Patents

Literature

465results about How to "Improve the strength of force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

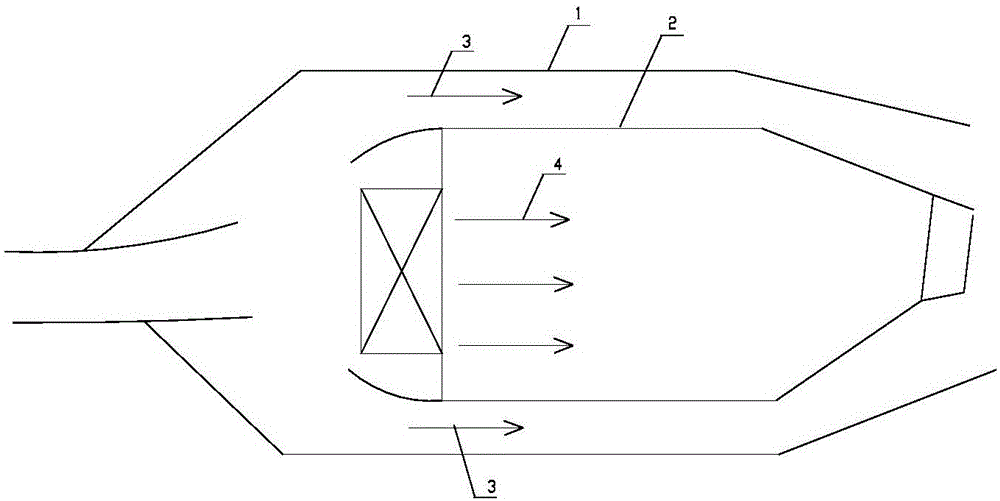

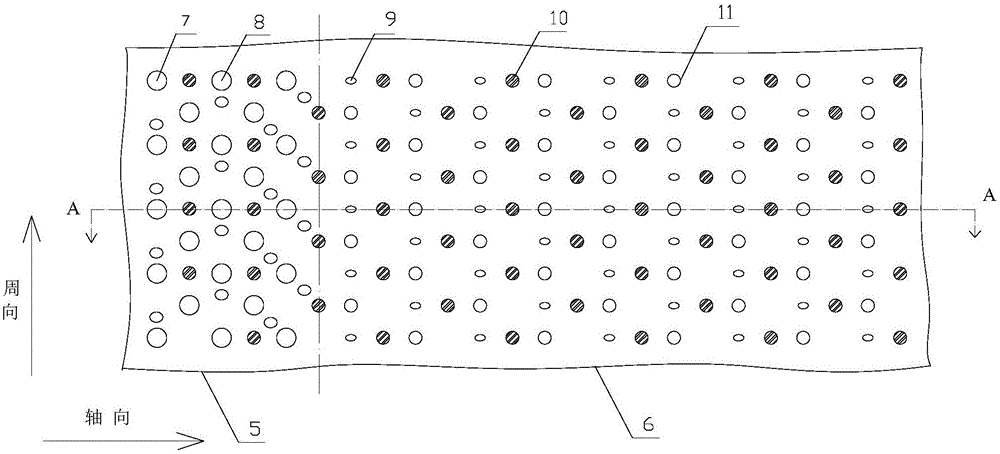

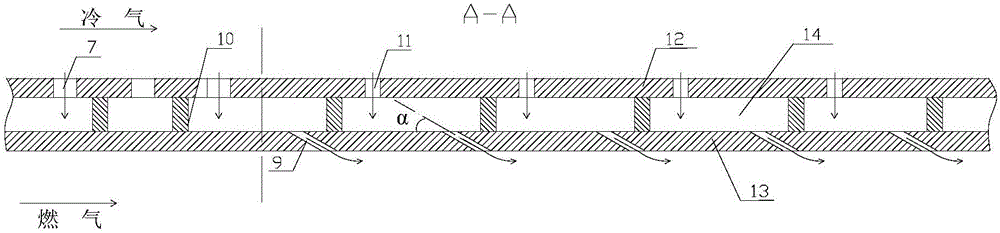

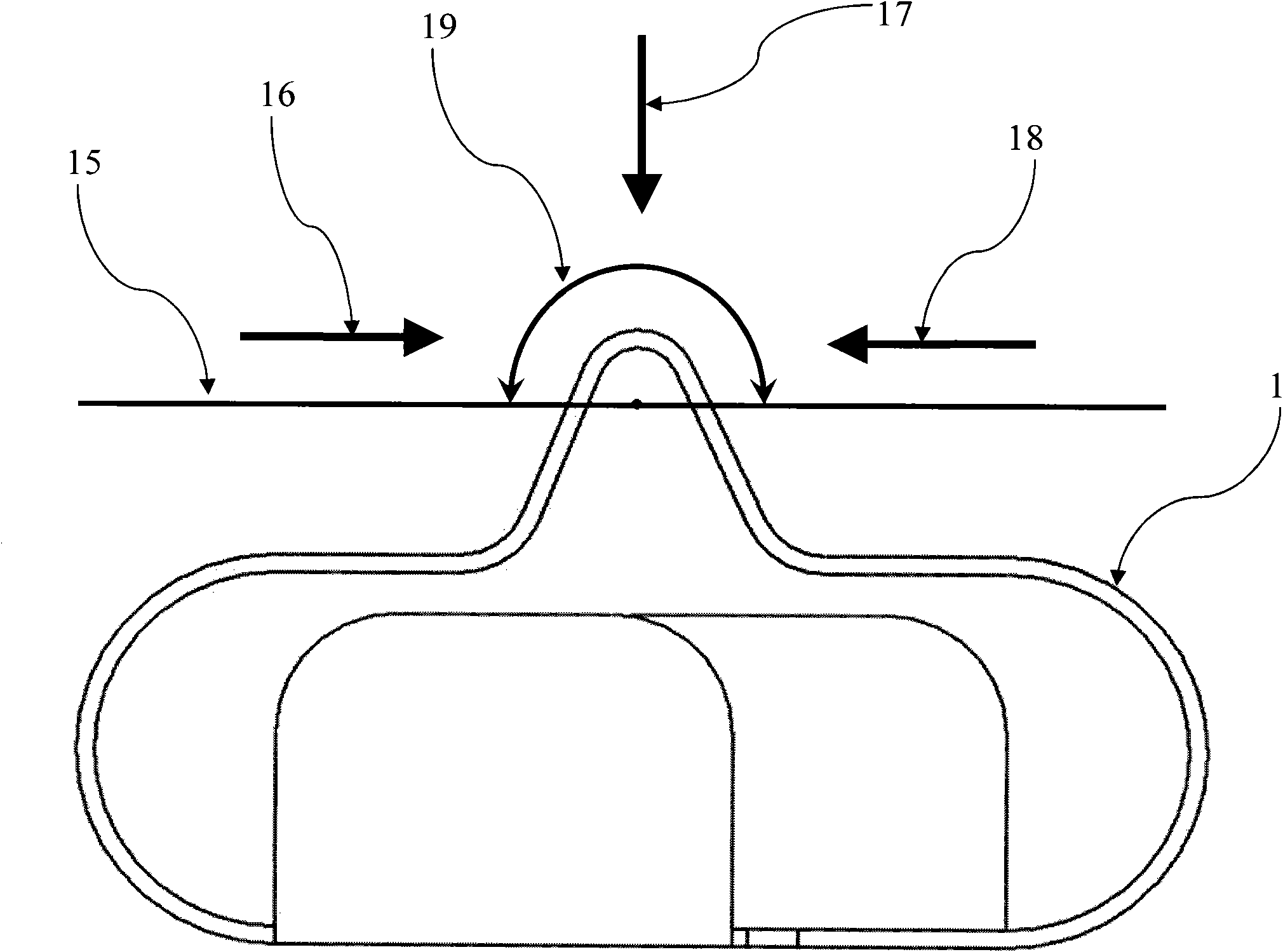

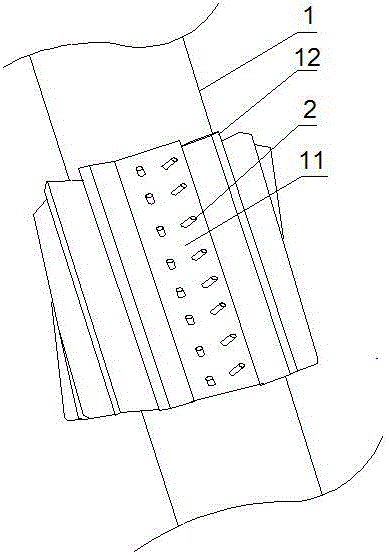

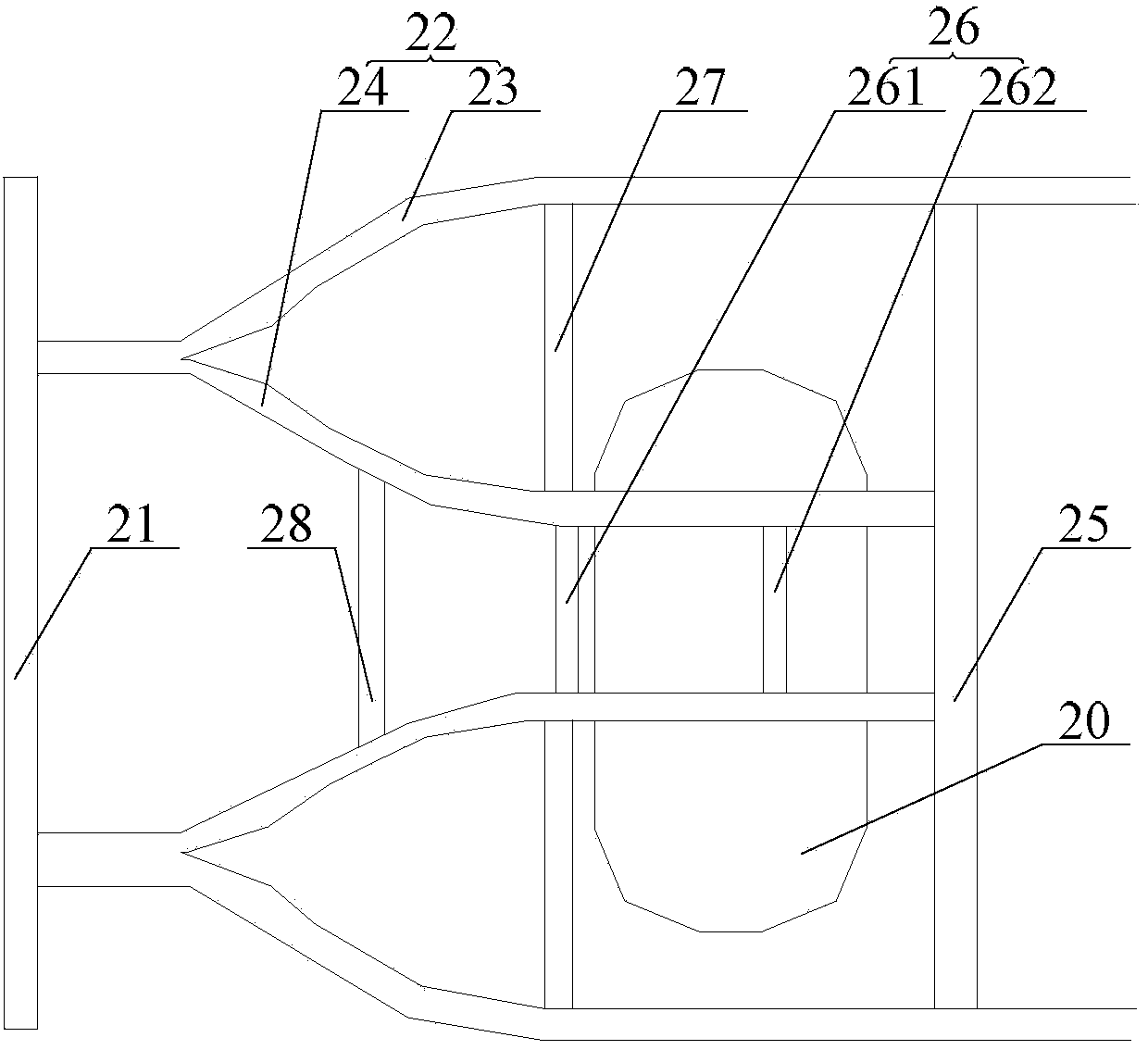

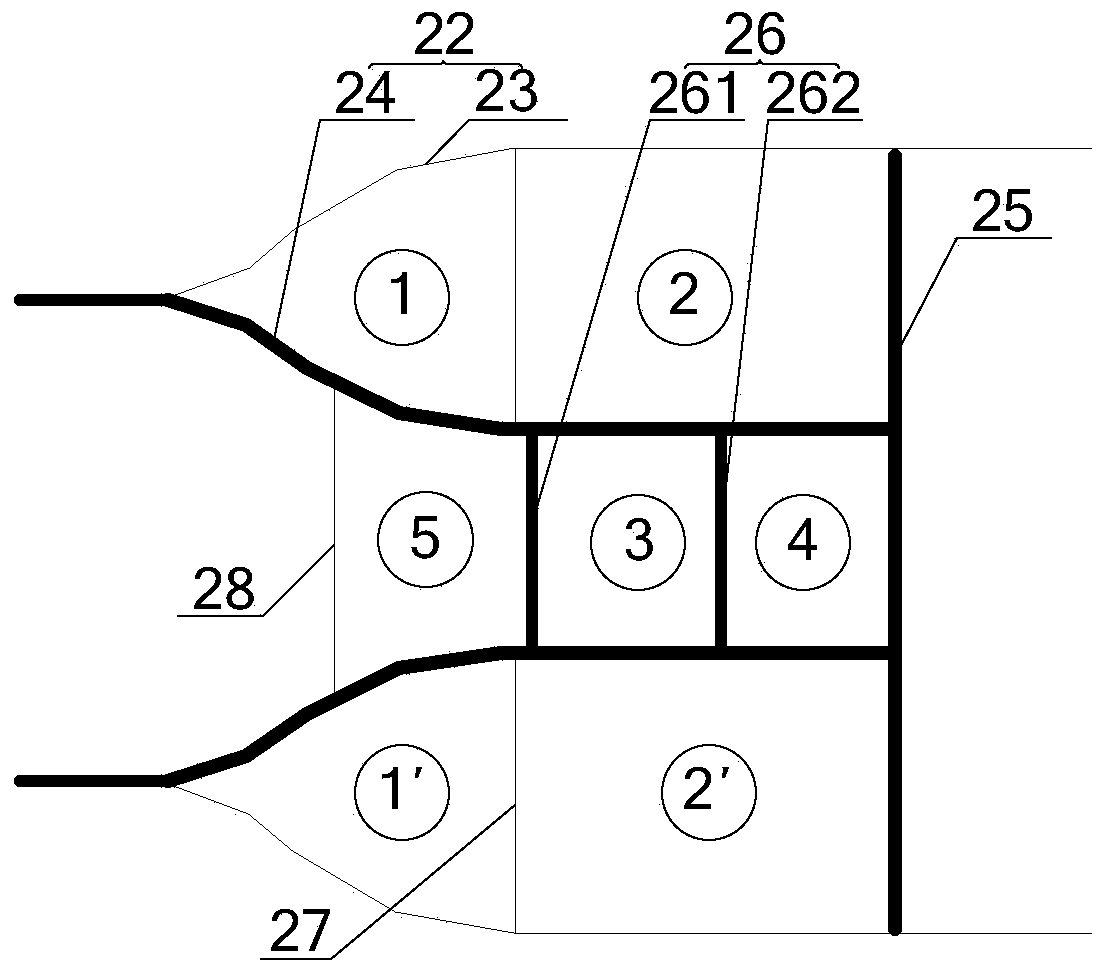

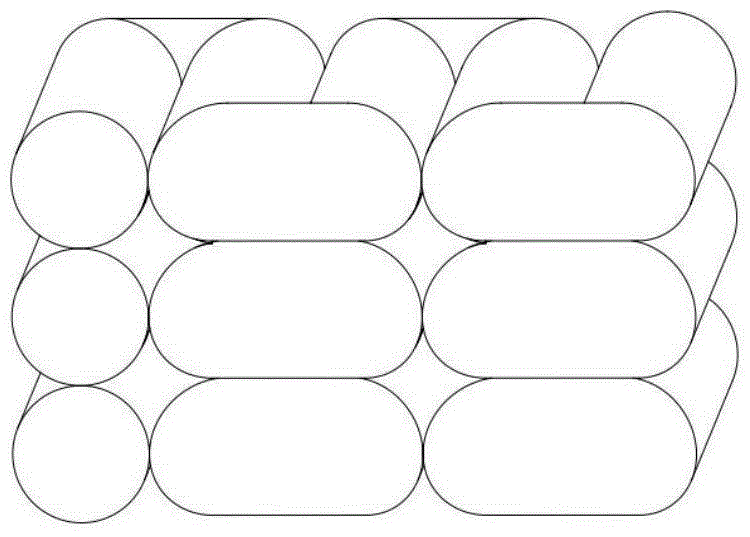

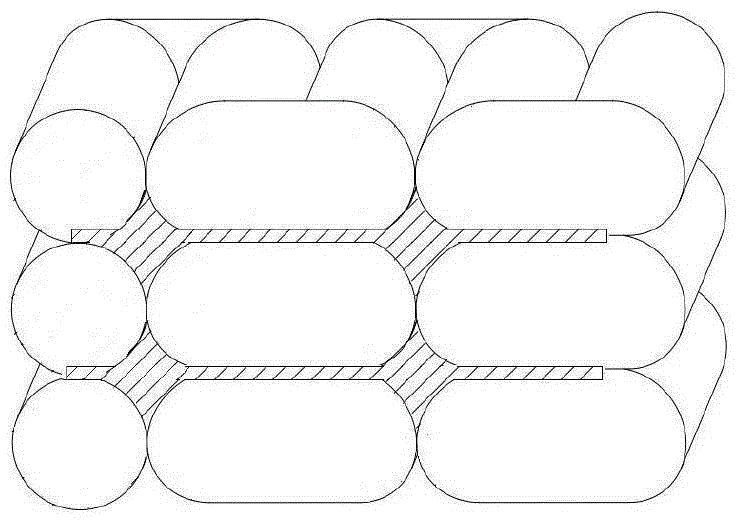

Cooling structure of flame tube of aero-engine combustor

InactiveCN105042640AReduce temperature gradientReduce wall temperatureContinuous combustion chamberCombustion chamberEngineering

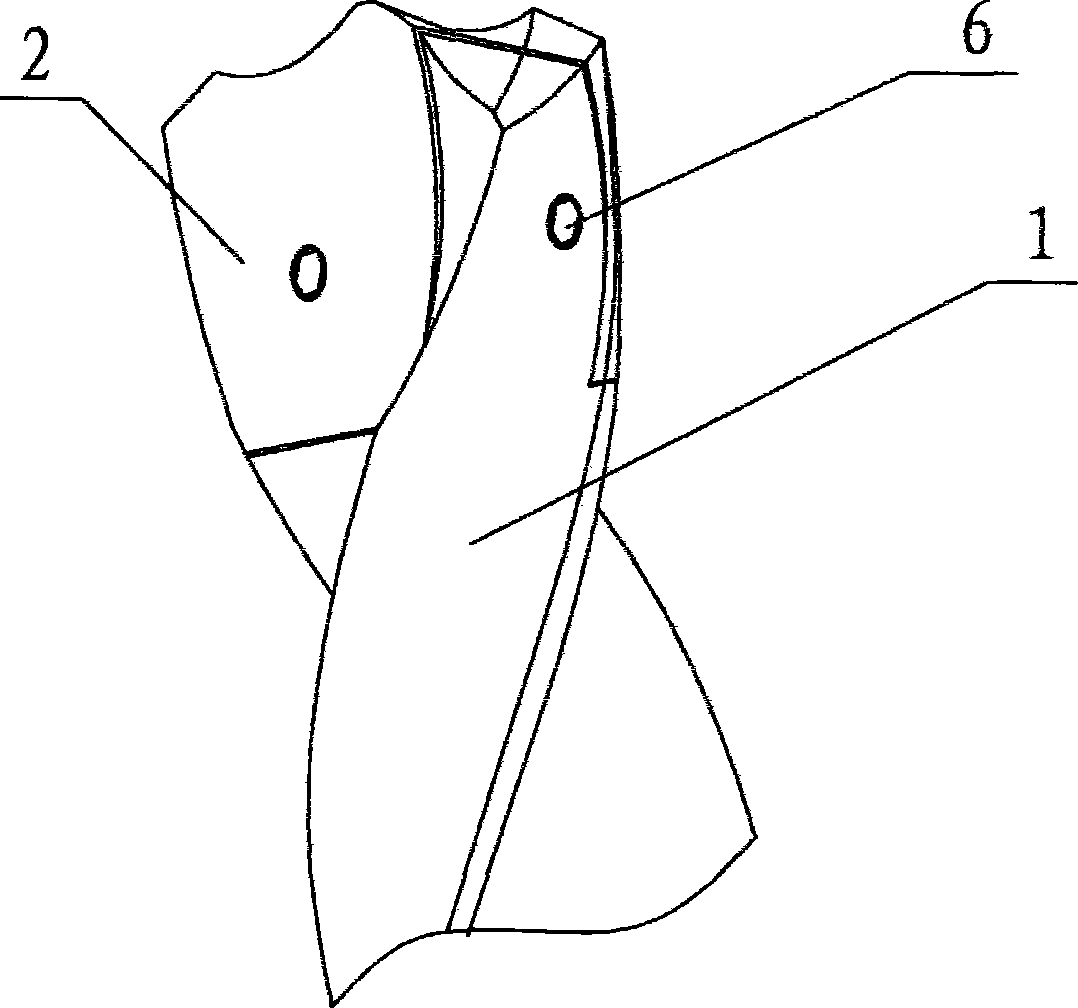

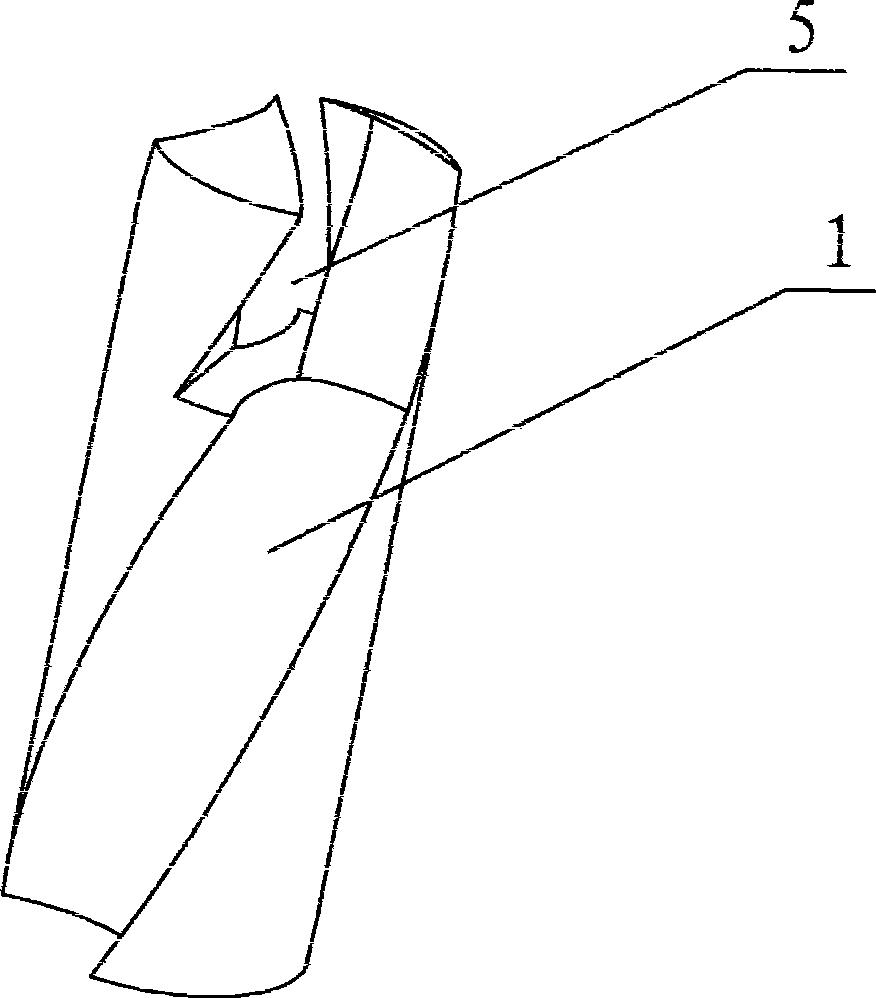

The invention discloses a cooling structure of a flame tube of an aero-engine combustor. The cooling structure comprises a flame tube wallboard. The flame tube wallboard comprises an outer wallboard body and an inner wallboard body. The inner wallboard body is provided with a plurality of diffusion holes, the outer wallboard body is provided with a plurality of impact holes, and all the diffusion holes and impact holes are distributed in a crossing mode. Meanwhile, the inner wallboard body and the outer wallboard body are connected through a plurality of pin fins. The flame tube wallboard is divided into two parts in the axial direction, namely, a front flame tube wallboard segment close to a high-temperature area of the combustor and a rear flame tube wallboard segment far away from the high-temperature area of the combustor. The aperture of the front-segment impact holes in the front flame tube wallboard segment is larger than that of the rear-segment impact holes in the rear flame tube wallboard segment, and meanwhile the aperture of the front-segment diffusion holes in the front flame tube wallboard segment is larger than that of the rear-segment diffusion holes in the rear flame tube wallboard segment. Therefore, a traditional flame tube wall cooling structure is improved, and on the premise of not increasing cold capacity, the cooling potential of the cooling structure is fully tapped, and cooling efficiency is improved. Meanwhile, too large heat stress caused by the excess temperature and uneven temperature distribution of the wall of the flame tube is avoided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

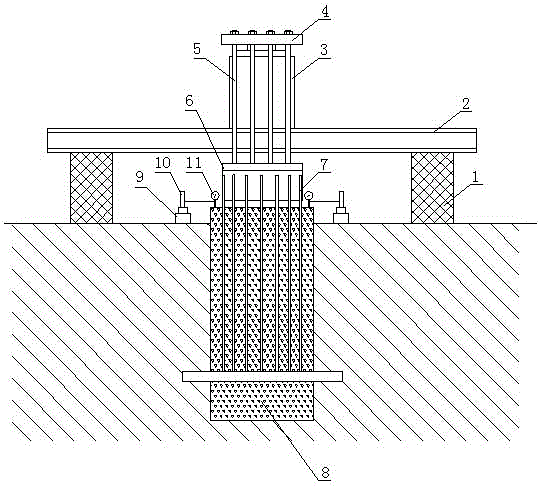

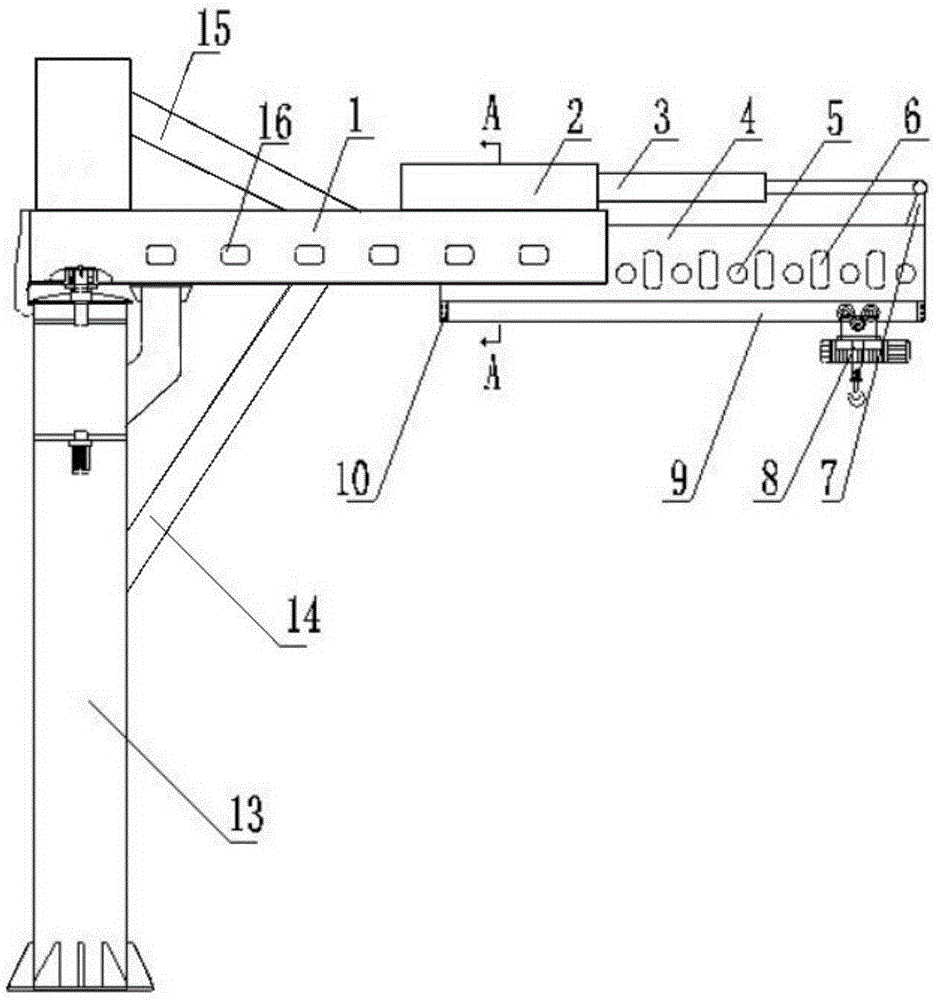

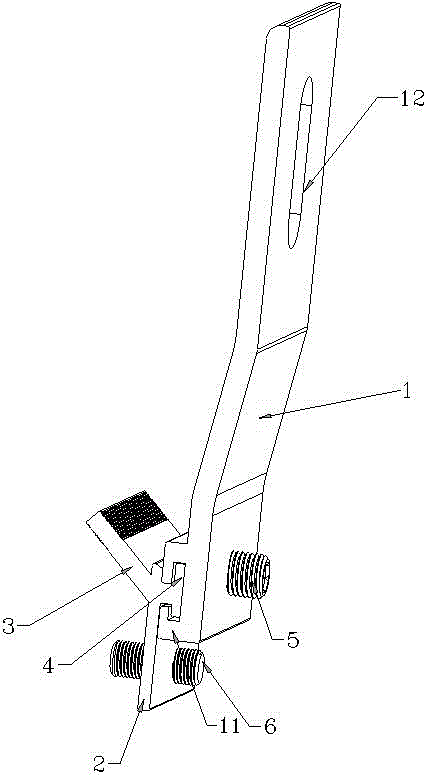

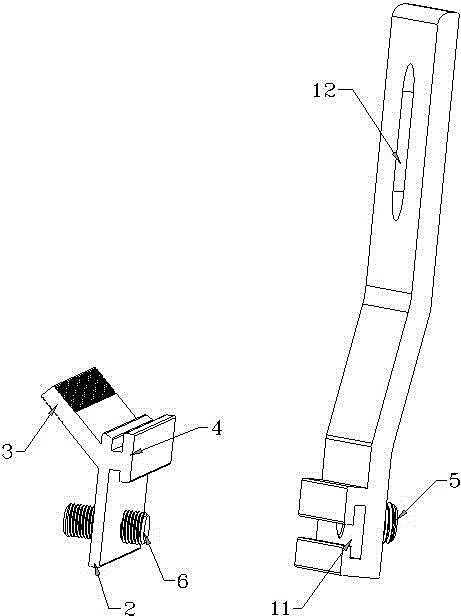

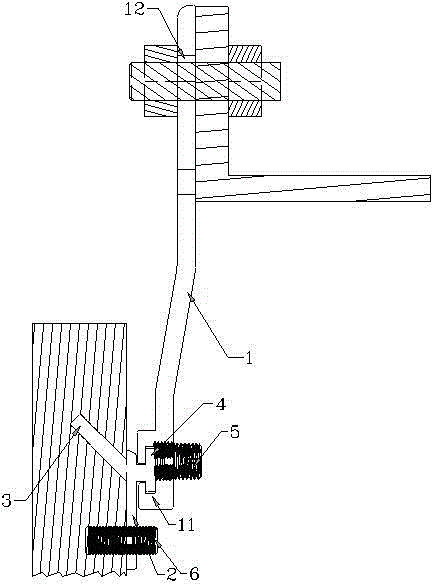

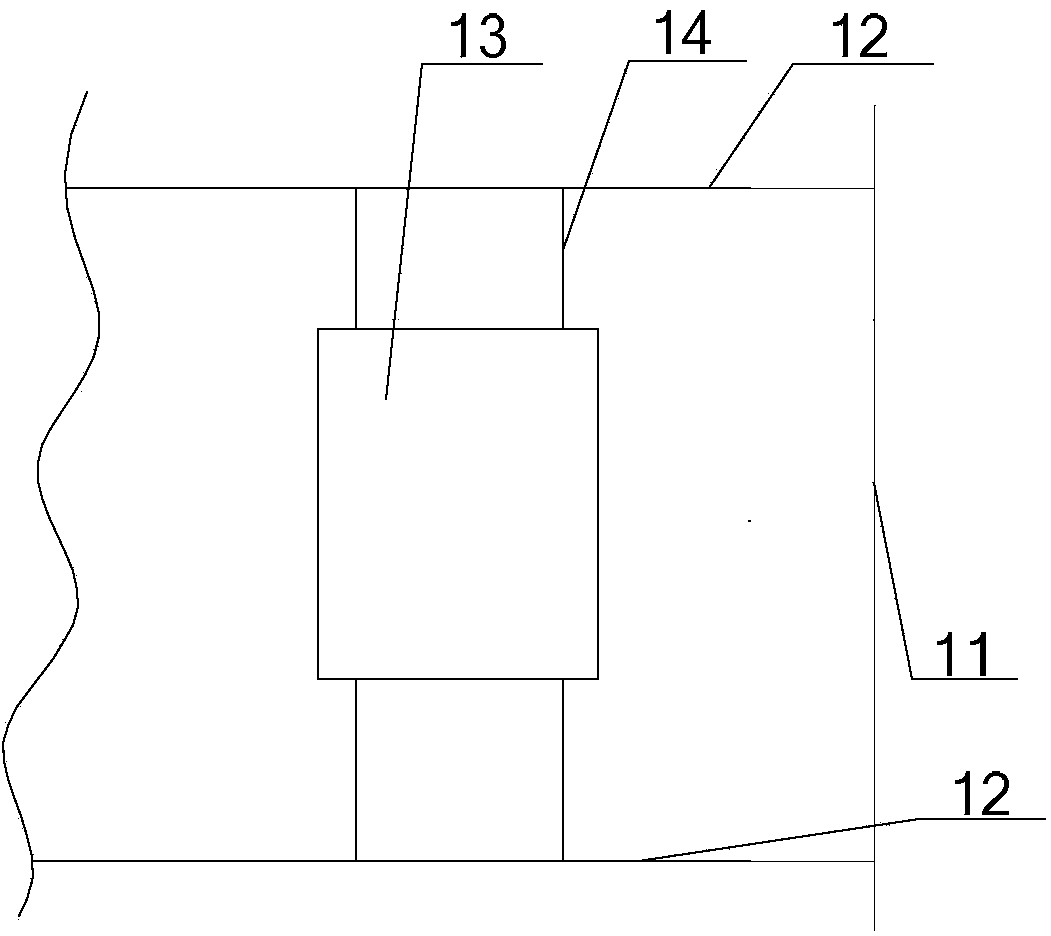

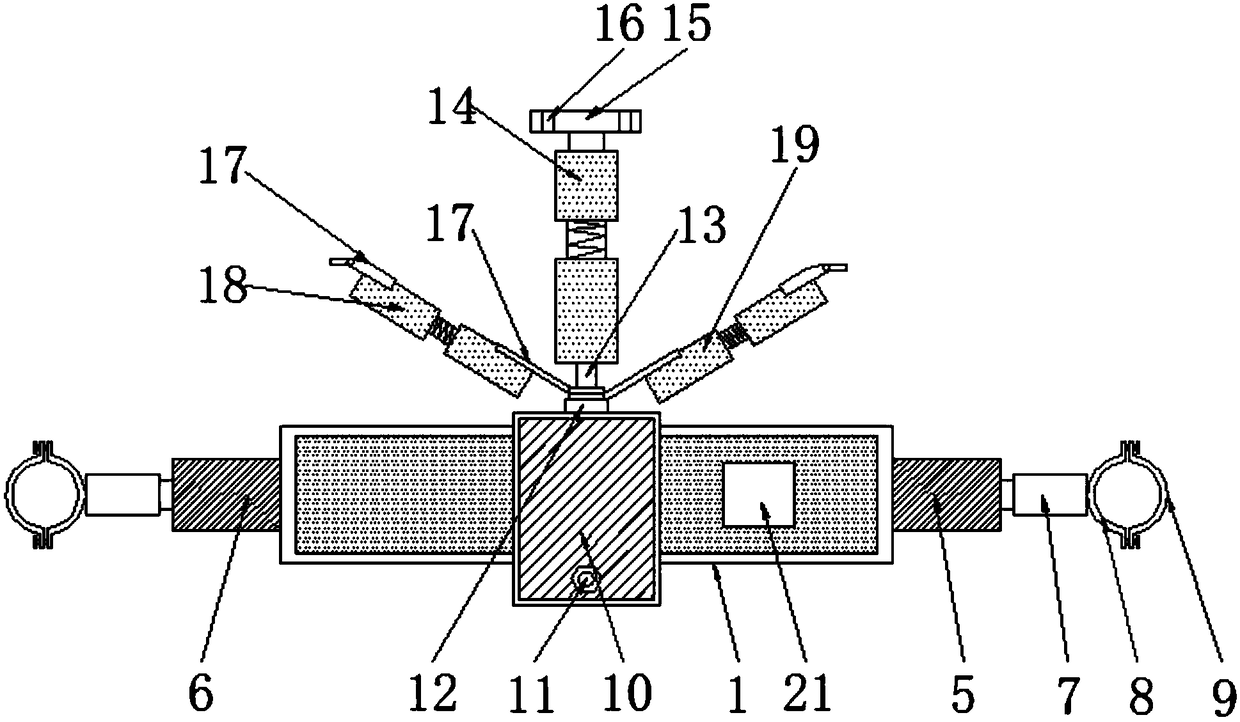

Foundation pile vertical uplift detecting connector

InactiveCN104099955ASmooth connectionImprove the strength of forceFoundation testingArchitectural engineeringStructural engineering

The invention discloses a foundation pile vertical uplift detecting connector which comprises a counter-force beam, a jack, a support plate, a pull rod and a cylinder. The counter-force beam is rested right above a foundation pile. The jack is located on the counter-force beam. The support plate is disposed on the jack. The cylinder is fixedly connected with the main reinforcement cage of the foundation pile. Two ends of the pull rod are respectively fixedly connected with the support plate and the cylinder. The foundation pile vertical uplift detecting connector has the advantages that the jack and the support plate are disposed on the counter-force beam, the cylinder is connected with the main reinforcement cage of the foundation pile, traditional point contact is replaced by surface contact, stress strength is increased, the cylinder is in even connection with the main reinforcement cage to allow main reinforcement bars to be parallel and even in stress, and safety, reliability and high operability during an uplift process are achieved.

Owner:NORTHWEST RES INST CO LTD OF C R E C

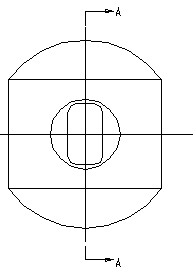

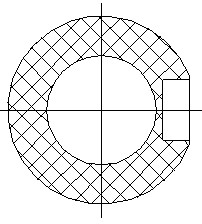

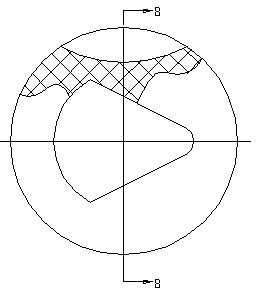

Ball body of rupture-preventing heavy-caliber composite ceramic ball valve, composite ceramic ball valve and manufacture methods thereof

ActiveCN102635700ASimple manufacturing processHigh hardnessPlug valvesValve housingsComposite ceramicUltimate tensile strength

The invention discloses a ball body of a rupture-preventing heavy-caliber composite ceramic ball valve, the composite ceramic ball valve and manufacture methods of the ball body and the composite ceramic ball valve. The ball body of the rupture-preventing heavy-caliber composite ceramic ball valve is formed by assembling a ceramic cylinder, a metal ring, a left ceramic spherical cap and a right ceramic spherical cap, the metal ring is fixed in the center of the outer wall of the ceramic cylinder, the metal ring is combined with the ceramic cylinder by adopting a hot charging process or cement process, the left and the right ceramic spherical caps are sleeved outside the ceramic cylinder and then transferred to a center line for covering the metal ring, end faces of the left and the right ceramic spherical caps are tightly fitted, high-temperature and high-strength glue is filled between the left and the right ceramic spherical caps and used for firmly adhering the left and the right ceramic spherical caps, and the metal ring is provided with an arc-shaped groove matched with a valve rod or milled with an elliptical hole matched with the valve rod. The invention also discloses the composite ceramic ball valve comprising the ball body, and the manufacture methods of the ball body and the composite ceramic ball valve. With the adoption of the composite ceramic ball valve, the difficulty of incapability of producing the heavy-caliber composite ceramic ball valve is solved.

Owner:郑州鼎盛工程技术有限公司 +1

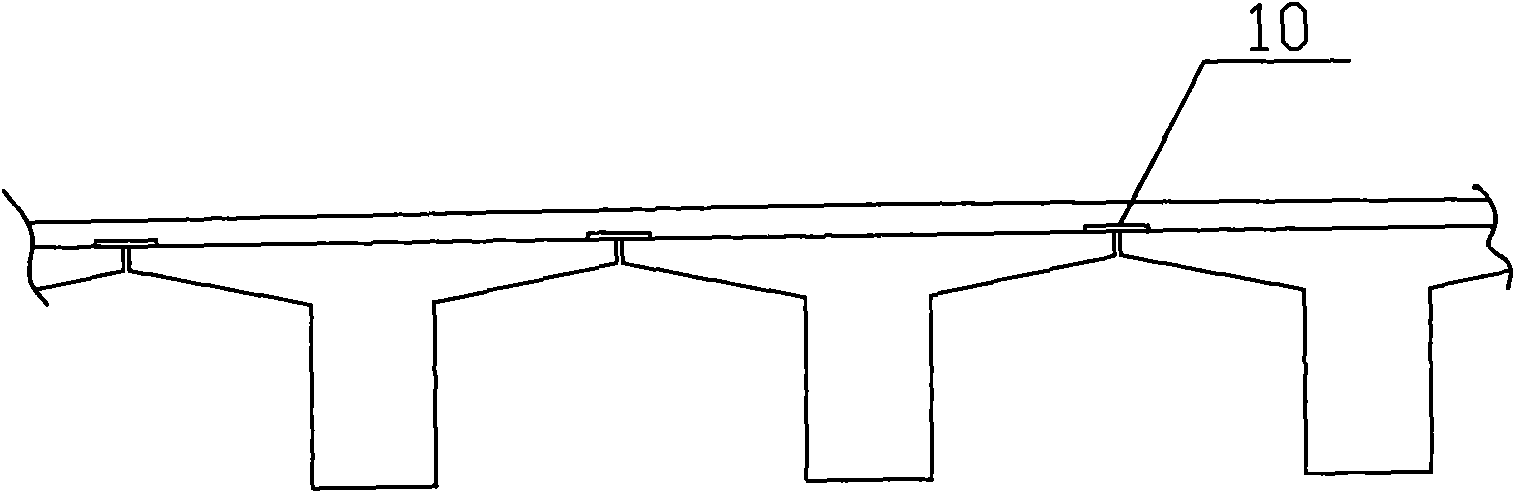

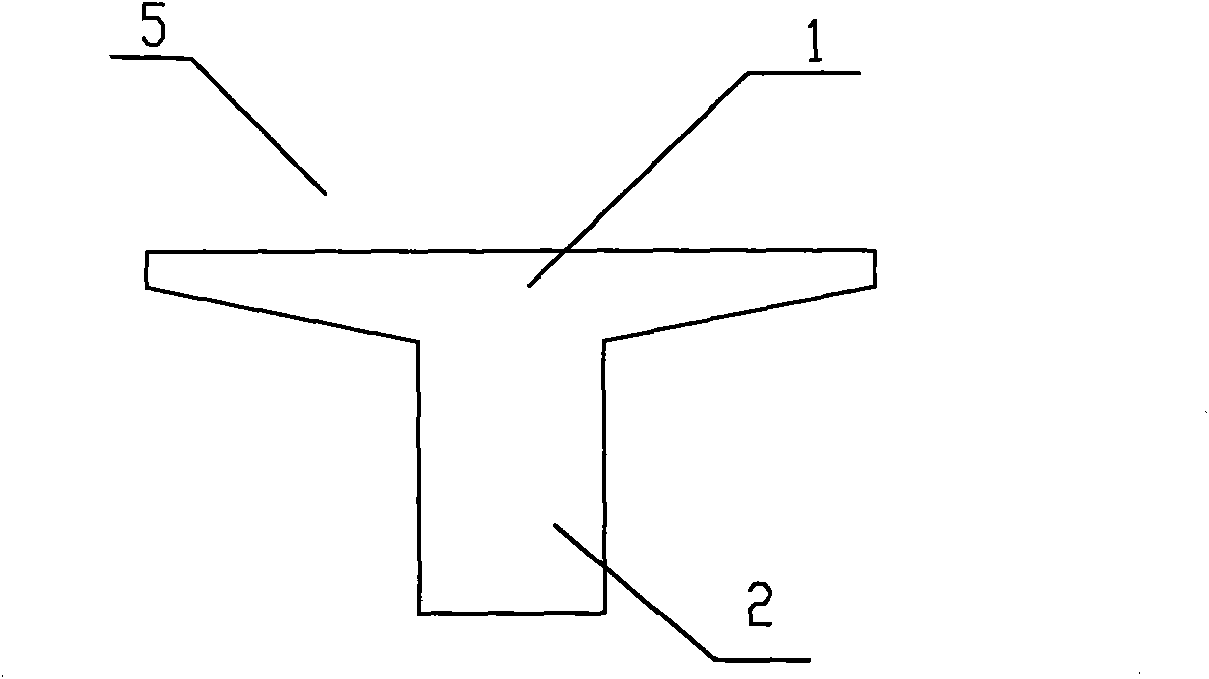

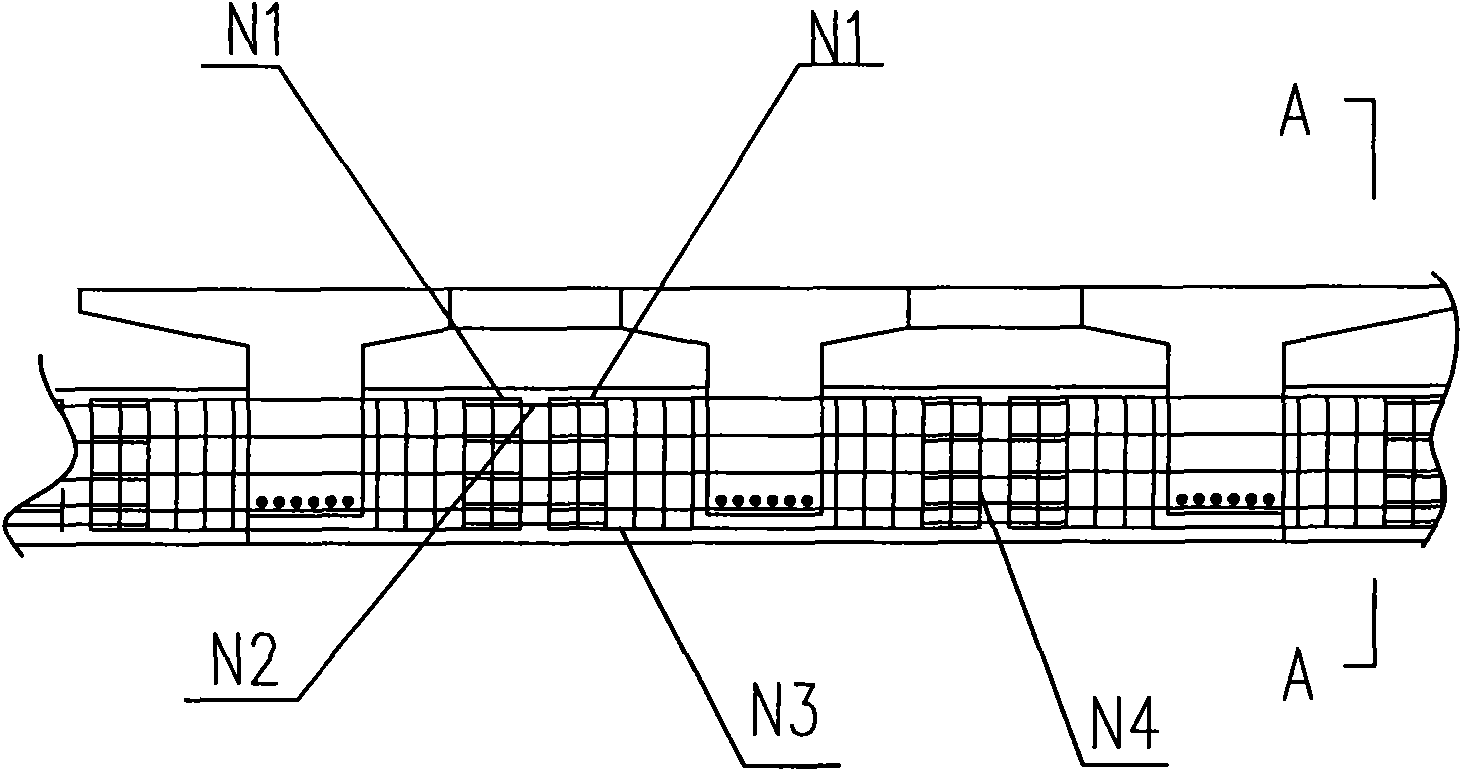

Fastening method of T-shaped beam bridge

InactiveCN101570960AIncrease stiffnessImprove rigidityBridge erection/assemblyBridge strengtheningShaped beamT-beam

The invention relates to a fastening method of a T-shaped beam bridge. The T- shaped beam bridge comprises a plurality of T-shaped beams with the sections being T-shaped; the T-shaped beams comprise a wing plate positioned in a horizontal part and a ventral shield positioned in a vertical part; the fastening method comprises the following steps: reinforcing steel bars are embedded between the ventral shields of the adjacent T- shaped beams and concrete is poured thereinto so that the at least one concrete cross beam along the T-shaped beam span direction is arranged between the ventral shields of the adjacent T- shaped beams. The fastening method of the T-shaped beam bridge solves the problems existing in the prior art fastening the hinge T- shaped beam that the articulation connection is lacking; the jointing position of the articulation seam is easy to weaken and even fails; the whole rigidity of the bridge is not high.

Owner:BEIJING MUNICIPAL ENG PROFESSIONAL DESIGNINST

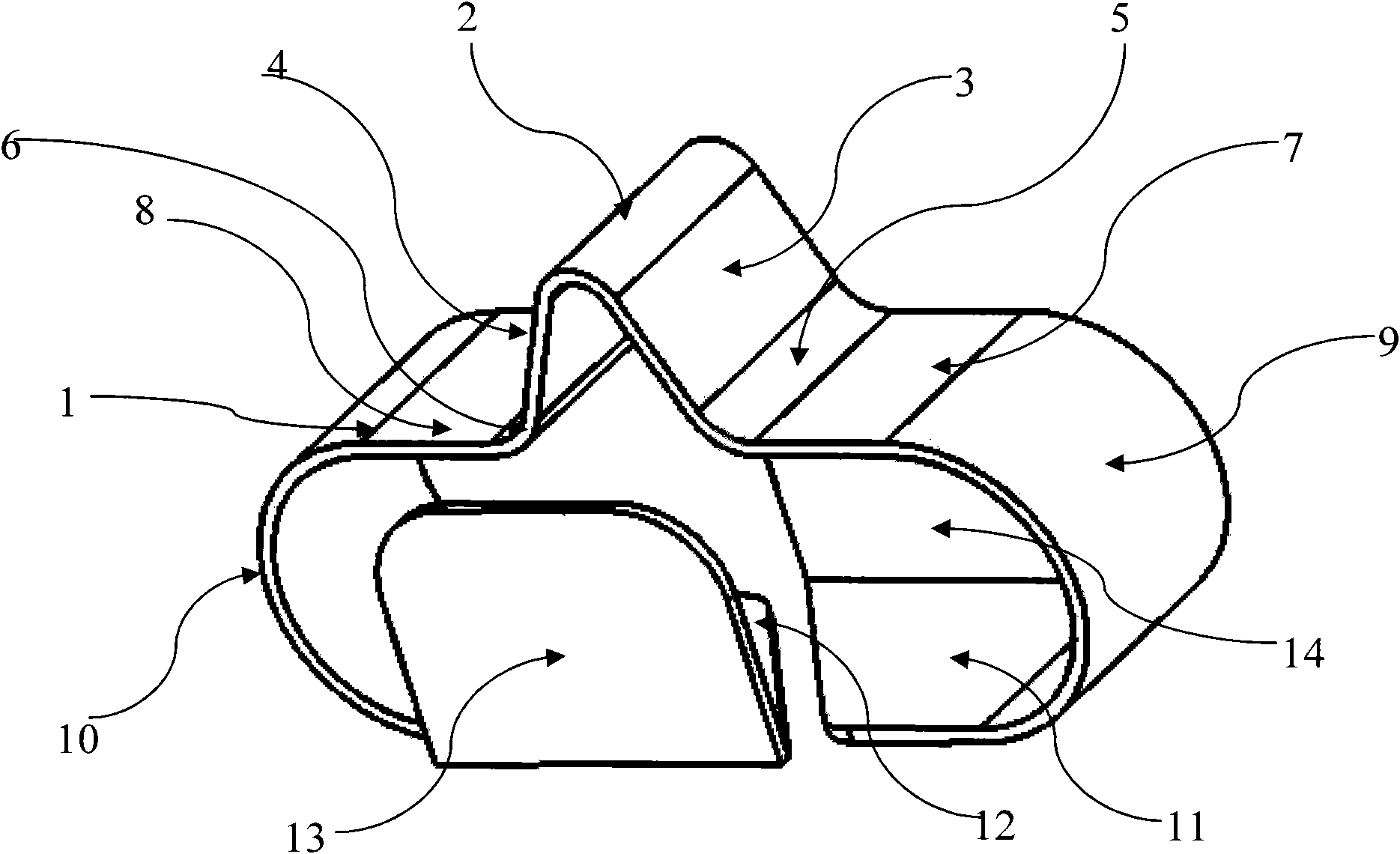

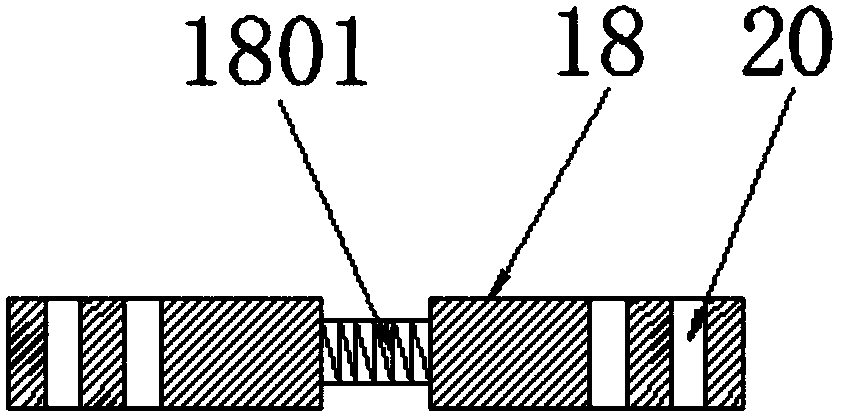

Metal spring leaf

ActiveCN101841092AIncrease the force directionImprove the strength of forceCoupling contact membersFixed connectionsStress strengthEngineering

The invention discloses a metal spring leaf, which comprises a contact part, bending parts extending from two bottom ends of the contact part respectively, and fixing parts extending from the bending parts respectively, wherein the contact part is provided with a contact end contacting a conducting device; the bending parts and the contact part are elastic; and the fixing parts are used for fixing the metal spring leaf on a PCB board or other electronic devices. Relative to a relevant technique, because the two ends of the contact part are provided with the bending parts by extending to increase a stressed direction and make the stress strength at a contact end stronger, the metal spring leaf is difficult to damage.

Owner:ZTE CORP

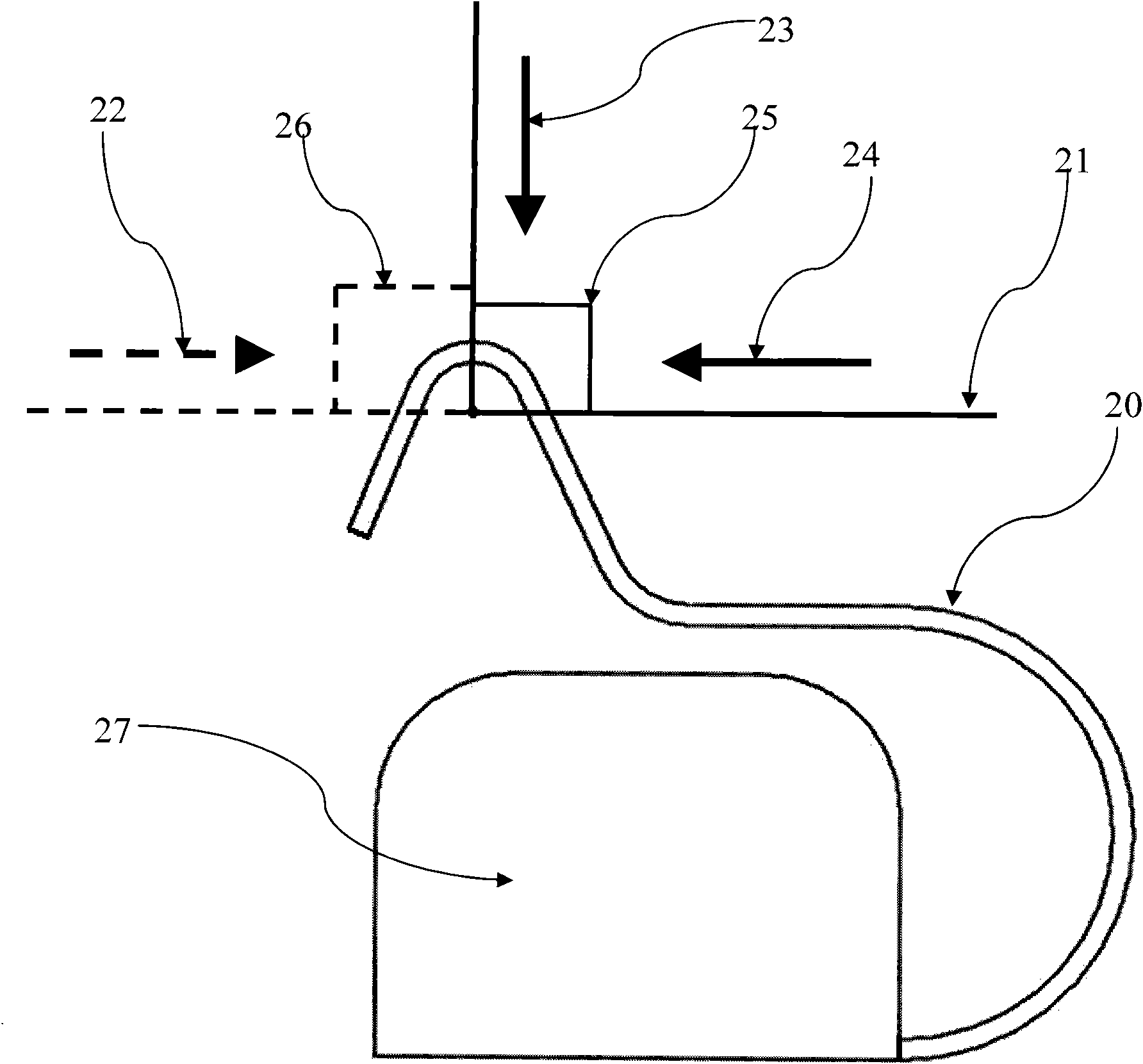

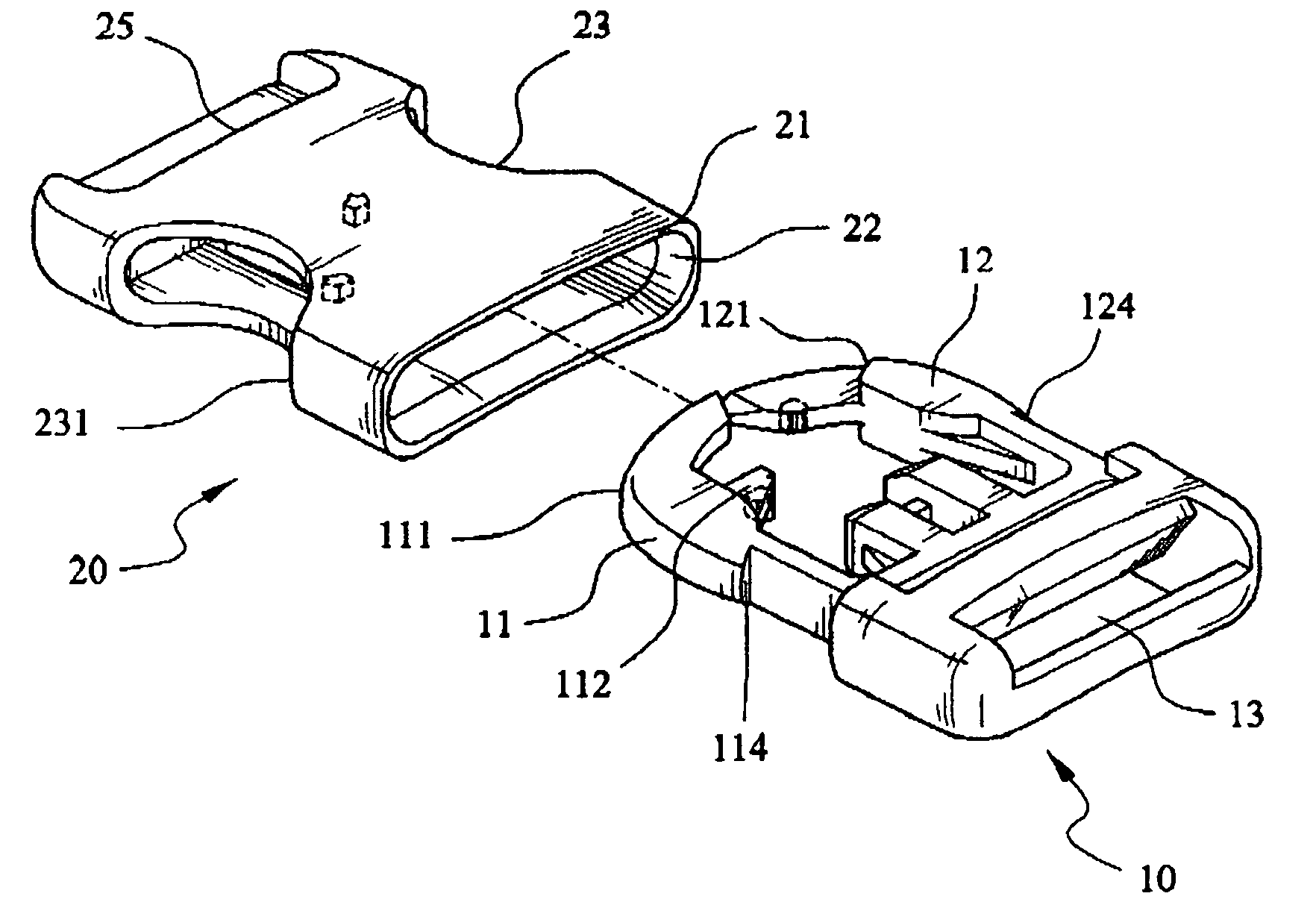

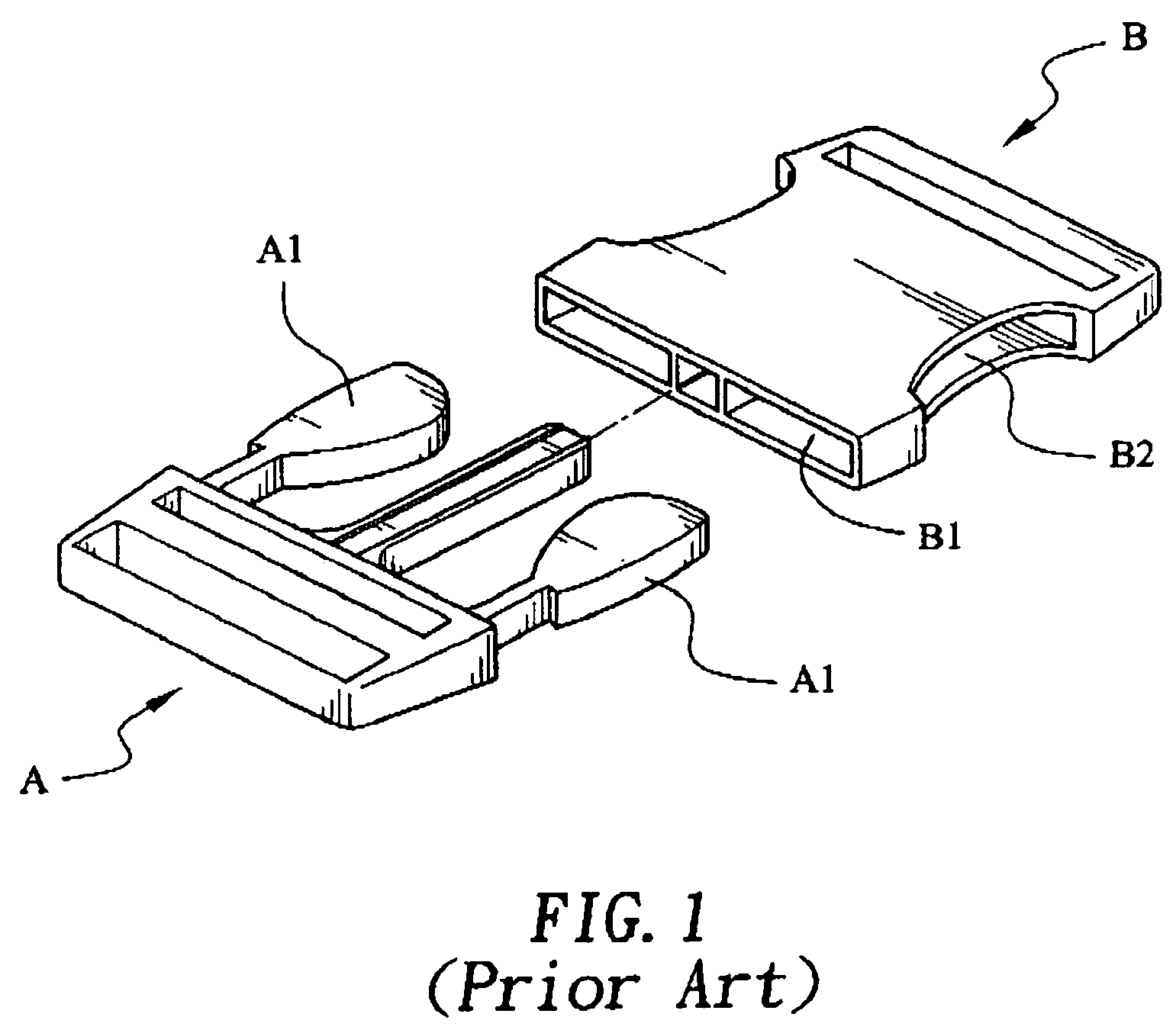

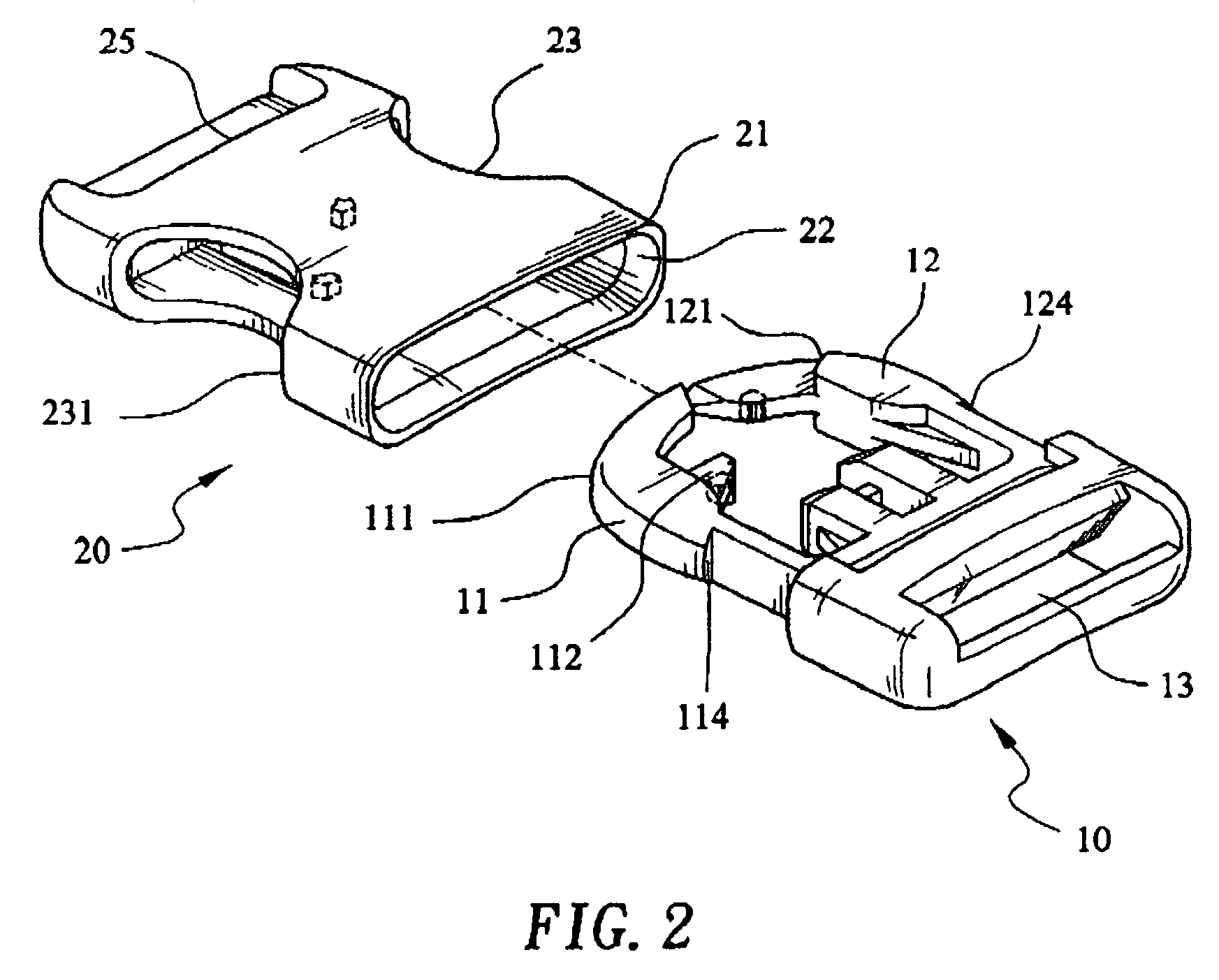

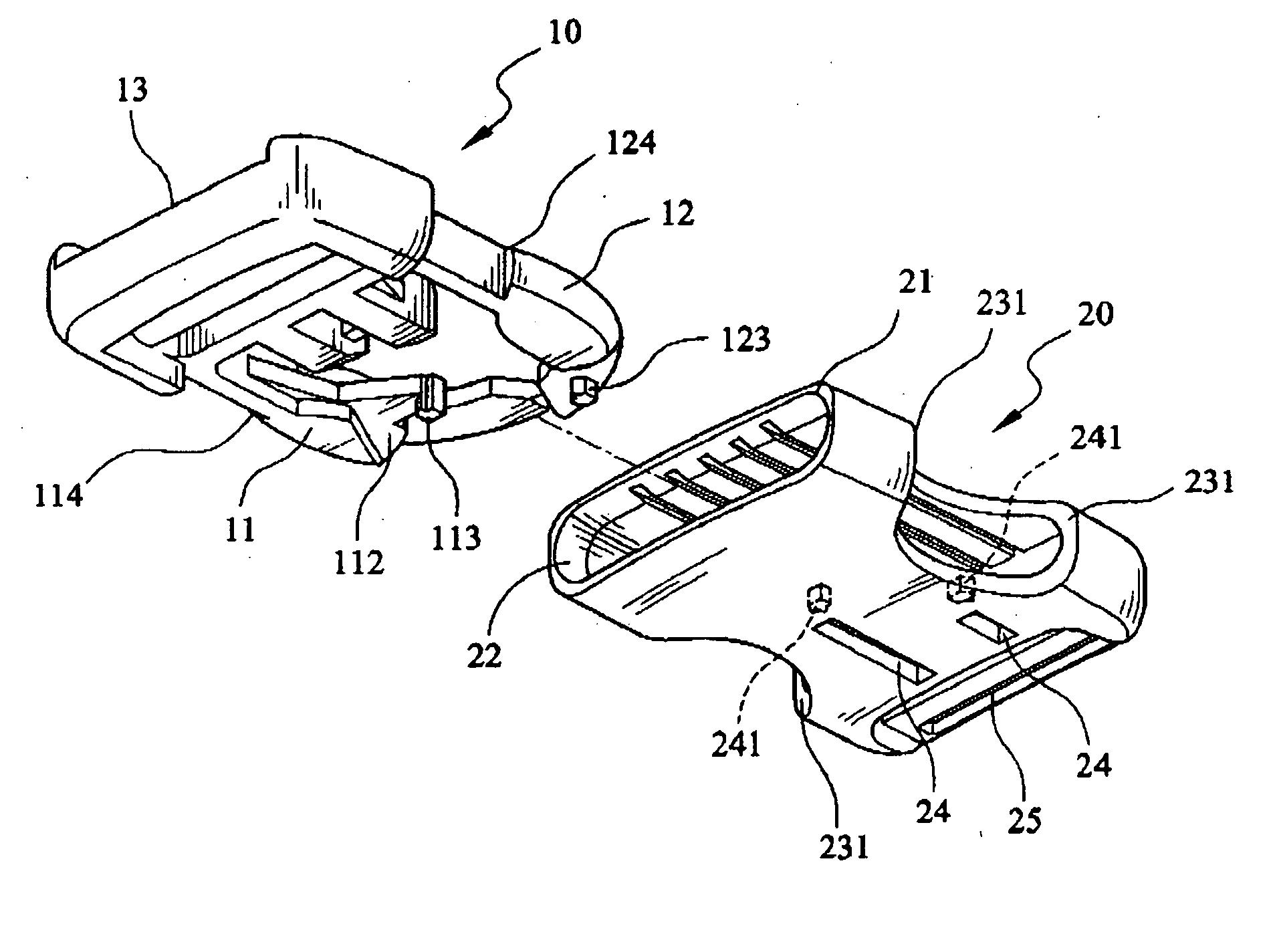

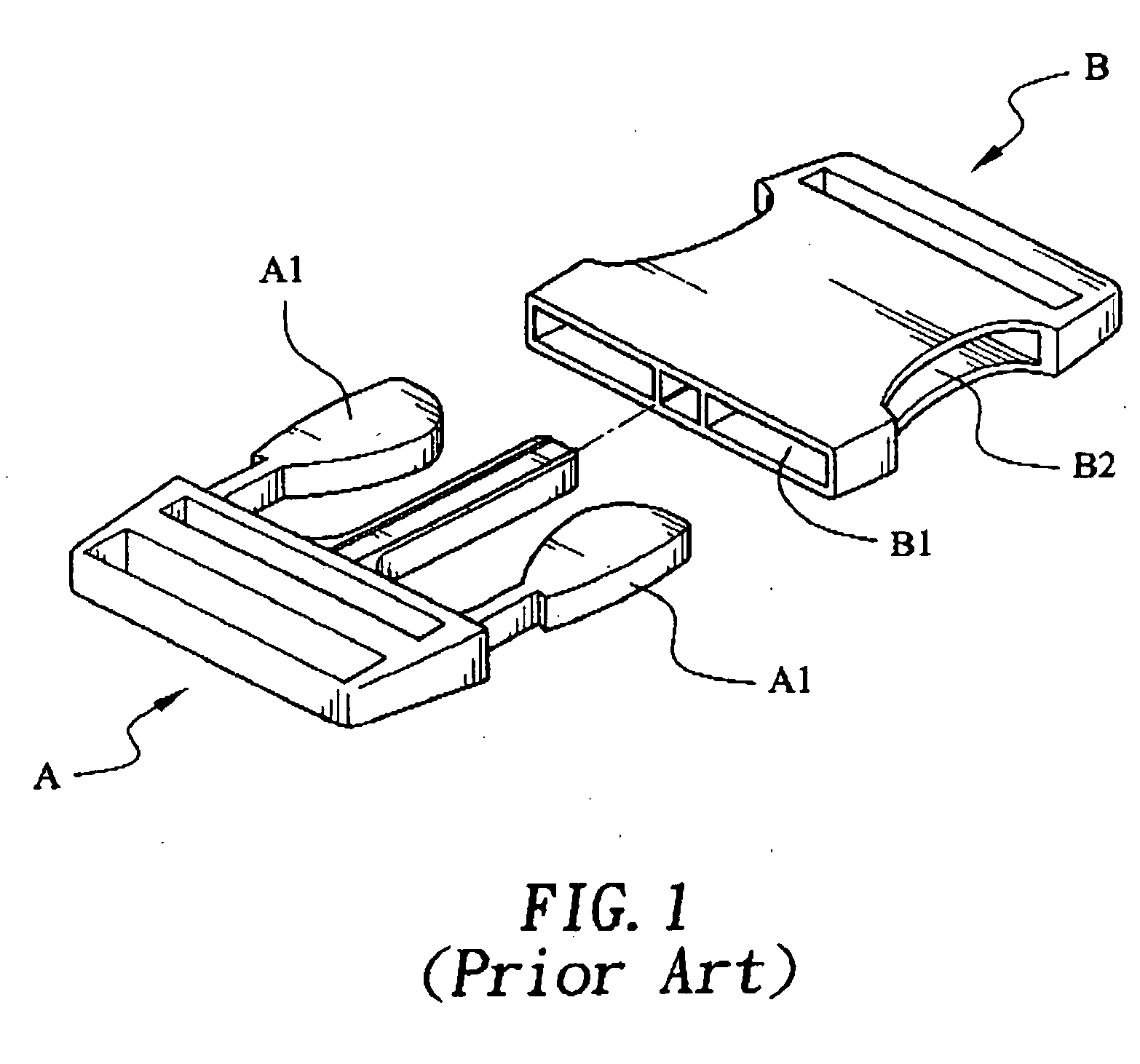

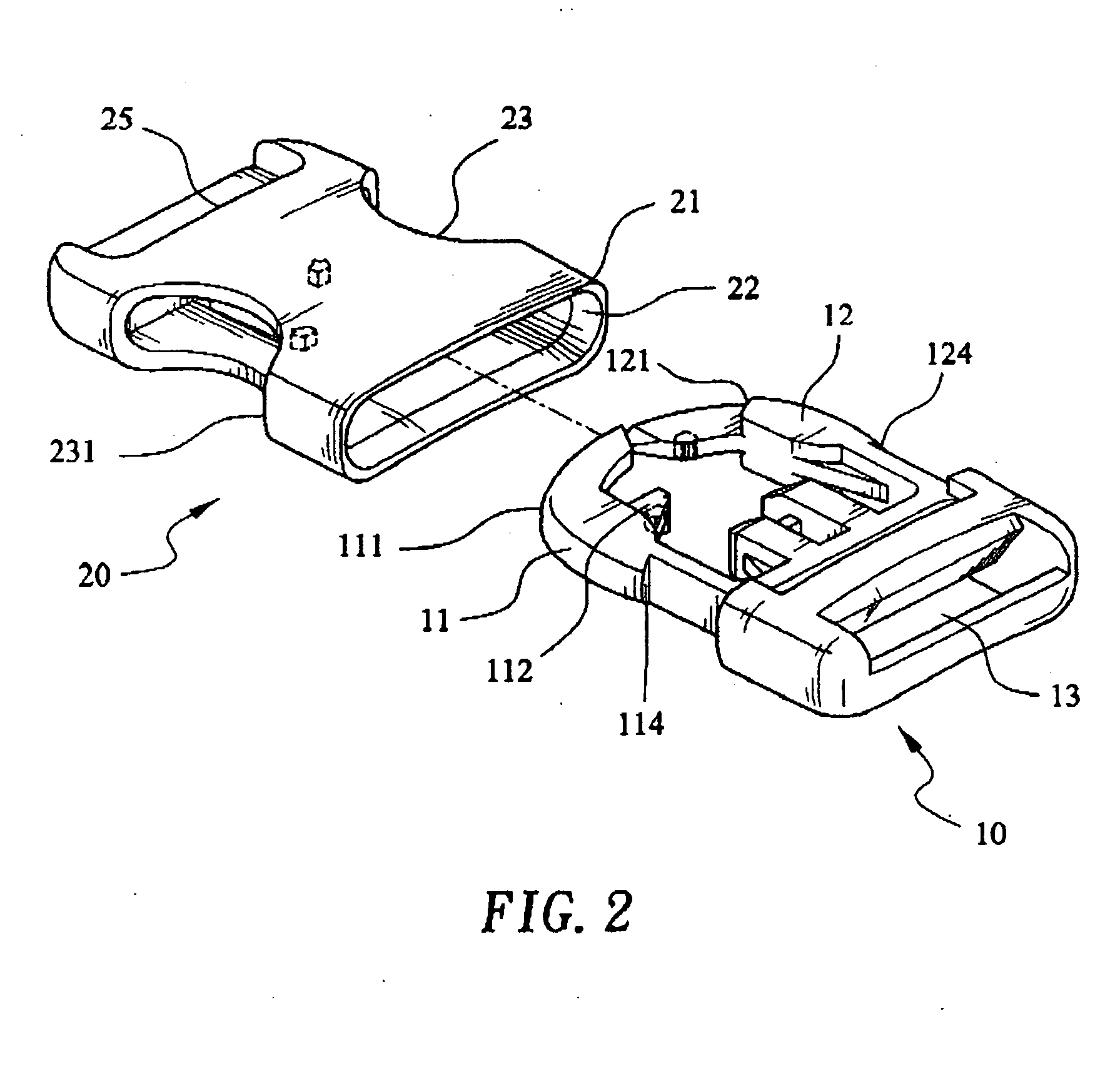

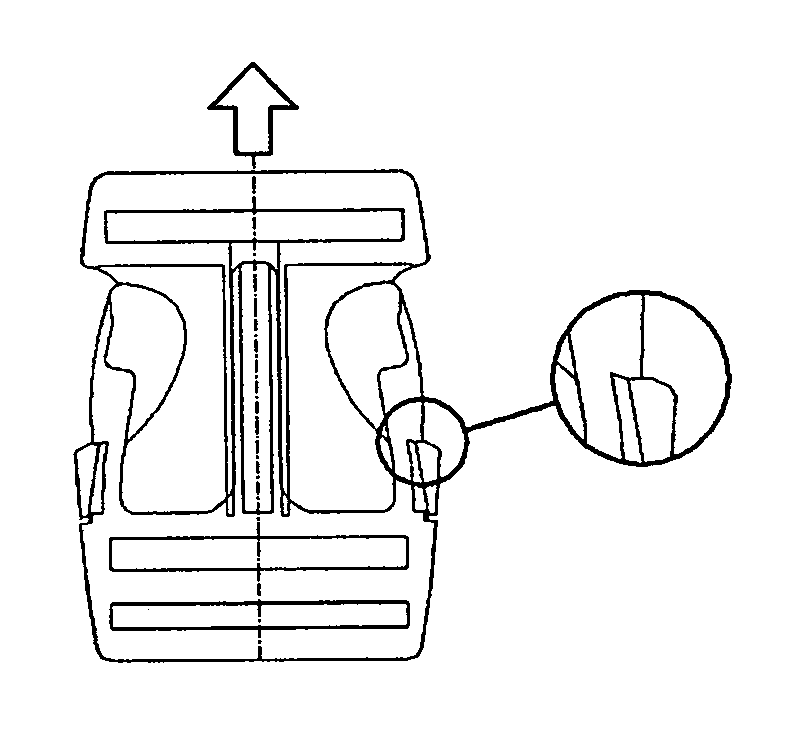

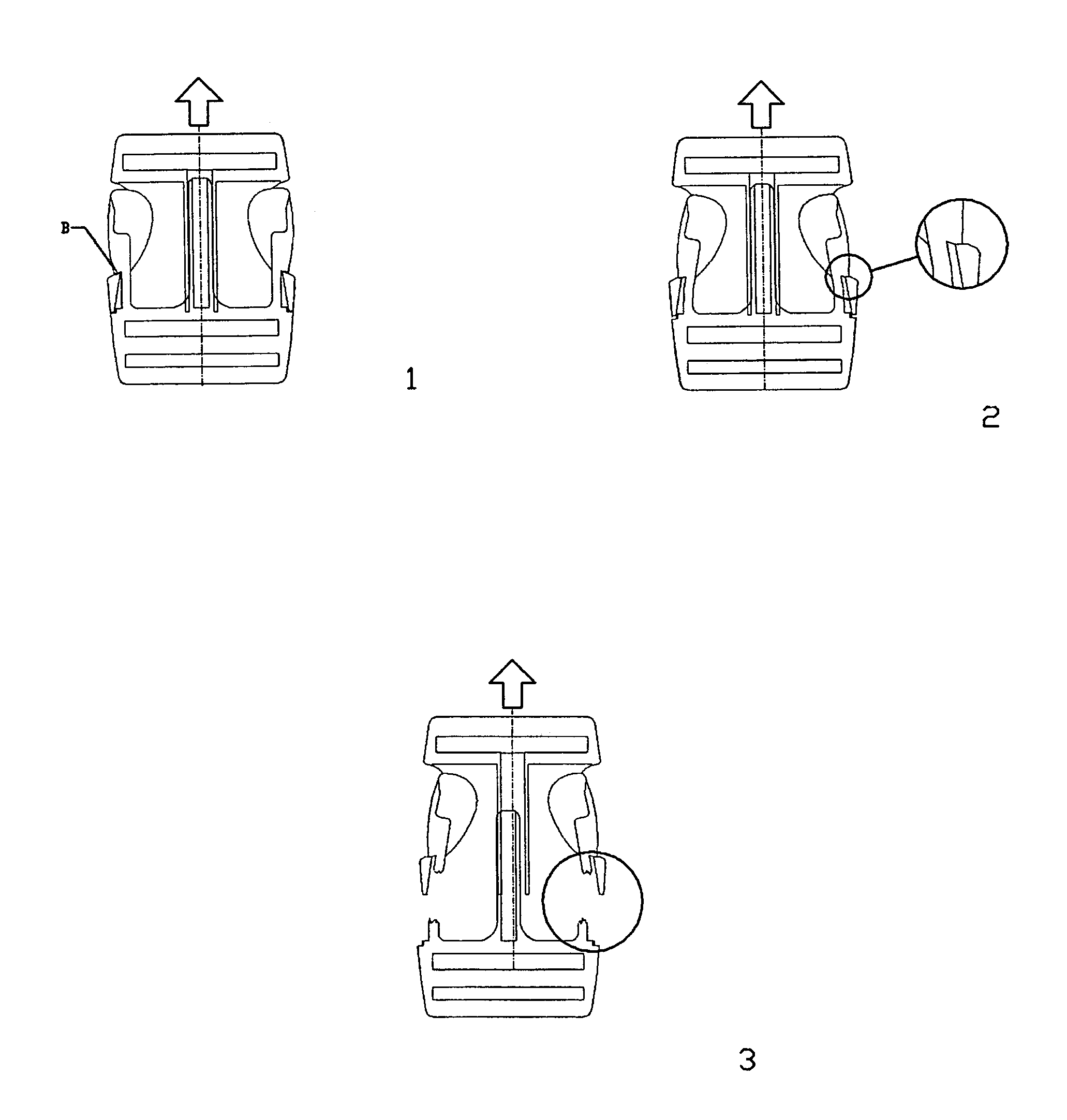

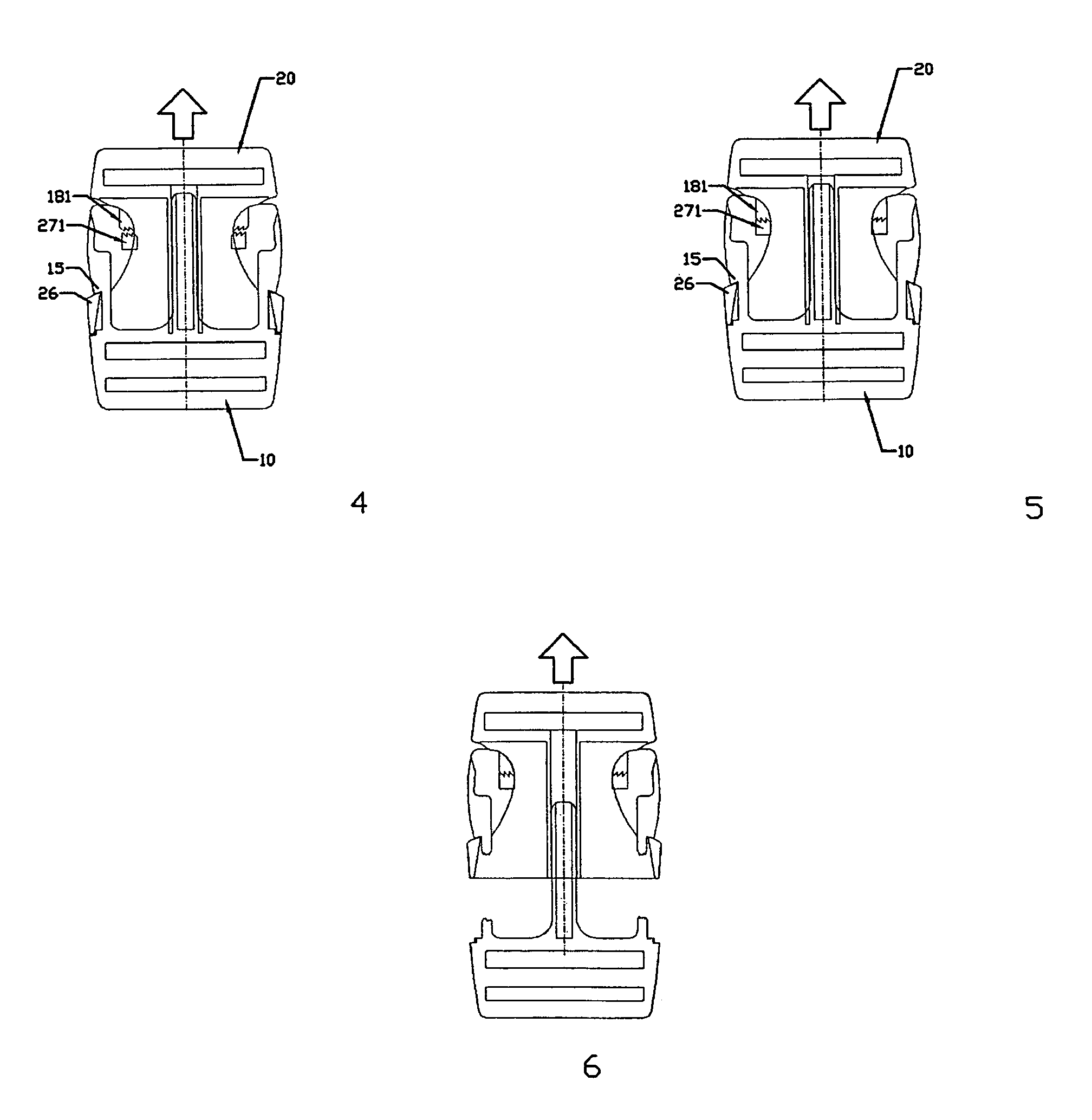

Side release buckle allowing locking from an angular position

ActiveUS7140082B2Improve the strength of forceHigh strengthSnap fastenersClothes buttonsMechanical engineering

Owner:BUTTON INT CO LTD

Method for preparing grinding-free drill head and drill head

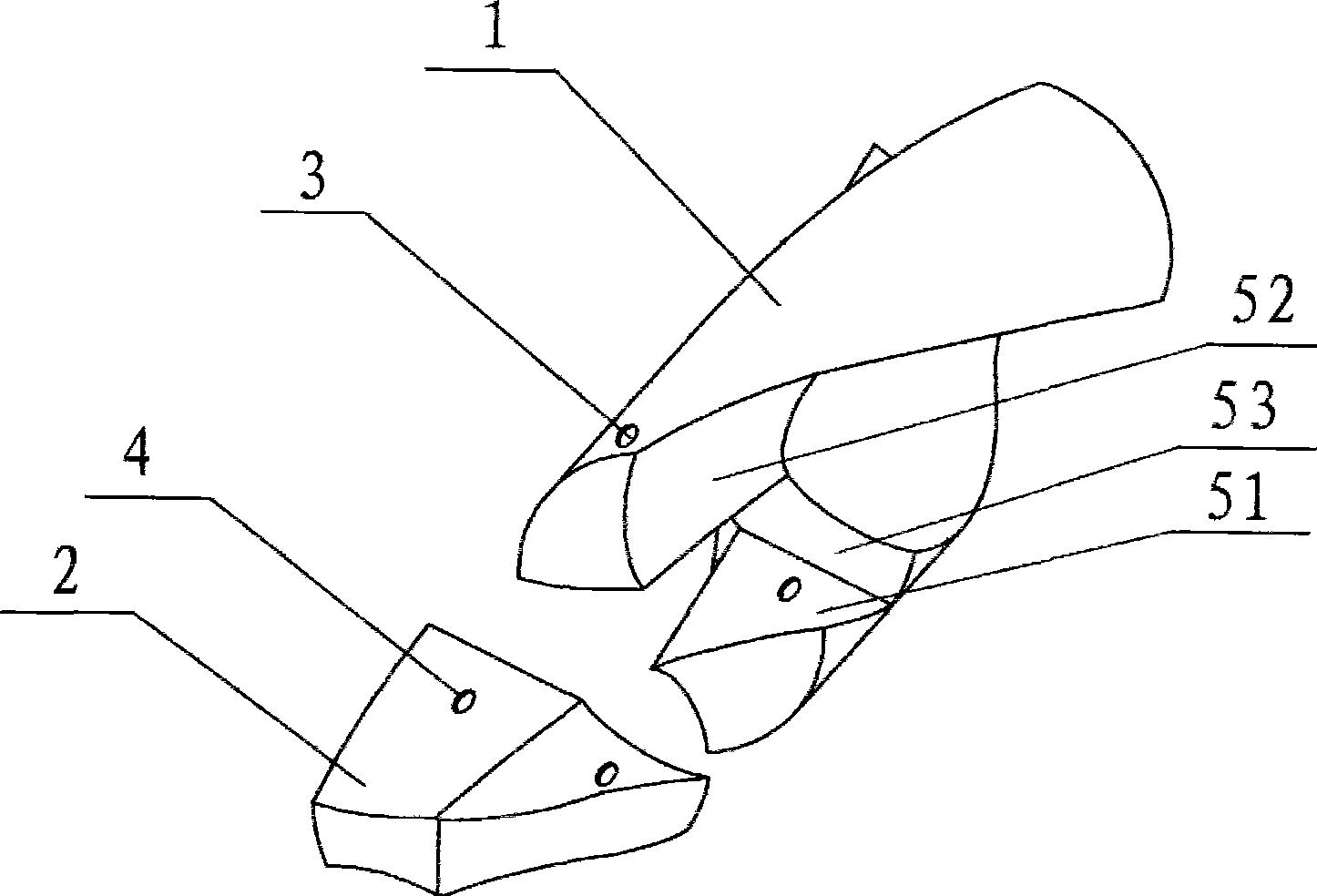

The invention provides a manufacturing method of a grinding-free drill bit, which comprises a drill body and a detachable cutting blade connected on the front end of the drill body; the manufacturing method is characterized by comprising the following steps: (1) according to the set depth and width, the front end of the drill body is equipped with a spiral groove for holding the cutting blade; both inner side walls of the spiral groove are arcwall faces, and the two arcwall faces are of central symmetry, so that the entire outline of the spiral groove is of S shape; each arcwall surface is a parallelogram after being unfolded; (2) the cutting blade with side walls being two symmetrical arcwall faces and matched with the inner wall shape of the spiral groove is prepared; (3) the cutting blade is placed into the drill spiral groove, and connected to prepare the grinding-free drill bit. No sequence exists between step (1) and step (2). The manufacturing method also provides the grinding-free drill bit prepared by using the method.

Owner:苏茂均

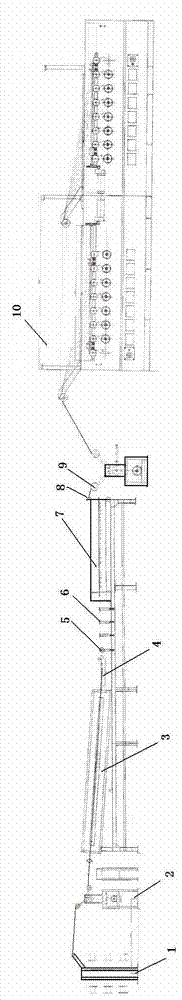

Annealing system for multi-strand superfine copper wires and annealing method of annealing system for multi-strand superfine copper wires

ActiveCN102787232AIncrease production speedSimplify the subsequent weaving processFurnace typesHeat treatment furnacesElectricityCopper wire

The invention discloses an annealing system for multi-strand superfine copper wires. The system comprises a wire payoff rack, a first capstan, a first drying oven, a water tank, a felt, a second capstan, a second drying oven, a cooling gas blowing kettle and a wire winding disc, wherein a gas outlet of the cooling gas blowing kettle is located on an outlet of the second drying oven. The invention also discloses an annealing method by the annealing system for multi-strand superfine copper wires. With the adoption of the method provided by the invention, the time, electricity and power can be saved and large output is obtained; and meanwhile, the produced superfine copper wires is strong in antioxidant capability and long in service life.

Owner:TAICANG LINYUAN CABLES & CORDS CO LTD

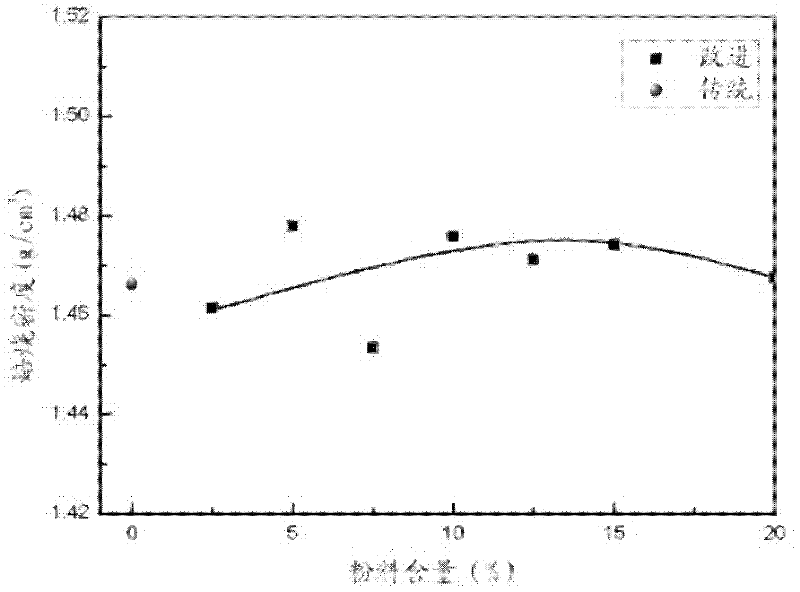

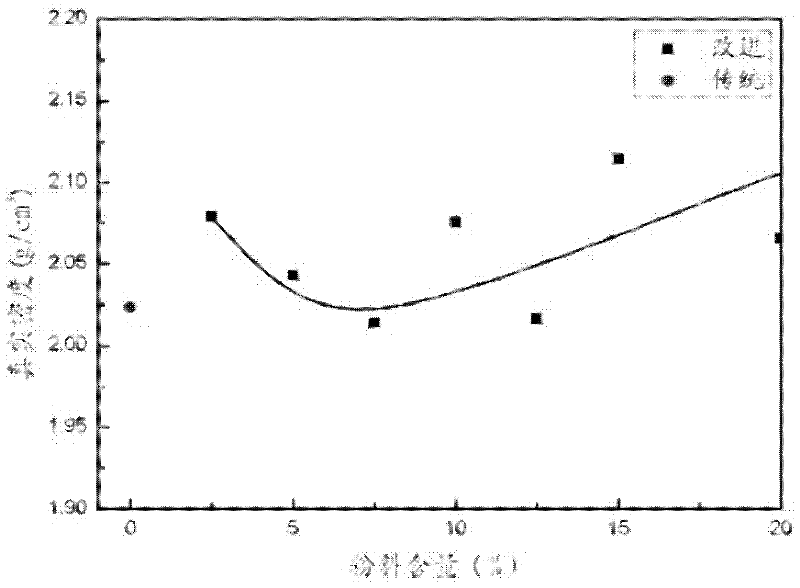

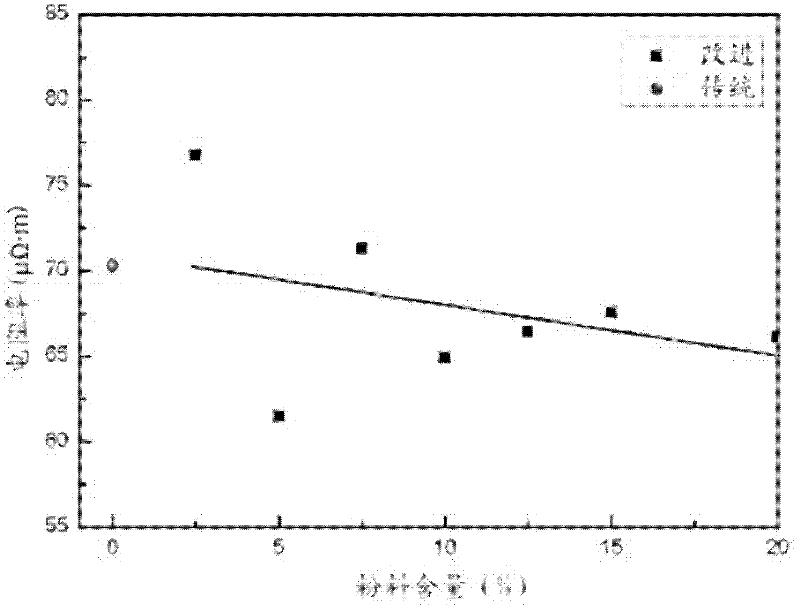

Method for mixing and kneading carbon anode paste for aluminum electrolysis

The invention relates to a method for mixing and kneading carbon anode paste for aluminum electrolysis. The method comprises the steps of: adding partial powder (namely carbon ball milled powder or dust collection powder of a calcining or intermediate crushing procedure during the production of carbon) in a carbon anode formula to a molten coal tar pitch used as a bonding agent in advance, uniformly stirring, then mixing and kneading with dried materials, forming, and roasting to obtain an anode. The method aims at improving the volume density, true density, compression strength, resistivity,thermal expansibility and other properties of the carbon anode, and has the advantages of low implementation cost, simplicity in operation and cleanness.

Owner:CENT SOUTH UNIV

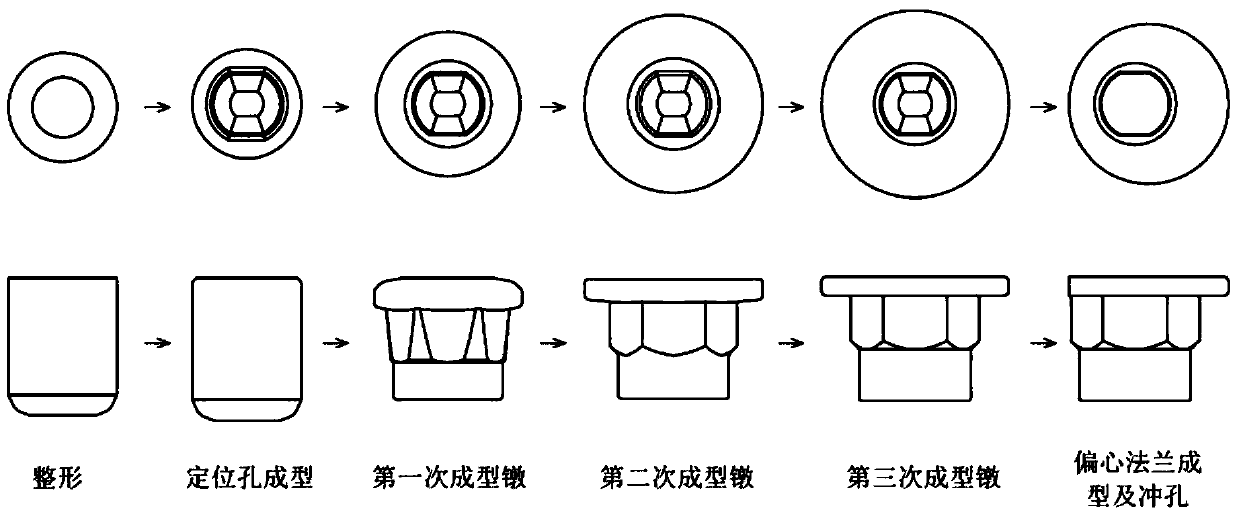

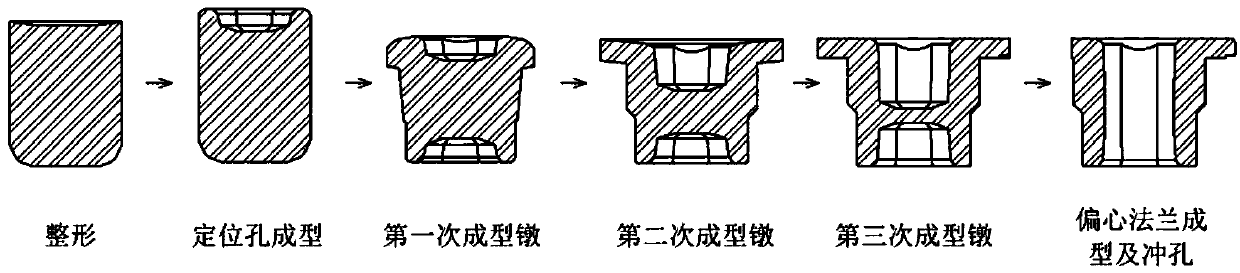

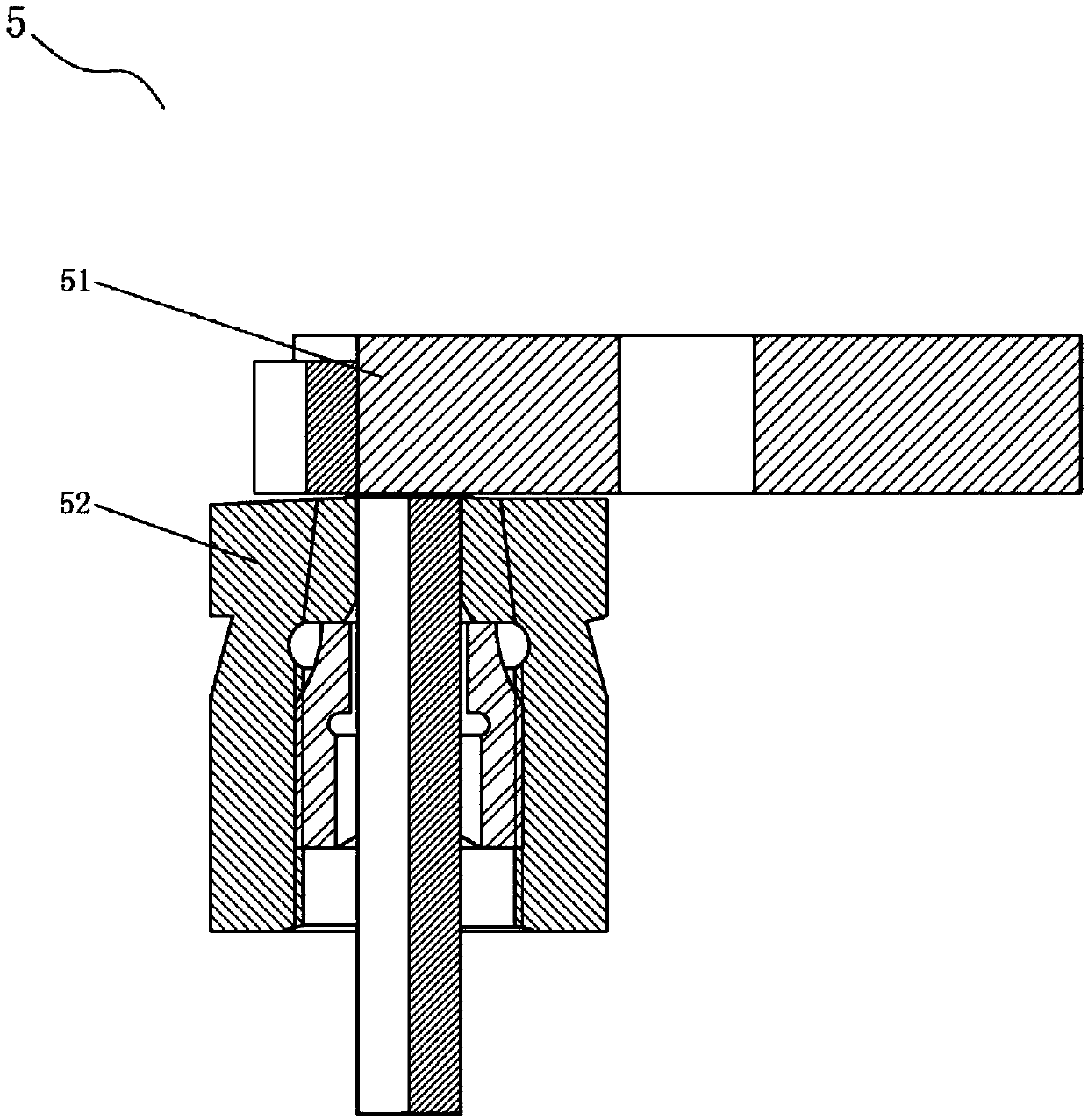

Cold heading forming technology of eccentric flange nut with bosses and combined mold applied to cold heading forming technology

PendingCN109622872AA large forceExtended service lifeNutsForging/hammering/pressing machinesPunchingEngineering

The invention discloses a cold heading forming technology of an eccentric flange nut with bosses and a combined mold applied to the cold heading forming technology. The cold heading forming technologyof the eccentric flange nut with the bosses comprises the steps of a blanking process, a shaping process, a punching process, and three heading forming processes and an eccentric flange forming process sequentially following the shaping process; in the three heading forming processes, a forward flange section, a hexagonal prism section, and a boss section are sequentially formed in a blank threetimes, kidney-shaped counterbores with sequentially increased depths are formed in the blank three times, and kidney-shaped locating holes with sequentially increased depths are formed in the blank three times; the forward flange section is coaxial with the hexagonal prism section and the boss section; and in the eccentric flange forming process, the blanking process is conducted on the forward flange in the axial direction to form the desired eccentric flange section. The cold heading forming technology of the eccentric flange nut with the bosses has the advantages that the technology is simple, the production efficiency is greatly improved, the production process is stable, the stripping is convenient, the service life of the mold is prolonged, the flange face of the formed eccentric flange nut is uniform and attractive, and the product precision is high.

Owner:厦门恒耀金属有限公司

Side release buckle allowing locking from an angular position

ActiveUS20060150376A1Enhance buckling strengthImprove the strength of forceSnap fastenersClothes buttonsMechanical engineeringEngineering

Owner:BUTTON INT CO LTD

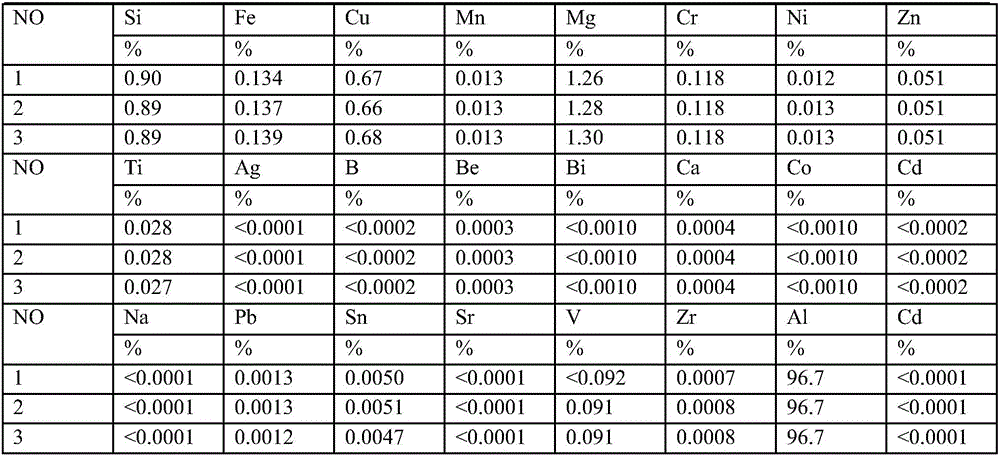

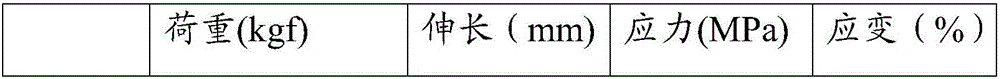

Aluminum alloy material used for manufacturing bicycle frame and production process for aluminum alloy material

The invention discloses an aluminum alloy material used for manufacturing a bicycle frame and a production process for the aluminum alloy material. The production process comprises the following steps: firstly, putting a small part of aluminum leftover waste materials into a furnace for bottoming, and then, adding Si, Fe, Cu, Mn, Cr and V according to the components; carrying out ignition heating and smelting while fire is needed to be ceased and waste materials are added, repeating the step until all wastes are added into the furnace, and controlling the temperature of molten aluminum to be lower than 950 DEG C; adding a fluxing medium into the furnace, slagging off from the interior of the furnace, and completely slagging visible impurities on the surface of the molten aluminum off the furnace; adding magnesium into a prefabricated iron cage, and then, inserting the prefabricated iron cage into the molten aluminum until magnesium is completely molten; and refining, carrying out test in front of the furnace, slagging off for the second time, stewing, and carrying out cast molding. The aluminum alloy material can improve the mechanical strength and the mechanical property of the bicycle frame, and can reduce the weight of the bicycle frame.

Owner:SHENZHEN XIDESHENG BICYCLE

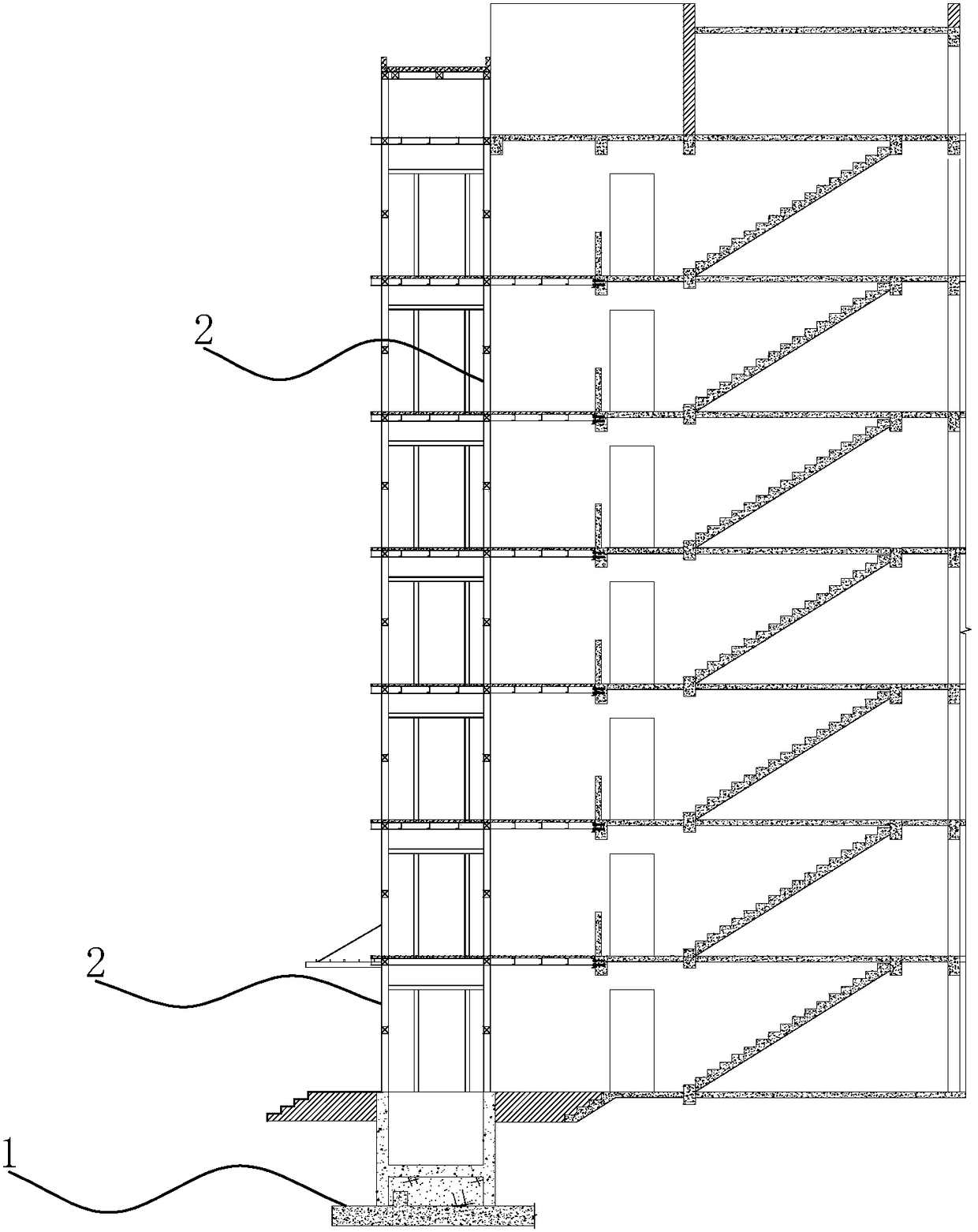

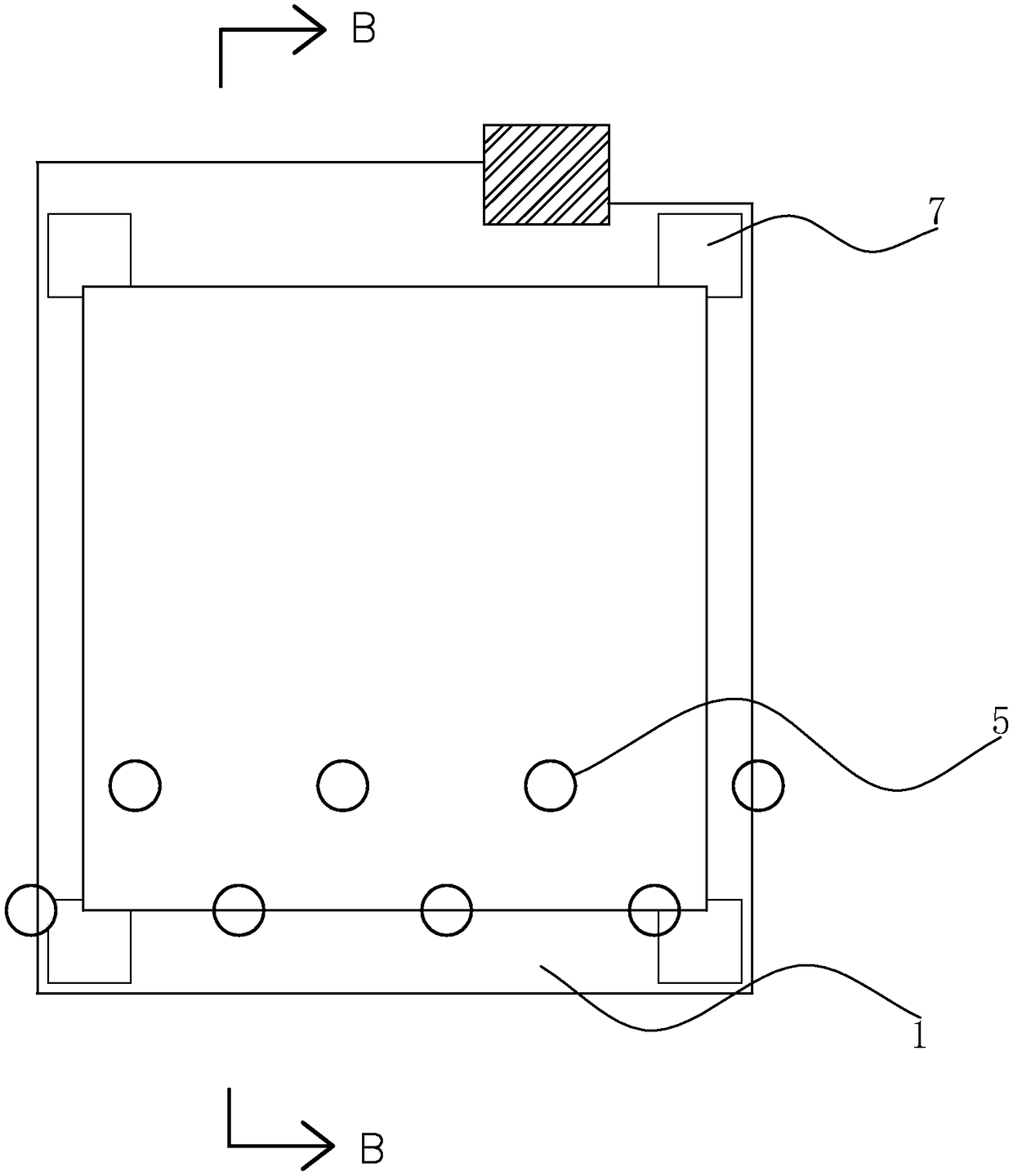

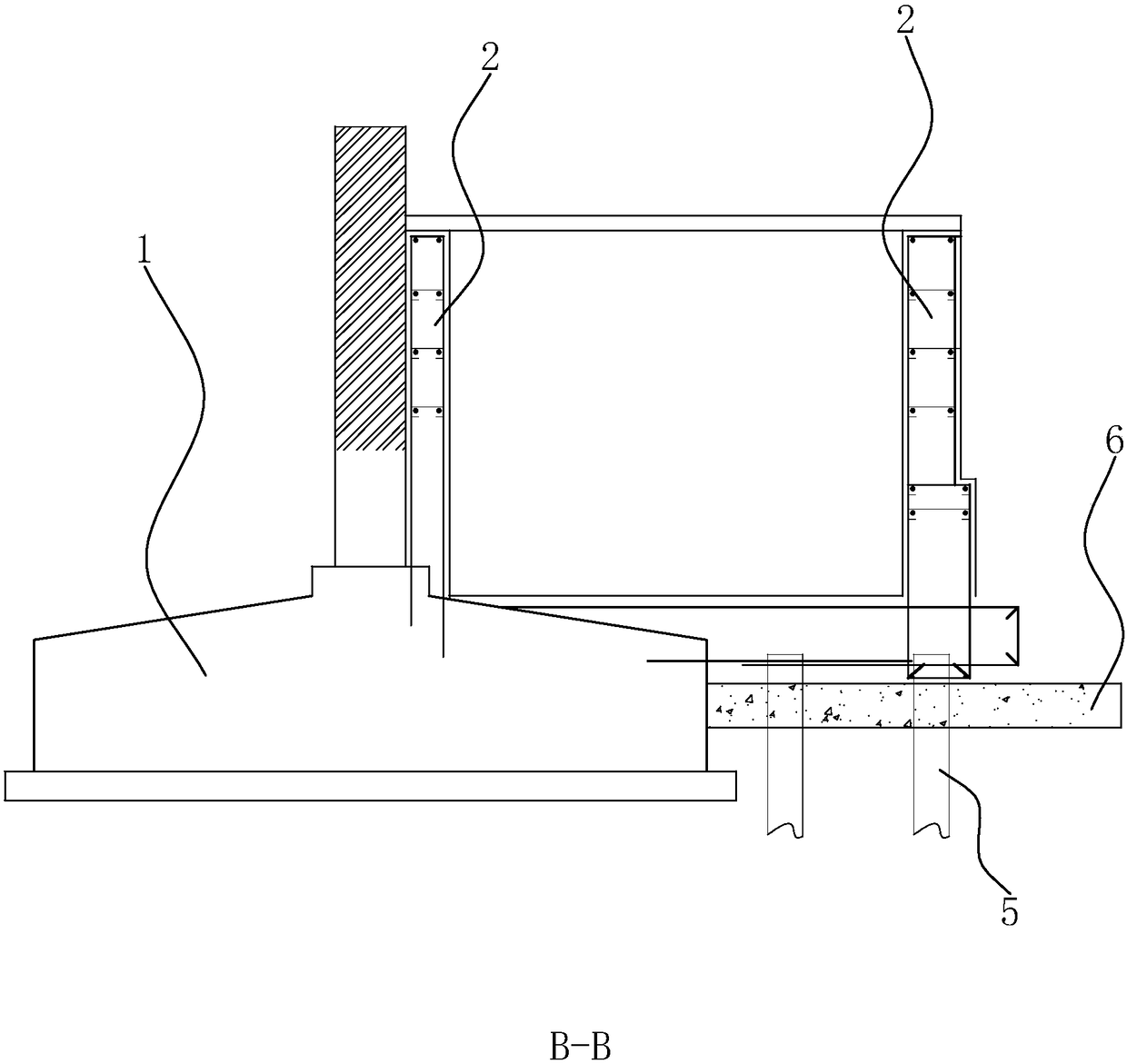

Construction method for additionally arranging of elevators to existing multi-storey residence

ActiveCN108343257AGuarantee smooth constructionGuaranteed uptimeBuilding repairsResidenceEngineering

The invention discloses a construction method for additionally arranging of elevators to an existing multi-storey residence. The construction method comprises the steps of construction preparation, excavation of an elevator foundation pit and installation of a base of an elevator shaft, construction of the top of the elevator shaft, installation, connection and fixation of the elevator shaft, installation and trial operation of the elevator and periodic maintenance and repair. The elevator foundation pit is arranged on an original foundation of the existing multi-storey residence, and the baseof the elevator shaft is fixed on the original foundation of the existing multi-storey residence. The installation, connection and fixation of the elevator shaft comprise the installation and fixation between elevator shaft main supporting columns and the installation and fixation between the elevator shaft and the existing multi-storey residence. According to the arrangement, reasonable workingprocedures are conducive to the smooth construction and follow-up stable operation of the elevator, and at the same time, the connection relationship and structure of the base and supporting columns of the elevator shaft are further opened, so that the connection between the elevator and the existing multi-storey residence is firmly and stably, the operation of the elevator is guaranteed to a certain extent; and the structure and method for reinforcement can be widely applied to the additionally arranging of elevators in various buildings.

Owner:杭州市建筑设计研究院有限公司

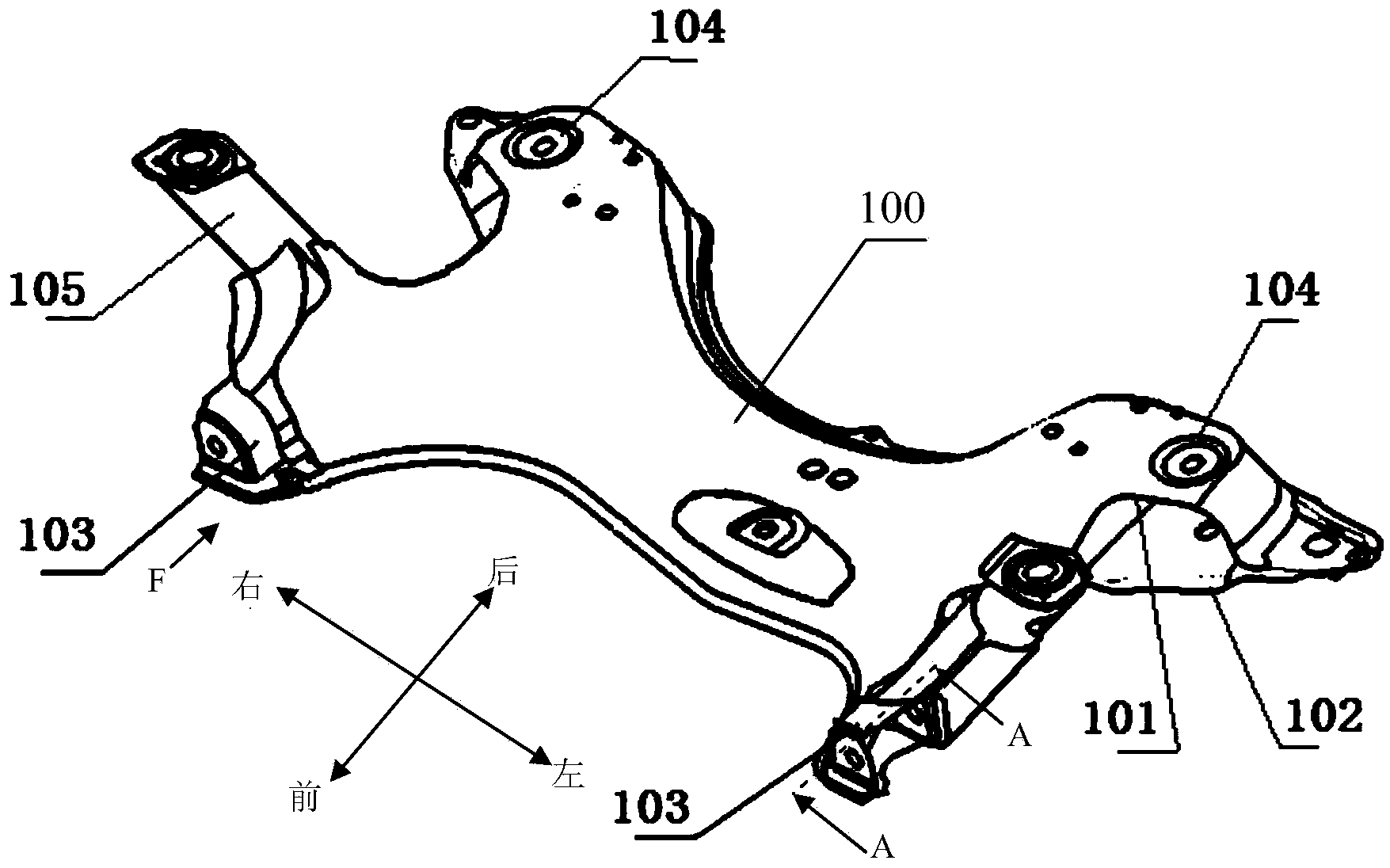

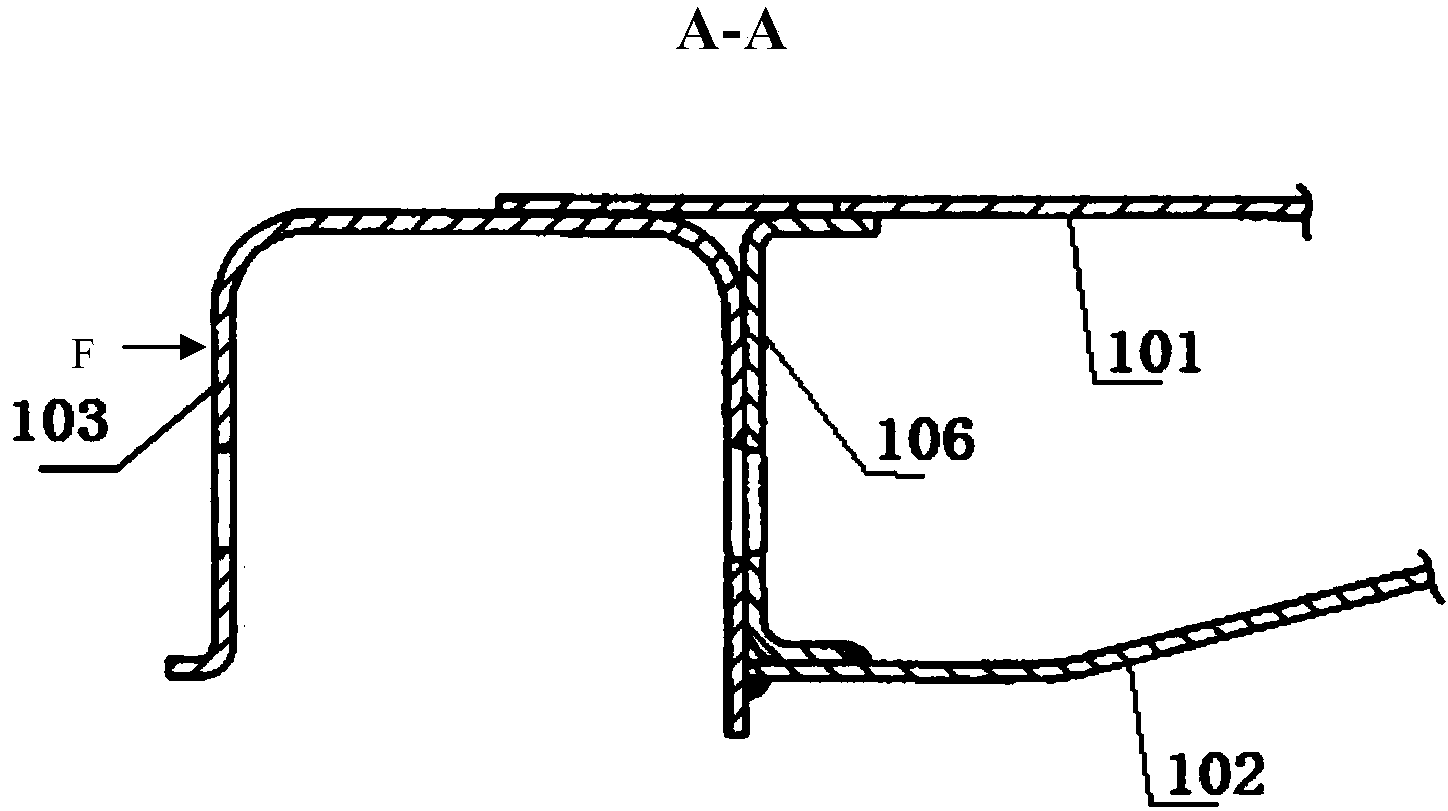

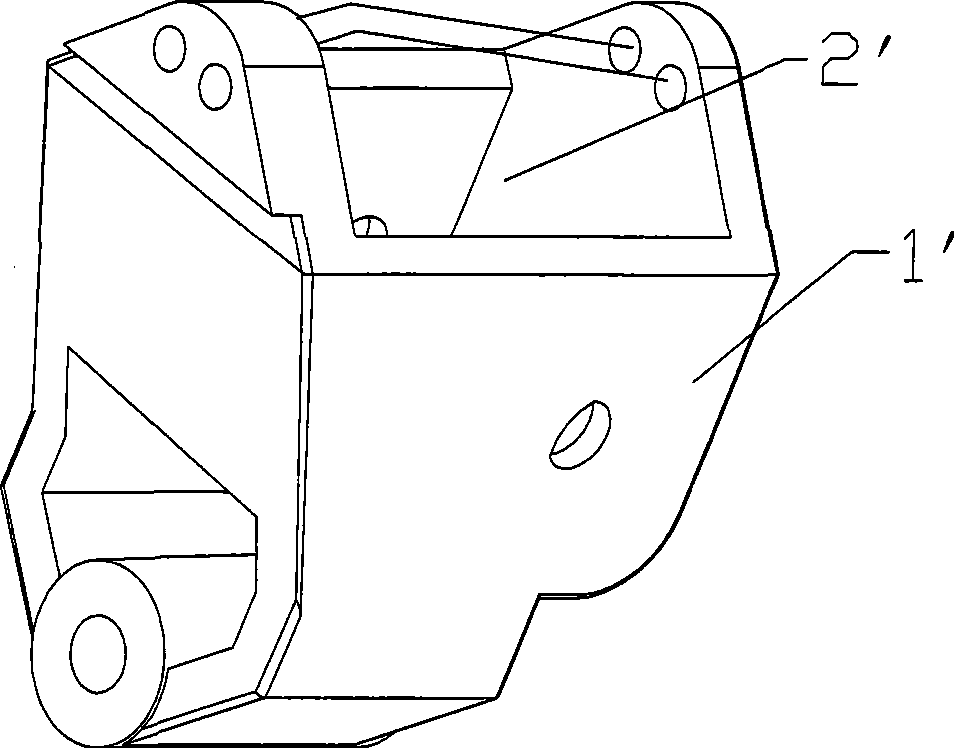

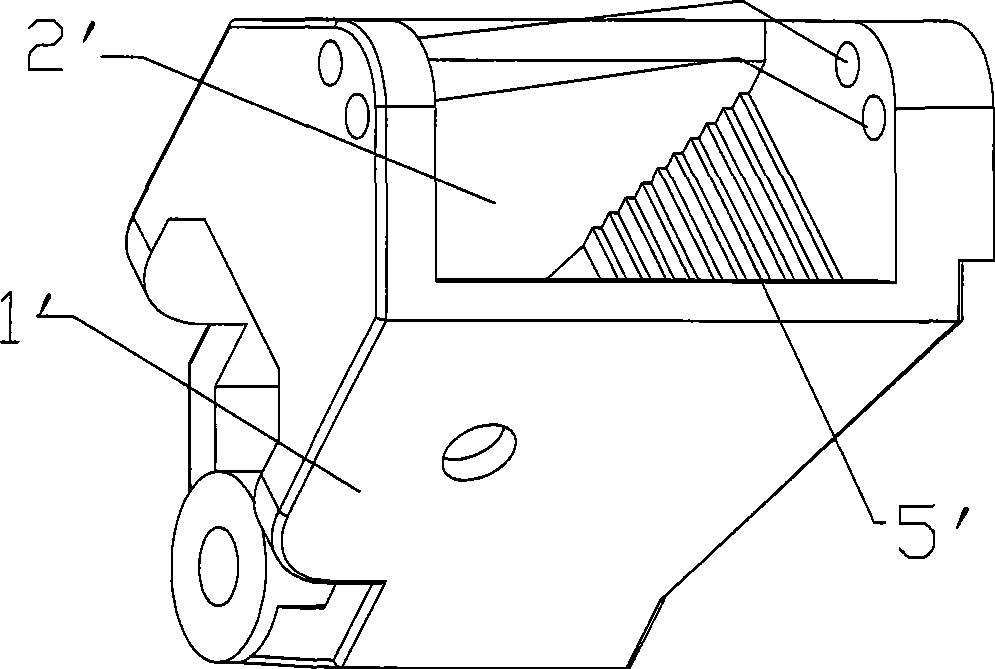

Front auxiliary frame

ActiveCN103832473ATroubleshoot Connection Strength IssuesImprove the strength of forceUnderstructuresPunchingVehicle frame

The invention provides a front auxiliary frame. The front auxiliary frame comprises a front auxiliary frame body and a front side component. The front auxiliary frame body comprises an upper plate and a lower plate, the upper plate and the lower plate are connected together, and a front mounting support of a lower suspension arm and a rear mounting portion of the lower suspension arm are arranged between the upper plate and the lower plate. The front side component is used for connecting the front auxiliary frame body onto a vehicular body. The front side component and the front mounting support are integrally formed by punching, and the front side wall of the front mounting support is connectedly welded to the upper plate or the lower plate while the bottom wall is connectedly welded to the lower plate to form a front-rear double-layer reinforcement structure and an upper-lower double-layer reinforcement structure. A cushion plate is welded between two side walls of the front side component, and the cushion plate and an upper end cover of the front side component jointly clamp a sleeve. The front auxiliary frame has the advantages of high strength, convenience in welding and high positioning precision.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

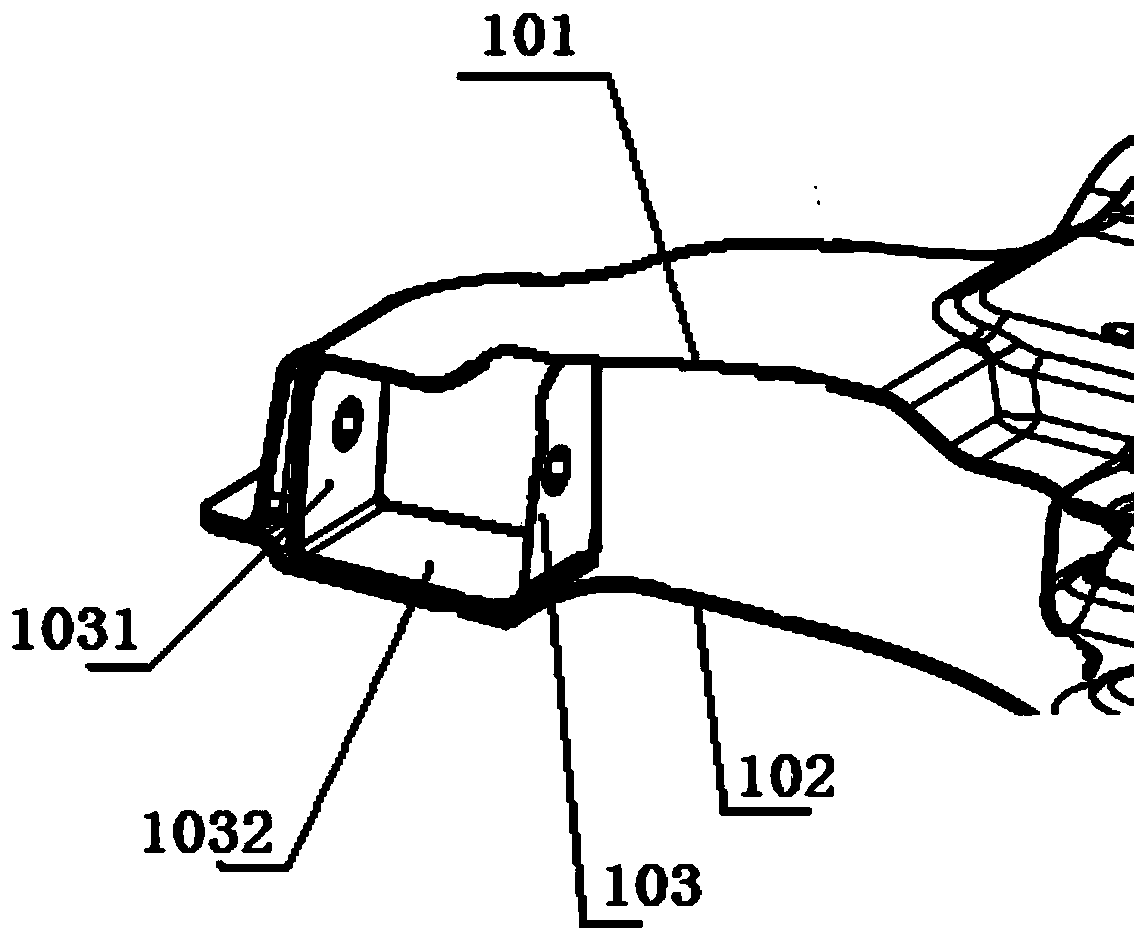

Double-reinforced type crane girder lengthening device

InactiveCN105460811AImprove the strength of forceImprove structural strengthCranesArchitectural engineeringUltimate tensile strength

The invention discloses a double-reinforced type crane girder lengthening device which comprises a fixed beam and a movable beam. A telescopic cylinder is mounted on the upper side face of the fixed beam, and a piton rod is arranged in the telescopic cylinder. Second lightening holes are formed in the left side wall and the right side wall of the fixed beam, and rolling wheel grooves are symmetrically formed in the left side wall and the right side wall of the fixed beam. A fixing frame is arranged on the top of the right end of the movable beam and connected with the top end of the piston rod, I steel is welded at the bottom end of the movable beam, and an electric hoist is mounted on the I steel. A safety hook is arranged at the right end of the fixed beam and connected with a stand column, and the stand column penetrates through the fixed beam and extends to the position above the fixed beam. A first oblique rod is arranged under the fixed beam, and a second oblique rod is arranged above the fixed beam. According to the double-reinforced type crane girder lengthening device, the structure strength of a whole girder is improved.

Owner:ANHUI CHAOSHENG HOISTING MACHINERY CO LTD

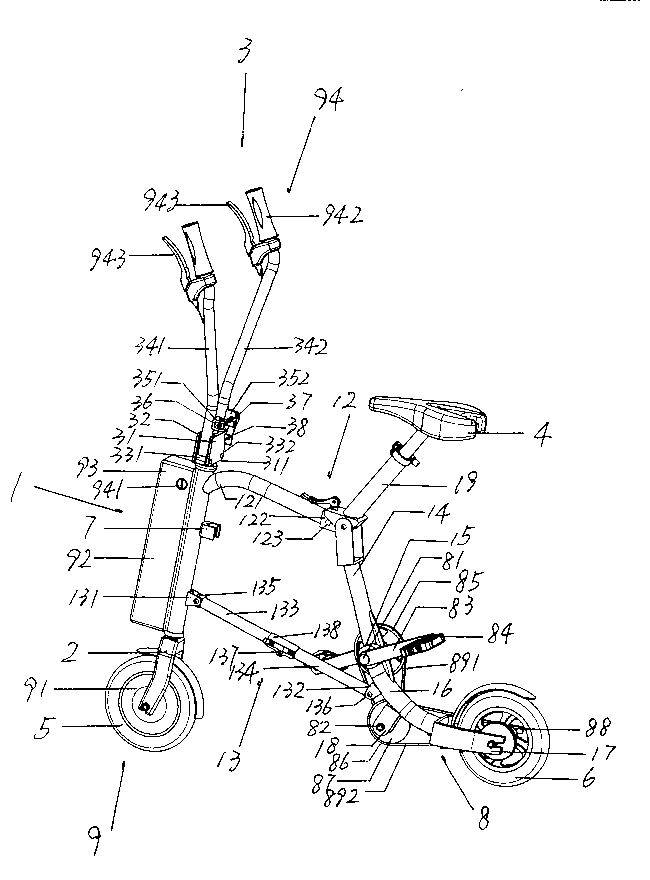

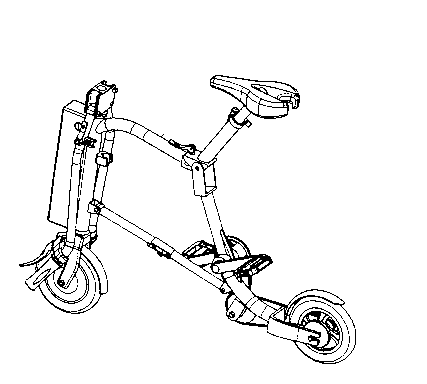

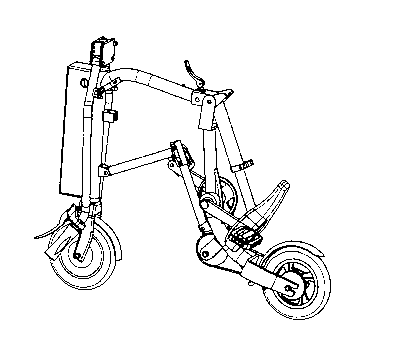

V-handlebar portable electric bicycle normally walked after being folded

A V-handlebar portable electric bicycle normally walked after being folded comprises a body, a front fork, a V-shaped folding handlebar, a saddle, a front wheel, a rear wheel, a positioning hook, a manual drive mechanism and an electric drive system. A rear vertical beam, a bottom bracket, a rear oblique beam, an auxiliary shaft seat and a rear fork in the body are welded in sequence. A second channel part on the rear vertical beam, a bottom vane of a lower seat tube and a first channel part of an upper crossbeam are connected with a latch bolt. The V-shaped folding handlebar is disposed on the front fork. A handlebar holder of the V-shaped folding handlebar is an extruded cut aluminum profile part with a hole in the middle and grooves on two sides, two U-channel plastic liners are inserted into the two grooves of the handlebar holder. A left handlebar and a right handlebar are connected mutually locked through a quick release. The front wheel is mounted on the front fork. The rear wheel is mounted on the rear fork. The manual drive mechanism is mounted on the bottom bracket, an auxiliary shaft and the rear wheel. The electric drive system comprises a hub motor, a battery, a controller and a control switch. The hub motor is disposed on the front wheel. Both the battery and the controller are disposed in a rectangular hole of a front tube.

Owner:徐州新南湖科技有限公司

Broken tooth fastening device of giant gear and repair method

ActiveCN106064286AIncrease tooth surface hardness and strengthExtended service lifeWelding accessoriesEngineeringHardness

The invention relates to a broken tooth fastening device of a giant gear and a repair method. The repair method comprises the following steps of (1) polishing; (2) detecting; (3) drilling: uniformly drilling at least three drilling holes in each tooth root repair surface of the gear; (4) fastening: respectively performing interference driving on metal bars into each drilling hole of the step (3), using the metal bars as reinforcing ribs in the repair gear, and welding the metal bars and the gear into a whole; (5) welding; (6) recovering. The invention further discloses the broken tooth fastening device of the giant gear. According to the broken tooth fastening device and the repair method, on one hand, the hardness and mechanical strength of the tooth surface of the gear can be greatly increased, thereby prolonging the service life of the gear, and the operating reliability is high; on the other hand, the operation is simple, the repair speed is high, and postweld heat treatment is not needed, so that equipment cannot be delayed for a long time so as not to cause heavy losses due to shutdown, the cost is greatly reduced, and economic benefits and social benefits are effectively increased.

Owner:华能湖南岳阳发电有限责任公司

Back groove type hanging piece assembly of stone materials and installation method

InactiveCN104060732AThe combination is safe and reliableImprove protectionCovering/liningsWallsAdhesiveStress strength

A back groove type hanging piece assembly comprises an embedded support and a Z-shaped hanging piece, wherein the embedded support comprises a planar guide plate for guiding the support and an upturned embedded hook plate obliquely arranged on the planar guide plate; a T-shaped tenon is arranged on one surface, opposite to the upturned embedded hook plate, of the planar guide plate; a T-shaped groove matched with the T-shaped tenon is formed in the Z-shaped hanging piece; a lock screw is further arranged on the Z-shaped hanging piece; one end of the lock screw extends into the T-shaped groove. The installation method of the back groove type hanging piece assembly of stone materials is further provided by the invention on the basis, short grooves with different lengths can be formed in the back faces of decoration panels according to different materials, the embedded support can be embedded and anti-slip off limit screws are screwed in, then the embedded support and a decoration panel are fully adhered into a whole safely and solidly through structural adhesive, the stress strength is increased, any additional stresses are not produced, so that the back groove type hanging piece assembly is safer and more reliable, and the hanging piece assembly adopts aluminum alloy materials or stainless steel materials, so that the corrosion resistance is excellent, and the environmental protection effect is good.

Owner:FUDING RUILAIBO CURTAIN WALL TECH

Automobile rear frame assembly and automobile

The invention discloses an automobile rear frame assembly and an automobile, relates to automobile parts techniques and solves the problem that the application of the prior rear frame assembly causes inefficiency of collision energy absorption and ease of oil tank damage and decreases safety of the automobile. The automobile rear frame assembly according to the embodiments comprises a rear impact beam; rear rail structures identical to each other are fixed to two ends of the same side of the rear impact beam; each rear rail structure comprises an outer longitudinal side member and an inner longitudinal middle member, the longitudinal side member and the longitudinal side member gather at the rear impact beam and then split and extend in parallel; the part, from the gathering position to the extension end, of each longitudinal side member is in arc structure, and the part, from the gathering part to the extension end, of each longitudinal middle member is in an arc structure; a rear cross beam is fixed between the longitudinal side members; the longitudinal middle members extend to the rear cross beam from the gathering positions; an oil tank is fixed on the longitudinal middle members; a connecting beam is fixed between the longitudinal middle members, corresponding to an oil tank area. The automobile rear frame assembly is mainly applied to automobiles.

Owner:GREAT WALL MOTOR CO LTD

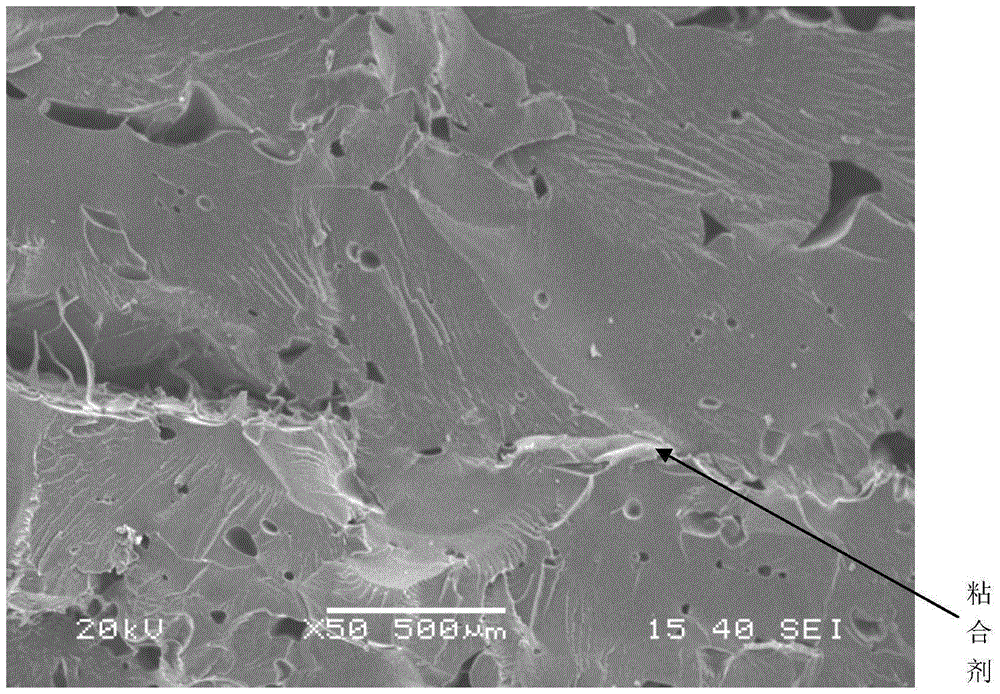

Method for improving adhesion quality of polymer three-dimensional printed product by using instant adhesive

ActiveCN105196545AImprove bonding qualityReach tensile strengthAdditive manufacturing apparatusPorosityPolymer science

The invention discloses a method for improving the adhesion quality of a polymer three-dimensional printed product by using an instant adhesive. The method comprises the following steps: (1) uniformly mixing polymer raw materials added with an adsorbent, and then printing filaments through common plastic extrusion; (2) putting the filaments prepared in the step (1) to a polymer three-dimensional printer, and carrying out layering according to a three-dimensional model to be printed to obtain three-dimensional processing data of each layer and then carrying out an operation of three-dimensional printing; (3) in a printing process, uniformly adding the instant adhesive to certain layer of several layers of an object to be printed. According to the method disclosed by the invention, the problem that the three-dimensional printed product internally has higher porosity can be solved by adding the instant adhesive, and therefore the adhesion quantity and a stress strength between two layers can be improved by adopting the method; from the view of the effect, the adhesion strength of the printed product can exceed over 30% of that of a common three-dimensional printed product, and the tensile strength of the printed product can basically reach that of a common injection.

Owner:JIANGSU YONGHAO HIGH STRENGTH BOLT

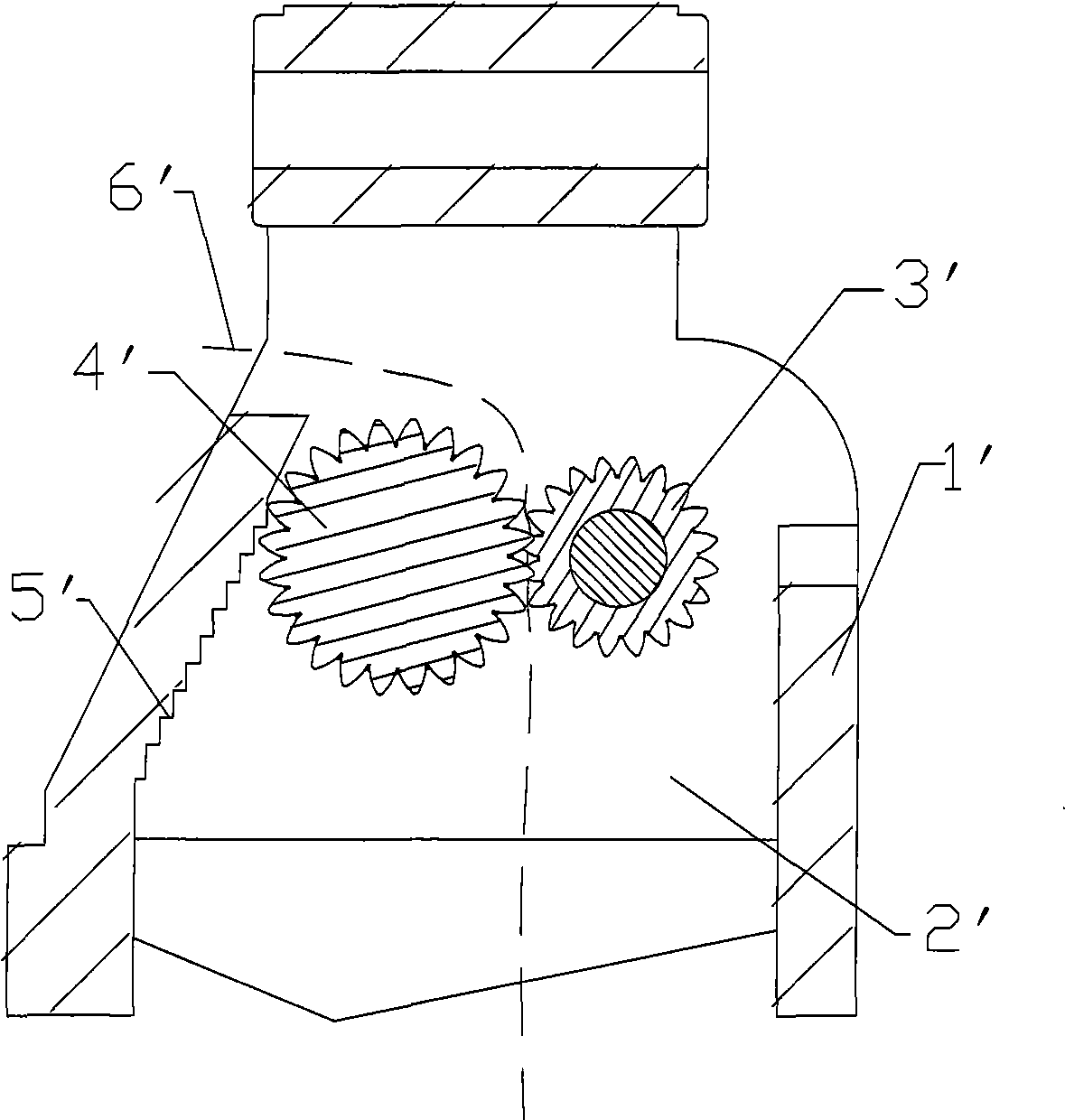

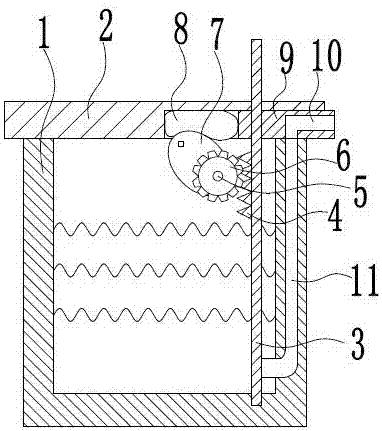

Window curtain lockset

InactiveCN101485535AEasy to crackImprove the strength of forceDoor/window protective devicesCurtain accessoriesGear wheelEngineering

The invention discloses a curtain lockset, which comprises a lockset shell with an inner cavity, wherein the lockset shell is provided with two gears capable of being meshed inside; one gear is rotatably arranged in the lockset shell, and the other gear is movably arranged in the lockset shell; the inner surface of the side wall of the lockset shell is provided with a gear surface on which the movable gear can roll up and down; the teeth of the gear surface and the teeth of the movable gear are arranged in a matching way; the movable gear has a clamping state and a loosening state, when the movable gear is in the clamping state, the movable gear is clamped between the rotatable gear and the gear surface; when the movable gear is in the loosening state, the movable gear is separated from the rotatable gear or the gear surface; and the side wall of the lockset shell with the gear surface is provided with a reinforcer. When the movable gear is stably clamped between the gear surface and the rotatable gear, the gear surface is stressed and easy to crack. The side wall with the gear surface is provided with the reinforcer, so that the stress strength of the gear surface is increased to prevent the cracking of the position and prolong the service life of the lockset.

Owner:黄介仁

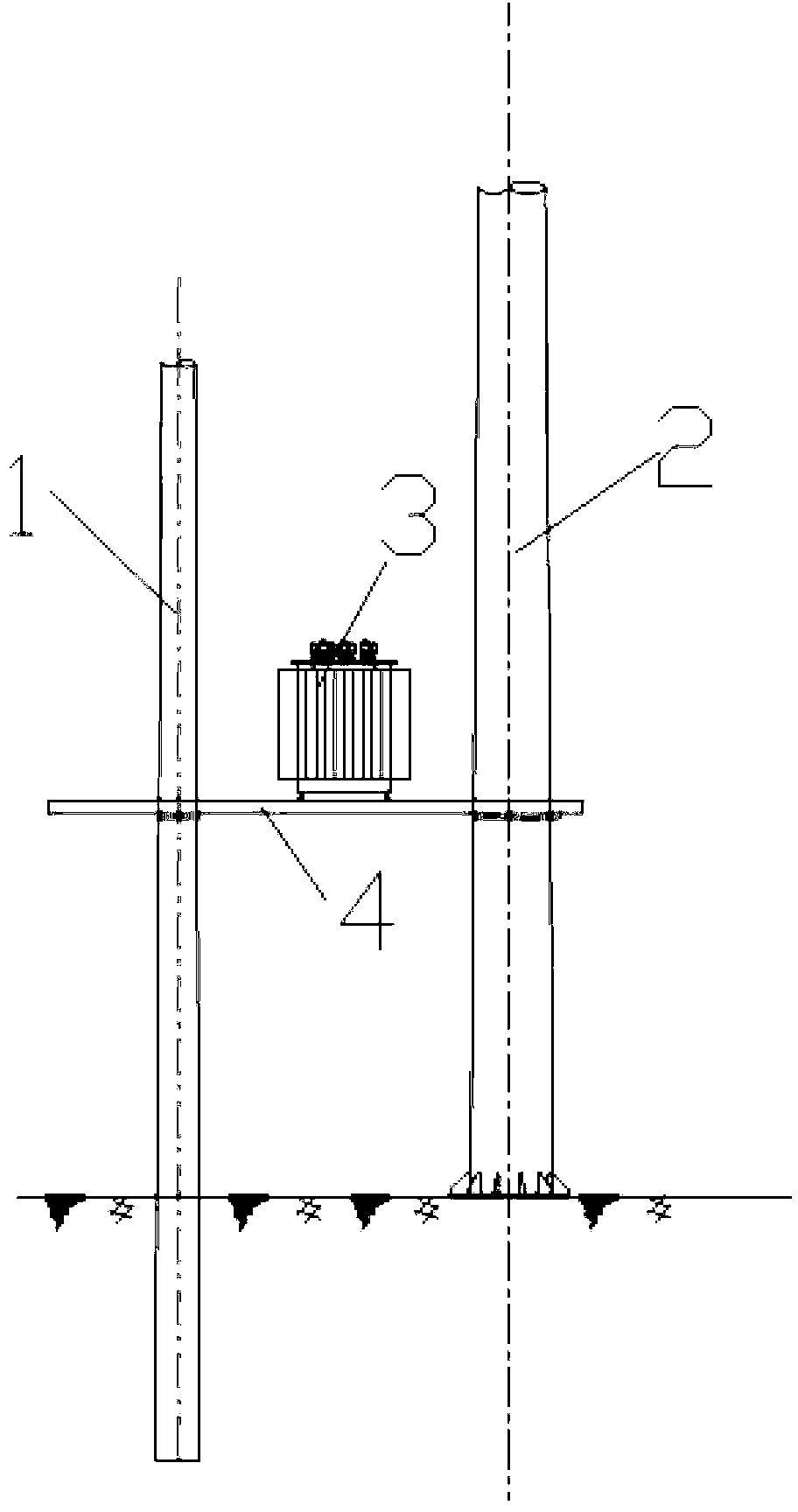

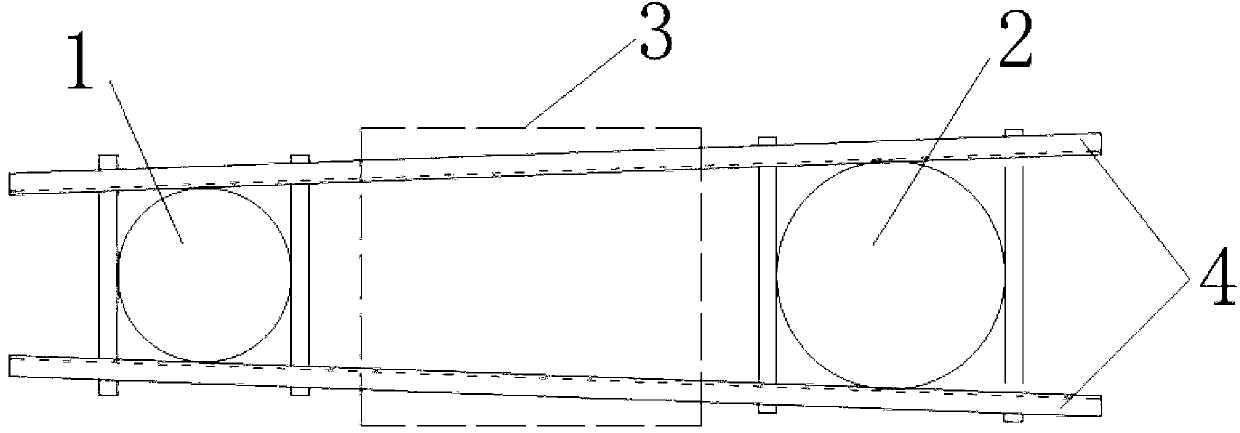

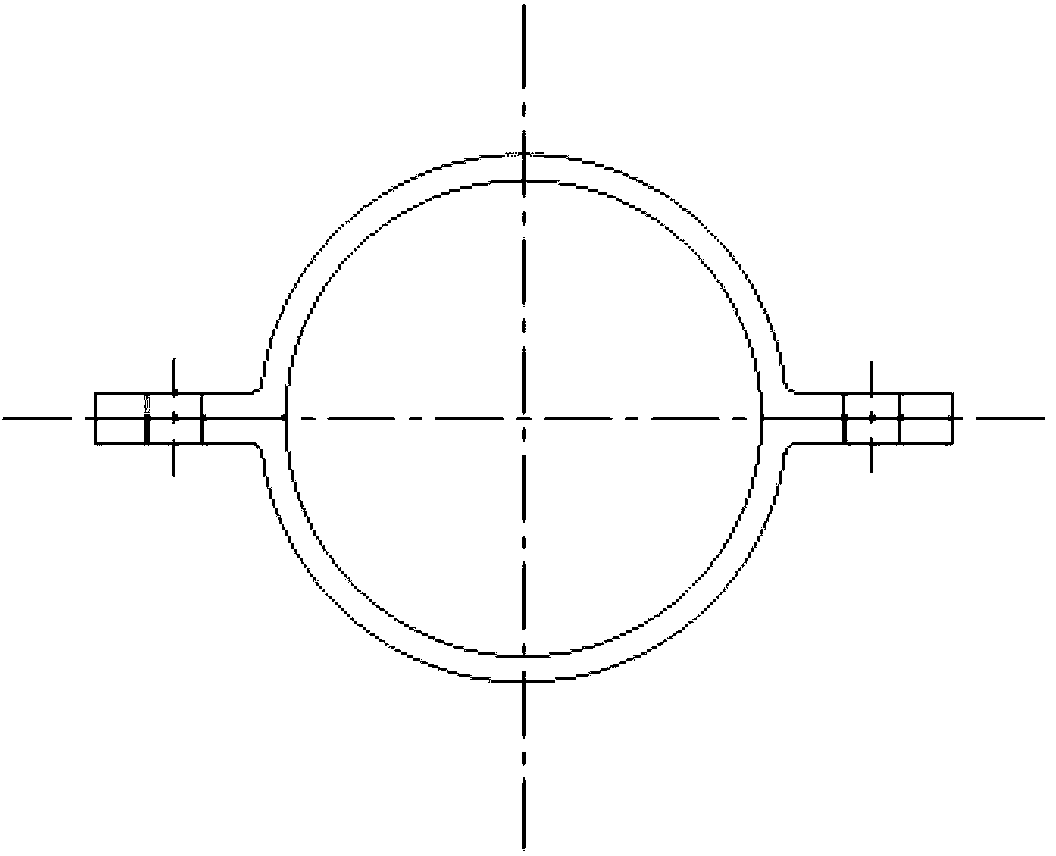

Embracing hoop applied to auxiliary pole mounting of transformer and transformer rack assembling method

ActiveCN102996585ASimple structureEasy to installTransformers/reacts mounting/support/suspensionSubstation mounted on poleTransformerBand shape

The invention discloses a transformer rack assembling method which employs an embracing hoop. The method comprises the following steps: 1, embracing and sleeving two hoop plates on an auxiliary pole, clamping U-bars with corresponding thickness between long ears of the two hoop plates; 2, placing the long ears on the both outsides of the auxiliary pole, then locking the two hoop plates by a bolt connection piece connected and fixed on the two hoop plates, the connecting piece being used for detaching locking mechanism, 3, arranging two mounting clamp plates which are used for bearing the transformer at the two sides of the auxiliary pole and a main pole, and arranging the two mounting clamp plates on the two long ears of the hoop plates in a clamping manner. The embracing hoop applied to the auxiliary pole mounting of the transformer and the transformer rack assembling method have the advantages that the structure is simple, the difficulty of mounting is reduced, the effective mounting can be carried out in a manner that the situation that the circular diameter gap of the two poles is large is overcome, and the requirements on the mounting and designing are better met.

Owner:SHANGHAI INTELLIGENCE POWER ENG CO LTD

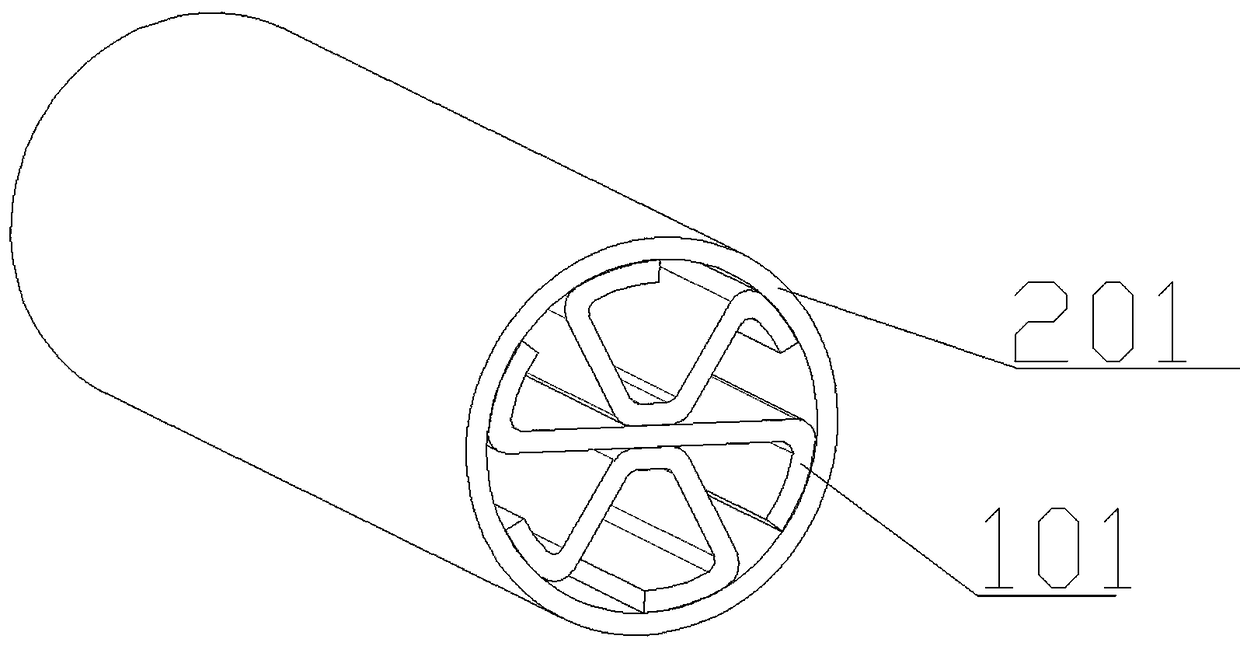

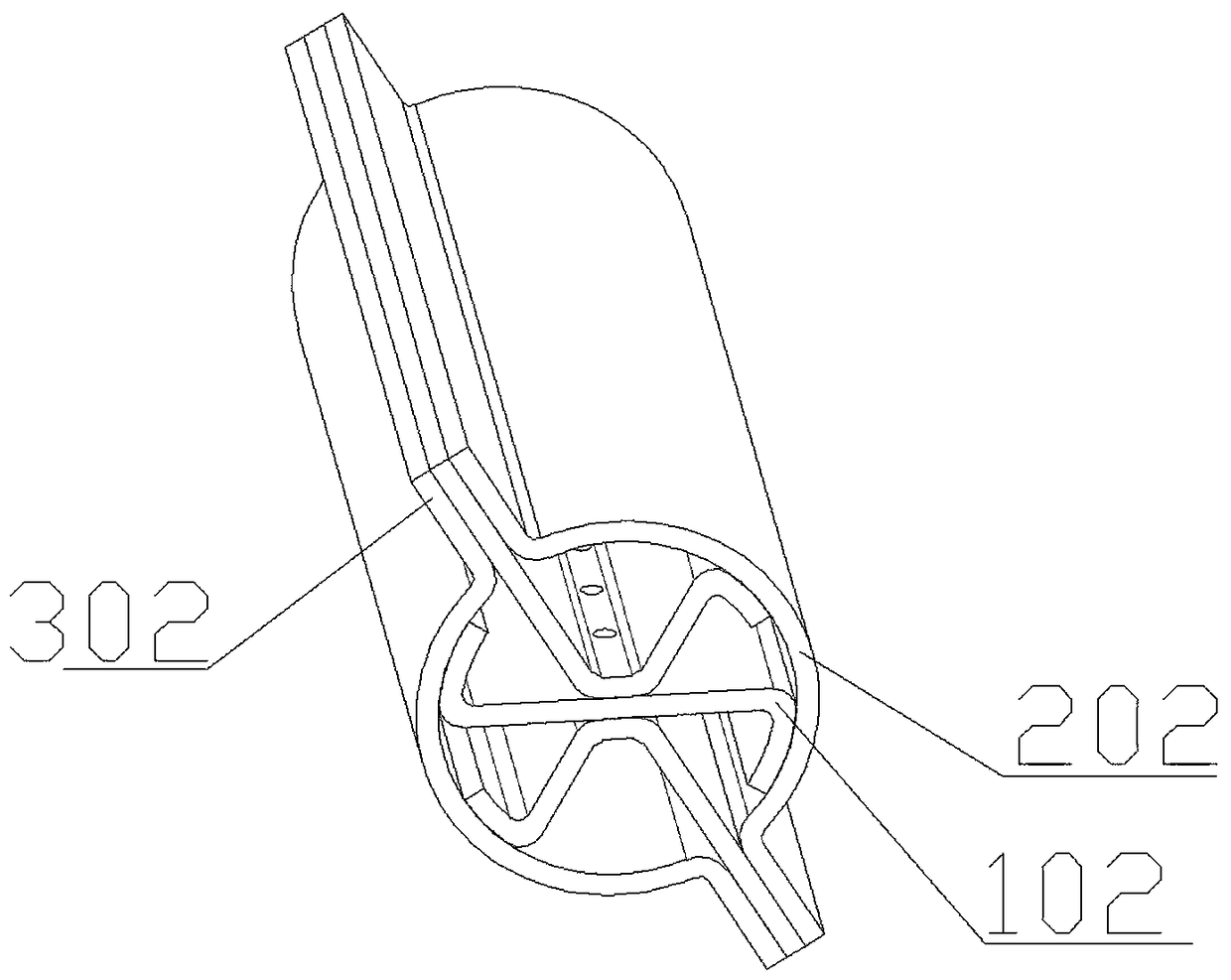

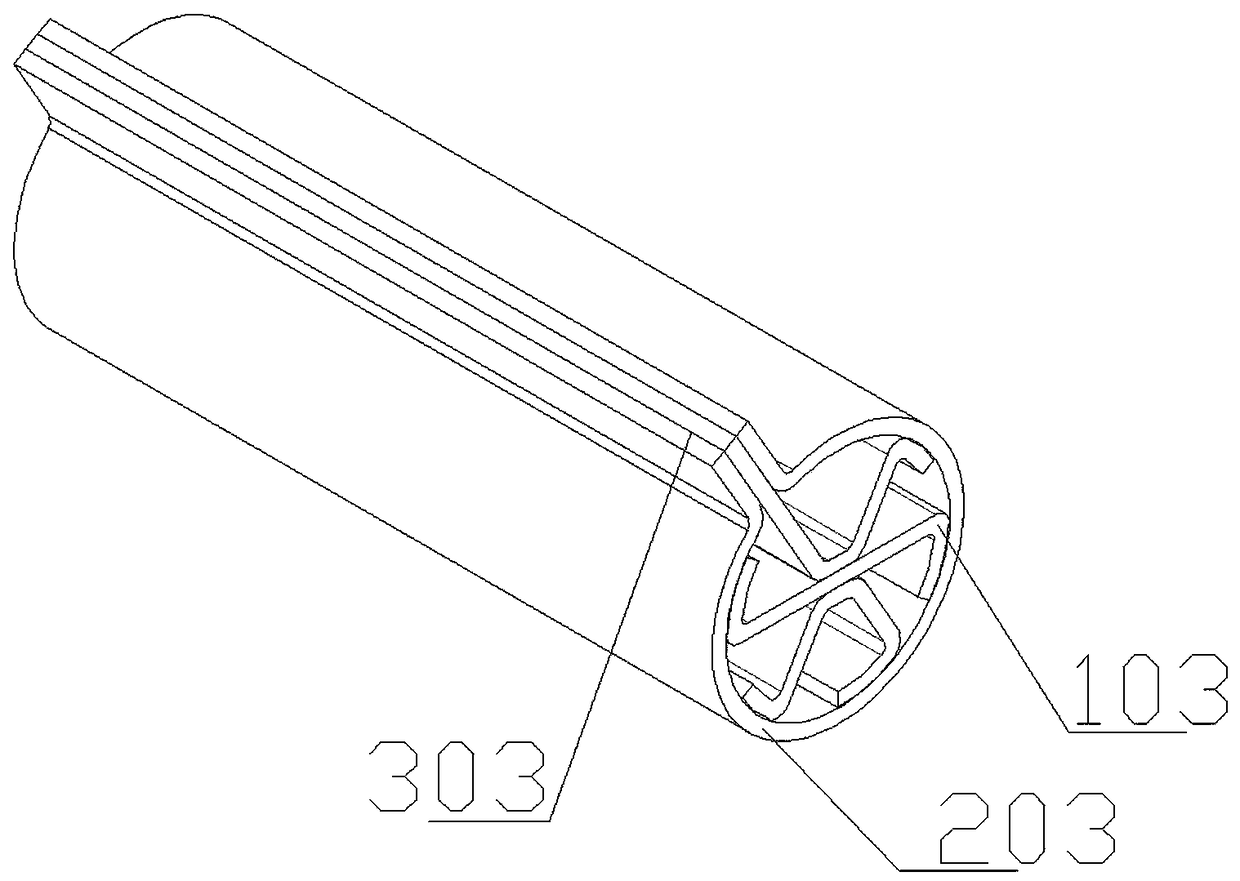

Fiber-fabric-composite-material structural piece and preparing method thereof

InactiveCN108262984AIncrease the degree of stressExpand the scope ofDomestic articlesTubular articlesFiberHoneycomb

The invention discloses a fiber-fabric-composite-material structural piece. The shape of the structural piece is tubular, and the tubular structural piece is a fiber-fabric-composite-material honeycomb tube supported by a fiber-fabric composite material. The fiber-fabric composite material is prepared into the honeycomb-shaped-support tubular structural piece, when the structural piece prepared with a method is stressed, bearing force can be distributed all honeycomb-shaped branches and are evenly distributed on the structural piece, and the whole stress degree of the structural piece is enhanced; a common carbon fiber composite material can bear high pressure, but the pressing bearing capacity is low, an in-tube support of the structural piece is achieved through the honeycomb-shaped carbon fiber fabric composite material, the structural piece can bear pressure to a certain degree, and the stress range and the stress direction of the structural piece are widened. According to the fiber-fabric-composite-material structural piece, the structural piece is prepared into a honeycomb shape, compared with a solid structural piece, in the fiber-fabric-composite-material structural piece,materials and the weight are reduced, the cost is saved, and meanwhile compared with a hollow structural piece, the fiber-fabric-composite-material structural piece has the higher stress capacity.

Owner:河南吉地专利运营有限公司

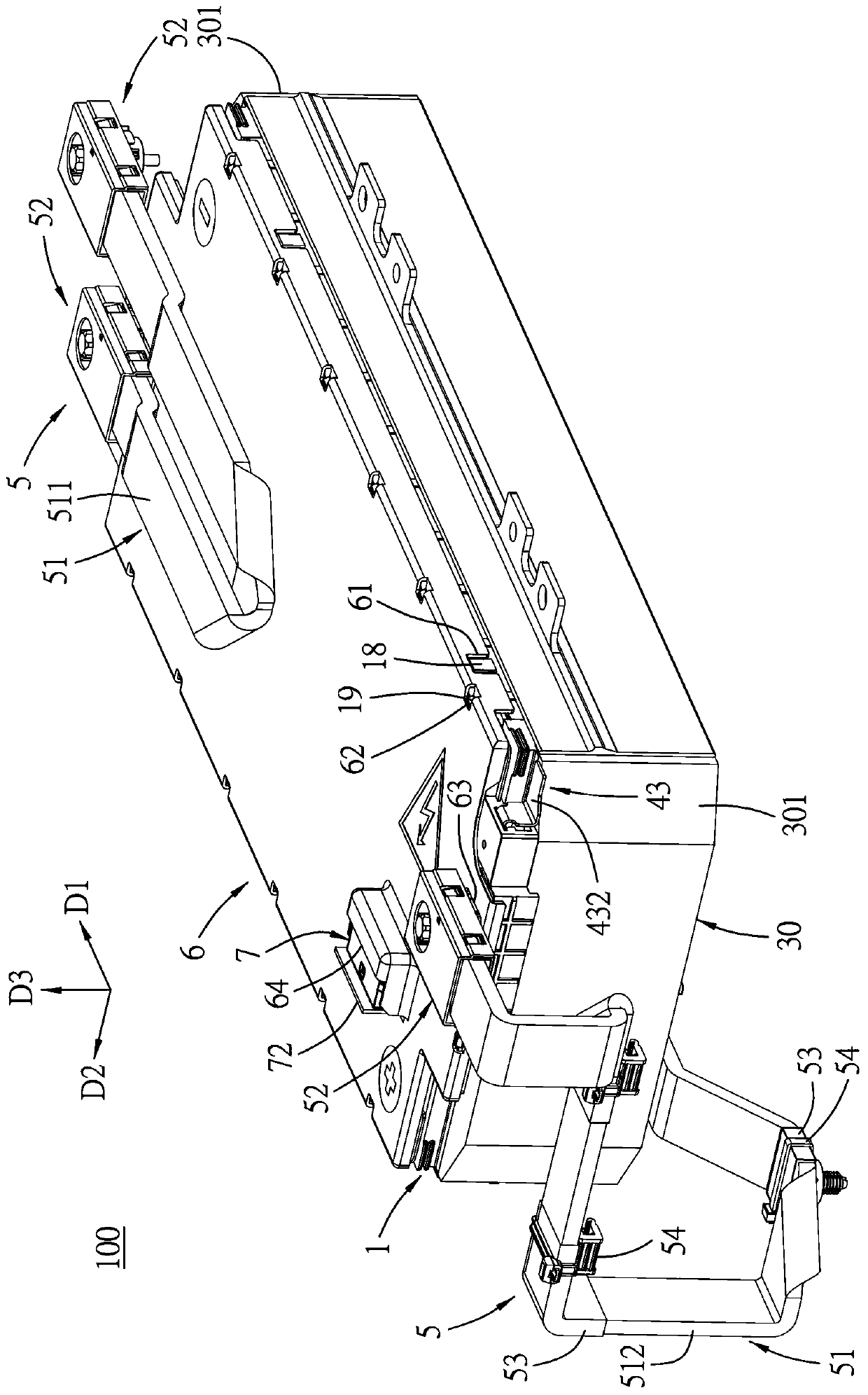

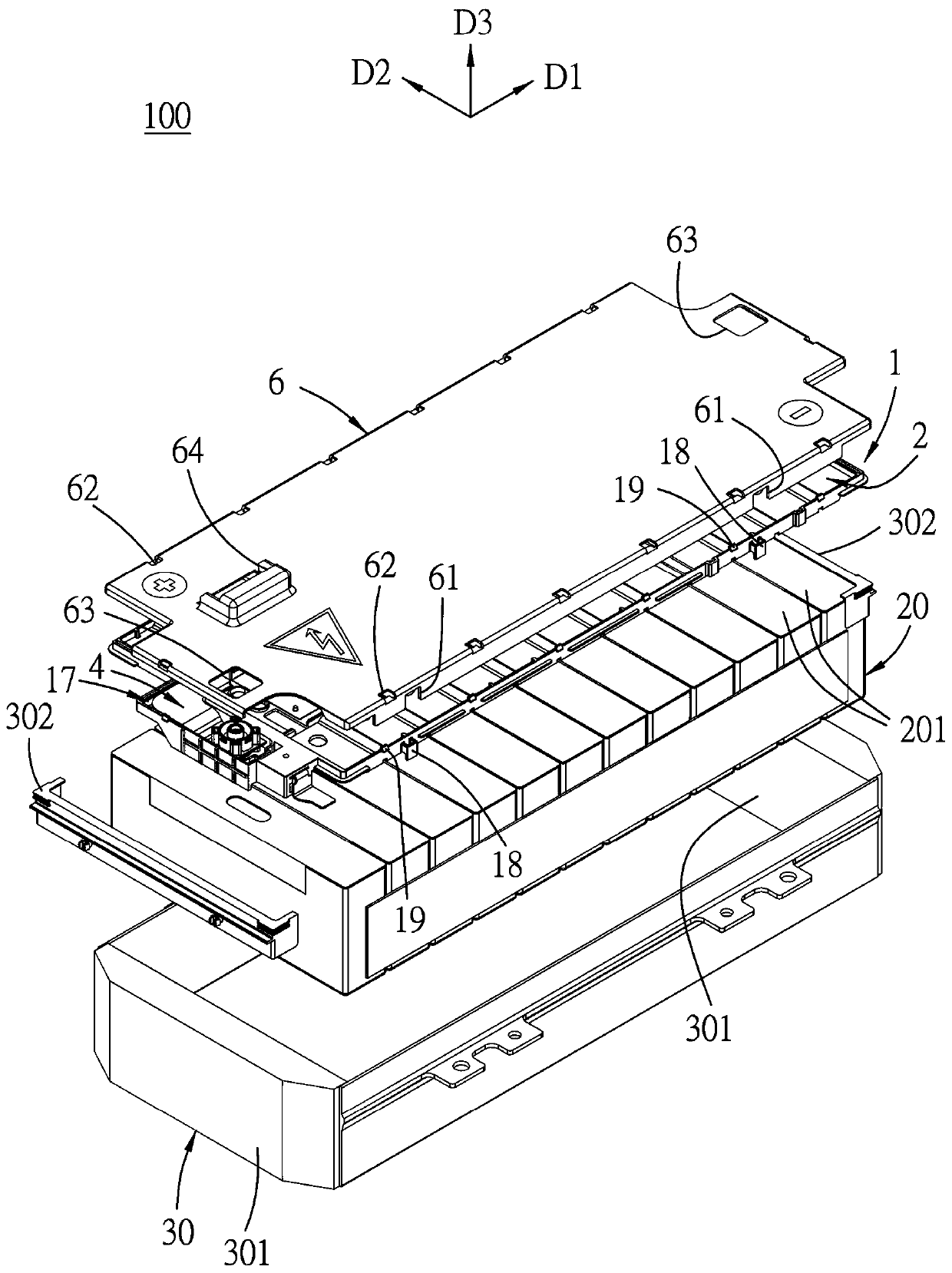

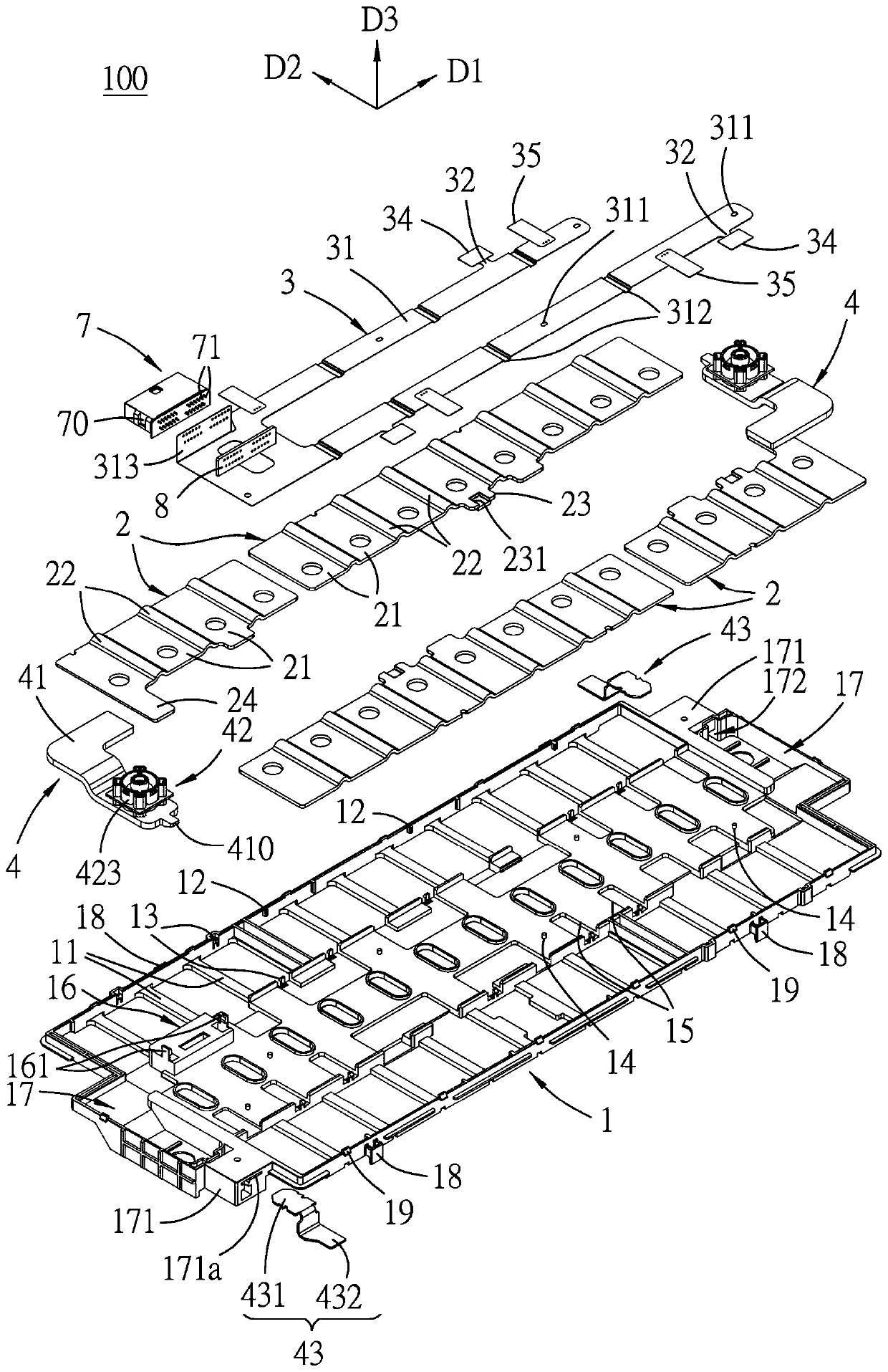

Battery connection module

ActiveCN111384347AImprove the strength of forceAvoid displacementPrimary cell maintainance/servicingCurrent conducting connectionsFlexible circuitsElectrical battery

A battery connection module comprises: a plurality of bus members, two bridging bus members, a flexible circuit board, an electrode unit and a power connection strip. Each bridging type bus member isprovided with a first bus section suitable for being electrically connected with a first battery pack, a second bus section suitable for being electrically connected with a second battery pack, and abridging section connected between the first bus section and the second bus section. The flexible circuit board comprises an extension arm and a temperature sensor arranged on the extension arm, and aconcave part for correspondingly accommodating the temperature sensor is formed in the bus member. The electrode unit comprises an electrode slice lapped on the bus member, an electrode slice holderfor holding the electrode slice, and a power connection seat arranged on the electrode slice. The electric power connecting strip is provided with an electric power connector which is in butt joint with the electric power connecting base through a buckling structure, an alignment structure, a fastener and a sleeve.

Owner:DONGGUAN MOLEX INTERCONNECT +1

Low-profile heavy-duty buckle

Owner:BUTTON INT CO LTD

Wine storage device

InactiveCN107384727AAvoid excessive drinkingEasy to operateAlcoholic beverage preparationAirbag deploymentCam

The application of the present invention discloses a wine storage device, which comprises a tank body with an open top and a lid used to cover the tank body; the tank body has a side wall; And extend into the wine delivery pipe inside the tank; the lid is sealed with a baffle extending into the tank to seal the wine delivery pipe; the baffle is provided with a sliding part used to make the baffle slide up and down on the cover And a rack part in the shape of a rack located below the sliding part; a cross bar is connected between the other two side walls of the tank body; a gear meshing with the rack part and a cam driven by the gear are connected to the cross bar in rotation; The cams and racks are alternately arranged; the bottom surface of the cover is provided with grooves, and the airbags and movable blocks that can slide along the grooves and extend out of the grooves are sequentially arranged in the grooves; the movable blocks An extraction hole that can communicate with the wine delivery pipe and the outside world is arranged on the top.

Owner:ZUNYI JINHONG METAL EQUIP

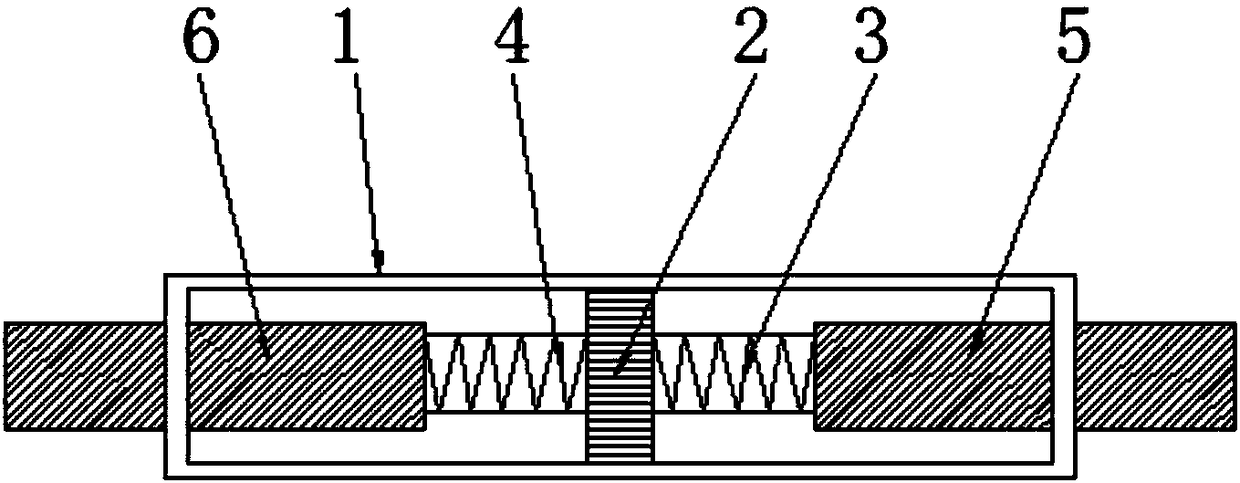

Long-life fixing device applied to installation connection of anti-shock support-hangers

PendingCN108180320AImprove the strength of forceImprove installation efficiencyPipe supportsNon-rotating vibration suppressionSingle supportSoftware engineering

The invention discloses a long-life fixing device applied to installation connection of anti-shock support-hangers. The long-life fixing device comprises a fixing sleeve, a fixing plate, a first pressure-resisting spring, a second pressure-resisting spring, a first movable rod, a second movable rod, fixing rods, left clamping blocks, right clamping blocks, a clamping plate, a screw hole, a fixingblock, a connecting rod, a main limiting rod, a mounting plate, mounting holes, connecting parts, channel steel plates, limiting holes, articulating shafts, fixing lugs, first secondary limiting rods, buffer springs, second secondary limiting rods, fixing holes and a vibration sensor. According to the long-life fixing device disclosed by the invention, the three limiting rods can be used for connecting the support-hangers so as to prevent occurrence of a situation that the use of a pipeline system is affected by loosening of a single support-hanger; the limiting rods are connected with the overall long-life fixing device by the connecting parts, so the installation efficiency of the support-hangers is improved; the fixing sleeve is connected with the movable rods by virtue of the pressure-resisting springs; and the middle part of each limiting rod is provided with the corresponding buffer spring for achieving a buffering effect when the support-hangers are loosened, so the service life of the pipeline system is prolonged.

Owner:JIANGSU YIDINGGU ELECTROMECHANICAL TECH CO LTD

Building wallboard and production method for same

InactiveCN102659356AImprove the strength of forceImprove insulation performanceCeramic shaping apparatusVolumetric Mass DensityHigh stress

The invention provides a building wallboard, which is produced by adding mortar in a mould and then performing compression moulding, wherein the mortar is prepared by adding water in raw materials containing perlite and one material selected from cement, gypsum or the mixture of the cement and the gypsum, and then stirring. More preferably, the density of the building wallboard after being compression-moulded and dried is 100-350 kg / m<3>. More preferably, the raw materials further contain cellulosic substances and adhesive powder. More preferably, the weight ratios of the perlite, the material selected from cement, gypsum or the mixture of the cement and the gypsum, the cellulosic substances, and the adhesive powder are as follows: the perlite: 5-85%, the material selected from cement, gypsum or the mixture of the cement and the gypsum: 10-90%, the cellulosic substances: 0.05-8%, and the adhesive powder: 0.2-15%. The building wallboard produced according to the invention has high stress intensity, high heat-insulating performance and high sound-insulating performance, can be used as a partition wall of an indoor space in a building, an outdoor heat-insulating material, and a wall material of a temporary building, and has excellent weatherability.

Owner:刘稳

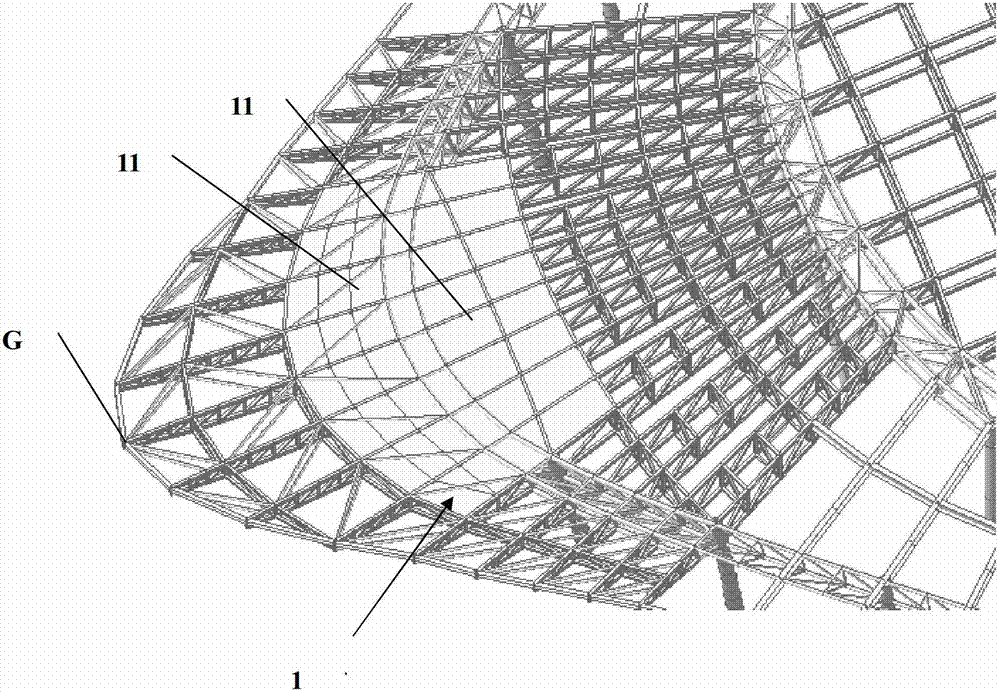

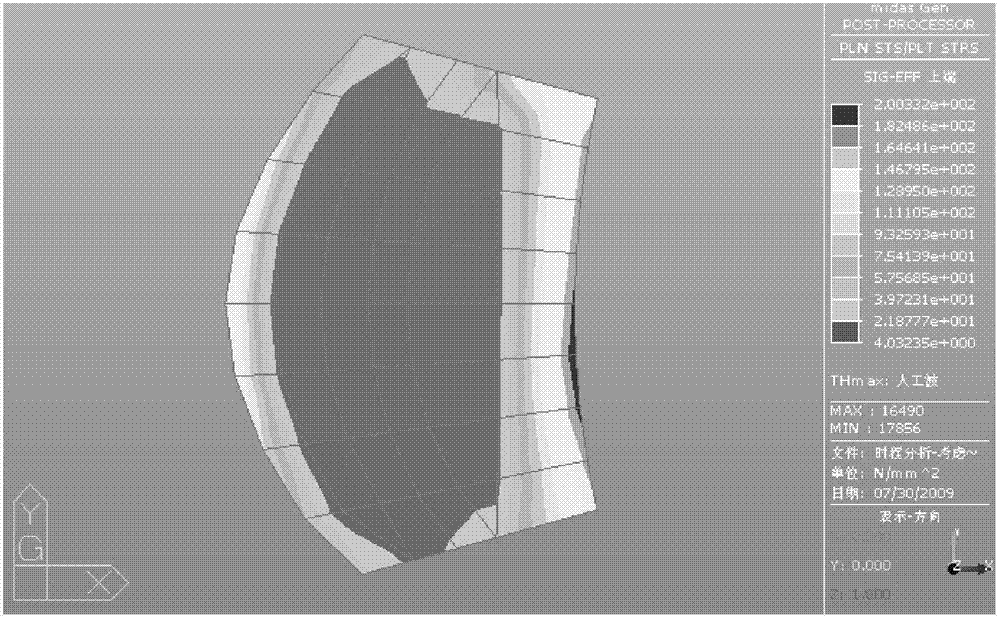

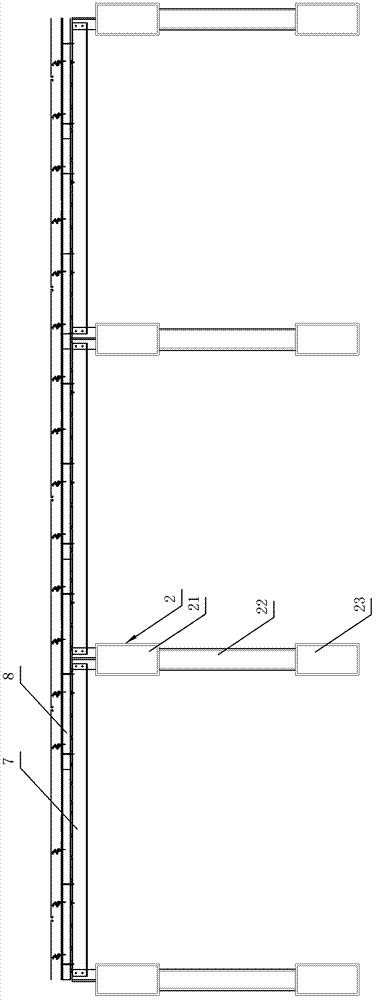

Composite structure of locally applying skin on truss and method for analyzing and calculating safety thereof

The invention discloses a composite structure of locally applying a skin on a truss, comprising a truss and a purline, wherein a skin steel plate is paved on the upper surface of the truss or the lower surface of the truss, and the purline is arranged above the skin steel plate. The invention also discloses a method for analyzing and calculating the safety of the composite structure. According to the invention, the work of modeling is small, the practical operation is simple, the calculation is simple, convenient and accurate, the quantitative analysis of the skin effect can be realized, the bearing behavior of the skin steel plate can be fully presented, the bending resistance, tensile strength and compressive strength of the truss or lower members connected with the skin steel plate are greatly enhanced, the tensile strength and compressive strength of top flanges of the members or top chord of the truss are actually enhanced; and the main structure of buildings can be designed reasonably, thus the technical effects of strengthening structure space stiffness and reducing the consumption of structural steel.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE +1

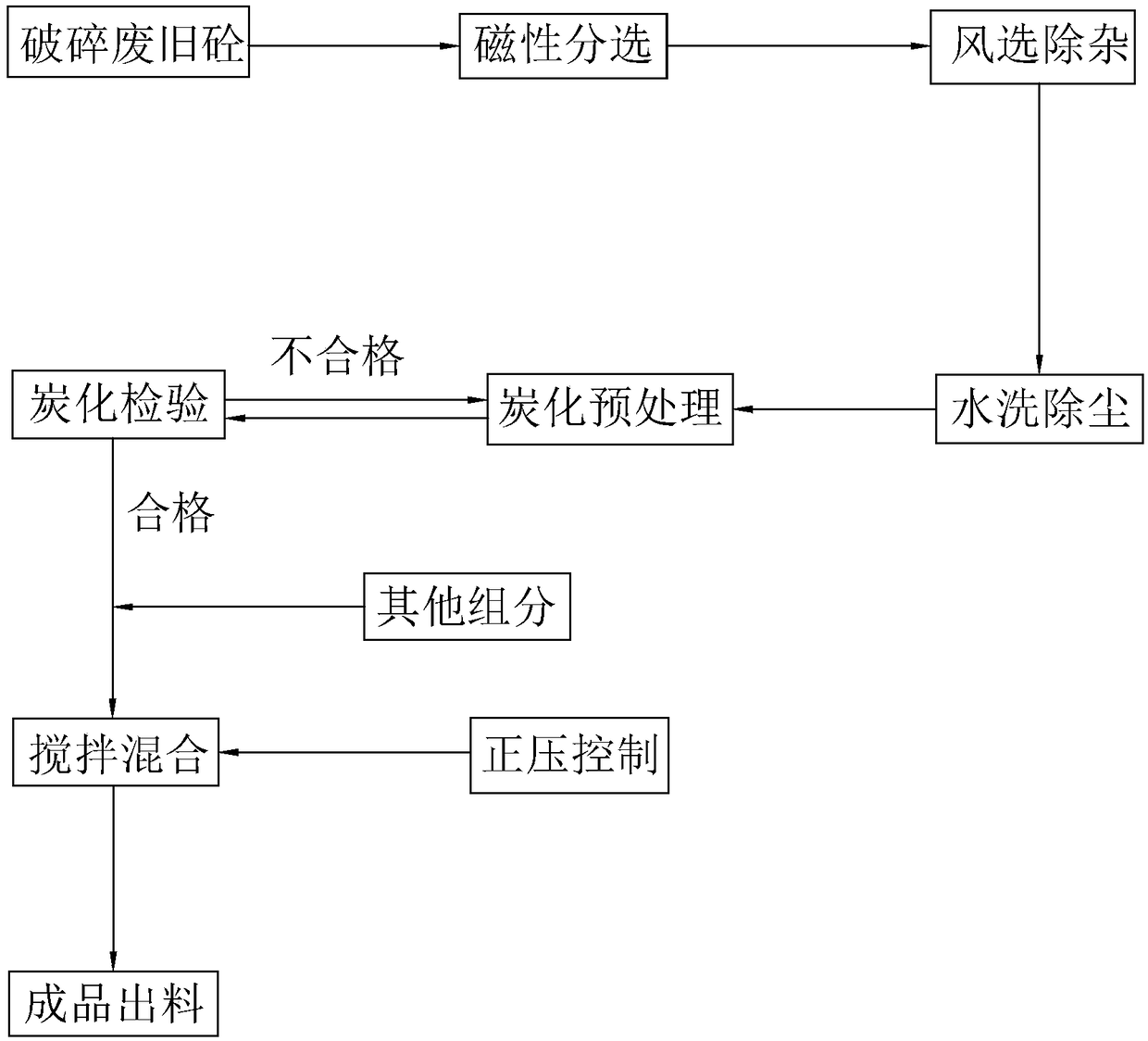

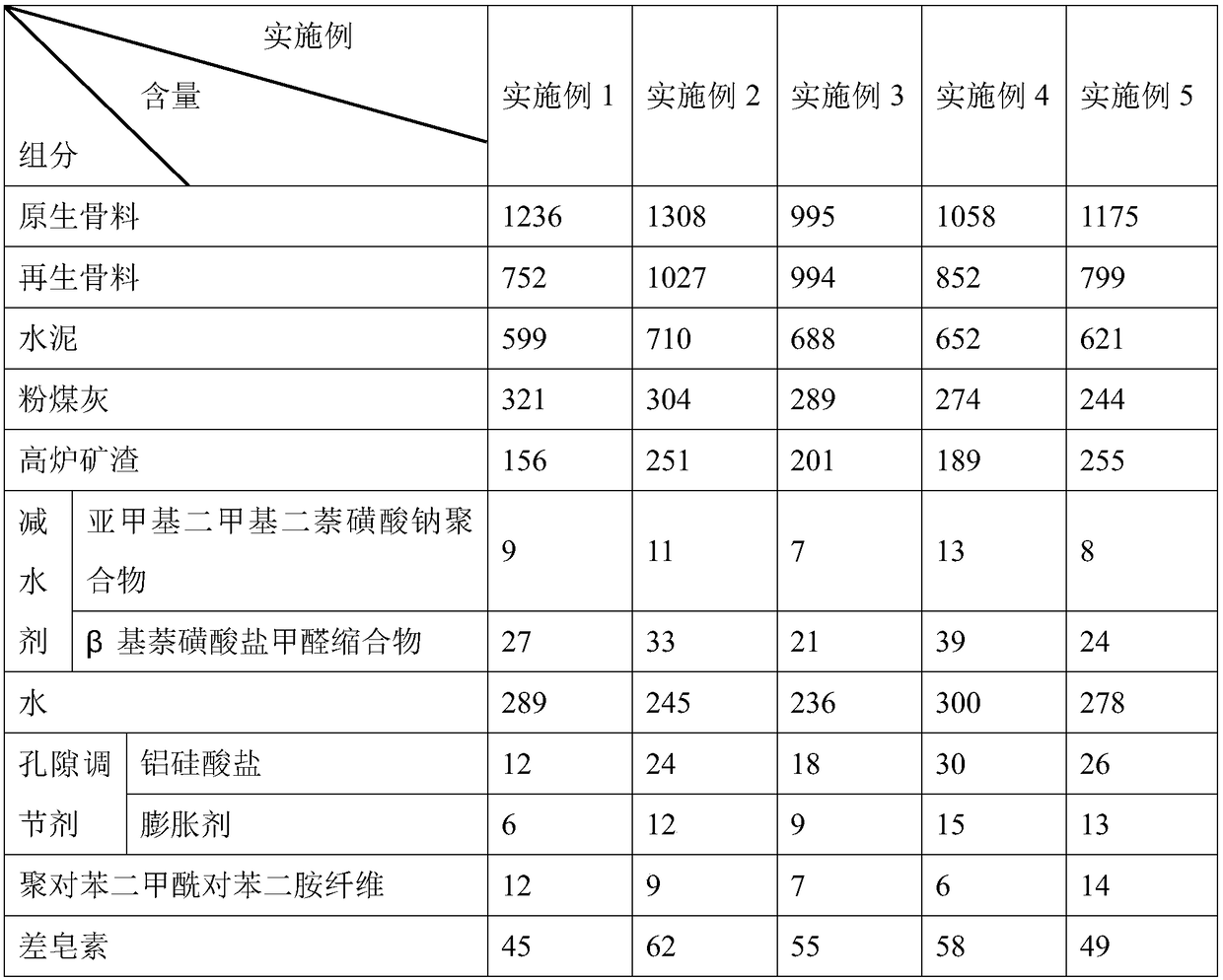

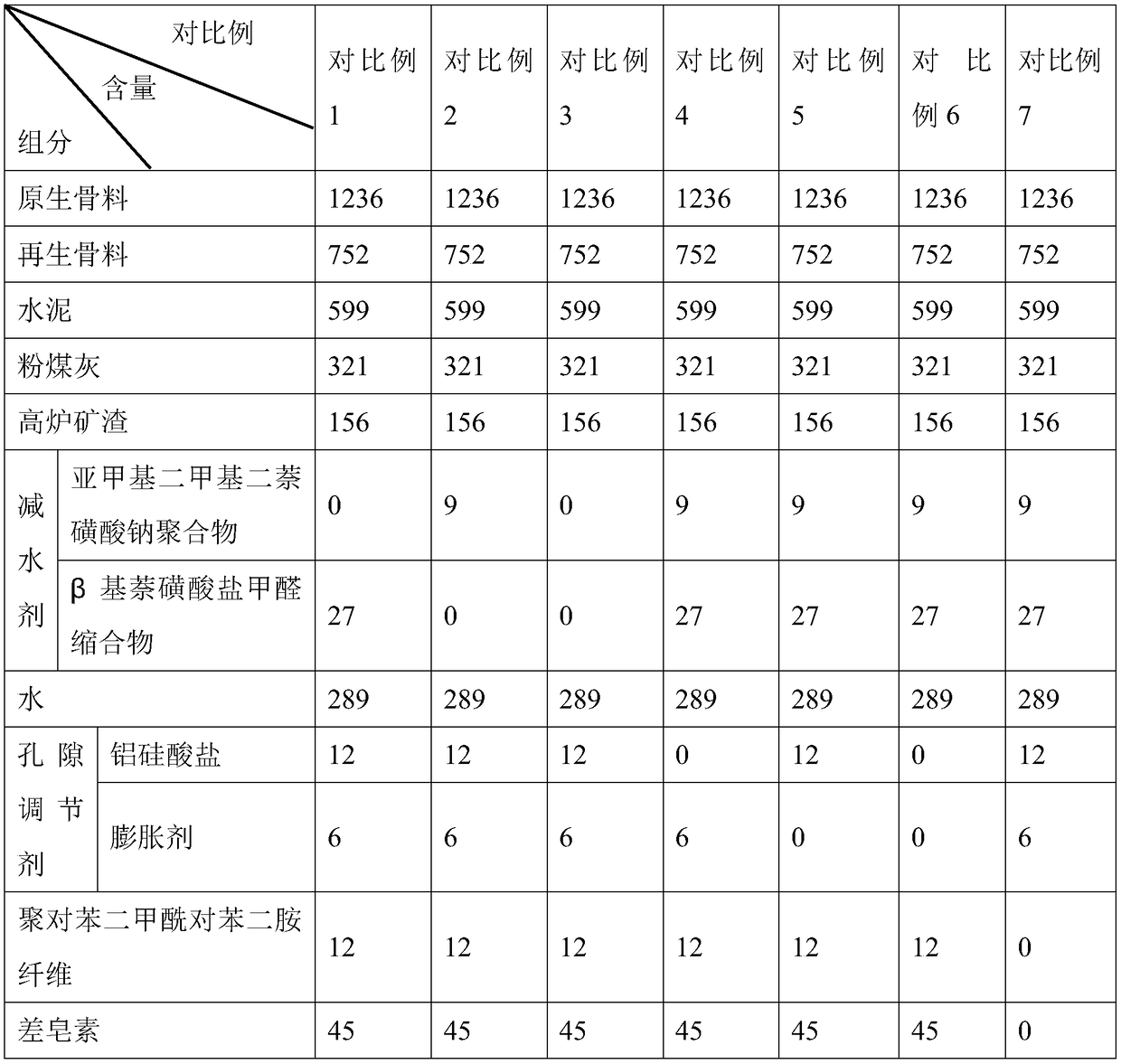

Regenerated concrete and production process thereof

The invention discloses a process for collecting and production of regenerated concrete. The regenerated concrete includes, by weight, 965-1328 parts of primary aggregate, 659-1123 parts of recycled aggregate, 566-720 parts of cement; 231-322 parts of fly ash, 118-266 parts of blast furnace slag, 25-55 parts of a water reducing agent, 221-308 parts of water, and 18-45 parts of a pore space regulator. The water reducing agent consists of sodium methylene dimethyl bisnaphthalenesulfonate polymer and a beta naphthalene sulfonate-formaldehyde condensate in a weight ratio of 1:1.5-3.5. The pore space regulator includes a sustained release agent and a swelling agent, in a weight ratio of 1:0.5-0.8, which are capable of releasing carbon dioxide. Through the arrangement, the recycled aggregate reasonably replaces a part of the primary aggregate, the fly ash and the blast furnace slag are adopted for improving concrete workability, water is reduced through the water reducing agent so as to reduce pores generated after water evaporation, and most pore space can be filled or sealed with the pore space regulator, thus improving inner structure of concrete, enhancing stress strength of concreteand improving the grade of impermeability.

Owner:武汉华强新型建筑材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com