Turbine lifting device for fluidized exploitation of natural-gas hydrate

A lifting device and natural gas technology, applied in the direction of pump devices, mining fluids, earth drilling, etc., can solve the problem of lack of mature equipment that can realize hydrate crushing and pumping recovery at the same time, low energy utilization efficiency, and low return efficiency of ore slurry, etc. problems, to achieve the effects of improving energy utilization efficiency, increasing hydrate pumping height, and saving drilling time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

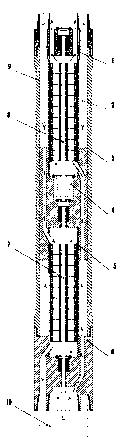

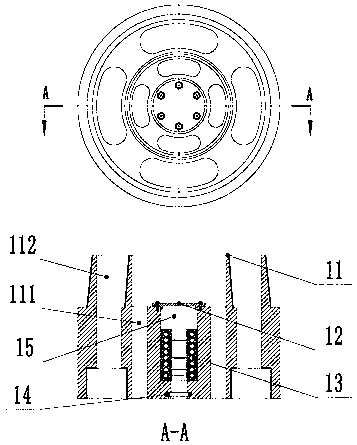

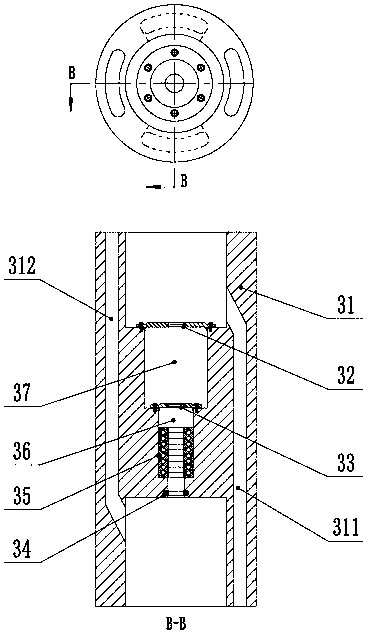

[0025] A turbine lifting device for natural gas hydrate fluidized exploitation of the present invention, such as figure 1 As shown, the device mainly includes an upper joint 1, a turbo pump 2, a bridge channel 3, a cardan shaft assembly 4, a turbine motor 5, a lower joint 6 and other components. The whole device is connected and installed with the double-layer pipe through the upper joint 1, and the high-pressure fluid from the offshore platform is introduced into the turbine motor 5, and the turbine motor 5 converts the pressure energy of the fluid into kinetic energy, and drives the central shaft 8 of the turbine pump through the cardan shaft assembly 4 The rotation forms a negative pressure, and the hydrate slurry containing solid-liquid multiphase is sucked in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com