Patents

Literature

208results about How to "No labor required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

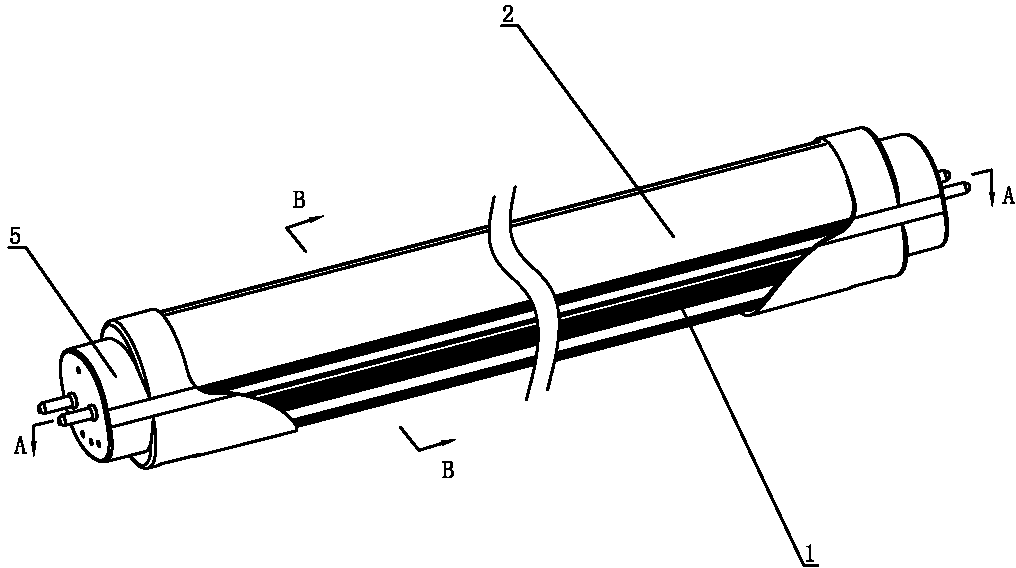

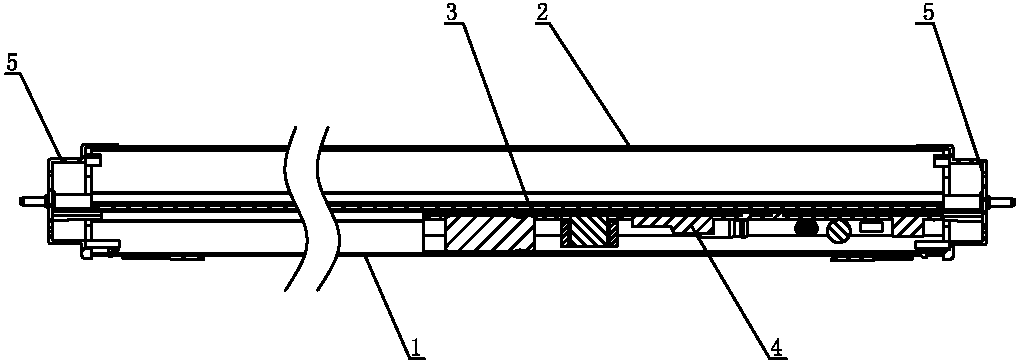

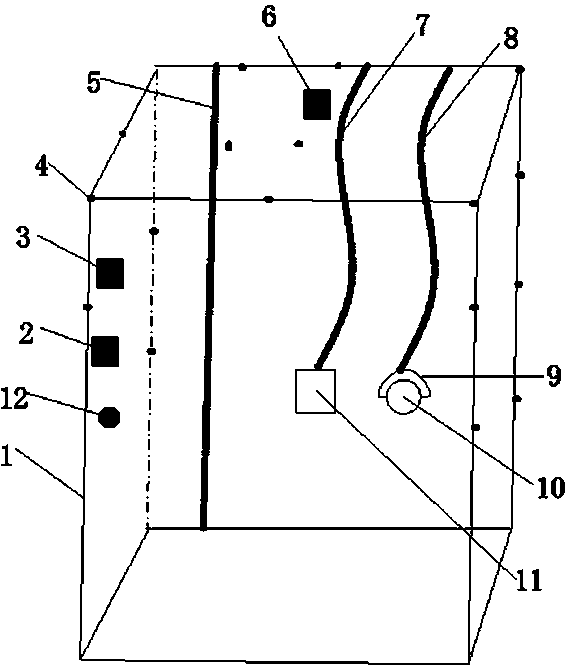

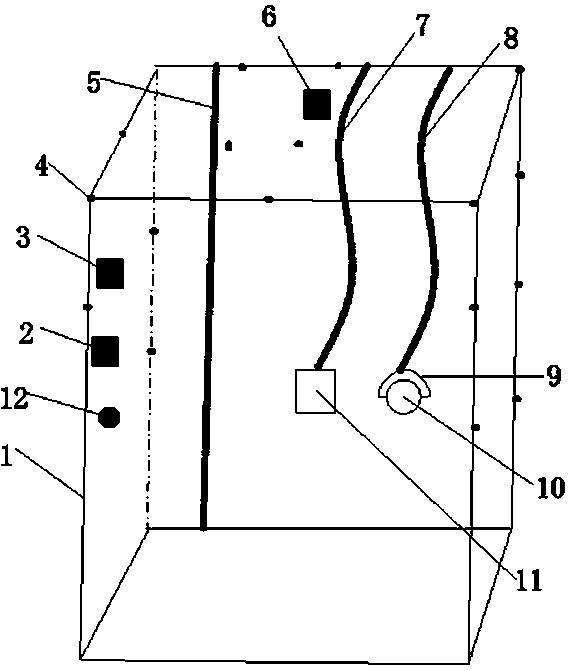

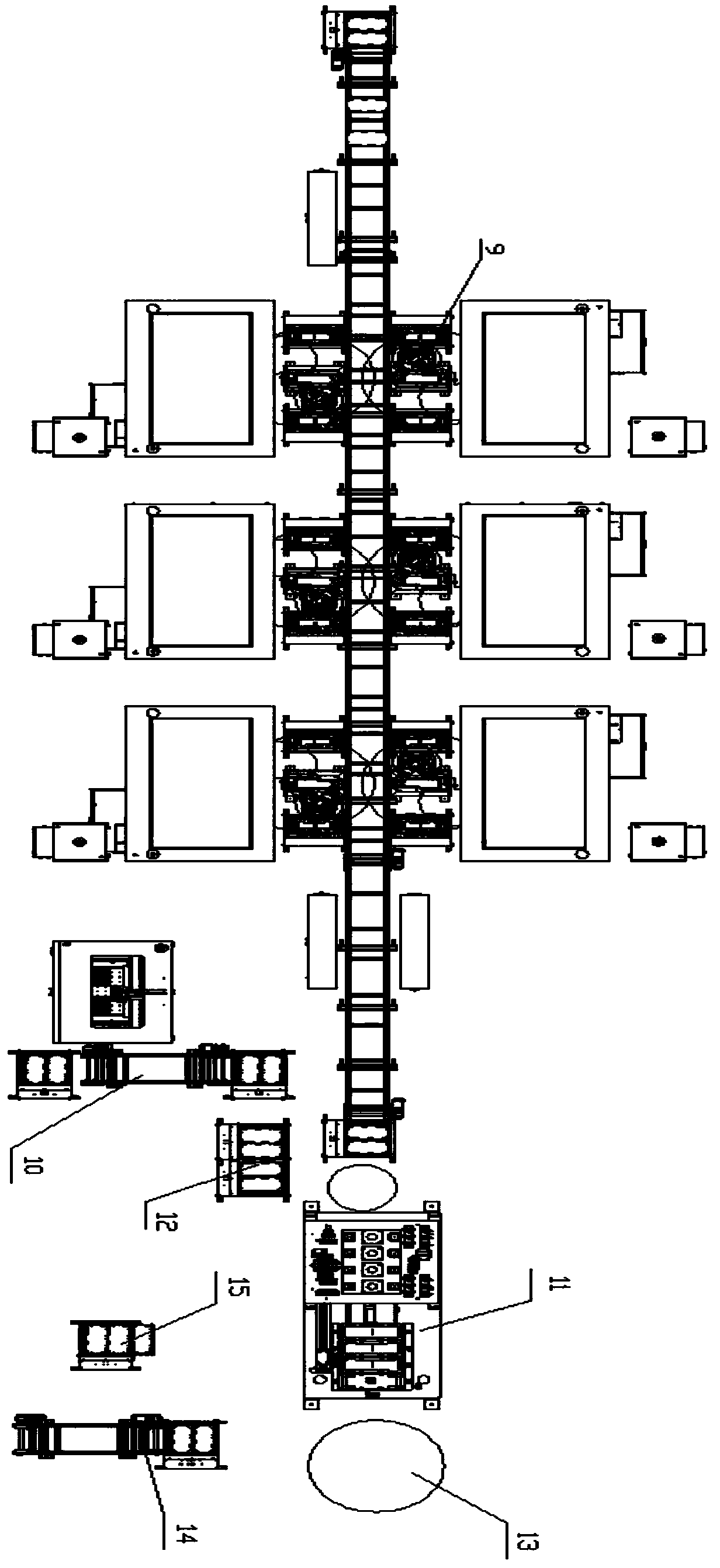

Patrol robot system for overhead high-voltage transmission line

InactiveCN104269777AAvoid sun and rainReduce accidentsApparatus for overhead lines/cablesMicrocontrollerUltra high voltage

The invention discloses a patrol robot system for an overhead high-voltage transmission line. The patrol robot system comprises a robot, the overhead line and a ground base station. The overhead line is supported through a cross bar. The robot comprises a robot body, a battery, a walking device, a single-chip microcomputer, a monitor device and a mobile communication device. The ground base station comprises a ground communication device and a ground monitor device. The ground base station and the robot are connected in a satellite communication mode. A robot platform is arranged on one side of the overhead line. The walking device comprises a walking mechanism and an obstacle avoidance mechanism. The walking device is connected with the single-chip microcomputer. The monitor range of the patrol robot is wider, environmental interference resistance is higher, the better obstacle avoidance mechanism is provided, a rest area is provided for the patrol robot, the service life of the patrol robot is prolonged, an automatic charging device is provided, work loads of workers are reduced, and the work of patrolling high-voltage lines and ultra-high-voltage lines can be completed excellently.

Owner:STATE GRID CORP OF CHINA +1

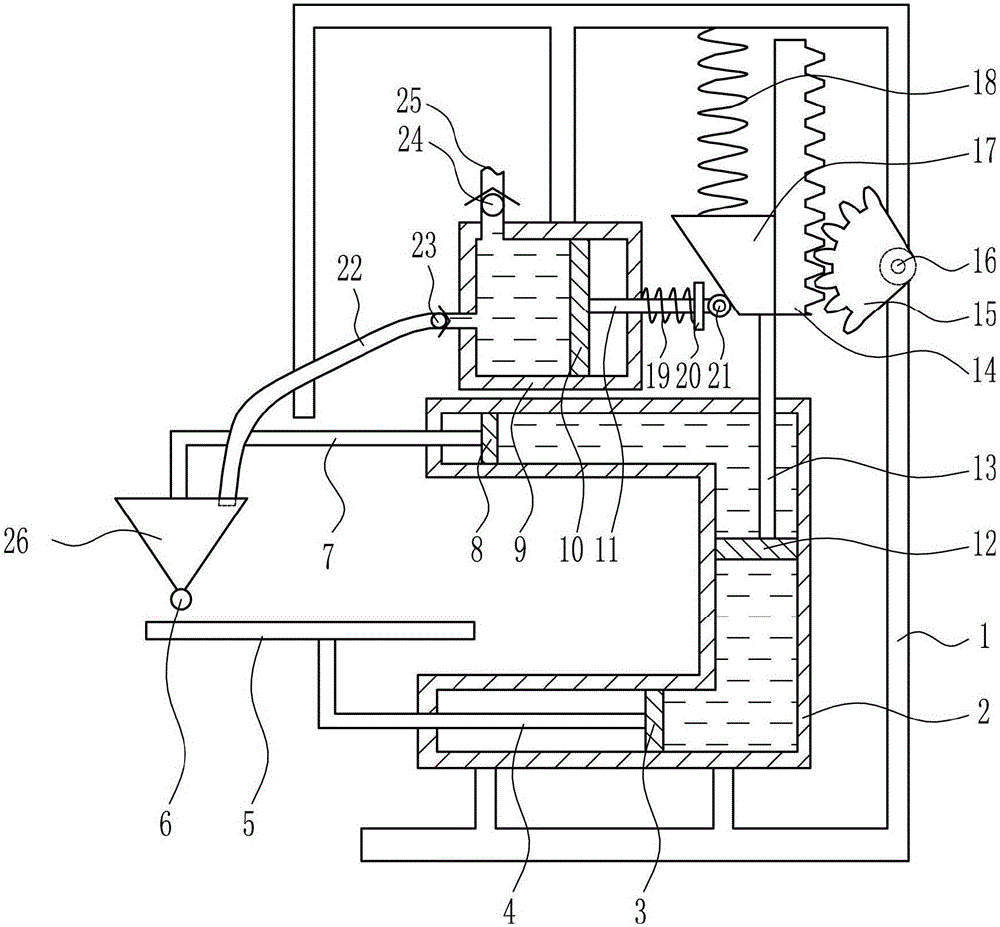

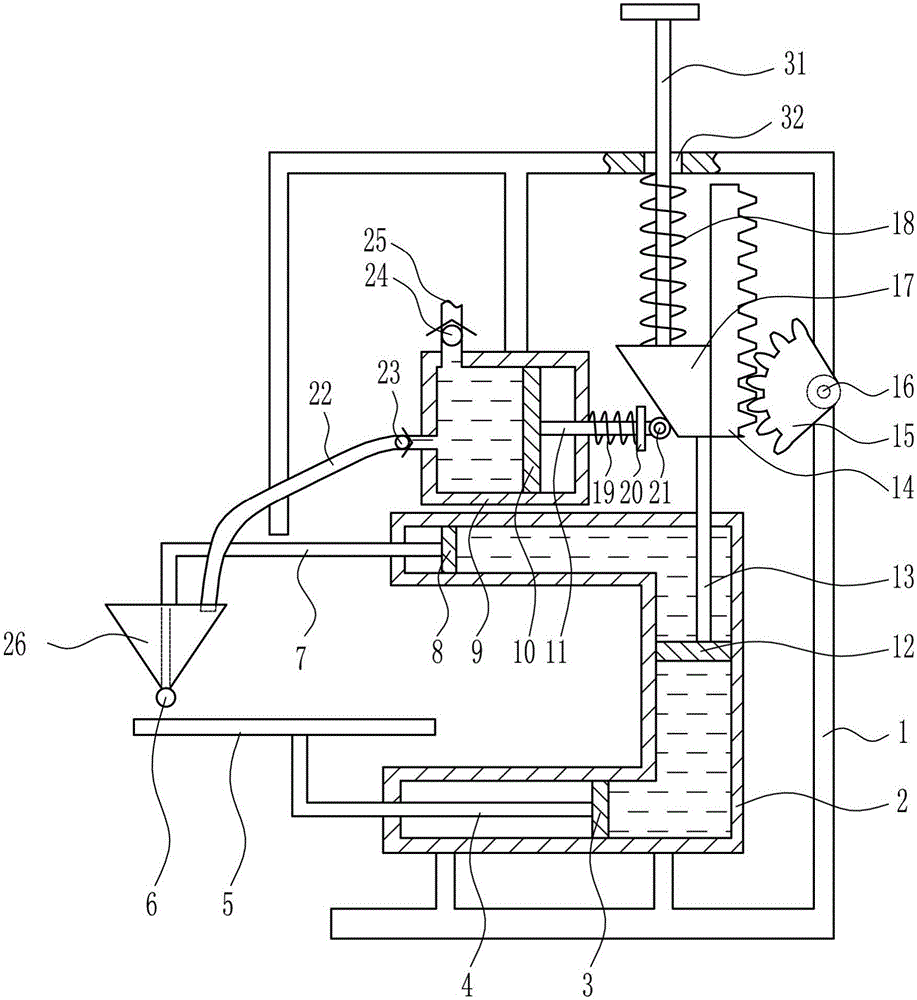

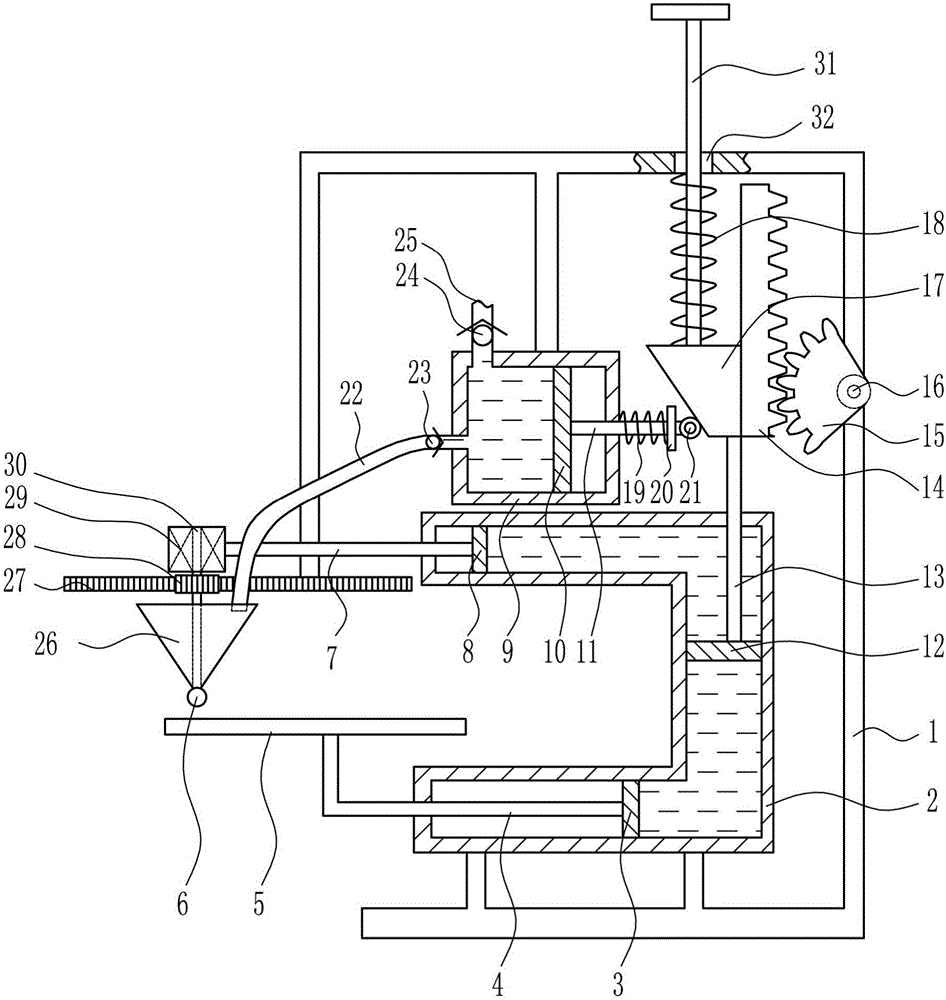

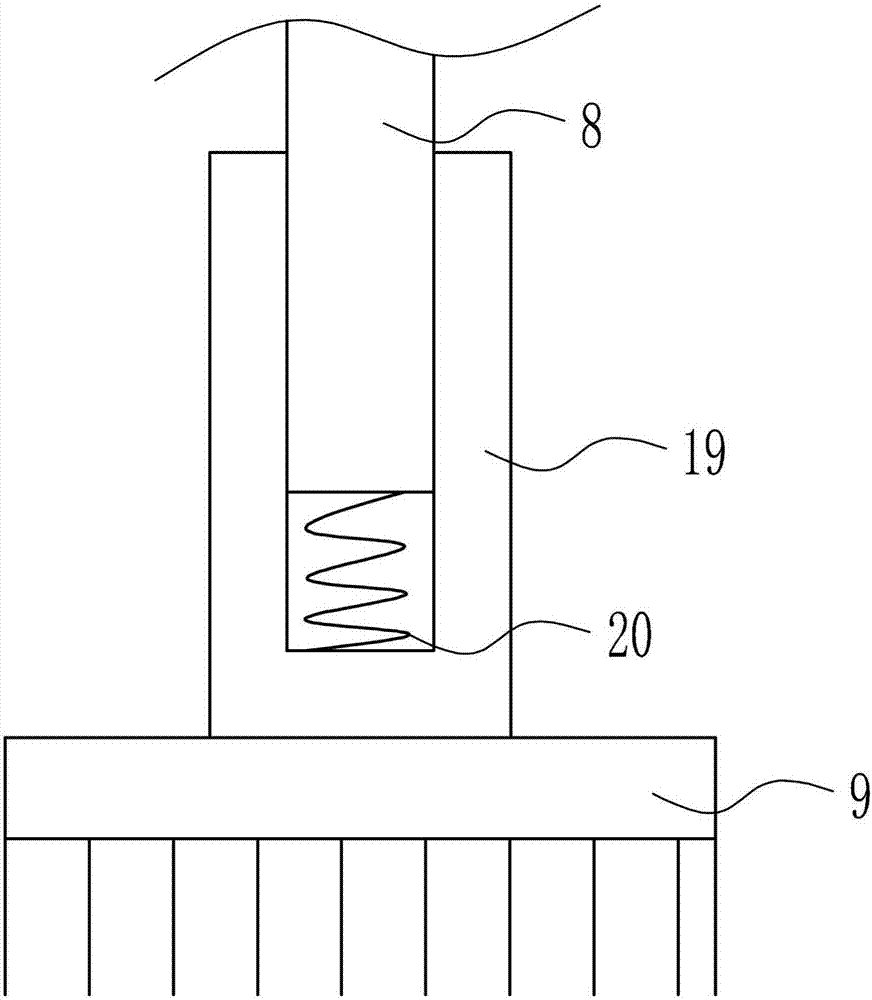

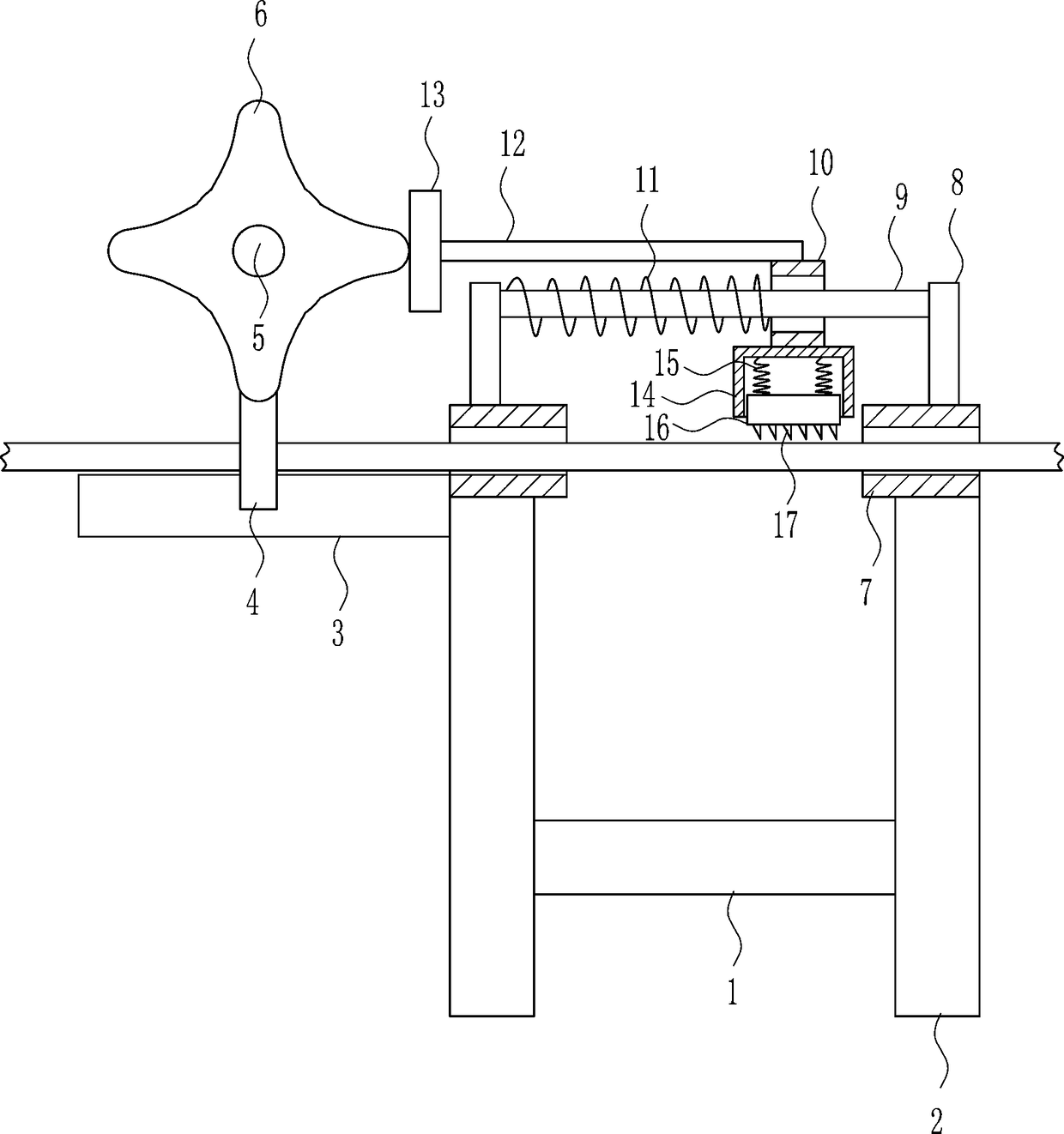

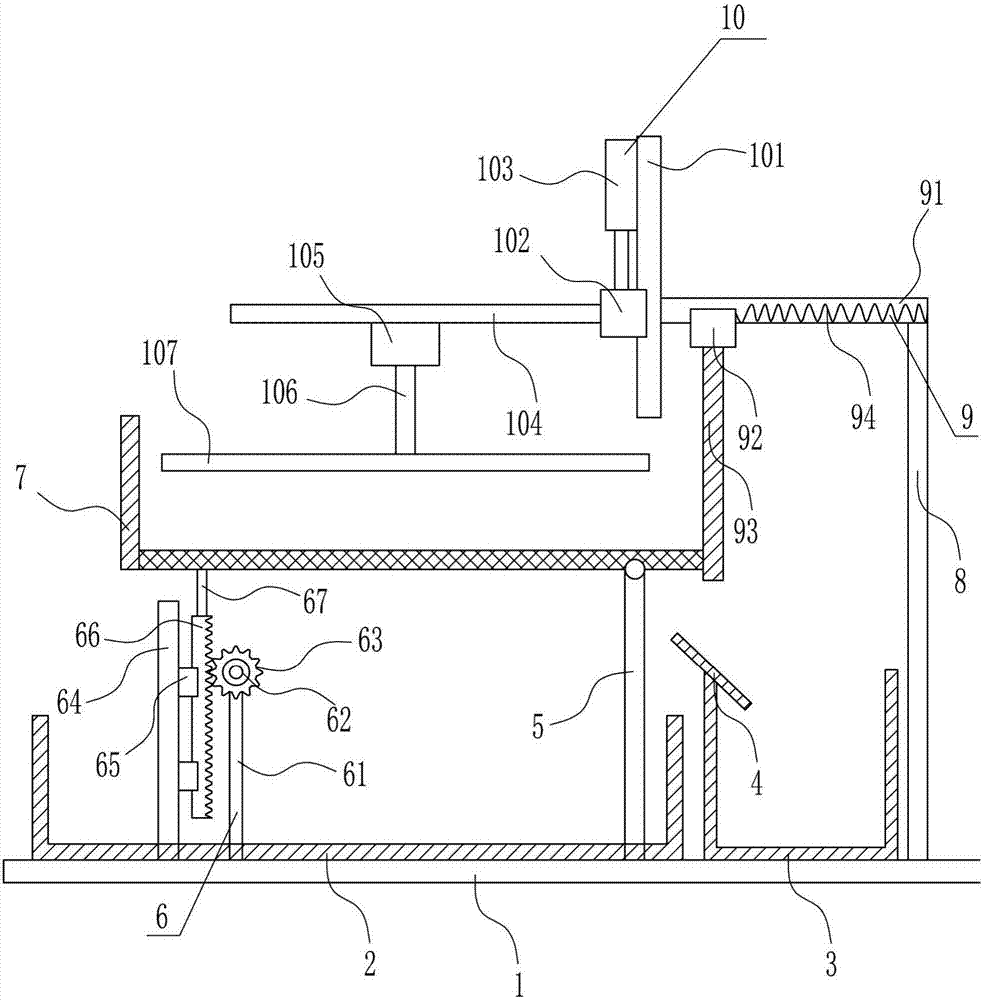

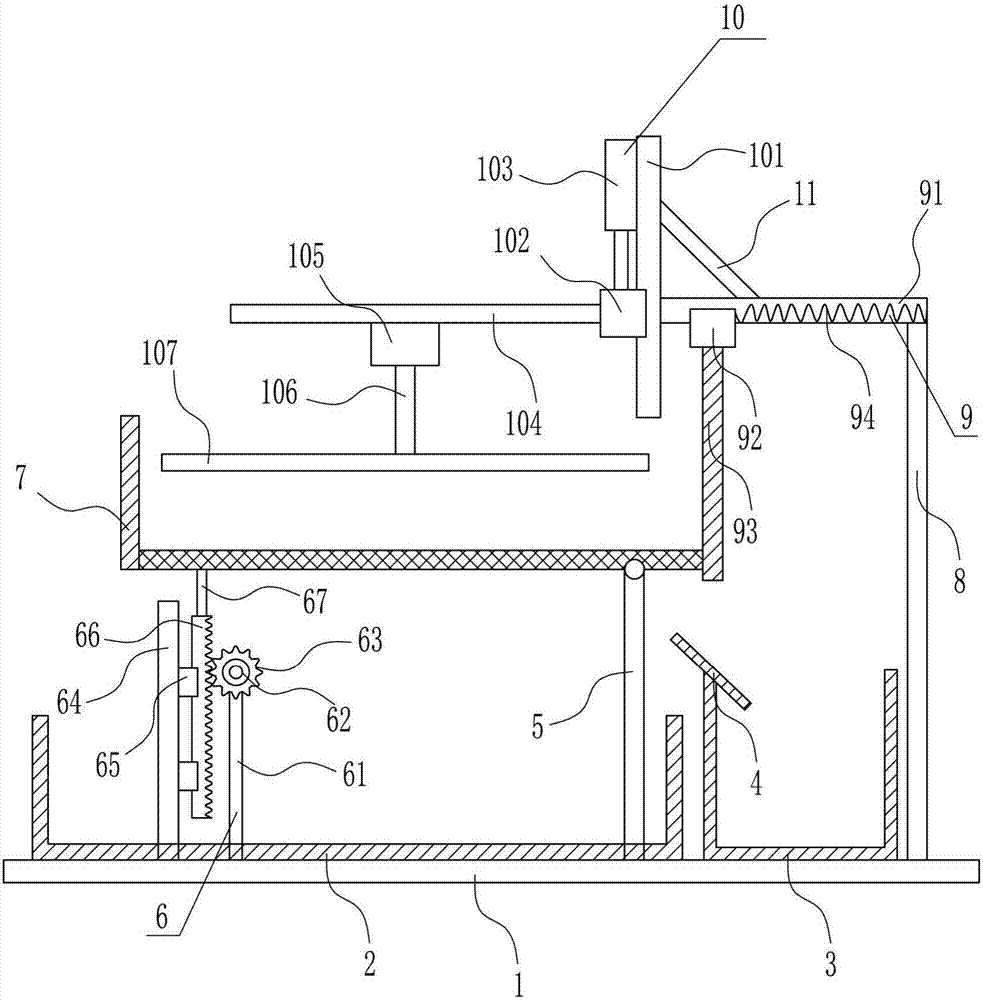

Efficient gluing equipment for shoemaking in shoe factories

InactiveCN106670056AApply glue evenlyDevice stableLiquid surface applicatorsCoatingsPistonFixed frame

The invention relates to gluing equipment, in particular to efficient gluing equipment for shoemaking in shoe factories. According to the efficient gluing equipment for shoemaking in the shoe factories, rapid gluing can be conducted, the gluing effect is good, and the gluing efficiency is high. The efficient gluing equipment for shoemaking in the shoe factories comprises a fixed frame, a U-shaped cylinder body, a first piston, a first left-right movement rod, a placing plate, a gluing head, a second left-right movement rod, a second piston, a small cylinder body and the like. The small cylinder body, a motor and the U-shaped cylinder body are arranged on the fixed frame in sequence from top to bottom. The motor is provided with a fan-shaped gear. The first piston is arranged in the lower portion of the U-shaped cylinder body in a matched mode. The first left-right movement rod is arranged on the left portion of the first piston. The efficient gluing equipment for shoemaking in the shoe factories achieves the effects of being good in gluing effect and high in gluing efficiency; a large number of gluing tasks can be rapidly completed through the efficient gluing equipment; in addition, a large amount of labor force is not needed; and a glued finished product is beautiful.

Owner:林永远

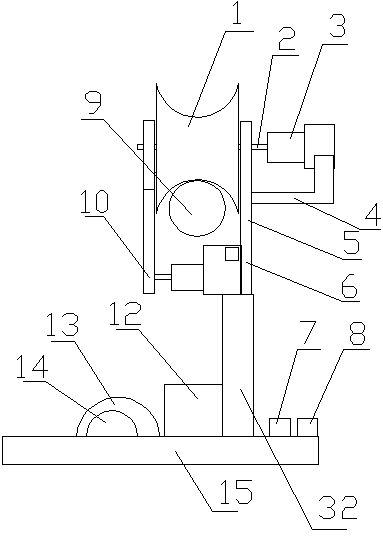

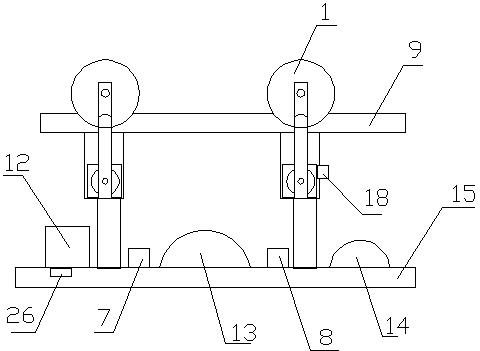

Efficient steel bar rust removing equipment for construction

InactiveCN106944908AComprehensive rust removalImprove rust removal effectGrinding carriagesGrinding drivesArchitectural engineeringEngineering

The invention relates to a derusting device for steel bars for construction, in particular to a high-efficiency derusting device for steel bars for construction. The technical problem to be solved by the present invention is to provide a high-efficiency derusting equipment for building steel bars that does not require a large amount of labor, has short derusting time, and is not easy to be injured during the derusting process. In order to solve the above technical problems, the present invention provides such a high-efficiency derusting equipment for steel bars for construction, which includes a bottom plate, legs, support plates, top plate, first motor, cam, frame, vertical bar, etc.; Outriggers are installed on the sides by bolts, support plates are installed on the left and right sides of the top of the bottom plate by bolts, and a top plate is installed on the top of the support plate by bolts. In the present invention, the first steel wire brush and the second steel wire brush move left and right to double derust the steel bar, so that the derusting effect of the steel bar is better, and at the same time, the rotation of the steel bar is improved.

Owner:孔军玲

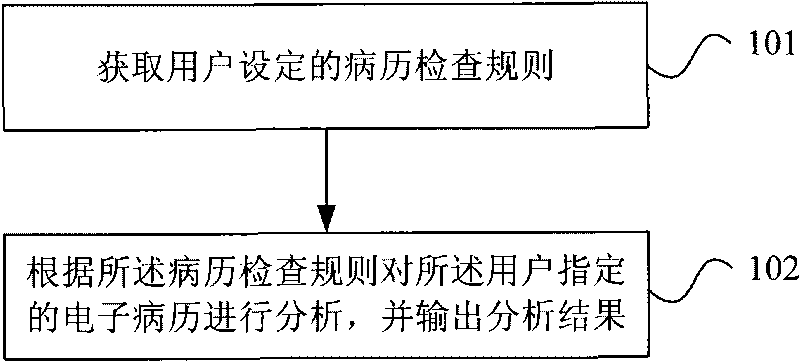

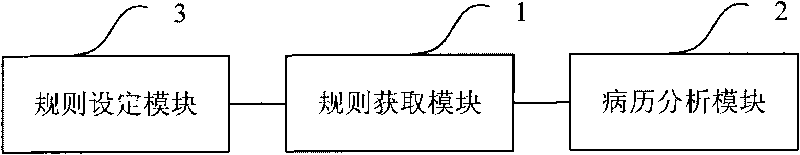

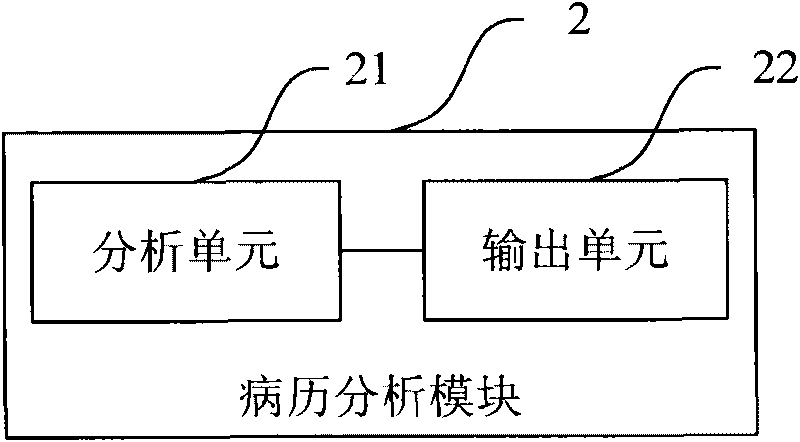

Quality control method and device for electronic medical records

InactiveCN101714191ASave human effortImprove efficiencySpecial data processing applicationsQuality controlQuality check

The invention discloses quality control method and device for electronic medical records. The method comprises the following steps of obtaining a medical record check rule set by a user; and analyzing the medical record appointed by the user according to the medical record check rule, and outputting the analysis result. The device comprises a rule acquiring module and a medical record analyzing module. The invention can perform quality check on the electronic medical records according to the medical record check rule appointed by the user, effectively enhance the efficiency of the electronic medical record check, and improve the accuracy and reliability of the electronic medical records.

Owner:江苏曼荼罗软件股份有限公司

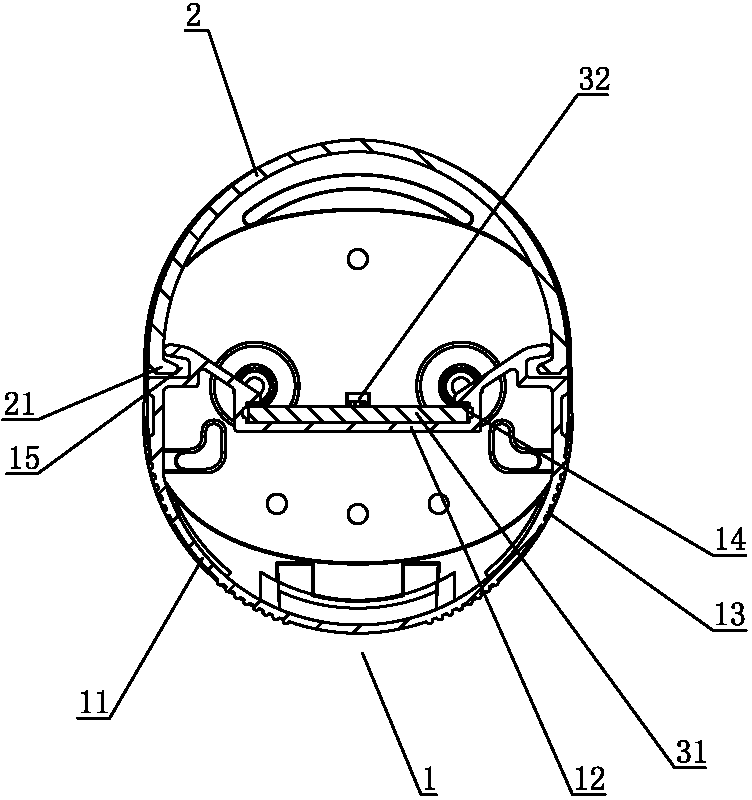

Automatic assembling method of light emitting diode (LED) lamp tube

ActiveCN103231243AImprove assembly efficiencyNo manual labor requiredAssembly machinesEngineeringLight head

The invention discloses an automatic assembling method of a light emitting diode (LED) lamp tube. The automatic assembling method includes that a mechanical arm is controlled to take a casing onto a special clamp located on an automatic conveyor; (2) the special tool clamping the casing is conveyed to a first station; (3) the mechanical arm is controlled to take and insert an LED light source into a first clamp slot; (4) the casing is conveyed to the next station; (5) the mechanical arm is controlled to take a lampshade and insert a clamp strip of the lampshade into a second clamp slot; (6) the casing is conveyed to the next station; (7) a lead wire is welded between the LED light source and an electrode; (8) the casing is conveyed to the next station; (9) the mechanical arm is controlled to take a lamp head, the lamp head is arranged at two ends of the casing, the casing and two ends of the lampshade are clamped into the clamp slots, and a buckle is clamped onto a bayonet at the moment to complete installation of the LED lamp tube; and (10) the LED lamp tube is detached from the special clamp. The automatic assembling method improves assembling efficiency of the LED lamp tube and reduces cost.

Owner:GUANGZHOU LEDIA LIGHTING CO LTD

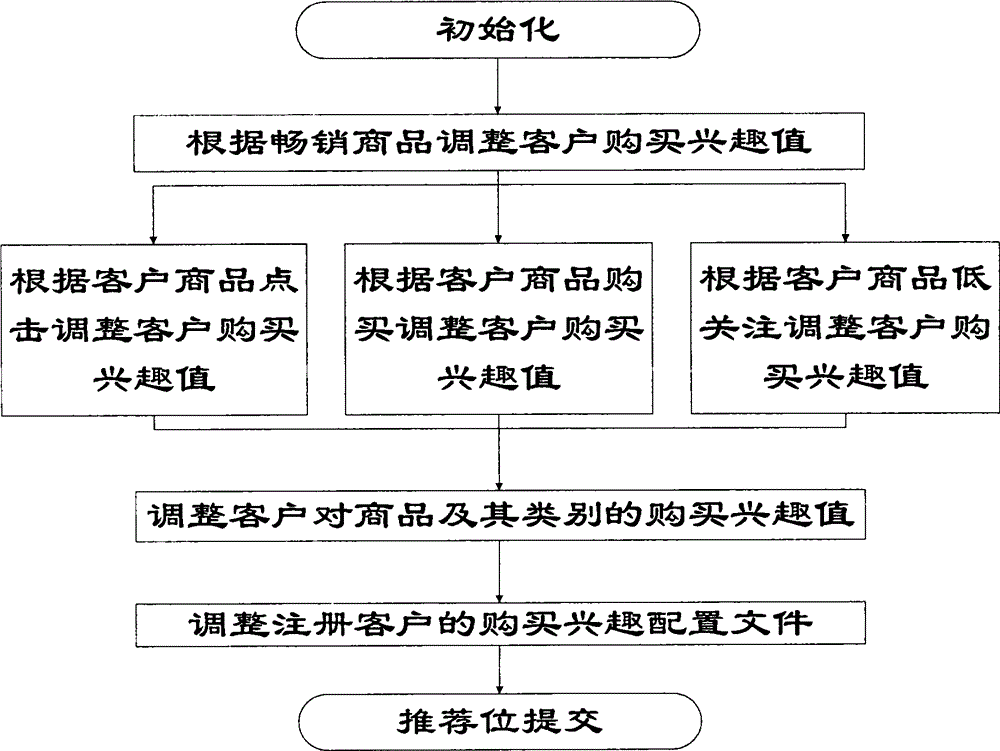

Commodity recommendation optimizing method based on customer behavior

InactiveCN102722842ARecommended product personalizationFix cold startMarketingRegistered nurseRanking

The invention discloses a commodity recommendation optimizing method based on a customer behavior. The method comprises the following steps of: 1, initializing; 2, adjusting a purchase interest configuration file of a registered customer according to best-selling commodities; 3, adjusting the purchase interest configuration file of the registered customer according to the clicking of recommended commodities by the customer; 4, adjusting the purchase interest configuration file of the registered customer according to the purchase of the recommended commodities by the customer; 5, adjusting the purchase interest configuration file of the registered customer according to low-concern recommended commodities of the customer; 6, adjusting the recommended position ranking of commodities according to the concern of the customer on recommended commodities; and 7, adjusting the purchase interest configuration file of the registered customer according to the purchase interest values of the customer on commodities, and arranging commodities with higher purchase interest values in recommended positions.

Owner:姚明东

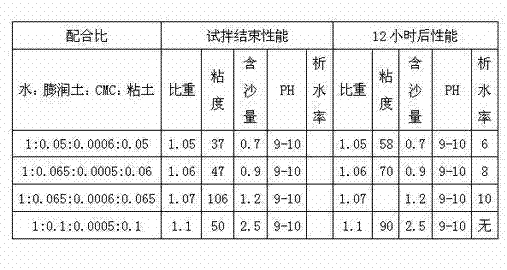

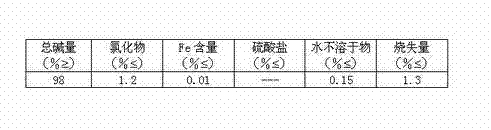

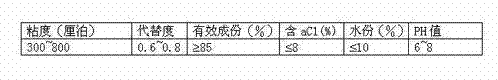

Construction slurry for rotary pile drilling

InactiveCN102226077ARich and stableEnrich and perfect mechanicsDrilling compositionSlurry wallSodium Bentonite

The invention discloses a type of construction slurry for rotary pile drilling. The slurry is a type of compound slurry comprising water, bentonite, hydroxypropyl methyl cellulose solution, clay and soda ash. The construction slurry provided by the present invention can be widely applied in fields of well drilling, rotary pile drilling, and underground diaphragm wall. During a preparing process, the slurry can be mixed quickly and well. The slurry also has advantages of high efficiency, low pollution, low energy consumption and low cost.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HIGHWAY ENG

Citronella essential oil sprout inhibitor and application thereof to potato preservation

InactiveCN101999451ANo pollution in the processNo pollutionFruit and vegetables preservationEssential-oils/perfumesCitrus medicaSolanum tuberosum

The invention relates to a citronella essential oil sprout inhibitor and application thereof to potato preservation, and discloses the citronella essential oil serving as a novel sprout inhibitor and the application thereof to the suppression of sprouting during potato preservation. The citronella essential oil is applied to the potato preservation environment by methods such as fumigating, spraying and the like, wherein the concentration of the essential oil is controlled to be in a range from 0.01 to 0.1mL / L through direct fumigating during fumigation; and spraying or dipping is adopted during liquid processing so as to control the concentration to be 0.1 to 1 percent. By using the citronella essential oil originated from a natural plant as an active ingredient, the sprouting during the potato preservation can be effectively suppressed, chemical substances are reduced or avoided, and the sprout inhibitor has the advantages of good sprout inhibition effect and environmental friendliness.

Owner:NAT ENG AN TECH RES CENT FOR PRESERVATION OF AGRI PROD TIANJIN +1

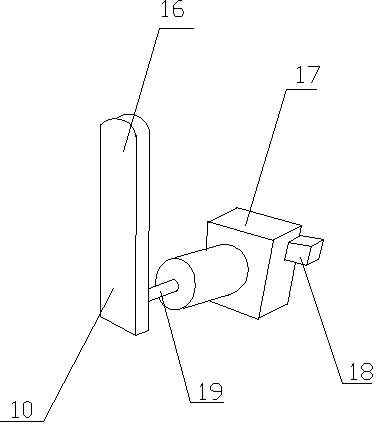

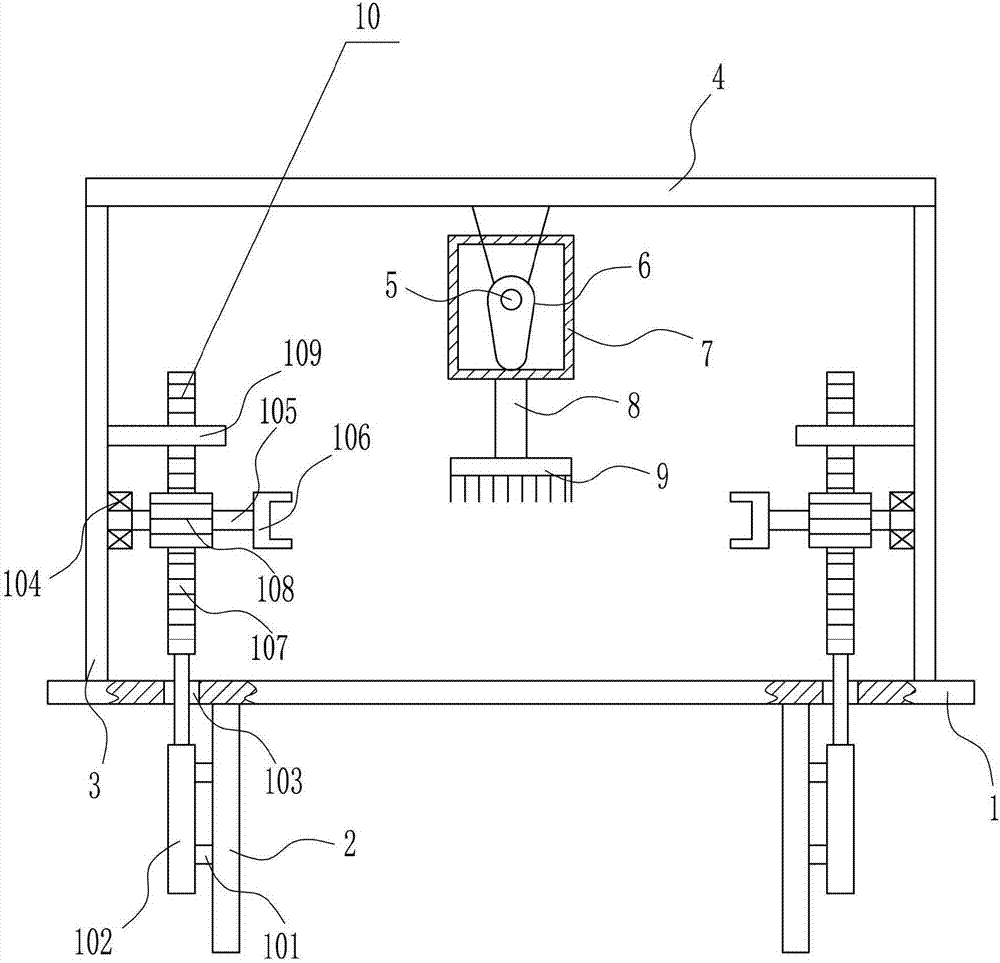

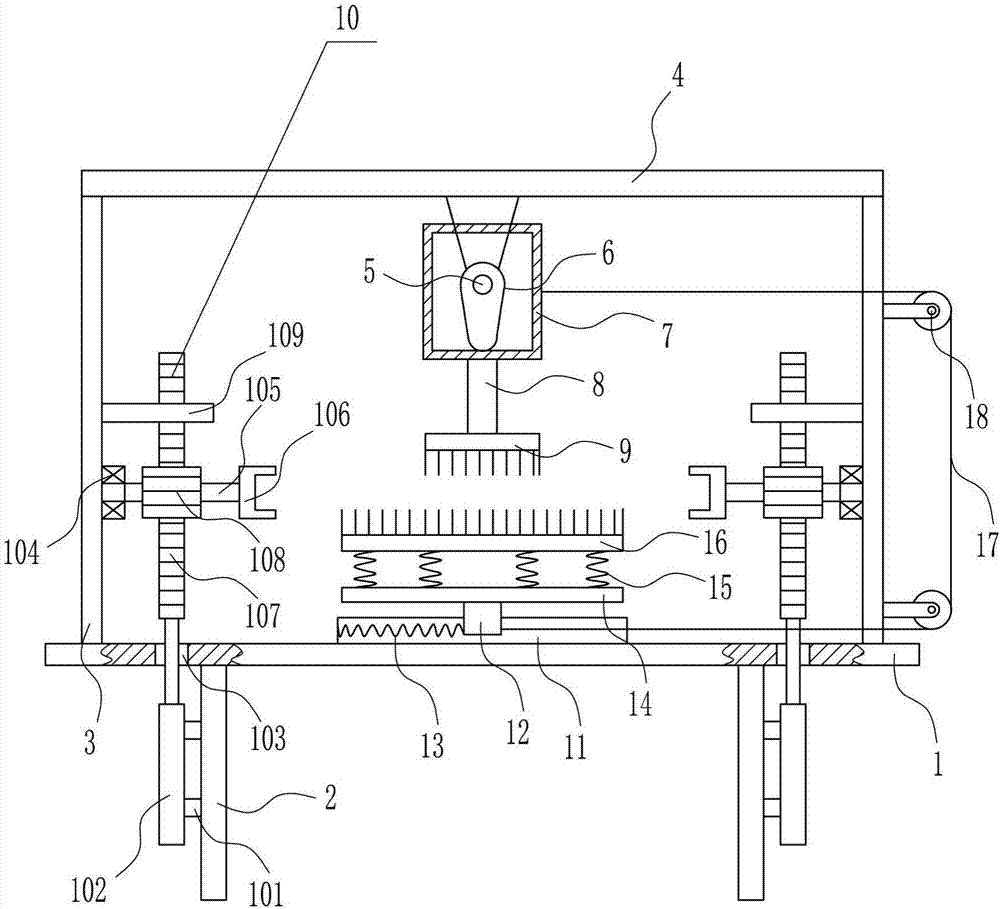

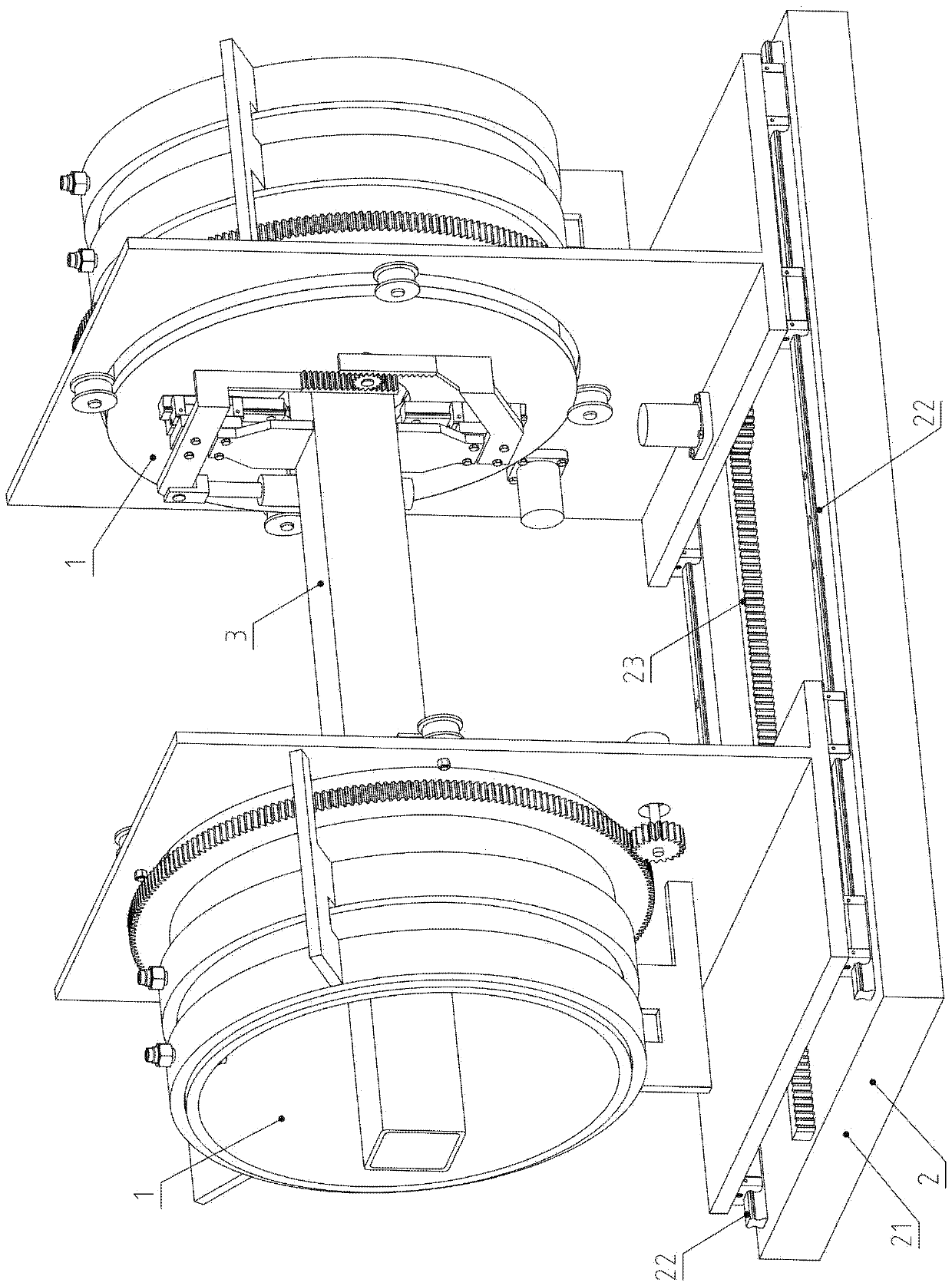

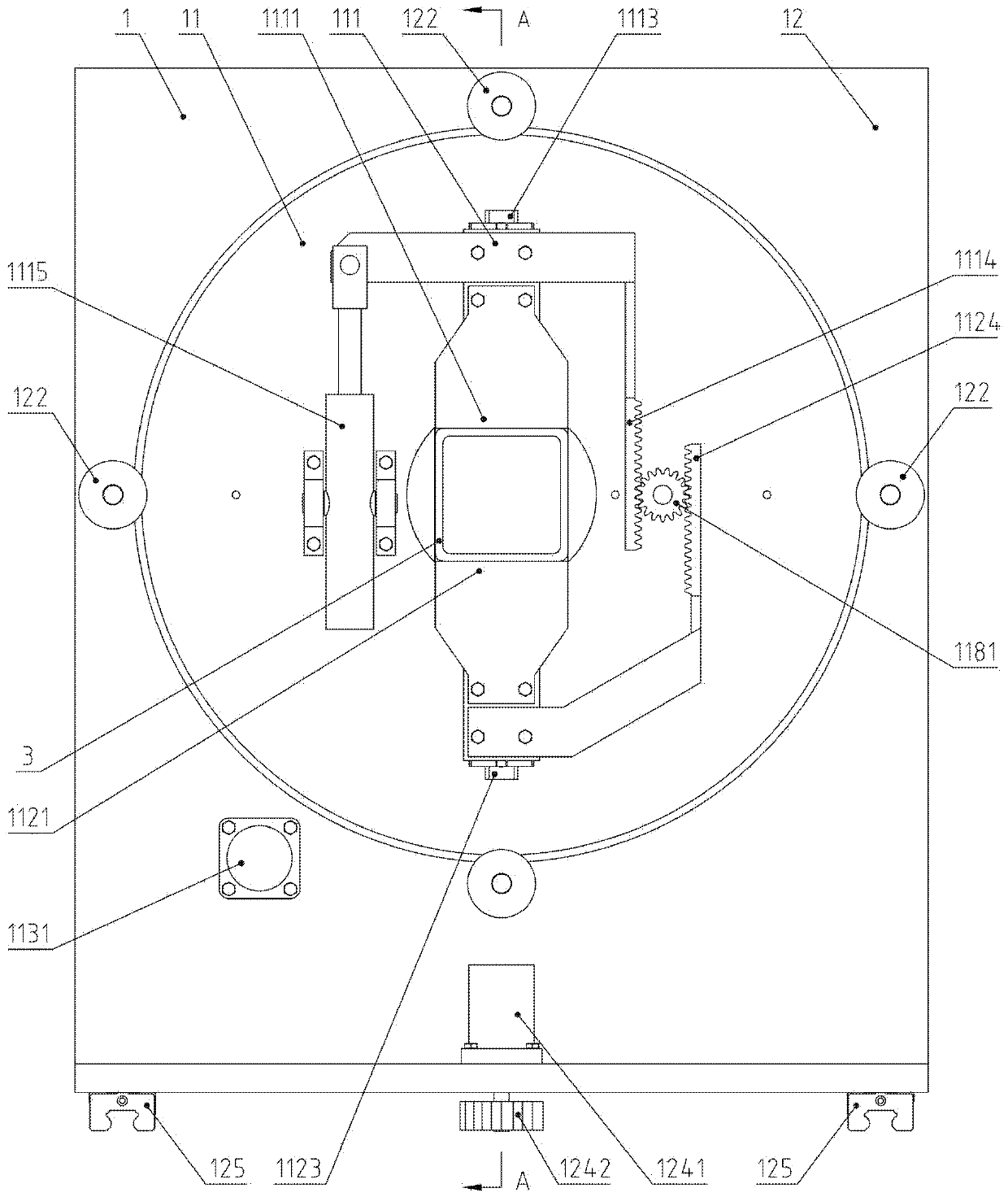

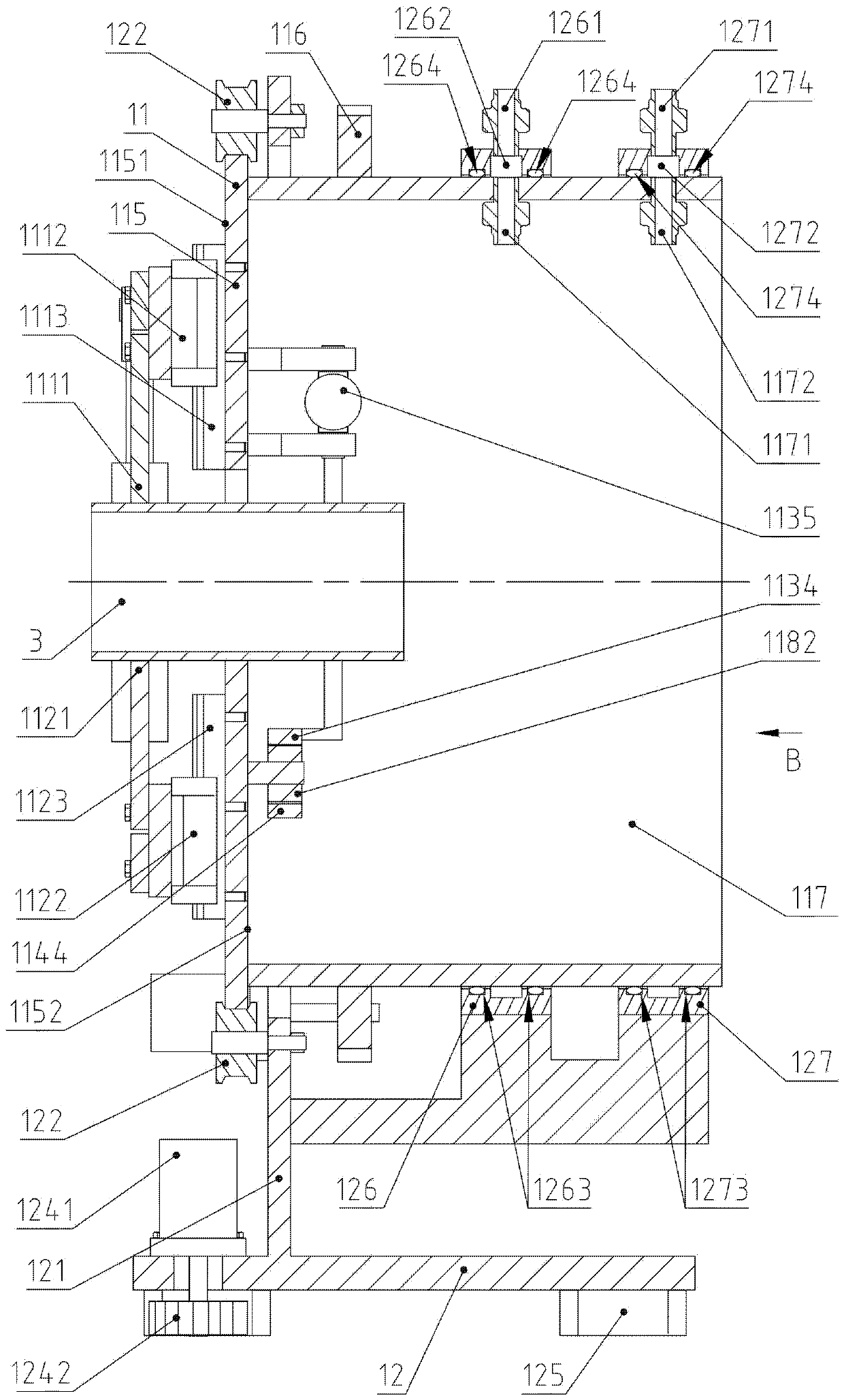

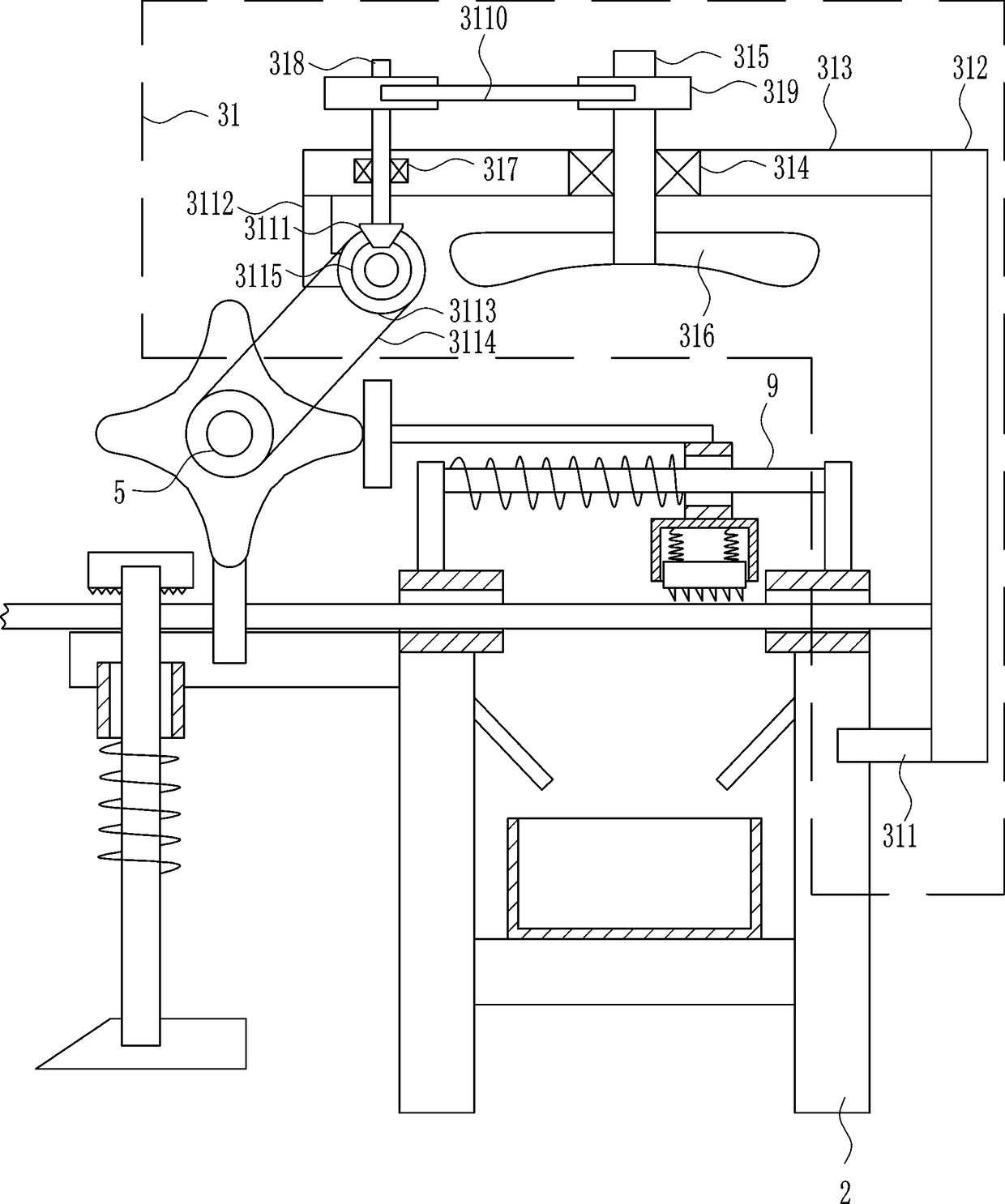

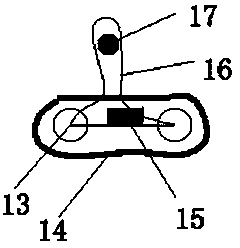

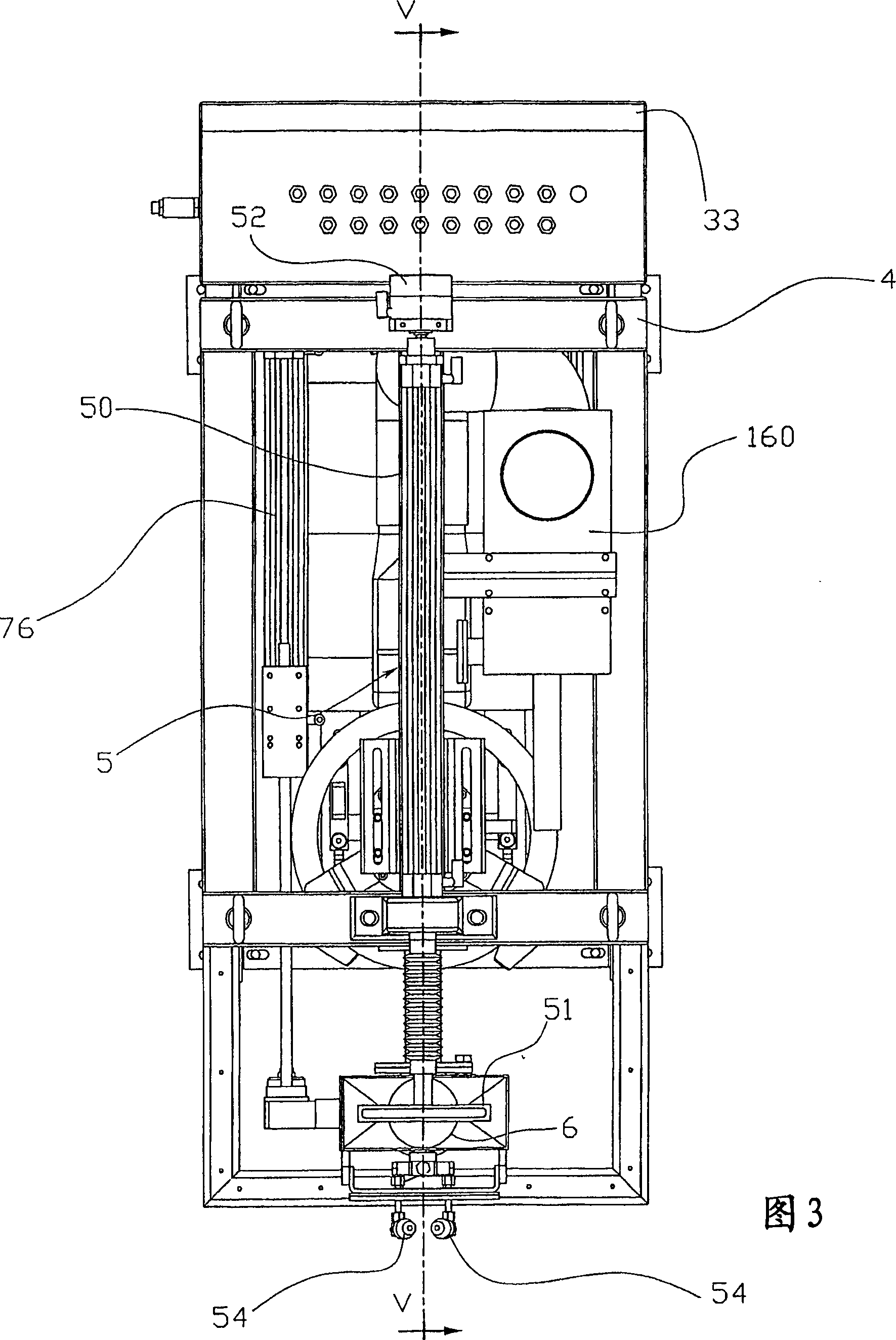

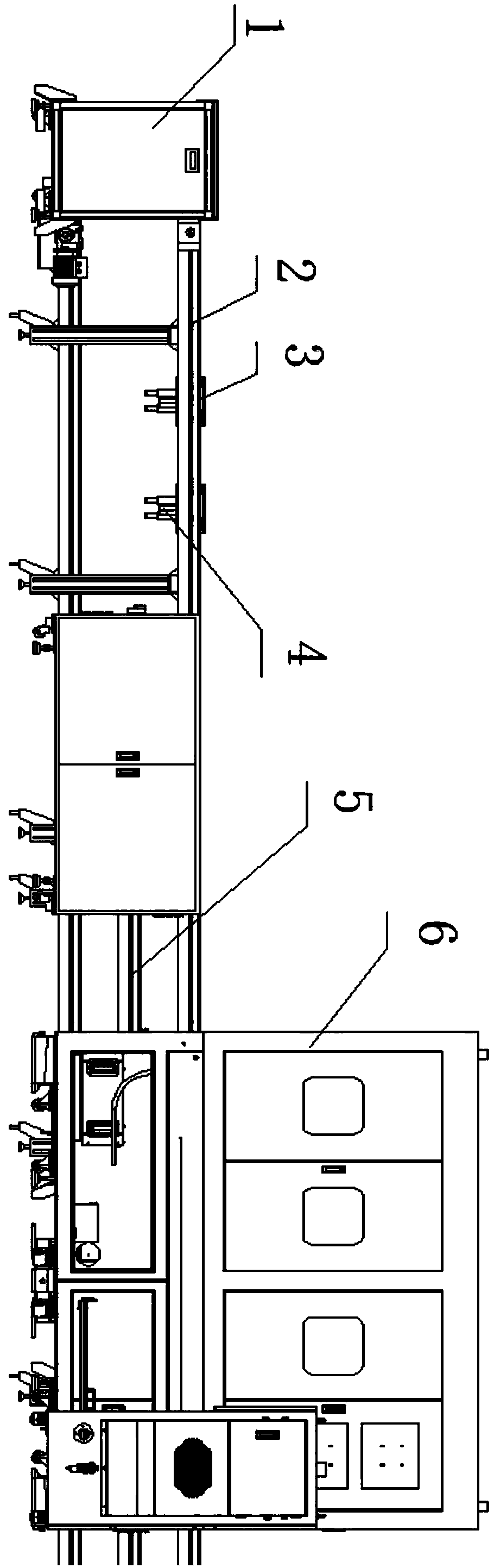

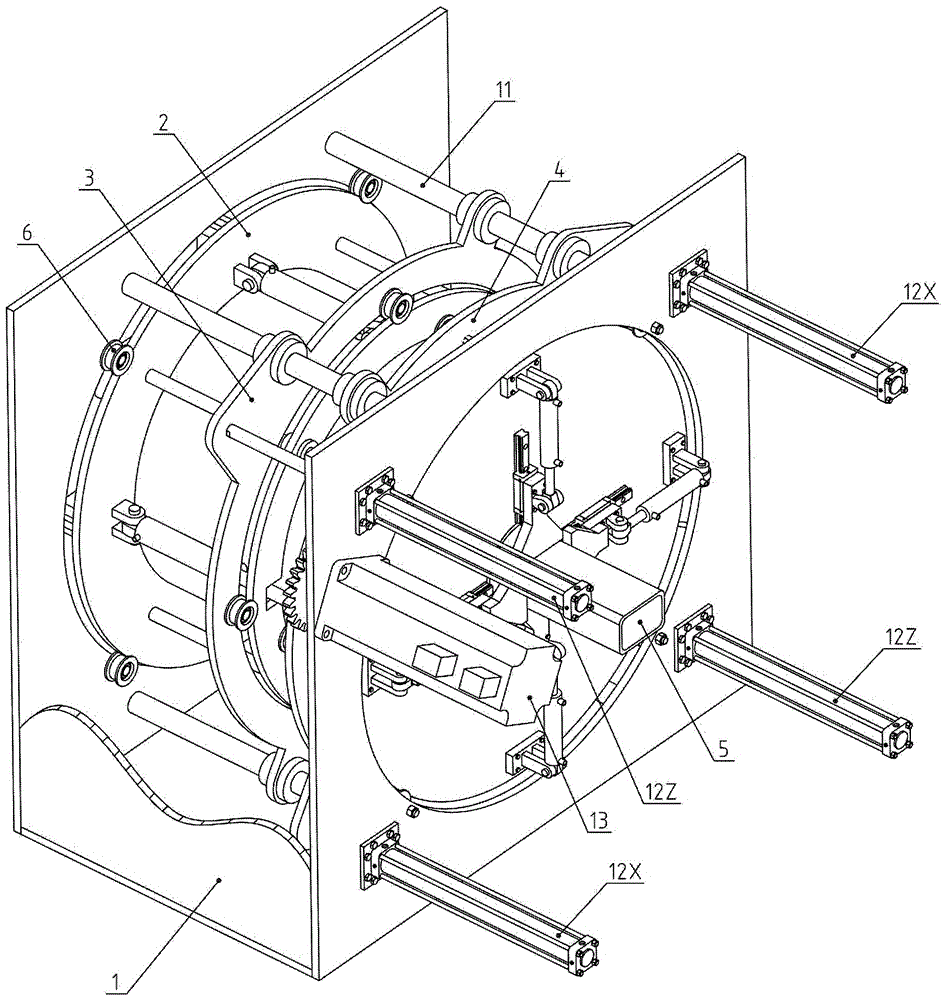

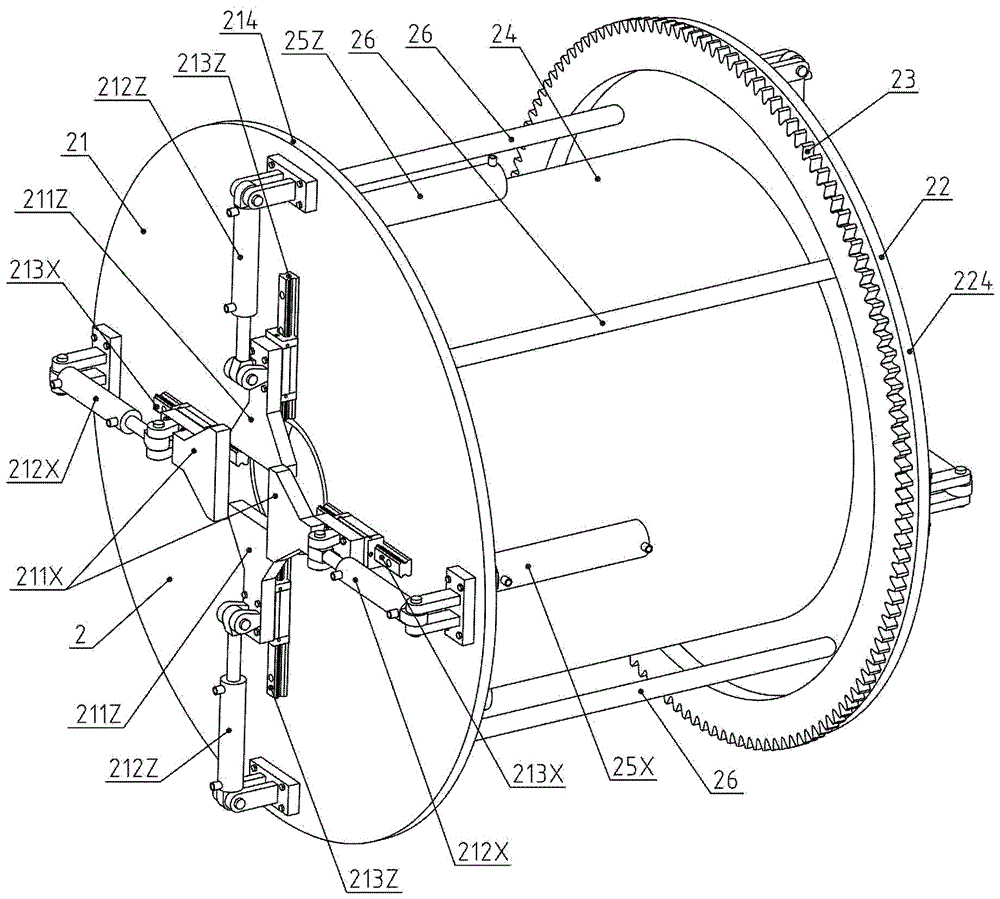

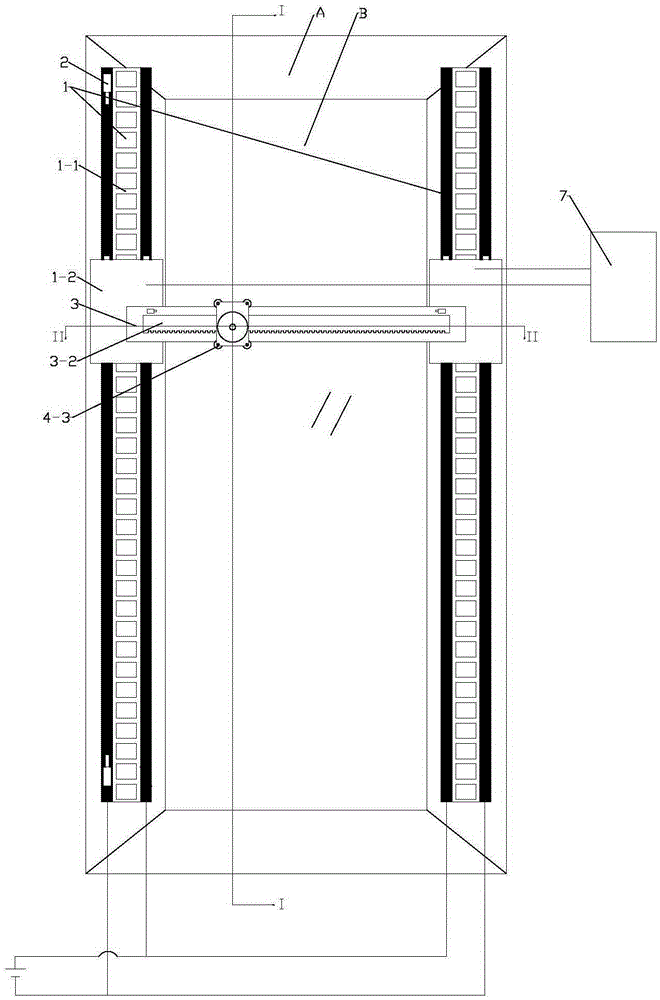

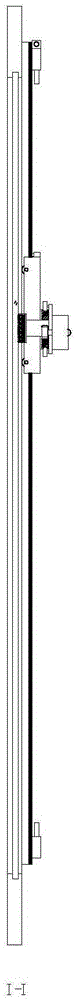

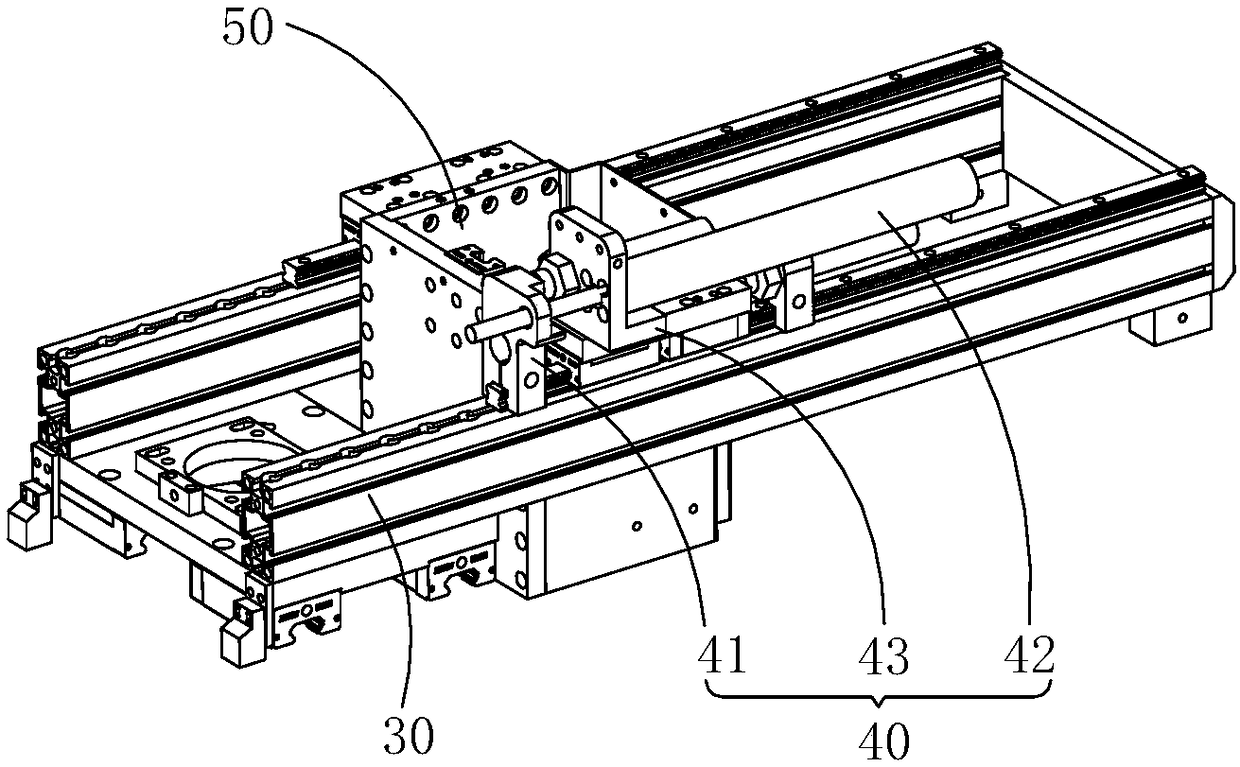

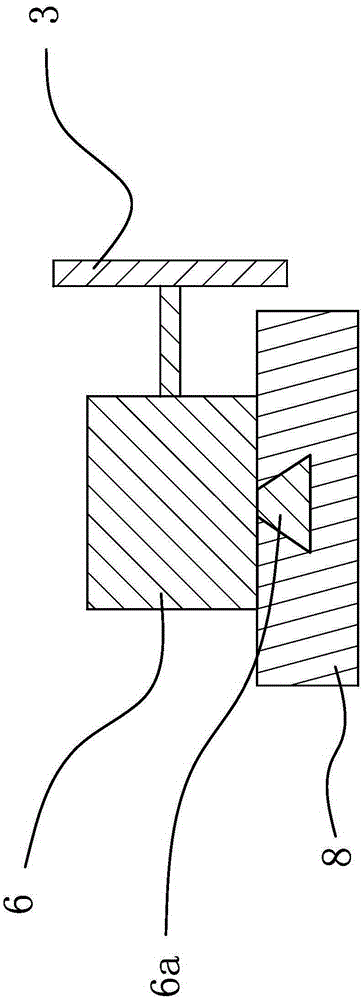

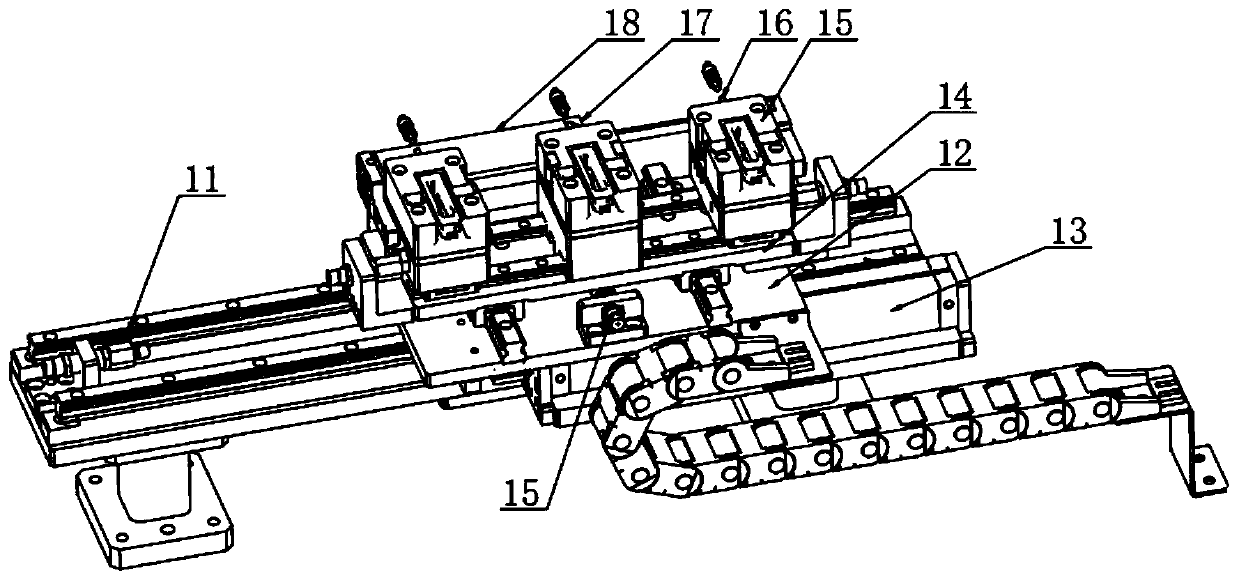

Rectangular tube or circular tube intelligent centering, clamping and rotating device

InactiveCN107855670APrevent twistingUnlimited continuous spinsPlasma welding apparatusLaser beam welding apparatusEngineeringMechanical engineering

The invention belongs to the technical field of intelligent manufacturing equipment, and relates to a rectangular tube or circular tube intelligent centering, clamping and rotating device. According to the device, pressure hydraulic oil is ingeniously is introduced into a rotary system through a sealed oil passing groove formed between two mutually rotary parts, and a hydraulic hose is prevented from being twisted so that a rotary part can continuously rotate without limitation, and the use is very convenient. A cog gear is ingeniously used for driving two racks to synchronously and horizontally move in opposite directions so that the center line of a rectangular tube can well coincide with the center line of a circular ring turntable, the device is very beneficial to demonstration or programming of intelligent cutting equipment, a cylindrical coordinate system is conveniently built, coordinate conversion is not needed, and the device is more convenient to use compared with an eccentric clamping mode. The device is matched with the intelligent work equipment so that intersection lines such as round holes and elliptical holes can be cut out and complex hollowed-out patterns or characters can also be cut out. The device achieves automatic clamping, turning and position changing, manual work is not needed, and manpower is saved.

Owner:李大德

Reinforcement surface removing equipment containing concrete slag

The invention relates to construction concrete equipment, in particular to reinforcement surface removing equipment containing concrete slag. The reinforcement surface removing equipment containing the concrete slag is high in speed, saves both time and labors in the working process, and cannot injure worker hands. The reinforcement surface removing equipment containing the concrete slag comprisesa mounting plate, brackets, a fixed plate, a support rod, an electric wheel, a flange cam, a slide sleeve, a fixed block, a first guide rail, a first guide sleeve, a first spring, a push rod and thelike; the brackets are connected to the left and right ends of the mounting plate; and the fixed plate is connected above the left side of the bracket on the left side. The reinforcement surface removing equipment containing the concrete slag achieves the effects of high speed, time and labor saving in the working process and incapability of injuring the worker hands, and can quickly remove reinforcement surfaces through adopting a mode of the flange cam driving reverse teeth to scrape concrete blocks on the reinforcement surfaces without needing labors so as to liberate the labors.

Owner:汤国忠

High-efficiency sand screening equipment for construction

Owner:江苏苏南建筑安装工程有限公司

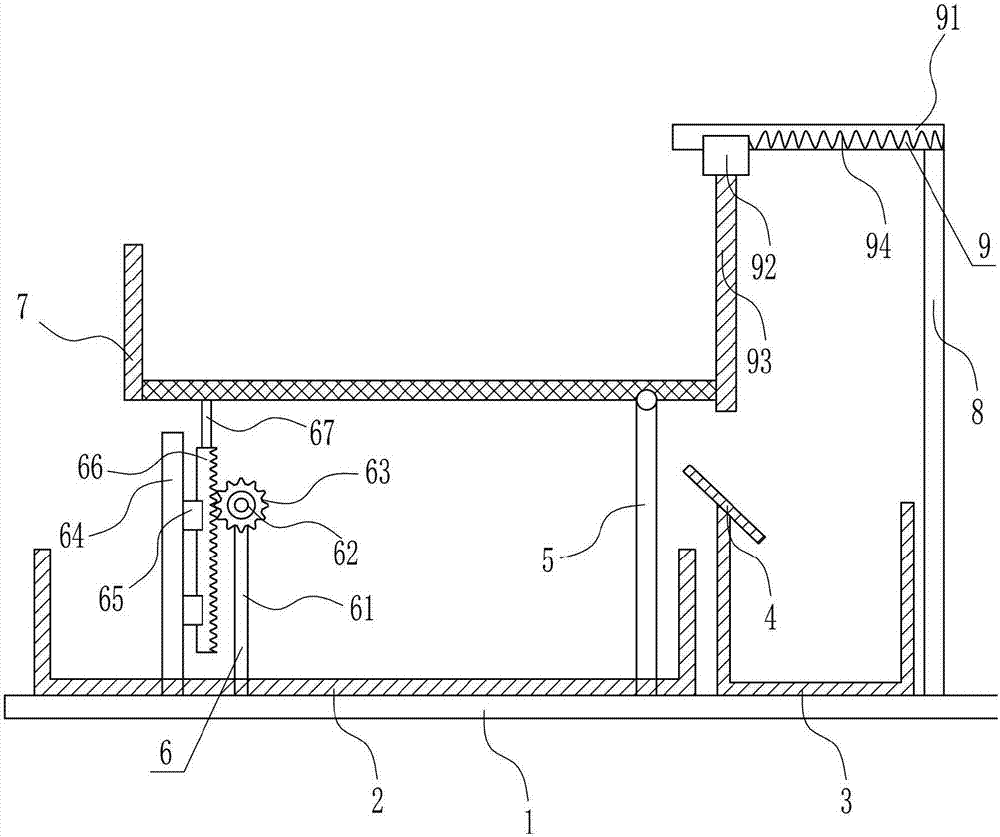

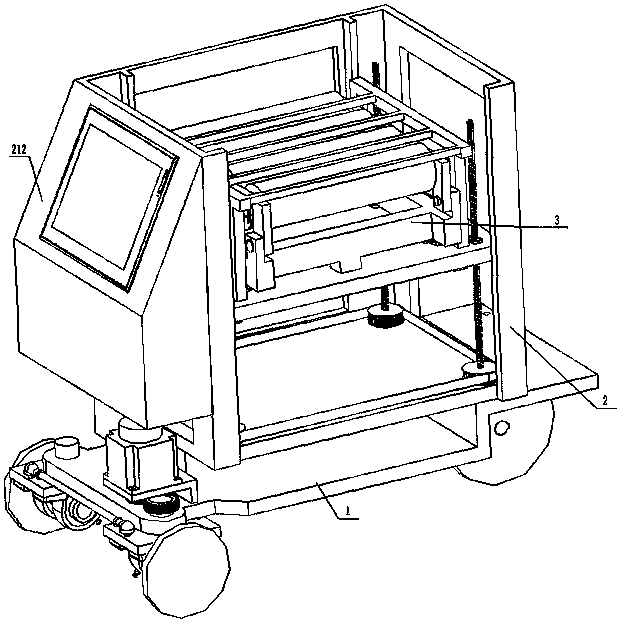

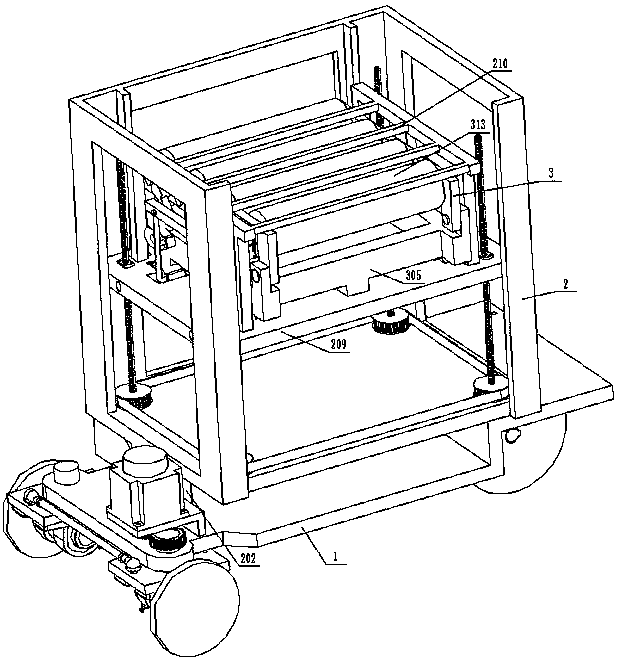

Robot used for logistics warehousing

InactiveCN109292342AAchieve tilt rotationRealize automatic unloadingStorage devicesLogistics managementSimulation

The invention discloses a robot used for logistics warehousing. The robot comprises an AGV (Automatic Guided Vehicle), a main lifting assembly and an auxiliary lifting assembly, wherein a first-levellifting platform of the auxiliary lifting assembly is inserted into first-level lifting platform inserting holes in the main lifting assembly; first-level camshafts of the auxiliary lifting assembly are fixedly mounted on a lifting platform in the main lifting assembly; first-level cams I and first-level cams II are both positioned in cam placement holes of the lifting platform; carrying rollers of the auxiliary lifting assembly are positioned below a carrying frame in the main lifting assembly; and the main lifting assembly is positioned on the AGV. The robot has the following beneficial effects: through the rotation of screw rods, the lifting platform is raised, so as to drive the auxiliary lifting assembly to rise to achieve a series of linked actions that the carrying rollers rotate obliquely and that goods contact the carrying rollers to slide out for unloading, so that the robot achieves automatic unloading, does not need labor, saves time and effort and is high in efficiency; and especially when the environment of a warehouse is not good, workers do not need to enter the warehouse for unloading, so that the robot is safe, healthy and highly-practical.

Owner:HANDAN COLLEGE

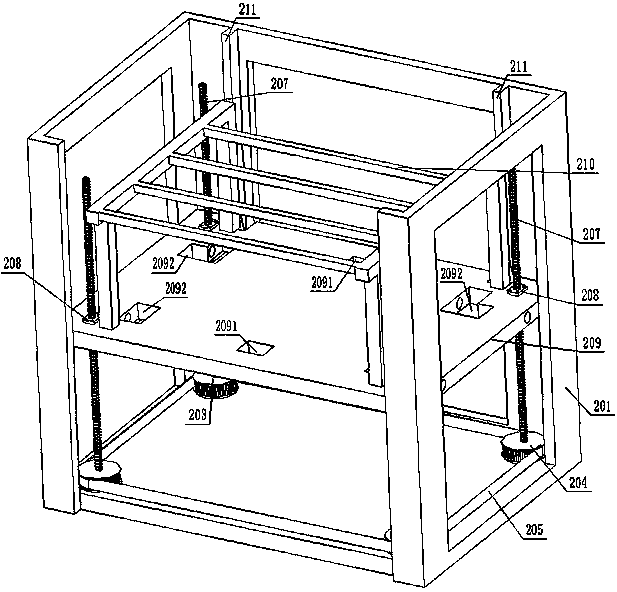

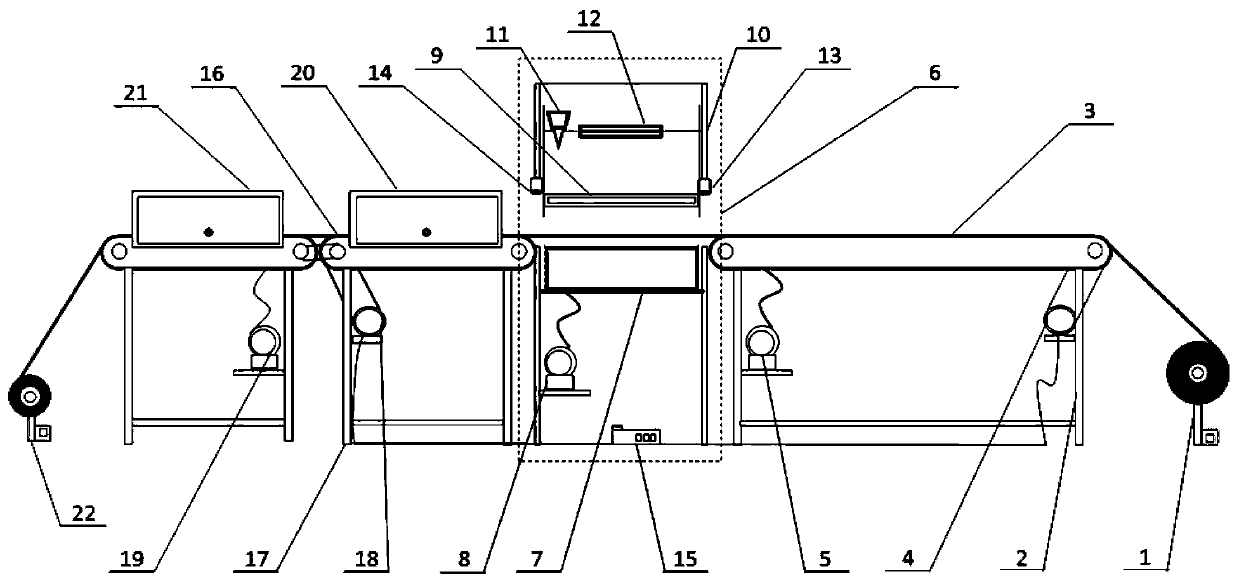

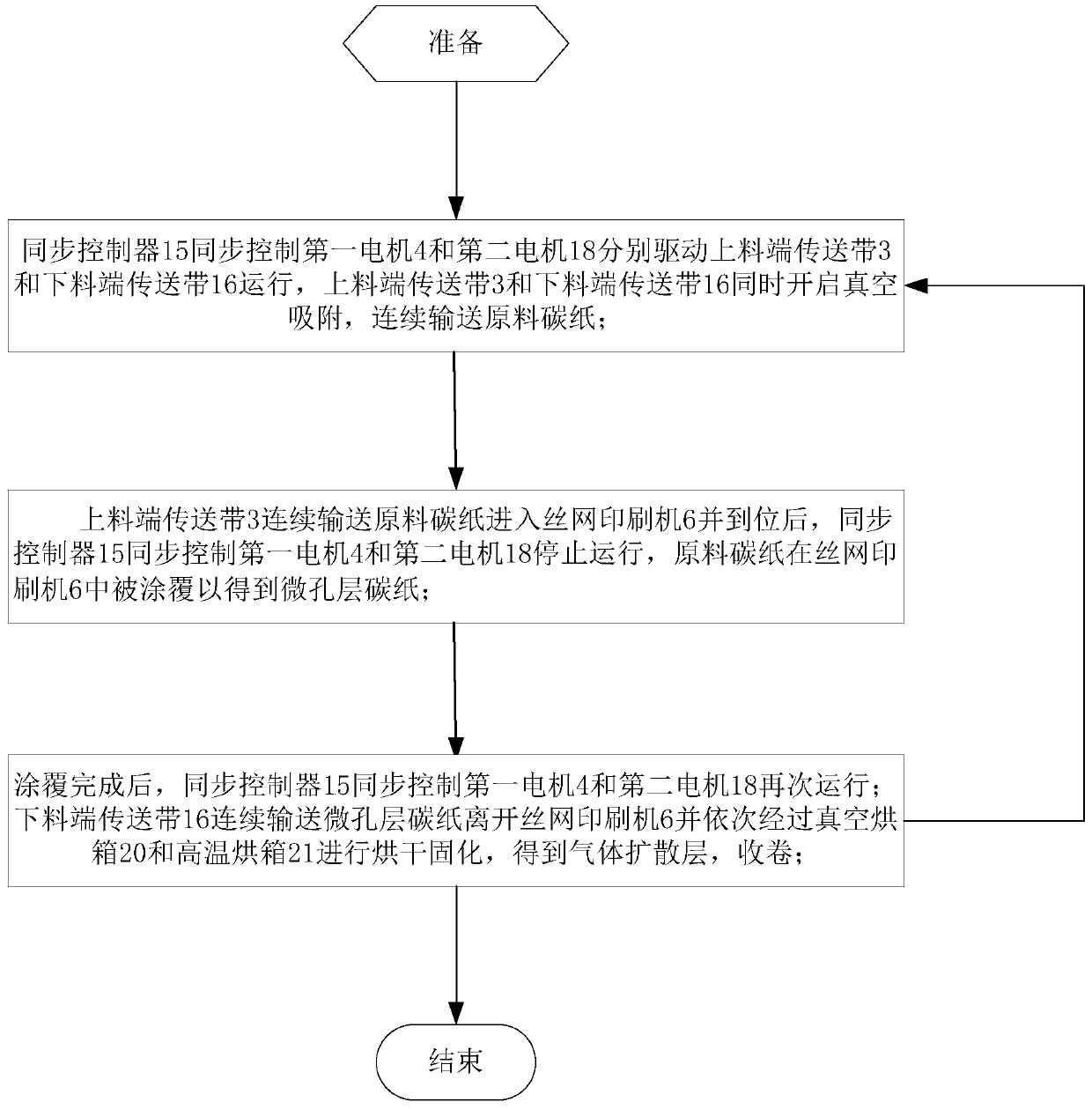

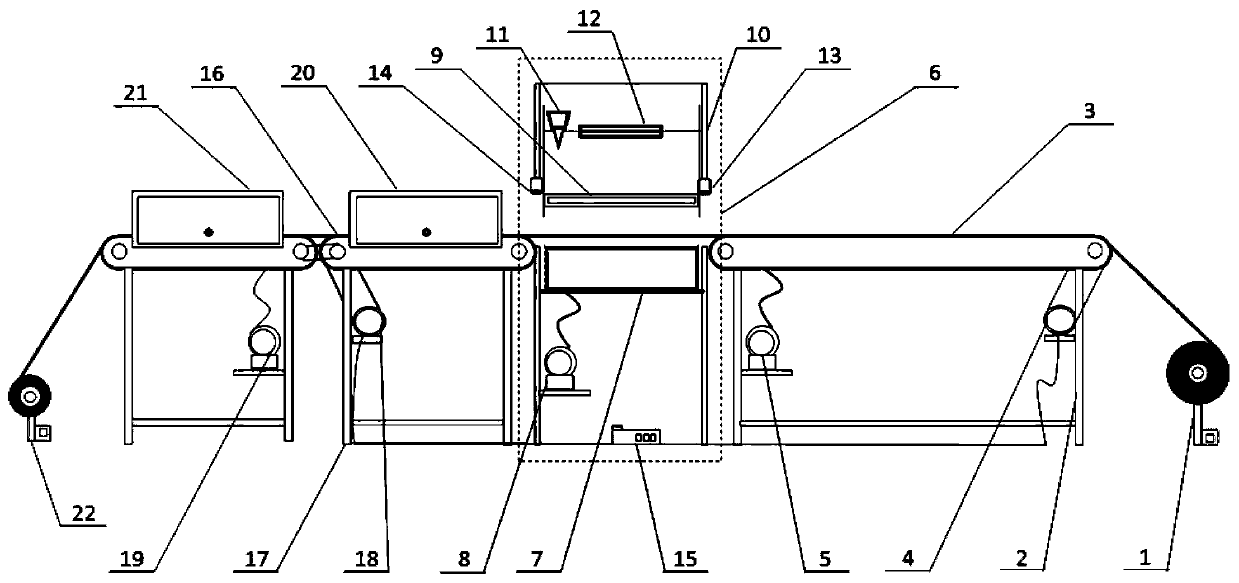

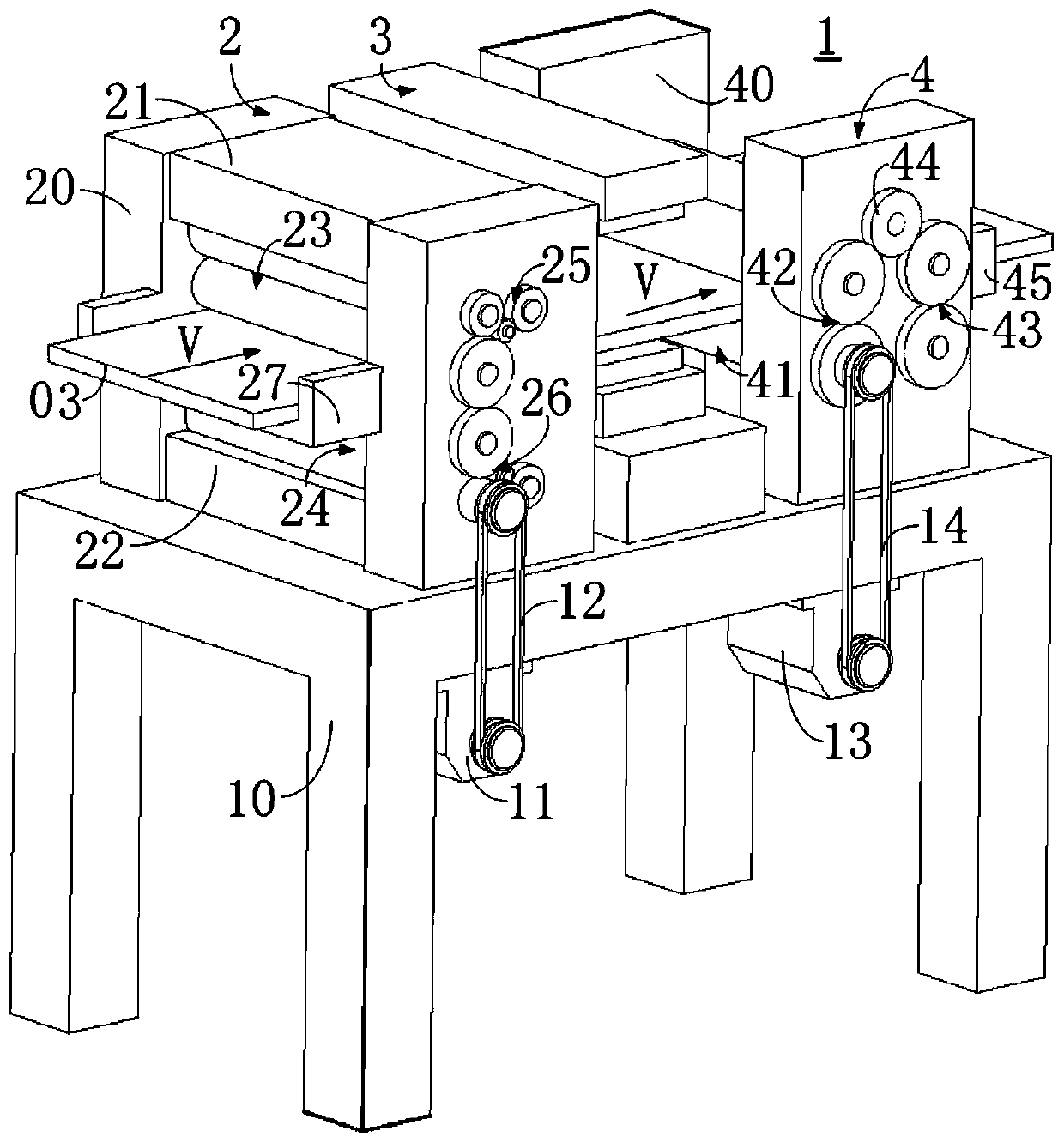

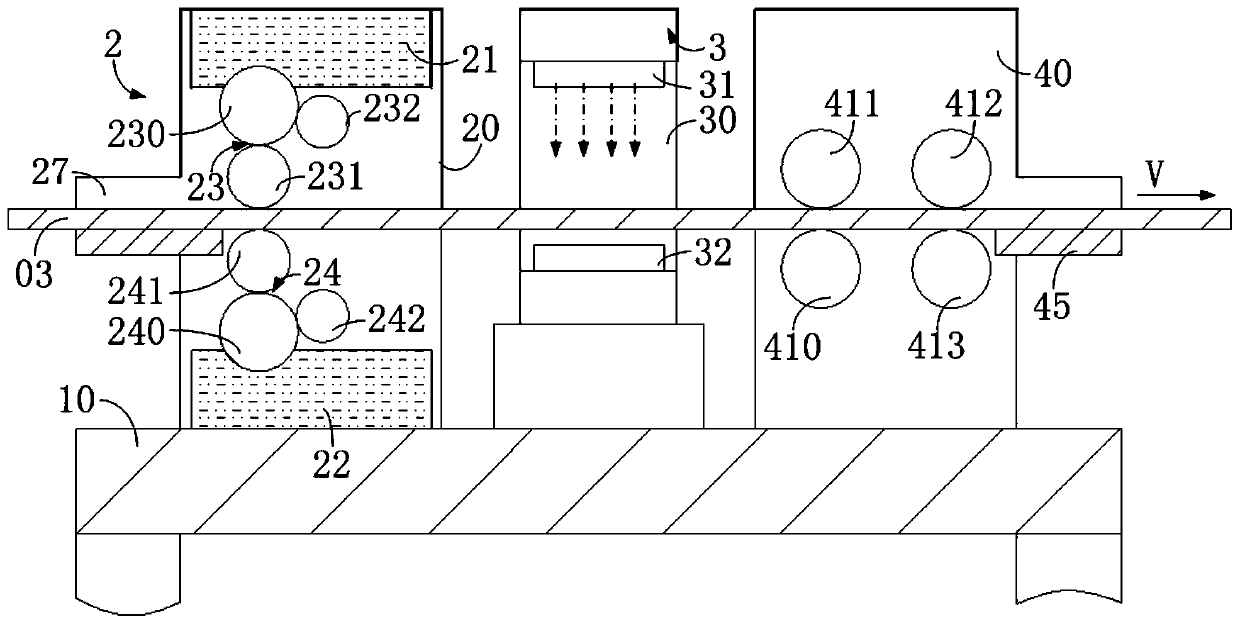

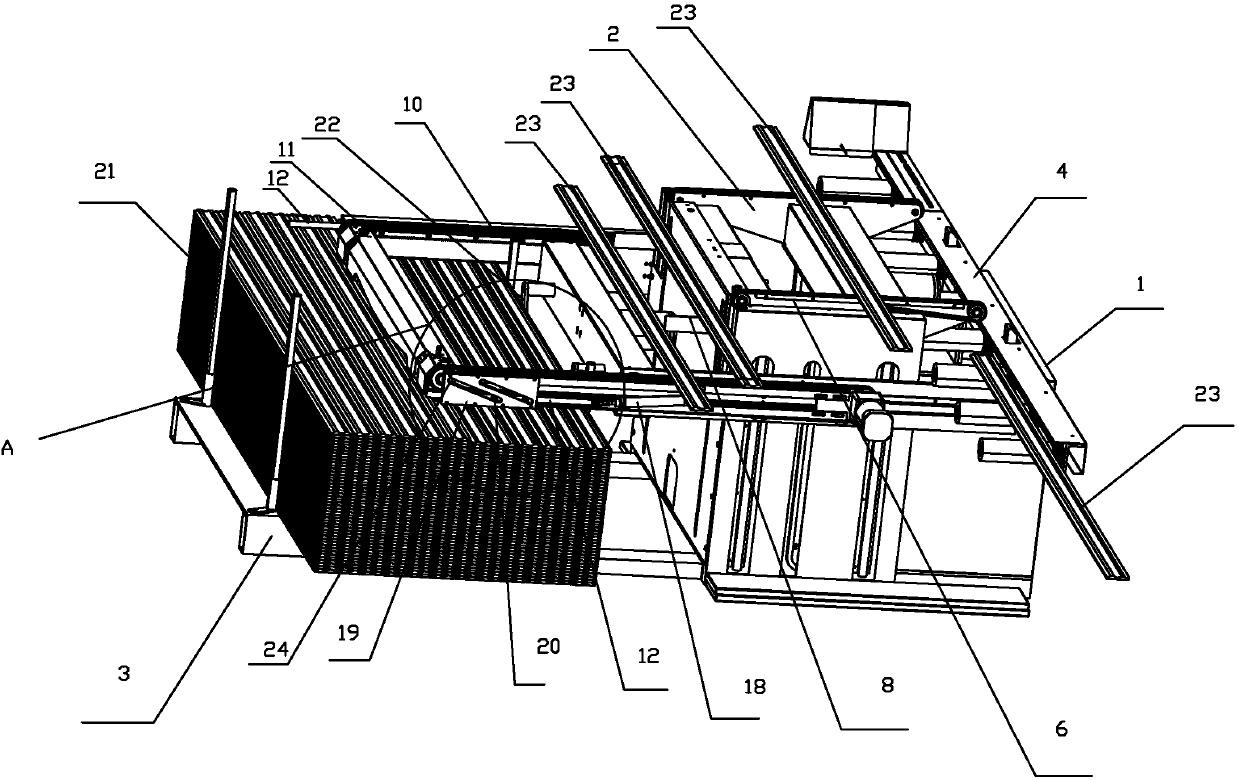

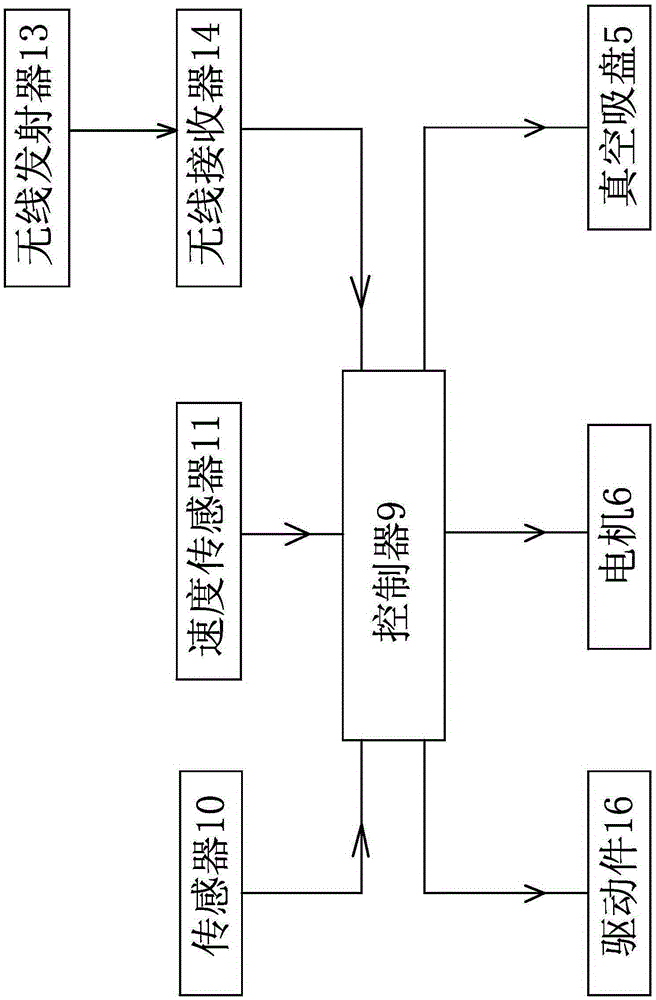

Device and method for continuously preparing gas diffusion layer of fuel cell

ActiveCN111146450AStable and continuous deliveryImprove production taktCell electrodesScreen printersScreen printingFuel cells

The invention belongs to the technical field of fuel cells, and discloses a device and a method for continuously preparing a gas diffusion layer of a fuel cell. The device comprises: a feeding end conveying belt which is driven by a first motor to continuously convey raw material carbon paper from a raw material carbon paper support; a screen printing machine which is used for coating to obtain microporous layer carbon paper; a discharging end conveying belt which is driven by a second motor to operate and continuously convey the microporous layer carbon paper to sequentially pass through thevacuum drying oven and the high-temperature atmosphere drying oven to obtain a gas diffusion layer to roll the gas diffusion layer; a feeding end conveying belt which is connected with a first vacuumpump, wherein the discharging end conveying belt is connected with a second vacuum pump; and a synchronous controller which controls the first motor and the second motor to start and stop synchronously. The feeding end conveying belt and the discharging end conveying belt are connected with the first vacuum pump and the second vacuum pump correspondingly to provide vacuum adsorption, and stable and continuous conveying of raw material carbon paper is guaranteed; the synchronous start and stop of the first motor and the second motor are beneficial to accelerating the production takt and realizing the continuous coating of the raw material carbon paper.

Owner:FAW JIEFANG AUTOMOTIVE CO

Safety warning method and device

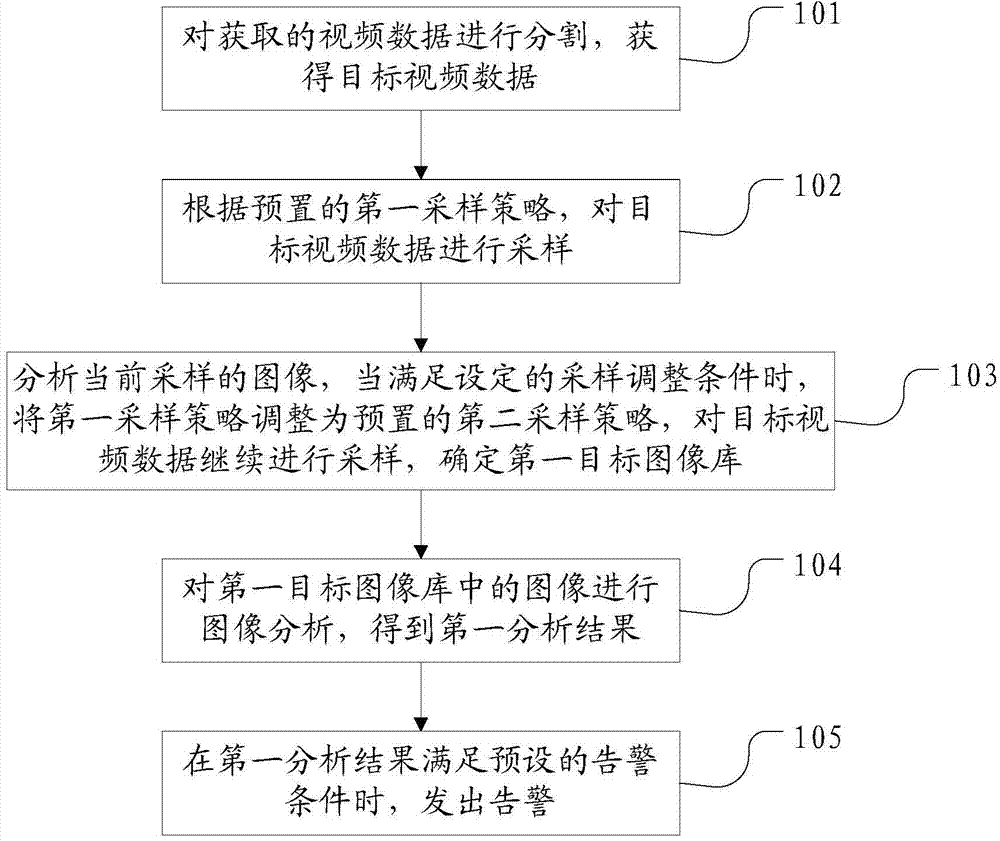

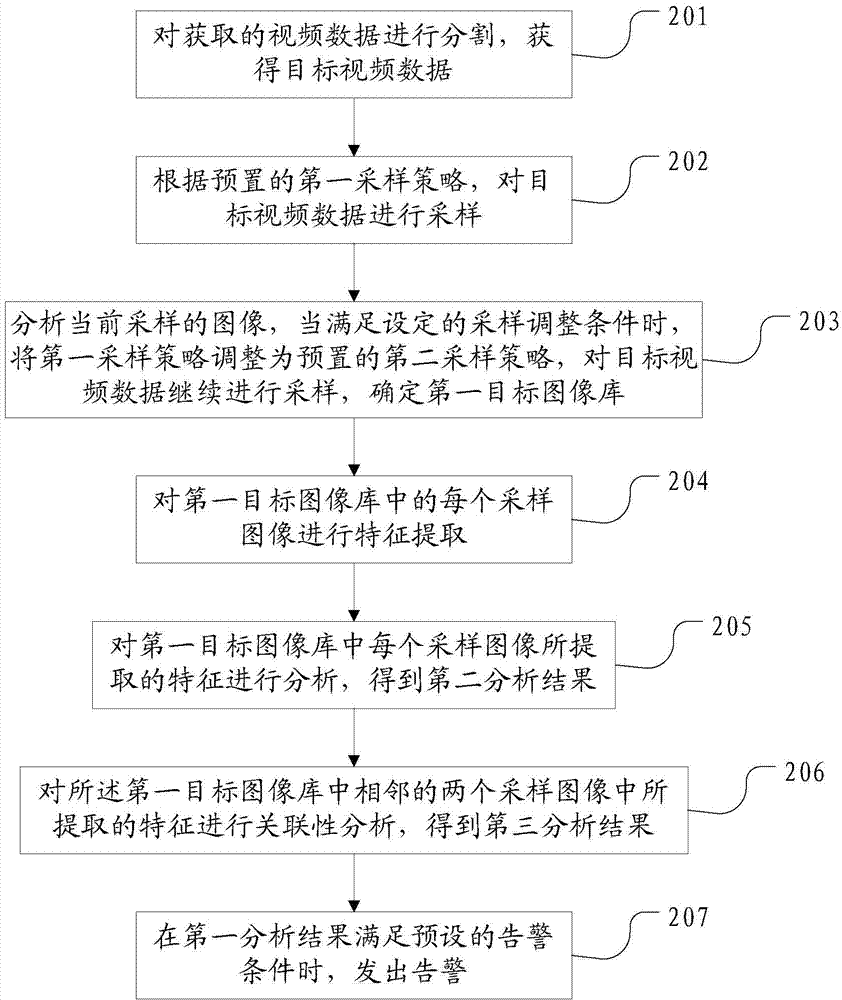

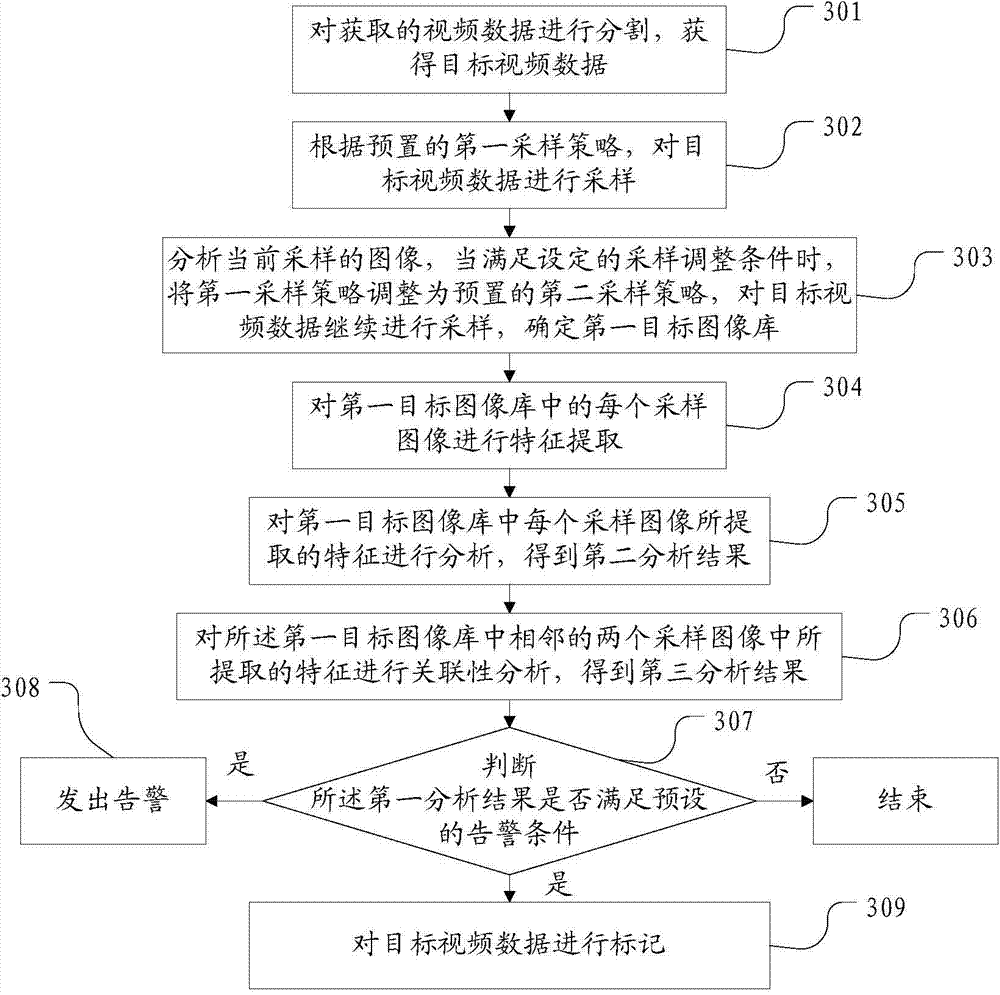

ActiveCN104270619ANo labor requiredNo need for manual real-time monitoringImage analysisClosed circuit television systemsSample imageImage analysis

The embodiment of the invention discloses a safety warning method and device. The method in the embodiment of the invention comprises the following steps: partitioning the acquired video data to obtain target video data; according to a preset first sampling strategy, sampling the target video data; analyzing the currently sampled image, when the image meets the set sampling adjustment condition, adjusting the first sampling strategy to a preset second sampling strategy, continuously sampling the target video data, and determining a first target image library; conducting image analysis on the images in the first target image library to obtain a first analysis result, and when the first analysis result meets the preset warning condition, giving out warning. The safety warning method and the device disclosed by the embodiment of the invention are not required to be monitored manually in real time, and are intelligent and efficient in monitoring video data processing.

Owner:CHINA CONSTRUCTION BANK

Omnibearing intelligent shower

The invention belongs to the toilet and bathroom article field, and specifically relates to omnibearing intelligent shower; a plurality of nozzles are arranged in surrounding so as to realize omnibearing water spraying; induction control is arranged, so a bath lotion automatic applier can rotate a bath ball filled with bath lotion; an automatic rubber is arranged, and a motor drives an annular bathing towel to rotate, thus improving showering intelligentization and comfort level.

Owner:CHANGGE TENGDA PRECISION IND BUILDING MACHINERY FACTORY

Method for continuously controlling the particle size distribution of powders used in the ceramics industry, and plant for its implementation

InactiveCN1864059AAffect particle sizeNo labor requiredParticle size analysisParticle-size distributionMaterials science

Method for continuously controlling the particle size distribution of ceramic powders leaving the powder forming plant, comprising at least the following steps: withdrawing at least one powder sample at predetermined intervals; measuring the particle size distribution of the withdrawn sample; comparing the measured particle size distribution with a reference particle size distribution by means of a processor; regulating at least one parameter of said powder forming plant influencing the particle size distribution, on the basis of the differences between the measured particle size distribution and the reference particle size distribution; and plant for its implementation.

Owner:SACMI COOP MECCANICI IMOLA S C R L

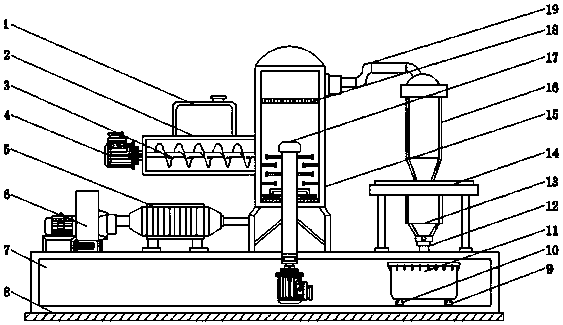

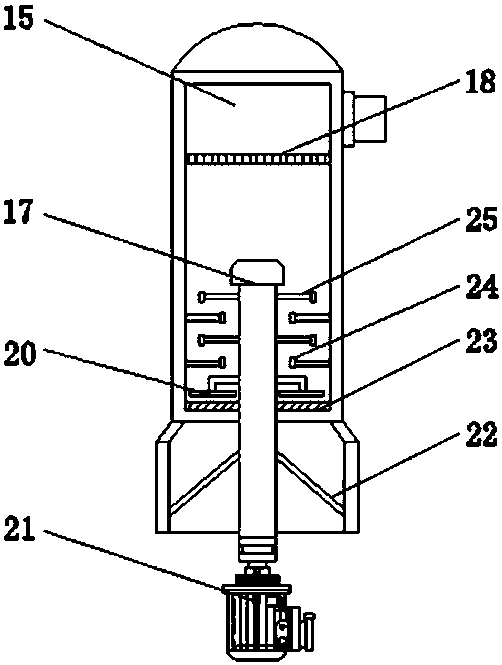

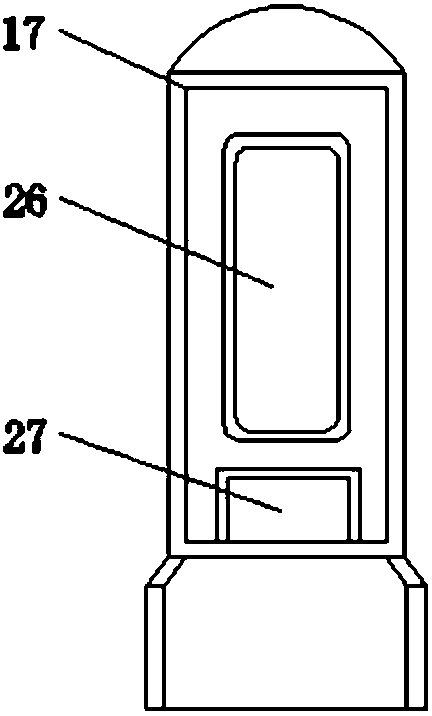

Efficient sodium alginate flashing drying machine

InactiveCN107606906AKeep dryNot easy to stickDrying gas arrangementsDrying machines with non-progressive movementsDrive motorPulp and paper industry

The invention discloses an efficient sodium alginate flashing drying machine which comprises a spiral feeding chute, a base, a flashing drying machine body and a cyclone separator, wherein a second drive motor is mounted in the base; a collecting barrel is mounted at one end of the interior of the base; an air blower is mounted at the end, far away from the collecting barrel, of the base; a steamradiator is mounted at the top end of the base and at the position on the side, close to the second driving motor, of the air blower; and the flashing dryer body is mounted at the top end of the baseand at the position on the side, away from the air blower, of the steam radiator. According to the efficient sodium alginate flashing drying machine, through mounting the cyclone separator, a discharging hopper and the collecting barrel, sodium alginate can be further dried by the cyclone separator after being dried by the flashing drying machine body, so that the drying effect is the best; and ataking out opening is formed in the bottom of the obverse side of the flashing drying machine body, so that internal blocked material can be conveniently cleared, and high rapidity and convenience arerealized.

Owner:南宁钛银科技有限公司

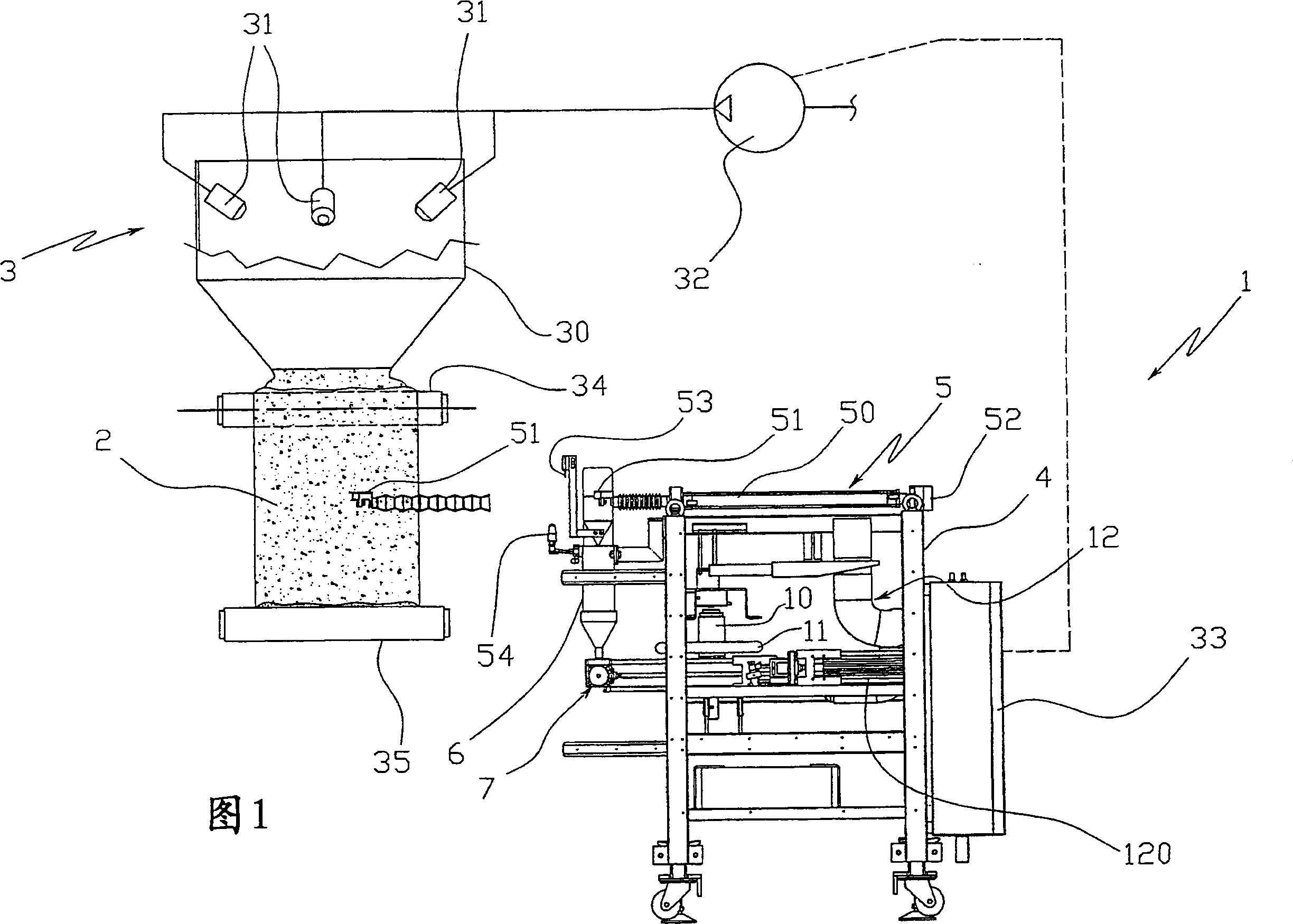

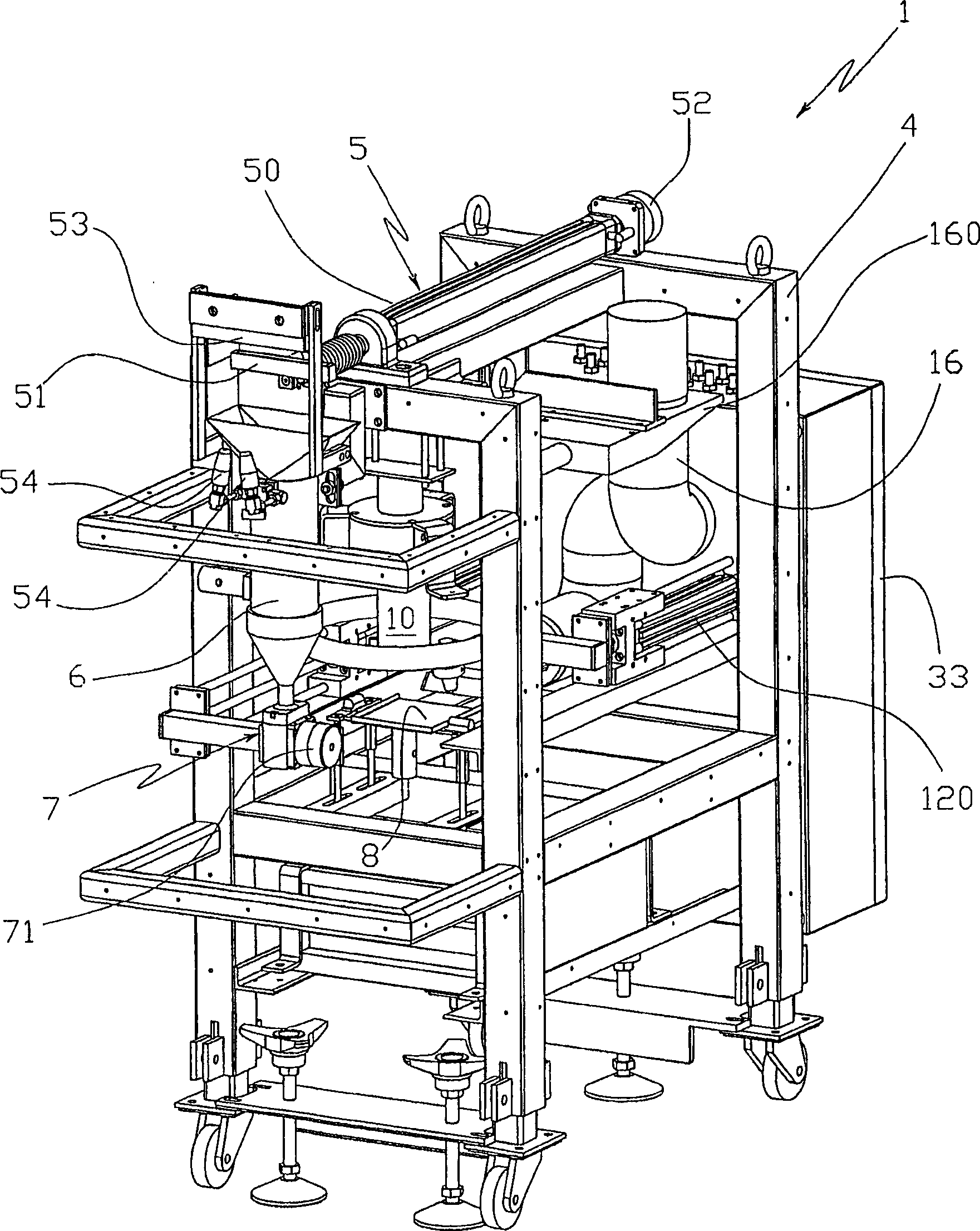

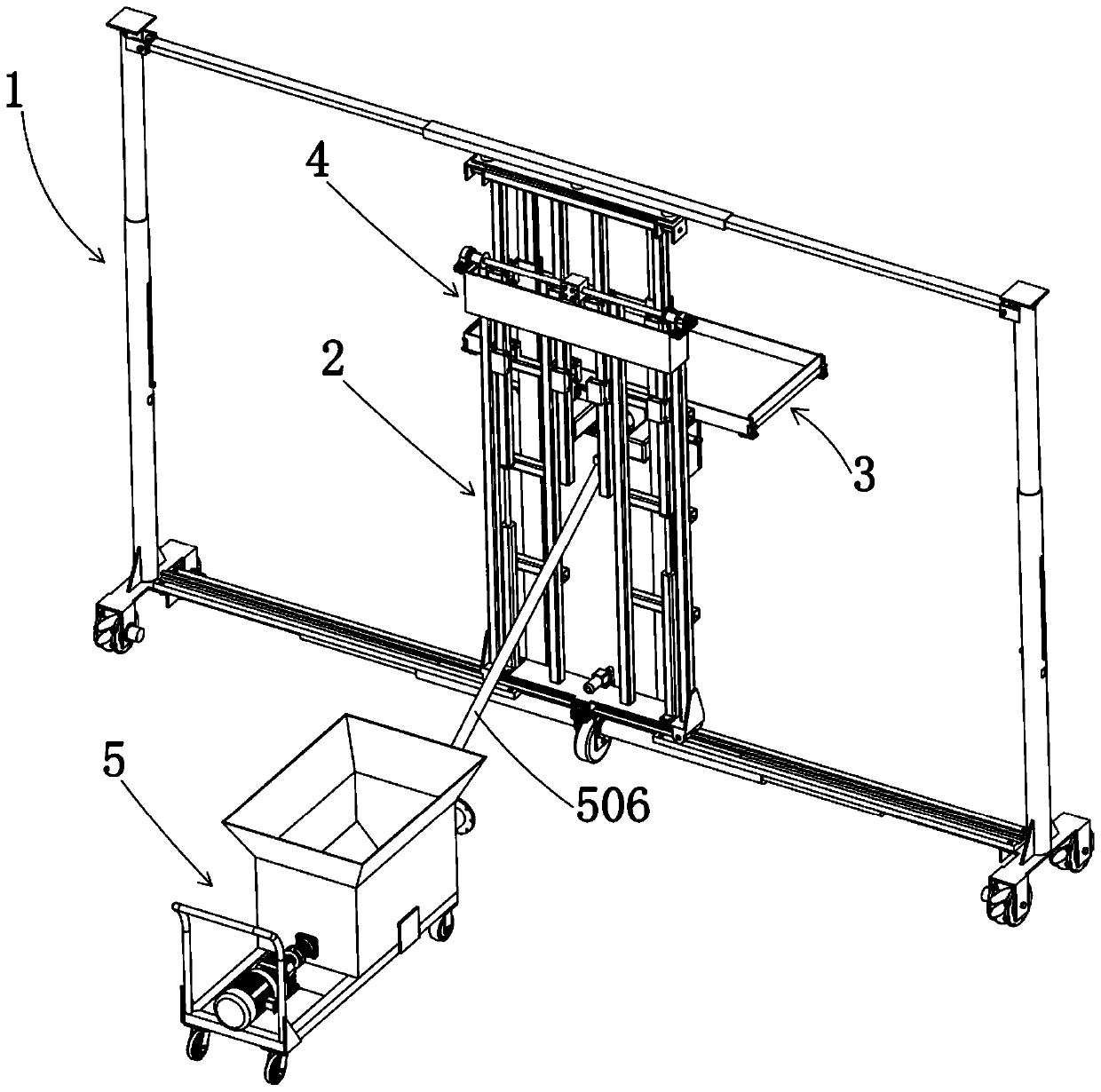

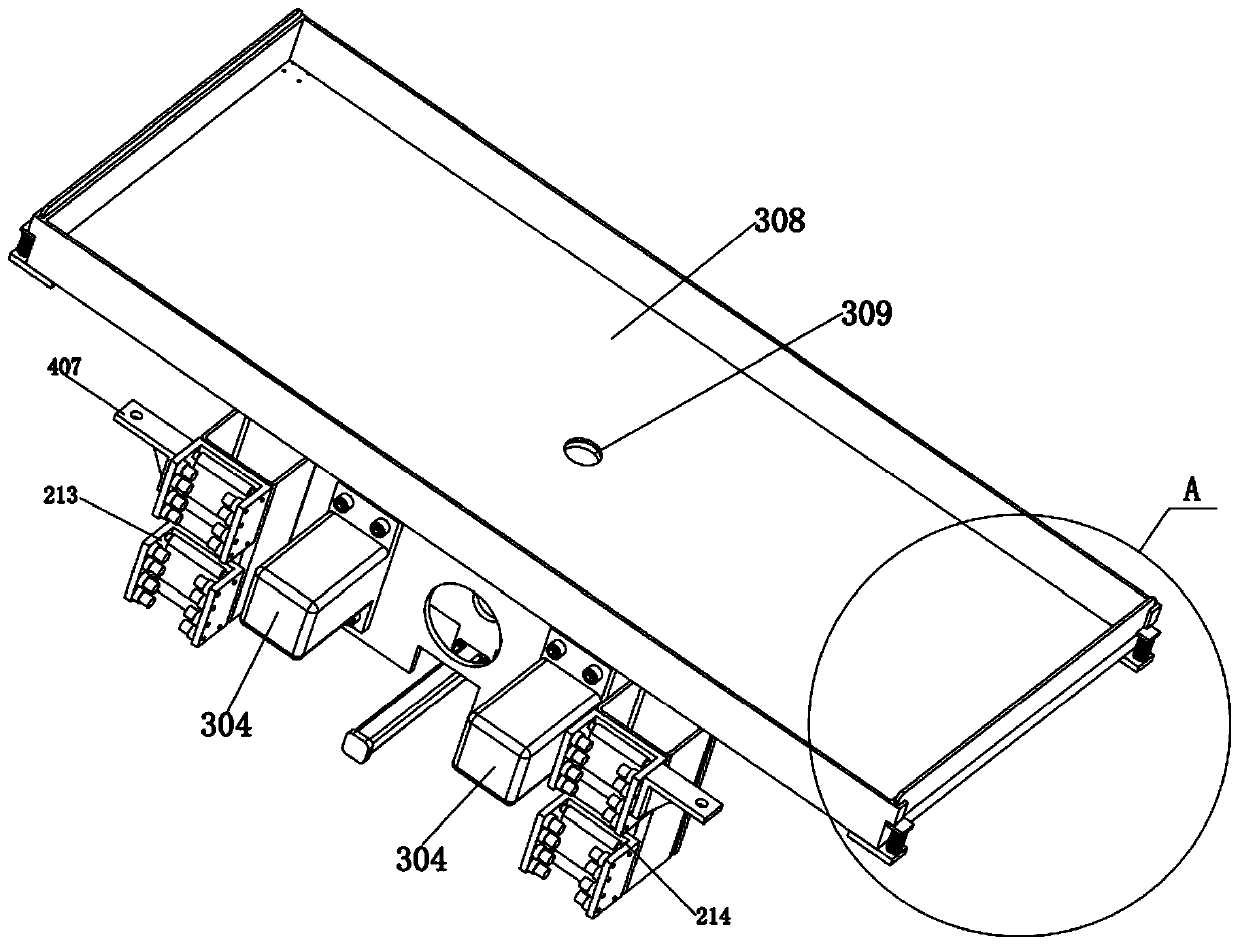

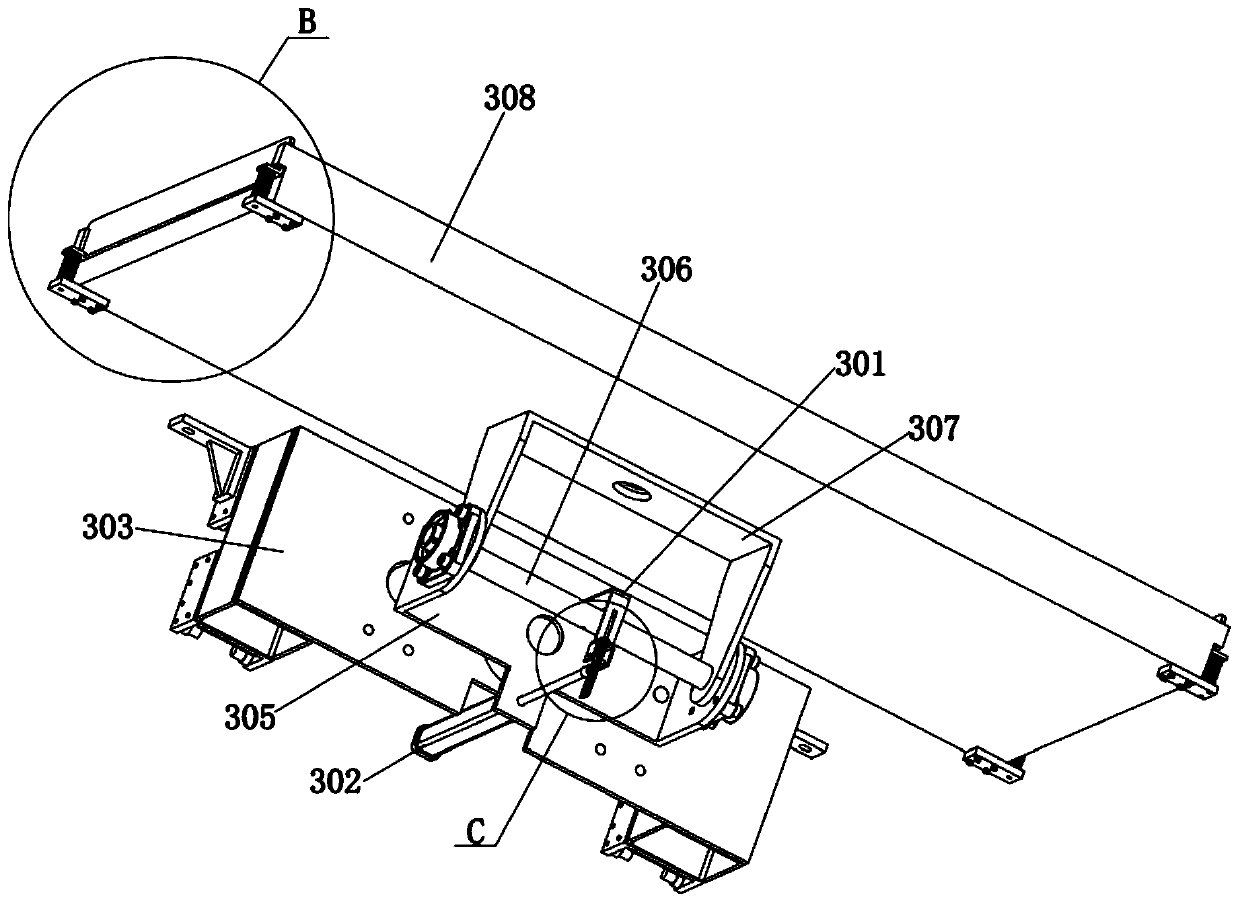

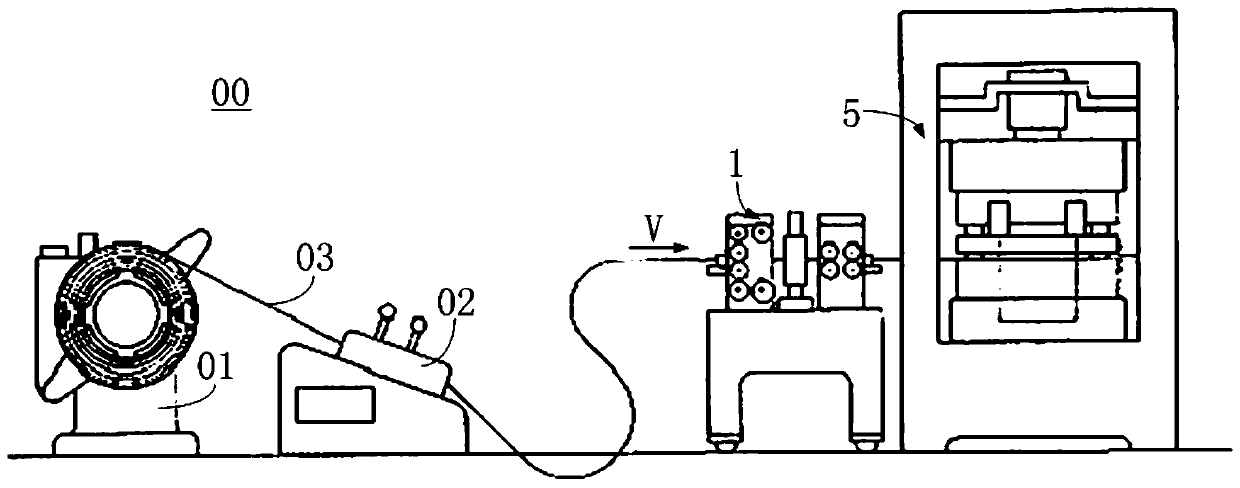

Automatic plastering robot for building

ActiveCN109914758ANo labor requiredFlexible walkingBuilding constructionsEngineeringMechanical engineering

The invention discloses an automatic plastering robot for building. The automatic plastering robot comprises a first frame mechanism, a second frame mechanism arranged in the first frame mechanism, aplastering mechanism arranged on the second frame mechanism, a driving mechanism which is arranged on the second frame mechanism and is used for driving the plastering mechanism to move up and down, and a feed mechanism for conveying a lime material to the plastering mechanism. The automatic plastering robot for building not only can replace manual work so as to increase the efficiency, but also can enable the plastered wall to be flat.

Owner:聊城九洲建设集团有限公司

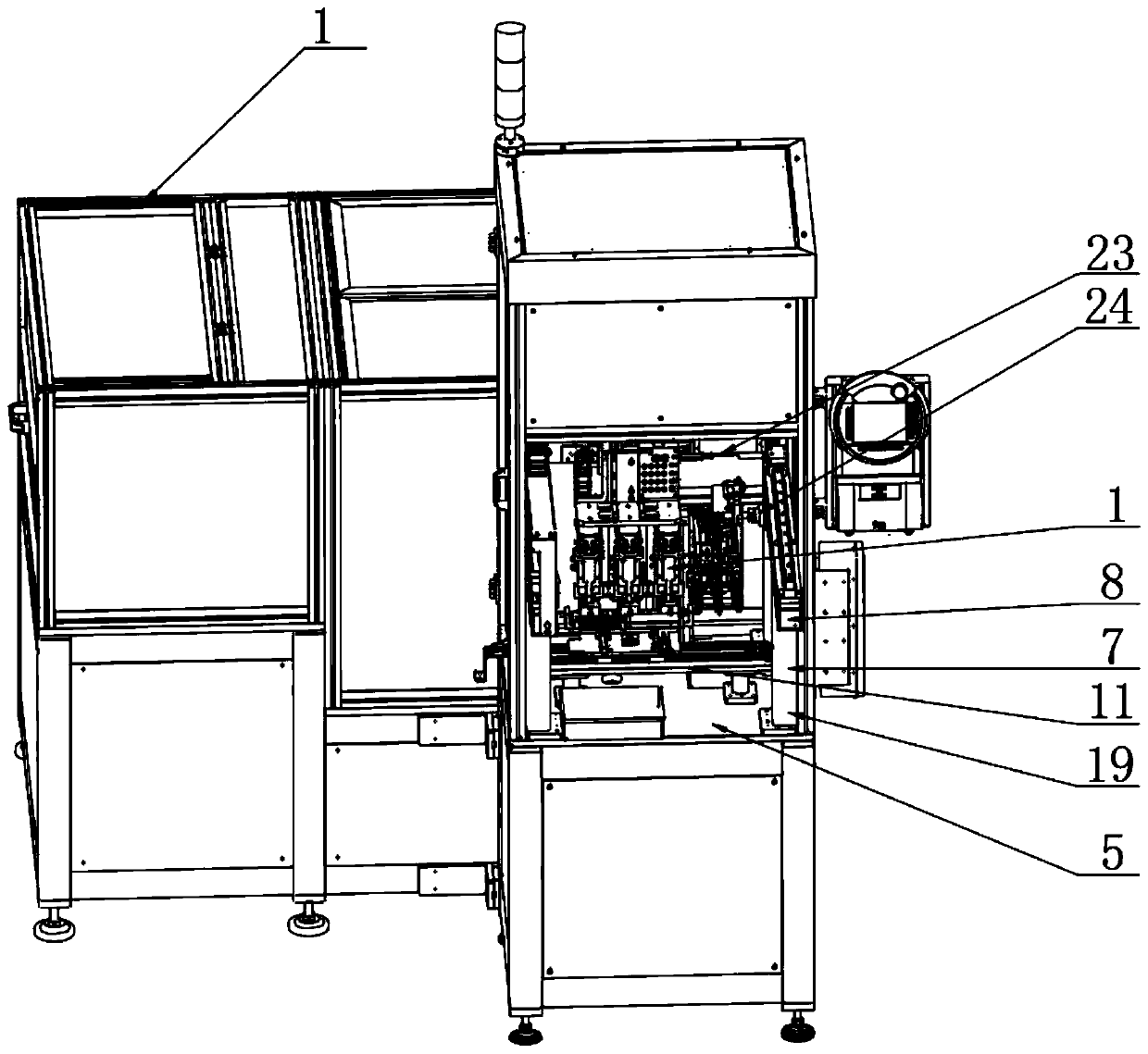

Fuel cell bipolar plate welding production process

ActiveCN109623191AHigh degree of automationIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineFuel cells

The invention discloses a fuel cell bipolar plate welding production process. The process comprises single pole plate feeding, hydrogen pole plate welding, oxygen pole plate welding, bipolar plate transferring, manual spot detecting, air tightness detecting, and bipolar plate discharging; the single pole plate feeding is that two pieces of single pole plates, namely the hydrogen pole single pole plate and the oxygen pole single pole plate are placed on bipolar plate transferring in pair; the hydrogen pole single pole plate and the oxygen pole single pole plate are welded when reaching the poleplate welding station, and after welding, the hydrogen pole single pole plate and the oxygen pole single pole plate are compounded into a bipolar plate to be transferred to bipolar plate transferringagain; and the bipolar plate is sent to the manual spot detecting station and the air tightness detecting station through bipolar plate transferring, and the bipolar plate subjected to air tightnessdetection is packaged at the bipolar plate discharging position. According to the process, suction mechanical hands are arranged at multiple places including front end position of a speed chain, the welding position, the tail end position of the speed chain, the air tightness detection feeding position and the air tightness detection discharging position, the bipolar plate is packaged through thedischarging mechanical hands after the welding and air tightness detection processes are completed, the whole production line is completed by matching an electric structure with a fully-automatic mechanical structure.

Owner:安徽明天氢能科技股份有限公司

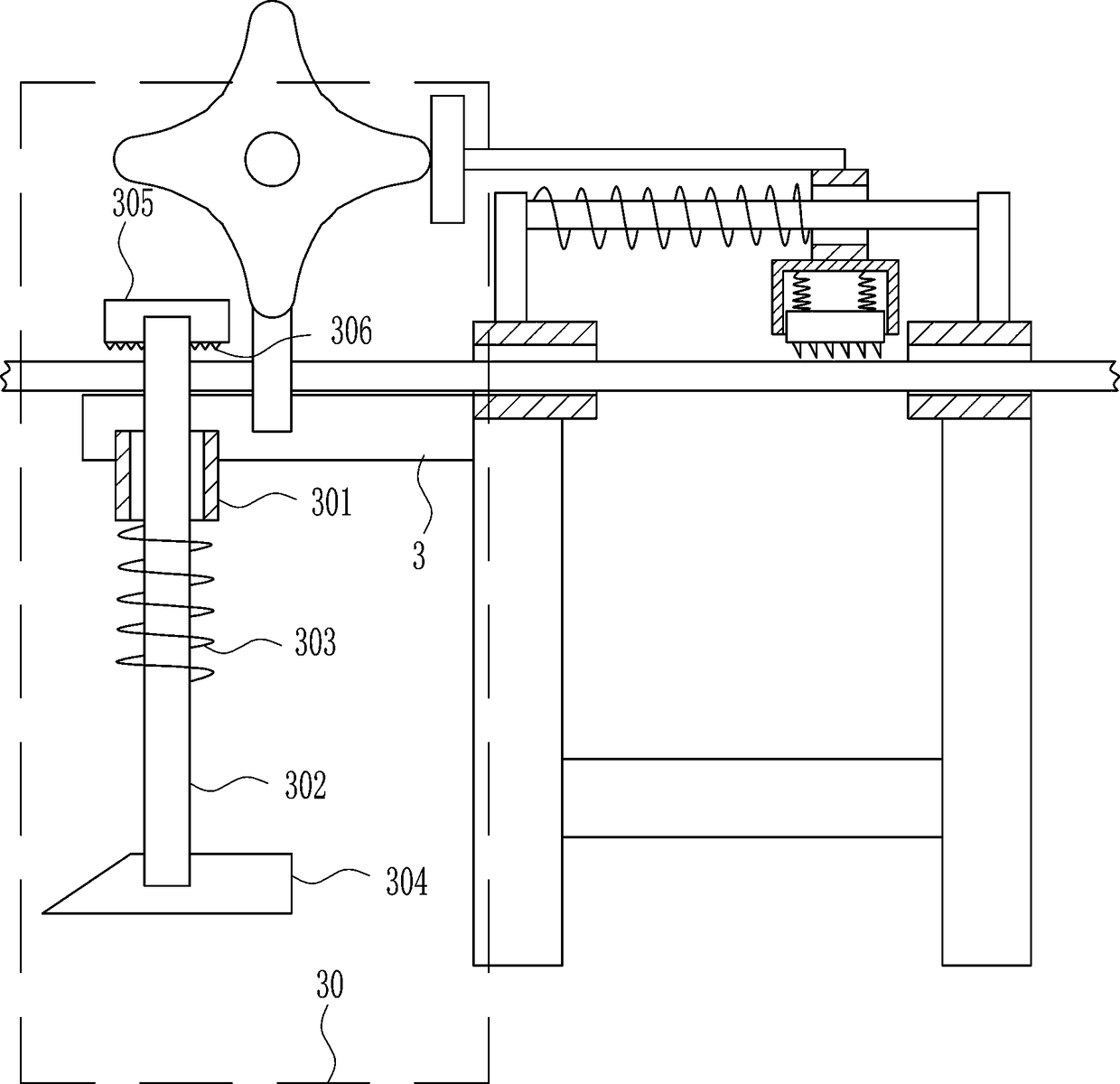

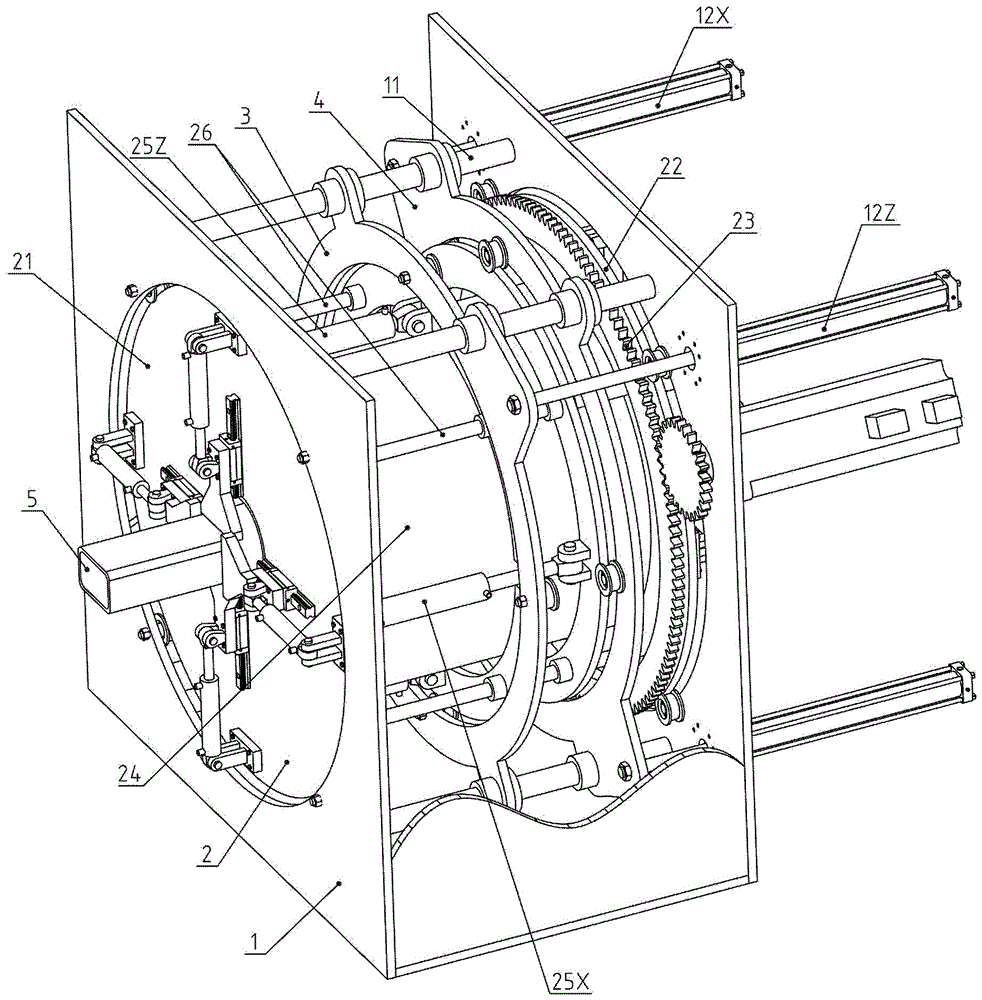

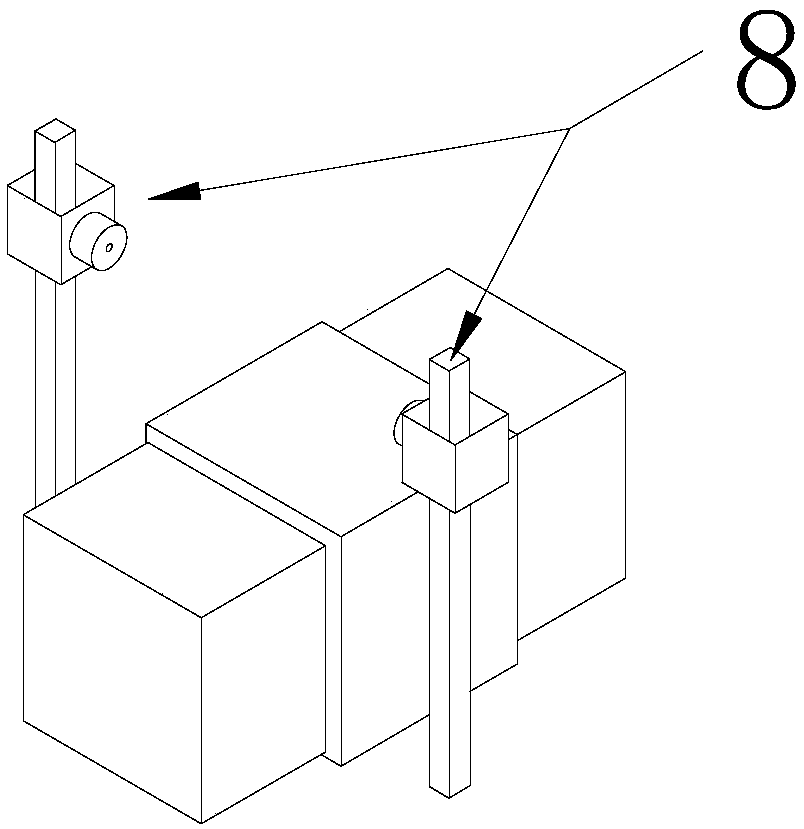

Intelligent clamping and rotary cutting device of rectangular pipes

InactiveCN106181203AEasy to set upNo labor requiredWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderHeat-affected zone

The invention belongs to the technical field of intelligent manufacturing equipment, and relates to an intelligent clamping and rotary cutting device of rectangular pipes. A hydraulic cylinder consisting of a middle hydraulic cylinder barrel and a translation rotating piston rod is skillfully and reversely used for converting applied push or pull mechanical force to hydraulic energy to transfer to a front X-direction hydraulic cylinder, a front Y-direction hydraulic cylinder, a back X-direction hydraulic cylinder and a back Y-direction hydraulic cylinder; the four hydraulic cylinders synchronously rotate along with a drum module, are communicated through hydraulic pipes, and are communicated with other parts without hydraulic pipes to prevent twisting rotation of the hydraulic pipes, so that the drum module can drive the rectangular pipes to continuously rotate without limit; flow distributing and collecting valves are matched to enable clamping jaws to synchronously advance and retreat; and when the rectangular pipes are clamped, the rotating center line of the drum module is overlapped. The intelligent clamping and rotary cutting device of the rectangular pipe can cut complex patterns, hollow patterns or characters, is intelligent in loading and unloading, saves labors, is fast in cutting speed and precise in size, has no burrs, is small in heat affected area and low in incision deformation, needs no refinishing during using, and improves the working efficiency.

Owner:浙江山川科技股份有限公司

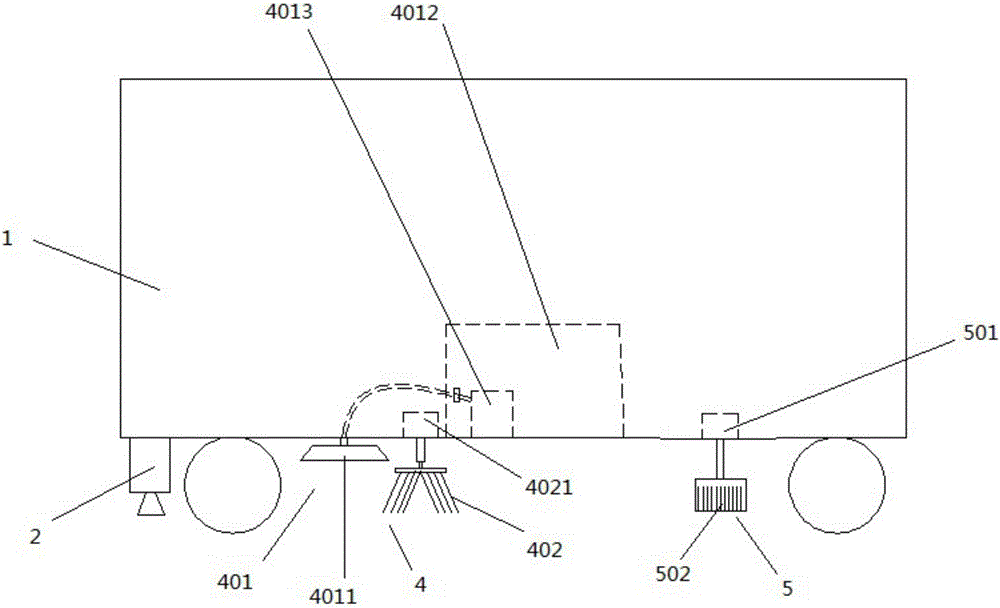

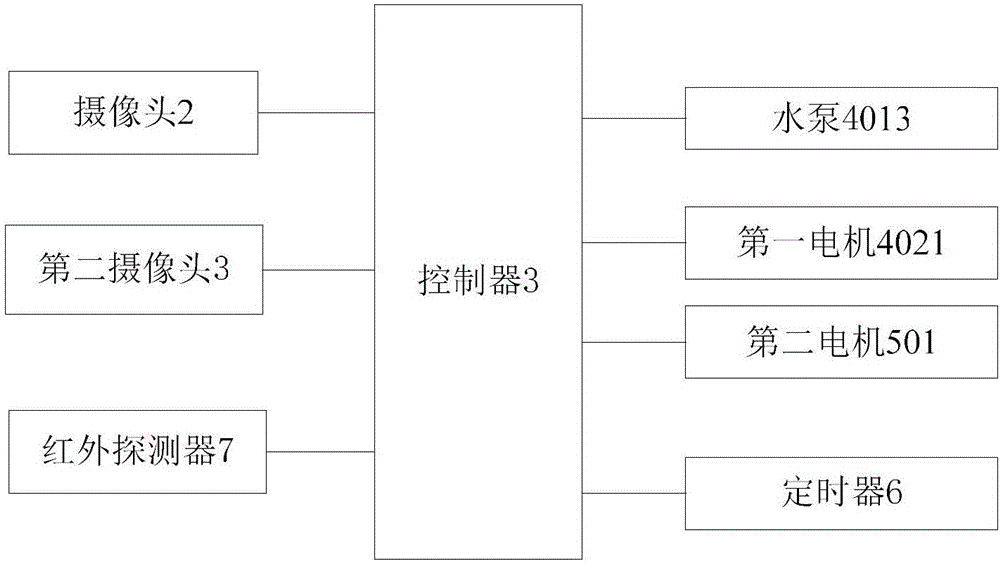

Automatic cleaning apparatus for cleaning ground

InactiveCN106214077AAvoid wrestlingEasy to cleanCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention discloses an automatic cleaning apparatus for cleaning ground. The automatic cleaning apparatus for cleaning the ground comprises an automatically walking trolley body, a camera, a controller, a cleaning device and a ground mopping device, wherein the camera is mounted at one end, which approaches a trolley head, of the bottom of the automatically walking trolley body; the cleaning device and the ground mopping device are both mounted at the bottom of the automatically walking trolley body; the cleaning device is located between the camera and the ground mopping device in a horizontal direction; the cleaning device comprises a spraying device and a washing brush which are arranged in sequence; the spraying device comprises a spraying head, a water tank and a water pump immersed in the water tank; the water pump is connected with the spraying head through a guiding pipe; the washing brush is driven by a first motor fixedly mounted on the automatically walking trolley body; the ground mopping device comprises a mop head driven by a second motor; an input end of the controller is connected with the camera; an output end of the controller is connected with the water pump, the first motor and the second motor. The automatic cleaning apparatus for cleaning the ground is high in cleaning efficiency, good in cleaning effect, and is quite applicable to a stain which is difficult to wash and high in adhesive force.

Owner:JIANGSU BOYINGTE ELECTRONICS TECH CO LTD

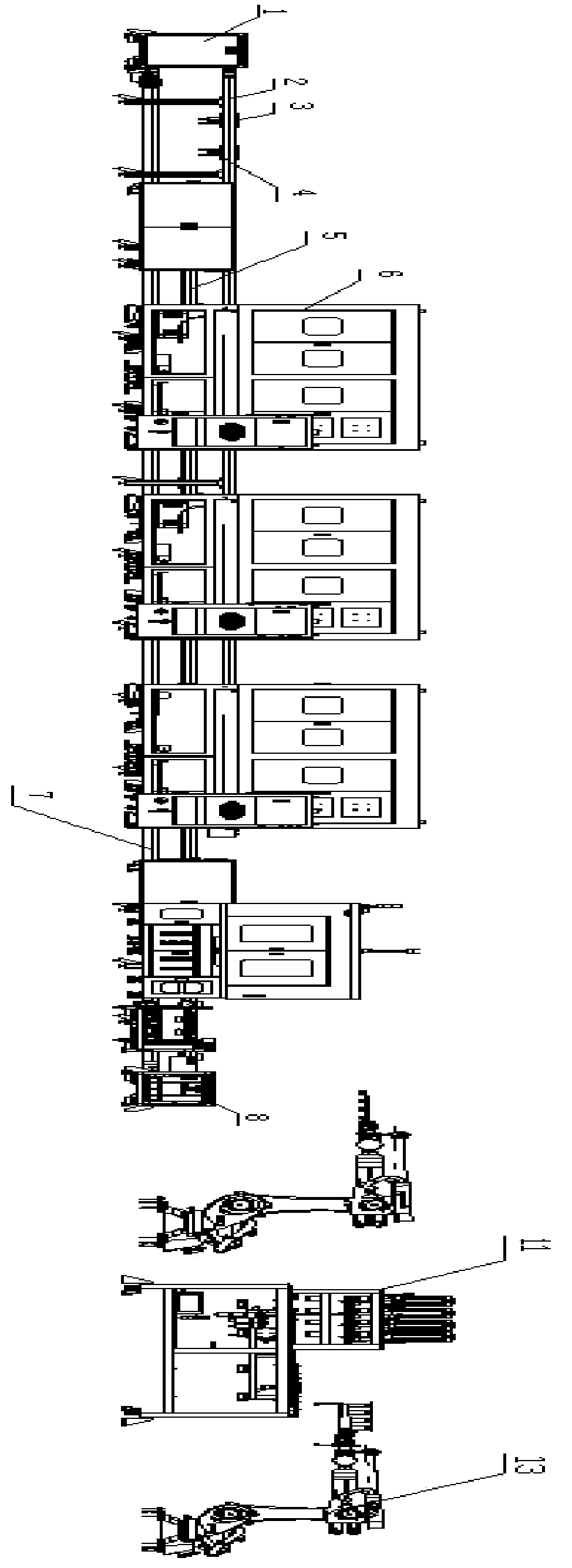

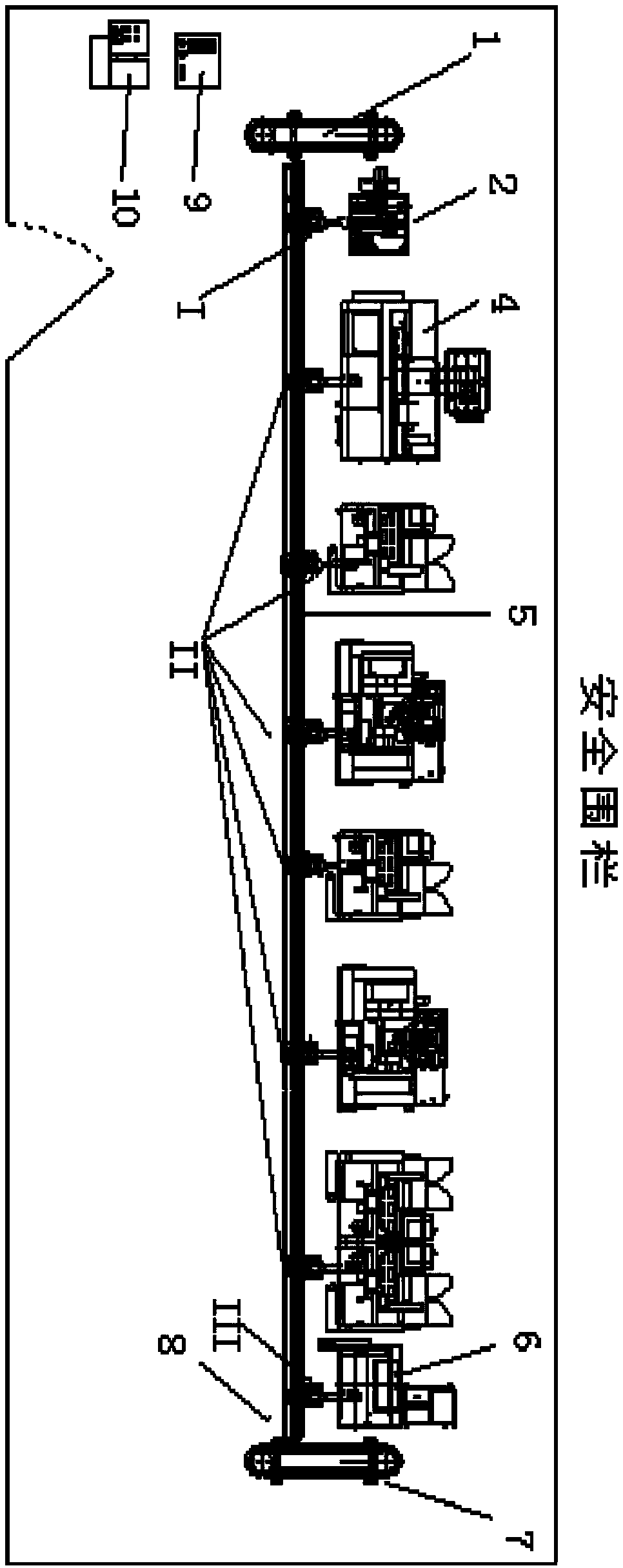

Full automatic intelligent production line of piston

InactiveCN108608245AImprove reliabilityIncrease productivityMetal working apparatusNumerical controlNumerical controlProduction line

The invention discloses a full automatic intelligent production line of a piston. The production line comprises a charging area, a processing area, a discharging area, a piston conveying line, a PLC control module and an industrial personal computer, wherein the charging area comprises a charging platform, a two-dimensional code marking machine, a robot I and a photoelectric switch; the processingarea comprises a plurality of numerical control machine tools; robots II are arranged on the numerical control machine tools; the discharging area comprises a detecting platform, a discharging platform and a robot III; a piston detector is arranged on the detecting platform; the two-dimensional code marking machine, the photoelectric switch, the robot I, the numerical control machine tools, the robots II, the piston detector and the robot III are correspondingly connected to the PLC control module; and the PLC control module is connected to the industrial personal computer. With the adoptionof the full automatic intelligent production line of the piston, the piston production efficiency is improved; the labor cost is decreased; the product processing reliability is improved; and the difficulty in production management is reduced.

Owner:青岛默森智能科技有限公司

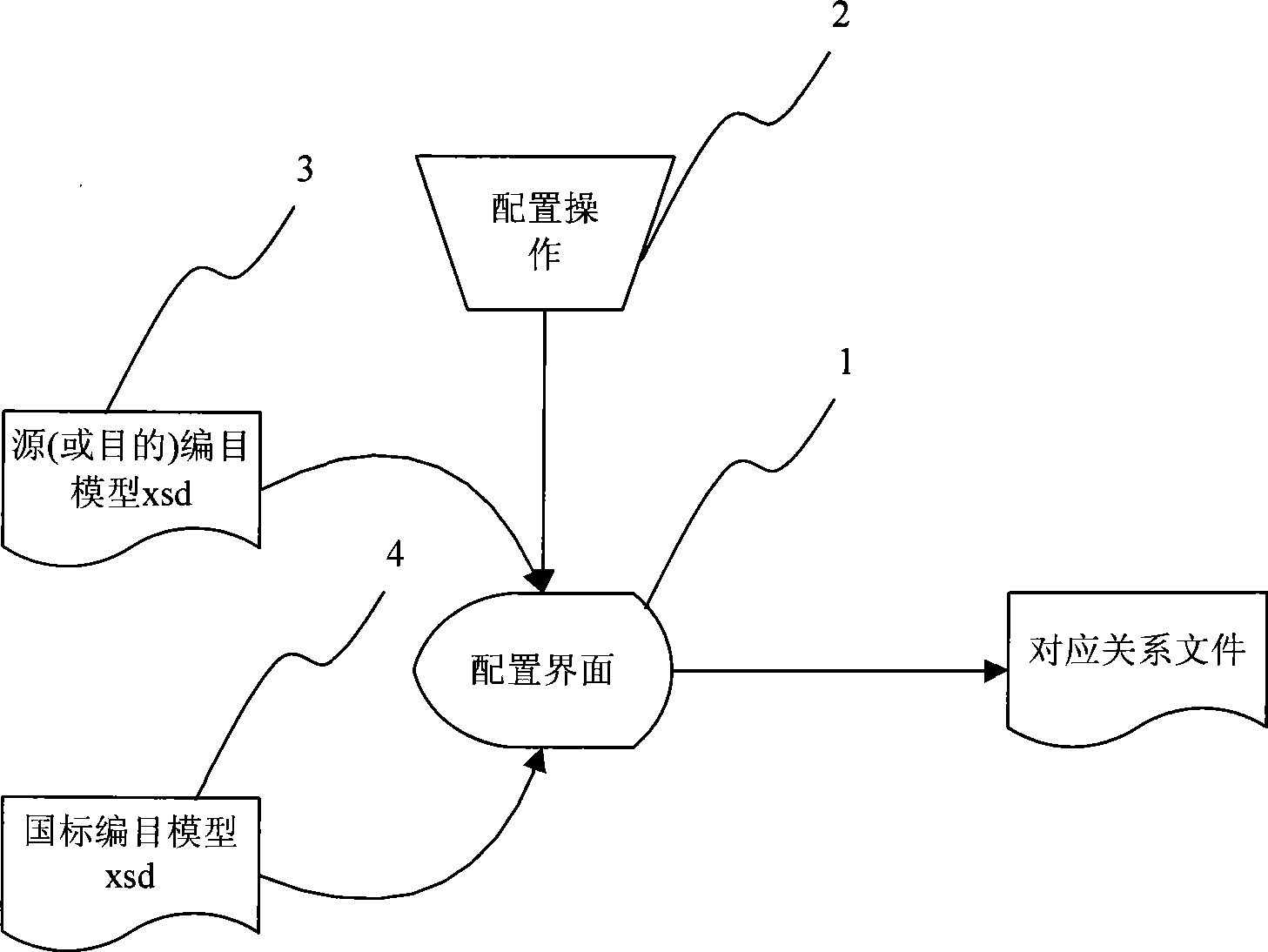

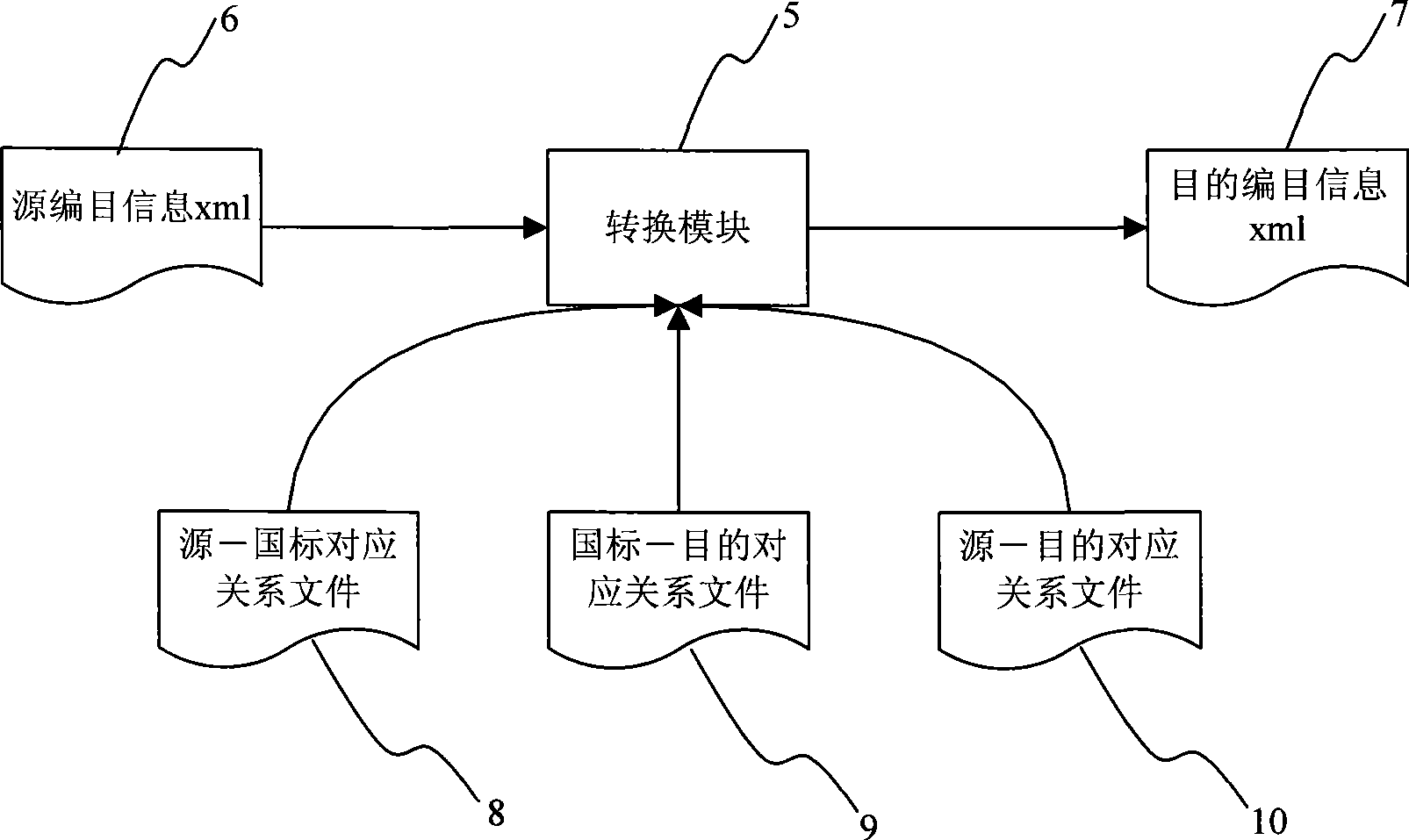

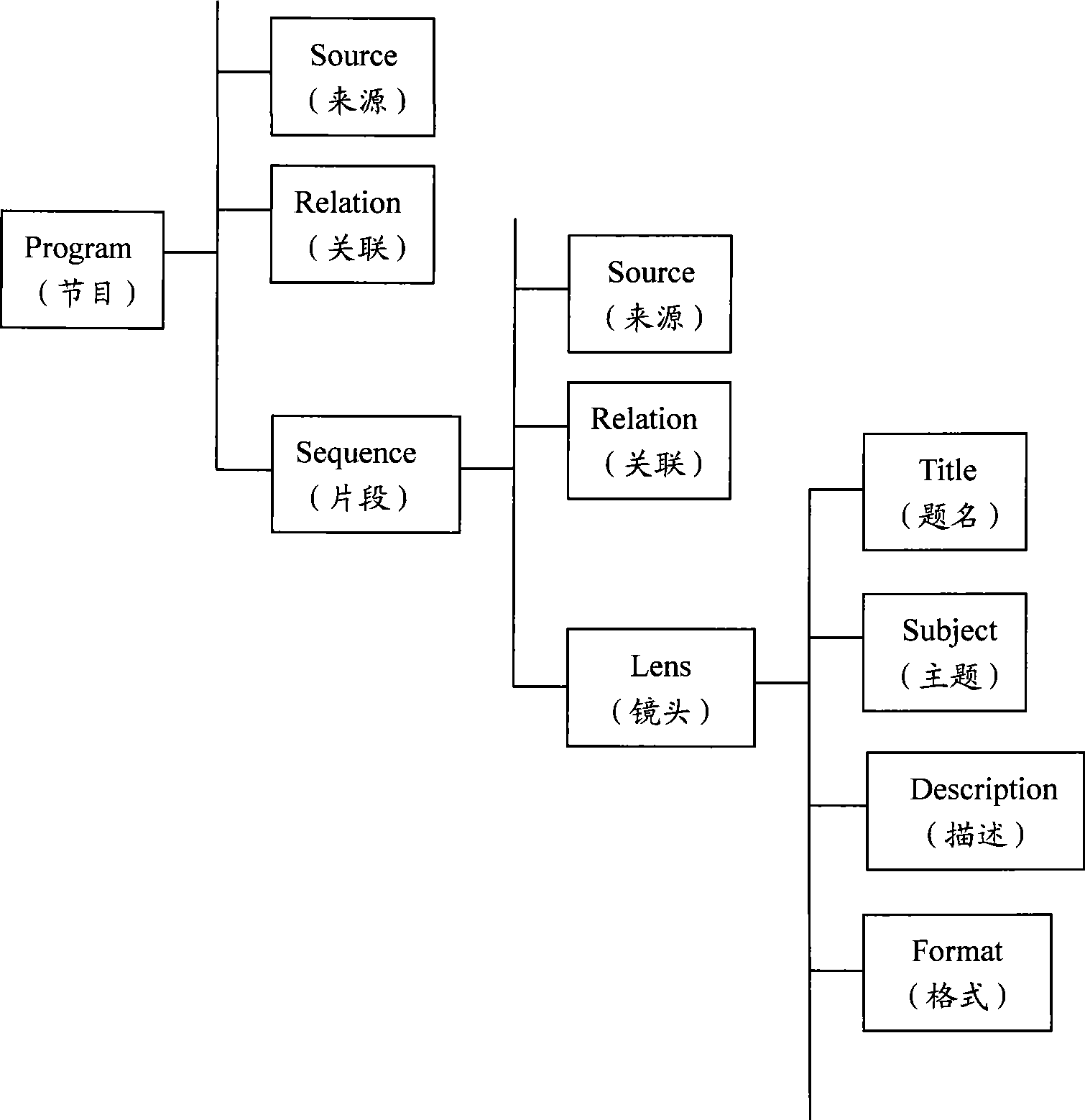

System for implementing catalogue information format conversion based on XML

InactiveCN101464865AVersatileNo labor requiredCarrier editingCarrier indexing/addressing/timing/synchronisingCable televisionConversion method

The invention relates to a method based on XML to realize catalogue information format conversion, and belongs to the information format conversion field. In the field of broadcast and television, when different units carry out program exchange and share, different catalogue molds are formed due to different focuses and adopted systems, and are unavailable for using in another system. When the catalogue information enters another system, manual recataloguing is required, so that the labor and financial resource waste are caused. The invention discloses a general conversion method, and aims to enable that the catalogue information can be passed and exchanged in different systems. By adopting the invention, the format conversion of the catalogue information can be automatically completed by the system and manual recataloguing is not needed.

Owner:CHINA DIGITAL VIDEO BEIJING

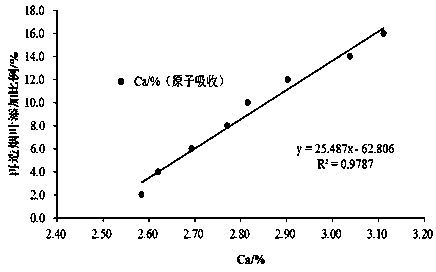

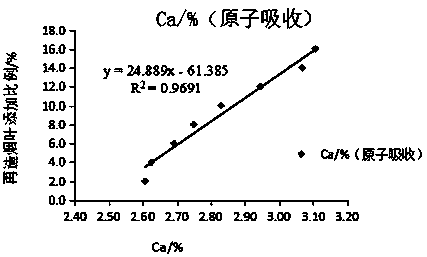

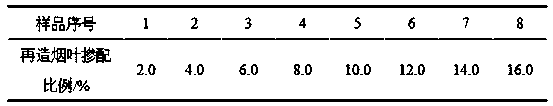

Method for determining ratio of reconstituted tobacco leaves obtained by paper-making method in cigarettes

ActiveCN108168991AEasy to operateNo labor requiredPreparing sample for investigationFuel testingLinear fittingIon

The invention relates to a method for determining a ratio of reconstituted tobacco leaves obtained by a paper-making method in cigarettes and belongs to the technical field of processes of reconstituted tobacco leaves. The method comprises carrying out linear fitting on a ratio of reconstituted tobacco leaves obtained by a paper-making method in cigarettes and a calcium ion calculation formula, building a standard working curve of different doping ratios of reconstituted tobacco leaves obtained by a paper-making method and calcium ion contents, detecting Ca<2+> content of the cigarettes and determining a doping ratio of the cigarettes through the Ca<2+> content and the standard working curve. The method is easy to operate, is free of a large amount of labor, saves time and has a single detection variable. The method can accurately determine the actual blending ratio of reconstituted tobacco leaves in the sample to be tested, can optimize the blending process and can help to improve thequality stability of cigarette products.

Owner:KUNMING UNIV OF SCI & TECH

Adhesive cleaner

The invention discloses an adhesive cleaner. According to the adhesive cleaner, a pair of rollable linear motors with an adsorption function are attached to parallel window frames; a cross beam is connected between linear rotors of the pair of rollable linear motors, and is connected with an inner cleaning head capable of reciprocating along the cross beam; a strong magnet is arranged at the center of the inner cleaning head, the arrangement of the strong magnet aims at providing magnetic force to an outer cleaning head on the other side of glass, so that the outer cleaning head and the inner cleaning head can move synchronously to clean the outer glass surface; and the cross beam and the cleaner are driven by the motors. Glass cleaning can be automatically completed by utilizing longitudinal and transverse movement of inner and outer cleaning heads on the glass surface, burden of workers can be reduced, and the safety problem is not worried.

Owner:徐建芳

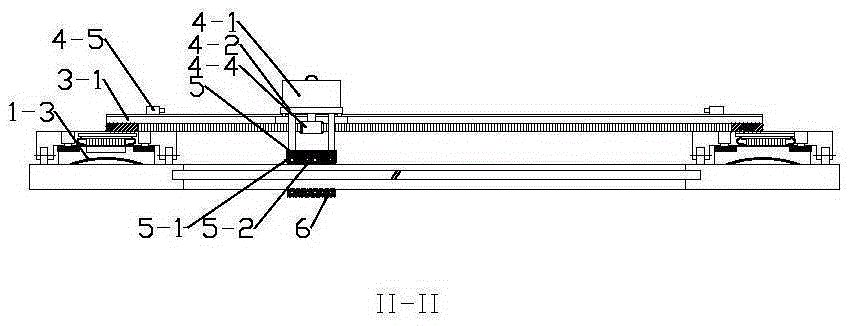

Processing device and processing method for high-performance motor iron core

ActiveCN110064562AImprove processing efficiencyEasy to processPretreated surfacesManufacturing stator/rotor bodiesPunchingEngineering

The invention relates to the technical field of motor manufacturing, in particular to a processing device and a processing method for a high-performance motor iron core. The processing device comprises a coiling device, a leveling device, a coating and thickness measuring device and a punching device. A steel strip coiled on the coiling device in the processing device can be automatically releasedby depending on self tension and elastic force, the discharged steel strip is leveled by the leveling device to become more flat, and subsequent processing is facilitated. The coating and thickness measuring device can apply coating to the upper and lower surfaces of the steel strip and can detect the thickness of the steel strip and the thickness of the coating on the steel strip, and excessivecoating and moisture on the steel strip can be squeezed out. The punching device can punch the steel strip into steel sheets in a certain size, the steel sheets can be heated and solidified, and the steel sheets are automatically stacked and transported. The entire processing device can be automatically carried out, the processing efficiency is high, manual work is not needed, labor cost is saved,automated production is facilitated, and the modern processing needs can be better met.

Owner:曹海东 +2

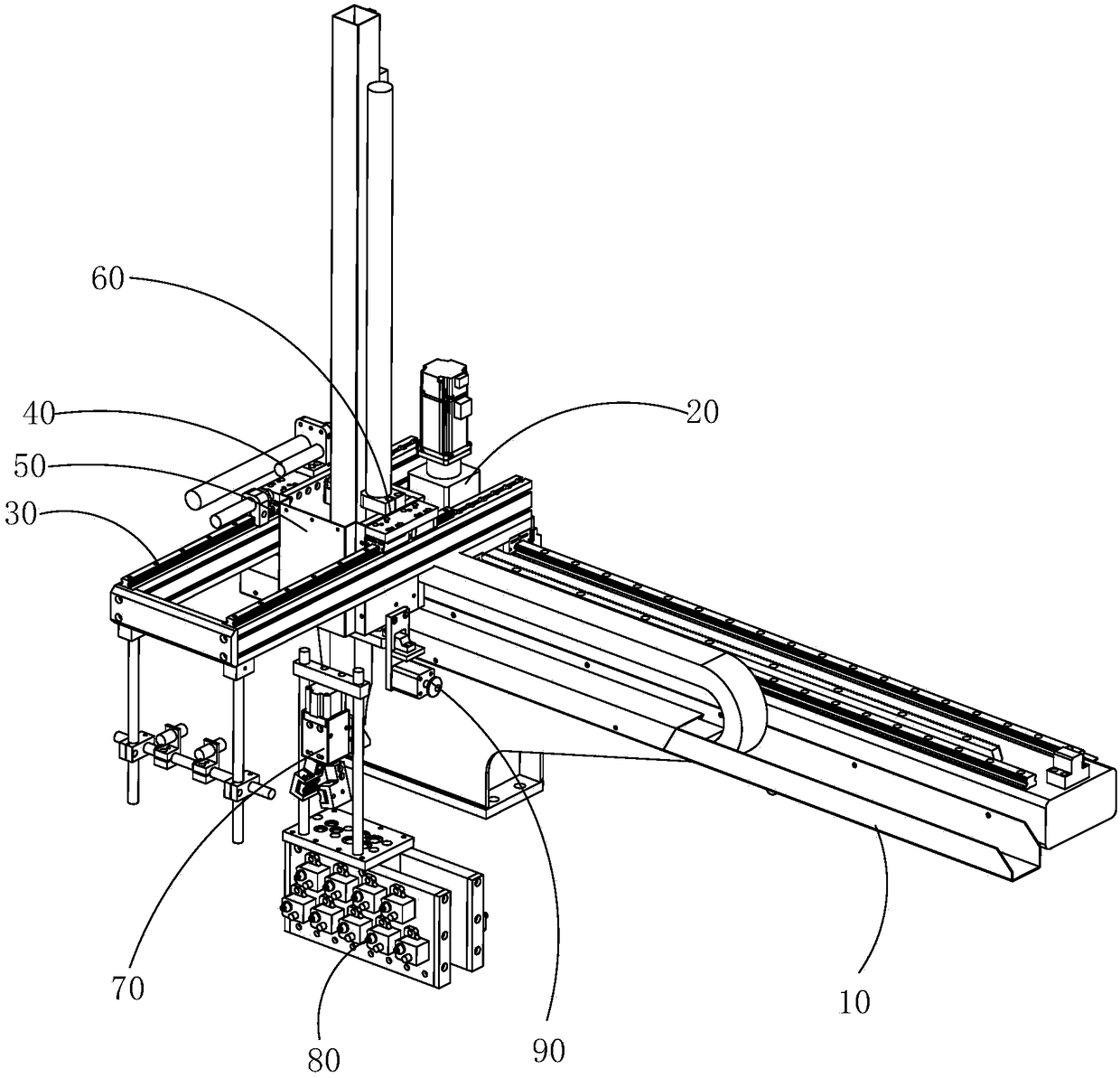

Special linear robot for die casting

The invention discloses a special linear robot for die casting. The special linear robot for die casting comprises an X-axle translation driving device, a transverse moving frame connected with the X-axle translation driving device, a Y-axle translation driving device arranged on the transverse moving frame, a longitudinal moving frame connected with the Y-axle translation driving device, a Z-axletranslation driving device arranged on the longitudinal moving frame, a clamping device connected with the Z-axle translation driving device, and a spraying device connected with the clamping device;the clamping device comprises a mounting base, two connecting modules, two movable clamping blocks and a clamping cylinder; the two connecting modules are connected with the clamping cylinder; the two movable blocks are movably arranged on the two connecting modules; and V-shaped grooves are correspondingly formed in the opposite side surfaces of the two movable clamping blocks. The special linear robot for die casting can realize automatic casting taking and spraying without needing labors, reduces the labor intensity of workers, and protects the health of the workers; and the clamping device can realize clamping of cylindrical castings with different sizes and clamping of conical castings with different tapers, so that the generality is higher.

Owner:东莞国开智能制造有限公司

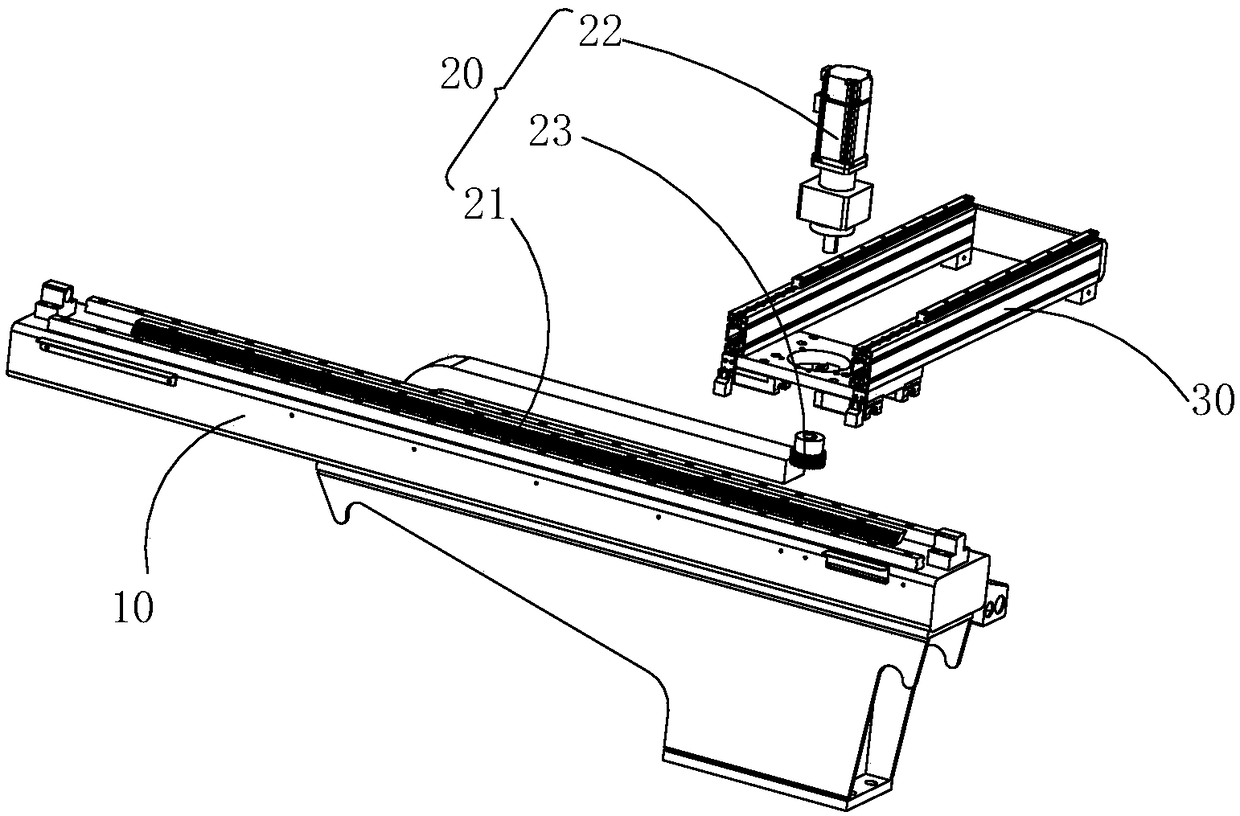

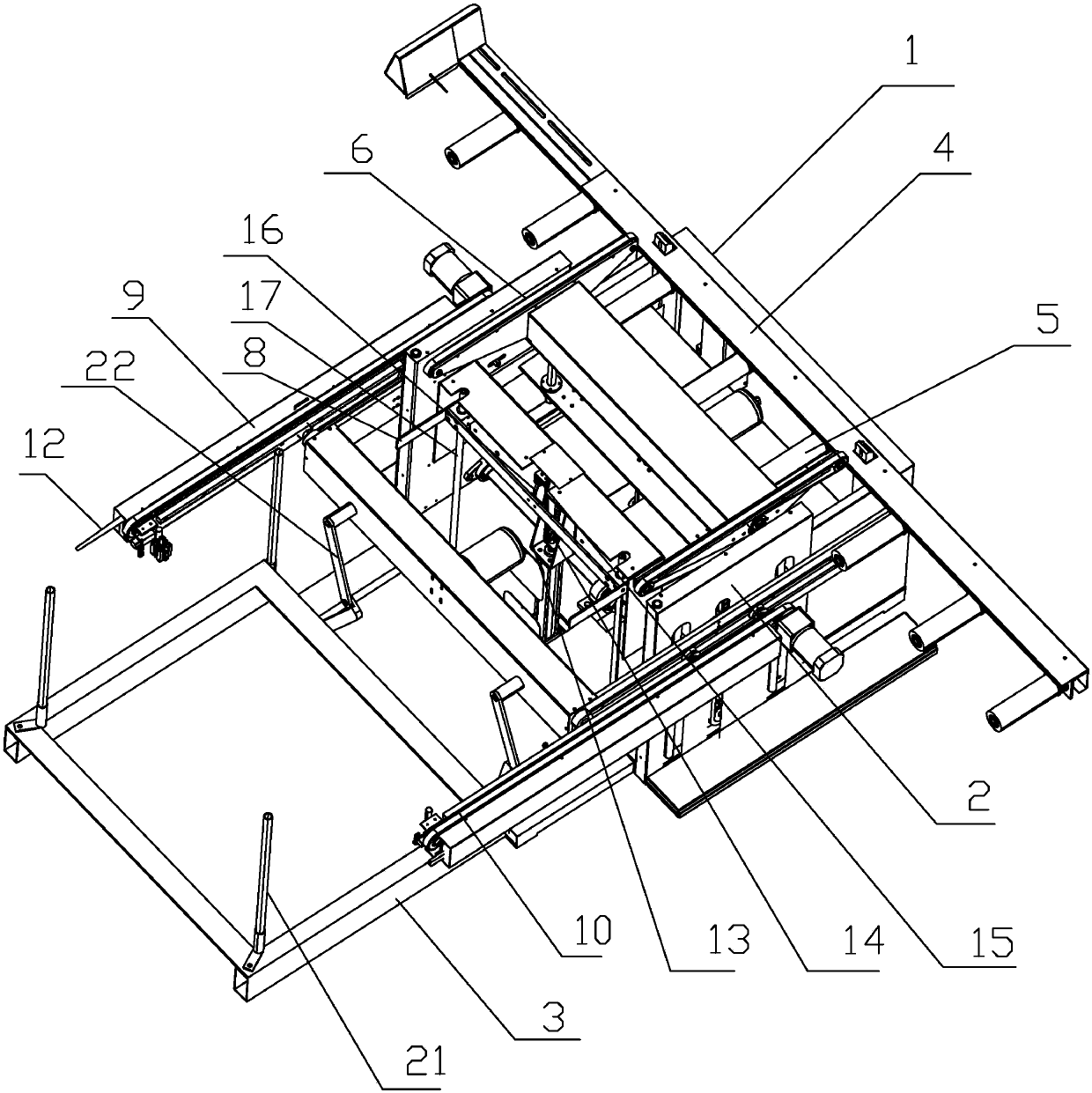

Plate stacking machine

PendingCN107892185AImprove efficiencyNo labor requiredStacking articlesConveyor partsStructural engineeringStacker

The invention discloses a plate stacking machine. The plate stacking machine comprises plates, and further comprises a first frame, a second frame and a stacking frame; the first frame, the second frame and the stacking frame are arranged in sequence from right to left; a feeding device is arranged on the first frame; a conveying device is arranged on the second frame; a stacking arm is arranged at the end, near the stacking frame, of the second frame; a stacking device is arranged on the stacking arm; and the plates move onto the stacking frame in sequence through the feeding device, the conveying device and the stacking device. The plate stacking machine is high in efficiency and low in cost.

Owner:佛山市顺德区奥派木工机械有限公司

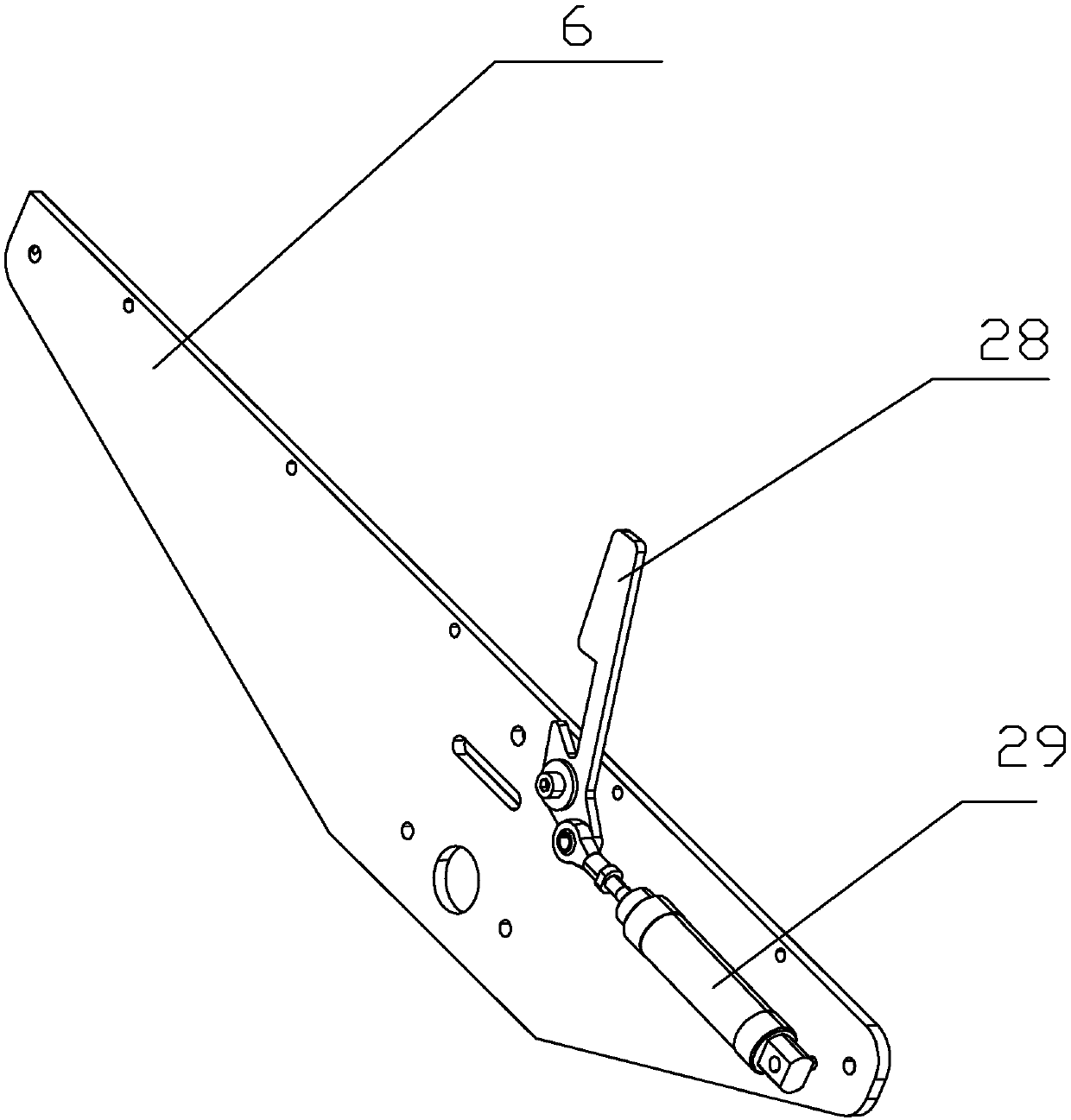

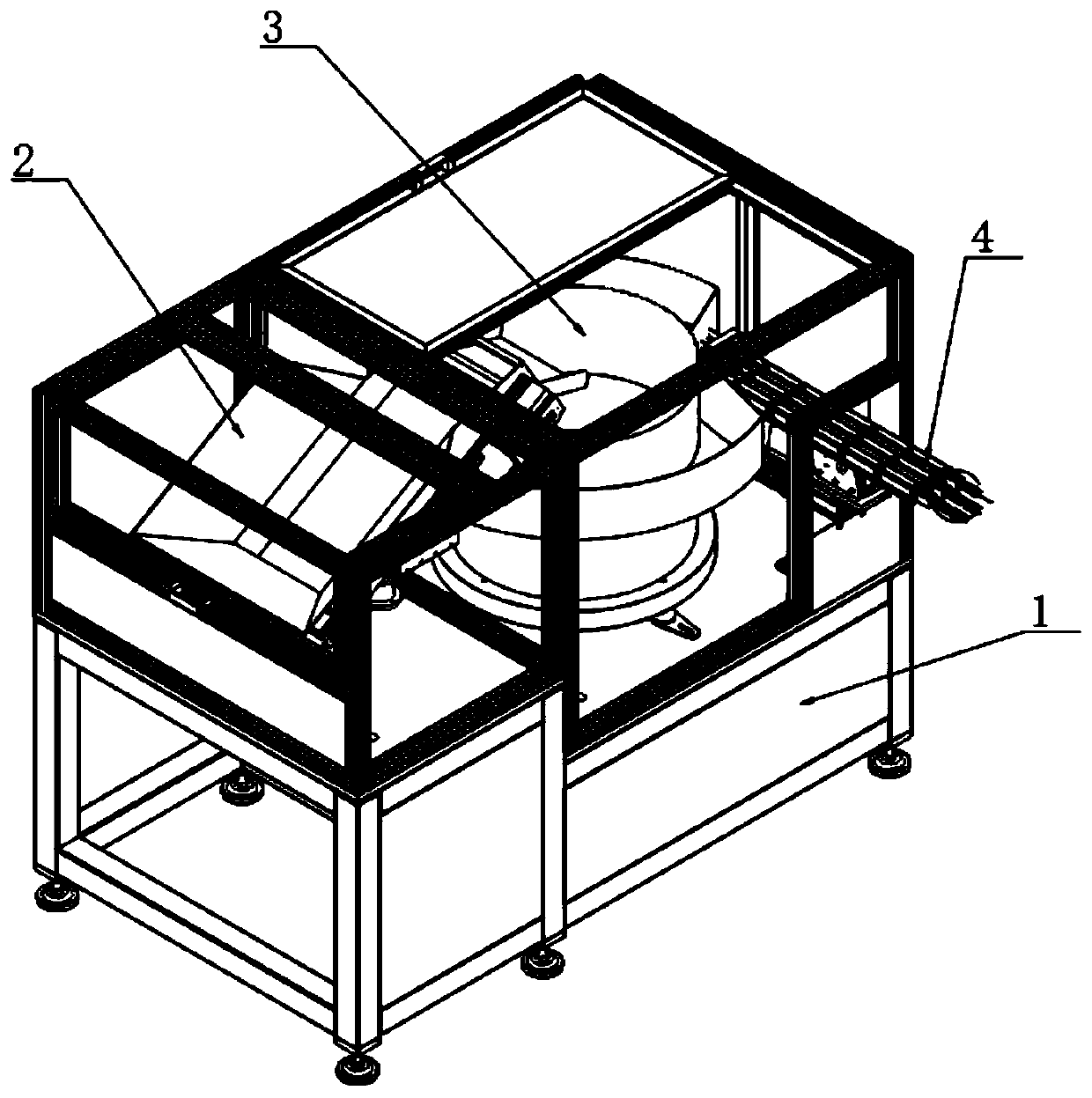

Unpacking device for traditional Chinese medicine decoction piece package

InactiveCN105253405ANo labor requiredImprove work efficiencyUnpacking by cuttingMedicineConveyor belt

The invention provides an unpacking device for traditional Chinese medicine decoction piece package, belongs to the technical field of machinery and solves the problem that current unpacking efficiency for traditional Chinese medicine decoction piece package is low. The unpacking device for the traditional Chinese medicine decoction piece package comprises a feeding hopper, a conveyor belt, a cutting tool and a material collecting hopper used for storing traditional Chinese medicine decoction piece package, wherein a plurality of vacuum chucks capable of adsorbing the traditional Chinese medicine decoction piece package are arranged on the conveyor belt; the feeding hopper is positioned above a feeding end of the conveyor belt; the cutting tool is positioned at one side of a discharge end of the conveyor belt, and is opposite to the discharge end of the conveyor belt; a gap between the cutting tool and the discharge end of the conveyor belt forms a cutting channel; the cutting tool is driven by a motor and capable of cutting the traditional Chinese medicine decoction piece package which passes through the cutting channel; and the material collecting hopper is arranged below the conveyor belt. The unpacking device for traditional Chinese medicine decoction piece package is automatic in whole unpacking process, and relatively high in working efficiency, and does not need a great deal of labor force.

Owner:陈福春

Automatic feeding mechanism

PendingCN110065791AEasy to holdConvenience for subsequent useControl devices for conveyorsAutomationEngineering

The invention discloses an automatic feeding mechanism of the technical field of feeding mechanisms. The automatic feeding mechanism comprises a mounting rack I. The left side of the top of the mounting rack I is provided with a vibrating disk corresponding to the right end of a stock bin. Three material channels are arranged at a discharge port of the vibrating disk side by side. The outer wall of the front side of a push plate is uniformly provided with push protrusions matched with trays. The left side of the bottom of a mounting plate is movably connected with the output ends of electric cylinders. Clamping jaws are located in front of the push plate. The automatic feeding mechanism conducts automatic conveying through the three material channels in sequence. A stop mechanism is arranged and can stop products when the products are fed into the trays. The automatic feeding mechanism feeds the products into the trays comprehensively through a push cylinder, the push plate and the push protrusions. An up-down taking cylinder drives an L-shaped mounting plate to enable the clamping jaws to move downwards to clamp the products. The automatic feeding mechanism can convey the productsto mounting positions through the electric cylinders and horizontal movement cylinders II without manual operation. The automatic feeding mechanism is high in automation degree and tidy, stable and well-aligned in product feeding and facilitates later use.

Owner:RULAMATE AUTOMATIC TECHN SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com