Extrusion type closing method for joint of pecast concrete utility tunnels

A prefabricated concrete and comprehensive pipe gallery technology, applied in the field of municipal engineering, can solve problems such as water leakage at the joint, reduce the service life of the comprehensive pipe gallery, and affect the progress of the project, and achieve the effects of convenient maintenance, strong detachability, and slow down corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

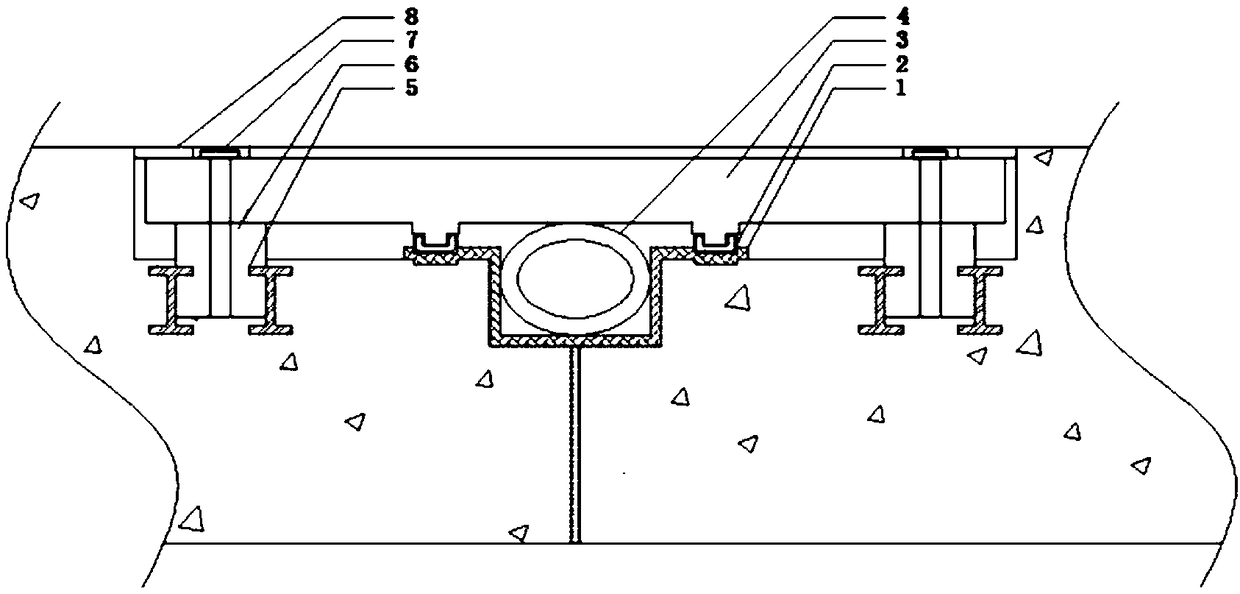

[0024] Such as Figure 1-3 As shown, a method for closing the junction of prefabricated concrete comprehensive pipe gallery by extrusion, including the following steps:

[0025] 1) A groove is provided at the joint of two prefabricated concrete integrated pipe galleries, and grooves parallel to it are respectively arranged on both sides of the groove, and a steel member 5 parallel to it is pre-embedded outside the groove;

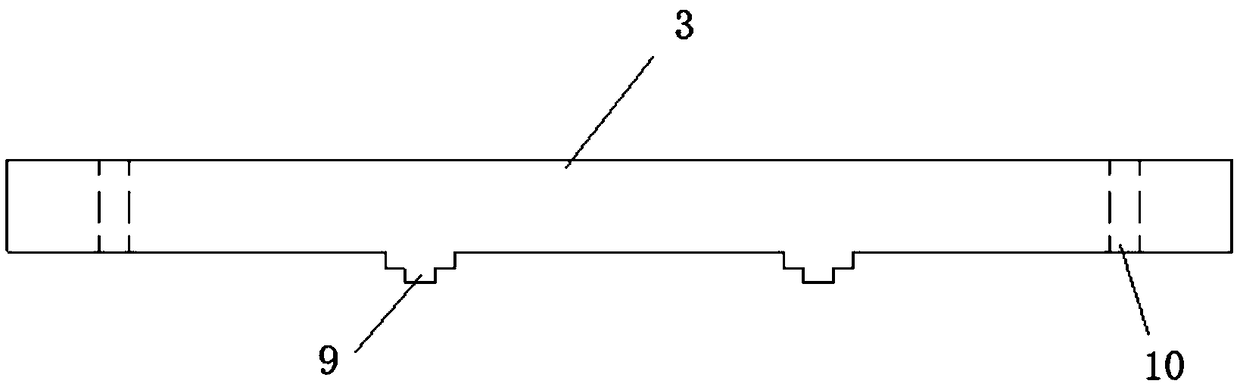

[0026] 2) Lay the waterstop 1 in the groove, the thickness of the waterstop 1 is 8 mm, the outer edge of the waterstop 1 covers the outside of the groove, and the waterstop airbag 4 in the shape of a cylinder is placed on the In the groove where the waterstop 1 is laid, the volume of the waterstop airbag 4 is larger than the volume of the groove;

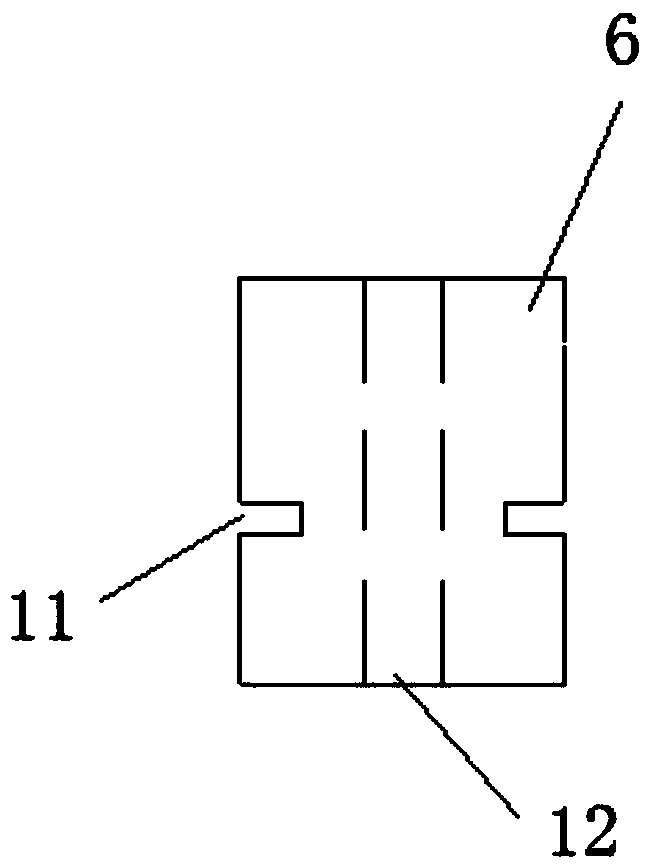

[0027] 3) Both sides of the nut fastener 6 are provided with clips 11, the nut fastener 6 is provided with a threaded hole 12, and the nut fastener 6 is clamped on the section steel member 5 through the clip slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com