Patents

Literature

3777 results about "Cleaner production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cleaner production is a preventive, company-specific environmental protection initiative. It is intended to minimize waste and emissions and maximize product output. By analysing the flow of materials and energy in a company, one tries to identify options to minimize waste and emissions out of industrial processes through source reduction strategies. Improvements of organisation and technology help to reduce or suggest better choices in use of materials and energy, and to avoid waste, waste water generation, and gaseous emissions, and also waste heat and noise.

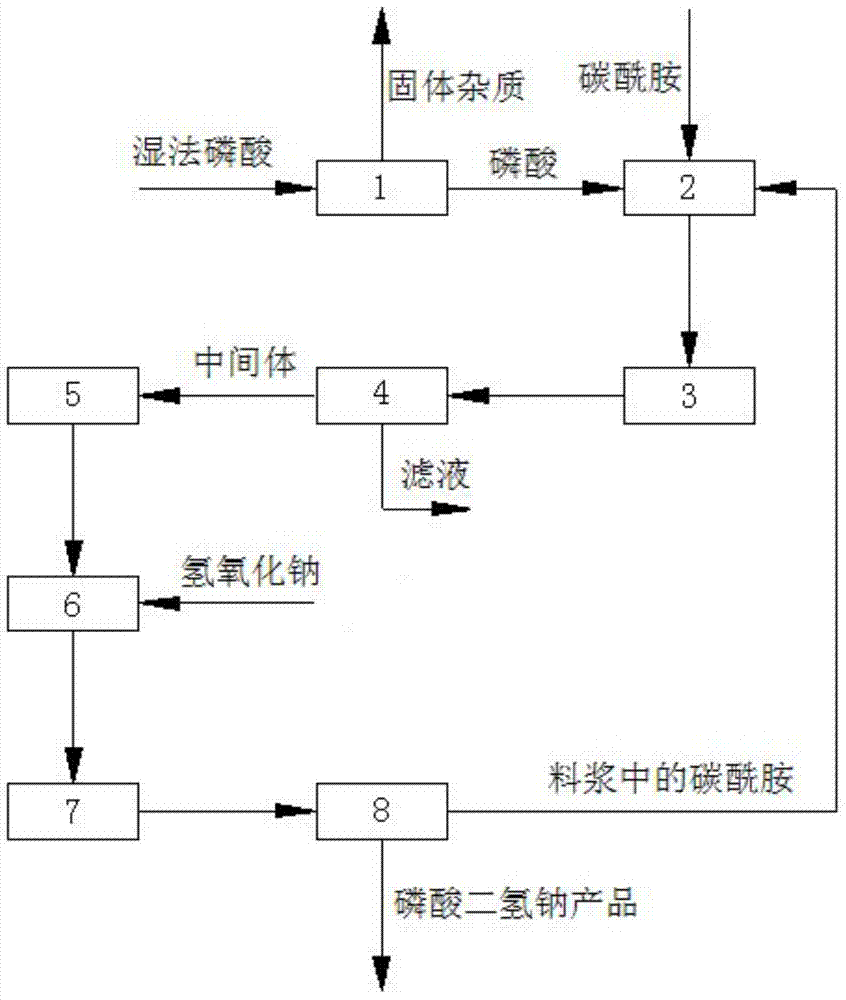

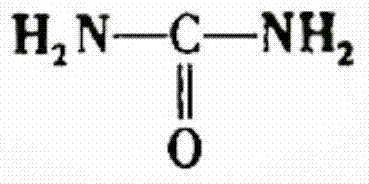

Method for preparing sodium dihydrogen phosphate by utilizing phosphoric acid by wet process

InactiveCN103787293AReduce manufacturing costShort process routePhosphorus compoundsHigh energyPhosphoric acid

The invention discloses a method for preparing sodium dihydrogen phosphate by utilizing phosphoric acid by wet process. The method comprises the steps of carrying out reaction on carbamide and the phosphoric acid by the wet process to obtain intermediate, and then carrying out a reaction on the intermediate and sodium hydroxide to obtain the sodium dihydrogen phosphate product. The method is short in process route, low in energy consumption, stable in product quality, low in production cost, convenient to operate and safe in production; the by-product slurry can be completely recycled; the whole production process is environment-friendly, clean and free from pollution as well as emission of waste gas, waste water and waste residue; therefore, the method responses to the policy of energy conservation and emission reduction as well as clean production, and solves the problems of complicated technology, unstable product quality, high energy consumption, environmental pollution and the like in the prior art; the obtained sodium dihydrogen phosphate product has the purity of more than or equal to 98%.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

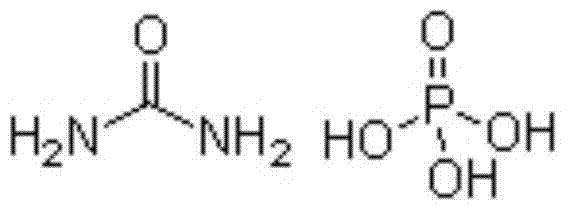

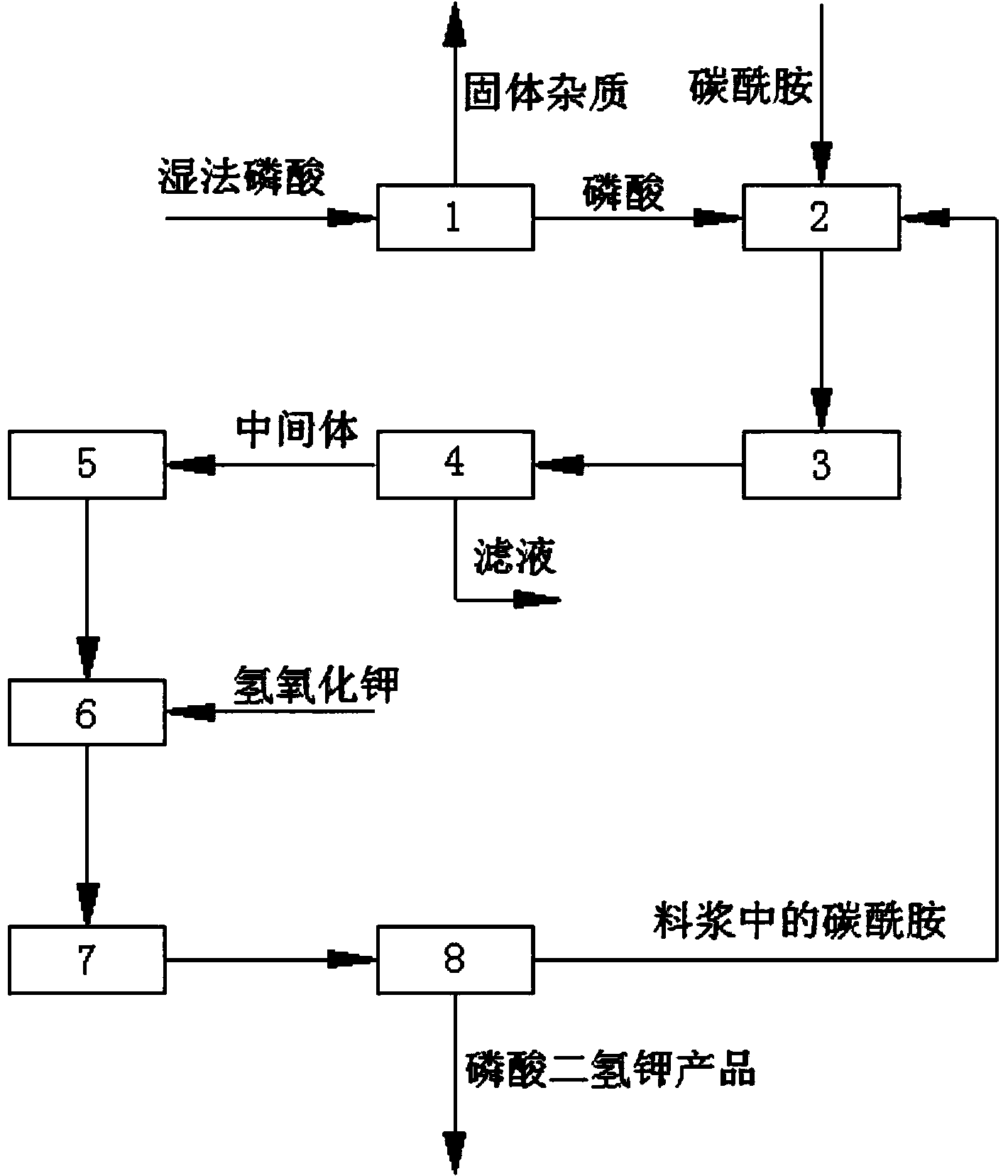

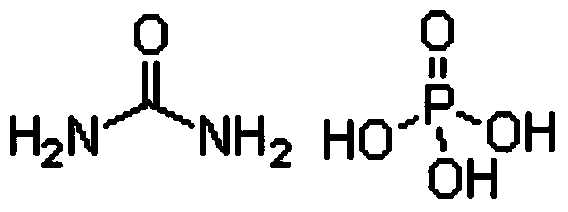

Method for preparing monopotassium phosphate by using wet-process phosphoric acid

InactiveCN103803518AReduce manufacturing costNo pollution in the processPhosphorus compoundsFertilizer mixturesEnvironmental resistanceHigh energy

The invention discloses a method for preparing monopotassium phosphate by using wet-process phosphoric acid. The method comprises the following steps: reacting carbonyl diamide and wet-process phosphoric acid to obtain an intermediate; reacting the intermediate and potassium hydroxide to prepare a monopotassium phosphate product. The method has the advantages of short process route, low energy consumption, stable product quality, low production cost, convenience in operation and safety in production. A side product, namely, slurry can be recycled completely, an entire production process is environment-friendly, clean and free from pollution, and no waste gas, waste water or waste residues are discharged. A response is made to the policy calling of energy saving, emission reduction and clean production, the problems of complex process, instable product quality, high energy consumption and environmental pollution existing in the prior art are solved, and the purity of the obtained monopotassium phosphate product is more than or equal to 98 percent.

Owner:GUIYANG KAILIN FERTILIZER CO LTD +1

Method for preparing xylose by using squeezed waste alkali in viscose fiber production process

ActiveCN102643935AReduce preprocessingAvoid events that pollute the environmentSaccharides productionHazardous substanceIon exchange

The invention relates to a method for preparing xylose by using squeezed waste alkali in the viscose fiber production process. According to the method, xylose finished products are obtained through work procedures of hemicellulose solution preparation, hemicellulose extraction, hemicellulose hydrolysis, neutralization and deacidification, preconcentration, decoloration, ion exchange, ordinary concentration, crystallization, separation and drying. When the technical scheme provided by the invention is adopted, harmful environment-pollution substances such as waste alkali and waste water generated in the viscose production process can be thoroughly eliminated, the standard of full-flow-process clean production can be reached, viscose production enterprises can also produce xylose in the viscose production process, the goal of environment protection is reached, and meanwhile, the waste reutilization is also realized.

Owner:YIBIN GRACE +2

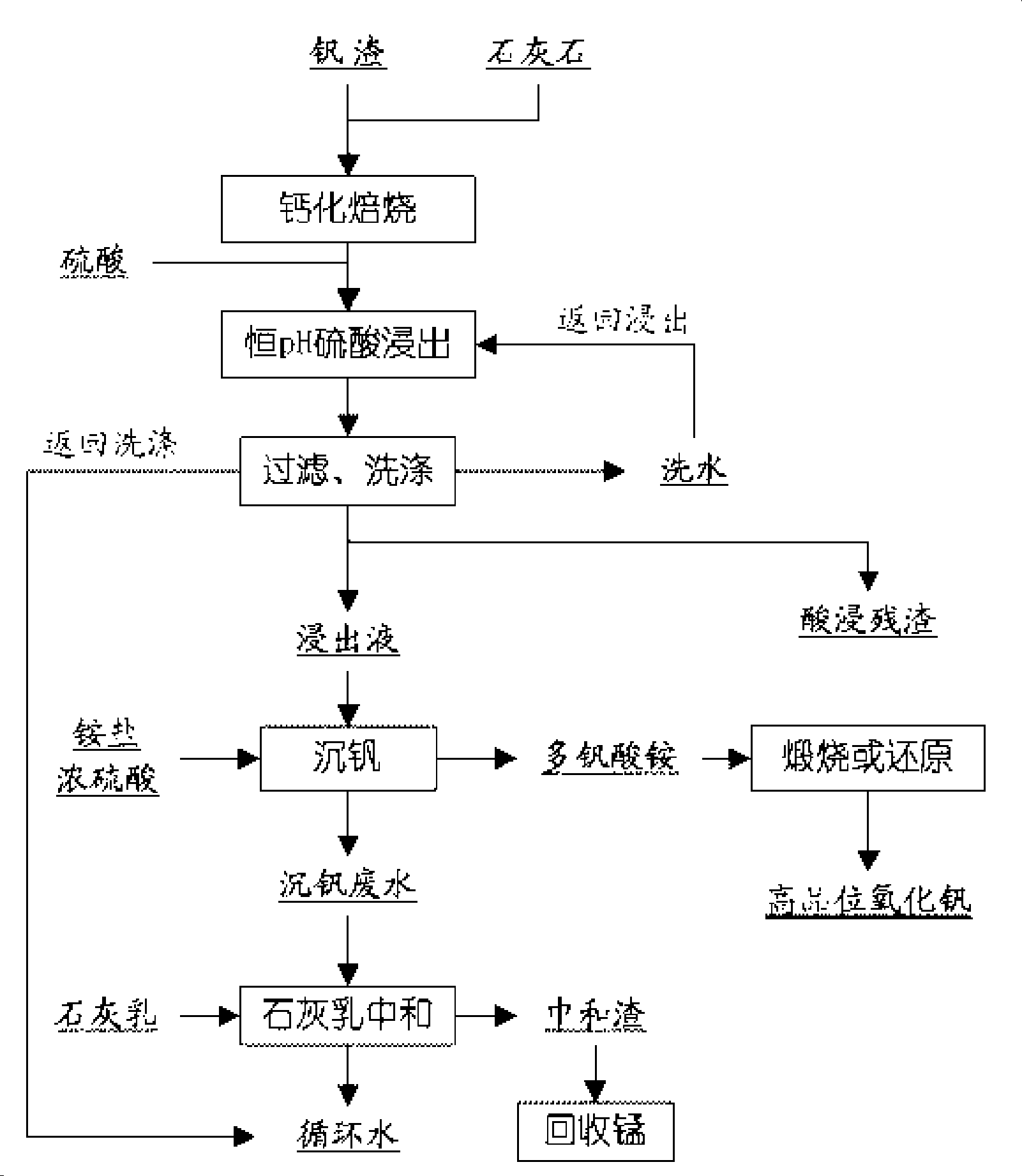

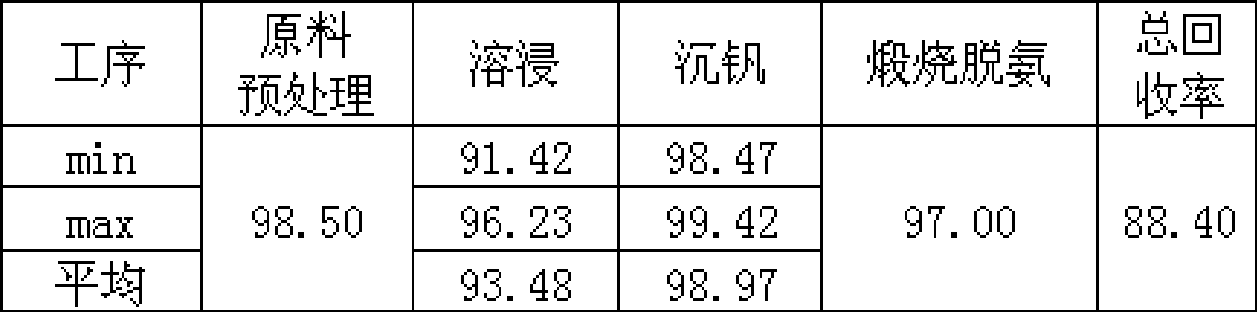

Clean production process for vanadium oxide

ActiveCN101412539ASolve difficult environmental problemsSolve the technical problem of not being able to obtain high-quality vanadium productsVanadium oxidesProcess efficiency improvementSlagWastewater

The invention relates to a method for cleanly producing vanadium oxide, which belongs to the field of extraction of vanadium oxide. The technical problems to be solved by the invention is to provide the method for cleanly producing the vanadium oxide which not only can obtain a high-quality vanadium product, but also can ensure that vanadium waste water can be reclaimed. The method for producing the vanadium oxide comprises the following steps: preparing roasting raw materials, calcification roasting; infiltrating, separating solid and liquid, precipitating vanadium by ammonium salt, calcining for deaminating or reducing, and the like. Waste water after vanadium extraction can be returned to a system for recycling after the waste waster is subjected to neutralizing treatment by lime cream so as to realize zero drainage of the waste water. The method also improves the reclamation rate of vanadium to be superior to that of the prior process, and reduces production cost. Through combining with other technologies, the method can change extracted slag and other waste into secondary resource to be used once again, and realize clean production.

Owner:攀钢集团西昌钒制品科技有限公司

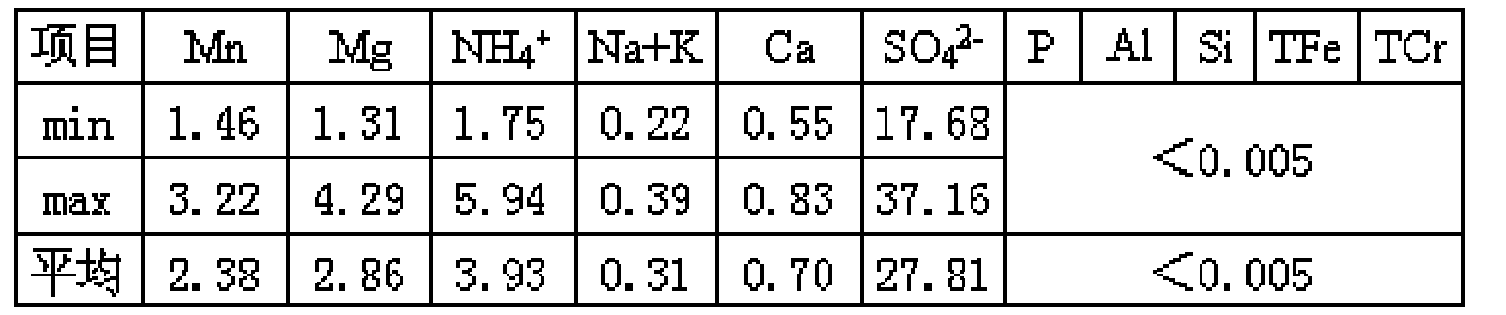

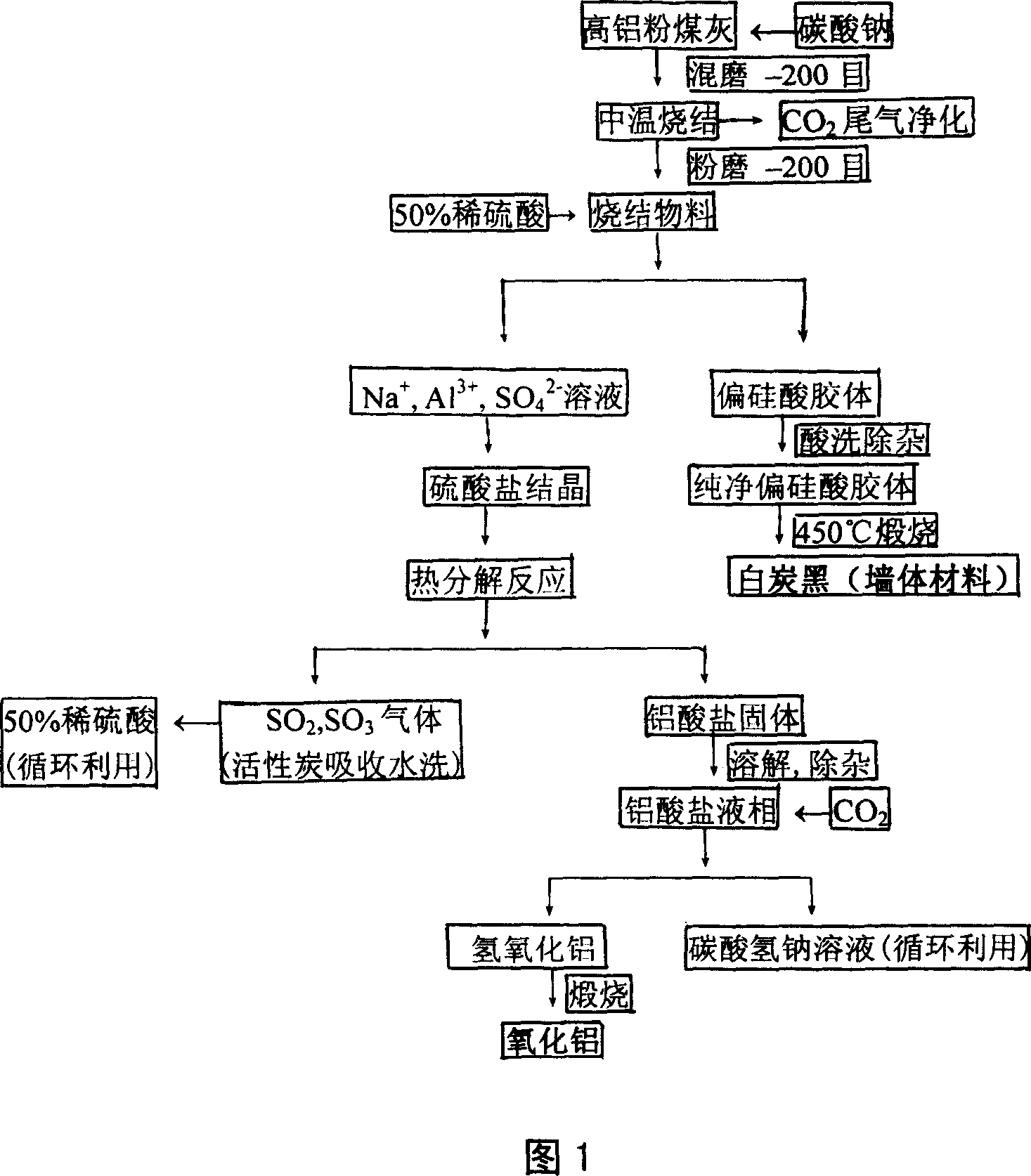

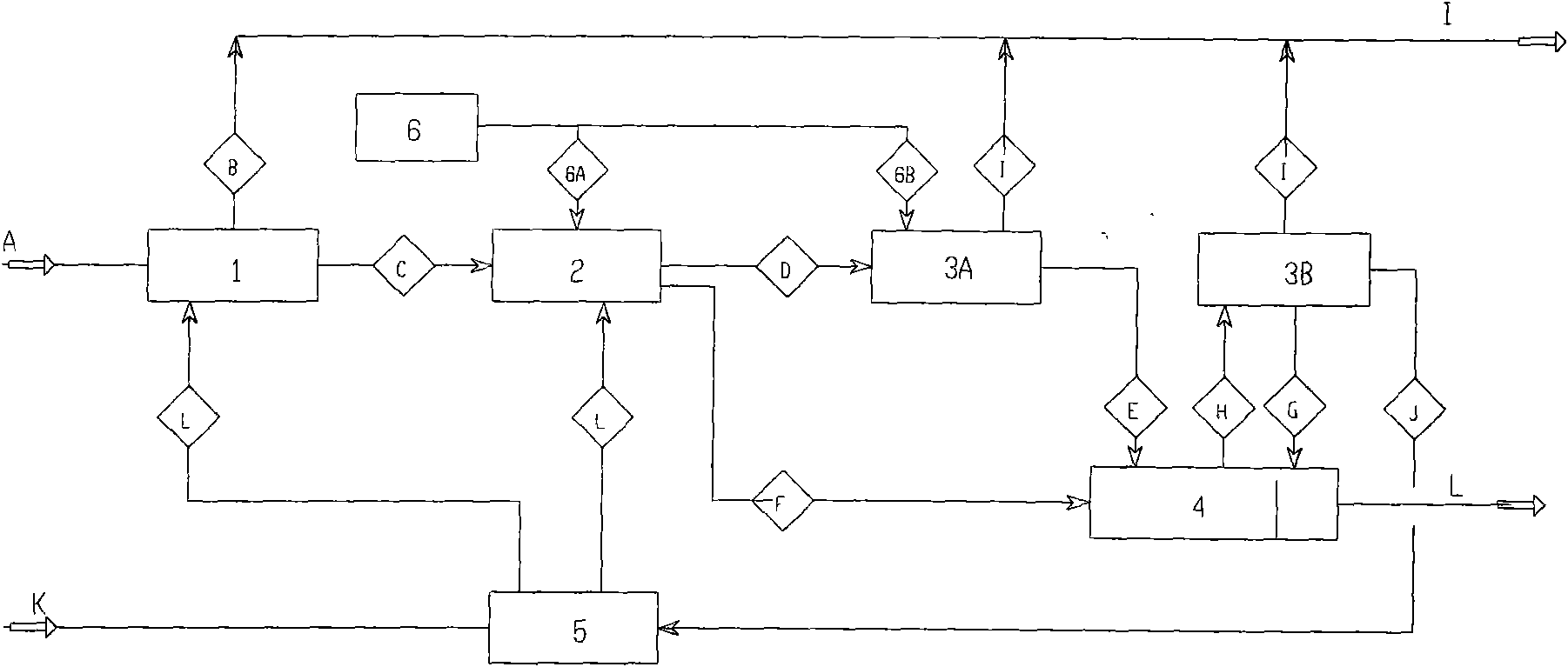

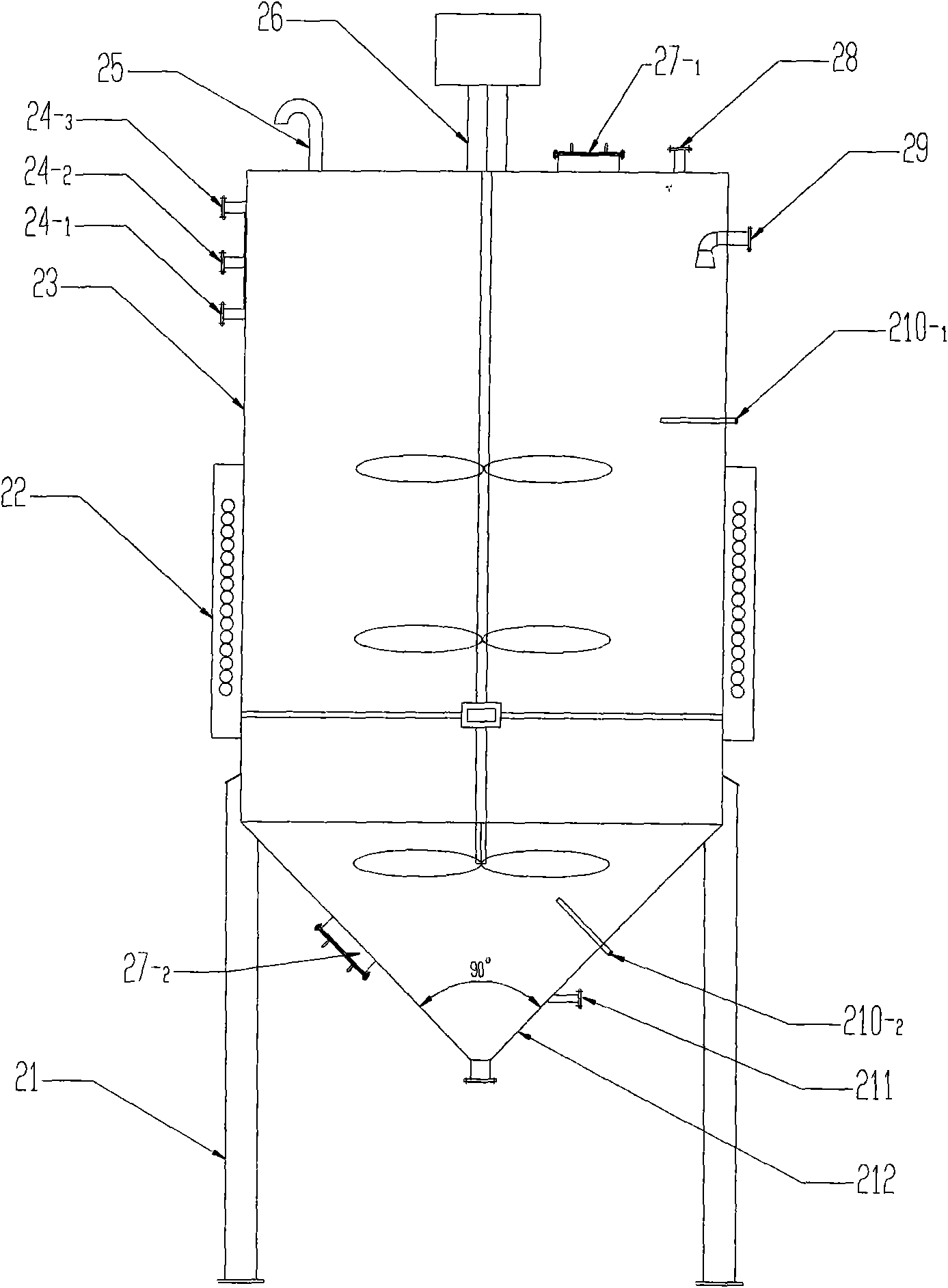

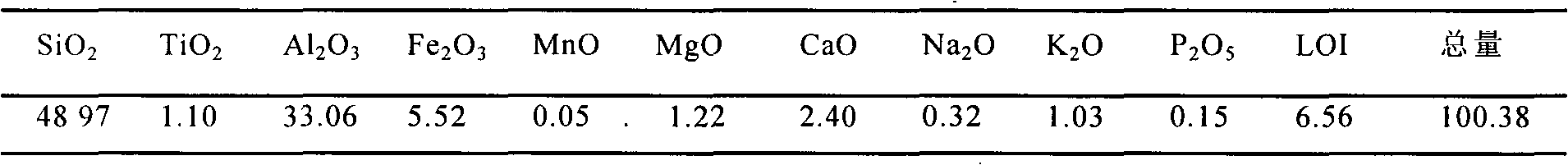

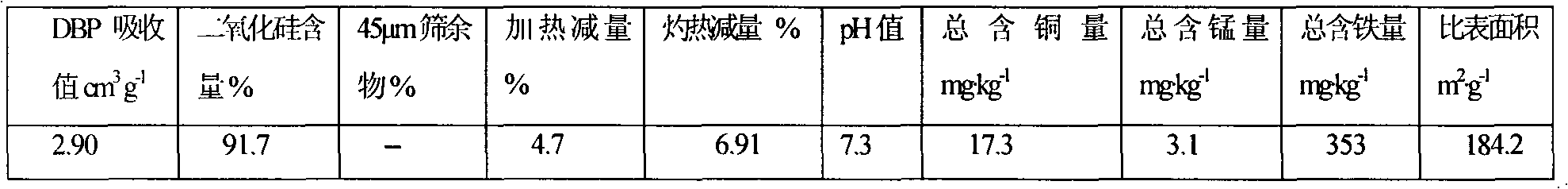

Clean production technique for preparation of aluminium oxide and white carbon black by using high-alumina coal ash

InactiveCN101041450ATake advantage ofWide variety of sourcesSilicon oxidesAluminium oxides/hydroxidesSodium bicarbonateSilica gel

The invention discloses a clean producing craft of aluminum oxide and white carbon black comprehensively with high-alumina coal ash, which comprises the following steps: making sodium carbonate as raw material; disintegrating high-alumina coal ash under medium-temperature; generating acid dissoluble aluminosilicate materials; using dilute sulphuric acid to acid dip; separating aluminum oxide and silica in the high-alumina coal ash; further treating aluminous liquid part; generating hydrated alumina deposition; finishing gamma-alumina or alpha- alumina product through calcining; washing, purifying, drying; calcining the silica gel part; getting white carbon black, silica aerogel, ultra-fine silica, porous silica and so on inorganic silicide.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Novel process for comprehensively treating oily sludge of oil field

ActiveCN101602566AAvoid secondary pollutionHarmlessSludge treatment by de-watering/drying/thickeningSolid particleSlurry

The invention provides a novel process for comprehensively treating oily sludge of an oil field, which comprises processes for separating oil, water and sludge from the oily sludge. The process is characterized in that the processes for separating oil, water and sludge comprise a first process of fluidizing and pre-treating sludge, a second process of hardening and tempering the sludge, and a third process of mechanically separating the oily sludge; water separated through the processes can be used as process water to a circulating water recycling process; the separated cleaned oil enters an oil chamber of an oil-water separation device; and solid particles, namely the centrifuged sludge, are discharged through a screw conveyer. The process has the recovery ratio reaching 95 percent for recovering effluent oil to the utmost extent; and the treated sludge has water content less than 60 percent and oil content less than 2 percent, and can be used for underlaying a road of a well site or carrying out subsequent depth treatment. The process cyclically utilizes wastewater, prevents secondary pollution of sewage and slurry, and has large treatment capacity, wide treatment range, advanced technical proposal, high automatic degree, low operation cost, simple operation and clean production.

Owner:北京惠博普能源技术有限责任公司

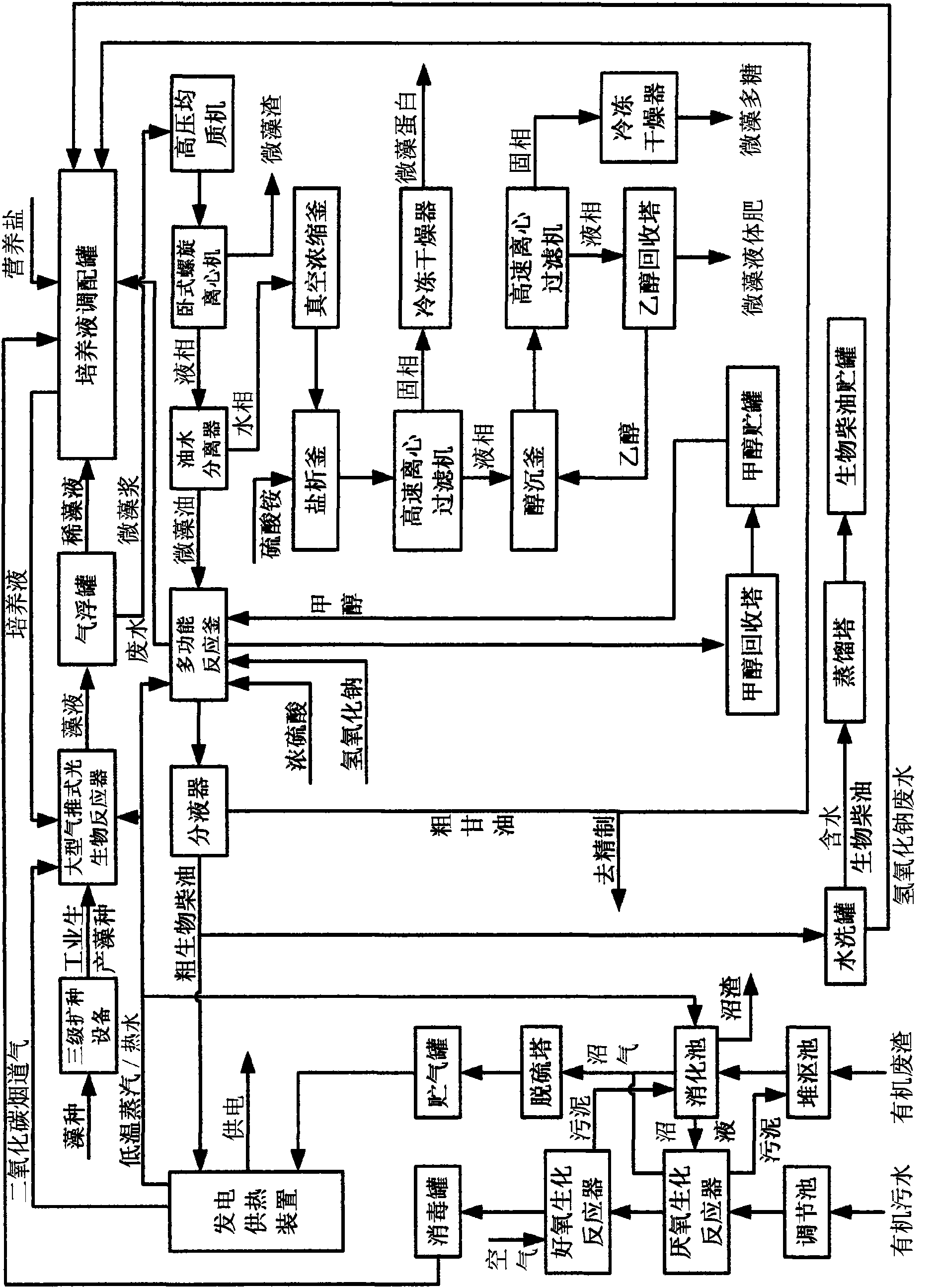

Integrated production method of organic sewage/waste residue treatment, microalgae culturing and oil refining

The invention relates to the environmental protection field, the microalgae cultivation engineering field and the biodiesel refining field, specifically an integrated production method of organic sewage / waste residue treatment, microalgae culturing and oil refining. The method comprises: treating the organic sewage and organic waste residue respectively by anaerobic biochemical technology to generate biogas for generating electricity and supplying heat; performing aerobic biochemical treatment to the sewage and biogas slurry; blending into nutrient solution, and adding into large-scale photobioreactor; passing into biogas, burning to generate carbon dioxide waste gas for culturing oil-containing microalgae; collecting the obtained microalgae by air floatation method and breaking the walls; separating the oil-containing microalgae into microalgae oil, microalgae protein, microalgae polysaccharide and microalgae residue; and refining biodiesel accorded with the national standard using the microalgae oil as raw oil. The invention integrates the organic sewage and waste residue treatment, microalgae culturing and processing, and biodiesel refining; reduces production cost; realizes biodiesel clean production; and treats the 'three wastes'.

Owner:启东市三江建筑机械有限公司

Ultrafine lead oxide prepared by using waste lead plaster and preparation method thereof

InactiveCN103374657AReduce energy consumptionSimple ingredientsReclaiming serviceable partsLead oxidesFiltrationTwo step

The invention discloses an ultrafine lead oxide prepared by using a waste lead plaster and a preparation method thereof. The preparation method comprises the following steps of: carrying out desulphurization process by mixing the waste lead plaster with an aqueous solution containing a composite desulfurizer for reaction; carrying out filtration to remove the desulphurization filtering solution to obtain the desulfurated lead plaster (filter residue); carrying out a leaching and crystal transformation process by adding a citric acid solution and a reducing agent into the desulfurated lead plaster obtained in the process, and carrying out filtration, washing, and drying to obtain the lead citrate after the desulfurated lead plaster reacts with the citric acid solution; carrying out a roasting process by roasting the lead citrate to obtain the ultrafine lead oxide. According to the preparation method disclosed by the invention, the ultrafine lead oxide is prepared from the waste lead storage lead plaster; a two-step leaching process is adopted; the filtering solution is simple in ingredient and can be recycled; a side product is recycled from the desulphurization solution. The preparation method disclosed by the invention is low in energy consumption, simple in equipment, high in lead recycling rate, and high in ultrafine lead product quality, and has the characteristics of good resource recycling effect, environmentally-friendly and pollution-free production process, and capability of clean production.

Owner:湖北金洋冶金股份有限公司 +1

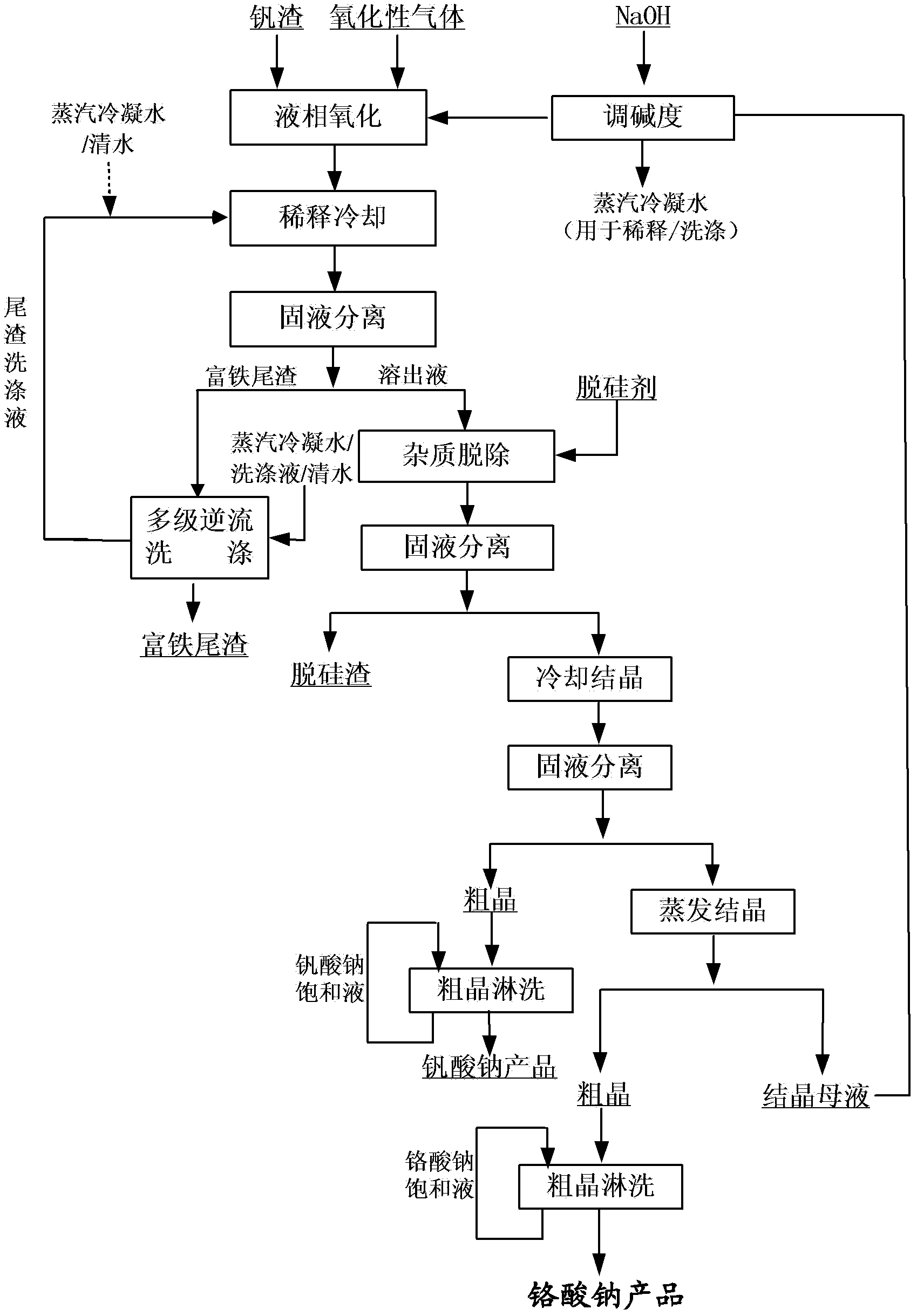

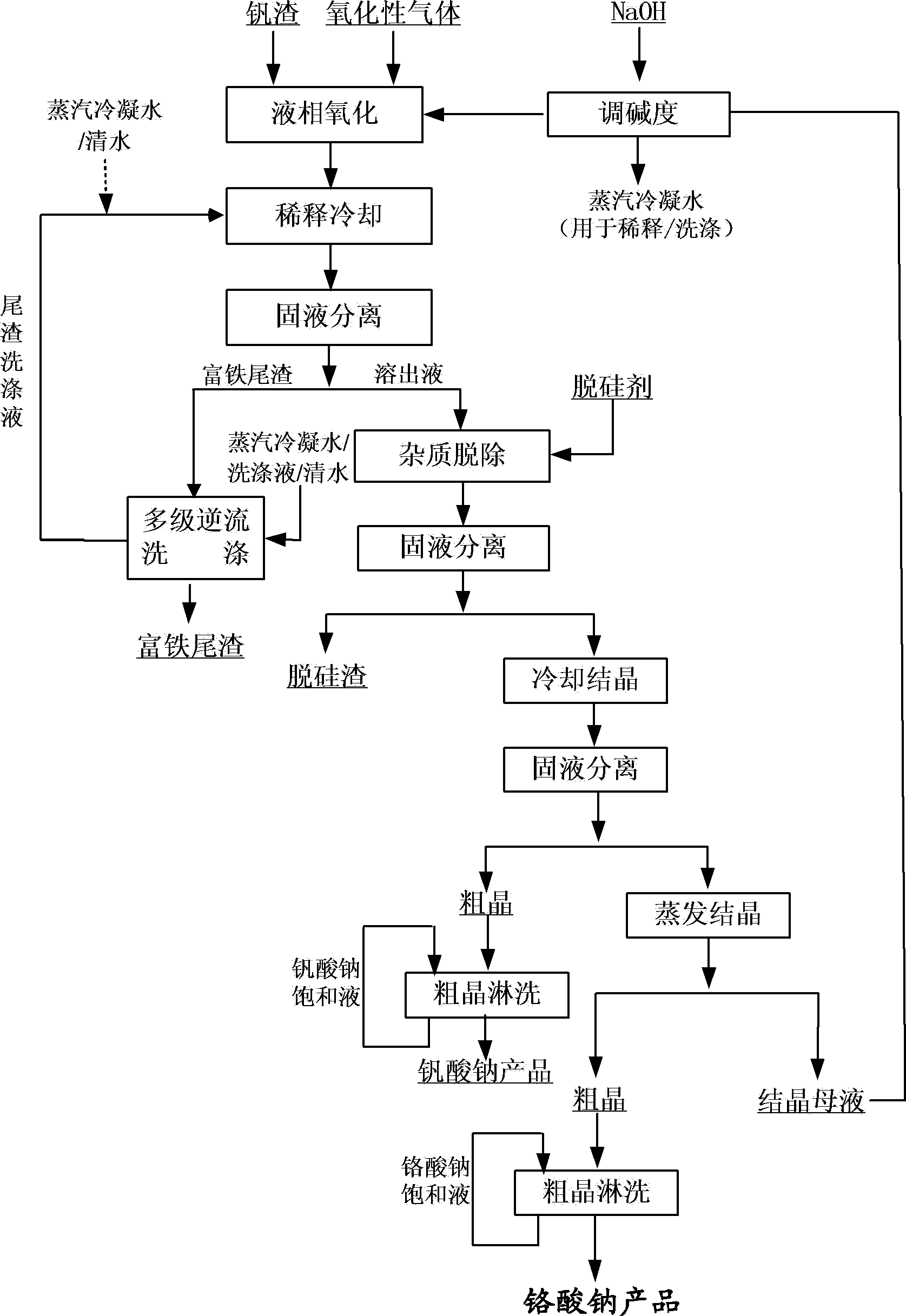

Method for cleaner production of sodium vanadate and sodium chromate by pressure leaching of vanadium slag

ActiveCN102531056ASimple ingredientsAchieve separationChromates/bichromatesVanadium compoundsSlagSlurry

The invention relates to a method for cleaner production of sodium vanadate and sodium chromate by pressure leaching of vanadium slag. The method comprises the following steps of: (1) mixing materials, namely mixing the vanadium slag and a solution of NaOH to obtain a reaction material; (2) reacting, namely performing oxidization reaction on the vanadium slag and oxidizing gas in the solution of NaOH under high pressure to obtain solid-liquid mixed slurry of a solution containing NaOH, Na3VO4, Na2CrO4 and water-soluble impurity components, and iron-rich tailings; (3) performing solid-liquid separation; (4) removing impurities; (5) crystallizing sodium vanadate; and (6) crystallizing sodium chromate. The method is easy to operate and is high in safety; and the operating temperature is greatly lower than the temperature of the traditional vanadium extraction process, energy consumption is low, the high-efficiency co-extraction of vanadium and chromium is realized, and the extraction rate of vanadium and chromium is over 95 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

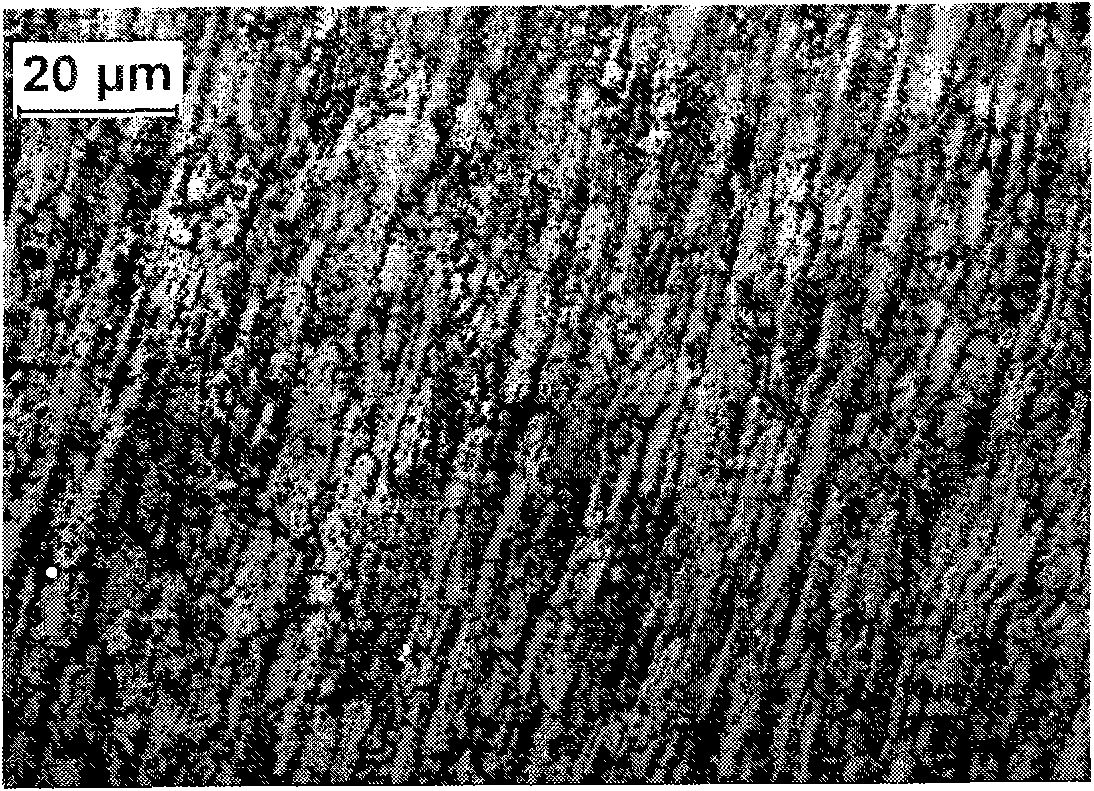

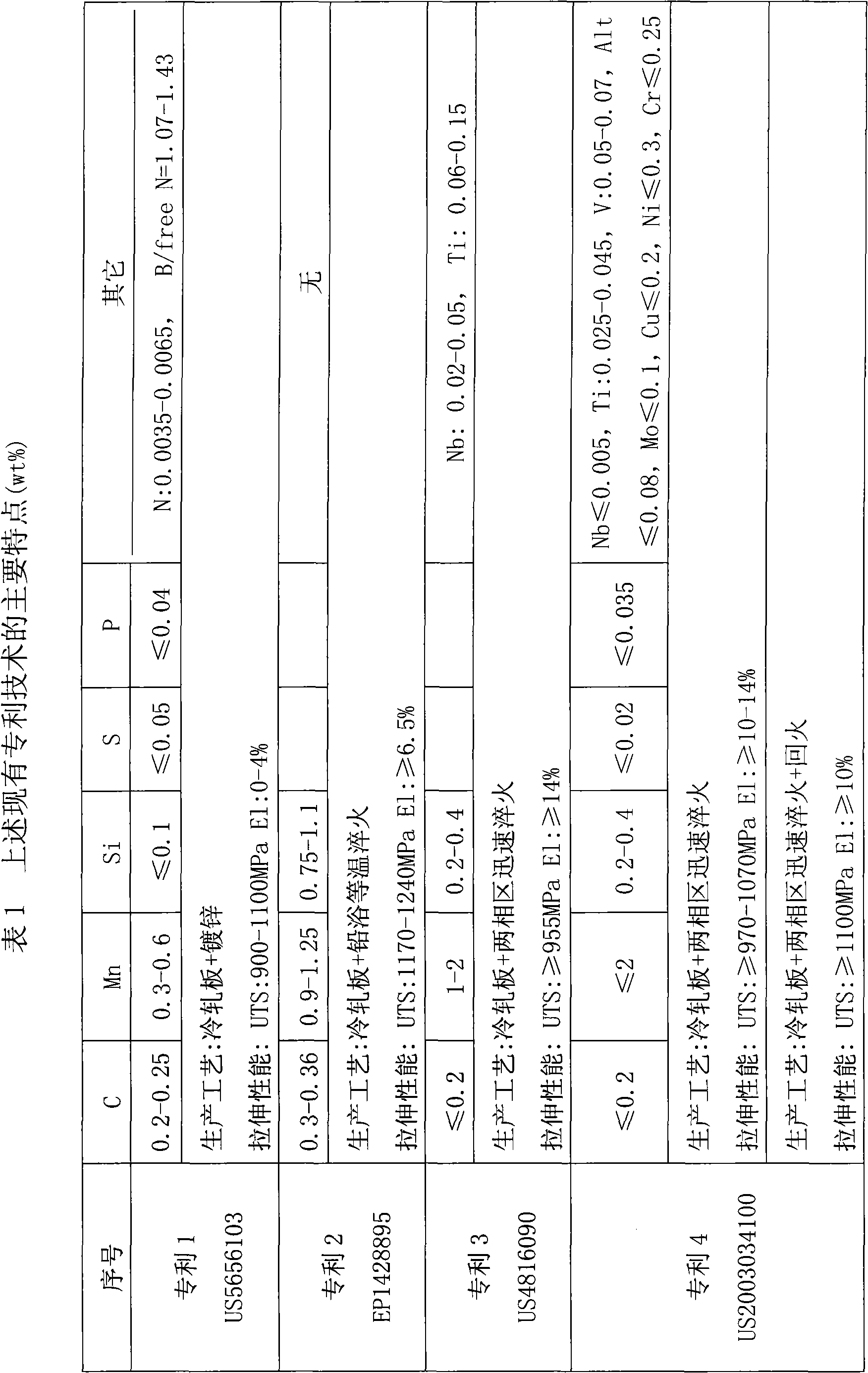

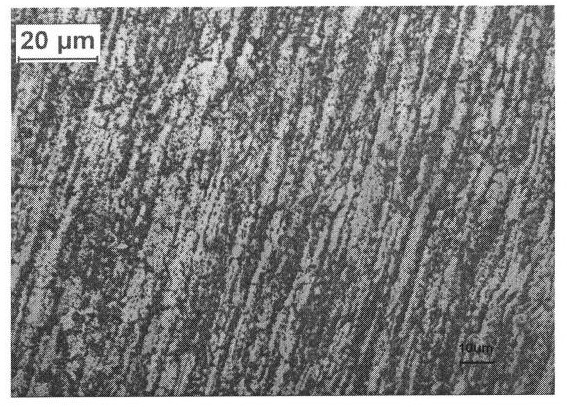

High strength strapping steel with tensile strength over 1,100 MPa and manufacturing method thereof

The invention discloses high strength strapping steel with tensile strength over 1,100 MPa and a manufacturing method thereof. The high strength strapping steel comprises the following components in percentage by weight: 0.25 to 0.35 percent of C, 1.0 to 2.0 percent of Mn, less than or equal to 0.45 percent of Si, less than or equal to 0.04 percent of S, less than or equal to 0.04 percent of P, and the balance of Fe and inevitable impurities. The manufacturing method comprises a steel smelting process, hot rolling process, cold rolling process and ferrite-austenite two-phase region quick quenching and annealing heat treatment process for smelting pure steel while controlling the state of impurities. The method can realize the excellent combination of strength and plasticity, realizes the clean production of the high-strength strapping steel which has a tensile strength over 1,100MPa and an elongation over 10 percent, and has the advantages of easy-to-implement production operation, high production efficiency, low production cost, light environmental pollution. Thus, the method has a good application prospect.

Owner:BAOSHAN IRON & STEEL CO LTD

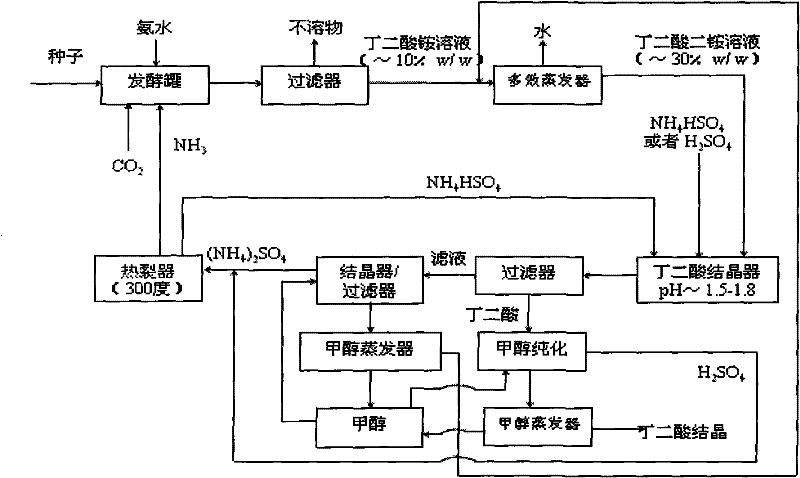

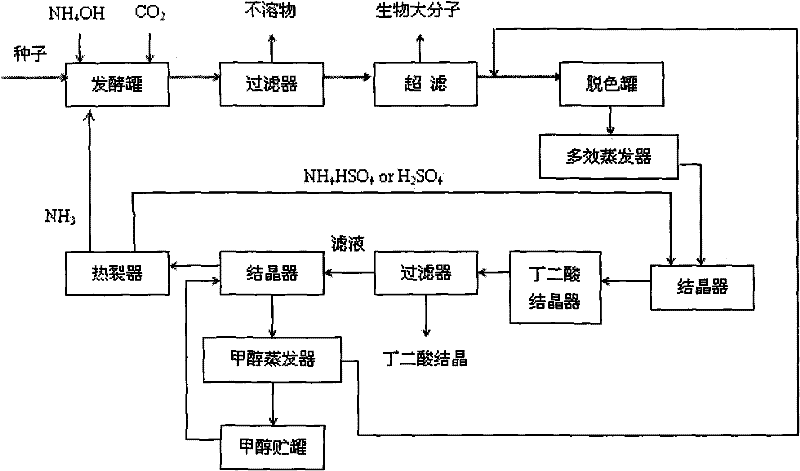

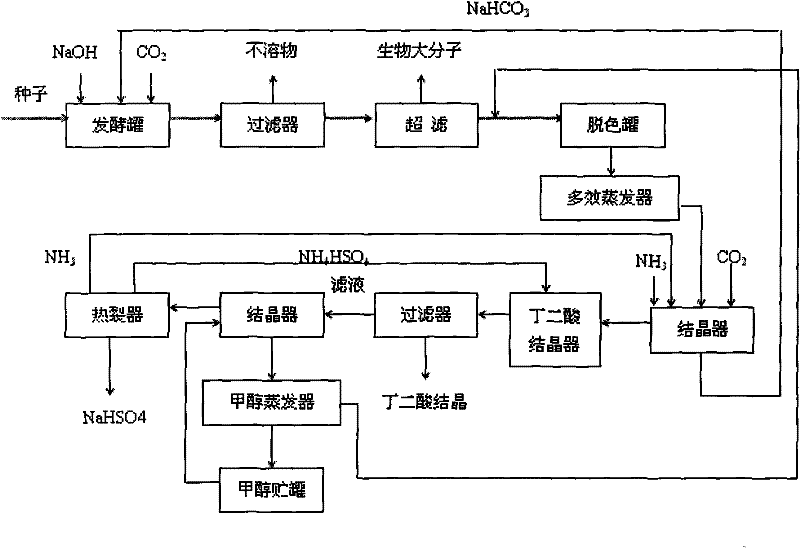

Succinic acid purification process through anaerobic fermentation

InactiveCN101748161APrevent pigmentationQuality assuranceMicroorganism based processesFermentationButanedioic acidEcological environment

The invention belongs to the technical field of biological engineering and discloses a novel succinic acid purification process through anaerobic fermentation. By adopting the separation process based on solid-liquid separation, ultrafiltration, decoloration, acidification and crystallization and by introducing ammonium sulfate thermal cracking technology, the invention realizes cyclic utilization of the acid and the alkali, forms a closed clean production flow and effectively ensures the quality of the succinic acid used for food and medicine. The invention not only reduces the fermentation cost and improves the economic benefits but also reduces environment pollution, improves the ecological environment and promotes the sustainable development of the national economy. Therefore, the invention has wide social benefits.

Owner:NANJING UNIV OF TECH

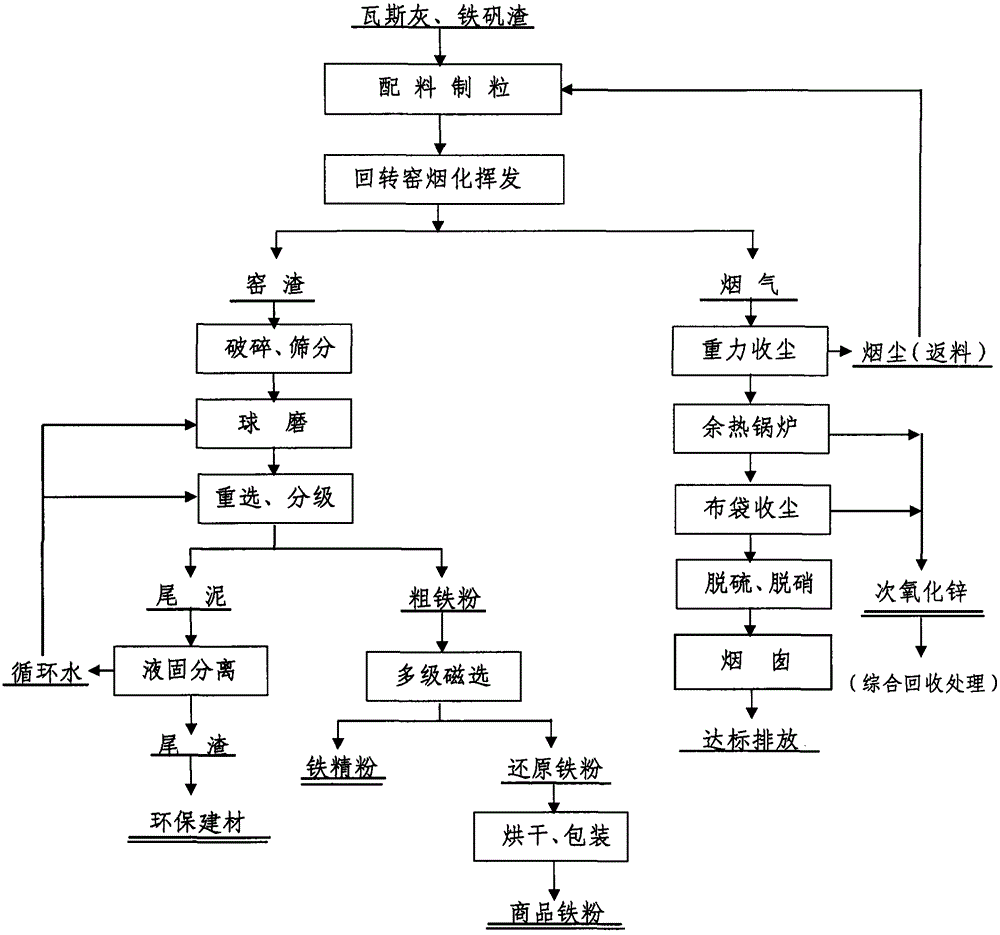

Comprehensive recovery technology of solid waste gas ash and zinc-containing ferrovanadium slag

ActiveCN104911356AImprove the level of comprehensive utilizationAchieve reductionProcess efficiency improvementSlagHigh energy

The invention provides a comprehensive recovery technology of solid waste gas ash and zinc-containing ferrovanadium slag. By combining advantages of low iron content and rich carbon of gas ash and characteristics of high iron content and rich precious metals of ferrovanadium slag, and by the adoption of a rotary-kiln fire method fuming enrichment technology, the material undergoes comprehensive recovery. Advanced equipment such as a waste heat boiler, a negative-pressure bag collector, a pneumatic emulsification desulfurization tower and the like are configured to carry out efficient recovery and harmless environmental-protection processing of flue gas so as to achieve the purpose of clean production. By a beneficiation combined method, iron-containing kiln slag undergoes high added-value exploitation. Thus, the environmental protection problem of resource disposition is solved, and the effect of comprehensive utilization with low energy consumption, high yield and high added-value is achieved. Problems of short kiln age, high energy consumption and low concentration of SO2 during the treating process of ferrovanadium slag can be solved by the technology provided by the invention, and problems of poor iron separation effect and overhigh content of fluorine and chlorine in zinc hypoxide also can be solved. The technology has good economic benefit and high popularization and practical value.

Owner:北京事竟成有色金属研究所

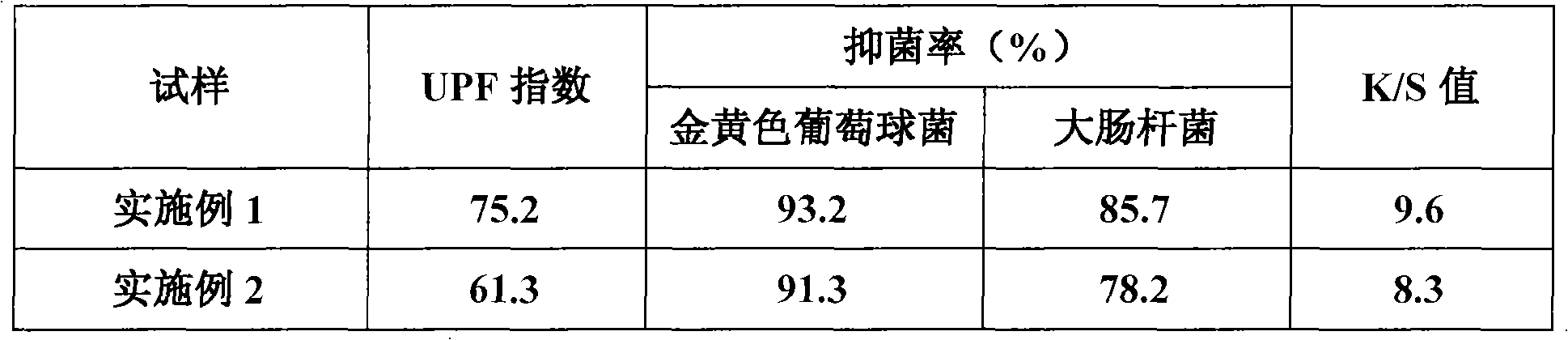

One-bathing integrated finishing method for real silk fabric by natural extract

InactiveCN101338518AAchieve antibacterialReduce processing stepsDyeing processAnimal fibresEngineeringTextile dyeing

The invention discloses a method for real silk fabric functional finishing, especially relates to a method for one-bath multifunctional finishing of real silk fabric by utilizing natural extract, which pertains to textile dyeing and finishing technical field. The invention includes the following steps: placing real silk fabric in solution with 5-20%(o.w.f) natural extract, liquor ratio of 1:10 to 1:100 and PH value of 2-8, treating for 10-100min; then treating for 10-100min in solution with 3-15%(o.w.f.) metal salt, liquor ratio of 1:10 to 1:100 and PH value of 4-8; after washing, dehydrating and furnace drying, completing one-bath finishing with dyeing, antimicrobial and anti-ultraviolet function to real silk fabric. The invention reduces manufacturing procedure of real silk fabric, has effect of energy-saving and emission-reduction, improves cleaning production of textile processing, is harmless to human body and surroundings, and conforms to ecological textile processing requests.

Owner:SUZHOU UNIV +1

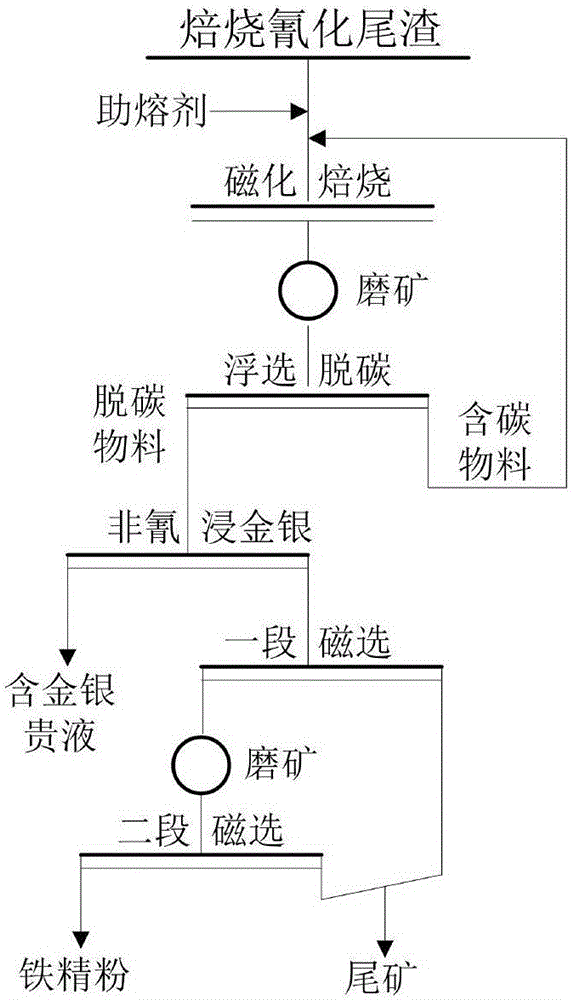

Method for recycling and synchronous harmless treatment of gold, silver and iron in roasting-cyanidation tailings

ActiveCN106498177ARealize harmless treatmentLow toxicityProcess efficiency improvementSilicate mineralsGold leaching

The invention provides a method for recycling and synchronous harmless treatment of gold, silver and iron in roasting-cyanidation tailings, and belongs to the technical field of metallurgical waste residue utilization. The method comprises the following steps: mixing dried roasting-cyanidation tailings with a fluxing agent and a reducing agent; carrying out roasting at 750 to 900 DEG C for 3 to 5 hours; conducting water quenching on hot roasted sand for cooling; carrying out ore grinding and flotation to remove residual carbon; leaching gold and silver with an environment-friendly gold leaching agent; and conducting magnetic separation on the leaching residue to obtain fine iron powder. Containing no highly toxic cyanide, the rejects belong to general industry solid waste. As the fluxing agent is added for magnetic roasting, not only can gold and silver coated with an iron mineral be exposed, but also the fluxing agent can perform a solid-phase reaction with a silicate mineral to generate a dissoluble silicate, and gold and silver coated with the dissoluble silicate can also be exposed after ore grinding. According to the method, gold, silver and iron in the roasting-cyanidation tailings are recycled, harmless treatment is realized synchronously, and the purpose of clean production is realized.

Owner:UNIV OF SCI & TECH BEIJING

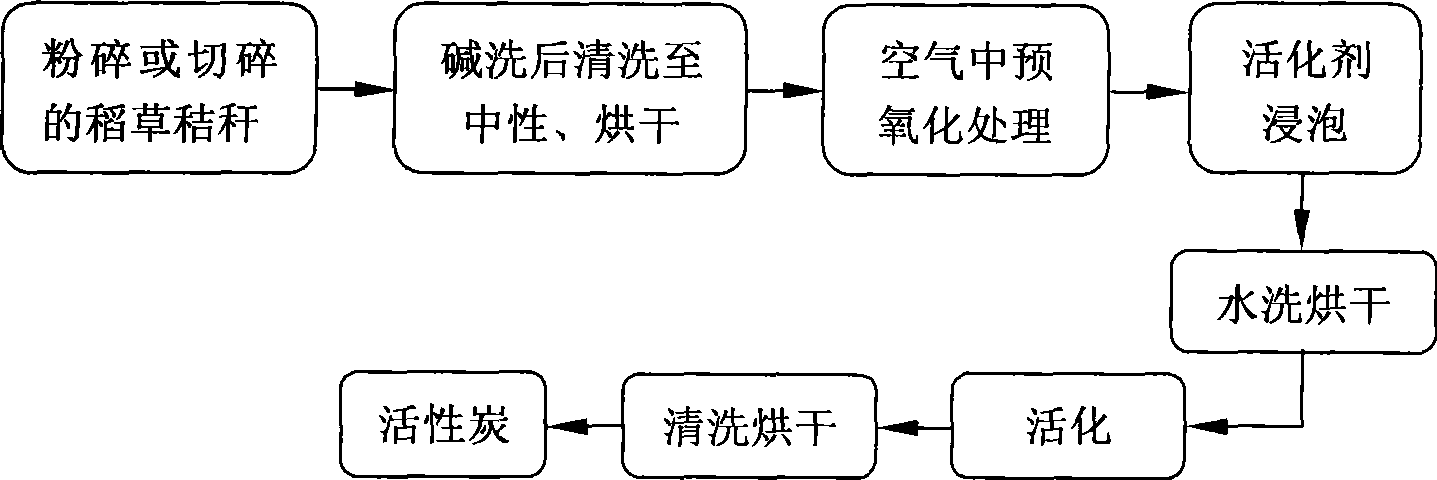

Method for preparing active carbon from straw stalk

The invention relates to a method for preparing active carbon from rice straw. The method comprises taht: (1) the collected rice straw is subjected to alkali cleaning, cleaned to neutrality, dried, and cut or pulverized; (2) the rice straw is added into an activator solution, evenly stirred, soaked for 12 to 24 hours, subjected to solid-liquid separation, cleaned and dried; (3) the rice straw prepared in step (2) is put in a barrate type oven and pre-oxygenated for 1 to 2 hours; (4) the pre-oxygenated rice straw is put in a tube-type carbide furnace, heated for temperature rise under the protection of nitrogen gas, and activated; and (5) the activated rice straw is washed by water till pH is between 6.5 and 7.5, and dried at 105 DEG C to prepare the active carbon. The active carbon prepared by the method has good adsorption performance; the adsorptive value of methylthionine chloride reaches between 200 and 300 mL / g; and the preparation process is simple, economical and environment-friendly, meets requirement of clean production and circular economy development, and has good industrial application prospect.

Owner:DONGHUA UNIV

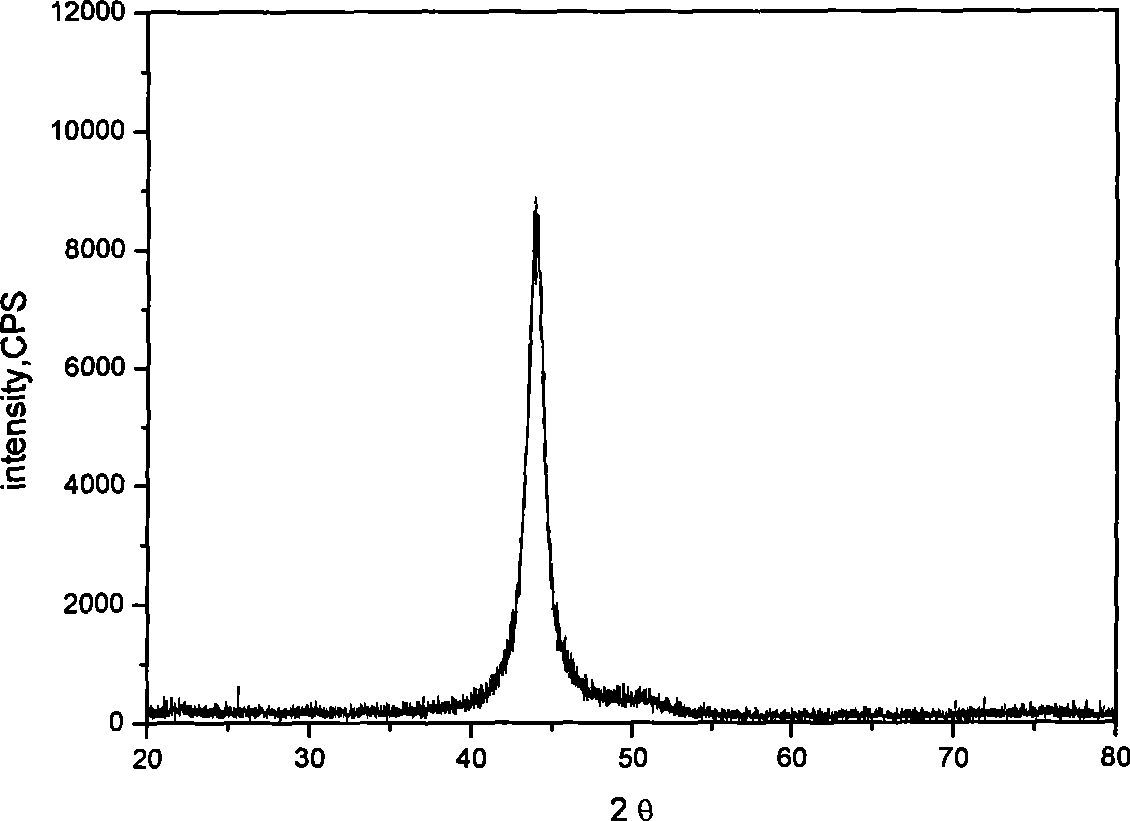

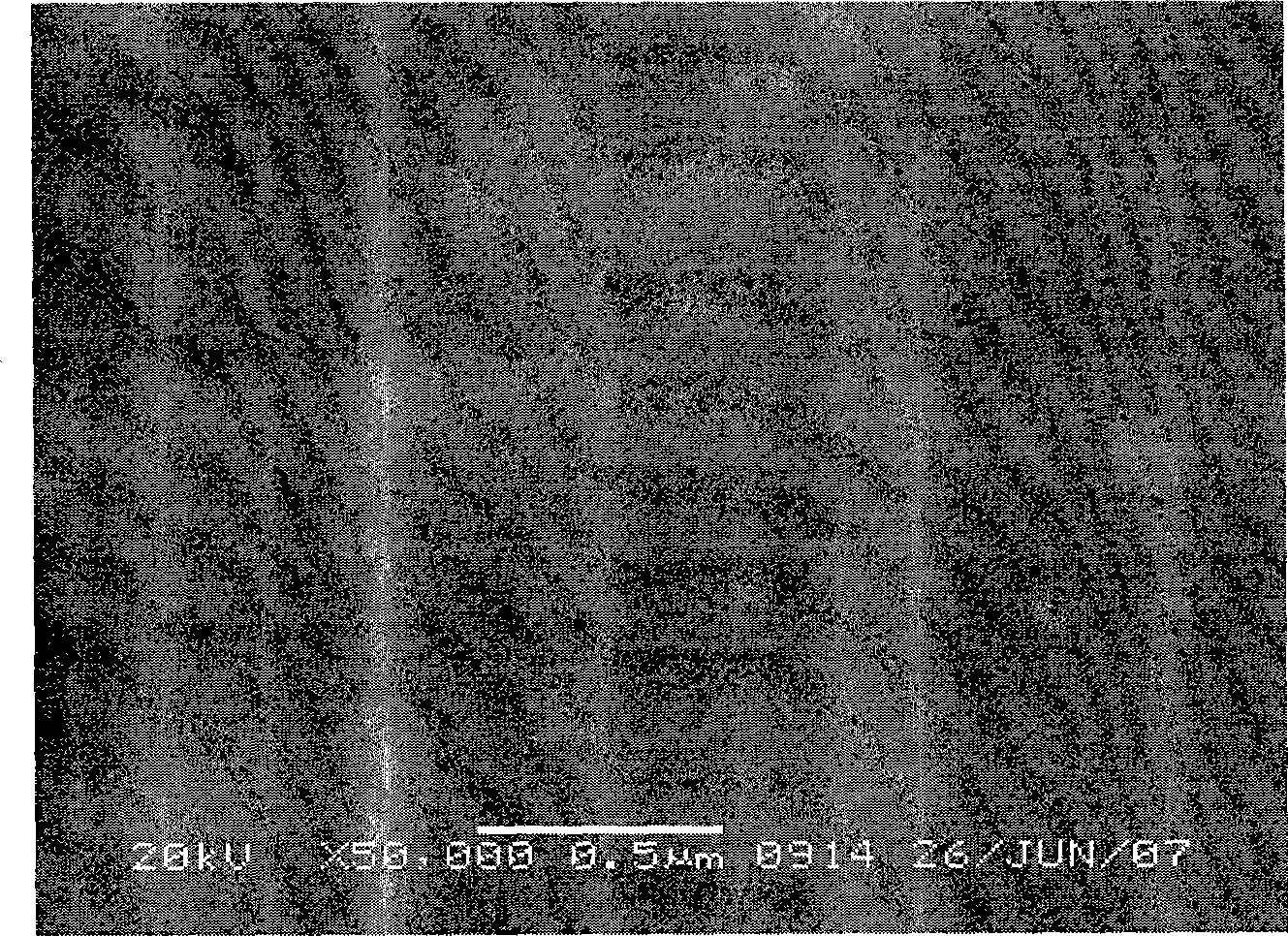

Anticorrosive wearable electrodeposit clad layer of Ni-W-P ternary alloy and manufacturing technique and electroplate liquid thereof

The invention relates to an anticorrosive wearable electrodeposit clad layer of Ni-W-P ternary alloy and manufacturing technique and electroplates liquid thereof, which takes the nickel sulfate, sodium tungstate, phosphate as the main material, electrically depositing the Ni-WP amorphous mixture of amorphous or nanocrystalline alloy coating. The characteristics of the electroplate technique are following: corrosive solution is very small, the entire production of the use of cleaner production, less emissions, in line with the requirements of sustainable production. W of the coating for the content of 1-45wt%, P content of 0.1-5wt%, nickel is the residue. The plating layer is bright and dense; the hardness is 400-1100Hv, which is resistant to acid, alkali, salt and hydrogen sulfide corrosion, wear resistance is better than or equivalent to chrome plating, can not only replace decorative chromium or hard chromium is widely used, and can be used for oil field exploration equipment to deal with wear-resistant anti-corrosion.

Owner:湖南纳菲尔新材料科技股份有限公司

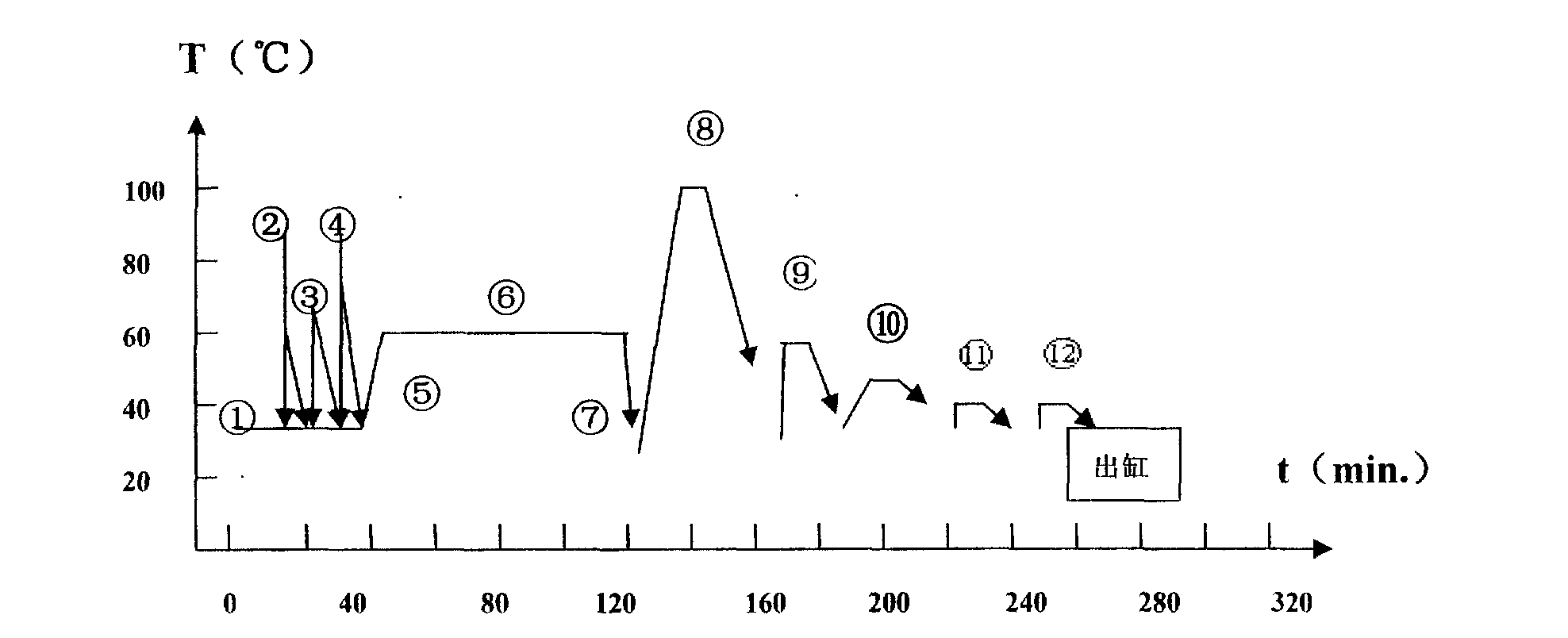

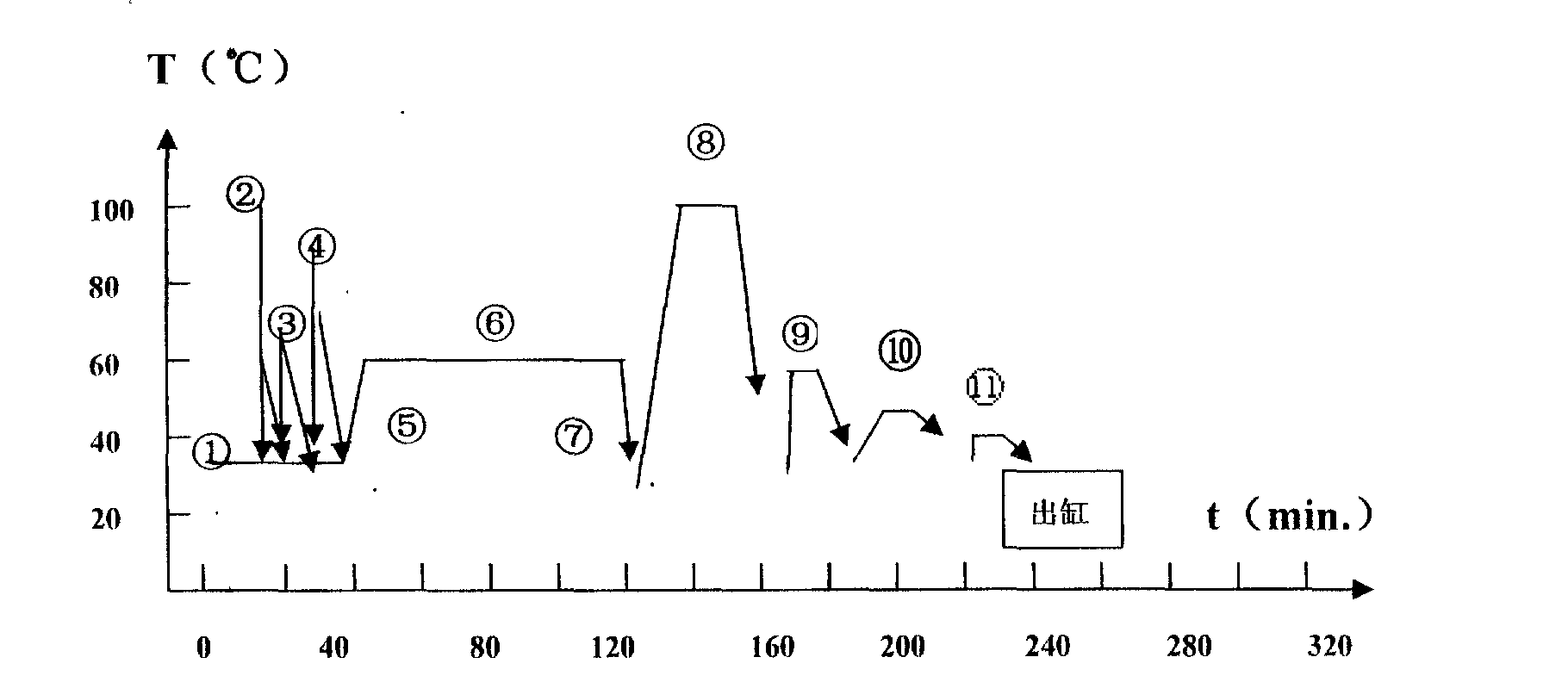

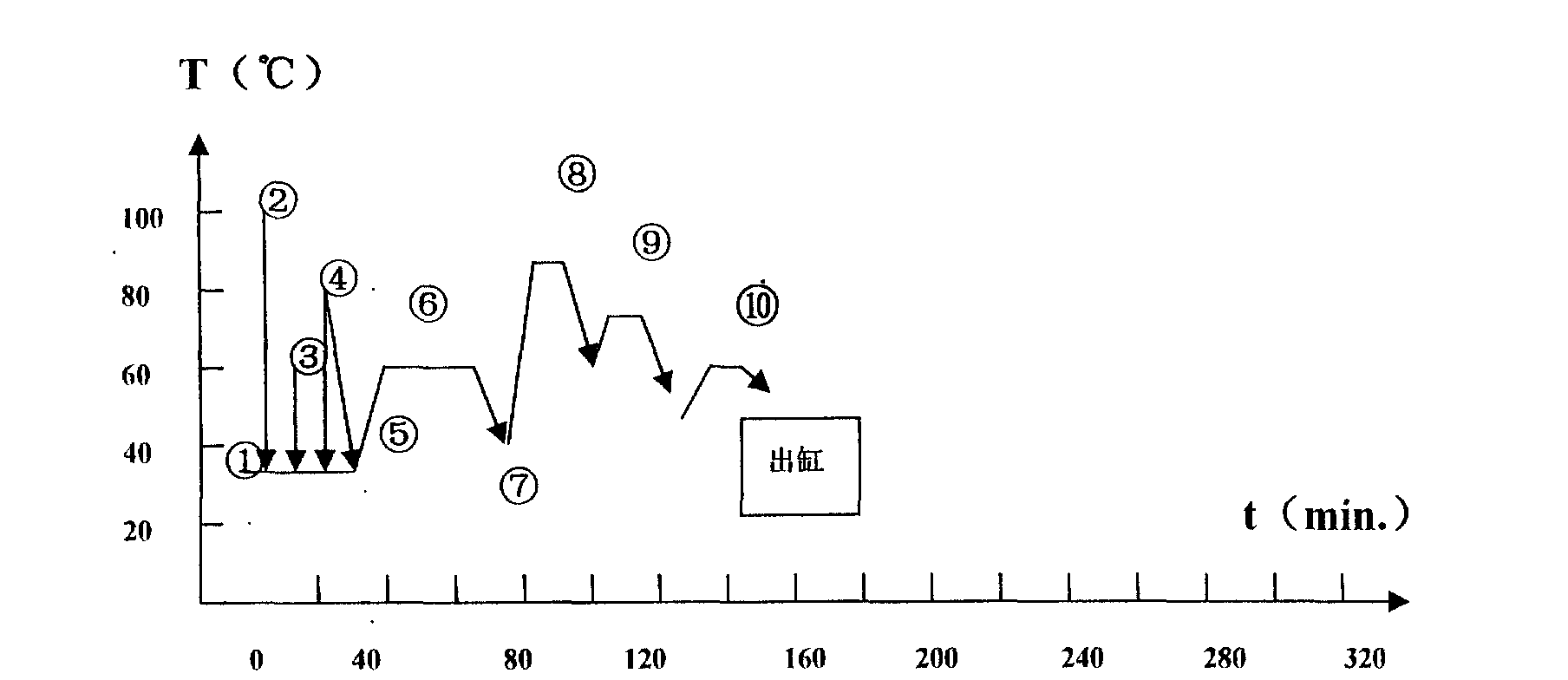

Reactive dye ultra-short rapid dyeing and fixation technology method

The invention relates to a reactive dye ultra-short rapid dyeing and fixation technology method. The method is realized by effectively minimizing auxiliary time such as feeding, shortening and optimizing post-processing processes, especially carrying soap boiling (one bath color mending) only once in advance to the greatest extend, merging washing, using less hot water and controlling the use of water aiming at various substances to be dyed according to dyeing requirements and the conditions of normal or abnormal and with the help of various accessory ingredients, thereby the reactive dye normal or abnormal dyeing conditions (especially mediate high color with a dye usage higher than 1percent of o. W. f) by the single one bath process, the multifunction composite one bath process, or the like, comprising pre-processing, dyeing, polishing with enzyme, and color mending, and even the pre-processing and the whole dyeing procedure in conventional equipment in an ultra-low bath ratio limit state can be completed well within 2.5-8h. The effects of thorough energy saving and emission reduction, efficiency increasing and consumption reduction, cleaner production and environmental protection are achieved.

Owner:罗海航 +1

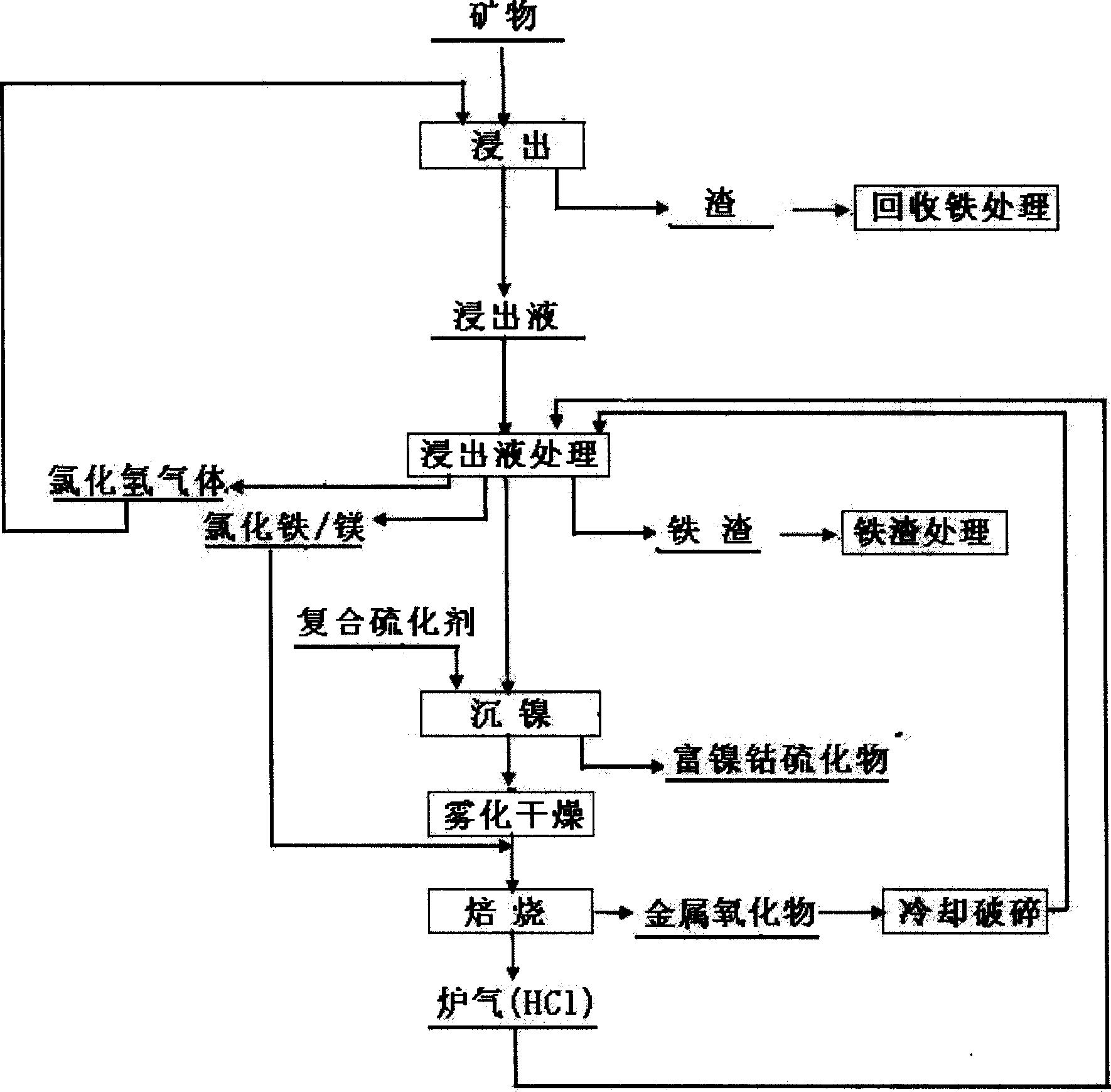

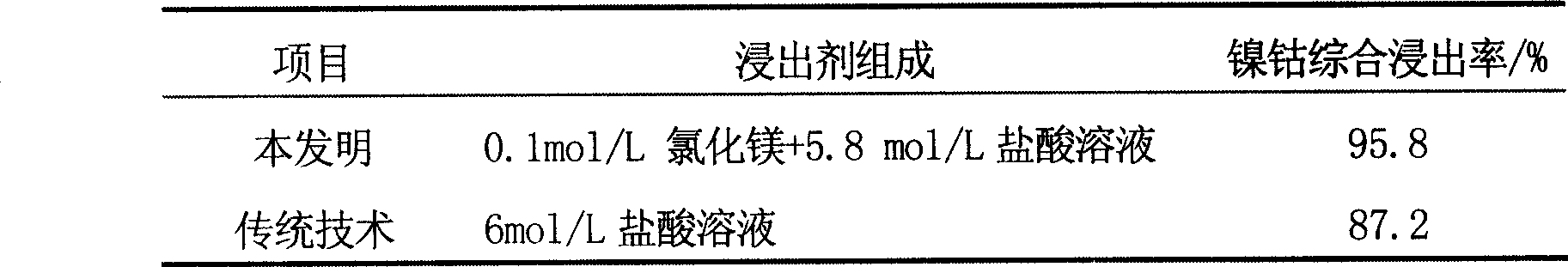

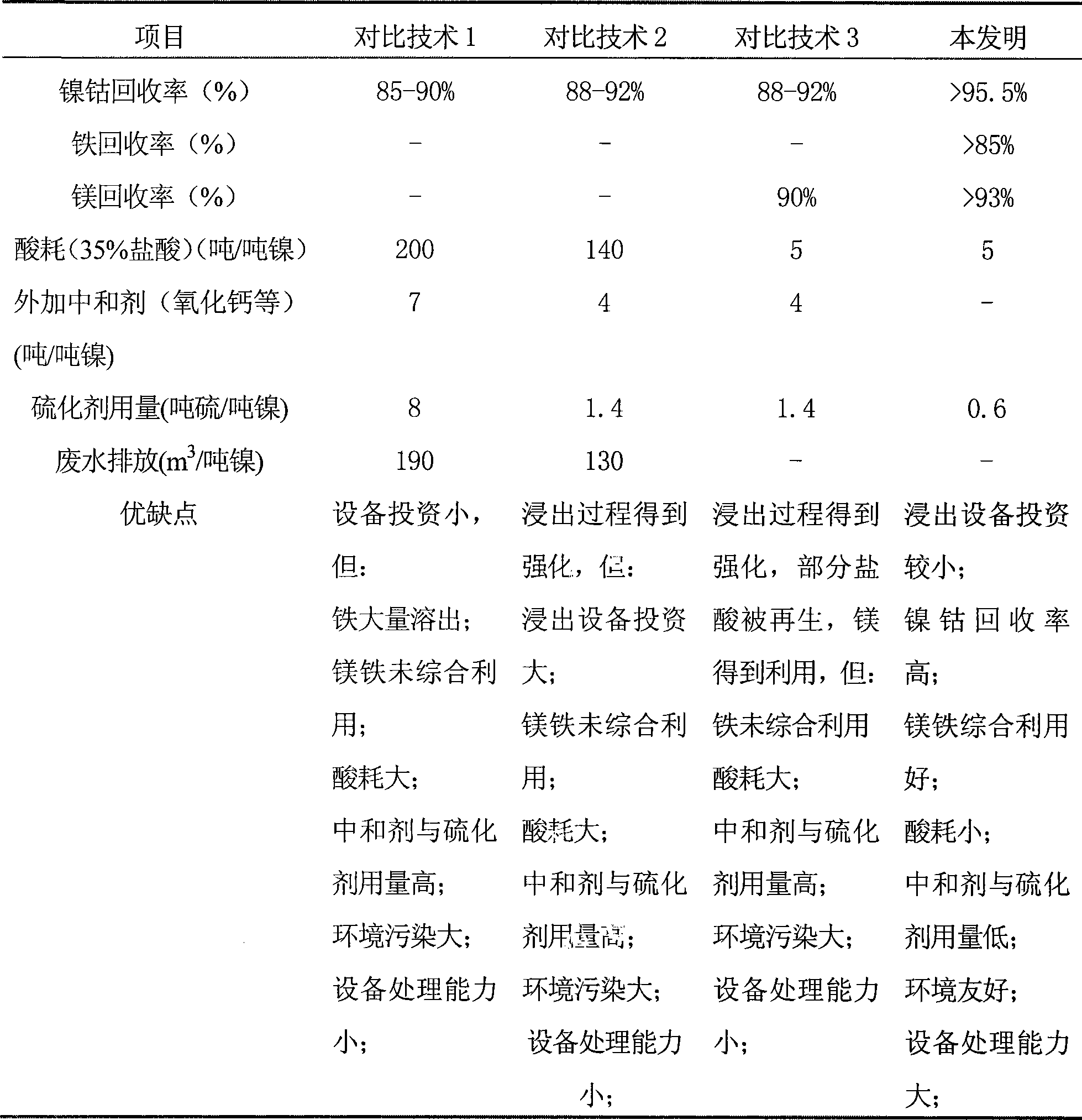

Method for extracting valuable metals from laterite nickel mine with hydrochloric acid full-closed circulation method

ActiveCN101509072AImprove leaching efficiencyIncrease profitMagnetic separationProcess efficiency improvementMetal chlorideWastewater

A method for extracting valuable metals from laterite nickel ore on the basis of the hydrochloric acid fully-closed circulation method belongs to the field of non-ferrous metallurgy. Crushed laterite nickel minerals are taken as raw material and the technique comprises the following technological steps: chlorination-leaching; recovering iron (Fe) from leaching residue; extracting nickel (Ni) and cobalt (Co); spray-drying the mother liquor; and calcining. By leaching the laterite nickel minerals with a mixed solution of hydrochloric acid and metal chlorides as a leaching agent under the proper conditions of heating and pressurizing and further precipitating nickel and cobalt with a compound vulcanizing agent, the overall recovery rate of nickel and cobalt is high; the closed circulation of hydrochloric acid is realized while processing the laterite nickel minerals with water and hydrochloric acid, therefore, the method is environment-friendly by realizing the zero discharge of waste water; comprehensive utilization of the resources, such as Ni, Co, Fe and Mg, in the laterite nickel ore can be realized; and the resources can be efficiently utilized and the clean production can be realized by recovering and reutilizing the waste heat and the residue acid during the production.

Owner:CENT SOUTH UNIV

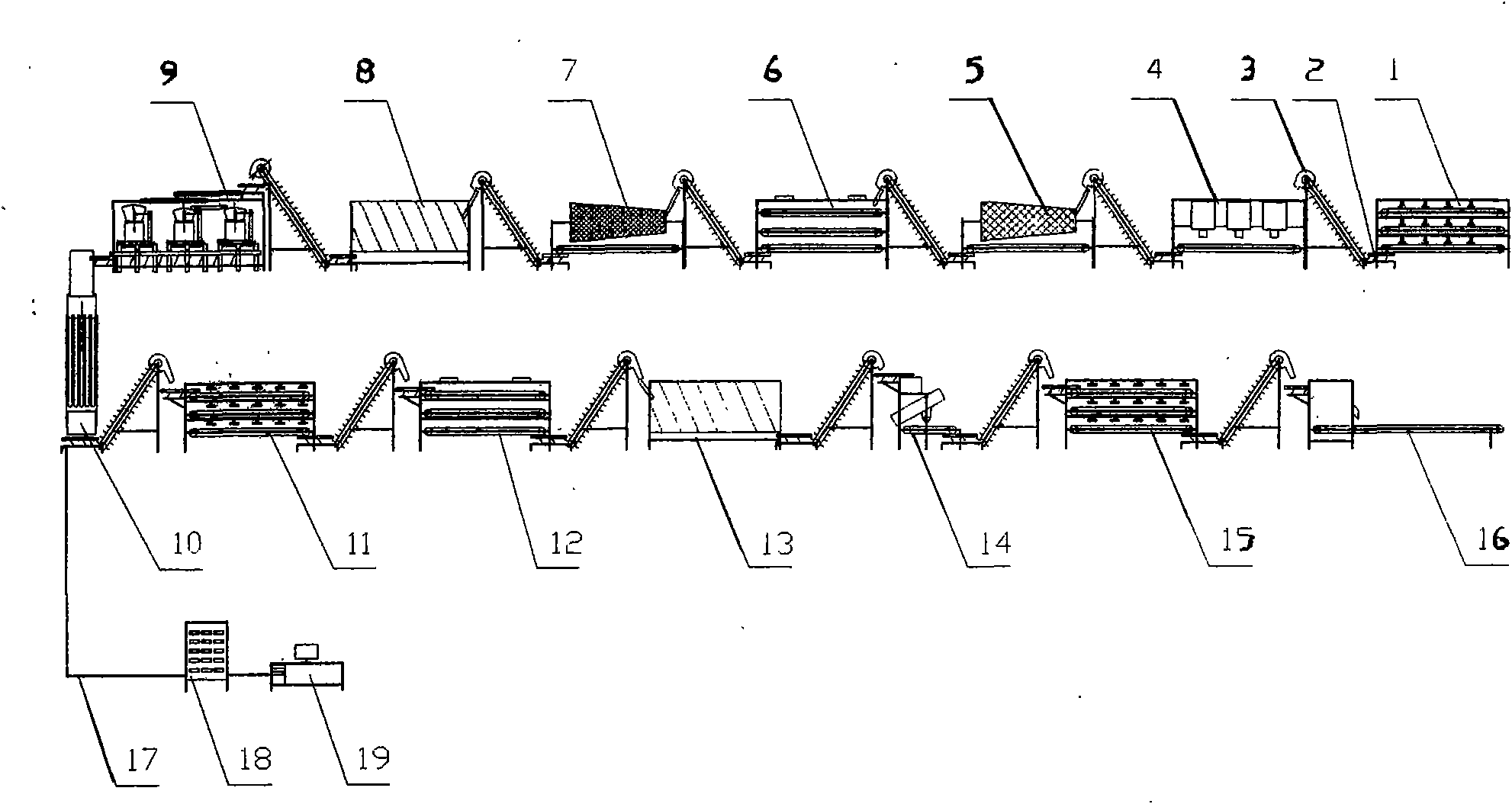

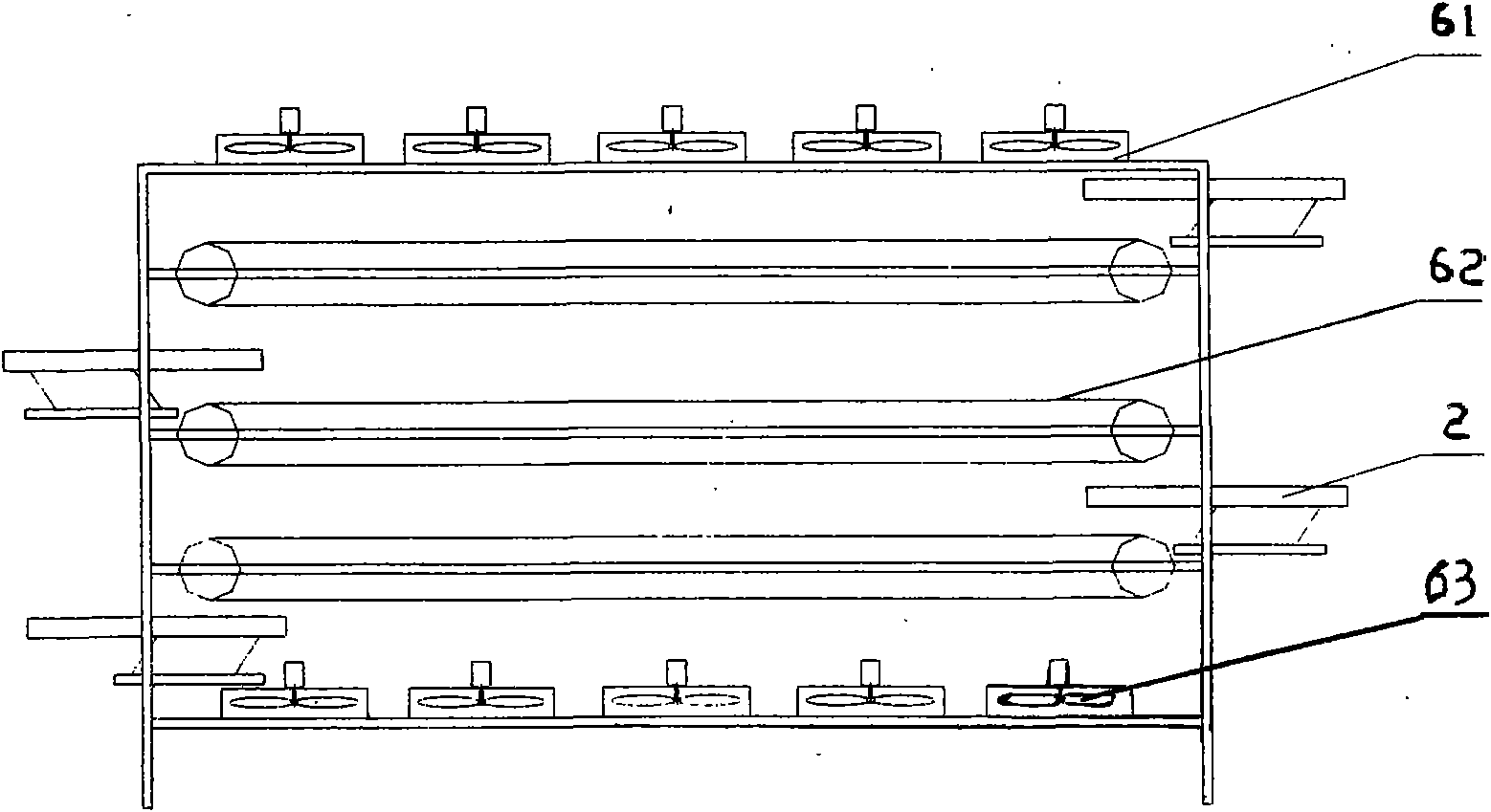

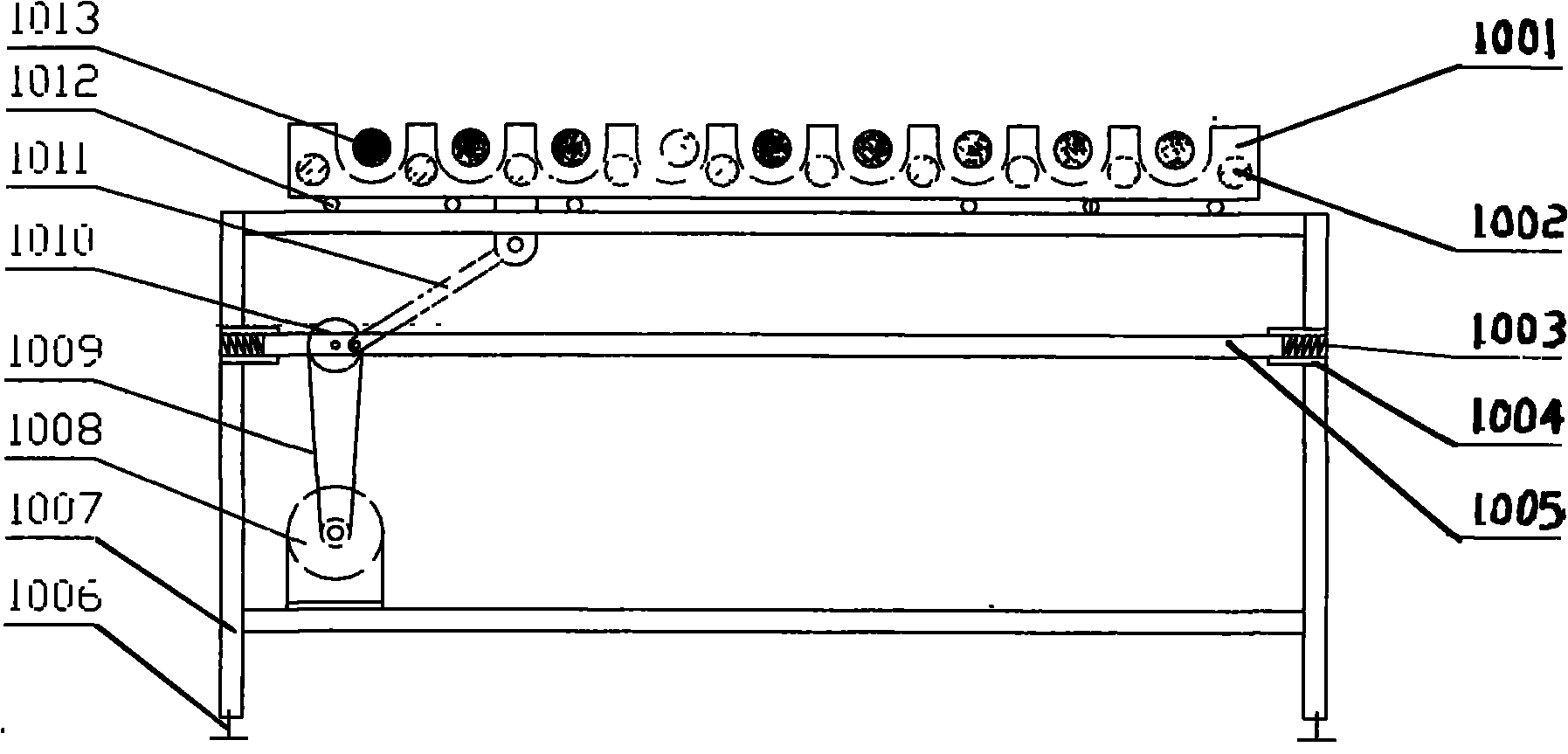

Tea mechanization and clean production line

InactiveCN101953405ASimple processing equipmentAvoid secondary pollutionPre-extraction tea treatmentMicrocomputerElectric machinery

The invention relates to a tea mechanization and clean production line, which belongs to the technical field of tea processing equipment. The invention provides a tea production line which is mechanized, standardized, automated, serialized, clean and dimensions scaled. The production line comprises various process devices which are composed of a cleaning machine, a dehydrater, a grader, a green-unfolding machine, a green-shaking machine, a rotary-drum removing green machine, a knead entwist machine, a multislot pot type continuous strip-managing machine, a low temperature far infared baker, a WXTL, a treating pot machine, a tea color sorter a high temperature far infared baker and a tea package mechanism, a material conveying mechanism composed of an elevator and a conveyor and a control mechanism composed of a microcomputer and a central control cabinet; the adjacent process devices are respectively connected by the conveyor and the elevator; electrical machines of the various process devices and the electrical machine of the material conveying mechanism both are variable frequency motors which are controlled by the control mechanism.

Owner:ANHUI AGRICULTURAL UNIVERSITY +1

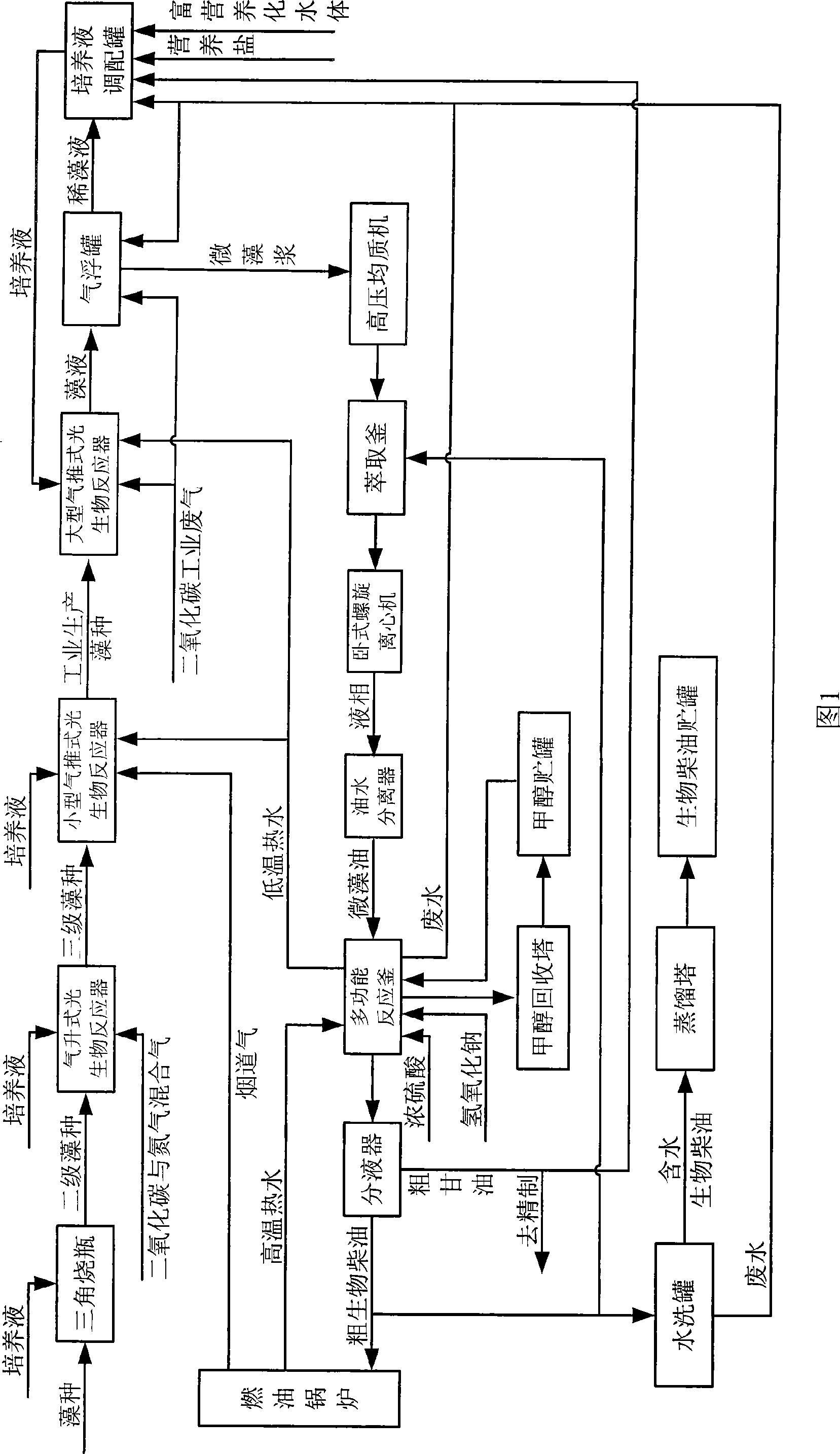

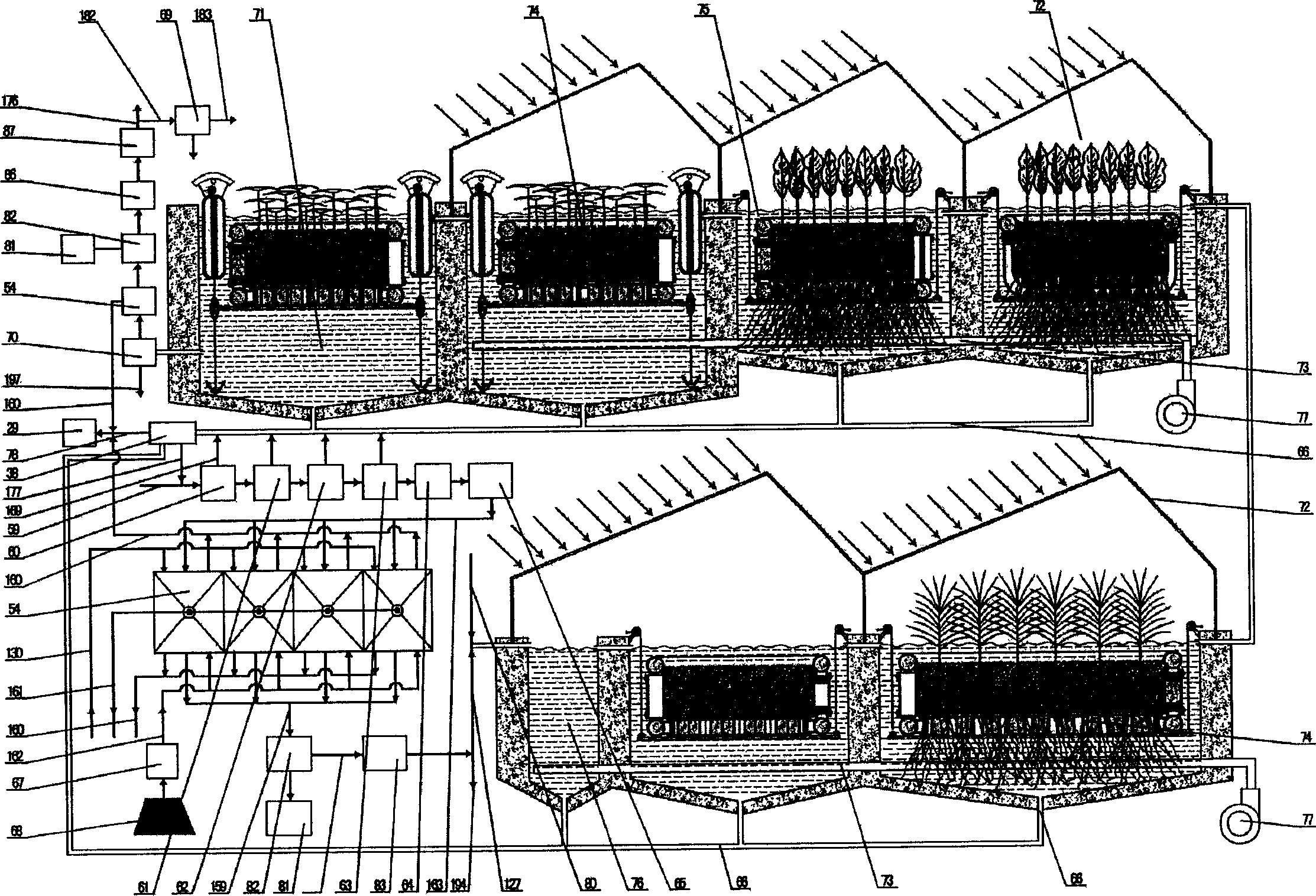

Process for preparing fine algae cultivation coupling biological diesel oil refining

The invention relates to the fields of microalgae culturing project, biodiesel refining and environment protection, in particular to a production method for refining the biodiesel through microalgae culturing and coupling. In the method, carbon dioxide industrial waste water and eutrophicated surface water or industrial waste water is used as main material to extensively culture the microalgae containing oil, and microalgae oil is used as the material to refine the biodiesel and simultaneously realize the drainage reducing of carbon dioxide, the control of polluted water and the cleaning production of biodiesel. The method is characterized in that the waste gas of carbon dioxide and the eutrophicated water are firstly used to culture and collect the microalgae; and then extraction, pre-processing and interchange esterification reaction of microalgae is carried out. In the invention, the two processing of culturing the microalgae and refining the biodiesel are coupled together; the ''three wastes'' and waste heat generated during the reefing process of the biodiesel and the unsalable outgrowth of crude glycerine are used as the materials and the heat source for culturing the microalgae; therefore, not only the production cost is reduced, but also the discharge of the ''three wastes'' is eliminated.

Owner:王彤

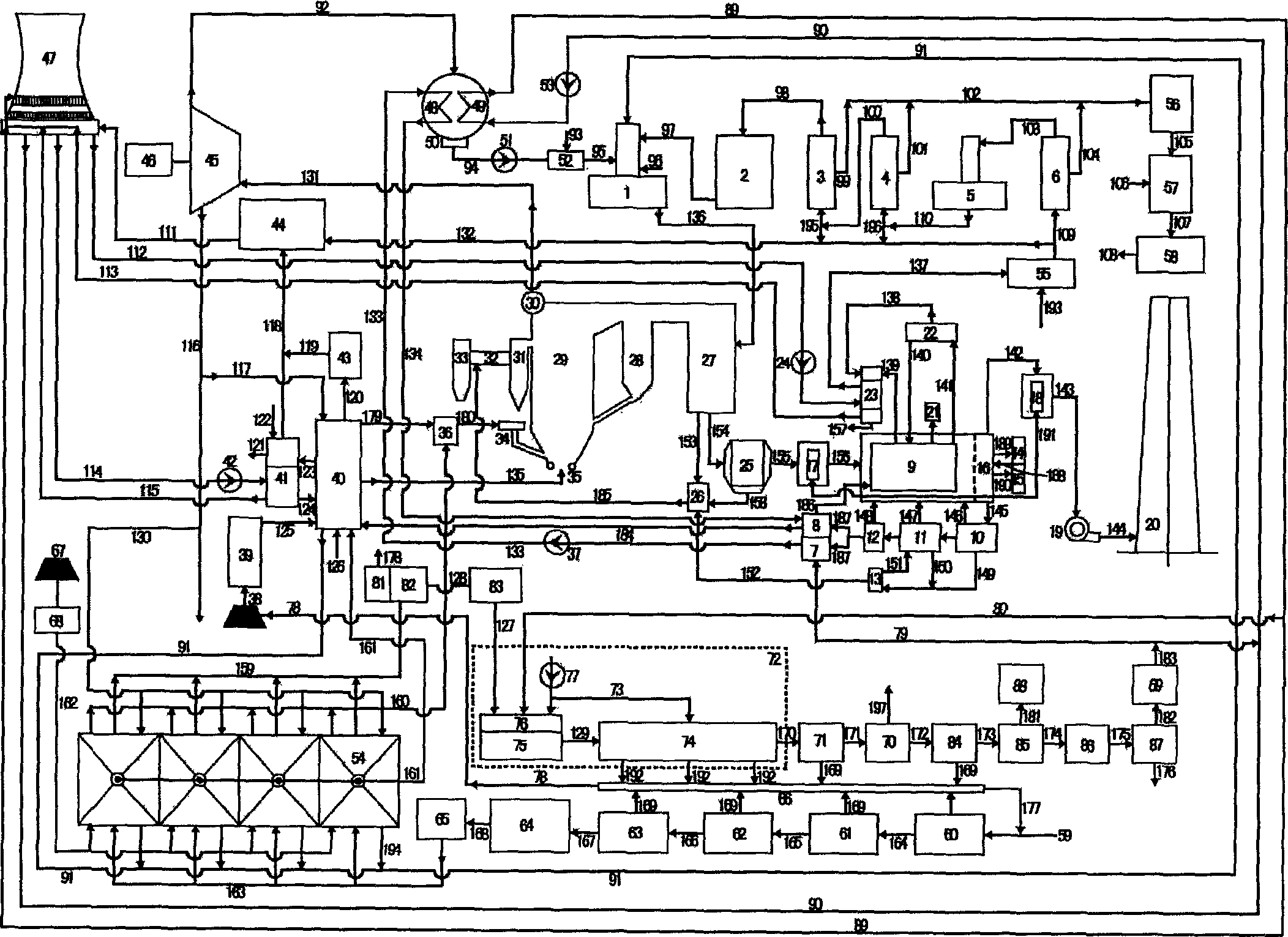

Sewage-refuse treatment clean-production system at the center of generating plant

InactiveCN1743284AImprove efficiencyComplete desulfurizationWater/sewage treatment by irradiationSolid waste disposalSteam condensationCoal

This sewage and garbage treatment system centrally designed for power plant includes sewage treatment unit, fuel processing unit, garbage combustion boiler, fly ash processing unit, smoke processing unit, the de-oxygenating draining steam of turbine steam-extraction heat-supply boiler and circulated water cooling unit. The effluent of sewage treatment unit with coal as filter is led into magnetic water strainer, and condensed water from the domestic garbage dehydration-drying condensed water-recovering combustion-supporting device is cleared by the coal filtration and normal water treatment system to feedback the circulated water-cooling system, the steam condensed water is heated and delivered into the de-oxygenating device. Treated sewage is introduced into multi-medium condenser and the distillation-desalination device; discharged smoke from fly ash incineration device is led into garbage combustion boiler; acid water discharged from distillation unit and alkaline water from coal filter are neutralized and discharged. Water distillation system and the circulation cooling water of the steam turbine condensator are led to the air- water cooling tower.

Owner:徐宝安

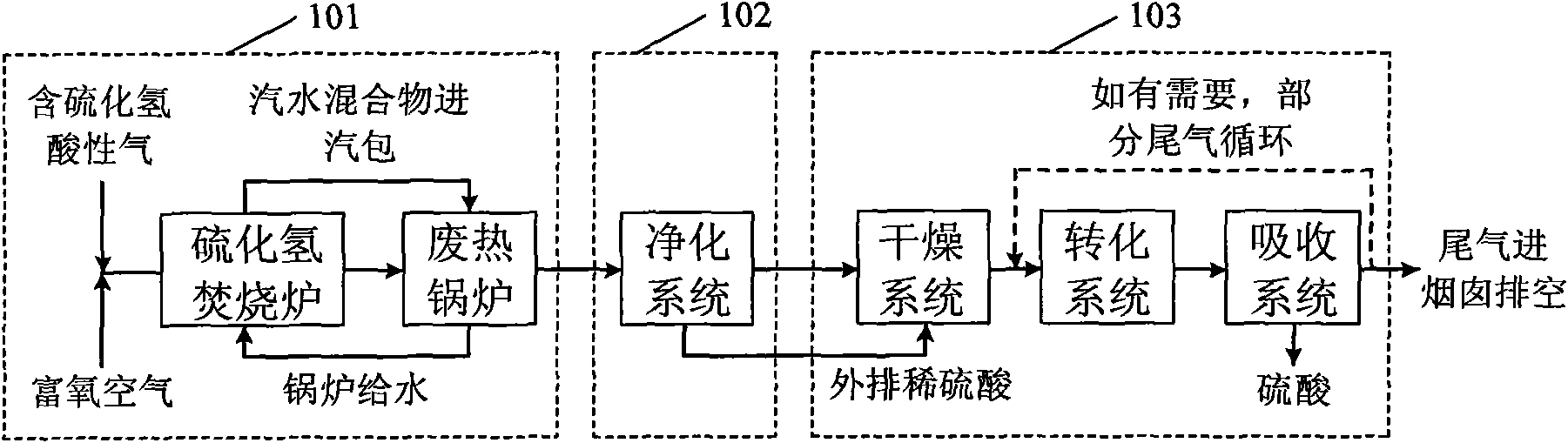

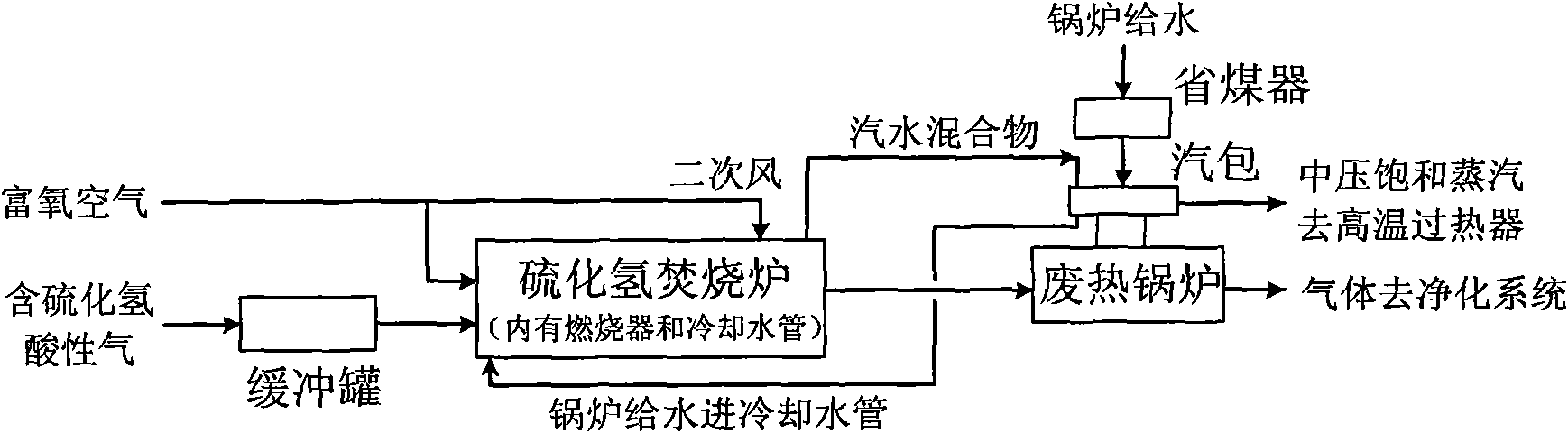

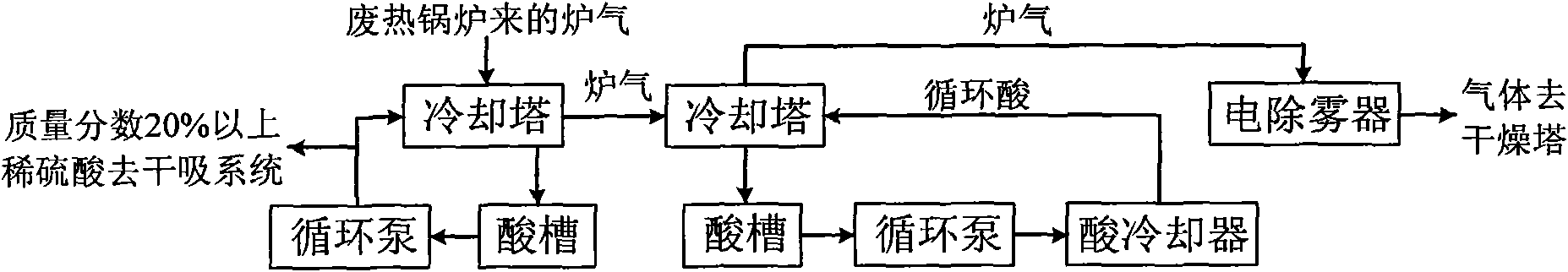

Method for producing sulfuric acid by oxygen-enriched air incineration of acid gas containing hydrogen sulfide

InactiveCN102371108AIncinerate completelyImprove waste heat recovery efficiencyDispersed particle separationSulfur compoundsThermal energyPollution

A method for producing sulfuric acid by oxygen-enriched air incineration of acid gas containing hydrogen sulfide belongs to the technical field of environment protection technology and comprises the following steps of: sending the acid gas containing hydrogen sulfide and oxygen-enriched air into a hydrogen sulfide incinerator for incineration, discharging the furnace gas after incineration, and recovering high-temperature furnace gas heat energy of an outlet; adding water into the furnace, and heating by the utilization of heat released from incineration; using dilute sulfuric acid discharged from a purification system as addendum water; demisting and drying the cooled furnace gas, entering into a conversion system for heat exchange preheating so as to generate sulfur trioxide, carrying out heat exchange on the discharged conversion gas, and entering into an absorbing tower for absorption. According to the invention, high and medium grade heat energy generated during the sulfuric acid production process is fully utilized, and dilute sulfuric acid is fully recovered and used, thus realizing less investment, low cost, high recovery rate of waste heat, clean production and no pollution in the production of sulfuric acid.

Owner:CHINA PETROCHEMICAL CORP +1

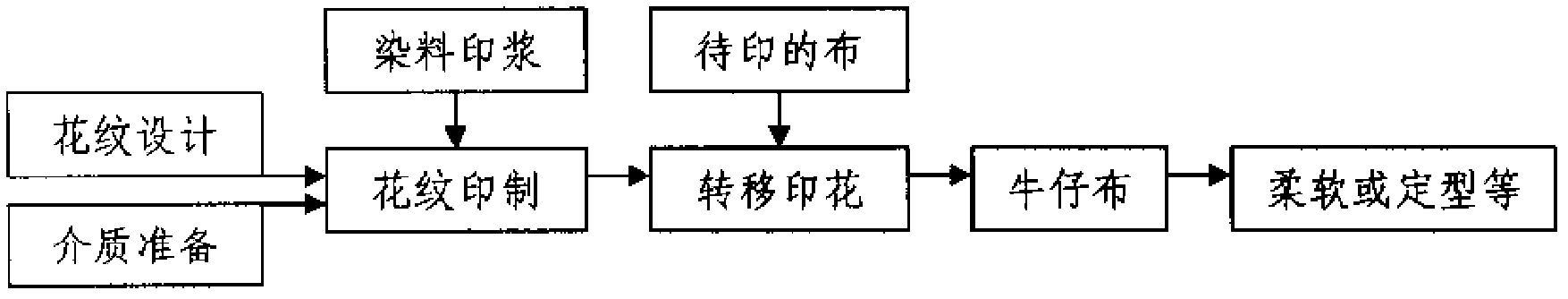

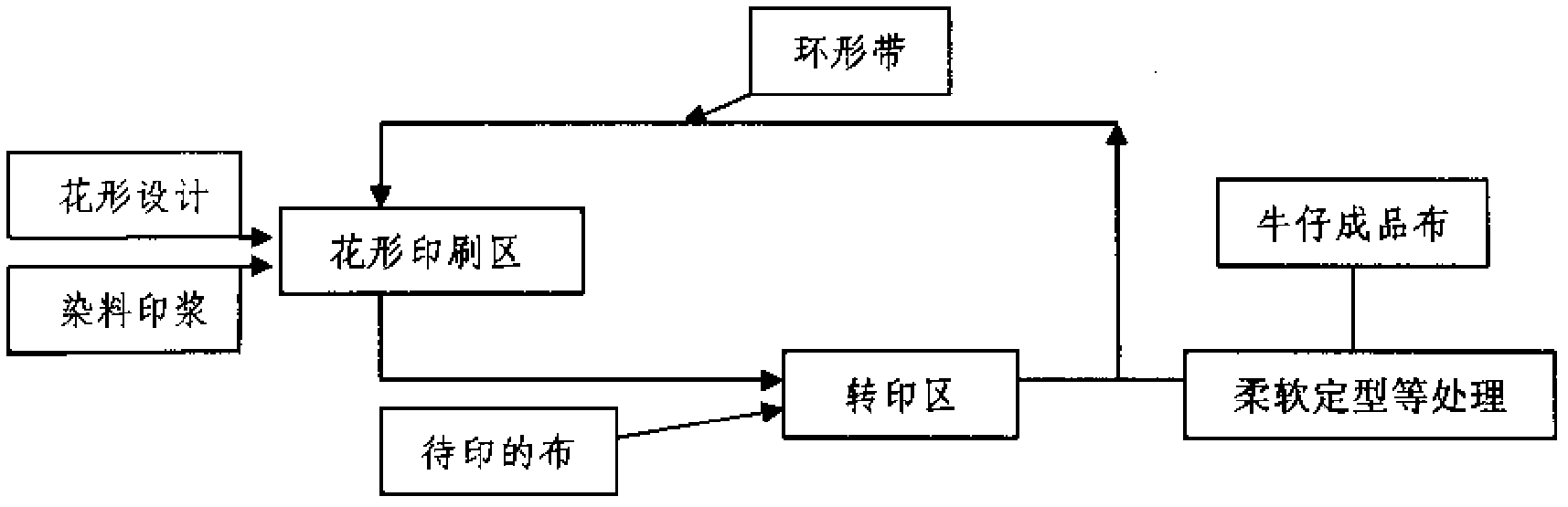

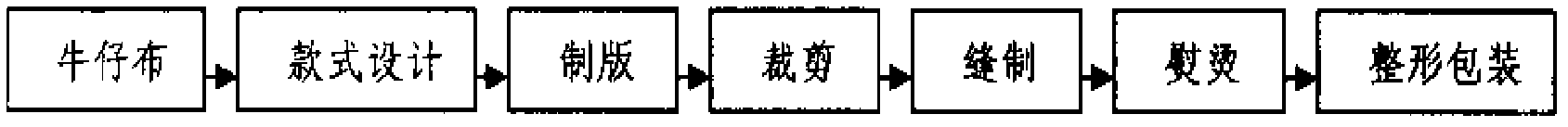

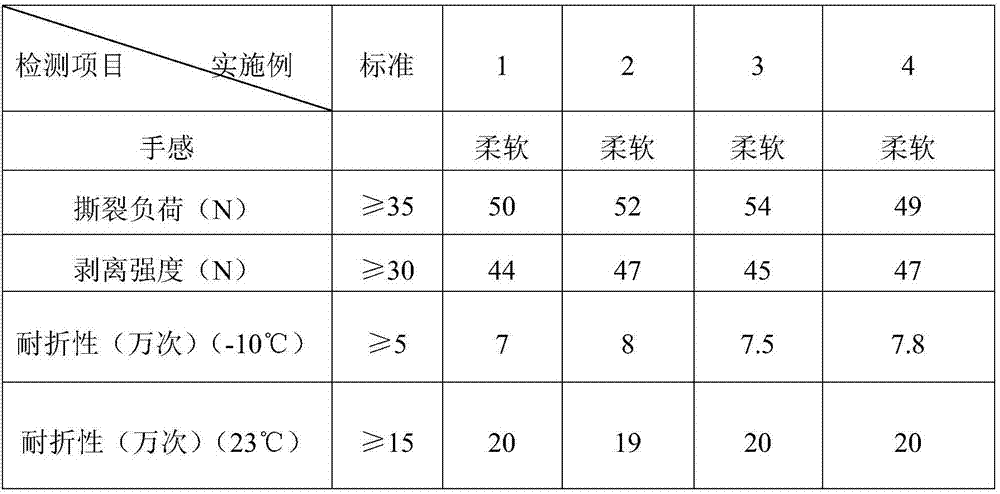

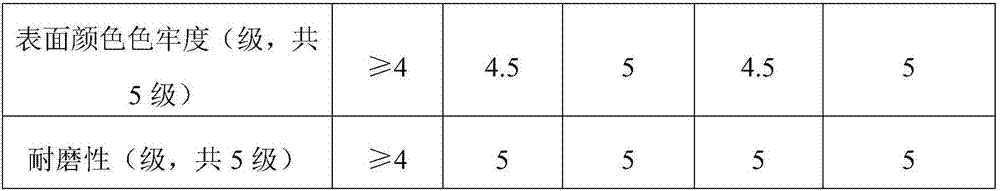

Printing technology for pure cotton or polyester-cotton jean

InactiveCN102304862APrinting process does not consume waterNo sewageTransfer printing processDyeing processWater basedFiber

The invention discloses a printing technology for pure cotton or polyester-cotton jean, belonging to the technical field of textile printing and dyeing. The printing technology comprises the following steps: firstly, preparing a dye into water-based ink suitable for intaglio printing; pretreating fiber fabrics to be served as cloth to be printed; preparing a medium capable of undertaking the printing of figures; designing figure patterns; printing the designed figure patterns on the medium in a common printing mode to obtain a transfer printing medium; carrying out transfer printing of the figures on the transfer printing medium to the cloth by a transfer machine to finish the printing of the jean; and carrying out the processes of softening, shaping and the like with the traditional padding-shaping machine as required. The printing technology has the beneficial effects that the jean with the traditional jean style can be printed, no water is consumed for printing, no sewage is generated, and the printing technology belongs to the clean production technology.

Owner:北京三丽科技有限公司

Waterborne polyurethane wet-process automobile leather and preparation method thereof

InactiveCN107299539ASolve pollutionSolve residual problemsRoad vehiclesTextiles and paperSurface layerOrganic solvent

The invention provides waterborne polyurethane wet-process automobile leather and a preparation method thereof. The method comprises the following steps: 1) base fabric treatment: firstly, impregnating a non-woven fabric with impregnation liquid in an impregnating tank, then, carrying out pre-coagulation through a coagulating solution in a coagulating tank, and carrying out ironing and baking by an ironing roller; 2) coating: coating the treated non-woven fabric with foaming slurry; 3) coagulation: carrying out coagulation on the foaming slurry coated non-woven fabric through the coagulating solution in the coagulating tank; 4) rinsing and baking: clearing superfluous coagulating solution through a rinsing bath, and carrying out baking sizing so as to obtain a waterborne automobile leather base; 5) dry-process facing: coating release paper with waterborne surface layer slurry in a scraping manner, carrying out baking, coating a waterborne bonding material in a scraping manner, carrying out laminating by using the waterborne automobile leather base, carrying out baking, and carrying out stripping, thereby obtaining the waterborne polyurethane automobile leather. According to the waterborne polyurethane wet-process automobile leather and the preparation method thereof, by adopting waterborne polyurethane resin slurry and waterborne environment-friendly auxiliaries, the automobile leather is free of any organic solvent during preparation and use, the solvent-type solvent contamination of the automobile leather is avoided, and the clean production is achieved.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +1

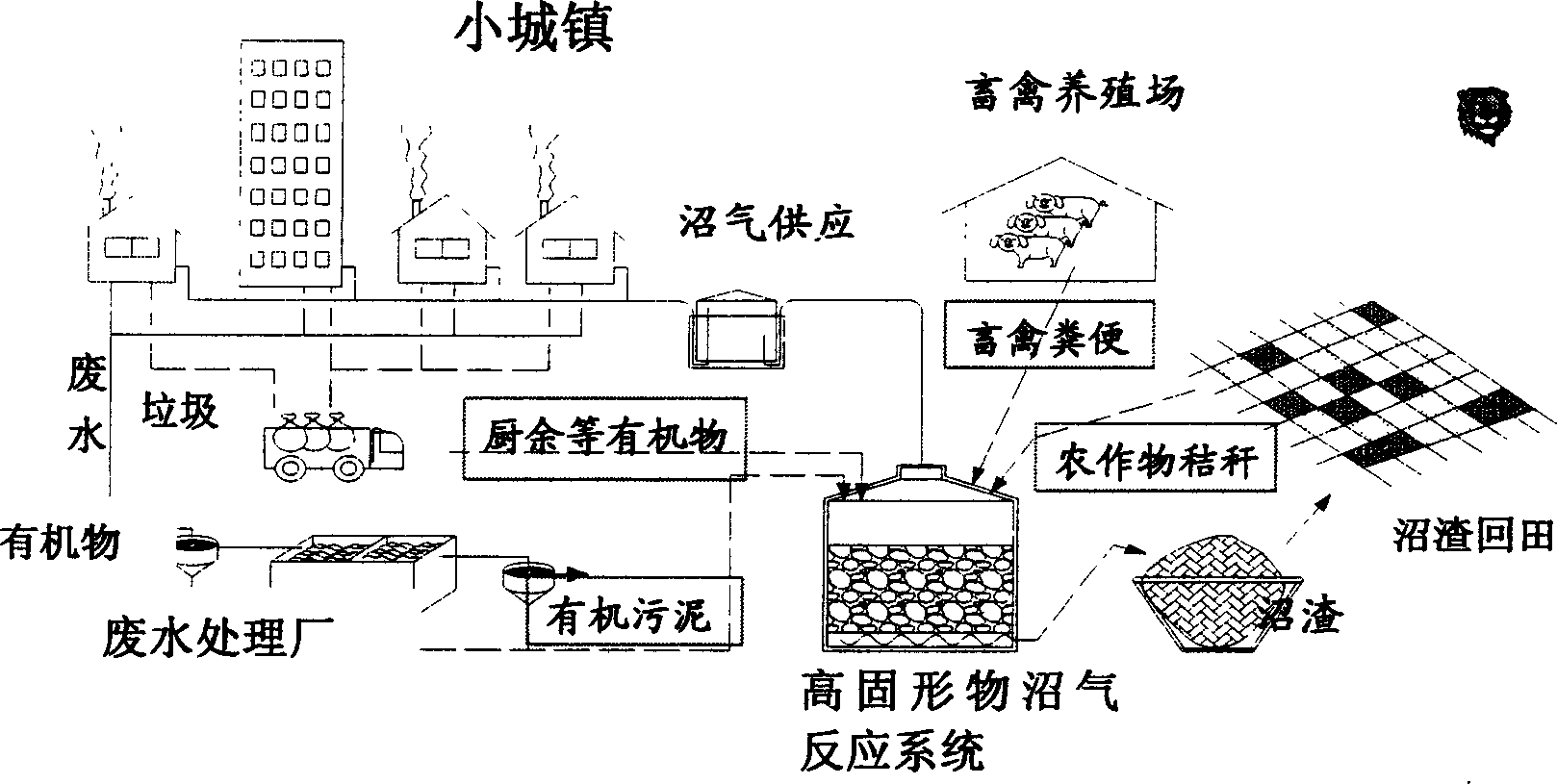

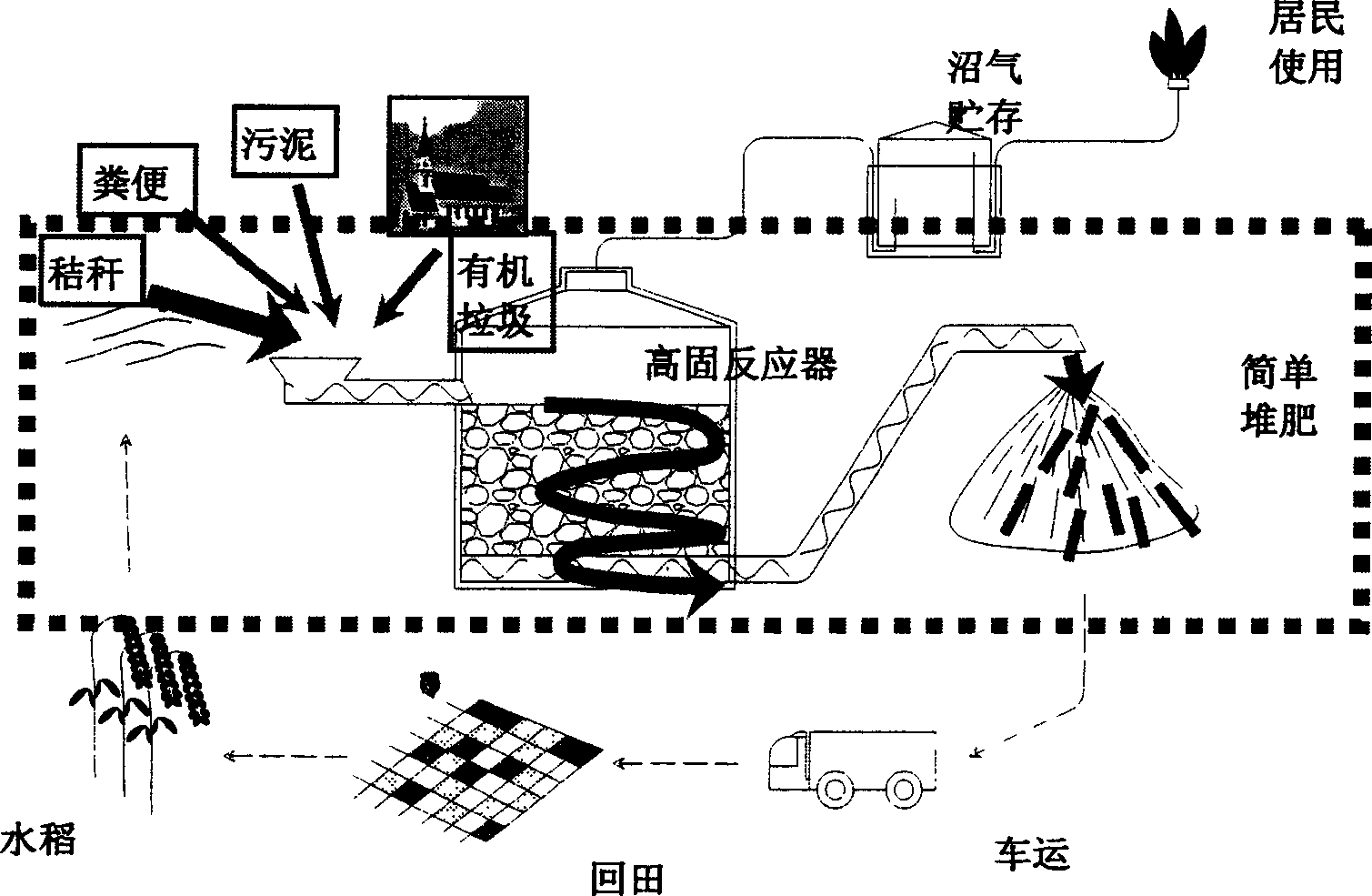

Marsh gas production technology using kitchen residue, straw, stock and fowl dejecta and active mud as material

InactiveCN1769220AReduce pretreatment costsHigh outgassing rateWaste based fuelEnergy based wastewater treatmentBiotechnologyFowl

The invention discloses a technique for producing methane with kitchen residue, straw fecal and active sludge as raw material, and relates to the key technique of methane production and a high solid methane fermentation reactor. It is characterized in: rigid anaerobic environment, adequate and good inoculum, necessary fermentation temperature, proper acid-base scale, proper fermentation concentration and carbon-hydrogen ration; the breeding speed safeguard of zymogeneous bacteria in fermentate; the killing of toxic and harmful bacterium; and the high solid reactor of stable operation. The invention is characterized in that it has significant academic meaning and practical meaning for producing methane with low investment, high stability and clean production.

Owner:JIANGNAN UNIV

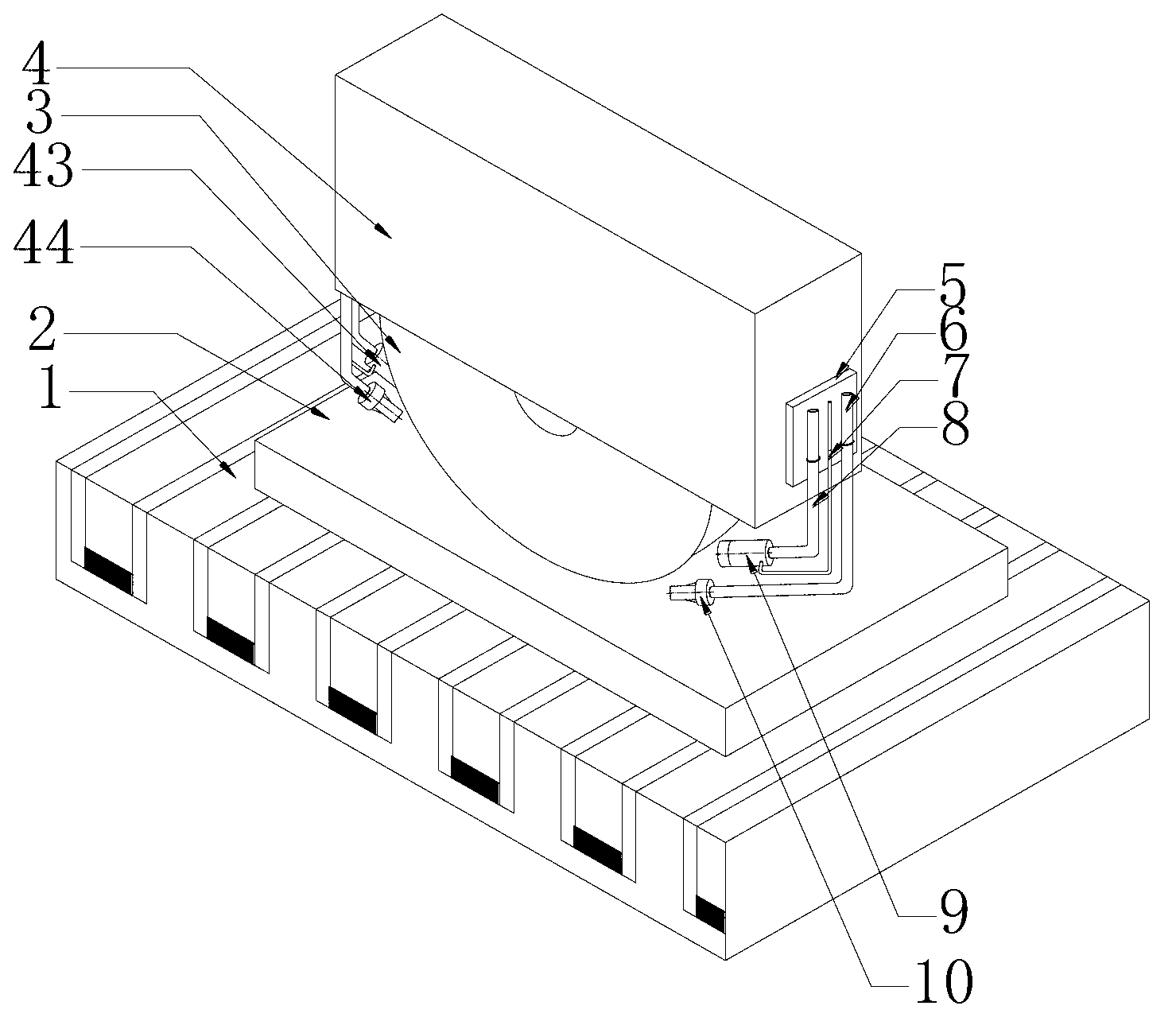

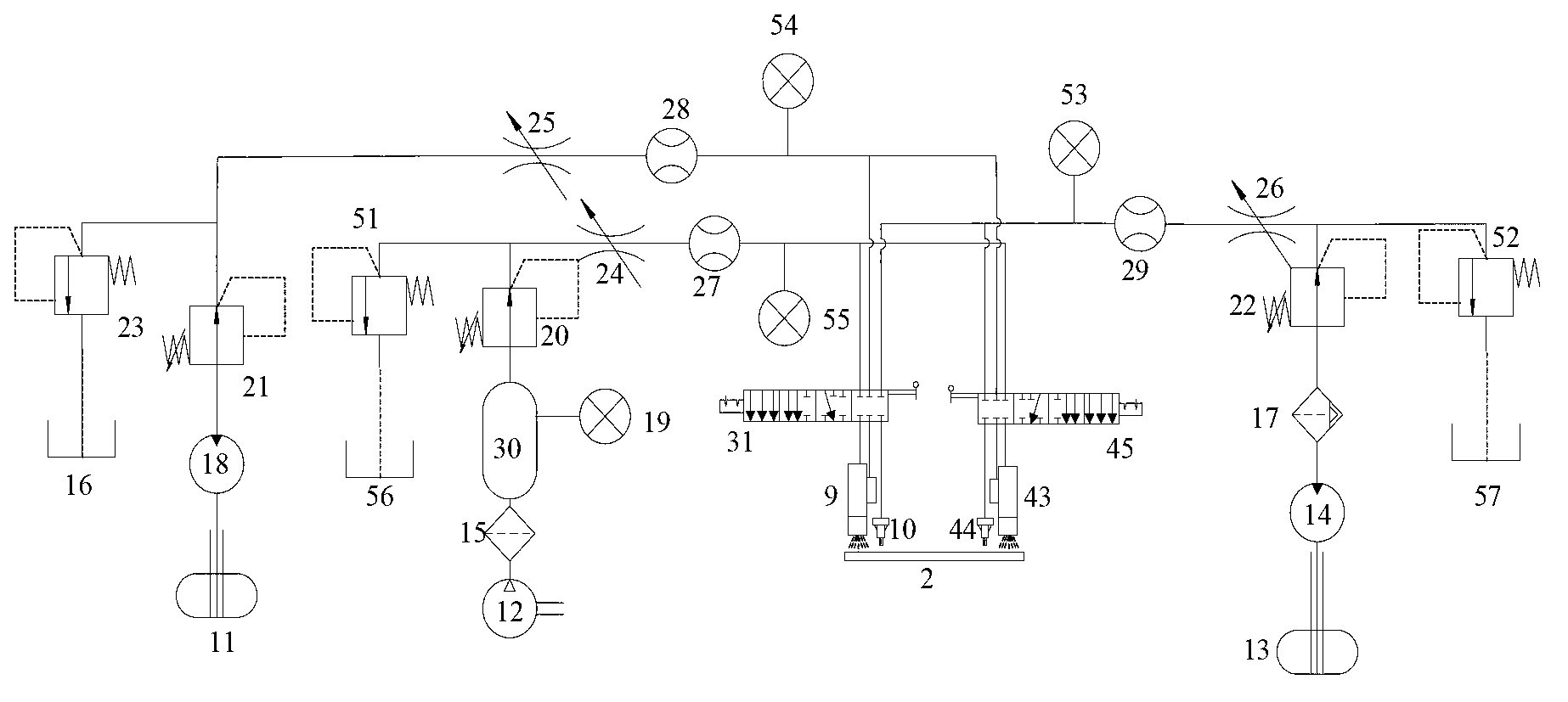

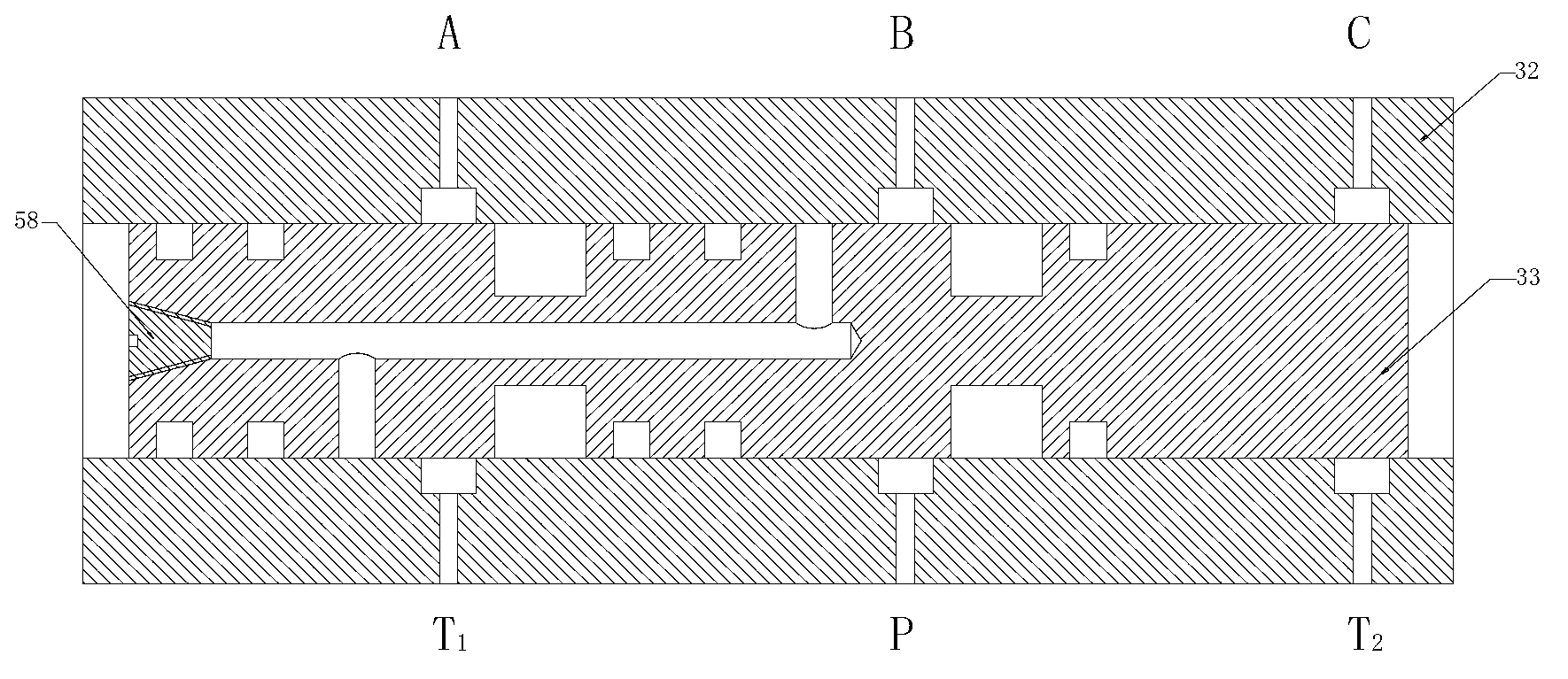

Supply system for sub-cooling and nano particle jet flow minimal quantity lubrication coupled grinding medium

ActiveCN103231310AReduce evaporationAvoid coolingGrinding/polishing safety devicesSpray nozzleControl valves

The invention relates to a supply system for a sub-cooling and nano particle jet flow minimal quantity lubrication coupled grinding medium. The supply system comprises at least one minimal quantity lubrication and sub-cooling jet nozzle combined unit which is arranged on the side of a grinding wheel guard of a grinding wheel and is matched with a workpiece on a workbench. Each minimal quantity lubrication and sub-cooling jet nozzle combined unit comprises a minimal quantity lubrication atomization minimal jet nozzle and a sub-cooling jet nozzle, wherein the minimal quantity lubrication atomization minimal jet nozzle is connected with a nano fluid pipeline and a compressed air pipeline, and the sub-cooling jet nozzle is connected with a sub-cooling fluid pipeline; the nano fluid pipe, the compressed air pipeline and the sub-cooling liquid pipeline of each unit are connected with a nano fluid supply system, a low-temperature medium supply system and a compressed air supply system through control valves; and the nano fluid supply system, the low-temperature medium supply system and the compressed air supply system are connected with a control device. By means of the supply system, grinding burn is effectively eliminated, the surface quality of workpieces is improved, and efficient low-consumption environment-friendly energy-saving low-carbon clean production is achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

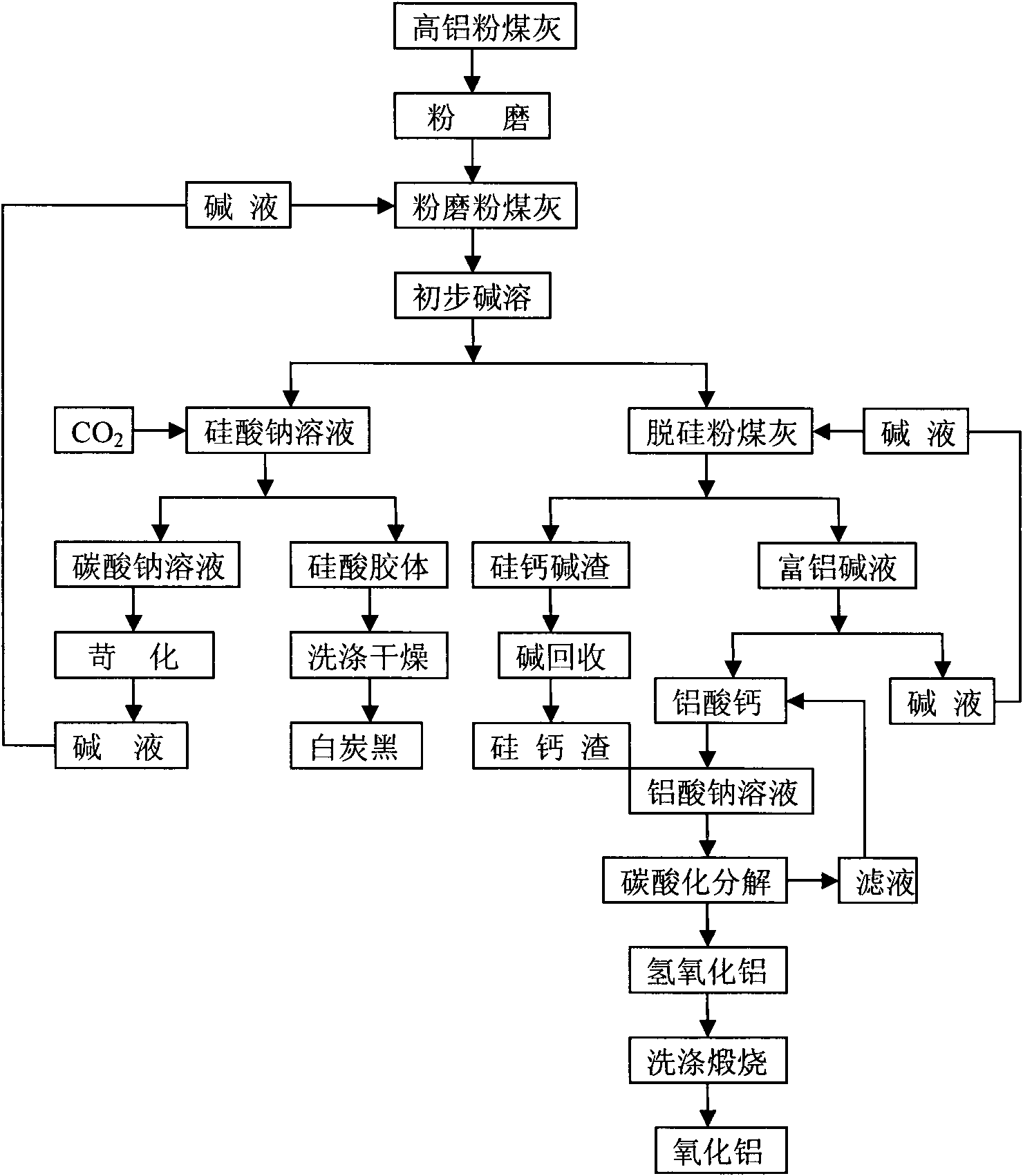

Method for extracting aluminum oxide and white carbon black through two-step alkaline leaching method by adopting high-alumina fly ash

ActiveCN101966999AReduce consumptionNo secondary pollutionSilicaSolid waste disposalSlagDecomposition

The invention discloses a process for preparing aluminum oxide and white carbon black by taking high-alumina fly ash as a raw material and adopting a two-step alkaline leaching method, comprising the following process steps of: preparing a sodium silicate solution by carrying out first-step alkaline leaching on the high-alumina fly ash; preparing the white carbon black by carrying out carbonation decomposition on the sodium silicate solution; preparing aluminum rich alkaline liquor by carrying out second-step alkaline leaching on desiliconization fly ash; preparing a sodium aluminate solution through the aluminum rich alkaline liquor; and preparing the aluminum oxide through the sodium aluminate solution, and the like. The invention prevents the high-temperature sintering in the process of the aluminum oxide prepared through the high-alumina fly ash, has low energy consumption and cyclic utilization of the alkaline liquor obtained through the first-step alkaline leaching and the second-step alkaline leaching, little material consumption; and in addition, silicon-calcium slag generated in the process course are used as raw materials for producing wall materials without generating secondary pollution, therefore the invention meets the requirements for clean production.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

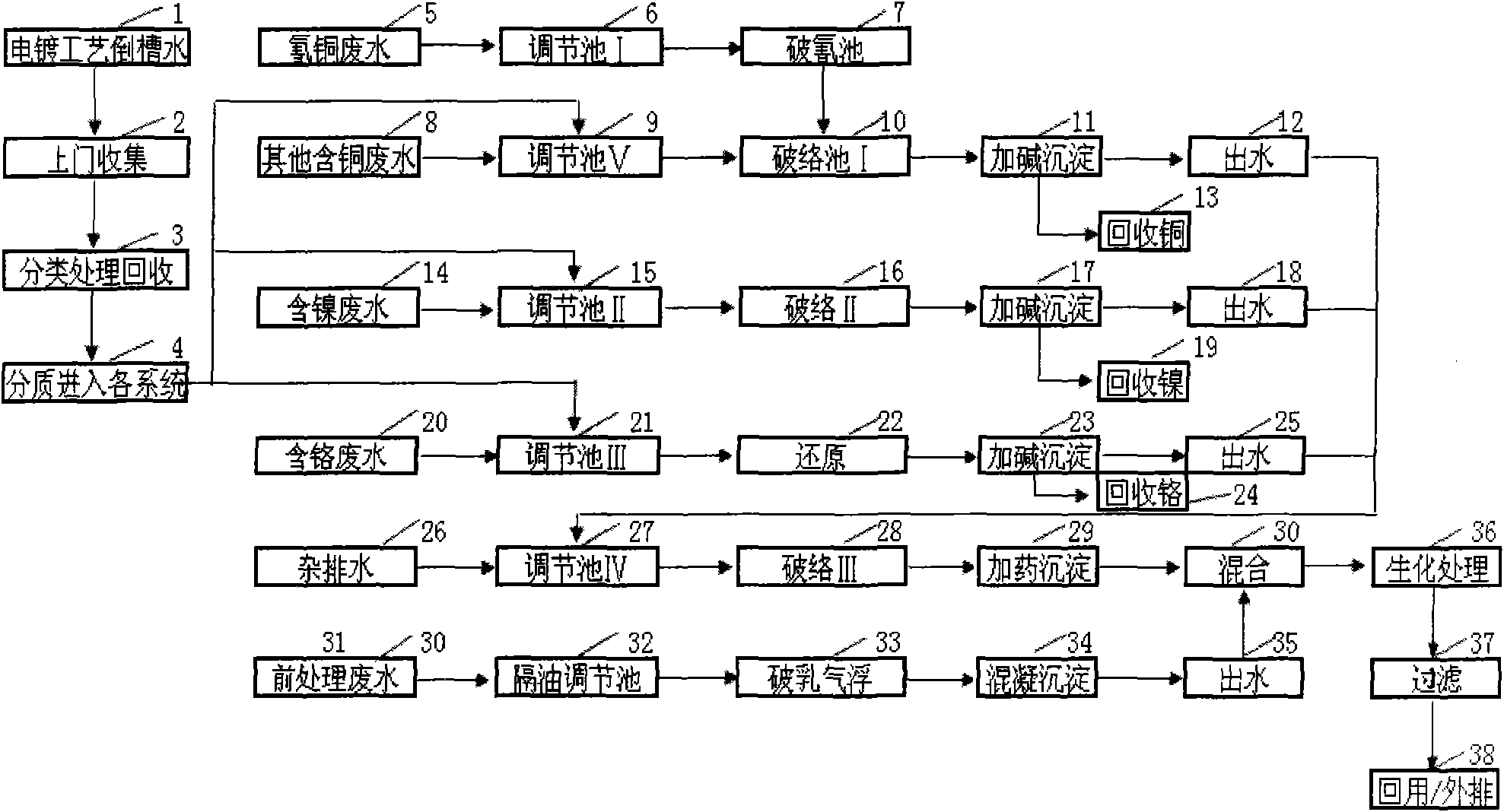

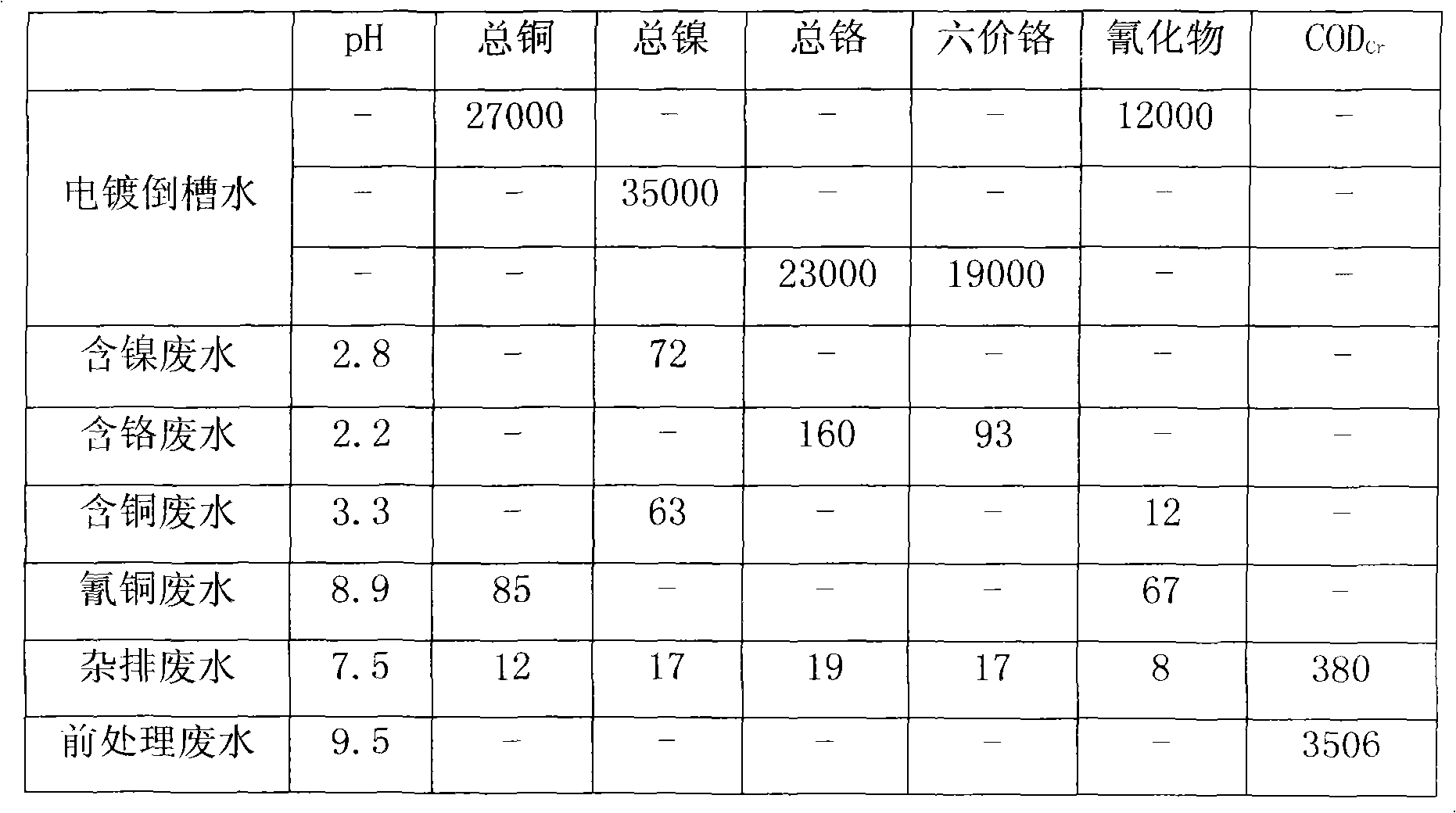

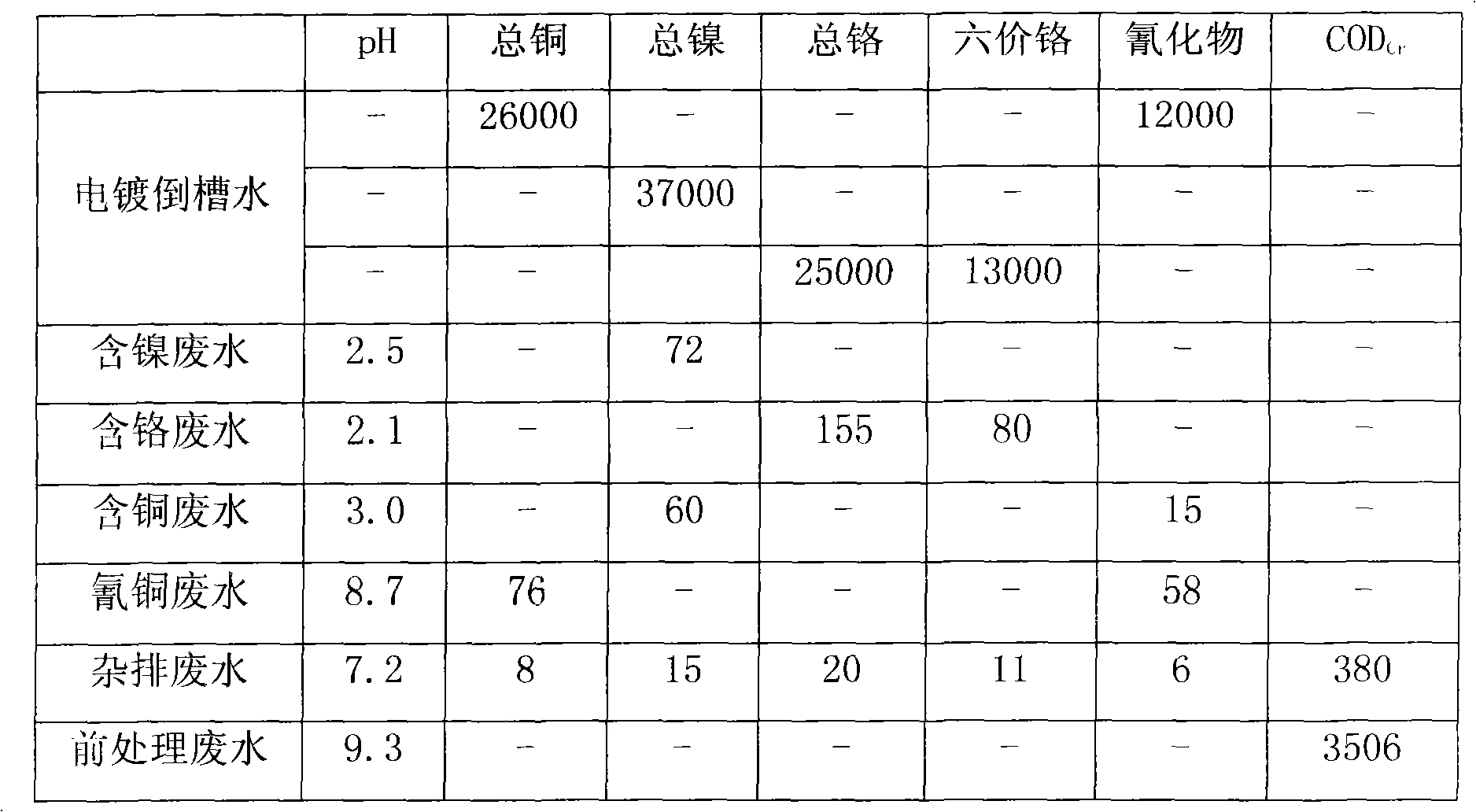

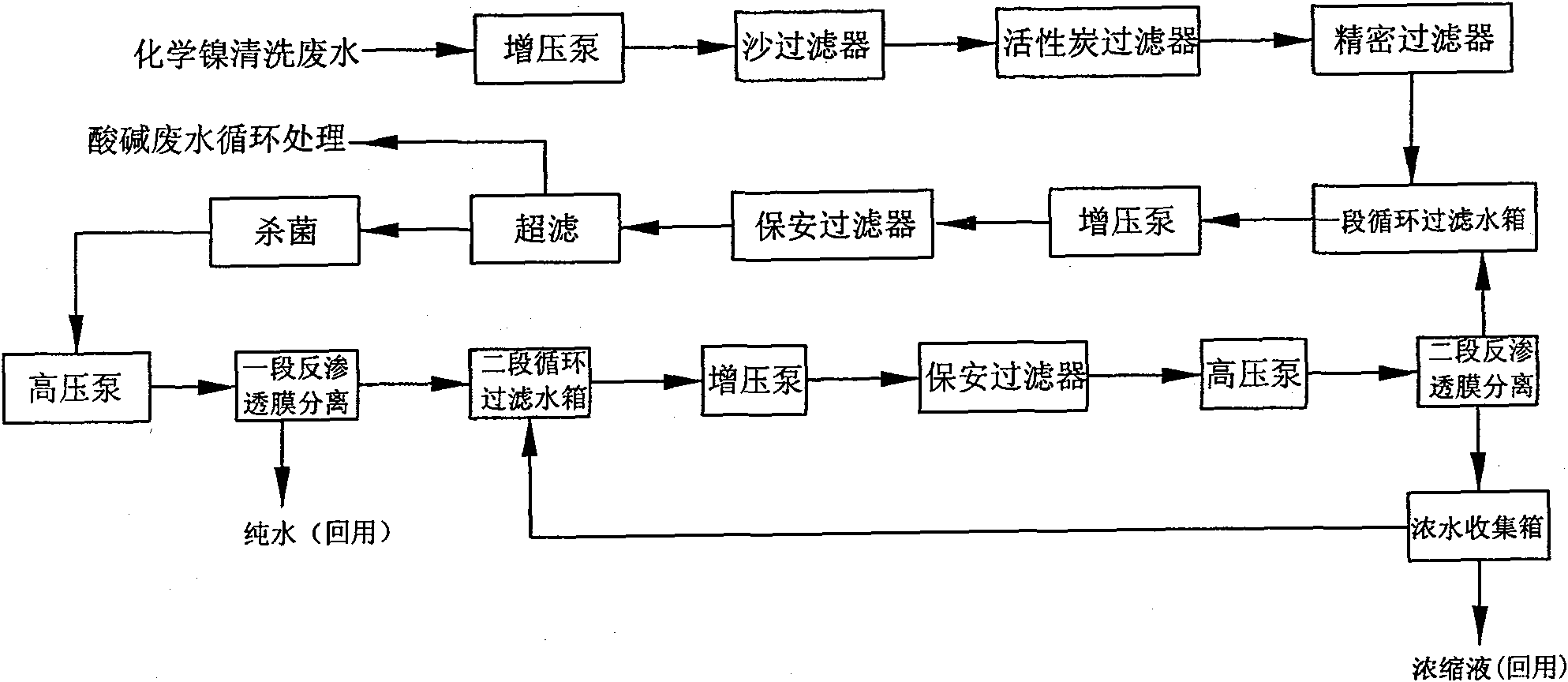

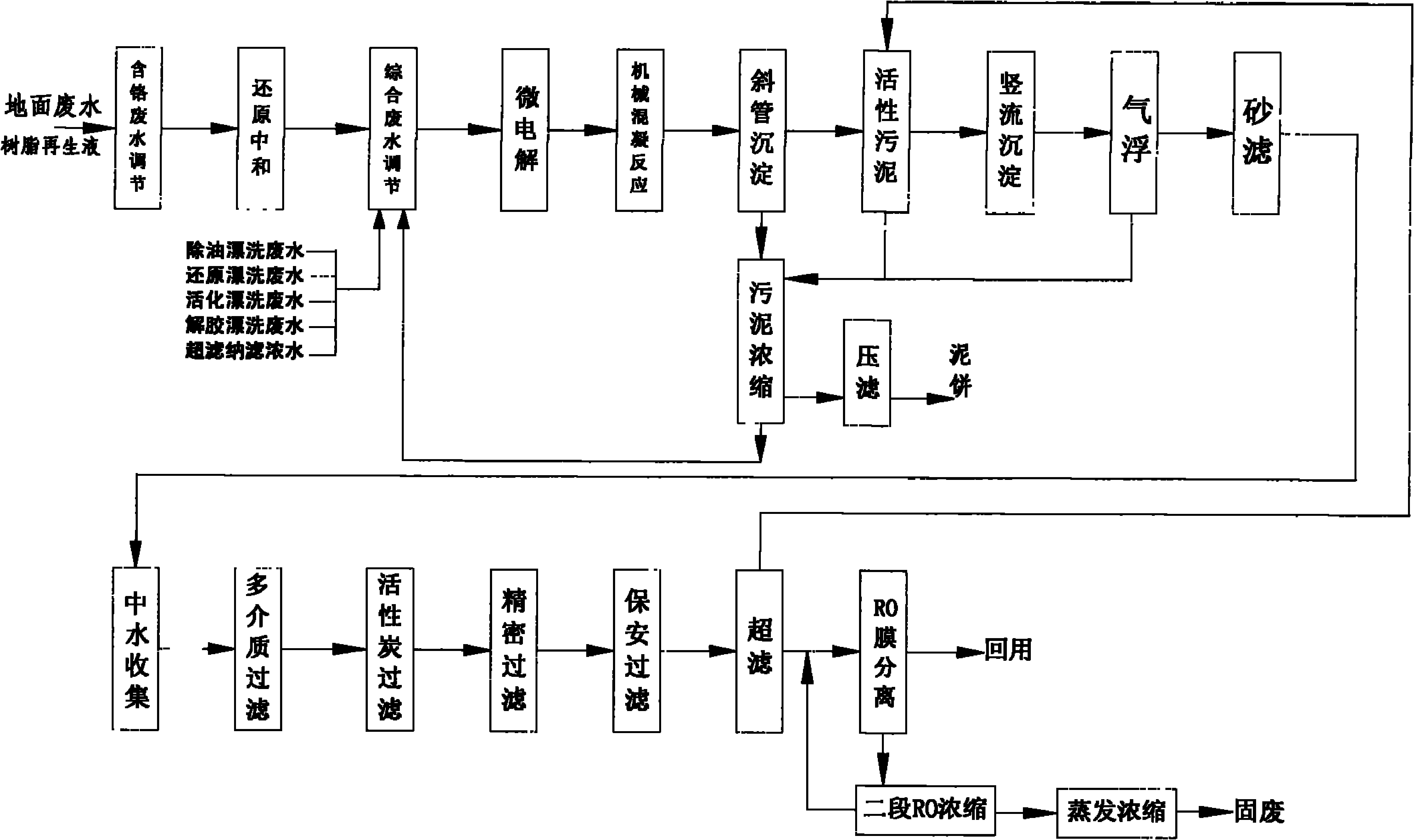

Processing method for recycling electroplating concentrated control zone electroplating waste water resource

ActiveCN101633544AMaximize quality recoveryIncrease contentFatty/oily/floating substances removal devicesWaste water treatment from metallurgical processHandling systemPollution

The invention relates to a processing method for recycling an electroplating concentrated control zone electroplating waste water resource, which comprises the following steps: firstly, preprocessing the inverted trough water in the electroplating production process, recycling valuable metals in the inverted trough water, and respectively filling the pretreated tail water in corresponding processing systems according to kinds; then, recycling copper, nickel and chromium resources in the corresponding processing system; afterwards, mixing other drain away water in a base station and the waste water with recycled copper, nickel and chromium resources, and then carrying out integrated structure breaking, neutralizing and coagulating sedimentation, and mixing the treated waste water and the pretreated water by treatment of oil separation, oil removal and coagulating sedimentation for biochemical treatment; and finally, discharging the effluent which reaches the standard. The method not only enables the electroplating waste water to reach the standard and can be discharged stably, but also recycles the valuable resources in the waste water in low cost, greatly reduces the secondary pollution and realizes the clean production of electroplating waste water control and the environmental requirements of the electroplating concentrated control zone.

Owner:ZHEJIANG HI TECH ENVIRONMENTAL TECH

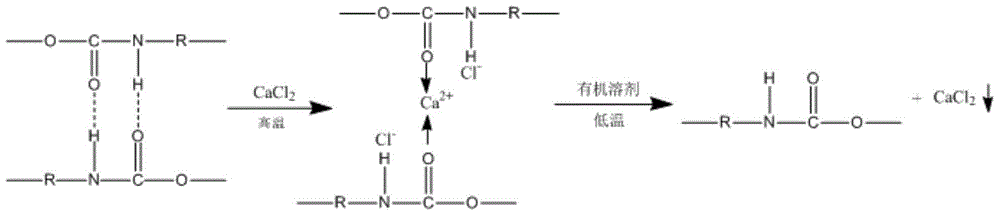

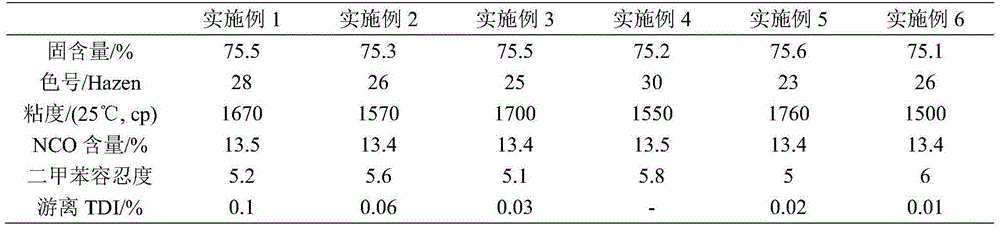

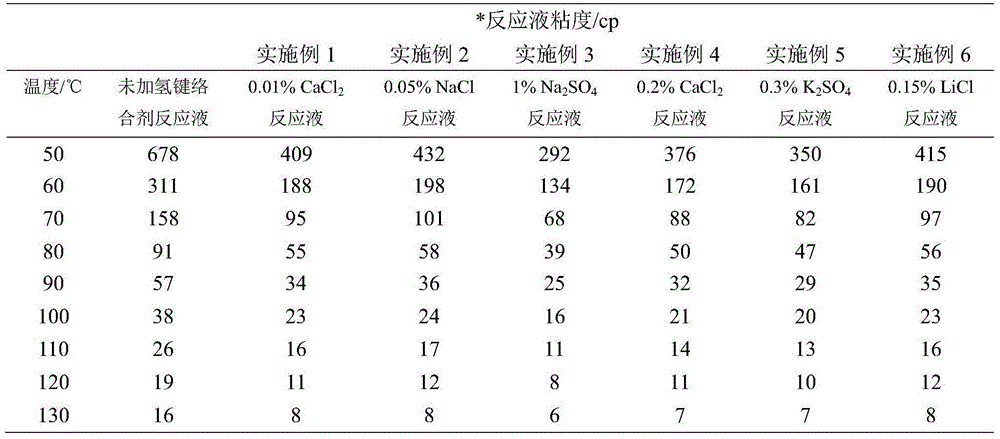

Preparation method of polyurethane curing agent

ActiveCN105218780ALow monomer contentUniform molecular weight distributionPolyurea/polyurethane coatingsToluene diisocyanateNitrogen gas

The invention relates to a preparation method of a polyurethane curing agent. The method comprises the steps of: 1, under the protection of nitrogen, adding mixed alcohol to a reaction kettle filled with toluene diisocyanate (TDI), and insulating for standby; 2, adding 0.01wt-1wt% of a hydrogen bond complexing agent based on toluene diisocyanate, stirring and dissolving; then separating by a thin film evaporator, diluting the prepolymer after separation to obtain a polyurethane curing agent; and cooling and stirring to precipitate a hydrogen bond complexing agent, filtering to obtain a polyurethane curing agent with solid content of 50-80 wt% and free TDI content of 0-0.1wt%. The invention has the advantages that the product has extremely low free isocyanate monomer content, is environment-friendly and non-toxic, and can reduce separation energy consumption and improve the separation efficiency, effectively recover TDI monomer and inorganic salt, improve the utilization rate, achieve cleaner production and reduce the cost of production.

Owner:WANHUA CHEM GRP CO LTD

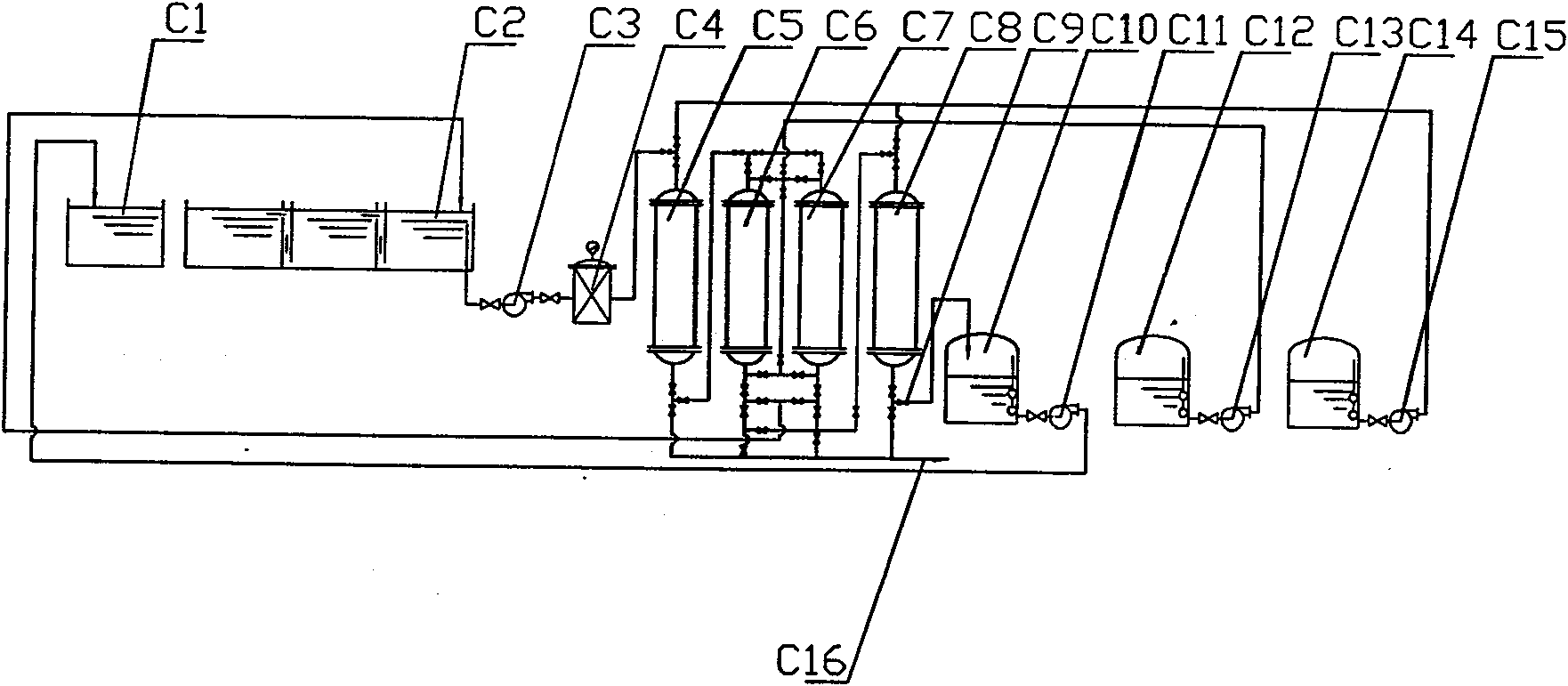

Method for classifying, treating and recycling plating washing water on line

ActiveCN101891323AAvoid cross contaminationStrong targetingWater contaminantsWater/sewage treatment by ion-exchangeCopper platingWater cycling

The invention discloses a method for classifying, treating and recycling plating washing water on line, which comprises the following steps of: removing oil, coarsening, reducing, activating, peptizing, chemically plating nickel, preplating nickel, plating copper, plating nickel and plating chromium in a plating process; and treating water and washing water during production and cleaning. The method specifically comprises the following steps of: preparing pure plating water, circularly processing acid and alkaline waste water, coarsening, circularly treating chromium-plating washing water, circularly treating chemically nickel-plating washing water, circularly treating copper-plating washing water and circularly treating nickel-plating washing water. Waste water in each procedure is directly used beside a tank edge in a closed cycle by an economical and effective means after being treated, no wastewater is discharged, and the cross contamination of different water qualities among the procedures is avoided. The method is a technological innovation for realizing zero emission of plating waste water and plating cleaner production.

Owner:NANJING YUANQUAN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com