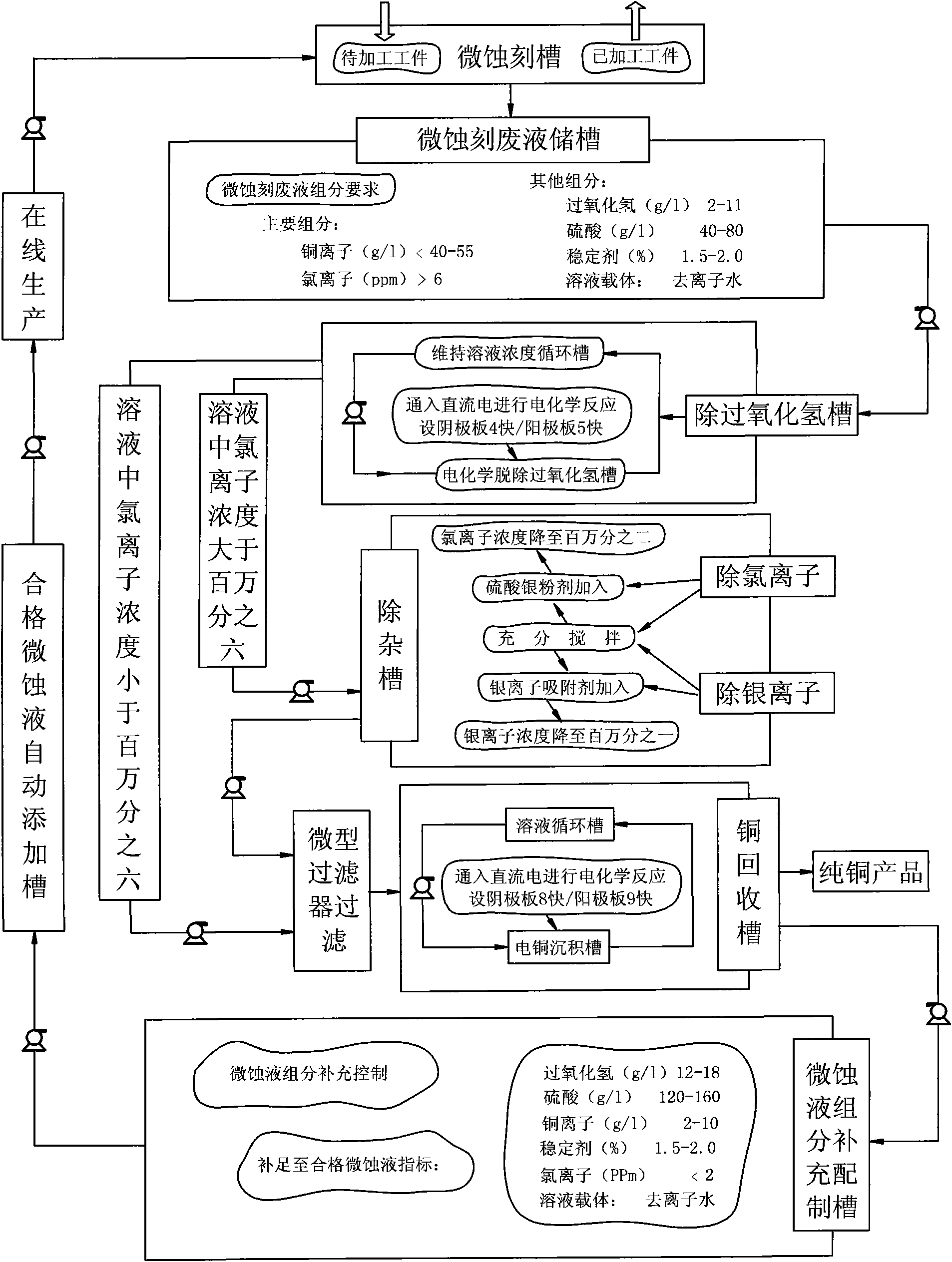

Technology for regenerating and cycling circuit board microetching waste liquid

A circuit board and micro-etching solution technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of no waste liquid recycling, low copper ion concentration, increased operating costs, etc., to achieve convenient maintenance, obvious economic benefits, automatic control high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0155] The making of embodiment 1-1 adsorbent

[0156] a) After measuring, mix well to form a mixed material, ball mill and pulverize the mixed material, put it into a tray, put it into a furnace, control the temperature at 145°C, keep it warm for 40 minutes, and then lower it to room temperature to obtain a sintered body;

[0157] b) The sintered body is coarsely crushed to obtain powder;

[0158] c) Pack the powder and store it for future use.

Embodiment 1-2

[0159] The making of embodiment 1-2 adsorbent

[0160] a) After measuring, mix well to form a mixed material, ball mill and pulverize the mixed material, put it into a tray, put it into a furnace, control the temperature at 155°C, keep it warm for 30 minutes, and then lower it to room temperature to obtain a sintered body;

[0161] b) The sintered body is coarsely crushed to obtain powder;

[0162] c) Pack the powder and store it for future use.

Embodiment 1-3

[0163] The making of embodiment 1-3 adsorbent

[0164] a) After measuring, mix well to form a mixed material, ball mill and pulverize the mixed material, put it into a tray, put it into a furnace, control the temperature at 150°C, keep it warm for 35 minutes, and then lower it to room temperature to obtain a sintered body;

[0165] b) The sintered body is coarsely crushed to obtain powder;

[0166] c) Pack the powder and store it for future use.

[0167] (11) Examples of chlorine and silver ion removal in the impurity removal tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com