Patents

Literature

107results about How to "Fast construction on site" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

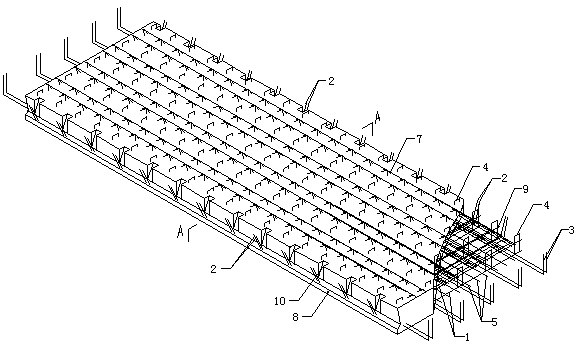

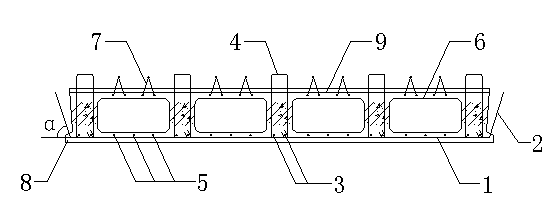

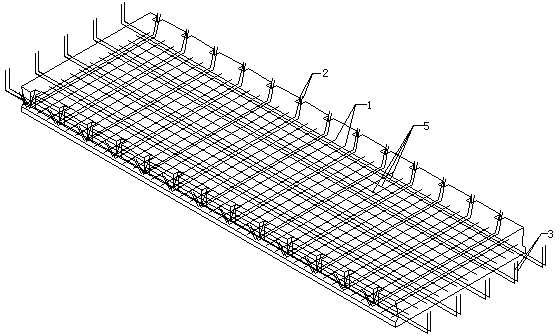

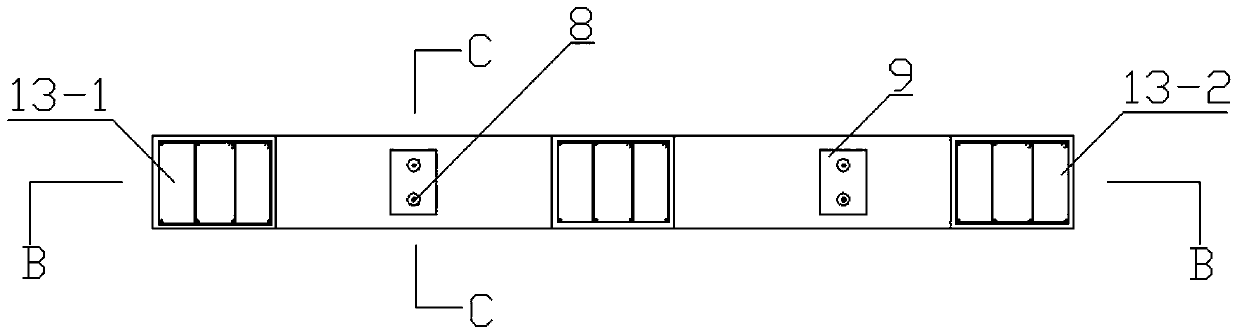

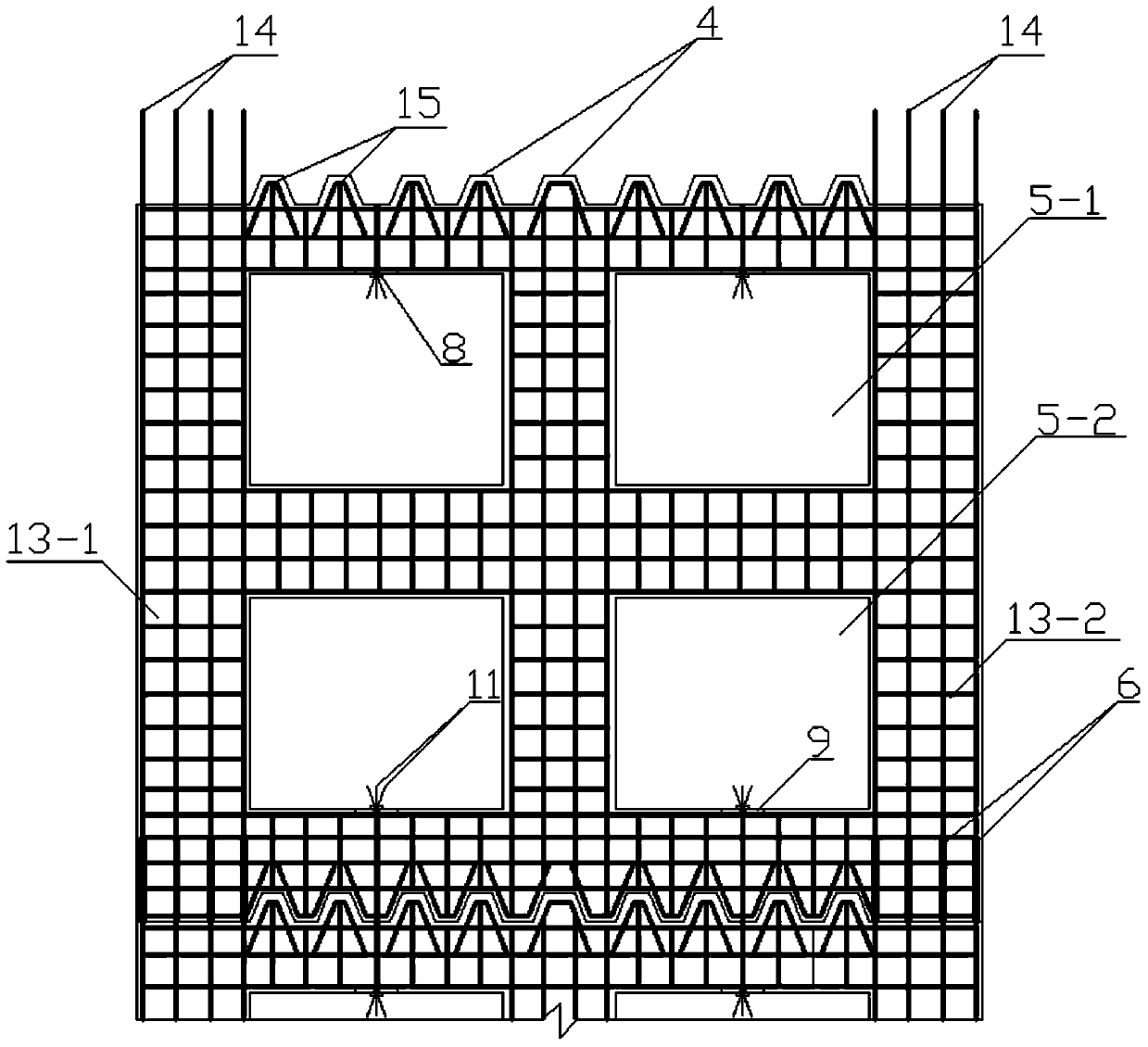

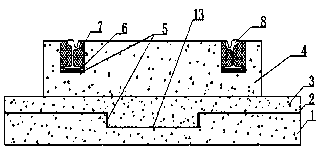

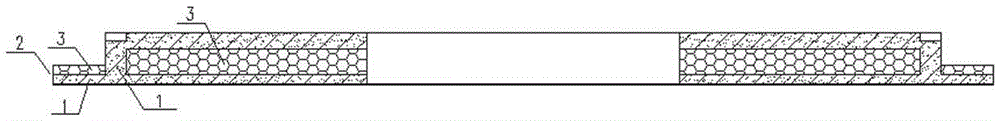

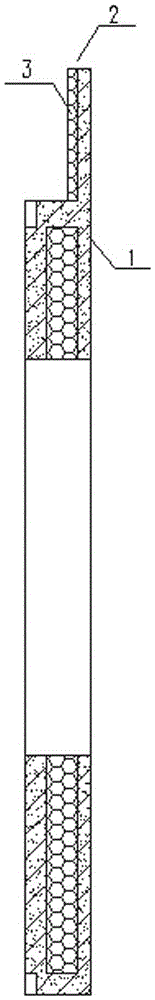

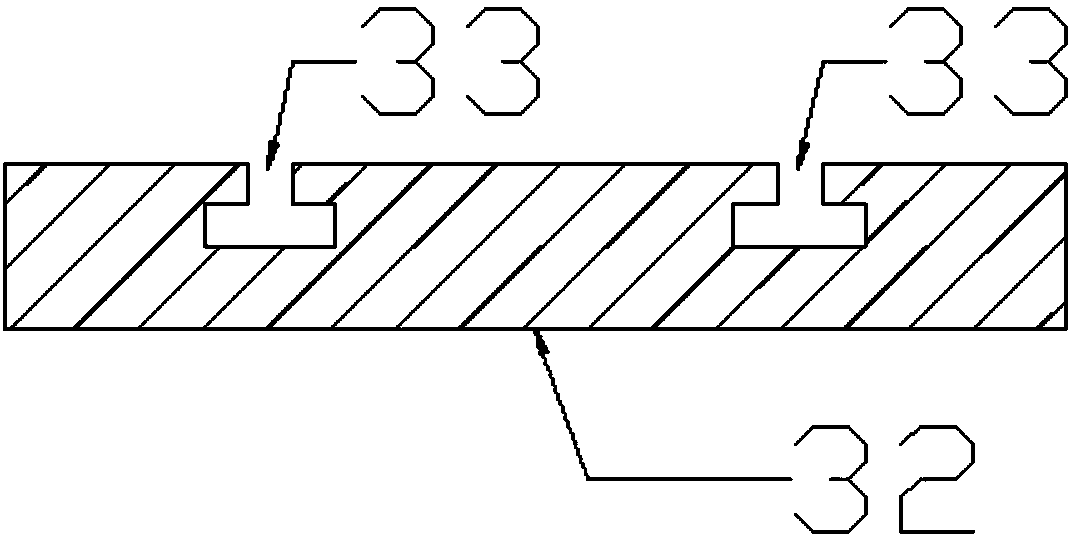

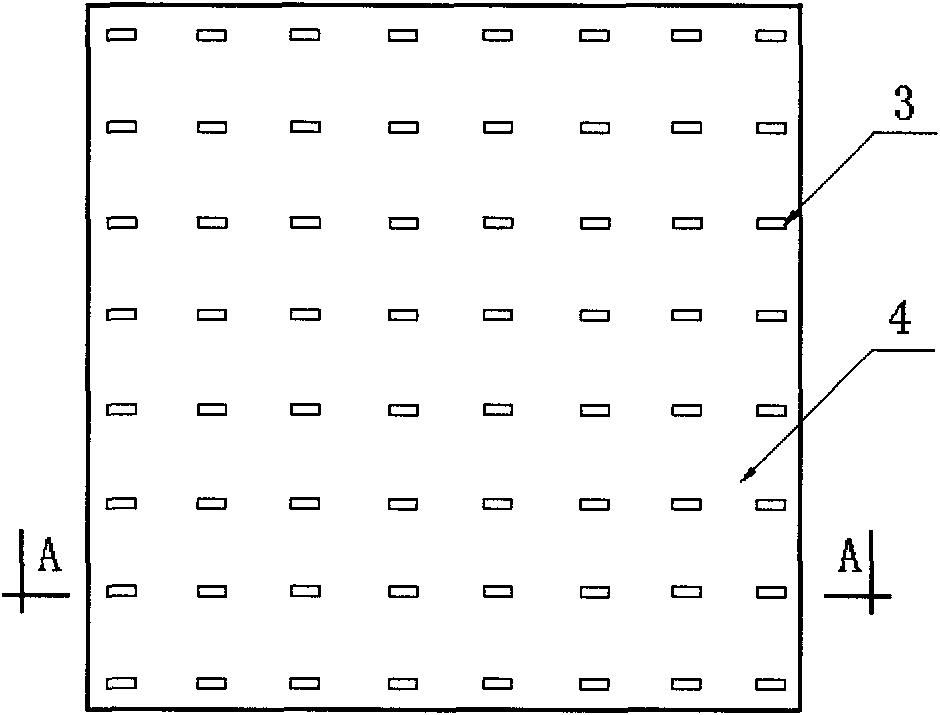

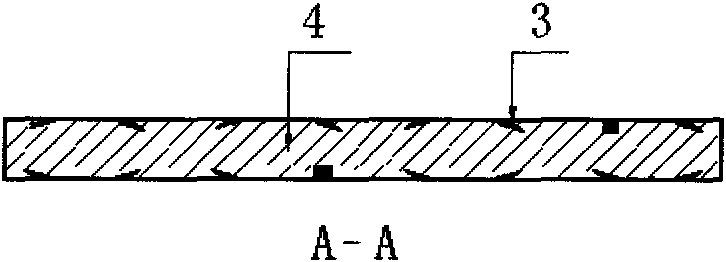

Integrally fabricated box-shaped multi-ribbed composite floor

The invention relates to an integrally fabricated box-shaped multi-ribbed composite floor, and belongs to a prefabricated concrete structural component. The integrally fabricated box-shaped multi-ribbed composite floor is characterized in that the composite floor mainly comprises bottom transverse reinforcement bars, bottom linkage reinforcement bars, lower ribbed beam longitudinal ribs, ribbed beam stirrups, bottom longitudinal reinforcement bars, shutterings, truss ribs, flanges, top transverse reinforcement bars, wedge-shaped grooves and a concrete layer, wherein the bottom linkage reinforcement bars, the bottom transverse reinforcement bars, the lower ribbed beam longitudinal ribs, the bottom longitudinal reinforcement bars, the ribbed beam stirrups, the top transverse reinforcement bars and the truss ribs form a steel reinforcement framework of the composite floor; the concrete layer is poured with a conventional concrete pouring method, the flanges are arranged at the bottoms of the front side and the rear side of a concrete slab body, the connecting position of two composite floors forms a U-shaped groove by the flanges, and crack pouring of post-poured concrete is facilitated; and the wedge-shaped grooves are formed in the front side part and the rear side part of the concrete slab body at intervals respectively, the wedge-shaped grooves between every two adjacent composite floors form shear keys, and the shearing resistance between the composite floors is increased.

Owner:CHINA MCC17 GRP

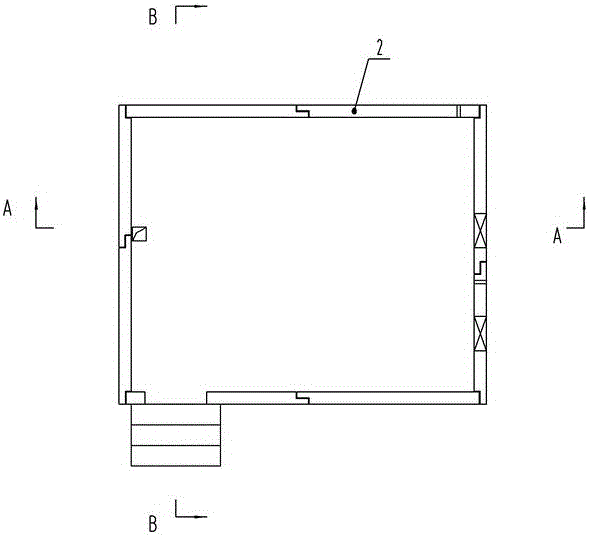

Fully-prefabricated structure and construction method thereof

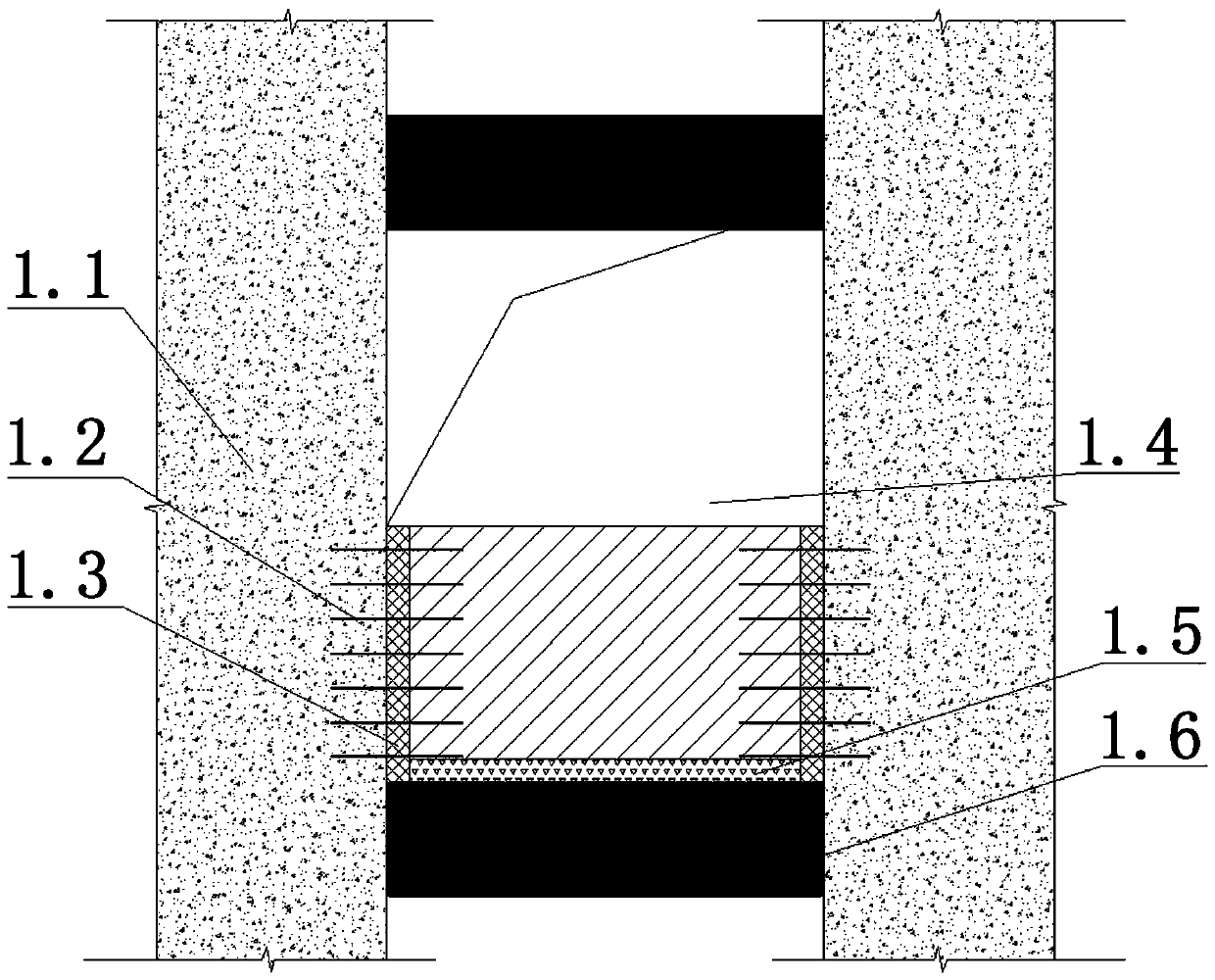

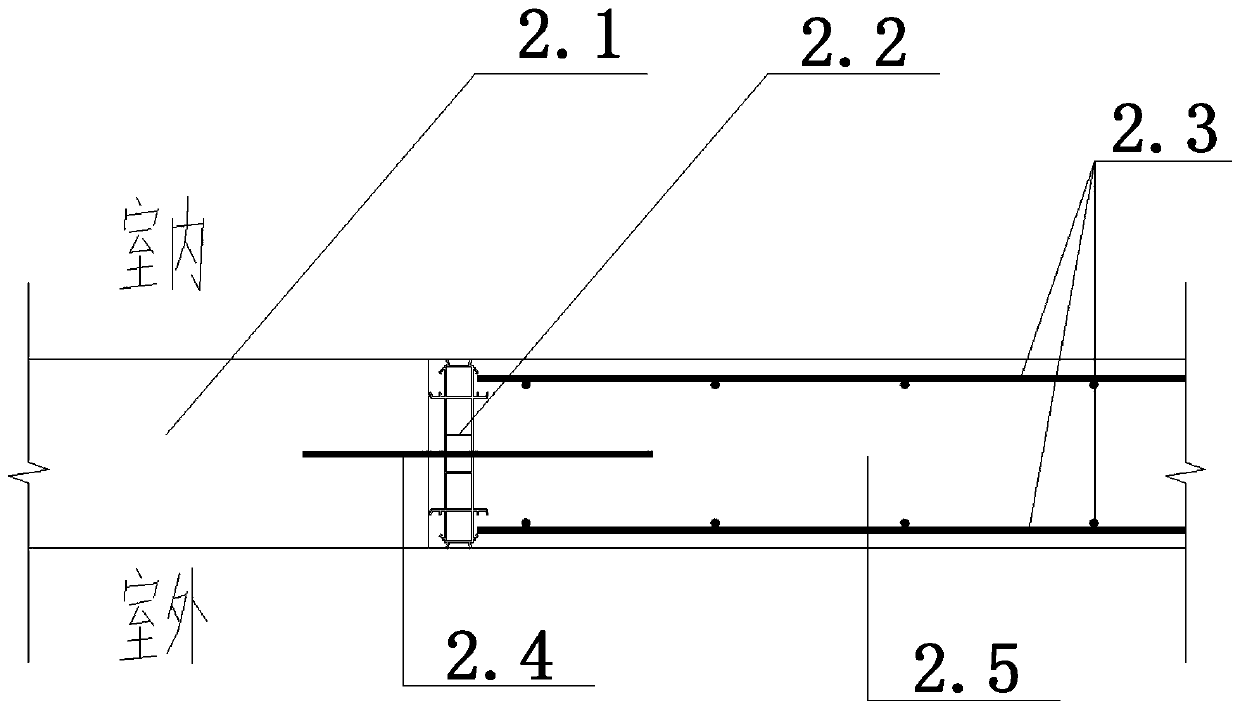

The invention belongs to the technical field of building construction and in particular relates to a fully-prefabricated structure and a construction method thereof. The fully-prefabricated structure comprises a top plate, peripheral wall boards and base plate concrete precast members, wherein an assembly clearance joint is preserved between every two adjacent concrete prefabricated members; joints connected with the concrete prefabricated members in parallel adopt L-shaped stagger-jointed lapping; in addition, the prefabricated wall panels are connected by embedded split bolts or connected by grouting and casting of reserved steel bars and matched holes; vertical joints between the prefabricated wall panels and the top plate and the base plate adopt grouting and casting connection through the reserved steel bars and the matched holes; water-expandable rubber water-stop strips are arranged in the reserved assembly clearance joints and are grouted with cement-based grouting materials; sealants are arranged on openings in two sides of the reserved assembly clearance joints. The fully-prefabricated structure and the construction method thereof disclosed by the invention have the advantages that the construction speed is high, the quality is easy to control, and materials such as a template scaffold are saved; the members are good in appearance quality and durability; field wet operation is reduced, so that environment friendliness is facilitated; the fully-prefabricated structure and the construction method thereof are suitable for construction of single-storey assembled buildings and multi-storey assembled buildings having no seismic requirements.

Owner:鹤壁东江建筑工业科技有限公司

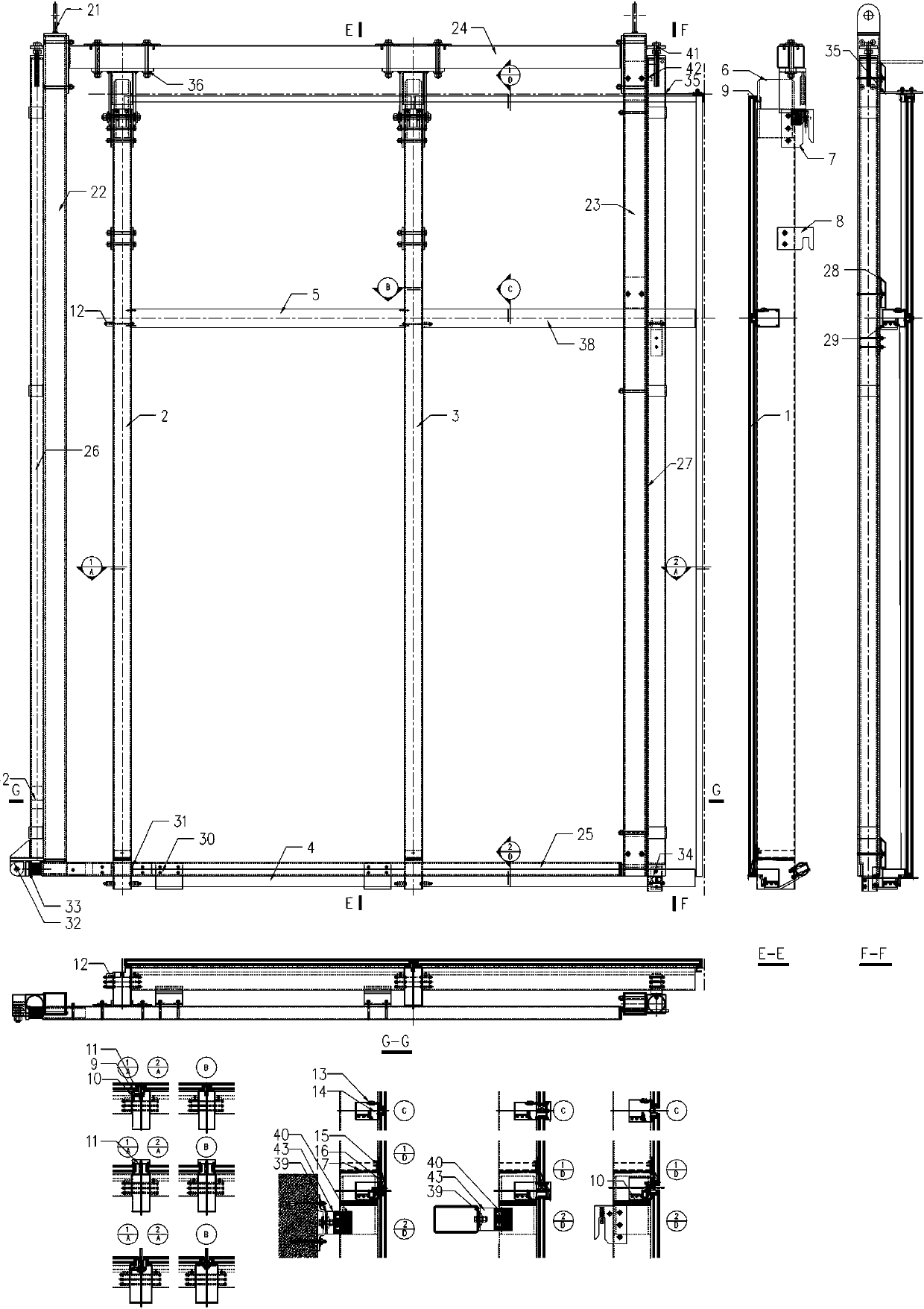

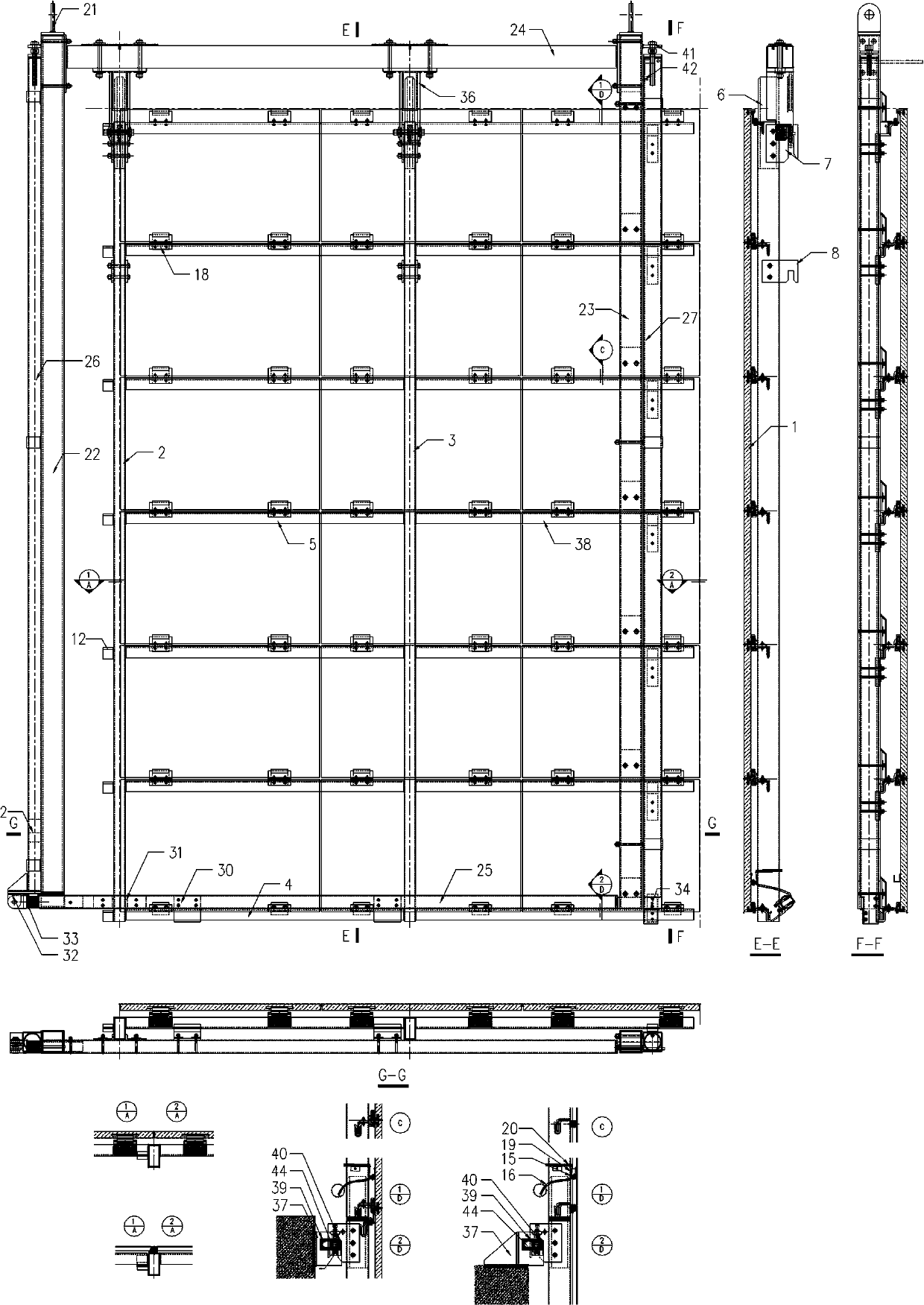

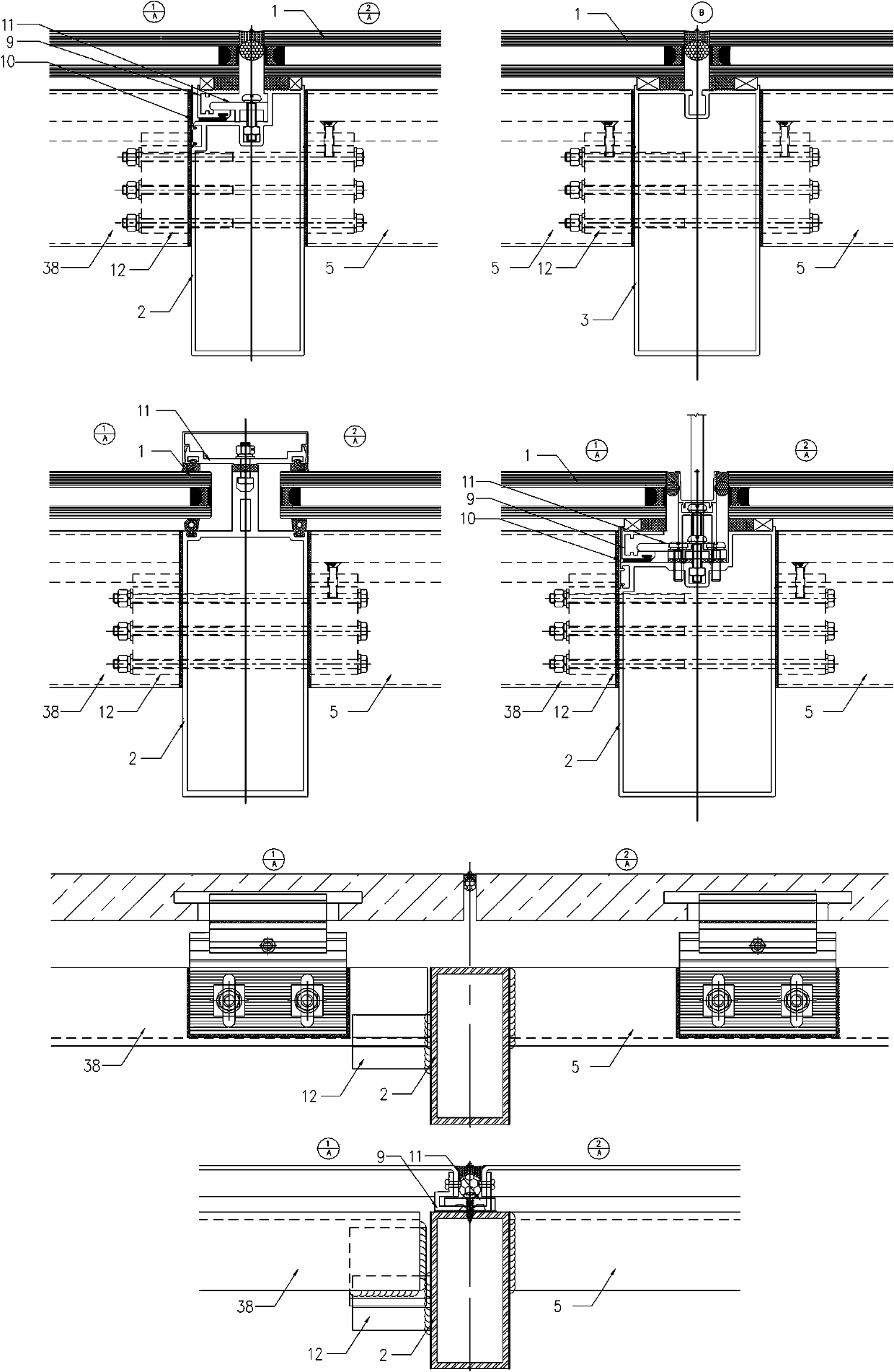

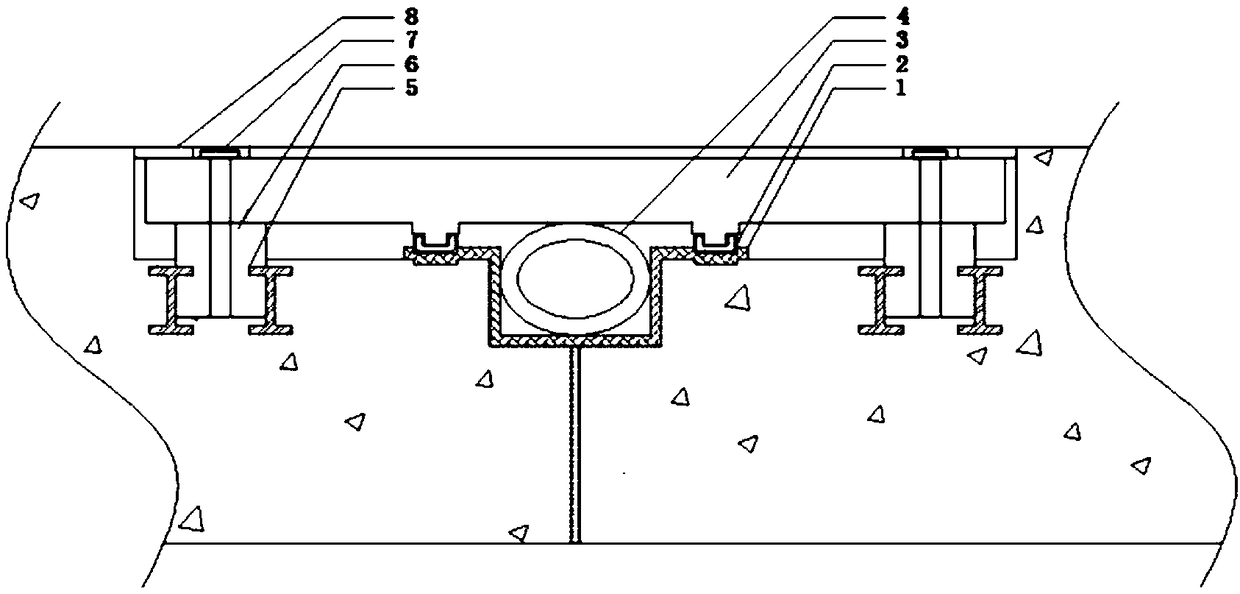

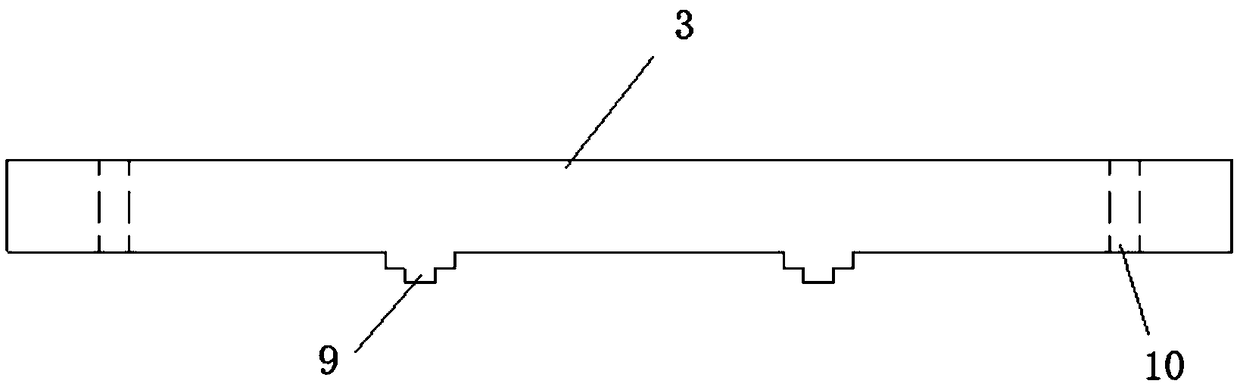

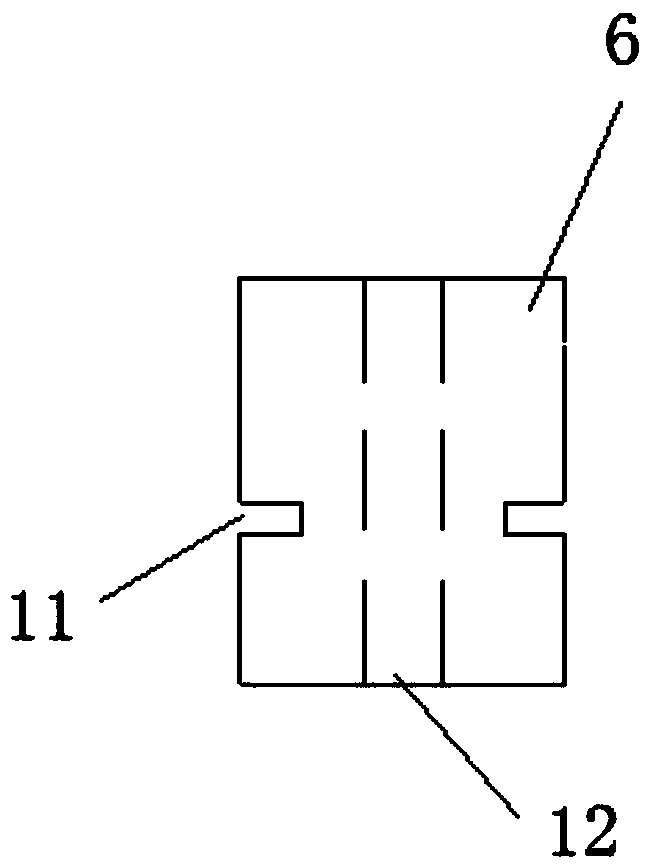

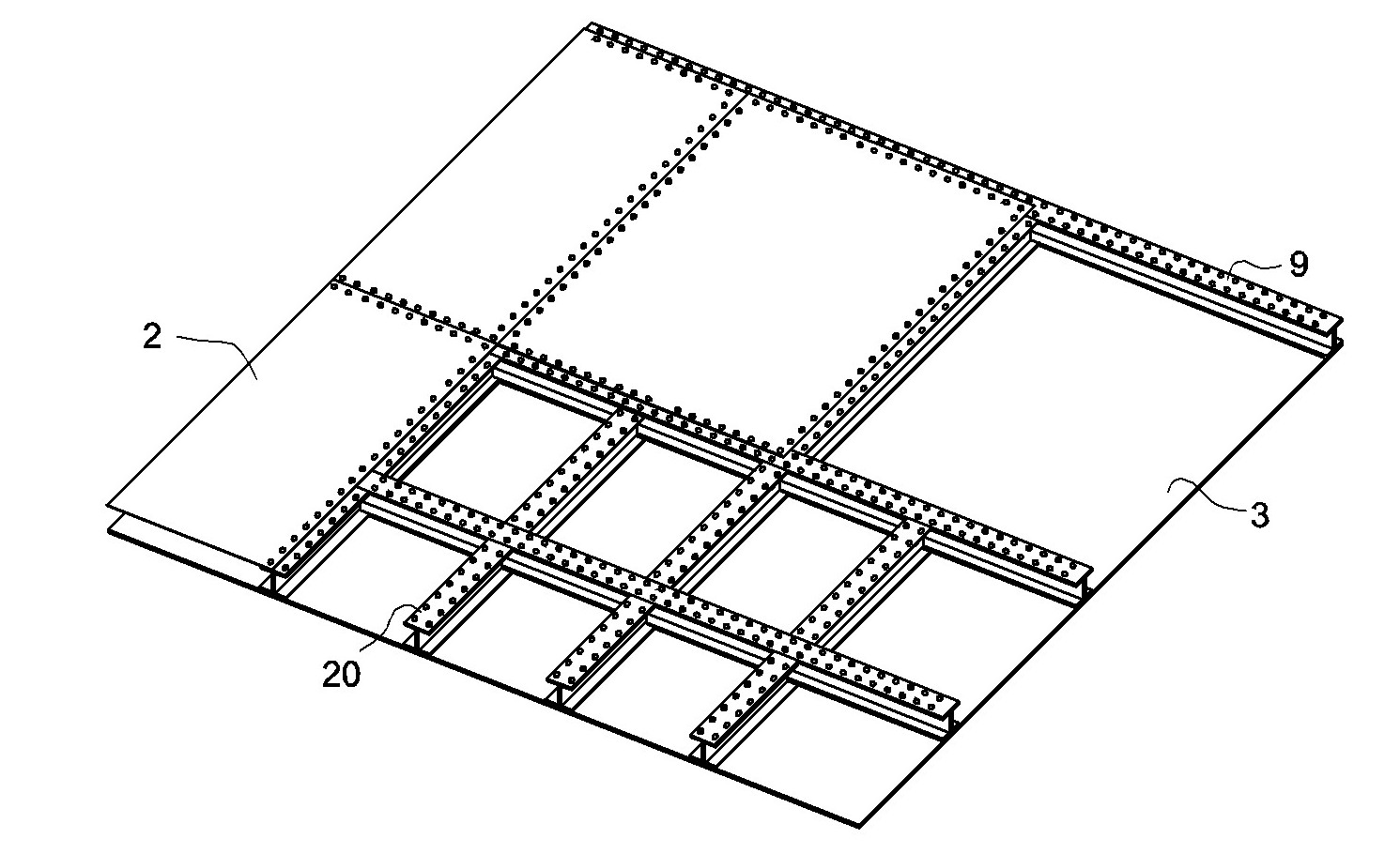

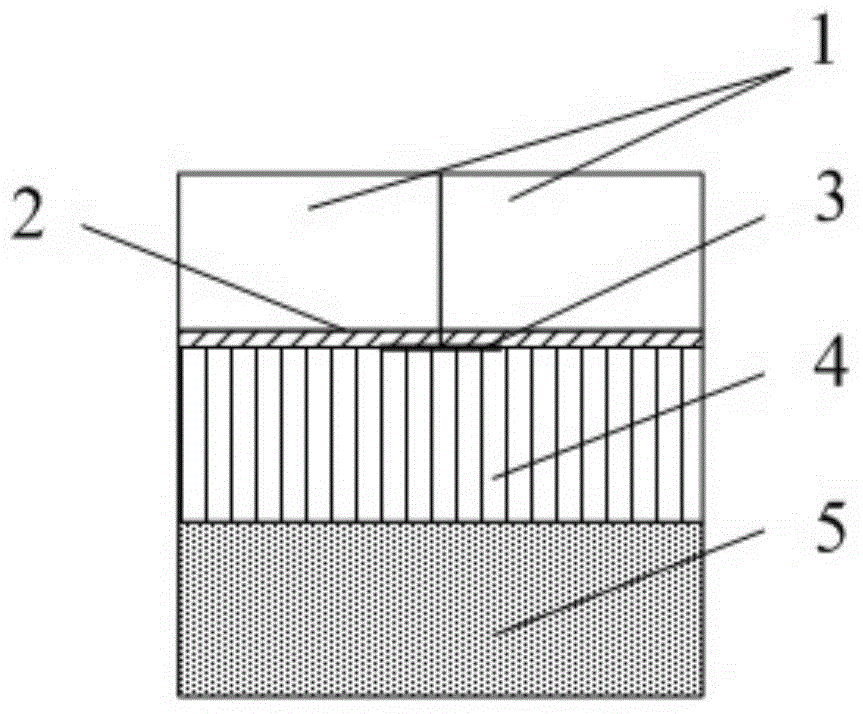

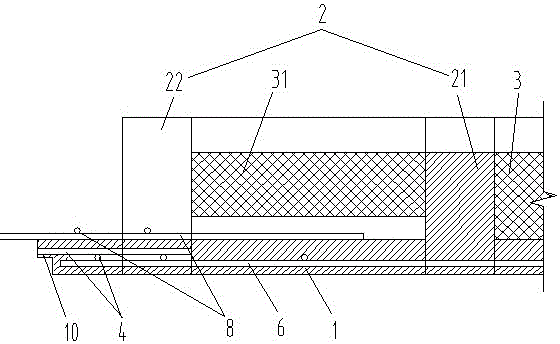

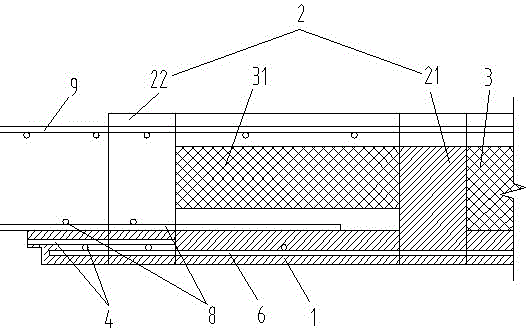

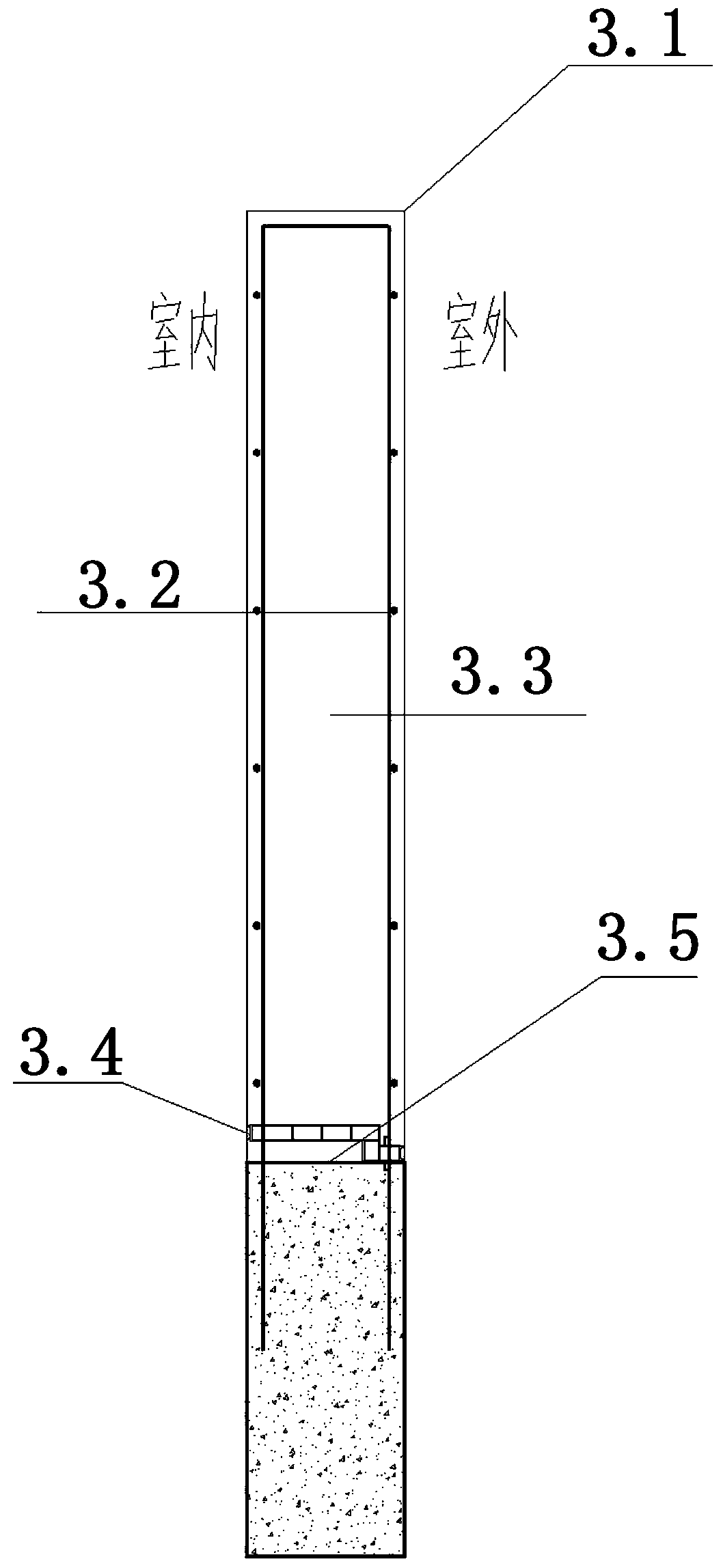

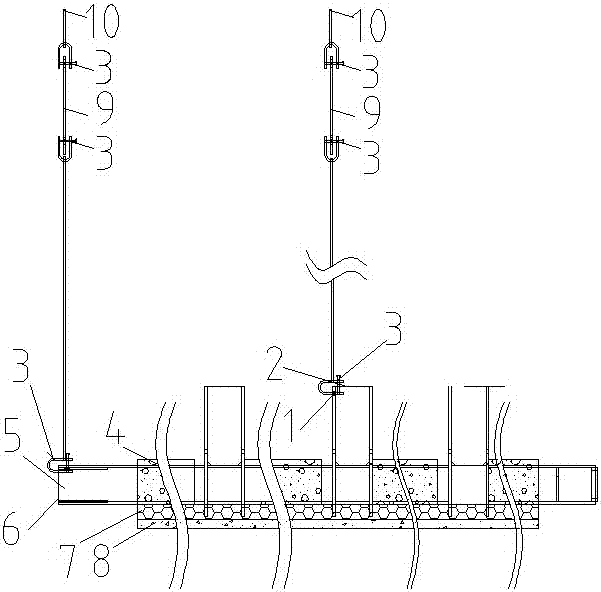

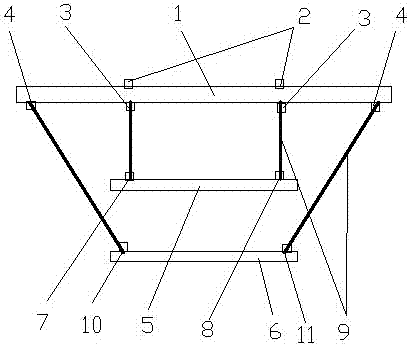

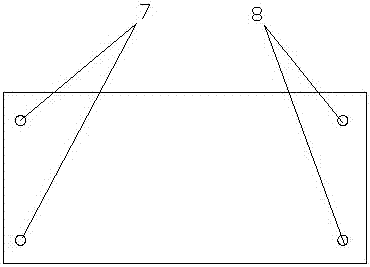

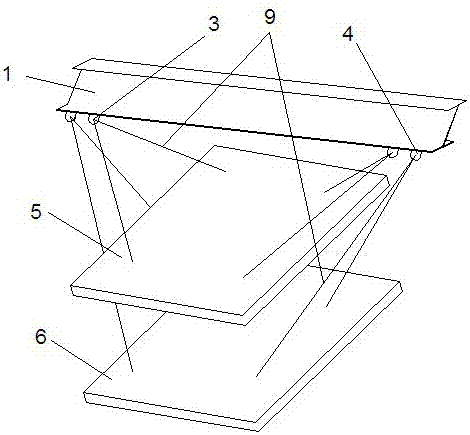

Frame type unit curtain wall adopting auxiliary installing rack, tooth profile angle and tooth profile support

The invention relates to the field of curtain walls of buildings, in particular to a frame type unit curtain wall adopting an auxiliary installing rack, a tooth profile angle and a tooth profile support. The frame type unit curtain wall adopting the auxiliary installing rack comprises a panel (1), end columns (2), middle columns (3), end cross beams (4), middle cross beams (5), inserting cores (6), an auxiliary frame (9), a cover plate and the like. The frame type unit curtain wall adopting the auxiliary installing rack, the tooth profile angle and the tooth profile support are long in service life, low in cost, good in machinability, short in field construction period and good in sealing performance.

Owner:何志胜

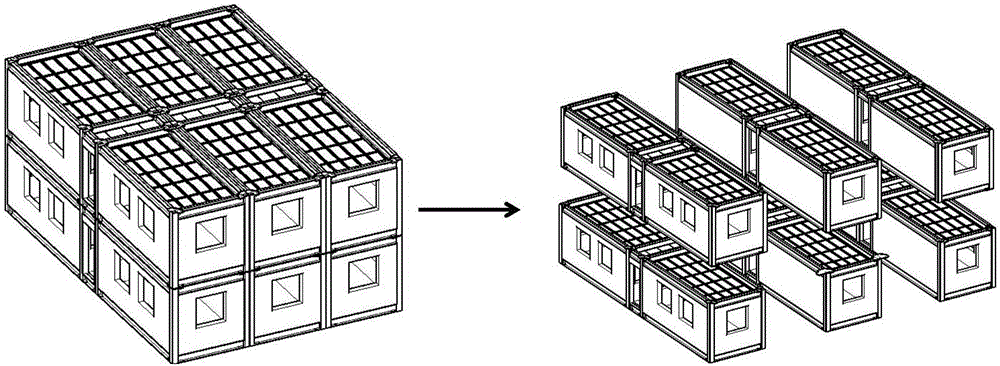

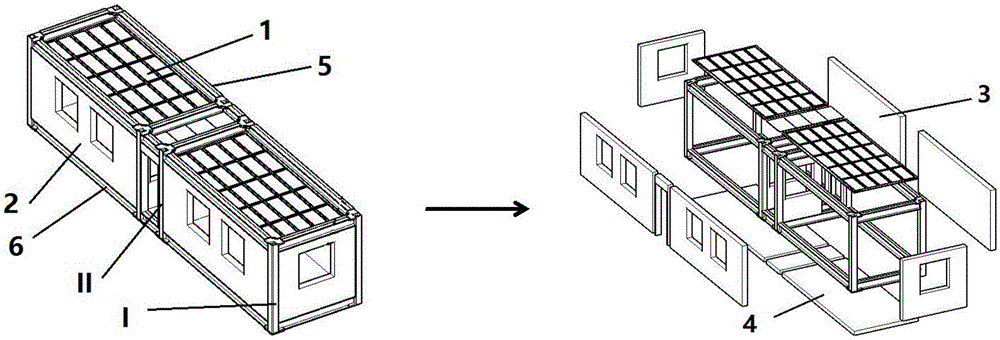

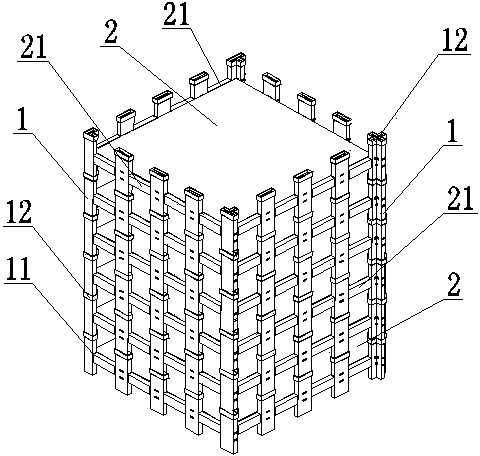

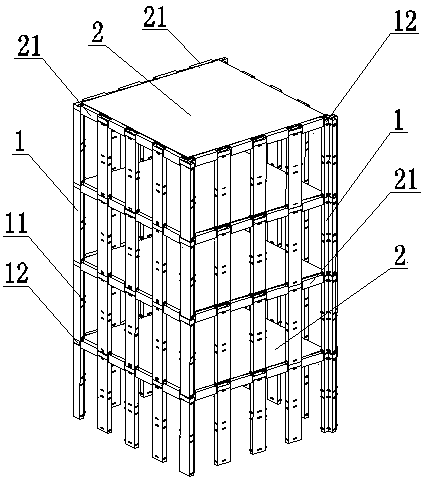

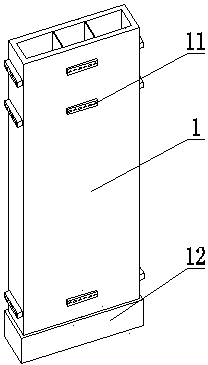

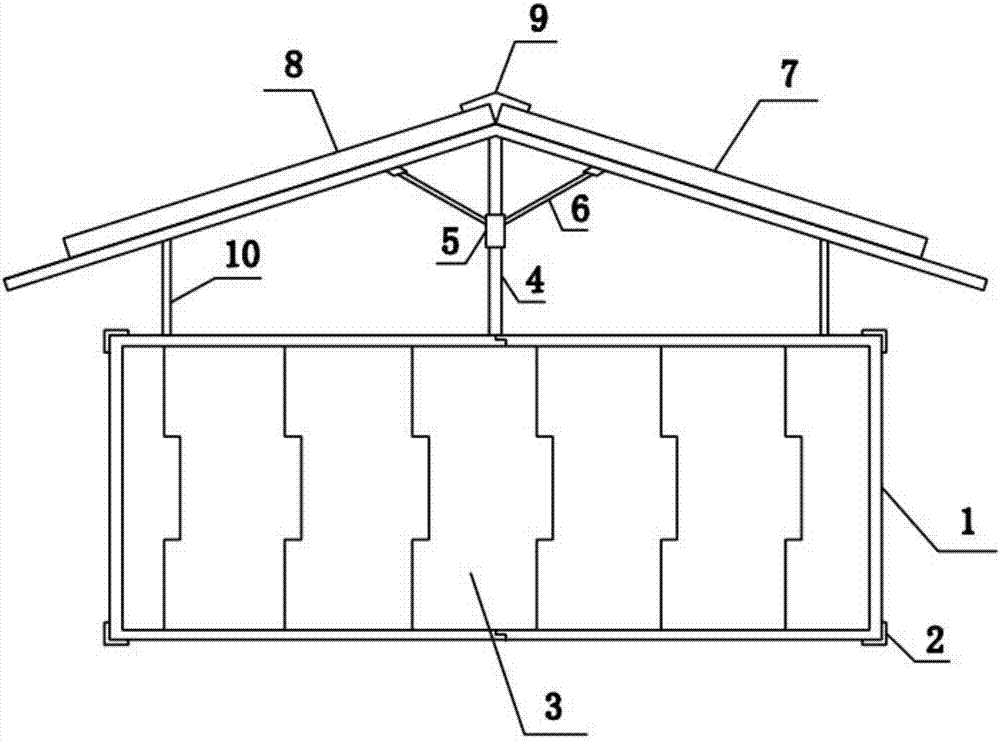

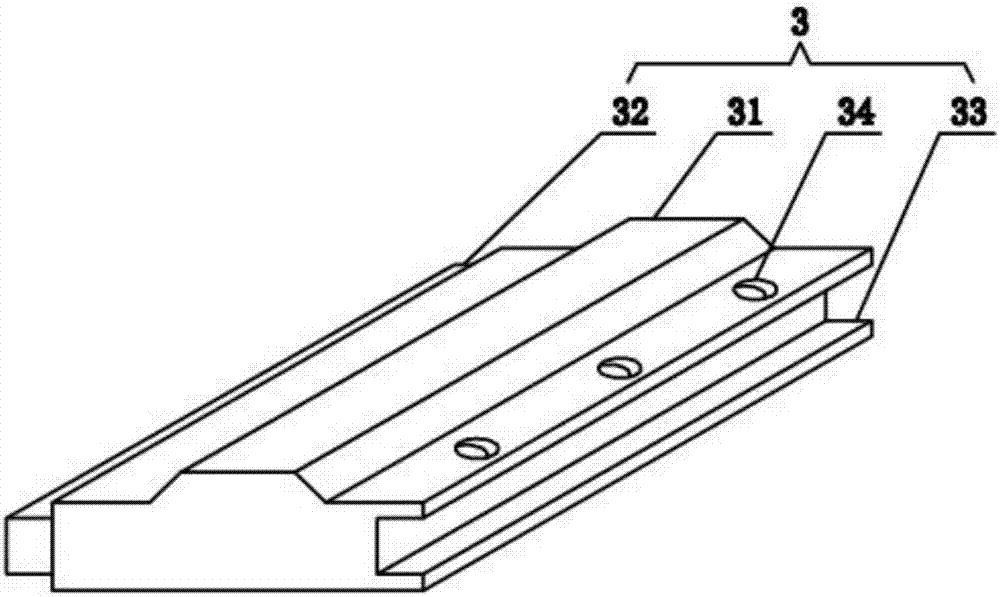

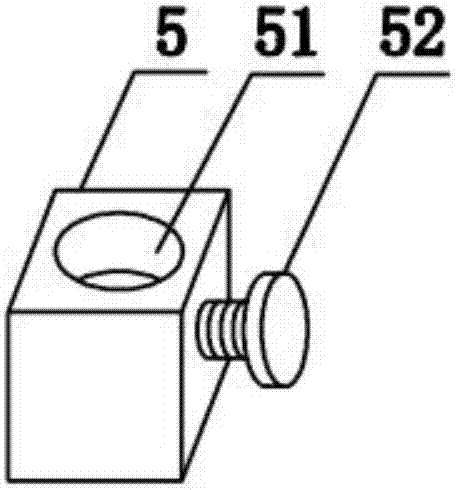

Modularized assembly type steel structure house building system

InactiveCN106337500AHigh degree of specializationImprove construction efficiencyBuilding constructionsArchitectural engineeringHouse building

The invention discloses a modularized assembly type steel structure house building system and belongs to the technical field of structural engineering. According to the purpose of the modularized assembly type steel structure house building system, construction and decoration of the unified specification are carried out in a factory in batches, every construction step of all produced assembly type steel structure apartment modules can be carried out by the same construction team, and therefore the degree of specialization of a constructed building is largely increased, the construction efficiency and construction quality are greatly improved, and meanwhile the probability of occurrence of sudden engineering accidents or errors is greatly decreased. According to assembly type apartment modules, all the construction steps except for connection and fixation of the assembly type steel structure apartment modules are finished in the factory. The modularized assembly type steel structure house building system comprises the assembly type apartment modules and connection components, wherein the assembly type apartment modules comprise beams, columns, floor boards, structures and devices; the structures and the devices are added according to project requirements. At the construction site, apartment units can be connected and fixed through the connecting components.

Owner:BEIJING UNIV OF TECH

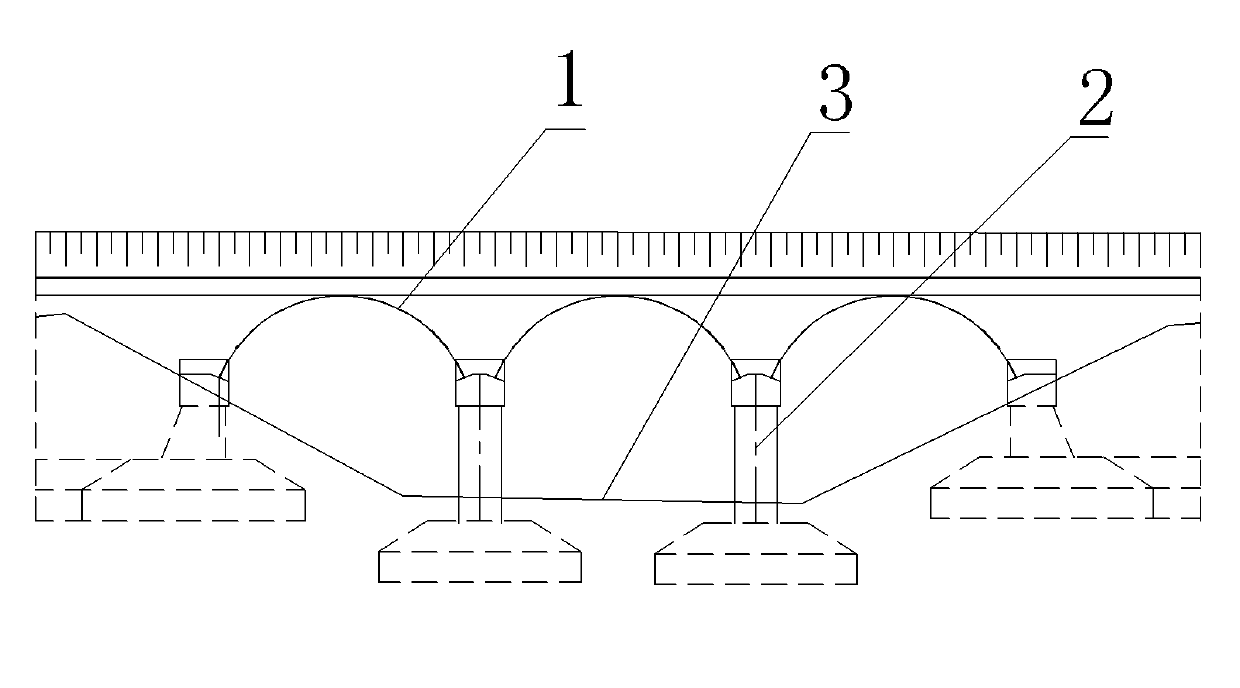

Circular-arched steel-corrugated-plate bridge and culvert structure

InactiveCN103276675AHigh tensile strengthNo cracking damageGround-workStress concentrationReinforced concrete

The invention relates to a circular-arched steel-corrugated-plate bridge and culvert structure. A circular-arched bridge and culvert with a reinforced concrete structure is not adaptable to foundation deformation and uneven settlement well, damages caused by earthquakes cannot be buffered effectively, construction cost is high and construction period is long. Bases are arranged at the lower portion of the bridge and culvert structure. Single-span or multi-span bridge arches are arranged on the upper portions of the bases, are steel-corrugated-plate circular arches and are formed by assembly and fixation of steel corrugated plates through bolts. The radius of each steel-corrugated-plate circular arch is 2.1648m, central angle is 135 degrees, arc curvature radius is 4.33m, single span is 4m, and rise height is 1.3365m. A circular-arched bridge and culvert with the structure has axial corrugations and excellent mechanics characteristics, stress strain caused by load is simultaneously distributed axially and radially, stress concentration of the load is effectively dispersed, advantages of a steel structure are exploited better, and wide application prospect is provided.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

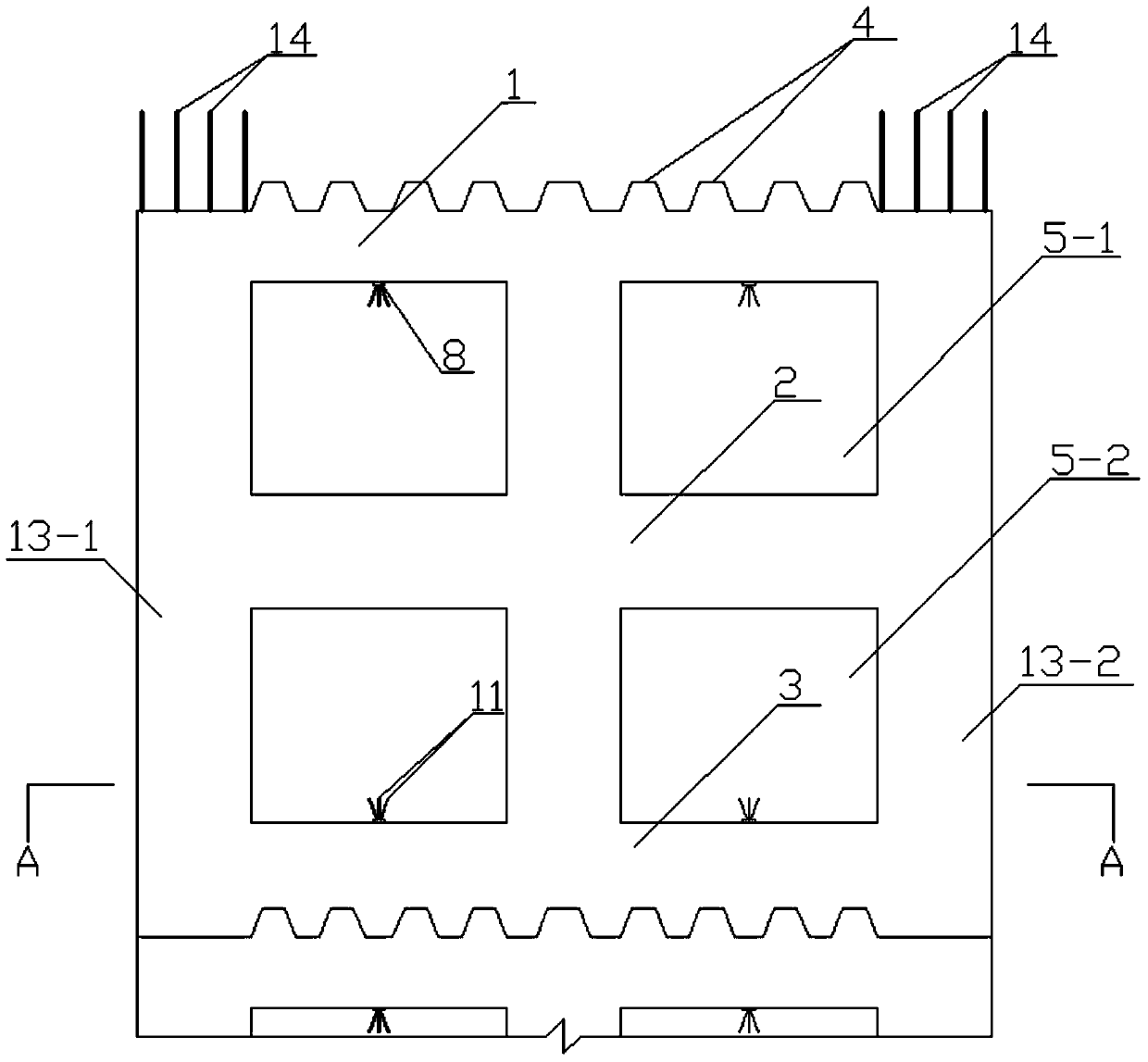

Lightweight fabricated shear wall structure

InactiveCN103741842AHigh degree of assemblyReduce the amount of on-site reinforcement worksConstruction materialWallsReinforced concreteEngineering

The invention discloses a lightweight fabricated shear wall structure made by assembling a plurality of reinforced concrete wall panels. Each wall panel is provided with holes and divided into an upper beam, a lower beam, a left embedded column and a right embedded column by the holes; each of the left and right embedded columns is provided with embedded vertical rebars inside. The adjacent upper and lower wall panels are connected through the embedded column vertical rebars and prestressed strands; the prestressed strands are pulled and connected between the bottom of the upper beam at the holes of the lower wall panel and the top of the lower beam at the holes of the upper wall panel. Part of the shear wall vertical distributed rebars are replaced with the prestressed strands connected to the wall panels having holes, and a lightweight shear wall is assembled; construction speed is high, field construction period can be shortened, labor intensity for field construction is reduced, engineering cost is reduced, and building structure quality can be guaranteed in the same time.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING +1

Extrusion type closing method for joint of pecast concrete utility tunnels

InactiveCN109083194ARealize sealing and waterproofingImprove sealingArtificial islandsProtective foundationEngineeringUtility tunnel

The invention relates to the technical field of municipal engineering, in particular to an extrusion type closing method for a joint of pecast concrete utility tunnels. The technical scheme provided by the invention is that nut fasteners are clamped on profile steel members and are screwed with bolts; by tightening the bolts, a gland compresses a water stop airbag, the water stop airbag expands and compresses water stop belts and further sealing water resistance of the joint of two pecast concrete utility tunnels is realized. The extrusion type closing method for the joint of the pecast concrete utility tunnels, provided by the invention, can realize sealing water resistance and has the advantages of simple structure, high construction speed and low cost.

Owner:NORTHEASTERN UNIV

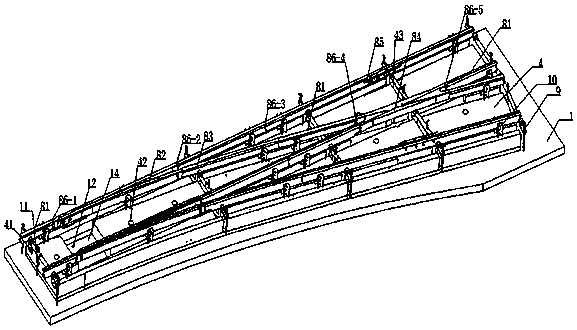

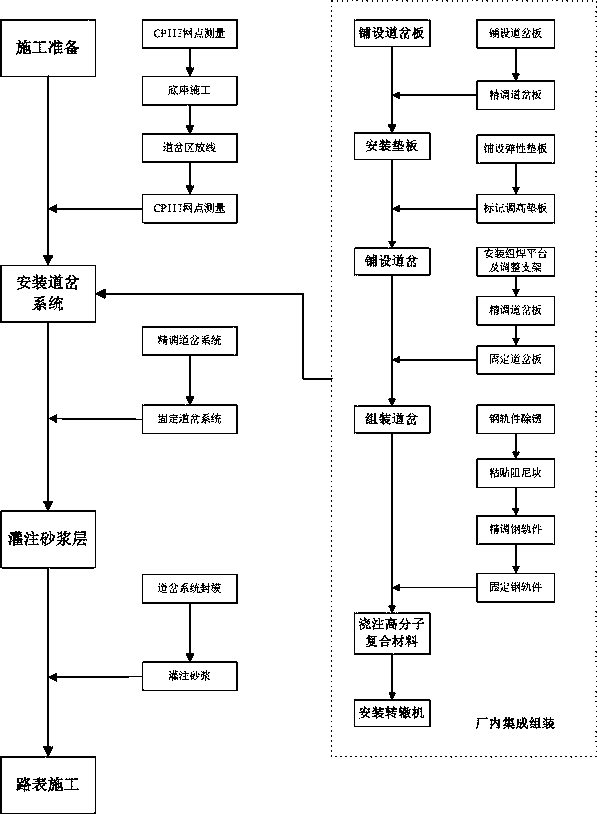

Fast construction method for embedded turnout system

ActiveCN108286210AHigh precision requirementsSafe and stable operationRail switchesIsolation layerEngineering

The invention discloses a fast construction method for an embedded turnout system. The fast construction method comprises the steps that a base is poured on a construction site, positions of a road center line, an outline of a turnout plate and an outline of a slab joint are marked on the top surface of the base, and an isolation layer is paved on the top surface of the base; the turnout plate ispaved in a precast factory, a plate adjusting tool for adjusting the horizontal position and elevation is installed on a lifting position; an elastic pad plate and a height adjusting pad plate are installed in a rail bearing groove of the turnout plate; a steel rail part is placed in the rail bearing groove of the turnout plate and installation and welding are completed; after a rail waist of thesteel rail part is bonded with a damping block, a geometric form and position is adjusted, and the steel rail part is fixed temporarily; a switch rail is installed; macromolecule composites are poured; a point machine is connected with a traction point of the tip of the switch rail by a screw rod; positioning and fixation of the embedded turnout system is performed; and a mortar layer is poured. According to the fast construction method for the embedded turnout system, most of the steps can be completed in the factory, the construction speed on the site is extremely fast, and the whole construction process is scientific and reasonable.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

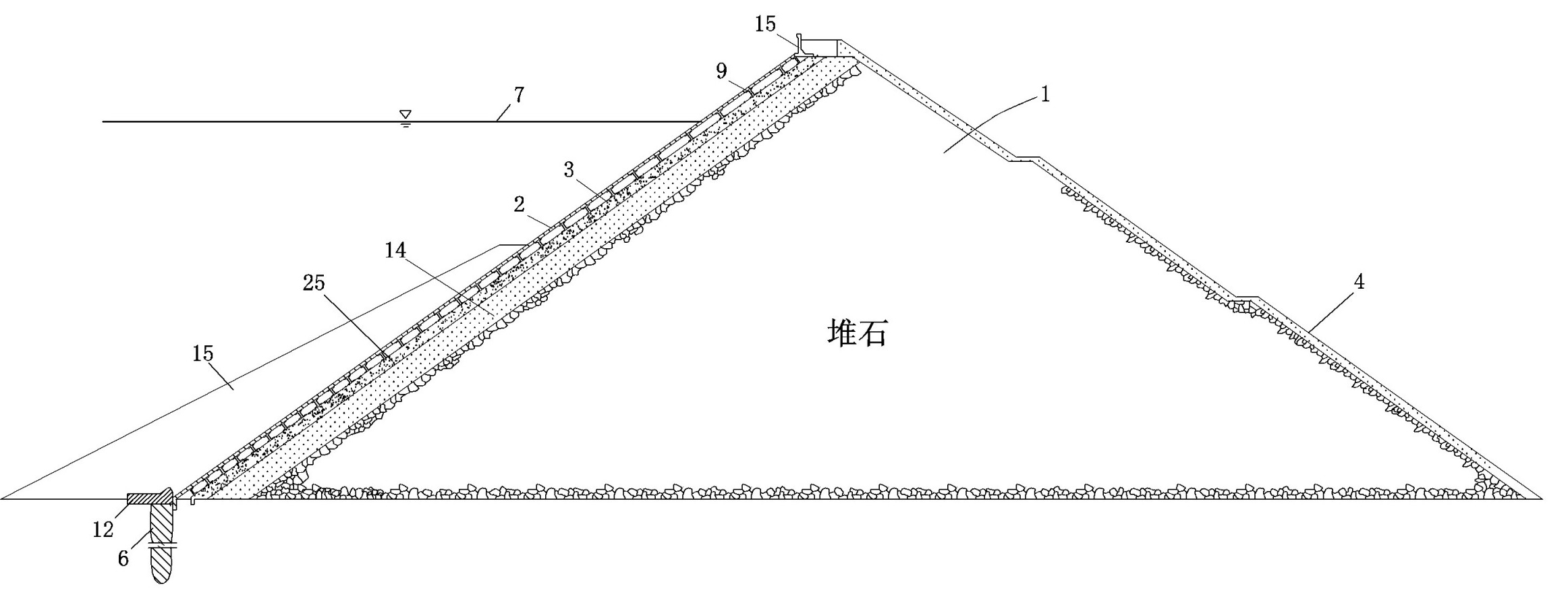

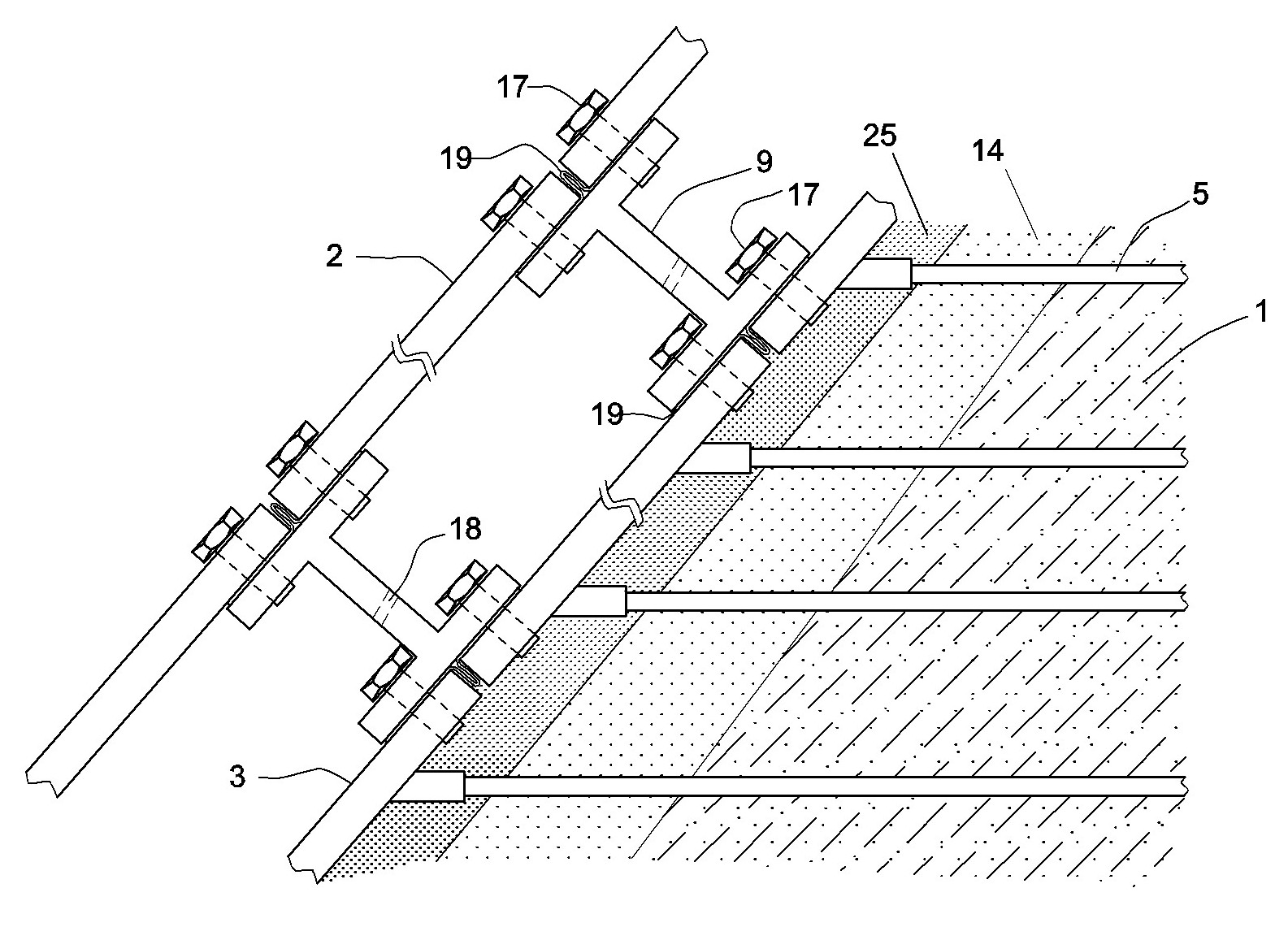

Steel structure combined-type sandwich steel plate rock-fill dam

ActiveCN102155004AEasy to buildLower performance requirementsEarth-fill damsRock-fill damsRiver bedPolyurea

The invention relates to a steel structure combined-type sandwich steel plate rock-fill dam, comprising a cushion layer region, a transition region, a rock fill region, a wave wall and a downstream slope protection. A water blocking panel, two side toe boards and a river bed toe board jointly form an impermeable structure, a combined-type sandwich steel plate of an upstream riverside surface of a dam body comprises an inner steel plate and an outer steel plate as well as a support skeleton, a plurality of fixed joint bars which are deeply inserted in the dam body are transversely arranged on the back surface of an inner single steel plate, and all the surfaces, the joint bars and butt joints or connecting bolts are all coated with a layer of antiseptic impermeable coating polyurea material. The rock-fill dam provided by the invention has the advantages of a gravity dam and a steel structure dam, is stable and is easy to construct, the structural form is flexible, the rock-fill dam can better adapt to topographic conditions, the performance requirement on damming material is low, multiple building materials can be used, environmental disruption produced by damming is reduced, and the rock-fill dam can be processed in batch in a factory, the site construction speed is fast, and the rock-fill dam is convenient to maintain or replace.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

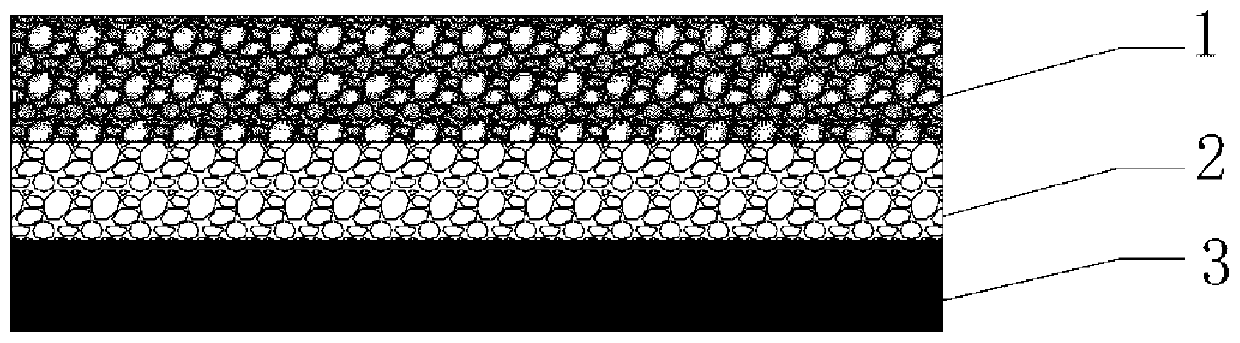

Assembly asphalt pavement for desert highway and construction method of assembly asphalt pavement

InactiveCN104532716ARealize water-saving constructionNo need to consume water resourcesIn situ pavingsSingle unit pavingsWater savingRoad surface

The invention discloses an assembly asphalt pavement for a desert highway and a construction method of the assembly asphalt pavement. The asphalt pavement comprises an aeolian sand subgrade, wherein a macadam base and an asphalt pavement precast block combination layer are sequentially laid on the upper surface of the aeolian sand subgrade from bottom to top according to a laminated structure, and the asphalt pavement precast block combination layer is formed by assembling and paving a plurality of asphalt pavement precast blocks; a plurality of reinforcing units are laid on the upper surface of the macadam base, correspond to joints of every two asphalt pavement precast blocks one to one, and are used for reinforcing the joints of the asphalt pavement precast blocks, and the macadam base and the asphalt pavement precast block combination layer are fixed by bonding; each asphalt pavement precast block sequentially comprises an asphalt surface course and a base plate from top to bottom according to a laminated structure, and each asphalt surface course and the corresponding base plate are fixed into a whole by bonding. The assembly asphalt pavement provided by the invention has the advantages of water-saving construction, prolonged construction season, rapid construction, rapid maintenance and the like.

Owner:SOUTH CHINA UNIV OF TECH

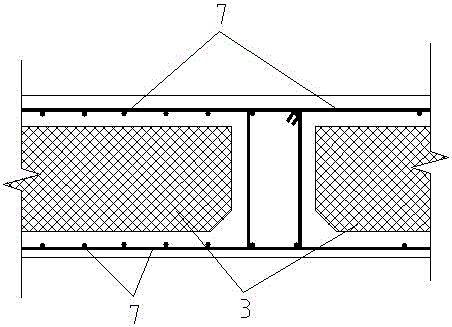

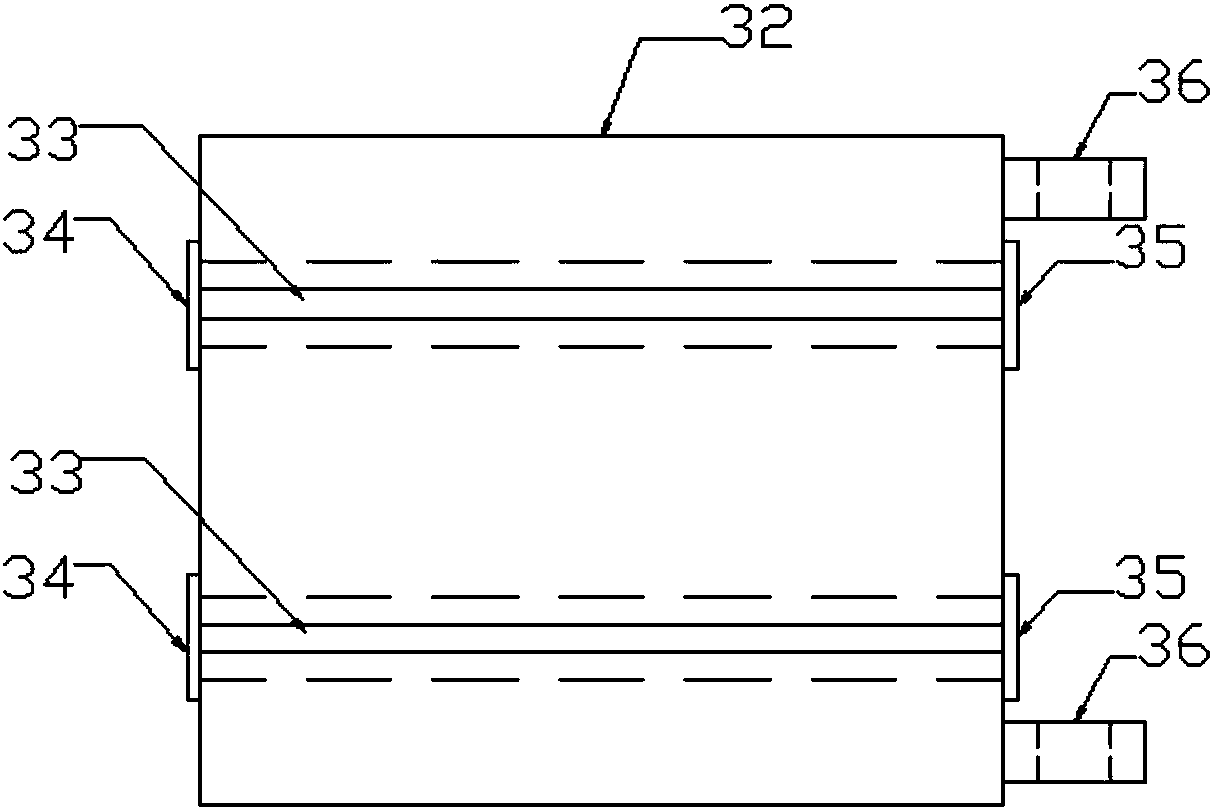

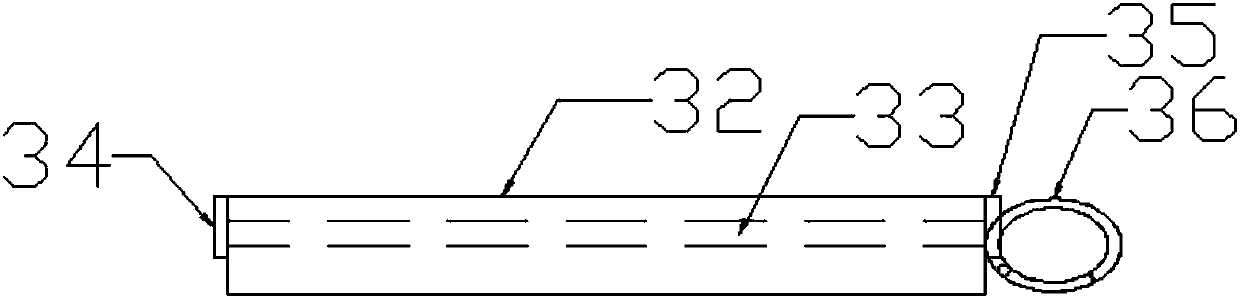

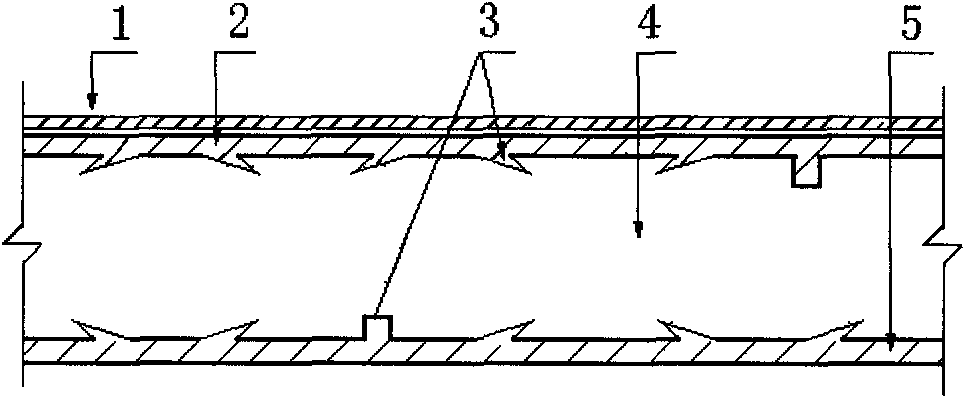

Connecting method of prefabricated composite multi-ribbed floor slabs and steel beams of assembly type steel structure house

The invention relates to a connecting method of prefabricated composite multi-ribbed floor slabs and steel beams of an assembly type steel structure house. Ribbed beams and steel beams at the joints of the multi-ribbed floor slabs and the steel beams are cast in place, and the fire prevention effect of the connecting joints of steel columns and the steel beams and the fire prevention effect of the steel beams are achieved; the multi-ribbed floor slabs are filled with light materials, and the heat insulation effect is achieved; and prefabricated composite multi-ribbed floor slab components are produced in advance and mounted in the field, the field construction speed is increased, lots of revolving materials such as supporting steel tubes, battens, web filmed multilayer boards and bamboo plywood are reduced, the construction speed is increased, and the construction cost is lowered.

Owner:CHINA 22MCC GROUP CORP

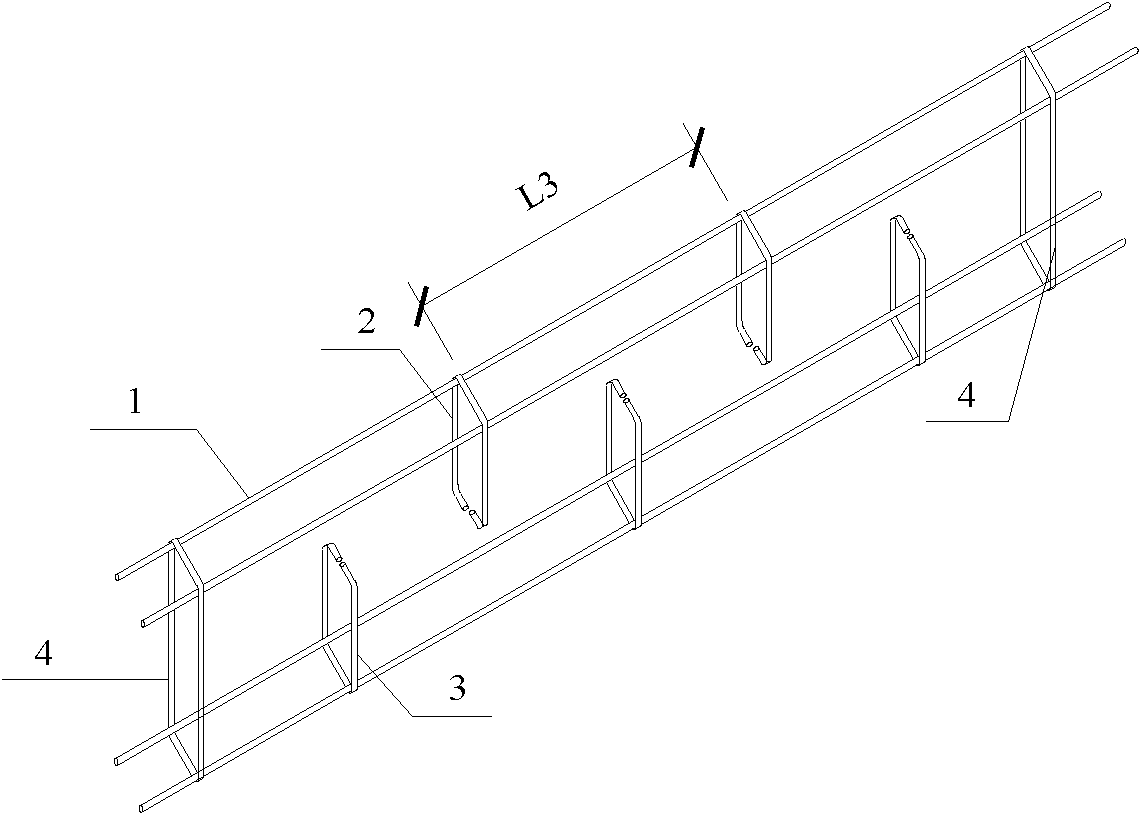

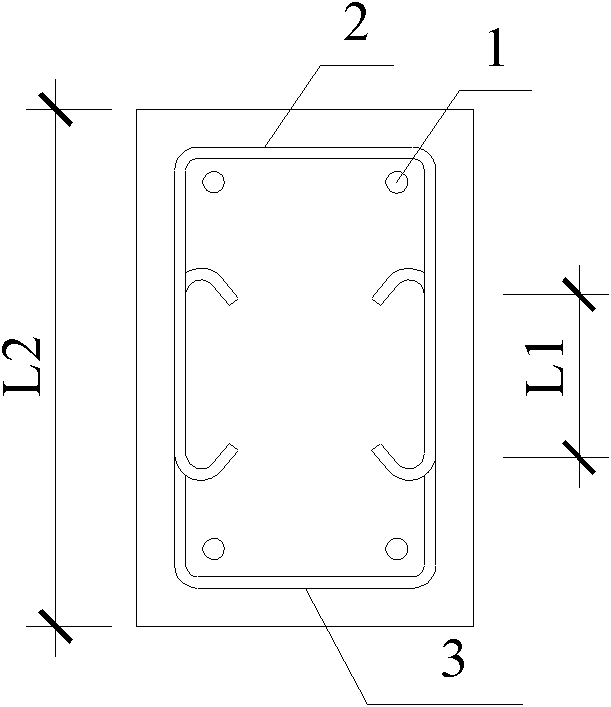

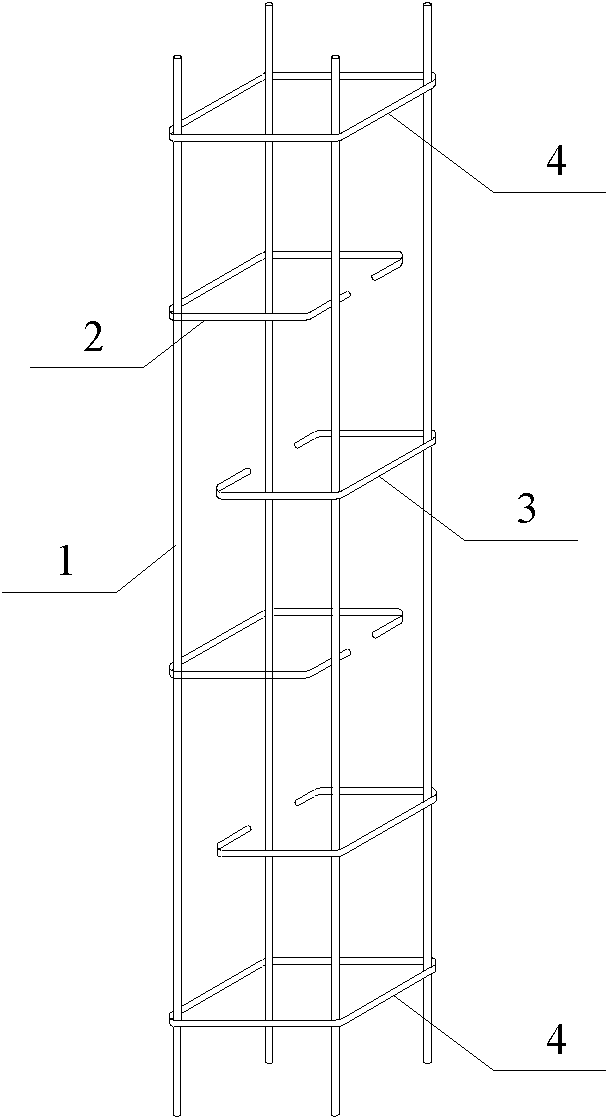

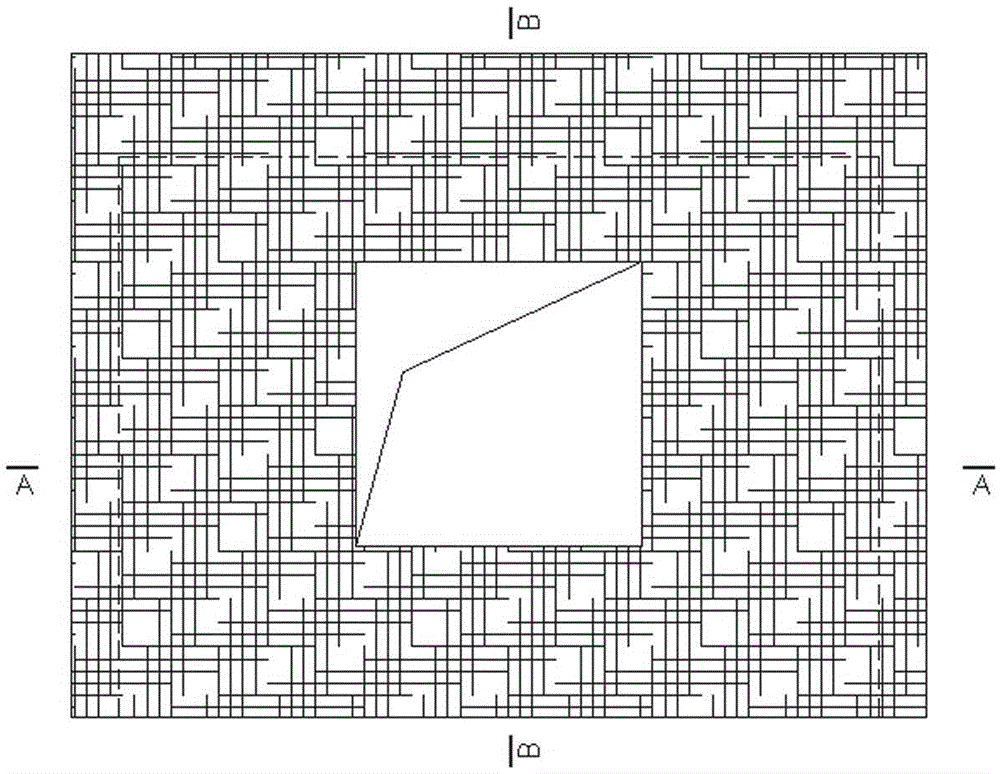

Steel reinforcement cage for multi-ribbed composite wall and method for installing steel reinforcement cage

InactiveCN102051931ASpeed up lashingFast welding speedWallsBuilding reinforcementsLeft halfReinforced concrete

The invention provides a steel reinforcement cage for a multi-ribbed composite wall and a method for installing a steel reinforcement cage. The steel reinforcement cage comprises a longitudinal reinforcement, a first semicircular stirrup, a second semicircular stirrup and a positioning closed stirrup, wherein the first semicircular stirrup is in the shape of a groove the lower / right end of which is opened; the second semicircular stirrup is in the shape of a groove the upper / left end of which is opened; two side edges of the first semicircular stirrup and the second semicircular stirrup are respectively perpendicular to the bottom edges of the first semicircular stirrup and the second semicircular stirrup, and the ends of the two side edges are bent to the interiors of the grooves; the stirrup surfaces of the first semicircular stirrup, the second semicircular stirrup and the positioning closed stirrup are respectively mutually perpendicular to the trending direction of the longitudinal reinforcement; and the positioning closed stirrup is horizontally bundled around the whole longitudinal reinforcement, the first semicircular stirrup is horizontally bundled around the upper / left half part of the longitudinal reinforcement, and the second semicircular stirrup is horizontally bundled around the lower / right half part of the longitudinal reinforcement. The steel reinforcement cage and method provided by the invention have the advantages of reducing the workload for bundling reinforcements applied to reinforced concrete member or structure construction sites, and accelerating the construction speed.

Owner:BEIJING JIAOTONG UNIV

Connecting structure for prefabricated regenerated block concrete beam and construction method thereof

PendingCN107143040AFast construction on siteIncreasing the thicknessGirdersJoistsRebarWater resistance

The invention discloses a connecting structure for a prefabricated regenerated block concrete beam. The connecting structure comprises a bracket which is simultaneously prefabricated with a column, a prefabricated beam with a notch in an end part, a positioning plate with a hole, an erecting rib, a hoop rib, a common longitudinal rib, a bent longitudinal rib, a steel sleeve with an internal thread, a rebar rod with an external thread, an anti-shearing steel and an axial pore channel. The invention also discloses a construction method for the connecting structure for the prefabricated regenerated block concrete beam. According to the invention, the site pouring volume is less and the construction speed is high and the bent longitudinal rib is adopted, so that the thickness of a concrete protecting layer of the axial pore channel filled with the structure glue is obviously increased, the degradation of the fire disaster for the structure glue is effectively relieved, the effective connection in a connection area between the bracket which is simultaneously prefabricated with the column and the prefabricated beam with the notch in the end part is guaranteed, the beam has excellent water resistance, the connecting area is yielded and forms a plastic hinge in advance under an earthquake effect and the realization of the 'strong-column weak-beam' anti-seismic thought is guaranteed.

Owner:SOUTH CHINA UNIV OF TECH

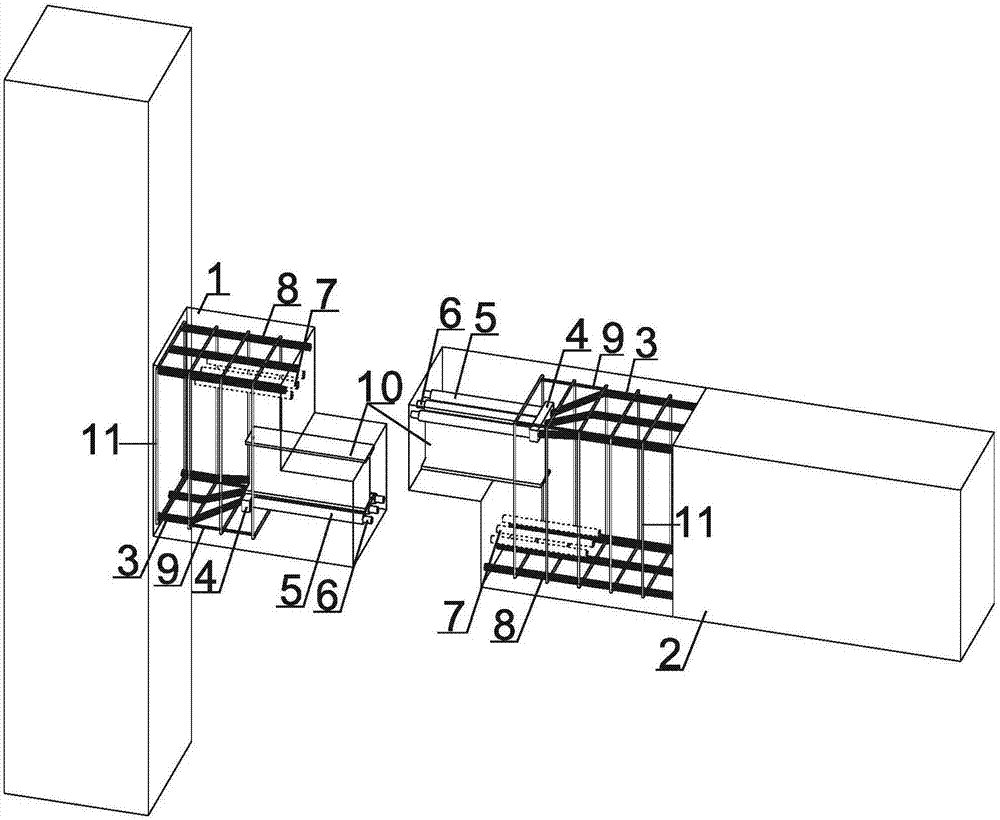

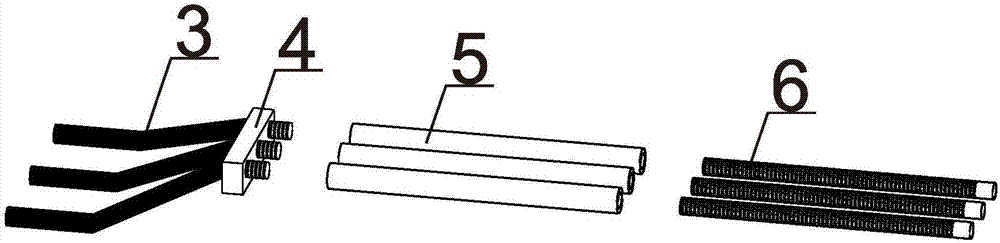

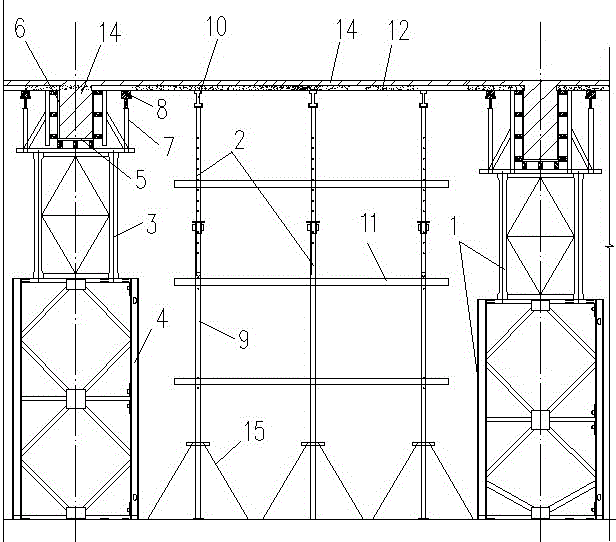

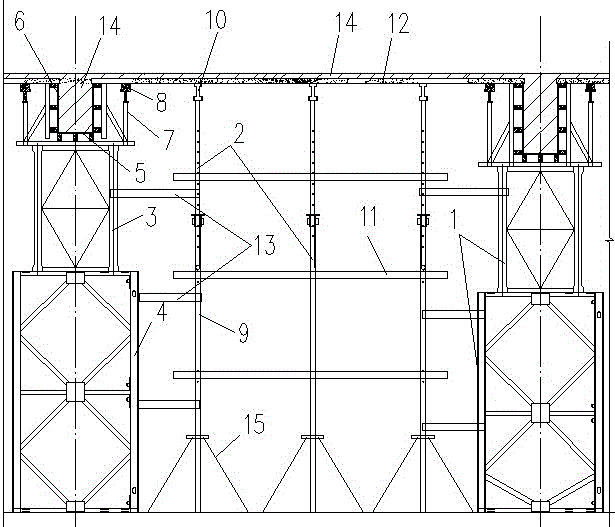

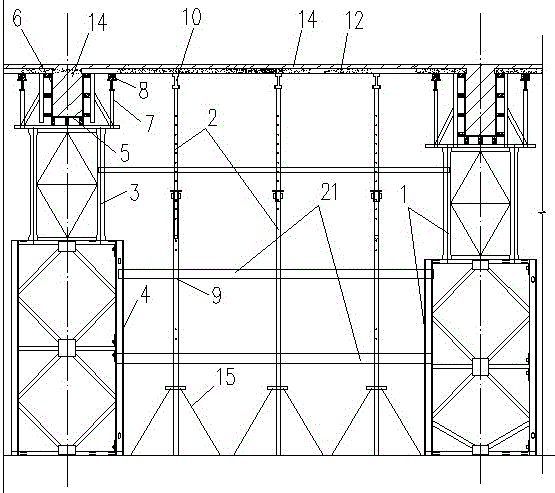

Supporting method of concrete ultrahigh heavy beam and laminated slab combined structure

ActiveCN106193589AReduce in quantityGuarantee the construction qualityForms/shuttering/falseworksSupporting systemBatten

The invention relates to a supporting method of a concrete ultrahigh heavy beam and laminated slab combined structure. The supporting method comprises the following steps: mounting an ultrahigh and ultra-heavy framework beam supporting frame and mounting a laminated slab supporting frame; adopting a Bailey truss to form an ultrahigh and ultra-heavy framework beam template supporting frame; mounting a framework beam bottom template and mounting a framework beam lateral template; setting laminated slab supporting rods on the two sides of the framework beam lateral template; mounting the laminated slab supporting frame after beam steel bars are bundled; mounting a special supporting rod for a laminated slab; and mounting a laminated slab supporting I-shaped wood beam at the top of the special supporting rod for the laminated slab. According to the supporting method of the concrete ultrahigh heavy beam and laminated slab combined structure, on the basis of guaranteeing the construction quality, compared with a tradition construction method, the quantity of steel pipes and battens, needed by an in-site supporting system, is reduced; and the in-site construction speed is improved, the engineering quality is improved, the manpower is reduced, materials are saved and the engineering cost is saved.

Owner:CHINA 22MCC GROUP CORP

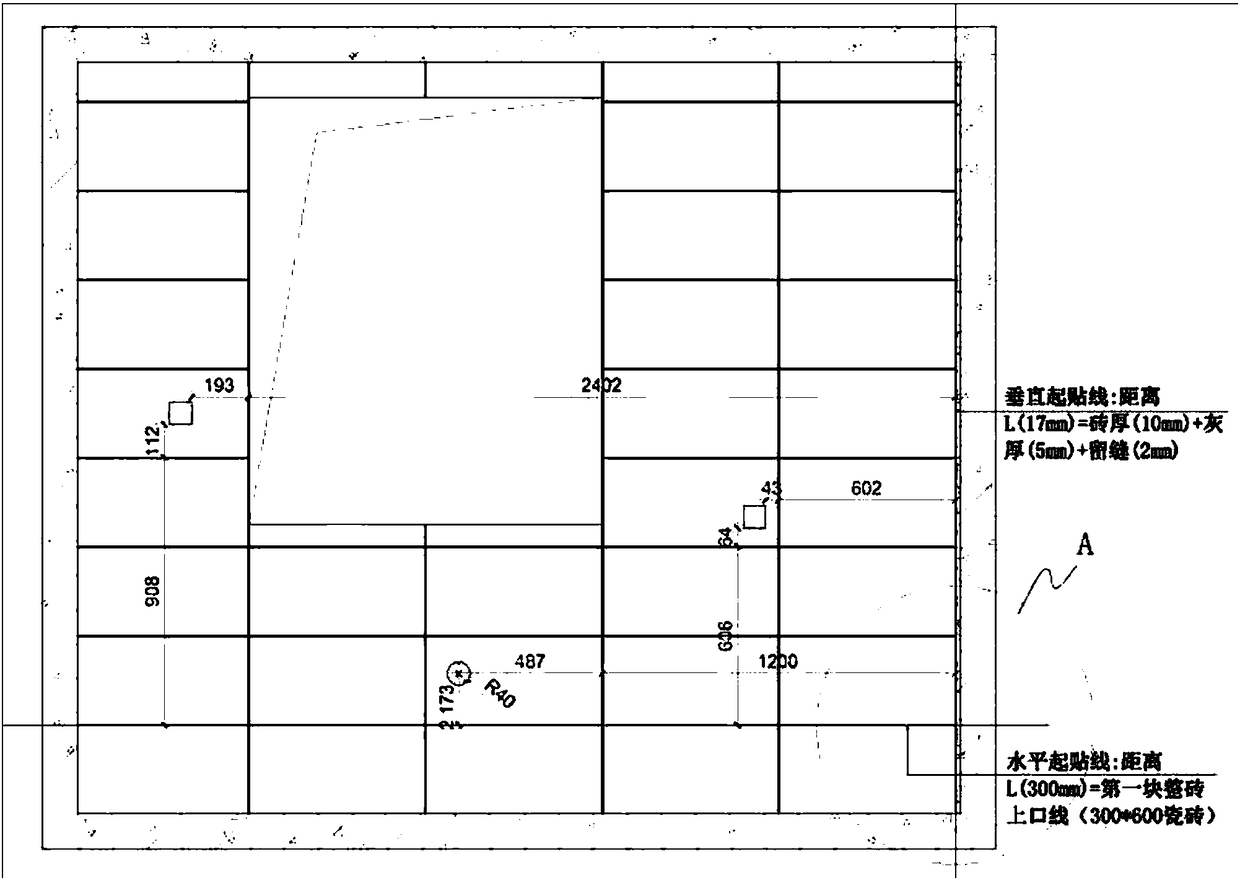

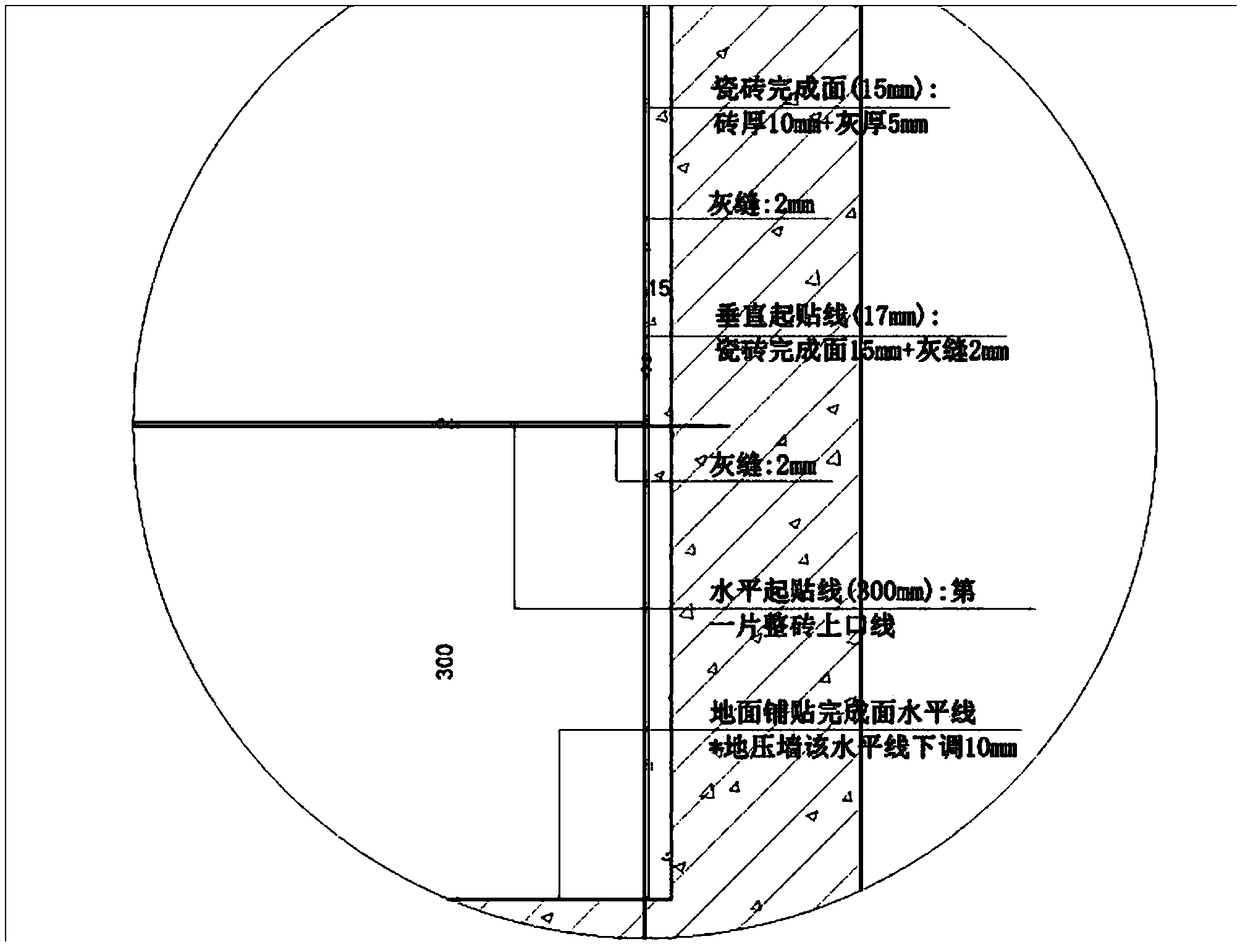

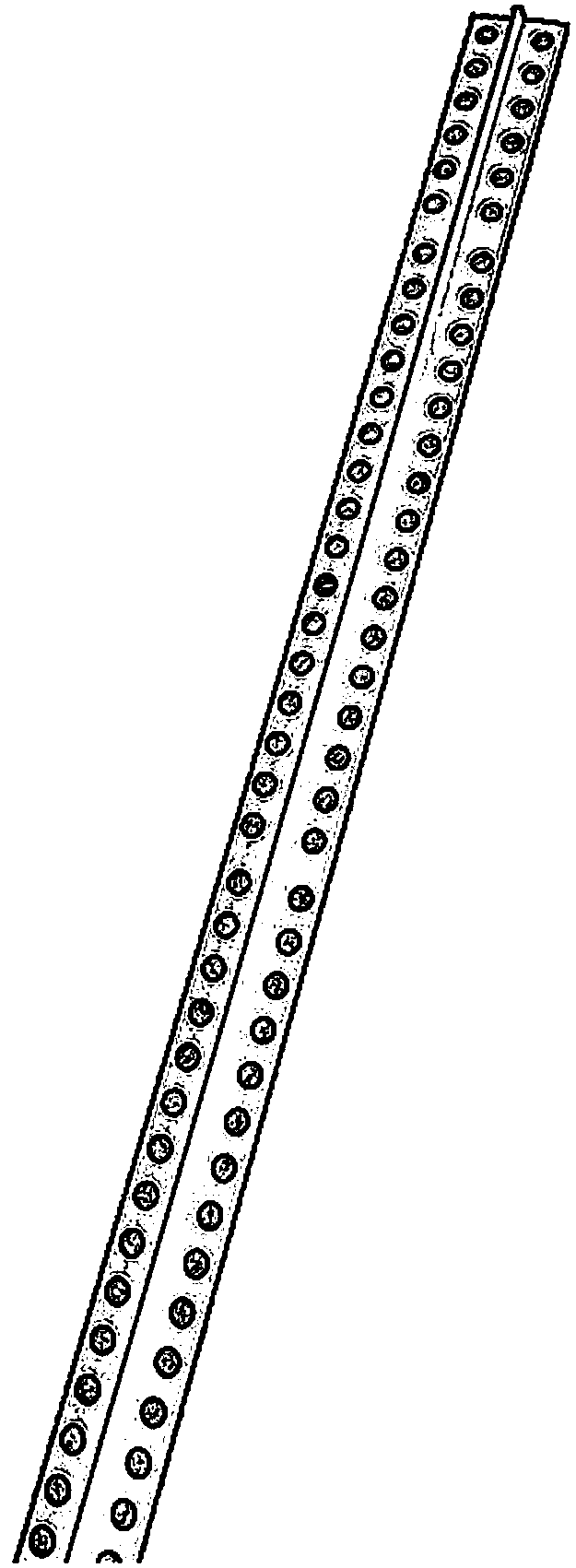

Method and tool for mounting assembly type ceramic tiles

InactiveCN108571154AImprove construction efficiencyPaste firmlyBuilding constructionsAdhesiveSurvey result

The invention relates to a method and a tool for mounting assembly type ceramic tiles. The mounting method comprises the following steps: carrying out a survey by a surveyor on a site where tiles arepre-tiled to obtain a survey result, wherein indexes of the survey include the flatness, verticality and squareness of internal and external corners of a base layer; according to the survey result, leveling a substandard wall or ground base by a leveling bricklayer; according to a preset tiling plan, sticking a start tiling line for positioning a tiling position of a single tile on the leveled base by the surveyor, and determining a processing size of the single tile according to the start tiling line; processing the ceramic tile in a factory according to the processing size, wherein the processing comprises cutting and punching the ceramic tile; and according to a construction drawing, scraping an adhesive on the base and the processed tile by a tiling bricklayer along the start tiling line with a tiling tool to tile the tiles. The method and tool provided by the invention improve the construction efficiency and ensure the construction quality.

Owner:上海相品家居建材有限公司

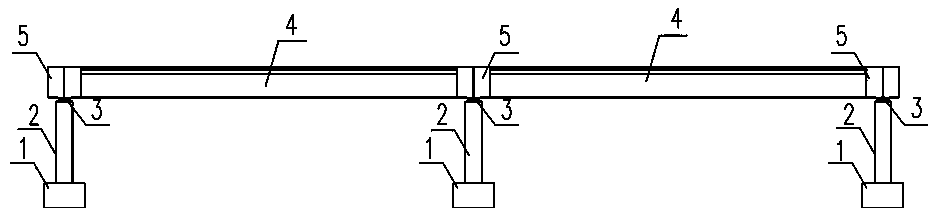

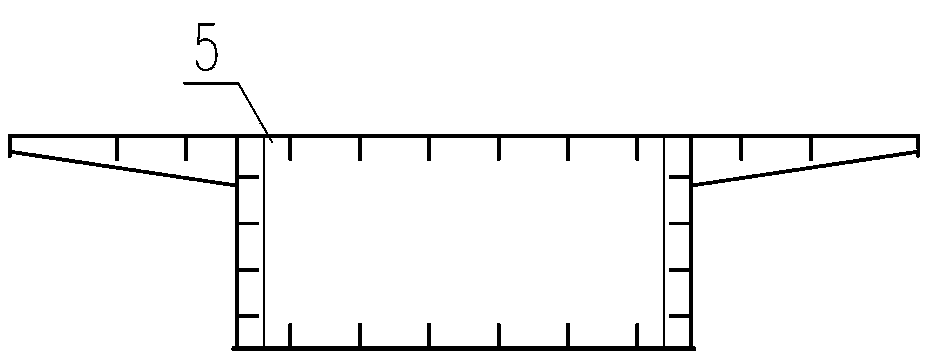

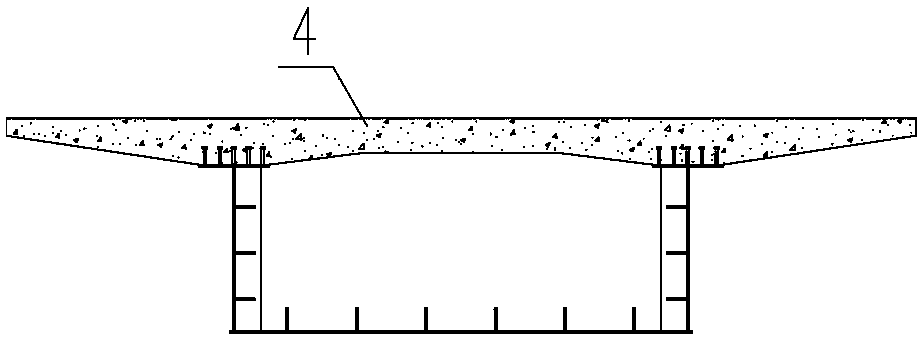

novel Steel-Concrete Composite Continuous Box Girder Bridge and Its Scaffolding-Free Industrial Construction Method

PendingCN108978434AReasonable structureFast construction on siteBridge structural detailsBridge erection/assemblyFillet weldIndustrial construction

The invention discloses a novel stee-concrete composite continuous box girder bridge, including spaced cast caps and piers fixed on each caps, each pier top mounted with bearings and steel erected between two adjacent bearings. Mixed composite box girder segments; Steel box girder segments are hoisted at the top of each bearing. The web plate and bottom plate of the joint part of the composite boxgirder segment and the steel box girder segment adopt the high-strength bolt + double-sided splice plate fillet welding connection structure, and the top plate adopts the steel cell structure filledwith concrete. The invention also discloses a support-free industrial construction method of the bridge. The whole bridge structure of the invention is reasonable, the main structural parts can be prefabricated in advance, assembled on the spot, and the field construction speed is fast, which accords with the development trend of bridge industrialization construction. The pier top adopts steel boxgirder, and the whole bridge has steel. The structural advantages of concrete composite continuous box girder bridges can also effectively overcome the shortcomings of The stee-concrete composite continuous box girder bridge. The problem that the negative moment zone near the pivot of concrete composite continuous box girder bridge is unreasonable is resolved.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

Building frame system and assembly method thereof

The invention relates to the technical field of a building, in particular to a building frame system and an assembly method of the building frame system. The building frame system is composed of columns and floor slab groups in a connected and combined mode. The building frame system has the advantages that factory prefabrication production can be achieved, the field assembly speed is high, refuse in a construction site is less, materials are saved, and the anti-seismic property is high.

Owner:张跃

Anti-cracking structure for joint of full-concrete outer wall under-window filling wall and shear wall and construction method thereof

InactiveCN111335490AReduce wasteReduce the risk of water leakageWallsForms/shuttering/falseworksWater leakageFloor slab

The invention belongs to the technical field of concrete outer wall construction, and provides an anti-cracking structure for a joint of a full-concrete outer wall under-window filling wall and a shear wall and a construction method thereof in order to prevent the problem that cracks are generated at the positions such as the under-window wall due to concrete shrinkage. Anti-cracking steel bars and joint pulling plates are arranged in a concrete pouring layer at intervals, wherein the joint pulling plates comprise horizontal structure joint pulling plates and vertical structure joint pulling plates; the horizontal structure joint pulling plates are arranged between floors or beams of all layers and the under-window filling wall; and the vertical structure joint pulling plates are arrangedbetween the shear wall and the under-window filling wall; transverse anti-cracking steel bars are arranged at the joint of the shear wall and the under-window filling wall, and the transverse anti-cracking steel bars penetrate through the vertical structure joint pulling plates to be bound and overlapped with wall body steel bars of the shear wall and the under-window filling wall on the two sides. The anti-cracking structure is convenient to assemble and disassemble, construction joints are avoided, the hidden danger of water leakage of the structure is reduced, and the applicability is improved. The operation is convenient, the construction quality and effect are good, the change of the overall rigidity is avoided, the construction period is shortened, and the structural safety is guaranteed.

Owner:CHINA SHANXI SIJIAN GRP

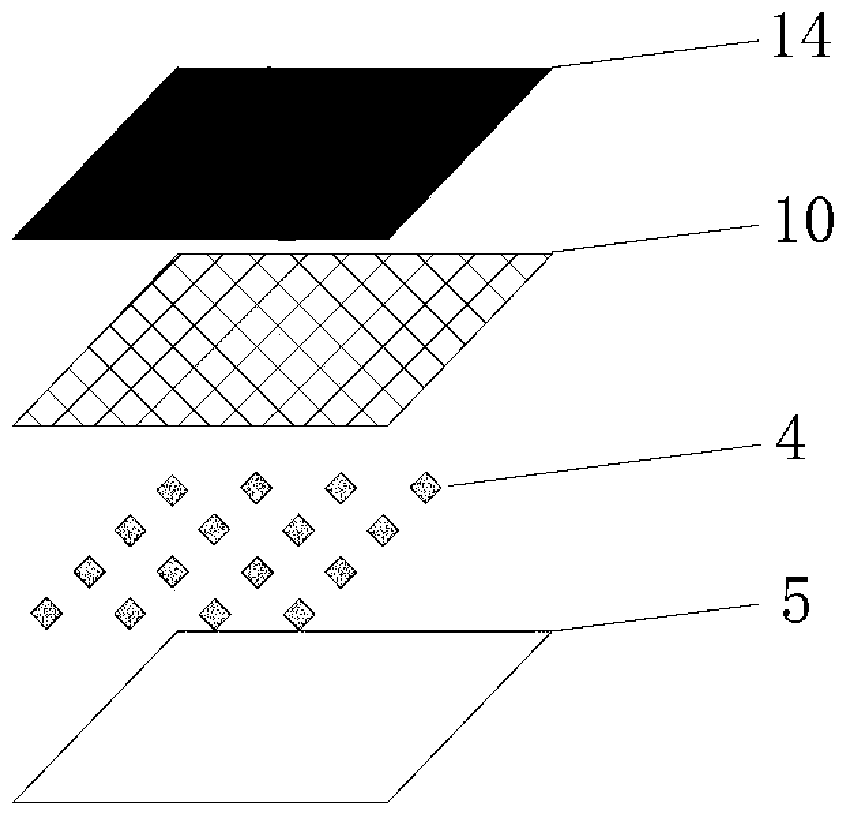

Self-heating curly asphalt blanket and preparation and construction methods thereof

InactiveCN111005280AStay softenedImprove adhesionSingle unit pavingsRoads maintainenceGeogridAsphalt pavement

The invention discloses a self-heating curly asphalt blanket and a preparation and construction method thereof. The self-heating curly asphalt blanket comprises an asphalt mixture layer, a middle layer and a self-heating bonding layer, and is characterized in that the asphalt mixture layer, the middle layer and the self-heating bonding layer are sequentially laid from top to bottom to form an asphalt blanket; the asphalt mixture layer is composed of modified asphalt, coarse aggregate, fine aggregate and filler, the middle layer is composed of modified asphalt and fine aggregate, the self-heating bonding layer is composed of a heating bag, self-heating bonding layer modified asphalt, an isolating membrane and a geogrid, and the preparation process comprises the following steps: preparing the asphalt mixture layer; preparing the middle layer; preparing the self-heating bonding layer; performing curling into a blanket, sealing and storing; when the curly asphalt blanket is constructed, bonding the asphalt blanket with an asphalt pavement through three times of heating of the heating bag and melting of asphalt of the self-heating bonding layer and the middle layer, so that the bondingstrength between the asphalt blanket and the asphalt pavement is improved, the operation is simple, the construction can be quickly completed, and the influence on the environment is reduced.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

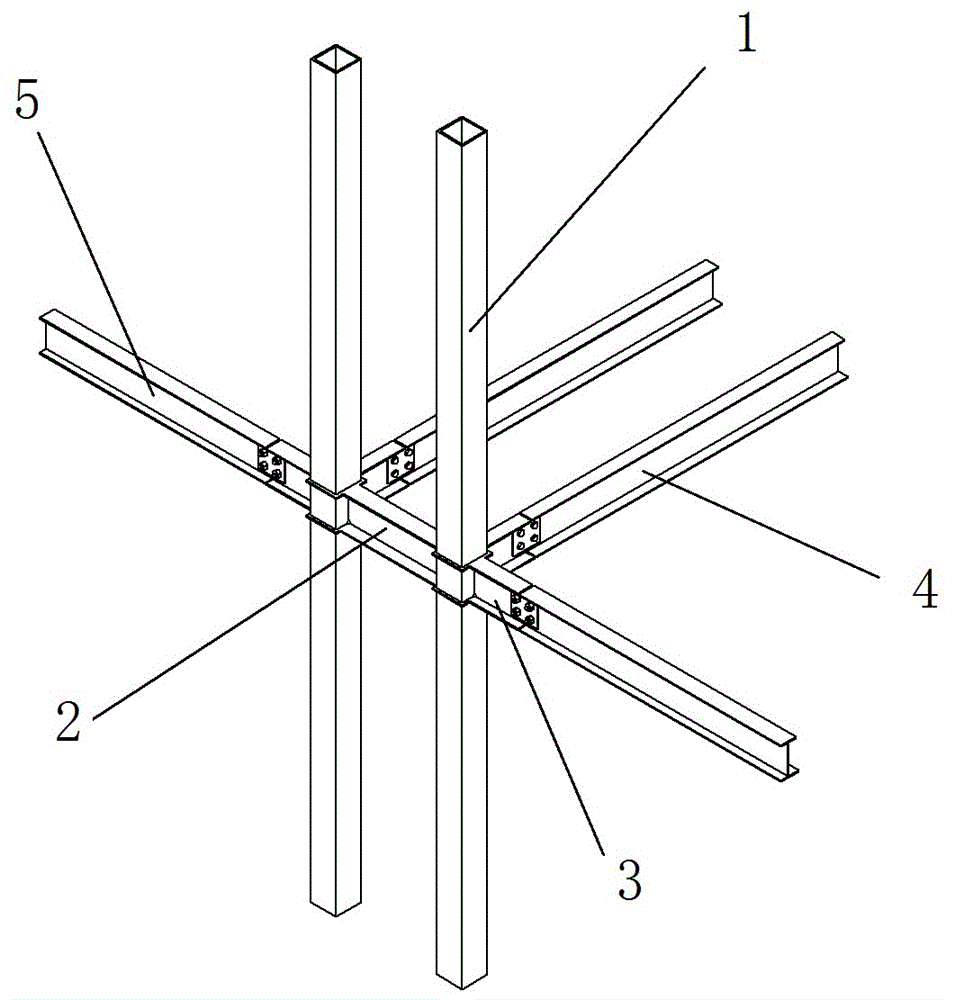

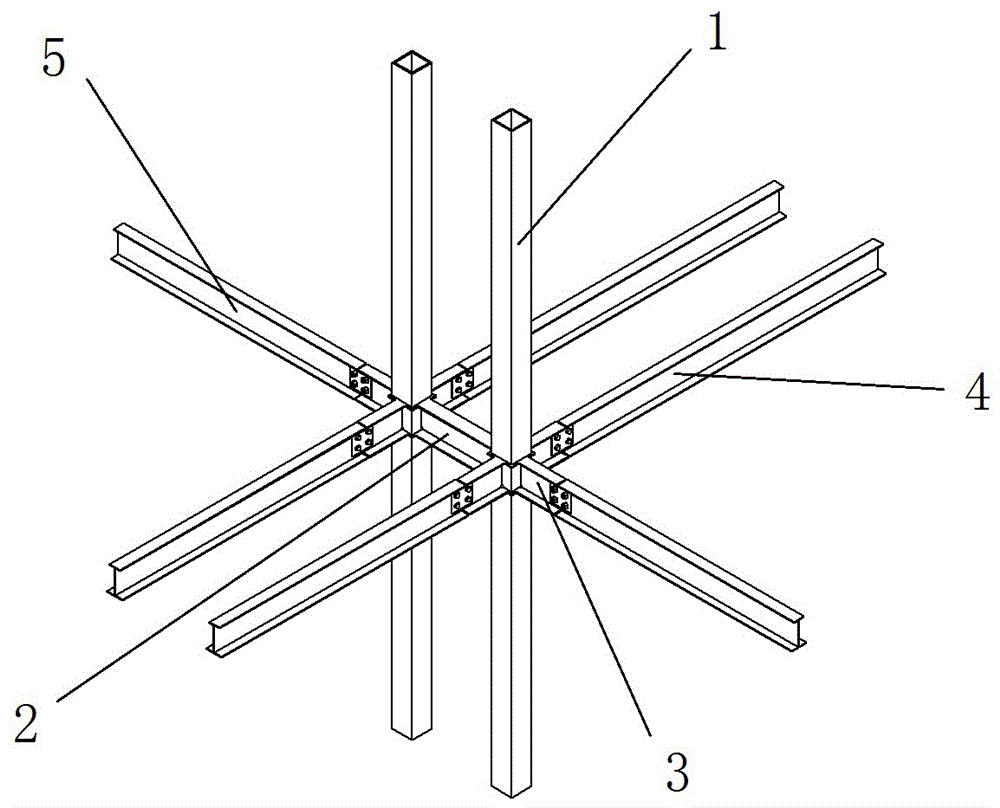

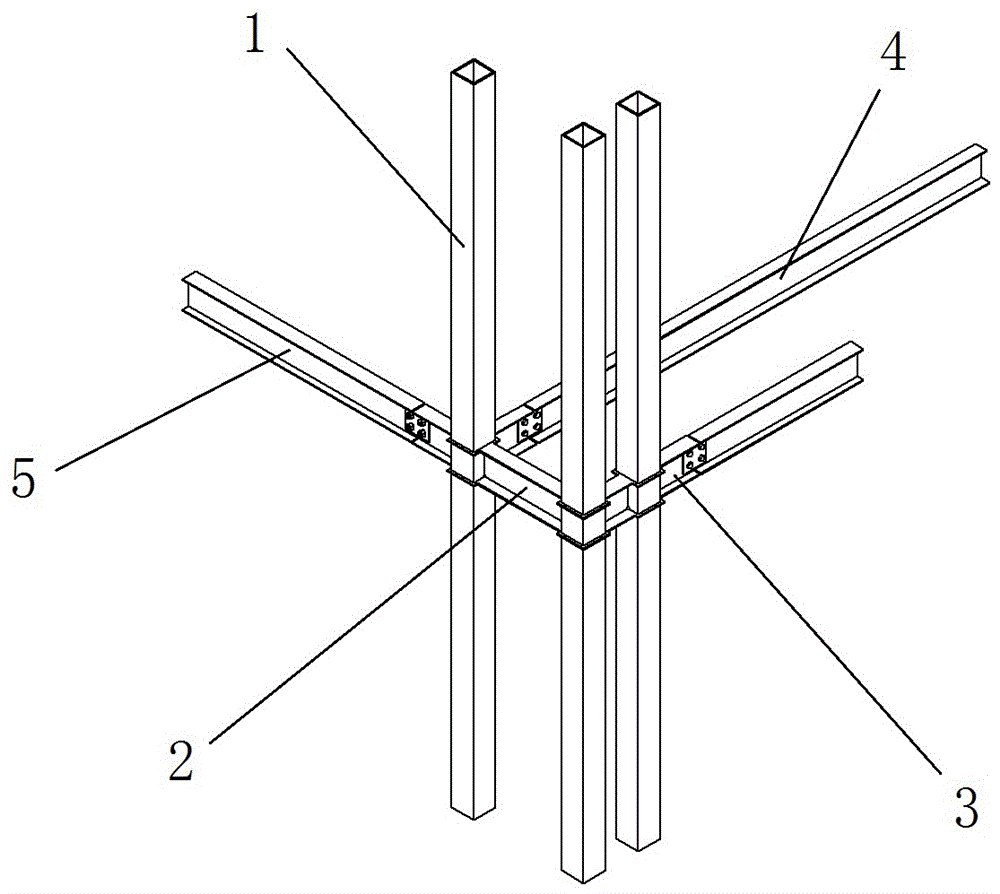

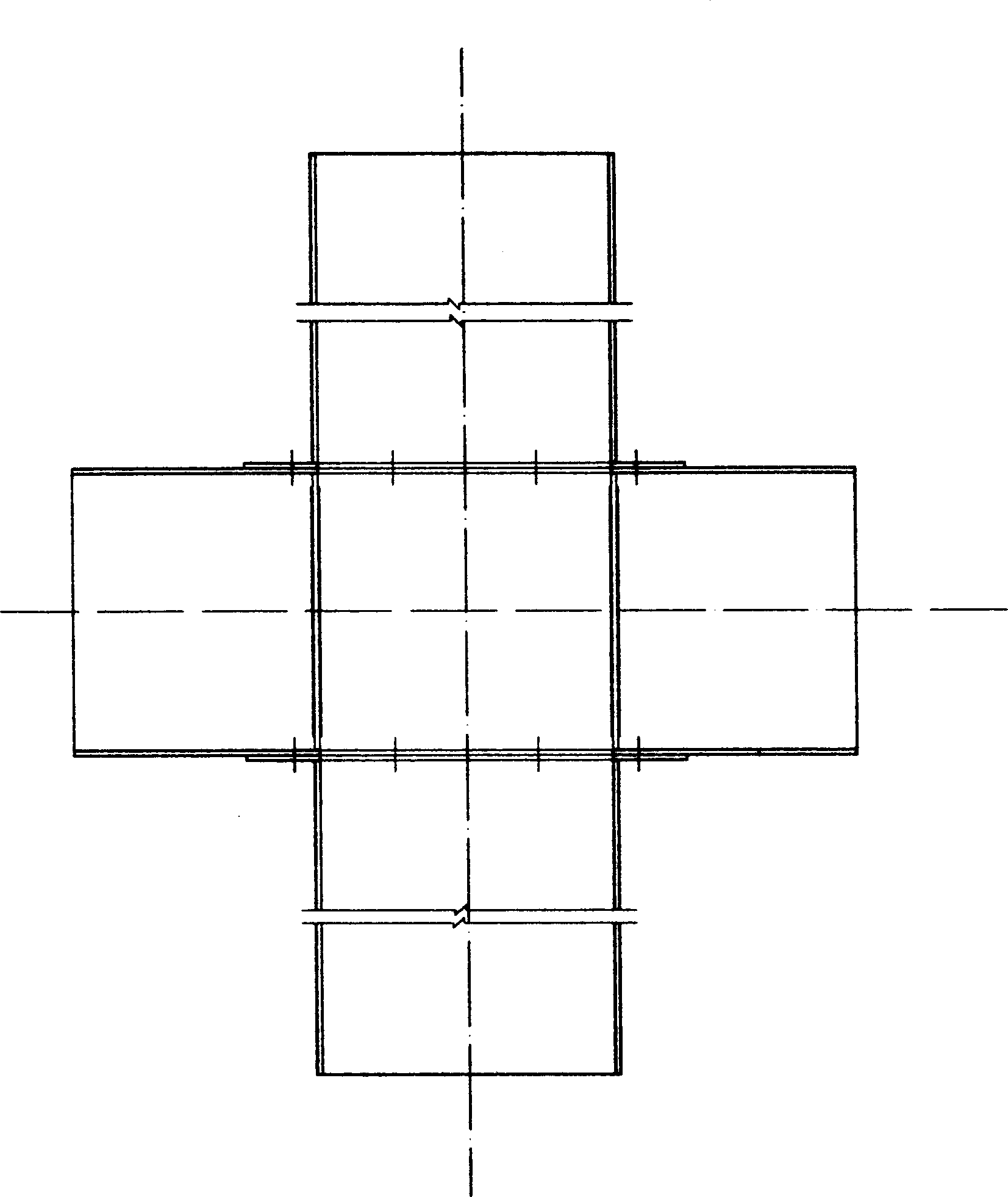

Double-pipe combined column having energy dissipation and shock absorption effects and construction method

ActiveCN106121043AReduce section sizeHigh section efficiencyStrutsProtective buildings/sheltersDouble tubeHigh rise

The invention discloses a double-pipe combined column having energy dissipation and shock absorption effects. The column comprises two steel pipe column branches, multiple groups of inter-column beams and column side bracket beams, wherein the inter-column beams are arranged between the column branches and are in welded connection with the column branches; the same groups of column side bracket beams and inter-column beams are located on the same plane; and bolt mounting holes are formed in the column side bracket beams. The double-pipe combined column having the energy dissipation and shock absorption effects has the small section size and can be hidden in a wall body, and column edges are not exposed; simple and convenient joint connection is realized, and the onsite construction speed is high; the column is high in applicability and can be applied to center columns, side columns and corner columns; the column is high in cross-section efficiency and flexible to arrange, the distance between the column branches of the double-pipe combined column is adjustable, and the column can be adapted to change of door and window holes; and the column has multiple advantages that the cross-section is closed, anti-corrosion and fireproof costs are saved and the like, can be applied to structures such as steel structure houses, multi-story and high-rise buildings and the like, and has the better popularization and application prospect.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

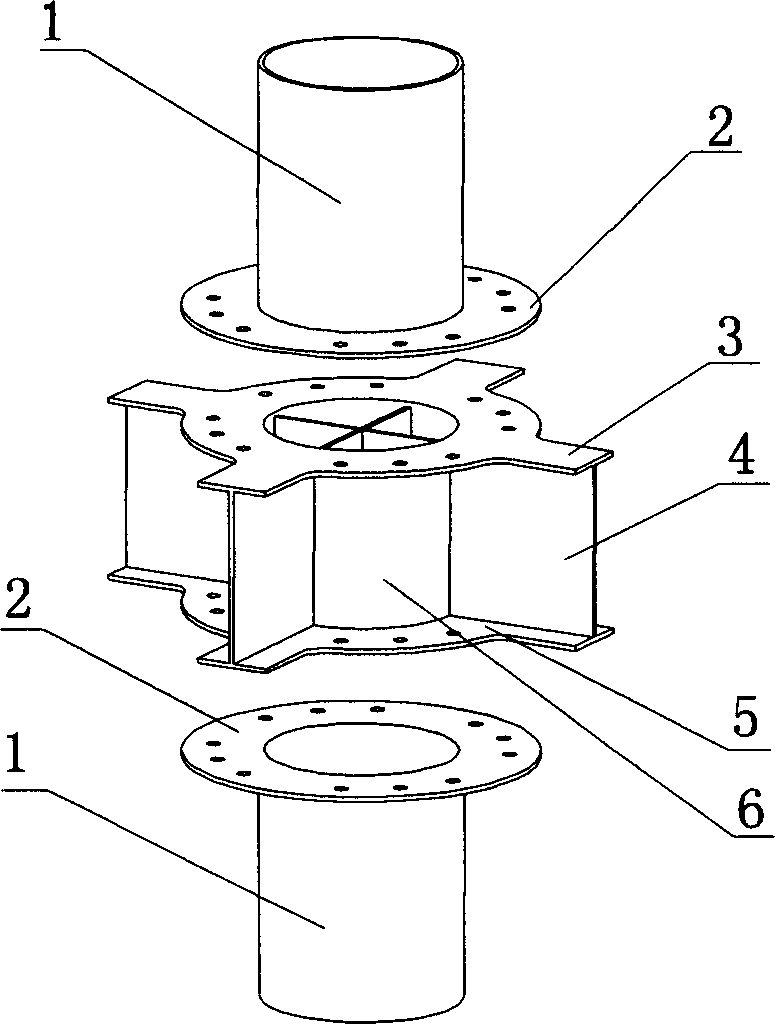

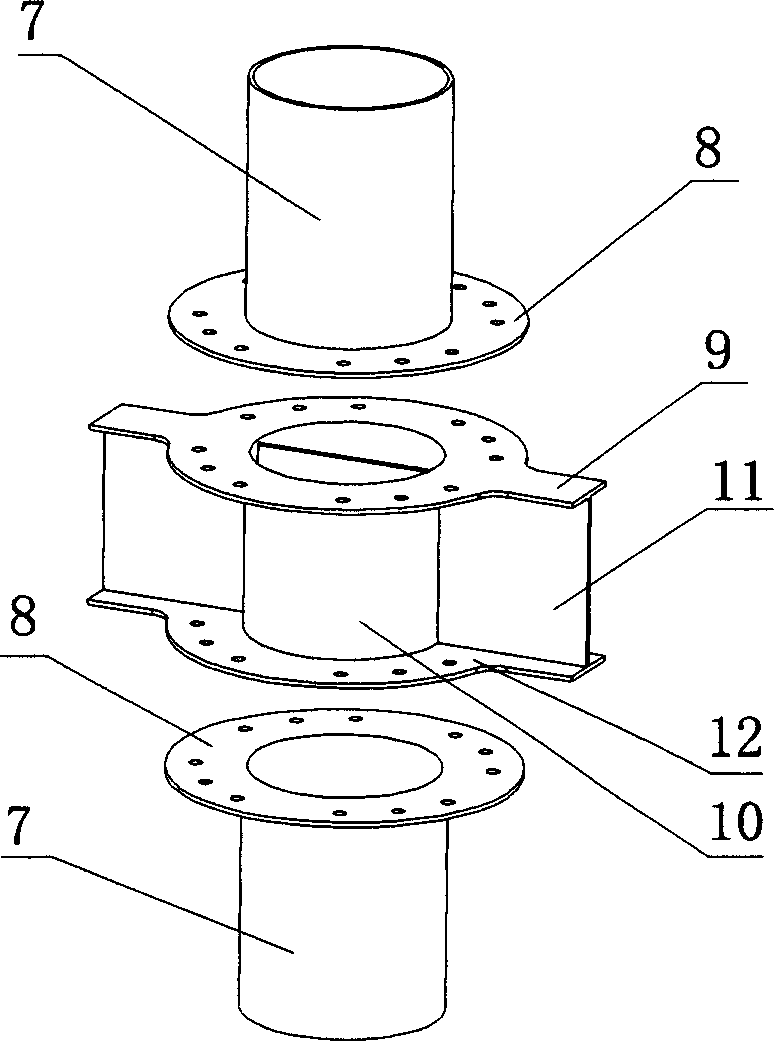

Steel pipe high strength concrete column reinforcing joint and method for manufacturing same

InactiveCN1095018CReduce the impactInfluence is not easy to happenStrutsPillarsHigh strength concreteSteel columns

The invention provides a steel pipe high-strength concrete column joint for beam-column connection and a manufacturing method thereof. The high-strength concrete steel tube column joint is composed of two parts: the column body and the joint section; the manufacturing method of the steel tube high-strength concrete column joint is that the joint section includes the joint section steel pipe, pull ring, pressure ring and piercing web, and the column body includes the steel pipe and flange of the column body section Ring; during installation, the end face of the pull ring and the end face of the pressure ring of the node section are respectively fitted with the end face of the flange ring of the column body, and the node section is connected with the column body by high-strength bolts. The steel pipe high-strength concrete column joint has reasonable stress, clear force transmission, good reliability, convenient construction, and easy control of welding quality.

Owner:SOUTH CHINA UNIV OF TECH

Prefabricated compound integrated wall board and application thereof

InactiveCN105256941ALight weightSolving Thermal Bridge ProblemsBuilding insulationsThermal bridgeRebar

The invention relates to a prefabricated compound integrated wall board and application thereof. Flanges which extend outwards are arranged at the two sides and upper end of the wall board; the prefabricated compound integrated wall board comprises a concrete layer and a heat-preservation layer; the heat-preservation layer is divided into two layers according to the thickness. The prefabricated compound integrated wall board is internally provided with a steel wire net rack and a steel bar welding net rack is formed by welding two layers of steel bar welding nets with stressing or construction effect by a web bar; the heat-preservation layer is clamped between the two layers of steel bar welding nets; reinforcing steel bars are arranged at the end part and a hole of the steel wire net rack. The prefabricated compound integrated wall board integrates decoration, heat preservation and containment; field construction work of an outer decoration layer and the heat-preservation layer can be effectively avoided, and heat bridge problems of beams and columns and phenomena that the area of a wall body is too great and cracks are formed are effectively solved; the prefabricated compound integrated wall board can be combined with an assembling type framework column and a steel structure so as to form an assembling type framework / steel structure-prefabricated wall board integrated structure system.

Owner:河北省建筑科学研究院有限公司

Fixed telescopic type crevasse plugging device and method

The invention discloses a fixed telescopic type crevasse plugging device. The fixed telescopic type crevasse plugging device is characterized by comprising a fixing tower, a flow intercepting baffle set and ropes; the fixing tower is located on a dam, and is used for hanging the ropes for plugging a crevasse; the rope comprises a thick rope and a thin rope; the flow intercepting baffle set has thetelescopic function, and is used for building a water blocking partition-off layer into plate-shaped matter for flow intercepting during flow intercepting of the crevasse; and the flow intercepting plate set can be hung on the ropes. According to the fixed telescopic type crevasse plugging device, the fixing tower is located on the dam, has a certain height and is a building which cannot be movedor is not convenient to move; and the fixing tower plays a role of guiding the direction of the ropes for plugging the crevasse, and can be used for moving one end of each rope. The fixed telescopictype crevasse plugging device can be fast and efficiently deployed, can be used at various weather, is easy to operate and can be used for dealing with different crevasse conditions.

Owner:郑州玄一机器人有限公司

Steel structure simple house capable of being rapidly dismounted and mounted

InactiveCN106988426AFactory highImprove completenessBuilding constructionsBrickArchitectural engineering

The invention discloses a steel structure simple house that can be quickly disassembled and assembled in the technical field of steel structures, which includes a frame, a support rod is installed on the top of the frame, a sliding block is sleeved on the support rod, and the left and right sides of the sliding block The side is movably connected with a bracket, the left side of the bracket is movably connected with the first roof, the right side is movably connected with the second roof, the first roof and the second roof are connected by hinges, and the first roof and the second roof are movably connected. The bottom of the second roof is connected with a support column, and the bottom end of the support column is fixed to the top of the frame. The light steel structure fittings of the present invention have a high degree of industrialization and mechanization, a high degree of commercialization, and a fast on-site construction speed without affecting It is conducive to civilized construction to nearby residents. Compared with traditional brick-concrete structure houses, the wall thickness is smaller, which can increase the effective use area, and the light steel structure houses are light in weight and have good shock absorption performance.

Owner:华新顿现代钢结构制造有限公司

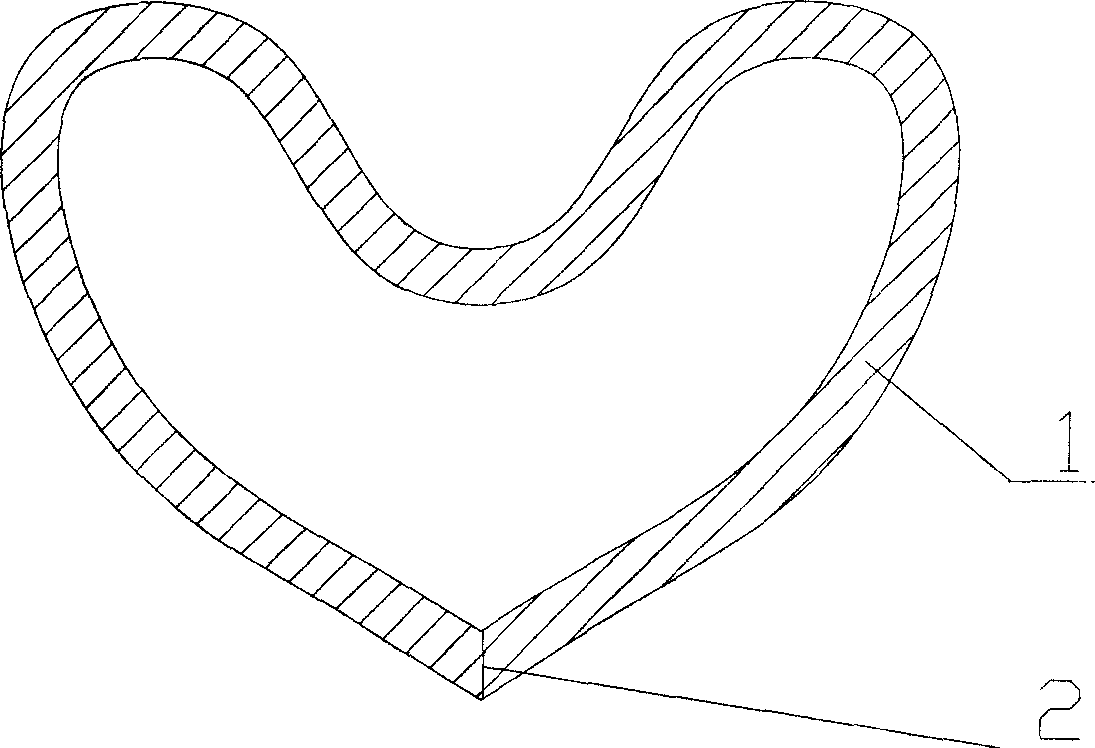

Non-digging and integral repairing method for underground pipeline

The present invention is integal no-excavation pipeline repairing method. The method includes the following steps: in-situ argon arc welding stainless steel belt of 0.2-1 mm thickness into single-seam stainless steel pipe in the outer diameter equal to the inner diameter of the pipeline to be repaired; pressing the stainless steel pipe into pipe of heart-shaped cross section; connecting one end of the stainless steel pipe with soft steel cable and the other end to one rubber obliterator; transmitting the rubber obliterator with a pressure fan from one end of the pipeline to the other end; drawing the stainless steel pipe into the pipeline and blocking two ends of the pipeline; and introducing pressured water to expand the heart-shaped completely.

Owner:大庆油田建设集团

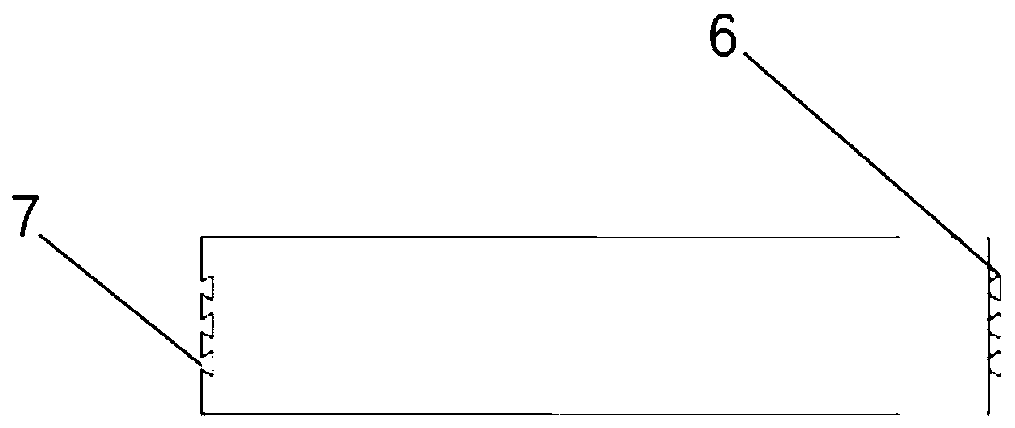

Splicing-free composite base metal surface heat insulation decorative plate and manufacturing method thereof

InactiveCN101608495AFast constructionExempt from dehumidificationCovering/liningsWeather resistanceBasic level

The invention relates to a splicing-free composite base metal surface heat insulation decorative plate and a manufacturing method thereof. A foamed heat-insulation plate is arranged between an upper layer and a lower layer; a metal decorative surface is arranged on the superior surface of the upper layer; a teeth structure is arranged at the inferior surface of the upper layer and the superior surface of the lower layer; the upper layer and the lower layer are cement cast-in-situ or rolled splicing-free basic levels; the superior surface and the inferior surface of the formed heat-insulation plate are provided with non-penetrating holes which are matched with the teeth structure. The manufacturing method is as follows: a plastic film plate is put on a laminator and spread with sizing agent for preparing the lower layer; the formed heat-insulation plate with the non-penetrating holes is put on the laminator and spread with sizing agent for preparing the upper layer; the lower layer and the upper layer form an integral composite base level plate which is set aside and maintained till being dry; and a splicing surface metal plate is pressed. The teeth structure of the decorative plate fixes the formed heat-insulation plate between base level composite boards; and the formed heat-insulation plate does not easily come off or peel off adjacent layers. Products manufactured by the invention are plate structures, have light weight, high integral strength, good heat-insulation performance, decorative performance, weather resistance, and better fireproof performance.

Owner:HUBEI MEIHENG NEW KEEP WARM DECORATION MATERIALS

Assembled-type steel structural residence three-layer composite steel-column filled heat-insulation outer wall plate lifting method

ActiveCN107503519AAvoid crackingImprove construction qualityBuilding material handlingResidenceSteel columns

The invention discloses an assembled-type steel structural residence three-layer composite steel-column filled heat-insulation outer wall plate lifting method. The method includes the steps that two hoisting machines are adopted to lift components; the main hoisting machine sets a lifting point at the top of an outer-wall-plate steel column, the auxiliary hoisting machine sets a lifting point at the middle end of the outer-wall-plate steel column, and the lifting points are fixed firmly; the two hoisting machines synchronously conduct lifting, and the top main lifting speed of the main hoisting machine at the top is greater than that of the middle-end auxiliary hoisting machine; when an outer wall plate is lifted to be five meters away from the ground, middle-end lifting tools are removed; the main hoisting machine starts to lift the outer wall plate, after a perching height is reached, the outer wall plate moves horizontally relative to a perching point, then, a mounting position is reached, and mounting is completed. The assembled-type steel structural residence three-layer composite steel-column filled heat-insulation outer wall plate lifting method improves the construction quality and the mounting accuracy, accelerates the on-site construction, manual operation is reduced, engineering costs are saved, and the situation is prevented that in the process of lifting the outer wall plate, due to steel structural concrete deforms, concrete outer wythes crack.

Owner:CHINA 22MCC GROUP CORP

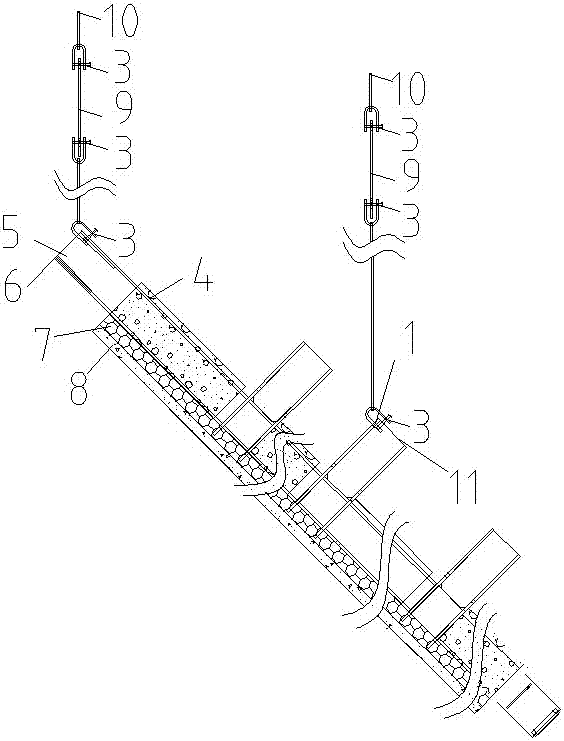

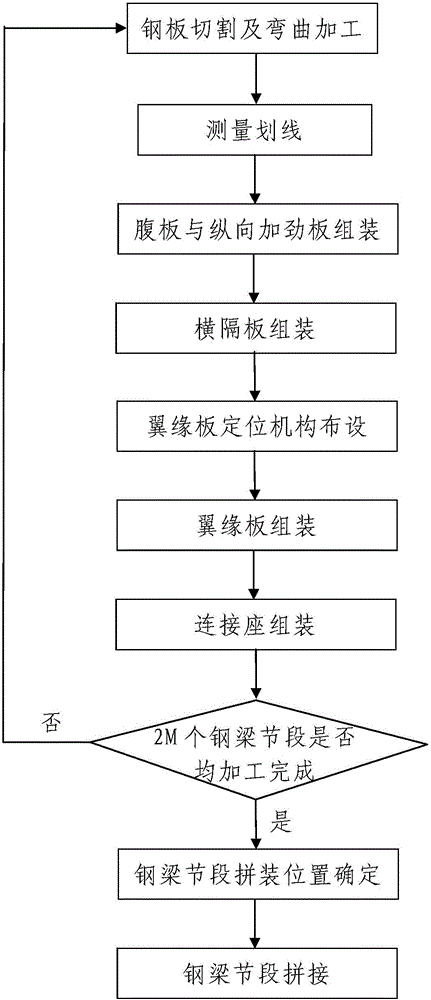

Curved ribbed beam processing and assembling construction process

ActiveCN104989107AThe process steps are simpleReasonable designBuilding roofsBuilding material handlingSteel platesFlange

The invention discloses a curved ribbed beam processing and assembling construction process. A processed curved ribbed beam is a curved steel beam, the cross-section of the curved steel beam is in the shape of a Chinese character ri, an outer side beam body and an inner side beam body of the curved ribbed beam are connected with each other through straining beams, and each of the outer side beam body and the inner side beam body is spliced by a number M of steel beam sections, each steel beam section comprises a top flange plate, a bottom flange plate, two webs and a vertical stiffening plate, and each steel beam section is provided with a connecting base. The curved ribbed beam processing and assembling construction process comprises steps of (1) processing the steel beam sections in a factory, cutting steel plates, carrying out bending processing to the steel plates, carrying out measuring and scribing processes, assembling the webs and the vertical stiffening plate, assembling diaphragm plates, laying flange plate positioning mechanisms, assembling the flange plates and assembling the connecting bases; and (2) assembling the curved ribbed beam, determining the splicing positions of the steel beam sections, and splicing the steel beam sections. The curved ribbed beam processing and assembling construction process has simple steps, and is reasonable in design, convenient to implement and good in usage effect, and the processing and assembling construction process of the curved ribbed beam steel structure can be completed simply and quickly in high quality.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

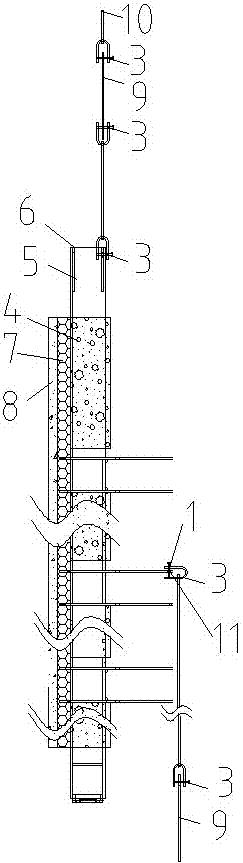

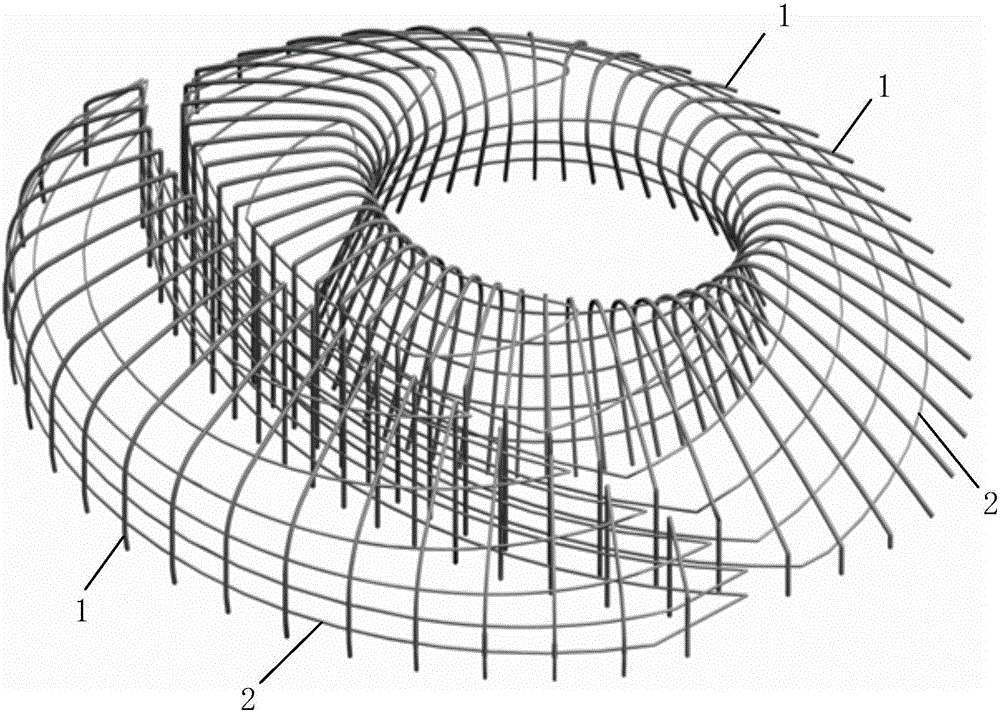

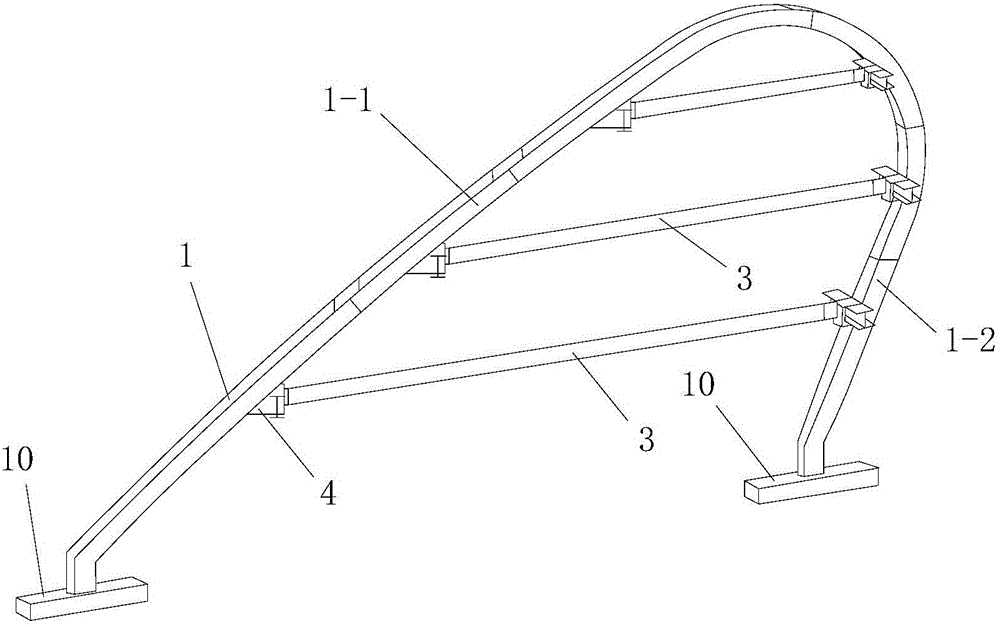

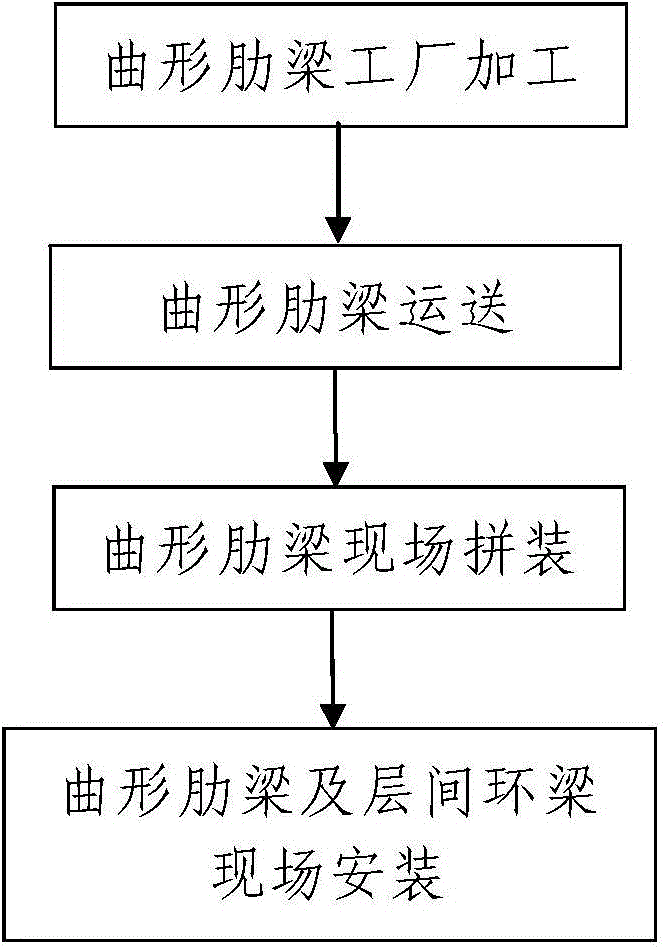

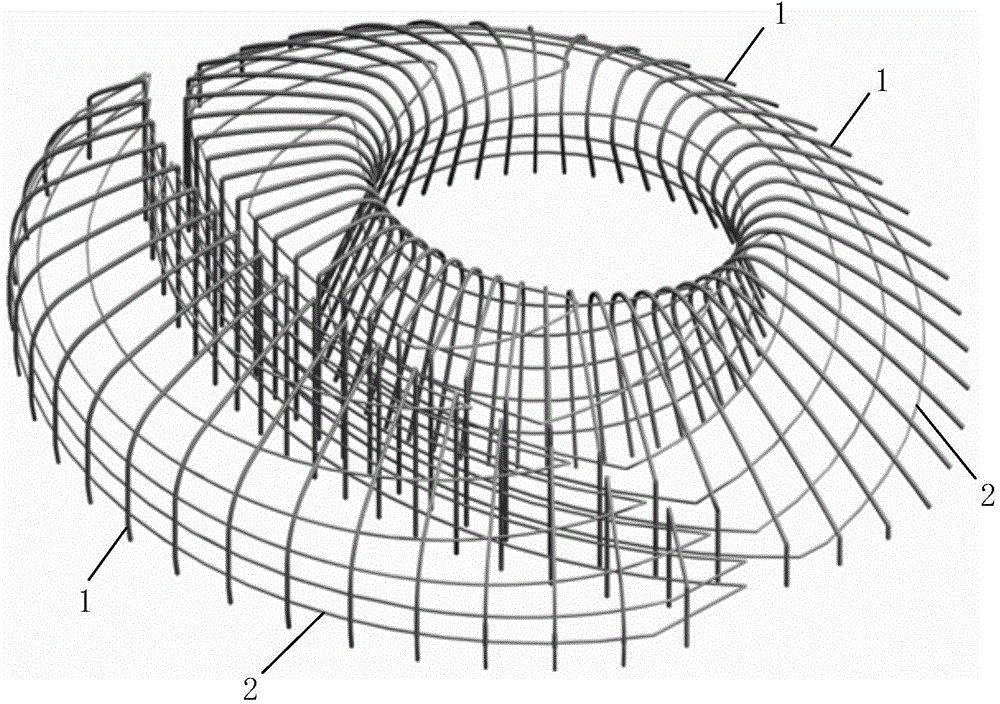

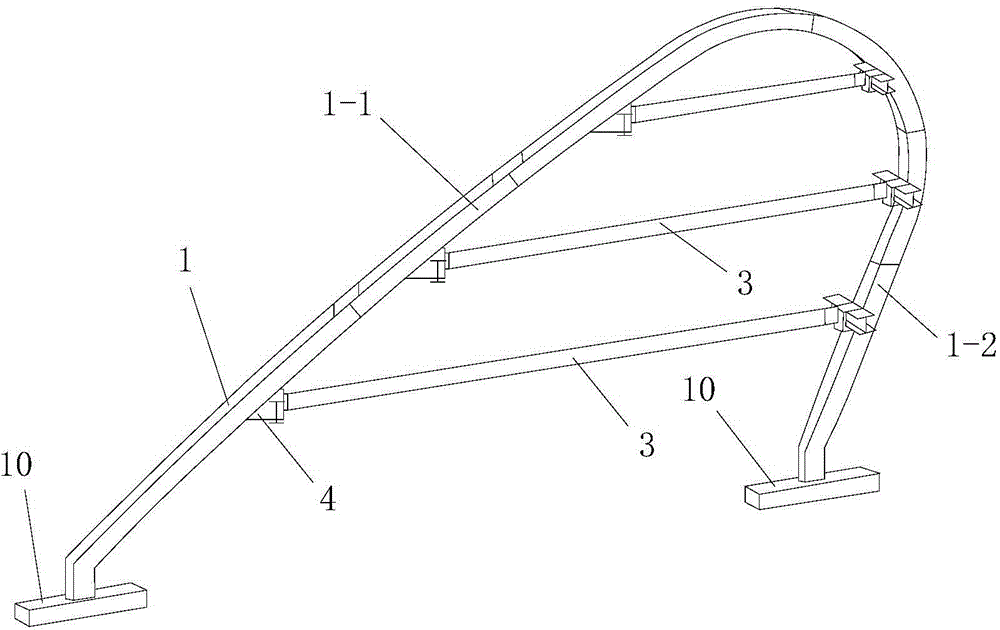

Construction method for space curved rib girder steel structure

ActiveCN104818849AThe method steps are simpleReasonable designBuilding material handlingFlangeBox girder

The invention discloses a construction method for a space curved rib girder steel structure. The constructed space curved rib girder steel structure comprises several curved rib girders distributed on a horizontal foundation from front to back; the cross section of the curved rib girders is H-shaped and its outer girder body and inner girder body are formed by splicing M steel girder sections; several curved rib girders are integrally connected by interlayer ring beams; the steel girder section comprises an upper flange plate, a lower flange plate, two webs and a longitudinal stiffening plate; and each steel girder section is provided with a connecting base. The construction process of the space curved rib girder steel structure comprises the steps: firstly, curved rib girder factory processing, processing each steel girder section of the curved rib girder; secondly, curved rib girder conveying; thirdly, curved rib girder field splicing; and fourthly, curved rib girder and interlayer ring beam field installation. The process is simple, the design is rational, the construction is convenient, and the using effect is good. The construction process of the space curved rib girder steel structure can be simply and conveniently completed, the construction process is safe and the construction period is short.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

Prefabricated laminated plate lifting method

The invention relates to a prefabricated laminated plate lifting method. The prefabricated laminated plate lifting method comprises a laminated plate lifting beam; a connecting lifting lug for connecting a tower crane with the laminated plate lifting beam is arranged at the top of the laminated plate lifting beam; an inner side lifting lug is arranged at the bottom of H-shaped steel opposite to the connecting lifting lug; an outer side lifting lug is arranged on the outer side of the inner side lifting lug; the connecting lifting lug is connected with a lifting hook of the tower crane through a rope; a first laminated plate is connected with the H-shaped steel; a second laminated plate is connected with the H-shaped steel; the second laminated plate reaches on site, and the rope is removed to connect with the second laminated plate; and the first laminated plate reaches on site, and the rope is removed to connect with the first laminated plate. The prefabricated laminated plate lifting method uses a special lifter for lifting the laminated plates, is high in generality and not easy to damage, can be used for a long time, shortens the lifting time, improves the use efficiency of the tower crane, improves the mounting efficiency of the laminated plates, accelerates the site construction speed, reduces labors, and reduces the construction cost.

Owner:CHINA 22MCC GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com