Water-based magneto-rheological polishing liquid for optical processing and preparation method thereof

A technology of magnetorheological polishing and optical processing, which is applied in the direction of polishing compositions containing abrasives, magnetic liquids, etc., can solve the problems of reduced shear stress, complex processes, and high prices, and achieves large shear yield stress and formulated The effect of simple process and high static stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

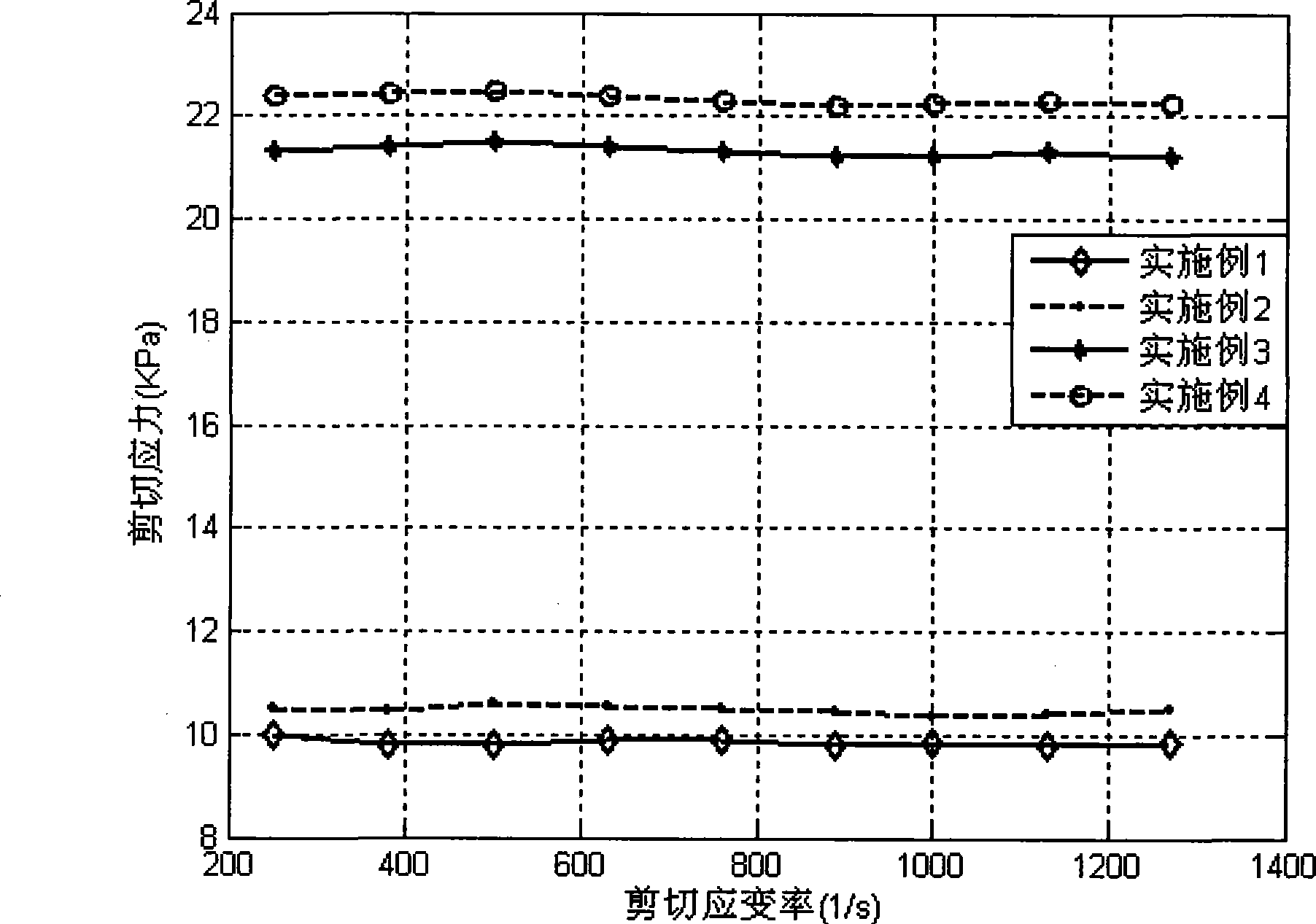

Embodiment 1

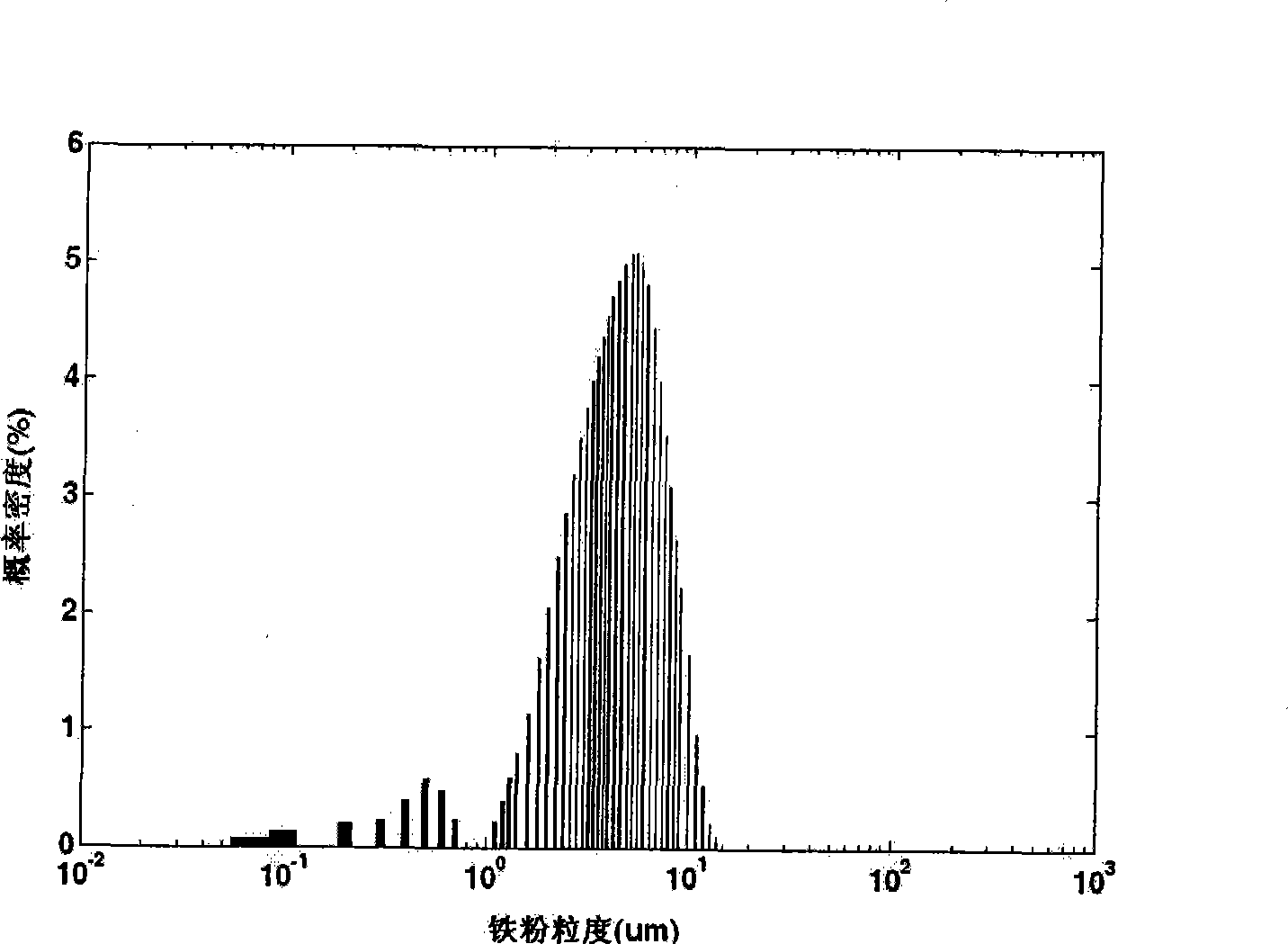

[0055] A water-based magnetorheological polishing fluid was prepared, and its added components were: 15ml of polishing powder cerium oxide with an average particle size of 0.5um, 130ml of carbonyl iron powder with an average particle size of 5μm, and 8ml of nano-iron powder with an average particle size of 50nm.

[0056] The water-based compound carrier liquid is: 240ml of deionized water, 10ml of organic bentonite as a thixotropic agent, 14ml of ethylenediaminetetramethylphosphate as a dispersant, 14ml of glycerol as a wetting agent, 0.5ml of sodium nitrite as an antioxidant, and Foam agent mineral oil 1ml and PH value regulator sodium carbonate 0.5ml.

[0057] The preparation steps are as follows:

[0058] Step 1. Add 10ml (3.57%) of thixotropic organobentonite to 240ml (85.71%) of deionized water, and stir at room temperature for 1 hour to obtain a suspension;

[0059] Step 2. Add 14ml (5%) dispersant ethylenediaminetetramethylphosphate into the suspension obtained in step...

Embodiment 2

[0066] A water-based magnetorheological polishing solution was prepared, and its additive components were: 12ml of polishing powder diamond micropowder with an average particle size of 0.5um, 130ml of carbonyl iron powder with an average particle size of 5μm, and 6ml of nano-iron powder with an average particle size of 50nm.

[0067] The water-based compound carrier liquid is: 240ml of deionized water, 10ml of organic bentonite as a thixotropic agent, 14ml of ethylenediaminetetraacetate as a dispersant, 14ml of glycerol as a wetting agent, 0.5ml of sodium nitrite as an antioxidant, and 0.5ml of defoaming agent Agent mineral oil 1ml and PH value regulator borax 0.5ml.

[0068] The preparation steps are as follows:

[0069] Step 1. Add 10ml (3.57%) of thixotropic organobentonite to 240ml (85.71%) of deionized water, and stir at room temperature for 1 hour to obtain a suspension;

[0070] Step 2. Add 14ml (5%) dispersant ethylenediamine tetraacetate to the suspension obtained in...

Embodiment 3

[0077] The water-based magnetorheological polishing fluid was prepared, and its added components were: 33ml of polishing powder cerium oxide with an average particle size of 0.5um, 570ml of carbonyl iron powder with an average particle size of 5μm, and 67ml of nano-iron powder with an average particle size of 50nm.

[0078] Its water-based compound carrier liquid is: 240ml of deionized water, 10ml of thixotropic agent sodium carboxymethyl cellulose, 14ml of dispersant ethylenediamine tetramethyl phosphate, 14ml of wetting agent glycerin, and antioxidant sodium nitrite 0.5ml, defoamer mineral oil 1ml and PH value regulator sodium carbonate 0.5ml.

[0079] The preparation steps are as follows:

[0080] Step 1. Add 10ml (3.57%) of the thixotropic agent sodium carboxymethylcellulose into 240ml (85.71%) of deionized water, and stir at room temperature for 1 hour to obtain a suspension;

[0081] Step 2. Add 14ml (5%) dispersant ethylenediaminetetramethylphosphate into the suspensio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com