Prefabricated assembly FRP-reinforcing steel-bar-concrete combined bridge deck and construction method

A technology of prefabricated assembly and construction method, applied in the direction of erecting/assembling bridges, bridges, bridge materials, etc., can solve the problems of difficult installation of prefabricated components, easy construction, lack of applicability, and difficulty in ensuring construction quality, and achieves a reduction in structural Maintenance cost, convenient construction, excellent effect of factory production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

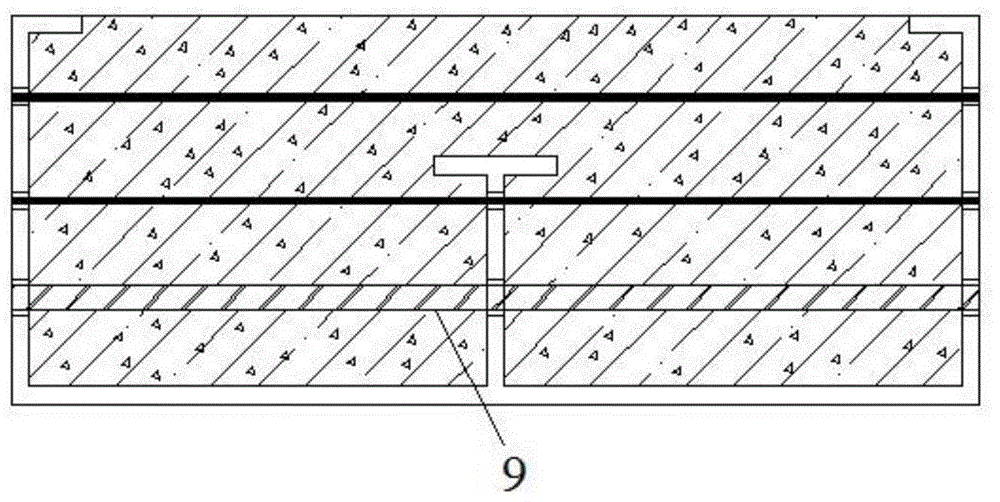

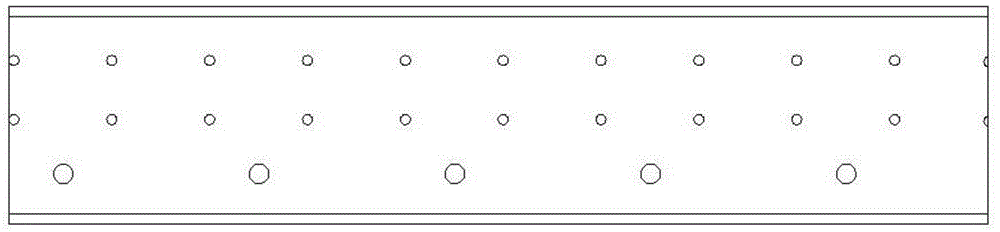

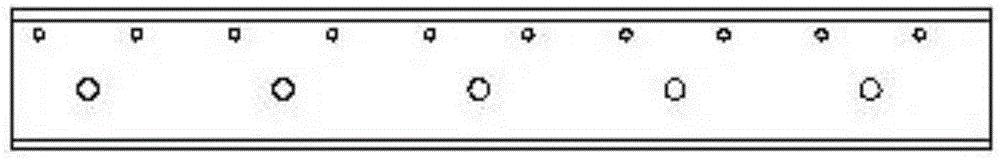

[0040] Prefabricated assembled FRP-reinforcement-concrete composite bridge deck, including, including prefabricated components of FRP-concrete composite panel with reserved channels ( figure 1 ) and transverse prestressed steel bars 8 and anchors 10. The FRP-concrete composite panel prefabricated component with reserved channels includes a semi-closed FRP groove 5, the two side plates of the FRP groove 5 are inverted L-shaped, and the upper edge of the inverted L-shaped side plate 1 is flush with the upper edge of the concrete 2, forming The three-sided FRP groove wraps the concrete structure. There is a T-shaped rib 4 in the middle of the FRP groove. The T-shaped rib 4 is connected to the upper surface of the FRP groove 5 bottom plate. The height is slightly lower than the inverted L-shaped side plate. The transverse prestressing tendon channel 6 is reserved in the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com