Patents

Literature

369results about How to "Same direction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

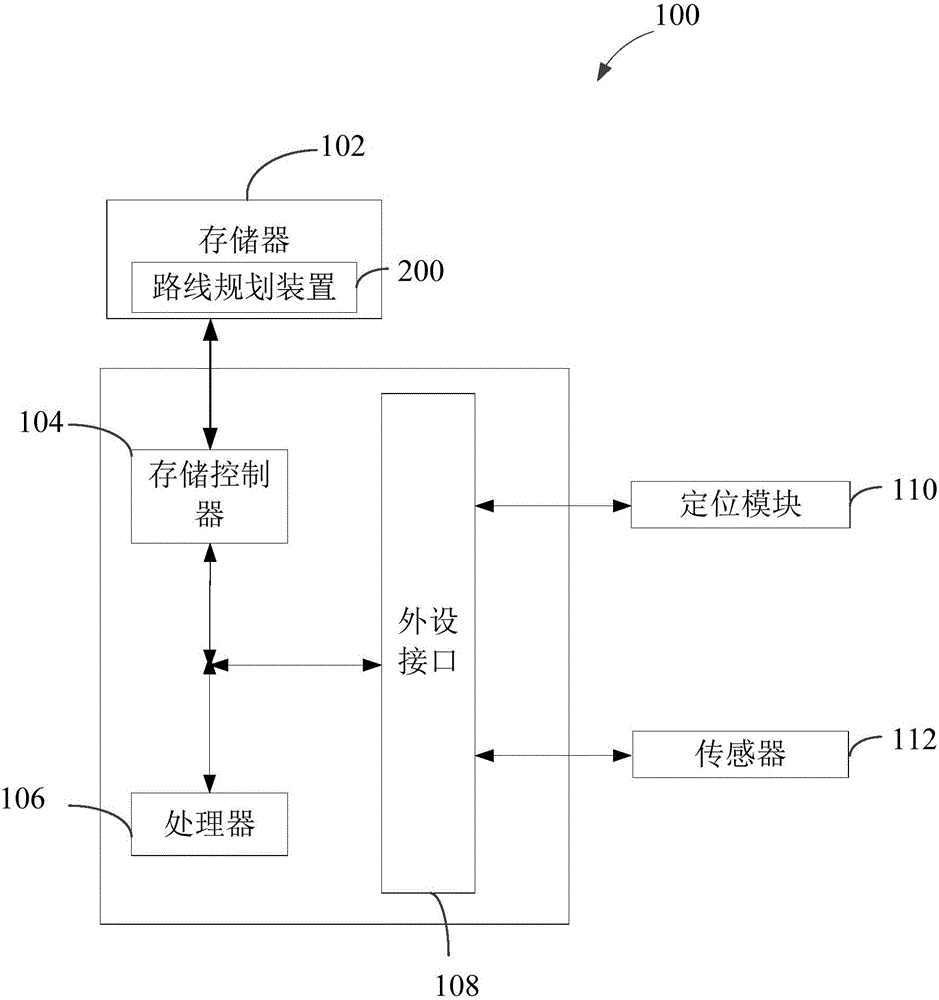

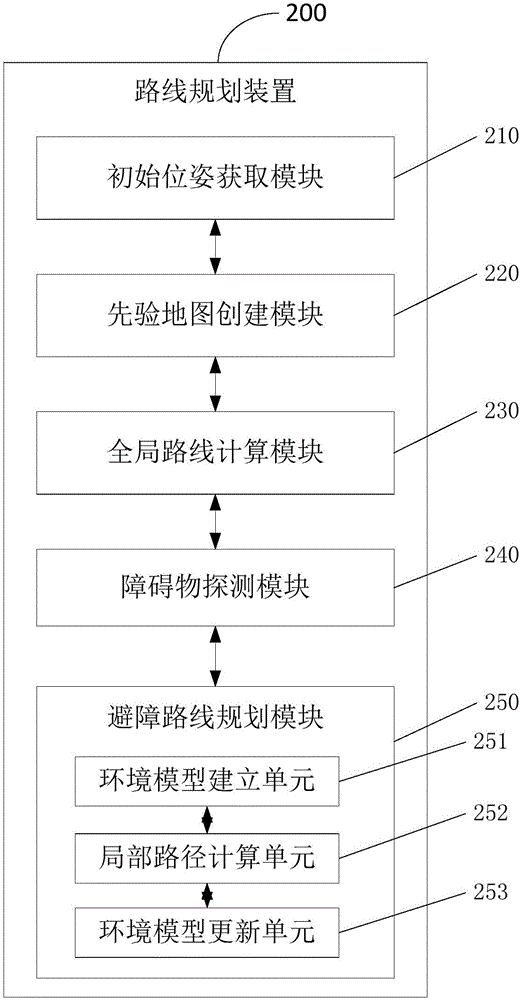

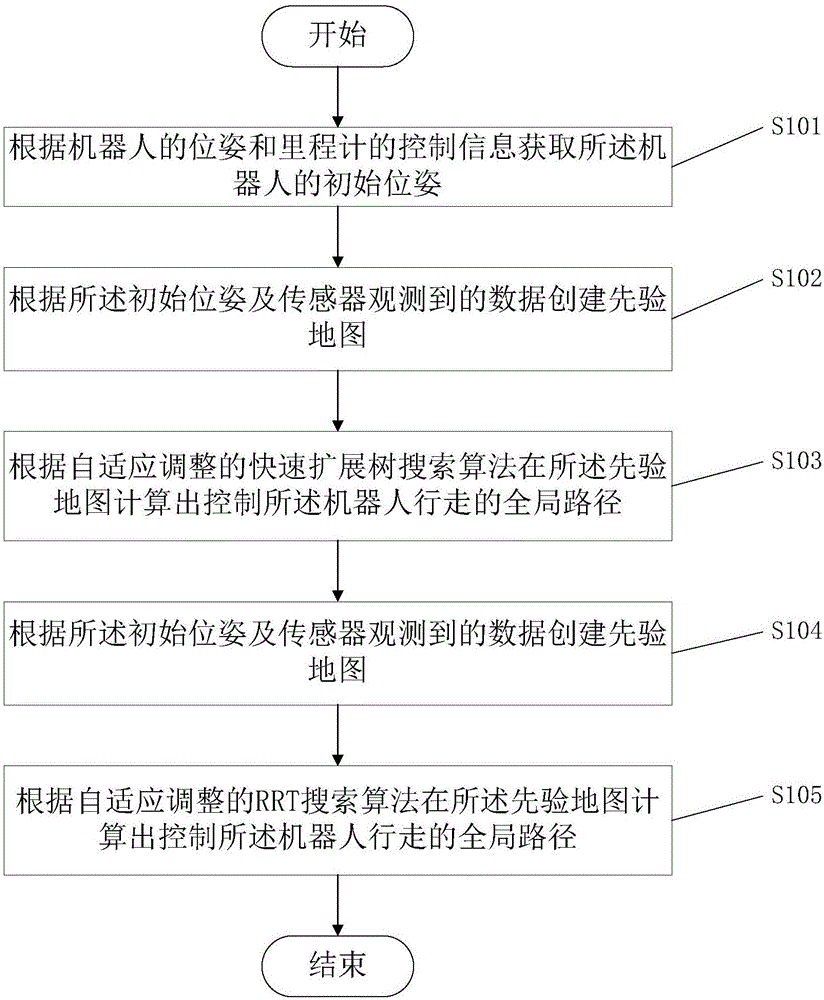

Robot path planning method and robot planning route

InactiveCN106406320AEfficient searchSame directionPosition/course control in two dimensionsRobot planningSimulation

Embodiments of the invention provide a robot path planning method and a robot planning a route. The method comprises the following steps of according to a pose of a robot and control information of a speedometer, acquiring an initial pose of the robot; according to the initial pose and data observed by a sensor, creating a prior map; according to a rapid expansion tree algorithm of adaptive adjustment, calculating a global path used to control walking of the robot in the prior map; acquiring real-time detection data of the sensor of the robot, and determining whether the sensor detects a barrier in the global path when the robot is in a walking process; and when the sensor detects the barrier in the global path, establishing a dynamic window model to plan a local barrier avoiding route of the robot so as to make the robot avoid the barrier according to the local barrier avoiding route.

Owner:重庆重智机器人研究院有限公司

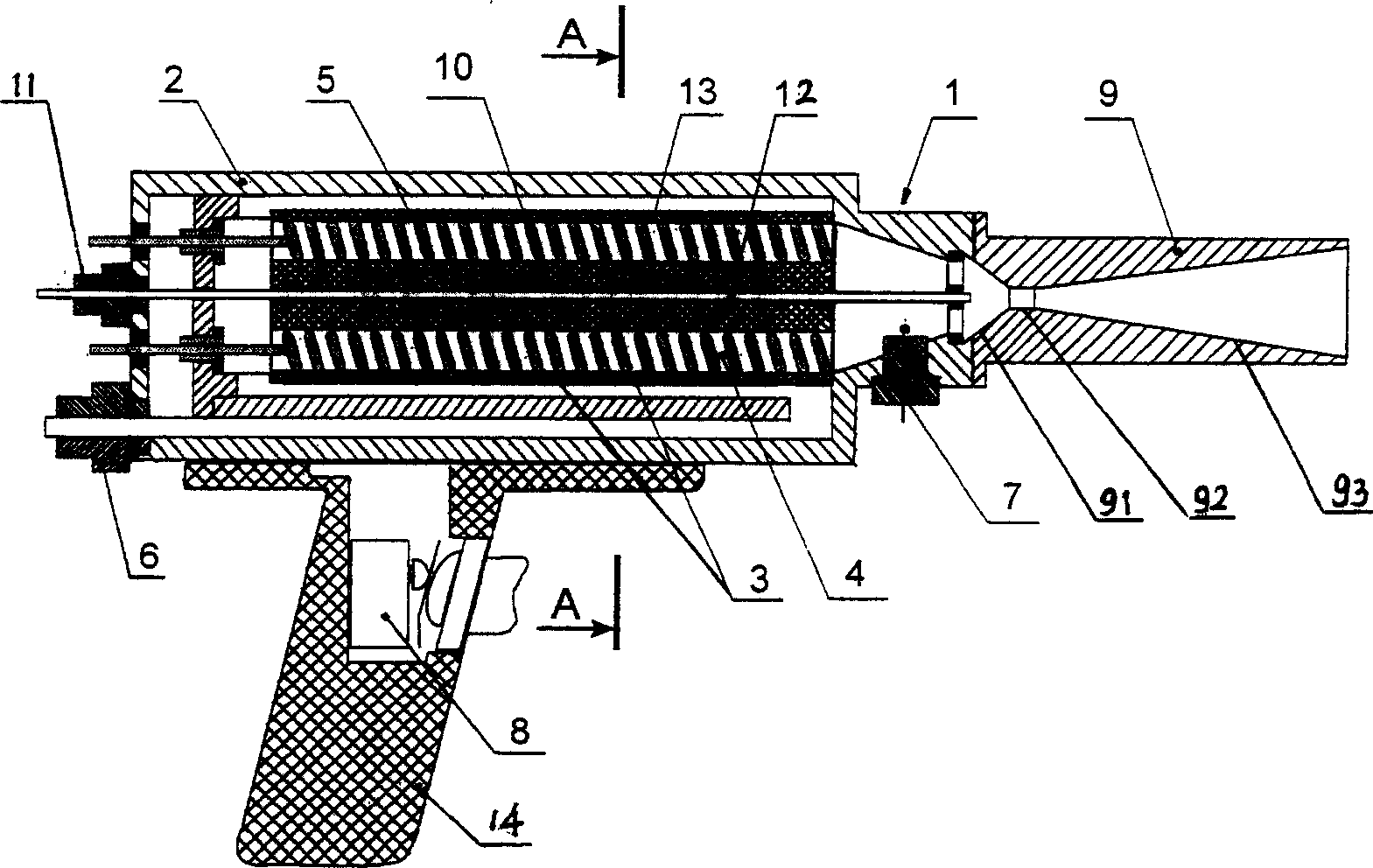

Pneumatic powder spraying apparatus

InactiveCN1603008ABroaden the scope of industrial applicationsEasy to carryLiquid spraying apparatusPressure inorganic powder coatingGas heaterMechanical energy

This invention opens one kind of gas dynamic powder spraying device which is composed with compression gas source,powder feed unit and spray mechanism.The spray mechanism includes gas heater and supersonic nozzle that is rigid linkage structure of coaxial setting.Gas heater includes metal shell,heat element and electrothermal insulator.One end of metal shell is fixed coaxial with the supersonic nozzle,the other end of metal shell is equipped with carrier gas joint and feed powder joint.The electrothermal insulator which is installed in the metal shell is composed with two coaxial emboitement internal and external tube,the center of the internal tube has a channel which two ends respectively connect powder feed unit and supersonic nozzle.In the exine of the internal tube,there are agroove gas direct channels which connect to the compress gas source,the heat element lies in the agroove gas direct channals.This invention which can be used to prepared monolayer and multi-layer coating widens industry application,reduces equipment weight,simplifies design structure and equipment maintanance and improves the spraying efficiency,being suitable for mechanical energy and metallurgy etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

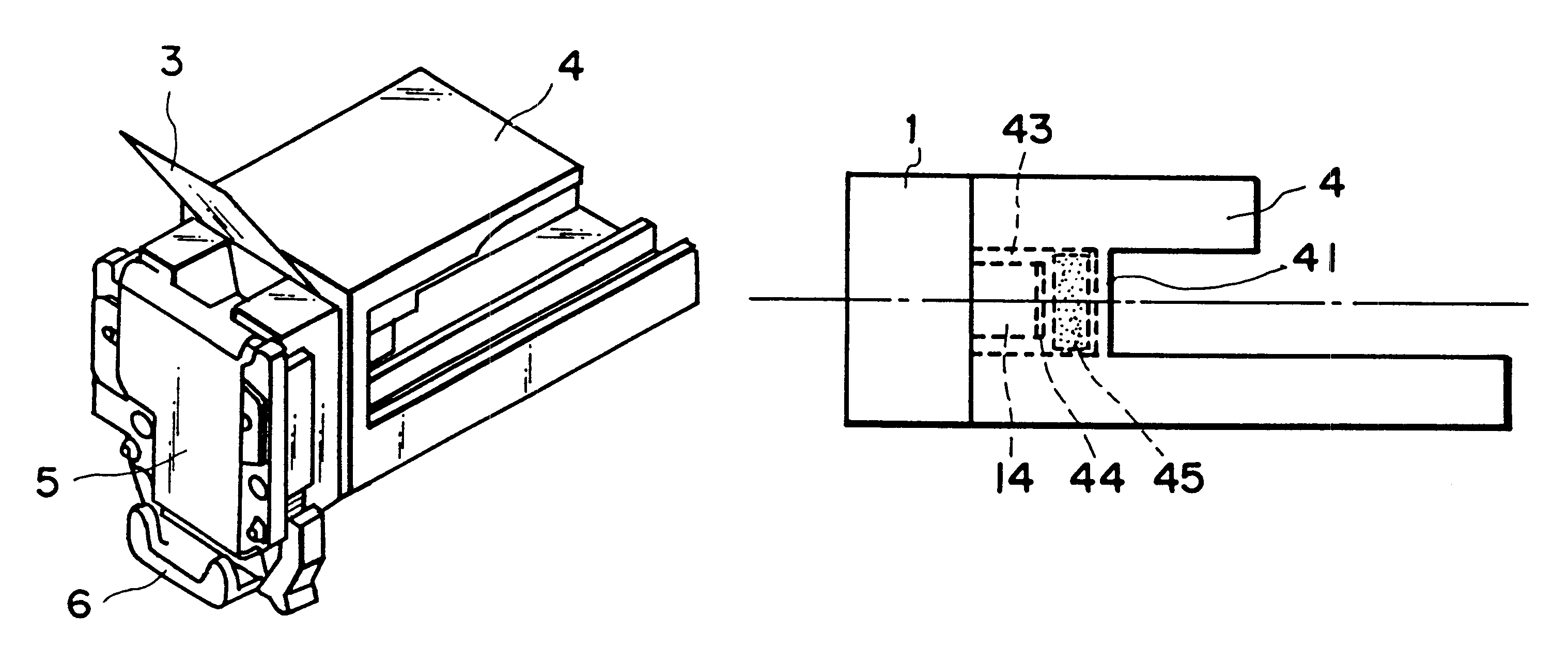

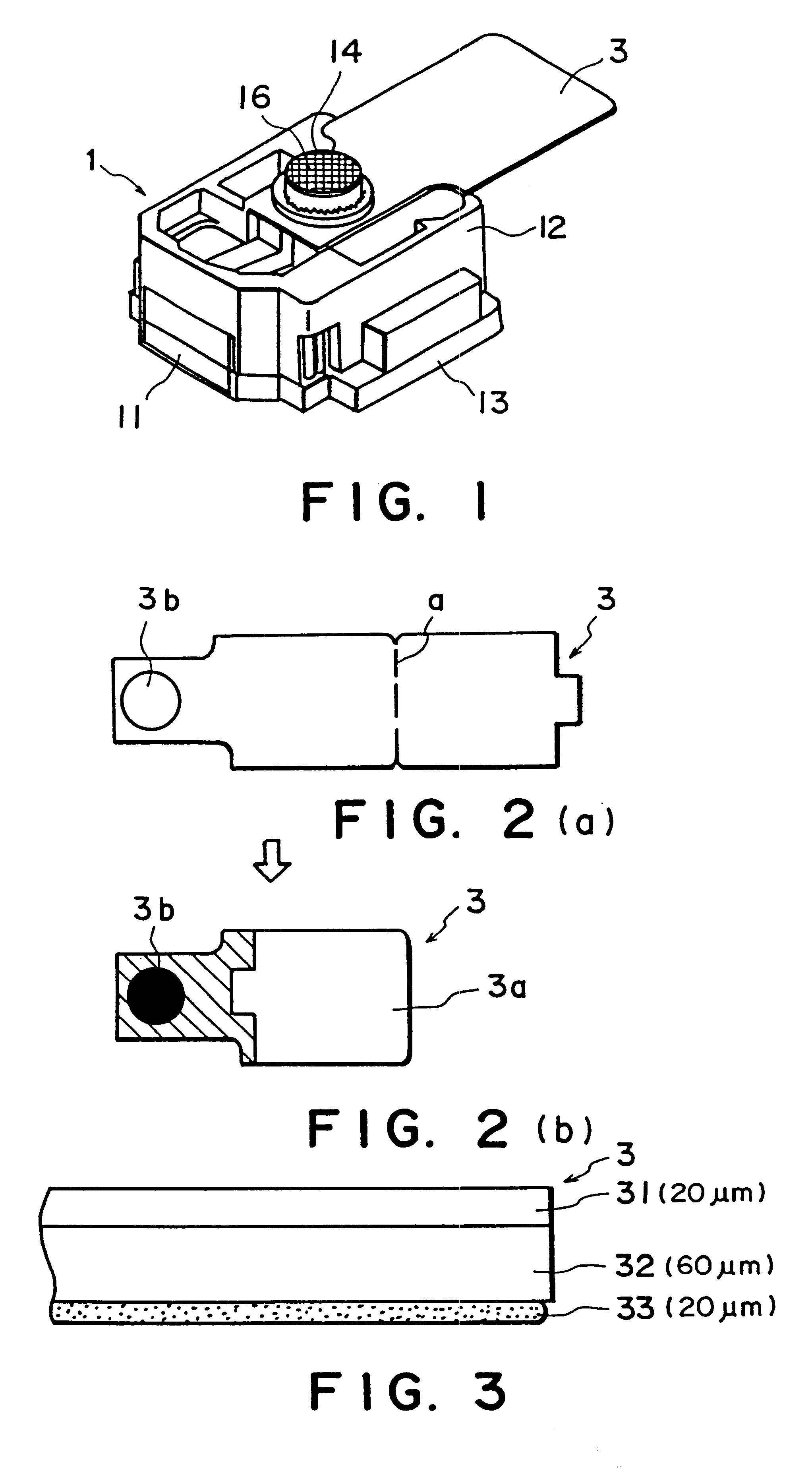

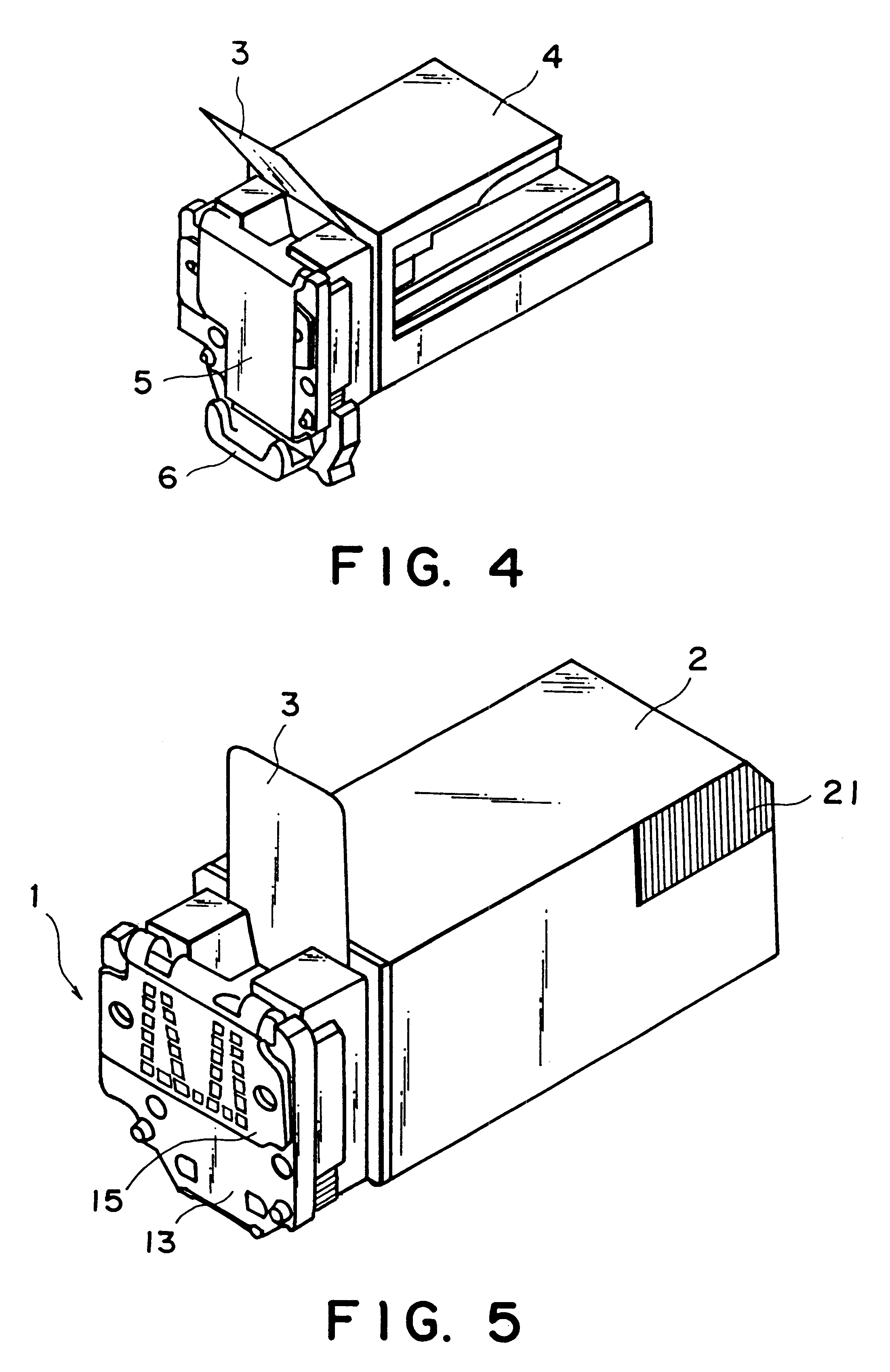

Ink jet head cartridge and ink jet apparatus having same

InactiveUS6338546B1Easy to operateGuaranteed reliabilityPower drive mechanismsRecording headEngineering

An ink jet head cartridge having a recording head without an ink container includes a casing with an ink ejection device; and a structural member on the casing for improving handling of the recording head.

Owner:CANON KK

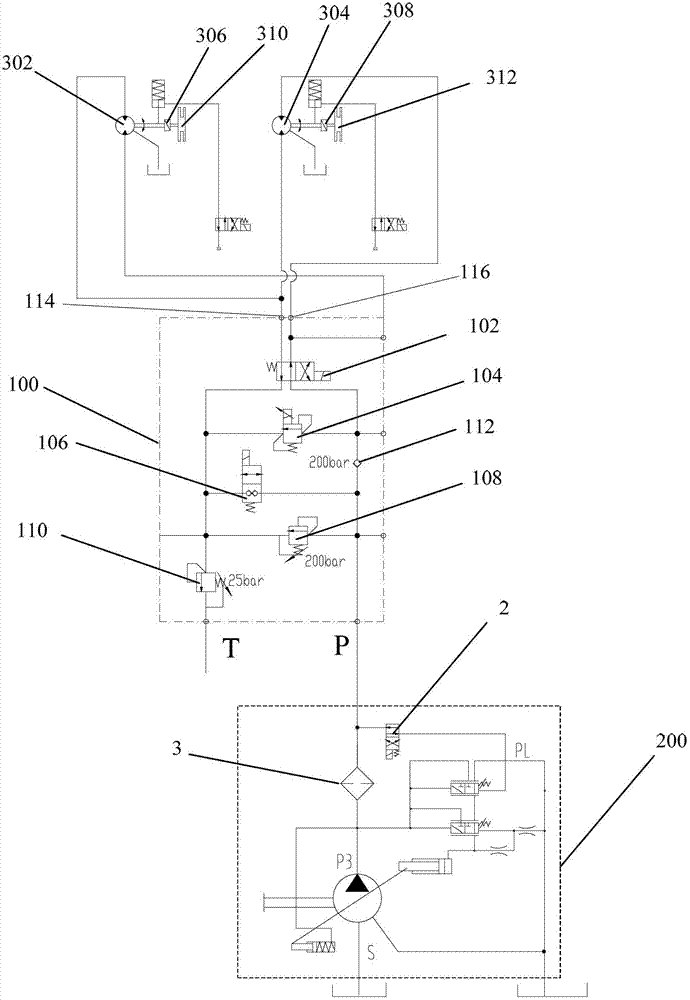

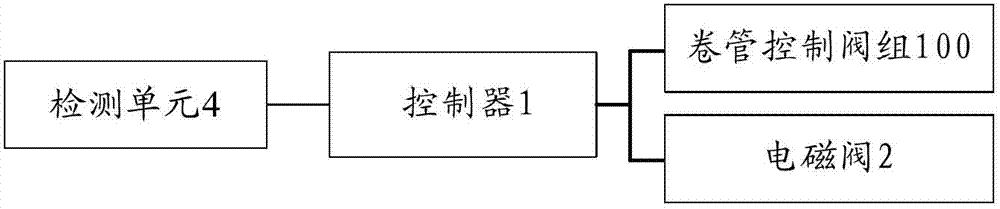

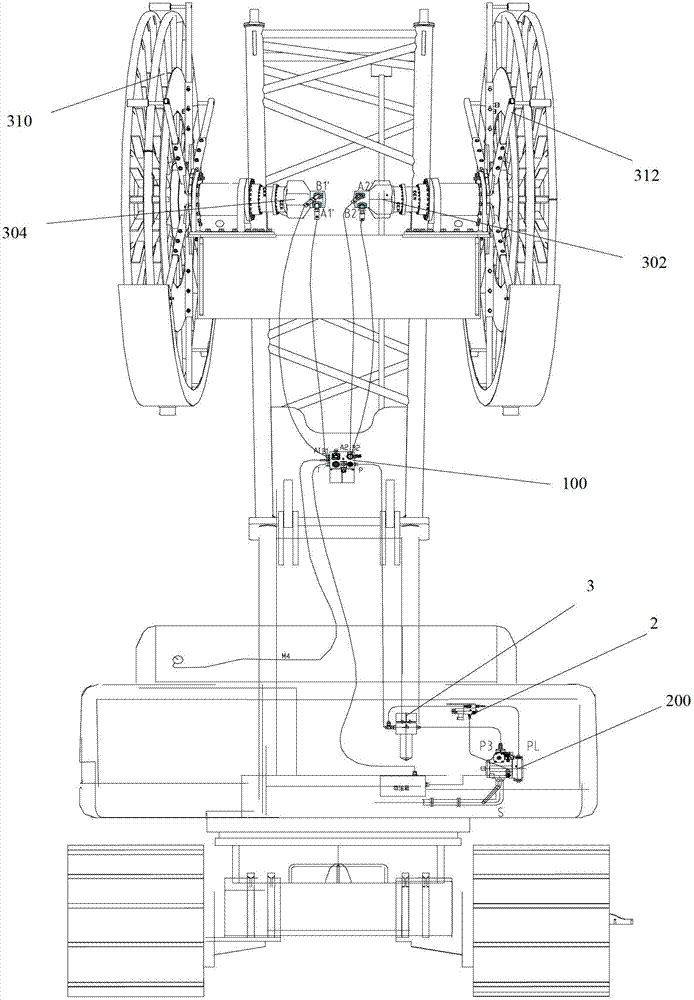

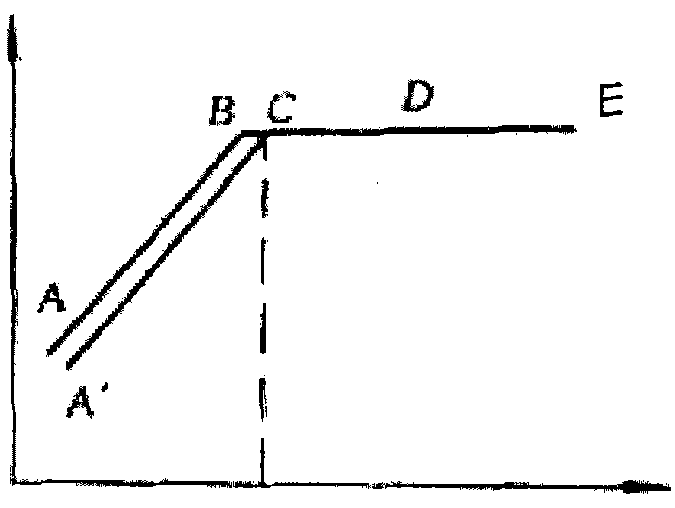

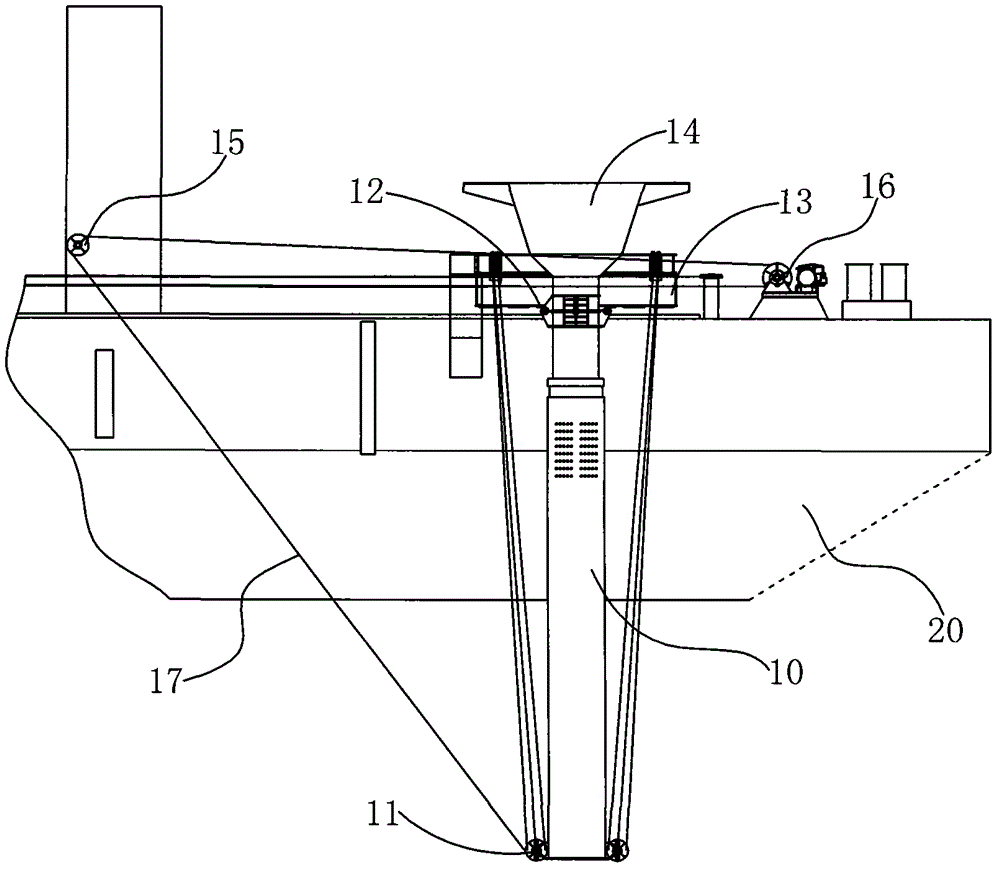

Hydraulic reel-pipe control system, continuous wall grab bucket and chambering drilling machine

ActiveCN102756952ADirection of same output torqueSame sizeDrilling rodsServomotorsControl systemEngineering

The invention provides a hydraulic reel-pipe control system, comprising a first reel-pipe motor, a first reel, a second reel-pipe motor, a second reel, a pressure oil source, a reel-pipe control valve group, a detection unit and a controller, wherein the first reel-pipe motor is connected to the first reel; the second reel-pipe motor is connected to the second reel; pressure oil provided by the pressure oil source is introduced to the P opening of the reel-pipe control valve group through an inlet oil way; the T opening of the reel-pipe control valve group is communicated with an oil return way; the first working opening of the reel-pipe control valve group is connected with the first oil inlet of the first reel-pipe motor and the second oil inlet of the second reel-pipe motor; the second working opening of the reel-pipe control valve group is connected with the second oil inlet of the first reel-pipe motor and the first oil inlet of the second reel-pipe motor; the reel-pipe control valve group is used for regulating a pressure of the pressure oil output from the first working opening and the second working opening according to an electric signal of the controller; the detection unit is used for detecting depth variation data of a working device; and the controller is used for generating the electric signal for controlling the reel-pipe control valve group according to the depth variation data. The pressure of a reel-pipe changes proportionally as the lowering depth increases. The invention further provides a continuous wall grab bucket and a chambering drilling machine.

Owner:SANY HEAVY IND CO LTD (CN)

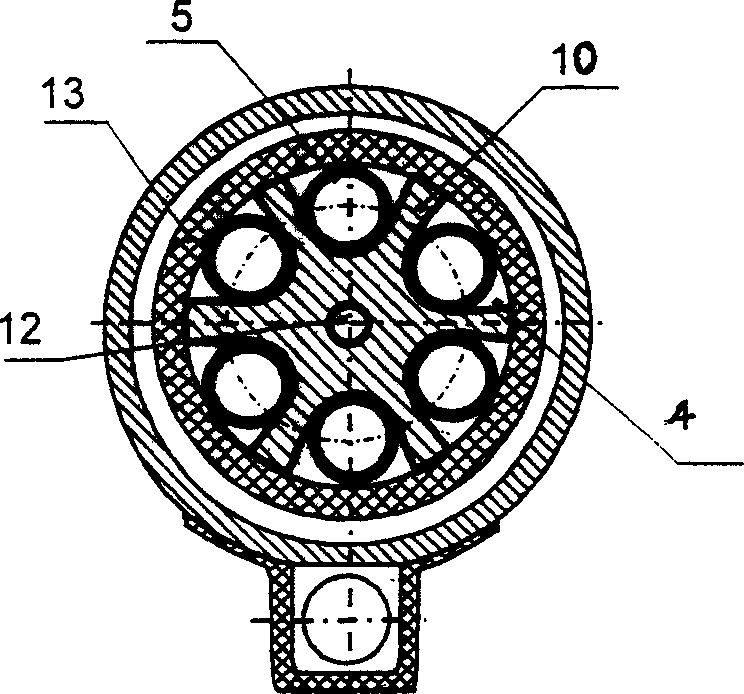

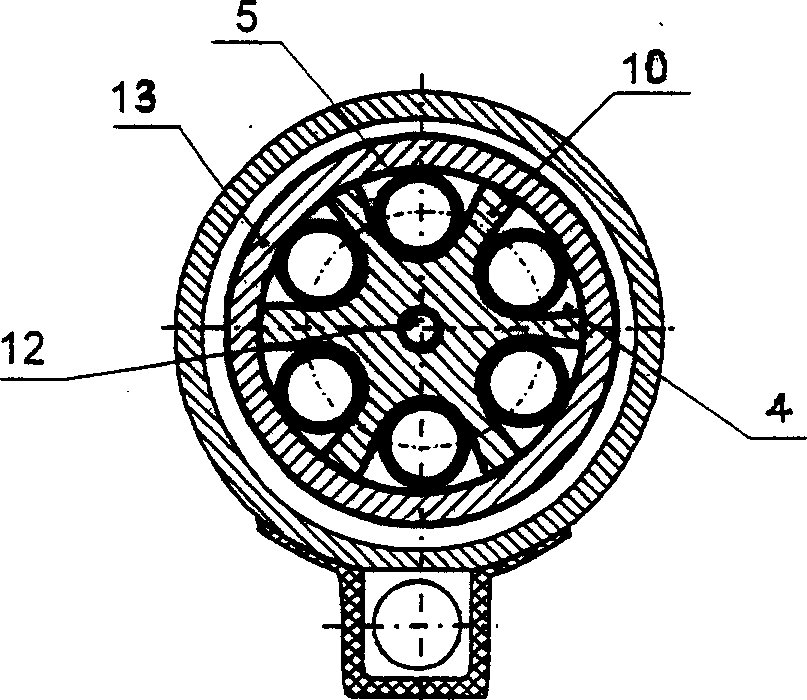

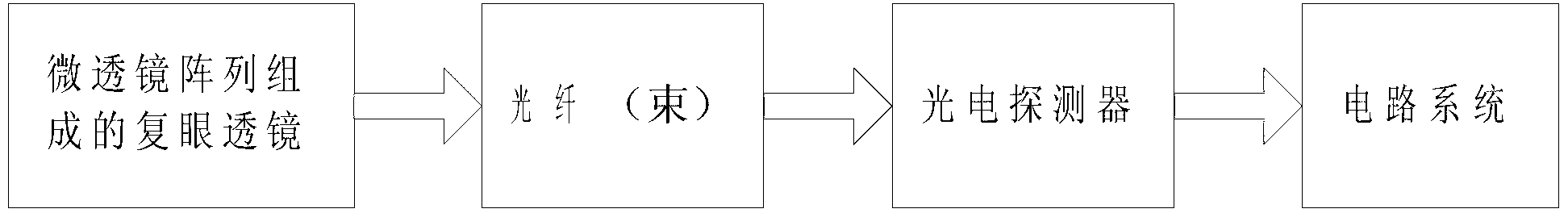

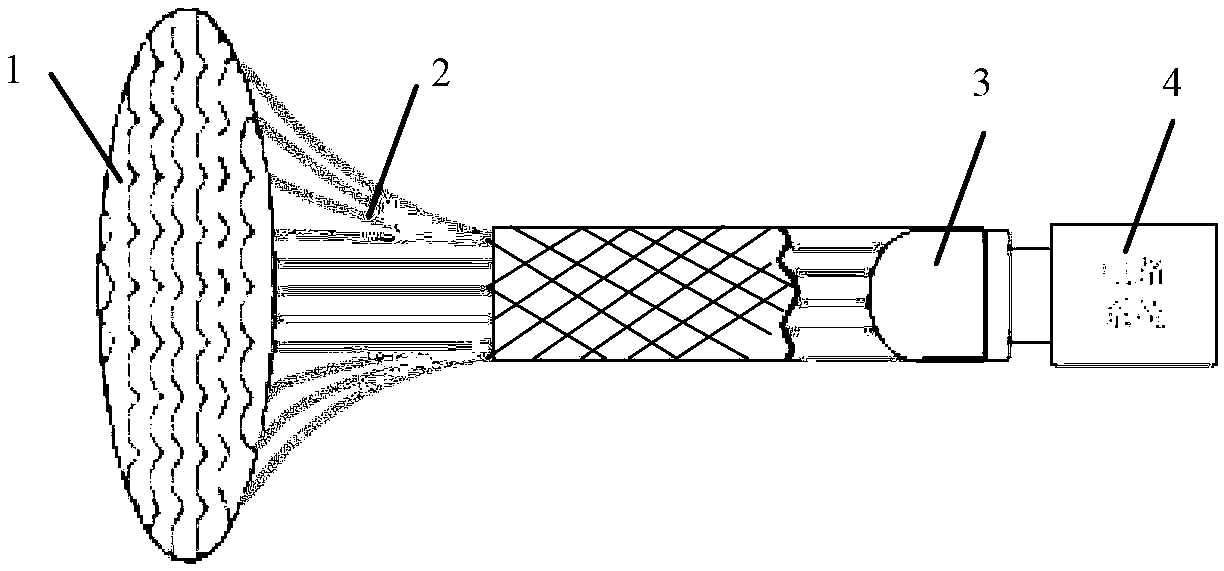

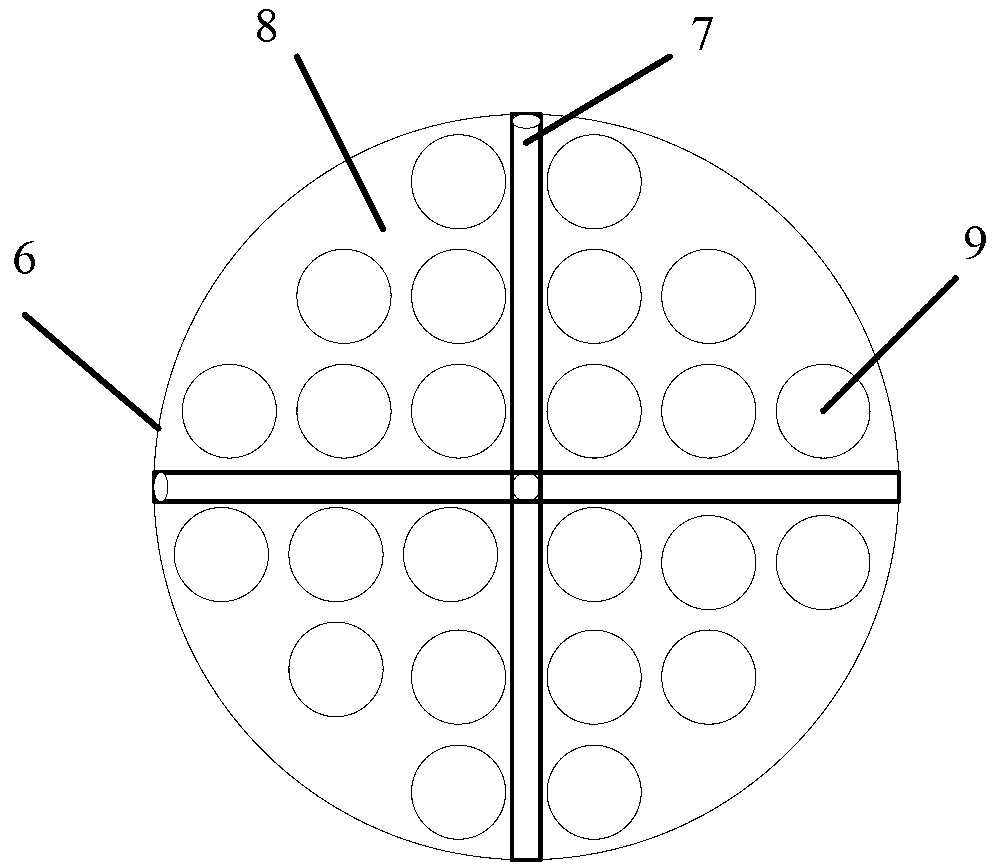

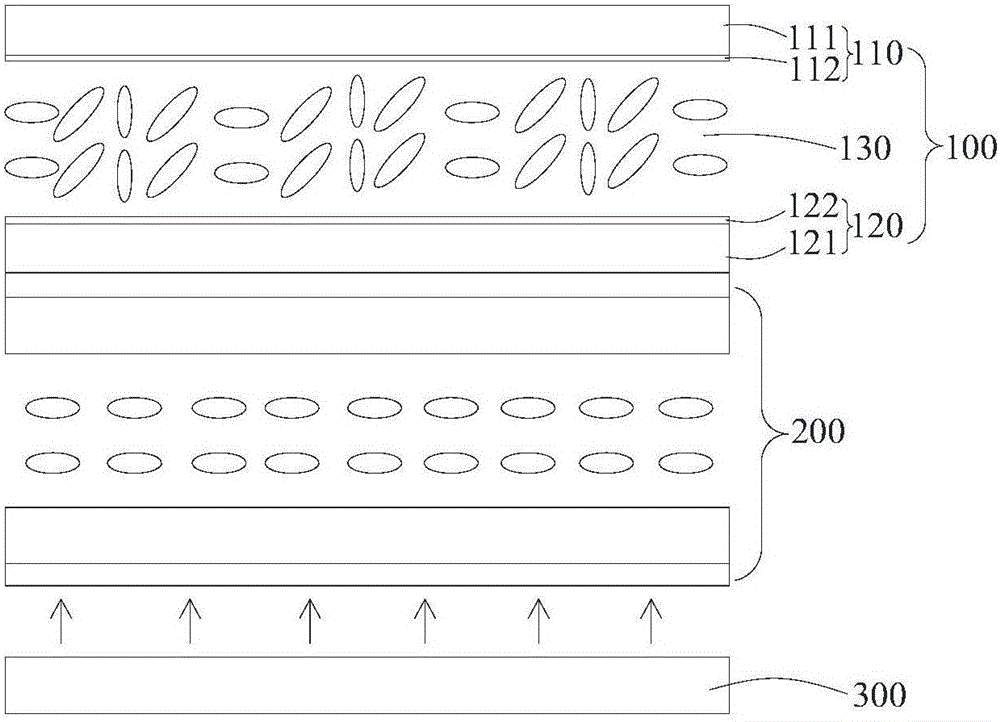

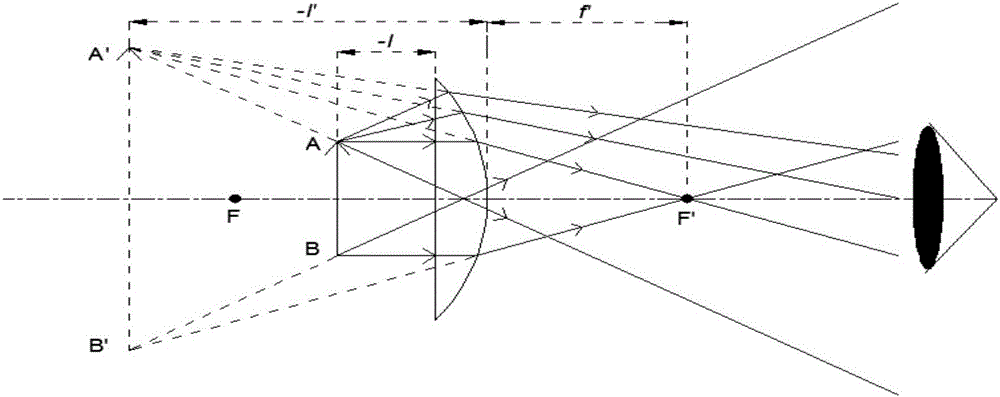

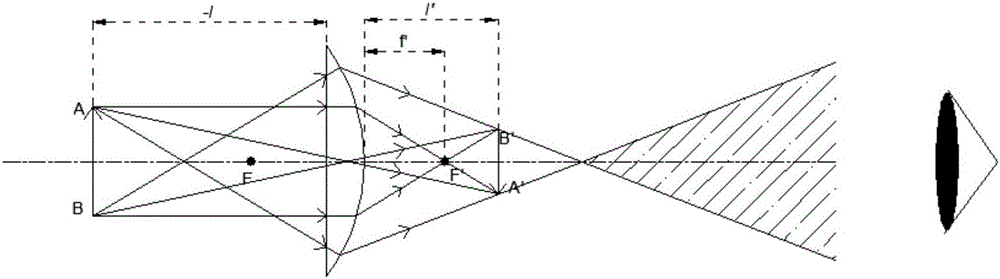

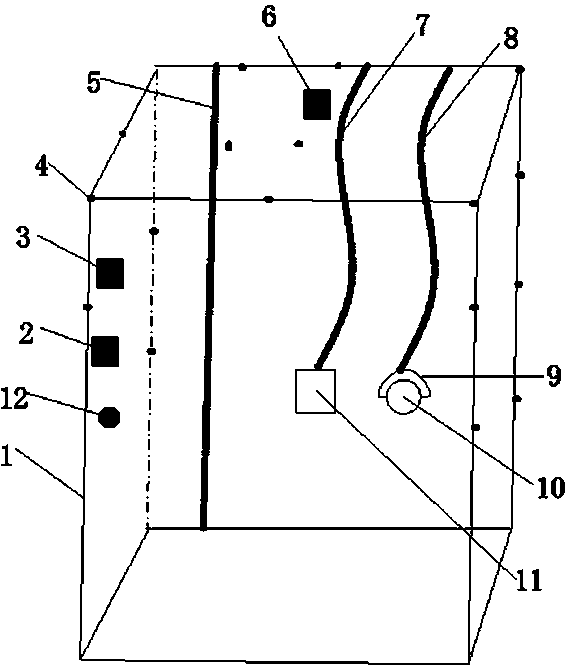

Adjustable compound eye structure optical receiver with visible light wireless communication large view field

InactiveCN102937733AReduce lossesLarge field of viewCladded optical fibreCoupling light guidesPhotovoltaic detectorsConvex side

The invention provides an adjustable compound eye structure optical receiver with a visible light wireless communication large view field, which is formed by a compound eye lens, optical fibers, a photoelectric detector and a circuit system, which are connected in sequence, wherein the compound eye lens is formed by a micro-lens array and a base; the base is formed by four equal organic glass flat plates and a cross-shaped connecting shaft; the cross-shaped connecting shaft and the organic glass flat plates are connected to form a circular base in a rotating manner; a circular rolling bead is embedded into a central crossed part of the cross-shaped connecting shaft; the four organic glass flat plates can rotate around the cross-shaped connecting shaft in the horizontal direction or the vertical direction; the base is provided with a plurality of through holes and lenses embedded into the through holes; the first surface of each micro lens is a convex surface and the second surface of each micro lens is a plane and is connected with the end surface of the optical fiber; and the diameter of each micro-lens is slightly larger than that of the optical fiber. The adjustable compound eye structure optical receiver with the visible light wireless communication large view field has a large receiving view field and a high light transmission rate.

Owner:JIANGSU UNIV

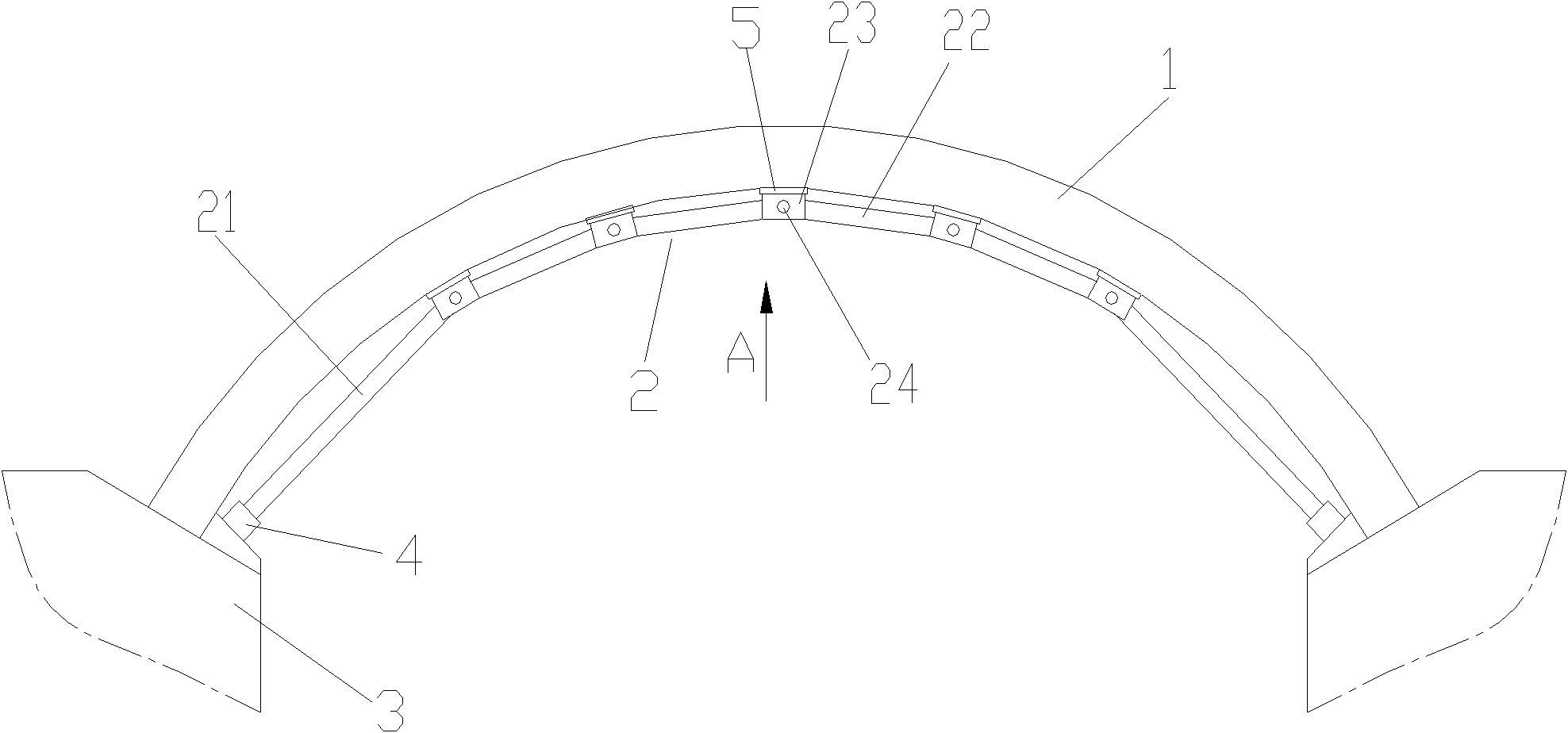

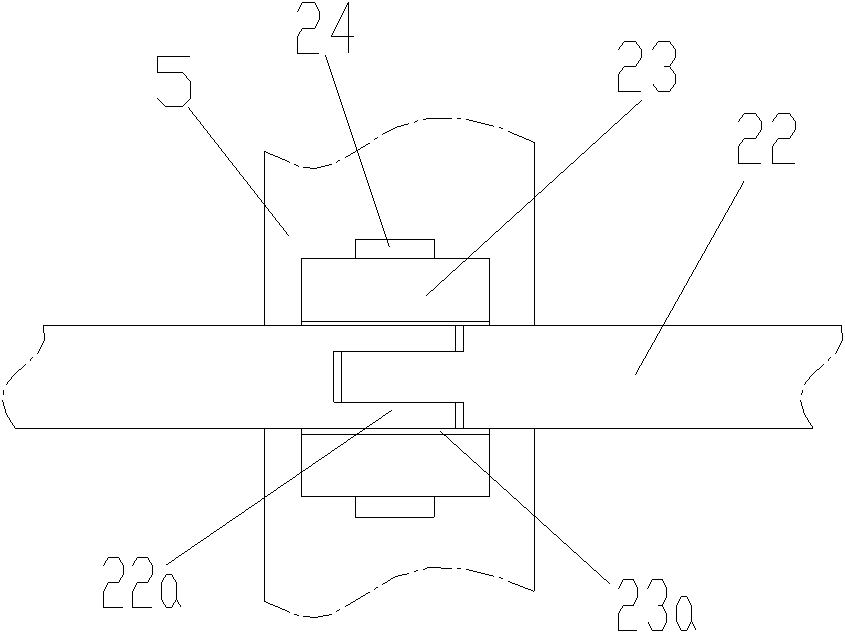

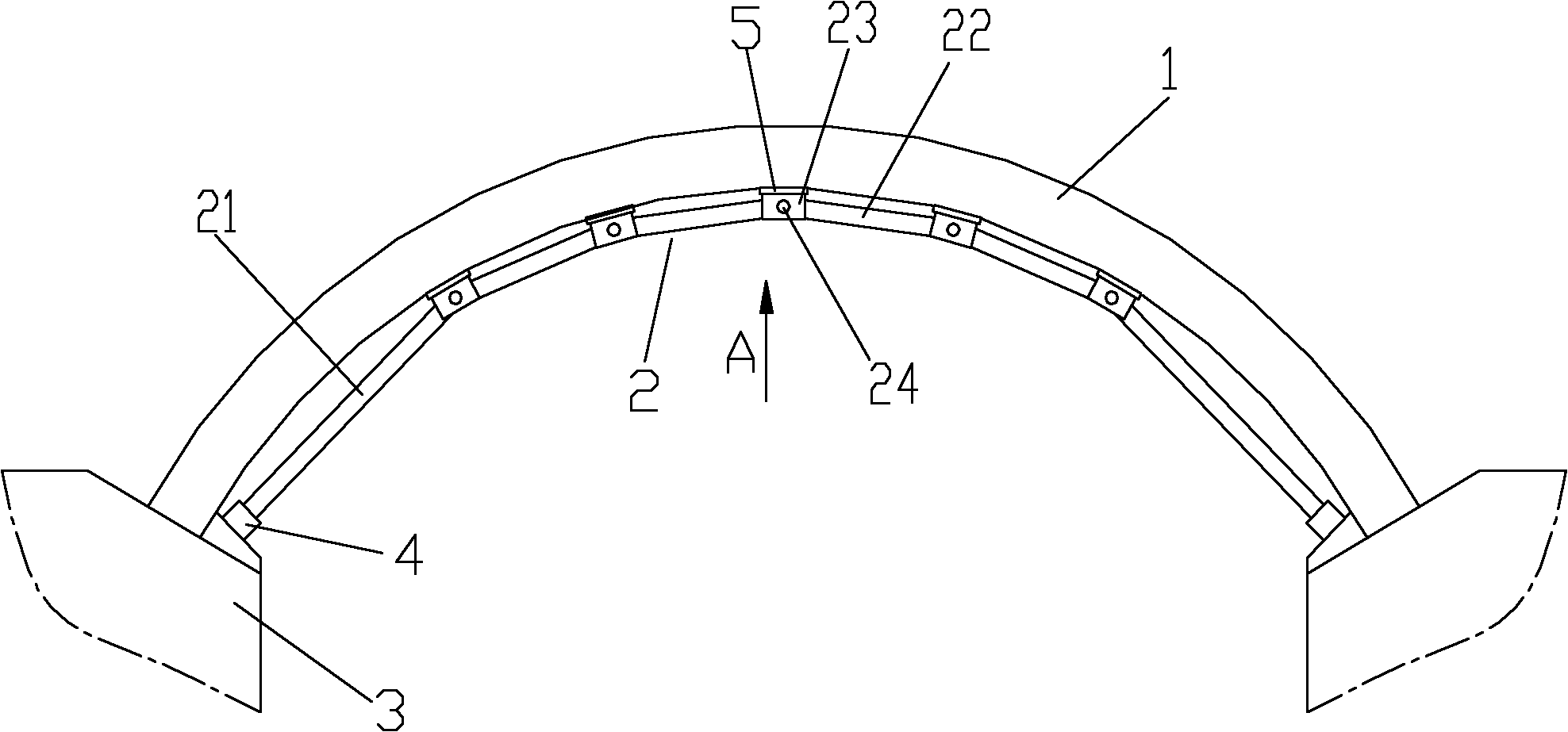

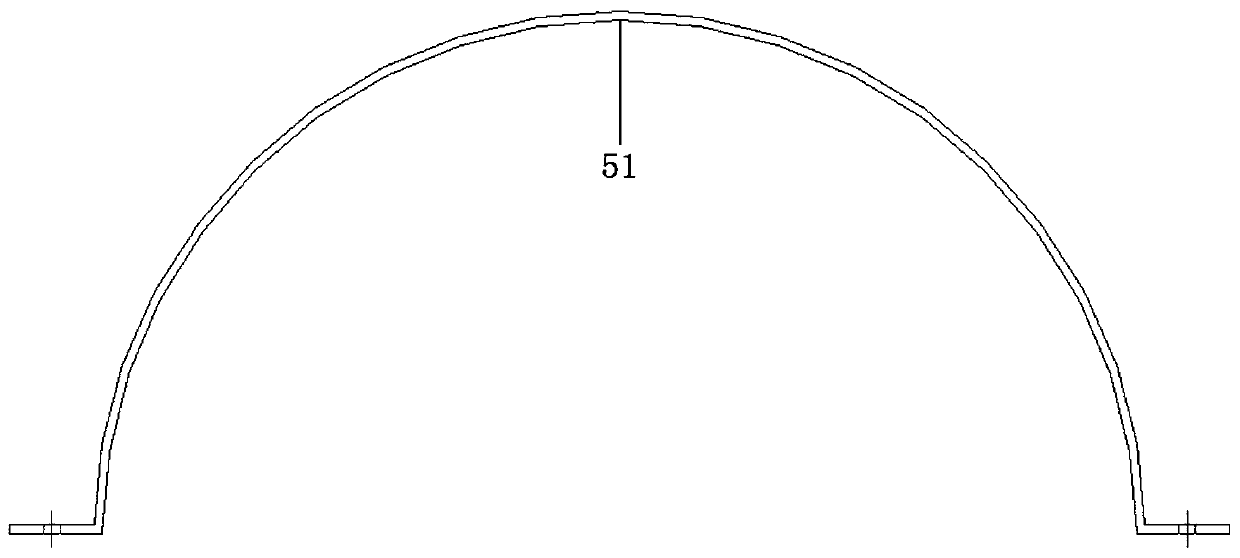

Reinforced combined arch ring for arch bridge

InactiveCN102425103ASimple component formFast and easy to transport and installBridge structural detailsBridge erection/assemblyLoad carryingBending moment

The invention discloses a reinforced combined arch ring for a arch bridge, comprising a main arch ring and a mansard hinge arch positioned at the lower part of the main arch ring, wherein adjacent hinged load-carrying rods are hinged to a load-carrying piece; compressive prestress is applied to the load-carrying rods at two ends of the mansard hinge arch; the load-carrying pieces are distributed at the lower part of the main arch ring, tightly propped against the lower surface of the load-carrying positive bending moment part of the main arch ring, and naturally separated with one another. The reinforced combined arch ring for the arch bridge is simple in structure, and convenient to install and transport; force magnitude and direction of prestressing applied to the main arch ring by each load-carrying piece at the hinge point are specific and can be flexibly adjusted according to requirements; the original constant load internal force distribution of the original main arch ring can be effectively modified without adding the load of the original structure; the special requirement on inner force adjustment at different sections of the main arch ring can be adapted well; and the components of the compressive prestress mansard hinge arch are detectable, maintainable and replaceable when in use, therefore, technical convenience is provided for maintenance management in the usage period of the arch ridge, the durability of the arch bridge can be effectively improved, and the service life of the arch bridge can be prolonged.

Owner:CHONGQING JIAOTONG UNIVERSITY

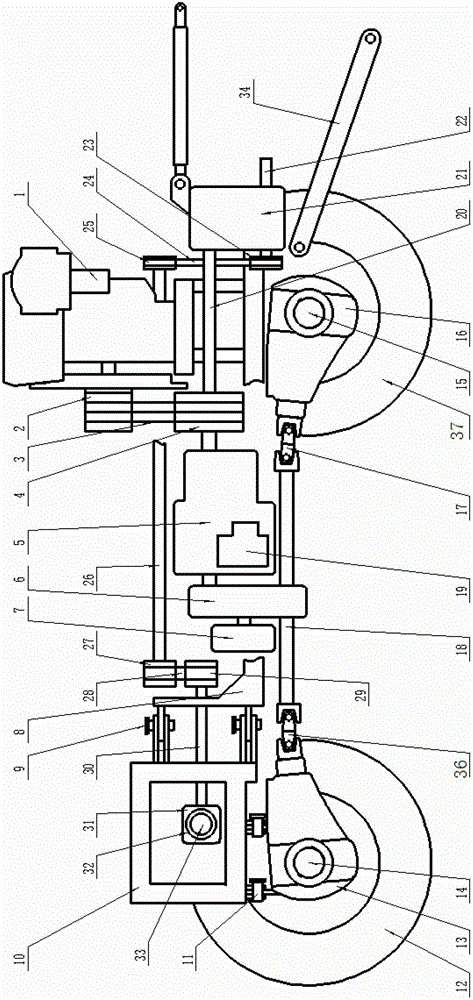

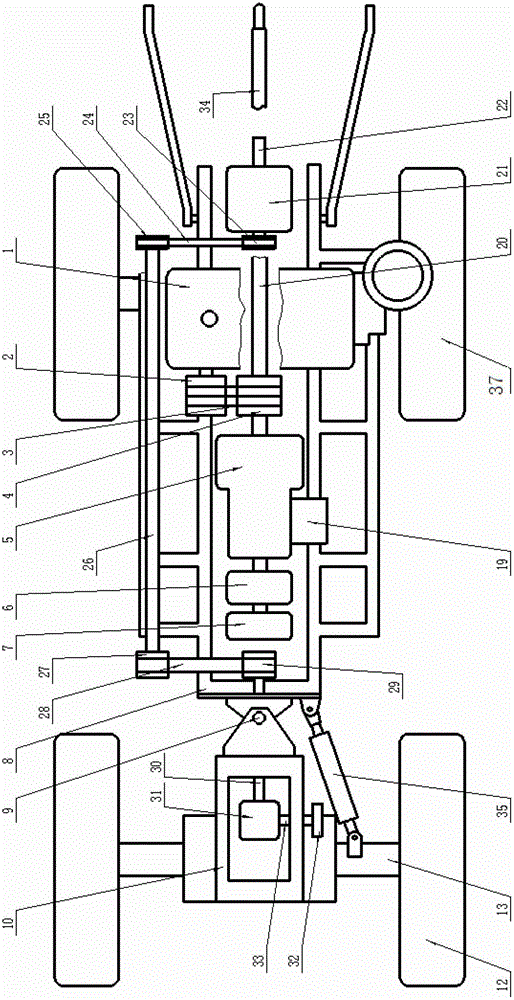

Four-wheel-drive bow-type steering multipurpose tractor

The invention discloses a four-wheel-drive bow-type steering multipurpose tractor which comprises a rear frame and a front frame, wherein the rear frame is provided with a diesel engine, a gear box, a transfer box, a braking hub, a power output reduction box, a rear axle and travelling wheels; the front frame is provided with a turning device, a front axle and travelling wheels; a driving belt wheel of the diesel engine is connected with a driven belt wheel of the gear box; an output shaft of the gear box is connected with an input shaft of the transfer box; the two ends of an output shaft of the transfer box are connected with differential mechanisms; the braking hub is mounted at a middle shaft of the transfer box; the driven belt wheel is internally provided with a clutch, and connected with a transmission shaft I; the other end of the transmission shaft I is connected with the power output reduction box; one end of a rear power output shaft achieves rear power output; a driving chain wheel is mounted at the other end of the rear power output shaft, and connected with a driven chain wheel at one end of a transmission shaft II; a small driving chain wheel at the other end of the transmission shaft II is connected with a small driven chain wheel on a transmission shaft III of the turning device; and a front power output shaft of the turning device is connected with matching machines and tools to achieve front power output. The four-wheel-drive bow-type steering multipurpose tractor is provided with multiple power output ports, and is flexible in steering and wide in application scope.

Owner:GUANGXI LANGUANG TECH

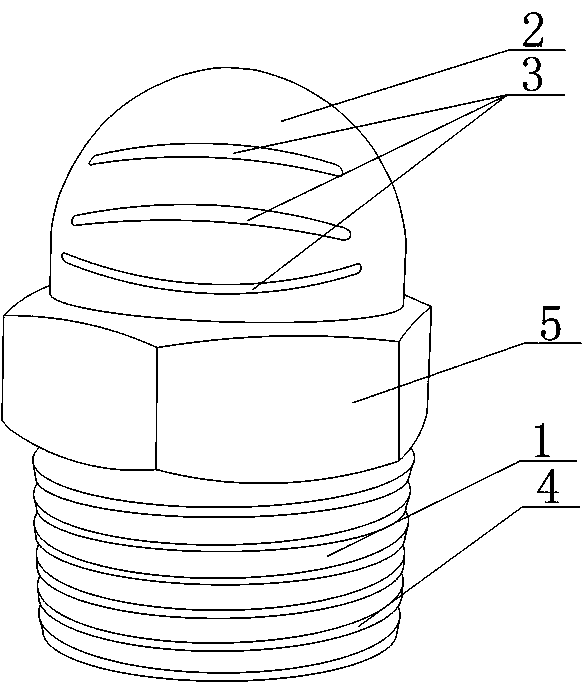

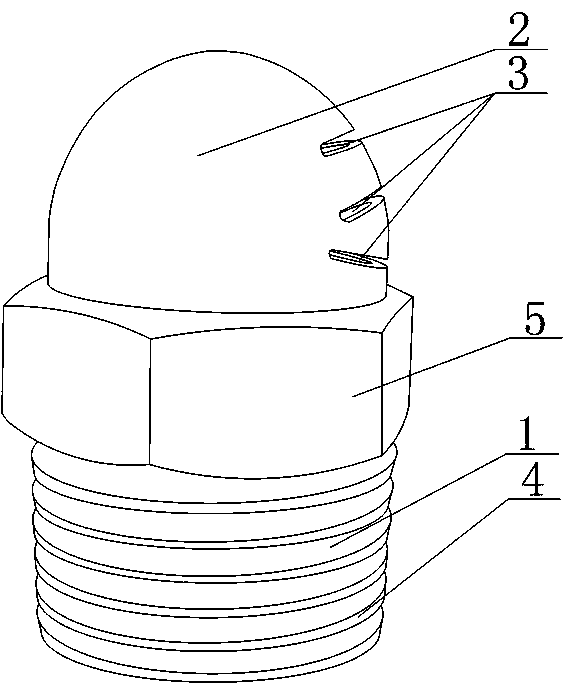

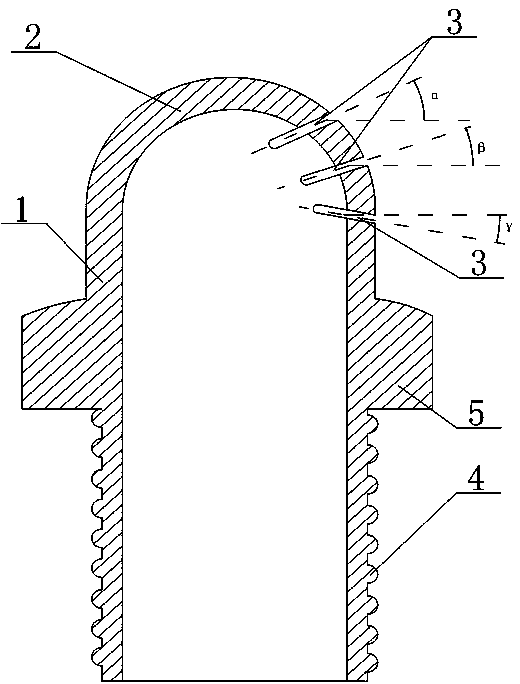

Scattering-structure spray head

InactiveCN103464313AHigh speed injectionSame directionSpray nozzlesAgricultural engineeringHigh pressure water

The invention discloses a scattering-structure spray head, comprising a barrel, wherein one end of the barrel is connected with a water inlet pipe; a closed spray end is installed on the other end of the barrel; at least one long strip type spray port is formed in the spray end and / or the barrel. According to the scattering-structure spray head, the spray head is connected onto a water pipe; the long strip type spray ports are arranged horizontally and can properly incline; when water in a water tank is sprayed out through the spray ports after being pressurized, fan-shaped water curtains are formed; one larger fan-shaped water curtain can cover a carriage; alternately, multiple fan-shaped water curtains cover the carriage in a way of forming a similar rectangle shape; only smaller clearance is left; in the course of loading or unloading, the high-pressure water curtains form a dust keeping-out structure; therefore, flying dust which results from material impact is kept out by the high-pressure water curtains and finally falls into the carriage in the course of loading or unloading; the problem of flying dust is fundamentally solved.

Owner:CHENGDU GAORONG HUALONG IND

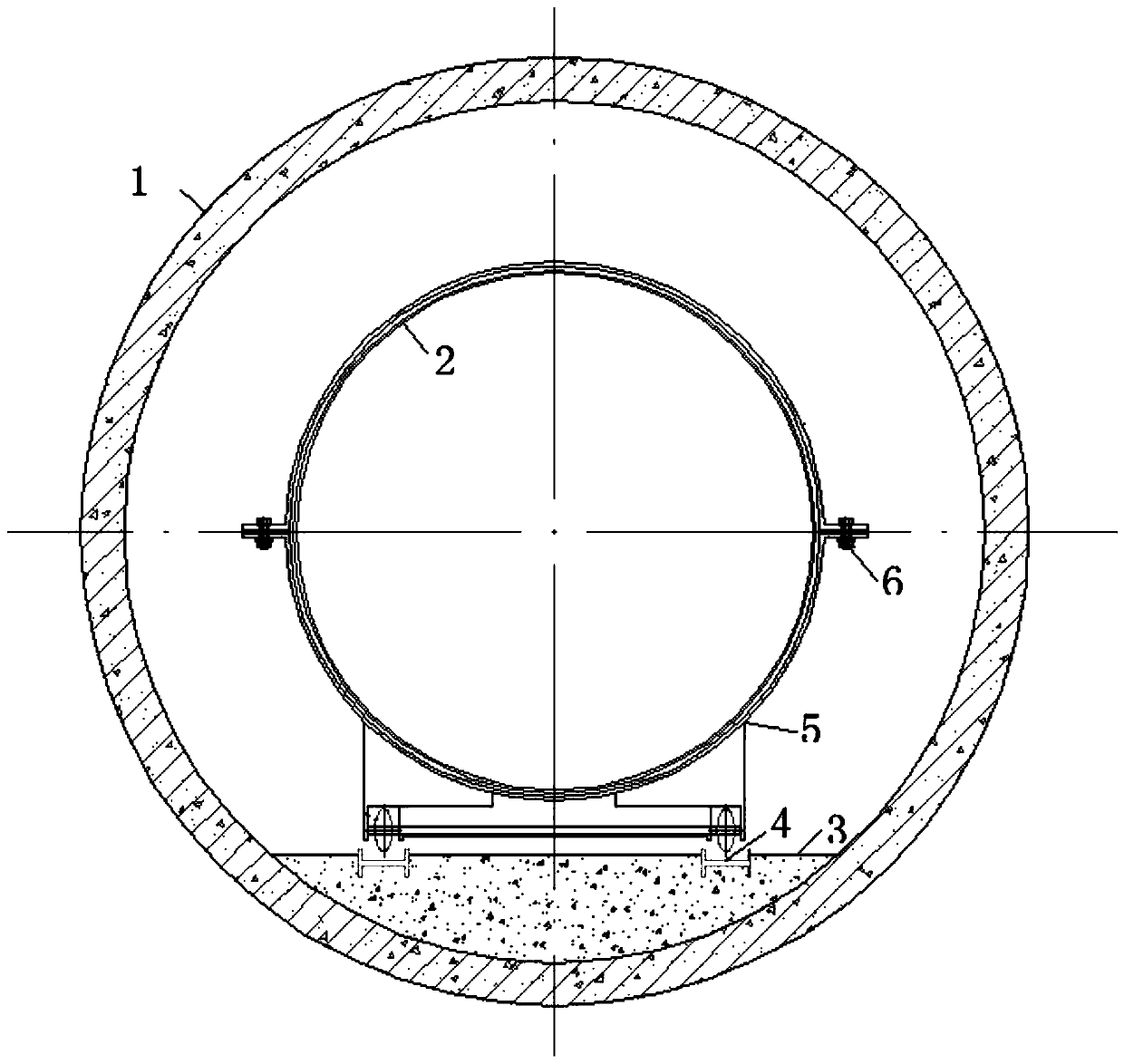

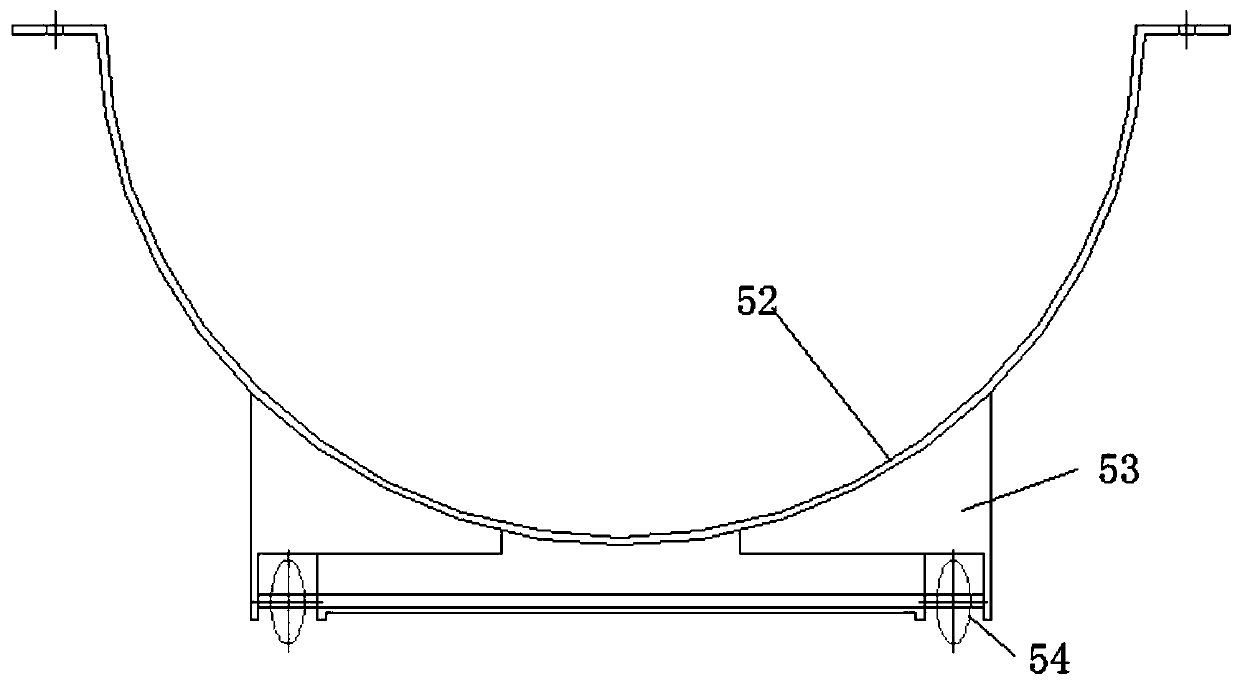

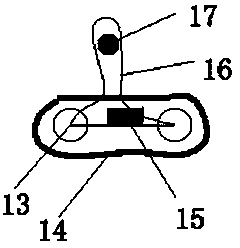

Pipe laying construction method and system inside sleeve pipe based on wheel-rail type pipe hoop

The invention relates to a pipe laying construction method and system inside a sleeve pipe based on a wheel-rail type pipe hoop. The method comprises the following steps that the sleeve pipe is constructed; after constructing of the sleeve pipe is completed, a concrete cushion layer is constructed inside the sleeve pipe; after constructing of the concrete cushion layer is completed, sliding railsare symmetrically arranged on set positions of the two sides of the central axis of the concrete cushion layer; the two ends of a steel pipe are correspondingly and fixedly provided with pre-machinedpipe hoops with pulleys; and the steel pipe is lifted to an inlet of one end of the sleeve pipe so as to be laid, the pulleys of the pipe hoops are connected to the sliding rails on the concrete cushion layer in a sliding mode, the sliding rails are used for providing a fixed advancing route for the pipe hoops, and therefore the steel pipe penetrates into the sleeve pipe. According to the method,aiming at the problems that the advancing track of the pulleys of a traditional steel pulley bracket method is difficult to be unified, and the matching degree and the stability of the steel pipe on the bracket are poor, the pipe laying construction method inside the sleeve pipe based on the wheel-rail type pipe hoop is provided, the sliding rails are utilized for providing the fixed advancing route for the pulleys, and it is ensured that the advancing tracks of the pulleys for conveying all the steel pipes are kept consistent, the steel pipes are free of dislocation, and the directions of thesteel pipes are free of deviation.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

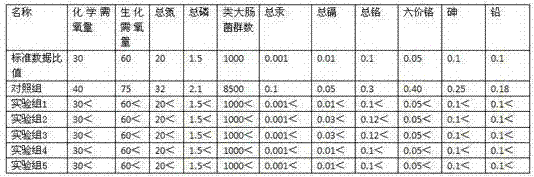

Composite microbial agent for treating domestic garbage and method for treating domestic garbage by using composite microbial agent

InactiveCN106978370AIncrease functional diversityImprove applicabilityFungiBacteriaPseudomonas putidaMicrobial agent

The invention relates to a composite microbial agent for treating domestic garbage and a method for treating the domestic garbage by using the composite microbial agent. The composite microbial agent for treating the domestic garbage is prepared from the following components: brevendimonas diminuta, pseudomonas stutzeri, pseudomonas maltophilia, pseudomonas fluorescens, pseudomonas putida, candida utilis, candida lipolytica, schizosaccharomyces pombe, schizosaccharomyces octosporus, bacillus megatherium, bacillus subtilis, bacillus cereus, alcaligenes faecalis, clostridium beijerinckii, achromobacter denitrificans, nocardia coralline, and the like, wherein the parts by weight of the brevendimonas diminuta are 1-5, the parts by weight of the pseudomonas stutzeri are 1-5, the parts by weight of the pseudomonas maltophilia are 1-5, the parts by weight of the pseudomonas fluorescens are 1-5, the parts by weight of the pseudomonas putida are 1-5, the parts by weight of the candida utilis are 1-5, and the parts by weight of the candida lipolytica are 1-5.

Owner:哈尔滨明慧生物技术开发有限公司

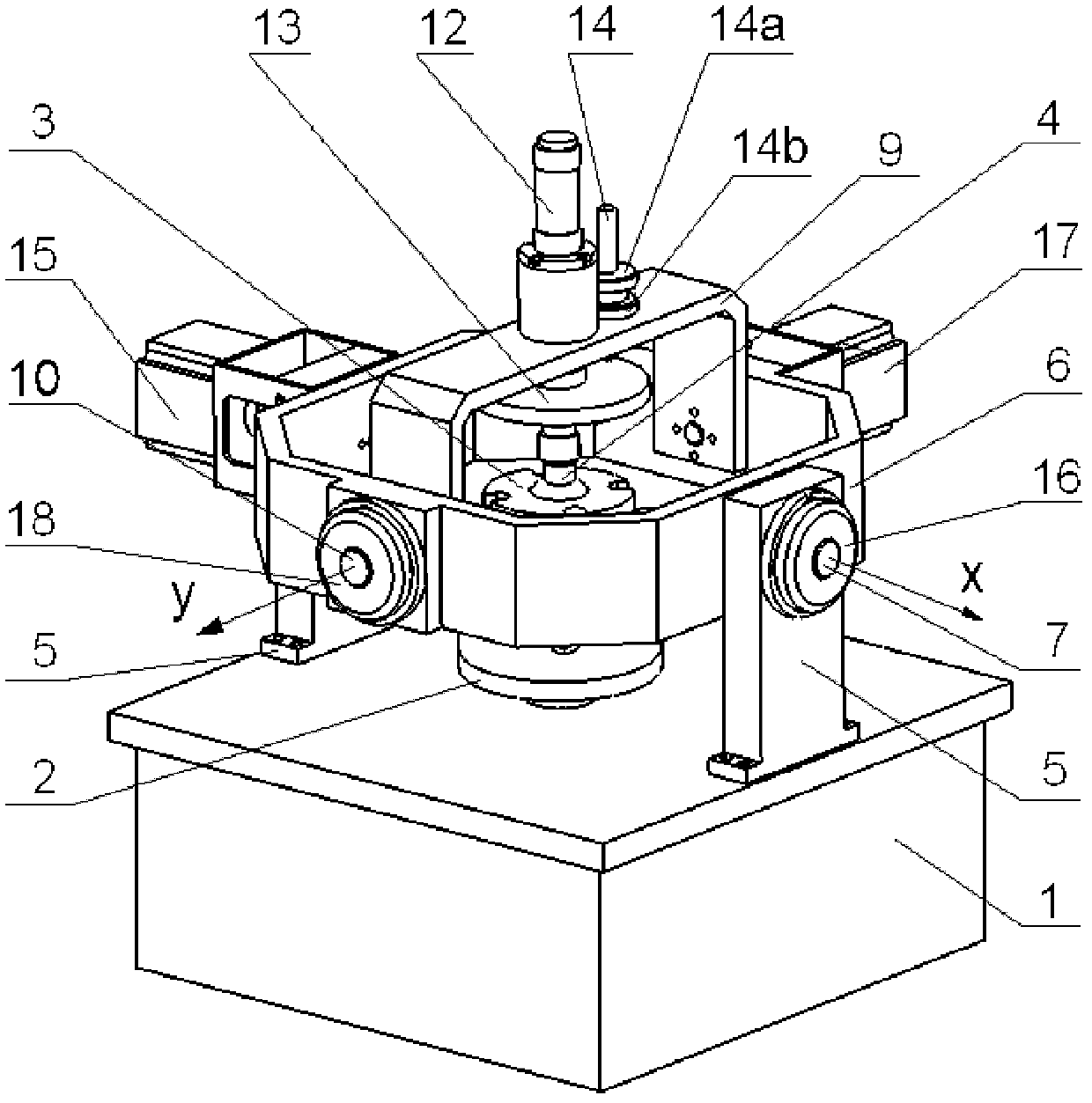

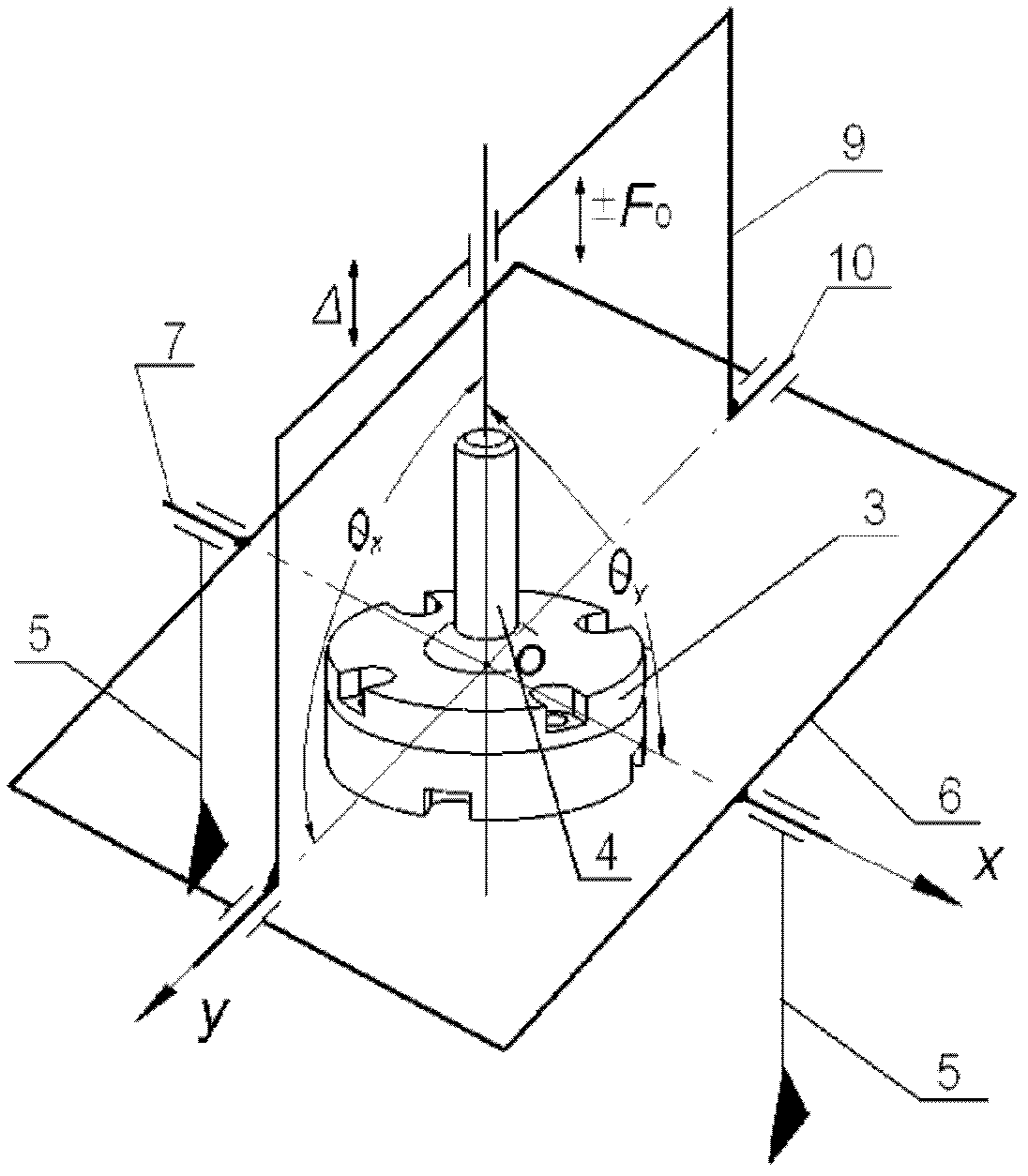

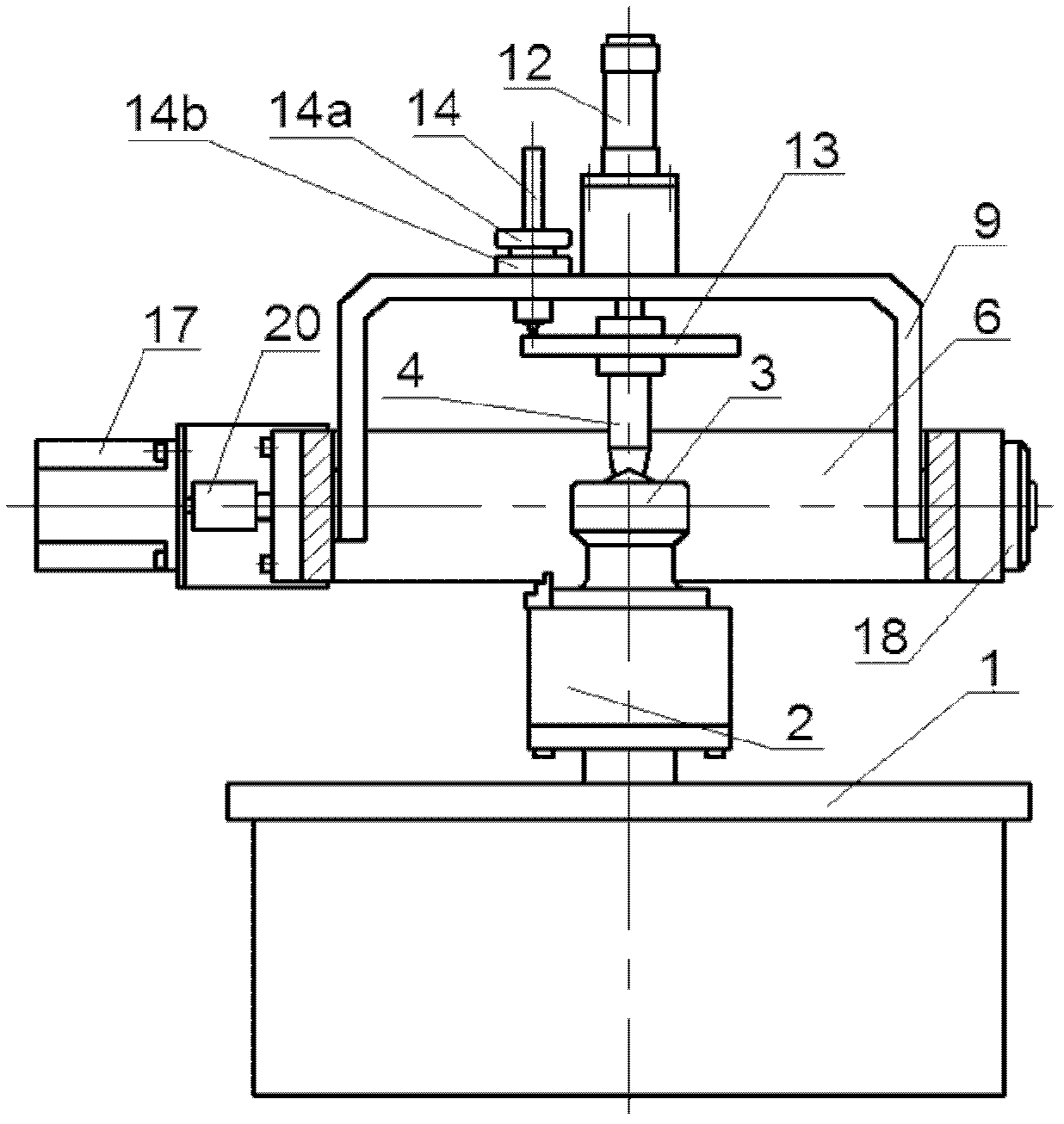

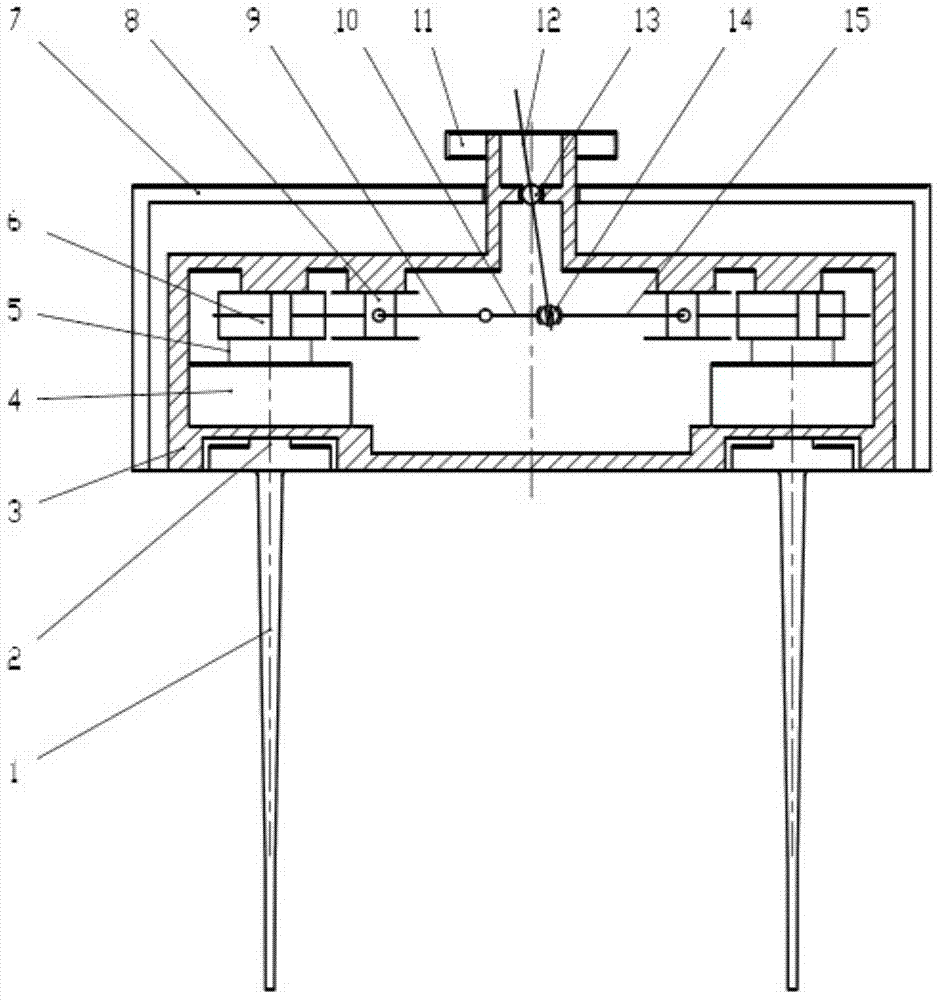

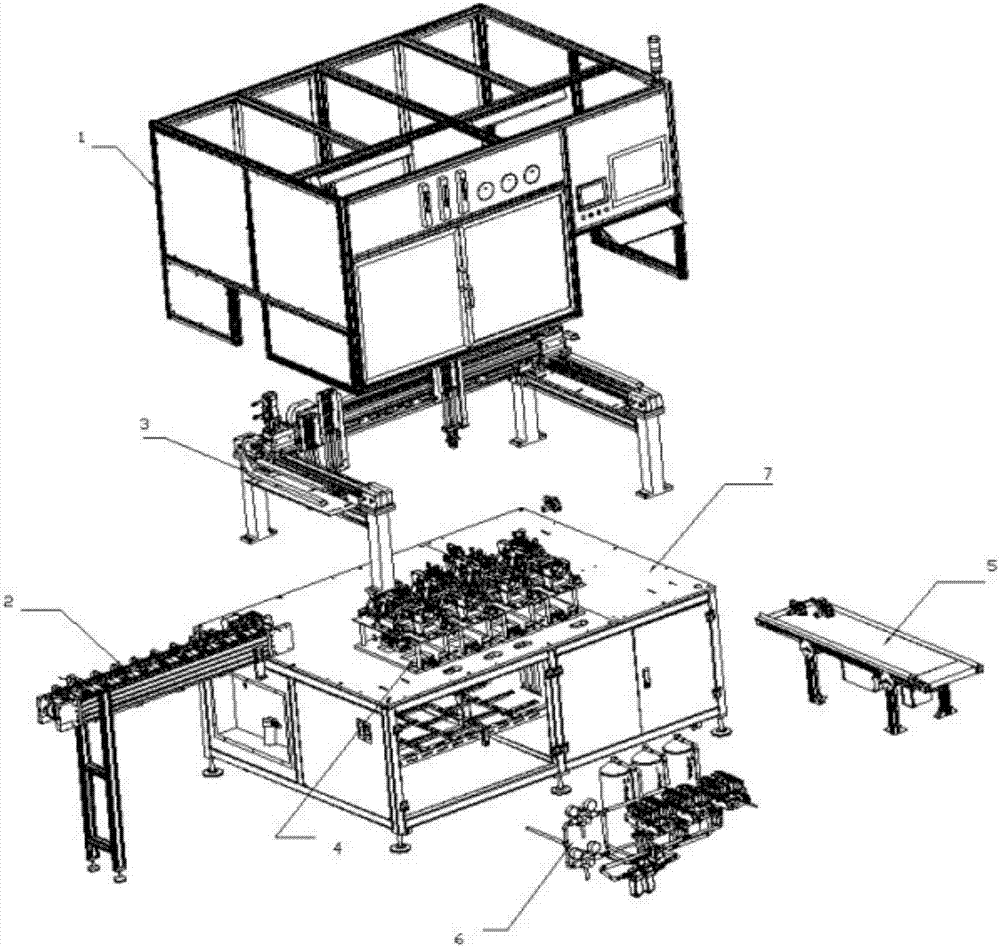

Precision spherical hinge clearance-measuring instrument and measurement method

ActiveCN102607400AAchieve rotationIncrease stiffnessUsing electrical meansThree-dimensional spaceMeasuring instrument

The invention discloses a precision spherical hinge clearance-measuring instrument and a measurement method. The precision spherical hinge clearance-measuring instrument is characterized in that the precision spherical hinge clearance-measuring instrument is provided with a horizontal base platform, a rectangular outer frame, an inverted U-shaped inner frame, a loading cylinder, an adapter disk and an inductive displacement sensor. Under the cooperation of the motion of the rotatable rectangular outer frame and the rotatable inverted U-shaped inner frame which are perpendicularly crossed by each other, the precision spherical hinge clearance-measuring instrument can acquire the raw clearance error measurement data of the assembling clearance of a spherical hinge, and can obtain the model and rule of the spherical hinge clearance error by means of subsequent corresponding data processing; the clearance error of the spherical hinge within a three-dimensional space can be efficiently, automatically and accurately measured, and the invention can promote the progress of the parallel mechanism error modeling and correction technique.

Owner:HEFEI UNIV OF TECH

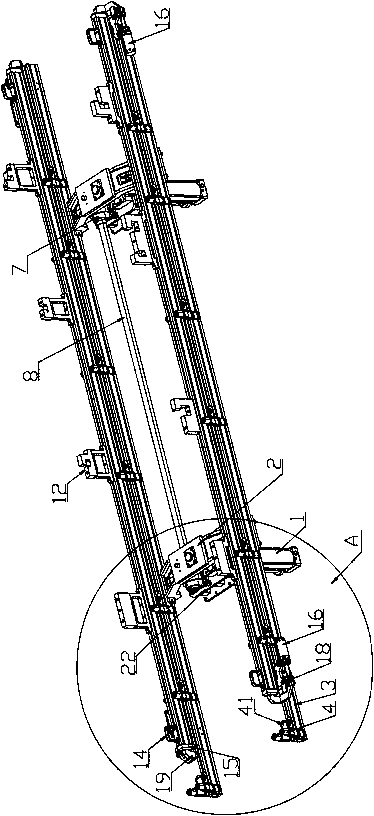

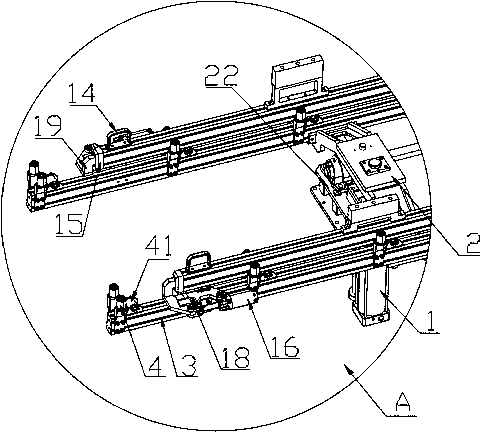

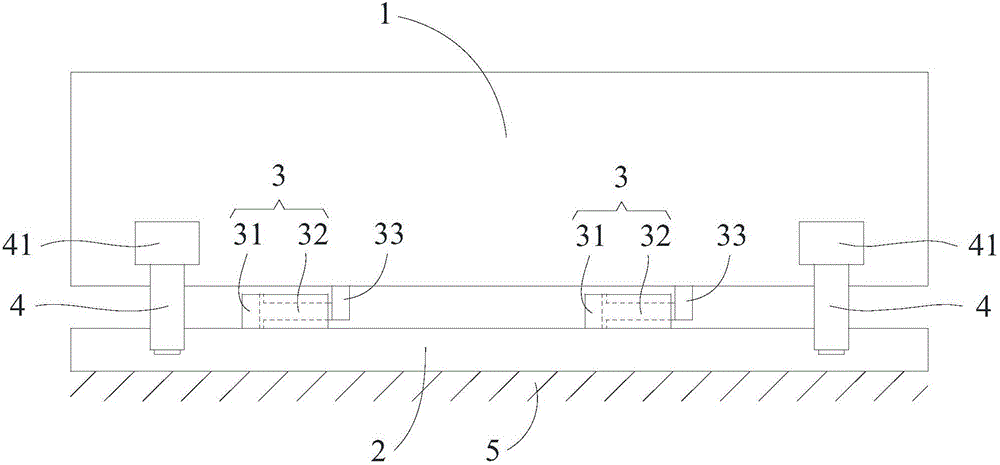

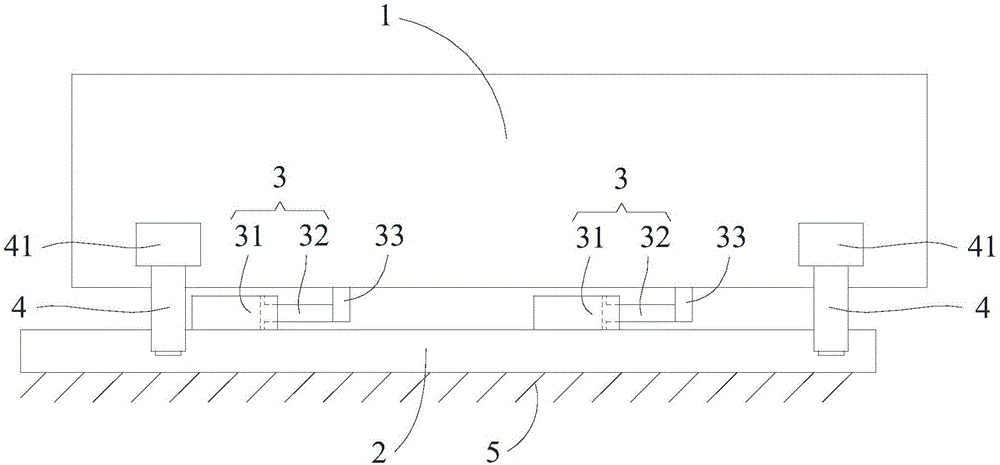

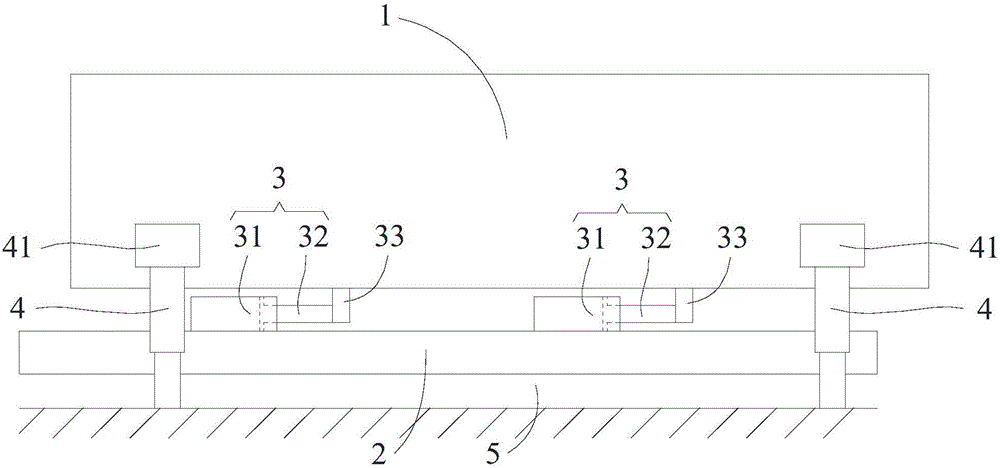

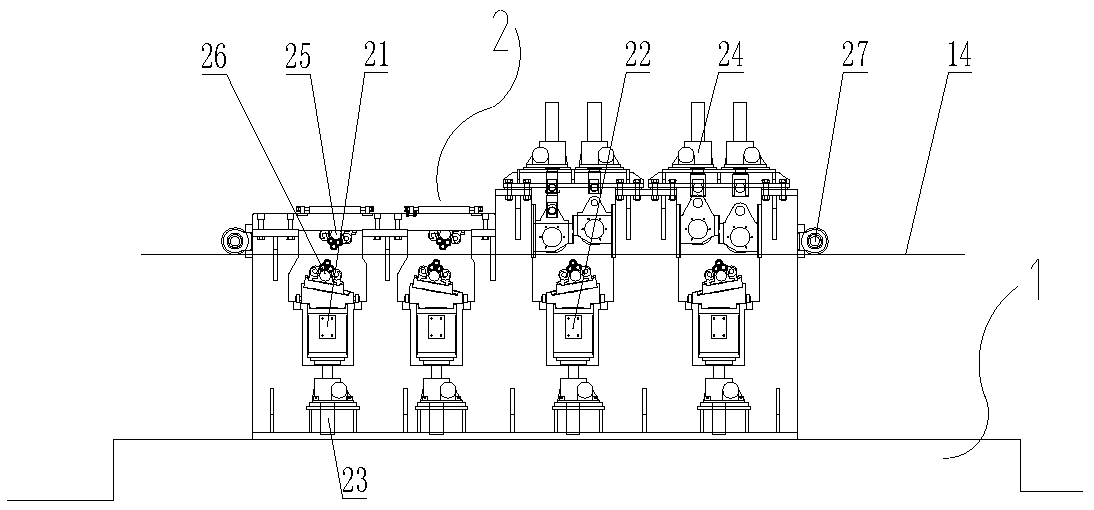

Automobile welding side wall line conveying mechanism

The invention relates to an automobile welding side wall line conveying mechanism comprising conveying beams, jacking cylinders and a synchronizing mechanism. The upper portion of a piston rod of each jacking cylinder is fixedly connected with a bracket, the parallel conveying beams are supported at two ends of each bracket, a conveying slide capable of sliding along the conveying beams is arranged on each conveying beam, a guide roller is arranged on each conveying beam, and the synchronizing mechanism is parallel to the jacking cylinders and used for controlling the jacking cylinders to lift simultaneously. Locking mechanisms used for limiting the conveying slides are arranged at two ends of each conveying beam. The automobile welding side wall line conveying mechanism is simple in structure and lightweight, labor intensity of worker is reduced, manpower and material resources are saved, proceeding of welding processes is facilitated, and processing efficiency of workpieces is improved greatly.

Owner:烟台宇信科技有限公司

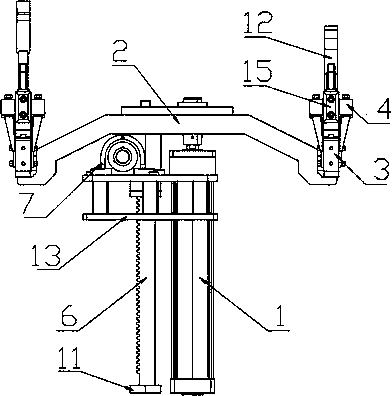

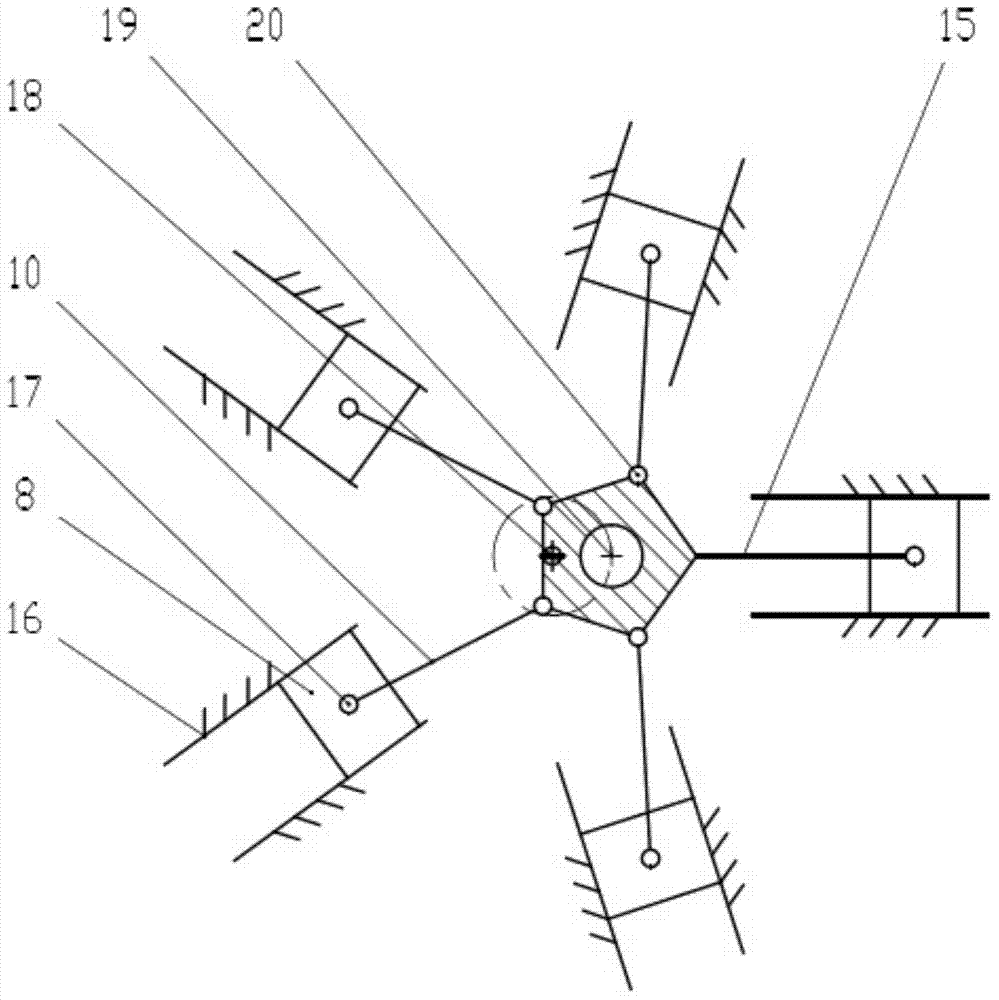

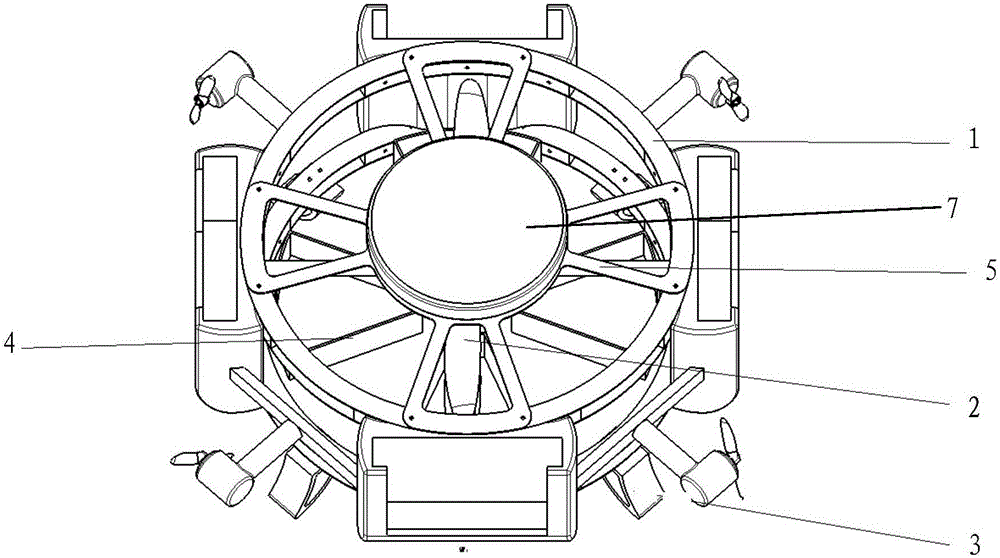

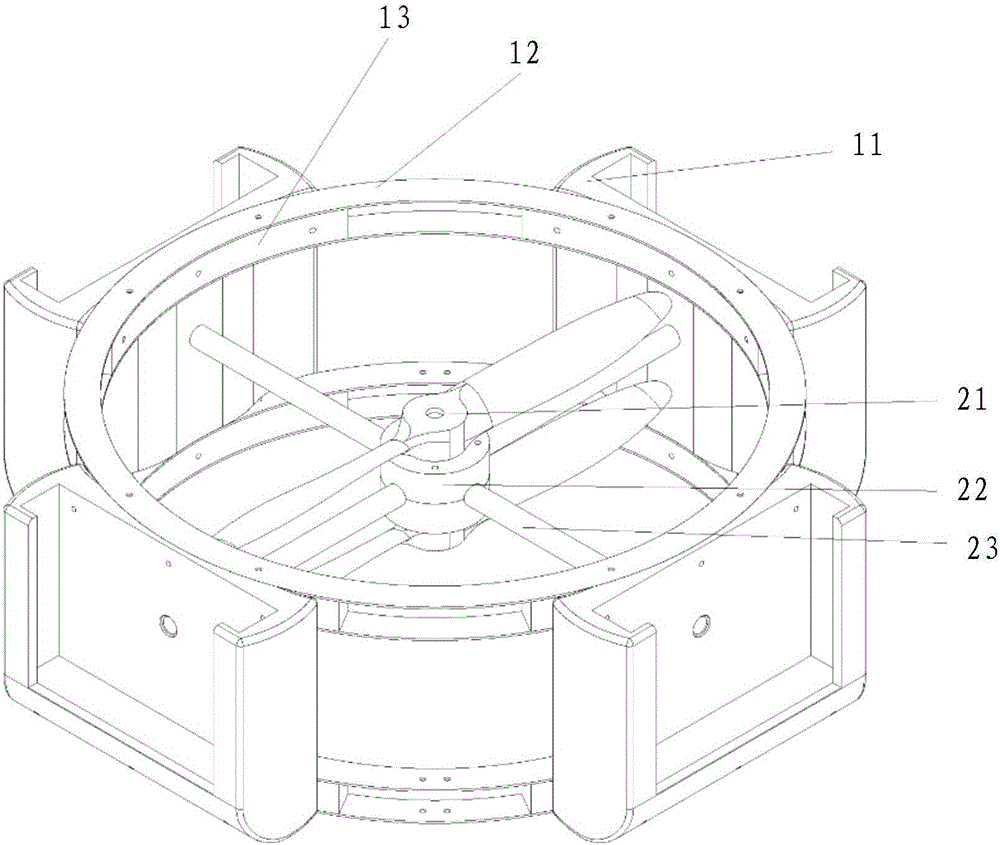

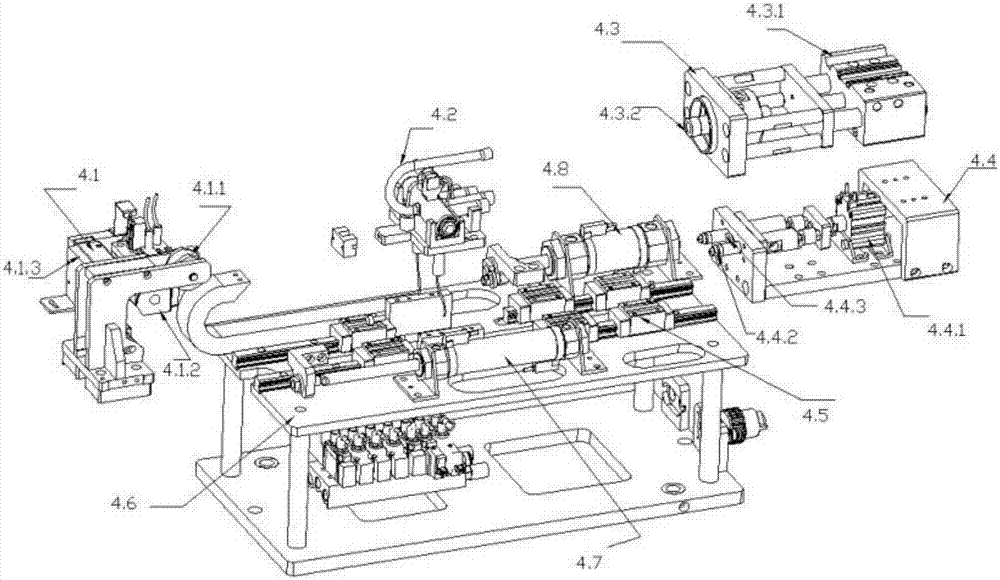

Crank and slider hydraulic transmission type cycloidal propeller mechanism

InactiveCN103921927AReduce axial sizeSame directionPropulsive elements of rotary typeTransmission with non-mechanical gearingHydraulic cylinderPropeller

The invention aims to provide a crank and slider hydraulic transmission type cycloidal propeller mechanism. Blades of the mechanism are straight blades, all the blades are vertically distributed at the bottom of a ship body, and the blades swing around the axes of themselves while rotating around a spindle. A shaft of each blade is connected with a shaft of a corresponding swing hydraulic cylinder, two oil ports of each swing hydraulic cylinder are connected with two cavities of a corresponding double-rod linear hydraulic cylinder, and a piston rod of each linear hydraulic cylinder is fixedly connected with a slider of a crank and slider mechanism. The sliders and pistons of the linear hydraulic cylinders are driven to do reciprocating rectilinear movement through circumferential rotation of the cranks, power transmitted by oil of the linear hydraulic cylinders enables the swing hydraulic cylinders to swing in a reciprocating mode, and therefore the blades are driven to swing in a reciprocating mode, and the impelling action of a cycloidal propeller is achieved. The axial size of the cycloidal propeller is reduced, and the direction of force can be changed easily.

Owner:HARBIN ENG UNIV

Display device

InactiveCN105866998ASame directionRealize surface displayNon-linear opticsIdentification meansSurface displayLiquid-crystal display

The invention provides a display device which comprises a display panel, a control module and an auxiliary panel arranged on the light-emitting side of the display panel. The auxiliary panel comprises a first liquid crystal layer, and a first base plate and a second base plate which are oppositely arranged. The first liquid crystal layer is packaged between the first base plate and the second base plate, the first base plate comprises a first substrate and a first transparent electrode layer arranged on the first substrate, the second base plate comprises a second substrate and a second transparent electrode layer arranged on the second substrate, and the control module can provide a control signal enabling different areas in the first liquid crystal layer to have different refractive indexes for the first transparent electrode layer and the second transparent electrode layer, so that light penetrating out of the display panel forms an image on a curved surface, and the opening of the curved surface faces towards the light-emitting direction of the display device. By means of the display device, curved surface display is achieved on the premise of not increasing the installation size of the display device.

Owner:BOE TECH GRP CO LTD

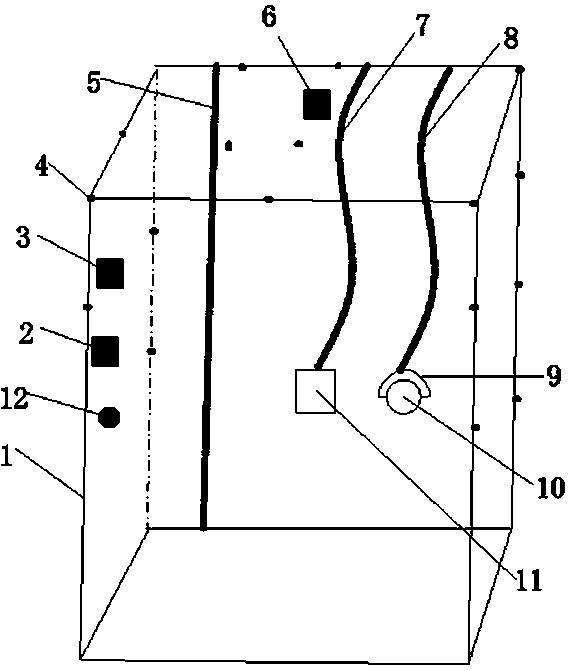

Station crossing device and method for shield tunneling machine

InactiveCN106640185ASimple structureSimple and fast operationTunnelsUnderground transportSteel platesPiston

The invention discloses a station crossing device for a shield tunneling machine. The station crossing device comprises a bracket, a piston mechanism and a jacking mechanism; the bracket is used for receiving and bearing the shield tunneling machine and serves as a reaction frame used when the shield tunneling machine starts tunneling, the piston mechanism comprise a piston component connected with the shield tunneling machine and the bracket and is used for horizontal moving between shield tunneling machine and the bracket, and the jacking mechanism comprises a jacking component connected to the shield tunneling machine and is used for jacking the shield tunneling machine and the bracket to be separated from a foundation. By applying the device, self-waling movement of the shield tunneling machine and the bracket is achieved by means of cooperation movement of the piston mechanism and the jacking mechanism, and a roller steel plate structure or a rail transportation structure which can enable the bracket to move does not need to be arranged for the bracket separately; meanwhile, after the shield tunneling machine crosses a station, the bracket directly serves as the reaction starting frame of the shield tunneling machine, the piston mechanism supports the shield tunneling to tunnel forwards, and the reaction starting frame does not need to be installed independently. The device is simple in structure and easy and convenient to operate, the station crossing working difficulty of the shield tunneling station is greatly reduced, the working time is shortened, the construction efficiency is improved, and the cost is reduced.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

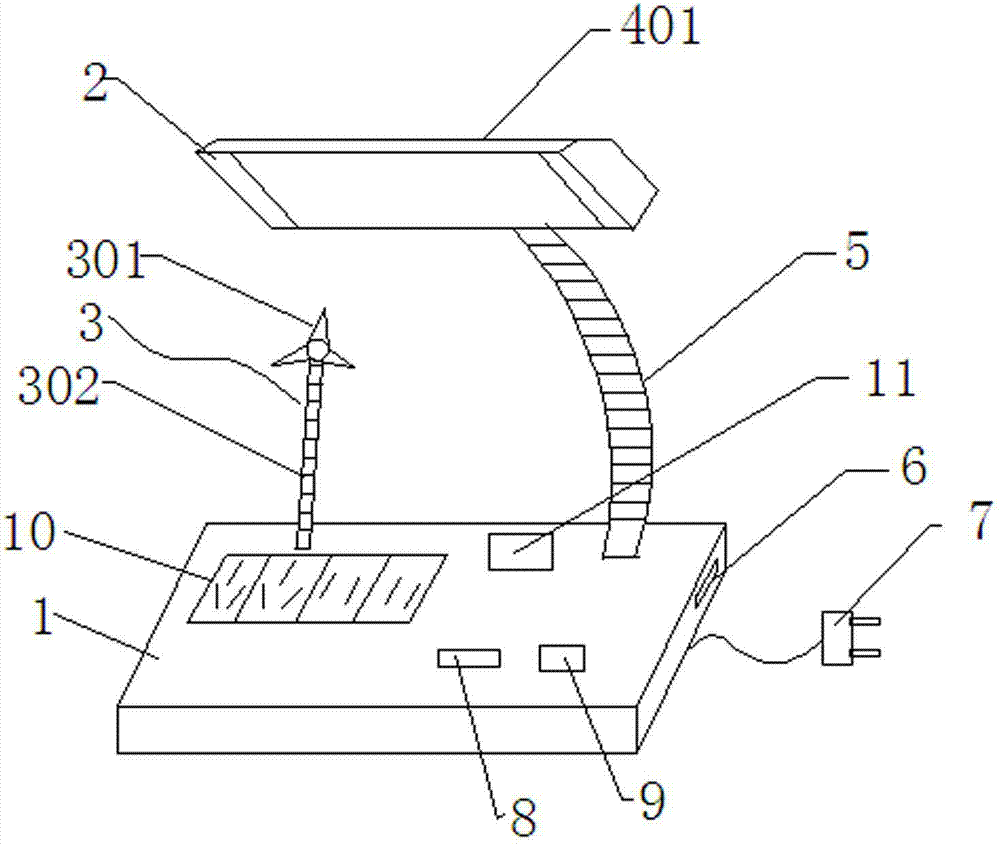

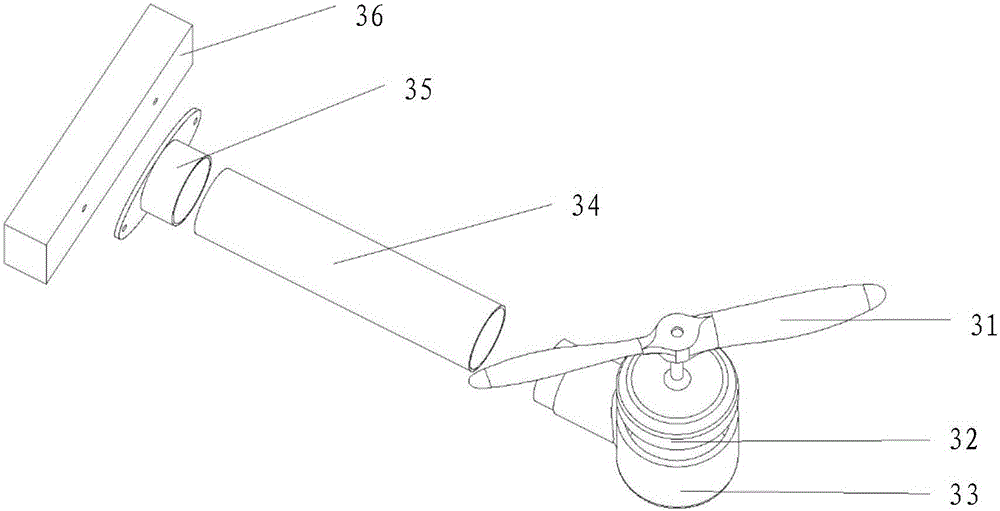

New energy resource table lamp

InactiveCN103791416ASame directionImprove wind power efficiencyElectric circuit arrangementsWith built-in powerNew energyUSB

The invention discloses a new energy resource table lamp. The new energy resource table lamp comprises a base, a lampshade, a solar assembly and a wind power generation assembly. The solar assembly comprises a solar cell panel, a storage battery and an inverter. The storage battery is arranged inside the base. The solar cell panel is arranged on a back plate of the lampshade. The wind power generation assembly is arranged on the base. The lampshade is arranged on the base through a flexible metal strut. The wind power generation assembly comprises a fan and a fan support. The fan support is made of flexible metal. The base is provided with a USB charging port. Compared with the prior art, power is supplied to the new energy resource table lamp through other electric appliances, the new energy resource table lamp is powered on through electric supply under the circumstance that power of the storage battery is insufficient, the direction of the fan is adjustable, the wind power generation efficiency is high, and multifunctional charging and power supply modes can be realized.

Owner:南京霞光新能源科技有限公司

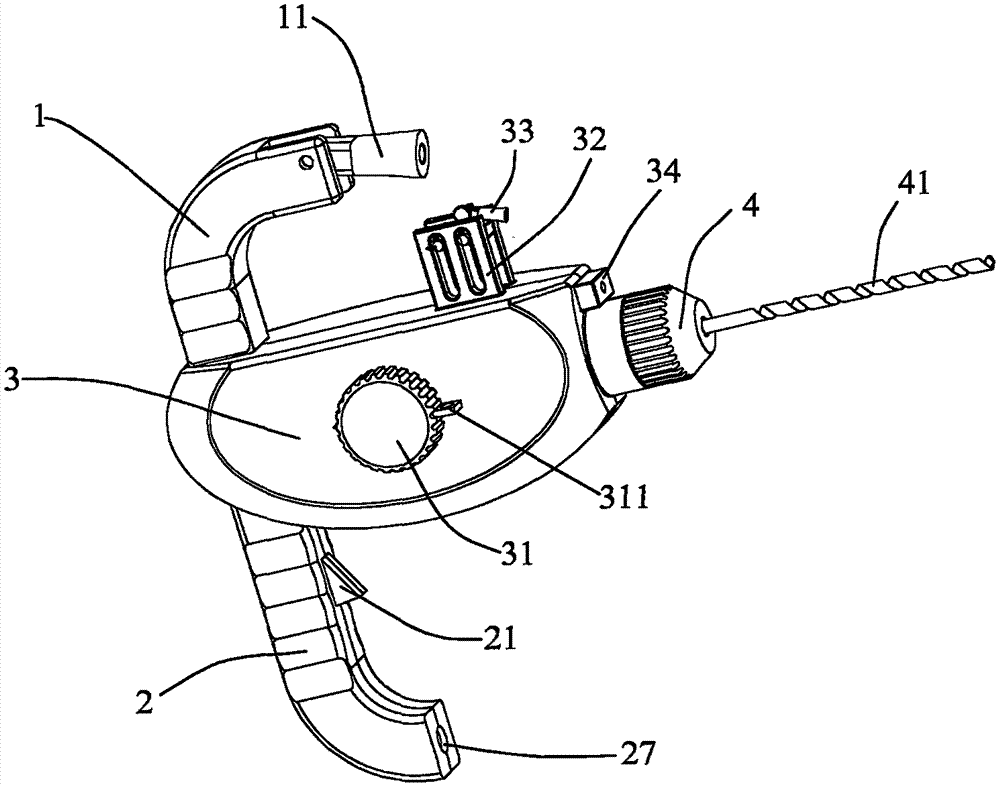

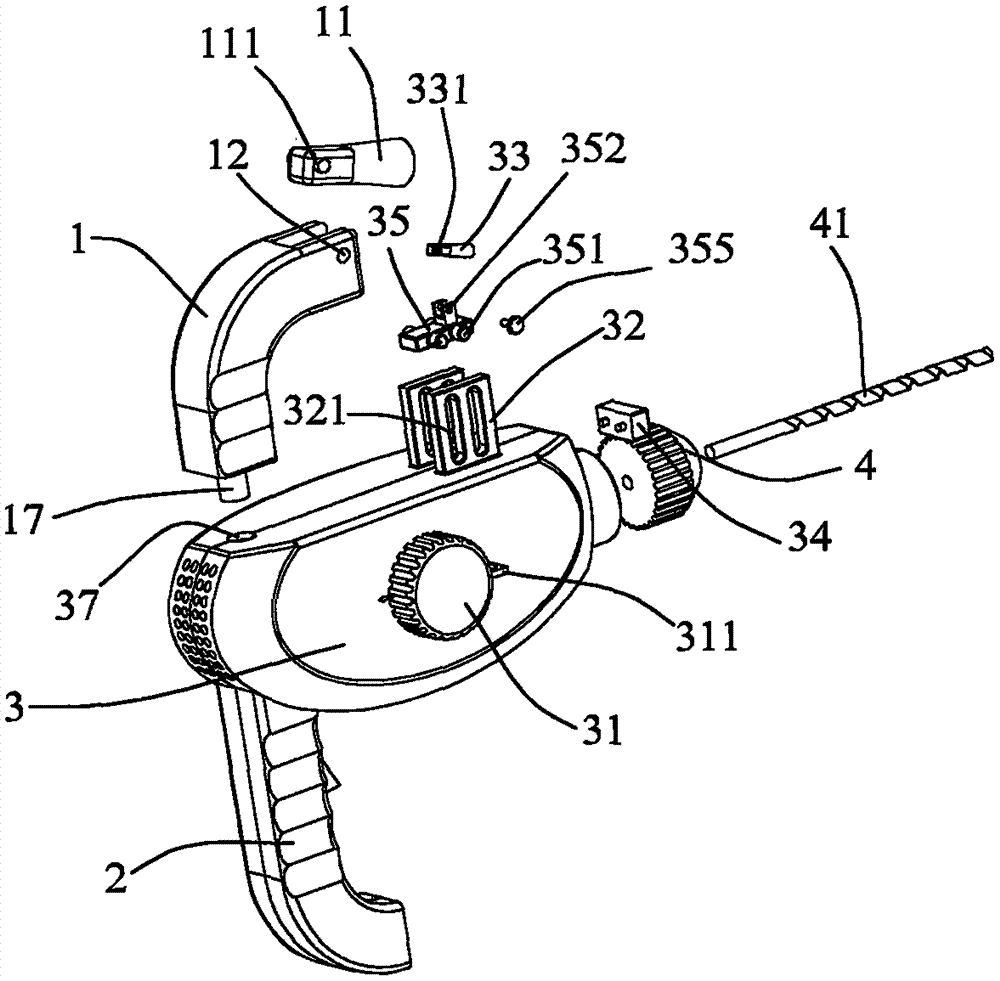

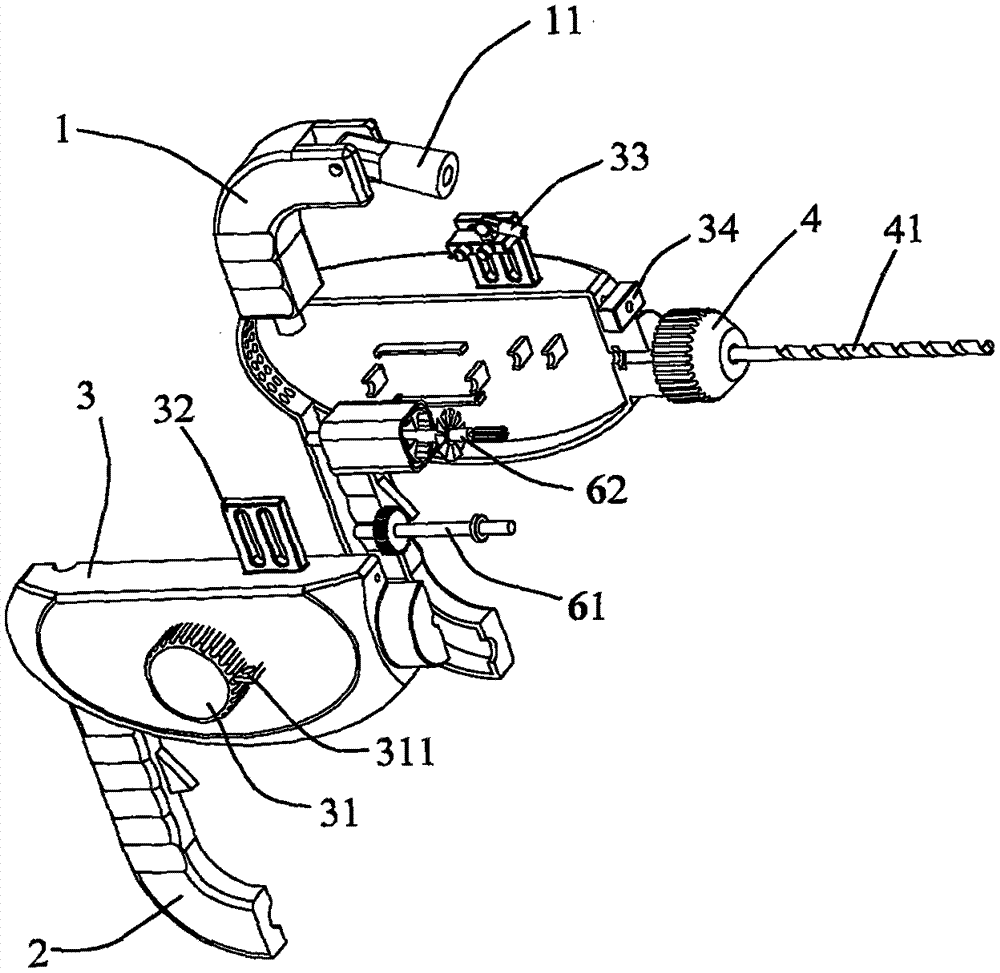

Multifunctional electric drill bringing convenience to processing

InactiveCN105436567AImprove stabilityAvoid Drilling Quality LossPortable power-driven toolsPortable drilling machinesLight beamEngineering

The invention provides a multifunctional electric drill bringing convenience to processing. The multifunctional electric drill comprises an electric drill body which is provided with a driving mechanism, wherein a handle for handholding, and a drill bit part for drilling a hole are arranged on the electric drill body; the drill bit part comprises a drill bit clamp, and a drill bit which is arranged on the drill bit clamp. The multifunctional electric drill further comprises a first laser lamp and a second laser lamp, wherein light beams generated by the first laser lamp and the second laser lamp meet each other in one point; the first laser lamp is movably connected to the electric drill body; the handle comprises a first handle and a second handle which are symmetrically arranged at two sides of the electric drill body. The multifunctional electric drill has the following beneficial effects that 1) the drilling depth can be controlled according to the location of the point where the two light beams meet each other, the structure is simple, and the operation is convenient; 2) the electric drill can be operated with both hands or one hand; in addition, a light source is provided and facilitates the work at night; 3) an inclined hole can be conveniently and accurately drilled.

Owner:JIANGSU SUOLIDE ELECTRICAL APPLIANCE

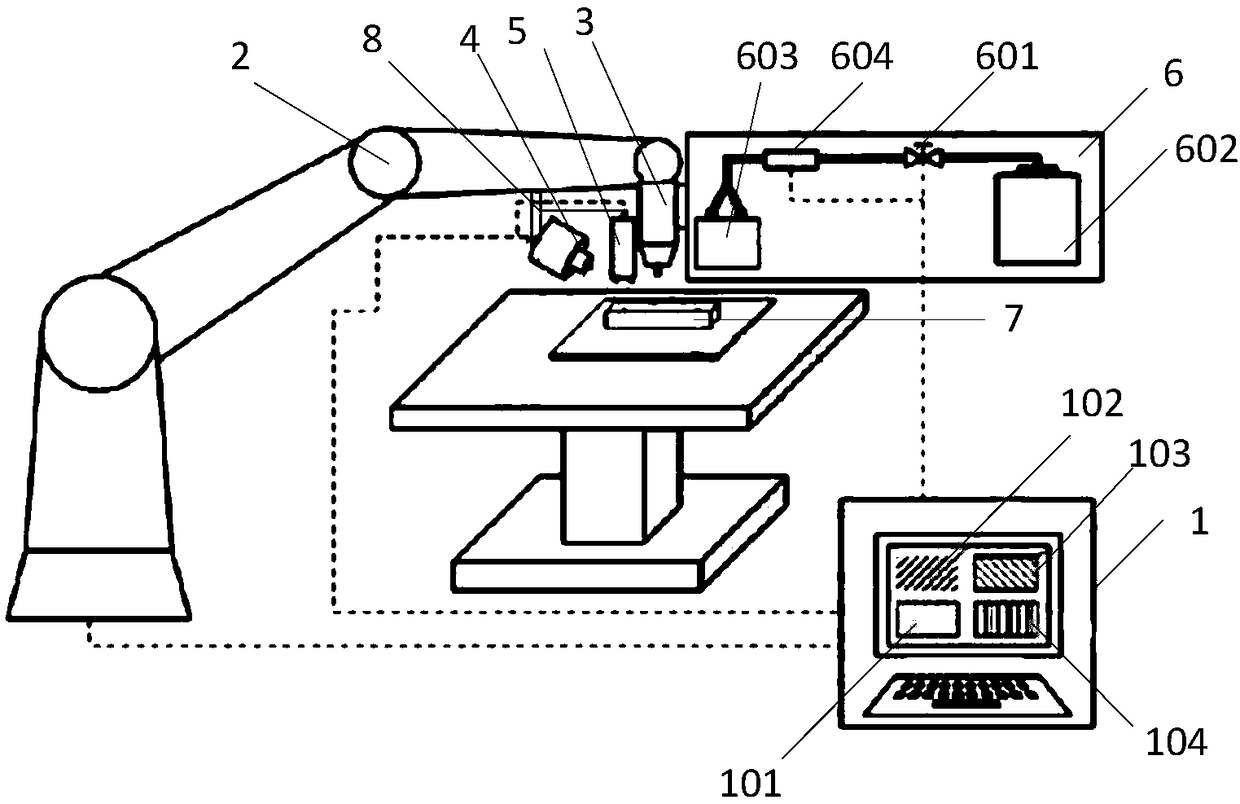

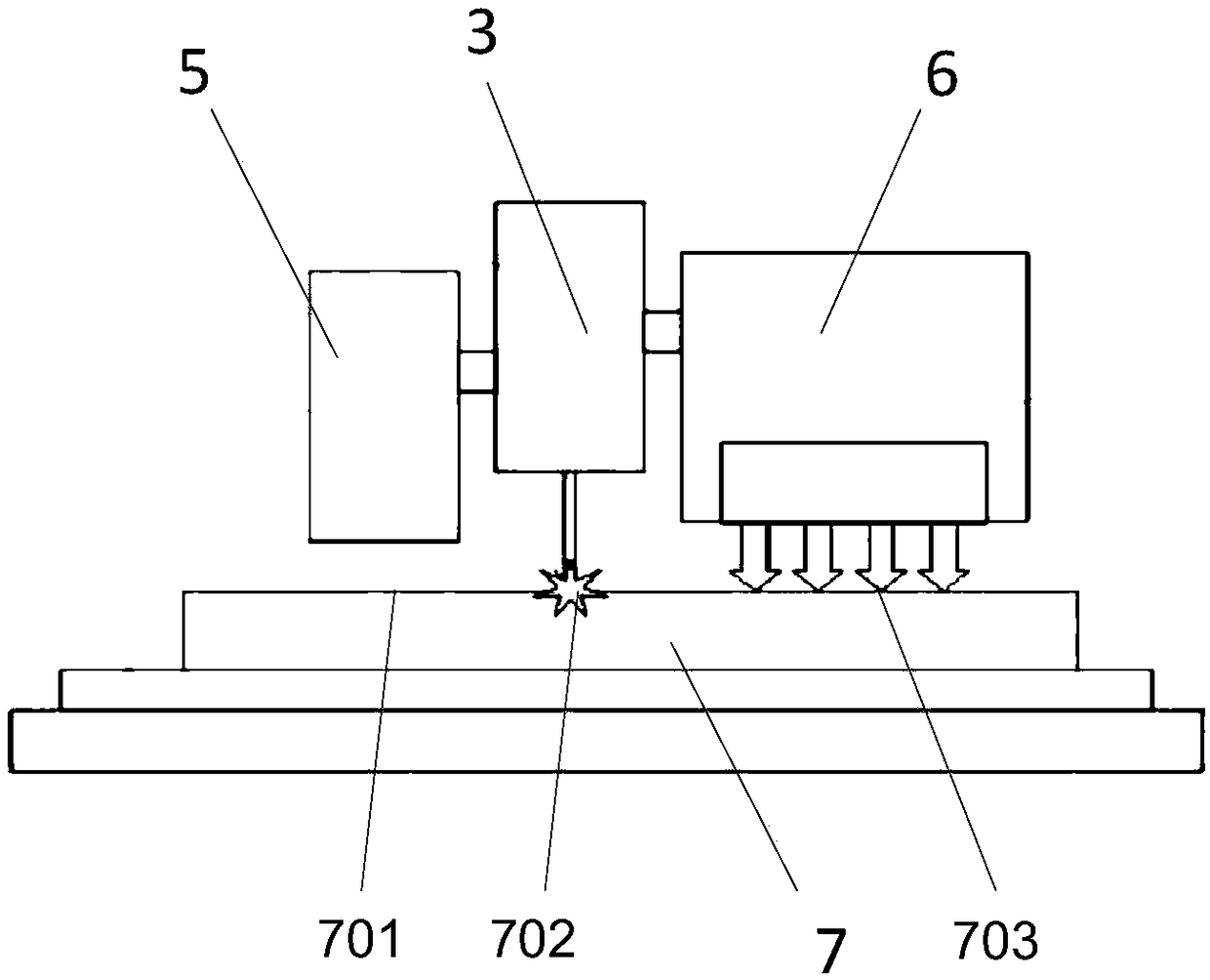

Temperature control device and method for additive manufacturing

PendingCN108907188AAccurate responsePrecise Response InflowAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankTemperature control

The invention discloses a temperature control device and method for additive manufacturing. According to the temperature control device, a front preheating part is arranged at the front end of a printing head, and a rear cooling part is arranged at the rear end of the printing head. Before a formed part enters a printing position, the difference between the surface temperature of the formed part and the temperature of a printing portion can be reduced, and the frequency of the phenomenon that due to the large temperature difference, the organizations of the formed part are not uniform can be reduced. Due to the fact that the rear cooling part is arranged behind the printing head, the formed part can be rapidly cooled by the cooling gas after printing is accomplished, the situation that dueto the fact that the temperature is too high, the formed part is oxidized by the surrounding air is avoided, and the surface quality of the formed part is improved. According to the temperature control system and method for additive manufacturing, on the basis of control over the temperature of a molten pool in the additive manufacturing deposition process and the cooling speed in the solidification process, the front preheating device and the rear cooling device are added, and therefore zone control of the temperature field of the formed part is achieved, the forming defect is avoided, the distribution of the temperature field in the additive manufacturing process is improved, and the internal property of the formed part can be improved.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

Omnibearing intelligent shower

The invention belongs to the toilet and bathroom article field, and specifically relates to omnibearing intelligent shower; a plurality of nozzles are arranged in surrounding so as to realize omnibearing water spraying; induction control is arranged, so a bath lotion automatic applier can rotate a bath ball filled with bath lotion; an automatic rubber is arranged, and a motor drives an annular bathing towel to rotate, thus improving showering intelligentization and comfort level.

Owner:CHANGGE TENGDA PRECISION IND BUILDING MACHINERY FACTORY

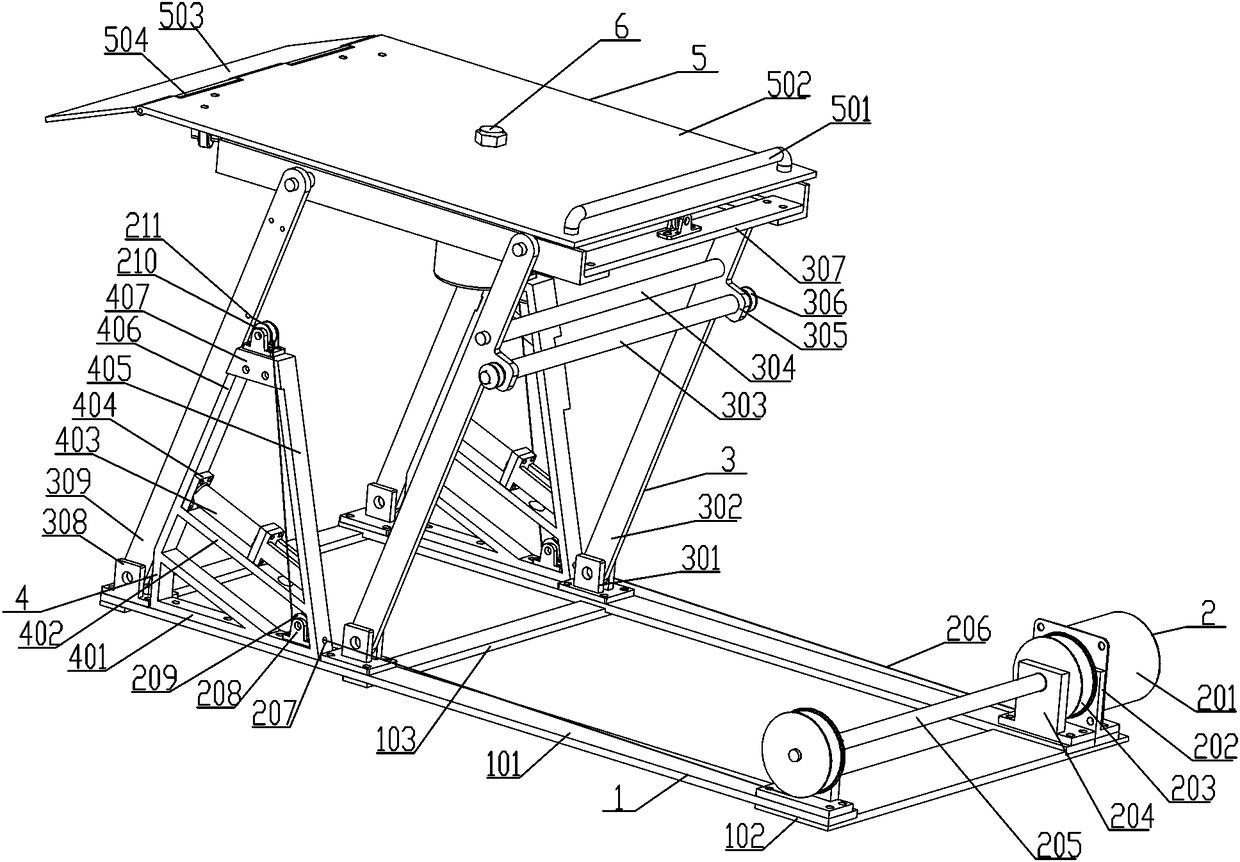

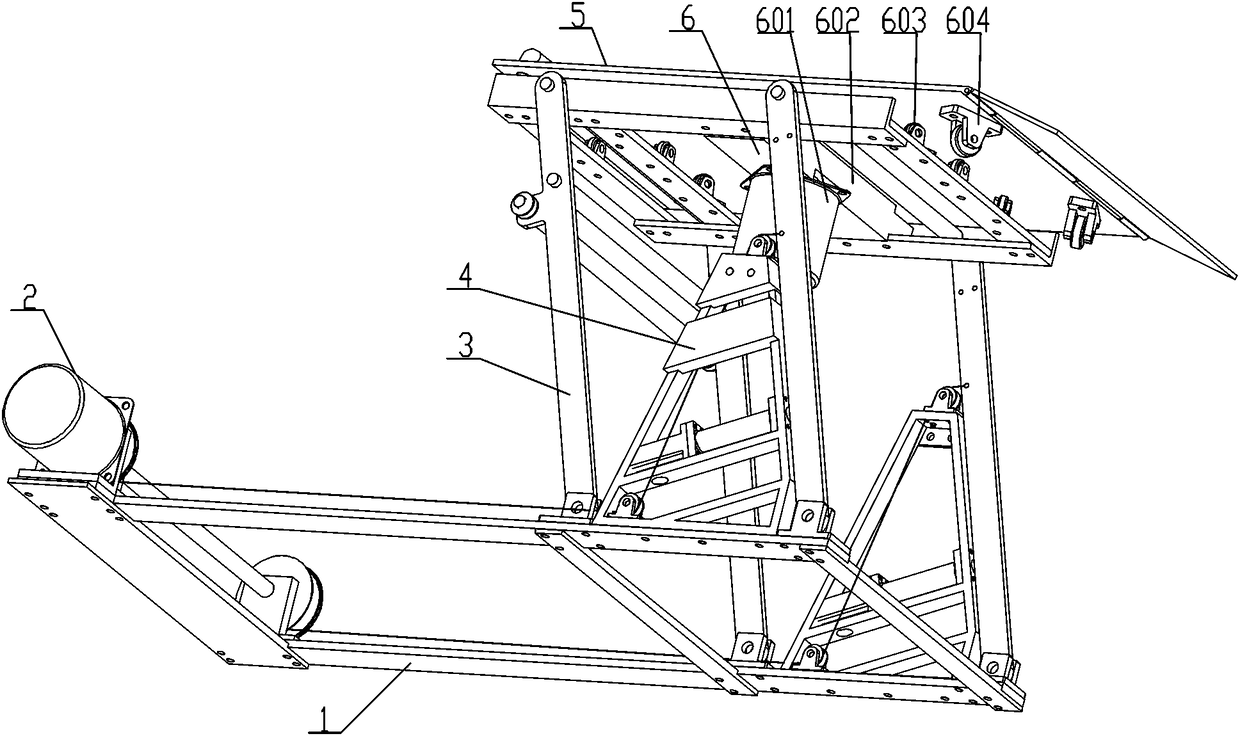

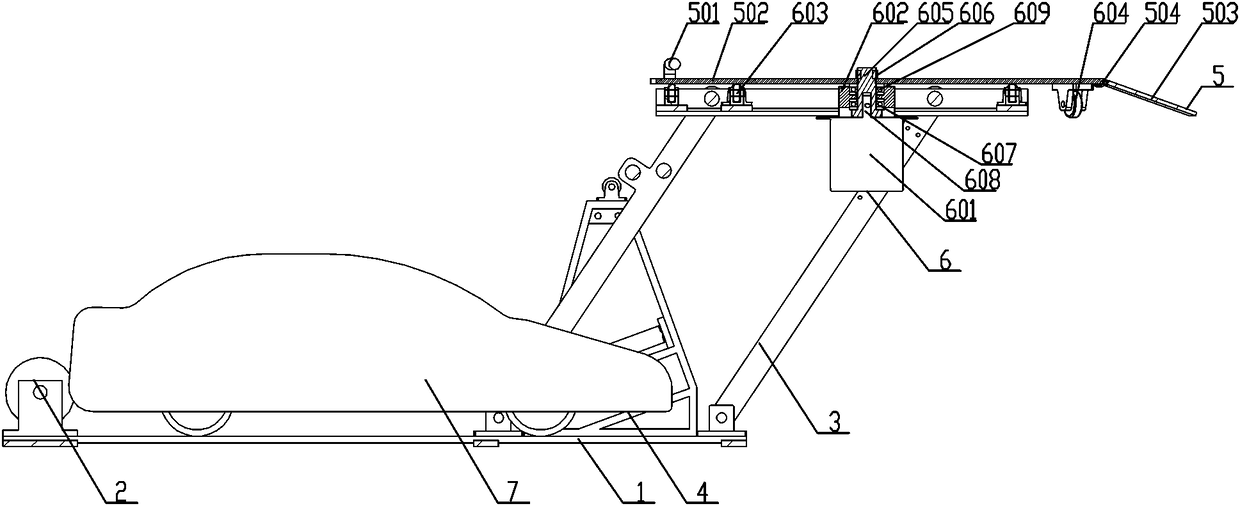

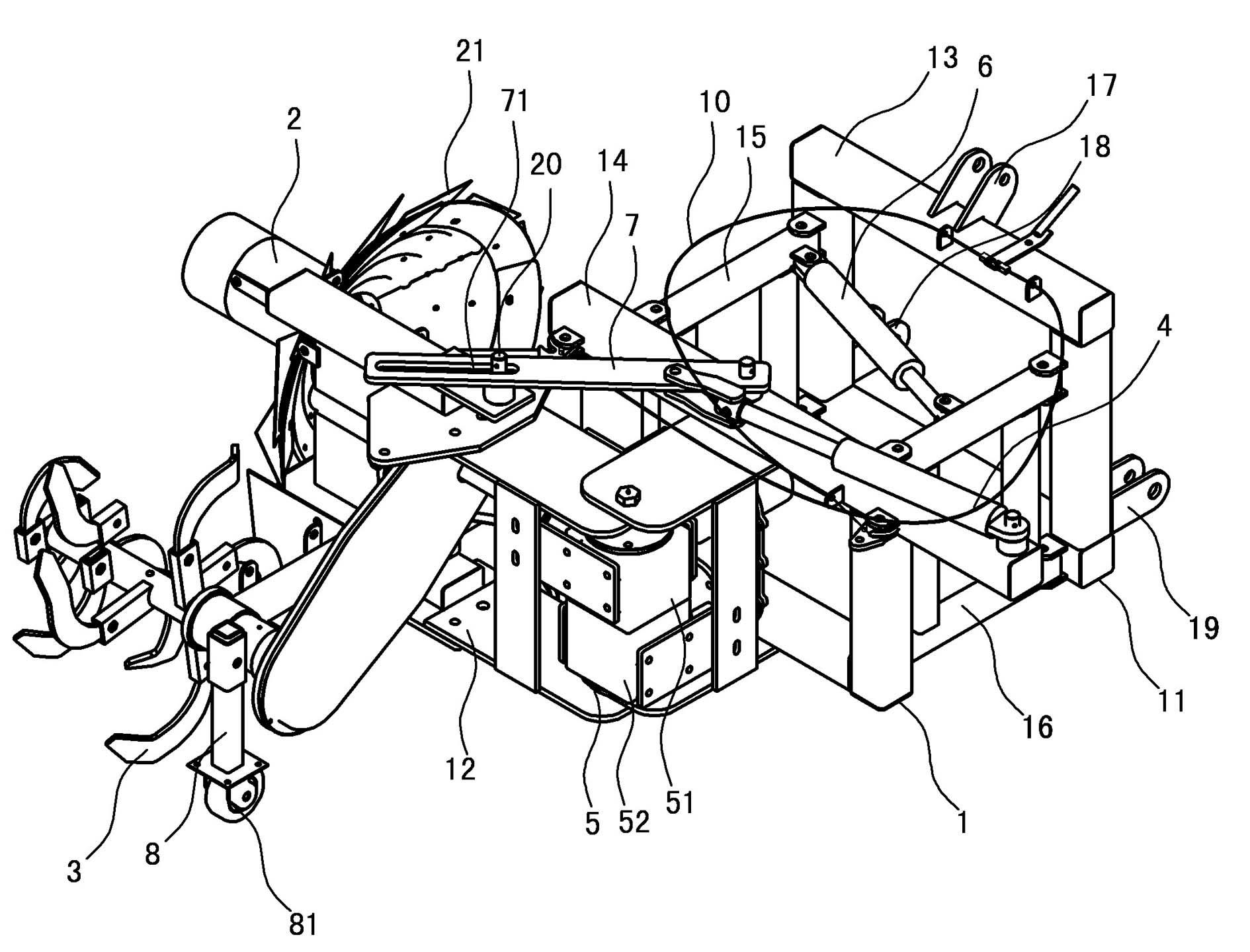

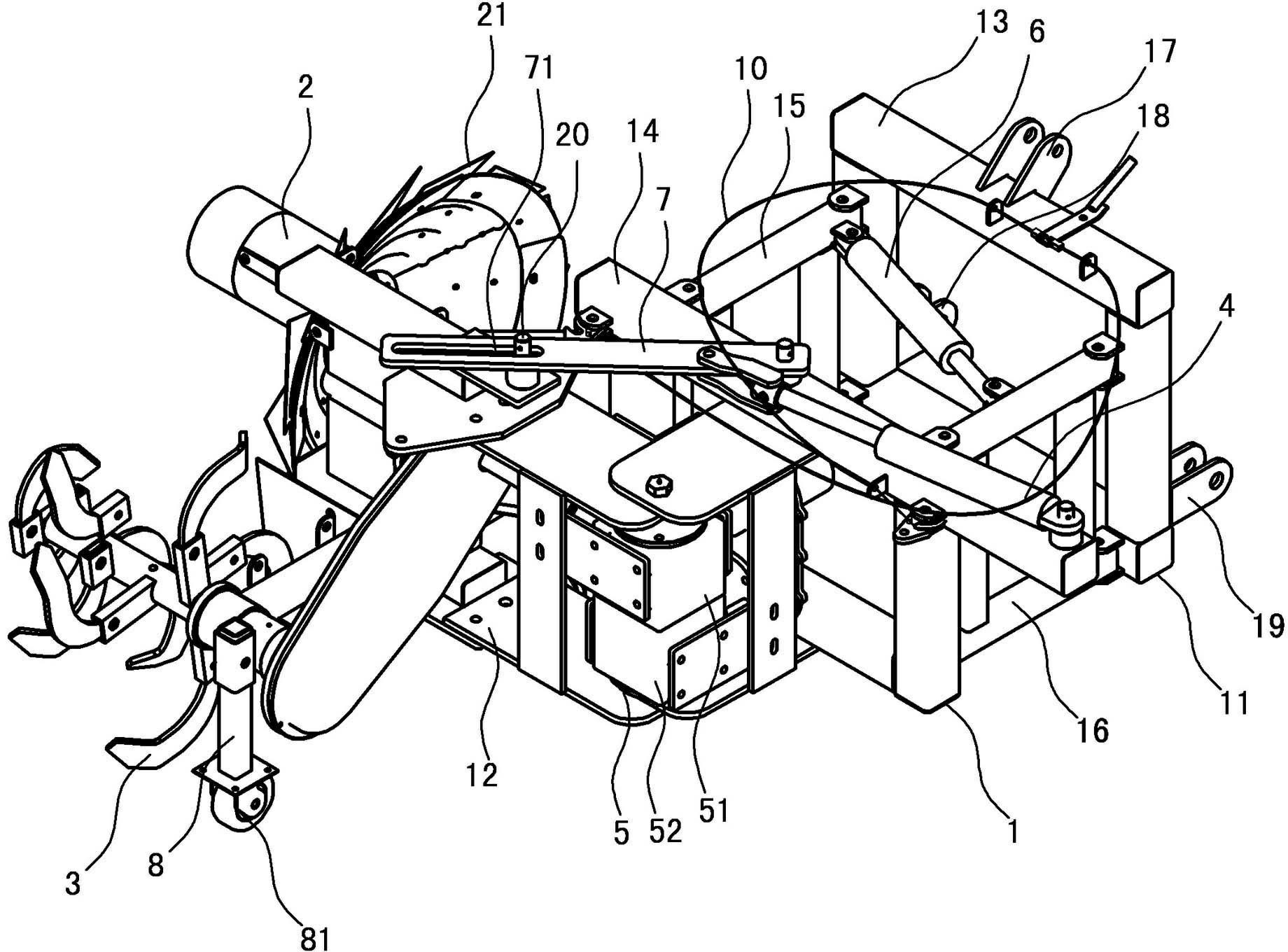

Rotary lifting parking device and operation method thereof

The invention relates to a rotary lifting parking device and an operation method thereof. The rotary lifting parking device comprises a fixed base assembly used for supporting the whole device. A swing rod lifting mechanism used for rising and falling is mounted at one end of the fixed base assembly, and a parking supporting plate device capable of rotating is mounted at the top of the swing rod lifting mechanism in a supporting mode. A rotary power device used for driving the parking supporting plate device to rotate is mounted at the connected position of the parking supporting plate deviceand the swing rod lifting mechanism. A triangular supporting mechanism used for supporting swing rods is mounted between the two swing rods of the swing rod lifting mechanism and fixedly mounted on the fixed base assembly. The swing rod lifting mechanism is connected with a winch mechanism used for driving the swing rod lifting mechanism to rise and fall. The rotary lifting parking device can be placed on the two sides of a road and does not occupy the lane space.

Owner:HUBEI THREE GORGES POLYTECHNIC

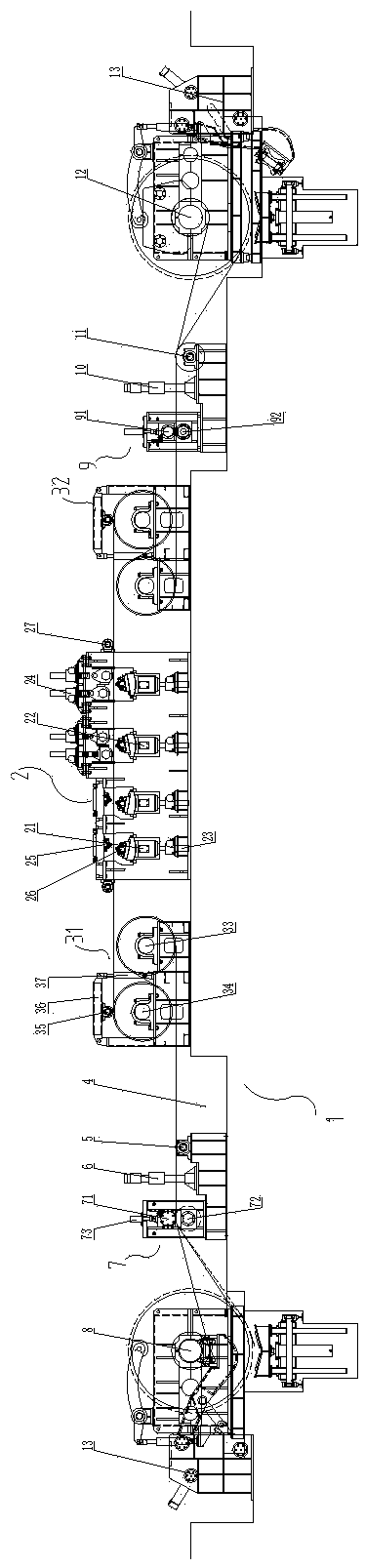

Strip steel stretching and straightening machine

The invention provides a strip steel stretching and straightening machine. By the strip steel stretching and straightening machine, the problem of proneness to deflection of strip steel in operation is greatly improved, and damages of the strip steel in a straightening process can be effectively avoided. The strip steel stretching and straightening machine comprises a base, a stretching and straightening machine is mounted on the base through a supporting seat, two tension S rollers are mounted on two sides of the stretching and straightening machine, the stretching and straightening machine comprises a bending section and a straightening section, the bending section comprises at least two bending machines, the straightening section comprises at least two straightening machines, a first driving device is mounted at the bottom end of each of the bending machines and the straightening machines, and a second driving device is mounted at the top end of each straightening machine. Each bending machine comprises an upper roller and a lower roller in vertical corresponding arrangement, each straightening mechanism comprises two upper rollers in bilateral parallel arrangement, and a lowerroller is correspondingly arranged below the position between the two upper rollers. Guide rollers are symmetrically mounted on two sides of the supporting seat of the stretching and straightening machine and arranged corresponding to gaps between the upper rollers and the lower rollers of the stretching and straightening machine.

Owner:WUXI CITY XIDONG RUBBER & PLASTICS MACHINERY

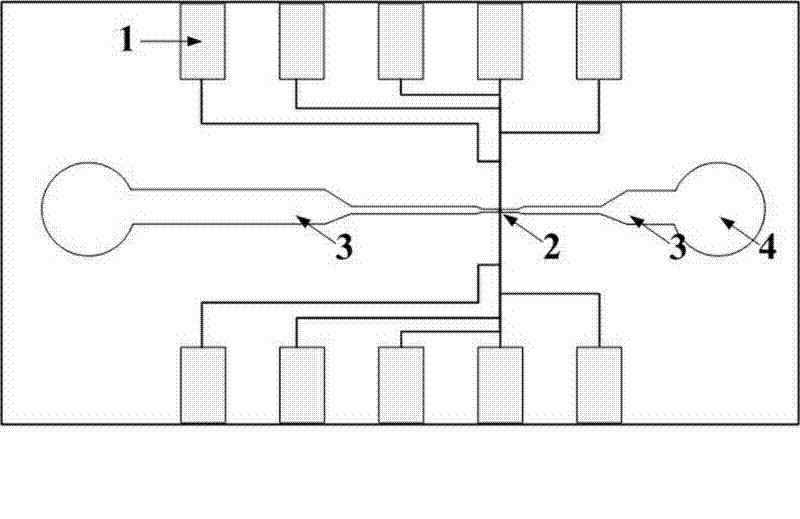

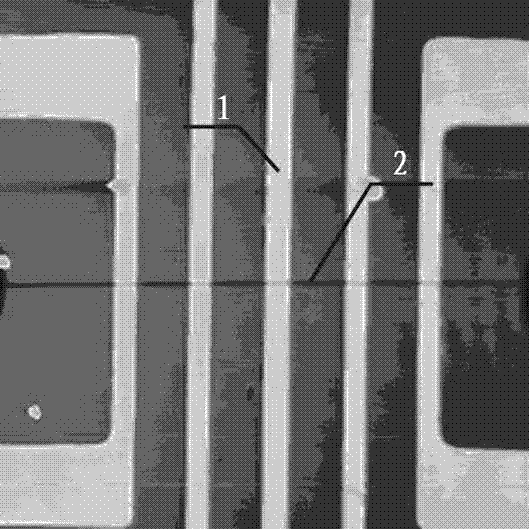

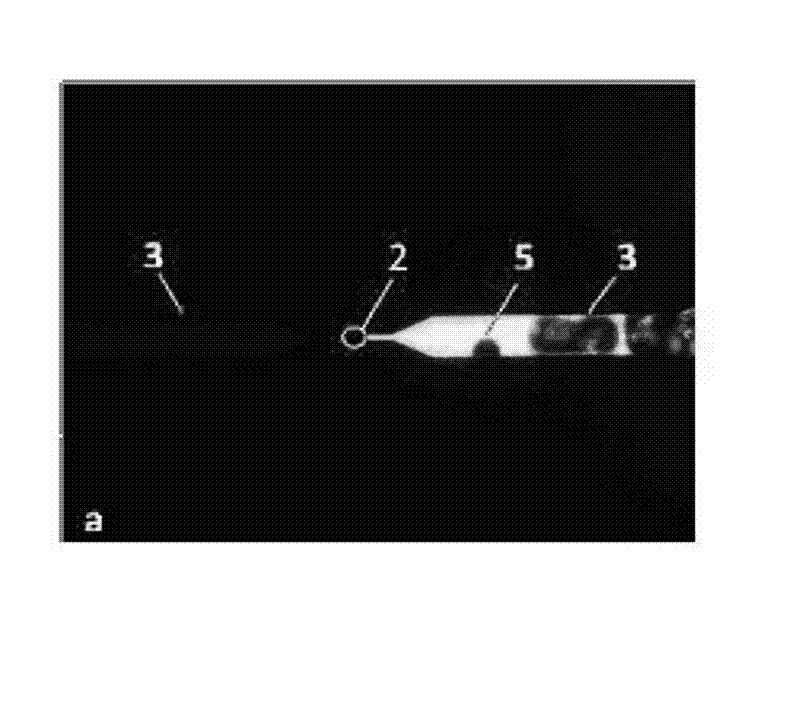

Nanofluidic chip, processing method based on atomic force microscopy (AFM), and application

InactiveCN102539503ALow costChange the speed of movementNanosensorsMaterial electrochemical variablesAtomic force microscopy3-deoxyribose

The invention discloses a nanofluidic chip, a processing method based on atomic force microscopy (AFM), and application. Each of two ends of the chip is provided with a liquid storage tank; each liquid storage tank is connected with a micron pipeline; a nano pipeline is arranged between two micron pipelines; and electrodes which are vertical to the pipelines are arranged on two sides of the nano pipeline. The nano pipeline which is communicated with the micron pipelines is processed by using an AFM probe. Certain voltage is applied between the liquid storage tanks of the chip, small voltage is applied to the electrodes on two sides of the pipelines simultaneously, and the change of a current signal is measured; and when an object flows through the electrodes in the nano pipeline, current changes, and signal detection can be used for analyzing the structural and physical characteristics of a nano material. Processing and signal detection methods for the nanofluidic chip can applied to low-cost and quick sequencing of deoxyribose nucleic acid (DNA) molecules.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Aircraft

The invention provides an aircraft which comprises an aircraft body, a main rotor device and a plurality of auxiliary propeller devices. The main rotor device is mounted on the aircraft body and is used for generating vertical thrust, the auxiliary propeller devices are mounted on the periphery of the aircraft body and are used for generating transverse thrust, and a plurality of pairs of aircraft turning screw propellers and a plurality of pairs of aircraft translation screw propellers are formed by the multiple auxiliary propeller devices. The aircraft has the advantages that the aircraft can be turned by the corresponding paired screw propellers formed by the multiple corresponding auxiliary propeller devices and can be subjected to translation by the corresponding paired screw propellers formed by the multiple corresponding auxiliary propeller devices, accordingly, the aircraft body can be prevented from being inclined when turning or translation actions are carried out by the aircraft, and the aircraft can assuredly stably fly; the aircraft can quickly respond to turning and translation instructions and accordingly can be flexibly and quickly controlled.

Owner:瑞电恩吉能源技术(深圳)有限公司

Ridger capable of forming ridge through overturn and reverse push

InactiveCN102612870ASame directionDoes not affect sturdinessTilling equipmentsClassical mechanicsEngineering

The invention relates to a ridger capable of forming a ridge through overturn and reverse push. The ridger comprises a machine frame (1), a ridge forming wheel (2) and a rotary cultivating wheel (3), wherein the machine frame (1) is composed of a traction and suspension frame (11) and a rotary cultivating and ridge forming frame (12), the ridge forming frame (12) is hinged on the traction and suspension frame (11), and can overturn horizontally, an overturning oil cylinder (4) is arranged between the traction and suspension frame (11) and the rotary cultivating and ridge forming frame (12), and is used for controlling the overturn of the rotary cultivating and ridge forming frame (12), and the ridge forming wheel (2) and the rotary cultivating wheel (3) are respectively installed on the rotary cultivating and ridge forming frame (12). The ridger is convenient to form the ridge at a plot end and to adjust transversely; when a transverse deviation exists between the ridger and the ridge, the transverse adjustment can be carried out conveniently to increase operating speed; the ridge forming wheel (2) and the rotary cultivating wheel (3) can rotate 180 degrees on the suspension frame; the ridge at the plot end can be conveniently formed by using traction machinery to reversely push the ridge forming wheel and the rotary cultivating wheel to work; the formed ridges are consistent in direction; and solidity of the ridges cannot be affected.

Owner:崔春鹤

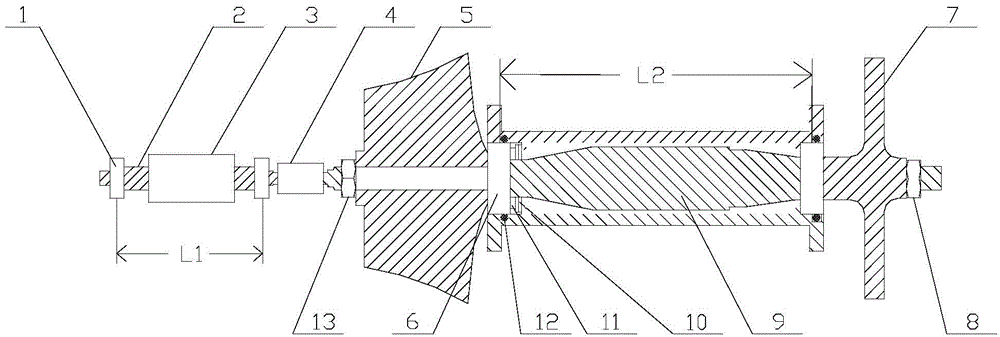

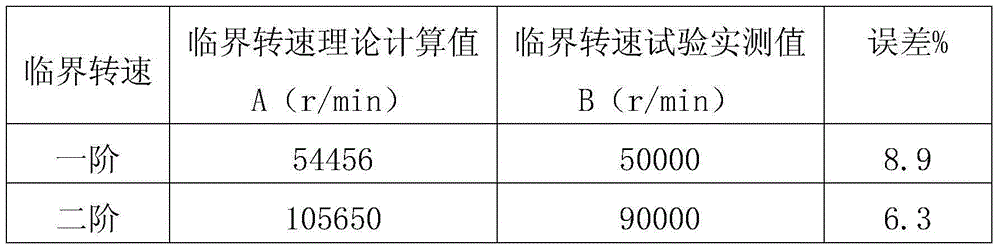

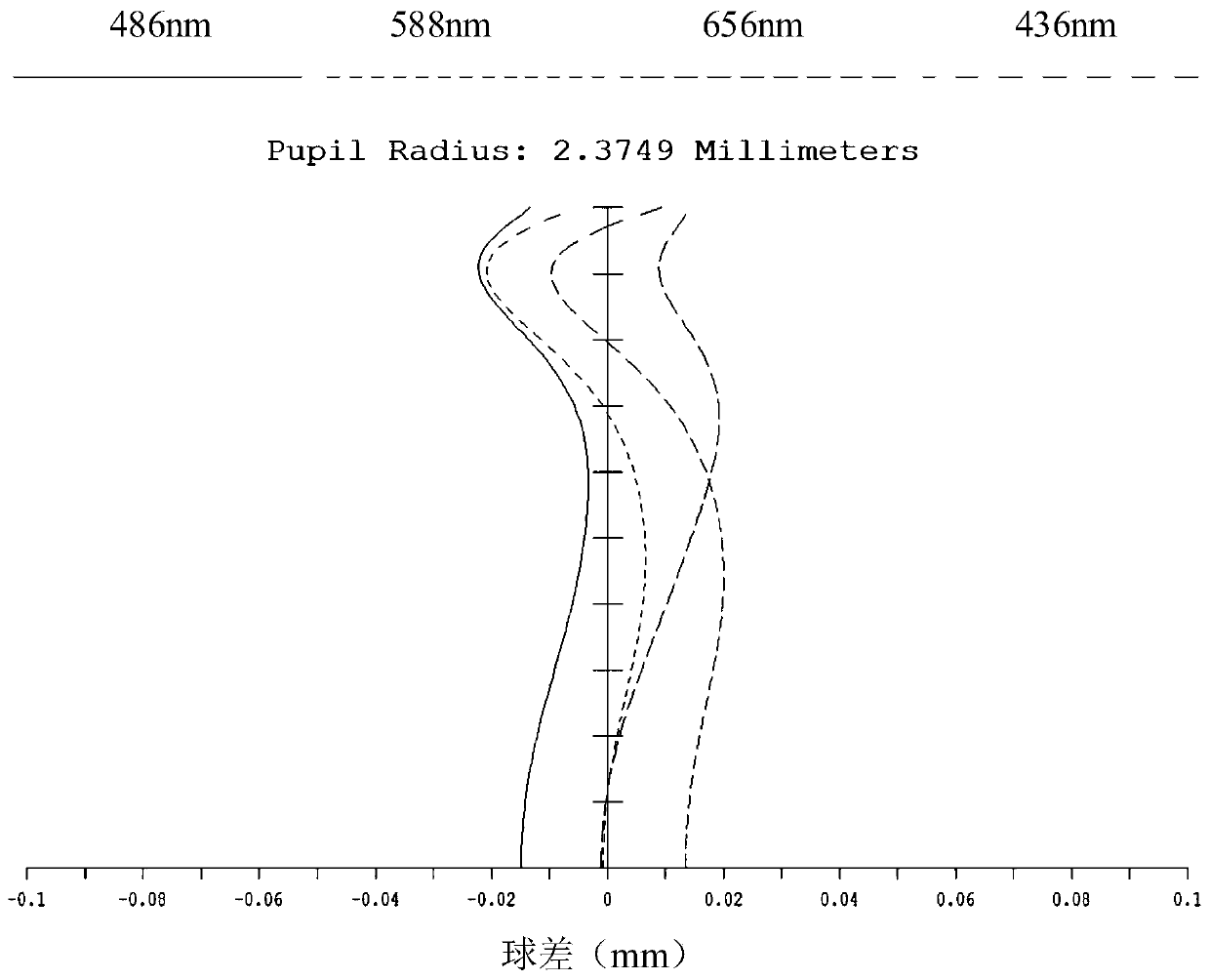

Method for adjusting the critical speed of high-speed combined rotor of micro turbojet engine

ActiveCN104536475ASame directionShorten the timeEngine testingSpecial data processing applicationsEngineeringTurbojet engine

The invention provides a method for adjusting the critical speed of a high-speed combined rotor of a micro turbojet engine. By adopting the method, no special critical speed adjusting device needs to be mounted outside an engine shafting. Thus, the aircraft space is saved, the weight is reduced, and the reliability is improved. The critical speed of a high-speed combined rotor is adjusted by changing the structure size of engine parts. The method is simple and feasible.

Owner:SICHUAN AEROSPACE ZHONGTIAN POWER EQUIP CO LTD

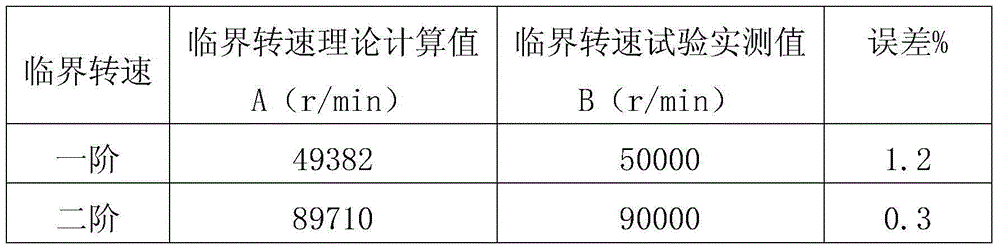

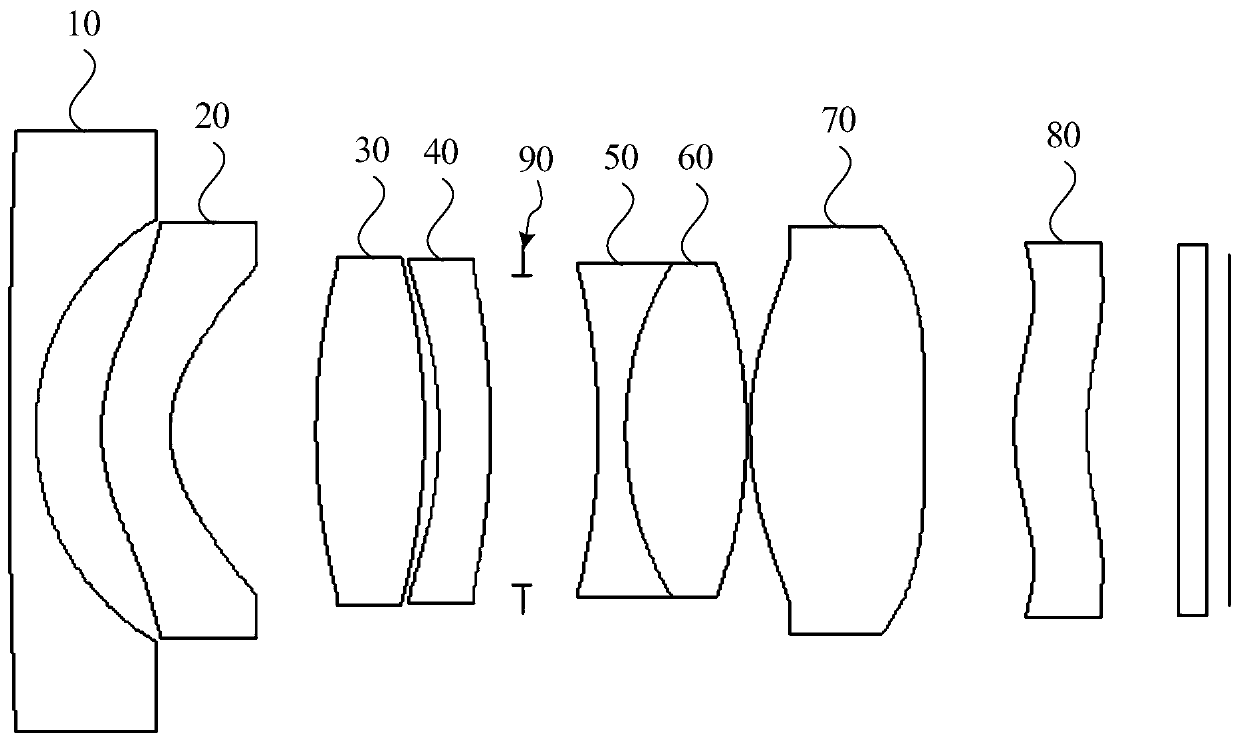

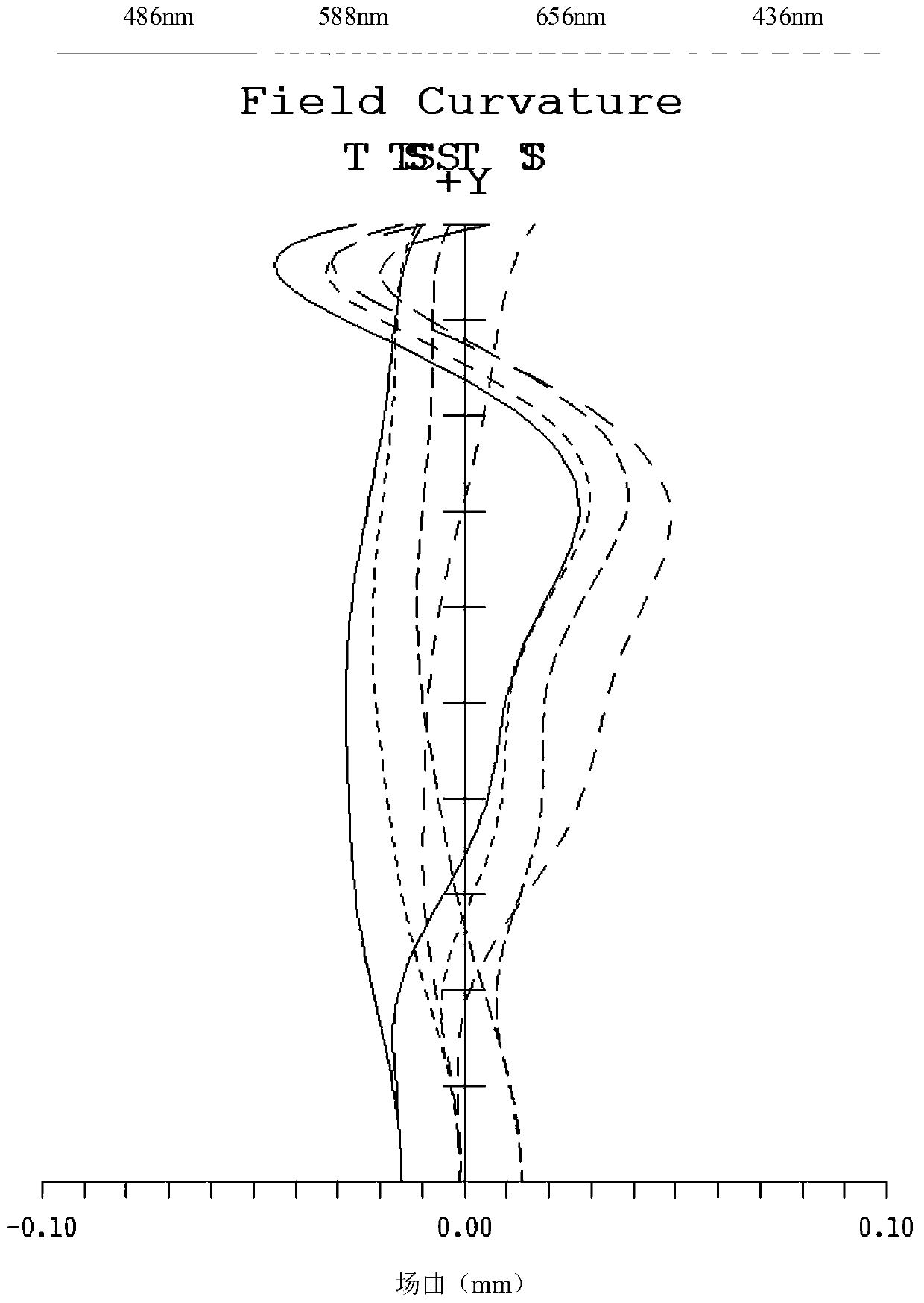

Prime lens

The embodiment of the invention discloses a prime lens. The prime lens comprises first lenses with negative focal power, which are sequentially arranged from an object side to an image side along an optical axis, a second lens with negative focal power, a third lens with positive focal power, a fourth lens with negative focal power, a diaphragm, a fifth lens with negative focal power, a sixth lenswith positive focal power, a seventh lens with positive focal power and an eighth lens with positive focal power or negative focal power. The first lens, the third lens, the fifth lens and the sixthlens are all spherical lenses, and the fifth lens and the sixth lens form a cemented lens. The second lens, the fourth lens, the seventh lens and the eighth lens are aspheric lenses. The prime lens provided by the embodiment of the invention has the characteristic of ultra-large light flux, is particularly suitable for monitoring requirements under complex conditions, can achieve a large apertureof F0.8-1.2, supports an image plane of 1 / 1.8 inch, and can achieve a field angle range of 90-130 degrees.

Owner:DONGGUAN YUTONG OPTICAL TECH

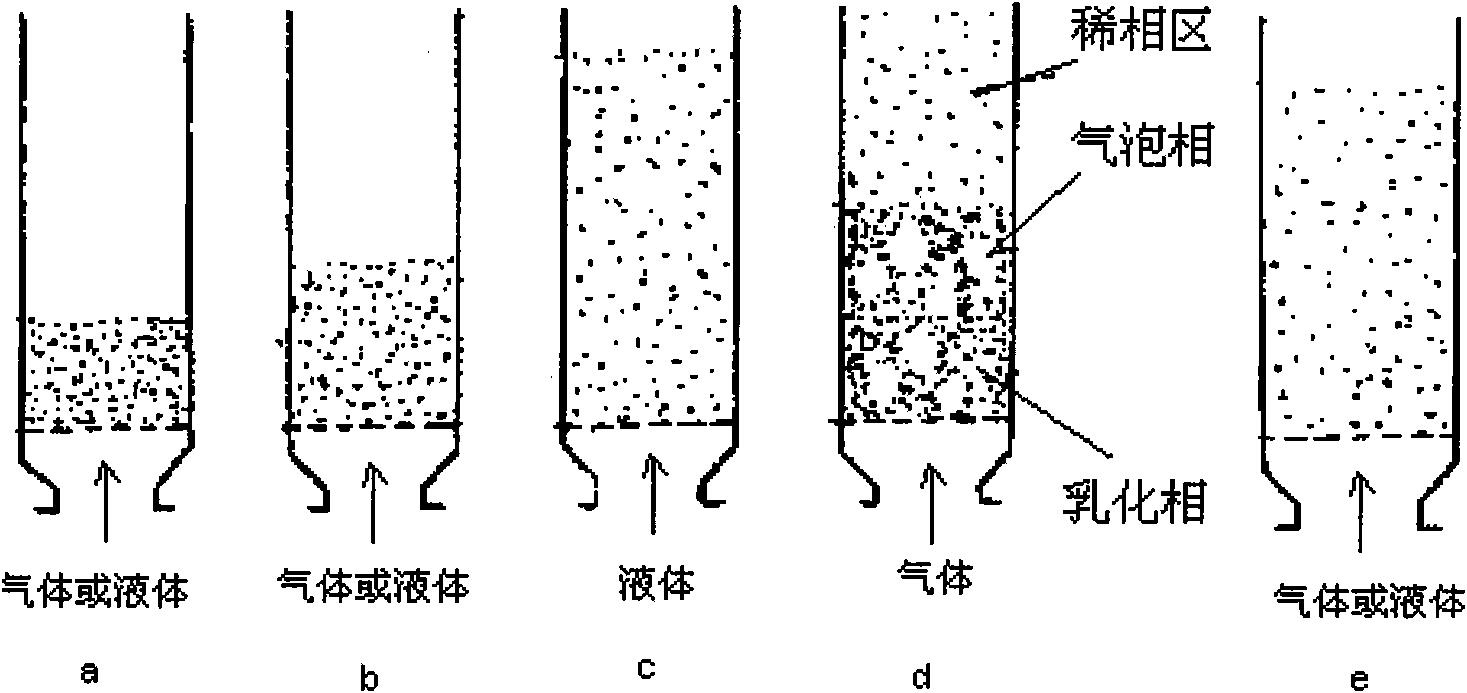

Solid particle player

ActiveCN101912752AEvenly distributedAvoid wall effectChemical/physical processesSpray nozzleInstability

The invention discloses a solid particle player which is in a coaxial segmented sealing cylindrical structure and comprises a base plate, a spray nozzle, an acceleration section, a rectifying section, a fluidized section and a cover plate. A rectifying plate which is uniformly provided with millimeter grade through holes is fixedly arranged at the inner wall of the connected part of the acceleration section and the rectifying section; an air distribution plate which is uniformly provided with nano-grade gaps is fixedly arranged on the inner wall at the connection part of the rectifying section and the fluidized section; solid particles are stacked on the air distribution plate; a plurality of layers of fluidized substance outlets are machined at the positions in different heights at the upper side of the fluidized section; and an included angle of 15-50 degrees is formed between the axis of the fluidized substance outlets and the axis of the solid particle player. The solid particle player is formed by sintering metal powder; air current is diffused by the air distribution plate with nano-grade gaps so as to obtain the uniformly-distributed incoming current and avoid the wall-surface effect; and according to the distance among various sections and the opening mode of the air distribution plate and the side wall, the invention ensures enough flowing resistance, reduces the wall-surface effect due to the nonuniform air inlet speed and pressure distribution, overcomes the instability of focus fluidization and inhibits the abnormal phenomenon of channeling and slugging in a bed layer.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

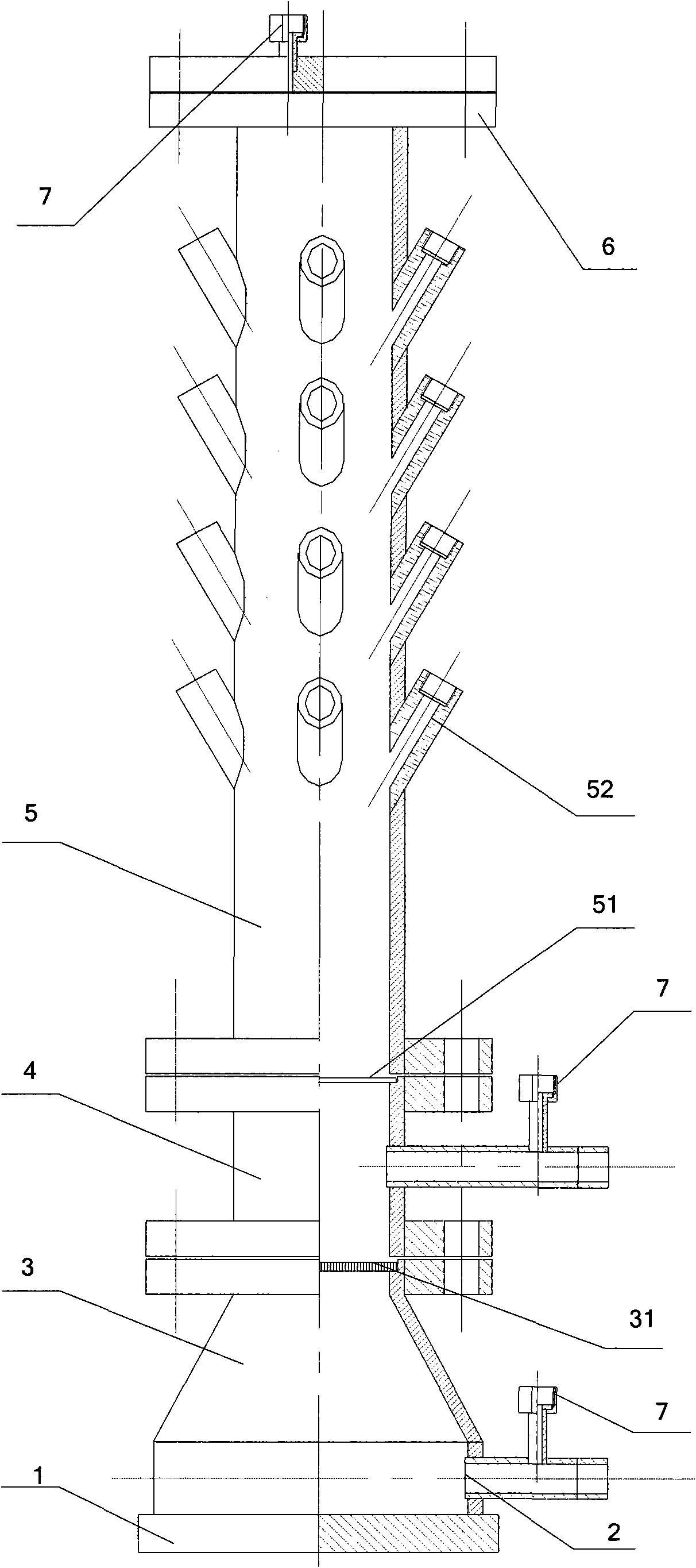

Riprap elephant trunk retraction system for immersed tube foundation construction

A rip-rap lephant trunk retraction system for immersed tube foundation construction is characterized in that the retraction system comprises a rip-rap lephant trunk and a retraction pulling cable, wherein the upper end of the rip-rap lephant trunk is arranged in a pivotally connected manner, the lower end of the rip-rap lephant trunk and the retraction pulling cable are arranged in a traction manner, and the lower end of the rip-rap lephant trunk is arranged in a rotating manner around the pivoted part between the vertical direction and the horizontal direction of the lephant trunk. The rip-rap lephant trunk retraction system for immersed tube foundation construction is simple and fast to operate, can effectively achieve lephant trunk retraction, is reasonable in design, occupies a small area, meanwhile can achieve the retraction operation of the lephant trunk on water in virtue of the driving force of a lephant trunk trolley, and can be operated repeatedly. The manufacturing manner of the retraction system is simple, the normal use of the rip-rap lephant trunk cannot be impacted, and also the security under a non-riprap state can be ensured.

Owner:NO 1 ENG COMPANY CO LTD OF CCCC FIRST HARBOR ENG COMPANY +1

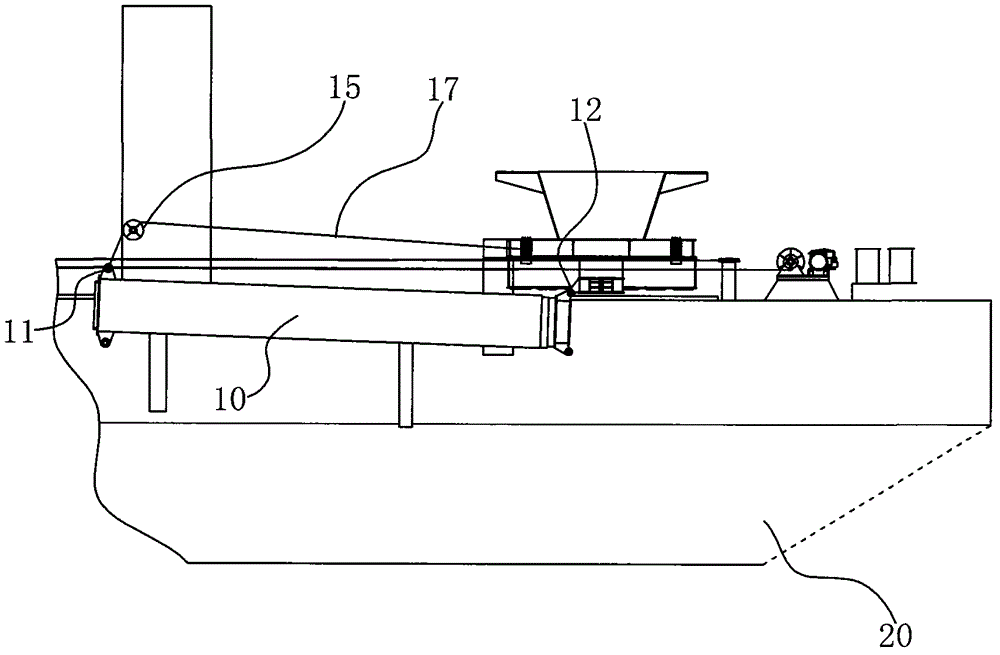

Online four-way valve detecting and sorting device and sealing detection method thereof

PendingCN106969880APrecise positioningSame directionSortingFluid-tightness measurement using fluid/vacuumFour-way valveEngineering

The invention provides an online four-way valve detecting and sorting device and a sealing detection method thereof. The device comprises a base with an upper frame. A three-axis carrying mechanism is arranged above the base. An automatic chain plate line is arranged on one side of the base. A defective product track is arranged on the other side of the base. A test carrier is arranged in the middle of the base, and the test carrier is connected with a test system inside the base. Four-way valves can be grabbed and placed automatically, and it is ensured that incoming four-way valves are located accurately and consistent in direction. Through the fully automatic process, the production efficiency is improved, the product quality is enhanced, and the production cost is reduced. Moreover, automatic location test is realized. For the problem of copper piping deviation of four-way valves, the precision of automatic shaping is high, the test pass rate is high, and the rejection rate is low. The problem of sealing failure caused by product size deviation is avoided.

Owner:上海藏望信息技术有限公司

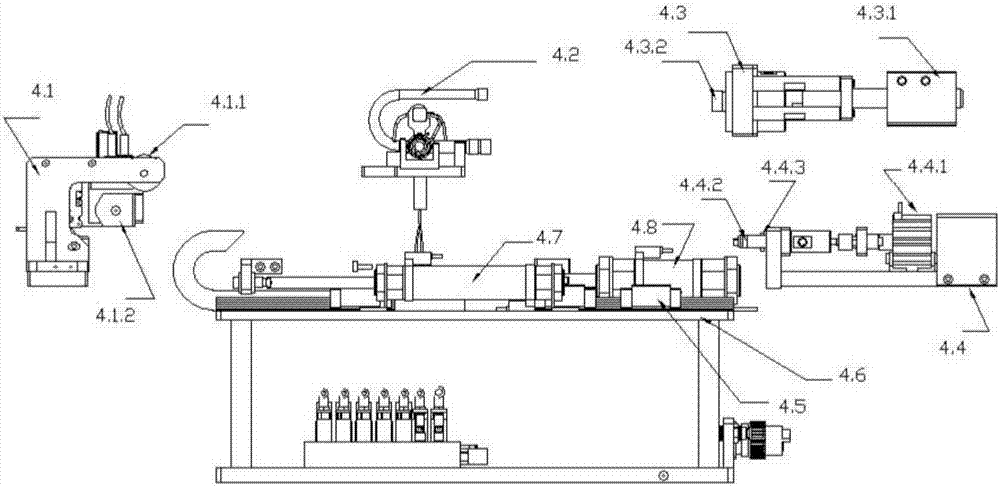

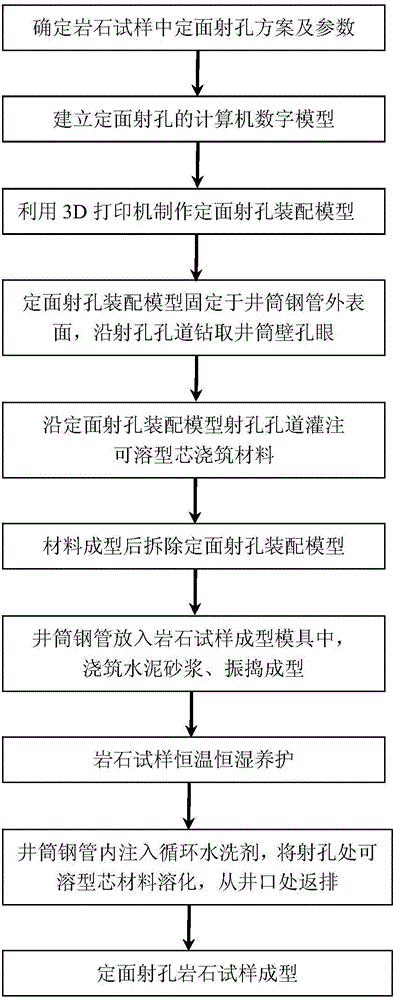

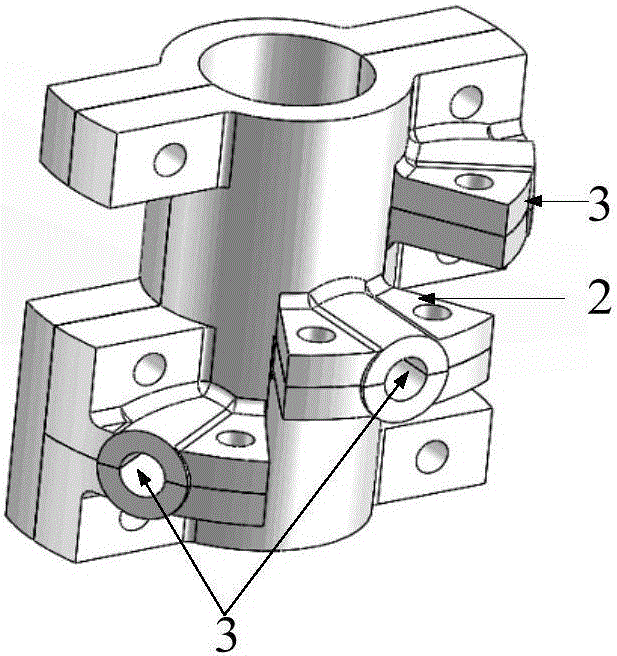

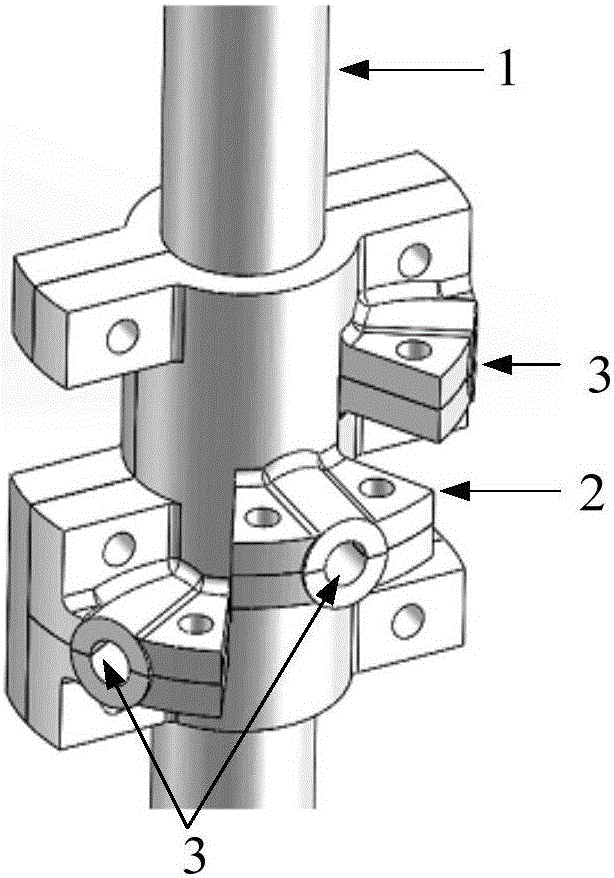

Preparation method of fixed perforation rock sample

InactiveCN106568637AEasy to operateReduce experiment costPreparing sample for investigationCeramic shaping mandrelsEngineeringRock sample

The invention discloses a preparation method of a fixed perforation rock sample. The preparation method comprises the following steps: according to the parameters of fixed perforation on a rock sample, directly obtaining multiple fixed perforation assembly models by a 3D printing machine; fixing the fixed perforation assembly models on the external surface of a steel tube in a well hole; drilling holes in the wall of the well hole along the direction of perforation channels; filling a soluble core material into the perforation channels of the fixed perforation assembly models; after the soluble core material is solidified, disassembling the fixed perforation assembly models; putting the steel tube into a rock sample moulding die, carrying out casting and moulding, performing maintenance under a constant pressure at a constant temperature; and injecting a circulation water detergent into the steel tube to dissolve the soluble core materials in the perforation holes to obtain the rock fixed perforation sample. The included angle between the fixed perforation channels is guaranteed; the included angle between the channels and the axis of the well hole is the same as that of designed scheme so as to satisfy the actual situation of engineering; and the key parameters of perforation channels such as shape, size, distance, and the like can be flexibly set.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com