Patents

Literature

107results about How to "Offset the pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

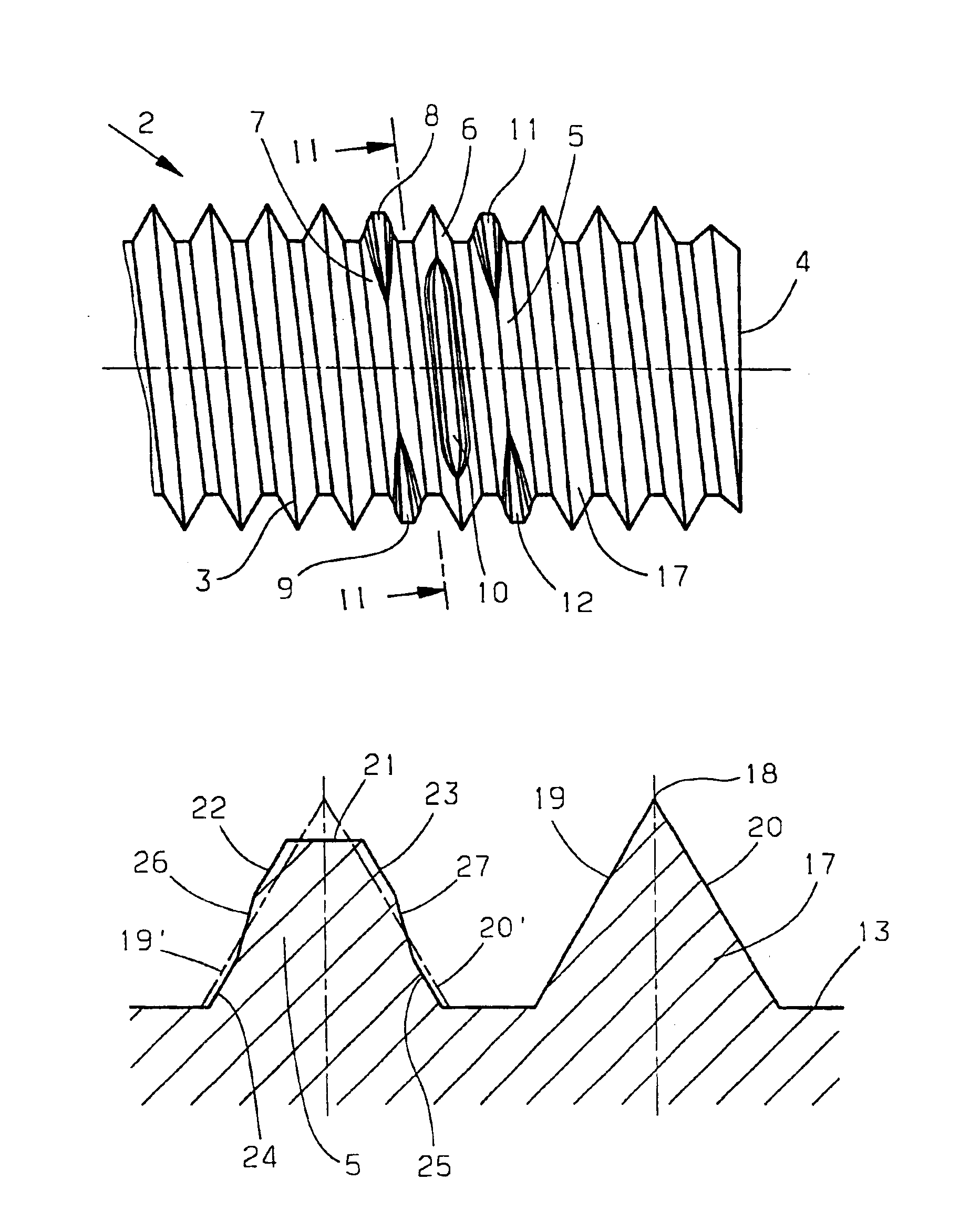

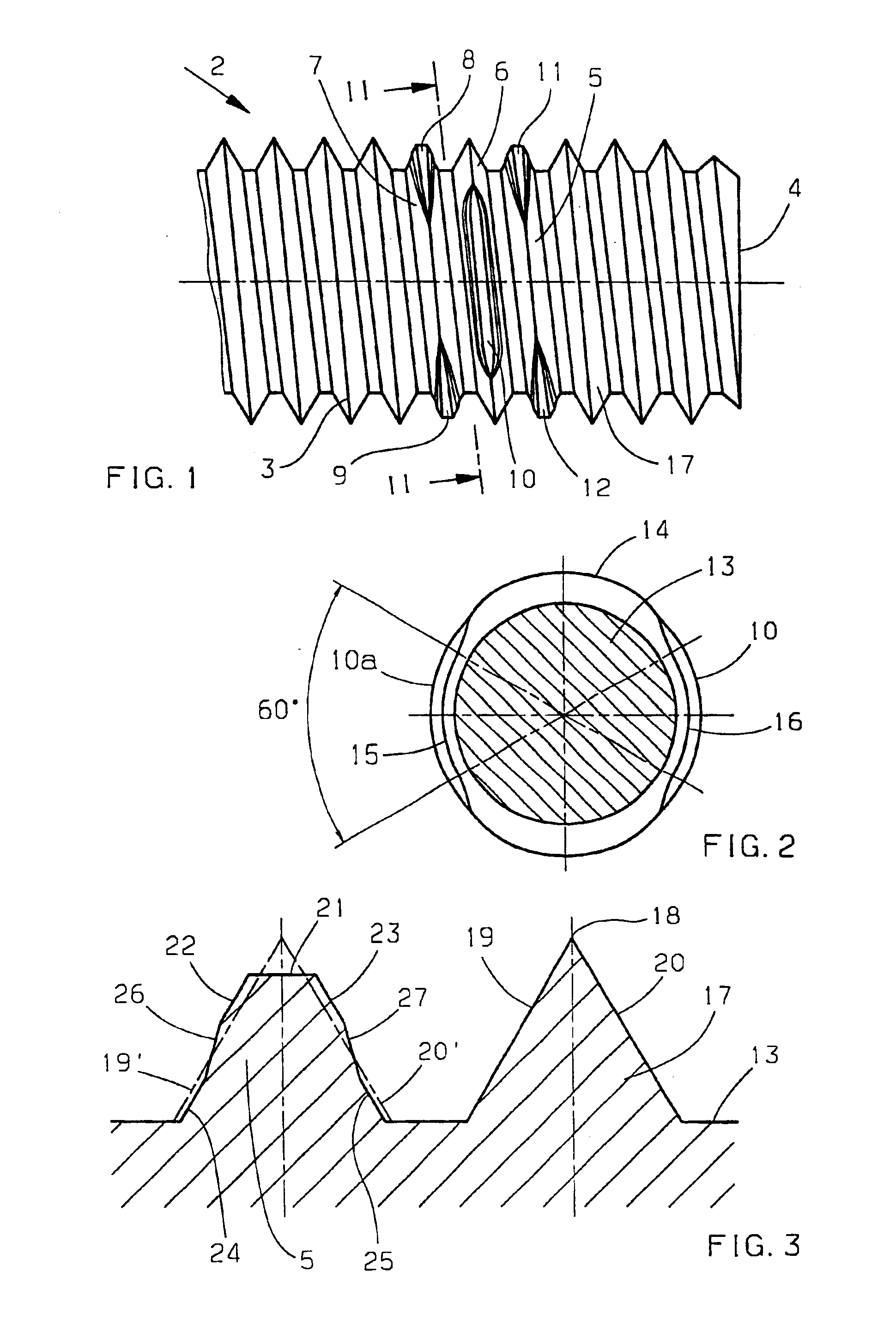

Screw provided with self-locking thread

Screw provided with self-locking rolled thread, wherein, in a plurality of places along its extent, the thread is deformed in relation to the normal thread cross section in that the thread outside diameter is reduced by radial compression of limited thread portions, the area of the thread cross section being substantially identical to that of the undeformed thread. While maintaining the slant of the thread flanks, the thread cross section is symmetrically widened in the outer region and reduced in the adjoining inner region, the transition from the widened to the reduced thread cross section lying approximately in the centre of the respective thread flank, and the limited thread portion extends over two parts of a thread turn such that there result two symmetrically opposite thread portions each of approximately ⅙ of the thread turn.

Owner:EJOT GMBH & CO KB

Metallographic grinding and polishing process

InactiveCN105437050AUniform colorPrevent oxidationPreparing sample for investigationLapping machinesRetention timeMegasonic cleaning

The invention discloses a metallographic grinding and polishing process. The metallographic grinding and polishing process comprises the steps that (1) the surface of a metallographic specimen is cleaned; (2) the surface of the metallographic specimen is ground; (3) the metallographic specimen is polished; and (4) cleaning is conducted. The metallographic specimen is cleaned and polished through vibration of an ultrasonic washing unit, when the metallographic specimen is cleaned, liquid inside the ultrasonic washing unit is industrial pure water, diamond abrasive grains, polishing paste and glycerinum are put into the ultrasonic washing unit for cleaning, resources can be saved, and influence on the subsequent grinding and polishing process can be avoided; a rubber soft bottom is arranged at the bottom of the metallographic specimen, so that the surface is prevented from being scratched in the grinding process, the metallographic specimen is dried for many times, oxidation of easily oxidized metals can be prevented in the operation process, and it is ensured that the surface of the metallographic specimen is even in color and has no water spot; coating of antirust agents is avoided, and the retention time is long in a vacuum environment.

Owner:HEXIAN LONGSHENG PRECISION MACHINERY CO LTD

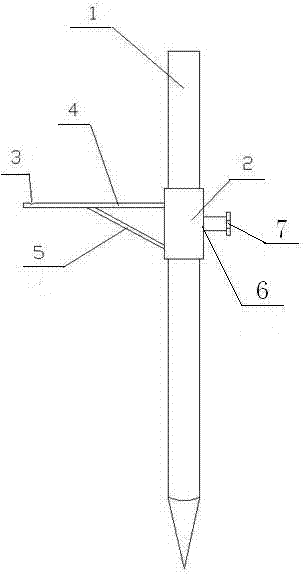

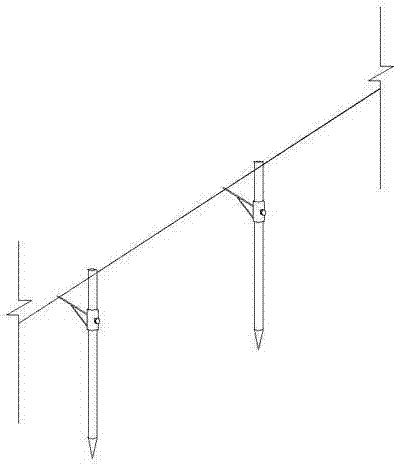

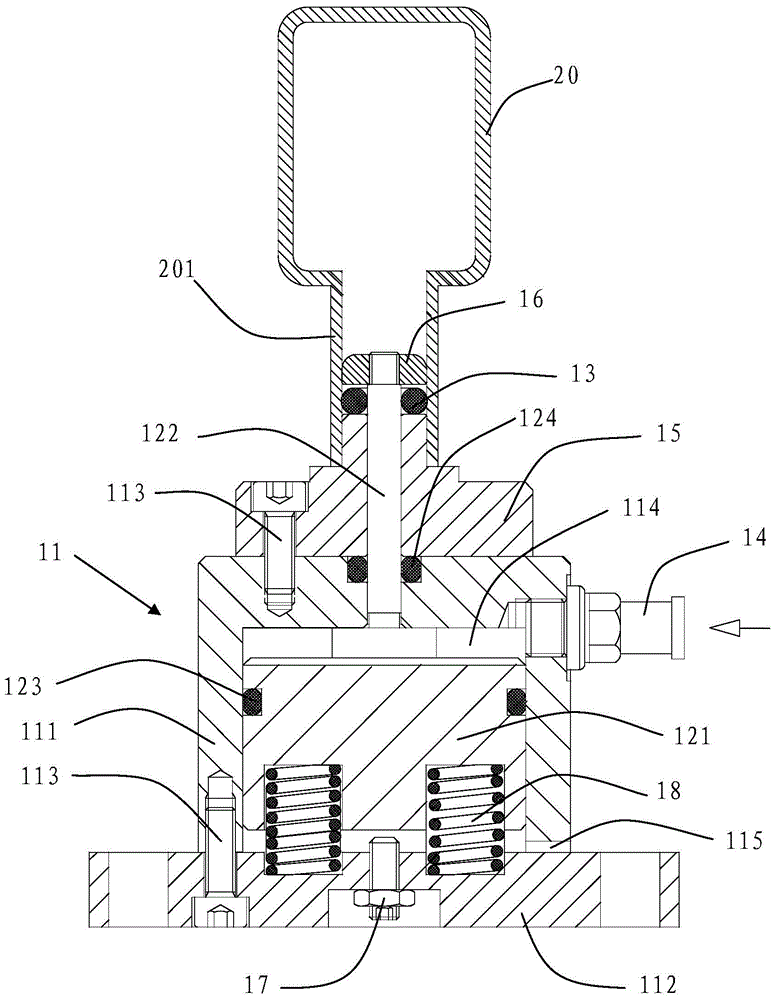

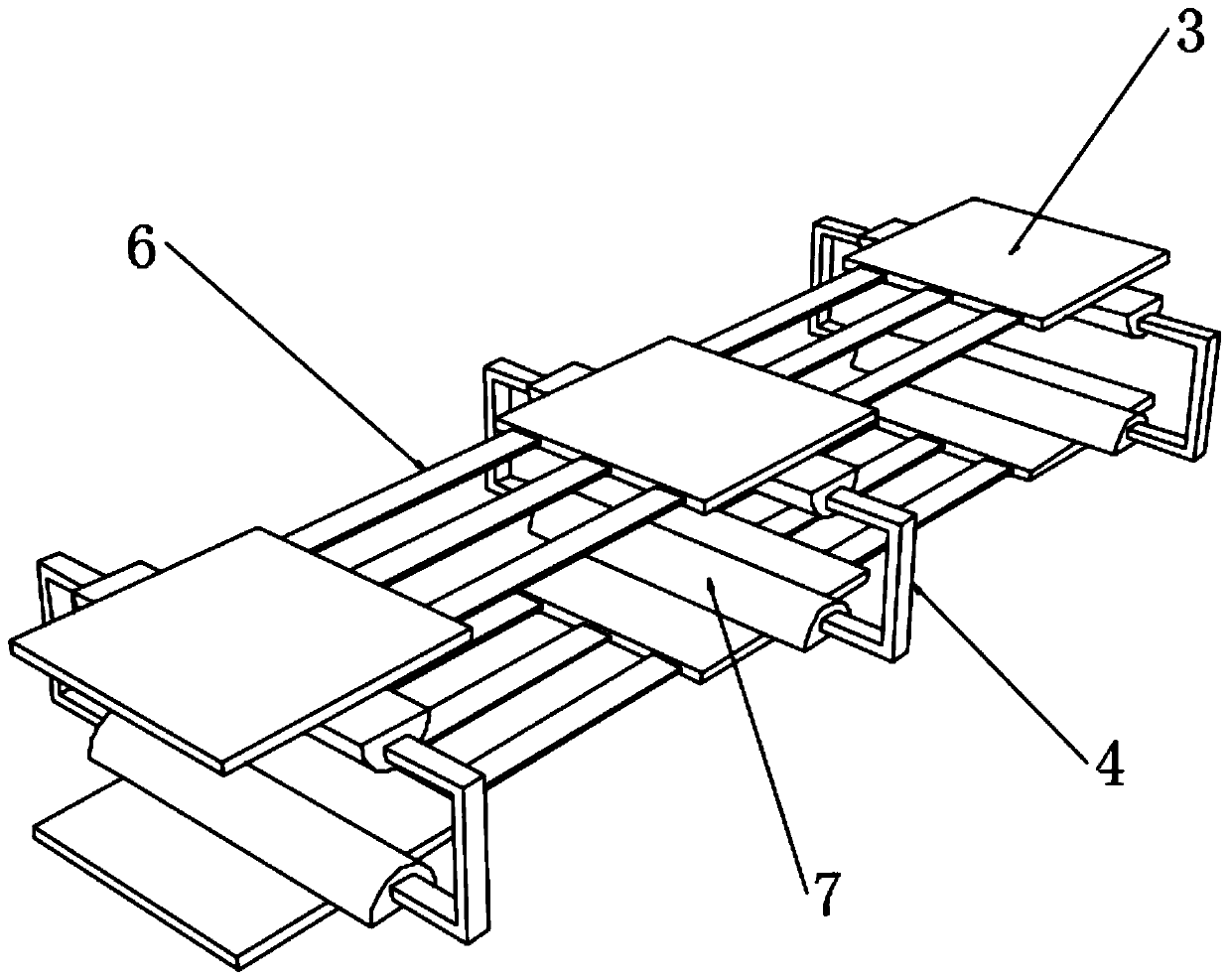

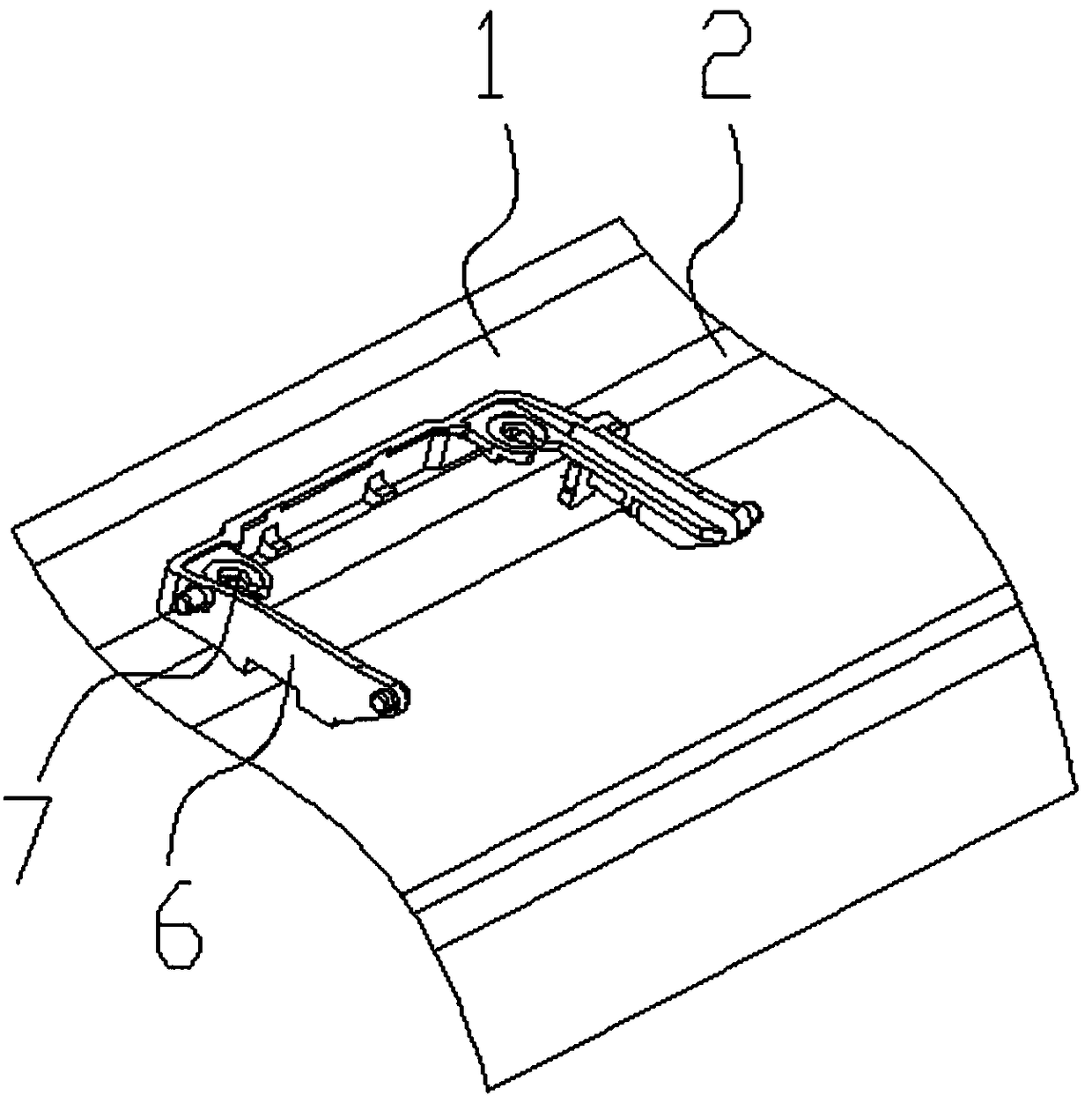

Pavement paving guide wire hanging pile and making method thereof

The invention discloses a pavement paving guide wire hanging pile and a making method thereof. The pavement paving guide wire hanging pile comprises a steel-bar pile (1) and a sleeve (2) and is characterized in that one end of the steel-bar pile (1) is a pointed end; the sleeve (2) is fixed on the steel-bar pile (1); one end of a cross beam (4) is fixed on the sleeve (2) to form a cantilever beam; and a steel wire (strand) clamping groove (3) is formed in the other end of the cross beam (4). A screw hole (6) is formed in the sleeve (2); and a fixing screw rod (7) fixes the sleeve (2) on the steel-bar pile (1) through the screw hole (6). One end of a diagonal bracing (5) is fixed on the sleeve and the other end of the diagonal bracing (5) is fixed on the cross beam (4). The pavement paving guide wire hanging pile has the advantages that reasonable control of flatness and elevation in pavement construction can be guaranteed, the paving continuity is good, the structure is simple and the pavement paving guide wire hanging pile is efficient and labor-saving.

Owner:GUIZHOU ROAD & BRIDGE GRP

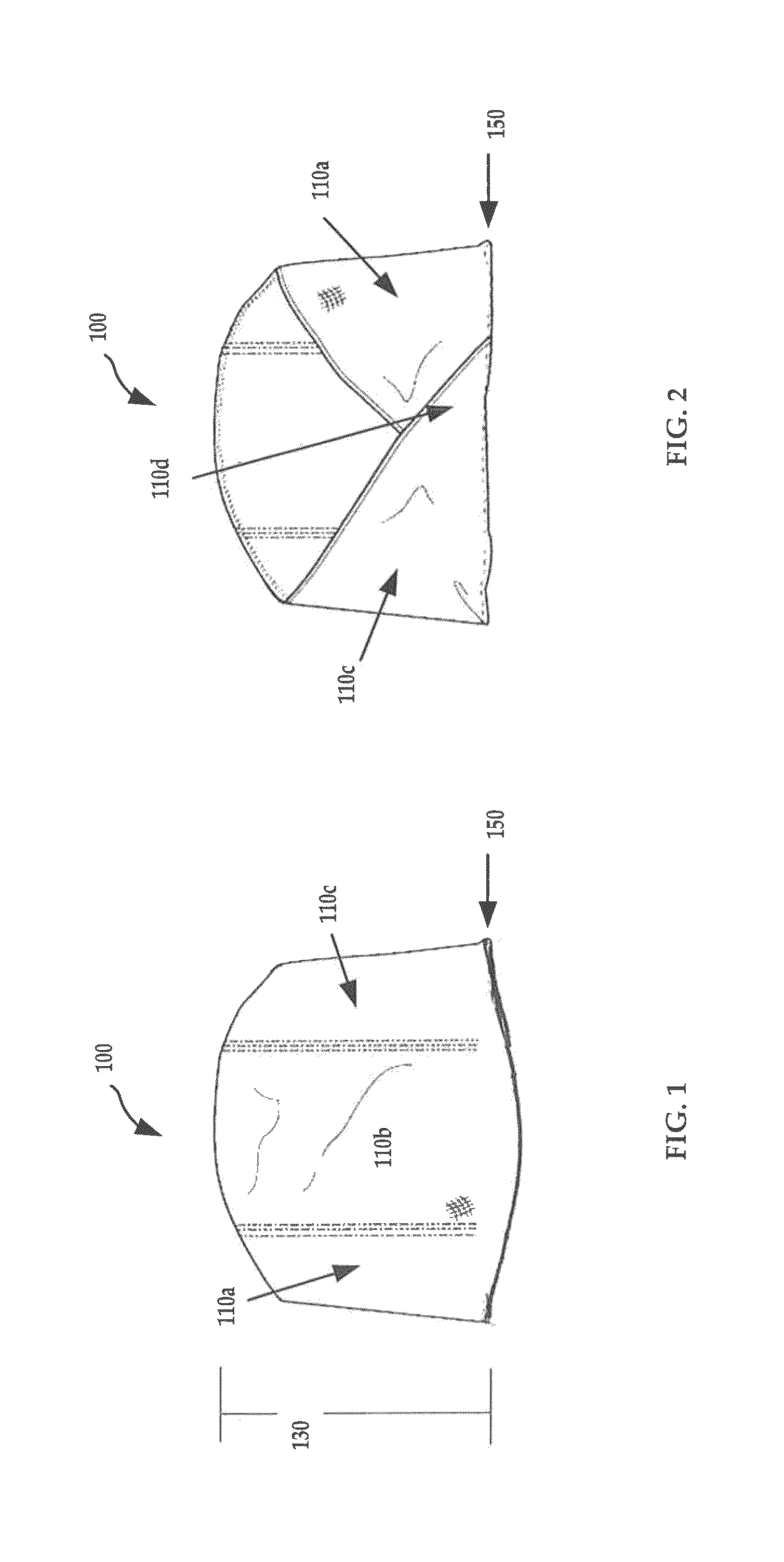

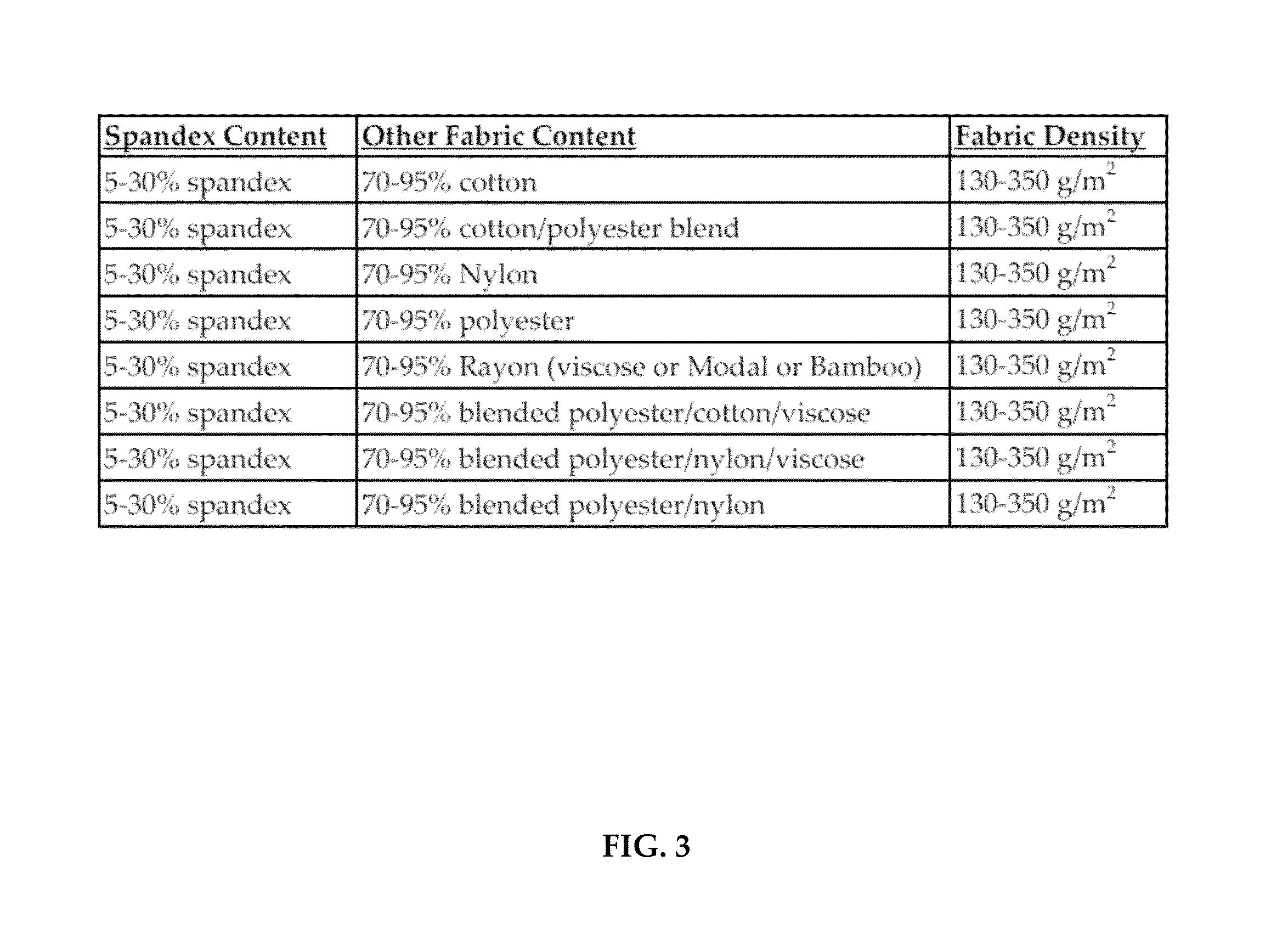

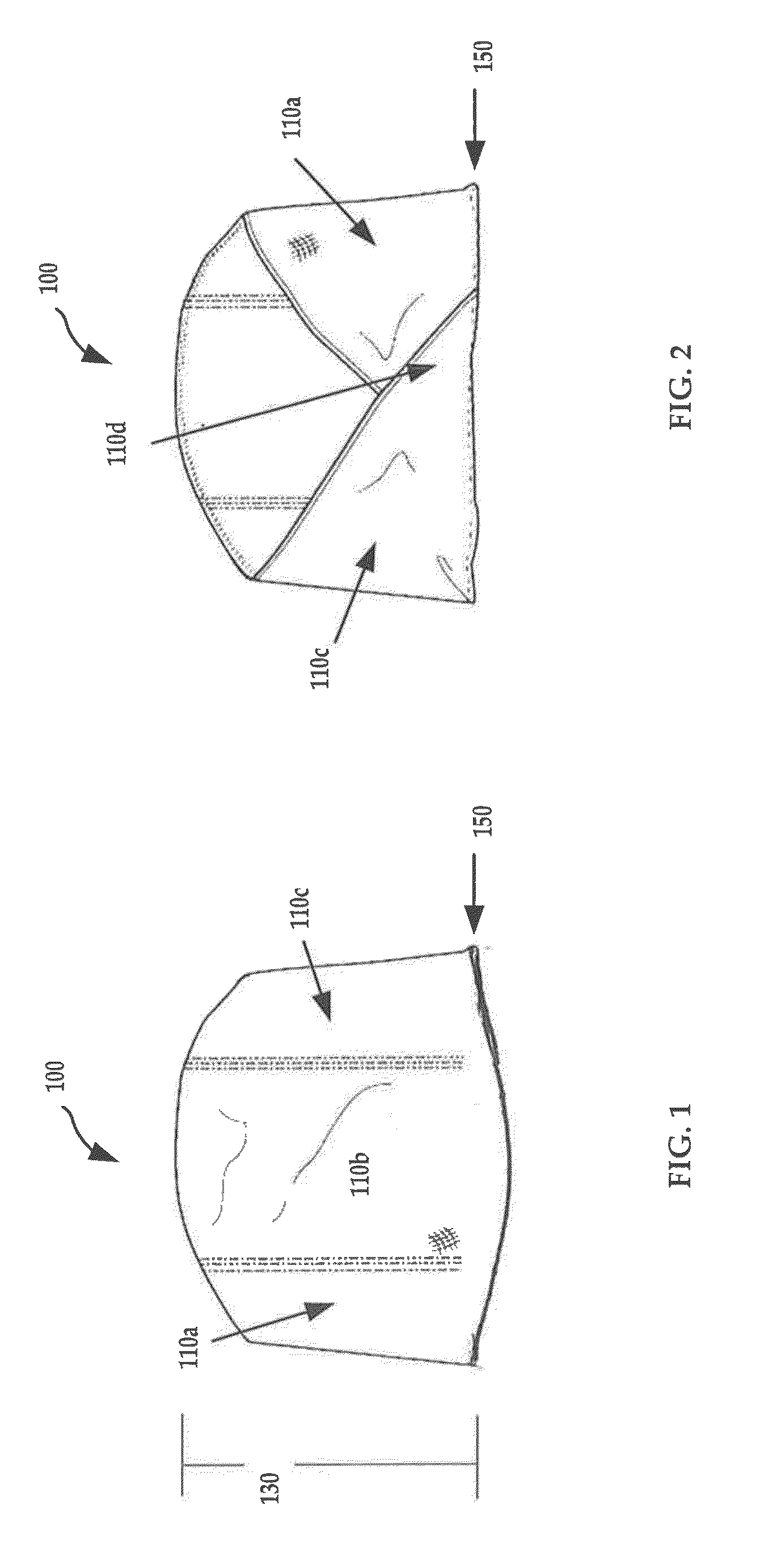

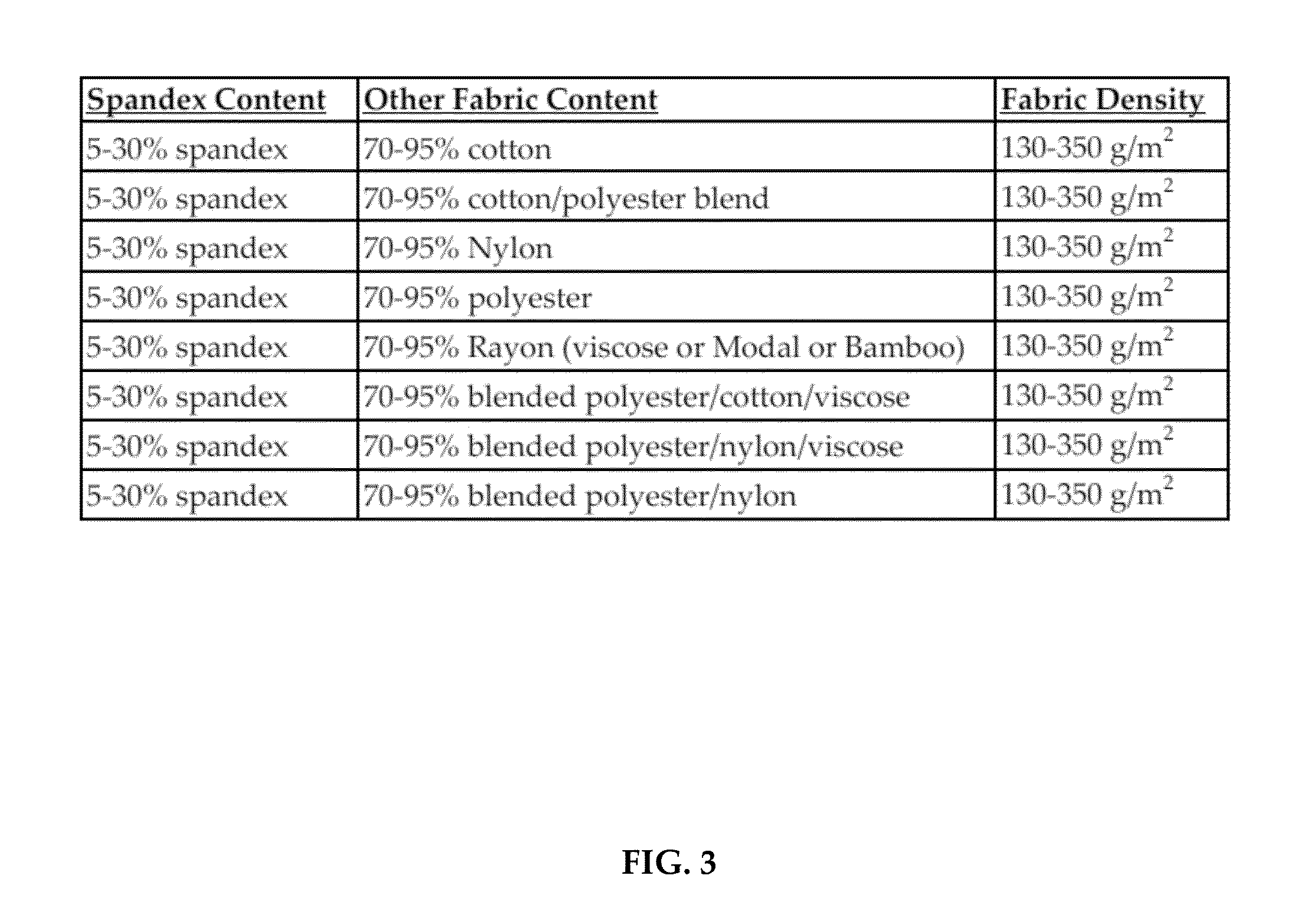

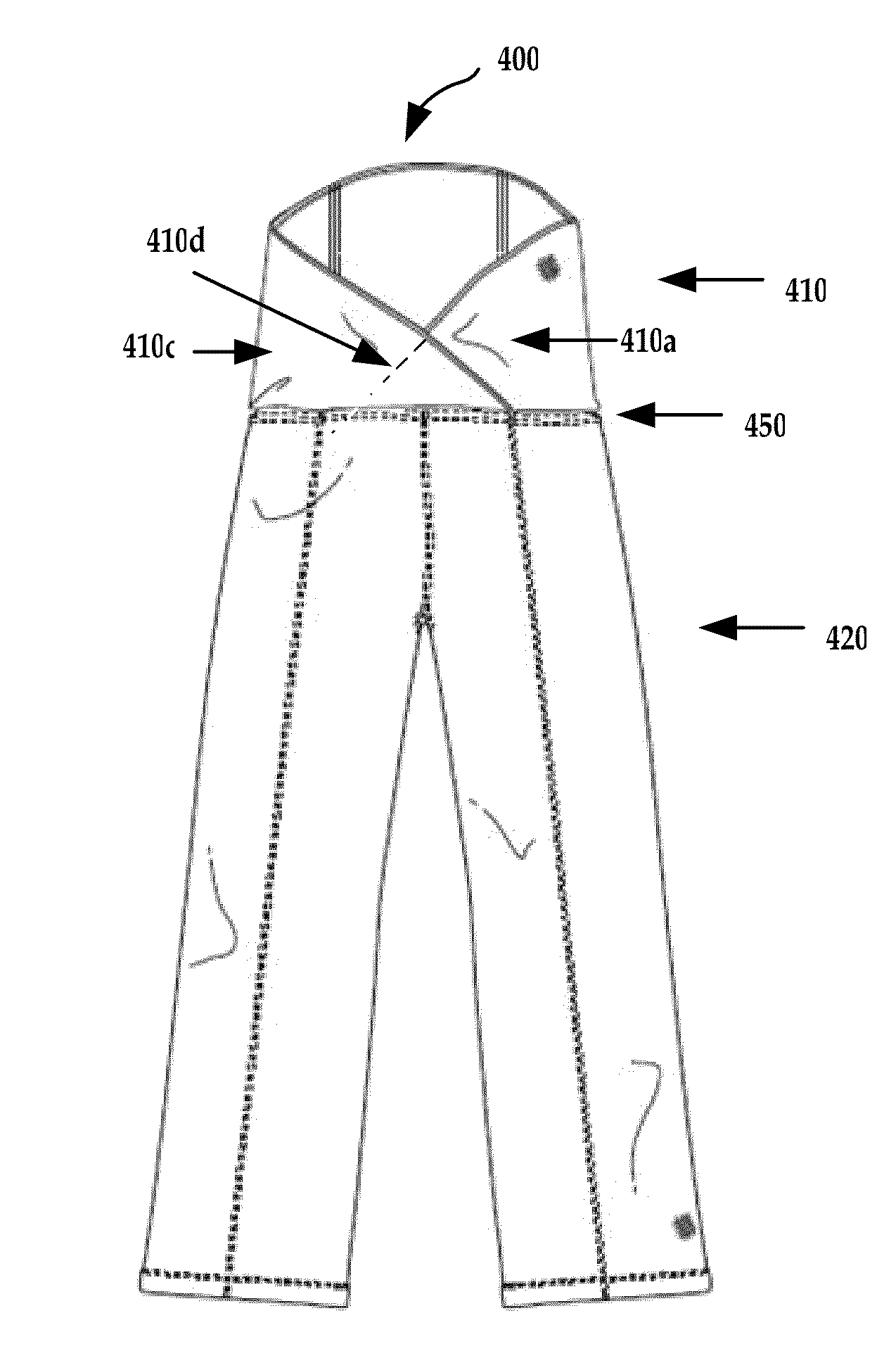

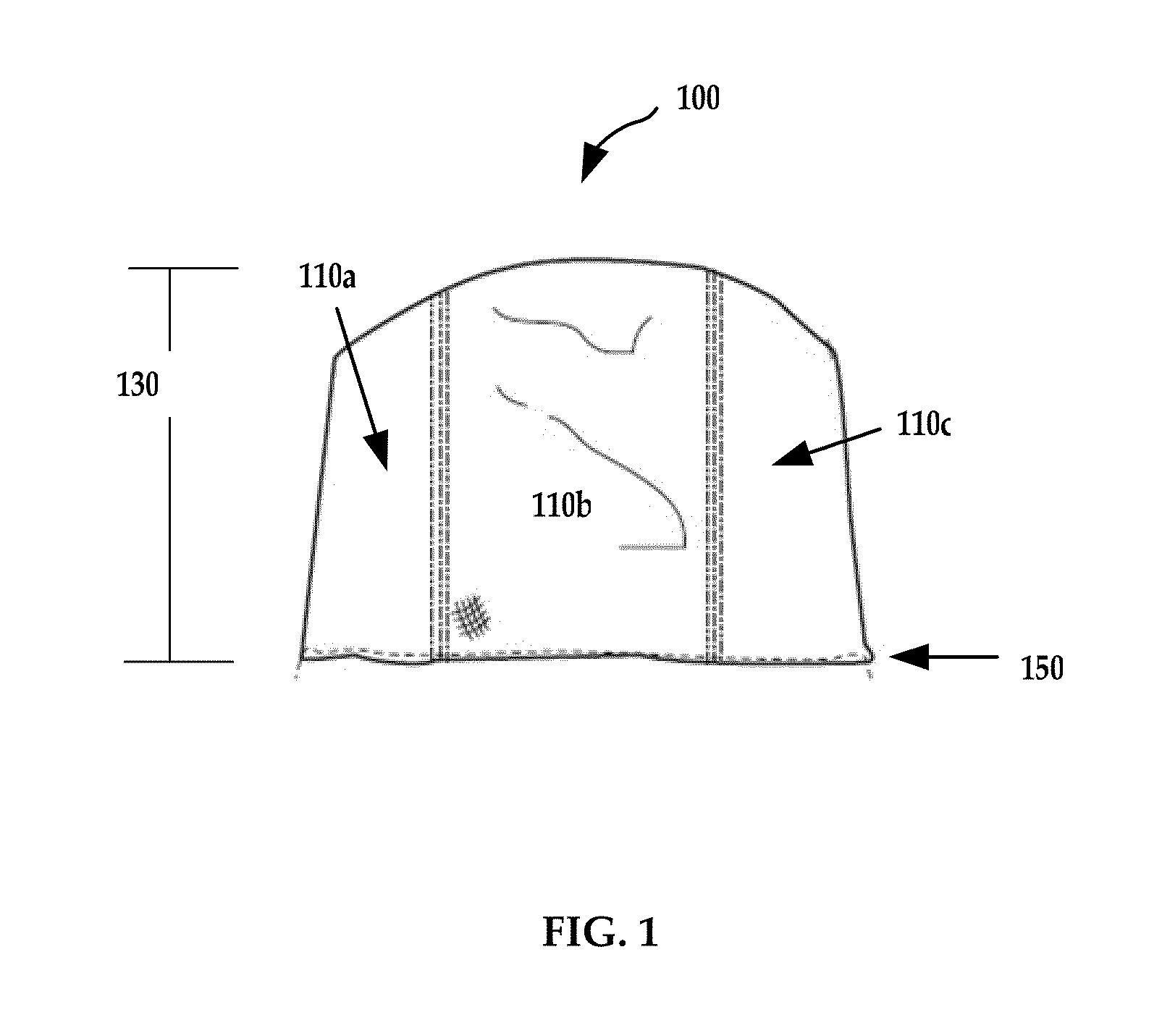

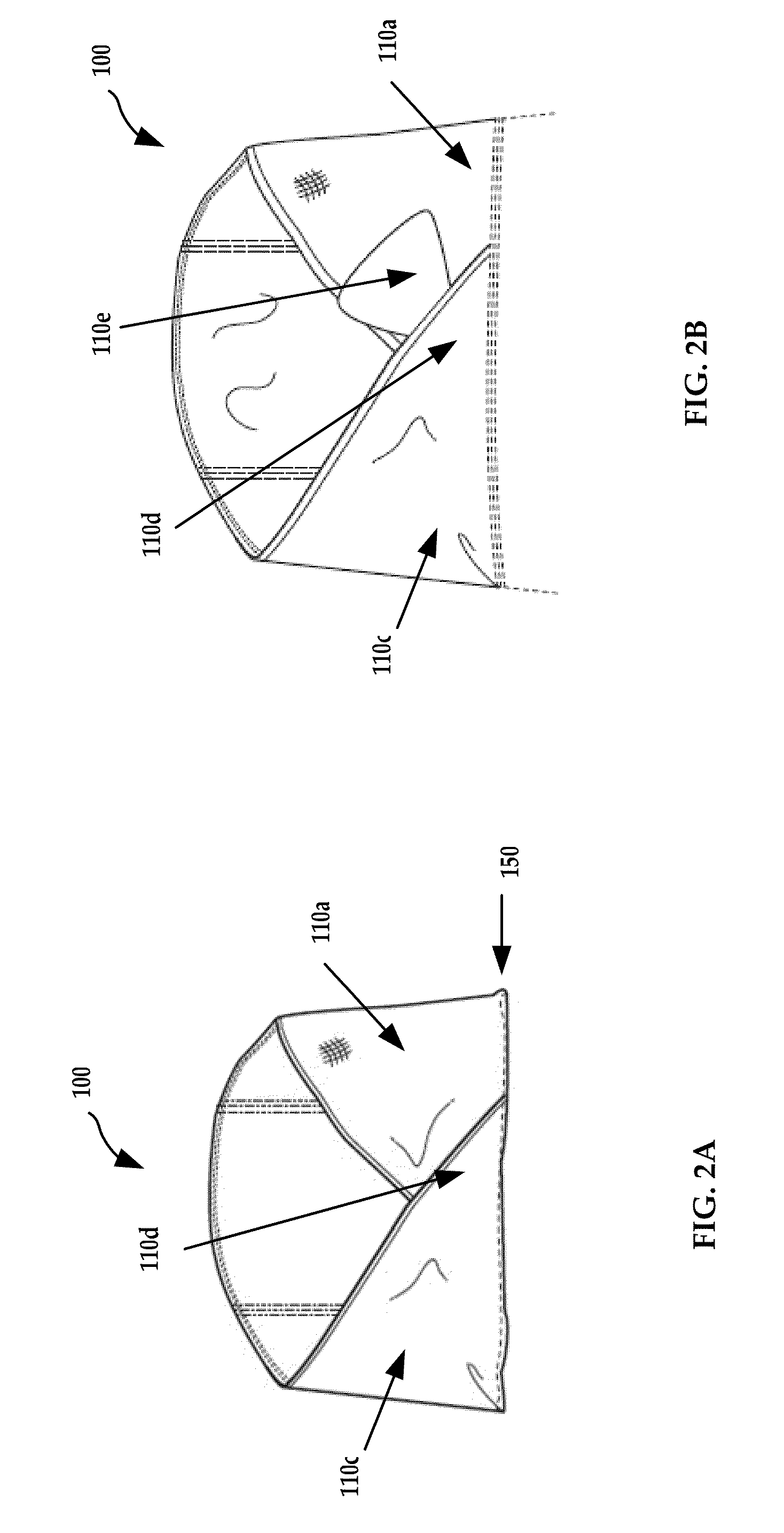

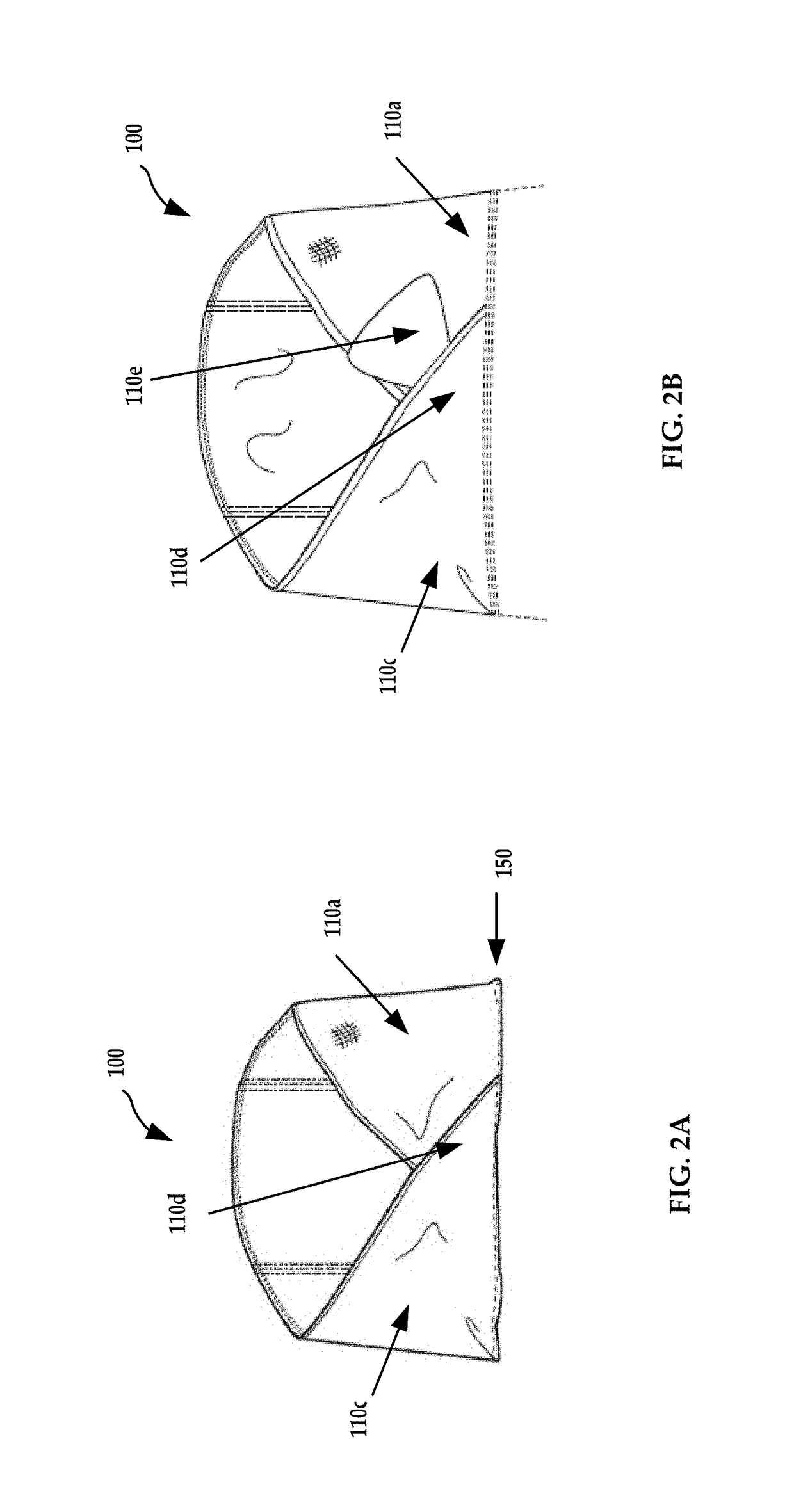

Crossover maternity panel

The present invention relates to a crossover maternity panel that may be attached to any lower garment worn throughout pregnancy and post-partum body changes. The crossover maternity panel may be a belly panel comprised of a single piece of fabric or multiple pieces connected with seams, and wrap around from the front to the back of the wearer. The portions may overlap in the back of the wearer as they decrease in height to create a crossover triangular section that provides support to the lumbar region of the wearer. The crossover maternity panel may be attached to any lower garment such as a pant, short, skirt, skort, or the like. The flexible and stretchable material of the crossover maternity panel allows the wearer to have support for the enlarged belly, support for increased pressure and laxity on the wearer's sacroiliac joints and lower back, as well as comfort and mobility.

Owner:INGRID & ISABEL

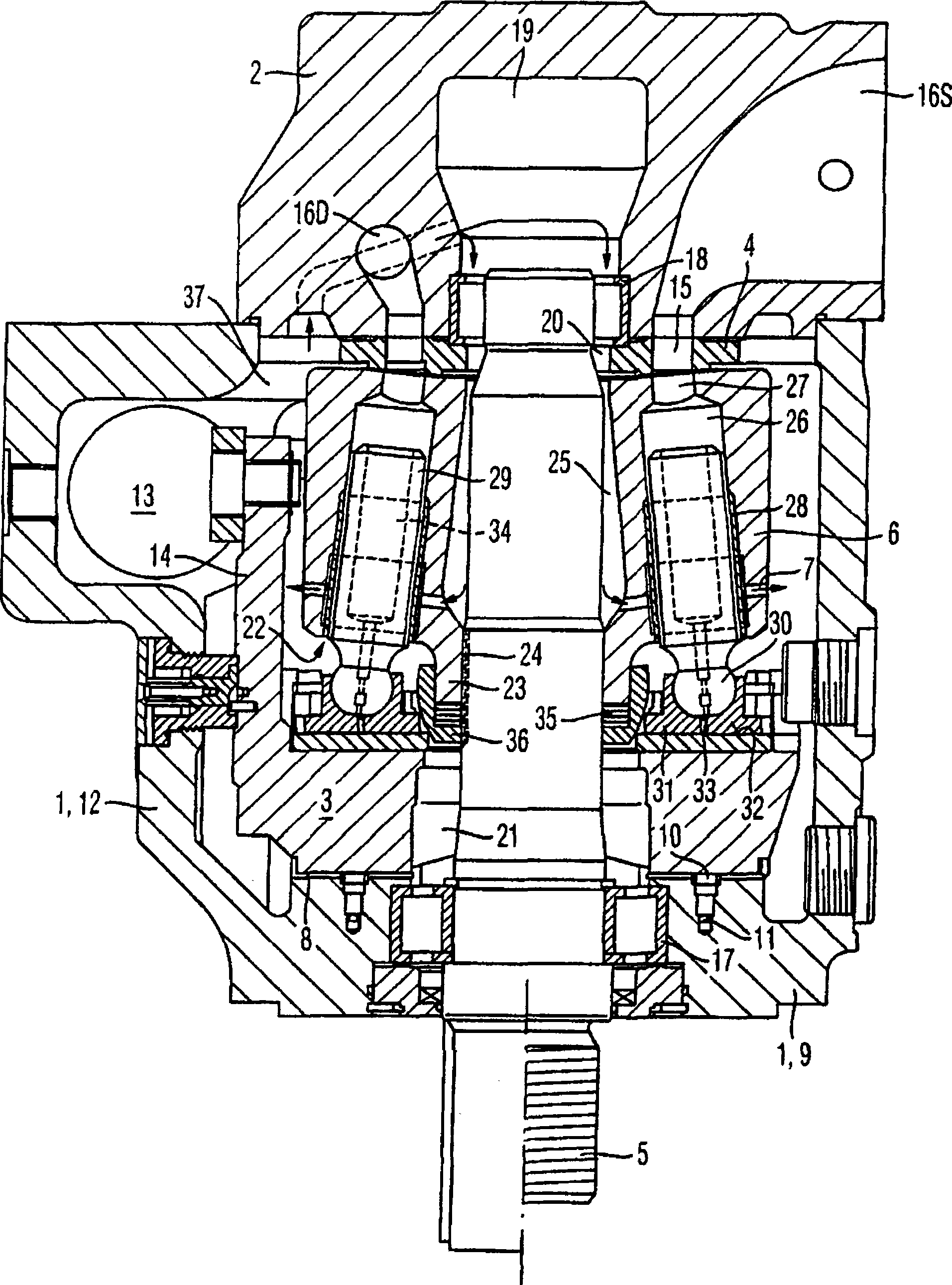

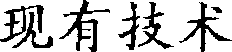

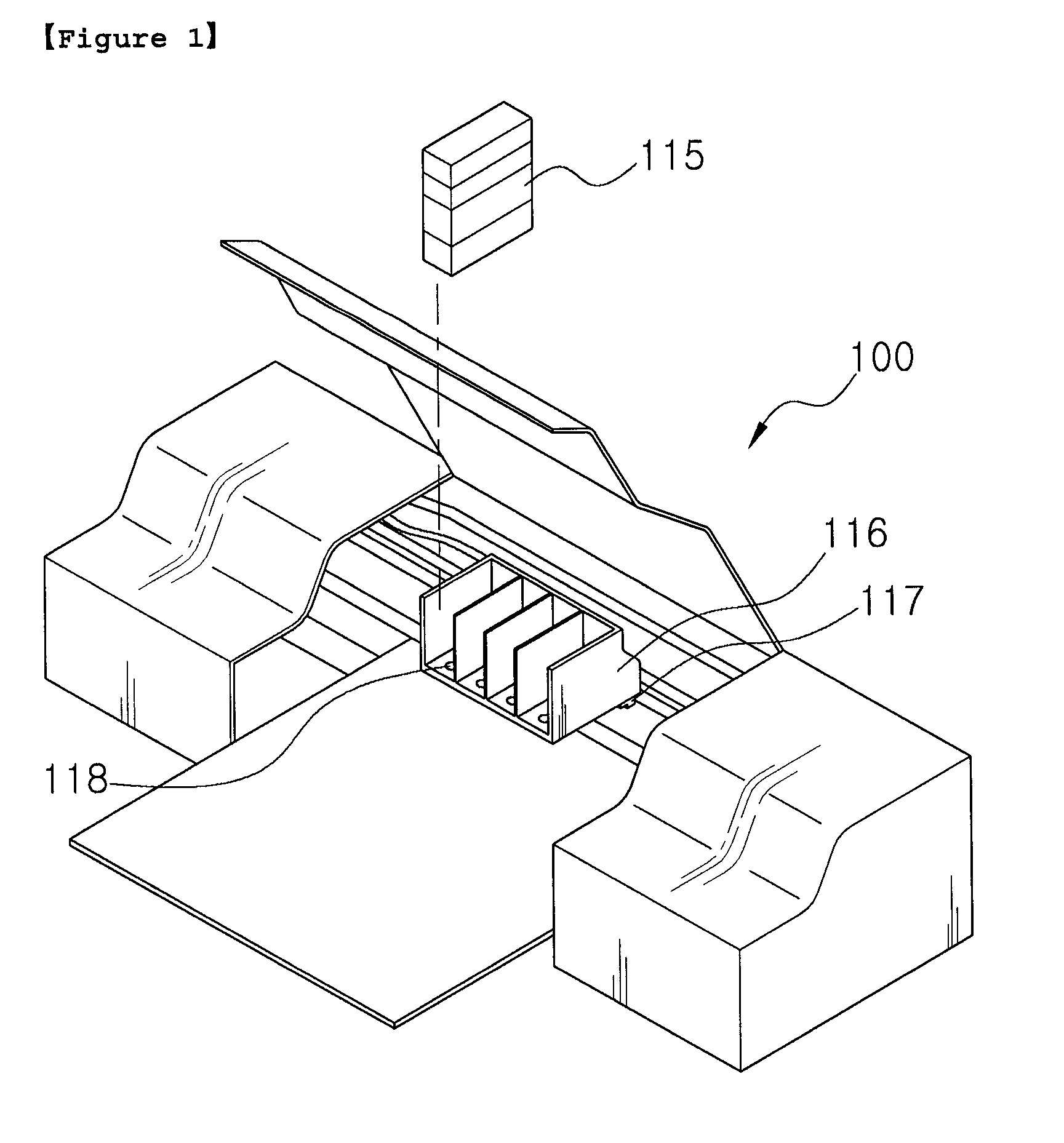

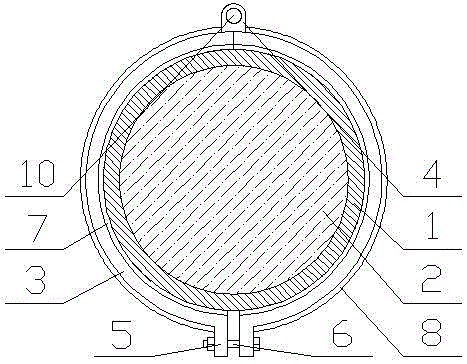

Axial piston machine having a hydrostatic support of the hold-down

InactiveCN101460741AOffset the pressureReciprocating piston enginesPositive-displacement liquid enginesReciprocating motionEngineering

An axial piston machine comprises a housing (1) which receives an eccentric disc (3) and a rotatably mounted cylinder drum (6) having cylinders (26, 28) and pistons (29) which can move to and fro in the former and the ends of which which protrude out of the cylinders (26, 28) are supported on the eccentric disc (3) via a sliding face (31) of a sliding disc (32), and also comprises a hold-down (36), by which the sliding face (31) is held in contact with the sliding disc (32). A pressure which prevails in a pressure space (40) under the sliding shoes (31) compensates partially for a pressure which is exerted on the sliding shoe (32) by the hold-down (36), via a connecting restrictor (43).

Owner:HYDROMATIK GMBH

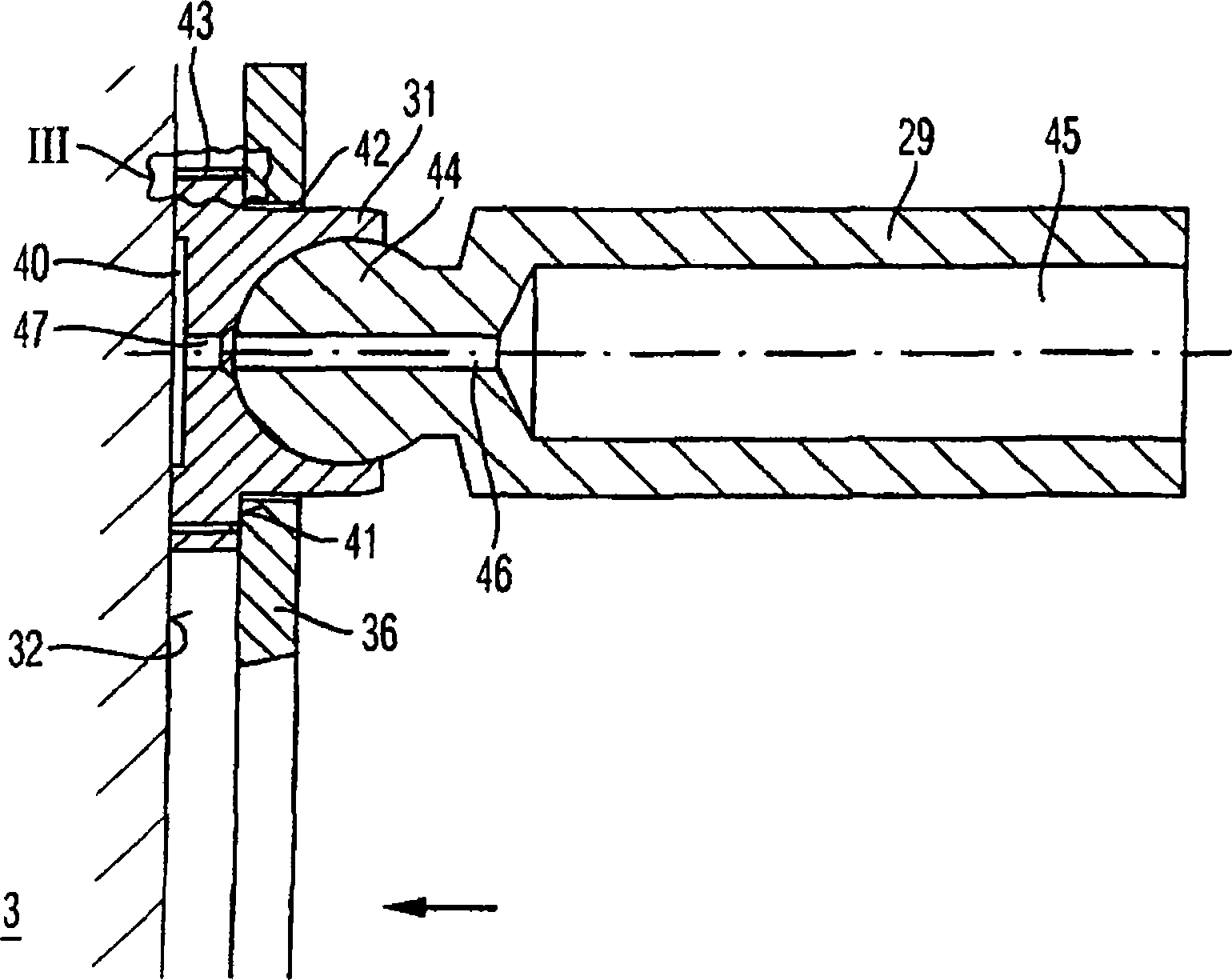

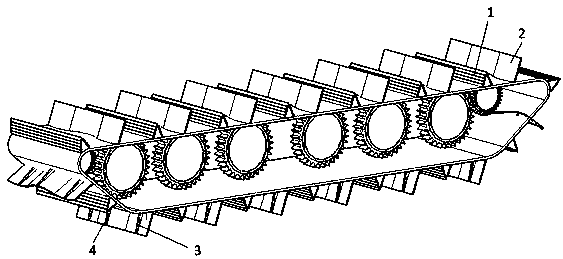

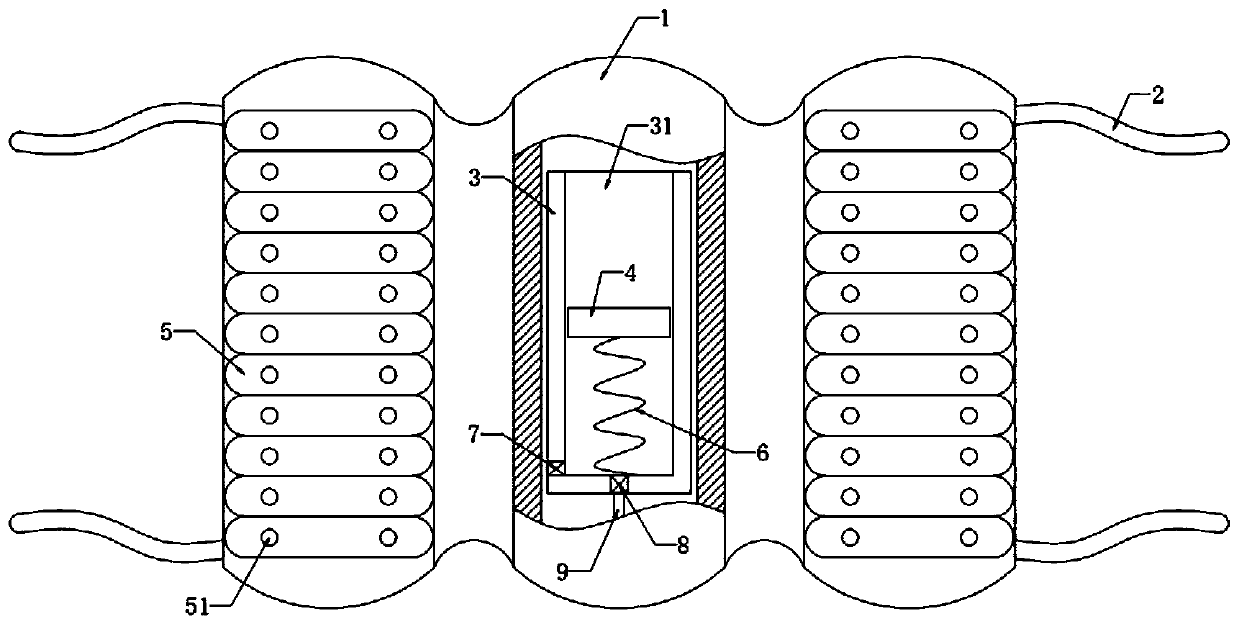

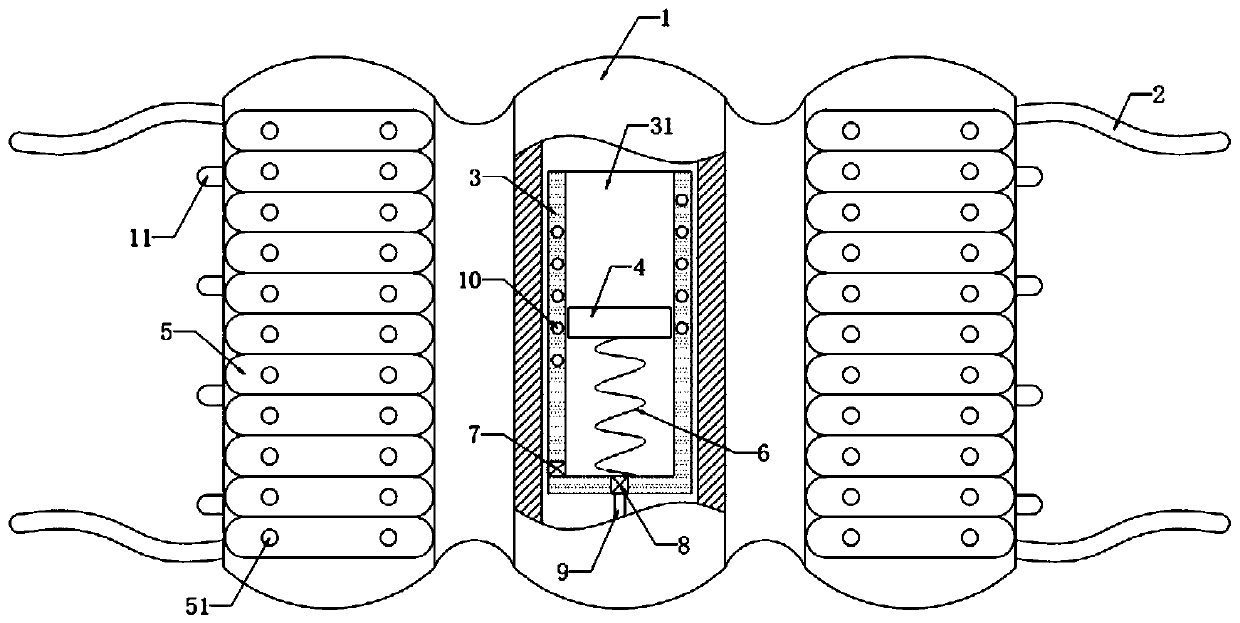

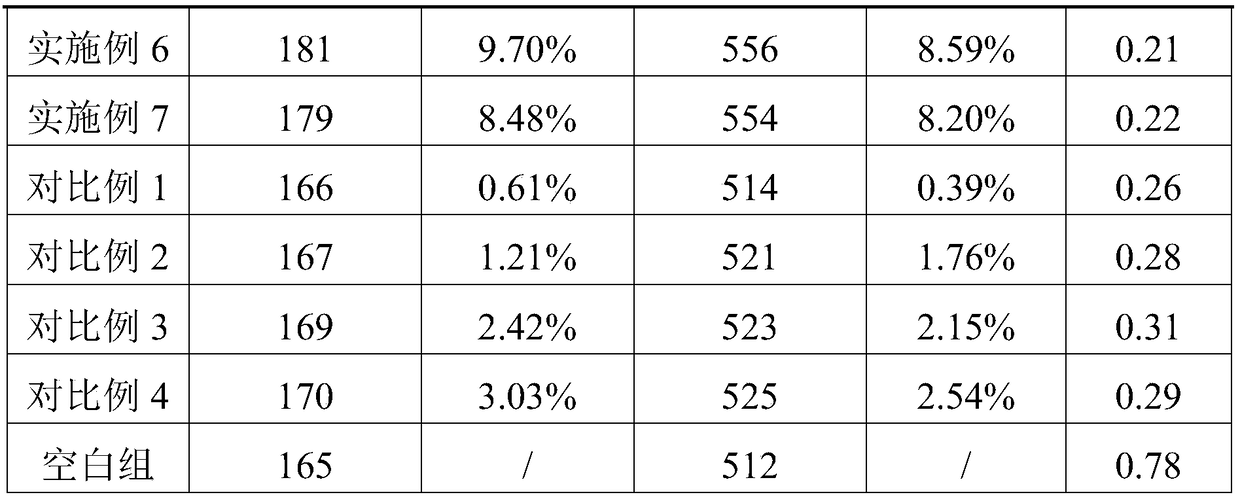

Walking crawler device of crawler-type deep-sea mining vehicle

ActiveCN111016560AAnti-skidPrevent subsidenceAmphibious vehiclesEndless track vehiclesDeep sea miningMining engineering

The invention discloses a walking crawler device of a crawler-type deep sea mining vehicle, which comprises two walking crawlers installed on the two sides of a crawler support, wherein a plurality oflong crawler teeth and a plurality of short crawler teeth are arranged on the walking crawlers at intervals, and the height of the long crawler teeth is greater than that of the short crawler teeth;when the long crawler teeth are completely inserted into soil, an acute angle is formed between the arrangement direction of the long crawler teeth and the advancing direction of the walking crawler;a long toothed plate is an arc plate, the middle part of the long crawler tooth is sunken backwards relative to the advancing direction of the mining vehicle, a middle reinforcing rib beam is vertically arranged in the middle of the convex surface, and side edge reinforcing rib beams are vertically arranged at the two ends of the convex surface; the short crawler tooth is a wedge-shaped body witha certain height and width, the interior of the wedge-shaped short crawler tooth is in a hollow state, a short crawler tooth rib beam for supporting and reinforcing is arranged in the middle of an inner cavity of the wedge-shaped short crawler tooth, and stepped micro bulges are arranged on the outer surface of the wedge-shaped short crawler tooth in the length direction. The walking crawler device can enable the crawler-type deep sea mining vehicle to have better propelling performance, and prevents the crawler-type deep sea mining vehicle from slipping, sinking and laterally moving.

Owner:OCEAN UNIV OF CHINA

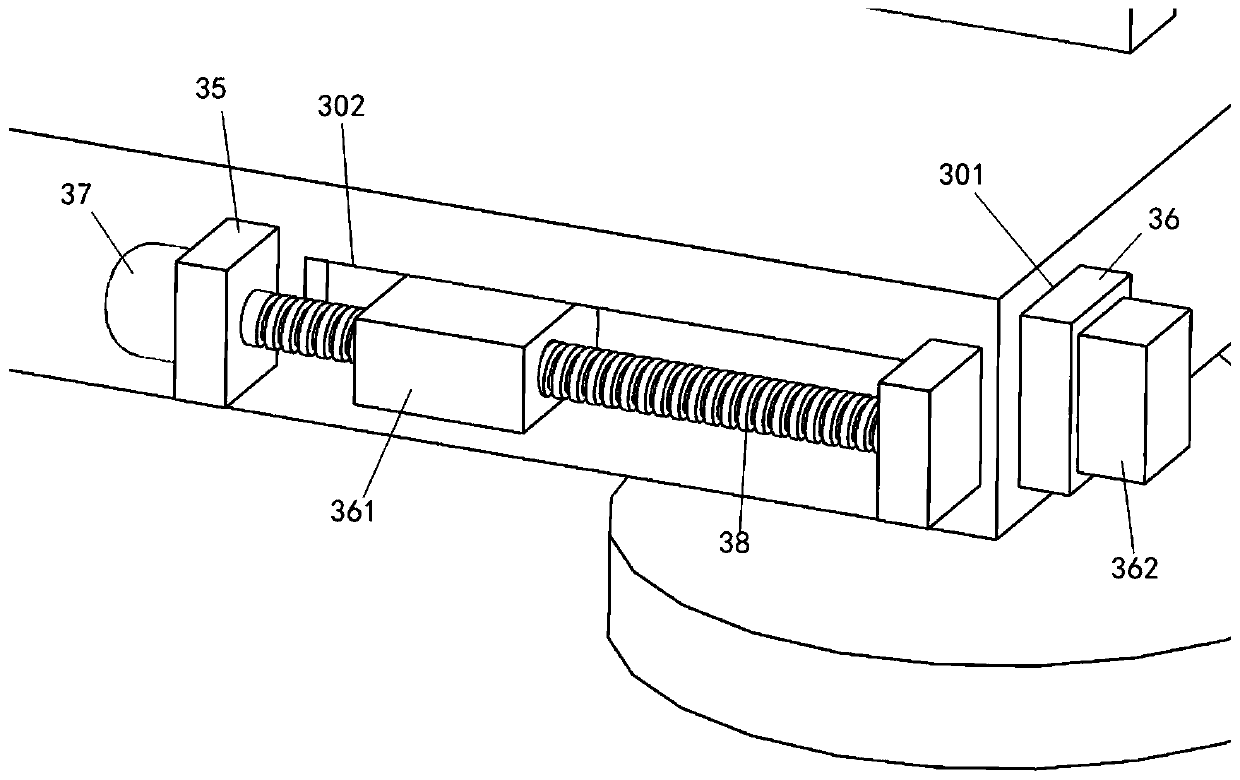

Building construction steel structural supporting beam

InactiveCN111236533AGuaranteed stabilityControl distanceGirdersJoistsArchitectural engineeringSteel columns

The invention discloses a building construction steel structural supporting beam. The building construction steel structural supporting beam comprises a fixed plate, a regulating mechanism is arrangedon the fixed plate, a screw and two moving rods are arranged on the regulating mechanism, moving grooves are formed in the two sides of the fixed plate, the two moving rods correspondingly penetratethrough the two moving grooves, auxiliary fixed mechanisms are arranged on the two sides of the fixed plate, and the two auxiliary fixed mechanisms are correspondingly connected with the two moving rods. According to the building construction steel structural supporting beam, the distance between the two moving rods can be convenient to regulate, so that the distance between two first U-shaped rods is rapidly regulated and fixed, the relative position between a first U-shaped plate and the moving rods can be well regulated, so that errors of the height and distance of two steel columns causedby misoperation and other reasons are well adapted, and the connecting firmness degree can be ensured; and meanwhile, the position of a cross beam can further be rapidly regulated, pressure of the outside world to a ceiling is effectively canceled, and the stability of the ceiling is effectively ensured.

Owner:凌池英

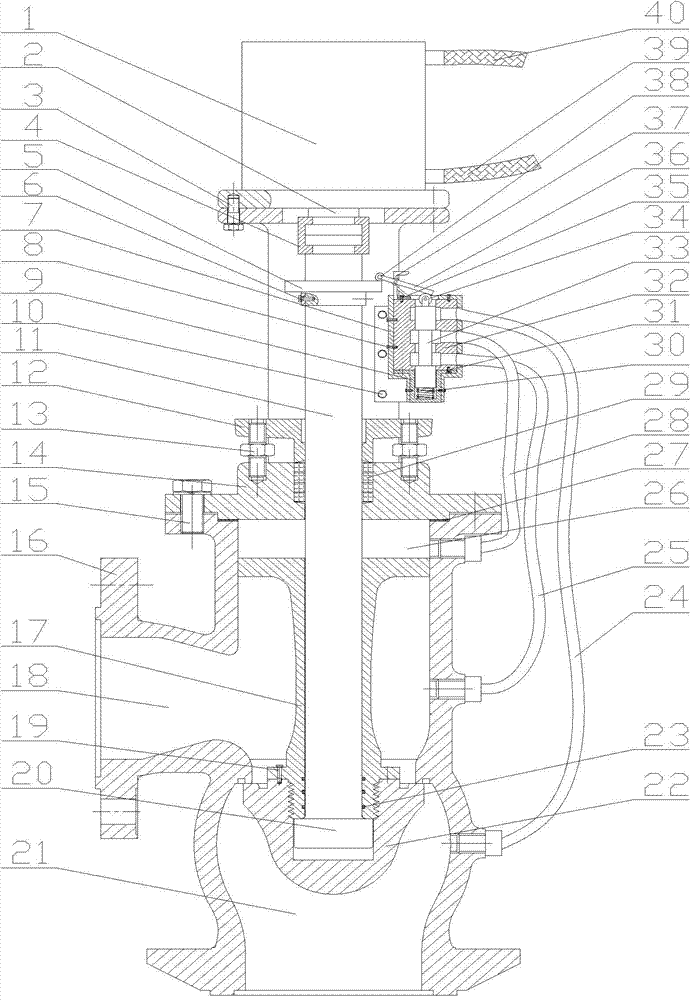

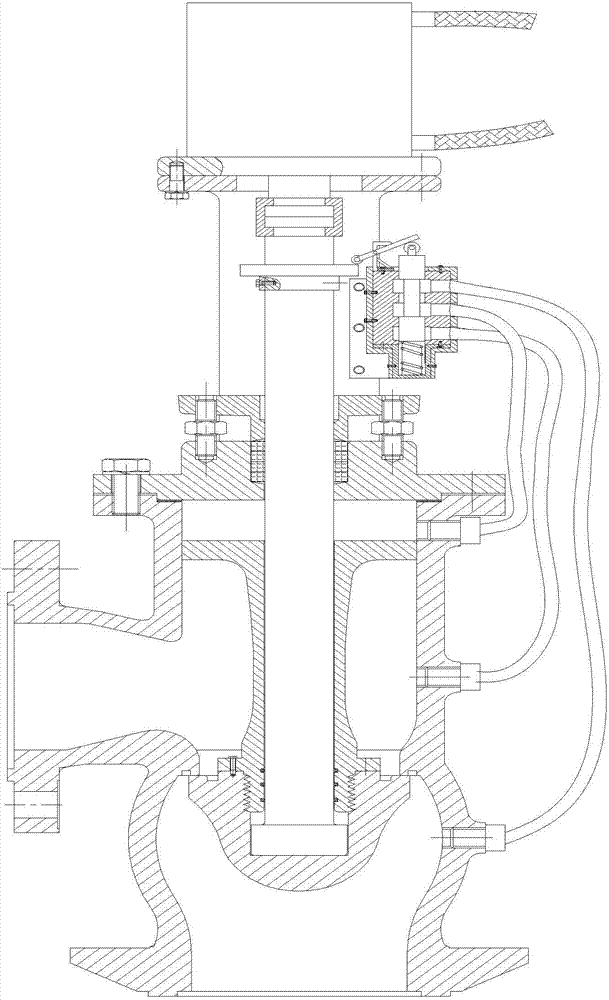

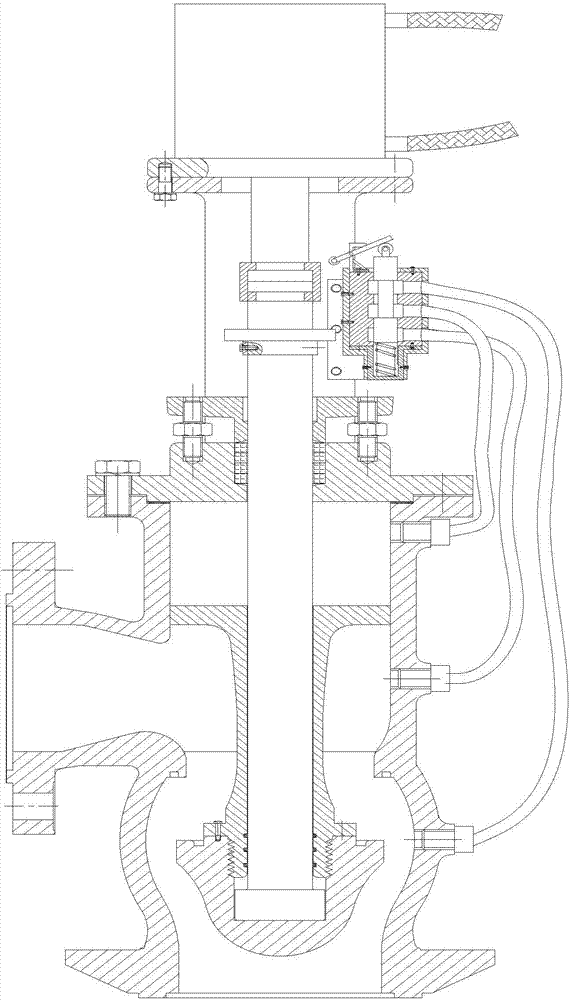

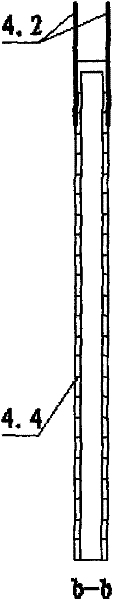

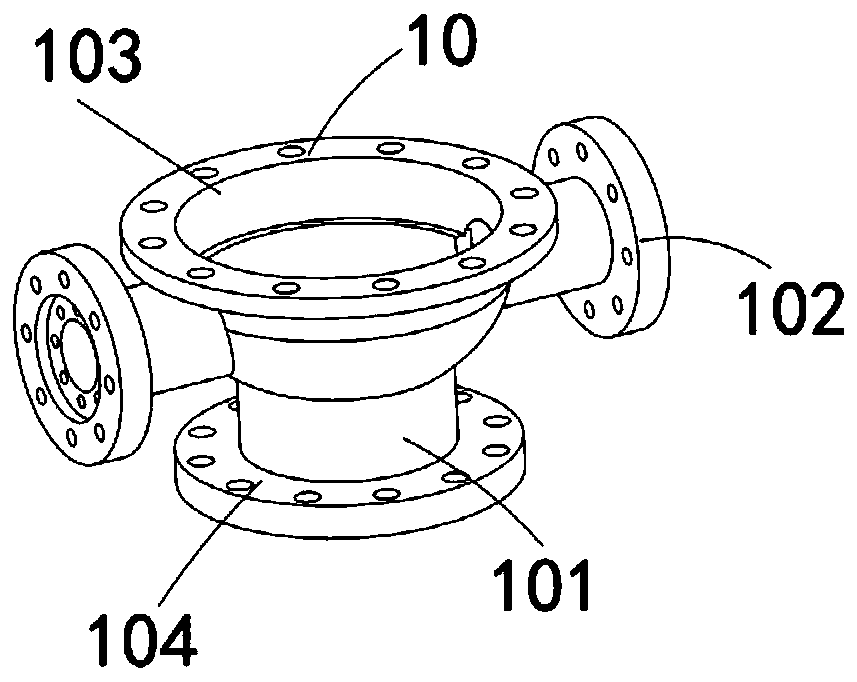

External pilot balance type kingston valve

InactiveCN103899764AEasy maintenanceExtended service lifeSpindle sealingsOperating means/releasing devices for valvesHigh pressure waterEngineering

The invention aims to provide an external pilot balance type kingston valve. The external pilot balance type kingston valve comprises a two-position and three-way reversing valve, wherein the two-position and three-way reversing valve comprises a reversing valve body and a reversing valve element; the reversing valve body is fixed to a valve cover; a spring sleeve is fixed to the lower end of the reversing valve body and is internally provided with a spring; the reversing valve element is arranged inside the reversing valve body and located on the spring; a valve element thrust wheel is installed at the top end of the reversing valve element; a pressure lever support is fixed to the top end of the reversing valve body and is provided with a pressure lever; a revolute pair is formed by the pressure lever and the pressure lever support; the first end portion of the pressure lever abuts against the valve element thrust wheel; the pressure lever is matched with the spring to control the reversing valve element to move vertically; the second end portion of the pressure lever is provided with a pressure lever rotary wheel. By the adoption of the balance pressure principle, a pilot tube guides high pressure water of a water inlet of the valve into a balance pressure cavity, backward backpressure on a valve head is formed, pressure on the valve head by the high pressure water of the water inlet of the valve is completely counteracted when the valve is switched on, and thus the valve is switched on easily.

Owner:HARBIN ENG UNIV

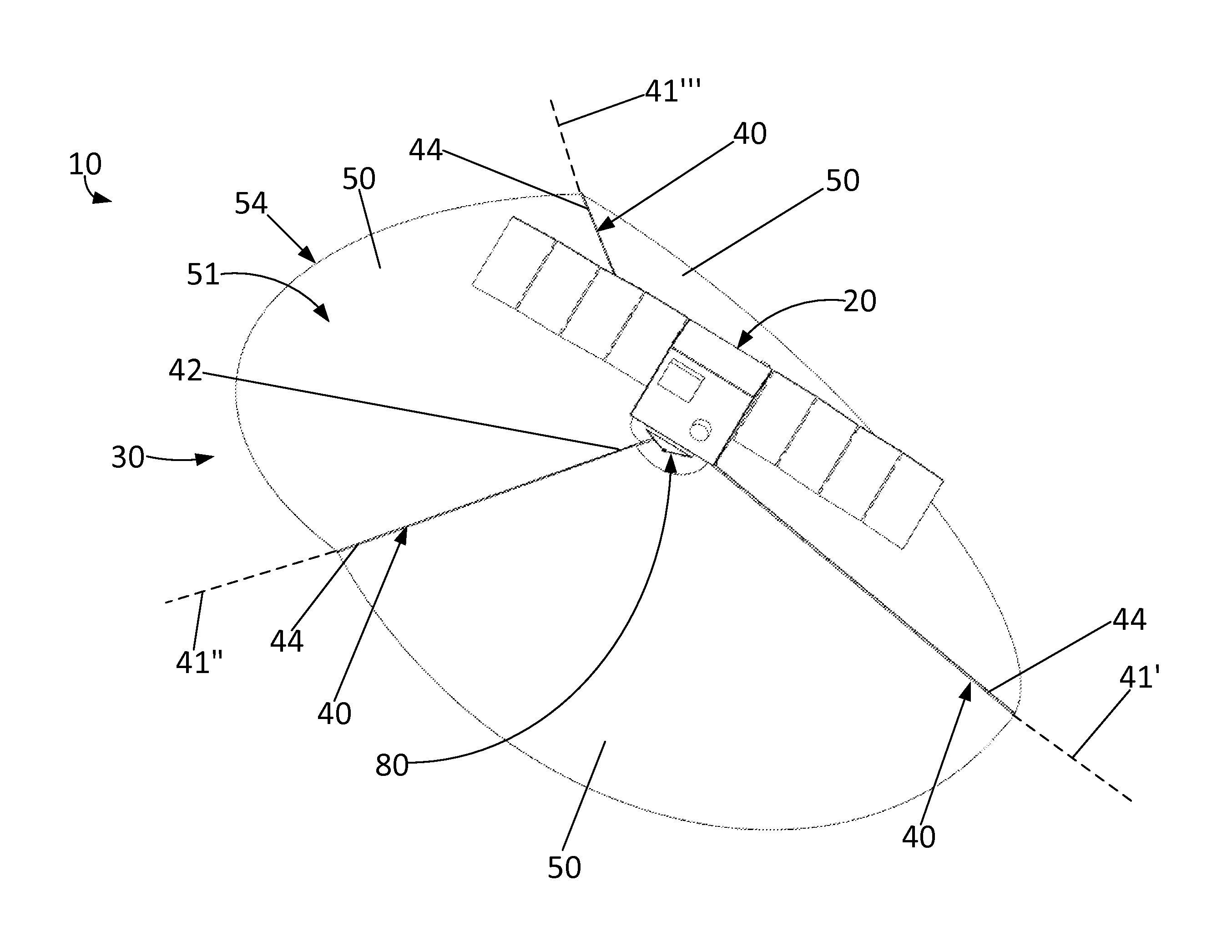

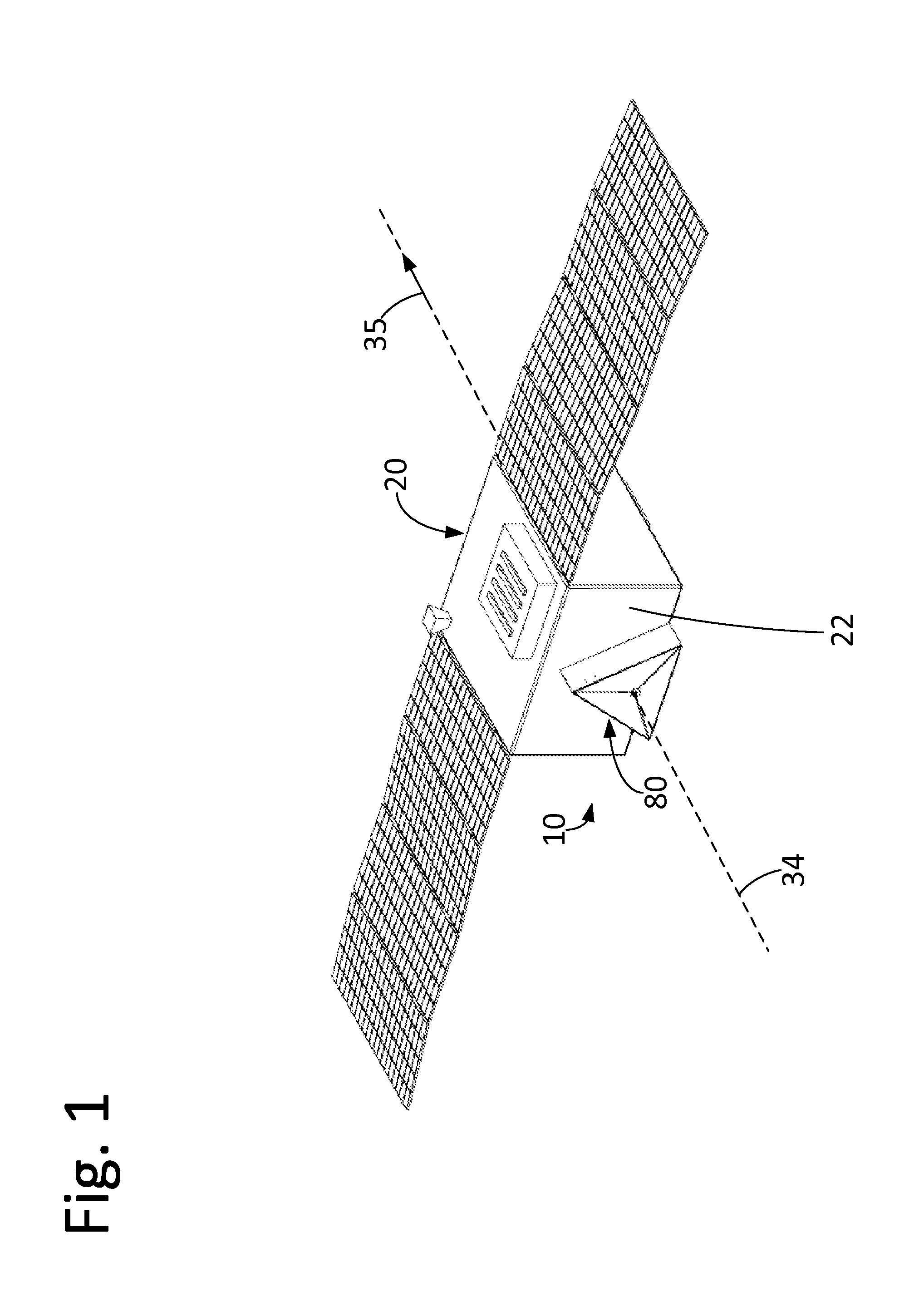

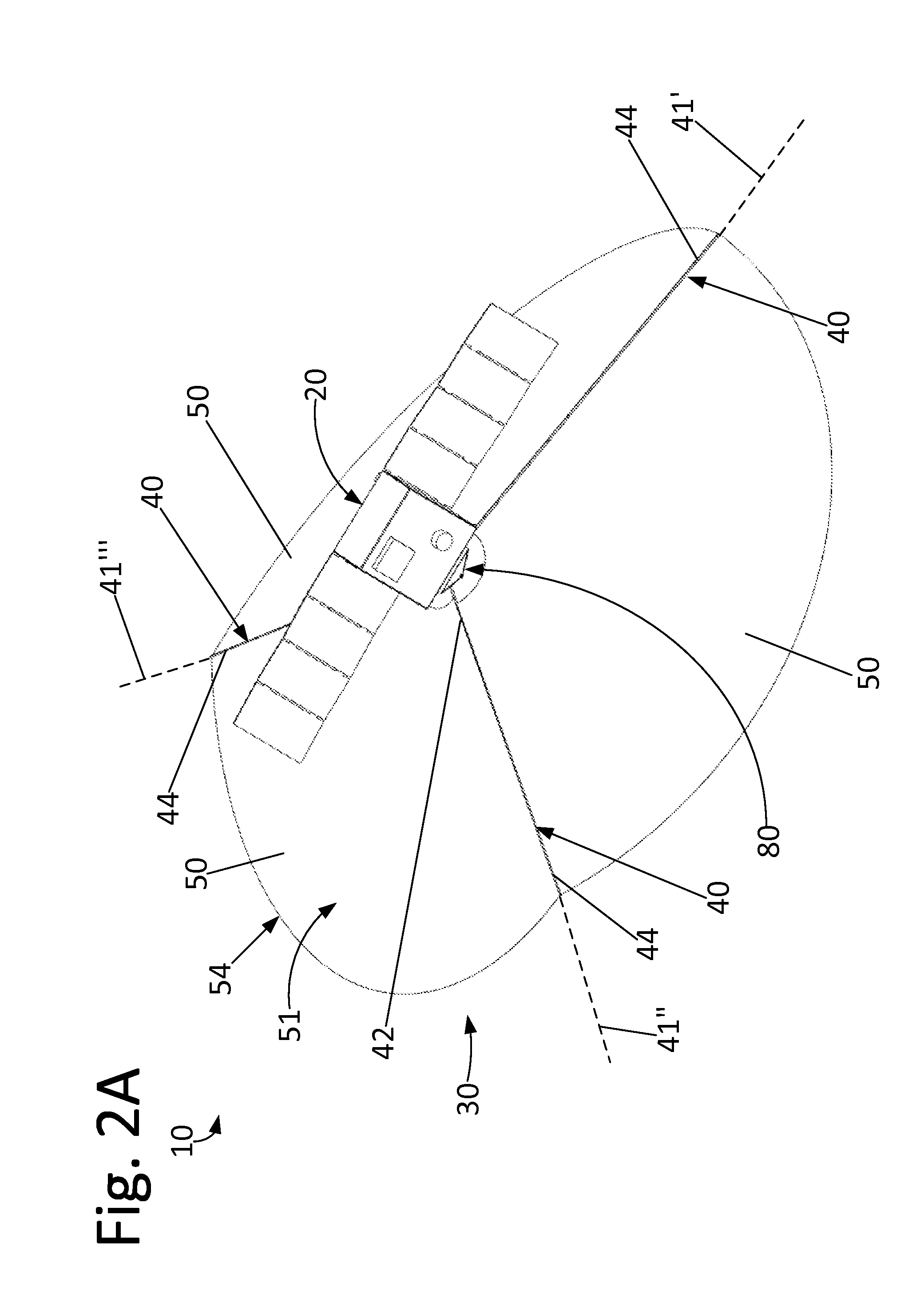

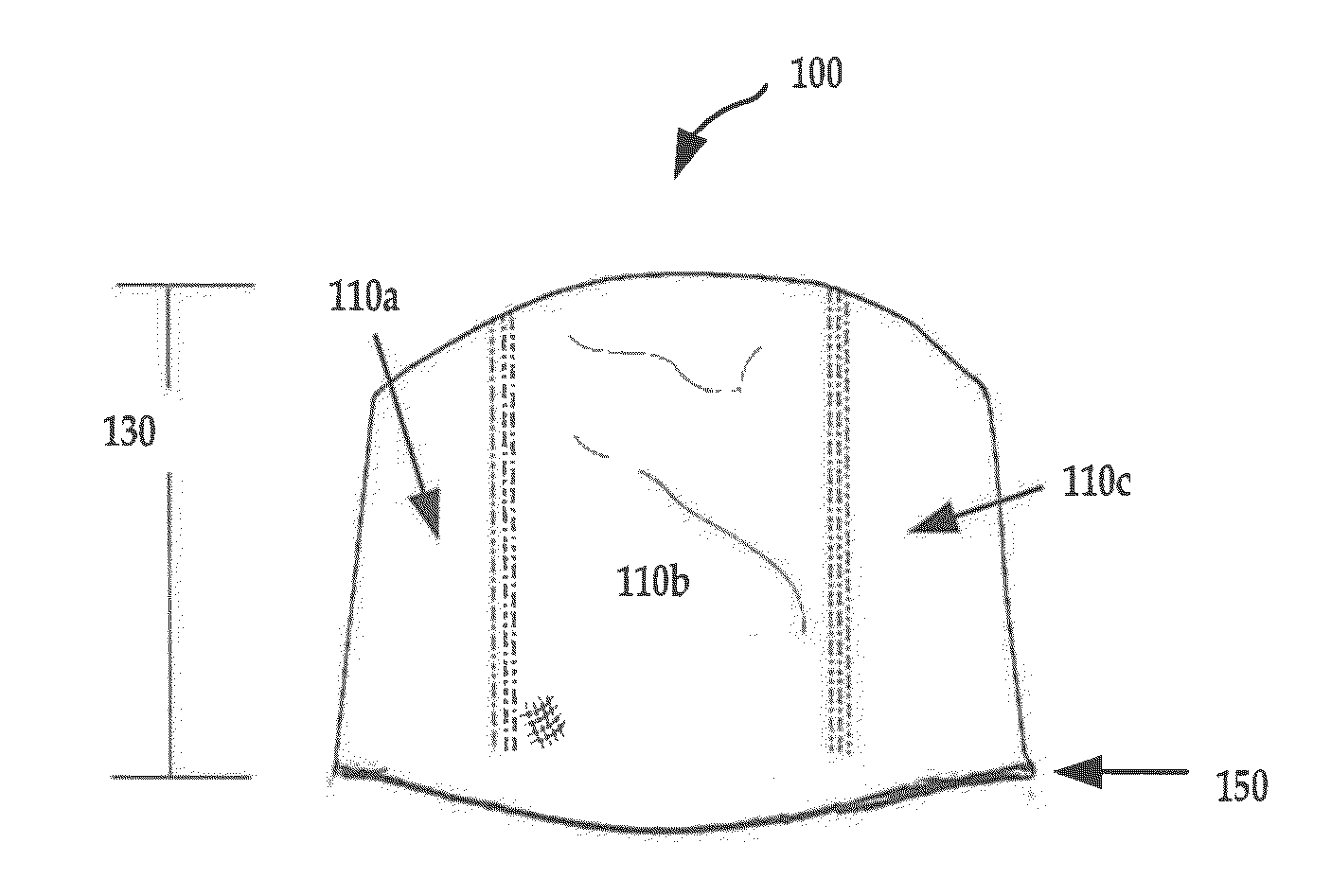

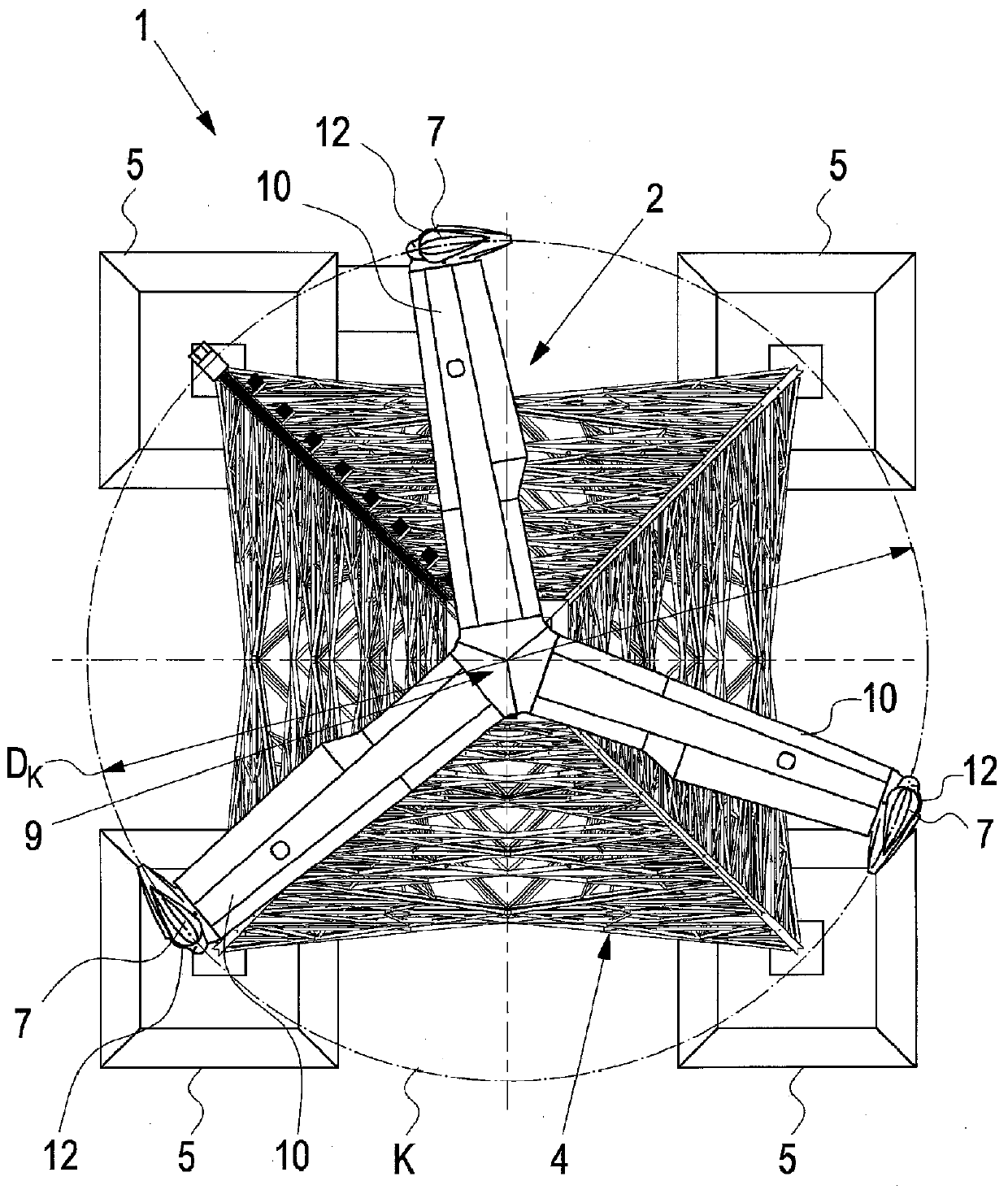

Gossamer apparatus and systems for use with spacecraft

ActiveUS9555904B2Reduce quality problemsLow costCosmonautic vehiclesCosmonautic propulsion system apparatusSpacecraftPotential energy

Gossamer apparatus and systems for use with spacecraft may include a deployable gossamer apparatus. The deployable gossamer apparatus may include a plurality rib members and gossamer material extending therebetween and may be configured in a stowed configuration and a deployed configuration. The rib members of the deployable gossamer apparatus store potential energy used for deployment of the deployable gossamer apparatus.

Owner:ANALYTICAL MECHANICS ASSOC

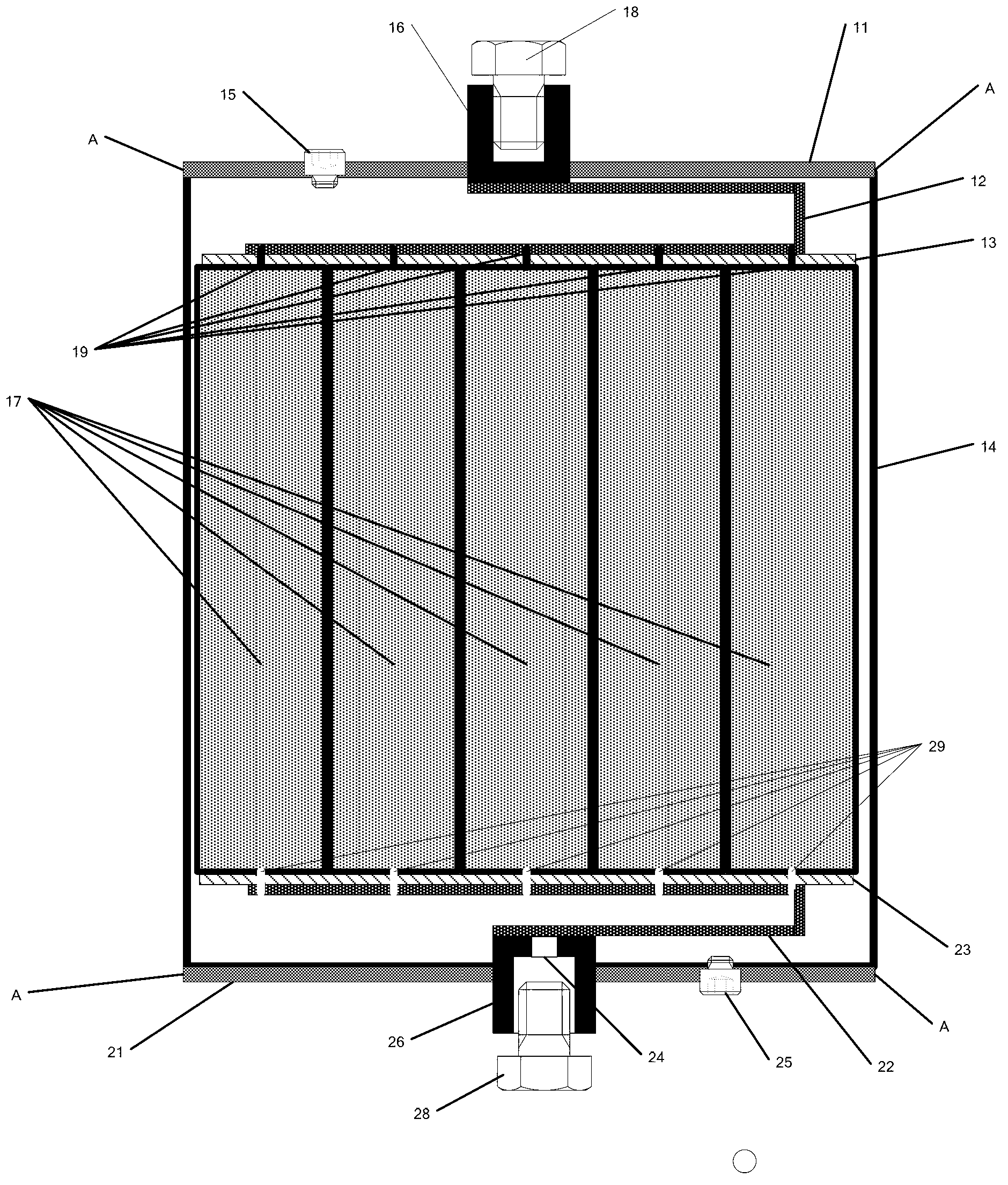

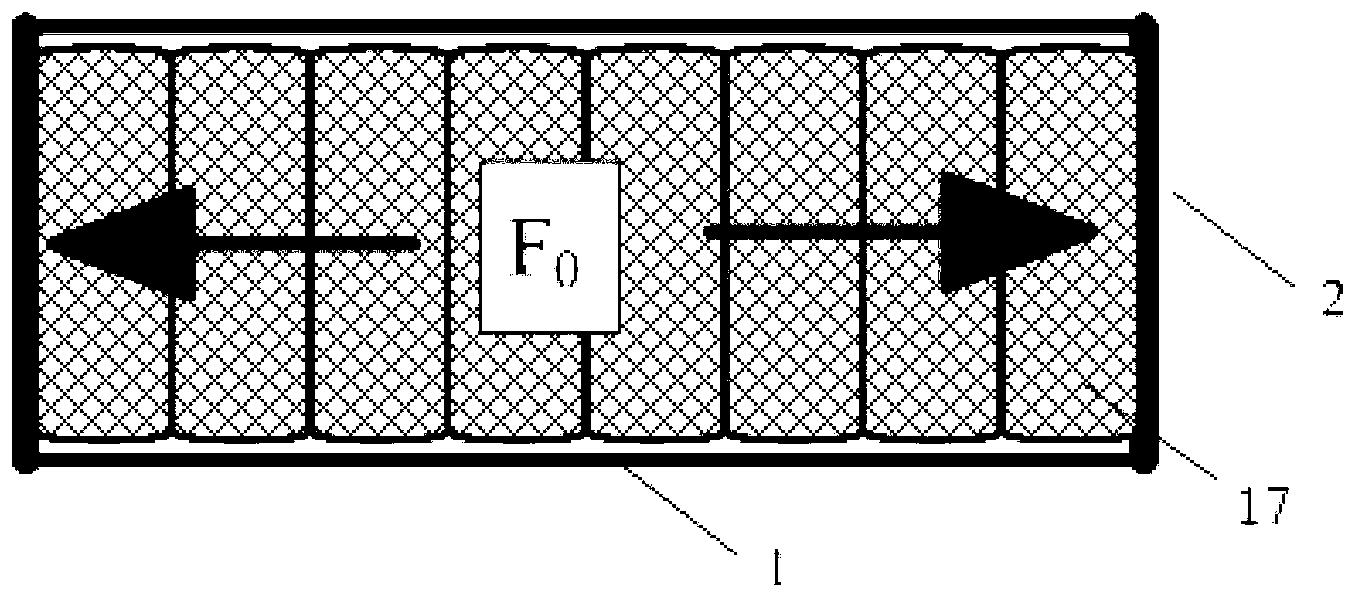

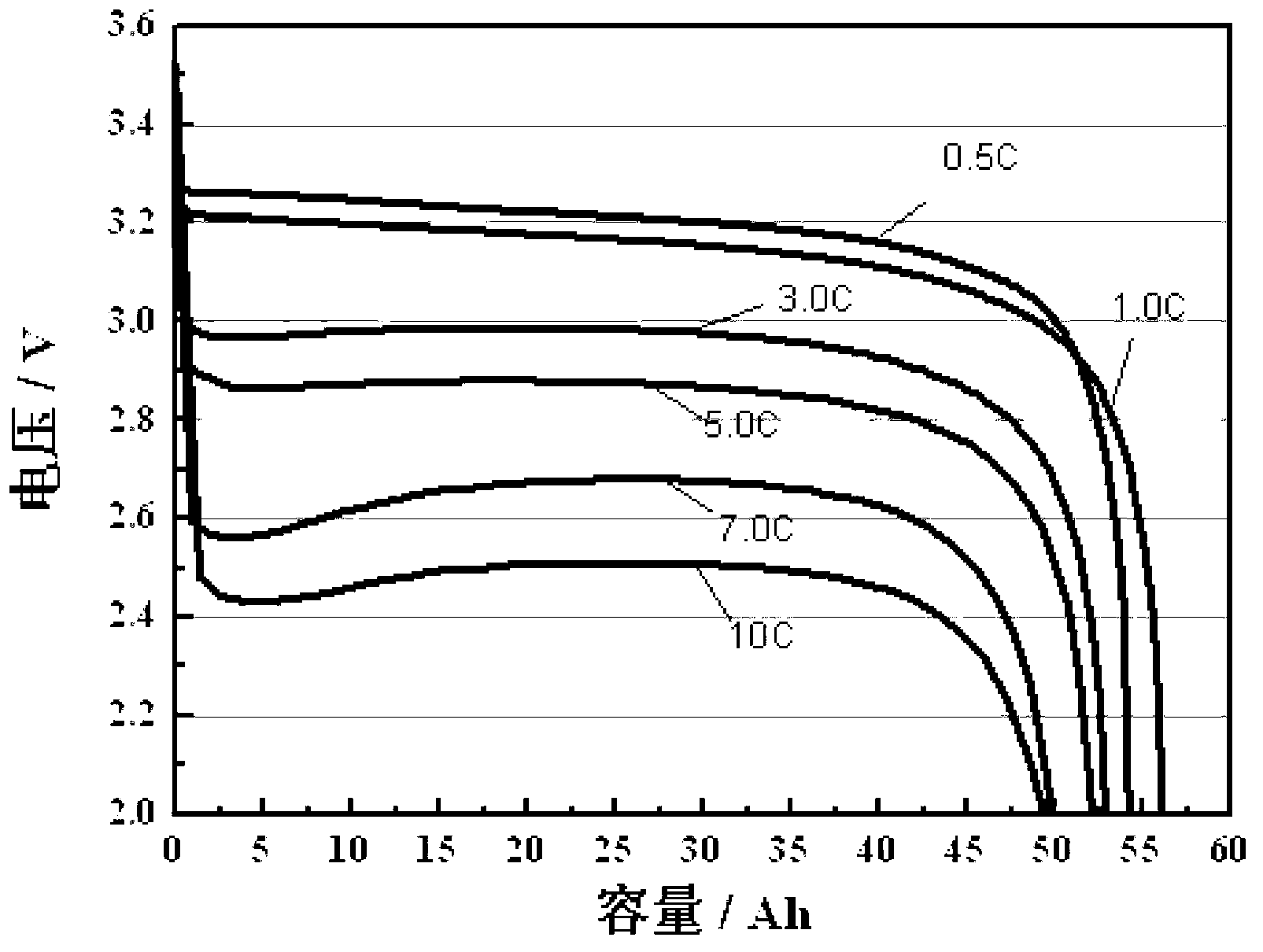

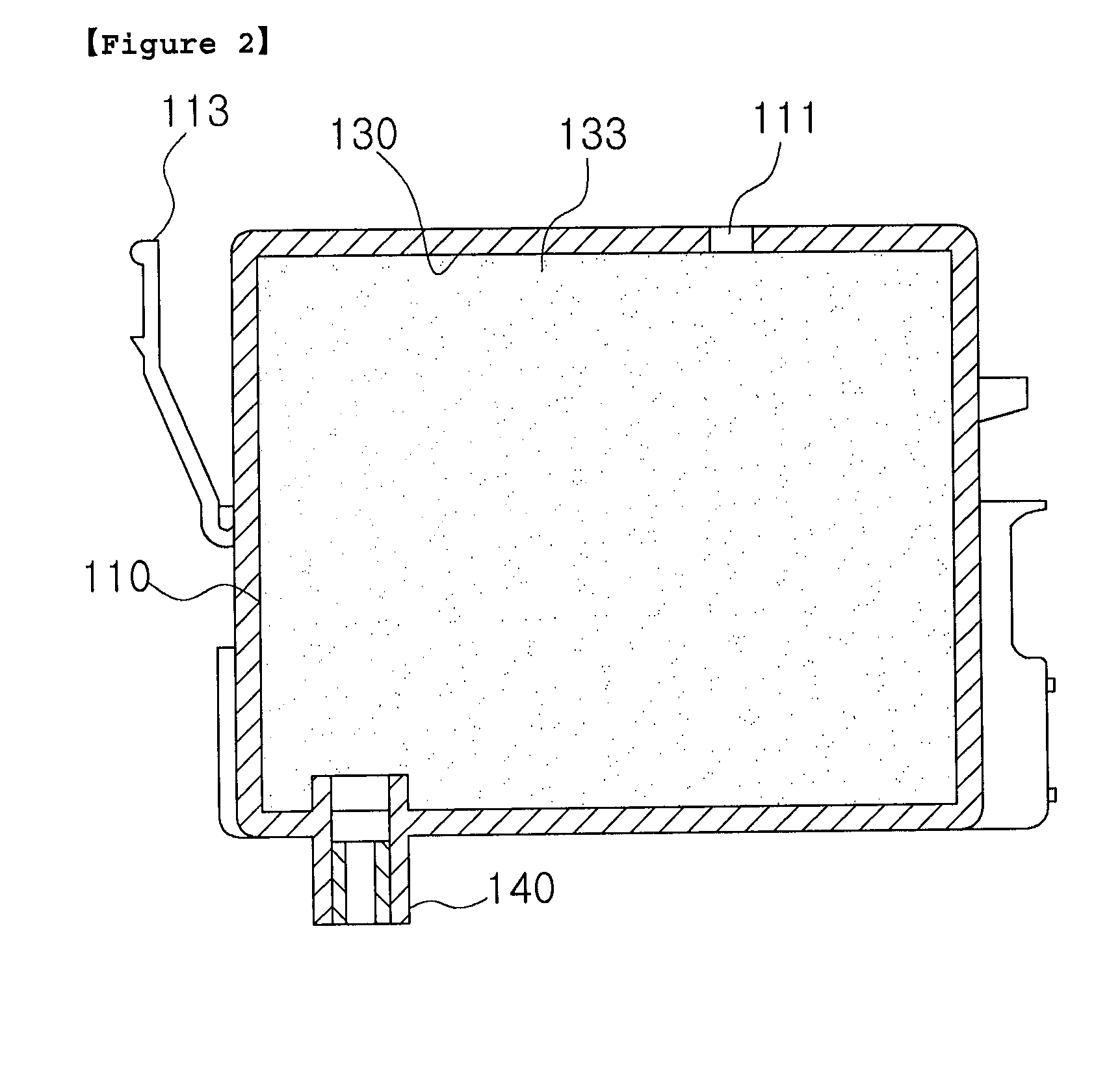

Square lithium ion battery with prestress structure

InactiveCN102800894AReduce bulge phenomenonIncrease stressFinal product manufactureSecondary cellsLithium-ion batteryBattery cell

The invention discloses a square lithium ion battery with a prestress structure. The square lithium ion battery comprises a battery cell, a battery shell used for packaging the battery cell, and an electrolyte, wherein the cross section of the battery shell is rectangular, the thicknesses on the battery shell are different, the thickness of the short edge of the battery shell is larger than that of the long edge of the battery shell; and the battery cell comprises a plurality of square coiling battery cells which are compressed in parallel, is installed in the battery shell and is matched with the battery shell tightly, and the distribution direction of the square coiling battery cell is parallel to the direction of the short edge of the battery shell. According to the square lithium ion battery with the prestress structure provided by the invention, the compression strength of the whole battery is improved, and the shell expansion in the charging and discharging processes of the battery is prevented.

Owner:ZHEJIANG GODSEND POWER TECH

Self-heat-dissipation type legging for running

ActiveCN111317963ARealize the massage functionImprove comfortVisible signalling systemsMuscle exercising devicesMassageEngineering

The invention discloses a self-heat-dissipation type legging for running. The legging comprises a plurality of cylindrical bags which are sewn together, a balancing weight is arranged in each cylindrical bag, binding belts are arranged on the two outermost cylindrical bags, sliding grooves are formed in the upper ends of the balancing weights, sliding blocks are connected into the sliding groovesin a sealed and sliding mode, the lower ends of the sliding blocks are elastically connected to the inner bottoms of the sliding grooves through springs, and a plurality of elastic air bags are arranged on the side walls of the cylindrical bags. According to the invention, a user continuously inflates the elastic air bags in the running process; the air bags are expanded one by one, the massage function on the legs can be realized; therefore, the comfort during use is improved; when the air pressure in the air bags reaches the threshold value of the pressure release valve; the pressure releasevalve is opened, air in the air bag is exhausted at a high speed and blown to the shank force exerting part, high-speed air flow can blow air to the legs for heat dissipation, meanwhile, part of pressure of the legs on the shanks can be counteracted through the air flow which is rapidly sprayed out, and the pressure of the legs on the shanks during long-time use is effectively reduced.

Owner:平邑仁安中医药产业发展有限公司

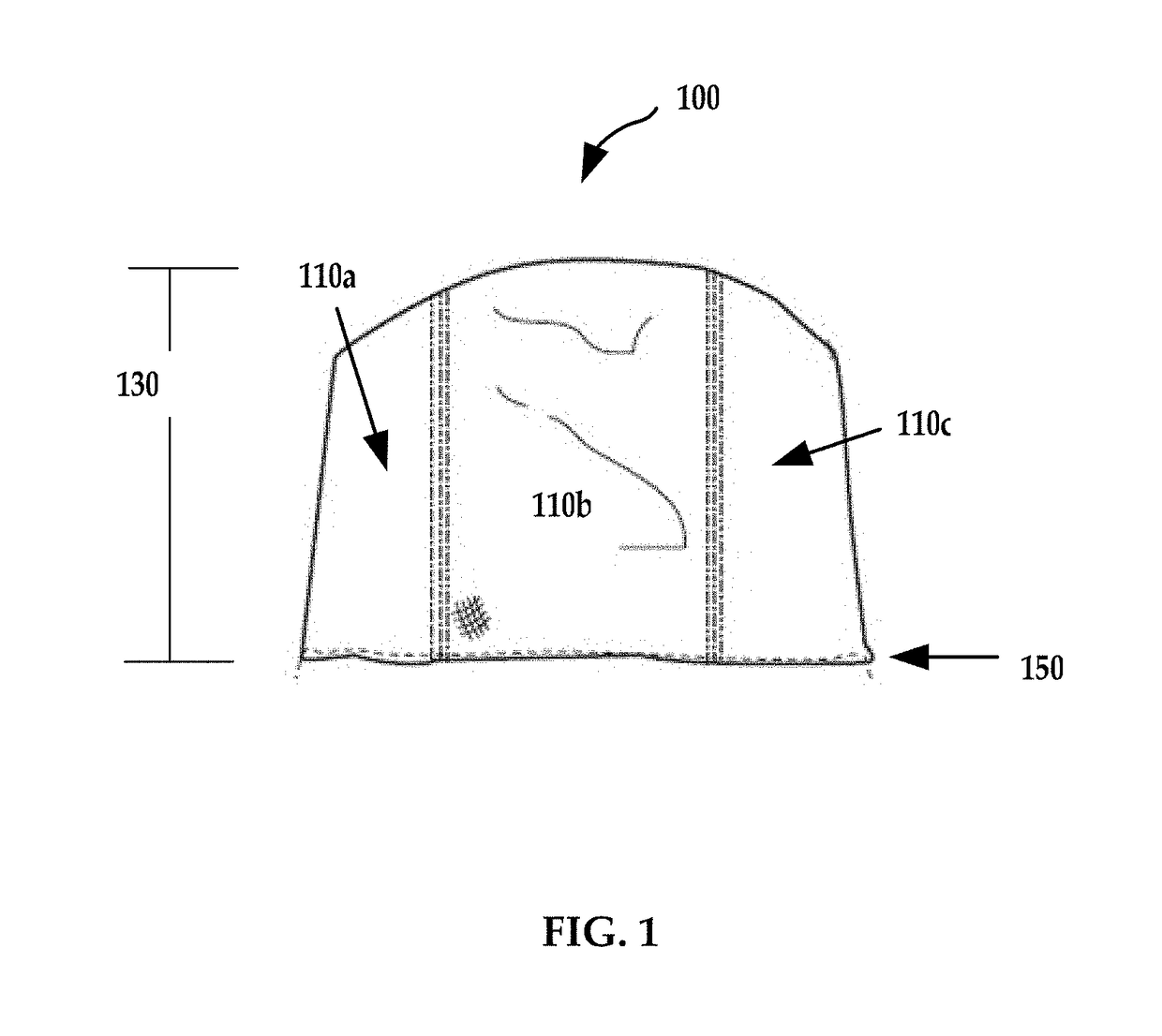

Crossover Maternity Panel

The present invention relates to a crossover maternity panel that may be attached to any lower garment worn throughout pregnancy and post-partum body changes. The crossover maternity panel may be a belly panel comprised of a single piece of fabric or multiple pieces connected with seams, and wrap around from the front to the back of the wearer. The portions may overlap in the back of the wearer as they decrease in height to create a crossover triangular section that provides support to the lumbar region of the wearer. The crossover maternity panel may be attached to any lower garment such as a pant, short, skirt, skort, or the like. The flexible and stretchable material of the crossover maternity panel allows the wearer to have support for the enlarged belly, support for increased pressure and laxity on the wearer's sacroiliac joints and lower back, as well as comfort and mobility.

Owner:INGRID & ISABEL

Crossover maternity panel with insert

The present invention relates to a crossover maternity panel that may be attached to any lower garment worn throughout pregnancy and post-partum body changes. The crossover maternity panel may be a belly panel comprised of a single piece of fabric or multiple pieces connected with seams, and wrap around from the front to the back of the wearer. The portions may overlap in the back of the wearer as they decrease in height to create a crossover triangular section that provides support to the lumbar region of the wearer. The crossover maternity panel may be attached to any lower garment such as a pant, short, skirt, skort, or the like. The flexible and stretchable material of the crossover maternity panel allows the wearer to have support for the enlarged belly, support for increased pressure and laxity on the wearer's sacroiliac joints and lower back, as well as comfort and mobility.

Owner:INGRID & ISABEL

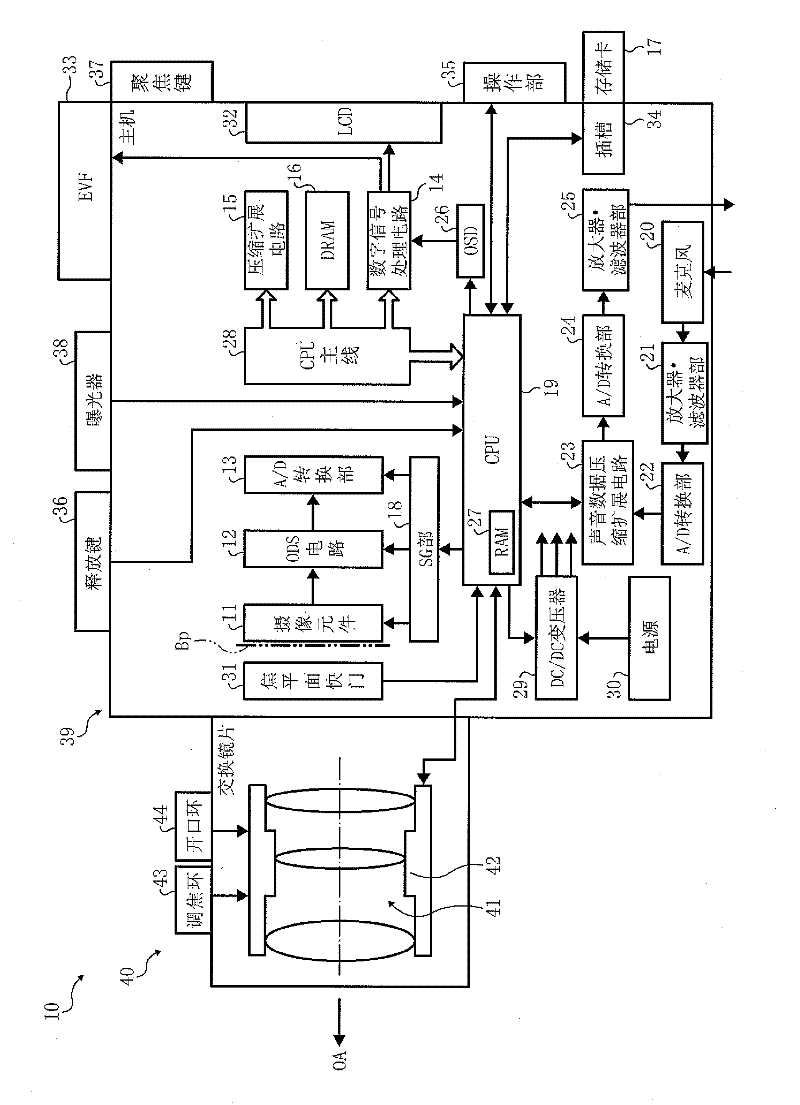

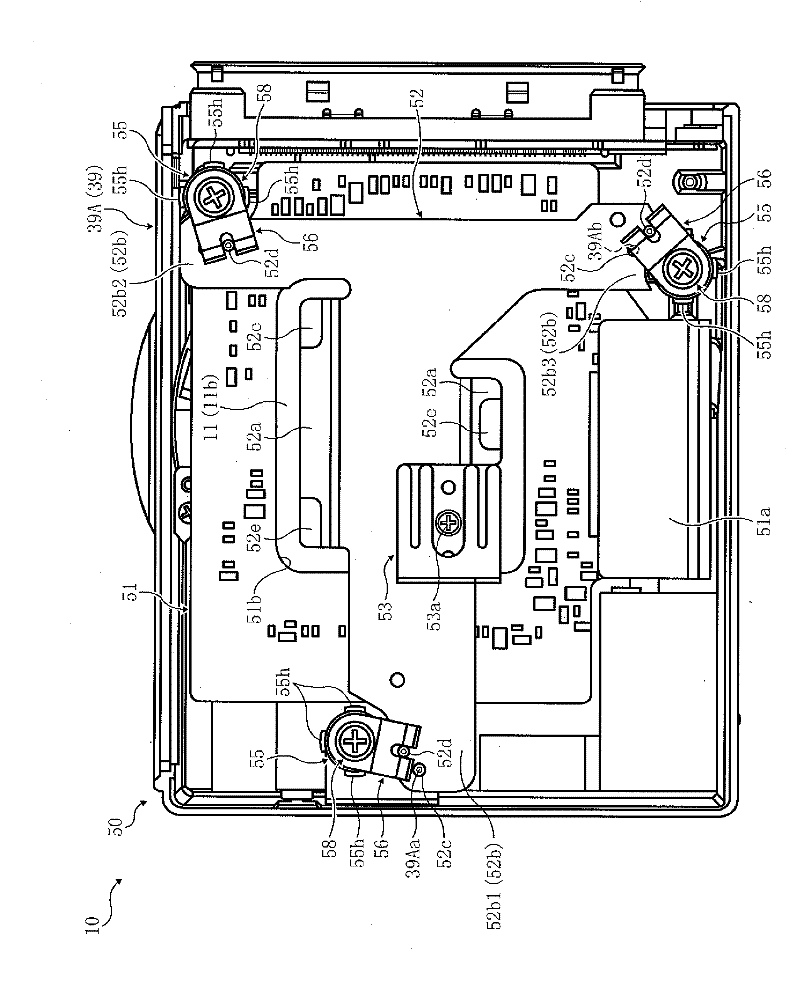

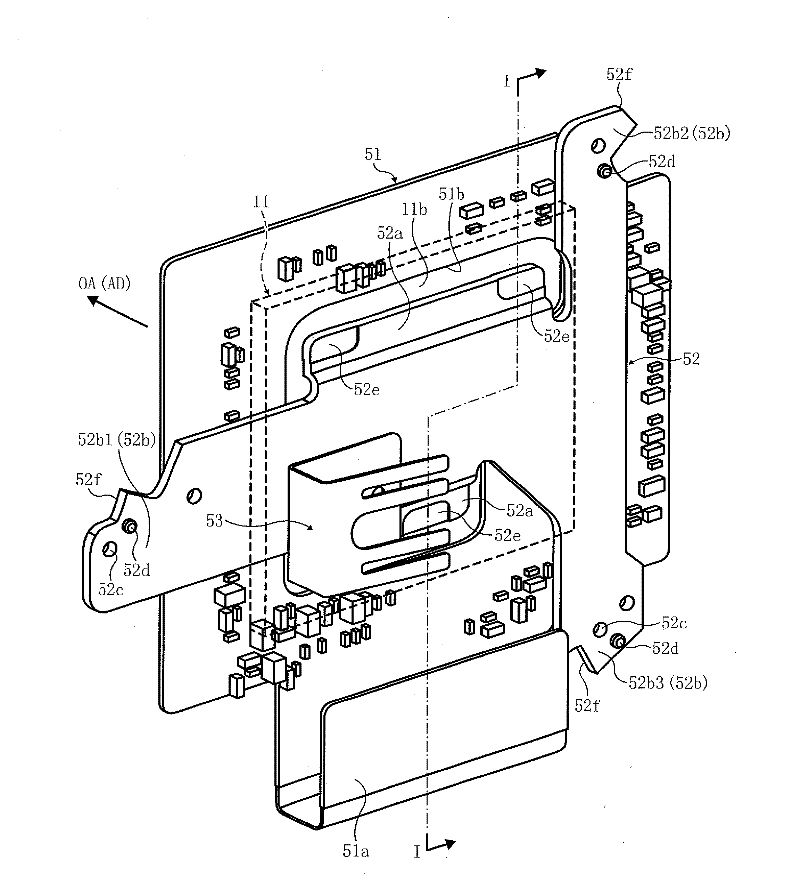

Inclination adjustment mechanism, imaging device and information terminal provided with inclination adjustment mechanism

InactiveCN102611843APrevent movementEasy tilt adjustmentTelevision system detailsPrintersEngineeringComputer terminal

The invention relates to an inclination adjustment mechanism, an imaging device and an information terminal provided with the inclination adjustment mechanism, wherein the inclination adjustment of imaging elements can be realized simply with high accuracy. The inclination adjustment mechanism (50) holds an imaging element (11) and can change the inclination state of the imaging element (11) relative to a basket body (39a), so that the imaging surface (11a) of the imaging element (11) is kept consistent with the reference surface of an imaging optical system. The inclination adjustment mechanism (50) comprises the holder plate (52) of an imaging element (11) and at least three support members (55). Support points for the holder plate (52) are formed on the cam surfaces (55c) of the support members (55). The supported holder plate (52) can move along the adjustment direction of the reference surface. The cam surfaces (55c) can be inclined with respect to the reference surface. Each support member (55) is configured to surround the imaging element (11) in the direction of the reference surface.

Owner:RICOH KK

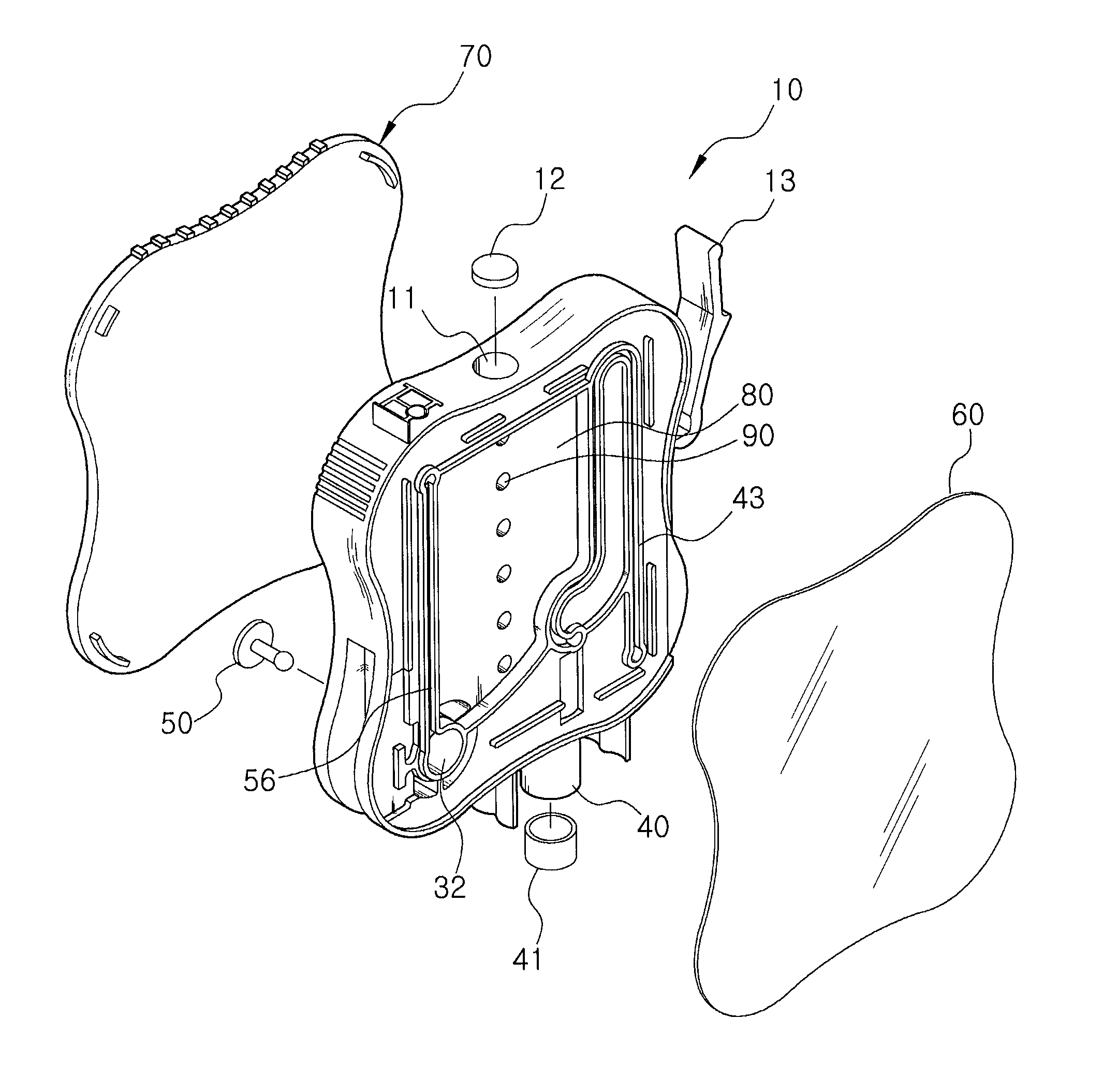

Ink-cartridge for printers and ink refilling method

An ink cartridge for printers and ink filling method that can expand the space where the ink is filled, and maintain pressure inside the ink cartridge. The ink cartridge includes a body formed in a predetermined shape and having a filling hold on one surface, a filling chamber where ink is filled inside the body, a discharging chamber connected to the filling chamber, an ink discharging port connected to the discharging chamber through an ink transferring channel, an air chamber connected to the filling chamber to supply air through an air transferring channel, an air suction valve in the air chamber, an air inducing channel that induces exterior air into the air suction valve, a blocking film attached to one surface of the body, a cover installed on another surface of the body, a pressure regulating part on one surface of outer body, which communicates with the filling chamber.

Owner:INKTEC CO LTD

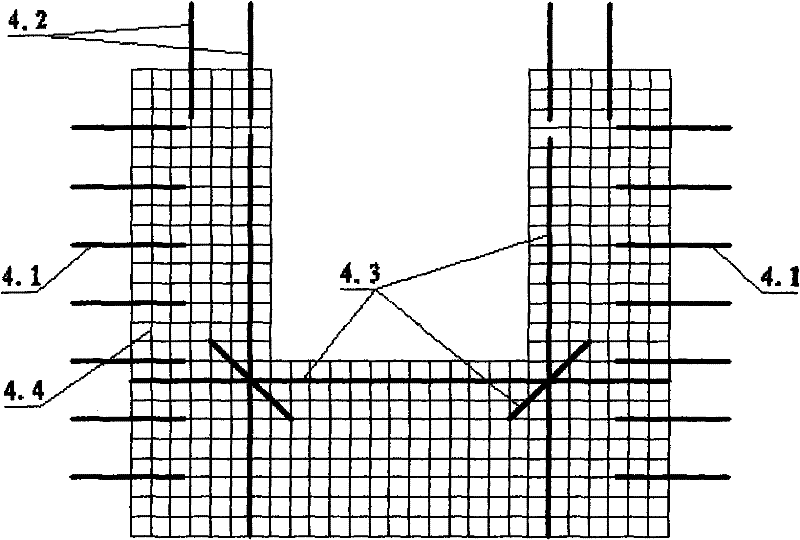

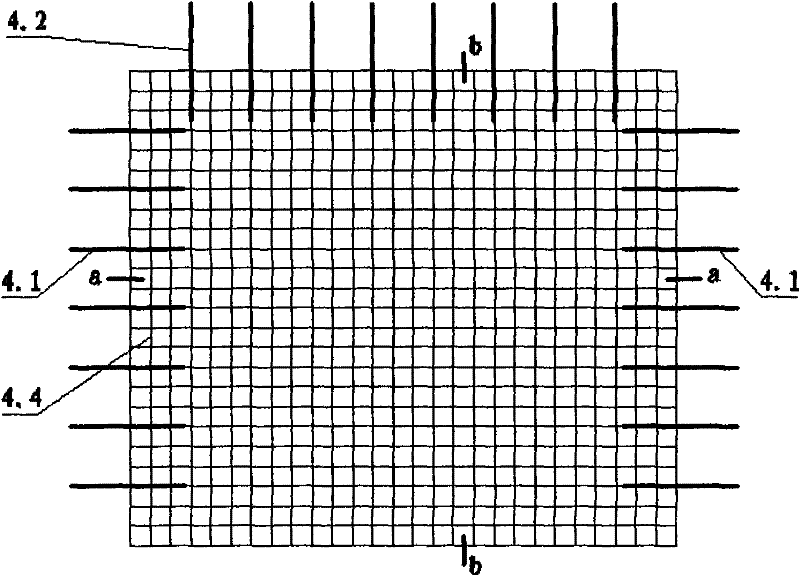

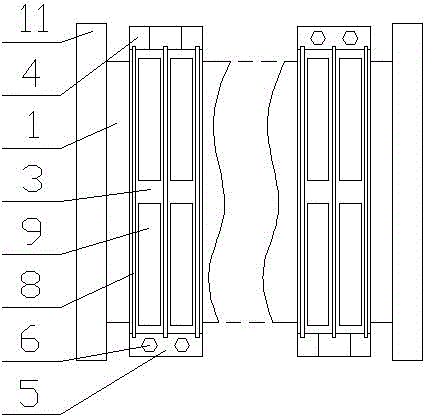

Spraying sandwiched concrete shear wall structure of clamp die fixing machinery and construction method

InactiveCN102220809AImprove flexural strengthImprove impact resistanceWallsBuilding material handlingShock resistanceUltimate tensile strength

The invention relates to a spraying sandwiched concrete shear wall structure of a clamp die fixing machinery and a construction method; the method comprises the following steps: a precast steel mesh core plate is installed on a poured-in-place underbeam / foundation correspondingly, then a clamp die column and a clamp die of a clamp die beam are installed, two side surfaces of the steel mesh core plate are fixed by the clamp die, a concrete layer is sprayed mechanically on the surface of the steel mesh core plate, a steel mesh of the steel mesh core plate is solidified in the concrete layer, then the clamp die column and the clamp die beam are poured in place, vibrating is conducted in the pouring process, and the poured concrete is densely solidified with the corresponding edge of the concrete layer, so that a frame light sandwiched concrete beating wall body can be formed. By adopting the method, the effects of integrity, strength, impact resistance, shock resistance, heat insulation, energy conversation and the like of the wall body can be greatly improved, the self weight of the wall body can be reduced, the pouring formwork can be saved by 60%, the working can be reduced, the construction period can be accelerated, the engineering manufacturing cost is lowered, and the invention is particularly suitable for shear walls of multi-layer and high-rise buildings and construction.

Owner:BEIJING HUAMEIKEBO TECH DEV +1

Compression expanding type pipe opening inner diameter high-pressure sealing device and method

InactiveCN104633115AImprove sealingSealing stability of the sealEngine sealsEngineeringHigh pressure

The invention discloses a compression expanding type pipe opening inner diameter high-pressure sealing device and method. The device comprises an air cylinder body and a piston component. A support which is inserted and blocked to the inner wall of a sealing pipe opening of a piece to be sealed is arranged at the top of the air cylinder body. The piston component comprises a piston body and a piston rod. The piston body is arranged in the air cylinder body. The piston rod penetrates through the top of the air cylinder body and the support. A first end of the piston rod is fixed at the top of the piston body. A second end of the piston rod is provided with a pressing disc which is inserted and blocked to the inner wall of the sealing pipe opening of the piece to be sealed. Sealing rings are arranged between the pressing disc, the support and the inner wall of the sealing pipe opening. A cavity is filled with compressed air, so that the piston body and the piston rod move downwards, accordingly, the pressing disc arranged at the second end of the piston rod compresses the sealing rings downwards, and the sealing rings expand and seal the inner diameter of the sealing pipe opening of the piece to be sealed.

Owner:SHANGHAI SIZE AUTOMATION EQUIP

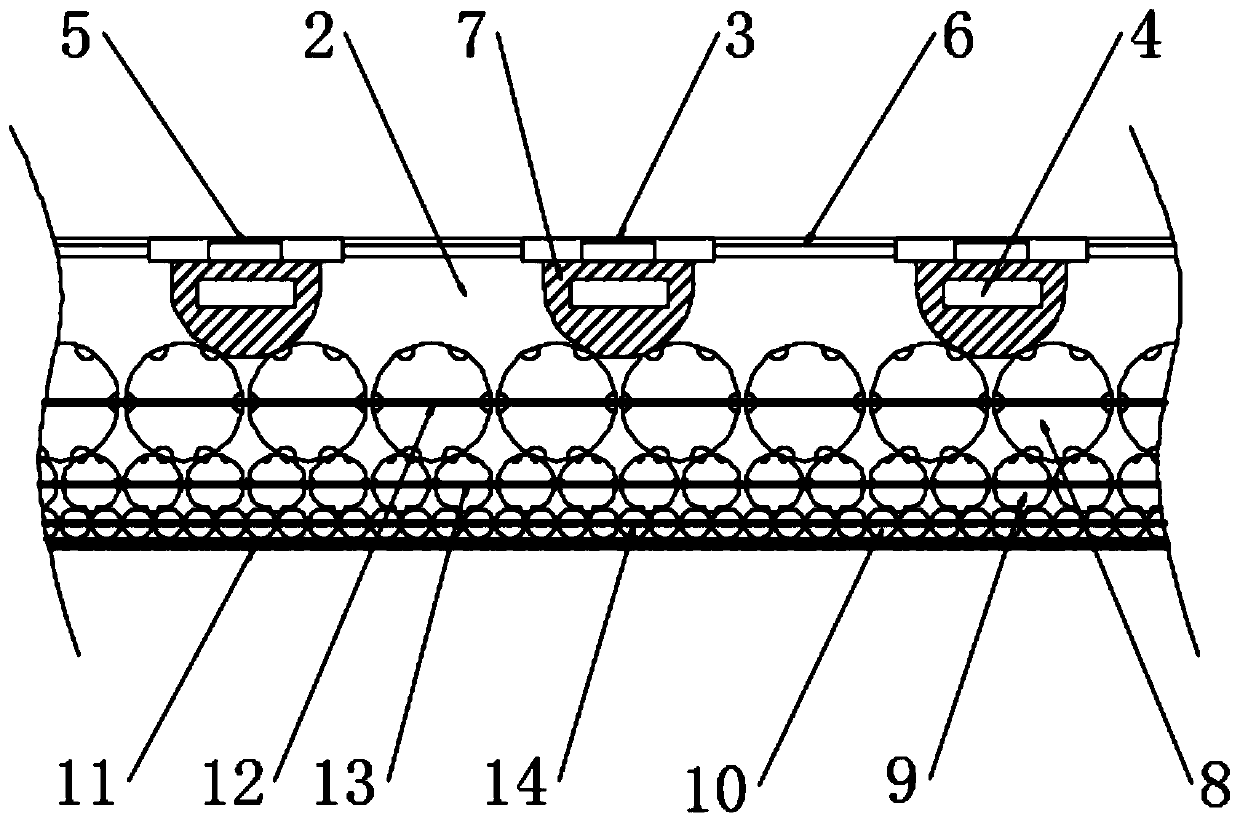

Force dispersion type cold-rolled shipment interlayer padding

PendingCN111216418AImprove the strength of forceReduce padding costsSynthetic resin layered productsVehicle componentsCushioningHigh density

The invention discloses a force dispersion type cold-rolled shipment interlayer padding. A three-layer fiberboard can be used as a core material, two sides of the core material are wrapped with high-density sponges, a composite force dispersion layer is inlaid in the high-density sponge, a force transmission structure arranged on the surface of the sponge is used for pre-dispersing the received force and then transmitting the pre-dispersed force to the composite force dispersion layer, the force is dispersed layer by layer and partially counteracted by utilizing the elasticity of the force dispersion layer itself and the distribution characteristics of a spherical structure, a good cushion protection effect can be achieved on the product, meanwhile, internal optimization is carried out ona single force dispersion layer, a special-shaped net is used for enhancing the integrality of the force dispersion layer, and a special force buffering layer is arranged among force dispersing ballsforming the force dispersion layer. According to the invention, a good elastic buffering effect is kept while the requirements for bundling, winding, cushioning and protection are met, the effect of coping with instantaneous impact hardening protection is also achieved, the force dispersion strength of the force dispersion layers is improved, the reliability of product cushioning and protection isextremely high, and the interlayer padding can be recycled, and the cushioning and protection cost of exported products can be greatly reduced in the long term.

Owner:TAIZHOU YUXIN HOISTING EQUIP

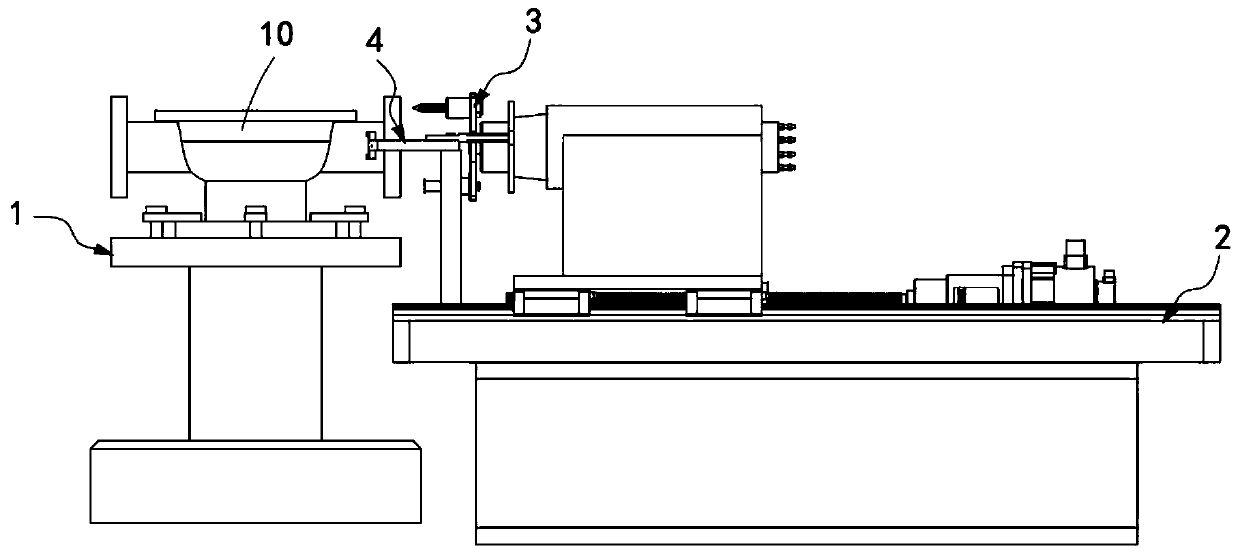

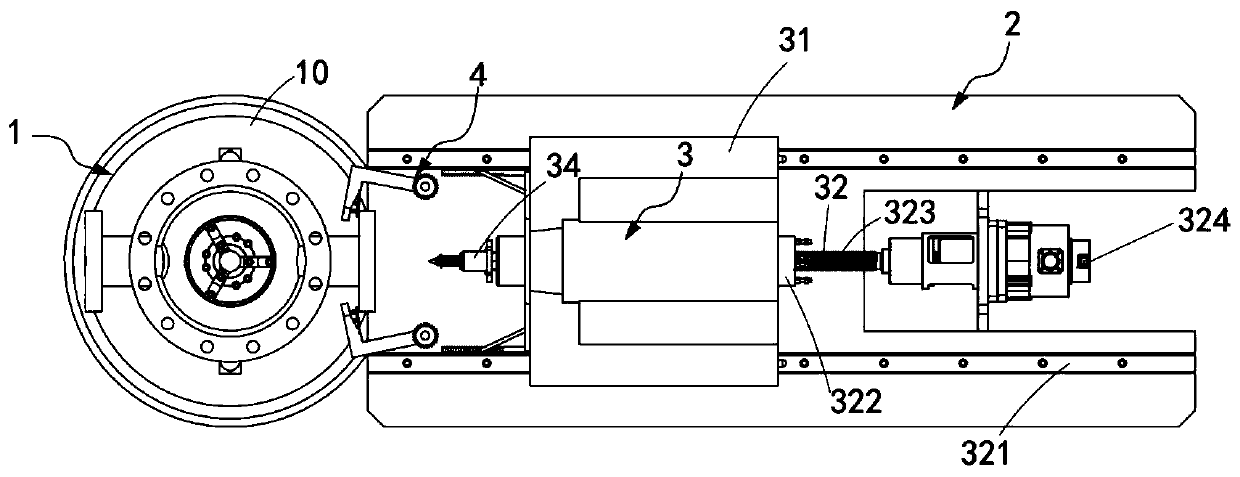

Valve body sunperfinish machining equipment

ActiveCN111375798AImprove machining accuracyGuaranteed stabilityFeeding apparatusOther manufacturing equipments/toolsPhysicsProcessing accuracy

The invention relates to the technical field of valve machining, in particular to valve body sunperfinish machining equipment. The valve body sunperfinish machining equipment comprises a clamping tooling for clamping and installing a valve body, a machining platform arranged to be adjacent to the clamping tooling, a hole drilling mechanism slidably installed on the machining platform and an enclasping mechanism installed on the machining platform and located between the clamping tooling and the hole drilling mechanism. According to the valve body sunperfinish machining equipment, by means of the manner that sliding of the hole drilling mechanism is utilized to drive the enclasping mechanism to enclasp connection mouth ends to be subjected to hole drilling machining, the pressure from holedrilling on the connection mouth ends by the hole drilling mechanism is counteracted, the valve body integrally will not generate a tendency of rotating in the hole drilling process due to the pressure of the hole drilling mechanism, and the technical problem that the machining precision is reduced due to the valve body is subjected to uneven force in hole drilling is solved.

Owner:ZHEJIANG VALOGIN TECH

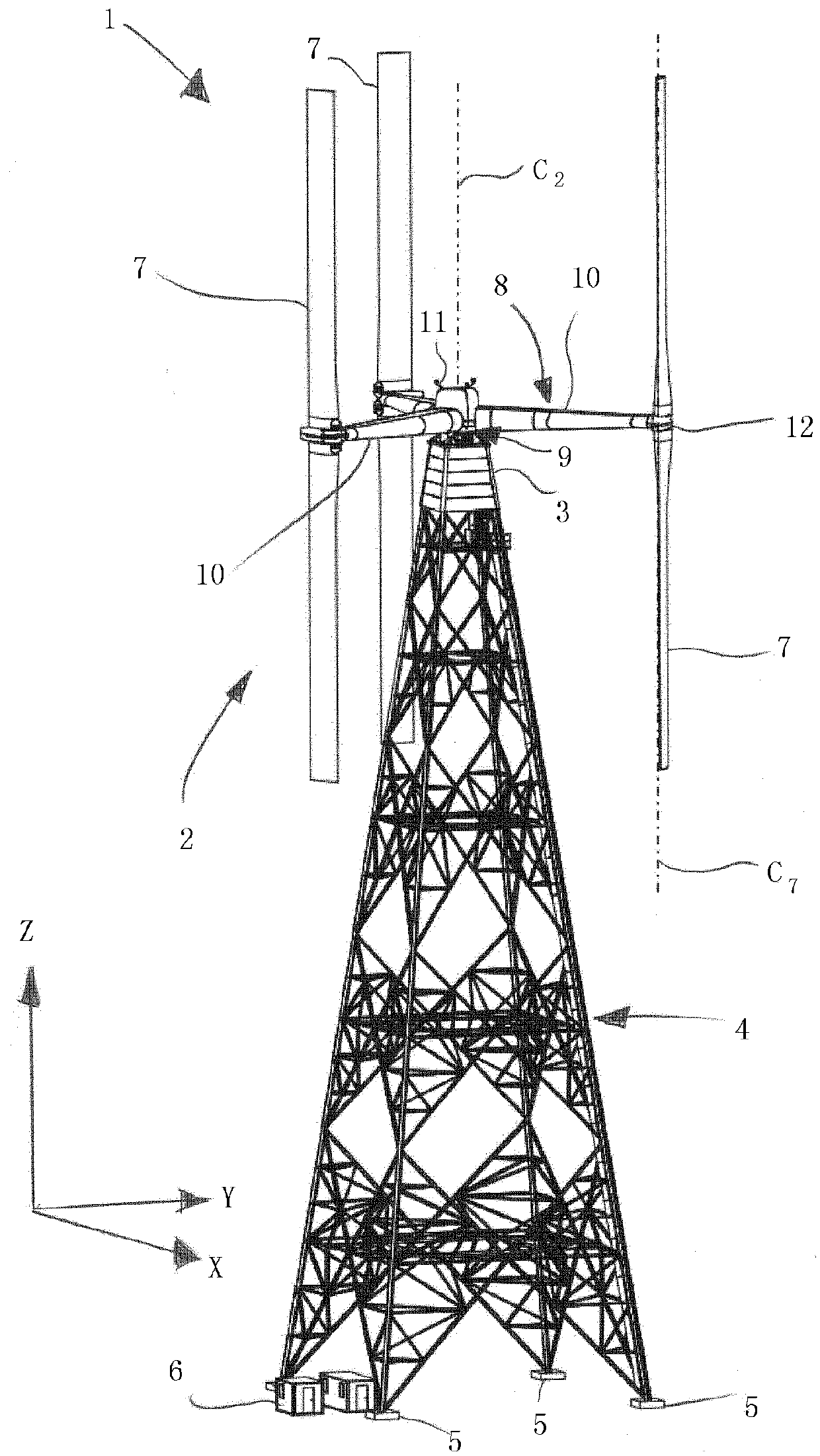

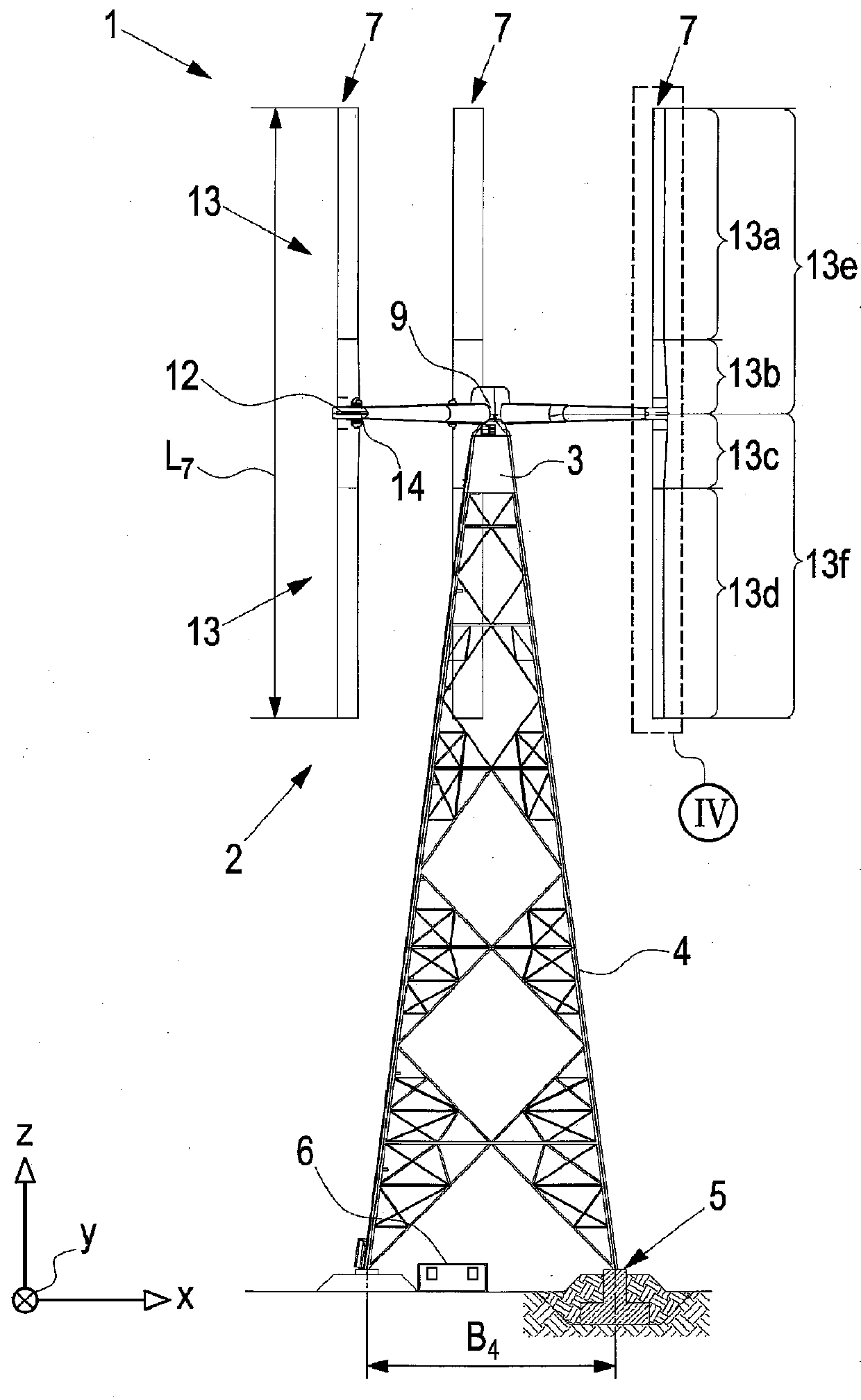

Vertical wind turbine comprising pitch motor with protruding rotor blades, kit for same, and method for operating same

PendingCN110892154APrecise and energy-efficient drivesEasy to adjustWind motor controlEngine fuctionsRotational axisClassical mechanics

Owner:AGILE WIND POWER

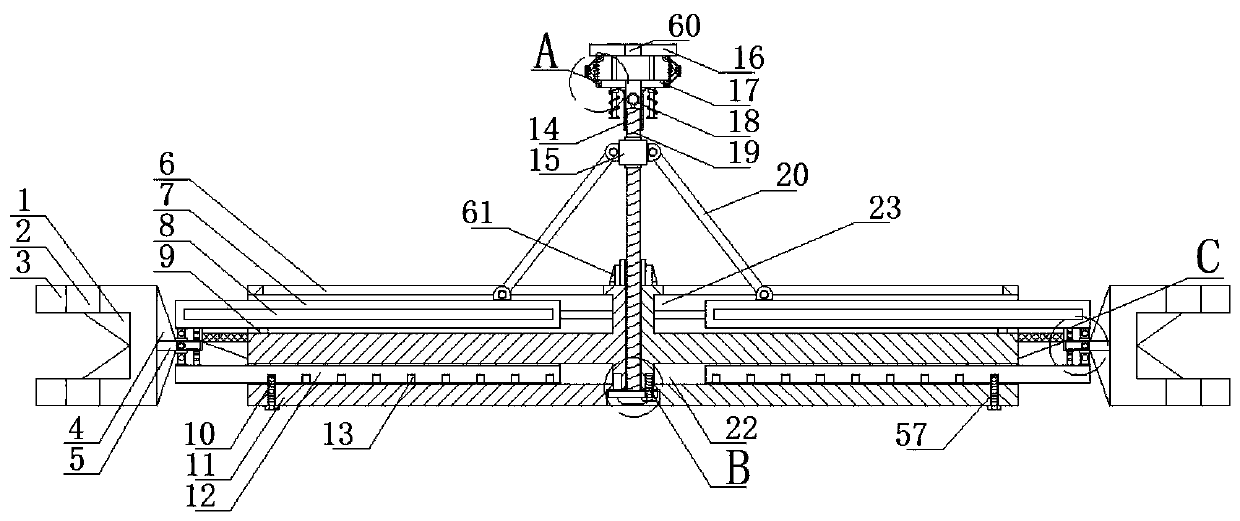

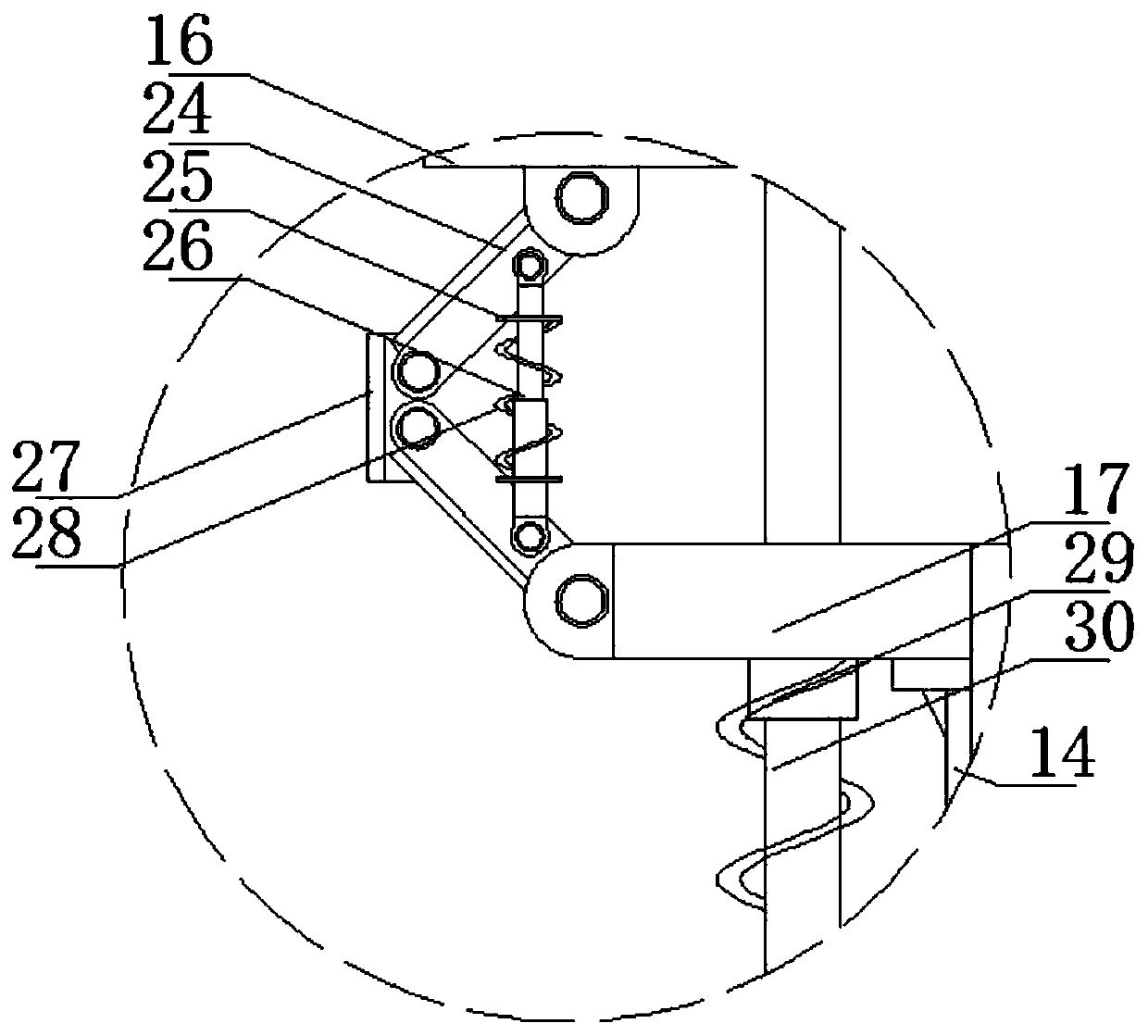

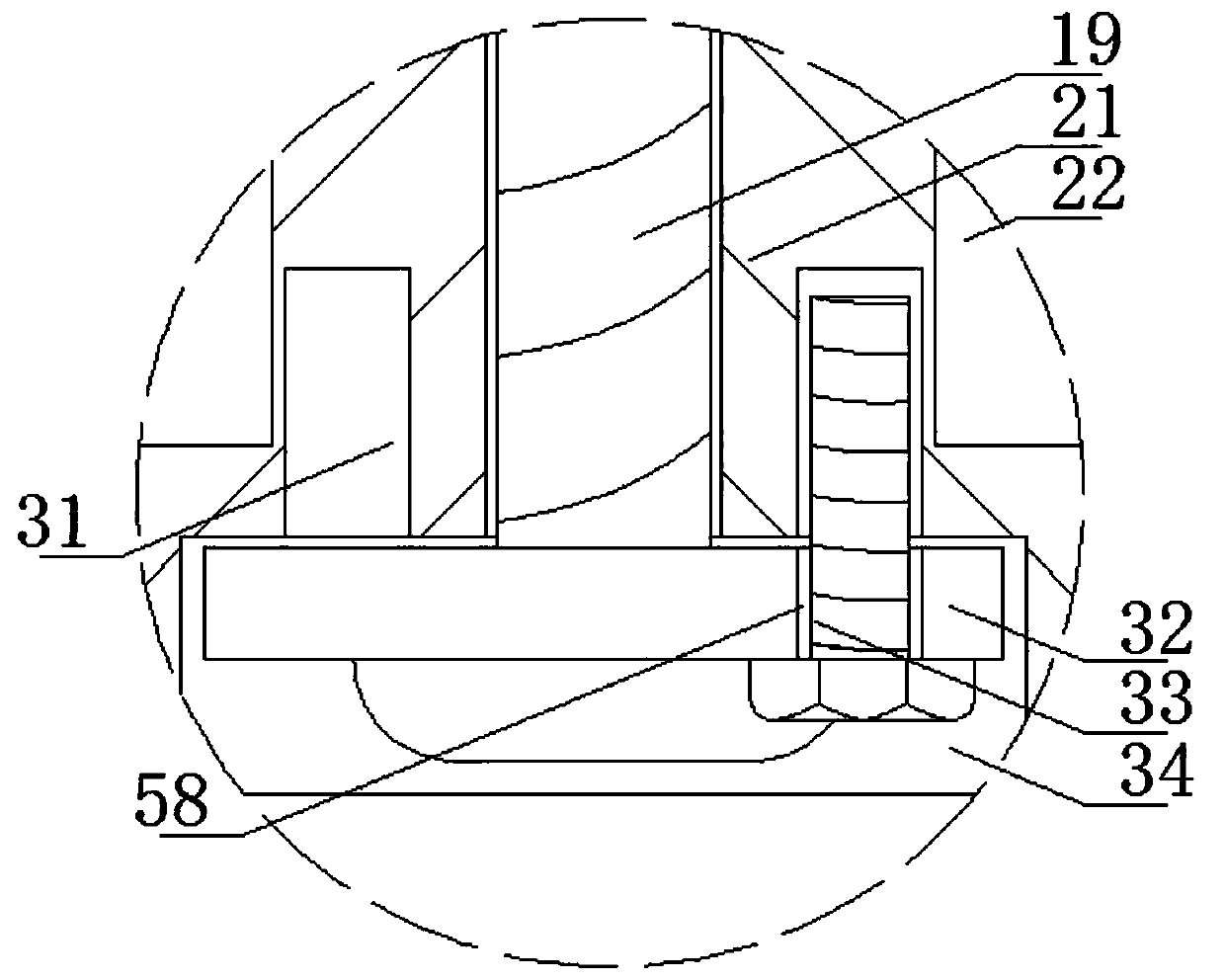

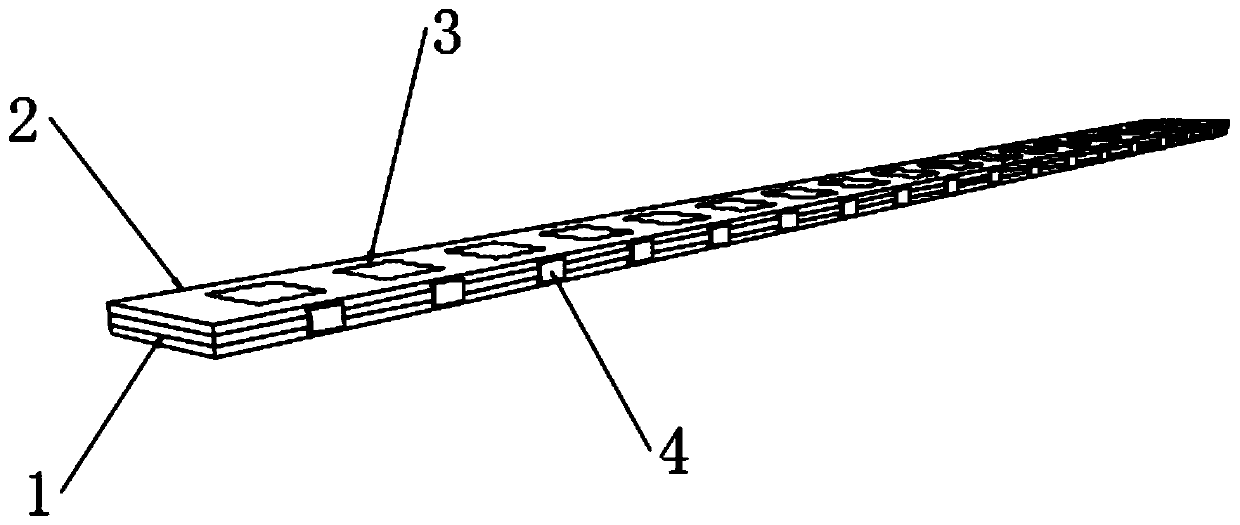

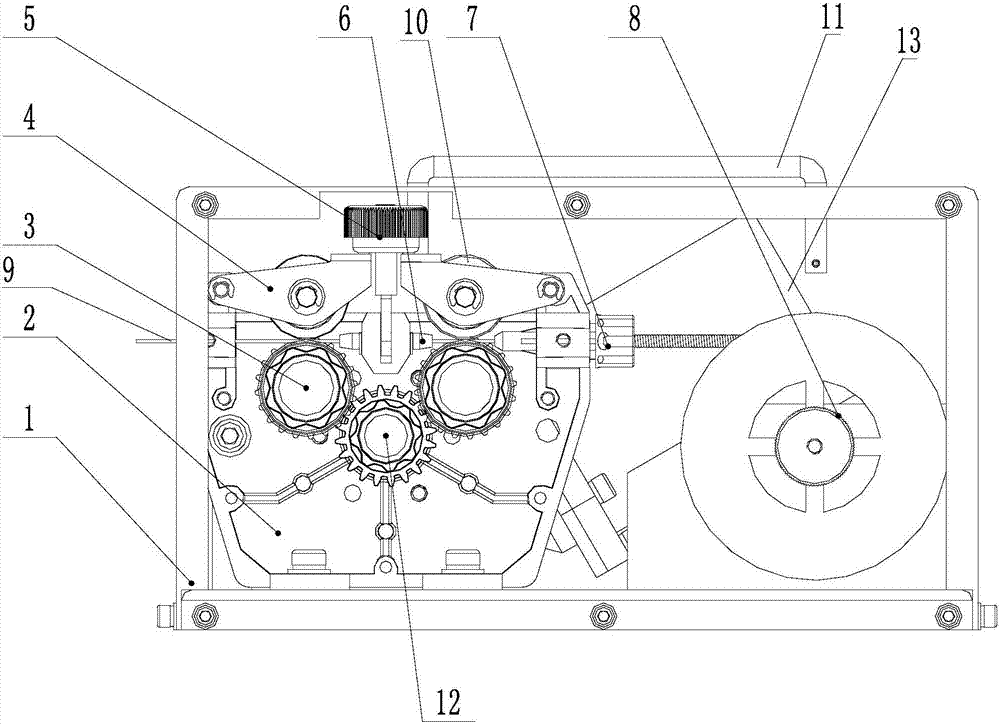

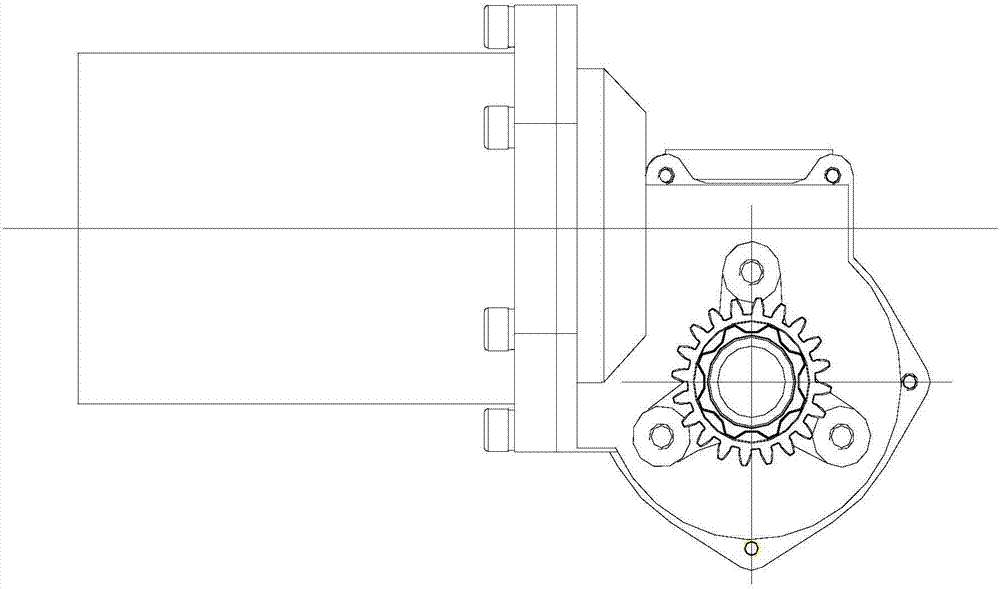

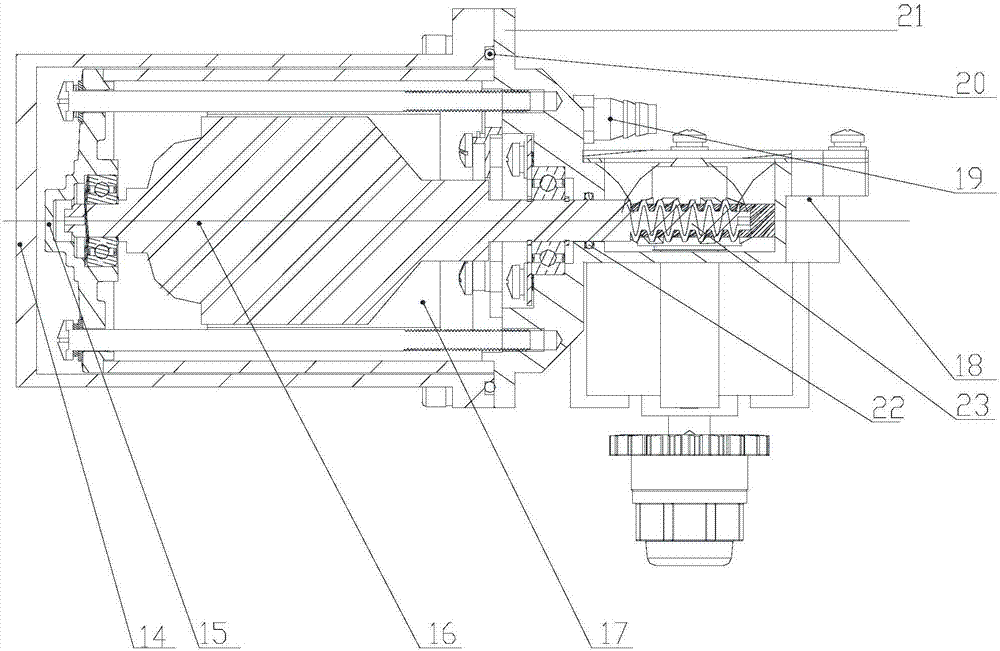

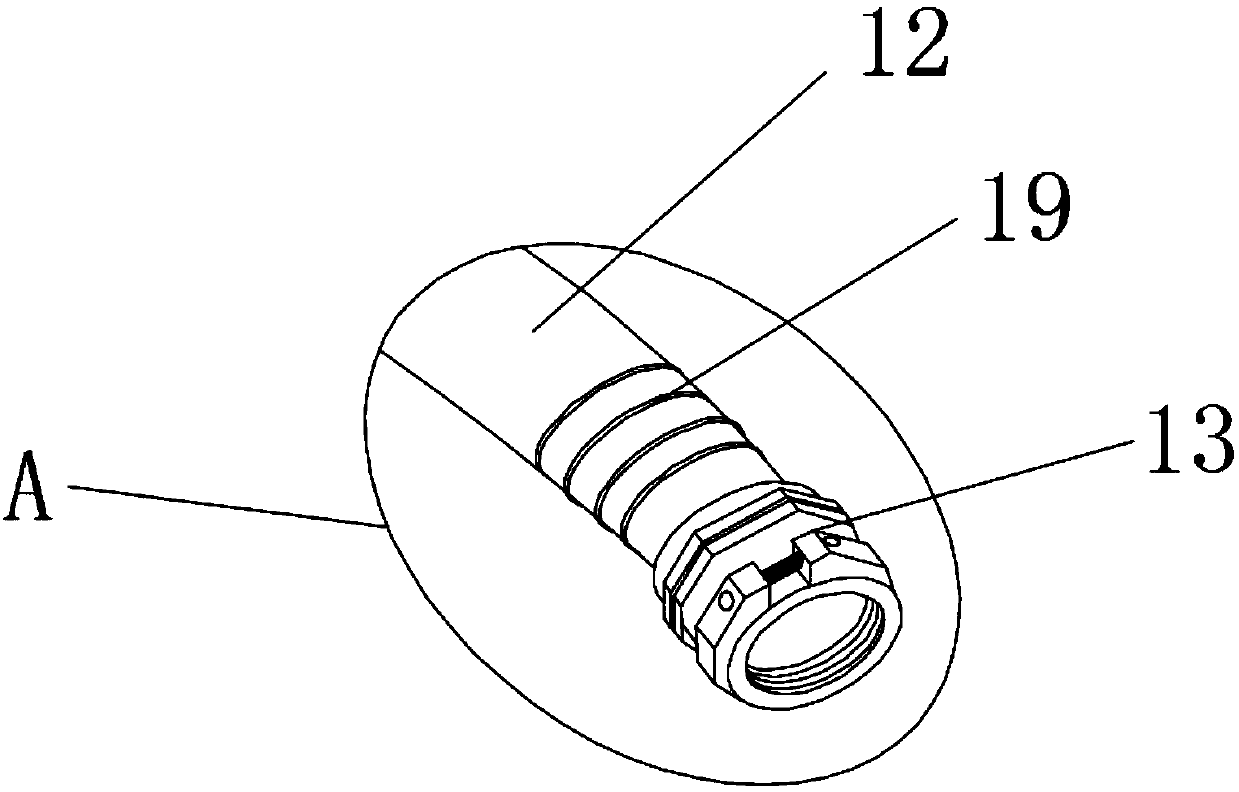

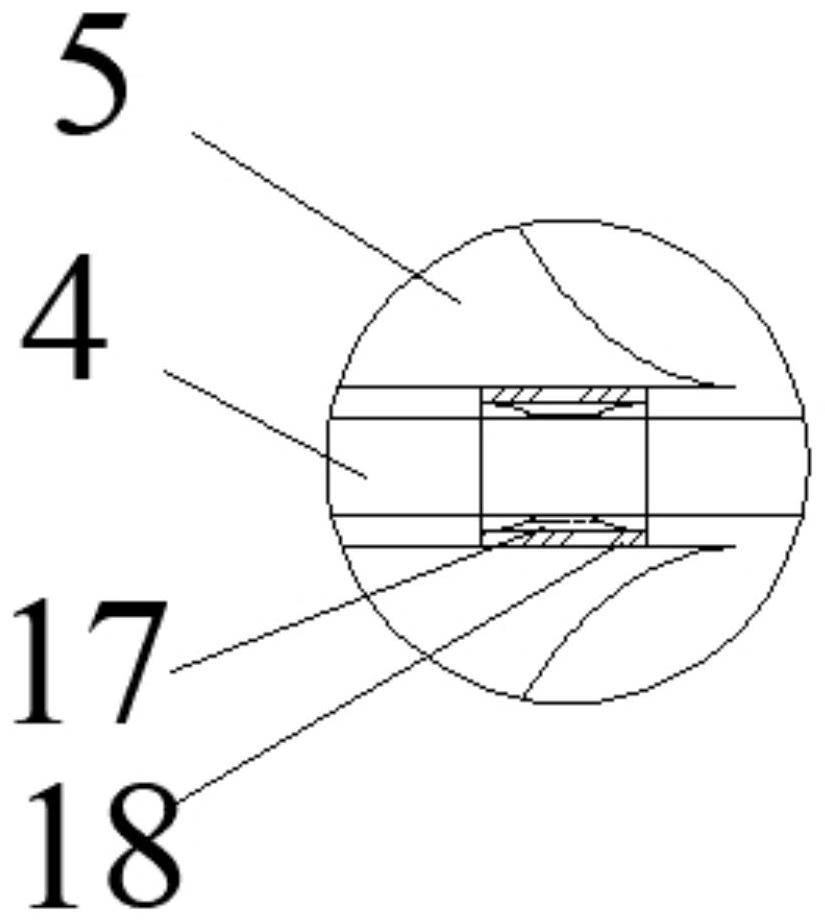

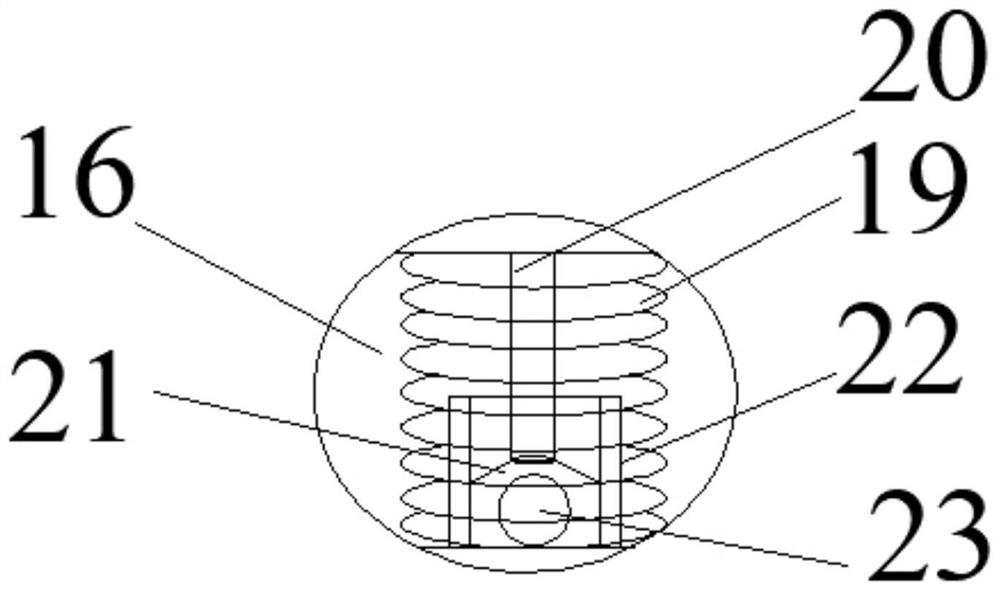

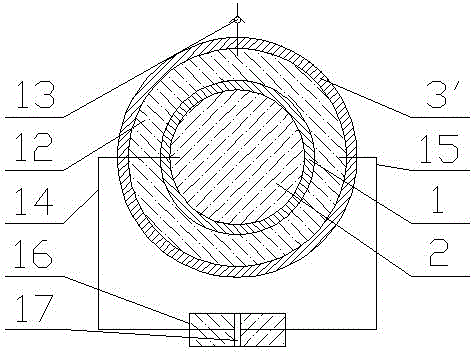

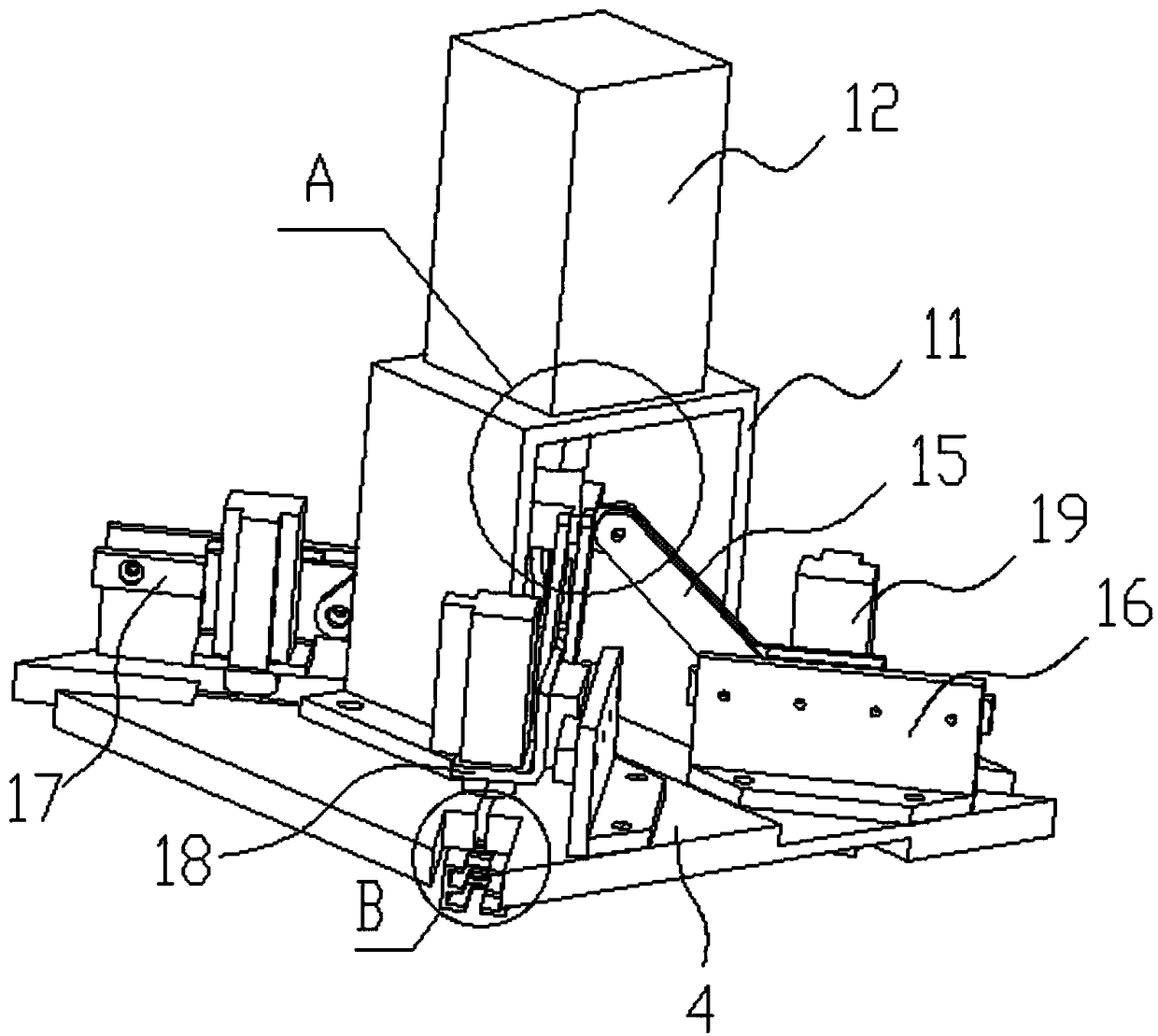

Underwater-welding local-sealing submersible wire feeding device

ActiveCN107186321AOffset the pressureEasy to operateArc welding apparatusMechanical engineeringGear transmission

The invention discloses an underwater-welding local-sealing submersible wire feeding device. The device comprises a wire feeding machine box, a sealing motor, a deceleration transmission mechanism, a gear transmission mechanism, a welding wire reel mechanism and a wire pressing handle mechanism; the gear transmission mechanism is arranged on a bottom plate of the wire feeding machine box; the deceleration transmission mechanism is arranged at the output end of the sealing motor which is fixed in the wire feeding machine box and has the waterproof function and is connected to the gear transmission mechanism; the wire pressing handle mechanism which is used for applying pressure to a welding wire is arranged on the gear transmission mechanism; and the welding wire conveyed by the welding wire reel mechanism penetrates through the gear transmission mechanism and the wire pressing handle mechanism, compresses and is conveyed to a welding gun interface of the wire feeding machine box by the gear transmission mechanism. The device has the advantages of being small in size and light in weight, secondary sealing treatment is not needed in the re-sealing process, and the device belongs to the technical field of underwater welding.

Owner:SOUTH CHINA UNIV OF TECH

Crossover maternity panel with insert

The present invention relates to a crossover maternity panel that may be attached to any lower garment worn throughout pregnancy and post-partum body changes. The crossover maternity panel may be a belly panel comprised of a single piece of fabric or multiple pieces connected with seams, and wrap around from the front to the back of the wearer. The portions may overlap in the back of the wearer as they decrease in height to create a crossover triangular section that provides support to the lumbar region of the wearer. The crossover maternity panel may be attached to any lower garment such as a pant, short, skirt, skort, or the like. The flexible and stretchable material of the crossover maternity panel allows the wearer to have support for the enlarged belly, support for increased pressure and laxity on the wearer's sacroiliac joints and lower back, as well as comfort and mobility.

Owner:INGRID & ISABEL

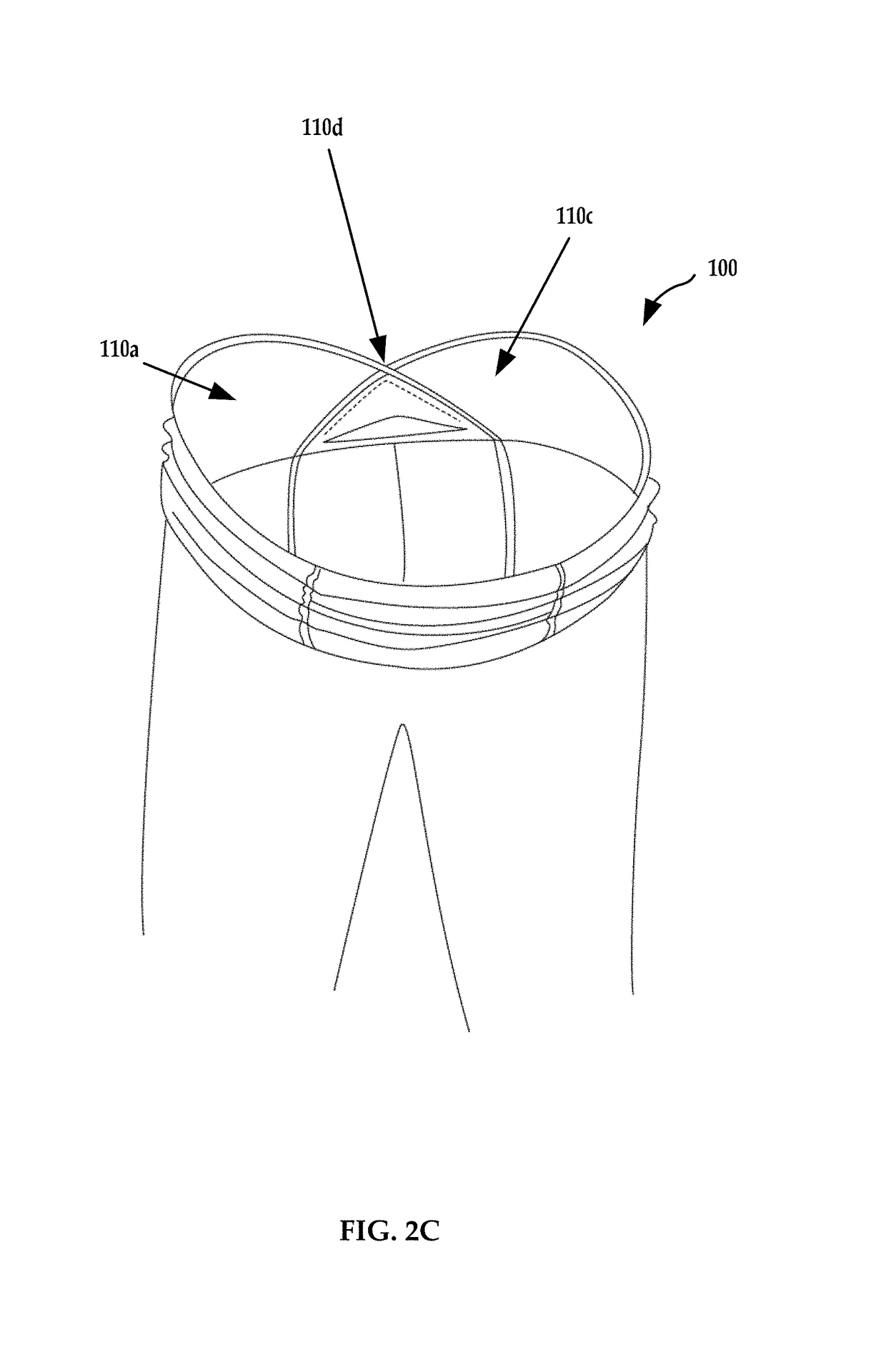

Tension-resistant charging pile cable

InactiveCN109637716ACompact layoutImprove charging efficiencyCouplings bases/casesExtensible conductorsNew energyEngineering

The invention relates to the technical field of new energy charging equipment, and discloses a tension-resistant charging pile cable. The cable includes a spiral cable sleeve. A hollow part is fixedlyarranged on the inner side of the spiral cable sleeve. A cable core is fixedly installed on the inner side of the hollow part. A first conductor, second conductors, a shielding conductor, a control conductor and a filling part are fixedly installed inside the cable core. A first conductor core is fixedly installed inside the first conductor. A second conductor core is fixedly installed inside each second conductor. A shielding layer and shielding conductor cores are fixedly installed inside the shielding conductor. First control conductor cores and second control conductor cores are fixedly installed inside the control conductor. Compressive devices are fixedly installed inside the hollow part. The tension-resistant charging pile cable has strong tension resistance and higher charging efficiency. The cable joint is waterproof, and the cable as a whole can well resist external pressure.

Owner:KUNMING SANCHUAN WIRE & CABLE CO LTD

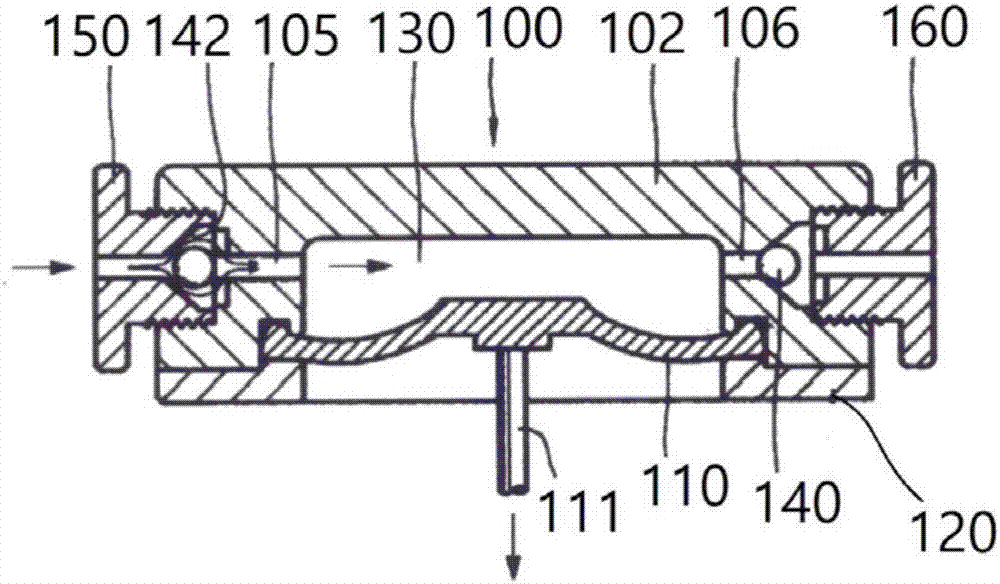

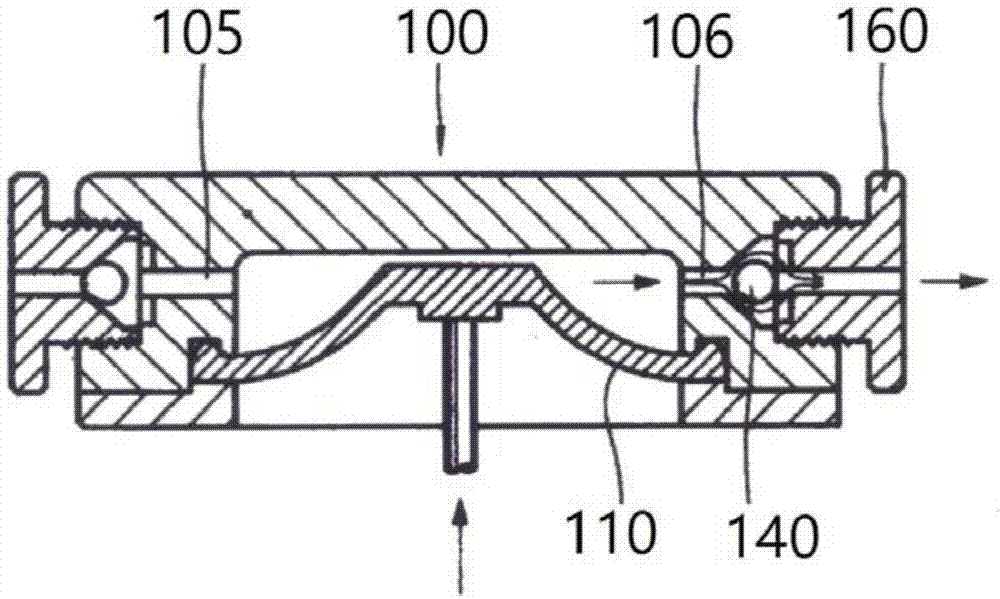

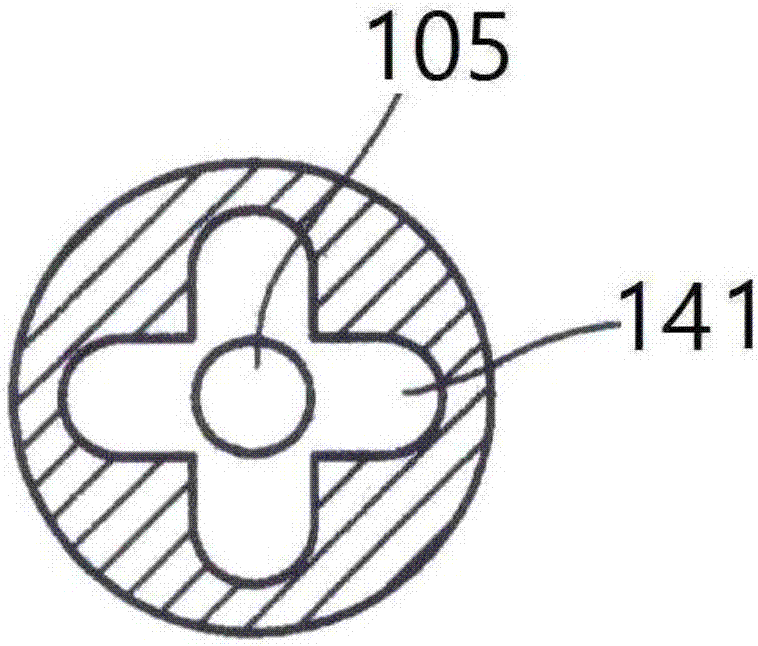

Dual pumping fluid pump

ActiveCN108012550AReduce vibrationReduce noisePositive displacement pump componentsFlexible member pumpsNoise generationPressure balance

The present invention relates to a dual pumping fluid pump which significantly reduces vibration and noise generation in the following manner. When a cam installed on a rotating shaft of a single electric motor is rotated, a pair of first and second diaphragms installed in connection to an eccentric shaft portion formed on both the left and right sides of the cam alternatingly rise and descend inopposite directions and cause first and second intake check valves and first and second discharge check valves provided on a fluid passage box integrally and connectedly installed on the top surface of a pump housing to open or close first and second intake holes and first and second discharge holes to admit fluid through a fluid inlet and simultaneously discharge fluid through a fluid outlet, sothat the simultaneous effects of the intake pressure and discharge pressure of fluid causes pressure balancing to occur. In addition, the present invention has tensioning spaces further formed at positions corresponding to a discharge check valve installation chamber and an intake check valve installation chamber at the undersurface of an upper cam, such that when a discharge pressure and an intake pressure of fluid are formed at the discharge check valve installation chamber and the intake check valve installation chamber, a lower pad is resiliently deformed upwardly and downwardly to mitigate pressure and more effectively prevent pulsation.

Owner:FOURL DESIGN

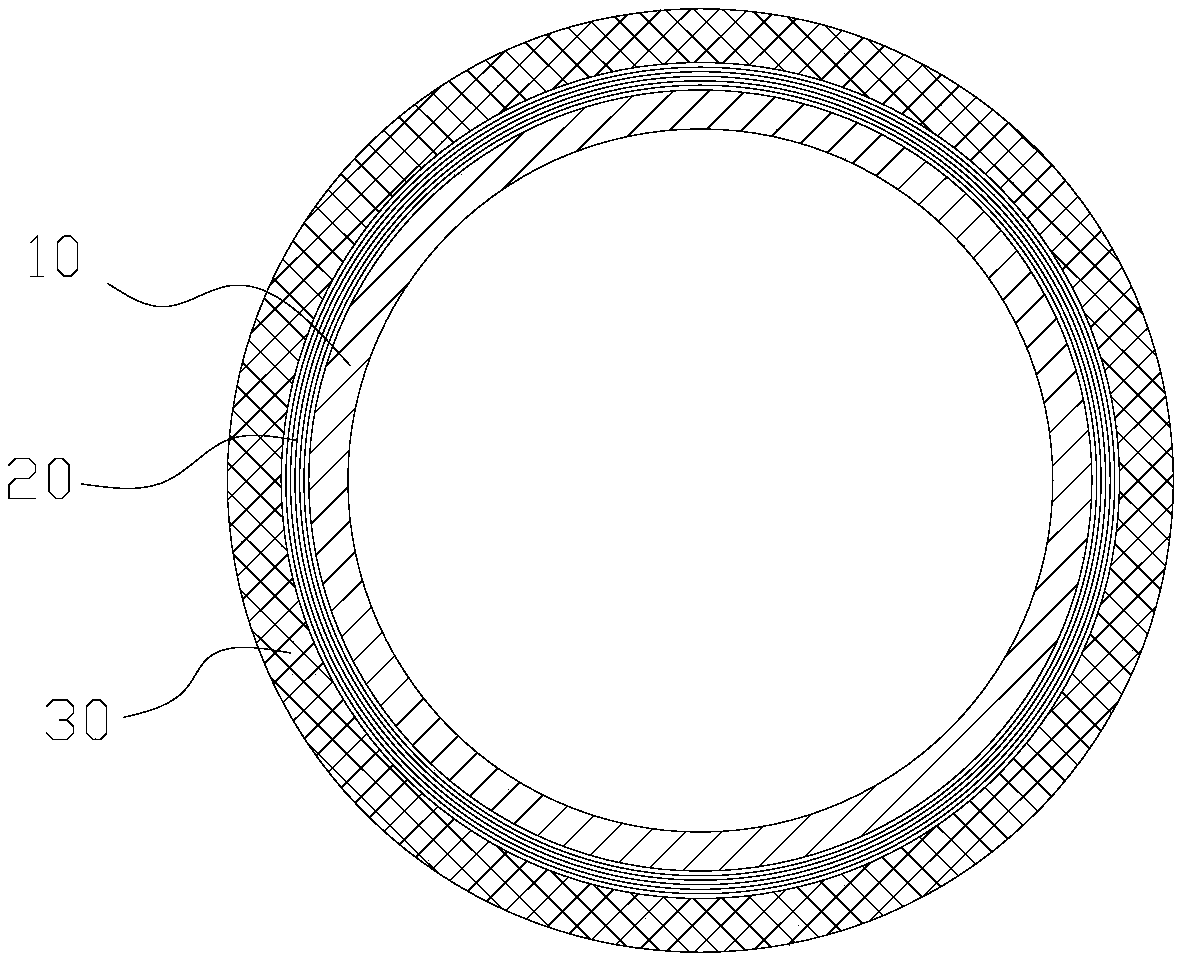

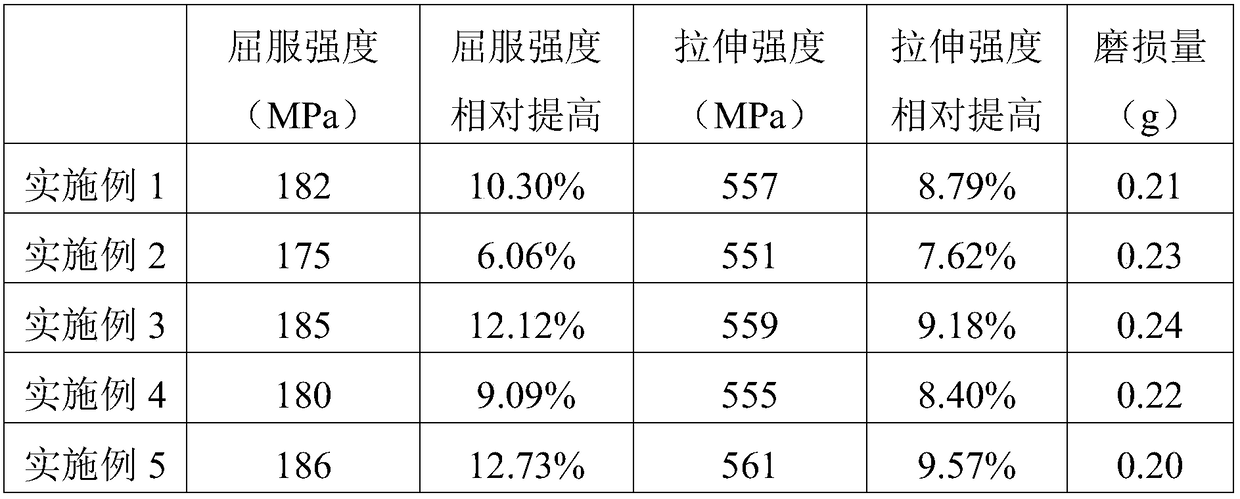

Wear-resistant and corrosion-resistant stainless steel composite tube

InactiveCN109506053AIncrease pipe wall strengthOffset the pressureRigid pipesGlass fiberWear resistant

The invention belongs to the technical field of stainless steel tubes, and particularly relates to a wear-resistant and corrosion-resistant stainless steel composite tube. The stainless steel composite tube comprises a glass fiber rib and a composite resin layer, wherein the glass fiber rib is wound around the outer surface of a stainless steel tube body, the glass fiber rib is provided with prestress during winding, and the composite resin layer is arranged on the outer surface of the glass fiber rib. According to the tube, the glass fiber rib is wound around the outer surface of the stainless steel tube body and is provided with the prestress, so that the strength of the tube wall of the stainless steel tube body can be effectively improved; in addition, the prestress can offset the pressure generated by conveying of a high-pressure fluid, so that the reliability and the safety of the stainless steel composite tube during the conveying of the high-pressure fluid are ensured; the wearresistance and the corrosion resistance of the stainless steel composite tube can be remarkably improved by the composite resin layer on the outer surface of the glass fiber rib, so that the stability of the stainless steel composite tube in the using process is improved.

Owner:安徽鹏远金属制品股份有限公司

Far-infrared hip bone repair device for postpartum care of gynaecology and obstetrics

The invention discloses a far-infrared hip bone repair device for postpartum care of gynaecology and obstetrics, and belongs to the technical field of medical instruments. The far-infrared hip bone repair device comprises shells, wherein a motor box is fixedly mounted in each shell, a motor is fixedly mounted in each motor box, and the input end of a screw rod is fixedly connected to the output end of each motor; and a transmission structure is in sleeving connection to the exterior of each screw rod, one end of each screw rod is inserted into an inserting groove, each inserting groove is formed in a pressing plate, the two sides of each pressing plate are slidably connected into sliding grooves A, the sliding grooves A are formed in the two sides of each moving cavity, each moving cavityis formed in one side of the corresponding shell, and a base is fixedly connected to the bottom ends of the shells. By mounted elastic structures, certain elastic buffering can be provided for a womanafter delivery when the woman after delivery receives hip bone repair, the situation that muscle fatigue is caused by muscle overuse due to long-time use of the woman after delivery is prevented, andtherefore the using effect is improved.

Owner:于蕾

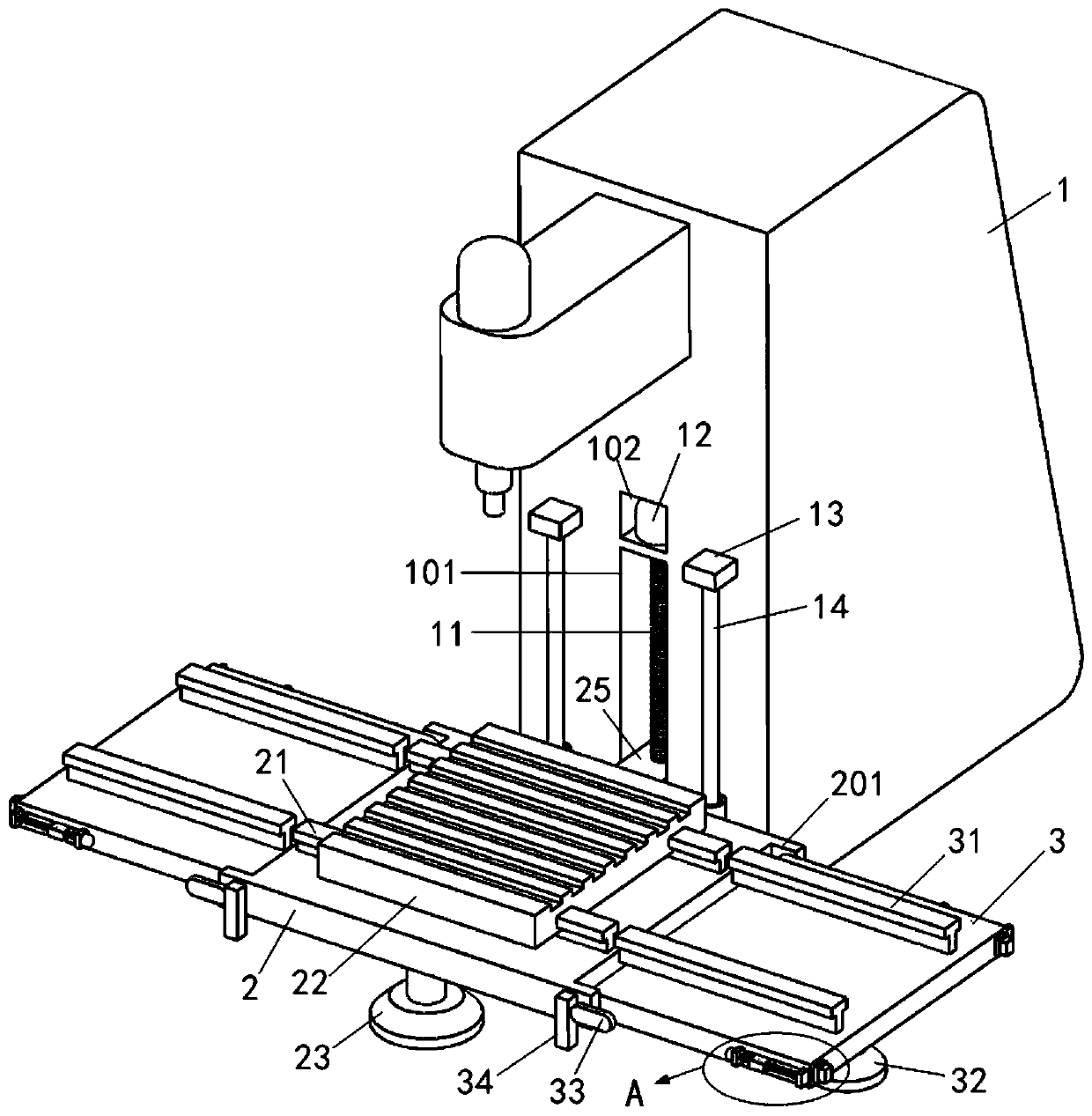

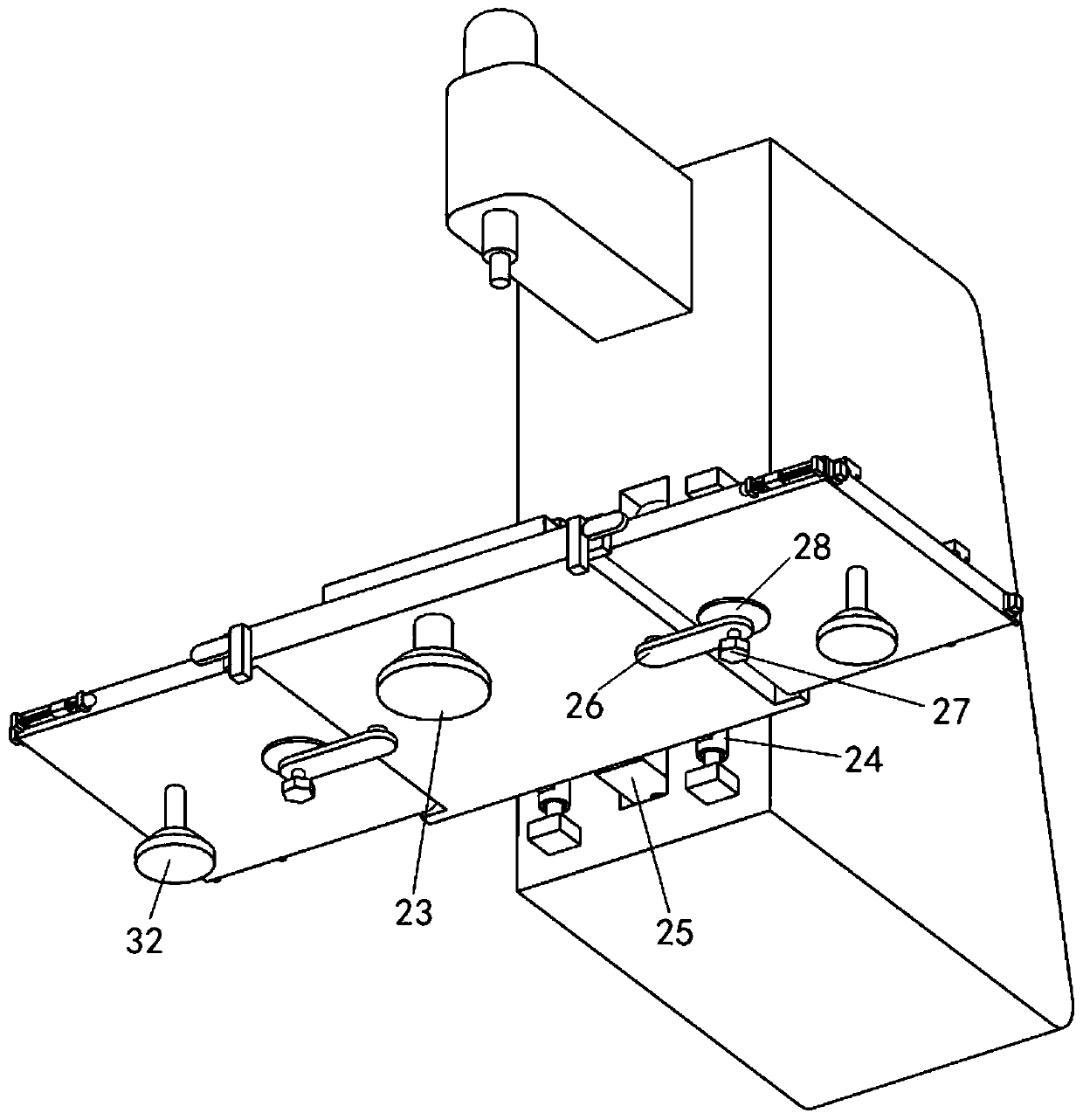

Lifting type drilling machine with machining platform capable of being folded and supported

InactiveCN111531373AOffset the pressureIncrease flexibilityLarge fixed membersDrill bitStructural engineering

The invention discloses a lifting type drilling machine with a machining platform capable of being folded and supported. The lifting type drilling machine comprises a drilling machine body. A liftingtrough is arranged in the center of the front side wall of the drilling machine body. A lifting block is arranged in the lifting trough in a sliding manner. A lifting table is arranged on the front side wall of the lifting block. Auxiliary platforms are rotationally arranged on the left side wall and the right side wall of the lifting table. The machining platform is arranged on the top face of the lifting table. The two ends of the outer side wall of each auxiliary platform are each provided with a pair of adjusting grooves. Supporting feet are inserted in the adjusting grooves. A pair of horizontal supports is arranged on the two sides of the bottom face of the lifting table. The lifting type drilling machine has the advantages that the machining platform of the drilling machine can ascend and descend and can be folded left and right; when heavy workpieces are machined, the auxiliary platforms can be rotated to the vertical state, and therefore the machining platform is supported, and the pressure of a drill bit is offset; and when workpieces with large areas are machined, the auxiliary platforms can be rotated to enlarge the area of the whole machining platform, and therefore the machining positions of workpieces are adjusted better, flexibility is large, and safety performance is high.

Owner:沈凤美

Cracking-resistant salt and chemical making equipment pipe

ActiveCN104565823AOffset the pressureExtended service lifePipeline systemsPipe protection against damage/wearStructural engineeringMechanical engineering

The invention discloses a cracking-resistant salt and chemical making equipment pipe. The cracking-resistant salt and chemical making equipment pipe comprises a salt and chemical making equipment pipe body, wherein a plurality of tightening rings sequentially sleeve the outer side wall of the salt and chemical making equipment pipe body along the length direction of the slat and chemical making equipment pipe body; each tightening ring consists of two symmetric half arcs; one sides of the tightening rings are connected to one another through hinges; the other sides of the tightening rings are fixed through bolts; the tightening rings apply a radial pre-compression force pointing to an axis to the salt and chemical making equipment pipe body; and the radial pre-compression force is equal to or greater than pressure of brine in the salt and chemical making equipment pipe body. By the structure, the radial pre-compression force is applied to the salt and chemical equipment pipe body of the cracking-resistant salt and chemical making equipment pipe, pressure of the brine in the salt and chemical making equipment pipe body on the salt and chemical making equipment pipe body is counteracted, even if the inside of the salt and chemical making equipment pipe body is subjected to pitting corrosion under a long-term effect of the brine in the salt and chemical making equipment pipe body, the circumstance that pitting corrosion portions crack due to pressure stress of the brine is avoided, and the service life of the salt and chemical making equipment pipe body is prolonged.

Owner:江苏淮盐矿业有限公司

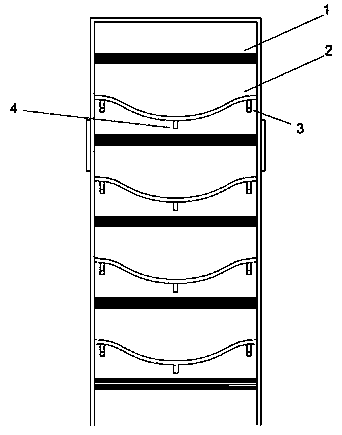

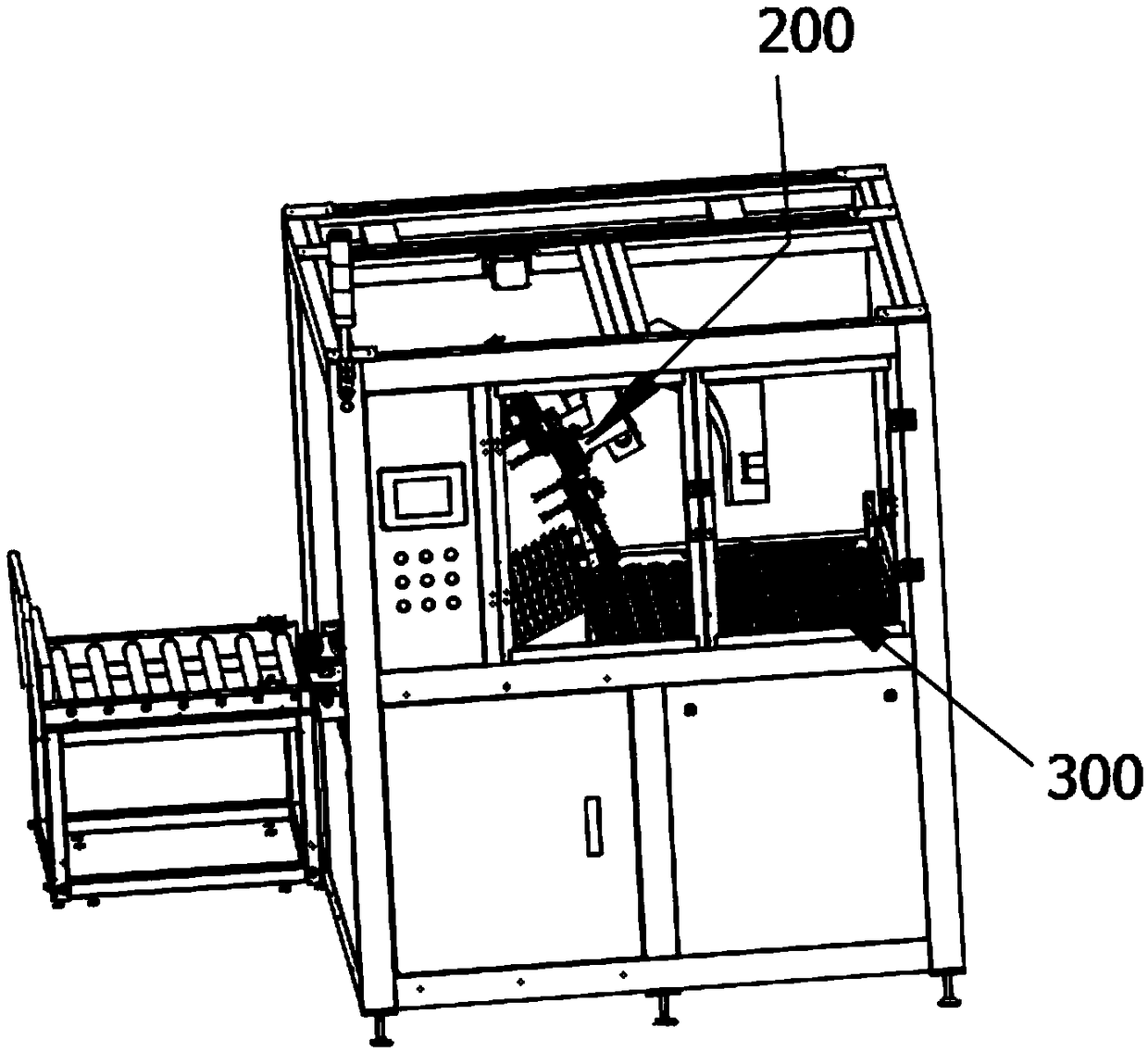

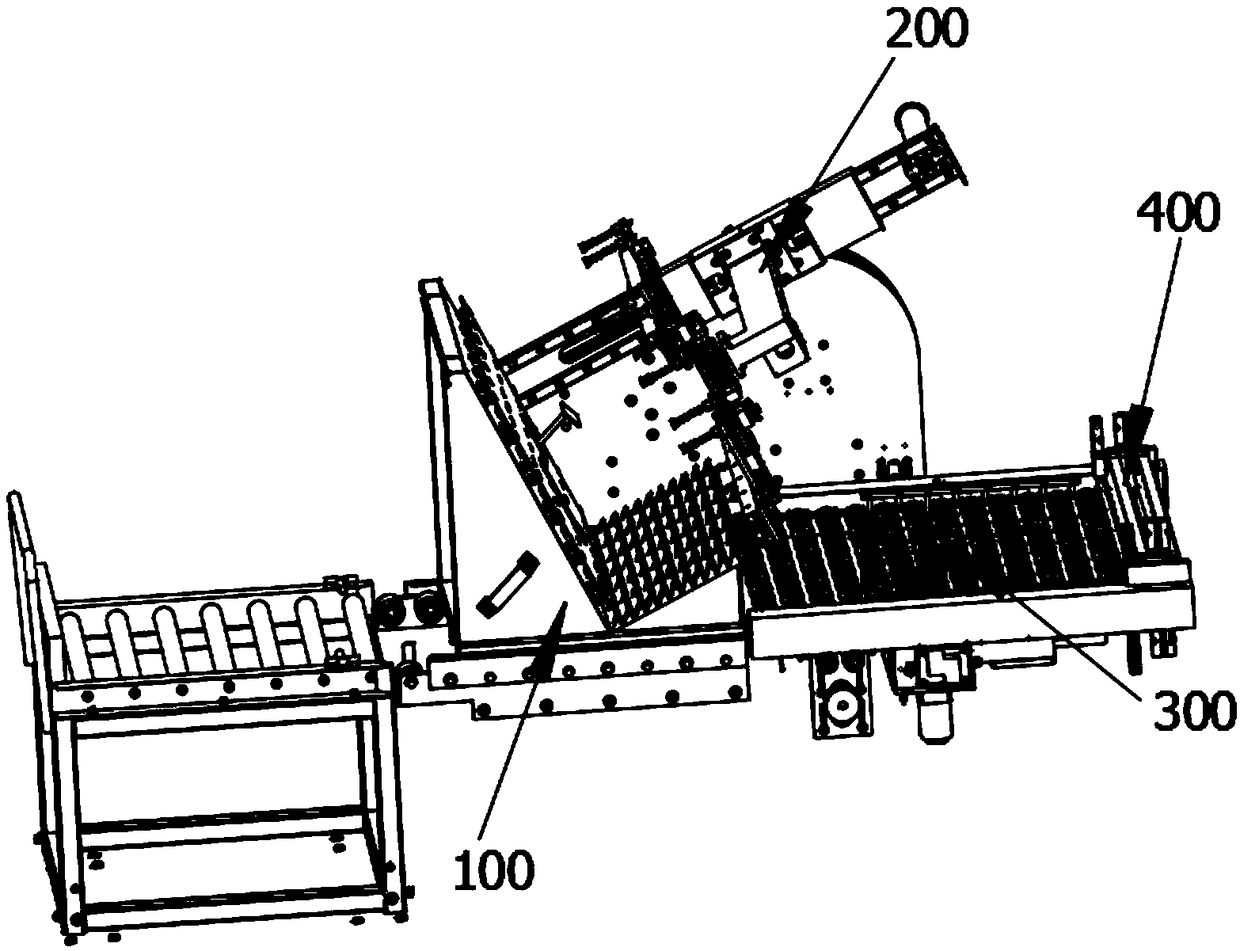

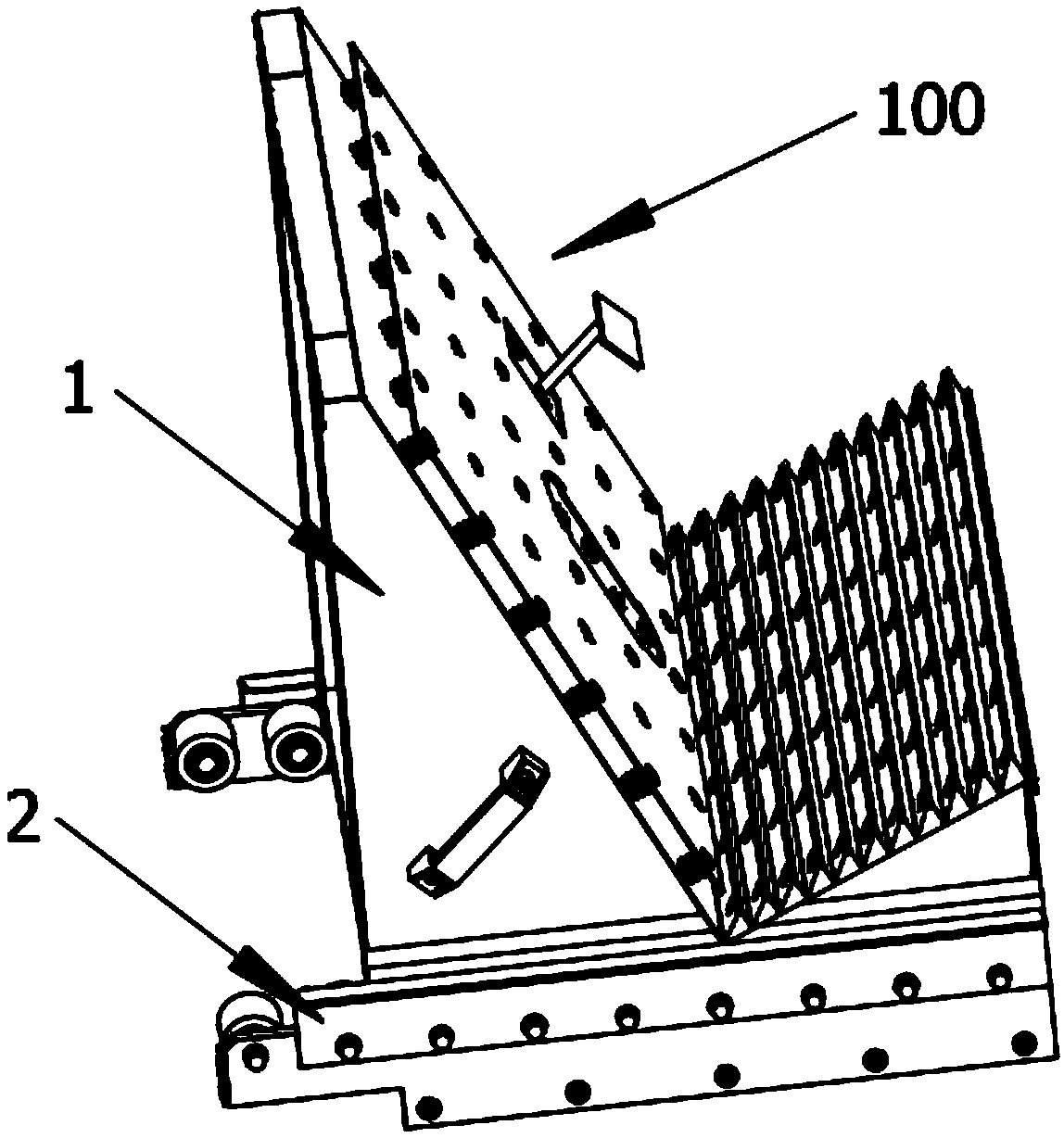

Side wall type plate discharging machine applied to printed circuit board

InactiveCN109335705AReduce crushWill not affect absorptionConveyorsCleaning using gasesPrinted circuit boardBackplane

The invention discloses a side wall type plate discharging machine applied to a printed circuit board. The side wall type plate discharging machine applied to the printed circuit board comprises a loading mechanism, a grabbing mechanism, a feeding mechanism, a dust removal mechanism and an electric cabinet; the loading mechanism comprises an 'L'-shaped back plate rack; the back plate rack comprises a rear back plate and a lower supporting plate; the rear back plate is provided with a stopping structure for stopping materials and an insulating plate; the lower supporting plate comprises a plurality of stopping protrusions; the dust removal mechanism comprises first-stage dust blowing structures and second-stage dust adhering structures; each first-stage dust blowing structure comprises a hollow round tube and a first lifting structure; each second-stage dust adhering structure comprises at least two dust adhering rolls, a second lifting structure and hollow rotating shafts which are inserted in the dust adhering rolls; and one end of each hollow rotating shaft is provided with an air suction opening while the other end is provided with a reverse air blowing opening. The side wall type plate discharging machine applied to the printed circuit board can effectively remove foreign matters on the surfaces of plates and in miniature holes, and the integral quality of electronic products is improved; and furthermore, single adsorption of a vacuum sucker can further be realized, the plate discharging machine continuously discharges plates on rollers favorably, and mounting smoothness of a downstream station is ensured.

Owner:大江南电子科技(昆山)有限公司

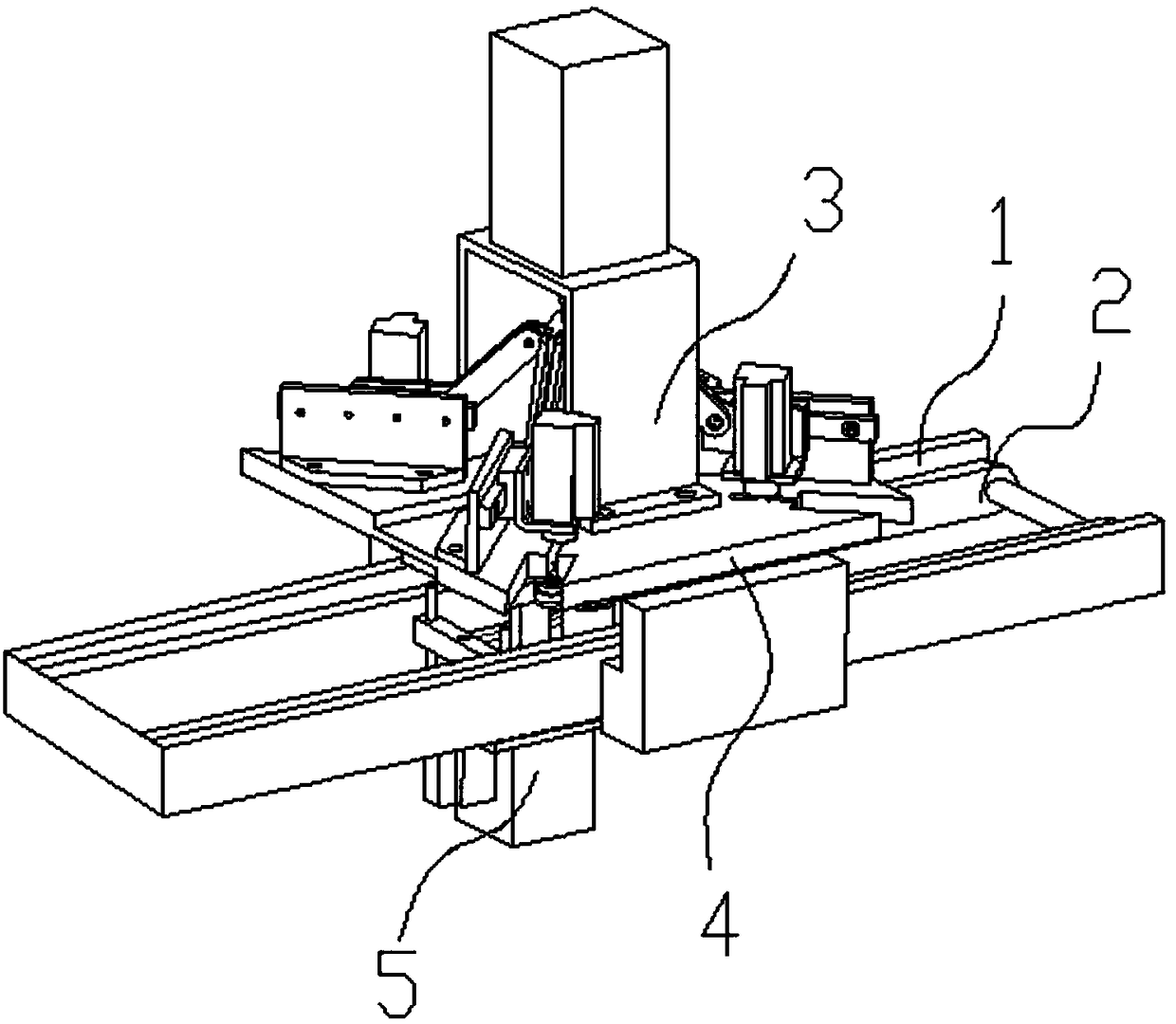

A rubber pad installation mechanism for frame parts

ActiveCN106671431BImprove installation efficiencyShorten the timeMetal working apparatusCylinder headEngineering

The invention relates to a rubber pad mounting mechanism facilitating ejection. The mechanism comprises a conveying frame, a conveying belt matched with a product is arranged on the conveying frame, atransverse frame of the product is attached to the conveying frame, and a pad feeding device matched with the product is arranged on the conveying frame. The pad feeding device comprises a square upper fixing plate above the conveying frame, a material taking groove is formed in the upper fixing plate in the diagonal direction, the material taking groove is matched with a material taking air cylinder, and the material taking air cylinder is connected with a pushing device. An air cylinder head of the material taking air cylinder penetrates through the material taking groove and is matched with a rubber pad. A pushing device and the material taking air cylinder are connected to a controller. The rubber pad mounting mechanism facilitating ejection is provided with the conveying belt matchedwith the product, and a rubber pad feeding device matched with the product is arranged on the conveying belt. The rubber pad is taken and placed through the material taking air cylinder. The rubber pad is pressed in through the pushing device, meanwhile, conveying is not affected, the rubber pad installation efficiency is greatly improved, and the rubber pad installation time is shortened.

Owner:大千纺织(安徽)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com