Double-shell-structure carbonyl iron powder composite wave-absorbing material and preparation method thereof

A technology of composite absorbing materials and carbonyl iron powder, which is applied in chemical instruments and methods, electrical components, and other chemical processes, can solve problems such as low absorbing performance, single absorbing mechanism, and poor impedance matching performance, and achieve package Excellent covering effect, good oxidation resistance, and strong wave-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

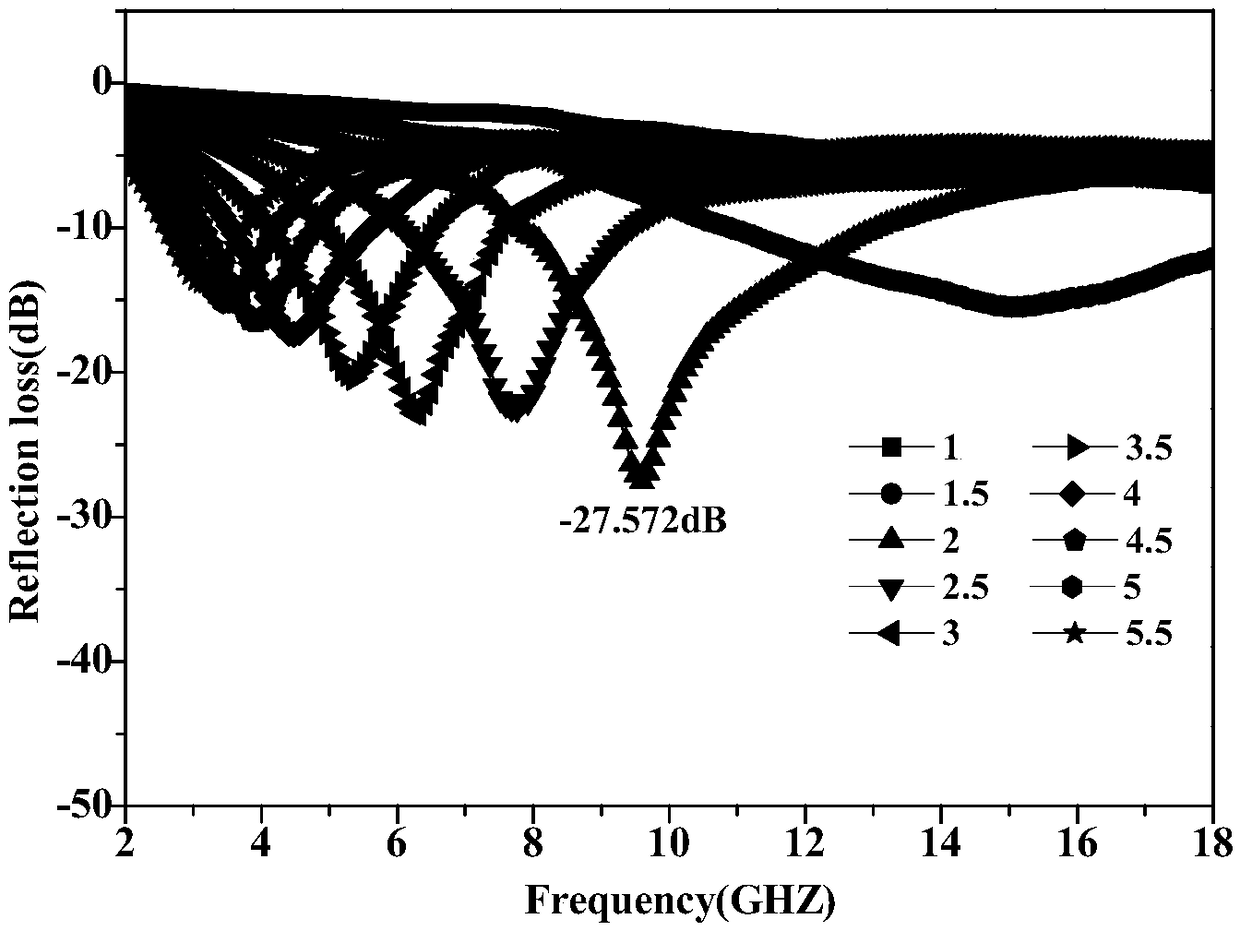

Embodiment 1

[0049] mn 0.6 Zn 0.4 Fe 2 o 4 / SiO 2 / Preparation of carbonyl iron powder composite absorbing material:

[0050] Take 100g of carbonyl iron powder and wash it twice with alcohol to remove impurities and oil stains on the surface. Mix the cleaned carbonyl iron powder with deionized water, stir, add KH550 surface modifier dropwise, and stir for 1 hour. Then add tetraethyl orthosilicate TEOS to the mixture, and drop an appropriate amount of ammonia water NH 4 OH, adjust the pH of the solution to about 10, and stir vigorously for 4 hours until the reaction is complete. The mass percentages of carbonyl iron powder, deionized water, surface modifier and TEOS in the reaction system are: 1:10:0.02:0.1. After the reaction, carbonyl iron powder / SiO with core-shell structure was magnetically separated 2 powder, washed with absolute ethanol or deionized water until the filtrate was clear, and dried at 50°C for 1 h for later use.

[0051] Prepared Mn 0.6 Zn 0.4 Fe 2 o 4 Ferri...

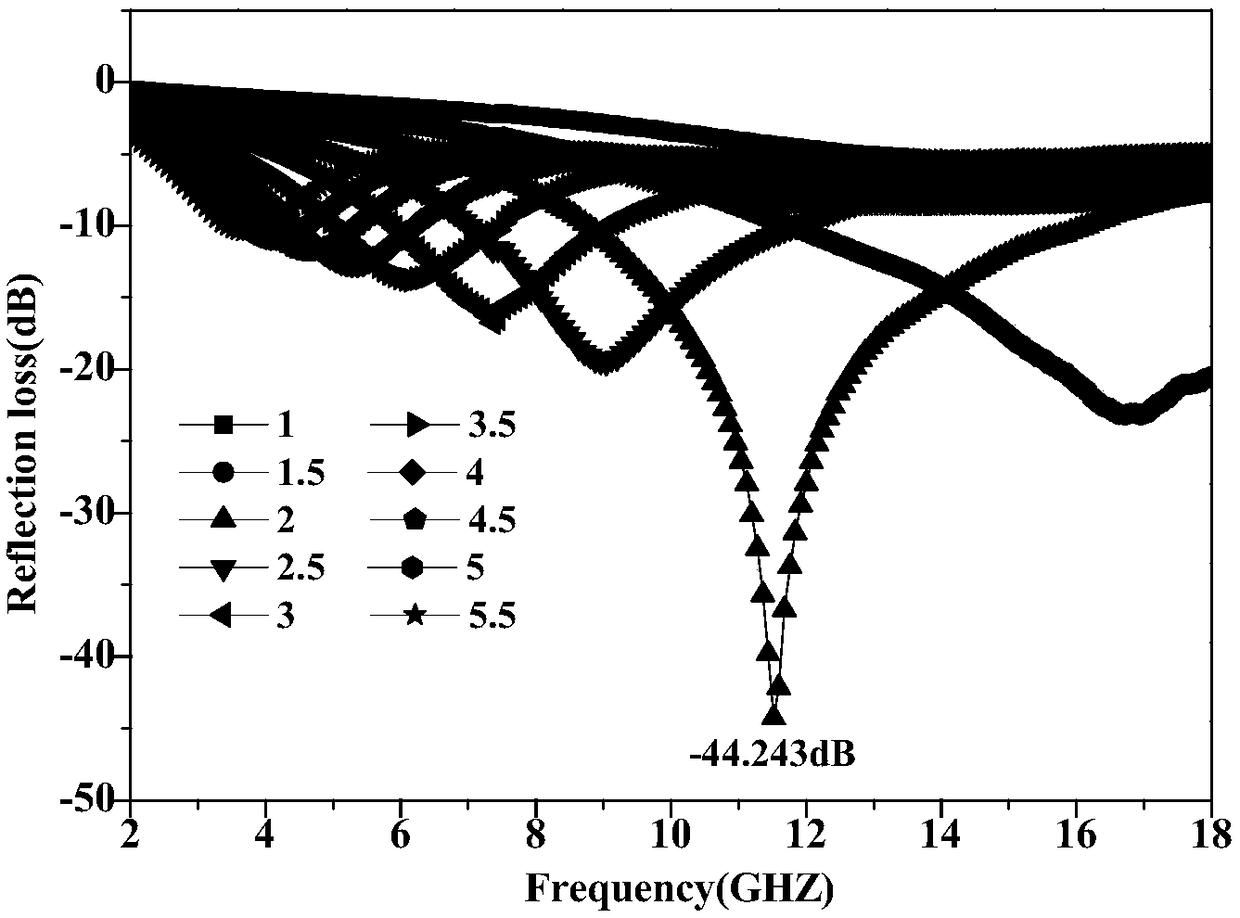

Embodiment 2

[0054] NiFe 2 o 4 / SiO 2 / Preparation of carbonyl iron powder composite absorbing material:

[0055] Take 100g of carbonyl iron powder and wash it with alcohol for 3 times to remove impurities and oil stains on the surface. Mix the cleaned carbonyl iron powder with alcohol, stir, add KH560 surface modifier dropwise, and stir for 0.5h. Then, tetraethyl orthosilicate TEOS was added to the mixture, and an appropriate amount of NaOH solution was added dropwise to adjust the pH value of the solution to about 9, and the mixture was vigorously stirred for 2 hours until the reaction was complete. The mass percentages of carbonyl iron powder, alcohol, KH560 and TEOS in the reaction system are: 1:3:0.01:0.02. After the reaction, carbonyl iron powder / SiO with core-shell structure was magnetically separated 2 powder, washed with absolute ethanol or deionized water until the filtrate was clear, and dried at 100°C for 1 h for later use. Weigh an appropriate amount of Ni(NO 3 ) 2 ·6...

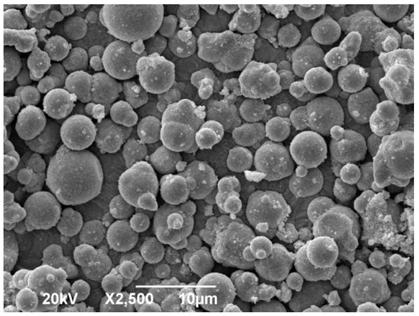

Embodiment 3

[0058] CoFe 2 o 4 / SiO 2 / Preparation of carbonyl iron powder composite absorbing material:

[0059] Take 100g of carbonyl iron powder and wash it twice with alcohol to remove impurities and oil stains on the surface. Mix the cleaned carbonyl iron powder with alcohol, stir, add KH550 surface modifier dropwise, and stir for 1h. Then add tetraethyl orthosilicate TEOS to the mixture, and add an appropriate amount of ammonia water dropwise to adjust the pH value of the solution to about 7, and stir vigorously for 2 hours until the reaction is complete. The mass percentages of carbonyl iron powder, alcohol, KH550 and TEOS in the reaction system are: 1:8:0.05:0.3. After the reaction, carbonyl iron powder / SiO with core-shell structure was magnetically separated 2 powder, washed with absolute ethanol or deionized water until the filtrate was clear, and dried at 50°C for 1 h for later use. Weigh an appropriate amount of CoCl 2 and FeCl 3 ·6H 2 O, dissolved in deionized water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Return loss | aaaaa | aaaaa |

| Maximum reflection loss | aaaaa | aaaaa |

| Maximum reflection loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com