Patents

Literature

207 results about "Microetching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A method of roughening the surface of a natural tooth or a dental restoration, most likely the inside of a metal crown or the facial side of a metal crown to prepare it for repair, utilizing a gas-impelled jet of a fine abrasive. It enhances the attachment of resin cements or restorative materials to the surface.

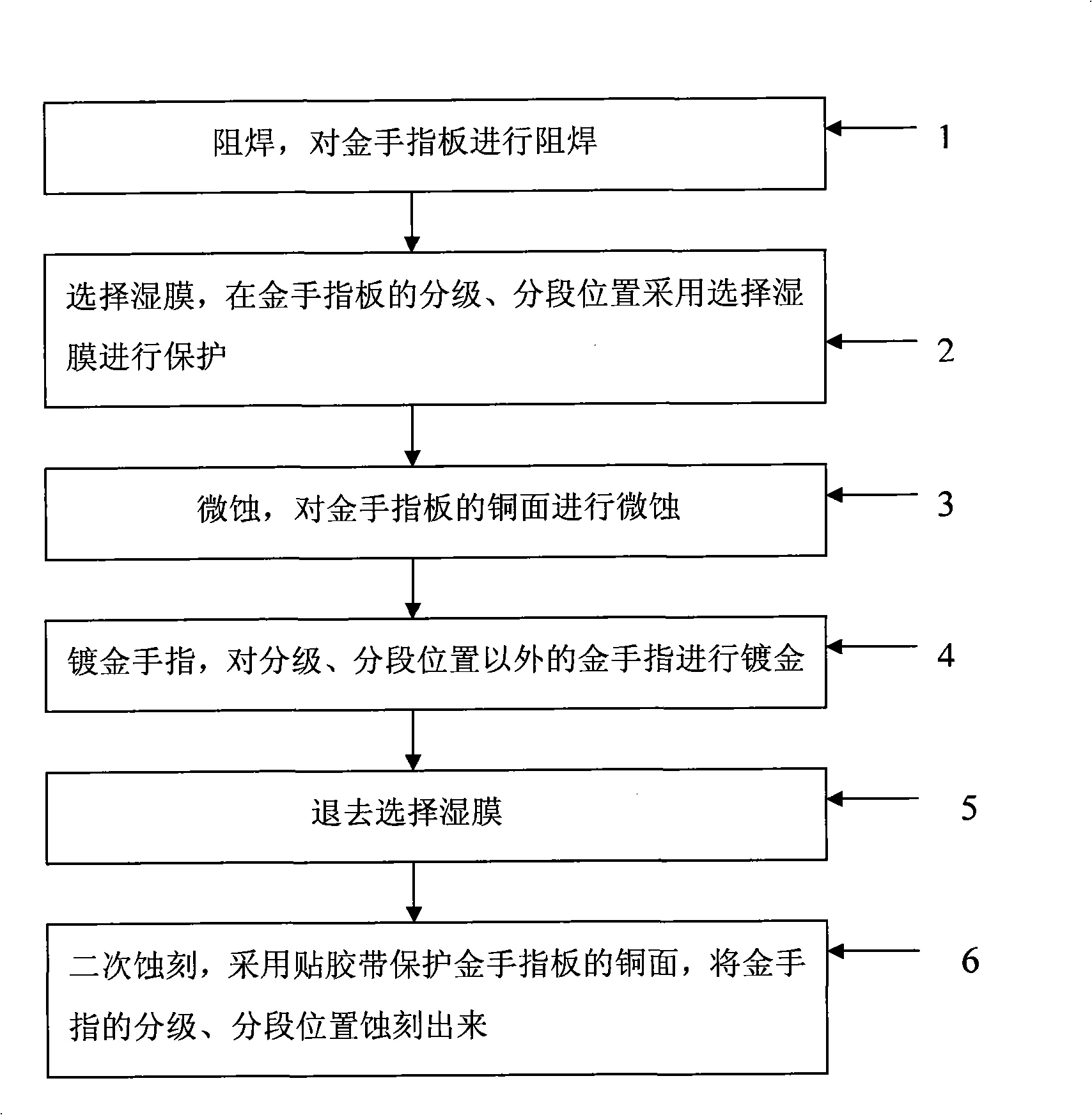

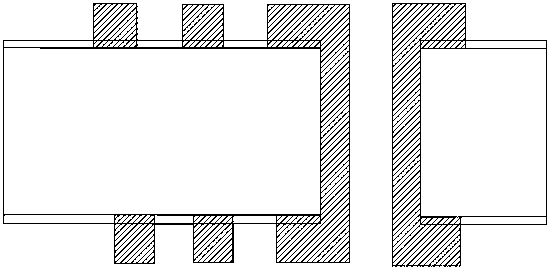

Method for preparing hierarchical and grading gold finger plate using method of selecting wet film

ActiveCN101355856AEasy to controlLow signal distortionPrinted element electric connection formationMembrane methodLow distortion

The invention relates to a method for manufacturing a sectional and segmented gold fingerplate by a selective wet membrane method, comprising the following: a step of resistance welding, in which the gold fingerplate is subjected to resistance welding; a step of selecting a wet membrane, in which the wet membrane is selected to protect the sectional and segmented position of the gold fingerplate; a step of microetching, in which the copper surface of the gold fingerplate is microetched; a step of plating a gold finger, in which the gold fingers except the sectional and segmented position is gilded; a step of removing the selective wet membrane; and a step of etching for the second time, in which an attach tape is adopted to protect the copper surface of the gold fingerplate, and the sectional and segmented positions of the gold finger are etched. The method manufactures the sectional and segmented gold fingerplate by the selective wet membrane method, is used for removing plating lead wires, has easily controlled production process, and has low distortion rate of the signal and high accuracy when a client uses the method on a core network.

Owner:DONGGUAN SHENGYI ELECTRONICS

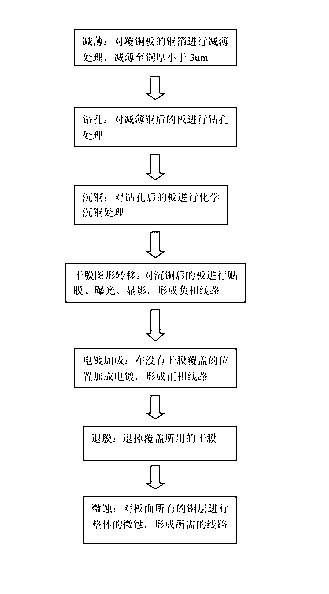

Method for manufacturing circuit board by addition method

The invention provides a method for manufacturing a circuit board by an addition method. The process is as follows: thinning, drilling; precipitating copper; transferring a dry film image; and conducting electroplating addition, film withdrawing and microetching. By adopting the circuit board manufactured by adopting the method, the line width / interval being smaller than 4mil / 4mil can be realized easily, a circuit board with ultra-thick copper can be manufactured, and the quality problems of blocked holes and line breakage can be reduced greatly.

Owner:凯迪思科技股份有限公司 +1

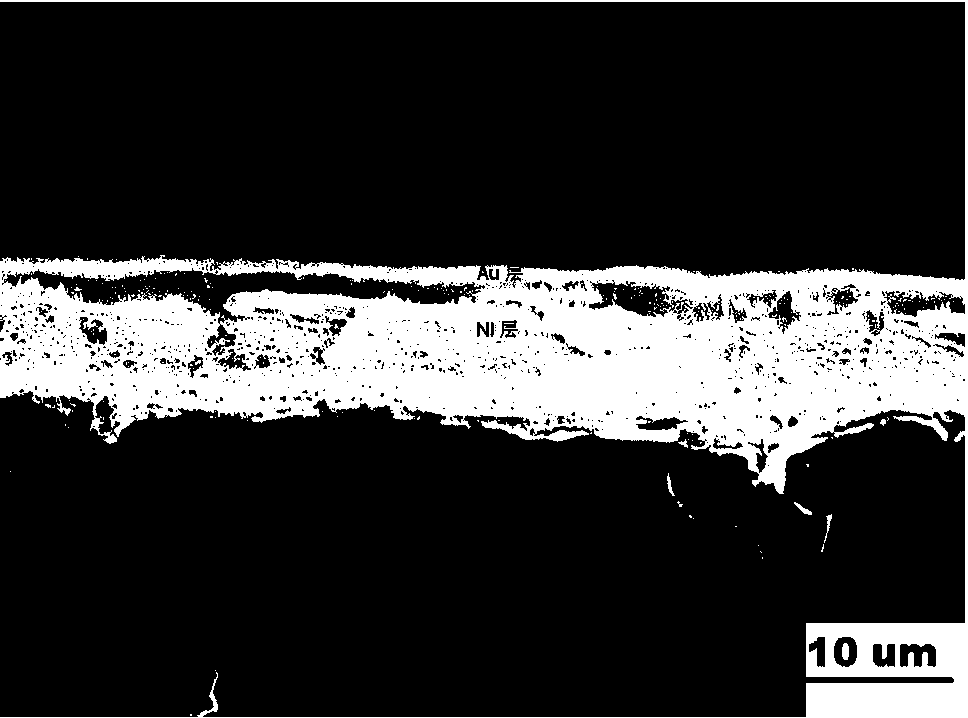

Surface gold plating method of diamond and copper composite material

InactiveCN104195603ATo achieve the purpose of micro-coarseningLiquid/solution decomposition chemical coatingChemical platingSolderability

The invention relates to a surface gold plating method of a diamond and copper composite material. The method specifically comprises the following steps: degreasing and deoiling the diamond and copper composite material; carrying out alkaline deoiling; micro-etching; acid-activating; sensitization activating; acidic chemical nickel-plating; vacuum annealing treatment; alkaline chemical plating; electro nickelling; and electrogilding to form a gold material layer which is 2-3 mu m thick on the surface of the diamond and copper composite material. By adopting a sensitive-active two-step method, a palladium salt center with catalytic activity is formed on the surface of a diamond and copper composite material test piece. Good solid solution diffusion is formed between an acidic chemical nickel-plating layer and a substrate is formed by means of a vacuum thermal treatment method, so that the interface bonding force is enhanced. The adhesive force is enhanced between the surface plating layers of the diamond and copper composite material by means of a method of three-step nickel plating to form multiple layers of combined nickel, so that the stress of the plating layer is released. By plating gold with cyanogen gold salt as an electroplating gold salt formula, the obtained plating layer is excellent in appearance quality and excellent in weldability.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

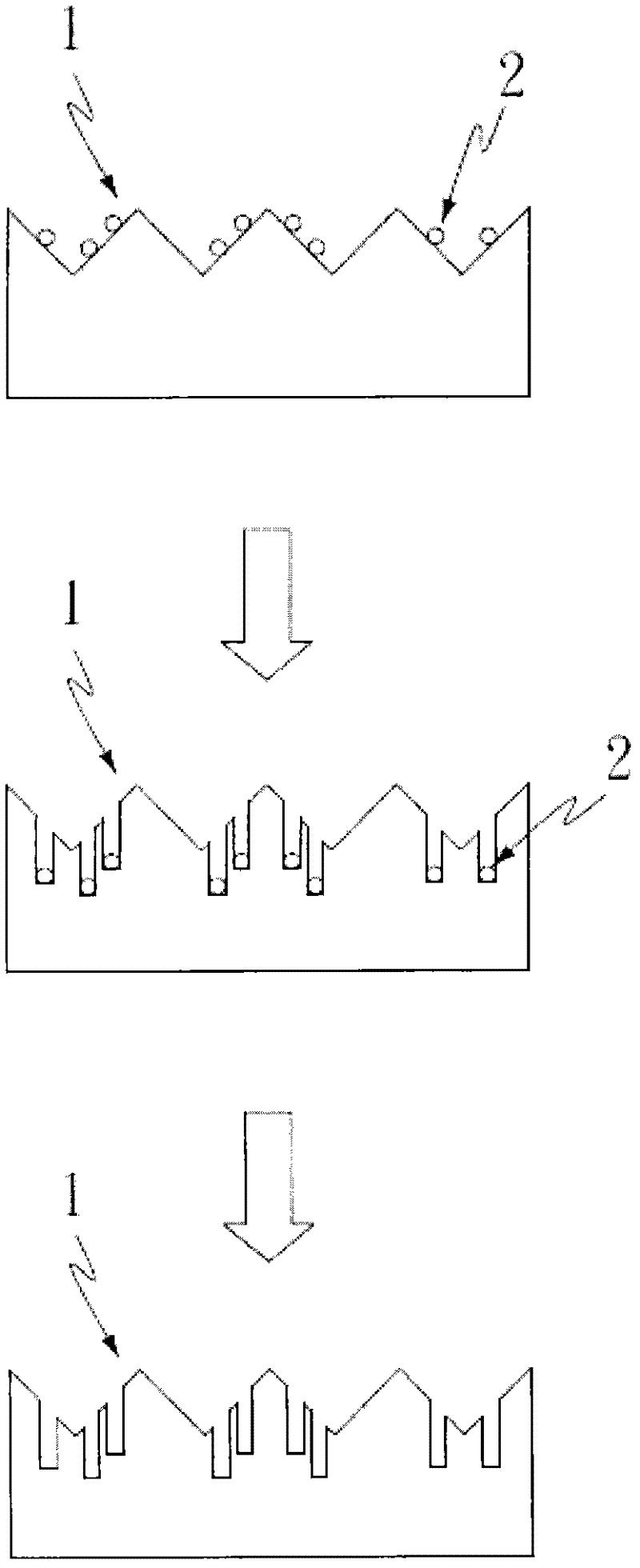

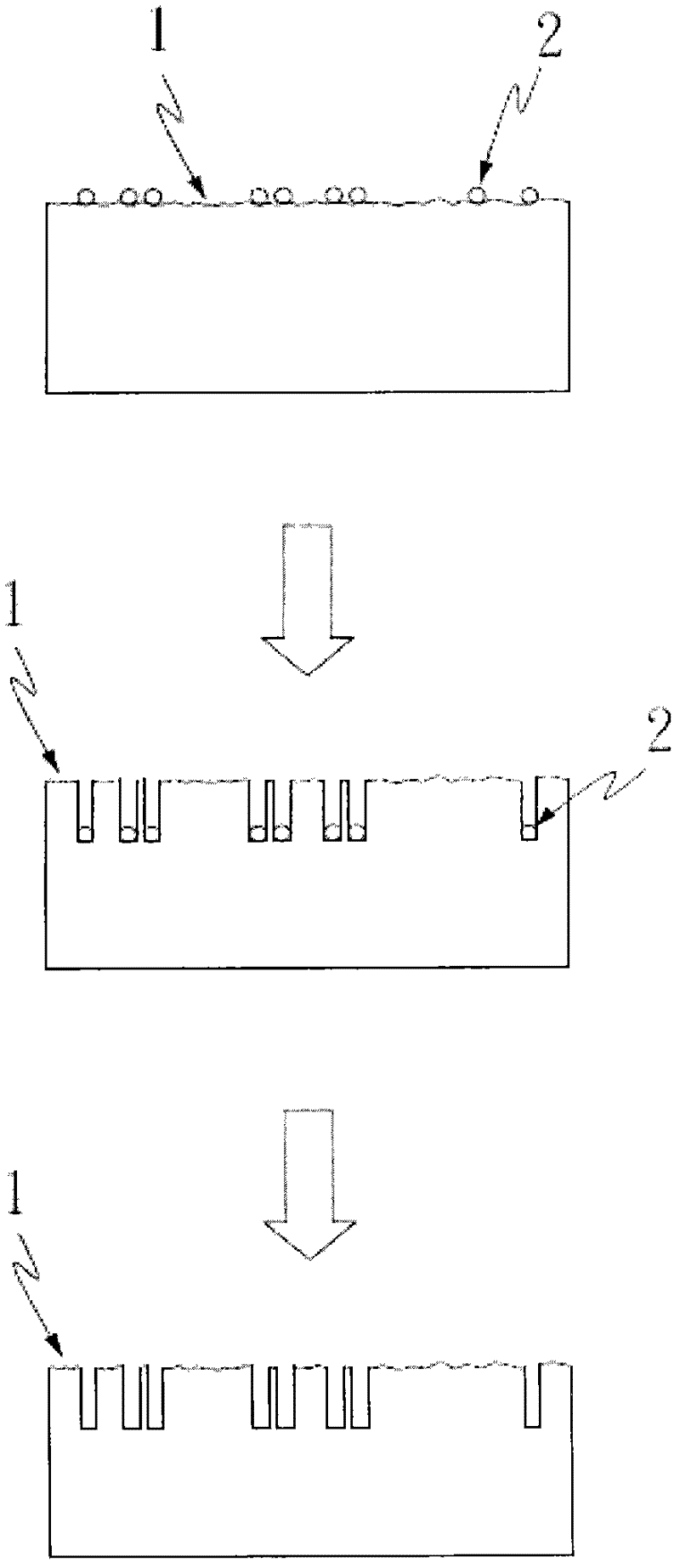

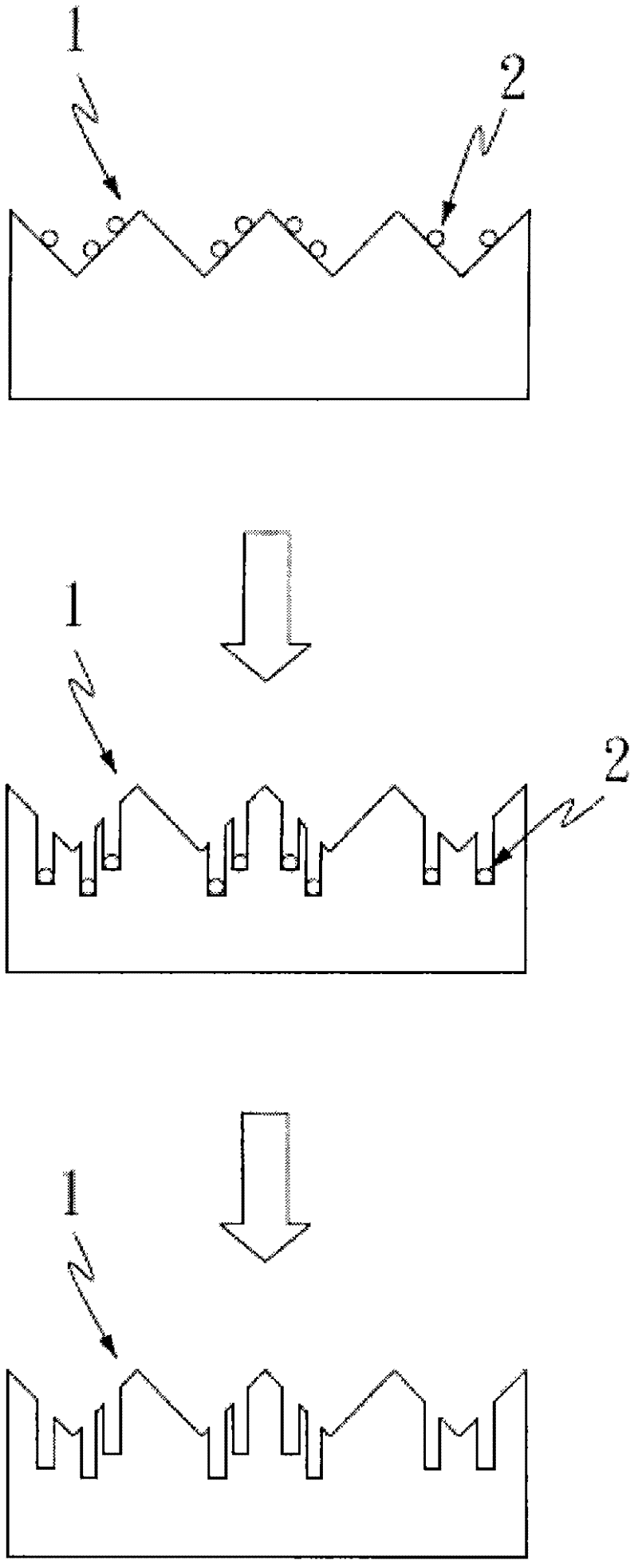

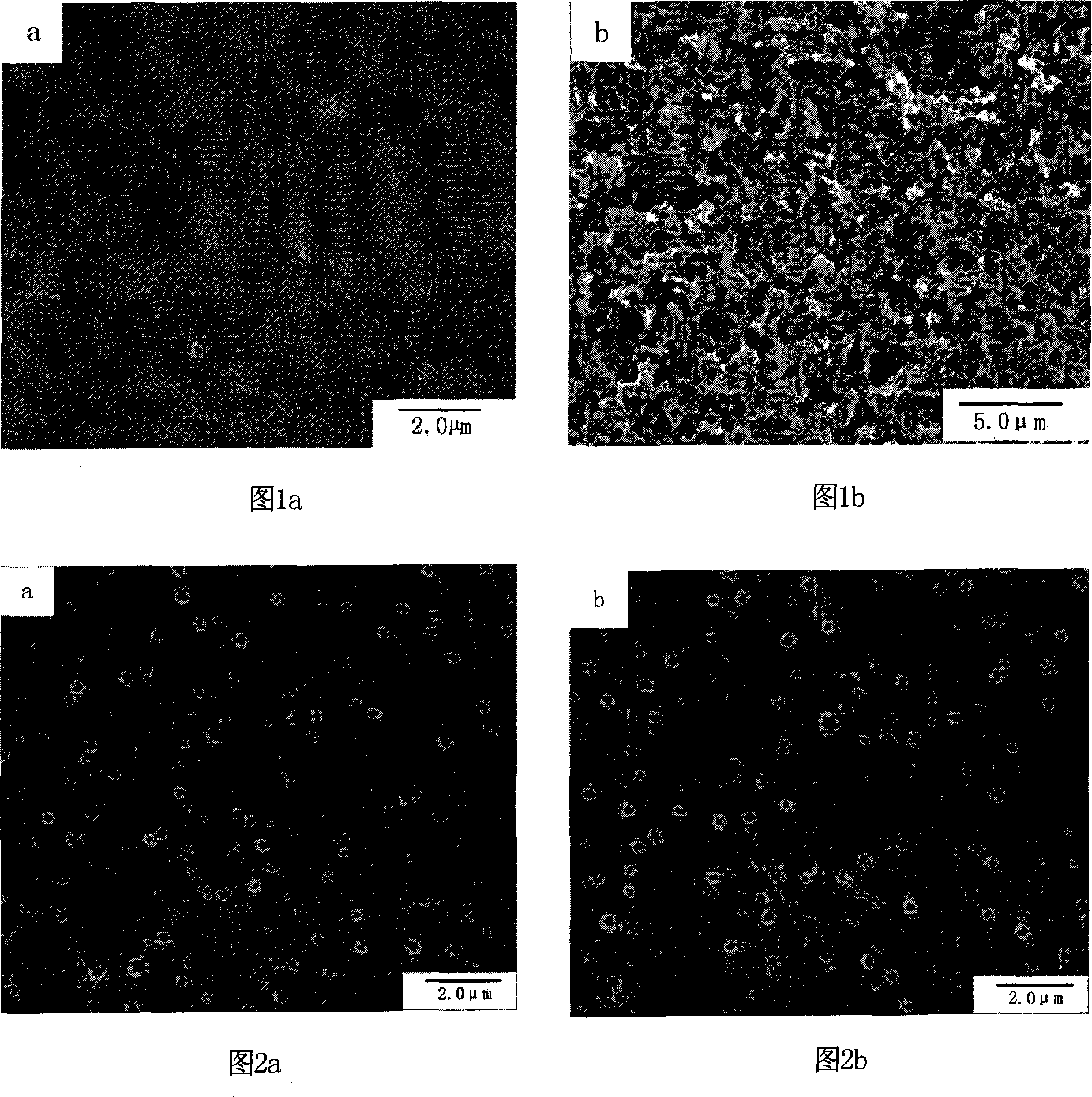

Method of forming micro-pore structures or trench structures on surface of silicon wafer substrate

InactiveCN102443801AReduce surface reflectivityImprove power generation efficiencySemiconductor/solid-state device manufacturingPhotovoltaic energy generationManufacturing cost reductionEtching

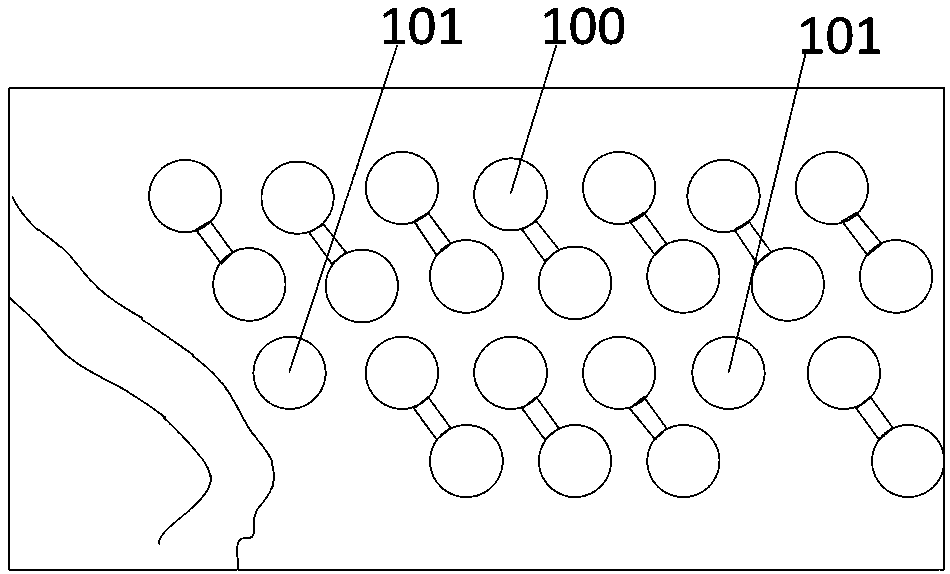

A method of forming micro-pore structures or trench structures on a surface of a silicon wafer substrate comprises (A) forming at least a noble-metal alloy particle on the surface of the silicon wafer substrate; and (B) then followed by employing a chemical wet etching on the surface of the silicon wafer substrate. During the processes, noble-metal alloy particle is used to catalyze the oxidation of the silicon wafer substrate surface in contact therewith, and an etchant is used to simultaneous etch the silicon dioxide to result in local micro-etching at the surface of the silicon wafer substrate, thereby forming micro-pore structures or trench structures on the surface of the silicon wafer substrate. Surface reflectivity of the silicon chip substrate can be effectively reduced. The method increases the power conversion efficiency of the solar cells and reduces the manufacturing costs so as to increase the production benefits of the solar cells.

Owner:纮泰科技股份有限公司

Chemical copper plating pretreatment process for printed wiring board

InactiveCN105887053AUniform depositionLiquid/solution decomposition chemical coatingConductive pattern polishing/cleaningCopper platingSurface-active agents

The invention discloses a chemical copper plating pretreatment process for a printed wiring board. The process comprises the following steps that 1, the printed wiring board is drilled at first and burrs at a drilled hole are removed; 2, the printed wiring board is put into a swelling agent aqueous solution to be soaked for 3-10 minutes; 3, the printed wiring board is put into a potassium permanganate strong alkali solution to be soaked for 5-25 minutes; 4, the printed wiring board is put into an aqueous solution of a reducing agent and a complexing agent to be soaked for 1-10 minutes; 5, the printed wiring board is put into an alkali oil removing solution with the concentration of 0.1-100 ml / L and containing polymer cationic surface active agents to be soaked for 5 minutes; 6, a microetching solution containing sulfuric acid and oxidizing agents is used for microetching, and bite etching is conducted under the acid condition; 7, the printed wiring board obtained after microetching enters a pre-dip solution; 8, the printed wiring board is transferred to 45-DEG C active fluid containing colloidal palladium to be soaked for 5 minutes from the pre-dip solution; and 9, the activated printed wiring board is subjected to dispergation through acid or alkaline or oxidized accelerating fluid with the concentration of 0.001-5 mol / L.

Owner:GUANGDONG LEAR ELECTROCHEM LTD

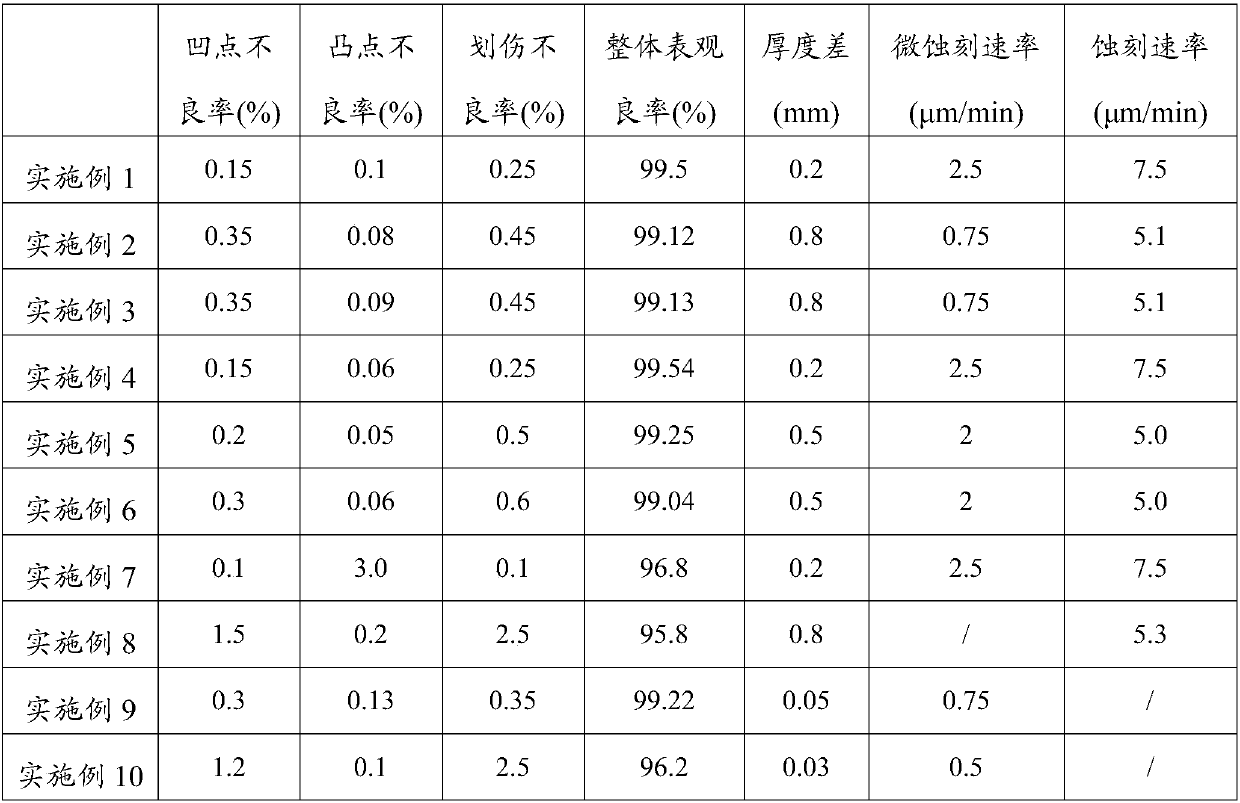

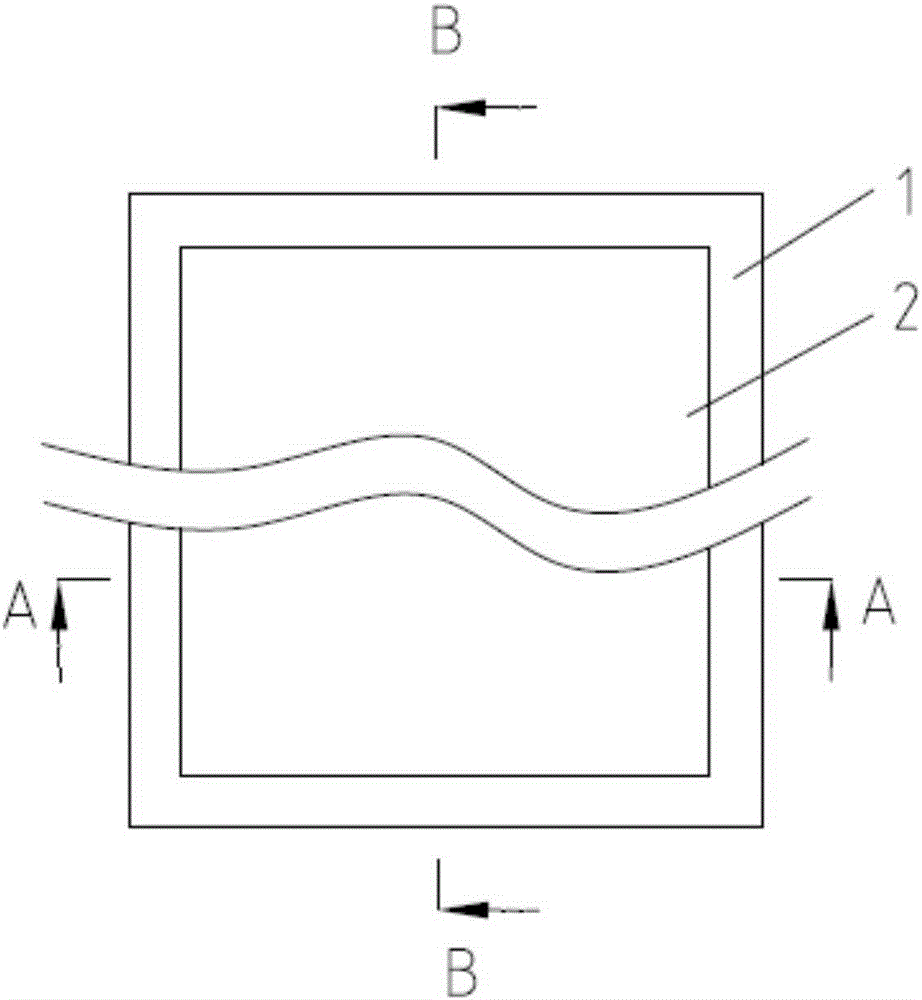

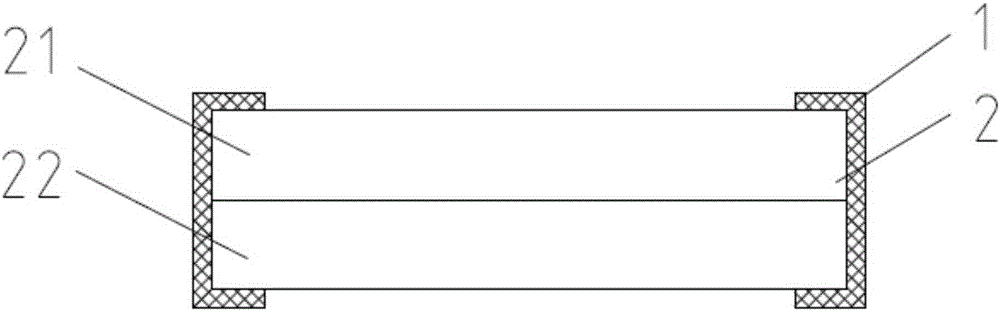

Glass panel thinning method, thinned glass panel and display device

The invention relates to a glass panel thinning method, a thinned glass panel and a display device. The glass panel thinning method comprises the following steps of: cleaning the glass panel; microetching the cleaned glass panel cleaned by a microetching liquid; and etching the microetched glass panel with an etching solution to obtain the thinned glass panel. The thinned glass panel obtained by the thinning method has a lower surface salient point defect rate, a lower concave spot defect rate, and a lower scratch defect rate, and overall apparent yield rate is higher, and no polishing treatment is required.

Owner:WGTECH JIANGXI

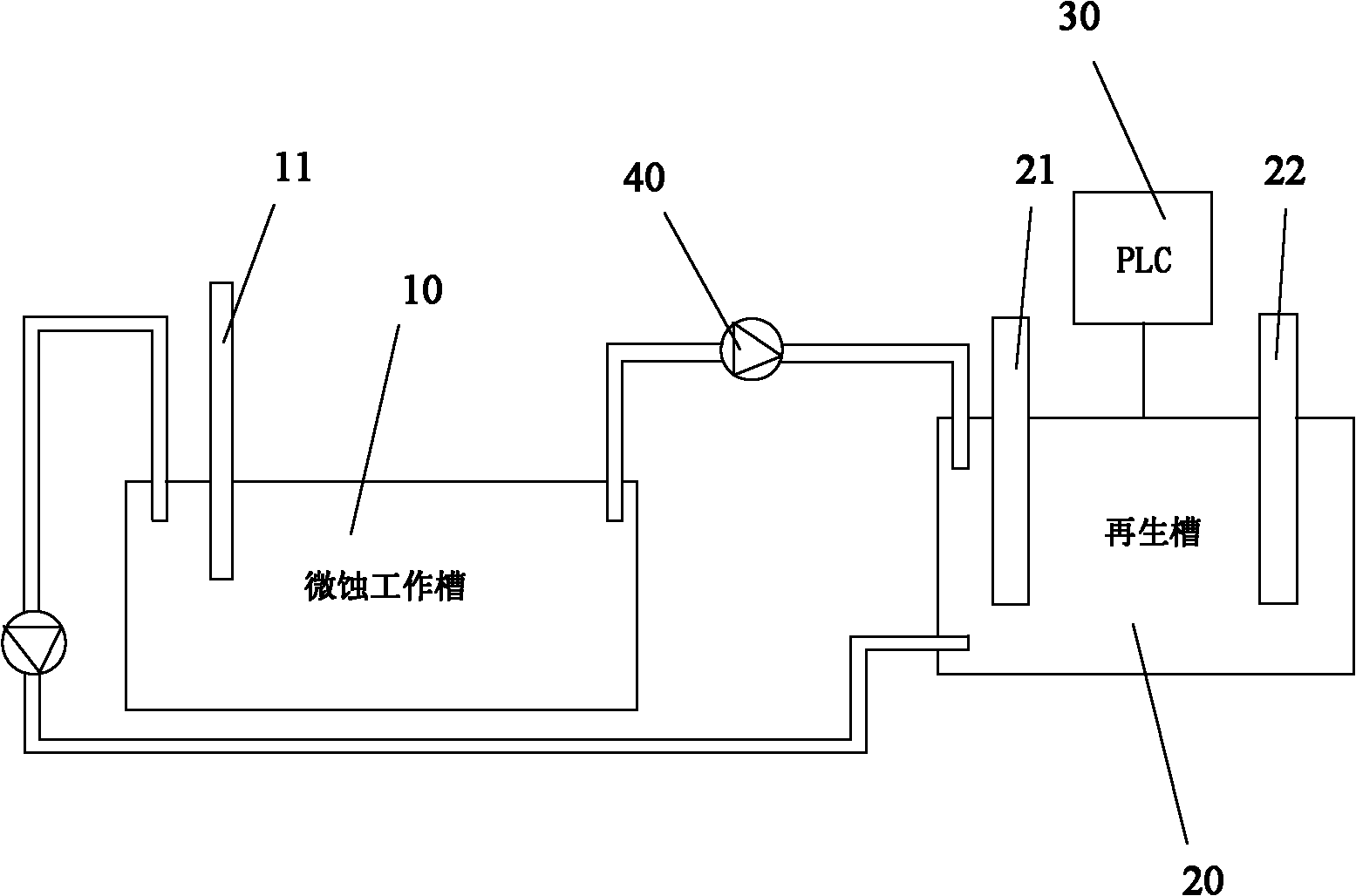

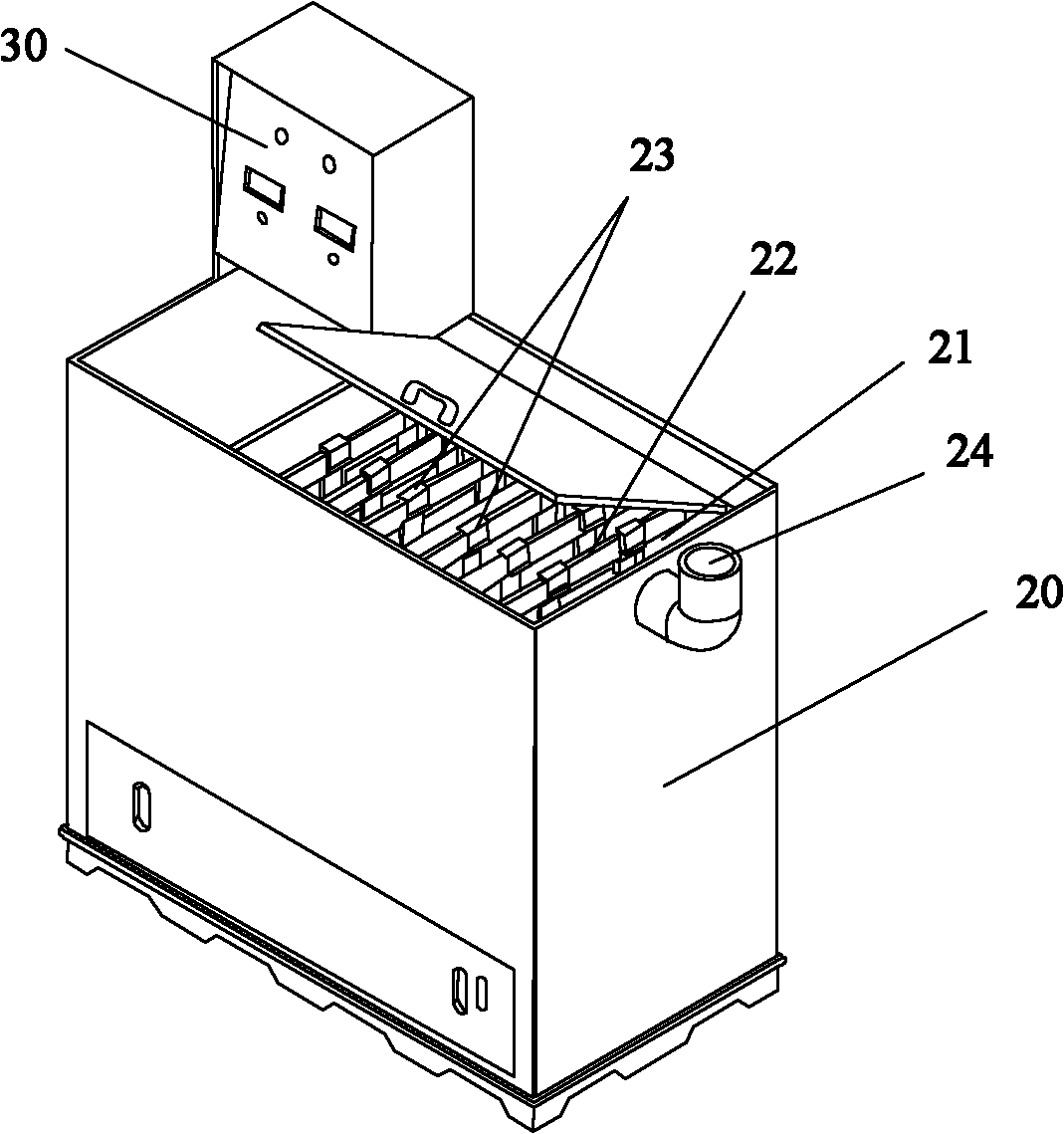

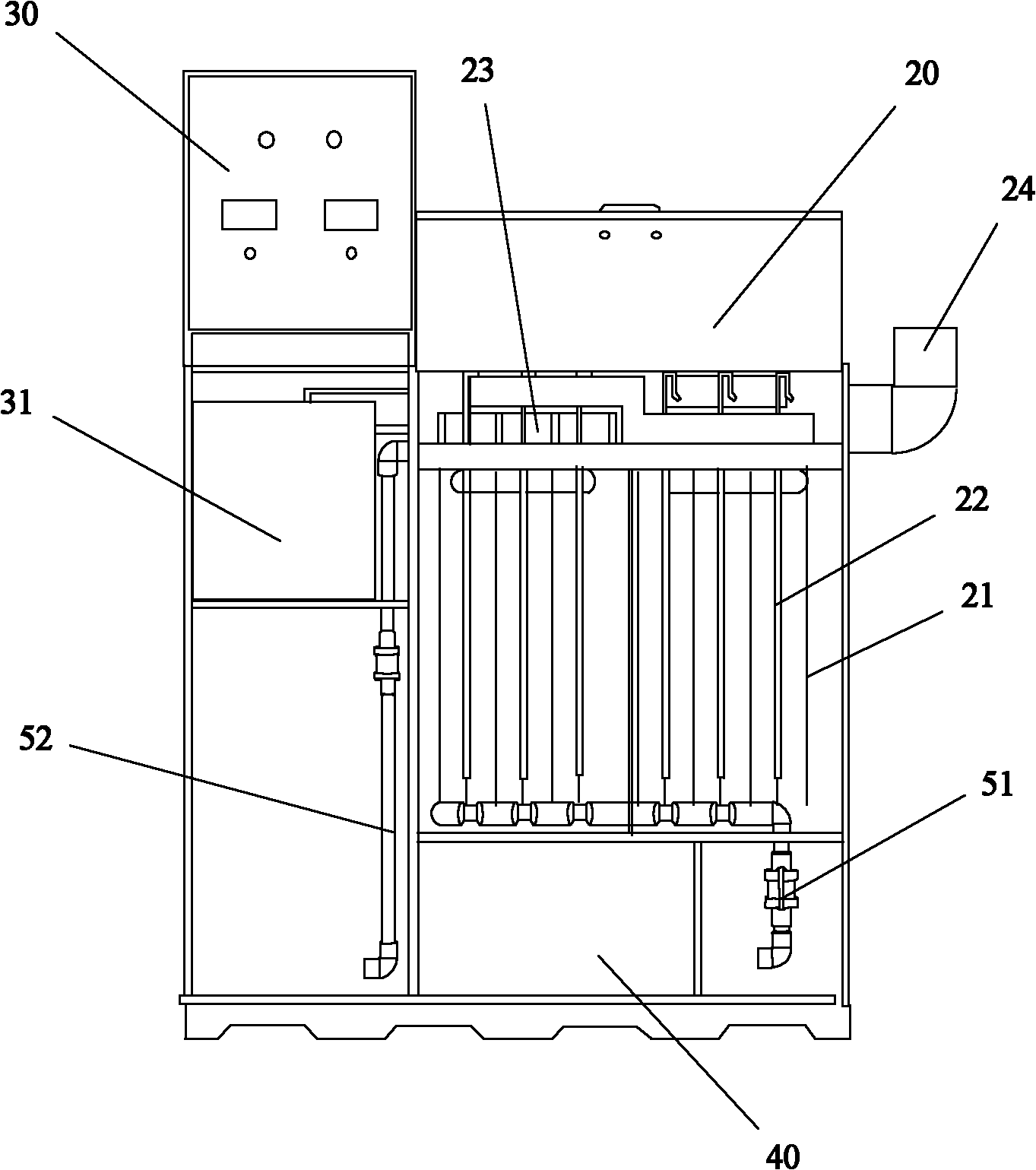

Treating agent and treating system for micro-etching surfaces of recyclable copper and copper alloys

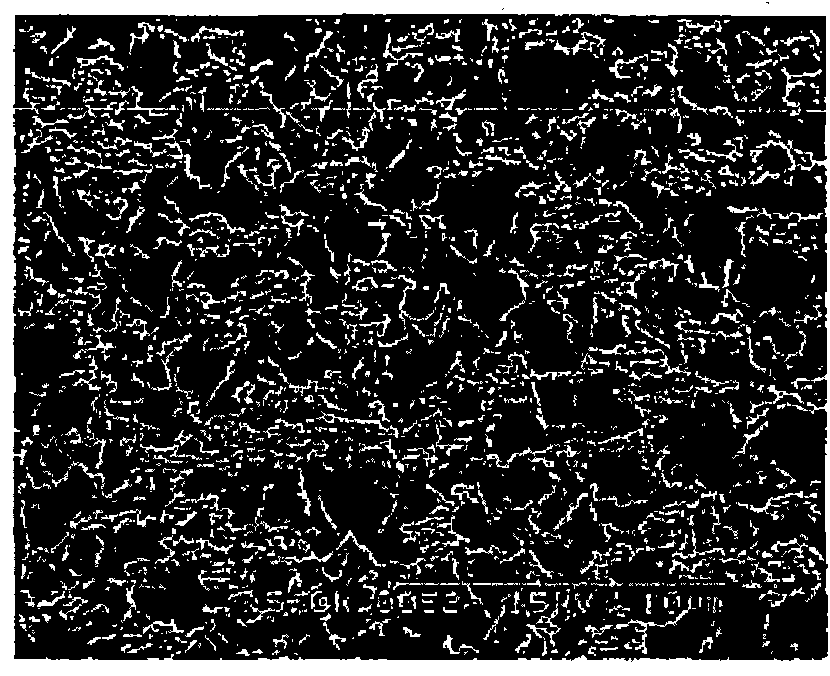

InactiveCN102181865ASuperior Surface MicrostructureIncrease uniform roughnessElectrolysisAutomatic control

The invention discloses a treating agent and treating system for micro-etching surfaces of recyclable copper and copper alloys. The treating agent comprises the following components by weight: 1-20% of sulfuric acid or / and nitric acid, 1.5-35% of ferric sulfate or / and ferric nitrate, 0.005-0.2% of anionic fluorinated surfactant, 0.005-5% of additive and the balance of deionized water. Besides, the treating system comprises a micro-etching working tank, an electrolytic drug regeneration and copper recovery system and an automatic control system for connecting the micro-etching working tank with the electrolytic recovery and regeneration tank and realizing automatic stable control. The circuit board micro-etching regenerative cycle process and equipment have the beneficial effects of reducing the production cost of the micro-etching process, improving the level of the process for micro-etching the surfaces of the copper and copper alloys and achieving the aims of cleaner production and zero emission.

Owner:GUANGDONG SKYCHEM TECH LTD

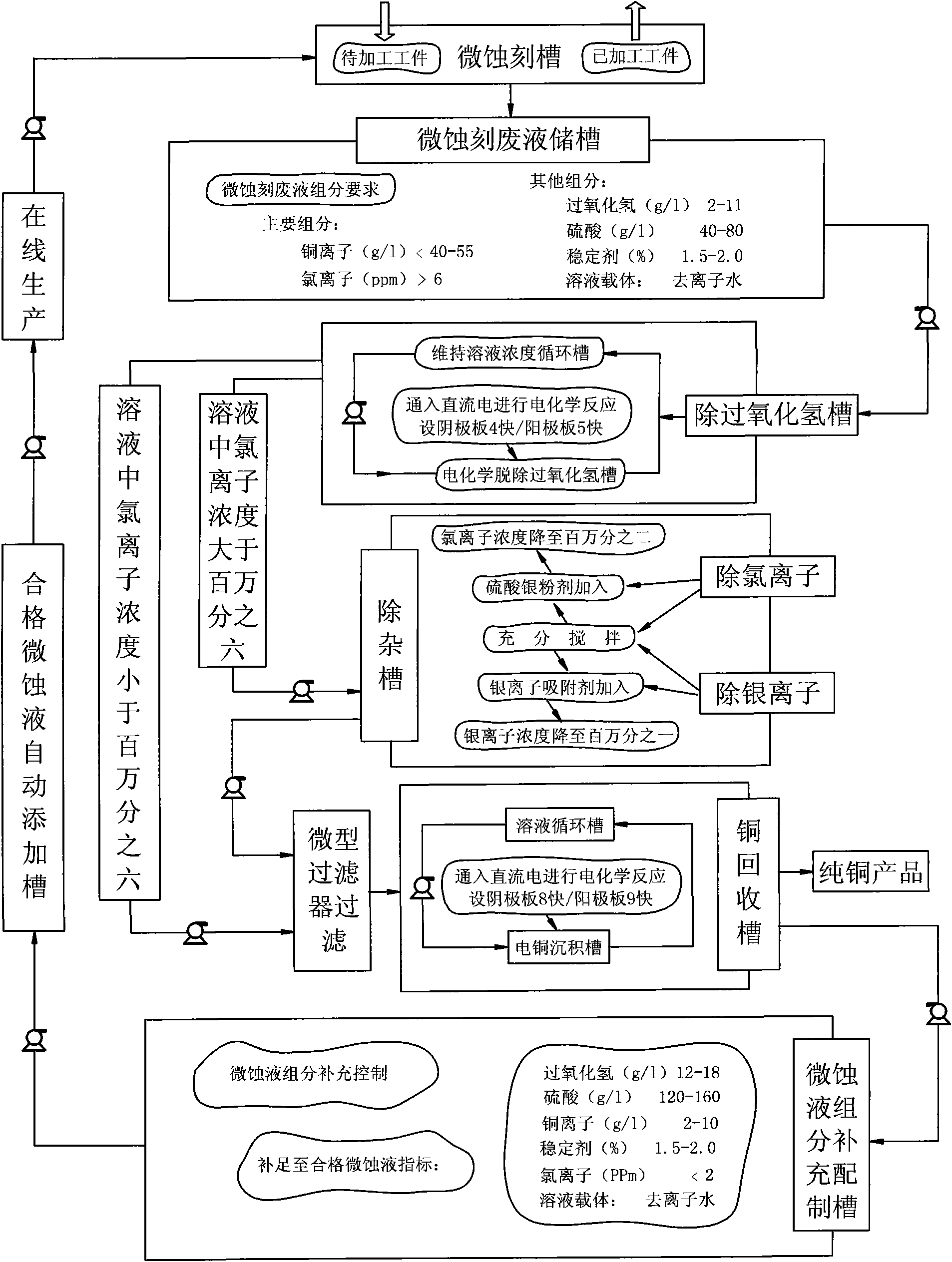

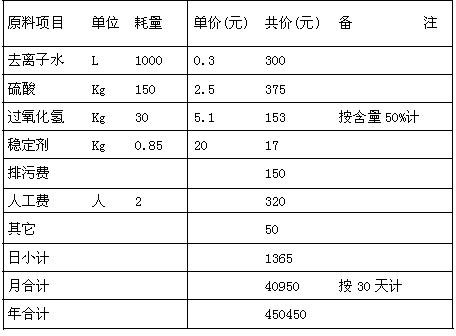

Technology for regenerating and cycling circuit board microetching waste liquid

InactiveCN101608337ASimple processEasy to implementElectrolysis componentsLiquid wasteChemical reaction

The invention relates to a technology for regenerating and cycling circuit board microetching waste liquid, which comprises procedures as follows: peroxide microetching waste liquid generated in the microetching chemical reaction process of processing an online produced workpiece to be processed of a circuit board into a processed workpiece in a microetching bath is taken as the raw material, peroxide, chloridion and silver ions are removed from the raw material, the raw materials recovers pure copper and complements lost components to become a regenerated microetching liquid, and the qualified microetching liquid automatically returns to the circuit board online producing microetching bath for regeneration and cycling. The invention adopts the technical scheme that peroxide microetching waste liquid discharged from online production is used as the raw material, peroxide, chloridion and silver ions are removed from the raw material, the raw material recovers pure copper and complements lost components to become a regenerated qualified microetching liquid, and the qualified microetching liquid automatically returns to the microetching bath and overcomes the defects that the microetching liquid in the circuit board microetching technology adopted by the prior PCB enterprises is discharged just after being treated simply, a great amount of waste is caused during the processing, and resources are lost severely, thereby being suitable for regenerating and cycling of various circuit board microetching waste liquid of circuit board online production enterprises.

Owner:深圳市惠尔能科技有限公司

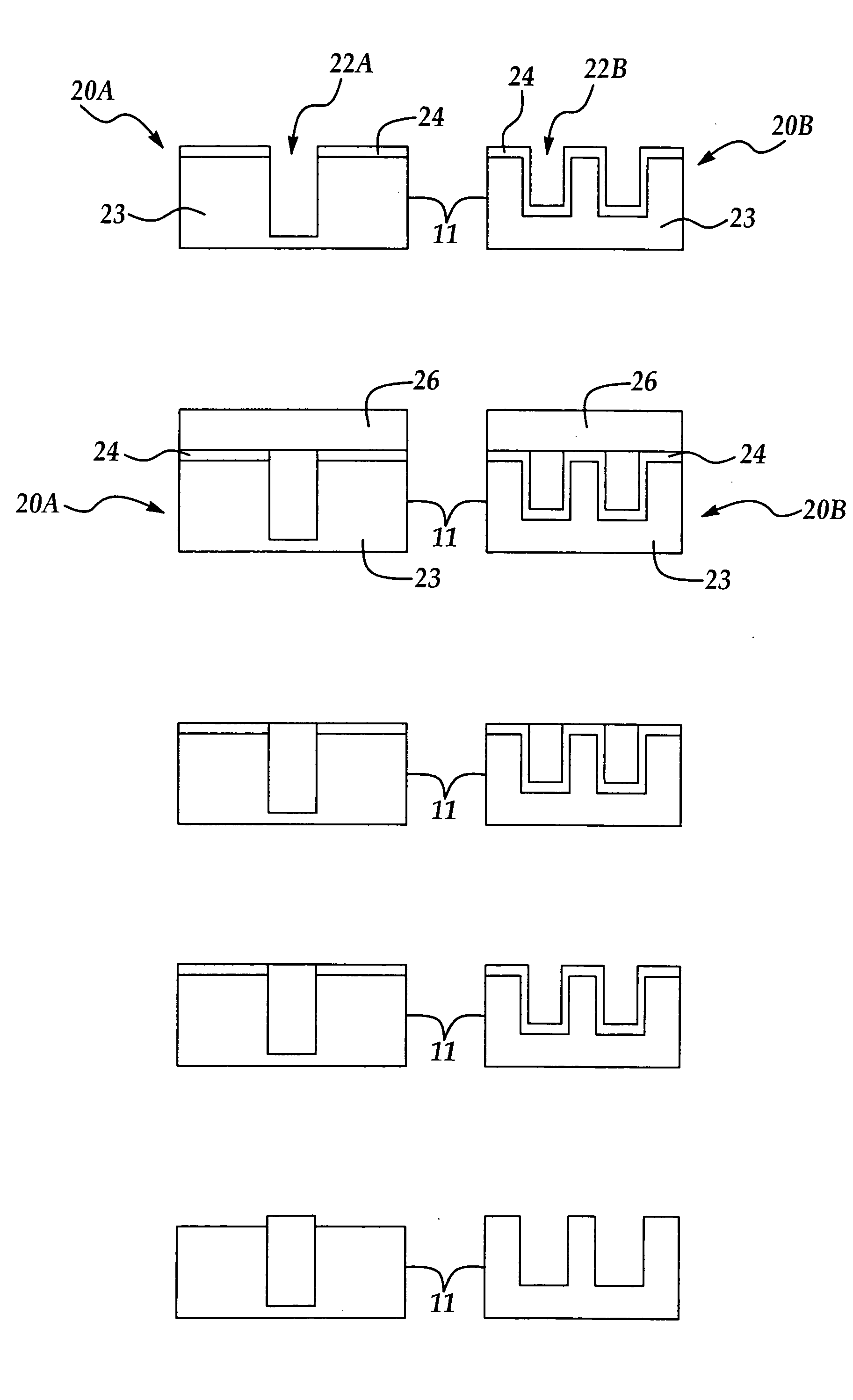

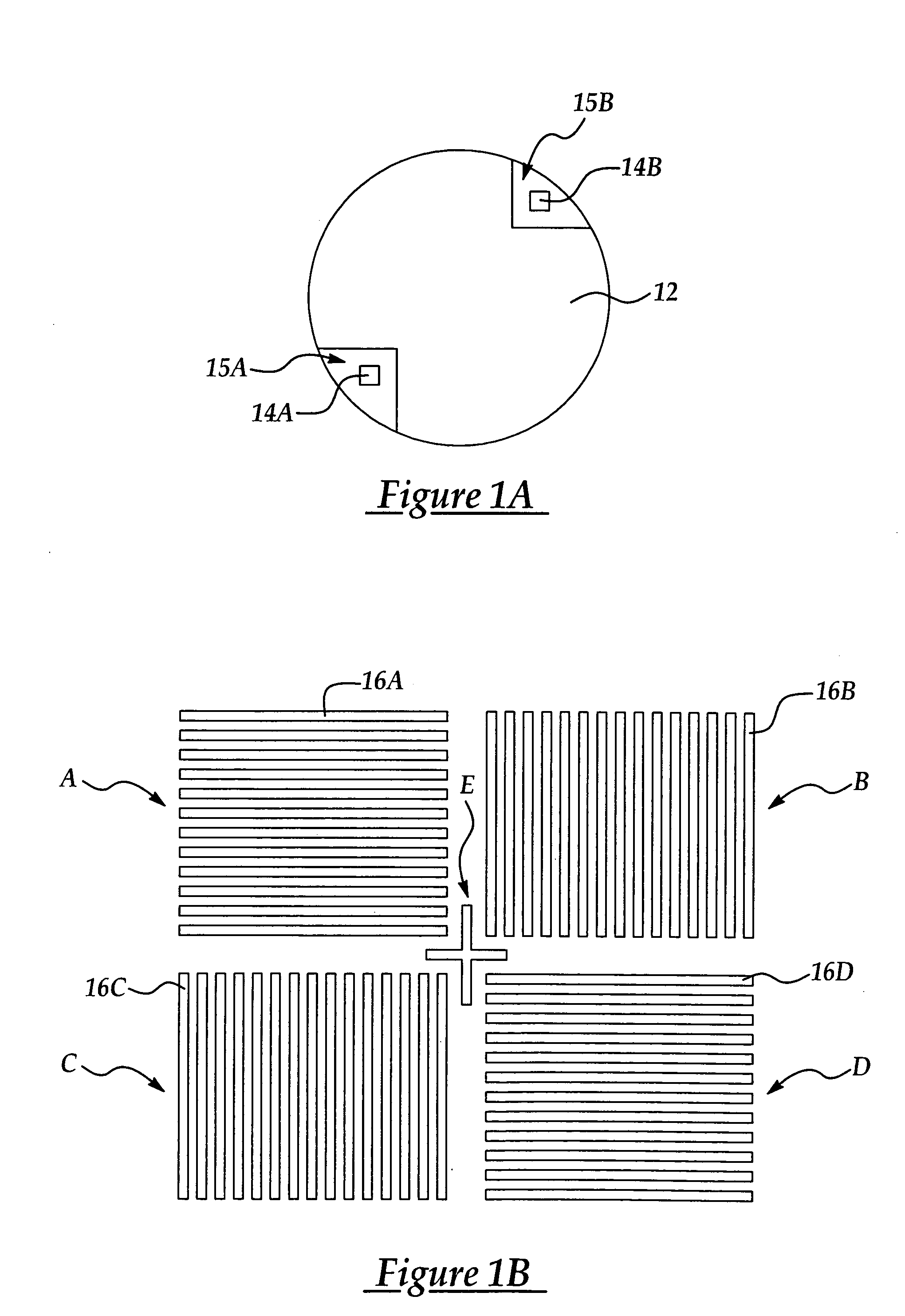

Micro-etching method to replicate alignment marks for semiconductor wafer photolithography

InactiveUS20050282396A1Semiconductor/solid-state device detailsSolid-state devicesSemiconductorPhotolithography

A method and apparatus for locally etching a substrate area the method including providing a substrate comprising a process surface; depositing a material layer over the process surface; and, applying a wet etchant to cover a targeted etching portion of the process surface while excluding an adjacent surrounding area to selectively etch the material layer overlying the targeted etching portion.

Owner:TAIWAN SEMICON MFG CO LTD

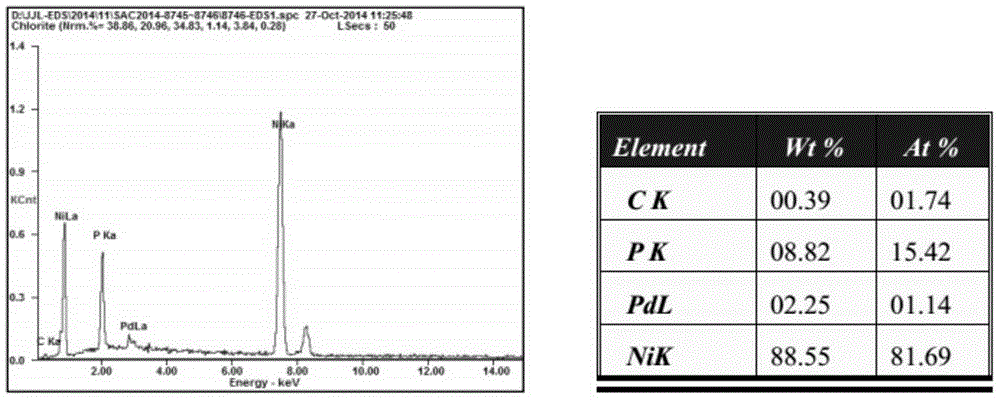

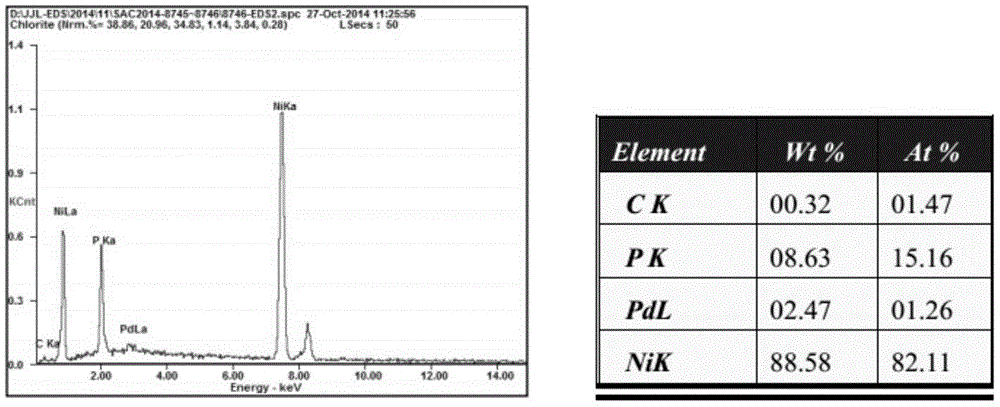

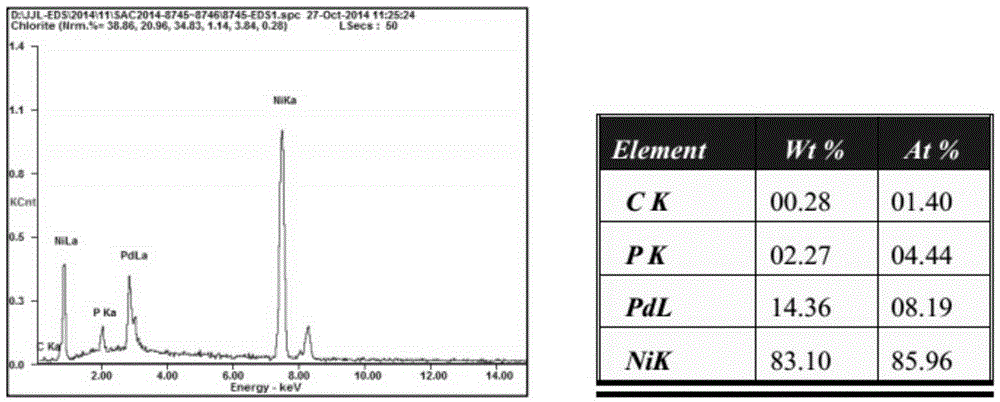

Chemical nickel-palladium alloy plating process for circuit boards

ActiveCN104561943AImprove solderabilityHigh hardnessLiquid/solution decomposition chemical coatingBiological activationFingerprint

The invention discloses a chemical nickel-palladium alloy plating process for circuit boards. The chemical nickel-palladium alloy plating process is characterized by comprising the following steps: (1) degreasing: placing a circuit board in an acidic degreasing agent to remove greasy dirt and fingerprints on the surface of the circuit board; (2) microetching: placing the degreased circuit board in microetching liquid to slightly etch the copper surface; (3) activation: placing the micro-etched circuit board in a palladium activating liquid to be activated, so that a layer of activated palladium is deposited on the surface of the circuit board; (4) chemical nickel plating: placing the activated circuit board in nickel plating liquid so as to deposit a layer of nickel on the copper surface; (5) microetching: placing the circuit board plated with nickel in acid liquid so as to slightly etch the nickel surface; (6) activation: placing the micro-etched circuit board in the palladium activating liquid to be activated, so that a layer of activated palladium is deposited on the surface of the circuit board; (7) chemical nickel-palladium plating: placing the activated circuit board in nickel-palladium alloy plating liquid to be plated, and depositing a nickel-palladium alloy plated layer on the nickel surface; (8) washing and drying the circuit board: washing the board surface to remove medicine liquids in former preparation processes, and drying. Through the adoption of the chemical nickel-palladium alloy plating process disclosed by the invention, the production cost can be reduced effectively, and the application of the surface treatment process of circuit boards is facilitated.

Owner:广东致卓环保科技有限公司

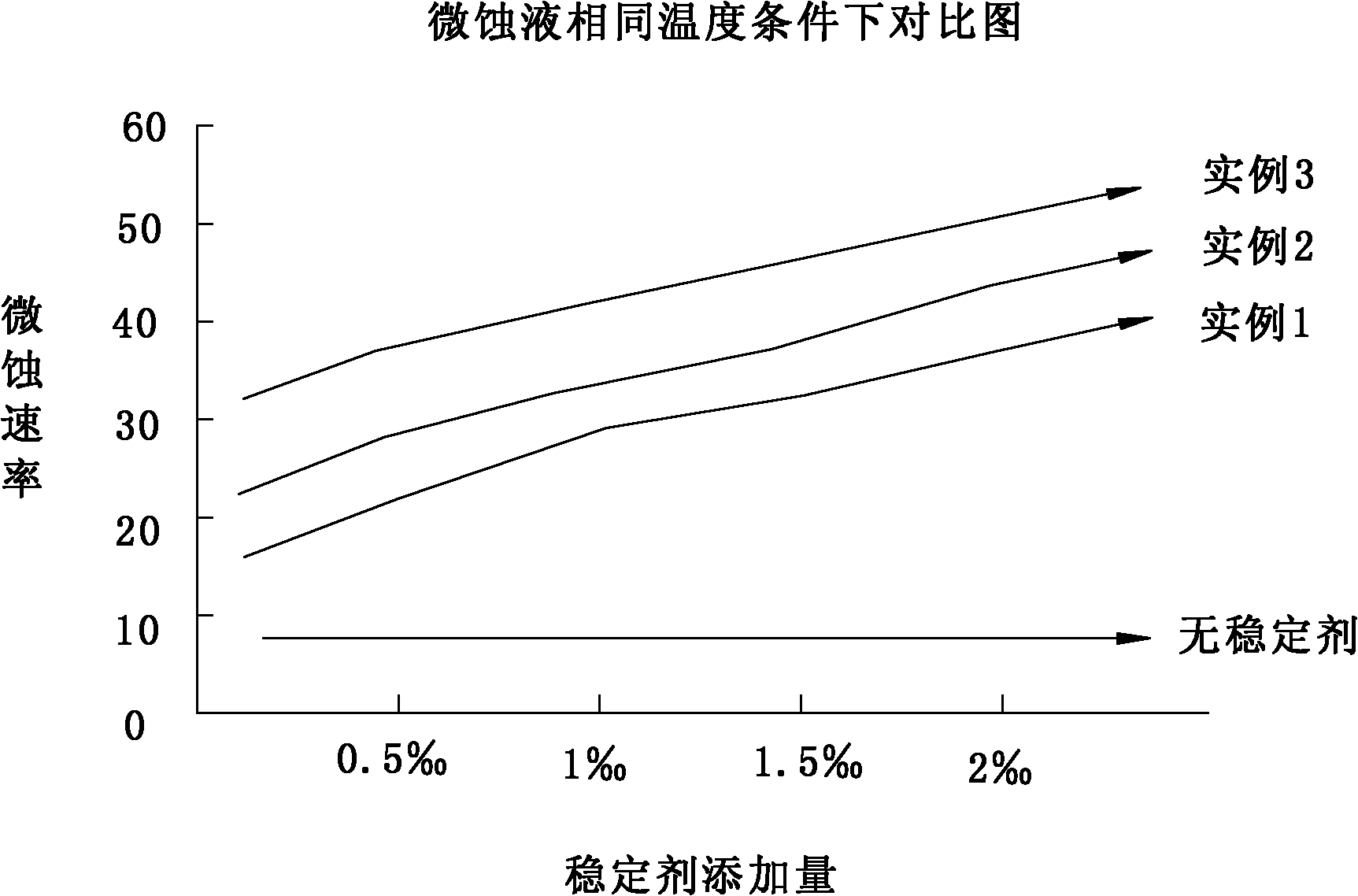

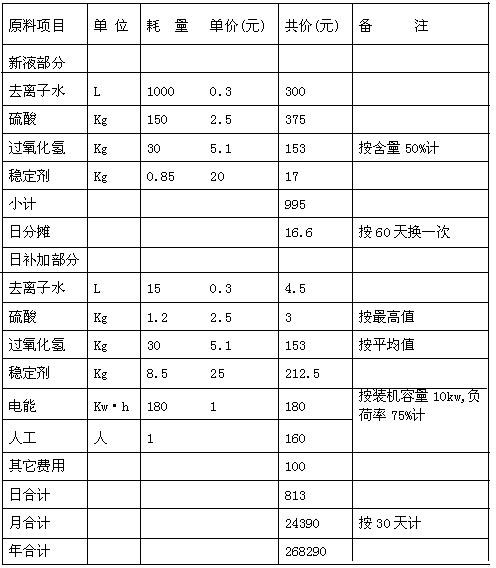

Sulfuric acid/hydrogen peroxide microetchant stabilizer and preparation method thereof

The invention is applied in the field of microetching, and provides a sulfuric acid / hydrogen peroxide microetchant stabilizer and a preparation method thereof. The sulfuric acid / hydrogen peroxide microetchant stabilizer comprises the following components in percentage by weight: 3 to 6 percent of alcohol, 10 to 15 percent of organic amine, 2 to 5 percent of sulfonic acid and 40 to 85 percent of water. High-negativity O and N atoms of the alcohol, the organic amine and the sulfonic acid in the stabilizer form hydrogen bonds with free groups [HO.2] decomposed by hydrogen peroxide, so the sulfuric acid / hydrogen peroxide microetchant stabilizer effectively reduces the activity of the [HO.2], greatly reduces the decomposition of the hydrogen peroxide, maintains the concentration of the hydrogen peroxide in microetchant, and ensures stable microetching rate in the microetching process of the sulfuric acid / hydrogen peroxide (H2SO4 / H2O2) microetchant, and smooth, uniform and non-black board surfaces after the microetching.

Owner:SHENZHEN JECH TECH

Method for plating tin on aluminum and aluminum alloy coiled material

The invention discloses a method for tinning aluminum and aluminum alloy coils. After the coils are unrolled, the following main steps are successively and continuously carried out: (1) degreasing, degreasing and pickling of the coil surfaces; (2) coiling Zinc immersion on the surface twice; (3) Nickel plating on the zinc layer and activation; (4) tin plating on the nickel layer, passivation after micro-etching; (5) use of organic matter to block micropores on the surface of the tin layer; (6) The coil is blown and dried. The invention realizes the continuous electroplating process of aluminum and aluminum alloy coils, that is, the tinning process of aluminum and aluminum alloy coils. The electroplated products have good electrical conductivity, strong weldability, fast heat dissipation, light weight, easy stamping, Low cost and other characteristics, the aluminum material after electroplating has the properties of tin material, which can achieve the purpose of replacing tin material.

Owner:尼尔金属(苏州)有限公司

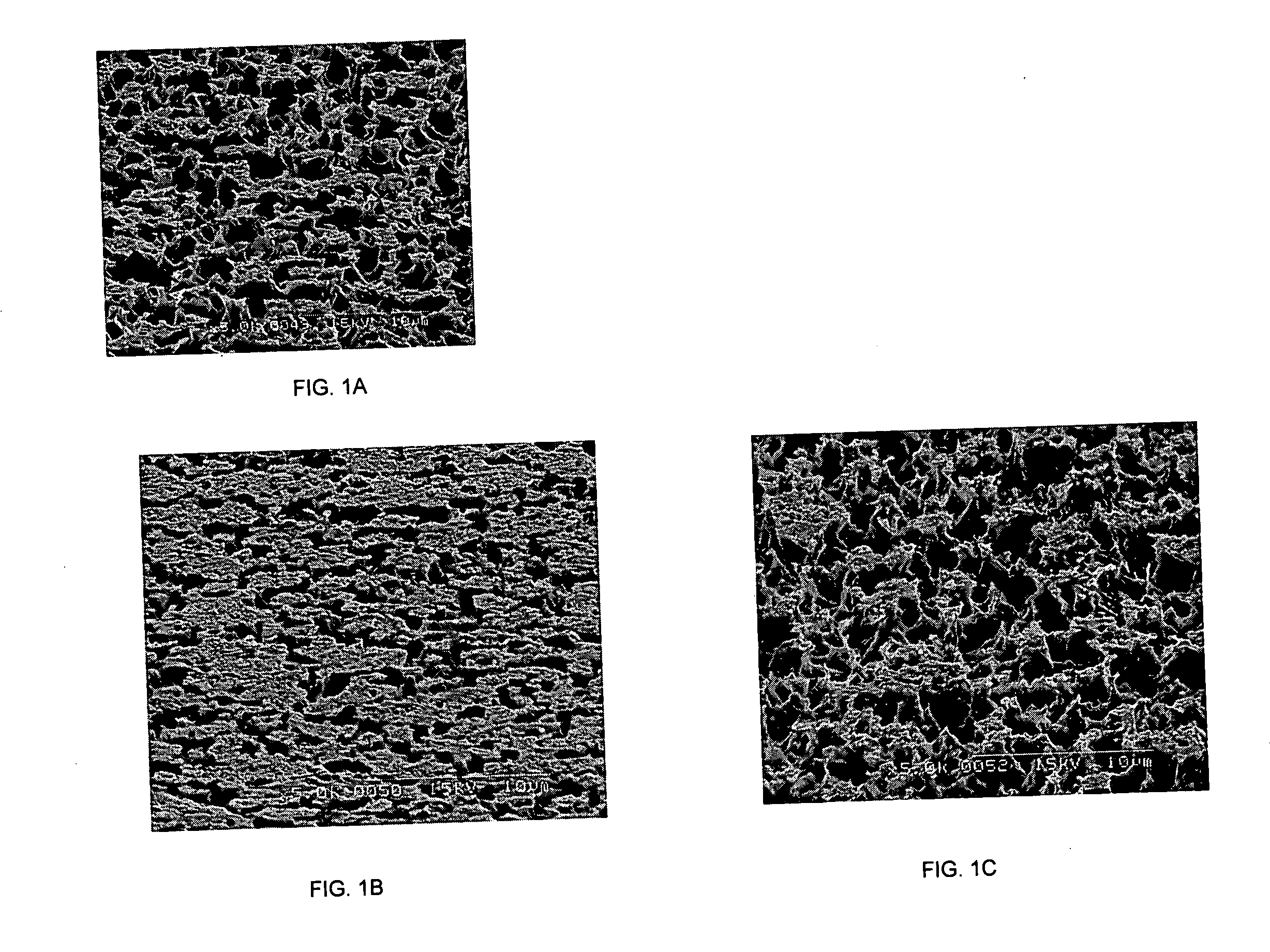

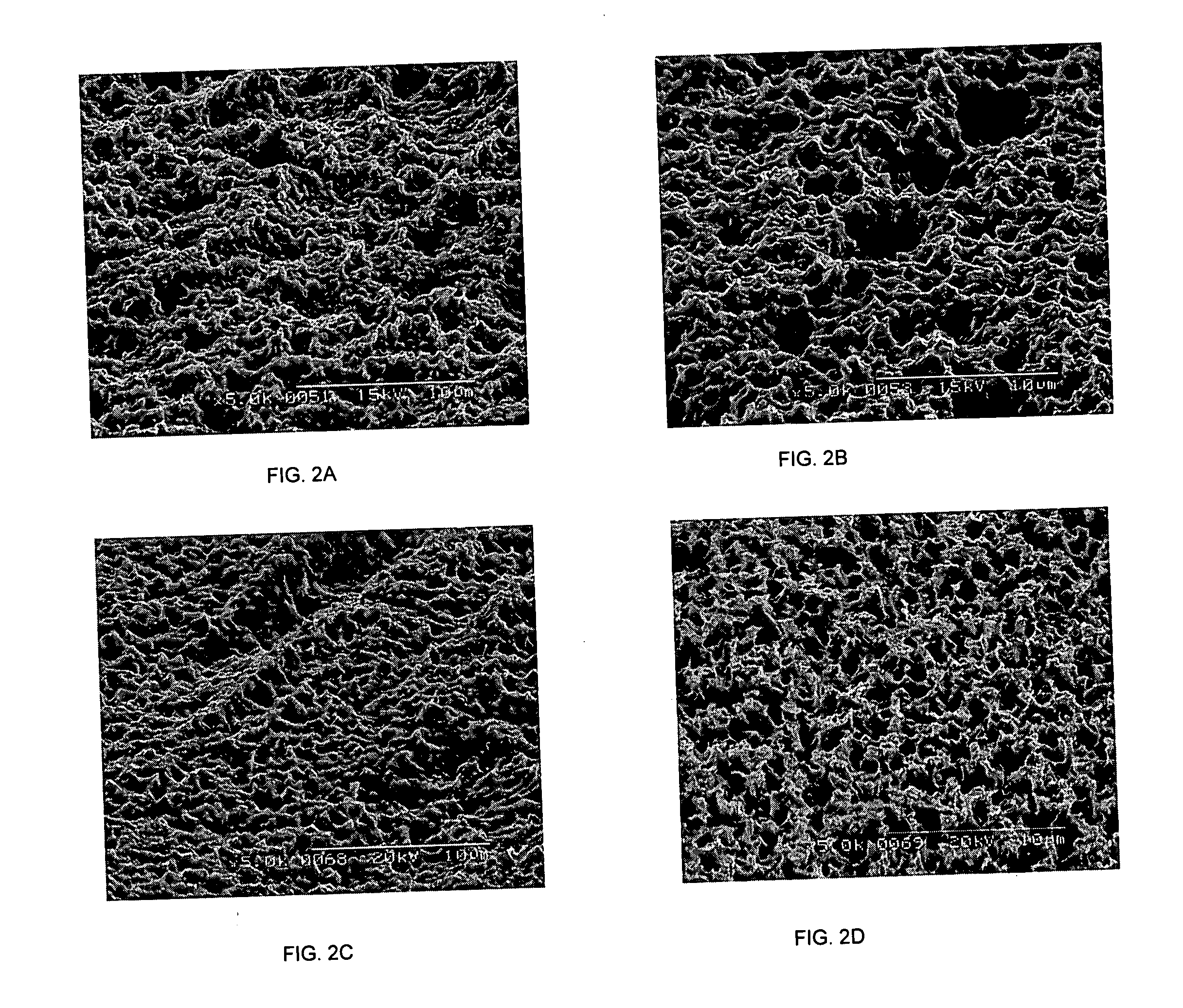

Microetching composition and method of using the same

InactiveCN101778923ALess quantityGood adhesion promotionPrinted circuit manufactureSurface treatment compositionsOrganic solventCupric Ion

The present invention is directed to a microetching composition comprising a source of cupric ions, acid, a nitrile compound, and a source of halide ions. Other additive, including organic solvents, a source of molybdenum ions, amines, polyamines, and acrylamides may also be included in the composition of the invention. The present invention is also directed to a method of microetching copper or copper alloy surfaces to increase the adhesion of the copper surface to a polymeric material, comprising the steps of contacting a copper or copper alloy surface with the composition of the invention, and thereafter bonding the polymeric material to the copper or copper alloy surface.

Owner:MACDERMID INC

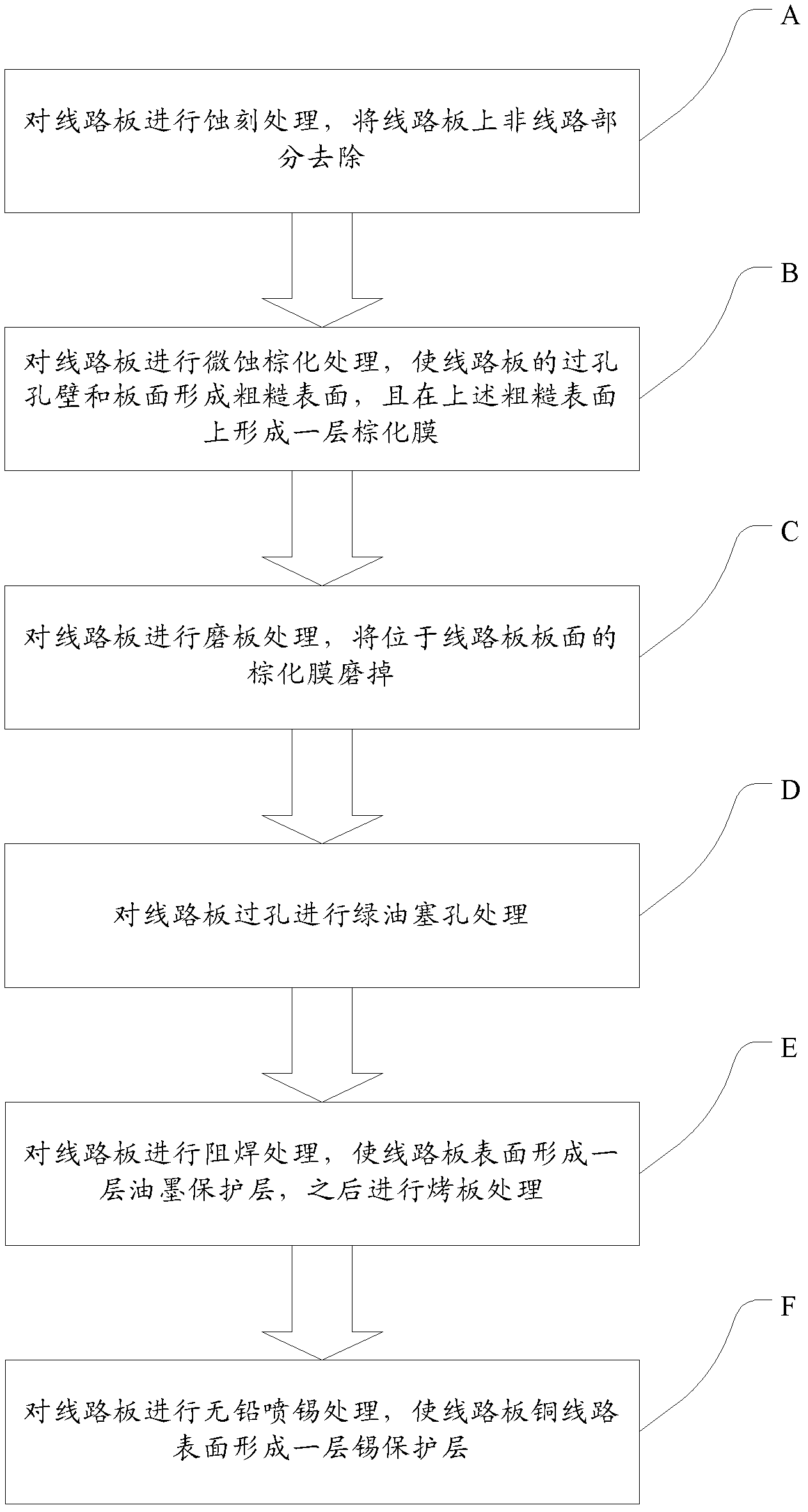

Method of preventing via hole from oil dropping in lead-free HASL process of circuit board

ActiveCN102883544AGuaranteed not to fall offThere will be no oil lossConductive pattern reinforcementPrinted element electric connection formationHot air solder levelingHigh heat

The invention discloses a method of preventing a via hole from oil dropping in the lead-free HASL (Hot Air Solder Leveling) process of a circuit board, which comprises the steps of etching, microetching and brownification, volcanic ash scrubbing, green oil jacking, solder resisting and lead-free HASL. According to the method, a microetching and brownification procedure is added after the etching, and a hole wall is subjected to micro coarsening to increase the adhesion of jacking green oil to the hole wall, thereby achieving the purpose of preventing the subsequent lead-free HASL technology from resulting in the oil dropping of the via hole due to high temperature. Compared with the prior art, the method solves the problem of oil dropping of the via hole in the green oil jacking in the lead-free HASL technology, the technology is simple, and the product quality is improved effectively.

Owner:SHENZHEN SUN & LYNN CIRCUITS

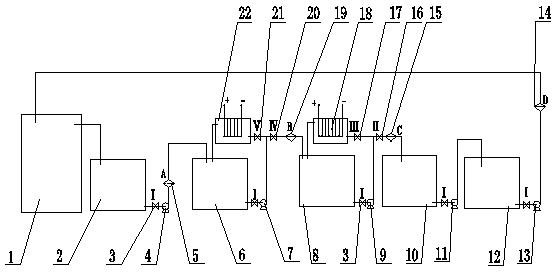

Device for regenerating waste microetching liquid and recovering copper

InactiveCN101974756ASolve the costLow costPhotography auxillary processesProcess efficiency improvementLiquid wasteLiquid copper

The invention discloses a device for regenerating waste microetching liquid and recovering copper. A processed workpiece is formed in a microetching groove by a workpiece to be processed of a circuit board; hydrogen peroxide and sulfuric acid solution are taken as microetching liquid in the process; copper oxide and minute quantity of metallic copper on the surface of the workpiece are removed to lead the concentration of microetching liquid copper ion to be increased into the waste microetching liquid; the remnant hydrogen peroxide in the waste microetching liquid is removed; the copper ion is electrodeposited as the metal copper; and the lost components in the microetching liquid are replenished to qualified microetching liquid which is returned to the regenerating cycle process of the microetching groove. The device overcomes the defects that the waste microetching liquid in the circuit board microetching process of the existing circuit board enterprises is only simply processed to be discharged immediately, the processing procedure has large wastes, and serious resource loss; and the device is suitable for the regenerating cycle of copper-containing waste microetching liquid of the circuit board and the copper recovering in the various circuit board production enterprises.

Owner:罗忠凯

Method for treating microetching liquid waste and copper sulfate liquid waste

ActiveCN103787400AEfficient removalReduce dosageCopper oxides/halidesCopper sulfatesLiquid wasteChemical oxygen demand

The invention discloses a method for treating microetching liquid waste and copper sulfate liquid waste. The method is characterized in that usable materials in the microetching liquid waste and copper sulfate liquid waste are utilized, and the reasonable process conditions are controlled, so as to reach the purpose of treatment of wastes with processes of wastes against one another; in addition, the COD (Chemical Oxygen Demand) value in the mixed solution of the microetching liquid waste and copper sulfate liquid waste is greatly decreased, the copper-iron separation is effectively carried out, and as a result, copper ions in the microetching liquid waste and copper sulfate liquid waste can be further recycled. According to the method, the COD in the prepared mixed copper-containing liquid waste is decreased by more than 98.5%; under the control on the process conditions, the copper-containing acid liquid obtained by the method can be used for producing electroplating grade copper oxide or electroplating grade copper sulfate, and thus the waste is turned into wealth.

Owner:GUANGZHOU KECHENG ENVIRONMENTAL PROTECTION TECH

Manufacturing process of fine circuits of printed circuit board

ActiveCN101977480AImprove yieldImprove qualityConductive material chemical/electrolytical removalEngineeringCopper foil

The invention relates to the field of printed circuit board (PCB) manufacturing, in particular to a manufacturing process of fine circuits of a printed circuit board. The process comprises the following steps of: 1) manufacturing internal patterns, and performing AOI scanning; 2) laminating a copper foil; 3) microetching the printed circuit board to reduce copper; 4) drilling; 5) electroplating and transferring external patterns; and 6) electroplating and etching the patterns, wherein mixed liquid medicine of which H2SO4 and H2O2 serve as active ingredients is adopted to perform microetching in step 3). Compared with the prior art, the manufacturing process has a simple process flow and high operability. The final printed circuit finished board has high yield and stable quality and is suitable for mass production.

Owner:HUIZHOU ZHONGJING ELECTRONICS TECH CO LTD

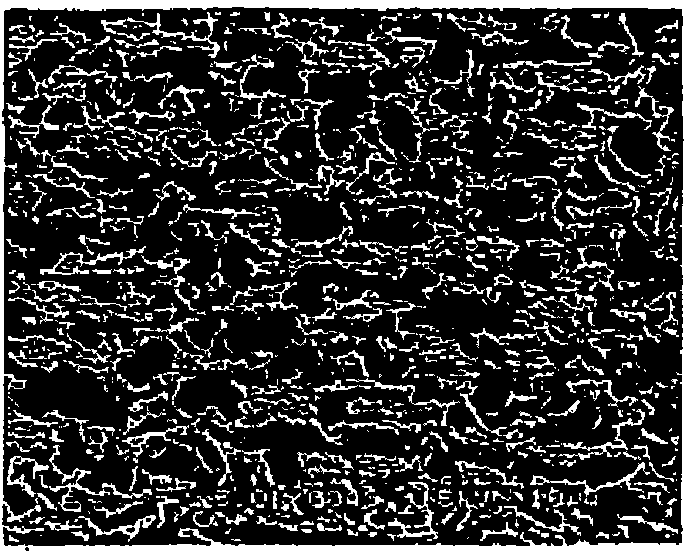

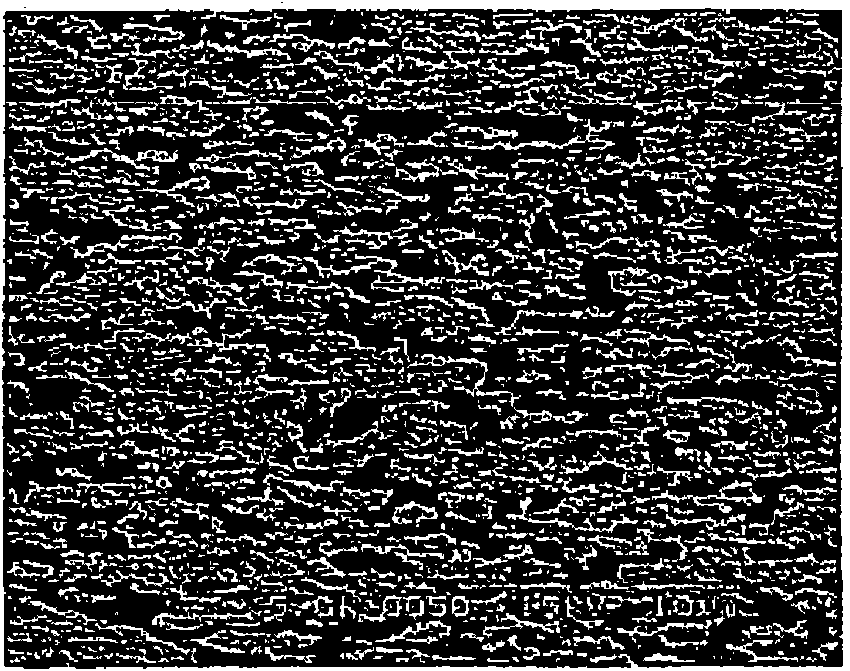

Microetching and roughening liquid for copper surface and preparation method thereof

The invention relates to a microetching and roughening liquid for a copper surface. The microetching and roughening liquid comprises the following components by mass concentration: 5-50 g / L bivalent copper ions from a copper ion source, 20-150 g / L organic acid, 3-105 g / L chloride ions from a chloride ion source, a 0.0005-2 g / L water-soluble polymer and a 0.001-10 g / L pyridine derivative; a solventis water; the organic acid is at least one of formic acid, acetic acid, malic acid, citric acid, tartaric acid, edetic acid, iminodisuccinic acid, monochloro acetic acid, dichloroacetic acid and trichloroacetic acid; and the water-soluble polymer is a polymer of which a molecular chain contains a Imidazole or ammonium salt structure. The microetching and roughening liquid can form uniform roughening on the copper surface, is not affected by the crystal structure of the copper surface, and in the follow-up processes, can effectively increase the adhesive force of a solder-resist coating with which the copper surface is coated.

Owner:KUNSHAN CITY BANMING ELECTRONICS SCI & TECH

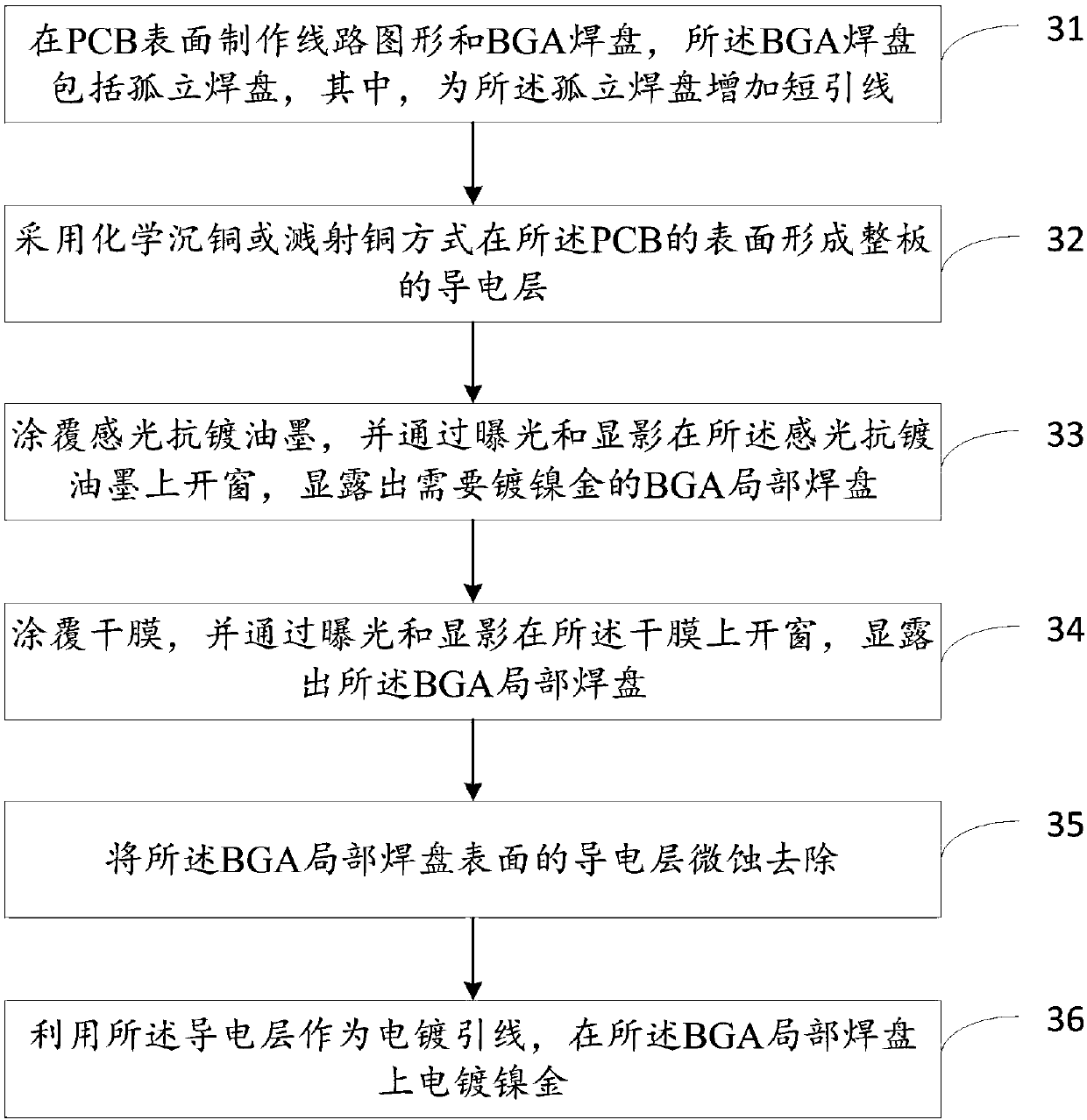

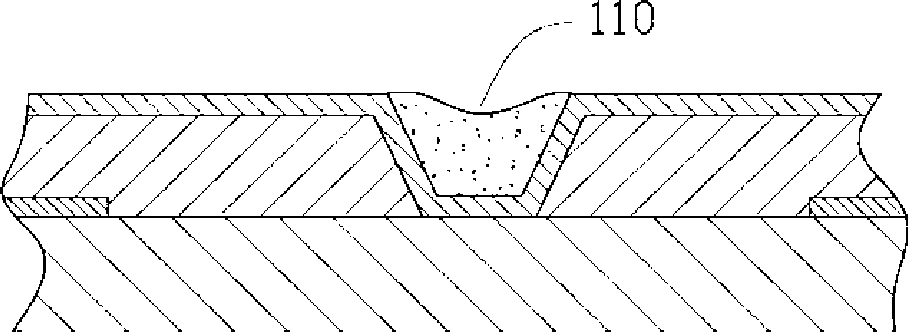

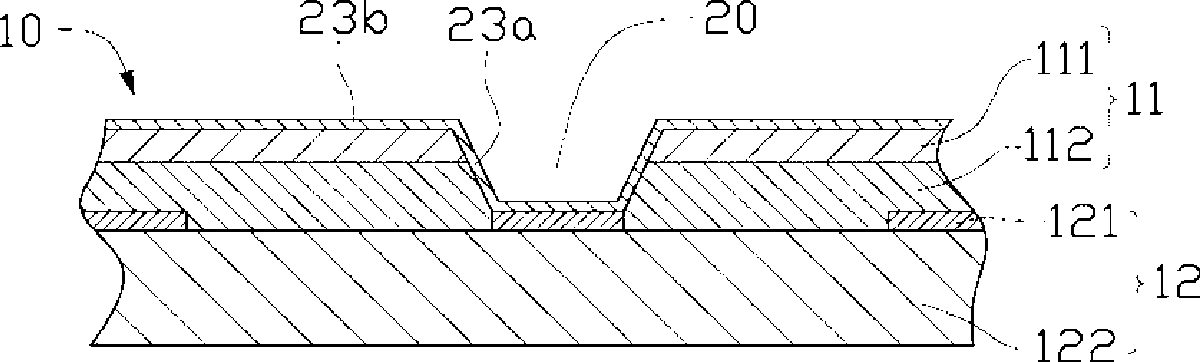

Manufacturing method of BGA partial pad gold plating for PCB

ActiveCN107645844ASolve the problem of nickel-plated goldSolve the problem of nickel and gold falling off easilyConductive material chemical/electrolytical removalConductive pattern reinforcementGold platingNickel electroplating

The invention discloses a manufacturing method of BGA partial pad gold plating for a PCB. The manufacturing method comprises the steps of manufacturing a circuit pattern and a BGA ad on the surface ofthe PCB, wherein the BGA pad comprises an isolated pad; adding a short lead to the isolated pad; forming a conductive layer of the whole plate on the surface of the PCB by adopting a chemical copperdeposition or sputtering mode; coating a photosensitive anti-plating ink on the surface of the PCB; windowing on the photosensitive anti-plating ink through exposure and development to expose a BGA partial pad requiring nicke-gold plating; continuously coating a dry film on the surface of the PCB; windowing in the dry film through exposure and development to expose the BGA partial pad; microetching and removing the conductive layer on the surface of the BGA partial pad; and plating nickel-gold on the BGA partial pad. The problem of nickel-gold plating of an isolated pad is solved, the bondingforce of a plating layer can be improved, and the nickel-gold can be prevented from falling.

Owner:SHENNAN CIRCUITS

Acid etching solution used for copper or copper alloy surface and surface treatment method

InactiveCN101230461ASimple processing methodPlay the role of cleaning and degreasingAcid etchingOxidation resistant

The invention relates to an acidic microetching solution used for the surface of copper or copper alloys, is characterized in that the solution contains poly-guanidine. The invention still relates to a method of treating the surface of copper or copper alloys and includes the following steps: firstly, the acidic microetching solution of the invention is used for contacting the surface of copper or copper alloys; and secondly, the surface is covered by an organic coating. Compared with the prior art, the invention has the advantages that the following requirements can be met at the same time, i.e. firstly, the copper surface is provided with a desirable roughness, which can provide enough adhesive power for the combination of the copper surface and the organic coating (a dry film for example); secondly, the treated copper surface is light-colored, friction-resistant and oxidation-resistant; thirdly, the copper surface does not need cleaning in advance, and the microetching and degreasing can be accomplished at the same time; and fourthly, the microetching amount can be as small as possible to meet the lamination requirement of the selective dry film.

Owner:SHANTOU ULTRASONIC PRINTED BOARD NO 2 FACTORY

Microetching processing method used before copper deposition of printed circuit board

InactiveCN101935838AReduce microetch depthReduce consumptionInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentSewageMaterials science

The invention discloses a microetching processing method used before the copper deposition of a printed circuit board, belongs to the technical field of processing of the printed circuit board and aims to provide circuit board processing technology with long using period of microetching solution, low consumption of metal copper and small sewage quantity. The key point of the technical scheme is that: after being subjected to the conventional preprocessing, the printed circuit board which needs to be subjected to the copper deposition is put into a microetching solution tank to be subjected to microetching processing, wherein the microetching depth of a copper layer of the printed circuit board during the microetching processing is controlled in the range of 0.2 to 0.5 micron. The microetching processing method is used for the microetching processing of the printed circuit board.

Owner:BOMIN ELECTRONICS CO LTD

Circuit board manufacturing method and circuit board

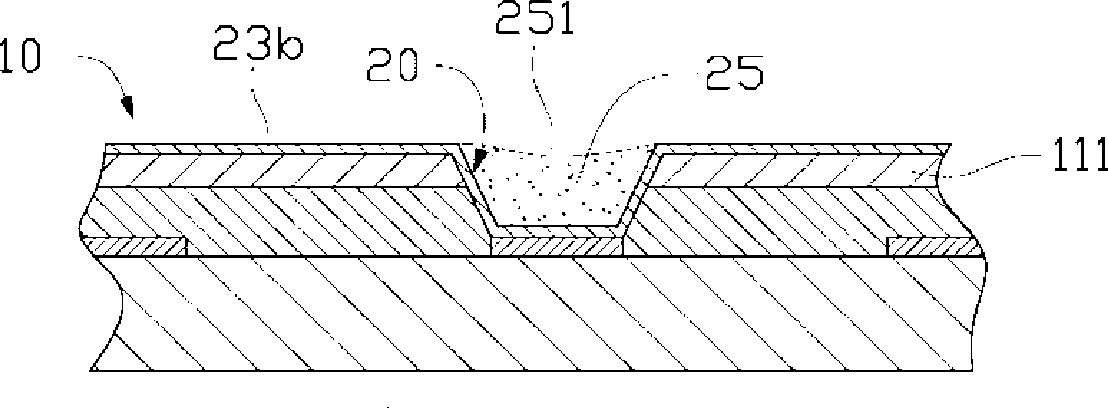

InactiveCN101460011AReduce thicknessEasy to manufacturePrinted circuit detailsPrinted element electric connection formationFine lineHigh density

The invention provides a manufacture method for circuit board, which comprises providing a copper-coating base plate with at least a guide hole, connecting the conductive layer of the guide hole and a copper layer on the surface of the copper-coating base plate, filling the guide hole with filling material, arranging a guide hole baffle strip on the copper layer of the copper-coating base plate to completely cover the guide hole, micro-etching the copper layer of the copper-coating base plate outside the guide hole baffle strip to form a convex portion besides the guide hole which is filled with filling material, and removing the convex portion to ensure that the surface of filling material and the surface of the copper layer of the copper-coating base plate are in the same level. The invention also provides a circuit board made according to the method. The manufacture method for circuit board of the technical proposal effectively avoids pore depression of the guide hole during circuit board manufacture, ensures facial flatness of the copper-coating base plate, and reduces the depth of the copper layer of the copper-coating base plate, which benefits to manufacture high-density fine lines.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Microetching composition and method of using the same

ActiveUS20080041824A1High bonding strengthImprove bindingDecorative surface effectsSemiconductor/solid-state device manufacturingOrganic solventCupric Ion

The present invention is directed to a microetching composition comprising a source of cupric ions, acid, a nitrile compound, and a source of halide ions. Other additive, including organic solvents, a source of molybdenum ions, amines, polyamines, and acrylamides may also be included in the composition of the invention. The present invention is also directed to a method of microetching copper or copper alloy surfaces to increase the adhesion of the copper surface to a polymeric material, comprising the steps of contacting a copper or copper alloy surface with the composition of the invention, and thereafter bonding the polymeric material to the copper or copper alloy surface.

Owner:MACDERMID ACUMEN INC

Technological method for deburring steel piece through chemical milling

InactiveCN102337102AEasy to useLow costOther chemical processesLapping machinesBenzoic acidMaterials science

The invention relates to a technological method for deburring a steel piece through chemical milling. The technological method comprises the following steps: mixing chemical raw materials hydrogen peroxide H2O2, ammonium bifluoride NH4HF2, carbamide CO(NH2)2, benzoic acid C6H5COOH and a small amount of additives according to a certain volume / weight ratio to obtain a concentrated solution, and then mixing with water according to a volume ratio of 1:(2-4) to obtain a chemical milling liquid; and carrying out ultrasonic deoiling, degreasing, microetching and cleaning on a punched piece or finished steel piece, immersing in the chemical milling liquid prepared in the step (1), and soaking for 30-90 seconds while ensuring the temperature of the chemical milling liquid to be 10-35 DEG C, thus cleanly deburring the piece. The technological method has the characteristics of convenient use, low cost, reliable operation process, good deburring effect and the like, and is comparable with CPL-100. Besides, the technological method is more than 100 times cheaper than CPL-100.

Owner:PHENIX OPTICAL CO LTD

Microetching method on ABS engineering plastic element surface without chromium pollution

The invention relates to a method for processing microetching of the surface of ABS engineering plastic parts without chromium pollution, which consists of the steps of oil removal, swelling, microetching treatment and neutralization reaction. The steps of microetching treatment are that 20-50g of MnO2 is added into 1L of sulfuric acid aqueous solution with the concentration of 77.7-86.3 percent, thus obtaining MnO2H2SO4 microetching solution; after swelling, the ABS engineering plastic parts are soaked into the microetching solution for stirring and microetching treatment for 10-40 minutes at 60-80 DEG C. The steps of the neutralization reaction are that oxalic acid is added into a beaker and then added with distilled water until the oxalic acid is completely dissolved; sulphuric acid is added into oxalic acid water solution for preparing neutralized solution; in the neutralized solution, the molar concentration of the oxalic acid is 0.1-0.5mol / L and the molar concentration of the sulphuric acid is 1.0-3.0mol / L; after being carried out by microetching treatment, the ABS engineering plastic parts are soaked in the neutralized solution, stirred and have neutralization reaction for 2-10 minutes at 40-60 DEG C and then washed by the distilled water. The method for processing microetching of the surface of ABS engineering plastic parts does not have environmental pollution and can be used for carrying out the microetching treatment on the ABS engineering plastic parts.

Owner:SHAANXI NORMAL UNIV

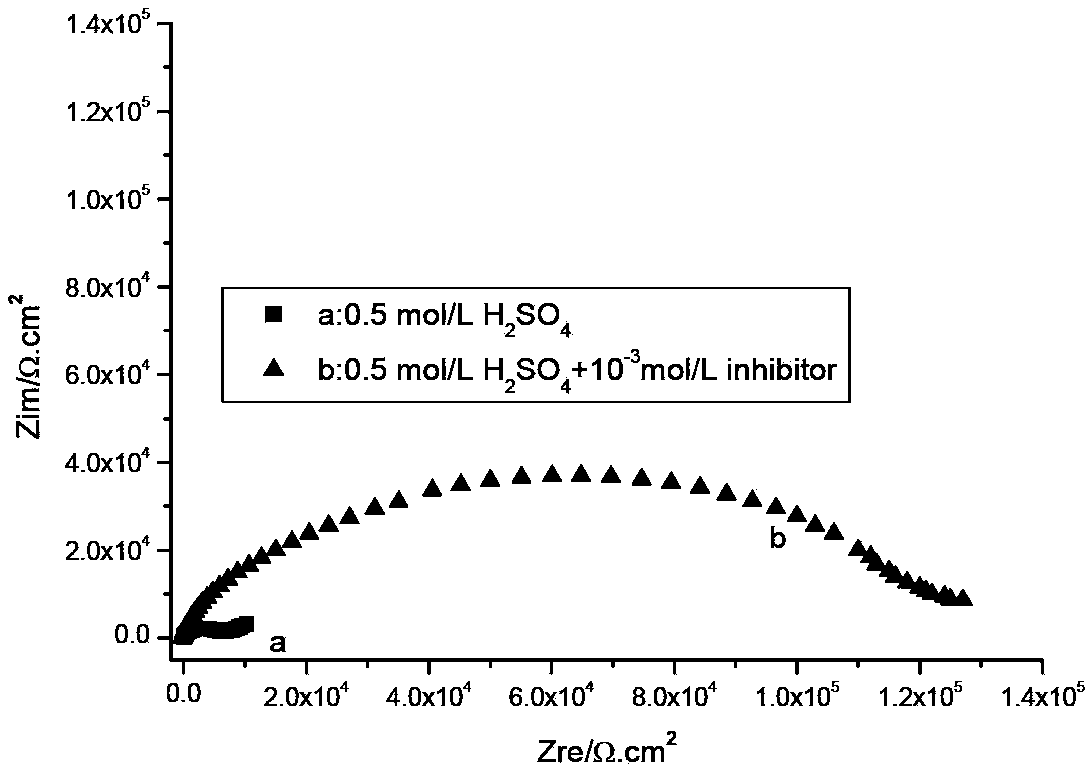

Copper-based material pickling liquor with corrosion inhibition effect

The invention belongs to a copper-based material pickling liquor with corrosion inhibition effect, and relates to a pickling / microetching treatment process before electrocoppering in manufacture of printed circuit boards, and specifically the copper-based material pickling liquor with corrosion inhibition effect is used to prevent over etching of acidic mediums to copper of a printed circuit board or a printed circuit board product during pickling / microetching. Aiming at the disadvantages of high cost, low corrosion inhibition efficiency, bad biodegradability and the like of a corrosion inhibitor in a conventional copper-based material pickling liquor, 2-(4-chlorophenyl)-3-cyclopropyl-2-(1H-1, 2, 4-triazol-1-yl)butan-1-ol usually as a plant bactericide is employed as a corrosion inhibitor, and is added to an acid liquor for preparation of the copper-based material pickling liquor with corrosion inhibition effect. Cyproconazole as the corrosion inhibitor in the pickling liquor is low in usage amount, low in cost, easy to obtain, naturally degradable in the sun, none in environmental problems after used, and accord with development trend of green corrosion inhibitors; and the pickling liquor has high corrosion inhibition efficiency of up to 80-99% and stable corrosion inhibition performance.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

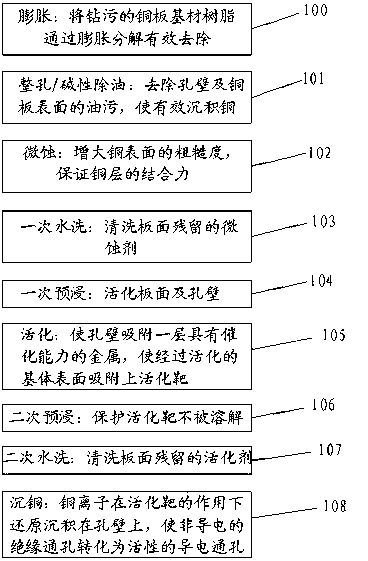

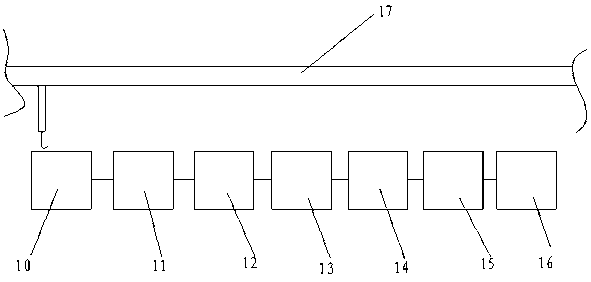

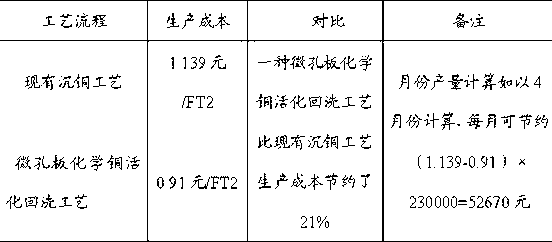

Microwell plate chemical copper activating back scrubbing process and system thereof

ActiveCN103108501AReduce the risk of poor backlightingImprove qualityPrinted element electric connection formationMicrowell PlateBiological activation

The invention provides a microwell plate chemical copper activating back scrubbing process and a system of the microwell plate chemical copper activating back scrubbing process. The process includes the steps of microetching, first time wash, first time preimpregnation, activation, second time wash, copper deposition and second time preimpregnation. The microetching is used for increasing roughness of the surface of copper and ensuring combining force of a copper layer. The first time wash is used for washing remaining micro corrosion agent of a panel. The first time preimpregnation is used for activating the panel and hole wall. The activation is used for enabling the hole wall to adsorb a layer of metal which has catalytic ability and enabling the surface of the matrix to attach to a activation target. The second wash is used for washing remaining activation agent of the panel. The copper deposition is used for enabling non-conductive insulation hole to be transformed into an active conductive through hole under the action of copper ions in the activation of target reduction deposition on the hole wall. The second time preimpregnation is used for ensuring that the activation target is not solved. Due to the fact that the microwell plate chemical copper activating back scrubbing process and the system of the microwell plate chemical copper activating back scrubbing process are conducted, the activation target in a printed circuit board (PCB) is not solved, the risk of poor backlight is reduced, quality of products is improved, and production cost is reduced.

Owner:金悦通电子(翁源)有限公司

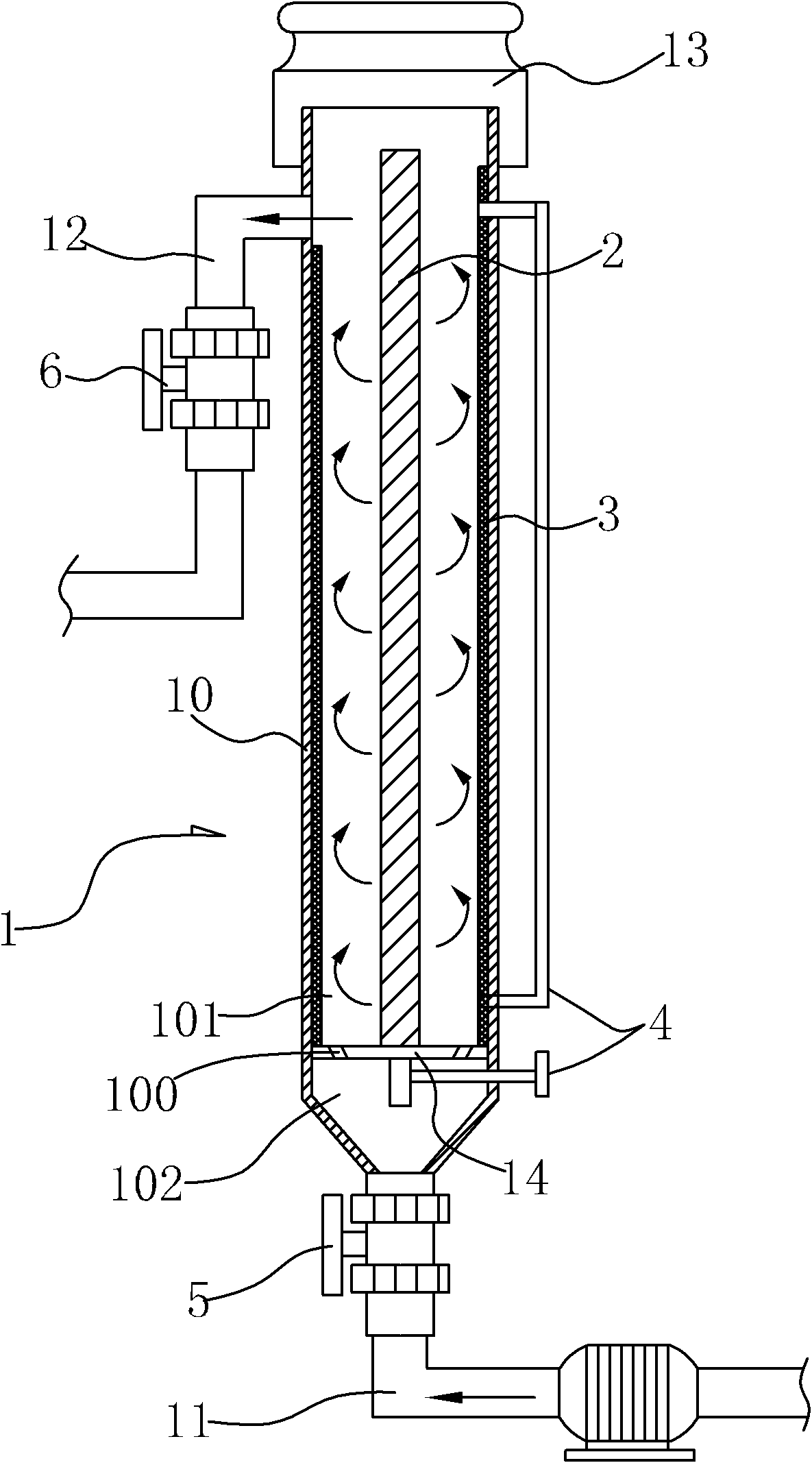

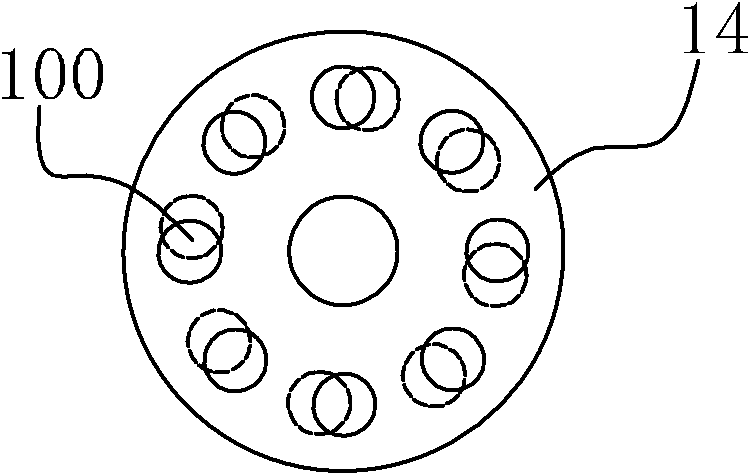

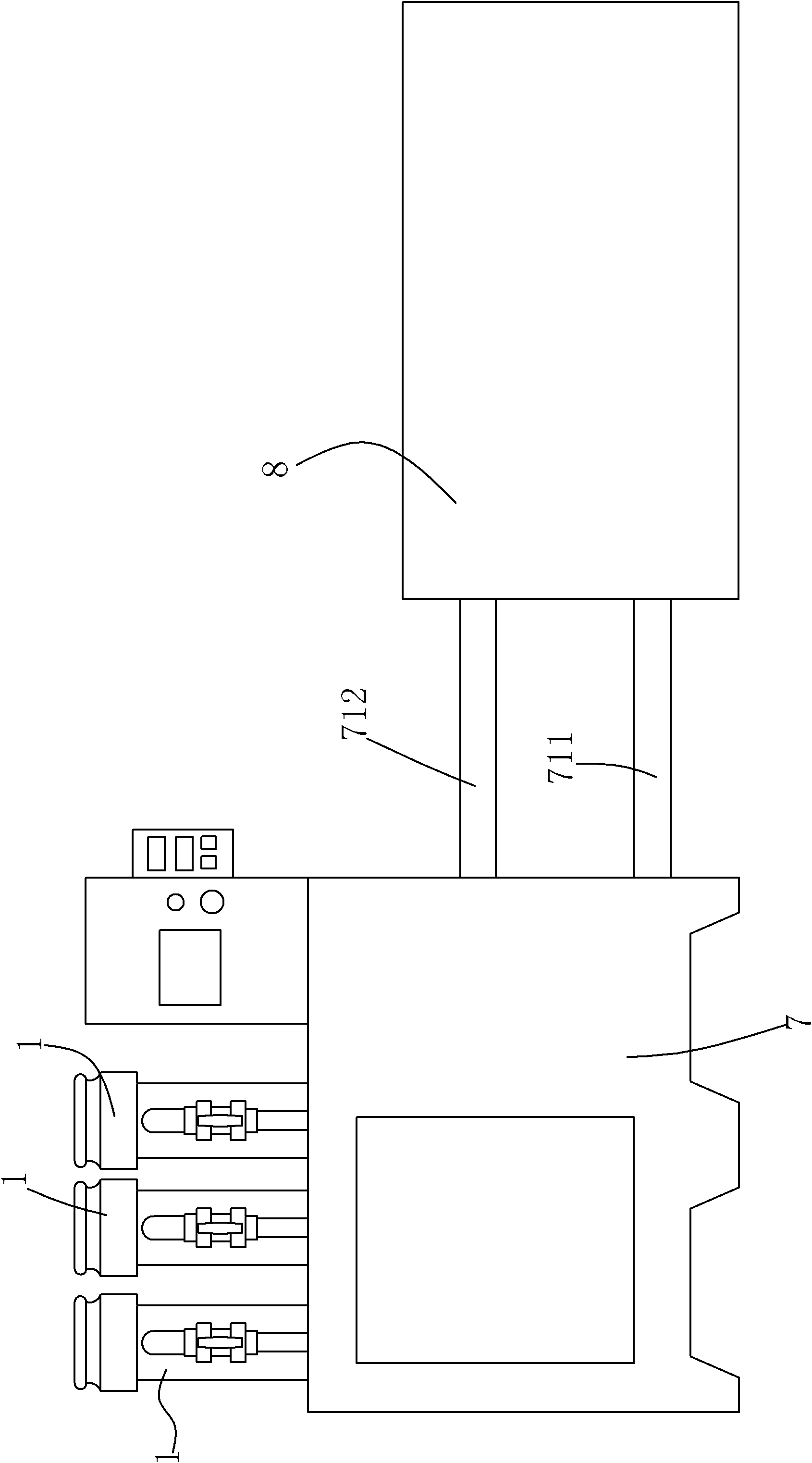

Circular treatment equipment for recovery of copper from microetching liquid and special eddy flow electrolysis unit thereof

InactiveCN102251254AReduce pollutionTo achieve the effect of recyclingPhotography auxillary processesProcess efficiency improvementElectrolysisEngineering

The invention discloses circular treatment equipment for recovery of copper from microetching liquid and a special eddy flow electrolysis unit thereof. The equipment comprises a mainframe and modularized eddy flow electrolysis units, wherein, the eddy flow electrolysis units have inlets for microetching liquid to flow in and outlets for microetching liquid to flow out, the inlet and outlet of each eddy flow electrolysis unit are respectively in parallel with or in series with a main inlet and a main outlet of the mainframe through pipelines and the main inlet and the main outlet communicate with an inlet and outlet of a microetching groove; a cathode and an anode are provided in the cylinder of the main body of the eddy flow electrolysis unit and communicate with a cathode and an anode in the mainframe; the anode is located in the inner wall of the cylinder of the main body and the cathode made of metal column is located at the center of the cylinder; deflector holes are provided in the cylinder of the main body; microetching liquid enters from the inlet at the upper part of the main body and passes through the deflector holes to form rotary liquid flow which flows out through the outlet at the upper part of the main body. According to the invention, microetching liquid discharged from the microetching groove is rich in copper ions, and when copper in the discharged microetching liquid is extracted by the eddy flow electrolysis units of the circular treatment equipment, the treated microetching liquid can be allowed to enter into the microetching groove again for utilization, thereby achieving the effect of cyclic utilization, reducing cost and abating pollution to environment.

Owner:深圳市惠尔能科技有限公司

Cleaning composition

InactiveUS20050261152A1Lower the volumeExtended service lifeInsulating substrate metal adhesion improvementSurface-active detergent compositionsAdjuvantPersulfate

A composition composed of a persulfate, boric acid, a fluorine containing acid and an inorganic acid. Adjuvants also may be included in the composition. The composition may be employed as a microetch solution in the fabrication of microelectronic packages.

Owner:SHIPLEY CO LLC

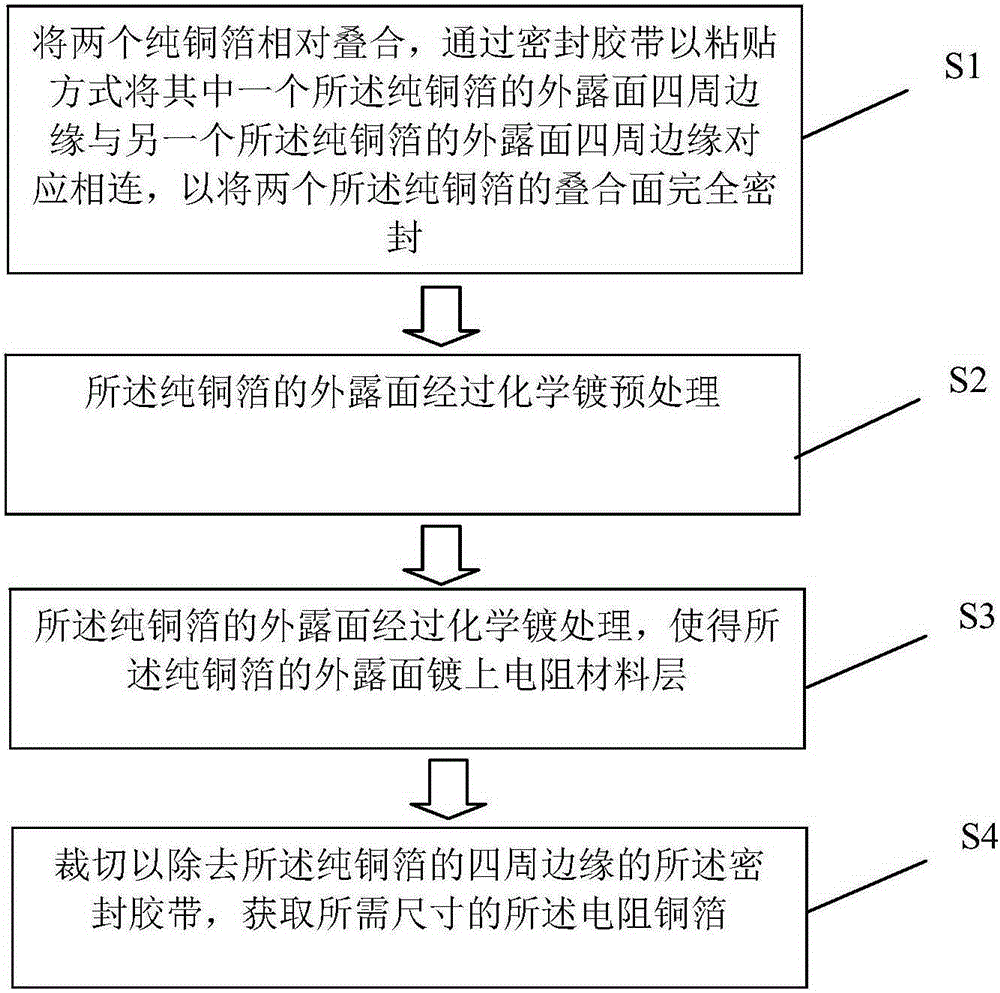

Manufacturing method of resistance copper foil

ActiveCN105177535AUniform thicknessImprove thickness uniformityLiquid/solution decomposition chemical coatingElectrolysisCopper foil

The invention relates to a manufacturing method of resistance copper foil. The manufacturing method comprises the following steps: two pure copper foil is overlapped, the overlapped surfaces of the two pure copper foil are sealed through sticking with a sealing tape, the exposed surfaces are pretreated through chemical plating, and are plated with resistance material layers through chemical plating, and the sealing tape is cut to obtain the resistance copper foil; especially, the pure copper foil is made of electrolytic copper which is 1 / 2 oz or 1 / 3 oz in thickness, and 1-2 [mu]m in copper teeth size; the rough surfaces of the pure copper foil are the exposed surfaces; the chemical plating pretreating process includes oil removing, acid pickling, microetching, presoaking and activating, wherein the activating time is 2-3 minutes; a medium-low-temperature alkaline chemical nickel-plating process is adopted in chemical plating, and a plating solution comprises 20-30 g / L nickel sulfate, 20-40 g / L sodium hypophosphite, 50-80 g / L sodium pyrophosphate, 30-60 g / L ammonium chloride, and 30-60 g / L ammonium hydroxide; and the chemical plating temperature is 25-50 DEG C, and the deposition time is 1-10 minutes. The manufacturing method maintains the characteristics of low chemical plating cost and simplicity in operation, and above all, only a single side of the copper foil can be plated with the resistance material layer through chemical plating according to the manufacturing method, and plating is good in uniformity and high in adhesion strength.

Owner:AKM ELECTRONICS INDAL PANYU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com