Patents

Literature

821 results about "Carbonyl iron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbonyl iron is a highly pure (97.5% for grade S, 99.5+% for grade R) iron, prepared by chemical decomposition of purified iron pentacarbonyl. It usually has the appearance of grey powder, composed of spherical microparticles. Most of the impurities are carbon, oxygen, and nitrogen.

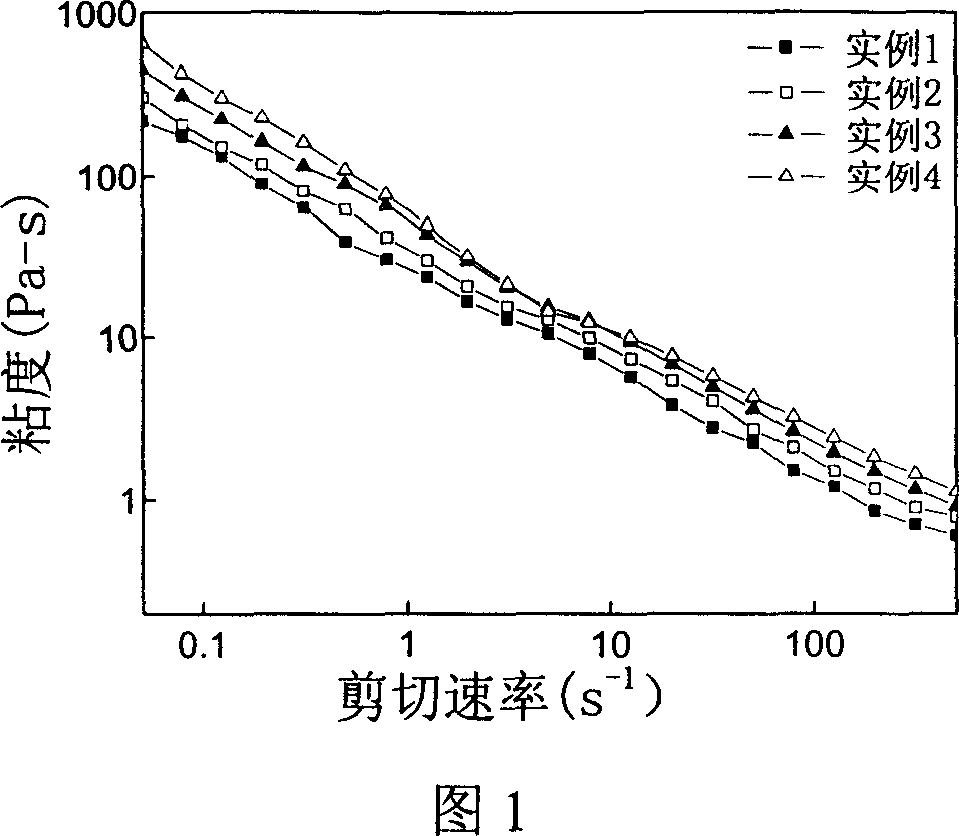

Stable magnetic rheological liquid and its preparation method

InactiveCN1414075AImproving magnetorheological propertiesImprove wear resistanceAdditivesSuspended particlesIron powder

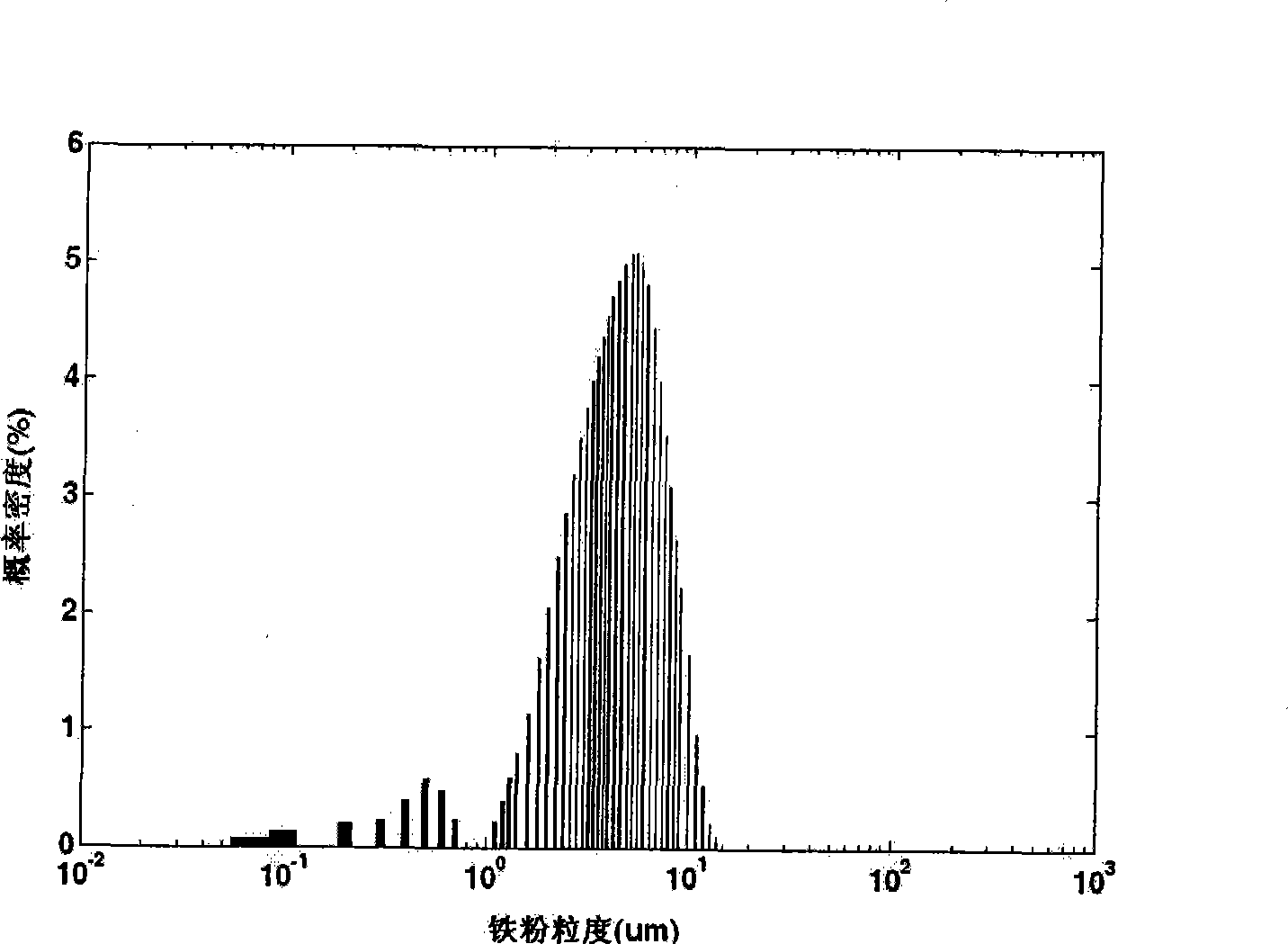

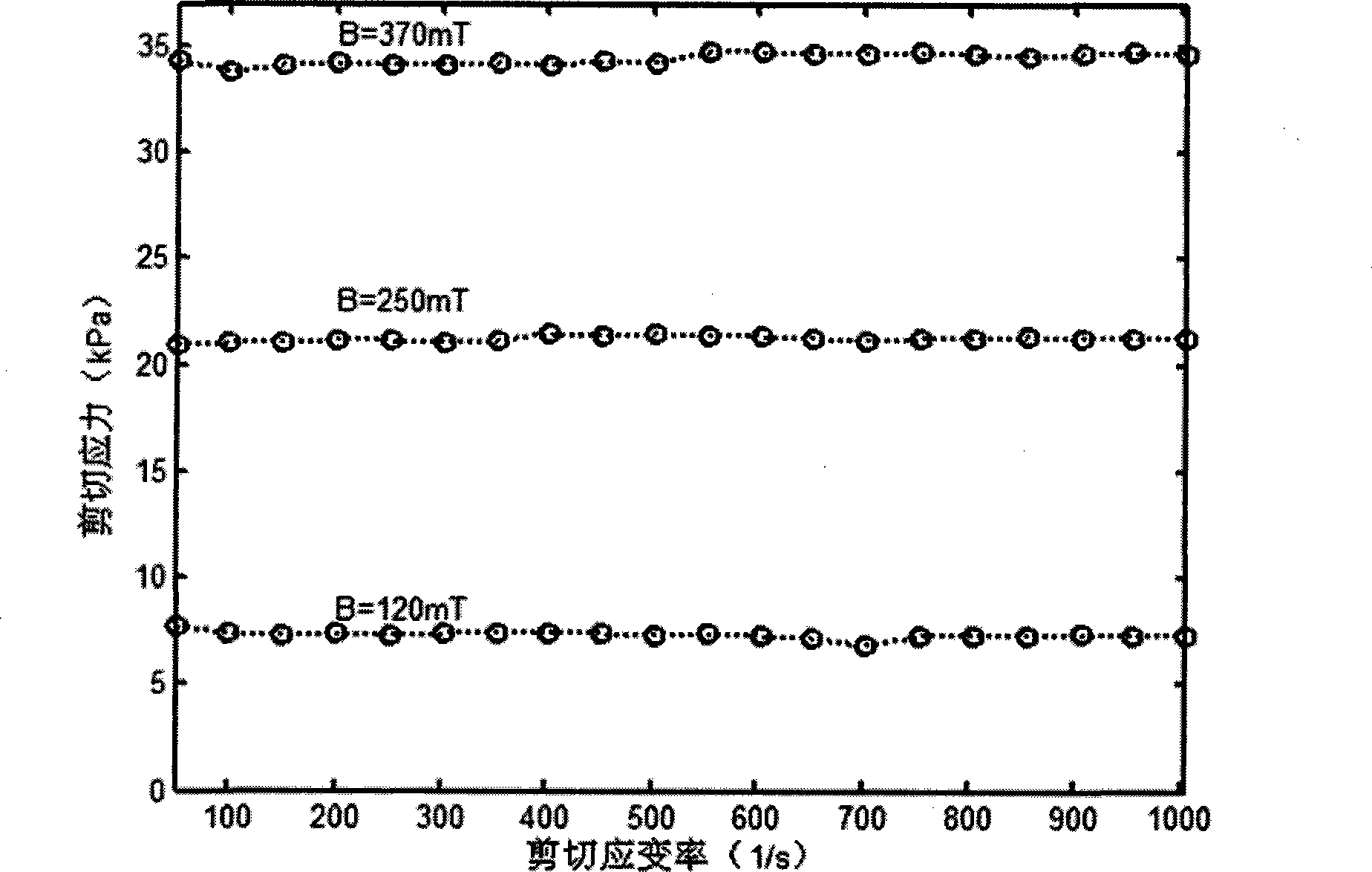

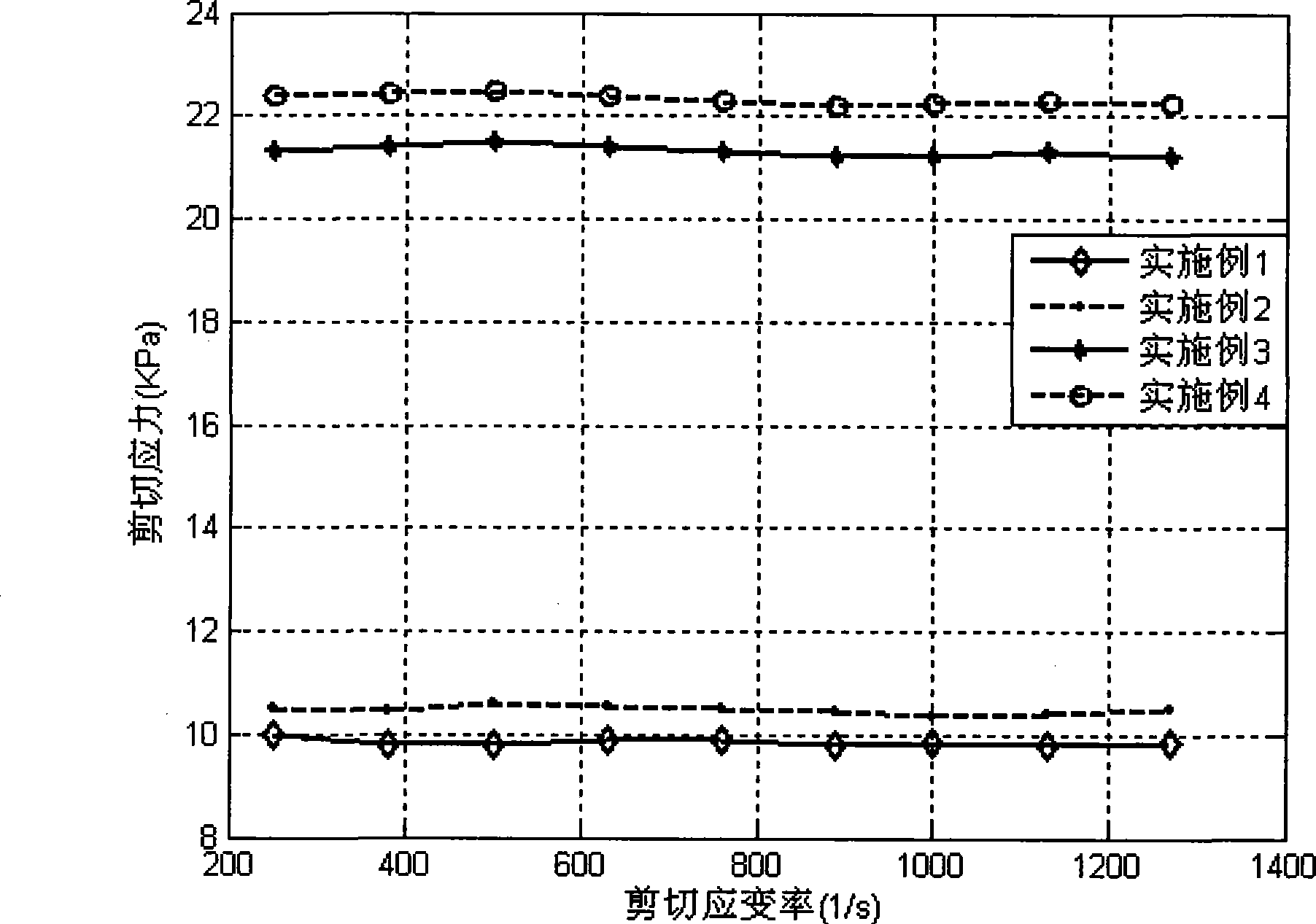

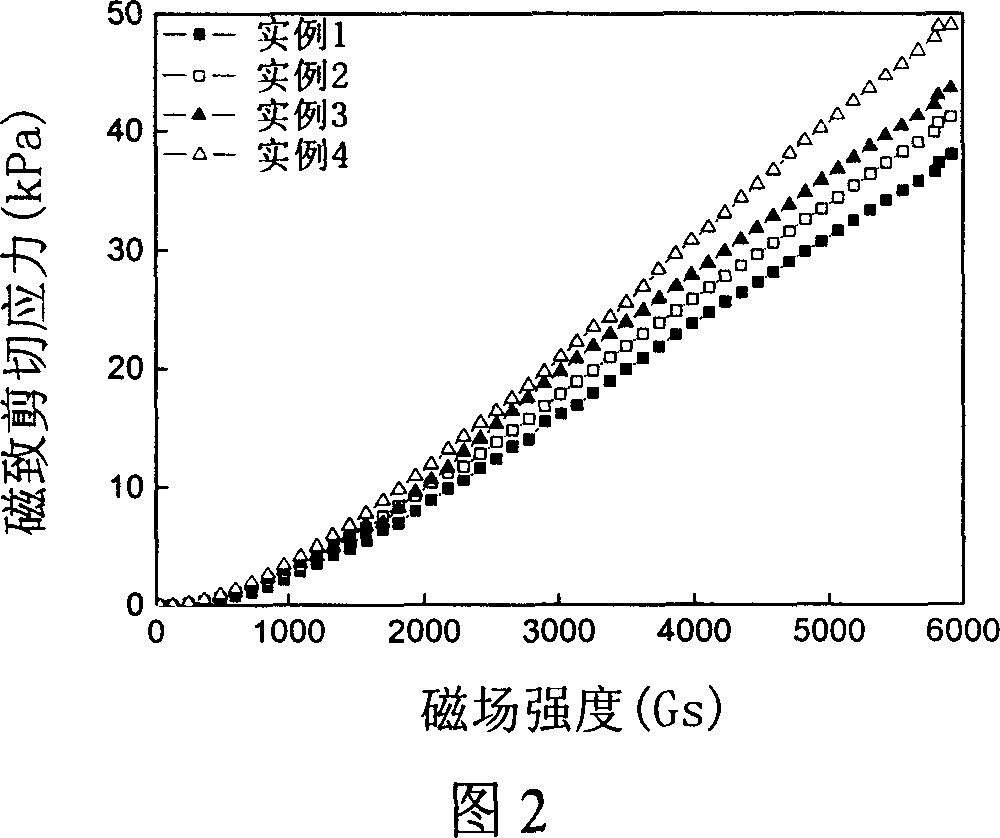

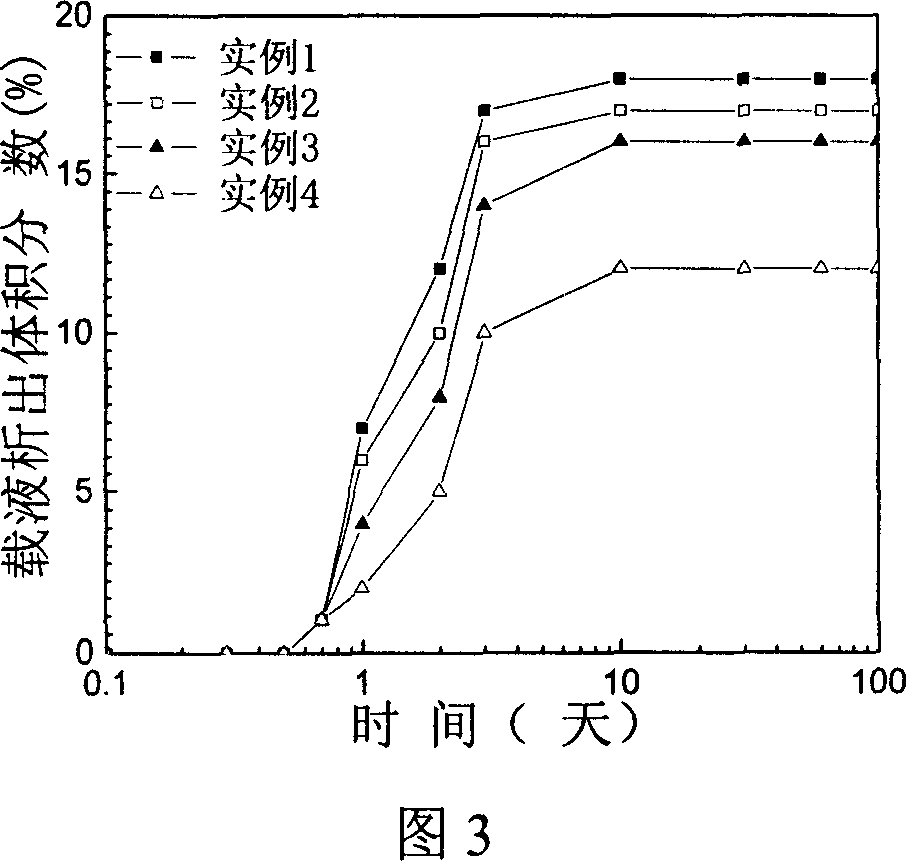

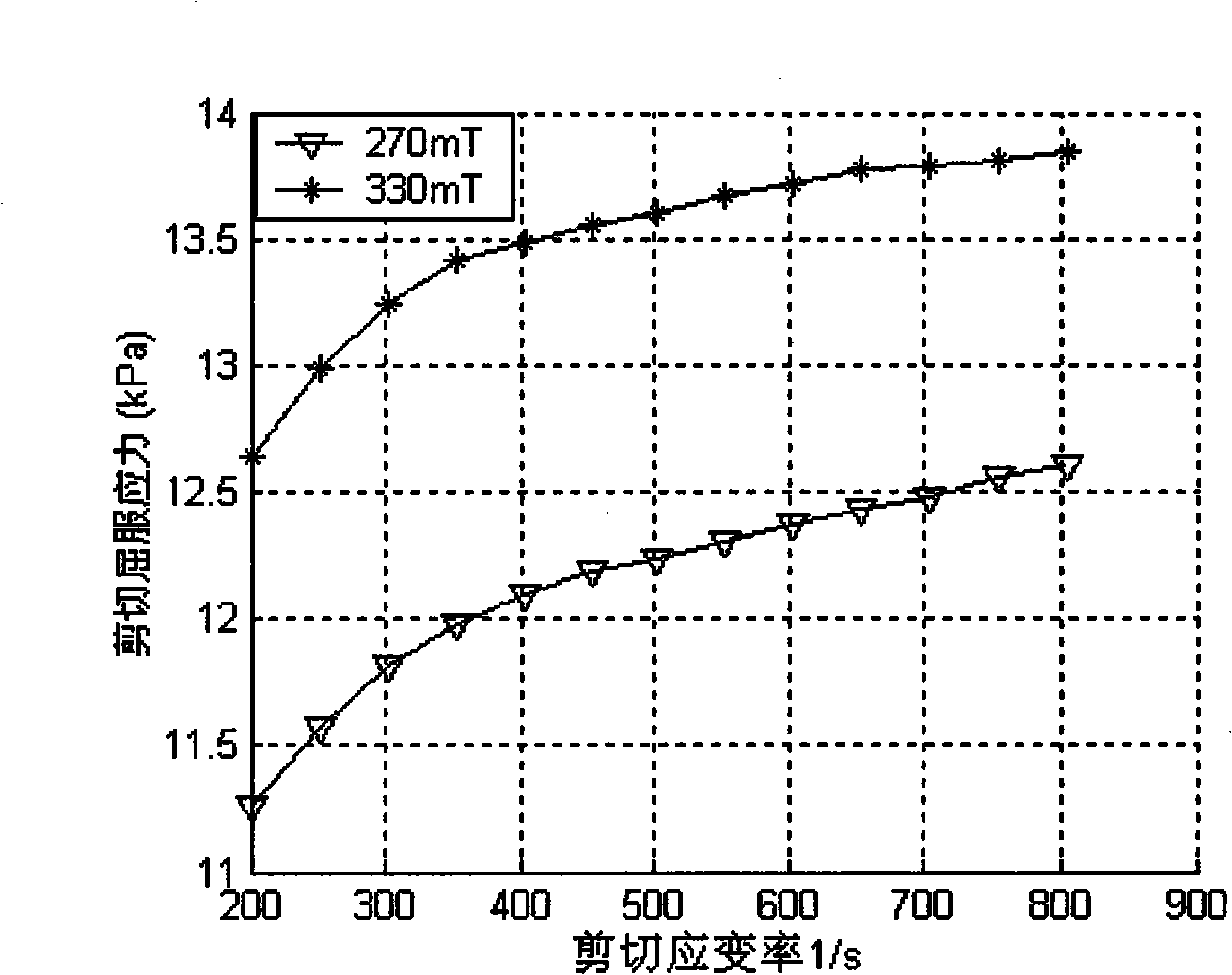

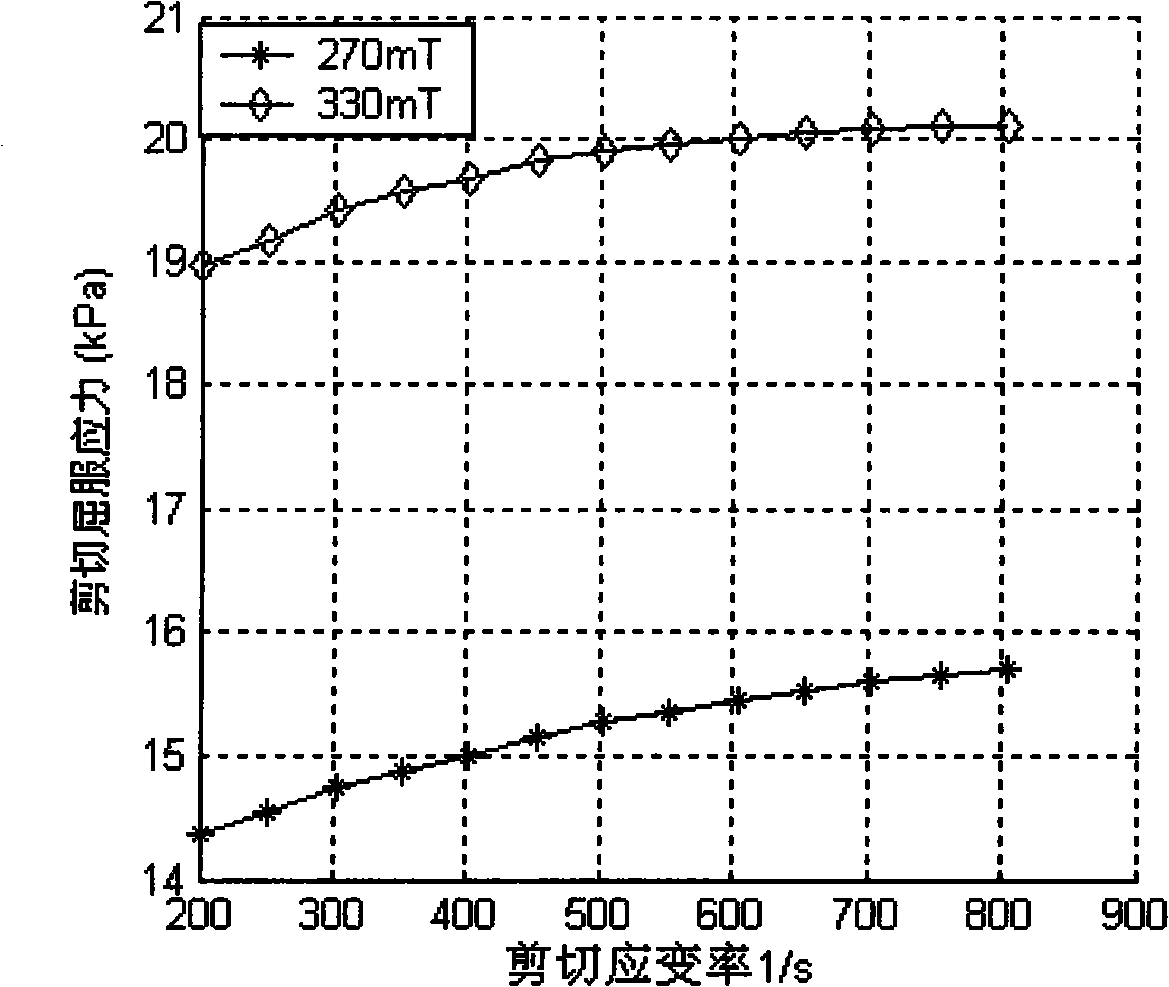

A high-stability magnetic rheopectic liquid is prepared from the magnetic suspended phase including reduced and phosphonated carbonyl iron powder, liquir carrier, nano-class inorganic bentonite or silica oxide-type thixotropic agent and surfactant through cleaning the surface of suspended particles, activating and synthesizing the magnetic rheopectic liquid. Its advantages are high stability without deposition, better antiwear nature, zero field viscosity and ideal rheopectic characteristics.

Owner:CHONGQING MATERIALS RES INST

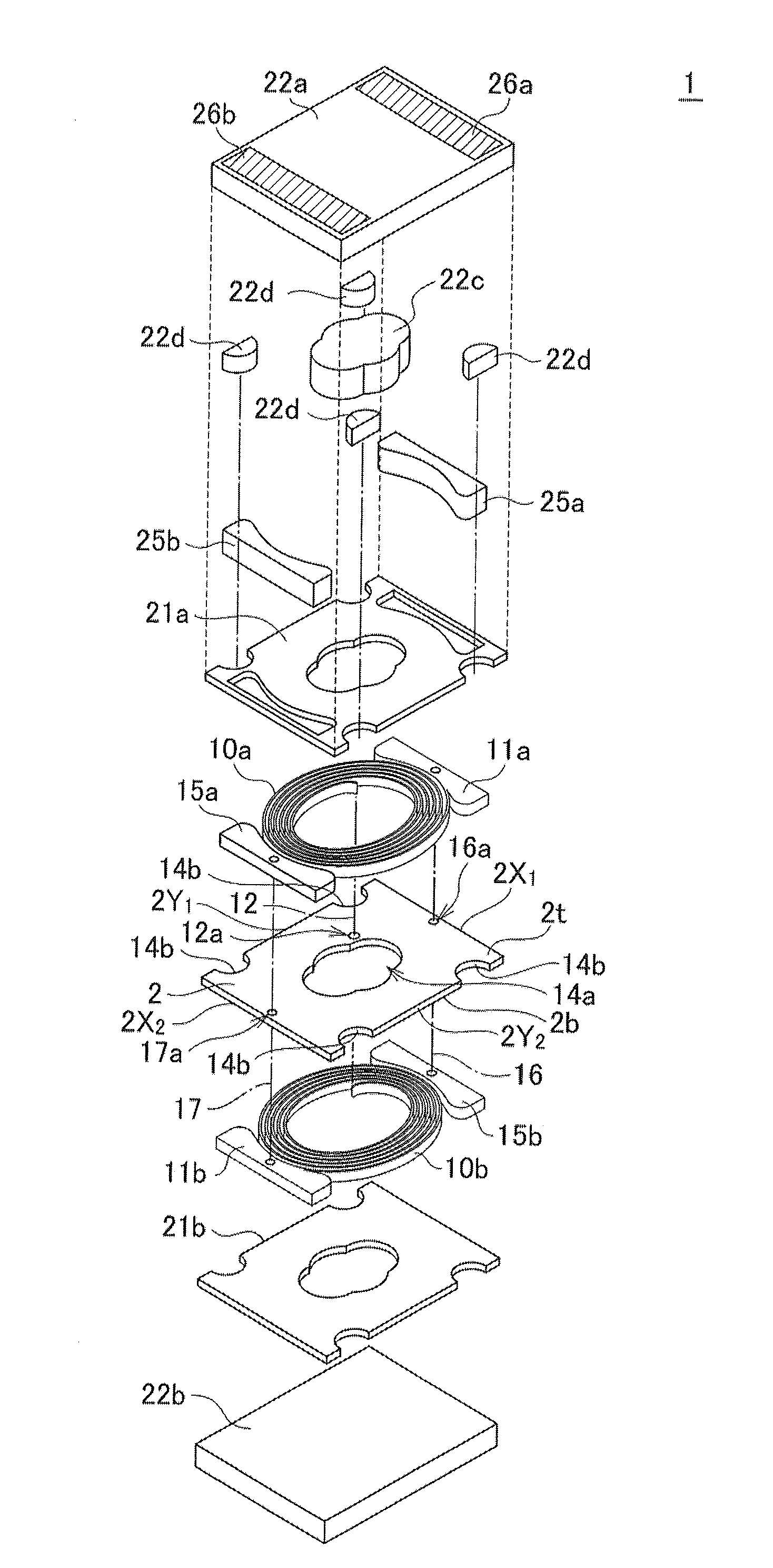

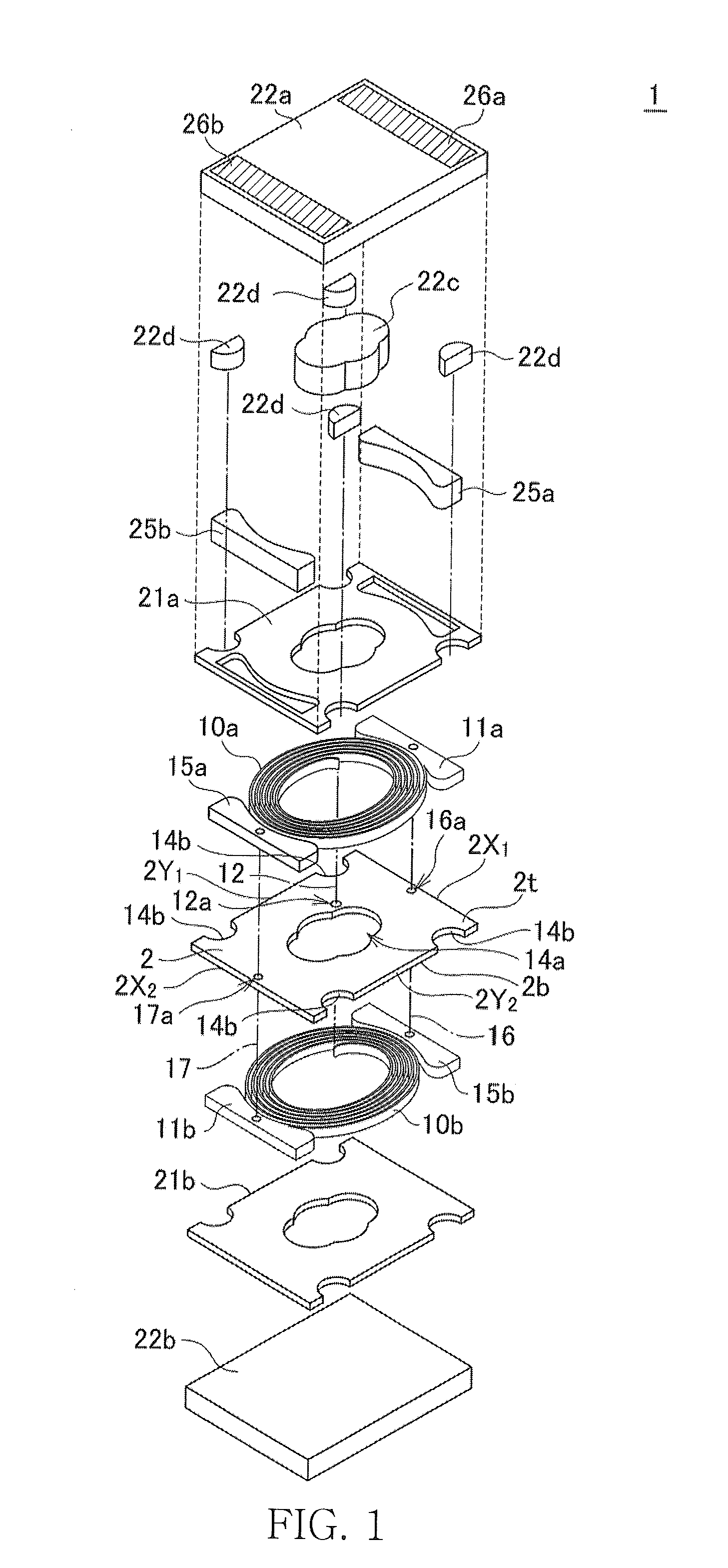

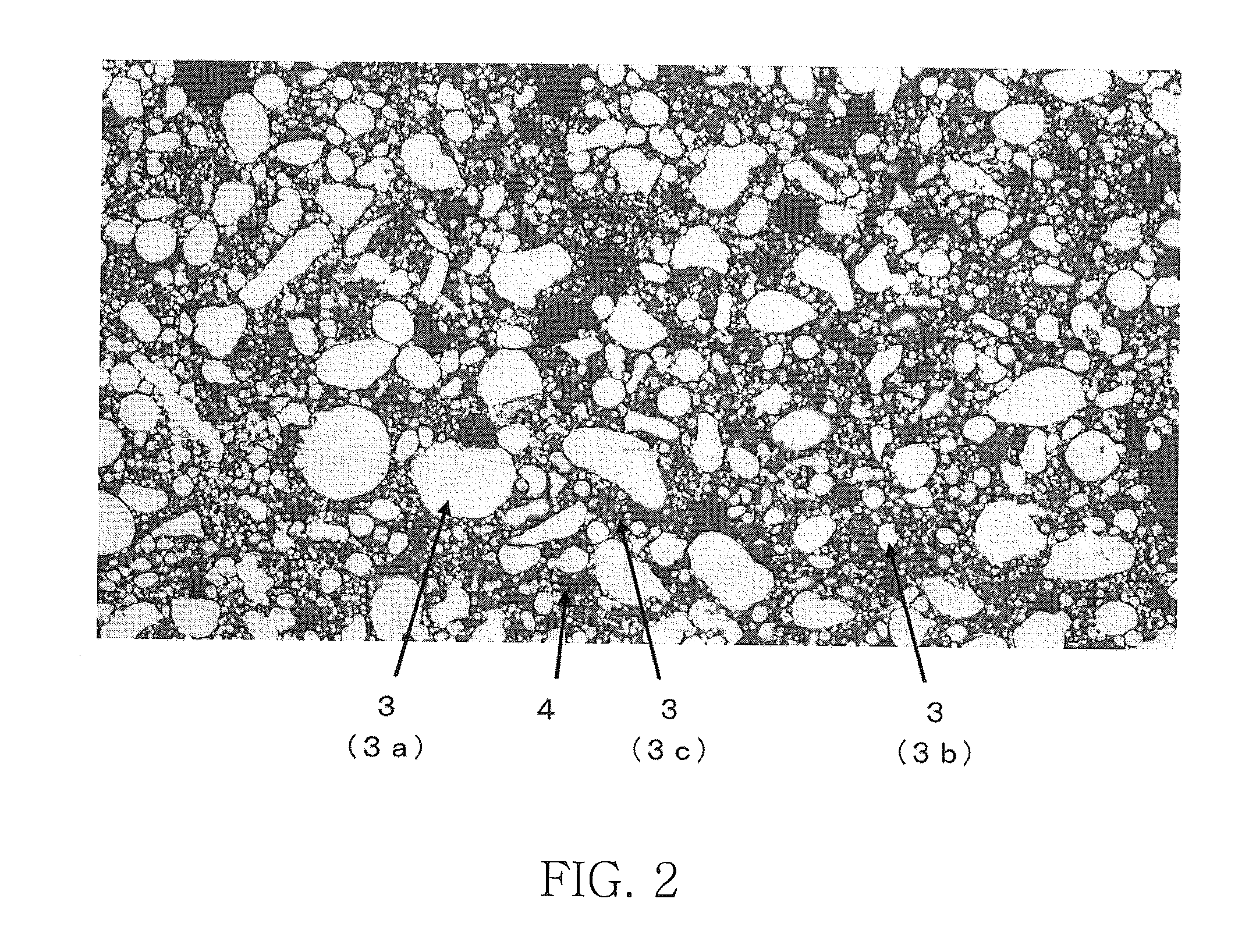

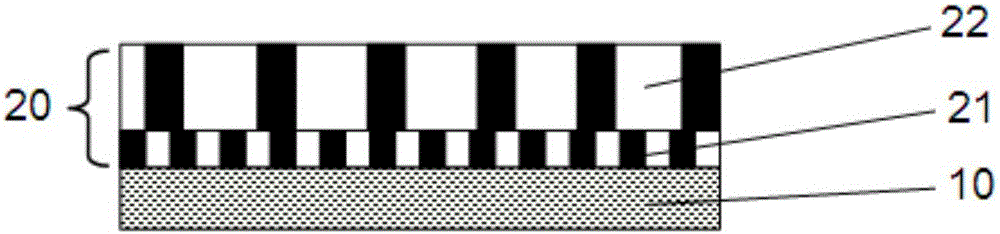

Coil component and magnetic metal powder containing resin used therefor

ActiveUS20140077914A1Increase distanceReducing core lossInorganic material magnetismTransformers/inductances detailsElectrical conductorPermalloy

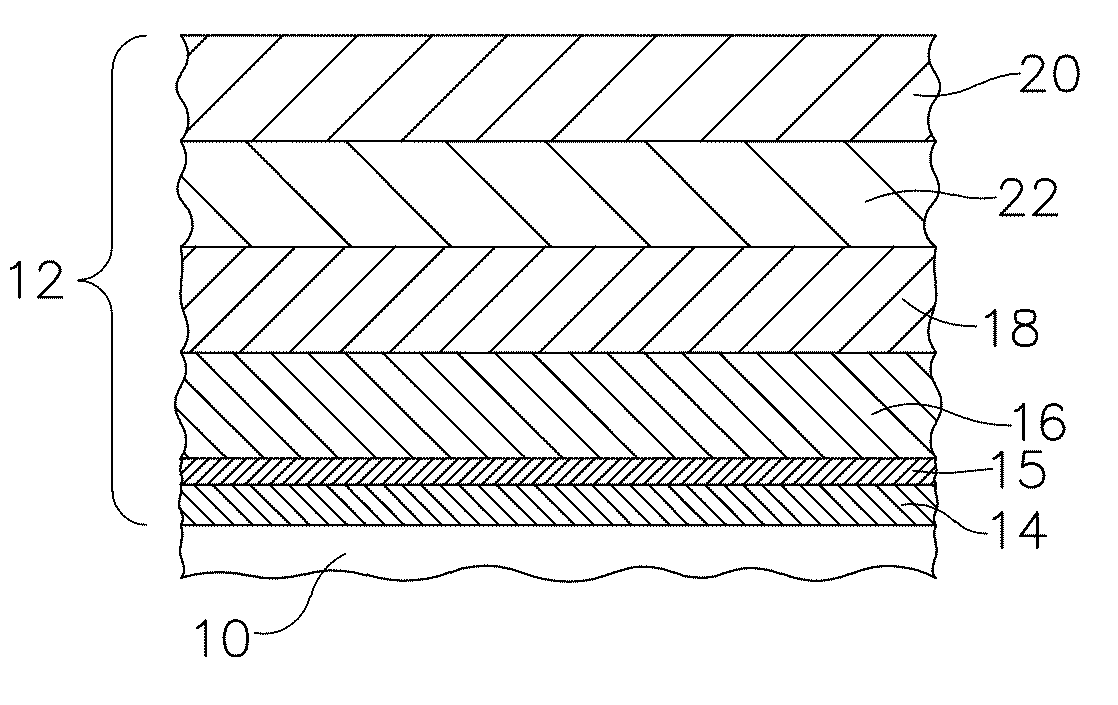

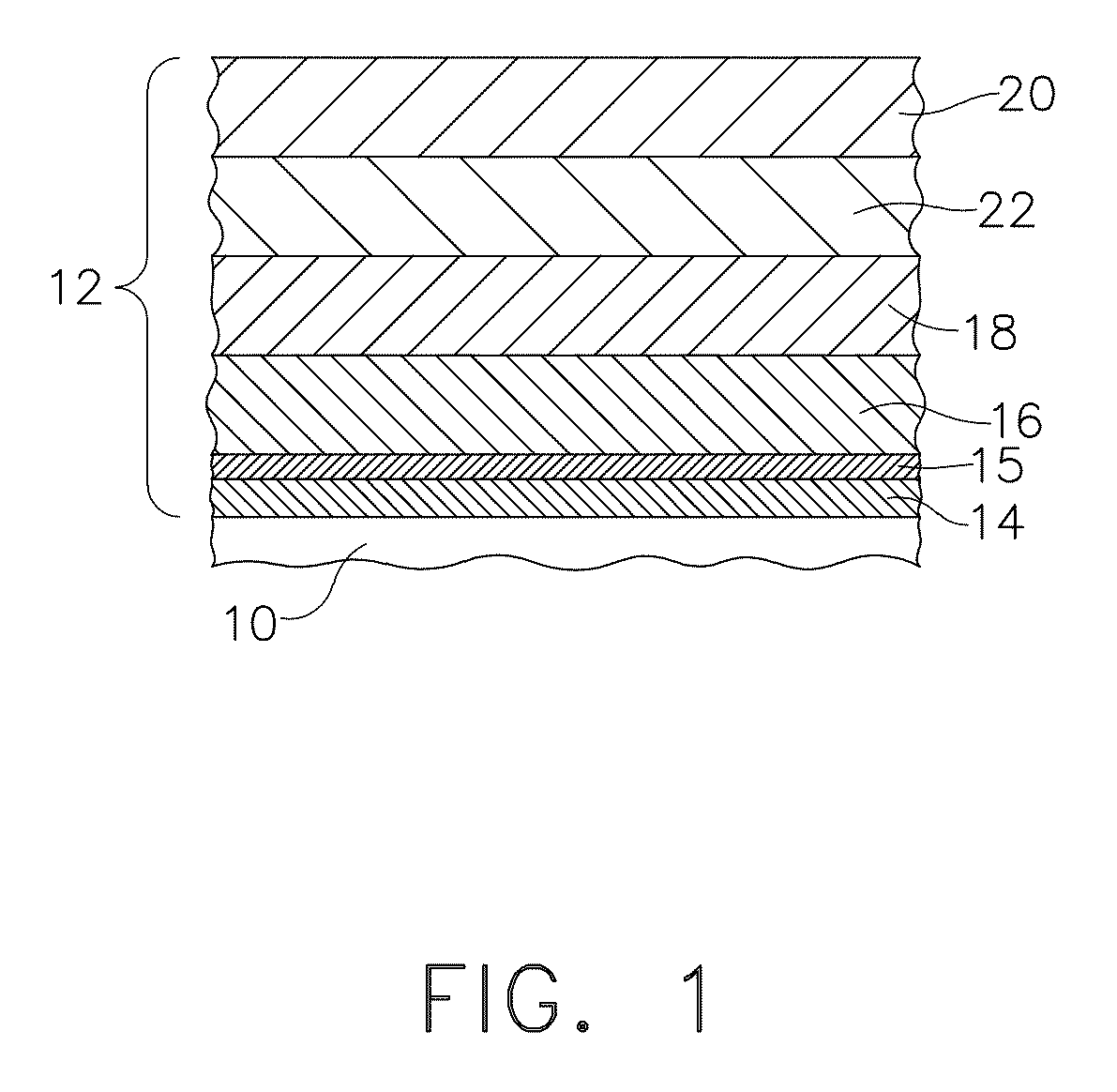

A coil component 1 is provided with coil conductors 10a and 10b and a magnetic metal powder containing resin 22 (22a and 22b) covering the coil conductors 10a and 10b. The magnetic metal powder containing resin 22 includes first metal powder having a first average grain diameter, second metal powder having a second average grain diameter that is smaller than the first average grain diameter, and third metal powder having a third average grain diameter that is smaller than the second average grain diameter. The first average grain diameter is 15 μm or more and 100 μm or less. The third average grain diameter is 2 μm or less. The first metal powder mainly contains Permalloy and the second and third metal powders mainly contain carbonyl iron.

Owner:TDK CORPARATION

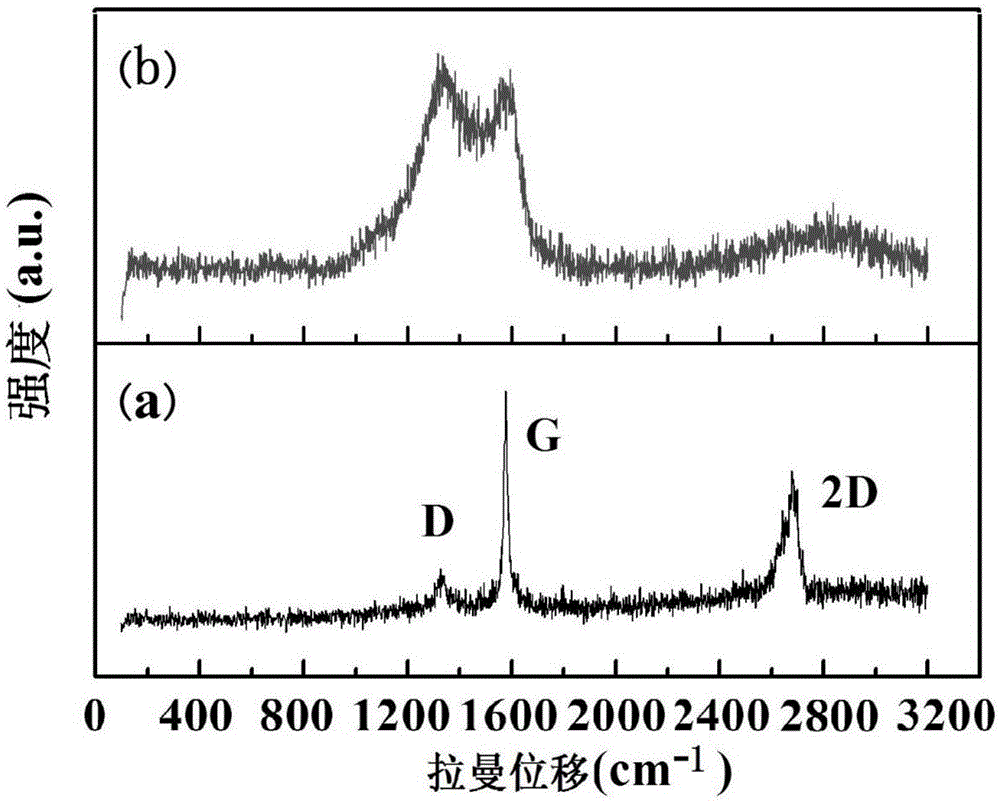

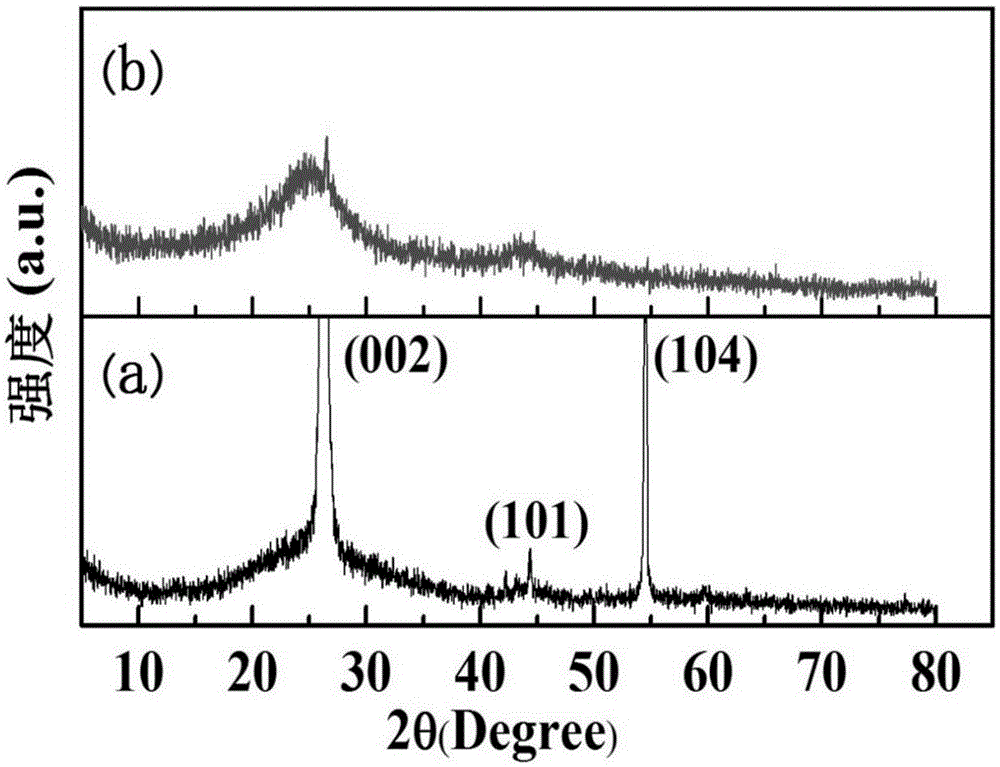

Wave-absorbing material based on grapheme and preparation method thereof

InactiveCN105647468AImprove absorbing abilityImprove absorbing performanceOther chemical processesDielectricElectromagnetic shielding

The invention discloses a wave-absorbing material based on grapheme and a preparation method thereof. The wave-absorbing material is formed by mixing graphite powder (or taking graphite powder as a main material) with one of three magnetic dielectric materials: ferrite, carbonyl iron powder and ultrafine metal powder, wherein the graphite powder is prepared by flake graphite through a mechanical stripping method and has a mass percentage content of 60-99 percent. The wave-absorbing material provided by the invention has the characteristics of being high in absorption strength, wide in absorption band, low in density and the like and has the excellent characteristics of the grapheme and the magnetic dielectric materials in electromagnetic performance; the preparation method is easy for large scale, low in cost, environment-friendly and suitable for industrialized production. The wave-absorbing material has wide application potential and market prospect in the fields of wave-absorbing materials, anti-electrostatic materials and electromagnetic shielding.

Owner:兰州天烁新能源有限公司

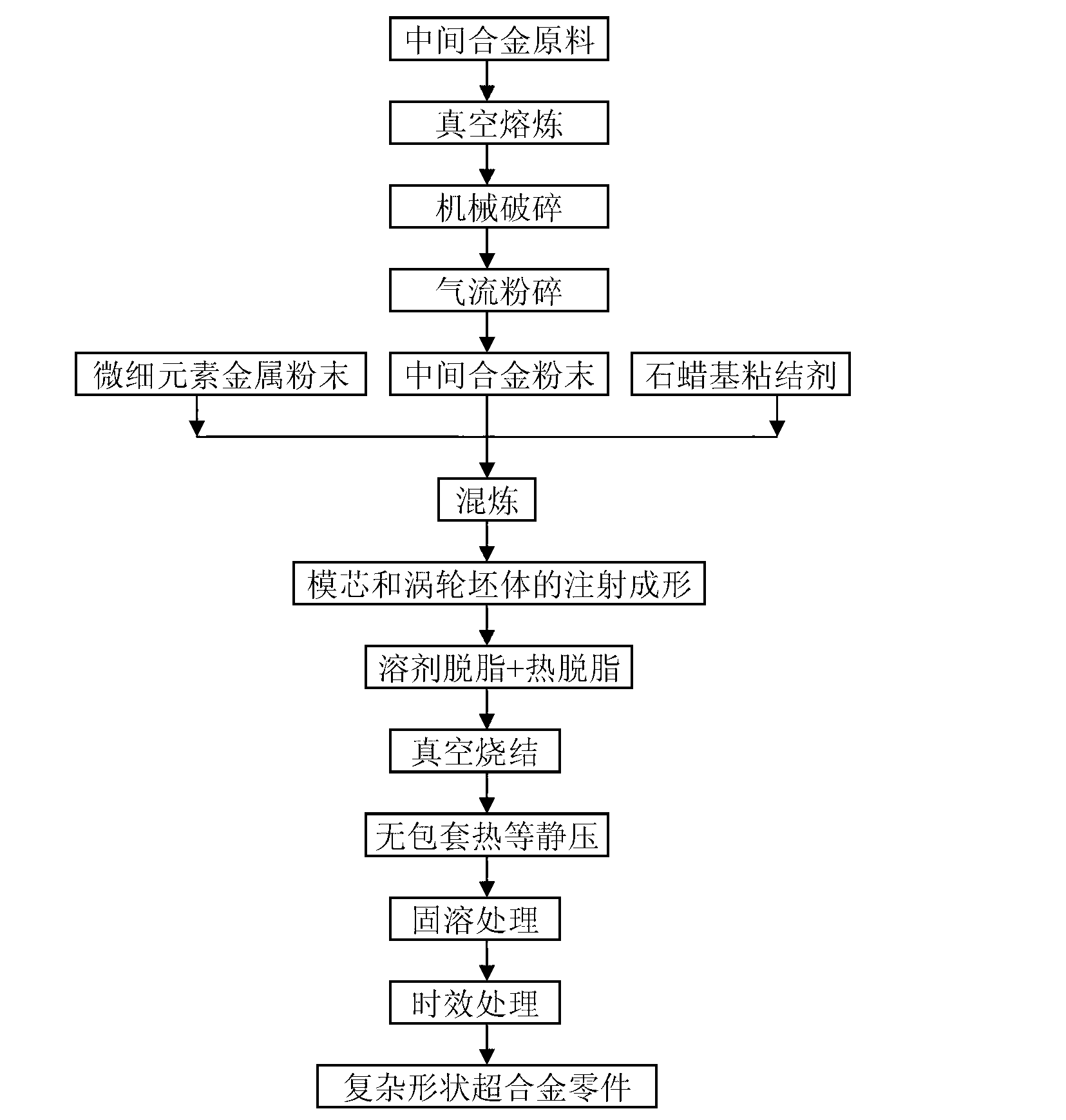

Method for preparing powder super-alloy by near net shape

Disclosed is a method for preparing powder super-alloy by a near net shape. Firstly, high-purity intermediate alloy powder is prepared by the aid of vacuum melting and air jet pulverization technology. Secondly, the intermediate alloy powder and fine particle diameter metal powder (such as carbonyl nickel powder, carbonyl iron powder, reduction tungsten powder and reduction molybdenum powder) are mixed in a high-energy ball mill with protective atmosphere to obtain mixed powder. The mixed powder and paraffin base binders are uniformly premixed, feedstock with a uniform rheological performance is obtained by mixing and is formed on an injection forming machine to obtain a blank in a complicated shape. The binders are removed from the blank in the complicated shape by the aid of solvent degreasing and hot degreasing technologies, the degreased blank is sintered in the vacuum atmosphere, the sintered blank is further compacted by the aid of unjacketed hot isostatic pressure, and finally, a super-alloy part in the complicated shape is obtained by the aid of solid solution and aging treatment. Raw material powder cost and technological energy consumption are remarkably reduced, and prepared super-alloy is almost fully compact, uniform in structure and excellent in comprehensive mechanical property.

Owner:UNIV OF SCI & TECH BEIJING

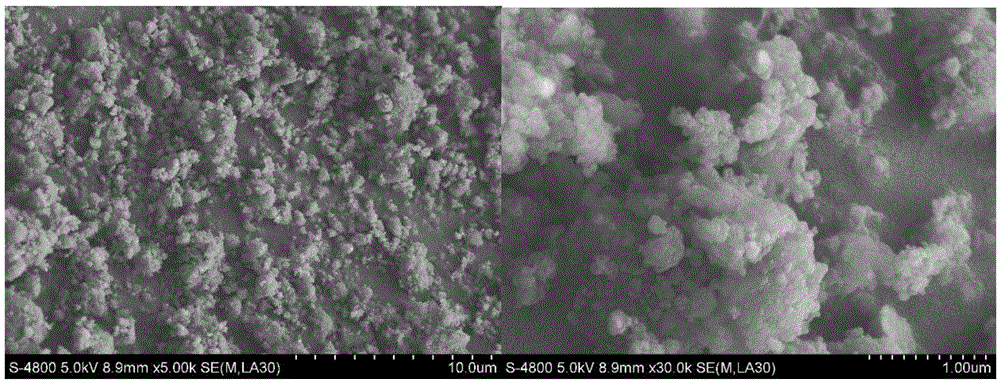

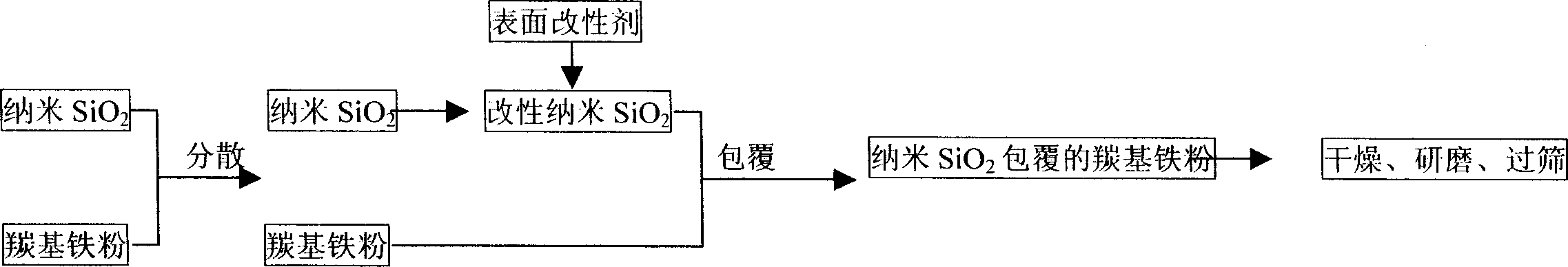

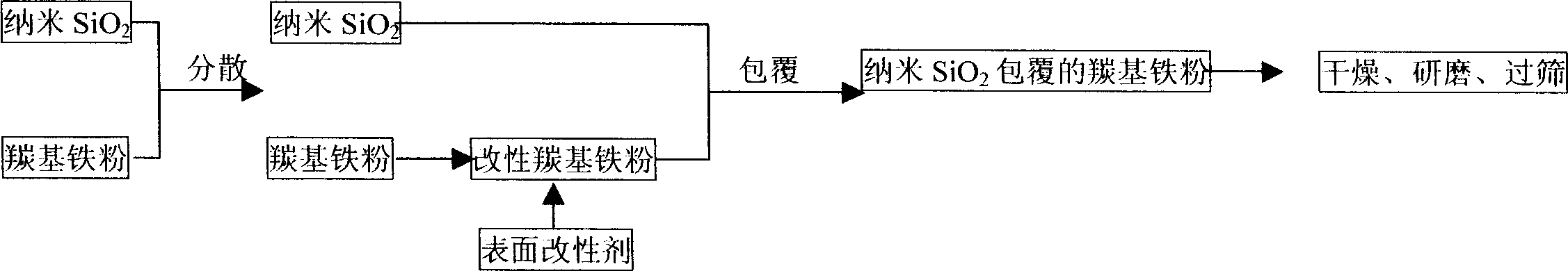

Production of nano-SiO2 for coating carbonyl iron powder

A process for preparing the nano-SiO2 coated carbonyl iron particles includes such steps as dispersing SiO2 nanoparticles and carbonyl iron particles by grinding, modifying the surface polarity of both particles by soluble caustic substance, coating the SiO2 nanoparticles on the surface of each carbonyl iron particle by physical adsorption, backing in vacuum or protective atmosphere, grinding, sieving and packing.

Owner:JIANGSU TIANYI ULTRA FINE METAL POWDER

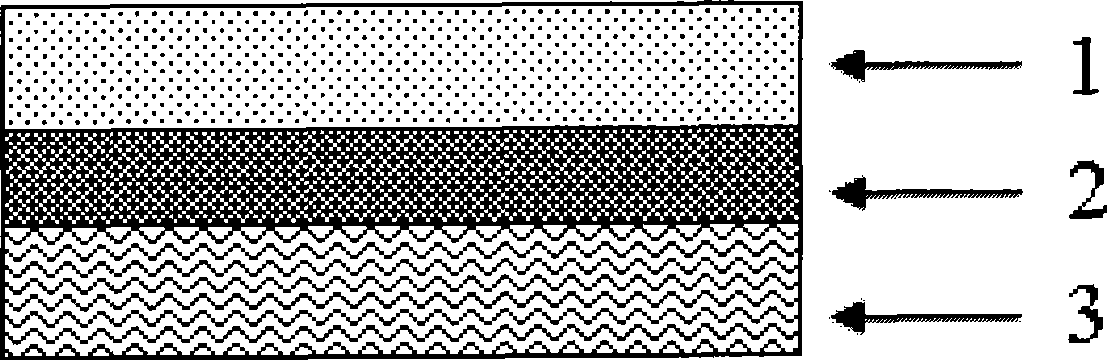

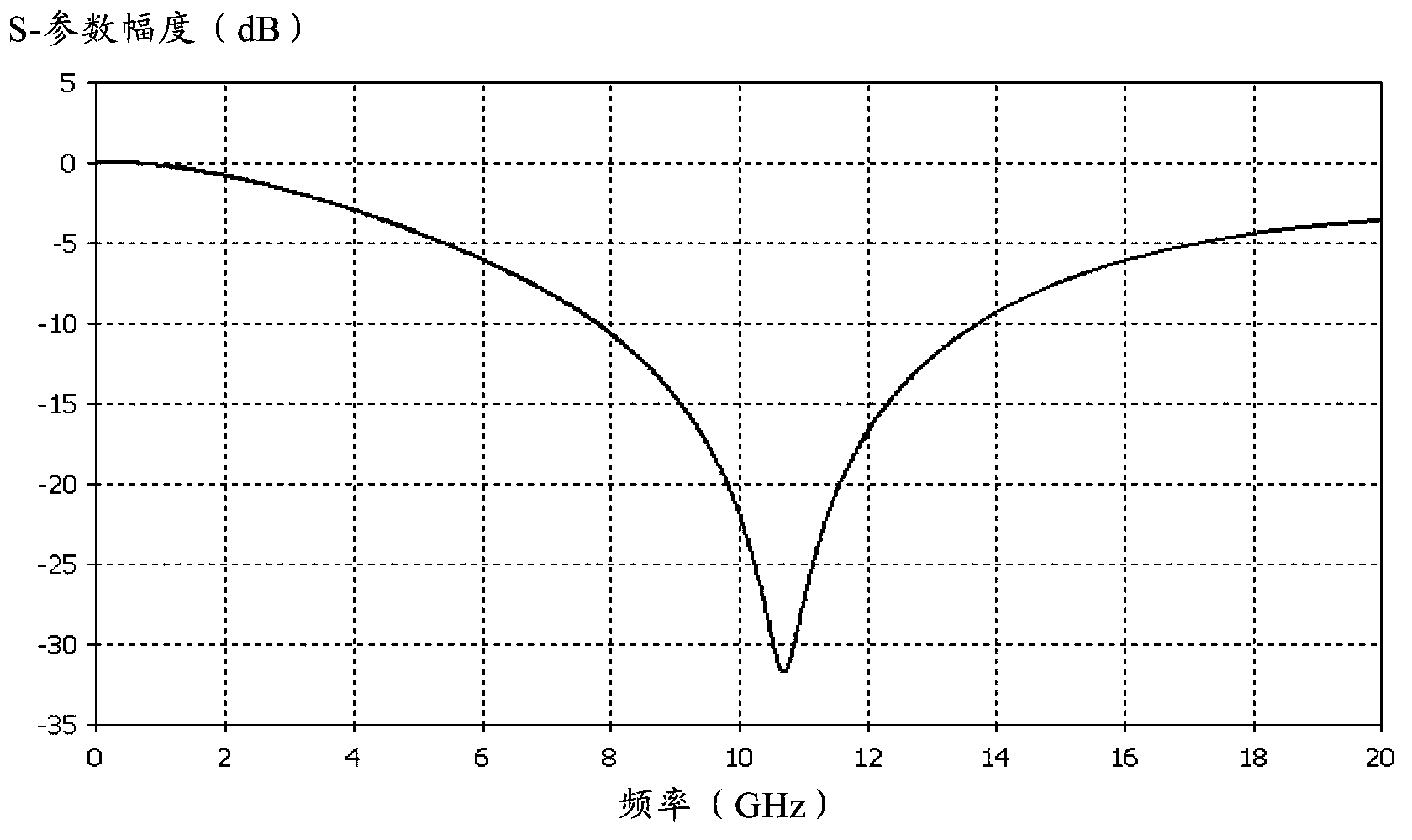

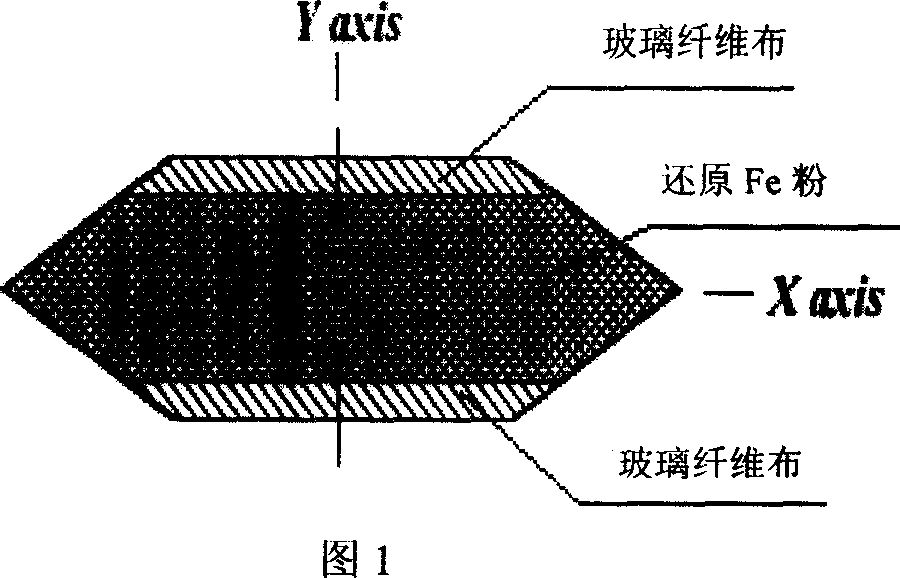

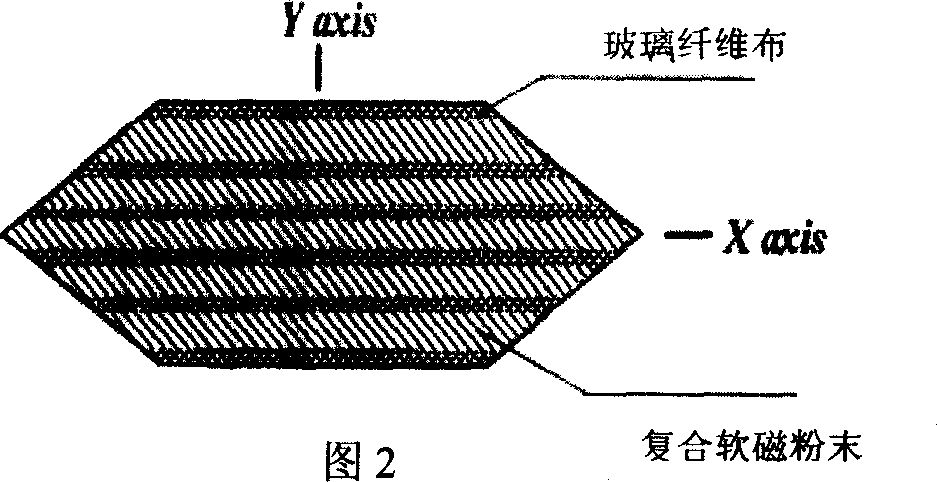

Broadband multi-layer structured wave absorbing composite material and preparation thereof

InactiveCN101434134AWith electrical lossWith magnetic lossLamination ancillary operationsSynthetic resin layered productsGlass fiberSurface layer

The invention relates to a broadband wave absorption composite material with a multilayer structure and a preparation method thereof. The broadband wave absorption composite material is characterized in that the material comprises three parts, namely a surface layer, a sandwich layer and a bottom layer; the surface layer comprises, by mass percentage, 20 to 50 percent of carbonyl iron dust, 30 to 48 percent of polymer and 20 to 32 percent of fiberglass cloth; the sandwich layer comprises, by mass percentage, 2 to 6 percent of carbon nanometer tube, 56.4 to 58.8 percent of polymer and 37.6 to 39.2 percent of fiberglass cloth; and the bottom layer comprises, by mass percentage, 50 to 80 percent of carbonyl iron dust, 12 to 30 percent of polymer and 8 to 20 percent of fiberglass cloth. The broadband wave absorption composite material has the advantages of low surface density, thin thickness and high mechanical strength, and improves the bearing performance and the engineering application value.

Owner:BEIJING UNIV OF CHEM TECH

New corrosion resistant composite wave absorbing material

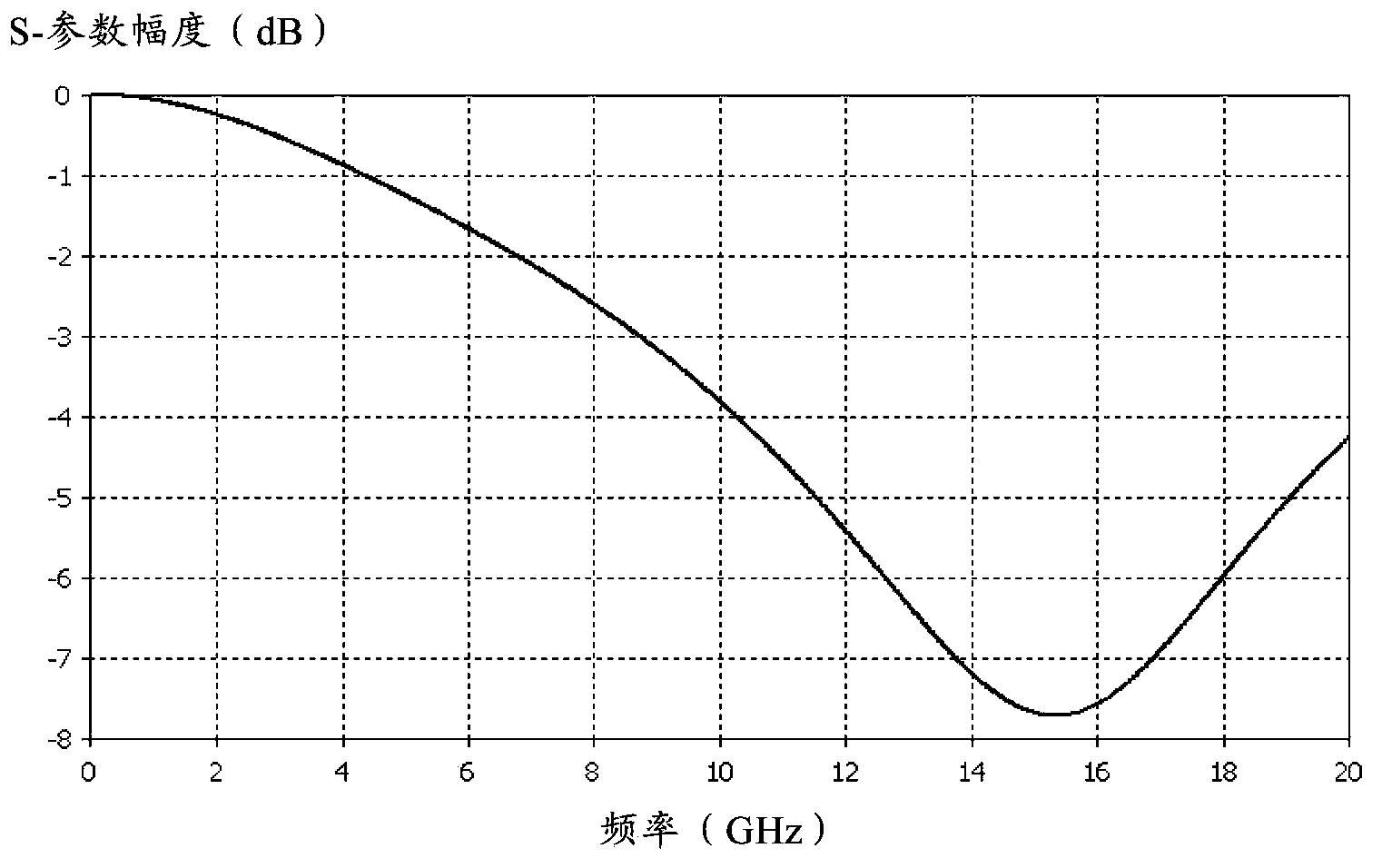

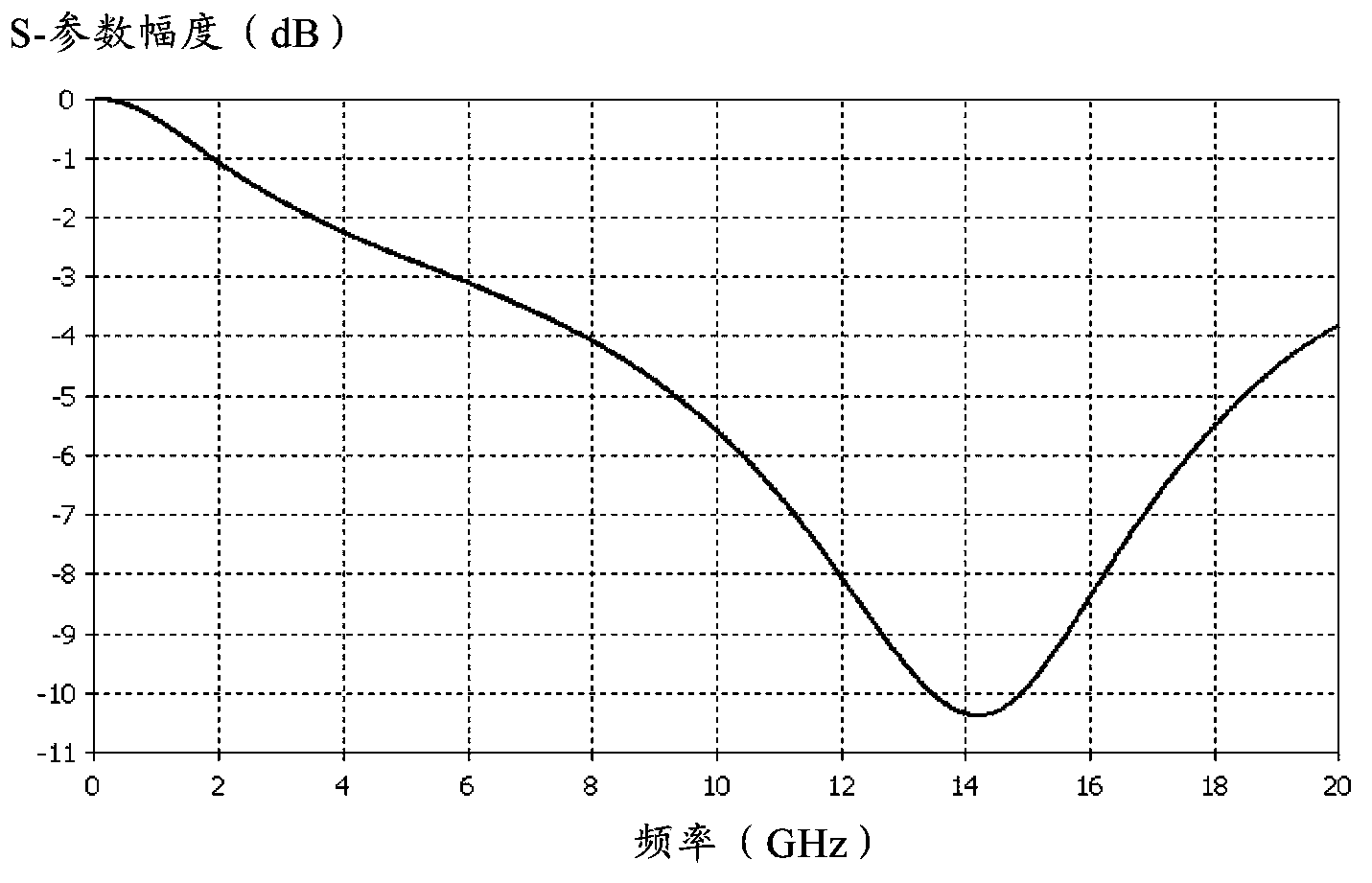

InactiveCN104371271AImprove corrosion resistanceImprove absorbing performanceOther chemical processesPolymerCarbonyl iron

The invention discloses a novel corrosion resistant composite wave absorbing material and a preparation method thereof, and belongs to the field of electromagnetic wave absorbing materials. The wave absorbing material includes 60-100 parts of resin polymer matrix, 50-100 parts of a curing agent, 20-30 parts of ferrite, 20-30 parts of carbonyl iron powder and 5-10 parts of a hollow granular material. The preparation method is as follows: adding a magnetic filler, a conductive filler and a semi conductive filler into resin solution for evenly mixing, and adding the curing agent. The electromagnetic wave absorbing material prepared by the method has the coating thickness of less than or equal to 3mm; in the 2-18GHz, the absorption reflectivity is less than or equal to-10dB; and the electromagnetic wave absorbing material is stealth material with good corrosion resistance, strong wave absorbing performance and wide wave absorbing band.

Owner:BEIJING GUOHAO SENSOR TECH RES INST GENERAL PARTNERSHIP

Broadband wave-absorbing material and preparation method thereof

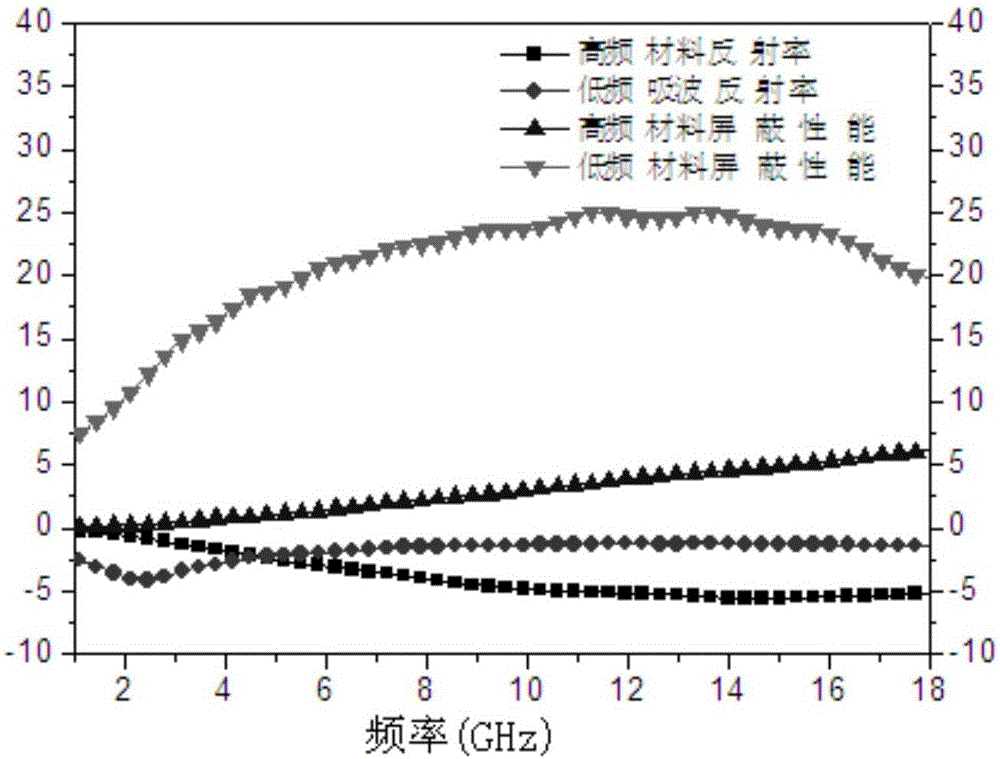

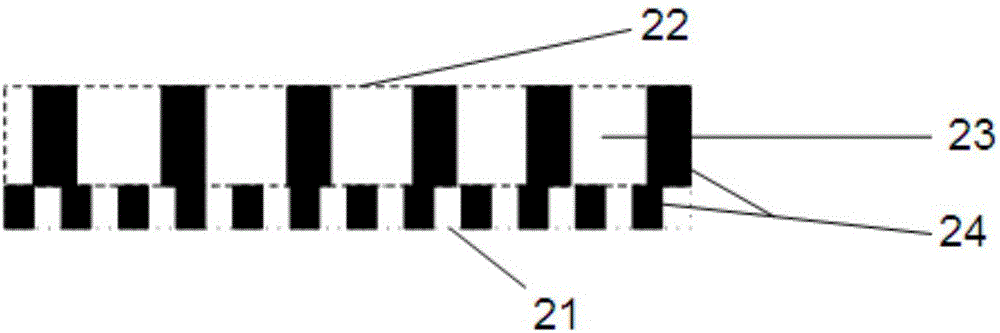

The invention discloses a broadband wave-absorbing material and a preparation method thereof. The broadband wave-absorbing material is composed of a low frequency wave-absorbing material bottom layer and a high frequency wave-absorbing material surface layer. The high frequency wave-absorbing material surface layer comprises a plurality of high frequency wave-absorbing layers with different concentrations. FeSi or FeSiAl particles are taken as the additive of the low frequency wave-absorbing material, and carbonyl iron particles are taken as the additive of the high frequency wave-absorbing material. A rolling method is adopted to prepare the low frequency wave-absorbing material bottom layer, and a three-dimensional moulding technology is adopted to prepare the high frequency wave-absorbing material surface layer. The multilayer lamination manufacturing method combines a multi-rolling technology and three-dimensional moulding together and has the advantages that the binding force between layers can be ensured, multiple repeated mould pressing is avoided, the thickness of each layer, the internal structure, and particle distribution can be adjusted so as to satisfy the predetermined electromagnetic property requirements; the broadband wave-absorbing performance of the wave-absorbing material and designable performance of a shielding material can be realized; the integrated manufacturing of space structure of the wave-absorbing material is achieved, and the preparation cost is low at the same time.

Owner:SHANGHAI RADIO EQUIP RES INST

Water-based magneto-rheological polishing liquid for optical processing and preparation method thereof

InactiveCN101250380ALow magnetic field viscositySuitable for recyclingMagnetic liquidsPolishing compositions with abrasivesWater basedIron powder

The invention relates to a water-based magnetorheological polishing solution for optical manufacture, which is formed by the following volume components, water-based remixed carrier liquid 25%-75% and additive component 25%-75%, wherein the additive component is dispensed by the following volume percentage, carbonyl iron powder 80%-90%, nanometer iron powder 4%-10% and polishing powder 4%-10%, the water-based remixed carrier liquid which is measured according to volume percentage comprises deionized water 85%-90%, dispersing agent 3%-5%, wetting agent 2%-5% and thixotropic agent 3%-5%, the method for preparing comprises the following steps: mixing deionized water and thixotropic agent, stirring in indoor temperature for 1-2 hours, and adding dispersing agent, stirring in indoor temperature for 0.5-1 hour, and then adding wetting agent, stirring in indoor temperature for 0.5-1 hour, getting water-based remixed carrier liquid, mixing additive component and water-based remixed carrier liquid, adding into a ball-milling tank, adding into a steel ball according to mass ratio which is 1:10, grinding for 3-5 hours in the speed which is 20-30r / m, separating out a steel ball, and getting products. The polishing solution of the invention has the advantages of excellent stability, high rheological property, excellent oxidation resistance property and simple and environmental-friendly preparation technology.

Owner:NAT UNIV OF DEFENSE TECH

Magnetic nanoparticle-based immobilized laccase and ionic liquid composite particle and application thereof

InactiveCN103007847AImprove stabilityHigh reuse rateOn/in inorganic carrierMicroballoon preparationSilicic acidSilanes

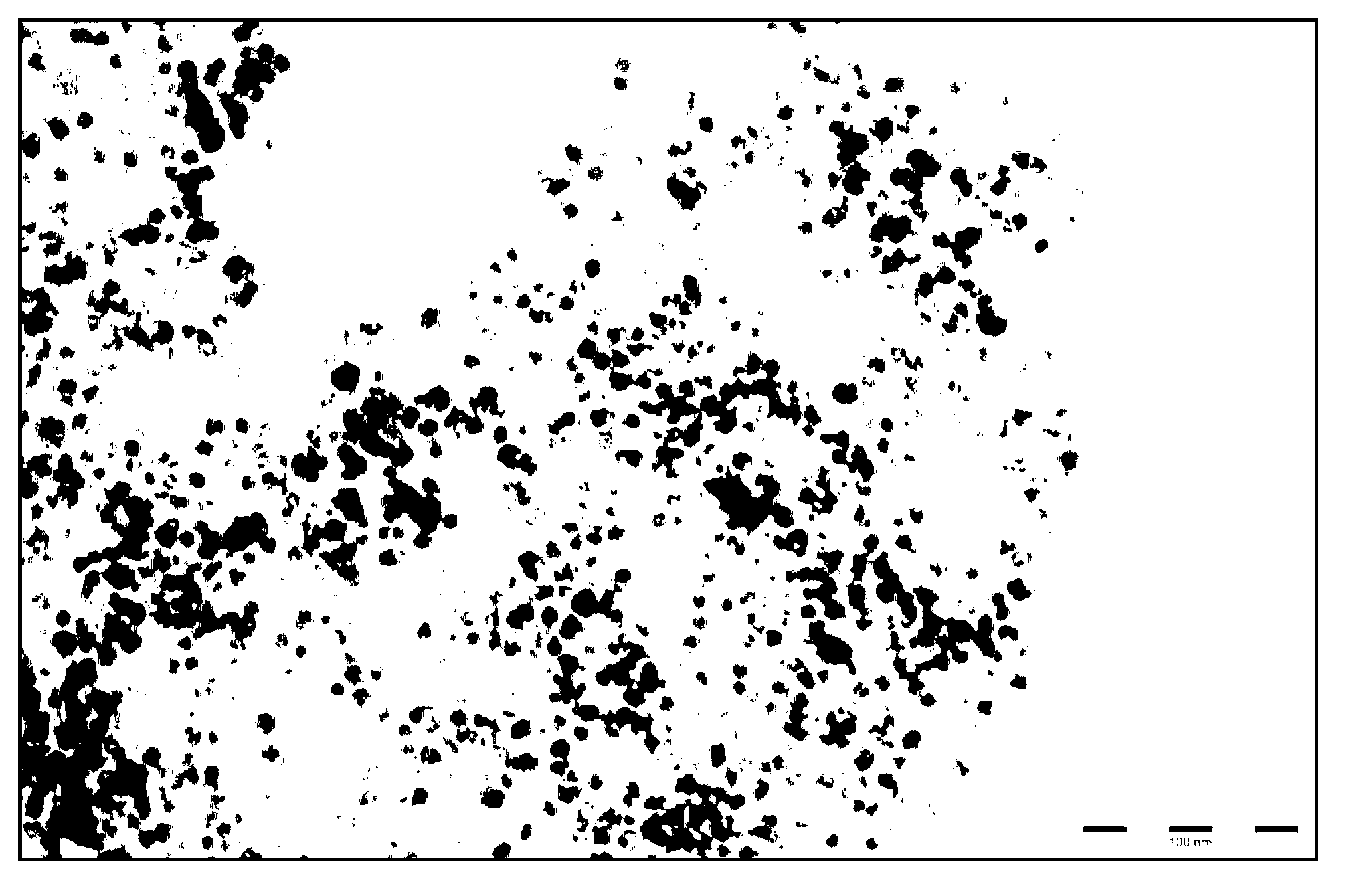

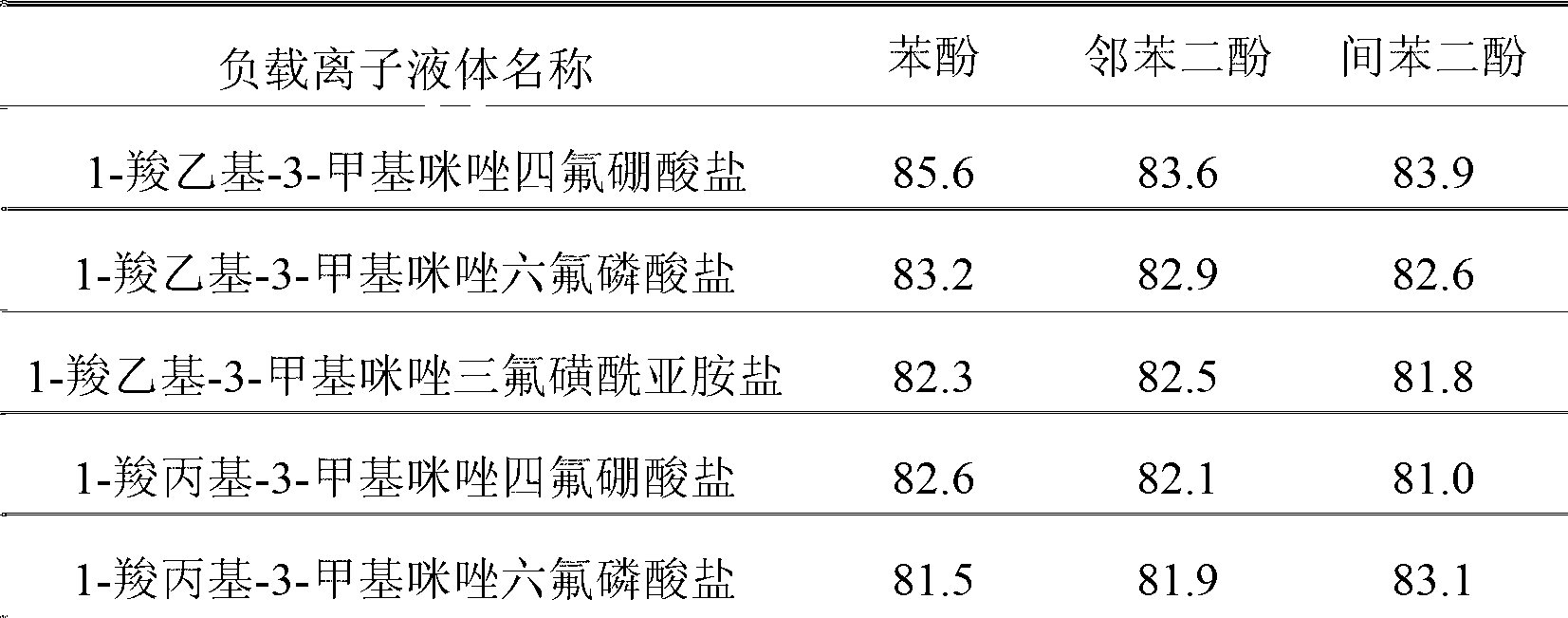

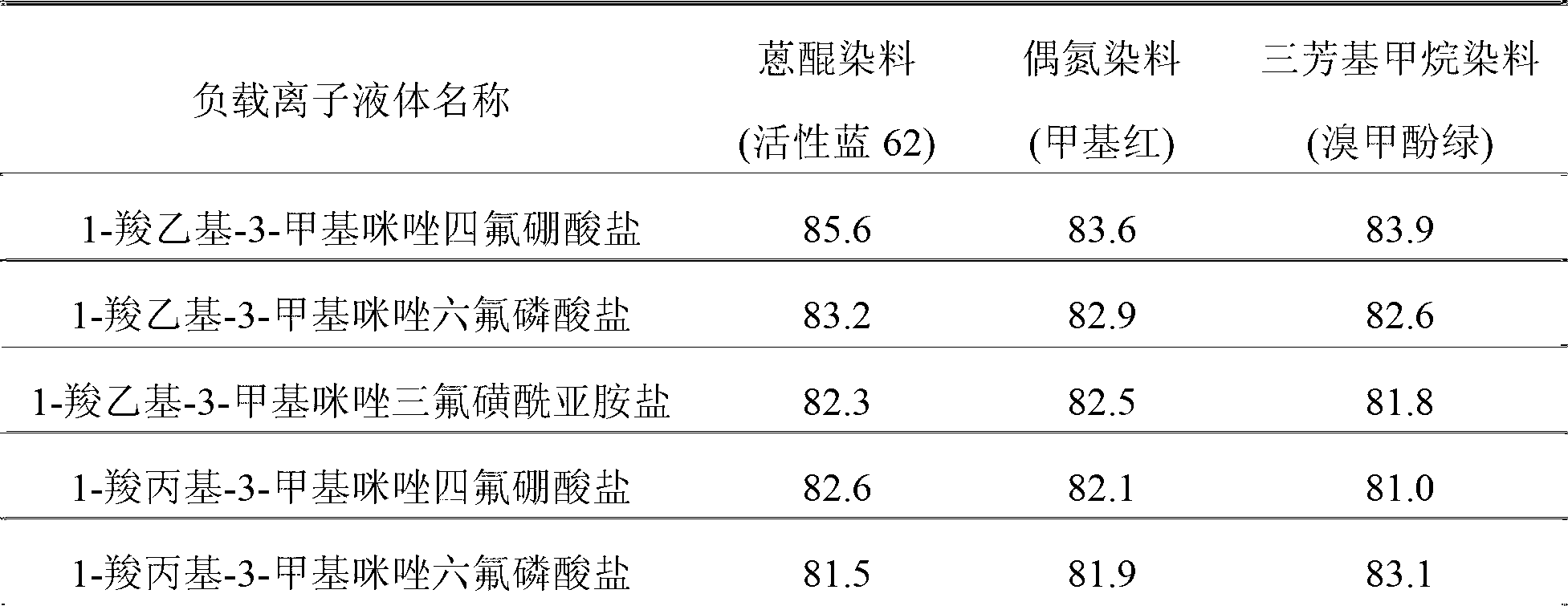

The invention discloses a magnetic nanoparticle-based immobilized laccase and an ionic liquid composite particle, a preparation method thereof and application in removal of contaminants in water. The preparation method comprises the steps that carbonyl iron is taken as an iron source and is synthesized to be gamma-Fe2O3 nano-particles through a chemical precipitation method; the magnetic nanoparticles are taken as cores, tetraethoxysilane and a silane coupling agent are taken as a silicon source, and by means of a sol-gel method, surface amino-functionalized nano core-shell type magnetic silicon dioxide is prepared; 1-ethyl-(3-dimethyllaminopropyl) carbodiie hydrochlide is taken as a coupling agent, and laccase is bonded on the surface of the nano core-shell type magnetic silicon dioxide in a covalent bond manner to obtain the immobilized laccase of the magnetic nanoparticle silicon dioxide particles; and then the immobilized laccase is reacted with a functionalized ionic liquid which is synthesized by reacting N,N-carbonyldiimidazole and an ionic carboxy contained liquid to prepare the magnetic nanoparticle immobilized laccase and ionic liquid composite particle, and the composite particle is applied to the removal of the contaminants in water.

Owner:SOUTH CHINA UNIV OF TECH

Novel multi-element structure composite conductive filling material

The invention discloses a multi-element structure composite conductive filling material. A surface of lightweight inorganic powder (hollow glass beads, mica, carbon fibers, flake graphite and the like) is plated with a layer of wave absorbing magnetic material (Ni, Fe, Co, Ni-P, Co-P, Ni-Co-P, Co-W-P, barium ferrite, ferriferrous oxide, carbonyl iron and the like), and then is plated with a layer of conductive material (such as metal of silver, nickel, copper and the like or inorganic oxides of doped tin oxide, doped indium oxide, doped zinc oxide, titanium dioxide and the like), and a novel multi-element structure composite conductive filling material-inorganic powder core / magnetic material coating layer / conductive material coating layer is prepared. The electromagnetic shielding performance of the composite conductive filling materials can be raised further by utilization of wave absorbing performances of the wave absorbing material to electromagnetic waves and the reflection performances of the conductive material to electromagnetic waves. The composite conductive filling material has advantages of light weight, low cost, wide shield frequency band, good shielding properties and the like, and has great application values in the electromagnetic shielding composite material field.

Owner:GUANGDONG UNIV OF TECH

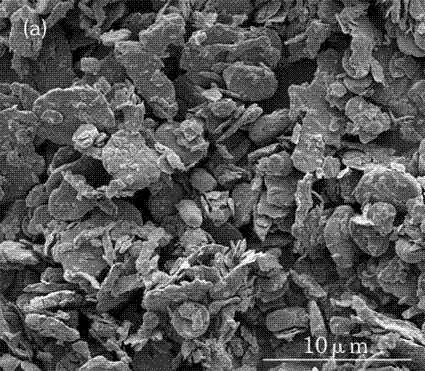

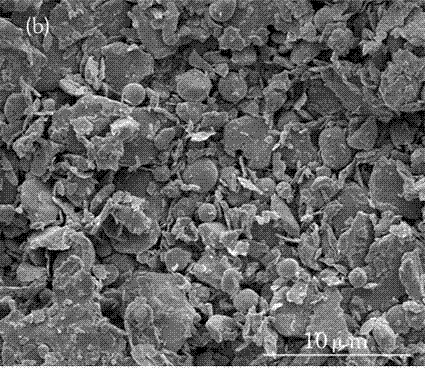

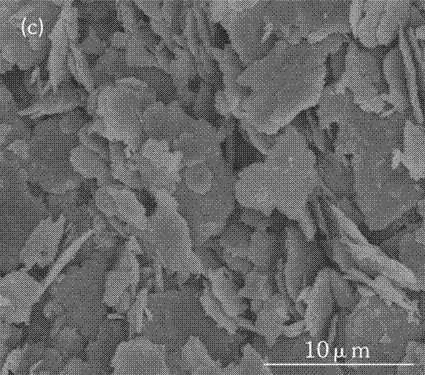

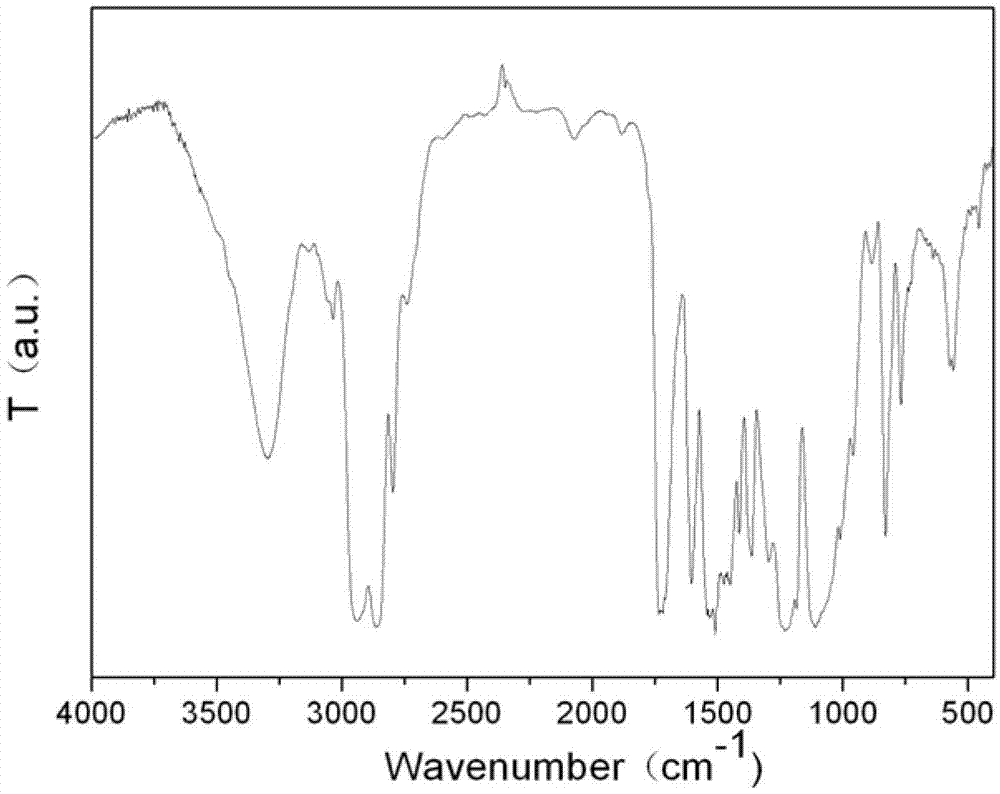

Preparation method for flaky carbonyl iron powder with high magnetic permeability

InactiveCN102815754ASimple materialEasy to operateMaterial nanotechnologyIron carbonylsIron powderActive agent

The invention relates to a preparation method for flaky carbonyl iron powder with high magnetic permeability, and belongs to the field of magnetic wave absorbing materials. The method comprises the following steps: 1, carrying out a primary ball milling process: at a room temperature, weighing 100-150 g of steel balls with a diameter of 3-6 mm, 5-10 g of carbonyl iron powder, and 0.01-0.1 g of a surfactant calcium stearate, measuring 30-50 ml of an organic solution, adding the materials and the solution to a 100 ml ball mill tank, and carrying out ball milling in a planetary type ball mill; 2, washing the carbonyl iron powder with the primary ball milling three times by using ethanol, and carrying out blow-drying at a room temperature or carrying out rapid drying at a temperature of 50-70 DEG C; 3, carrying out a secondary ball milling process: mixing the dried carbonyl iron powder and steel balls with a diameter of 3-6 mm according to the ratio of the primary ball milling process described in the step 1, and then carrying out ball milling for 2-10 minutes at a speed of 400-600 rotation / min; and 4, cooling the ball milling tank, and then separating the iron powder and the steel balls to obtain the flaky carbonyl iron powder sample. The process of the preparation method of the present invention is simple. With the preparation method of the present invention, a dielectric property is not changed while high magnetic permeability is provided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Stable water based magnetic rheologic liquid, and preparation method

InactiveCN1959871APrevent agglomeration and sedimentationImprove anti-sedimentation stabilityMagnetic liquidsInductances/transformers/magnets manufactureAntioxidantChelation

The magnetic rheologic liquid is composed of following components according to portions of mass: magnetic particles 60-90 portions, water based compound assorted carrier liquid 10-40 portions, additive 1-10 portions. The said magnetic particles include ferrocarbonyl powder, reduced iron powder, iron cobalt alloy particles, or ferrite particles with mean grain size 1-10 micro. The water based compound assorted carrier liquid includes following materials according to mass percent: water 70%-90%, and chelation type surfactant 10%-30%. The surfactant includes following components according to percents of total mass of magnetic rheologic liquid: 0.05-2% thixotropic agent, 0.1%-1% antioxidant, 1%-3% antiwear additive, 0.1%-1% pH value regulator, and 0.1%-1% surfactant. Features are: better magnetic rheologic effect, and better standing stability. The magnetic rheologic liquid is applicable to polishing process, civil engineering, and damper for cars.

Owner:WUHAN UNIV OF TECH +1

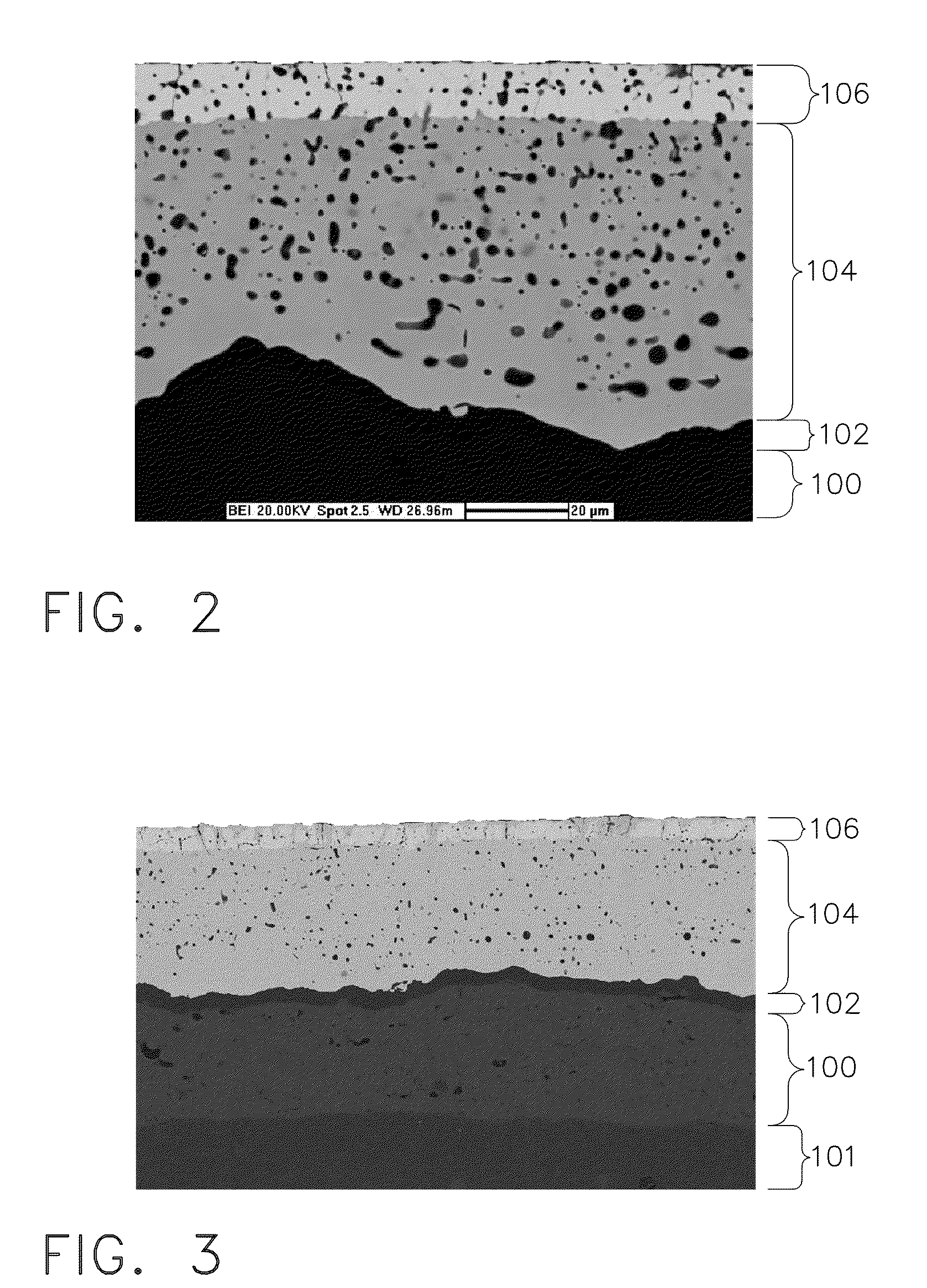

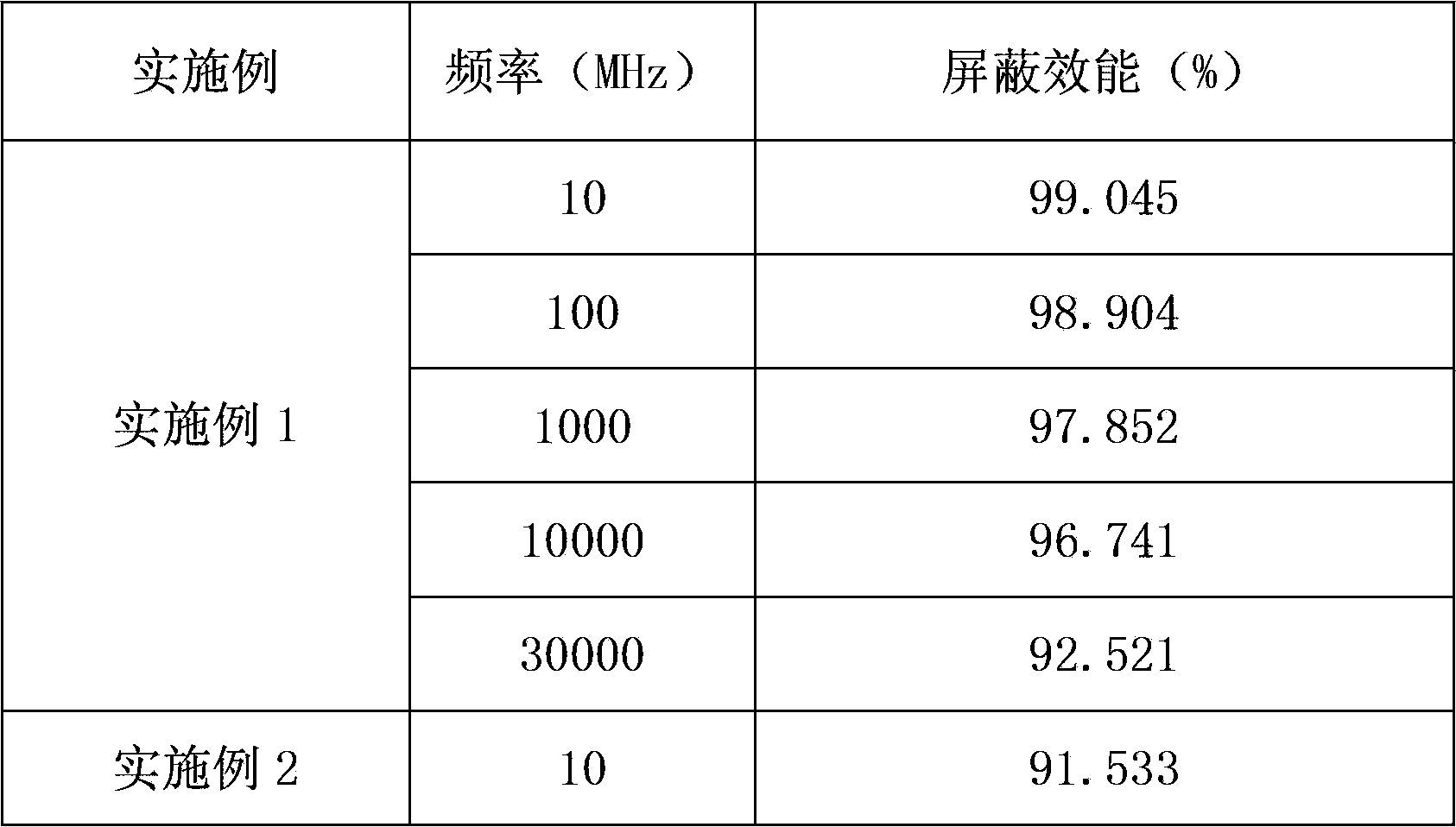

Methods of improving surface roughness of an environmental barrier coating and components comprising environmental barrier coatings having improved surface roughness

Methods for improving surface roughness of an environmental barrier coating including providing a component having a plasma sprayed environmental barrier coating; applying a slurry to the environmental barrier coating of the component, the slurry being a transition layer slurry or an outer layer slurry; drying the environmental barrier coating having the applied slurry; and sintering the component to produce a component having an improved surface roughness where the slurry includes a solvent; a primary transition material, or a primary outer material; and a slurry sintering aid selected from iron oxide, gallium oxide, aluminum oxide, nickel oxide, titanium oxide, boron oxide, alkaline earth oxides, carbonyl iron, iron metal, aluminum metal, boron, nickel metal, iron hydroxide, gallium hydroxide, aluminum hydroxide, nickel hydroxide, titanium hydroxide, alkaline earth hydroxides, iron carbonate, gallium carbonate, aluminum carbonate, nickel carbonate, boron carbonate, alkaline earth carbonates, iron oxalate, gallium oxalate, aluminum oxalate, nickel oxalate, titanium oxalate, solvent soluble iron salts, solvent soluble gallium salts, solvent soluble aluminum salts, solvent soluble nickel salts, solvent titanium salts, solvent soluble boron salts, and solvent soluble alkaline earth salts.

Owner:GENERAL ELECTRIC CO

Radiation protective paint

ActiveCN101497757AEasy to useNo secondary electromagnetic pollutionRadiation-absorbing paintsRadiation resistantFilm-forming agent

The invention relates to aqueous radiation-resistant coating belonging to the chemical engineering technology field. The aqueous radiation-resistant coating takes flaky graphite powder, acetylene carbon power, carbonyl iron powder and ferrite power as main materials with electromagnetic wave absorption function and takes diffusant, cement, film forming agent, ammonia and pure water as auxiliary materials. The aqueous radiation-resistant coating has the electromagnetic wave absorption frequency of 1.0-20000 MHz, can attenuate the electromagnetic wave absorption by 2-20 dB according to the different coating thickness, can solve the unsolvable problem of purifying environment polluted with electromagnetic radiation by shielding material and effectively prevent the harm of electromagnetic radiation to surrounding equipment and personnel.

Owner:安徽宇航派蒙健康科技股份有限公司

Wave absorption and radiation protection plastic and preparation method thereof

The present invention discloses a wave absorption and radiation protection plastic and a preparation method thereof. The wave absorption and radiation protection plastic comprises a plastic raw material, a wave absorption and radiation protection function powder material and an auxiliary agent, wherein the plastic raw material contains PC (polycarbonate), PP (polypropylene), PVC (polyvinyl chloride) and the like, and the wave absorption and radiation protection function powder material is prepared through mixing acetylene carbon powder and carbonyl iron powder. The preparation method comprises: mixing raw materials to obtain a mixed material, and carrying out extrusion molding, compression molding or injection molding to obtain the product. The wave absorption and radiation protection plastic has a function of strong electromagnetic wave and microwave absorption, wherein energy of the absorbed electromagnetic waves and the absorbed microwaves is converted into heat energy to be volatilized so as to reduce electromagnetic wave radiation.

Owner:安徽宇航派蒙健康科技股份有限公司

Irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables

The invention provides an irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables. The cable material is prepared from the following raw materials in parts by weight: 40-50 parts of polyethylene (PE), 30-40 parts of polyvinyl chloride resin, 20-30 parts of CSM2305, 10-12 parts of ethylene-acrylate copolymer, 10-15 parts of epichlorohydrin rubber T3100, 5-10 parts of epoxidized soybean oil, 2-3 parts of carbonyl iron powder, 10-12 parts of high abrasion carbon black N330, 5-10 parts of light calcium carbonate, 1-2 parts of zinc oxide, 5-10 parts of wollastonite powder, 4-5 parts of vermiculite, 1-2 parts of polytetrafluoroethylene micro powder, 1-2 parts of graphite, 1-2 parts of nano boron carbide, 2-3 parts of ferric oxide, 0.1-0.2 part of UV-O, 0.1-0.2 part of UV-53, 0.1-0.2 part of flame retardant TBC, 10-12 parts of aluminium hypophosphite, 5-8 parts of decabromodiphenyl ether, 8-10 parts of dioctyl terephthalate, 6-8 parts of trioctyl trimellitate, 8-10 parts of triethyl citrate, 1-2 parts of calcium stearate, 0.2-0.4 part of stearic acid, 0.1-0.2 part of oxidized polyethlene wax, 0.2-0.3 part of ethylene bis stearamide, 0.1-0.2 part of DCP, and 12-15 parts of modified filler. The cable material has the characteristics of high flame retardance, high ultraviolet resistance and high ageing resistance, and meanwhile, has a good mechanical property, and is environment-friendly.

Owner:温州市粤来电子加速器应用有限公司

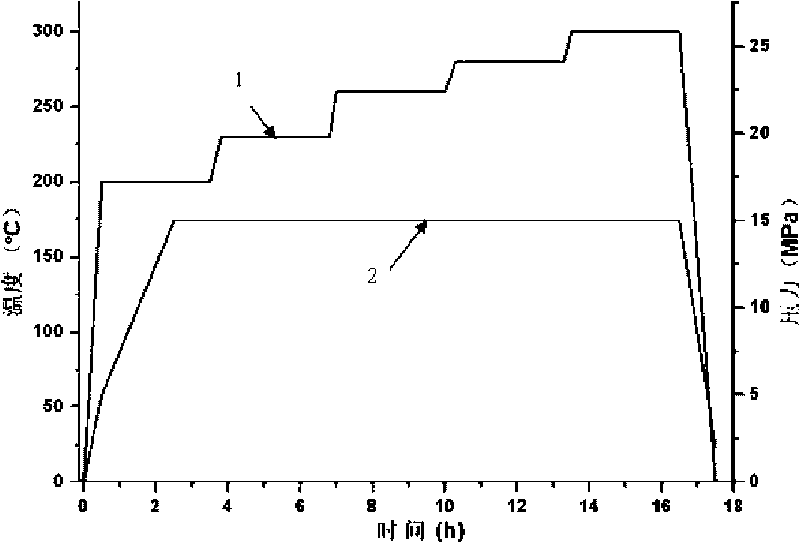

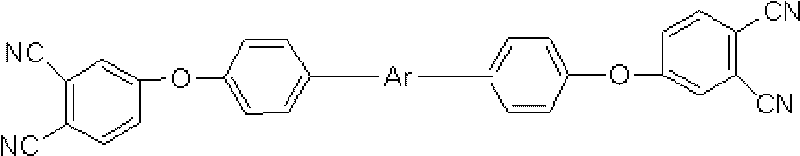

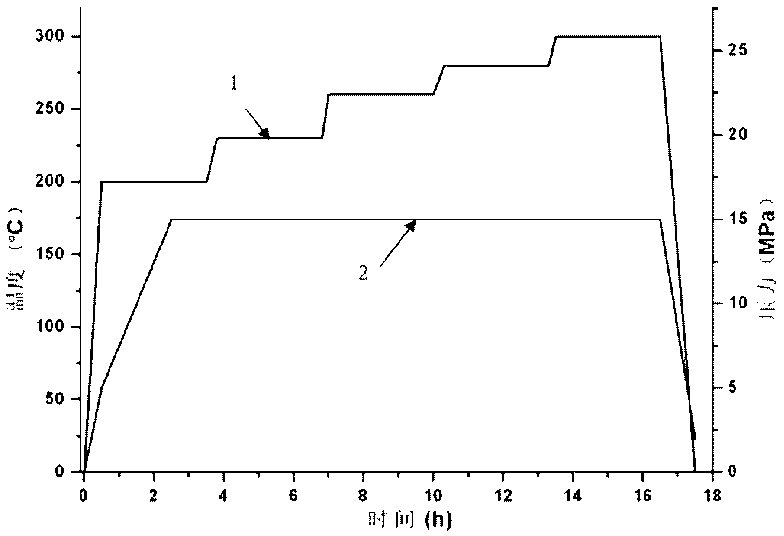

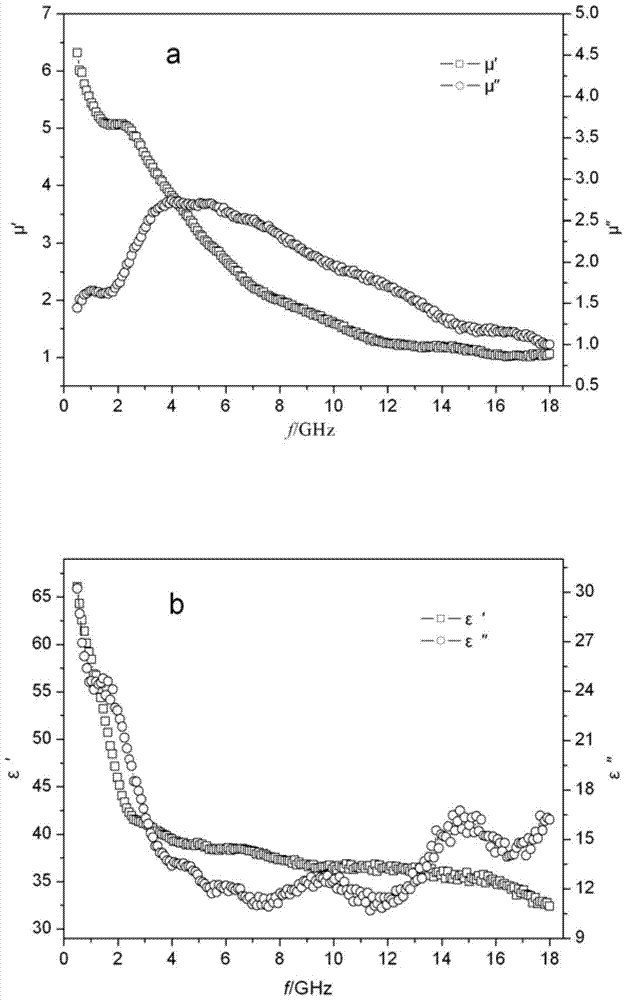

Thermosetting resin glass fiber laminating composite material and preparation method thereof

ActiveCN101700705AImprove thermal stabilityHigh mechanical strengthShieldingGlass/slag layered productsFiberGlass fiber

The invention belongs to the field of high molecular material and in particular to a thermosetting resin glass fiber laminating composite material and a preparation method thereof; the solved technical problem is that the thermosetting resin glass fiber laminating composite material which can adsorb electromagnetic waves is provided, and the thermosetting resin glass fiber laminating composite material is prepared by compounding and laminating double-terminal-group phthalonitrile-benzoxazine resin, which is shown by formula I, filling material, low boiling polar solvent and glass fiber cloth;the filling material is micron-sized carbonyl iron dust or multi-walled carbon nanotube. The thermosetting resin glass fiber laminating composite material has the characteristic that the mechanical structure performance and the electromagnetic wave adsorption performance are integrated, the material is applied to the electromagnetic wave adsorption material, compared with the carbon fiber, the glass fiber is used as reinforcing material, the cost is low, and the processing production is easy.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

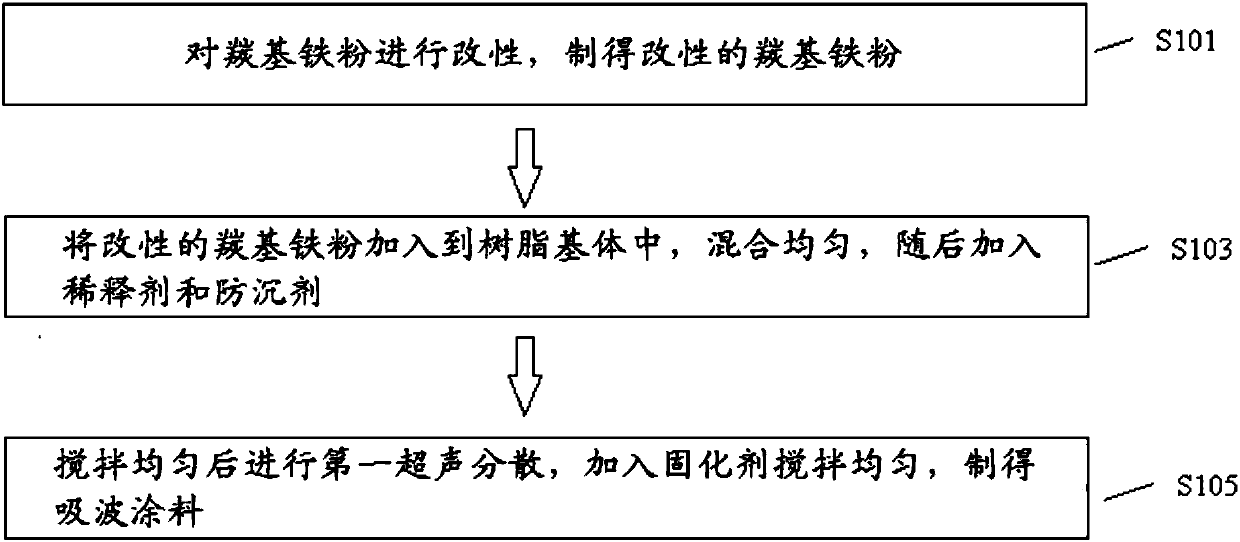

Wave-absorbing coating material and preparation method thereof

PendingCN107760149AImprove performanceExcellent broadband absorbing performancePolyurea/polyurethane coatingsRadiation-absorbing paintsEpoxyHigh absorption

The invention discloses a wave-absorbing coating material, which comprises, by mass, 1-2 parts of a resin matrix, 5-10 parts of modified carbonyl iron powder, 0.5-1 part of a diluent, 0.2-0.4 part ofan anti-settling agent, and 0.2-0.4 part of a curing agent. According to the present invention, the carbonyl iron magnetic particles are subjected to surface coating through the wet modification method, and the coated particles are compounded with the epoxy resin so as to prepare the wave-absorbing coating material; and the wave-absorbing coating material prepared through the method has advantagesof excellent wave absorbing, good broadband wave absorbing performance, light weight, wide application range and complex-environment resistance, and can achieve the broadband and high absorption performance at a maximum.

Owner:LUOYANG INST OF CUTTING EDGE TECH +1

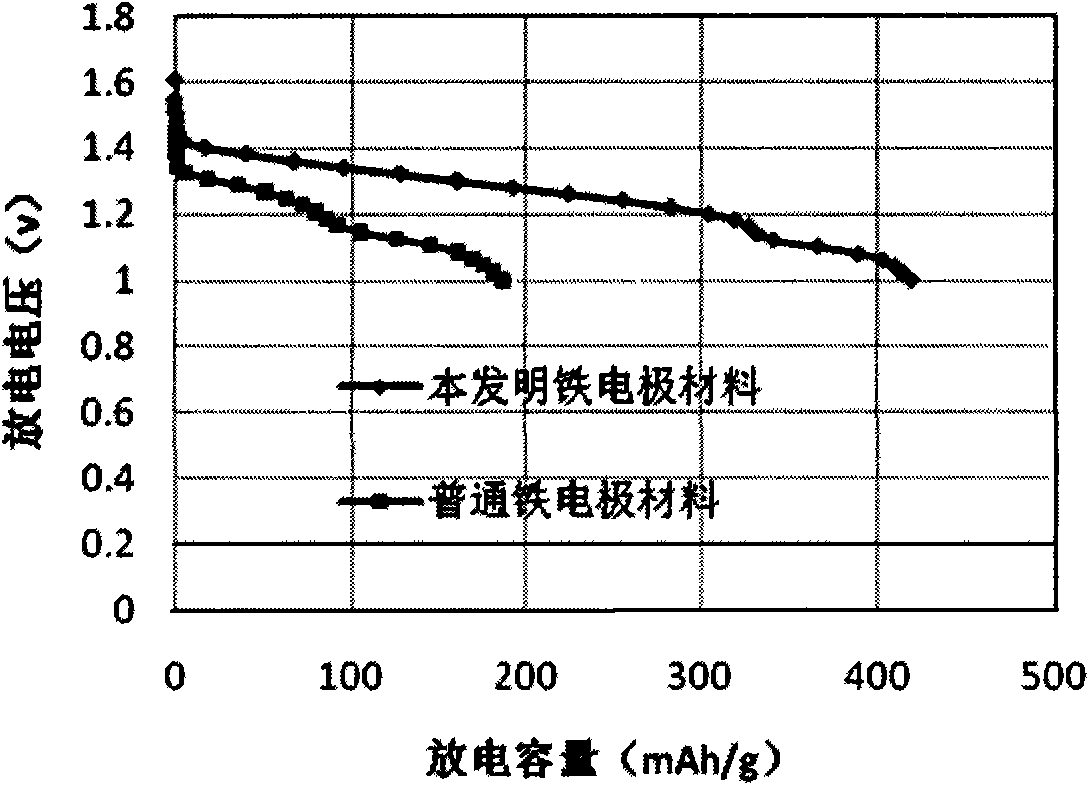

High-capacity iron electrode material

ActiveCN101645505AIncrease capacityAlkaline accumulatorsAlkaline accumulator electrodesHigh energyRare earth

The invention provides a high-capacity iron electrode material, which is characterized by consisting of an active matter and an additive. The active matter is iron or a compound of iron and comprisesone or more of Fe3O4, Fe(OH)2, Fe(OH)3, Fe2O3, reduced iron powder, and carbonyl iron powder; and the additive comprises 1) 1 to 10 percent of rare earth oxides and 2) 1 to 3 percent of nickel hydroxide or saturated nickel sulfate solution, wherein the rare earth oxides comprise one or more of La2O3, CeO2, Nd2O3, Pr2O3, Y2O3, Gd2O3, Sm2O3 and the like. The iron electrode material has the advantages that: 1) poisonous heavy metals (such as Hg, Cd, Pb and the like) are not added, so that the iron electrode material is an environmental protection type electrode material; 2) precious metals (suchas In, Ga and the like) are not added, so the cost of the iron electrode material is extremely low; and 3) the capacity of the active matter of the electrode exceeds 400mAh / g. The material is used formanufacturing high-energy environment-protecting iron-nickel batteries.

Owner:宝生集团有限公司

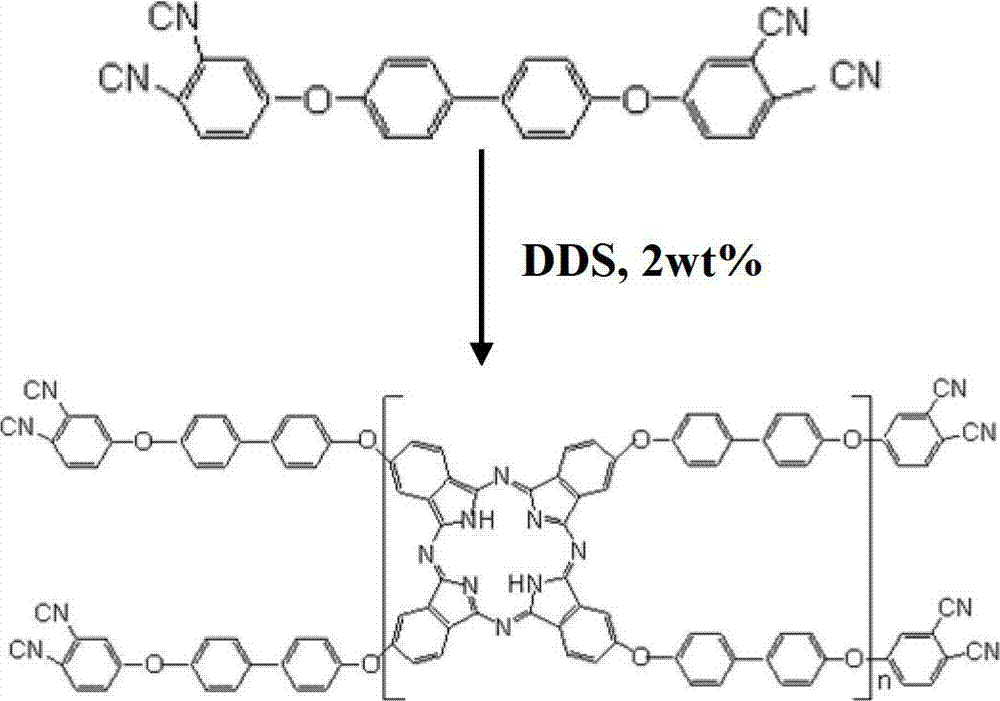

Polyaryl ether nitrile (PEN) and carbonyl iron powder (Fe(CO)5) composite magnetic material and preparation method thereof

ActiveCN102775755AImprove mechanical propertiesHigh strengthOrganic/organic-metallic materials magnetismPigment treatment with macromolecular organic compoundsPhthalonitrileMechanical property

The invention discloses a PEN and Fe(CO)5 composite magnetic material and a preparation method thereof, and belongs to the technical field of magnetic polymer materials. PEN serves as an organic matrix, Fe(CO)5 serves as an inorganic filler, and the composite magnetic material is obtained after blending and prilling. Firstly, the Fe(CO)5 is subjected to surface modification, and a layer of phthalonitrile prepolymer is generated on the surface of the Fe(CO)5; due to a layer of organic matters rich in cyan coated on the surface, the Fe(CO)5 after surface modification can improve the interfacial adhesive force between the Fe(CO)5 inorganic filler and the PEN organic matrix, so that the PEN and the Fe(CO)5 are provided with a high-strength magnetic property while maintain an excellent mechanical property of the PEN after composition. According to the magnetic material and the preparation method thereof, the Fe(CO)5 can be filled as much as possible on the premise that the good mechanical property of the composite material is maintained, so that magnetic saturation strength of the composite material can be improved, the compatibility of inorganic fillers with polymers is improved, and processing defects are overcome.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Carbonyl nickel powder and carbonyl iron powder on palygorskite carrier and their preparing method

InactiveCN1857775AOrganic-compounds/hydrides/coordination-complexes catalystsMetal/metal-oxides/metal-hydroxide catalystsPalygorskiteEvaporation

The present invention discloses carbonyl nickel powder and carbonyl iron powder on palygorskite carrier. Palygorskite with intragranular tunnel pores can adsorb great amount of small molecular weight gas, such as H2, CO, CO2 and CH4, and is favorable to the synergistic effect of carbonyl nickel powder and carbonyl iron powder and can raise the catalytic efficiency. In addition, palygorskite is one kind of alkali mineral and can inhibit carbon accumulation during use to prolong the service life of the catalyst. The preparation process is one chemical evaporation and deposition process, and Ni(CO)4 or Fe(CO)5 vapor and palygorskite powder preheated to 180-300 deg.c are made to react inside a pyrolysis oven, so that the vapor is decomposed into fine Ni or Fe particles distributed homogeneously on the surface of palygorskite. The catalyst has high catalytic activity and long service life, and is used in petroleum hydrocracking and other hydrogenation reaction.

Owner:ZHEJIANG UNIV

High-temperature resistance radar wave absorbing coating and preparation method thereof

ActiveCN103073981ALight in massThe overall thickness is thinPolyurea/polyurethane coatingsRadiation-absorbing paintsEpoxyCyclohexanone

The invention discloses a high-temperature resistance radar wave absorbing coating and a preparation method thereof, and relates to an electromagnetic wave absorbing coating. The absorbing coating comprises the following components: carbonyl iron powder, epoxy resin, polyurethane prepolymer, silane coupling agent and mixed ketone organic solvent, and particularly comprises the following components in part by weight: 65-69 parts of carbonyl iron powder, 19-22 parts of epoxy resin, 30-33 parts of polyurethane prepolymer, 0.4-0.8 parts of KH560 silane coupling agent and 25-35 parts of butanone and cyclohexanone mixed solvent. The absorbing coating provided by the invention can be applied to a wide range of frequency bands, and the application frequency of the absorbing coating can achieve a loss effect of more than minus 3.5 dB in a range of X, Ku wave bands (8-18 GHz).

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

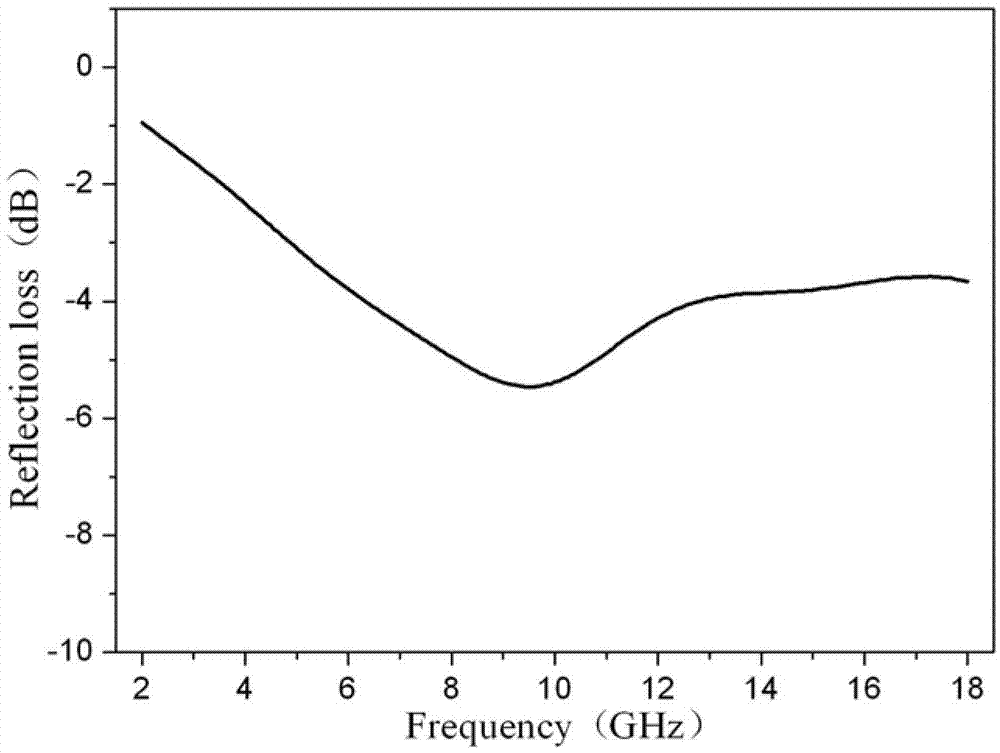

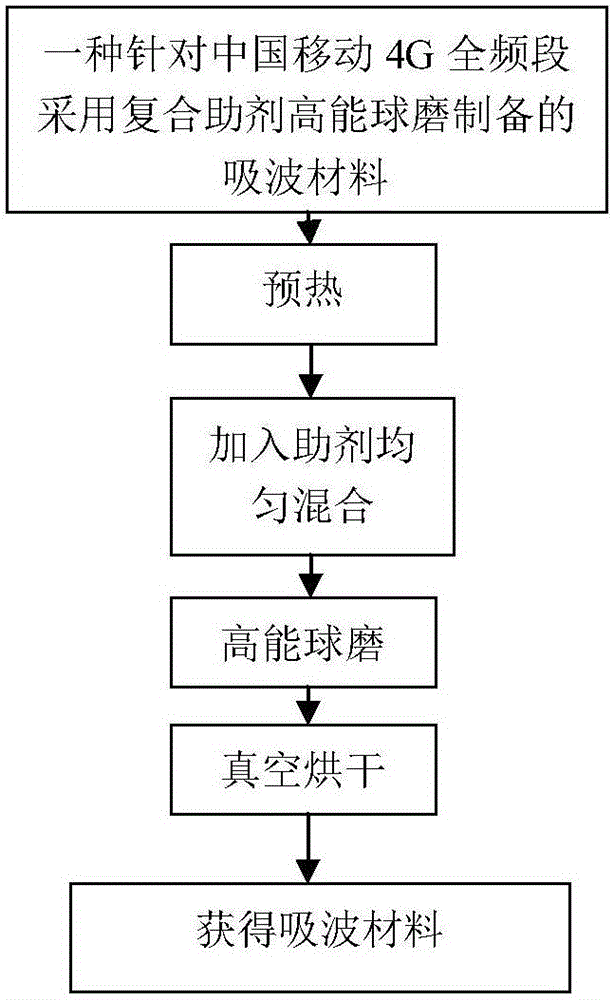

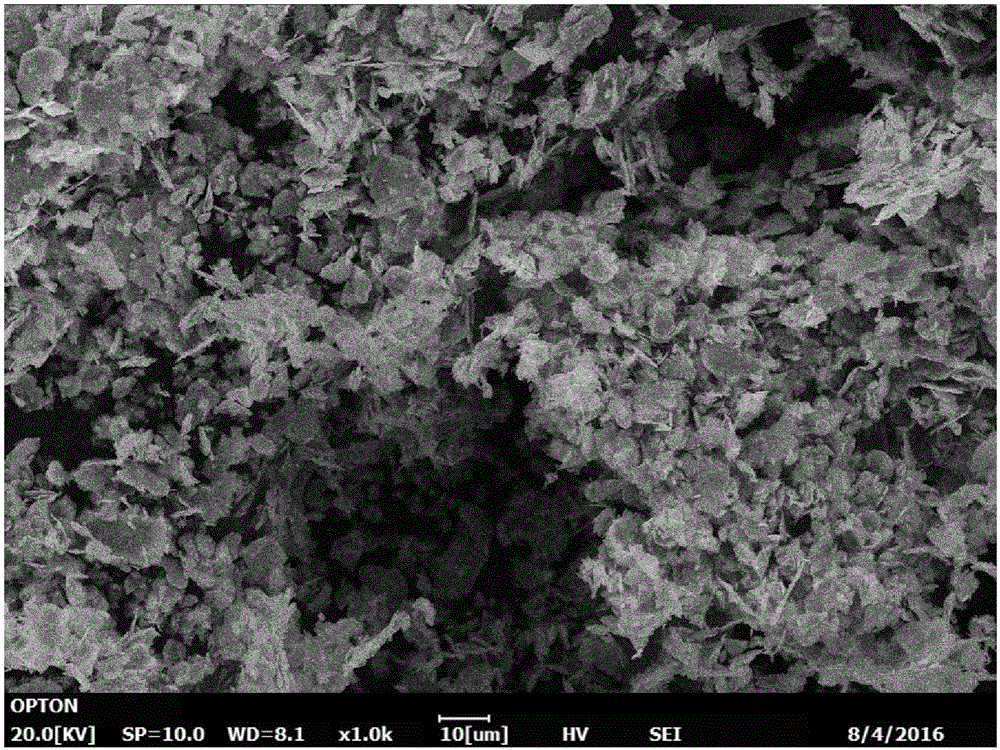

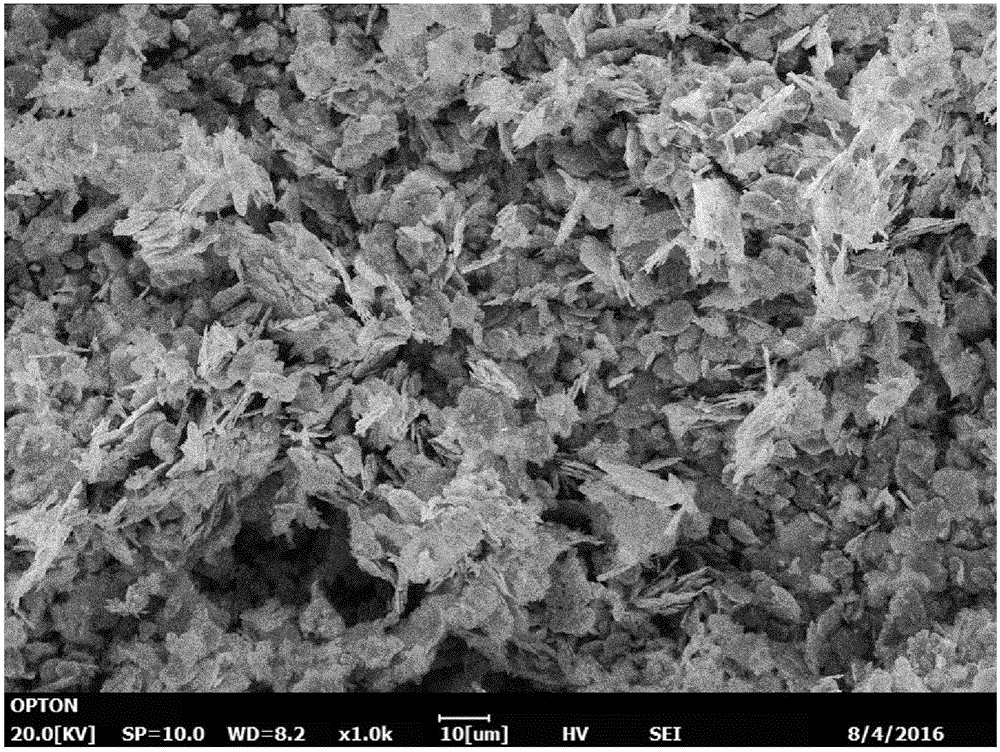

China Mobile 4G full band absorbing material, and preparation method and application thereof

ActiveCN106064837AImproved signal-to-noise ratio performanceImprove communication qualityOther chemical processesIron carbonylsHigh energyImpedance matching

The invention discloses a China Mobile 4G full band absorbing material, and a preparation method and application thereof. A composite auxiliary agent of a silane coupling agent and a stearate surfactant is added to a carbonyl iron powder, and a high-energy ball milling process is carried out to prepare a sheet-shape carbonyl iron powder absorbing material with excellent impedance matching performance. The material can meet the following requirements: in the frequency range from 1 to 18 GHz, an absorbing coating has thickness of less than or equal to 2mm; the absorbing material has -8dB absorption bandwidth reaching 1.5GHz (1.3-2.8GHz), which completely covers the whole band of China Mobile 4G (1.8GHz-2.8GHz); the proportion of the silane coupling agent and stearate can be adjusted to obtain proper sheet structure and size, thus changing the relationship between the complex permittivity and complex permeability to reach impedance matching, and then adjusting the absorption peak position. The material achieves the purpose of selecting absorption interference noise at three arbitrary main frequencies of China Mobile 4G and improving the signal-to-noise ratio of the base station and mobile terminal.

Owner:南京威勒信息技术科技有限公司

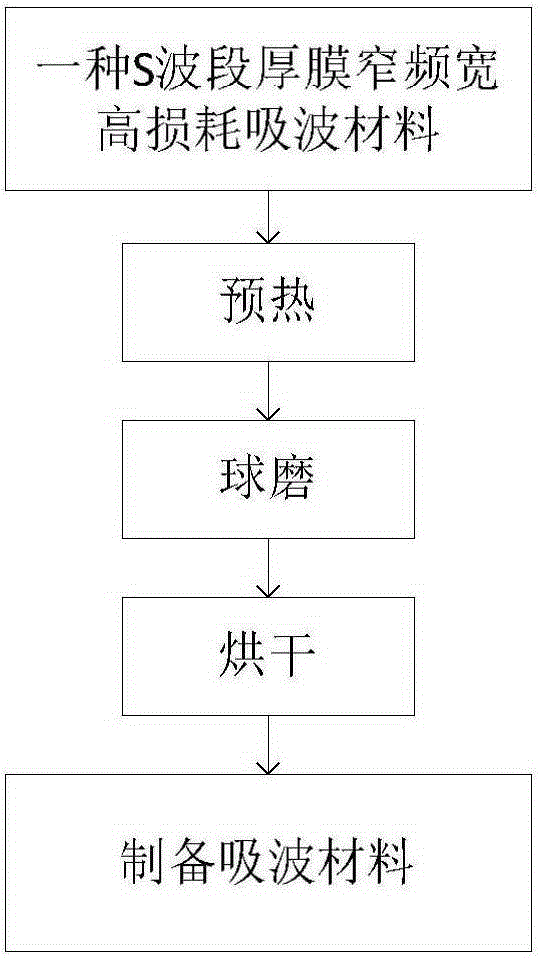

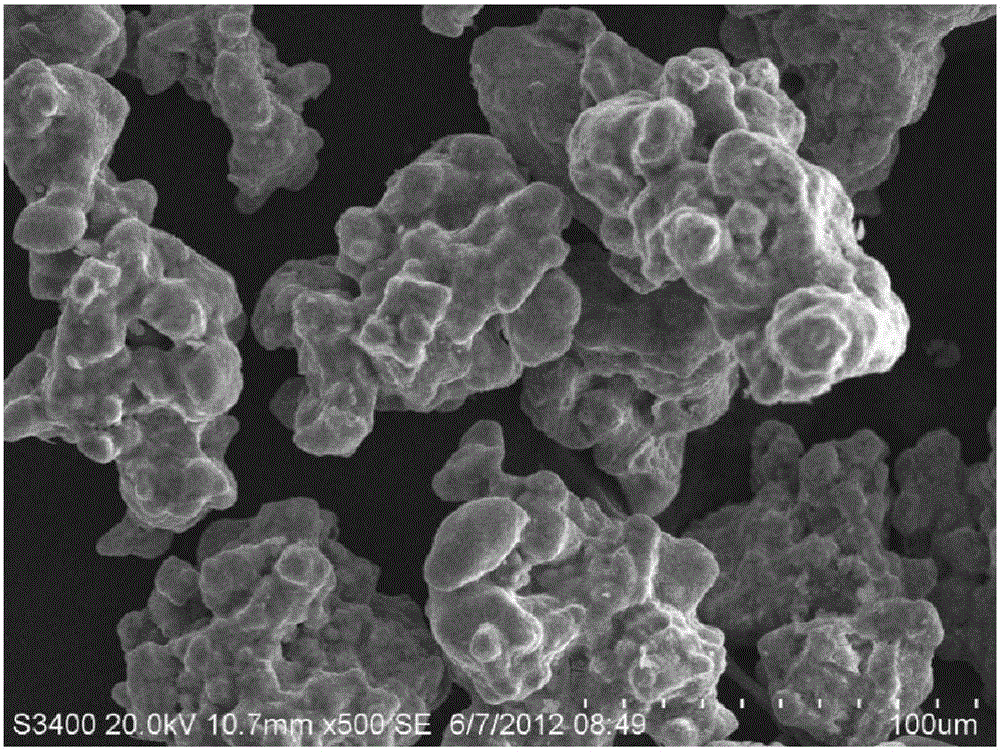

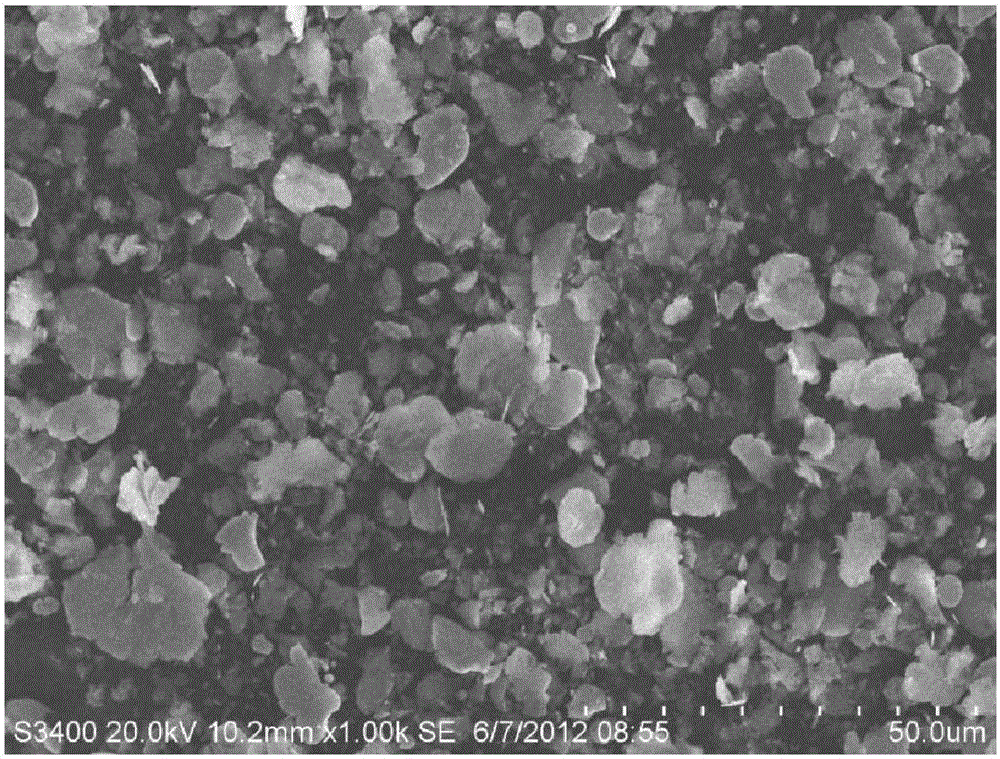

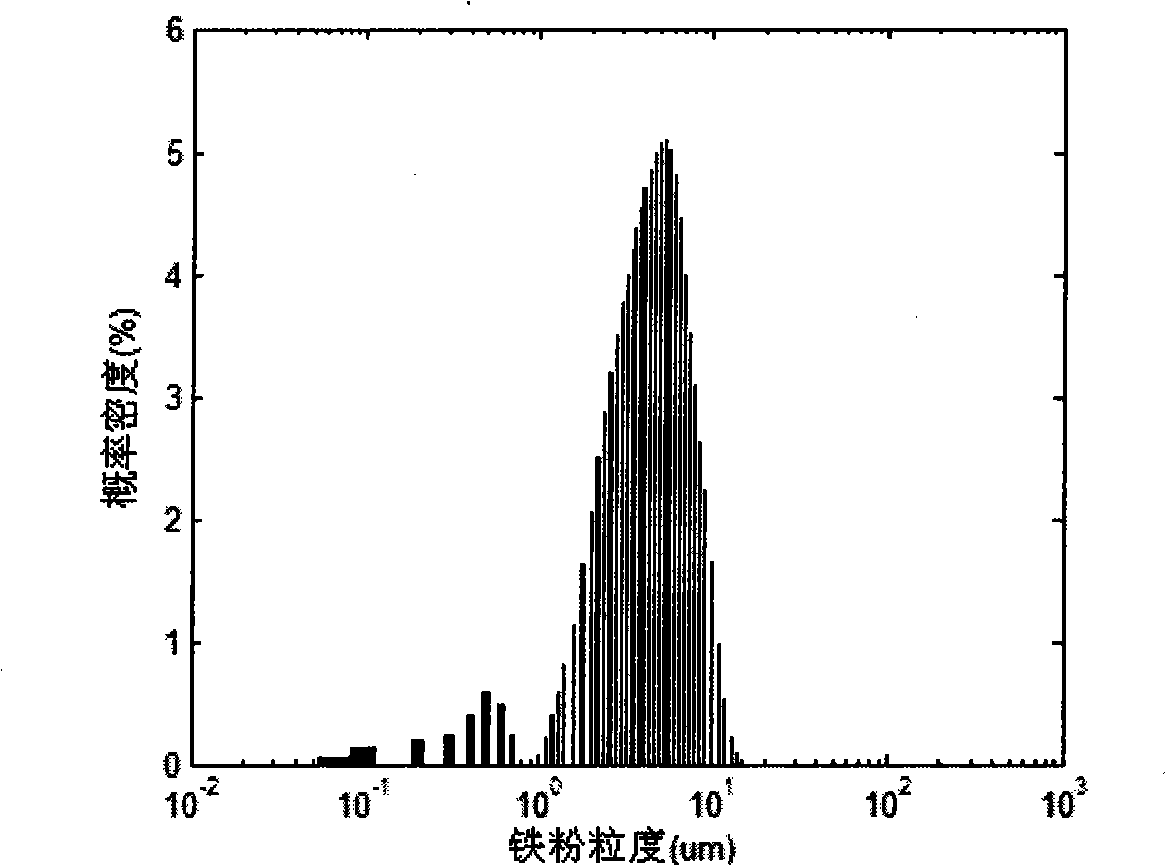

Preparation method of S-waveband wave absorbing material

ActiveCN105290421ASimple preparation processRaw materials are easy to getAnhydrous ethanolReflection loss

The invention aims at proving a preparation method of an S-waveband wave absorbing material. The method includes the following steps that carbonyl iron powder is preheated under argon gas protection; the preheated carbonyl iron powder, a coupling agent KH-560, anhydrous ethanol and stainless steel balls are placed in a ball milling tank and are subjected to ball milling in a horizontal planetary ball mill; and sizing agents where ball milling is performed are heated for 2-3 h at the temperature of 40-60 DEG C and then are dried, and then the S-waveband wave absorbing material can be prepared. The S-waveband wave absorbing material has good wave absorbing performance; the S waveband of the S-waveband wave absorbing material at the frequency of 2.2-2.8 GHz is calculated according to measured electromagnetic parameters of the wave absorbing material, and when the thickness is 2.5 mm or lower, reflection loss (RL) is smaller than -15 dB. Raw materials of the wave absorbing material are easy to obtain, the technology is simple, cost is low, and the wave absorbing material is suitable for large-scale production.

Owner:YANGZHOUSRKLE INDAL

Low viscosity stability non-water-base magnetic rheology polishing liquid and preparation method thereof

InactiveCN101260279ALow magnetic field viscositySuitable for recyclingMagnetic liquidsPolishing compositions with abrasivesWater basedCarrier fluid

Owner:NAT UNIV OF DEFENSE TECH

Wave-absorbing material, wave-absorbing substrate and manufacturing method

ActiveCN104341716AImprove heat resistanceHigh mechanical strengthLamination ancillary operationsOther chemical processesEpoxyPropanol

The invention discloses a wave-absorbing material with high wave-absorbing performance. The wave-absorbing material comprises the following components in parts by weight: 100 parts of epoxy resin, 23-26 parts of a curing agent, 200-400 parts of carbonyl iron powder and 40-100 parts of an organic solvent, wherein the curing agent is phenolic resin, anhydride resin, amine resin or a mixture thereof; and the organic solvent is acetone, butanone, propanol methyl ether or a mixture thereof. The invention further discloses a manufacturing method of a wave-absorbing material substrate.

Owner:KUANG CHI INST OF ADVANCED TECH

Rare earth high-magnetic-permeability soft magnetic ferrite and preparation method thereof

The present invention discloses a rare earth high-magnetic-permeability soft magnetic ferrite and a preparation method thereof, wherein the rare earth high-magnetic-permeability soft magnetic ferrite is prepared from the following raw materials by weight: 55-65 parts of ferroferric oxide, 1-13 parts of zinc oxide, 15-18 parts of manganese oxide, 4-8 parts of copper oxide, 0.4-0.6 part of lanthanum oxide, 0.2-0.6 part of tantalum pentoxide, 0.3-0.4 part of carbonyl iron powder, 6-10 parts of chlorinated polyethylene, 0.4-1 part of carbon powder, 1-2 parts of sodium lignin sulfonate, 6-9 parts of an organosilicon resin, and a proper amount of deionized water. The rare earth high-magnetic-permeability soft magnetic ferrite of the present invention has characteristics of high magnetic-permeability, low loss, easy operation, low environmental pollution, cost reducing, high qualification rate, and stable quality.

Owner:MAANSHAN KEXIN CONSULTING

Composite soft magnetic powder magnetic conducting material for slot wedge of electric machine and preparation thereof

InactiveCN1949406AHas a relative magnetic permeabilityImprove insulation performanceWindingsInorganic material magnetismHigh resistivityLoad loss

The invention relates to a dynamo using slot wedge using compound soft magnetic powder magnetic conductance material. The powder is the compound soft magnetic powder compounded from MnZn ferrite powder and reduced iron powder or carbonyl iron dust. The radio is 10-90wt% high resistivity magnetic powder, and 10-90wt% high magnetic permeability magnetic powder. Adding certain quantity glass fiber into compounded magnetic powder layer, separating structure would be formed. The invention could decrease supplementary load loss of dynamo, as well as eddy current loss, and improve efficiency of dynamo.

Owner:SICHUAN UNIV

Preparation method of high performance metal magnetic powder core for high frequency nonpolar lamp circuit

ActiveCN101127269AMagnetic permeability range adjustableHigh magnetic permeability and high stabilityInductances/transformers/magnets manufactureElectric discharge lampsOxygenOperating frequency

The utility model discloses a preparation method for a high performance magnetic powder core used for high frequency electrodeless lamp circuits, which is characterized in that first, the carbonyl iron dust with 0.4 to 0.5% carbon, 0.4 to 0.6% oxygen and 0.5 to 0.6% nitrogen, as well as a mean particle size of 1 to 8 micron, is dehumidified; second, the carbonyl iron dust is phosphatized by wet method; third, the carbonyl iron dust is compounded and covered by high temperature resistant silicone and is dried under vacuum and room temperature conditions to get finished carbonyl iron magnetic powder core; fourth, the carbonyl iron magnetic powder core is put into the mold and is processed by dry pressing, thus the high performance magnetic powder core used for high frequency electrodeless lamp circuit is acquired. The utility model has the advantages of adjustable range of magnetic permeability (Me:3 to 35), excellent factor of quality (Q value) under the circumstances that the working frequency is in the range of 100KHz to 100MHz, high stability of high direct current deflector field and low temperature rise magnetic permeability, and therefore is applicable to high frequency electrodeless lamps with the working frequency 2.65MHz.

Owner:JIANGXI YUEAN SUPERFINE METAL

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com