Patents

Literature

591results about How to "Guarantee smooth construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

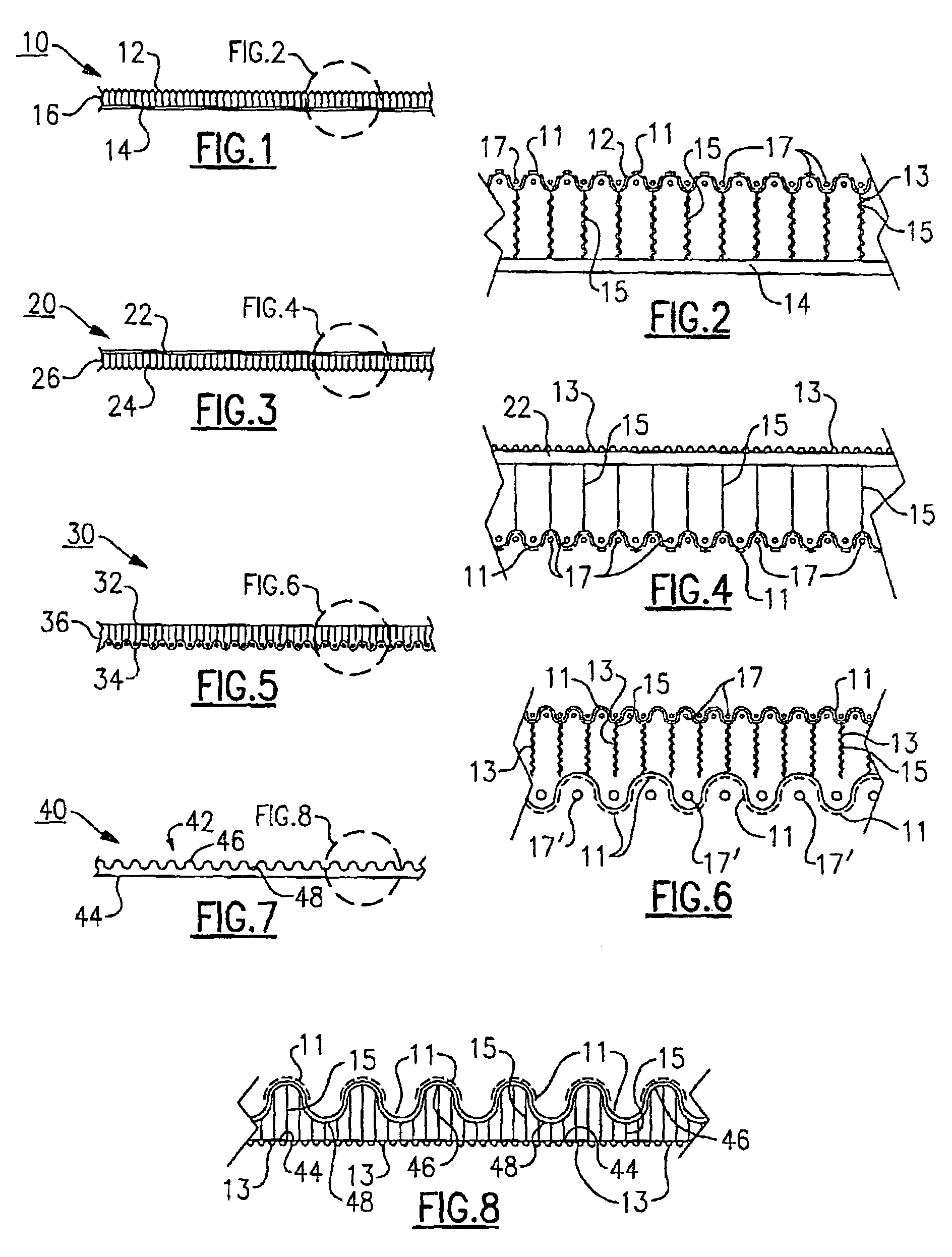

Moisture management system

InactiveUS7169720B2Efficient evaporationReduce capacityOrnamental textile articlesInsolesEngineeringWater repellent

Owner:ETCHELLS MARC D +2

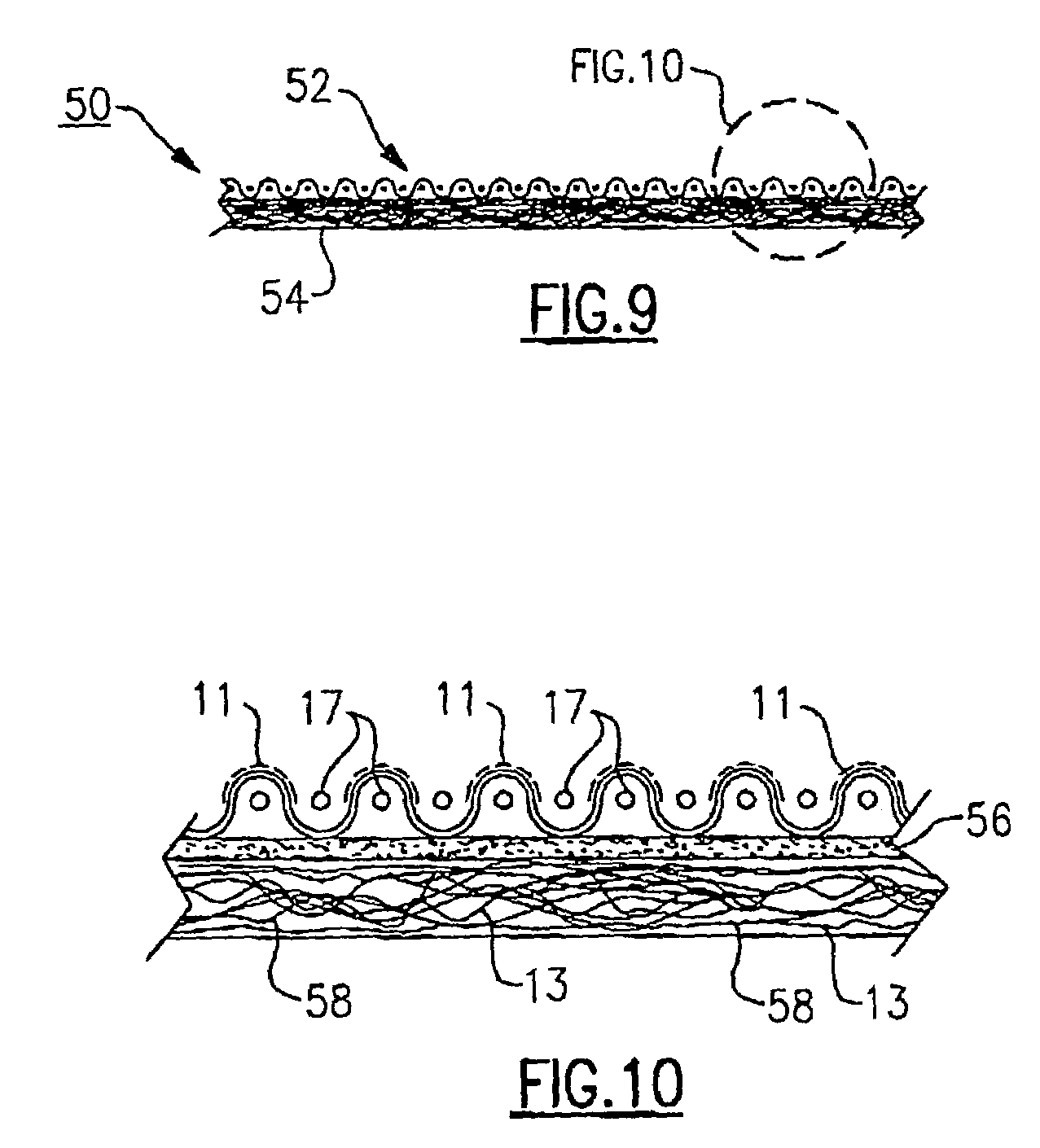

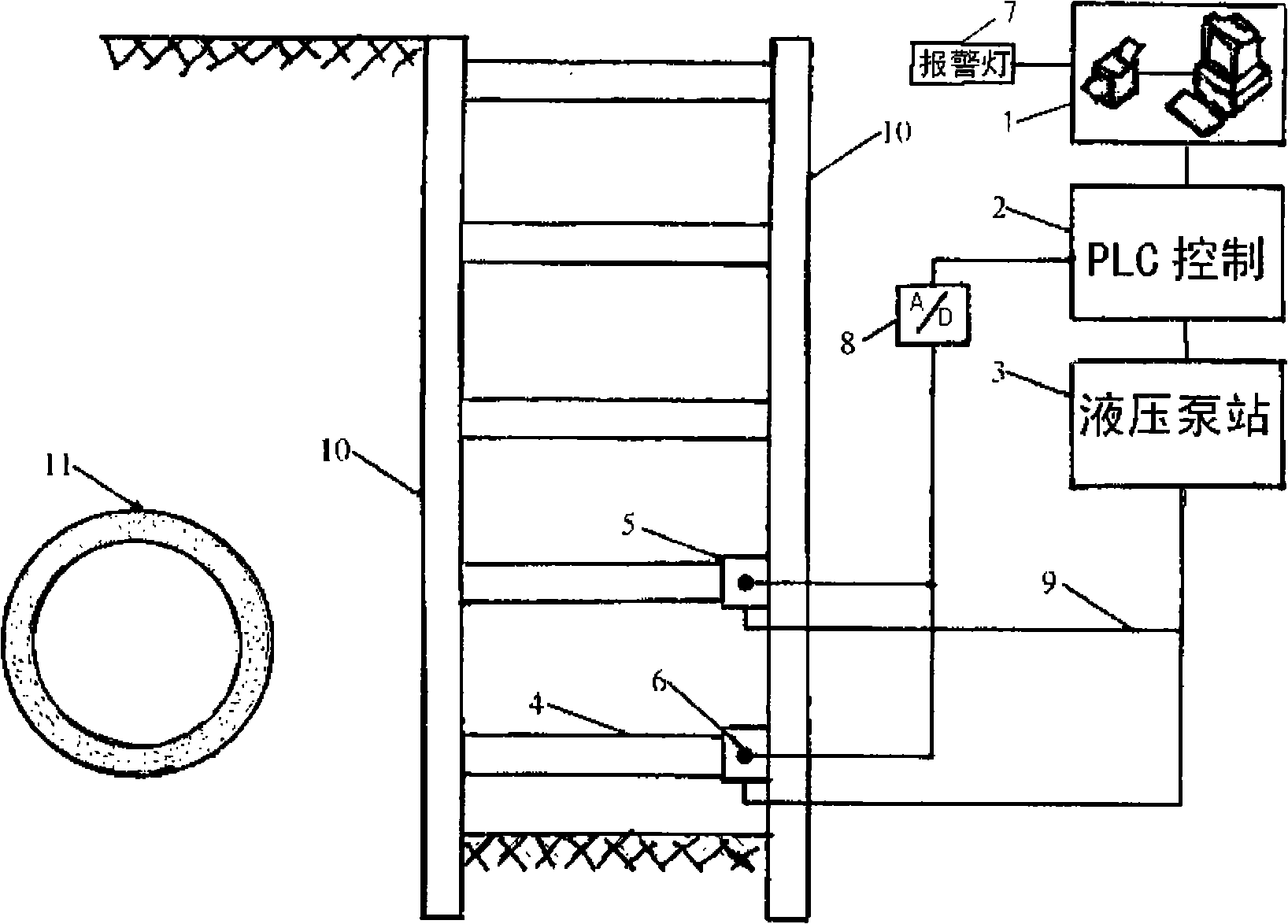

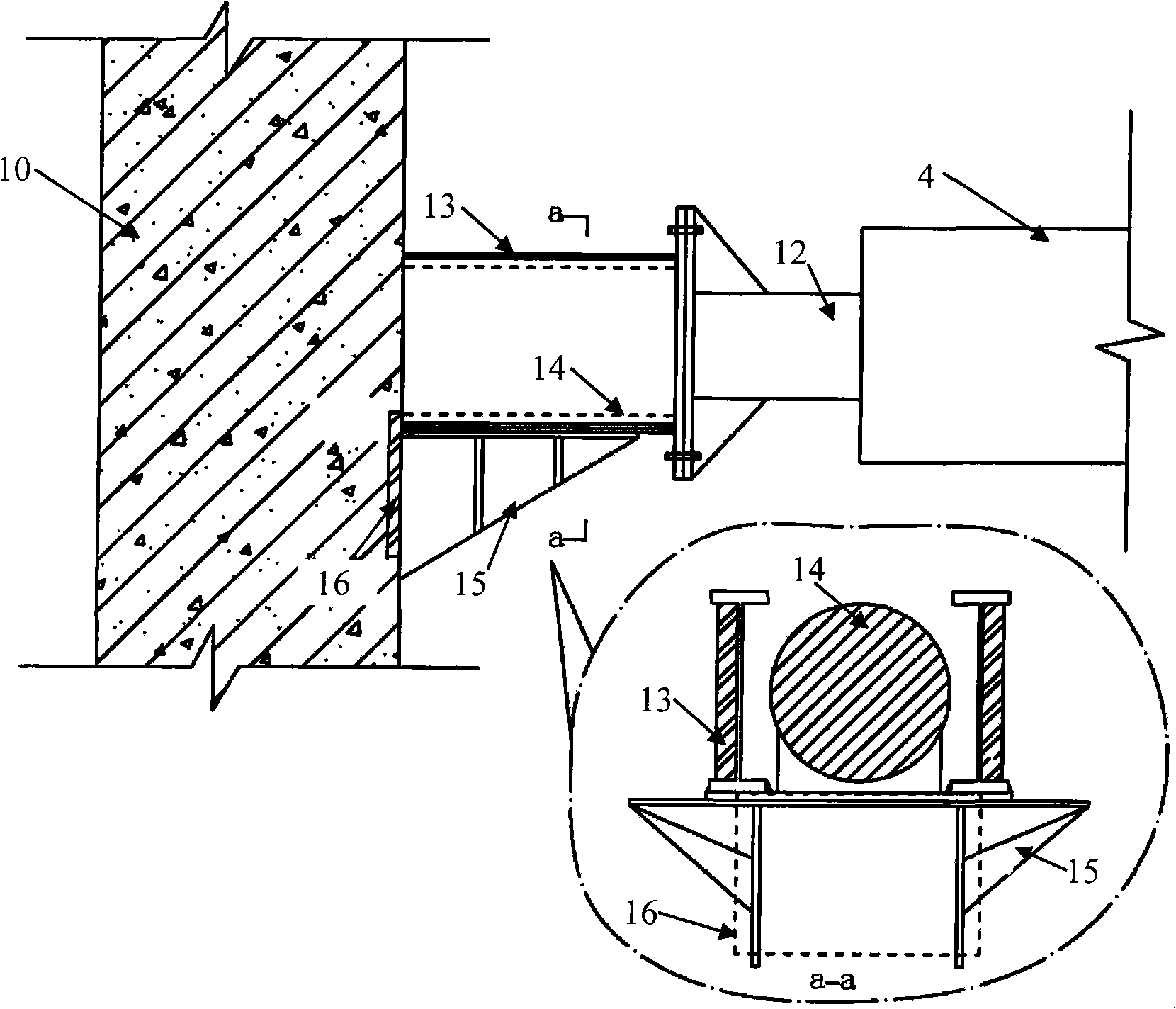

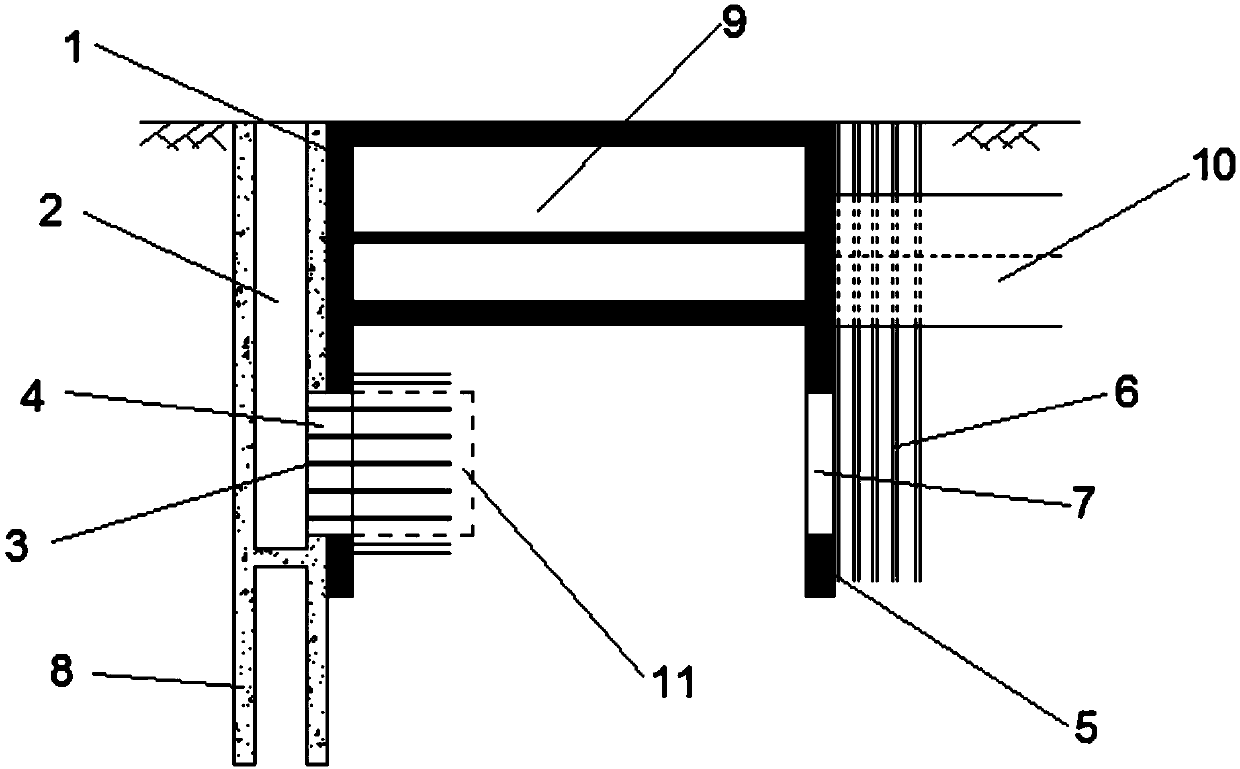

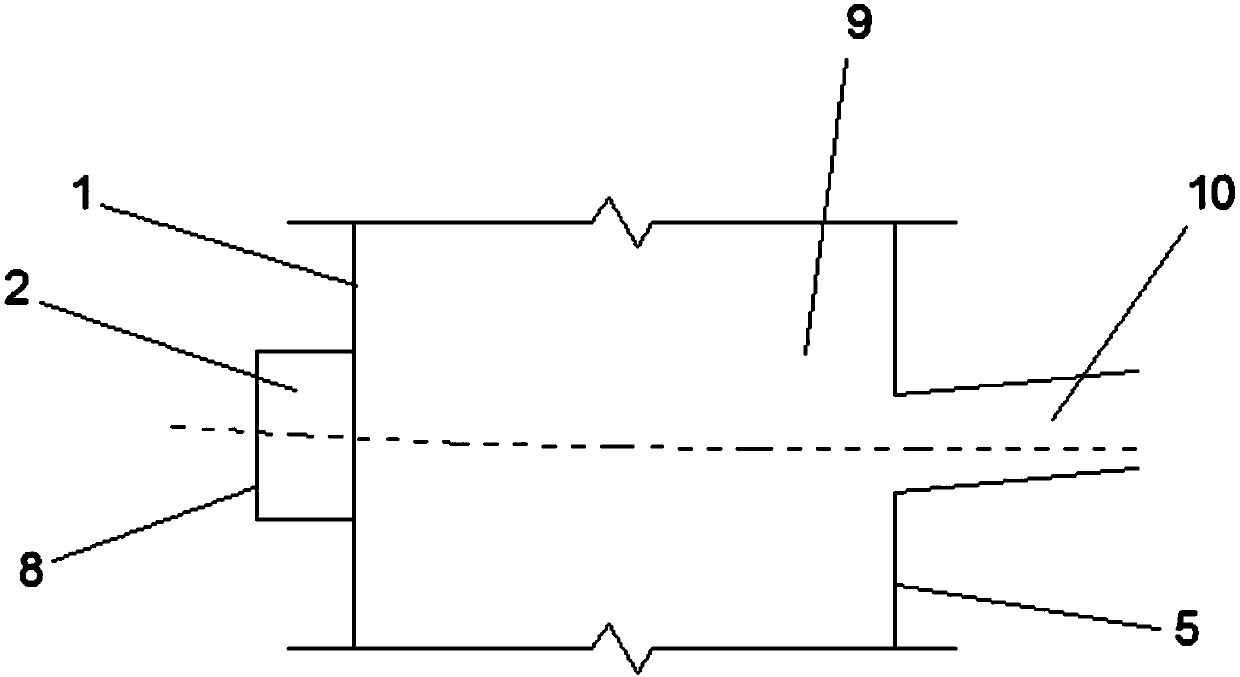

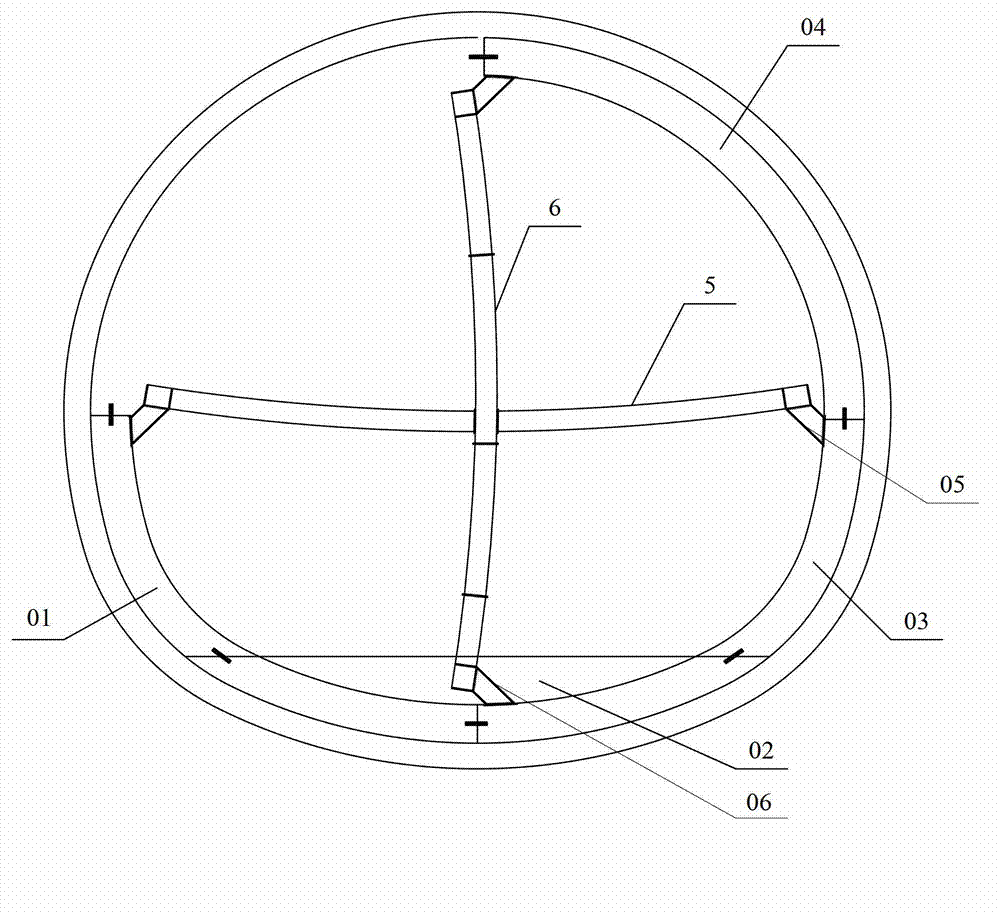

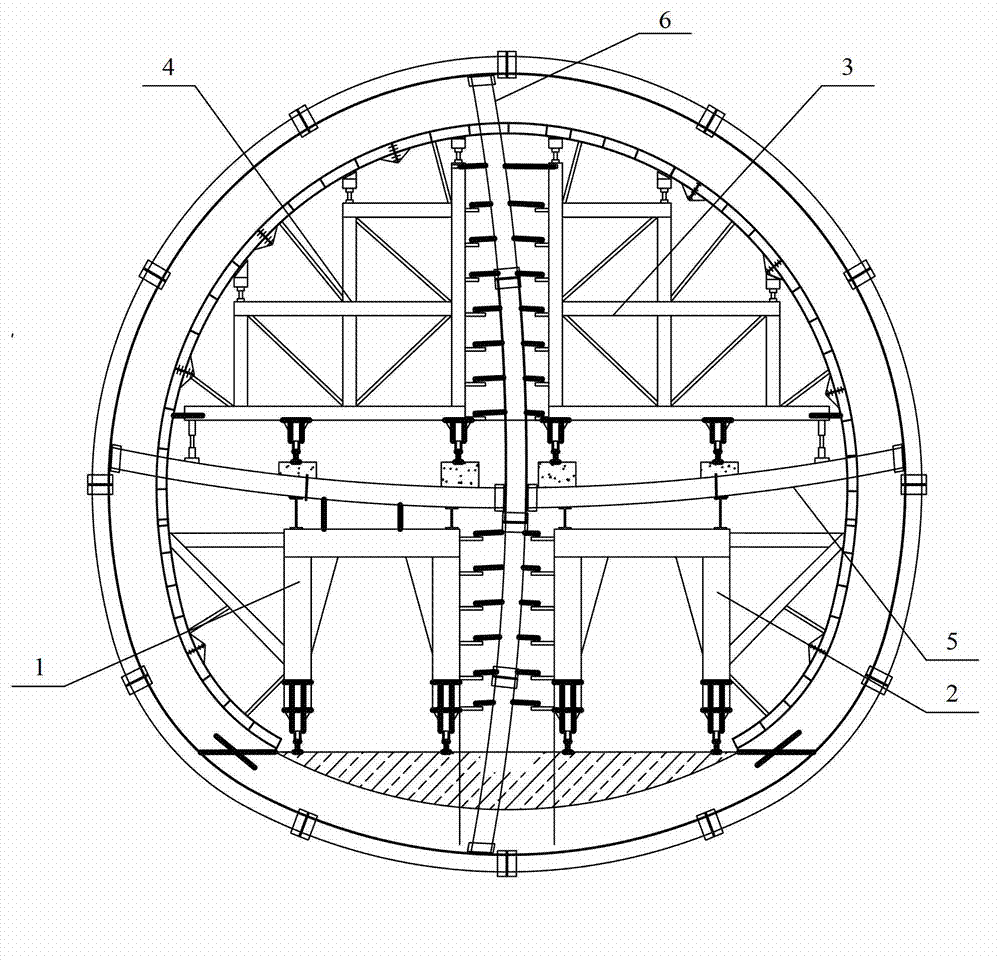

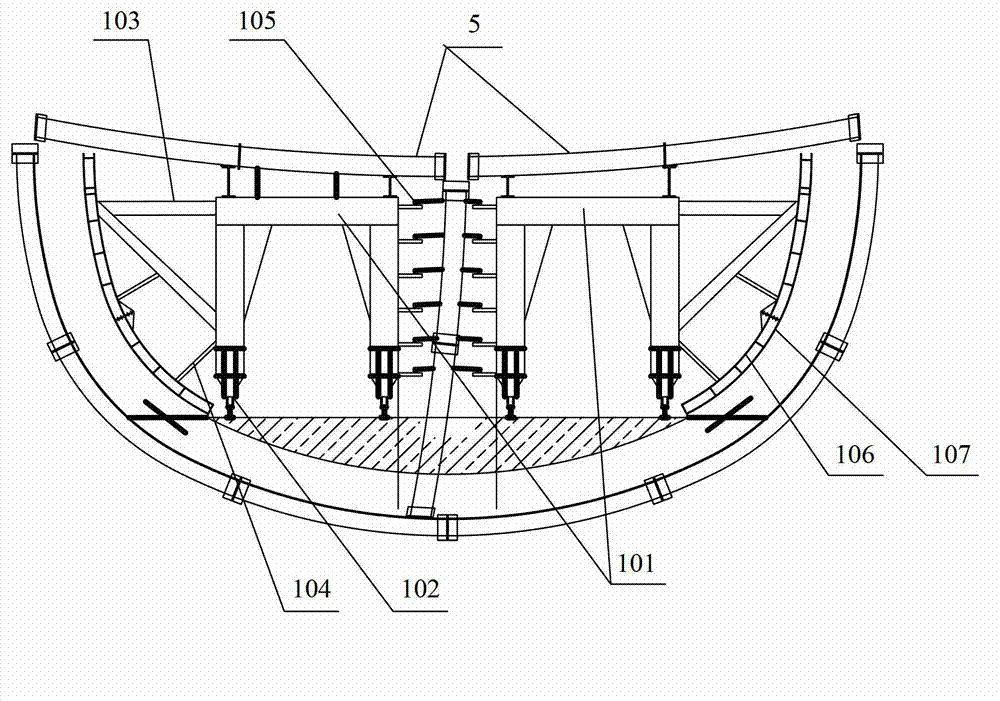

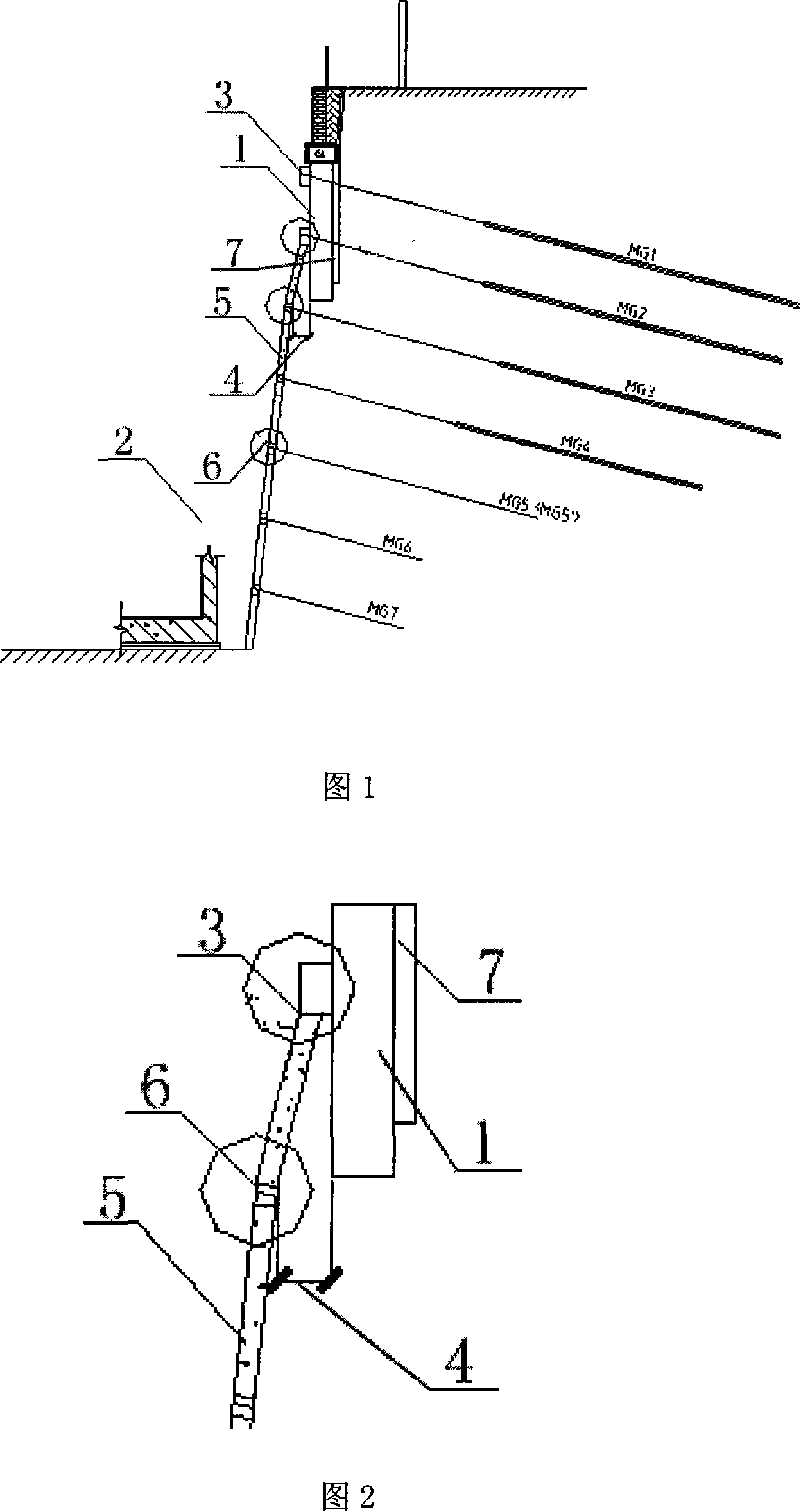

Steel shotcrete support internal force self-compensation, displacement control system and control method

InactiveCN101294389AImprove the force deformation performanceControl deformationExcavationsShotcreteAutomatic control

The invention belongs to the building support component technology field including the stress automatic control and monitoring as well as the structural safety, and relates to a steel tube supporting internal force automatic compensating and displacement controlling system. The system comprises an upper system, a PLC control system module and a field executive system. A steel support is arranged on a reinforced concrete diaphragm wall, a hydraulic jack is arranged on the steel support, and real time pressure monitoring values are fed back through a pressure sensor. The steel support and the hydraulic jack form a pre-stressed steel support structure, the hydraulic jack is connected with a hydraulic pump station through an oil circuit, and is connected with the PLC control system module through the pressure sensor, the hydraulic pump station is connected with the PLC control system module, and a PLC controlling device is connected with the upper system. Through auto-control software and a PLC control system, the automatic control to the axial force of the steel support is realized, thereby controlling the displacement and the settlement of the deep excavation supporting structure and the adjacent basic facilities.

Owner:CSCEC INT CONSTR +1

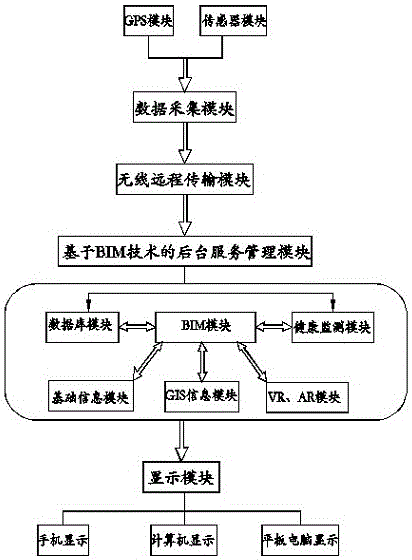

BIM-based intelligent monitoring system

ActiveCN106595565AAuxiliary construction managementOptimized designMeasurement devicesPotential riskData acquisition module

The invention discloses a BIM-based intelligent monitoring system which comprises a GPS, a sensor module, a data acquisition module, a wireless remote transmission module, and a backstage service management module based on BIM technology. The backstage service management module based on BIM technology comprises a database, a BIM module, a GIS information module, VR, an AR module, a health monitoring module, and a display module. According to the system, the real-time monitoring of a foundation pit can be realized, the foundation pit visual display is realized through the BIM and a GIS, the combination of virtuality and reality is realized through VR and AR technology, through a health monitoring module, the early alarm and alarm of the potential risk of the foundation pit are realized through the health monitoring module, and thus the construction of the foundation pit is safely and smoothly completed.

Owner:SUN YAT SEN UNIV

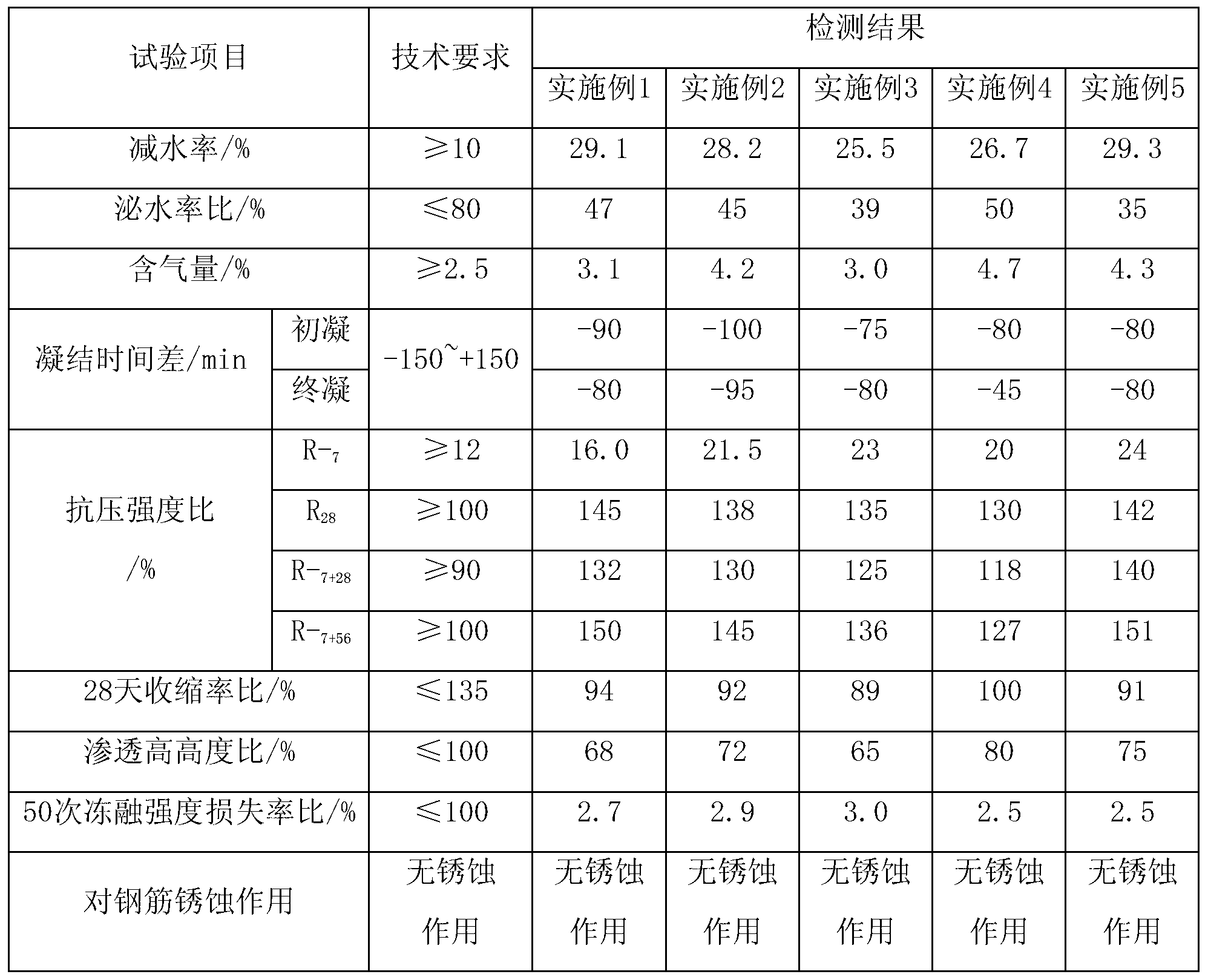

High-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof

The invention relates to a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof, belonging to the field of construction materials. The invention aims to provide a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent is prepared from the following raw materials in parts by weight: 17.5-32.5 parts of polycarboxylic-acid water reducing agent, 1-3 parts of sodium lignosulfonate, 7-36 parts of early-strength admixture, 2-8 parts of antifreezing agent, 0-0.5 part of air entraining agent and 20-72.5 parts of water. The early-strength admixture is composed of 1-8 parts by weight of organic early-strength component and 6-28 parts by weight of inorganic early-strength component. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent has the advantages of high early strength, favorable anti-freeze-thawing effect and the like.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

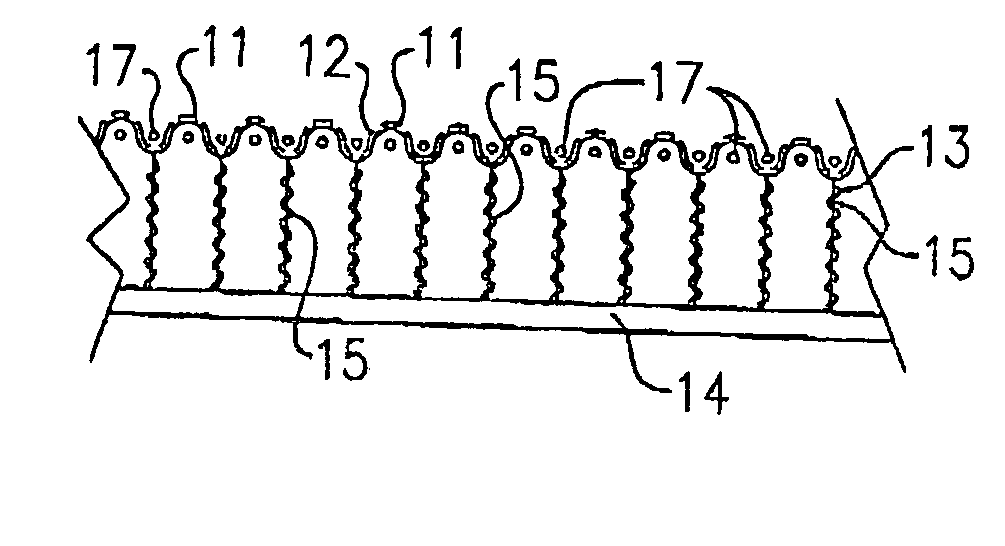

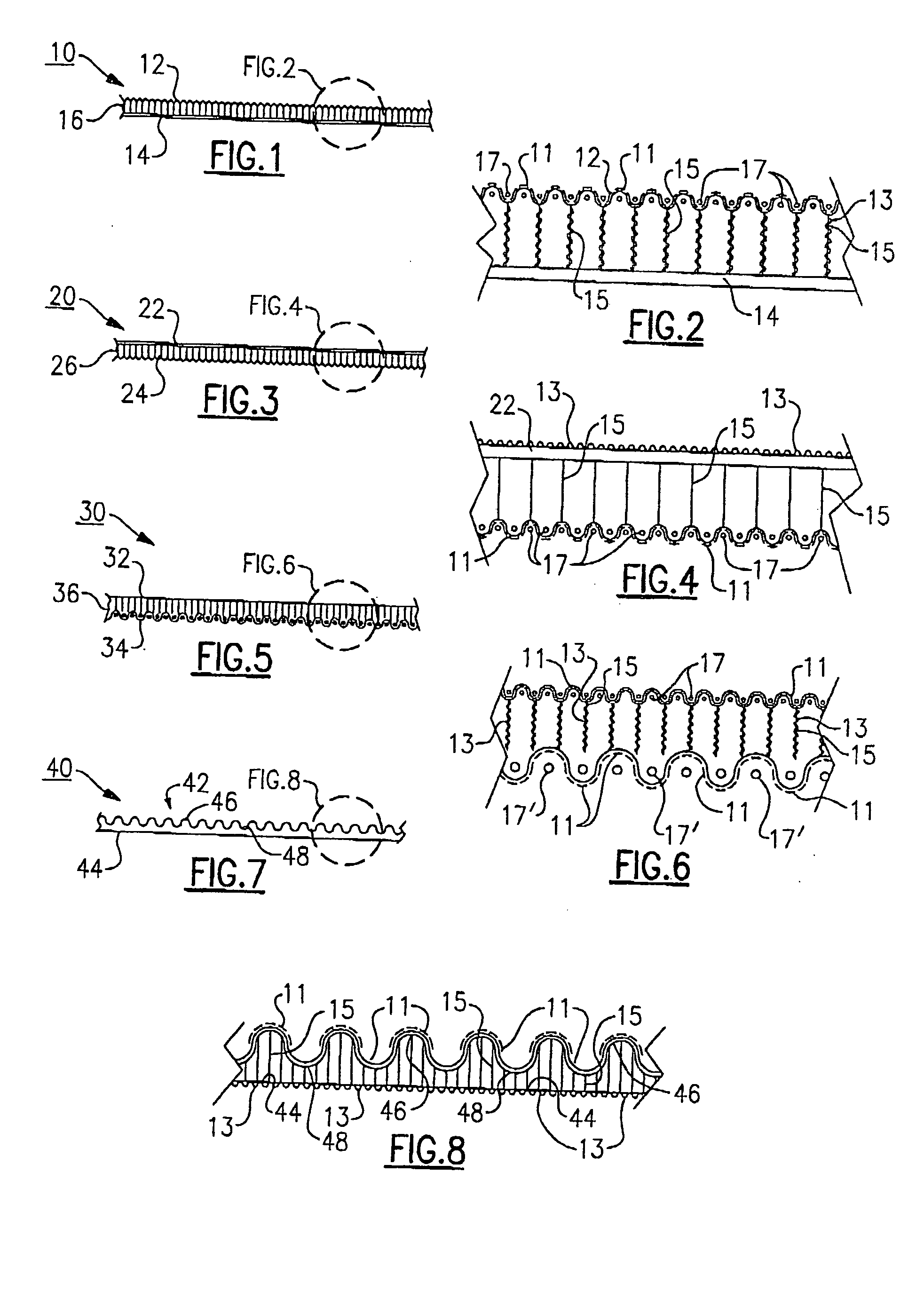

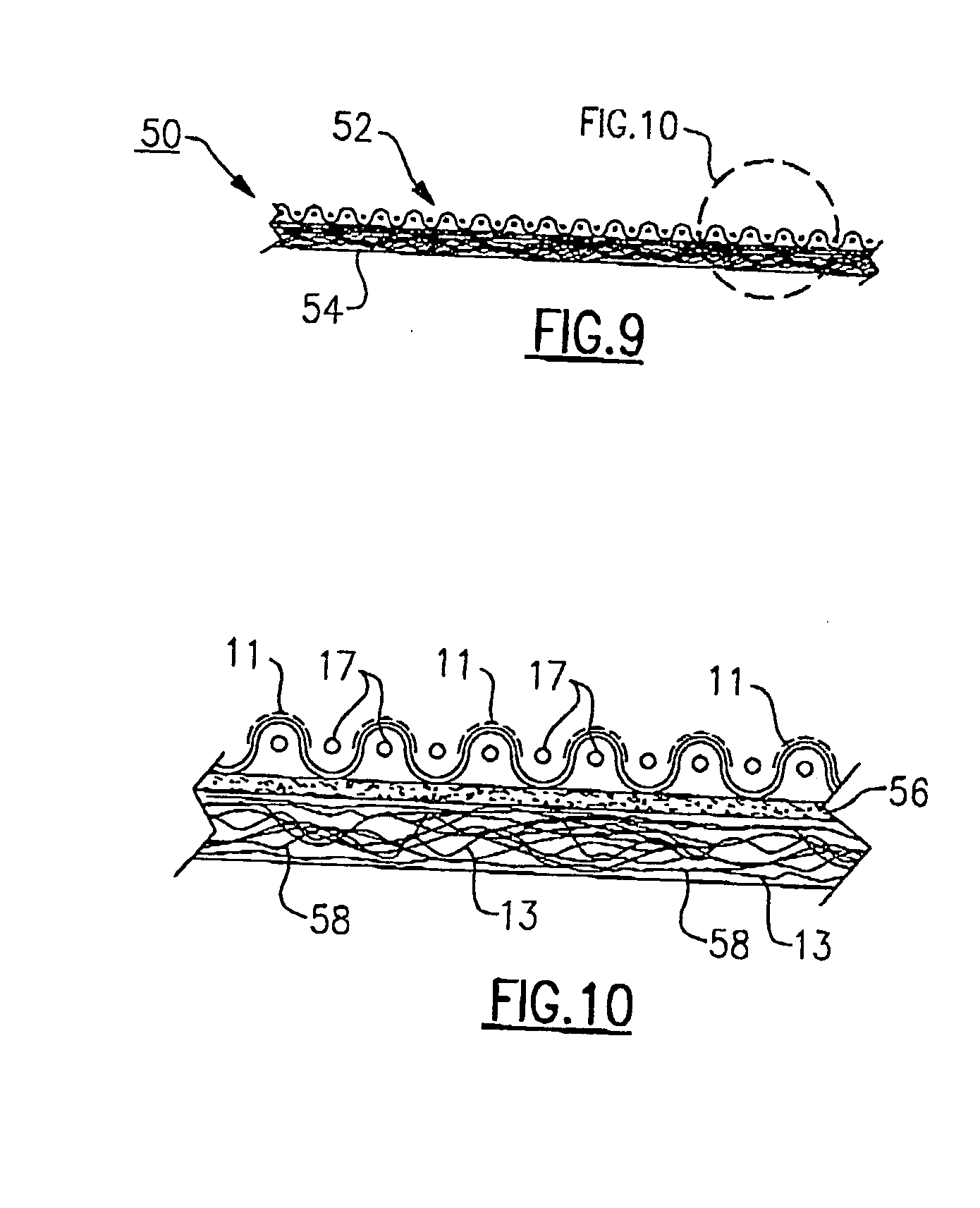

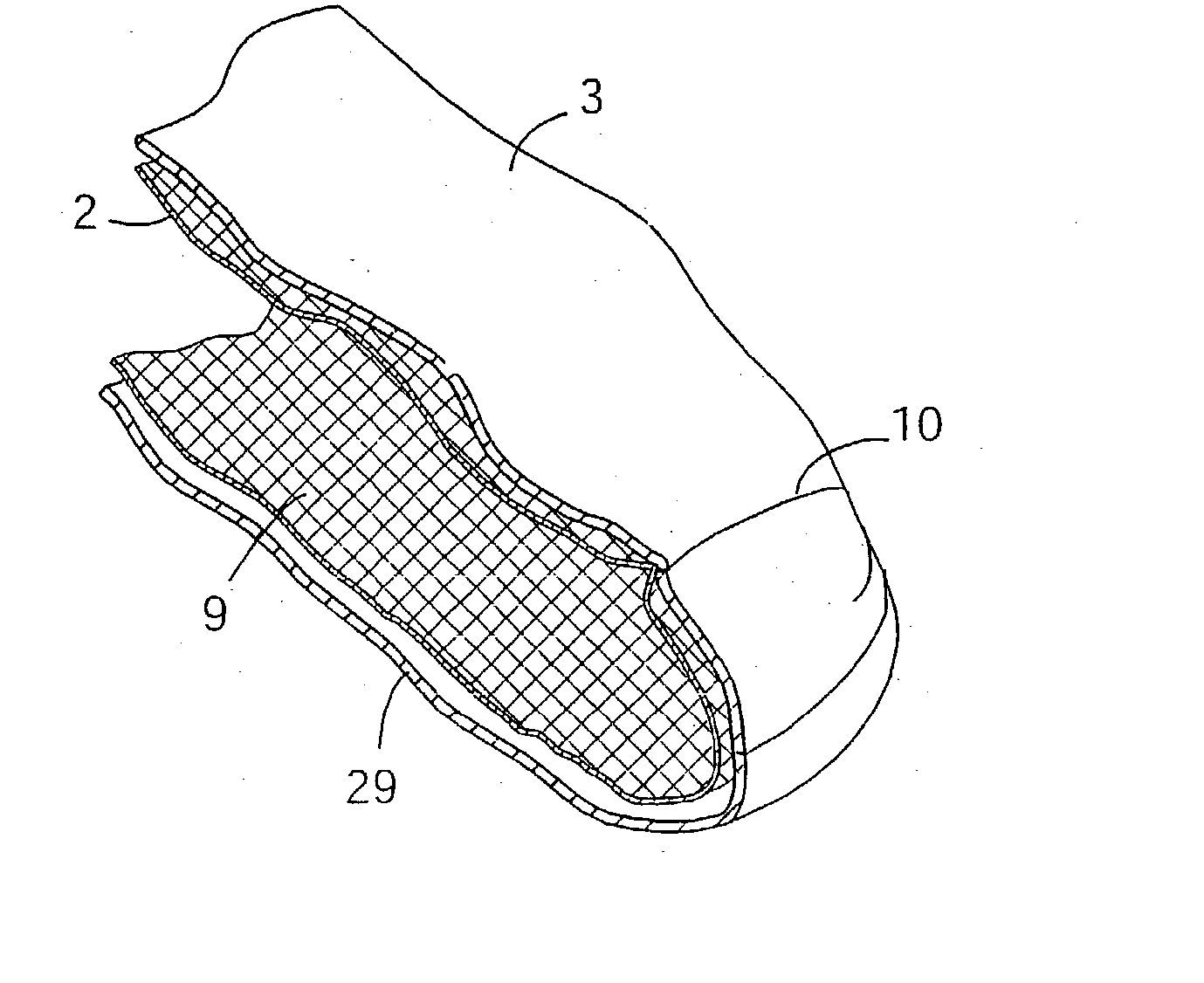

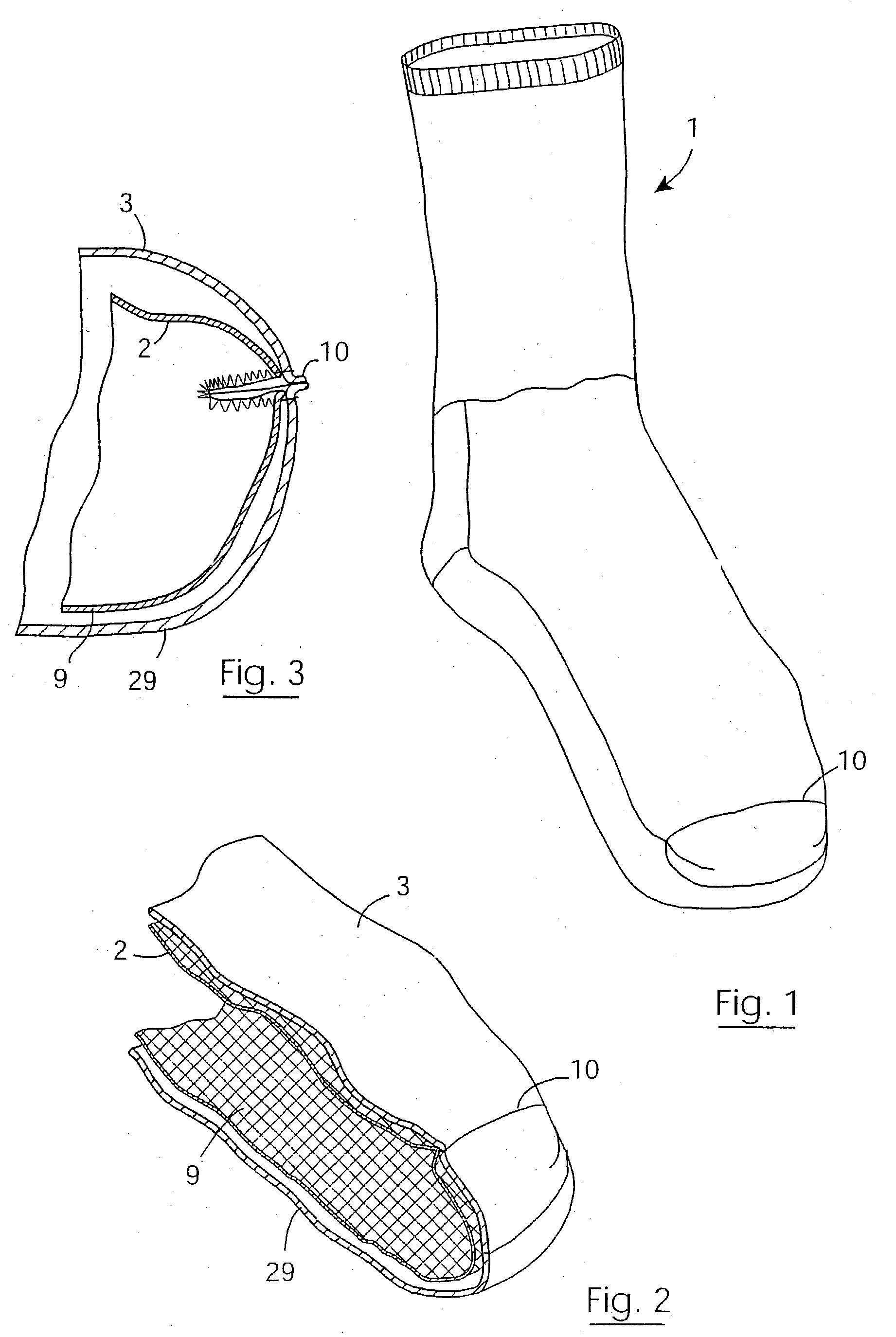

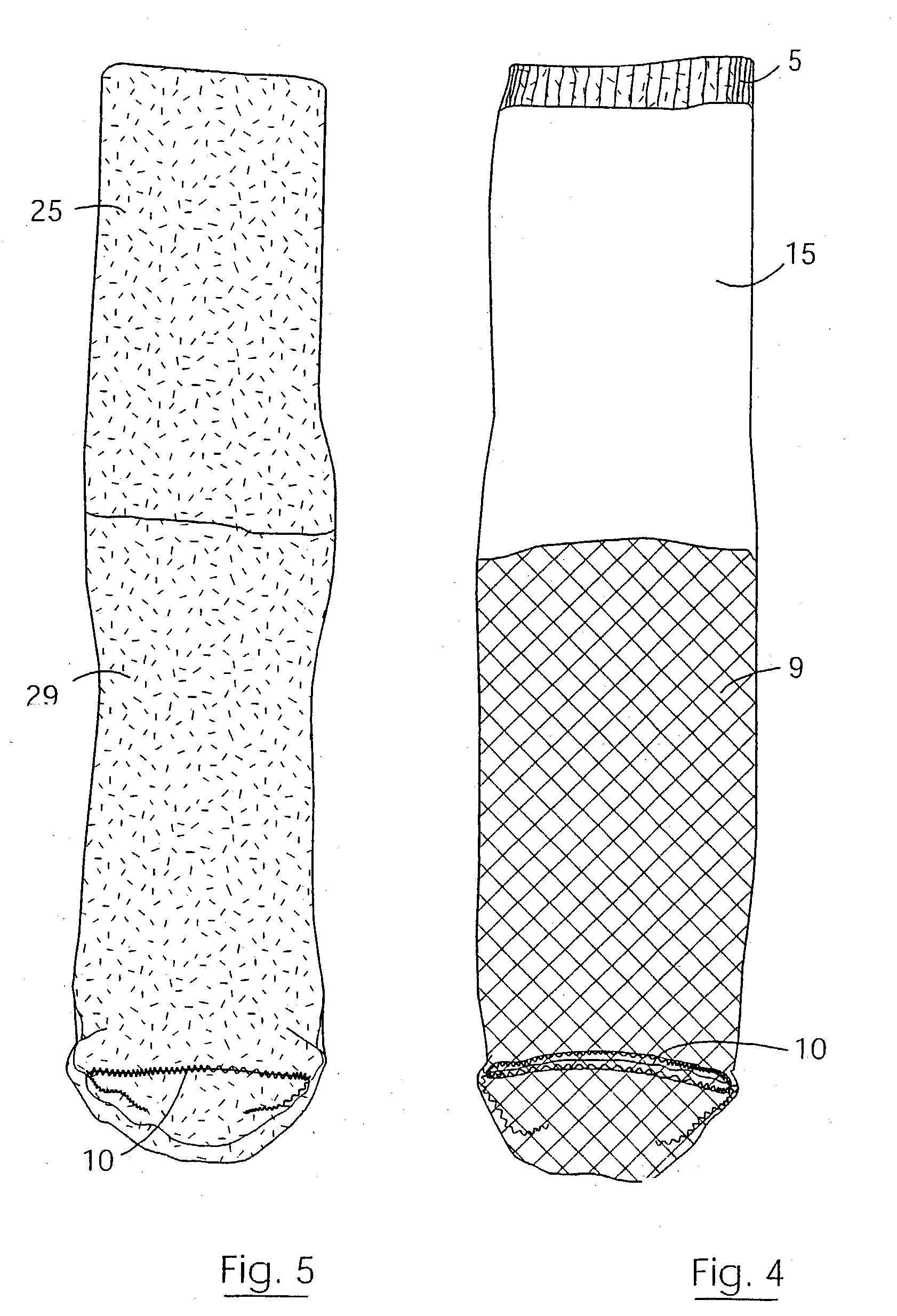

Moisture management system

InactiveUS20050075027A1Efficient evaporationReduce capacityOrnamental textile articlesInsolesEngineeringWater repellent

A three dimensional fabric suitable for use as a moisture management system for footwear and apparel which includes a first surface and a second surface which encase a center section. At least one surface is water repellent and may include pores of a predetermined size to allow moisture to pass therethrough. The fabric further contains a moisture absorbing agent which functions to capture and hold moisture which is later evaporated within a predetermined time period.

Owner:ETCHELLS MARC D +2

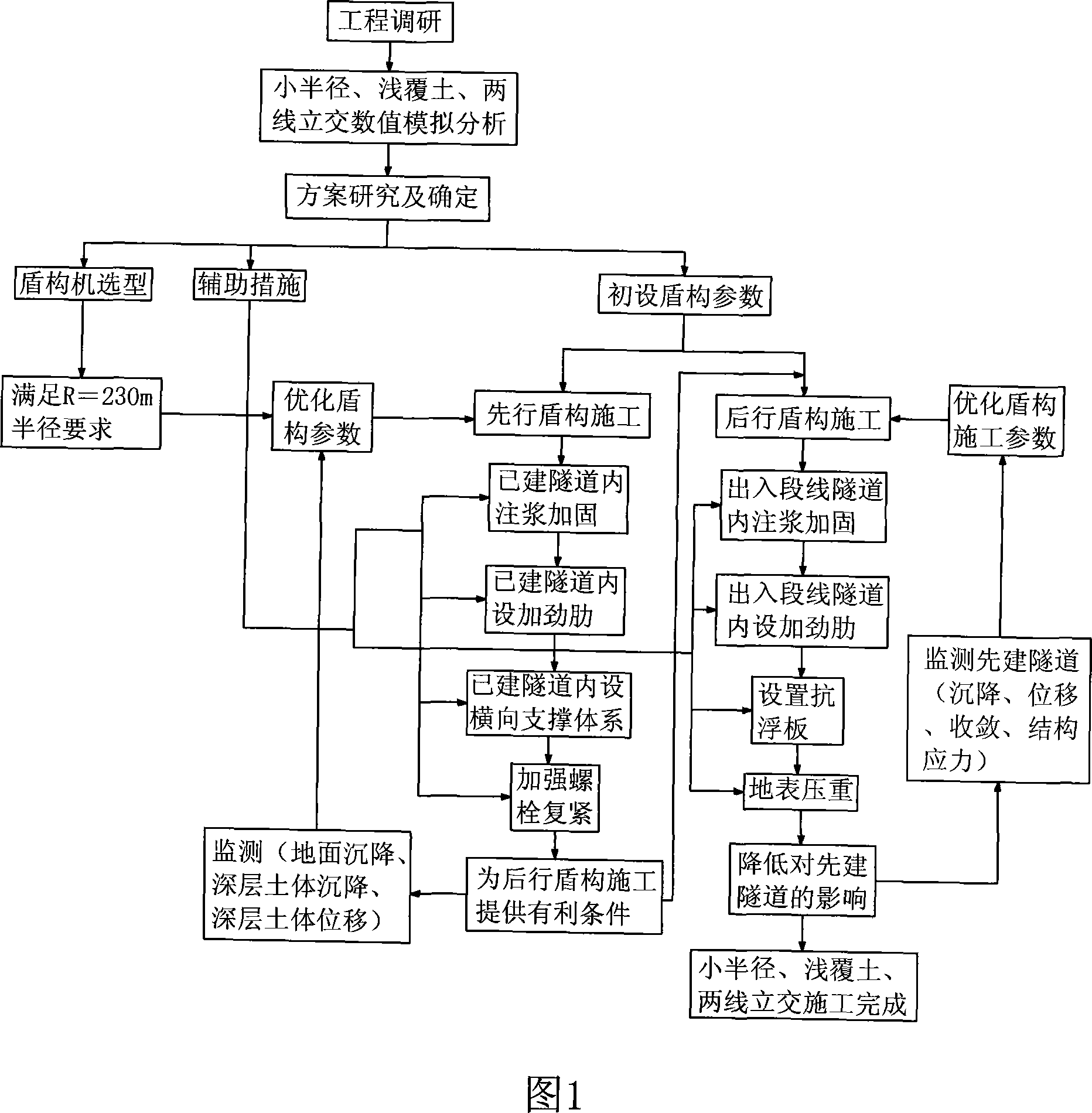

Two lines intersection small radius, shallow earth covering and large longitudinal slope complicated linetype shield construction method

ActiveCN101182772AHigh sensitivityControl deformationArtificial islandsUnderground chambersEarth surfaceShield tunneling

The invention discloses a shield construction method for a two-line overpass with small radius, shallow covering soil and large longitudinal slope complex linear tunnel, which belongs to the technical field of tunnel construction. The construction method of the present invention includes the following steps: determining the advancing sequence of the two-line interchange, selecting a shield machine type, taking auxiliary strengthening measures for the ground surface, strata, and segments, shield advancing, axis control and construction monitoring, and shield tunneling. In the present invention, since the shield increases the hinged part, the sensitivity of the shield is increased, and the control of the axis of the tunnel is more convenient; a suitable reinforcement and pressure scheme, a segment typesetting method and a stiffening rib scheme are selected to make the outer arc of the segment broken. Cracks and segmental water seepage can be improved; and through high-frequency monitoring and information feedback, the shield propulsion parameters are strictly controlled. By taking the above measures, the deformation and displacement of the ground surface and the tunnel are effectively controlled, which effectively reduces the cost of tunnel construction and The complex influence of the post-construction tunnel ensures the smooth progress of the construction and the effective control of the tunnel deformation.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

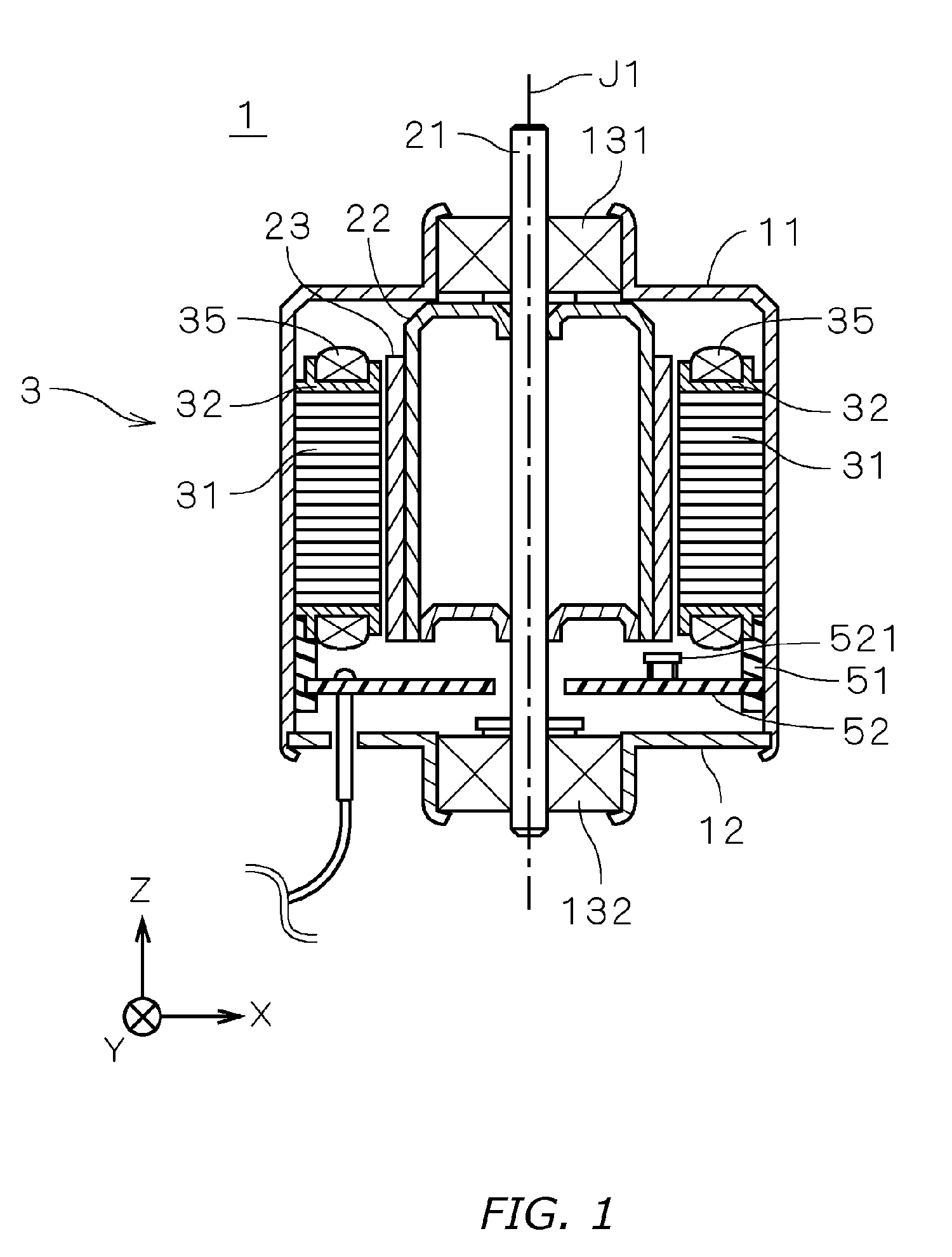

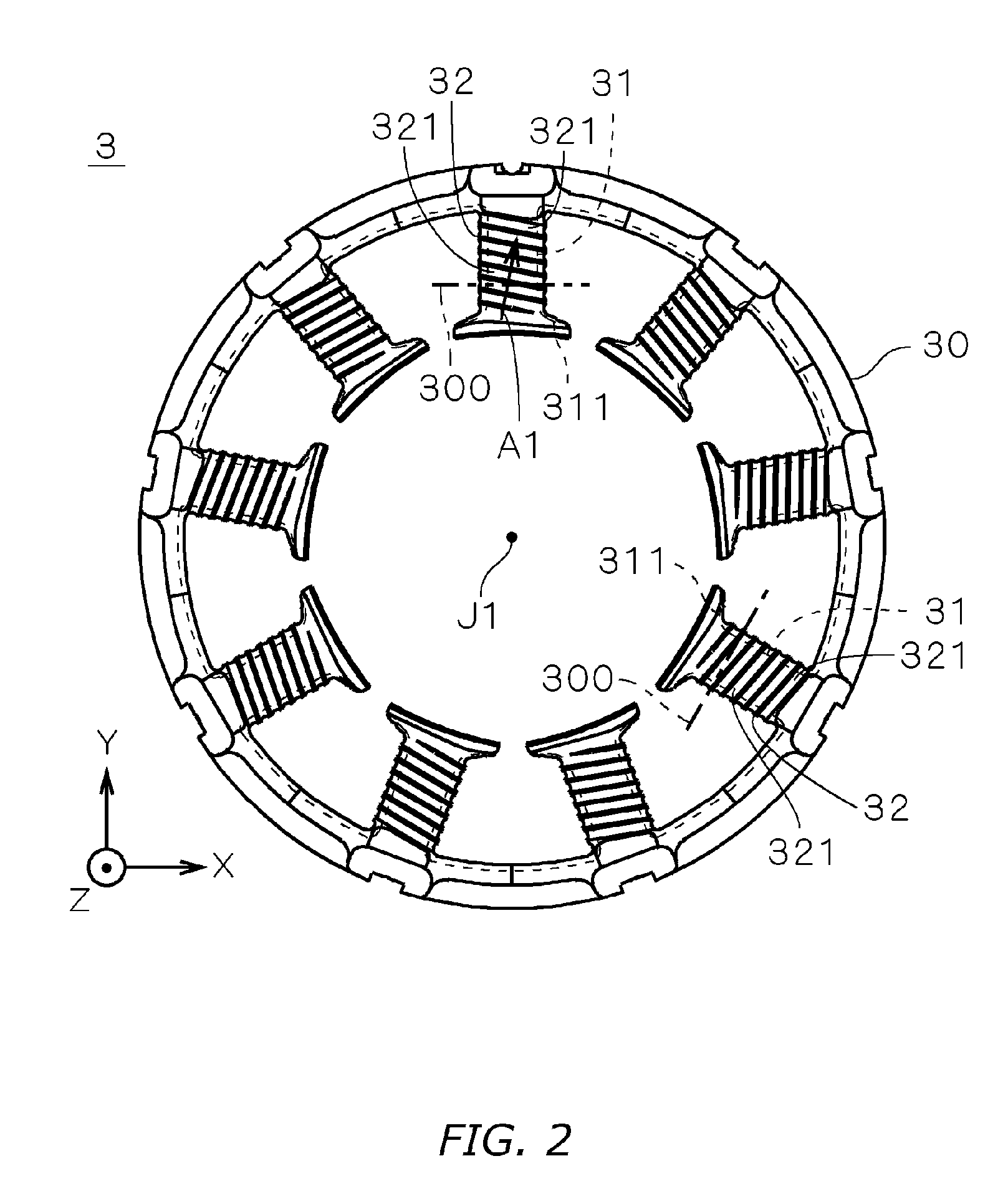

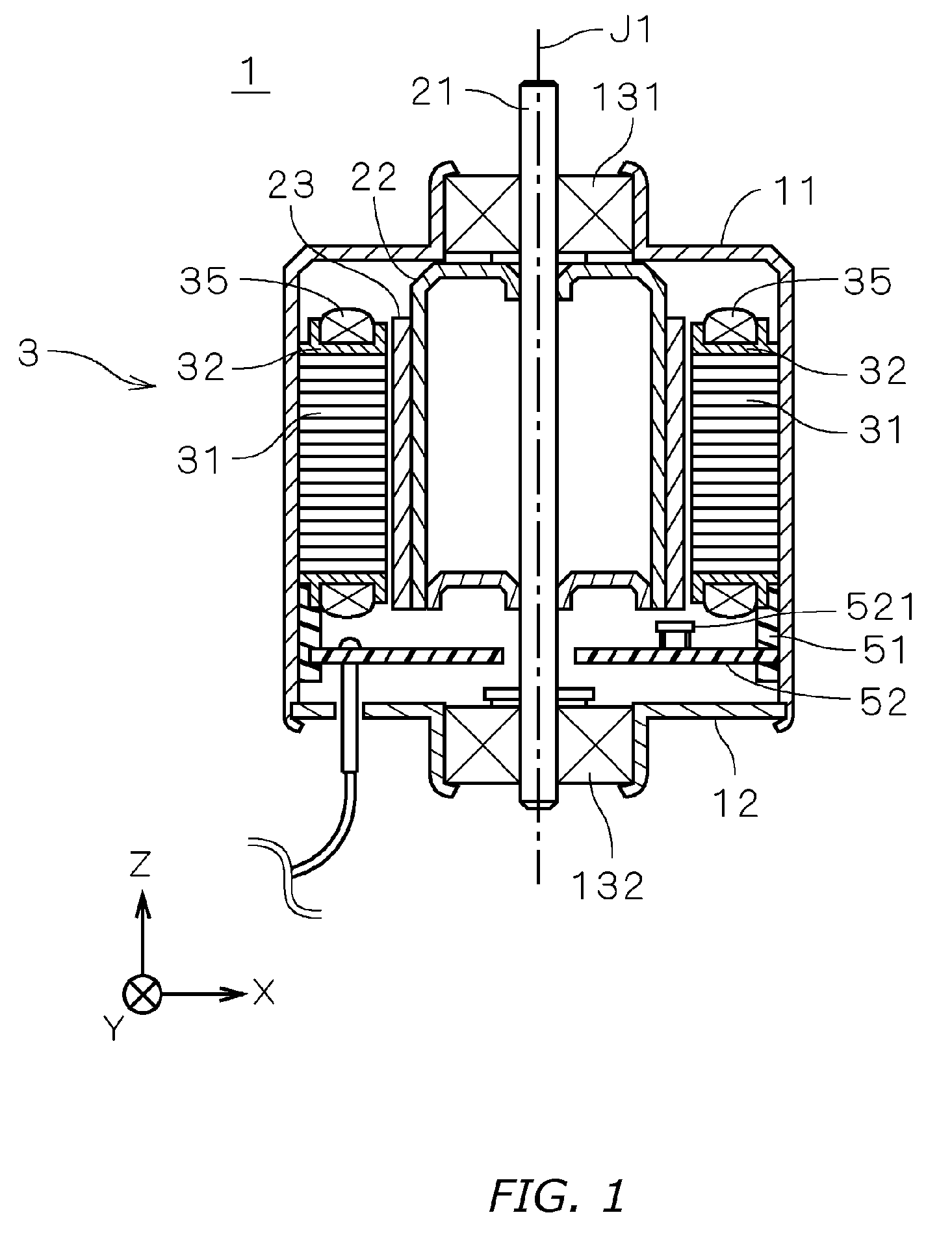

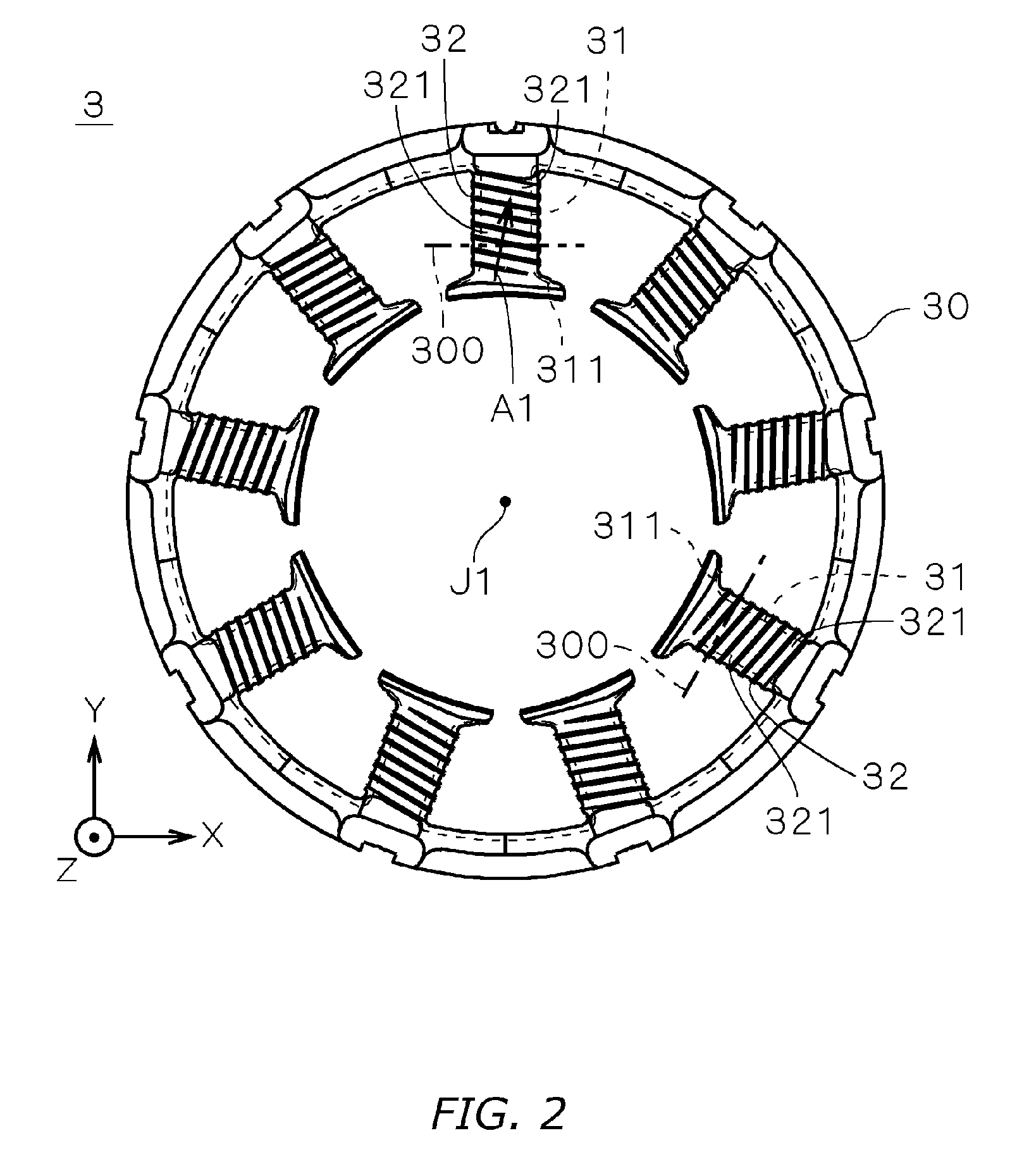

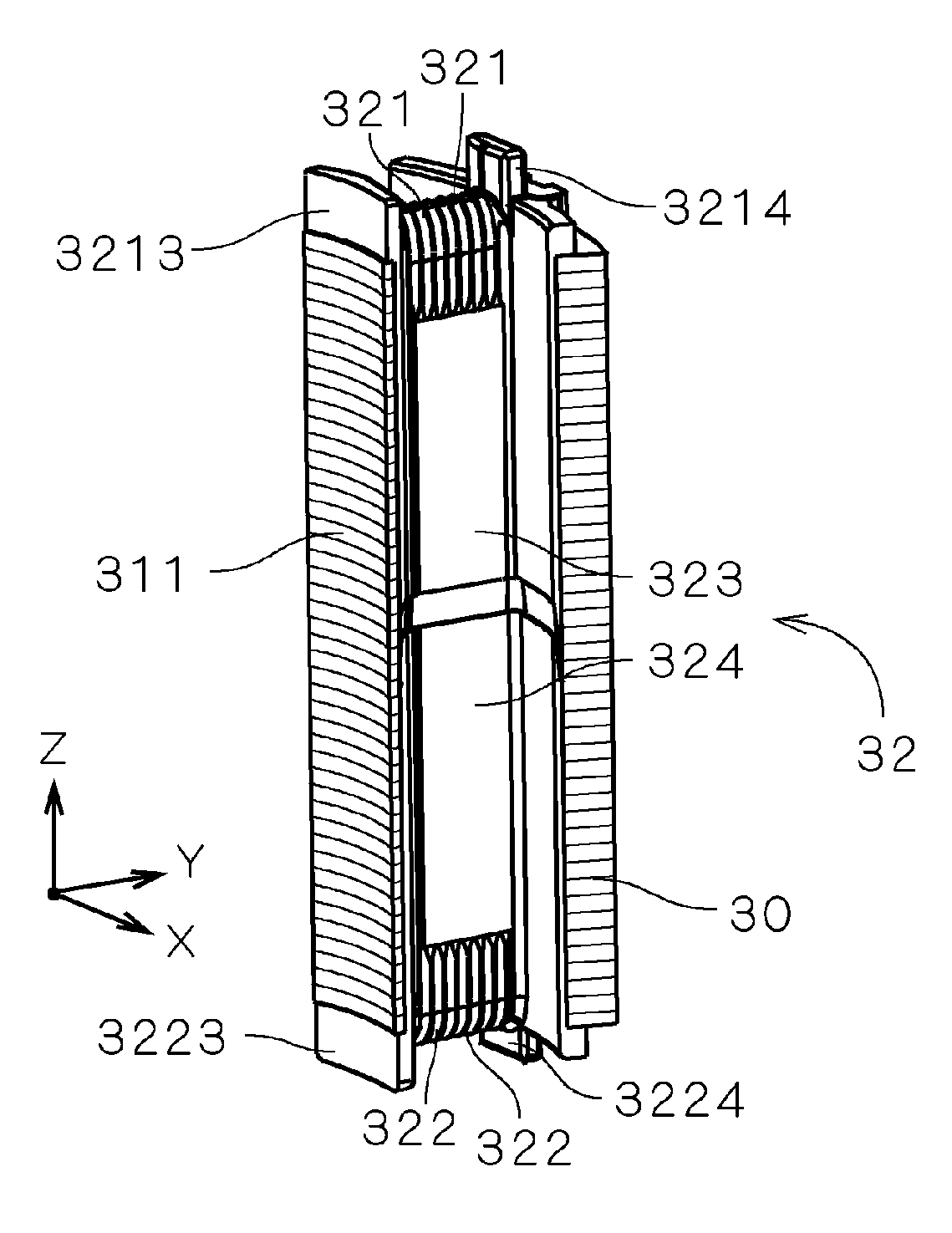

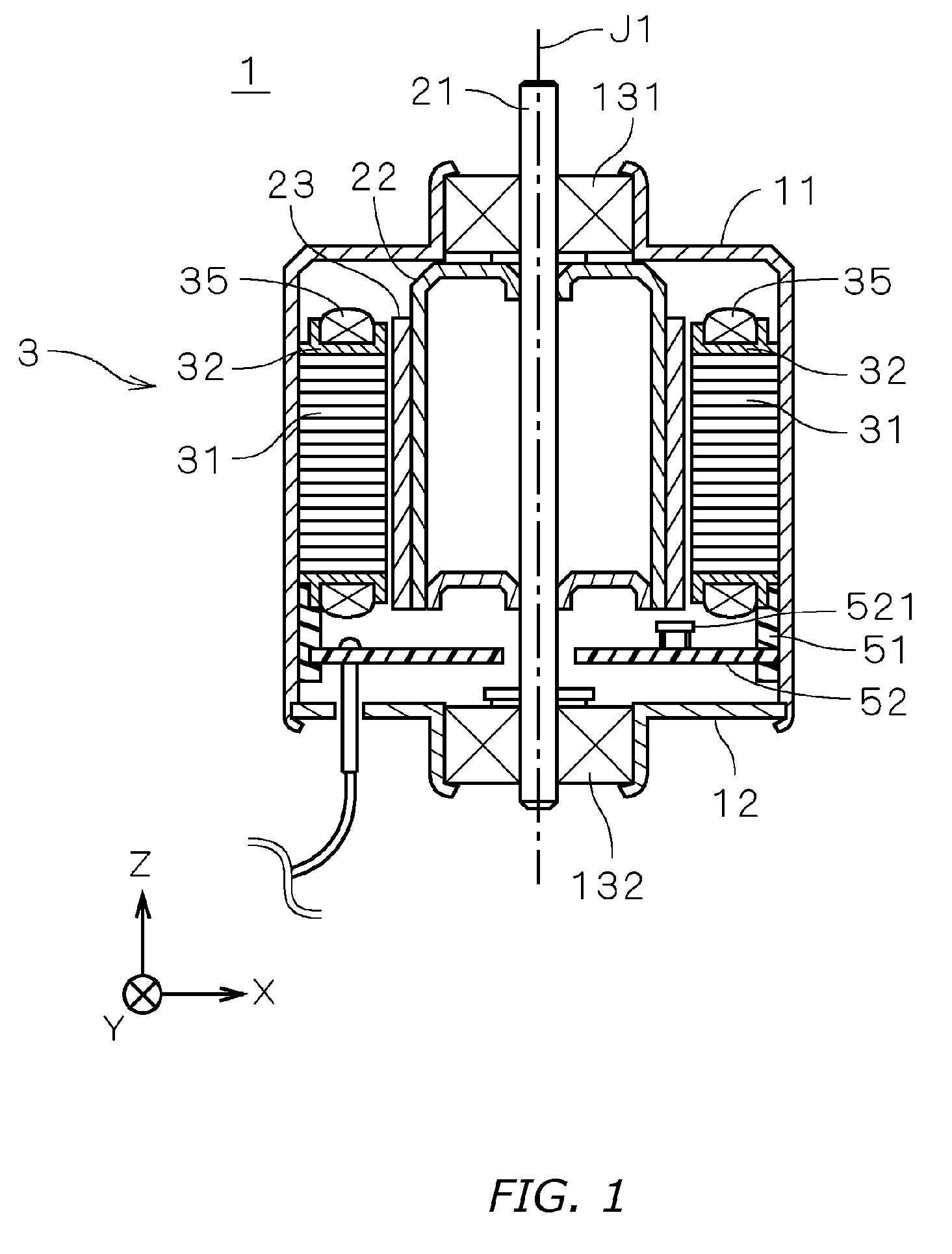

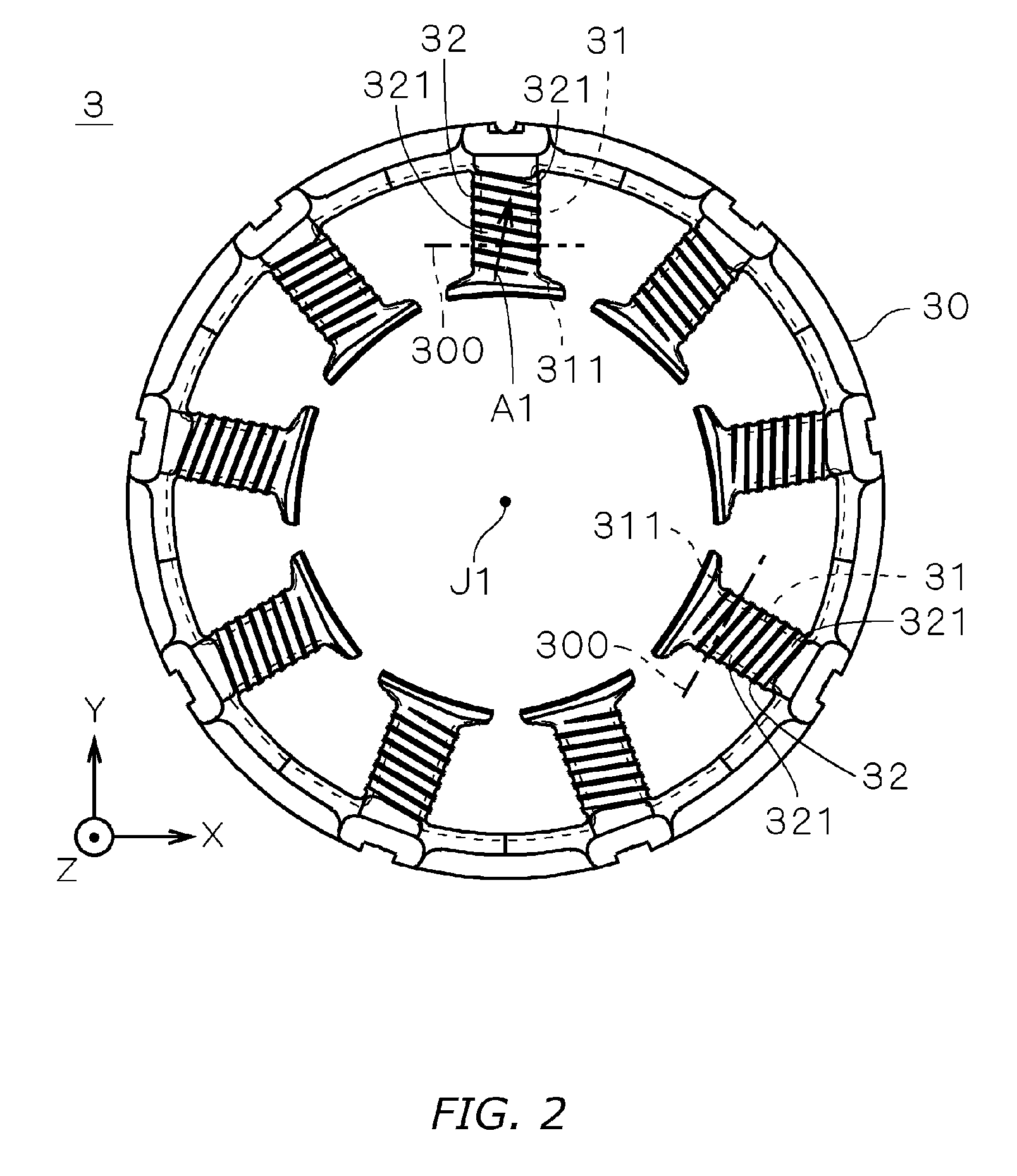

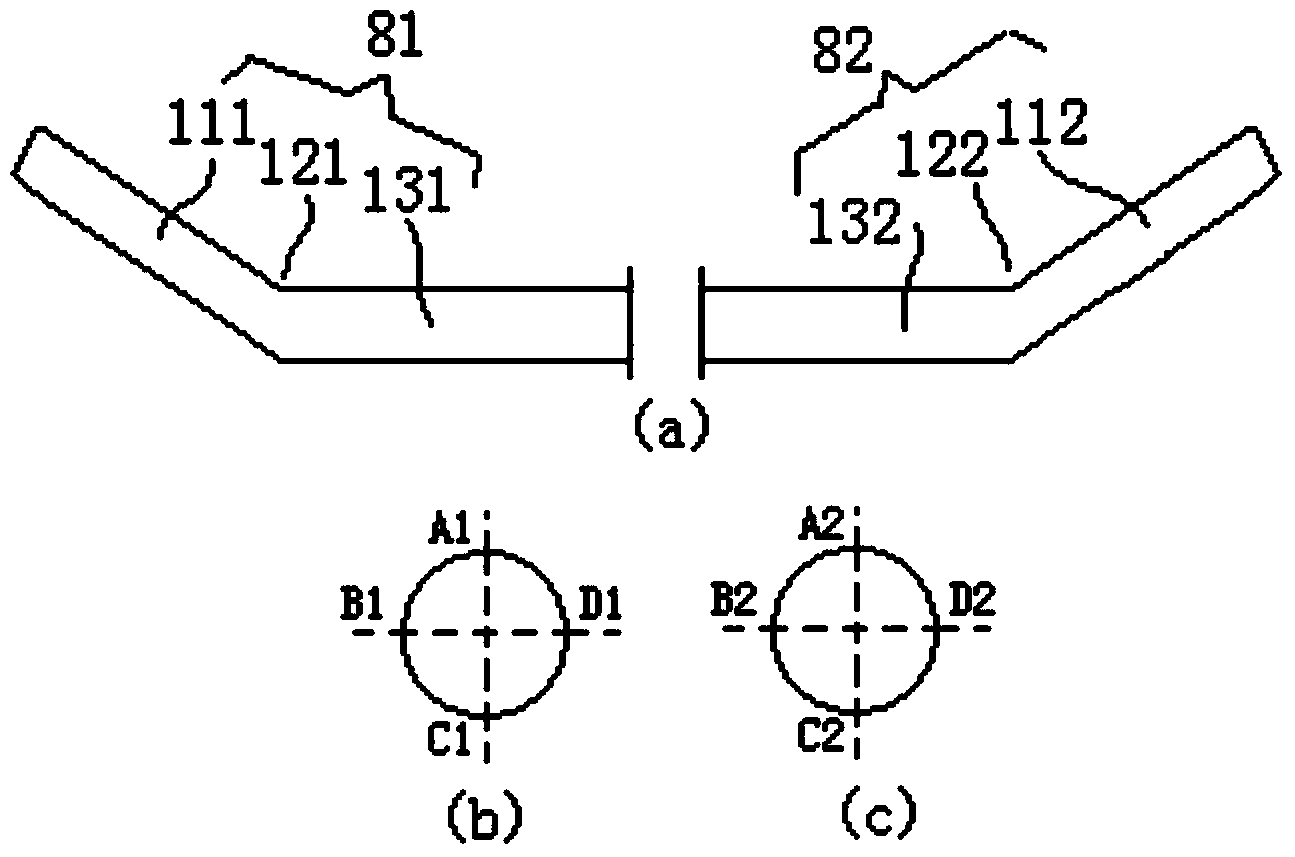

Motor Stator and Motor

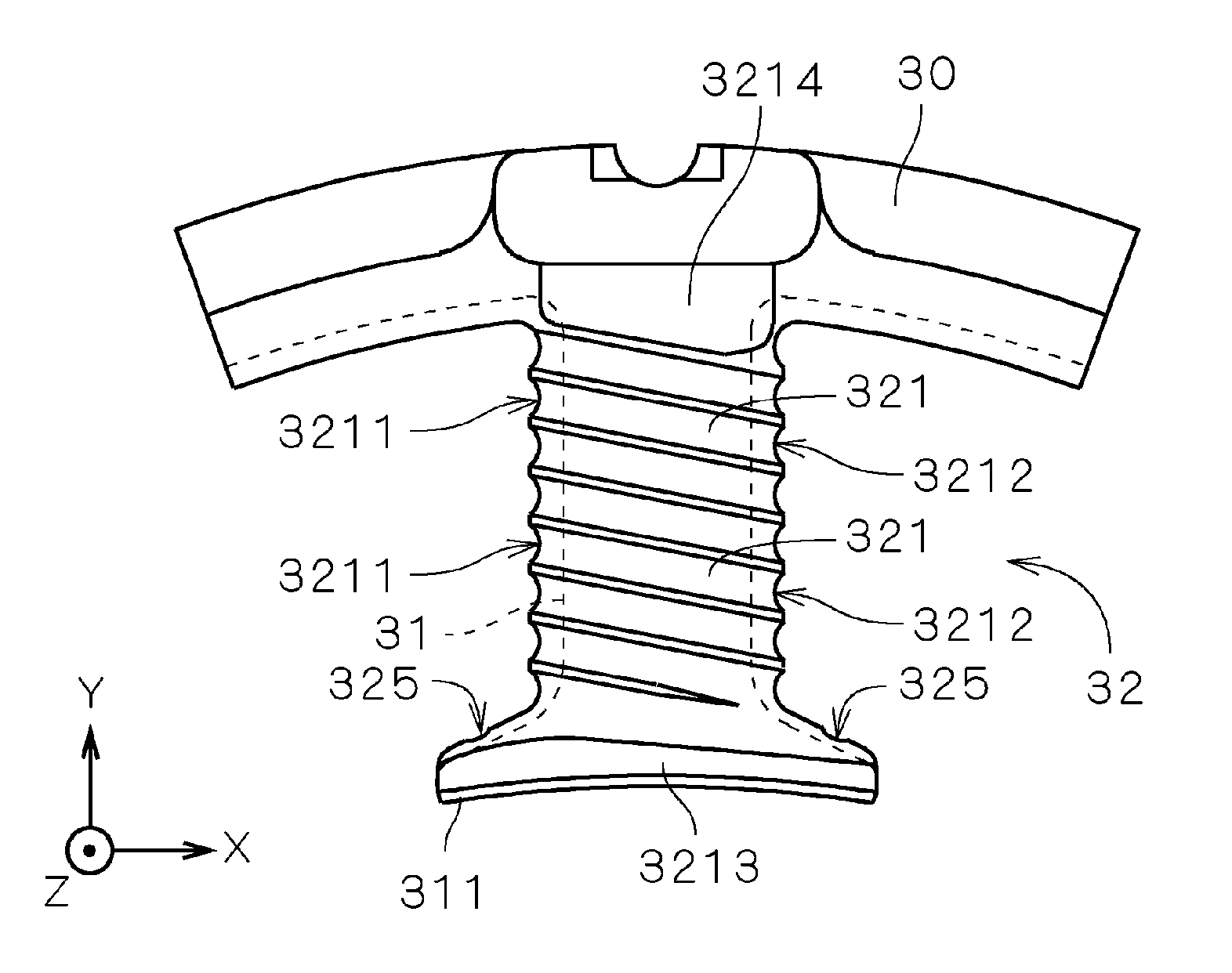

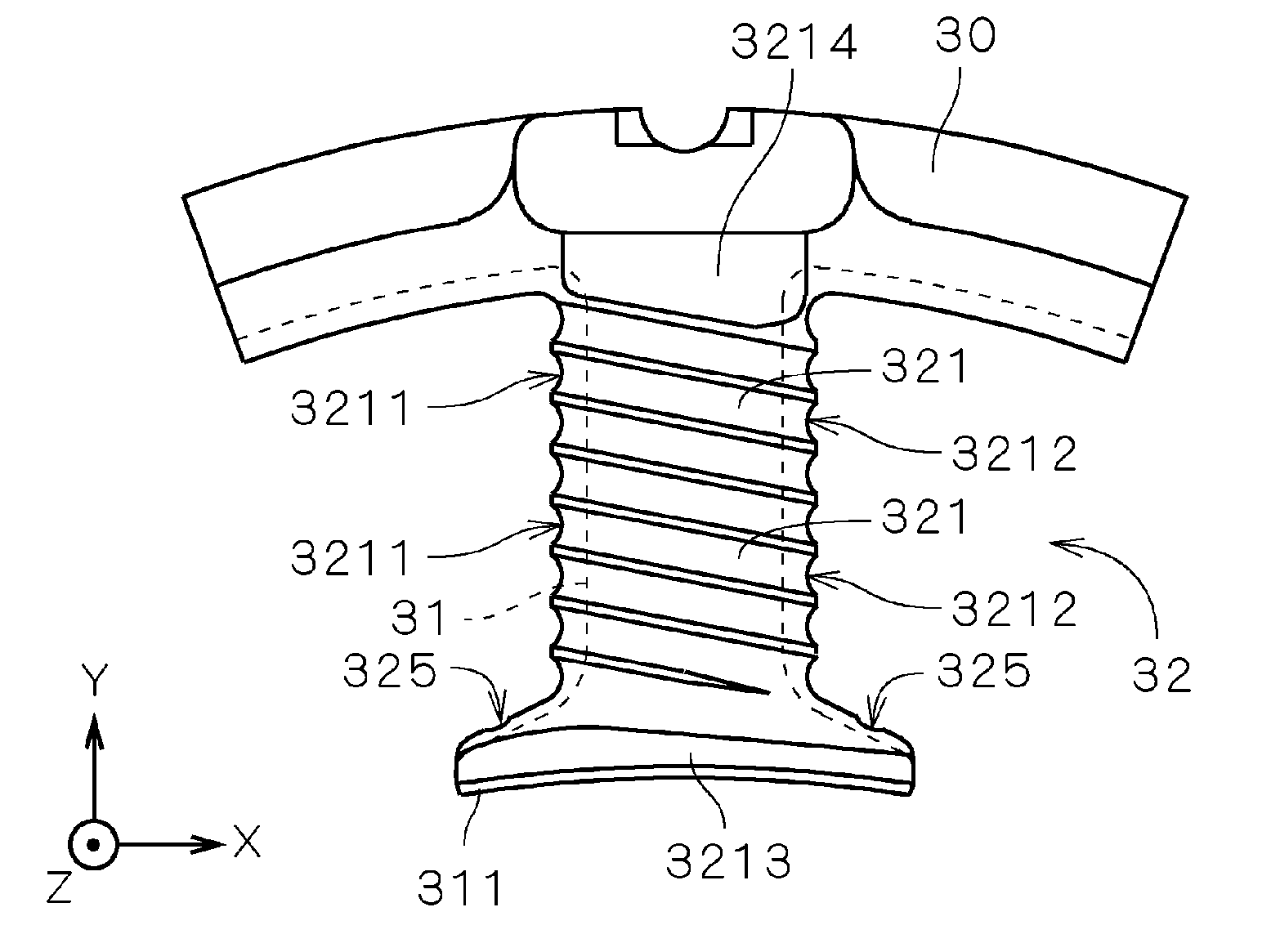

InactiveUS20060022549A1Reduce thicknessAvoid separationWindingsMagnetic circuitElectrical conductorEngineering

Motor stator in which a plurality of first guide grooves (321) and second guide grooves (322) that govern the winding position of conductors are formed on the upper end portion and lower end portion of insulators (32) which cover each of the stator teeth (31). The inclination of the first guide grooves is equal to the pitch of the first guide grooves, and the inclination of the second guide grooves is configured to be 0. The second-guide-groove start and end points are positioned on a straight line extending in the (−Z) direction from the first-guide-groove end point (3212) and from the adjoining first-guide-groove start point (3211) on the (−Y) side.

Owner:NIDEC CORP

Motor Stator and Motor

ActiveUS20060022550A1Reduce thicknessAvoid separationSynchronous generatorsWindingsElectrical conductorEngineering

A motor stator in one implementation includes a plurality of teeth disposed in a radial form centered about a predetermined center axis, insulators covering the plurality of teeth, and a plurality of coils provided on each of said plurality of teeth by winding conductors onto said insulators through to multiple layers. At one axial end of the plurality of areas where said insulators cover each of said plurality of teeth, the radius of curvature of the conductor windings on the ending side is larger than the radius of curvature on the starting side. The insulators in a motor stator in another implementation are provided with a first partition and a second partition that, relative to the axial center of the plurality of teeth, respectively cover one side and the other side each tooth.

Owner:NIPPON DENSAN CORP

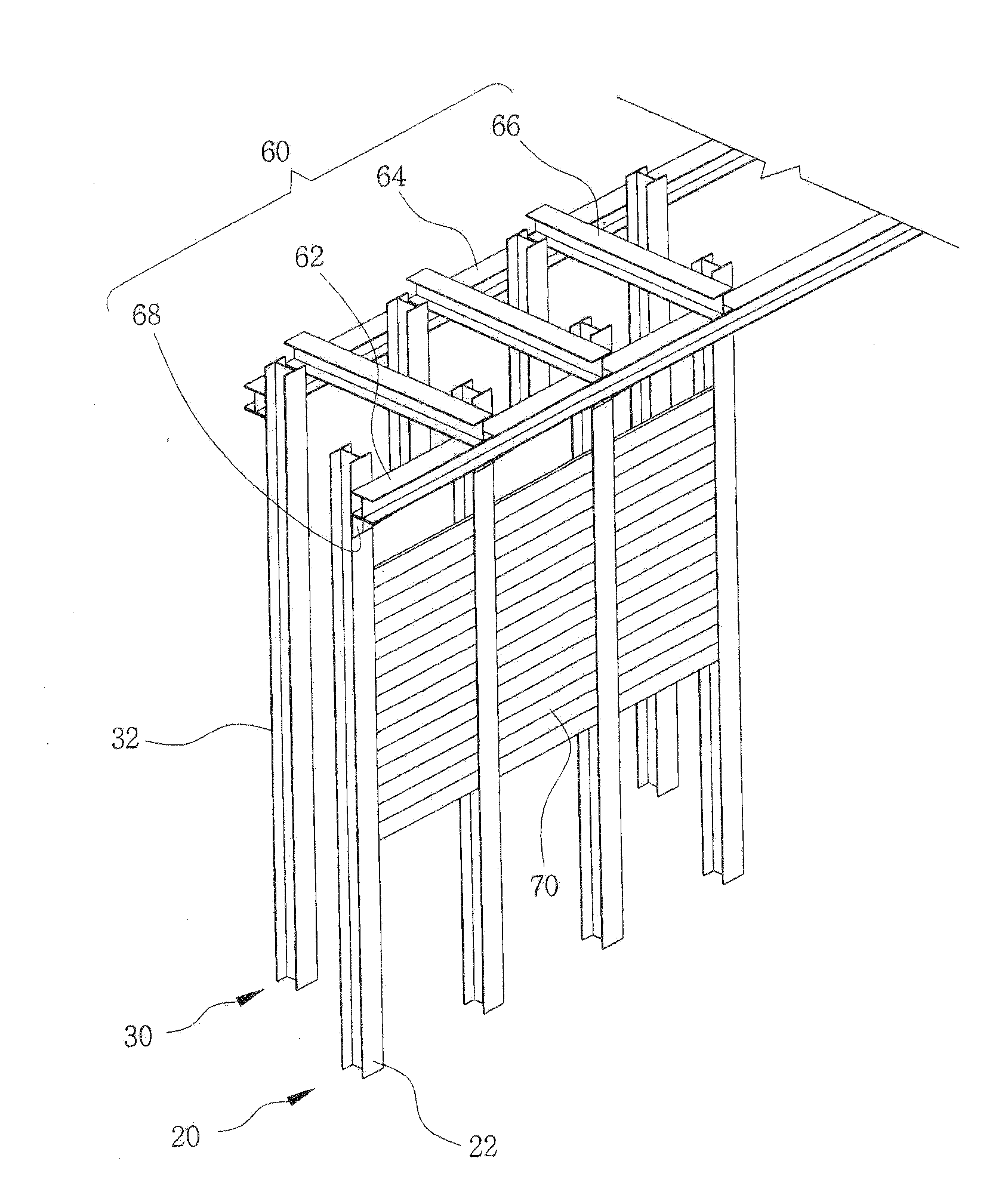

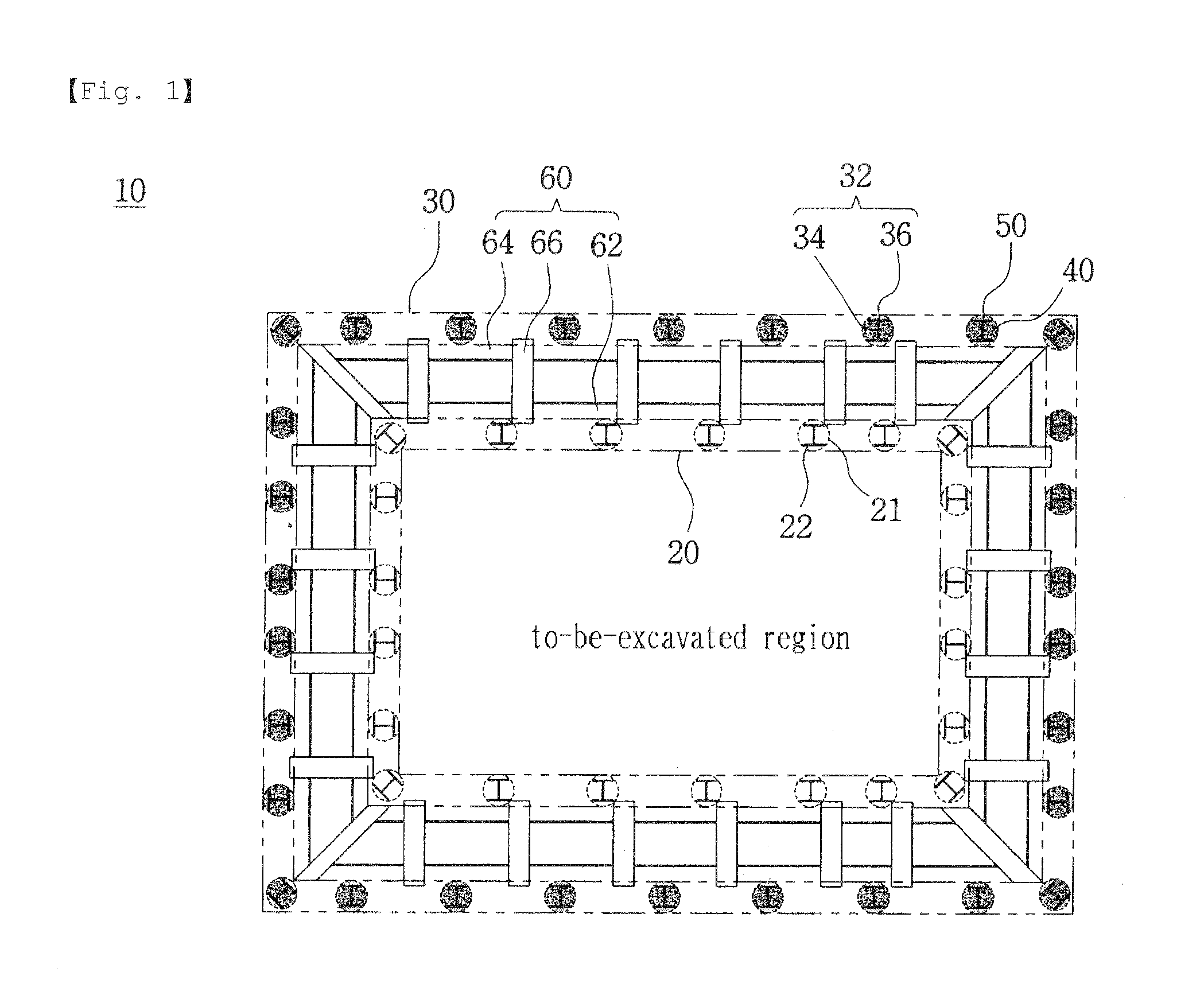

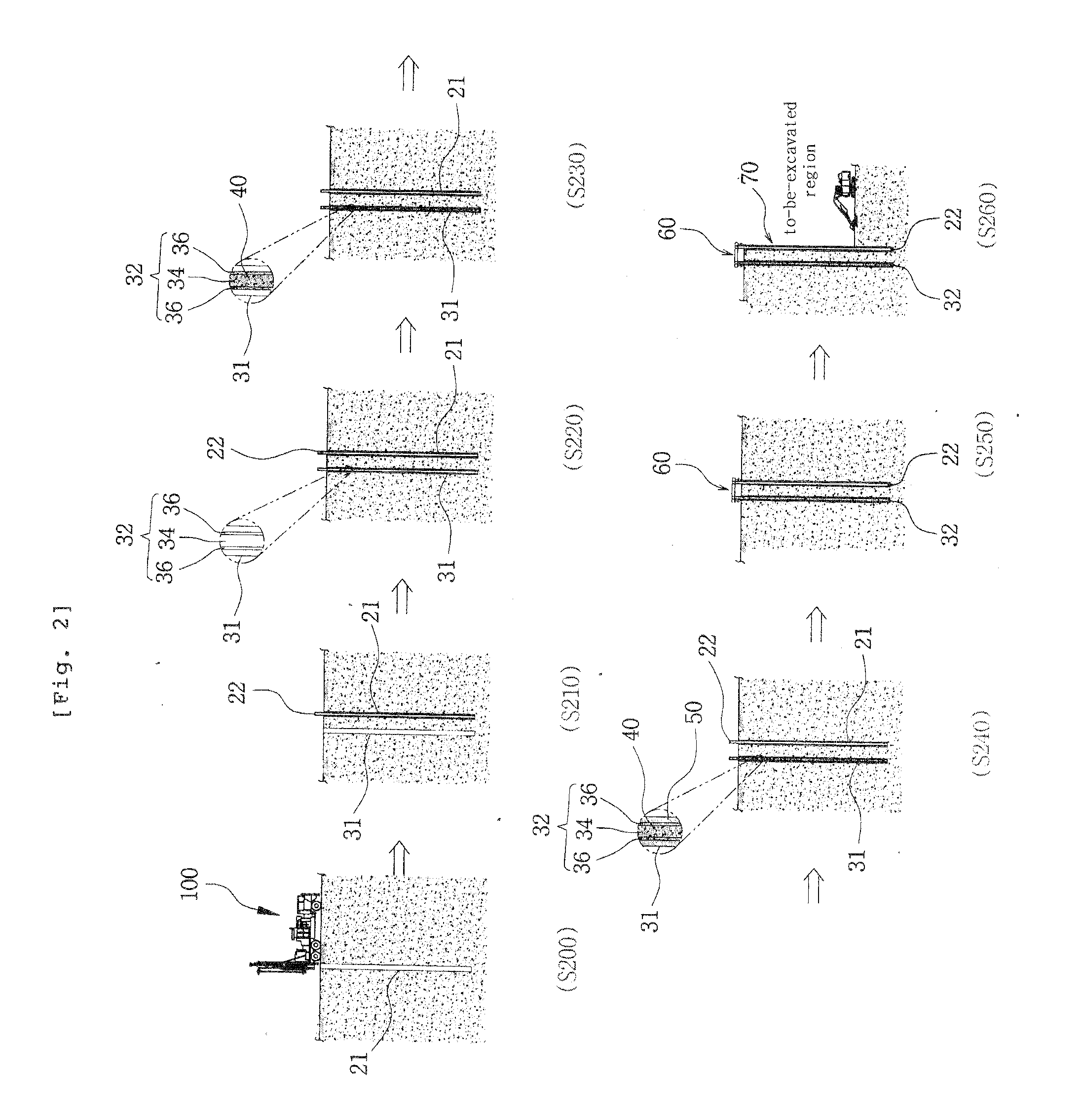

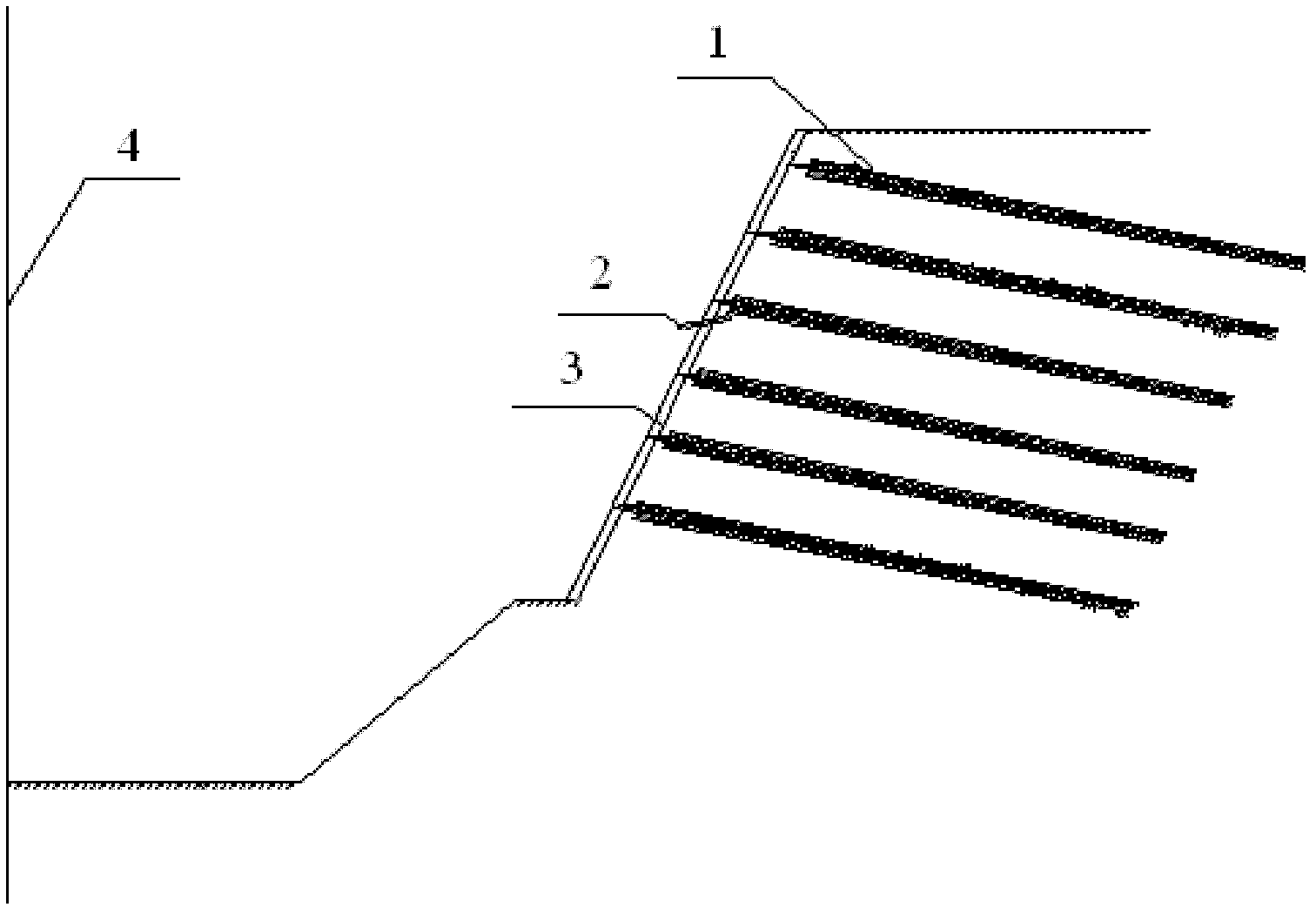

Method for constructing a chair-type, self-supported earth retaining wall

InactiveUS20110142550A1Low construction costShorten the construction periodArtificial islandsExcavationsRetaining wallOuter space

The present invention provides a method for constructing a chair-type, self-supported earth retaining wall used for retaining external forces such as earth pressure prior to an excavation. The method of the present invention forms a first column of piles having a plurality of piles arranged along the circumference of the region to be excavated. Subsequently, the method comprises forming a second column of piles having a plurality of piles by consecutively perforating a plurality of holes by a predetermined spacing at predetermined positions outwardly from the first column of piles, along the circumference of the region to be excavated, inserting H-beams into the respective holes, filling left and right spaces of the webs of the H-beams with soil, and filling the outer spaces of the flanges of the H-beams with a flowable stiffening material. The method subsequently comprises interconnecting the first column of piles and the second column of piles by a connection member. The first column of piles and the second column of piles are formed along the circumference of the region to be excavated, with an outward spacing, and connected to each other by the connection member.The present invention provides a method for constructing a chair-type, self-supported earth retaining wall used for supporting external forces such as earth pressure prior to an excavation. The method of the present invention comprises forming a first pile array 20 having a plurality of piles 22 arranged along a circumference of an region to be excavated. Subsequently, the method comprises forming a second pile array 30 having a plurality of piles arranged along a circumference of the to-be-excavated region by consecutively drilling a plurality of boreholes 31 at predetermined intervals at predetermined positions outwardly spaced apart from the first pile array, inserting H-beams into the respective boreholes, filling left and right spaces of webs 34 of the H-beams 32 with soil 40, and filling the outer spaces of flanges 36 of the H-beams with a flowable hardening material 50. The method subsequently comprises fixedly interconnecting the first pile array and the second pile array using a connection member. The first pile array and the second pile array are formed in such a fashion as to be outwardly spaced apart from each other along the circumferences of the to-be-excavated region, and are connected to each other by the connection member to construct an underground earth retaining wall.

Owner:KOLON CONSTR CO LTD

Development method of novel water-based timber rubbling coloring agent

The invention discloses a development method of a novel water-based timber rubbling coloring agent, relates to a decorative coloring material, and especially discloses a coloring agent of products such as wooden interior and exterior decoration, floors and wood doors. The novel water-based timber rubbling coloring agent has diaphaneity and vividness and also has coloring, porefilling and primary coat sealing functions, the required different rare timber colors can be obtained by rubbing the coloring agent on the surface of a product through fabric, the application method is simple and convenient, the cost is low and reasonable, the water is utilized as a solvent, and the novel water-based timber rubbling coloring agent is green, innoxious and tasteless.

Owner:唐述华 +1

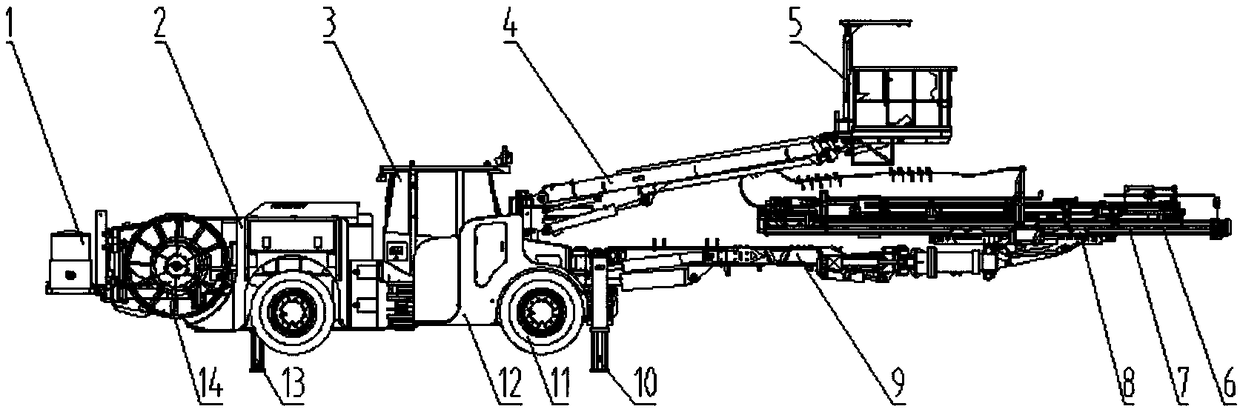

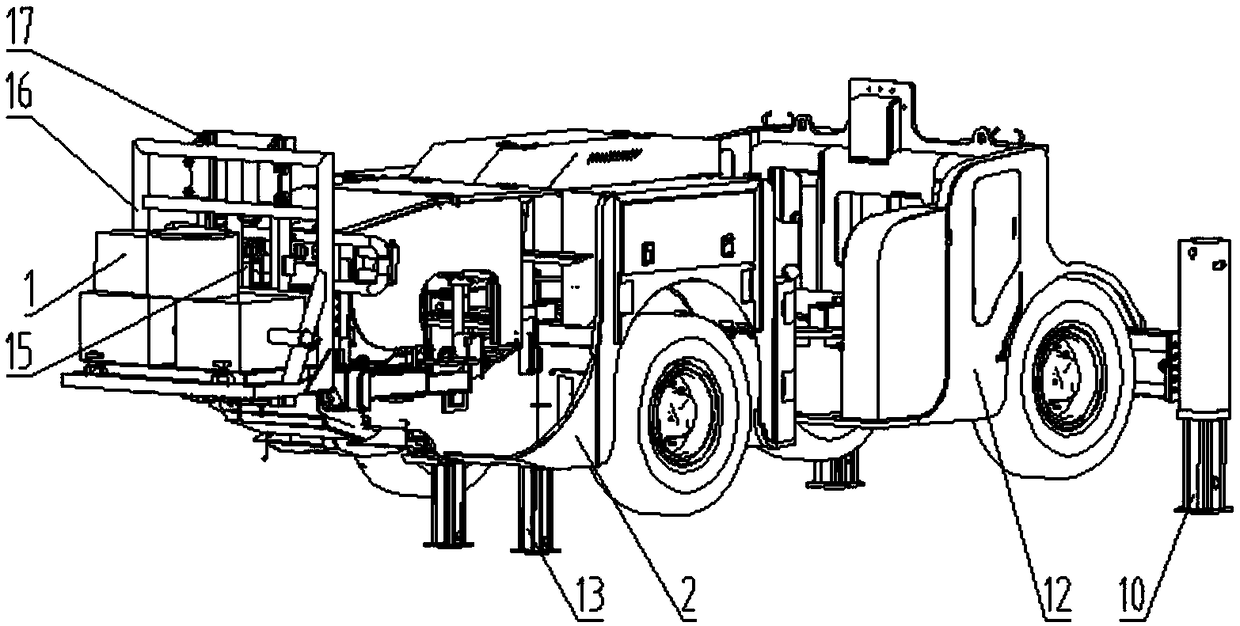

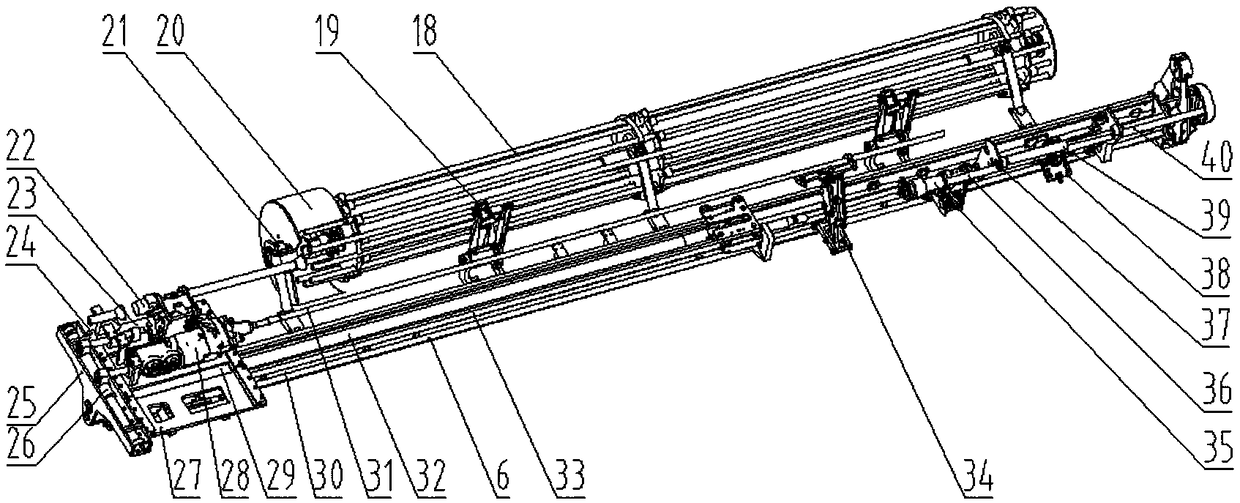

Full-automatic rock bolting jumbo

The invention provides a full-automatic rock bolting jumbo which comprises a chassis and a frame mounted on the chassis. A work arm and a bolt element are arranged at the front end of the frame, the bolt element is arranged at one end of the work arm and comprises a propulsion beam device and a grouting pipe frame, the grouting pipe frame is arranged on one widthwise side of the propulsion beam device and close to a bolt hole, a grouting device is arranged at the rear end of the frame and comprises a grouting pipe, and the grouting pipe moves into the bolt hole through swing and horizontal drive of the grouting pipe frame and performs grouting. The full-automatic rock bolting jumbo has the advantages that an automatic grouting function is achieved, grouting efficiency and reliability are high and the like.

Owner:CHINA RAILWAY CONSTR HEAVY IND

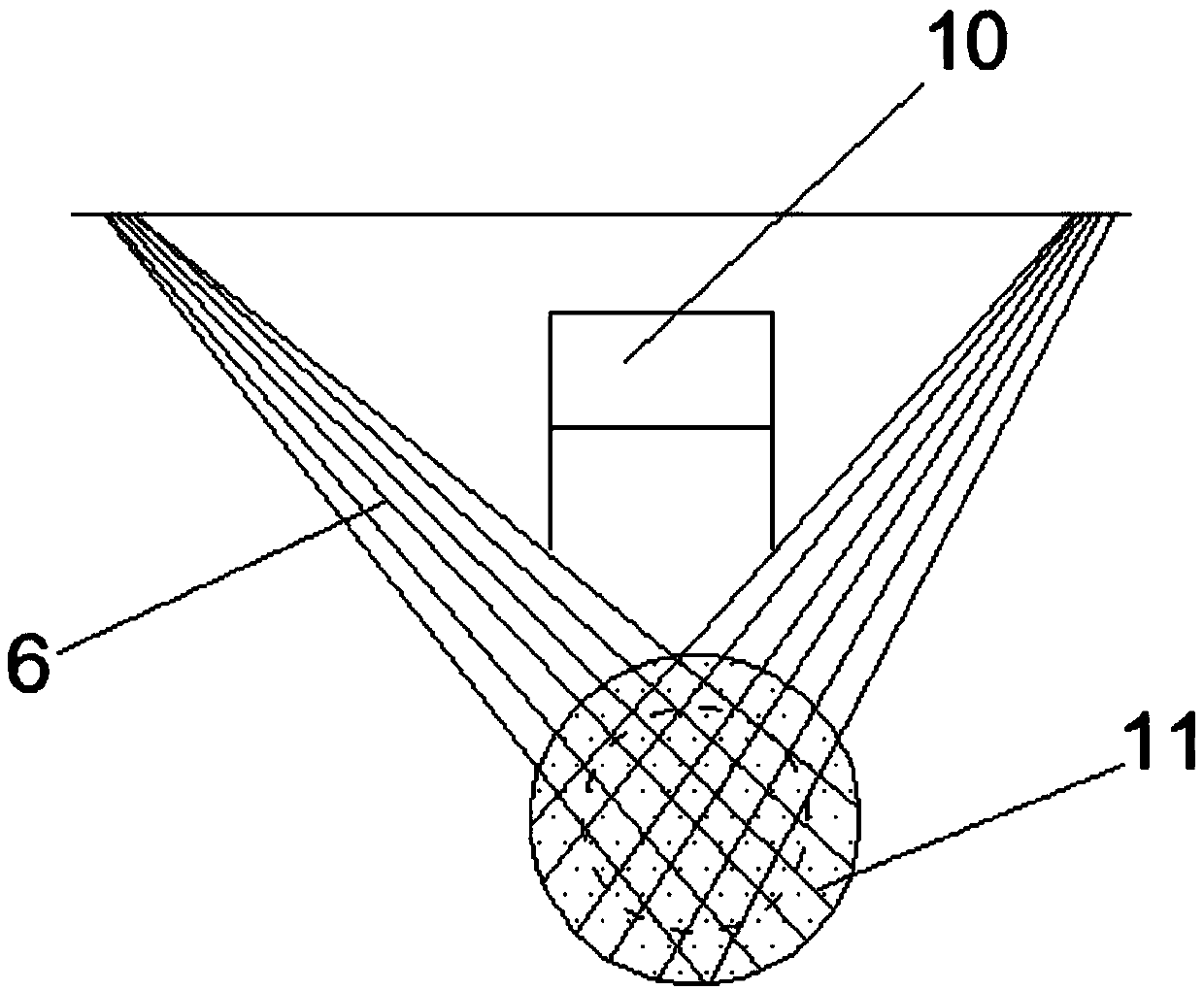

Full-enclosed type flexible deepwater enclosure

InactiveCN101158149AStrong enoughSolve the problem of aging damageMarine site engineeringEngineeringCoating

A totally enclosed flexible deep water enclosure can effectively separate open water body. The main body comprises a flexible bar shape floating body, a cork rope, a wall cloth, a ground rope, and a stone dragon. The stone dragon is buried in a sealed close bottom end of a silt layer, and the flexible bar shape floating body floats on the water to form separation. A mooring cable is used for fixing the ground rope on two under water wood piles at two sides, preserving degree relaxation in the vertical and horizontal directions. An under water anchoring mooring cable, the ground rope, a wall cloth longitudinal stiffening rib, and the cork rope constitutes the network-shape mechanics structure of the enclosure. The flexible bar shape floating body uses a flue to wrap a flexible closed-hole foam plastic strip, and the outside is protected by a changeable coating for structural durability. The enclosure subsections are connected by zipper fashion blanket stitches, convenient for processing, transportation, installation, dissembling, maintenance, and reuse, and can be used for contemporary separation of part water areas of the open water body, such as the boundary control of water surface project area, the separation and diversion of polluted water mass. The invention is suitable for natural conditions such as deep water (10m above), storm, water current, water level fluctuating, with the service life of 5-10 years.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

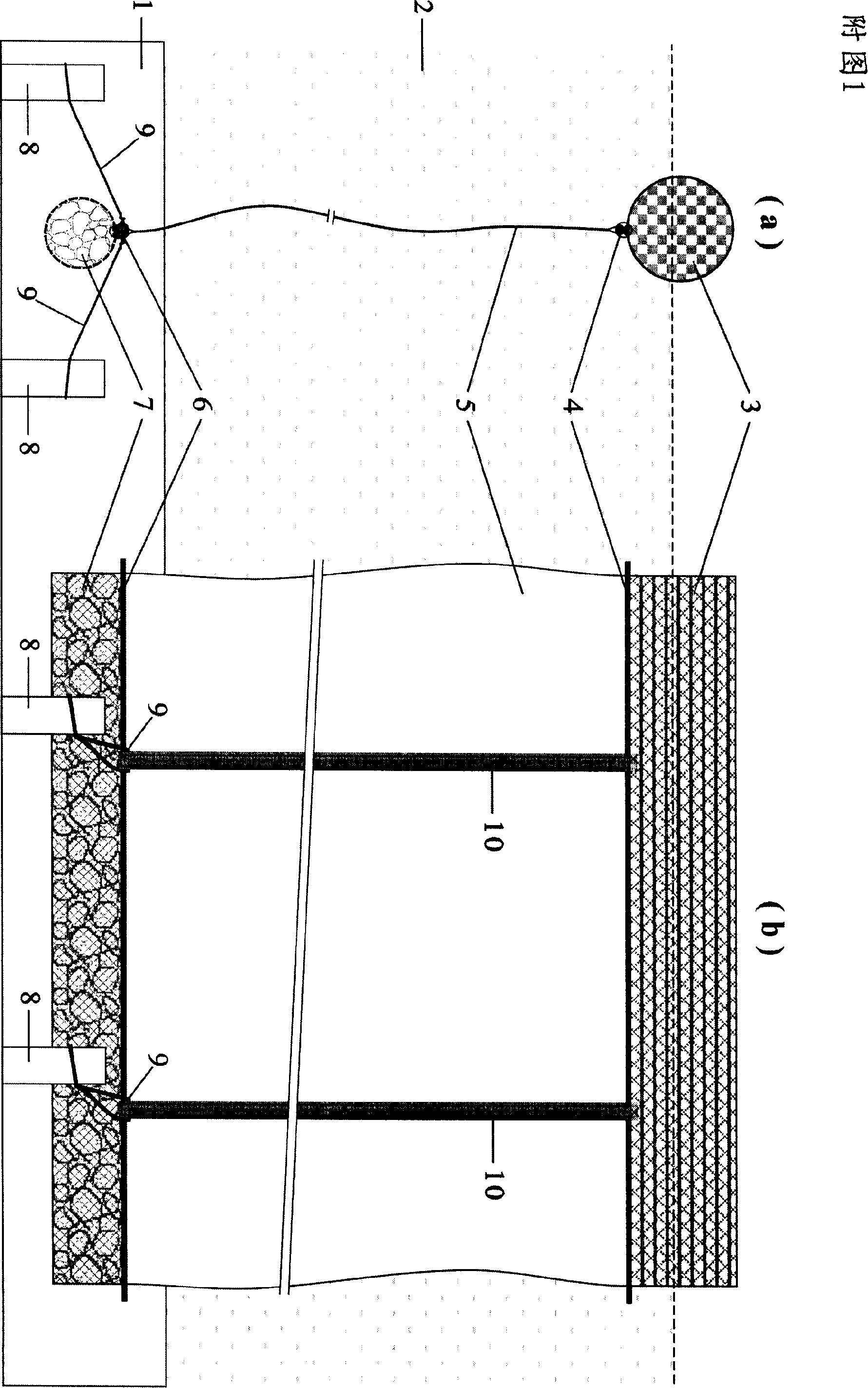

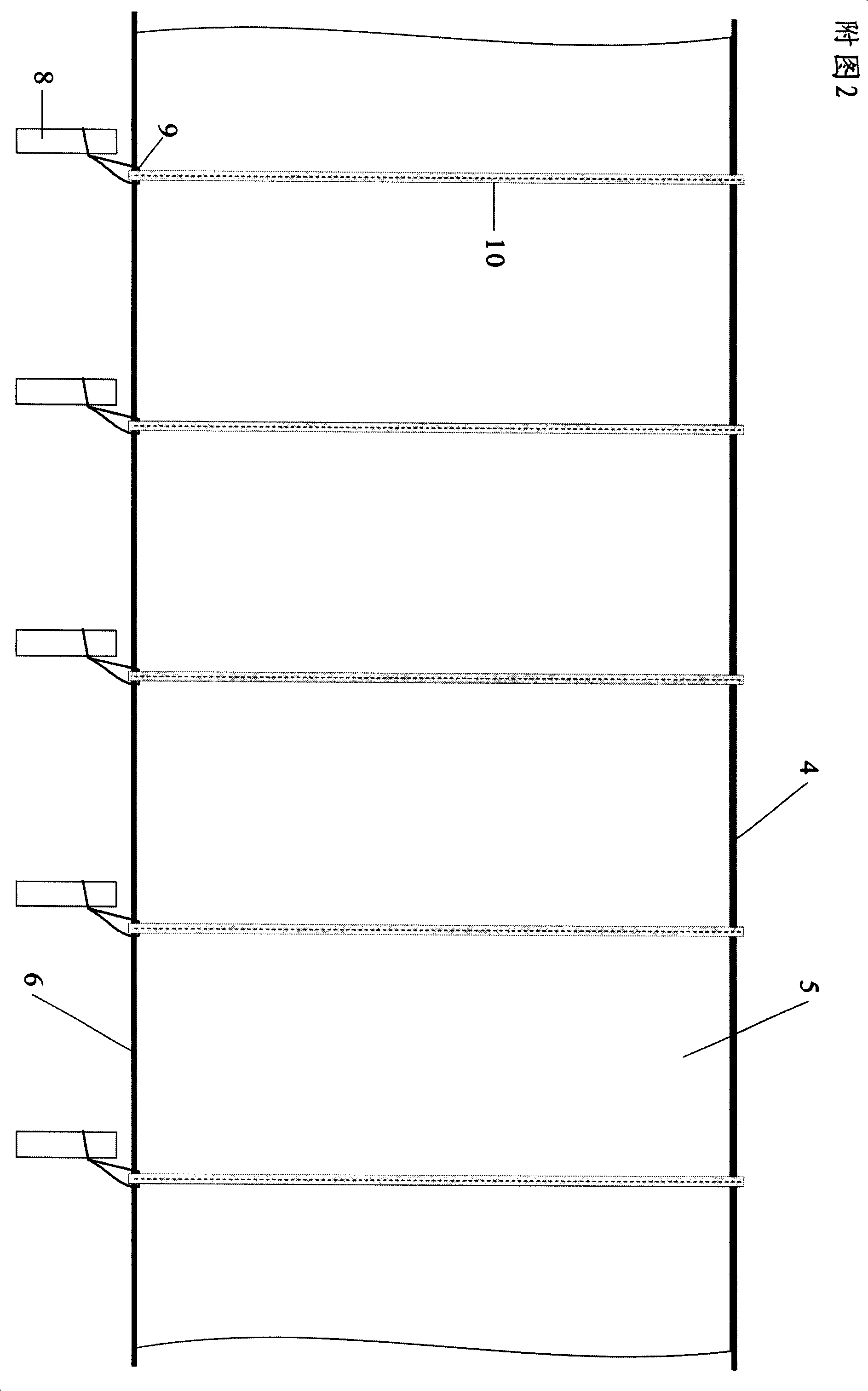

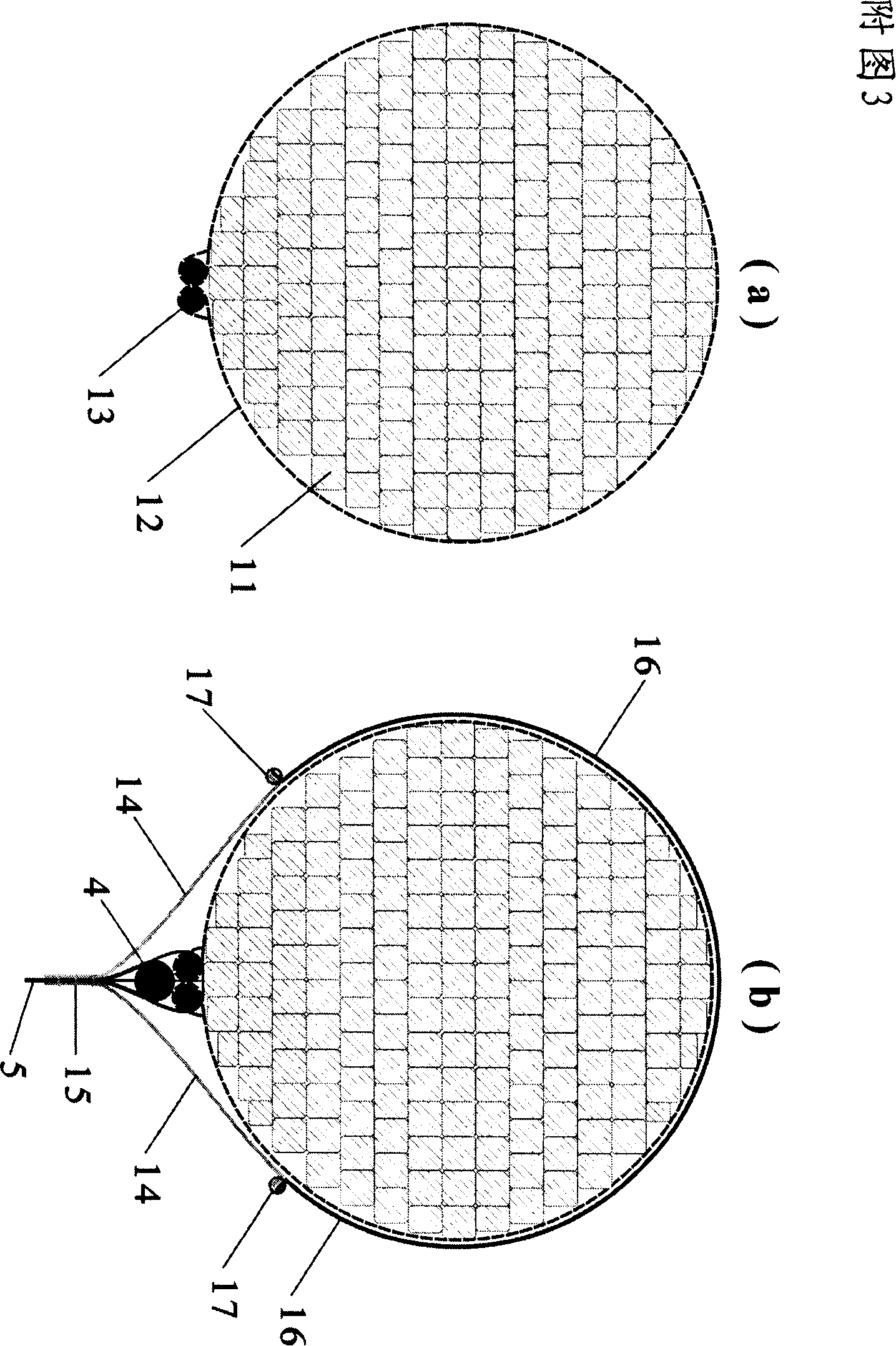

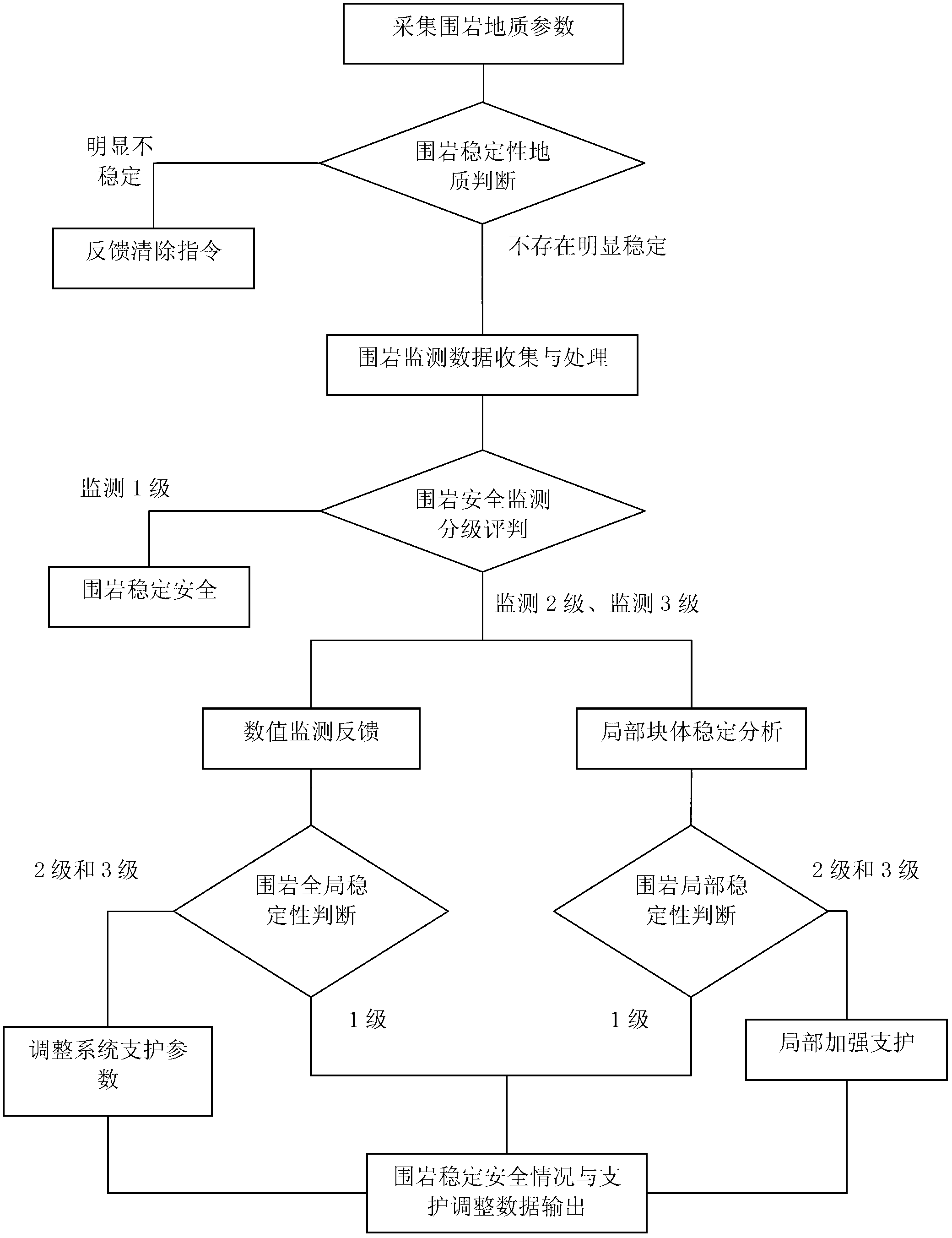

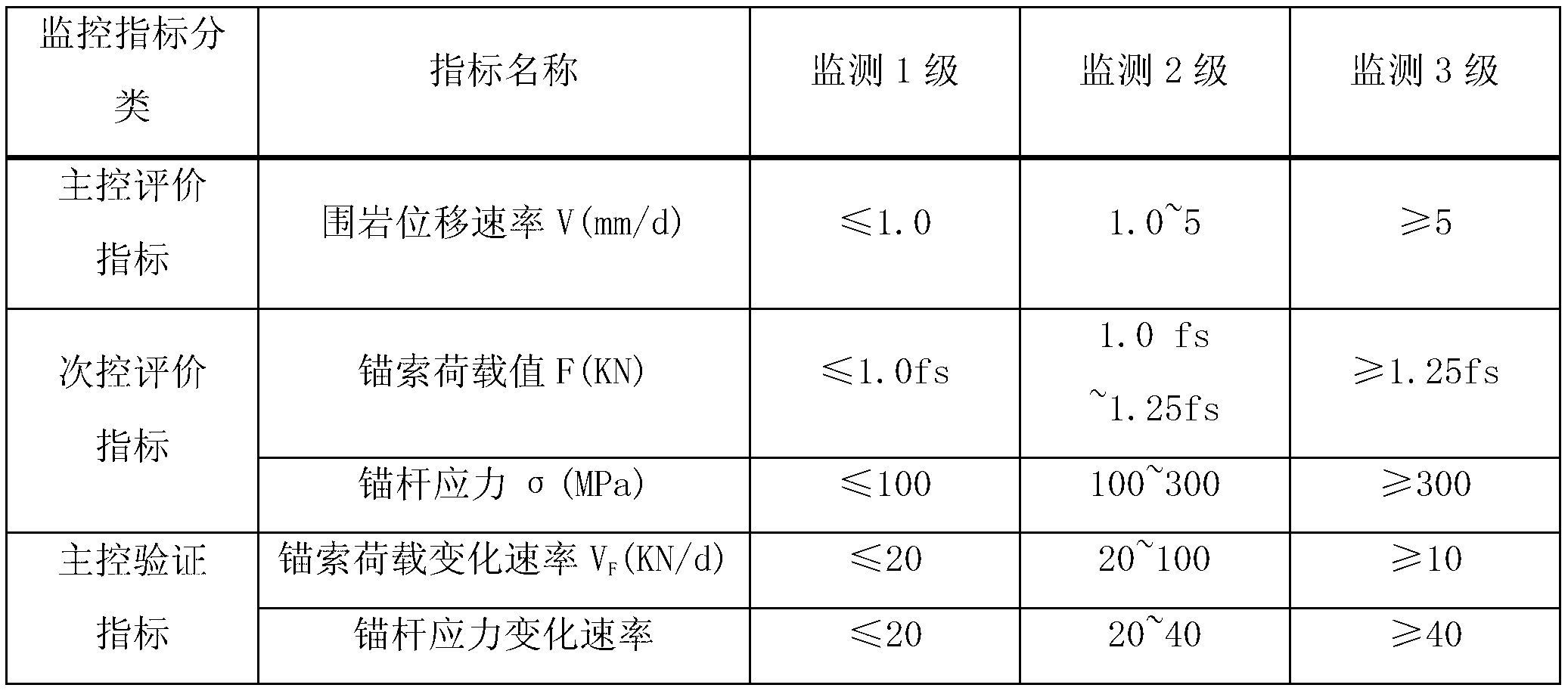

Method for quantitatively evaluating surrounding rock stability of ultra-large underground cavern group in construction period

ActiveCN103233741AGuarantee smooth constructionIntuitive and accurate stability judgment dataTunnelsUnderground cavernCollection methods

The invention relates to a method for monitoring the surrounding rock stability of an ultra-large underground cavern group in a construction period, in particular to a method for monitoring the surrounding rock stability of an ultra-large underground cavern group and used in a hydropower station construction period. The method includes the following steps: collecting geological parameters of surrounding rock through various geological collection methods, judging whether the geology of the surrounding rock is instable remarkably according to the collected geological parameters, processing the collected geological parameter information on yes judgment and grading the processed data with each grade of data corresponding to the preset stability degree judging value. The method for effectively and quantitatively evaluating the surrounding rock stability of the ultra-large underground cavern group in the construction period has the advantages of being capable of acquiring directly-perceived accurate stability judgment data and favorable for stabilizing the surrounding rock, ensuring construction safety and guaranteeing smooth engineering construction and long-term safe stable operation. The method is especially suitable for monitoring the surrounding rock stability of the ultra-large underground cavern group in the construction period.

Owner:POWERCHINA CHENGDU ENG

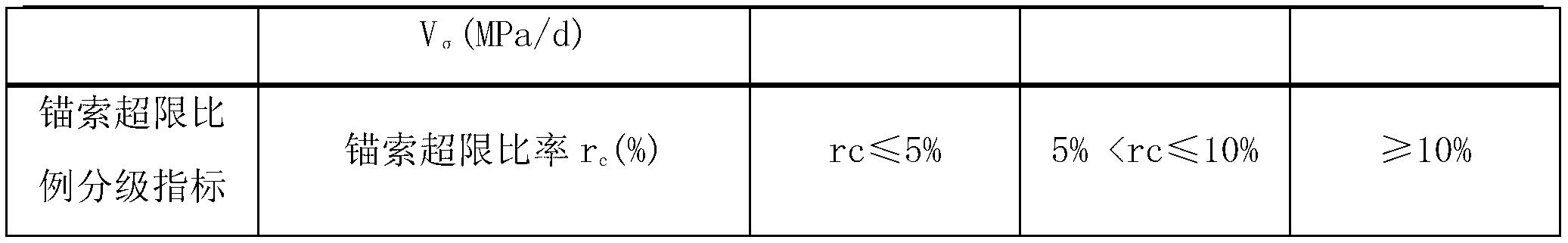

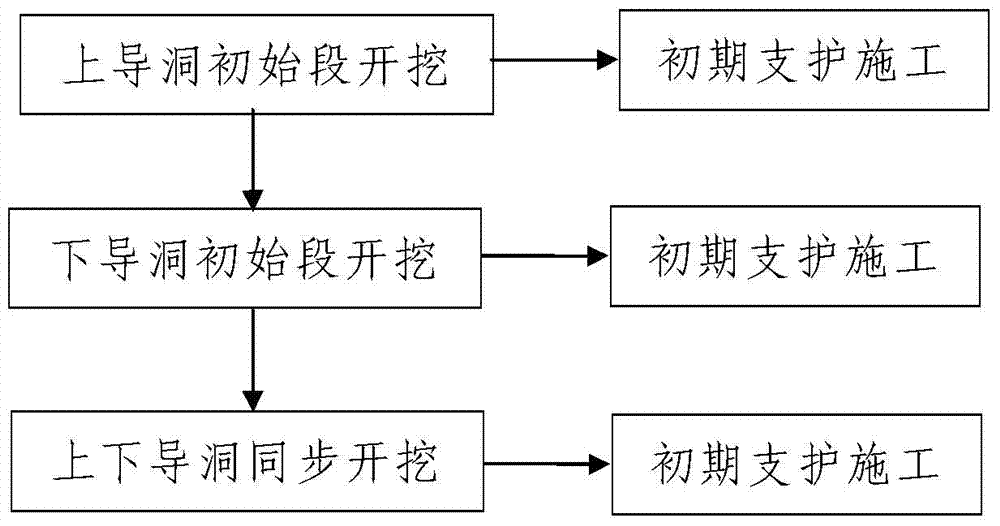

Construction method for enabling shallowly buried and darkly excavated tunnel to pass through cottage area

ActiveCN104500077AThe method steps are simpleReasonable designUnderground chambersTunnel liningRebarInitial segment

The invention discloses a construction method for enabling a shallowly buried and darkly excavated tunnel to pass through a cottage area. The construction method comprises the following steps: excavating a tunnel hole of the constructed shallowly buried and darkly excavated tunnel from back to front through a step excavation process, and performing preliminary bracing on the tunnel hole formed by excavating from back to front in an excavating process, wherein the tunnel hole consists of an upper guide hole and a lower guide hole positioned right below the upper guide hole, the rear part of the tunnel hole is connected with a vertical well, the preliminary bracing structure of the tunnel hole comprises a plurality of grating steel frameworks for supporting the tunnel hole from back to front, a layer of bar-mat reinforcement suspended on the inner wall of the tunnel hole and a concrete layer jetted on the inner wall of the tunnel hole. The process for excavating the tunnel hole of the shallowly buried and darkly excavated tunnel comprises the following steps: I, excavating the initial segment of the upper guide hole; II, excavating the initial segment of the lower guide hole; III, synchronously excavating the upper and the lower guide holes. The construction method disclosed by the invention is simple in step, reasonable in design, convenient in construction, good in construction effect, capable of simply completing the construction process of the shallowly buried and darkly excavated tunnel that passes through the cottage area, and safe and reliable in a construction process.

Owner:CHINA RAILWAY 20 BUREAU GRP

Motor stator teeth with insulators

ActiveUS7291955B2Reduce thicknessAvoid separationSynchronous generatorsMagnetic circuitElectrical conductorElectric machine

A motor stator in one implementation includes a plurality of teeth disposed in a radial form centered about a predetermined center axis, insulators covering the plurality of teeth, and a plurality of coils provided on each of said plurality of teeth by winding conductors onto the insulators through to multiple layers. At one axial end of the plurality of areas where the insulators cover each of the plurality of teeth, the radius of curvature of the conductor windings on the ending side is larger than the radius of curvature on the starting side. The insulators in a motor stator in another implementation are provided with a first partition and a second partition that, relative to the axial center of the plurality of teeth, respectively cover one side and the other side each tooth.

Owner:NIDEC CORP

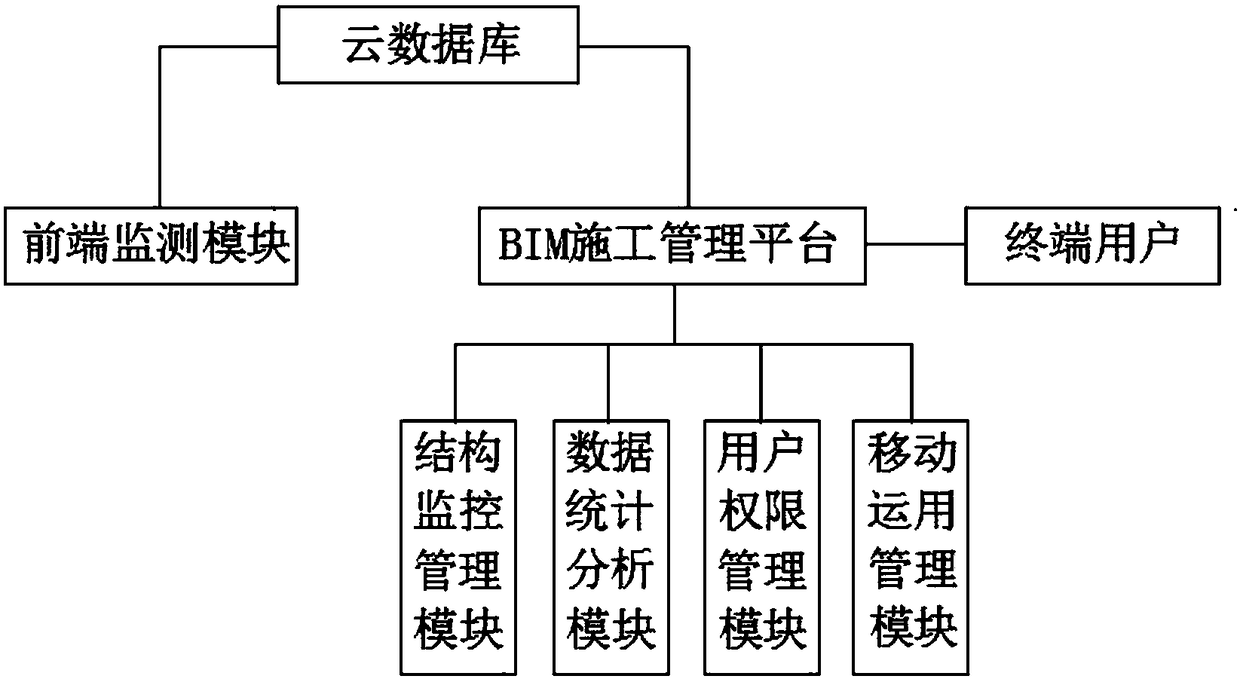

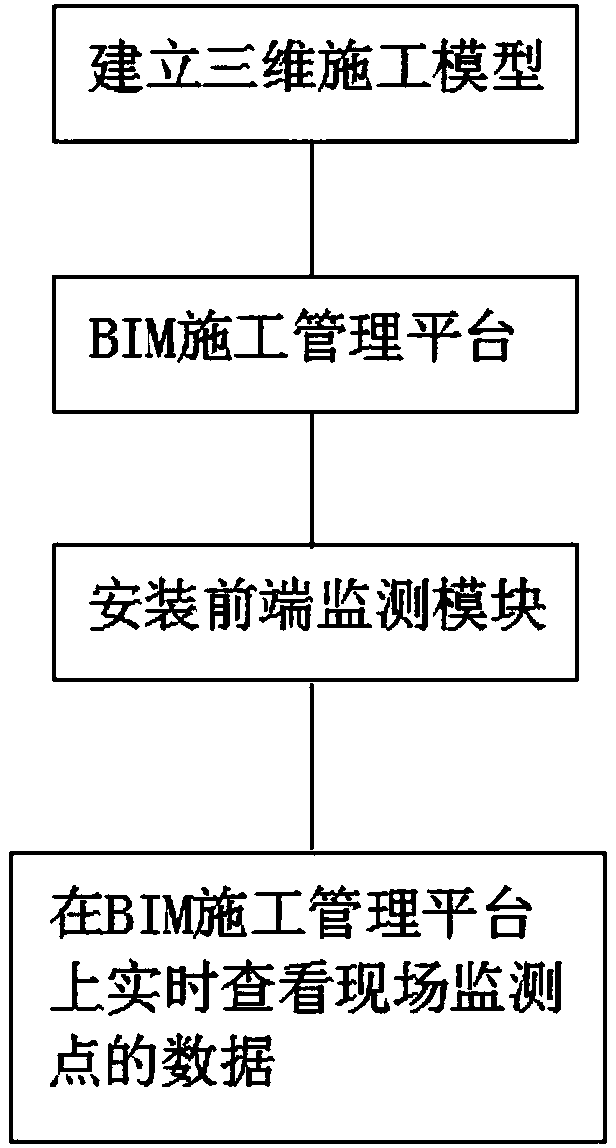

Construction monitoring system and construction monitoring method for cast-in-site bridge supporting system based on BIM

InactiveCN108537463AOptimize post-designConstruction safetyResourcesApparatus for force/torque/work measurementData informationStructure of Management Information

The invention relates to a construction monitoring system for a cast-in-site bridge supporting system based on BIM. The construction monitoring system comprises front end monitoring modules, a cloud database, a BIM construction management platform and a terminal user, wherein a plurality of front end monitoring modules are arranged on key position points of the supporting system and transmit information, monitored in real time, about pressure, stress and the like of the supporting system to the cloud database according to a wireless transmission technique; the cloud database analyzes and processes the received data information for the BIM construction management platform to automatically read; the BIM construction management platform analyzes and processes the data of the pressure, the stress and the like of a front end, namely a construction site supporting system and transmits the processed data to the terminal user. The construction monitoring system disclosed by the invention has the characteristics of real-time safe monitoring, automatic early warning report, accurate emergency disposal measures and the like, can realize three-dimensional and picture and text integrated intelligent management for structure quality of an engineering project and monitors the change of site monitoring points in real time anytime and anywhere; the construction monitoring system also has the advantages of simple and visual operation, labor conservation, and high popularization and application value.

Owner:THE THIRD CONSTR CO LTD OF CTCE GRP +1

Muck improving and slip casting method for sandy gravel stratum tunnel shield construction

PendingCN111350509AEnsure the amount of groutConstruction safetyUnderground chambersTunnel liningSupporting systemSupport system

The invention discloses a sandy gravel stratum tunnel shield construction method which comprises the following steps that an end portal is reinforced, and a starting bracket is installed; a reaction frame supporting system is mounted; and shield muck, portal extension steel ring and sealing installation is achieved, shield excavation parameter optimization is carried out, and measurement, adjustment and the like are achieved. Shield construction is ensured to be safe, smooth and rapid, and the ideal working condition during shield excavation into a sand-gravel stratum is achieved.

Owner:NO 1 ENG CO LTD OF CHINA RAILWAY 22ND CONSTR BUREAU +1

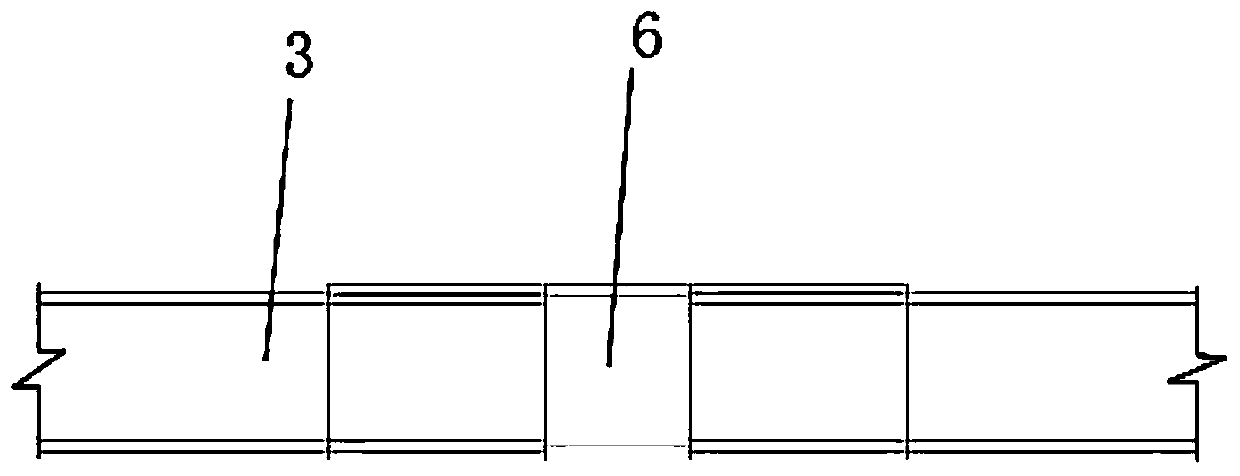

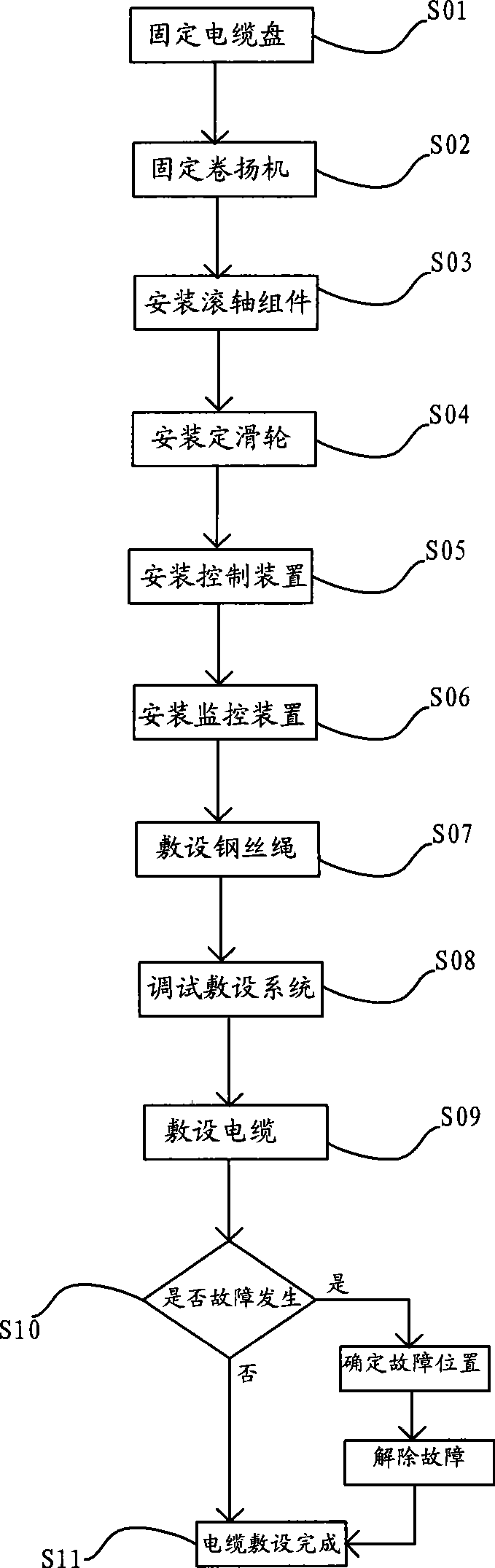

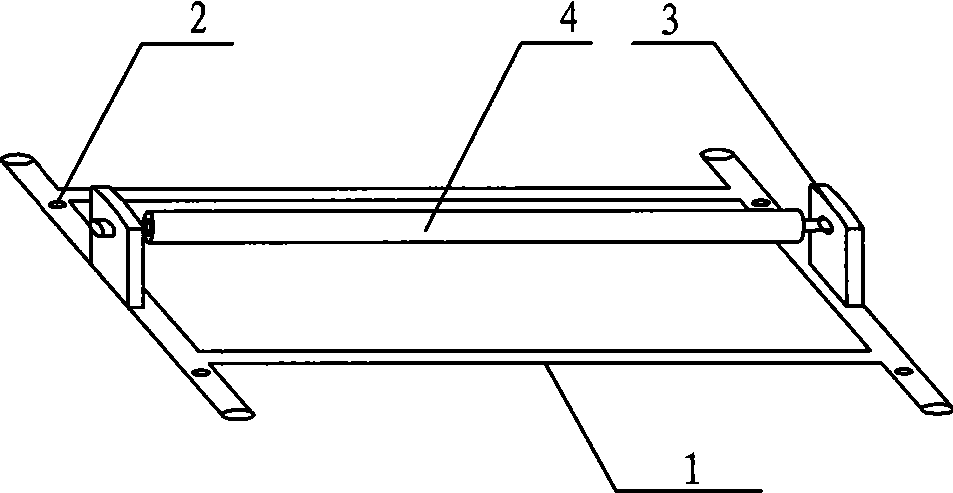

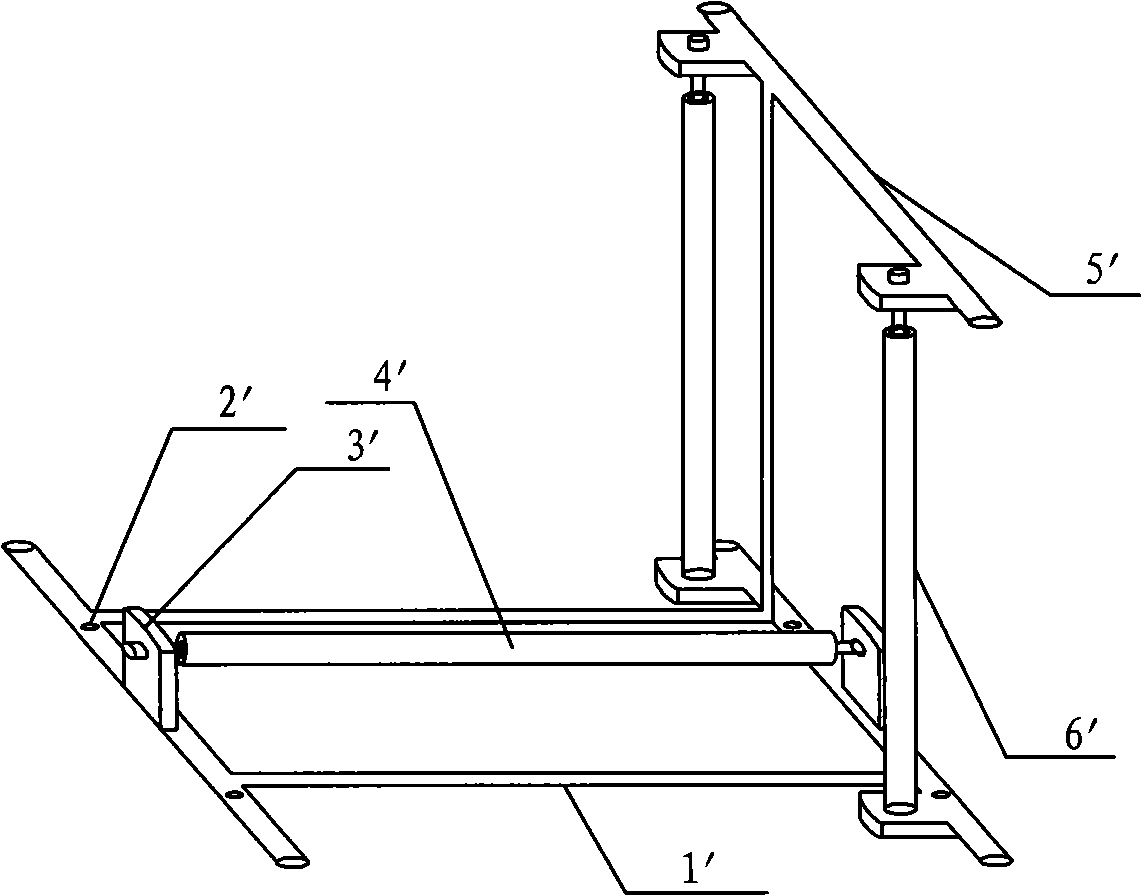

Automatic laying method for electric cable and apparatus thereof

The invention discloses a method and a device for automatically laying cables. The method comprises the steps of (1) preparing for construction, and installing and configuring a cable controller, a cable reel support and a windlass; (2) installing a group of guide brackets at proper intervals on the path where cables need laying; (3) laying wire ropes along the guide brackets, wherein, one end of each of the wire ropes is connected with the windlass, and the other end thereof is connected with one end of a cable; (4) turning the windlass to lay the cables on the guide brackets by the controller. The invention has the advantages of less labor, little investment, wide application, reducd labor intensity of workers, and convenient maintenance.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD +1

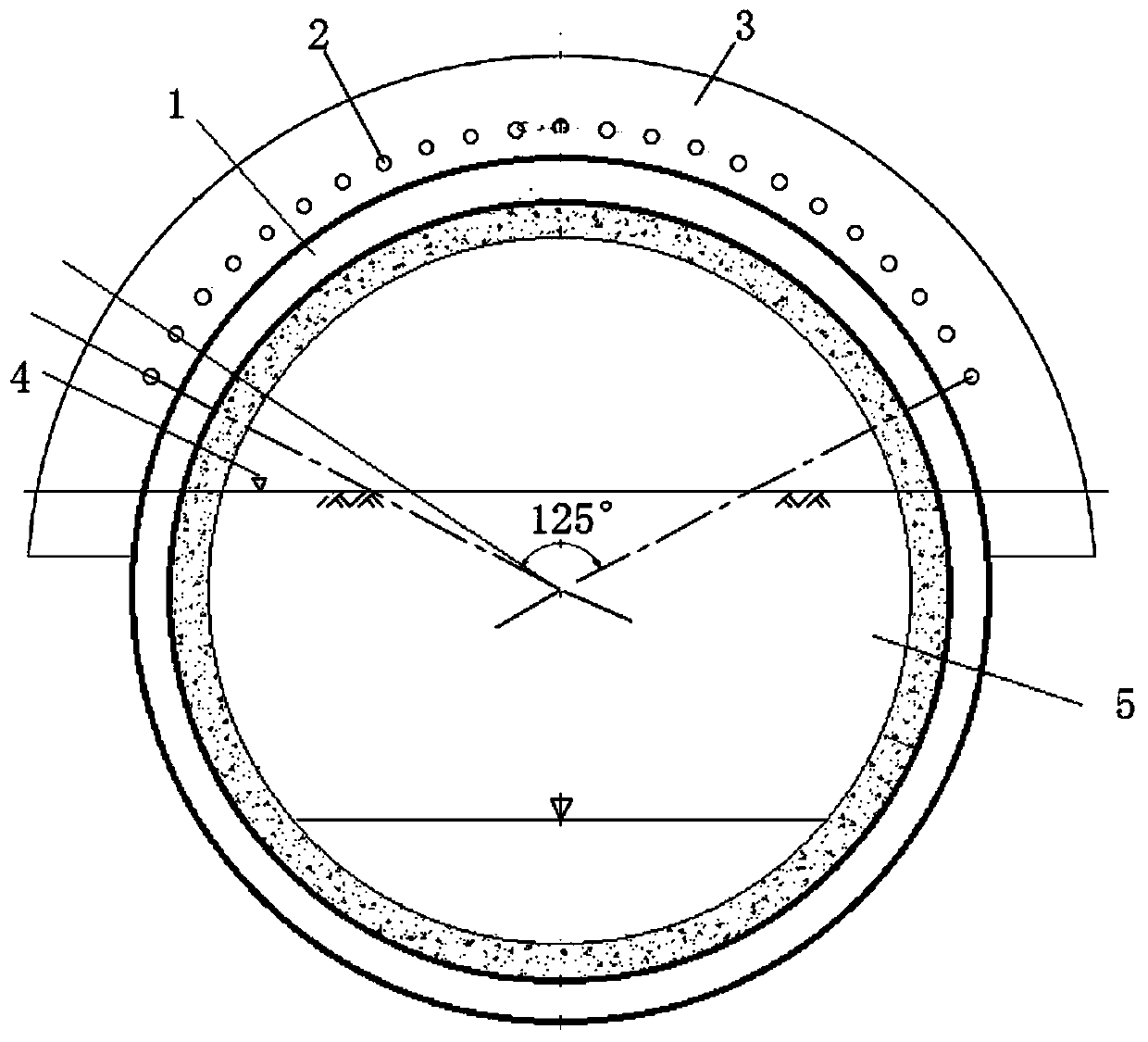

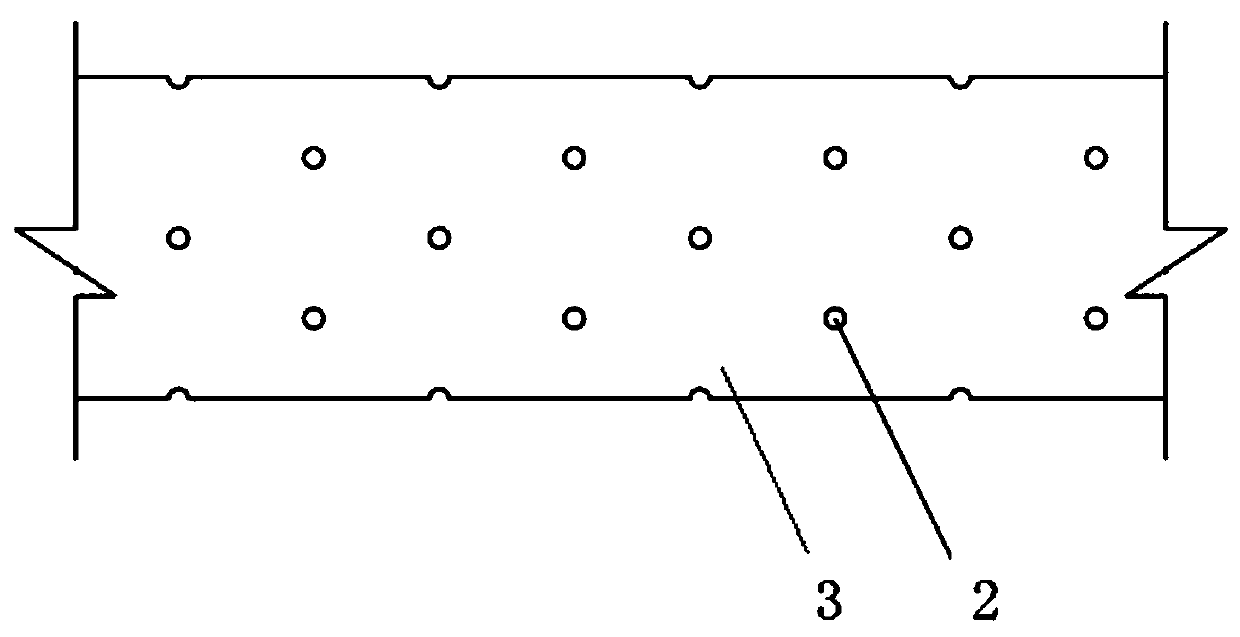

Novel precast concrete pipe die and construction method thereof

InactiveCN102373803ARealize the use functionReduce usageStrutsForms/shuttering/falseworksPre stressEngineering

The invention discloses a novel precast concrete pipe die, which is a precast concrete pipe pile of a hollow structure. The wall of the precast concrete pipe die is internally provided with annular and vertical reinforcing steel bars, the inner surface of the pipe die is provided with dowel bars connected with post-poured concrete into a whole and an electric heating wire for heating, the upper end and the lower end of the pipe die are provided with tooth-shaped connectors which are mutually matched, the wall of the pipe die is internally provided with preset pore canals for prestress reinforcing steel bars, and the pore canals are through longitudinally. A construction method of the novel precast concrete pipe die comprises the steps of: after positioning the precast concrete pipe die, switching on a power supply of the electric heating wire, and performing high-dropping self-compacting concrete pouring on the middle of the concrete pipe die; and after a first section of cylinder core of the pipe die is poured, performing hoisting positioning and concrete pouring on a second section of the concrete pipe die. The invention has the advantages that by precasting the concrete pipe die, the special requirement on the use functions of a concrete column surface and a column template can be met, and the heating functions of the novel precast pipe die can also ensure the smooth construction in winter; and the novel precast concrete pipe die and the construction method thereof have the advantages of simplicity and rapidness for construction, less required construction equipment, and capability of greatly reducing the construction cost and the comprehensive manufacturing cost.

Owner:TIANJIN UNIV

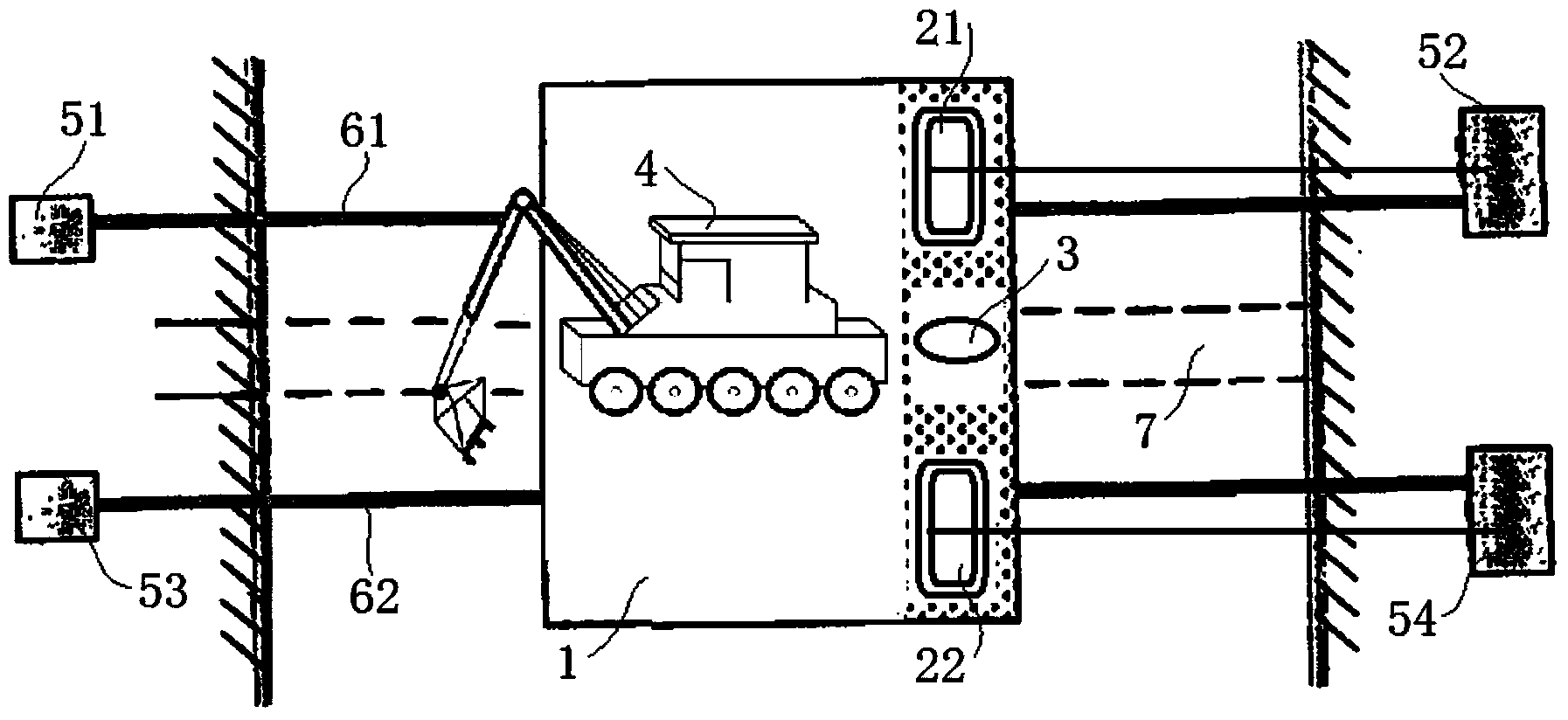

Construction method of subway tunnel penetrating through underground continuous walls of subway station

The invention discloses a construction method of a subway tunnel penetrating through underground continuous walls of a subway station. The construction method comprises the following steps that a vertical shaft is excavated on the outer side of the first continuous wall, and a space enclosing structure is arranged; construction is conducted on a first freezing pipe to reinforce a first freezing pipe of soil mass in the rear of the first continuous wall in the vertical shaft in the direction of a newly-built subway tunnel, and the first freezing pipe is removed after reinforcing is completed; the first continuous wall is broken away in the direction of the newly-built subway tunnel, and thus a first tunnel portal is formed; slag and accumulated water in the vertical shaft are cleaned, and backfilling is conducted on the vertical shaft; a shield tunneling machine penetrates through the vertical shaft and the first continuous wall in the opening direction of the first tunnel portal; the shield tunneling machine is utilized to tunnel to the position of the second continuous wall, and tightly attached to the second continuous wall; a second freezing pipe for reinforcing soil mass is arranged on the outer side of the second continuous wall in a mode of obliquely drilling from the ground surface, and the second freezing pipe penetrates through the position below the newly-built subwaytunnel; shield position opening is conducted, the second continuous wall is broken away in the direction of the newly-built subway tunnel, and thus a second tunnel portal is formed; and the second freezing pipe is removed, and the shield tunneling machine penetrates through the second continuous wall in the opening direction of the second tunnel portal.

Owner:GUANGZHOU METRO DESIGN & RES INST

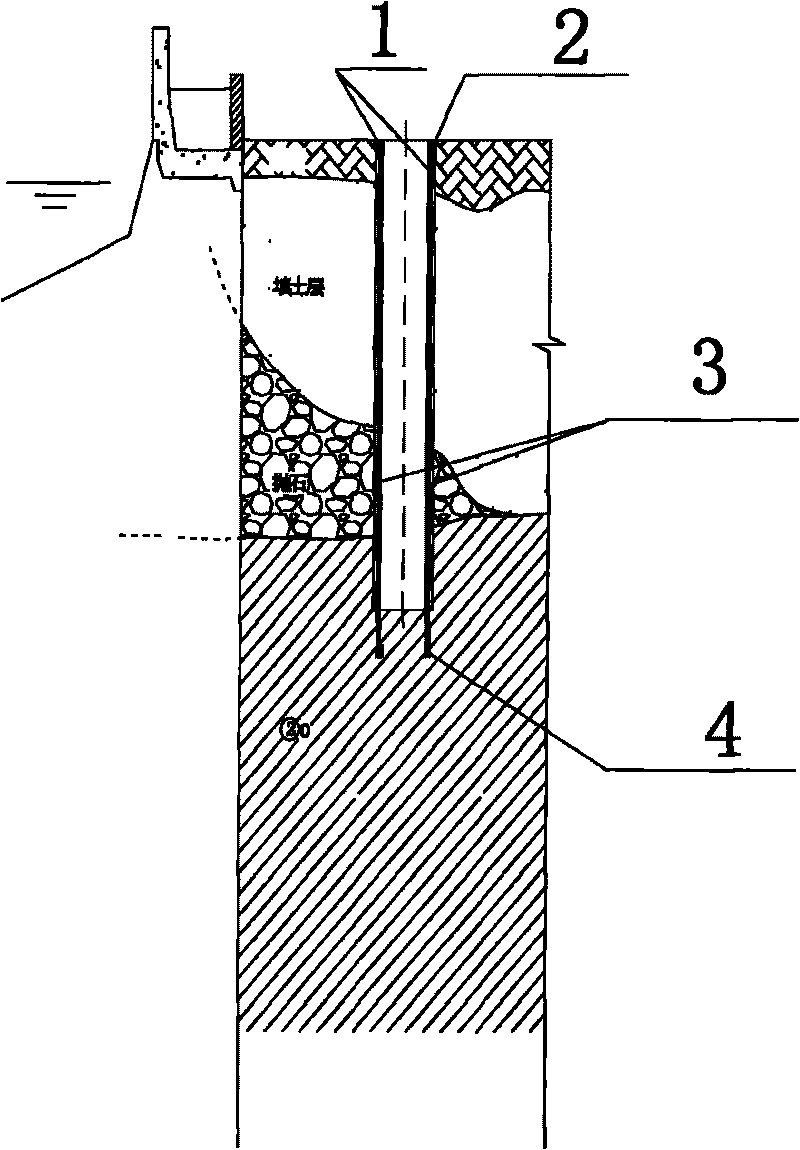

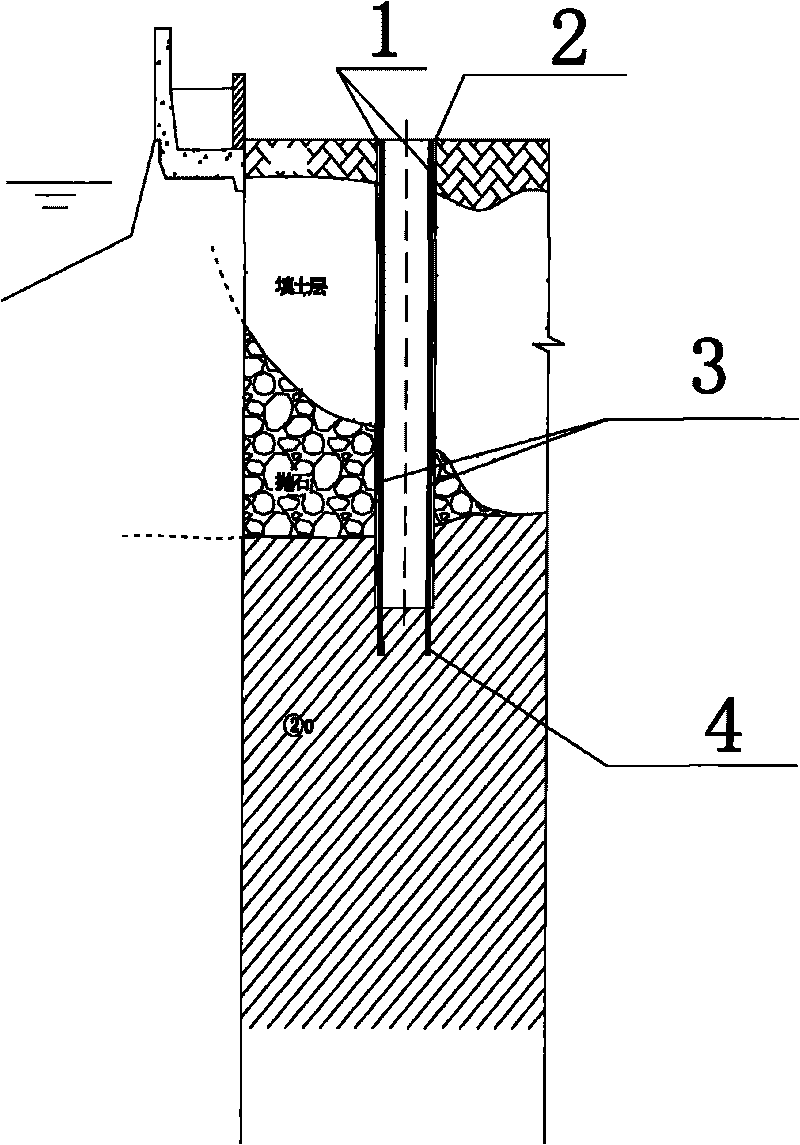

Construction process for bored pile close to flood wall through riprap layer

ActiveCN101761072AGuarantee smooth constructionGuarantee the quality of pile bodyBulkheads/pilesRebarGeotextile

The invention relates to a construction process for a bored pile close to a flood wall through a riprap layer. A bent frame is lapped close to the side of a flood wall and erected above the flood wall to form a drilling platform, and a pile driver is placed on the bent frame for construction; and the concrete process flow is as follows: firstly, obstacle clearing and outer shielding canister burying; secondly, inner shielding canister burying; thirdly, drilling machine replacing for continuous drilling; fourthly, hole cleaning, fifthly, reinforcement cage hanging; sixthly, underwater concreting; and lastly, inner shielding canister pulling. The construction process solves the problems of obstacle clearing, hole forming and stability of hole wall of the bored pile in the thick riprap layer by combining the inner sleeve and the outer sleeve; the geotextile is arranged on the inner side of the sleeve of the full-rotating drilling machine for recycling the outer shielding canister, therefore, the construction process has a certain economical efficiency, and the underwater concreting is carried out when the Huangpu River is in high water level to ensure the slurry return for the bored pile close to the flood wall by the Huangpu River and to ensure the smooth construction of the pile foundation and the quality of the pile body of the bored pile close to the flood wall by the Huangpu River.

Owner:SHANGHAI FOUND ENG GRP

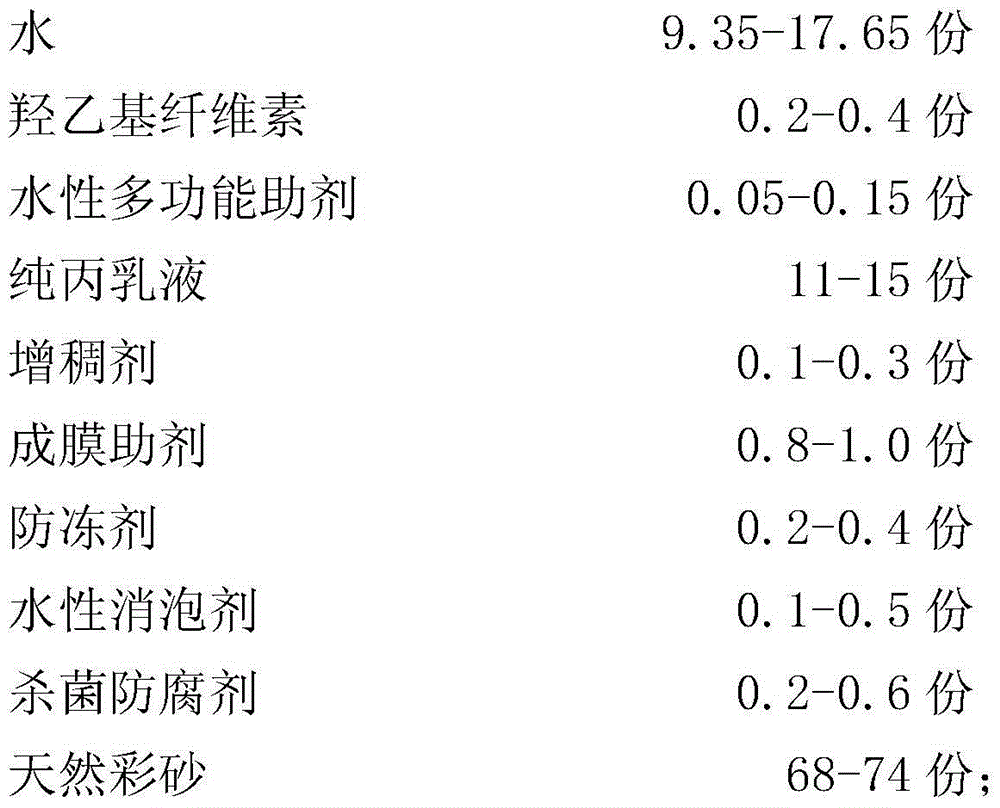

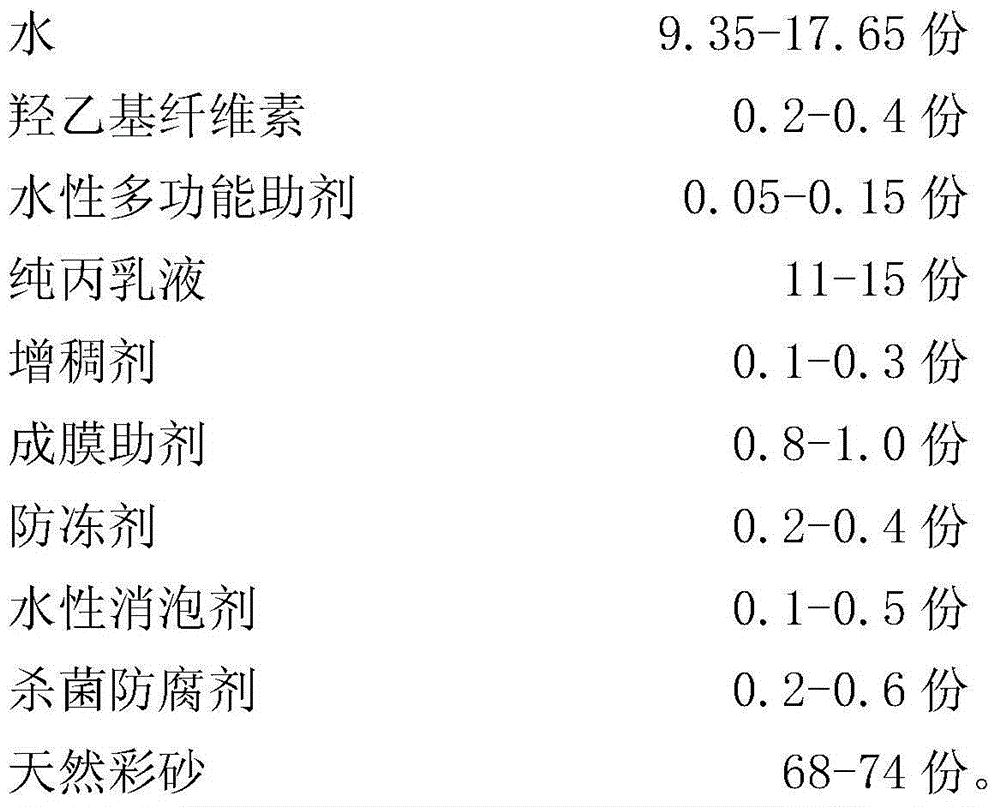

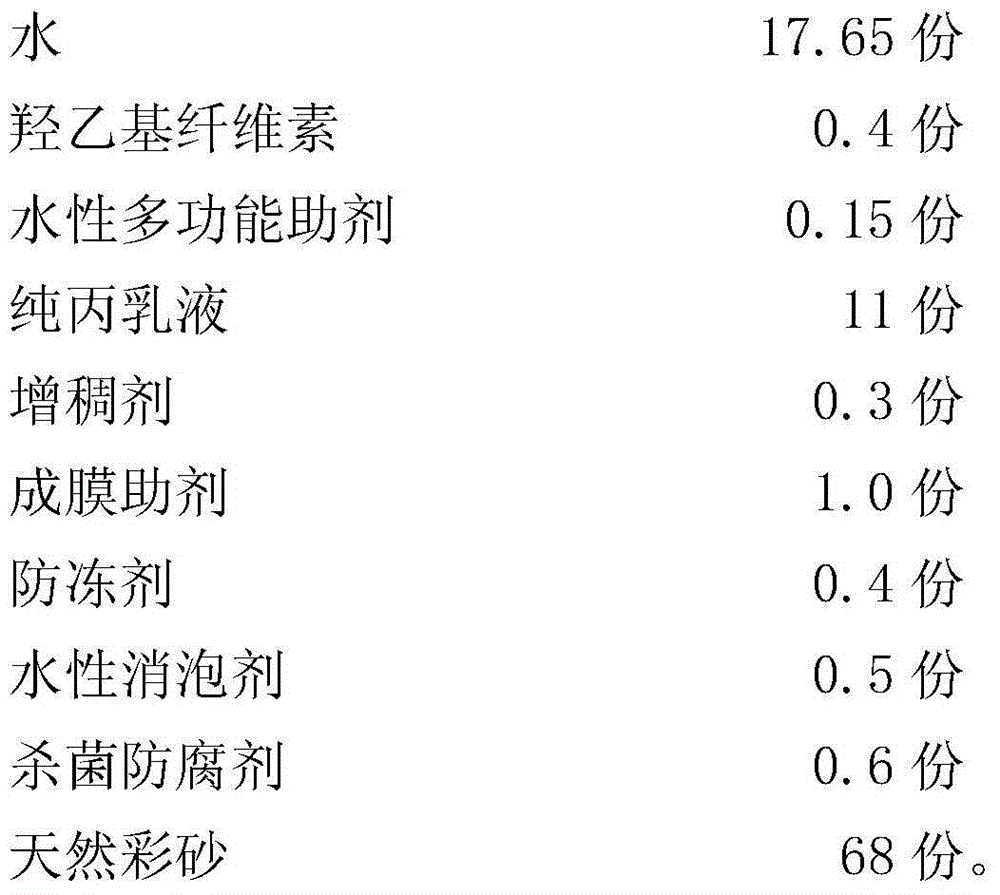

Really stone paint and preparation method thereof

The invention relates to a really stone paint and a preparation method thereof. The really stone paint is prepared from the following components in part by weight: water, hydroxyethyl celluloses, a waterborne multifunctional assistant, polyacrylic emulsion, a thickener, a coalescing agent, an antifreezing agent, a water-based defoamer, a fungicidal preservative and natural colored sand. The really stone paint prepared by the preparation method can realize the effects of good water resistance and good adhesive force under the condition of low temperature and high humidity and under the condition of low temperature and low humidity.

Owner:SKSHU PAINT

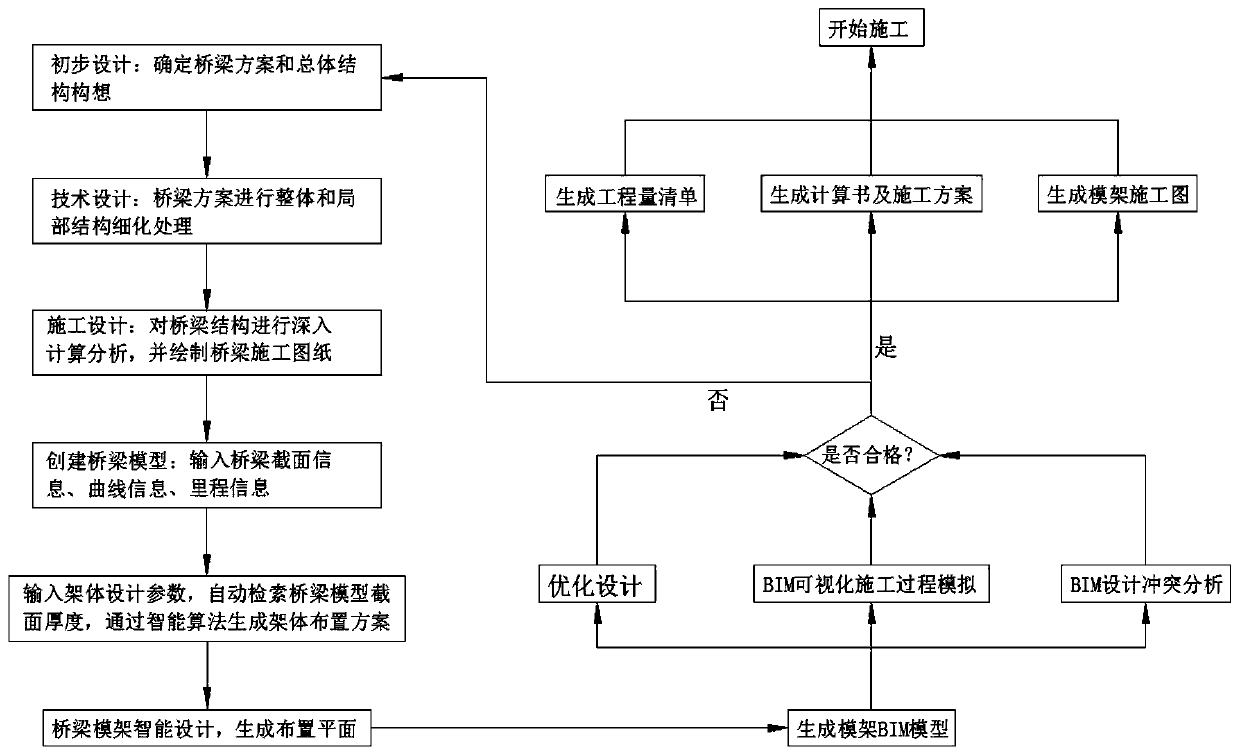

Bridge formwork intelligent design method based on BIM

ActiveCN109753753AImprove design efficiencyImprove accuracySpecial data processing applicationsIntelligent designShop drawing

The invention discloses a bridge formwork intelligent design method based on BIM, and belongs to the field of BIM bridges, and comprises the following steps: 1) preliminary design: determining a bridge scheme and overall structure concepts, such as arrangement of a bridge plane, a vertical surface and a cross section, by professionals; and 2) technical design: carrying out integral and local structure refinement processing on the bridge scheme determined in the preliminary design. The bridge formwork intelligent design method provided by the invention has a powerful rapid modeling function. Abridge three-dimensional model can be quickly created according to a CAD construction drawing. The problem that traditional two-dimensional design expression is not perfect, visual and clear is solved, through design conflict analysis, possible problems in the bridge construction process are found in advance and solved in advance, the traditional management thought is changed, namely, passive management of a waiting problem is converted into active management of an active discovery problem, and the working efficiency is improved.

Owner:广东星层建筑科技股份有限公司

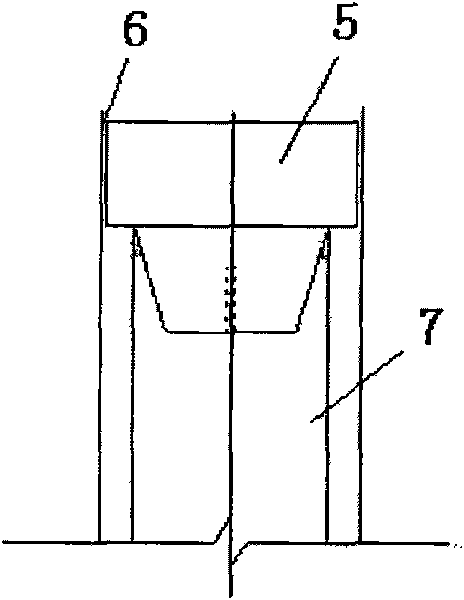

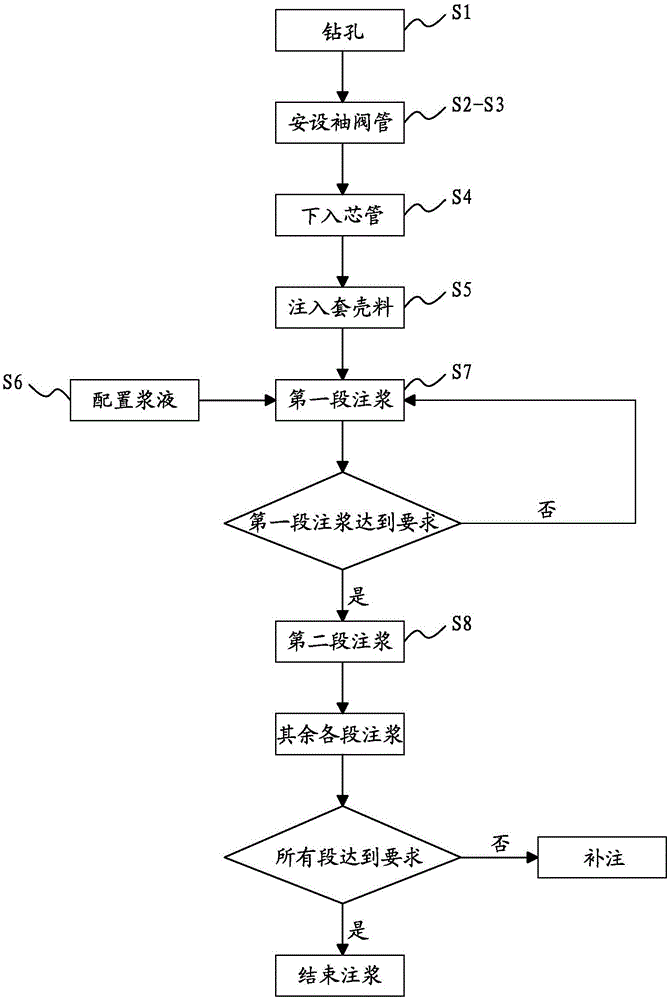

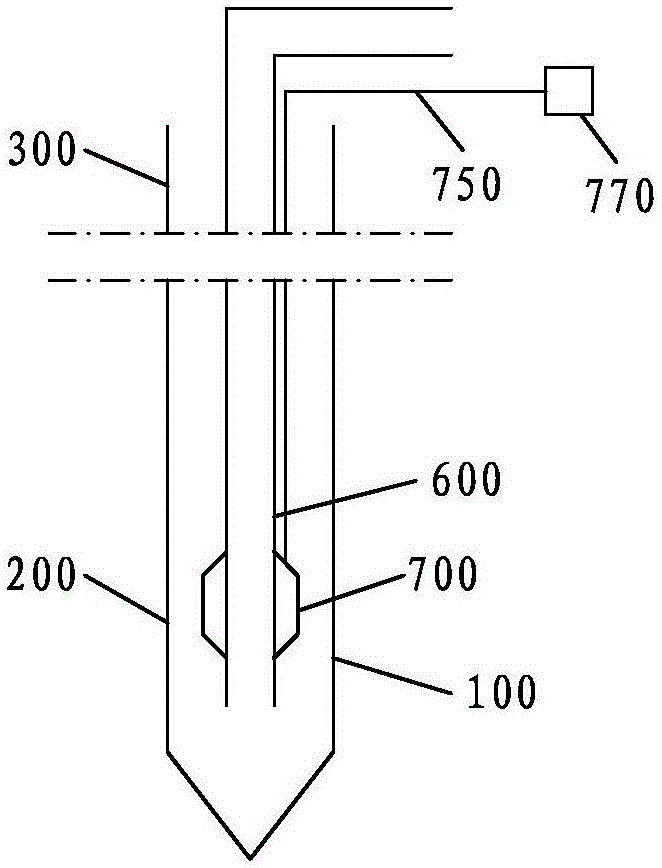

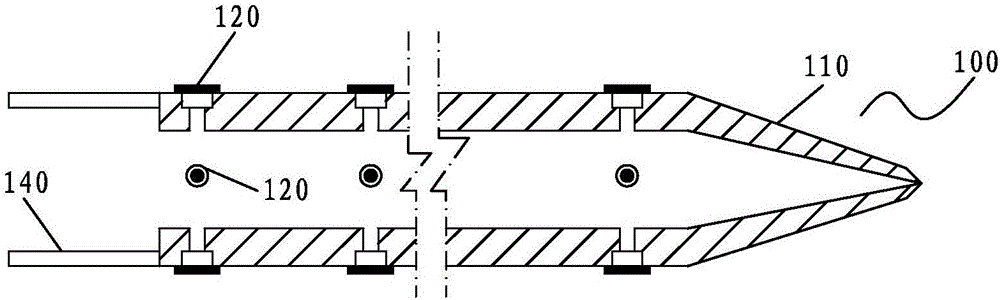

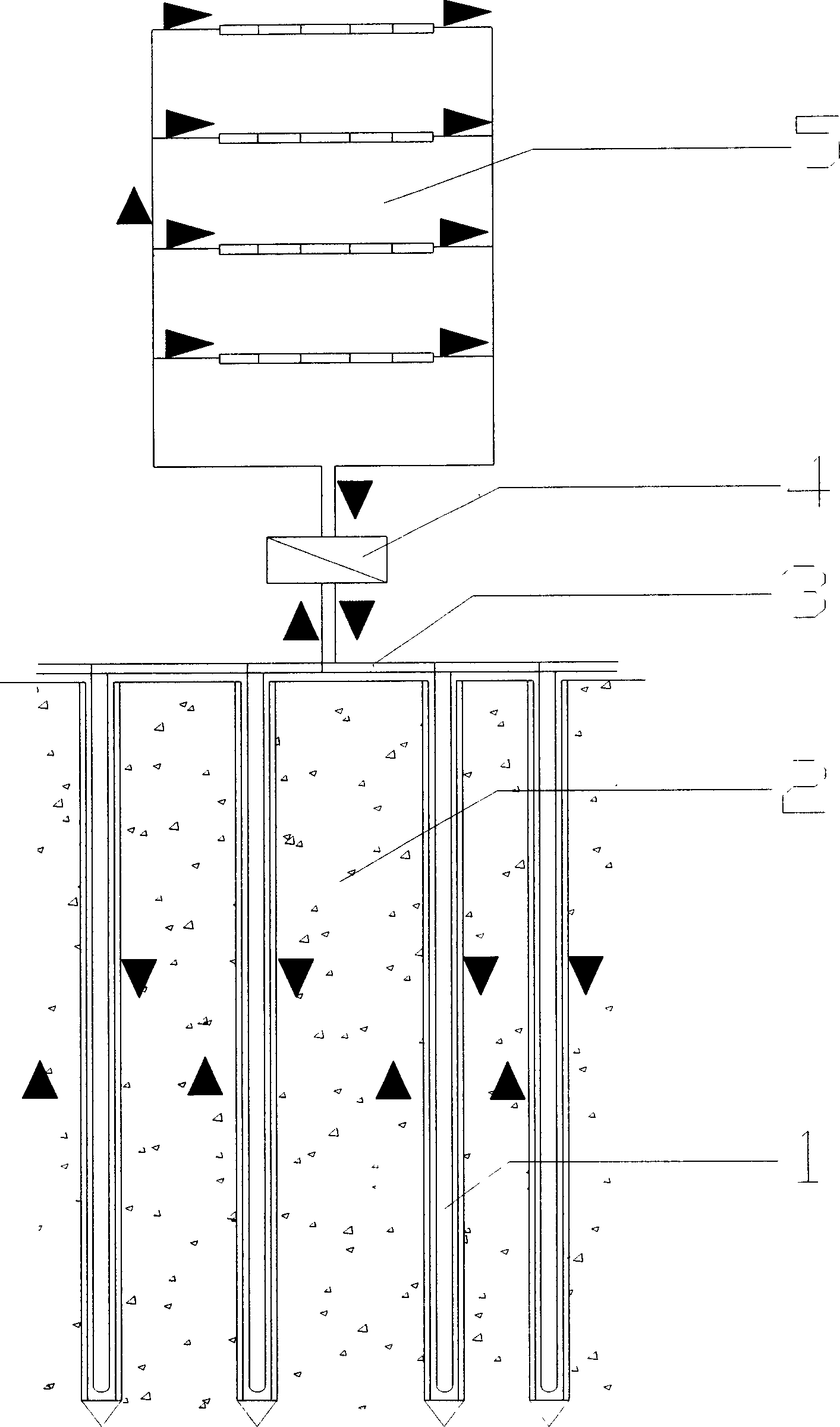

Ground-surface fixed-point deep hole layered grouting construction method

ActiveCN106640120AGuaranteed implementabilityAvoid the problem of difficult liftingUnderground chambersTunnel liningSleeve valveDeep hole

The invention discloses a ground-surface fixed-point deep hole layered grouting construction method. The method comprises the steps that vertical drilling is conducted from the ground surface of a construction area to the interior of the area needing to be grouted, wherein the hole depth is set to range from 80 meters to 150 meters; after the depth of a finished hole reaches the designed depth, a type-I sleeve valve tube (100) is put into the tail end of the drilled hole, designed grouting segments, put into the drilled hole, of a type-II sleeve valve tube (200) are connected segment by segment, and non-designed grouting segments, put into the drilled hole, of a type-III sleeve valve tube (300) are connected segment by segment; after the sleeve valve tubes are installed, a casing shell material is injected into a gap formed between the outer walls of the sleeve valve tubes and the inner wall of the drilled hole for hole sealing; after hole sealing is completed and solidifying is achieved, grouting core pipes (600) are put into the drilled hole; the tail end of the first grouting core pipe (600) penetrates through a stop-grouting plug (700) to be connected with the stop-grouting plug (700), and the other grouting core pipes (600) are connected segment by segment and then put into the sleeve valve tubes till the stop-grouting plug (700) is put into the bottoms of the sleeve valve tubes; a grouting pipe is connected to the core pipe end, grouting liquid is prepared, and then grouting operation starts through the grouting core pipes (600).

Owner:北京瑞威世纪铁道工程有限公司

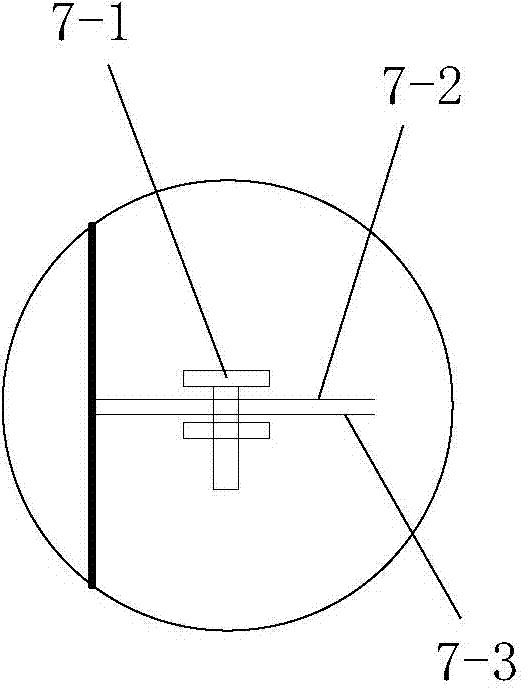

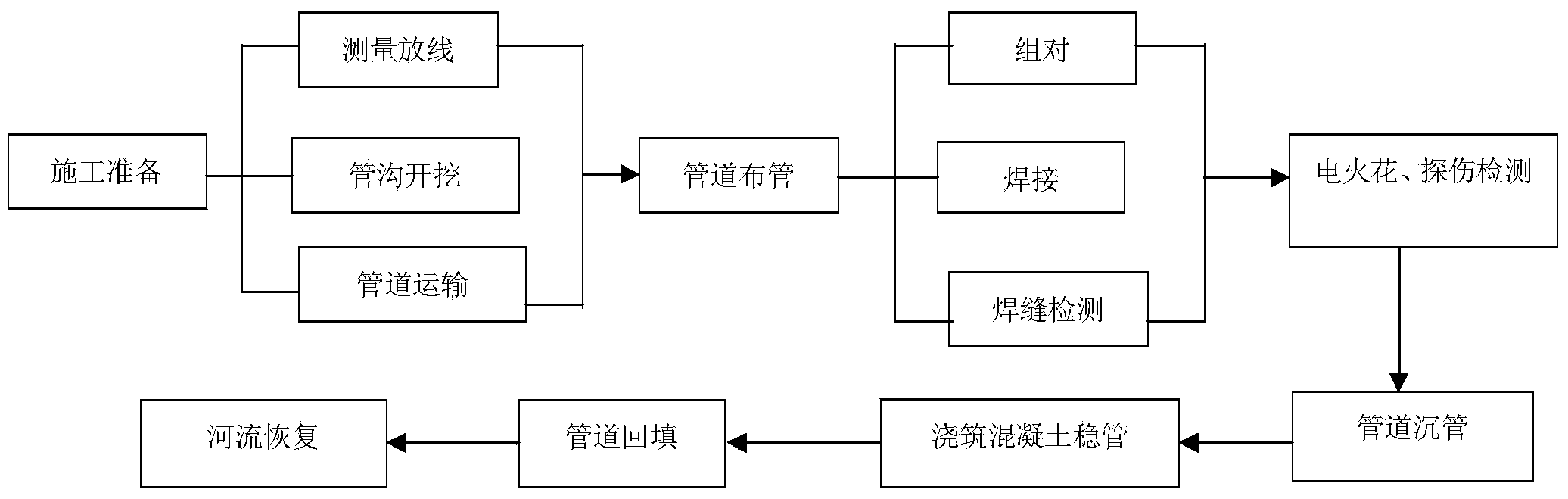

Supporting method for construction of swirl well

InactiveCN102635119ASimple construction processReduce construction costsExcavationsBulkheads/pilesRebarSoil horizon

The invention discloses a supporting method for the construction of a swirl well. By using the supporting method, thin and long rod piece soil nails which are more densely arrayed are placed into an in-situ soil body in a foundation pit excavation process and a reinforced concrete pavement layer is sprayed on a slope surface. A composite soil body is formed by the common work of the soil nails, the soil body and the sprayed concrete pavement layer. A construction of the swirl well supported by a soil nail well comprises the following steps of: excavating one section of the base groove of the swirl well according to a small sloping coefficient; drilling holes by utilizing a drilling machine and putting an anchor rod; grouting and blocking; suspending a steel bar net sheet and spraying fine stone concrete to form a foundation side wall; gradually excavating and gradually carrying out combined bolting and shotcrete on the soil nails until the designed elevation of the foundation pit of the swirl well is achieved; and then, carrying out the section construction process of the cylinder wall of the reinforced concrete and an inner structure from bottom to top. By using the method, the supporting problem of a super-deep foundation pit under a hard soil layer environment is solved; and compared with a drop shaft sinking method, an underground diaphragm wall and a reverse process construction method, the method disclosed by the invention has the characteristics of simple construction process, low construction cost and fast construction speed.

Owner:TIANJIN 20 CONSTR

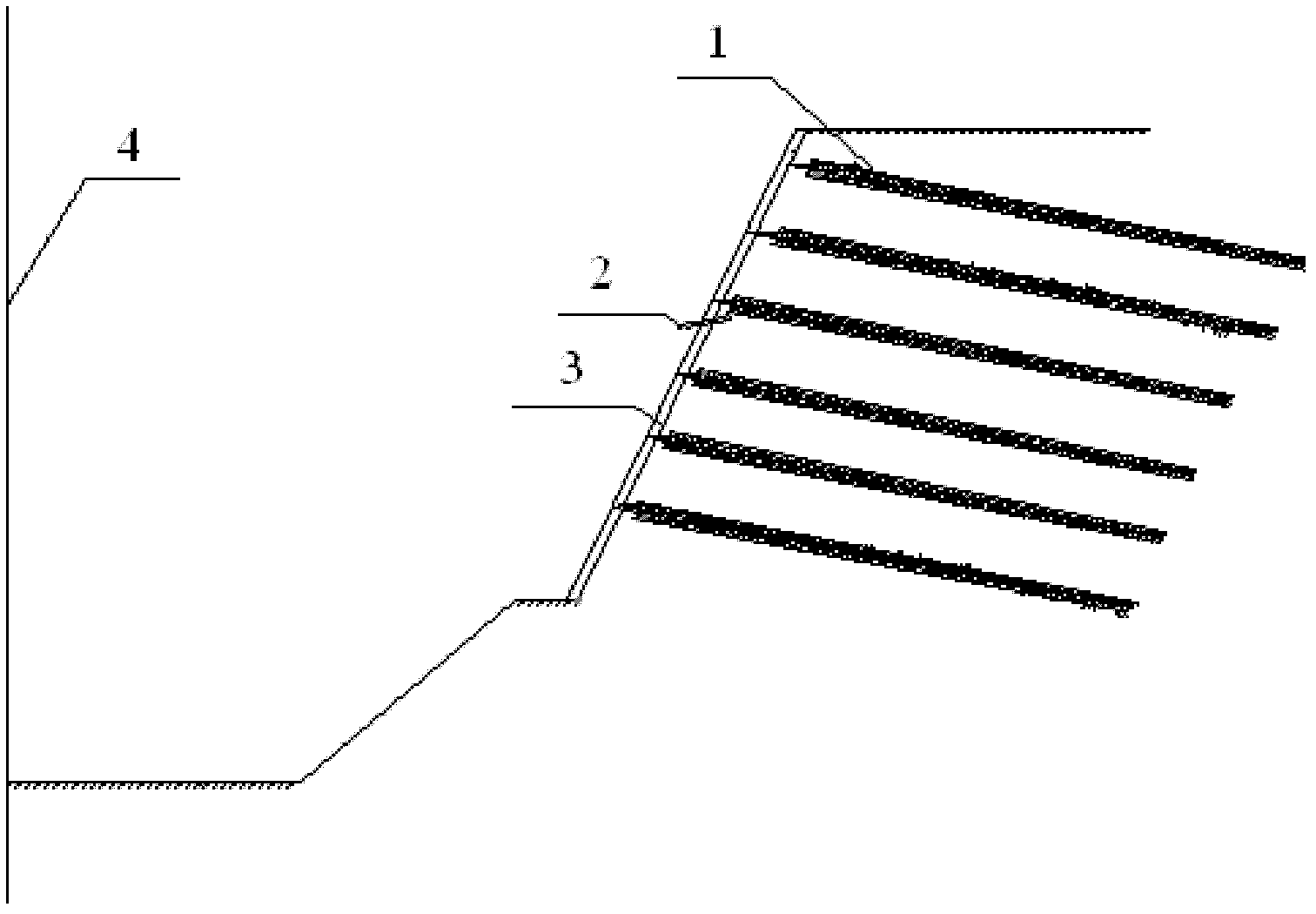

Underwater grooving and pipe sinking river traversing construction method

ActiveCN103912721AImprove pairing accuracyGuarantee smooth constructionWater resource protectionPipe laying and repairEngineeringFluvial

The invention discloses an underwater grooving and pipe sinking river traversing construction method, and belongs to the field of underwater pipeline laying technologies. The underwater grooving and pipe sinking river traversing construction method includes steps of preparing for construction; arranging pipes of pipelines, performing preliminary assembling procedures and photon assembling procedures in assembling procedures for arranging the pipes of the pipelines, particularly, preliminarily assembling the first pipelines to be preliminarily assembled and the second pipelines to be preliminarily assembled on river banks, marking location point information on the end surfaces of the pipelines, and assembling straight pipe sections of first river beds and straight pipe sections of second river beds on platforms of photons; sinking the pipes of the pipelines, implementing an integral pipeline sinking technology in procedures for sinking the pipes of the pipelines, tying first buoys at first elbow sections on the pipelines, tying second buoys on second elbow sections on the pipelines, and controlling first valves, second valves, the first buoys and the second buoys to always keep the first valves, the second valves, the first buoys and the second buoys on the center lines of pipe trenches so as to guarantee that the pipelines are accurately sunken in the pipe trenches; pouring concrete and stabilizing the pipes; refilling the pipelines and restoring rivers. The underwater grooving and pipe sinking river traversing construction method has the advantage that the integral pipelines can be accurately and stably sunken in the specified pipe trenches under the control of the underwater grooving and pipe sinking river traversing construction method.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

Sock

InactiveUS20030131635A1Maximum flexibilityMinimises overall bulk and weightOrnamental textile articlesHandkerchiefsFiberYarn

A knitted sock has an inner layer 2 comprising a toe end 4 and an outer layer 3 comprising a toe end 7. The inner and outer toe ends are aligned and joined wale stitch to wale stitch to form a composite toe end, which is closed to provide a flat toe seam 10. The layered sock is manufactured complete in a single process being knit continuously from the inner toe end to the outer toe end. It comprises reciprocated heel and toe portions. The foot portion of the inner layer is knit from a yarn with properties such as a low coefficient of friction and / or antifungal / antibacterial properties. The low friction fiber is a fluoropolymer such as polytetrafluroethylene. The outer layer may comprise a cushion structure.

Owner:LEGEND CARE I P

Support change process of second liner construction of large-cross-section tunnel

ActiveCN103075163AImprove stabilityGuarantee smooth constructionUnderground chambersTunnel liningEngineeringStructural engineering

The invention discloses a support change process of second liner construction of a large-cross-section tunnel. The support change process comprises the following steps of: (1) pre-burying a first support-changing steel plate on the top surface before backfill of an inverted arch of a left lower hole; (2) removing the end part of a temporary vertical support by cutting first, welding the end part of the temporary vertical support on the first support-changing steel plate by using I-shaped steel, and connecting the temporary vertical support with backfill concrete, wherein the next support can be changed after the last support is well connected; (3) pre-burying a second support-changing steel plate before casting of second liner concrete on a lower side wall, removing the end part of a temporary transverse support by cutting after the casting of a second liner of the lower side wall and demolding are finished, welding the end part of the temporary transverse support on the second support-changing steel plate by using I-shaped steel and connecting the temporary transverse support with second liner concrete, wherein the next support can be changed after the last support is well connected; (4) constructing a second liner of a right upper hole and a second liner of a left upper hole; and (5) after the strength of the second liner concrete reaches 75 percent, gradually removing the temporary transverse support and the temporary vertical support. According to the support change mode, after the end part of the temporary transverse support or vertical support is removed, the stability is improved and the smooth construction can be ensured.

Owner:RANKEN RAILWAY CONSTR GROUP

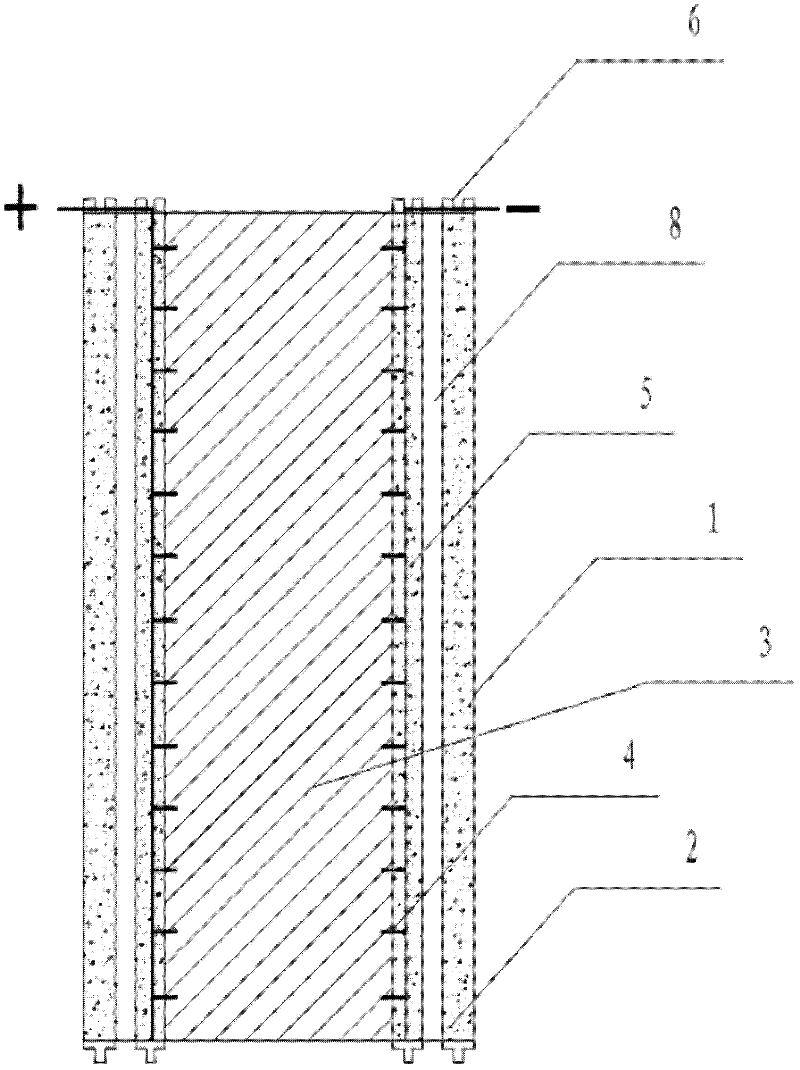

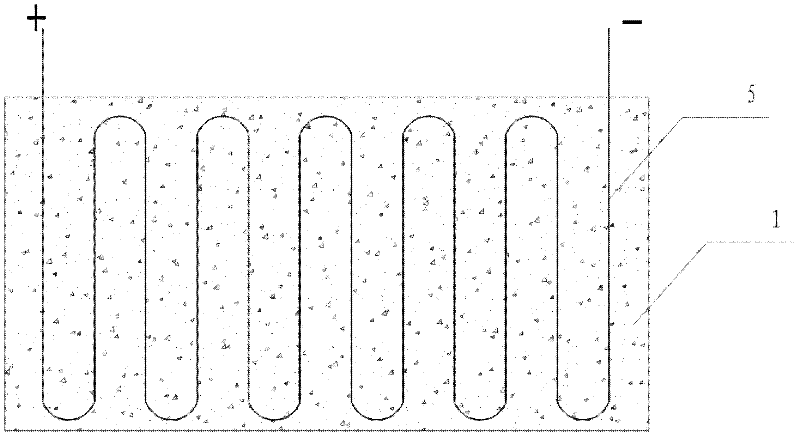

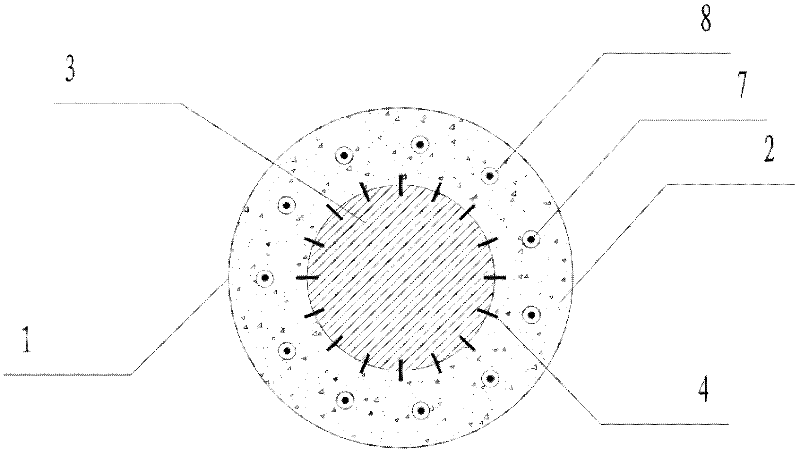

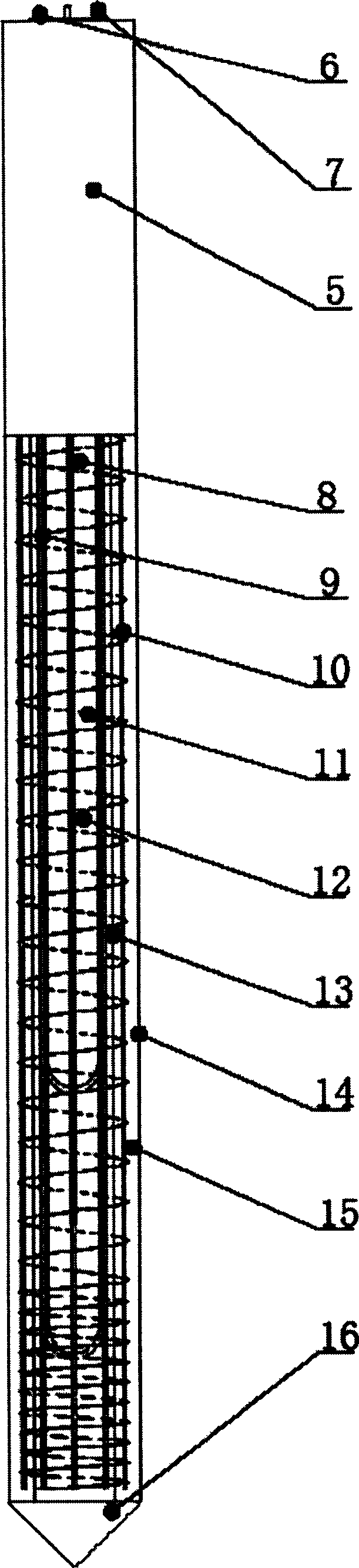

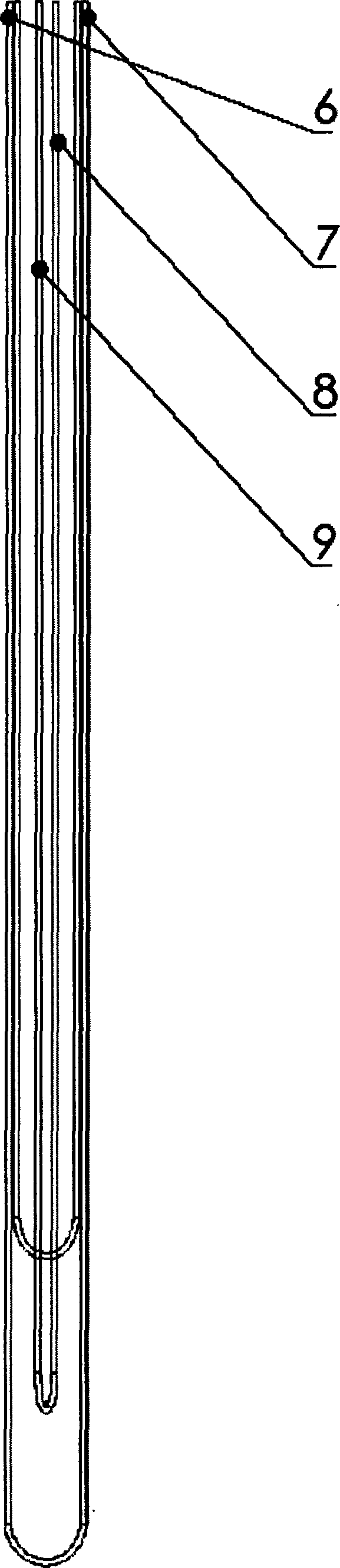

Prestressing force concrete pipe pile for low-temperature geothermal energy conversion

InactiveCN1800510AConvenient closed loop conversionTraditional mechanics have no effectOther heat production devicesGeothermal energy generationPlate heat exchangerPre stress

The invention relates to a low-temperature terrestrial heat exchange pre-stress concrete post, which arranges pipe heat exchange devices in variable shape in the posts to carry, baffle soil and strengthen the base, while it can process low-temperature terrestrial heat exchange in lower layer to realize the function of pipe heat exchange laid by post and terrestrial heat pump prefabricated hole. In the inner hole of pre-stress concrete post operated by closed steel post sharp, the U-shape heat exchanger, screw coil-pipe heat exchanger or other pipe heat exchanger is directly laid, while the space between the inner wall of post and the pipe heat exchanger is filled by stuffing. The pipe heat exchangers in the post are connected to the ground pipe line, and the pipe line of heat exchanger is filled by exchanging liquid. The invention via the heat exchange between exchange liquid, stuffing, post, and around soil-water system, form a underground low-temperature terrestrial heat exchanger of closed terrestrial heat pump.

Owner:张延军 +1

Method for supporting deep building pit using non bulit-in end pile anchor in combination with anchor slab wall

InactiveCN101250878ALow costGuarantee smooth constructionExcavationsBulkheads/pilesPre stressEngineering

The invention discloses a deep foundation pit support method using a no build-in end piled anchor to combine with an anchor plate wall, which is characterized in that the depth of a retaining pile only enters into an upper pressing belt of a strong weathered rock. Foundation pit excavation and prestressing anchors are respectively arranged on the upper end, the middle portion and the lower end of the retaining pile along with the foundation pit excavation, and 0.5-1.0m rock step which is obligated on the lower end of the retaining pile. A concrete retaining wall is jetted on the side surface of a foundation pit which is arranged under the rock step, the prestressing anchors are arranged on the concrete retaining wall, and a retaining anchor plate wall is formed. Comprised with a row pile or a piled anchor retaining mode, the deep foundation pit support method has the advantages of saving cost and reducing construction period.

Owner:青建集团股份公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com