Rectangular tube or circular tube intelligent centering, clamping and rotating device

A technology for rotating devices and round tubes, which is applied in plasma welding equipment, laser welding equipment, manufacturing tools, etc. It can solve problems such as blanks in the technical field, and achieve the effects of accurate dimensions, no burrs, and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

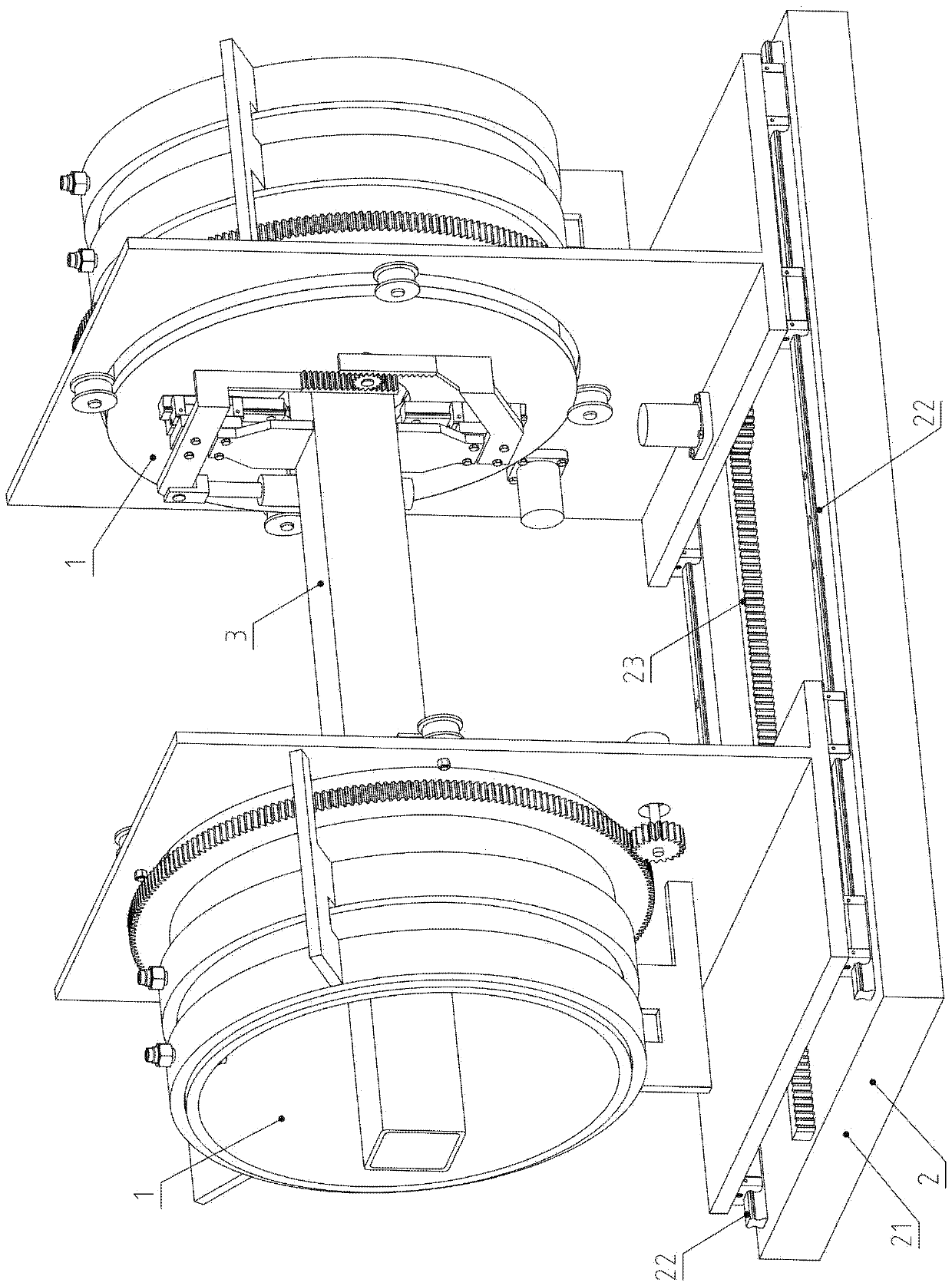

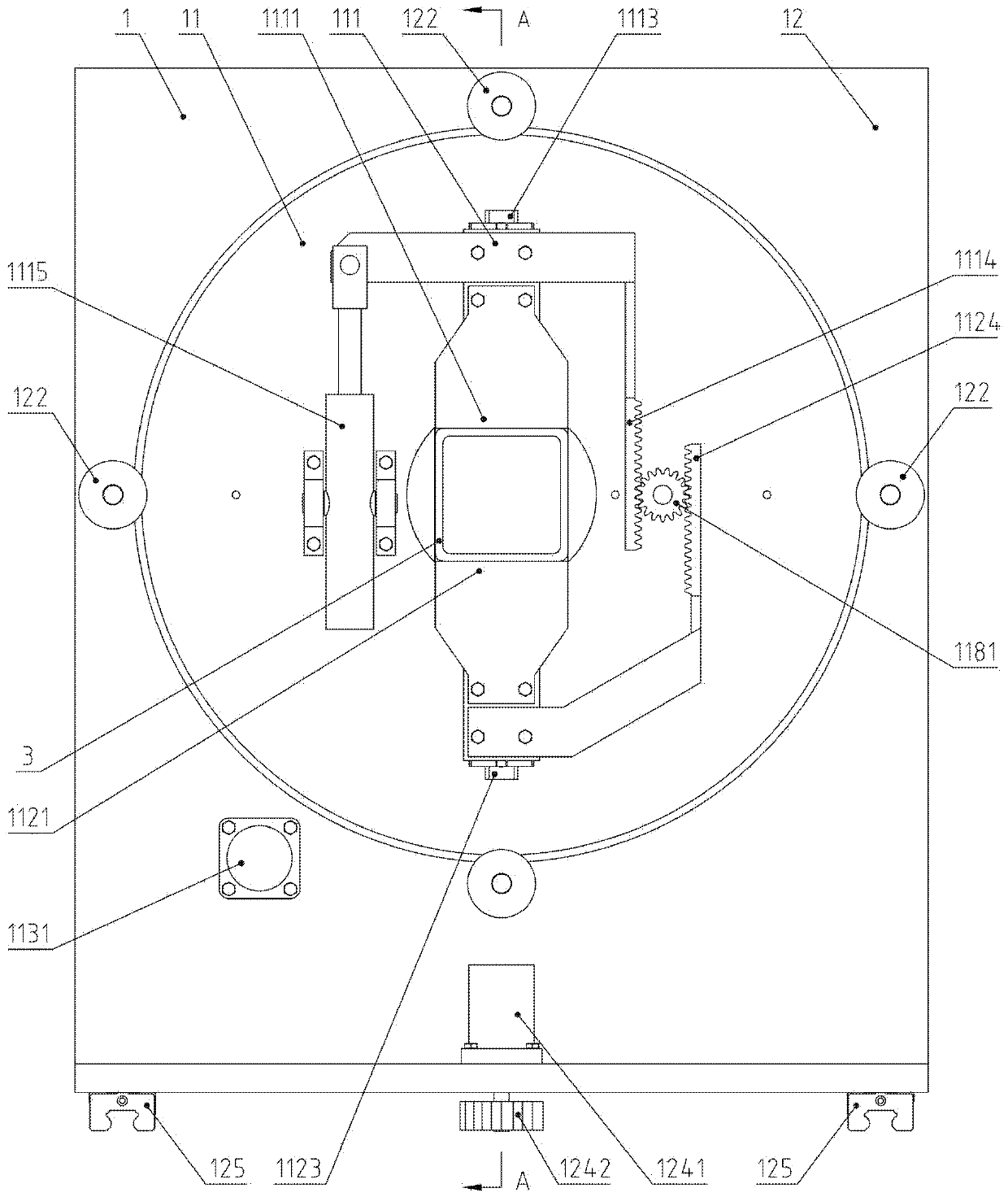

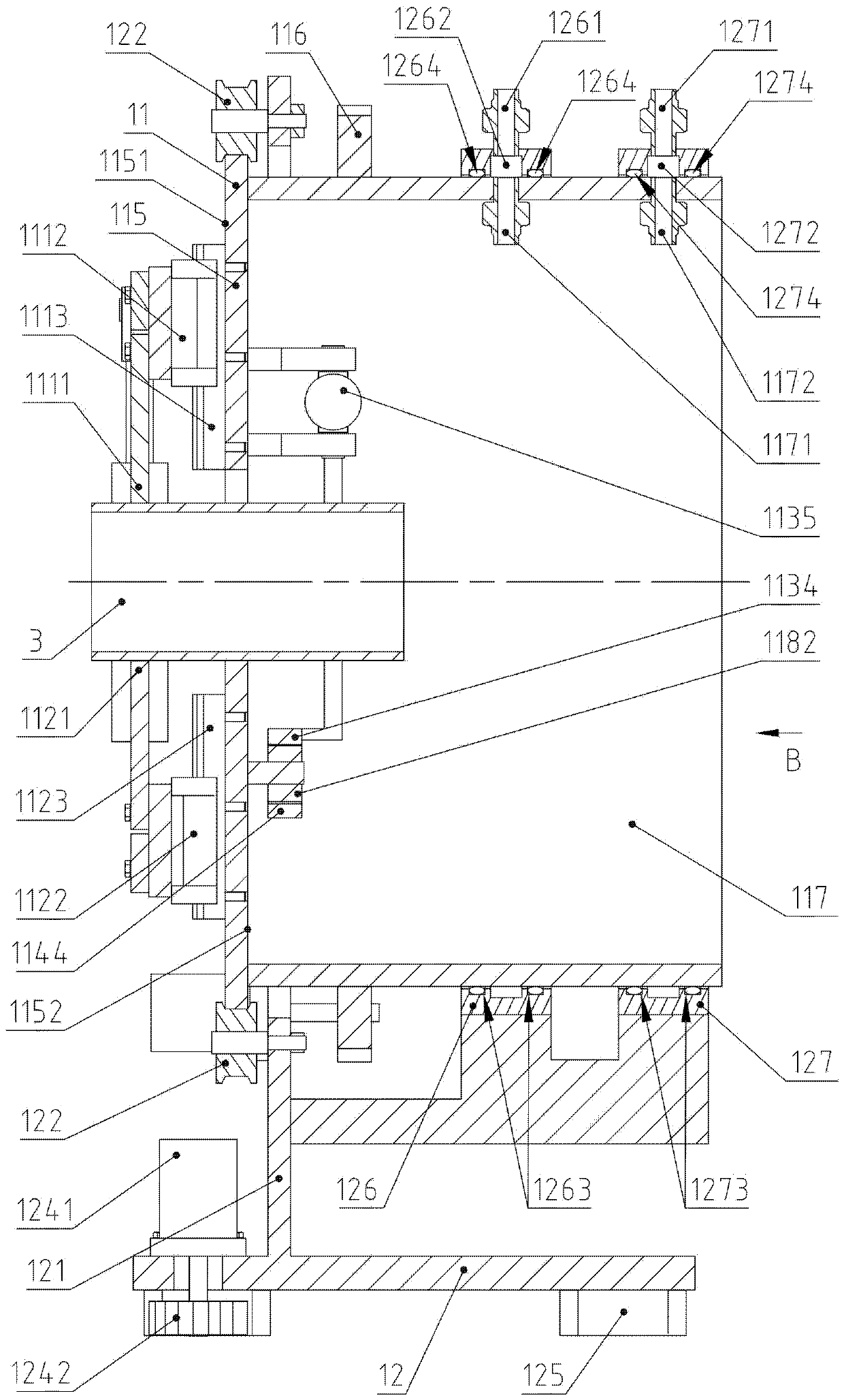

[0051] Example: see Figure 1 to Figure 15 .

[0052] An intelligent centering clamping and rotating device for rectangular or round pipes, comprising two centering clamps 1 and a base assembly 2;

[0053] The centering clamp 1 includes a rotating part 11 and a translation part 12. The translation part 12 includes a translation bracket 121, a translation motor 1241, a translation gear 1242 and a translation slider 125. The housing flange of the translation motor 1241 and the translation slider 125 are respectively connected to The translation support 121 is fixedly connected, and the output shaft of the translation gear 1242 and the translation motor 1241 is fixedly connected; the base assembly 2 includes a base 21, a base guide rail 22 and a base rack 23, and the base guide rail 22 and the base rack 23 are respectively fixedly connected to the base 21; The translation slider 125 and the base guide rail 22 form a linear guide rail pair, the translation gear 1242 meshes with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com