Air-floating pretreatment method and device for high-concentration organic sewage

A pretreatment device, organic sewage technology, applied in the field of sewage treatment equipment, air flotation water treatment, can solve the problems of large bubble size, small specific surface area, fast rising speed, etc., to save cost and operating cost, shorten Response time, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

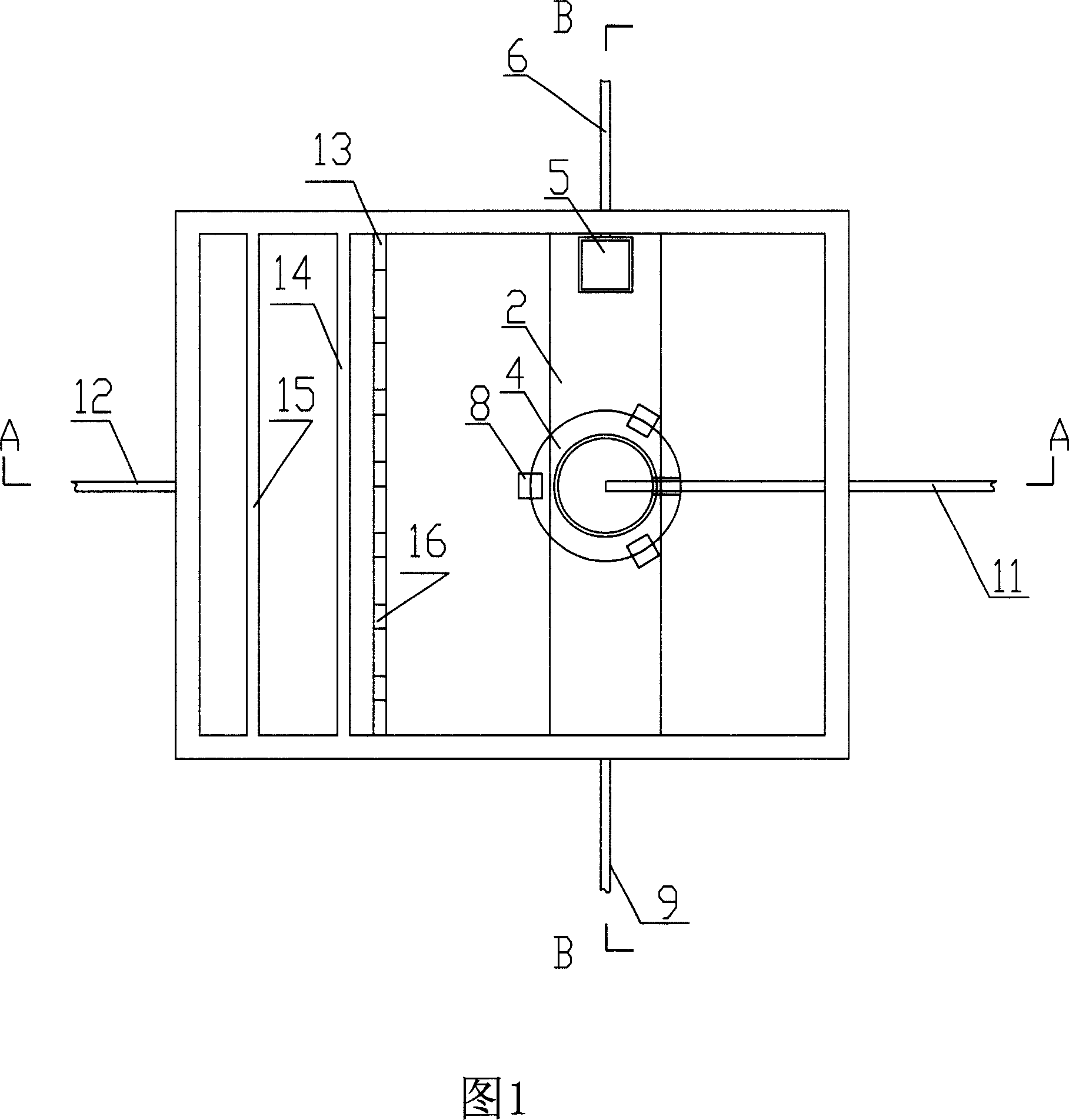

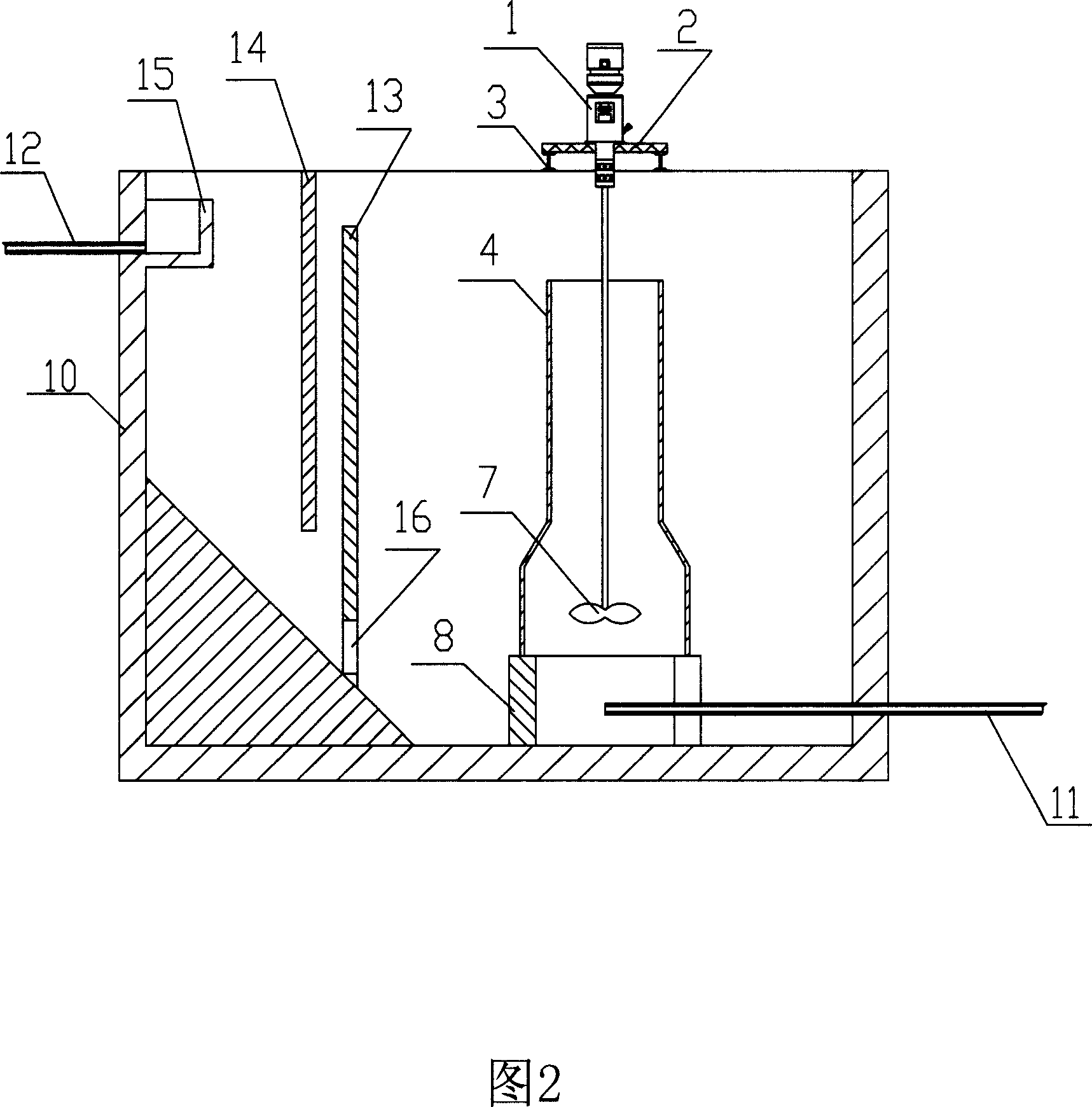

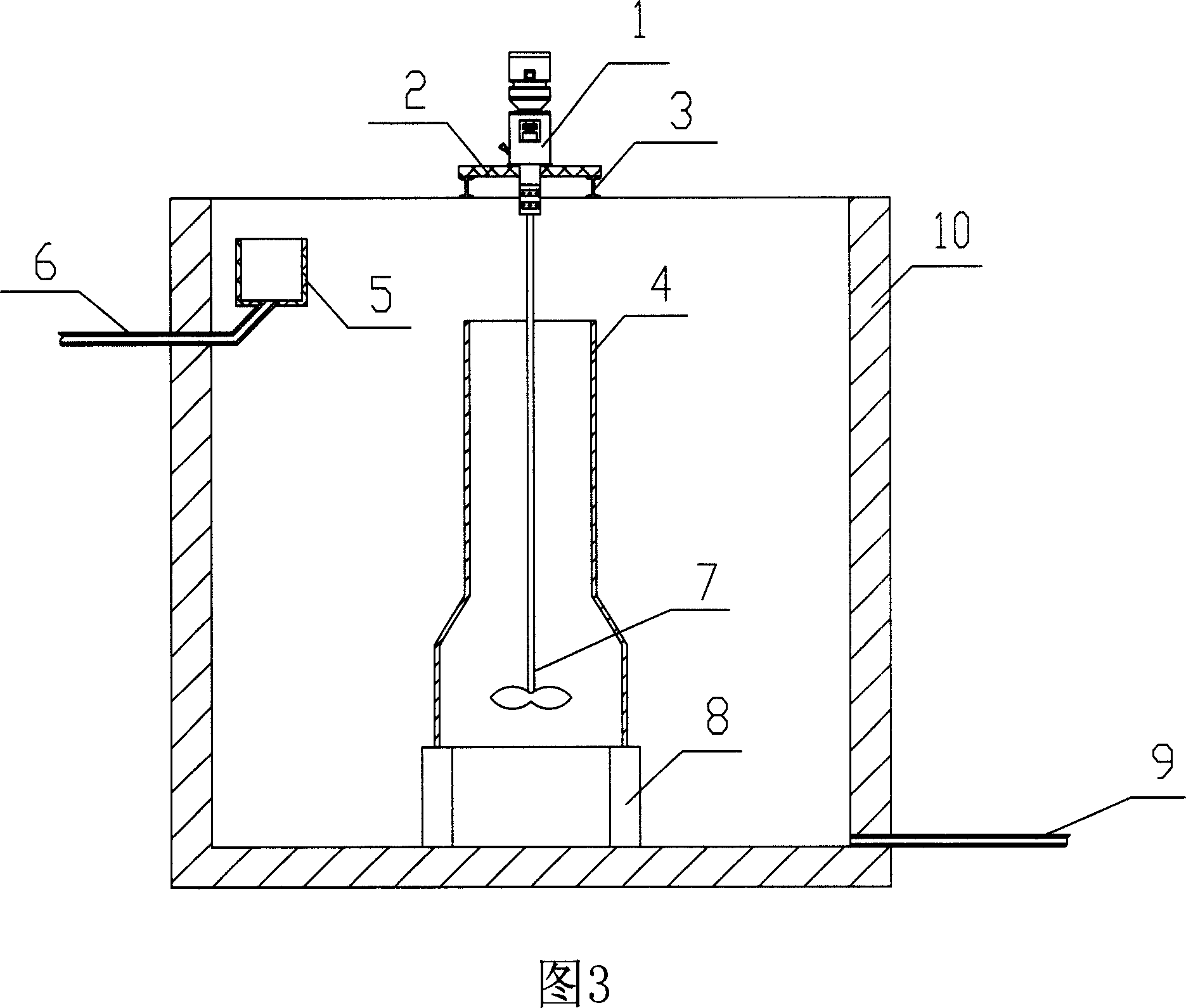

[0024] Embodiment 1: Referring to accompanying drawings 1 to 3, an air flotation pretreatment device for high-concentration organic sewage includes a reaction tank body 10 with an opening at the top of the tank body, and its interior is separated by a partition at the bottom of the tank. The plate 13 is divided into a reaction zone and a separation zone. The top of the pool wall on the side of the reaction zone is provided with a slag discharge pipe 6, and the bottom is respectively provided with a water inlet pipe 11 and a vent pipe 9. The reaction zone is provided with a guide tube 4. The diversion cylinder is erected on the sludge bed at the bottom of the pool through 3 buttresses 8, a steel pedal 2 is erected on the top of the pool body above the diversion cylinder, and the agitator 1 is fixed to the steel pedal through the I-shaped steel bracket 3. The stirring paddle 7 extends into the guide tube 4, the top of the pool wall on the side of the separation zone is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com