Patents

Literature

249results about How to "Cover tightly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of double-layer coated water-based aluminum pigment

The invention discloses a preparation method of a double-layer coated water-based aluminum pigment, which comprises the following steps: coating ethyl orthosilicate on lamellar aluminum powder to form a single-layer coated aluminum pigment; and under the action of an azo initiator, coating a hydrophilic ester monomer on the single-layer coated aluminum pigment to form the double-layer coated water-based aluminum pigment. The double-layer coated water-based aluminum pigment prepared by the method provided by the invention has the advantages of high coating tightness and favorable water resistance, and the coating layer can not be easily damaged. The organic layer on the outer layer is easily compatible with high-molecular rein in the paint, has favorable dispersity in the paint, and is mainly used in various water-based paints and water-based inks.

Owner:HEFEI SUNRISE PIGMENTS

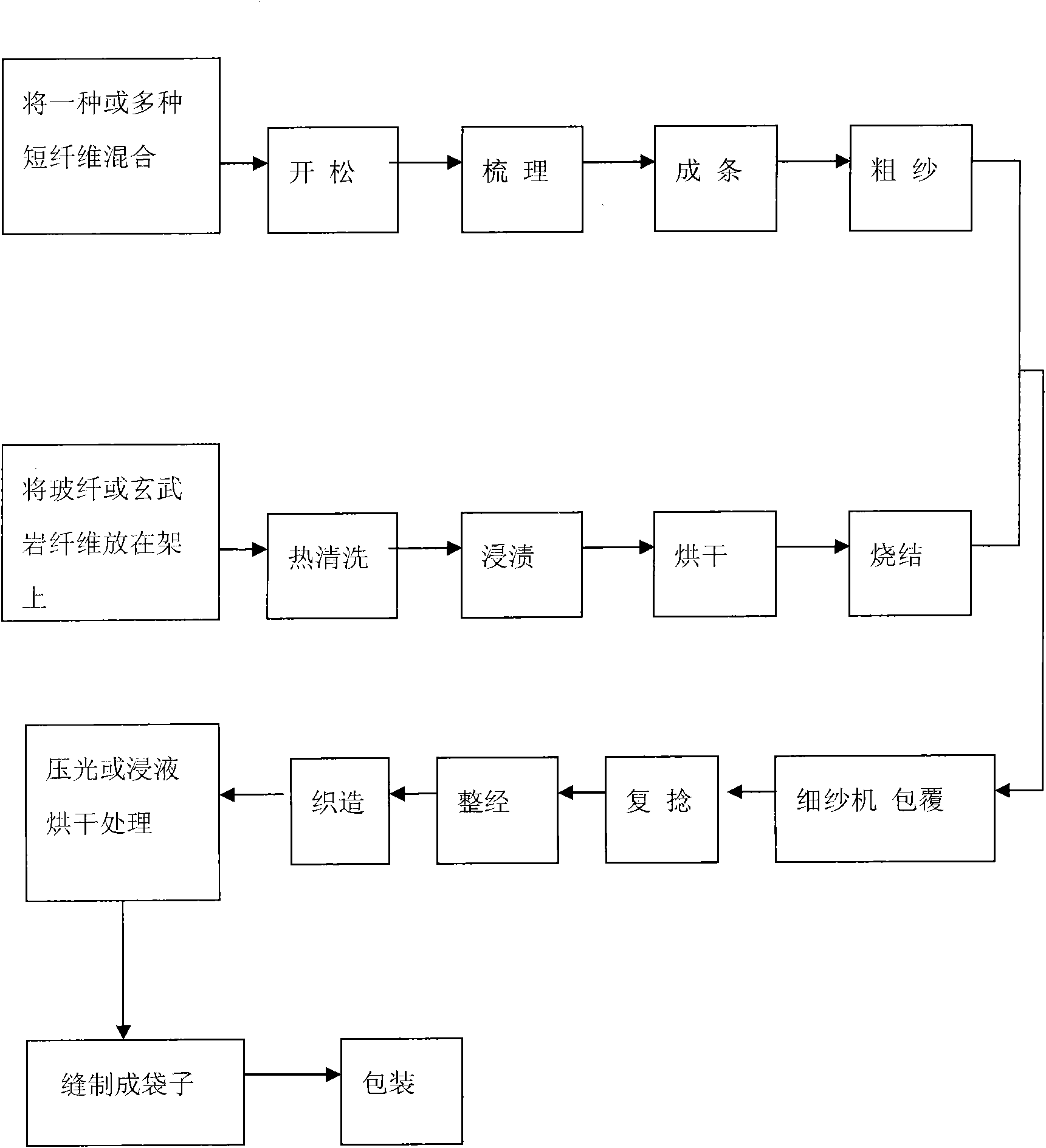

Composite covered yarn, and manufacturing method and use thereof

The invention relates to a composite covered yarn and a manufacturing method thereof and also relates to a high-temperature filter cloth. The composite covered yarn comprises an outer layer of coveredyarn made of short fiber and an inner layer of reinforcing rib made of long fiber, wherein the composite covered yarn is formed by using the covered yarn, made of one or a plurality of types of shortfibers, to cover the reinforcing rib or the metal wire reinforcing rib made of one or a plurality of types of long fibers by thermal cleaning, dipping, drying and sintering. The composite covered yarn manufactured by the method not only saves cost, but also combines the characteristics of high strength of the long fiber and good abrasion resistance and toughness of the short fiber and enhances service life, strength, high-temperature resistance and stability of the composite covered yarn. The composite covered yarn can be made into the filter cloth.

Owner:辽宁新洪源环保材料有限公司

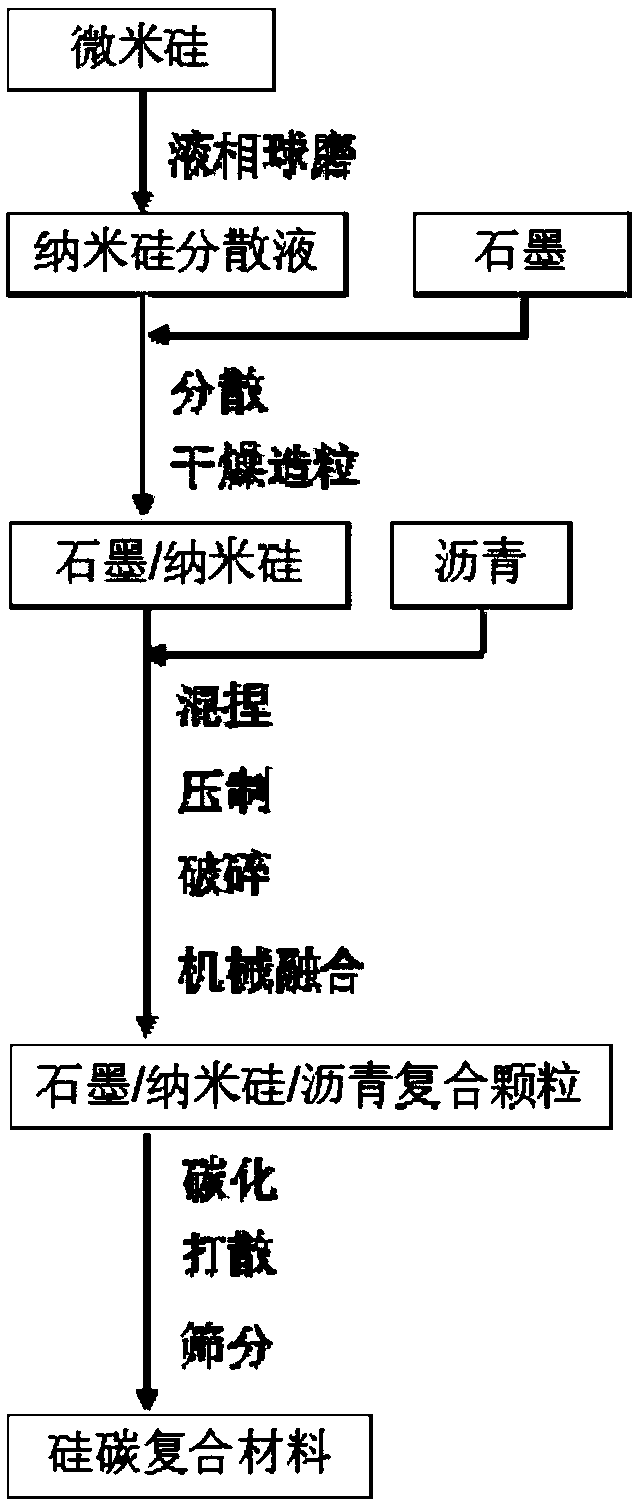

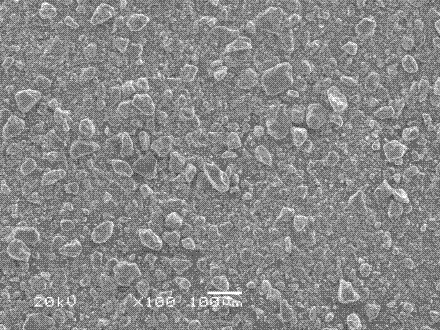

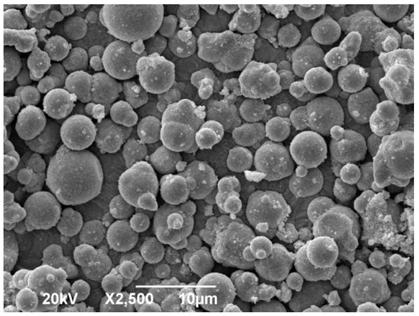

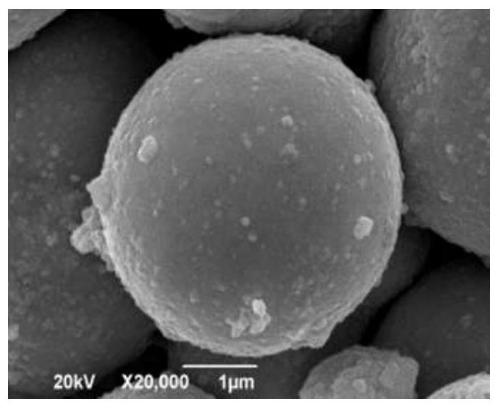

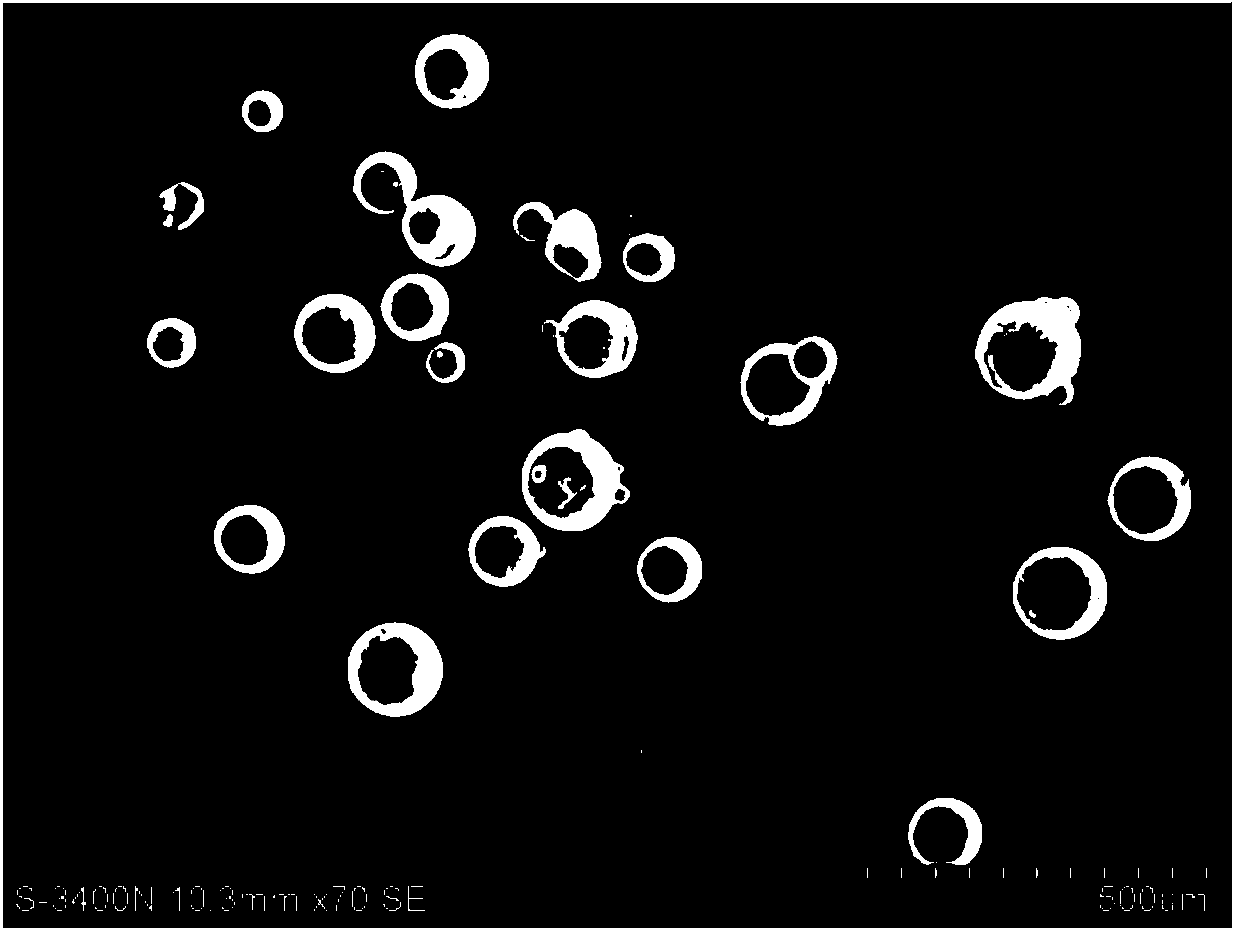

High-performance silicon-carbon cathode material and preparation method thereof

ActiveCN107785560ACover tightlyCoated evenlyNegative electrodesSecondary cellsNano siliconCarbonization

The invention relates to a high-performance silicon-carbon cathode material and a preparation method thereof. The preparation method comprises the following steps: (1) dispersing silicon into a solvent, carrying out liquid-phase ball-milling, so as to obtain nano-silicon dispersion liquid, adding graphite, and carrying out liquid-phase ball milling so as to uniformly mix nano-silicon with graphite; (2) carrying out granulation on slurry obtained the step (1), so as to obtain graphite / nano-silicon composite particles; (3) carrying out granulation on the product of the step (2) and asphalt by virtue of a mixed kneading-pressing-crushing method, so as to obtain graphite / nano-silicon / asphalt composite particles, and carrying out mechanical fusion so as to realize spheroidization and uniform coating of the graphite / nano-silicon / asphalt composite particles in one step; and (4) carrying out carbonization, scattering and sieving, so as to obtain the high-performance silicon-carbon cathode material. The preparation method is simple and low in cost and can be used for easily producing the high-performance silicon-carbon cathode material in large scale.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

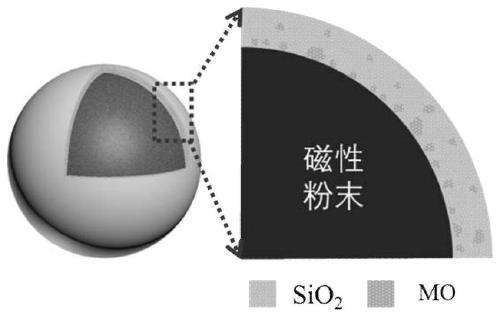

Preparation method of magnetic aluminum pigment

InactiveCN103319917AStrong magnetismCover tightlyPigment treatment with non-polymer organic compoundsKetone solventsSilicon dioxide

The invention provides a preparation method of magnetic aluminum pigment. The preparation method comprises the following steps of: washing flaky aluminum pigment through a ketone solvent, and performing press filtering to obtain a filter cake; placing the filter cake, an alcohol solvent, a magnetic powder material and a silane coupling agent into a reactor to be stirred and dispersed; simultaneously dropwise adding an alcohol diluent of ammonia water and an alcohol diluent of tetraethoxysilane for reaction; aging and performing press filtering on the mixed solution to obtain magnetic aluminum pigment coated by silicon dioxide; placing a ester solvent into the reactor, uniformly dispersing the magnetic aluminum pigment coated by the silicon dioxide into the ester solvent, dropwise adding acrylate monomers and an azo initiator into the reactor, sealing the reactor, and introducing inert gas into the reactor to wrap the mixture; performing press filtering on the mixture to obtain the double-layer coated magnetic flaky aluminum pigment. The magnetic aluminum pigment has excellent magnetism, the compactness in wrapping is achieved, a wrapping film is thin and uniform, the dispersion performance of the pigment in paint is good, and the magnetic aluminum pigment can be applied to 3D (three-dimensional) magic art paint.

Owner:HEFEI SUNRISE PIGMENTS

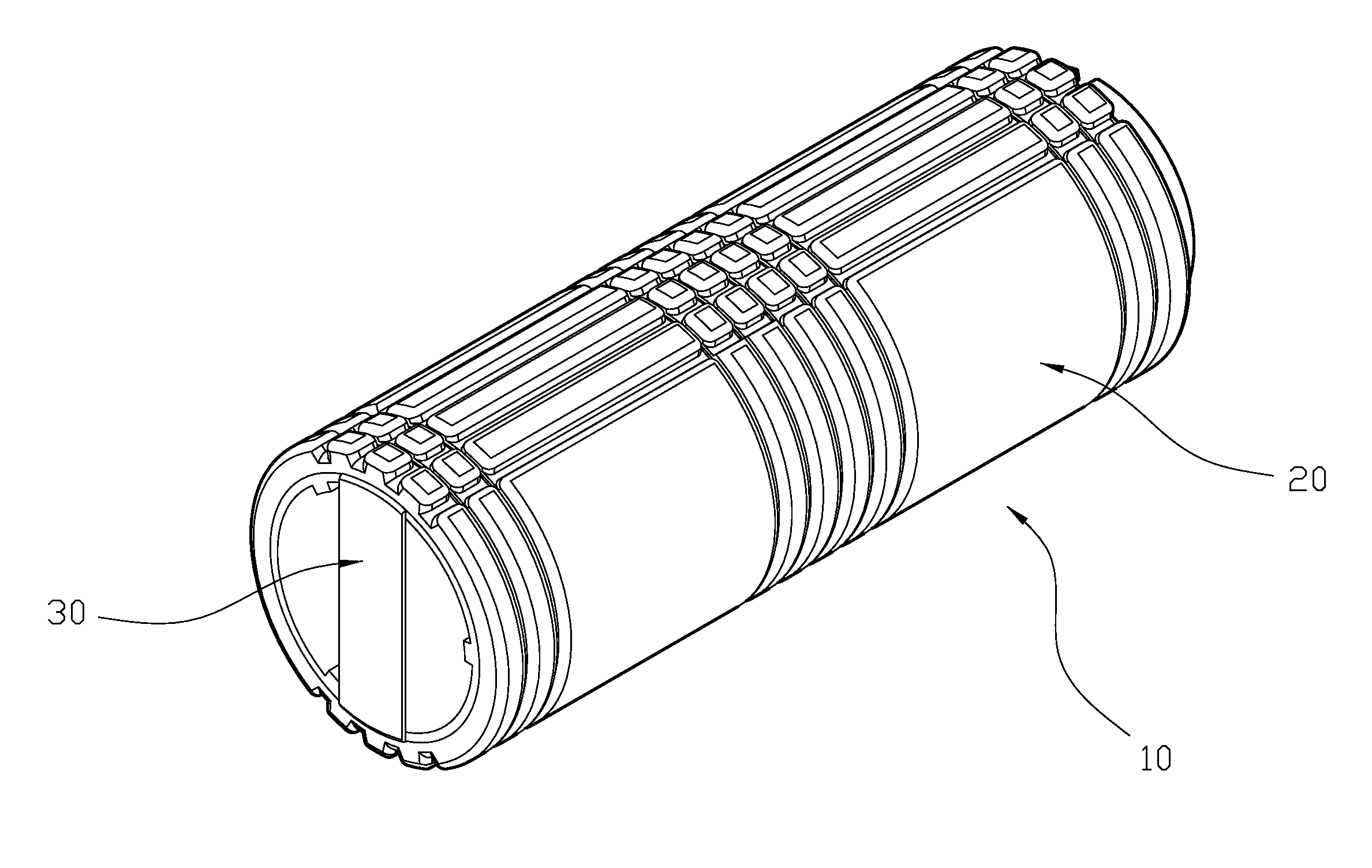

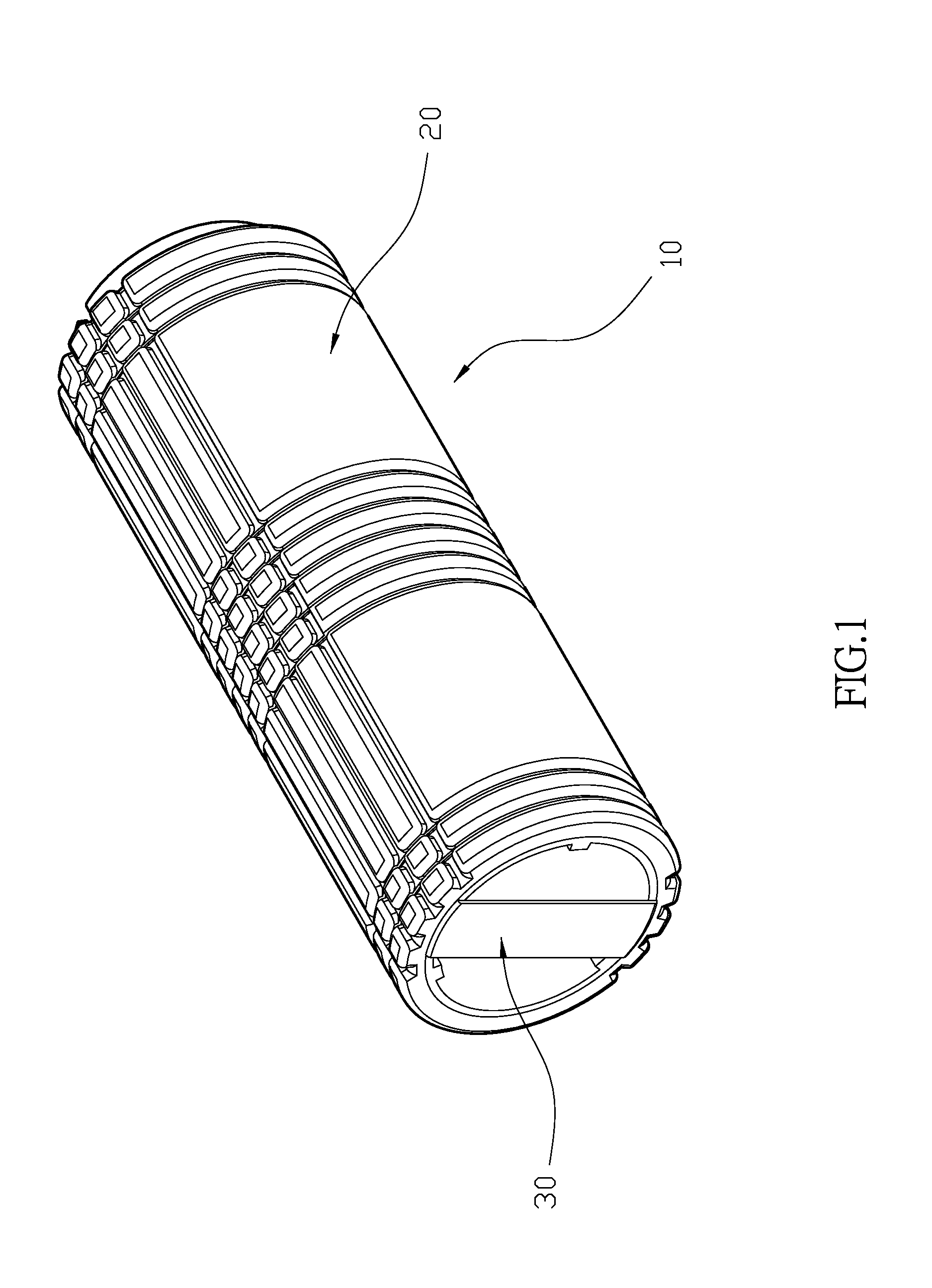

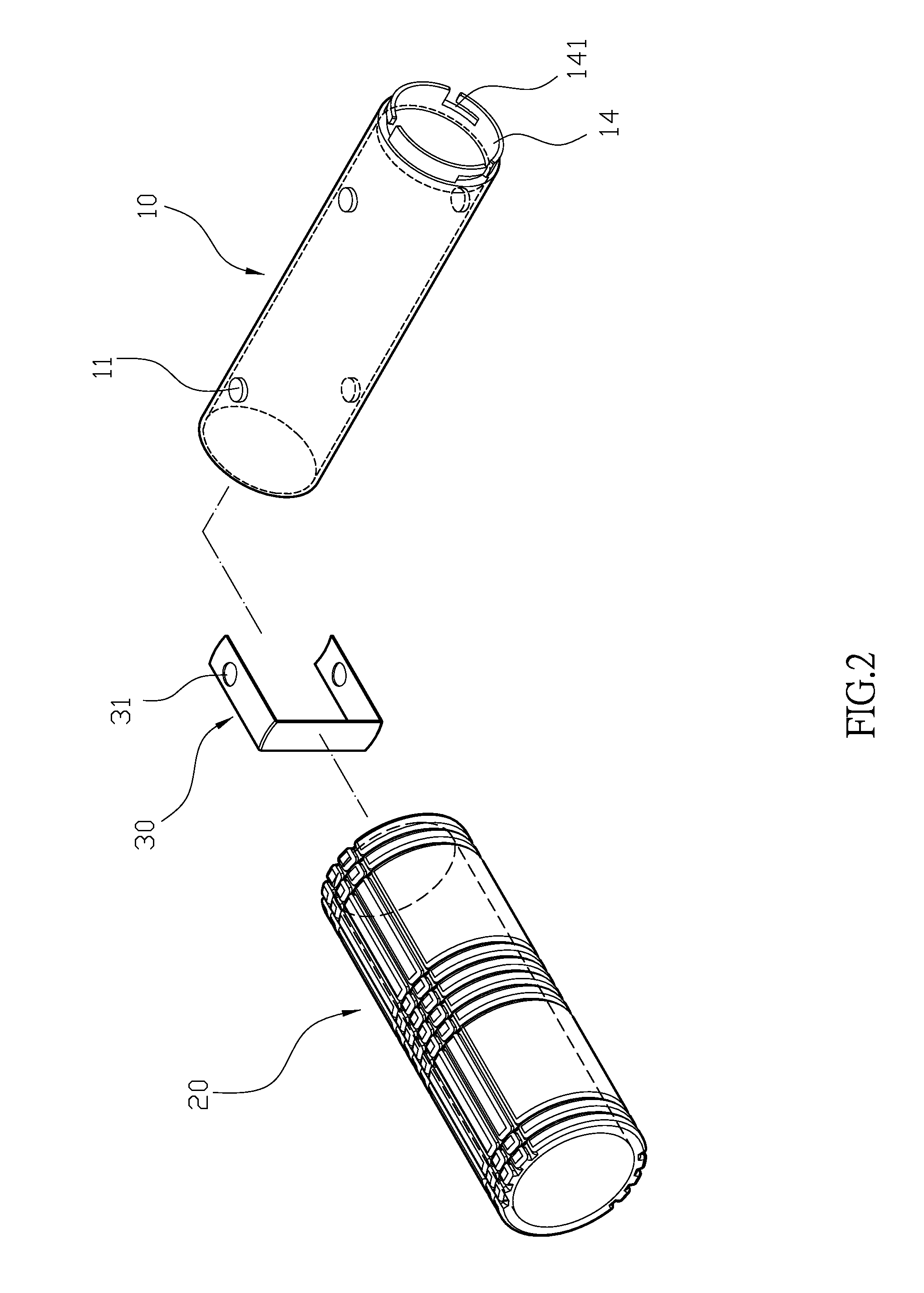

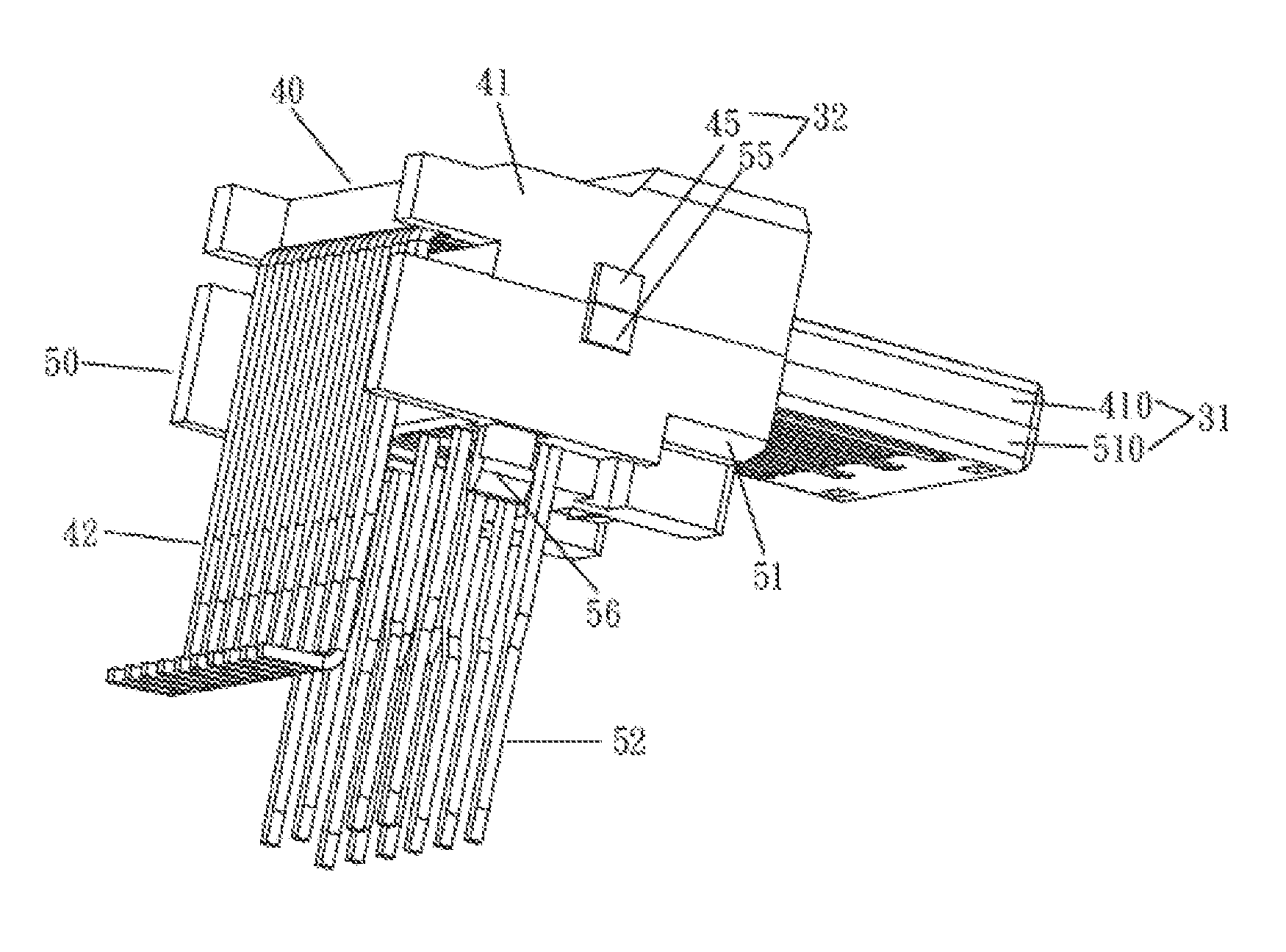

Exercise equipment

InactiveUS20150005146A1Cover tightlyIncrease variabilityRoller massageStiltsExercise equipmentEngineering

An exercise equipment comprising: a column body that is hollow and has a plurality of engaging ribs protruding at outer surface of the column body. One end of the column body has a U-shaped handle that has two through holes on both sides of the column body corresponding to the engaging ribs of the column body, so that the handle is able to conjugate the engaging ribs at the outer surface of the column body through the through holes. A cover layer covers outer surface of the column body, wherein inner surface of the cover layer has recessed slots corresponding to the engaging ribs, so that the cover layer can tightly cover the outer surface of the column body through the engagement of the engaging ribs and the recessed slots to avoid sliding and misalignment between the column body and the cover layer.

Owner:EVER GYM ENTERPRISES

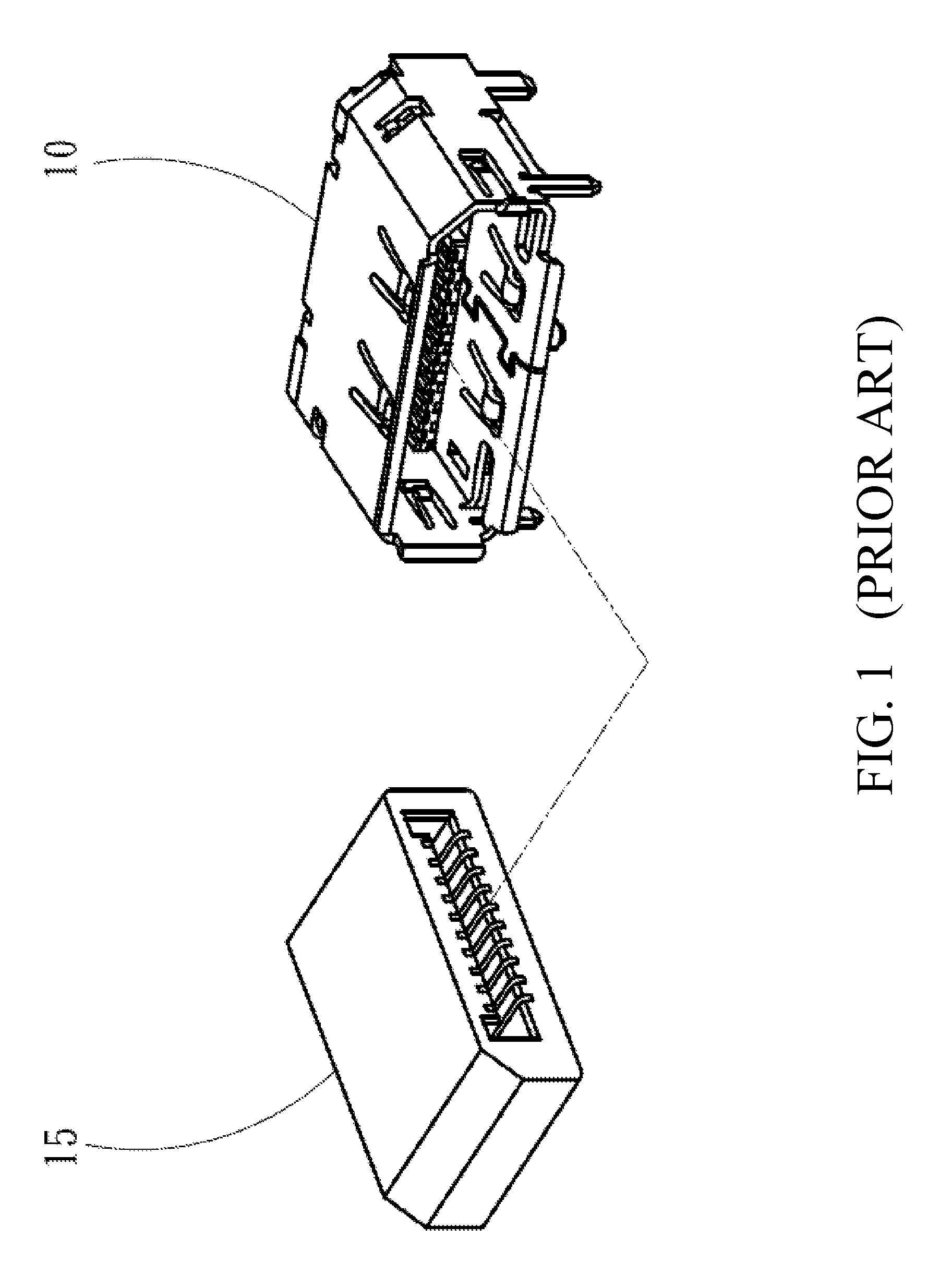

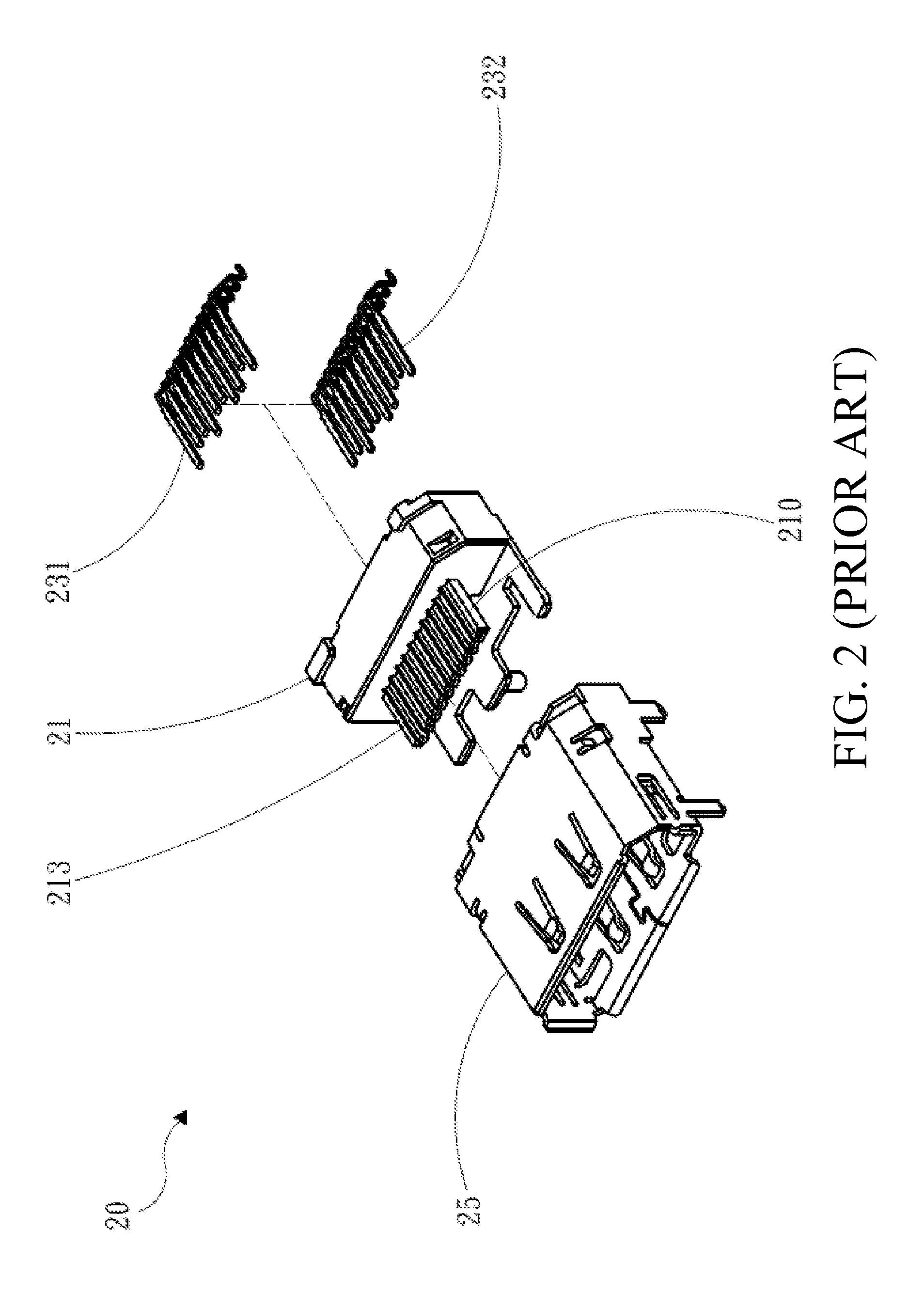

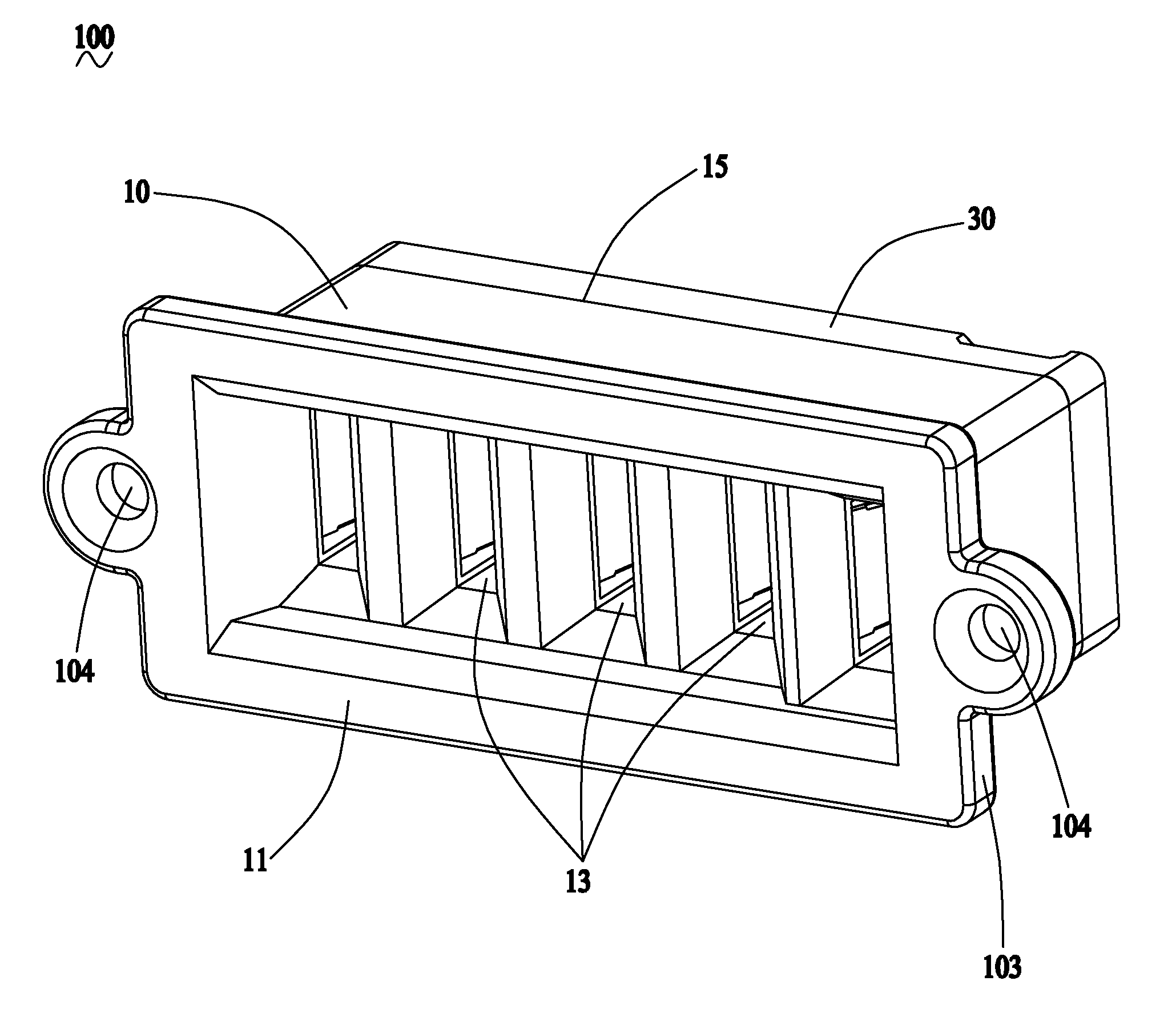

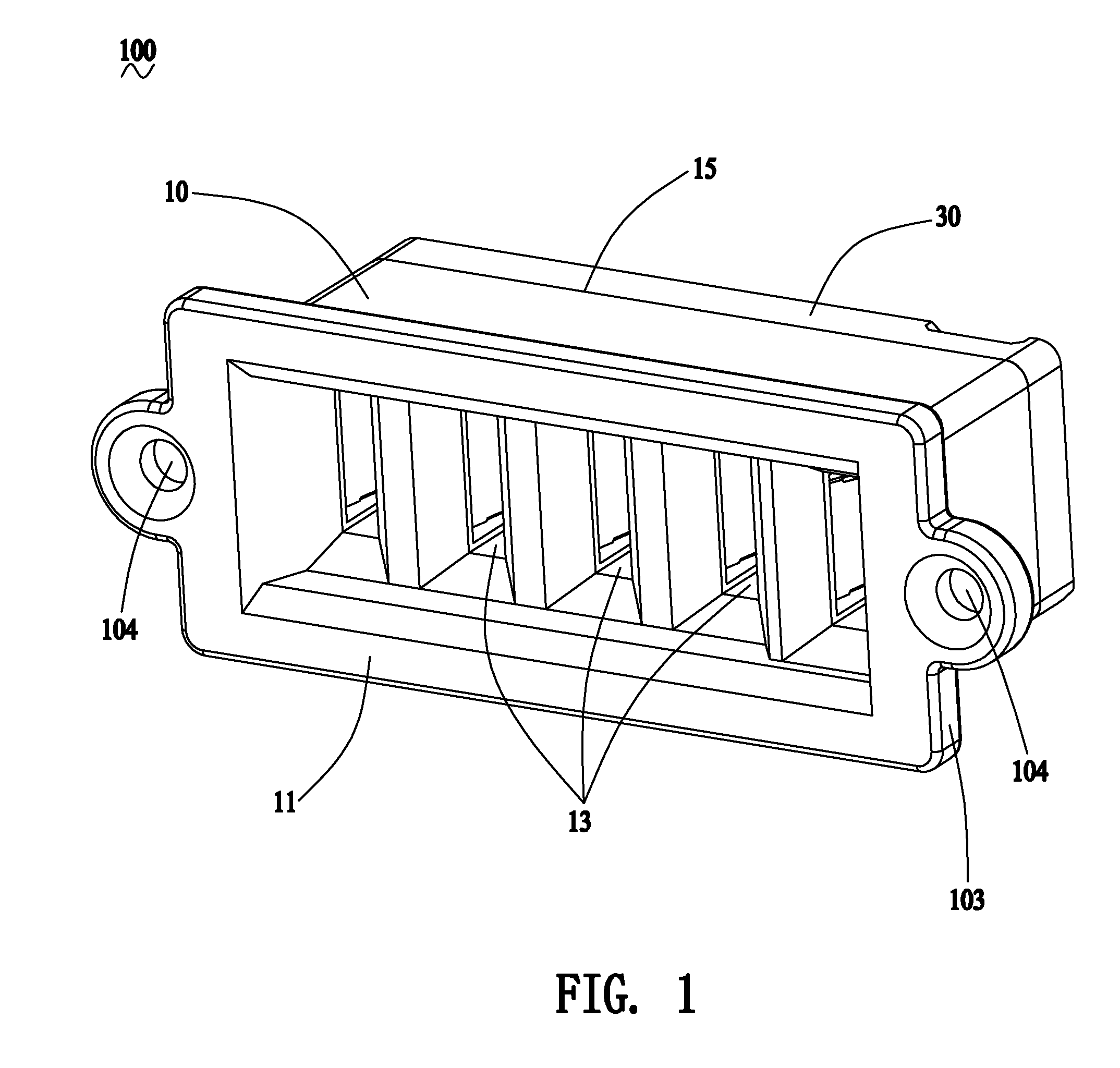

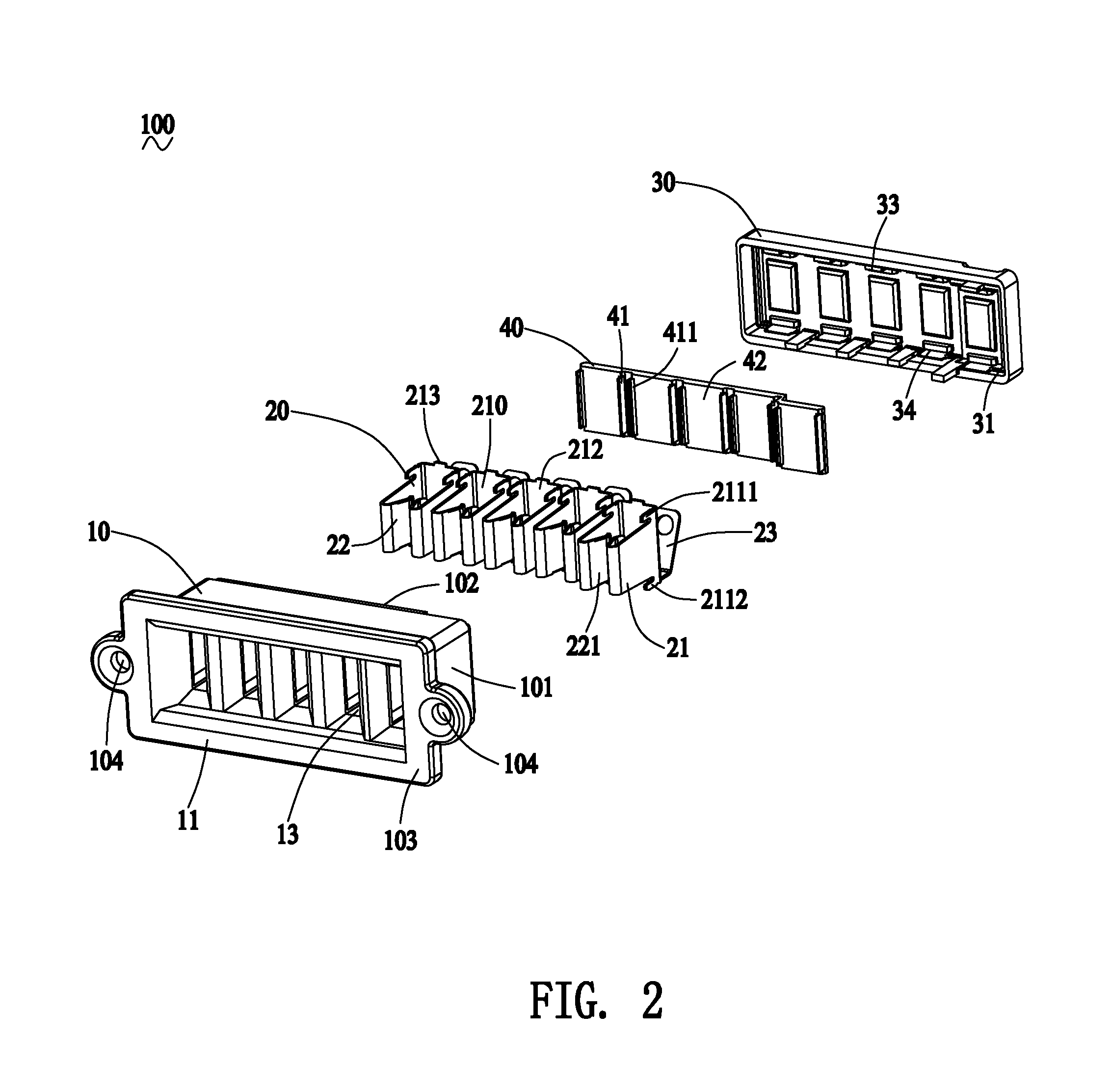

Display port socket

InactiveUS7845982B1Cover tightlyStable positionTwo-part coupling devicesFixed connectionsCouplingComposite element

A DisplayPort socket includes a first composite element and a second composite element. The first composite element includes a first insulating body partially and tightly covering plural terminals so that the terminals are exposed on a plate of the first insulating body and form plural conduction zones. The second composite element includes a second insulating body partially and tightly covering plural terminals so that the terminals are exposed on a plate of the second insulating body and form plural conduction zones. The plates of the first and second composite elements are stacked flat on each other to form a coupling plate for coupling buttingly with a DisplayPort connector. By integrating the first and second insulating bodies with their corresponding terminals to form the first and second composite elements and then assembling the first and second composite elements together, the terminals are securely positioned, thus increasing the reliability of the socket.

Owner:COMPUPACK TECH

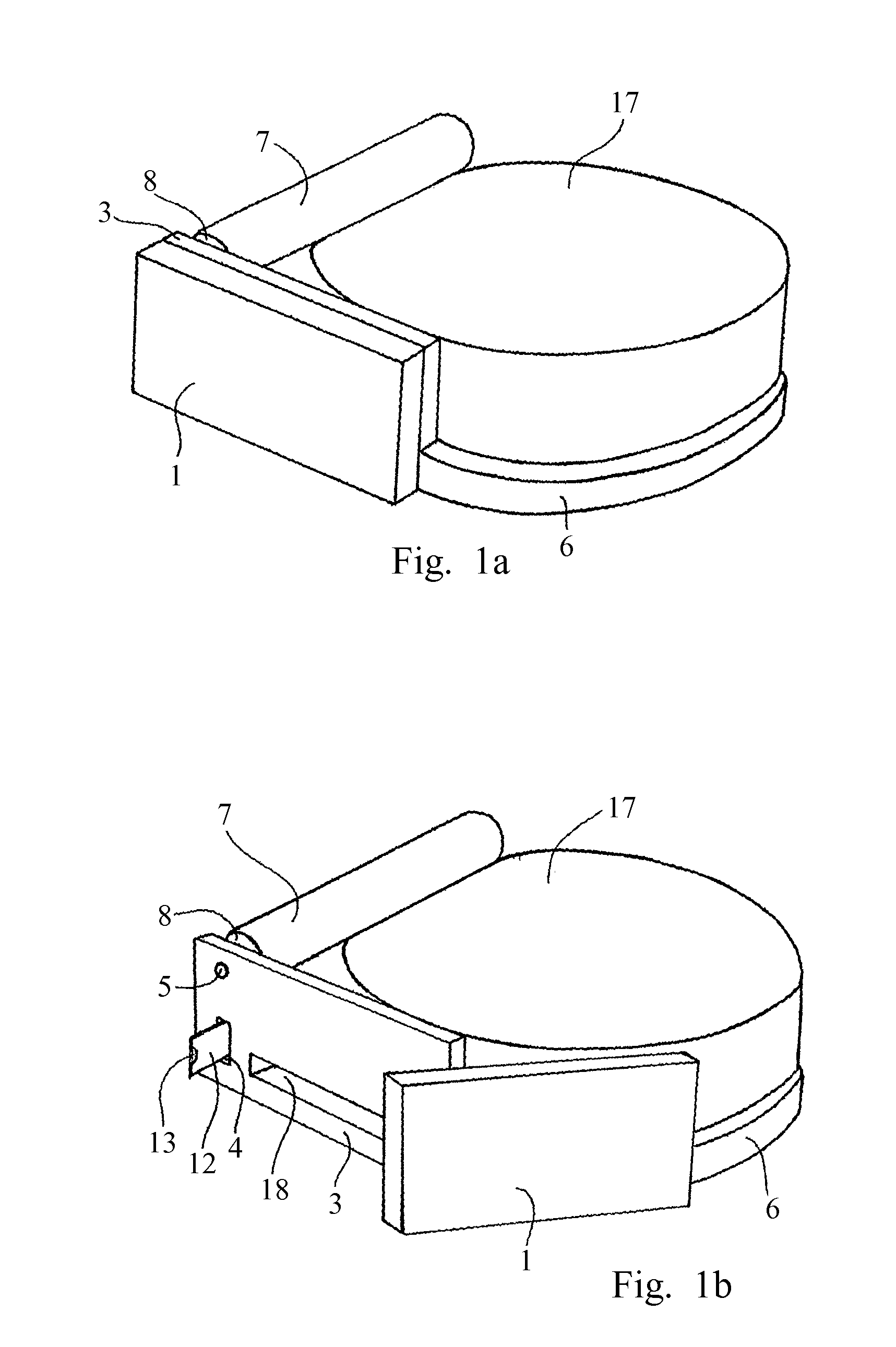

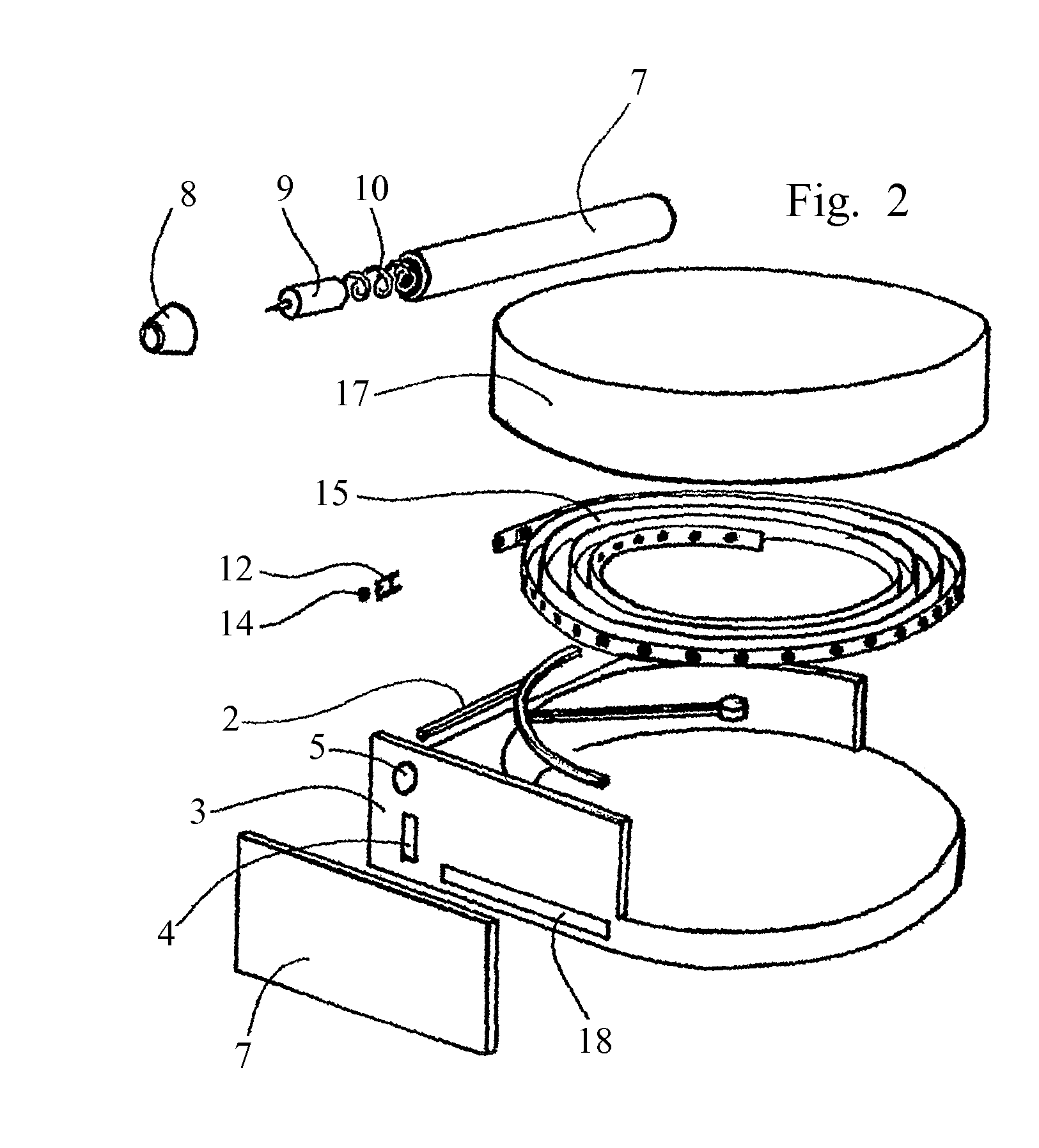

Health monitoring device, device modules and method

InactiveUS8062235B2Simple and less conspicuousCover tightlyCatheterSensorsComputer moduleBiomedical engineering

The present invention relates to a health monitoring device for measuring blood or tissue indicators and a strip cassette. The device comprises a body having first and second openings, a piercing means being connected to the body and having a piercing head, the piercing means being arranged to extend from the first opening and cockable and releasable for piercing the skin with the piercing head, and a space, into which a number of sensor strips can be arranged so that the strips can be brought out from the body one at a time. The device further comprises a shutter that is functionally connected to the body and has a first position arranged to tightly close the first and second openings, and a second position for allowing one sensor strip to be pushed from the first opening into sampling position and for exposing the first and second openings.

Owner:I SENS INC

Preparation method of brewing type instant dry bird's nest products

InactiveCN102715507AStay true to shapeFor long-term storageFood preparationFreeze-dryingRefrigerated temperature

The invention discloses a preparation method of brewing type instant dry bird's nest products. The preparation method comprises the following steps: taking a selected raw dry bird's nest product, adding clear water to stew, holding in a glassware after being cooled, the stewed bird's nest product is not more than 10 mm in thickness, placing in a refrigerator to be cooled to -18 DEG C and forming an icy bird's nest product; electrifying a freeze dryer, starting up a compressor for pre-cooling to enable cold trap to be cooled to -40 DEG C; placing the obtained icy bird's nest product and the holding glassware into a division plate of the freeze dryer; starting up a vacuum pump of the freeze dryer to enable the pressure of the icy bird's nest product and the holding glassware to be reduced to 10 Pa and start to be frozen dry; after the icy bird's nest product is frozen dry for 24 hours, blowing off the freeze dryer to a normal pressure, closing the vacuum pump of the freeze dryer, taking out the dry bird's nest product under a dry environment and closing the compressor; and under the dry environment, placing the dry bird's nest product into a packing bag quickly to be sealed. When people eat the dry bird's nest product, all that is needed is to place the dry bird's nest product into a bowl, brew with boiling water, add favorite seasoning and cover closely for 5 minutes. The brewing type instant dry bird's nest product is favorable for storage and carrying, and facilitates instant eating of people in household life, during a trip or in a working gap.

Owner:郭佳宏

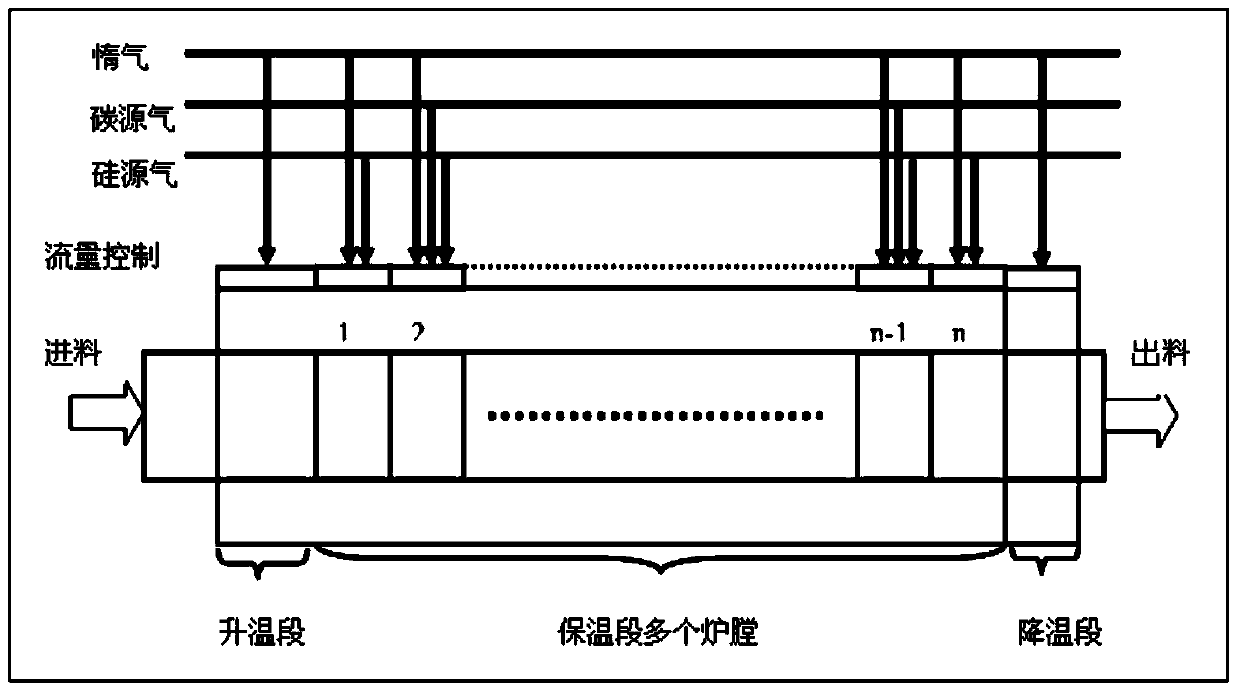

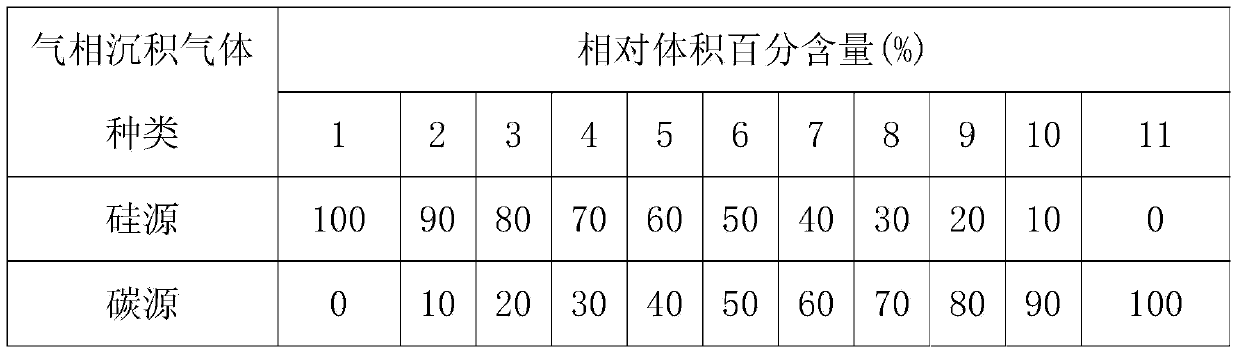

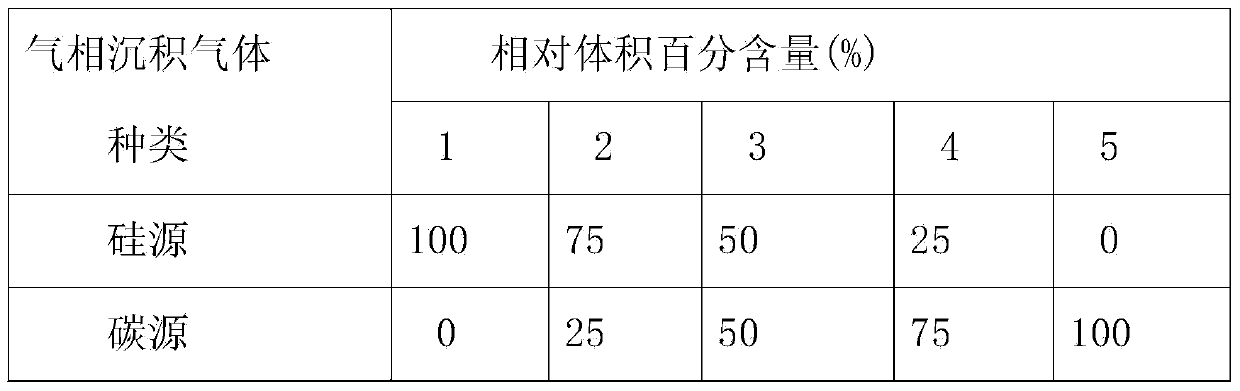

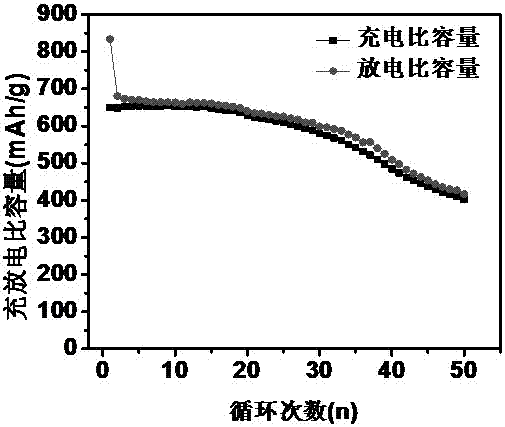

Preparation method of silicon composite anode material provided with gradient change coating layer on surface

ActiveCN103700819AControl heat treatment timeImprove cycle stabilityCell electrodesGas phaseChemical vapor deposition

The invention discloses a preparation method of a silicon composite anode material provided with a gradient change coating layer on the surface, and aims to overcome conventional modification defects of a silicon anode material. According to the preparation method, a porous silicon material is prepared firstly, and on the basis, a chemical vapor deposition method is adopted to uniformly deposit a coating layer on the surface of the porous silicon material, wherein the coating layer adopts an elemental Si-SiC-C transition structure. A test is performed in a vapor deposition reacting furnace provide with segmented temperatures, independently controllable atmosphere and a plurality of furnace chambers. Compared with the prior art, a gradient change process is achieved through the surface coating layer, an obvious interface structure is not formed, the coating layer is tight, so that a volume effect and electric conductivity of the silicon-based anode material in a battery charge-discharge process are inhibited effectively, and the cycling stability of the material is improved greatly. The preparation method is simple in technology and suitable for large-scale industrial production, and has wide application prospect in the field of lithium ion batteries.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

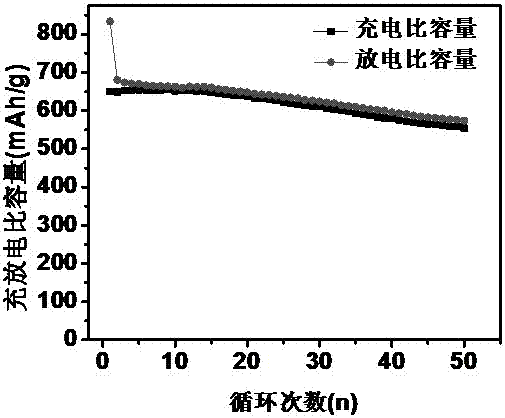

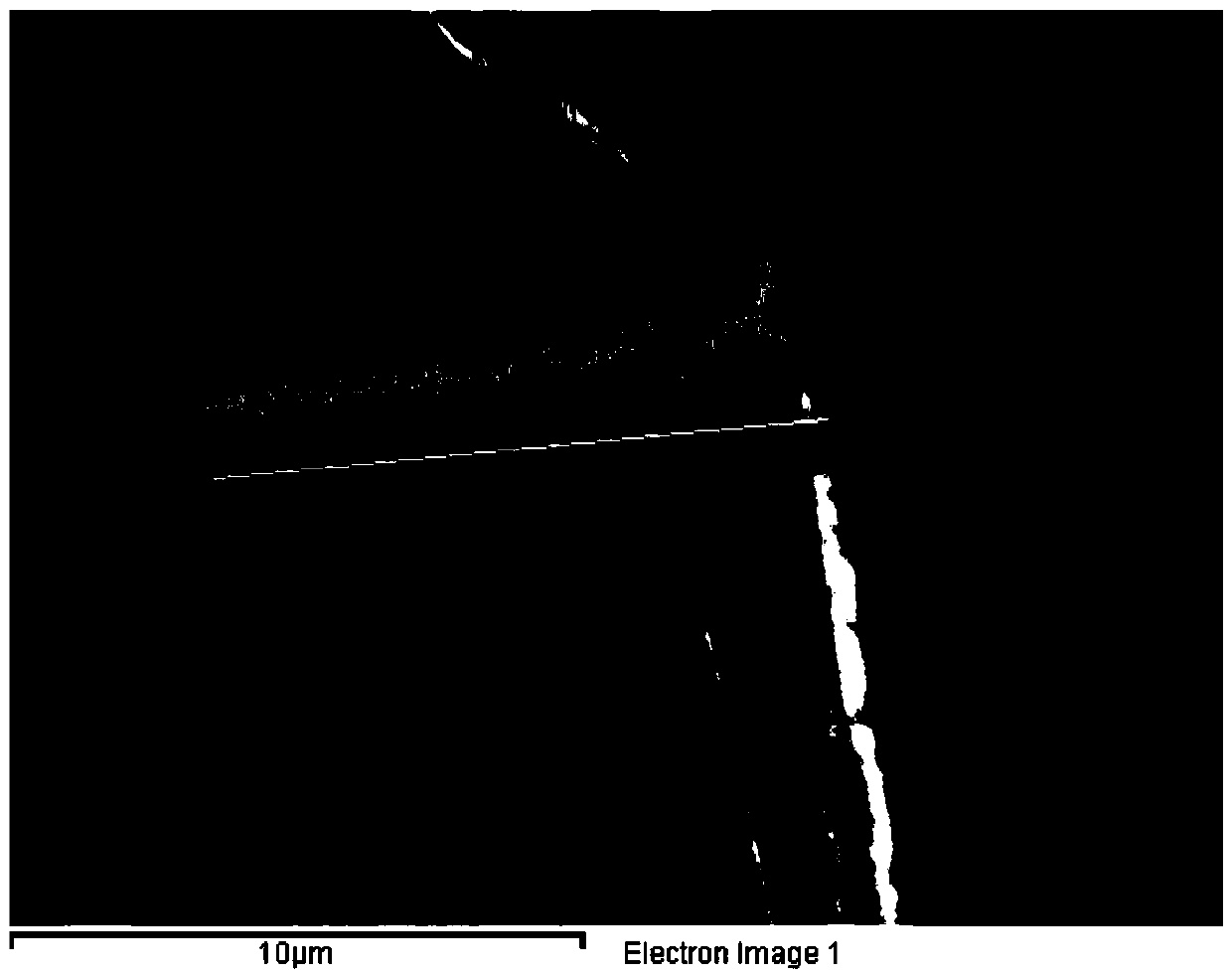

Preparation method for silicon-carbon composite negative electrode material

InactiveCN107017384AImprove liquidityCover tightlyCell electrodesSecondary cellsCarbon compositesCarbonization

The invention discloses a preparation method for a silicon-carbon composite negative electrode material. The preparation method comprises the steps of performing dispersing on nanometer silicon, graphite and an organic matter separately and mixing in proportion; next, performing heating and drying and heating until the temperature reaches an organic matter softening point temperature or above, and performing fusing and binding and low-temperature carbonization to obtain an organic matter cracked carbon-coated primary coating material; performing dispersing on the organic matter and the primary coating material separately and mixing in proportion; and next, performing heating and drying and heating until the temperature reaches an organic matter softening point temperature or above, and performing fusing and coating and high-temperature carbonization to obtain an organic matter cracked carbon-coated secondary coating material, namely the silicon-carbon composite negative electrode material provided by the invention. The initial reversible capacity of the negative electrode material prepared by the method can reach 649mAh / g, and the capacity retention ratio after 50 cycles can be maintained at 85.36%, and quite excellent cycling performance is shown; and in addition, the preparation method has a simple and environment-friendly process, low energy loss, rich silicon and graphite raw material resource, low cost and high safety, and is suitable for industrial production and use.

Owner:SHAANXI COAL & CHEM TECH INST +1

Preparation method of water-based high flash aluminum pigment for automobiles

InactiveCN102604443ACover tightlyGood water solubilityCoatingsPigment physical treatmentChemistryWater soluble

The invention discloses a preparation method of a water-based high flash aluminum pigment for automobiles. The method comprises the steps of putting spherical aluminum powder, steel balls as grinding mediums, environmentally friendly solvent oil, oleic acid or erucic acid, and a surfactant into a ball mill, sealing the ball mill, performing ball milling, discharging with the environmentally friendly solvent oil, conveying the materials into a vibrating sieve through a pipeline to sieve, removing screen tailings, performing filter pressing to obtain filter cakes with the solid content being of 80 percent, putting the filter cakes and alcohol or ether solvents with good water compatibility into a reactor for mixing and dispersing, sealing the reactor, increasing the temperature under the protection of inert gases, then dropping water-soluble high polymer monomers and azo-initiators, increasing the temperature after the dropping is finished, holding the temperature, discharging, and performing filter pressing to obtain finished products. The method has the advantages that the environmental protection effect is good; the coating is tight, and a coating layer is difficult to be damaged; the water solubility is good, and the pigment can be directly diluted with water; and the pigment is easy to dissolve in water-based automobile paint systems, and is beneficial to the dispersion of the aluminum pigment.

Owner:HEFEI SUNRISE PIGMENTS

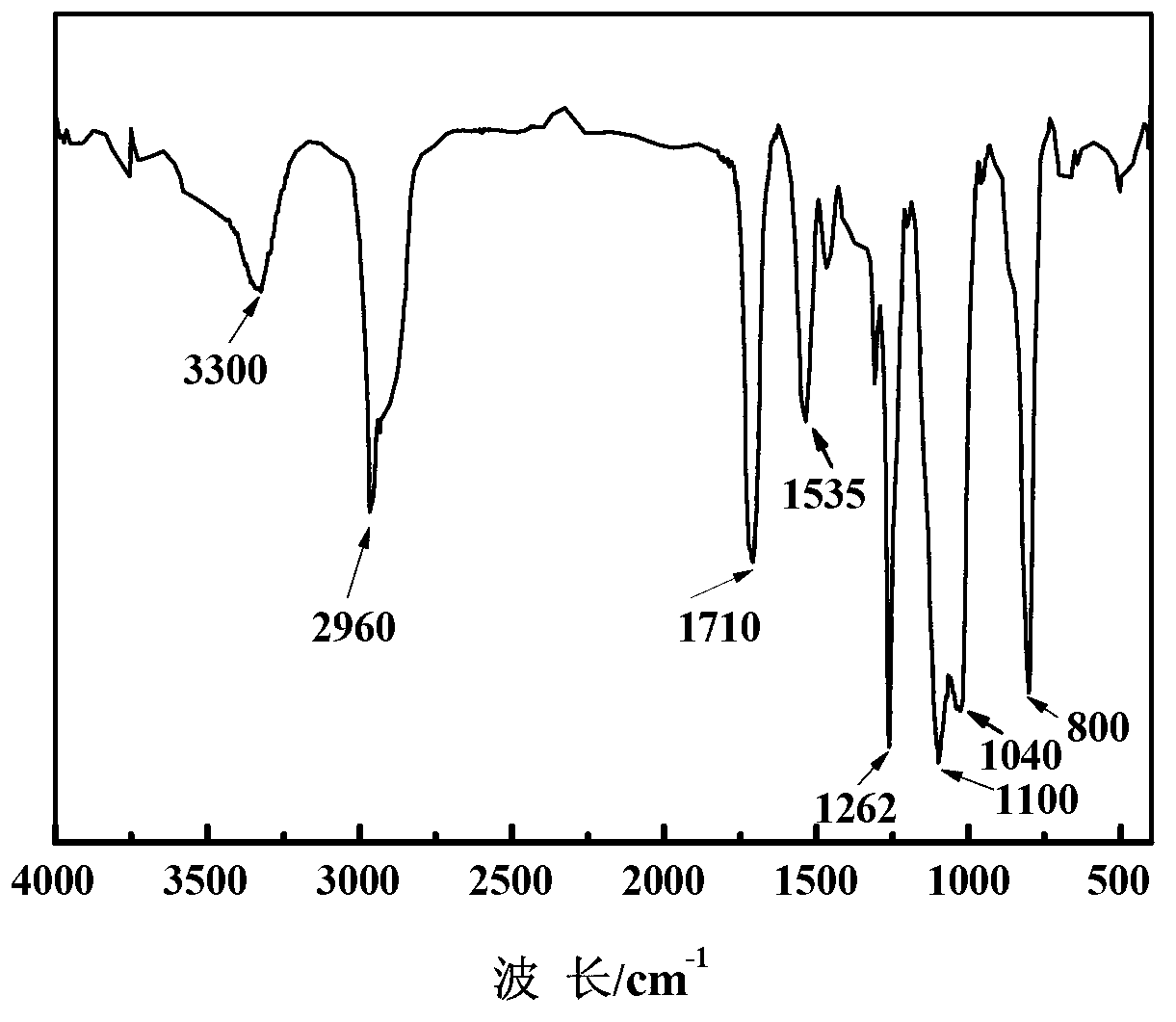

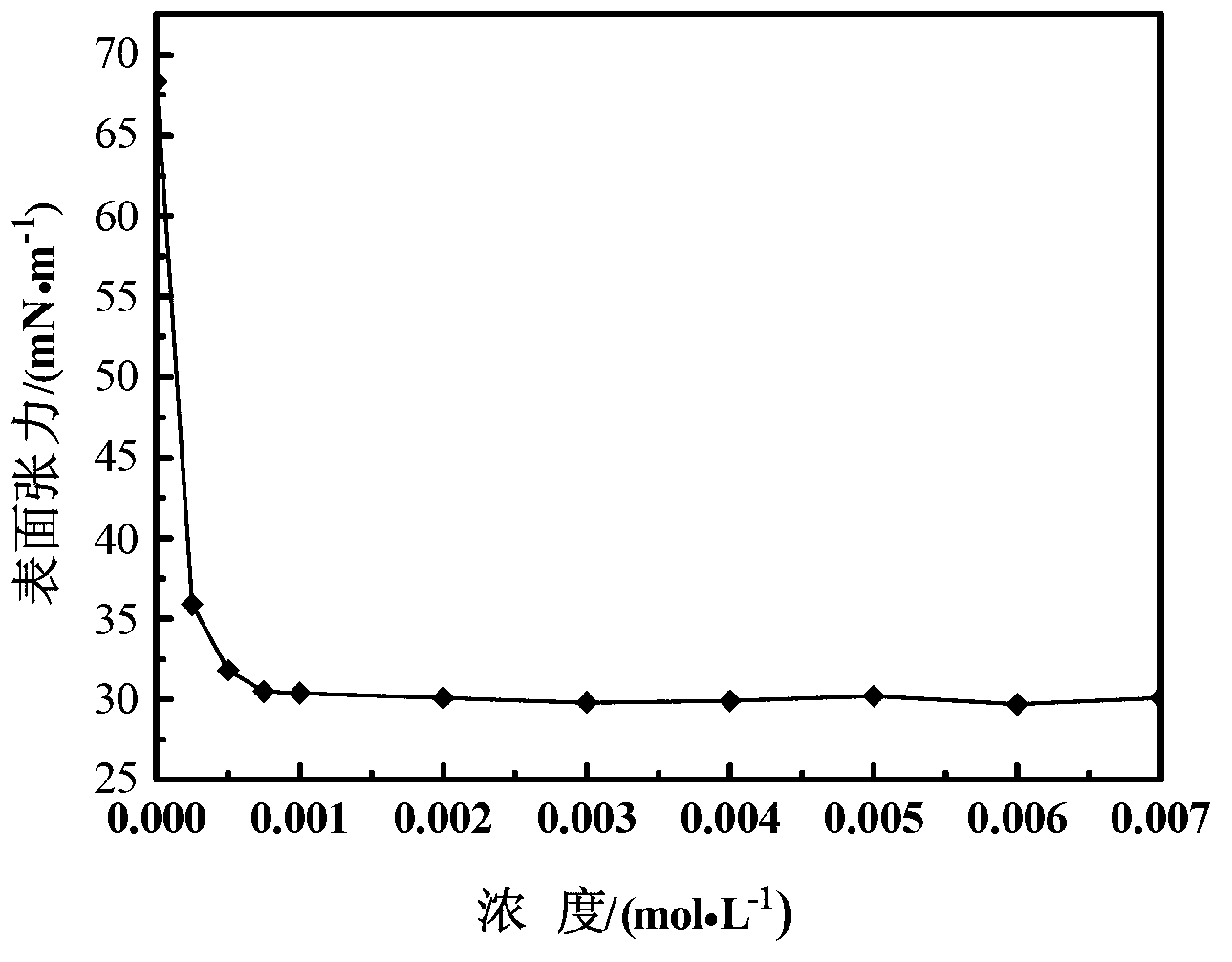

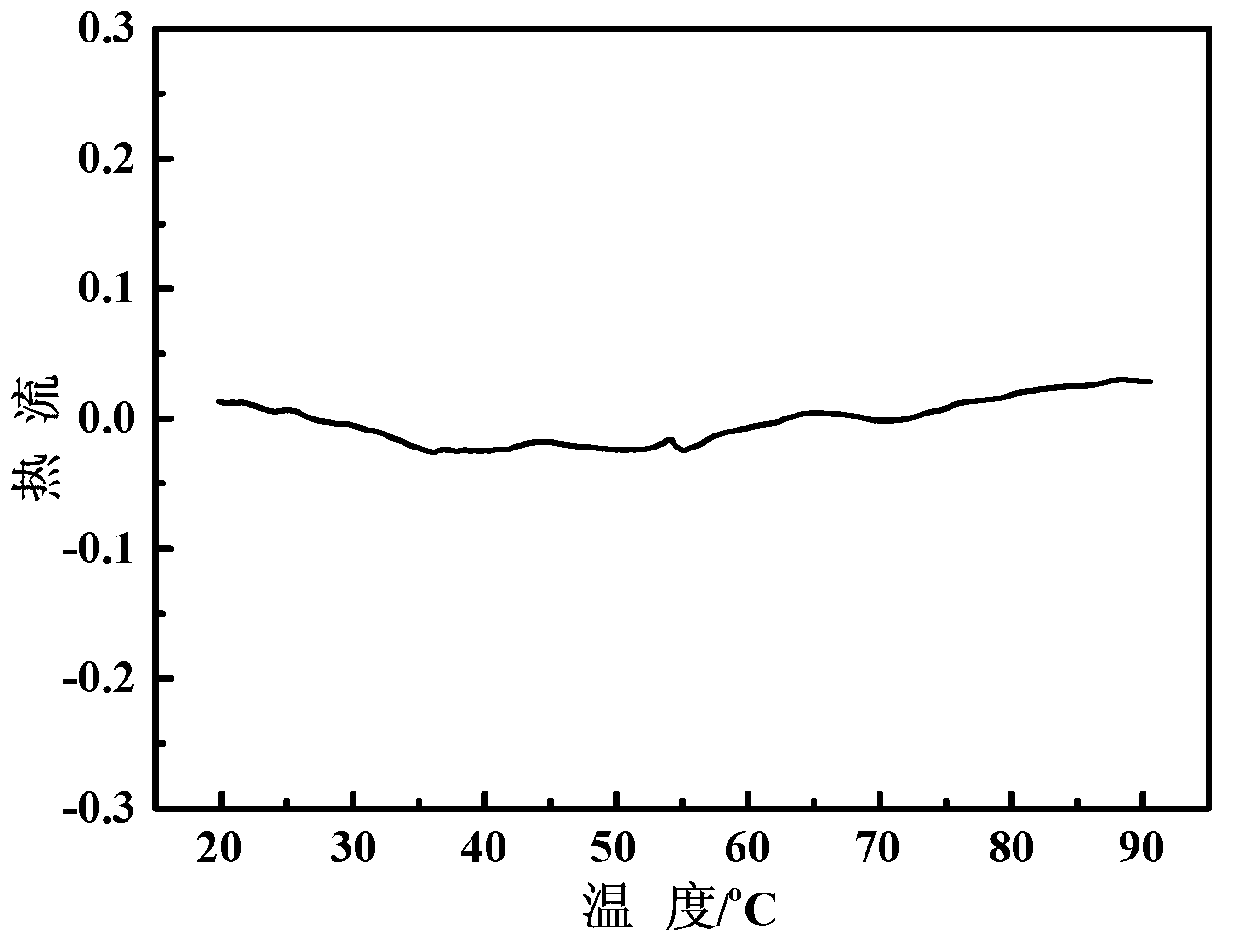

Silicon-containing polyurethane surfactant and preparation method thereof

The invention discloses a preparation method of a silicon-containing polyurethane surfactant. The method is characterized by comprising the following steps of: heating hydrophobic silicon oil and a hydrophilic dihydric alcohol monomer while stirring in the molar ratio of 10:1-1:10 in a solvent in an inert atmosphere to 50-60 DEG C, adding a catalyst, and slowly adding isocyanate at the temperature of 70-80 DEG C for reacting for 2-3 hours; and cooling to 60 DEG C, adding a neutralizing agent, evaporating a solvent out at the temperature of 50-55 DEG C 30-60 minutes later, precipitating in methanol of 20-25 DEG C, and drying at the temperature of 50-60 DEG C to constant weight to obtain a product. A silicon oil chain segment with low surface tension is introduced into polyurethane molecules, so that the surface tension of polyurethane is reduced; and a hydrophilic part of the product consists of an ionic monomer and a nonionic monomer, so that the defect of the sensitivity of a single nonionic emulsifier to temperature is overcome, and a product aqueous solution is prevented from undergoing phase splitting emulsion breaking at the temperature of 20-90 DEG C, and can be applied in the industries of spinning, papermaking, oilfields and the like.

Owner:佛山市方普防护技术有限公司

Coating modification method of lithium manganate

The invention is a coating modification method of lithium manganate. A novel powder processing apparatus with a mixing-fusion function is selected; micron-level lithium manganate powder is coated by nanometer metal oxide powder, and a mechanical fusion state is reached; and the coated modified lithium manganate material with a uniform surface is obtained by calcination. The processing method is simple, has high coating efficiency, good effect, no material loss, and is an industrial production method.

Owner:CHINA NAT OFFSHORE OIL CORP +1

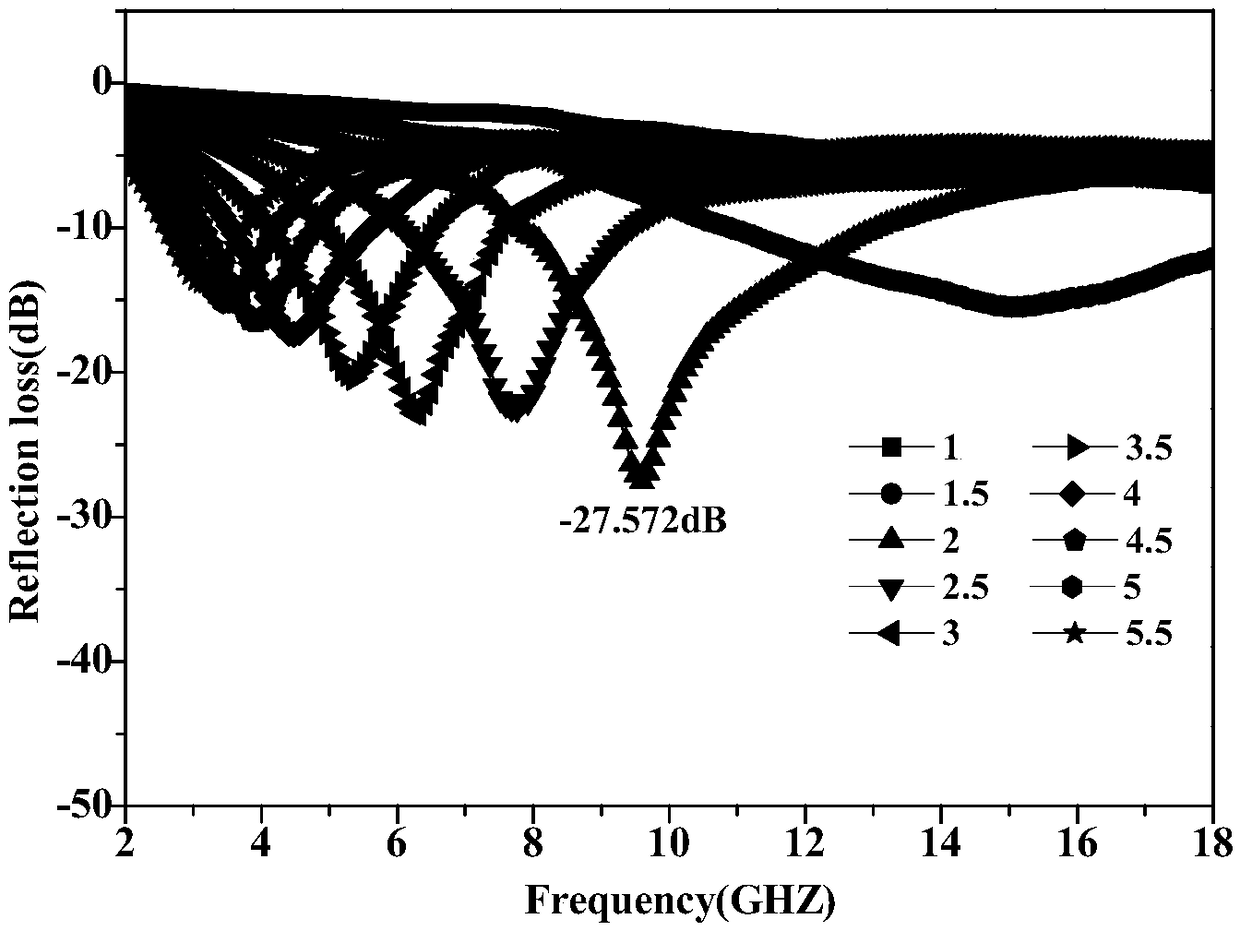

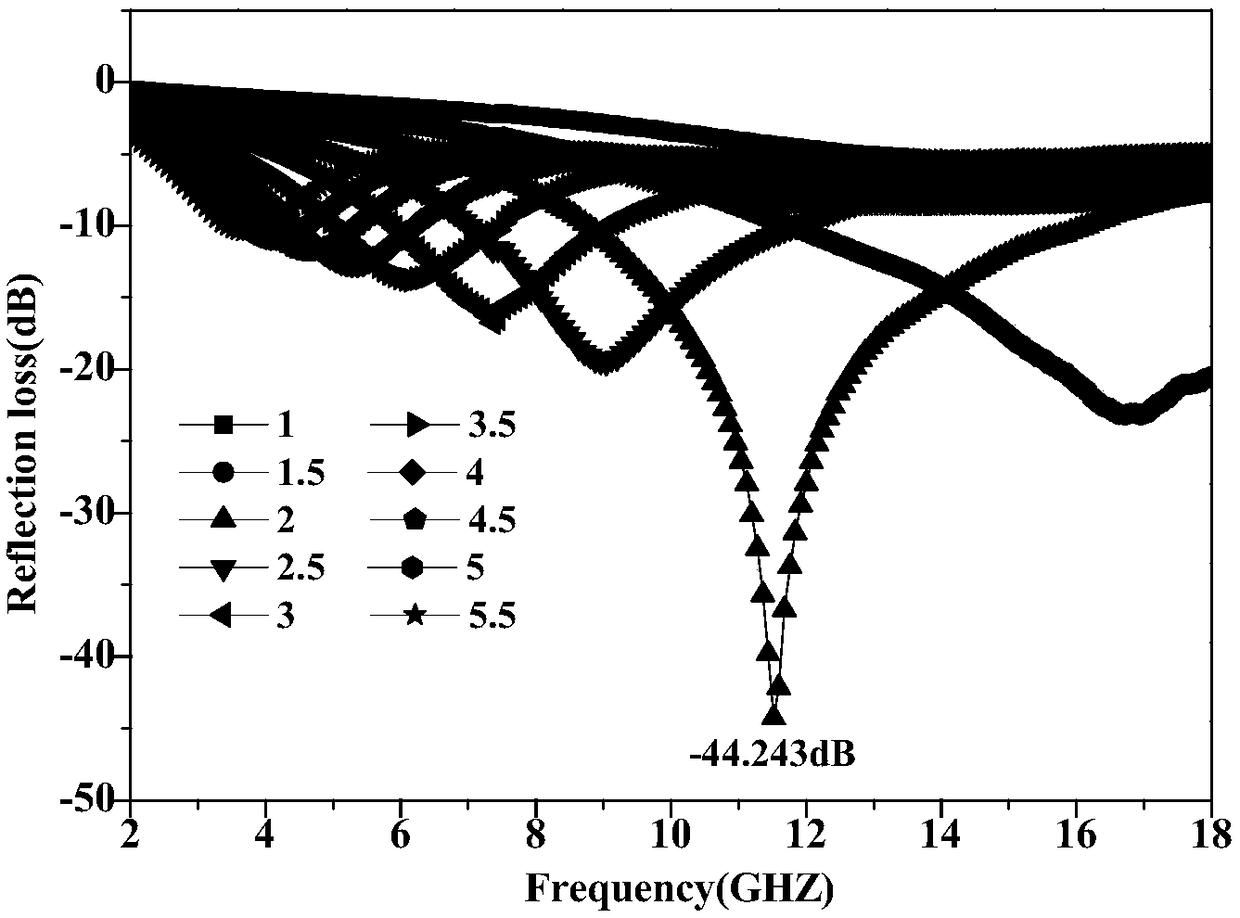

Double-shell-structure carbonyl iron powder composite wave-absorbing material and preparation method thereof

ActiveCN109207123ACoated evenlyControllable thicknessOther chemical processesMagnetic/electric field screeningCoprecipitationMagnetic layer

The invention discloses a double-shell-structure carbonyl iron powder composite wave-absorbing material and a preparation method thereof, wherein the composite wave-absorbing material is of a double shell layer core-shell structure, the core is carbonyl iron powder, the inner layer of the double-shell layer is an insulating layer, and the outer layer of the double-shell layer is a magnetic layer;the thickness of the insulating layer is 1 nm-1 [mu] m; and the thickness of the magnetic layer is 1nm-5 [mu] m; the preparation method comprises the following steps: coating the surface of the carbonyl iron powder with the insulating layer and coating the surface of a core-shell structure precursor by a chemical coprecipitation method. The surface of the carbonyl iron powder is coated with the double-shell layer by the chemical coprecipitation method. The impedance matching characteristic of the material is greatly improved, meanwhile, a large amount of nano-interface heterojunction is formedat the interfaces of the inner core and the double-shell layer, so that interface polarization is effectively induced, the scattering effect is formed for electron migration, and electromagnetic waveloss mechanisms such as multi-reflection absorption, strong ] ferromagnetic resonance and eddy current loss and the like of the material are greatly improved, so that the wave absorbing performance of the material is remarkably improved; the composite wave-absorbing material is simple in preparation method, is uniform and compact in coating and controllable in coating layer thickness and particlesize.

Owner:CENT SOUTH UNIV

Inhomogeneous nucleation insulation coating processing method of metal soft magnetic composite material

ActiveCN104028747APrecise thickness controlPrecise control of its chemical compositionInorganic material magnetismInsulation layerSpray coating

The invention discloses an inhomogeneous nucleation insulation coating processing method of a metal soft magnetic composite material. The method includes the following steps that (1) particle size distribution is conducted on metal magnetic powder after sieving is conducted; (2) insulation coating is conducted on the distributed metal powder through an inhomogeneous nucleation method, and then the metal powder is dried; (3) the dried magnetic powder and a binding agent are evenly fixed, a release agent is added to conduct dry pressing and forming, and the mixture is pressed to form blank samples; (4) heat preservation is conducted on the blank samples for half an hour to two hours in a protective atmosphere, and air cooling and spray coating are conducted to obtain the target product. The composite powder prepared through the inhomogeneous nucleation method is even and compact in coating and controllable in coating layer thickness, and has high oxidation resistance, high resistivity, high saturation magnetization intensity, the good magnetic property and the good mechanical property; the surface of the metal magnetic powder is evenly coated with an A12O3 insulation layer through the inhomogeneous nucleation method, so that the coating effect is superior to that of an existing method, the operability is high and volume production is facilitated.

Owner:ZHEJIANG UNIV

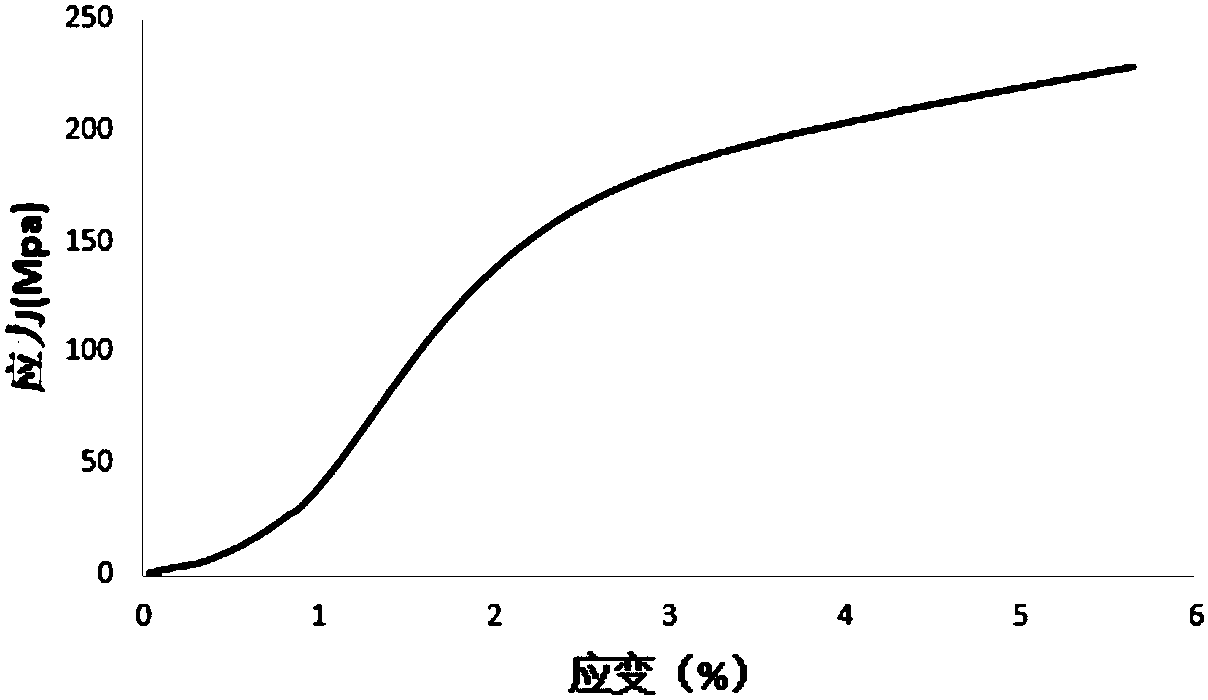

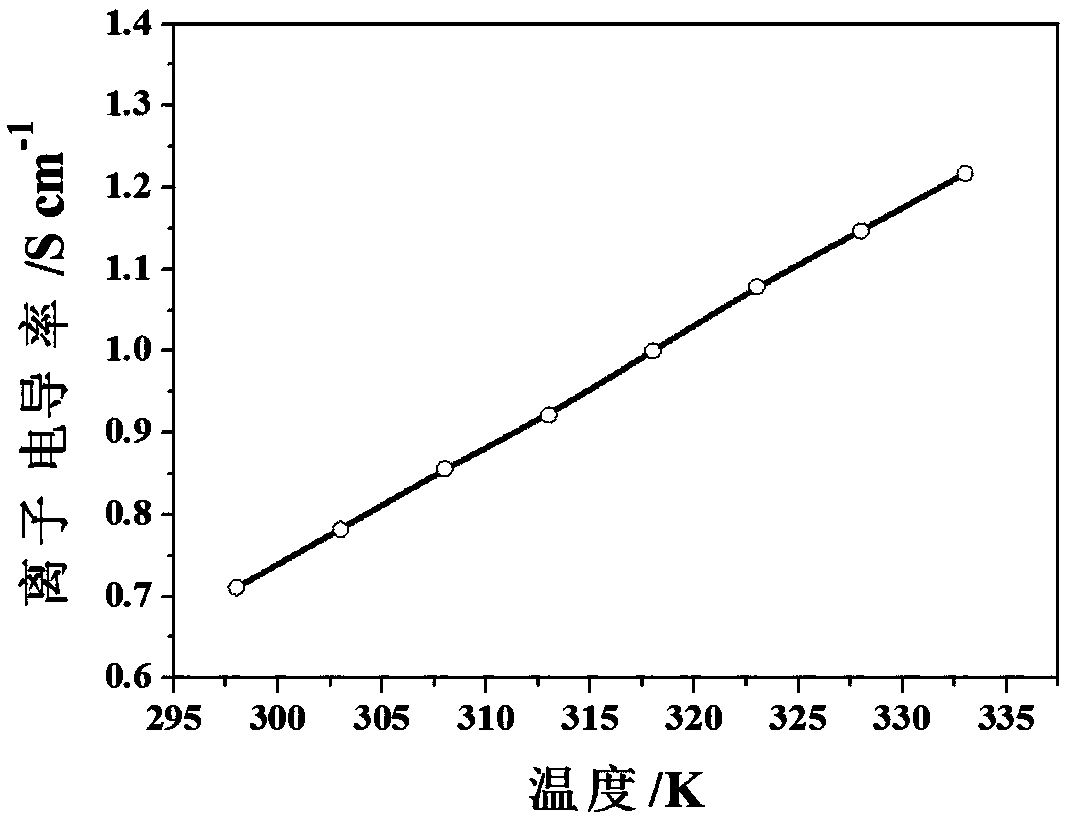

Cellulose nanofibril/metal-organic framework composite lithium ion battery separator and preparation method

ActiveCN108428841AImprove wettabilityWide variety of sourcesMaterial nanotechnologySecondary cellsCelluloseMetal-organic framework

The invention belongs to the crossing field of lithium battery materials, organic coordination materials and biomass and particularly relates to a cellulose nanofibril / metal-organic framework composite lithium ion battery separator and a preparation method. The separator is prepared from components in percentage by weight as follows: 20wt.%-99wt.% of cellulose nanofibril and 0.1wt.%-80wt.% of a metal-organic framework; the diameter of the cellulose nanofibril is 5-100 nm. The provided composite lithium ion battery separator has the characteristics of high mechanical strength, uniform pore sizedistribution and high binding force between the cellulose nanofibril and the metal-organic framework, has higher ionic conductivity and excellent electrochemical interface stability; the preparationmethod is simple and facilitates large-scale production.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

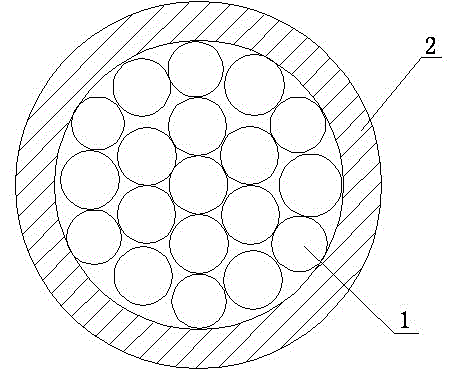

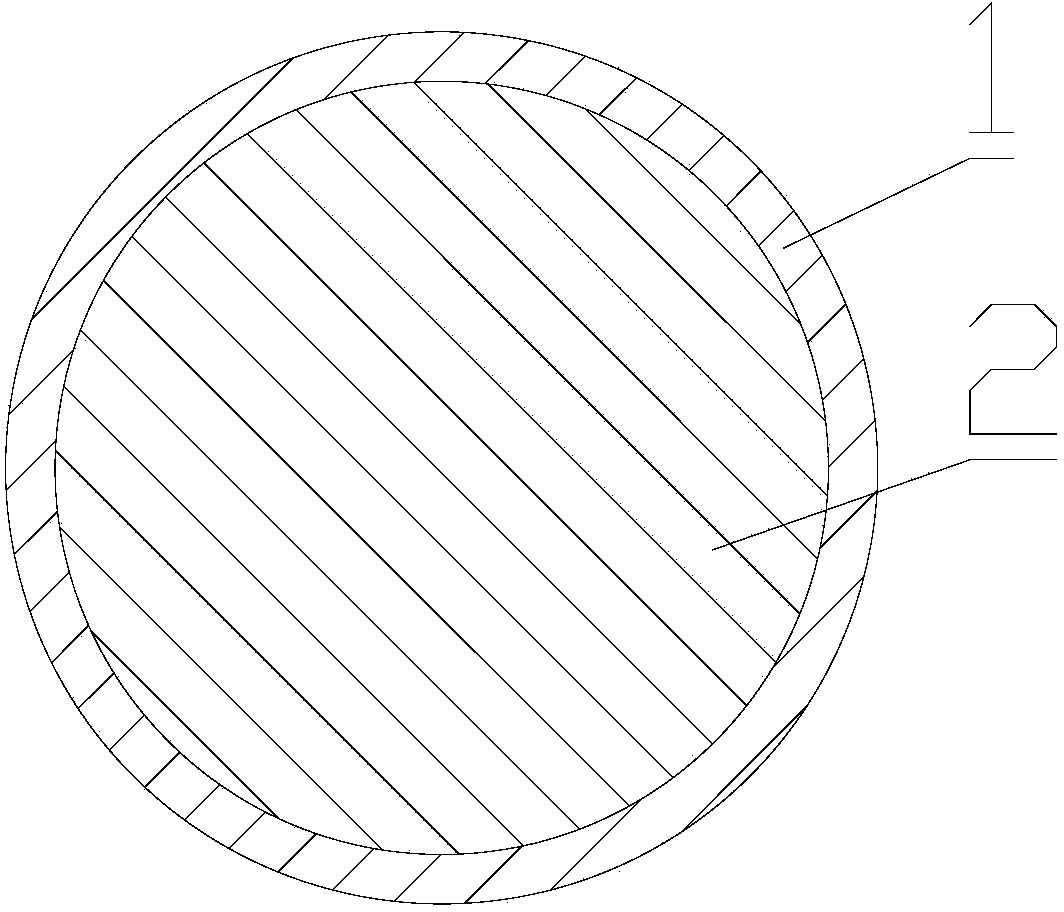

Railway through ground wire and preparation process thereof

ActiveCN103337294AQuality assuranceGuaranteed lifeInsulated cablesManufacturing rigid-tube cablesAnti stressRare earth

The invention relates to a railway through ground wire. The railway through ground wire comprises copper stranded wires (1); the exterior of the copper stranded wires (1) is coated with an outer sheath layer (2) which is made of a rare earth copper alloy material. The outer sheath of the through ground wire is made of rare earth copper alloy, and therefore, defects of zinc-containing brass can be eliminated, and the outer sheath has strong waterproof, anti-corrosion and anti-stress performances, so the quality and the service life of the railway through ground wire can be ensured; the outer sheath has strong tensile strength and high elongation at break and low resistance, and is not easily influenced by stress, and therefore, usage requirements of the railway through ground wire can be better satisfied; the contents of mercury, lead, cadmium and chromium in the outer sheath are lower, and therefore, after being used for a long term, the outer sheath of the railway through ground wire will not pollute environment; and the copper stranded wires are sheathed in the outer sheath which is a seamless pipe, and therefore, problems of cracks appearing on existing outer sheaths and affected conductivity of the copper stranded wires caused by welding-caused high temperature can be solved.

Owner:江阴和宏精工科技有限公司

High-bonding-strength insulated coating treatment method of metal soft magnetic composite material

The invention discloses a high-bonding-strength insulated coating treatment method of a metal soft magnetic composite material. The method comprises the following steps: (1) sieving metal magnetic powder, and performing particle size distribution; (2) performing insulated coating on the distributed metal magnetic powder by using a sol-gel method, and then drying the metal magnetic powder; (3) uniformly mixing the dried magnetic powder and an adhesive, adding a release agent, and performing dry pressing to obtain a magnetic ring; (4) performing heat preservation, air cooling and spraying on the magnetic ring in protective atmosphere to obtain a target product. The bonding strength of composite powder prepared by using the sol-gel method and magnetic powder particles is high, the powder is coated uniformly and densely, and a coating layer is controllable in thickness, good, oxidation resistance and high saturation magnetization intensity are achieved, excellent in magnetic property and mechanical property, high in bonding strength, and not prone to disengagement; the coating effect is superior to that of an existing method; the method is high in operability and facilitates batch production; the resistivity of soft magnetic metal particles is effectively improved, and the magnetic core loss of the soft magnetic composite material is greatly reduced.

Owner:ZHEJIANG UNIV

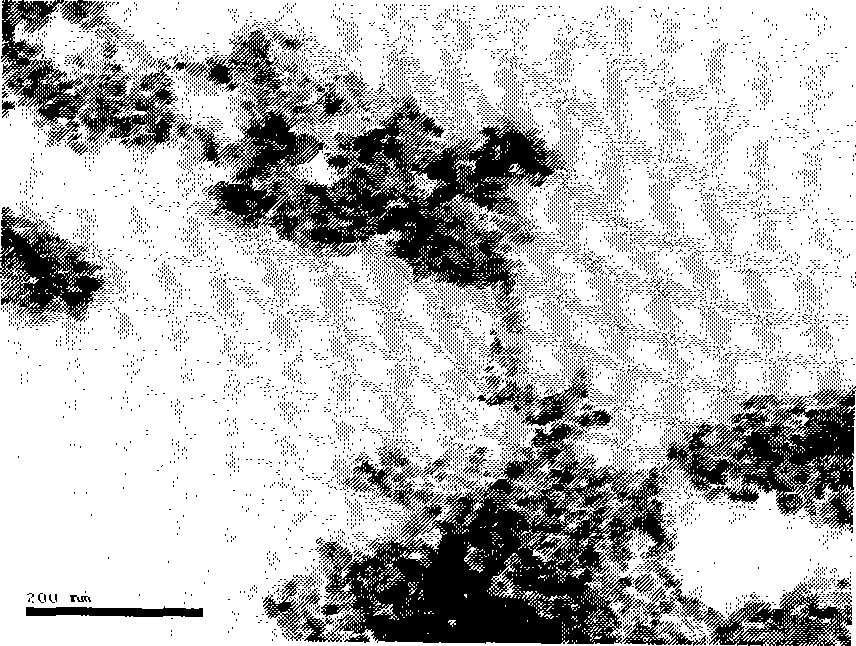

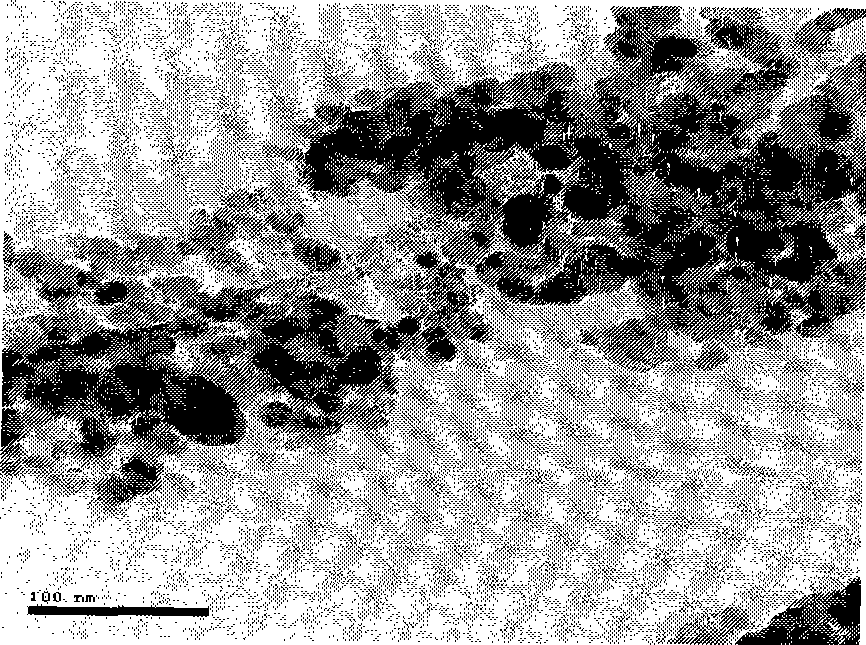

Method for coating carbon nano-tube with metal doped zinc oxide nano-particle

InactiveCN101372330ALarger than surfaceUniform particle size distributionGas detectorCarbon nanotube

The invention relates to a method for coating a carbon nanotube with metal-doped zinc oxide nano-particles, which mainly comprises the following steps: an alkaline solution and a mixed acid are adopted to treat the carbon nanotube; and then zinc acetate and metal acetate are taken as raw materials, absolute ethyl alcohol is taken as a solvent, oxalic acid is taken as a complexing agent, and co-precipitation method and subsequent heat treatment are adopted to prepare the carbon nanotube coated by the metal-doped zinc oxide nano-particles. The method utilizes a simple method to functionalize the carbon nanotube, so that the carbon nanotube is coated evenly and compactly by the zinc oxide nano-particles can be realized, and the nano-particles obtained have the advantages of even particle size distribution, small particle size, simple preparation process, low cost, etc. The major characteristic of the method is that: a surfactant is non-essential for modifying the carbon nanotube. The composite powder obtained not only can be taken as a powder raw material for preparing high-performance carbon nanotube / metal-based and carbon nanotube / ceramic-based composite materials, but also can be applied to the fields of optical devices, spinning electron devices, gas sensors, and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Microcapsule guar gum and preparation method thereof

ActiveCN103045212AMicroencapsulationIncrease the use concentrationDrilling compositionHigh concentrationPetroleum resin

The invention provides microcapsule guar gum which comprises guar gum and C5 petroleum resin coating the guar gum. The invention further provides a preparation method of the microcapsule guar gum. According to the embodiment of the application, the guar gum is coated with the C5 petroleum resin, so that the microencapsulation of the guar gum is achieved, a use concentration of the guar gum is increased under the condition that the guarant viscosity is not increased, the microcapsule guar gum with a very high concentration can be pumped over, the gum strength of the guar gum can be improved greatly, and cracks and solution caves of strata can be blocked off well.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Battery connector with water-proof protective cover

InactiveUS20150200485A1Cover tightlyVehicle connectorsCoupling contact membersEngineeringElectrical and Electronics engineering

A battery connector includes an insulative housing, a contact retained in the insulative housing and a water-proof protective cover tightly covering the insulative housing. The insulative housing includes a mating surface, a mounting surface and a receiving space extending forwardly through the mating surface. The contact is retained in the receiving space. The contact includes a rear section, a mounting tail extending beyond the protective cover, first and second protrusions extending forwardly from opposite lateral sides of the rear section, and first and second contacting sections extending inwardly and backwardly from the first and the second protrusions, respectively. The water-proof protective cover tightly covers the mounting surface of the insulative housing.

Owner:ALLTOP ELECTRONICS SU ZHOU

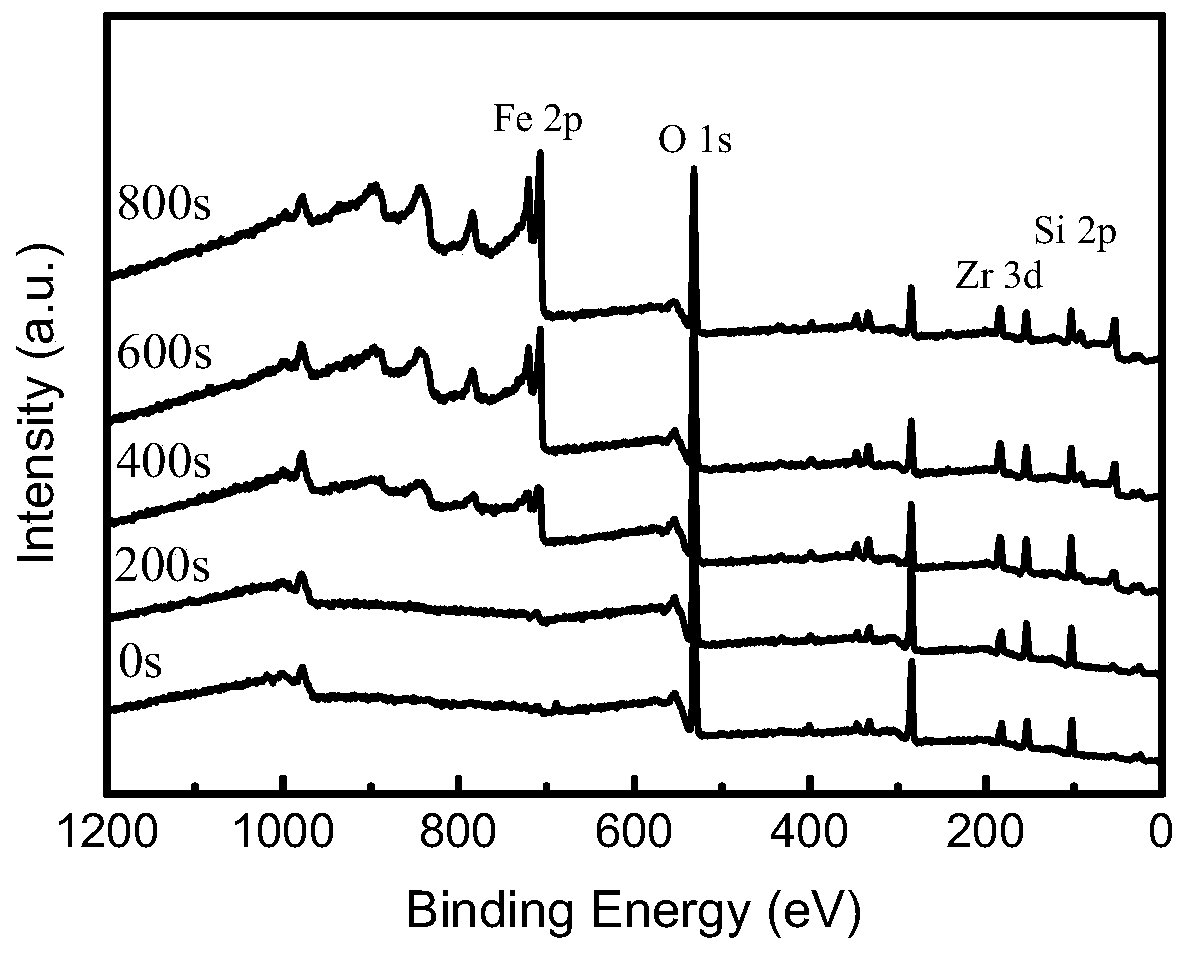

Magnetic powder surface gradient coating structure and coating method and soft magnetic composite

ActiveCN110405201ACoated evenlyCover tightlyTransportation and packagingMetal-working apparatusHigh resistivityThermal expansion

The invention relates to a magnetic powder surface gradient coating structure and coating method and a soft magnetic composite. The gradient coating structure is prepared from a coating layer which isformed on the surface of ferromagnetic powder by silicon dioxide and other coated components, and the contents of the silicon dioxide and other coated components in the coating layer are gradiently distributed. The coating method comprises the step of depositing the silicon dioxide and other coated components on the surface of the ferromagnetic powder in one step by adopting a chemical coprecipitation method, wherein the pH value of the system is adjusted in the deposition process. The soft magnetic composite is obtained by sectionally annealing the ferromagnetic powder with the coating layeron the surface after being pressed and formed. The coefficient of thermal expansion of the coating layer prepared by using the method can be controlled, the prepared soft magnetic composite has the advantages of low eddy current loss, high magnetic conductivity, high resistivity and high saturation magnetization, and the defects of low resistivity, mismatching of the coefficient of thermal expansion between coating layers and the like of the material in the prior art are overcome; in order to solve the problems of the reduction of the medium-high frequency magnetic conductivity, high eddy current loss, serious heating and the like of an existing magnetic powder core, a good method is provided.

Owner:CENT SOUTH UNIV

Double cladding water-based magnetofluid and method for producing the same

InactiveCN101256870AGood magnetic responseGood biocompatibilityMagnetic liquidsInorganic material magnetismWater basedPolyethylene glycol

The present invention relates to a double covered water-based magnetic fluid and manufacture method thereof, the magnetic fluid includes water, nano Fe3O4 granule and dispersing agent, which is characterized in that grain diameter of nano Fe3O4 granule is 1-16 nm, dispersing agent is medicinal agaragar and polyethylene glycol at the covered surface of nano Fe3O4 granule, compound granule particle diameter obtained by medicinal agaragar and polyethylene glycol at the covered surface of nano Fe3O4 granule is smaller than 45nm; medicinal agaragar and polyethylene glycol is taken as dispersing agent, a double covered water-based magnetic fluid is produced by synthesizing of nano Fe3O4 granule and modus of surface step-by-step modification, which surface has function group; activity group of carboxy group and hydroxyl group, etc make the double covered water-based magnetic fluid with good magnetic responsiveness, biological affinity, biodegradability and suspension stability, saturation magnetization of magnetic fluid is 1.0-10.0emu / g used in biomedicine field for special therapy and diagnose of medicine carrier etc.

Owner:JIAYING UNIV

Magnetic bronze powder preparation method

InactiveCN103333533AAvoid breakingImprove water resistancePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsKetone solventsBall mill

The invention discloses a magnetic bronze powder preparation method. The method comprises the following steps: cleaning sheet bronze powder ball-milled in a ball mill in a cleaning tank with a ketone solvent, press-filtering, and carrying out solid-liquid separation to obtain a filter cake; adding the filter cake, an alcoholic solvent and a titanate coupling agent to a reaction container, and stirring; taking ammonia water and distilled water, and mixing ammonia water with distilled water for dilution; taking ethyl orthosilicate, and diluting with the alcoholic solvent; simultaneously adding to the reaction container in a dropwise manner; ageing for 6-10h, taking out, press-filtering, and carrying out solid-liquid separation to obtain inorganic silicon coated bronze powder; taking the inorganic silicon coated bronze powder and an ether solvent, and uniformly dispersing the inorganic silicon coated bronze powder in the ether solvent; and taking an acrylate monomer and an azo initiator, adding to the reactor, coating, taking out, press-filtering, and carrying out solid-liquid separation to obtain magnetic bronze powder. The method allows the surfaces of the sheet copper-zinc particles to be coated with the surface of a magnetic material through organic-inorganic double layer coating, so the aqueous copper-zinc particles are magnetic, and a very good stereo artistic effect is formed.

Owner:HEFEI SUNRISE PIGMENTS

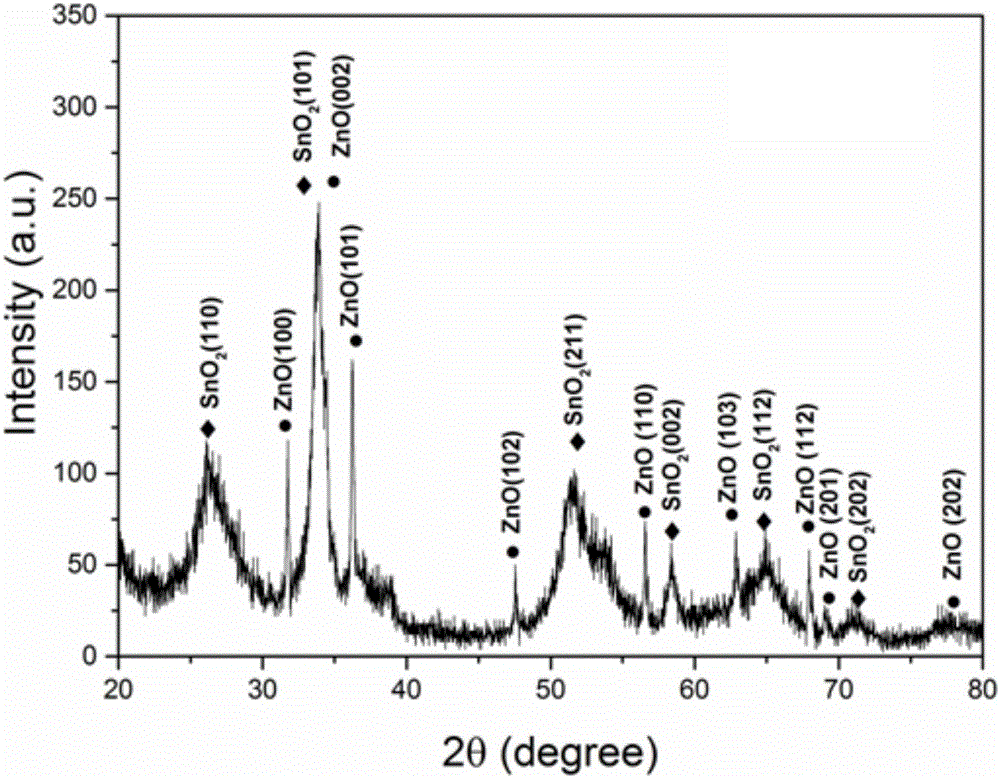

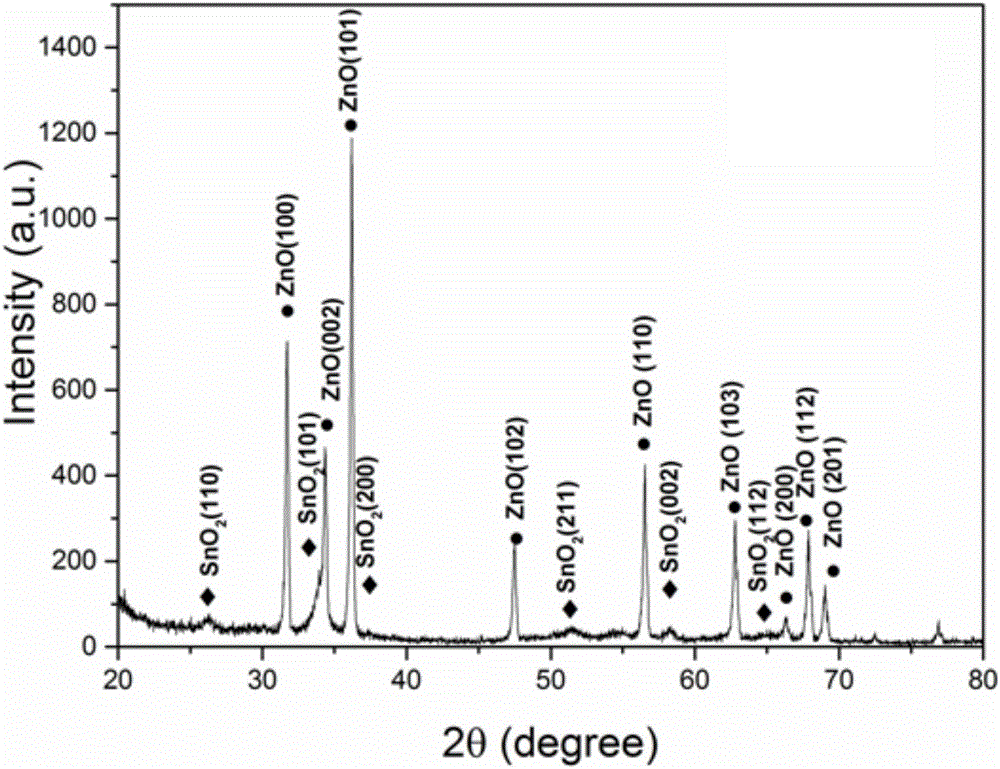

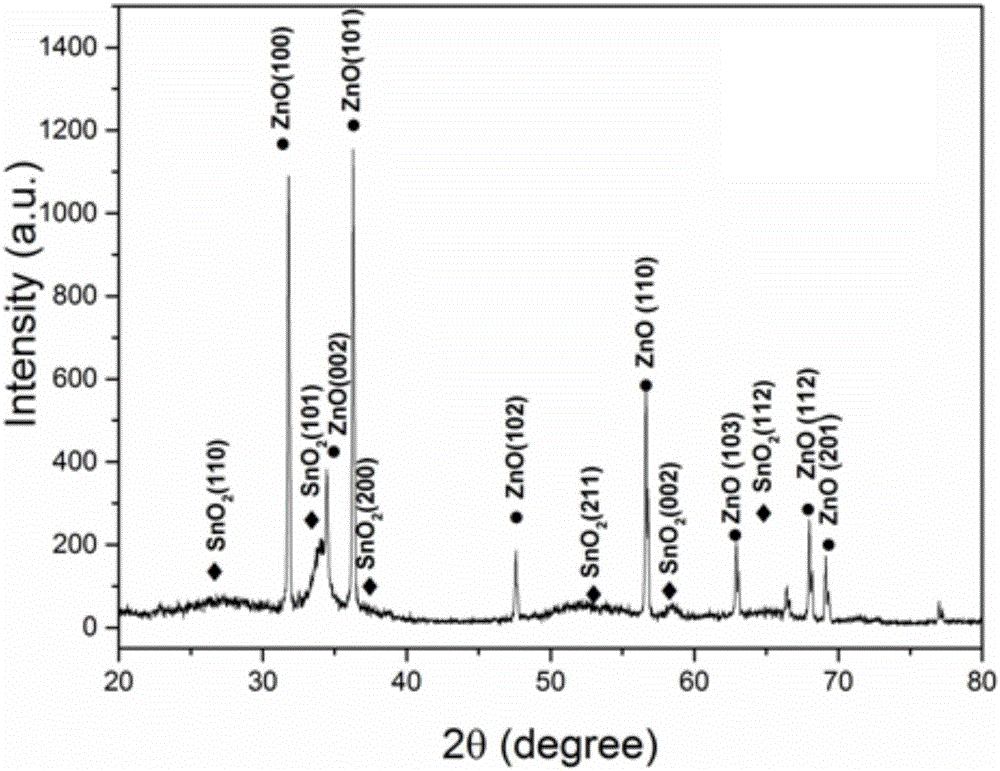

SnO2/ZnO nanocomposite and preparation method thereof

InactiveCN105836793ALarge specific surface areaExtend your lifeMaterial nanotechnologyZinc oxides/hydroxidesLevel structureGas detector

The invention discloses SnO2 / ZnO nanocomposite and a preparation method thereof. The SnO2 / ZnO nanocomposite comprises a ZnO nanorod and an SnO2 nanorod growing on the ZnO nanorod, and is characterized in that the two-level structure SnO2 nanorod directly grows on the main structure ZnO nanorod, the ZnO nanorod in a wurtzite structure is prepared through a microwave-assisted hydrothermal method, the SnO2 nanorod of a rutile structure grows on the ZnO nanorod through a microwave-assisted hydrothermal method, and templates and catalysts are not needed in the microwave-assisted hydrothermal process. The speed is high, the process is simple, the yield is high, cost is low, the SnO2 / ZnO nanocomposite is suitable for batch production, and the prepared nanocomposite is uniform in form and tight in coating, and can be used as a radar infrared compatible camouflage material, a photocatalysis material, a solar cell material, a gas sensor material and a lithium ion battery cathode material.

Owner:NORTHWEST UNIV(CN)

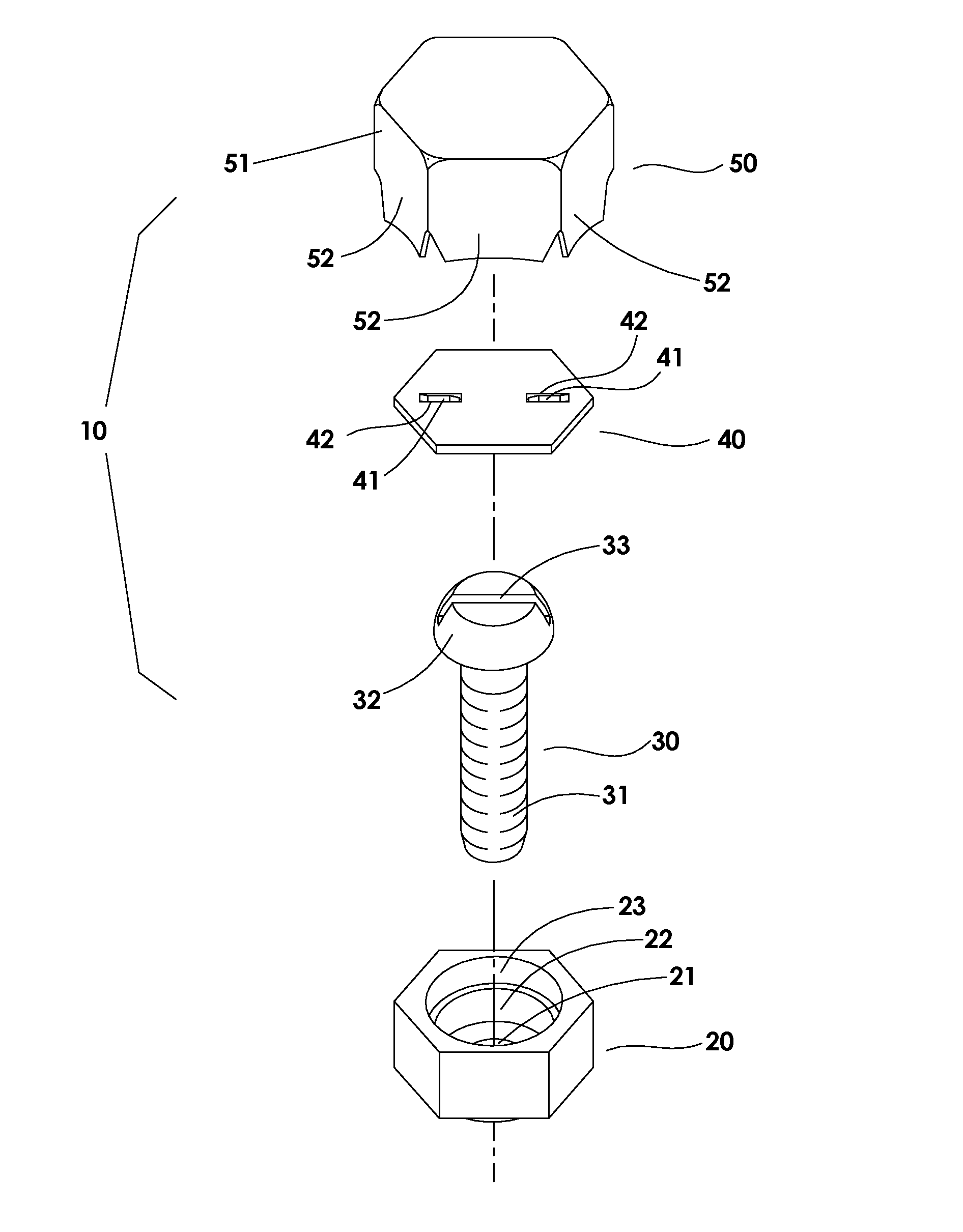

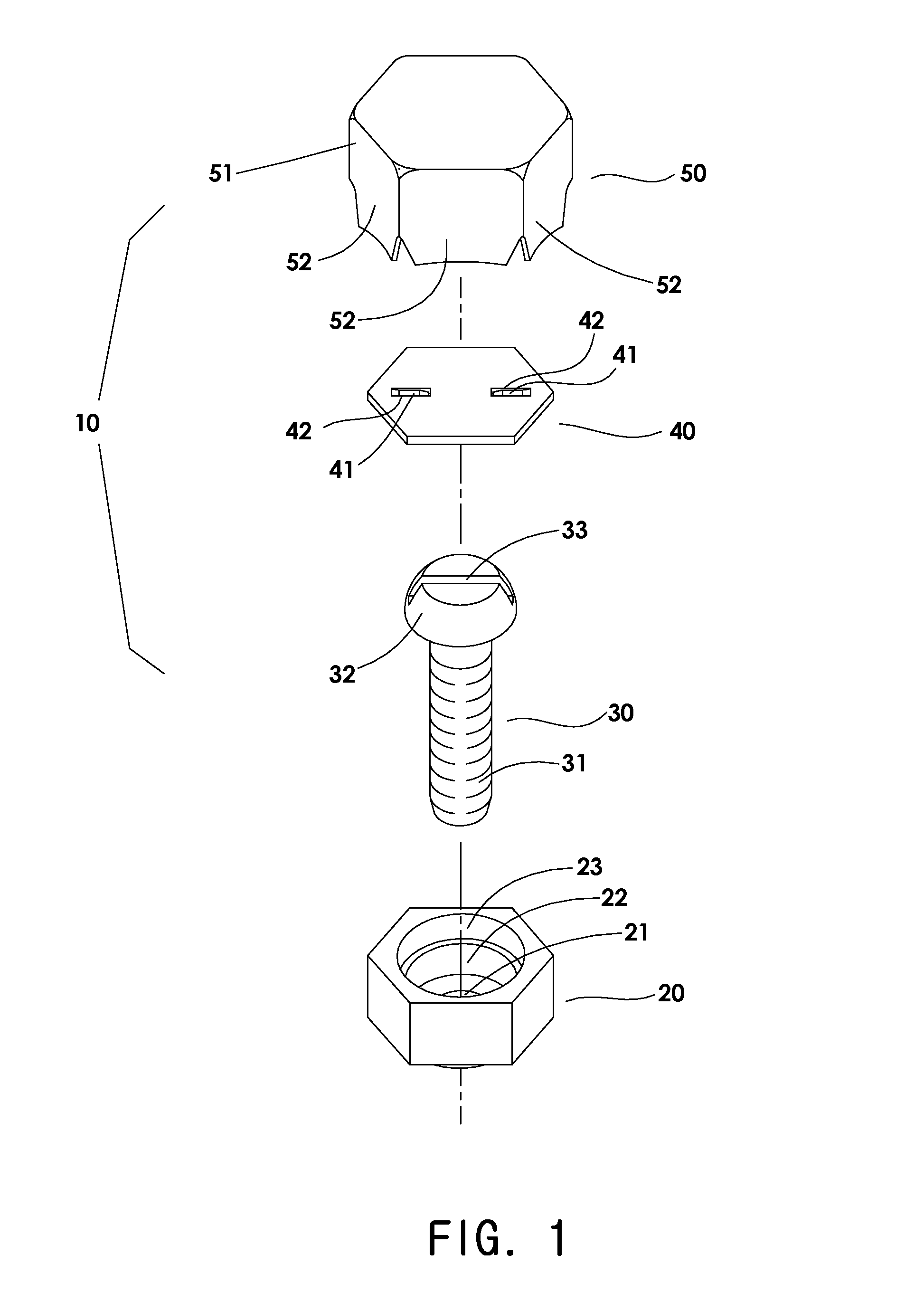

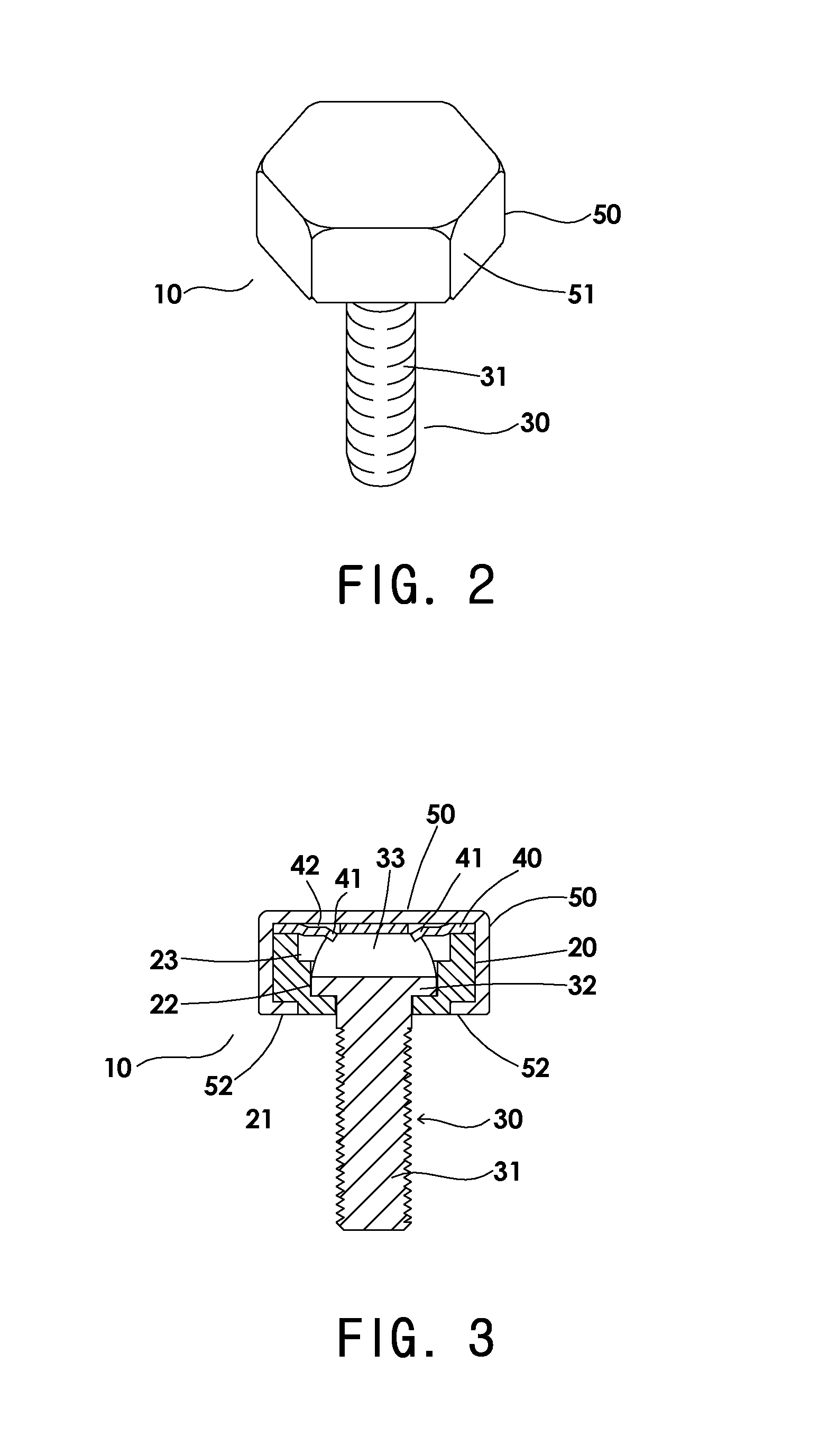

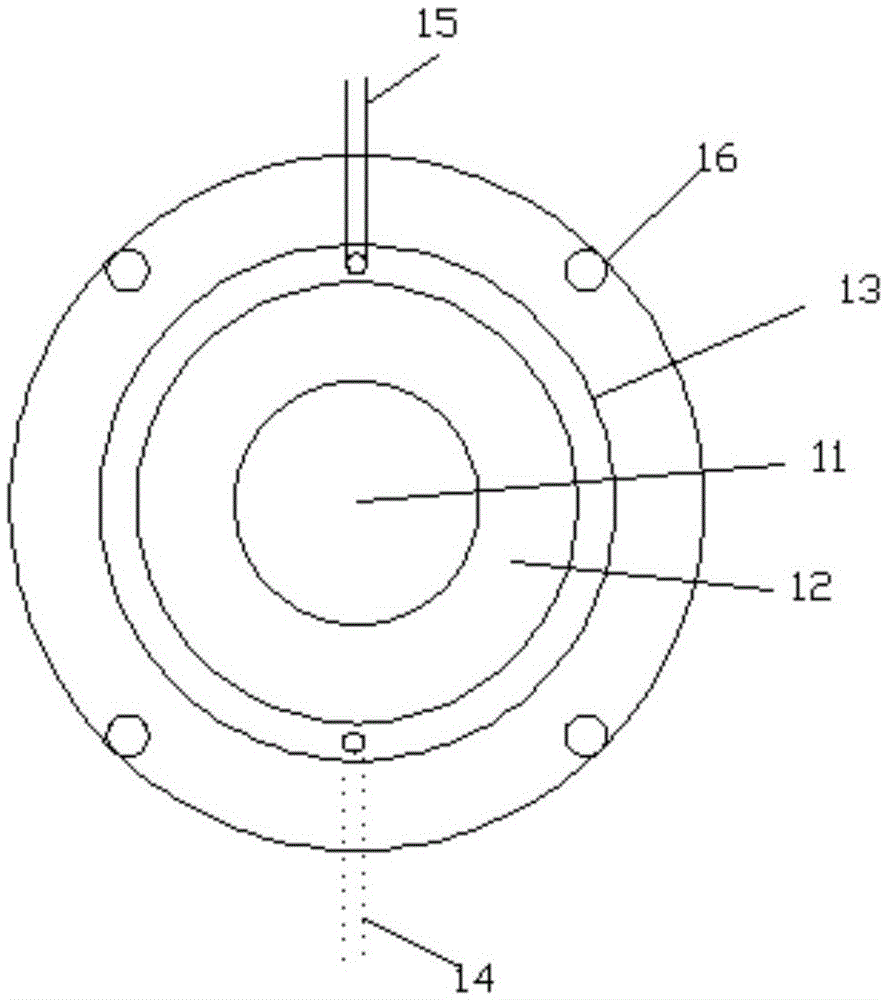

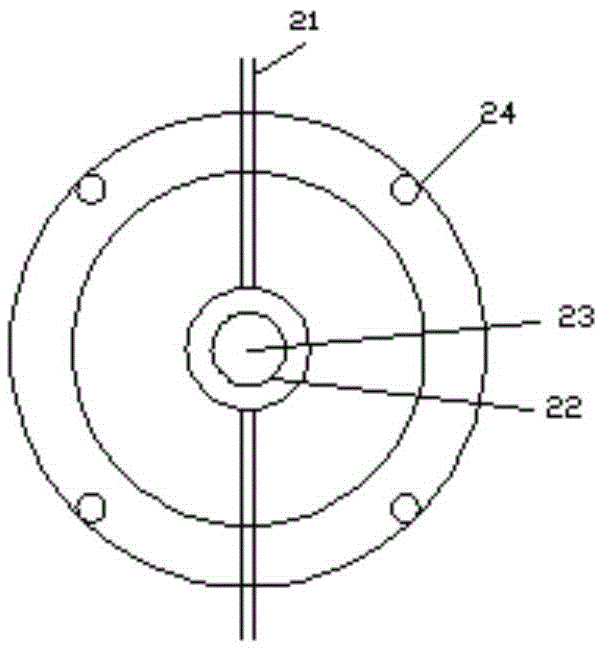

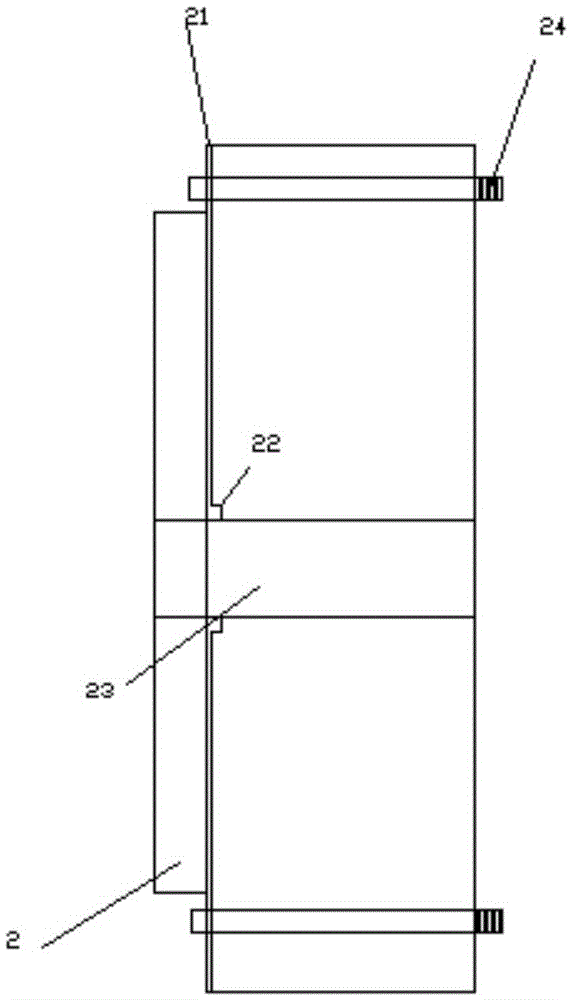

Bolt assembly

InactiveUS20130136557A1Cover tightlyLow production costPinsLoad modified fastenersEngineeringScrew thread

A bolt assembly is provided with a bearing seat, a screw, a pull member and a cover. The bearing seat has a through hole, a concave portion and an accommodation room. The screw is coupled to the bearing seat. The screw includes a threaded portion, a head portion and a pull groove. The threaded portion extends out of the through hole. The head portion is positioned in the concave portion. The pull groove is located corresponding to the accommodation room. The pull member is located on top of the bearing seat. The pull member has at least one pull point at a lower end thereof. The pull point extends in the accommodation room and is located corresponding to the pull groove of the screw. The cover is adapted to cover the bearing seat and confines the pull member in the cover.

Owner:WANG YUAN YU

Extrusion die

The invention discloses an extrusion die which comprises a die face and a die cushion. The extrusion die is characterized in that the die cushion comprises a die hole, a die hole acting layer and a cooling interlayer; a die working belt, a gas guide groove and a gas inlet hole are arranged in the die face; and inert gas enters the extrusion die from the gas inlet hole of the die face and flows into the die working belt through the gas guide groove. According to the extrusion die, aluminum oxide particles can be effectively prevented from being generated, the product yield is increased, and meanwhile die losses are reduced.

Owner:QINGHAI MOLD MFG TECH CO LTD

Composite powder and preparing method thereof

The invention provides a composite powder and a preparing method thereof and belongs to the field of material engineering. The composite powder is prepared with the method which includes the following steps that metal or alloy is smelted to obtain metal liquid or alloy liquid; in the time of smelting, the degree of superheat is controlled between 50 DEG C and 200 DEG C and the metal liquid or the alloy liquid naturally flows downwards; meanwhile, blended gases are used for spraying and atomizing the metal liquid or the alloy liquid and the composite powder is obtained after cooling is carried out. The inner core and the shell of the powder obtained in the method can form metallurgical bonding, coverage is compact, bonding force is strong, texture is compact and the degree of sphericity is high. As no chemical agents do not need to be used in preparing, the environment will not be polluted; in addition, in the time of preparing, the thickness of the shell of an oxide can be controlled by controlling the oxygen concentration in the blended gases, the thickness is controllable, the technological process is stable and controllable and processing in a batched mode can be carried out with high efficiency.

Owner:XIHUA UNIV

Radiation crosslinked polyethylene thermally-shrinkable cladded sheet materials and preparation method therefor

InactiveCN1970677AGood waterproof sealingIncrease stressOther chemical processesCorrosion preventionNuclear radiationCompound (substance)

The invention discloses a water-proof radiating crosslinking polyethylene heat-condensing clad piece of oil, chemical and insulating pipe, which is composed of polyethylene base and fusing gel layer, wherein the polyethylene, carbon black and chlorcosane are fused and crosslinked to mould, which are extended transversely through nuclear radiation; the fused gel is coated on the inner surface or inner periphery of base evenly; each hole is opened on the clad piece along two sides intervally, which fixes the interface of clad piece.

Owner:吉林石油集团有限责任公司 +1

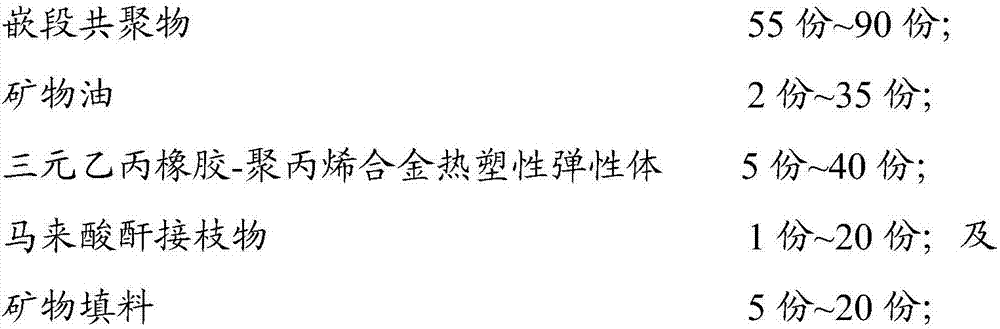

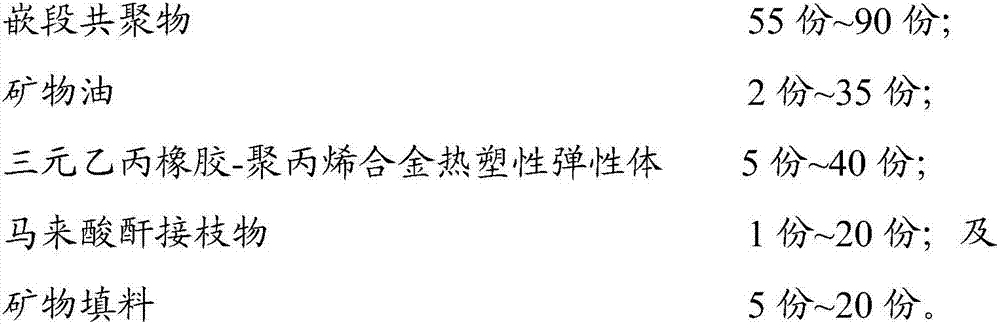

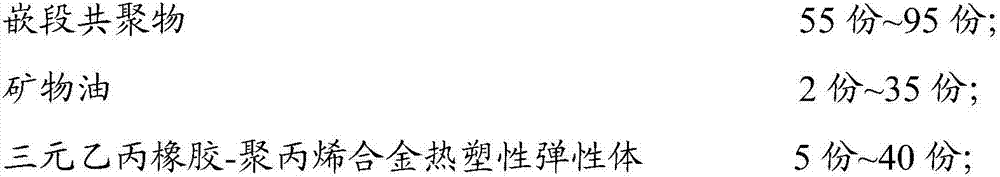

Thermoplastic elastomer material for secondary overmolding and preparation method of thermoplastic elastomer material

The invention relates to a thermoplastic elastomer material for secondary overmolding and a preparation method of the thermoplastic elastomer material. The thermoplastic elastomer material for secondary overmolding is prepared from the following components in parts by mass: 55 to 95 parts of segmented copolymer, 2 to 35 parts of mineral oil, 5 to 40 parts of ethylene propylene diene terpolymer-polypropylene alloy thermoplastic elastomer, 1 to 20 parts of maleic anhydride-grafted polymer and 5 to 20 parts of mineral filler, wherein the segmented copolymer is selected from at least one of a styrene-ethylene-butadiene-styrene block copolymerized elastomer, a styrene-butadiene-styrene block copolymer and a styrene-butadiene block copolymer. The thermoplastic elastomer material for secondary overmolding is higher in stripping strength.

Owner:SUNGALLON PLASTICS SHENZHEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com