Patents

Literature

10623 results about "Simulation system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

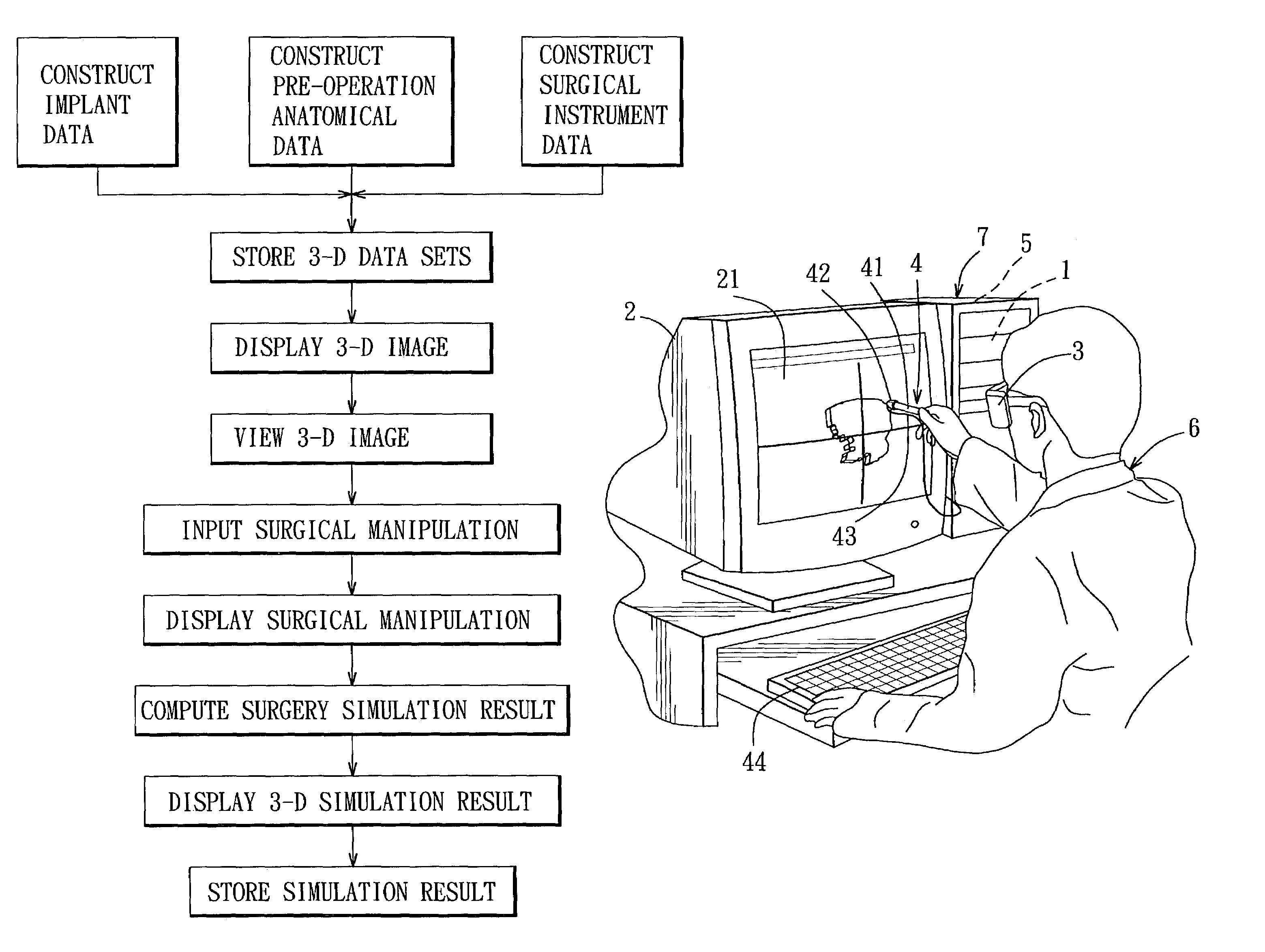

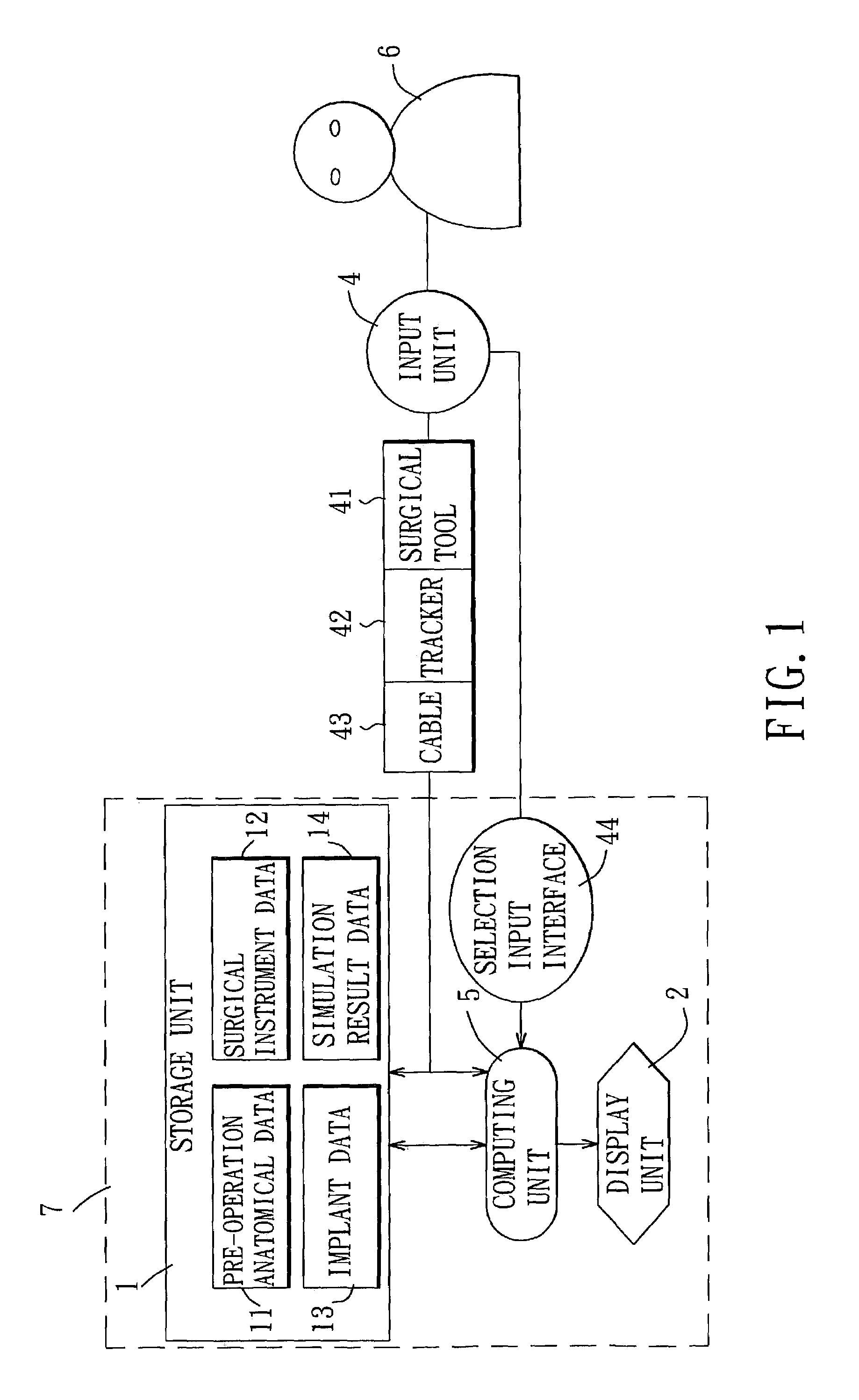

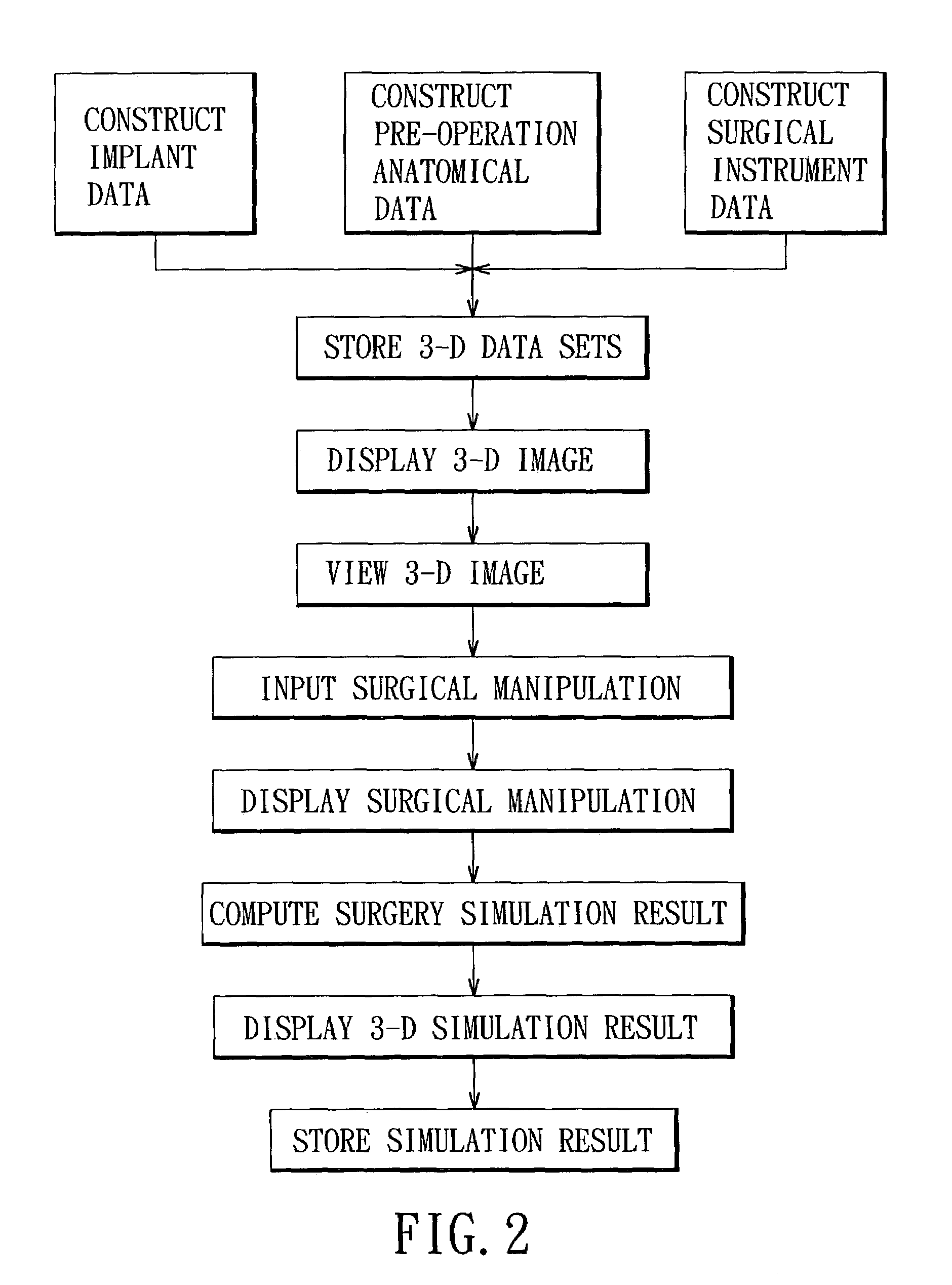

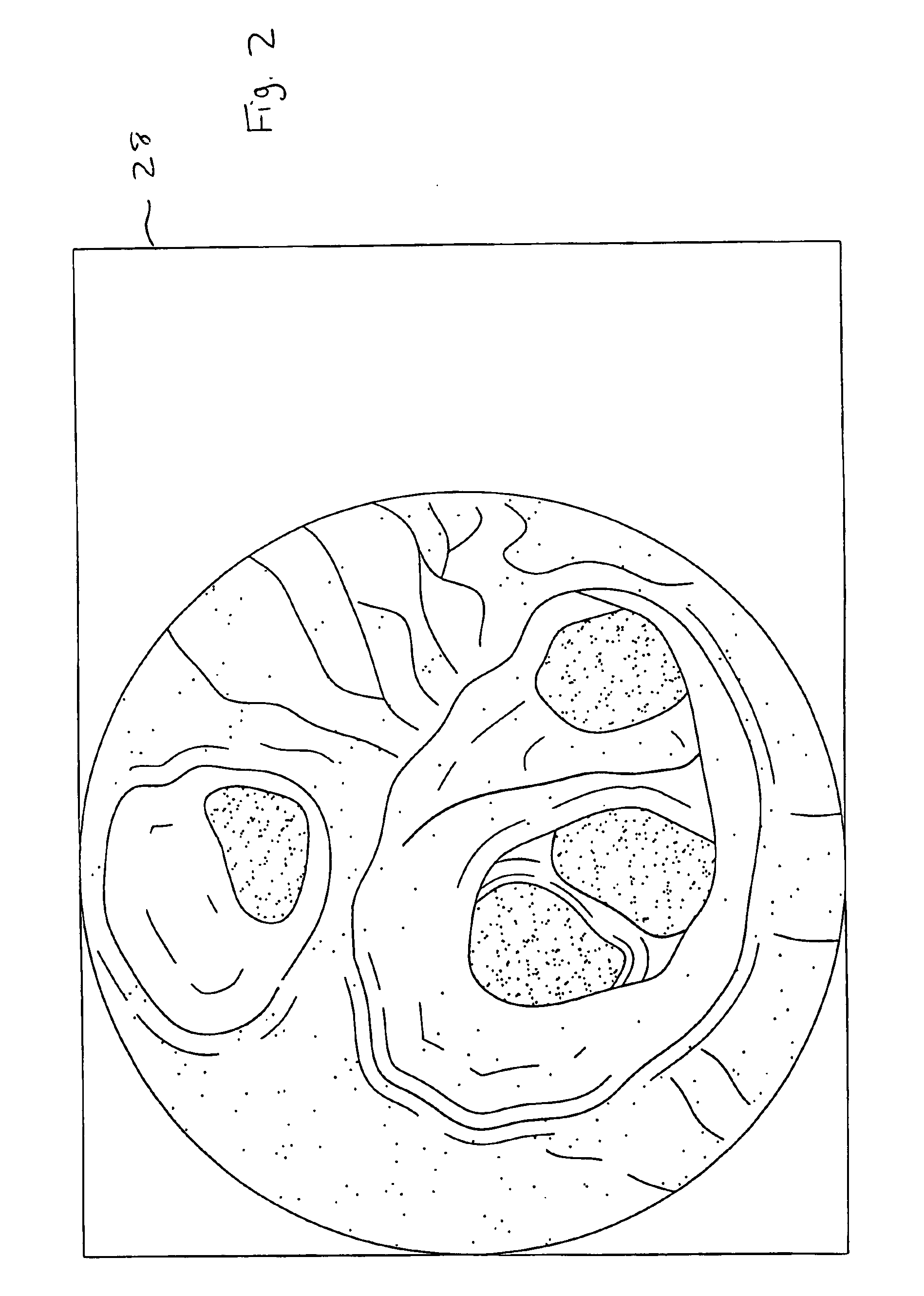

Three-dimensional surgery simulation system

ActiveUS7121832B2High simulationImprove accuracyCathode-ray tube indicatorsEducational modelsData setAnatomic Site

A three-dimensional surgery simulation system is provided for generating a three-dimensional surgery simulation result of an anatomical part undergoing a simulated surgical procedure. The system includes a display unit, a three-dimensional visual imaging unit, a storage unit for storing a plurality of voxelized three-dimensional model image data sets, an input unit for controlling progress of the simulated surgical procedure, and a computing unit for computing the simulation result data in accordance with the voxelized three-dimensional model image data sets and under the control of the input unit, and for controlling the display unit to permit viewing of the surgery simulation result in three-dimensional form thereon by an operator wearing the visual imaging unit.

Owner:OSSIM TECH INC

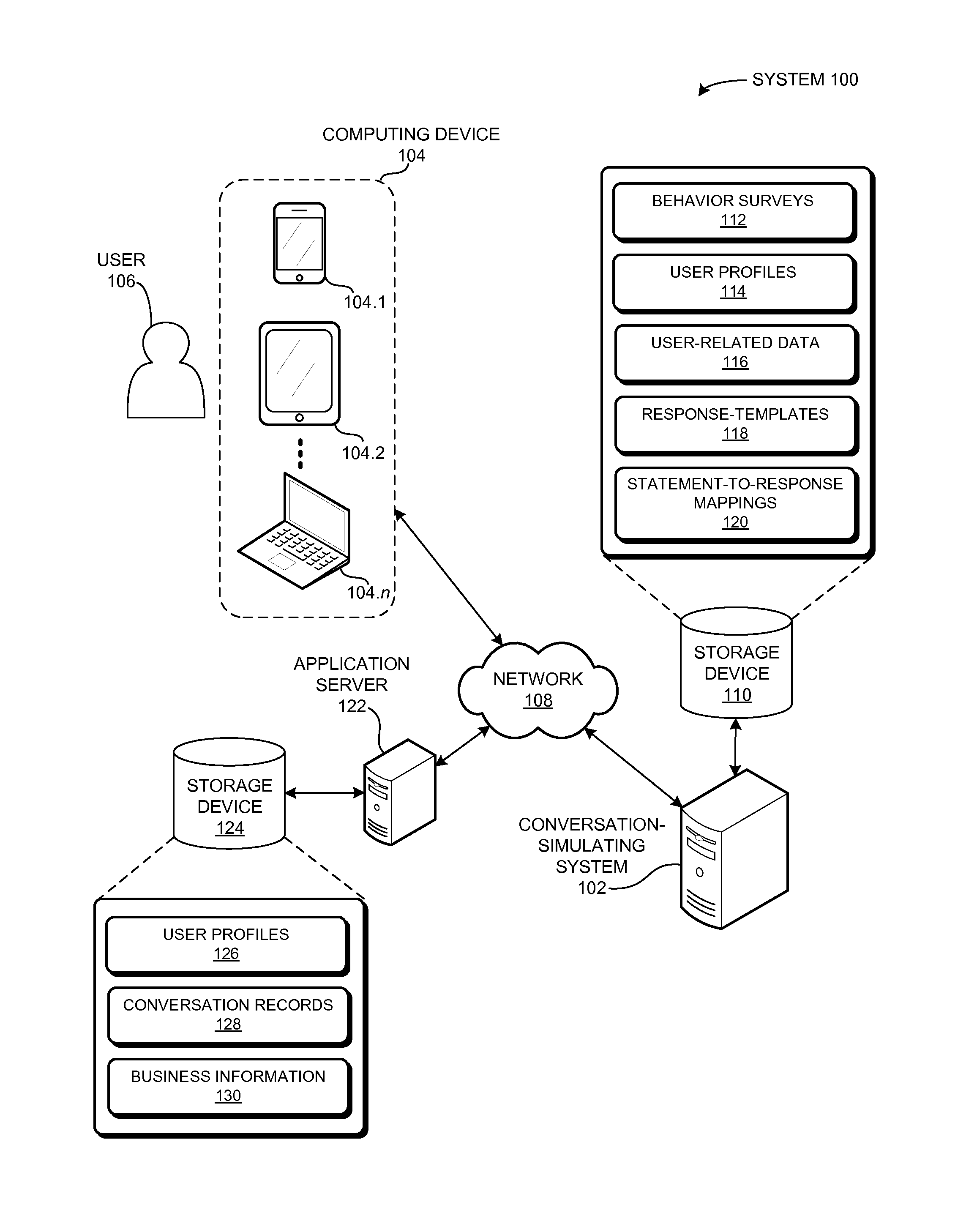

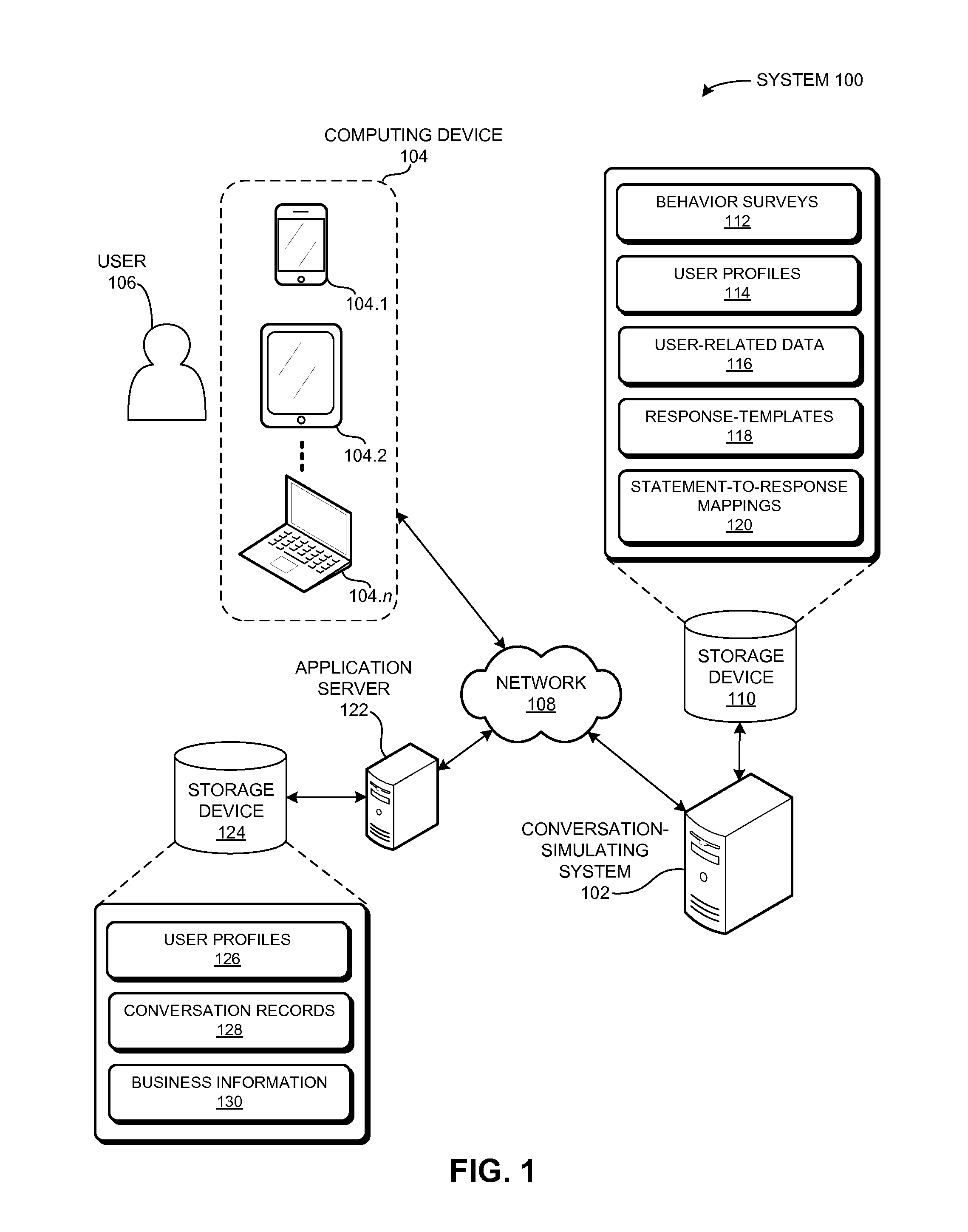

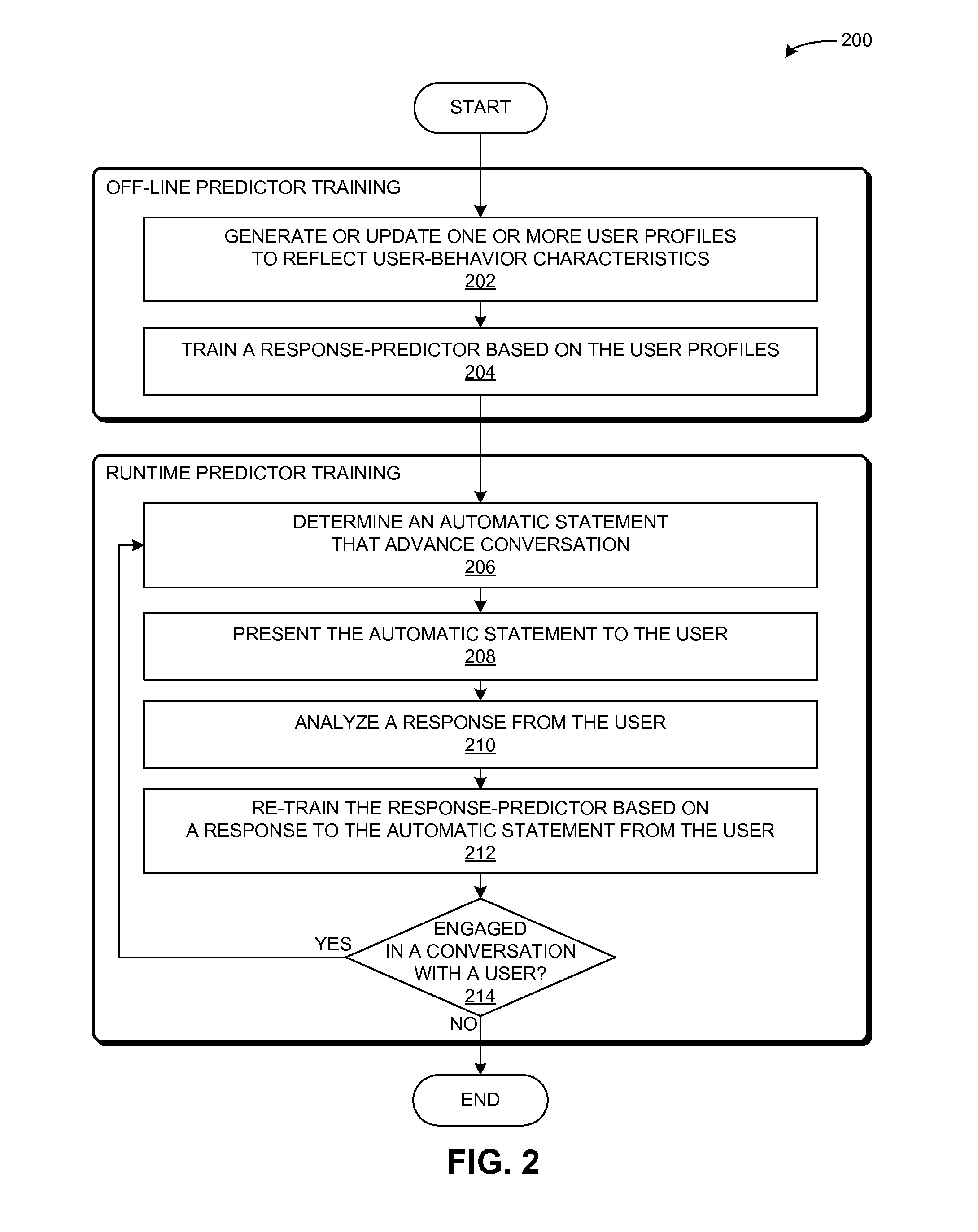

Method and apparatus for customizing conversation agents based on user characteristics

ActiveUS20140317030A1Improve accuracyFacilitate dialogueCustomer relationshipDigital computer detailsHuman–computer interactionSimulation system

A conversation-simulating system facilitates simulating an intelligent conversation with a human user. During operation, the system can receive a user-statement from the user during a simulated conversation, and generates a set of automatic-statements that each responds to the user-statement. The system then determines a set of behavior-characteristics for the user, and computes relevance scores for the automatic-statements based on the behavior-characteristics. Each relevance score indicates an outcome quality that the user is likely to perceive for the automatic-statement as a response to the user-statement. The system selects an automatic-statement that has a highest relevance score from the set of automatic-statements, and provides the selected automatic-statement to the user.

Owner:XEROX CORP

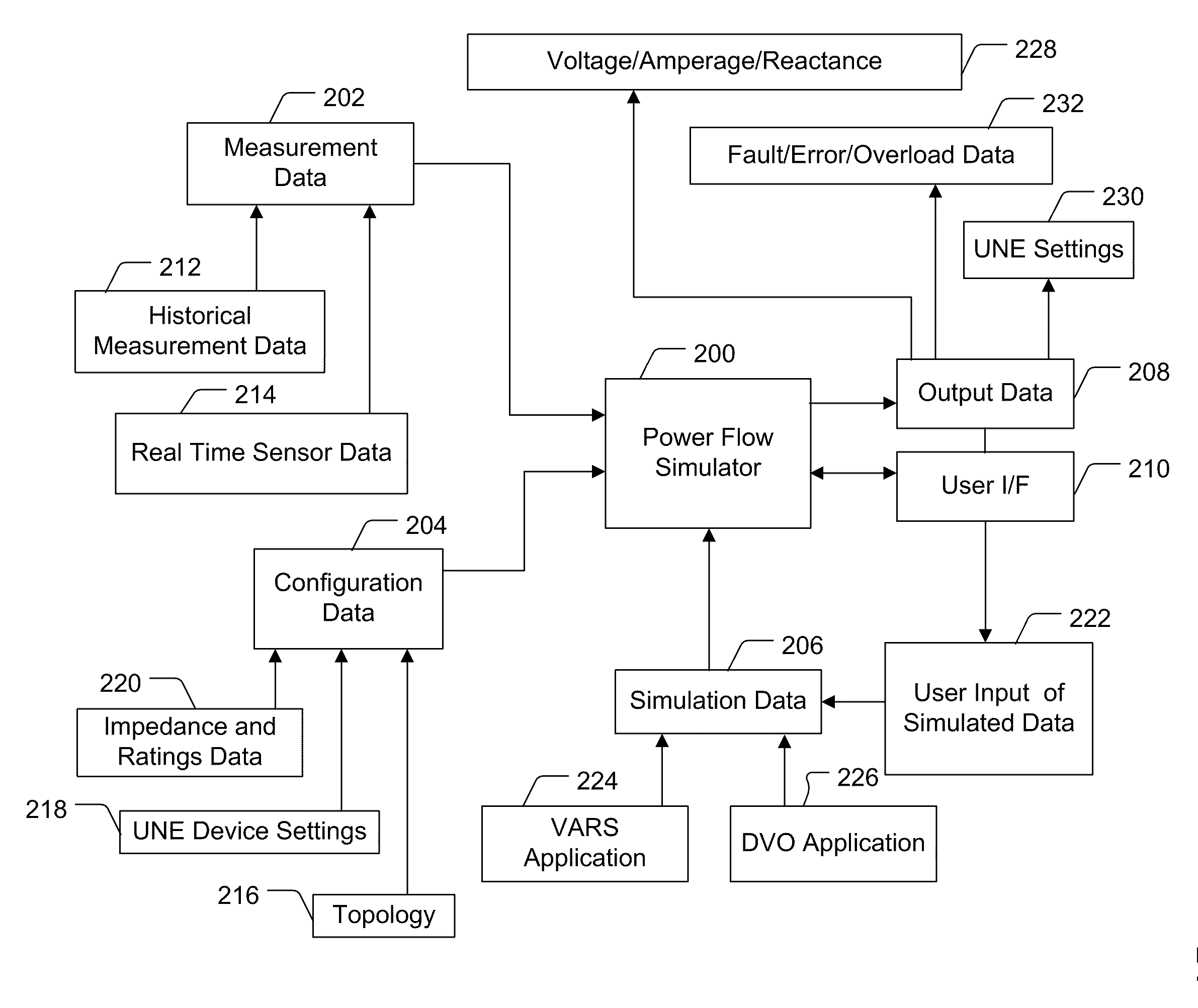

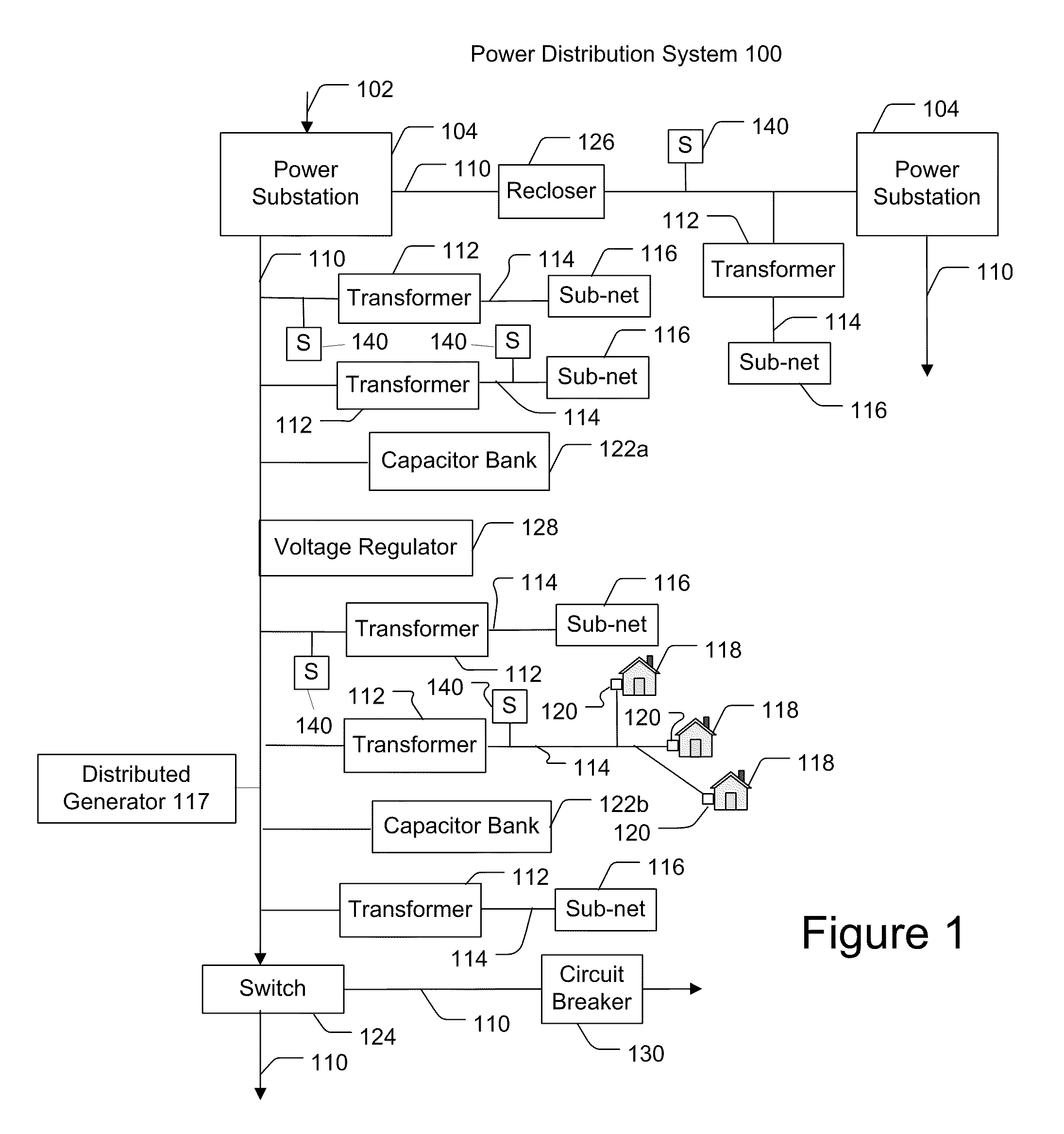

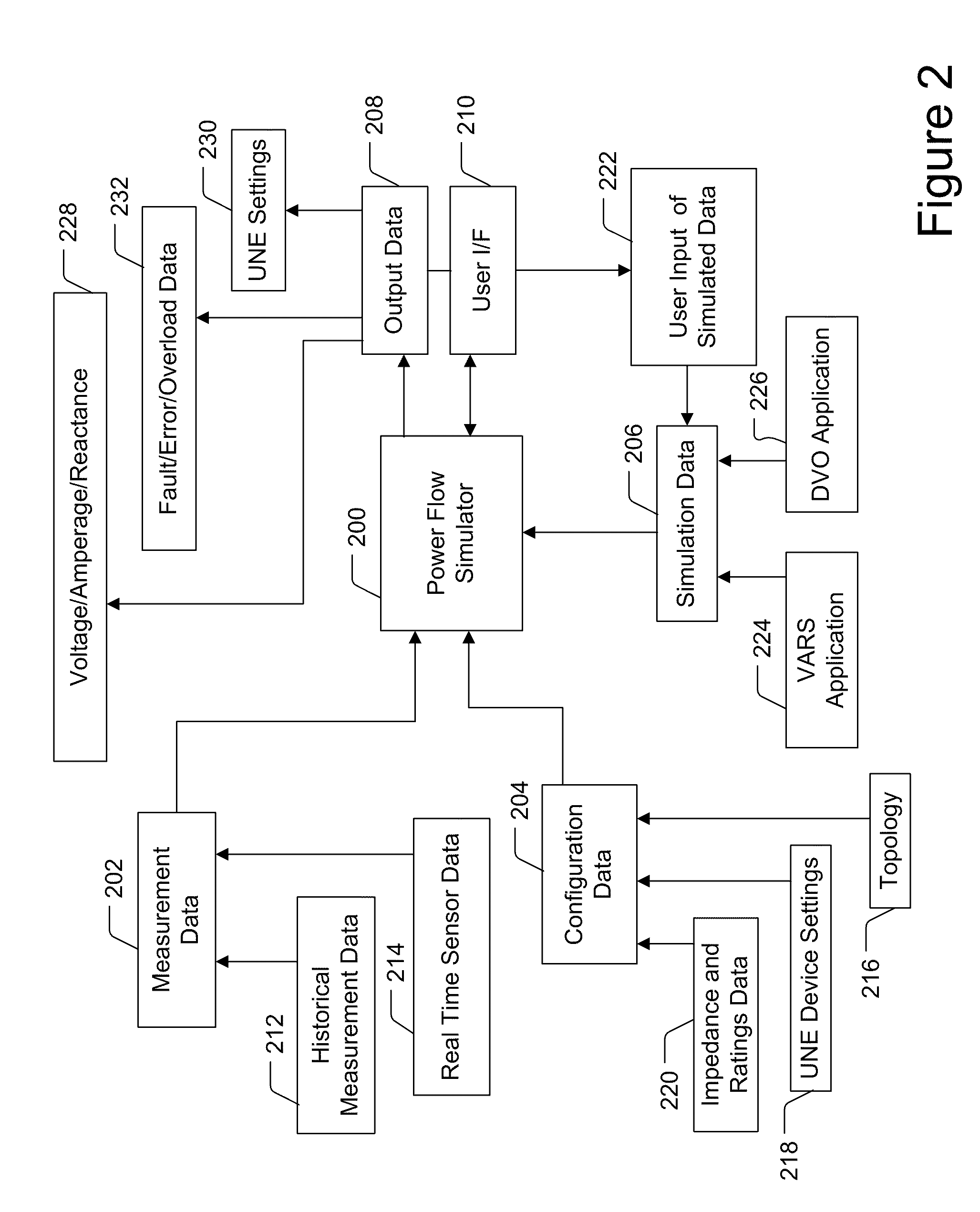

Power Flow Simulation System, Method and Device

InactiveUS20120022713A1Mechanical power/torque controlLevel controlDistribution systemElectric power

Embodiments of the present invention provide power flow analysis and may process electrical power distribution system data in real time to calculate load, current, voltage, losses, fault current and other data. The power flow analysis system may include a detailed data model of the electrical power distribution system, and may accept a variety of real time measurement inputs to support its modeling calculations. The power flow analysis system may calculate data of each of the three distribution system power phases independently and include a distribution state estimation module which allows it to incorporate a variety of real time measurements with varying degrees of accuracy, reliability and latency.

Owner:S&C ELECTRIC

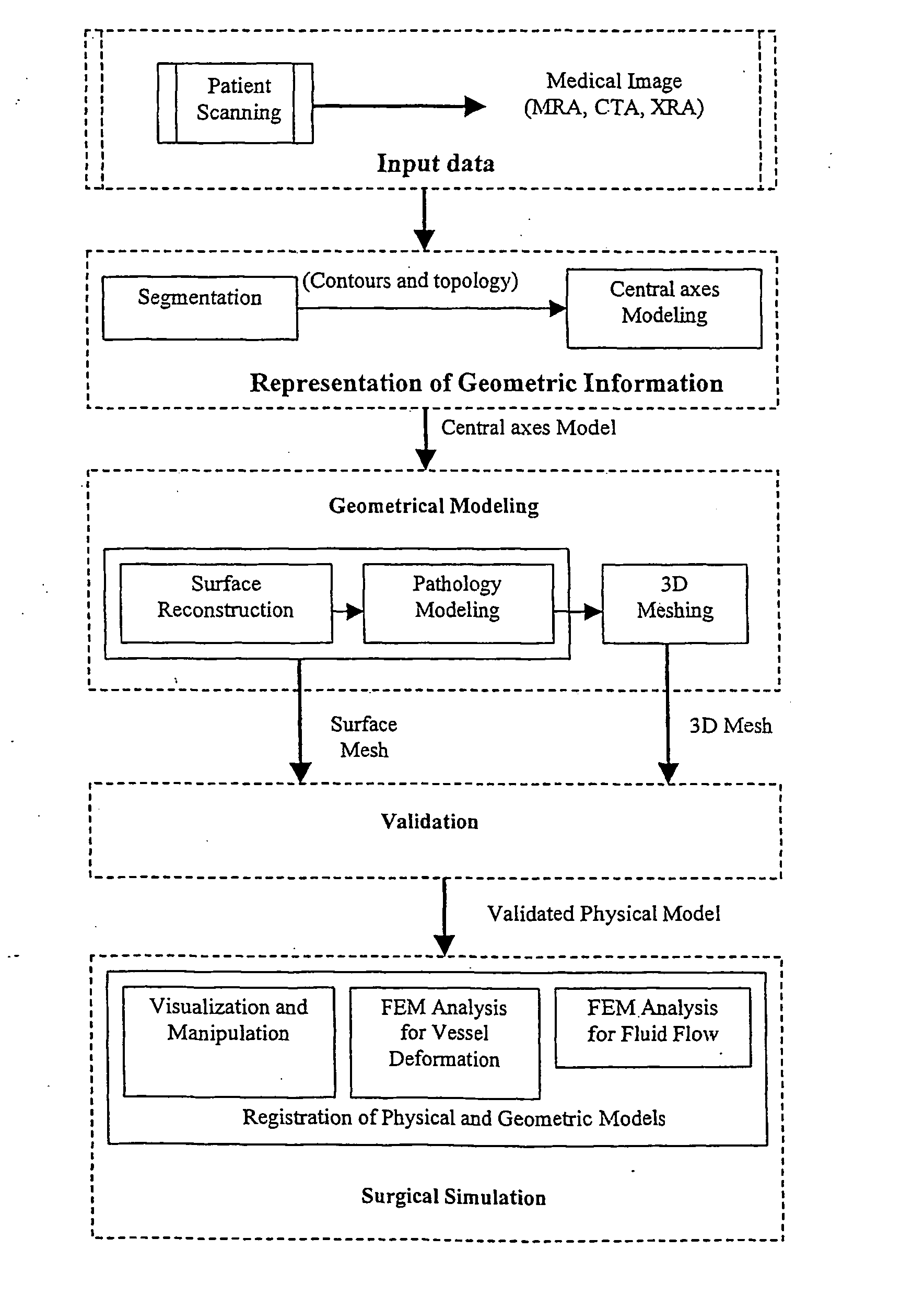

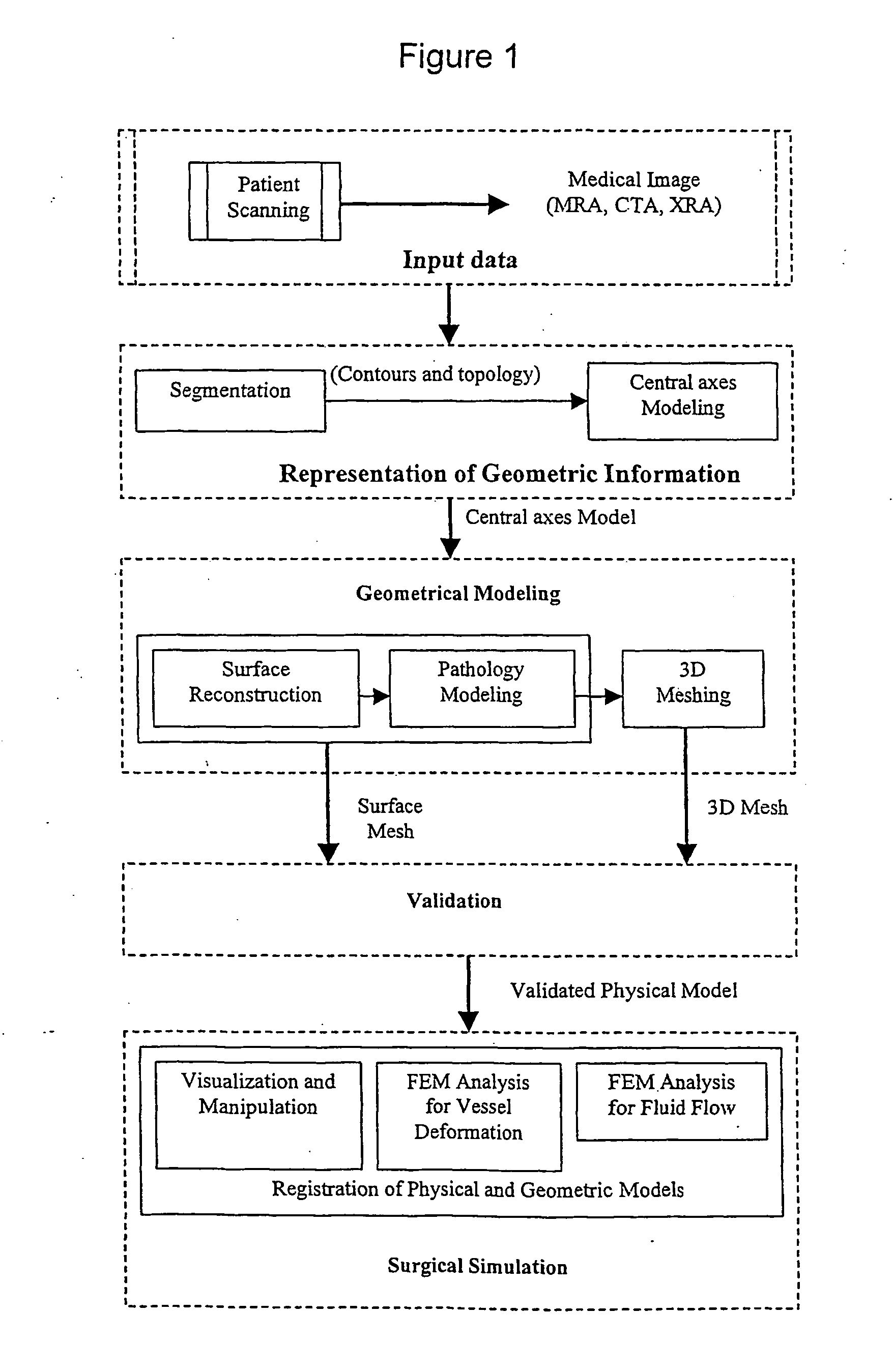

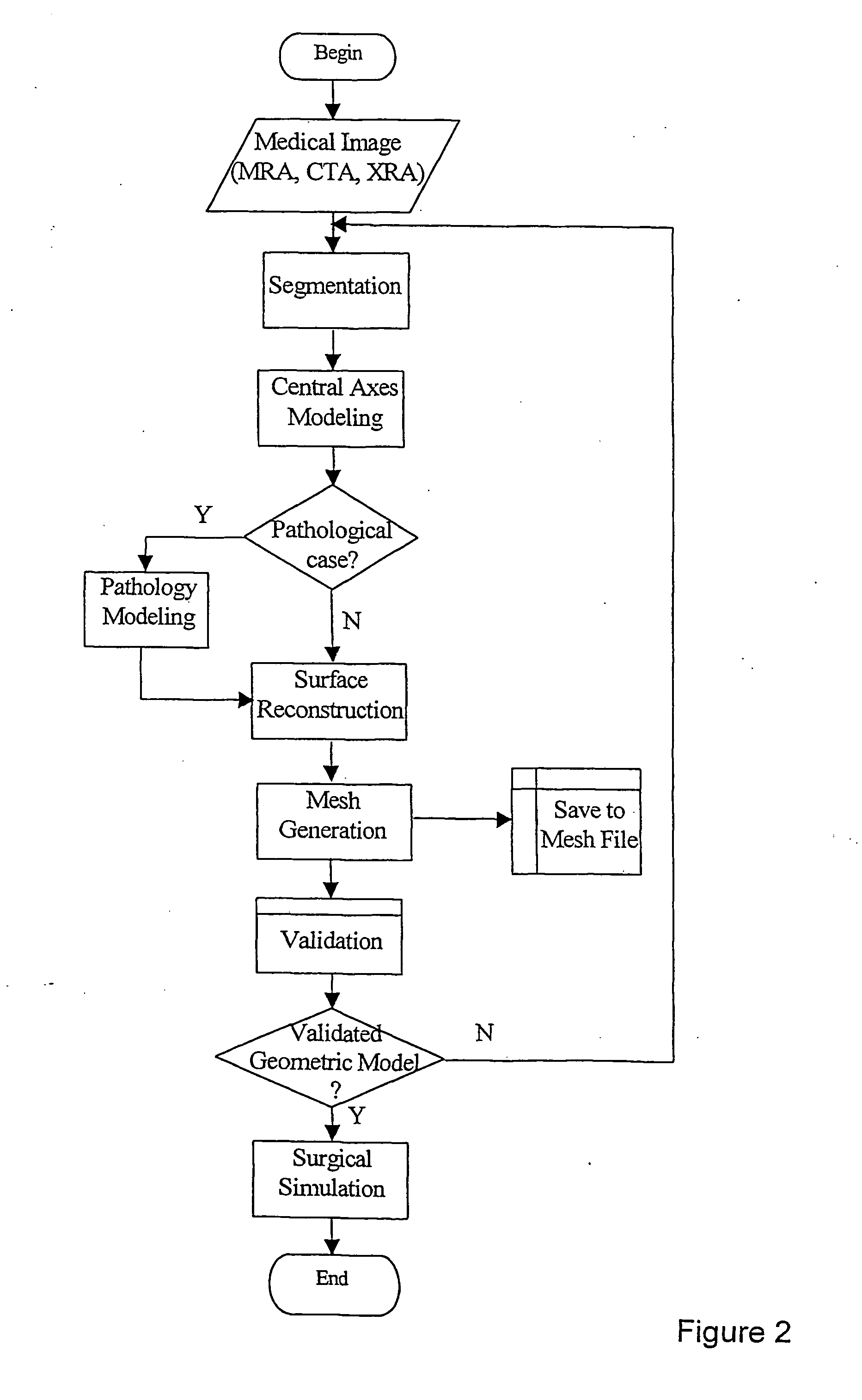

System and method of anatomical modeling

InactiveUS20050018885A1Conveniently stored and compiledFlexible performanceCharacter and pattern recognition3D modellingAnatomical structuresElement analysis

Methods of modeling anatomical structures, along with pathology including the vasculature, spine and internal organs, for visualization and manipulation in simulation systems. A representation of on the human vascular network is built up from medical images and a geometrical model produced therefrom by extracting topological and geometrical information. The model is constructed using topological and geometrical information. The model is constructed using segments containing topology structure information, flow domain information contour domain information and skeletal domain information. A realistic surface is then applied to the geometric model, by generating a trajectory along a central axis of the geometric model, conducting moving trihedron modeling along the generated trajectory and then creating a sweeping surface along the trajectory. A novel joint reconstruction approach is also proposed whereby a part surface sweeping operation is performed across branches of the joint and then a surface created over the resultatn holes therebetween. A 3-D mesh may also be generated, based upon this model, for finite element analysis and pathology creation.

Owner:AGENCY FOR SCI TECH & RES

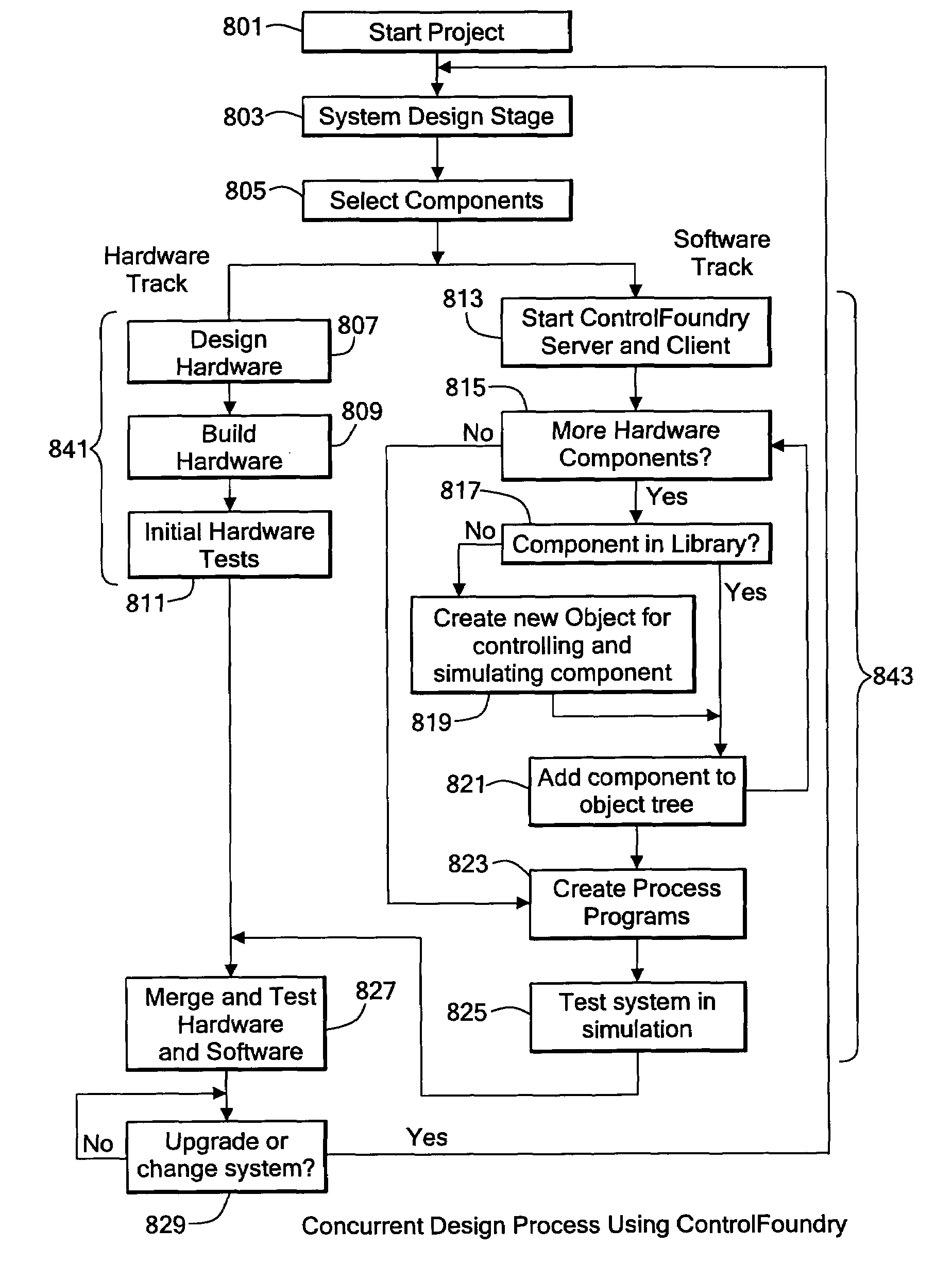

System and method for control and simulation

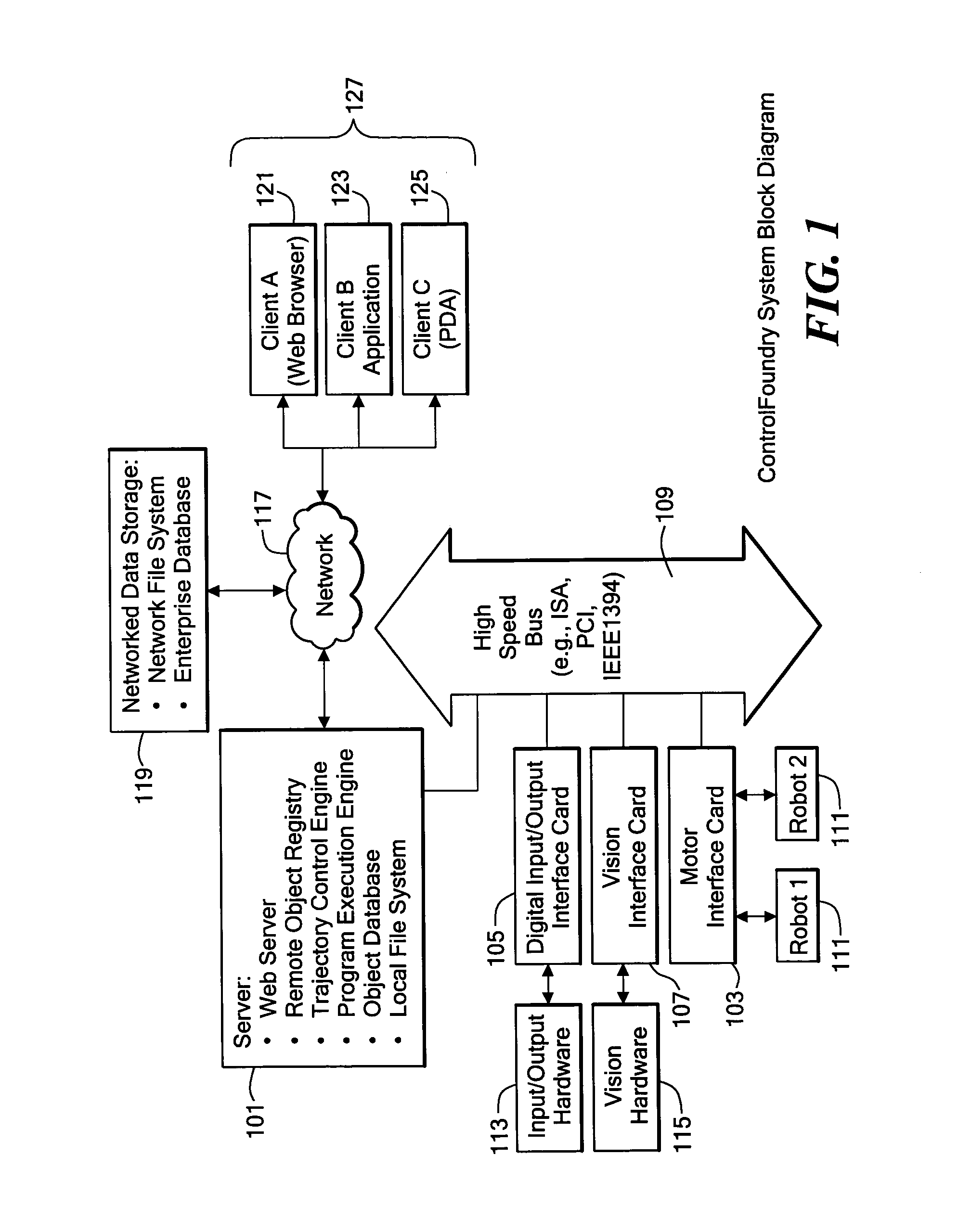

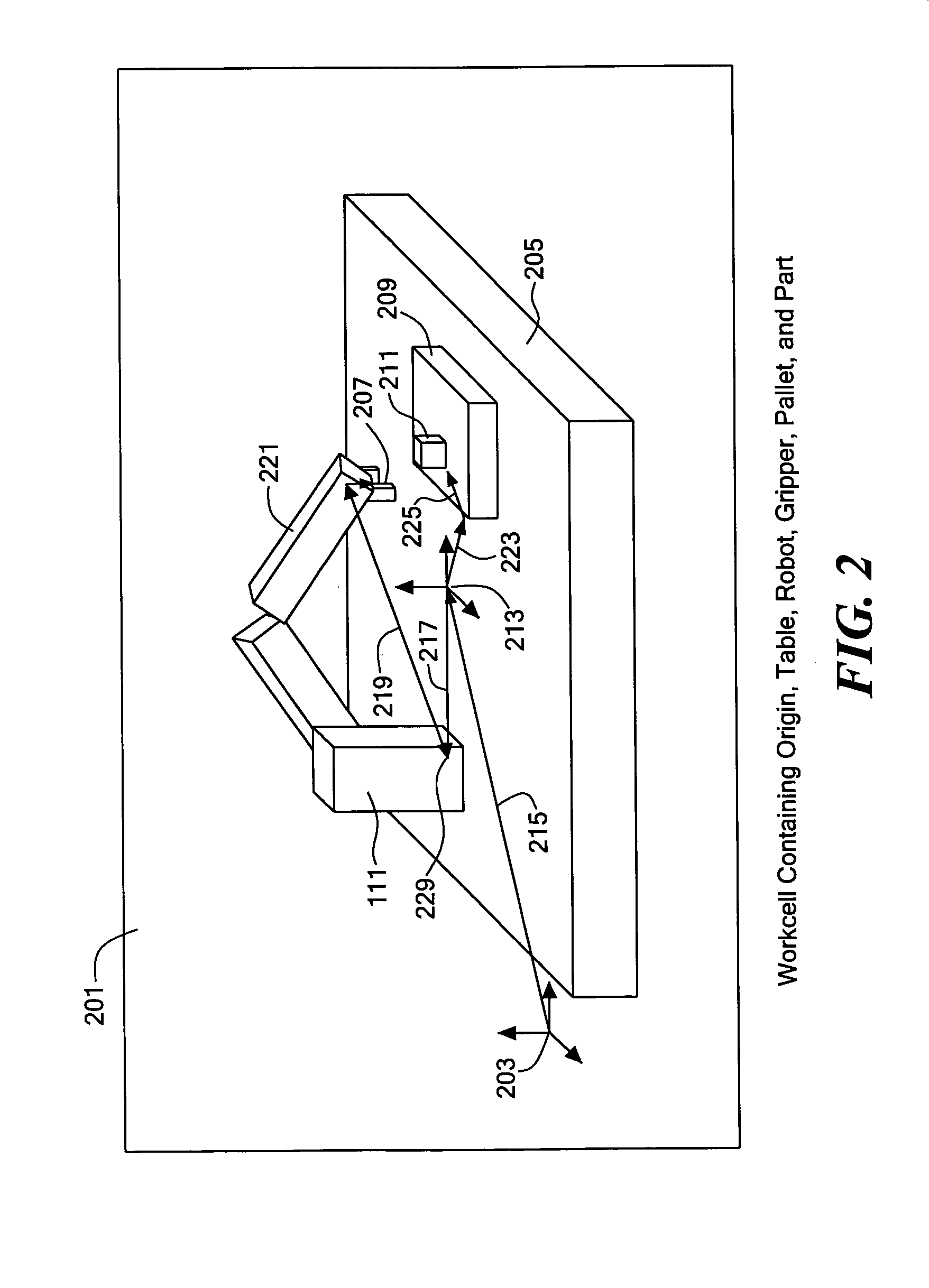

InactiveUS6944584B1Simplify the development processEasy to controlProgramme-controlled manipulatorComputer controlThree dimensional simulationUsability

A system that controls devices and integrally simulates the controlled motion of devices. The control and simulation system allows simultaneous development hardware and software in controlled device installations and increase operational ease-of-use and diagnostic capabilities. The control and three dimensional simulation system also allows client computers to remotely control the system and other devices connected to a network.

Owner:BOOKS AUTOMATION US LLC

Method, apparatus and computer program product for determination of noise in mixed signal systems

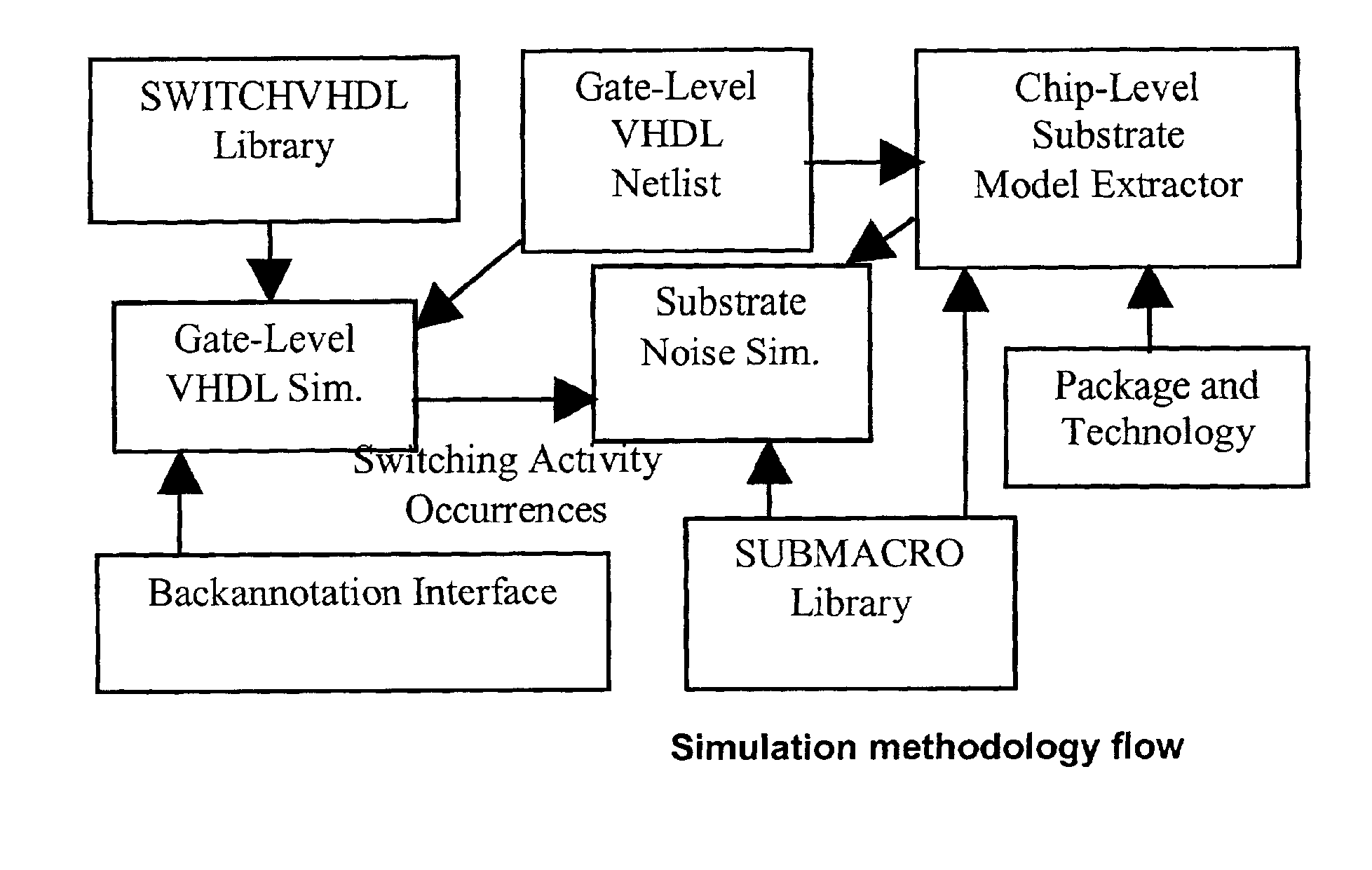

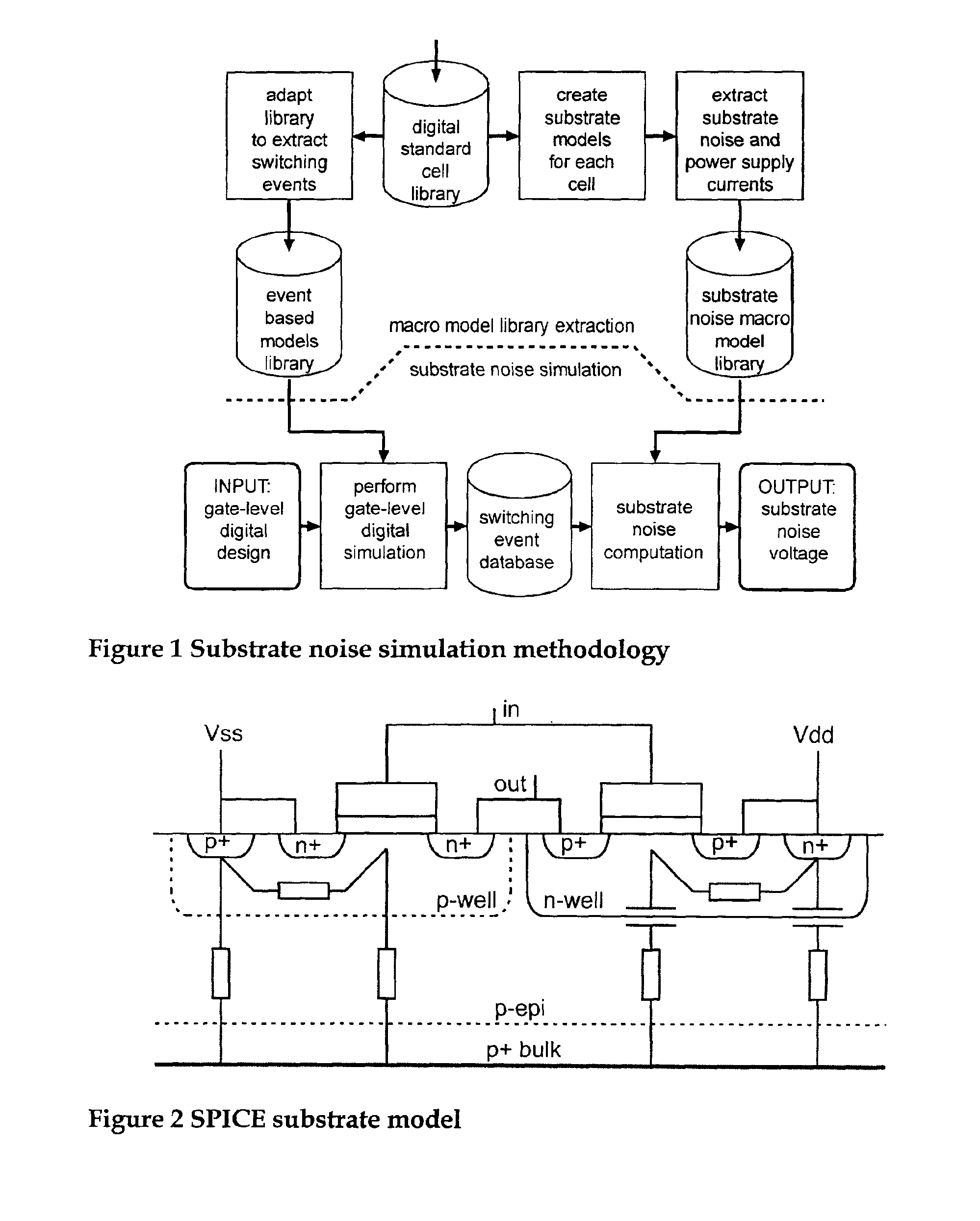

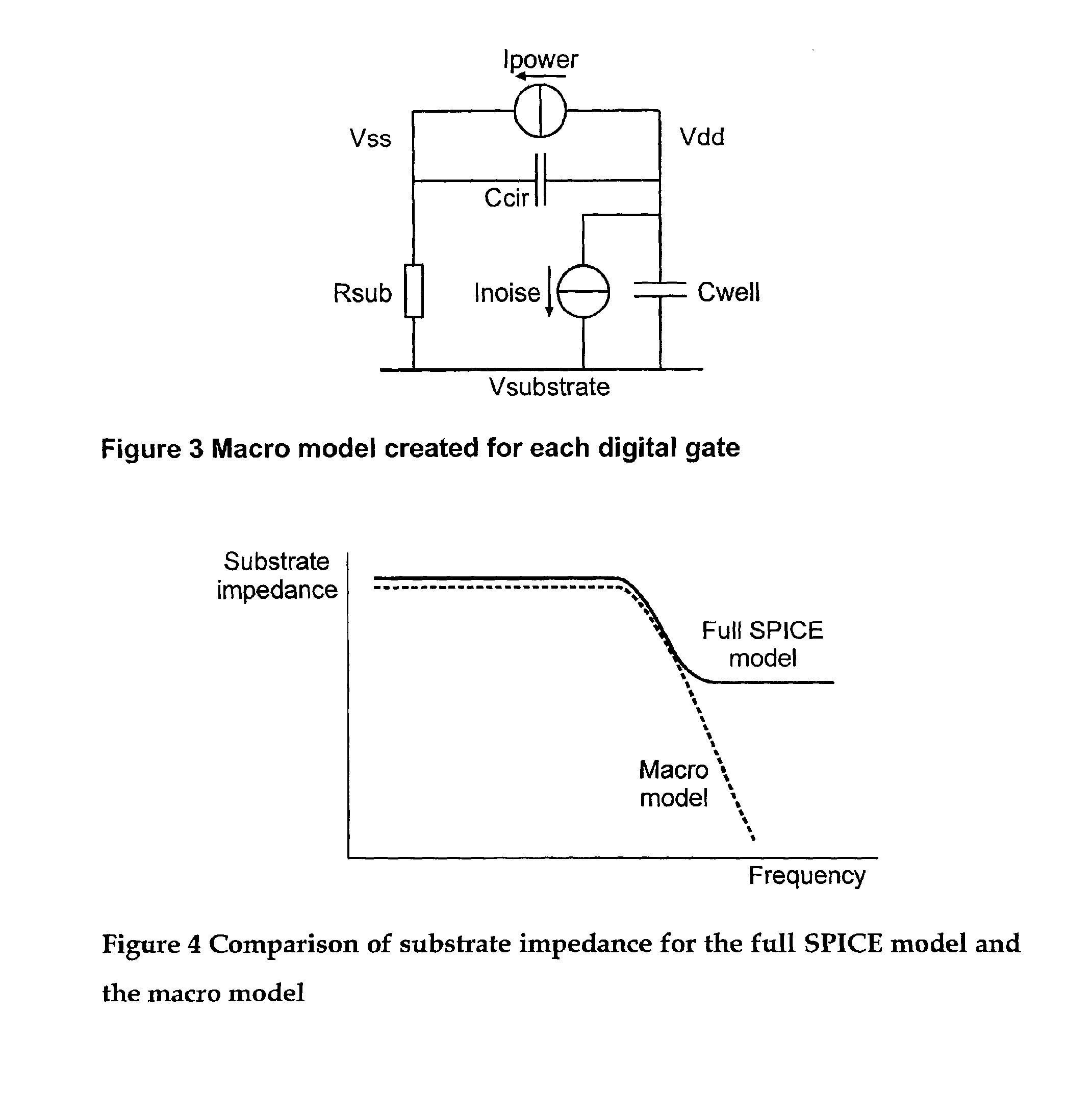

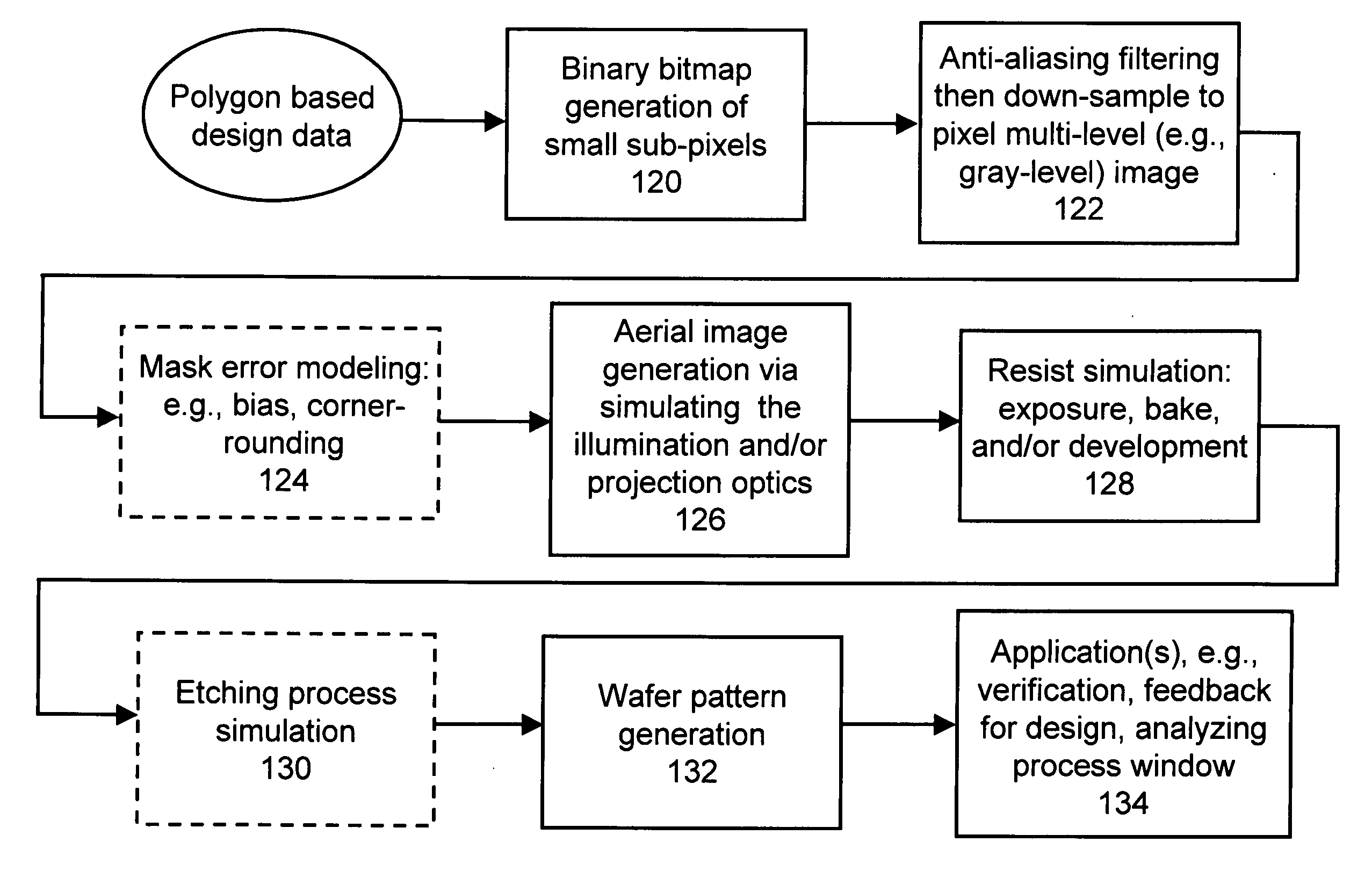

InactiveUS6941258B2Fast and accurate determinationAnalogue computers for electric apparatusDetecting faulty computer hardwareEngineeringSignaling system

A simulation system is described for computing the overall signal generated in a substrate by a digital system comprising a plurality of gates associated with the substrate, wherein each gate is configured to perform a switching event. Output of a transistor-level model is compared with output of a lumped circuit model for each gate and the substrate, and signal contributions from each gate and switching event are determined based on the comparison. The system determines switching event signals for each of the plurality of gates. The signal contributions and the switching event signals are combined, and a combined lumped circuit model is derived based on a combination of lumped circuit models of the plurality of gates. The overall signal is computed based on the combined gate signal contributions and switching event signals, which are configured as an input to the combined lumped circuit model.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

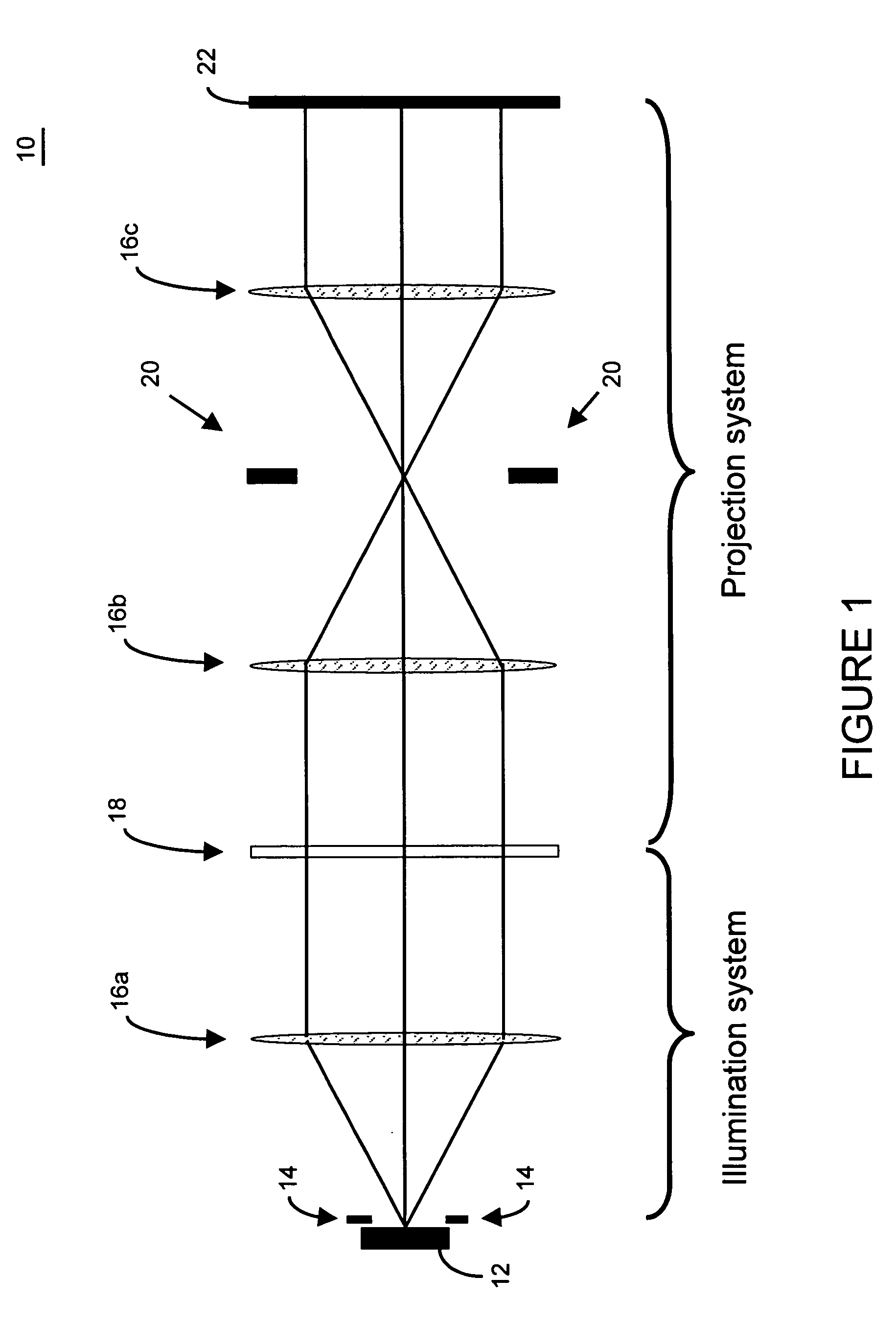

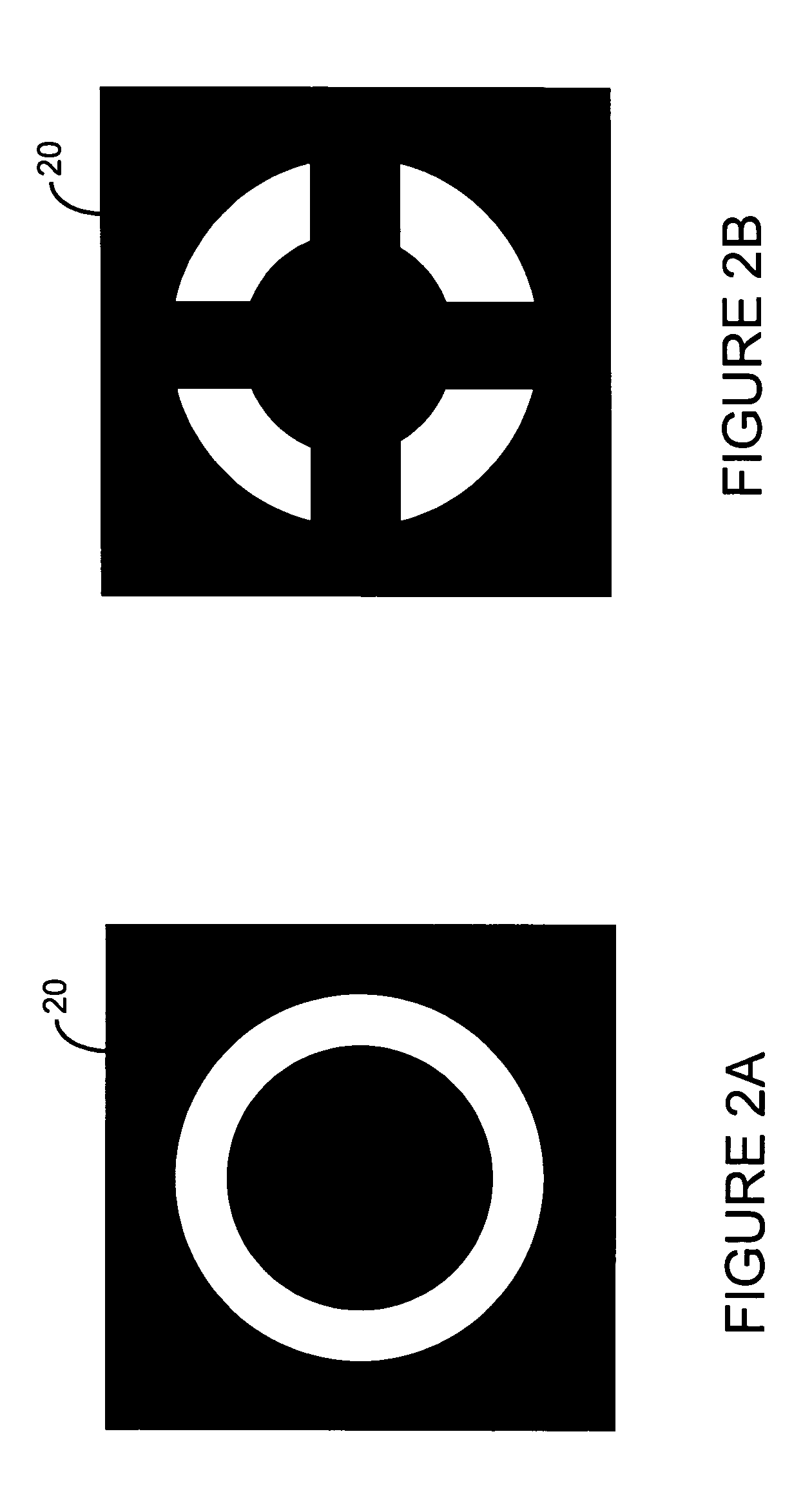

System and method for lithography simulation

There are many inventions described and illustrated herein. In one aspect, the present invention is directed to a technique of, and system for simulating, verifying, inspecting, characterizing, determining and / or evaluating the lithographic designs, techniques and / or systems, and / or individual functions performed thereby or components used therein. In one embodiment, the present invention is a system and method that accelerates lithography simulation, inspection, characterization and / or evaluation of the optical characteristics and / or properties, as well as the effects and / or interactions of lithographic systems and processing techniques. In this regard, in one embodiment, the present invention employs a lithography simulation system architecture, including application-specific hardware accelerators, and a processing technique to accelerate and facilitate verification, characterization and / or inspection of a mask design, for example, RET design, including detailed simulation and characterization of the entire lithography process to verify that the design achieves and / or provides the desired results on final wafer pattern. The system includes: (1) general purpose-type computing device(s) to perform the case-based logic having branches and inter-dependency in the data handling and (2) accelerator subsystems to perform a majority of the computation intensive tasks.

Owner:ASML NETHERLANDS BV

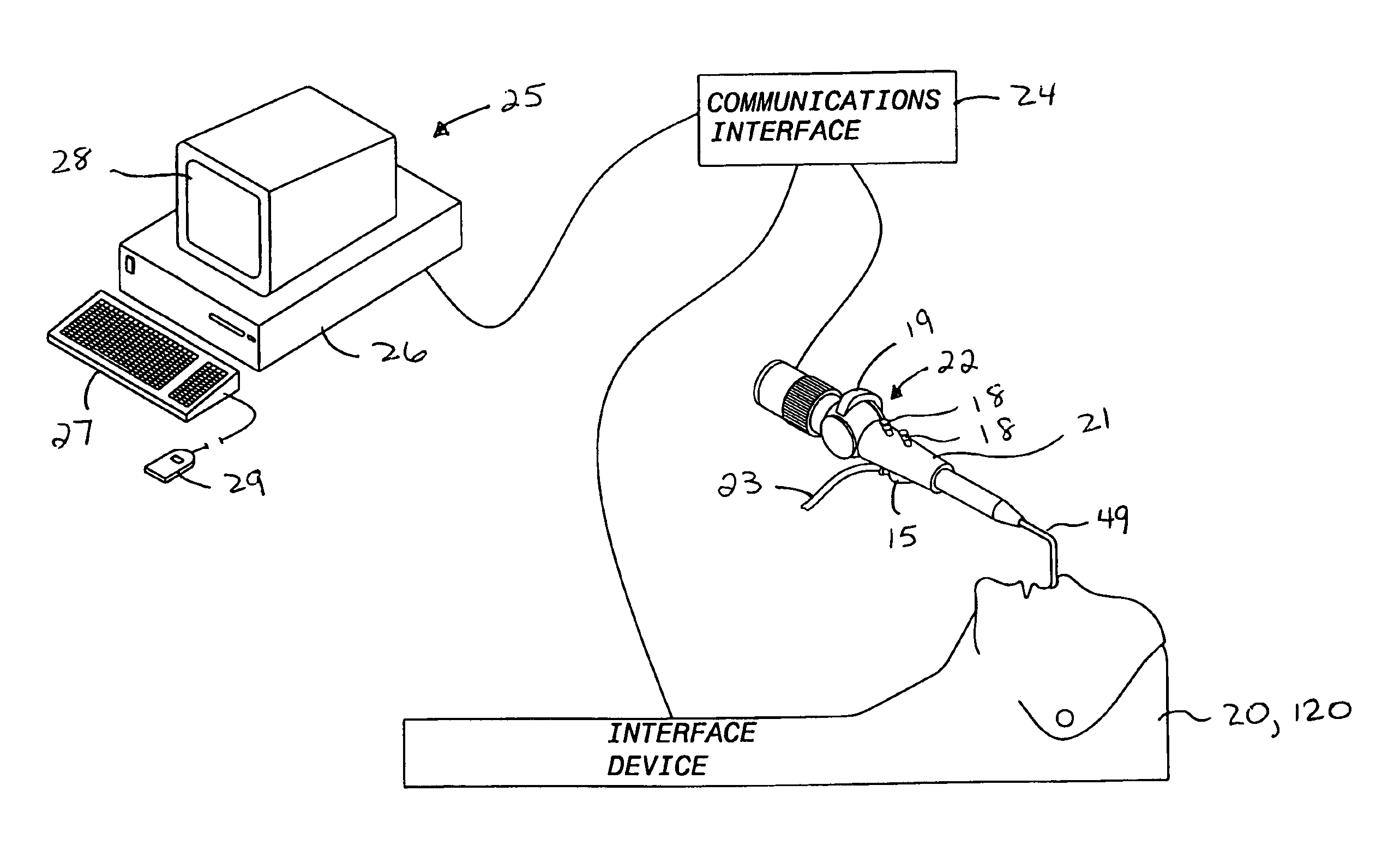

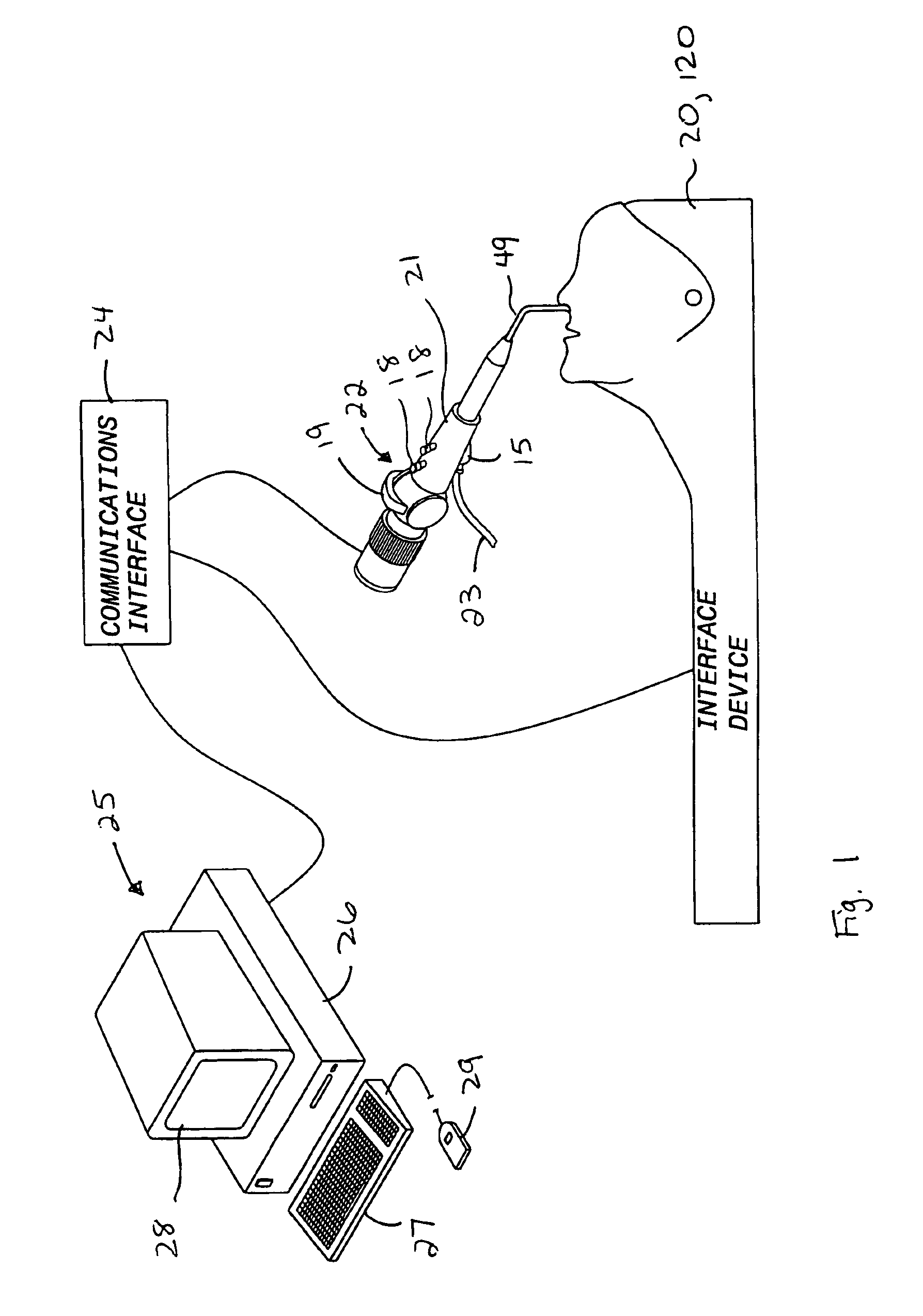

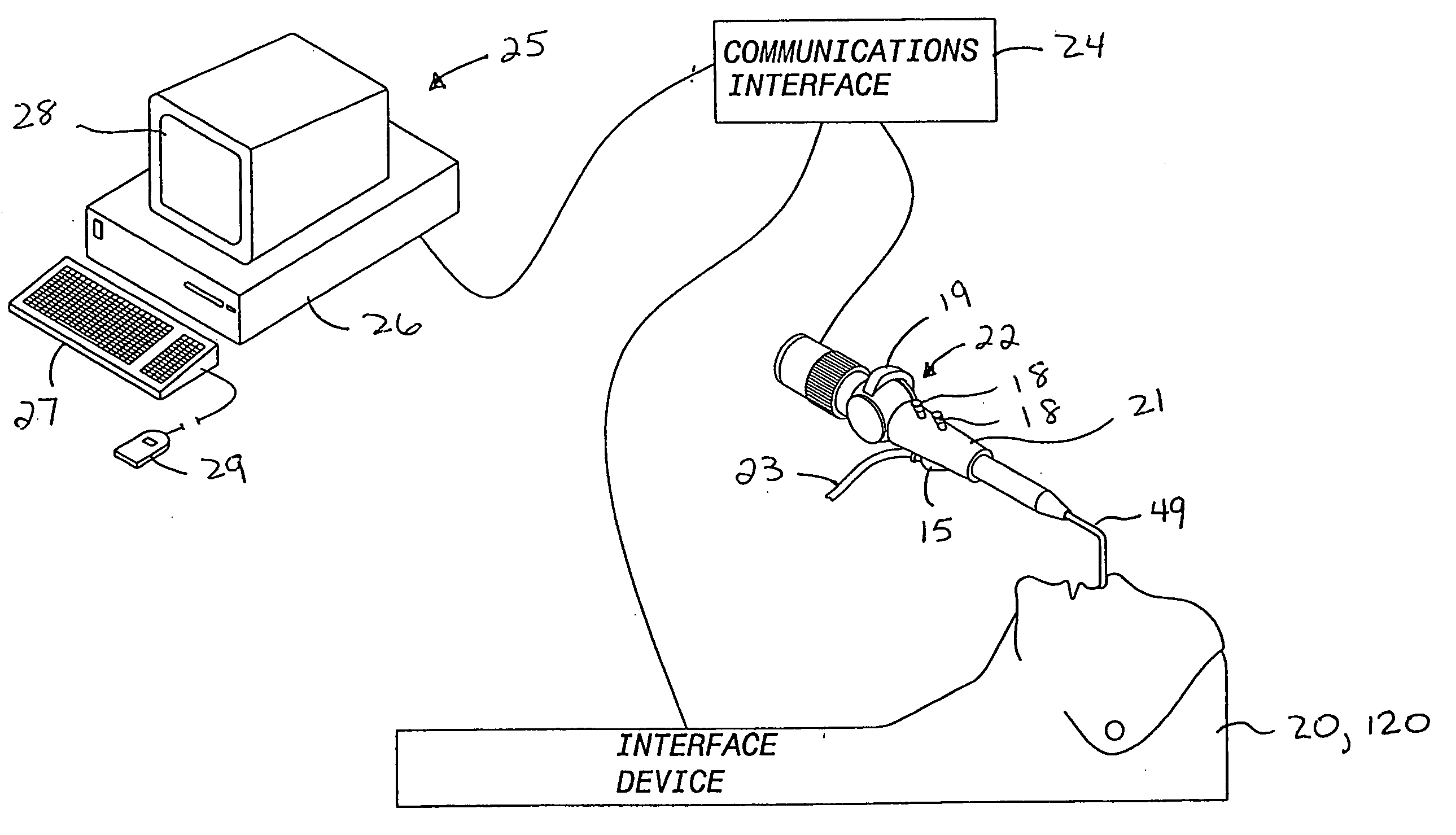

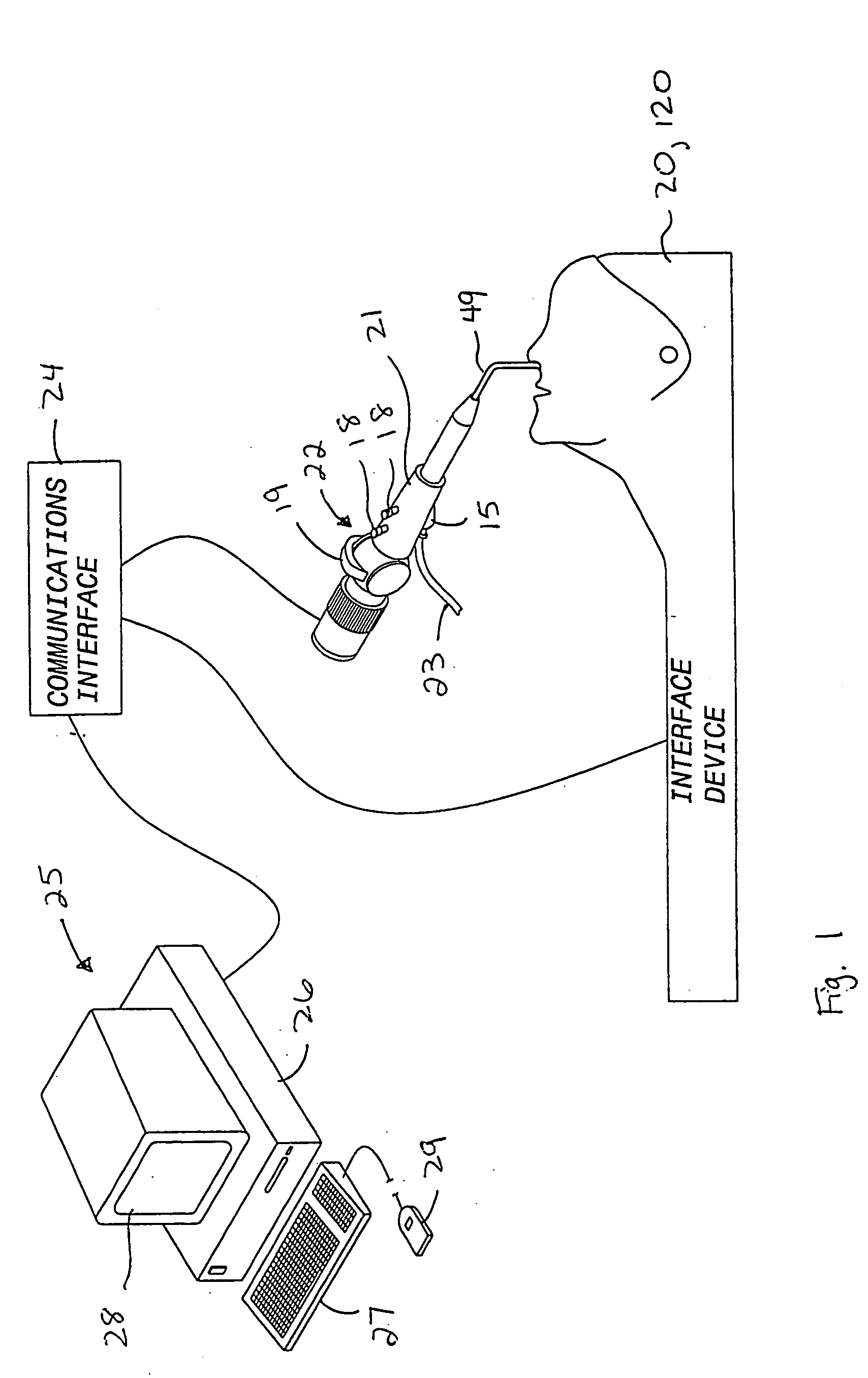

Interface device and method for interfacing instruments to medical procedure simulation systems

InactiveUS6929481B1Improve realismSimulate the realEducational modelsMeasuring instrumentDisplay device

An interface device and method for interfacing instruments to a medical procedure simulation system serve to interface peripherals in the form of mock medical instruments to the medical procedure simulation system computer to enable simulation of medical procedures. The interface device includes a housing having a mock bodily region of interest to facilitate insertion of a mock instrument, such as an endoscope tube, into the interface device. The mock bodily region of interest may be pivotable to simulate various patient orientations. The instrument is engaged by a capture mechanism in order to measure rotational and translational motion of the instrument. An actuator is disposed within the interface device to provide force feedback to the instrument. The measured motion is provided to the computer system to reflect instrument motion on the display during the simulation. Alternatively, the interface device may be configured to accommodate instrument assemblies having a plurality of nested instruments (e.g., sheath, catheter and wire), whereby the interface device individually grasps, measures manipulation of and provides force feedback to the nested instruments. In addition, the interface device may be configured to simultaneously accommodate a plurality of independently inserted instruments.

Owner:IMMERSION MEDICAL

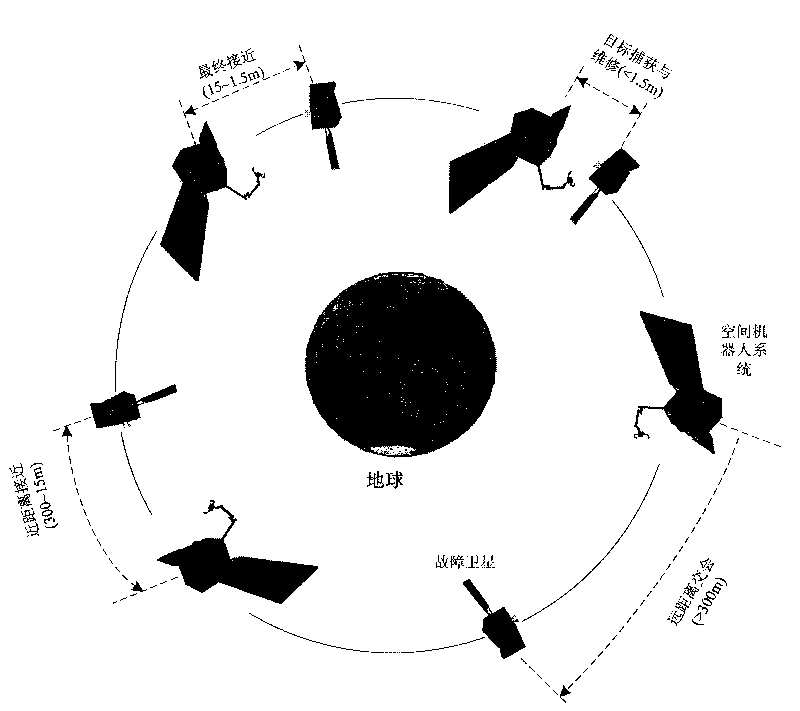

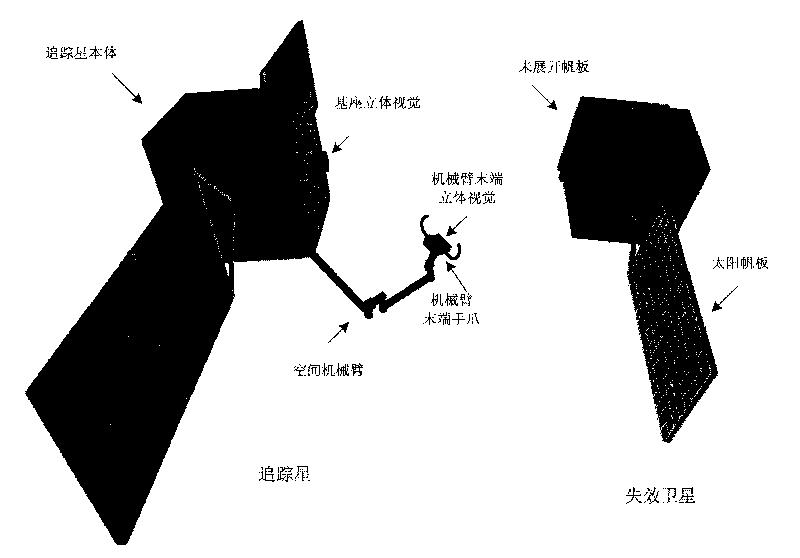

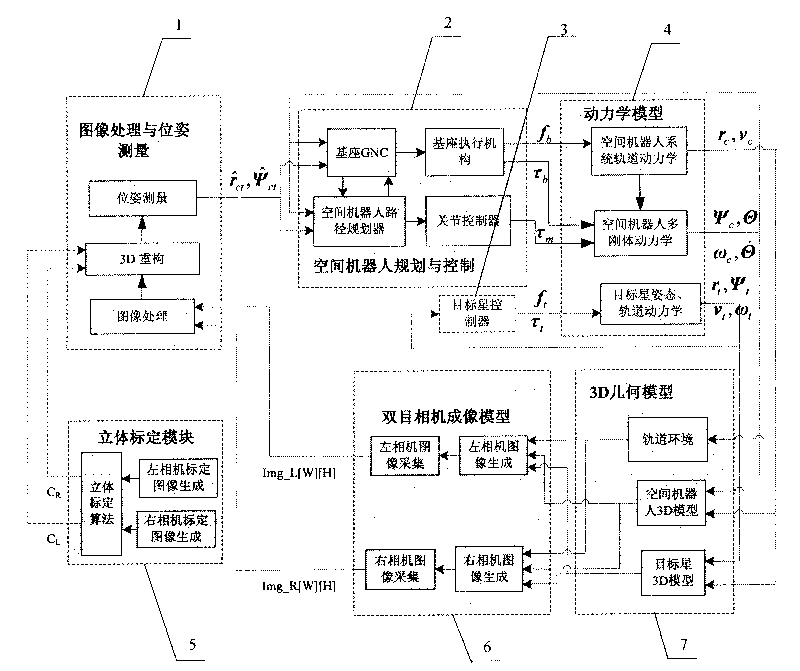

Vision measurement, path planning and GNC integrated simulation system for space robot

InactiveCN101726296APredict interference in real timeAdaptive control abilityInstruments for comonautical navigationImaging processingRobot planning

The invention relates to a vision measurement, path planning and GNC integrated simulation system for a space robot, which comprises an image processing and pose measuring module 1, a space robot planning and control module 2, a target controller module 3, a system dynamic model module 4, a system 3D geometric model module 7, a binocular camera simulation imaging module 6, a three-dimensional calibration module 5 and the like. The system integrates image processing and pose measurement, GNC algorithm, path planning, control, dynamics and the like, so that the closed-loop simulation and verification of all key algorithms in the process of tracking, approaching and capturing non-cooperative targets by the space robot can be performed on an independent PC. The system does not need to adopt real measurement equipment, a space robot system and targets, and is low in cost, good in safety and flexibility and easy to implement; and the system is good in expandability, and the closed-loop simulation and verification of cameras (installation positions and viewing angles) and space robots (kinematic and dynamic parameters) with different parameters can be implemented by modifying the parameters.

Owner:HARBIN INST OF TECH

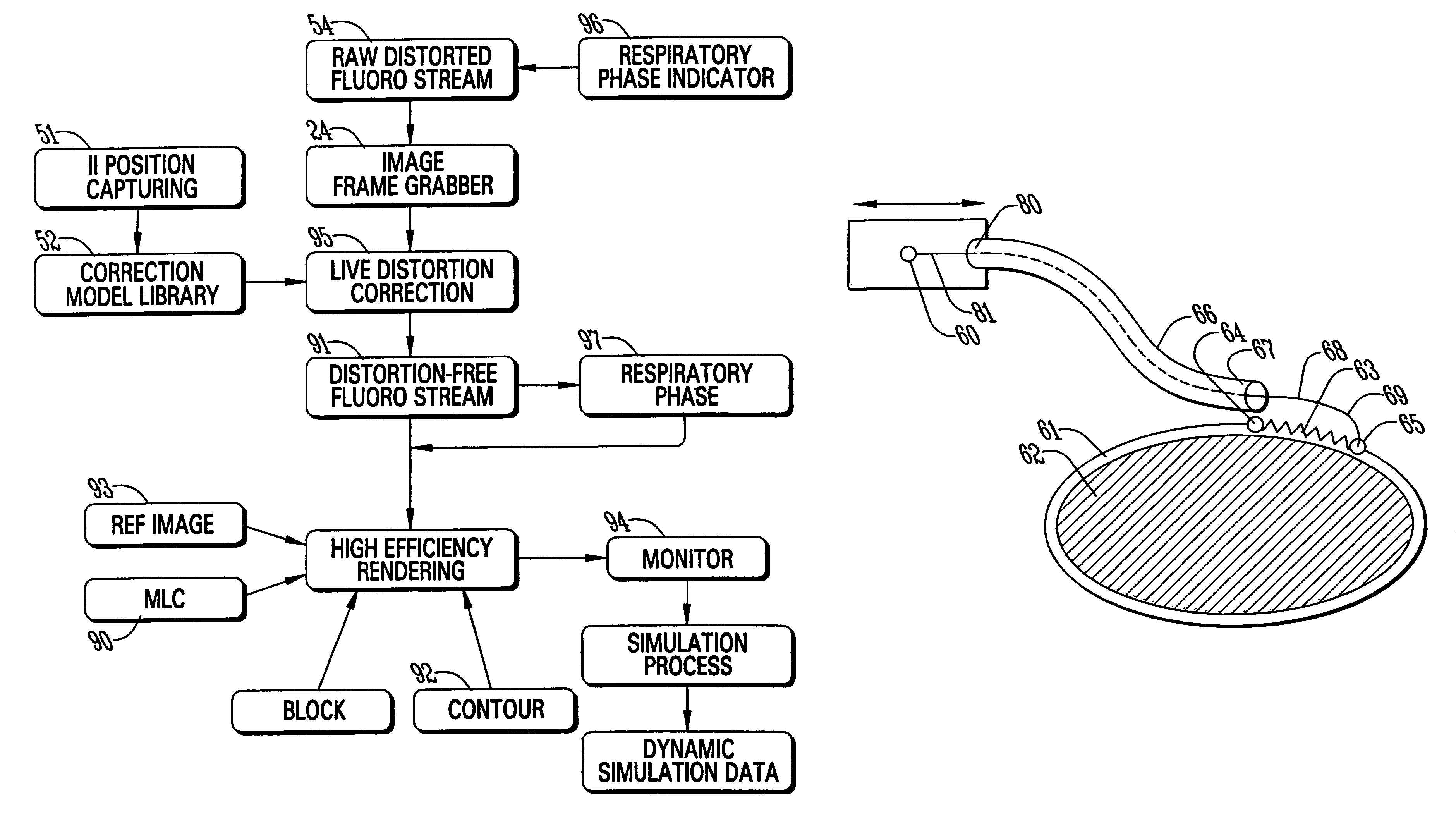

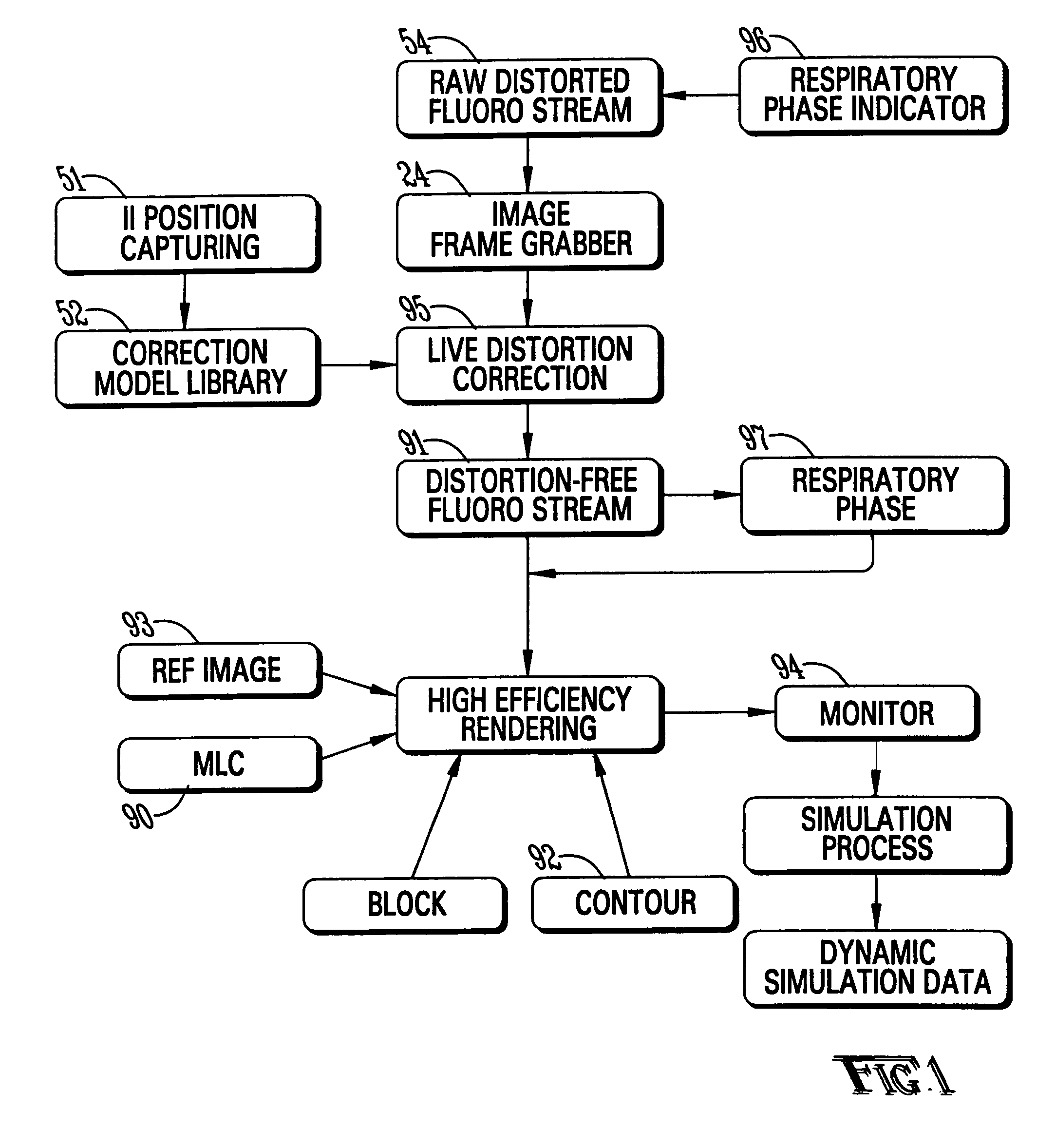

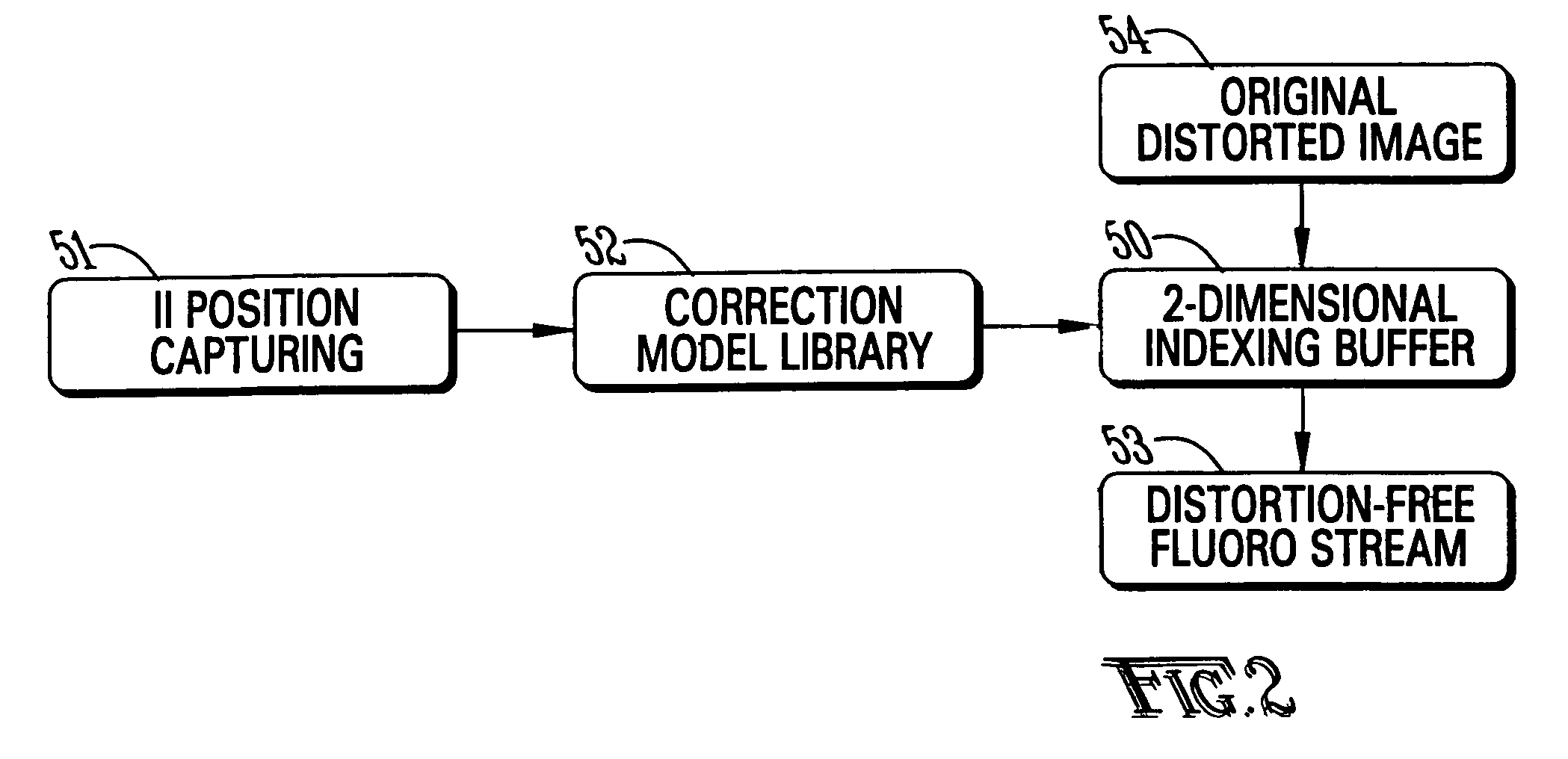

Dynamic radiation therapy simulation system

InactiveUS7349522B2Accurate treatment of tumorAccurate imagingMaterial analysis using wave/particle radiationRadiation/particle handlingFluoroscopic imageComputerized system

A system for dynamic treatment simulation for radiotherapy. Software is implemented on a computer system to perform dynamic simulation by displaying every segment of dynamic treatment beams on top of real-time fluoroscopic image sequences. Automated distortion correction of the fluoroscopic image due to the image intensifier is performed in real-time. A respiration phase indicator measures changes in circumference of the patient's chest through the movement of a radio-opaque marker that appears directly in the fluoroscopic images of the patient.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

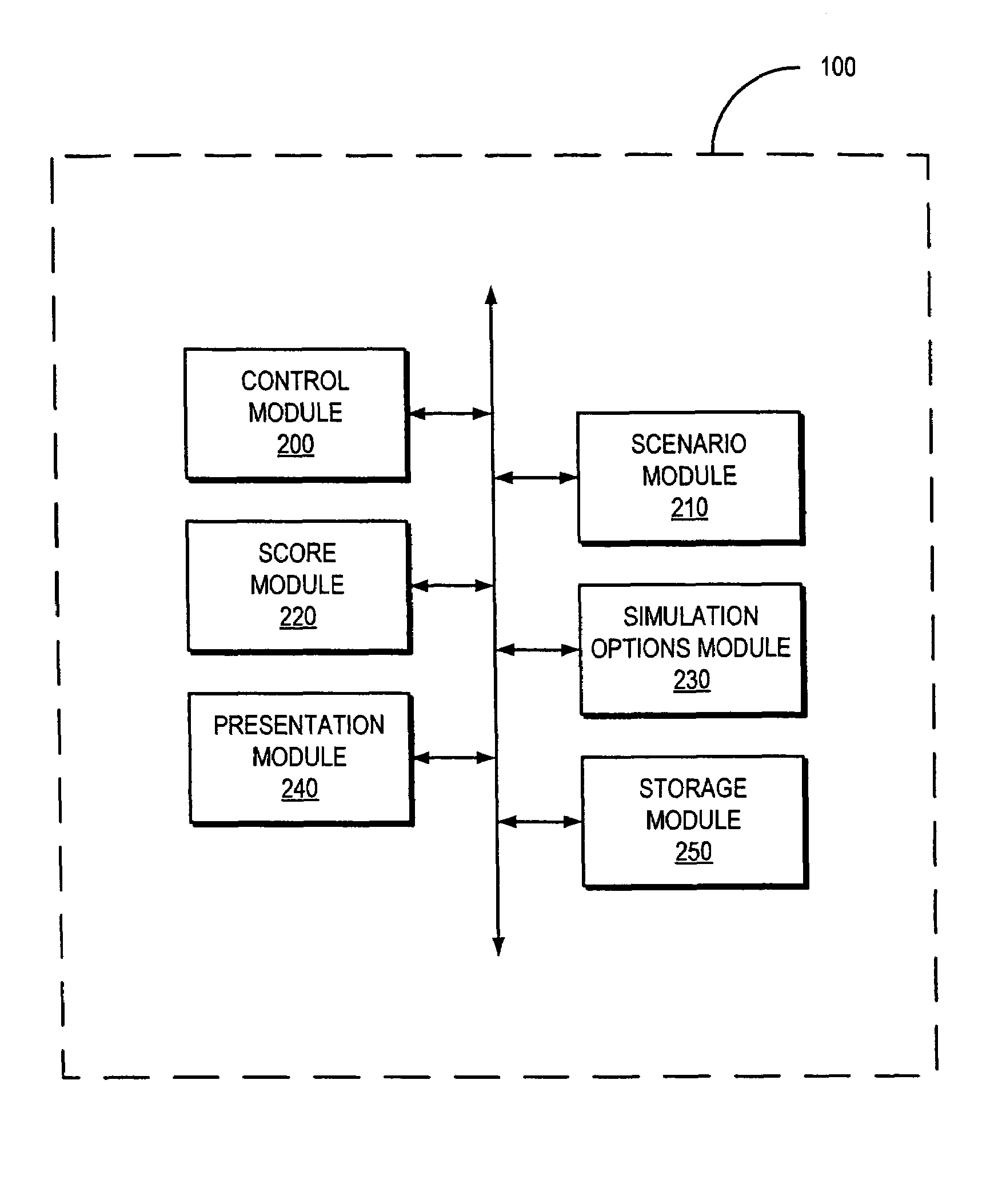

Credit score simulation

Systems and methods are described that simulate a credit score. The system enables a user to modify a credit data element in order to determine its effect on a credit score. The user can modify the element directly or simulate an action that, if performed, would modify the element. Since the number of possible modifications and actions can be overwhelming, in one embodiment, the system suggests modifications and actions to be simulated. These suggestions can be tailored to a user's goal, such as increasing a credit score by a particular number of points or allocating a particular sum of money in order to maximize a credit score. In one embodiment, the system obtains credit data from multiple credit bureaus and can determine credit scores using different algorithms, such as the different algorithms used by the different credit bureaus.

Owner:EXPERIAN INFORMATION SOLUTIONS

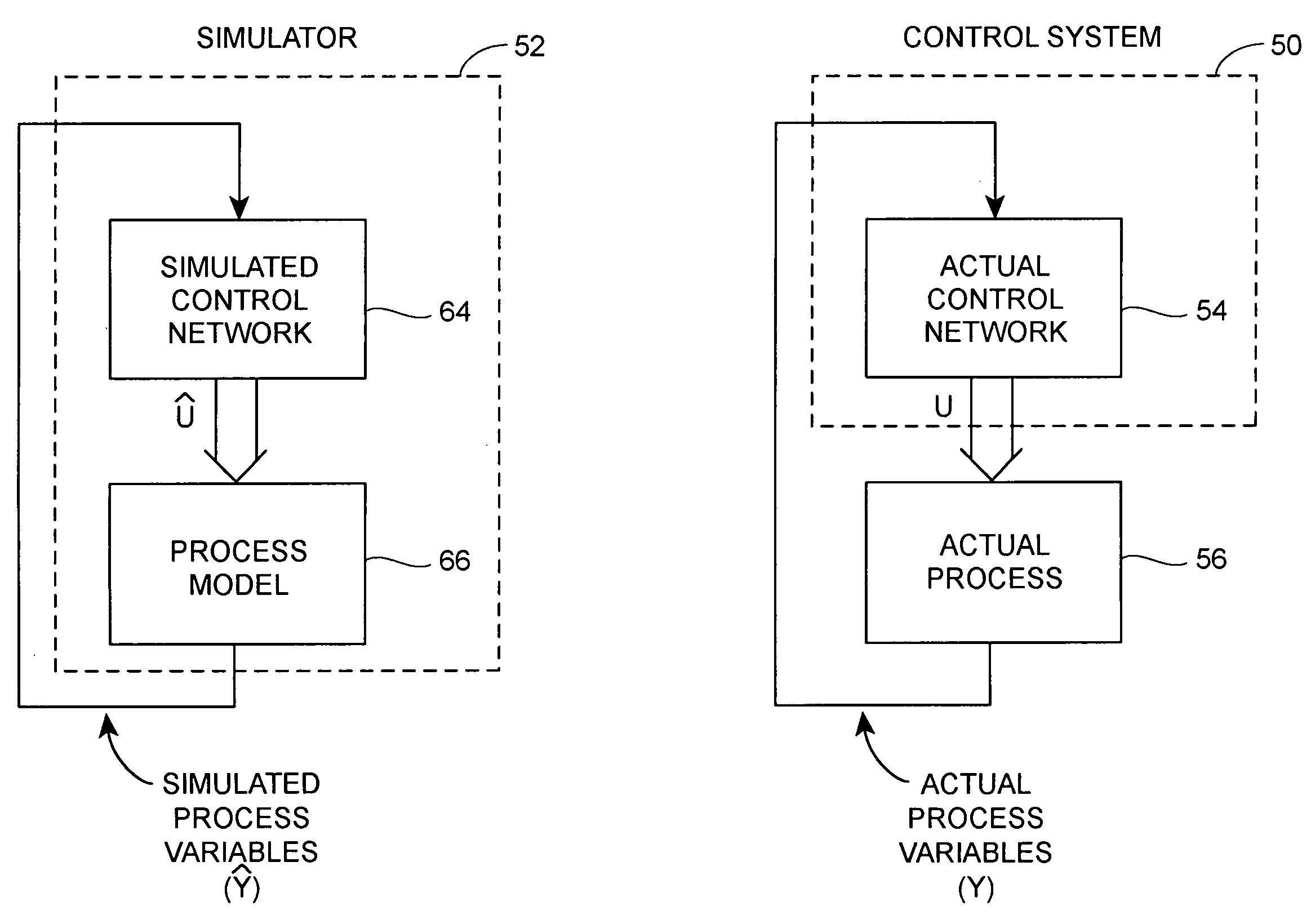

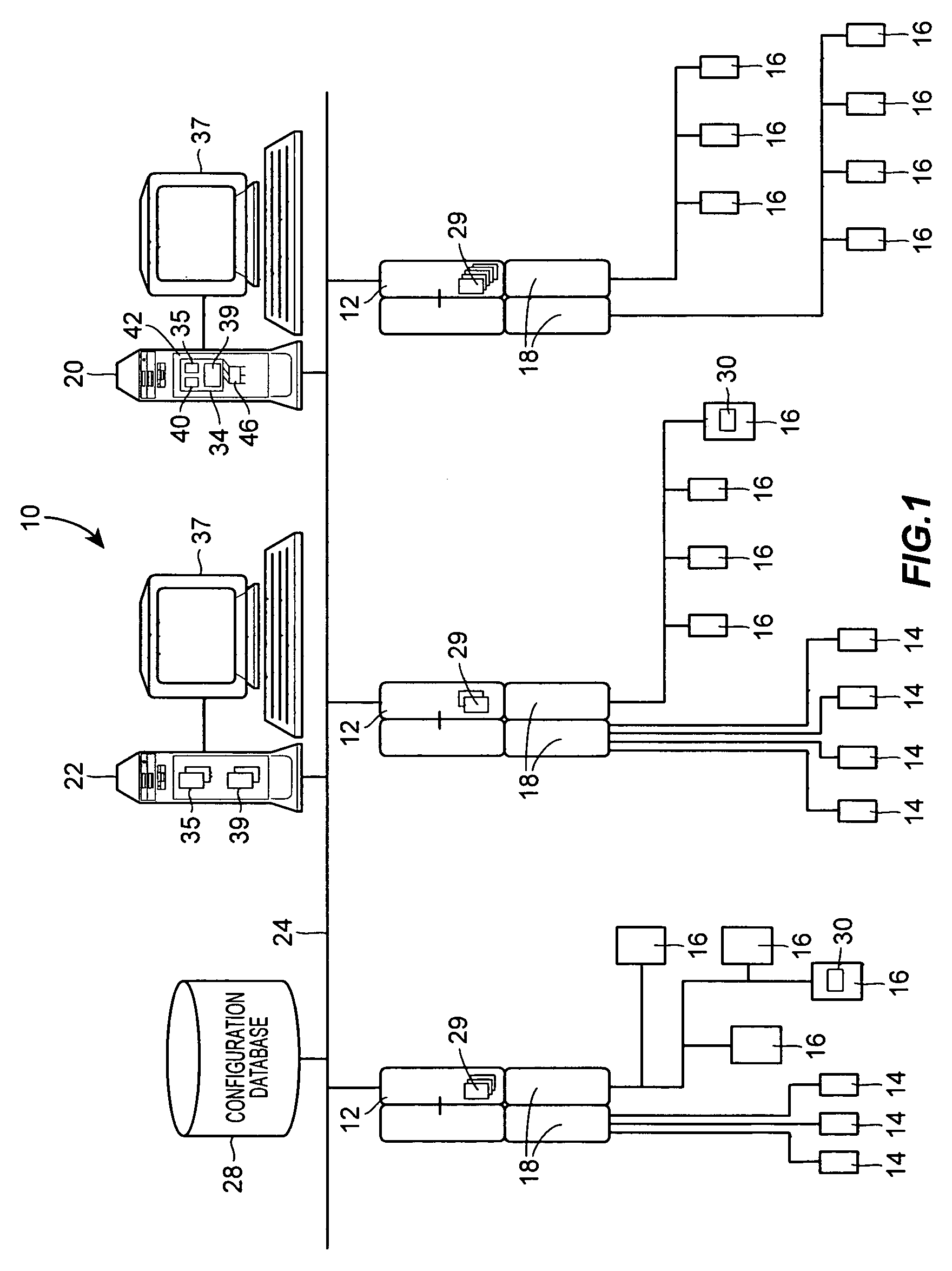

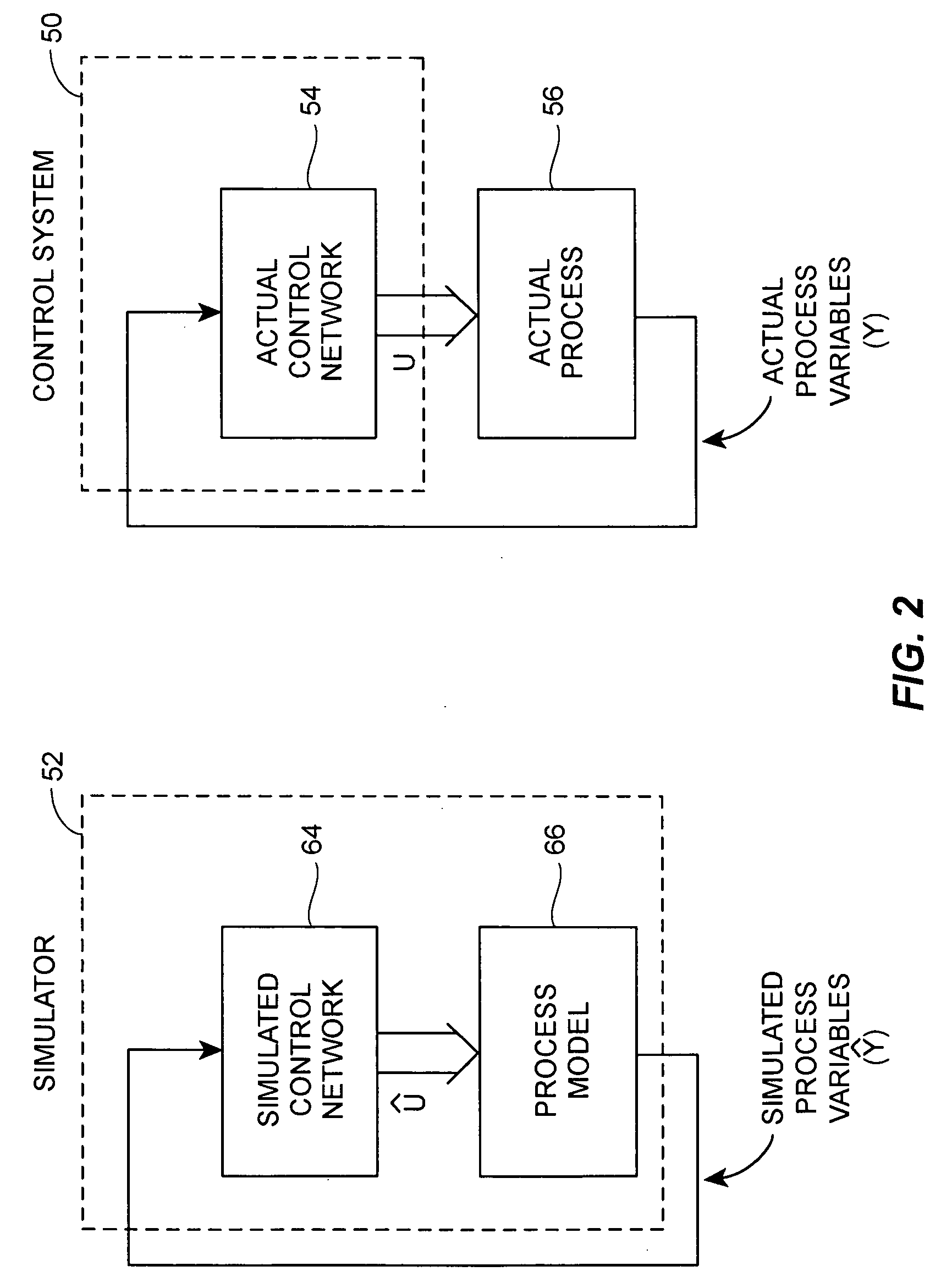

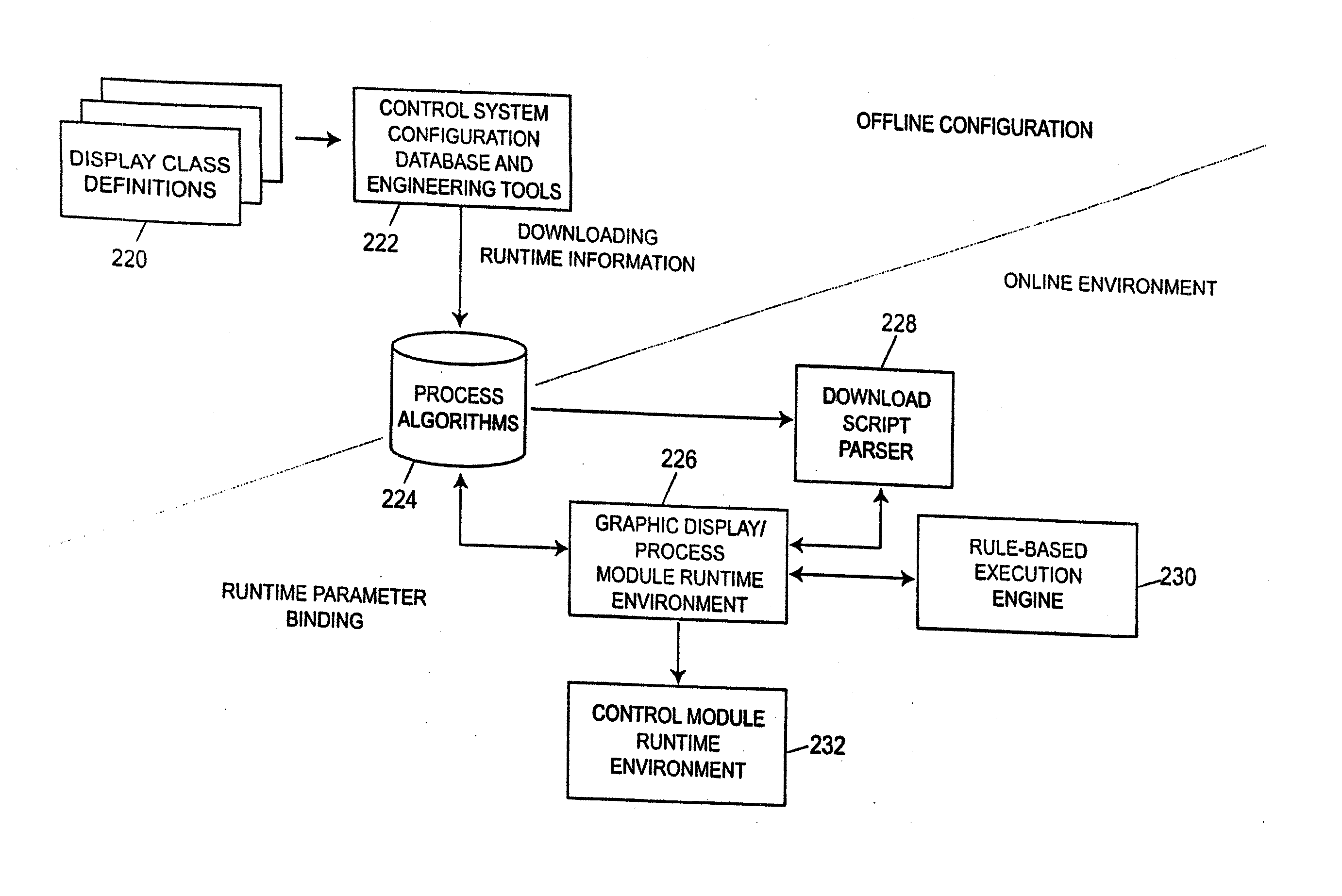

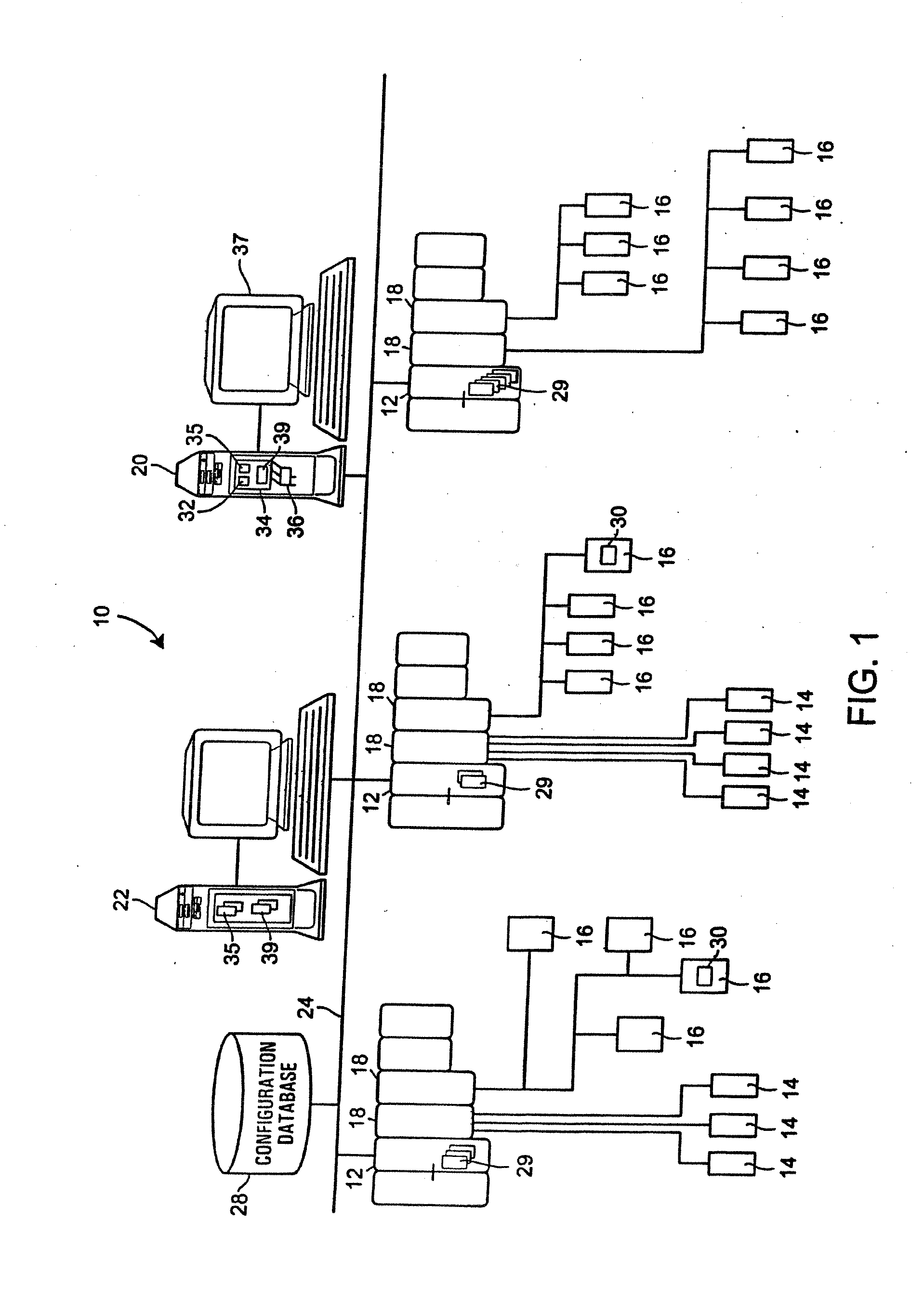

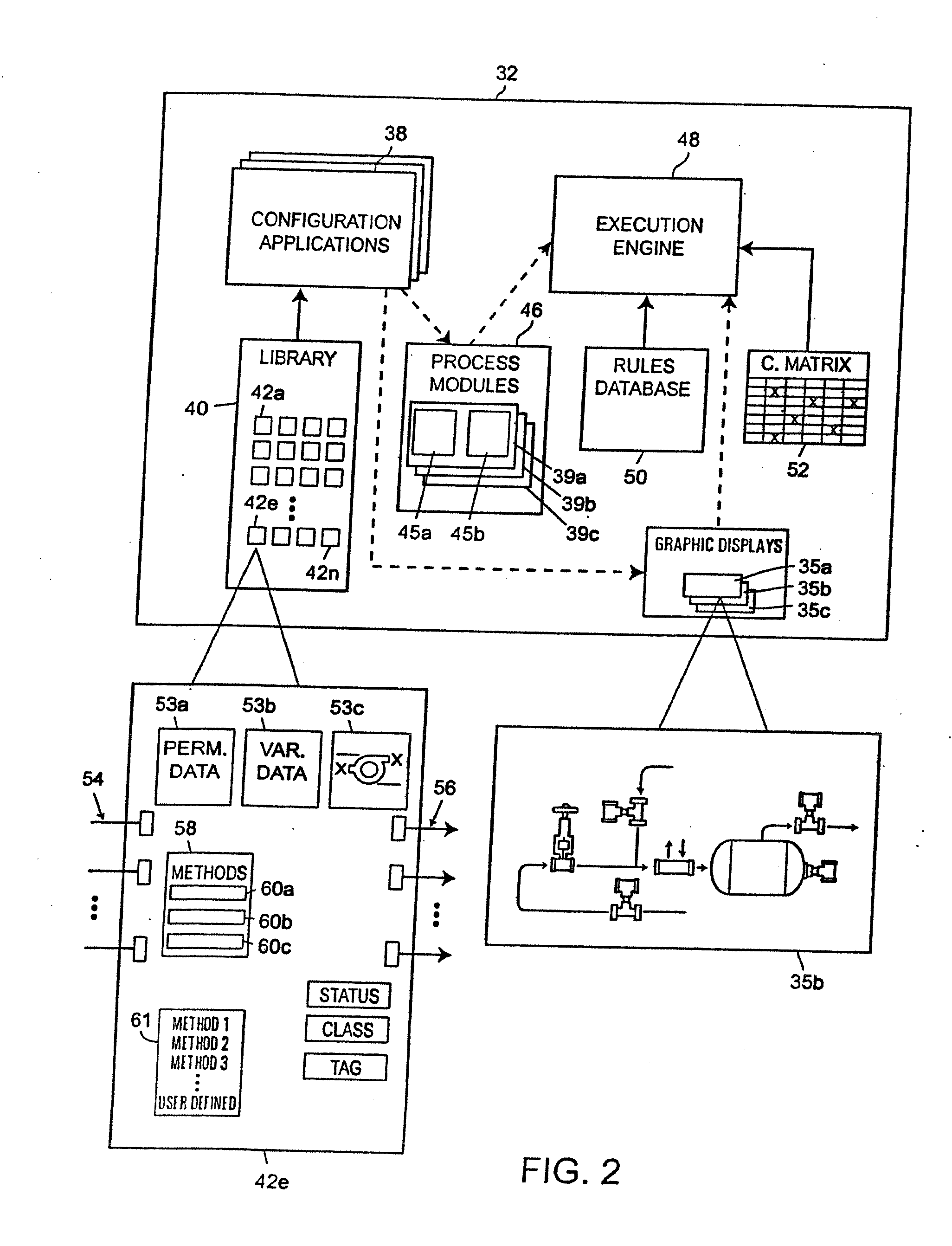

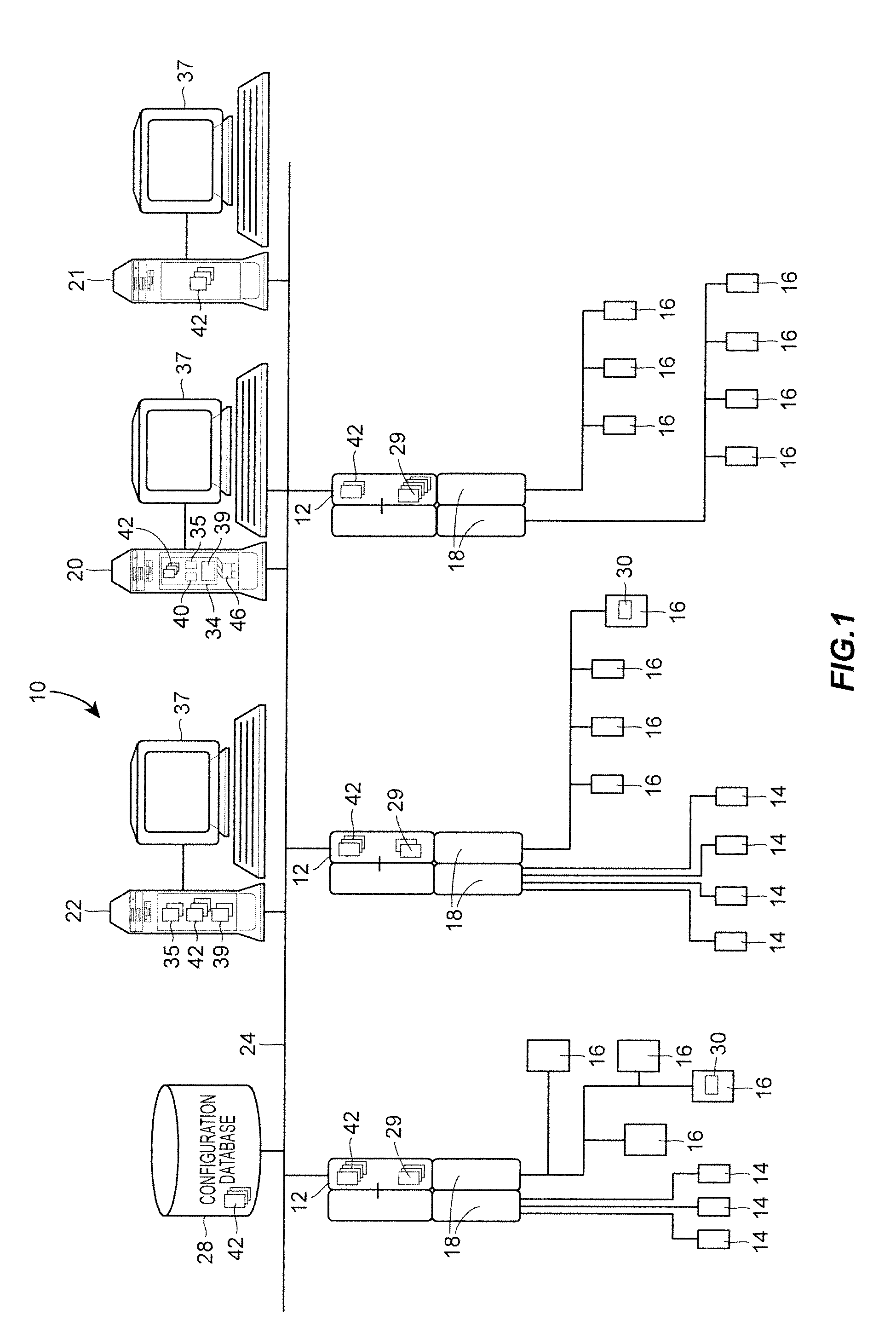

Real-time synchronized control and simulation within a process plant

ActiveUS20080027704A1Easy to useEasy to understandProgramme controlAnalogue computers for electric apparatusProcess control networkReal-time simulation

A process control system simulation technique performs real-time simulation of an actual process control network as that network is running within a process plant in a manner that is synchronized with the operation of the actual process control network. This real-time, synchronized simulation system includes a simulation process control network and a process model which are automatically updated periodically during the operation of the actual process control network to reflect changes made to the process control network, as well as to account for changes in the plant itself, i.e., changes which require an updated process model. The disclosed simulation system provides for more readily accessible and usable simulation activities, as the process control network and the process models used within the simulation system are synchronized with and up-to-date with respect to the current process operating conditions. Moreover, this simulation system is more accurate as it uses process models developed from the current state of the process whenever the simulation system beings to perform a simulation. Still further, the disclosed simulation system is easy to operate, as it uses the same user interface applications as the actual process control network and can be initialized and used at any time during operation the process plant without any significant configuration or set-up activities.

Owner:EMERSON PROCESS MANAGEMENT POWER & WATER SOLUTIONS

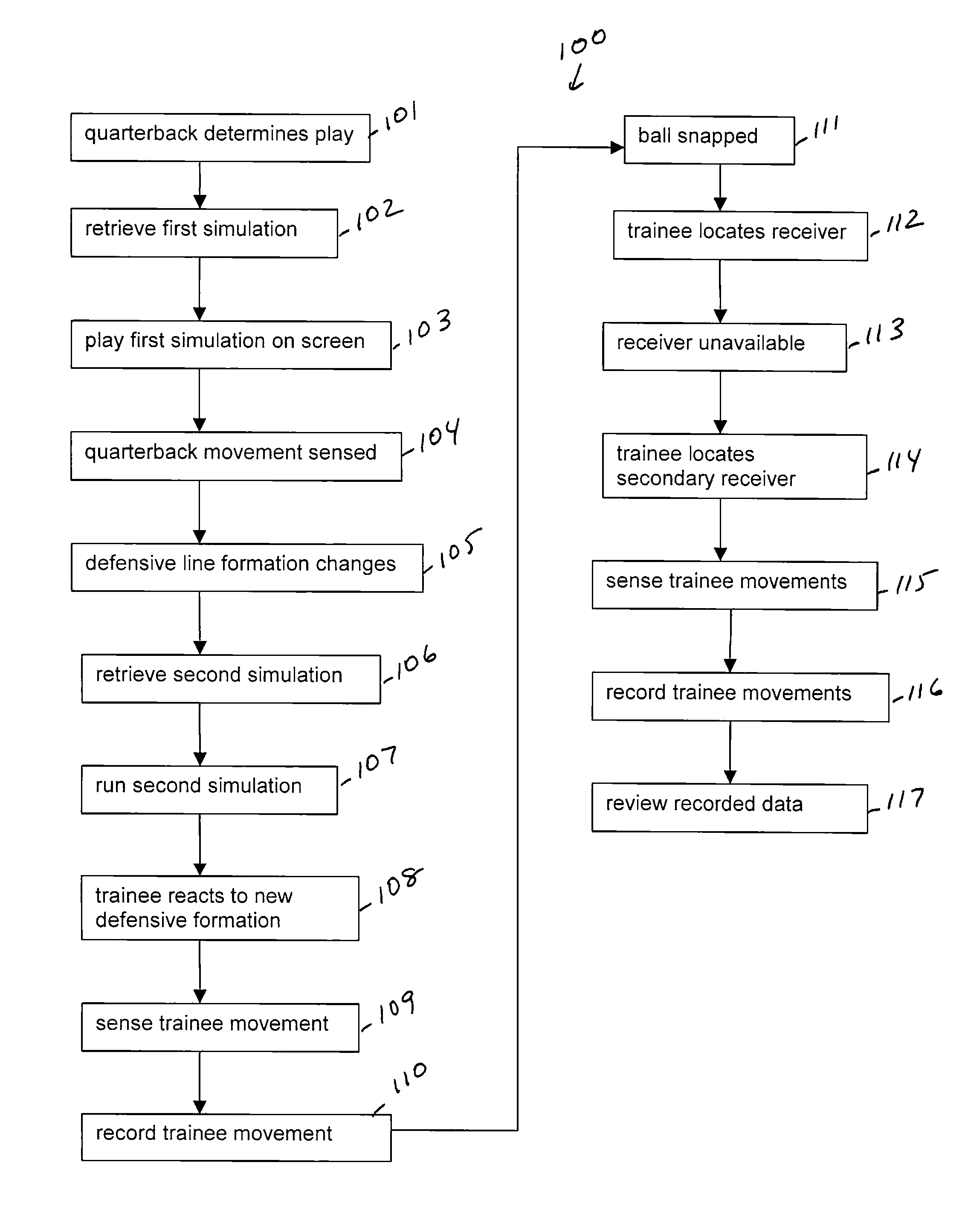

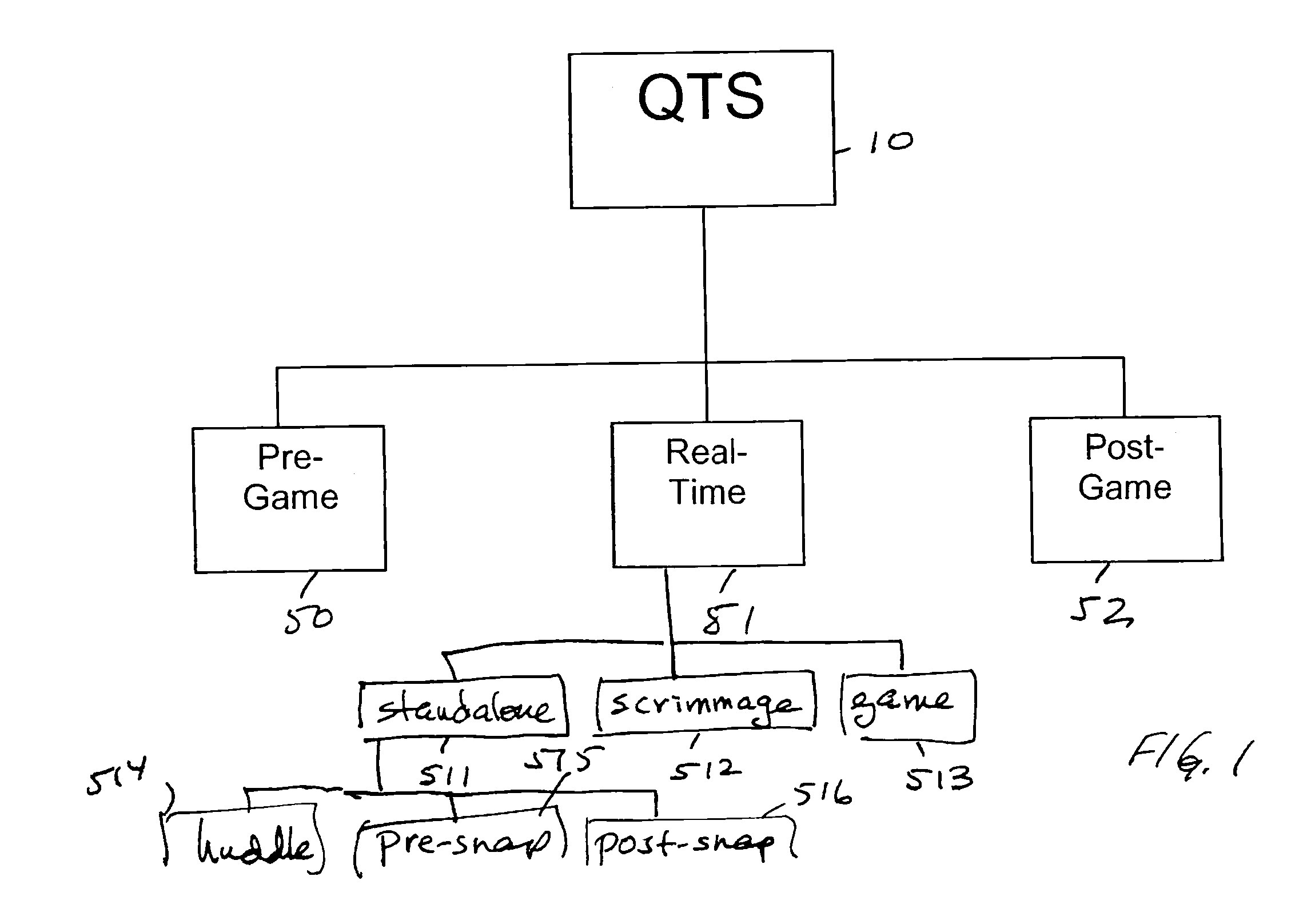

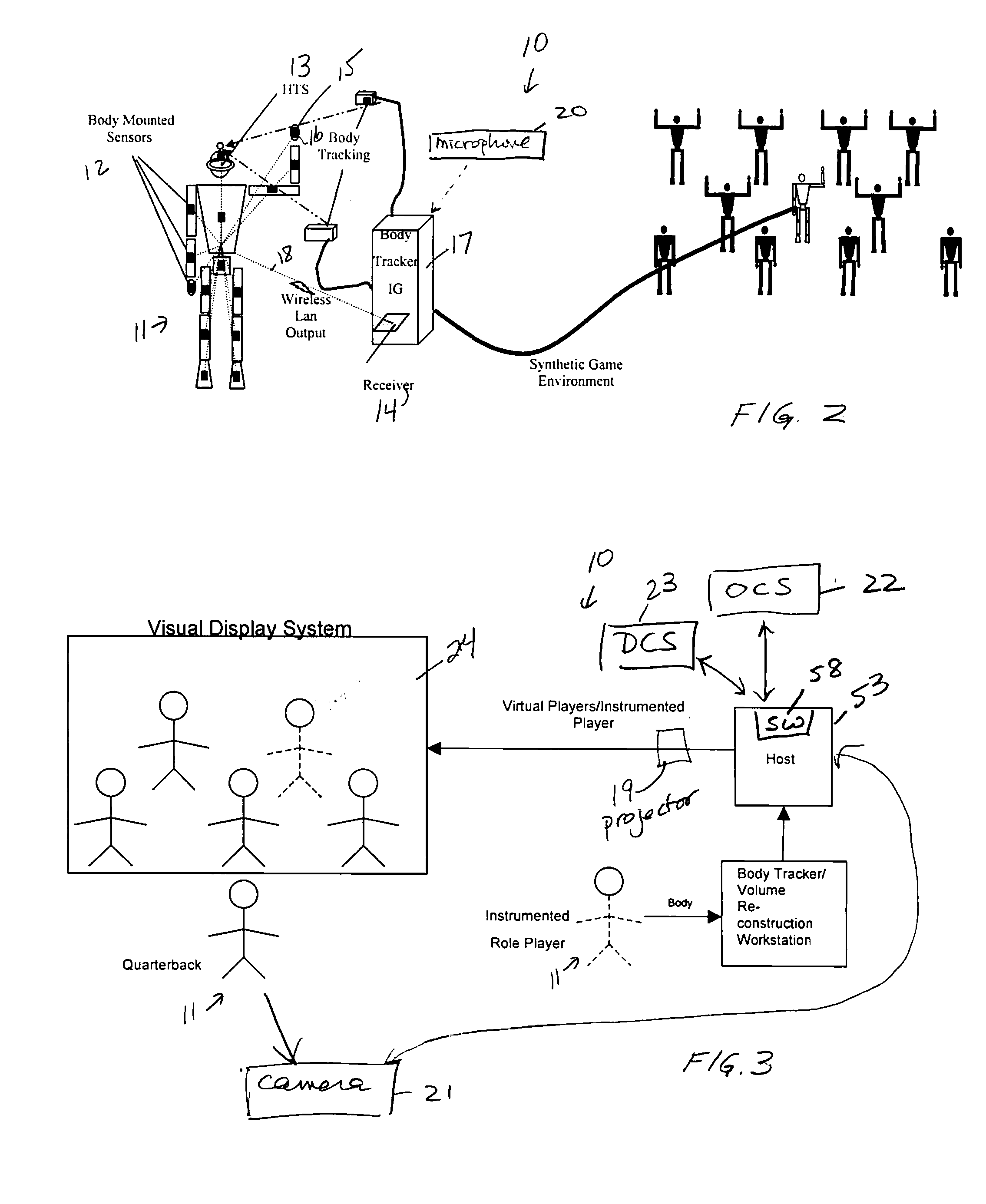

Sports Training Simulation System and Associated Methods

InactiveUS20060281061A1Cosmonautic condition simulationsGymnastic exercisingSoftware systemControl signal

A simulation system for training athletes in cognitive skills includes hardware incorporating imaging and tracking devices, sound generator and receiver, a projection screen, and a movie projector for creating a virtual environment that simulates the site specific to the sport. The system includes software installed on a processor that is in signal communication and in controlling relation to the hardware elements. The system inputs to the software a plurality of scenarios in which the athlete might find him / herself. The software acts to retrieve a scenario and output a plurality of control signals for presenting a visual and aural simulation. A body parameter is tracked in temporal coordination with elements of the scenario. The tracked parameter is saved for later review by the user and, in some cases, training personnel. The scenario evolves in response to the tracked parameter, and is thus interactive in nature.

Owner:TGDS

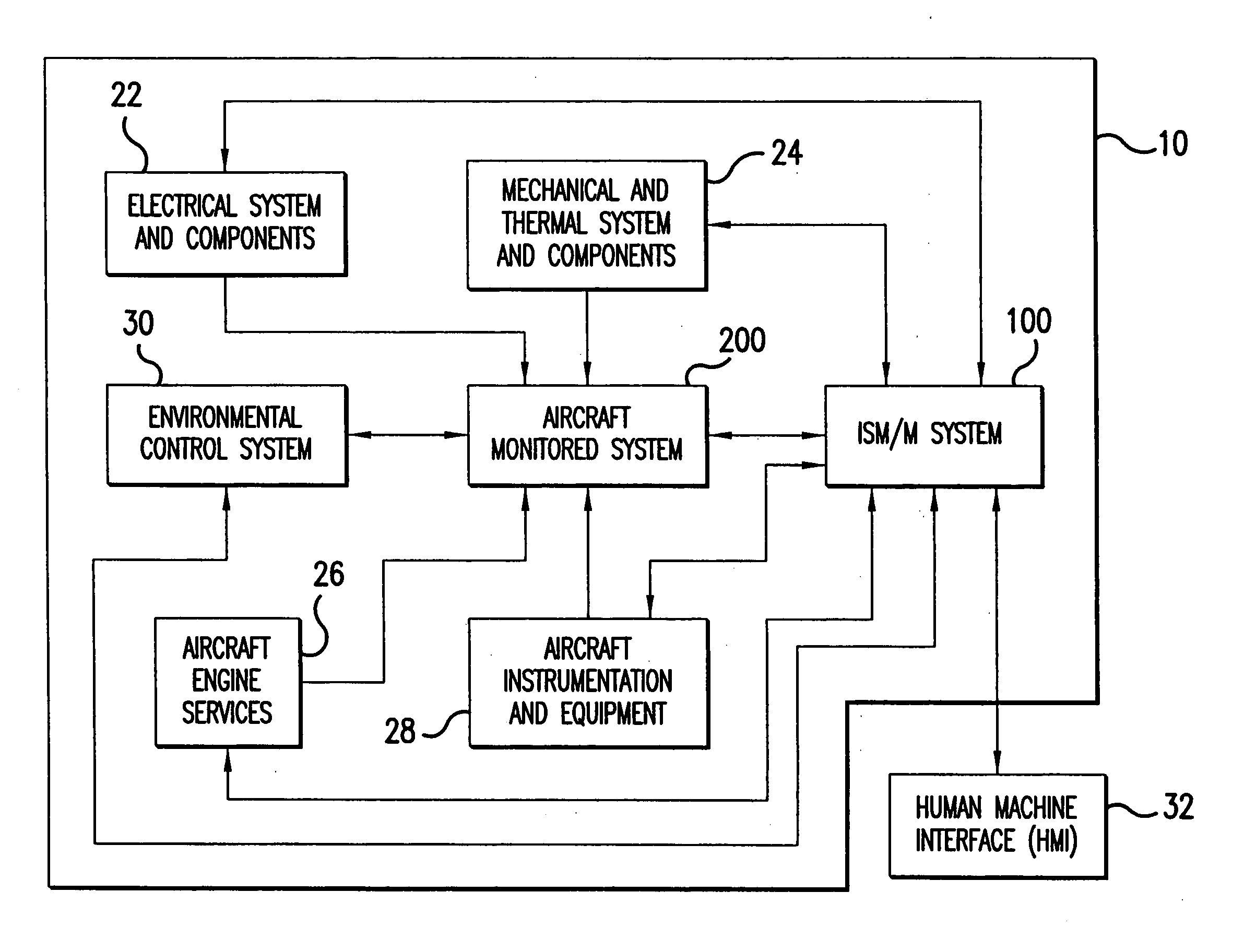

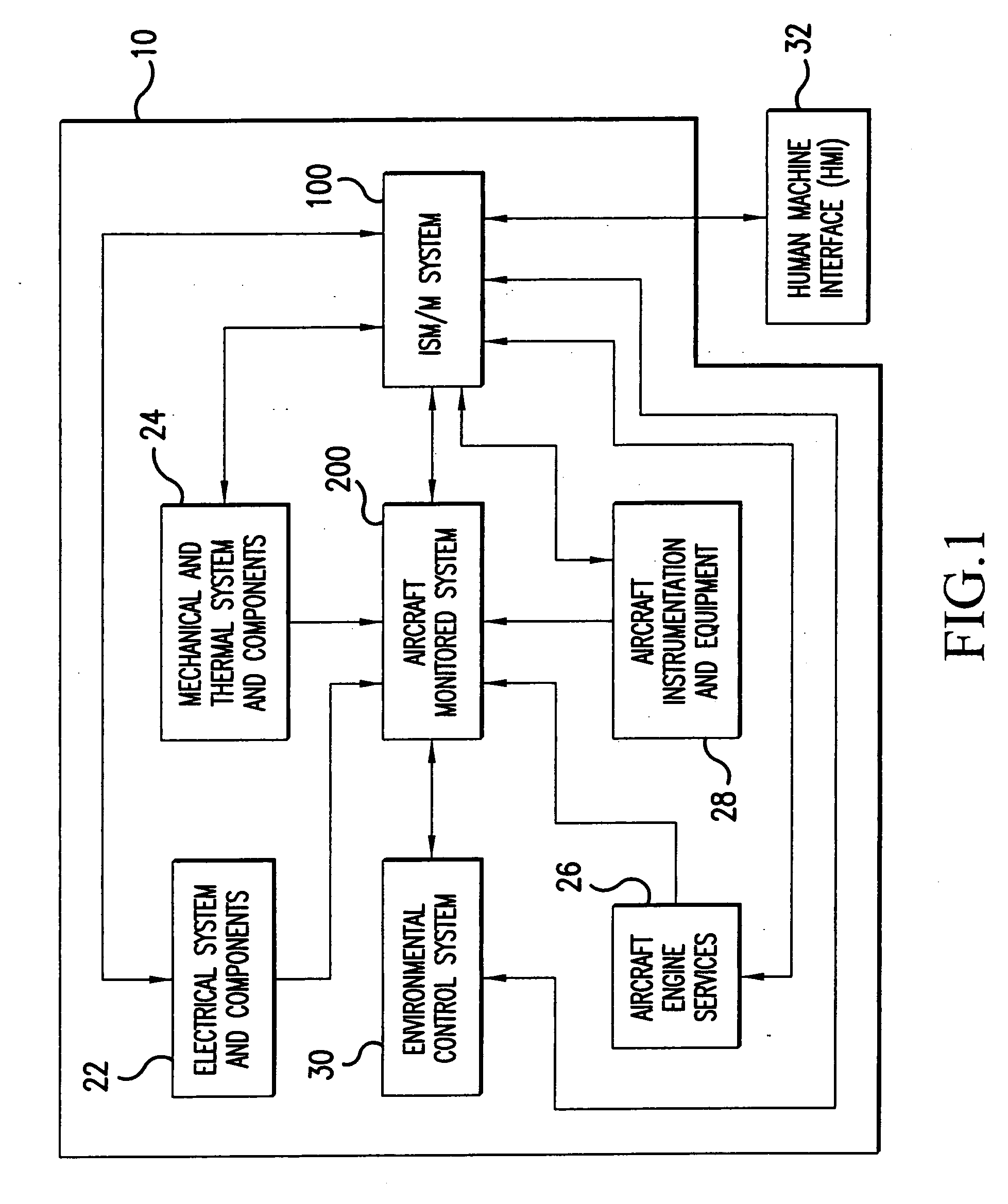

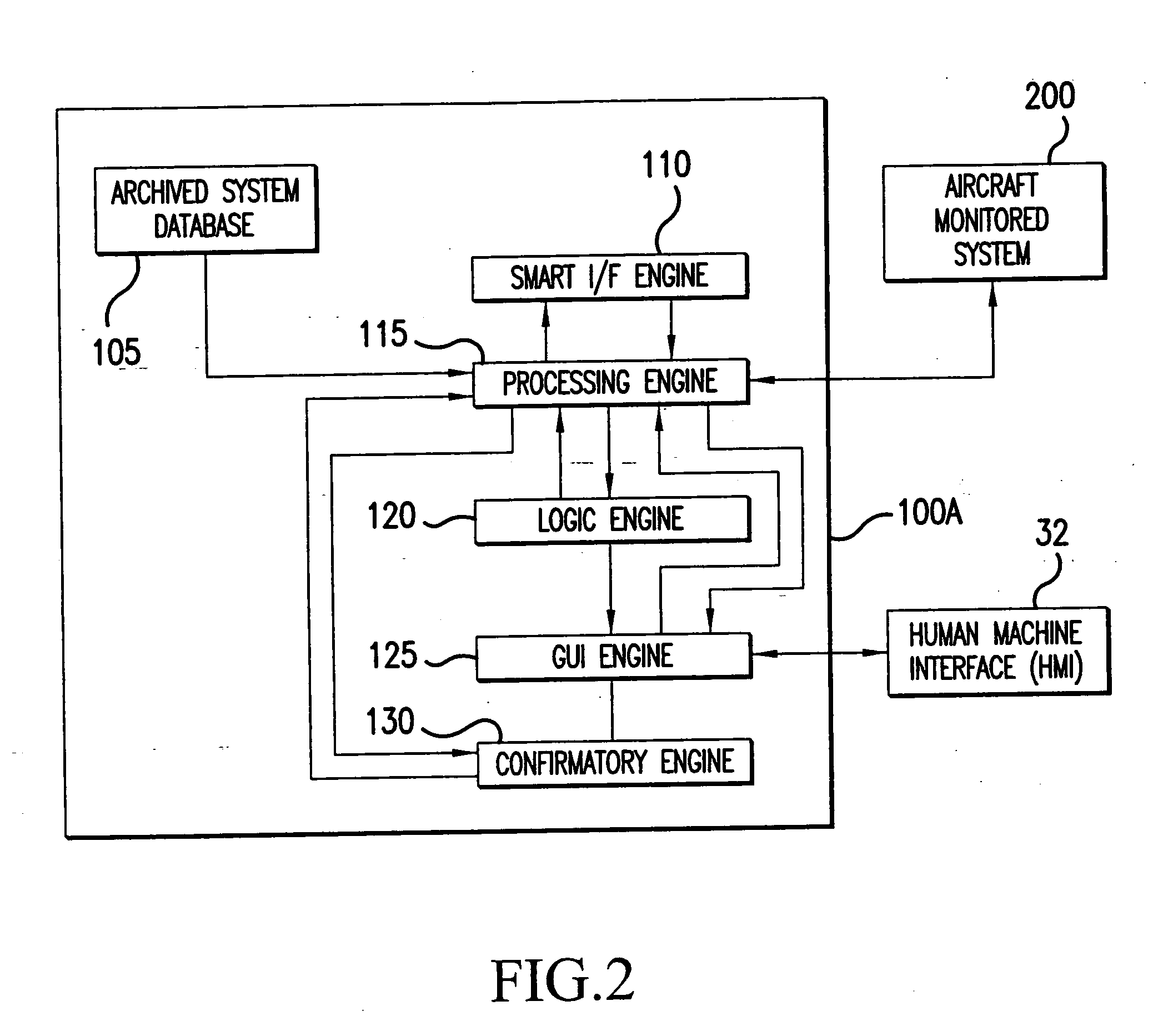

Method and apparatus for system monitoring and maintenance

InactiveUS20060126608A1Vehicle testingMultiplex system selection arrangementsFir systemComputer science

A method and an apparatus provide intelligent monitoring and maintenance of a system. The method according to one embodiment accesses data relating to functional components of the system; extracts parameter information for functional components of the system, the step of extracting parameter information including performing inferential processing and trend recognition of the data using previous knowledge about the system, and simulating performance of the system using models of the system and previous knowledge about the system; identifies new information about the system present in extracted parameter information; and provides the new information to the step of extracting parameter information, to be used as previous knowledge.

Owner:HONEYWELL INT INC

Updating and Utilizing Dynamic Process Simulation in an Operating Process Environment

InactiveUS20070208549A1Easy to useAdvanced and accurate simulationProgramme controlSimulator controlEngineeringProcess simulation

A simulation system that includes interconnected simulation blocks which use process models to perform simulation activities for a process plant is integrated into a process control environment for the process plant in a manner that makes the simulation system easy to use and easily updated for on-line process simulation. The disclosed simulation system enables future predicted values as well as the current predicted values of process parameters produced by the simulation system to be made available for performance evaluation as well as to guide plant operations. Additionally, the simulation system is connected to the operating process plant to receive various on-line process plant measurements, and uses these measurements to automatically update the process models used in the simulation system, to thereby keep the simulation system coordinated with the actual operating conditions of the process plant.

Owner:FISHER-ROSEMOUNT SYST INC

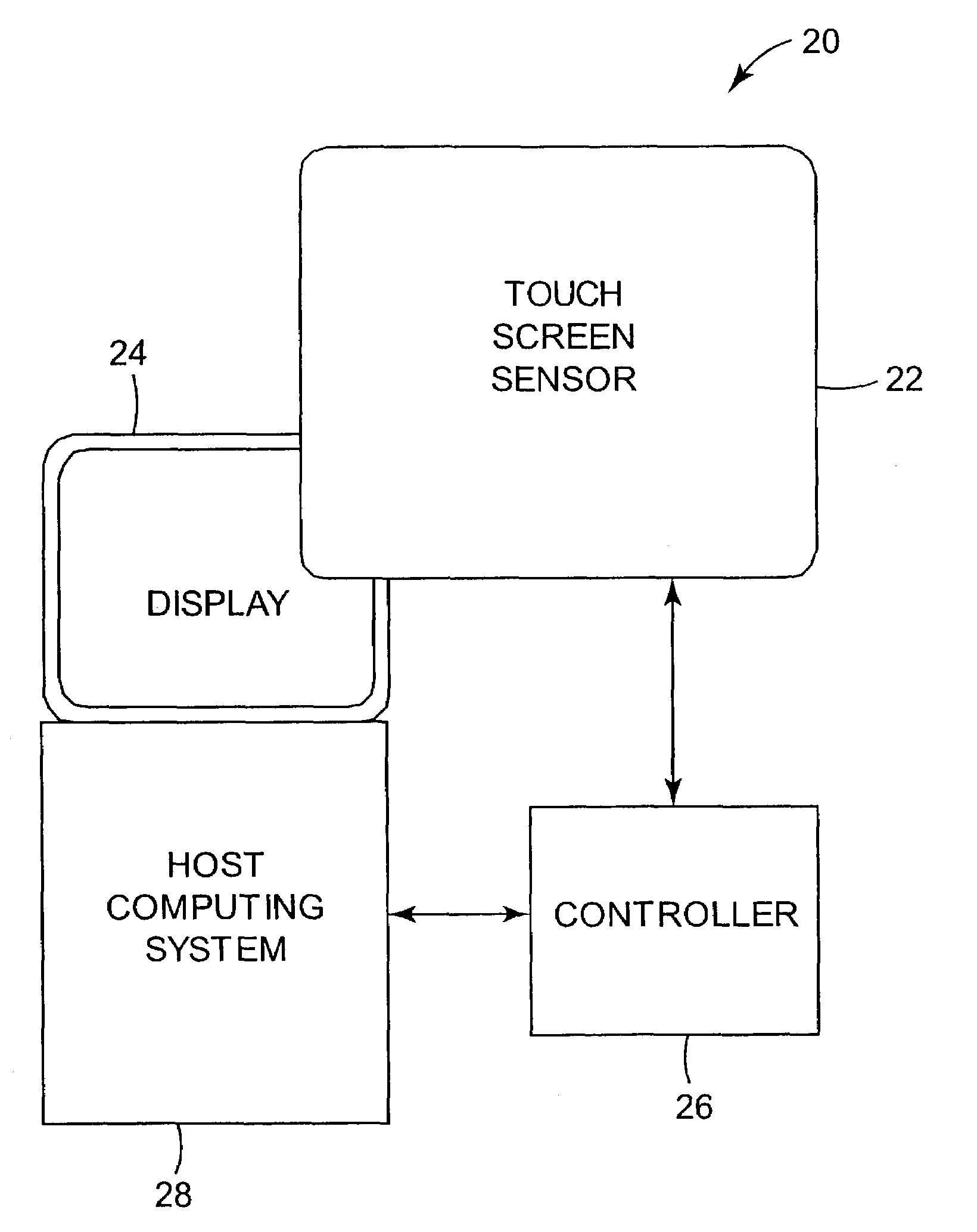

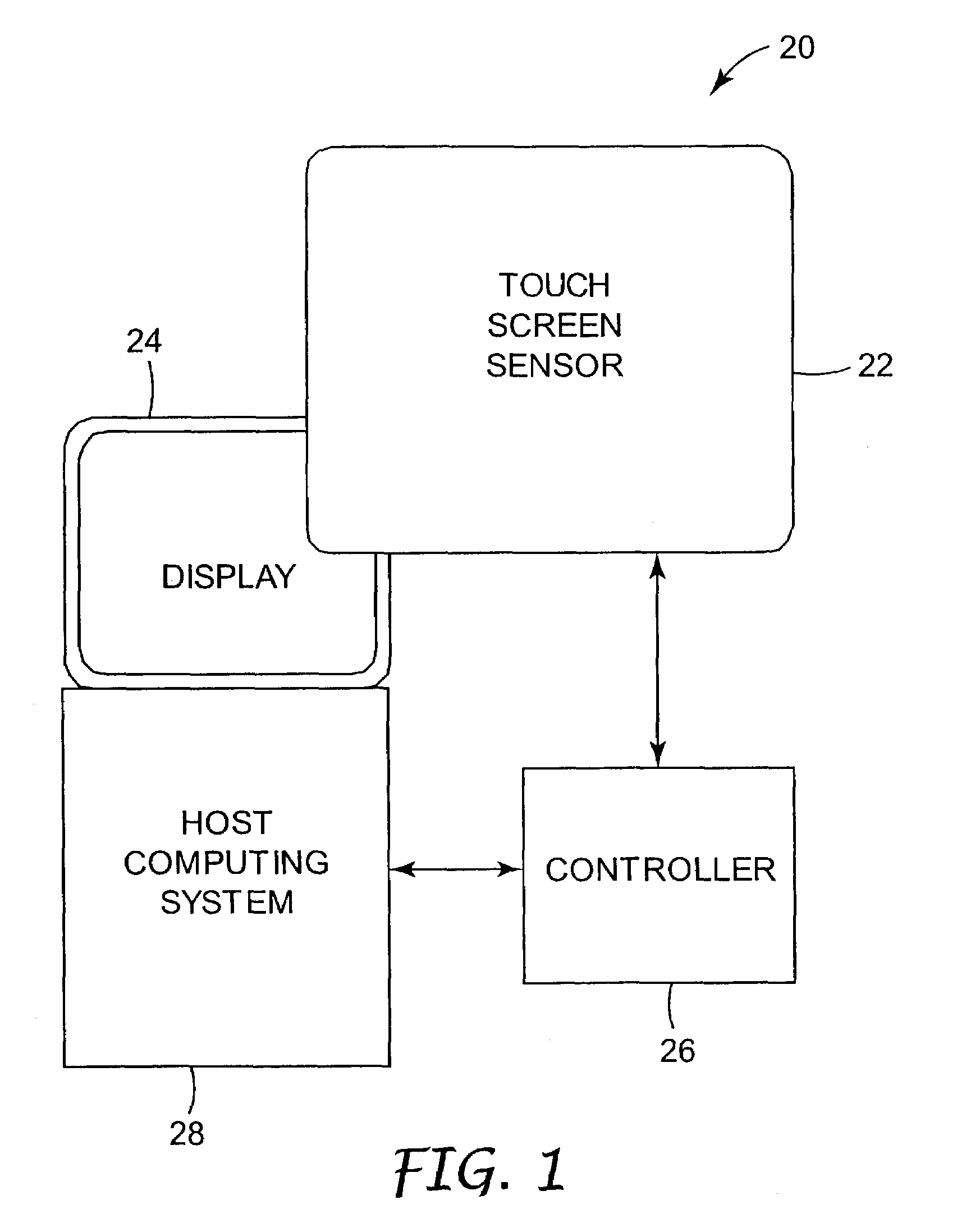

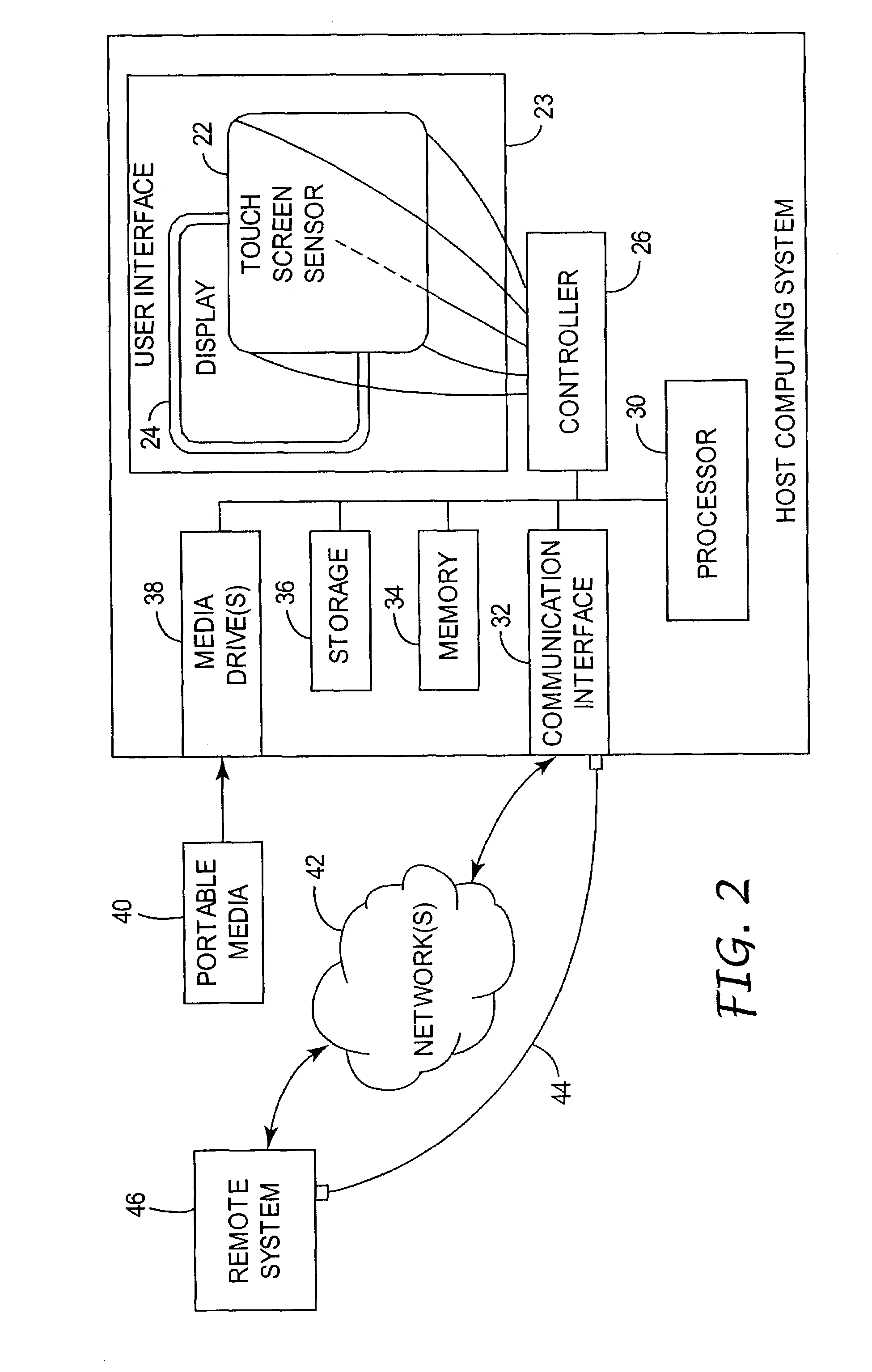

Touch simulation system and method

InactiveUS7362313B2Input/output for user-computer interactionCathode-ray tube indicatorsTouchscreenVoltage

Systems and methods provide for simulating an effective touch on a touch screen sensor. A touch screen sensor includes a first surface, an opposing second surface, and one or more electrodes disposed on or proximate to the second surface. Signals are applied to the first and second surfaces in a manner which results in a simulated touch to a particular location of the touch screen sensor. In another approach, a plurality of voltage drive signals are applied at various touch surface regions of the touch screen sensor. A current flow resulting from application of the voltage drive signals is detected as the simulated touch. Touch simulation can be initiated locally or remotely as part of automated monitoring, testing, calibration, and / or servicing procedures. Results of a touch simulation procedure can be acquired and used locally or remotely to assess the operational fitness of the touch screen sensor over time.

Owner:3M INNOVATIVE PROPERTIES CO

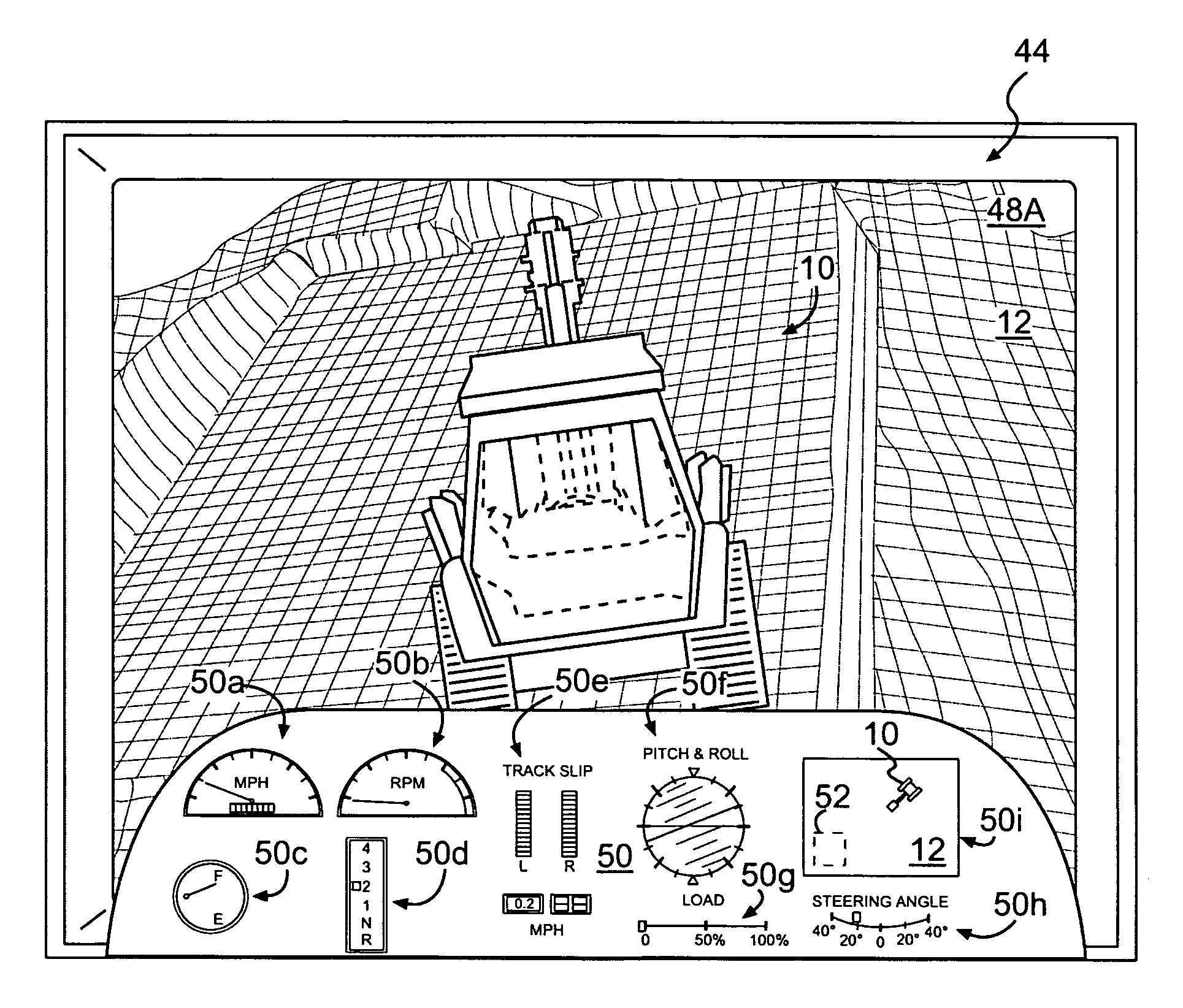

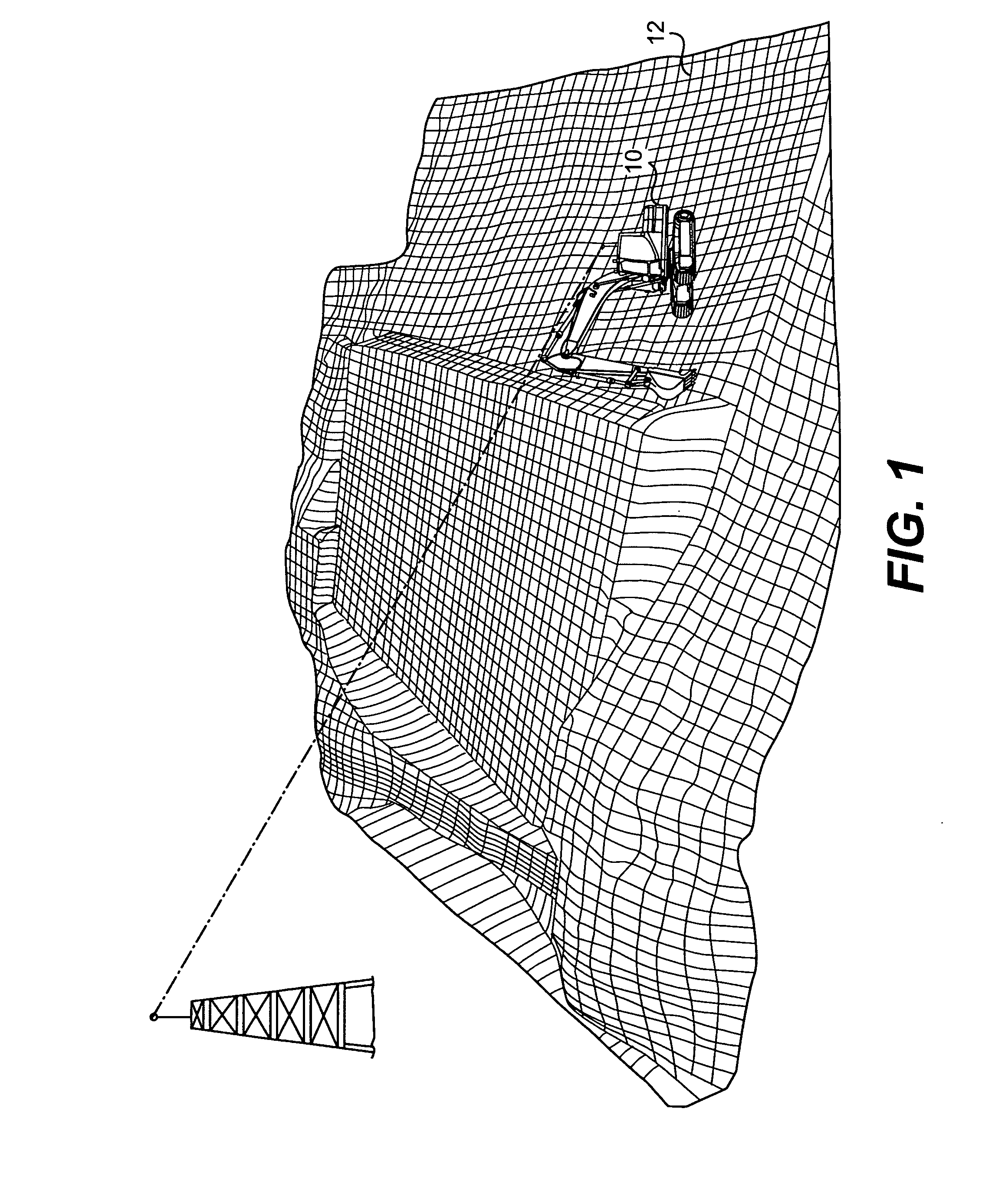

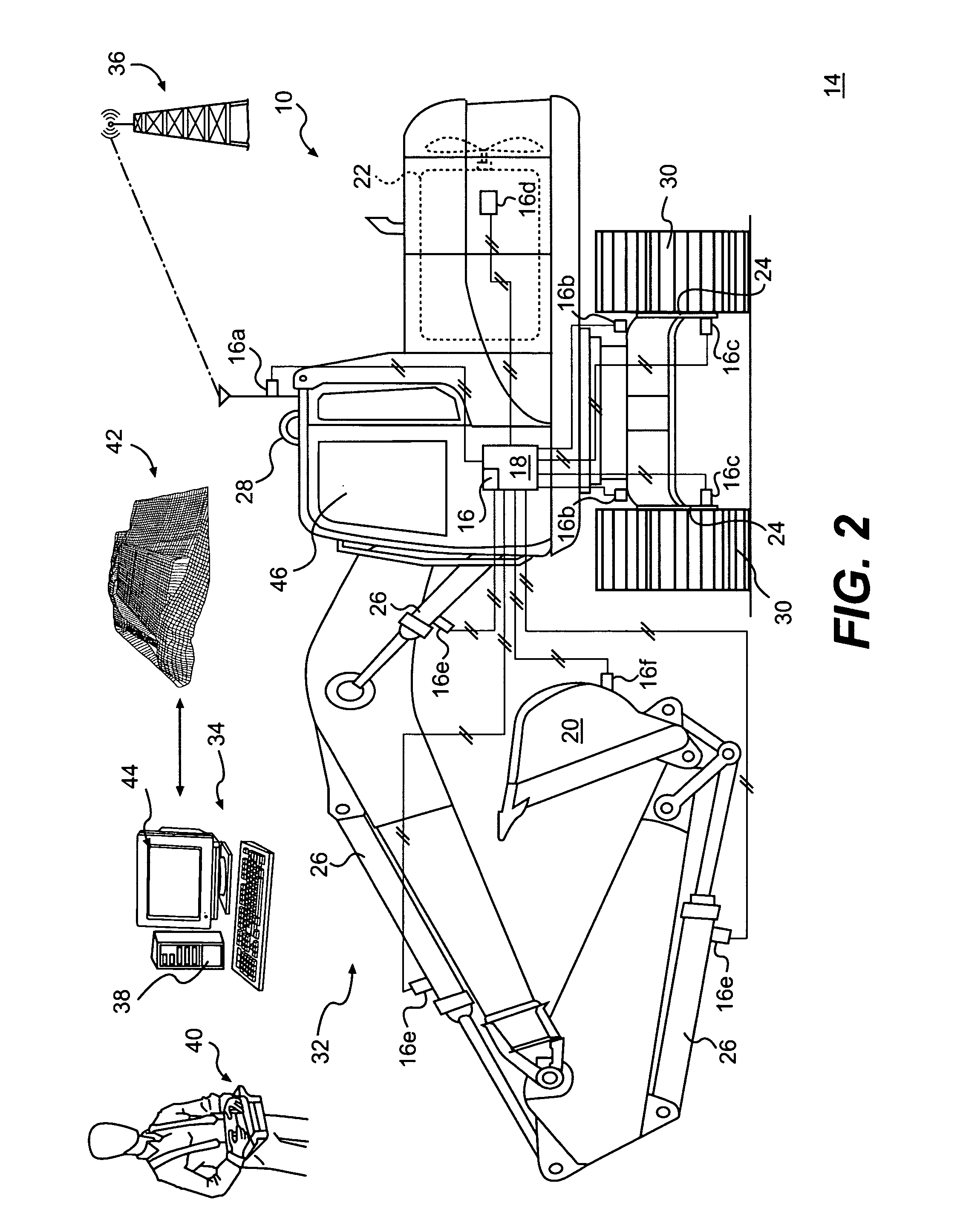

Simulation system implementing real-time machine data

ActiveUS20080180523A1Affect operationCosmonautic condition simulationsColor television detailsTime informationControl system

A simulation and control system for a machine is disclosed. The simulation and control system may have a user interface configured to display a simulated environment. The machine simulation and control system may also have a controller in communication with the user interface and a remotely located machine. The controller may be configured to receive from the machine real-time information related to operation of the machine at a worksite. The controller may also be configured to simulate the worksite, operation of the machine, and movement of a machine tool based on the received information. The controller may further be configured to provide to the user interface the simulated worksite, operation, and movement in the simulated environment.

Owner:CATERPILLAR INC

Interface device and method for interfacing instruments to medical procedure simulation systems

InactiveUS20060046235A1Improve realismSimulate the realEducational modelsMeasuring instrumentDisplay device

An interface device and method for interfacing instruments to a medical procedure simulation system serve to interface peripherals in the form of mock medical instruments to the medical procedure simulation system computer to enable simulation of medical procedures. The interface device includes a housing having a mock bodily region of interest to facilitate insertion of a mock instrument, such as an endoscope tube, into the interface device. The mock bodily region of interest may be pivotable to simulate various patient orientations. The instrument is engaged by a capture mechanism in order to measure rotational and translational motion of the instrument. An actuator is disposed within the interface device to provide force feedback to the instrument. The measured motion is provided to the computer system to reflect instrument motion on the display during the simulation. Alternatively, the interface device may be configured to accommodate instrument assemblies having a plurality of nested instruments (e.g., sheath, catheter and wire), whereby the interface device individually grasps, measures manipulation of and provides force feedback to the nested instruments. In addition, the interface device may be configured to simultaneously accommodate a plurality of independently inserted instruments.

Owner:IMMERSION MEDICAL

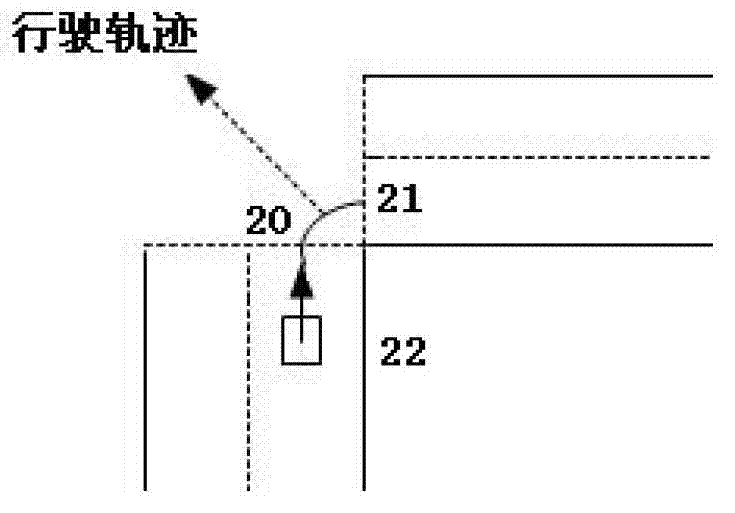

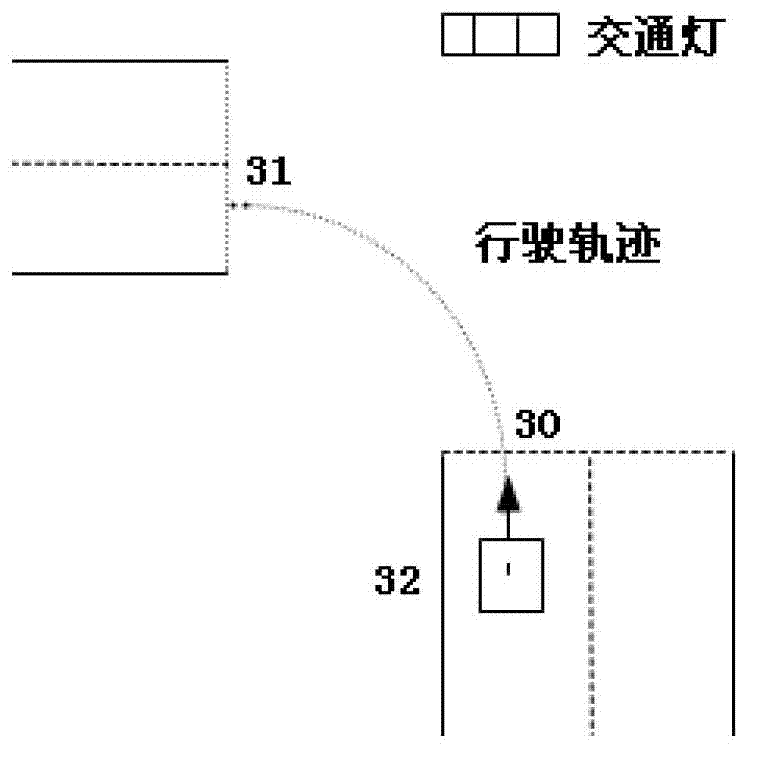

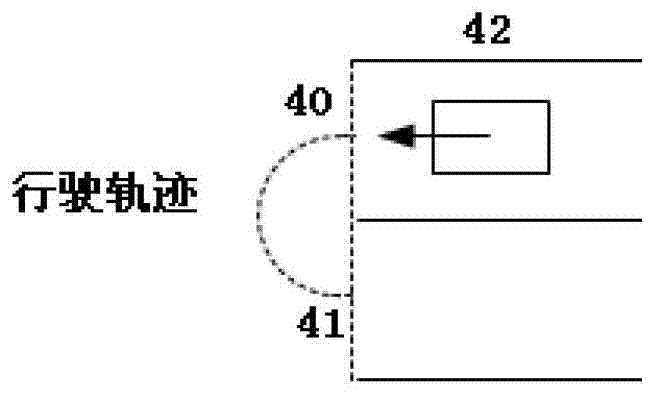

Driverless vehicle environment simulation test system and test method

ActiveCN103207090ASimulation is accurateReduce test time costsVehicle testingSimulation systemSimulation test

The invention discloses a driverless vehicle environment simulation test system. The system comprises an environment simulation system and a test system; the environment simulation system is used for establishing a real road environment model for a driverless vehicle and simulating the real road environment for the driverless vehicle; during test, the real road environment model for the driverless vehicle is converted into a task form file, and the task form file is input to a driverless vehicle-mounted control computer, wherein the task form file consists of three-dimensional world geodetic system1984 (WGS84) coordinates of each guide point of a driverless vehicle passing test road section and environmental element codes of the guide points; and the driverless vehicle-mounted control computer sends signals of the three-dimensional WGS84 coordinates of each guide point of the driverless vehicle passing test road section and the environmental element codes of the guide points to a tester held multifunctional box through a vehicle-mounted antenna in the test process, and the tester held multifunctional box receives and displays the signals.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

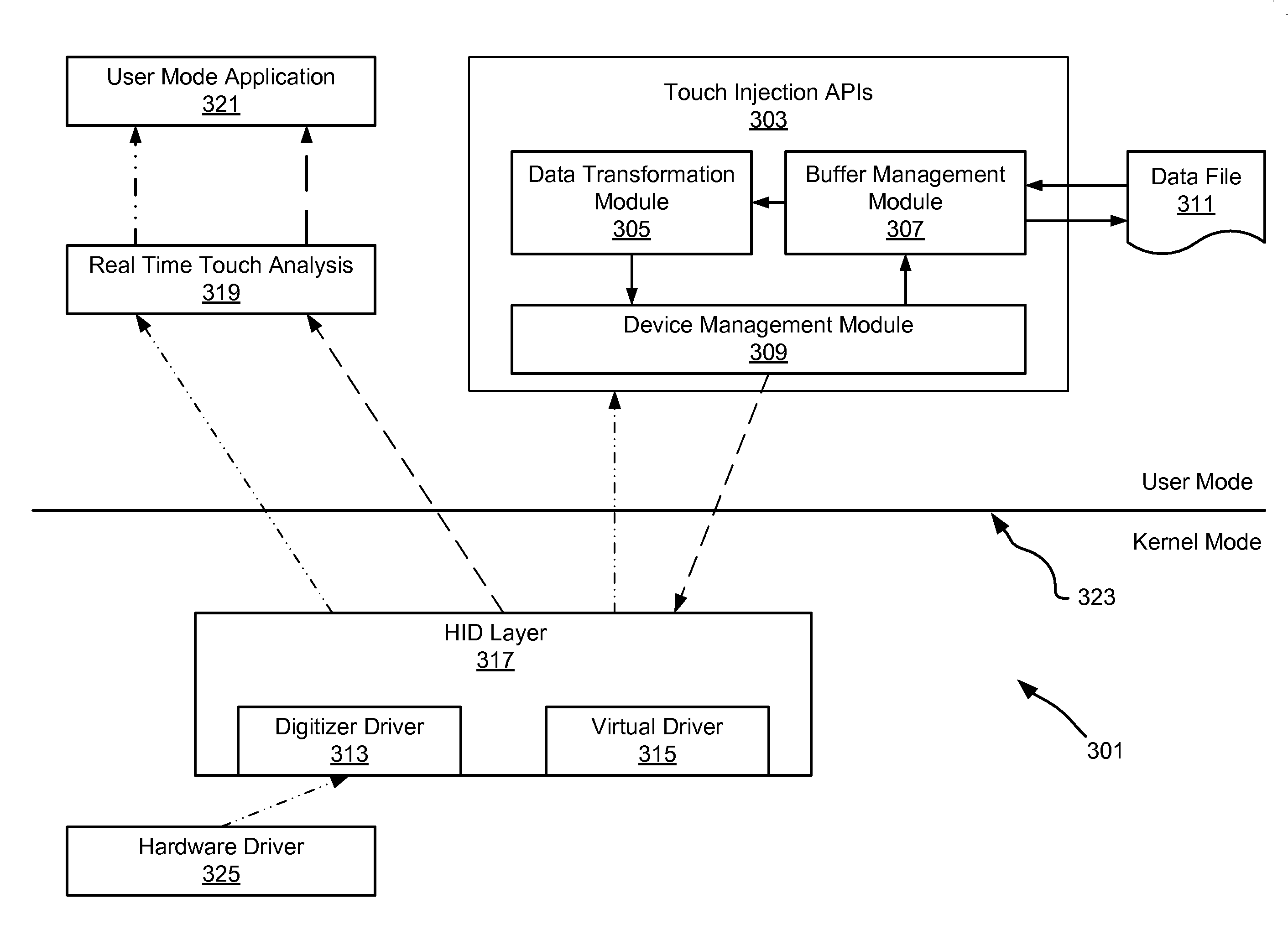

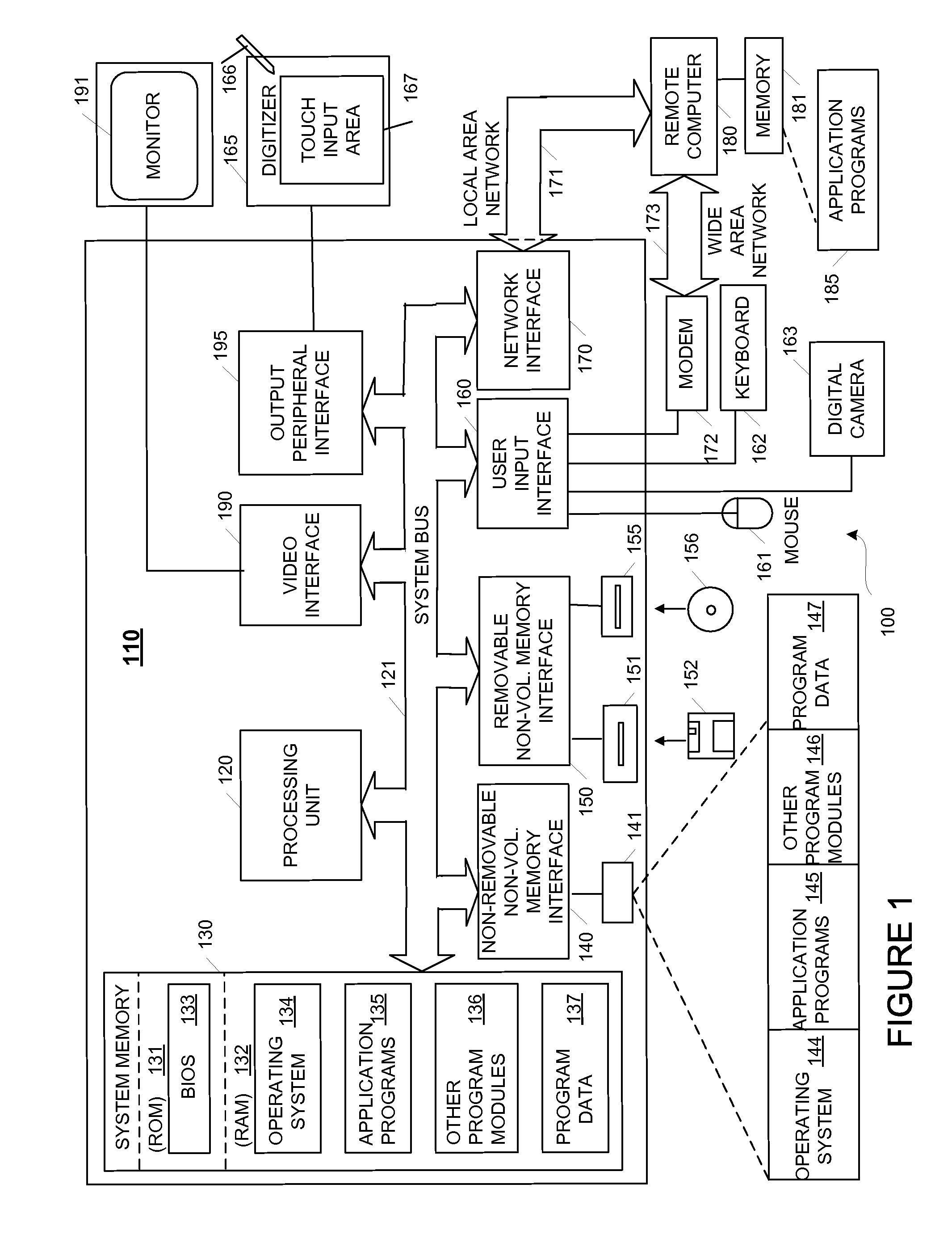

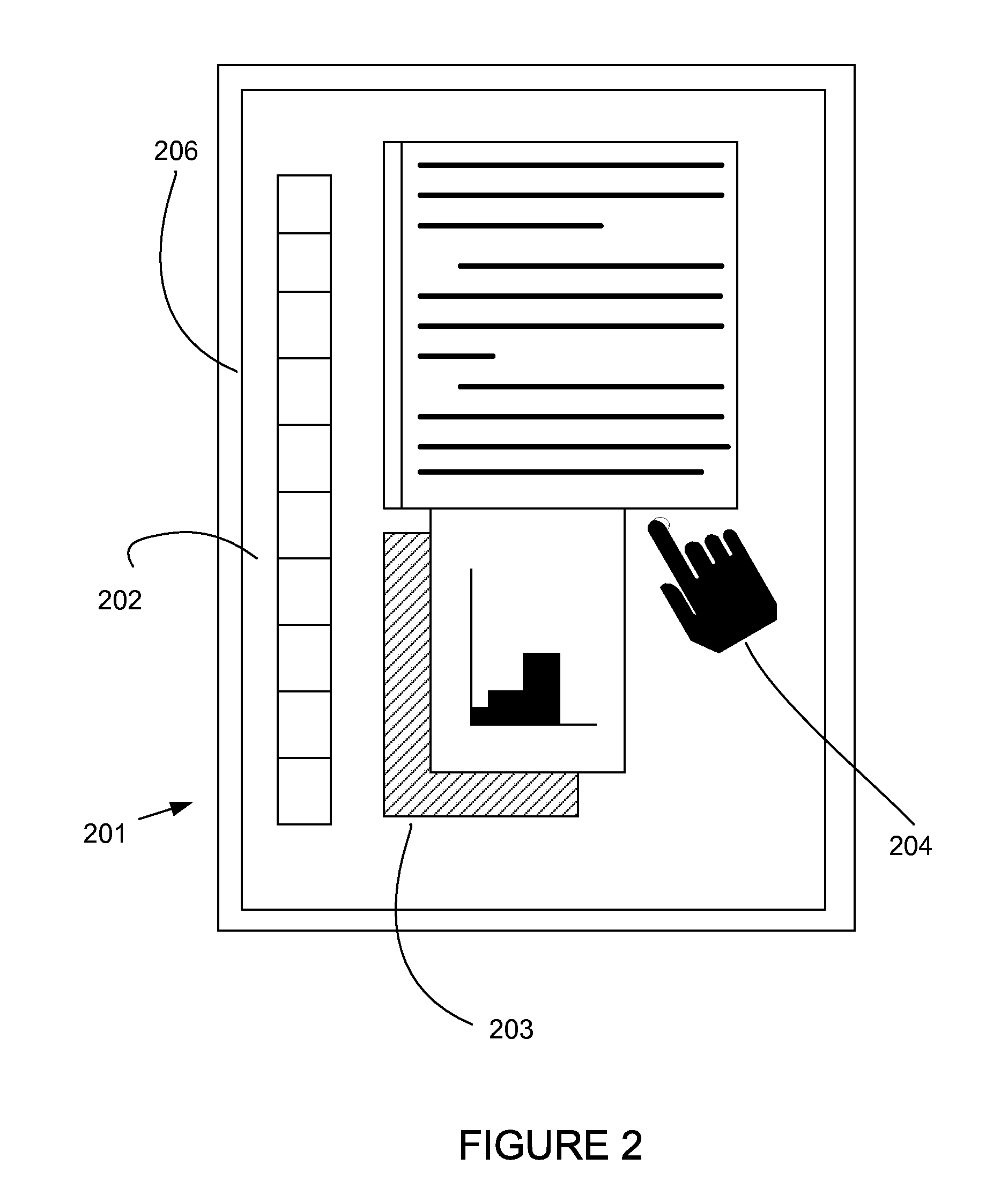

Input Simulation System For Touch Based Devices

Performance of automated touch data injection into a stack of software objects is provided. Previously stored data from a touch data file is received and transformed based upon a touch property. The transformed retrieved data is then injected into a lowermost layer of a stack of software objects. A computer-readable medium tool allows a user, such as a software developer, to create data that can consistently be employed to simulate the operation of movement of a user's finger across a touch input area. A buffer management module retrieves data from a touch data file. A data transformation module transforms the retrieved data based upon a touch property. A device management module injects transformed retrieved data into a human interface layer of a device.

Owner:MICROSOFT TECH LICENSING LLC

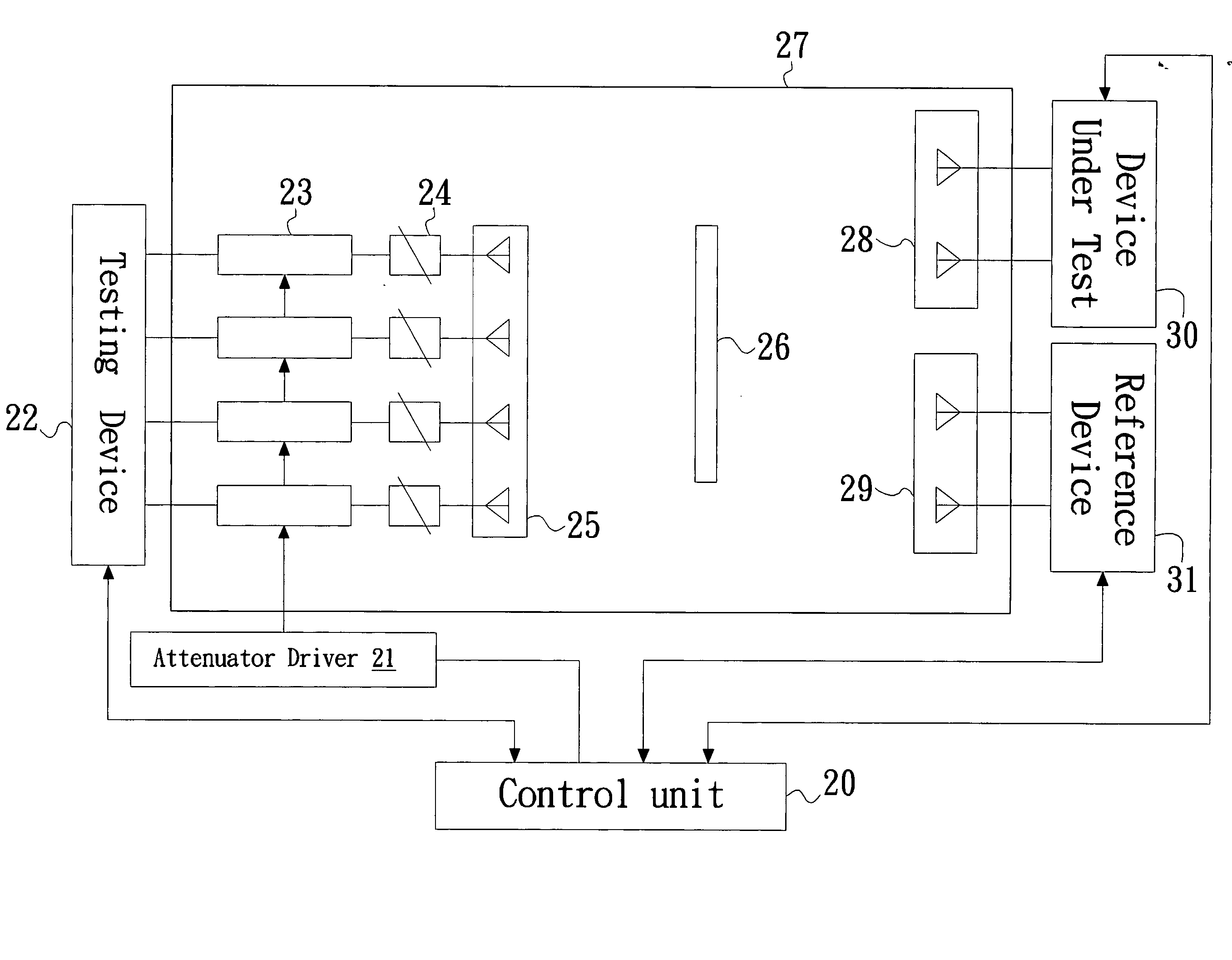

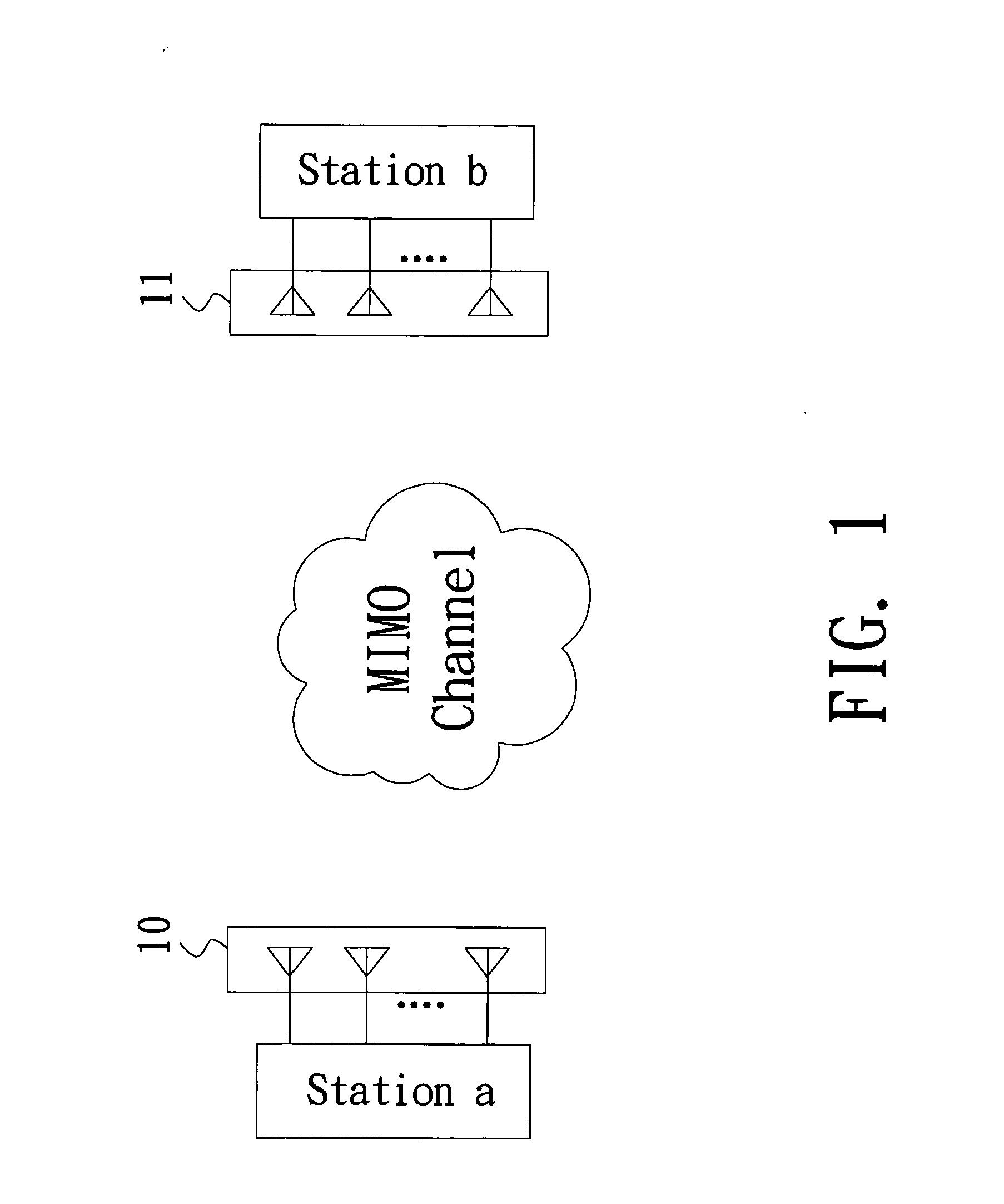

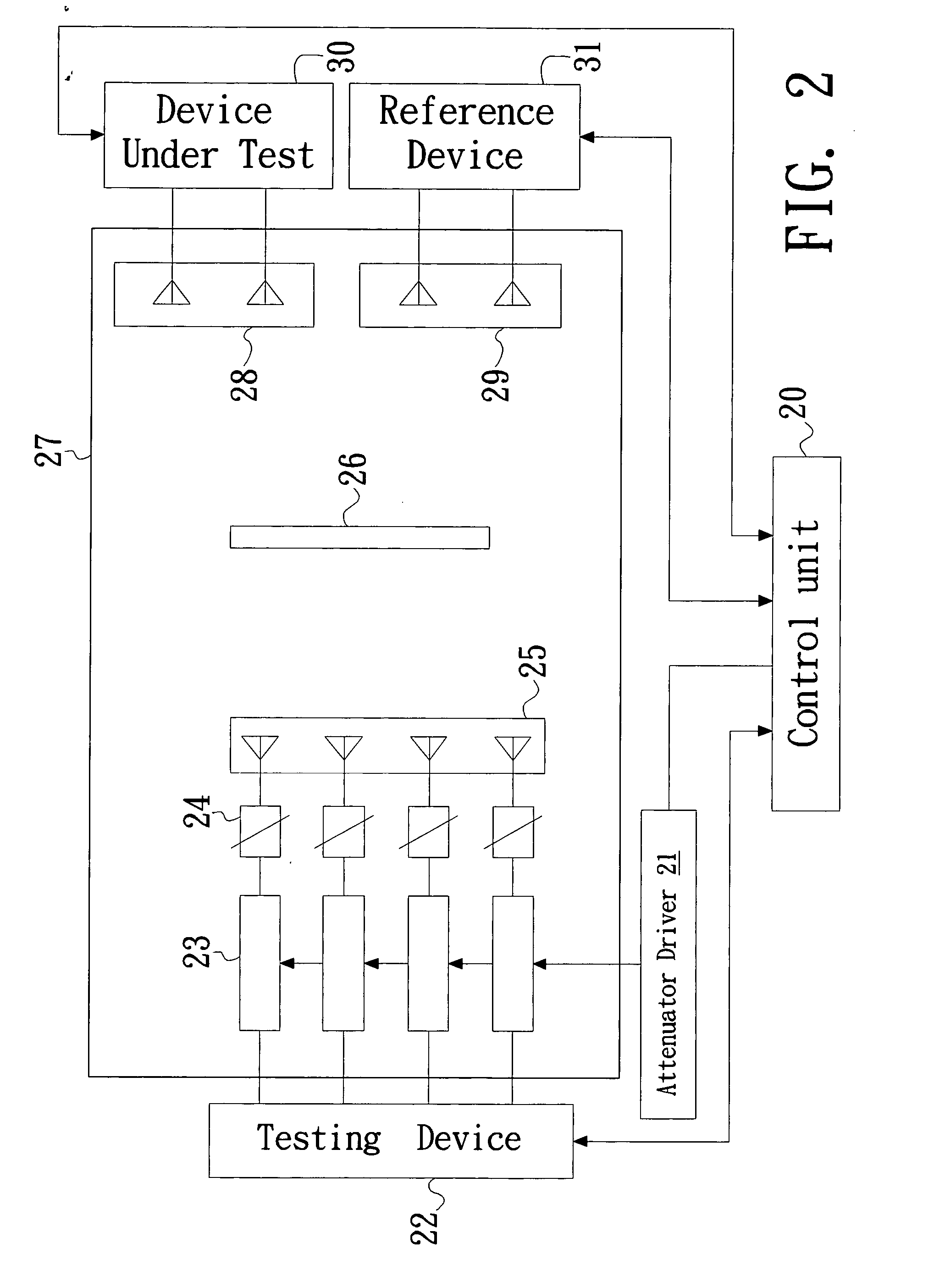

Testing apparatus and method for a multi-paths simulating system

InactiveUS20070243826A1Easy to controlLess processing timeTransmission monitoringUltrasound attenuationElectromagnetic interference

An innovative testing apparatus and method for a multi-paths simulating system is proposed. The testing apparatus comprises a shielded chamber to avoid the external electromagnetic interference and other unexpected transmission paths. The multi-paths simulating system is utilized by attenuators for simulating a communication effects in a MIMO channel propagation environment. A control unit can set of MIMO and SISO modes of TD, RD and DUT to determine attenuation difference and downlink, uplink throughputs difference of the TD, RD and DUT.

Owner:ACCTON TECHNOLOGY CORPORATION

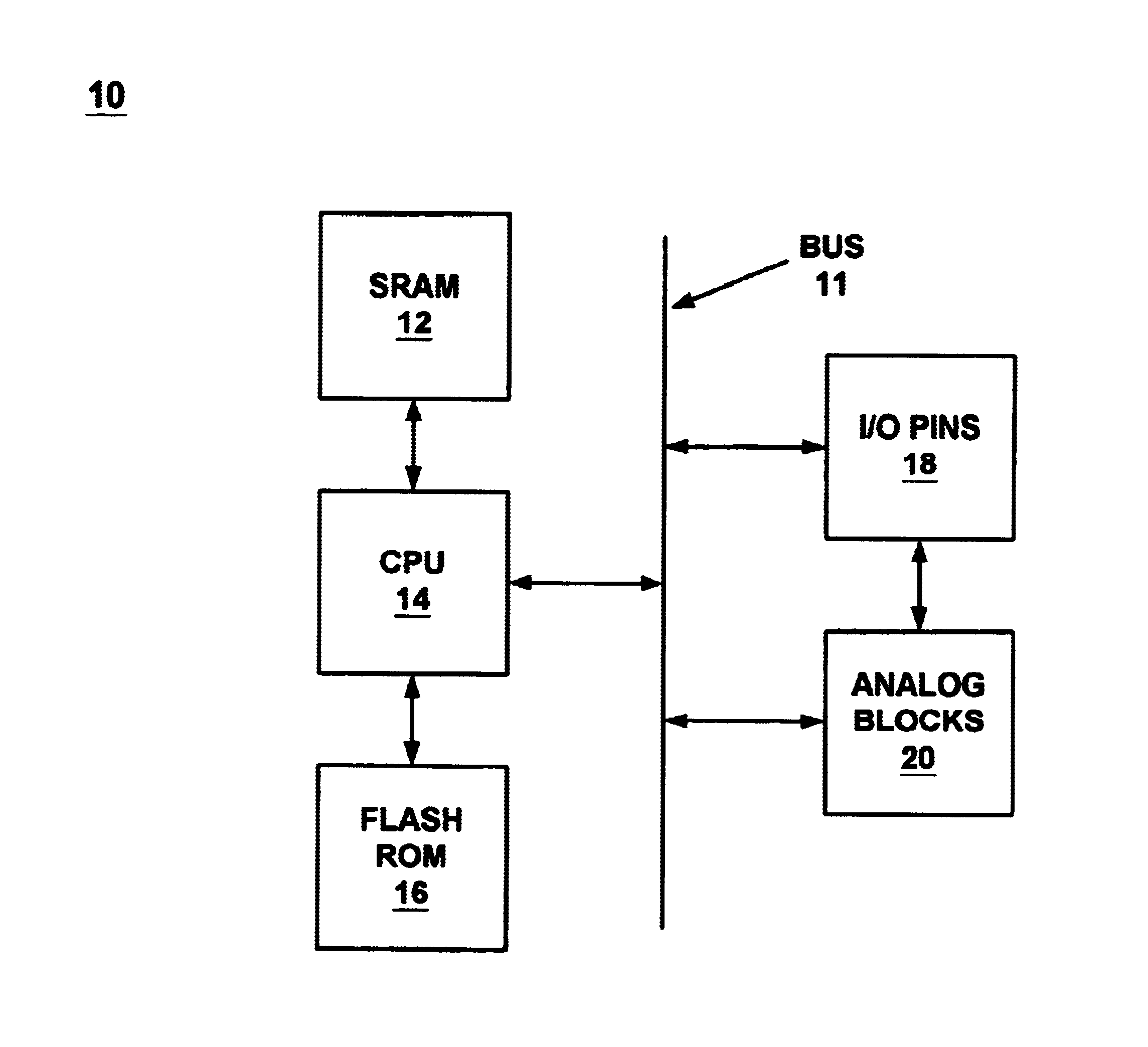

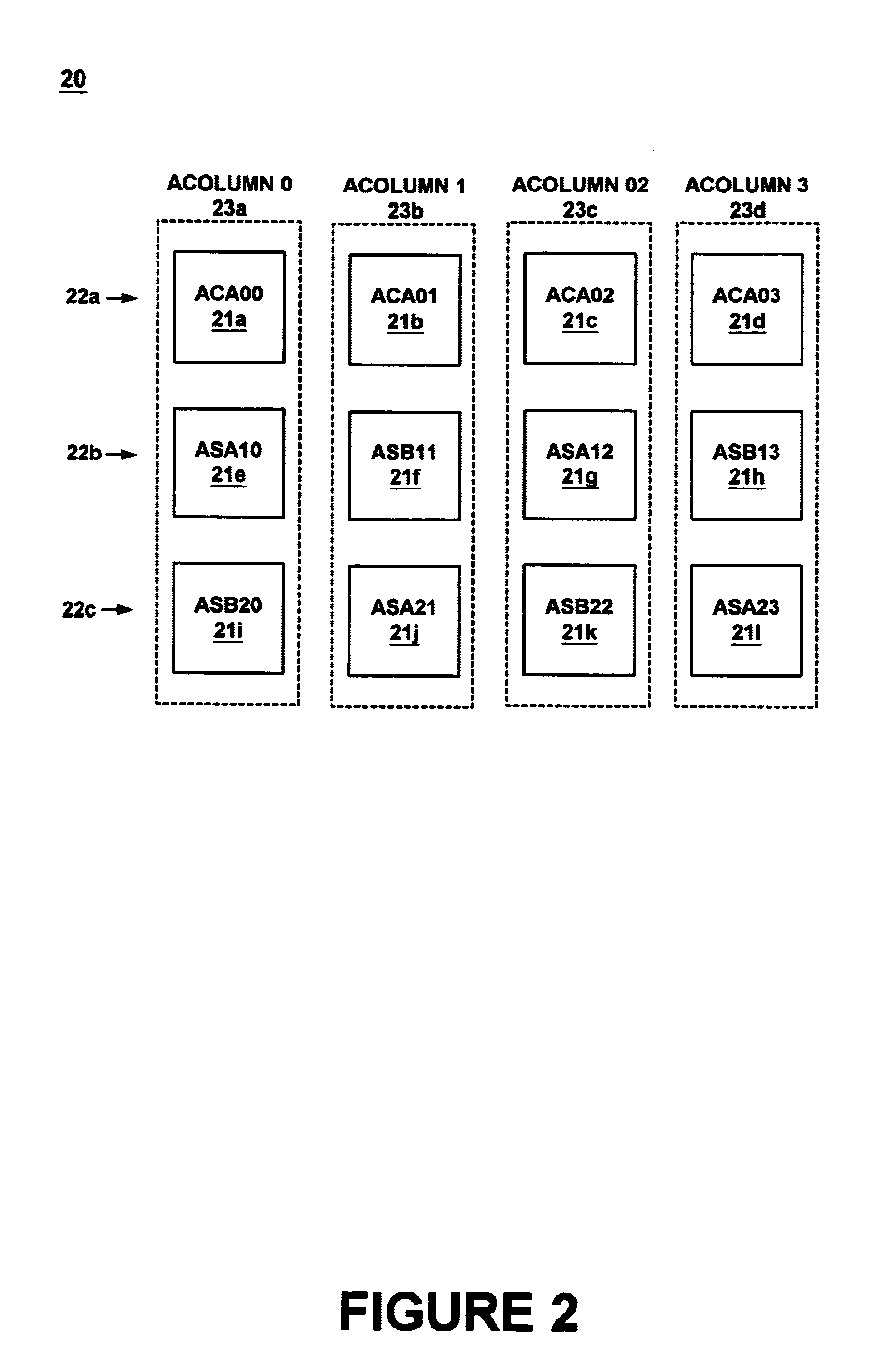

Programmable analog system architecture

InactiveUS6941336B1Shorten development timeReduce expensesProgramming arrangements for electric/magnetic computingElectric pulse generatorElectricityCapacitance

A programmable analog system architecture and method thereof are described. The analog system architecture and method introduce a single chip solution that contains a set of tailored analog blocks and elements that can be configured and reconfigured in different ways to implement a variety of different analog functions. The architecture includes an array of analog blocks, including continuous time blocks and different types of switched capacitor blocks. The analog blocks can be electrically coupled to each other in different combinations to perform different analog functions. Each analog block includes analog elements that have changeable characteristics that can be specified according to the function to be performed. The architecture thereby facilitates the design of customized chips at less time and expense.

Owner:CYPRESS SEMICON CORP

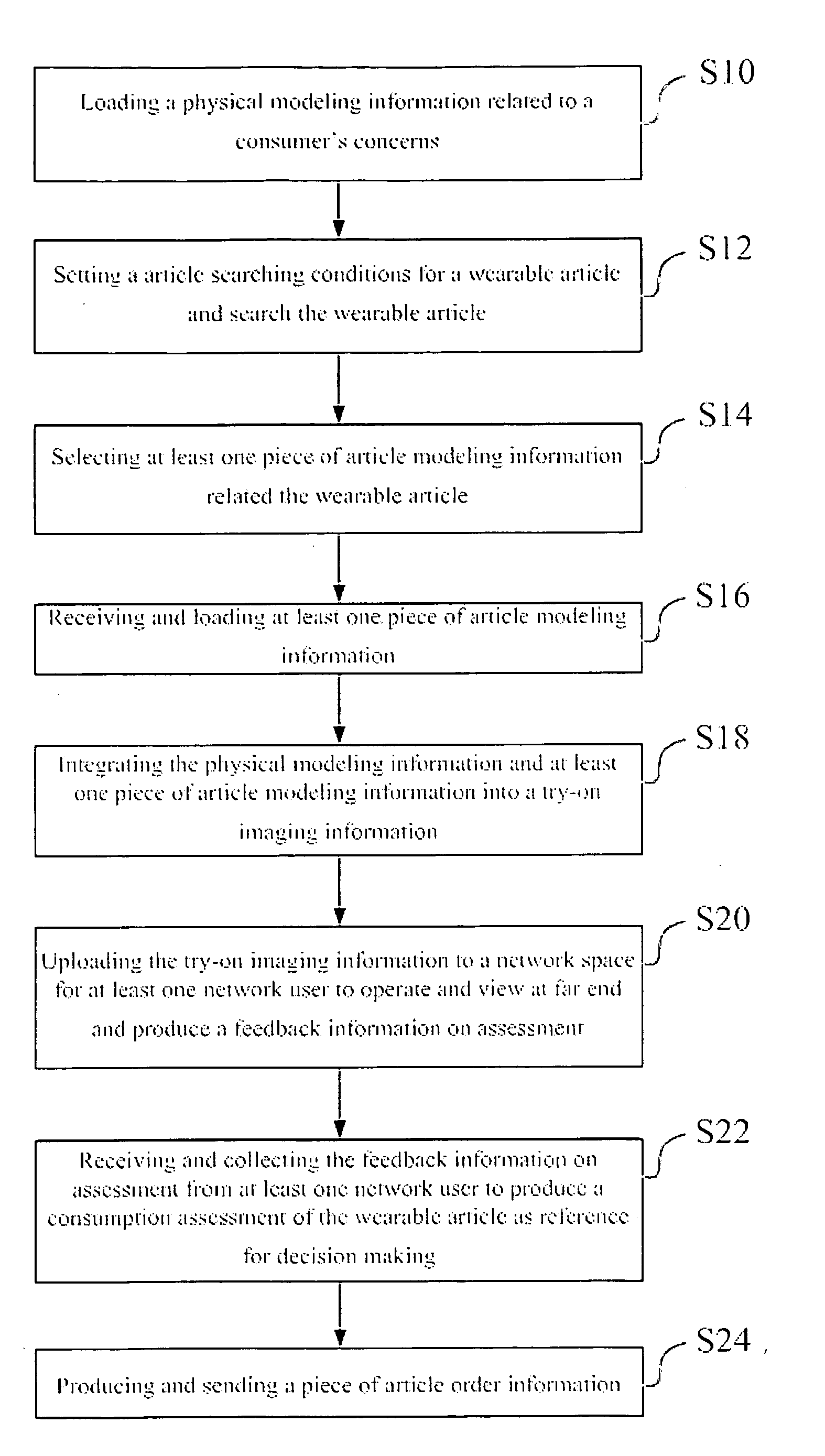

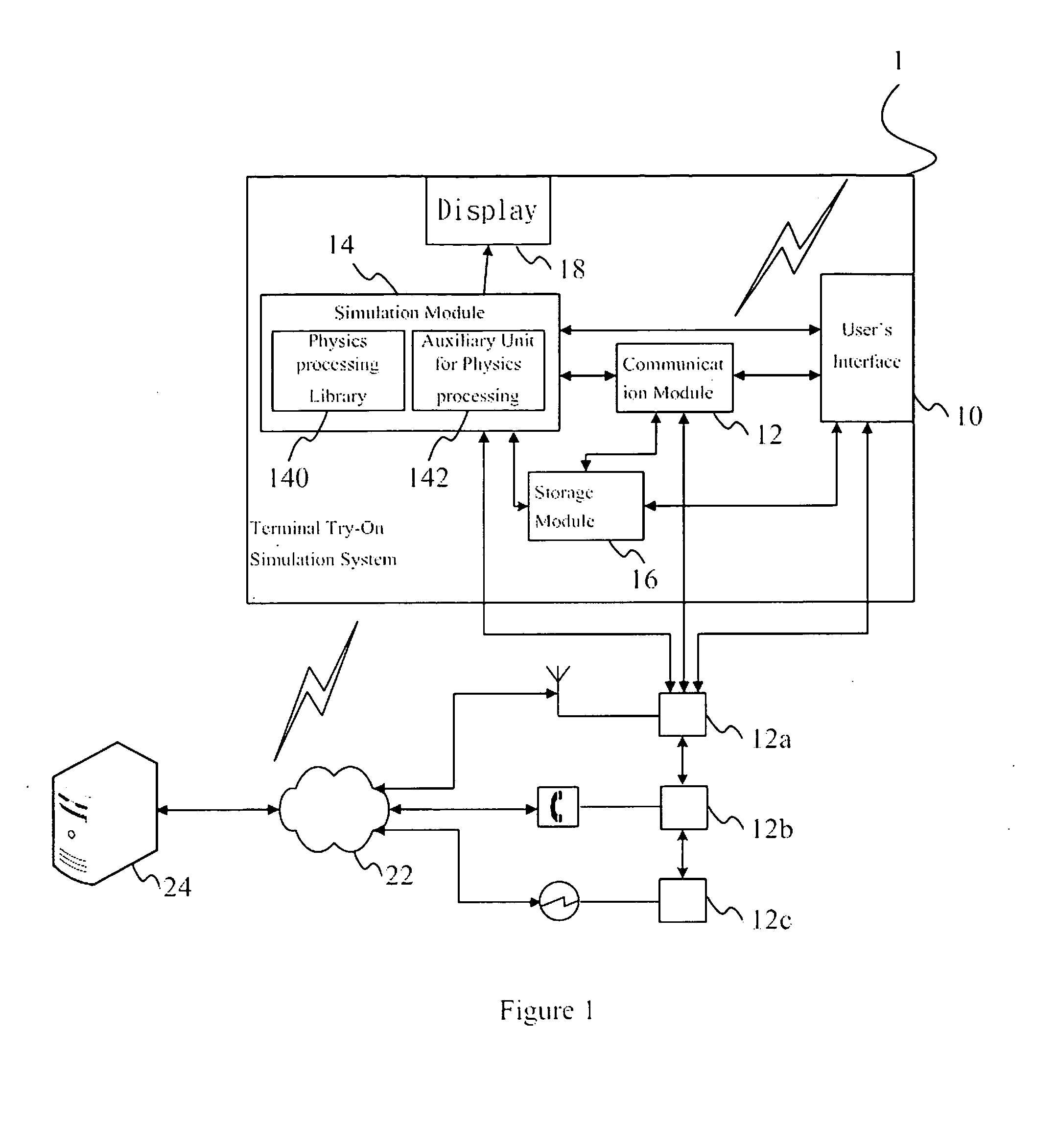

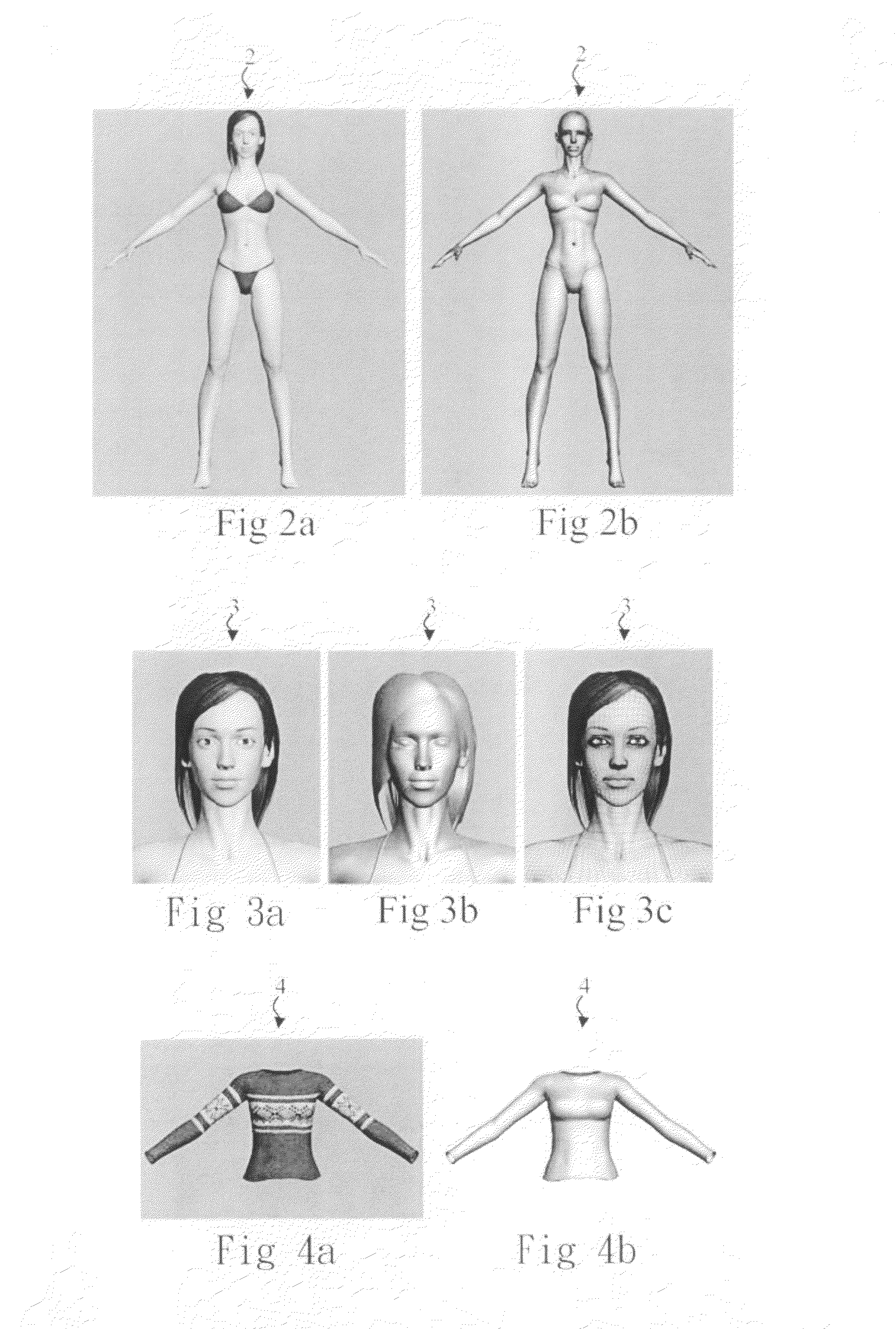

Terminal try-on simulation system and operating and applying method thereof

InactiveUS20080163344A1Practical and convenientDigital data processing detailsUser identity/authority verificationDisplay devicePhysical model

The present invention relates to the provision of a terminal try-on simulation system and the method thereof, which is used to establish a physical body modeling information and an article modeling information and respectively produce a 3D physical model and a 3D article model. The article modeling information is related with the wearable article. By integrating the 3D physical model and 3D article model, a stereoscopic image of the 3D try-on model can be produced and shown on the display. According to the said the stereoscopic image on the display, the user can judge if the wearable article fit well and assess the actual wearing style; and by virtue of the arrangement and combination of different 3D article models, different effects of the stereoscopic image can be produced.

Owner:YANG CHENG HSIEN

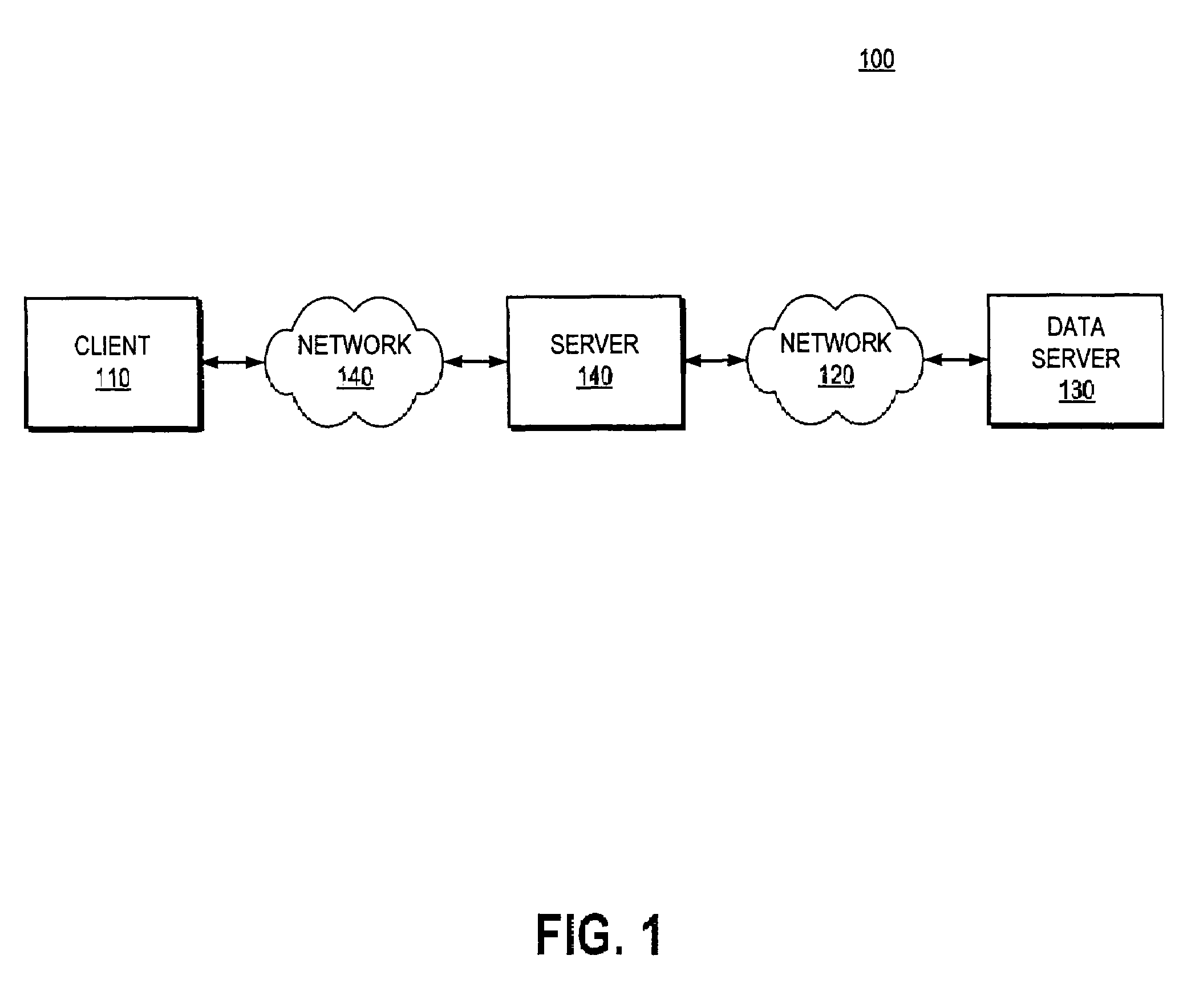

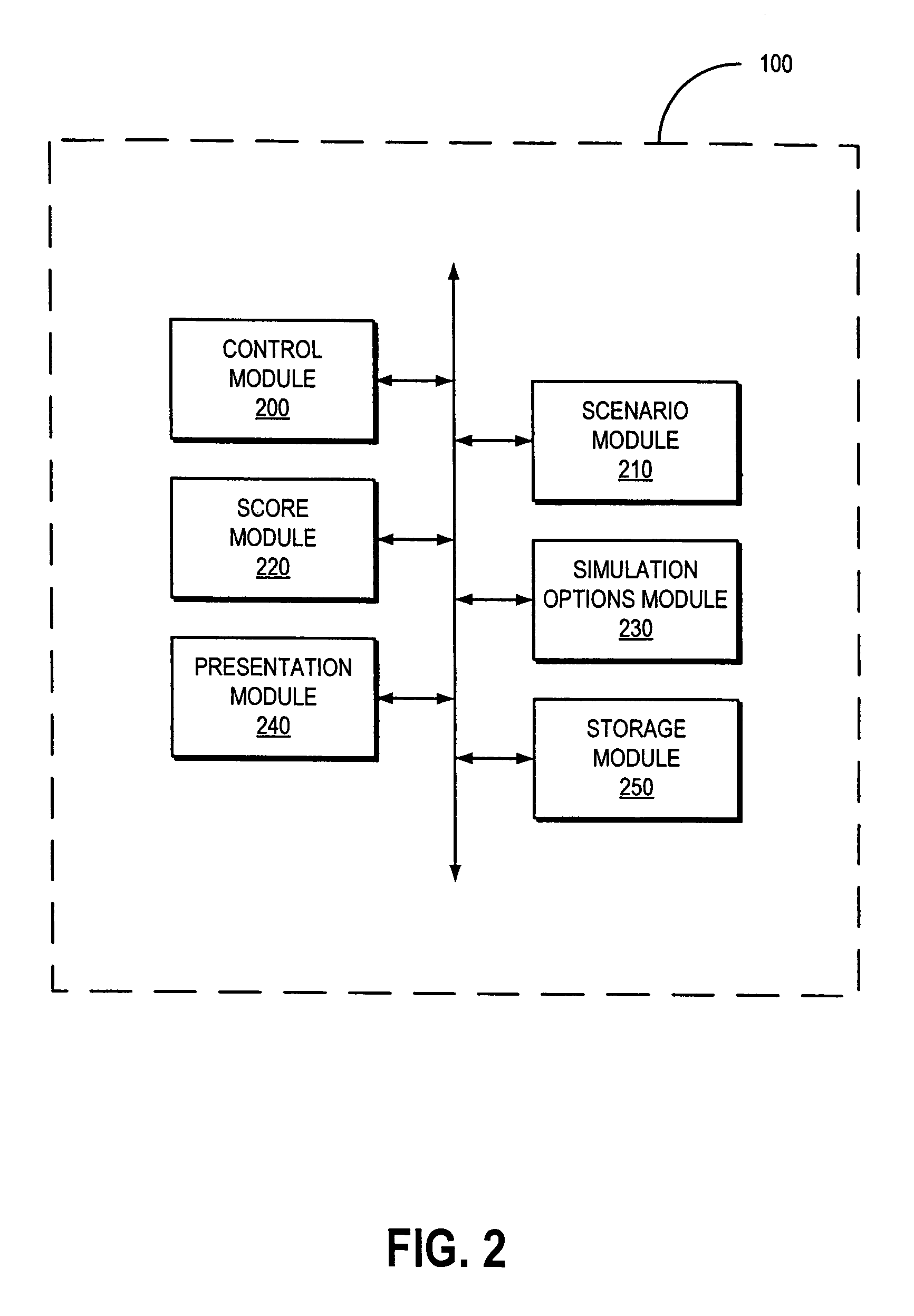

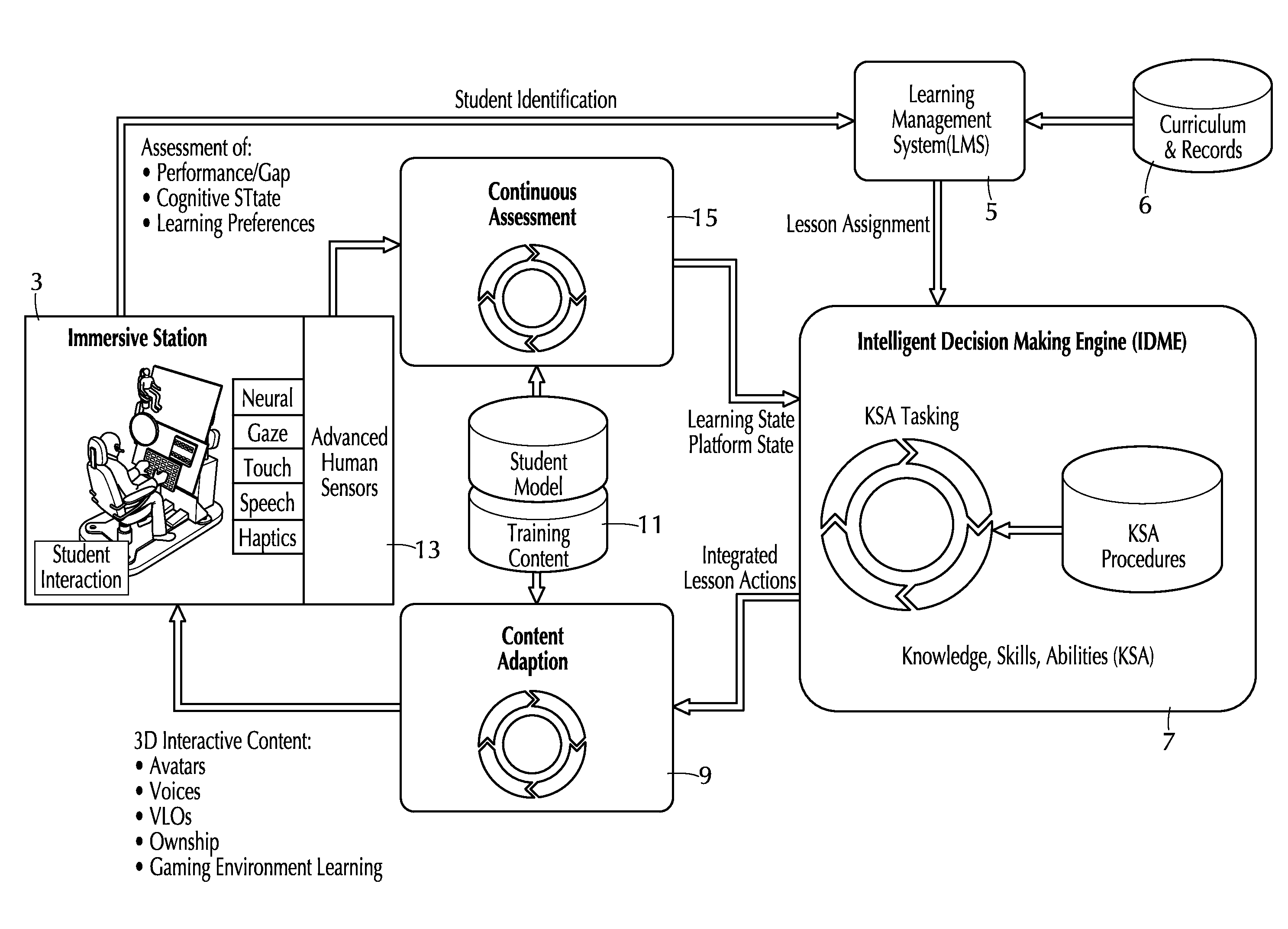

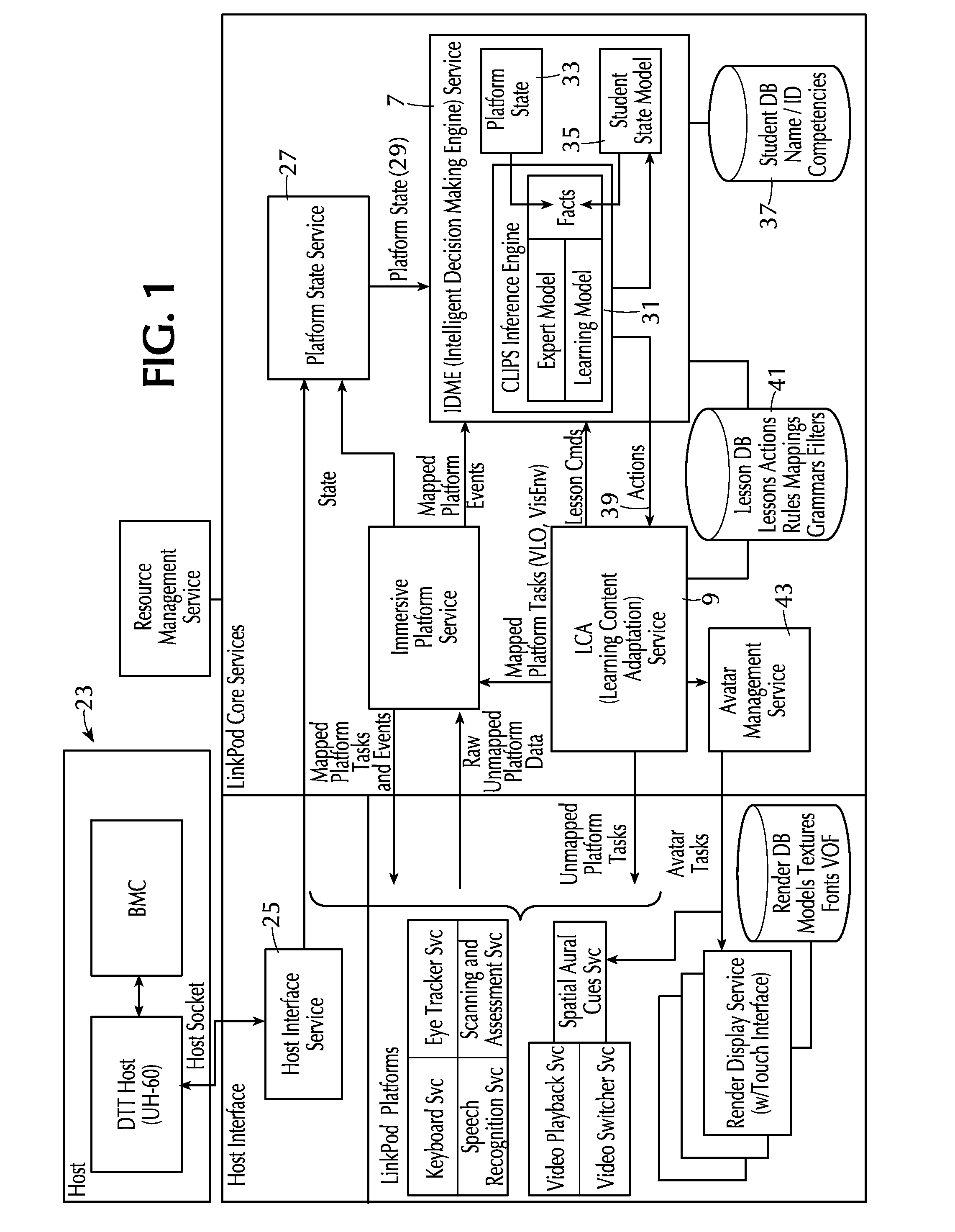

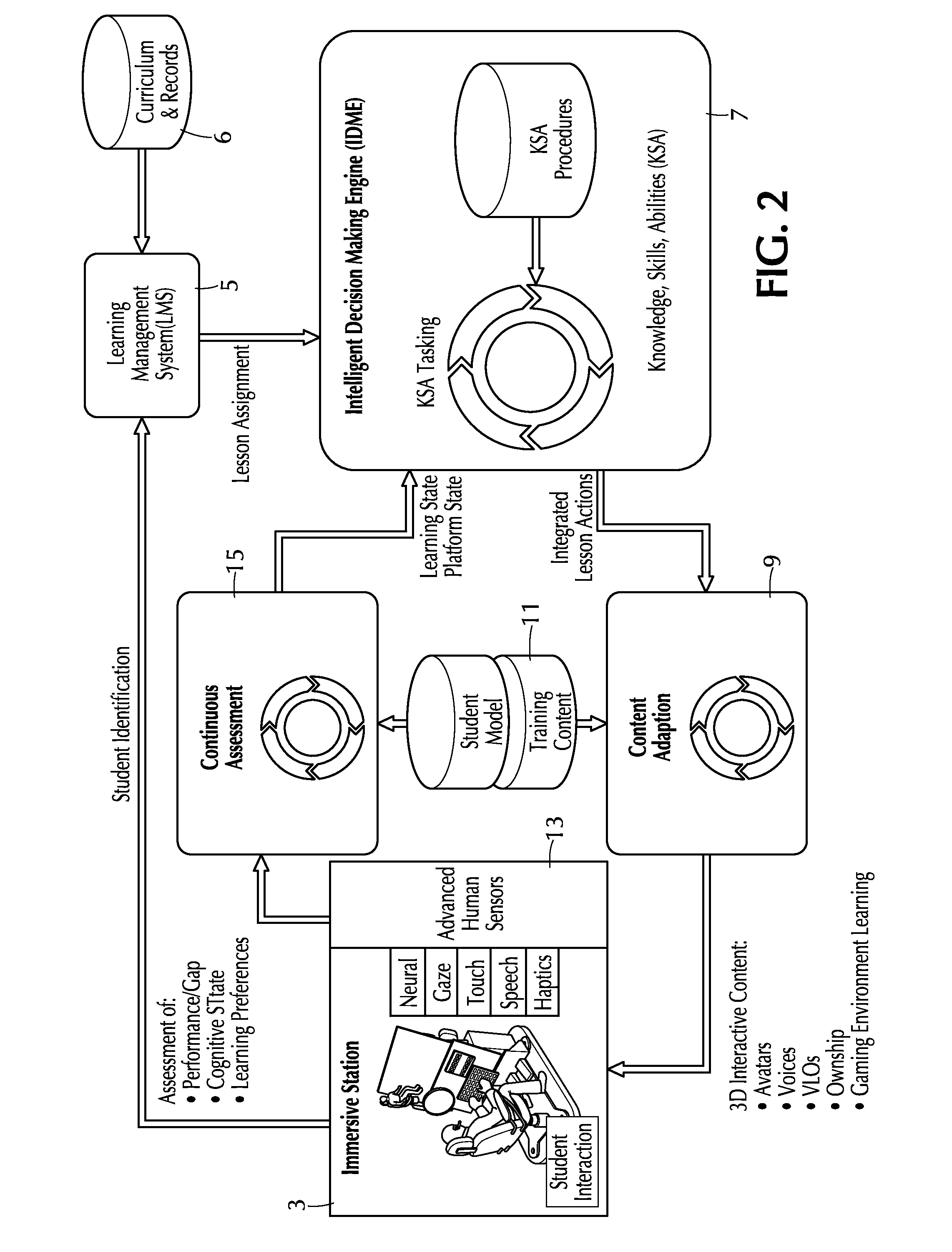

Adaptive training system, method and apparatus

ActiveUS20150050623A1Effective instructionEffective trainingCosmonautic condition simulationsBatteries circuit arrangementsComputerized systemData memory

A system and method for training a student employ a simulation station that displays output to the student and receives input. The computer system has a rules engine operating on it and computer accessible data storage storing (i) learning object data including learning objects configured to provide interaction with the student at the simulation system and (ii) rule data defining a plurality of rules accessed by the rules engine. The rules data includes, for each rule, respective (a) if-portion data defining a condition of data and (o) then-portion data defining an action to be performed at the simulation station. The rules engine causes the computer system to perform the action when the condition of data is present in the data storage. For at least some of the rules, the action comprises output of one of the learning objects so as to interact with the student. The system may be networked with middleware and adapters that map data received over the network to rules engine memory.

Owner:CAE USA INC

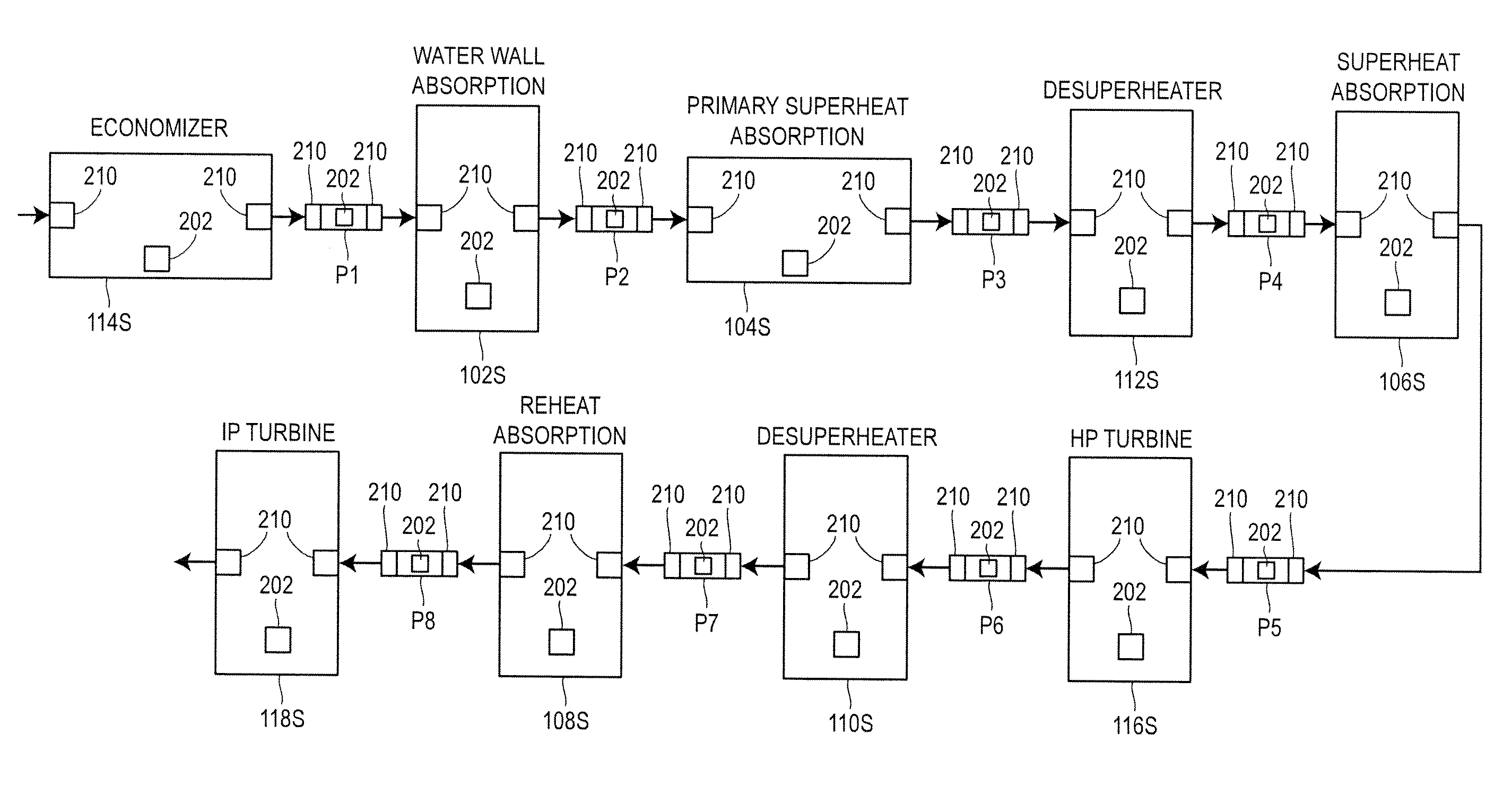

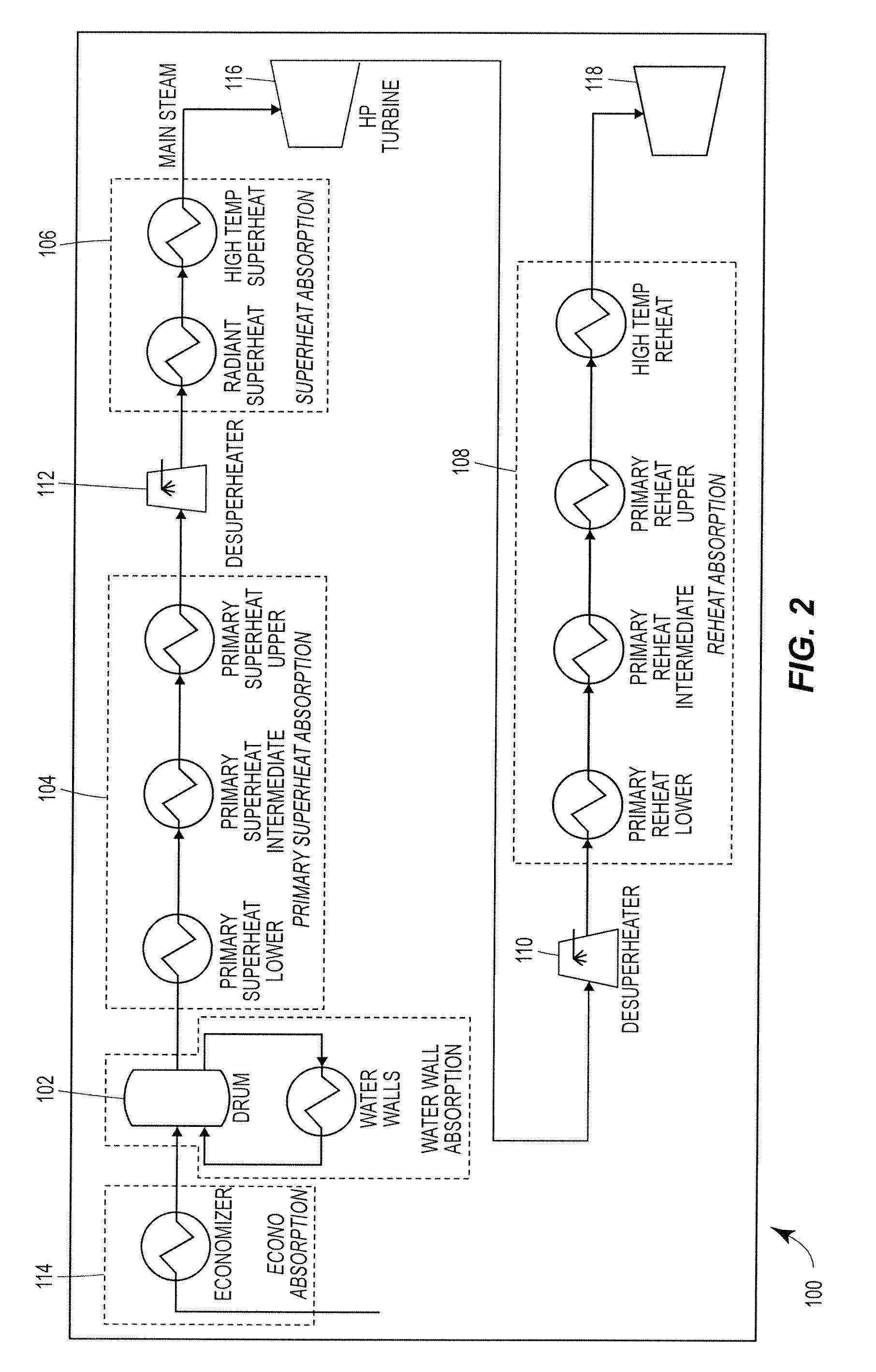

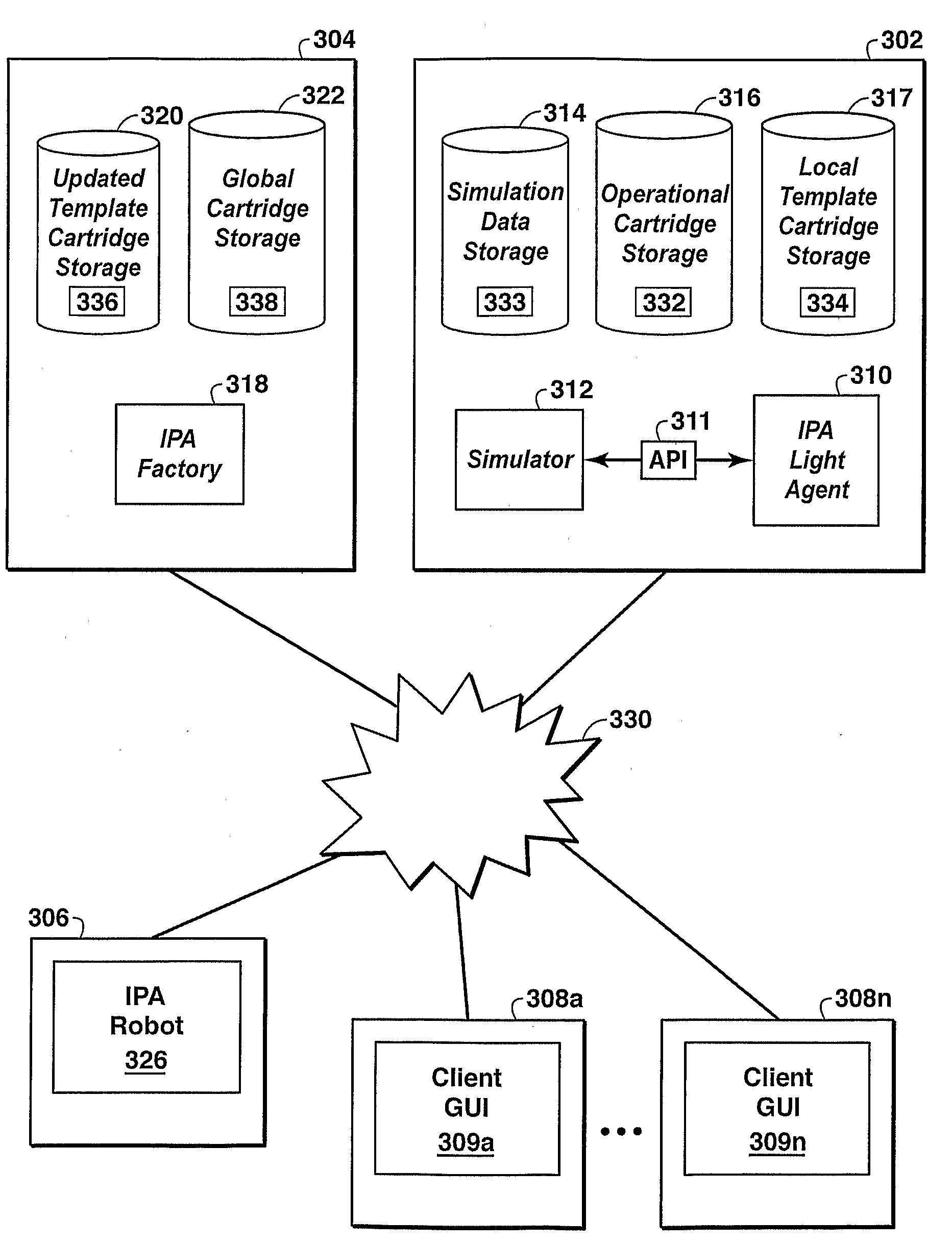

Decentralized industrial process simulation system

ActiveUS20110131017A1Accurately solves massAccurately flow balanceProgramme controlAnalogue computers for control systemsMass storageParallel computing

A high fidelity distributed plant simulation technique includes a plurality of separate simulation modules that may be stored and executed separately in different drops or computing devices. The simulation modules communicate directly with one another to perform accurate simulation of a plant, without requiring a centralized coordinator to coordinate the operation of the simulation system. In particular, numerous simulation modules are created, with each simulation module including a model of an associated plant element and these simulation modules are stored in different drops of a computer network to perform distributed simulation of a plant or a portion of a plant. At least some of the simulation modules, when executing, perform mass flow balances taking into account process variables associated with adjacent simulation modules to thereby assure pressure, temperature and flow balancing (i.e., conservation of mass flow) through the entire simulation system. In a dynamic situation, a transient mass storage relay technique is used to account for transient changes in mass flow through any non-storage devices being simulated by the simulation modules. Moreover, adjacent simulation modules located in different drops communicate directly with one another using a background processing task, which simplifies communications between adjacent simulation modules without the need for a central coordinator.

Owner:EMERSON PROCESS MANAGEMENT POWER & WATER SOLUTIONS

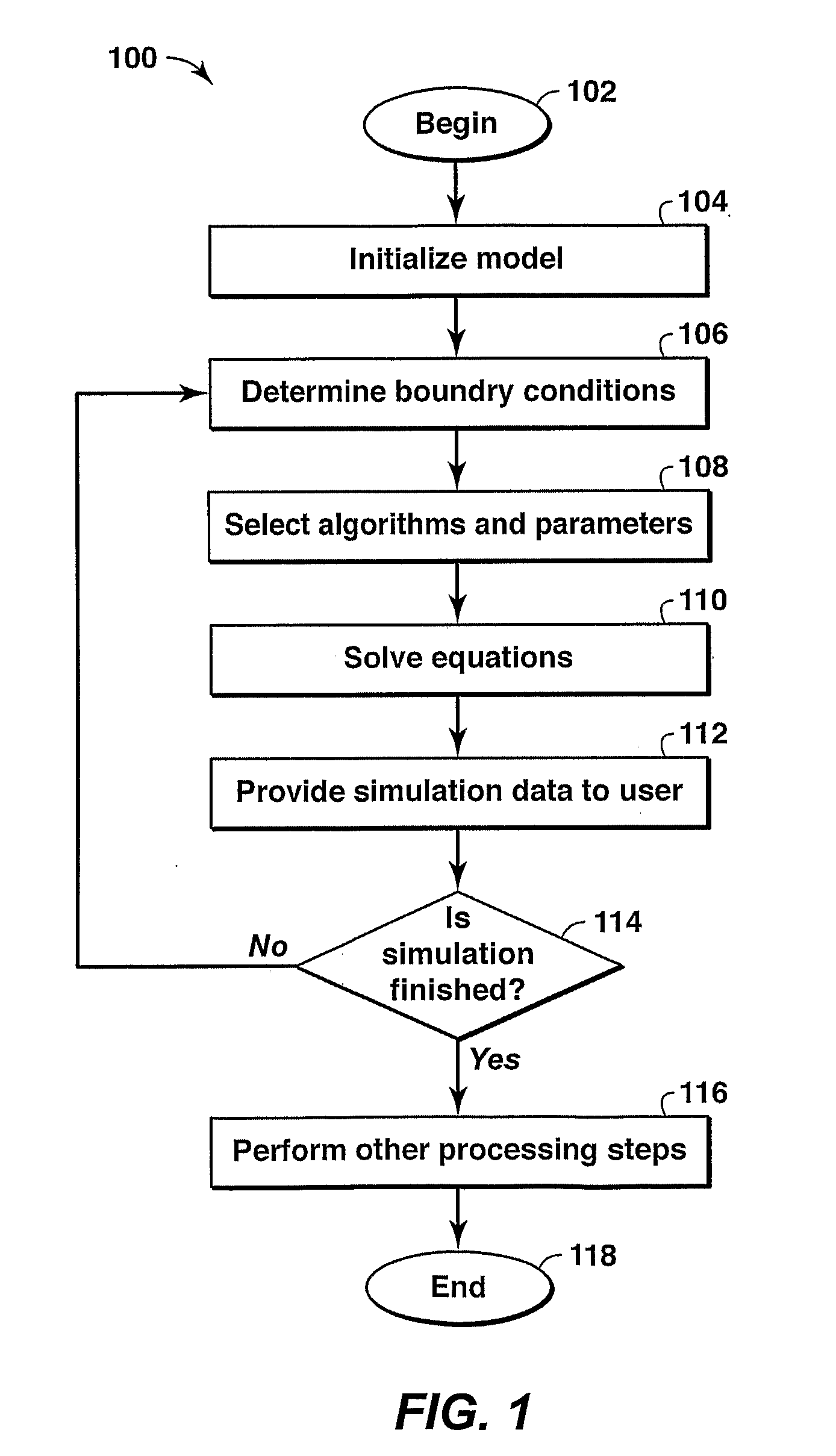

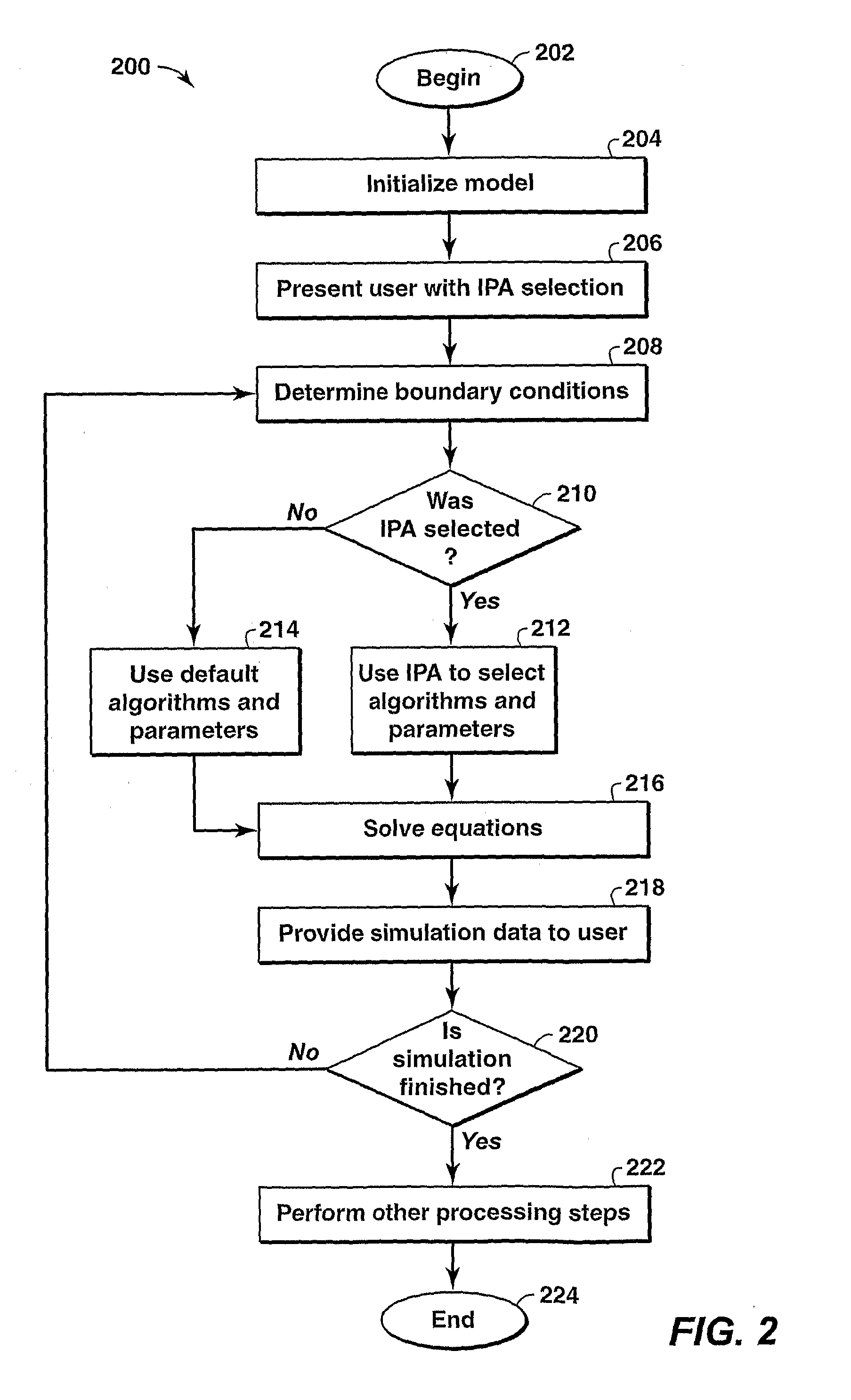

Simulation System and Method

InactiveUS20100082142A1Enhance run-time performanceImprove running stabilityComputation using non-denominational number representationDesign optimisation/simulationPorous mediumComputational simulation

A method and system are described that enhance the computational simulation, such as a fluid flowing through a porous media, under the present techniques. In particular, a computer implemented simulation method is described that includes initializing a simulator and utilizing an intelligent performance assistant to select a set of parameters and algorithms for the simulator. Then, equations are solved with the set of parameters and algorithms and the solution to the equations is then obtained.

Owner:USADI ADAM K +6

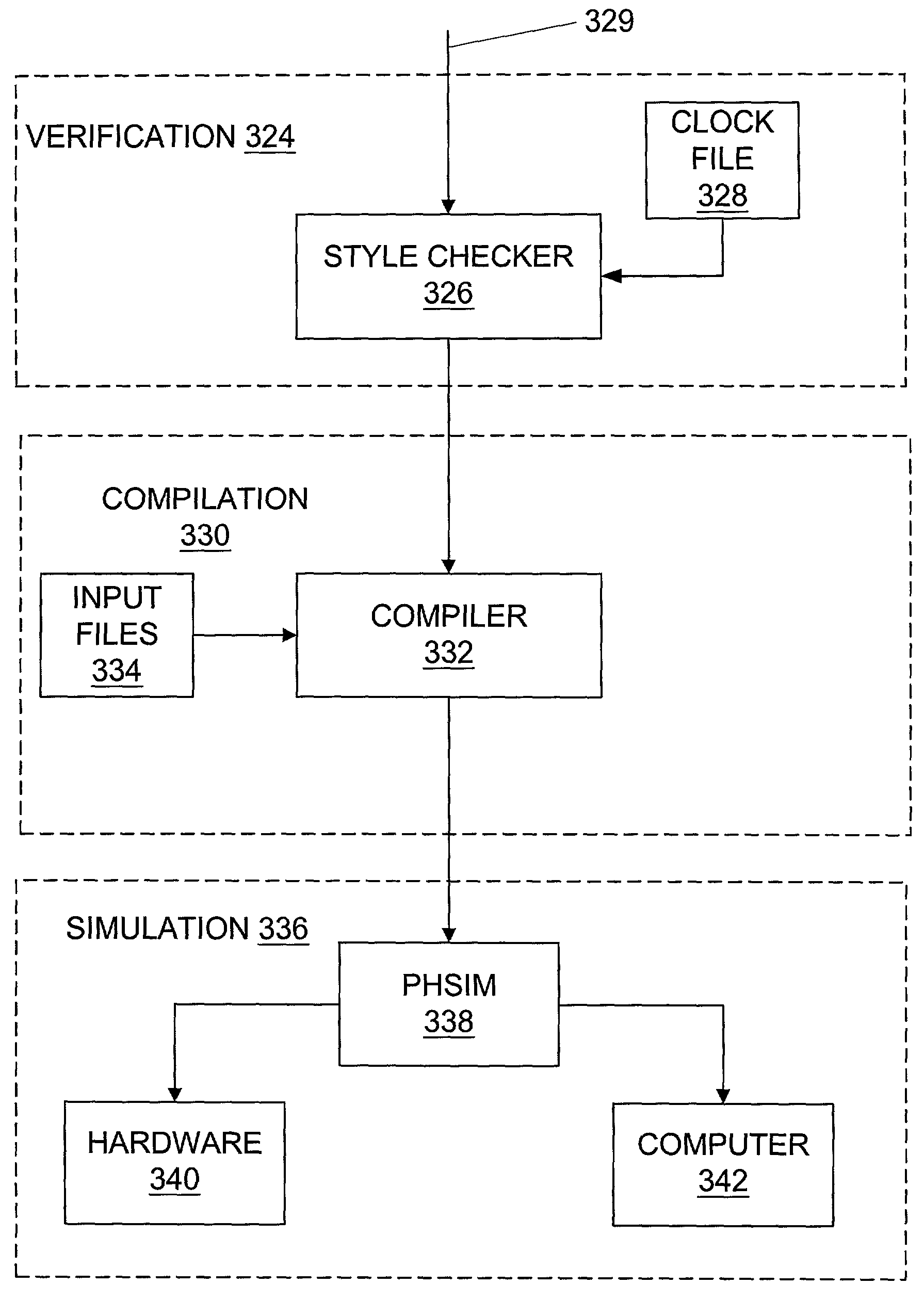

Method and apparatus for simulation system compiler

ActiveUS7080365B2CAD circuit designSoftware simulation/interpretation/emulationParallel computingIntermediate form

A method for compiling a cycle-based design involves generating a parsed cycle-based design from the cycle-based design, elaborating the parsed cycle-based design to an annotated syntax tree, translating the annotated syntax tree to an intermediate form, and converting the intermediate form to an executable form.

Owner:ORACLE INT CORP

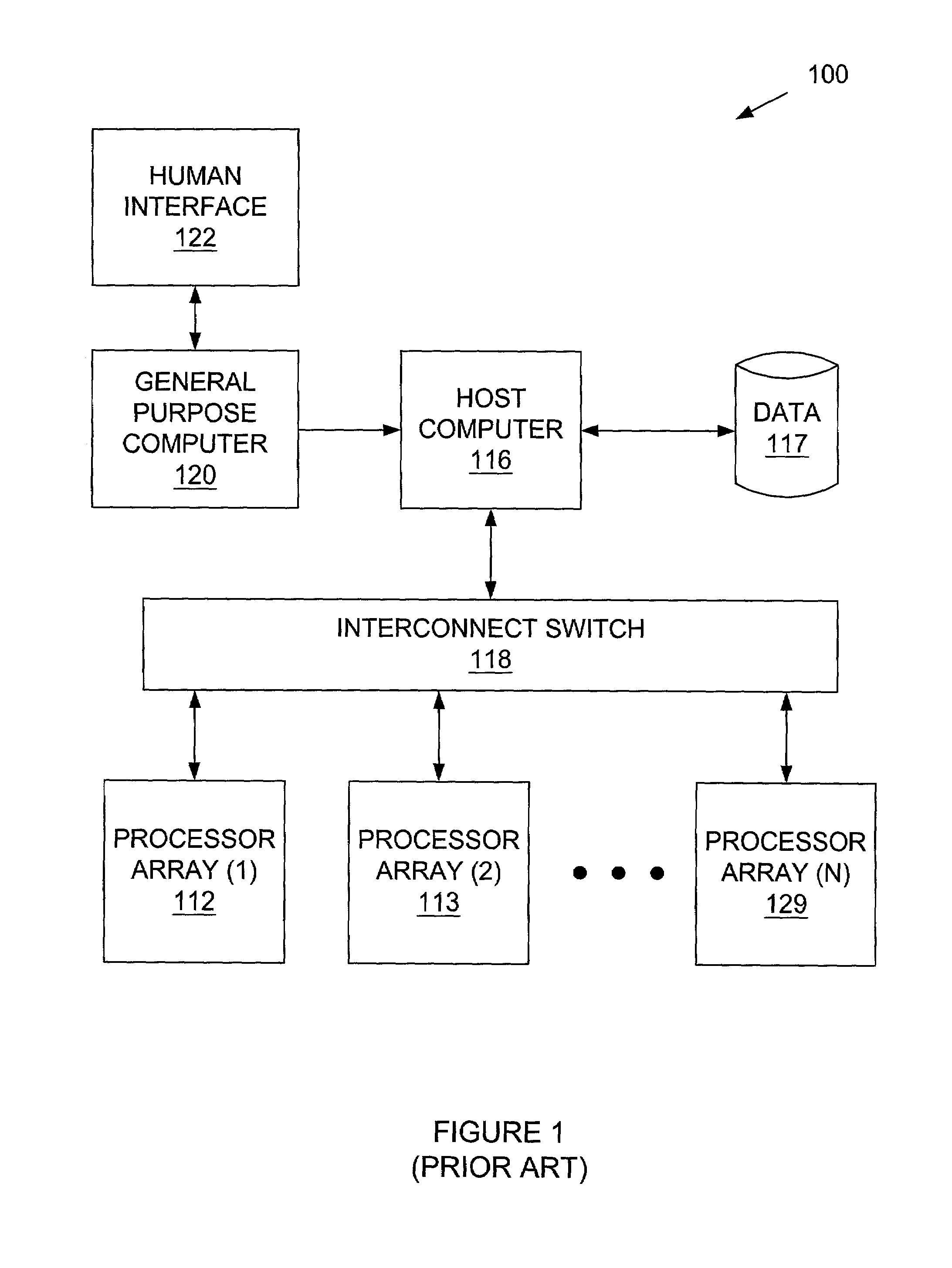

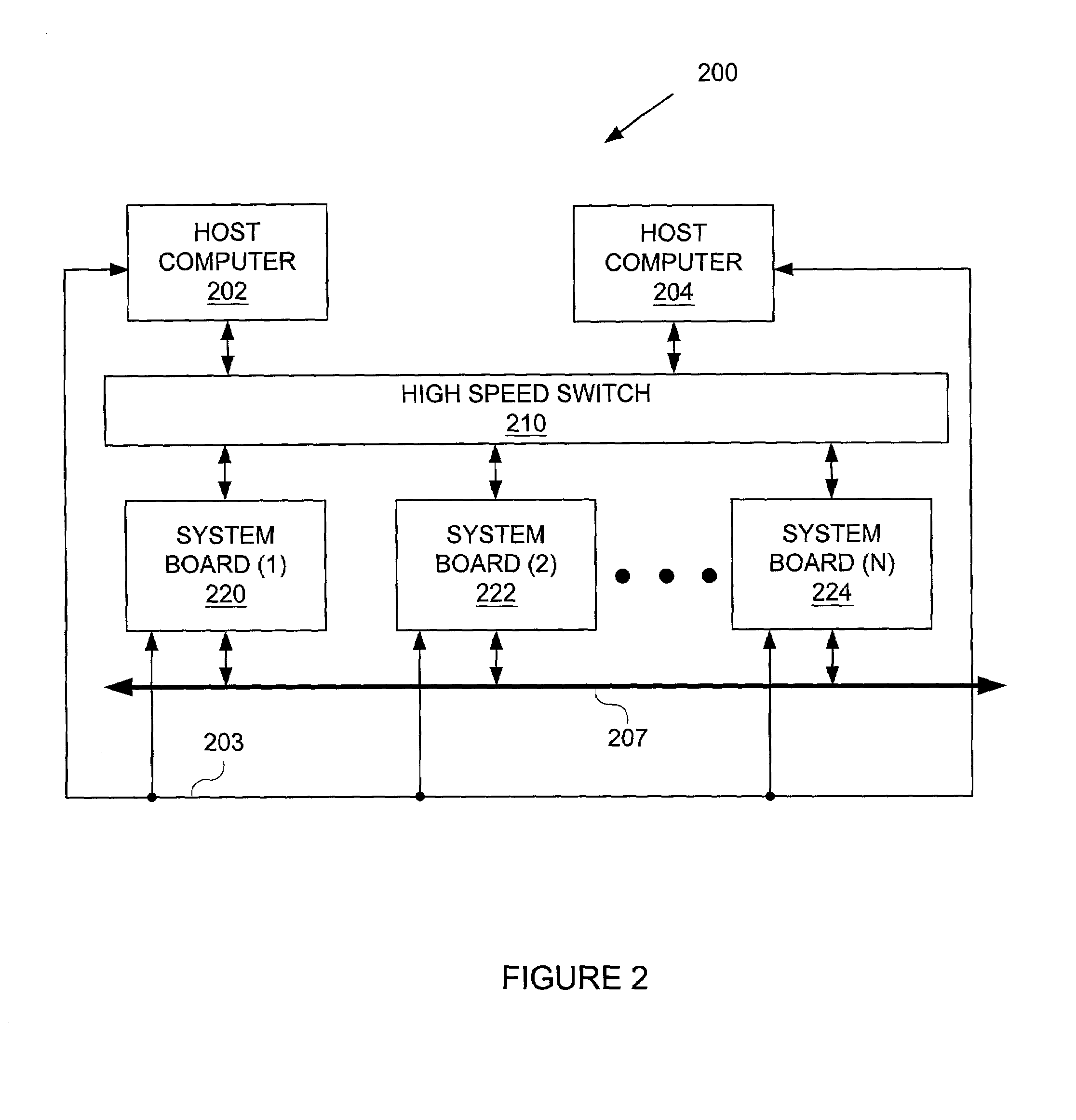

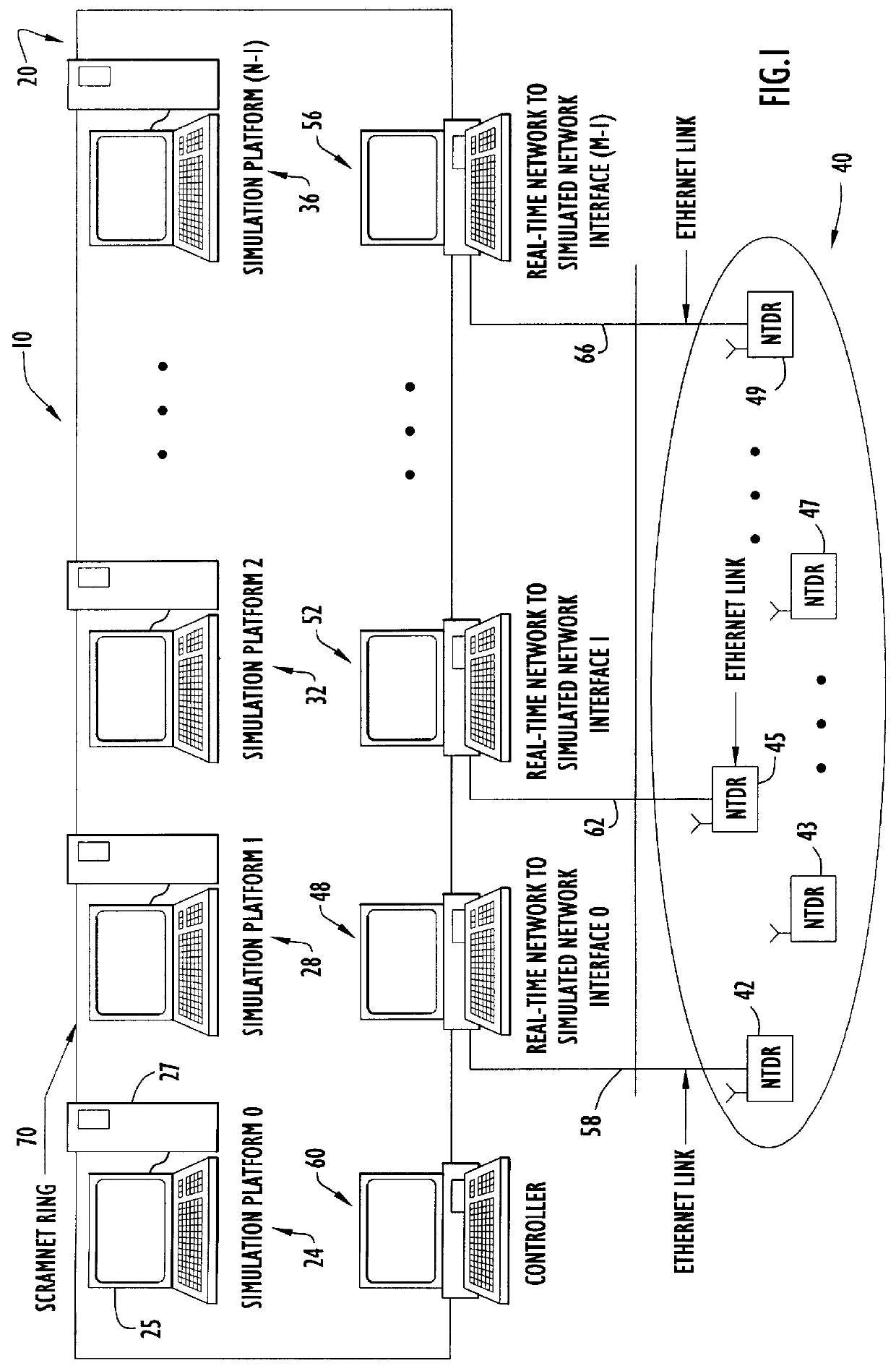

Large-scale network simulation method and apparatus

InactiveUS6134514AAnalogue computers for electric apparatusData switching networksTelecommunications linkChronological time

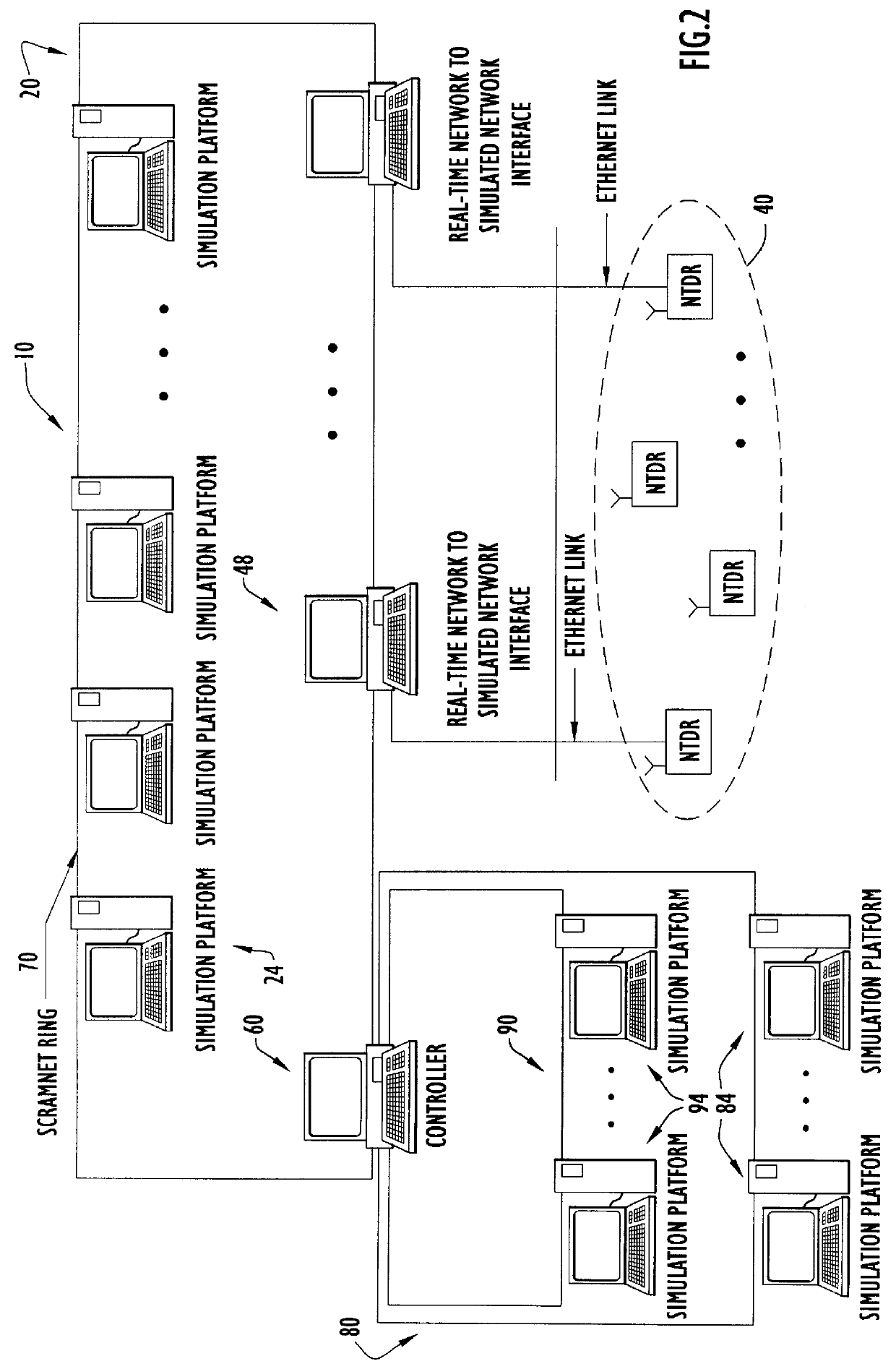

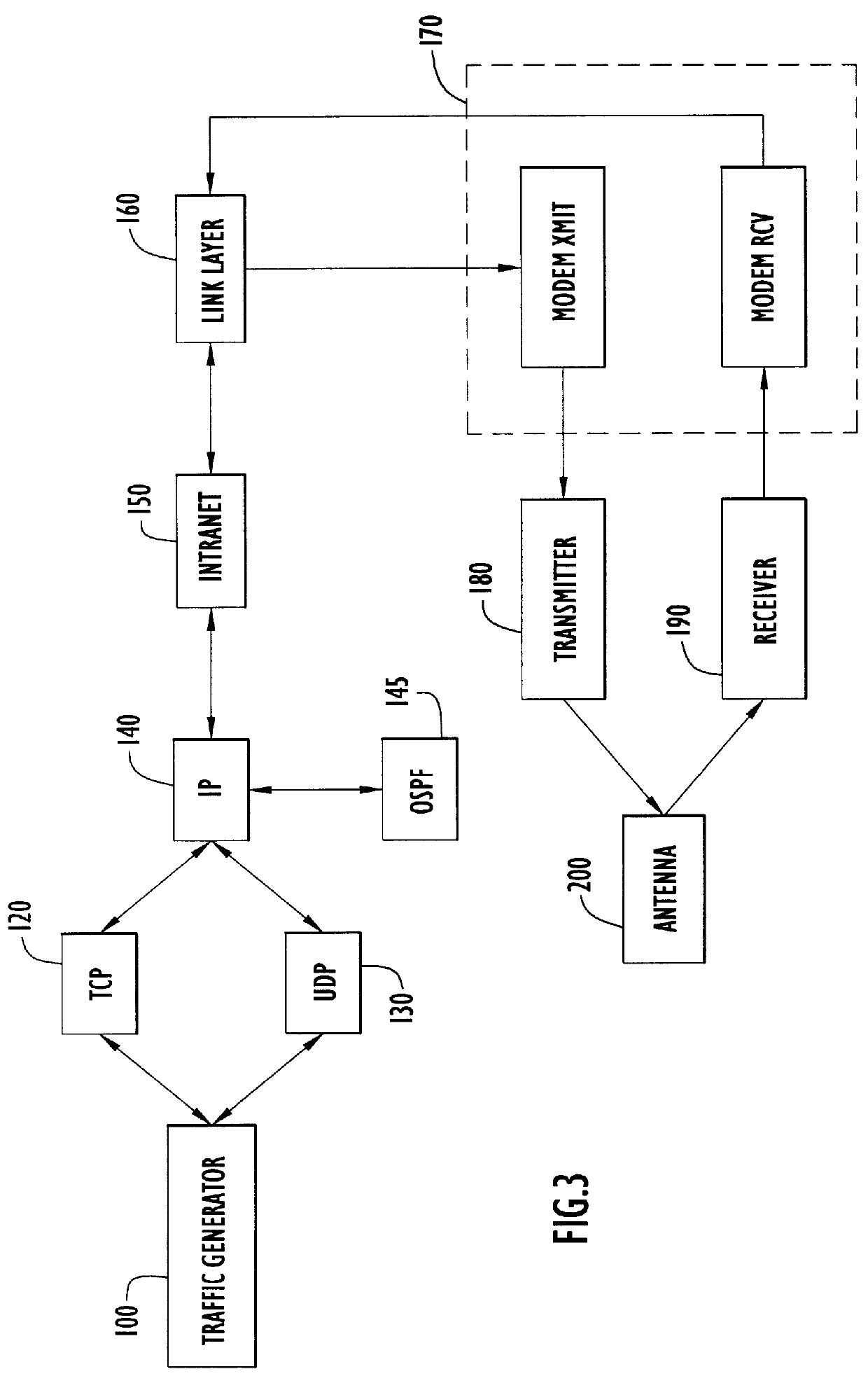

A distributed discrete-event simulation system operable for processing time-stamped events in chronological order for simulating a multinode communications network, the simulation system comprising a plurality of subsystem platforms (SPs) operable for transmitting message packets to other SPs for simulating node to node communications; and a system controller coupled via a communication link to the plurality of SPs for controlling synchronization and message packet processing associated with the plurality of SPs; wherein when a time-stamped event is received by one of the SPs, the receiving SP responsive to the time-stamped event triggers execution of tasks associated with the time-stamped event in the other SPs via the message packets to provide parallel task processing for the particular time-stamped event among the plurality of SPs.

Owner:HARRIS CORP

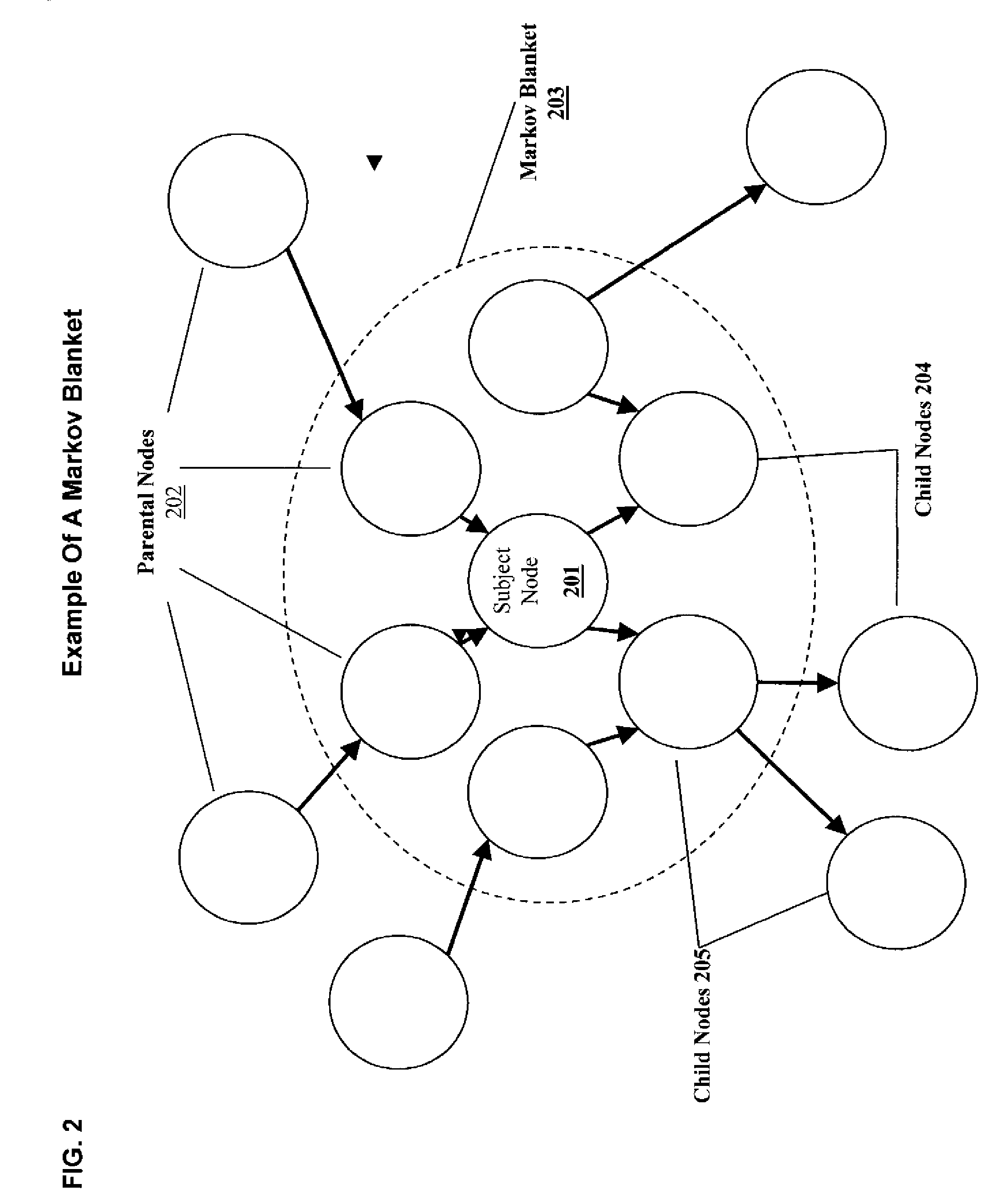

Extensible bayesian network editor with inferencing capabilities

A system for the representation, editing, evaluation, and inference of graphical models is disclosed which can be used to construct and evaluate a graphical model or graphical network and to calculate inference values. An efficient method of updating graphical models is demonstrated, and provides the basis for an improved system for manipulation and evaluation of probabilistic models. The graphical network editor is useful in the construction of graphical modes such as Bayesian Networks. The graphical network and network graphical user interface (GUI) are used in conjunction with each other to model a system wherein failure probabilities and the current state of components are taken into account to monitor the health and progress of a system for an engineer or engineering software to evaluate and monitor. The evaluation is useful in the monitoring of assets and other real systems having multiple, dependent, and independently operating components such as a pump, a manufacturing plant, a production line, an assembly line, where asset health and quality control is a concern. The asset components each influencing some overall outcome of a system or situation. Success or failure or probability of success, probability of failure and health of the system can be monitored and manipulated by altering the values of prior probability and posterior probability values. Failure correlation between components can be evaluated wherein failure rates of asset is unknown. Production and quality can be monitored and altered.

Owner:QUANTUM LEAP RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com