Patents

Literature

79 results about "Induced gas flotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Induced gas flotation (IGF) is a water treatment process that clarifies wastewaters (or other waters) by the removal of suspended matter such as oil or solids. The removal is achieved by injecting gas bubbles into the water or wastewater in a flotation tank or basin. The small bubbles adhere to the suspended matter causing the suspended matter to float to the surface of the water where it may then be removed by a skimming device.

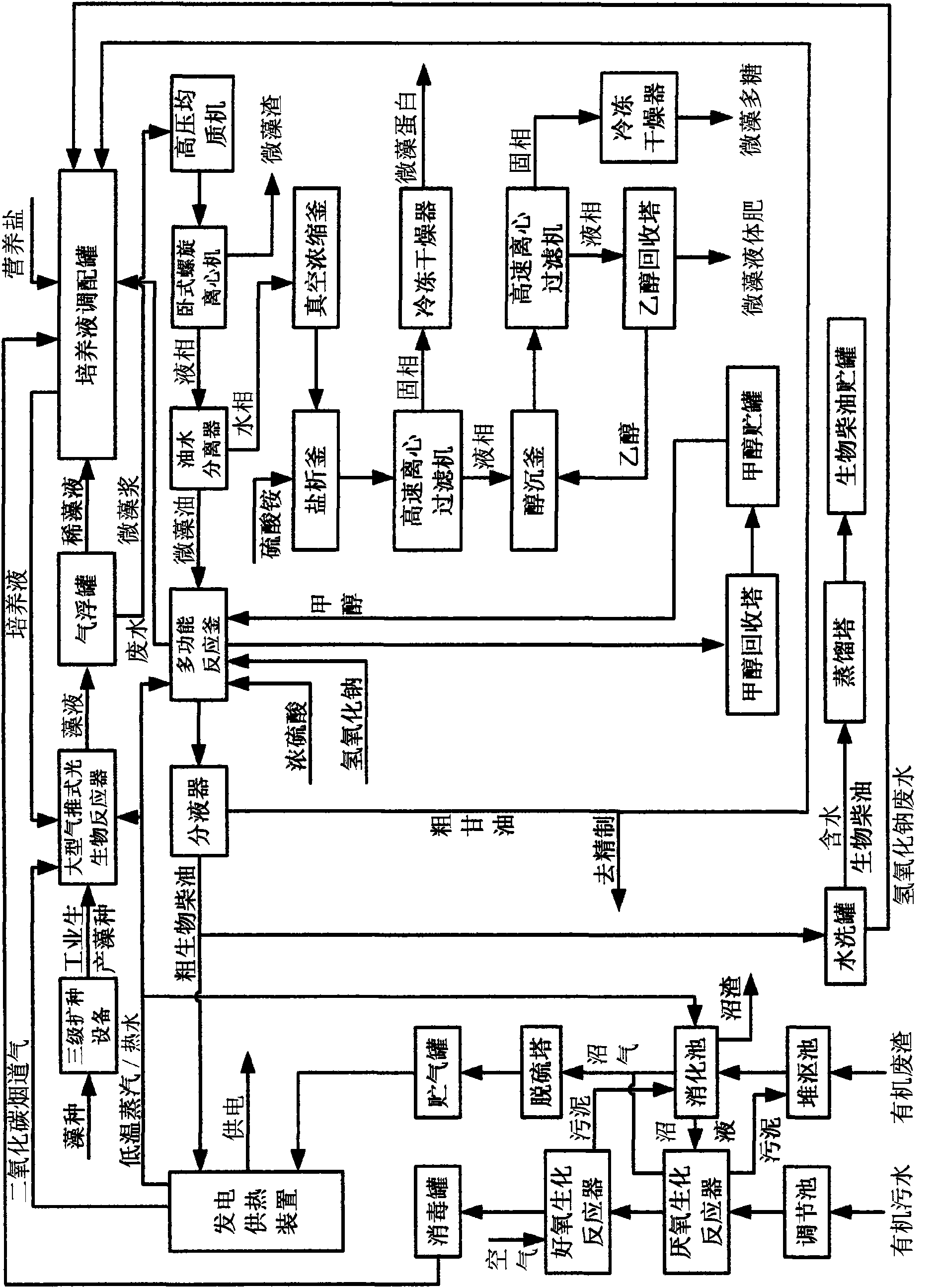

Integrated production method of organic sewage/waste residue treatment, microalgae culturing and oil refining

The invention relates to the environmental protection field, the microalgae cultivation engineering field and the biodiesel refining field, specifically an integrated production method of organic sewage / waste residue treatment, microalgae culturing and oil refining. The method comprises: treating the organic sewage and organic waste residue respectively by anaerobic biochemical technology to generate biogas for generating electricity and supplying heat; performing aerobic biochemical treatment to the sewage and biogas slurry; blending into nutrient solution, and adding into large-scale photobioreactor; passing into biogas, burning to generate carbon dioxide waste gas for culturing oil-containing microalgae; collecting the obtained microalgae by air floatation method and breaking the walls; separating the oil-containing microalgae into microalgae oil, microalgae protein, microalgae polysaccharide and microalgae residue; and refining biodiesel accorded with the national standard using the microalgae oil as raw oil. The invention integrates the organic sewage and waste residue treatment, microalgae culturing and processing, and biodiesel refining; reduces production cost; realizes biodiesel clean production; and treats the 'three wastes'.

Owner:启东市三江建筑机械有限公司

Deoiling of SAGD produce water

ActiveUS20110147316A1Waste water treatment from quariesWater/sewage treatment by centrifugal separationInduced gas flotationReverse osmosis

Methods of deoiling oily water such as SAGD and frac produce water. The oily water is treated with a natural coagulant selected from tannins and chitosan. A cationic and / or anionic flocculant may also be added to the treated oily water. The thus treated oily water may be subjected to conventional mechanical oil separation techniques such as hydrocyclonic separation, dissolved air flotation, entrapped air flotation, induced gas flotation, gravity filters, reverse osmosis filters, API, or Voraxial® bulk separators and the like.

Owner:BL TECH INC

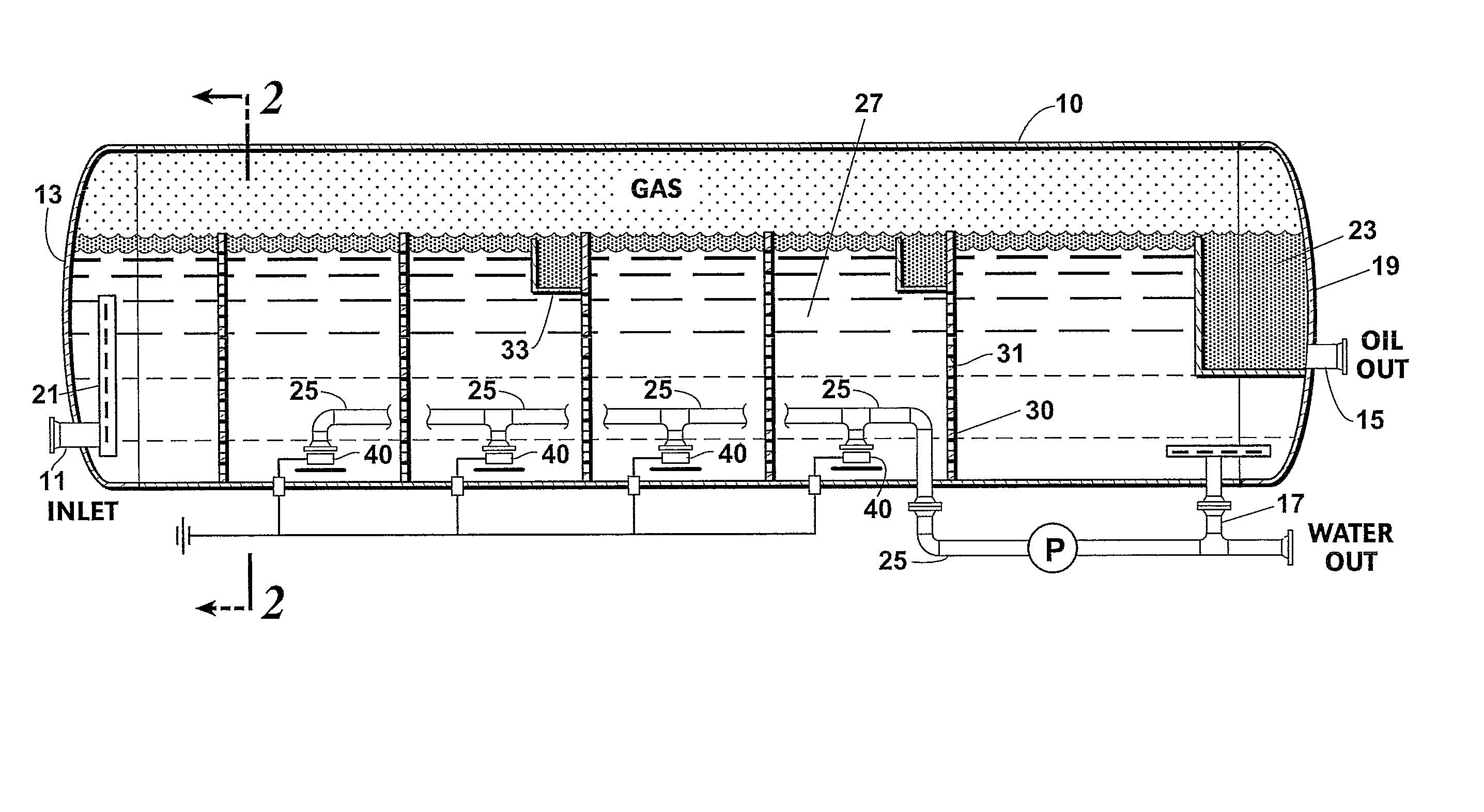

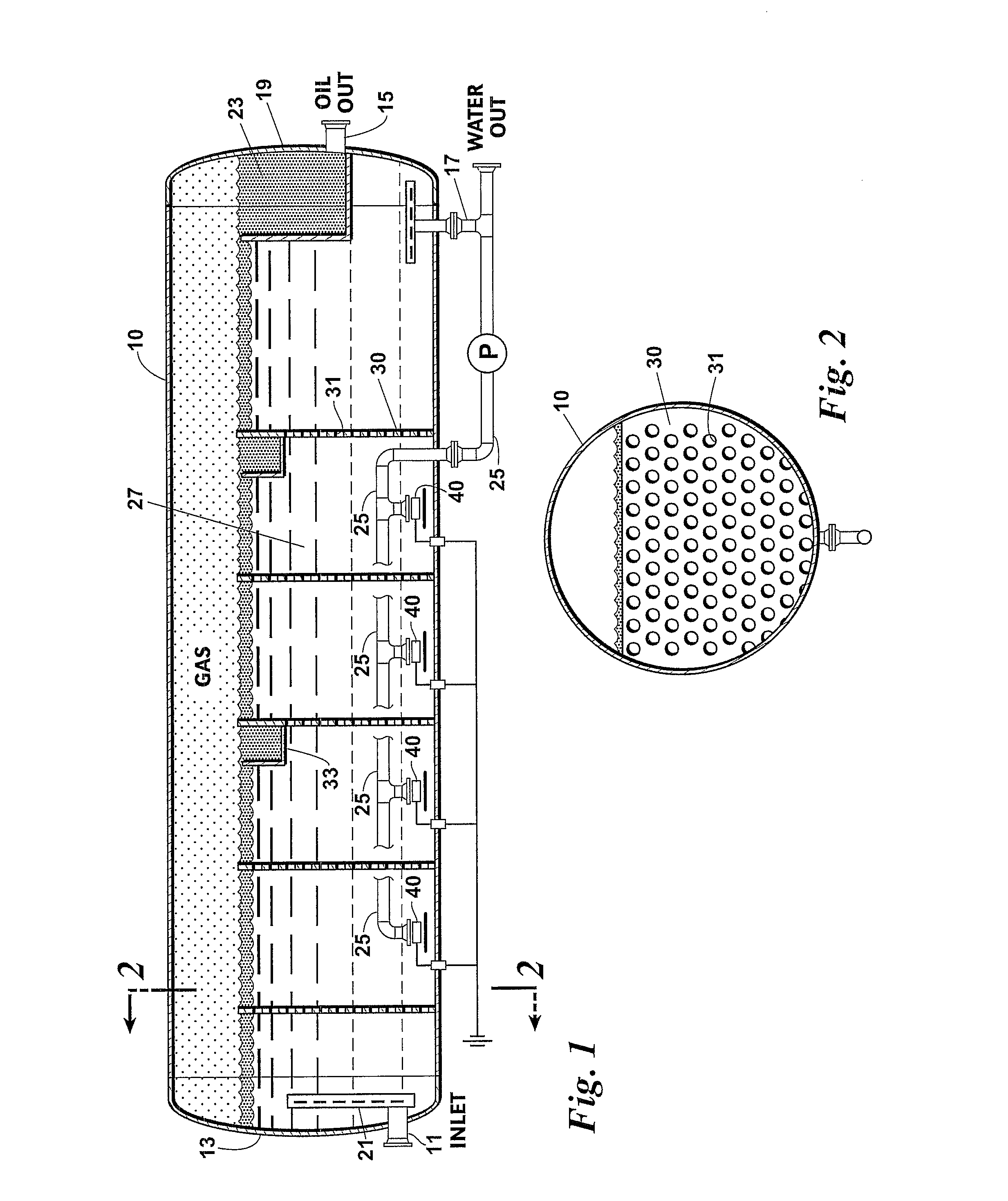

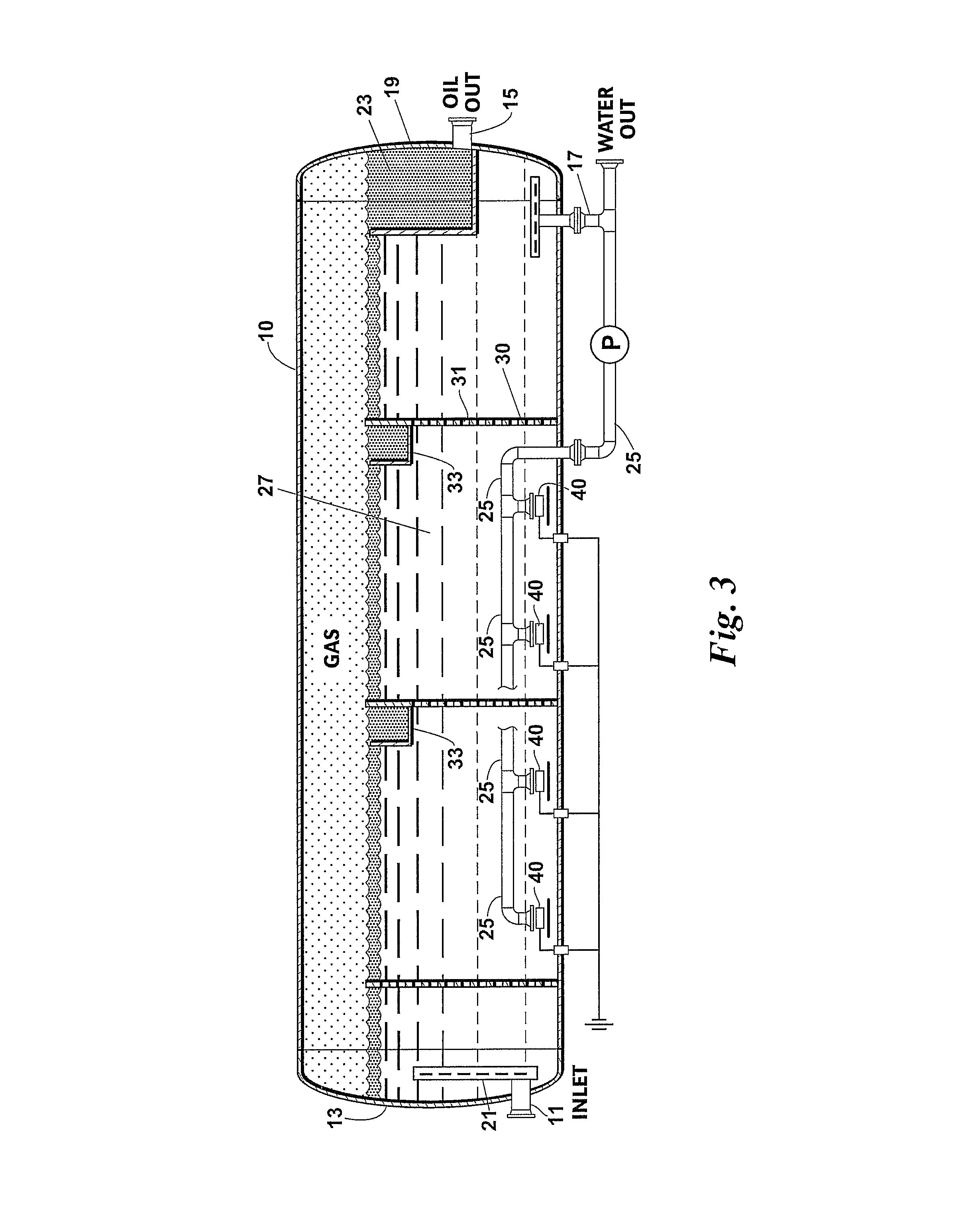

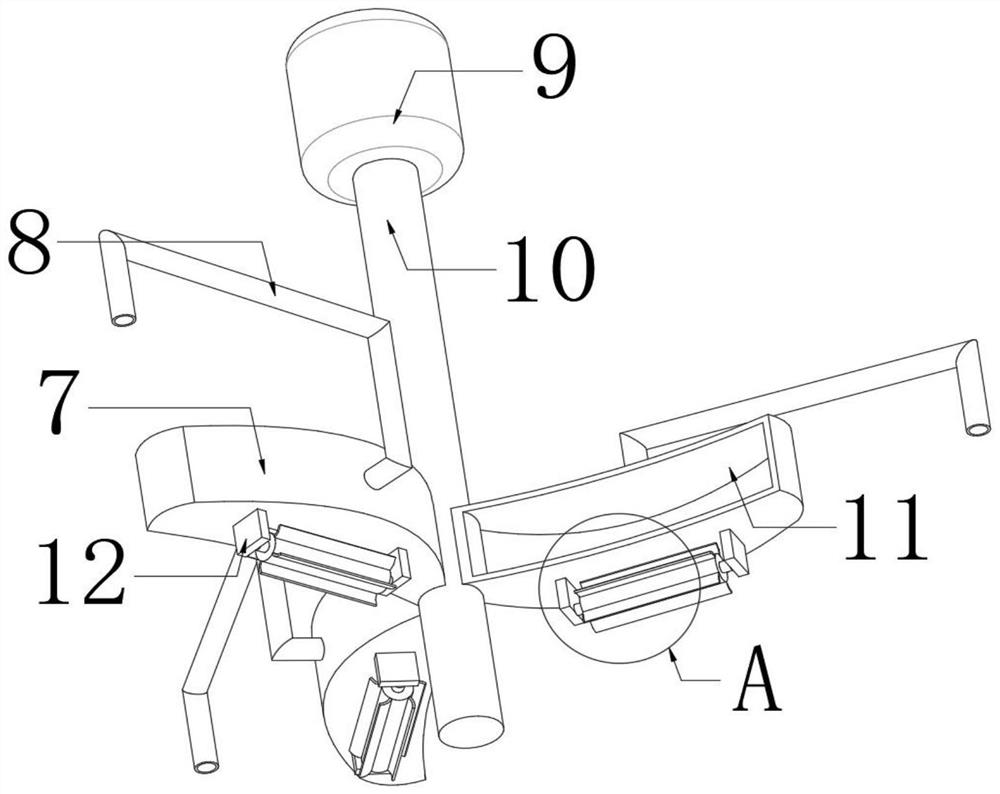

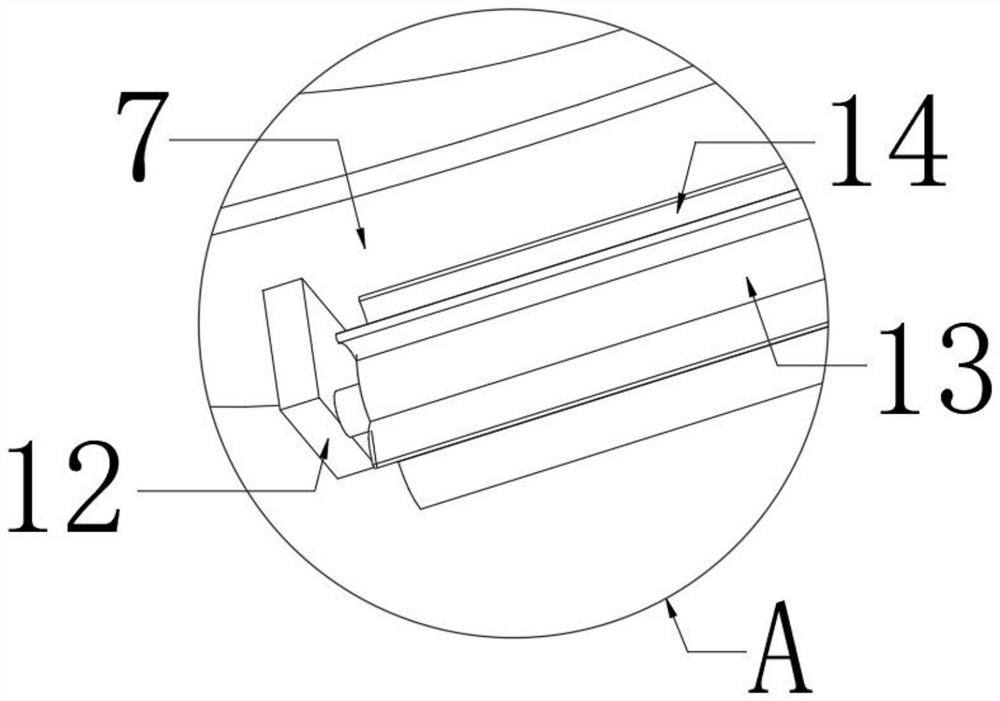

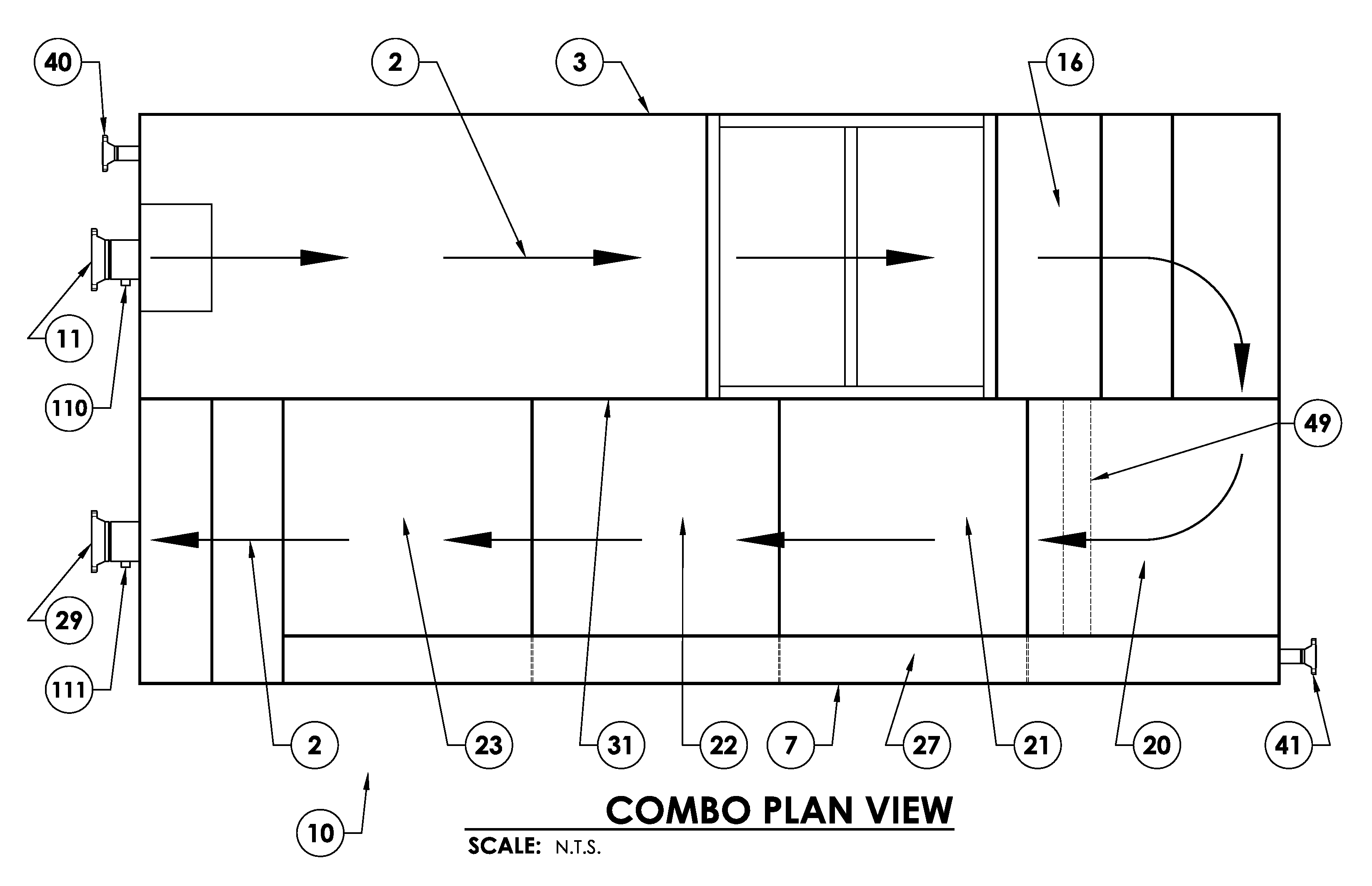

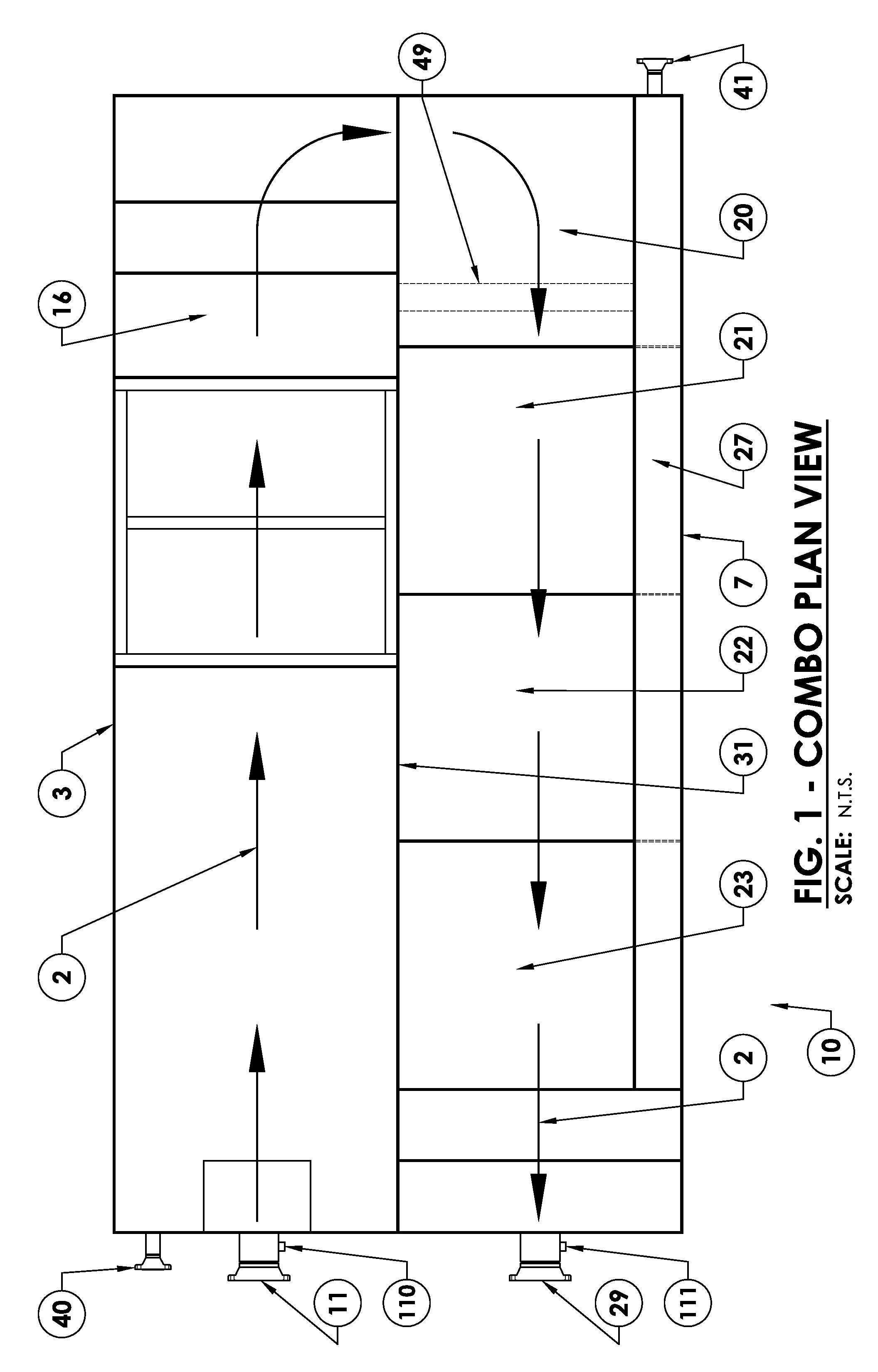

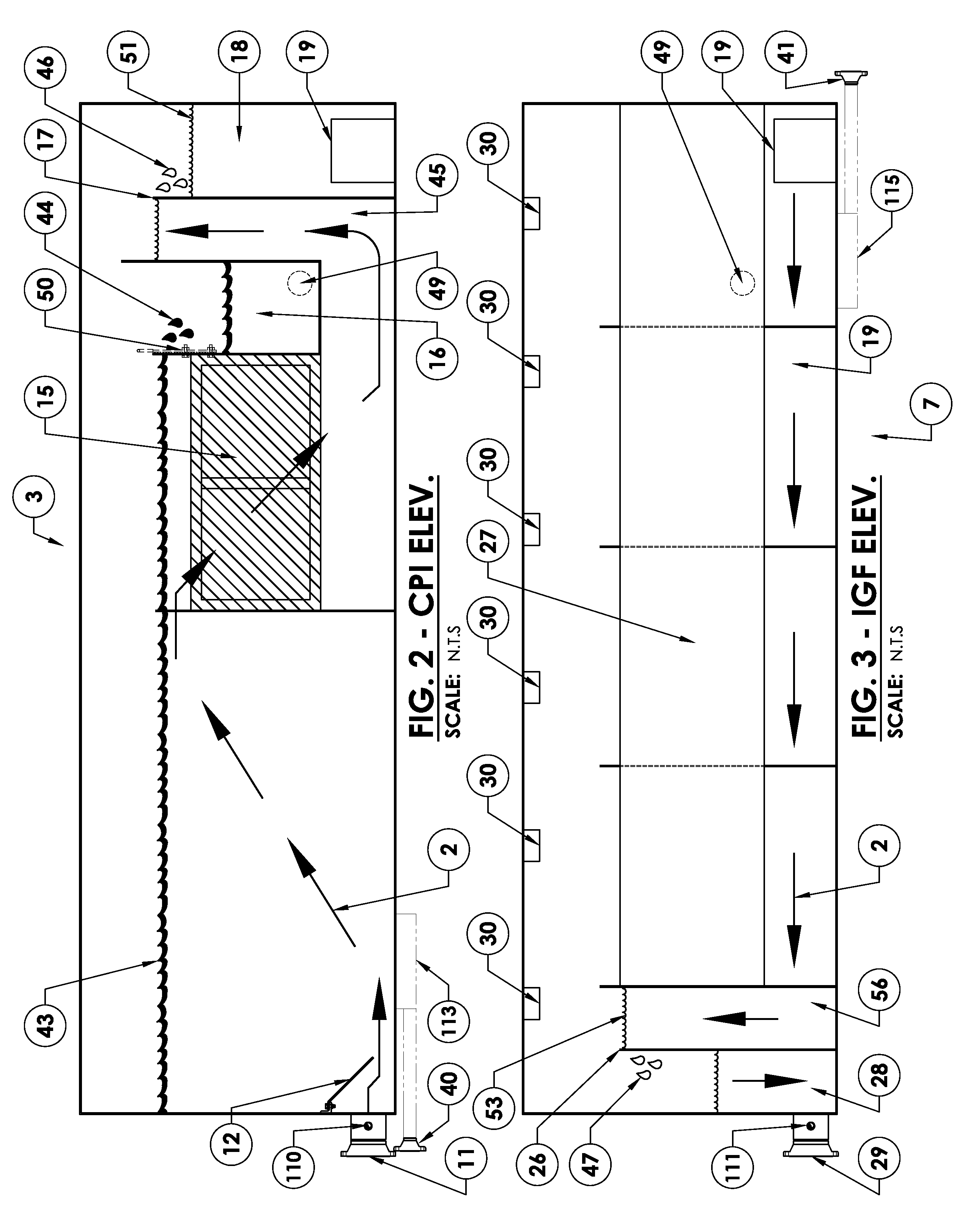

Induced-Gas Flotation Cell with Horizontal Flow

InactiveUS20130075338A1Fatty/oily/floating substances removal devicesWater contaminantsMomentumInduced gas flotation

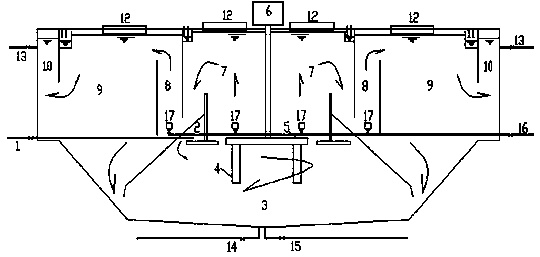

An improved induced-gas separation vessel made according to this invention and method for its use includes an elongated, horizontally oriented vessel having compartments defined by adjacent pairs of perforated baffles which span the width but not the height of the vessel. One or more gas eductors are located within each compartment. An inlet device controls the momentum or velocity of the incoming water stream and rapidly converts it to horizontal flow prior to it encountering the first perforated baffle. The design of each baffle is such that the flow of water through each perforated baffle is a laminar or smooth flow without any change in direction. By controlling incoming velocity and providing perforated baffles, water distribution within the vessel is increased as is volumetric utilization. The total volumetric use of the vessel is at least 50% and can be as great as 80%.

Owner:CAMERSON INT CORP

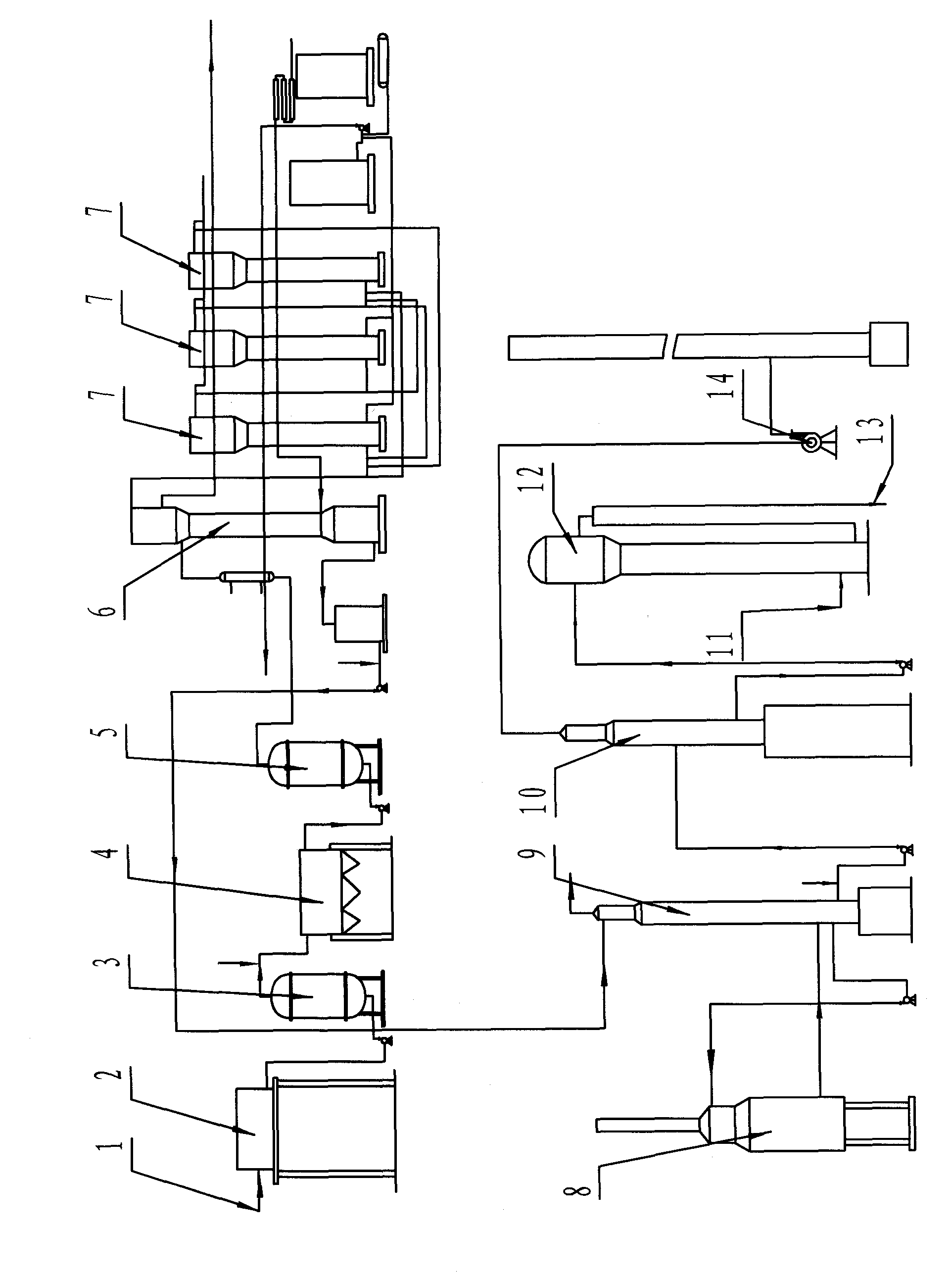

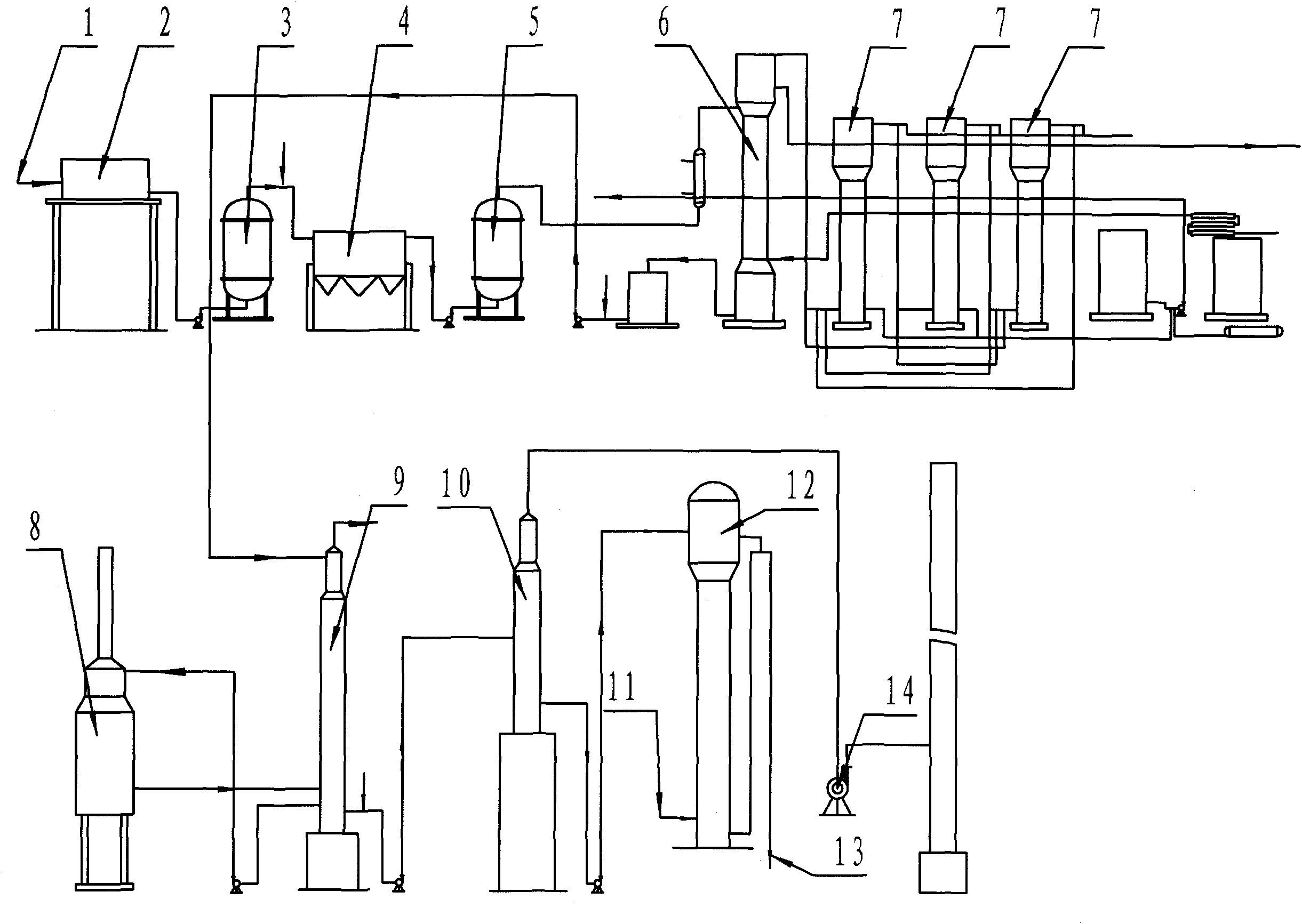

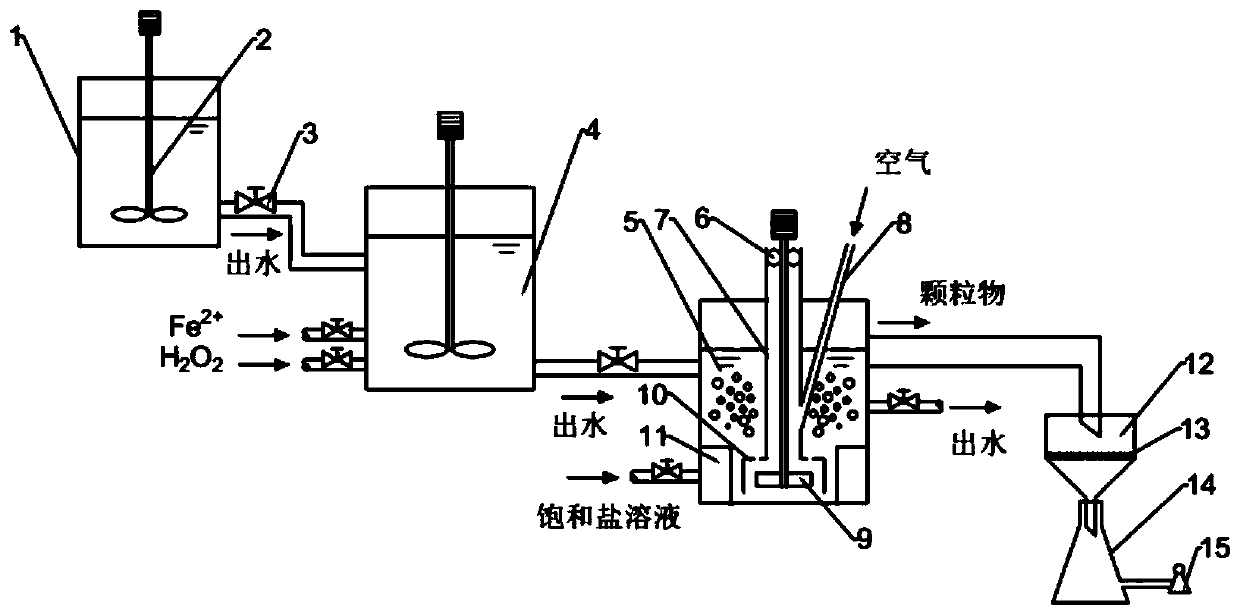

Phenol and cyanogen waste water physical chemical method control process and equipment

ActiveCN101781038ARealize resourcesSave dilution waterWater contaminantsMultistage water/sewage treatmentChemical treatmentInduced gas flotation

The invention discloses phenol and cyanogen waste water physical chemical method control process and equipment, which belongs to the treating technology of waste water or sewage, in particular to a waste water multi-stage treating technology including at least one chemical treating step. The phenol and cyanogen waste water physical chemical method control process is characterized in that the main process flow comprises oil removal of the waste water containing phenol and cyanogen by an air floating method, cyanogen removal and desulphurization by ferrous condensation, extraction to remove phenol, ammine evaporation by a tube type furnace method, evaporation to remove contaminants of NH3-N, phenol, organic matters, sulphur, cyanogen and the like by a depressurizing method, and catalyzing and oxidizing by ozone, and then the waste water achieving the standard is obtained for coke quenching. By the technology for treating the waste water containing phenol and cyanogen, the invention achieves the advantages of good treating effect, little investment, low running cost, changing wastes into resources, strong weather adaptability, and the like.

Owner:JINAN METALLURGICAL CHEM EQUIP CO LTD

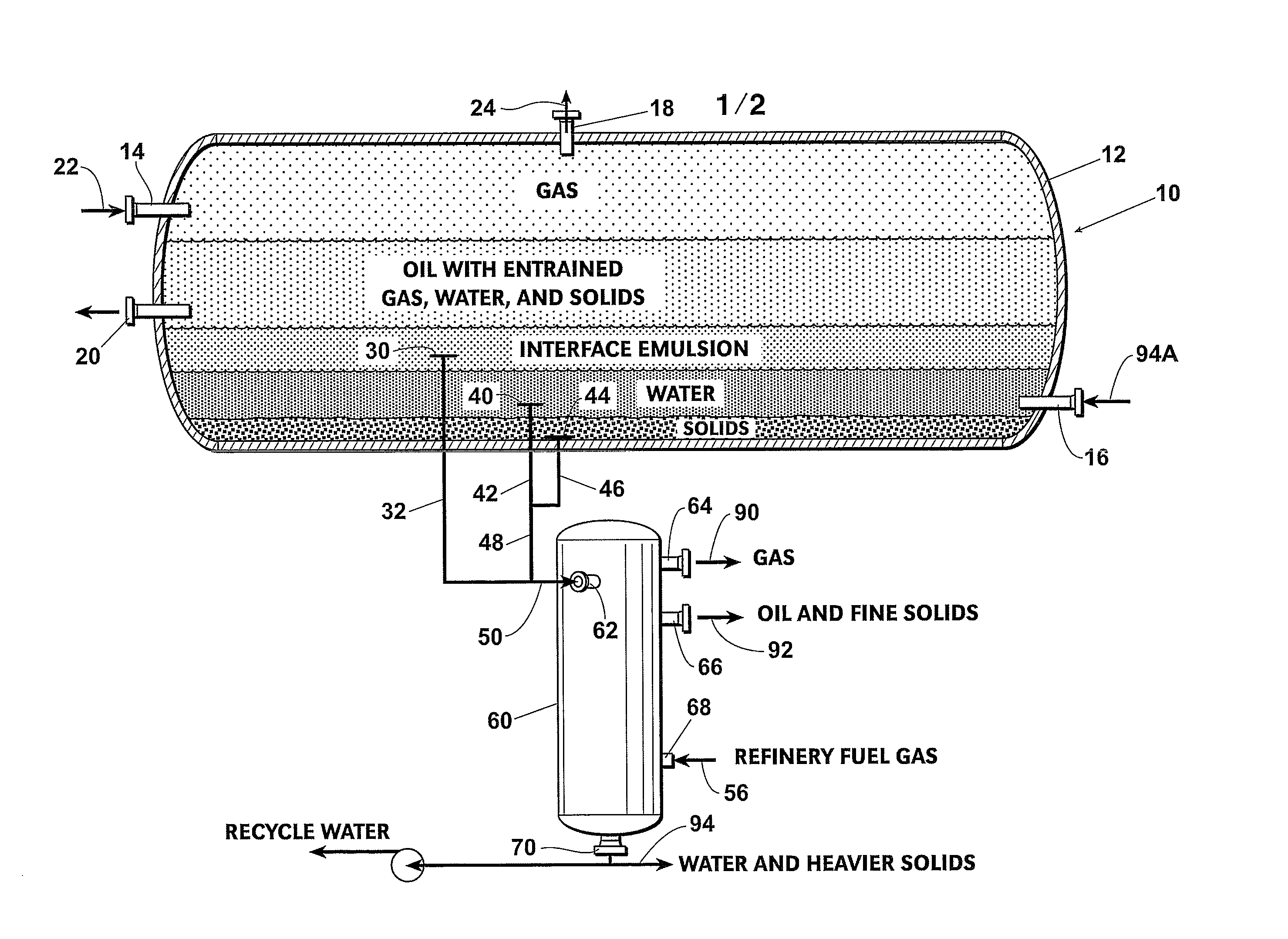

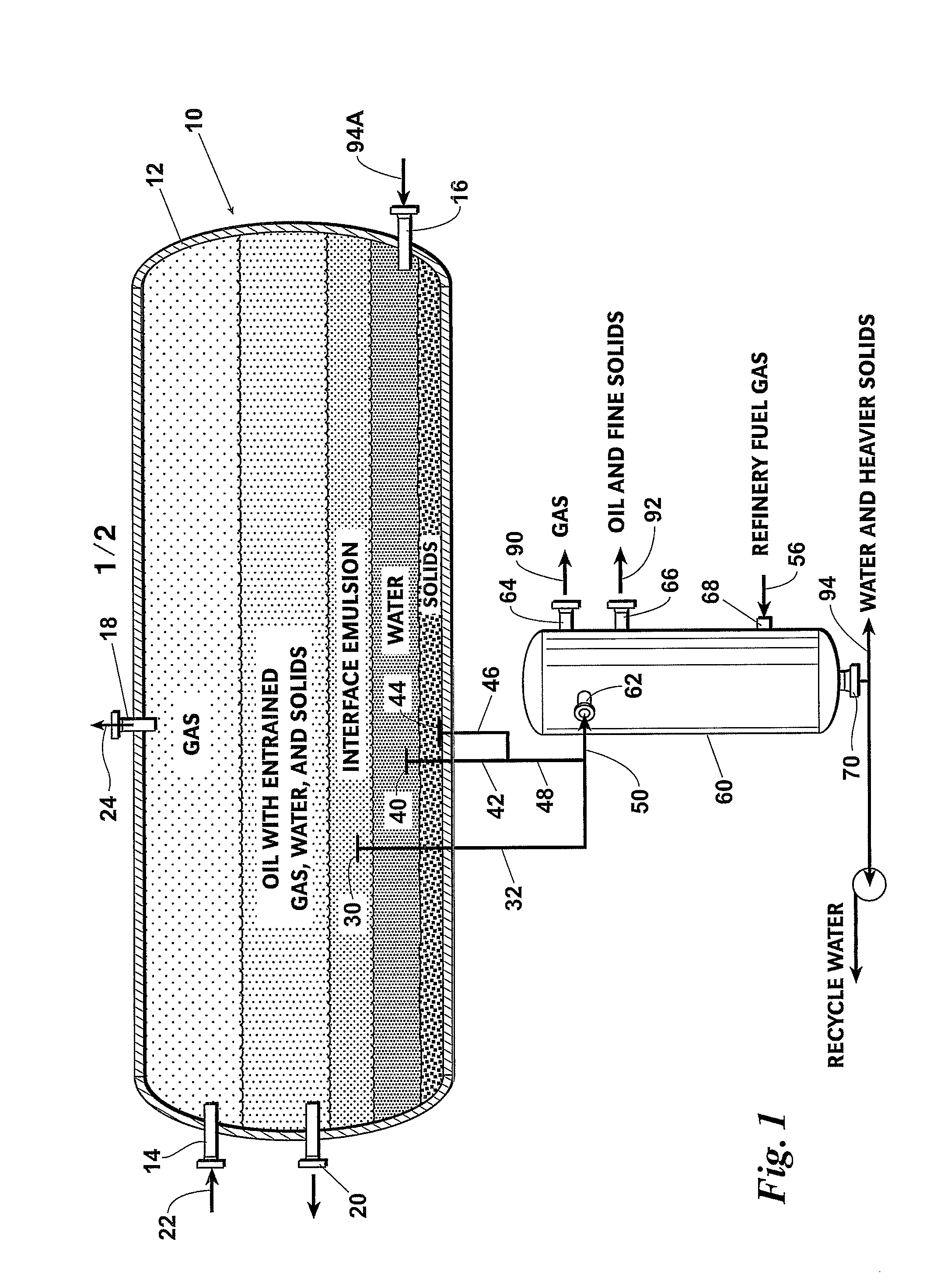

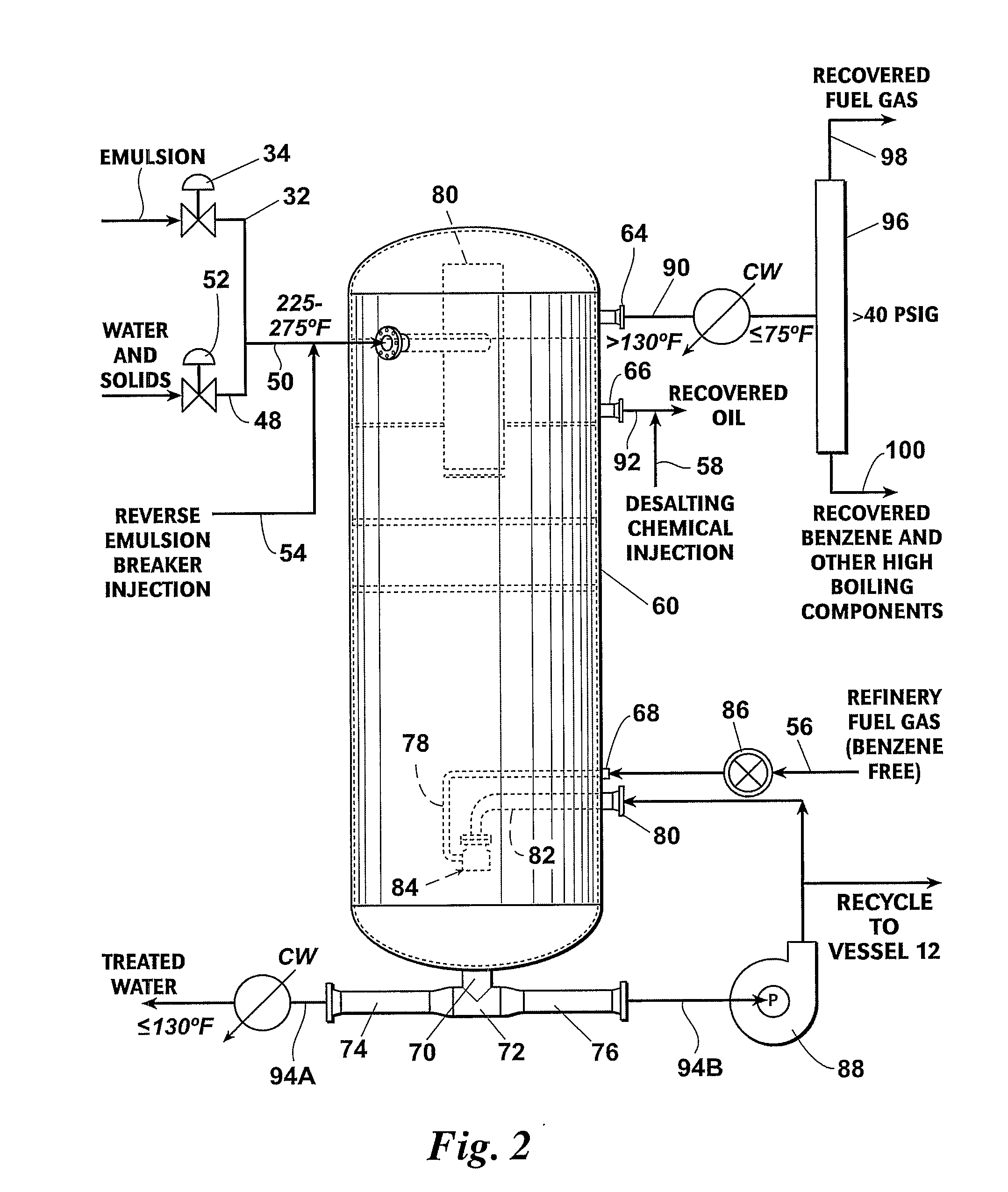

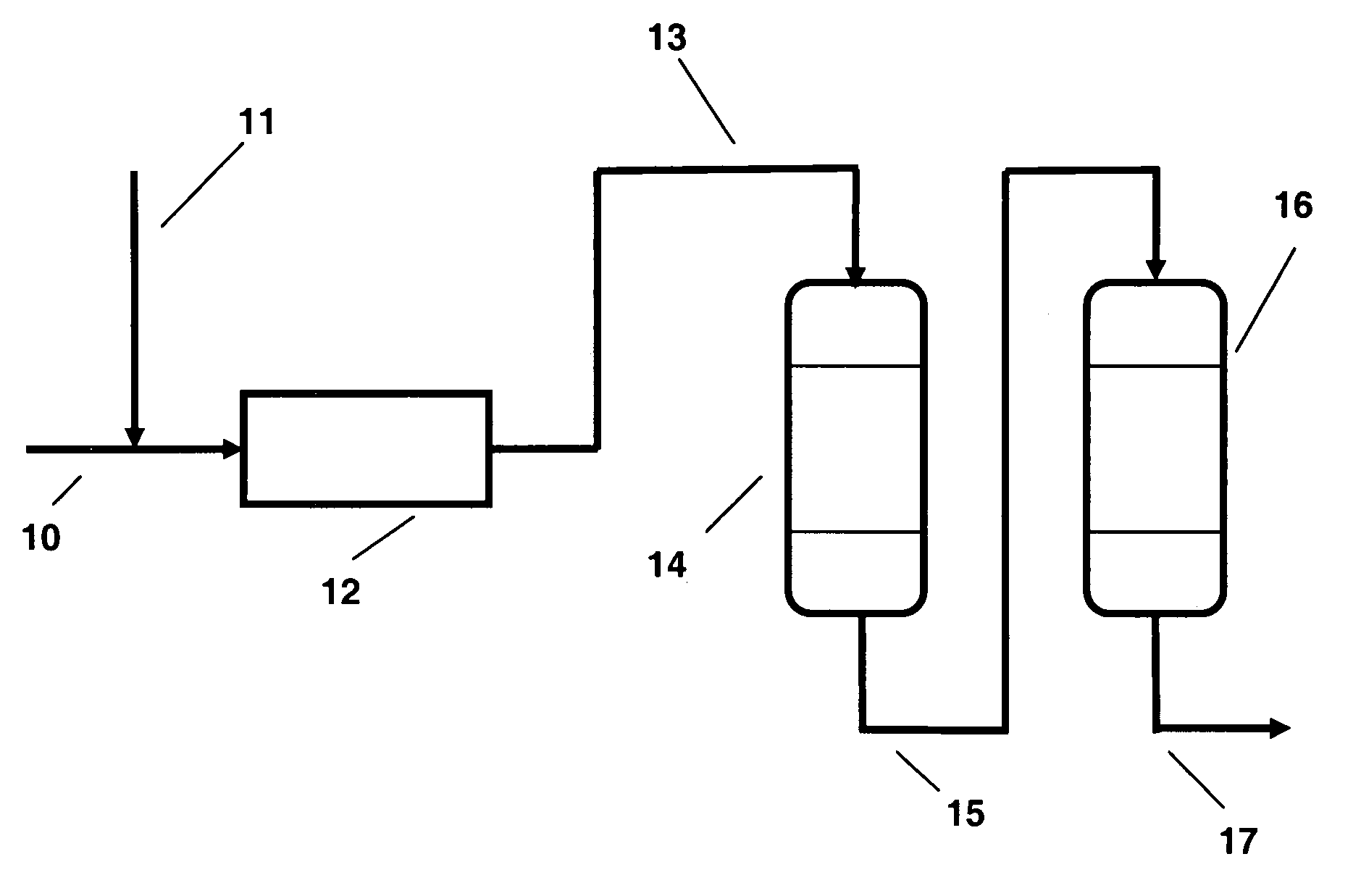

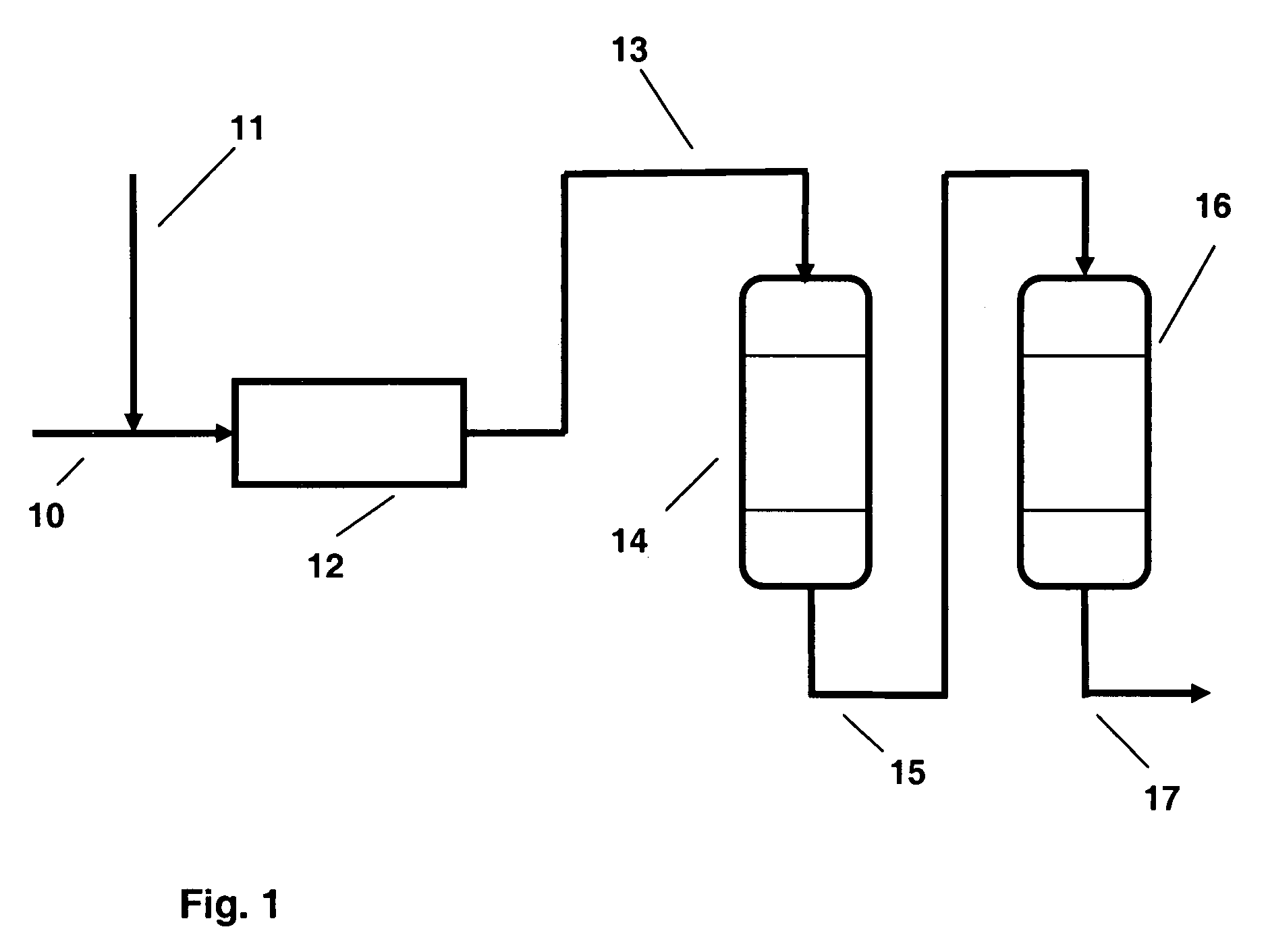

Method to Process Effluent Brine and Interface Rag from an Oil Dehydration/Desalting System

ActiveUS20130082005A1Water treatment parameter controlFatty/oily/floating substances removal devicesEmulsionInduced gas flotation

A method for processing interface emulsion, water, and solids contained within a separator vessel that comprises the steps of continually extracting those components from the vessel and then passing them through a gas flotation cell. The cell, which is preferably a vertical induced gas flotation cell, separates the oil and water contained in the interface emulsion and discharges recovered oil from an upper portion of the cell and treated water from a bottom portion of the cell. The recovered oil and treated water may be further processed and recycled to the vessel or sent elsewhere. The treated water may also be recycled to the cell or sent to a process sewer. Fuel gas residing in an upper portion of the cell may be cooled and passed through a splitter. All the steps of the method comprise a closed system with no air emissions.

Owner:CAMERSON INT CORP

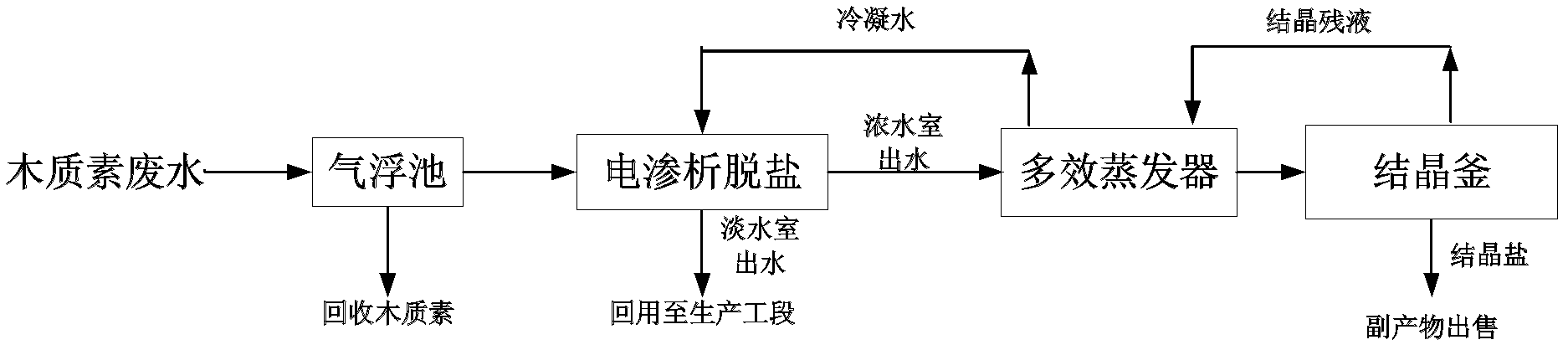

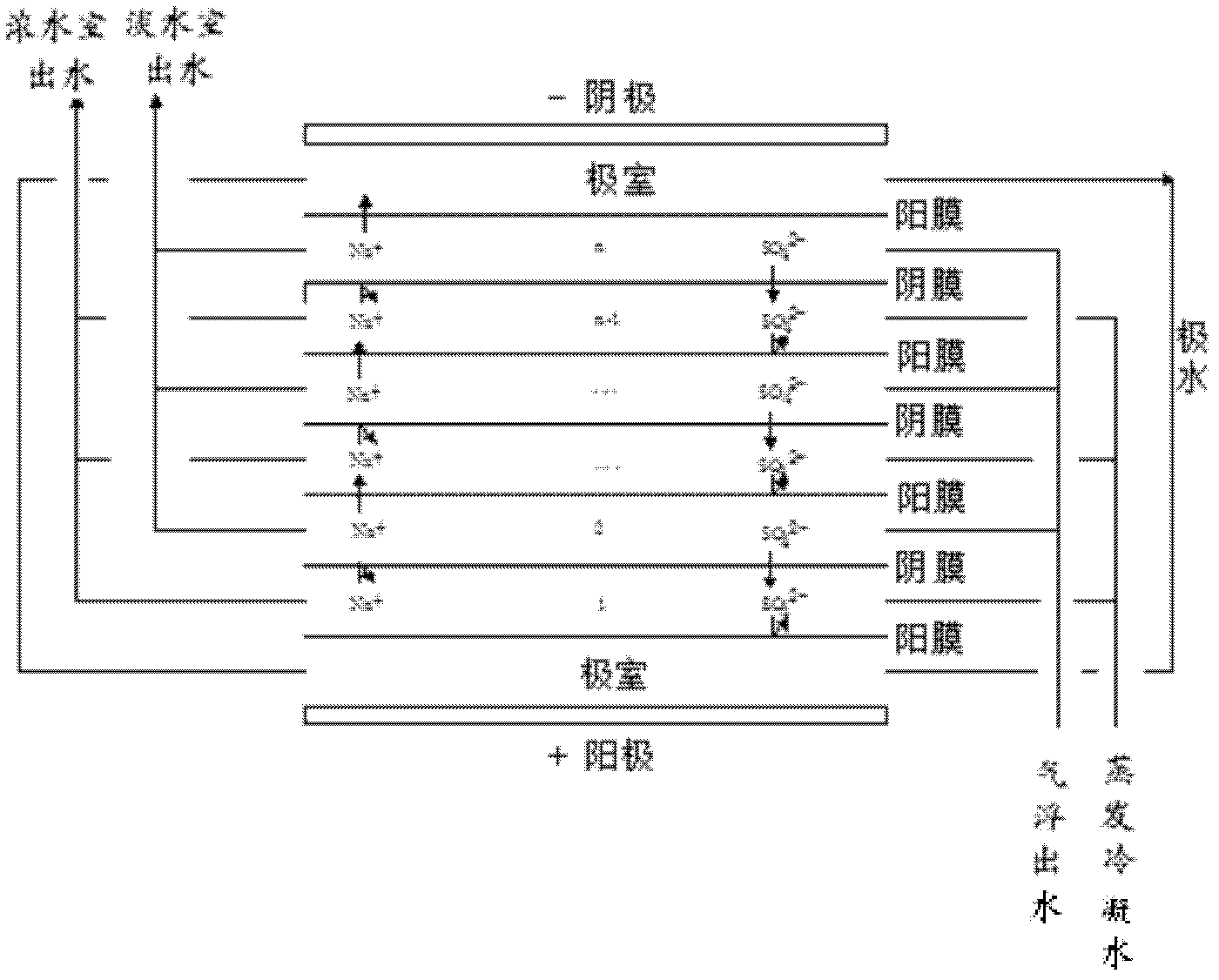

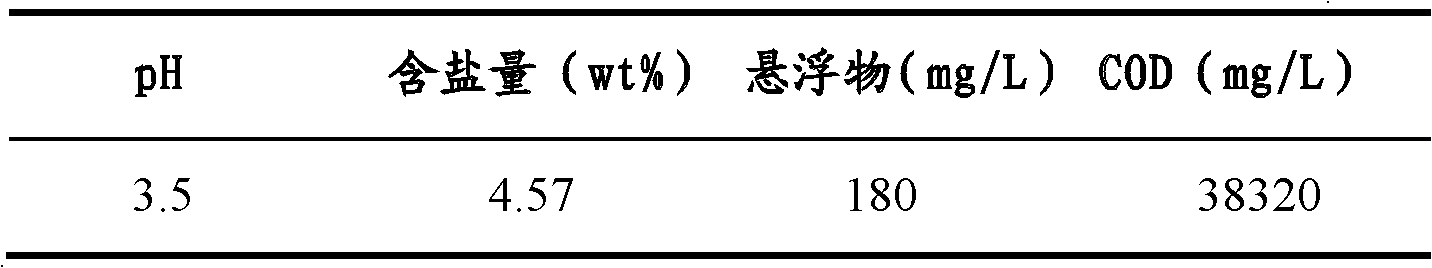

Treatment method of lignin production waste water

InactiveCN103172212AGuaranteed purityGuaranteed qualityGeneral water supply conservationDispersed particle separationElectricityInduced gas flotation

The invention relates to a treatment method of lignin production waste water, which comprises the following steps of: treating and recovering lignin residues in lignin waste water through a gas floatation method at first; respectively feeding gas floatation water and condensate water in a multi-effect evaporation stage into an electro-osmosis desalting device to obtain lignin waste water containing no salt basically and highly saline concentrated water; and recovering the lignin waste water containing no salt basically as supplementary water in the lignin production process, feeding the highly saline concentrated water into a multi-effect evaporation device to concentrate and crystallize, recovering the obtained evaporation condensate water in the electro-osmosis desalting device, and directly selling the obtained high-purity solid salt. Due to the process, resource recycling of waste water is realized; closed cycle of water is realized, so that the pollution abatement cost is reduced; organic combination of the electro-osmosis technology, multi-effect evaporation and the crystallization technology is sufficiently embodied; and the treatment method disclosed by the invention is a high-efficiency and economical treatment method.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Wastewater mercury removal process

InactiveUS8034246B2Ion-exchanger regenerationTreatment involving filtrationActivated carbonInduced gas flotation

A method for removing ionic, organic and elemental mercury from aqueous streams such as wastewater streams from hydrocarbon processing. The method comprises four primary removal steps. First, a mercury precipitant is added to the stream to convert dissolved ionic species of mercury water-insoluble form. The majority of these precipitated solids, as well as other forms of particulate mercury, are subsequently removed by means of gas flotation. Following the flotation step, additional particulate and precipitated ionic mercury removal is accomplished with media filtration and finally, activated carbon acts to remove the remaining dissolved ionic mercury species as well as elemental and organic forms of mercury.

Owner:EXXON RES & ENG CO

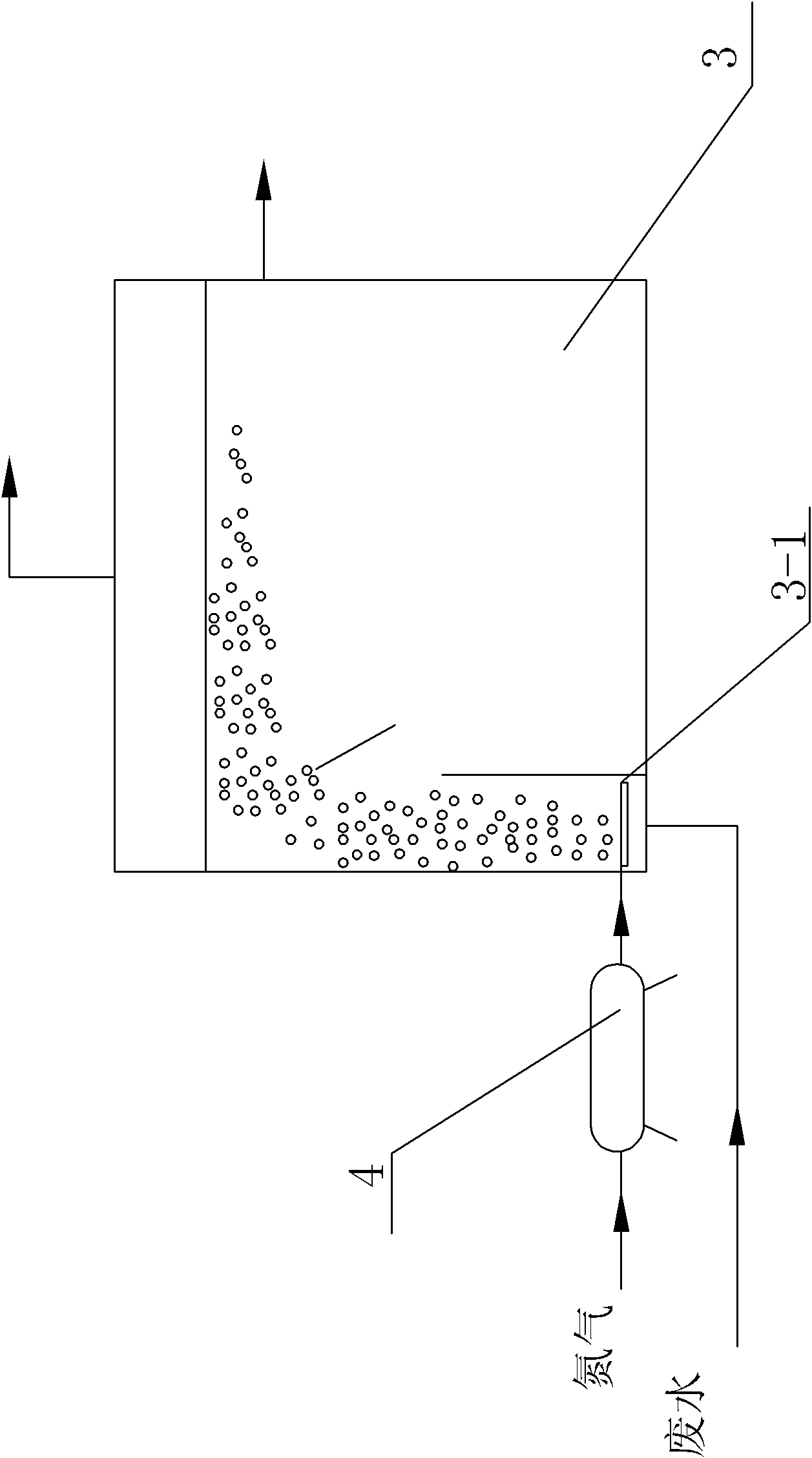

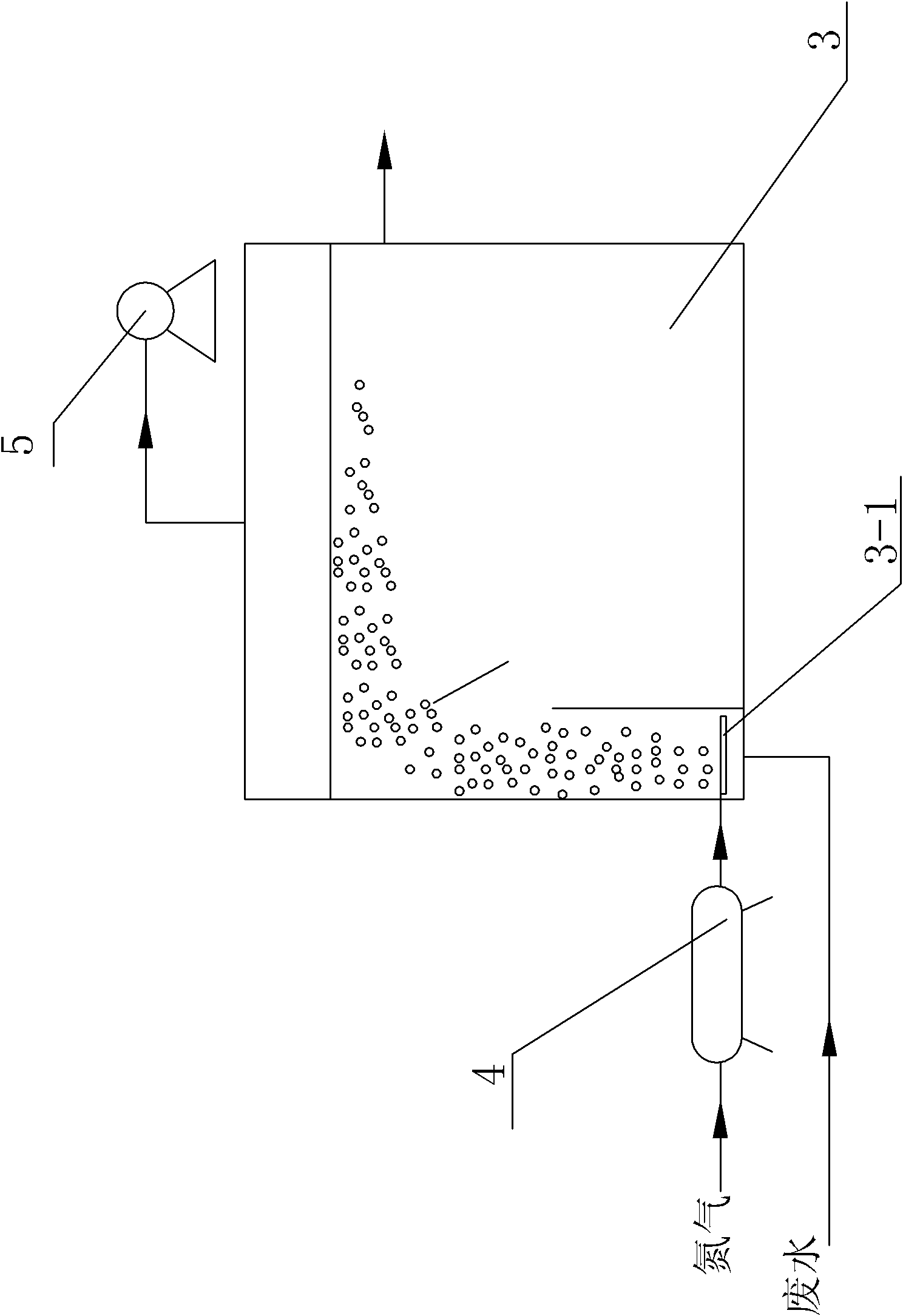

Method for treating coal gas wastewater by adopting nitrogen floating device

InactiveCN102050500AReduce energy consumptionColor deepeningWater/sewage treatment by flotationInduced gas flotationSlag

The invention discloses a method for treating coal gas wastewater by adopting a nitrogen floating device, relating to a method for treating coal gas wastewater. The invention aims to solve the problem that air is used a gas source when coal gas wastewater is treated with a floating method currently, which causes the deep color of the wastewater to easily generate oxides which affect the following biochemical treatment. In the first technical scheme, nitrogen is dissolved into wastewater and enters a floating tank; supersaturated nitrogen is released in a form of tiny bubbles and mixed with a second part of water, and dispersed oil pollutant in the wastewater is adhered to the surfaces of the tiny bubbles to form composite particles; and the composite particles are scraped by a slag scraping machine. The second technical scheme is characterized in that compressed nitrogen escapes from the surface of a diffusion plate or a diffusion tube arranged at the bottom of the floating tank in a form of tiny bubbles. The third technical scheme is characterized in that the upper space of the floating tank is kept at normal pressure, the nitrogen dissolved in the wastewater reaches a saturated or supersaturated state, and the upper space of the floating tank is in a vacuum state through a vacuum pump. The method is used for treating coal gas wastewater.

Owner:HARBIN INST OF TECH

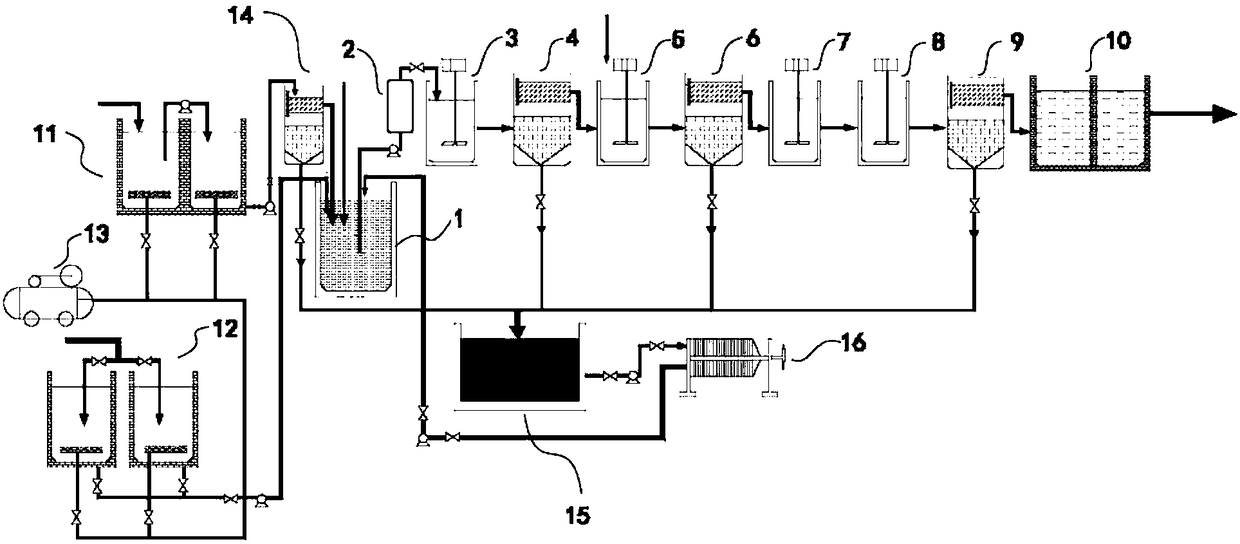

Method for recycling metal cyanide complex in gold mine cyanide-containing wastewater and recycling wastewater through precipitation-gas flotation process

InactiveCN108821472AHigh recovery rateEasy dischargeWaste water treatment from metallurgical processMultistage water/sewage treatmentPregnant leach solutionCyanide

The invention discloses a method for recycling metal cyanide complex in gold mine cyanide-containing wastewater and recycling wastewater through a precipitation-gas flotation process. The method comprises the following steps: adjusting the pH value of the wastewater to be 6-7 and enabling copper ions in the wastewater to mainly exist in form of [Cu(CN)3]<2->; adding a metal cyanide complex ion collecting agent into the wastewater, reacting with copper-cyanide complex ions and lead-cyanide complex ions to generate flocculent precipitates; carrying out gas flotation and recycling the precipitates in a gas flotation device; and adding coagulant and treating the remaining wastewater and recycling the precipitated supernatant liquor. The method is capable of removing 90% and above of metal cyanide complex ions in the wastewater; cyanide in the remaining wastewater mainly exists in the form of free cyanide; the method can effectively solve the problem of accumulation of metal ions in leachate in a cyaniding and gold-extracting process; the treated wastewater can be used as circulation water, is returned to the system and is recycled.

Owner:CHINA UNIV OF MINING & TECH

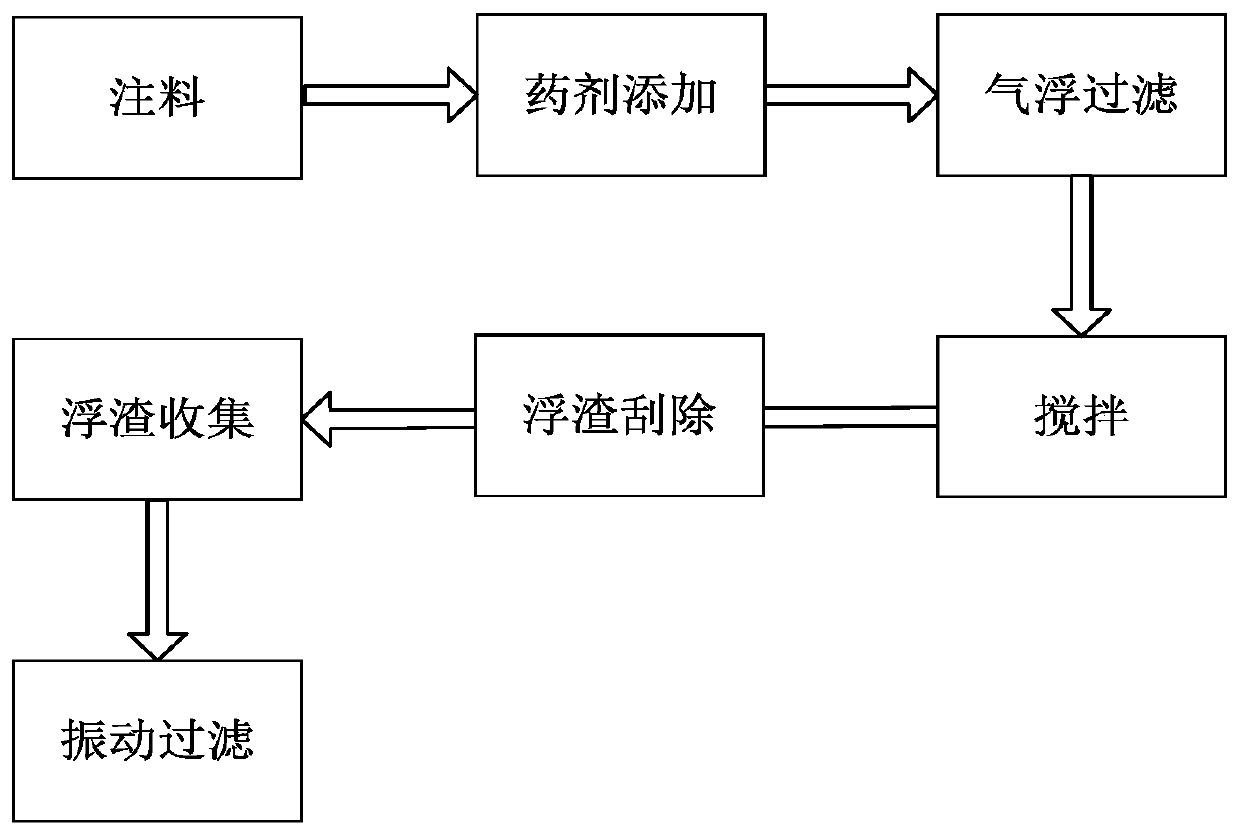

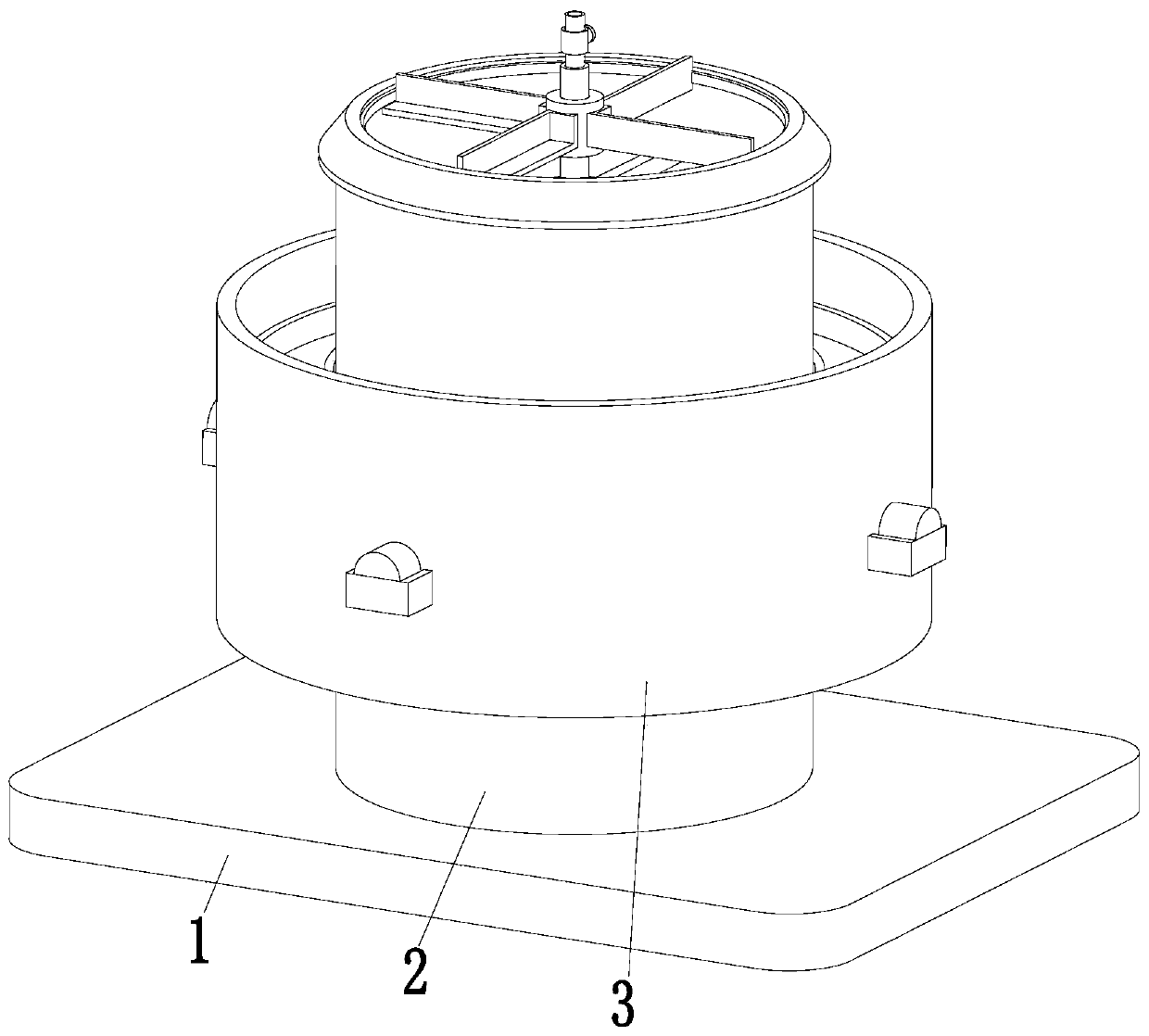

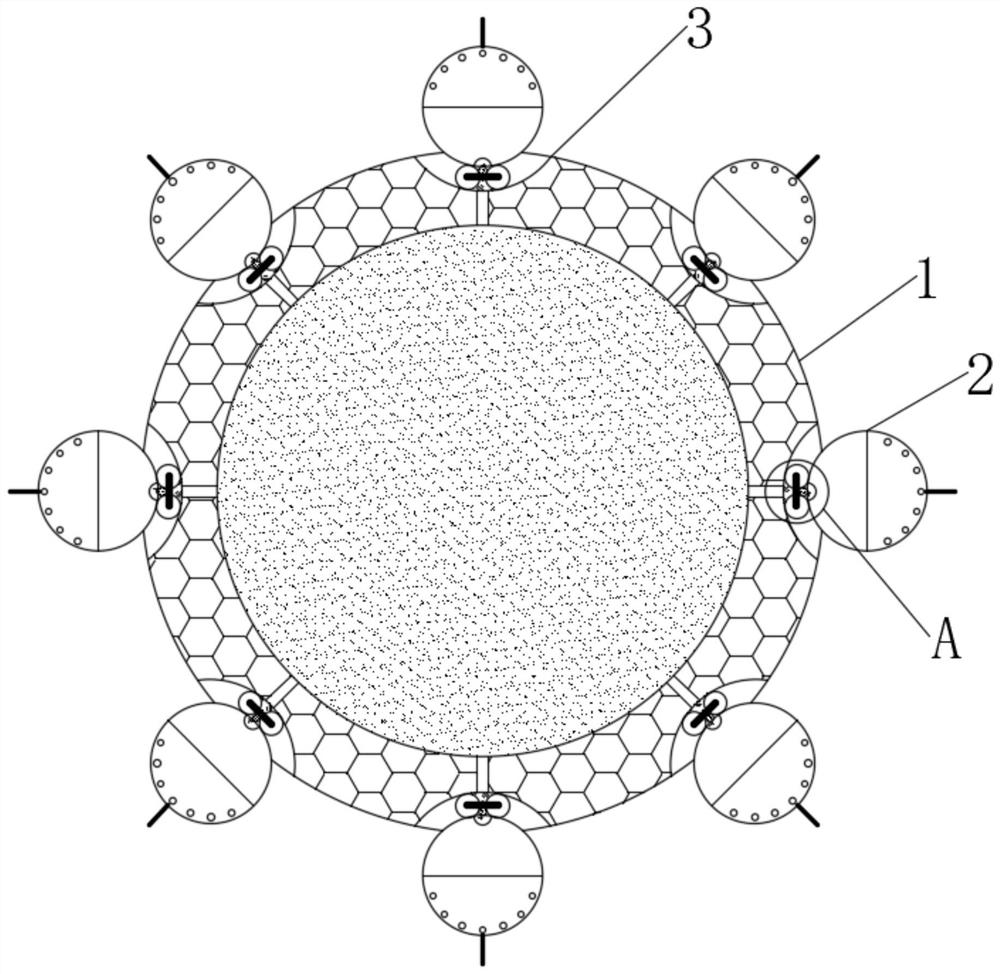

Pulp wastewater treatment processing method

ActiveCN111003847AGood removal effectReduce pollutionTreatment involving filtrationMultistage water/sewage treatmentInduced gas flotationProcess engineering

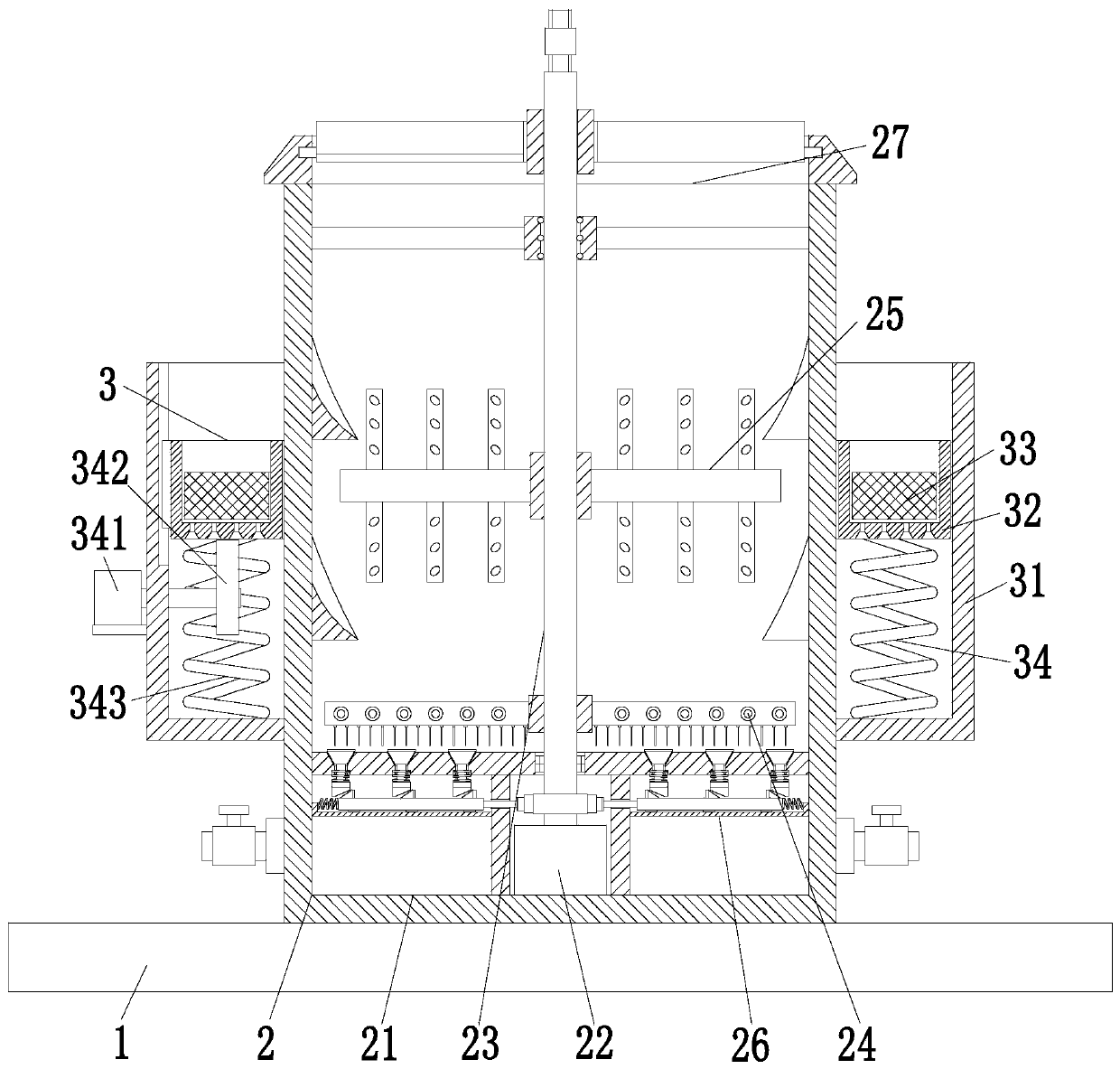

The invention relates to a paper pulp wastewater treatment processing method, which comprises a bottom plate, a filtering device and a collecting device, wherein the filtering device is installed in the middle of the upper end of the bottom plate, the collecting device is installed on the outer side of the filtering device, and the collecting device is of an annular structure. In the prior art, when the existing equipment treats paper pulp wastewater, the residual paper pulp fibers in the wastewater cannot be effectively collected, so that the paper pulp recovery effect is poor, the waste is serious, and different degrees of pollutions can be caused to the water body; and when an air flotation method is adopted to treat paper pulp wastewater, the contact effect of the wastewater and injected air is poor, the impurities in the wastewater cannot be completely collected, more impurities are left in the treated wastewater, and the stability of the floating foam formed by contacting the airis poor, so that secondary pollution to the wastewater and other problems are easily caused. With the method of the invention, the problems in the prior art can be solved.

Owner:GUIZHOU CHITIANHUA PAPERS

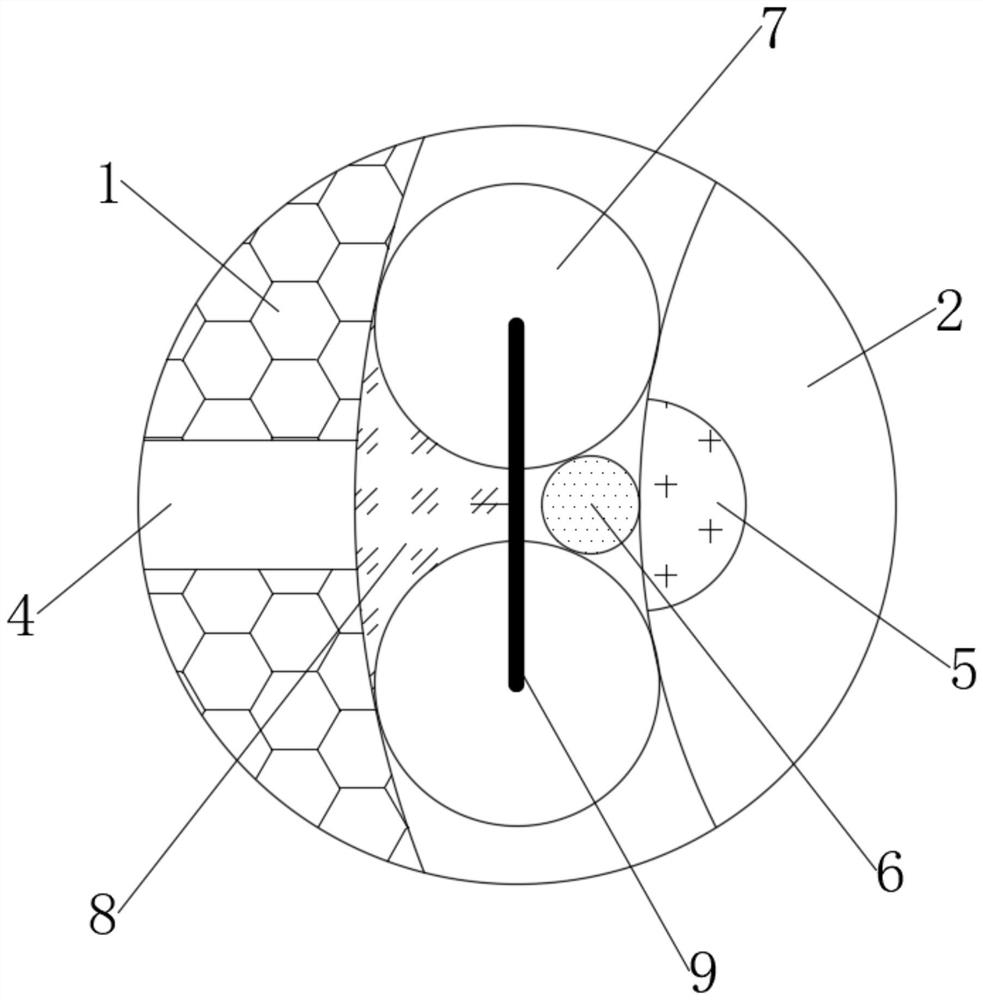

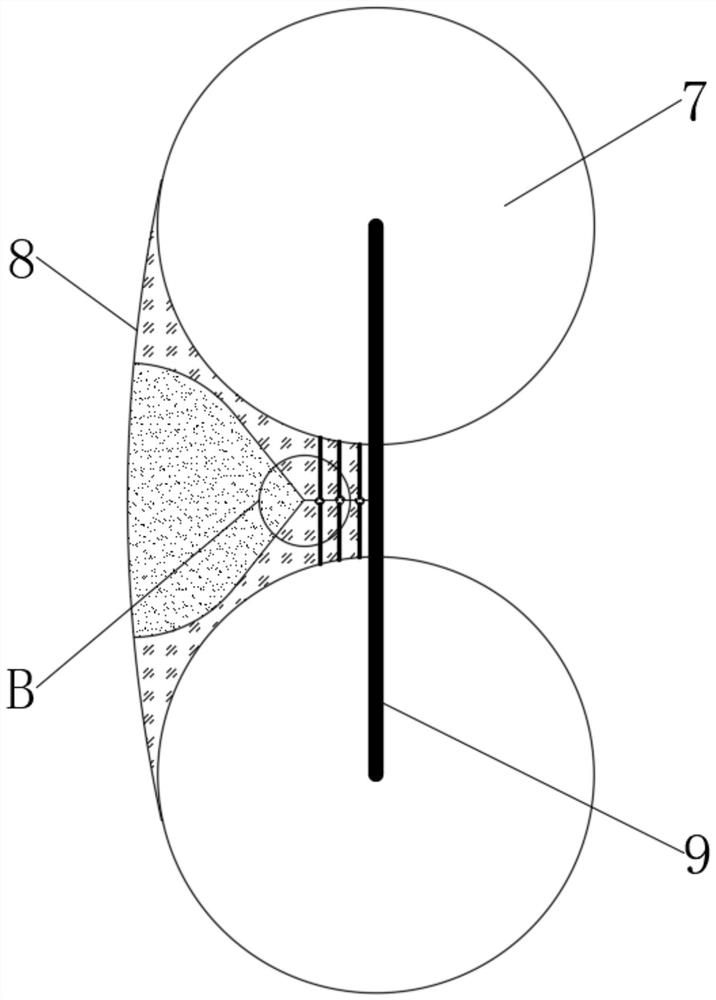

Method for sewage treatment through co-agglomeration gas flotation method

ActiveCN104310653AReduce dosageIncrease the chance of floc collisionMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFlocculationInduced gas flotation

The invention relates to a sewage treatment method, in particular to a method for sewage treatment through a co-agglomeration gas flotation method, which integrates a clarification function with a gas flotation function together. The method comprises the following steps: (1) feeding raw water to a primary flocculation zone to be flocculated; (2) feeding the water to a secondary flocculation zone for contact agglomeration, and further conducting agglomeration gas flotation; (3) feeding the water to a gas flotation contact zone, conducting contact agglomeration on the gas trapped flocculation particles with gas dissolved water released by a releaser, enabling the the gas trapped flocculation particles to be in full contact with microbubbles to form co-agglomerated large bubble flocculation; (4) feeding the water to a solid-liquid separation zone. The method disclosed by the invention has the benefits that the conventional mechanical agitation clarification tank is organically combined with the gas floatation technology, the method organically combines the working procedures comprising mixing, primary flocculation, secondary flocculation, gas floatation, settling, and sludge reflux contact flocculation together; the gas dissolved water microbubbles directly participate in agglomeration and are co-agglomerated with flocculation to become large; the bubbles are placed inside the flocculated particles, so that the effect of agglomeration of the bubbles is fully played and the bubbles are firmly adhered to the flocculated particles to achieve co-agglomeration gas flotation.

Owner:SHANDONG JIANZHU UNIV

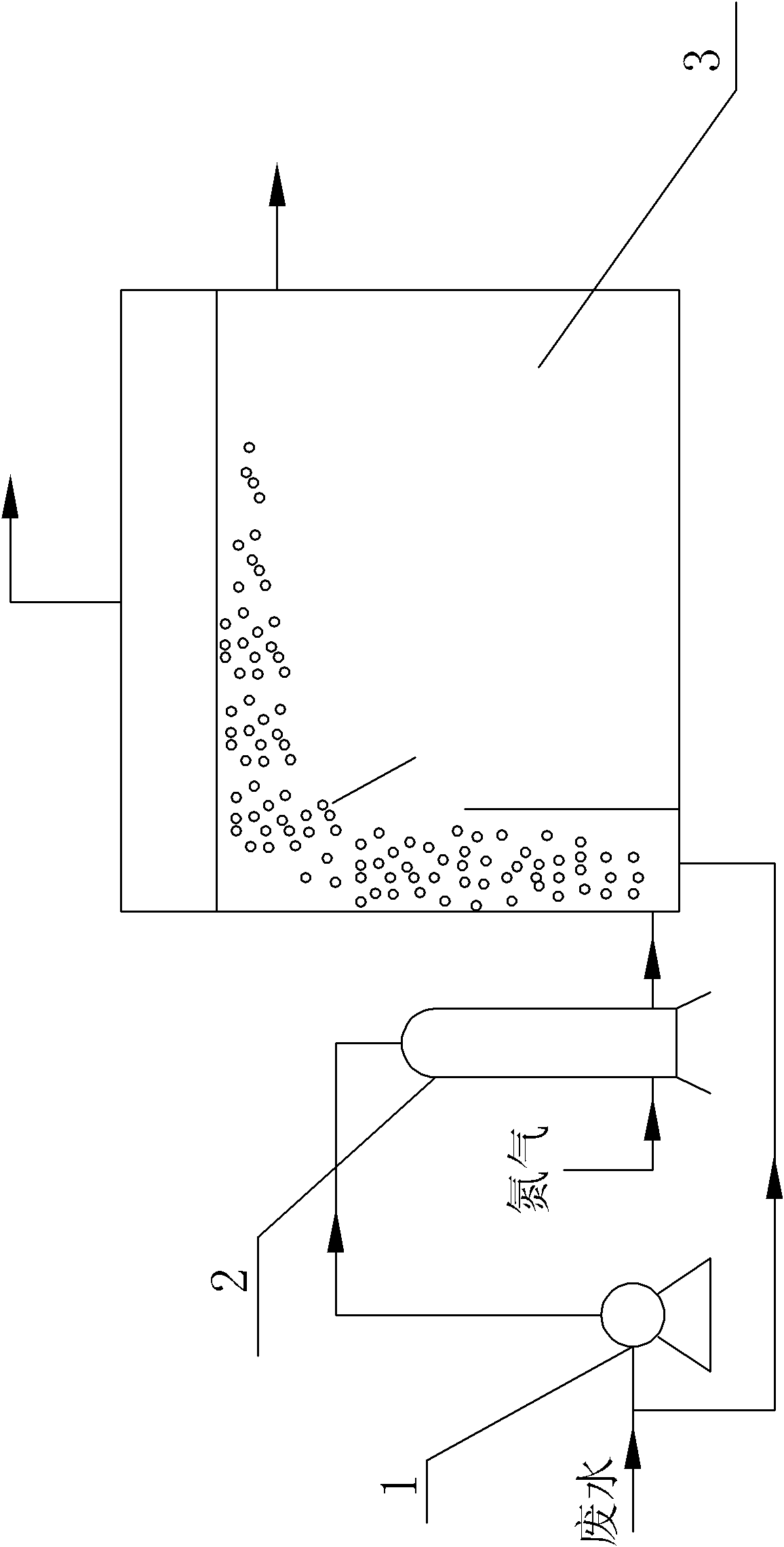

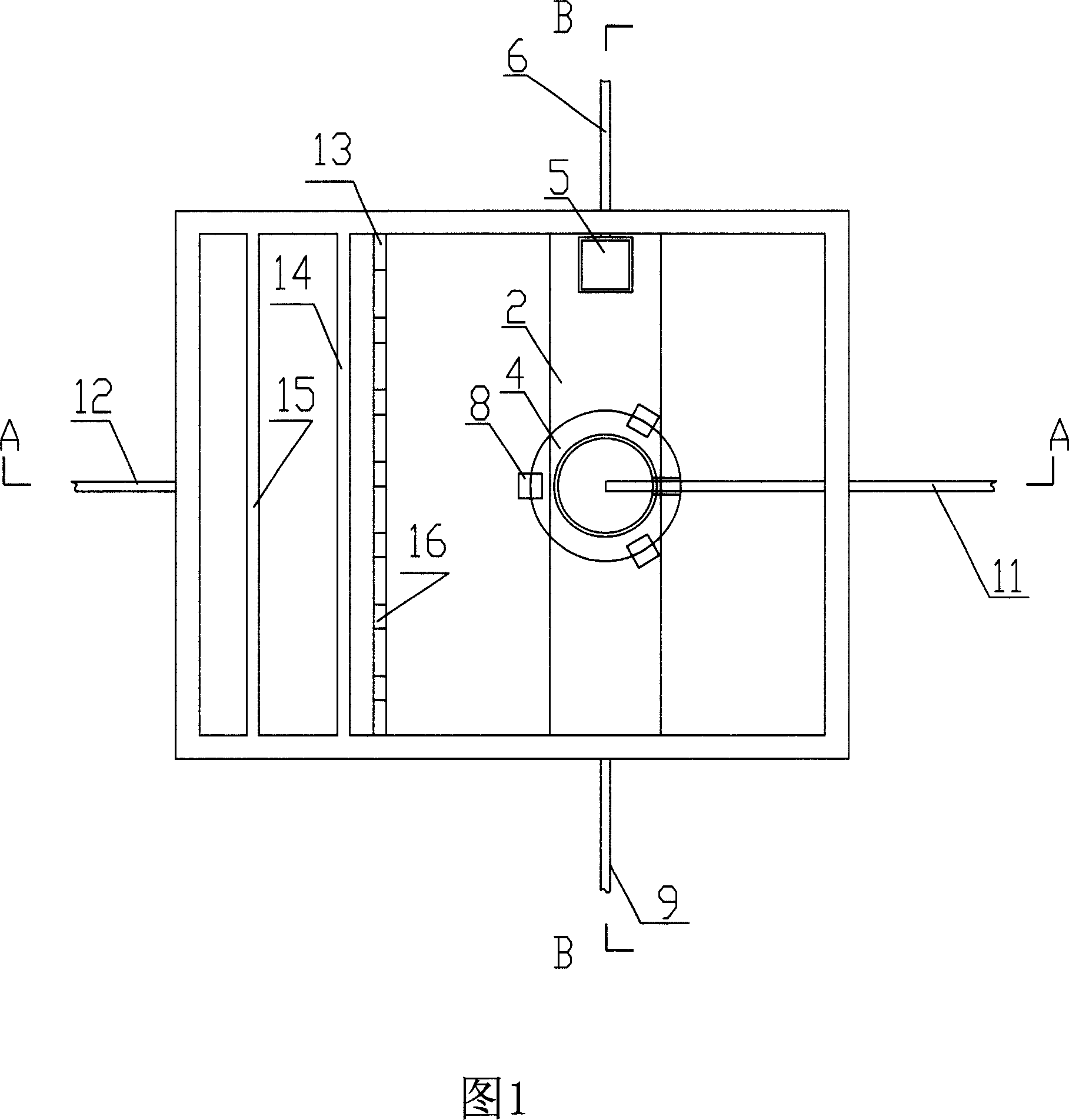

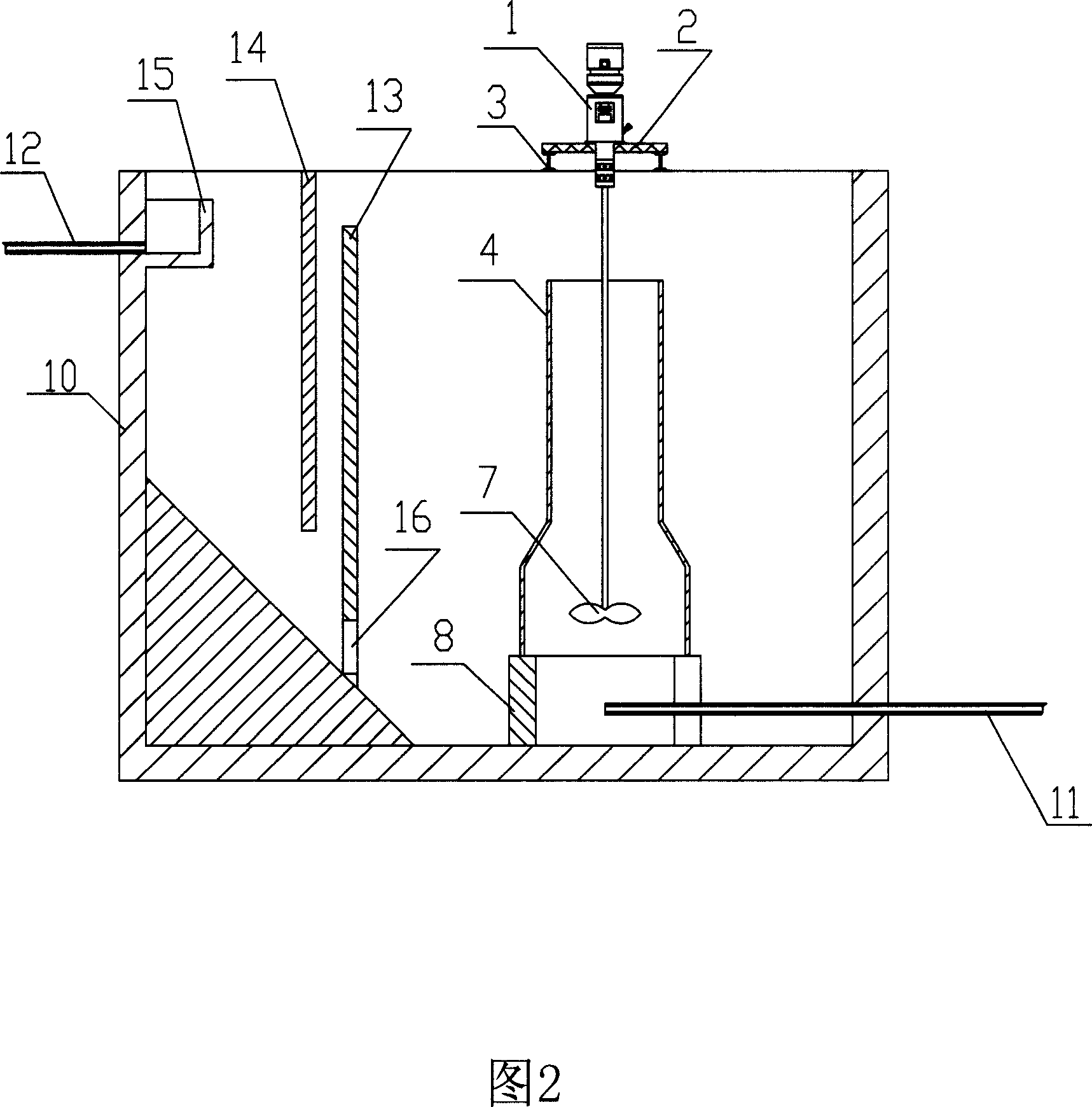

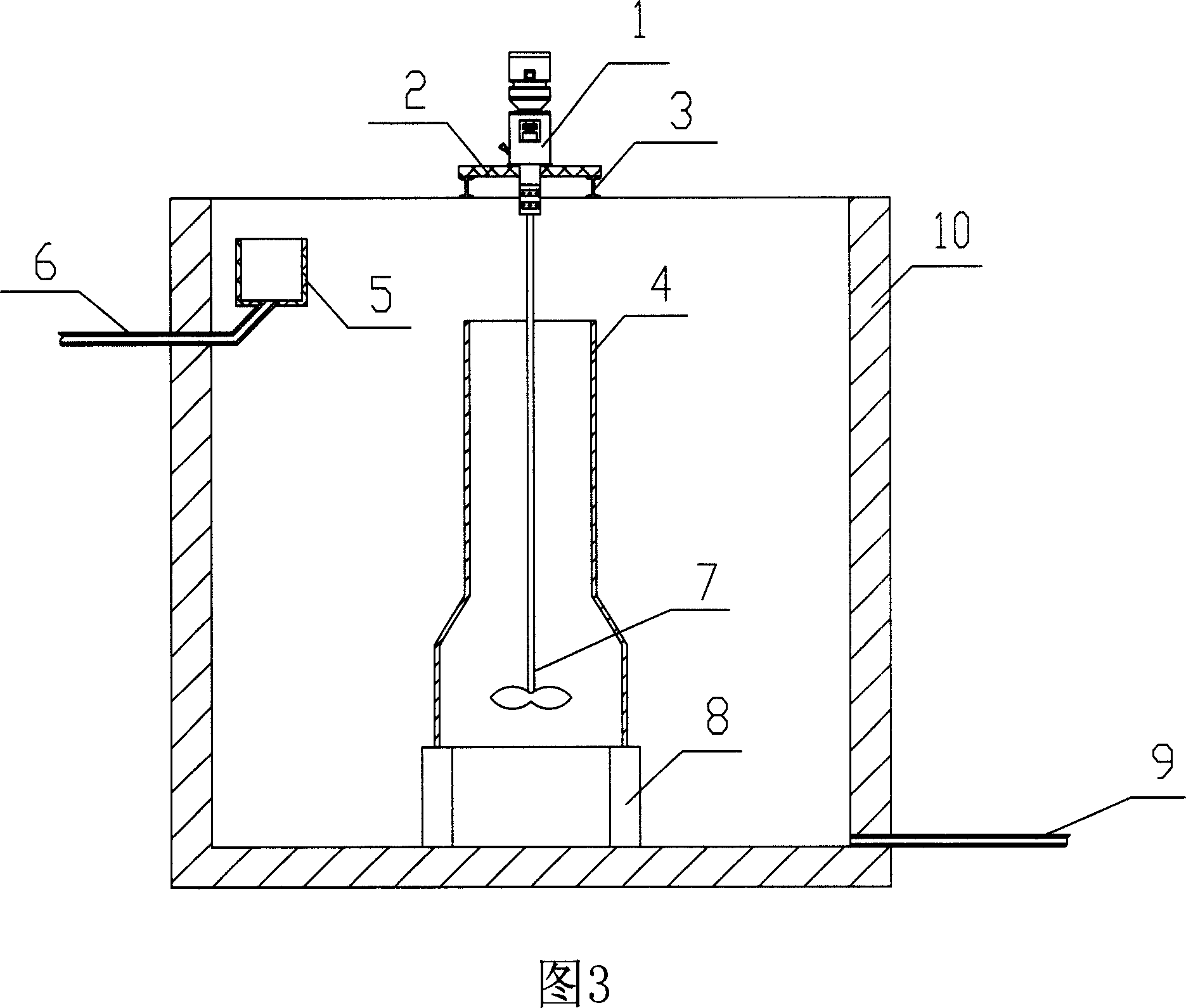

Air-floating pretreatment method and device for high-concentration organic sewage

InactiveCN1951838ACost savingsSave operating costsTreatment with anaerobic digestion processesWater/sewage treatment by flotationHigh concentrationReflux

The invention discloses an air-float predisposing method of organic effluent, which comprises the following steps: blending organic effluent and sludge with high-activity anaerobe; decomposing organics in the effluent under 15-60 deg.c through microbe; generating bubble; making non-decomposed particle impurity attached by bubble float on the water level; forming scum; remaining effluent for 1-2h to drain. the device contains a reacting pond bulk with reacting area and separating area separated by baffle on the pond bottom, wherein the pond wall top on the reacting area side possesses draining pipe with inlet pipe and blow-down pipe on the bottom; the diversion cylinder is set in the reacting area with stirrer on the diversion cylinder; the outlet pipe is set on the top of pond wall on the separating area side; the notch is opened on the top of baffle with reflux hole near the bottom.

Owner:SUZHOU UNIV OF SCI & TECH

Simple plasma water treatment device and method of coal tar wastewater

InactiveCN107324561AWater/sewage treatment by electrochemical methodsMultistage water/sewage treatmentFlocculationInduced gas flotation

The invention provides a simple plasma water treatment device and method of coal tar wastewater. By means of combination of a physicochemical method and a chemical method, treatment is conducted on the coal tar wastewater, and the method mainly adopts the following processes of flocculation, air flotation and low-temperature plasma oxidation. The water treatment device and the water treatment method belong to the technical field of water treatment. According to the water treatment device and method, by means of flocculation and sedimentation and air flotation, substances, influencing subsequent treatment processes, such as suspended solids and the like in the wastewater are greatly reduced; ultraviolet ray, ozone and the like generated by the low-temperature plasma technology have extremely high oxidability and can effectively decompose organic matter in the wastewater.

Owner:丹阳市百盛电器有限公司

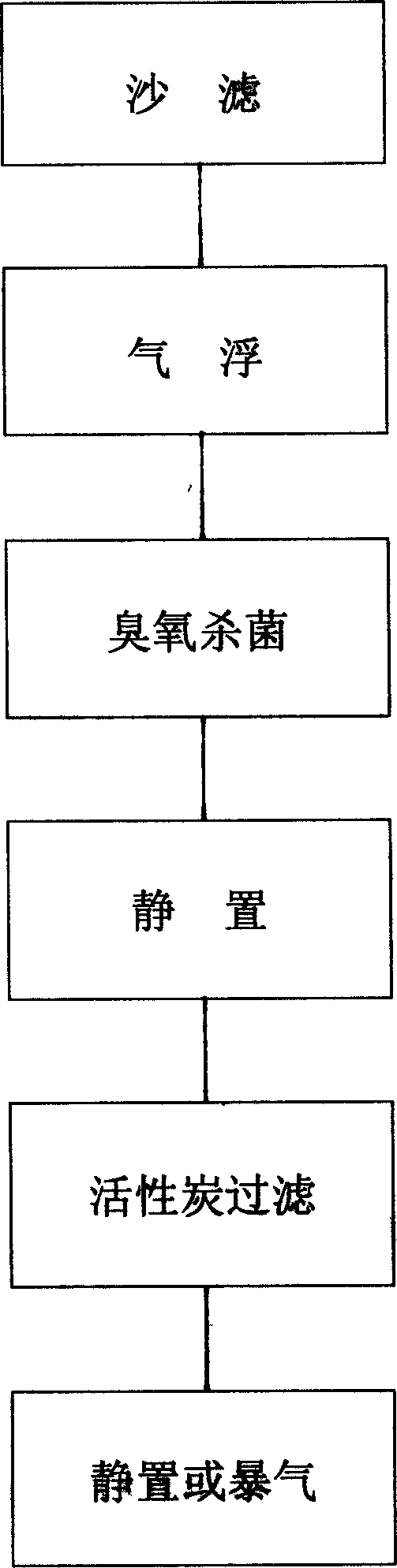

Water treatment method for rearing shrimp seedling

InactiveCN1565997AImprove survival rateSimple processMultistage water/sewage treatmentShrimpInduced gas flotation

The invention relates to a water treatment method for rearing shrimp seedling which comprises, conducting sand filtering to the cultivated shrimp seeds with sea water, removing the microtubule organic matter and foreign substance in the seawater through air-floating method, then performing short time sterilization and hazardous substance decomposition by means of circulating reflux mixing, stewing and filtering with activated charcoal, and stewing the filtered sea water.

Owner:唐进忠

Industrial waste water treatment method

InactiveCN101993167ASustainable processingReduce COD valueTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentIndustrial waste waterInduced gas flotation

The invention provides an industrial waste water treatment method and belongs to the technical field of industrial waste water treatment in the environmentally-friendly technology. The invention provides a treatment method for impurity content reduction and decoloration of industrial waste water. The method comprises the following steps of: removing macromolecular pollutant and solid matter from the industrial waste water by filtering or an air flotation method, and then discoloring the industrial waste water by an integrated process of physical-chemical precipitation (or air flotation), anaerobic treatment (and facultative treatment), aerobic treatment and physical-chemical precipitation.

Owner:李雁北

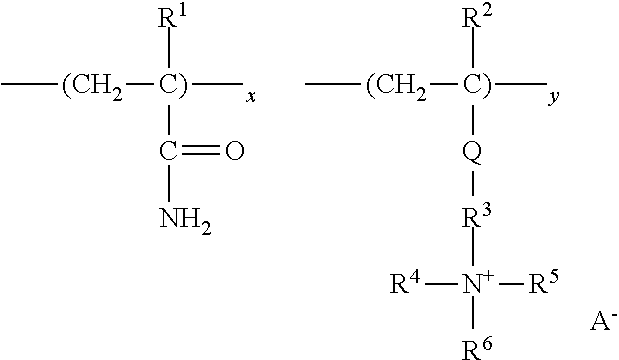

Method for performing microplastic separation on basis of gas floatation method

The invention belongs to the technical field of a solid waste treatment method and particularly relates to a method for performing microplastic separation on the basis of a gas floatation method. Themethod comprises the following steps: adding ammonium triheptyl dodecyl iodide into water in which microplastic is dispersed, mixing completely, adding inorganic acid into the dispersing liquid, mixing completely, continuously introducing air or oxygen, enabling the introduced air or oxygen form bubbles in the dispersing liquid to ascend, driving the microplastic in the water to float while the bubbles ascend, and separating out a large amount of microplastic-containing liquid on the upper layer of the water to realize separation of the water and the microplastic.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Spore-like water body suspended matter catching sinking ball

InactiveCN111924948AEffectively closedChange seal trackWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionSporelingInduced gas flotation

The invention discloses a spore-imitating water body suspended matter capturing sinking ball, and belongs to the technical field of water treatment. The characteristics of spore-producing plants can be imitated; a plurality of drug release mother balls are uniformly put into a polluted water area; magnetic spore-like adsorption balls are matched with the drug release mother balls; based on the characteristics that a disintegration column vibrates at high frequency after absorbing water and releases a large amount of gas, on one hand, an elastic self-sealing bag on the drug release mother ballis matched; a flocculating agent in the elastic self-sealing bag is continuously transported and dispersed into the water body along the spore-like adsorption balls, suspended matters around the flocculating agent is flocculated and then captured and collected; on the other hand, released gas is used for forming stable bubbles in the water body; suspended matters are gathered and floated to the water surface by a simulation air flotation method; meanwhile, after the disintegration columns in the spore-like adsorption balls are consumed, the overall mass is reduced, the disintegration columns float upwards, suspended matters floating upwards along with bubbles can be collected again, the balls can be recovered and reused, and the suspended matter collection efficiency and effect are greatlyimproved.

Owner:罗菁

Synchronous decoloring and nitrogen recovery method for printing wastewater

ActiveCN105668848ARealize simultaneous decolorizationHigh decolorization rateWater contaminantsWater/sewage treatment by ion-exchangeRecovery methodSolution treatment

The invention discloses a synchronous decoloring and nitrogen recovery method for printing wastewater.The synchronous decoloring and nitrogen recovery method is characterized by including the steps of adding cation exchange resin into the printing wastewater and stirring for 10-180 minutes; separating cation exchange resin precipitate from the wastewater; separating suspended matters in the wastewater from the wastewater by a conventional precipitation method or an air-flotation method; subjecting the precipitated cation exchange resin to dehydration and acid solution treatment sequentially, and recovering nitrogen to enable the resin to regenerate; adding the regenerated cation exchange resin into the printing wastewater and using circularly.The synchronous decoloring and nitrogen recovery method for the printing wastewater has the advantages that according to a treatment method, printing wastewater decolorizing ratio is above 99.5%, ammonium-nitrogen removal rate is above 85%, CODCr removal rate is above 90%, synchronous printing wastewater decoloring and nitrogen recovery are achieved, and the content of acid ions in the wastewater is not increased.

Owner:QINGDAO UNIV

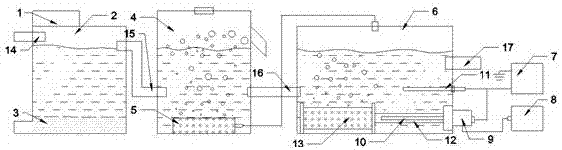

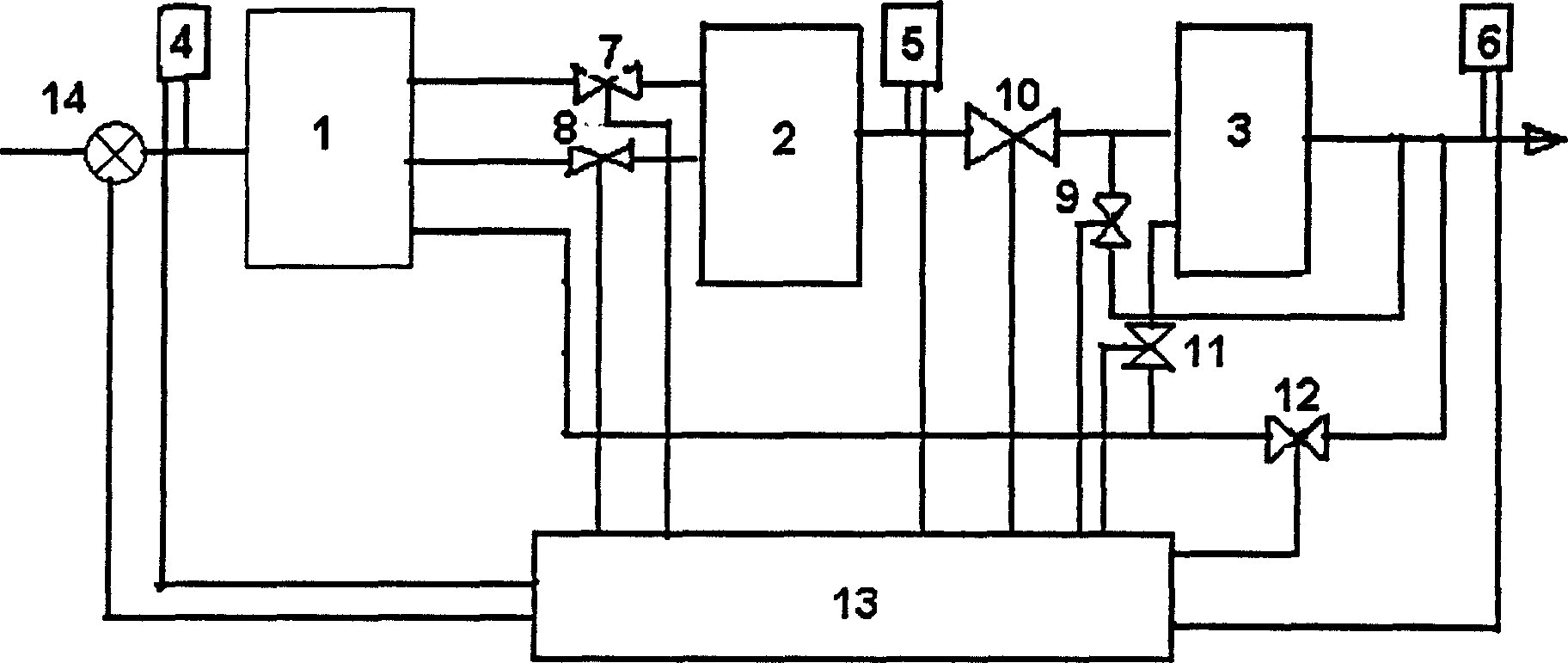

Integrated dynamic balance treating method for oily sewage and apparatus thereof

InactiveCN1709804AEasy to operateReduce processing costsFatty/oily/floating substances removal devicesLiquid separationTextile fiberIt equipment

The invention publicizes the integration dynamical equilibrium processing method and its equipment for the sewage which contained oil , this method connects the water-treating equipment of jet-style with flotation process, the modified textile fiber ball water-treating equipment as well as the ultra filter diaphragm water-treating equipment with the sewage pipeline contained oil through the pipeline which establishes and contacts in turn in the same place, between the above equipments was equipped with process-adjust valve. The said jet-style flotation water-treating equipment takes the first level oil-contained sewage treatment, the modified textile fiber ball water-treating equipment takes the second level sewage treatment, the ultra filter diaphragm water-treating equipment takes the third level sewage treatment. At the sewage import end establishes one flowmeter, on the pipeline supposes three on-line oil-containing concentration detector and dynamic control system which carries on-line control and adjustment to each treating process according to the set treatment standard, then choice the next level processing equipment, which makes the sewage treatment in optimization process.

Owner:XI AN JIAOTONG UNIV

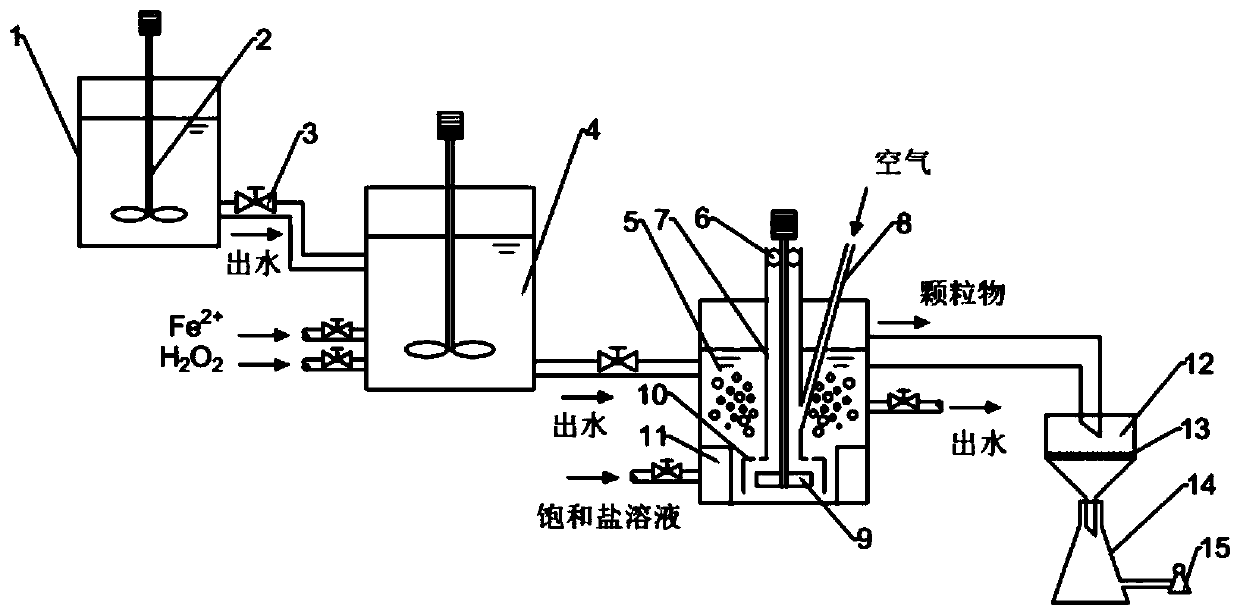

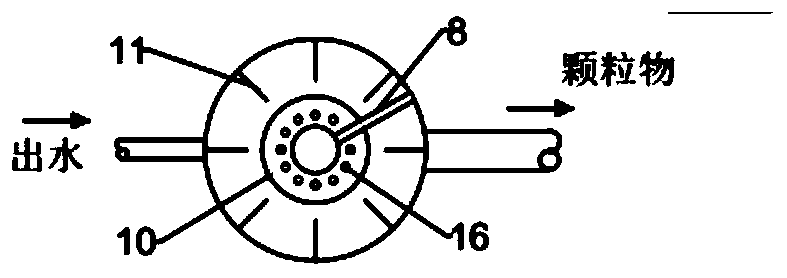

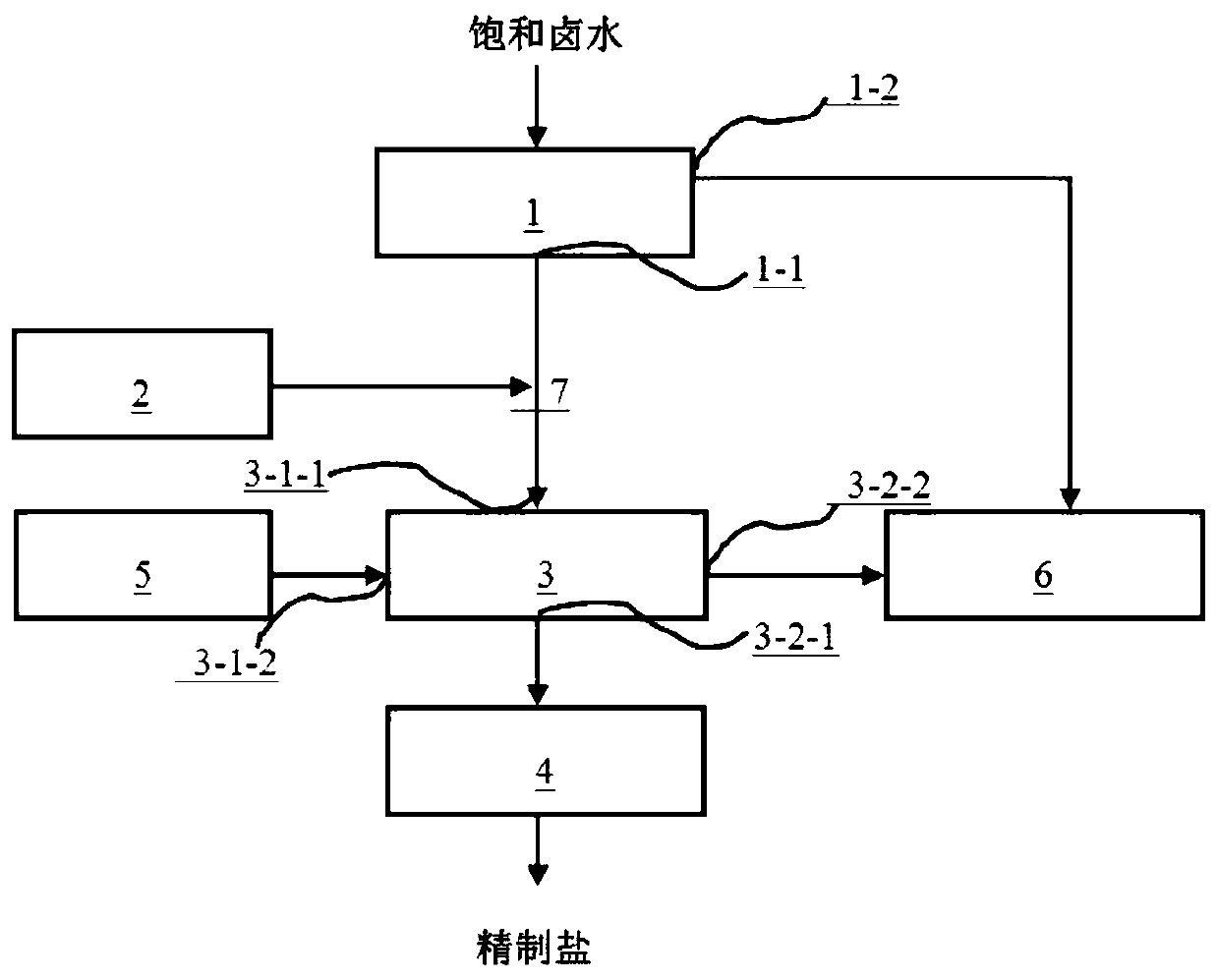

Method and device for refining brine by air floatation method

PendingCN111547924AQuality improvementLow costMultistage water/sewage treatmentWater/sewage treatment by heatingInduced gas flotationProcess engineering

Owner:ENG TECH INST CO LTD OF CNSIC +1

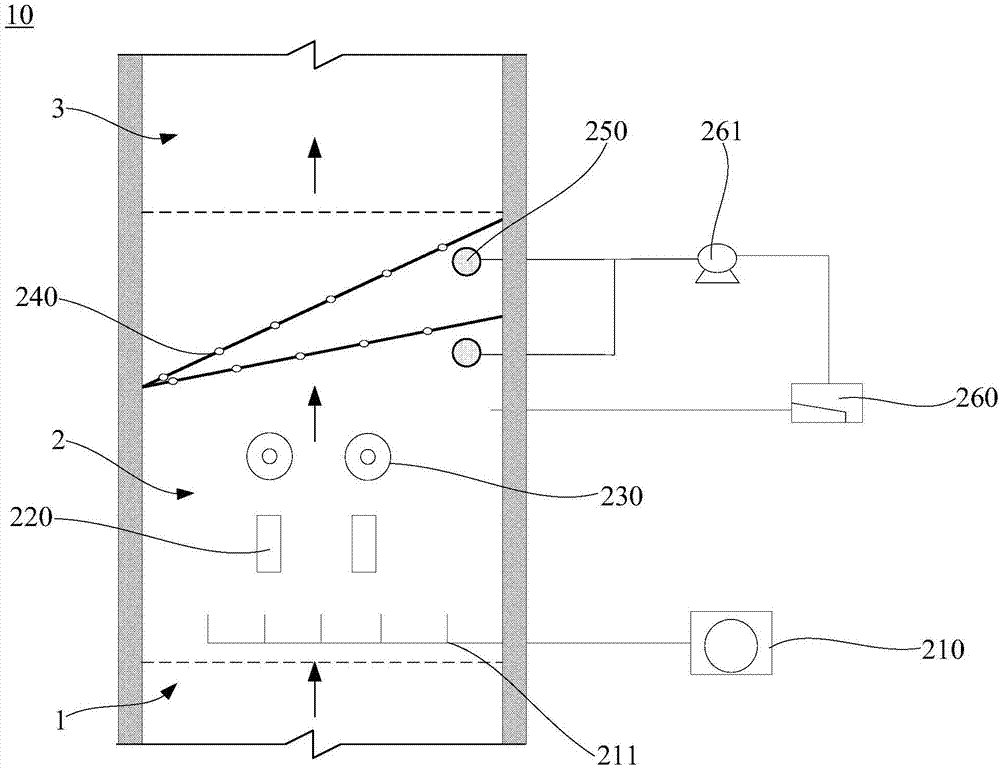

In situ air-flotation treatment system of riverway water body

PendingCN107352658AImprove efficiencyGood removal effectBiological water/sewage treatmentContaminated waterways/lakes/ponds/rivers treatmentFlocculationRiver routing

The invention relates to an in situ air-flotation treatment system of a riverway water body. The system comprises a feeding system, a push flow oxygen-increasing device, a micro-bubble generating device and a scum guiding device, wherein the feeding system comprises a feeding pipe and a material storage device used for storing a flocculating agent, and the feeding pipe is used for adding the flocculating agent to a pollution treatment zone; the push flow oxygen-increasing device is arranged in the pollution treatment zone and used for increasing the oxygen of the water body, making flows and flocculation stirring; the micro-bubble generating device is used for making the water body in the pollution treatment zone generate micro-nano bubbles; the scum guiding device is used for intercepting scum in the pollution treatment zone. Compared with a conventional land heterotopic air-flotation method, the in situ air-flotation treatment system of the riverway water body conducts in situ flocculating and air flotation treatment on pollution in the riverway water body, can obviously save floor space on the whole, can obviously save running energy consumption, and can simultaneously obviously improve the removal effect of the pollutants in the riverway water body through combination of multi-effect purification means namely flocculating, powerful aeration and micro-bubble air-flotation.

Owner:广州太和水生态科技有限公司

Treatment method and apparatus of electroplating wastewater

InactiveCN108178428ASimple process flowStart fastSludge treatment by de-watering/drying/thickeningWater contaminantsFenton reactionInduced gas flotation

The invention discloses a treatment method of electroplating wastewater. The method successively comprises the following steps: removing suspension liquid and floating oil in raw water by virtue of anair floating method, and regulating the PH to 3 to 4; adding a fenton reagent, performing primary fenton reaction, and regulating the PH to 8 to 9; precipitating, and regulating the PH of supernatantto 4 to 6; performing secondary fenton reaction, and regulating the PH to 9 to 10; precipitating, and regulating the PH of the supernatant to 2 to 4; performing reduction reaction, and removing hexavalent chromium ions; regulating the PH to 8 to 9, precipitating, and introducing the supernatant to a biochemical tank to be treated; and discharging the water treated in the biochemical tank up to standard. The electroplating wastewater treatment process provided by the invention is simple in process, rapid for workers to operate and low in treatment apparatus cost.

Owner:SHENZHEN LVQIN ENVIRONMENTAL PROTECTION TECH CO LTD

Extraction and utilization method for pollutants in black printing waste water

ActiveCN106315922ARealize resource utilizationHigh decolorization rateSludge treatment by de-watering/drying/thickeningWater contaminantsInduced gas flotationSludge

The invention discloses an extraction and utilization method for pollutants in black printing waste water, comprising the following steps: adding acid to the black plastic printing waste water, stirring the waste water for 10-30min to coagulate the pollutants, and carrying out mud water separation by an air flotation method or precipitation method; adding calcium mineral powder to the separated sludge, and after stirring uniformly, carrying out thermal dehydration on the sludge while stirring the sludge to form sludge blocks; taking out the sludge blocks, thermally pressing the sludge until the water content is below 30% and baking the sludge; heating the baked sludge to 400-700 DEG C under an air-free condition and insulating for 1-5h; cooling the sludge to below 50 DEG C, crushing and granulating the sludge, and uniformly sprinkling a wetting agent solution with mass concentration of 0.05-0.2%; adding sludge particles into cationic dye waste water, aerating and stirring the waste water for 10-60 min, and then precipitating or filtering waste water to remove the sludge particles to obtain almost colorless waste water; and recovering the sludge particles and carrying out heat regeneration at 400-700 DEG C for recycling. The extraction and utilization method for pollutants in black printing waste water realizes extraction of pollutants in the black printing waste water and reclamation and utilization of solid waste, and the decoloring rate of the cationic dye waste water is approximately 100%.

Owner:QINGDAO UNIV

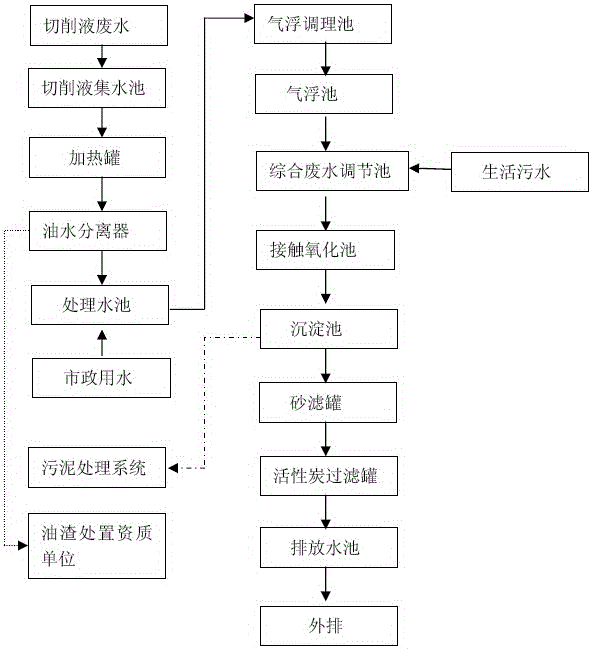

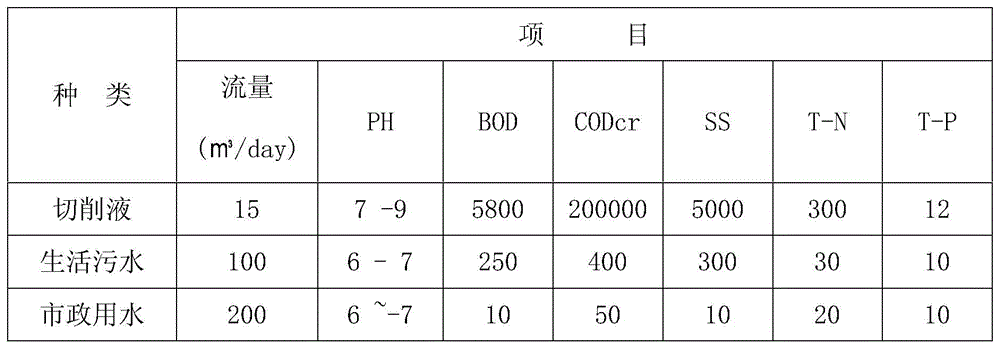

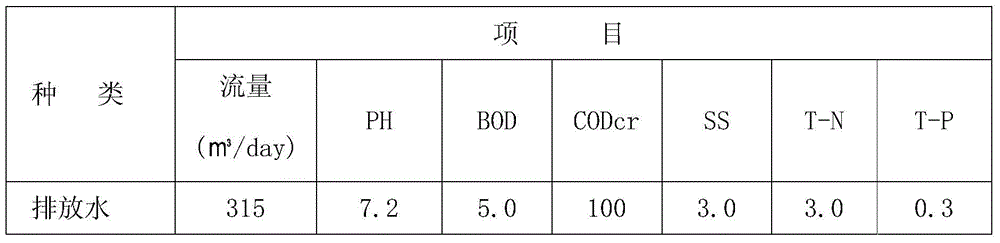

Treatment method of cutting fluid wastewater of automobile engine

InactiveCN105693015AReflect the effect of collaborative processingImprove processing efficiencyFatty/oily/floating substances removal devicesTreatment using aerobic processesWater basedInduced gas flotation

The invention provides a treatment method for automobile engine cutting fluid wastewater. The treatment method is carried out in the following steps: a. First, send the water-based cutting fluid wastewater to a heating device to heat to 90-100°C, and keep it warm for 12-14 hours to make the wastewater break milk, and then carry out oil-water separation of the waste water after demulsification; b. Add dilution water to the waste water after oil-water separation in step a according to the ratio of waste water: dilution water = 1: 4-6 parts by volume, and then use sodium hydroxide Adjust the pH value of the mixed solution to 8-9, and then add the flocculant according to the proportion of waste water: flocculant = 100: 0.95-1.05, and then send the air to the flotation tank, and use the air flotation method to further remove the suspended matter and organic matter in the waste water; c .Send the waste water treated by air flotation in step b to the biological contact oxidation system. The biological contact oxidation system maintains the pH value of the waste water at 8-9, dissolved oxygen 3-5mg / L, and the residence time is 24-72 hours; d. The effluent treated by the biological contact oxidation system is filtered through the sedimentation tank, the multi-media filter tank and the activated carbon filter tank in sequence, and then discharged up to the standard.

Owner:SHANDONG ENVIRONMENTAL PROTECTION IND CO LTD

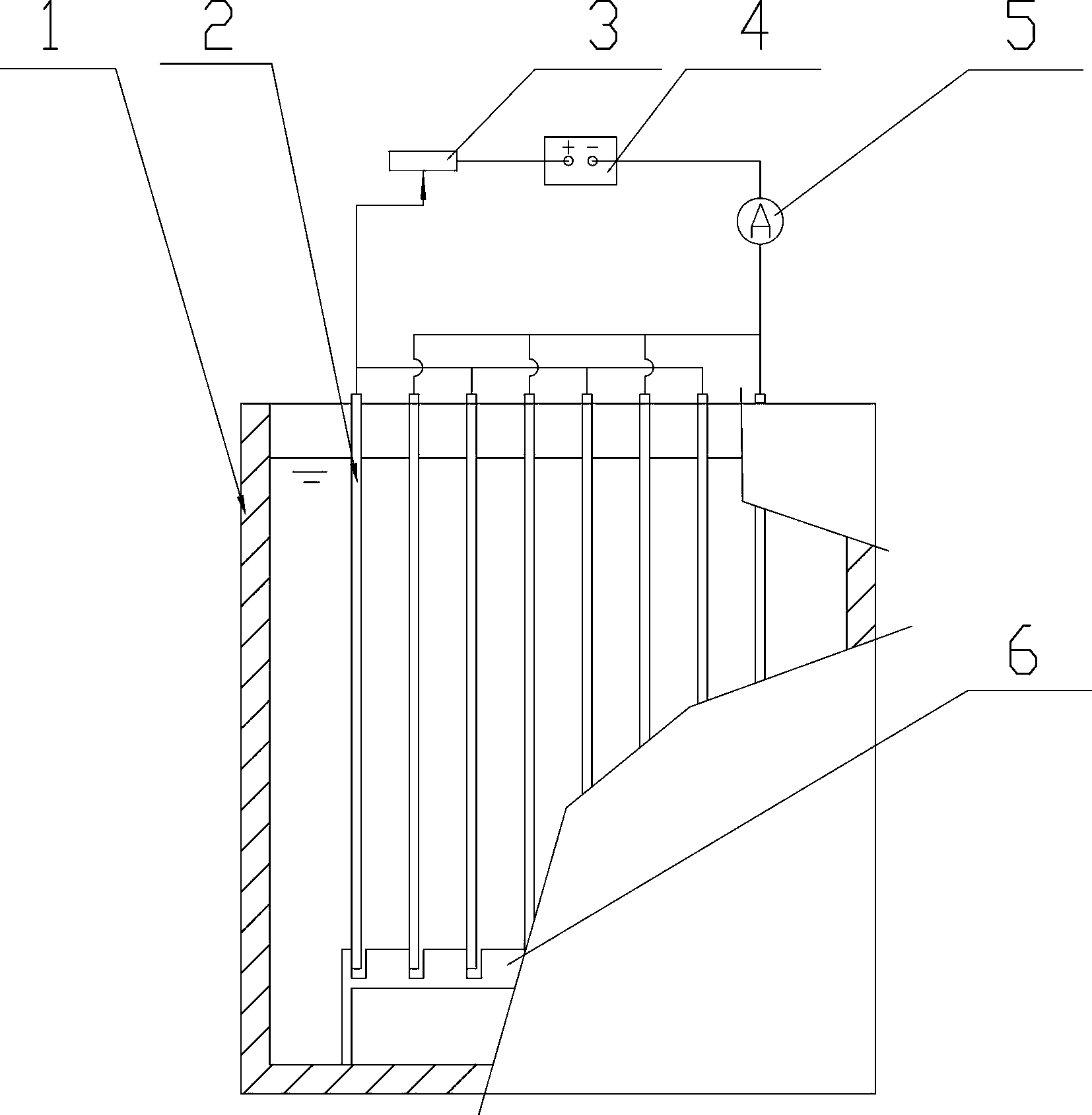

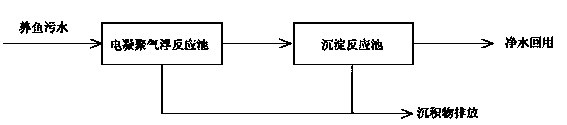

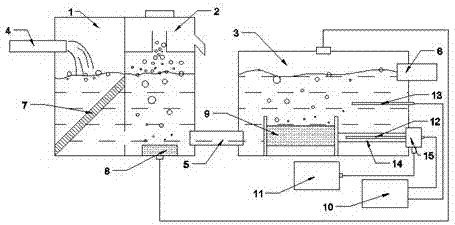

Process for clarifying fish-farming sewage with electro-coagulation air flotation method

InactiveCN104341065AReasonable structureEfficient solid-liquid separationMultistage water/sewage treatmentSedimentation settling tanksElectrochemical responseFlocculation

The invention relates to a process for clarifying fish-farming sewage with an electro-coagulation air flotation method. The process comprises the following steps: (1) fish-farming sewage is introduced into an electro-coagulation air flotation reaction tank; current density is 0.15-0.20A / dm<2>, and electrolysis time is 20-30min; dirt produced by air flotation separation is regularly discharged from a water discharge port in the upper part of the tank body; (2) a flocculation solution produced under the effect of an electrochemical reaction is delivered through a precipitation reaction tank and is subjected to solid-liquid separation, wherein a precipitation time is 15-25min; precipitate is accumulated at the bottom and is discharged together; and a supernatant which is the clarified solution is returned to a fish-farming tank. The structure of the electro-coagulation air flotation reaction tank is as the follows: an insulation positioning strip is arranged on the bottom of the tank body; the positioning strip is provided with recesses; a plurality of pole plates are suspended on the wall of the tank; the lower parts of the pole plates are divided by using the positioning strip recesses; and the pole plates are connected with a mono-polar parallel connection method. The precipitation reaction tank has the following structure: a support is fixed on the wall or bottom of the tank; and a plurality of inclined tube fillers are uniformly arranged on the support, wherein the space between the tank bottom and the inclined tube fillers is 300-350mm, and a tilt angle of the inclined tube fillers relative to the water level is 50-60 DEG. The filling rate of the inclined tube fillers filling the space above the support of the precipitation reaction tank is 65-80%.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Medium blocking discharging water treatment device for removing suspended solids by combining air flotation method and water treatment method

InactiveCN107324583AWater/sewage treatment by irradiationTreatment involving filtrationInorganic saltsInduced gas flotation

The invention relates to a medium blocking discharging water treatment device for removing suspended solids by combining an air flotation method and a water treatment method and belongs to the field of water treatment. A large amount of ozone can be generated during the work of the medium blocking discharging water treatment device, the ozone which is not completely consumed is collected and used for front aeration, on one hand, the use ratio of the ozone can be improved, on the other hand, a large amount of foam can be generated by aeration, the foam carries a large quantity of suspended solids, and the foam is collected and removed so that the suspended solids can be removed. The device is composed of a front filter device and a water treatment reaction device, the front filter device comprises two water tanks which are communicated with each other, and the two water tanks are a primary filter tank and a foam filter tank. Sewage enters the primary filter tank, is filtered through a filter layer, flows into the foam filter tank, is subjected to aeration treatment, and flows into the water treatment reaction device from a pipe; in the water treatment reaction device, pollutants react with active materials, ultraviolet rays and the like generated by the medium blocking discharging water treatment device and are decomposed into simple inorganic salt, and finally the function of water purification is achieved.

Owner:丹阳市百盛电器有限公司

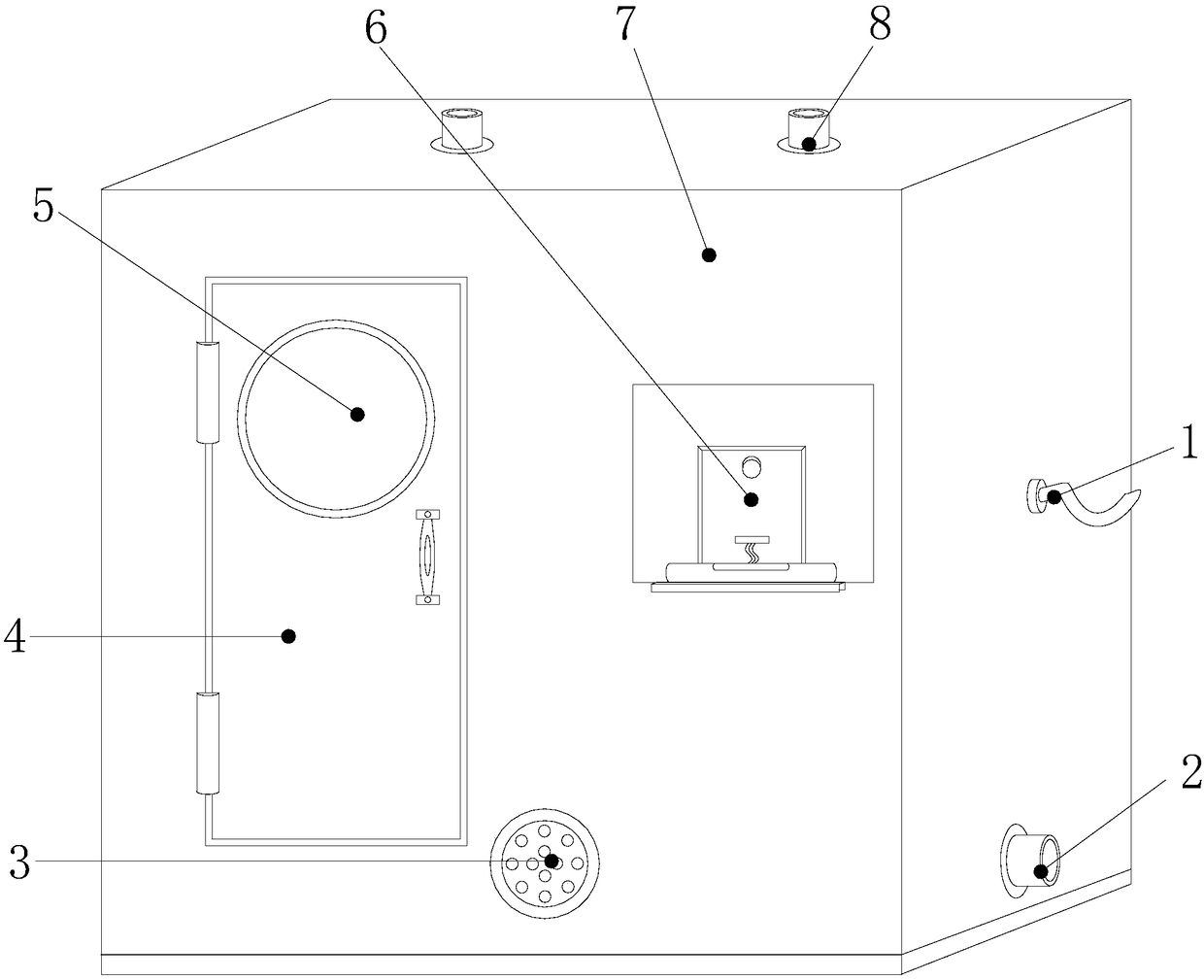

Oil-removing and slag-skimming device for sewage treatment plant

InactiveCN108483738AReduce purification costsFatty/oily/floating substances removal devicesTreatment involving filtrationFlocculationSlag

The invention discloses an oil-removing and slag-skimming device for a sewage treatment plant. The oil-removing and slag-skimming device structurally comprises an external power line, a water outlet,a multiple oil-removing and slag-skimming device, a maintenance door, a transparent observation window, a control panel, a protective shell and a water inlet, wherein the lower end of the water inletis vertically embedded into the upper end of the protective shell; the lower end of the control panel is welded with the front end of the protective shell by a pin rod; the left end of the external power line is embedded into the right end of the protective shell; the left end of the water outlet is embedded into the right end of the protective shell; the back part of the transparent observation window is embedded into the front end of the maintenance door. The oil-removing and slag-skimming device for the sewage treatment plant disclosed by the invention has the beneficial effects that the combination of an air flotation method and a flocculation method is adopted, oil-water separation can be quickly carried out by the air flotation method, the separated oil drops are adsorbed into floccules by the flocculation method and then are filtered, and raw water reaches the standard level for purification use in single purification, so that the purification cost is reduced.

Owner:莆田市余佳音贸易有限公司

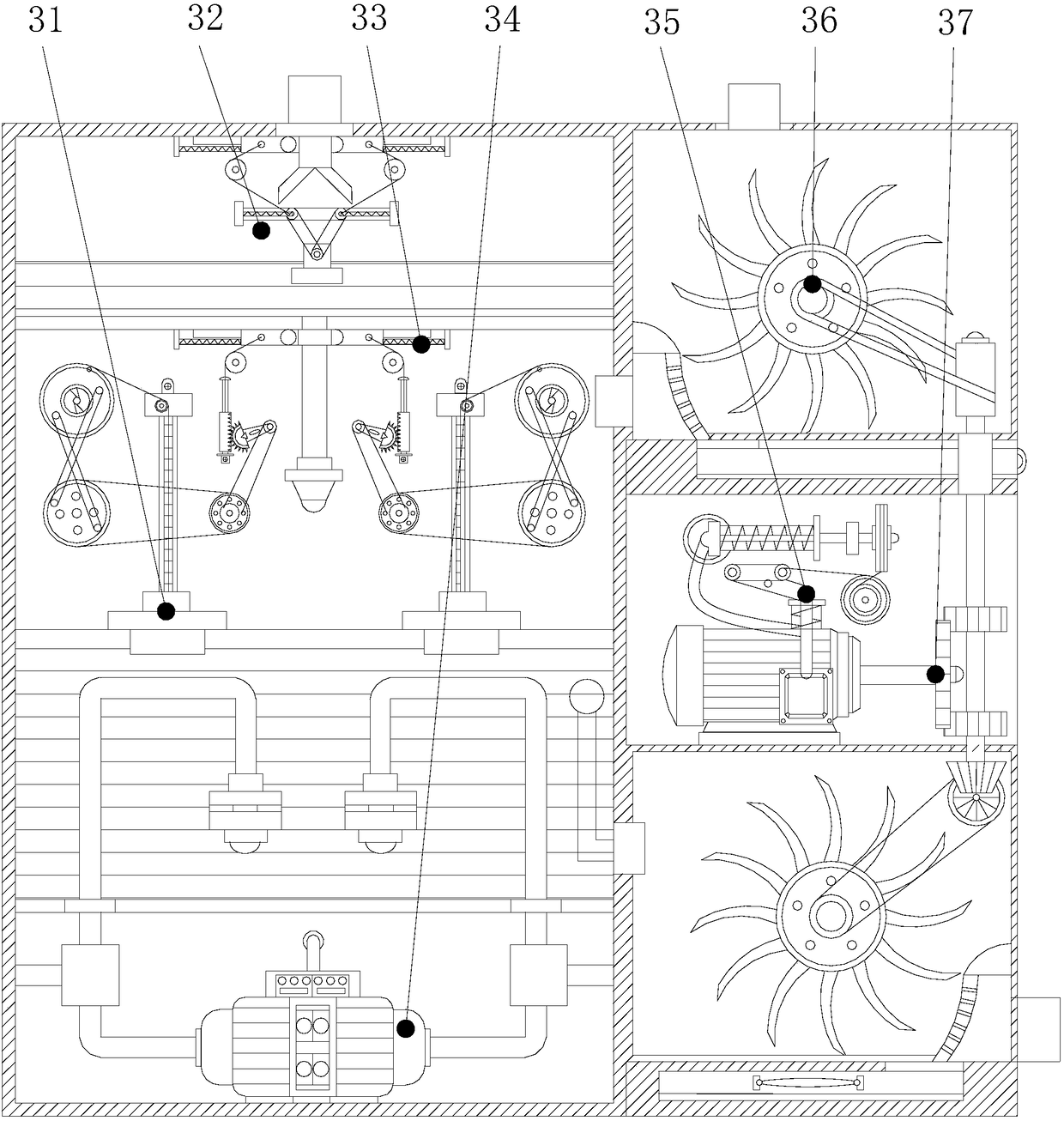

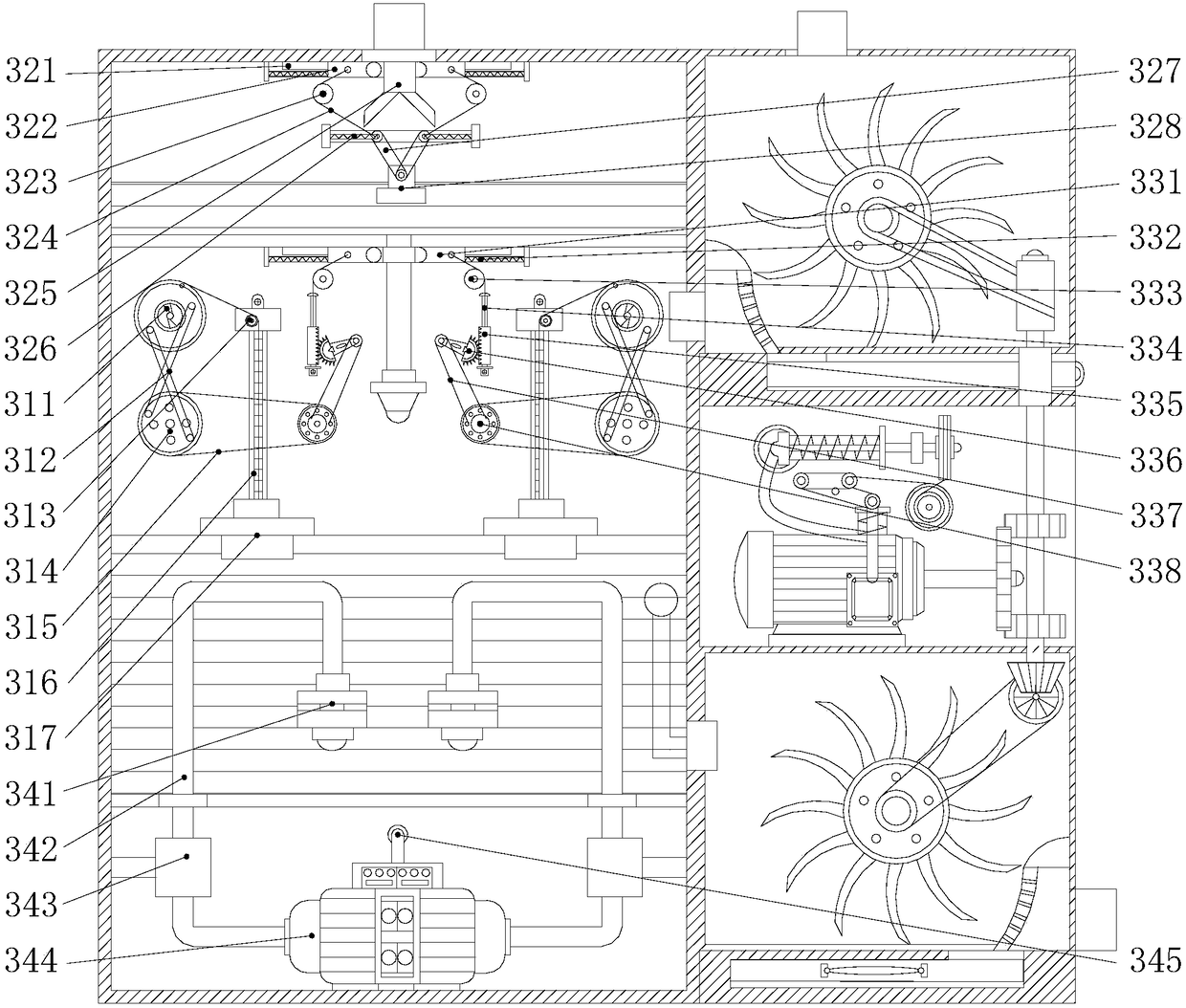

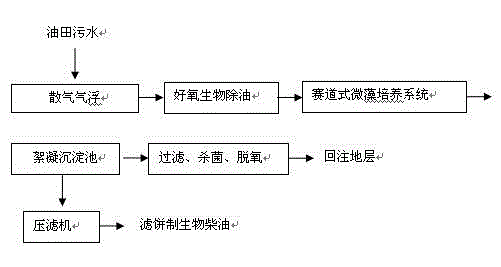

Method for fixing CO2 and treating oil field sewage by using microalgae

InactiveCN104556545ARealize coupling utilizationLow costWaste water treatment from quariesTreatment using aerobic processesActivated sludgeOil and grease

The invention provides a method for fixing CO2 and treating oil field sewage by using microalgae. The method comprises the following steps: a, firstly, performing oil removing pretreatment on oil field sewage in an oil field sewage union station by using an exhaust gas flotation method, feeding the oil field sewage of which most crude oil is removed through air flotation into an activated sludge method or biological membrane method oil removing treatment system for further removing crude oil, and adding N and P nutritive salts according to a weight part ratio of TOC:N:P being 100:(5-10):1 in the activated sludge method or biological membrane method oil removing process; b, introducing flue gas of which the content of CO2 is 3-15% into the oil field sewage after aerobic biological method treatment in the step a; then, feeding into a race track type microalgae culture system, adding microalgae seeds into the race track type microalgae culture system, growing for 5-15 days until the density of microalgae is greater than 10<7> / ml and the grease content is greater than 20%; c, feeding the alga-containing oil field sewage treated by the race track type microalgae culture system into a flocculation settling pond, collecting microalgae by using a flocculation method, filter-pressing the algal sapropel by using a filter-press to make alga cakes, extracting biodiesel oil from the alga cakes; filtering, sterilizing and deoxidizing settling effluent, and refilling the settling effluent back to a stratum to remove oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

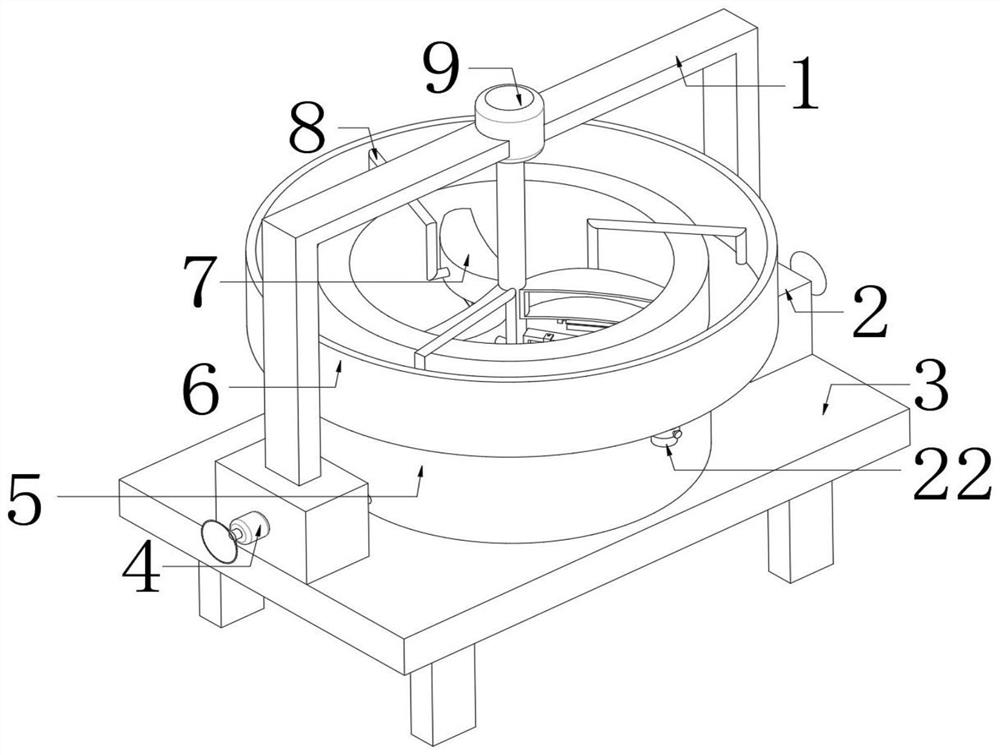

Oil refining wastewater oil stain separation device utilizing air flotation method

InactiveCN112374623AIncrease collection speedPracticalWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesInduced gas flotationProcess engineering

The invention belongs to the technical field of oil stain separation, particularly relates to an oil refining wastewater oil stain separation device utilizing an air flotation method, and provides thefollowing scheme aiming at the problems that an existing oil refining wastewater oil stain separation device can basically separate oil stains in wastewater, but solid impurities such as sand grainsin the wastewater are difficult to collect and separate. The device comprises a workbench, a separation cylinder is fixed to the outer wall of the top of the workbench through bolts, an air bag is fixed to the inner wall of the bottom of the separation cylinder through bolts, air outlet holes distributed at equal intervals are formed in the outer wall of the top of the air bag, and air outlet pipes are inserted into the inner walls of the air outlet holes. The slag scraping hopper can drive the rotating roller and the stirring blades to rotate while rotating, the stirring blades can further stir sand grains in waste water while rotating, accordingly, the sand grain collecting speed of the filtering net bag can be increased, and people can take down the filtering net bag through the fixingbuckles to treat solid impurities in the net bag after separation is completed.

Owner:WUXI GONGYUAN MACHINERY

Method and apparatus for separation of fluids within a single vessel

ActiveUS9095786B1Minimizes cost and operating expenseSave spaceFatty/oily/floating substances removal devicesNature of treatment waterSingle vesselOil and grease

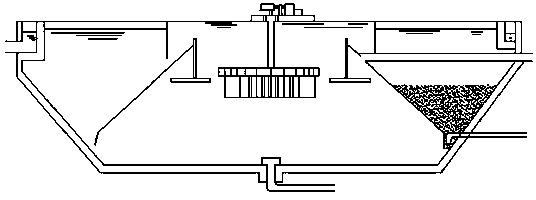

A process wherein a combination of two separation principles are combined into one space saving machine with portability to separate two distinct and different fluids one lighter in specific gravity than the other, including the steps of primary separation of fluids allowing for free and suspended solids along with free oil and grease to be removed in the primary separation chamber; utilizing parallel corrugated plates in the separation defining the distance of rise for a given oil droplet based on Stokes Law to remove the remaining large droplets of free oil and solids; and providing an induced gas flotation process which provides a finely dispersed bubble in the liquid to accelerate the lift necessary for separation of fine oil droplets, emulsified oil droplet, and suspended solids to meet a government discharge regulation. This combined technique can be configured in a single vessel without pumps or other methods of liquid movement.

Owner:ENVIRO TECH SYST L L C

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com