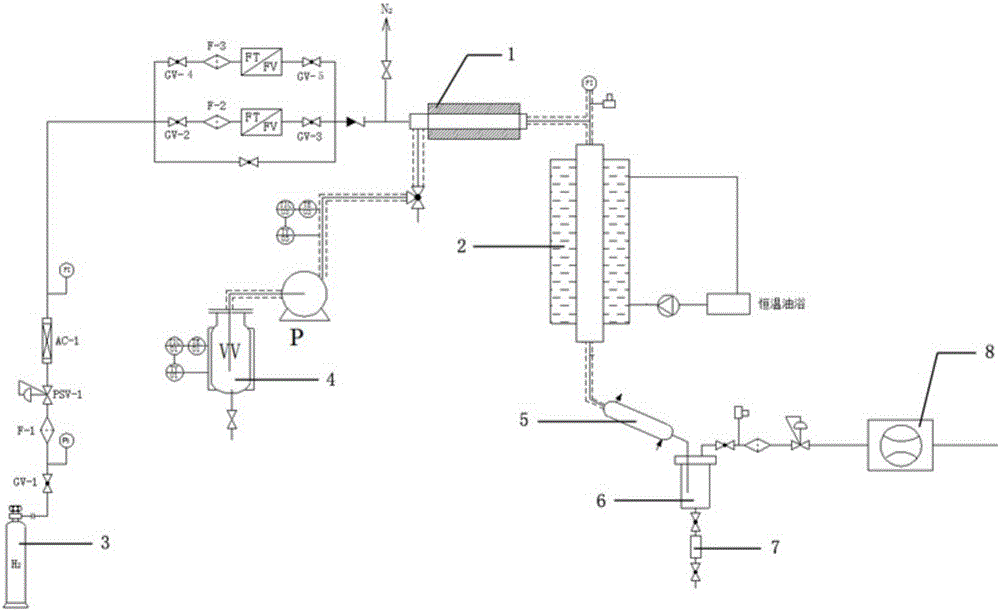

Continuous hydrogenation reaction system for liquid organic hydrogen storage carrier and hydrogenation reaction method

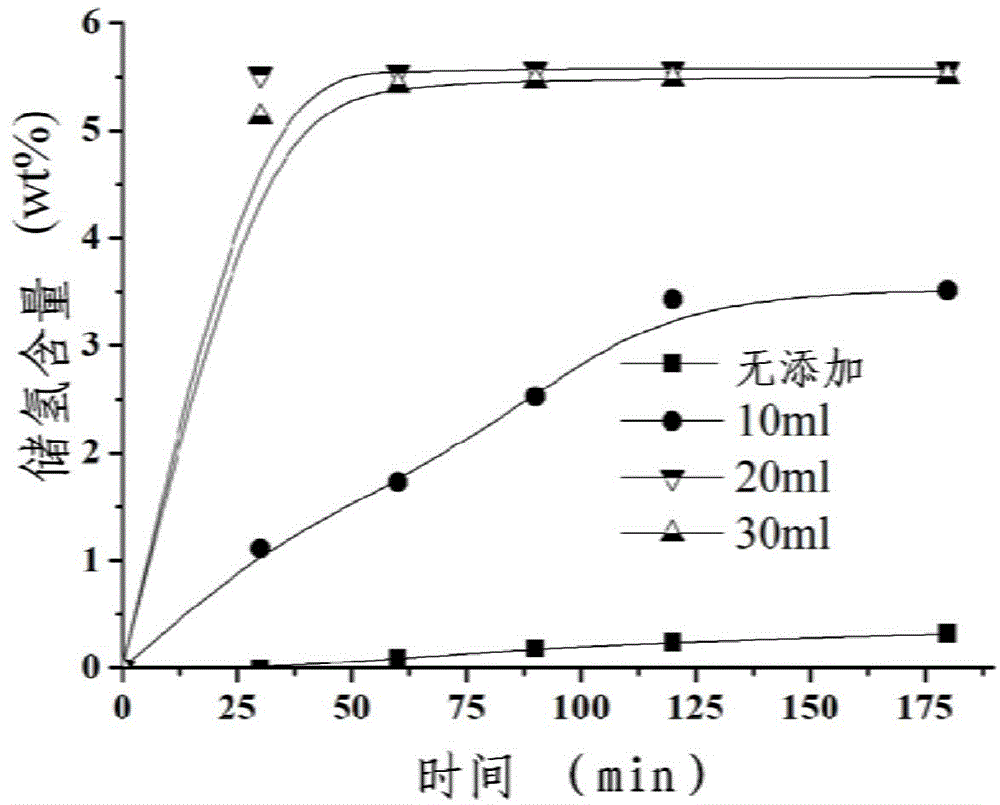

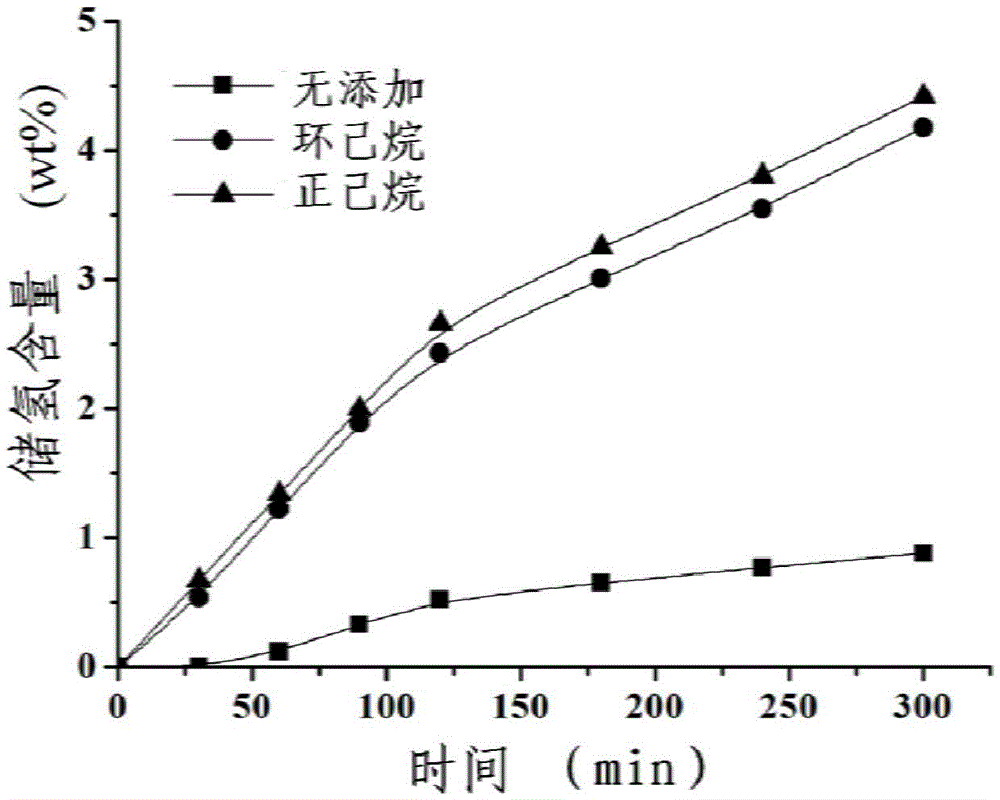

ActiveCN105060244AChange viscosityImprove responseHydrogenMetal/metal-oxides/metal-hydroxide catalystsTemperature controlHydrogenation reaction

The invention discloses a continuous hydrogenation reaction system for a liquid organic hydrogen storage carrier and a hydrogenation reaction method. The system comprises a feeding system, preheaters, static bed reaction stills and separation devices. The feeding system is communicated with inlets of the preheaters through pipelines. Outlets of the preheaters are communicated with inlets of the static bed reaction stills through pipelines. Outlets of the static bed reaction stills are communicated with inlets of the separation devices through pipelines. The static bed reaction stills are filled with hydrogenation catalysts and inert materials. The interiors of the reaction stills are kept at the constant temperature through circulation heat conduction media in interlayers of the surfaces of the static bed reaction stills. According to the continuous hydrogenation reaction system, the single-tube type static bed reaction stills are mainly adopted, the single-tube type static bed reaction stills are filled with the hydrogenation catalysts and the inert materials, heat tracing and heating control systems are arranged in all the pipelines in the liquid feeding system to be used for conducting temperature-control heating on liquid flowing through the system, a plurality of sets of gas quality and flow controller systems are designed in the system, the preheaters in the system are designed to be gas-liquid blending type preheaters, and the hydrogenation effect of the liquid hydrogen storage carrier is improved beneficially.

Owner:WUHAN HYNERTECH CO LTD

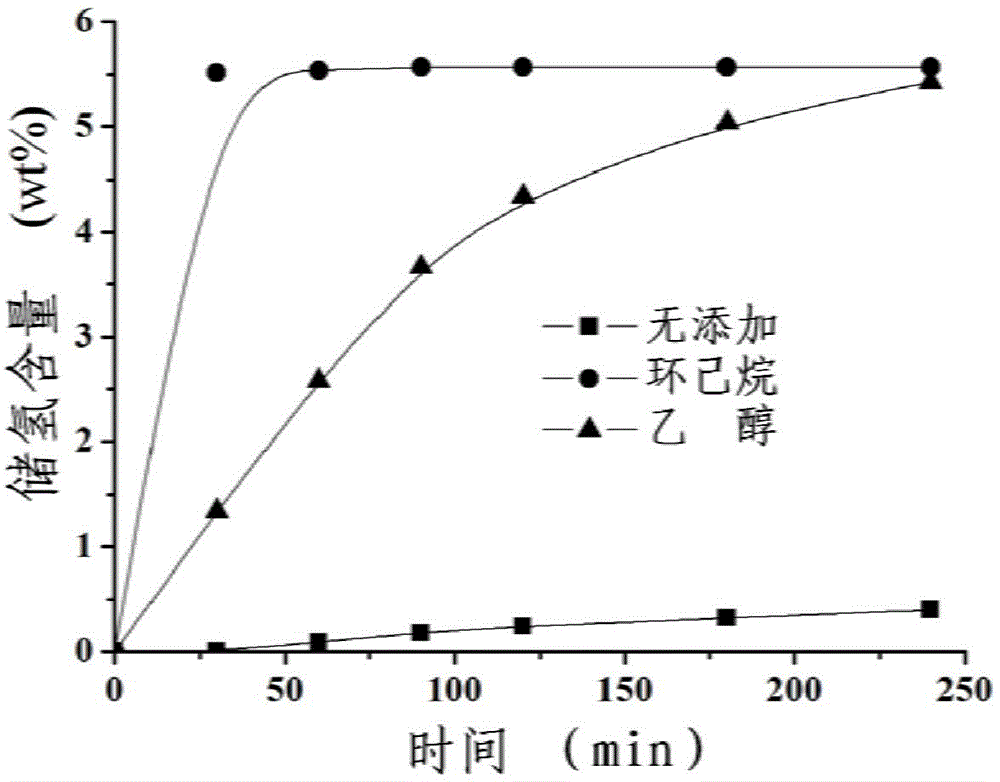

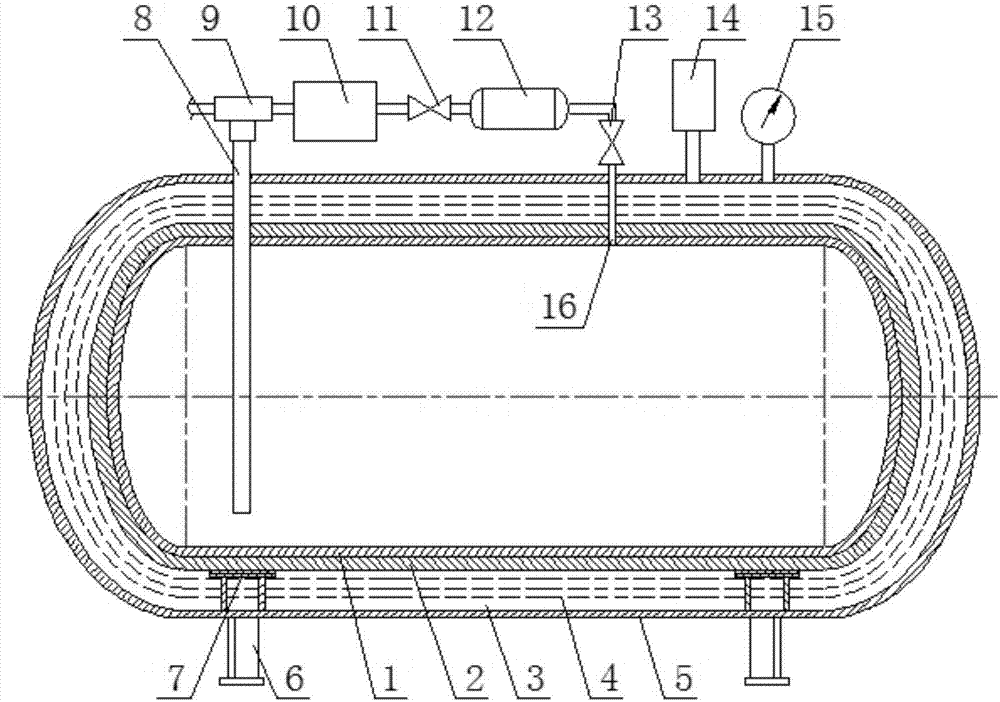

Liquid hydrogen storage system

ActiveCN104555914AImprove the problem of difficult dehydrogenationLow melting pointHydrogen productionHydrogen/synthetic gas productionLiquid stateRoom temperature

The invention discloses a liquid hydrogen storage system. The liquid hydrogen storage system comprises at least two different hydrogen storage components which are unsaturated aromatic hydrocarbons or heterocyclic unsaturated compounds, wherein at least one of the hydrogen storage components is a low-melting-point compound of which the melting point is lower than 80DEG C. The liquid hydrogen storage system actually is a multi-element mixed liquid fused heterocyclic aromatic hydrocarbon type hydrogen storage system. By adopting the liquid hydrogen storage system disclosed by the invention, after two or more types of fused heterocyclic unsaturated compounds are mixed together, a formed mixed system has a eutectic point which is at least lower than the melting point of one of the components. However, at least one type of low-melting-point compound of which the melting point is lower than 80 DEG C is selected from the two or more types of hydrogen storage components to ensure that the eutectic point of the hydrogen storage system is lowered to near room temperature, thereby obtaining a hydrogen storage system which is in a liquid state at room temperature.

Owner:WUHAN HYNERTECH CO LTD

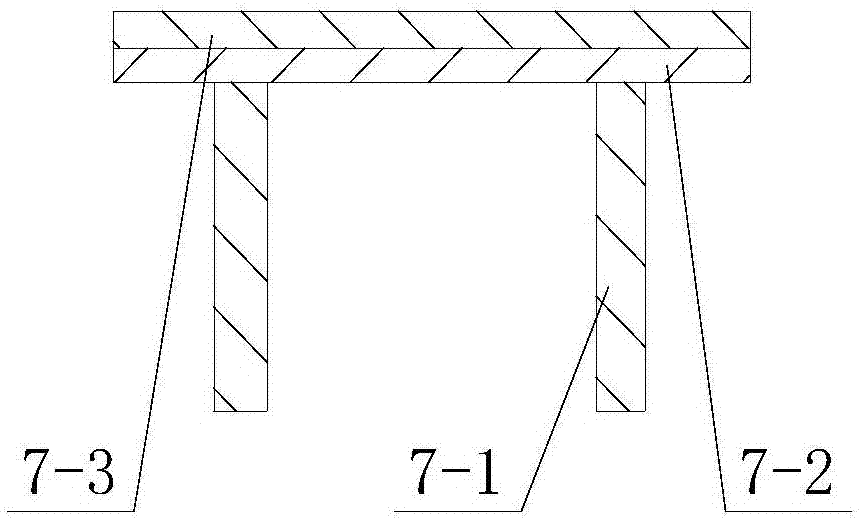

Fixed type multi-layered vacuum heat-insulating high-pressure liquid hydrogen storage tank

InactiveCN107228274ALarge hydrogen reservesReduce evaporationVessel geometry/arrangement/sizeVessel wallsLiquid hydrogenVolumetric Mass Density

The invention relates to the field of development of hydrogen energy source storage equipment, and aims to provide a fixed type multi-layered vacuum heat-insulating high-pressure liquid hydrogen storage tank. The liquid hydrogen storage tank comprises an inner tank and an outer tank; a fiber enhanced epoxy resin based composite material layer covers the outer shell of the inner tank and is fixed in a chamber body of the outer tank by a supporting part; the inner tank and the outer tank are of vacuum heat-insulating interlayers; multiple vacuum radiation-prevention heat insulating layers covering the whole inner tank are paved in the vacuum heat-insulating interlayers; a vacuumizing device and a vacuum meter which communicate with the vacuum heat-insulating interlayers are arranged on the outer tank. By comprehensively considering two factors of the temperature and the pressure in a hydrogen phase chart, the used fiber-wound aluminum inner container can bear the pressure, and the hydrogen storage density is improved more, the waste is avoided and an overpressure condition is also prevented, and the safety of the structure is ensured. The fixed type multi-layered vacuum heat-insulating high-pressure liquid hydrogen storage tank is suitable for liquid hydrogen filling stations and gas-state hydrogen filling stations.

Owner:ZHEJIANG UNIV

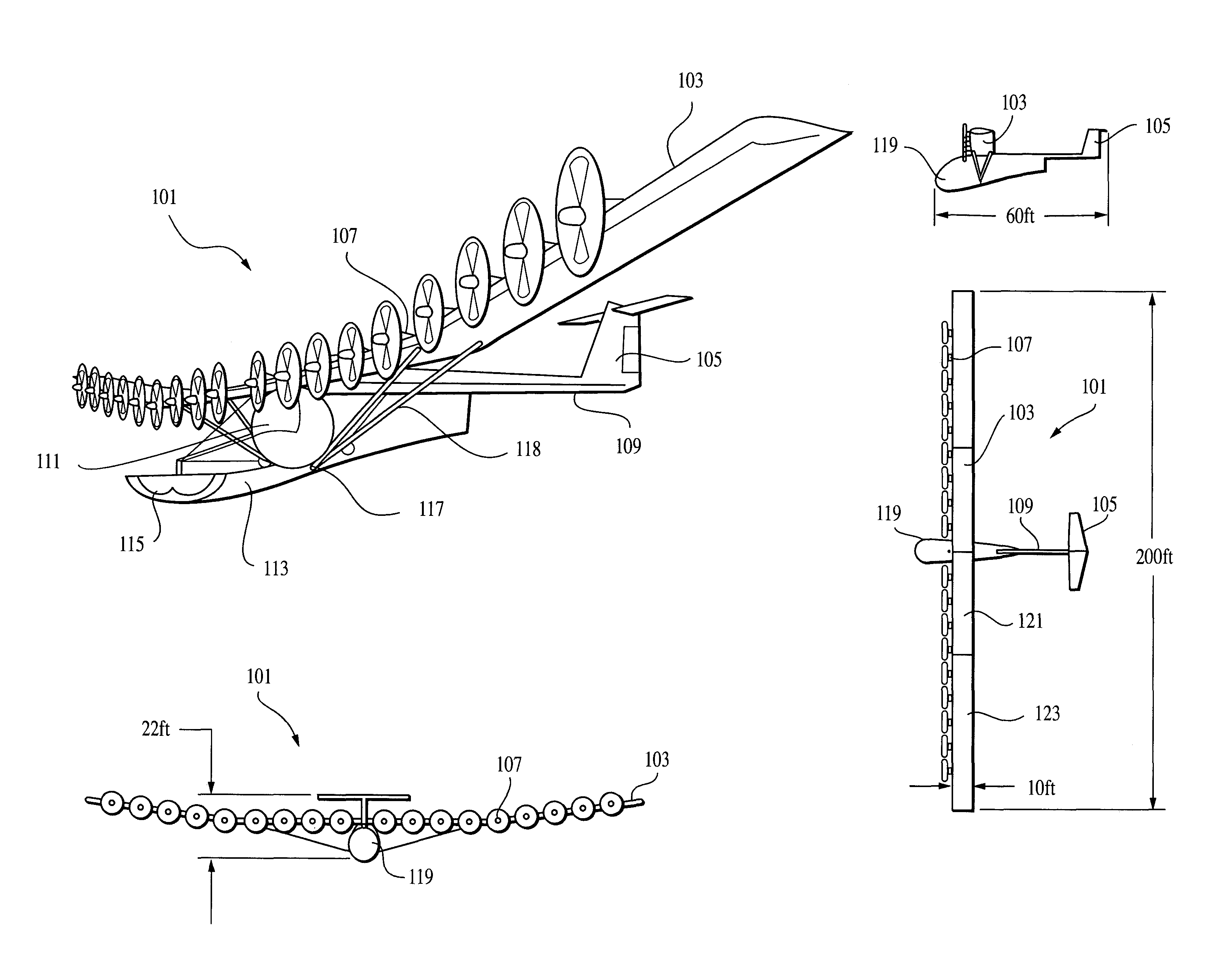

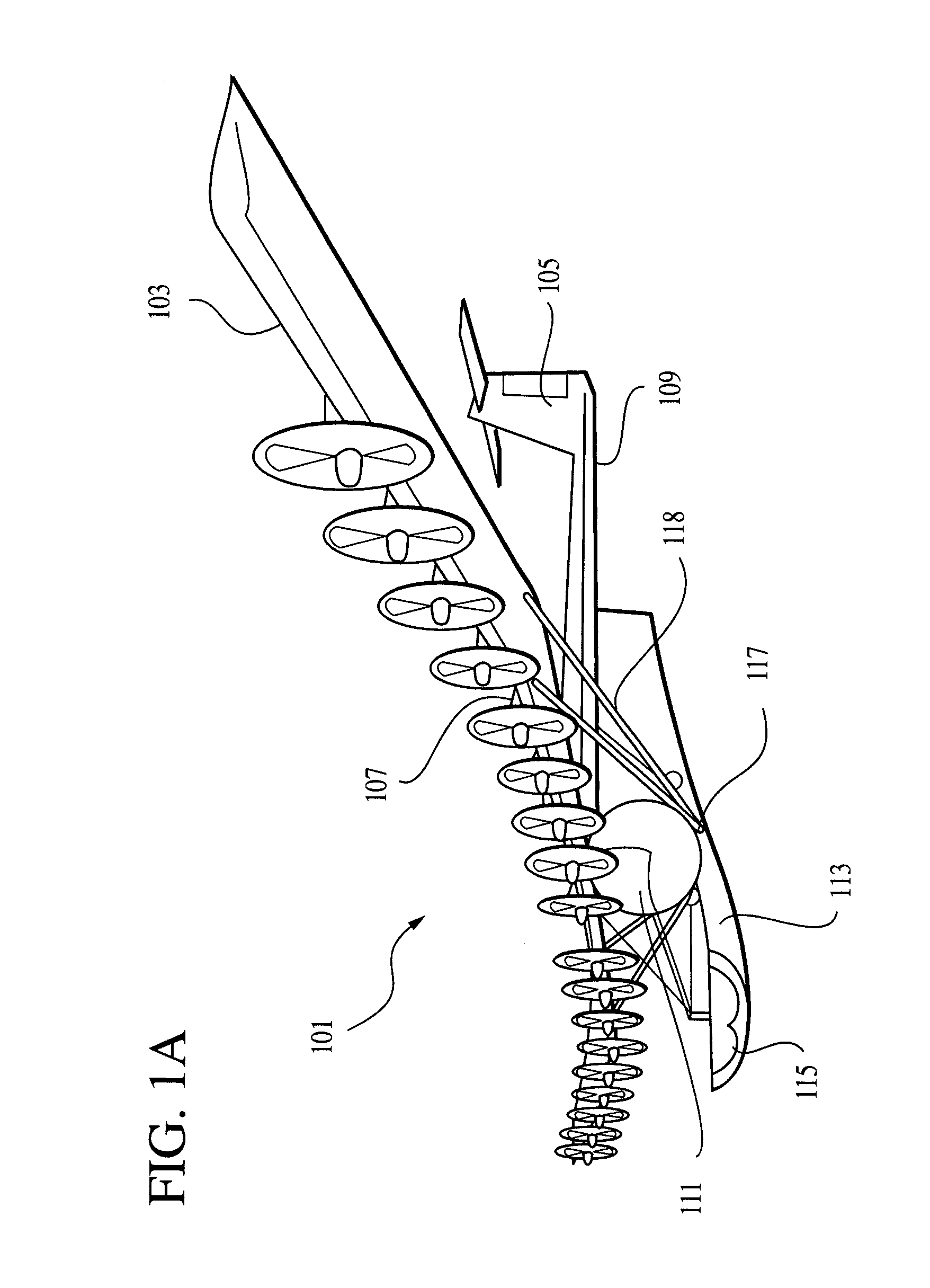

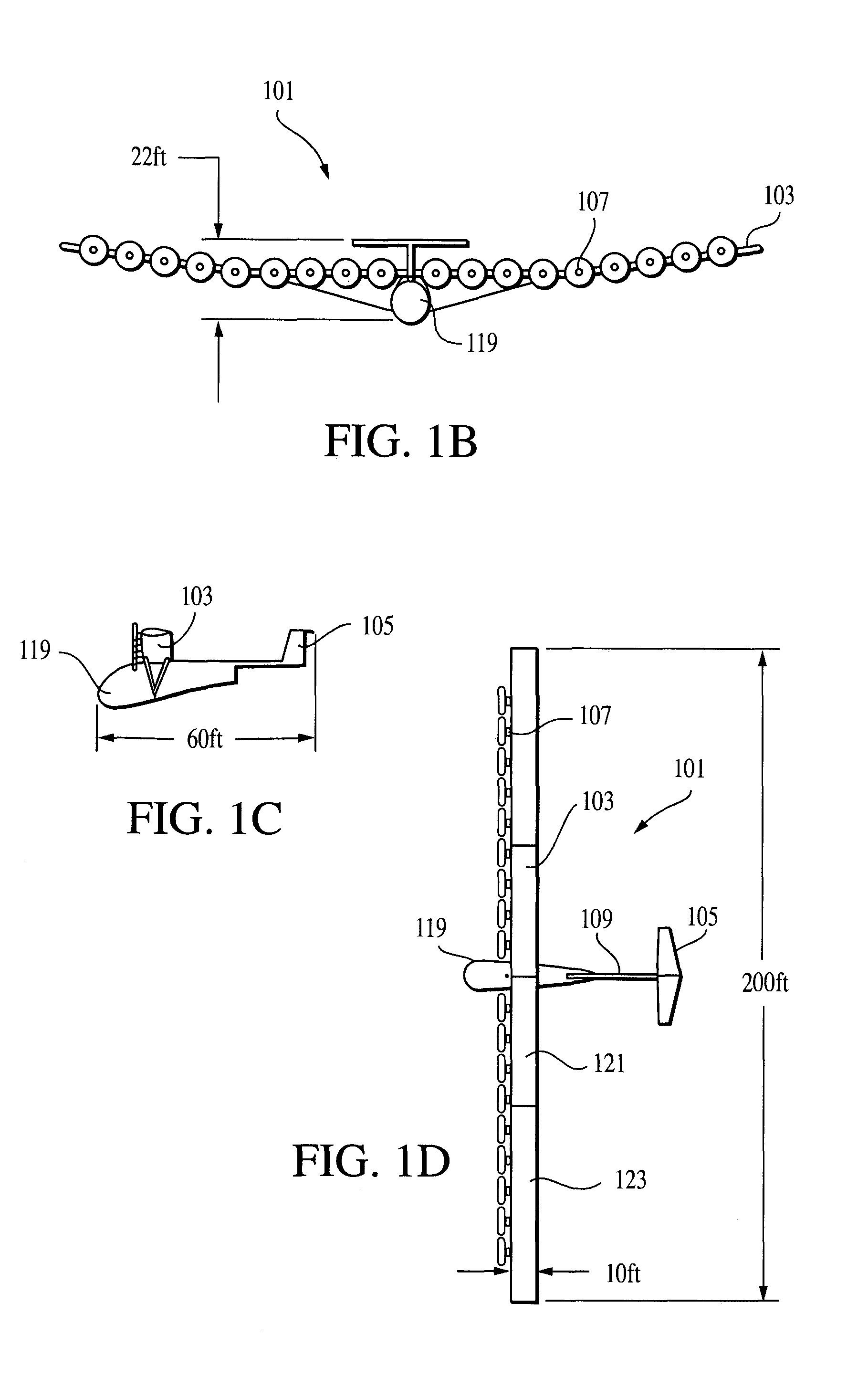

Hydrogen powered aircraft

InactiveUS7281681B2Reduce power consumptionSimple and reliable processWing shapesAll-wing aircraftFuel tankLiquid hydrogen

Disclosed is an aircraft, configured to have a wide range of flight speeds, consuming low levels of power for an extended period of time, while supporting a communications platform with an unobstructed downward-looking view. The aircraft includes an extendable slat at the leading edge of the wing, and a reflexed trailing edge. The aircraft comprises a flying wing extending laterally between two ends and a center point. The wing is swept and has a relatively constant chord. The aircraft also includes a power module configured to provide power via a fuel cell. The fuel cell stores liquid hydrogen as fuel, but uses gaseous hydrogen in the fuel cell. A fuel tank heater is used to control the boil-rate of the fuel in the fuel tank. The fuel cell compresses ambient air for an oxidizer, and operates with the fuel and oxidizer at pressures below one atmosphere. The aircraft of the invention includes a support structure including a plurality of supports, where the supports form a tetrahedron that affixes to the wing.

Owner:AEROVIRONMENT INC

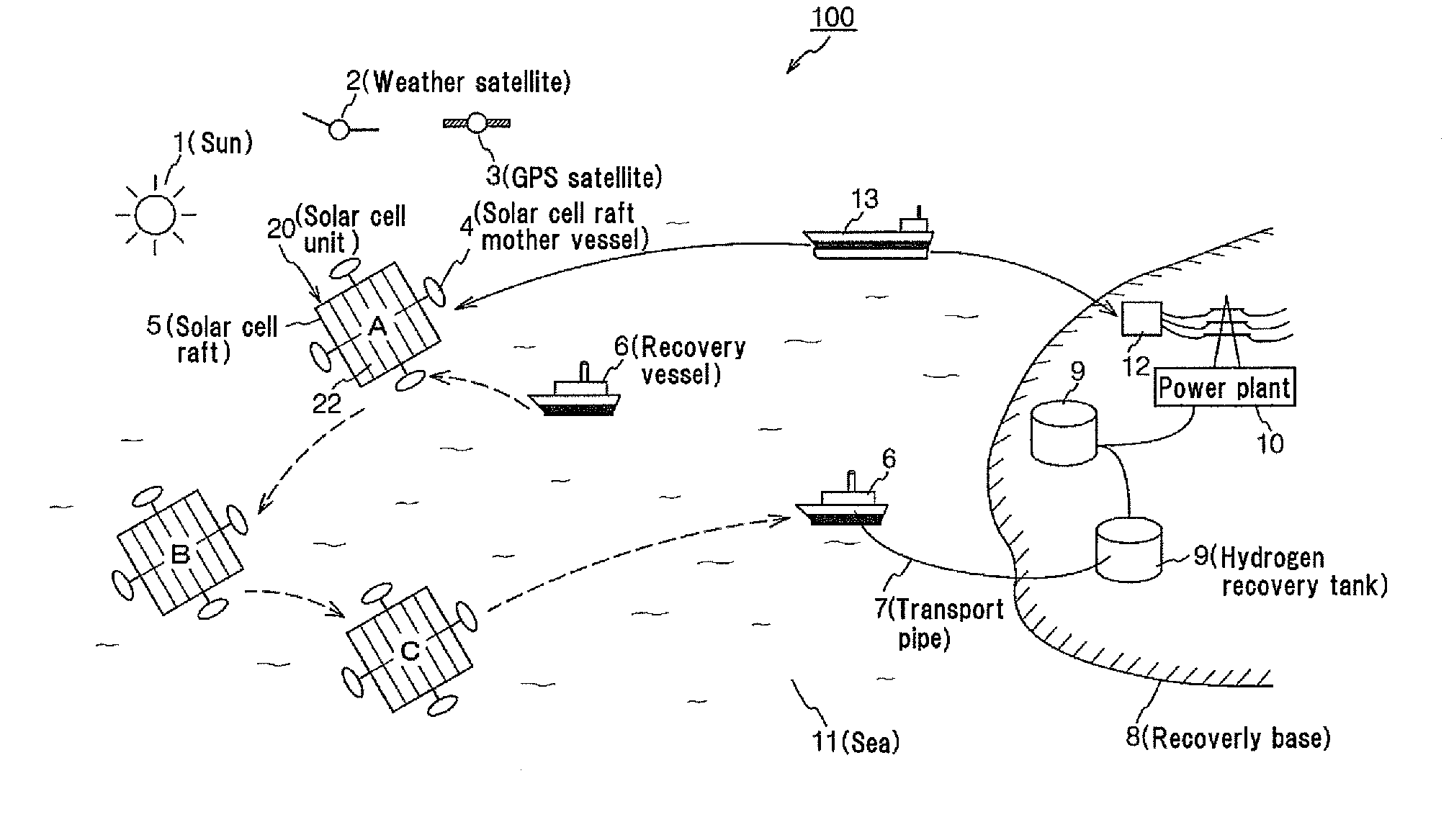

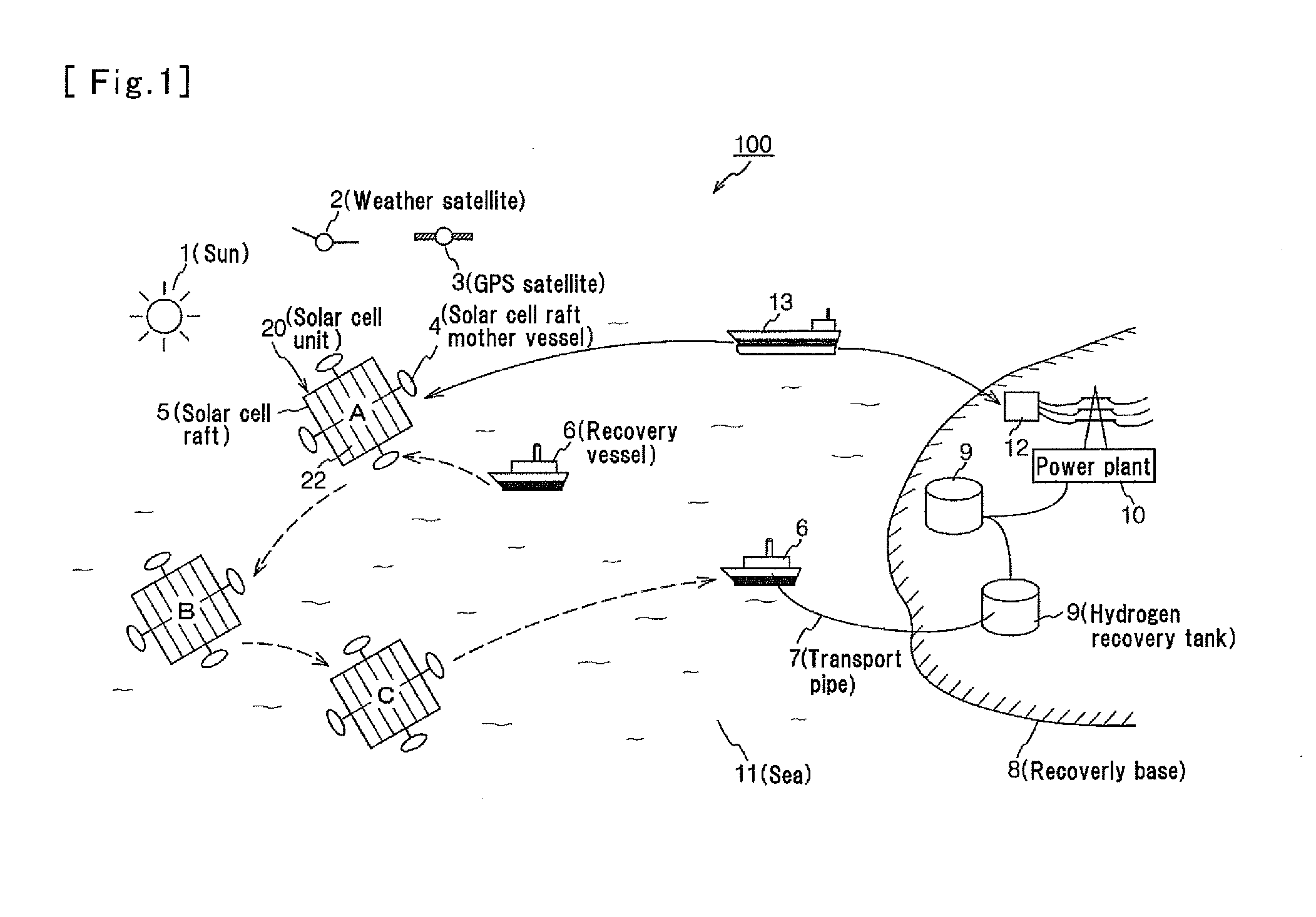

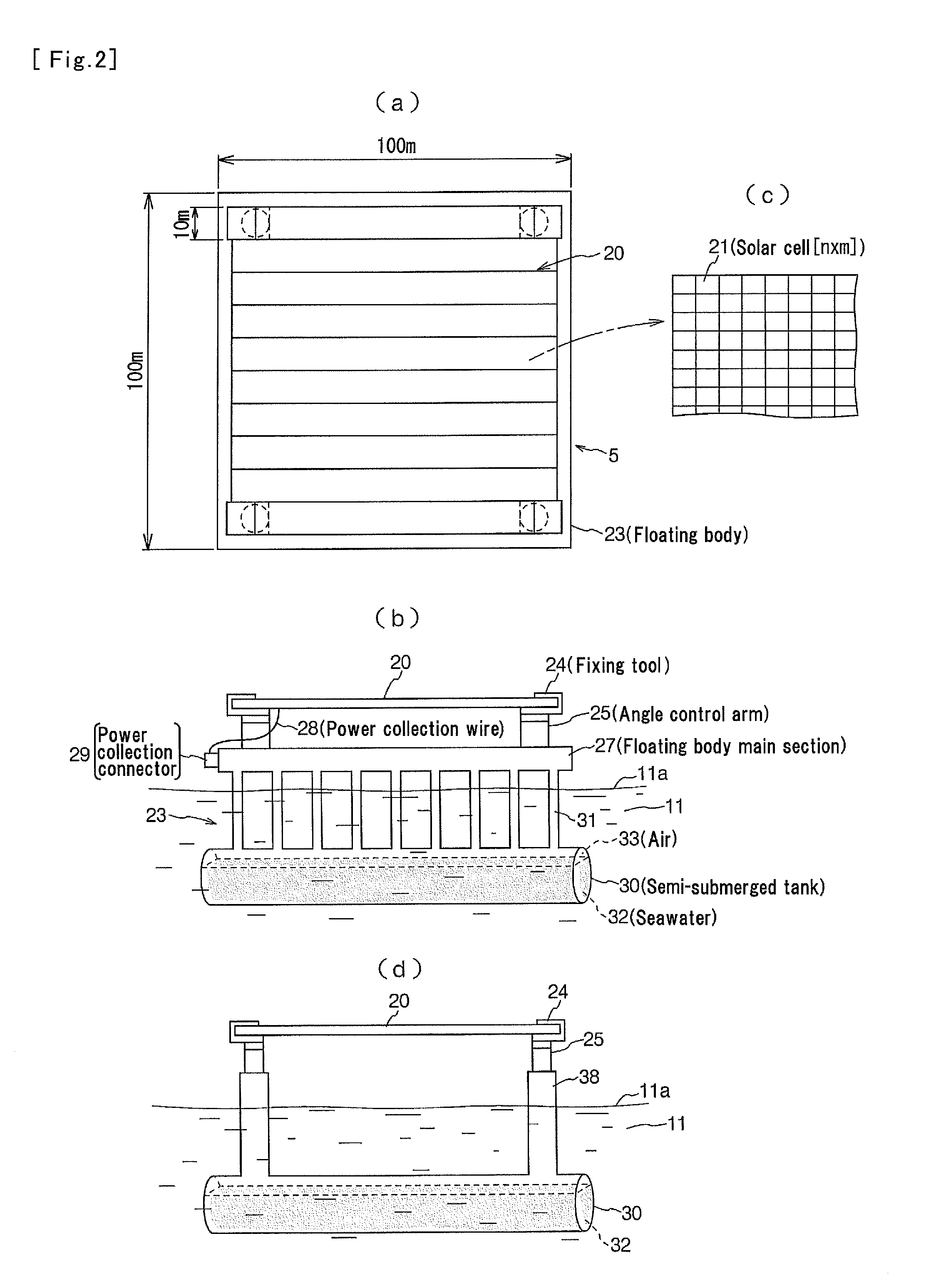

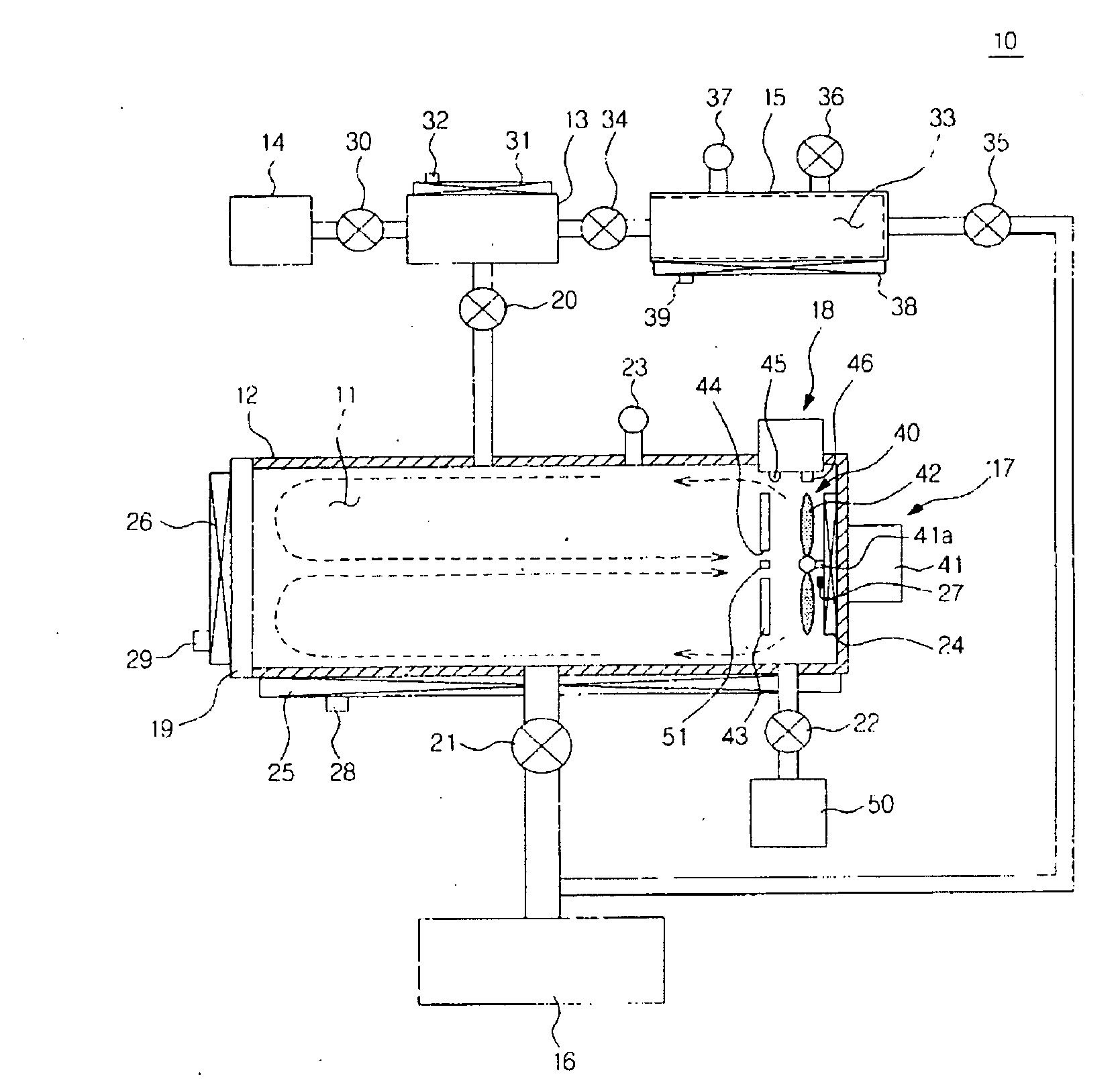

Large-scale ocean mobile solar power generation system

InactiveUS20120242275A1Transported efficiently and inexpensivelyEfficient storagePhotovoltaic supportsSolar heating energyLiquid hydrogenSeawater

A solar power generation system includes a solar cell raft which floats on the sea while being equipped with a solar cell unit formed by connecting a plurality of solar cells in the shape of a sheet on a floating body; a solar cell raft mother vessel which is equipped with a seawater electrolysis device for converting electric energy generated by the solar cell unit into hydrogen and a liquid hydrogen tank for storing the hydrogen obtained by the conversion, and can convey or tow the solar cell raft; a recovery vessel which is equipped with a hydrogen recovery / storage means for recovering the hydrogen stored in the liquid hydrogen tank; a hydrogen recovery tank which recovers the hydrogen from the recovery vessel and stores the hydrogen; and a power plant which converts the hydrogen stored in the hydrogen recovery tank into electric energy.

Owner:CHUO UNIVERSITY

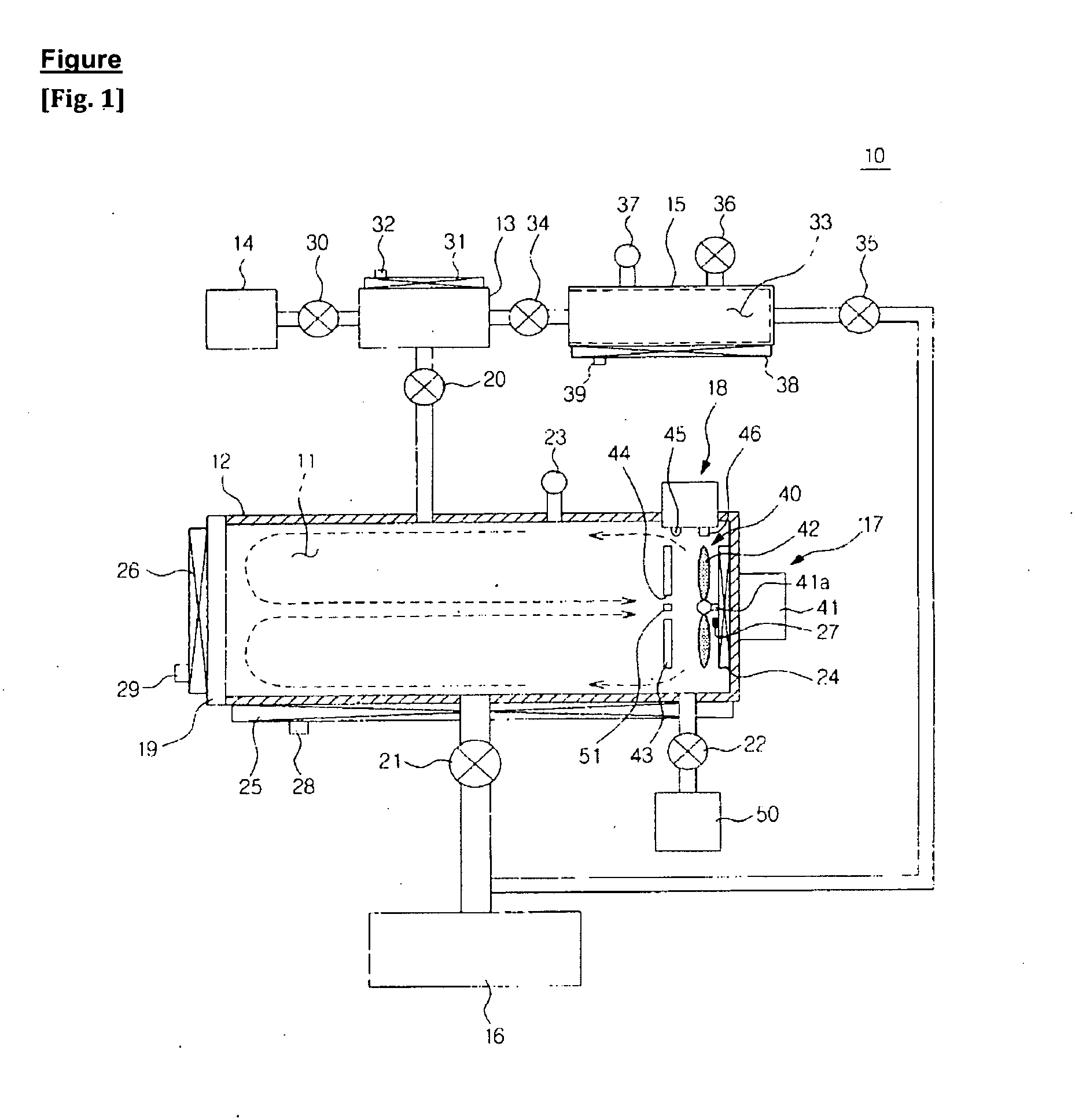

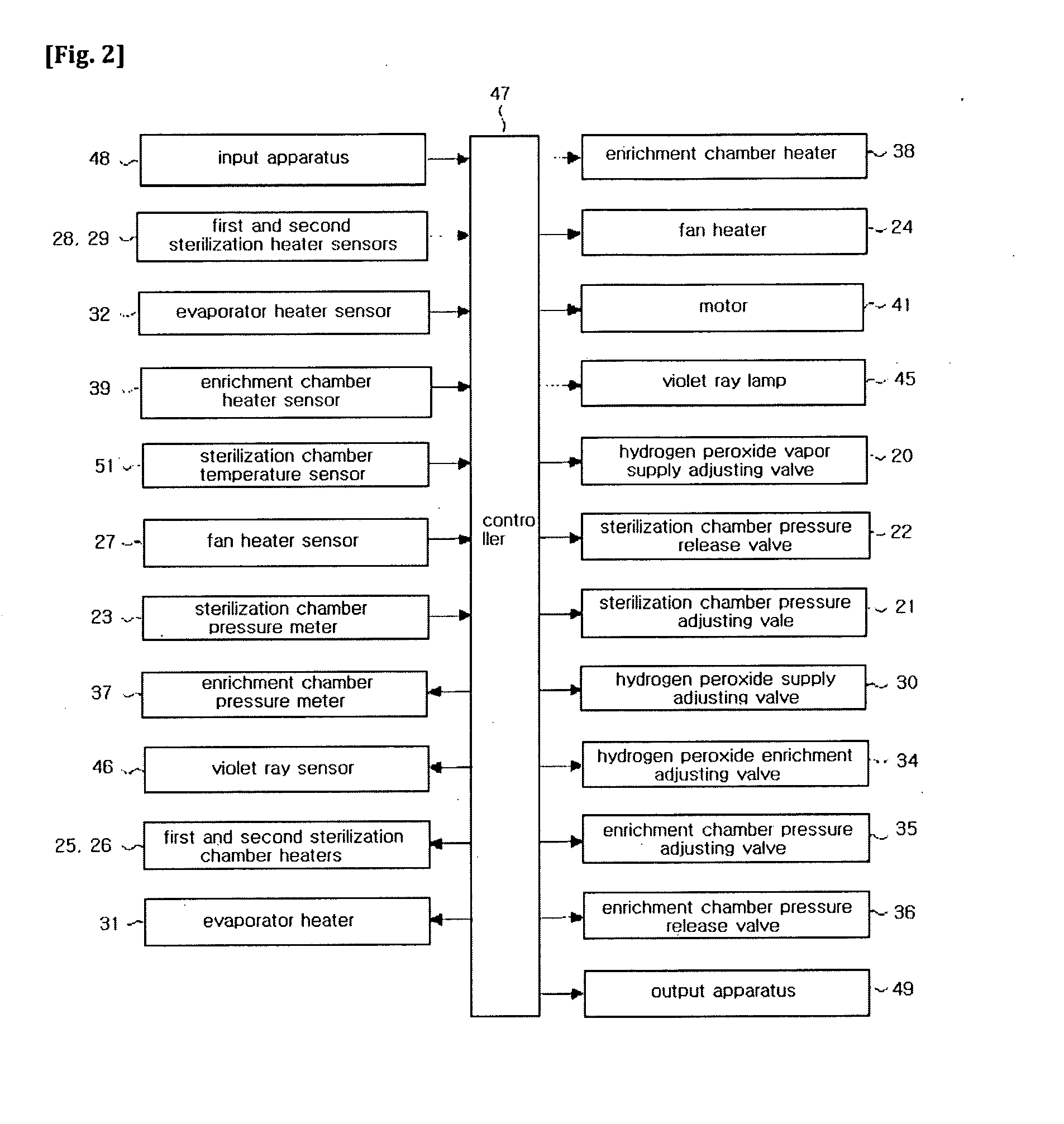

Sterilizing apparatus and method using hydrogen peroxide

InactiveUS20130004384A1Improve bactericidal powerReduce pressurePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesLavatory sanitoryVacuum pressureEngineering

Disclosed is a sterilization apparatus using hydrogen peroxide, which comprises a housing which has a sterilization chamber for accommodating to-be-sterilized objects; an evaporator connected with the sterilization chamber for supplying hydrogen peroxide vapor to the sterilization chamber for the purpose of sterilizing to-be-sterilized objects; a hydrogen peroxide supply apparatus connected with the evaporator for the purpose of supplying liquid hydrogen peroxide to the evaporator; an enrichment chamber connected with the evaporator for the purpose of evaporating moisture from the hydrogen peroxide supplied to the evaporator and sucking the evaporated moisture, thus enriching the hydrogen peroxide; a vacuum pump connected with the enrichment chamber for the purpose of providing a vacuum pressure to the enrichment chamber; a blower which includes a fan disposed in the interior of the sterilization chamber for forcibly flowing the air of the sterilization chamber and is a motor for driving the fan; and a fan heater disposed in the interior of the sterilization chamber for the purpose heating the air flowing by means of the fan. The sterilization apparatus using hydrogen peroxide according to the present invention makes it possible to enrich the hydrogen peroxide using an enrichment chamber, and the sterilization power with respect to the to-be-sterilized objects can be enhanced.

Owner:YOO CHUL WON

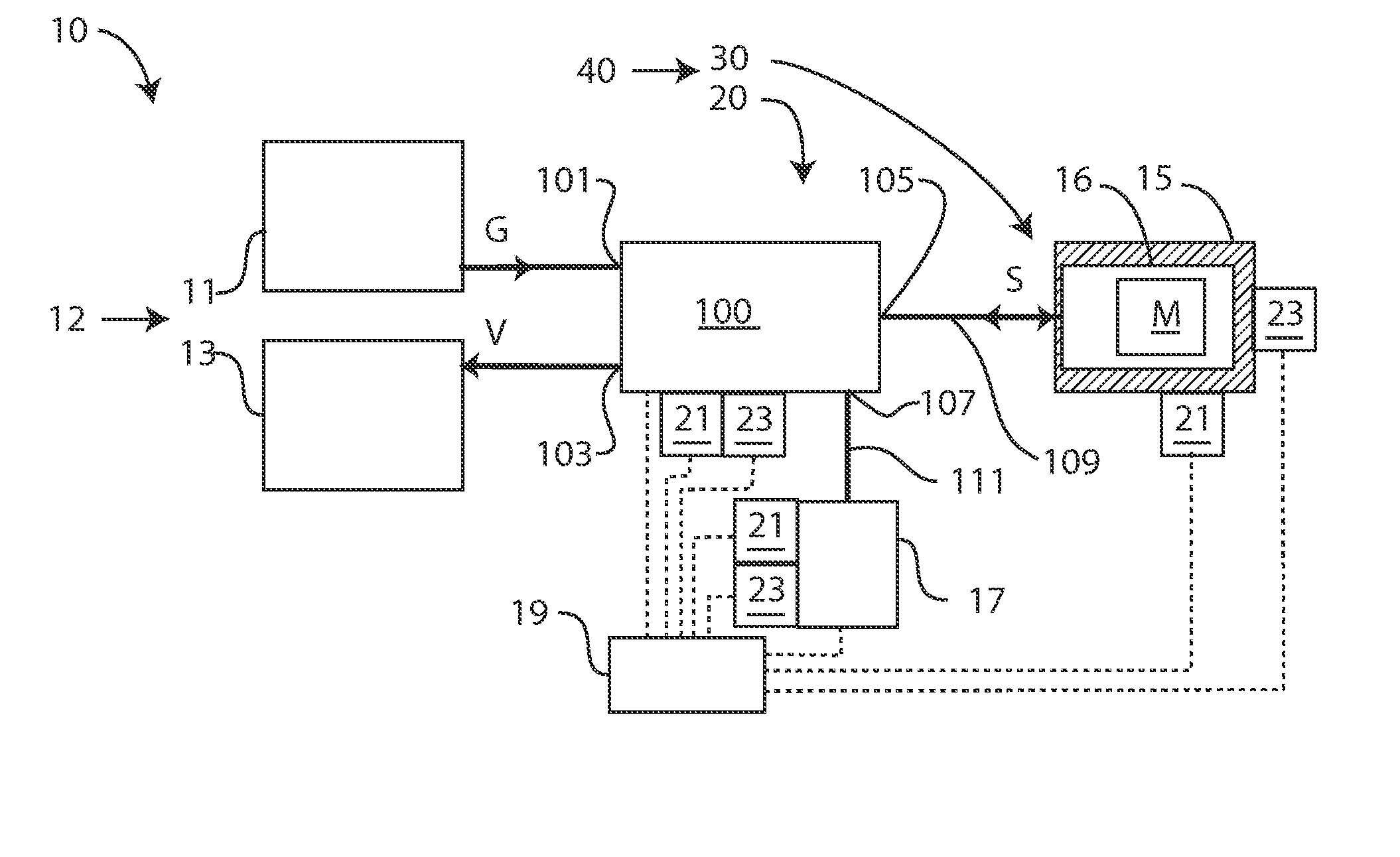

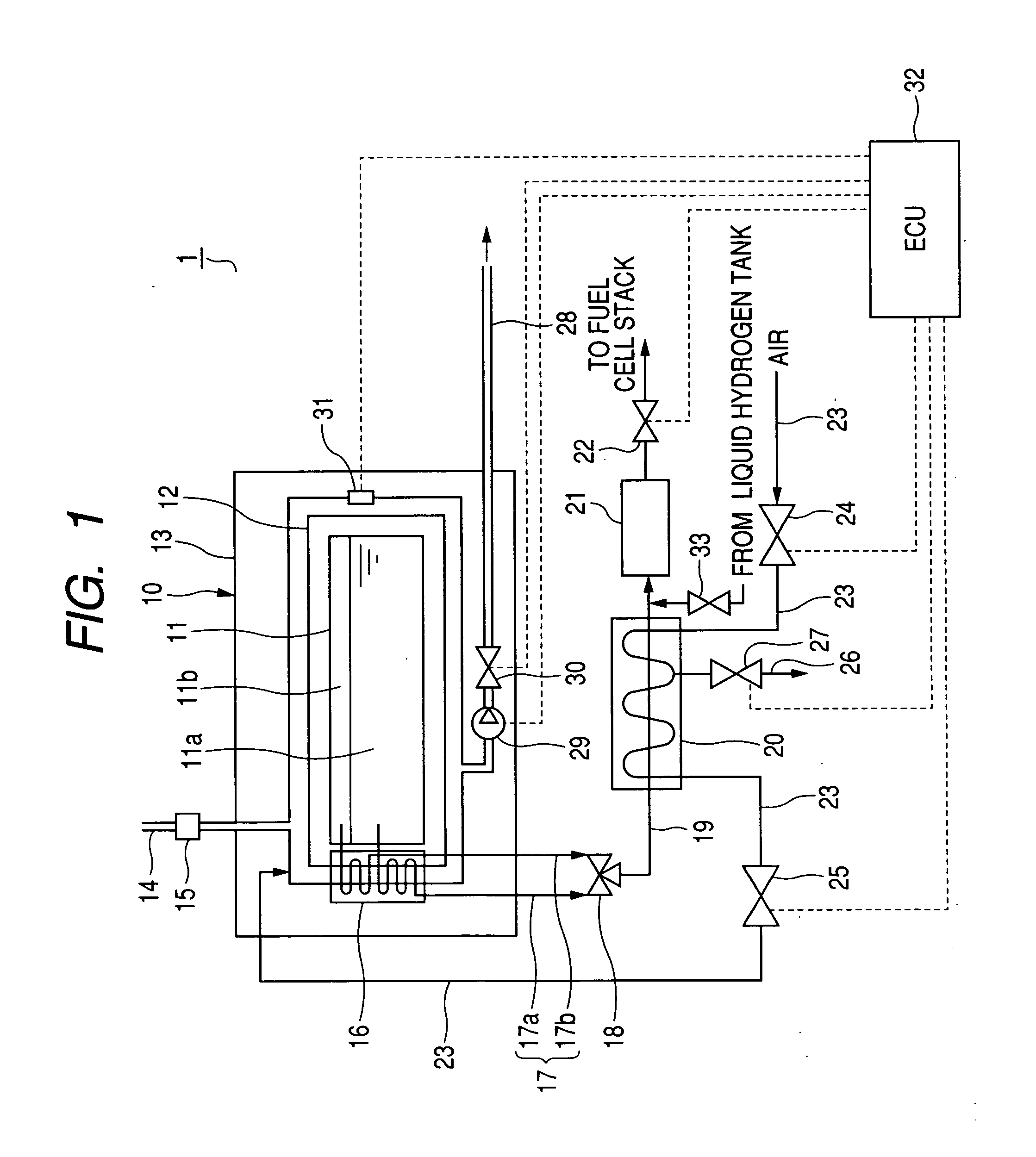

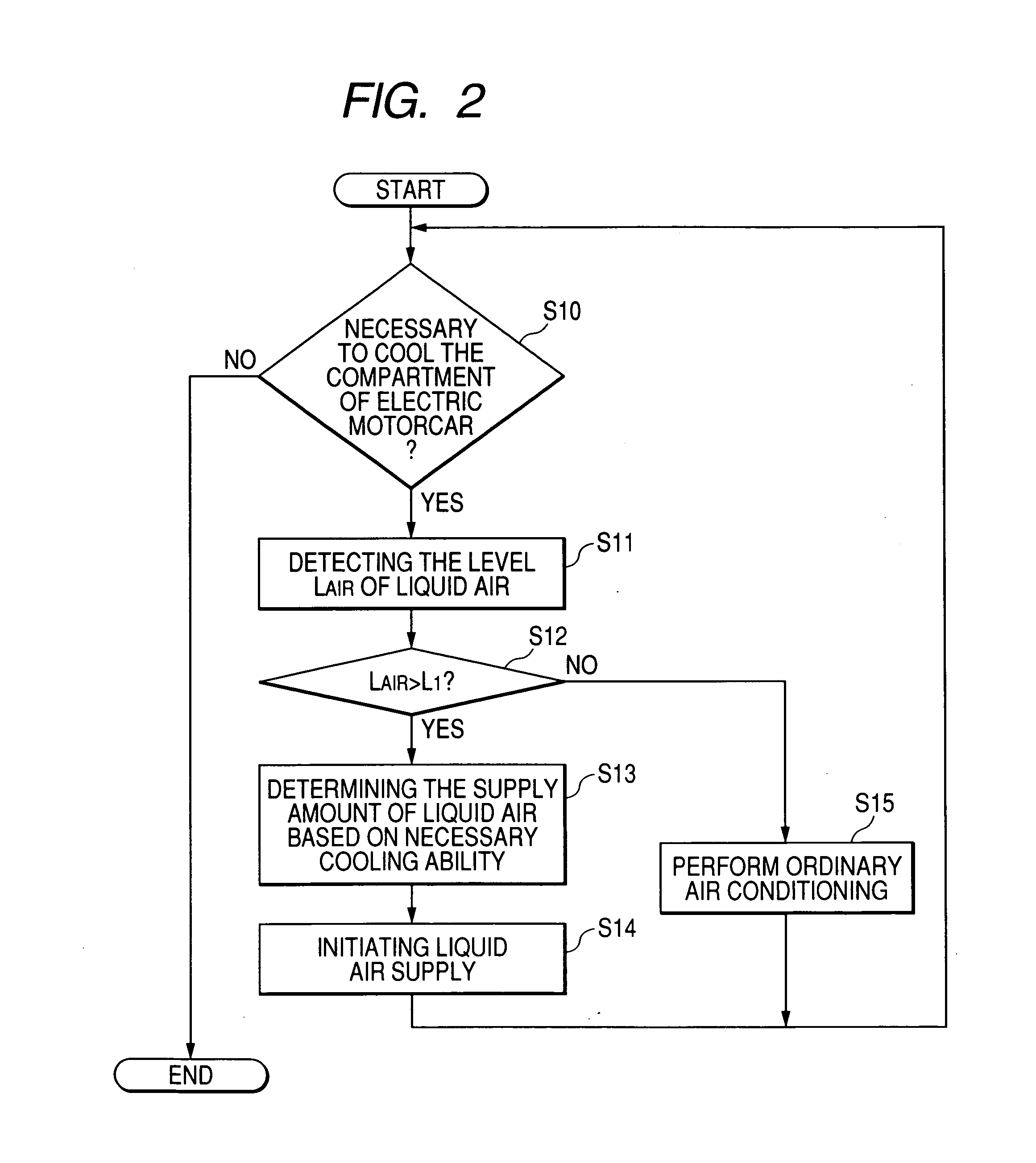

Thermal management system of hydrogen fuel cell vehicle and vehicle with the same

ActiveCN109466380AImprove performanceReduce energy consumptionAir-treating devicesVehicle heating/cooling devicesHeat managementHydrogen fuel cell

The invention discloses a thermal management system of a hydrogen fuel cell vehicle and a vehicle with a thermal management system. the thermal management system of the hydrogen fuel cell vehicle comprises a hydrogen gasifier, the hydrogen is provided with a hydrogen channel and a heat exchange channel through which heat exchange medium passes, the inlet end of the hydrogen channel is used for being connected with a hydrogen bottle, and the outlet end of the hydrogen channel is used for supplying hydrogen to the fuel cell stack; and the heat dissipation device is connected with the heat exchange channel in parallel. According to the heat management system of the hydrogen fuel cell vehicle, the heat exchange medium exchanges heat with the heat dissipation device in the hydrogen gasifier through the arrangement of the hydrogen vaporizer and the heat dissipation device, so that not only heat is provided for liquid hydrogen gasification, the cooled heat exchange medium can also be used forcooling the vehicle, thereby improving the efficiency of the thermal management system of the hydrogen fuel cell vehicle and further reducing the energy consumption of the vehicle.

Owner:BEIQI FOTON MOTOR CO LTD

Boil-off compensating cryoadsorption container for liquid gas storage

InactiveUS20060199064A1Reactant parameters controlContainer filling methodsProcess engineeringLiquid hydrogen

A hydrogen-based propulsion system is provided for storing hydrogen feed gas which evaporates over time from a storage vessel containing liquid hydrogen as a fuel. In particular, this system enables the evaporated hydrogen feed gas to be stored for later use in the propulsion unit and also provides a system for enabling the stored hydrogen gas to be cooled by evaporated hydrogen feed gas in transit to the propulsion unit.

Owner:GM GLOBAL TECH OPERATIONS LLC

Tank System For The Cryogenic Storage Of Hydrogen, And Aircraft With A Tank System For The Cryogenic Storage Of Hydrogen

InactiveUS20150336680A1Offset the pressureHigh strengthPower plant fuel tanksVessel geometry/arrangement/sizeLiquid hydrogenHydrogen tank

A tank system for the cryogenic storage of hydrogen includes a tank structure with at least one hollow body for accommodating liquid hydrogen and at least one insulating means, which encloses the tank structure, for insulating the at least one hollow body. The tank structure has an exterior shape that is integrateable in a load-bearing primary structure of an aircraft. The tank structure is load bearing and is designed to at least partially absorb a load introduced into the primary structure. This makes it possible to achieve a particularly efficient design of an aircraft in which the fuselage of the aircraft is not divided into two parts by the hydrogen tank integrated therein, can be arranged near the center of gravity, and essentially does not increase the additional weight of the aircraft.

Owner:AIRBUS OPERATIONS GMBH

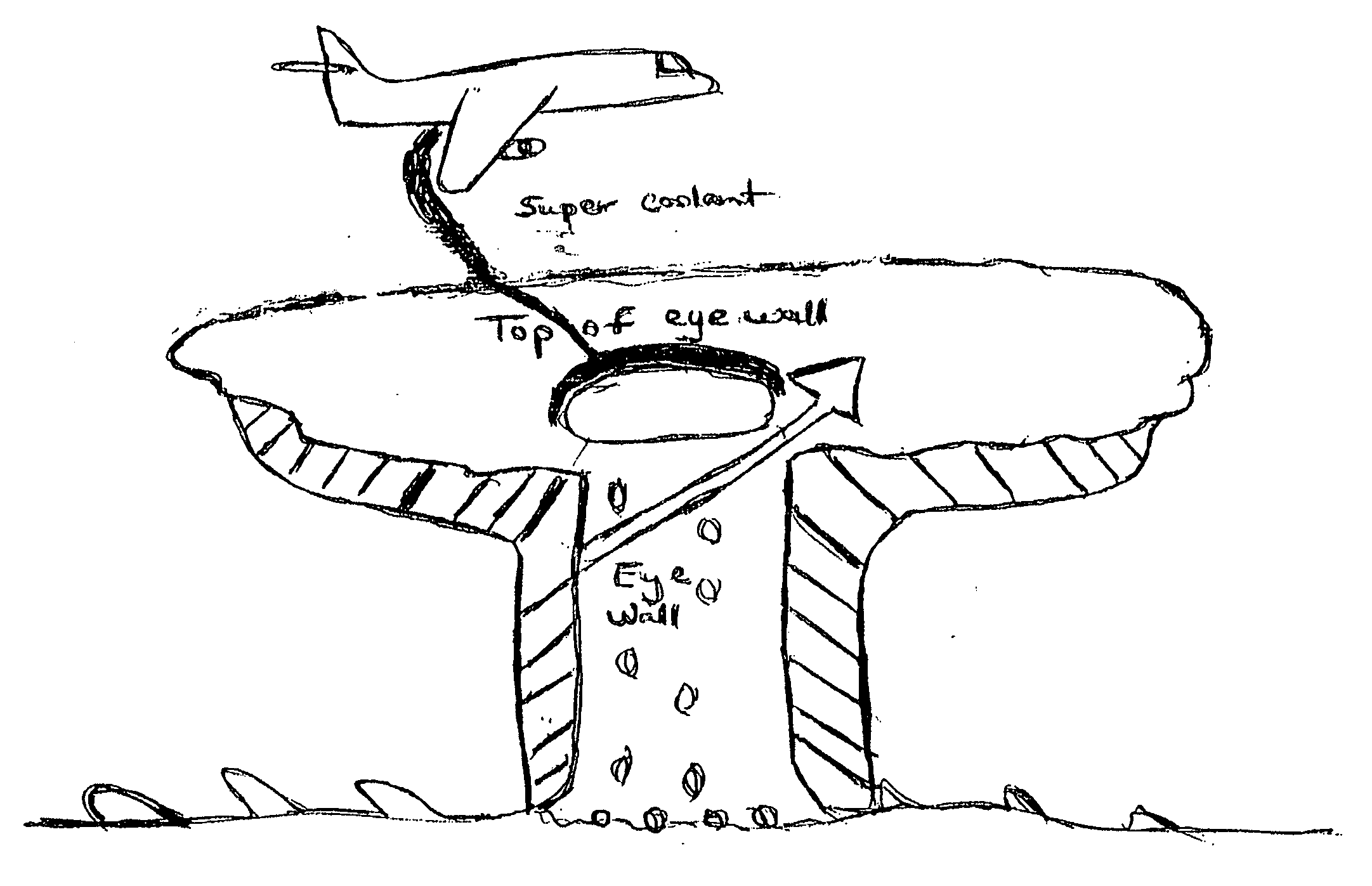

Tropical hurricane control system

InactiveUS20070158449A1Control and diminishes and eliminates monstrous forceEasy to controlAircraft componentsFog dispersionLiquid hydrogenTropics

The invention turns a hurricane / tropical cyclone into a tropical rainstorm by spraying a super coolant such as liquid oxygen, or liquid hydrogen, or liquid nitrogen, or other super cold liquid gas around the top of the eye wall and additionally if needed, into the front of the eye wall, or forming eye wall using aircraft with pre-measured amounts of super coolant. Based on actual results, a real time computer system will be developed to enable communications between aircraft and control the amount of super coolant dispersed. The result of the invention will reduce / eliminate the damage to life and property due to high winds and storm surge as well as the staggering costs for rebuilding.

Owner:HOFFMANN EUGENE J +1

Coal mine gas extraction hole sealing material

InactiveCN104592962AHigh compressive strengthReduce fluidityDrilling compositionCeramicwareLiquid hydrogenCoal mine methane

The invention relates to a coal mine gas extraction hole sealing material. The coal mine gas extraction hole sealing material comprises, by mass, 60-80% of ordinary portland cement, 15-25% of an expanding agent (such as calcium sulphoaluminate and calcium sulphoaluminate-calcium oxide), 0-10% of gypsum, 0.1-0.3% of a foaming agent (such as solid aluminum powder or liquid hydrogen peroxide producing gas in an alkaline environment), and 0.2-0.5% of caustic soda, and the above materials and water are blended according to a mass ratio of 1: 0.6-1. The coal mine gas extraction hole sealing material has good expansibility, has an expansion coefficient greater than 10%, compressive strength greater than 10Mpa, good fluidity and short solidification time, is convenient for use and has a low cost.

Owner:HENAN SHENHUA ENERGY ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com