Patents

Literature

181results about How to "Suitable for recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for high-efficiency recovery of waste circuit boards in vacuum

InactiveCN101444784ANo secondary pollutionSuitable for recyclingSolid waste disposalElectronic waste recyclingEngineeringPrinted circuit board

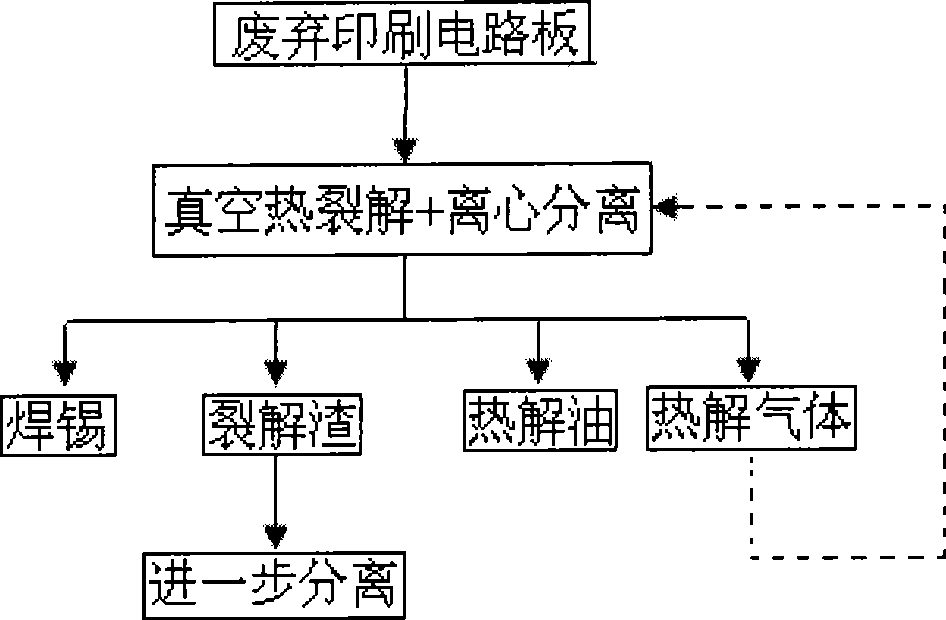

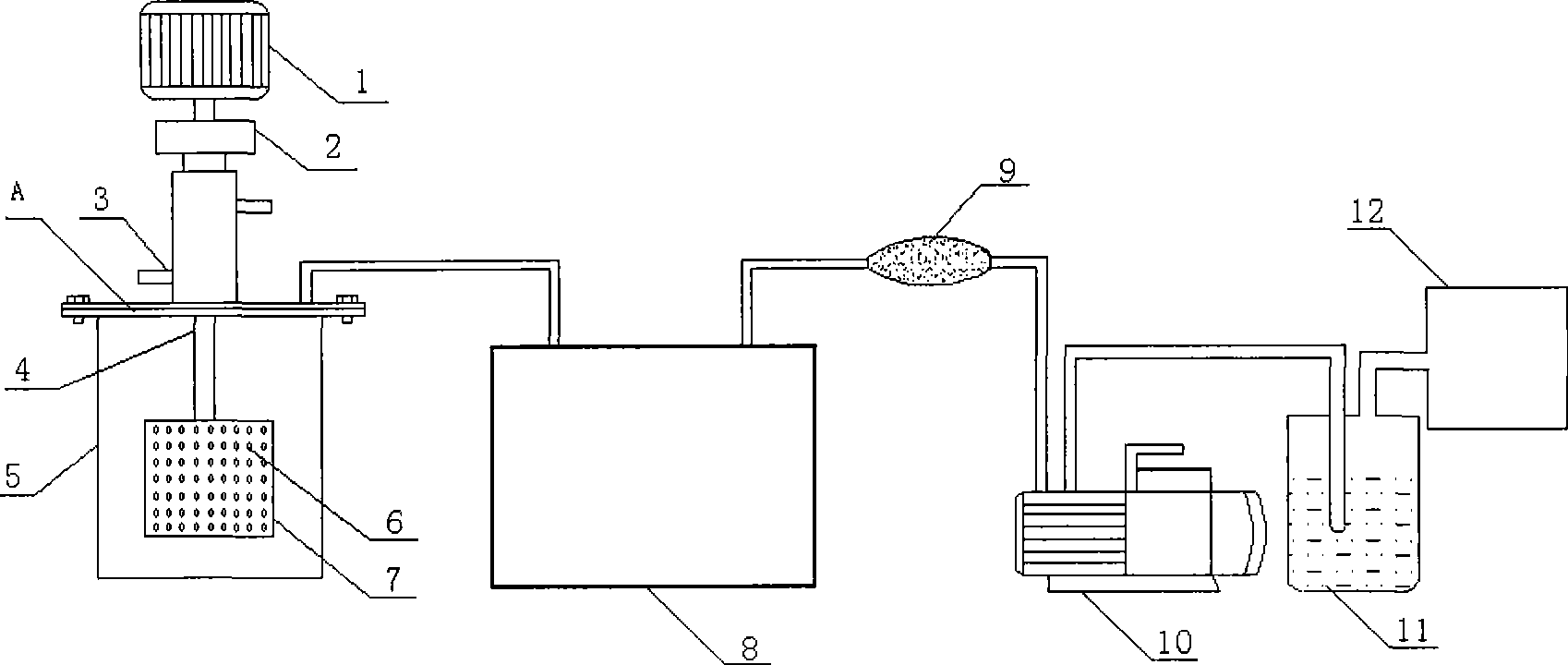

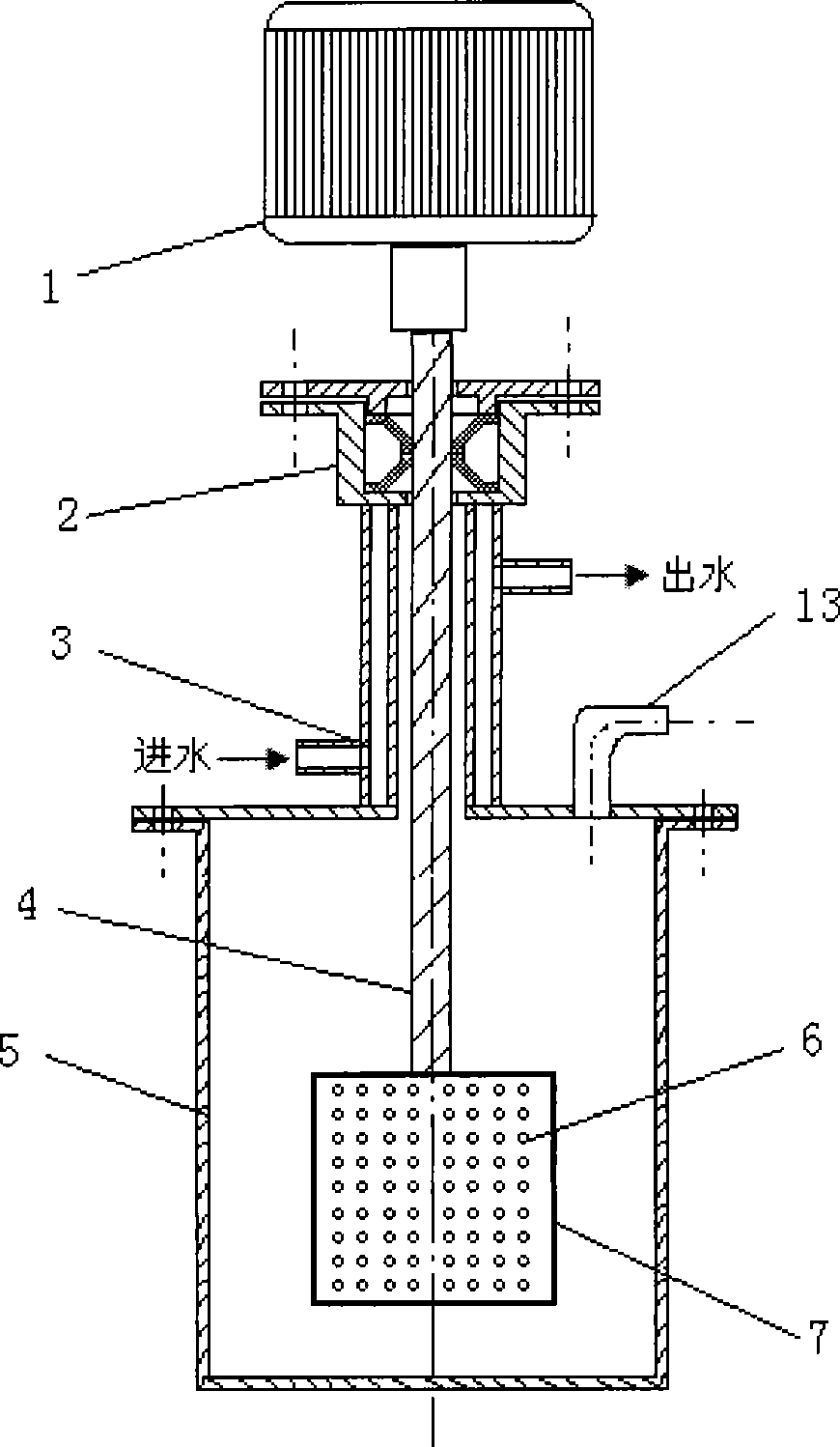

The invention discloses a method and a device for high-efficiency recovery of waste circuit boards in vacuum. The method comprises the following steps: the waste circuit board is arranged in a vacuum vessel and heated for pyrolysis, wherein, most of pyrolysis volatile matter is cooled and liquefied into liquid oil, and the rest is taken into a gas collector; a centrifuge device separates soldering tin from the circuit board during the pyrolysis; substrates and electronic components of the pyrolyzed circuit board are assorted and collected to be further separated and recovered. The device comprises a compound vacuum pyrolysis and centrifuge device, a cold trap, the gas collector and a vacuum pump. The vacuum vessel of the compound vacuum pyrolysis and centrifuge device is sequentially connected with the cold trap, the vacuum pump and the gas collector by pipelines. The device has the advantages of simple process, no pollution, low cost, high efficiency, and high recovery ratio of waste resources of the waste circuit boards. The soldering tin and organic substances of the waste circuit boards are synchronously recovered, and the soldering tin is separated from other metals at a high efficiency, thus creating a good condition for high-efficiency recovery of other metals. The method and the device are suitable for industrialized application and can help achieve large-scale recovery of the waste circuit boards.

Owner:CENT SOUTH UNIV

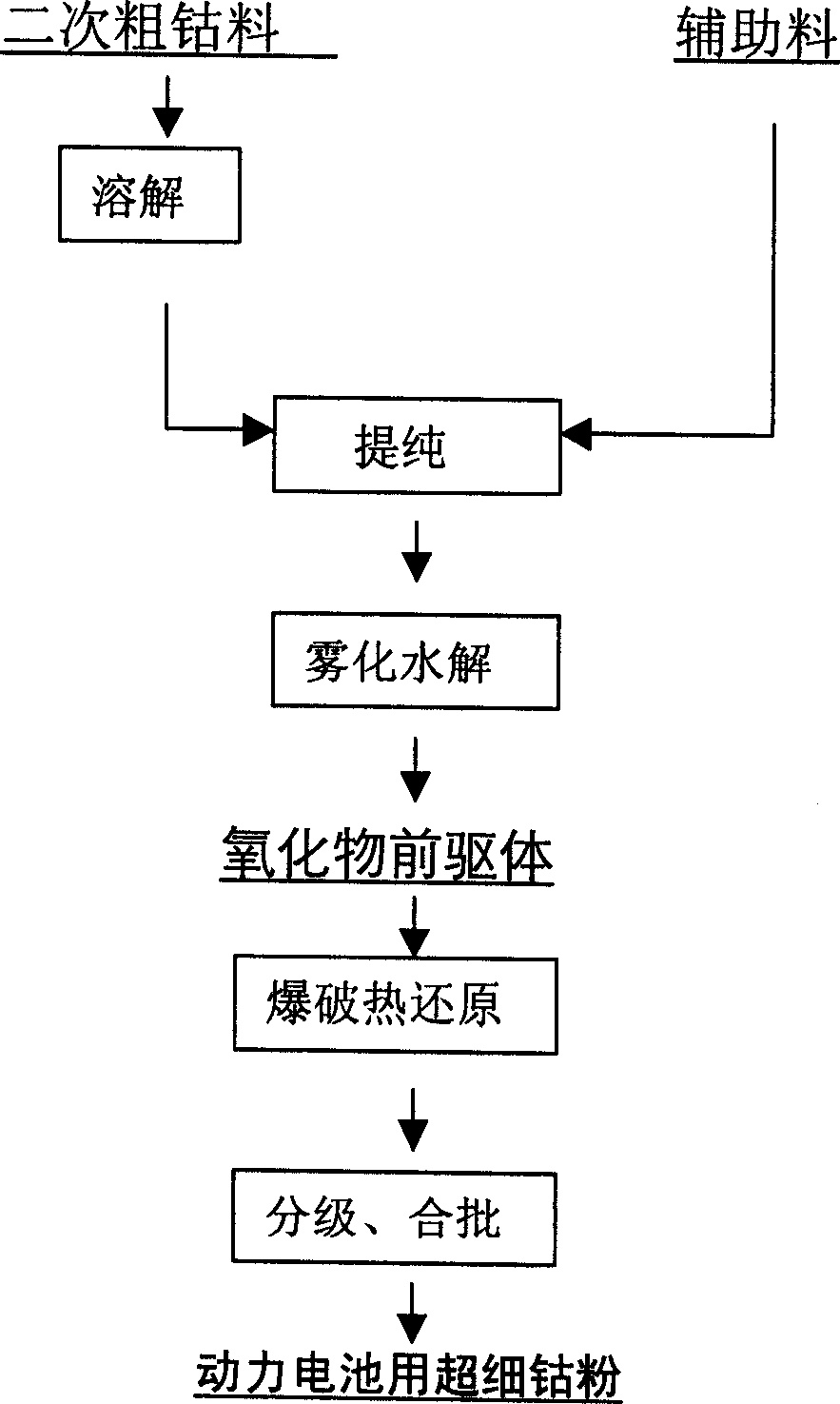

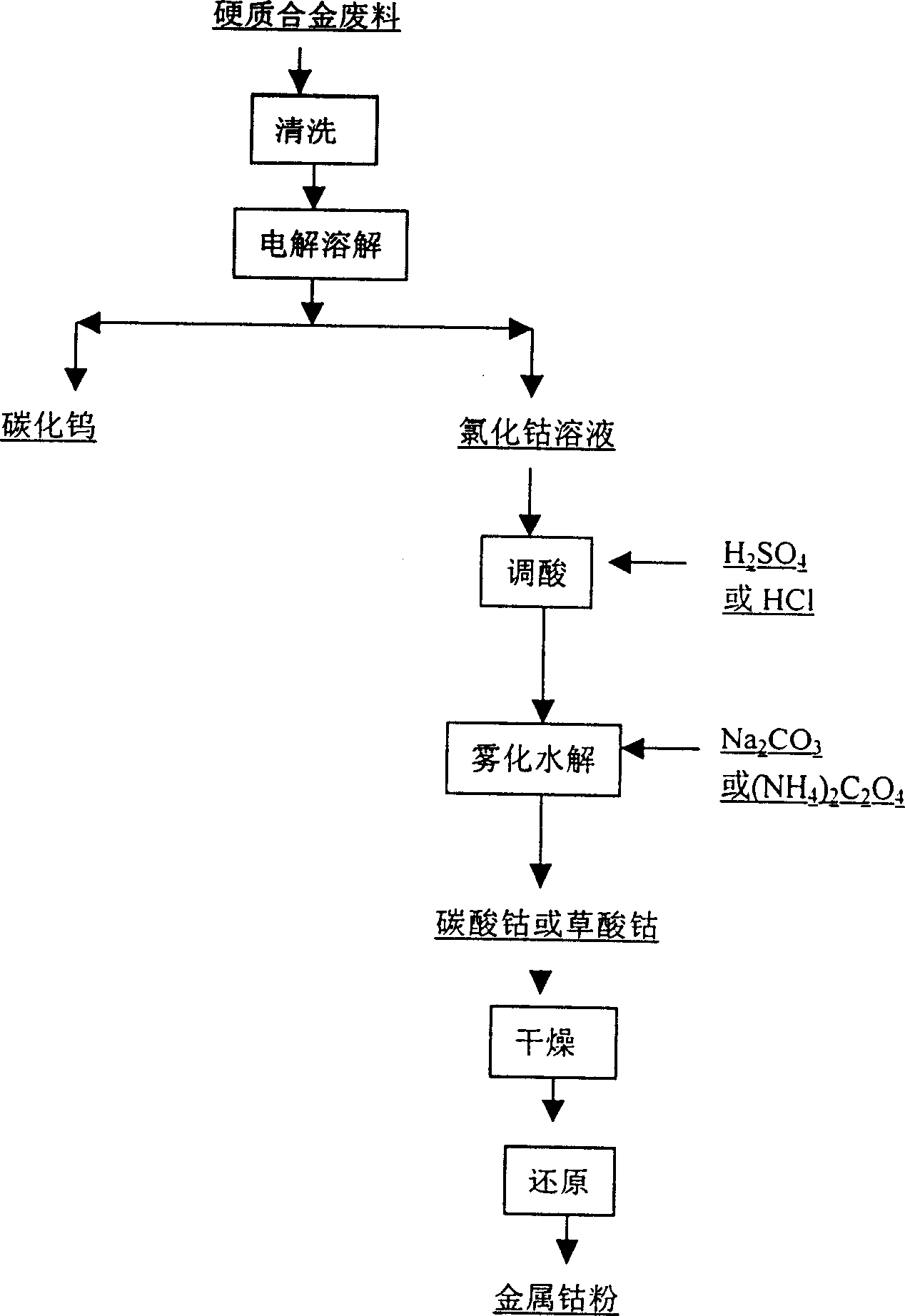

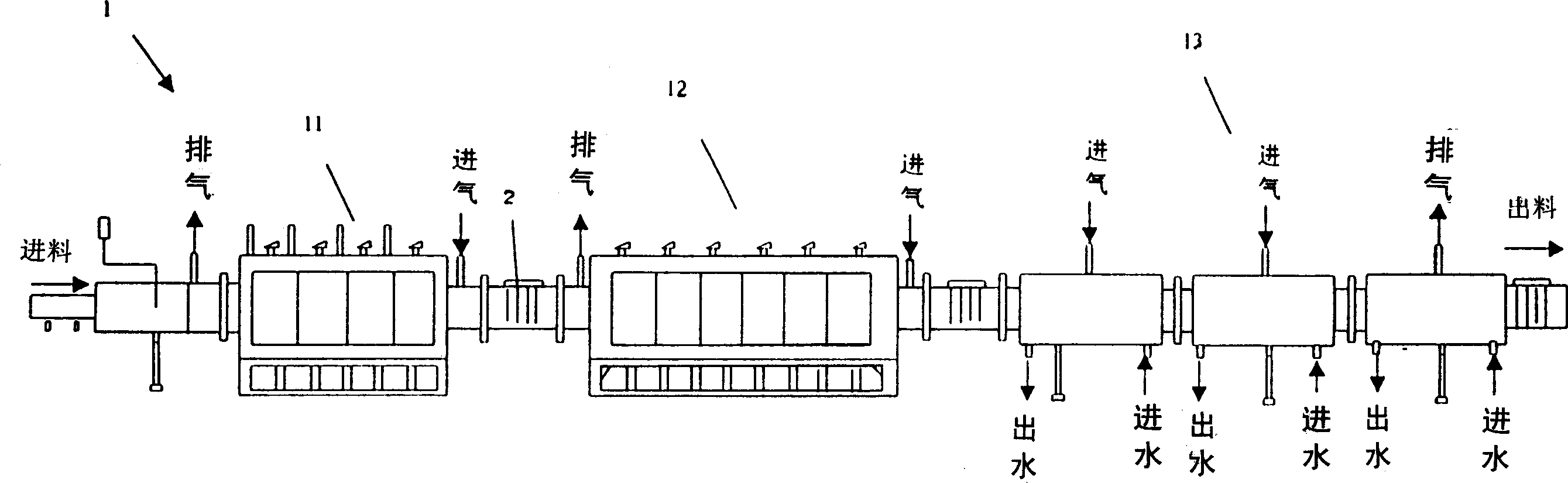

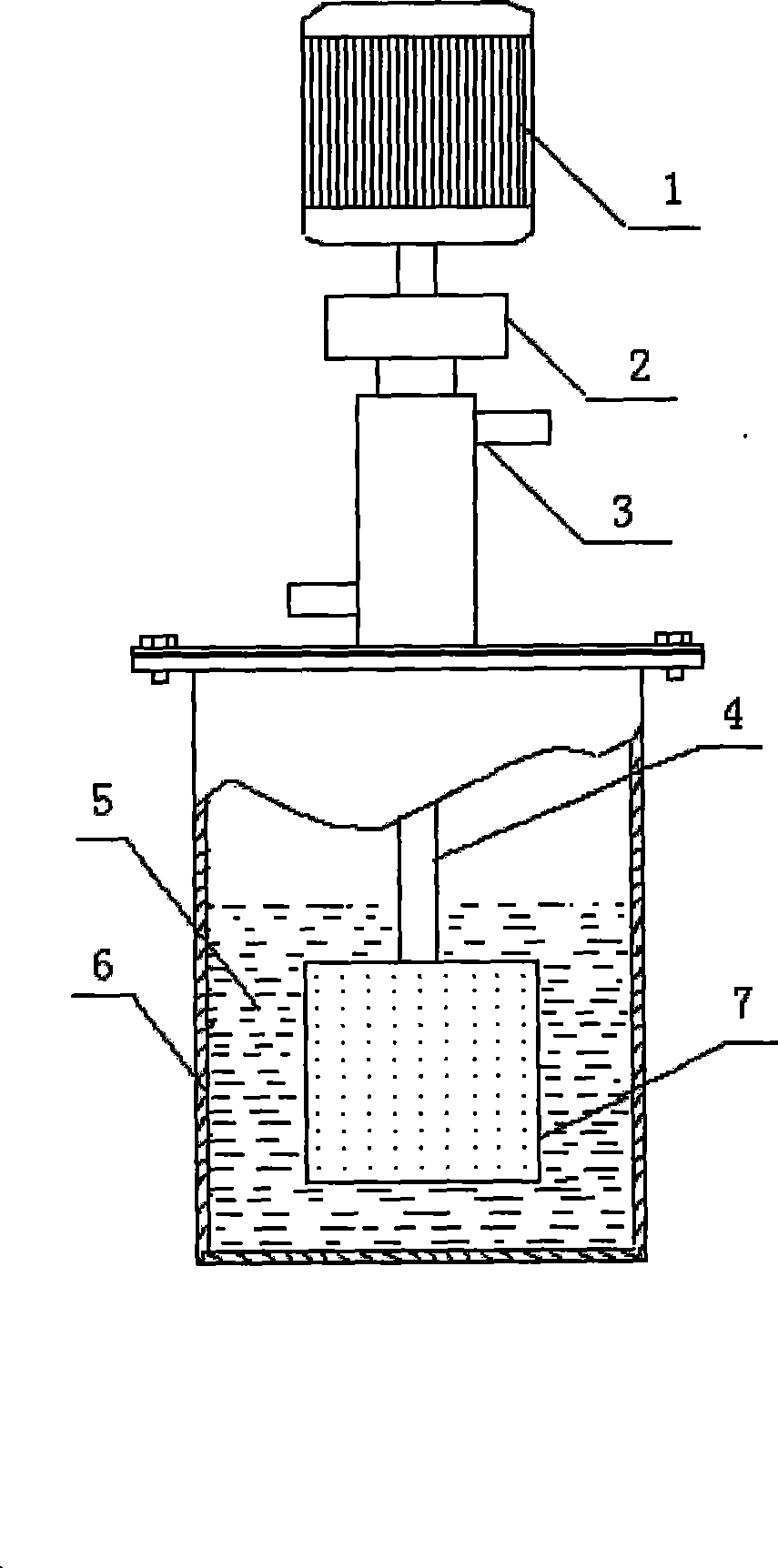

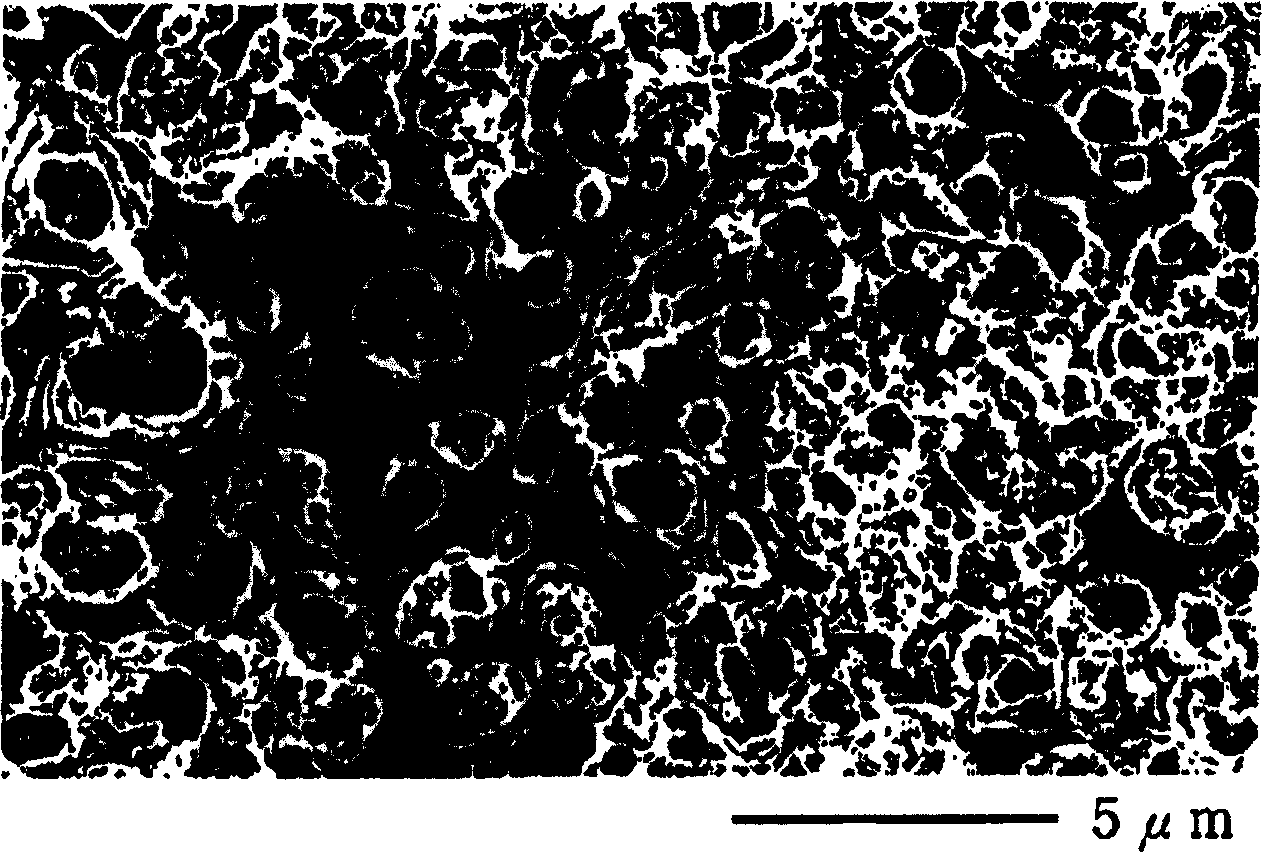

Production and producing apparatus for super fine cobalt powder by circulating technology

A process for preparing superfine spherical or fibrous Co particles from used battery by the circulation technique includes such steps as extracting twice for purifying, atomizing, hydrolyzing, depositing to obtain the Co compound precursor, and exploding for thermal reduction at multiple temp segments to obtain the superfine Co particles (0.1-0.2 microns) used for power battery and powder metallurgy. Its apparatus is also disclosed.

Owner:JINGMEN GEM NEW MATERIAL

Technique and device for effectively recovering waste printed circuit boards solder

InactiveCN101362143ARealize separation and recoveryNo secondary pollutionSolid waste disposalSoldering apparatusHeat conductingIngot

The invention relates to a technology for high-efficiently recycling soldering tin of discarded printed circuit boards, and a device. In a sealed system, in which liquid heat conducting medium exists, discarded printed circuit boards to be processed and welded with electronic parts are put in a swivel which is provided with a plurality of filtering holes and immersed in the heat conducting medium, the temperature is risen until the soldering tin is melted, after the temperature is constant, the swivel is rotated to centrifugally separate solid and liquid, the soldering tin leaks from the filtering holes, deposits at the bottom and is cooled into ingot, and the electronic parts are separated from the discarded printed circuit boards correspondingly. The method for recycling the soldering tin of discarded printed circuit boards has no environmental pollution, low energy consumption and high efficiency, and can create good condition for high-efficiently recycling other metals.

Owner:CENT SOUTH UNIV

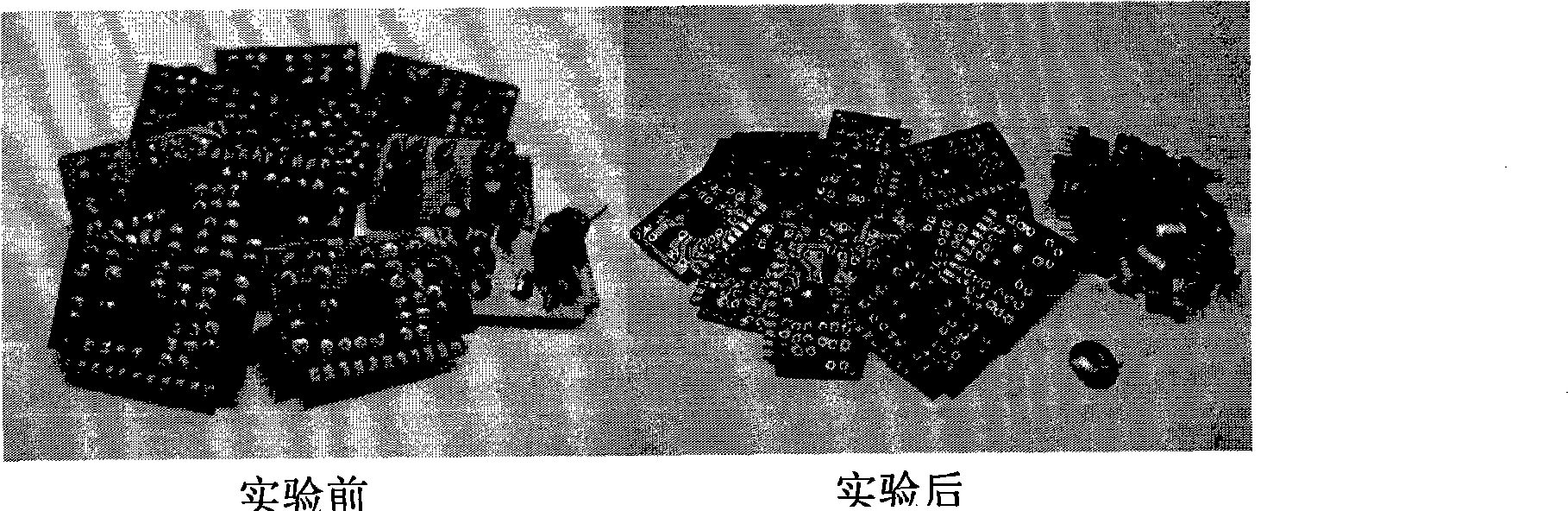

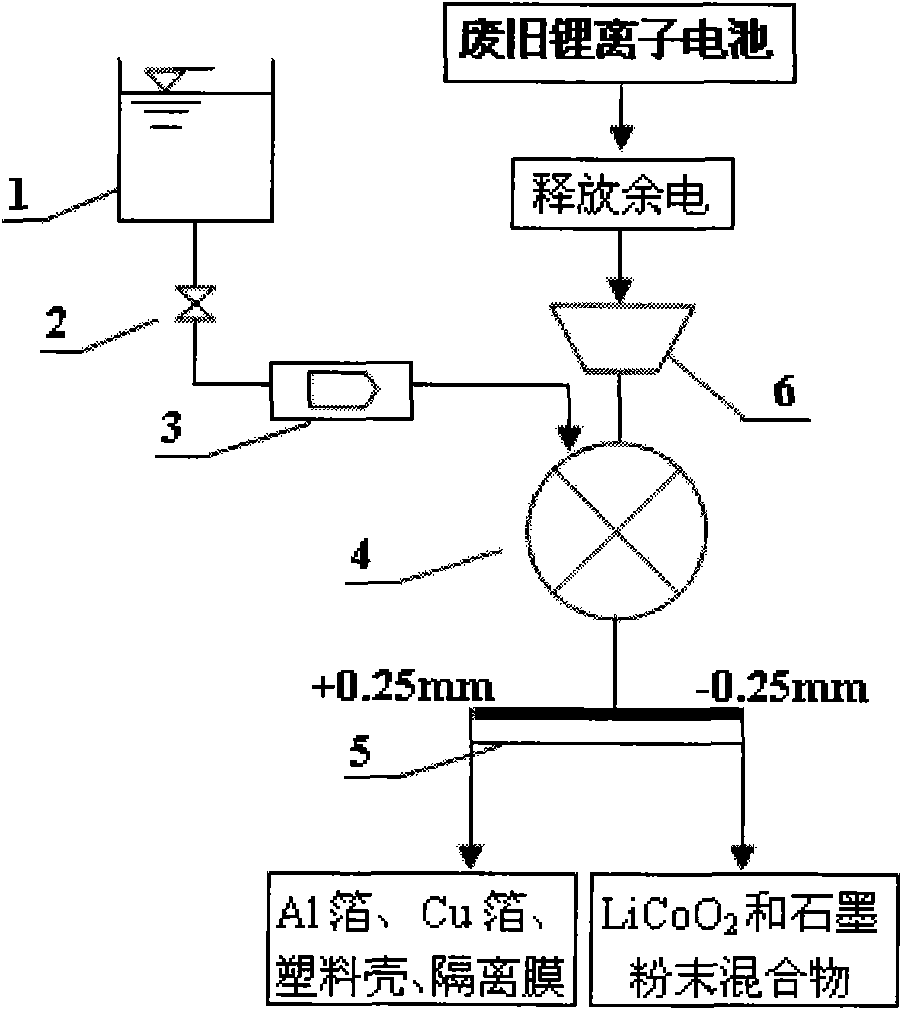

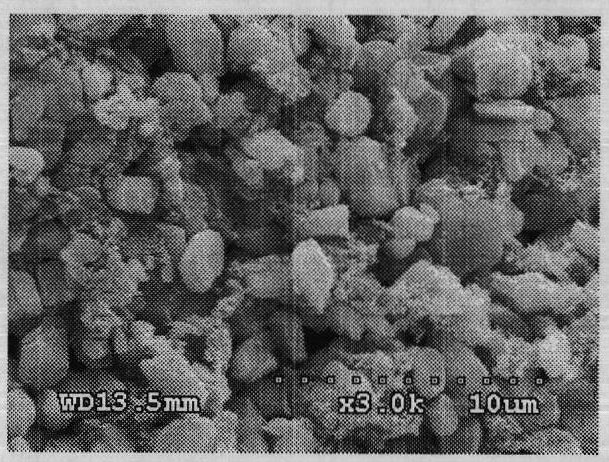

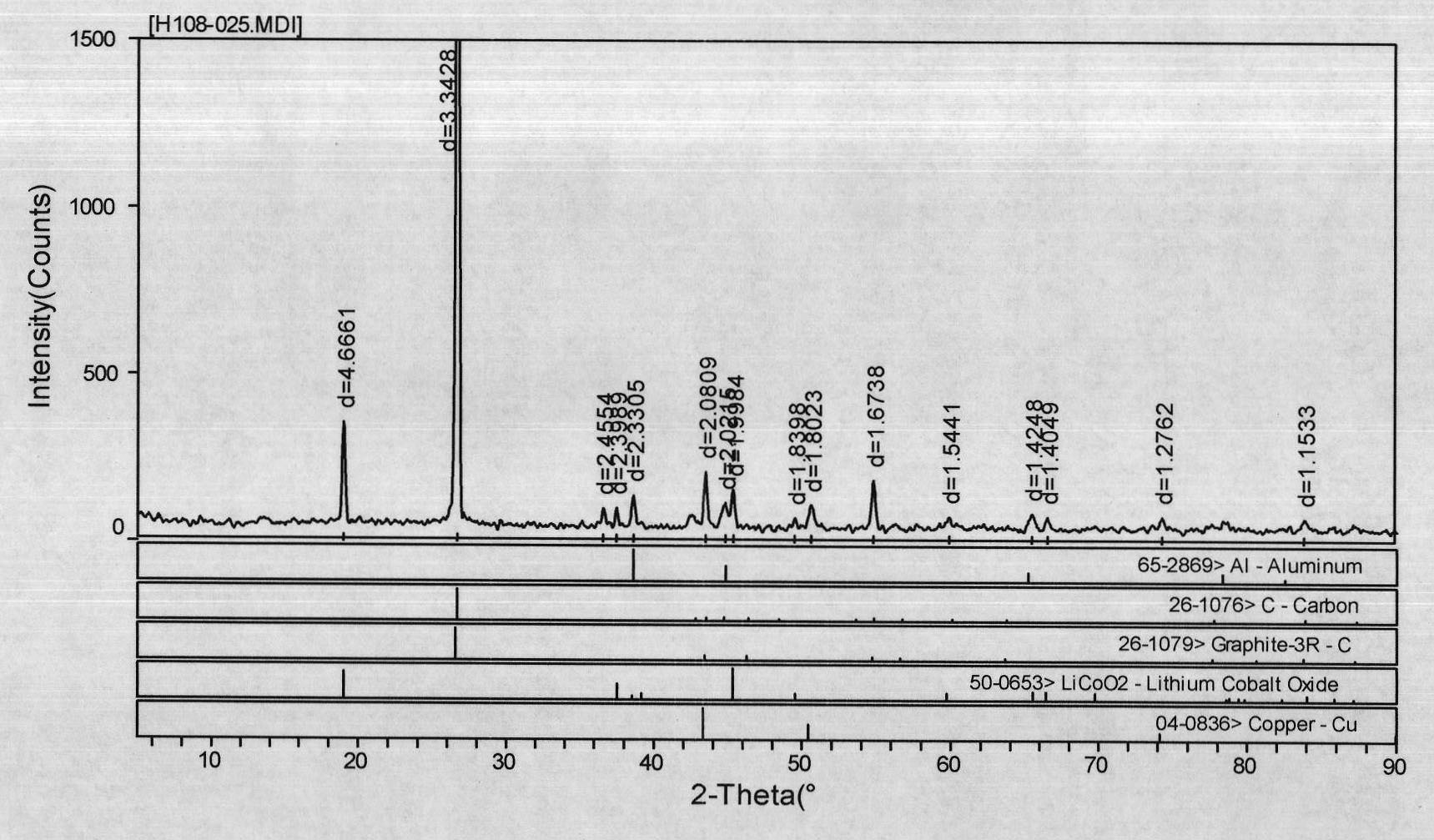

Novel process for efficiently crushing waste lithium ion battery

InactiveCN102009054AEfficient crushingGuaranteed efficient selectivitySolid waste disposalGrain treatmentsElectricitySlurry

The invention discloses a novel process for efficiently crushing a waste lithium ion battery. The process consists of residual electricity discharging, wet crushing and screening, wherein the residual electricity charging is to soak the waste lithium ion battery to be treated by using a 5 percent NaCl solution for 2 hours; the wet crushing is to crush the waste lithium ion battery subjected to the residual electricity charging in a blade impact crusher with water; and the screening is to screen the crushed slurry on a vibrating screen and settle materials enriched below a screen; the sediment is used for subsequent lithium cobaltate purification treatment; and materials on the screen can be treated in a classified mode. In the novel process, the waste lithium ion battery can be crushed efficiently and selectively, crushing time is short and crushing effect is good, and all materials such as lithium cobaltate, carbon materials and the like can be enriched below -0.25mm, so that an excellent raw material is provided for the subsequent treatment such as the lithium cobaltate recovery and the like and the recovery cost of the lithium cobaltate is greatly reduced. The novel process is suitable for the recovery treatment of the waste lithium ion battery.

Owner:EAST CHINA JIAOTONG UNIVERSITY

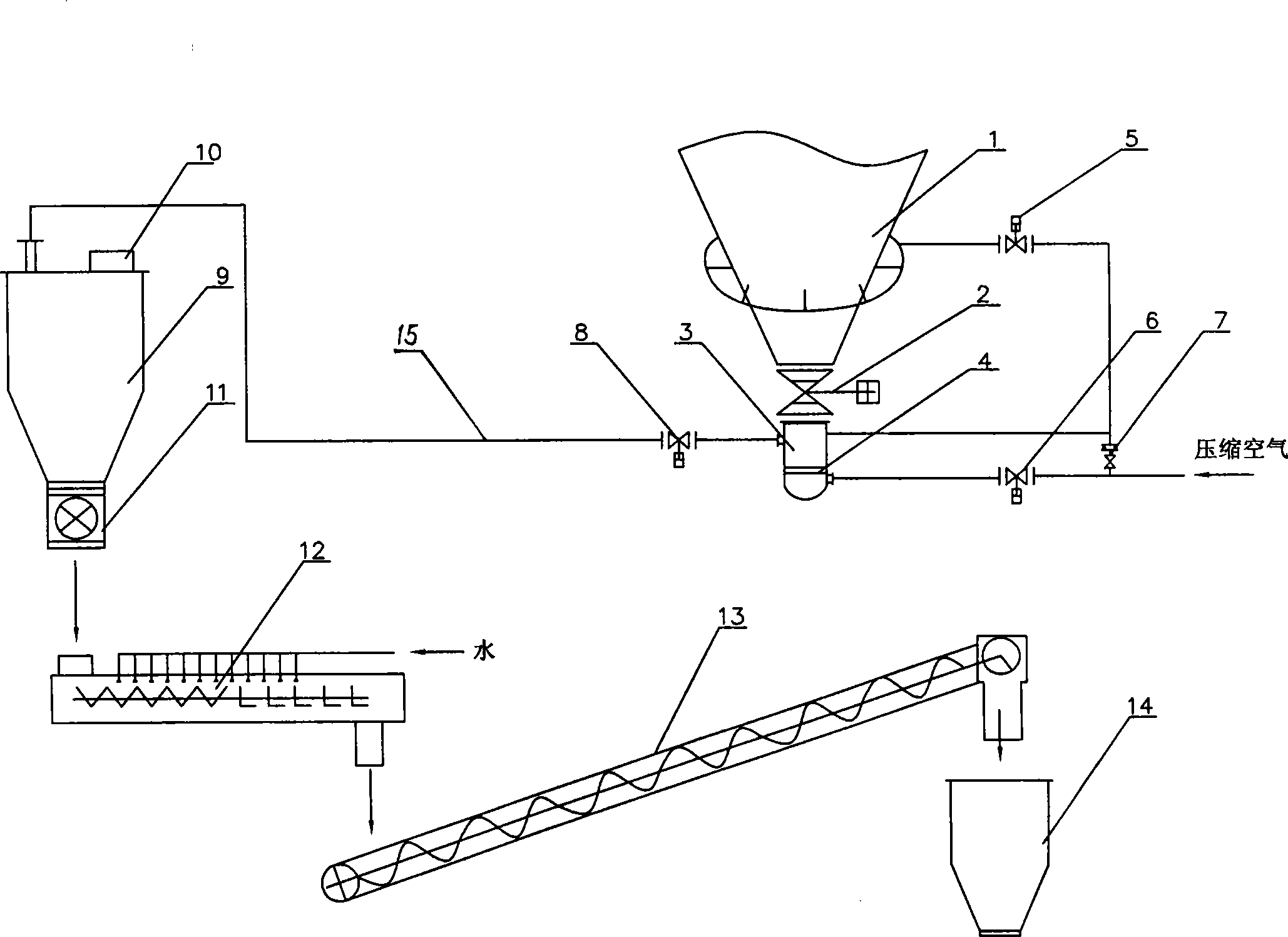

Dedusting dry powder recycling process

InactiveCN101224363ASimplify the recycling processNo spreading problemHuman health protectionDispersed particle filtrationDusting powdersMaterial scattering

The invention relates to a dust-removal dry powder recycling process. The process procedure consists of dust-removal ash hoppers, dust powder transferring devices, exhaust collecting cavities, wet ball machines and sealed transferring devices of each dust removal points of smelters or ironworks. The process includes three steps: dusts removing-transferring, dusts collecting and wet ball transferring, i.e. a set of dust powder air-transferring device is arranged below the dust-removal ash hopper of the dust catcher; compressed air is adopted for transferring the dust through a sealed transferring device into the dust collecting cavity far away, and then a ration feeding machine is adopted for transferring the dust to the wet ball machine; after wetting and balling by the wet ball machine, the finished small balls are finally transferred to a storing bin through a sealed transferring device as recycled materials for application. The invention adopts the novel dust disposal process of dust-removal dry powders to simplify the process procedure; a sealed state is guaranteed before wetting and balling and during the transferring process so as to avoid dust rising and material scattering; the recycling treatment is simple, thus saving investigation and manpower, and being environment-protective.

Owner:BAOSTEEL ENG & TECH GRP

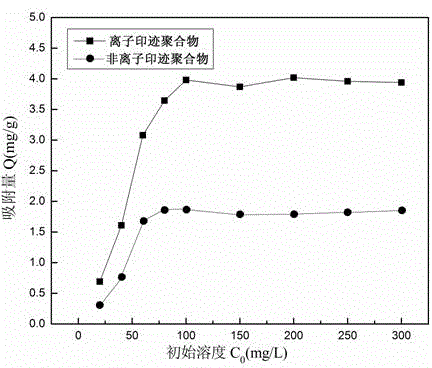

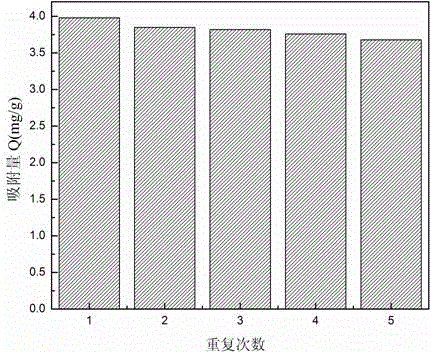

Method for preparing magnetic lithium ionic imprinting microspheres by using surface polymerization method implemented by taking macrocyclic polyethers as functional monomer

ActiveCN103601862AStrong adsorption specificityEasy to prepareOther chemical processesLithiumFunctional monomer

The invention discloses a method for preparing magnetic lithium ionic imprinting microspheres by using a surface polymerization method implemented by taking macrocyclic polyethers as a functional monomer, which comprises the following steps: (1) by taking FeCl3 and FeCl2 as raw materials, preparing magnetic nano Fe3O4 particles by using a microwave coprecipitation method; (2) enabling Fe3O4 to react with tetraethoxysilane and 3-(trimethoxysilyl) allyl trimethyl, so that MH-Fe3O4 @ SiO2 is obtained; (3) by taking a macrocyclic polyether compound with hydroxyl functional groups as raw materials, enabling the MH-Fe3O4 @ SiO2 and bromopropylene to have a nucleophilic substitution reaction; (4) by taking lithium ions as a template, carrying out imprinted polymerization on the surface of the MH-Fe3O4 @ SiO2 so as to obtain a polymer; and (5) carrying out eluting and vacuum drying on the polymer so as to obtain a lithium ionic imprinting polymer. The novel lithium ionic imprinting polymer synthesized according to the invention has the characteristics of simple preparation, large adsorption capacity, high selectivity and good regenerability.

Owner:SHANGRAO DINGXIN METAL CHEM

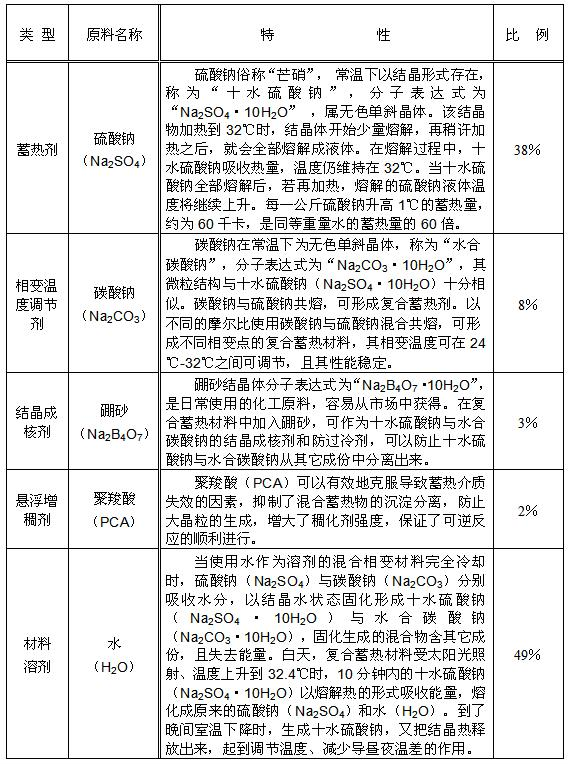

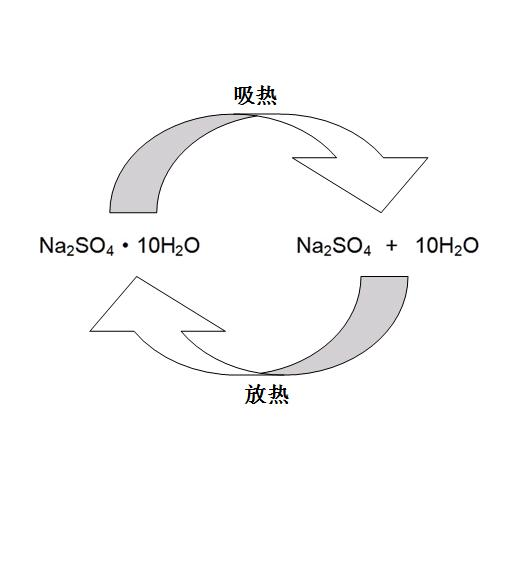

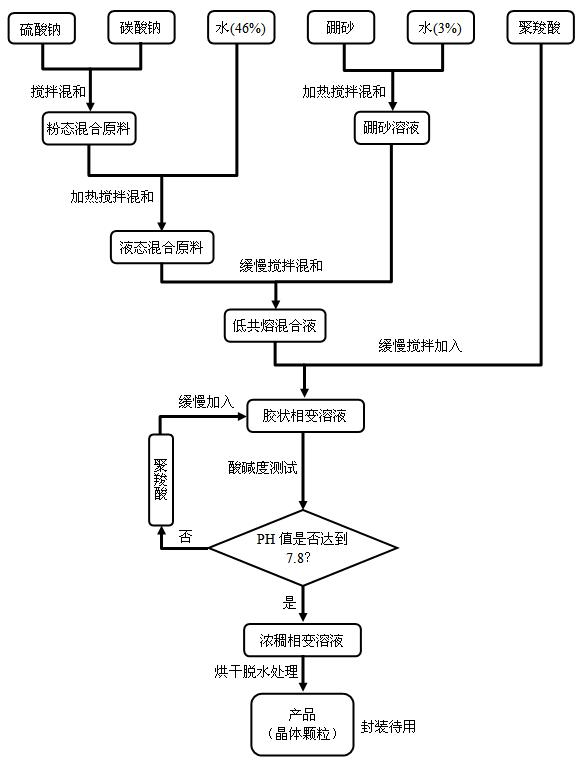

Composite phase-change heat storage material

InactiveCN102585774AHigh heat of solutionHigh heat storage densityRoof covering using slabs/sheetsRoof covering using tiles/slatesSolventPhase change temperature

The invention relates to a phase-change heat storage material, in particular to a composite phase-change heat storage material with sodium sulfate decahydrate as a main body. The composite phase-change heat storage material disclosed by the invention overcomes the defects of small heat capacity, low thermal conductivity, poor stability and the like of the traditional well-know phase-change material; a brand-new composite phase-change heat storage material is formed by co-melting sodium sulfate, sodium carbonate, sodium borate, polycarboxylic acid, water used as a heat storage agent of the material, a temperature regulator, a crystallization nucleating agent, a suspension thickener and a raw material solvent; the composite phase-change heat storage material has the advantages of high heat capacity, proper phase-change temperature, high thermal conductivity, difficulty in generation of super-cooling phenomenon and the like; the heat storage material not only is suitable for daily heating requirements of organizations, enterprises, troops, families and the like, but also is applicable to special occasions such as high altitude, polar regions, oceans, desert, highland and mountainous areas with large temperature difference between day and night; in addition, the composite phase-change heat storage material disclosed by the invention has the characteristics of simple implementation, simple and easy manufacturing, durability, broad market prospect, and higher economic added value and social application value.

Owner:郑小玲

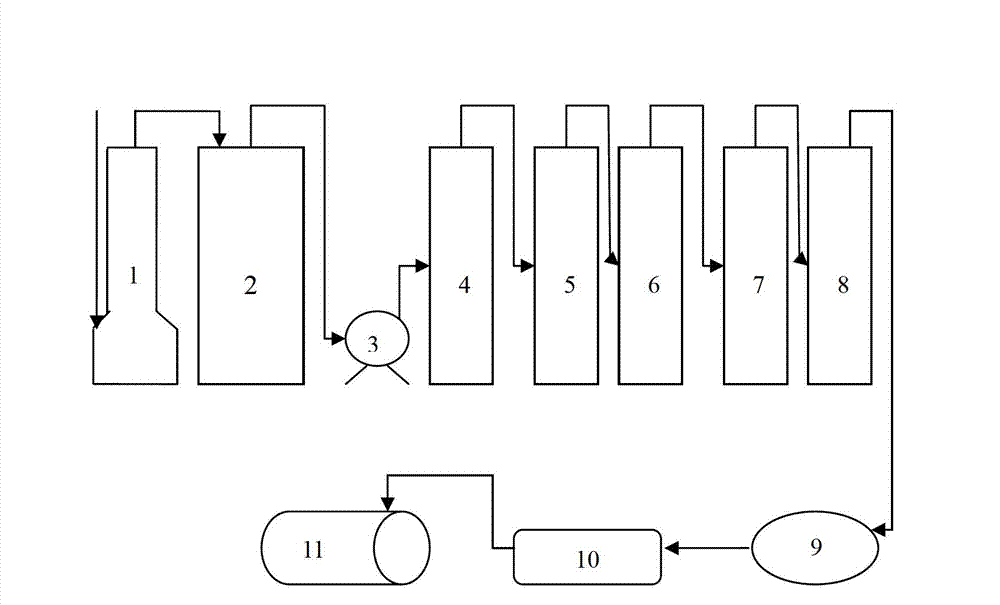

Method for recovering chloromethane from chloromethane-containing waste gas in maltol production

ActiveCN103044185AEffective recyclingReduce air pollutionHalogenated hydrocarbon separation/purificationSolventChemistry

The invention discloses a method for recovering chloromethane from chloromethane-containing waste gas in the maltol production and relates to the method for recovering chloromethane, and the method can be used for obtaining finished high-purity chloromethane and is simpler in process route and easy to realize. The method comprises the steps as follows: allowing the waste gas generated in the process of recovering a methanol solvent after chlorination reaction to pass through a hydrolysis kettle, and introducing the waste gas into an alkaline washing tower through a pipeline for alkaline washing; collecting the waste gas subjected to primary alkaline washing by a buffer tank; introducing the waste gas in the buffer tank into a water washing tower for water washing through a roots machine, and removing water-soluble substances; carrying out two-stage acid washing on the waste gas subjected to water washing; carrying out two-stage alkaline washing on the waste gas subjected to two-stage acid washing; and drying the waste gas subjected to two-stage alkaline washing, compressing by a compressor, cooling into a liquid phase by a condenser, and feeding into a finished product storage tank.

Owner:XIAMEN OMIC BIOTECH CO LTD

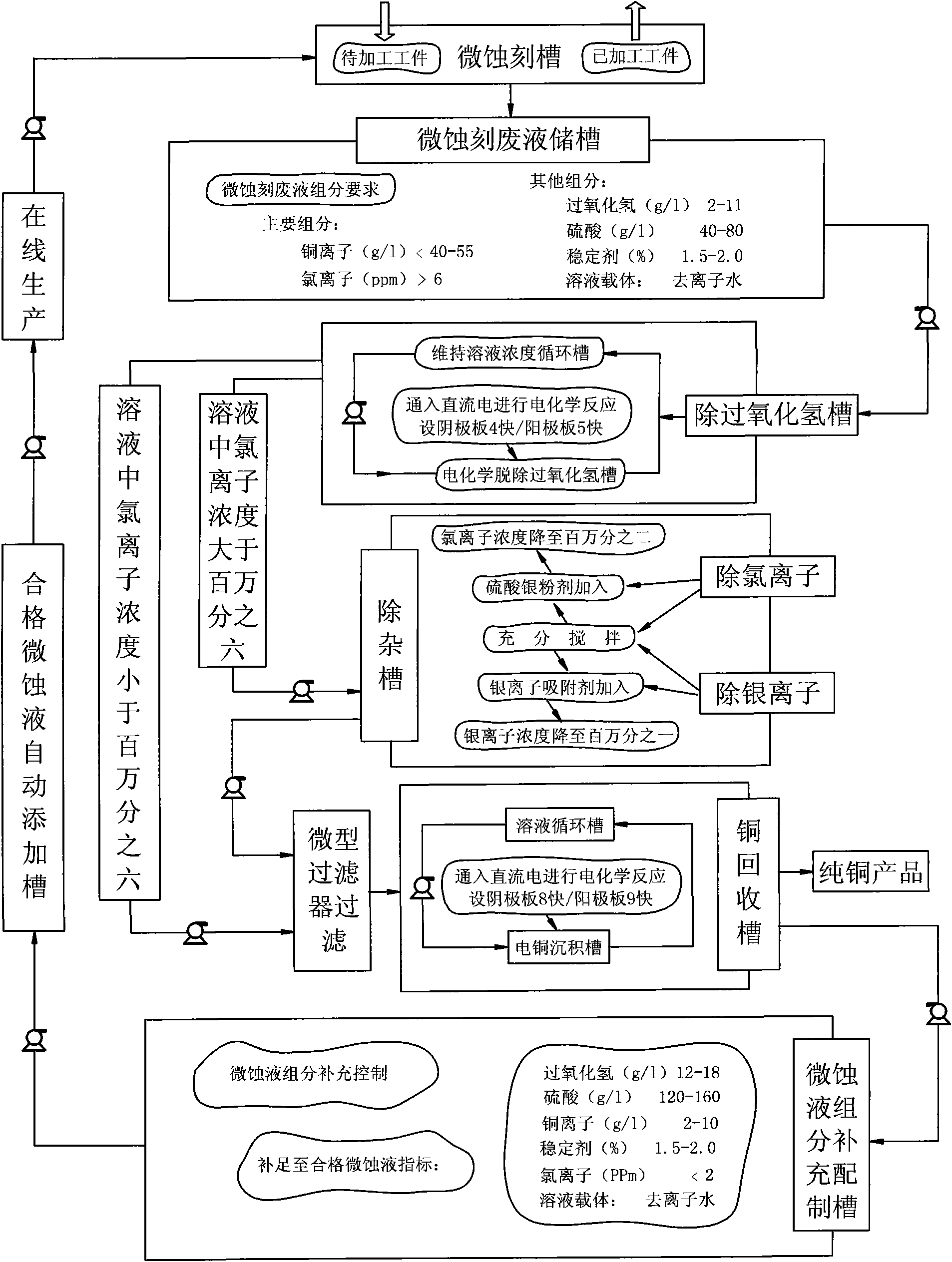

Technology for regenerating and cycling circuit board microetching waste liquid

InactiveCN101608337ASimple processEasy to implementElectrolysis componentsLiquid wasteChemical reaction

The invention relates to a technology for regenerating and cycling circuit board microetching waste liquid, which comprises procedures as follows: peroxide microetching waste liquid generated in the microetching chemical reaction process of processing an online produced workpiece to be processed of a circuit board into a processed workpiece in a microetching bath is taken as the raw material, peroxide, chloridion and silver ions are removed from the raw material, the raw materials recovers pure copper and complements lost components to become a regenerated microetching liquid, and the qualified microetching liquid automatically returns to the circuit board online producing microetching bath for regeneration and cycling. The invention adopts the technical scheme that peroxide microetching waste liquid discharged from online production is used as the raw material, peroxide, chloridion and silver ions are removed from the raw material, the raw material recovers pure copper and complements lost components to become a regenerated qualified microetching liquid, and the qualified microetching liquid automatically returns to the microetching bath and overcomes the defects that the microetching liquid in the circuit board microetching technology adopted by the prior PCB enterprises is discharged just after being treated simply, a great amount of waste is caused during the processing, and resources are lost severely, thereby being suitable for regenerating and cycling of various circuit board microetching waste liquid of circuit board online production enterprises.

Owner:深圳市惠尔能科技有限公司

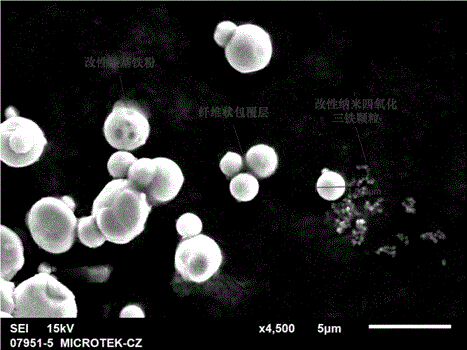

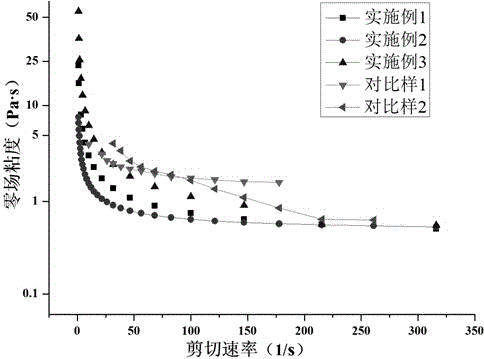

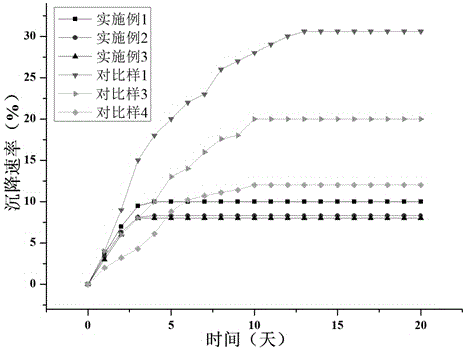

Mineral oil based magnetorheological fluid for high power transmission and preparation method thereof

The invention discloses mineral oil based magnetorheological fluid for high power transmission. The mineral oil based magnetorheological fluid comprises the following components by mass percent: 60-80% of magnetic particles, 15-40% of carrier liquid and 2-5% of additives, wherein the magnetic particles are carbonyl iron powder particles and nano ferriferrous oxide particles; the carrier liquid is mineral oil; the additives comprise a surface active agent, a thixotropic agent, an antioxidant and an antiwear agent, meanwhile, the invention further provides a preparation method of the magnetorheological fluid, and the prepared magnetorheological fluid has excellent sedimentation stability, lower zero field viscosity, higher shear yield stress and long service life, and can meet the application requirements of high power transmission devices.

Owner:CHINA UNIV OF MINING & TECH

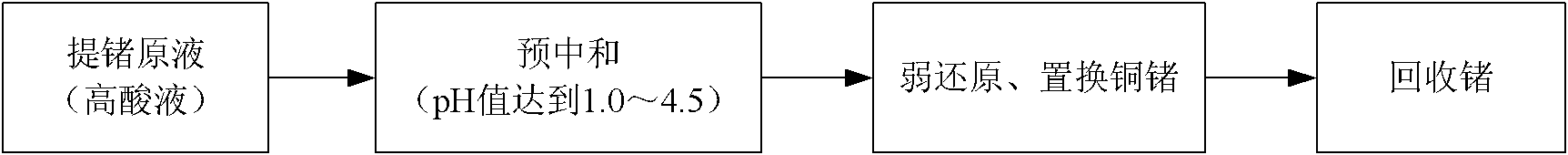

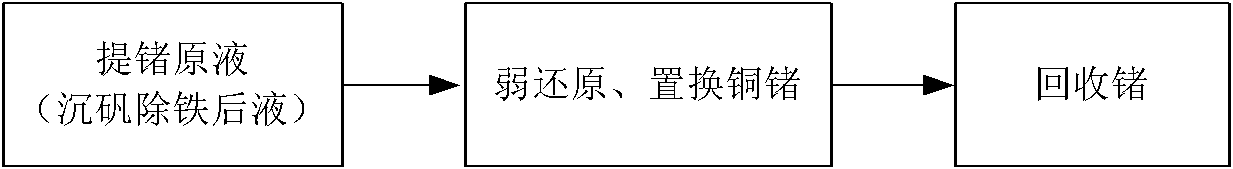

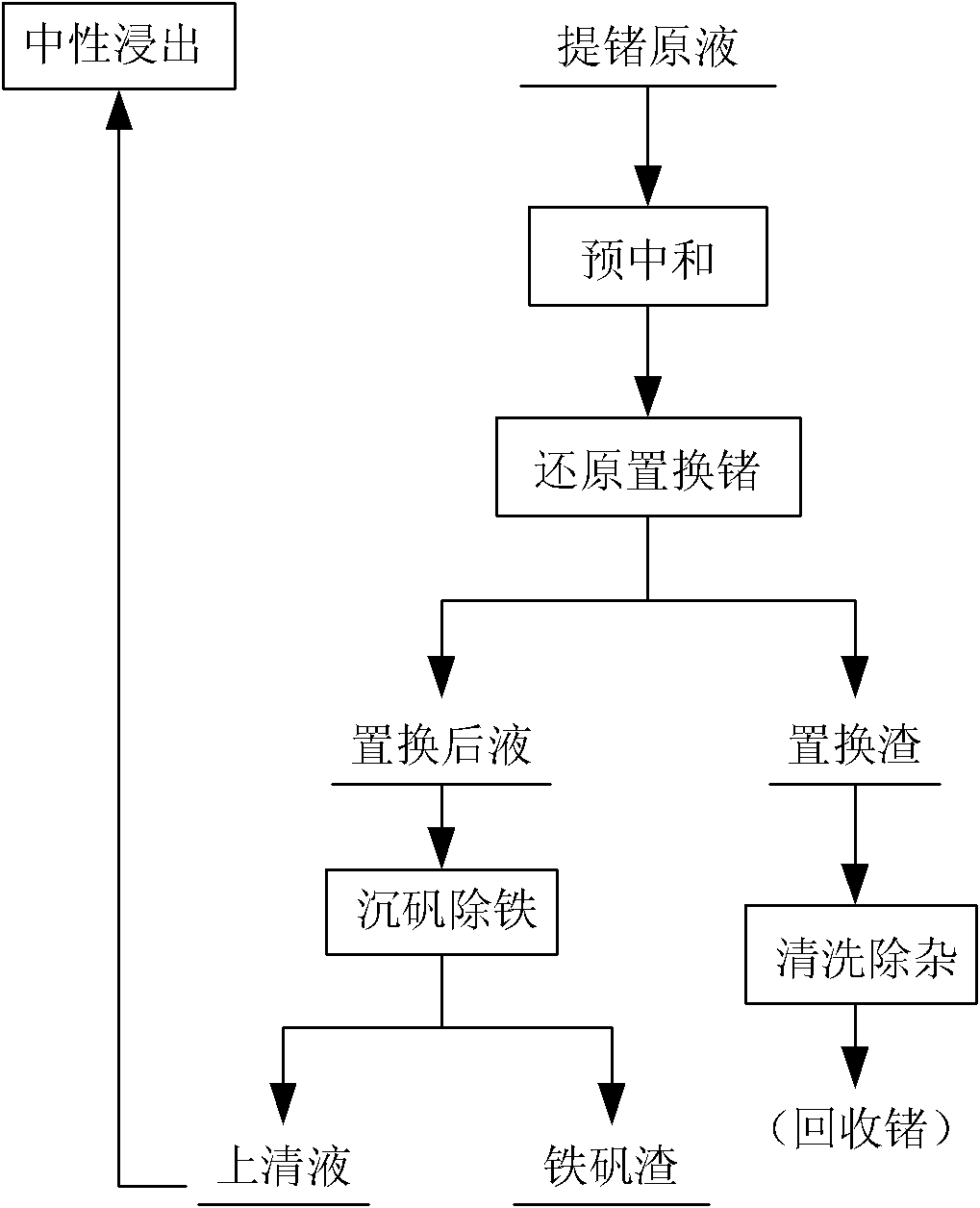

Method for enriching germanium from wet process zinc smelting system

ActiveCN102031371AShort processIncrease replacement rateProcess efficiency improvementIron removalZinc smelting

The invention discloses a method for enriching germanium from a wet process zinc smelting system. The method comprises the following process steps of: pre-neutralizing germanium extracting stock solution; weakly reducing; replacing reduced germanium; cleaning replacement residue; extracting germanium; opening a path and removing iron and the like. The method comprises the following specific steps of: firstly, pre-neutralizing pickle liquor (or liquid obtained from iron removal by jarosite process) with high germanium content by using a small amount of neutralizing agent and controlling the pH of a reaction final point to be between 1.0 and 4.5; secondly, adding a slightly excess amount of reducing agent such as zinc powder or scrap iron to replace germanium; and lastly, after reaction, separating excessive zinc powder or the scrap iron, separating solid from liquid to obtain copper germanium residue with high germanium grade and extracting germanium. Germanium replacement rate is high, and germanium residue has high grade and is easy to treat; moreover, the method is easy to operate, has easily-controllable process condition and low cost and is suitable for the requirement of industrial production.

Owner:CENT SOUTH UNIV +1

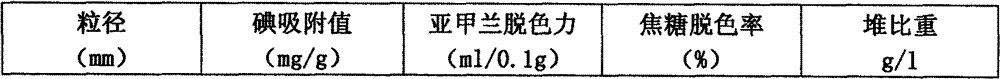

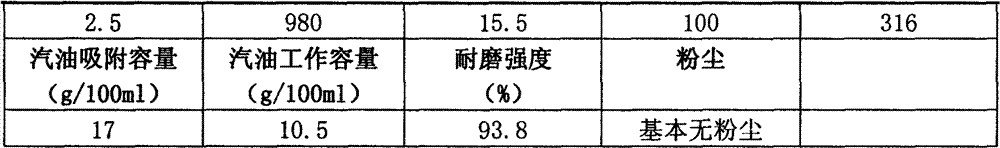

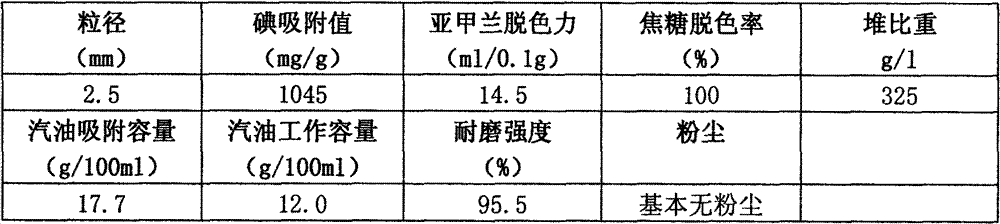

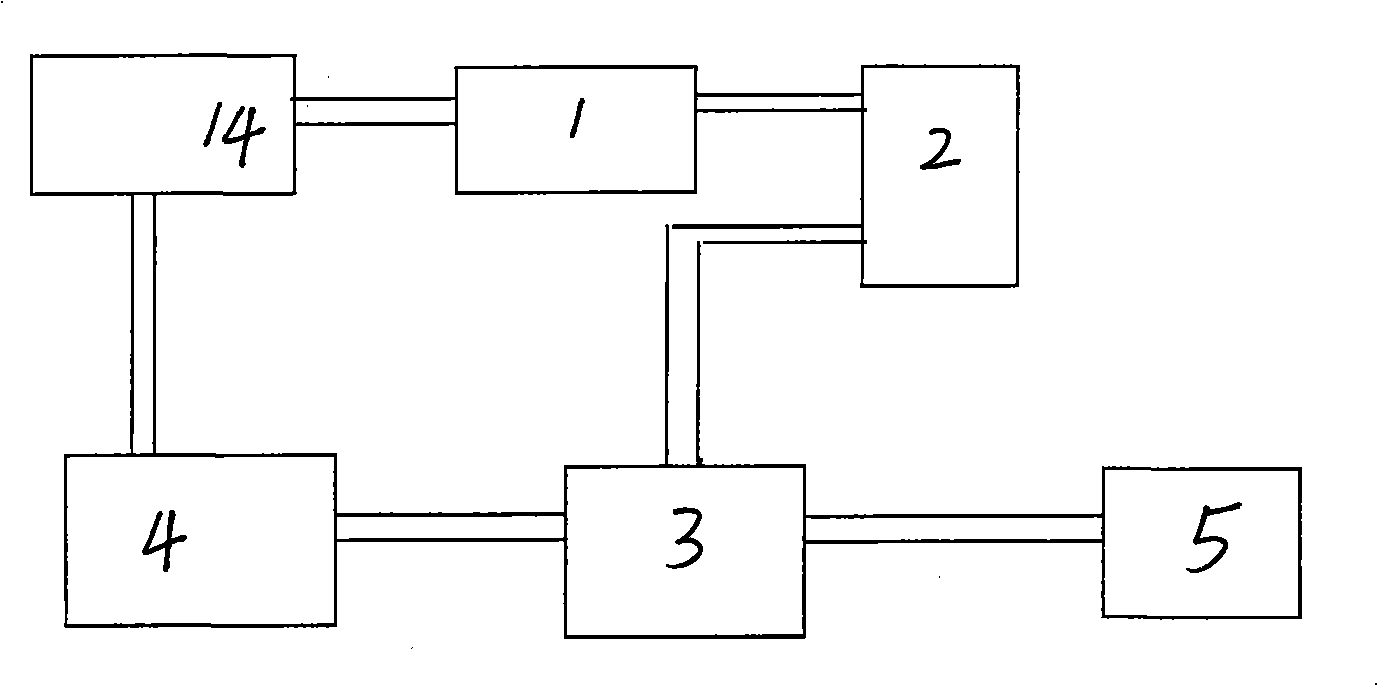

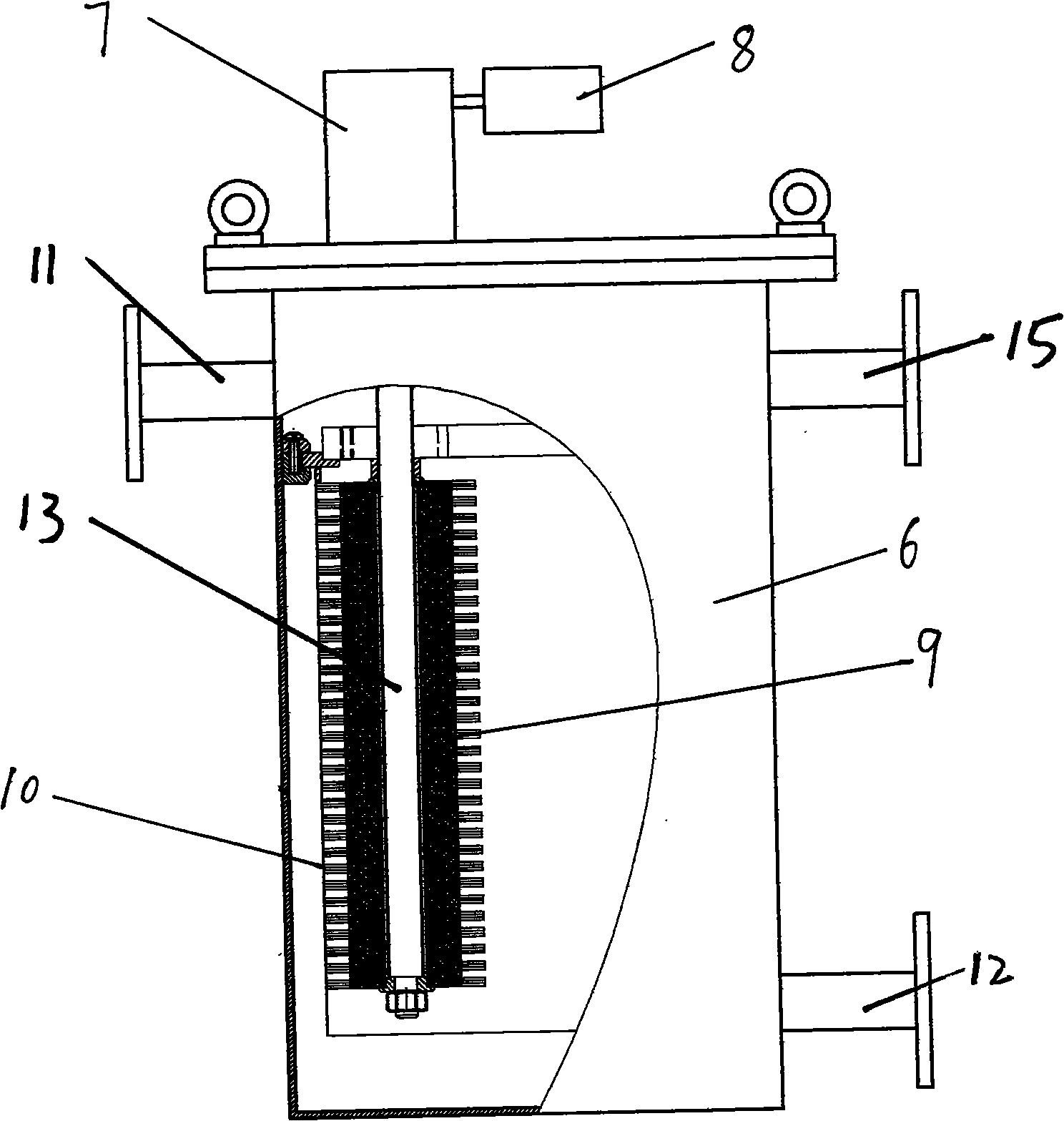

Method for producing active carbon for gasoline vapor adsorption

InactiveCN102698724AIncrease weight absorption capacityReduce working volumeOther chemical processesCarbon compoundsPhosphoric acidMechanical wear

The invention discloses a method for producing active carbon for gasoline vapor adsorption. The method comprises the steps of: taking other wood material containing carbon as raw materials, and taking zinc chloride, phosphoric acid and the like as activating agents, and mixing, kneading, extruding, drying, activating, soaking and conducting other steps to prepare a finished product. According to the method disclosed by the invention, bulk specific weight can be improved effectively, namely the weight adsorption amount of the carbon is improved, so that the gasoline adsorption amount of the active carbon for gasoline vapor adsorption can be improved to be 16g / 100ml; the displacement volume is improved to be 9g / 100ml; the working volume of an adsorption plant is reduced; the application range is expanded; the abrasive resistance of the active carbon for gasoline vapor adsorption is improved to be over 93%; mechanical wear of the active carbon in the using process is reduced; the operating life is prolonged; the floating dust on the surface of the active carbon is basically removed; airflow resistance is reduced, and the method is not only used for gasoline vapor adsorption, but also suitable for recovery of benzene and high-boiling point solvents.

Owner:淮北市大华环保科技有限公司

Heat reclamation method for wastewater of dyeing and printing industry

InactiveCN101294775AEasy to operateFast cost recoveryGravity filtersFiltration circuitsSewage treatmentWaste heat

The invention discloses a method for recovering and utilizing heat, and particularly relates to a method of recovering and utilizing the heat of waste water in the printing industry; the invention aims to provide a method of recovering and utilizing the heat of the waste water and a secondary filtering device used in the treatment of the waste water in the printing industry, wherein the method includes making full use of the waste heat in the waste water, and has no need for frequently cleaning the heat exchange equipment with the heat utilization ratio reaching 90%; after the single filter, the waste hot water passes through the secondary filtering device and a flat-plate type heat exchanger: the filtered hot water is reserved in an insulating hot water tank and the exchanged waste water is disposed. The method is characterized by easy operation, quick investment recovery and so on.

Owner:TONGXIANG XPS THERMAL EQUIP

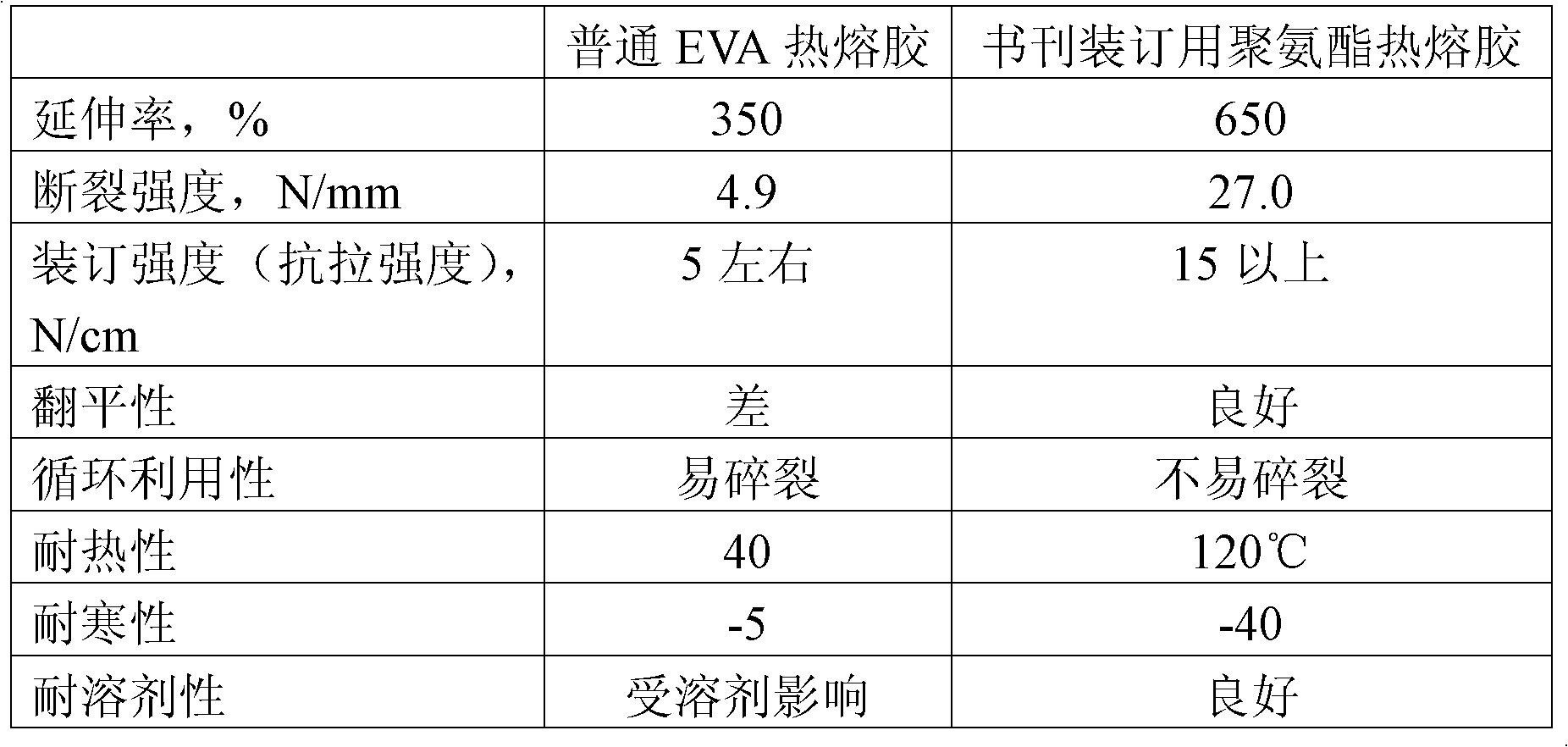

Polyurethane hot melt adhesive for bookbinding of books and magazines and preparation method thereof

ActiveCN102181259ANot easy to drop pagesGood high and low temperature resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPrinting ink

The invention relates to a polyurethane hot melt adhesive for bookbinding of books and magazines and a preparation method thereof, belonging to the technical field of preparation of polyurethane. Polyester polylol and additives are placed in a reaction kettle for heating, vacuum dehydration is performed under stirring, and then cooling is performed; hexamethylene diisocyanate and methylenediphenyl diisocyanate are taken, preheated and then added into the reaction kettle, and the pre-polymerization is performed under vacuum stirring; after completing the pre-polymerization, a chain extender isadded for performing chain extension reaction, a product is poured out under the condition of introducing nitrogen for protection, sealing and packaging are performed, and then the product, namely the polyurethane hot melt adhesive for bookbinding of the books and the magazines is obtained. The obtained hot melt adhesive has high bonding strength, the using quantity is small, and the hot melt adhesive further has excellent environment friendliness, solvent resistance, high and low-temperature resistance and excellent printing ink erosion resistance, and can meet the bonding requirements of different paper sheets. The technical process is the method which is well acquainted by technical staff in the field, and has great economic benefits and industrialized production prospects.

Owner:WUXI WANLI ADHESION MATERIALS

Method for recycling waste LCD (liquid crystal display) panels

InactiveCN103191903ARealize recyclingSimple methodWaste processingSolid waste disposalHydrofluoric acidOrganic solvent

The invention relates to a method for recycling waste LCD (liquid crystal display) panels. The method is characterized by comprising the following steps of: removing an upper layer of polaroids and a lower layer of polaroids on the LCD panel with an organic solvent; crushing left LED panel core into glass fragments with liquid crystal stuck on the surface; then putting into the organic solvent for dissolving the liquid crystal through ultrasonic; respectively obtaining pretreated glass fragments without liquid crystal and a solution with liquid crystal through filtering; separating the liquid crystal from the solution with liquid crystal through a distillation manner; soaking the pretreated glass fragments into a hydrofluoric acid solution; obtaining a solution containing indium and clean glass fragments through filtering, wherein the clean glass fragments are the glass substrate fragments of an upper layer of glass substrate and a lower layer of glass substrate; aerating the solution containing indium into a hydrofluoric acid evaporator for drying through evaporating; and obtaining a solid product rich in indium. The method realizes recycling of the waste LCD panels, is simple and thorough in recycling, and does not cause secondary pollution.

Owner:HEFEI UNIV OF TECH

Technique for preparing sodium fluosilicate by using raffinate extracted from smelting columbite-tantalite ore

InactiveCN1686842AApplicable to comprehensive managementSuitable for recyclingTungsten oxides/hydroxidesSulfate/bisulfate preparationAmmonium paratungstateNiobium

The present invention relates to a process for preparing sodium fluorosilicate from extracted residual liquor obtained by smelting tantalum-niobium ores, and said process includes the following steps: adding silica sand into the residual liquor to precipitate and separate out tungstic acid; then adding NaOH or NaCl into mother liquor to obtain sodium fluorosilicate, filtering, washing and drying; and adding NaOH into the mother liquor after which is used for extracting sodium fluorosilicate and making its pH value be 7-8, evaporating and crystallizing to obtain sodium sulfate; soaking the above-mentioned obtained tungstic acid in water, introducing ammonia to make pH value to greater than 8, dissolving crude tungstic acid to form ammonium paratungstate, filtering and separating quartz, evaporating acid crystallizing, drying and roasting to obtain tungsten trioxide.

Owner:NANCHANG UNIV

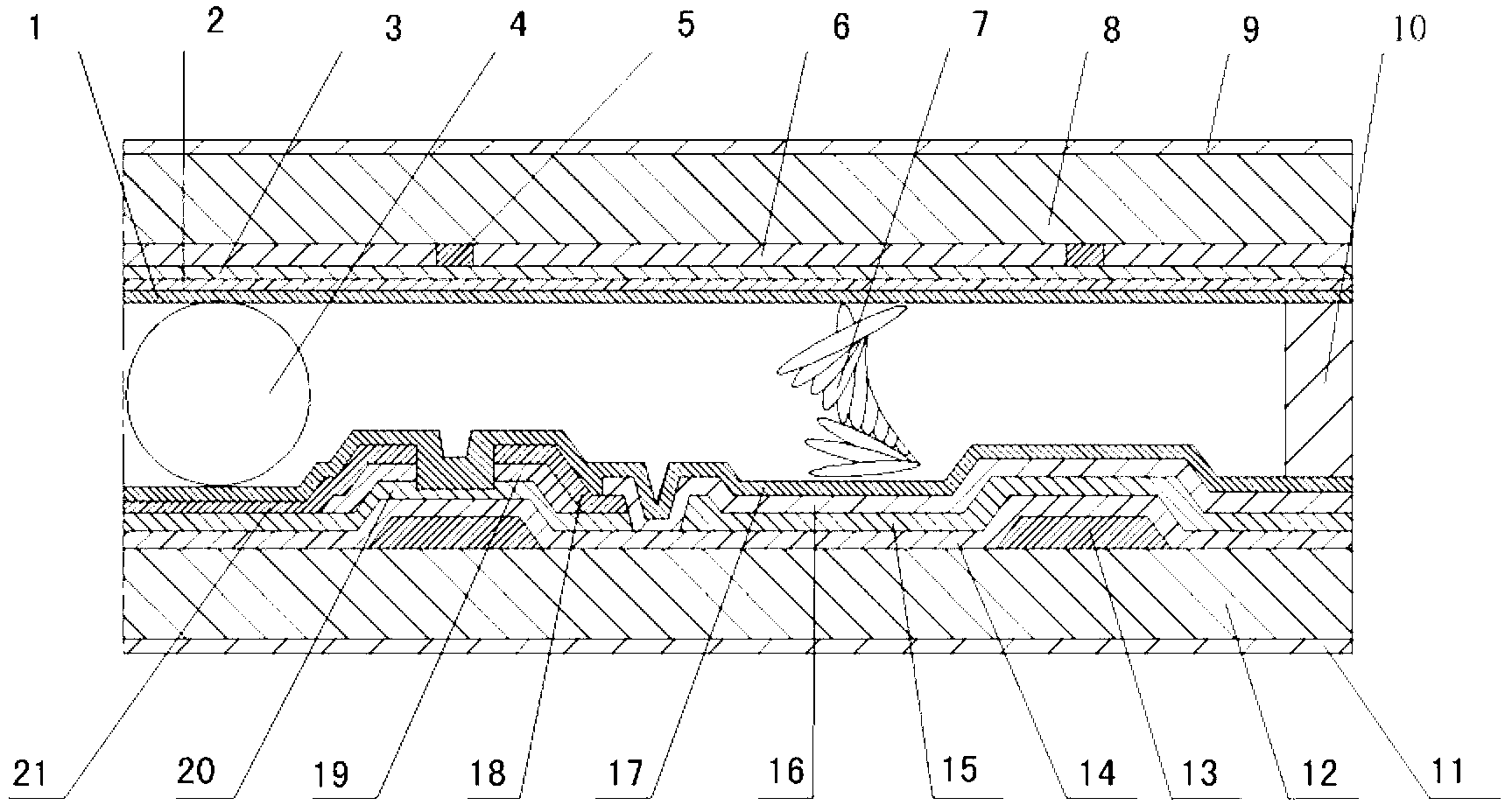

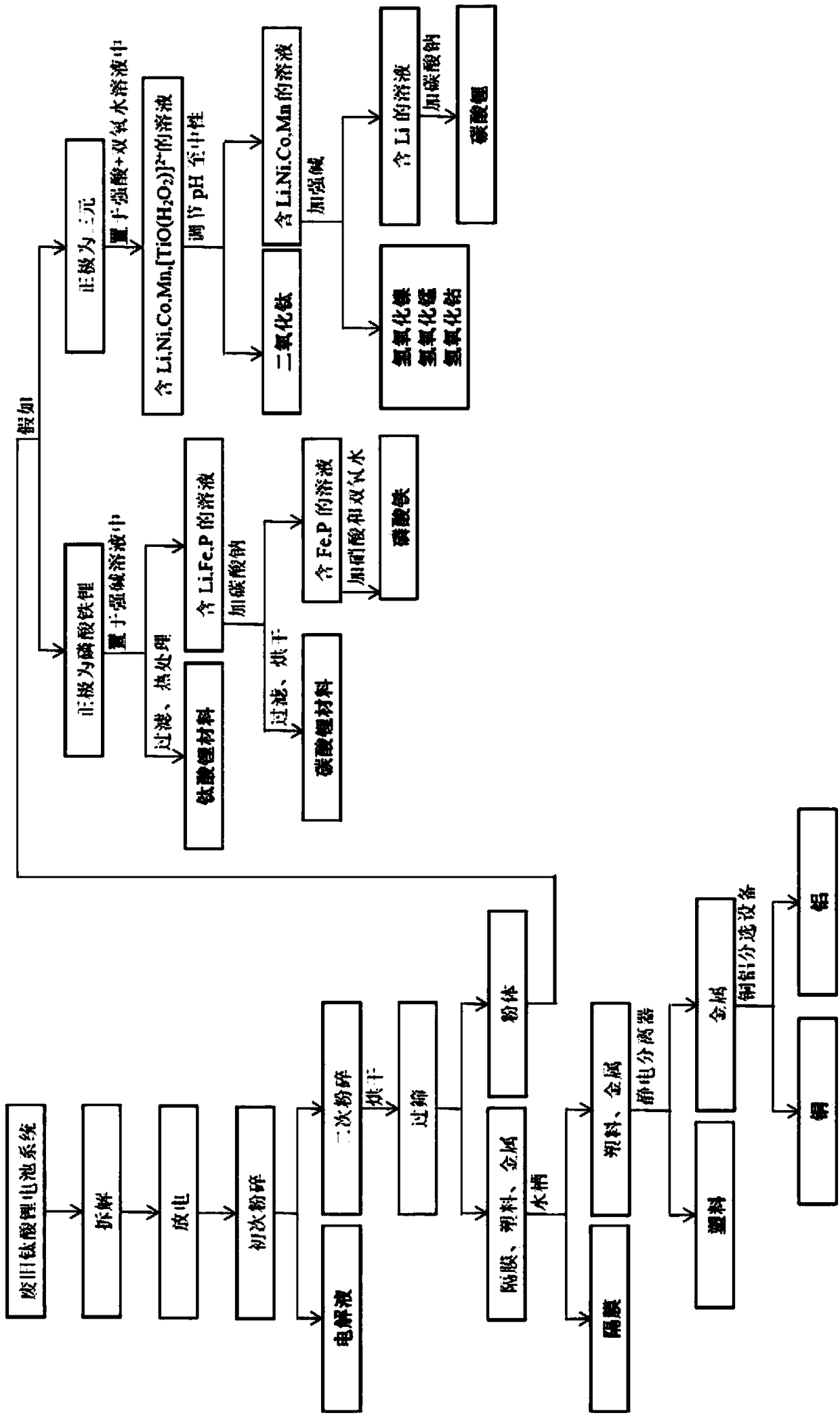

Method for recycling lithium iron phosphate/ternary-lithium titanate batteries

ActiveCN108390119ASimple methodEasy to implementWaste accumulators reclaimingBattery recyclingCobalt hydroxideIron phosphate

The invention belongs to the field of battery recycling, and in particular relates to a method for recycling lithium iron phosphate / ternary-lithium titanate batteries. The method comprises the following steps: disassembling, discharging, crushing, separating powder, separating diaphragms, separating plastic, separating metals, and separating lithium titanate, lithium carbonate and iron phosphate if a cathode material is lithium iron phosphate, or if the cathode material is a ternary material, separating titanium dioxide, manganese hydroxide, nickel hydroxide, cobalt hydroxide and the lithium carbonate. Compared with the prior art, the method realizes separated recovery based on the difference of physical and chemical properties of various valuable materials after full discharge, and has the advantages that all valuable elements of the lithium iron phosphate / ternary-lithium titanate batteries can be recovered from the system level to the battery cell level; in addition, the method provided by the invention is based on simple physical properties and chemical reactions such as acid-base precipitation; the method is simple and easy to implement, thus being suitable for industrial production.

Owner:SHANGHAI ENNEAGON ENERGY TECH CO LTD

Magnesium or magnesium alloy article having electroconductive anodic oxidation coating on the surface thereof and method for production thereof

InactiveCN1653212AImprove corrosion resistanceKeep dryAnodisationElectrical resistance and conductancePhosphate

The invention provides a product, in particular to a magnesium or magnesium alloy product with an anode oxydation coating with conductibility and excellent erosion resistance on the surface, comprising magnesium or a magnesium alloy. The magnesium or magnesium alloy product is characterized in that: an electric anode oxydation coating is arranged on the surface of the magnesium or the magnesium alloy, and the resistance value of the coating surface, mensurated between the two terminals with a mutual distance of 10mm, is below 100 Omega; the magnesium or the magnesium alloy is dipped in the electrolyte with a pH value of 8 to 14 comprising phosphate radical of 0.1 to 1mol / L and ammonia ion or ammonium ion of 0.2 to 5 mol / L, and an anodic oxydation treatment is processed on the surface of the magnesium or the magnesium alloy, and then the product can be manufactured.

Owner:HORI KINZOKU HYOMEN SHORI INDS +1

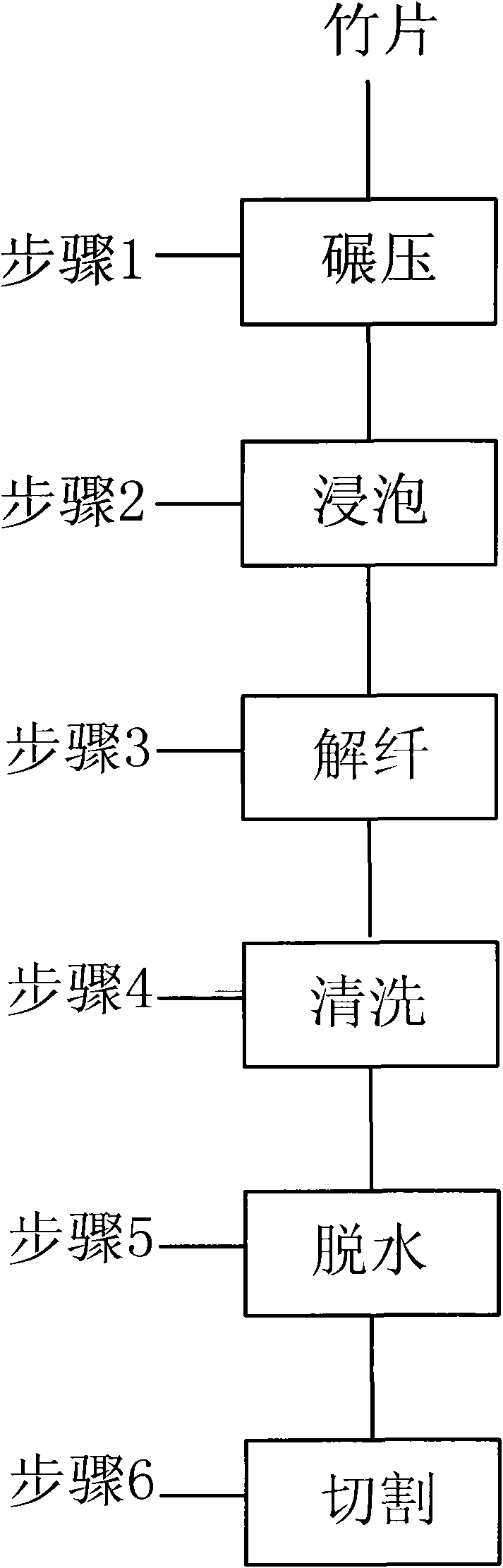

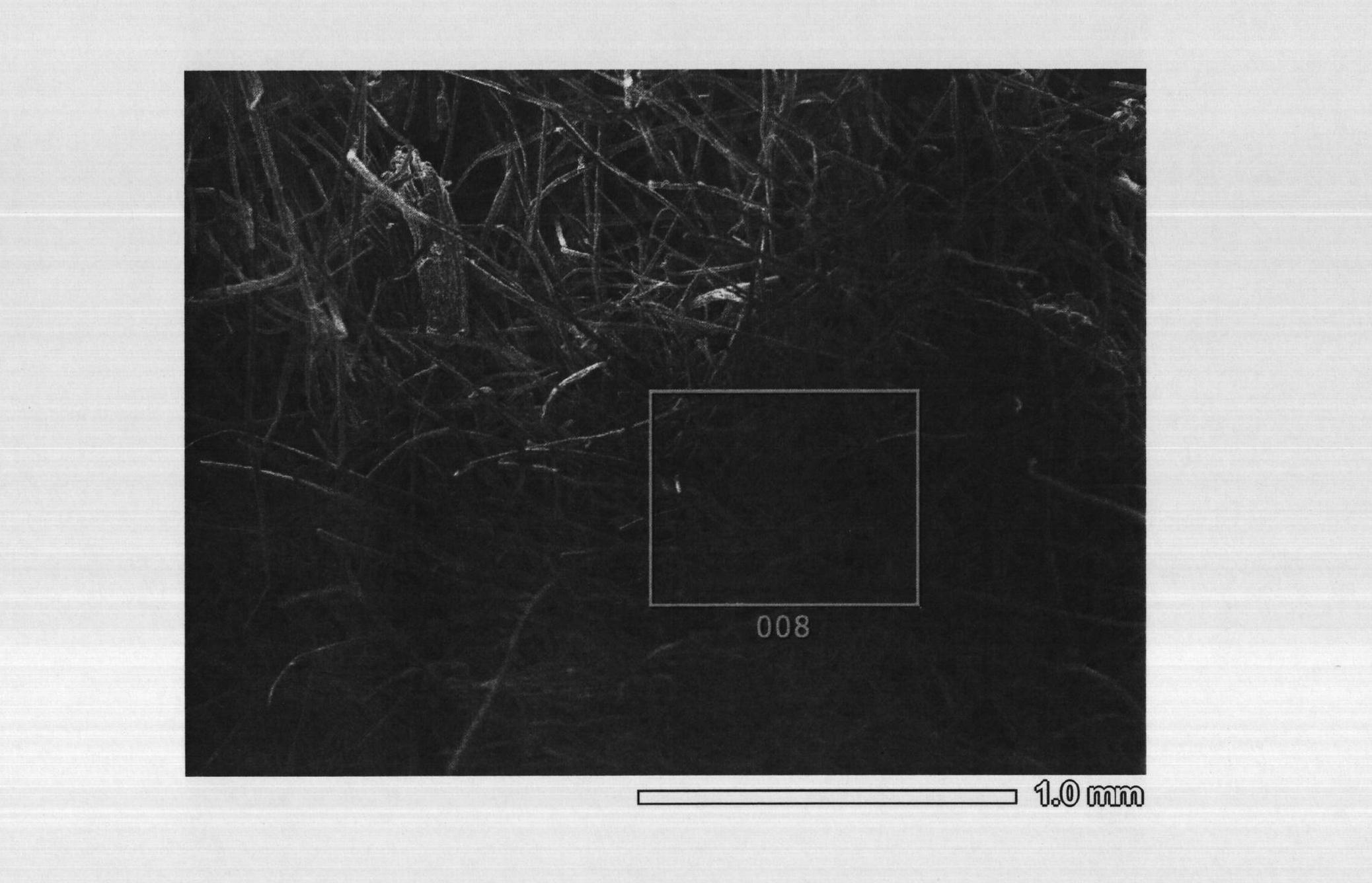

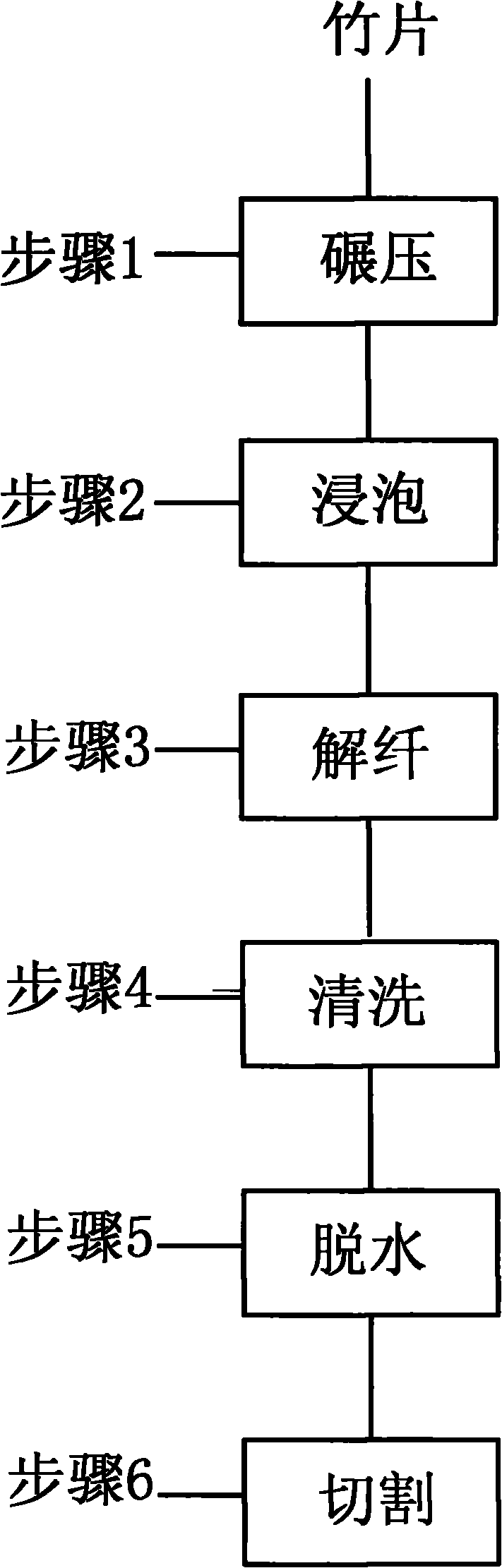

Method for manufacturing bamboo fibers

ActiveCN101934545AQuick removalReduce chemical pollutionWood working apparatusChemical reactionSingle fiber

The invention provides a method for manufacturing bamboo fibers. The method comprises the following steps of: 1) rolling: rolling to crack a bamboo chip to ensure that the bamboo fibers are possibly dispersed; 2) dipping: putting the bamboo chip into a reaction kettle, and mixing with a proper amount of reactant for 10 to 90 minutes to remove lignin, polysaccharide, colloid and protein on the surface of the bamboo fiber; 3) defibering: reducing the pressure instantaneously to standard atmospheric pressure to ensure that the bamboo chip is exploded in the reaction kettle and defibered to form a single-fiber bamboo chip; 4) cleaning: washing the bamboo fibers with hot water with the temperature of between 50 and 100 DEG C at least twice to remove byproducts from the surfaces of the bamboo fibers; 5) dewatering: drying the cleaned bamboo fibers to obtain a dry bamboo fiber finished product; and 6) cutting: cutting the bamboo fibers into bamboo fibers with a proper length. By adopting a physical instantaneous depressurized explosion mode and a chemical reaction reagent dipping mode, the bamboo chip is treated by steps, and the instantaneous depressurized explosion also accelerates thereacting speed of the chemical reagent and the bamboo chip to achieve the effect of quickly removing the lignin, the polysaccharide, the colloid and other substances from the surface of the bamboo chip.

Owner:宁波竹源新材料科技有限公司

Method for separating vanadium and chromium from mixing solution containing vanadium (V) and chromium (VI)

ActiveCN102424913ASuitable for recyclingSuitable for useProcess efficiency improvementVanadateChromium

The present invention provides a method for separating vanadium and chromium from a mixing solution containing vanadium (V) and chromium (VI). The method comprises the following steps: adjusting the pH value of the mixing solution to 10.4-10.5; adding a calcium salt to the mixing solution; adjusting the pH value of the resulting mixing solution to 10.4-10.5; filtering the mixing solution to obtain a first vanadium-containing filter cake and a chromium-containing filtrate; soaking the first vanadium-containing filter cake by an alkaline solution with the pH value of 11-11.1, and filtering to obtain a second vanadium-containing filter cake; cleaning the second vanadium-containing filter cake by clear water, and drying to obtain calcium vanadate; treating the chromium-containing filtrate to obtain the chromium product. With the method of the present invention, the vanadium and the chromium can be effectively separated and recovered from the mixing solution containing the vanadium (V) andthe chromium (VI) so as to contribute to the recovery and the utilization of the vanadium resources and the chromium resources. In addition, the method of the present invention has advantages of simpleness and easy operation.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +1

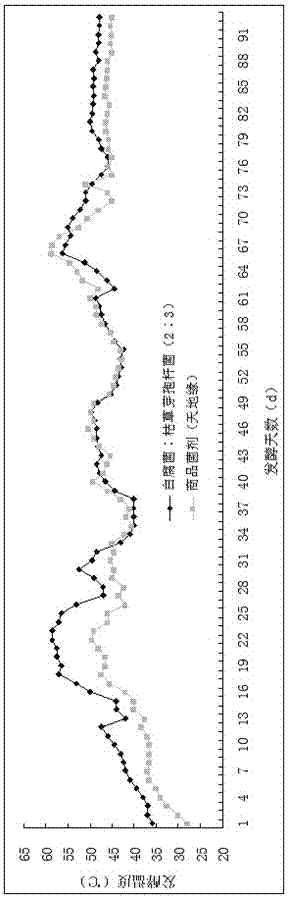

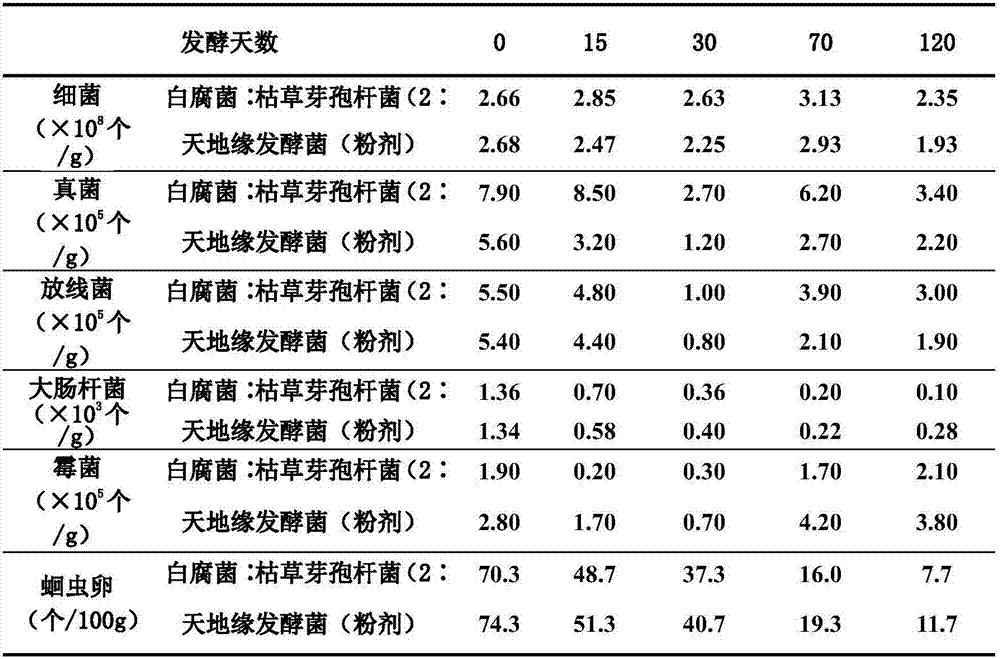

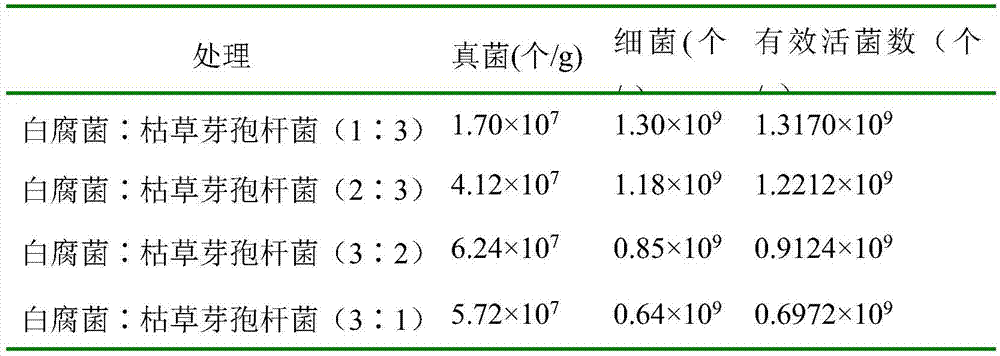

Preparation method of hard straw fermentation preparation

The invention discloses a preparation method of a hard strawfermentation preparation. The method comprises the following steps: step one, selecting strains; step two, culturing the strains, includingculturingwhite rot fungi and culturingbacillus subtilis; step three, uniformly mixing the white rot fungi subjected to enlarged culture and the bacillus subtilis subjected to enlarged culture in a mass ratio of 2:3, and loading the white rot fungi subjected to enlarged culture and the bacillus subtilis subjected to enlarged culture into a container subjected to disinfection and sterilization in advance, so as to obtain the hard strawfermentation preparation. A mixed agent obtained through the method is applied to the hard strawfermentation preparation, and can effectively improve the fermentation rate of hard straws, thereby being applied to manufacture of organic fertilizer and servicing agricultural production, and is applicable to recycling of straw in agricultural production.

Owner:GUIZHOU TOBACCO CORP QIANXINAN CORP

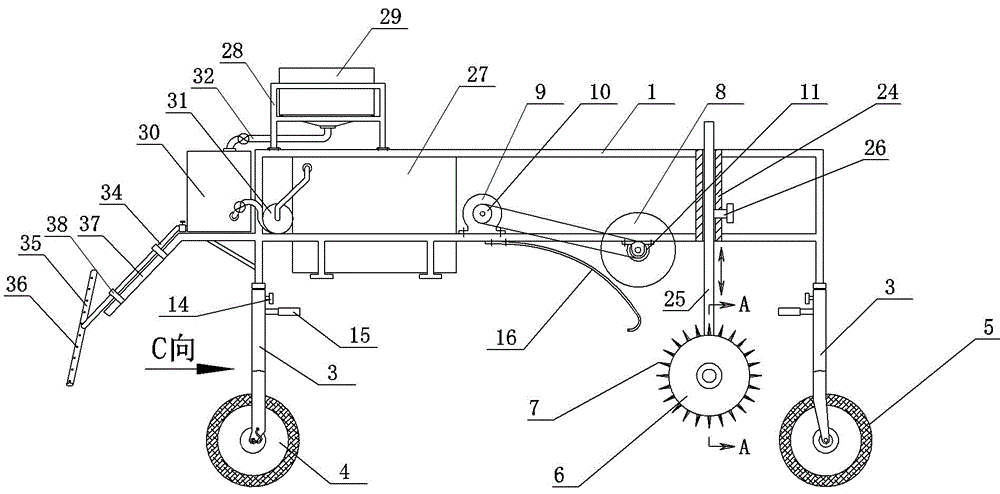

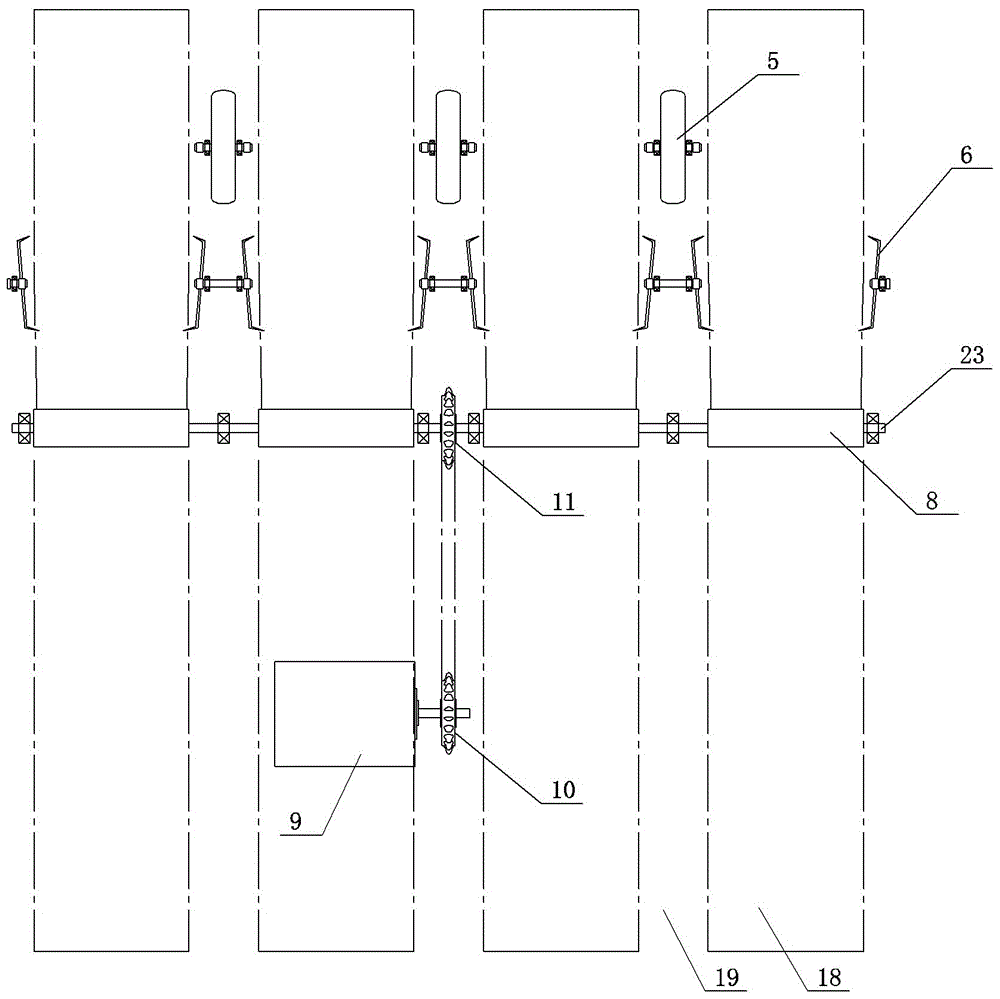

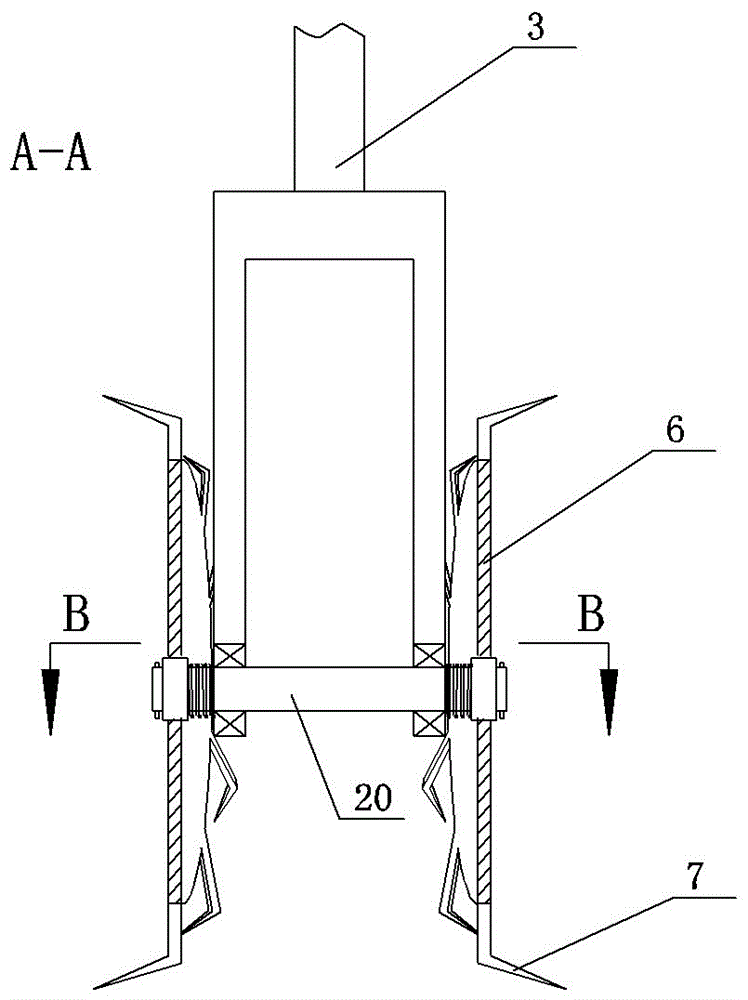

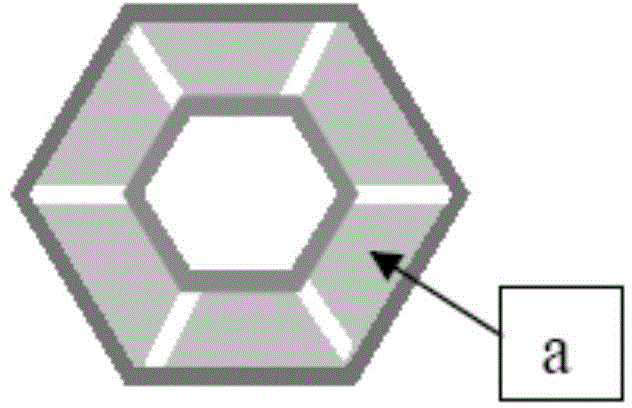

Water and fertilizer integrated multifunctional mulch film recovery machine

ActiveCN106576562AReduce pollutionEnsure sustainable developmentWatering devicesPlastic recyclingVehicle framePlastic mulch

The invention discloses a water and fertilizer integrated multifunctional mulch film recovery machine. The machine comprises a vehicle frame, wheels and a driving mechanism, wherein a water and fertilizer integrated spray system and a film winding mechanism are arranged on the vehicle frame; the wheels of the vehicle frame include motor wheels and follower wheels, and a storage battery and a controller are configured; meanwhile, a sliding way is vertically formed in the vehicle frame, a sliding rod is mounted in the sliding way in a matched way, and a locking bolt is arranged; and a film picking mechanism is arranged at the lower end of the sliding rod. The machine can enter a plurality of furrows and travel along the furrows to recovery films. The machine is particularly suitable for ridge and furrow planting modes, and is especially suitable for tobacco mulch film recovery. The land pollution is alleviated and the sustainable development of tobacco production is kept. The whole film can be recovered and the problem of rotted film residues does not exist; the machine integrates fertilization, water replenishment and film receiving, and can realize multifunctional operations; and the film picking mechanism can be adjusted in height, so that the machine can be adjusted and used according to specific application conditions.

Owner:广东莱德伯格生物科技有限公司

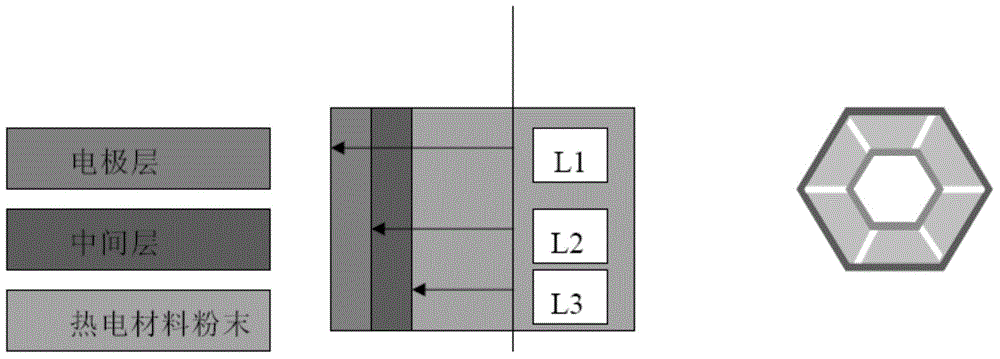

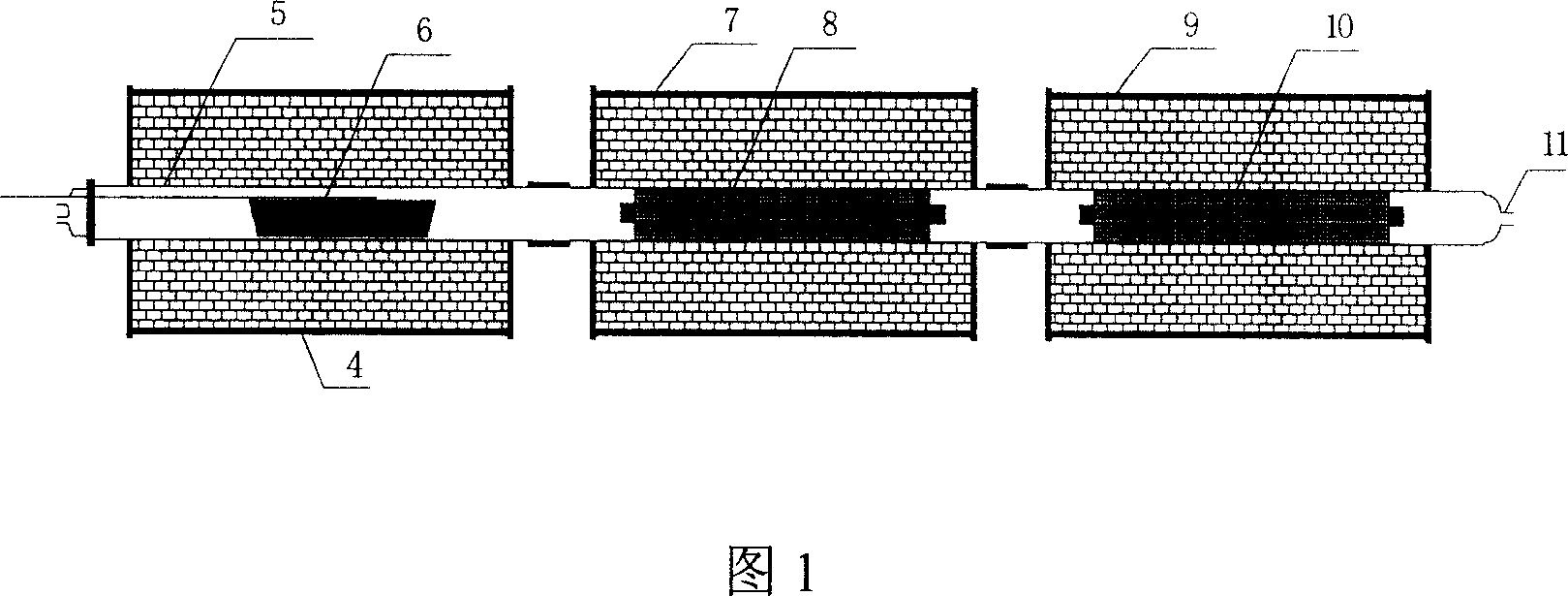

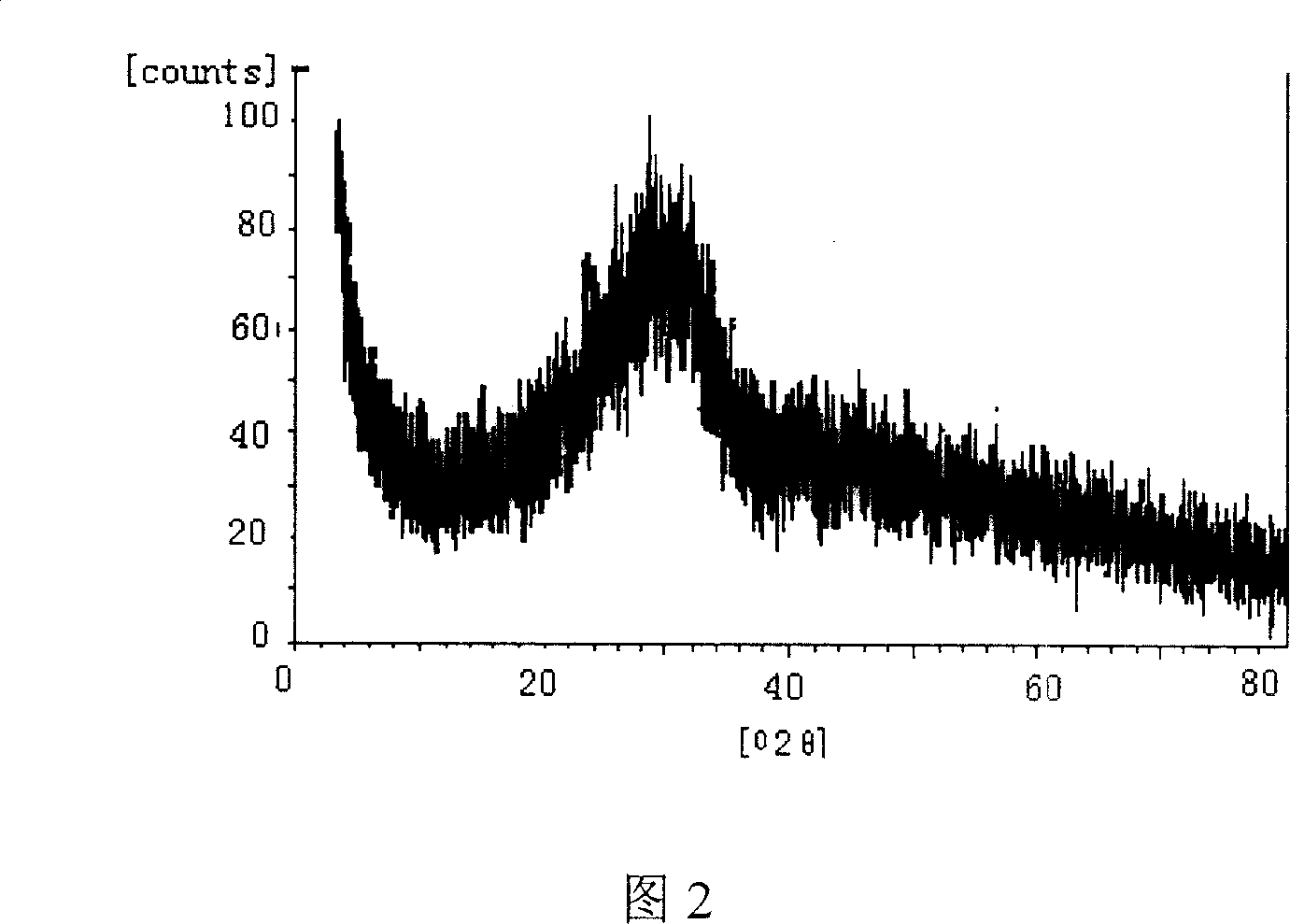

Method for preparing thermoelectric device and thermoelectric device

ActiveCN104638101AIncrease contact areaImprove energy conversion efficiencyThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsThermoelectric element

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

Method for reclaiming heavy metal in fly ash or secondary fly ash

InactiveCN1966743ASimple processEasy to operateProcess efficiency improvementHeavy metal compoundAirflow

The invention discloses a method for recovering heavy metals from fly ash or secondary fly ash with multi-circuit high temperature air electric furnace. The furnace has one high temperature part, at least one middle temperature part, and at least one low temperature part. The temperature in high temperature part is set as the melting point of the heavy metal, and the temperature in middle and low temperature parts are set as congelation point or solidifying point of the heavy metal. The fly ash or secondary fly ash is put in high temperature part, introducing air, the heavy metal in the ash is melted to mixed composition volatile, which is introduced into parts of middle and low temperature by the air, and then different heavy metals in the ash solidify in middle temperature part and low temperature part respectively. The invention has the advantages of low investment, simple equipments and high metal recovery rate.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

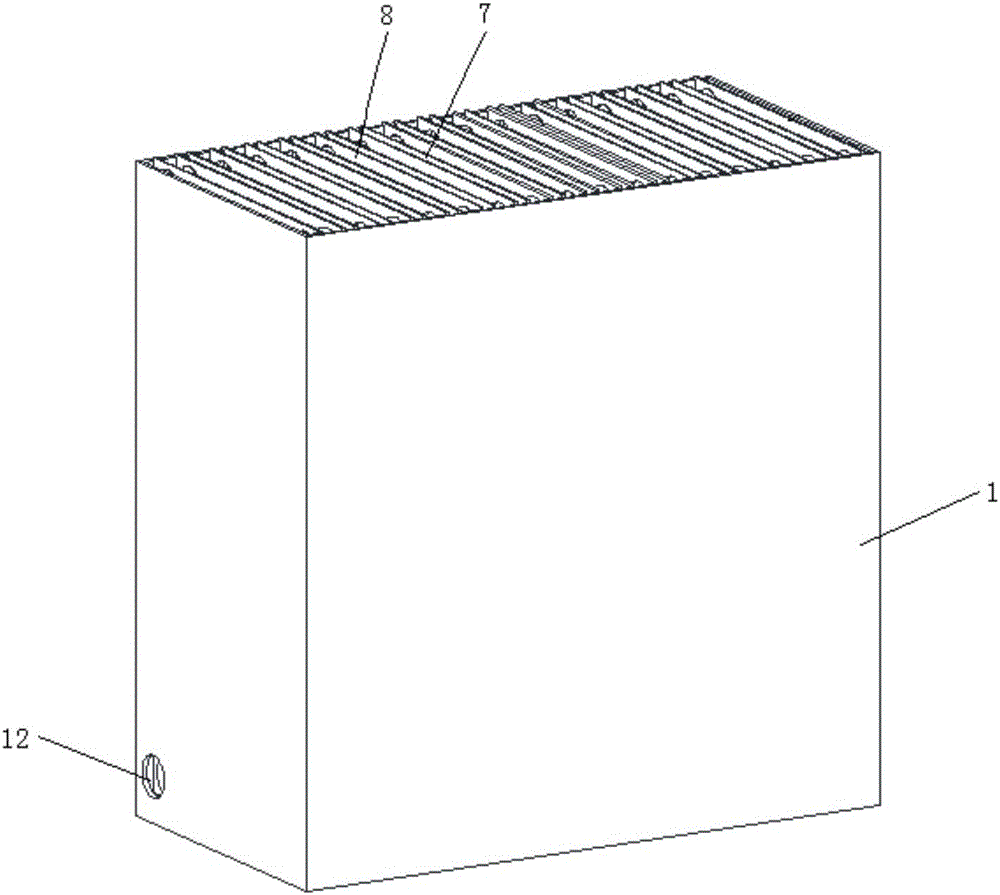

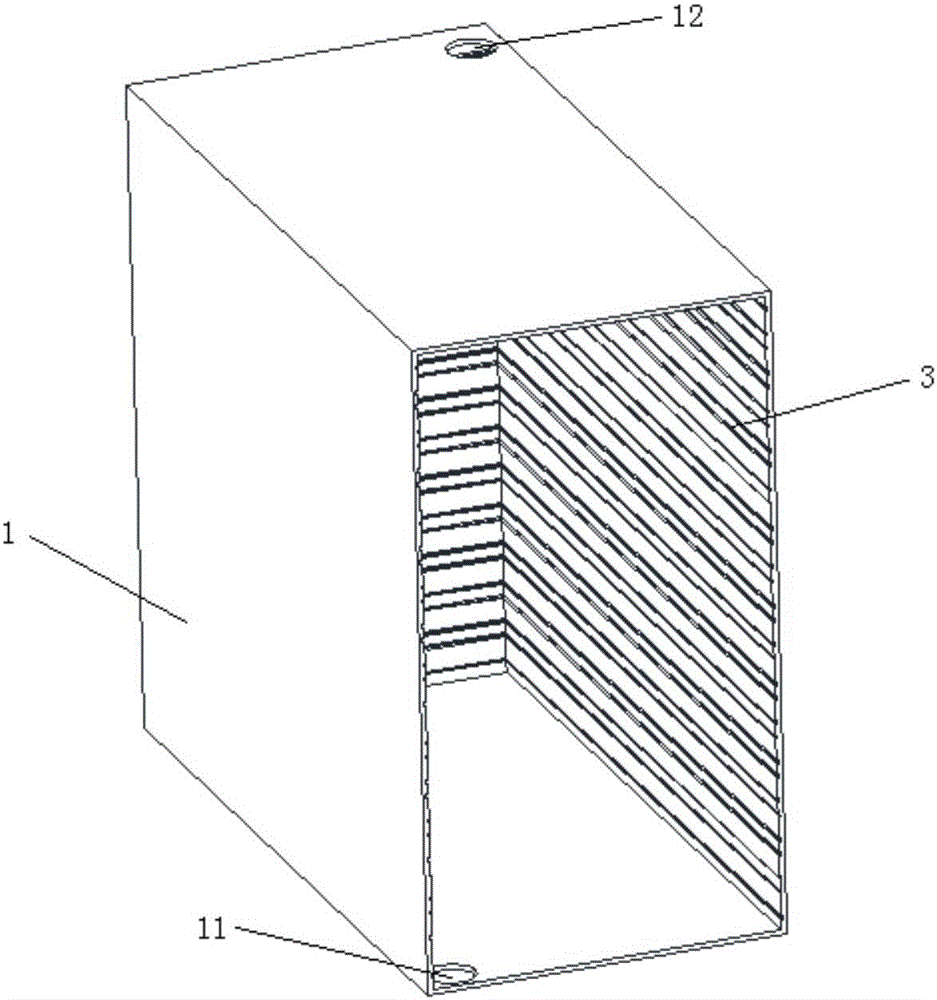

Novel heat accumulator based on phase-change heat accumulation materials

ActiveCN105910482AImprove heat transfer effectGood application effectHeat storage plantsStorage heatersEngineeringPhase change

The invention discloses a novel heat accumulator based on phase-change heat accumulation materials. The novel heat accumulator comprises a box; a plurality of heat exchange boards are arranged inside the box; a plurality of cavities are formed among the heat exchange boards as well as among the heat exchange boards and the box; every two adjacent cavities are the heat exchange fluid cavity and the heat accumulation cavity respectively; every two adjacent heat exchange fluid cavities communicate with each other through a first pipeline; the heat exchange fluid cavities and the first pipelines are filled with heat exchange fluid; every two adjacent heat accumulation cavities communicate with each other through a second pipeline; the heat accumulation cavities and the second pipelines are filled with the phase-change heat accumulation materials; and the phase-change heat accumulation materials and the heat exchange fluid carry out heat exchange. An independent heat accumulation system and an independent heat exchange system are formed inside the box and operate jointly to complete the heat release and heat accumulation functions of the heat accumulator, the structure is compact and simple, the novel heat accumulator is convenient to carry and easy to dismount and mount, the phase-change heat accumulation materials inside the heat accumulation system can be replaced according to use demands, the application range is wide, the novel heat accumulator is suitable for recycling waste heat in daily life for people, and energy conservation and environmental protection are achieved to a greater extent.

Owner:NORTHEASTERN UNIV

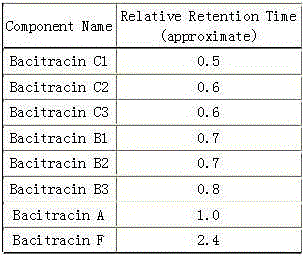

Method for preparing bacitracin and method for preparing zinc salt of bacitracin

InactiveCN105566458AHigh purityThe process is simple and easyPeptide preparation methodsBacitracinsBacitracin ZincEnergy consumption

The invention discloses a method for separating bacitracin from bacitracin fermentation liquid and purifying the bacitracin and a method for preparing zinc salt bacitracin zinc of the bacitracin. The method includes the steps that the fermentation liquid is acidized and filtered, and the filtered liquid is adsorbed and desorbed through macroporous cation exchange resin; after the desorbed liquid is desalted, decolorized, extracted and precipitated, the high-activity bacitracin is prepared. The extracted liquid is subjected to back extraction and enters an aqueous phase to be reacted with zinc salt, and the bacitracin zinc is obtained. The whole technology is simple and easy to operate, and the activity of the product is retained to the maximum degree; the technology is efficient, low in energy consumption and suitable for industrial production, the yield of the bacitracin is 60% or above, and the prepared bacitracin and the prepared zinc salt both meet the United States pharmacopeia standard.

Owner:NCPC NEW DRUG RES & DEV

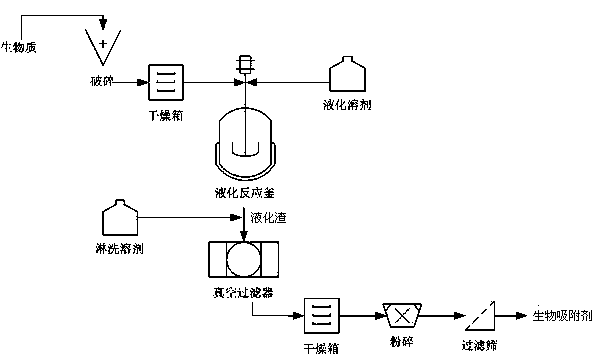

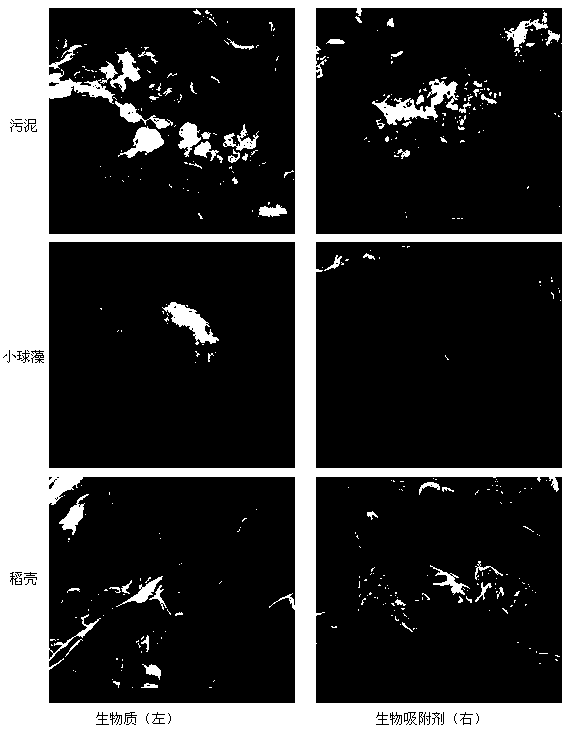

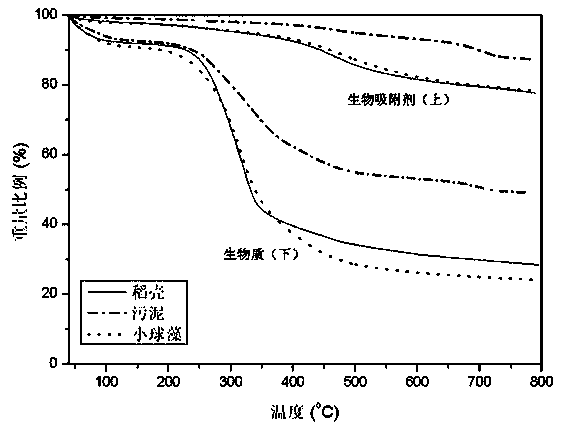

Biological adsorbent, preparation method thereof, and application thereof to removal of methylene blue dye of waste water

InactiveCN103657602AExtensive sources of raw materialsSimple preparation processOther chemical processesWaste water treatment from textile industrySlagBiomass

The invention relates to the technical fields of biomass liquefied slag phase products and purification of waste water, in particular to a biological adsorbent, a preparation method thereof, and application thereof to removal of methylene blue dye of waste water. The biological adsorbent using biomass as a raw material is prepared through the following steps: crushing the biomass and drying the biomass to obtain dry biomass; performing liquefaction on the dry biomass to obtain liquefied slag; performing leaching, vacuum filtration, drying, crushing and sieving on the liquefied slag to obtain the biological adsorbent. The invention also provides a preparation method and application of the biological adsorbent. The biological adsorbent is low in production cost, and is high in removal rate and large in adsorption quantity when being used for removing the methylene blue dye from waste water.

Owner:HUNAN UNIV

Method for producing single cell protein by use of methane

PendingCN108285884ALow costSuitable for recyclingBacteriaMicroorganism based processesBiotechnologyAquatic animal

The invention relates to a method for industrially producing a single cell protein by use of methane, and provides a new method for effectively solving the shortage of feed proteins of livestock and poultry and aquatic animals in China and solving the problems such as fast rising in production cost of aquaculture. According to the method, the single cell protein is prepared from one or more strains of Methylococcus capsulatus ATCC33009, Brevibacillus agri ACCC10247, and Aneurinibacillus thermoaerophilus ACCC10261 by use of the methane. The crude protein content of the produced single cell protein is over 70%, the fermenting strain has strong adaptability to fermentation conditions, and produced feeds are safe and non-toxic.

Owner:CHINA PHARM UNIV

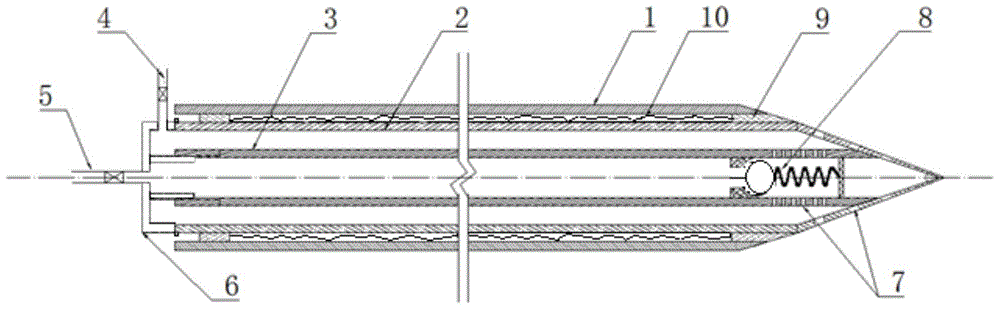

Mixed double-liquid grouting pipe for hole bottoms in fixed-point control fields

ActiveCN103821540AReduce the amount of re-drillingReduce the frequency of drilling accidentsUnderground chambersTunnel liningDouble bottomMaterials science

The invention discloses a mixed double-liquid grouting pipe for hole bottoms in fixed-point control fields. The mixed double-liquid grouting pipe comprises an auxiliary pipe, an outer grouting pipe, an inner grouting pipe and injection holes. The injection holes are formed in the outer grouting pipe and the inner grouting pipe, the inner diameter of the auxiliary pipe is larger than the outer diameter of the outer grouting pipe, portions, except for a conical end, of the outer grouting pipe are arranged in the auxiliary pipe, the inner diameter of the outer grouting pipe is larger than the outer diameter of the inner grouting pipe, a check ball valve is mounted at an end of the inner grouting pipe, the gradient of an end of the auxiliary pipe relative to the horizontal plane ranges from 15 degrees to 30 degrees, and a connecting end is mounted at the tail of the outer grouting pipe and the tail of the inner grouting pipe. The mixed double-liquid grouting pipe has the advantages that the mixed double-liquid grouting pipe is simple in structure and applicable to field manufacture and steel pipe and drilled hole recycling, follow-up drilling construction is unaffected, the repeated drilling quantity can be obviously reduced, the construction period can be shortened, the grouting expense can be saved, and a grouting effect can be improved.

Owner:SHANDONG UNIV

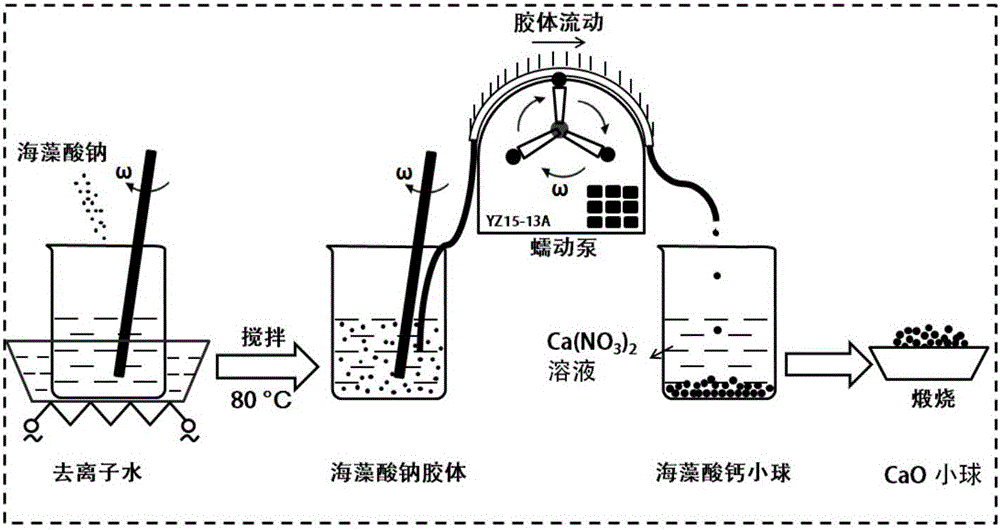

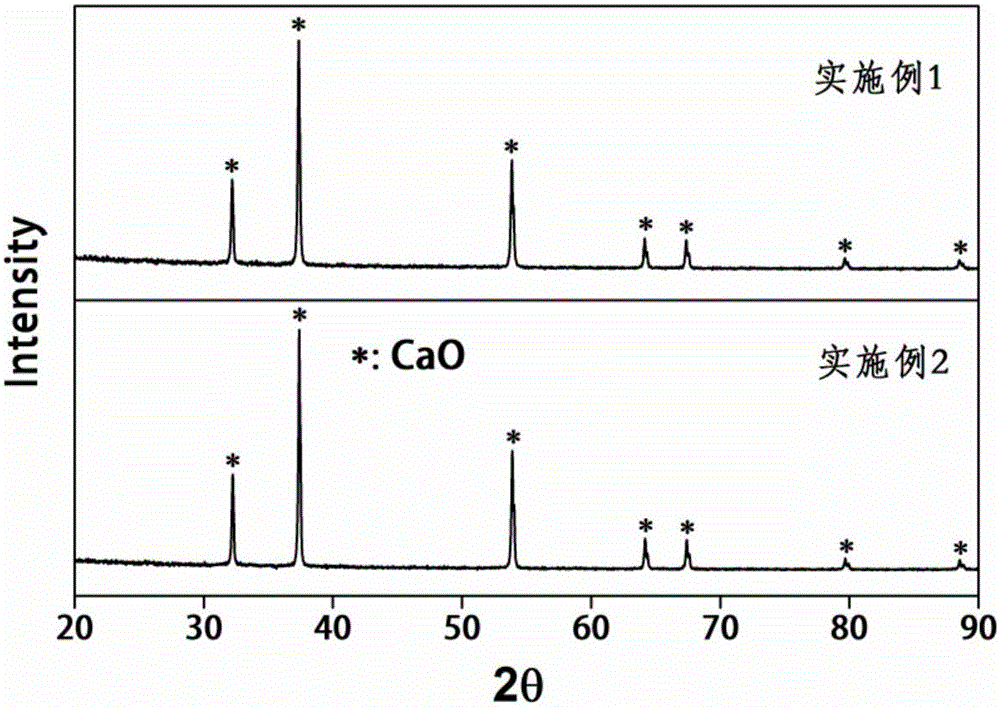

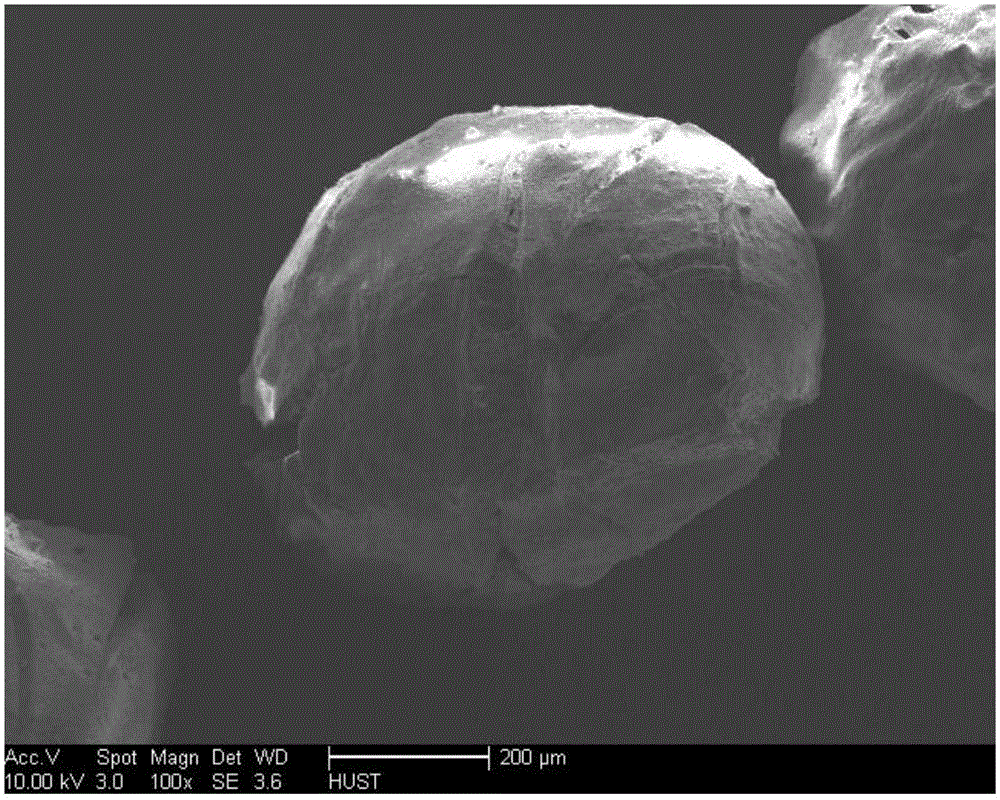

Preparation method of spherical calcium-based CO2 adsorbent

ActiveCN106000301AEasy to makeSimple and fast operationGas treatmentOther chemical processesSorbentCalcium alginate

The invention discloses a preparation method of a spherical calcium-based CO2 adsorbent. The preparation method comprises the following steps: adding 1 part by weight of sodium alginate to 1-1000 parts by weight of water, and uniformly mixing calcium alginate and water to obtain a colloidal solution; dripping the colloidal solution into a calcium salt solution to obtain spherical calcium alginate with the particle size of 1.5-4mm; and calcining the spherical calcium alginate at 600-1200DEG C in oxygen-containing atmosphere to realize complete thermal decomposition of the spherical calcium alginate in order to obtain the spherical calcium-based CO2 adsorbent. The preparation method is simple and is easy to operate, and the preparaed spherical calcium-based CO2 adsorbent has the advantages of good sphericity degree, smooth surface and outstanding CO2 cycle adsorption ability, so good prospect is provided for industrial application of calcium-based adsorbents.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com