Patents

Literature

38 results about "Robot planning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

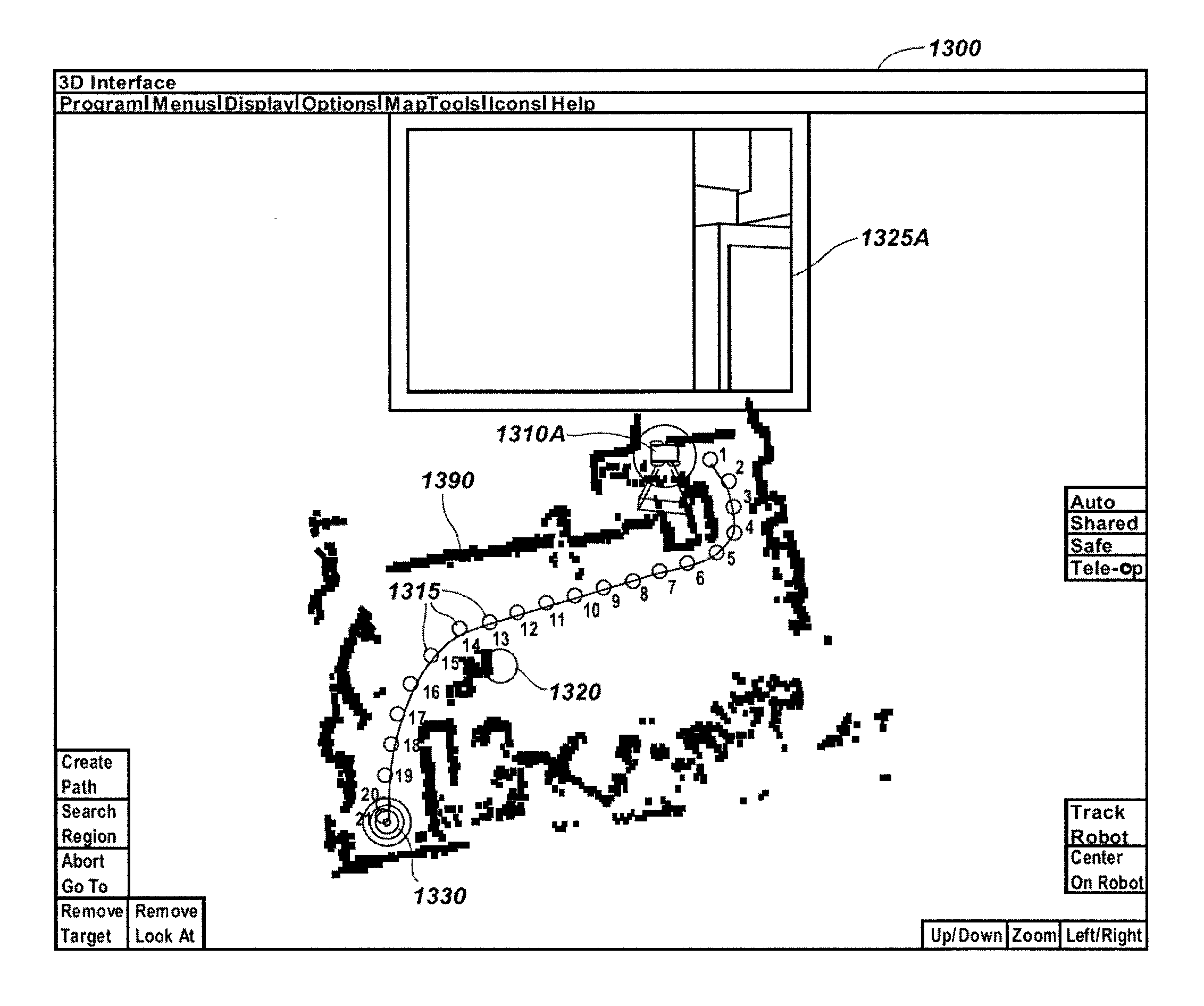

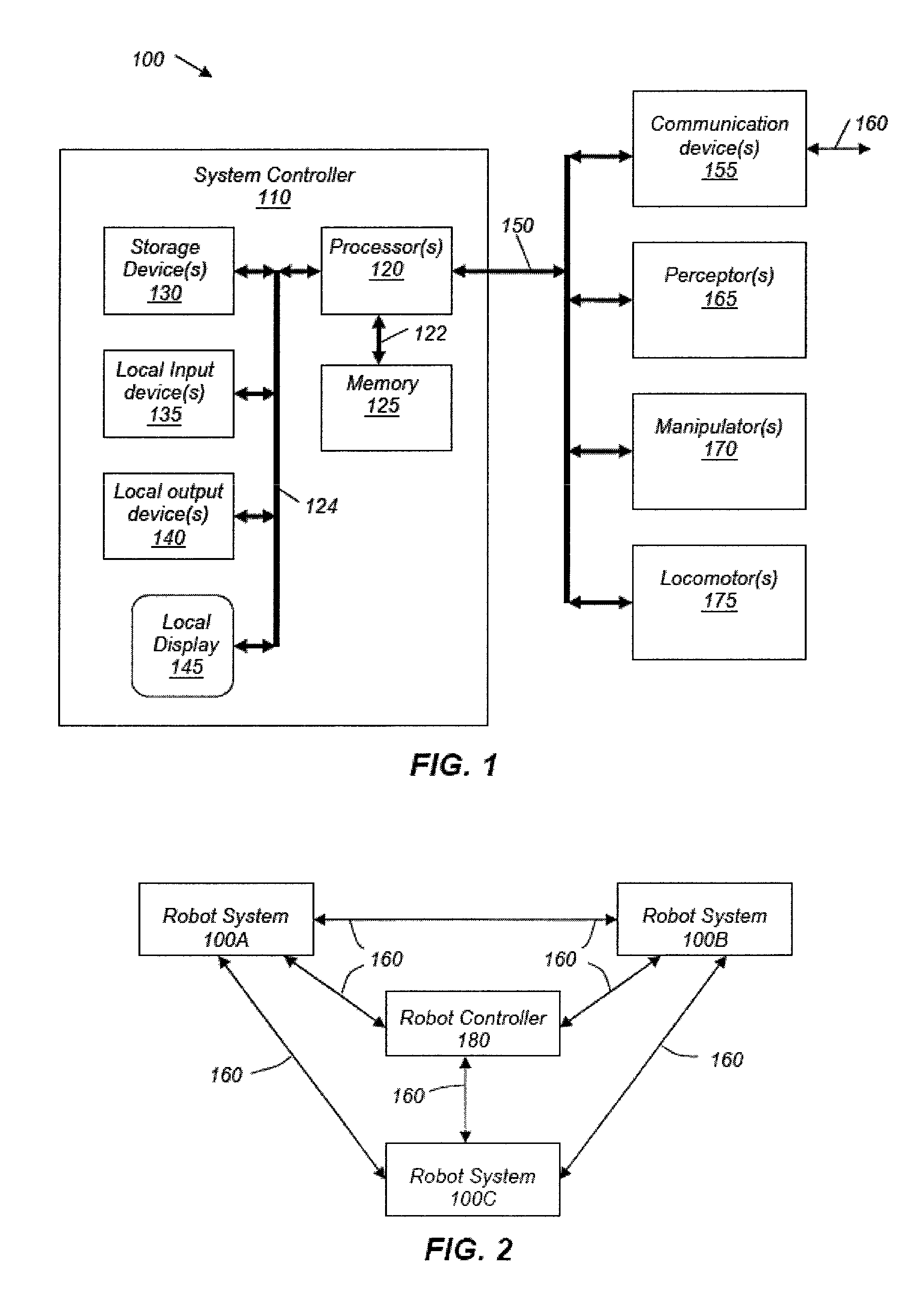

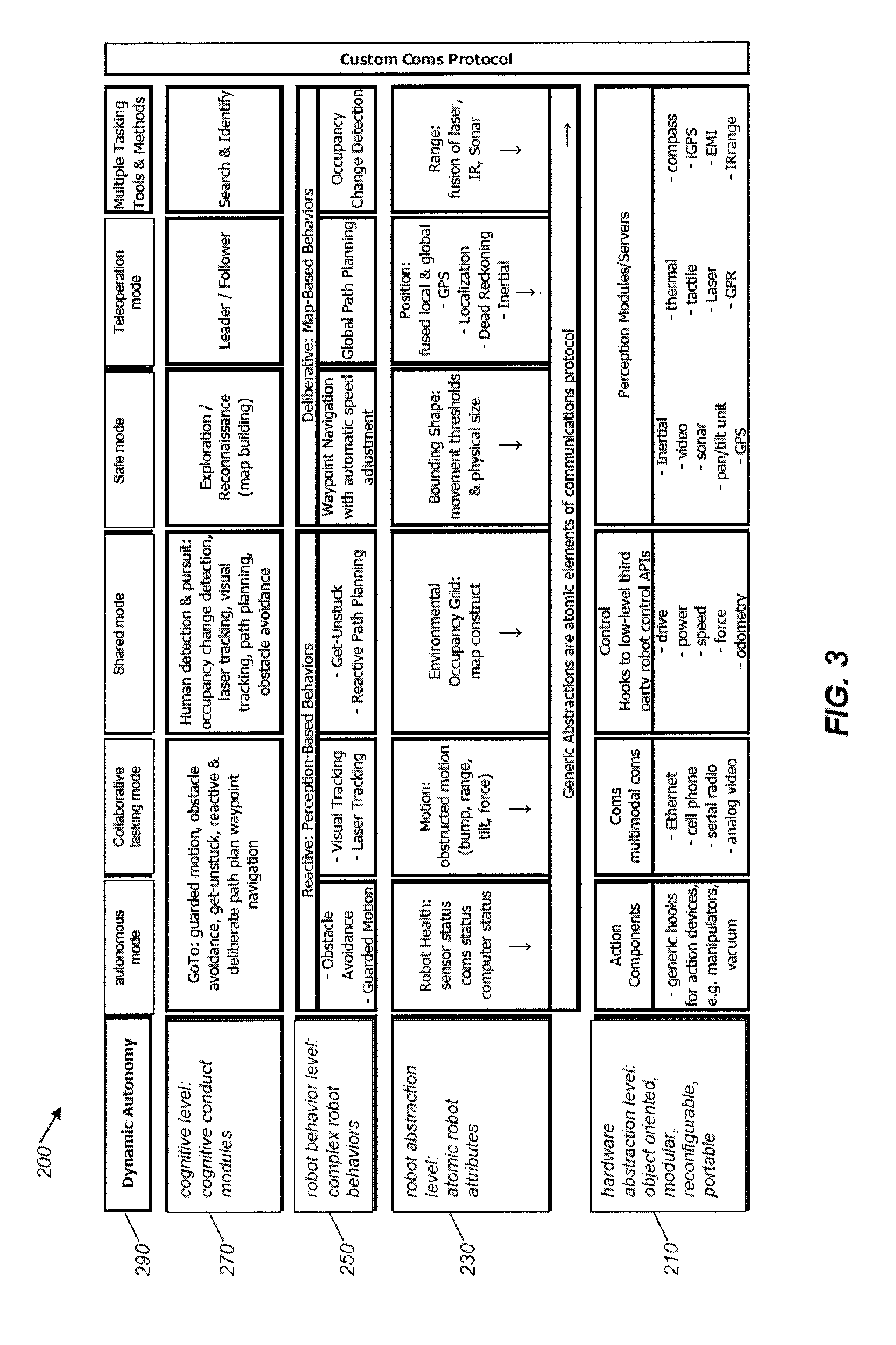

System and method for seamless task-directed autonomy for robots

ActiveUS20090234499A1Programme-controlled manipulatorAutonomous decision making processRobot planningProgram planning

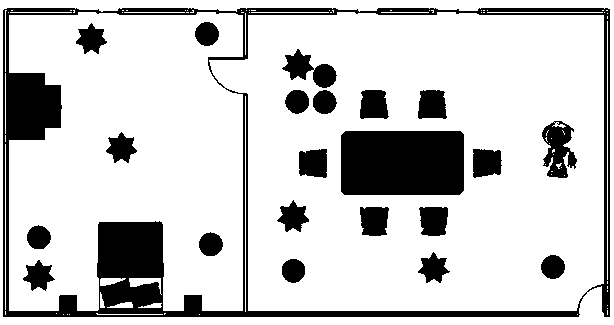

Systems, methods, and user interfaces are used for controlling a robot. An environment map and a robot designator are presented to a user. The user may place, move, and modify task designators on the environment map. The task designators indicate a position in the environment map and indicate a task for the robot to achieve. A control intermediary links task designators with robot instructions issued to the robot. The control intermediary analyzes a relative position between the task designators and the robot. The control intermediary uses the analysis to determine a task-oriented autonomy level for the robot and communicates target achievement information to the robot. The target achievement information may include instructions for directly guiding the robot if the autonomy level indicates low robot initiative and may include instructions for directing the robot to determine a robot plan for achieving the task if the autonomy level indicates high robot initiative.

Owner:BATTELLE ENERGY ALLIANCE LLC +1

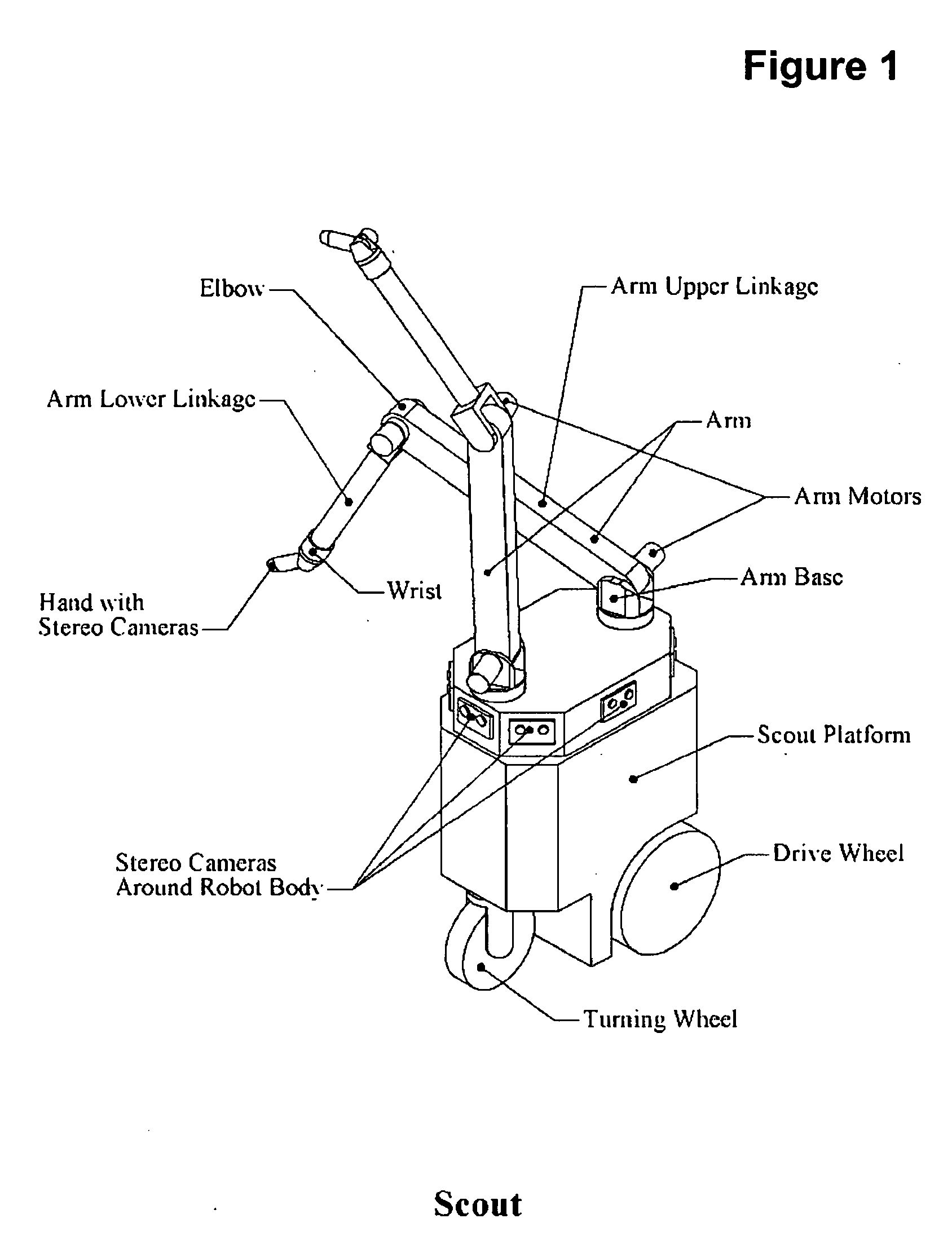

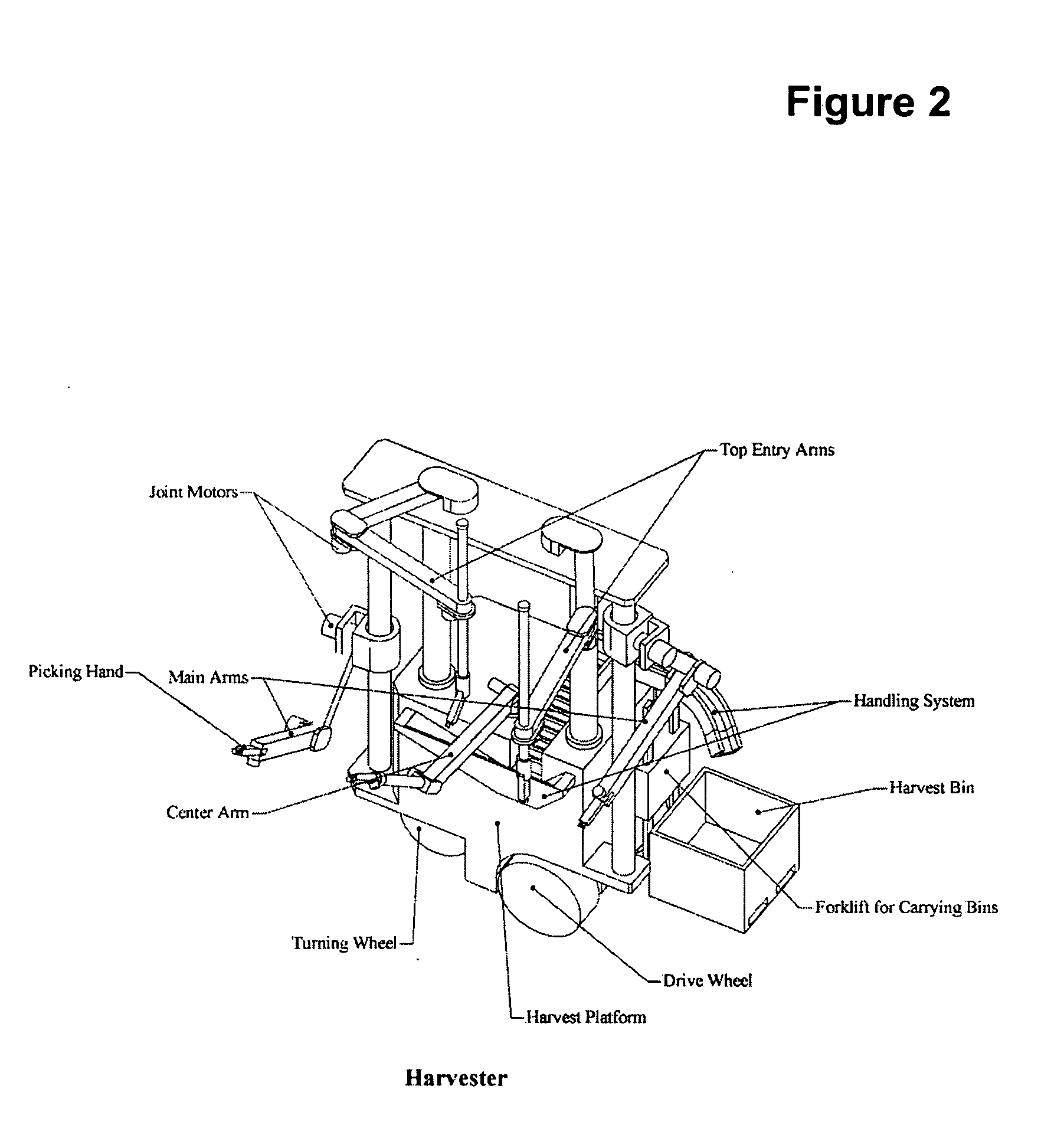

Robot mechanical picker system and method

InactiveUS20050126144A1Improve efficiencyLow costAnalogue computers for trafficMowersRobot planningSimulation

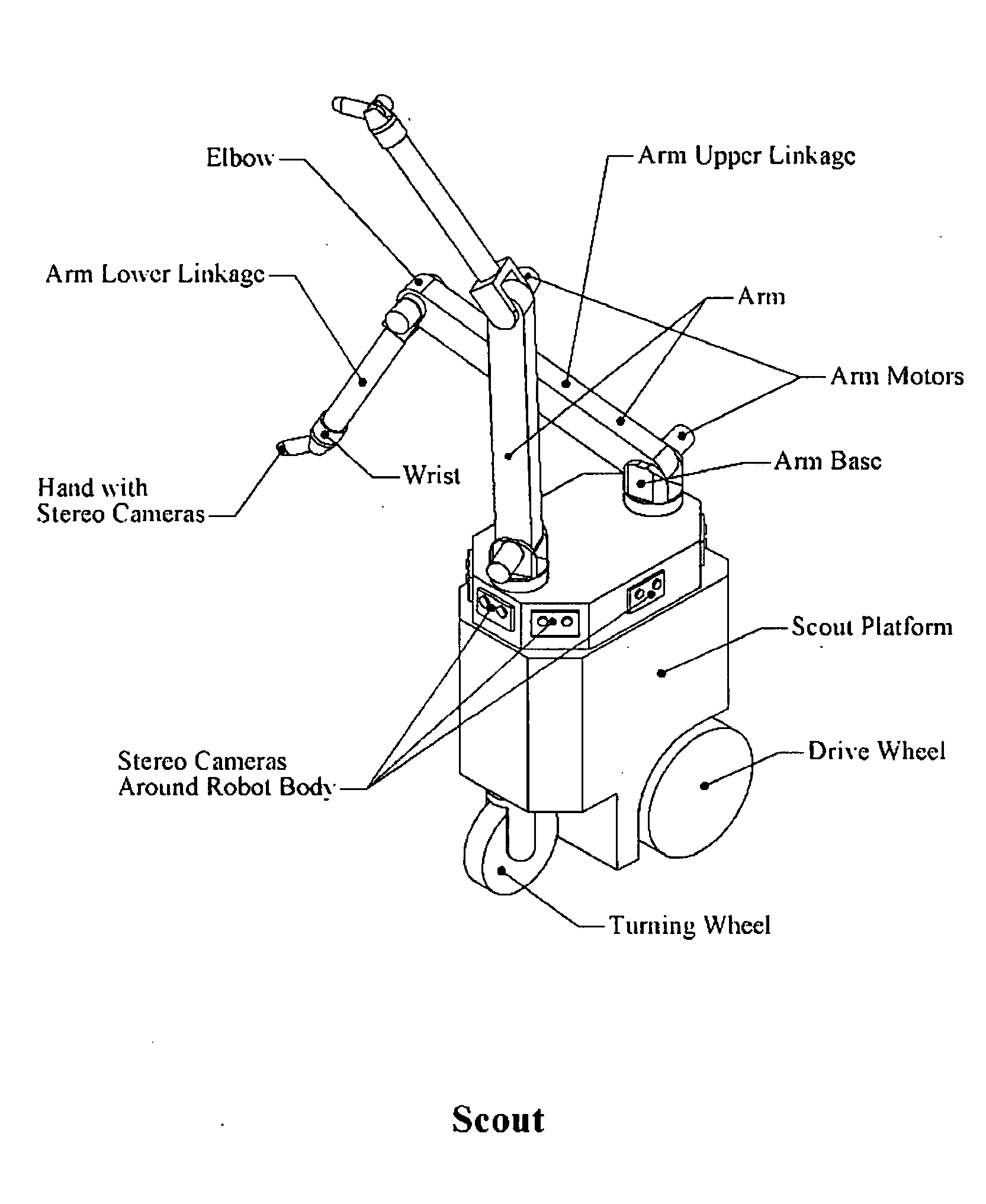

Embodiments of the invention comprise a system and method that enable robotic harvesting of agricultural crops. One approach for automating the harvesting of fresh fruits and vegetables is to use a robot comprising a machine-vision system containing rugged solid-state digital cameras to identify and locate the fruit on each tree, coupled with a picking system to perform the picking. In one embodiment of the invention a robot moves through a field first to “map” the field to determine plant locations, the number and size of fruit on the plants and the approximate positions of the fruit on each plant. A robot employed in this embodiment may comprise a GPS sensor to simplify the mapping process. At least one camera on at least one arm of a robot may be mounted in appropriately shaped protective enclosure so that a camera can be physically moved into the canopy of the plant if necessary to map fruit locations from inside the canopy. Once the map of the fruit is complete for a field, the robot can plan and implement an efficient picking plan for itself or another robot. In one embodiment of the invention, a scout robot or harvest robot determines a picking plan in advance of picking a tree. This may be done if the map is finished hours, days or weeks before a robot is scheduled to harvest, or if the picking plan algorithm selected requires significant computational time and cannot be implemented in “real time” by the harvesting robot as it is picking the field. If the picking algorithm selected is less computationally intense, the harvester may calculate the plan as it is harvesting. The system harvests according to the selected picking plan. The picking plan may be generated in the scout robot, harvest robot or on a server. Each of the elements in the system may be configured to communicate with each other using wireless communications technologies.

Owner:VISION ROBOTICS

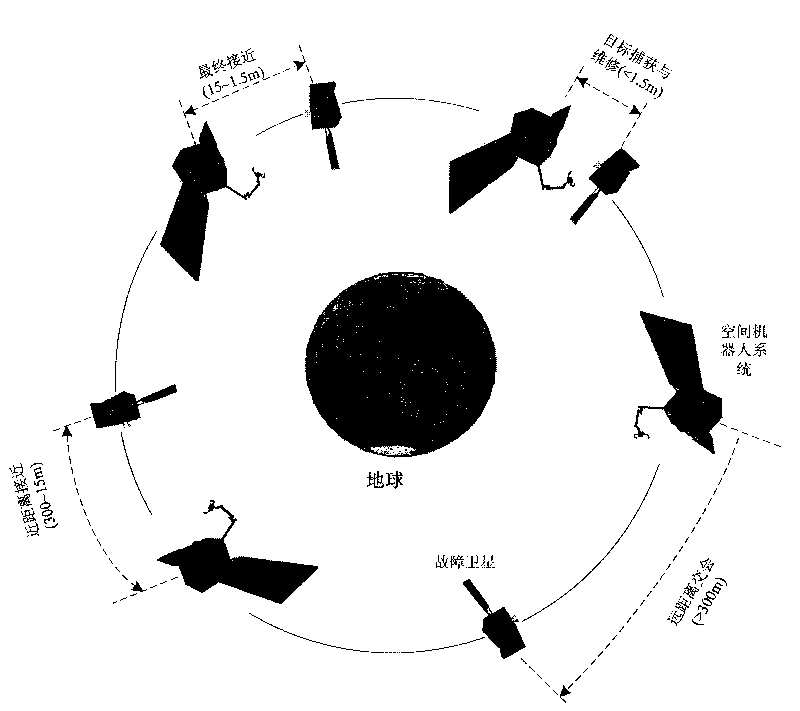

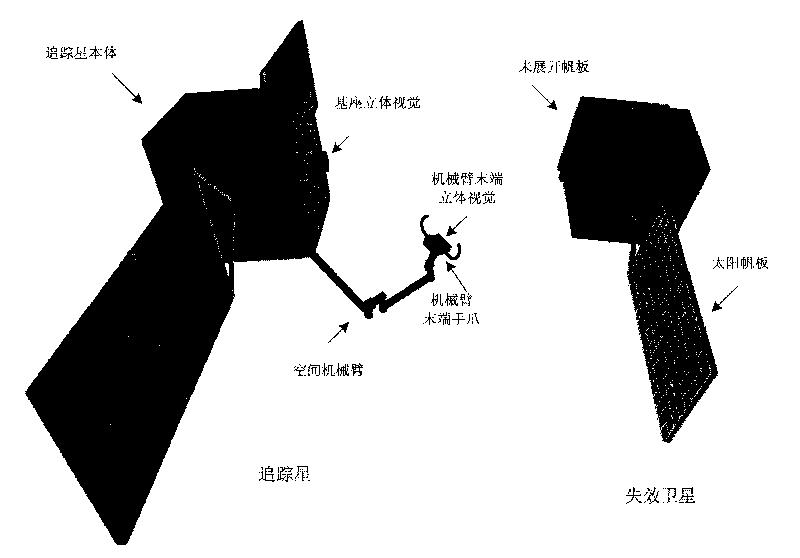

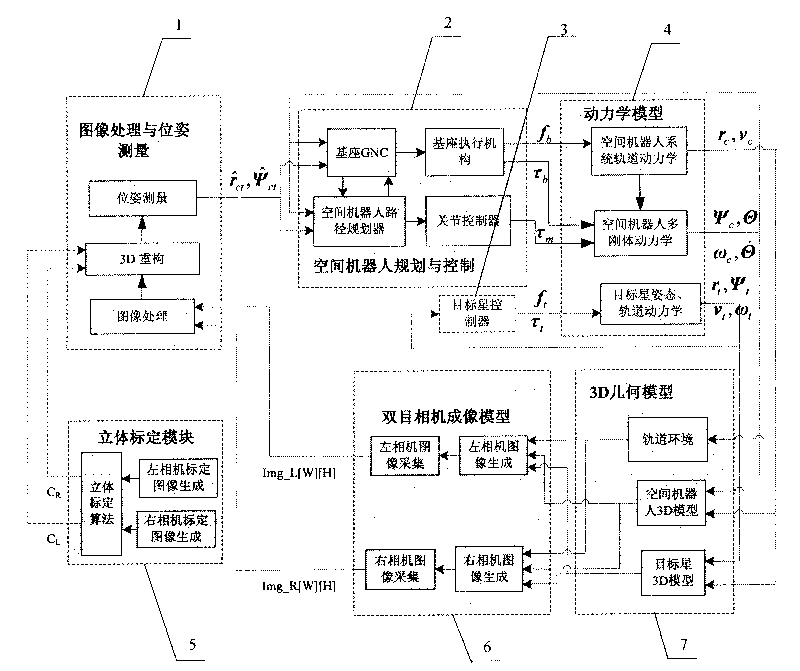

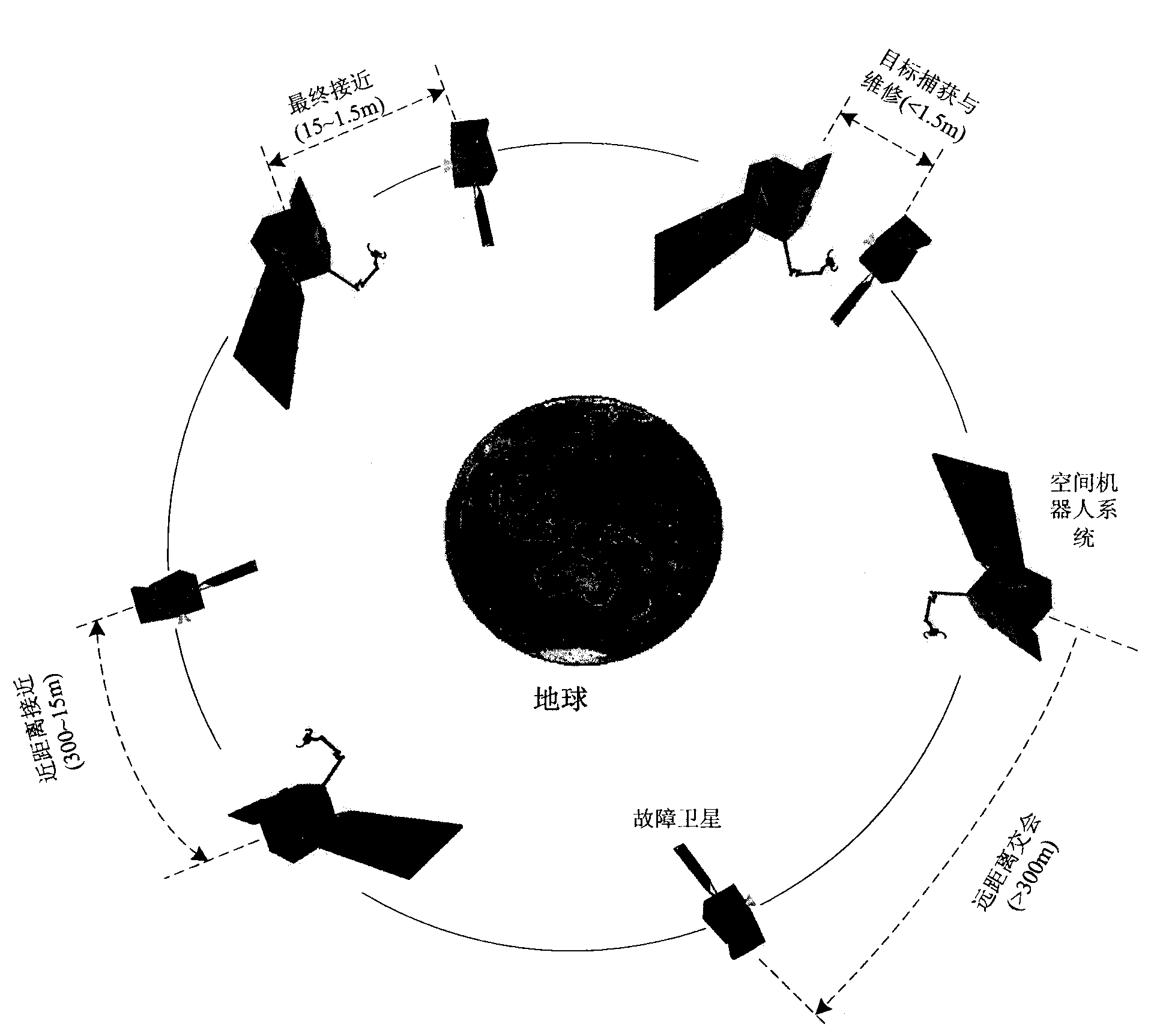

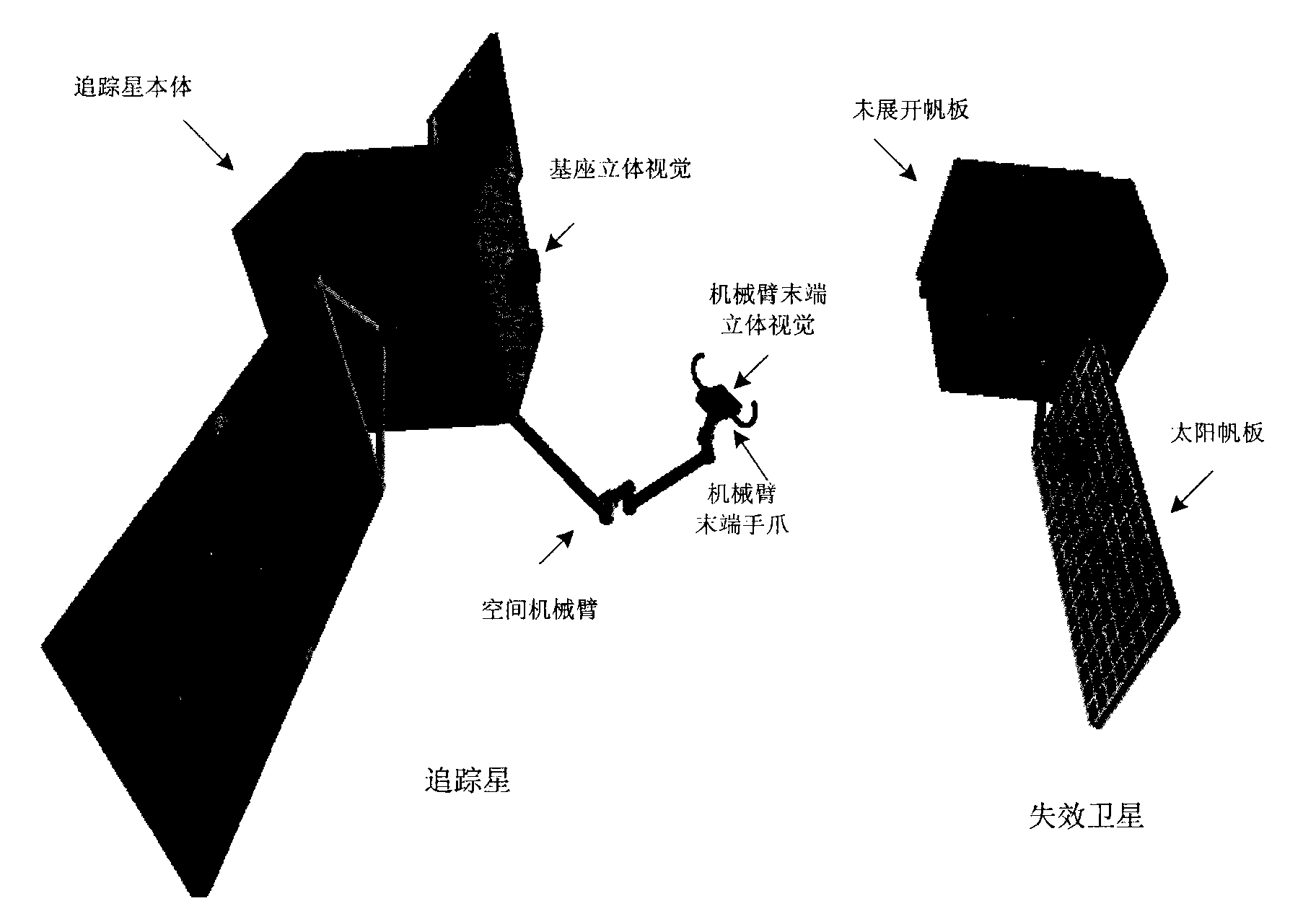

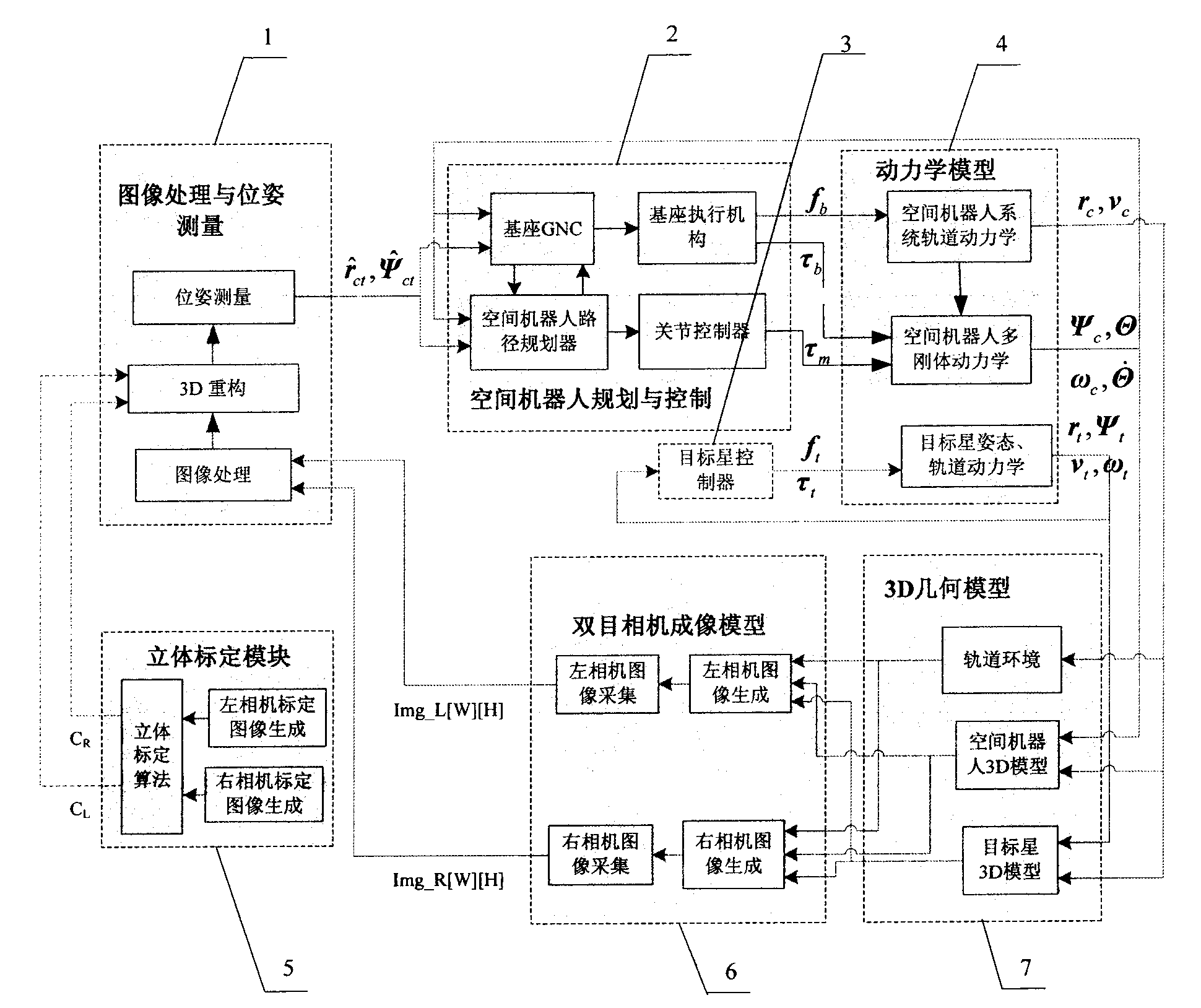

Vision measurement, path planning and GNC integrated simulation system for space robot

InactiveCN101726296APredict interference in real timeAdaptive control abilityInstruments for comonautical navigationImaging processingRobot planning

The invention relates to a vision measurement, path planning and GNC integrated simulation system for a space robot, which comprises an image processing and pose measuring module 1, a space robot planning and control module 2, a target controller module 3, a system dynamic model module 4, a system 3D geometric model module 7, a binocular camera simulation imaging module 6, a three-dimensional calibration module 5 and the like. The system integrates image processing and pose measurement, GNC algorithm, path planning, control, dynamics and the like, so that the closed-loop simulation and verification of all key algorithms in the process of tracking, approaching and capturing non-cooperative targets by the space robot can be performed on an independent PC. The system does not need to adopt real measurement equipment, a space robot system and targets, and is low in cost, good in safety and flexibility and easy to implement; and the system is good in expandability, and the closed-loop simulation and verification of cameras (installation positions and viewing angles) and space robots (kinematic and dynamic parameters) with different parameters can be implemented by modifying the parameters.

Owner:HARBIN INST OF TECH

System and method for seamless task-directed autonomy for robots

ActiveUS8271132B2Programme-controlled manipulatorAutonomous decision making processRobot planningProgram planning

Systems, methods, and user interfaces are used for controlling a robot. An environment map and a robot designator are presented to a user. The user may place, move, and modify task designators on the environment map. The task designators indicate a position in the environment map and indicate a task for the robot to achieve. A control intermediary links task designators with robot instructions issued to the robot. The control intermediary analyzes a relative position between the task designators and the robot. The control intermediary uses the analysis to determine a task-oriented autonomy level for the robot and communicates target achievement information to the robot. The target achievement information may include instructions for directly guiding the robot if the task-oriented autonomy level indicates low robot initiative and may include instructions for directing the robot to determine a robot plan for achieving the task if the task-oriented autonomy level indicates high robot initiative.

Owner:BATTELLE ENERGY ALLIANCE LLC +1

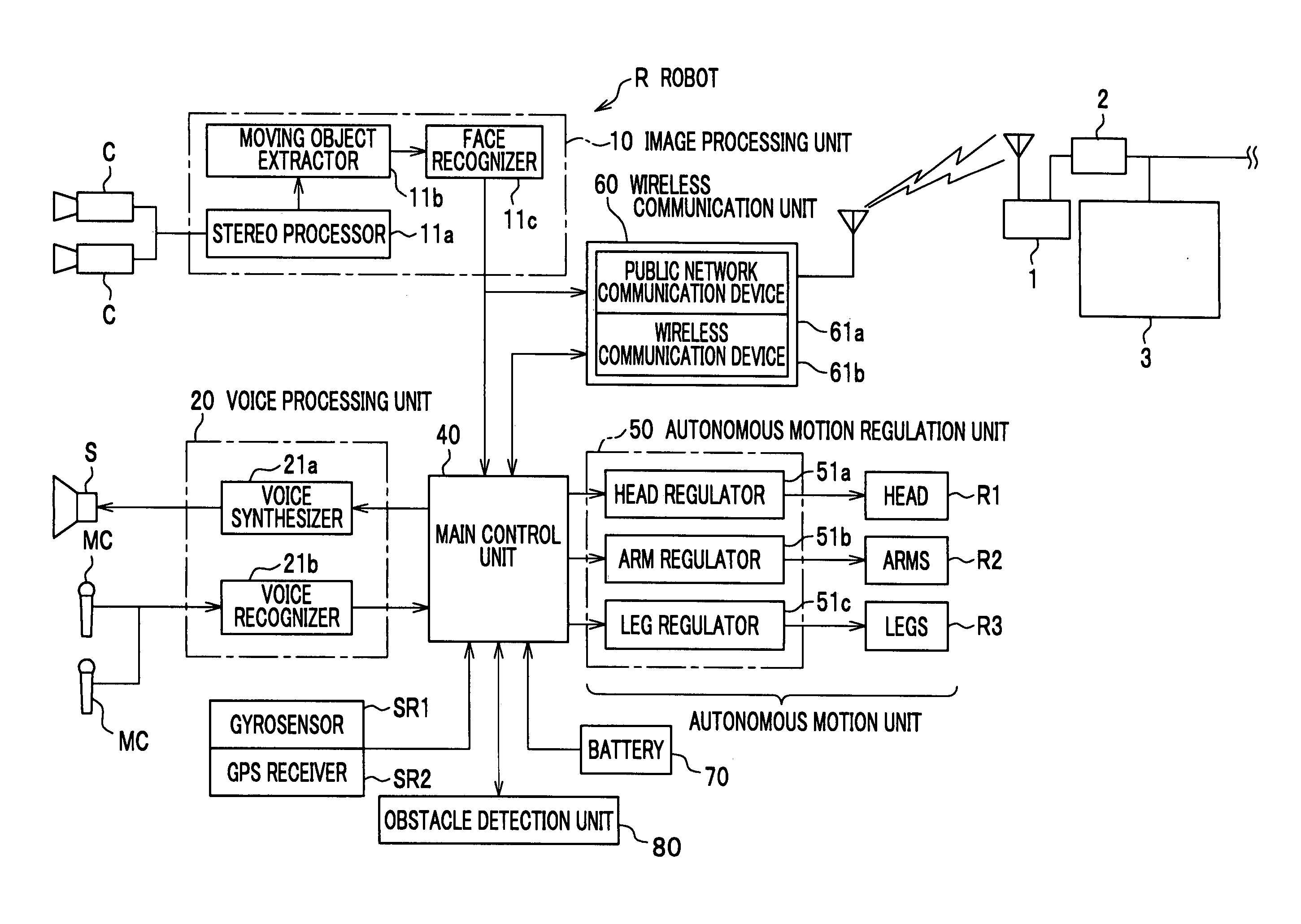

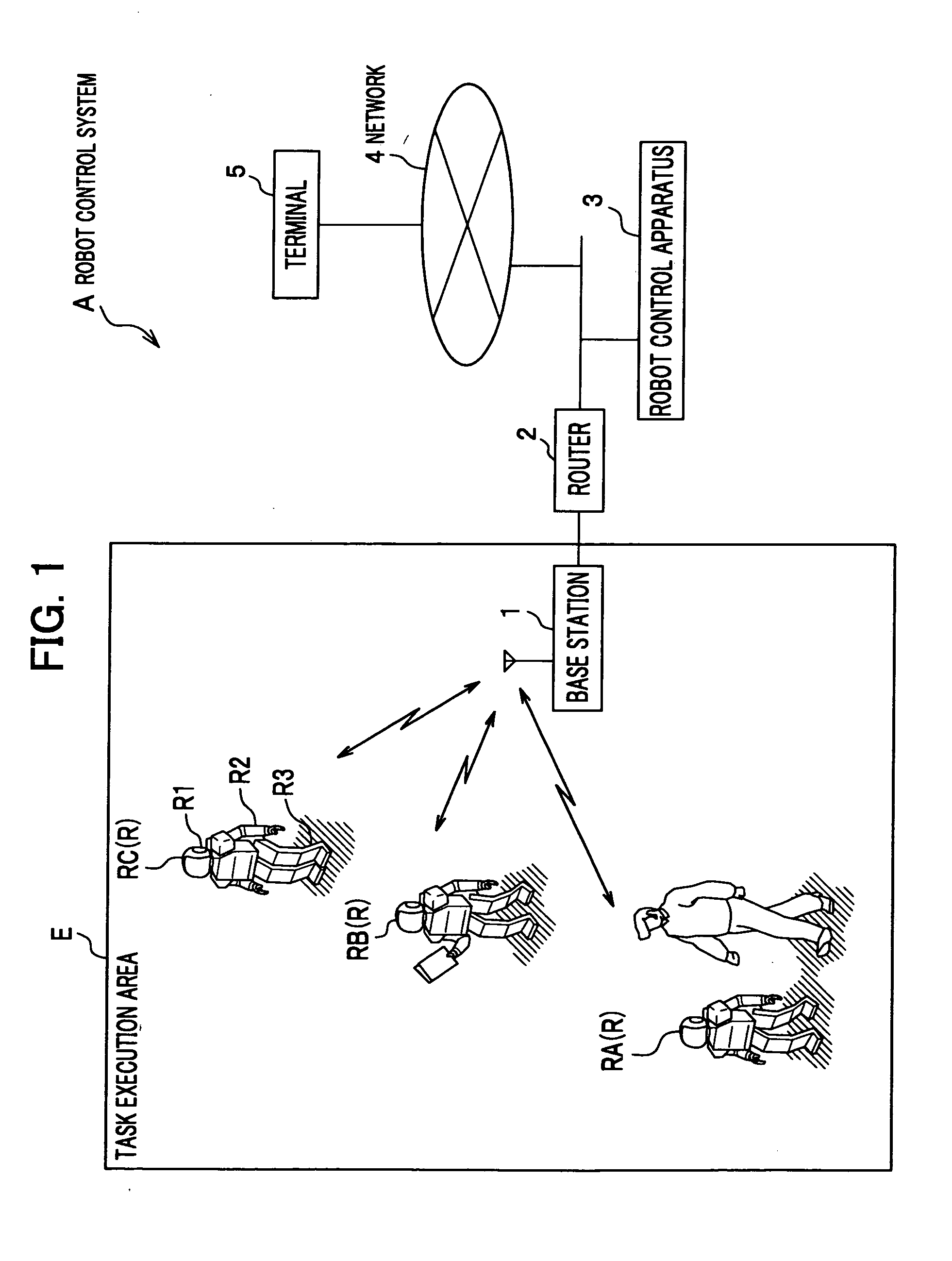

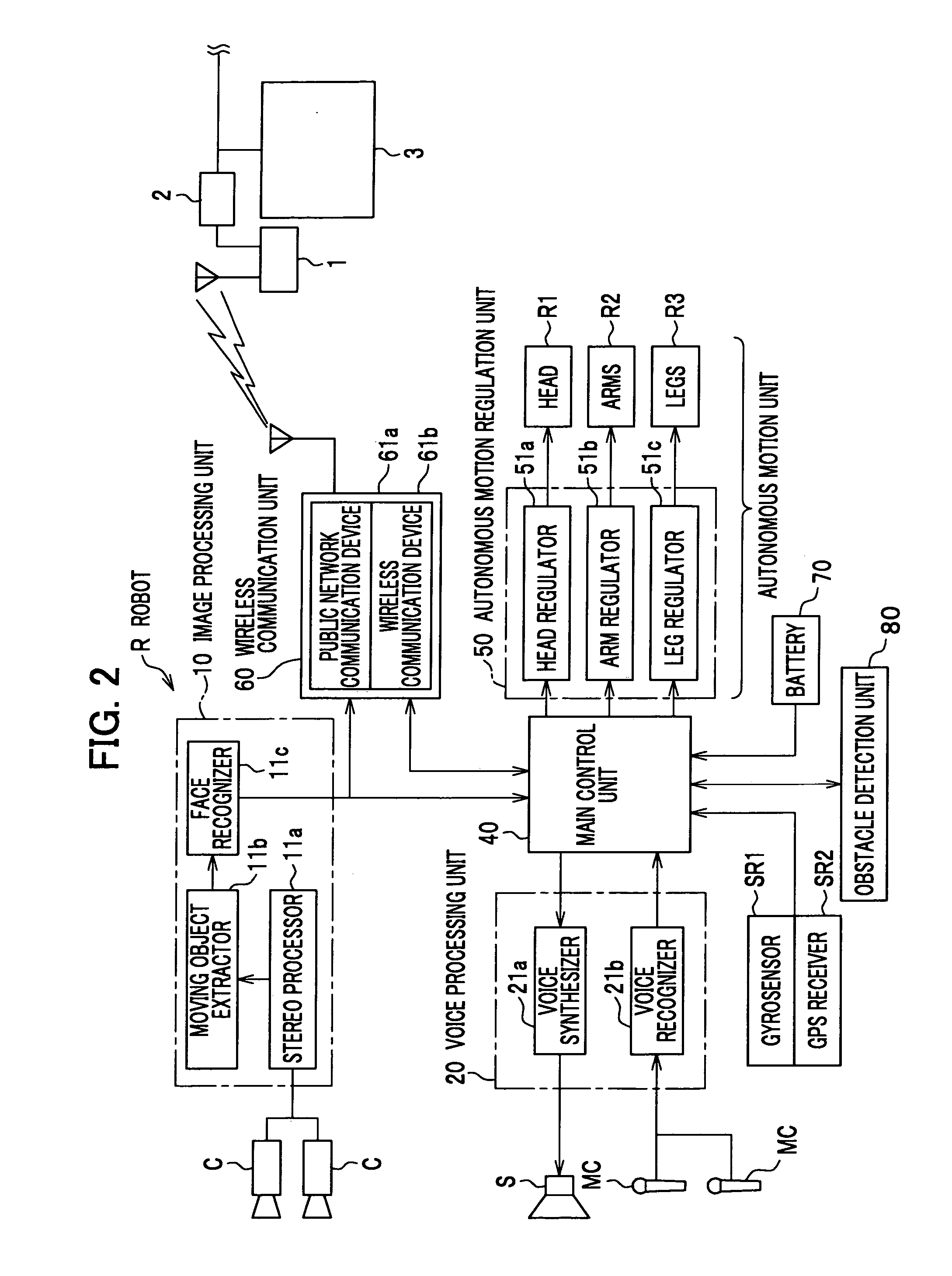

Robot control apparatus

InactiveUS20060265103A1Reduced and minimized costPromote sportsVehicle position/course/altitude controlSpecial data processing applicationsRobot planningProgram planning

A robot control apparatus allows a plurality of mobile robots to carry out tasks at a reduced or minimized cost as a whole with consideration given to costs derived from an encounter with an obstacle is provided. An action optimization controller provided in the robot control apparatus generates an instruction for optimizing actions of the plurality of mobile robots so that the plurality of mobile robots carry out the tasks at a minimized cost, based upon locomotion plan information indicative of locomotion plans of the plurality of mobile robots. A possibility that any robots have an encounter with an obstacle is determined by comparing distances from the robots to the obstacles. A locomotion plan implementation cost is calculated with consideration given to the possibility of encounter, and thus an optimum route is selected based upon the locomotion plan implementation cost with the encounter-derived cost. In accordance with the optimum route, the locomotion plan for the robot is modified.

Owner:HONDA MOTOR CO LTD

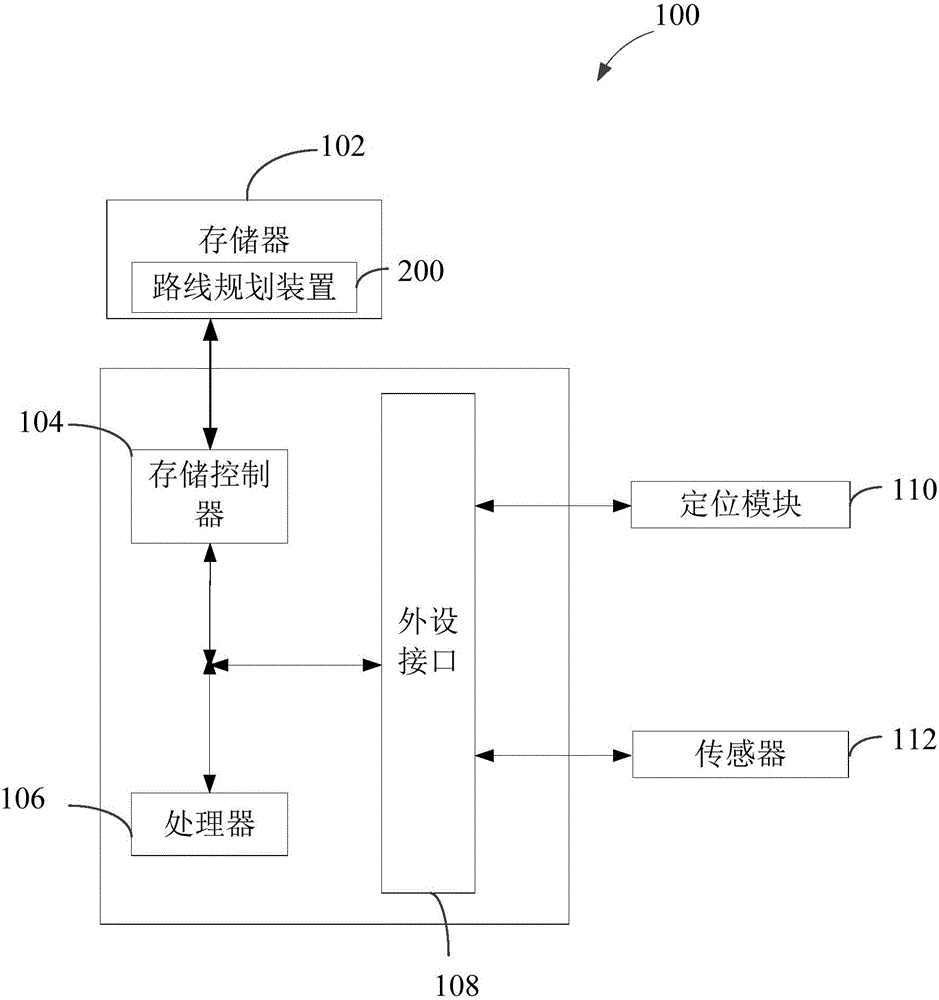

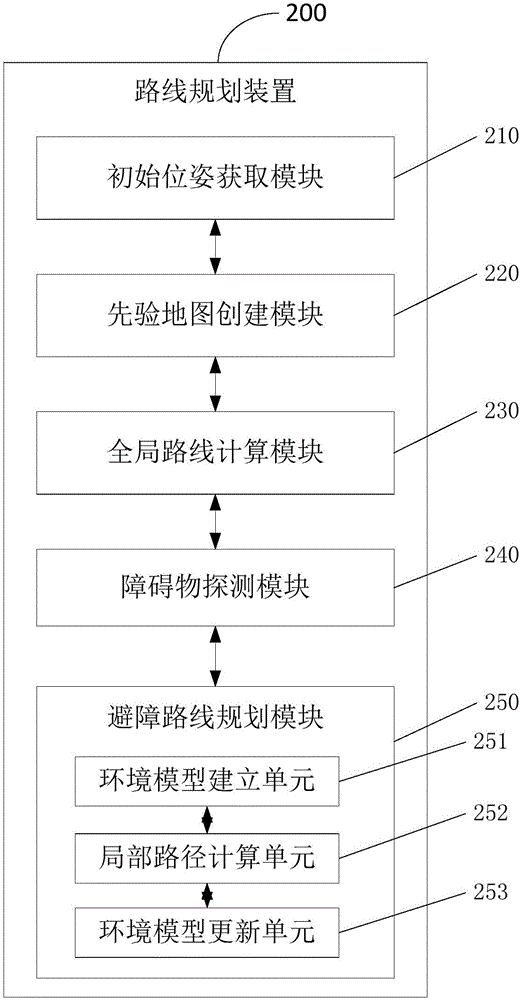

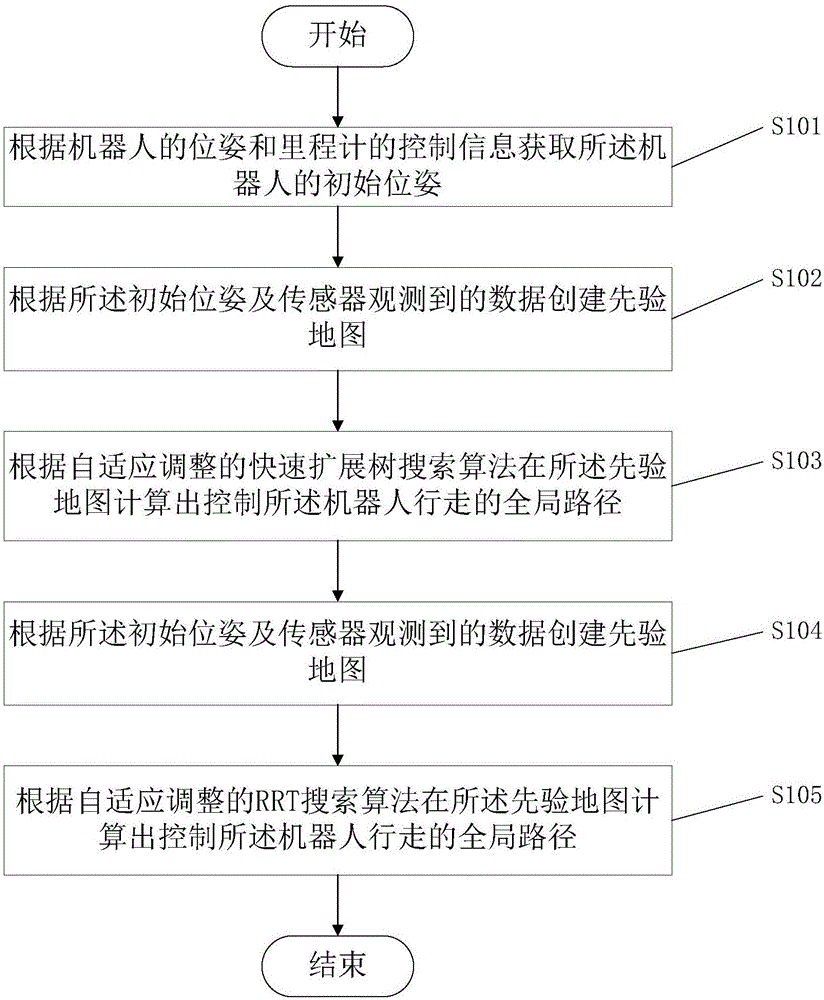

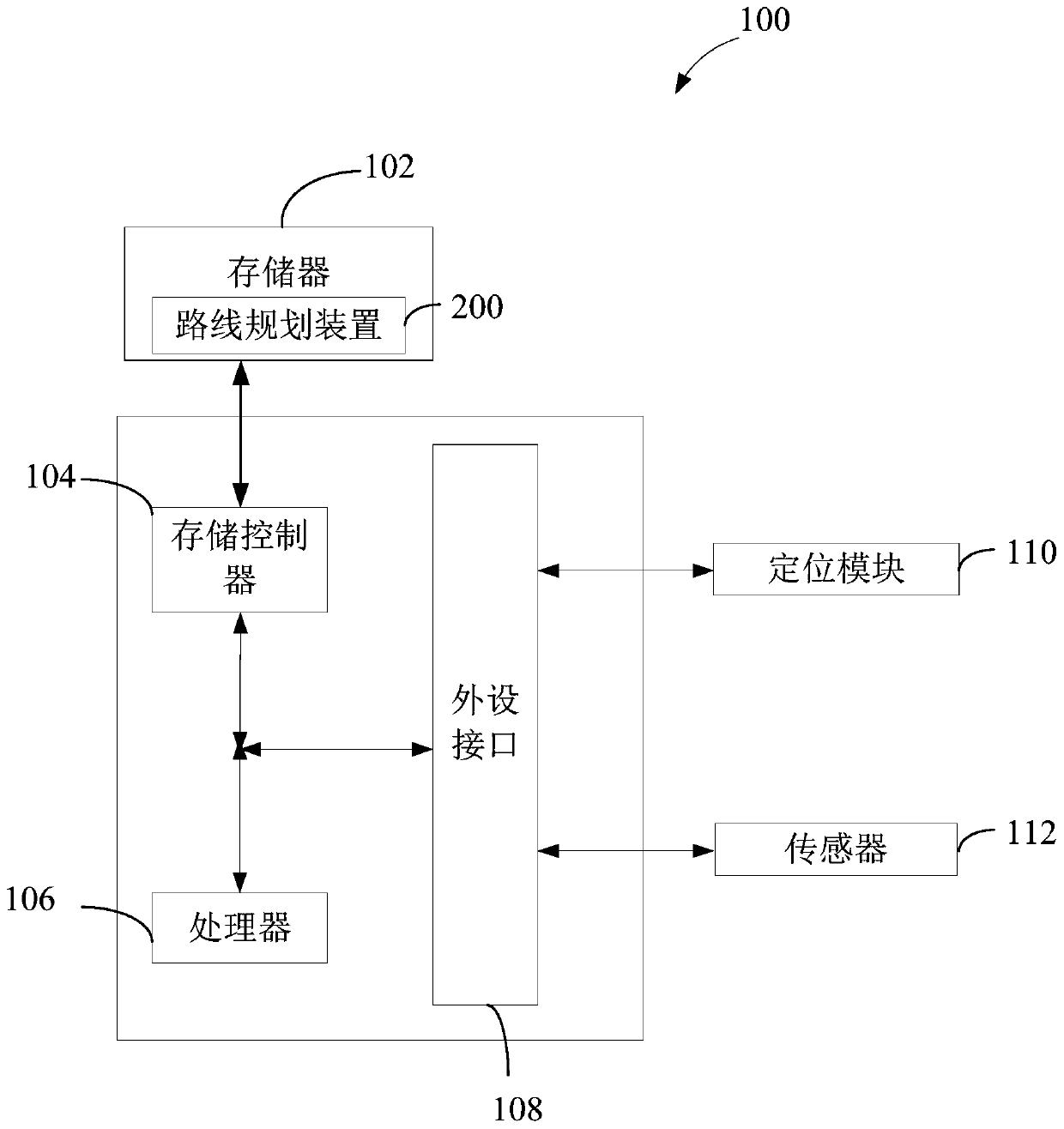

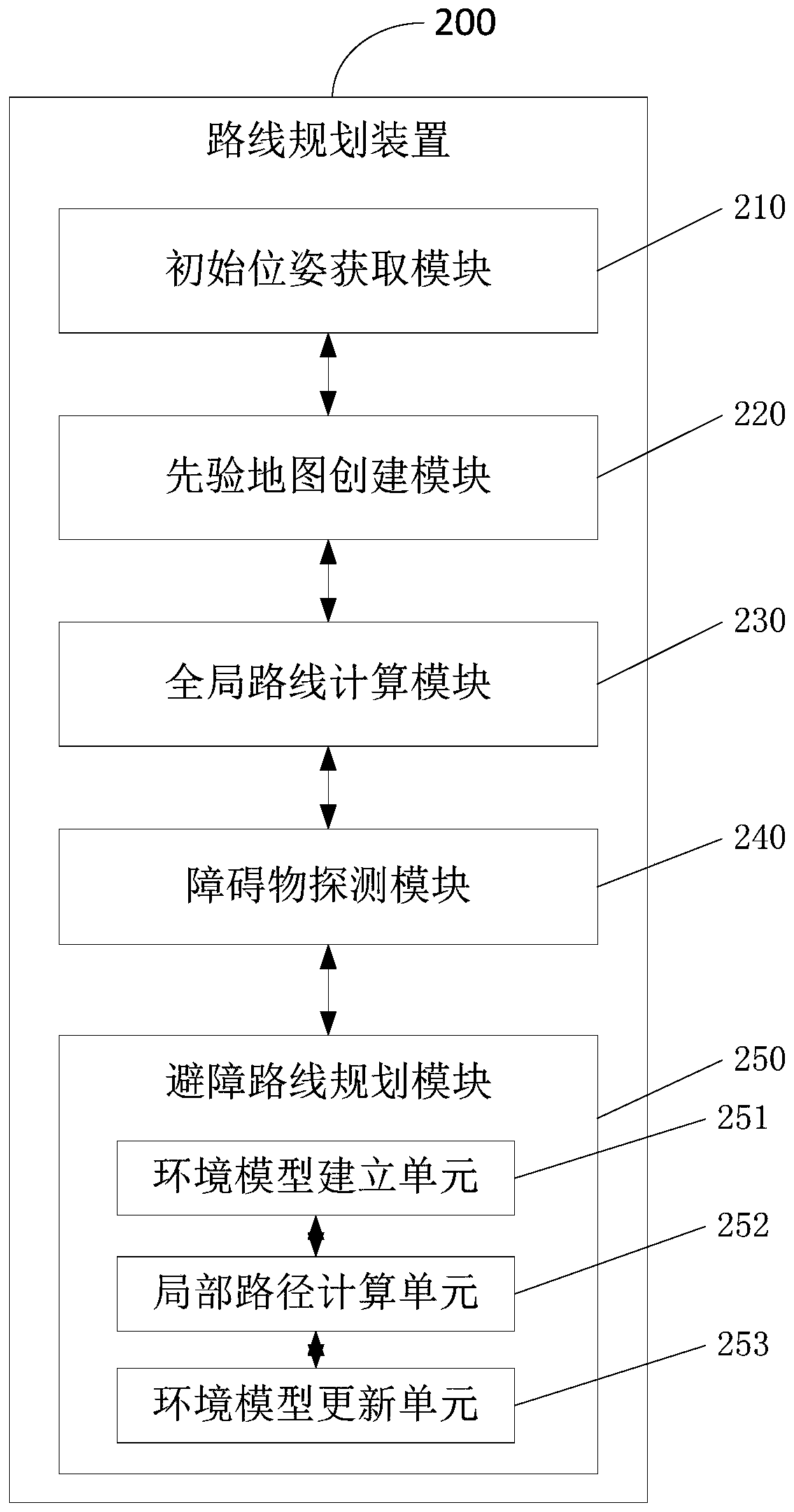

Robot path planning method and robot planning route

InactiveCN106406320AEfficient searchSame directionPosition/course control in two dimensionsRobot planningSimulation

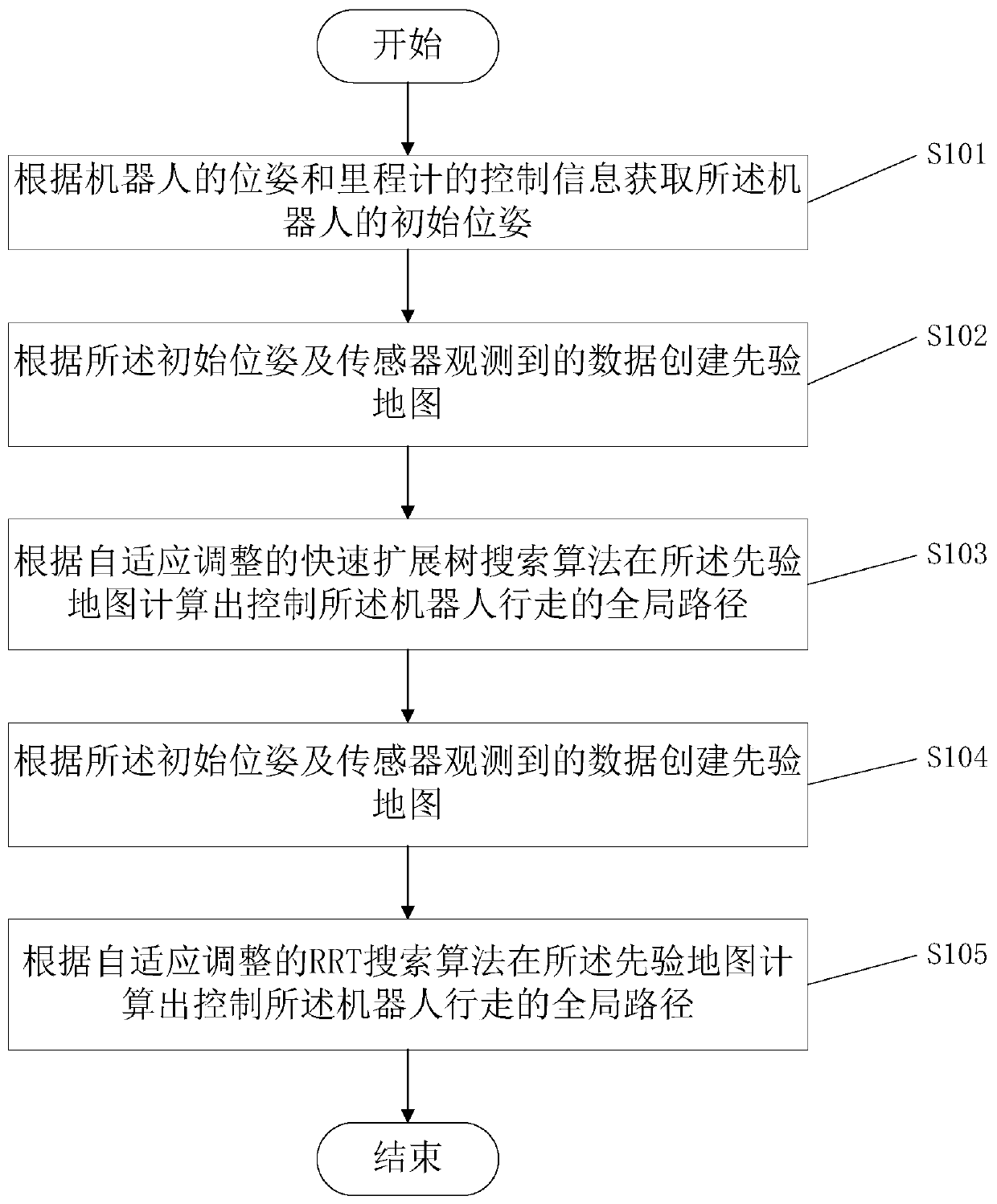

Embodiments of the invention provide a robot path planning method and a robot planning a route. The method comprises the following steps of according to a pose of a robot and control information of a speedometer, acquiring an initial pose of the robot; according to the initial pose and data observed by a sensor, creating a prior map; according to a rapid expansion tree algorithm of adaptive adjustment, calculating a global path used to control walking of the robot in the prior map; acquiring real-time detection data of the sensor of the robot, and determining whether the sensor detects a barrier in the global path when the robot is in a walking process; and when the sensor detects the barrier in the global path, establishing a dynamic window model to plan a local barrier avoiding route of the robot so as to make the robot avoid the barrier according to the local barrier avoiding route.

Owner:重庆重智机器人研究院有限公司

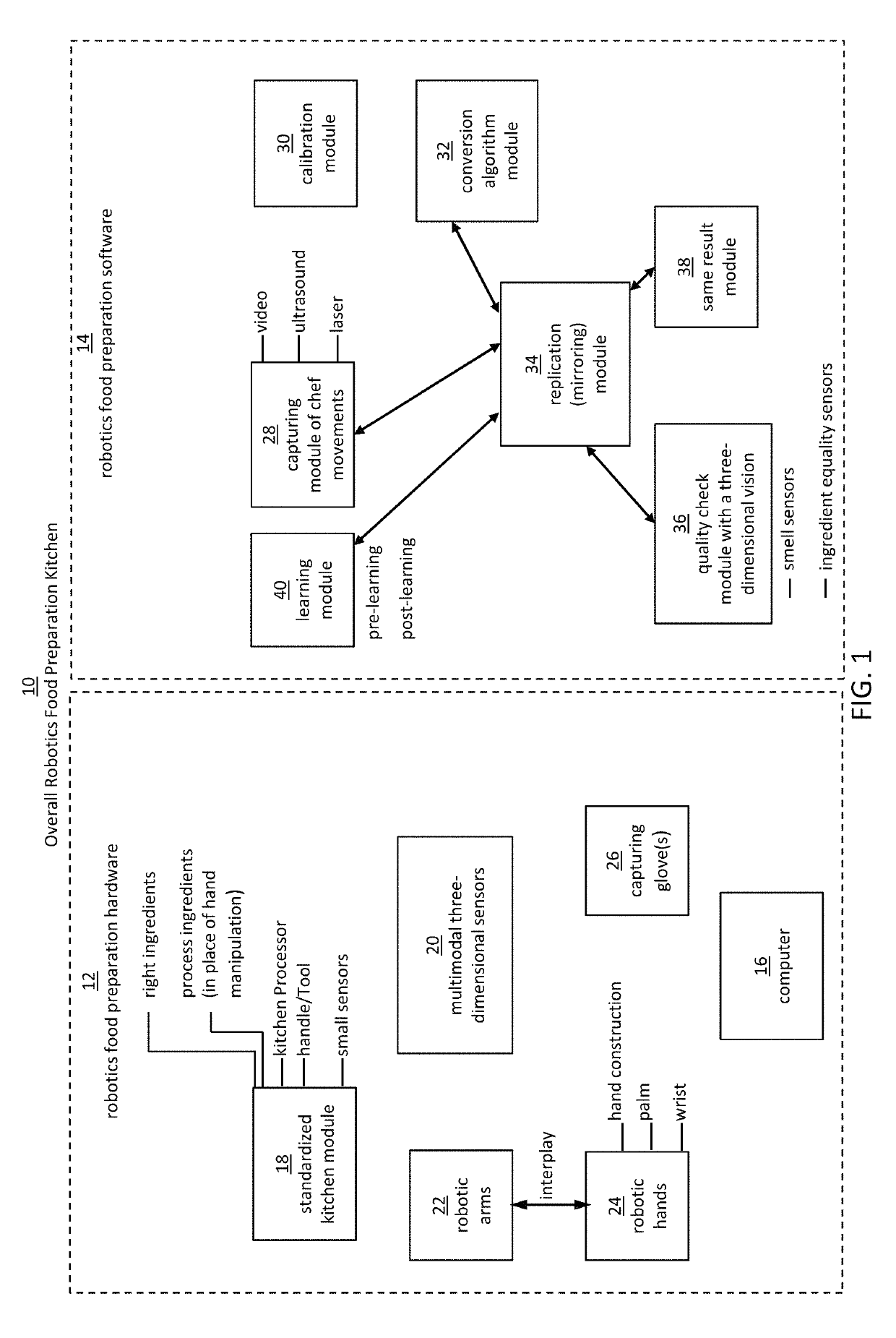

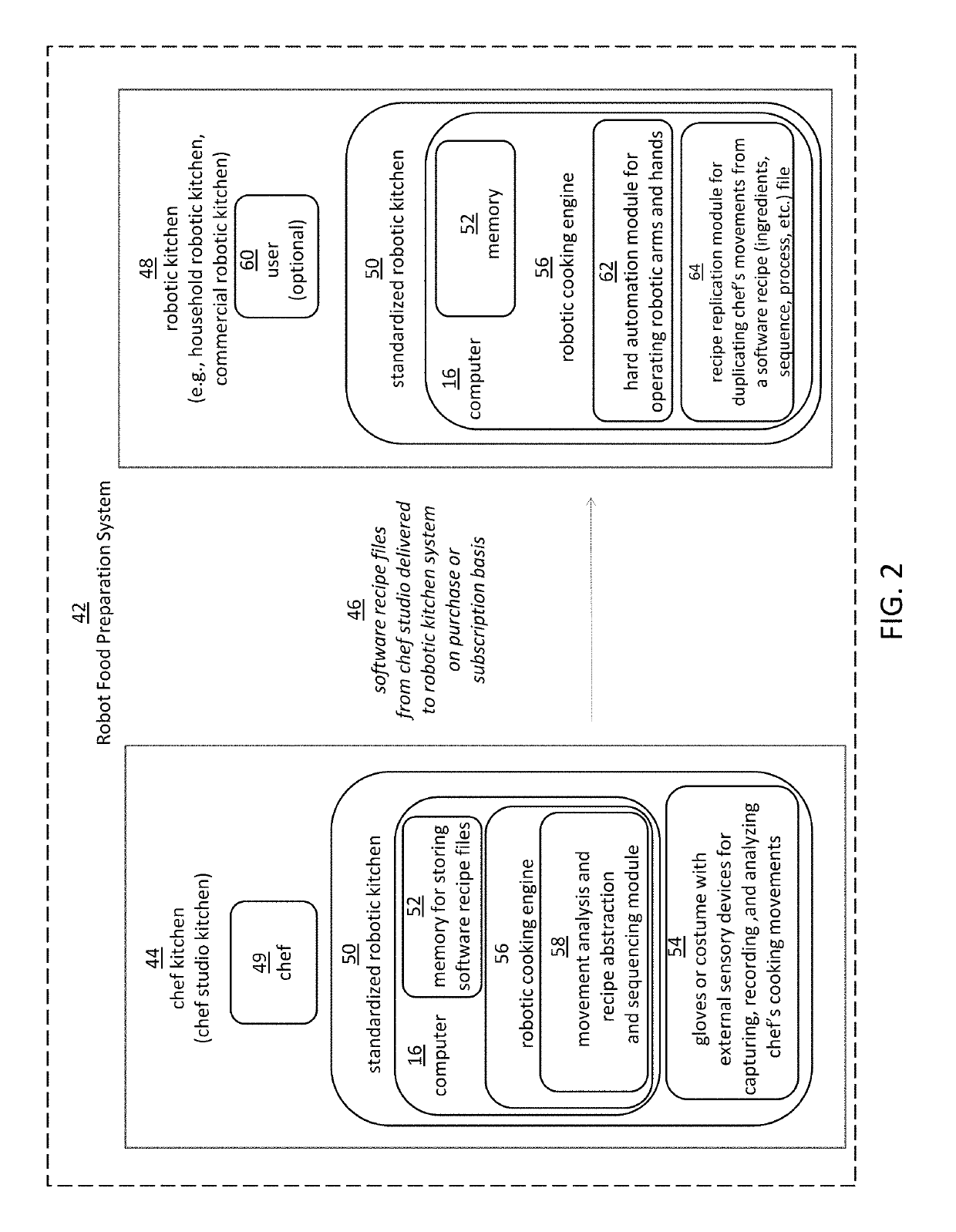

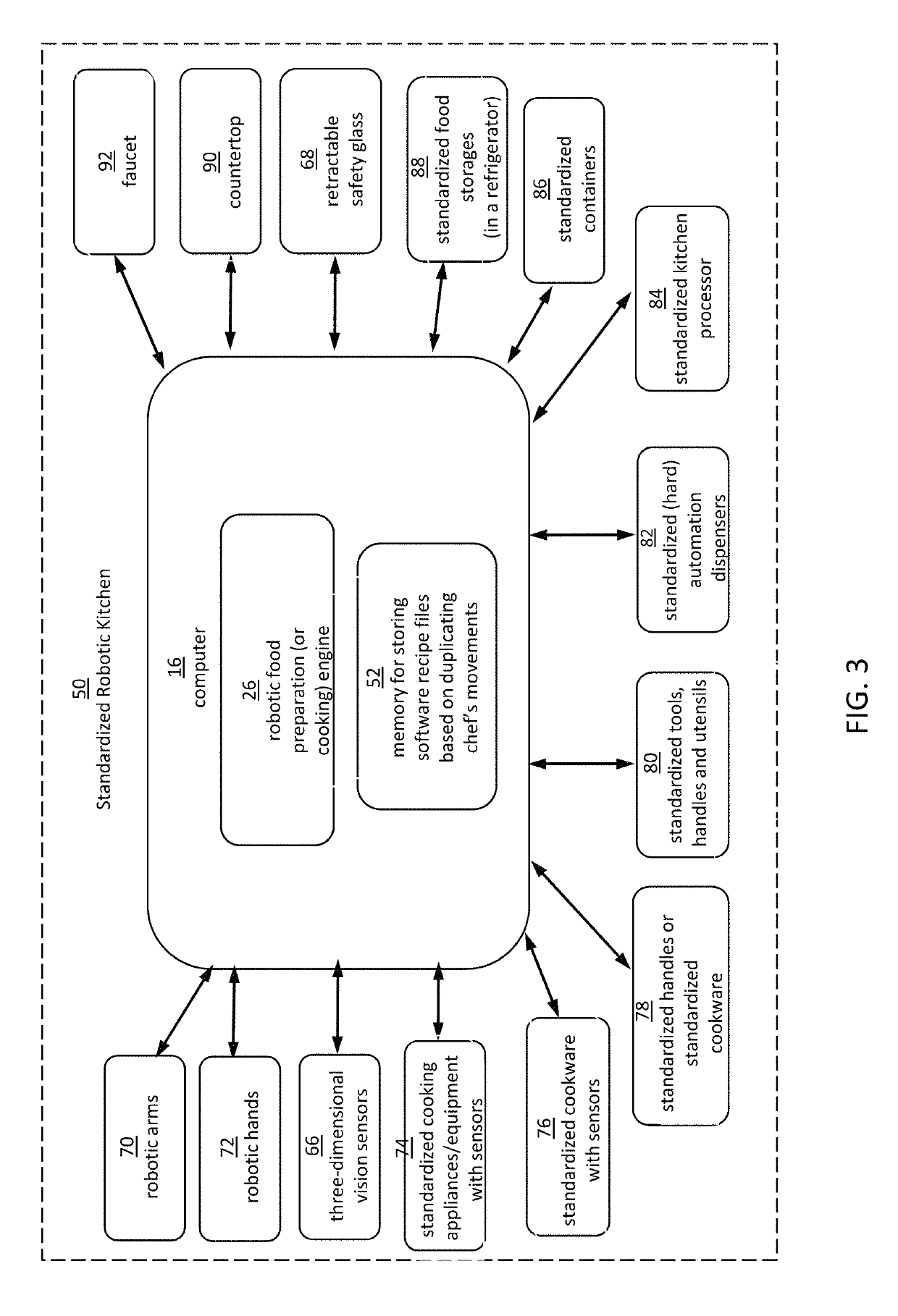

Robotic manipulation methods and systems for executing a domain-specific application in an instrumented environment with electronic minimanipulation libraries

ActiveUS10518409B2Deal with variationProgramme-controlled manipulatorGripping headsRobotic armSimulation

Owner:MBL LTD

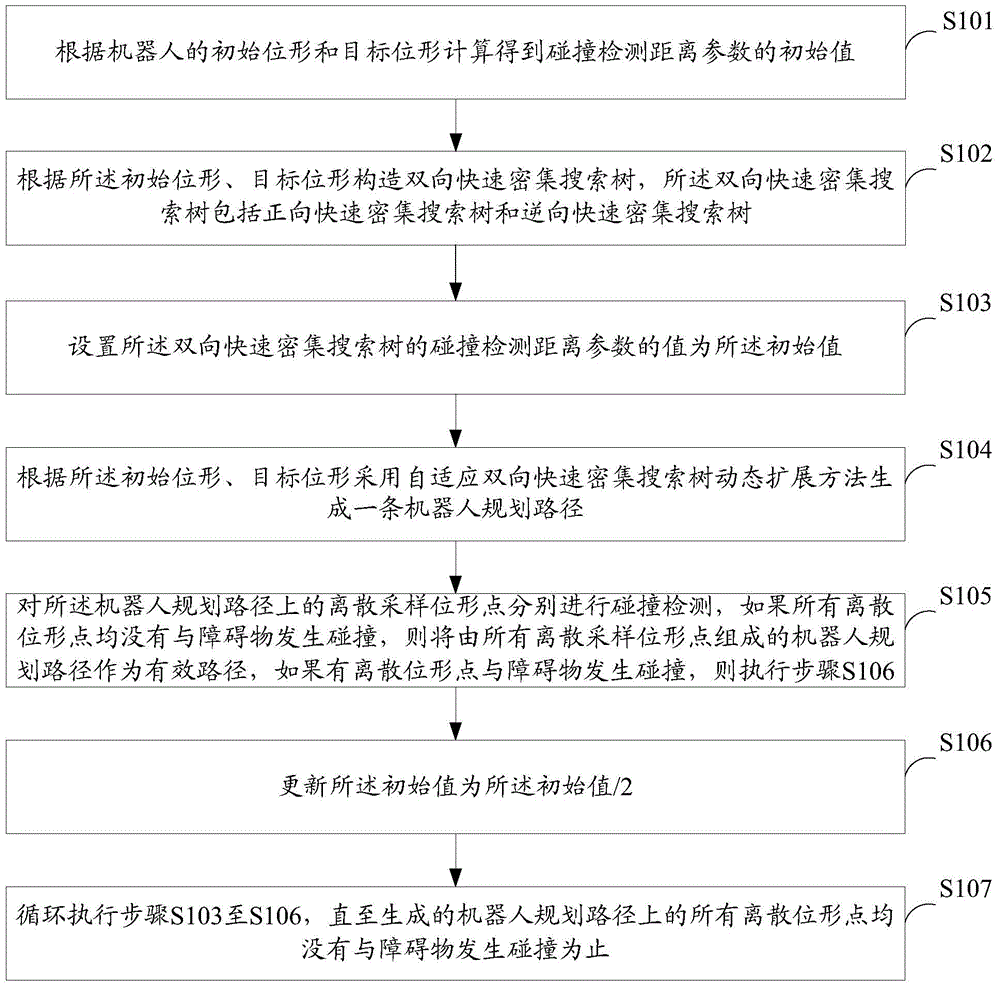

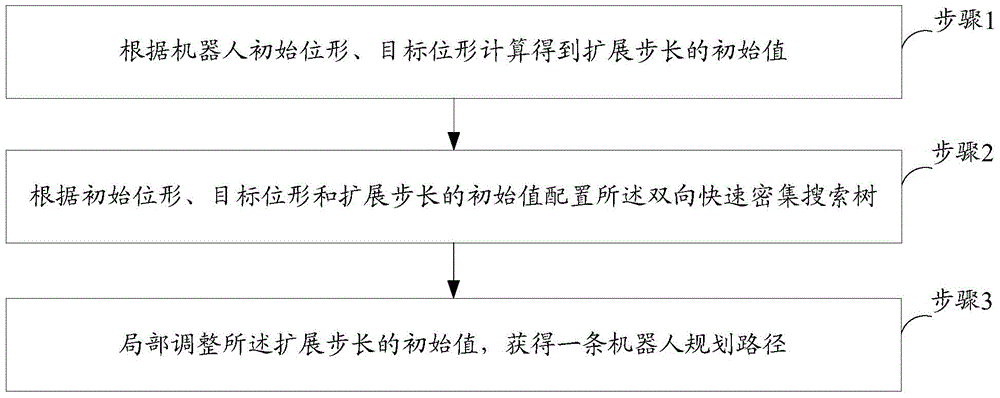

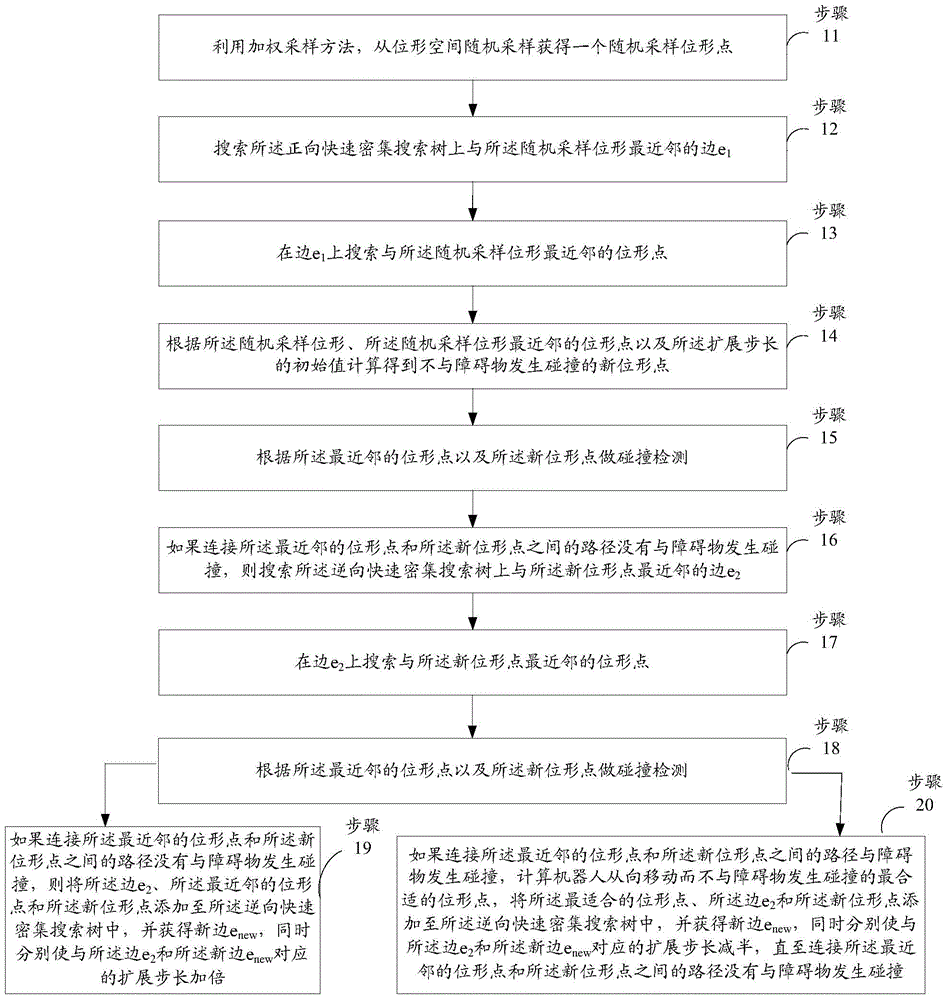

Planning method and device of robot collision prevention path

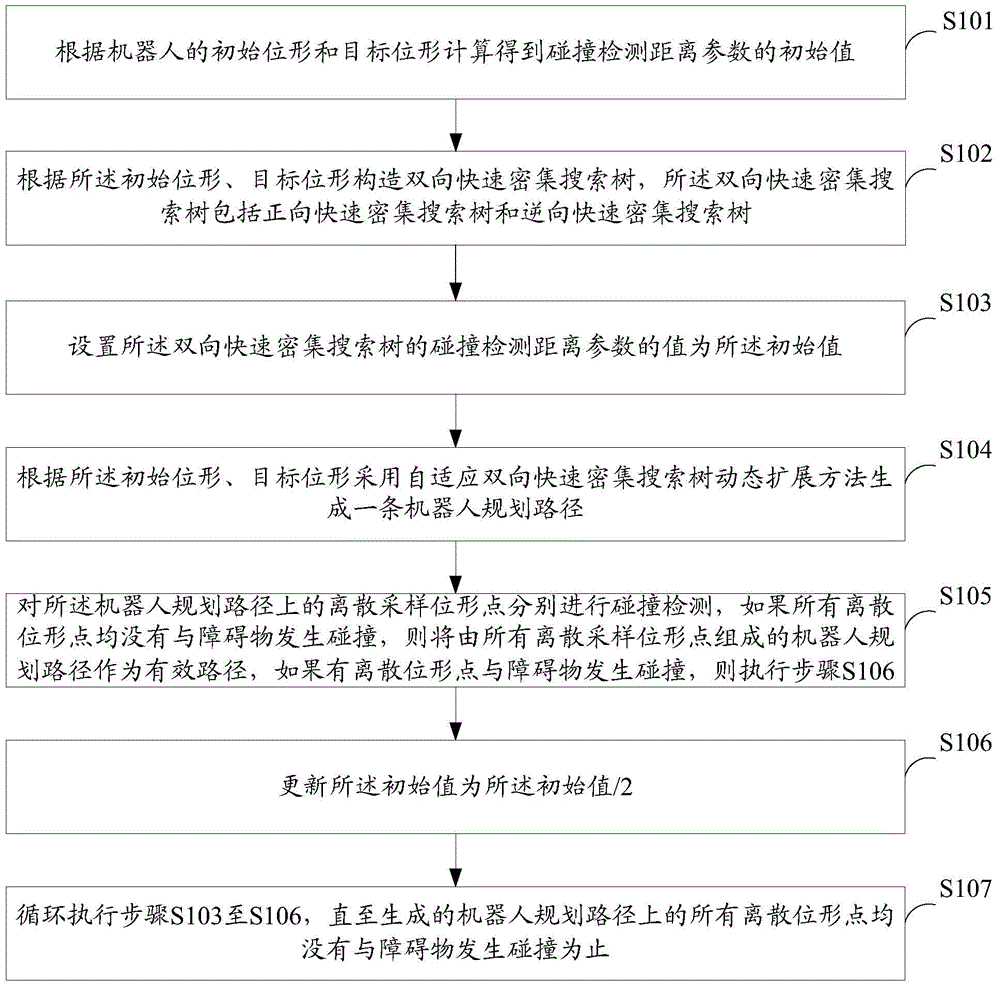

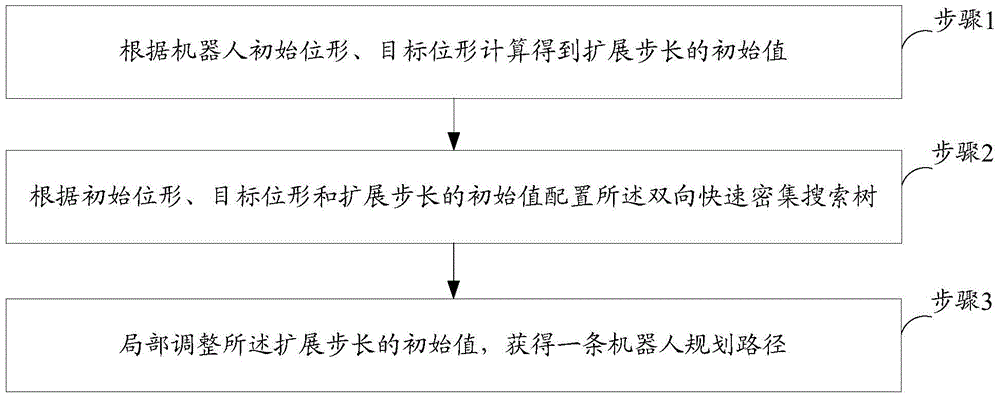

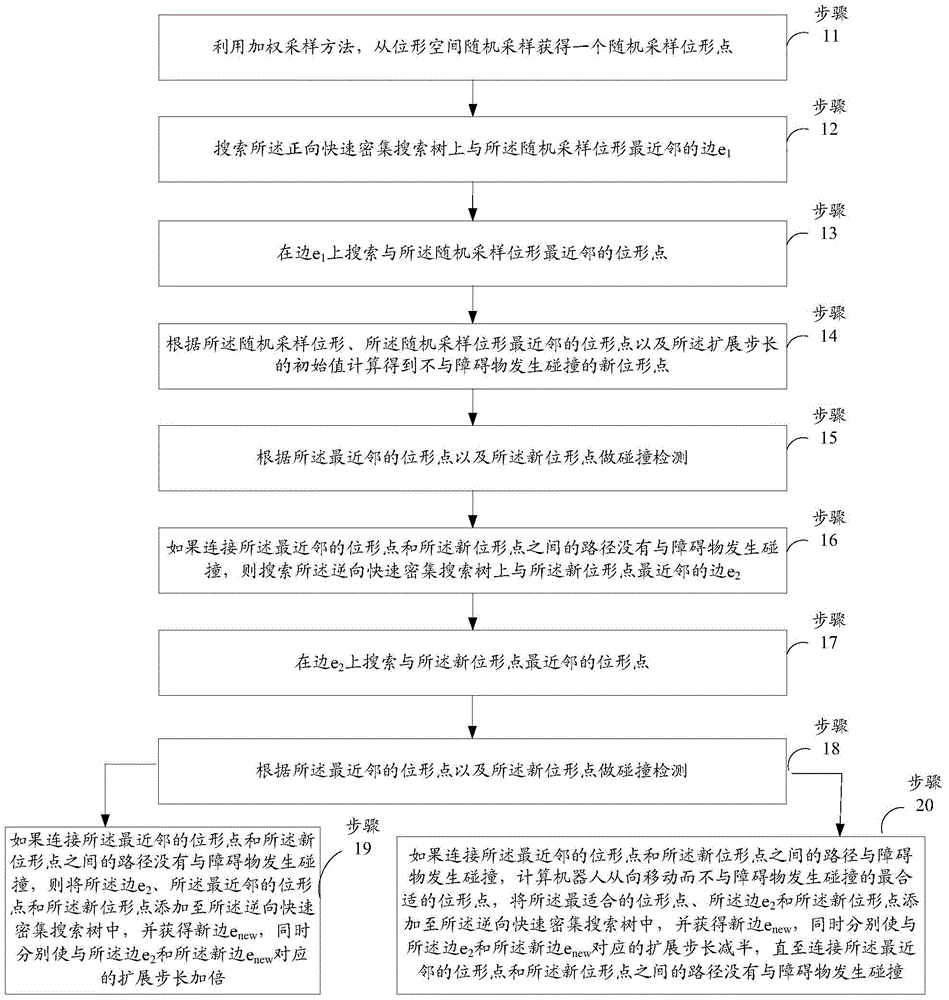

The invention is suitable for the field of robot collision prevention and control, and provides a planning method and device of a robot collision prevention path. The method comprises the following steps: firstly, calculating according to an initial configuration qs and a target configuration qg of a robot so as to obtain an initial value rcol of a collision detection distance parameter; then constructing a bidirectional rapid intensive search tree according to qs and qg, and setting the value of a collision detection distance parameter of the bidirectional rapid intensive search tree to be rcol; then generating a robot planning path according to qs and qg; carrying out collision detection on the robot at discrete sampling configuration points respectively on the robot planning path, and updating the value rcol to be half of rcol if the robot collides with a barrier at one discrete configuration point; and generating a novel robot planning path according to the updated rcol until the robot does not collide with the barrier at all discrete configuration points on the new robot planning path. According to the invention, if the robot collides with the barrier, the collision detection distance parameter rcol can be adaptively reduced by half, so that the robot can successfully pass through a narrow channel or a barrier intensive space.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY +1

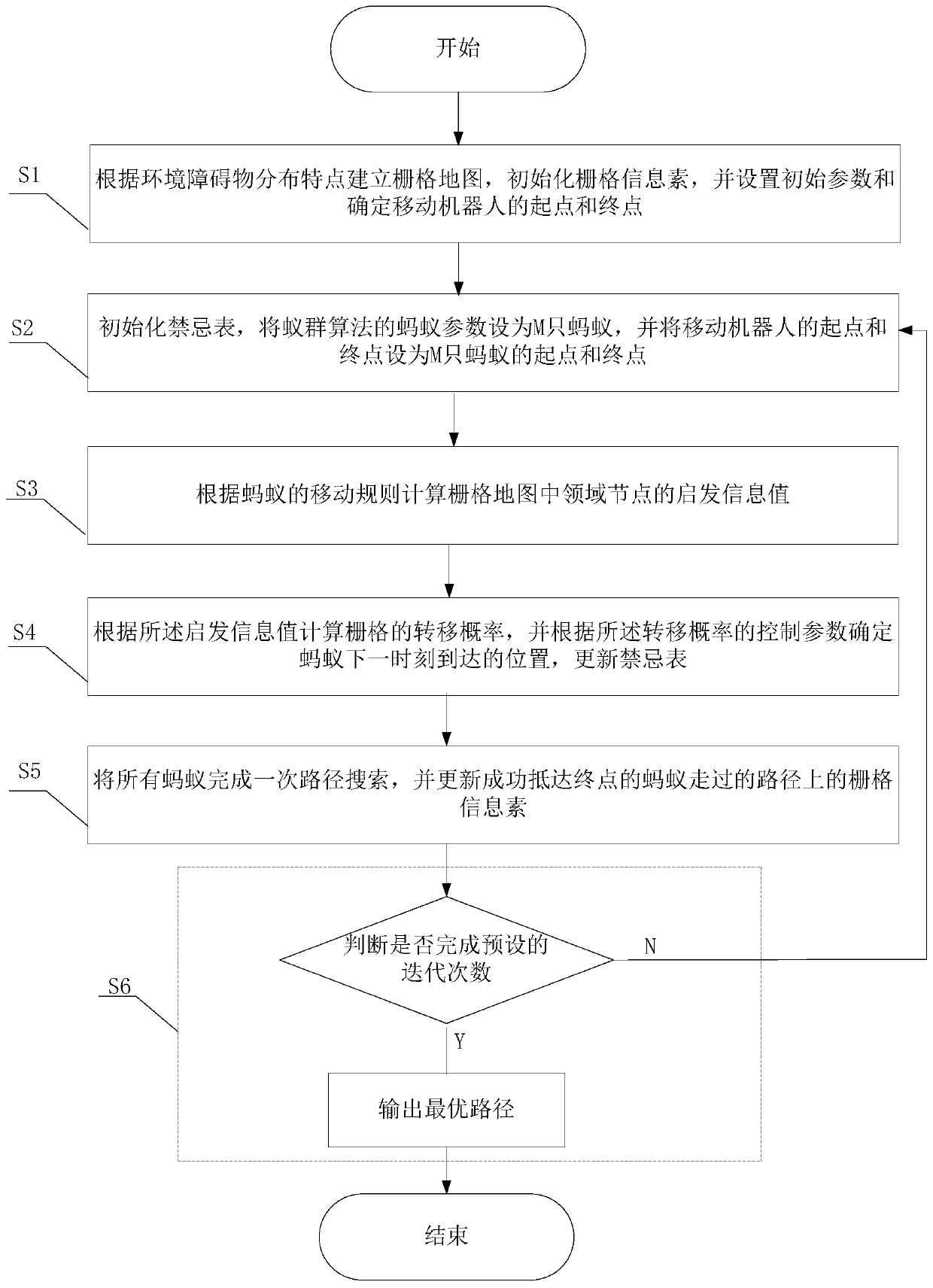

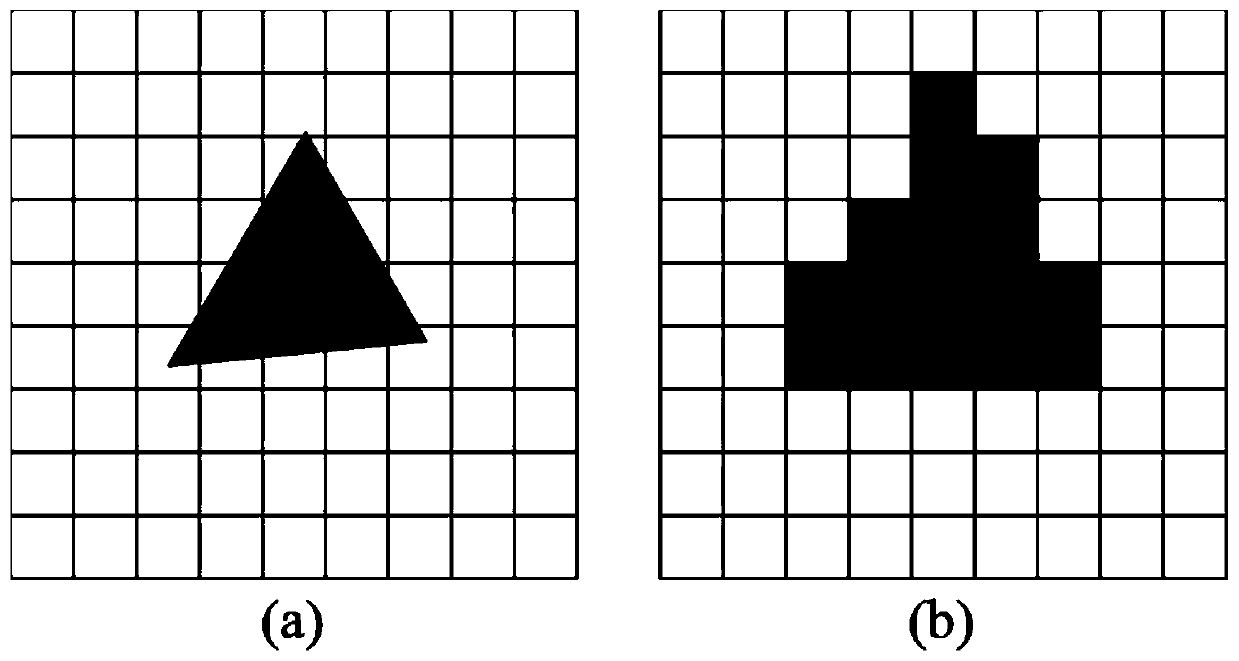

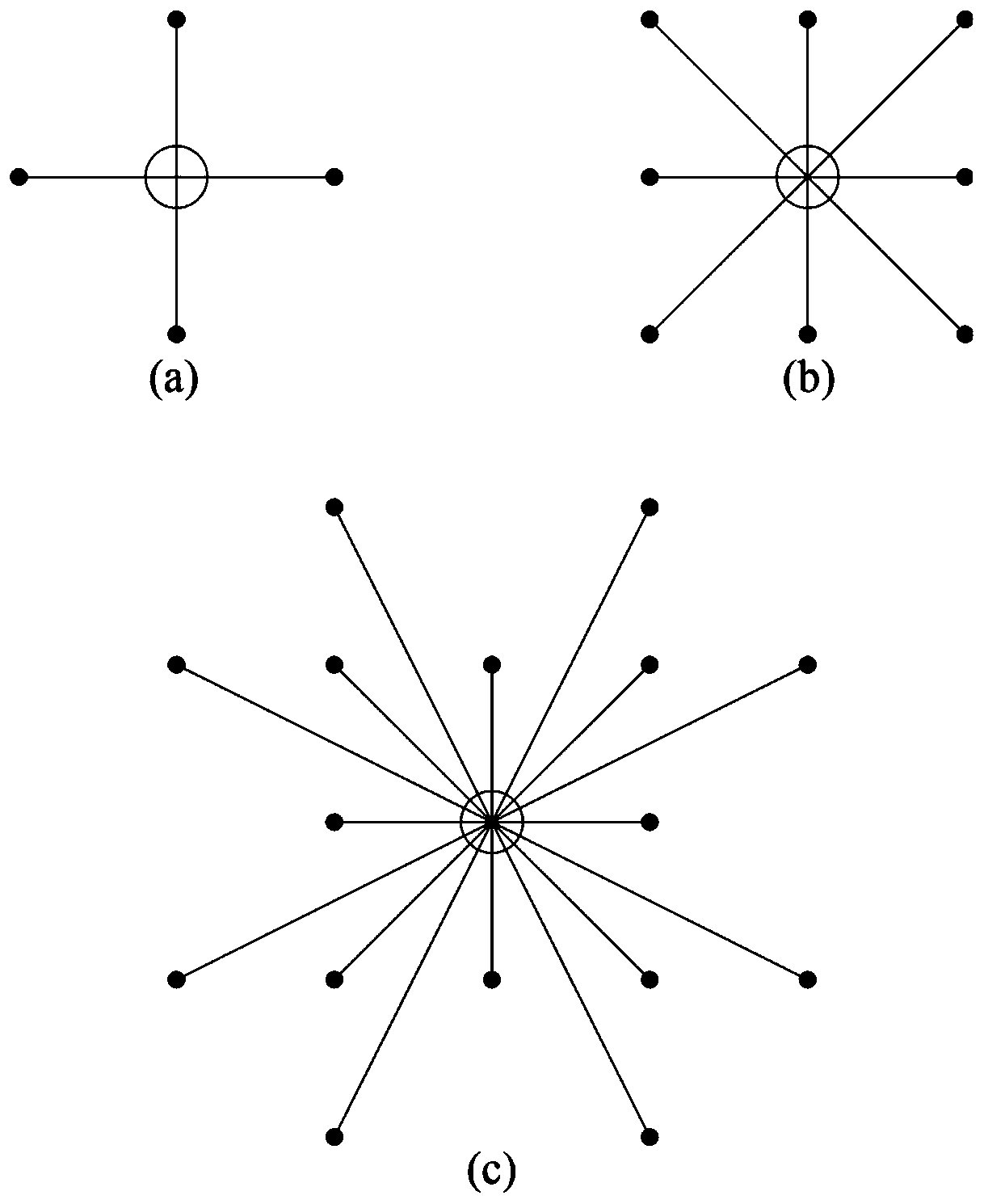

Mobile robot path planning method based on improved ant colony algorithm

ActiveCN110244733AImprove effectivenessMulti-directional choicePosition/course control in two dimensionsRobot planningMobile robots path planning

The invention provides a mobile robot path planning method based on an improved ant colony algorithm. The improved ant colony algorithm with sixteen search directions and twenty-four neighbor nodes is proposed, so that ants have more direction selections and wider search range in a robot planning path searching process, and two heuristic information computing methods based on a vector angle are designed; moreover, the effective search range of the ants in a raster map is controlled by introducing control parameters of transition probability in a transition probability part, an optimal global shortest path can be searched, the search effectiveness of the algorithm can be improved, and the randomness of search is reduced. According to the method, the optimal global shortest path can be searched through the improved ant colony algorithm, the search effectiveness of the algorithm can be improved, the randomness of search is reduced, and a good condition is provided for robot path planning.

Owner:SOUTHWEST JIAOTONG UNIV

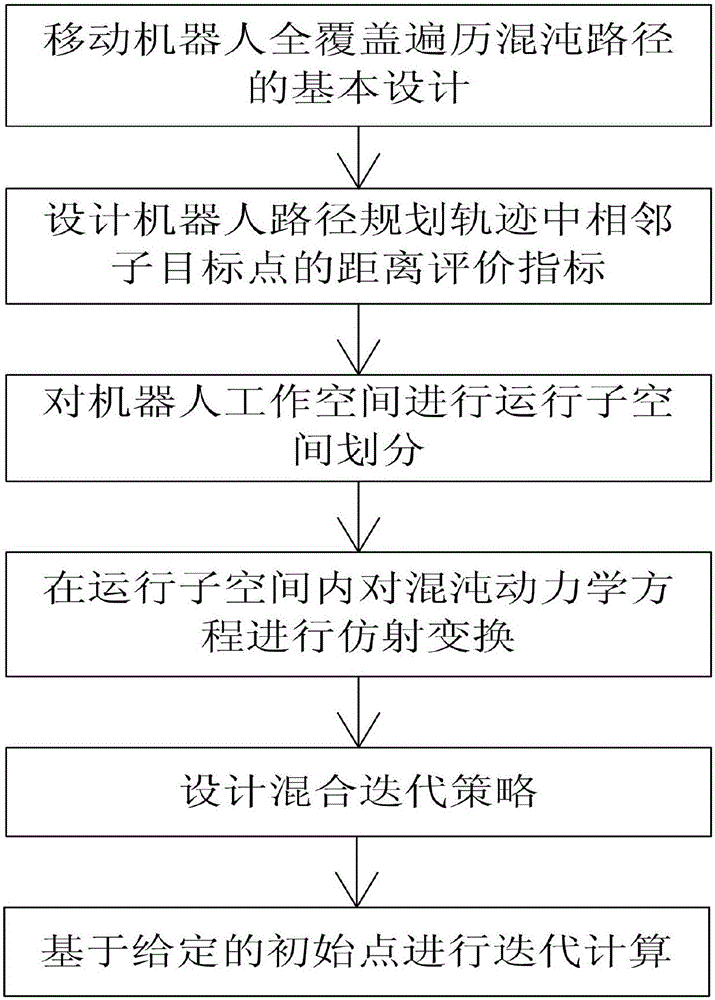

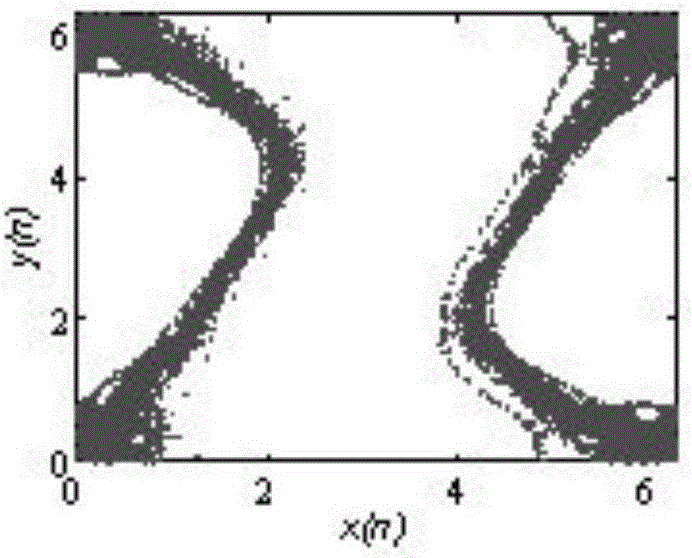

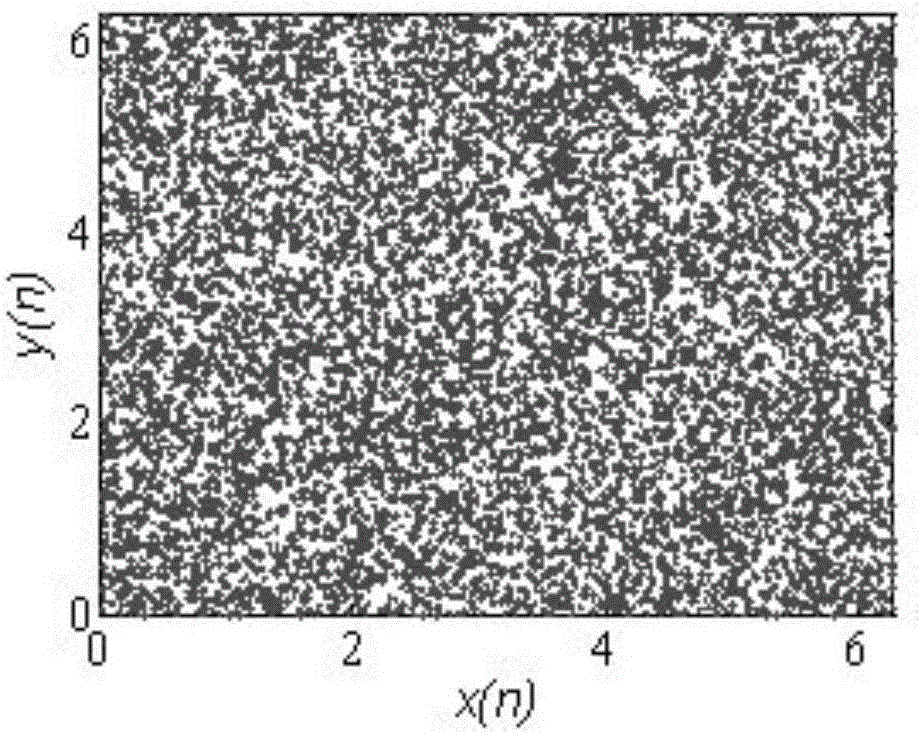

Mobile robot full-coverage traversal chaotic path planning method

InactiveCN105867370AImplement path tracingReduce distancePosition/course control in two dimensionsRobot planningSimulation

The invention discloses a mobile robot full-coverage traversal chaotic path planning method. The method comprises the following steps: carrying out basic design of a mobile robot full-coverage traversal chaotic path; designing a distance evaluation index of adjacent sub-target points in a robot path planning locus; performing operation sub-space division on a work space of a robot; performing affine transformation on a chaotic kinetic equation in operation subspaces; designing a mixed iteration strategy; and carrying out iterative computation based on a given initial point. First of all, a basic chaotic plan planning method is designed, in order to enable the designed chaotic path planning method to be more feasible, then the mixed iteration strategy combining iteration of a whole work area with iteration of the sub-spaces divided by the work area is employed, traversal of the work space is realized, and the chaotic feature of the robot planning locus is maintained basically unchanged, such that the iteration step pitch of the mobile robot is effectively reduced and effective tracking of a robot controller is realized.

Owner:SHANDONG UNIV OF TECH

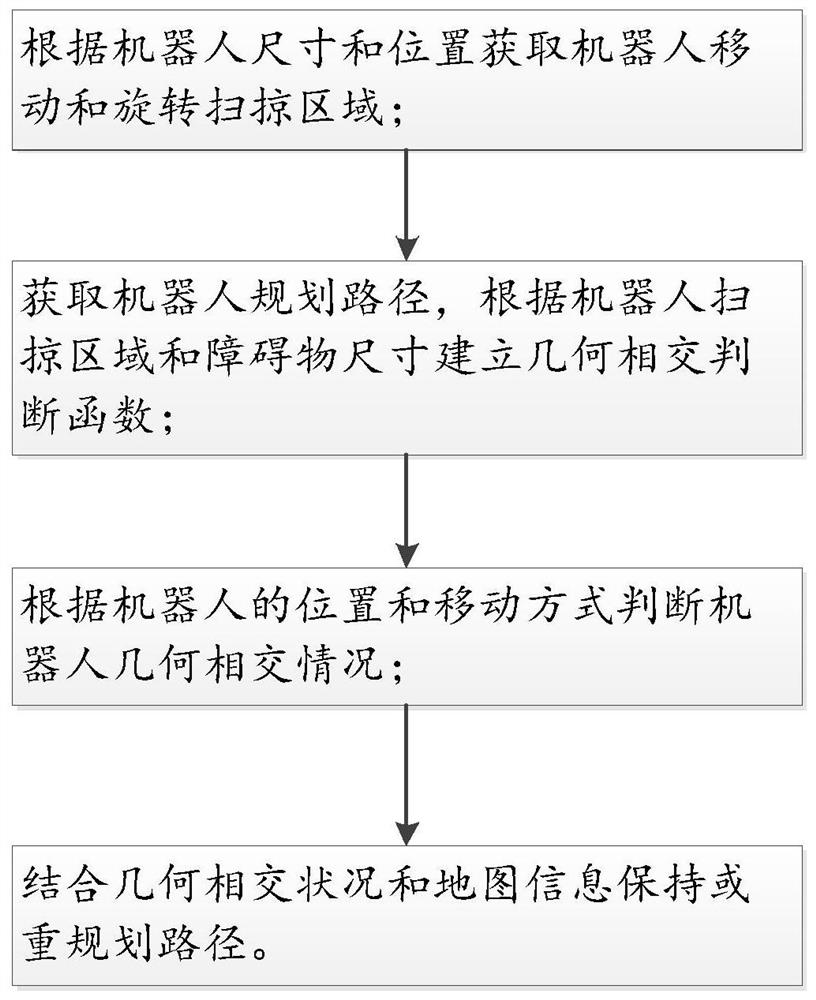

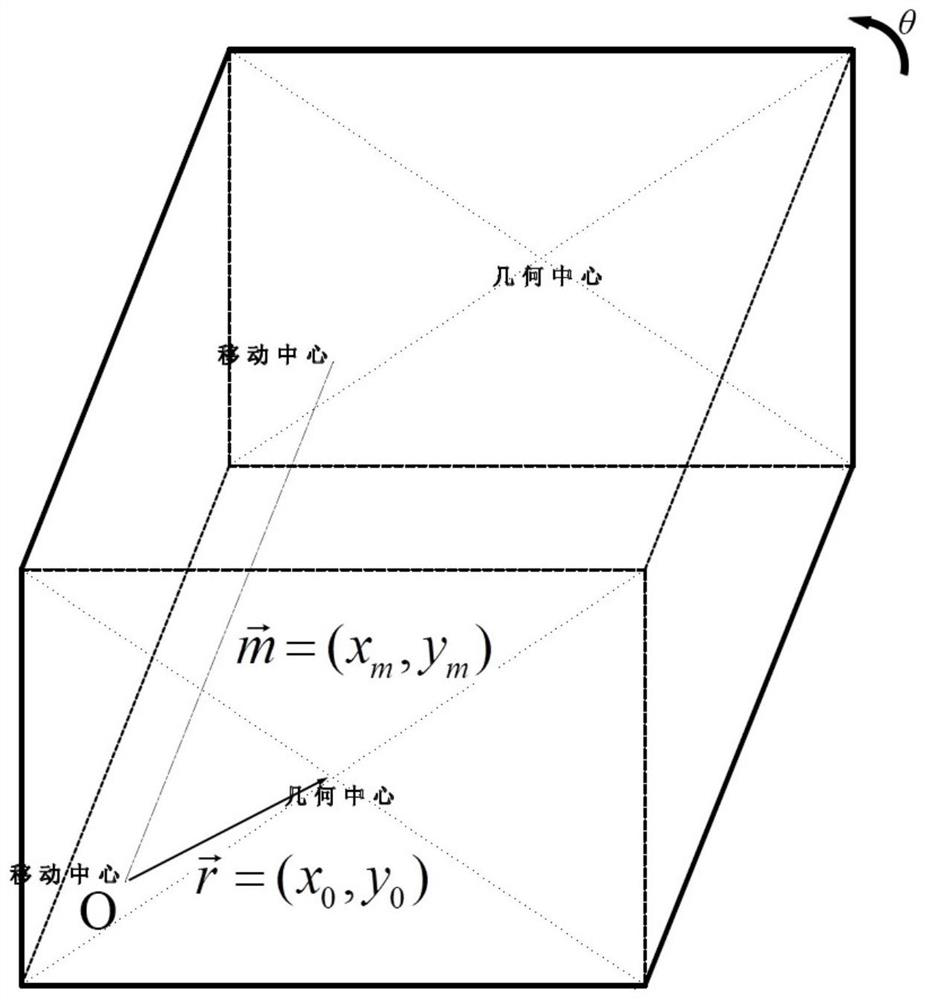

Mobile robot hybrid scheduling method based on topological map

ActiveCN111813124AImprove adaptabilityBreak down barriers to useTotal factory controlPosition/course control in two dimensionsRobot planningHybrid Scheduling

The invention provides a mobile robot hybrid scheduling method and system based on a topological map. The hybrid scheduling method pre-establishes the topological map and acquires size information andposition information of a target robot and an obstacle, and the method comprises the following steps: acquiring a robot moving and rotating sweeping area according to the size and position of the robot; obtaining a robot planning path, and establishing a geometric intersection judgment function according to the robot sweeping area and the obstacle size; judging the geometric intersection condition of the robot according to the position and moving mode of the robot; and maintaining or replanning path by combining geometric intersection condition and map information. According to the robot hybrid scheduling method provided by the invention, the accurate geometric intersection judgment function is established, and the robot scheduling operation is executed through algorithm deep optimizationso that the operand is reduced and the scheduling efficiency is improved on the basis of realizing a high space utilization rate.

Owner:浙江迈睿机器人有限公司

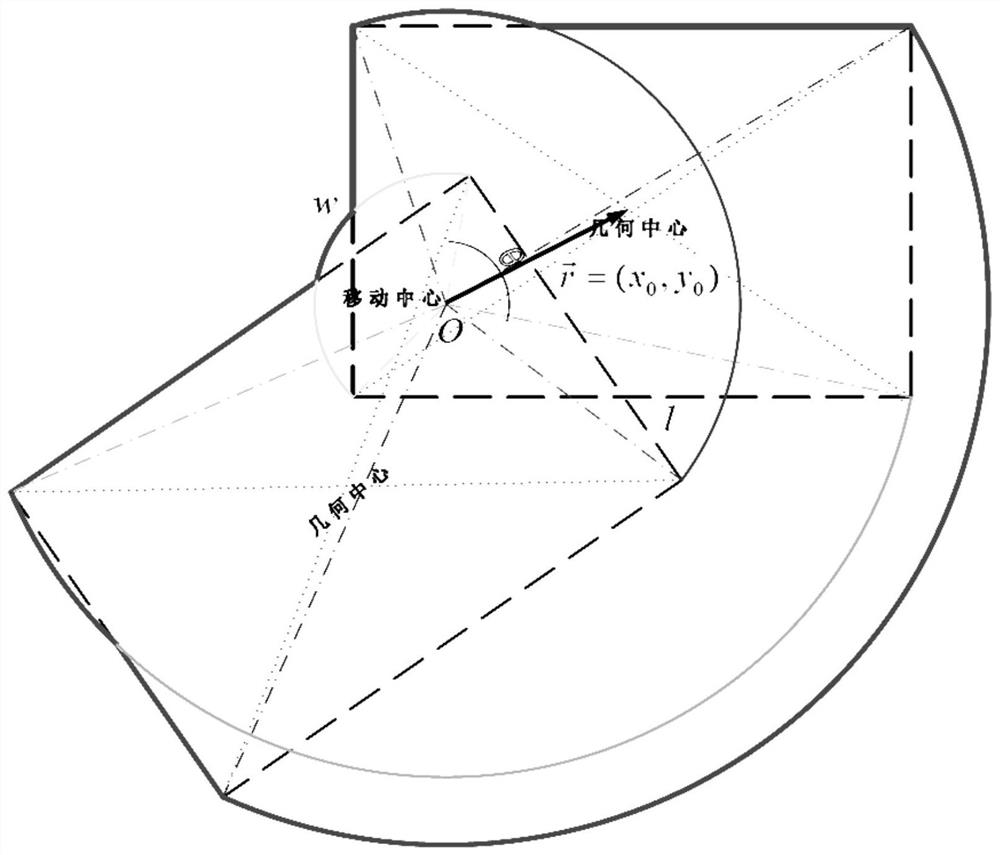

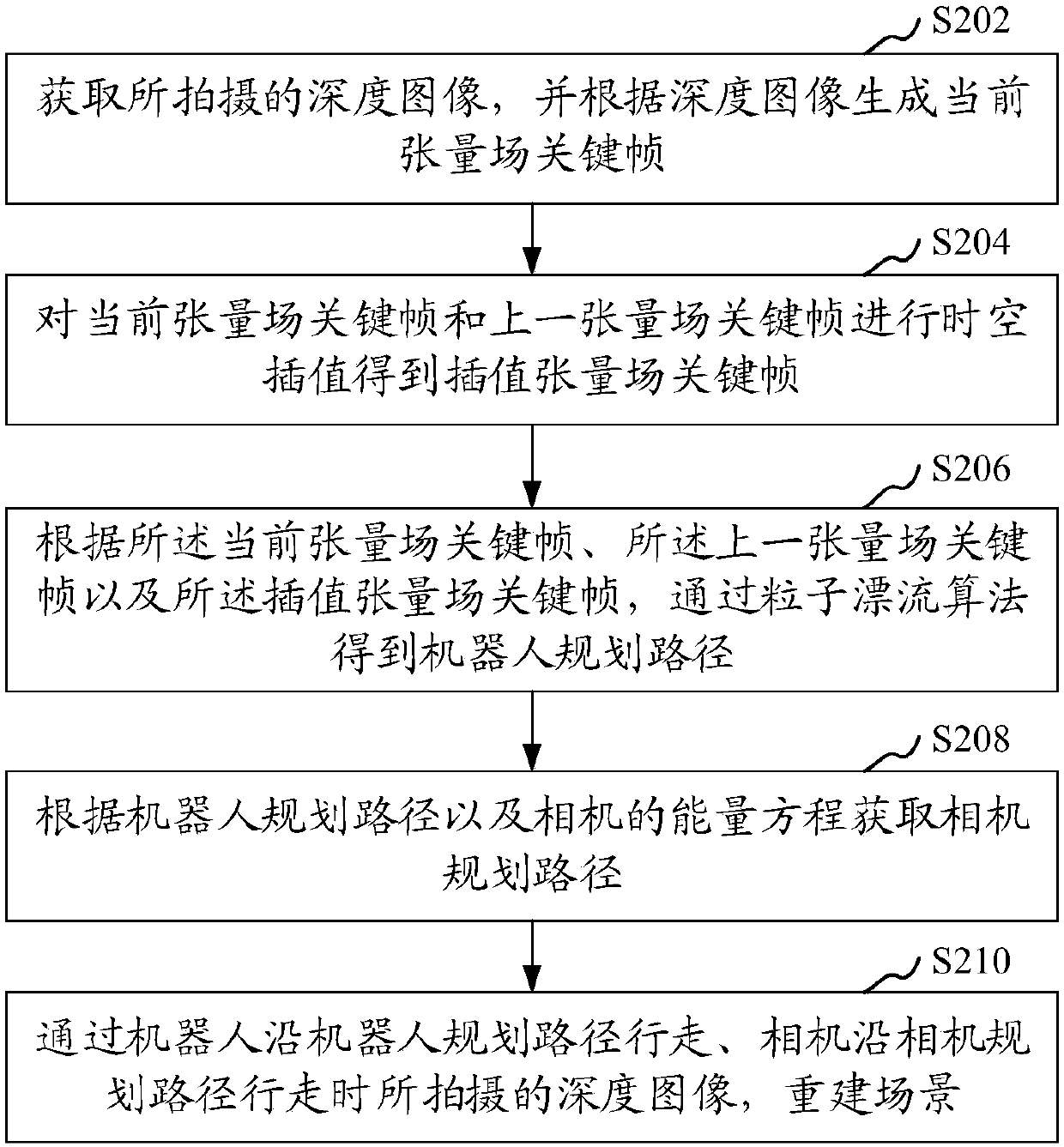

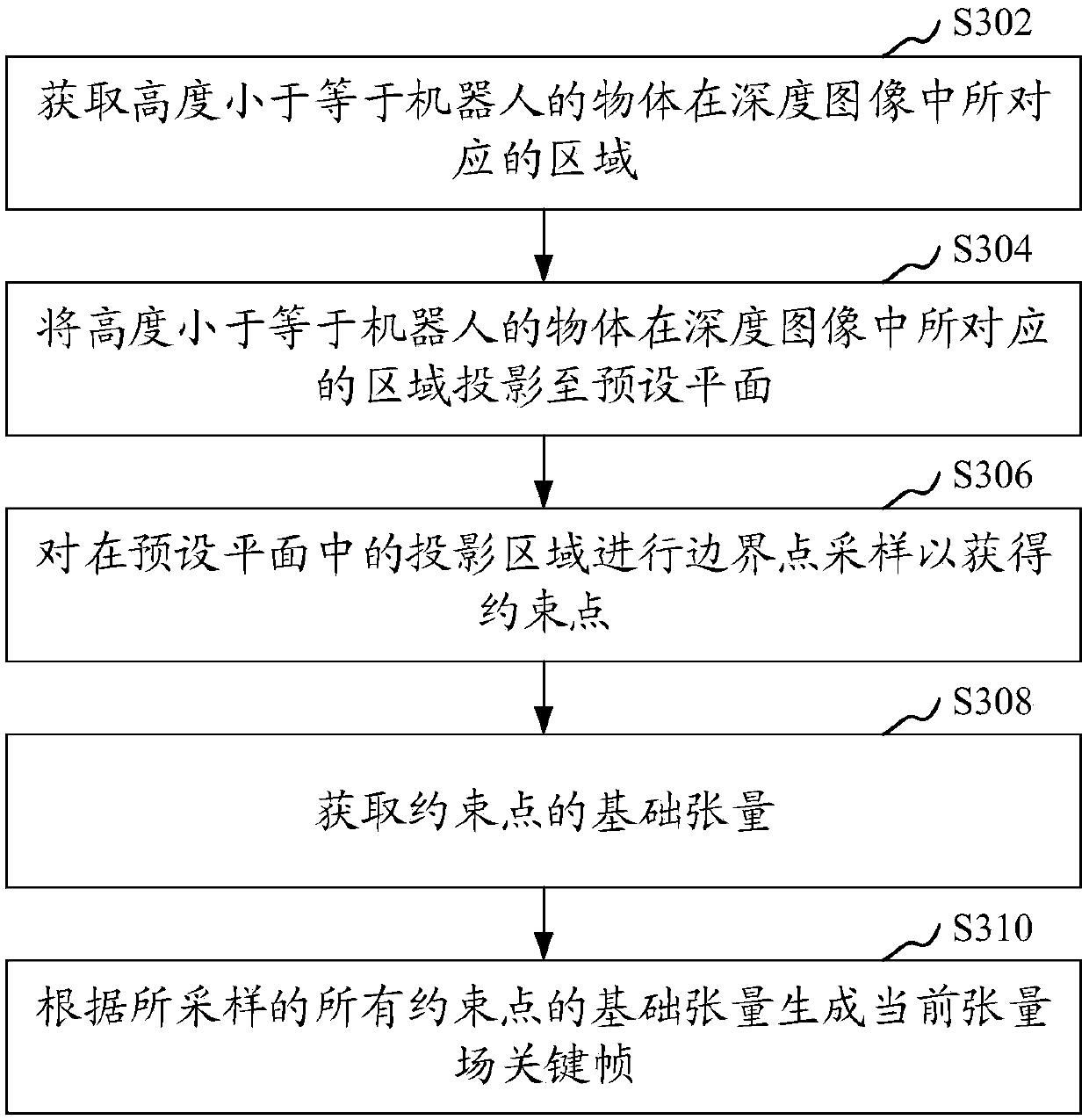

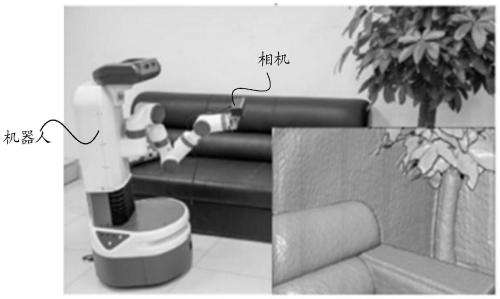

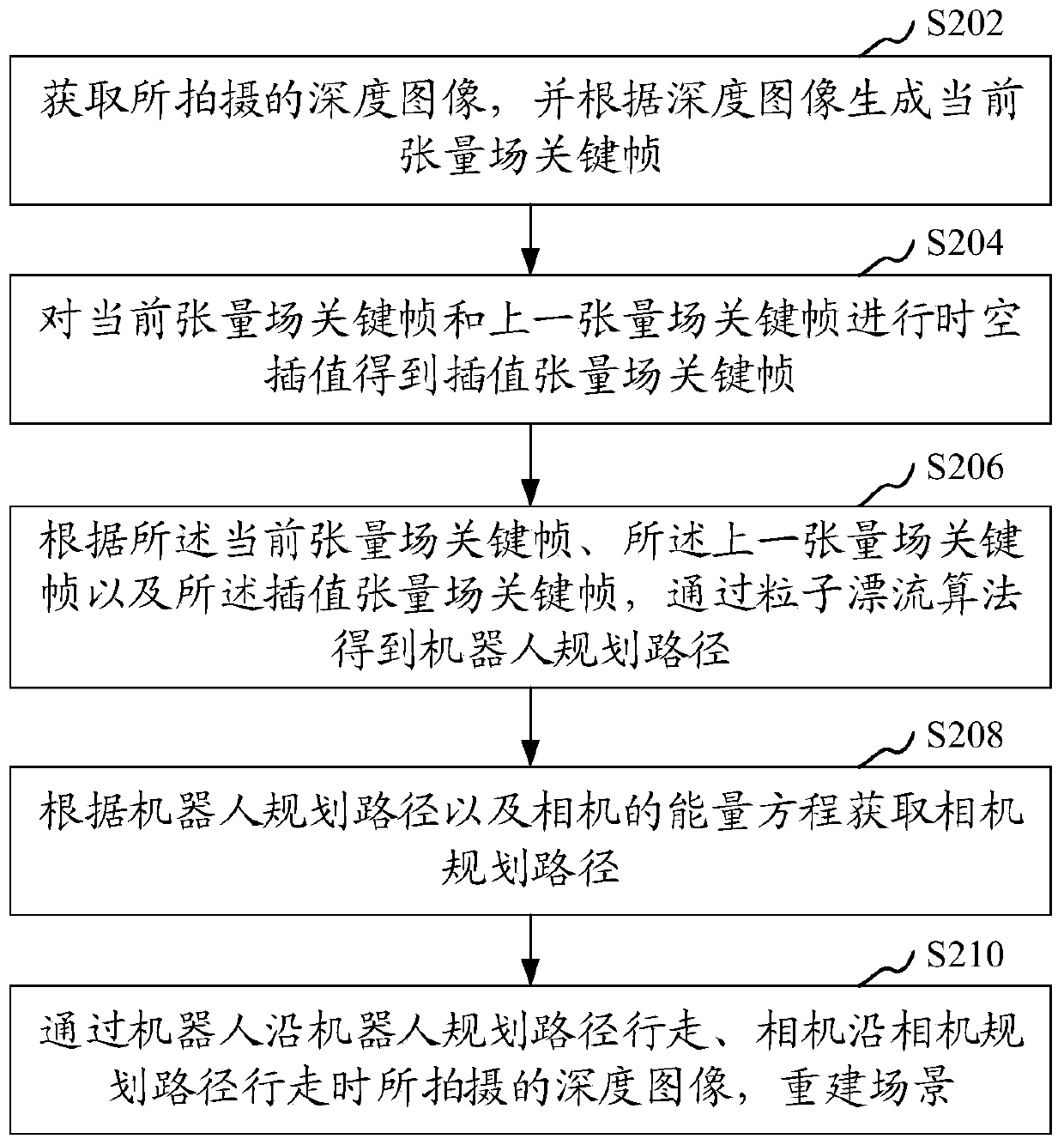

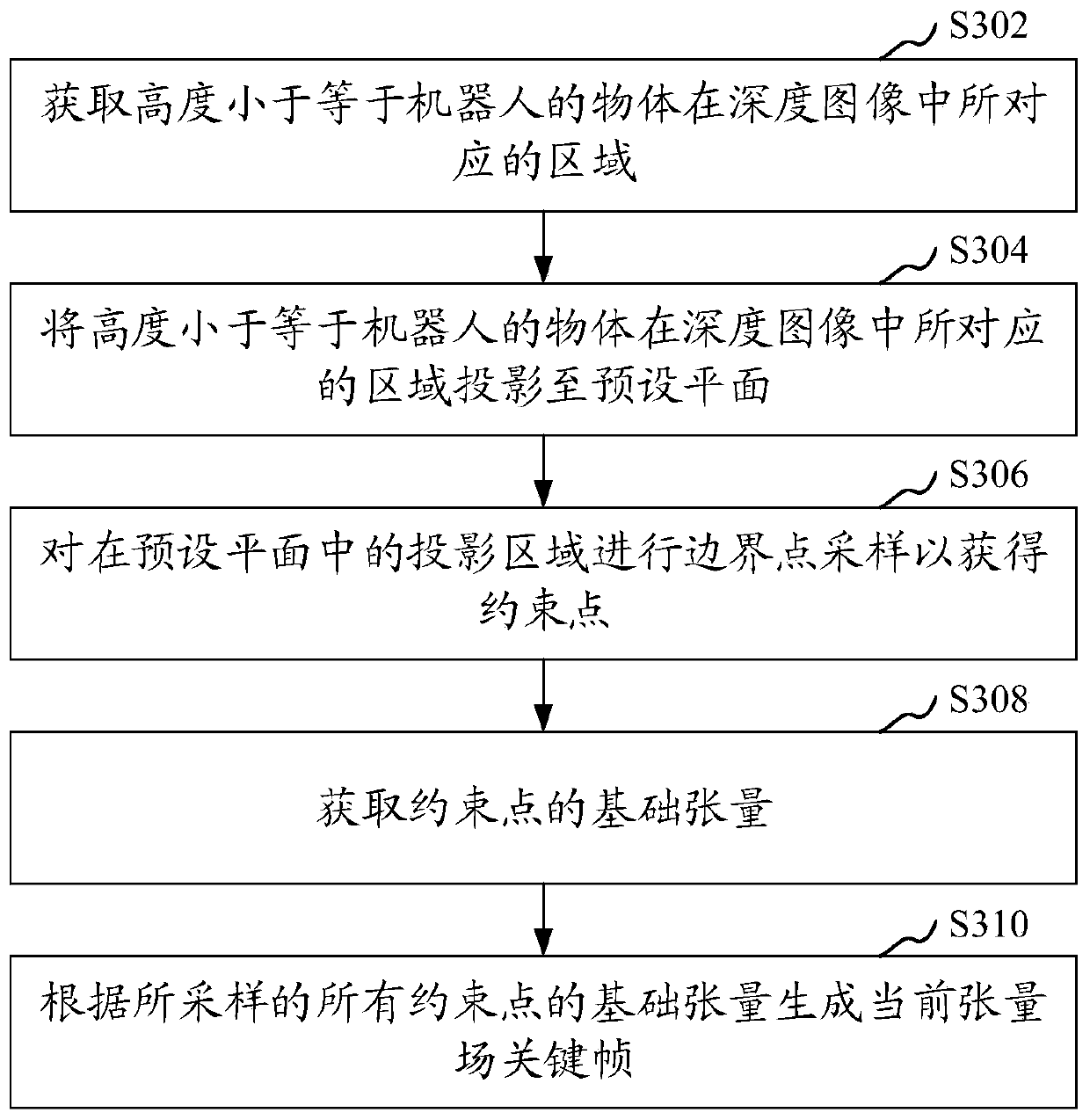

Scene reconstruction method and device, computer equipment, and computer storage medium

ActiveCN107610212ASmooth pathImage enhancementProgramme-controlled manipulatorRobot planningReconstruction method

The invention relates to a scene reconstruction method and device, computer equipment, and a computer storage medium. The method comprises the steps: obtaining a photographed depth image, and generating a current tensor field key frame according to the depth image; carrying out the spatial and temporal interpolation of the current tensor field key frame and a former tensor field key frame, and obtaining an interpolation tensor field key frame; obtaining a robot planning path through a particle drift algorithm; obtaining a camera planning path according to the robot planning path and an energyequation of a camera; and reconstructing a scene through the depth images collected when a robot walks along the robot planning path and the camera walks along the camera planning path. According to the invention, the camera planning path is obtained through the robot planning path and the energy equation of the camera, thereby achieving a purpose of enabling the robot which holds the camera to carry out the exploration and reconstruction of a complex scene at the same time.

Owner:SHENZHEN UNIV

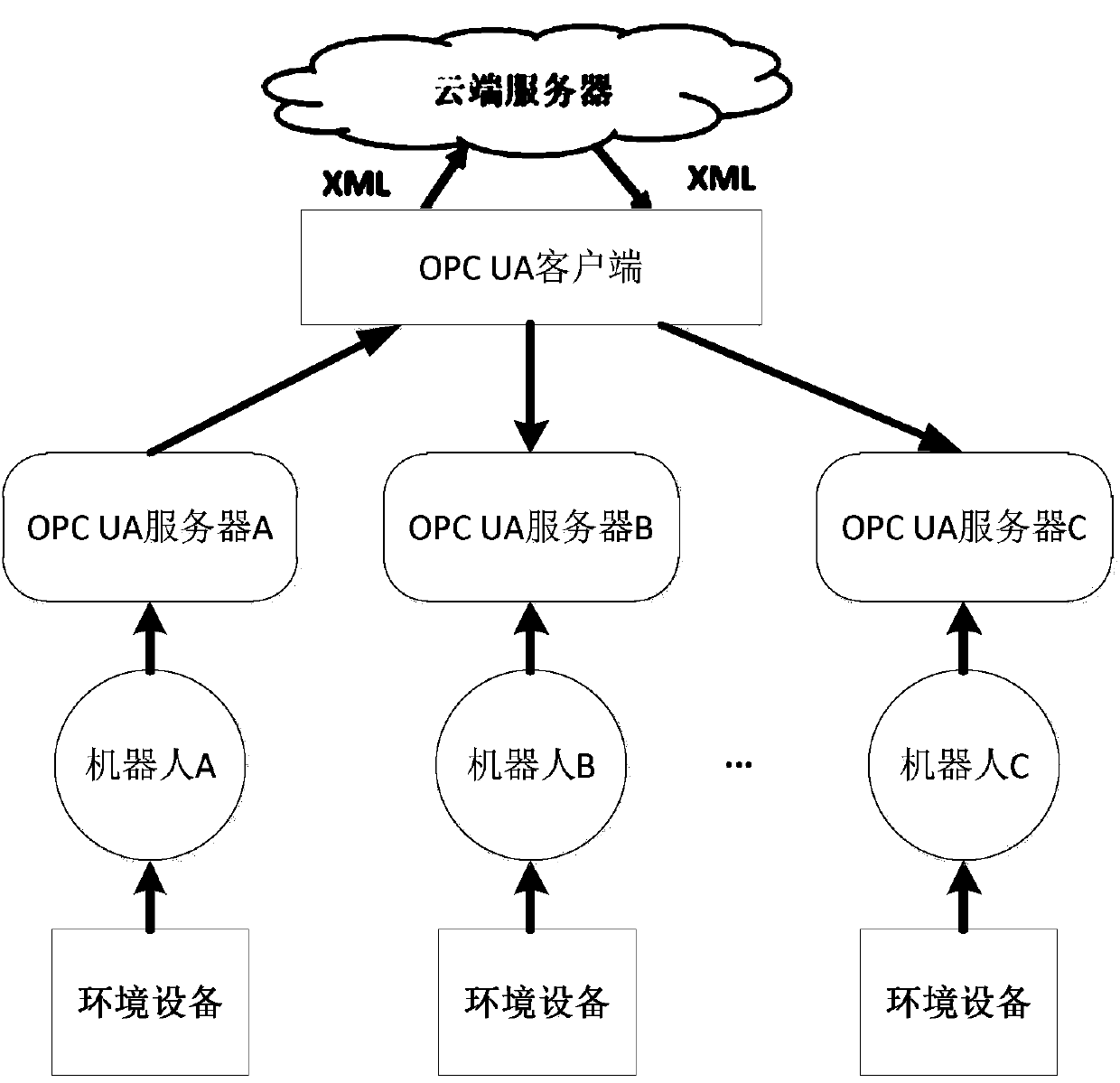

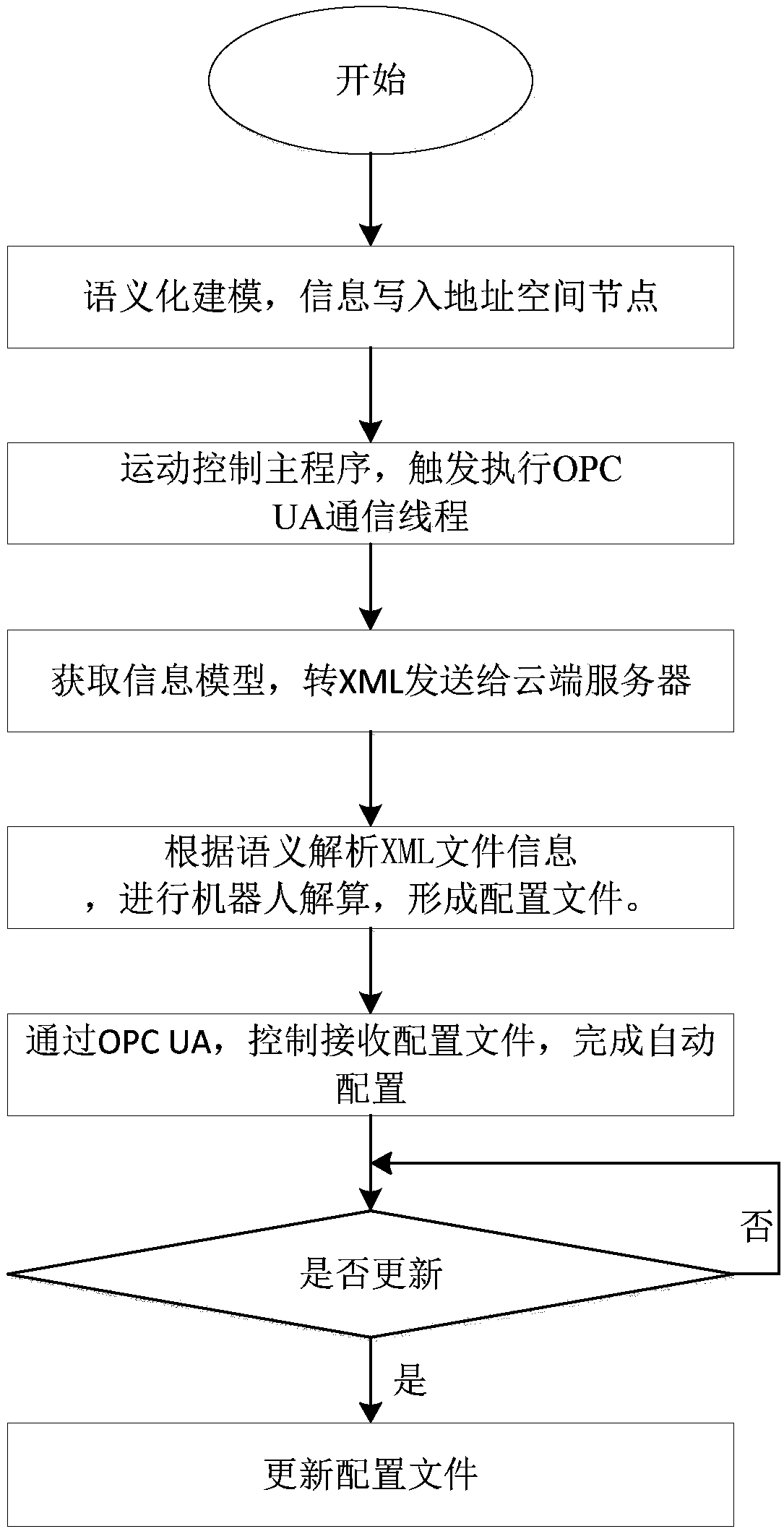

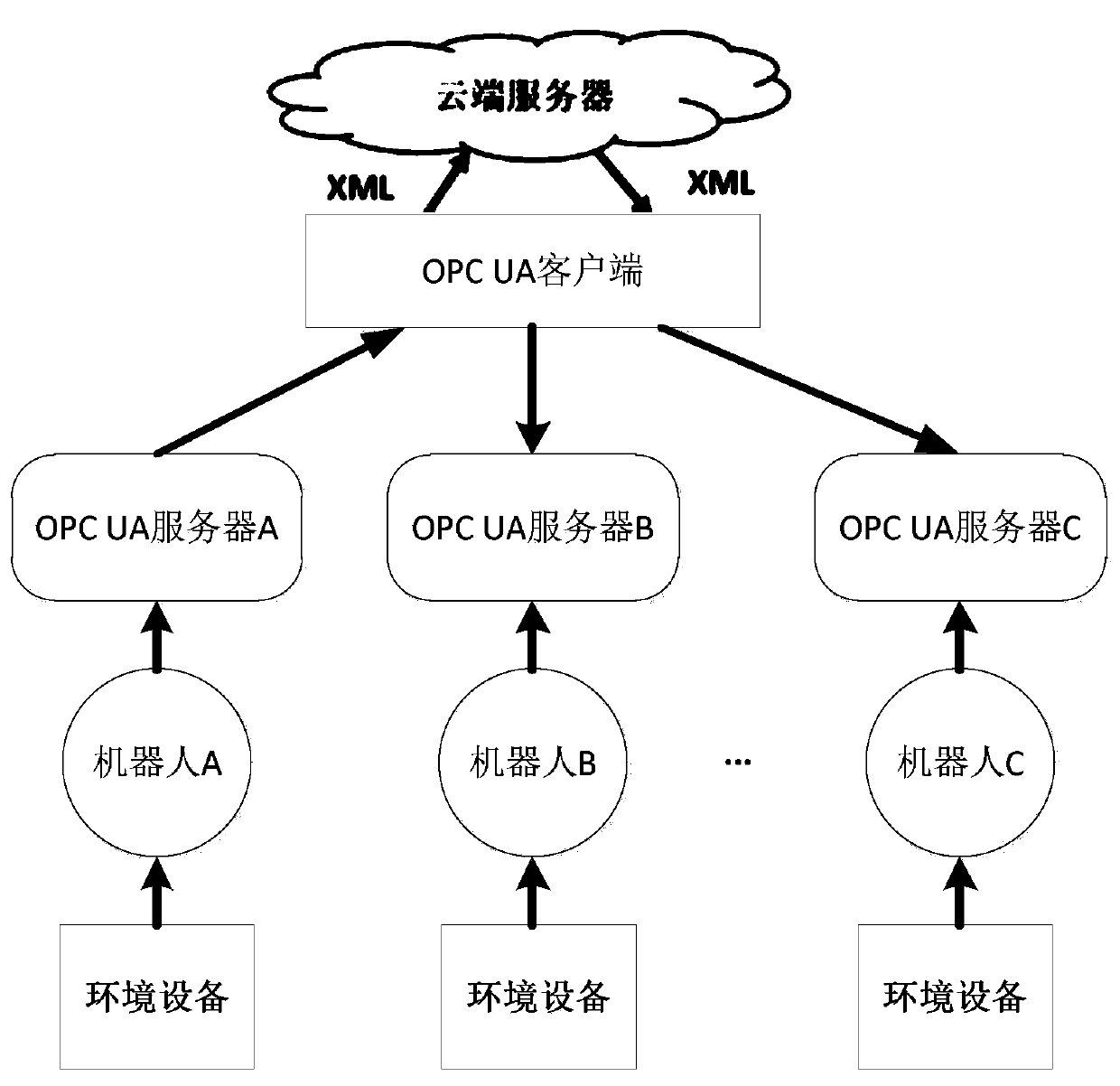

Method for preventing robot from repetitively demonstrating

InactiveCN107838922AAvoid the problem of repeated teachingSave manpower and material resourcesProgramme-controlled manipulatorTransmissionInformation repositoryRobot planning

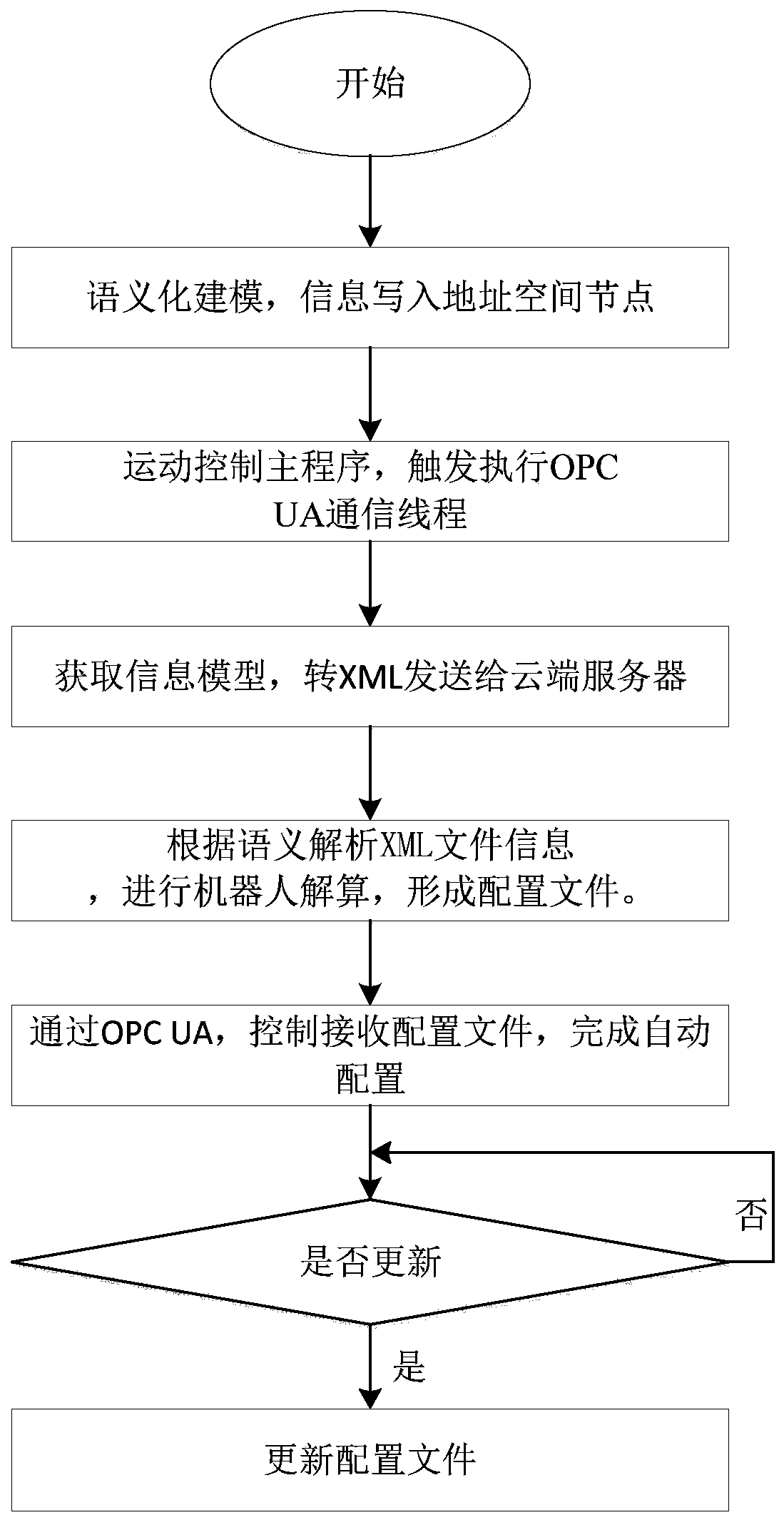

The invention relates to a method for preventing a robot from repetitively demonstrating. The method is characterized by comprising the following steps of: performing semantic modeling on environmentequipment information, robot information and demonstrating information, and writing information into a node of an OPC UA server-side address space; enabling an OPC UA server-side to visit the node ofthe OPC UA server-side address space, analyzing semantic modeling information and converting the semantic modeling information into an XML file to send to a cloud-side server, enabling the cloud-sideserver to analyze the XML file, calculating robot behaviors according to a robot body model information base to obtain a robot planning instruction, thereby forming a motion track point configurationfile; enabling the OPC UA server-side to receive the motion track point configuration file, and transmitting the motion track point configuration file to one or more robot controllers through an OPC UA communication stack, and enabling the robot to perform operation according to an obtained motion track point. The method adopts a semantic modeling mode to encapsulate equipment model information and working description information, realizes intercommunication and interconnection among equipment, quickly completes configuration, synchronizes equipment replacement and function update through OPCUA, and greatly improves application efficiency.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

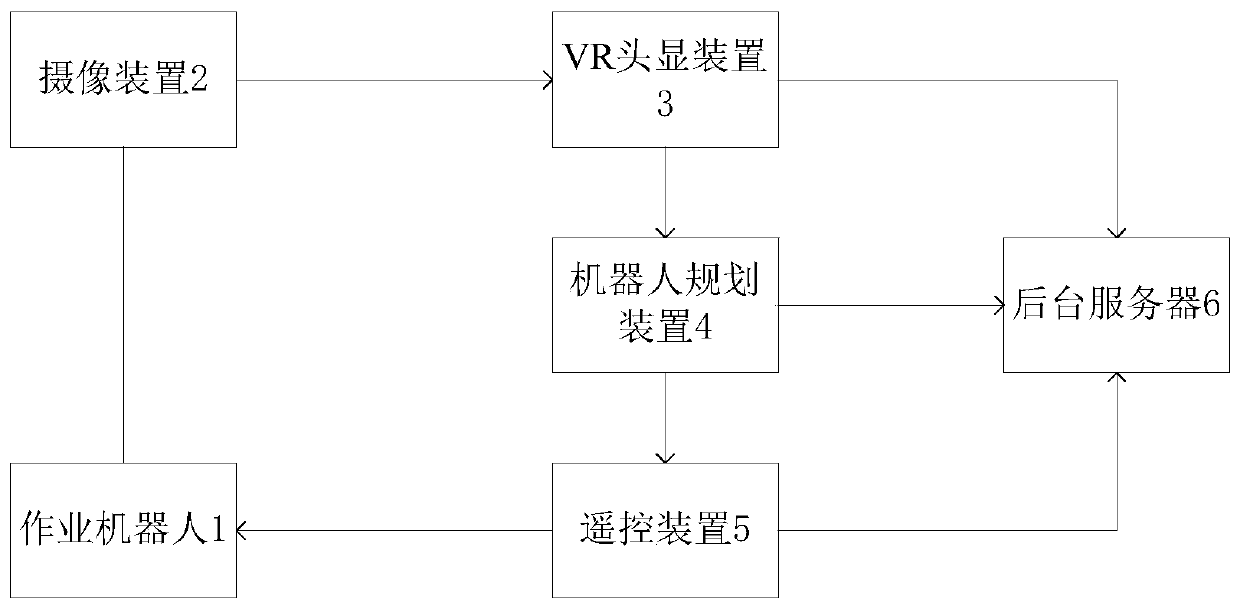

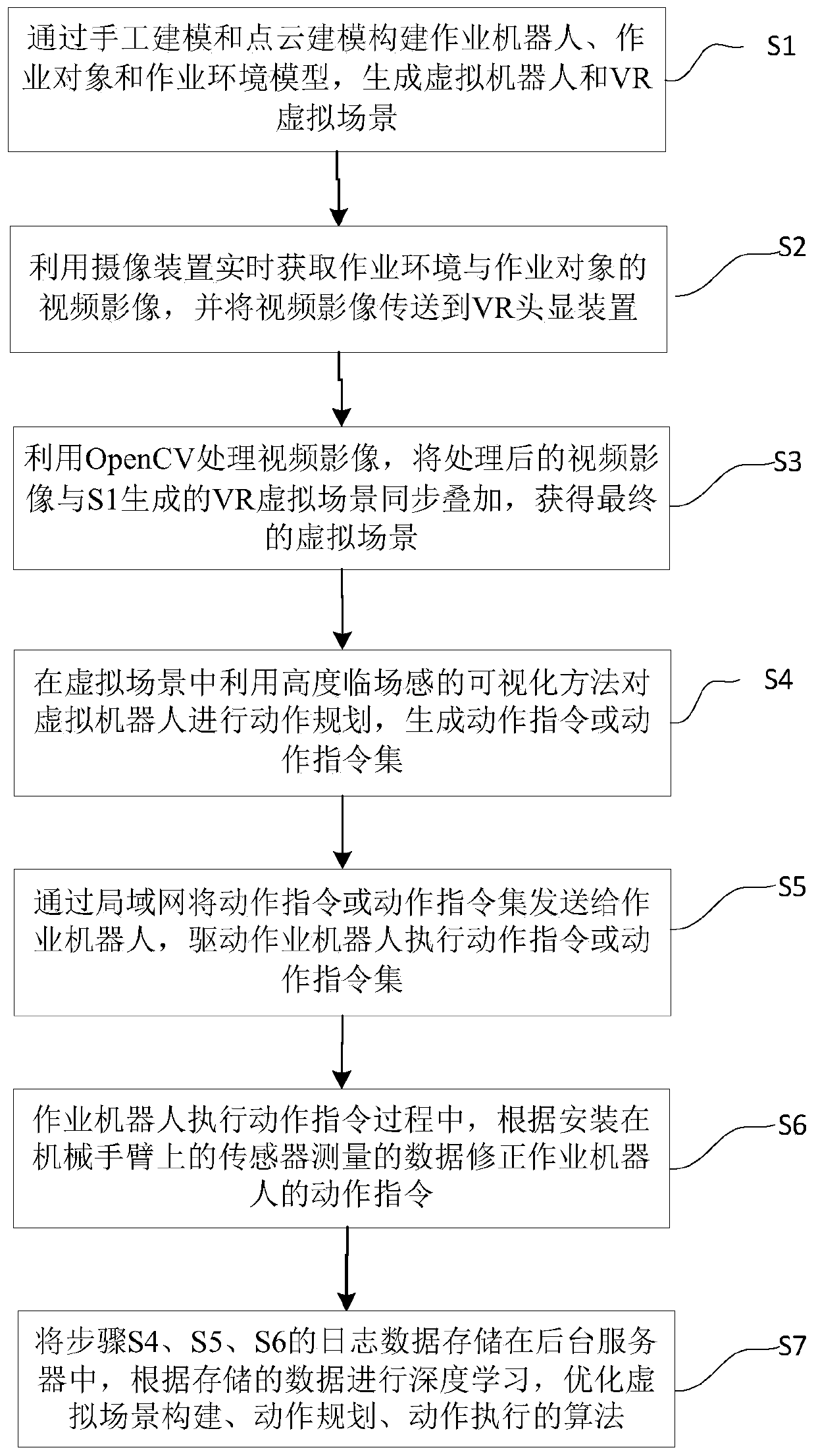

Robot remote operating system and method based on VR

ActiveCN110682291AAvoid misuseImprove securityProgramme-controlled manipulatorRobot planningSimulation

The invention discloses a robot remote operating system and method based on VR. The system comprises an operation robot, a camera shooting device, a VR head display device, a robot planning device, aremote control device and a background server. The method comprises the following steps that firstly, a virtual robot and a VR virtual scene are constructed; secondly, the camera shooting device is utilized for obtaining video images of the operation environment and an operation target in real time; thirdly, the video images and the VR virtual scene are synchronously overlapped; fourthly, action planning is conducted on the virtual robot in the virtual scene; fifthly, the operation robot is controlled to execute the actions; sixthly, the robot actions are corrected according to sensor data; and seventhly, log data in the fourth step, the fifth step and the sixth step are stored, and deep learning is conducted. The system and method have higher flexibility, safety and precision, manual workcan be replaced for electrification work, electrification work intelligence is achieved, the electrification work efficiency is improved, and personal risks of related operators are reduced.

Owner:JIANGSU ELECTRIC POWER CO +1

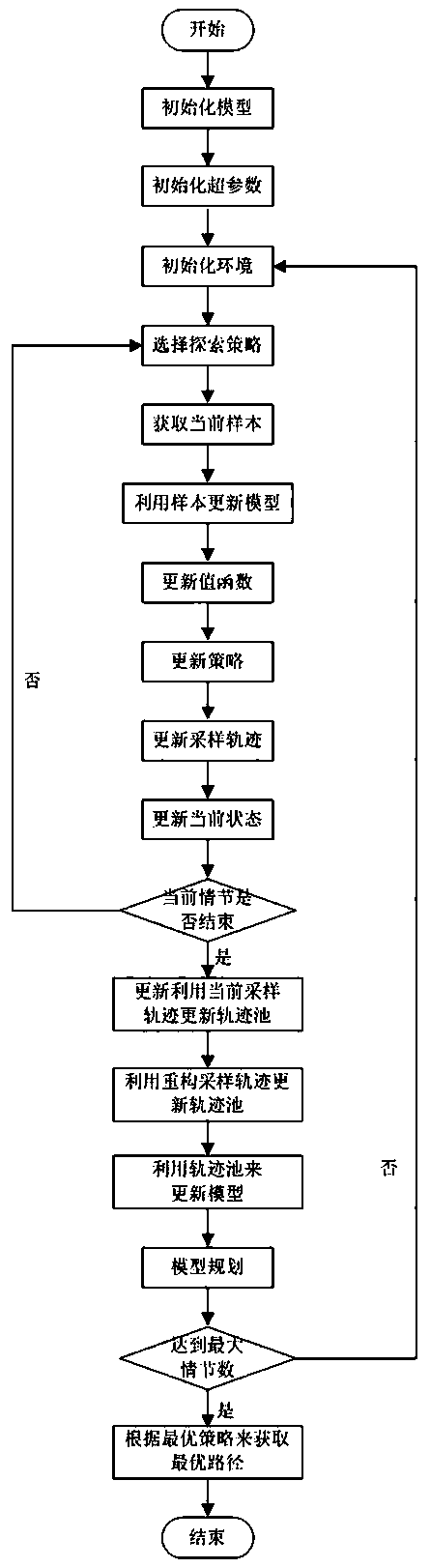

Cleaning robot optimal path planning method based on approximate model multi-step optimization

ActiveCN108762249AWell formedEnhance expressive abilityPosition/course control in two dimensionsCurrent sampleSingle sample

The invention discloses a cleaning robot optimal path planning method based on approximate model multi-step optimization. The method comprises steps: a model, hyperparameters and an environment are initialized; an exploration strategy is selected; the model is updated with the current sample; a value function, a strategy and the current state are updated; whether the current plot is ended is judged and further, the current sampling trajectory is used to update a trajectory pool; a reconstructed sampling trajectory is used to update the trajectory pool; all trajectories in the trajectory pool are used to update the model; the model is adopted for planning; whether to reach the maximum plot number is judged; and finally, according to a learnt optimal strategy, the optimal cleaning robot planning path is acquired. Through adopting the sampling trajectory and the single sample to update the model, the model learning precision is improved; the model is then used for planning, the learning speeds of the value function, the strategy and the whole algorithm are improved; and the sample utilization efficiency is also improved, and thus, the optimal cleaning robot planning path is acquired by adopting the fewer samples in the shorter time.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

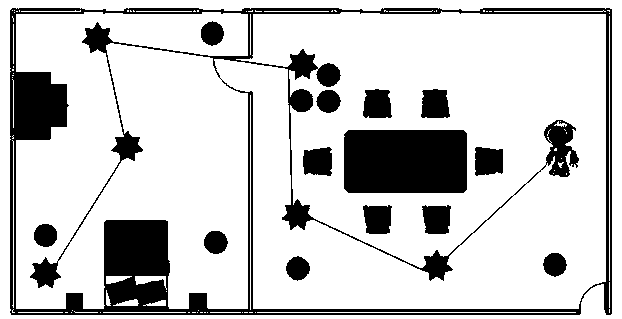

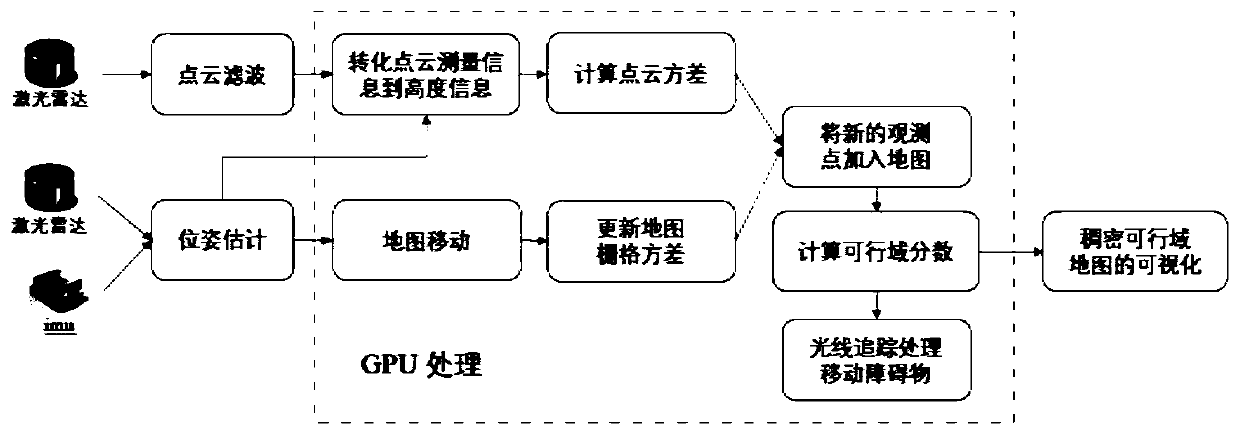

Dense height map construction method suitable for leg-foot robot planning

ActiveCN111596665AEasy to planEasy to handlePosition/course control in two dimensionsRobot planningHeight map

The invention discloses a dense height map construction method, and belongs to the technical field of dense height map construction. The construction method specifically comprises the following steps:using the Gaussian distribution model to estimate the measurement value of the laser radar, and mapping the same to corresponding grids of a local map so as to perform multi-frame data fusion; updating map grid covariance according to the robot pose information, correspondingly moving the local map, and clearing dynamic obstacles so as to form a complete local dense map. The method overcomes thedefects that an existing dense map is large in data size, large in construction calculation amount and not timely in updating, has the advantages of being convenient to construct, high in constructionprecision and the like, can complete real-time construction, and can be directly used for navigation tasks of the legged robot.

Owner:ZHEJIANG UNIV

Robot trajectory planning method and system

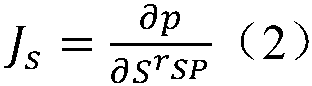

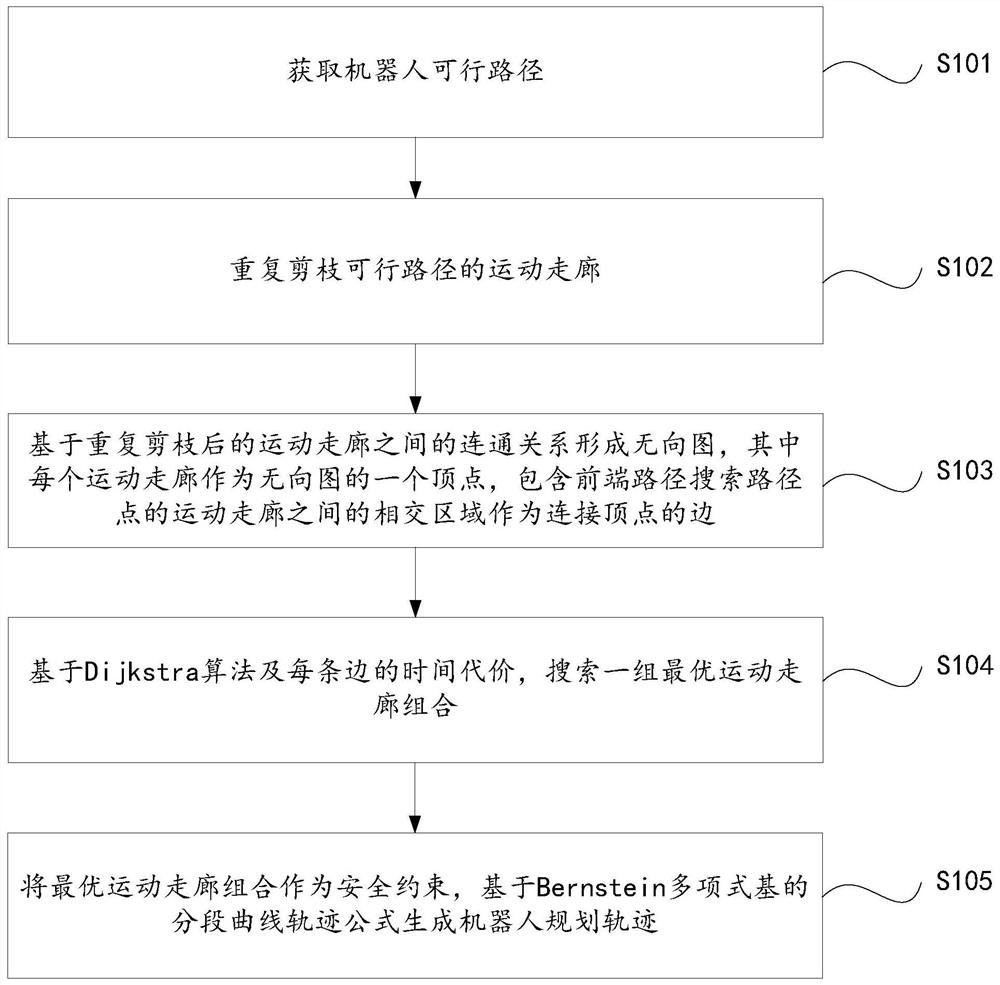

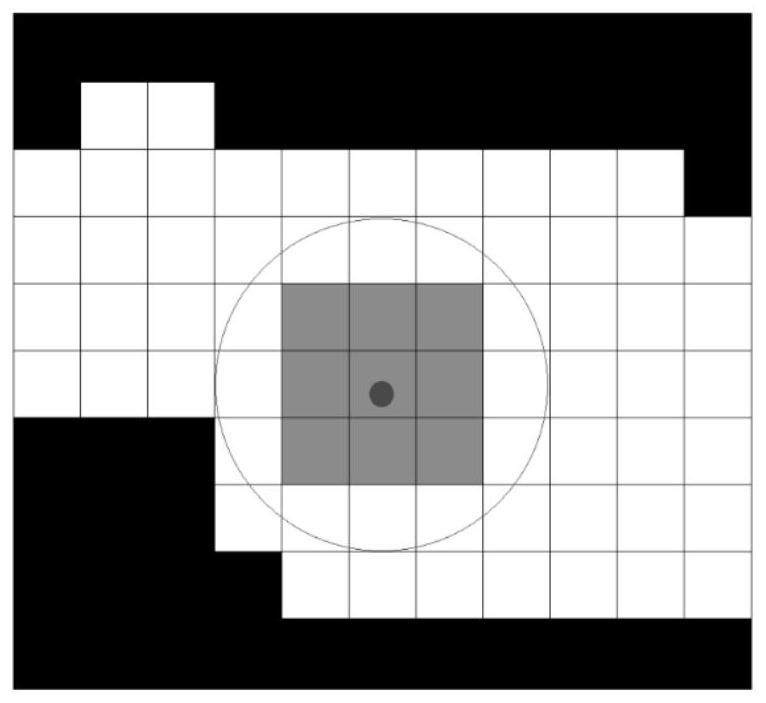

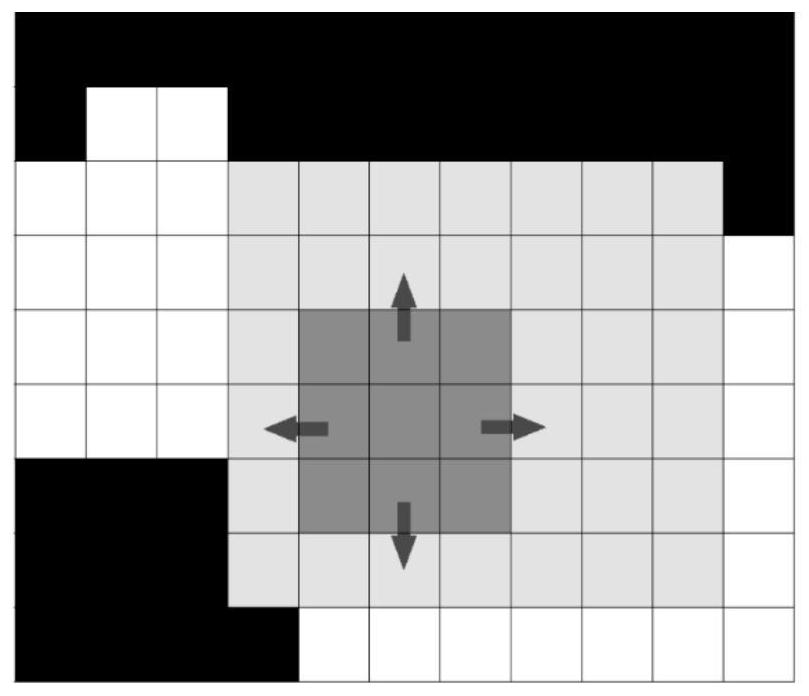

ActiveCN112129296AReduce the numberThe number of optimization parameters is smallNavigational calculation instrumentsForecastingUndirected graphRobot planning

The invention belongs to the field of robot trajectory planning, and provides a robot trajectory planning method and system. The robot trajectory planning method comprises the steps that a feasible path of a robot is acquired; motion corridors of the feasible path are pruned repeatedly; an undirected graph is formed based on the communication relation between the motion corridors obtained after repeated pruning, wherein each motion corridor serves as a vertex of the undirected graph, and intersection areas between the motion corridors containing front-end path search path points serve as edgesconnecting the vertexes; based on a Dijkstra algorithm and the time cost of each edge, a set of optimal motion corridor combination is searched for; and the optimal motion corridor combination servesas a safety constraint, and a robot planning trajectory is generated based on a Bernstein polynomial-based piecewise curve trajectory formula.

Owner:SHANDONG UNIV

Vision measurement, path planning and GNC integrated simulation system for space robot

InactiveCN101726296BPredict interference in real timeAdaptive control abilityInstruments for comonautical navigationImaging processingRobot planning

The invention relates to a vision measurement, path planning and GNC integrated simulation system for a space robot, which comprises an image processing and pose measuring module 1, a space robot planning and control module 2, a target controller module 3, a system dynamic model module 4, a system 3D geometric model module 7, a binocular camera simulation imaging module 6, a three-dimensional calibration module 5 and the like. The system integrates image processing and pose measurement, GNC algorithm, path planning, control, dynamics and the like, so that the closed-loop simulation and verification of all key algorithms in the process of tracking, approaching and capturing non-cooperative targets by the space robot can be performed on an independent PC. The system does not need to adopt real measurement equipment, a space robot system and targets, and is low in cost, good in safety and flexibility and easy to implement; and the system is good in expandability, and the closed-loop simulation and verification of cameras (installation positions and viewing angles) and space robots (kinematic and dynamic parameters) with different parameters can be implemented by modifying the parameters.

Owner:HARBIN INST OF TECH

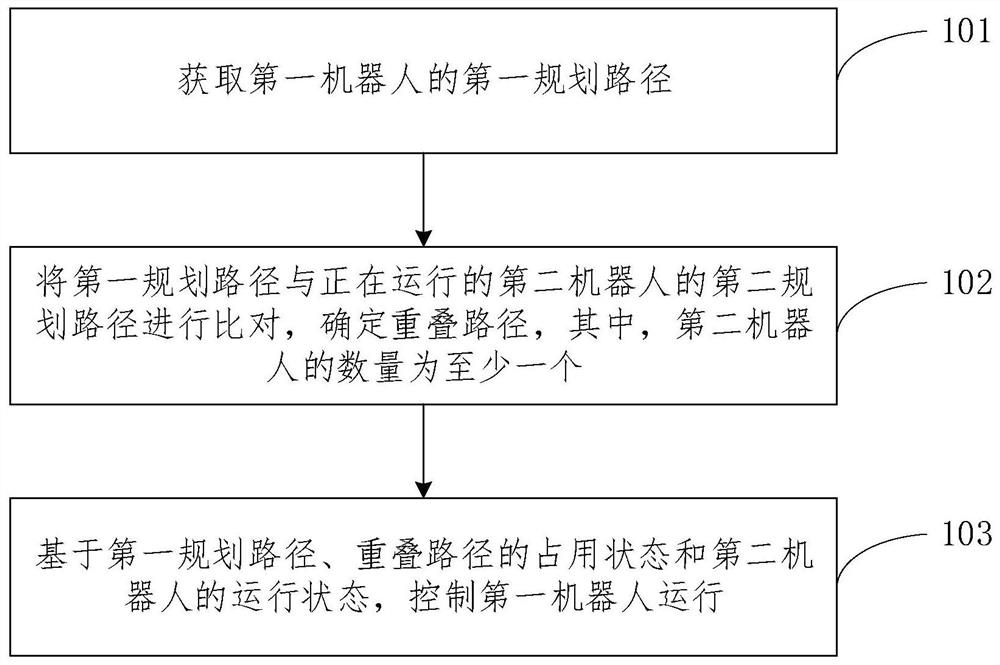

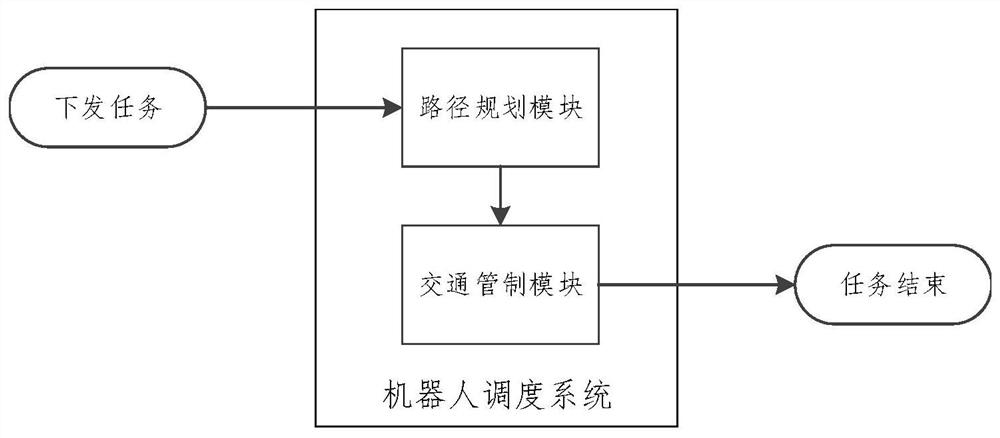

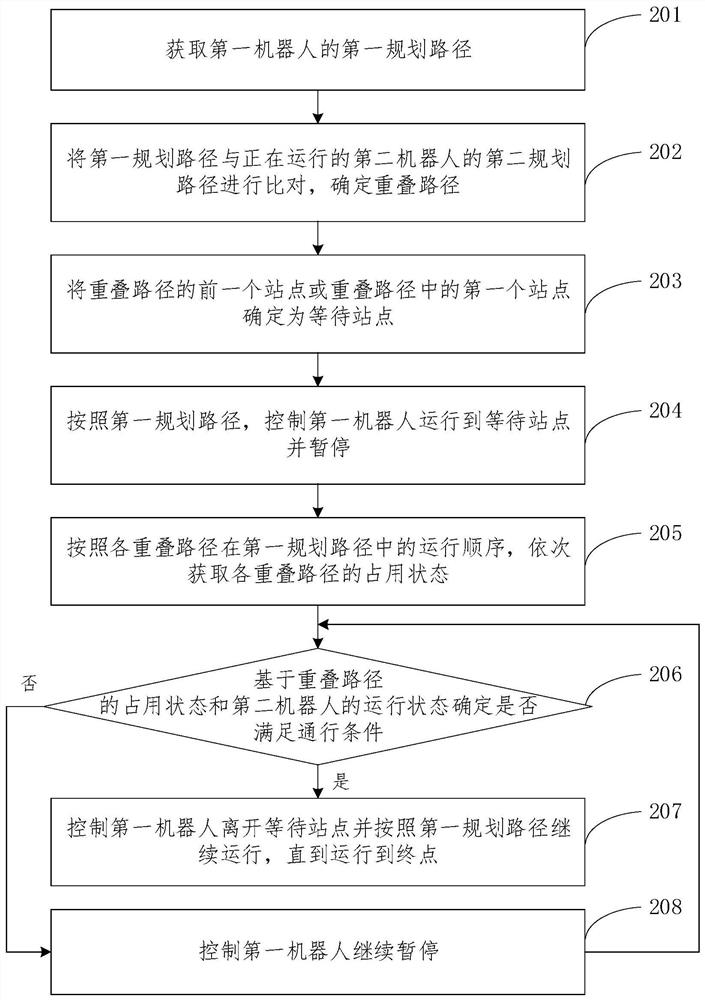

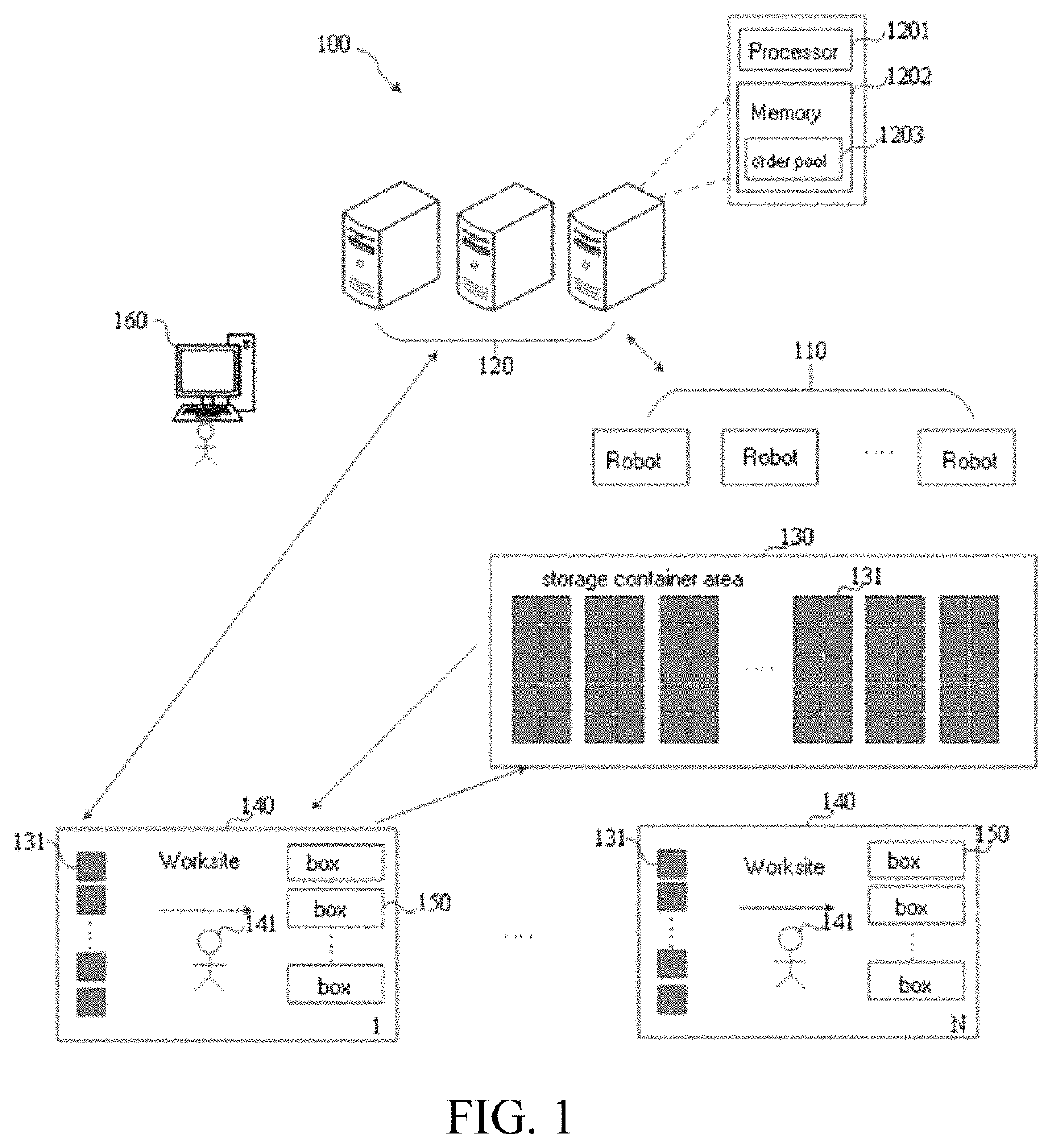

Robot scheduling method and device, equipment and medium

PendingCN112506198AImprove orderEfficiencyPosition/course control in two dimensionsRobot planningSimulation

The embodiment of the invention relates to a robot scheduling method and device, equipment and a medium. The method comprises the steps of: acquiring a first planned path of a first robot; comparing the first planned path with a second planned path of at least one second robot in operation to determine an overlapping path; and based on the first planned path, the occupation state of the overlapping path and the operation state of the second robot, controlling the first robot to operate. By the adoption of the technical scheme, the robot can be dispatched to run on special roads like a two-waysingle lane according to the occupation state of the overlapping path in the robot planning paths and the running states of other robots running at the same time, dispatching of the multiple robots atthe same time is achieved, and deadlock is effectively avoided, and the orderliness and high efficiency of passing of multiple robots are improved.

Owner:京信智能科技(广州)有限公司

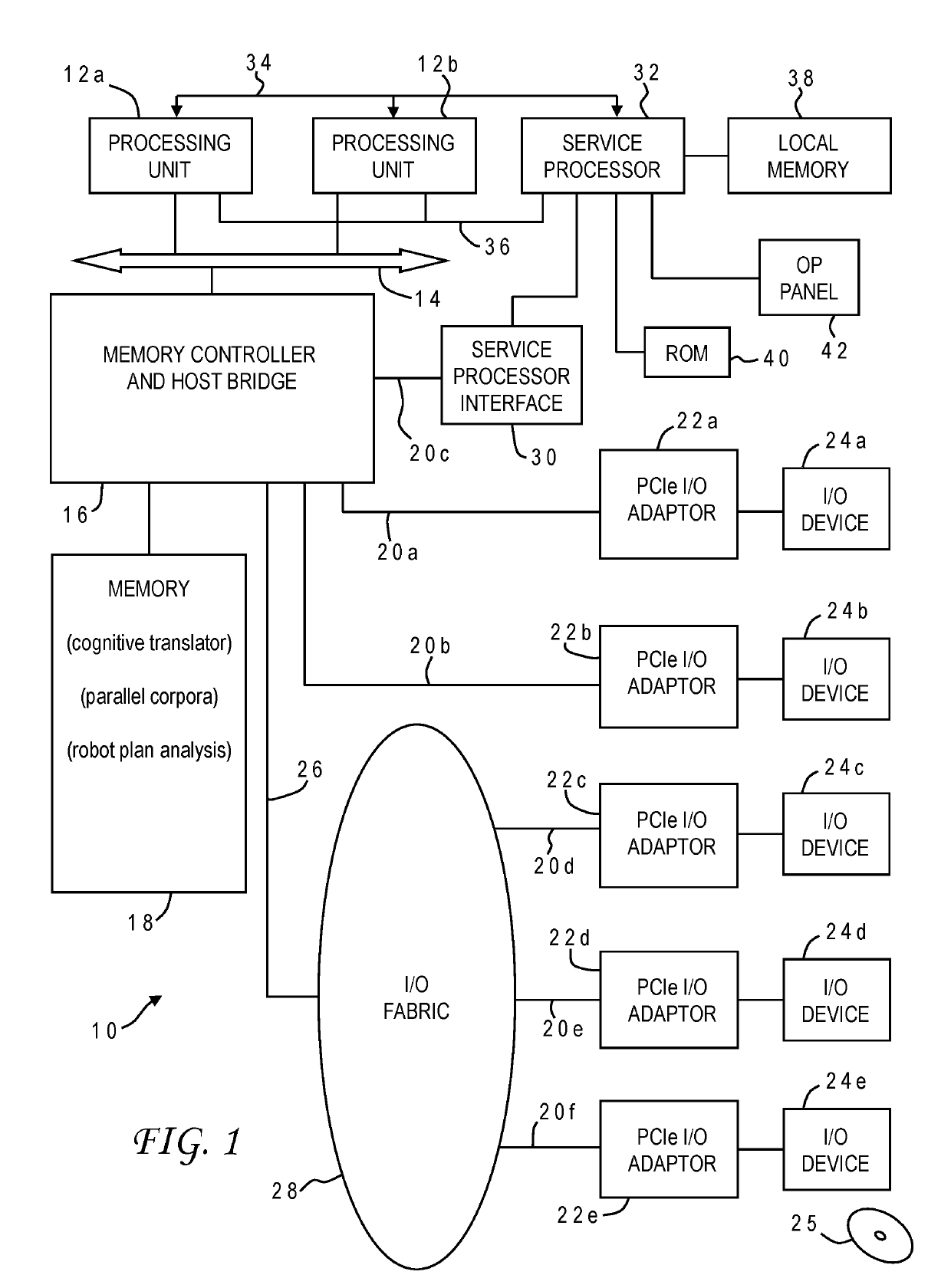

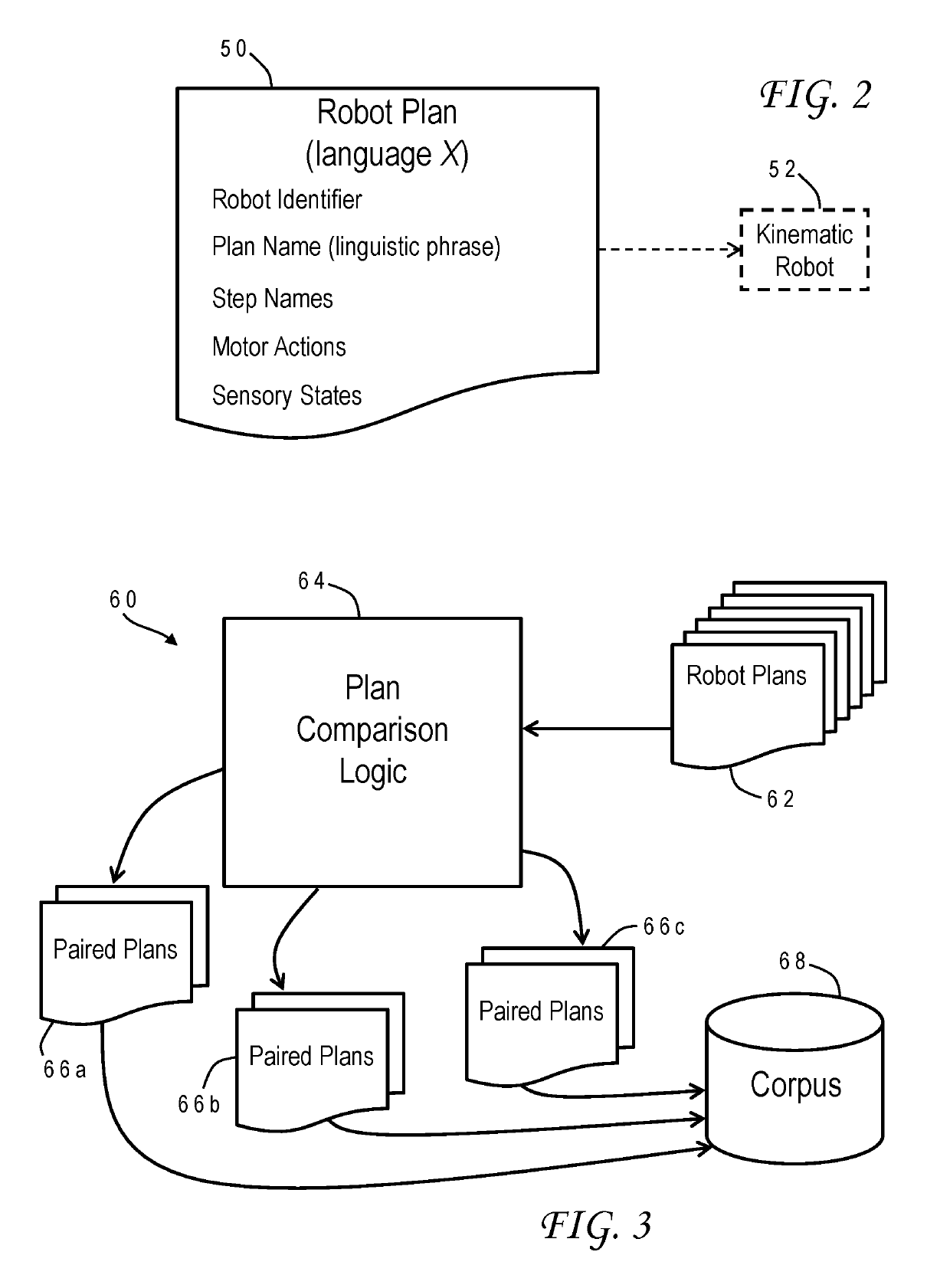

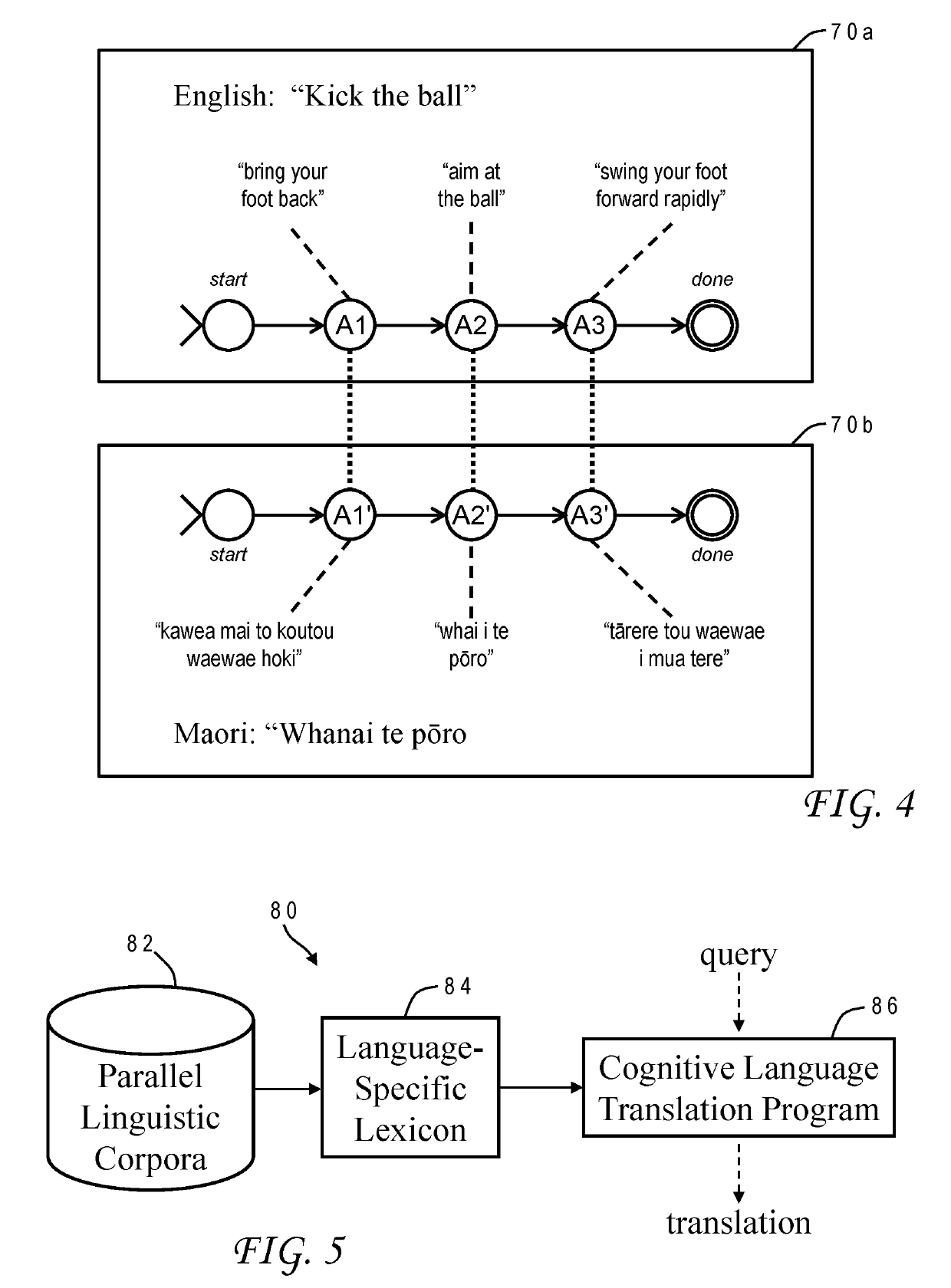

Using robot plans as parallel linguistic corpora

Parallel linguistic corpora used to train cognitive translation systems are built from robot plans. A collection of robot plans in various languages is analyzed in candidate pairings to see if any two plans are directed to the same task. If so, verbal instructions in different languages from the two plans (such as plan names) are assumed to have the same meaning, and are stored in association as part of the bilingual corpus. If each plan has multiple steps, the corresponding steps from the two plans can also be stored in association as part of the corpus. Robot plans are modeled as finite state automata having a plurality of links representing sensory states and a plurality of nodes representing motor actions, and the determination of plan similarity is based on a comparison of the two FSAs.

Owner:IBM CORP

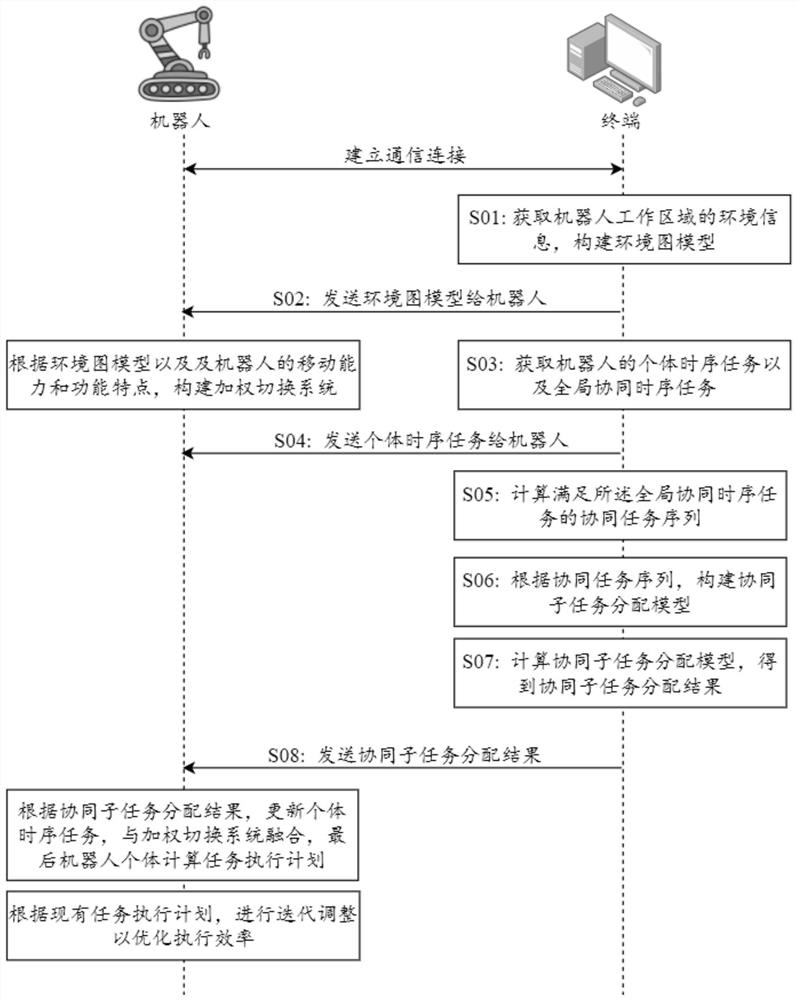

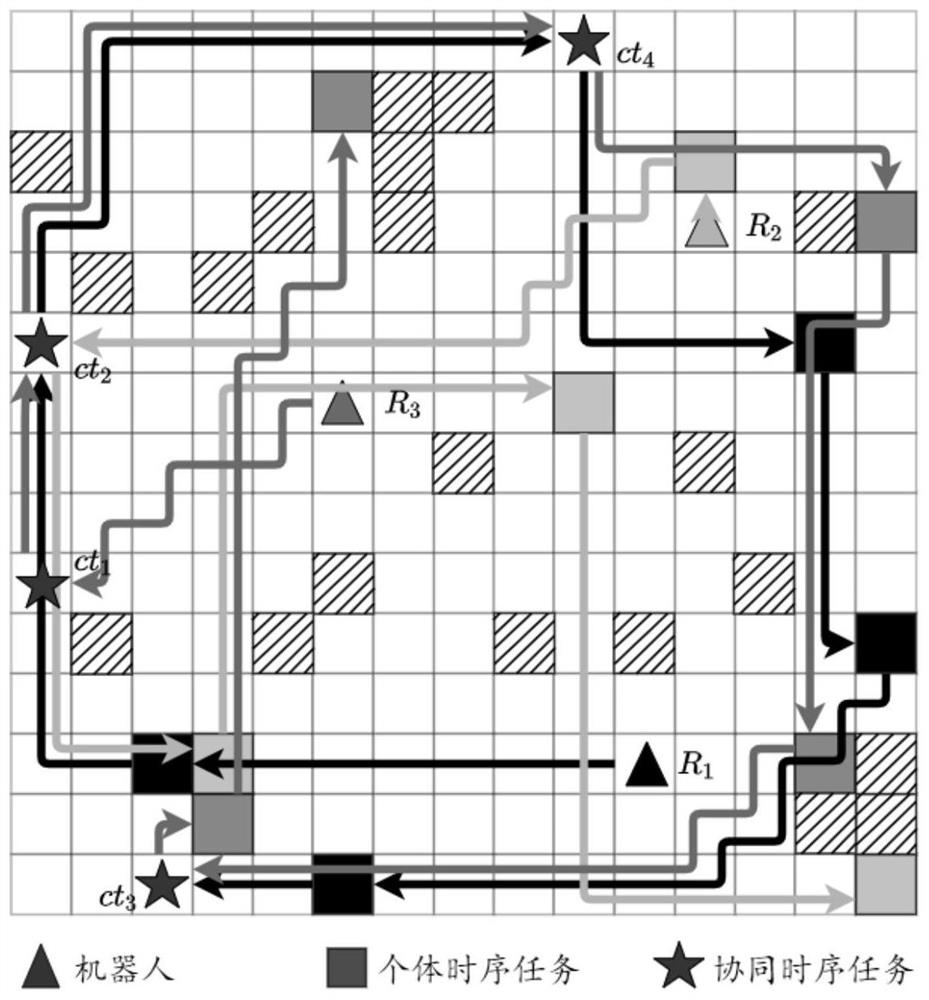

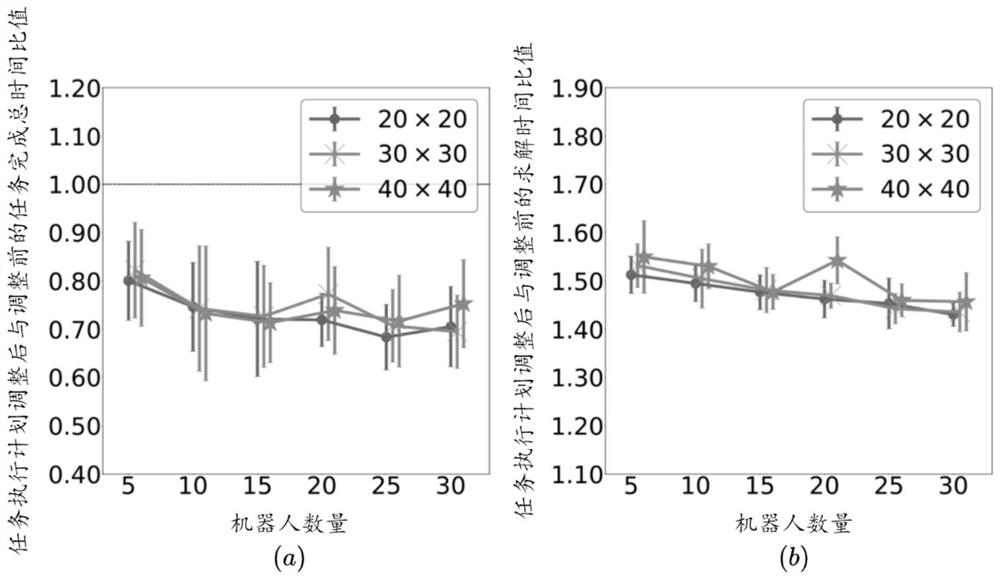

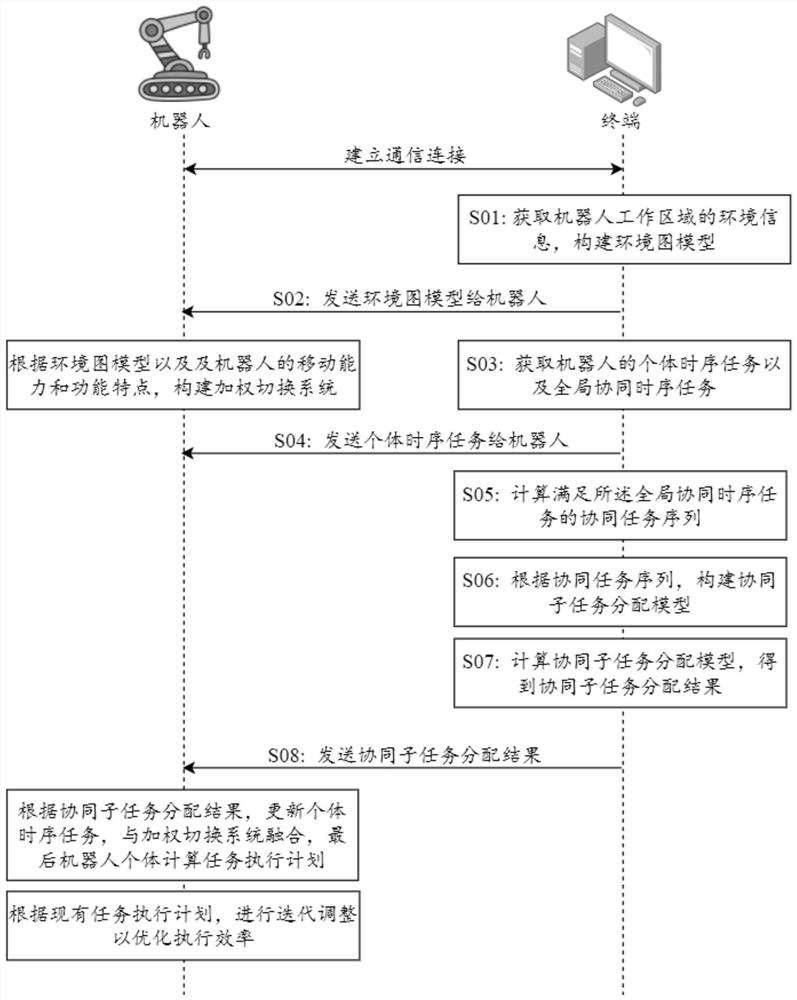

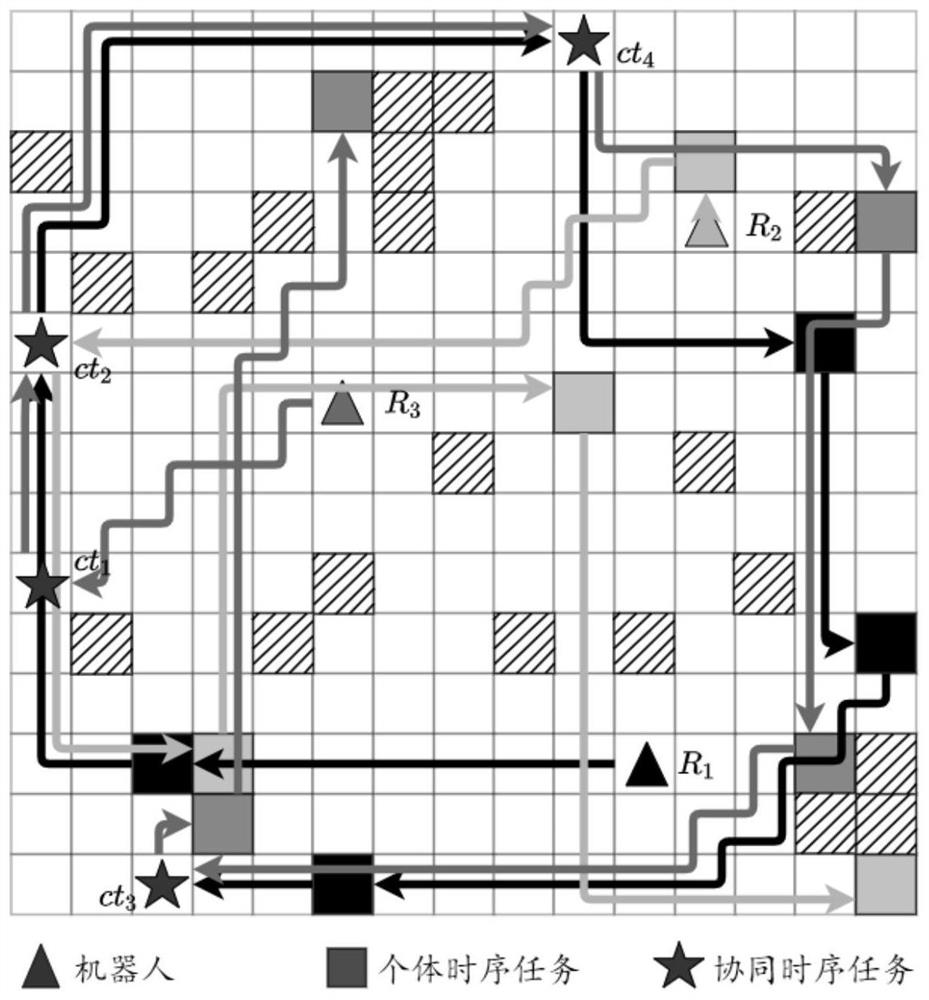

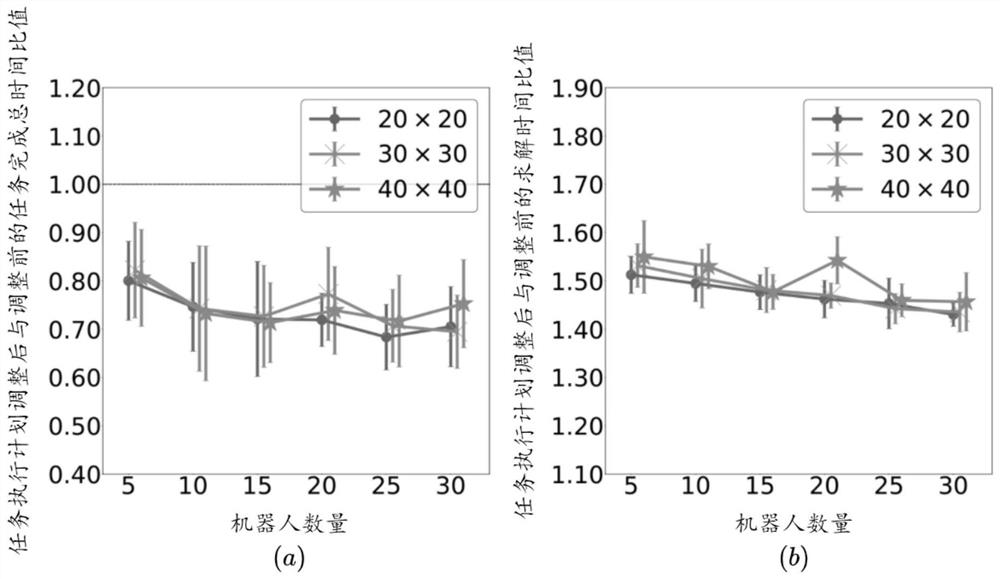

Robot time sequence task planning method and device and electronic equipment

ActiveCN113408949AReduce waiting timeProtect the privacy information of individual timing tasksDesign optimisation/simulationConstraint-based CADExecution planRobot planning

The invention belongs to the field of robot task planning, and provides a robot time sequence task planning method which comprises the following steps: acquiring environment information of a working area and performing discretization modeling on the working area; obtaining an individual time sequence task requirement and a cooperative time sequence task requirement of the robot; searching a collaborative task sequence according to collaborative time sequence task requirements; constructing a collaborative subtask allocation model according to the collaborative task sequence, and solving a collaborative subtask allocation result; and sending the collaborative sub-task allocation result to the robot, so that the robot individually calculates a task execution plan. According to the method, the problem of multi-robot planning under the constraint of individual and global complex time sequence tasks can be efficiently solved, the method has good expansibility, and the limitation of unstable regional communication can be overcome; in addition, the privacy information of the individual robot can be effectively protected while the calculation load is dispersed.

Owner:ZHEJIANG UNIV

Scene reconstruction method, device, computer equipment and computer storage medium

ActiveCN107610212BSmooth pathProgramme-controlled manipulatorImage enhancementPattern recognitionRobot planning

The present invention relates to a scene reconstruction method, device, computer equipment and computer storage medium. The method includes acquiring a captured depth image, and generating a current tensor field key frame according to the depth image; The tensor field key frame is interpolated in time and space to obtain the interpolated tensor field key frame; the robot planning path is obtained through the particle drift algorithm; the camera planning path is obtained according to the robot planning path and the energy equation of the camera; the robot walks along the robot planning path, and the camera follows the camera Depth images taken while planning path walking to reconstruct the scene. The above-mentioned scene reconstruction method, device, computer equipment and computer storage medium obtain the planned path of the camera through the planned path of the robot and the energy equation of the camera, thereby realizing the simultaneous exploration and reconstruction of complex scenes by the robot holding the camera .

Owner:SHENZHEN UNIV

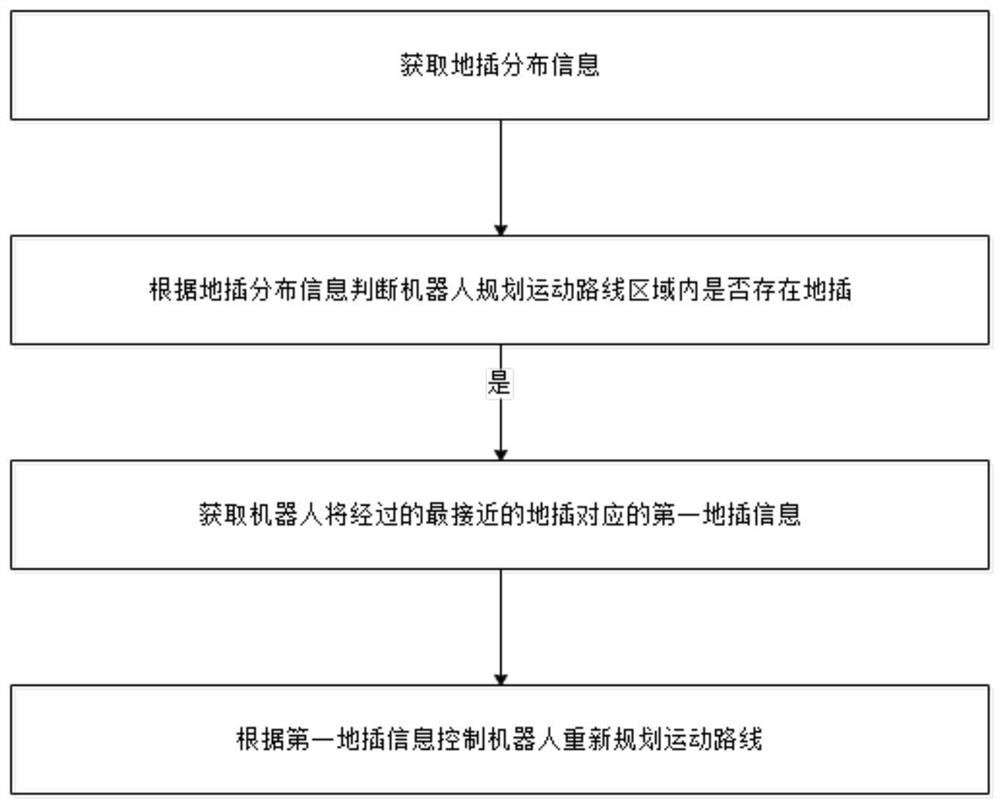

Robot control method based on ground plug detection, chip and robot

The invention discloses a robot control method based on ground socket detection, a chip and a robot. The control method specifically comprises the steps that ground socket distribution information is acquired; according to the ground insert distribution information, judging whether a ground insert exists in the robot planning motion route area or not; if the ground insert exists in the robot planning motion route area, obtaining first ground insert information corresponding to the nearest ground insert passed by the robot in the robot planning motion route area; and controlling the robot to re-plan the motion route according to the first ground insert information. The motion route is planned according to the first ground insert information obtained in real time, and the smoothness of the motion route of the robot is reasonably improved on the basis under the condition that it is guaranteed that the robot is not stuck by the ground insert.

Owner:AMICRO SEMICON CORP

A method, device, and electronic equipment for time-sequence task planning of a robot

ActiveCN113408949BReduce waiting timeProtect the privacy information of individual timing tasksDesign optimisation/simulationConstraint-based CADExecution planRobot planning

This application belongs to the field of robot task planning, and provides a robot timing task planning method, including: obtaining the environmental information of the working area and performing discrete modeling on the working area; obtaining the individual timing task requirements and collaborative timing task requirements of the robot; according to According to the requirements of the collaborative time sequence task, search for the collaborative task sequence; according to the collaborative task sequence, construct the collaborative subtask allocation model, and solve the collaborative subtask allocation result; send the collaborative subtask allocation result to the robot, so that the individual robot can calculate the task execution plan . This application can efficiently solve the multi-robot planning problem under the constraints of individual and global complex timing tasks, has good scalability, and can overcome the limitation of regional communication instability; in addition, this application can effectively protect the robot while dispersing the calculation load. Private information of individual robots.

Owner:ZHEJIANG UNIV

A method for avoiding repetitive teaching of a robot

InactiveCN107838922BAvoid the problem of repeated teachingSave manpower and material resourcesProgramme-controlled manipulatorTransmissionInformation repositoryRobot planning

The invention relates to a method for preventing a robot from repetitively demonstrating. The method is characterized by comprising the following steps of: performing semantic modeling on environmentequipment information, robot information and demonstrating information, and writing information into a node of an OPC UA server-side address space; enabling an OPC UA server-side to visit the node ofthe OPC UA server-side address space, analyzing semantic modeling information and converting the semantic modeling information into an XML file to send to a cloud-side server, enabling the cloud-sideserver to analyze the XML file, calculating robot behaviors according to a robot body model information base to obtain a robot planning instruction, thereby forming a motion track point configurationfile; enabling the OPC UA server-side to receive the motion track point configuration file, and transmitting the motion track point configuration file to one or more robot controllers through an OPC UA communication stack, and enabling the robot to perform operation according to an obtained motion track point. The method adopts a semantic modeling mode to encapsulate equipment model information and working description information, realizes intercommunication and interconnection among equipment, quickly completes configuration, synchronizes equipment replacement and function update through OPCUA, and greatly improves application efficiency.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

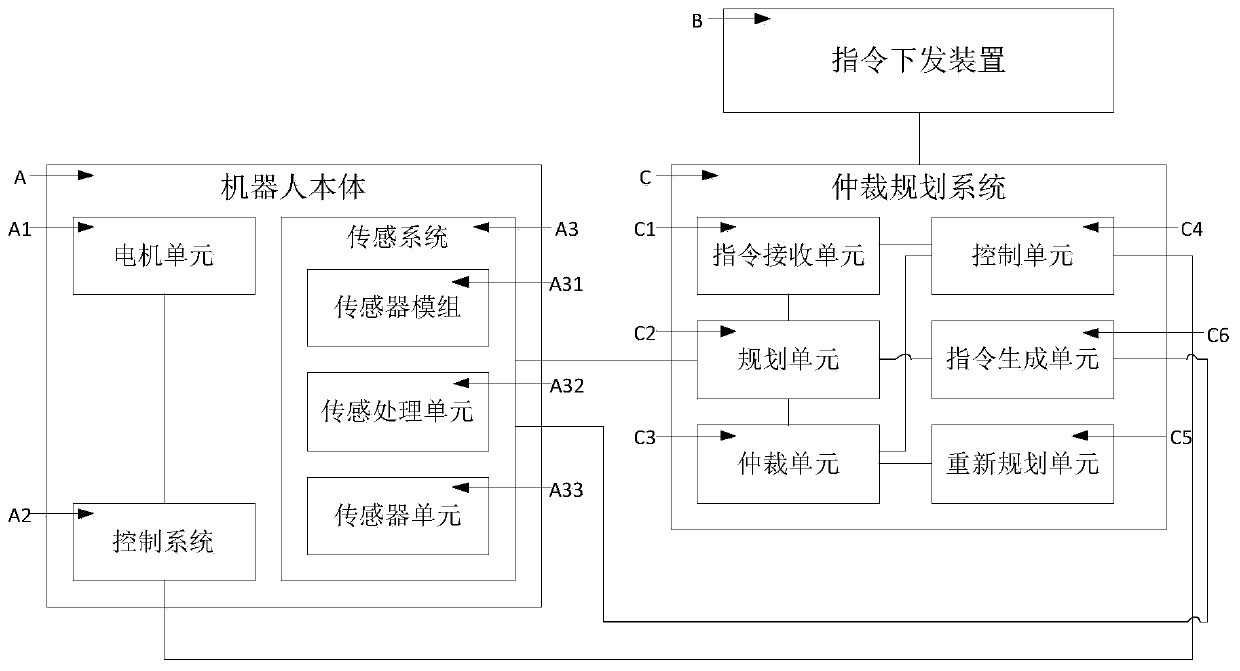

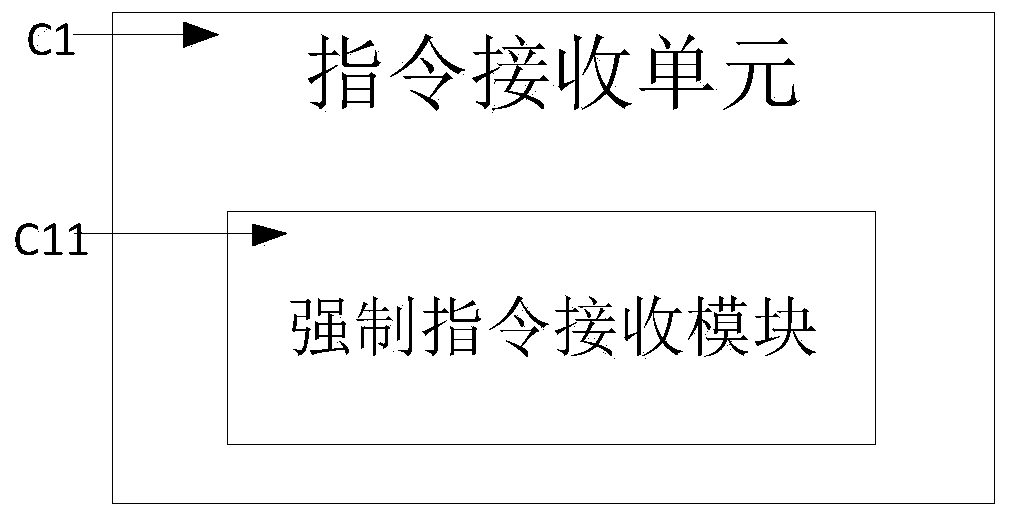

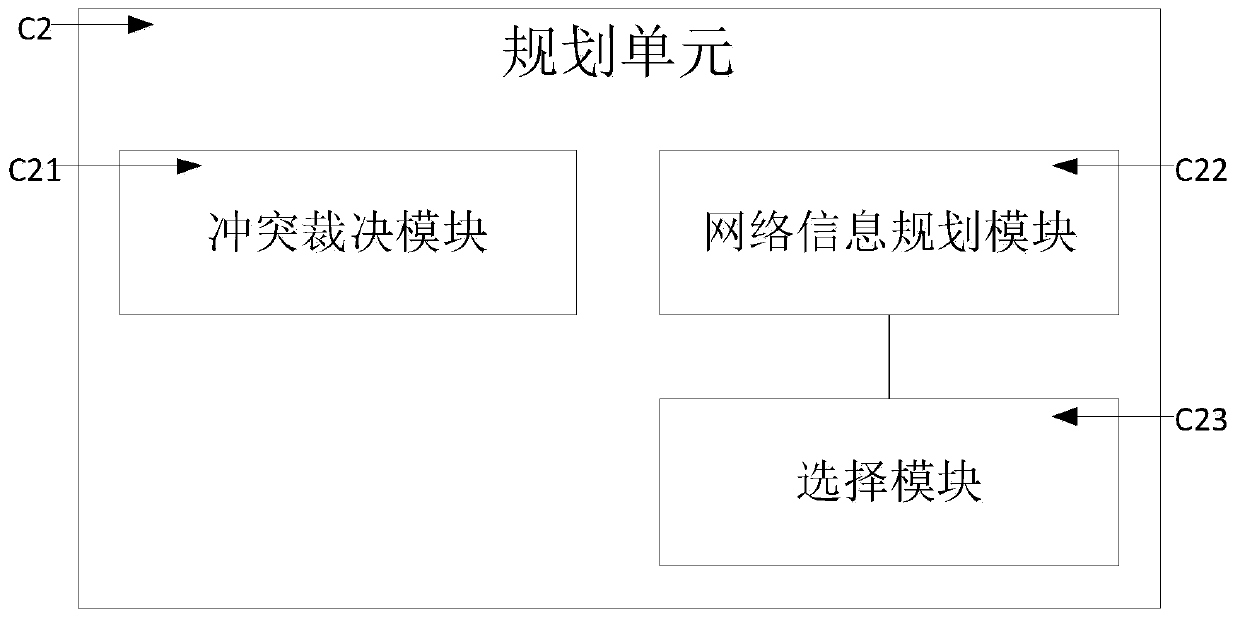

Arbitration planning system and method

ActiveCN111496790AImprove work efficiencyResolve arbitration issuesProgramme-controlled manipulatorExecution planRobot planning

The invention discloses an arbitration planning system and method, and belongs to the technical field of robot control. The arbitration planning method comprises the following steps of receiving, by the arbitration planning system, a plan command input from the external and converting to form an executing plan; simultaneously, receiving, by the arbitration planning system, external environment information sent by a sensing system; performing, by the arbitration planning system, conflict arbitration judgment on the executing plan and the external environment information; if a conflict is not generated, handing the executing plan and the external environment information to a control unit to generate a corresponding control command, issuing the control command to a control system of a robot,and controlling, by the control system, motor units of various movable joints of the robot to execute the control command; and if the conflict is generated, returning to the arbitration planning system and performing re-planning, wherein the re-planned executing plan is different from an originally executed plan. The technical scheme has the beneficial effects that an arbitration problem when theconflict is generated between a planned action of the robot and the external environment can be solved through the arbitration planning system and the arbitration planning method thereof, so that a predetermined executing plan is executed smoothly; the robot can complete a established action; and the work efficiency of the robot is improved.

Owner:深圳国信泰富科技有限公司

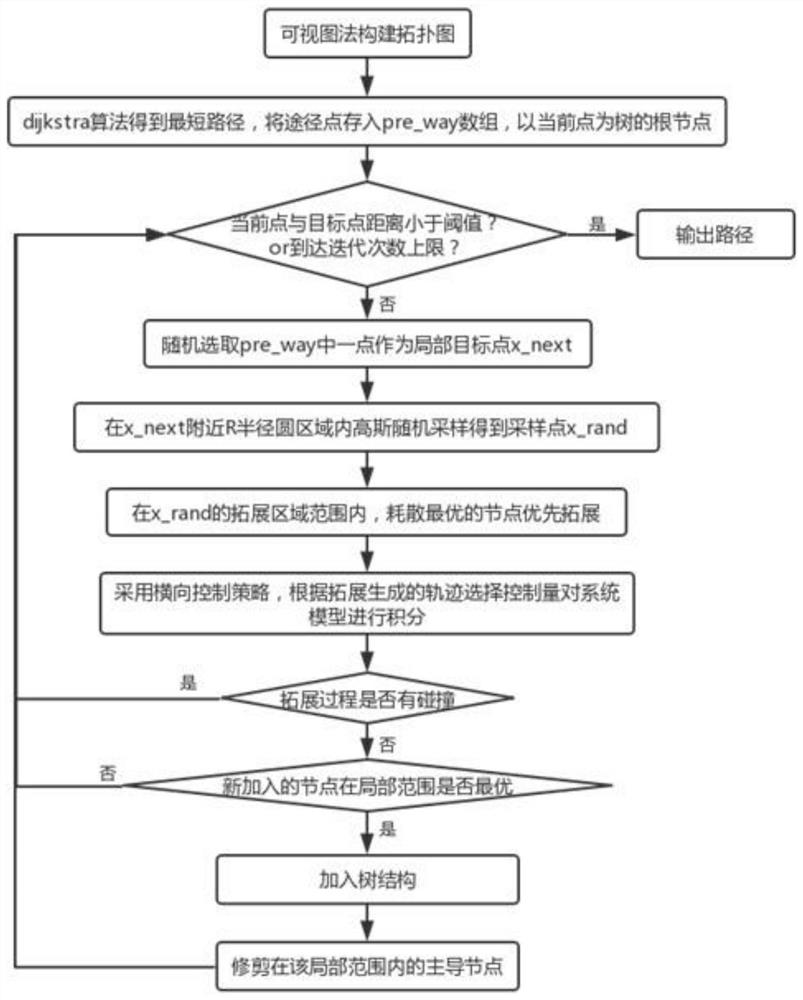

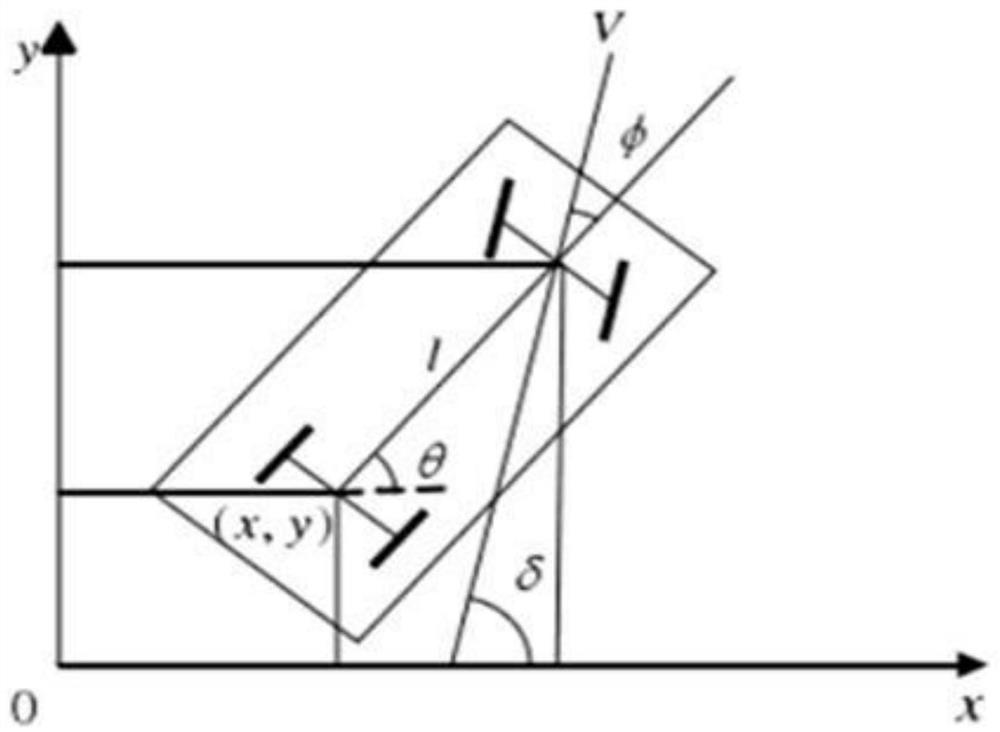

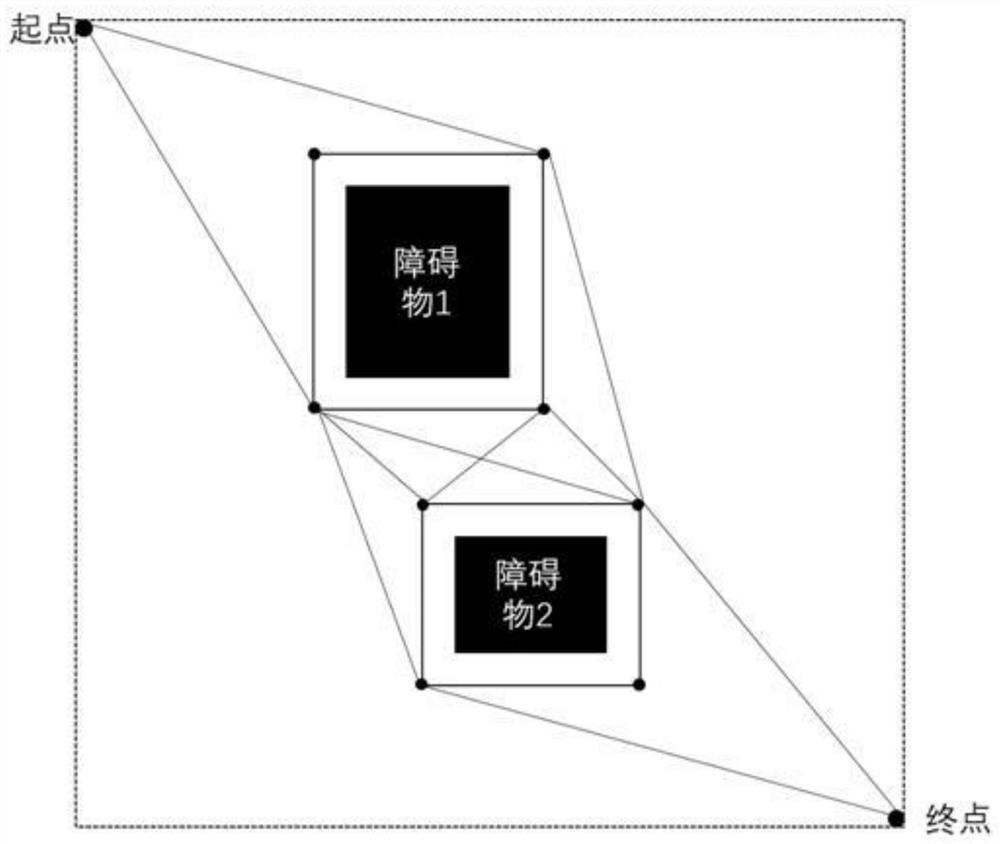

A Fusion Visual Graph Method and Stable Sparse Random Fast Tree Robot Planning Algorithm

ActiveCN110032182BImprove expansion efficiencyGuaranteed sparsityPosition/course control in two dimensionsVehiclesPathPingRobot planning

Owner:SUN YAT SEN UNIV

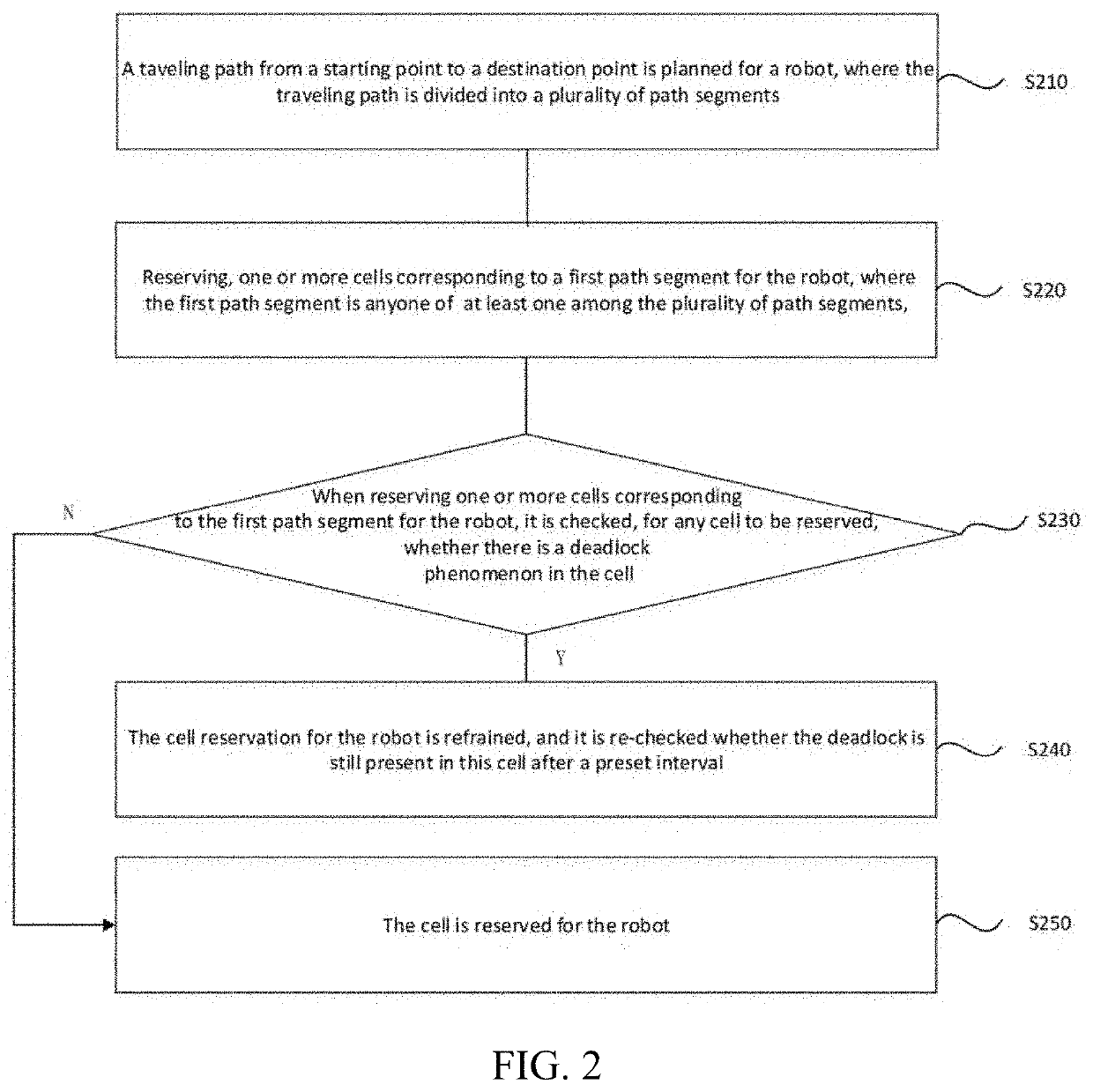

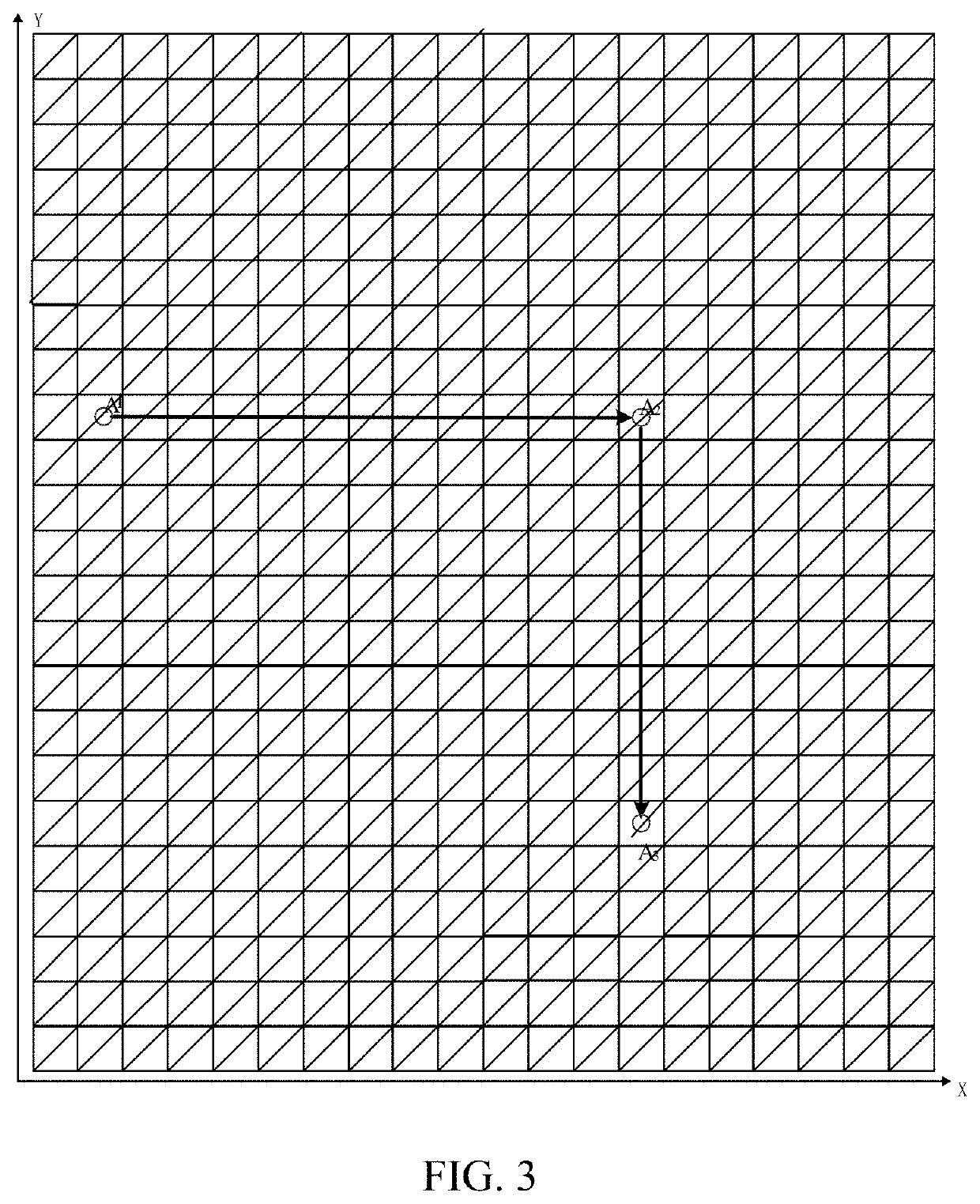

Method, server and storage medium for robot routing

ActiveUS11052539B2Improve system efficiencyImprove efficiencyProgramme-controlled manipulatorProgramme control in sequence/logic controllersRobot planningSimulation

Method, server and storage medium for robot routing are provided. An operation area of the robot is gridded into a plurality of cells arranged in rows and columns. The method includes: planning, for the robot, a traveling path from a starting point to a destination point, where the traveling path is divided into a plurality of path segments; and reserving, one or more cells corresponding to a first path segment for the robot, where the first path segment is anyone of at least one among the plurality of path segments, in case that there is the deadlock phenomenon, refraining from reserving the cell for the robot, and re-checking whether the deadlock phenomenon is still present in the cell after a preset interval; and in case that there is no deadlock phenomenon, reserving the cell for the robot.

Owner:BEIJING JIZHIJIA TECH CO LTD

Robot path planning method and robot for planning route

InactiveCN106406320BEfficient searchSame directionPosition/course control in two dimensionsRobot planningSimulation

Embodiments of the invention provide a robot path planning method and a robot planning a route. The method comprises the following steps of according to a pose of a robot and control information of a speedometer, acquiring an initial pose of the robot; according to the initial pose and data observed by a sensor, creating a prior map; according to a rapid expansion tree algorithm of adaptive adjustment, calculating a global path used to control walking of the robot in the prior map; acquiring real-time detection data of the sensor of the robot, and determining whether the sensor detects a barrier in the global path when the robot is in a walking process; and when the sensor detects the barrier in the global path, establishing a dynamic window model to plan a local barrier avoiding route of the robot so as to make the robot avoid the barrier according to the local barrier avoiding route.

Owner:重庆重智机器人研究院有限公司

A planning method and device for robot collision avoidance path

The invention is suitable for the field of robot collision prevention and control, and provides a planning method and device of a robot collision prevention path. The method comprises the following steps: firstly, calculating according to an initial configuration qs and a target configuration qg of a robot so as to obtain an initial value rcol of a collision detection distance parameter; then constructing a bidirectional rapid intensive search tree according to qs and qg, and setting the value of a collision detection distance parameter of the bidirectional rapid intensive search tree to be rcol; then generating a robot planning path according to qs and qg; carrying out collision detection on the robot at discrete sampling configuration points respectively on the robot planning path, and updating the value rcol to be half of rcol if the robot collides with a barrier at one discrete configuration point; and generating a novel robot planning path according to the updated rcol until the robot does not collide with the barrier at all discrete configuration points on the new robot planning path. According to the invention, if the robot collides with the barrier, the collision detection distance parameter rcol can be adaptively reduced by half, so that the robot can successfully pass through a narrow channel or a barrier intensive space.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com