Treating agent and treating system for micro-etching surfaces of recyclable copper and copper alloys

A recycling and processing system technology, applied in the field of recyclable copper and copper alloy surface micro-etching treatment agents and processing systems, can solve the problems of limited comprehensive benefits, unsatisfactory, low support for technical upgrades, etc., to achieve increased Uniform roughness, good economic benefits, and the effect of recovering microetching ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

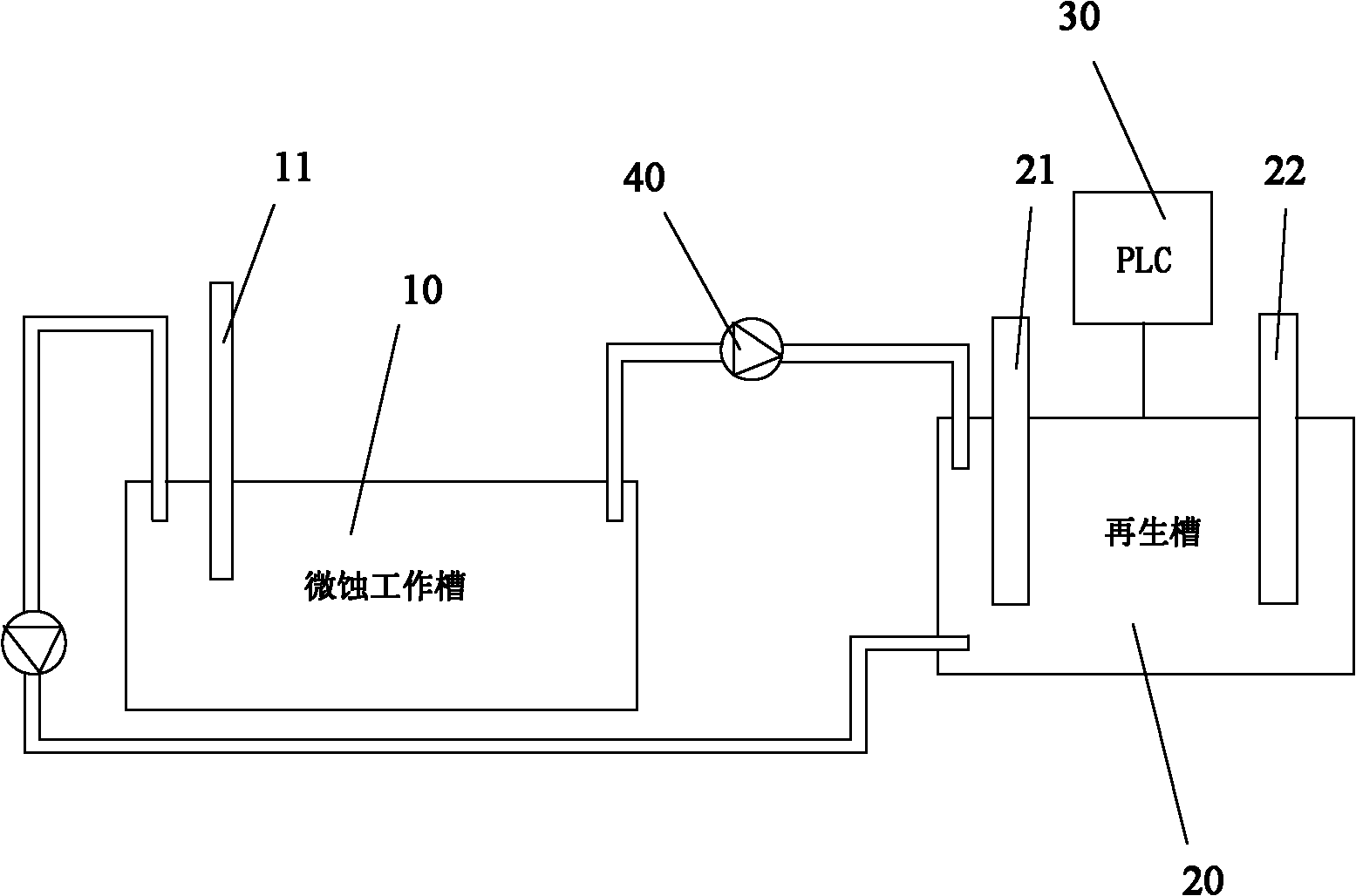

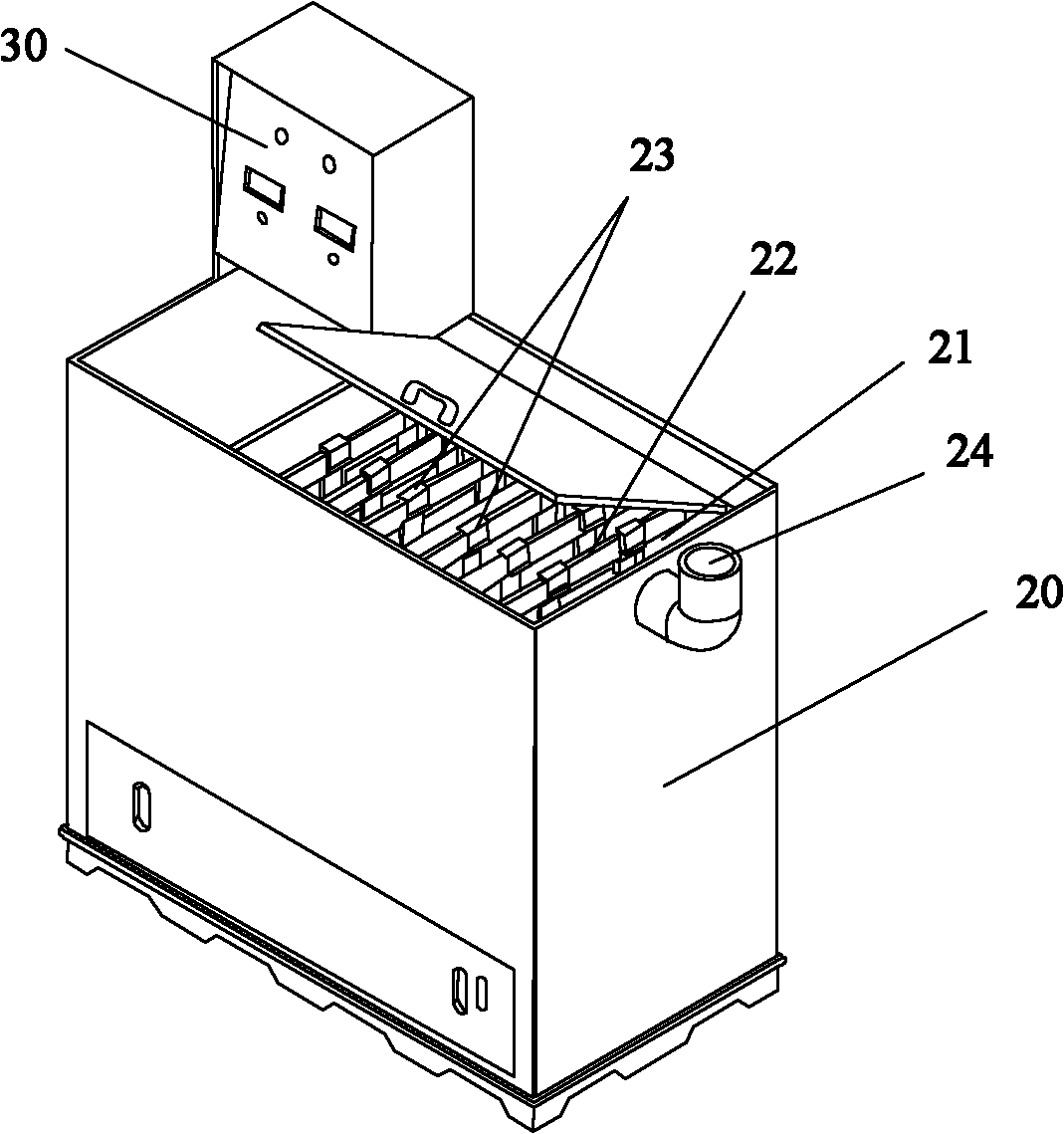

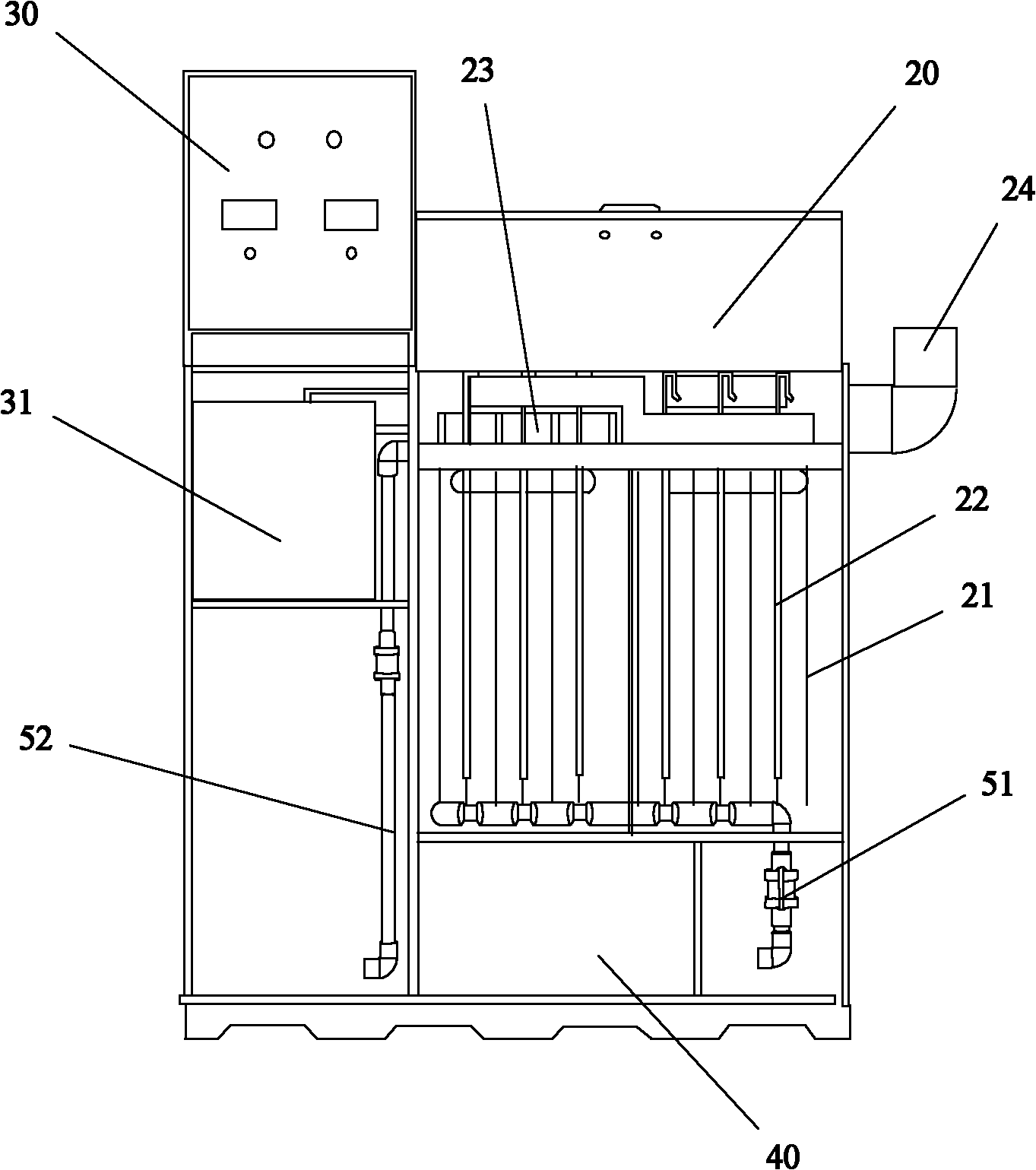

[0056] The copper surface treatment process is carried out on a circuit board, and the micro-etching treatment process system of the present invention is adopted. The workpiece to be processed is placed in the micro-etching work tank 10, that is, the recyclable copper and copper alloy micro-etching agent of the present invention is processed, and the micro-etching agent used is calculated by weight percentage and contains the following components :

[0057] Sulfuric acid 5%

[0058] Iron Sulfate 15%

[0059] Anionic fluorocarbon surfactant ( 1033D, Fluorinated Surfactant) 0.2%

[0060] Formic acid or acetic acid 0.2-2%

[0061] KI, NaBr or NaCl addition range can be 20-100ppm

[0062] Additives (sodium polydithiodipropane sulfonate, sodium 3-mercaptopropane sulfonate, sodium N, N-dimethyldithiocarbonylpropane sulfonate, inner salt of isothiourea propane sulfonate, 3-(benzothiazole -2-mercapto)-sodium propanesulfonate) or a mixture of two or more, the addition range can ...

Embodiment 2

[0075] The copper surface treatment process is carried out on a circuit board, and the micro-etching treatment process system of the present invention is adopted. The workpiece to be processed is placed in the micro-etching work tank 10, that is, the recyclable copper and copper alloy micro-etching agent of the present invention is processed, and the micro-etching agent used is calculated by weight percentage and includes the following groups: Minute:

[0076] Nitric acid 7%

[0077] Iron Nitrate 20%

[0078] Anionic fluorocarbon surfactant ( 1033D, Fluorinated Surfactant) 0.1%

[0079] Formic acid or acetic acid, the addition range can be 0.2-2%

[0080] KI, NaBr or NaCl, the addition range can be 20-100ppm

[0081] Additives (sodium polydithiodipropane sulfonate, sodium 3-mercaptopropane sulfonate, sodium N, N-dimethyldithiocarbonylpropane sulfonate, inner salt of isothiourea propane sulfonate, 3-(benzothiazole -2-mercapto)-sodium propanesulfonate) or a mixture of two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com