Patents

Literature

7802results about How to "Shorten the development cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

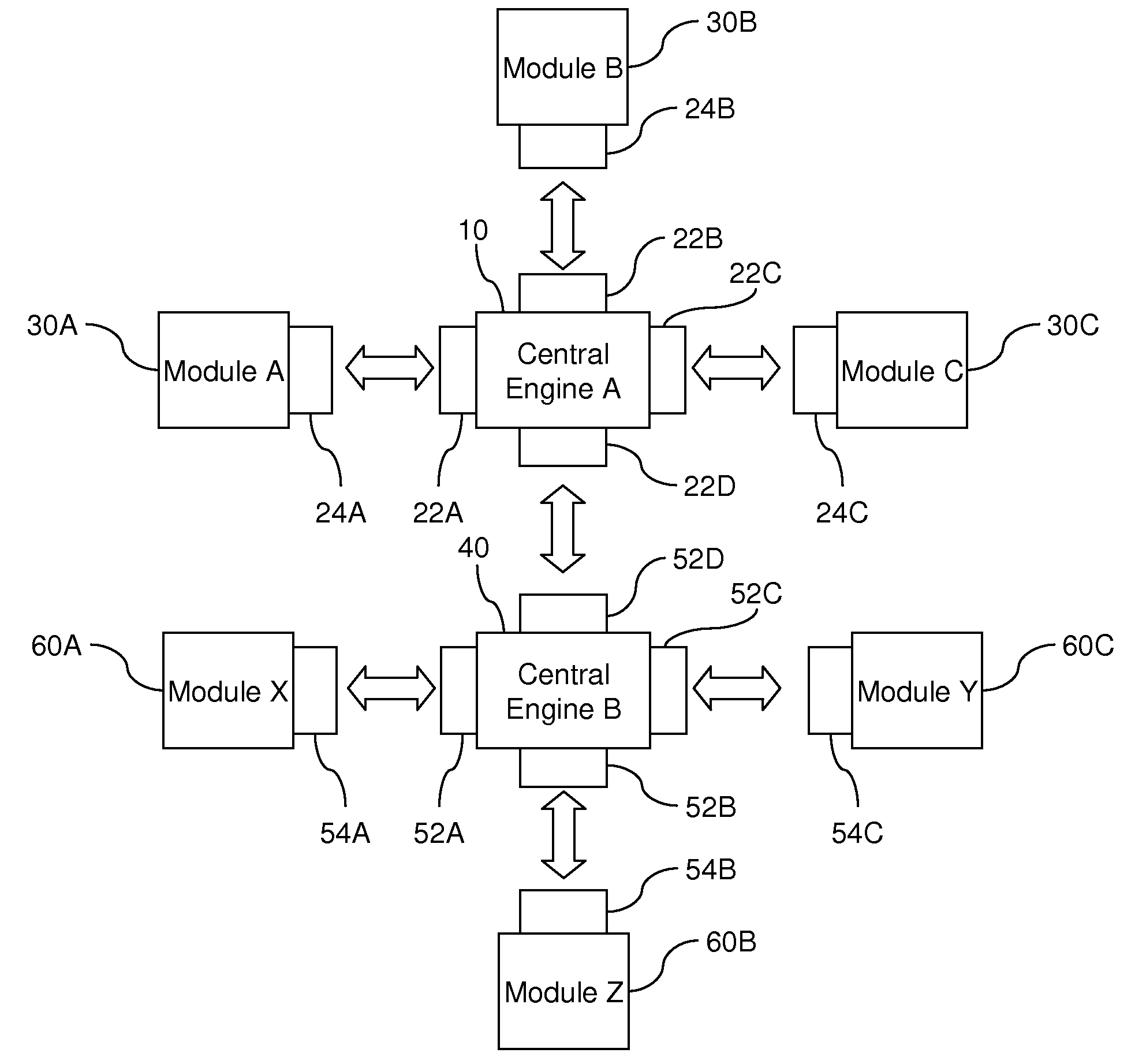

Architecture for health monitoring systems

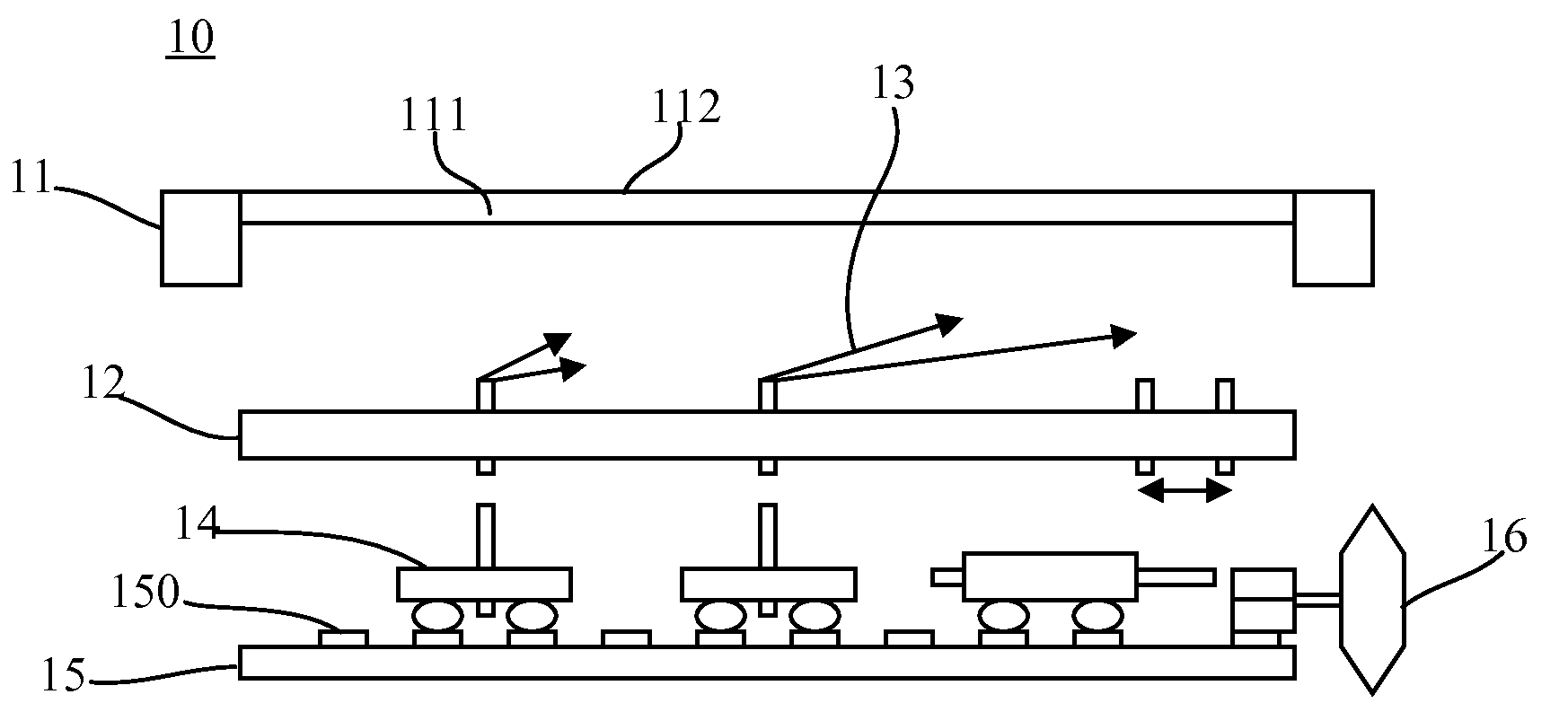

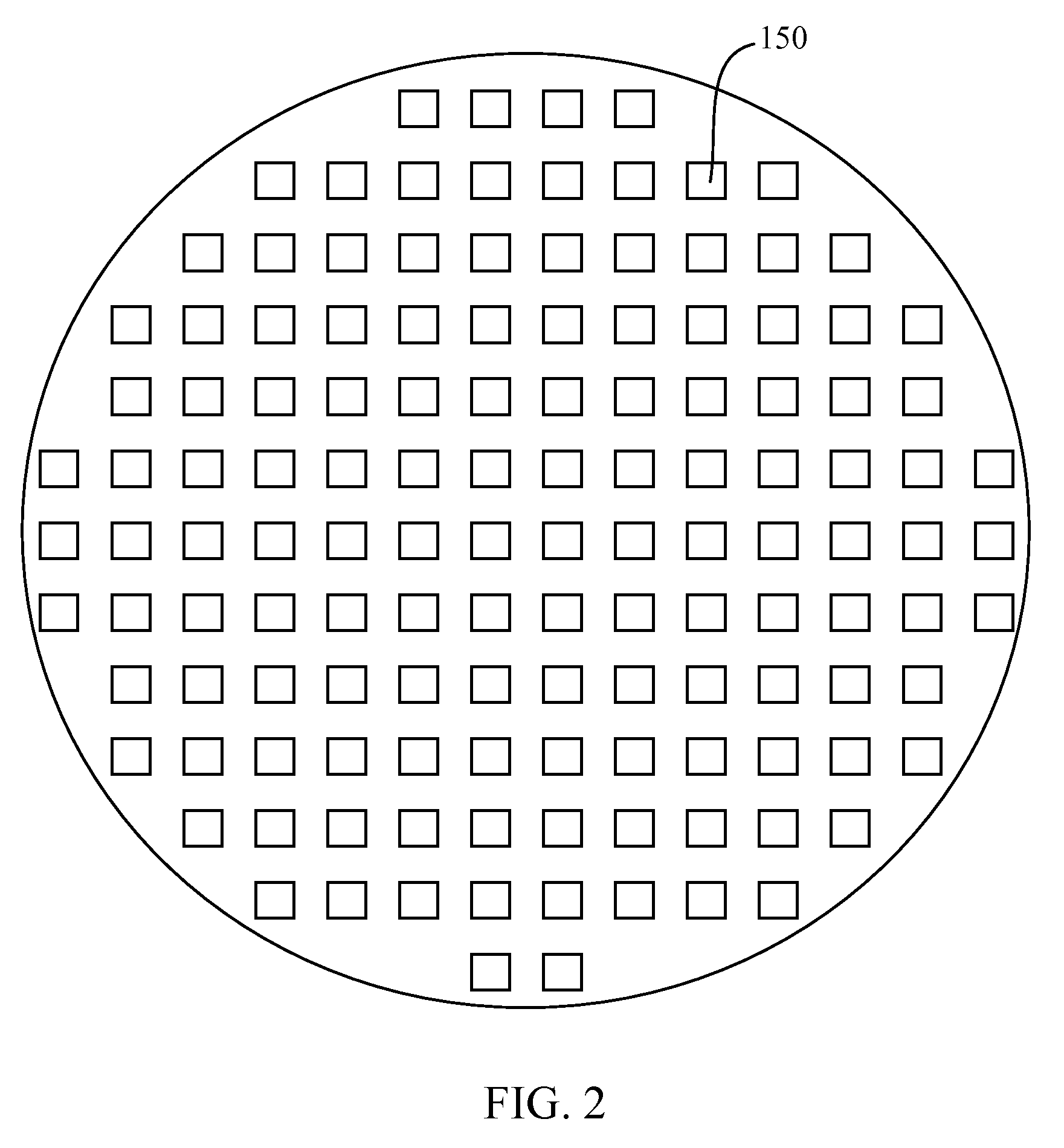

InactiveUS20080300919A1Shorten the development cycleIntroduce the product to consumers more quicklyDrug and medicationsVersion controlCommunication interfaceMonitoring system

An architecture allows individual system components to be developed and tested individually, i.e., as distinct modules, and to be subsequently combined through standardized electrical and communication interfaces. Any combination of these modules can be implemented to form different products that provide any number of functions, such as an integrated system for monitoring a health condition and / or delivering a medication. The architecture also provides an approach for dynamically updating the product and offering its users the latest generation of technology even after the users have already purchased the product. In particular, the embodiments employ the communication interfaces to also provide connection to a remote network that can update or upgrade the product's software when the product is out in the field.

Owner:BAYER HEALTHCARE LLC

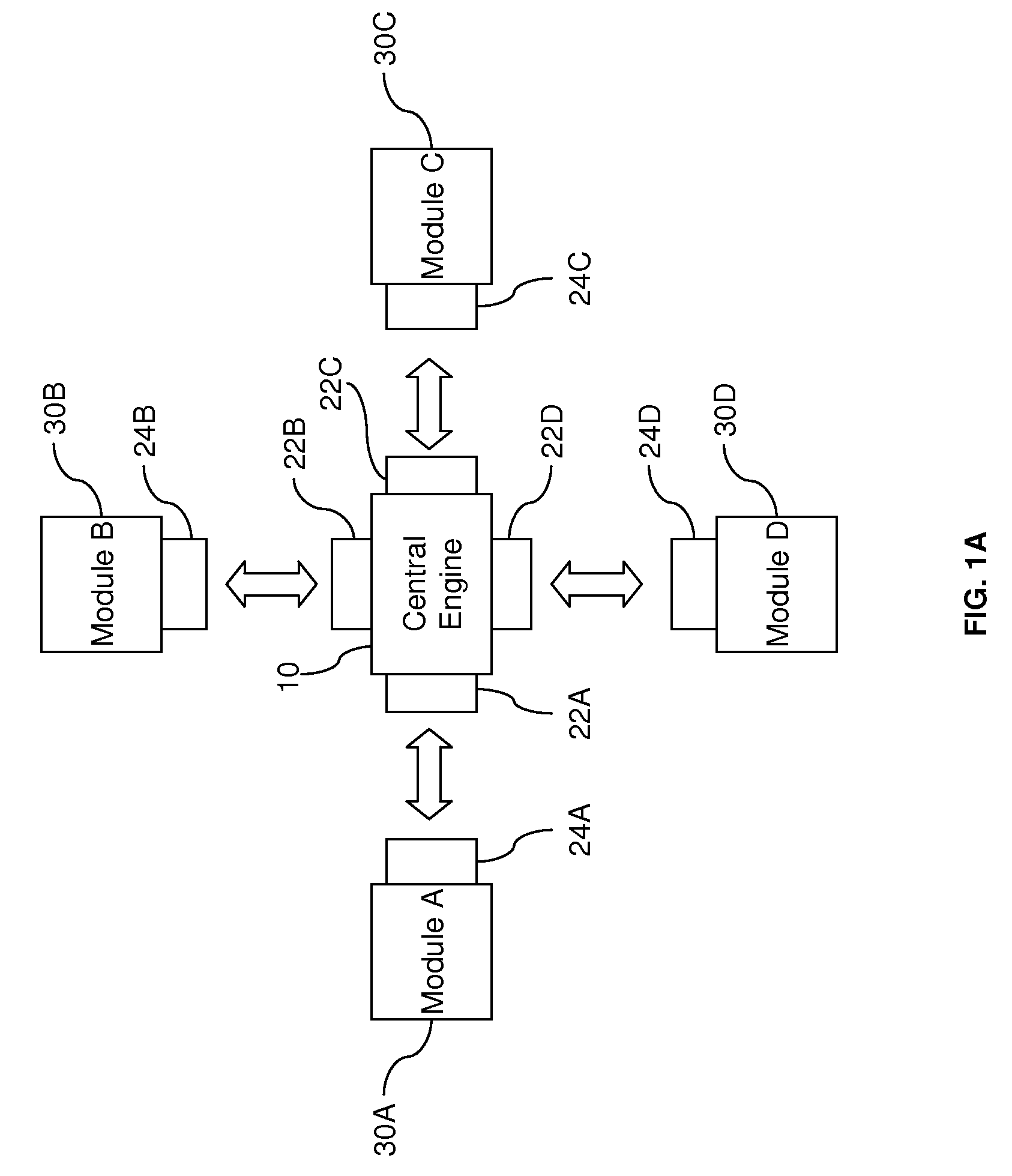

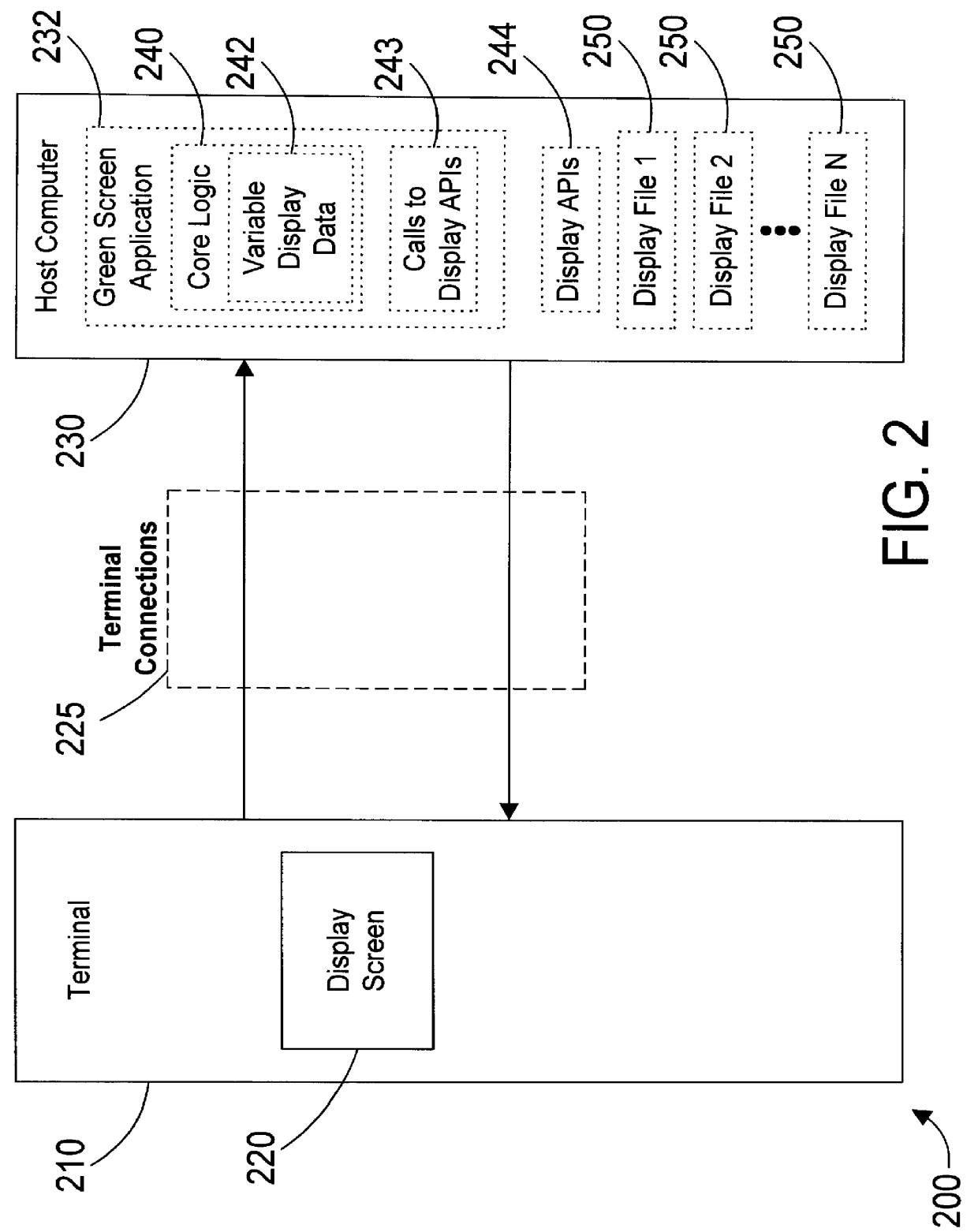

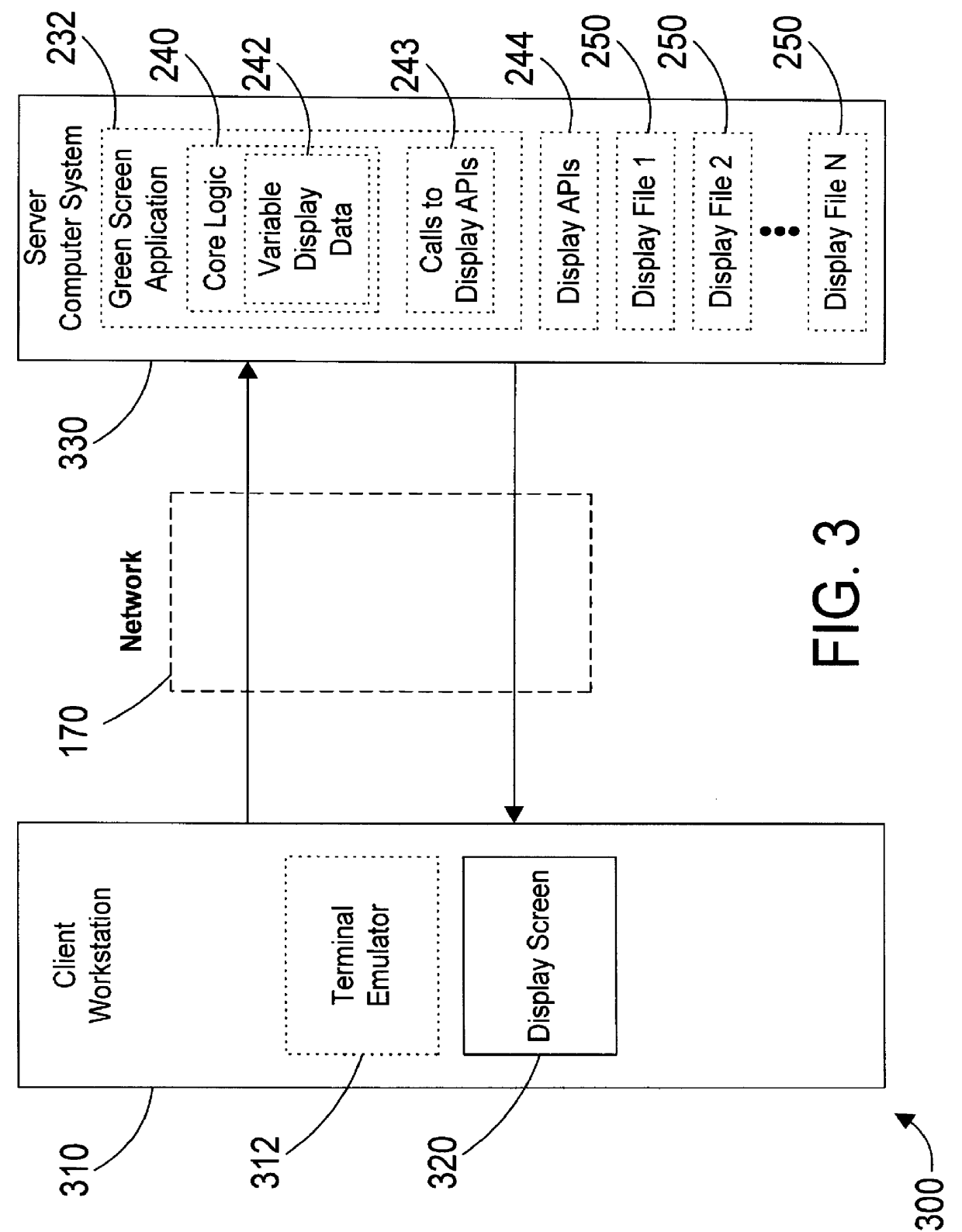

Object oriented apparatus and method for providing a graphical user interface for host-based software applications

InactiveUS6064382ANot affectQuickly and easily combined and re-usedMultiple digital computer combinationsExecution for user interfacesGraphicsGraphical user interface

An object oriented computer apparatus and method provides a graphical user interface (GUI) for existing host-based (i.e., green screen) applications by defining some object oriented classes that reside on the client workstation, and by substituting function calls for display data in the green screen application with function calls that interface with the object oriented GUI defined by the classes. In this manner the present invention takes advantage of the processing power of client workstations in a network computing environment by having the client run the GUI. The underlying green screen application is modified to replace all display function calls with new function calls to the GUI, but this change is relatively minor and does not affect the underlying core logic of the application. In addition, the new function calls access the GUI screens directly without having to determine which screen is being displayed.

Owner:IBM CORP

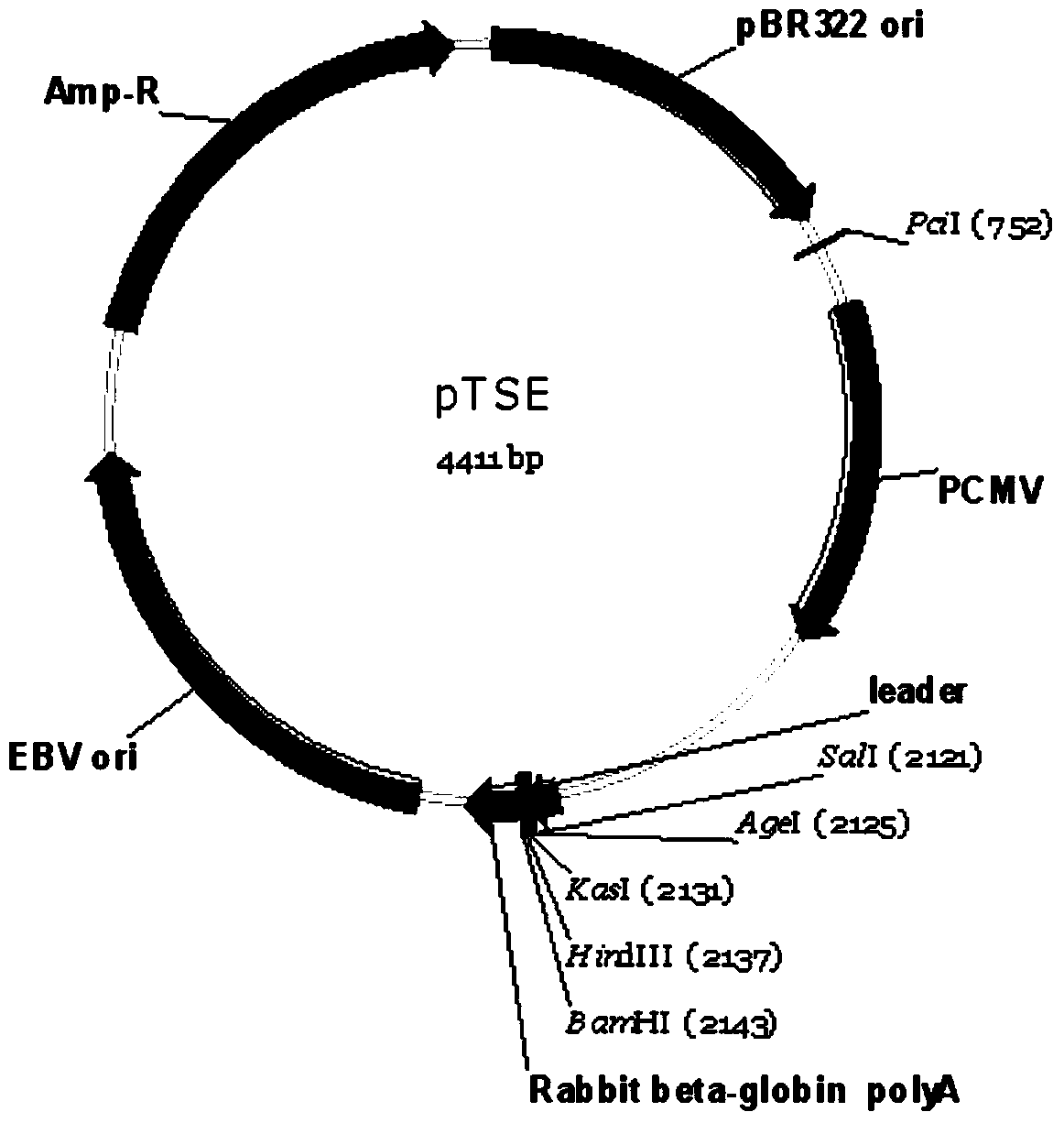

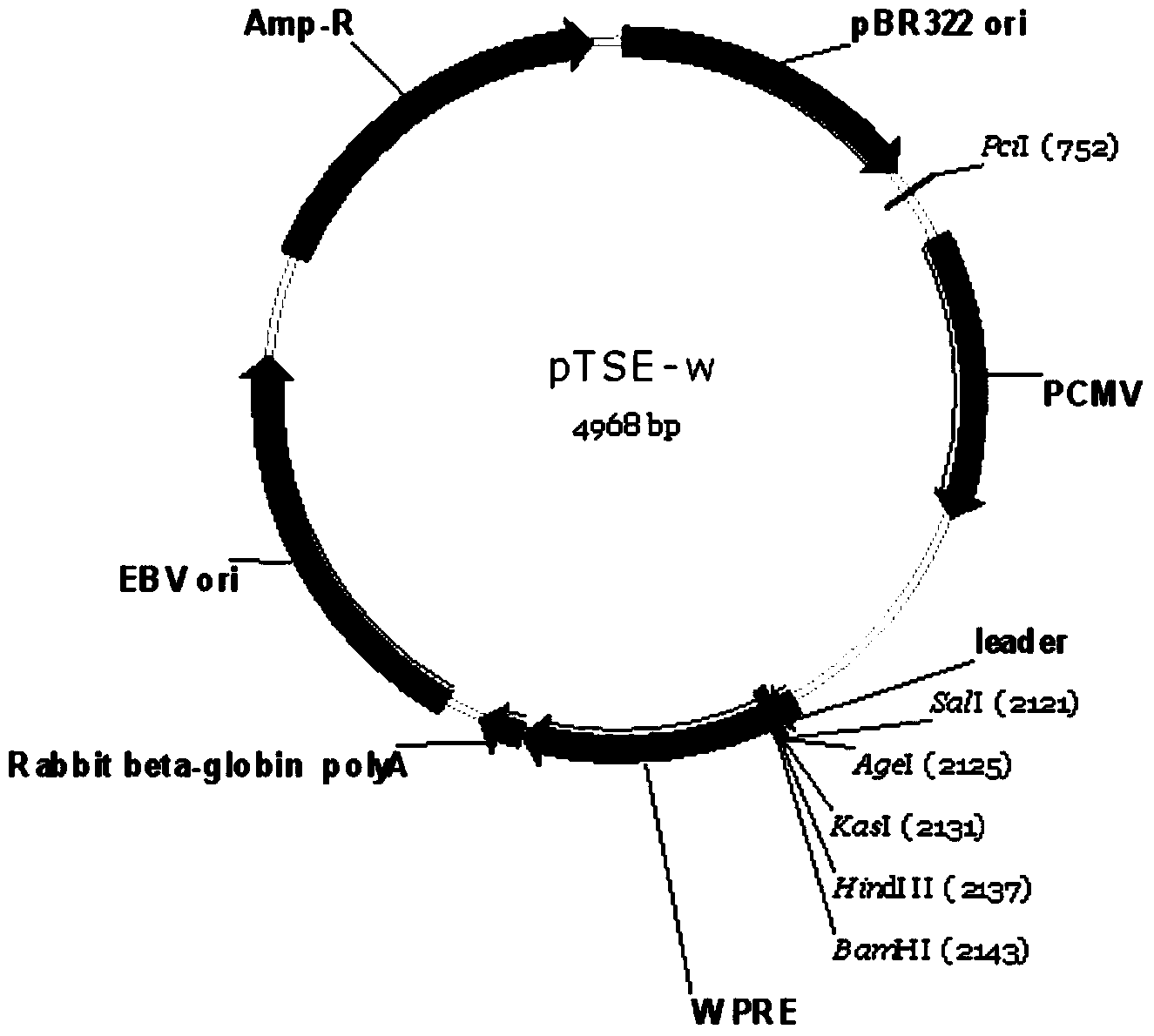

Construction and application of mammal cell high-efficiency expression vector

ActiveCN103525868AReduced transcript levelsShorten the development cycleVector-based foreign material introductionForeign genetic material cellsCloning SiteDeletion mutation

The invention relates to a mammal cell high-efficiency expression vector pSNEO. The vector is constructed on the basis of neomycin resistance screening gene NEO by combined strategy of weakening screening gene expression and reinforcing target gene expression. The screening gene weakening comprises the following two sides: introducing deletion mutant into the promoter to implement transcription weakening of the screening gene, and introducing a hairpin structure sequence before the translation initial site of the screening gene to implement the translation weakening of the screening gene. The expression reinforcement of the target gene is implemented by adding a transcription control element WPRE sequence between polyclone site and polyA tail of the target gene expression frame. The pSNEO vector can conveniently and quickly complete the construction of the stable high-expression cell strain of the target gene, and provides a new tool for preparing the high-polymer recombinant protein.

Owner:BIOTECH PHARMA CO LTD

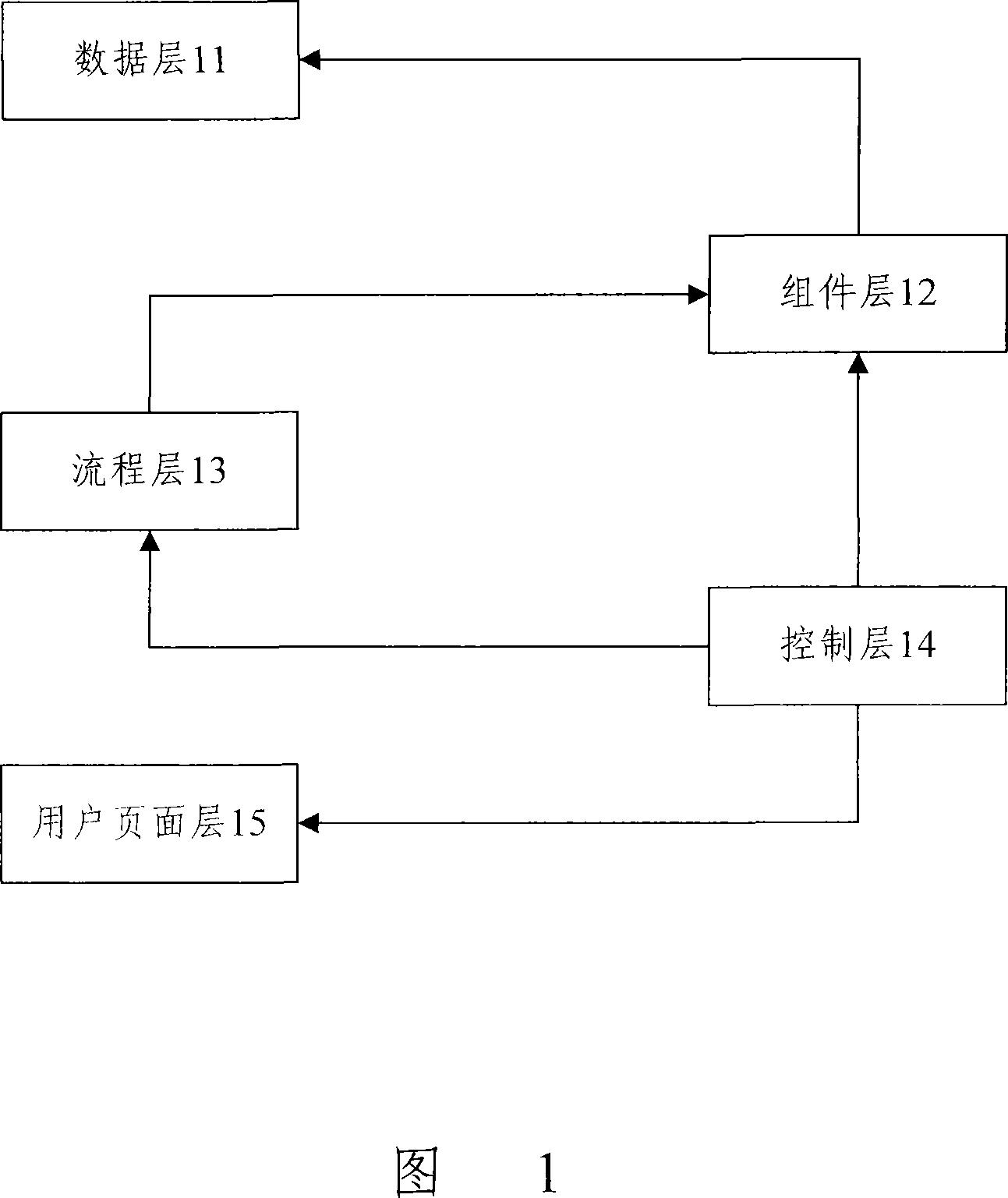

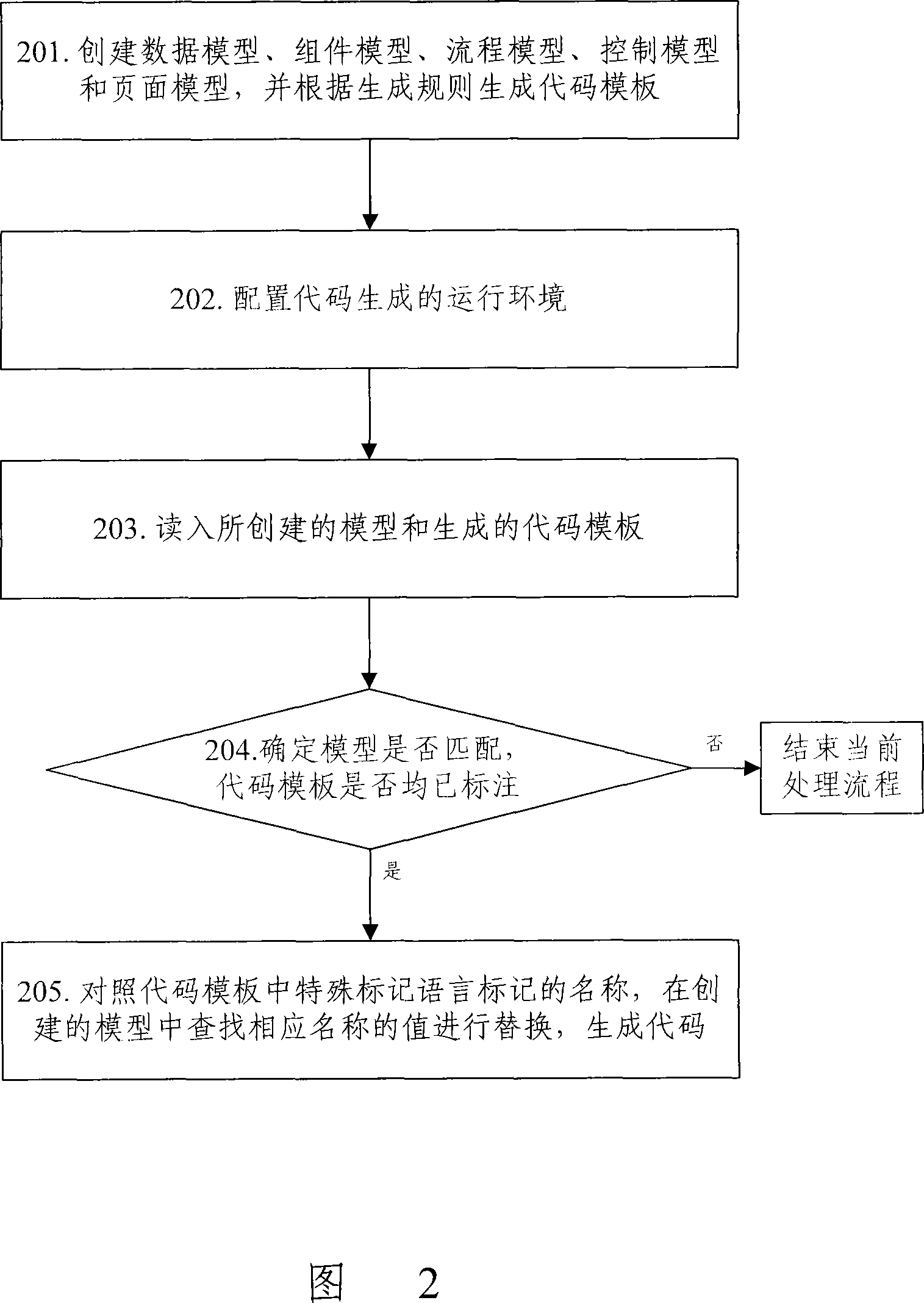

Code automatically generating device based on model component, system and method

InactiveCN101114226AClear structureEasy to implementSpecific program execution arrangementsHandling CodeComplete data

The invention discloses a code automatic generation method used for constructing a code automatic generation device, comprising a data layer, a component layer, a process layer, a control layer and a user interface layer, wherein, the five-layer structure is divided in accordance with functions, and every layer is independent and creates a corresponding processing model to complete data processing, component extraction, flow processing, function control and user interface processing. At the same time, a code template is created based on certain rules, and different processing codes are formed for different business objects. Based on the five-layer model and the code template, a code generating engine controls and calls the model of layers and the code template, which cooperate to complete the code automatic generation process. The invention also discloses a code automatic generation device and system; by adopting the invention, the development efficiency, the reusability and the standardization of software can be enhanced and code quality is improved.

Owner:北京中企开源信息技术有限公司

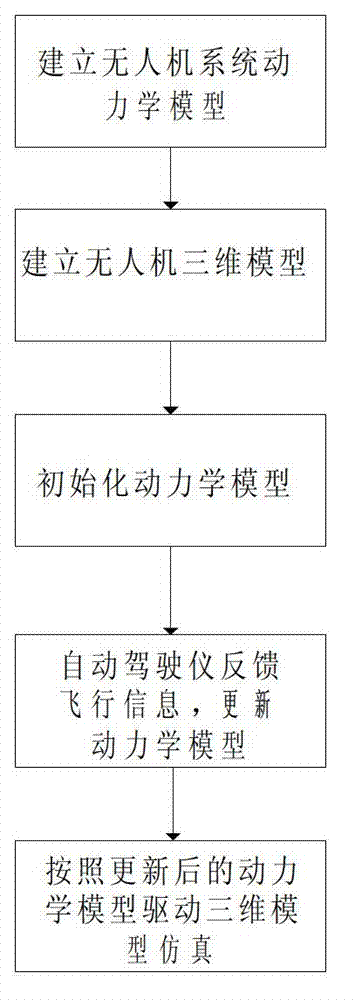

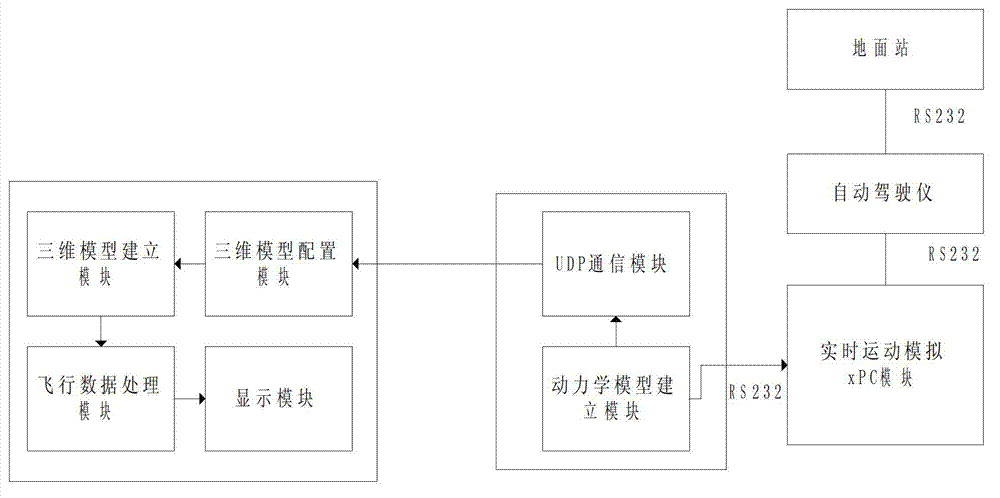

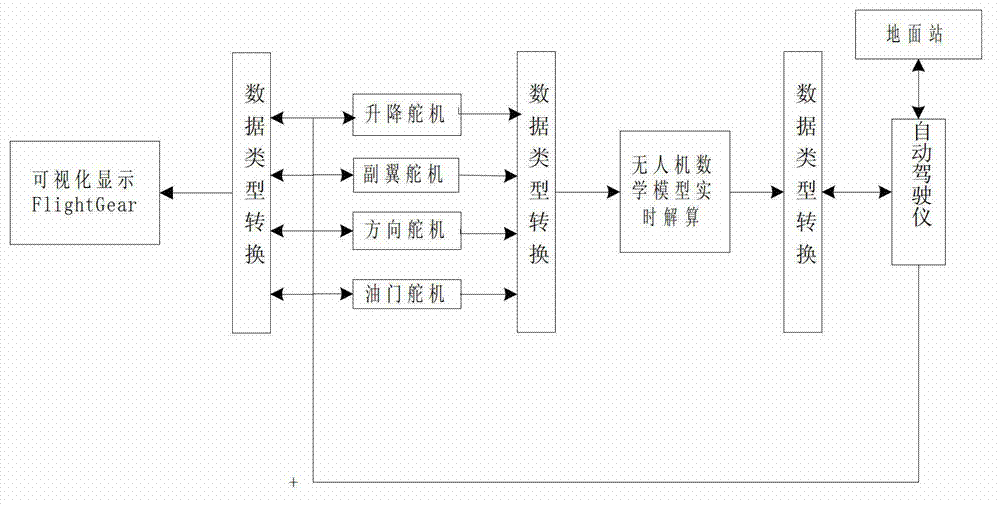

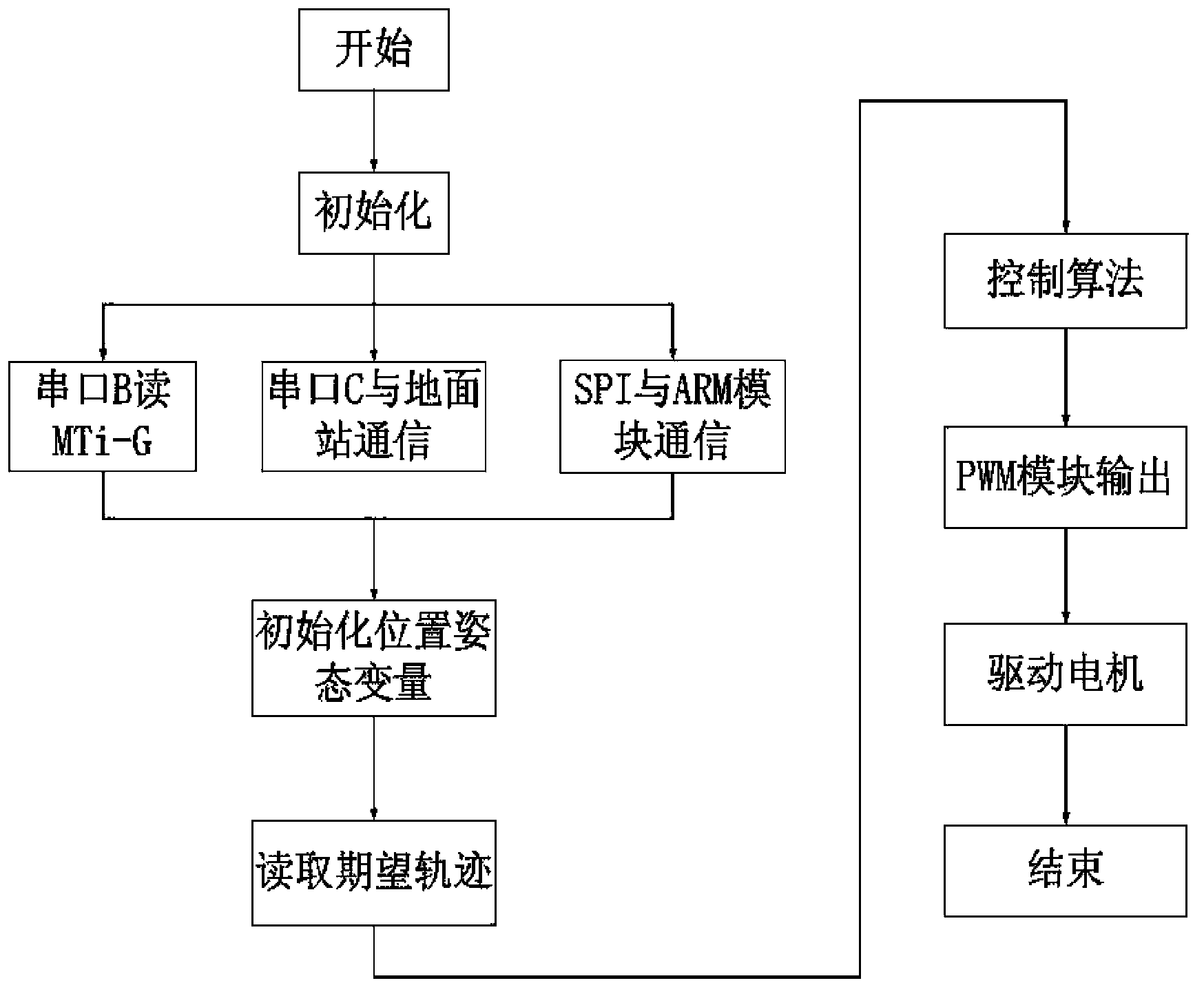

Method and system for semi-physical simulation test of visual unmanned aerial vehicle flight control

InactiveCN102789171AImprove Simulation EfficiencyReduce riskSimulator controlDynamic modelsUncrewed vehicle

The invention relates to a method and a system for a semi-physical simulation test of visual unmanned aerial vehicle flight control and belongs to the technical field of visual system simulation. The method includes building a dynamic model of an unmanned aerial vehicle system, initializing the dynamic model, enabling an unmanned aerial vehicle to fly along the track provided by the ground, feeding flight rudder quantity information to the dynamic model to be updated, driving a three-dimensional model of the unmanned aerial vehicle through the updated dynamic model to conduct simulation and outputting simulation image and data in real time. A system based on the method is further provided. The method and the system provide effective ways and development environment for design, experiments and verification of the flight control law, have the advantages of being simple, flexible, quick, vivid and real-time, improve simulation efficiency of a flight control system, reduce test risk and test cost of the unmanned aerial vehicle and shorten development period.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

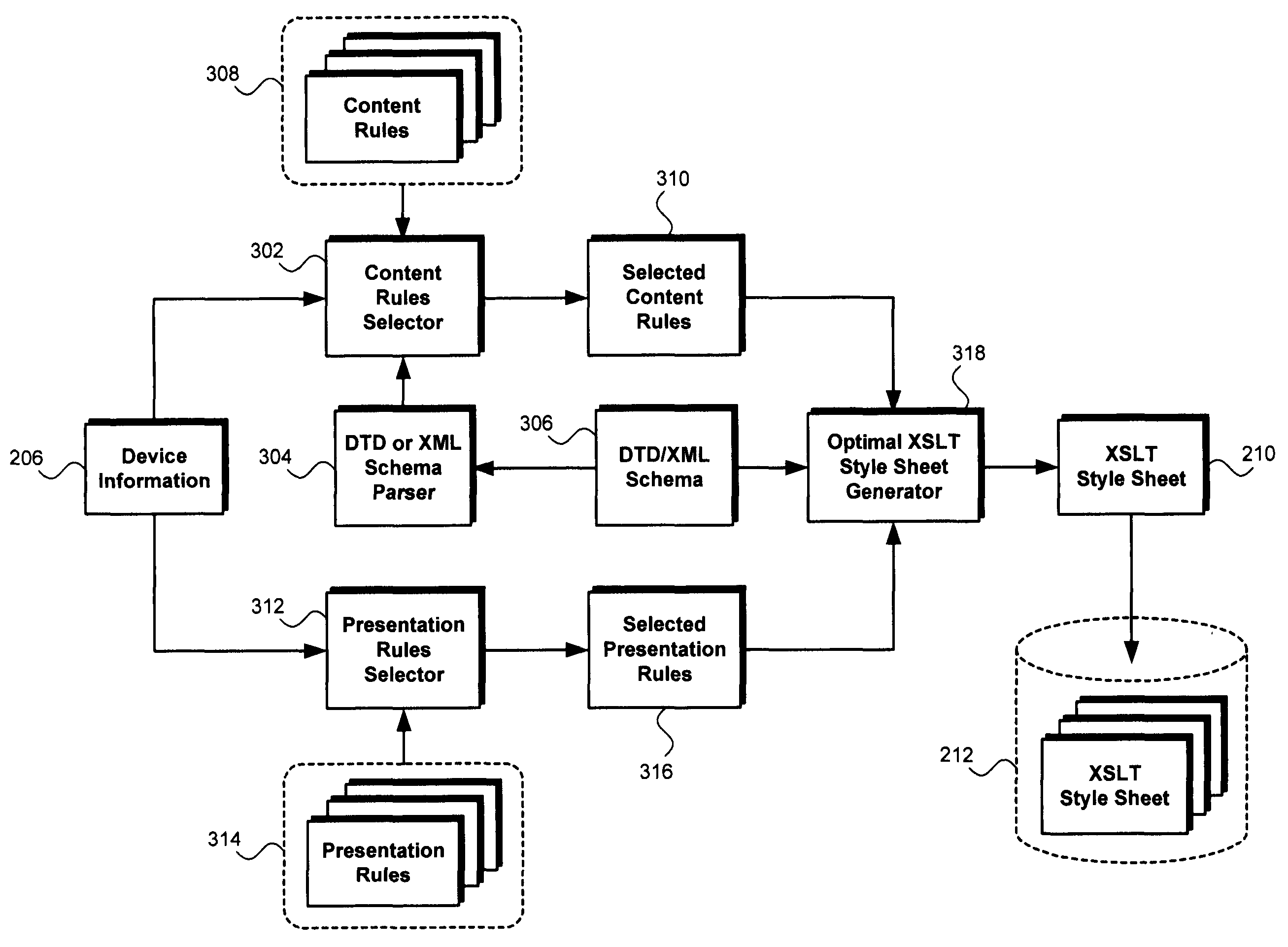

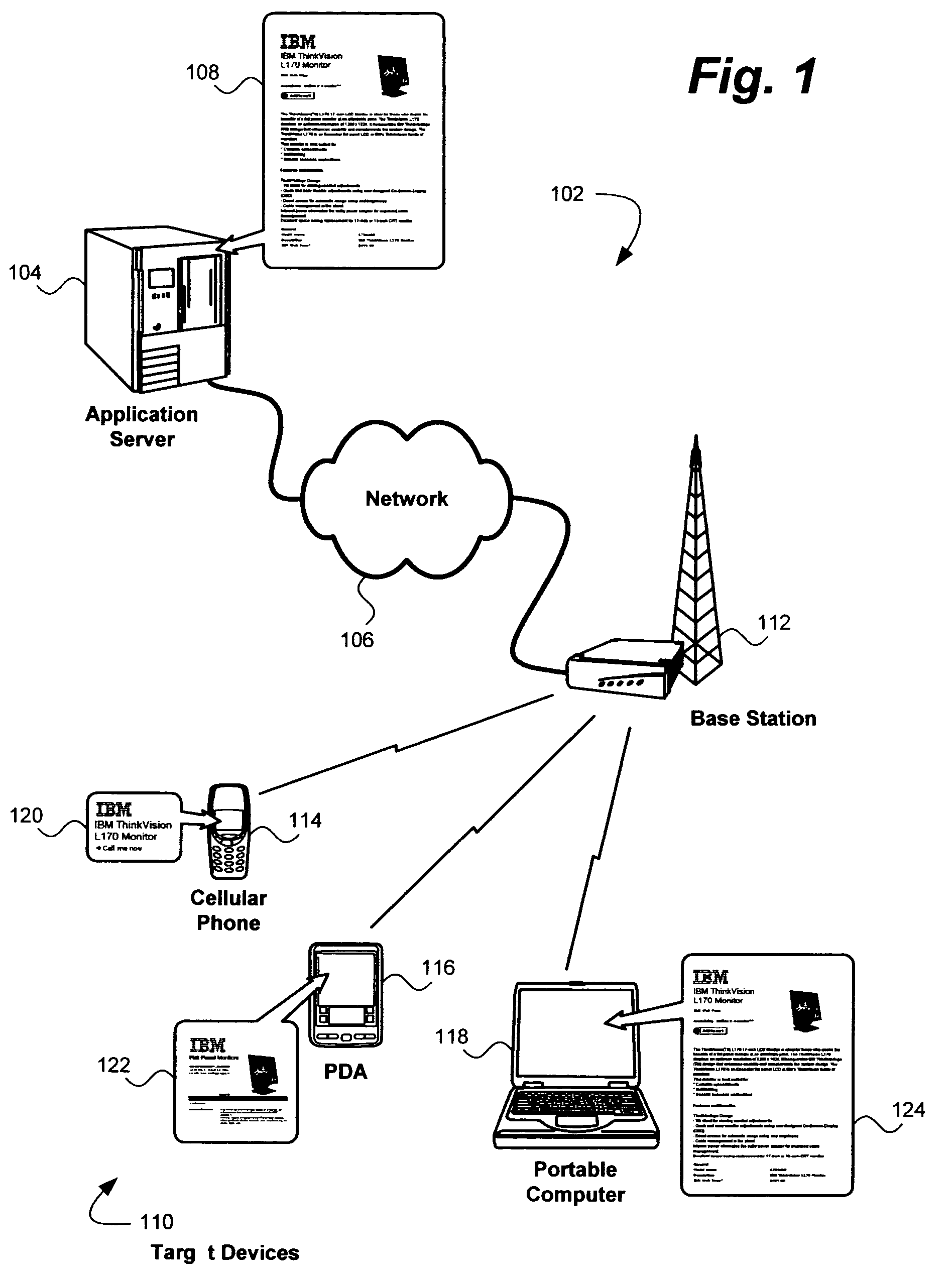

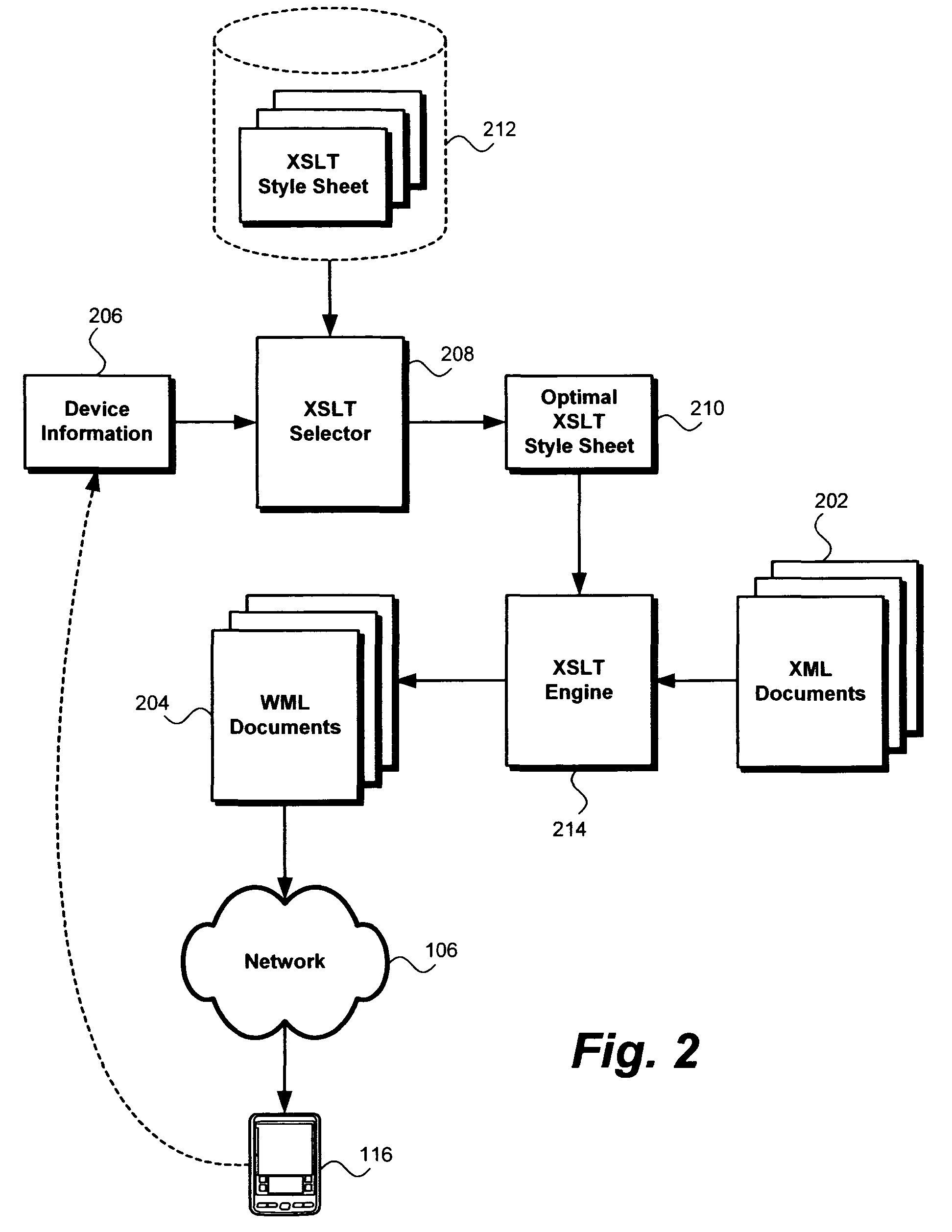

Generation of XSLT style sheets for different portable devices

ActiveUS20050050000A1Reduce developer overheadShorten the development cycleDigital data information retrievalDigital data processing detailsXSLTDocumentation

A method, system, and computer program for transforming a first document into a second document, whereby the second document is configured for use at an electronic device. The invention receives interface information about the electronic device. A content rules selector is configured to select content rules for modifying content in the first document. A presentation rules selector is configured to select presentation rules for presenting the content from the first document. A transformation generator is configured to combine the content rules and presentation rules to form transformation instructions for transforming the first document into the second document.

Owner:IBM CORP

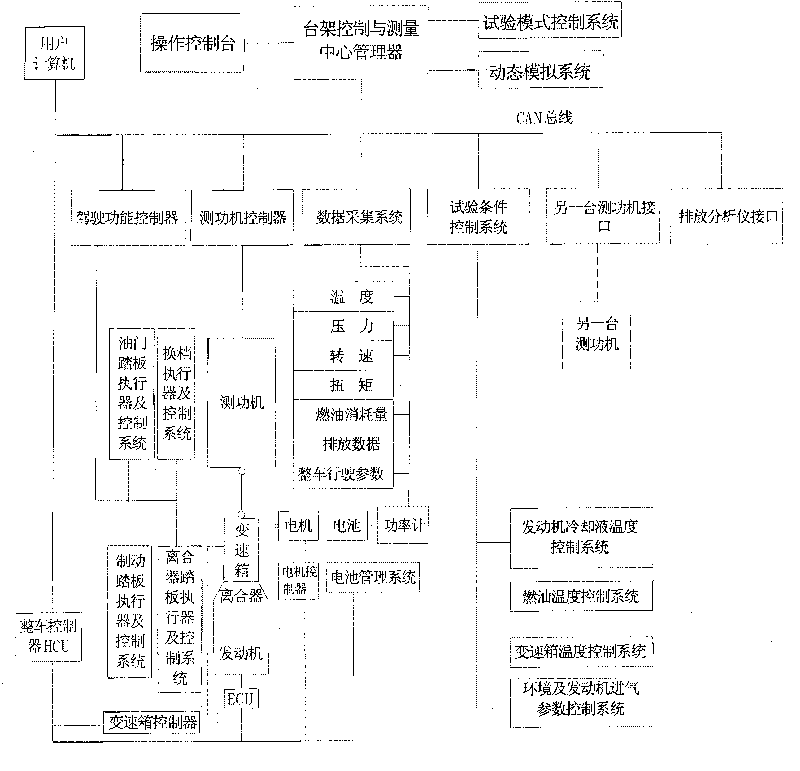

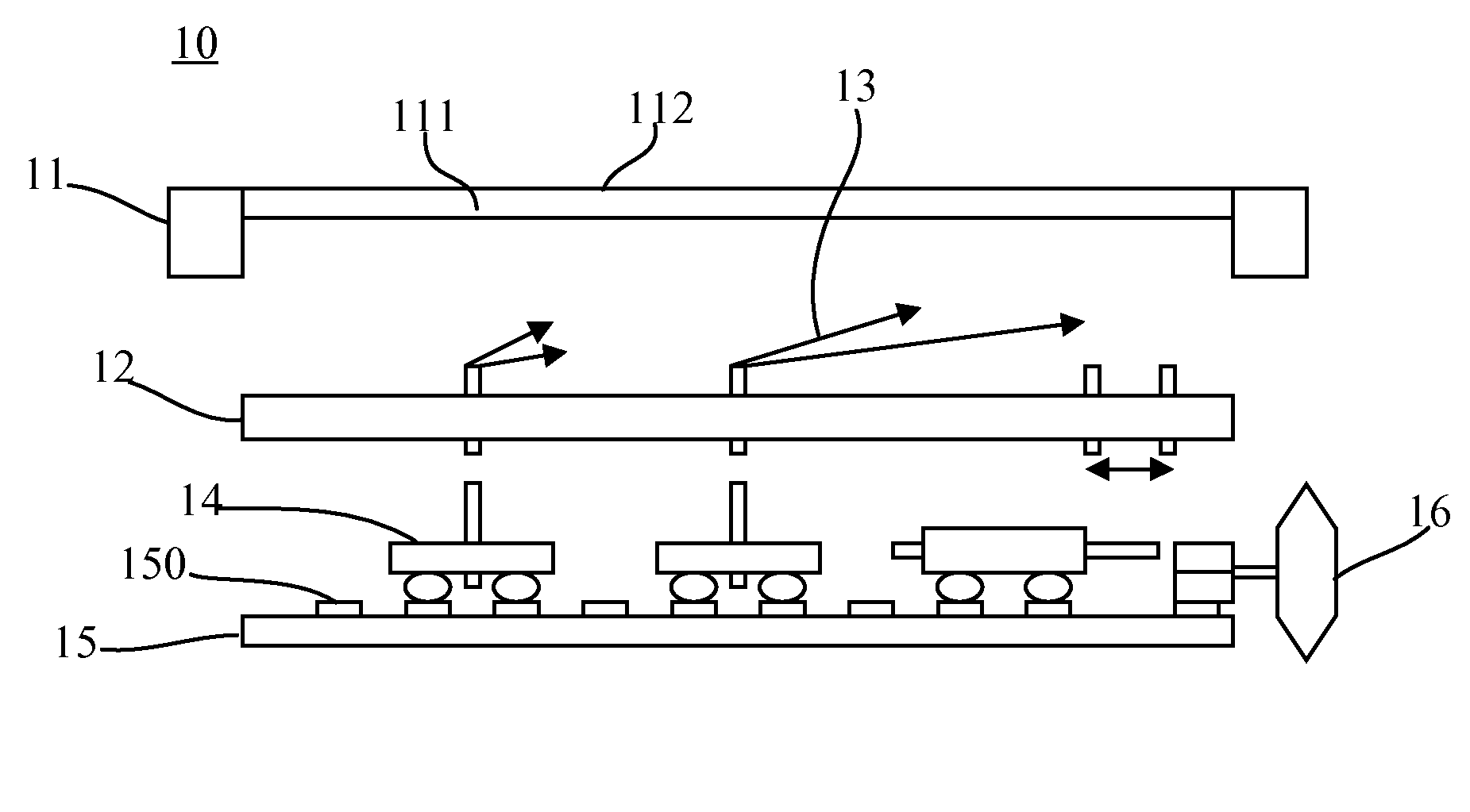

Hybrid vehicle powertrain test system capable of simulating working condition and inertia

InactiveCN101738320AReduce R&D testing costsMinus the workloadVehicle testingDynamometerMode control

The invention discloses a hybrid vehicle powertrain test system capable of simulating working condition and inertia, which comprises an operating console, a bench control and measuring centre manger, a test mode controlling system unit, a dynamic simulating system unit, a driving function controller unit, a dynamometer, a dynamometer controller unit, a data acquisition system unit and a test condition controlling system unit. The system can be used in the hybrid vehicle powertrain performance development tests; the bench test can replace most of the road tests and the vehicle rotating hub tests in the process of developing the products; meanwhile, assembly parts of the powertrain can be combined flexibly to form different coupling modes of motors and engines to carry out the development and research in the early stage of the development of the hybrid vehicle powertrain; compared with traditional research and development testing means, the test system can greatly improve the hybrid vehicle powertrain and the research and development test level of the key technologies thereof and greatly shorten the research and development period of the powertrain and the relative parts.

Owner:DONGFENG ELECTRIC VEHICLE

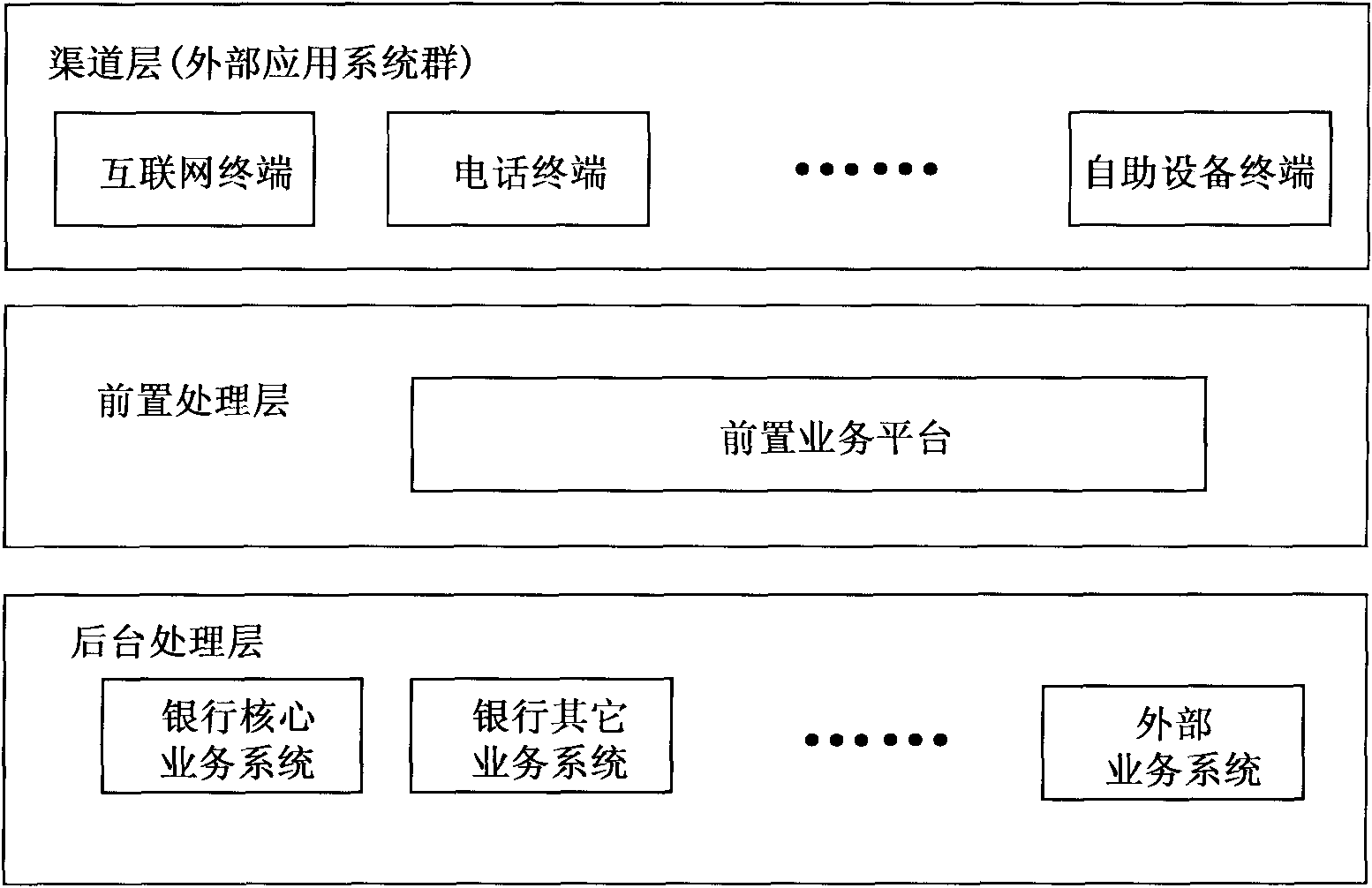

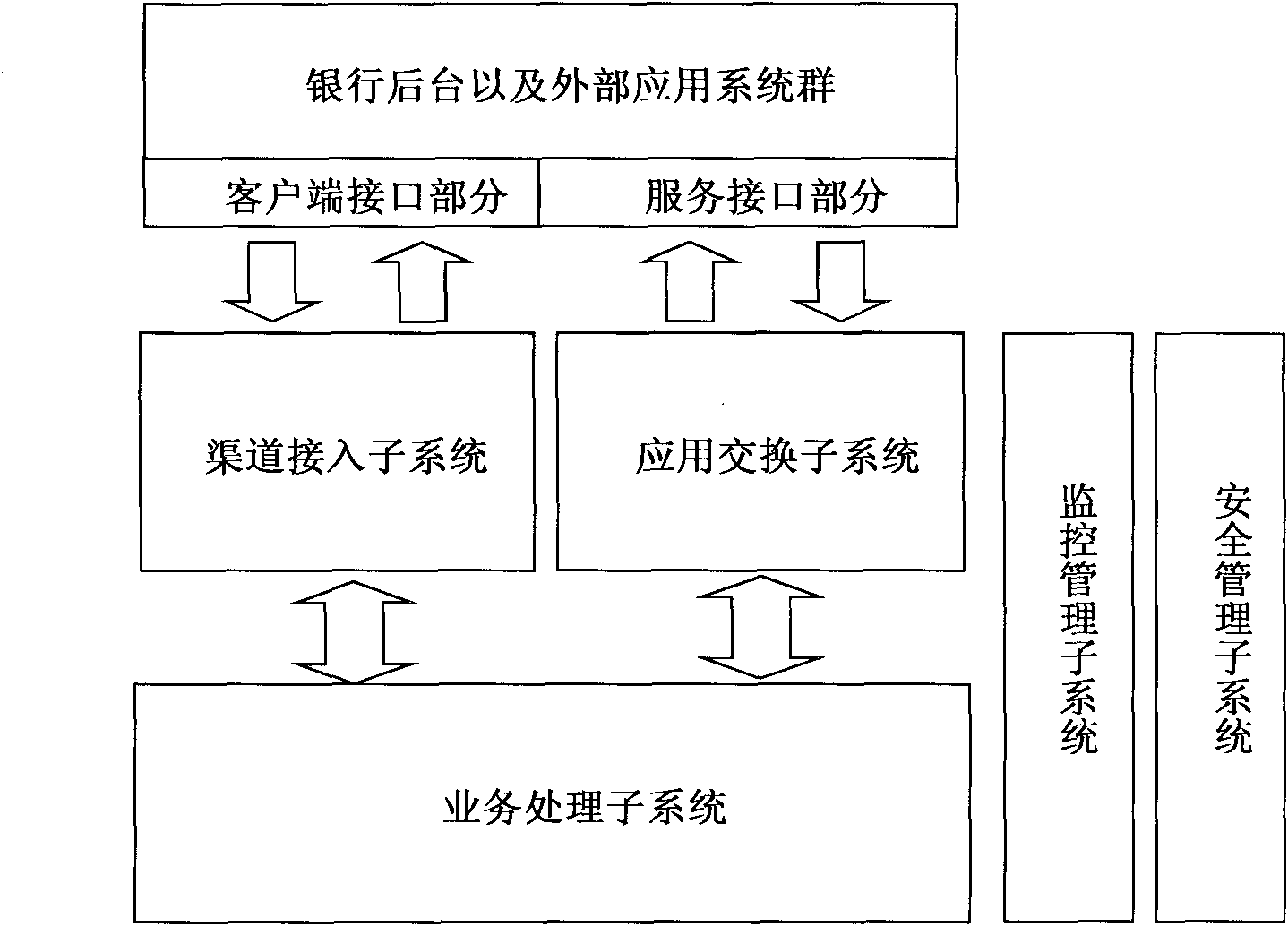

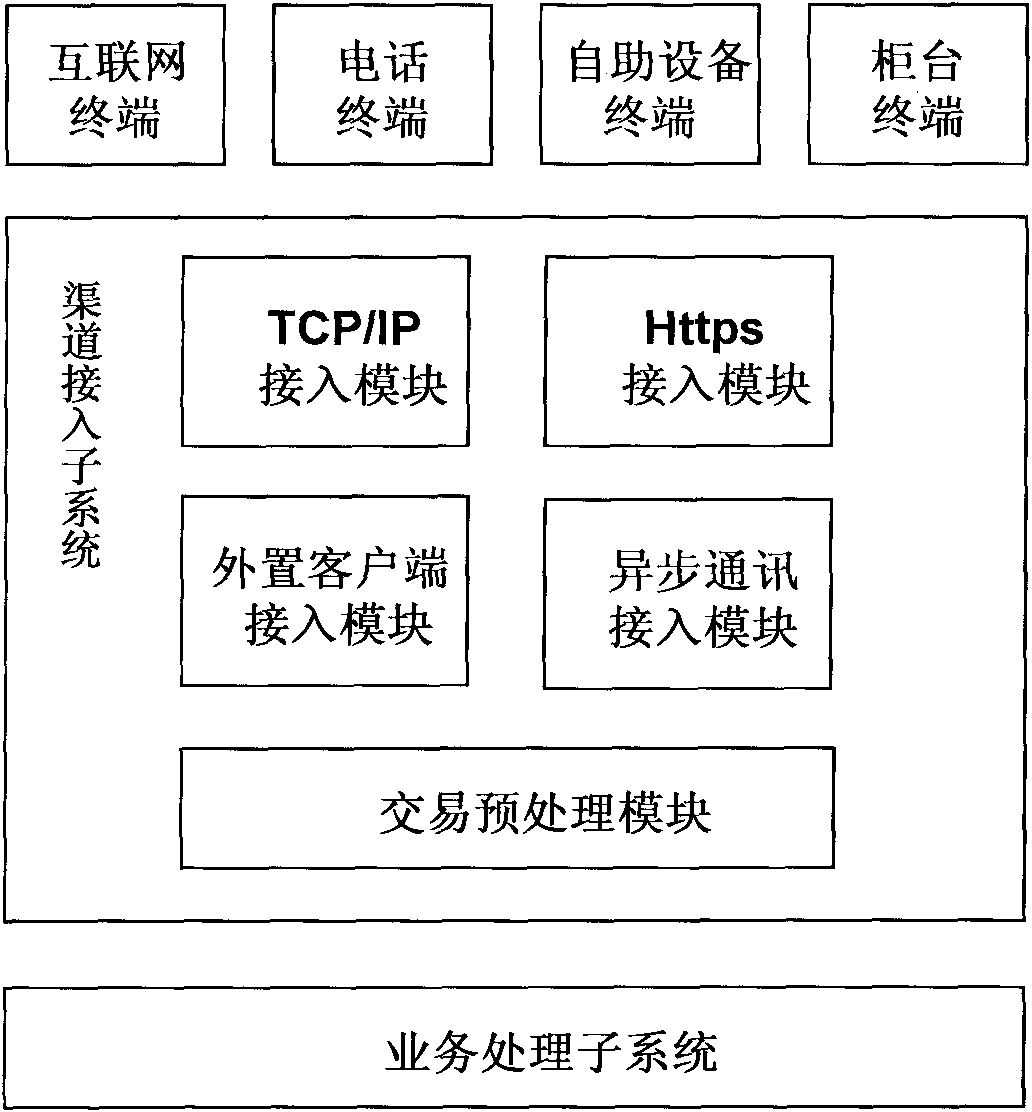

Front service platform of bank and operation processing method thereof

InactiveCN101877158AShorten the development cyclePowerfulComplete banking machinesTerra firmaSafety control

The invention provides a front service platform of a bank. The platform comprises a channel access subsystem for integrating transactions when various clients of a channel layer access each service system of a background processing layer in the bank, a service processing subsystem for integrating functions provided by a background service system and thus realizing novel bank services, an application switching subsystem serving as a channel for the front service platform to access each service system on the background, a monitoring management subsystem for monitoring the operating condition of the front service platform, and a safety control subsystem for ensuring safe operation of the front service platform. The invention has the advantages of providing a unified platform capable of supporting the development of various front services, making the whole service system of the bank simple and reliable, greatly reducing equipment cost, and laying a solid foundation for the extension of service products of the bank.

Owner:苏州德融嘉信信用管理技术股份有限公司

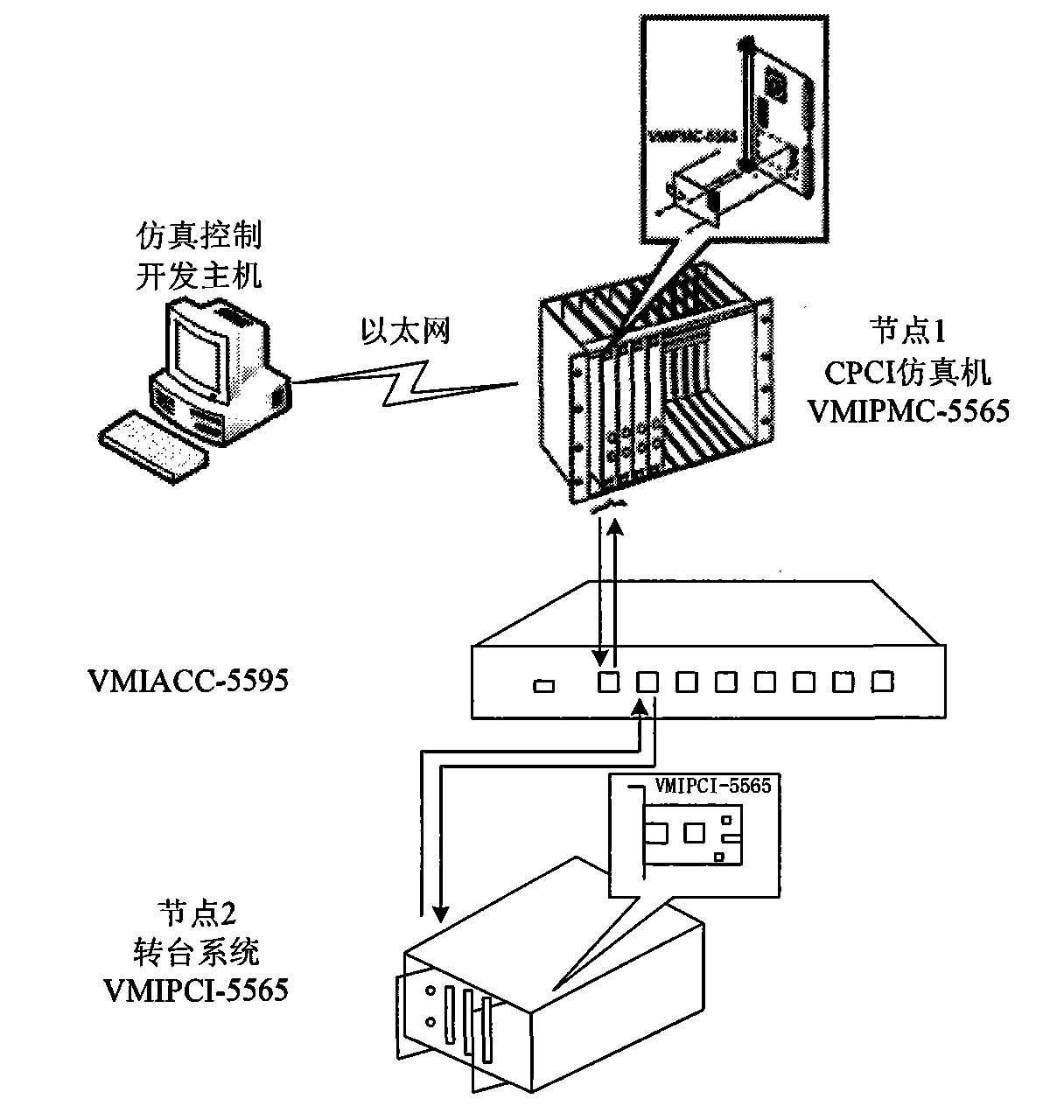

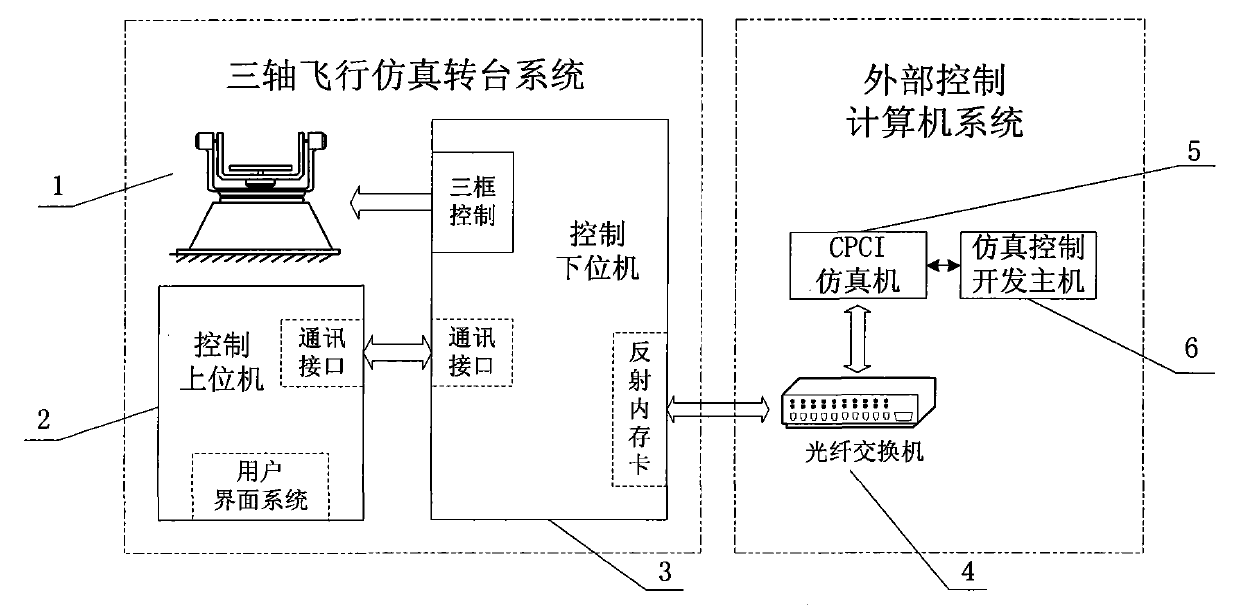

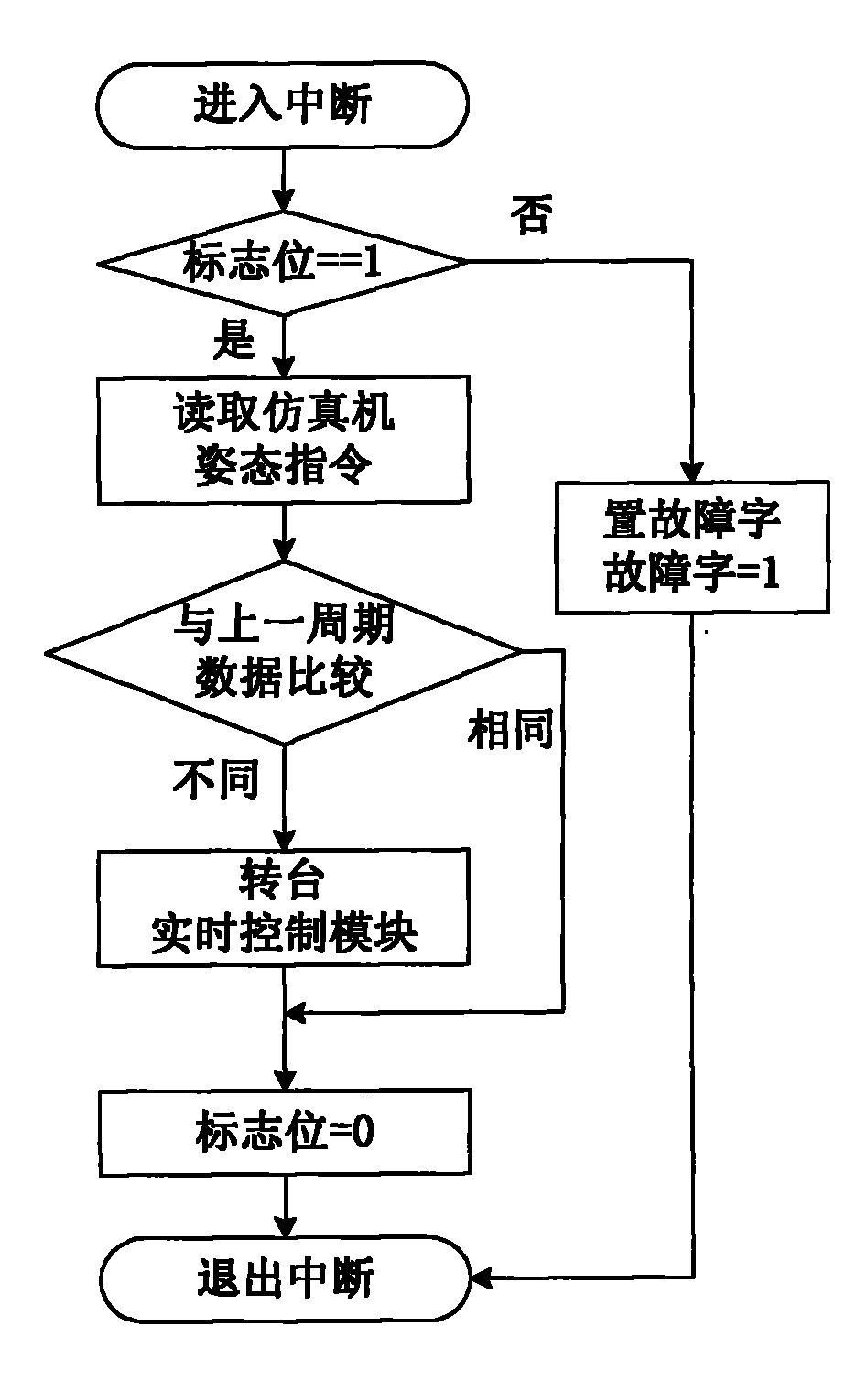

Flight simulation system with high instantaneity

InactiveCN101950157AShorten the development cycleEasy to expand and cropSimulator controlAerospace engineeringSoftware

The invention discloses a flight simulation system with high instantaneity, which is composed of two parts of a three-axis flight simulation turntable system and an external control computer system, wherein, the position and connection relation of the three-axis flight simulation turntable system and the external control computer system is as follows: the three-axis flight simulation turntable system is an actuating mechanism of a physical effect; and the external control computer system is a command sender of the physical effect; the external control computer system transmits the stimulated gesture result to the three-axis flight simulation turntable system through a reflected optical network; and the three-axis flight simulation turntable system carries out real-time gesture response. The five advantages of the flight simulation system of the invention are as follows: Matlab / Simulink is utilized to establish a stimulation model; a CPCI bus type is adopted in computer hardware, a fiber switch is utilized to build a reflection memory optical network; an interrupt response mechanism is adopted in the communication of the stimulation and the turntable system through the optical network, and AppSim stimulation software is used. The flight simulation system has practical value and wide application prospect in the technical fields of flight control and simulation.

Owner:BEIHANG UNIV

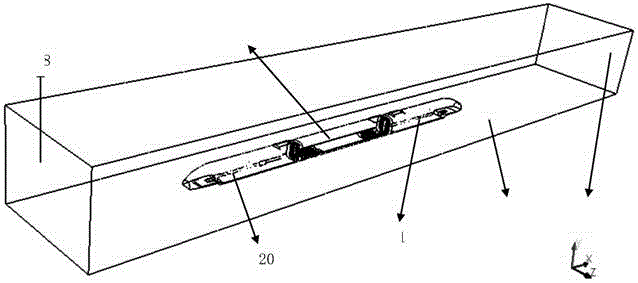

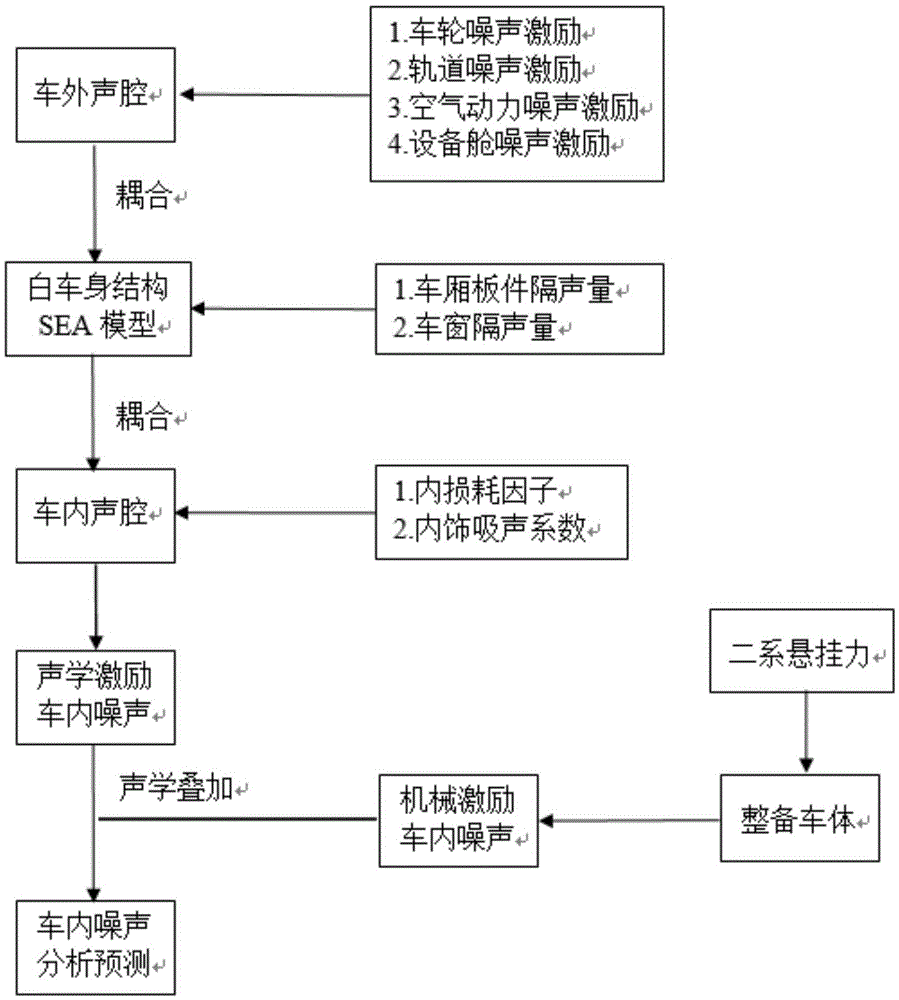

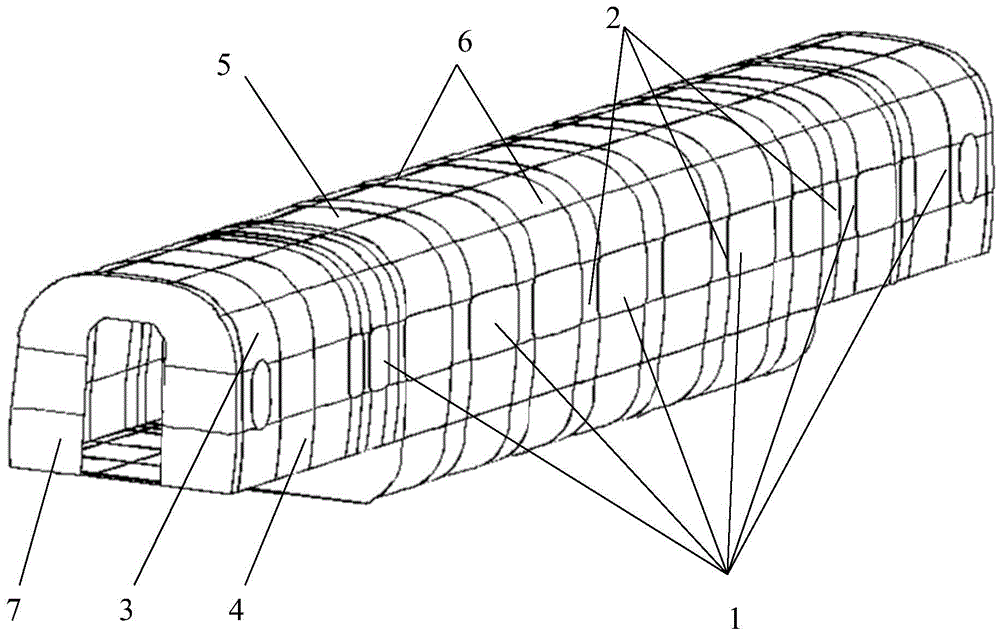

Interior noise analysis and prediction method of high speed train

InactiveCN105590003AShorten the development cycleAccuracy impactGeometric CADSustainable transportationEngineeringInterior noise

The invention discloses an interior noise analysis and prediction method of a high speed train. The method comprises the following steps: establishing a train reconditioning train body model, a statistical energy analysis model of a body in white structure and an interior and exterior vocal cavity statistical energy analysis model, and carrying out simplification and subsystem division; obtaining the statistical energy analysis parameters of the train body structure and an interior vocal cavity model, and loading the statistical energy analysis parameters onto a train body structure model plate subsystem and a vocal cavity model subsystem; and obtaining exterior vocal excitation source energy borne on the train body, applying the exterior vocal excitation source energy onto the exterior vocal cavity statistical energy analysis model, causing the exterior vocal excitation source energy to reach an interior vocal cavity after the exterior vocal excitation source energy is attenuated by the sound insulation property of a structural plate in a body in white structure model so as to obtain structural noise energy radiated into the train by the reconditioning train body under the function of the two-line suspension force of a compartment, and then, carrying out interior noise analysis and prediction. The problem that the interior noise of the train is difficult in prediction and the problems of the upper limit boundedness of a frequency domain, complex calculation flow, incomplete motivation consideration in the traditional method are overcome, calculation efficiency and prediction accuracy are improved, and development and test cost is lowered.

Owner:ZHEJIANG UNIV

Wristwatch structure, electronic crown for wristwatch, and wristwatch having display

InactiveUS9223296B2Solve needsShorten the development cycleElectronic time-piece structural detailsVisual indicationsElectricityDisplay device

The present invention provides a wristwatch structure, an electronic crown for wristwatch, and a wristwatch having a display. The wristwatch structure comprises an electric driving component; an electronic core having a plurality of two-dimensional joints; and an electronic crown comprising a rotating portion and a fixed detecting portion, the detecting portion detecting electronic signals according to a rotation of the rotating portion; wherein the detecting portion of the electronic crown exports the electronic signals to the electronic core via one of the joints, and the electric driving component is electrically connected to one set of joints among the two-dimensional joints. The present invention can improve compatibility for various designs, thereby shortening product development cycle. Also, the present invention is suitable for developing a product with appearance similar to a mechanical watch.

Owner:PRINCO MIDDLE EAST FZE

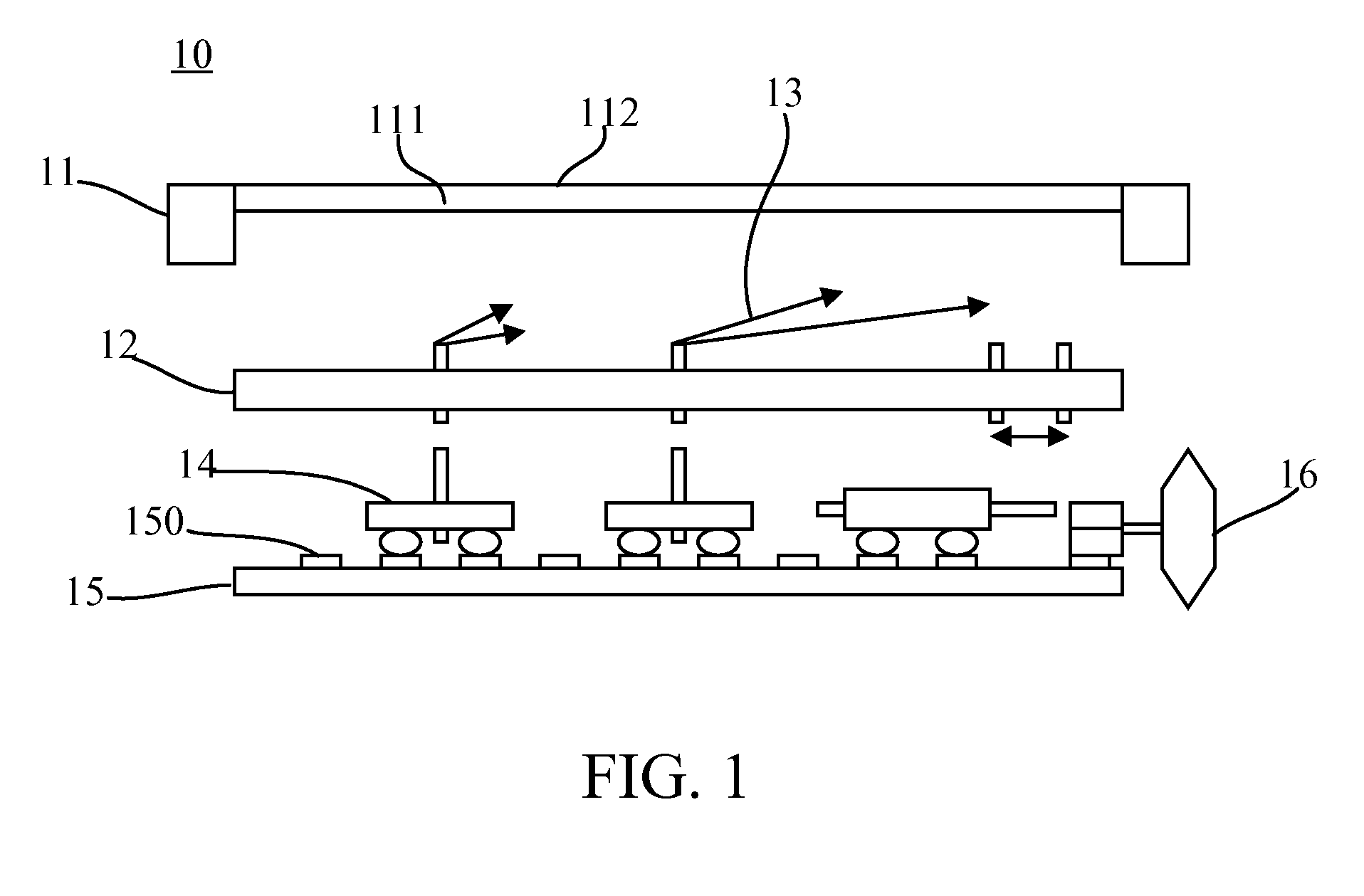

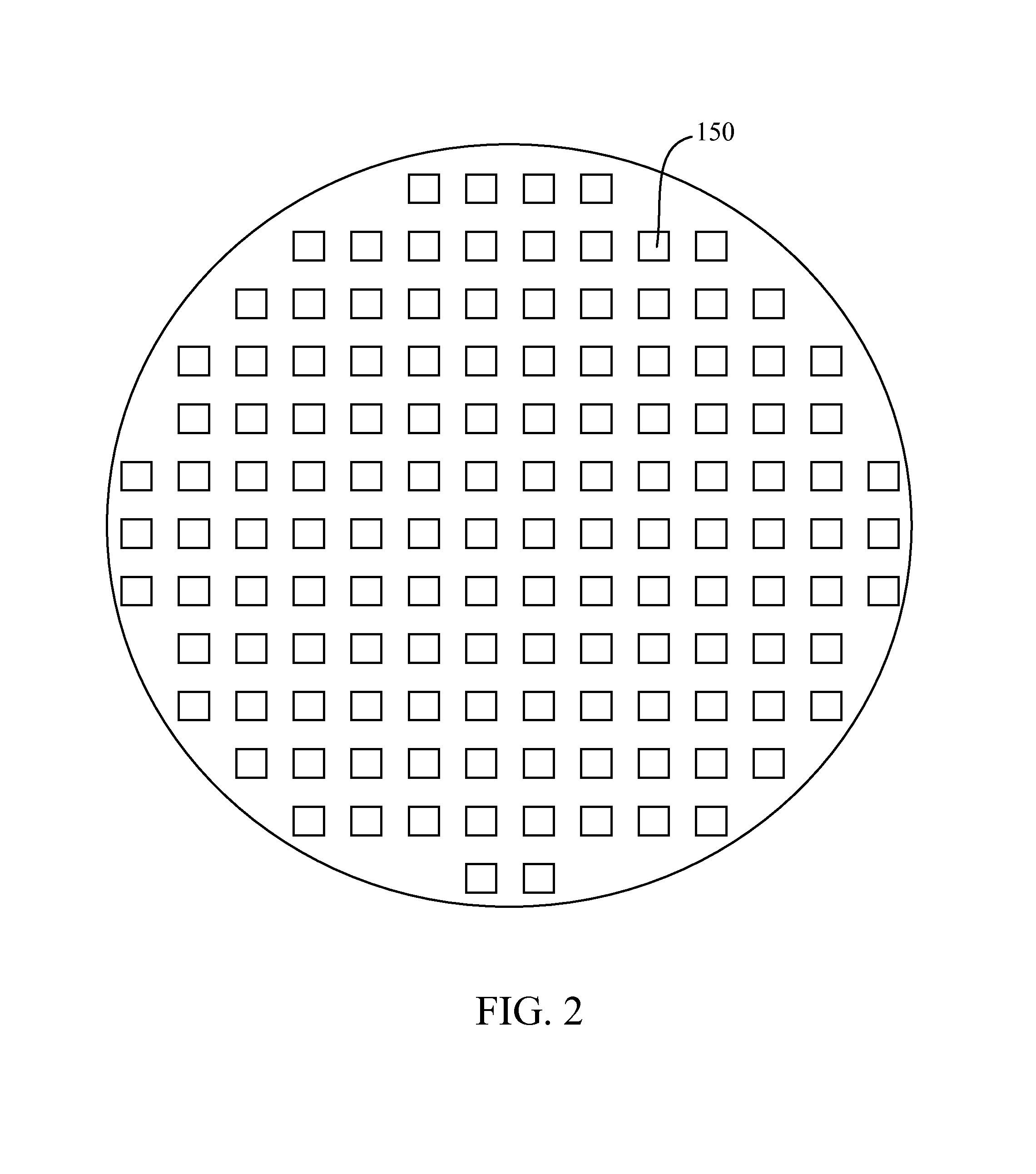

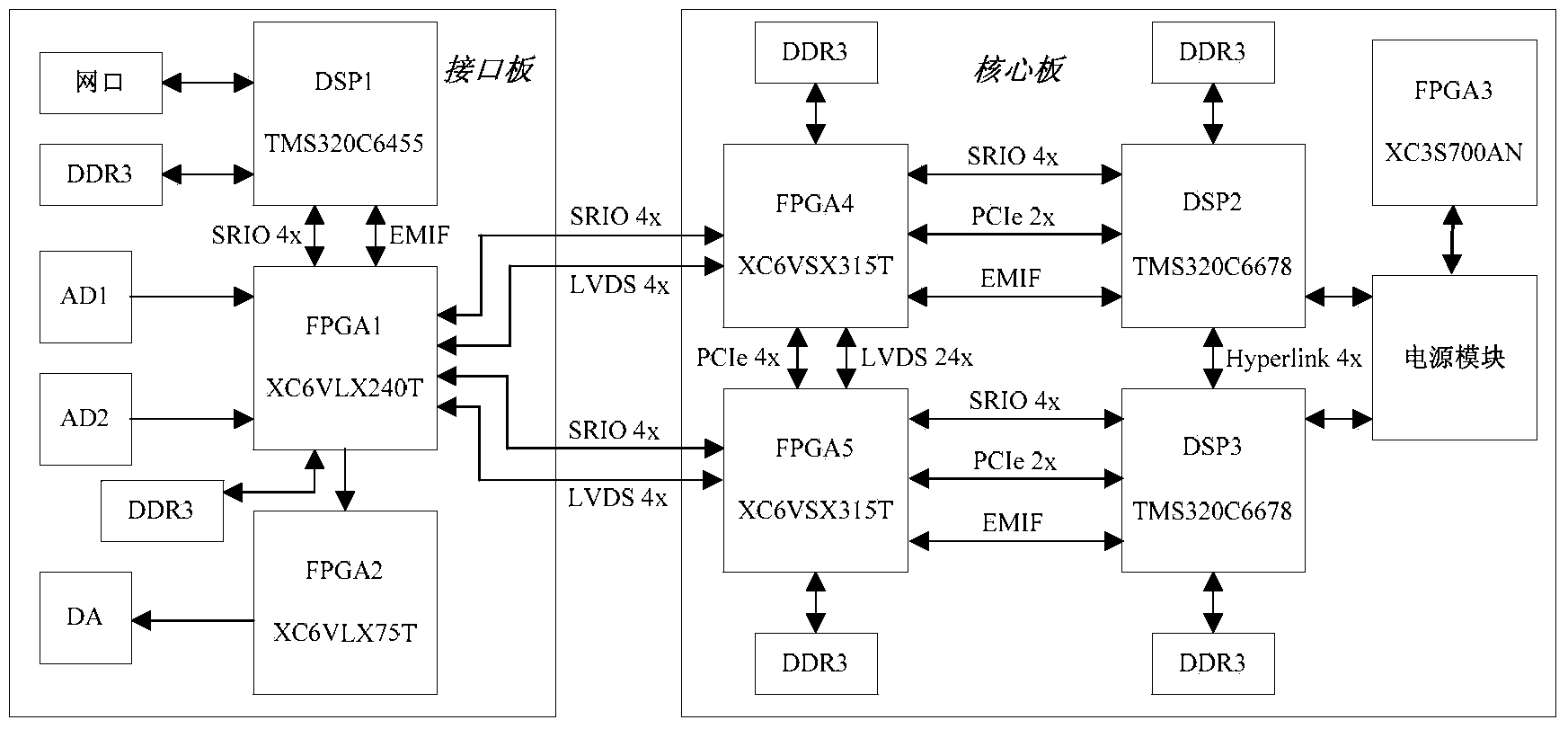

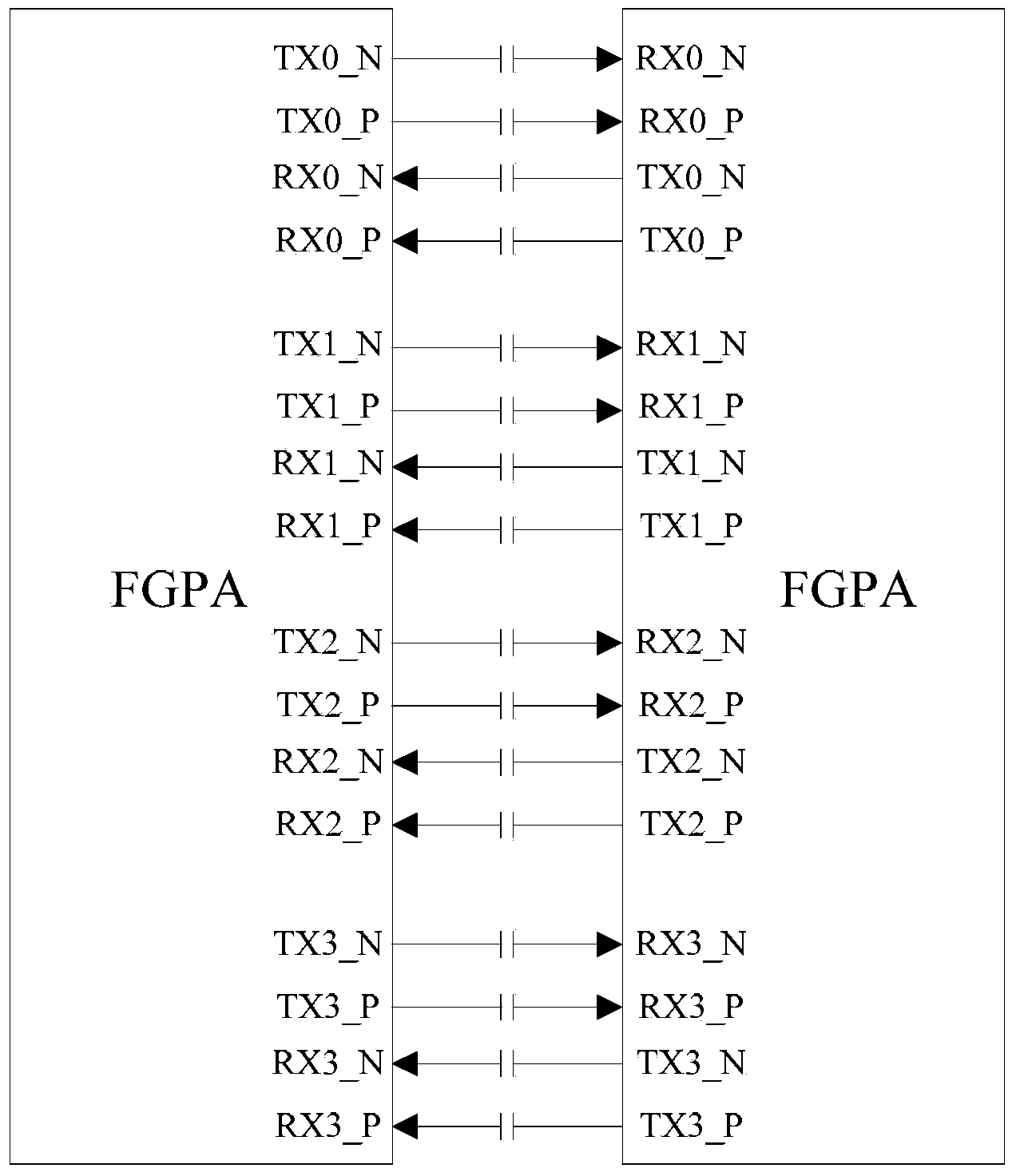

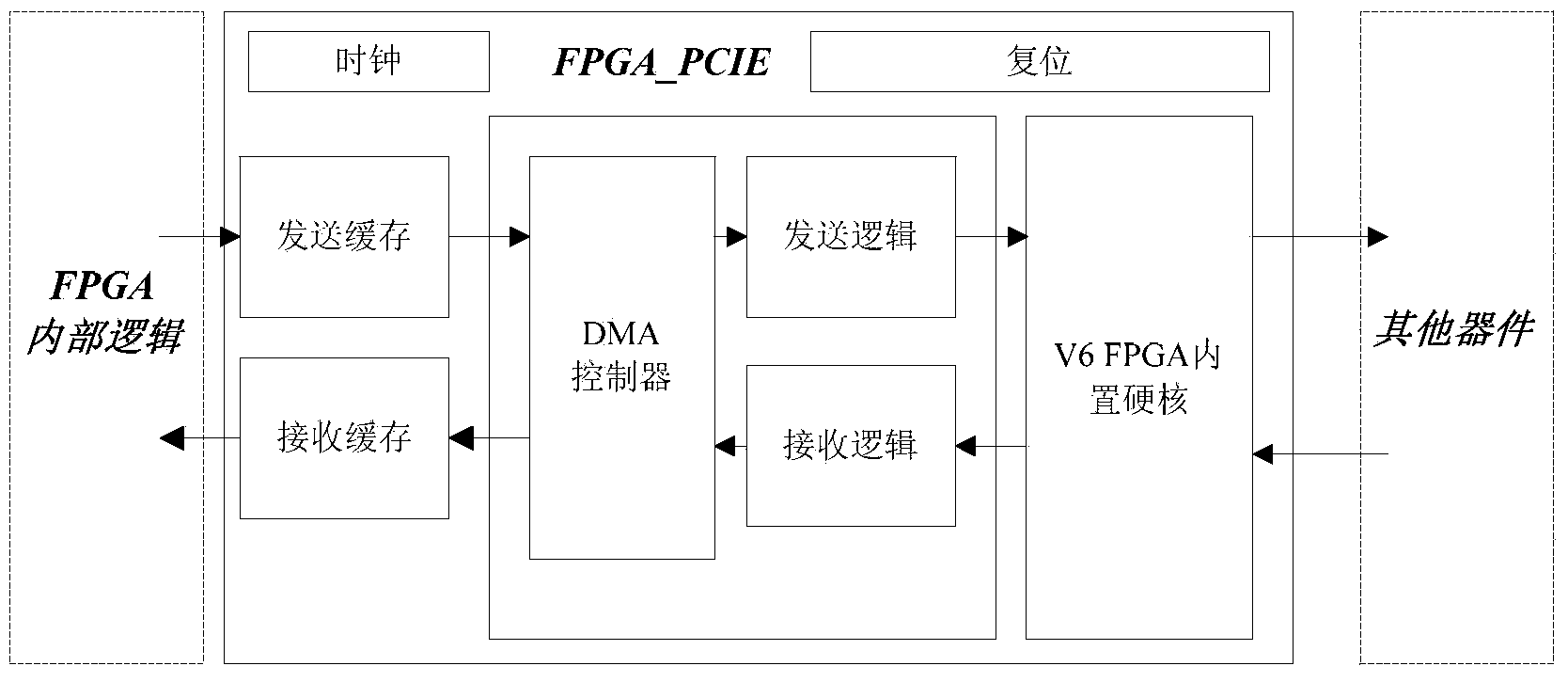

Multi-DSP and multi-FPGA parallel processing system and implement method

ActiveCN103885919AStrong interface capabilityImprove parallel processing capabilitiesElectric digital data processingHyperlinkExtensibility

The invention discloses a multi-DSP and multi-FPGA parallel processing system which comprises FPGAs, DSPs, ADs, a DA, DDR3s and power supply chips. An implement method of the multi-DSP and multi-FPGA parallel processing system includes the following five steps: (1) achieving PCIe interconnection between the FPGAs, (2) achieving PCIe interconnection between the FPGAs and the DSPs, (3) achieving SRIO interconnection between the FPGAs, (4) achieving SRIO interconnection between the FPGAs and the DSPs, and (5) achieving Hyperlink interconnection between the DSPs. The multi-DSP and multi-FPGA parallel processing system is high in parallel processing capacity, abundant in function and high in flexibility and extensibility, data transmission bottlenecks between processor chips are broken, and the multi-DSP and multi-FPGA parallel processing system is high in transportability and have the good practical value in the digital signal processing field.

Owner:杭州雷世科技有限公司

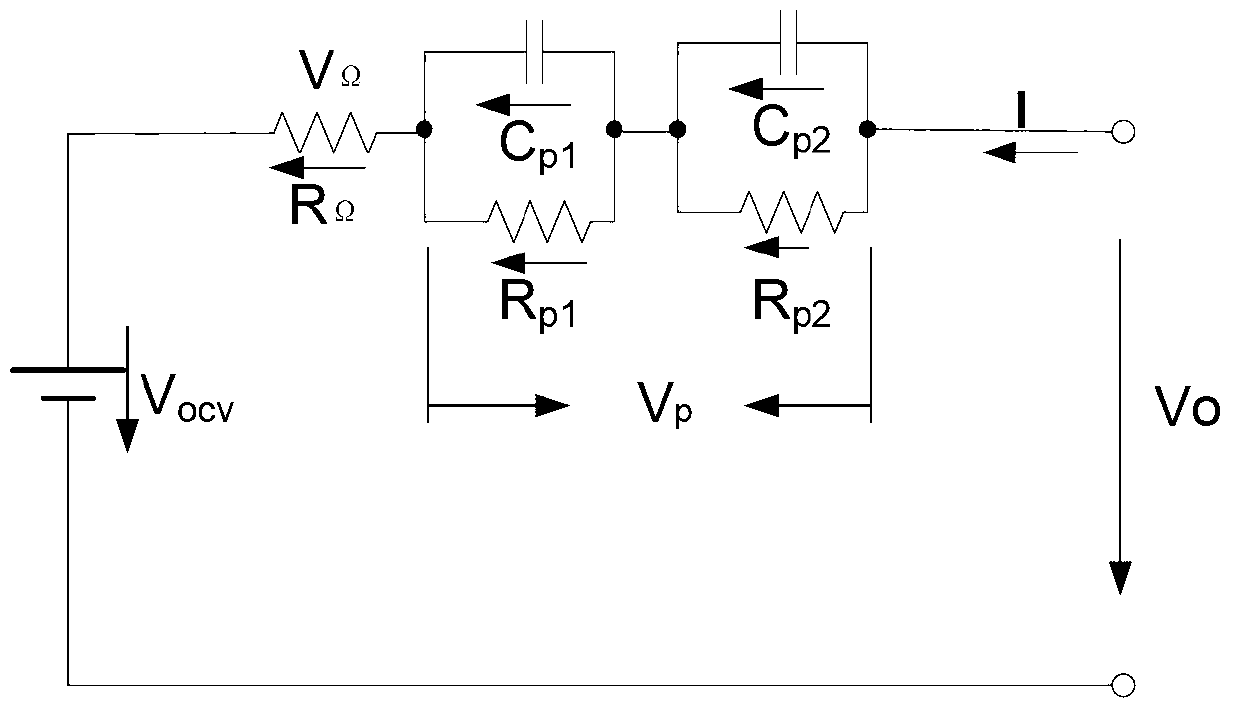

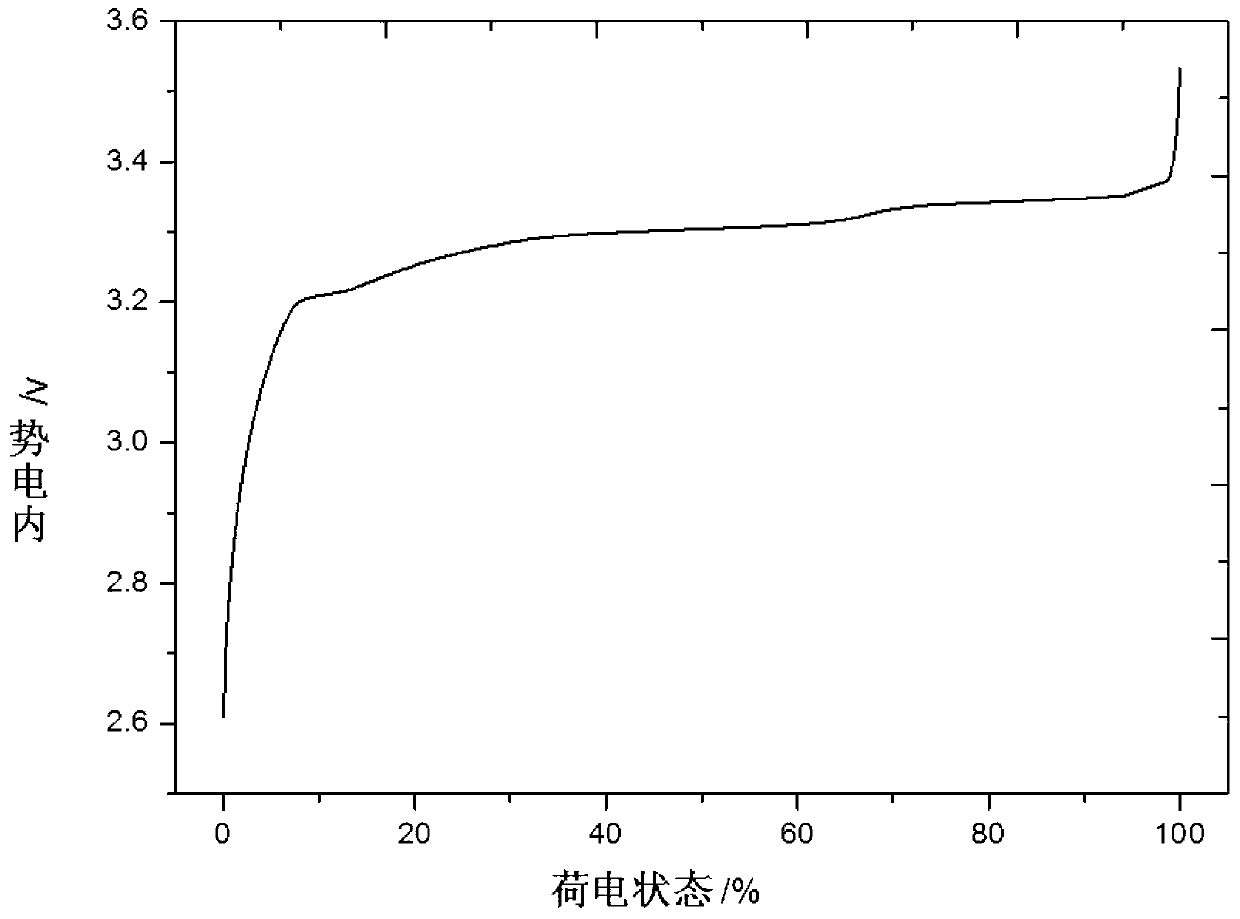

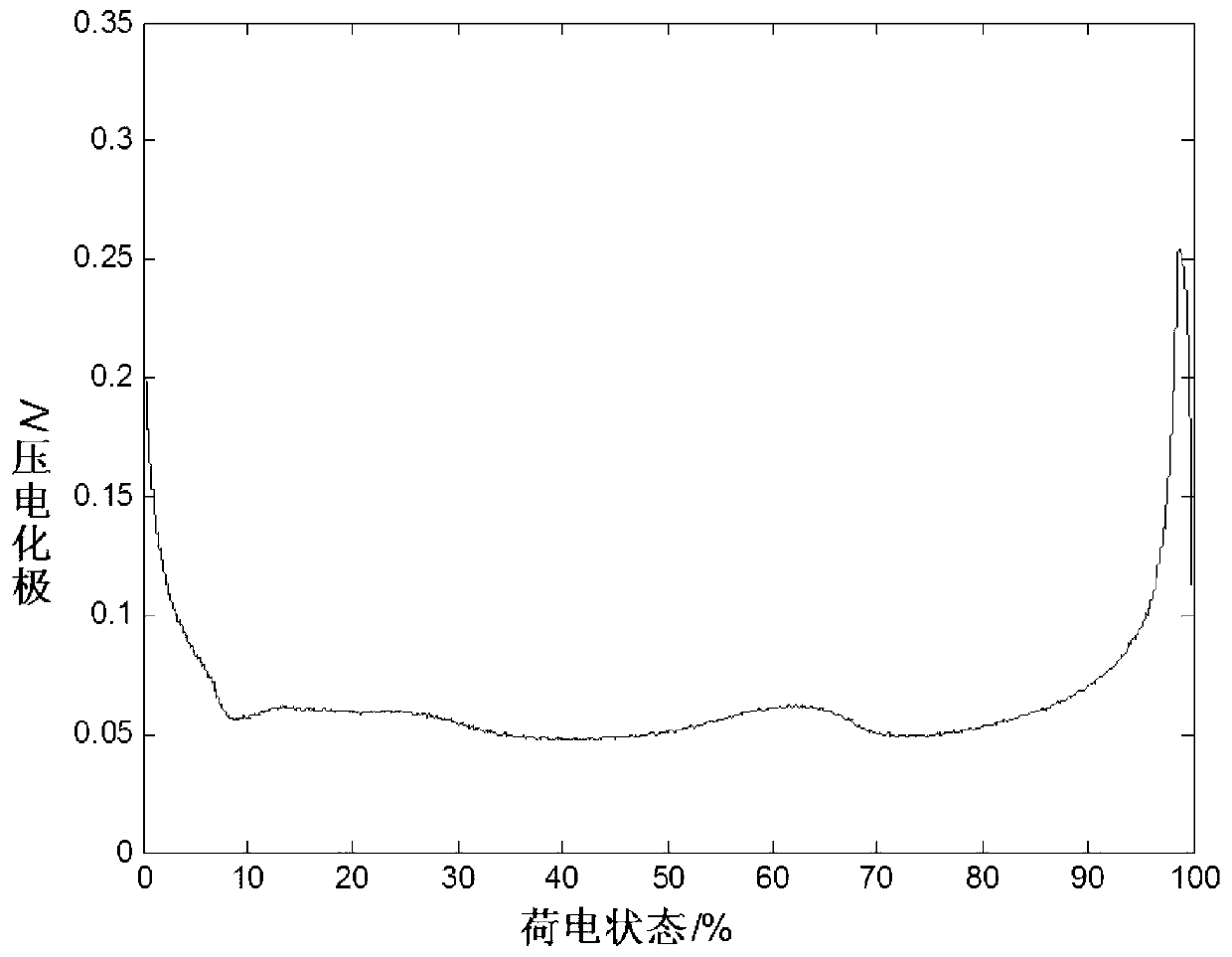

Lithium battery cycle life quick testing method

ActiveCN103344917AReduce designShorten the development cycleElectrical testingElectricityTest battery

The invention relates to the technical field of lithium battery parameter determination methods, in particular to a lithium battery cycle life quick testing method. The method includes the steps of step 1, determining charge state interval for cycle life quick testing according to polarization voltage characteristics of a battery sample, step 2, carrying out a battery cycle life quick test to obtain cycle life test experimental data, step 3, carrying out cycle life mathematic model deduction in partial charge interval, step 4, establishing cycle life deduction mathematic models in 0-100% charge interval, step 5, obtaining a cycle life formula of a battery in the 0-100% charge interval, and step 6, estimating the cycle life of the tested battery. The lithium battery cycle life quick testing method overcomes the defects that time for conventional testing is long, and difference between an accelerated cycle life testing method and the reality is large, and shortens design, development and testing periods of batteries.

Owner:BEIJING JIAOTONG UNIV +2

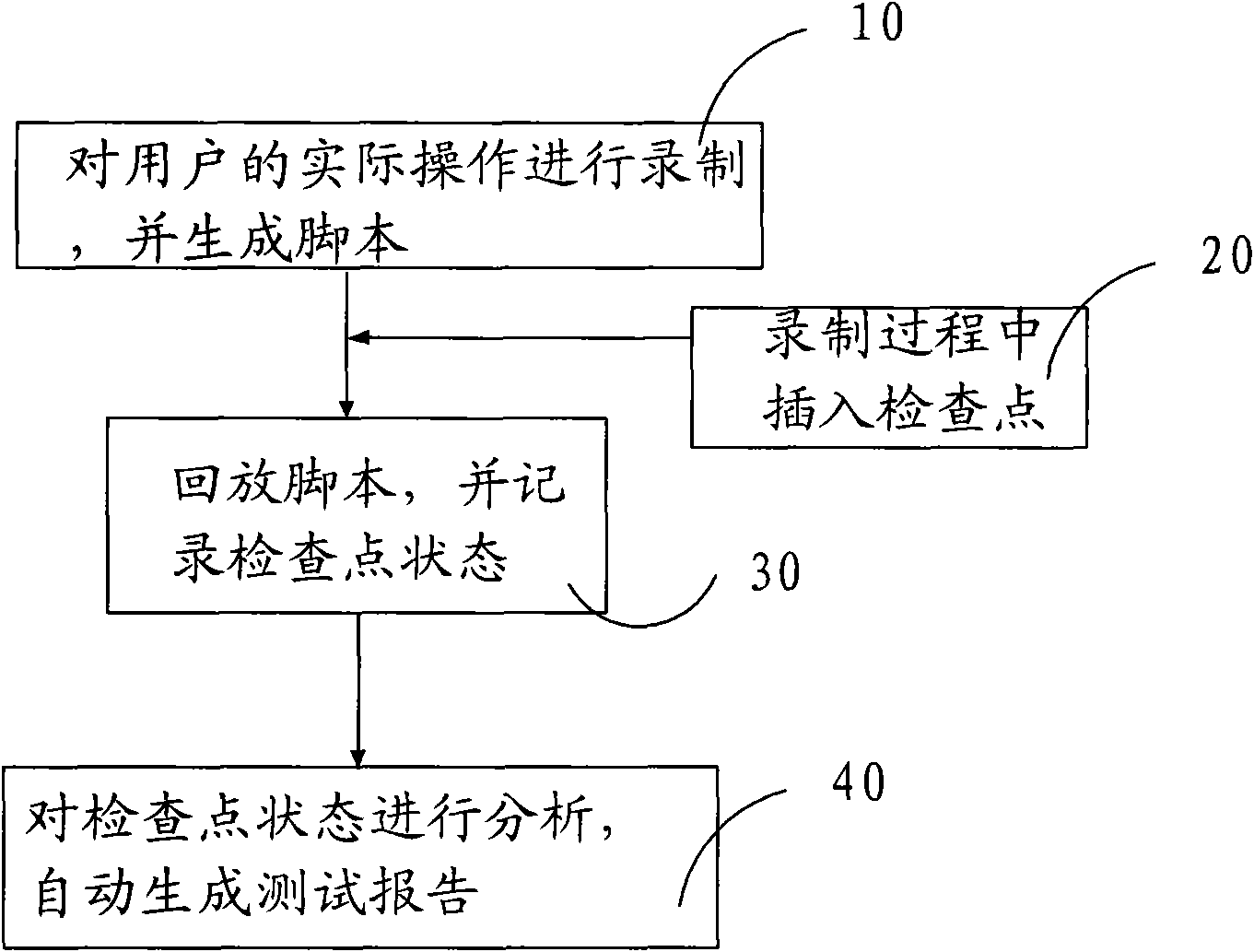

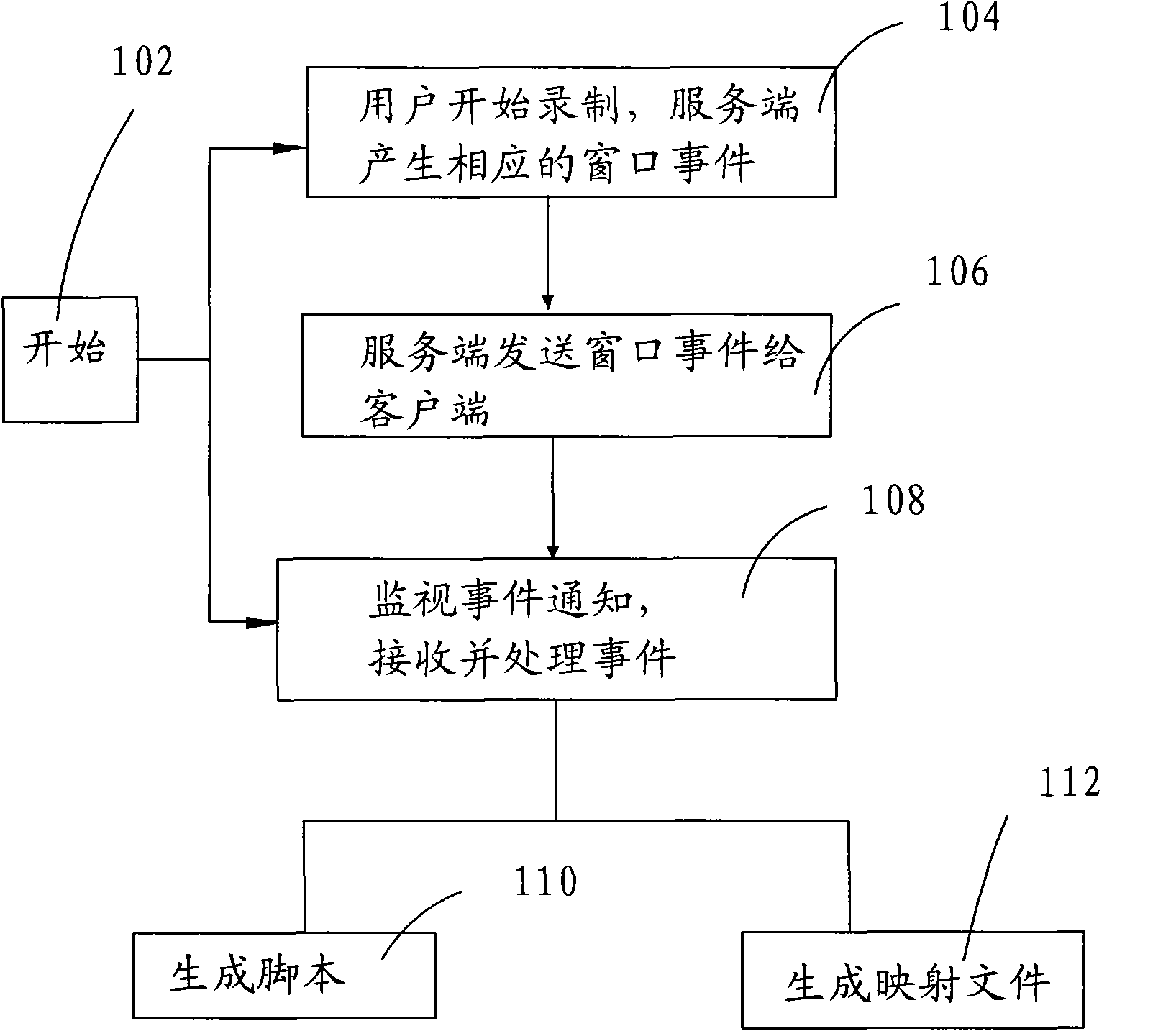

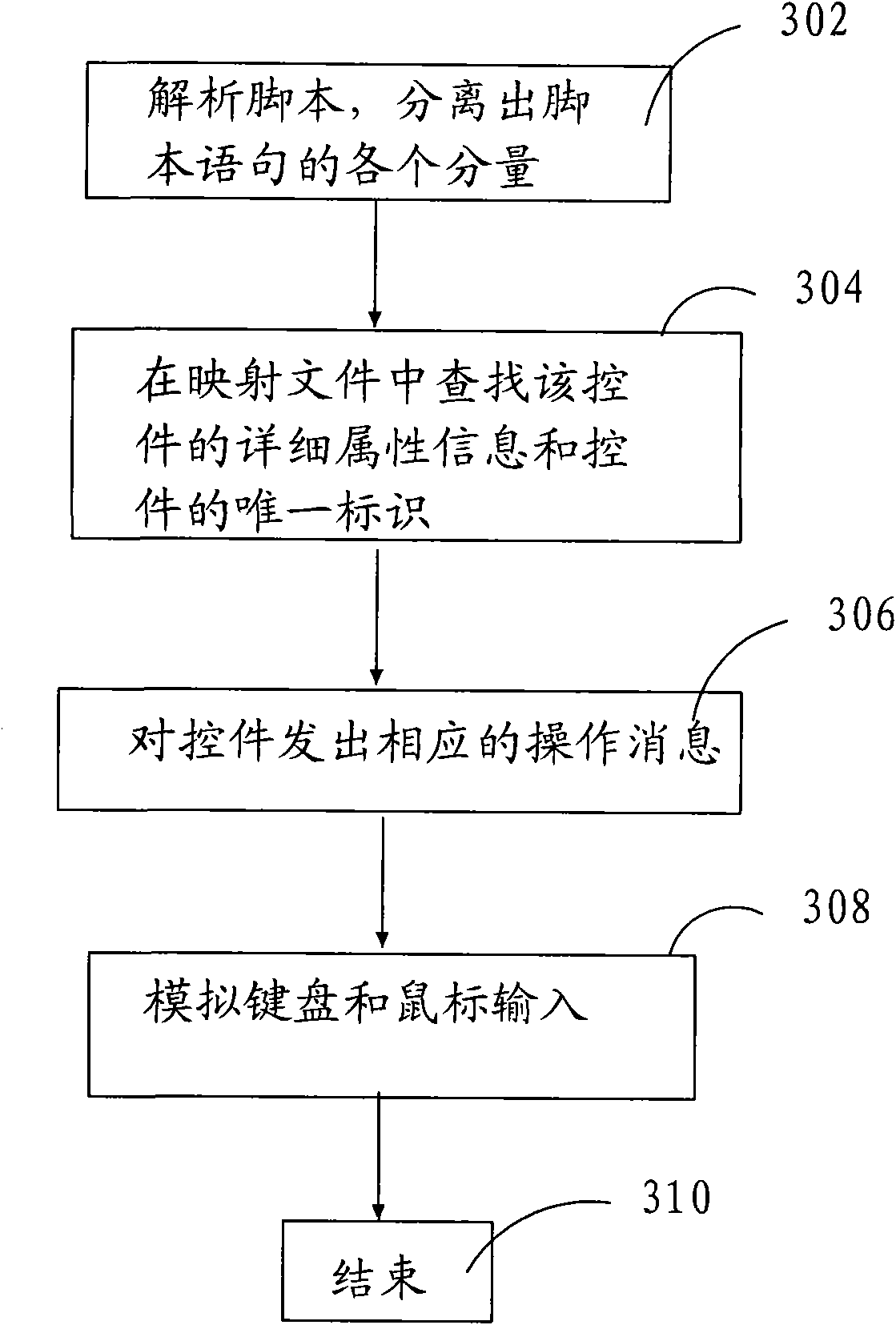

Method for automatically testing recording playback mode of terminal system

InactiveCN101620564ACheckpoints are reliableShorten test timeSoftware testing/debuggingCheck pointTerminal system

The invention relates to a method for automatically testing a recording playback mode of a terminal system, which comprises the following steps: 10, recording actual operation of a user, which comprises mouse operation and keyboard operation, and automatically generating a script which is easily understood by the user and can be edited manually; 20, in the recording process in the step 10, inserting a check point of which the state is required to be checked in an automatic test; 30, playing the script generated in the step 10 back, automatically executing the test, and recording the state of the check point; and 40, finishing the playback of the script, analyzing the recorded state of the check point, summarizing test results, and automatically generating a test report. The method has the advantages of being suitable for automatic functional tests of terminal embedded systems and non-embedded systems, supporting tests for functions of protocols such as ICA, RDP and the like, providing reliable check points for testing GUI functions, and saving testing time.

Owner:FUJIAN CENTM INFORMATION

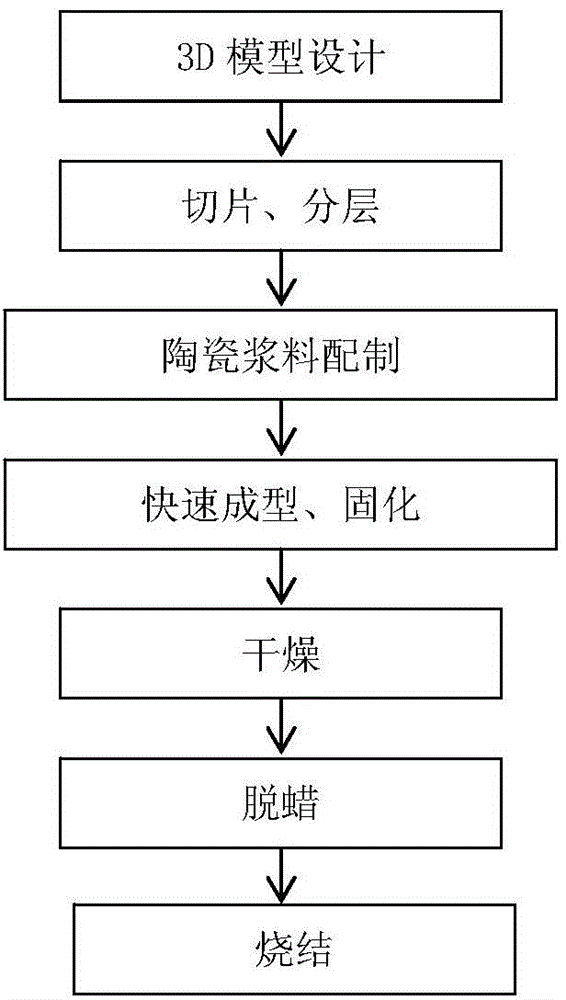

Method for 3D ceramic printing forming

ActiveCN104526838ARapid Dieless ManufacturingShorten the development cycleCeramic shaping apparatusSlurry3d printer

The invention discloses a method for 3D ceramic printing forming. The method comprises the following steps that (1) a 3D model of a target part is established; (2) layering processing is performed, and layered data are imported into a manufacturing program; (3) ceramic slurry is prepared; (4) the prepared ceramic slurry is added into a 3D printer to be made into a ceramic green body quickly formed; (5) the green body is cured at curing temperature for 10 min-60 min and then is placed in a drying oven for drying; (6) the dried green body is dewaxed and sintered to be made into the target part. The method is simple in technology and low in equipment cost; the distance between powder particles in the ceramic slurry can be reduced in the extrusion process, and therefore density is high; besides, the method is not limited by the type of ceramic particles and the shape of the part and is suitable for manufacturing ceramic products made of various ceramic materials and in various complex shapes.

Owner:NINGBO VULCAN TECH CO LTD

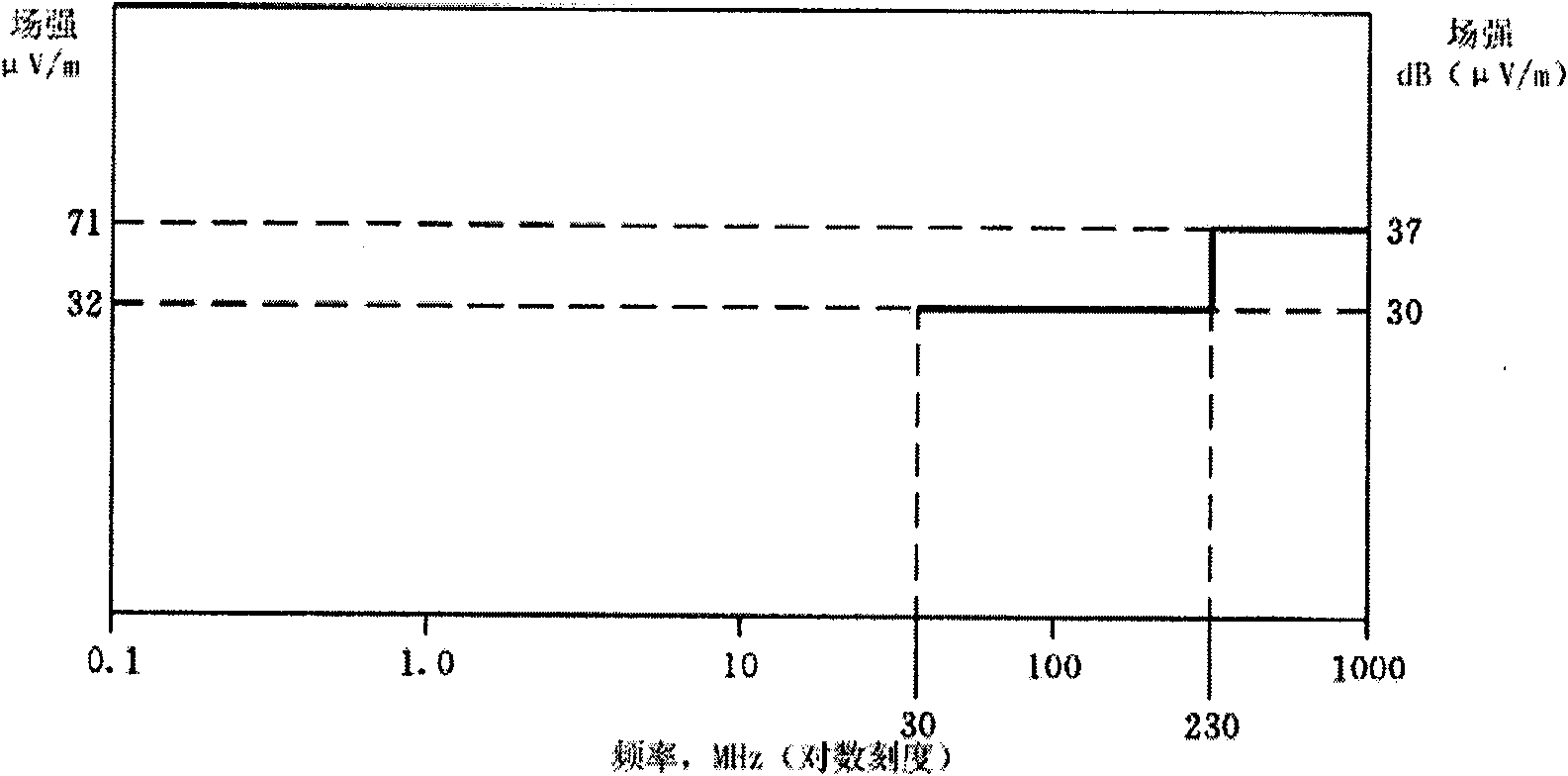

Method for testing electromagnetic compatibility (EMC) of electrically-driven automobile

InactiveCN102043101AShorten the development cycleReduce development costsTesting dielectric strengthElectricityElectronic systems

The invention provides a method for testing the electromagnetic compatibility (EMC) of an electrically-driven automobile. The electromagnetic interference of the electrically-driven automobile is different from that of the common internal combustion engine automobile, as far as the work principle of the electrically-driven automobile is concerned, the electrically-driven automobile has stronger electromagnetic disturbance property and higher anti-electromagnetic interference due to the application of a large-scale electronic system, the electrically-driven automobile is arranged on a loaded chassis dynamometer and runs on the chassis dynamometer at specific speed, the chassis dynamometer realizes energy absorption, and the electromagnetic compatibility of an automobile in a running state is evaluated from two angles of automobile electromagnetic interference (EMI) and automobile electromagnetic susceptibility (EMS), thereby when the automobile normally runs, the electromagnetic interference of the automobile can be accurately measured.

Owner:SHANGHAI MOTOR VEHICLE INSPECTION CERTIFICATION & TECH INNOVATION CENT CO LTD

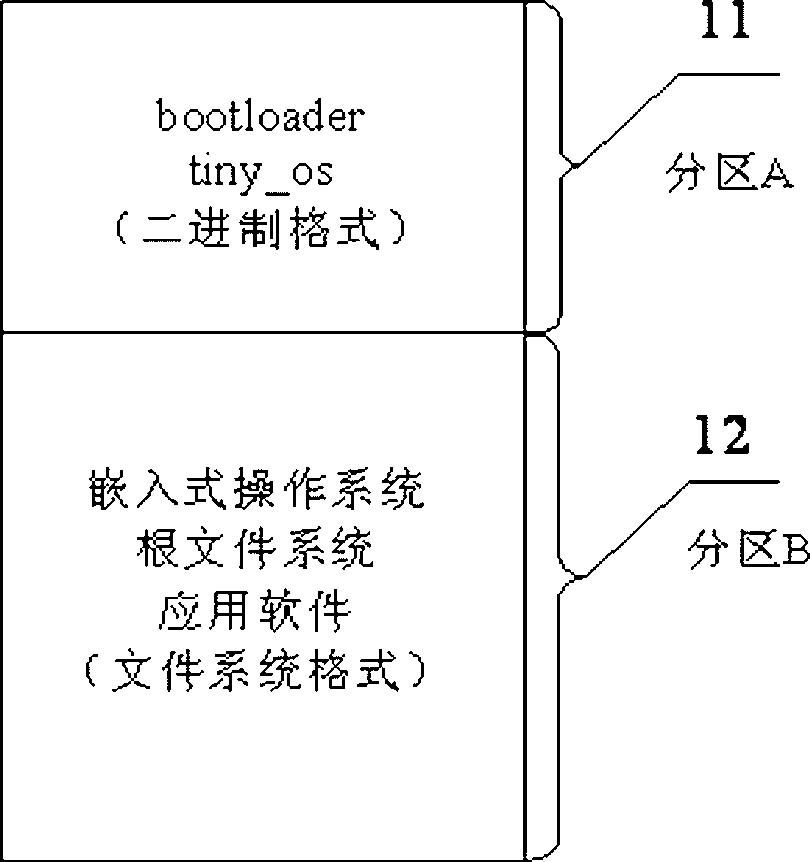

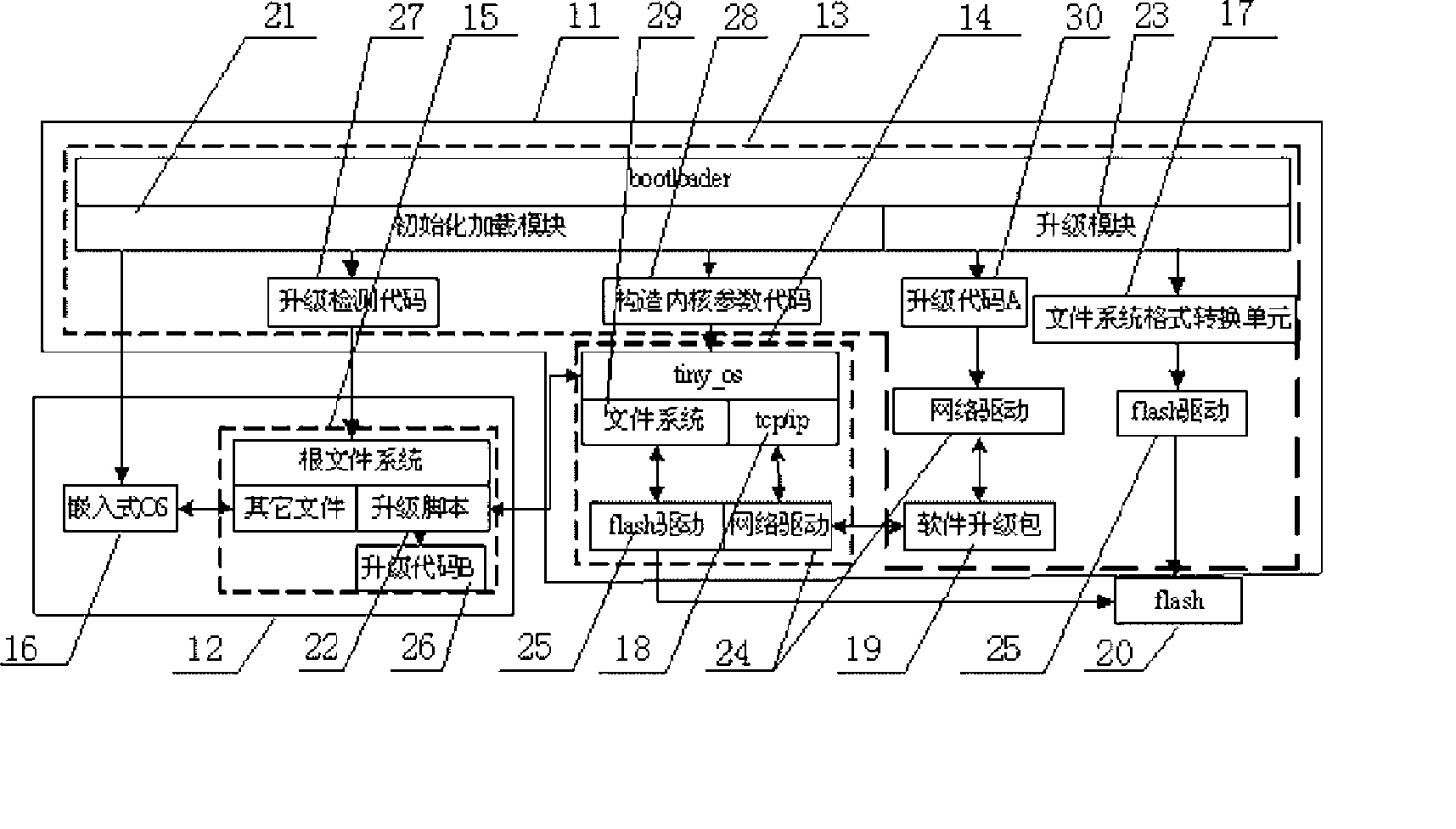

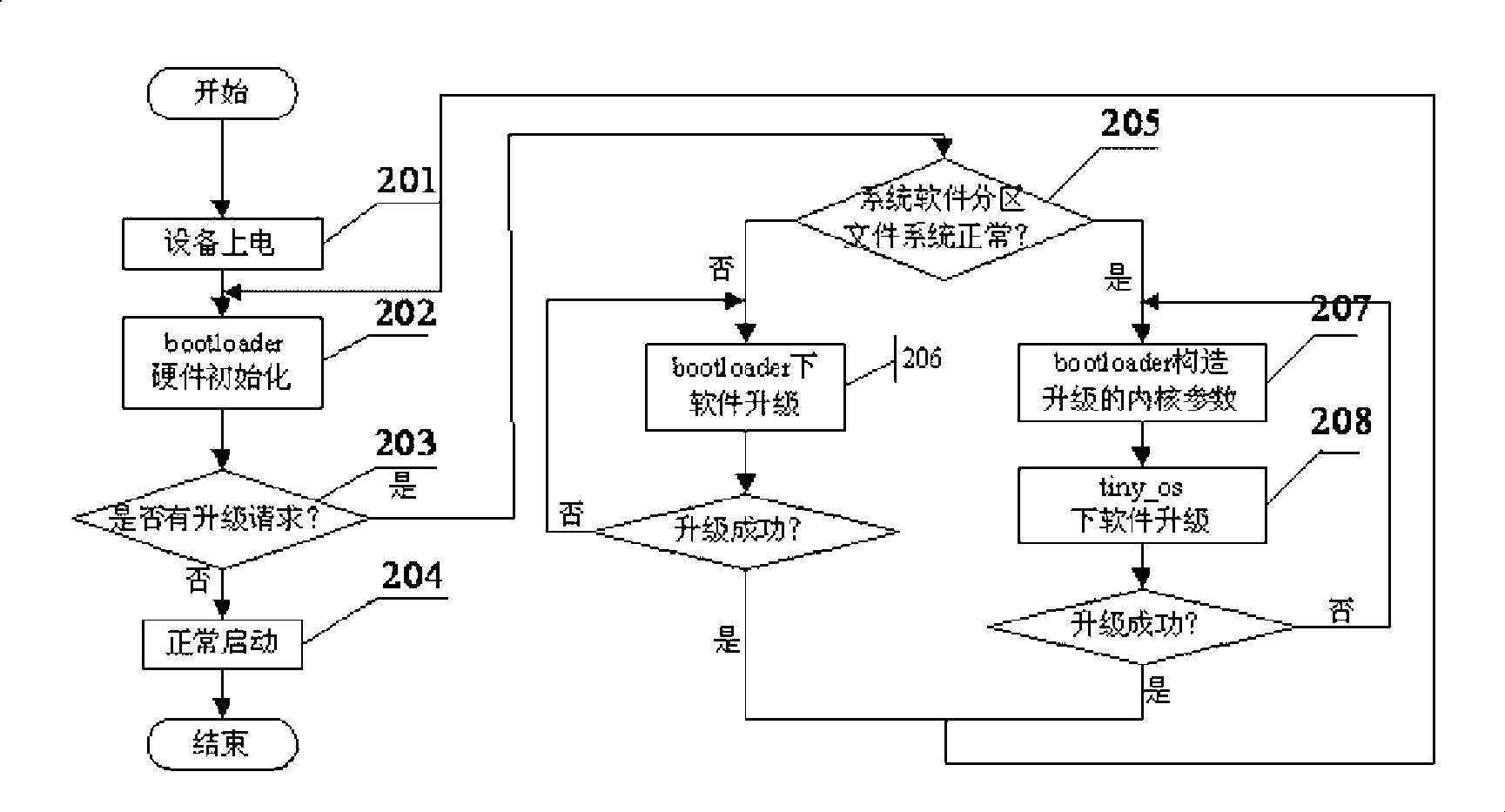

Embedded system firmware on-line upgrading system

ActiveCN101477471AReduce the difficulty of writingShorten the development cycleProgram loading/initiatingUpgradeFile system

The invention discloses an on-line upgrade method for embedded system firmware. A non-volatile memory is divided into two areas, the subareas to which a bootloader and a tiny_os belonging are protected, and an upgrade script is operated under the tiny_os to realize upgrading; the corresponding download request is provided by busybox of an open source; the support to a file system, a tcp / ip protocol stack and the like is provided by the tiny_os; the corresponding download request adopts dynamic linking technology and is shared with system software; different parameters are transmitted to a kernel through the bootloader, so as to tell upgrade operation from normal operation; and the entire upgrade system is only required to enlarge a storage space of about 400K, a plurality of download protocols and file systems can be supported. The invention further provides a spare upgrade method, so that when the subarea of the system software is damaged accidentally, the system upgrading also can be carried out, and the reliability and the safety of upgrading are ensured.

Owner:HANGZHOU HIKVISION DIGITAL TECH

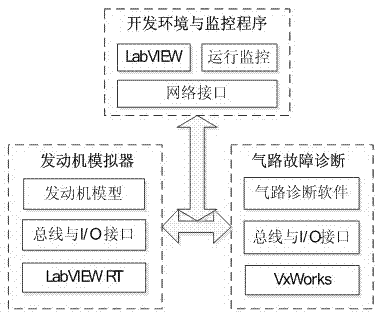

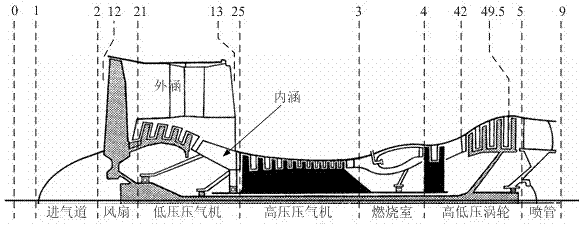

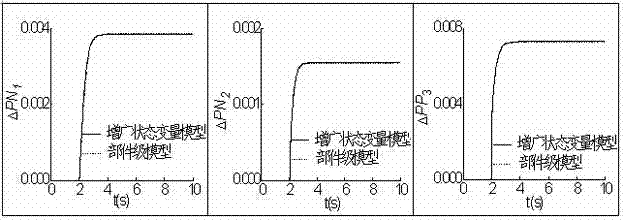

Quick prototype design method and platform for gas path fault diagnosis for aeroengine

InactiveCN102855349AHigh dynamic and steady state precisionRealize online estimationEngine testingSpecial data processing applicationsAviationOn board

The invention discloses a quick prototype design method for gas path fault diagnosis for an aeroengine. The quick prototype design method comprises the following steps of: building an adaptive model of the engine; designing a gas path fault diagnosis logic in the full service life of the aeroengine, and implementing abnormal monitoring and gas path performance on-line estimation; and designing a quick prototype design platform for gas path fault diagnosis for the engine, and checking abnormal monitoring and gas path performance on-line estimation functions of the platform. The adaptive model of the engine is built by a compound interference method; an engine on-board adaptive model is used for estimating performance parameters; an engine adaptive base line model is used for monitoring abnormities and performs off-line period updating; and the quick prototype design method is used for checking the engine gas path fault diagnosis logic. The invention also discloses a corresponding quick prototype design platform. The method and the platform are relatively high in capacity of monitoring abnormities and estimating the performance in the overall service life of the engine and have great significance for shortening the development period and reducing the test risk and the test cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

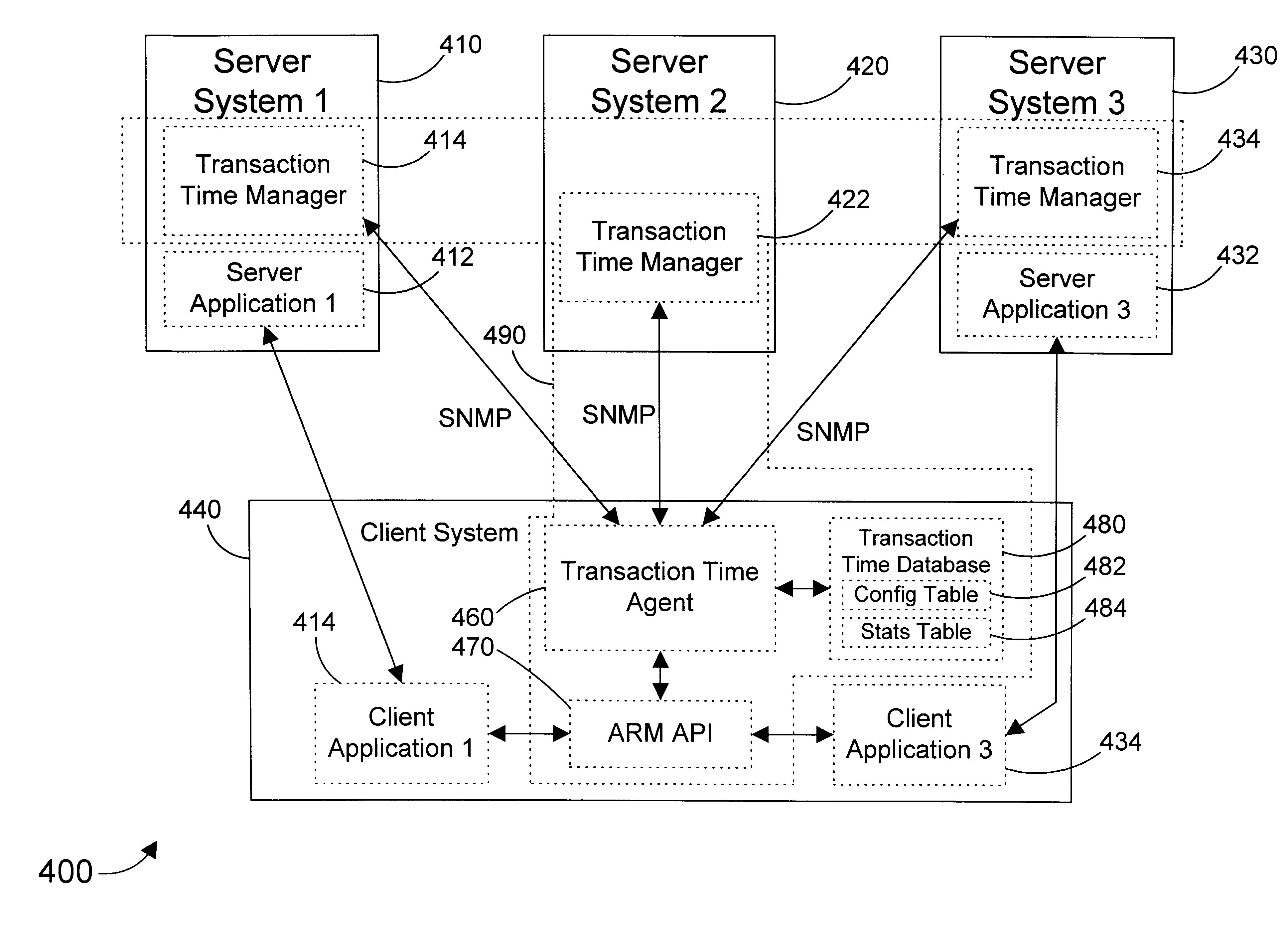

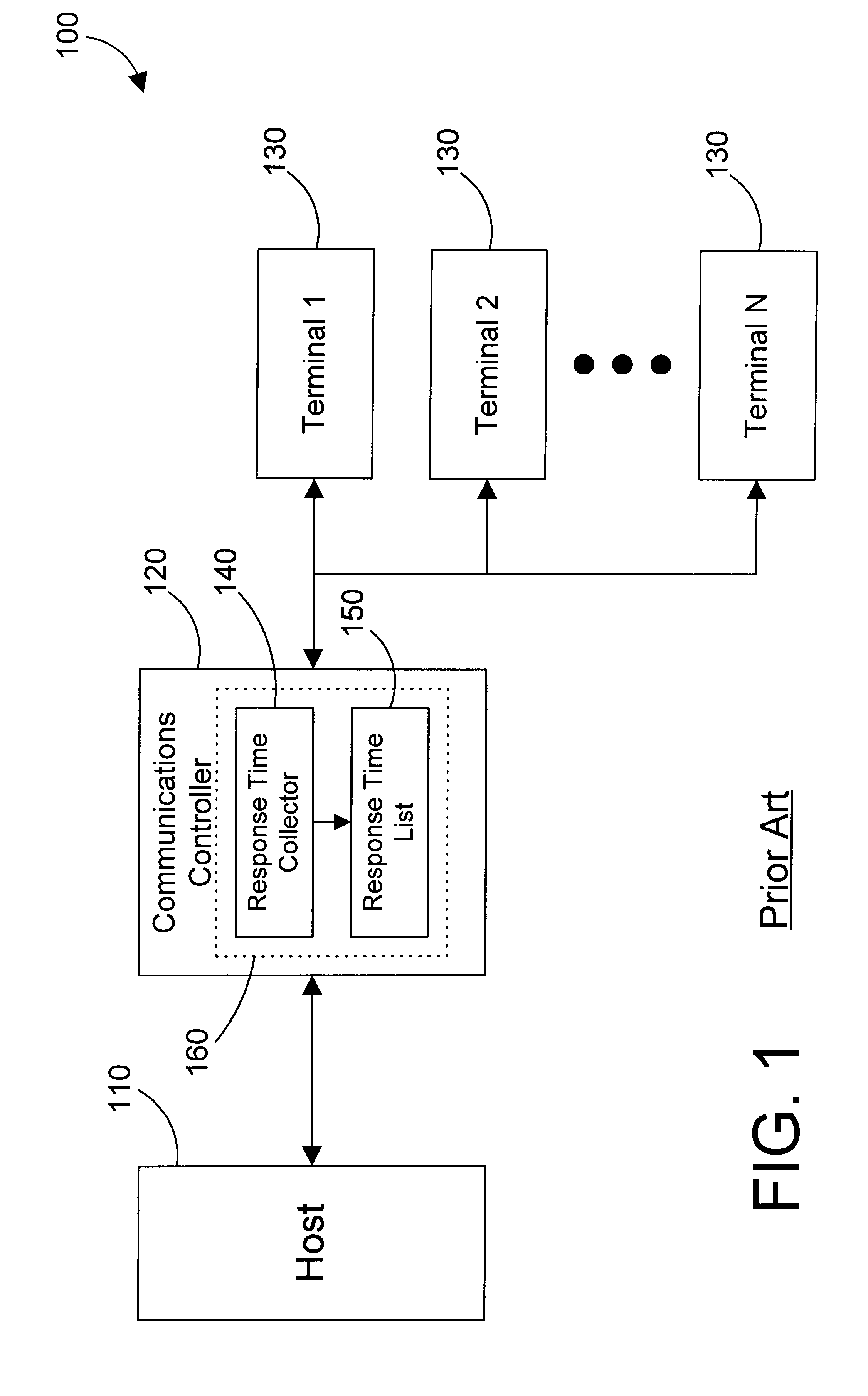

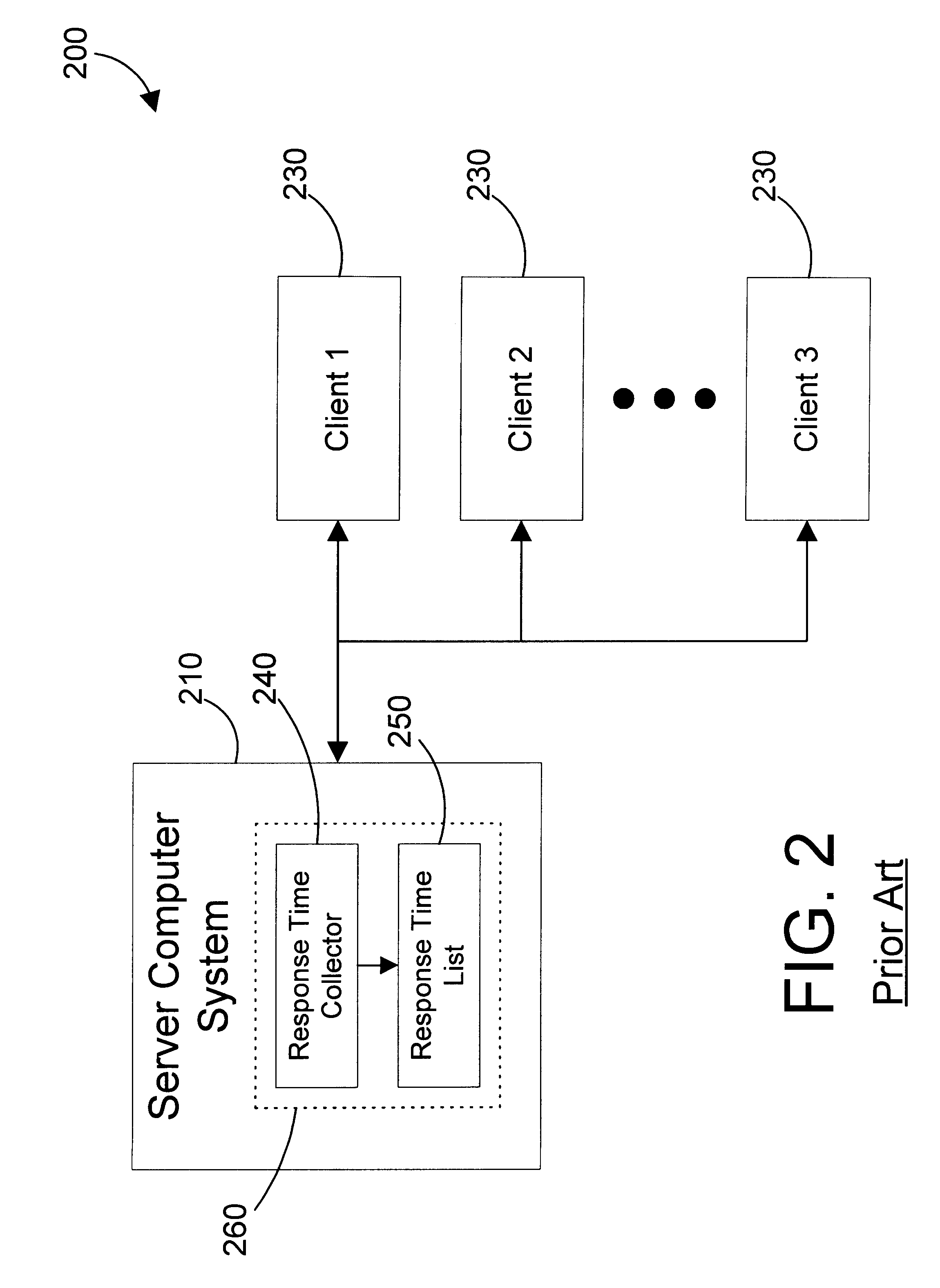

Apparatus and method for measuring transaction time in a computer system

InactiveUS6178449B1Simple protocolEfficient communicationHardware monitoringMultiple digital computer combinationsTime dataClient machine

A transaction time measurement mechanism has a transaction time manager running on a server computer system, a transaction time agent running on a client computer system that is coupled to the server computer system via a network, and a simple protocol for allowing them to directly and efficiently communicate. The transaction time agent is configured according to configuration data stored in a configuration table in a transaction time database, and stores transaction time data in a statistics table according to this configuration. The data in the statistics table is indexed to allow retrieving only the transaction time data of interest. The simple communication protocol supports multiple transaction time managers in a network computing environment that may all communicate with a single client.

Owner:IBM CORP

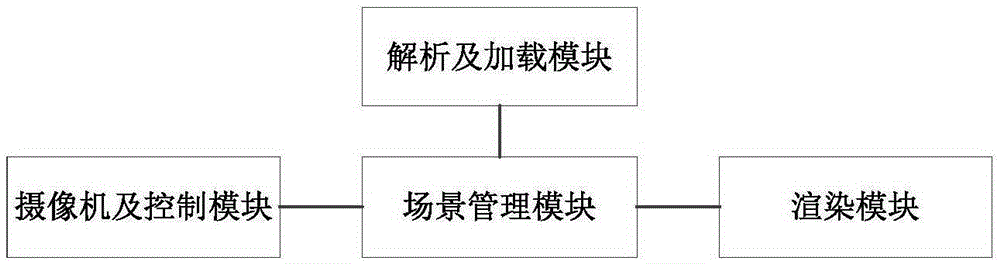

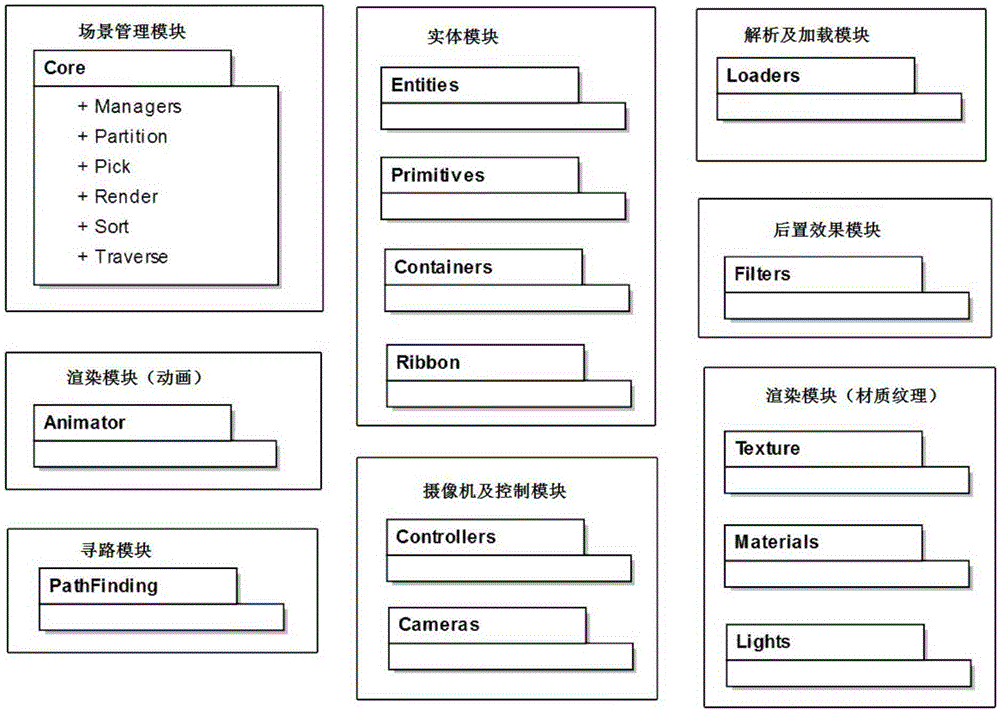

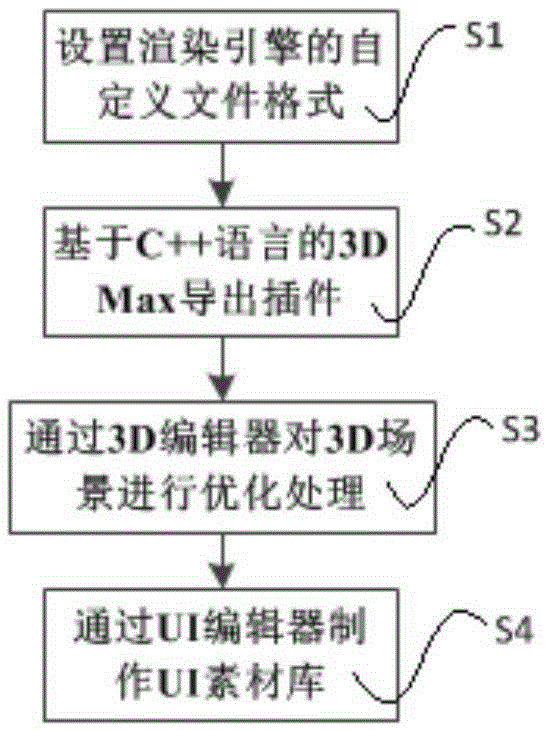

Rendering engine, implementation method and producing tools for 3D web game

ActiveCN105354872AShorten the development cycleImprove good performanceAnimationViewing frustumParsing

The present invention provides a rendering engine, an implementation method and producing tools for a 3D web game. The rendering engine comprises: a parsing and loading module, which is used for reading, decompressing, and parsing a self-defined file format that is finally output by a workflow, to obtain information required by specific rendering, so as to implement non-blocked parsing; a scene management module, which is used for implementing view frustum culling, traversing and classifying objects in a scene, dispatching pickup and mouse events, and managing a rendering process; a camera and control module, which is used for scene roaming and camera animation; and a rendering module, which is used for rendering all information required by an object, which comprises renderings for geometry, material quality, animation and a transformation matrix. The producing tools comprise an export plug-in, a self-defined file format, a 3D editor, a special effect producing tool and a UI producing tool. The rendering engine, implementation method and producing tools provided by the present invention have good cross-platform performance and scalability, and can greatly shorten a game development period and lower a development threshold.

Owner:深圳墨麟科技股份有限公司

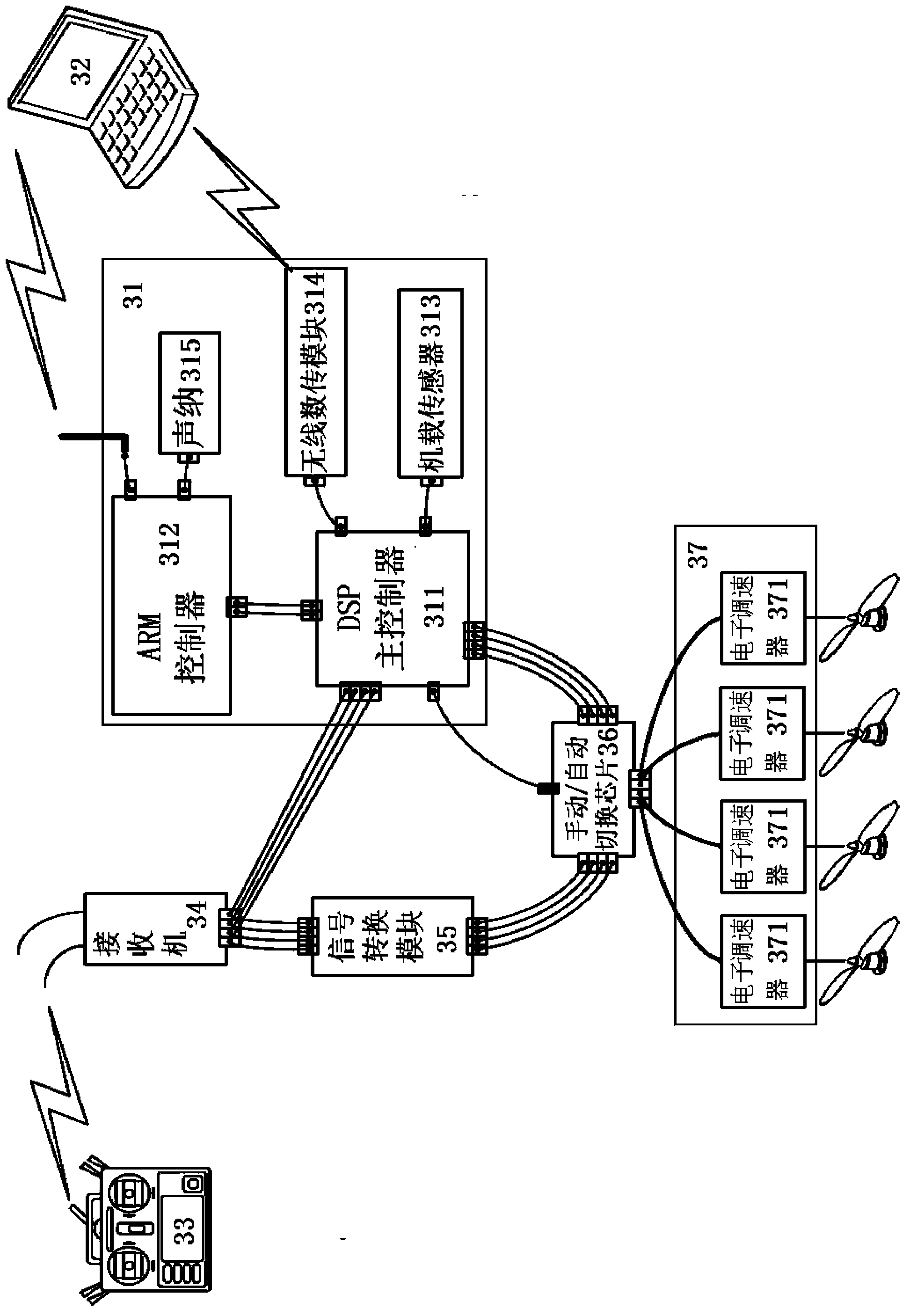

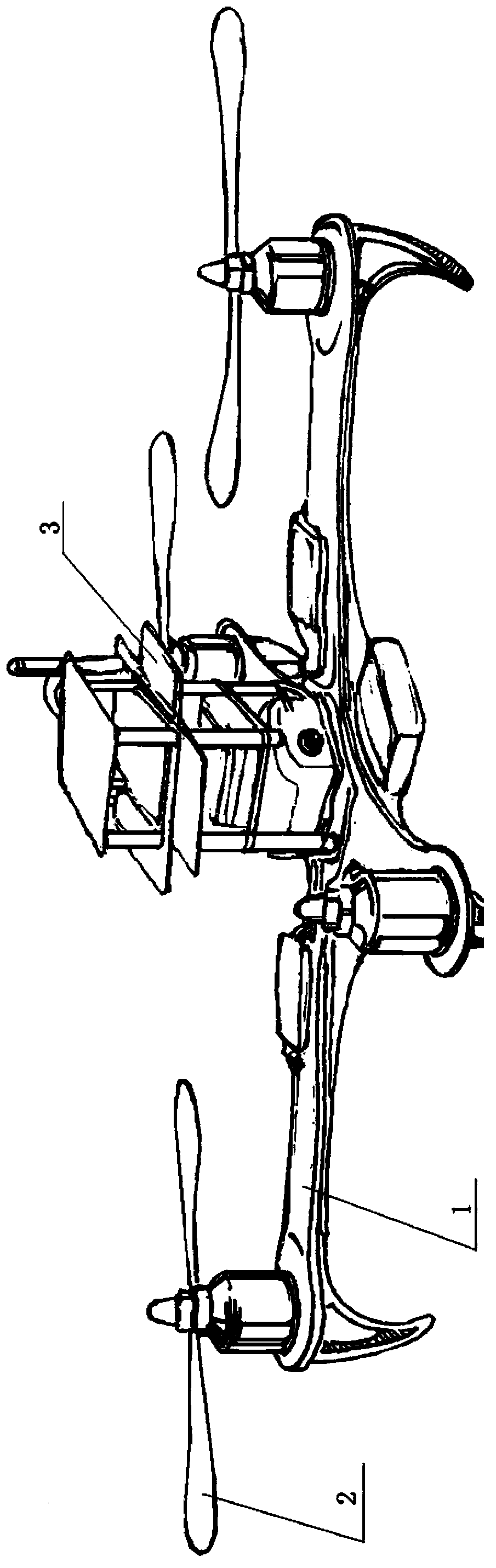

DSP (Digital Signal Processor)-based quad-rotor unmanned aerial vehicle autonomous hover control system and method

ActiveCN103365295ALow costEasy to replacePosition/course control in three dimensionsBrushless motorsQuad rotor

The invention discloses a DSP (Digital Signal Processor)-based quad-rotor unmanned aerial vehicle autonomous hover control system and method. The control system is provided with four screw propellers and control units which are arranged on four airfoils respectively; and each control unit is that a master control unit is connected to a ground computer through a wireless network, and a receiver is connected with a signal conversion module and a manual / automatic switching chip in sequence, transmits a received signal transmitted by a remote controller into the manual / automatic switching chip through the signal conversion module, is also connected with the manual / automatic switching chip through the master control unit and is used for transmitting the received signal to the manual / automatic switching chip through the master control unit for controlling driving units to drive direct current brushless motors on the four screw propellers to work. According to the method, kalman filtering processing is performed on sonar data to obtain accurate height data and driver control. According to the system and the method, the autonomous flight capacity of a micro quad-rotor unmanned aerial vehicle and the adaptability to the environment can be effectively enhanced, and the autonomous flight control under indoor environments and outdoor environments can be finished.

Owner:TIANJIN UNIV

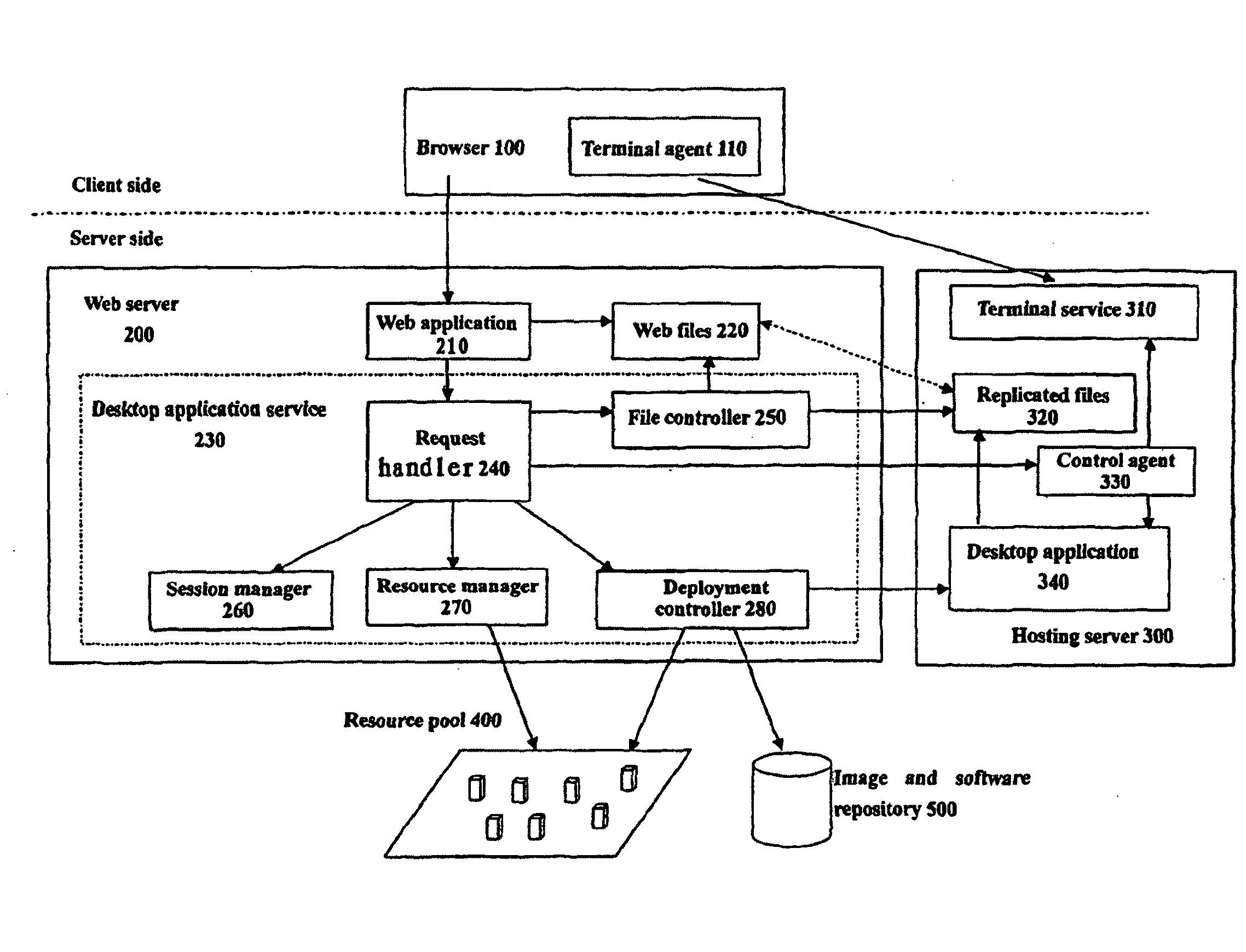

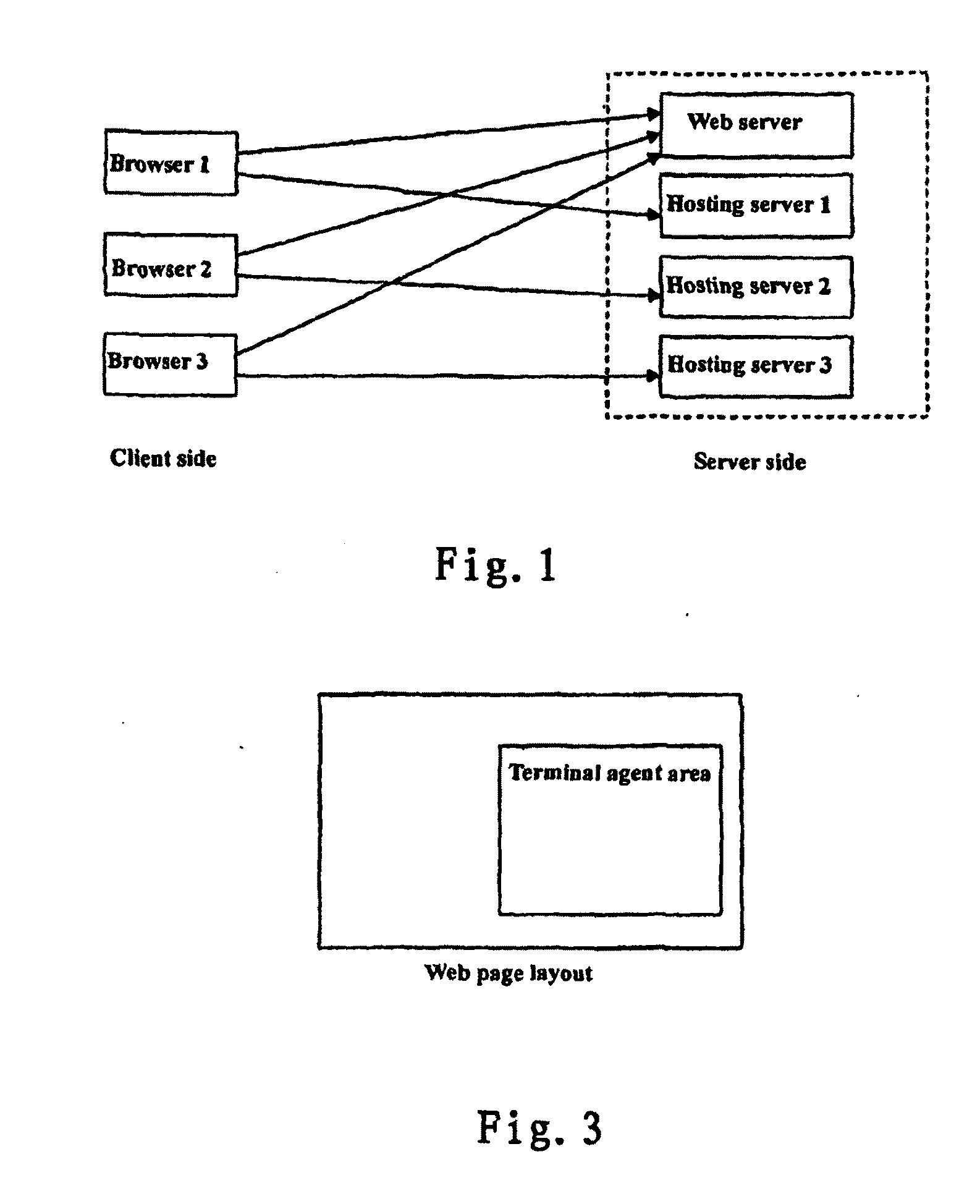

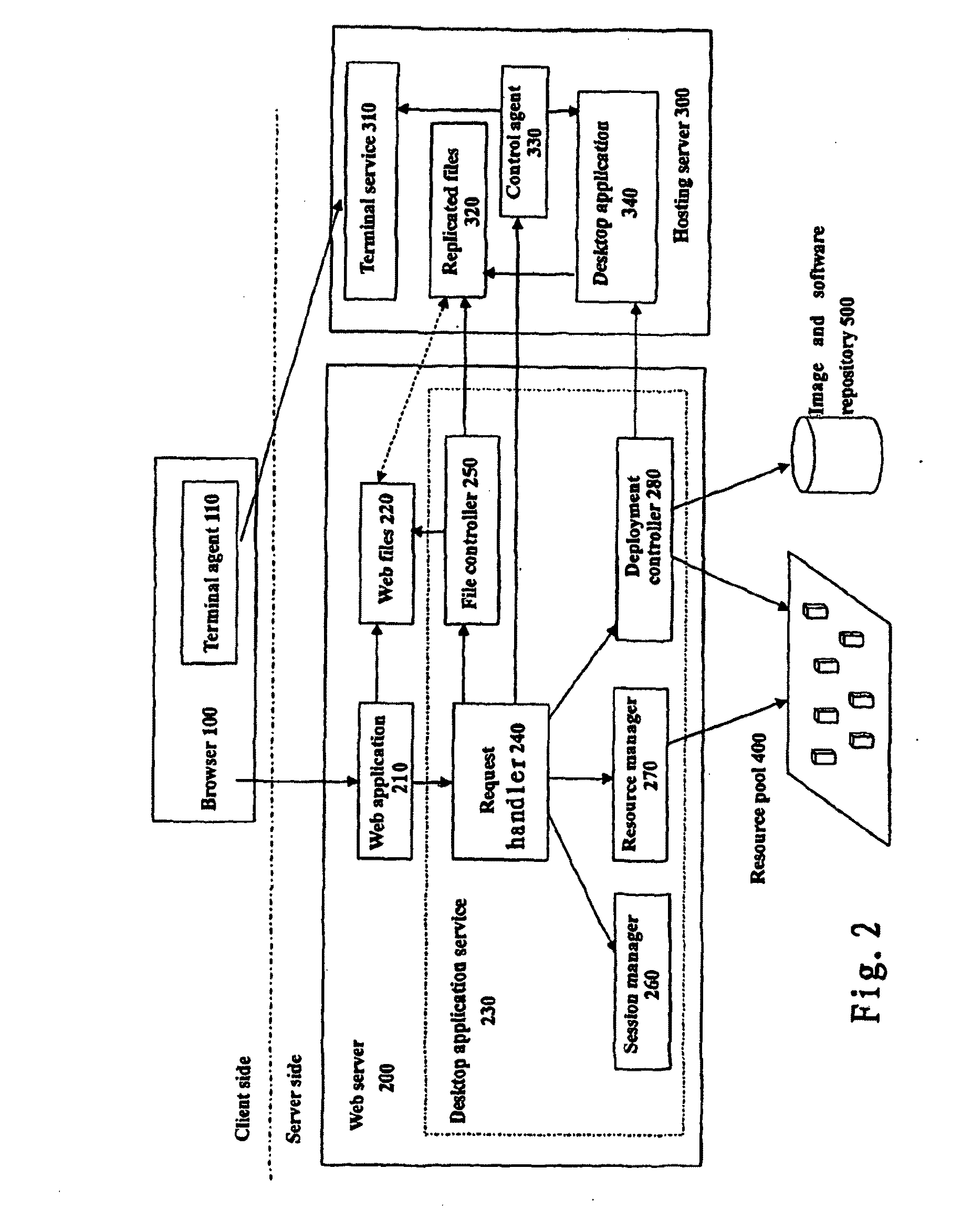

Method, Server and System for Converging Desktop Application and Web Application

ActiveUS20100313199A1Management effort for be simplifyDevelopment cycle of can be reduceMultiple digital computer combinationsProgram loading/initiatingClient-sideWeb server

The present invention provides a method, Web server and computer system for converging a desktop application and a Web application. The method may comprise: in response to a request from a client user for using a target desktop application, starting a desktop application initialization process on the Web server and determining an appropriate corresponding hosting server for the user; preparing and provisioning desktop application environment on the corresponding hosting server and starting the target desktop application; transmitting the corresponding hosting server's address to the client so as to make desktop application interaction between the client and the corresponding hosting server; and in response to the completion of the desktop application interaction, stopping and exiting the target desktop application on the corresponding hosting server. In accordance with the present invention, the client user is provided with a unified Web console for accessing desktop applications and Web applications and Web files can be shared between the desktop applications and the Web applications.

Owner:GREEN MARKET SQUARE LTD

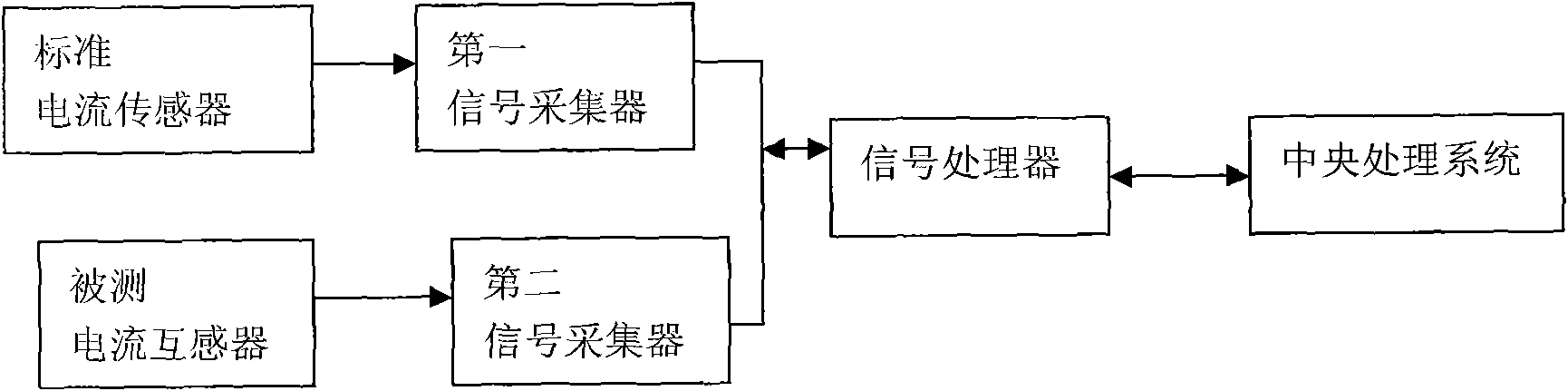

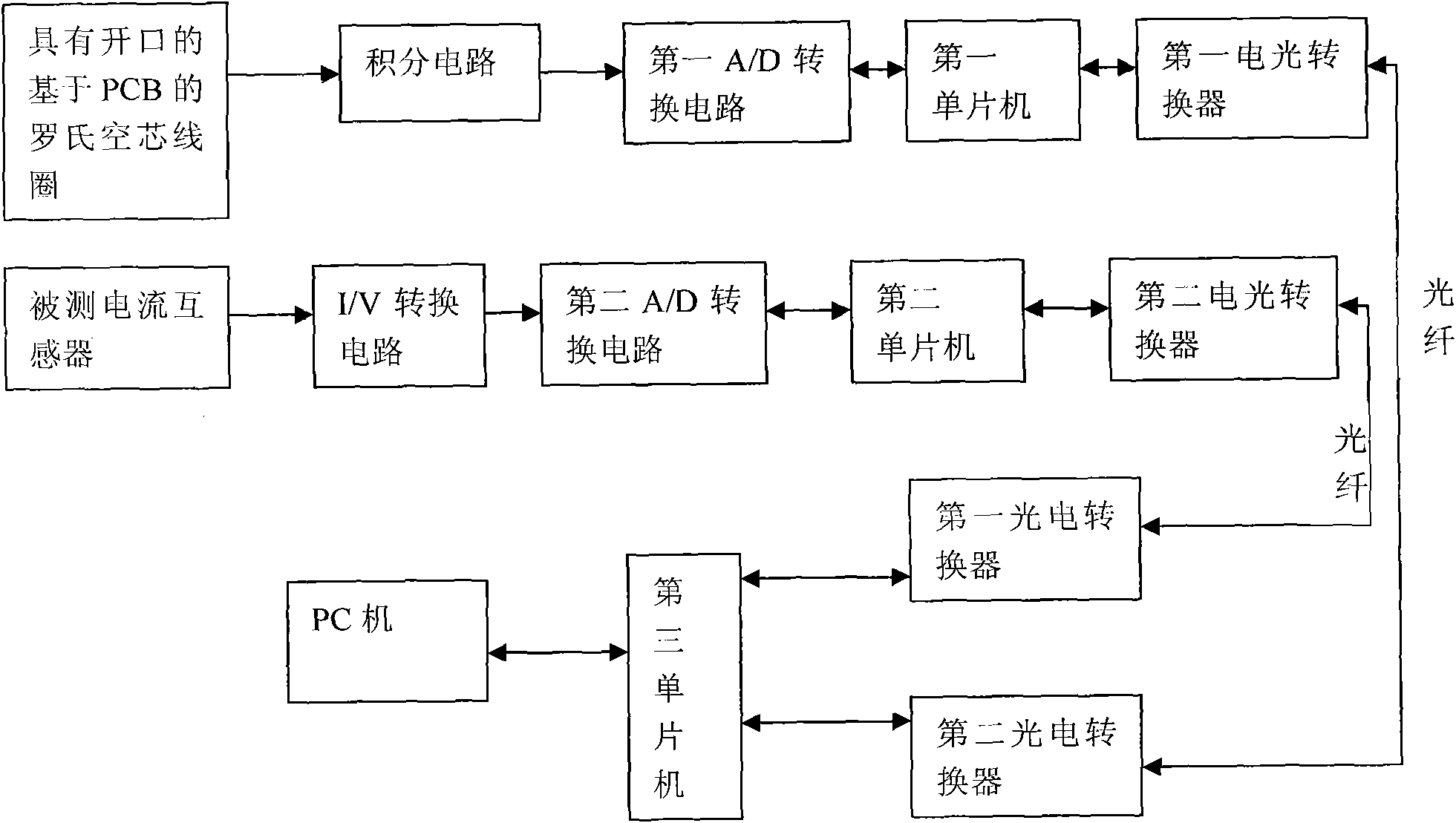

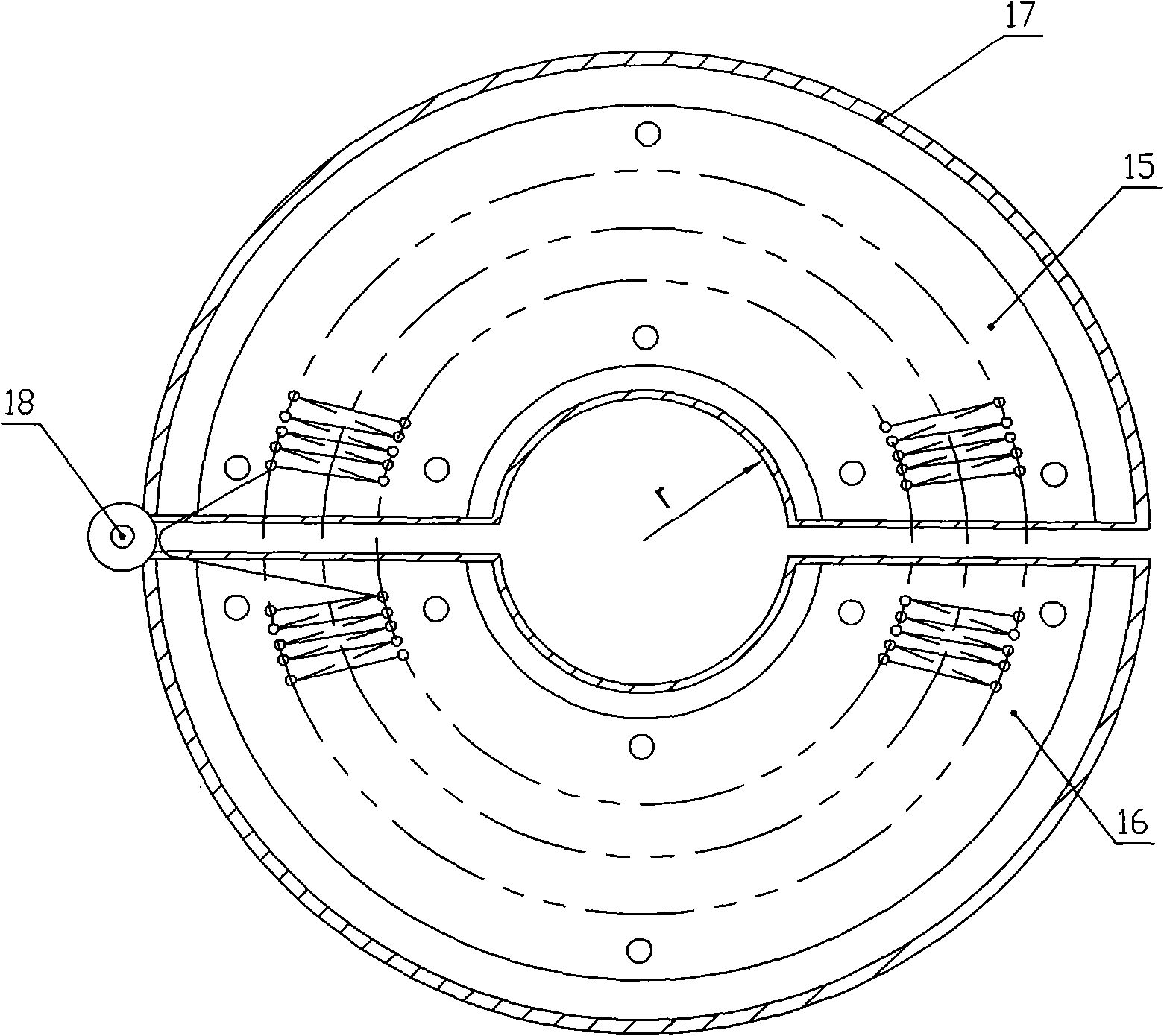

Online accuracy detection method and system of current transformer

InactiveCN101644752AEnable online assessmentGood effectElectrical measurementsSignal onCurrent sensor

The invention discloses online accuracy detection method and system of a current transformer. A standard current sensor is connected with a transmission line and collects a current signal on the transmission line; a current signal output by the current transformer and the current signal on the transmission line are collected by respective signal collectors and sent to a signal processor in sharingtime; and the signal processor synchronously sends the signals to a central processing system (CPU) which compares and processes the two signals received in the same clock and calculates the error conditions of the measured current transformer. The online accuracy detection system of the current transformer can be electrically connected or disconnected with a circuit of a transformer to be measured and can uninterruptedly carry out accuracy comparison measurement with the transformer to be measured under an electric operation condition for dozens of hours so as to estimate the current transformer under different operational working conditions and environmental characteristics, achieve the online accuracy estimation of the current transformer and have favorable effect.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST

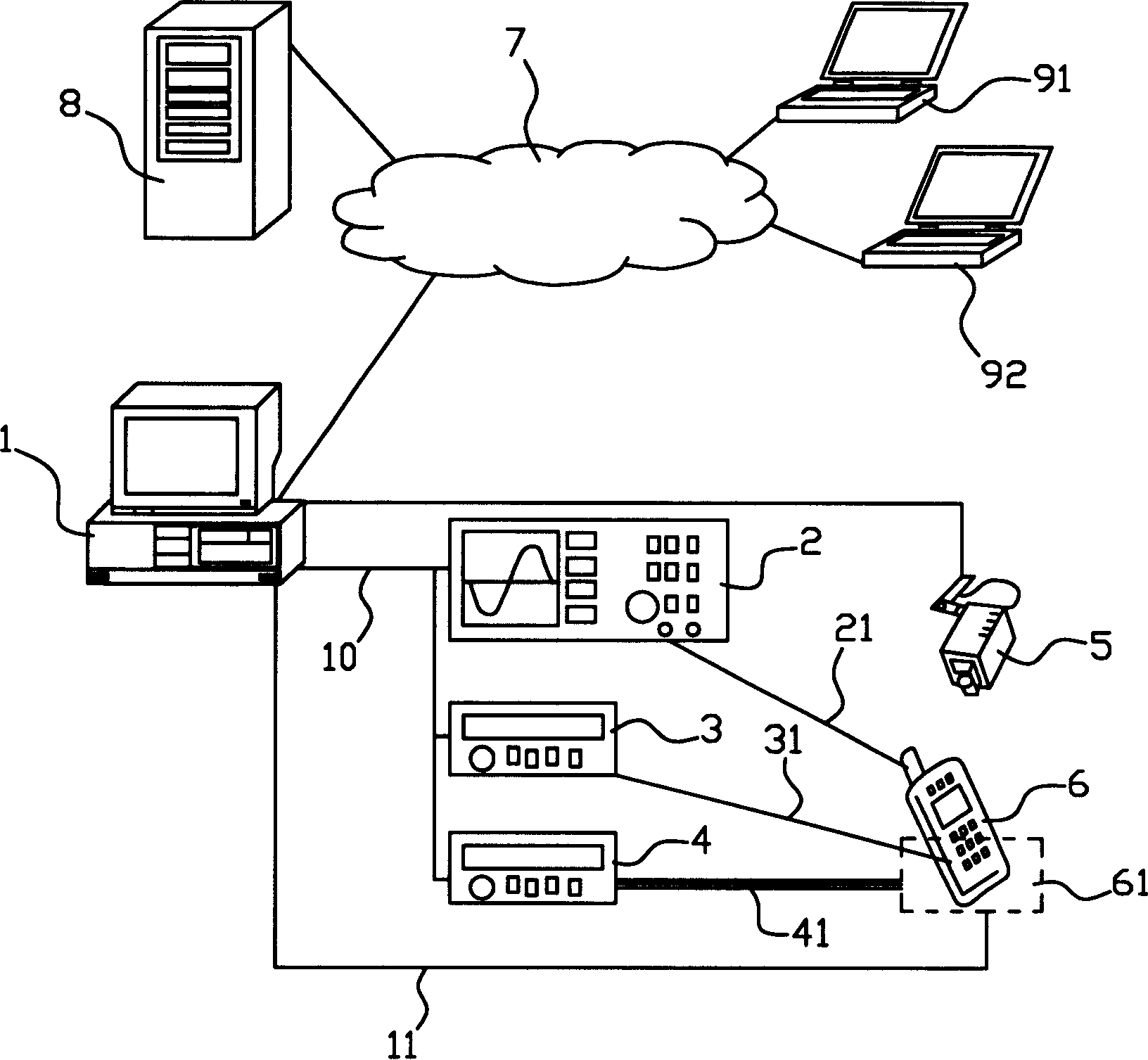

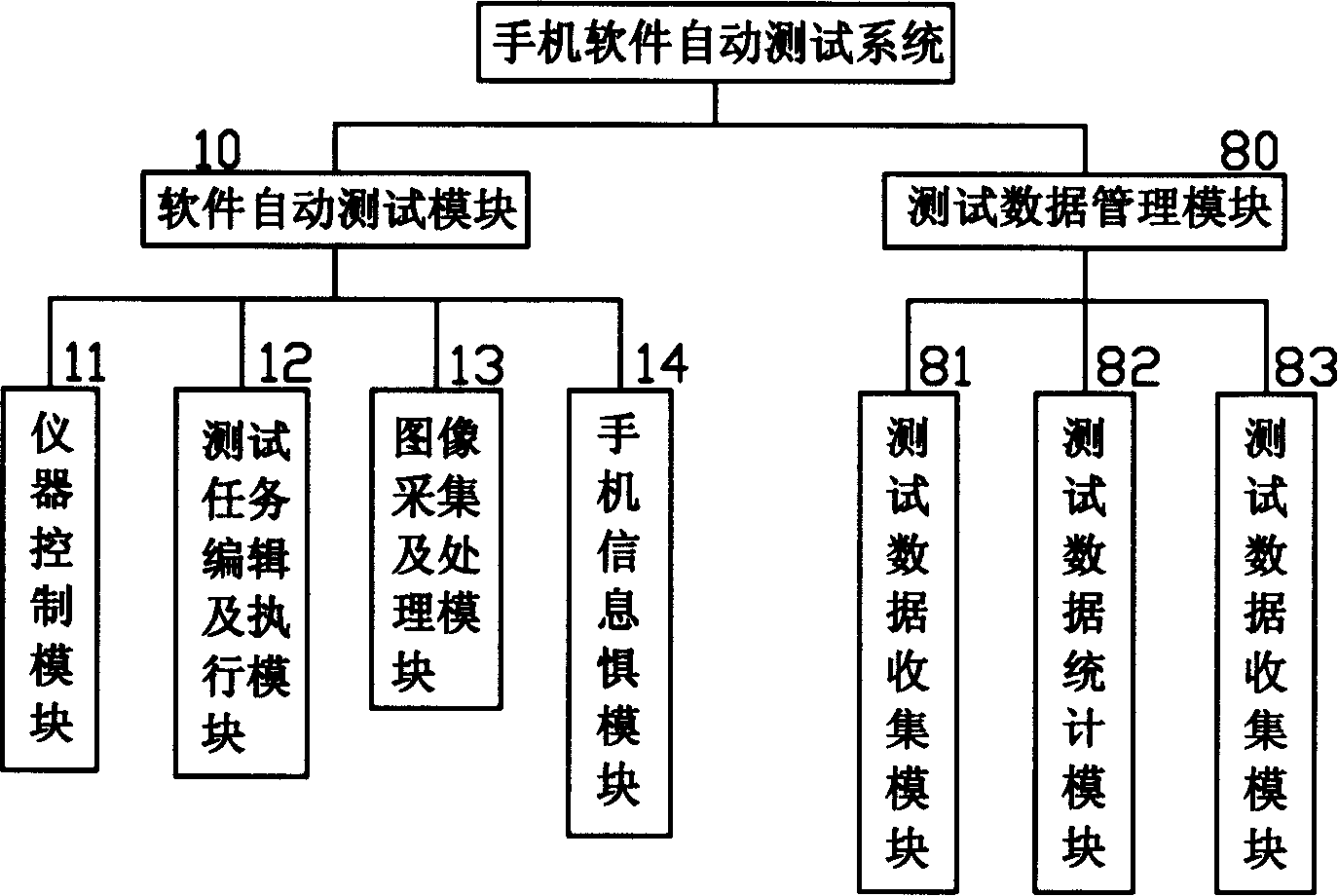

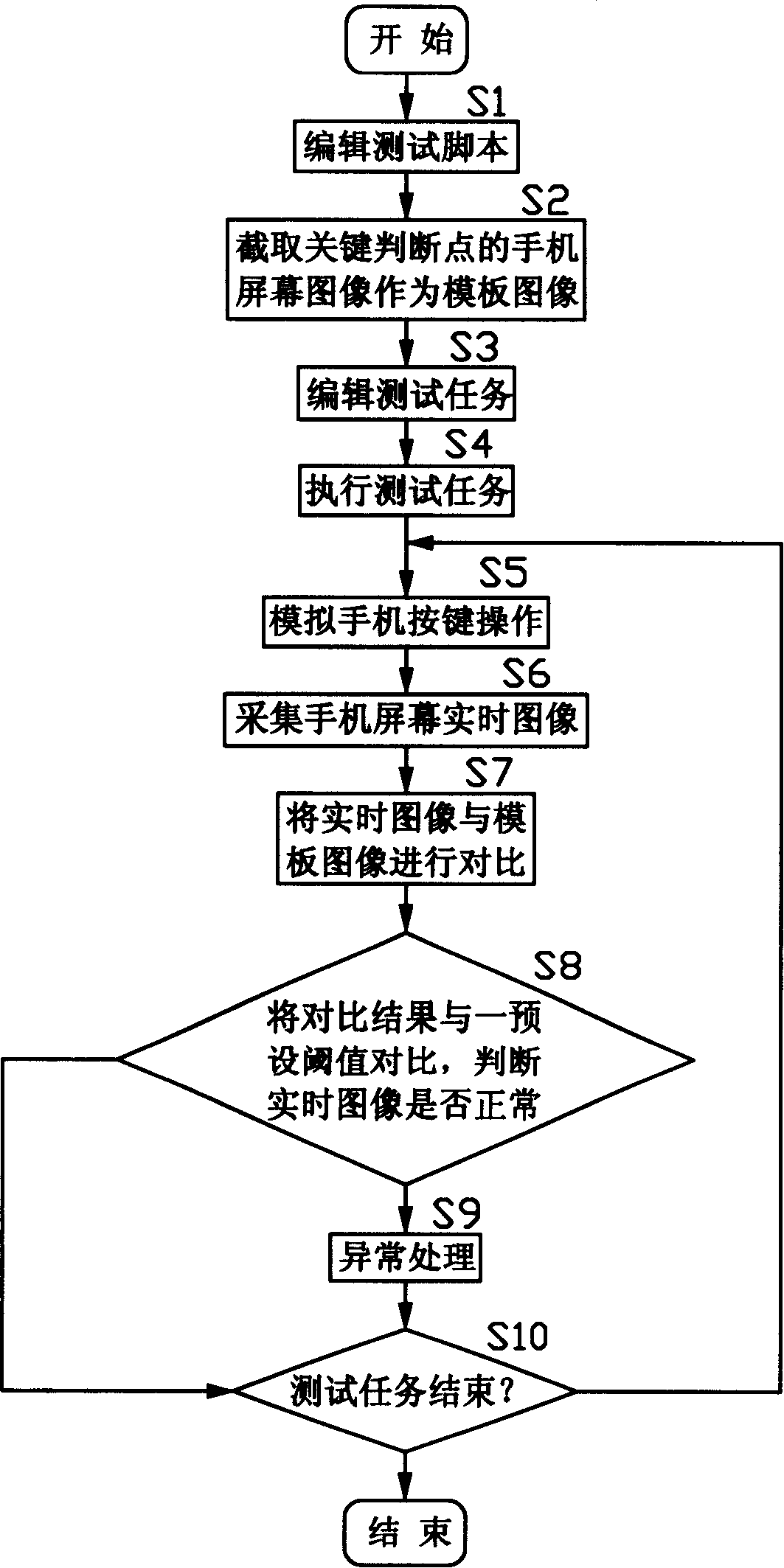

Automatic testing method and system for mobile phone software

InactiveCN101175285AShorten test timeIncrease coverageSoftware testing/debuggingSubstation equipmentTest efficiencyAutomatic test equipment

The present invention relates to the automatic test method and the system of mobile phone software. The method mainly includes five steps; firstly, the keystroke operation of a mobile phone is simulated by a program-controlled switching switch; secondly, communication between a base station and the mobile phone is simulated by a comprehensive mobile phone tester; thirdly, the images of the display screen of the mobile phone are real-timely collected by a camera; fourthly, according to a test task, an industrial control computer controls the unified operation of the program-controlled switching switch and the comprehensive mobile phone tester, collects information coming from the serial port of the mobile phone and the camera-collected real-time images of the display screen of the mobile phone and compares the collected real-time images with corresponding preset template images; fifthly, according to the information coming from the serial port of the mobile phone and the comparison result of the images, the industrial control computer judges the operation state of the mobile phone software. The present invention can accurately simulate the process in which a person operates a mobile phone, so the test result is more accurate. Moreover, the present invention can increase the test efficiency and ensure the comprehensive traversal of test cases.

Owner:LENOVO MOBILE COMM TECH

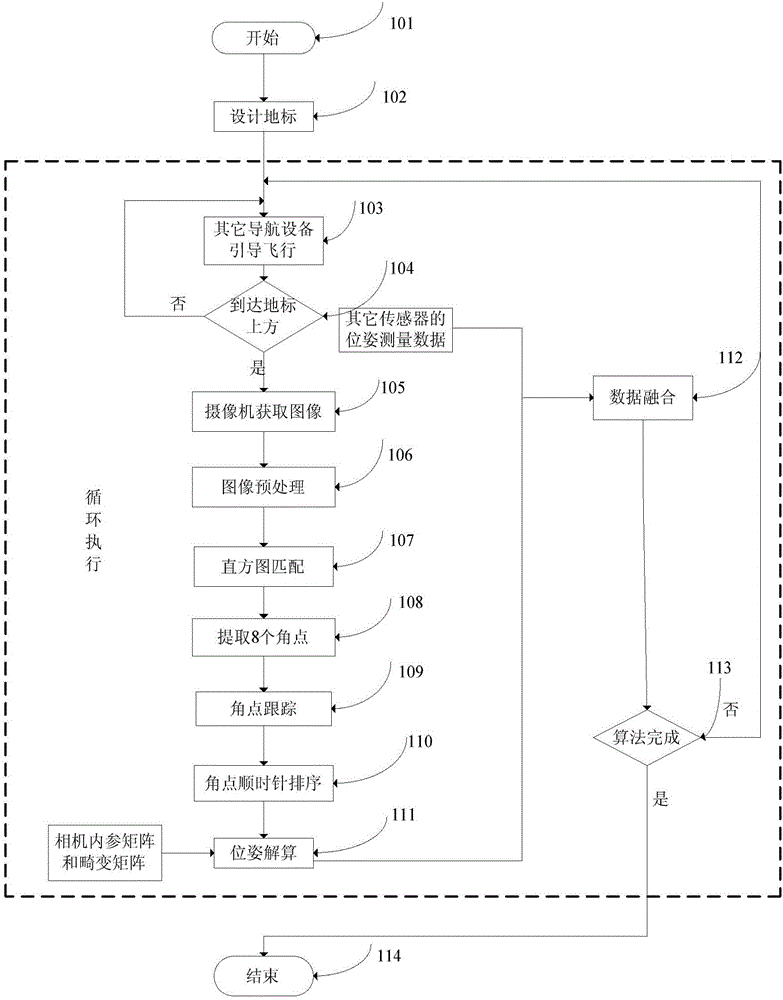

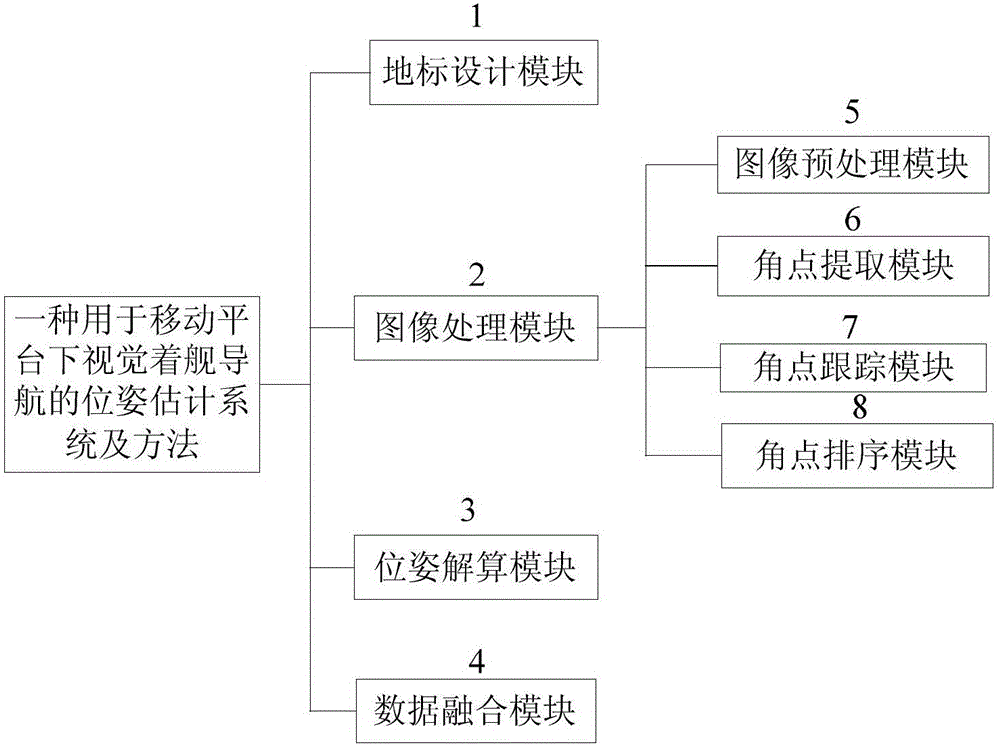

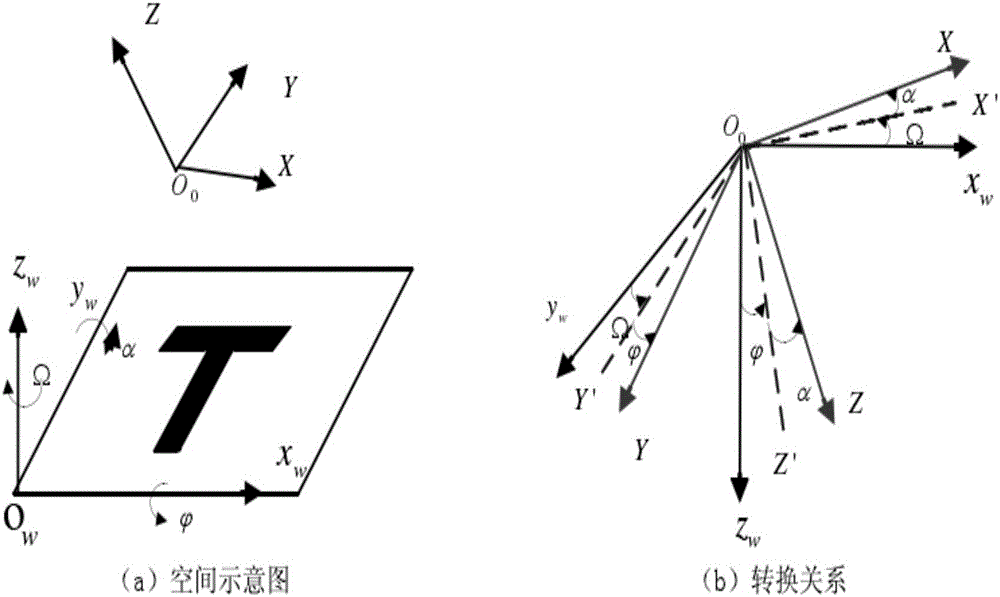

Pose estimation system and method for visual carrier landing navigation on mobile platform

ActiveCN105021184ASmall amount of calculationImprove real-time performanceNavigation instrumentsUncrewed vehicleComputer science

The invention belongs to unmanned aerial vehicle autonomous carrier landing field, and in particular relates to a pose estimation system and method for visual carrier landing navigation on mobile platform. The system and method can resolve the pose information of a moving ship relative to a UAV on a real-time basis through treatment of a collaborative landmark, have the advantages of small amount of calculation in the algorithm, good real-time property, and simple implementation, and provides a premise for safe landing of the UAV. The method uses a camera as a main sensor to reduce development costs and shorten the development cycle.

Owner:XIDIAN UNIV

Wristwatch structure, electronic core for wristwatch, and method for manufacturing wristwatch

InactiveUS9256209B2Solve needsShorten the development cycleElectronic time-piece structural detailsElectric windingElectricityElectric drive

The present invention provides a wristwatch structure, an electronic core for a wristwatch, and a method for manufacturing the wristwatch. The wristwatch structure comprises: a dial; an indicator designed with the dial; an electric driving component connected to the indicator, for driving the indicator and actuating it; and an electronic core having an integrated circuit unit packaged therein, the electronic core also having a plurality of two-dimensional joints distributed on an external surface thereof, wherein the electric driving component is electrically connected to the integrated circuit unit of the electronic core via one set of joints among the two-dimensional joints. The present invention can improve compatibility for various designs, thereby shortening the product development cycle.

Owner:PRINCO MIDDLE EAST FZE

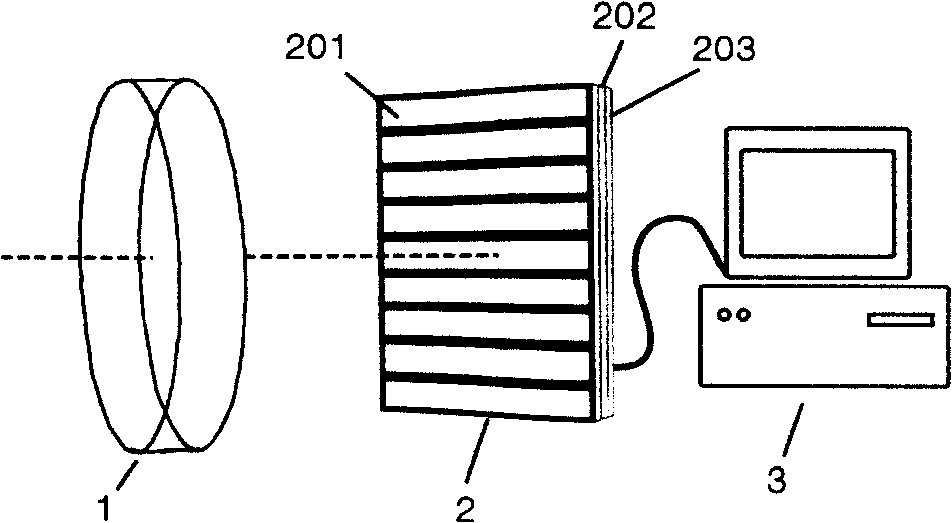

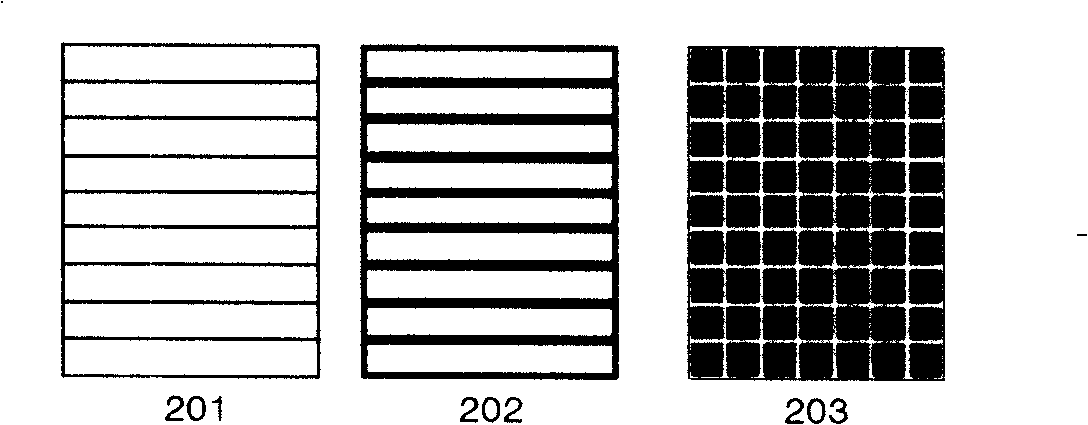

Method and equipment for simultaneously acquiring stereo and multispectral image

InactiveCN101320138AEasy to buyComplete specifications and modelsPhotogrammetry/videogrammetryOptical elementsDigital dataData acquisition

The invention relates to a method and a device for obtaining tri-dimensional and multi-spectral image simultaneously, which comprises an imaging optical system (1) and a focal plane component (2) which is arranged at the focus of the imaging optical system (1). The invention is characterized in that the focal plane component (2) comprises a light filter (201), a field diaphragm (202) and an area array CCD (203); the light filter (201), the field diaphragm (202) and the area array CCD (203) are arranged in sequence; the area array CCD (203) is connected with a digital data acquisition and processing system (3). The invention solves the technical problems of the complicated design and high price of the CCD chip of the area array CCD of a component. The invention has the advantages that the most important two parts in the system, which are a wide-angle optics and the area array CCD, can be easily bought in market, the specifications and models are many, the price is low, the development cycle is short, and the expense of the invention is lesser and the development cycle is shorter by comparing with the technical proposal of the specially developed CCD focal planes.

Owner:陕西光电子先导院科技有限公司

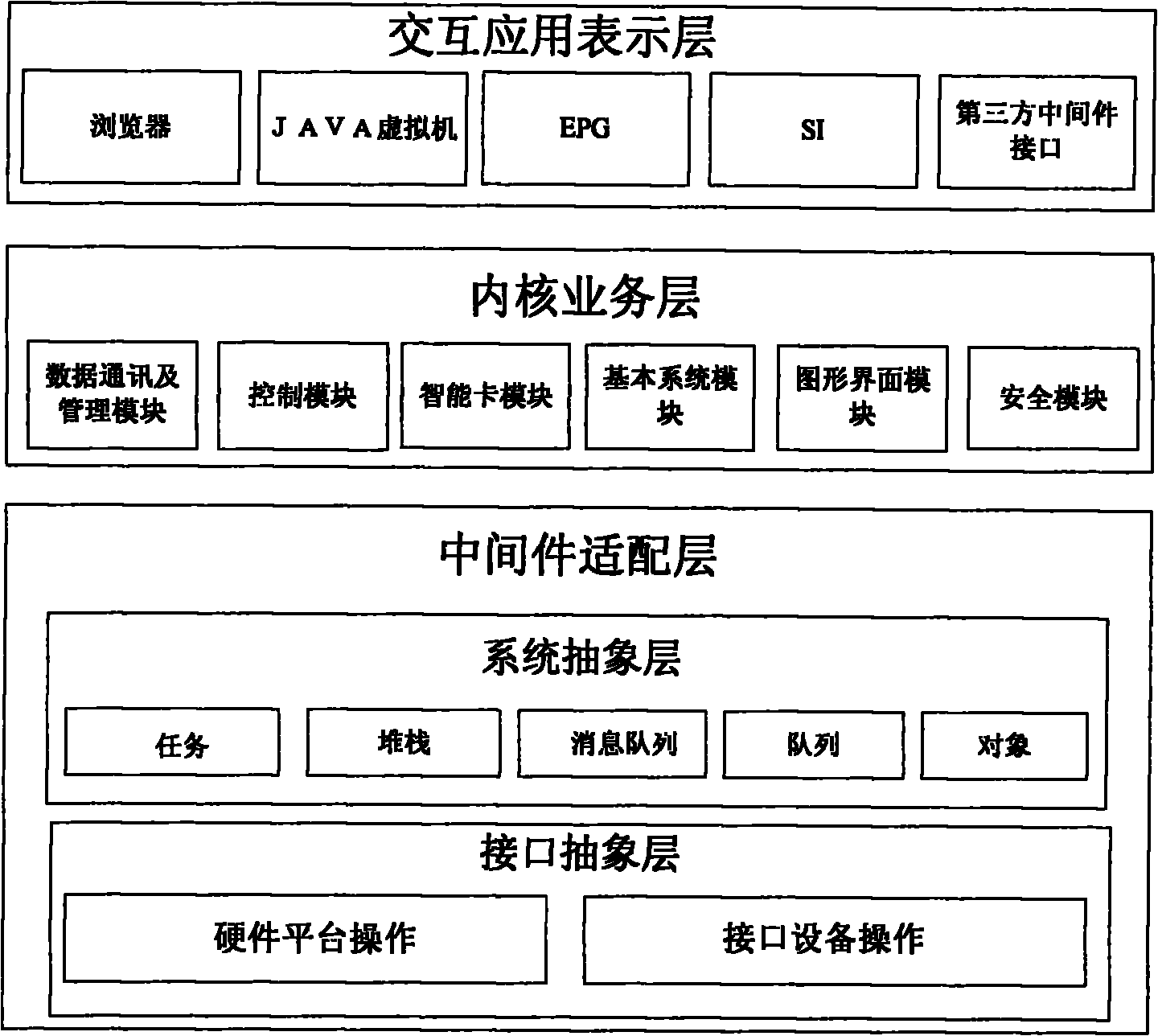

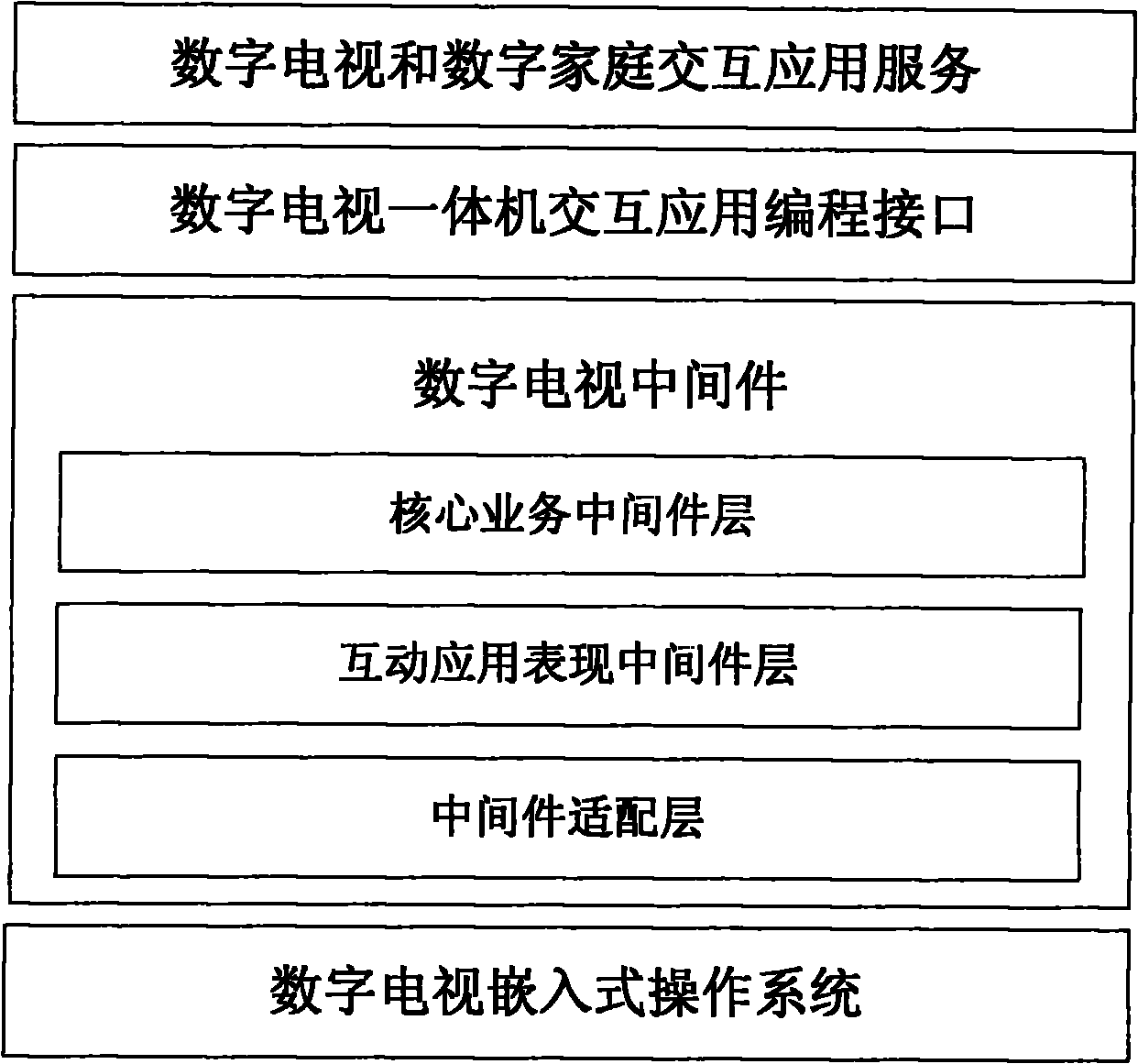

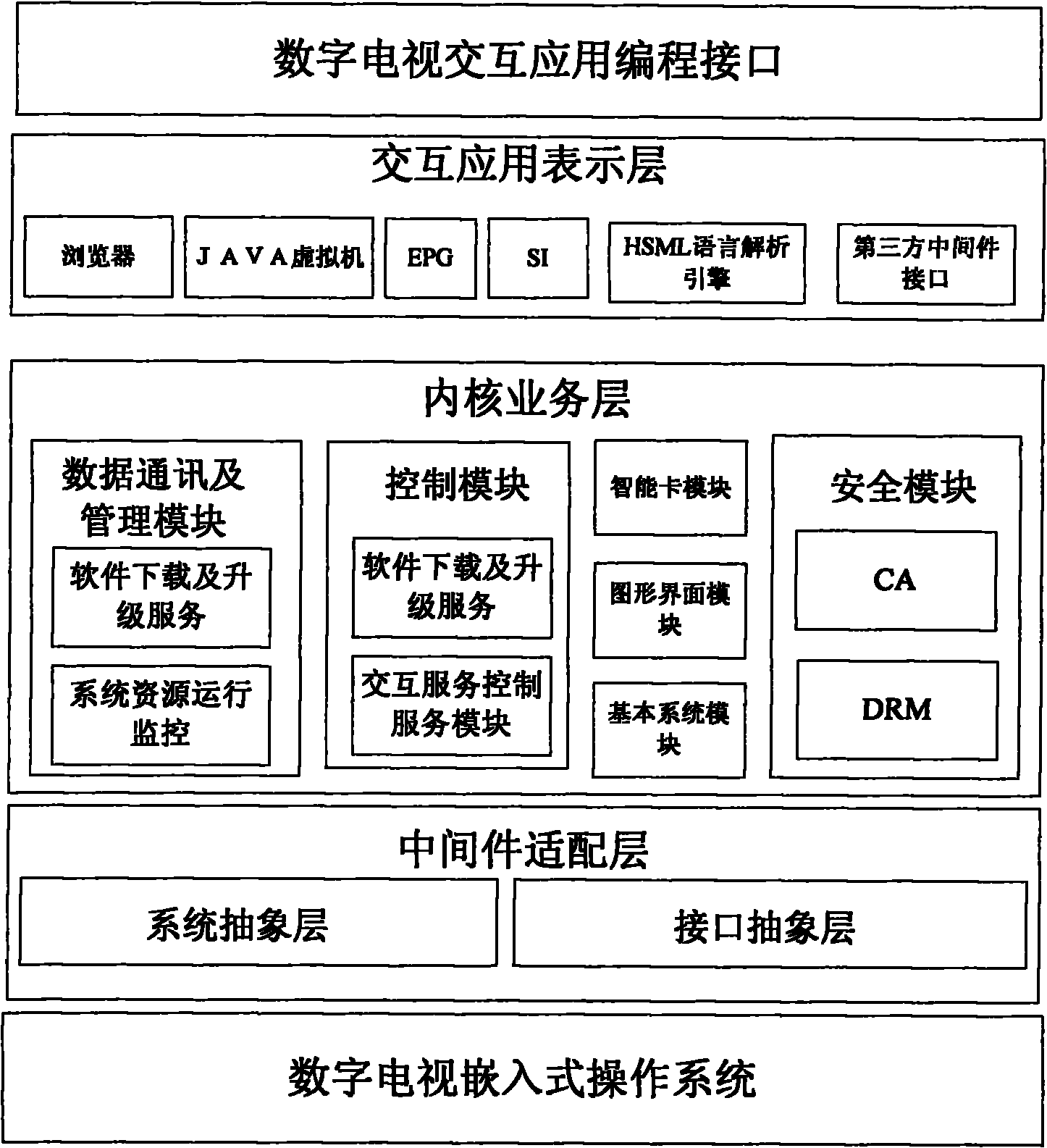

Universal digital television middleware system

InactiveCN101895670AShorten the development cycleReduce development costsTelevision system detailsColor television detailsComputer hardwareOperational system

The invention discloses a universal digital television middleware system, which comprises an interactive application presentation layer, a core service layer and a middleware adaptation layer. In order to realize intercommunication between application development and a platform system of each digital television manufacturer, digital television manufacturers successively launch digital television middleware products thereof. However, due to the absence of a uniform standard, the development difficulty is improved. In order to meet the requirements on digital television multi-hardware interfaces and customized products of the manufacturers and to shield the difference of the digital televisions, home gateway terminals and other products of the manufacturers on the hardware and operating systems, the universal digital television middleware system is provided. The system makes digital television application program-based development irrelevant to hardware lower layers and platforms, and can reduce the development difficulty of application programs and improve the efficiency by providing a universal API interface. Therefore, the application development becomes more simple and convenient, and the openness and portability of the products are stronger.

Owner:SHENZHEN IPANEL TECH LTD +1

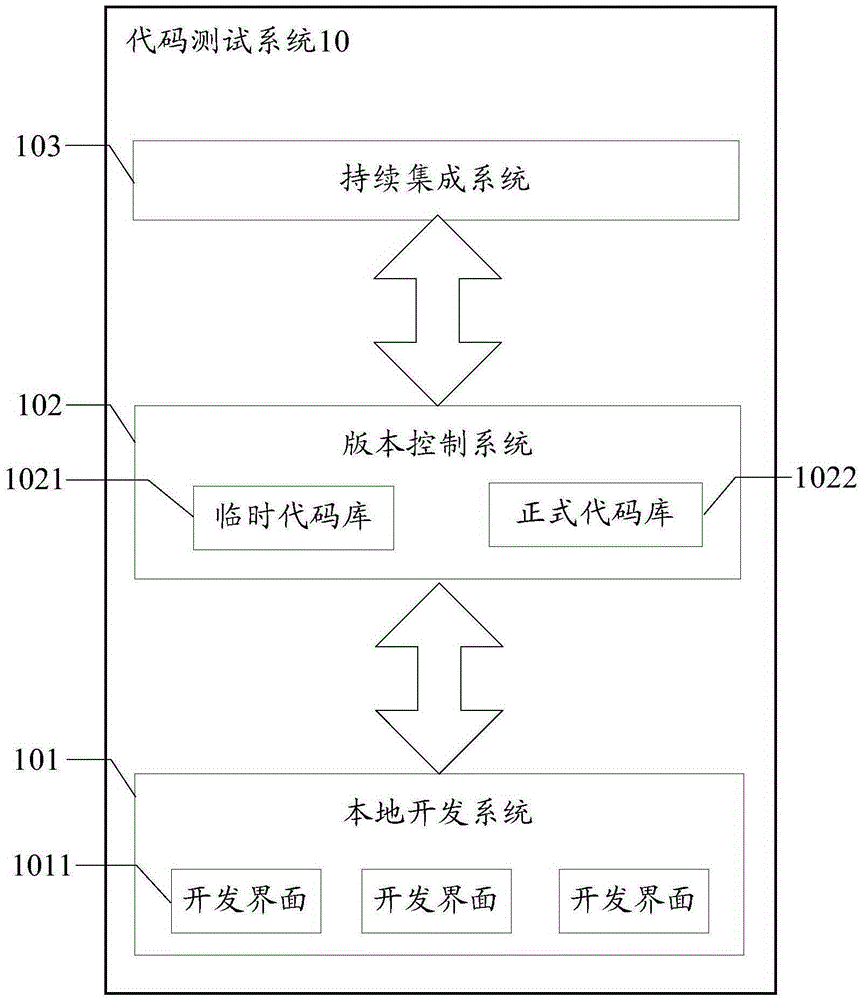

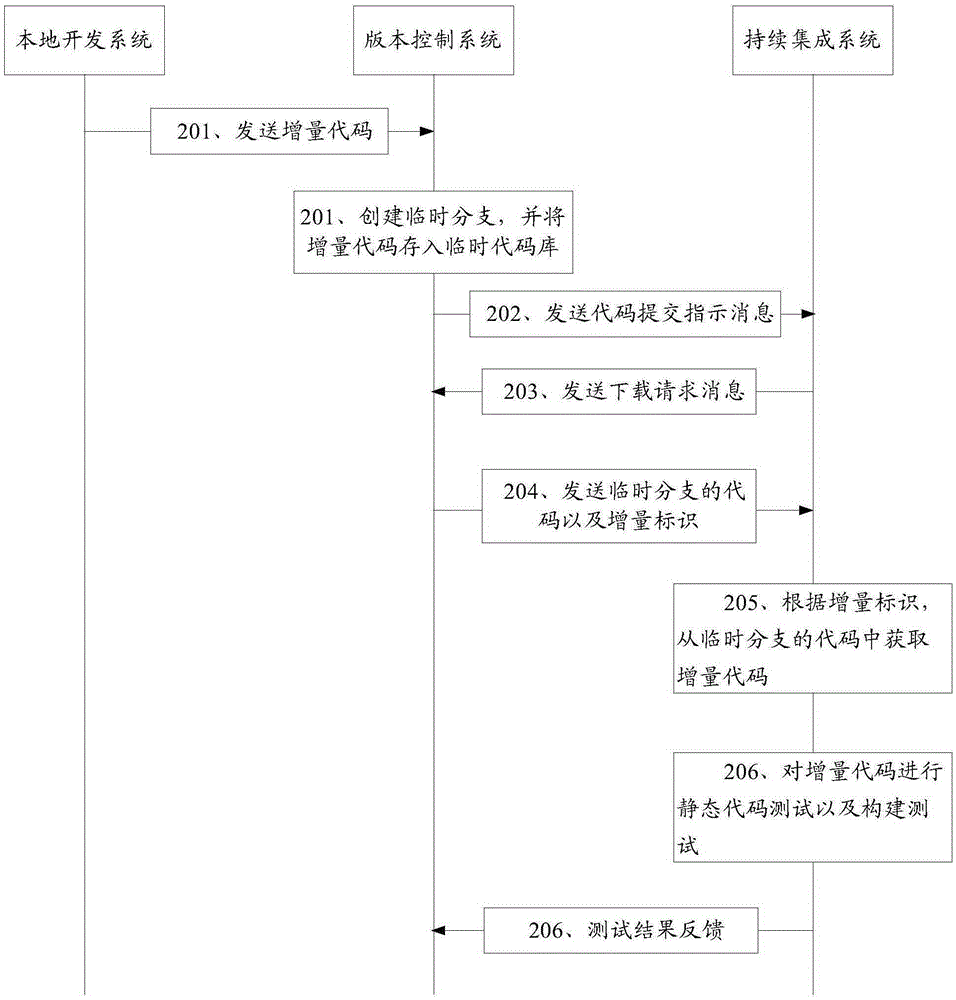

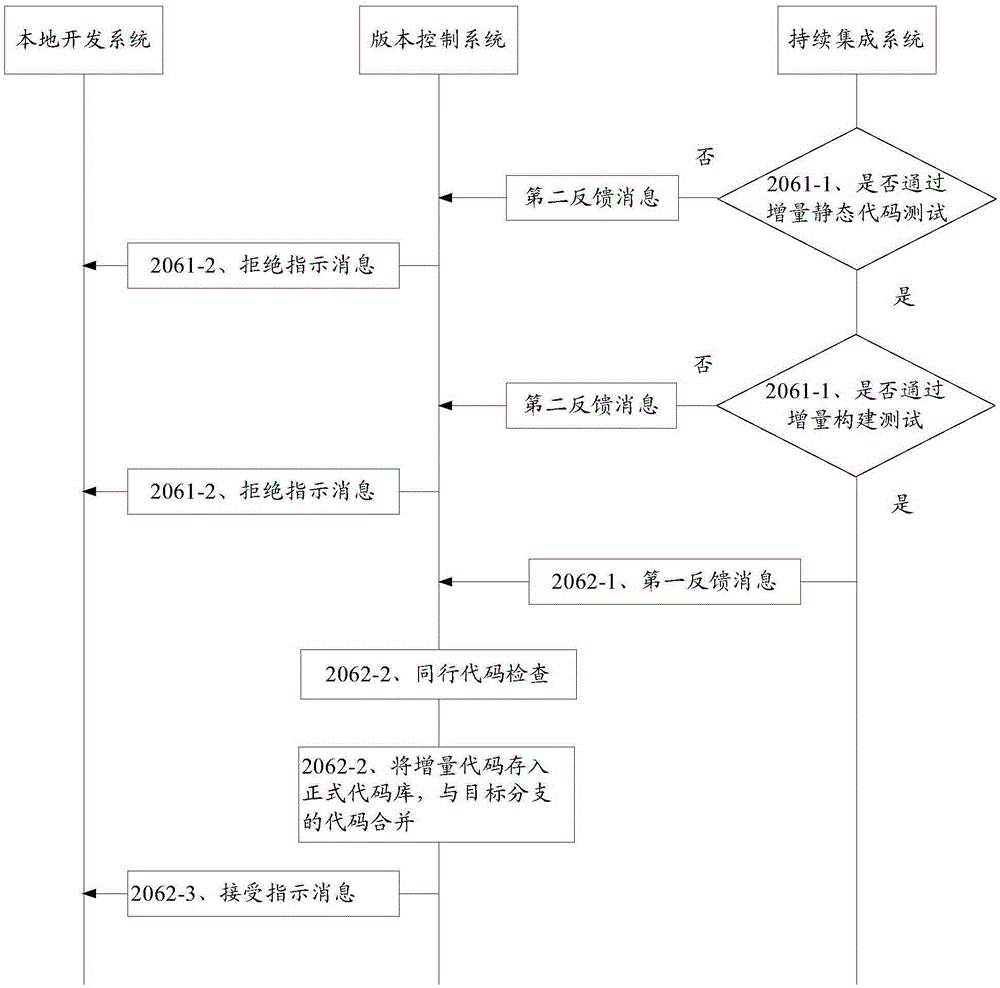

Version control method, code testing method and system

InactiveCN105404519AIncrease success rateShorten the development cycleSpecific program execution arrangementsSoftware developmentIntegrated systems

Embodiments of the invention provide a version control method, a code testing method and system, and relate to the technical field of software development. According to the version control method, the code testing method and the system, a mistake in a newly submitted code can be discovered in time; a successful rate of full amount static code testing is improved; and a development period of a software product is shortened. A specific scheme provided by the emobodiments of the invention comprises: a version control system receiving an incremental data; creating an interim branch, and storing the incremental data in an interim code base, wherein the interim branch is a subordinate branch of a formal branch, and the data of the formal branch is stored in a formal code base; sending the data of the interim branch and an incremental identification to a continuous integrated system; receiving a first feedback message sent by the continuous integrated system, wherein the first feedback message is used for indicating that the data of the interim branch has passed an incremental static code test and an incremental construction test; and combing the incremental data twith the data of the formal branch. According to the invention, the version control method, the code testing method and the system are used for software development.

Owner:HISENSE VISUAL TECH CO LTD

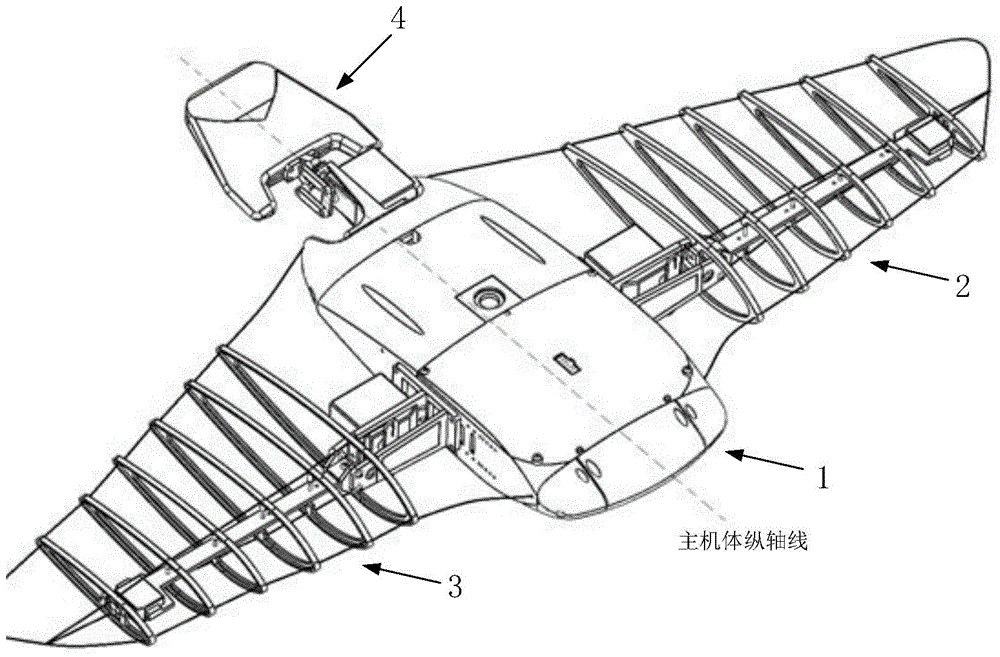

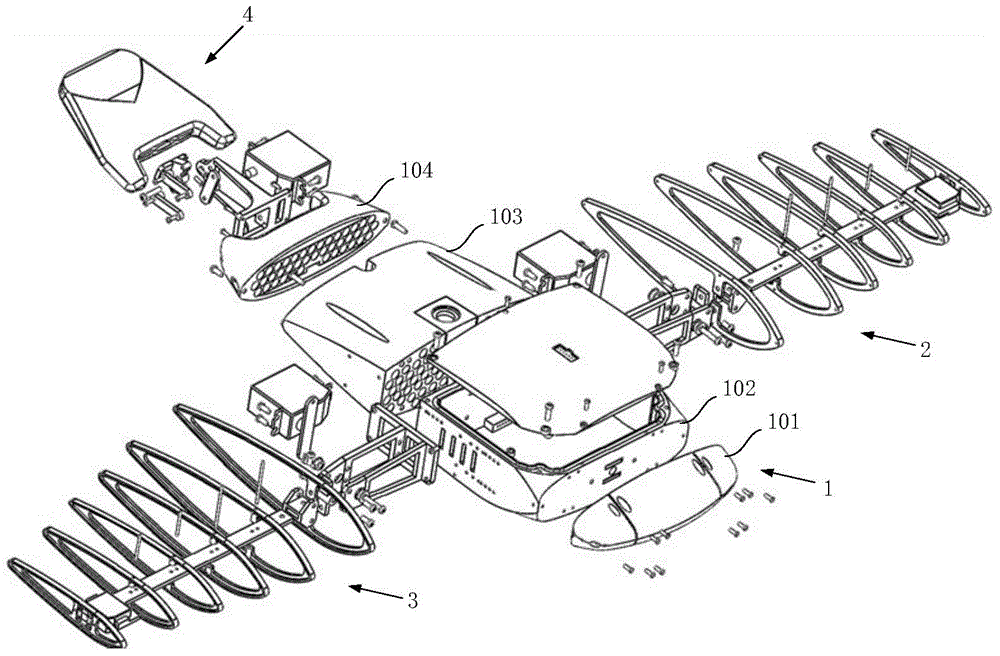

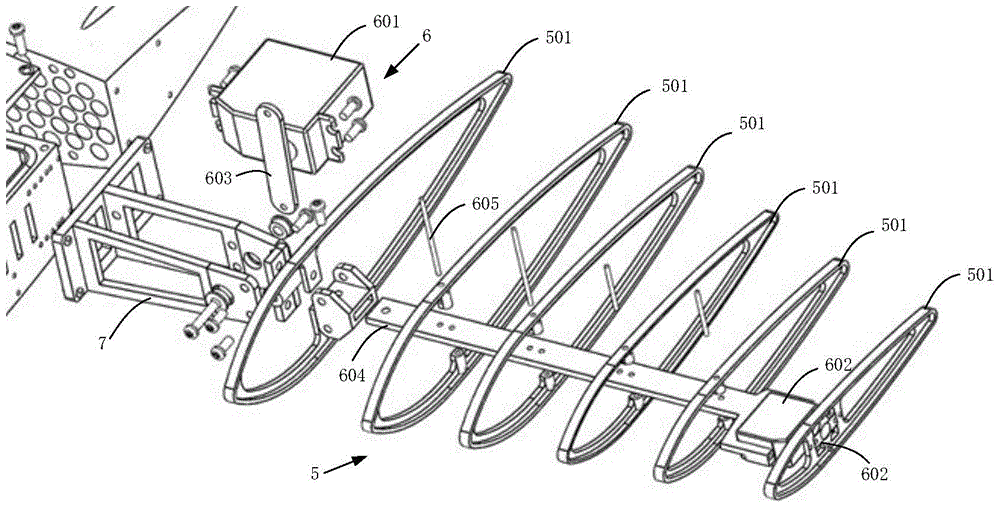

Novel modular bionic underwater robot based on full-flexible pectoral fins

InactiveCN104943839AImprove mobilityImprove concealmentPropulsive elements of non-rotary typePhase differenceBionics

The invention discloses a novel modular bionic underwater robot based on full-flexible pectoral fins. A hydrodynamic module of eagle ray pectoral fins is analyzed, and motion of the pectoral fins is decomposed into vertical bending flapping in the vertical body longitudinal axis direction and twisting motion taking the vertical body longitudinal axis direction as the axis. The whole robot comprises a sectioned main body, a left flexible pectoral fin module, a right flexible pectoral fin module and a tail fin module, and a group module is formed by connecting fin connecting parts; the left and right flexible pectoral fin modules are identical in structure and are in mirror symmetry; a pectoral fin framework adopts a structure similar to that of a plane rib, a symmetrical airfoil is taken as the basic shape, and the pectoral fin modules with streamline sections are spliced through serial connection of straight pectoral fin trunk bones and steel wires. A large steering engine and a small steering engine are arranged at the root and the tip of each pectoral fin to control vertical flapping and twisting motion of each pectoral fin. Through adjustment of motion amplitude, motion frequency and phase difference of the two steering engines of each pectoral fin, different pectoral fin motion postures can be realized, and fish body motion can be finished better.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com