Really stone paint and preparation method thereof

A technology of real stone paint and natural colored sand, which is applied in the field of exterior wall decorative coatings. It can solve the problems that affect the quality and decorative effect of real stone paint, the coating is not water-resistant, and the whitening of the coating is beautiful. The construction effect is beautiful and environmentally friendly, and the construction is smooth. The effect of improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

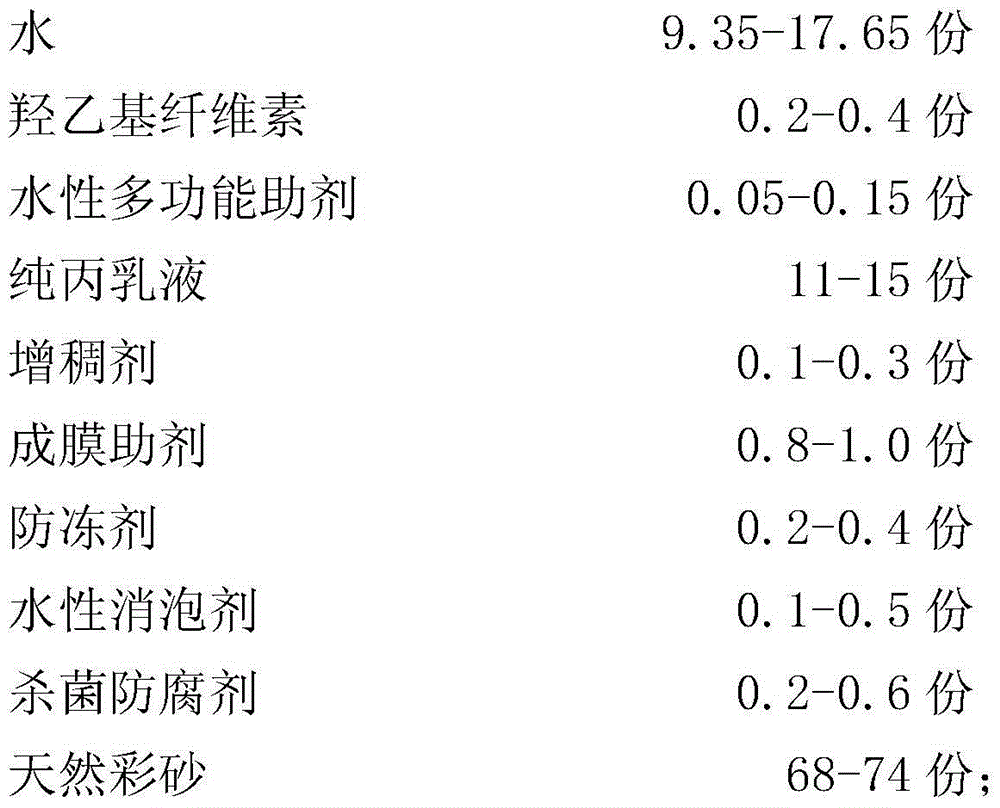

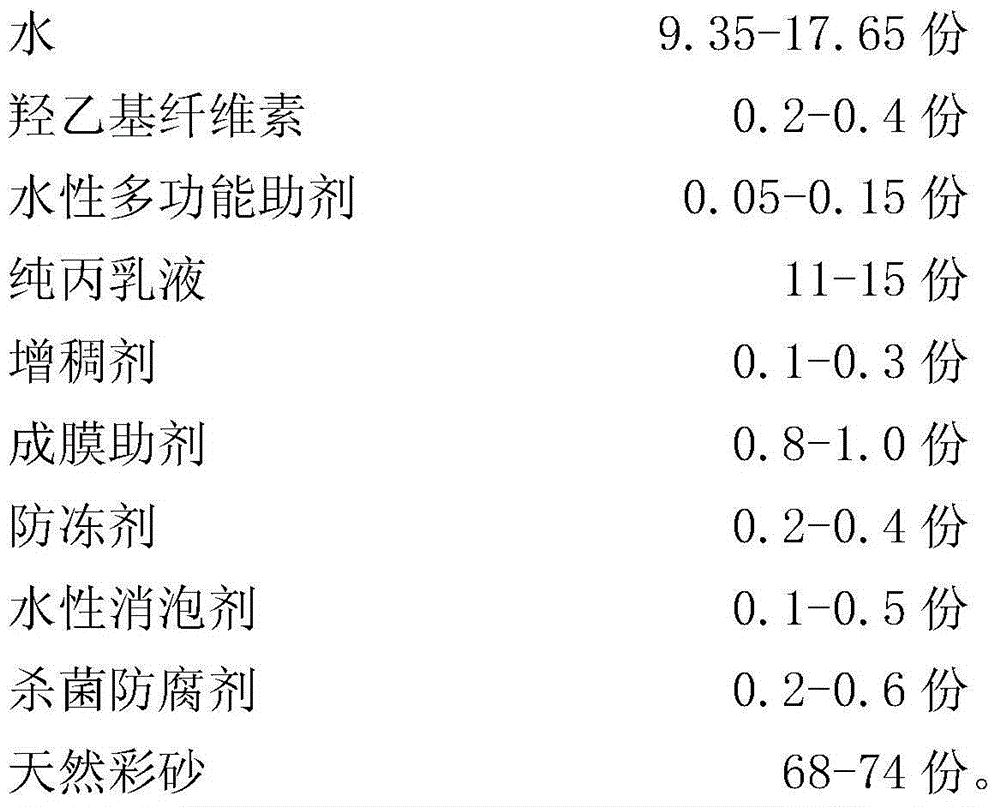

[0022] A kind of real stone paint, which is prepared from the following components and parts by weight ratio:

[0023]

[0024] A kind of preparation method of real stone paint, it comprises the steps that carry out in sequence as follows:

[0025] (a) Add 9.35-17.65 parts of water into the dispersion tank, add 0.2-0.4 parts of hydroxyethyl cellulose under stirring at 300-500 rpm, and stir for 5-10 minutes;

[0026] (b) Add 0.05-0.15 parts of water-based multifunctional additive at a speed of 300-500rpm, then increase the speed to 700-1000rpm, and stir at this speed for 10-15min until the hydroxyethyl cellulose is completely dissolved and stirred Evenly, adjust the pH to 8.0-10.0;

[0027] (c), after stopping the stirring, add 11-15 parts of pure acrylic emulsion, control the rotation speed and stir for 5-10min under the stirring state of 600-900rpm;

[0028] (d) After stirring evenly, continue to slowly add 0.1-0.3 parts of thickener, 0.8-1.0 parts of film-forming aids, ...

Embodiment 1

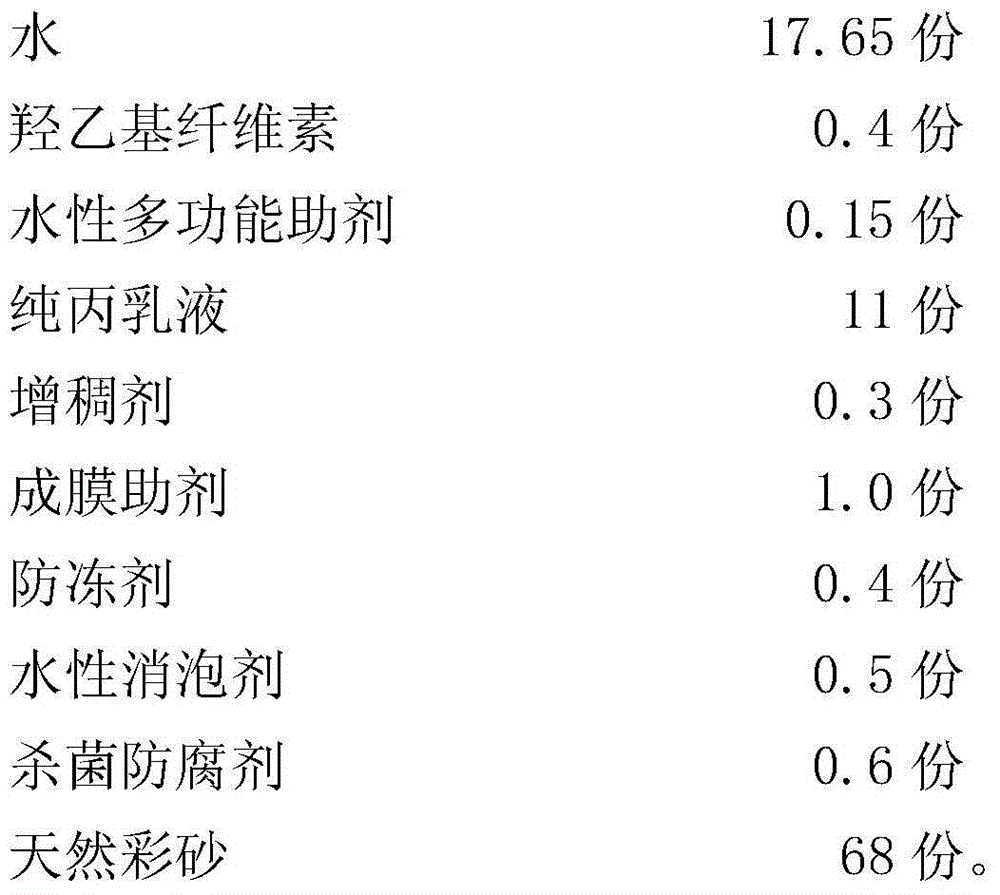

[0032] Embodiment 1: a kind of genuine stone paint, is formulated by following component and weight and number ratio:

[0033]

[0034] A kind of preparation method of real stone paint, it comprises the steps that carry out in sequence as follows:

[0035] (a) Add 17.65 parts of water into the dispersion tank, add 0.4 parts of hydroxyethyl cellulose under stirring at 500 rpm, and stir for 5 minutes;

[0036] (b) Add 0.15 parts of water-based multifunctional additive at a speed of 500 rpm, then increase the speed to 1000 rpm, and stir at this speed for 10 minutes until the hydroxyethyl cellulose is completely dissolved and stirred evenly, and adjust the pH to 8.0-10.0 ;

[0037] (c), after stopping the stirring, add 11 parts of pure acrylic emulsion, and stir for 5 minutes under the control speed of stirring at 900rpm;

[0038] (d), after stirring evenly, continue to slowly add 0.3 part of thickener, 1.0 part of film-forming aid, 0.4 part of antifreeze, 0.5 part of water-b...

Embodiment 2

[0041] Embodiment 2: a kind of real stone paint, is formulated by following component and weight and number ratio:

[0042]

[0043] A kind of preparation method of real stone paint, it comprises the steps that carry out in sequence as follows:

[0044] (a), add 9.35 parts of water into the dispersion tank, add 0.2 parts of hydroxyethyl cellulose under stirring at 300 rpm, and stir for 10 minutes;

[0045] (b) Add 0.05 parts of water-based multifunctional additive at a speed of 300 rpm, then increase the speed to 700 rpm, and stir at this speed for 15 minutes until the hydroxyethyl cellulose is completely dissolved and stirred evenly, and adjust the pH to 8.0-10.0 ;

[0046] (c), after stopping the stirring, add 15 parts of pure acrylic emulsion, and stir for 10 minutes at a stirring speed of 600 rpm;

[0047](d), after stirring evenly, continue to slowly add 0.1 part of thickener, 0.8 part of film-forming aid, 0.2 part of antifreeze, 0.1 part of water-based defoamer and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com