Automobile gear level switching device

A gear switching, vehicle technology, applied in the direction of control devices, transmission devices, vehicle components, etc., can solve problems such as inability to manually separate, gear damage, and reduced device durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

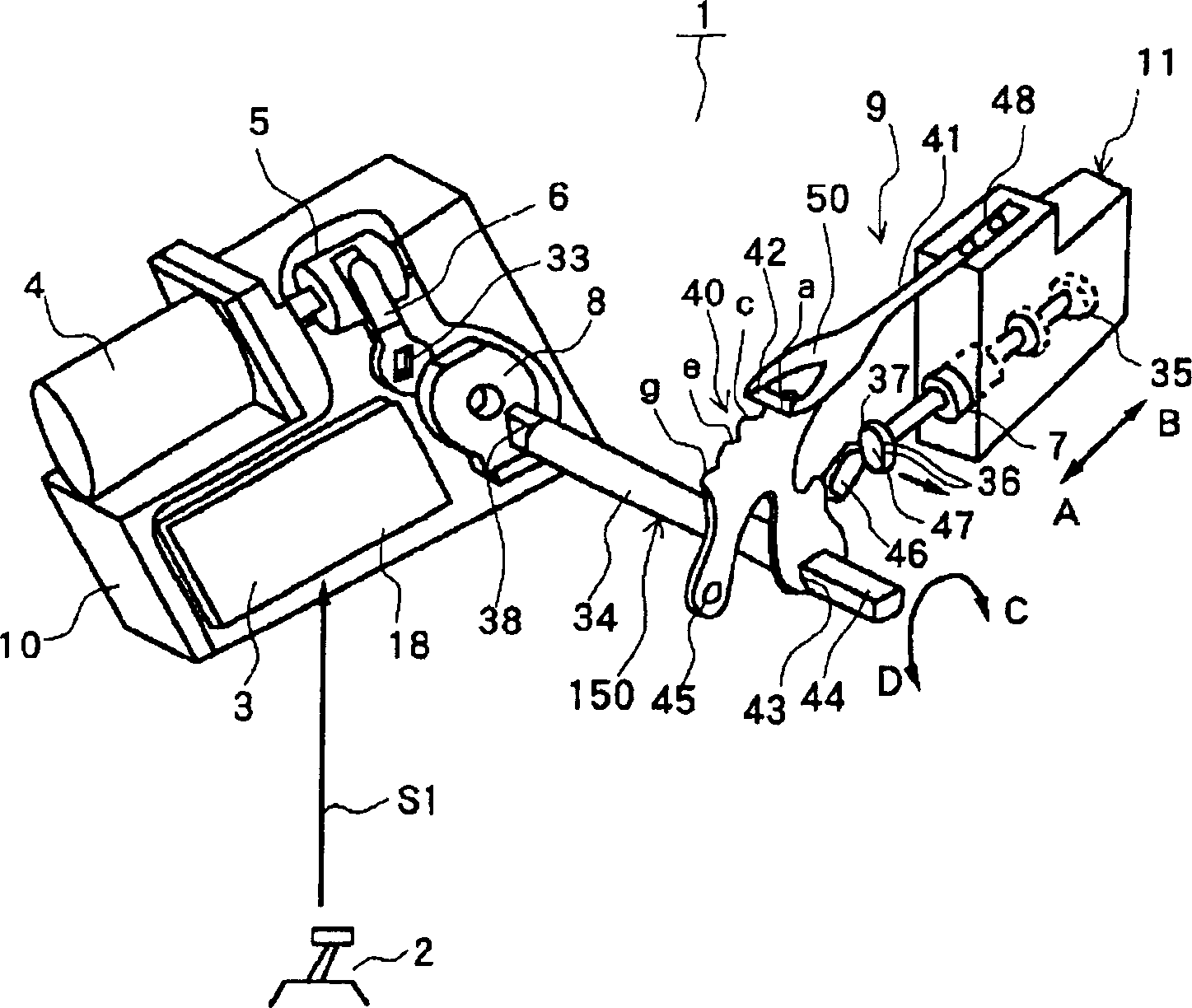

[0253] figure 1 As an example of the vehicle range switching device according to the present invention, the vehicle range switching device (hereinafter referred to simply as "the range switching device") 1 according to Embodiment 1 is shown. This figure is a perspective view schematically showing the overall structure of the range switching device 1 .

[0254] The range switching device 1 is incorporated into an automatic transmission (for example, a multi-stage automatic transmission or a continuously variable transmission (CVT)) mounted on a vehicle. Such as figure 1 As shown, the main structural components of the gear switching device 1 include: a shift lever 2 as a gear selection mechanism for the driver to select a driving gear, and an electric signal ( control signal), the motor 4 controlled according to the control signal from the first control mechanism 3, the conversion mechanism (transformation mechanism) 5 that converts the rotational motion of the motor 4 into a ...

Embodiment approach 2

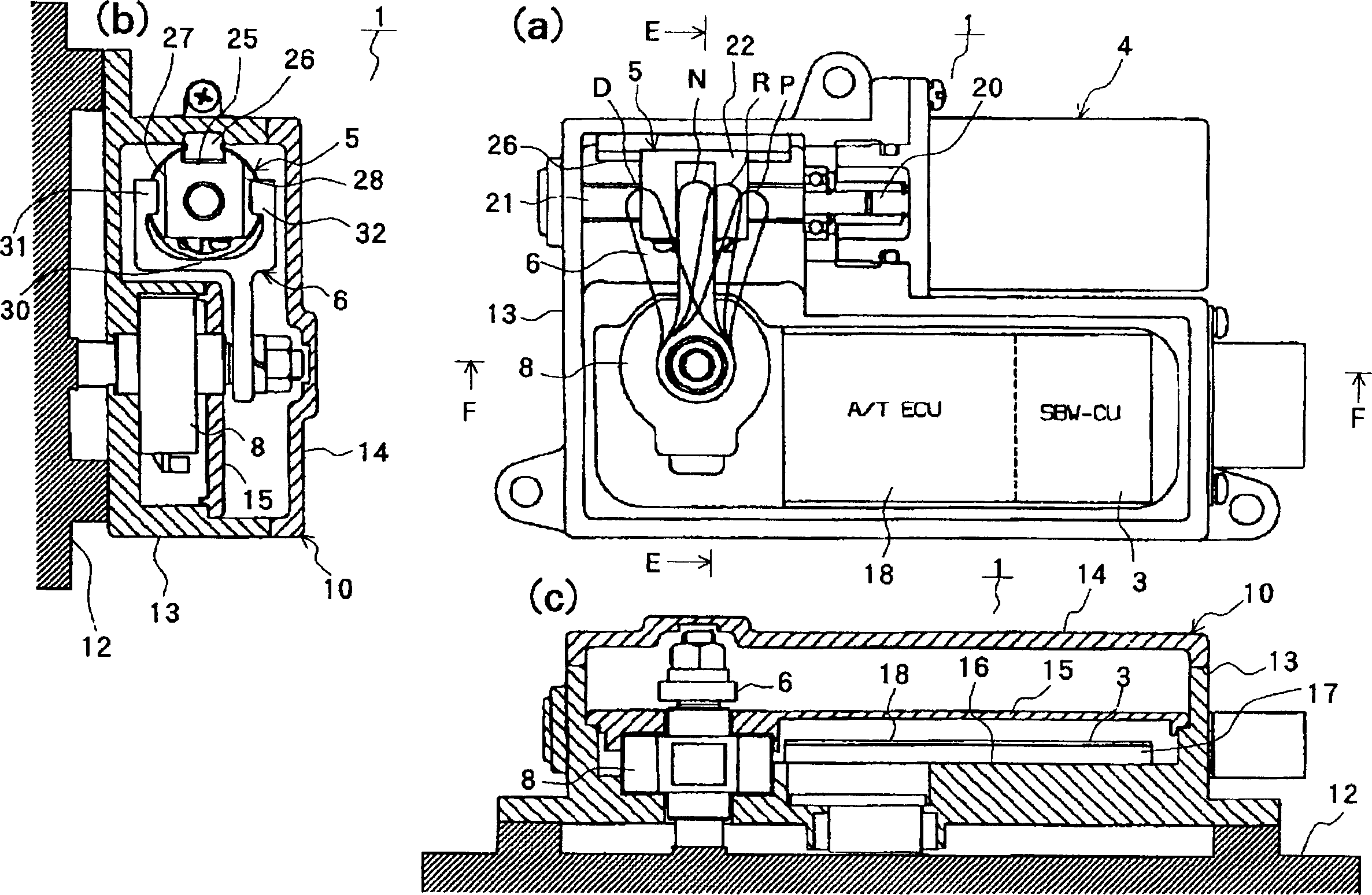

[0279] Figure 5 (a), (b), and (c) show the range switching device 50 related to this embodiment. These graphs in turn correspond to the above figure 2 (a), (b), (c). Additionally, with figure 2 The same parts shown in (a), (b) and (c) are given the same symbols and descriptions thereof are omitted.

[0280] In the present embodiment, the first control unit (SBW-CU) 3 and the second control unit (AT ECU) 18 are arranged in upper and lower layers.

[0281] The first control mechanism 3 is arranged on the bottom 16 of the casing body 13 of the casing member 10 , and the second control mechanism is arranged on the supporting member 51 provided above the first control mechanism 3 . The entirety of the first control mechanism 3 is arranged to overlap with the second control mechanism 18 .

[0282] According to this embodiment, it is possible to reduce the occupied area corresponding to the portion where the two overlap, compared to the horizontal arrangement. In addition, t...

Embodiment approach 3

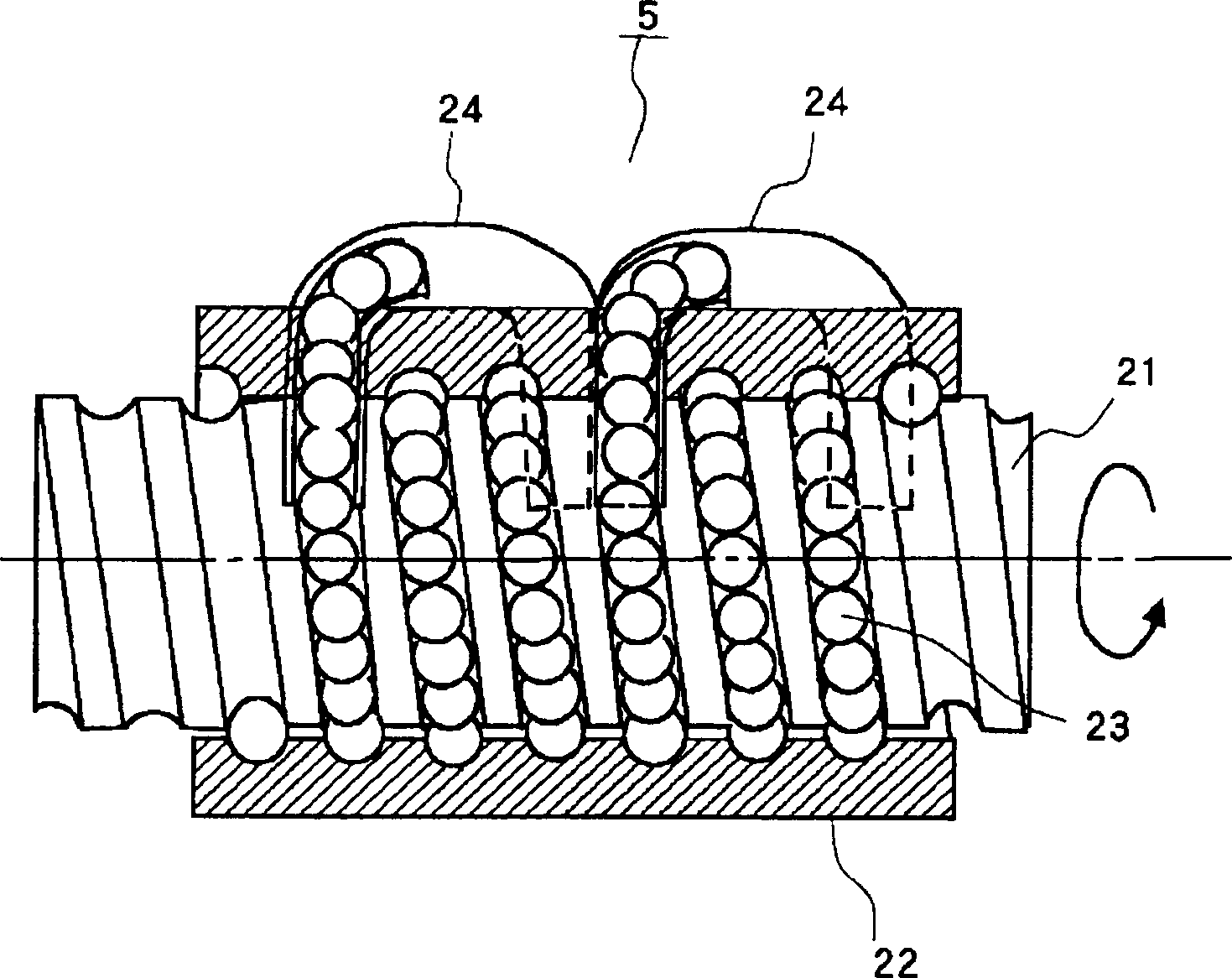

[0285] Figure 6 (a), (b), and (c) show the range switching device 60 related to this embodiment. In the shift switching device 60 shown in the figure, spur gears 52 a and 52 b are installed between the output shaft 20 of the motor 4 and the ball screw shaft 21 of the conversion mechanism 5 .

[0286] A small-diameter spur gear 52a is fitted to the output shaft 20 of the motor 4, while a large-diameter spur gear 52b is fitted to the ball screw shaft 21, and these spur gears 52a, 52b mesh with each other.

[0287] In this way, the gear ratio can be enlarged, and thus the size reduction of the motor 4 can be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com